Device and method for producing synthetic gas by continuous two-stage catalytic pyrolysis

A catalytic pyrolysis and synthesis gas technology, applied in hydrogen/synthesis gas production, chemical instruments and methods, gasification catalysts, etc., can solve the problems of difficulty in processing, reduce the utilization characteristics of solid-phase products, and easily produce melting, etc., to achieve reduction Investment and secondary pollution, the effect of solving energy utilization and hazard problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a continuous two-stage catalytic pyrolysis synthesis gas device and method. The specific technical method and device of the present invention will be described in detail and completely below in conjunction with the accompanying drawings and specific embodiments. The described specific implementation Ways are only some examples of the present invention, not all examples. All other examples obtained by those skilled in the art without creative efforts belong to the protection scope of the present invention.

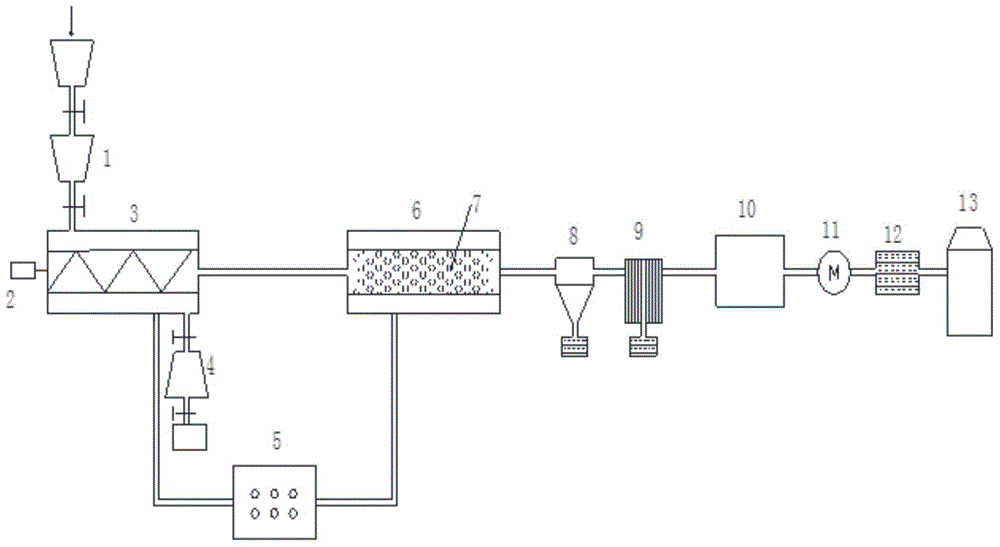

[0025] A continuous two-stage catalytic pyrolysis synthesis gas production device, double-valve closed feeding device 1, a first-stage medium-temperature pyrolysis furnace 3, a second-stage high-temperature catalytic pyrolysis furnace 6, a gas-liquid separator 8, and a water condenser 9 , water washing box 10, induced draft fan 11, purifier 12 and gas storage tank 13 are connected in sequence; a section of medium-temperature pyrolysis f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com