Patents

Literature

231 results about "Liquid Petroleum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquefied petroleum gas or liquid petroleum gas (LPG or LP gas), also referred to as simply propane or butane, are flammable mixtures of hydrocarbon gases used as fuel in heating appliances, cooking equipment, and vehicles.

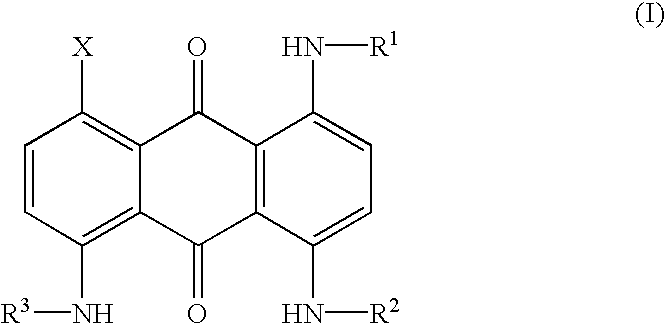

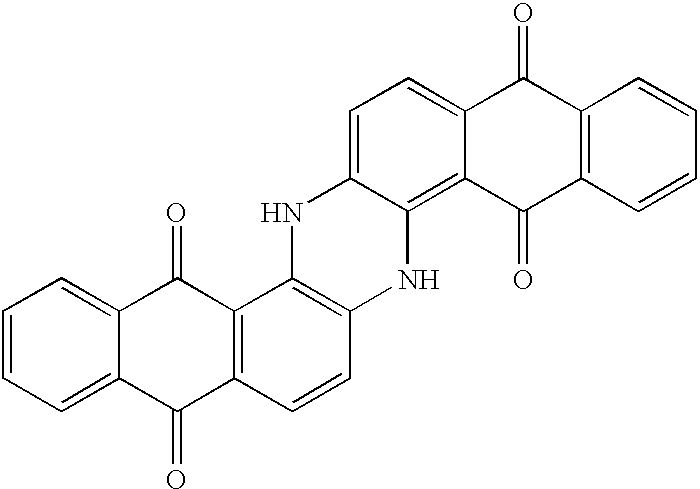

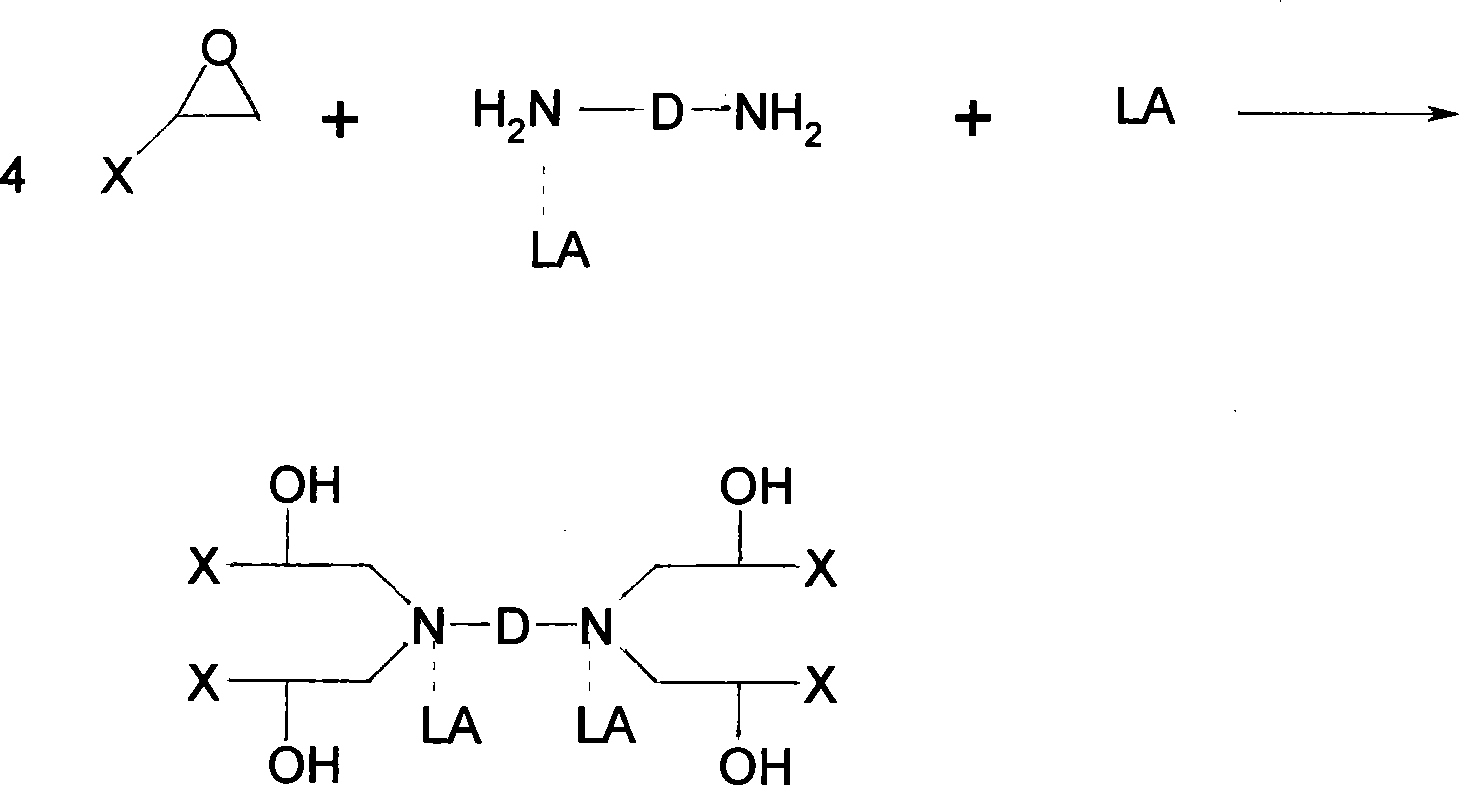

Method for marking hydrocarbons with anthraquinones

Method for invisibly marking a liquid petroleum hydrocarbon. The method comprises adding to the liquid petroleum hydrocarbon at least one dye selected from the group consisting of 1,4,5,8-tetrasubstituted anthraquinones and anthraquinone dimers. The absorption maximum of the dye(s) is in the range from 710 nm to 850 nm.

Owner:ROHM & HAAS CO

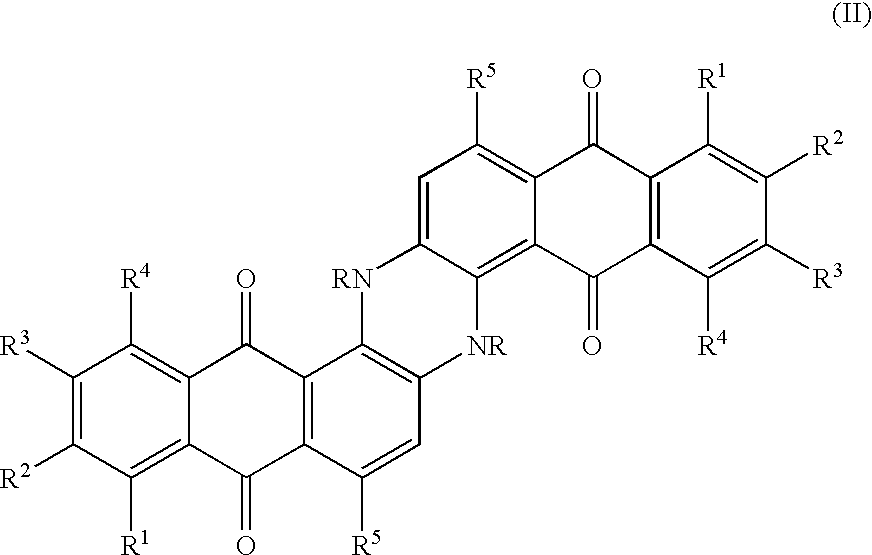

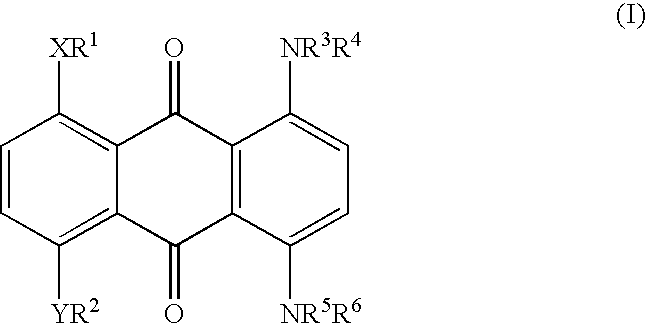

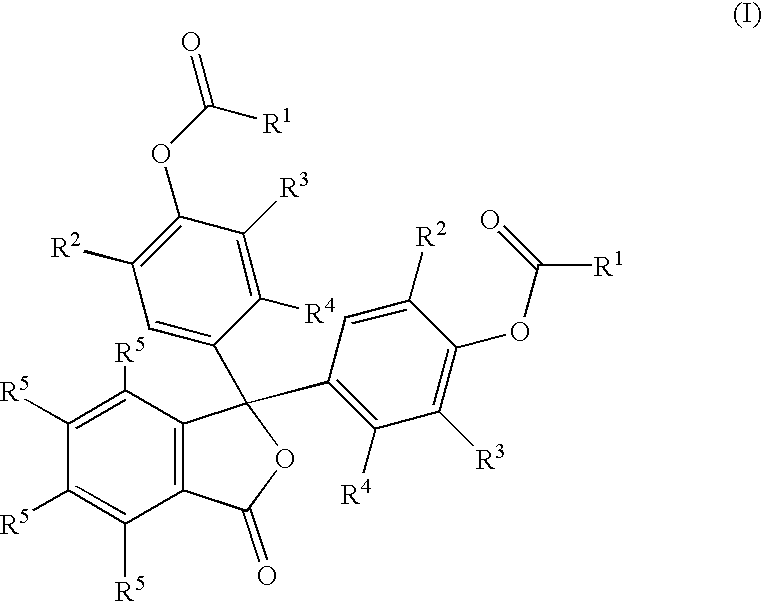

Method for marking hydrocarbons with substituted anthraquinones

ActiveUS20040250469A1Lower levelFacilitates quantitative spectrophotometric determinationEarth material testingLiquid carbonaceous fuelsArylAnthranil

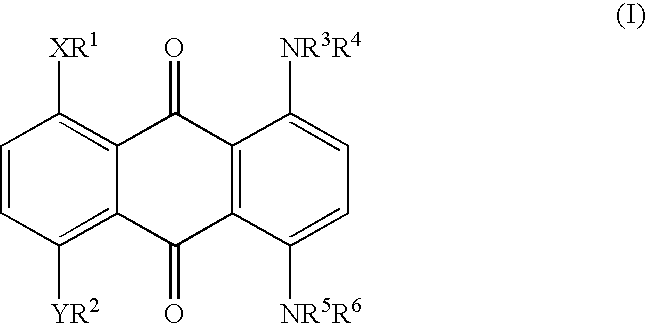

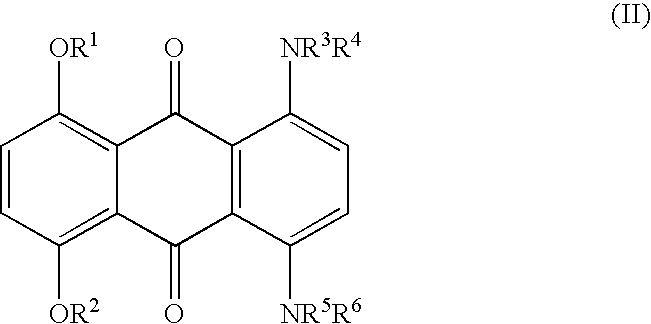

A method for marking a liquid petroleum hydrocarbon. The method comprises adding to the liquid petroleum hydrocarbon at least one substituted anthraquinone dry having formula (I) wherein X is O or S; Y is O, NR<7 >or S; R<1 >and R<2 >independently are hydrogen, alkyl, aryl, aralkyl, heteroalkyl, heterocyclic or alkanoyl; R<3 >and R<5 >independently are alkyl, aryl, aralkyl, heteroalkyl or heterocyclic; R<4 >and R<6 >independently are hydrogen or alkyl; R<7 >is hydrogen or alkyl; and wherein the substituted anthraquinone dye(s) has an absorption maximum in the range from 600 nm to 750 nm.

Owner:ROHM & HAAS CO

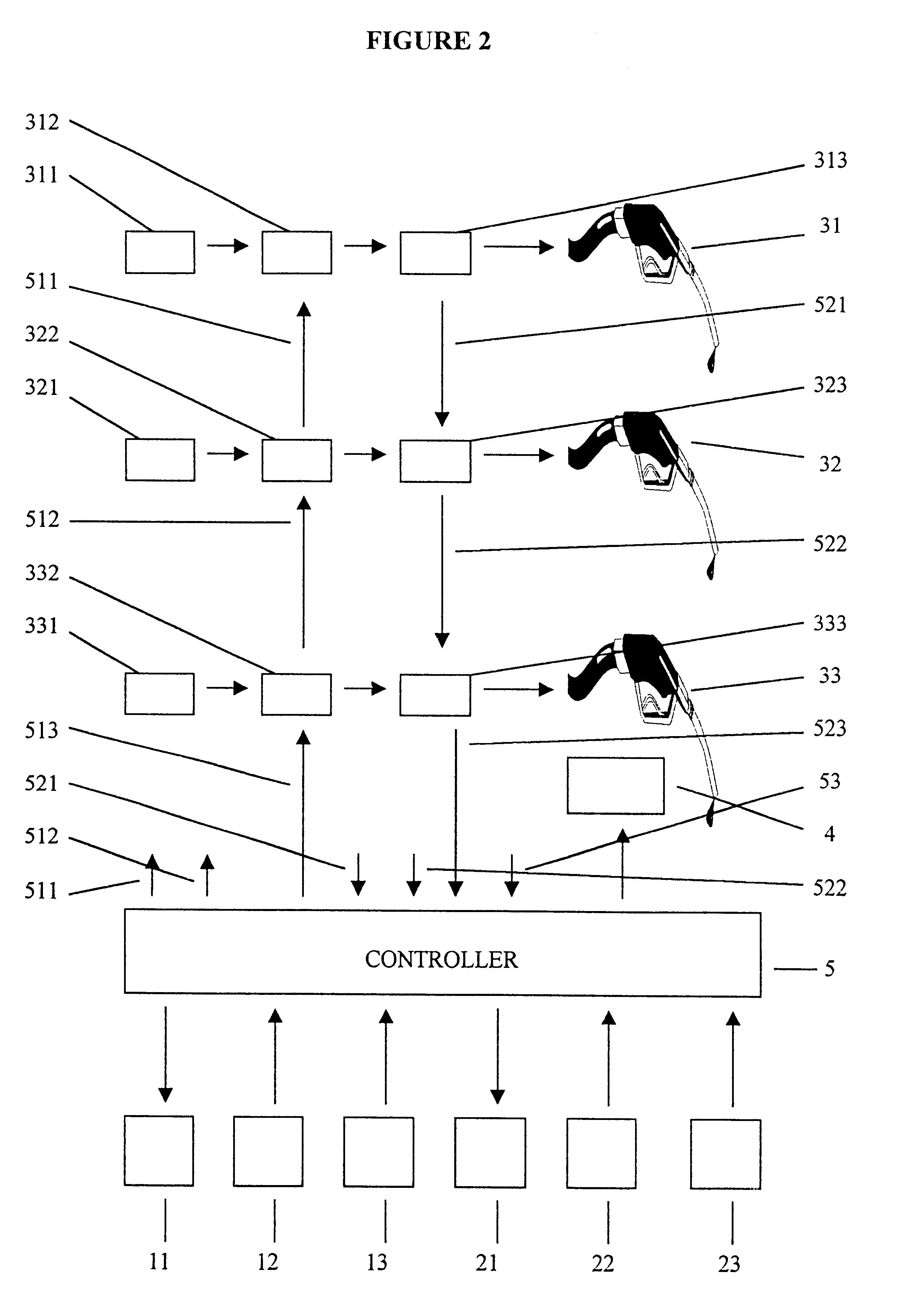

Gasoline pump system and method

InactiveUS6651706B2Increase the number ofReduce waiting timeLiquid flow controllersLiquid transferring devicesDriver/operatorCar driving

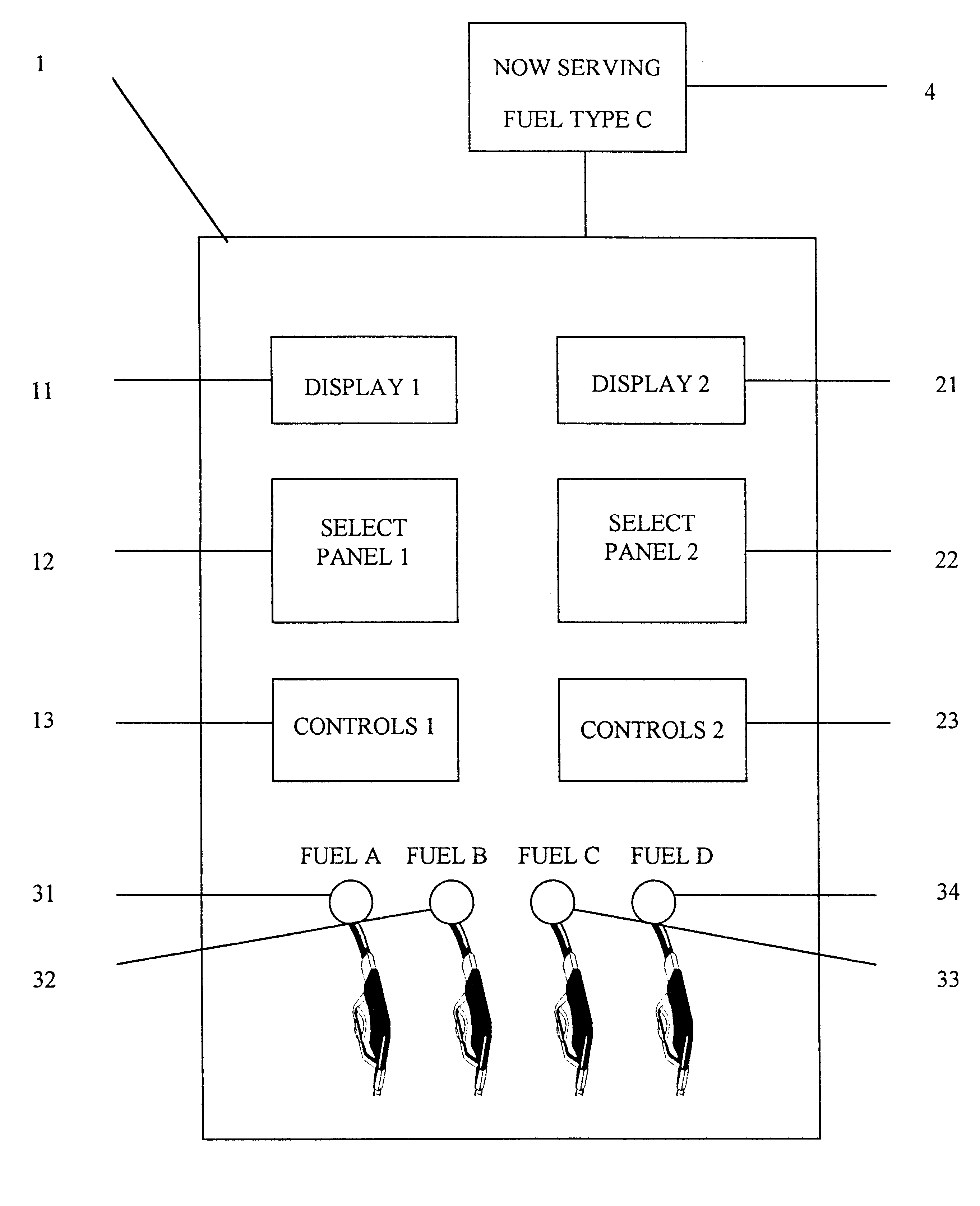

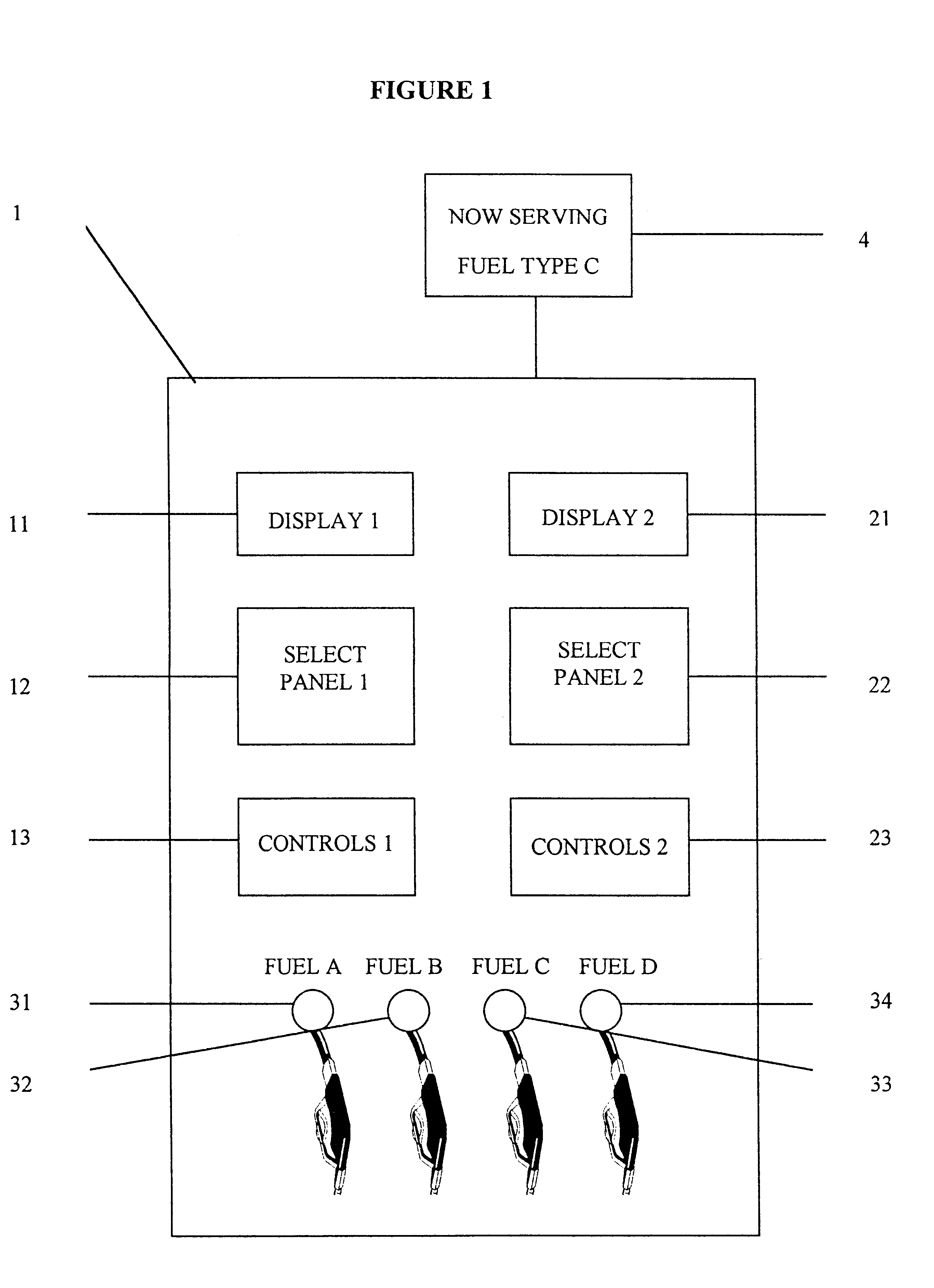

In a gasoline pump system, means for concurrent filling of more than one car, tank or container with gasoline or other liquid petroleum products, comprising a display for guiding car drivers to a gasoline pump system having an outlet available for fueling, and a display for enabling each driver to identify the outlet used for filling his / her car, and to distinguish it from outlets used for filling other cars. A method for concurrent filling of more than one car, tank or container with gasoline or other liquid petroleum products, comprising the steps of: A. Guiding car drivers to a gasoline pump system having an outlet available for fueling; and B. Enabling each driver to identify the outlet used for filling his / her car, and to distinguish it from outlets used for filling other cars.

Owner:LITT ARYEH

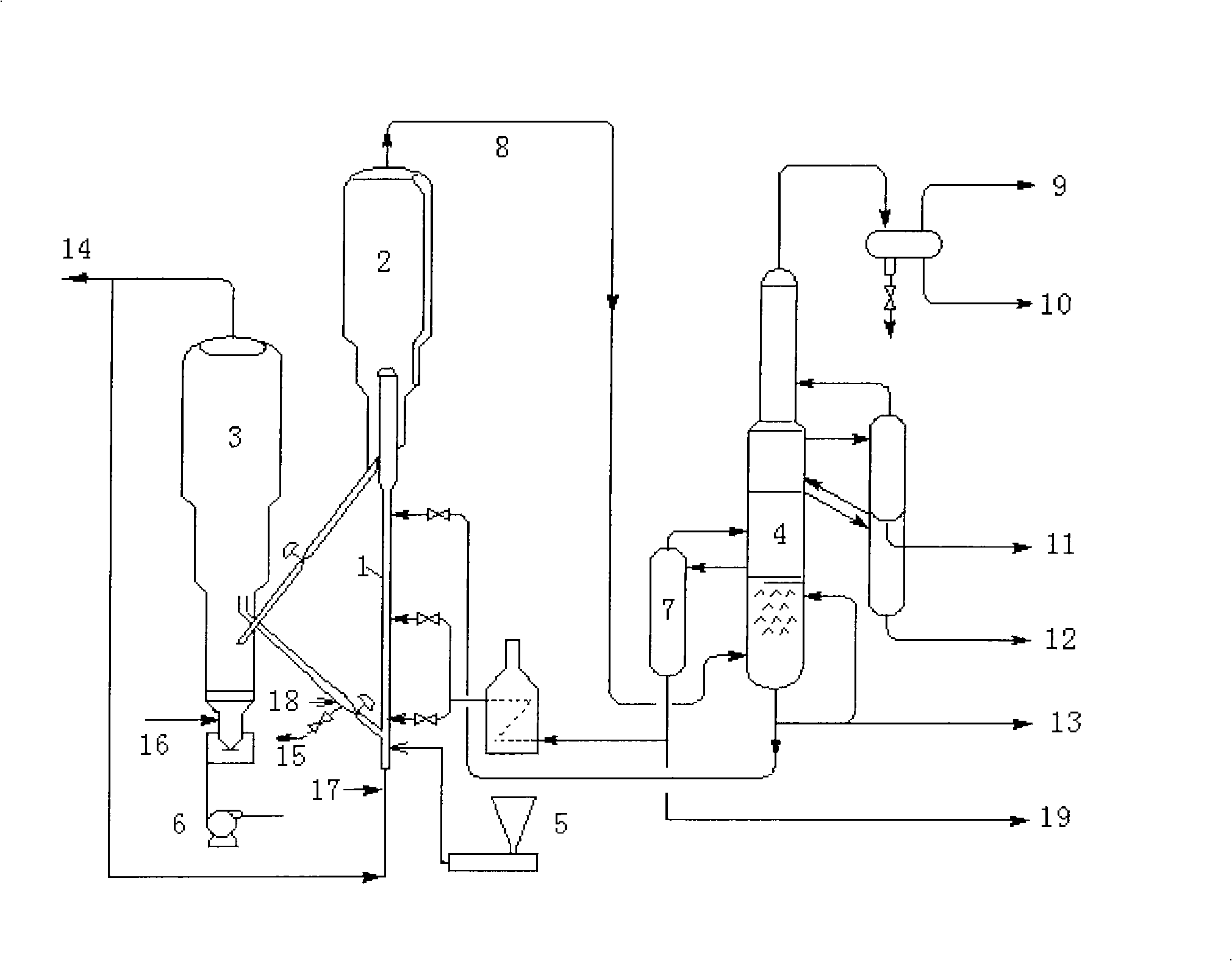

Piston type fluidized bed low temperature dry distillation technological process

InactiveCN101328415AReduce lossesIncrease profitSpecial form destructive distillationHeat carrierOxygen

The invention relates to a process method for low temperature carbonization on a fluidized bed. The process method uses the principle of a lift pipe fluid catalytic cracker, uses a lift pipe reactor of the lift pipe fluid catalytic cracker as a carbonization reactor, uses a catalyst regenerator of the lift pipe fluid catalytic cracker as a high-temperature water gas generator, and uses high-temperature water gas as a fluidizing medium and a heat carrier of a carbonization raw material. The carbonization method comprises the following steps that: a carbonizing raw material is conveyed to the lift pipe fluidized bed reactor for a carbonization reaction of the raw material; the reacted oil and gas are separated to produce a carbonized product; carbonized carbocoal enters the water gas regenerator; carbon in the carbonized carbocoal, oxygen and water vapour in air are subjected to oxidation reaction and water gas reaction; the water gas obtained in the reaction is used as the fluidizing medium and the heat carrier during the carbonization process; and solid clinkers produced after the carbonized carbocoal is subjected to the water gas reaction are discharged. Compared with the prior art, the method has the advantages of simple process, high production capacity, less equipment and so on, and can be used in oil shale, oil sand, coal and other substances to produce liquid petroleum products.

Owner:ZHUHAI TOP ENERGY TECH

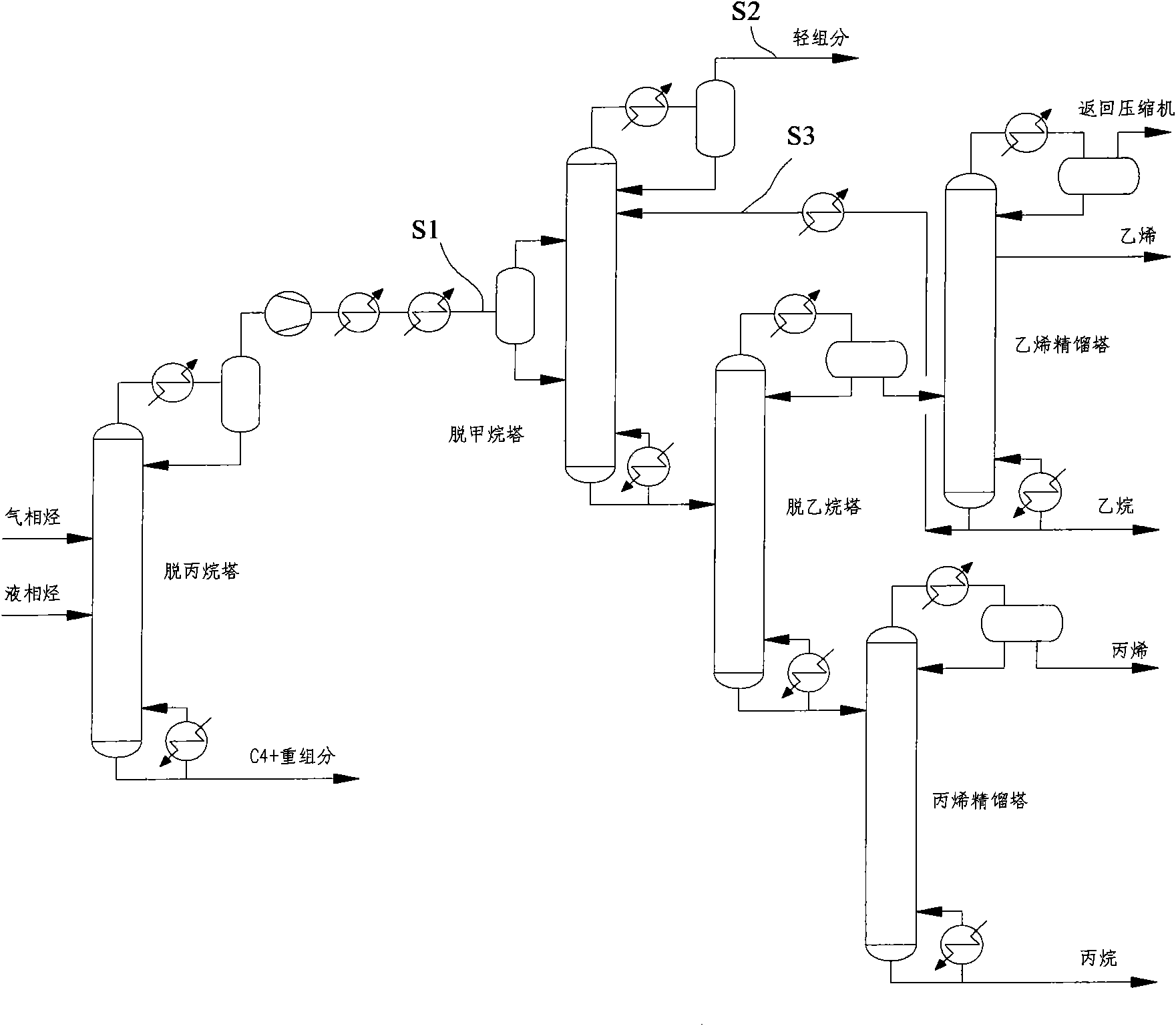

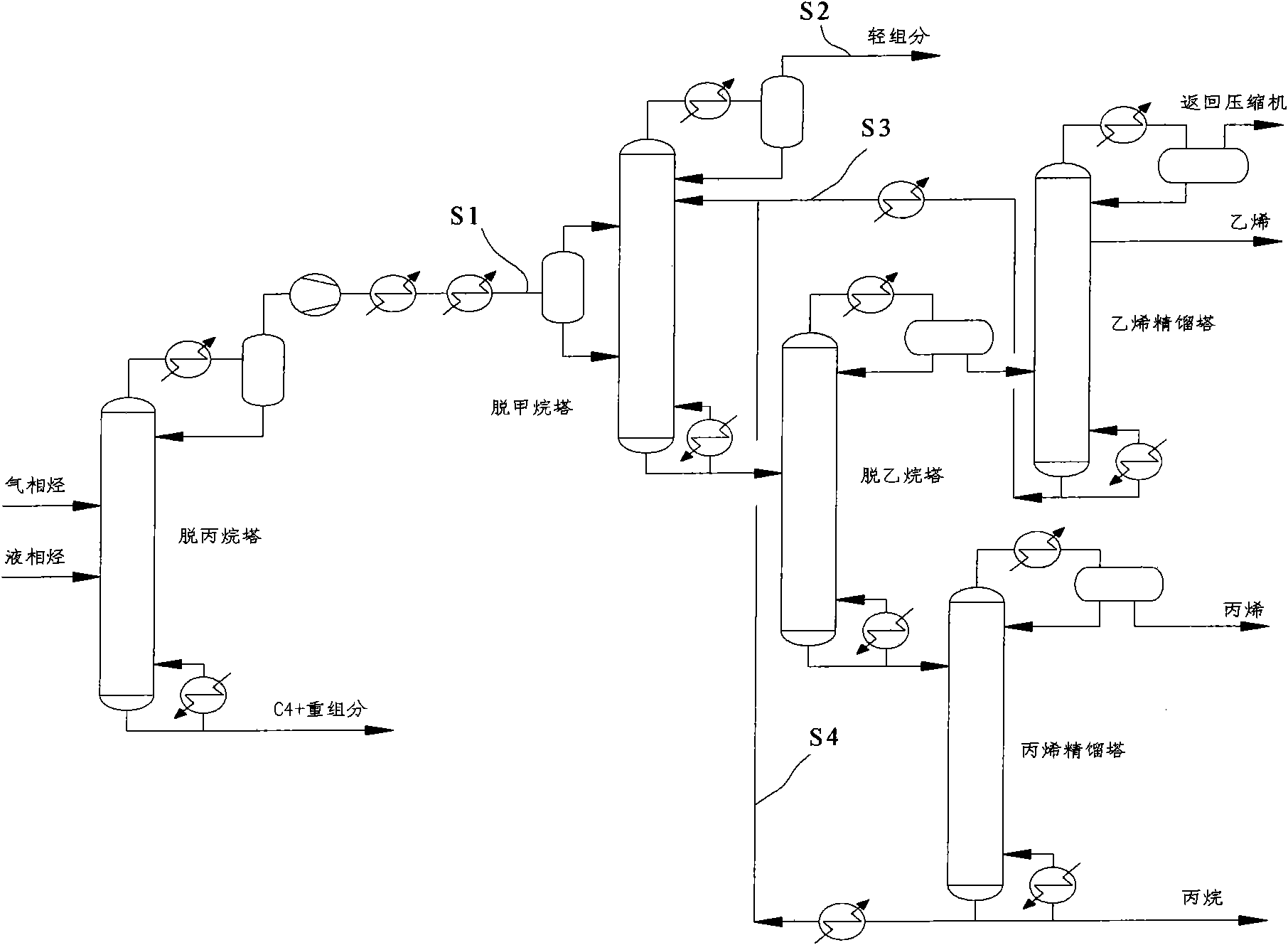

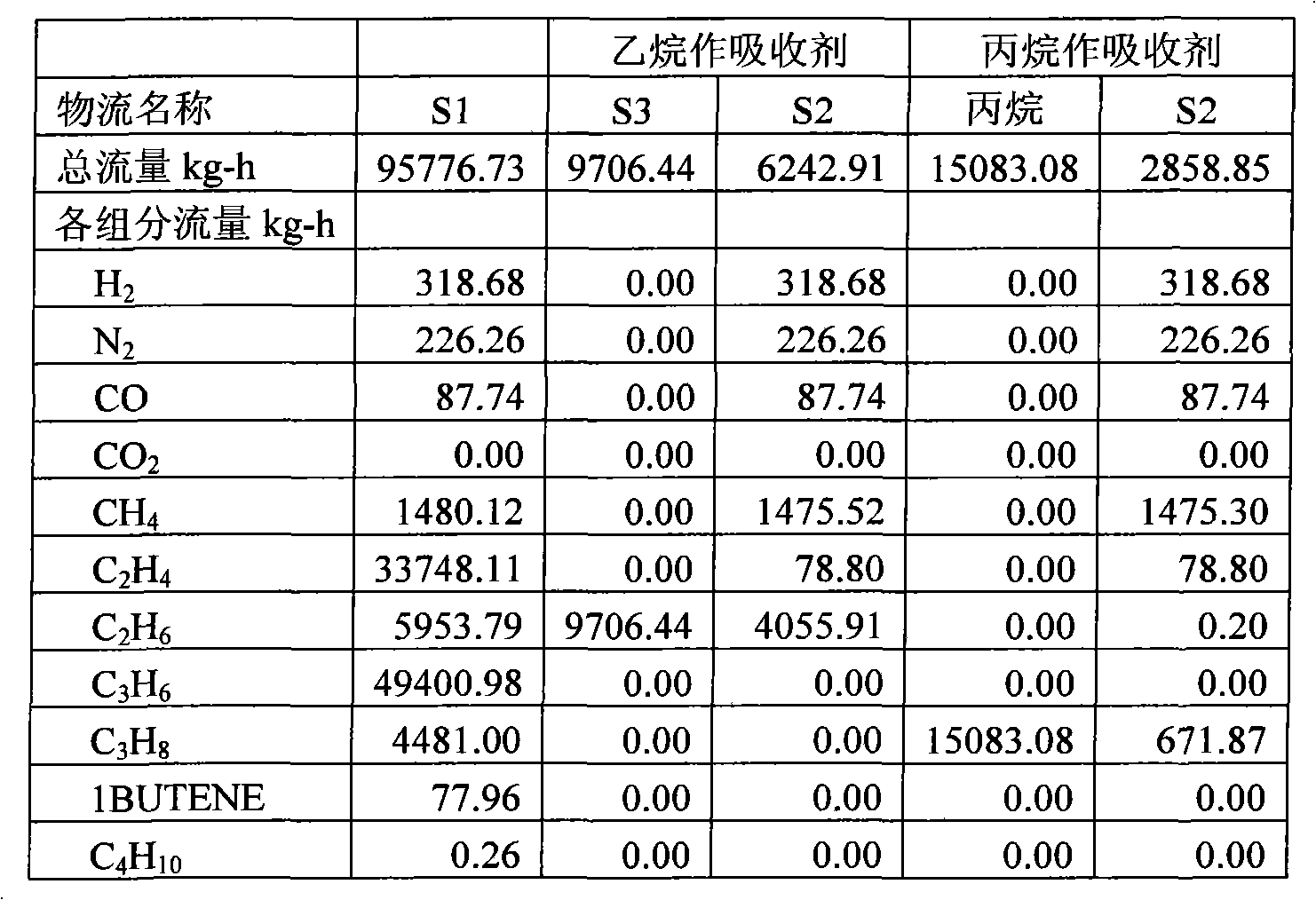

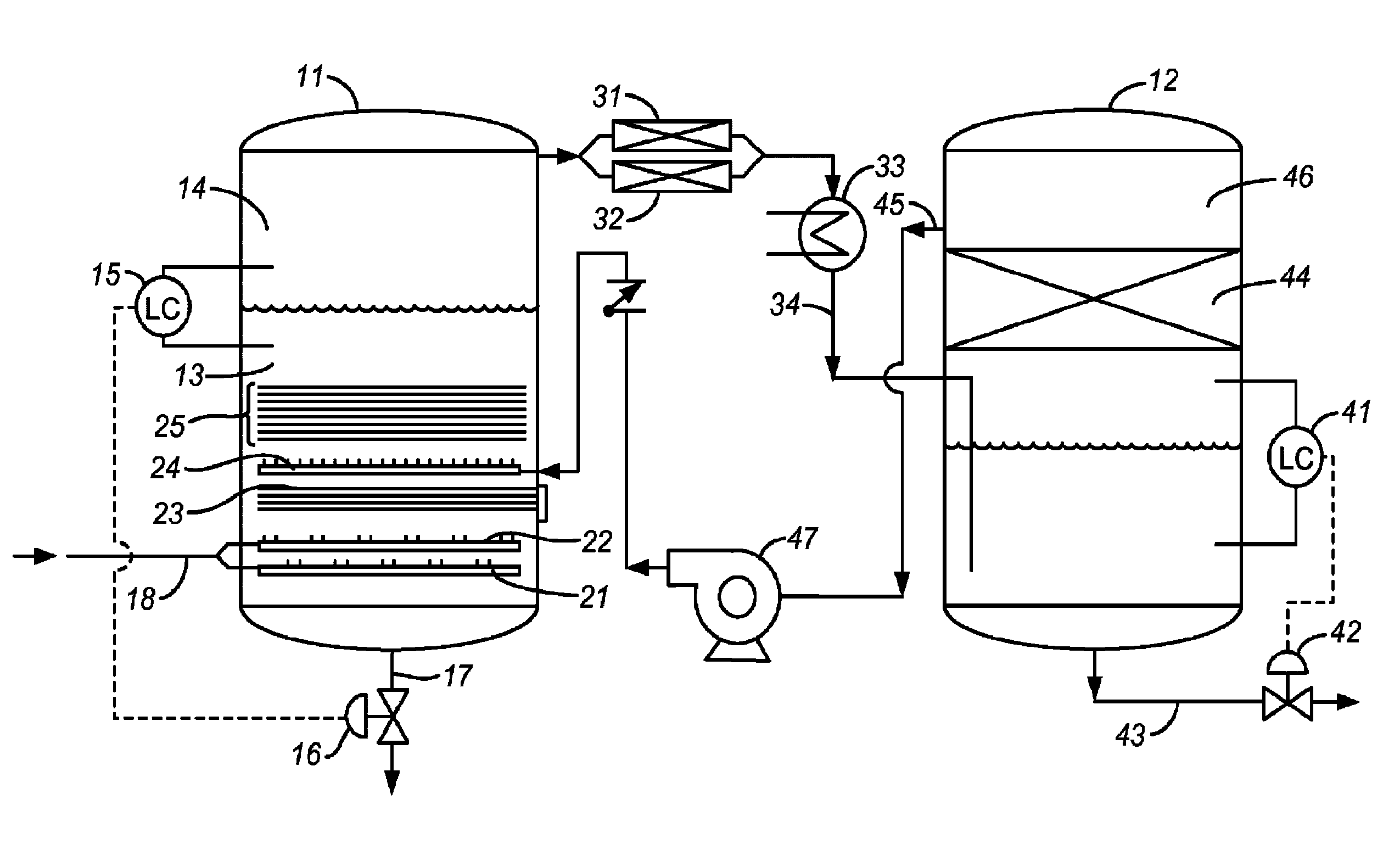

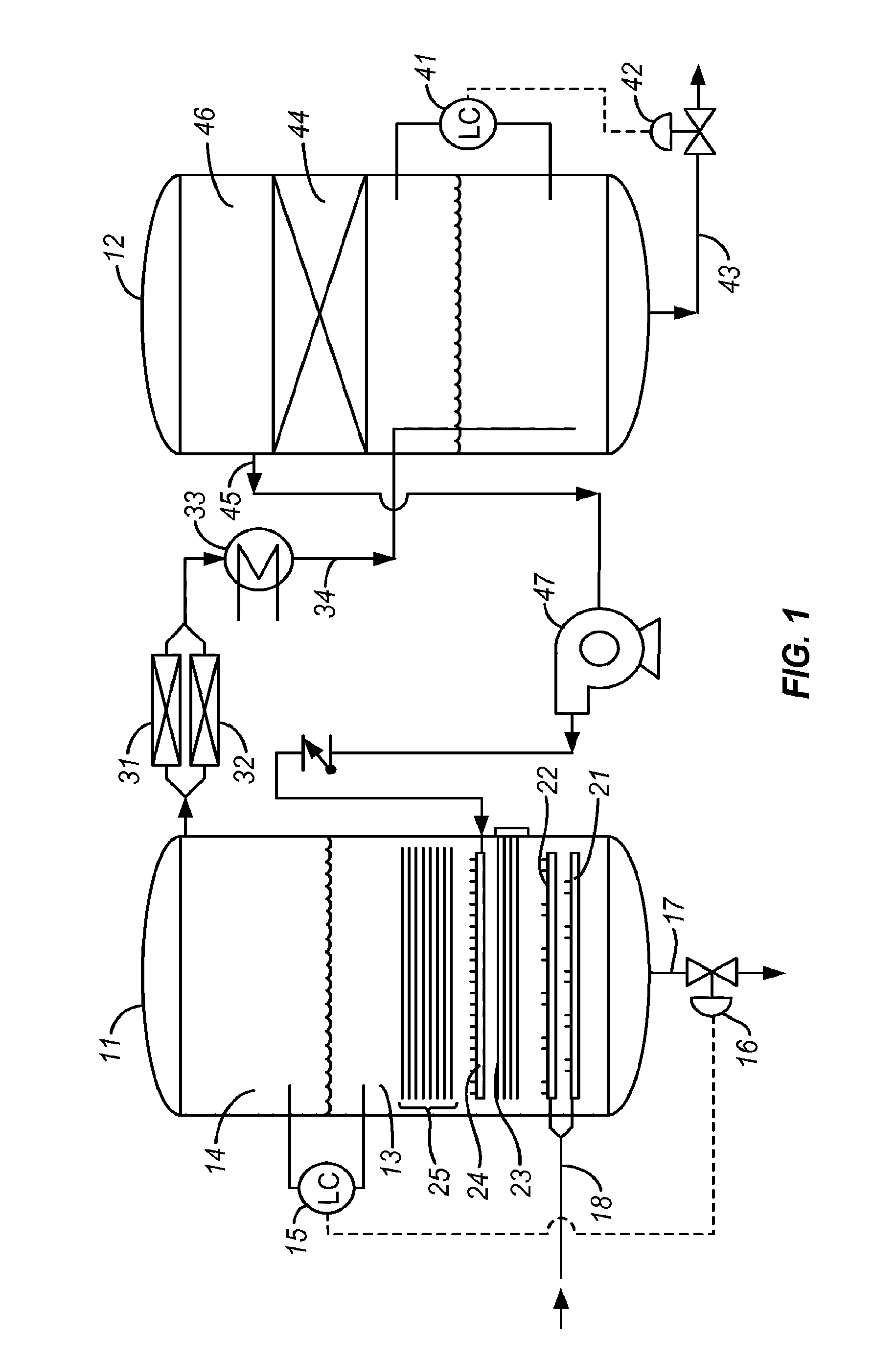

Separation method for producing light olefins from oxygenated chemicals

InactiveCN101973831AReduce investmentReduce the difficulty of operationGaseous fuelsEthylene productionGas phaseMethane

The invention discloses a separation method for producing light olefins from oxygenated chemicals. In the method, a product from a reactor for producing the light olefins from the oxygenated chemicals and / or a product generated from olefins catalytic cracking are mixed, and the mixture is treated by a series of pretreatment steps of heat recovery, compression, purification, cooling and the like and is separated into gas-phase hydrocarbon and liquid-phase hydrocarbon; the gas-phase hydrocarbon and the liquid-phase hydrocarbon respectively enter different column plates of a depropanizing column to be in (C3-)-(C4+) separation; after being subjected to further compressing and cooling, light components of C3 and below on the top of the depropanizing column enter the depropanizing column, and ethane is used as an absorbent on the top of the depropanizing column to enhance the recovery rate of the ethane; C2-C3 at the bottom of the depropanizing column enter a deethanizing column to separate C2 and C3; the C2 enters an ethylene rectifying column, ethylene is produced through side drawing, noncondensable gas on the top of the ethylene rectifying column returns to a compressor, after totally cooling, the ethane at the bottom of the column is recovered as an absorbent of a demethanizing column or partly as fuel gas; and C3 enters a propylene rectification tower, propylene is recovered on the tower top, and propane is recovered at the tower bottom, as an LPG (Liquid Petroleum Gas) byproduct. The invention has the advantages of high ethylene yield, low energy consumption, little investment and the like, and the byproduct can be effectively utilized.

Owner:EAST CHINA ENG SCI & TECH

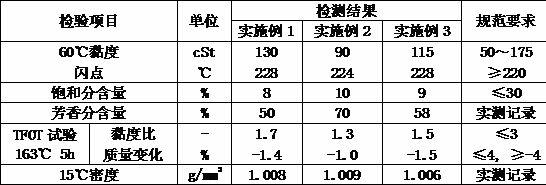

Asphalt recycling agent for hot recycling of asphalt on asphalt road surface

The invention discloses an asphalt recycling agent for hot recycling of asphalt on an asphalt road surface. The recycling agent comprises the following components by weight: 19-70% of an aromatic oil, 20-60% of heavy oil, 5-30% of liquid petroleum resin and 0.2-1% of a stabilizer. The invention also provides a preparation process of the asphalt recycling agent and a method for preparing recycled asphalt by use of the asphalt recycling agent. The recycling agent disclosed by the invention is good in recycling effect, easy for raw materials purchase, stable in quality, low in equipment investment, simple in processing steps, short in processing time of finished products, good in storage stability, stable in physicochemical property, and convenient for on-site operation, and is suitable for on-site hot recycling construction as a special recycling agent.

Owner:YINGDA HEAT REGENERATION

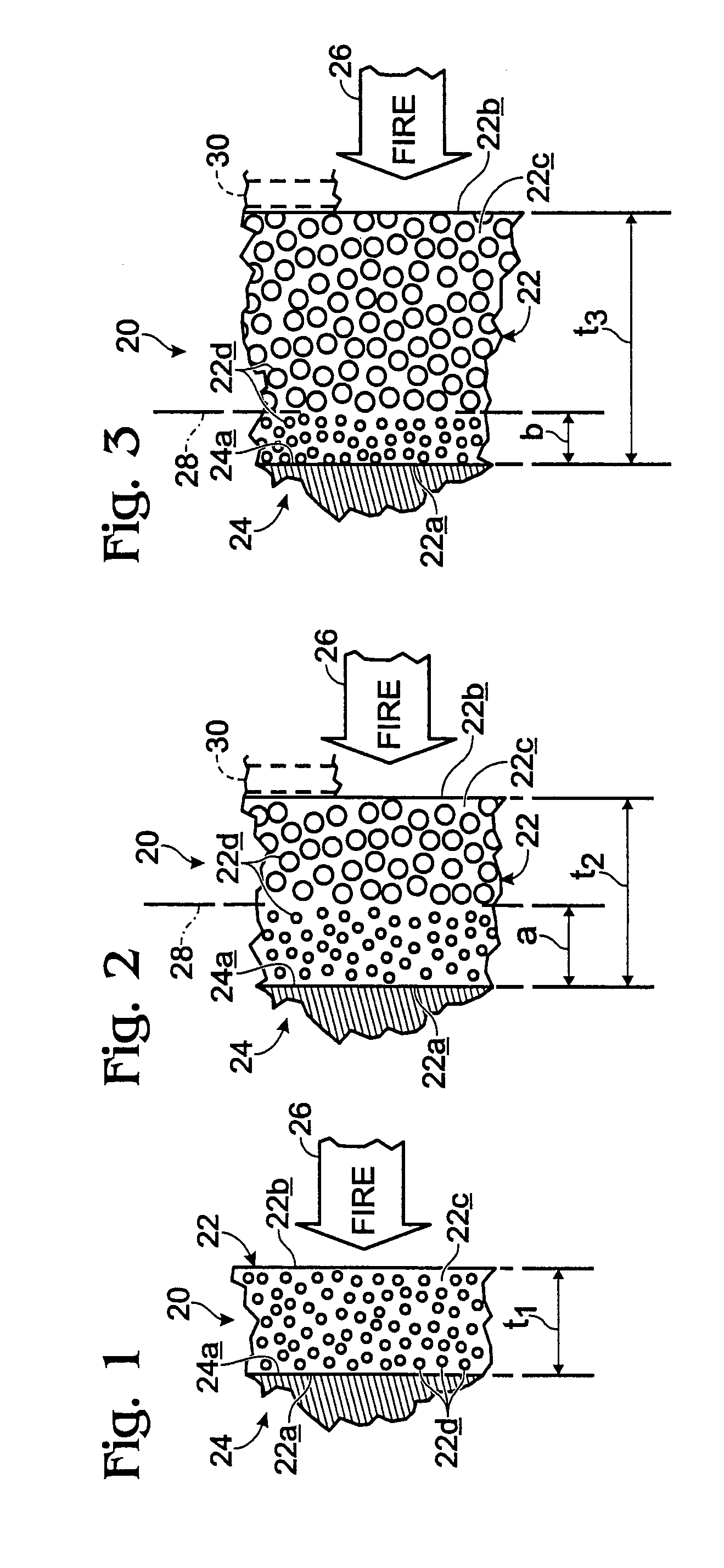

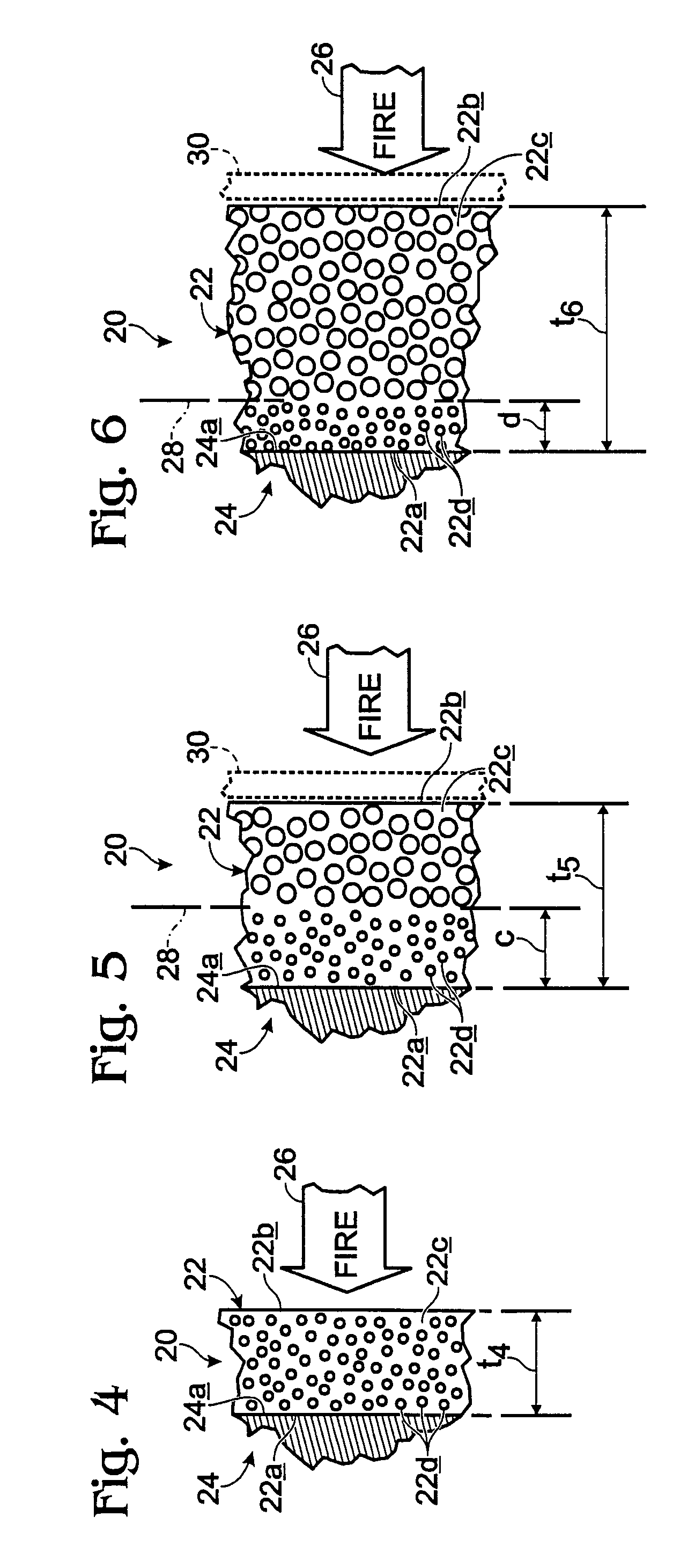

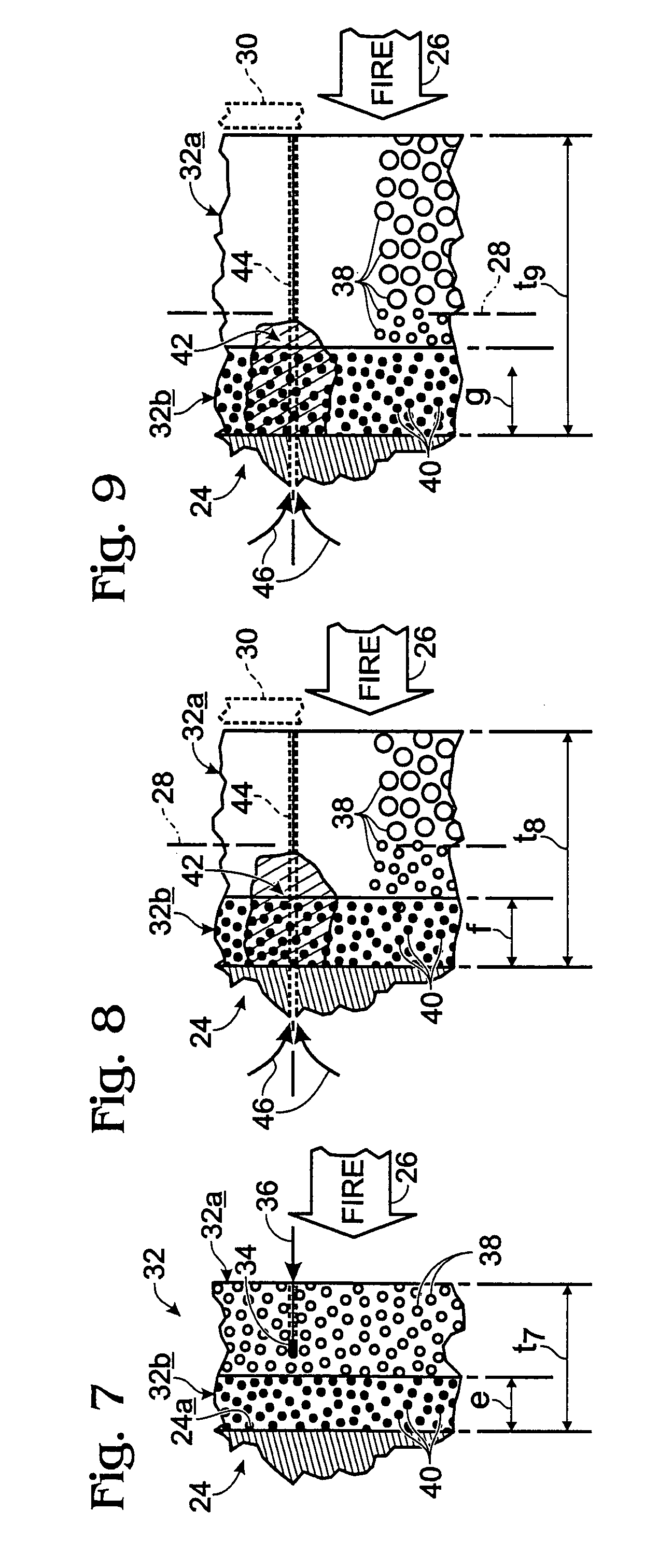

Multi-function surface-coating fire and fuel-leakage inhibition

InactiveUS7678453B2Increasing the thicknessThickness of coating quicklyFire rescueGlass/slag layered productsElastomerStructural engineering

Barrier structure for furnishing, selectively and variously, penetration and fire-threat protection on the outside surface of a target structure. The barrier structure includes a high-elastomeric coating having an inner face bonded to such a surface, an exposed outer face, and, within this coating, at least one elastomeric layer region extending to the outer face, and containing an embedded distribution of intumescence elements. Basic variations of this structure include (a) an additional layer region which is formed with elastomeric-material including an embedded distribution of liquid-imbiber beads, and (b) an additional layer region which is formed purely of elastomeric material. The elastomeric material employed, and the embedded liquid-imbiber beads where included, react to liquid petroleum-based substances (1) to imbibe such liquid, (2) to swell in size as a result of such imbibing, and (3) to coagulate into a sticky mass.

Owner:HIGH IMPACT TECH

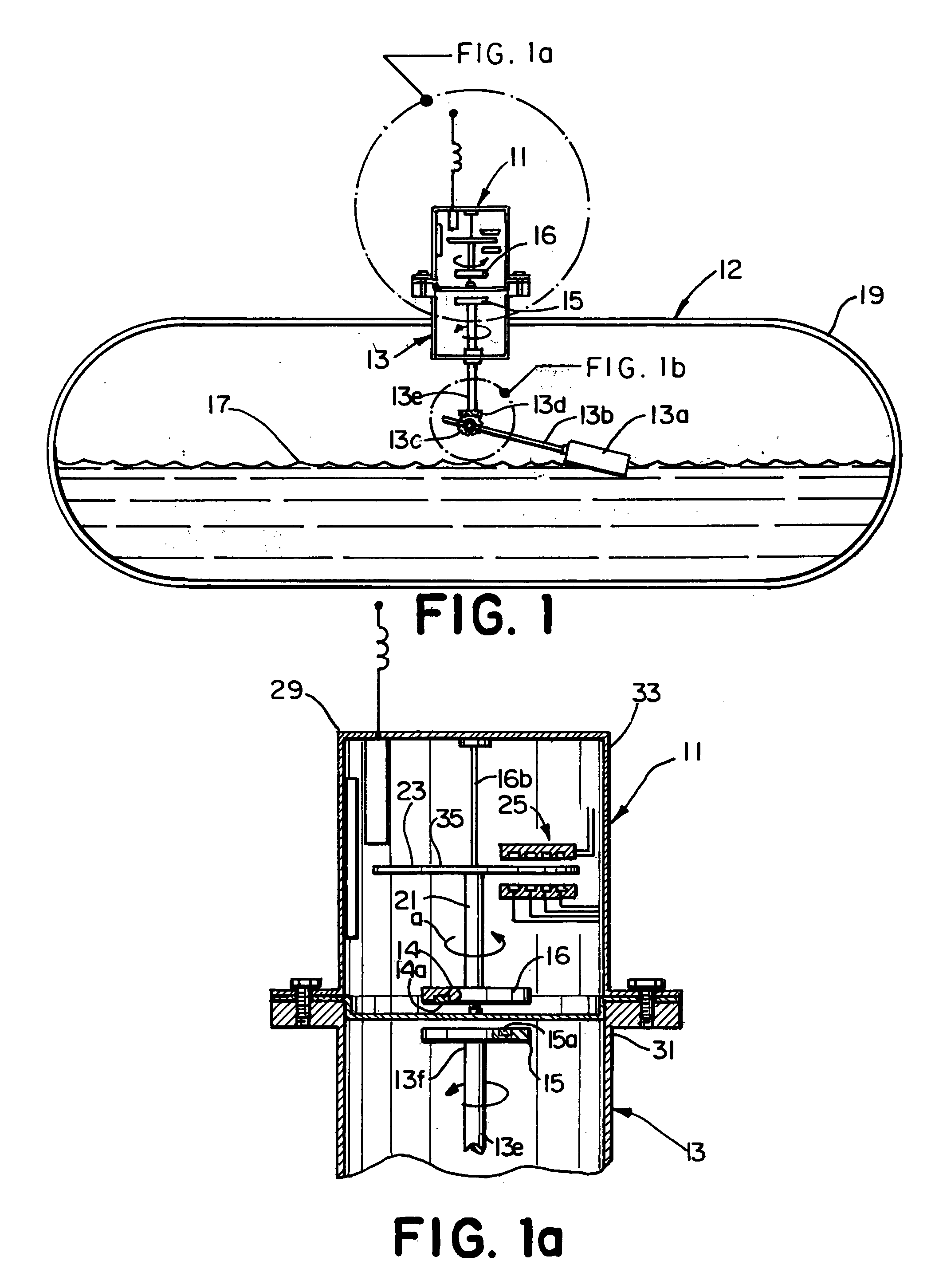

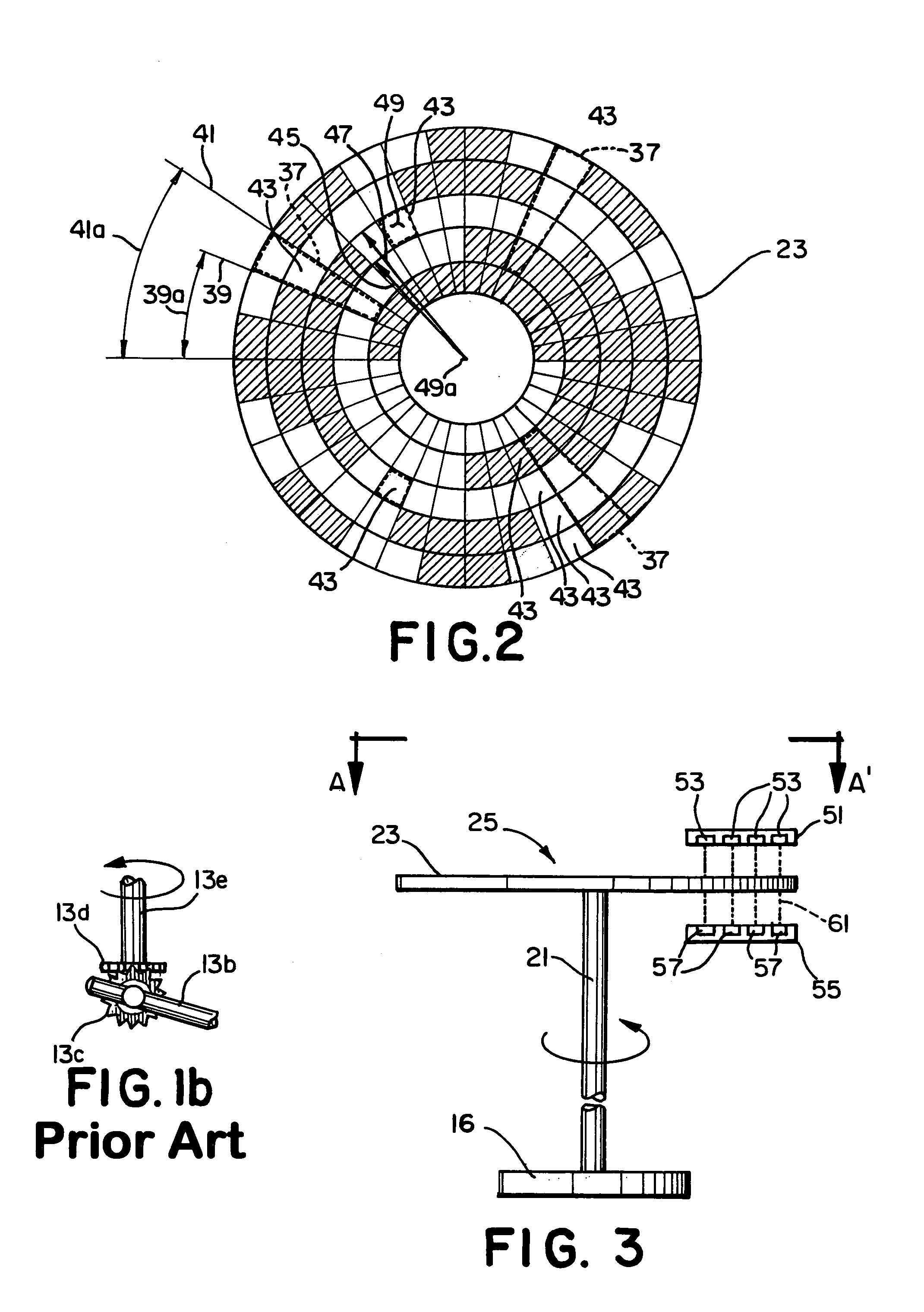

Remote liquid level gauge for remote sensing, system for employing the gauge and method of use

ActiveUS7155349B1Improving logistical inefficiencyImprove logistics efficiencyFlow propertiesFluid pressure measurement by mechanical elementsFuel oilLiquefied petroleum gas

A system, method and apparatus for improving the logistical inefficiencies associated with the delivery of liquid petroleum gas or fuel oil to remotely dispersed locations, including a gauge for detecting the level of fluid or liquid in a tank, and a transmission mechanism for transmitting the level detected by the gauge to a remote location for further evaluation and processing to facilitate delivery of the fuel.

Owner:AMERICAN WIRELESS GAUGE

Highly effective pour depressant for thermodynamic oil extraction process

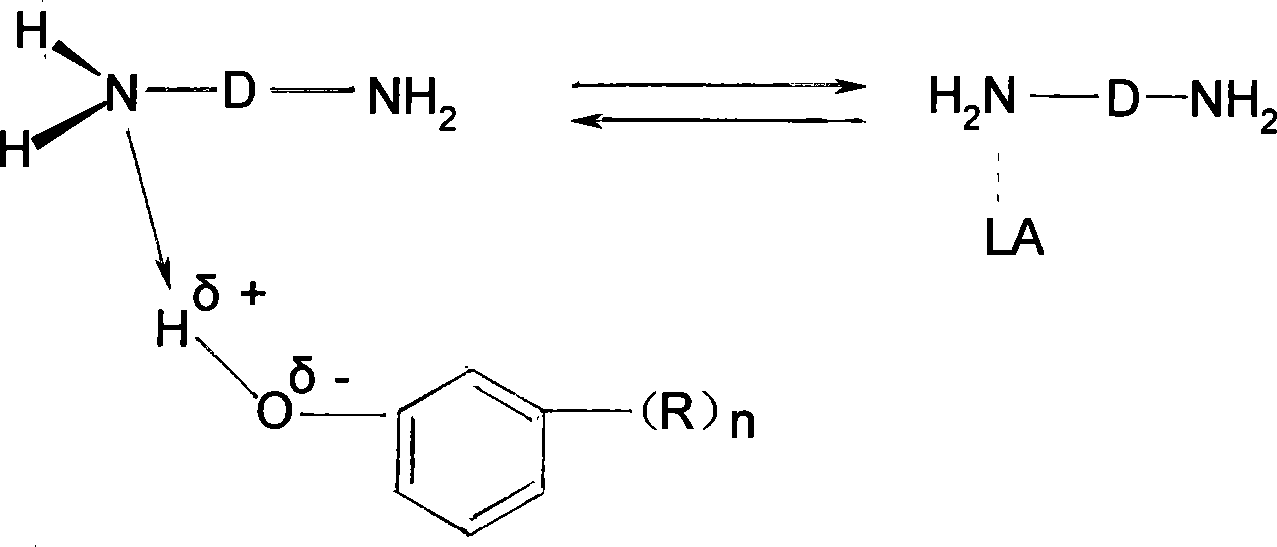

ActiveCN101210173AImprove applicabilityStrong pouring capacityDrilling compositionWater basedDepressant

A high-efficiency pour point depressant for thermal recovery process comprises (1) biphenyl, polycyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbon derivatives free of chlorine and sulfur elements; (2) liquid petroleum products containing arene larger than 5%, petroleum resin in liquid state at normal temperature or natural hydrocarbon aggregates in particle state at normal temperature; (3) surfactant; (4) fusel oil; (5) alcohol ethers having a closed cup flash point larger than 20 DEG C; and (6) oil-soluble or water-soluble polymers respectively having a nonpolar section eutectic with paraffin molecule and a polar section for twisting crystal form of wax crystal on a main chain and / or a branch chain. The high-efficiency pour point depressant of the invention performs all functions of both water-base pour point depressant and oil-base pour point depressant, and can efficiently assist the prior various thermal recovery processes in exploring high pour-point oil and heavy oil reservoirs, with the advantages of greatly reduced exploitation cost, prolonged production cycle of the oil well, increased output of the oil well, increased ultimate recovery of the oil reservoir,as well as significant economic benefit.

Owner:盘锦河升大地石油科技有限公司

Highly effective viscosity-reducing agent for thermodynamic oil extraction process

ActiveCN101235279ASolve the problem of emulsification blockageImprove timelinessDrilling compositionSolubilityPetroleum product

High efficiency viscosity-reducing agent which is used on THE thermal oil extraction technology, which is formed by the following raw materials with percentage by weight, firstly phenyl benzene, fused ring aromatic hydrocarbon or fused ring aromatic hydrocarbon derivative which does not contain chlorine element and sulfur element, secondly liquid petroleum product whose aromatic hydrocarbons content is no more than 5%, petroleum resin which is liquid state under the constant temperature or hydrocarbons natural aggregation which is particle state under the constant temperature, thirdly water-soluble anionic surface active agent, water-soluble non-ionic surface active agent, oil solubility anionic surface active agent or oil solubility non-ionic surface active agent, fourthly fusel oil, fifthly alcohol ether, sixthly oil solubility or water-soluble polymer which respectively has nonpolar portion which has eutectic crystal with ceresin wax molecular and polar portion which can make wax crystal system twisty on main chain and or branch chain, seventhly hyperoxide, eighthly carbamide, ammonium carbonate, ammonium acid carbonate or ammonium nitrite and ninthly ketone. The high efficiency viscosity-reducing agent has strong suitability, strong viscosity-reducing ability, safety and reliability, can largely reduce extract cost and increase the yield of oil pump, and increases the final recovery efficiency of oil reservoir.

Owner:盘锦河升大地石油科技有限公司

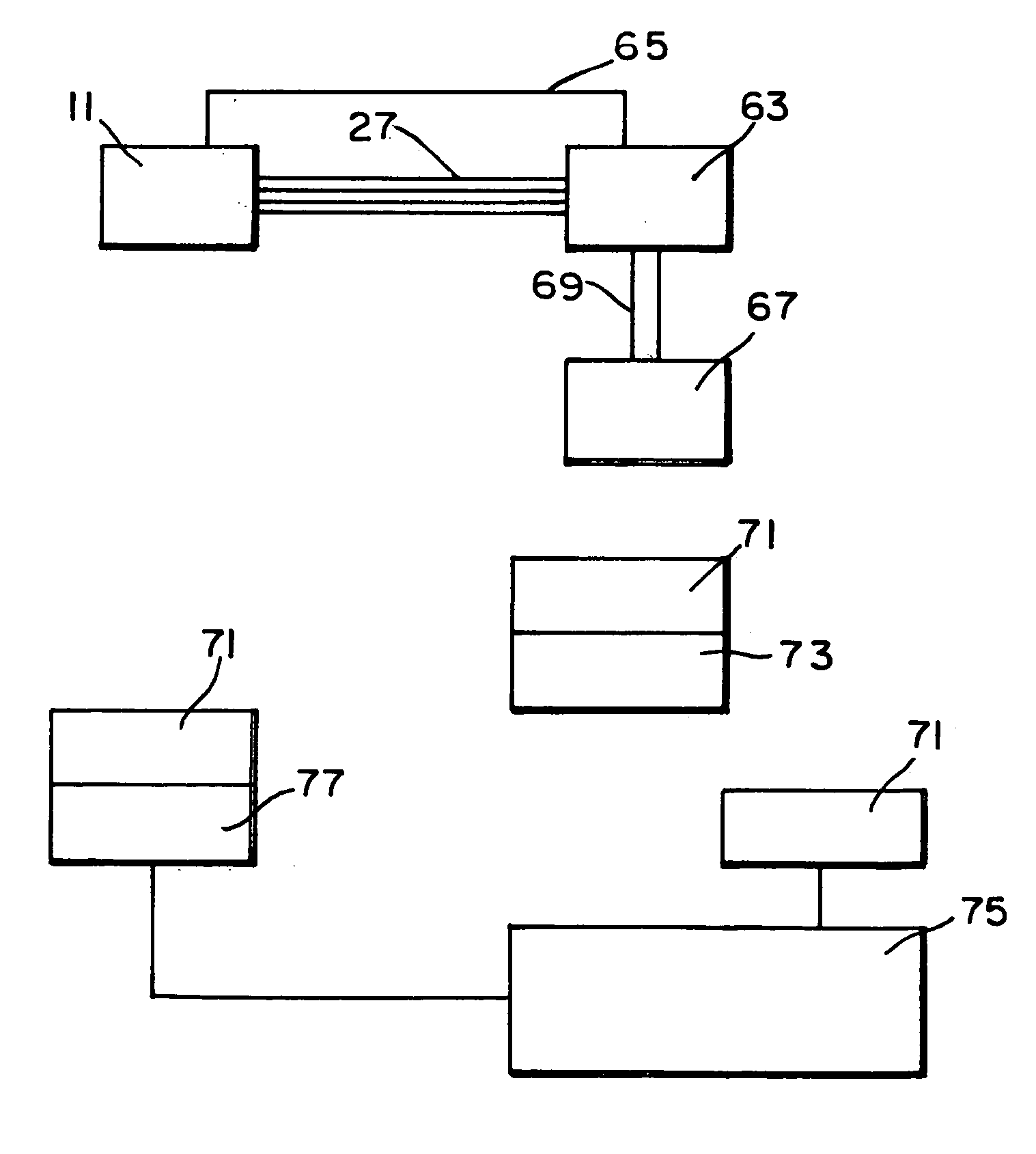

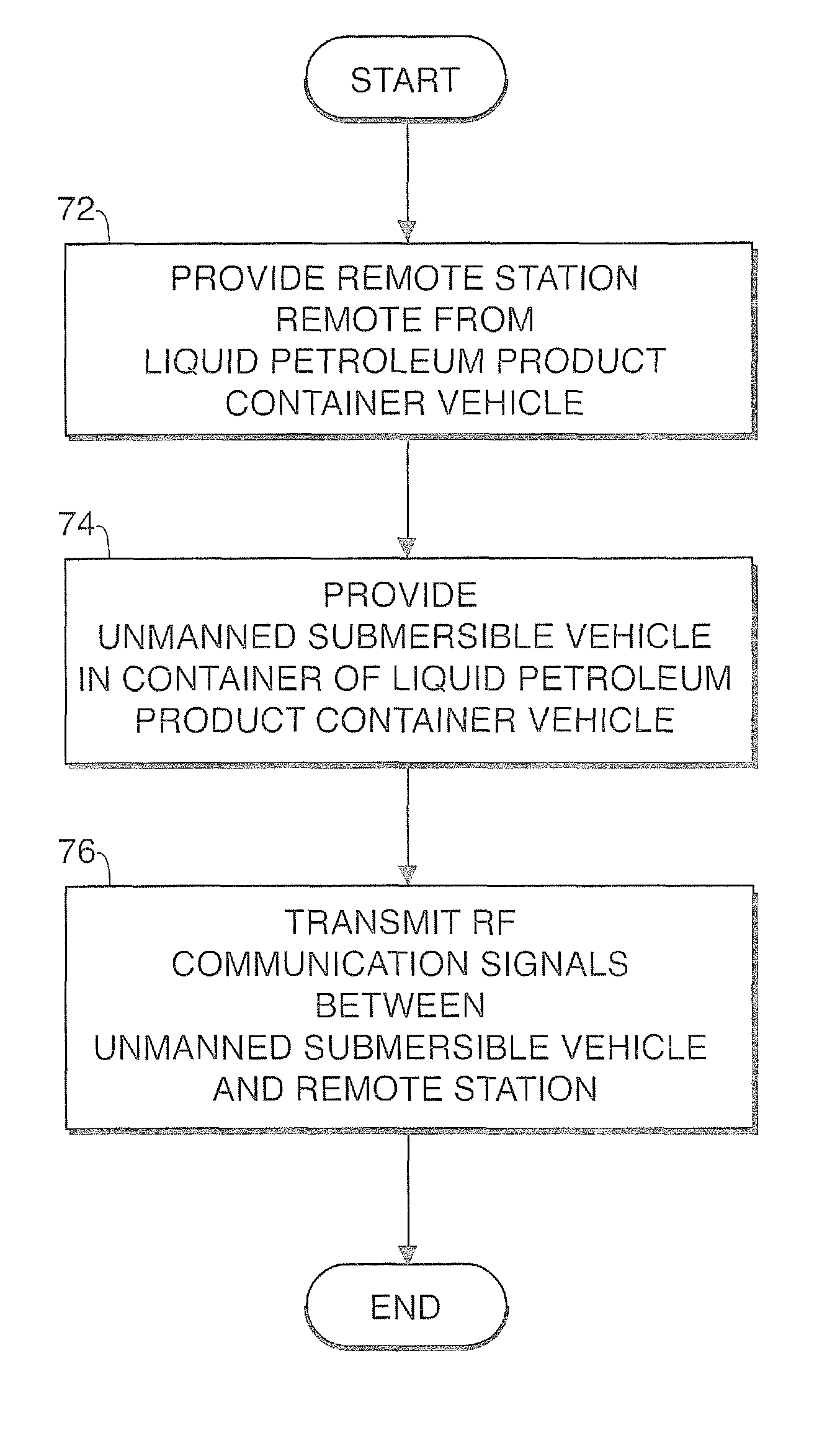

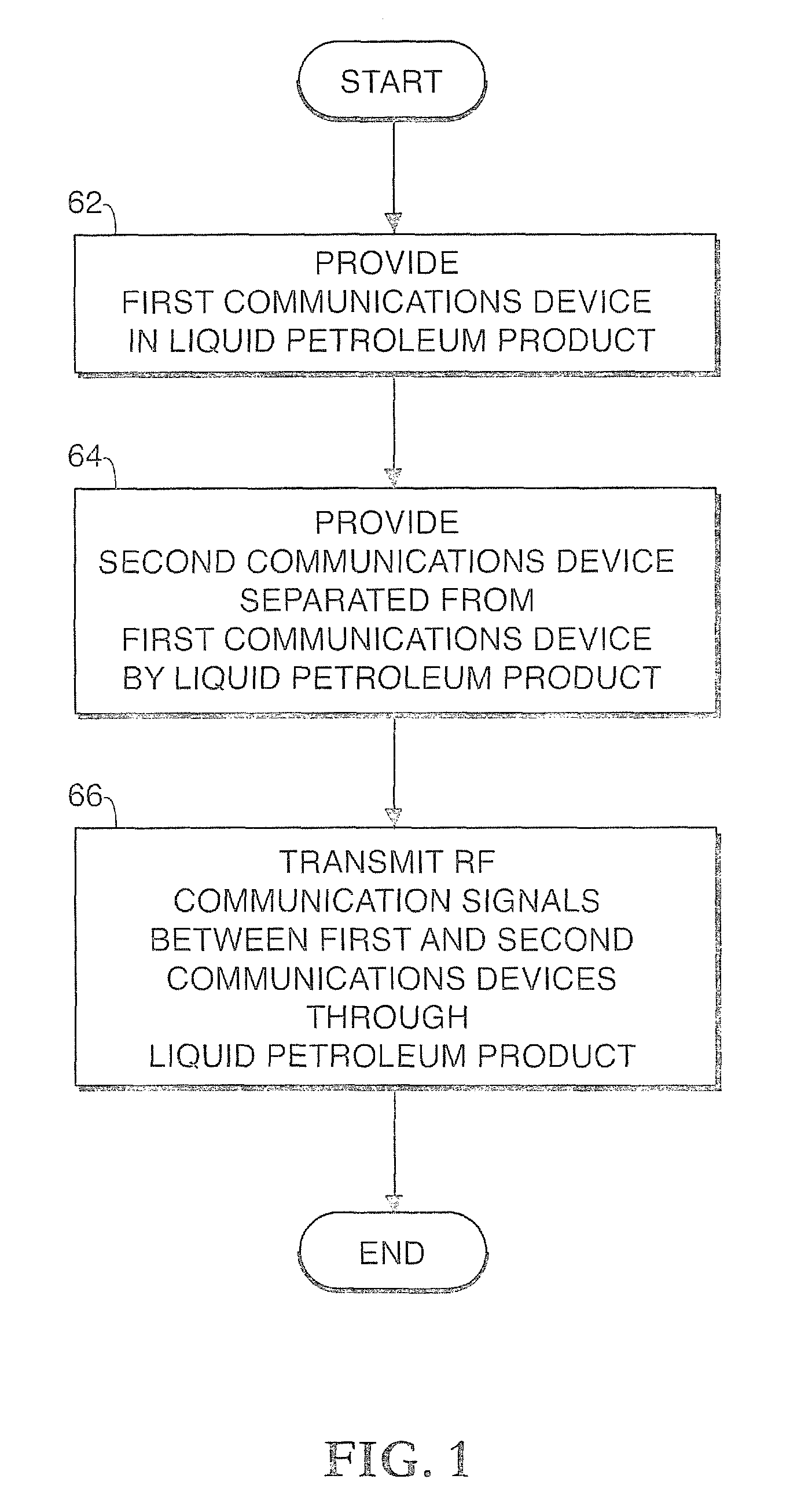

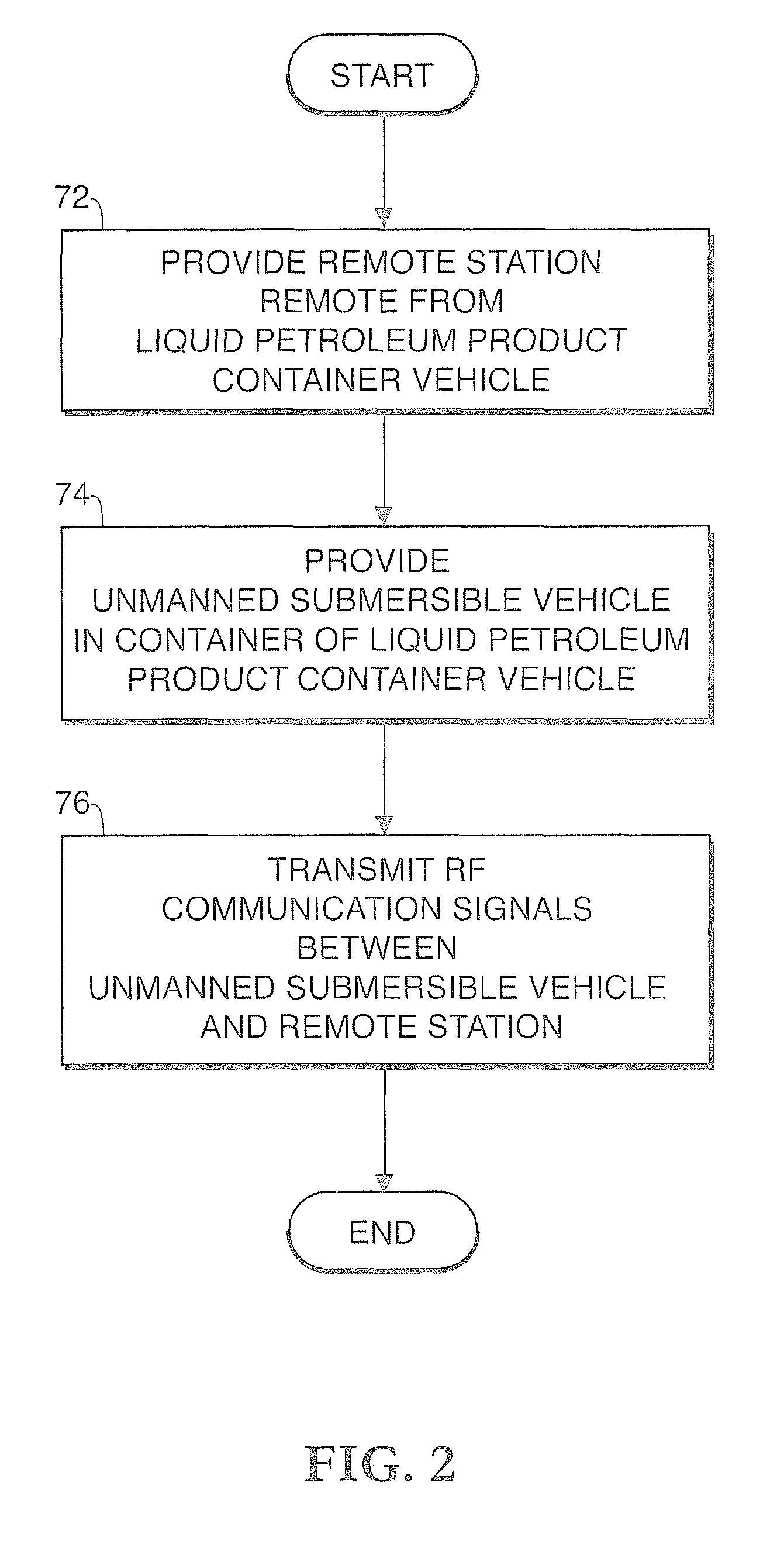

Systems and methods for inspection and communication in liquid petroleum product

A method for communicating in liquid petroleum product includes providing a first communications device disposed in the liquid petroleum product, providing a second communications device remote from and separated from the first communications device by the liquid petroleum product, and transmitting radiofrequency (RF) communication signals embodying data between the first communications device and the second communications device through the liquid petroleum product to enable wireless communications between the first communications device and the second communications device.

Owner:IROBOT CORP

Method of reducing smoke and particulate emissions from compression-ignited reciprocating engines operating on liquid petroleum fuels

InactiveUS6866010B2Reducing smoke and particulate emissionEmission reductionNon-fuel substance addition to fuelCombustion enginesExhaust fumesLiquid Petroleum

A method of reducing smoke and particulate emissions from an exhaust gas from a compression-ignited reciprocating engine by adding a fuel additive that contains an oil-soluble iron compound and an over-based magnesium compound to liquid petroleum fuel.

Owner:SFA INT INC

Shipping ballast cabin coating composition

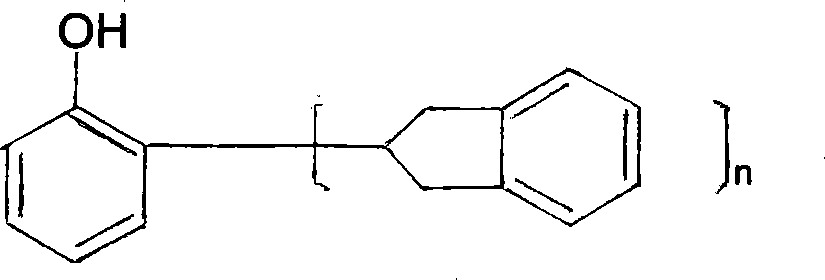

ActiveCN101134867AImprove water resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyAdhesion force

The present invention is one kind of paint composition for ship ballast tank and belongs to the field of paint chemical technology. The paint composition with special liquid petroleum resin modified epoxy resin has excellent performance, including high water tolerance, high corrosion resistance, excellent flexibility, great adhesion force and high leaching resistance. It consists of special liquid petroleum resin 5-30 %, epoxy resin-1 10-40 %, epoxy resin-2 10-40 %, titanium white powder 18-30 %, talcum powder 10-40 %, antisagging agent 0.5-1.5 %, anti-setting agent 0.5-2 %, xylene 2-10 %, and curing agent 15-39 %, where, the special liquid petroleum resin is liquid petroleum resin with hydroxyl group content as high as 1.0-10.0.

Owner:中山大桥化工集团有限公司

Stratified two-stroke engine and dual passage fuel system

InactiveUS20120247435A1Emission reductionSimple designInternal combustion piston enginesLighting and heating apparatusHydrogenFour-stroke engine

Owner:MAVINAHALLY NAH S

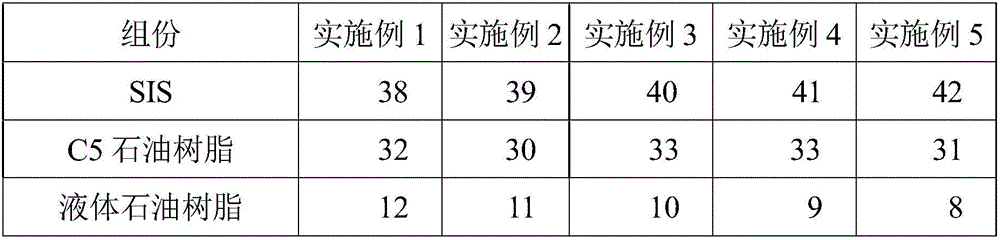

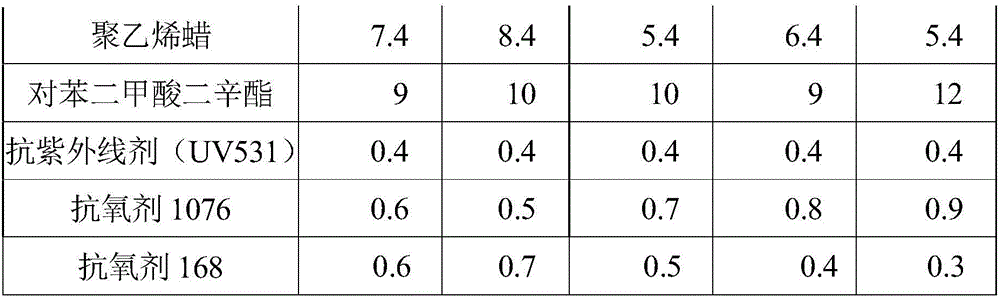

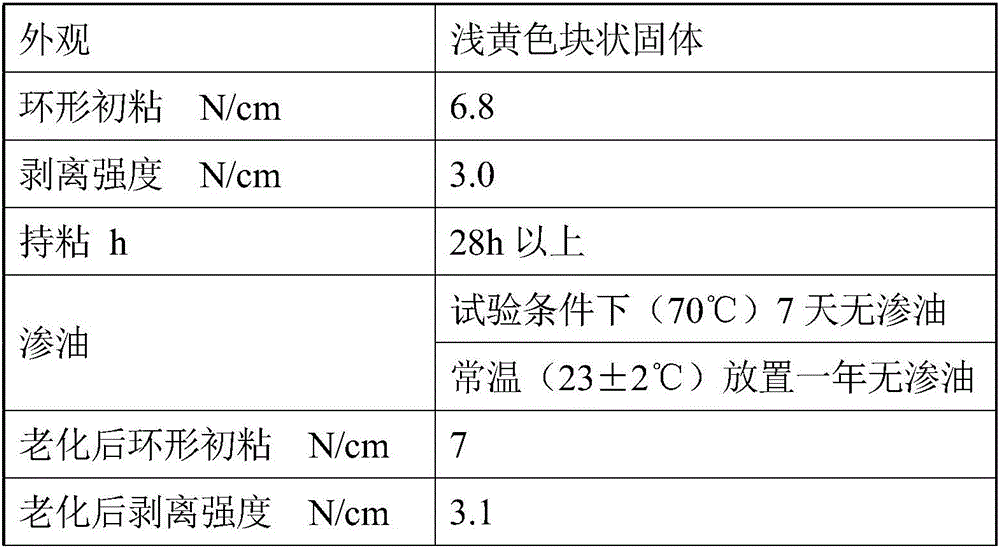

Removable hot-melt pressure-sensitive adhesive and preparation method

ActiveCN106318292AExcellent adhesionImprove retentionNon-macromolecular adhesive additivesFilm/foil adhesivesEnvironmental resistanceUltraviolet

The invention relates to a removable hot-melt pressure-sensitive adhesive and belongs to the technical field of adhesives. The pressure-sensitive adhesive is prepared from raw materials in parts by mass as follows: 35-45 parts of matrix resin, namely, a styrene-isoprene-styrene triblock copolymer, 30-40 parts of a tackifier, namely, C5 petroleum resin, 8-13 parts of a softener, namely, dioctyl terephthalate, 3-8 parts of a peel strength modifier, namely, polyethylene wax, 7-15 parts of a viscosity modifier, namely, liquid petroleum resin, 0.6-1.4 parts of an antioxidant and 0.4 parts of an ultraviolet absorbent. An adhesive tape prepared from the pressure-sensitive adhesive can be peeled and pasted repeatedly, and the adhesive cannot be transferred after the pressure-sensitive adhesive is pasted with paper, PE films, PP films and the like. The pressure-sensitive adhesive meets the environmental protection requirement of European Union REACH and RoHS on the basis of detection of specialized agencies and can completely meet the requirement of production of sealing labels, labels and removable adhesive bags.

Owner:河北方大新材料股份有限公司

Method of reducing smoke and particulate emissions from spark-ignited reciprocating engines operating on liquid petroleum fuels

InactiveUS6881235B2Reducing smoke and particulate emissionEmission reductionLiquid carbonaceous fuelsFuel additivesExhaust fumesLiquid Petroleum

A method of reducing smoke and particulate emissions from an exhaust gas from a spark-ignited reciprocating engine by adding a fuel additive which contains an oil-soluble iron compound and an over-based magnesium compound to liquid petroleum fuel.

Owner:SFA INT INC

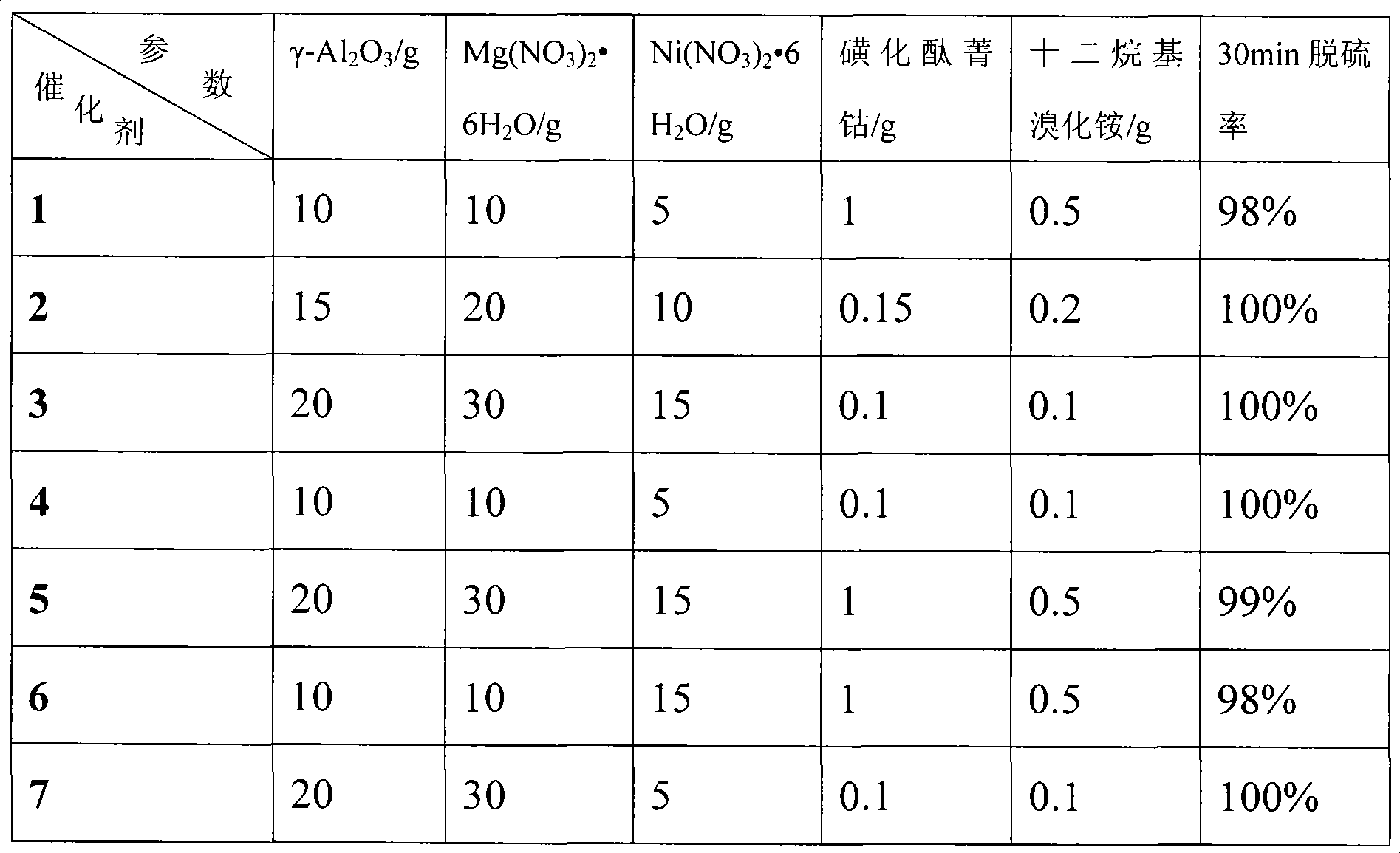

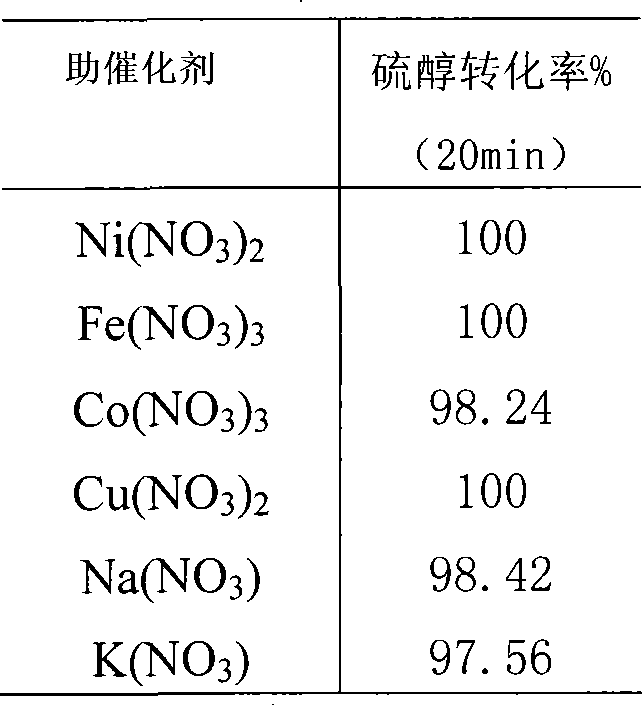

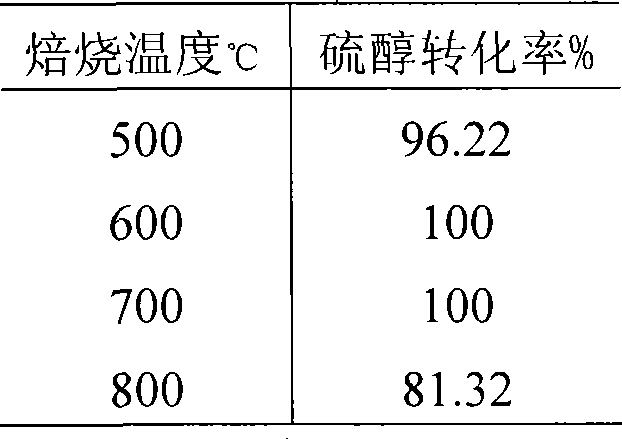

Solid catalyst for petroleum liquid component sweetening and preparation method

InactiveCN101474574AIncrease alkalinityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils refiningKeroseneAlkali metal oxide

Disclosed is a solid catalyst used for removal of mercaptans of petroleum liquid ingredients. The catalyst uses gamma-Al2O3 as a carrier, first loads a metal nitrate on the carrier by immersion method and then bakes the metal nitrate to realize loading of alkali metal oxide on the carrier gamma-Al2O3 so as to produce the alkali catalyst carrier, and then uses the mixed solution of sulfonated cobalt phthalocyanine and ethanol water added with quaternary ammonium salt or organic base as impregnating solution to impregnate the carrier to obtain the target catalyst after drying. The catalyst is mainly suitable for removal of mercaptans of liquefied petroleum gas, gasoline, kerosene, naphtha, aviation fuel, liquid propylene and other liquefied petroleum ingredients. Experiments prove that the thiol conversion rate can stand at 100% in 20min and the life of the catalyst exceeds 300h.

Owner:CHANGCHUN UNIV OF TECH

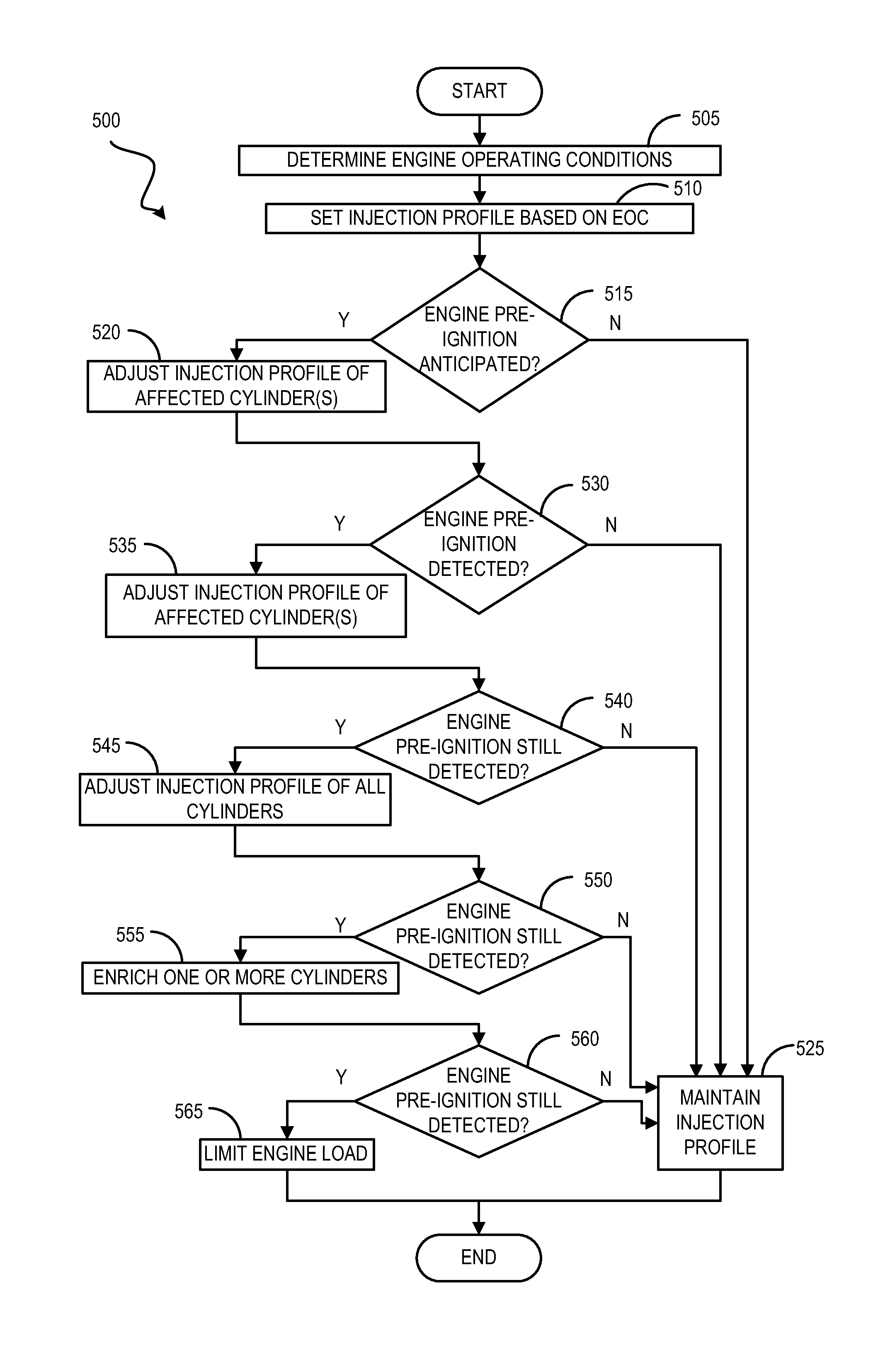

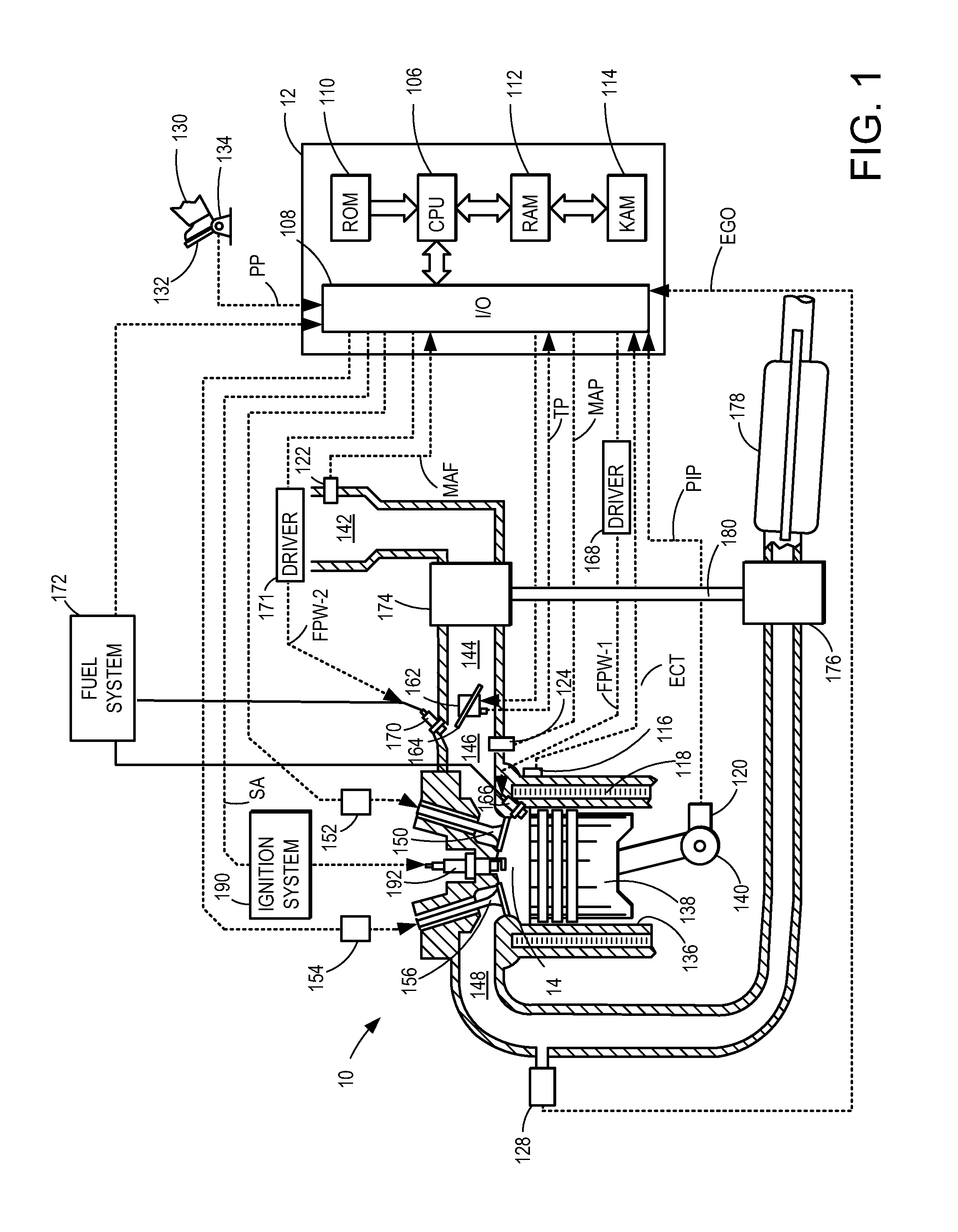

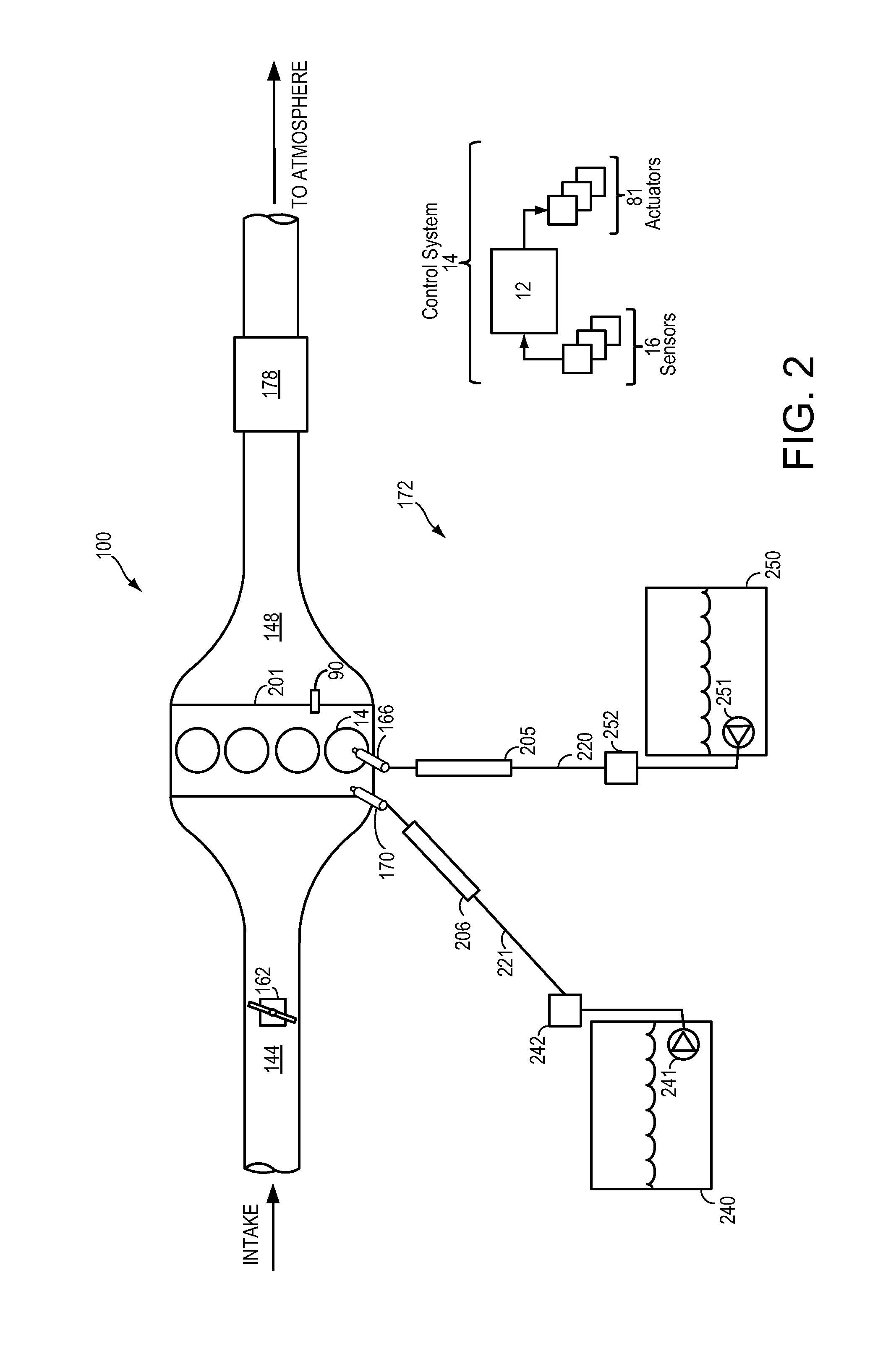

Engine control for a liquid petroleum gas fueled engine

InactiveUS20150059686A1Reduce burning rateReduced fuel economyElectrical controlInternal combustion piston enginesCombustionEngineering

A method for an engine, comprising: during a first condition comprising a high engine temperature, injecting a first quantity of liquid petroleum gas into a first engine cylinder at a first timing during an intake stroke; and injecting a second quantity of liquid petroleum gas into the first engine cylinder at a second timing during a compression stroke following the intake stroke. In this way, combustion knock and cylinder pre-ignition may be mitigated without retarding spark ignition and / or limiting engine load, thereby allowing for maximum engine performance.

Owner:FORD GLOBAL TECH LLC

Liquid hydrocarbon fuel from methane assisted by spontaneously generated voltage

A methane-containing gas such as natural gas is converted to a clean-burning hydrocarbon liquid fuel in a process wherein the gas is fed to a reaction vessel to contact a metallic catalyst grid that is formed from windings of a transition metal supported on an iron frame immersed in a liquid petroleum fraction, in such a manner that a voltage is generated in the grid between the windings and the frame. Product gas in the vapor phase is drawn from the head space above the liquid level and condensed to form the product fuel.

Owner:GUNNERMAN RUDOLF W +1

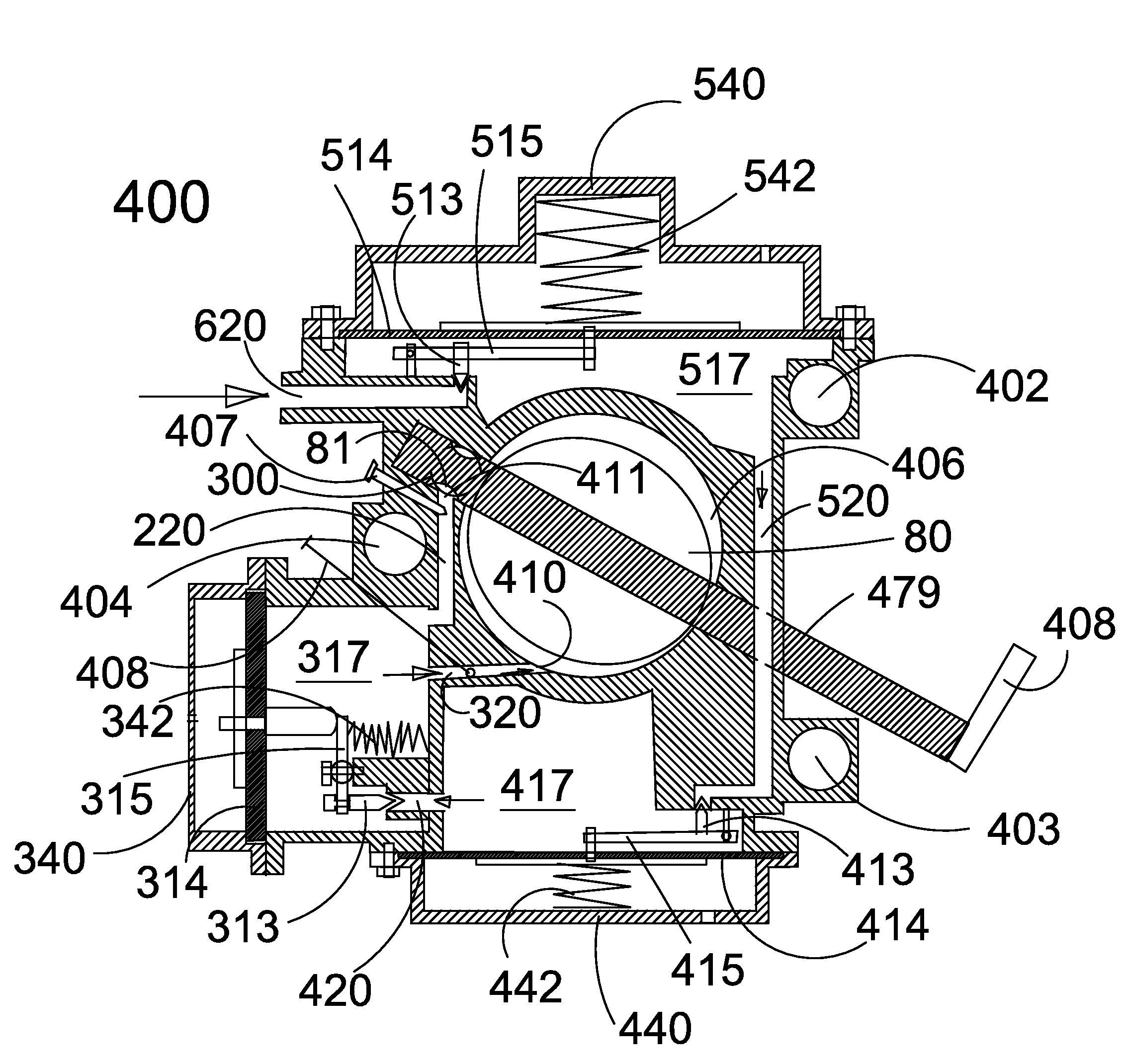

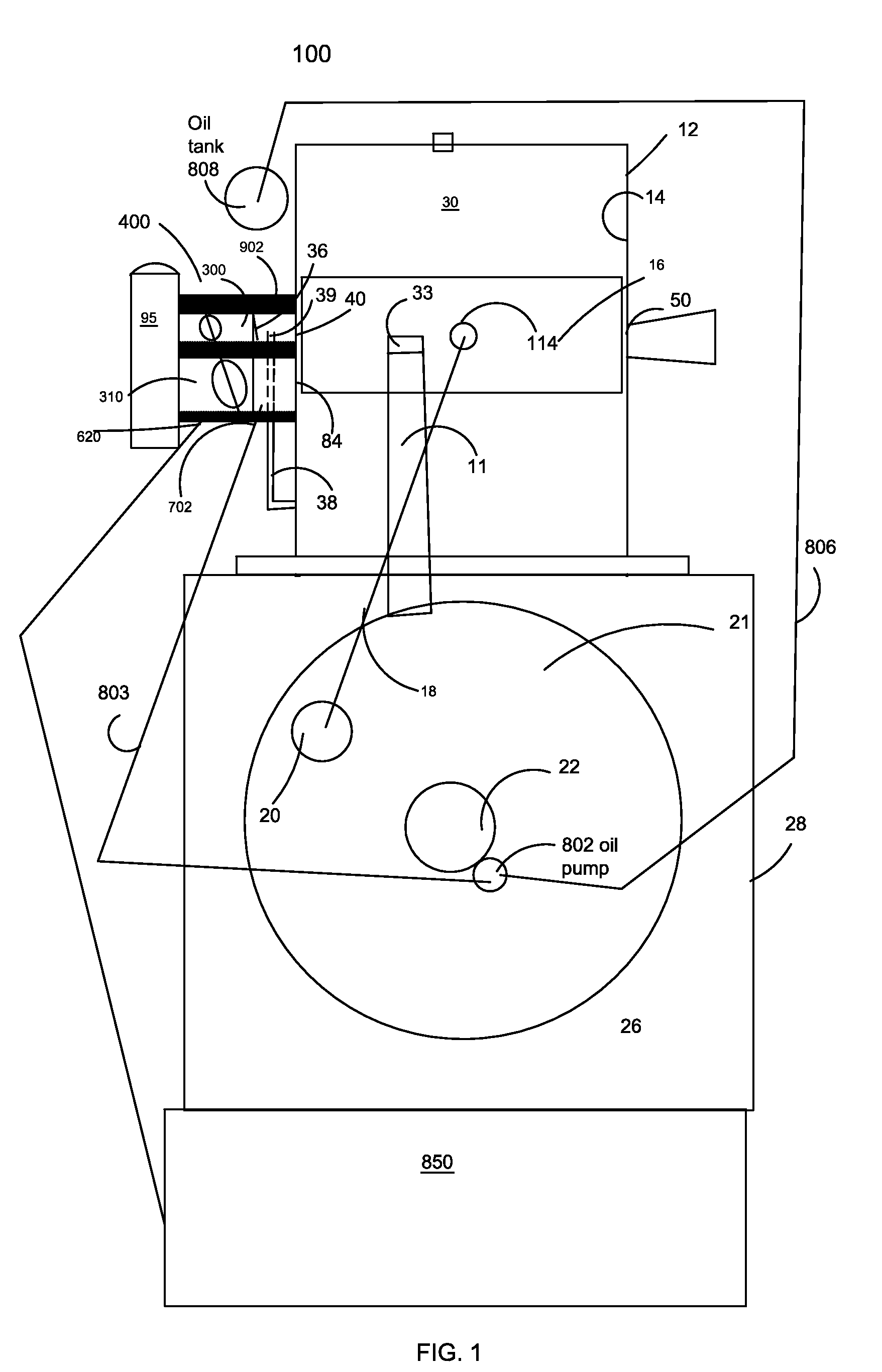

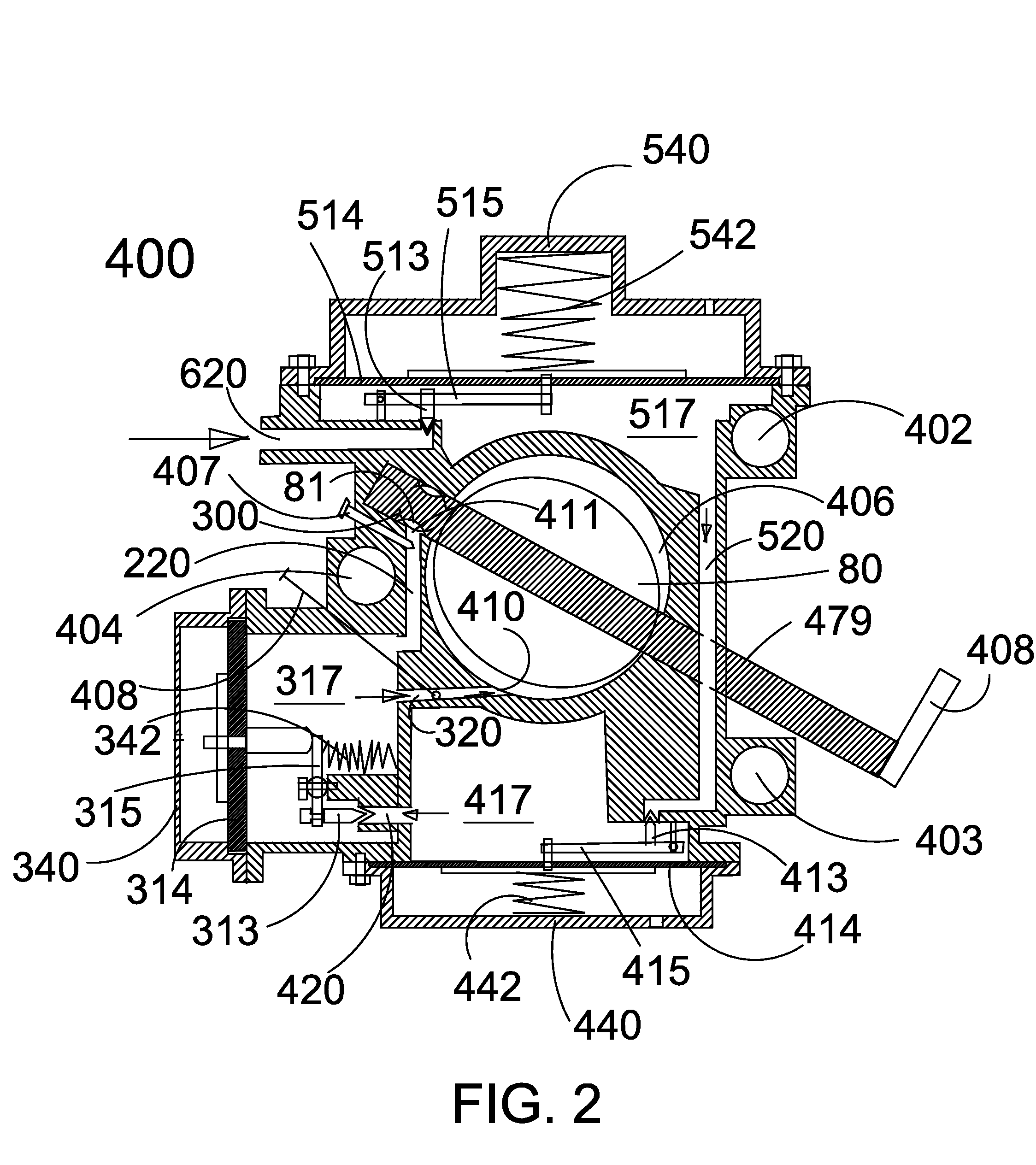

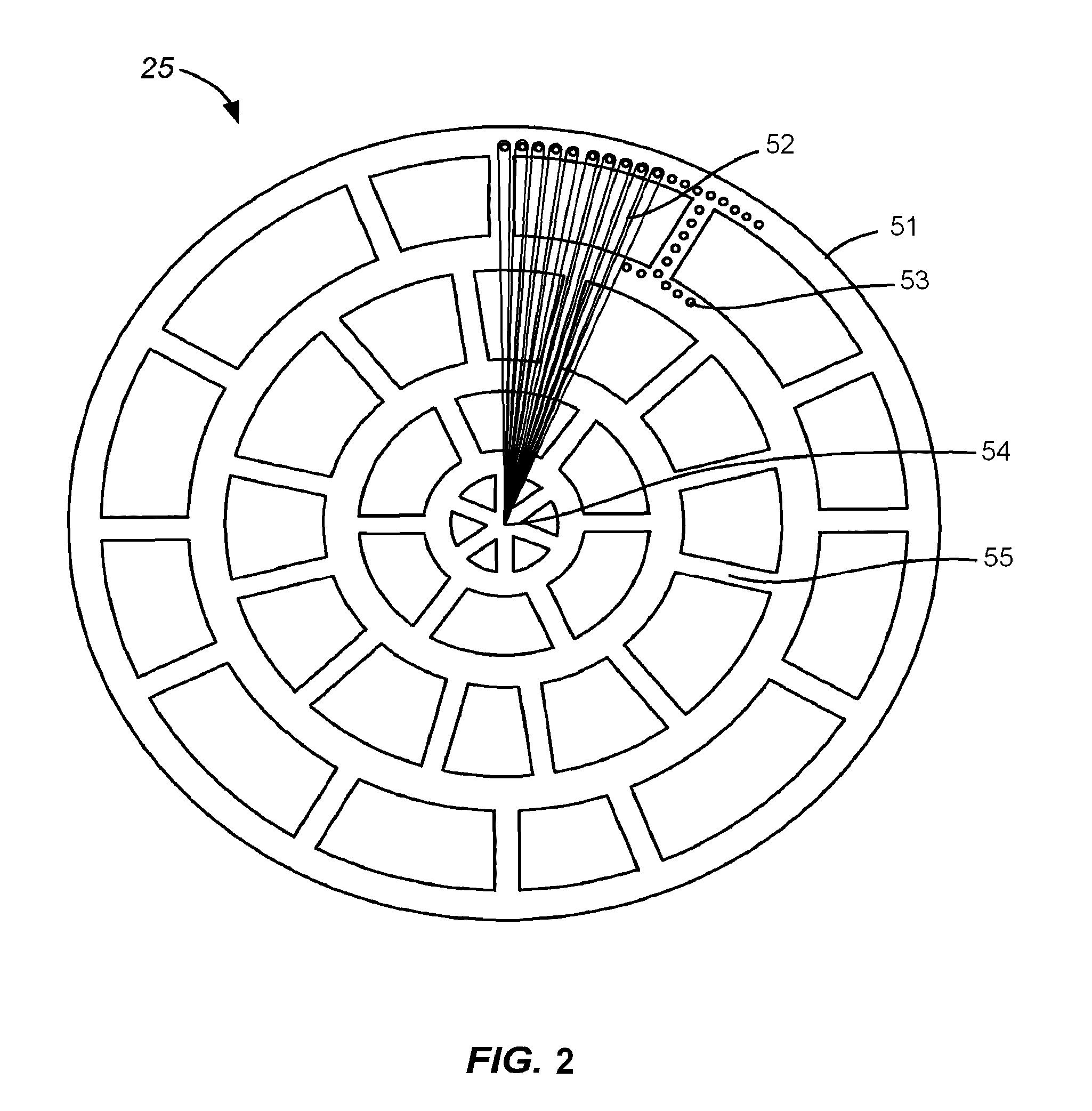

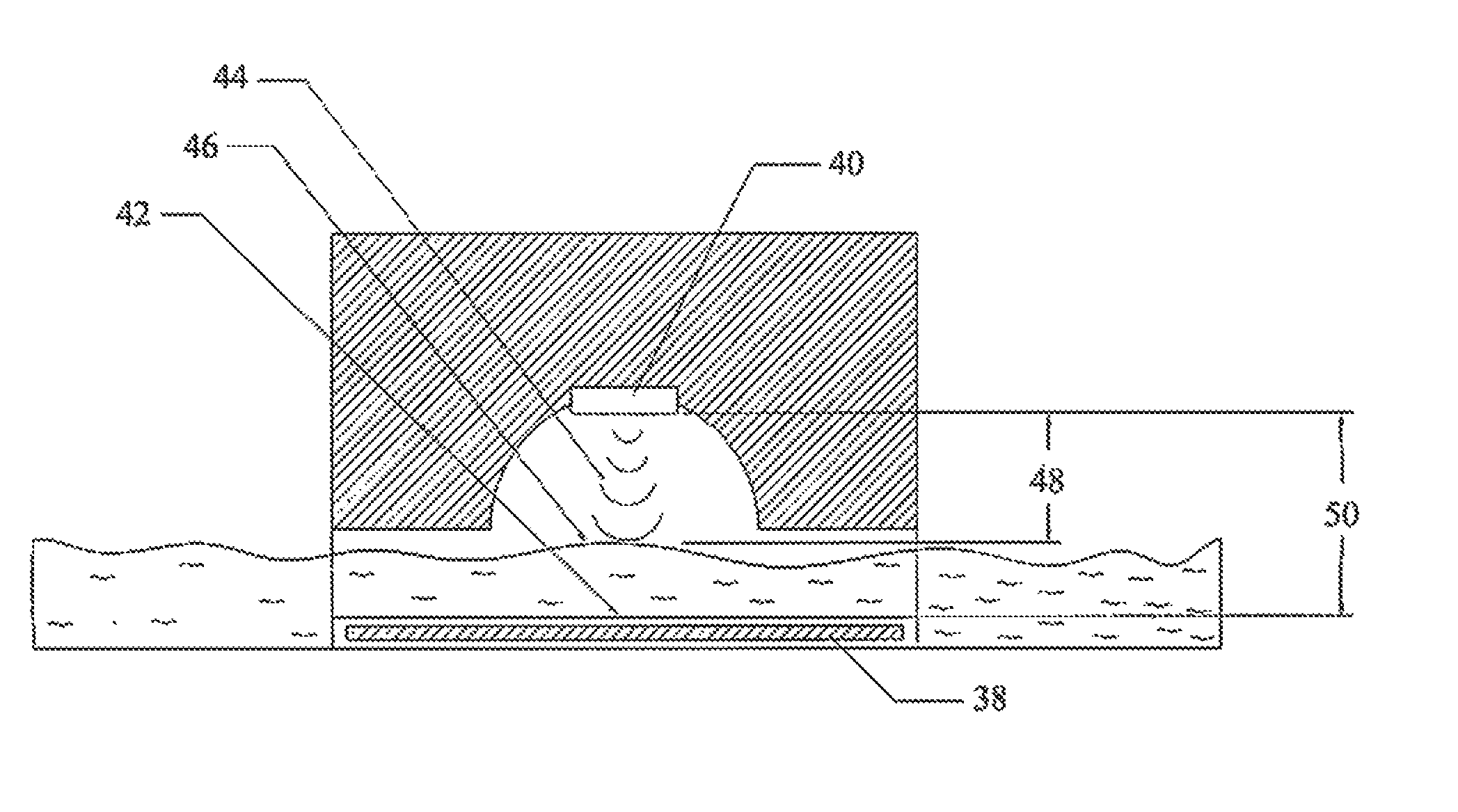

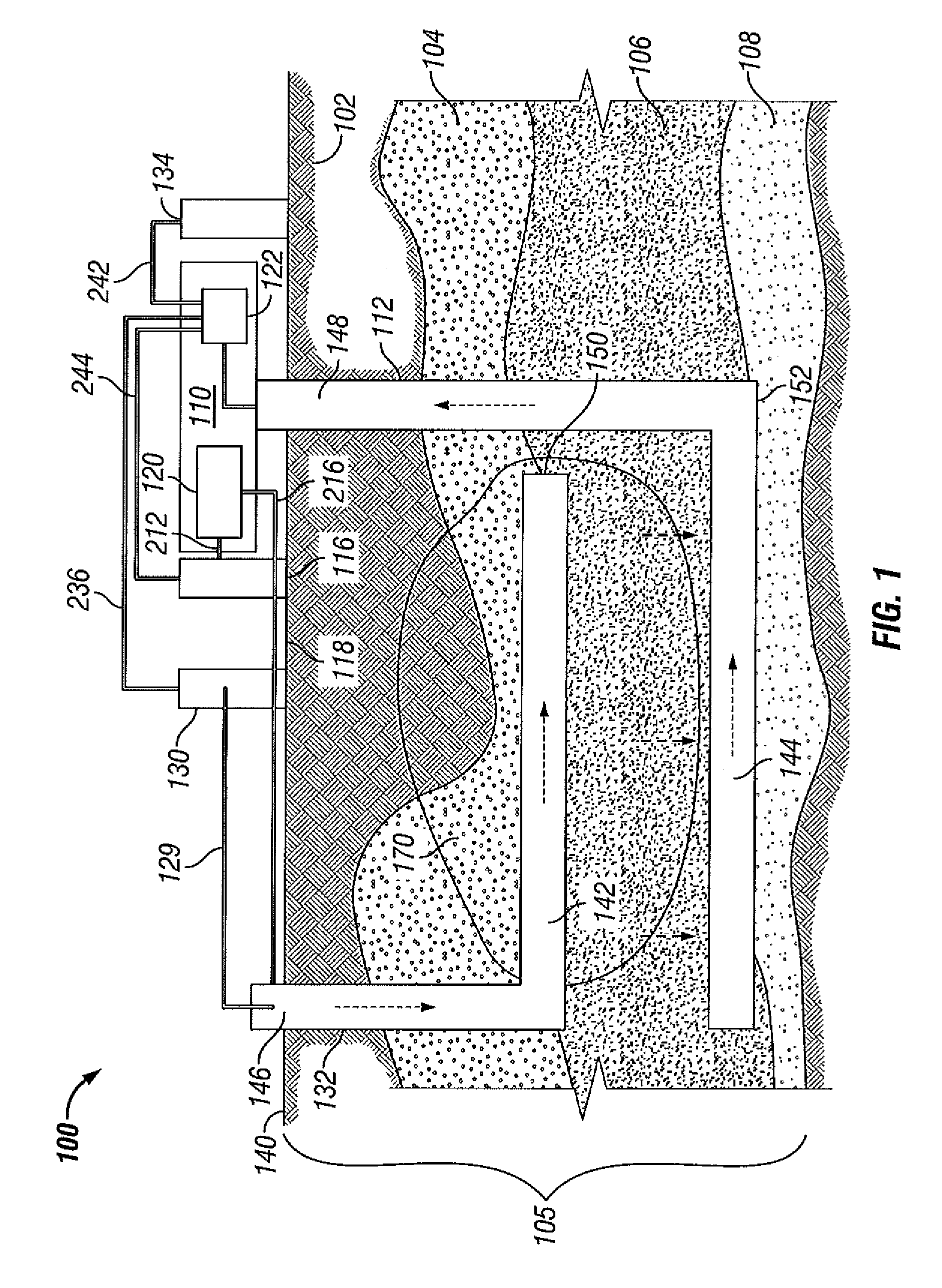

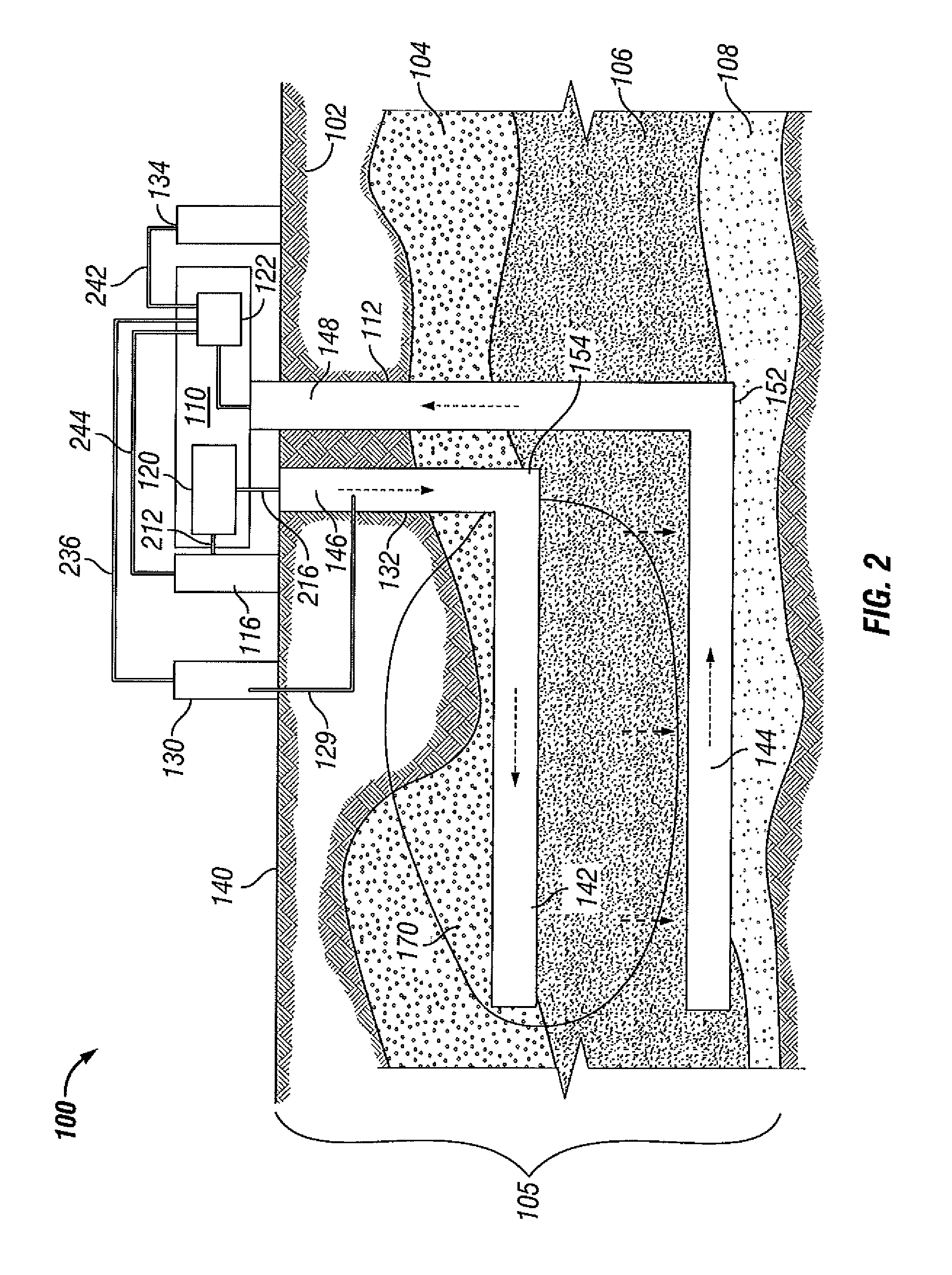

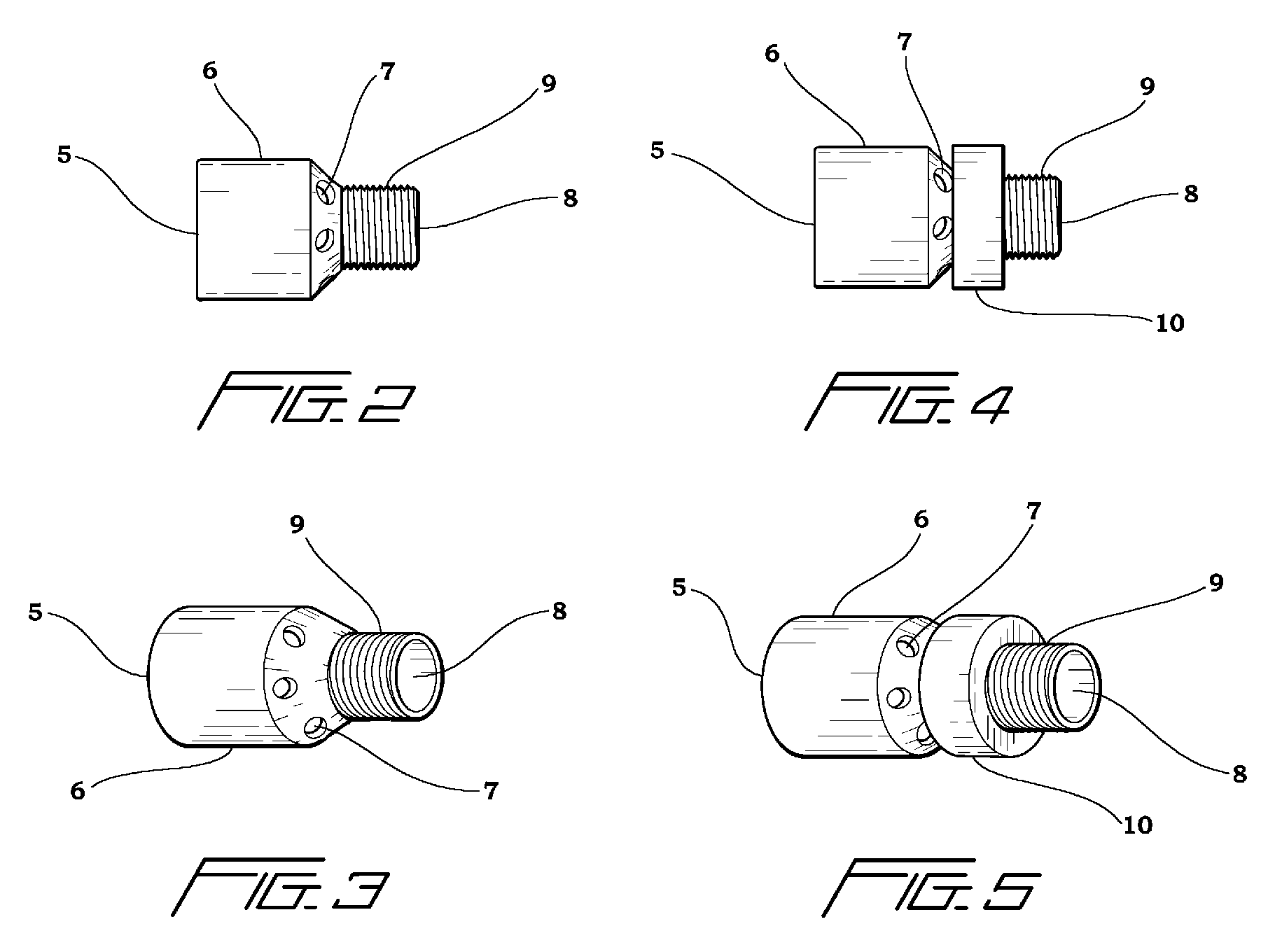

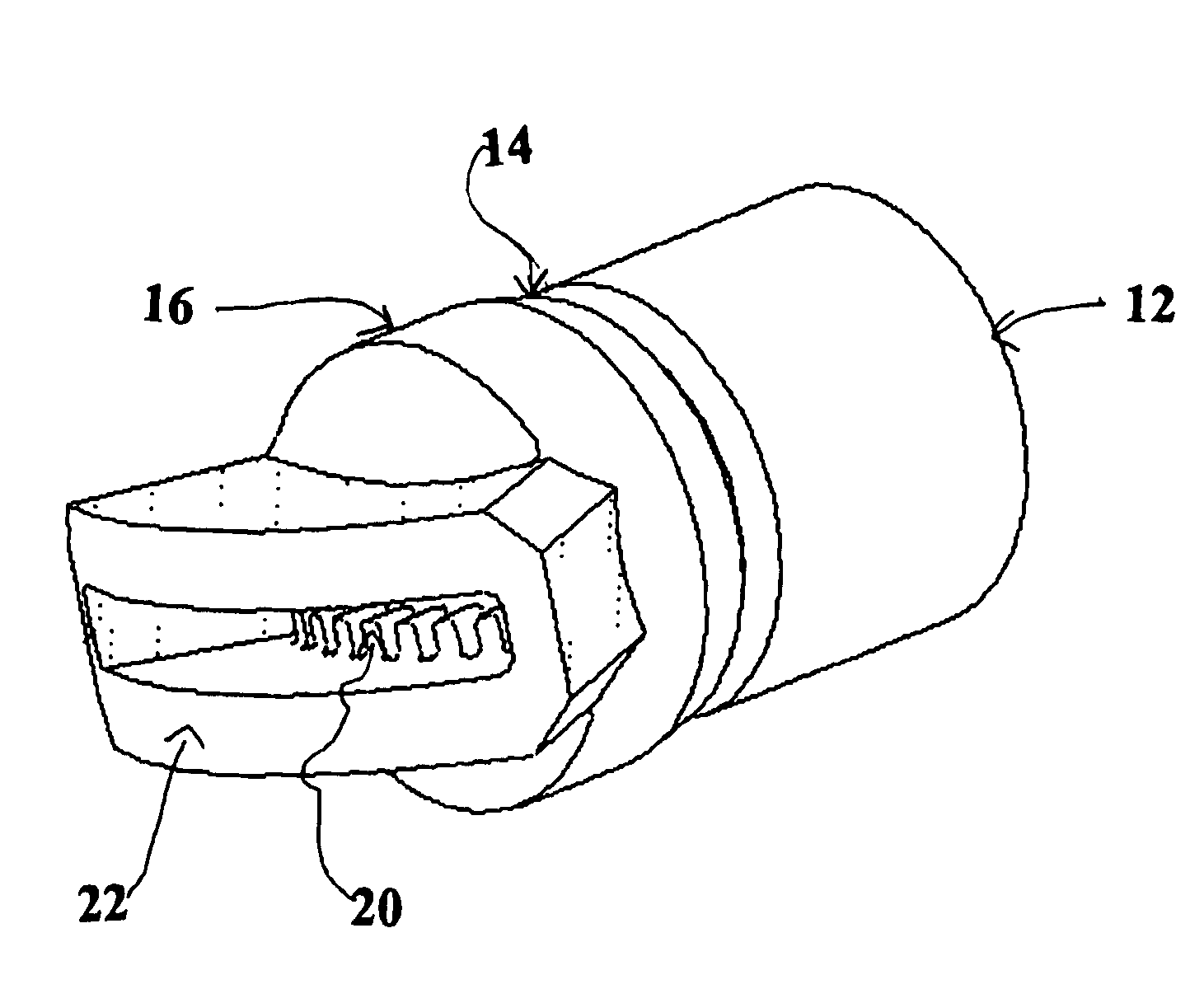

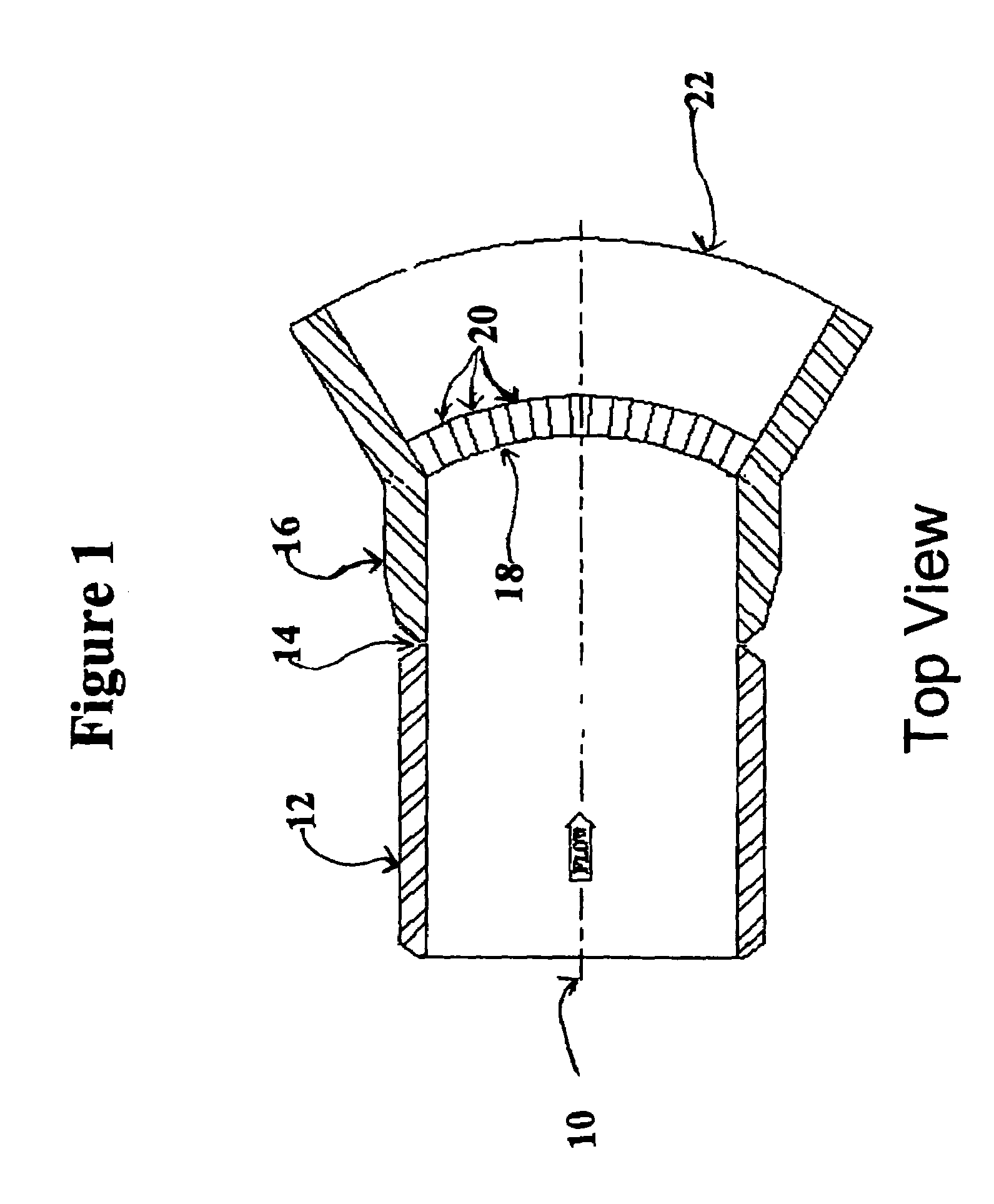

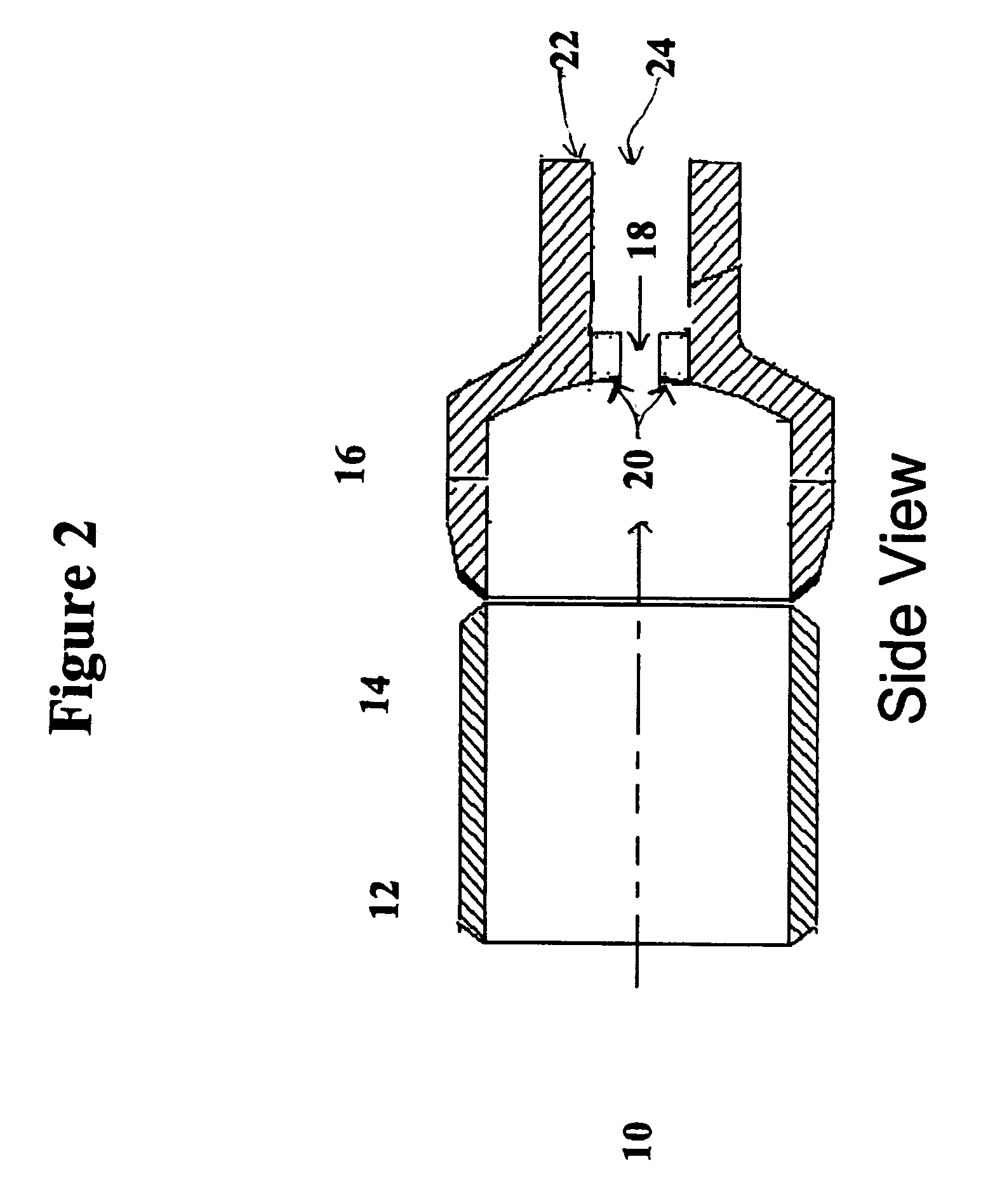

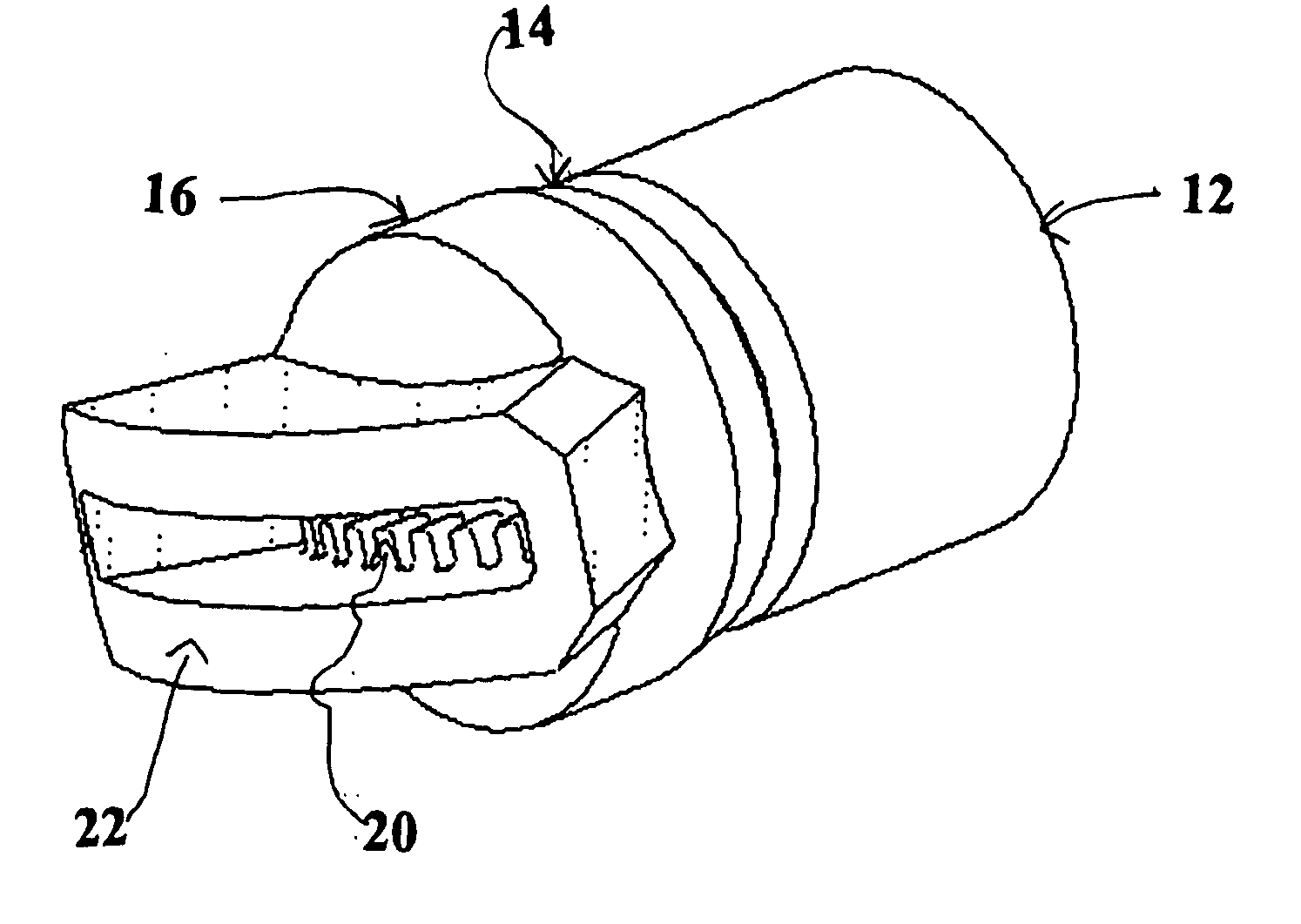

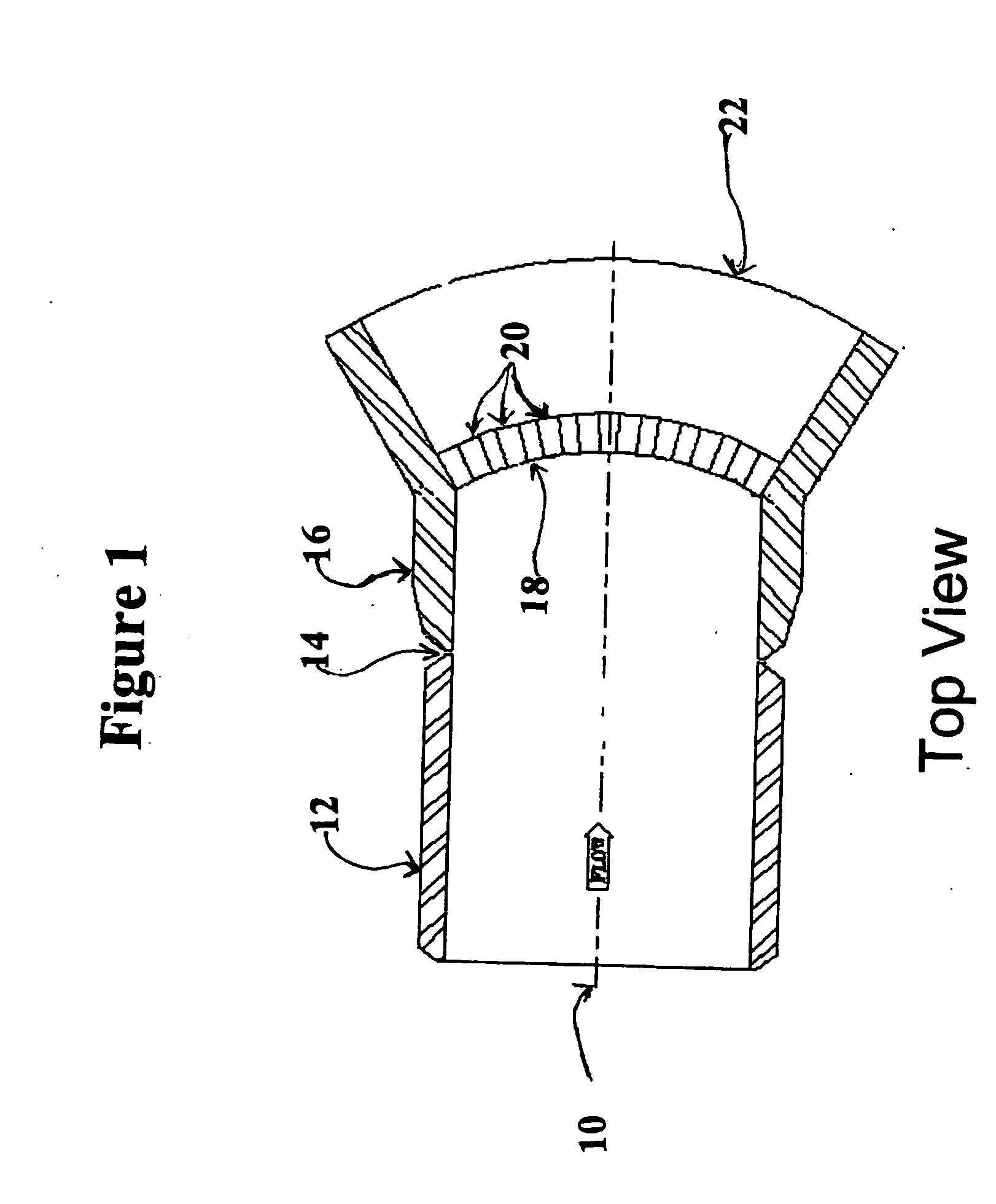

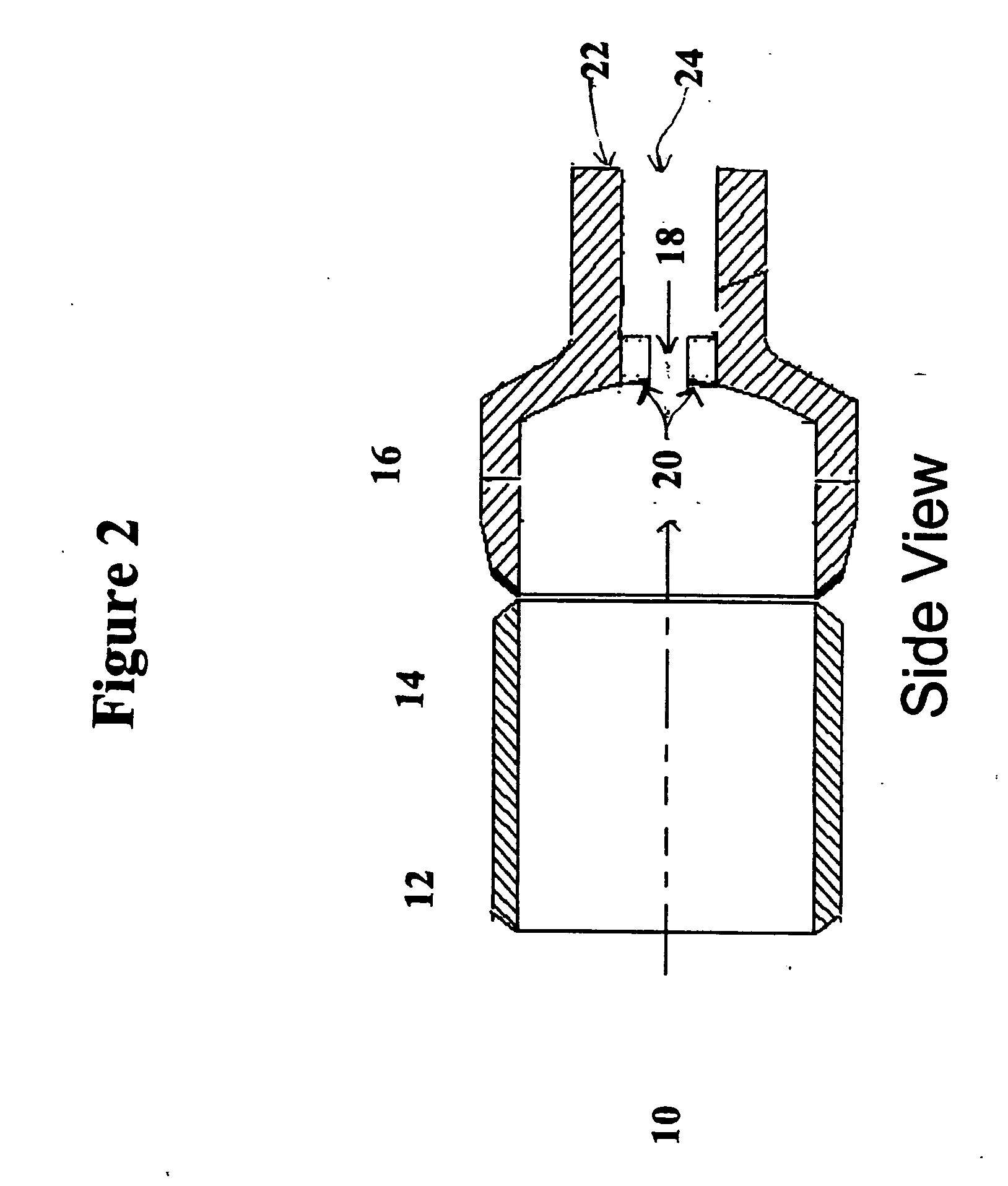

FCC feed injection system

This invention relates to an apparatus and process for injecting a petroleum feed. More particularly, a liquid petroleum feed is atomized with a nozzle assembly apparatus in which the apparatus has injection nozzles that produce a generally flat spray pattern of finely dispersed feed. The injection nozzles are each designed such that the overall effect of the different spray patterns from the individual nozzles provides a more uniform feed coverage across the catalyst stream.

Owner:EXXON RES & ENG CO

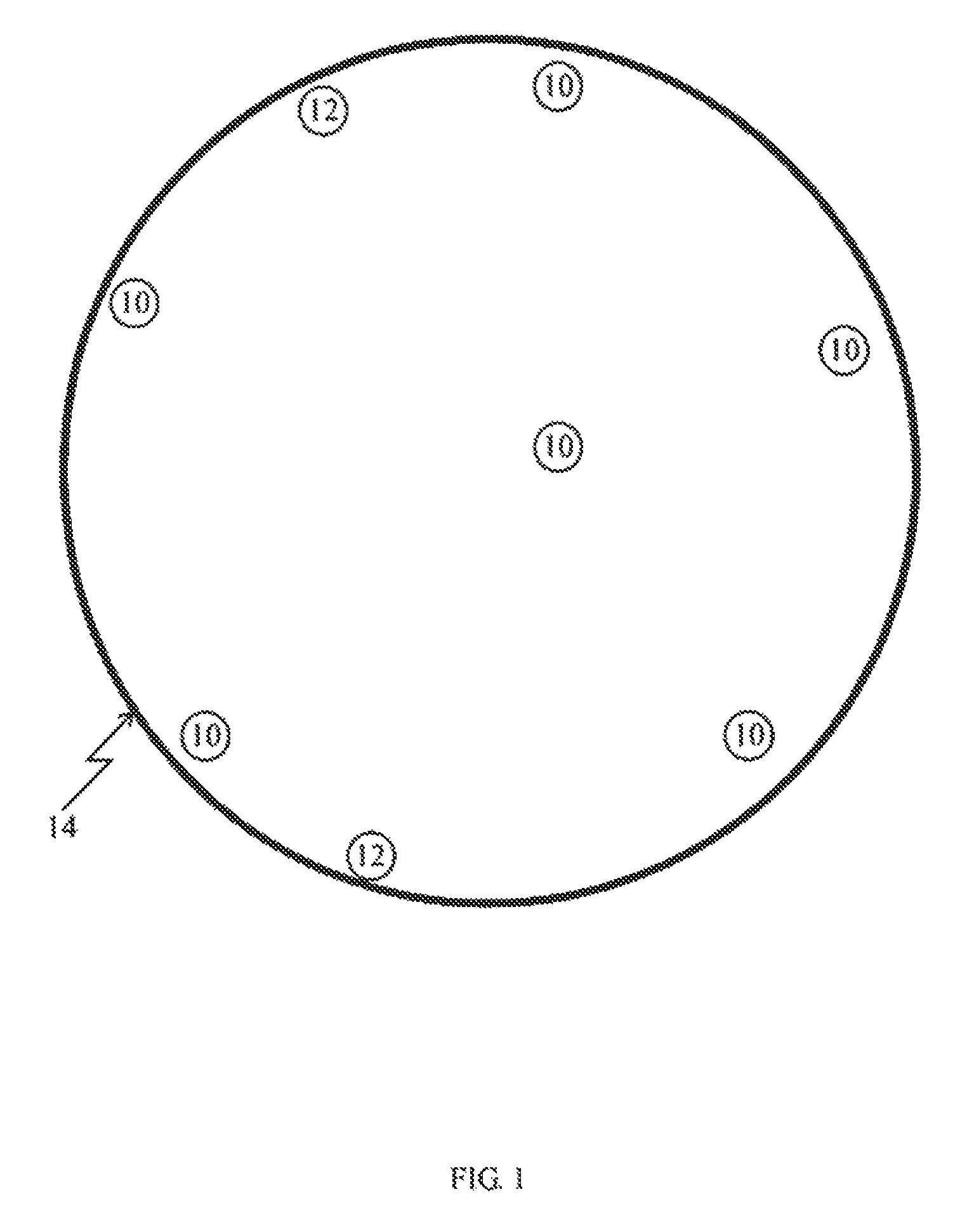

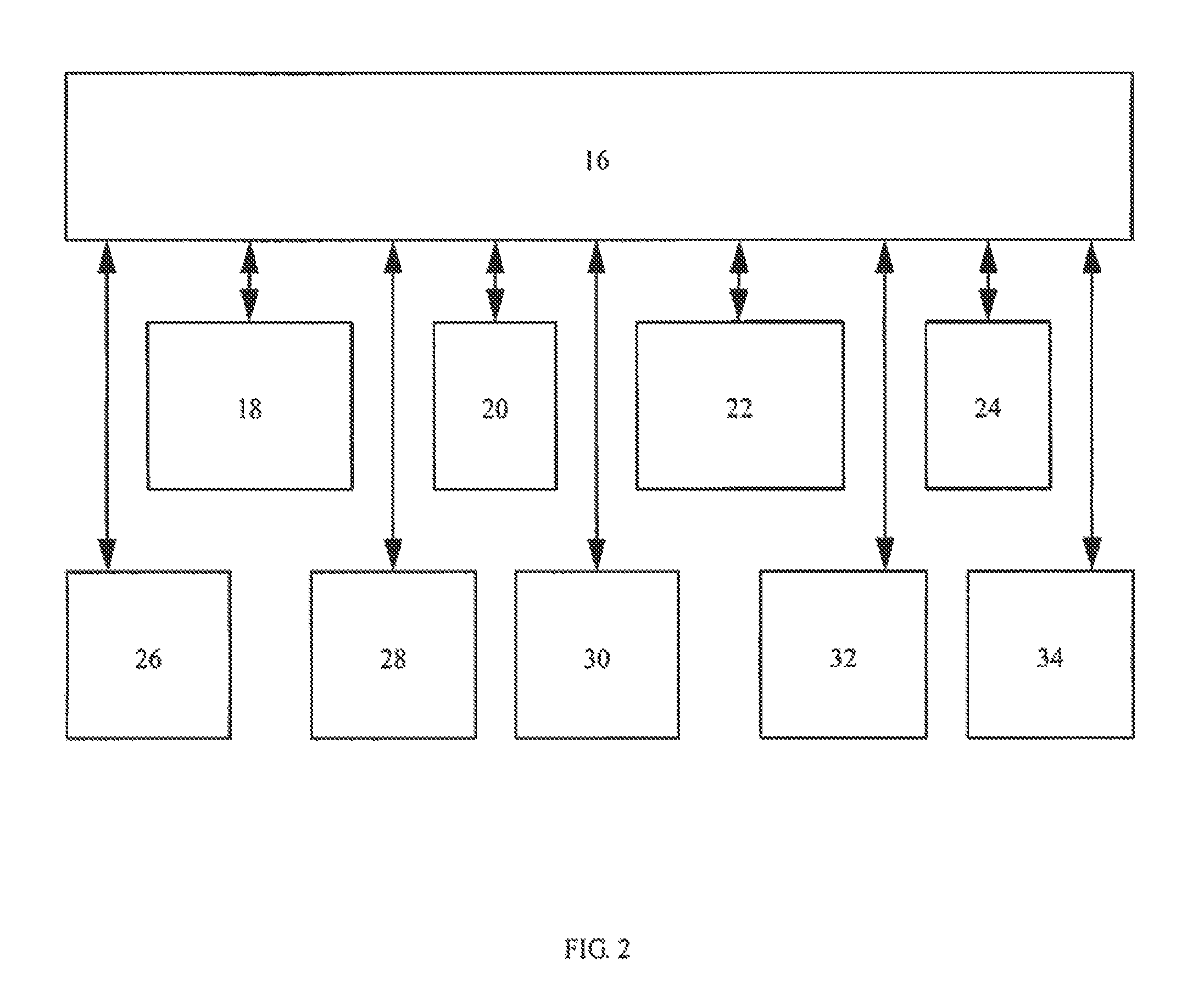

Apparatus for the wireless remote monitoring of storage tank roofs

ActiveUS8820182B2Easy to deployImprove reliabilityMain station arrangementsWired architecture usageMarine engineeringMonitoring system

This invention relates to the remote monitoring of the floating roofs of large storage tanks, including tanks used for storing liquid petroleum products or other chemicals. The invention is used to monitor the position and flexure of the roof and other conditions such as vibration; the presence of vapors or liquids from water, hydrocarbons, or other chemicals; the presence of snow; or the presence of intruders. The invention can be connected to a monitoring system using wired or wireless means and can be used for routine status monitoring or for notifying plant operators in the event of alarm conditions. The invention can be completely self-contained and is suitable for encapsulation and use in harsh environments.

Owner:SYSCOR CONTROLS & AUTOMATION

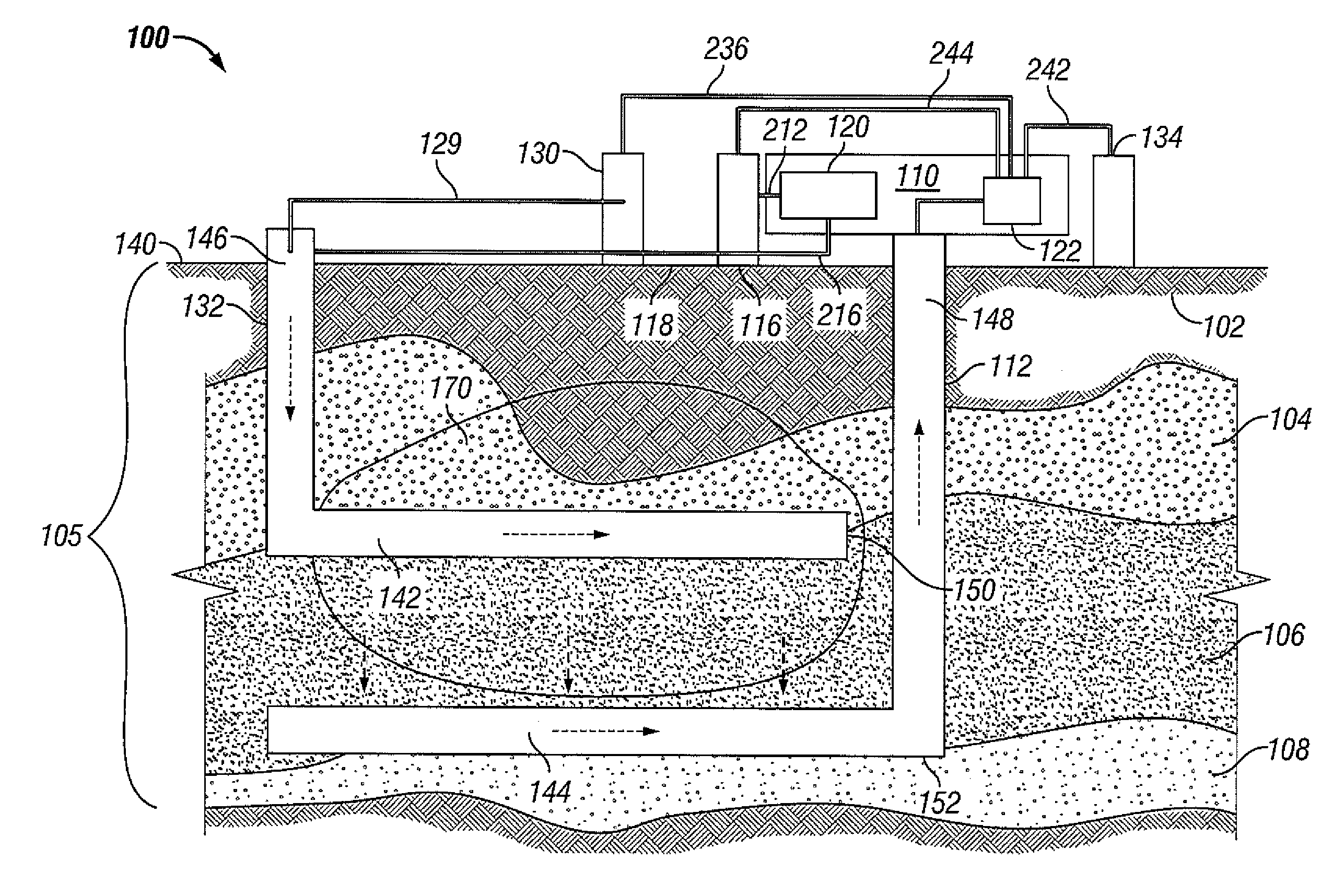

Oil recovery system and method

A system and process are provided for recovering oil from an oil-bearing formation. An oil recovery formulation that is first contact miscible with a liquid petroleum composition that is comprised of at least 15 mol % dimethyl sulfide is introduced together with steam or hot water into a subterranean oil-bearing formation comprising heavy oil, extra heavy oil, or bitumen, and oil is produced from the formation.

Owner:SHELL OIL CO

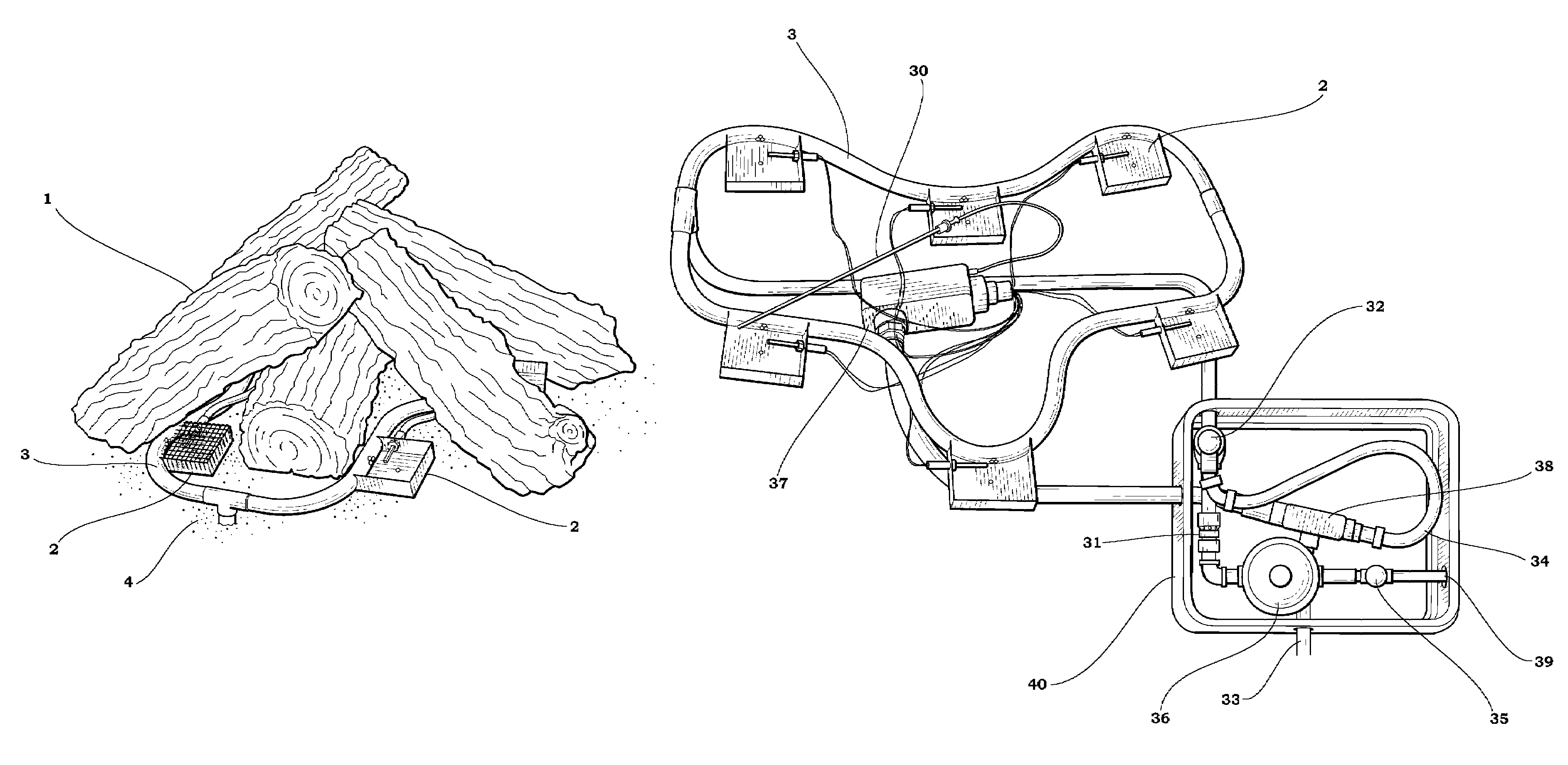

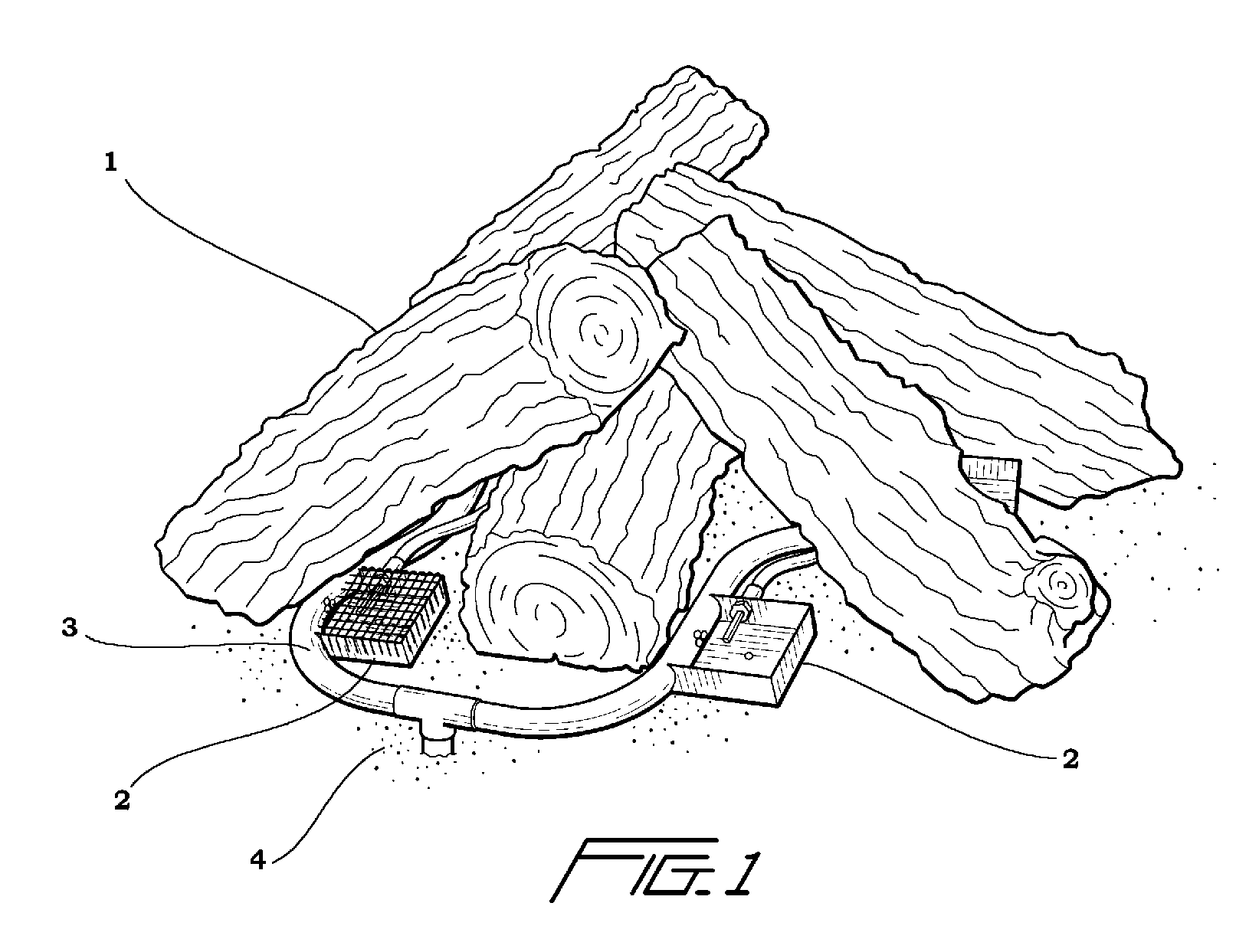

Burner apparatus

InactiveUS7479008B2Harmful emissionDomestic stoves or rangesLiquid heating fuelCombustorControl system

A burner apparatus for an indoor or outdoor fireplace, fire pit, stove or oven is shown. The burner apparatus operates to produce natural gas fueled or liquid petroleum fueled amber flames among artificial logs, coals or a combination of artificial logs and coals, simulating a natural fire. One embodiment of the burner apparatus comprises a burner tube loop for the distribution of fuel, a fuel / air mixing valve for mixing the fuel and air before ignition of the resulting fuel / air mixture, metal cups for the dissipation of the fuel / air mixture and flames, an ignition system for igniting the fuel / air mixture, a control system for monitoring and controlling the ignition of the fuel and for regulating the flow of fuel, and artificial logs, coals or a combination of logs and coals placed around the burner tube loop to provide for an aesthetically pleasing and natural looking display.

Owner:THOMAS PAUL DAVID

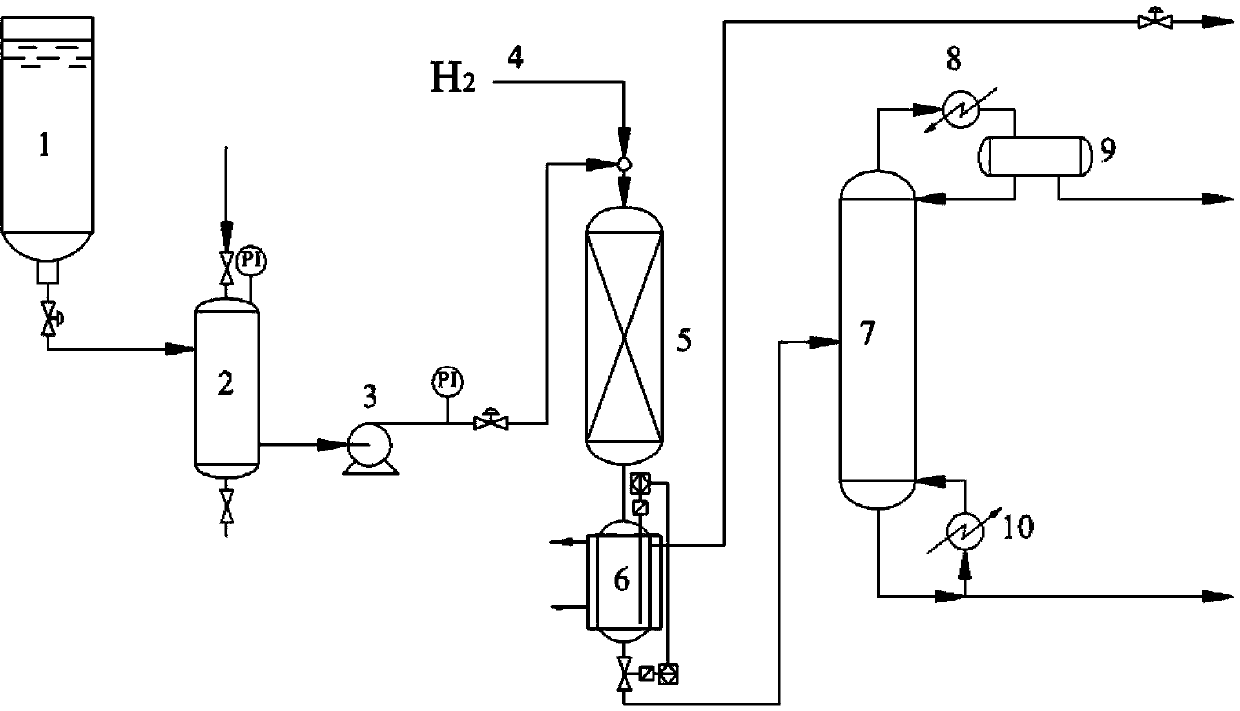

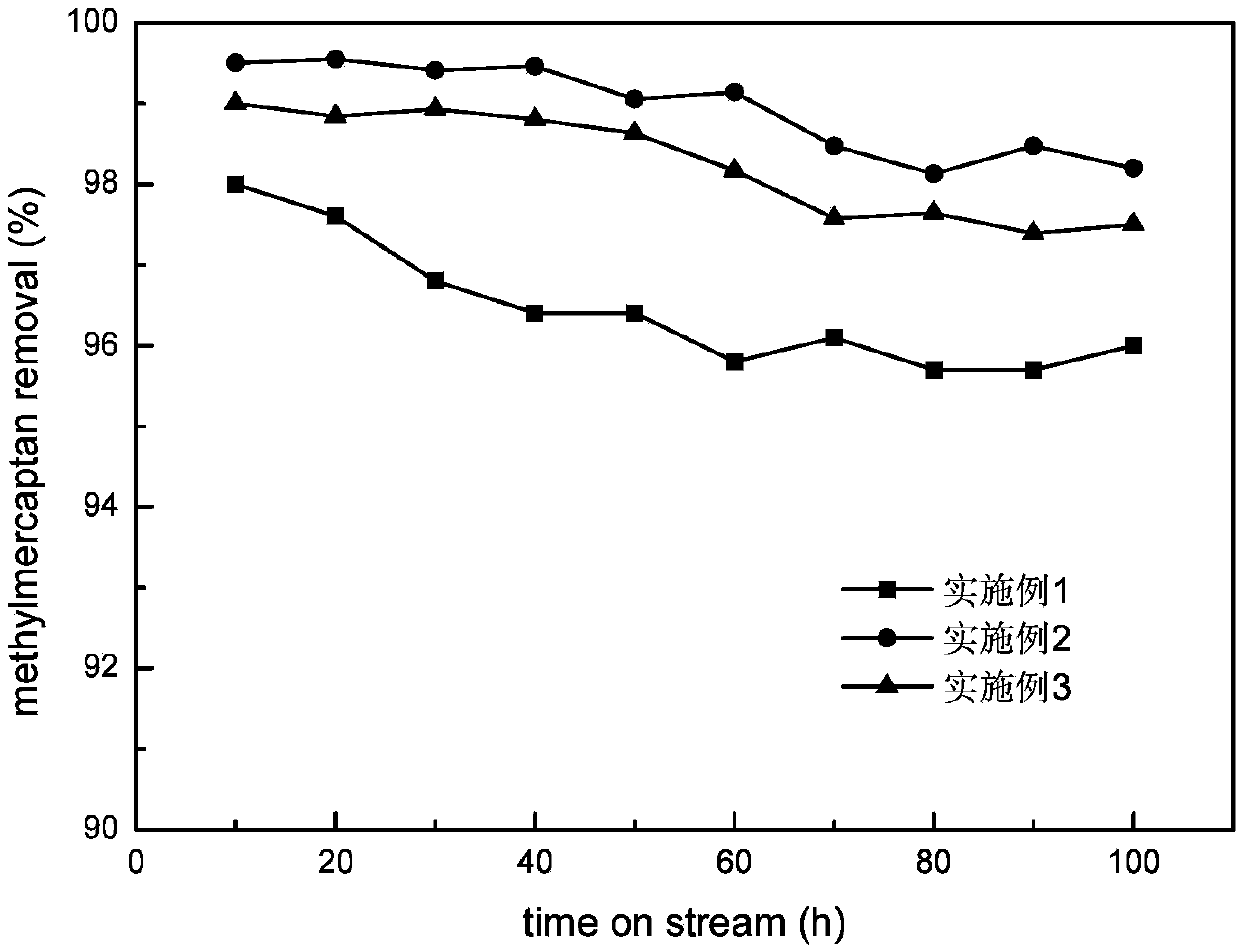

Method for removing mercaptan in liquefied petroleum gas through catalysis

The invention relates to a method for removing mercaptan in liquefied petroleum gas through catalysis. The method comprises the following steps: mixing liquefied petroleum gas with hydrogen, allowing an obtained mixture to enter a fixed bed reactor and contact with a catalyst in the fixed bed reactor for thiolation and allowing mercaptan in the liquefied petroleum gas to react with active unsaturated hydrocarbon in the liquefied petroleum gas under the action of the catalyst so as to produce a high-boiling point thioether compound, wherein a part of dialkene is selectively saturated and monoolefine is not saturated, so a liquefied petroleum gas mixture is obtained; and allowing the reacted liquefied petroleum gas mixture to enter a distillation column for distillation and separating a liquid petroleum gas fraction from the high-boiling point thioether compound so as to obtain a liquefied petroleum gas product without mercaptan. The method provided by the invention employs the catalytic reaction between raw materials to remove mercaptan without introduction of an auxiliary agent for participation in the reaction, has a high mercaptan removal rate and no discharge of alkaline residue and simplifies conventional process for removal of mercaptan in liquefied petroleum gas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Flexible fiber asphalt mixture and preparation method thereof

InactiveCN103951324AImprove deformation resistanceImprove fatigue resistanceCrack resistanceRoad surface

The invention discloses a flexible fiber asphalt mixture and a preparation method thereof. The flexible fiber asphalt mixture comprises the following raw materials in parts by weight: 0.6-3.5 parts of modifier, 4.5-11.5 parts of asphalt, 86-95 parts of mineral aggregate and 0.005-0.02 parts of fibers. The preparation method comprises the following steps: mixing the modifier and preheated aggregate under an agitating condition and evenly agitating; then adding liquid petroleum pitch and evenly agitating; then adding the fibers and evenly agitating; finally adding ore powder, and evenly agitating to obtain the flexible fiber asphalt mixture. The preparation method disclosed by the invention is simple, and the prepared flexible fiber asphalt mixture has good deform resistance, crack resistance, fatigue resistance and high temperature resistance and can be prefabricated into an asphalt pavement layer to be rolled and stored, and moreover, the rolled flexible fiber asphalt mixture can be paved and installed just like paving a carpet in field pavement, so as to quickly finish construction and quickly open traffic.

Owner:BEIJING MUNICIPAL BRIDGE MAINTENANCE MANAGEMENT +1

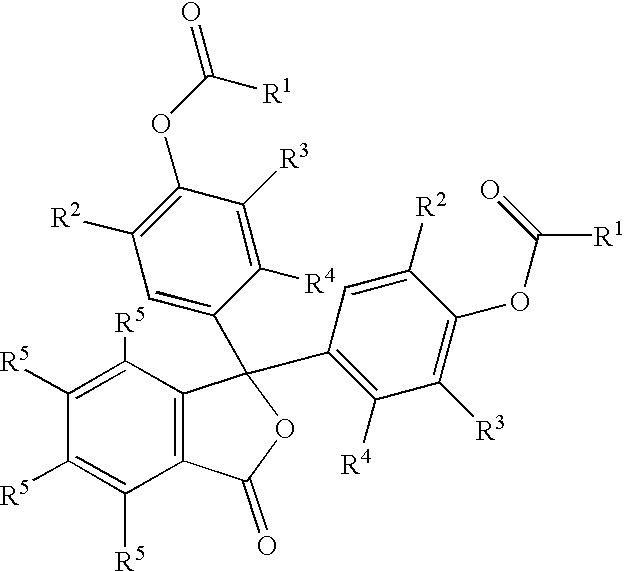

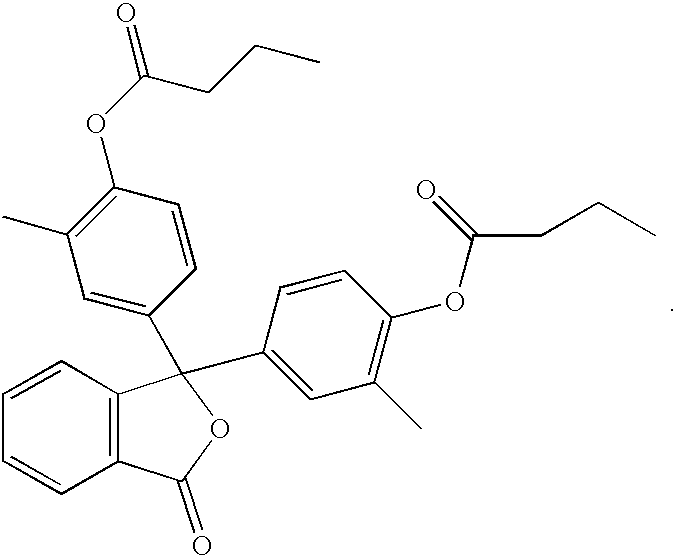

Colorless petroleum marker dyes

InactiveUS20020038064A1Diaryl/thriaryl methane dyesHydrocarbon purification/separationLiquid PetroleumChemistry

A composition comprising a liquid petroleum product and a colorless marker compound in an amount that is not detectable visually, and a method for marking a liquid petroleum product with a colorless marker compound.

Owner:ASGAONKAR ANJALI S

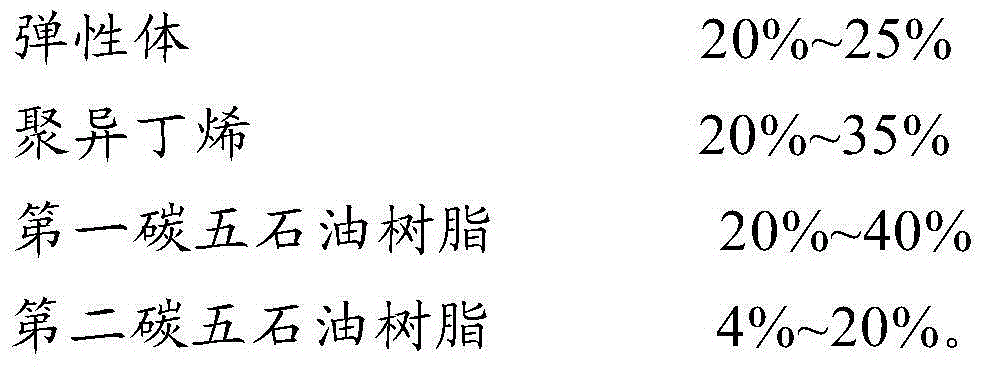

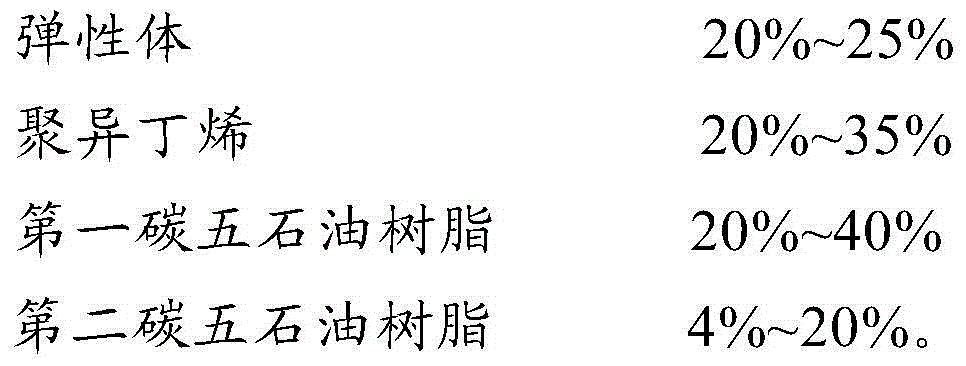

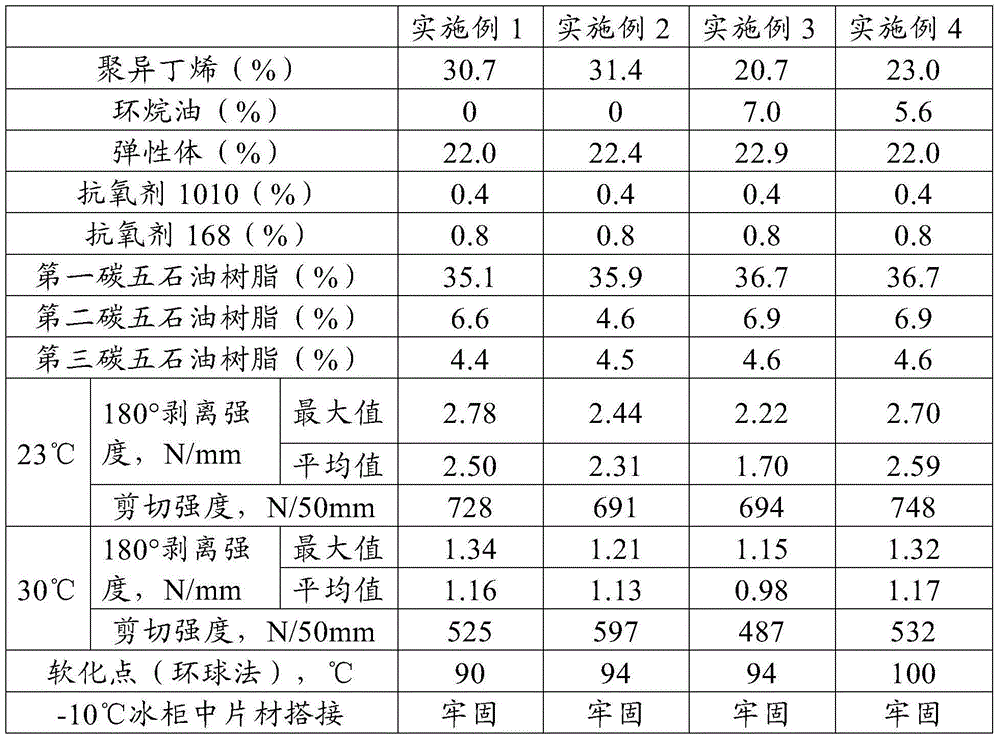

Hot-melt pressure-sensitive adhesive, preparation method of hot-melt pressure-sensitive adhesive and waterproof roll

InactiveCN104694047AHigh peel strengthSimple production processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPetroleum resin

The invention provides a hot-melt pressure-sensitive adhesive and a preparation method of the hot-melt pressure-sensitive adhesive. The hot-melt pressure-sensitive adhesive belongs to the technical field of waterproof rolls. The problem that the waterproof roll is unsuitable to be used in winter or tundra because the conventional pre-paving anti-adhesion construction only can be performed in a climatic environment of over 4 DEG C below zero can be solved. The hot-melt pressure-sensitive adhesive disclosed by the invention is prepared from raw materials comprising an elastomer, polyisobutene, a first C5 petroleum resin and a second C5 petroleum resin, wherein the first C5 petroleum resin refers to a solid alicyclic hydrocarbon type hydrogenated petroleum resin and has the softening point of 80-127 DEG C; and the second C5 petroleum resin refers to a liquid petroleum resin and has the softening point of less than or equal to 15 DEG C. According to the hot-melt pressure-sensitive adhesive disclosed by the invention, a high density polyethylene self-adhered film waterproof roll can be firmly overlapped under the condition of 10 DEG C below zero, and the hot-melt pressure-sensitive adhesive can be applied to sealing tapes, double sided tapes and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

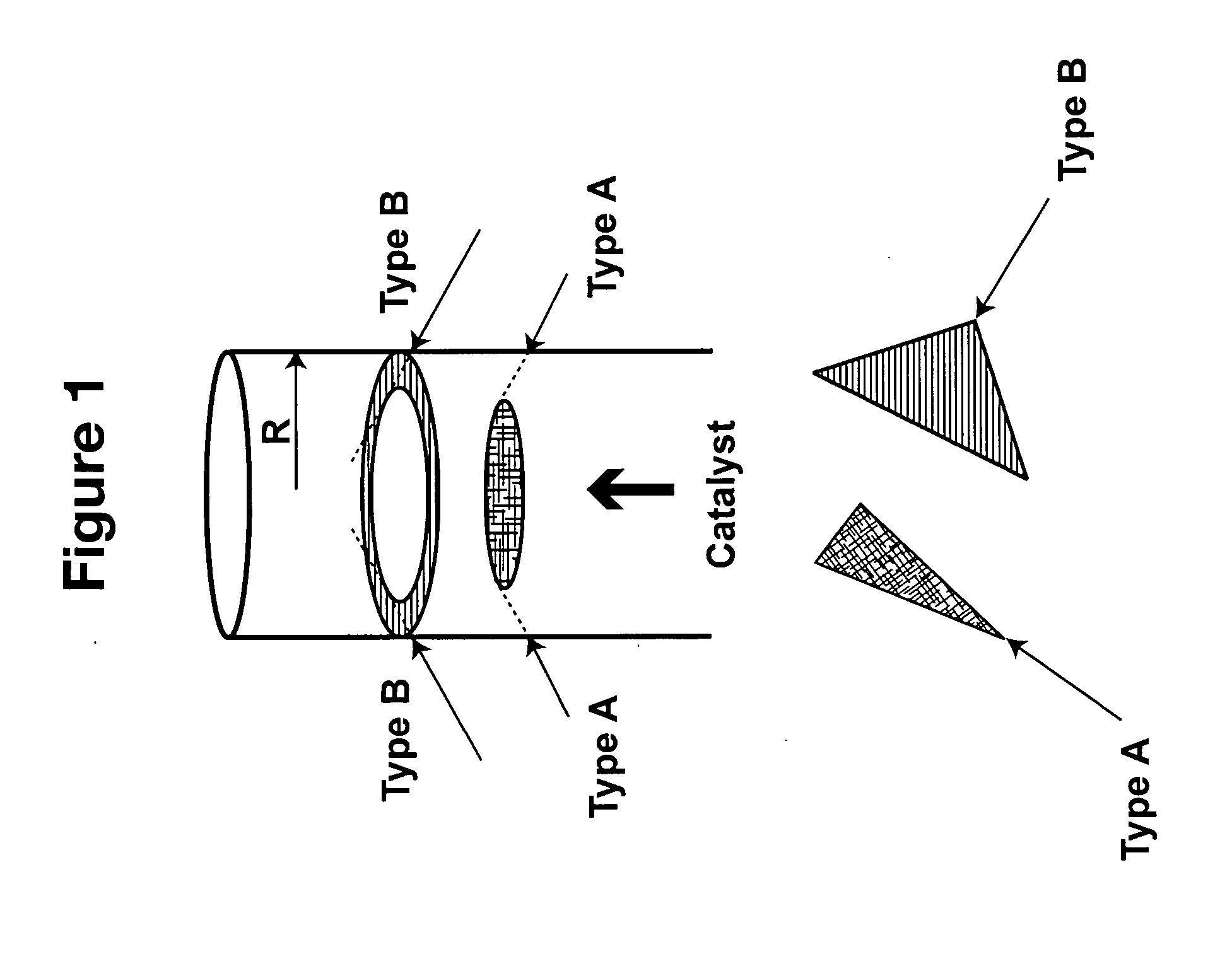

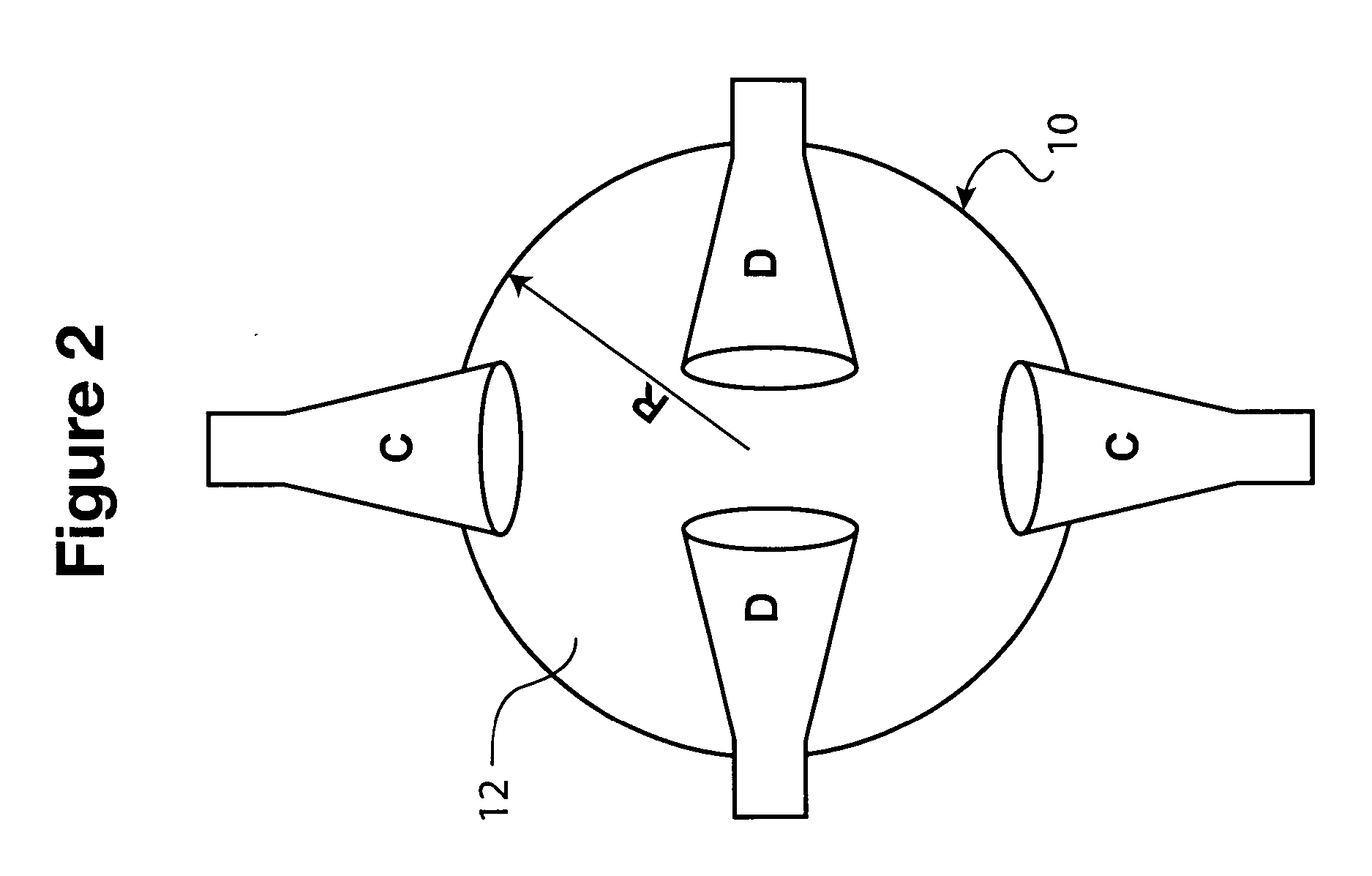

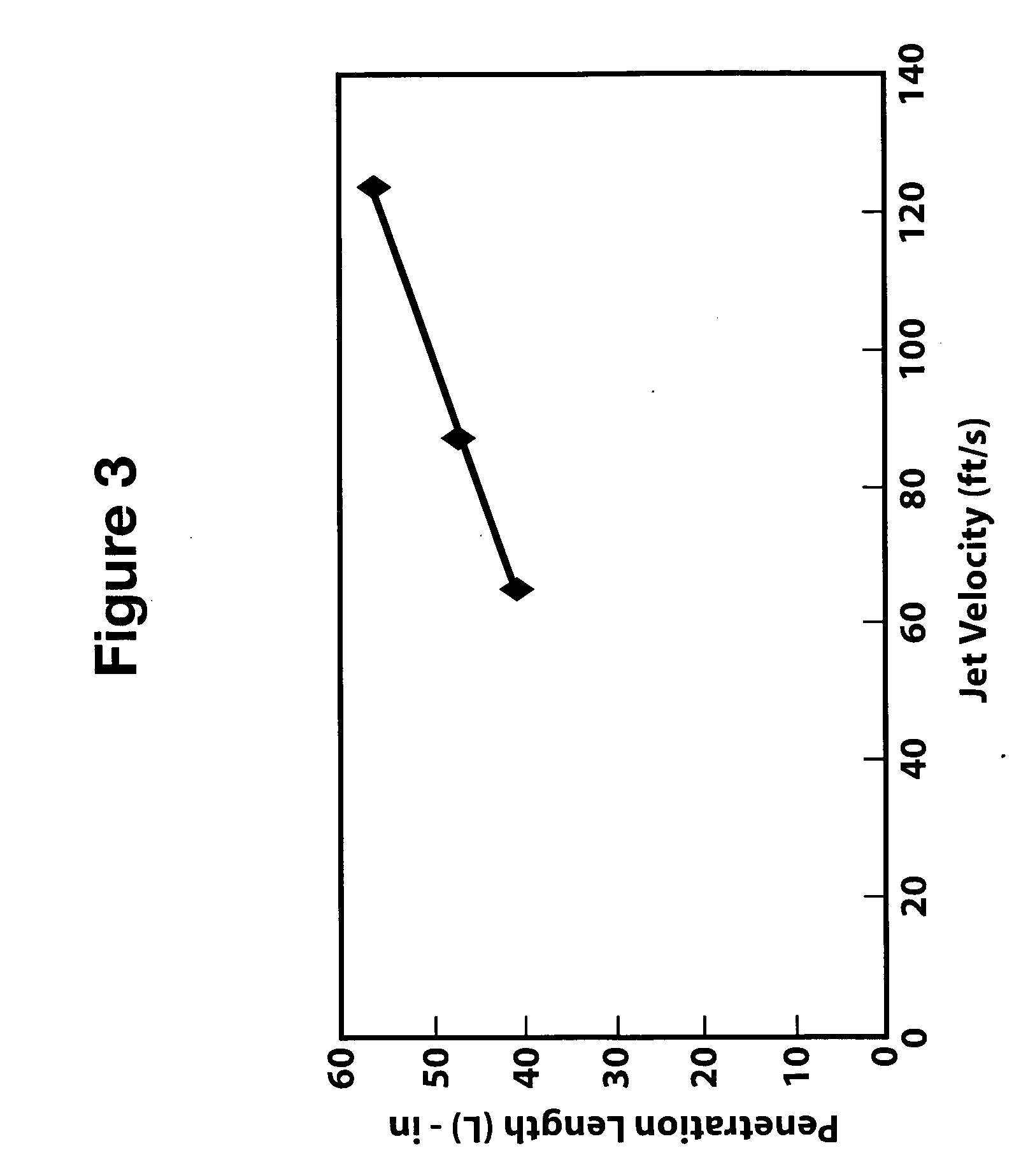

Feed injector

This invention relates to an apparatus and process for atomizing a petroleum feed. More particularly, a liquid petroleum feed is atomized with an atomization apparatus in which the apparatus has an orifice that produces a generally flat spray pattern of finely dispersed feed prior to contacting catalyst in a fluid catalytic cracking zone. The orifice has a general aspect ratio greater than 1.0 and a ratio of perimeter length-to-cross-sectional area greater than 1.5 relative to a perimeter-to-cross-sectional area ratio of a circular orifice of equivalent area. The apparatus can be used to atomize feed injected into the cracking zone of a fluid catalytic cracker.

Owner:EXXON RES & ENG CO

Waterproof coating and preparation method and application thereof, and asphalt waterproof coiled material

ActiveCN105368236AGood weather resistanceImproved ability to reflect sunlightReflecting/signal paintsBituminous waterproofingUltraviolet

The invention provides a waterproof coating and a preparation method and an application thereof, and an asphalt waterproof coiled material, belongs to the technical field of waterproof materials, and can be used for solving the problems of poor weather resistance and UV resistance of conventional waterproof coiled materials. The waterproof coating comprises the components in parts by weight: 50-70 parts of a polymer emulsion, 30-50 parts of a filler, 1-5 parts of liquid petroleum resin, 0.2-0.5 part of a coupling agent, 0.2-0.4 part of a dispersant, 0.1-0.2 part of a wetting agent, 0.5-1.5 parts of a film-forming auxiliary agent, 0.3-0.7 part of a thickening agent, 0.2-0.7 part of a defoaming agent, and 5-10 parts of water. The waterproof coating adopts the petroleum resin and the coupling agent to improve the compatibility and the oil resistance of asphalt, the filler combination can improve weather resistance and UV resistance of the coating and improve the ability to reflect sunlight. The waterproof coating not only can be in composite use with the asphalt waterproof coiled material, but also can be used as a single waterproof layer to be applied in leakage parts of roofing, exterior walls, kitchens and baths and the like.

Owner:苏州东方雨虹建筑材料有限公司

Feed injector

This invention relates to an apparatus and process for atomizing a petroleum feed. More particularly, a liquid petroleum feed is atomized with an atomization apparatus in which the apparatus has an orifice that produces a generally flat spray pattern of finely dispersed feed prior to contacting catalyst in a fluid catalytic cracking zone. The orifice has a general aspect ratio greater than 1.0 and a ratio of perimeter length-to-cross-sectional area greater than 1.5 relative to a perimeter-to-cross-sectional area ratio of a circular orifice of equivalent area. The apparatus can be used to atomize feed injected into the cracking zone of a fluid catalytic cracker.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com