Waterproof coating and preparation method and application thereof, and asphalt waterproof coiled material

A technology for waterproof coatings and preparation steps, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of poor weather resistance and ultraviolet resistance of waterproof coils, and achieve improved sunlight reflection, weather resistance, and phase Capacitance and Oil Resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

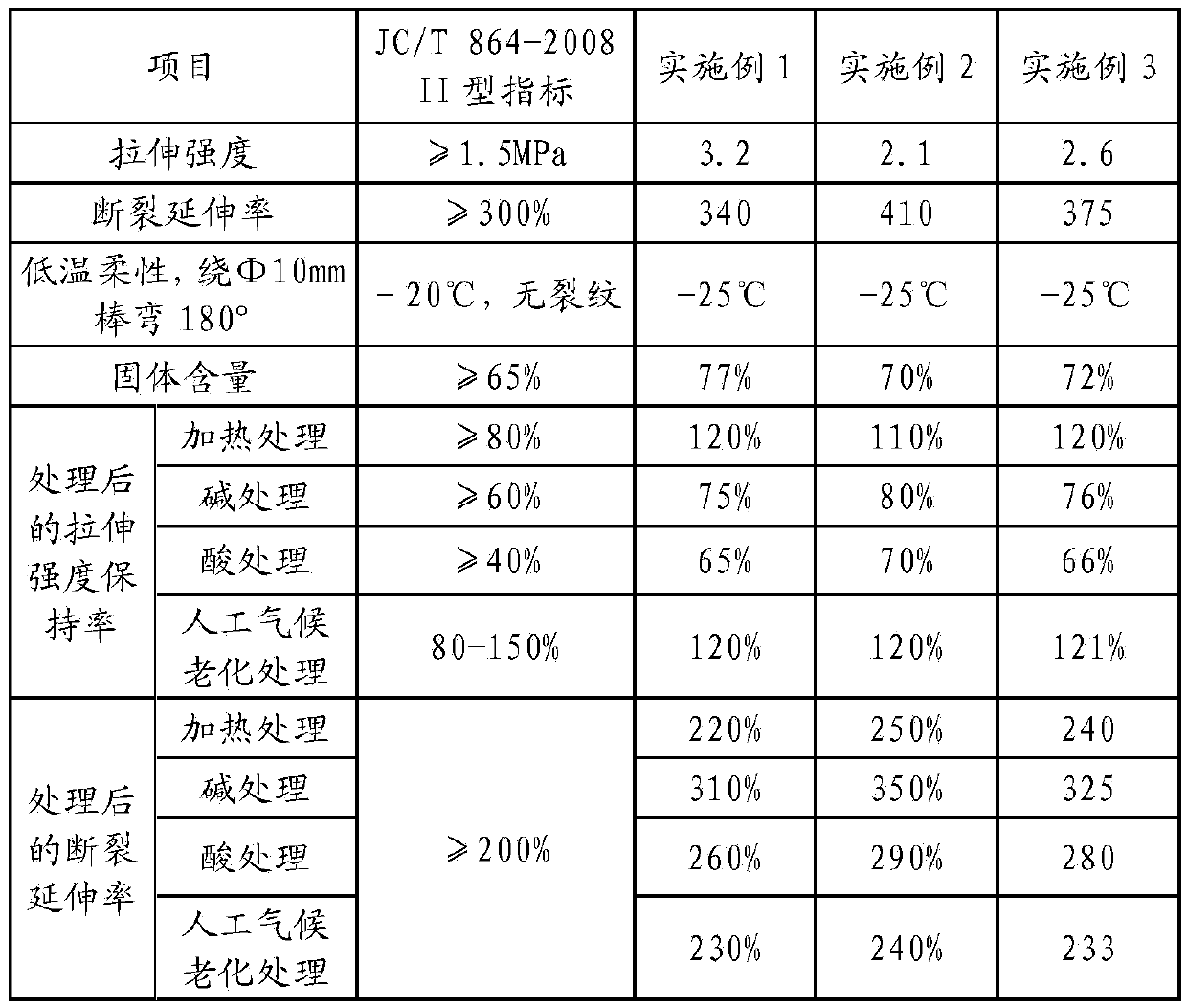

Examples

Embodiment 1

[0036] This embodiment provides a waterproof coating and a preparation method thereof, and the preparation steps are as follows:

[0037] With 50 parts of polymer emulsion, 5 parts of liquid petroleum resin (the liquid petroleum resin comprises one or more mixtures in carbon five, carbon nine, carbon five-carbon nine copolymer resins), 0.5 part of coupling agent (wherein , the coupling agent includes titanate coupling agent and silane coupling agent, and the weight mixing ratio of titanate coupling agent and silane coupling agent is 6:4), dispersant 0.4 parts, wetting agent 0.2 parts, Add 0.5 part of film-forming aid and 0.3 part of defoamer into the reactor, and stir at a slow speed for 5 minutes;

[0038] Add 50 parts of filler into the above reactor, and stir at high speed for 15 minutes; among them, the parts by weight of each raw material in the filler are: 12 parts of wollastonite, 6 parts of talc powder, 1.5 parts of montmorillonite, 13 parts of quartz powder, titanium ...

Embodiment 2

[0043] This embodiment provides a kind of waterproof coating, and the preparation steps are specifically:

[0044] 70 parts of vinyl acetate-acrylate copolymer emulsion, 1 part of liquid petroleum resin, 0.2 part of coupling agent, 0.2 part of dispersant glyceryl tristearate, 0.1 part of wetting agent fatty acid salt, film-forming aid dodecyl Add 1.5 parts of alcohol ester, 0.3 part of antifoaming agent silicone ether copolymer into the reactor, and stir at a slow speed for 5 minutes; (wherein, the coupling agent includes titanate coupling agent and silane coupling agent, and titanate coupling agent The weight mixing ratio of agent and silane coupling agent is 5:4)

[0045] Add 30 parts of filler into the above reactor, and stir at high speed for 15 minutes; wherein, the parts by weight of each raw material in the filler are: 8 parts of wollastonite, 3 parts of talc powder, 0.5 parts of montmorillonite, 10 parts of quartz powder, titanium 1 part white powder, 5 parts aluminum...

Embodiment 3

[0050] This embodiment provides a kind of waterproof coating, and the preparation steps are specifically:

[0051]Add 60 parts of polymer emulsion, 3 parts of liquid petroleum resin, 0.3 part of coupling agent, 0.2 part of dispersant, 0.1 part of wetting agent, 1 part of film-forming aid, and 0.2 part of defoamer into the reactor, and stir slowly 5 minutes; (wherein, the coupling agent includes titanate coupling agent and silane coupling agent, and the weight mixing ratio of titanate coupling agent and silane coupling agent is 7:4)

[0052] Add 40 parts of filler into the above reactor, and stir at high speed for 15 minutes; among them, the parts by weight of each raw material in the filler are: 10 parts of wollastonite, 5 parts of talc powder, 1 part of montmorillonite, 11 parts of quartz powder, titanium White powder 1.5 parts, aluminum powder 8 parts, mica powder 3.5 parts.

[0053] Mix 0.7 parts of hydrophobically modified polyether thickener and 7 parts of water, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com