Electro-optical device, method of manufacturing the same, and electronic apparatus

a technology of electro-optical devices and electronic devices, applied in the direction of optical waveguides, light guides, waveguides, etc., can solve the problems of deterioration of the reliability of the electro-optical devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(Basic Structure of Electro-optical Device)

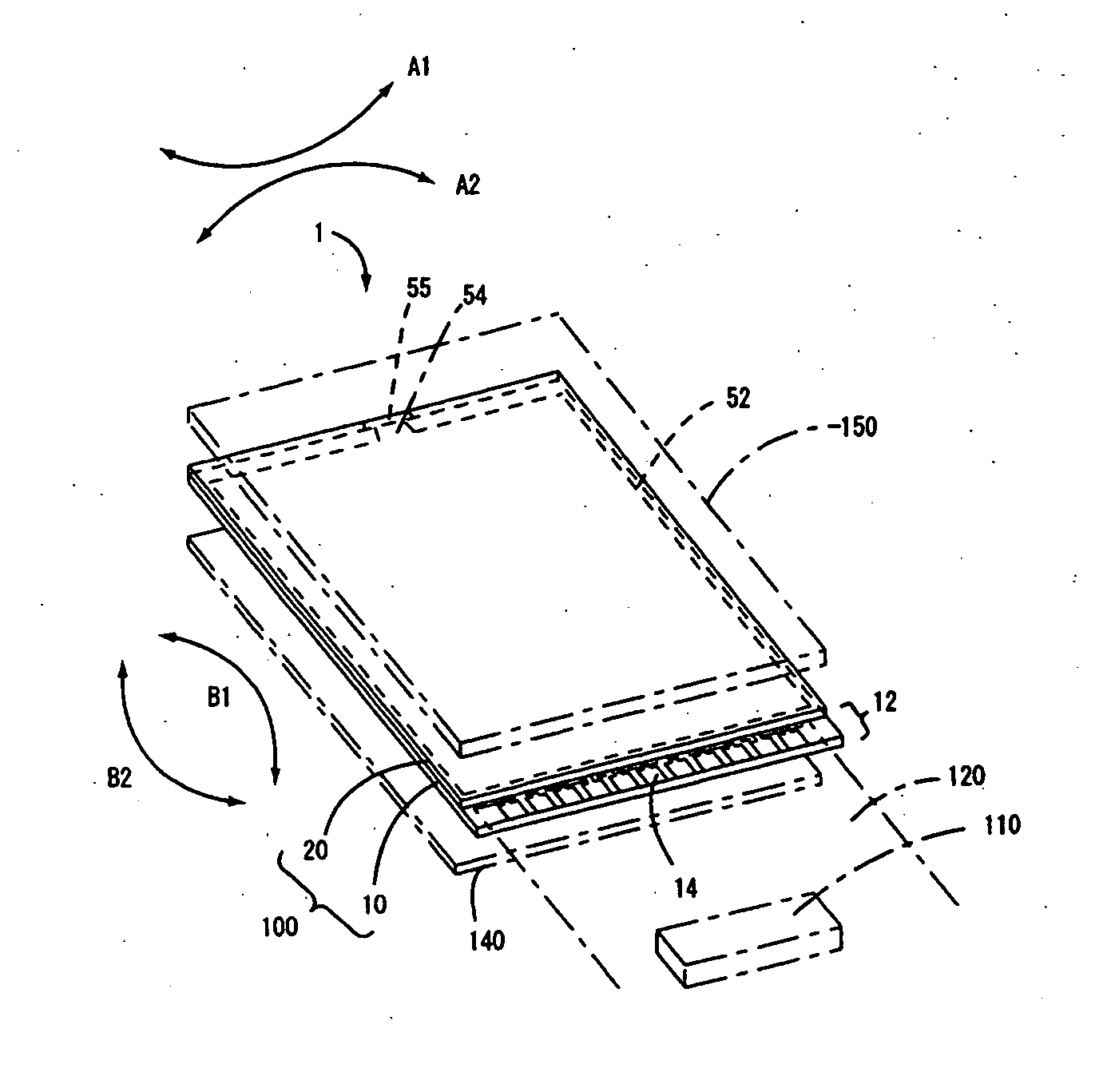

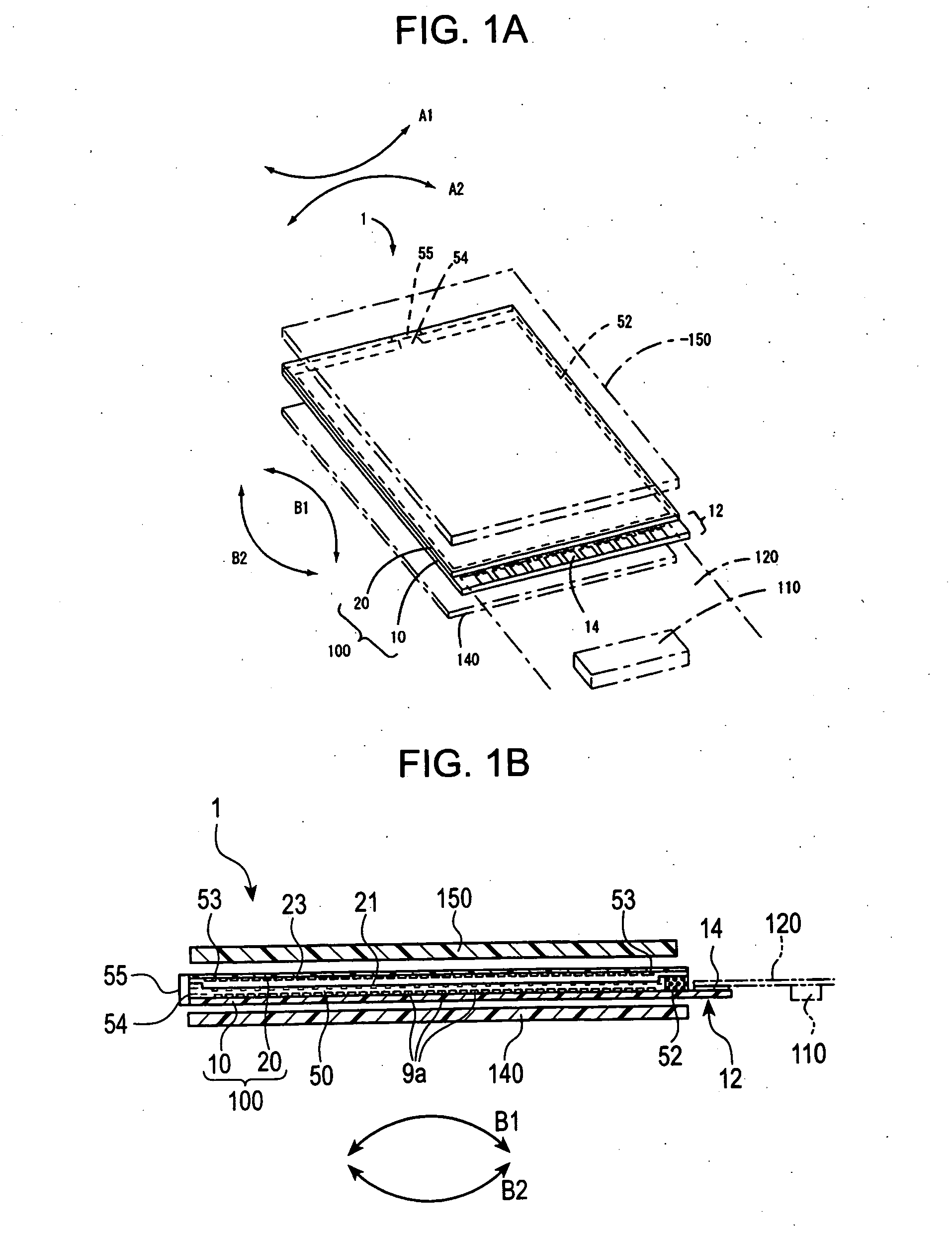

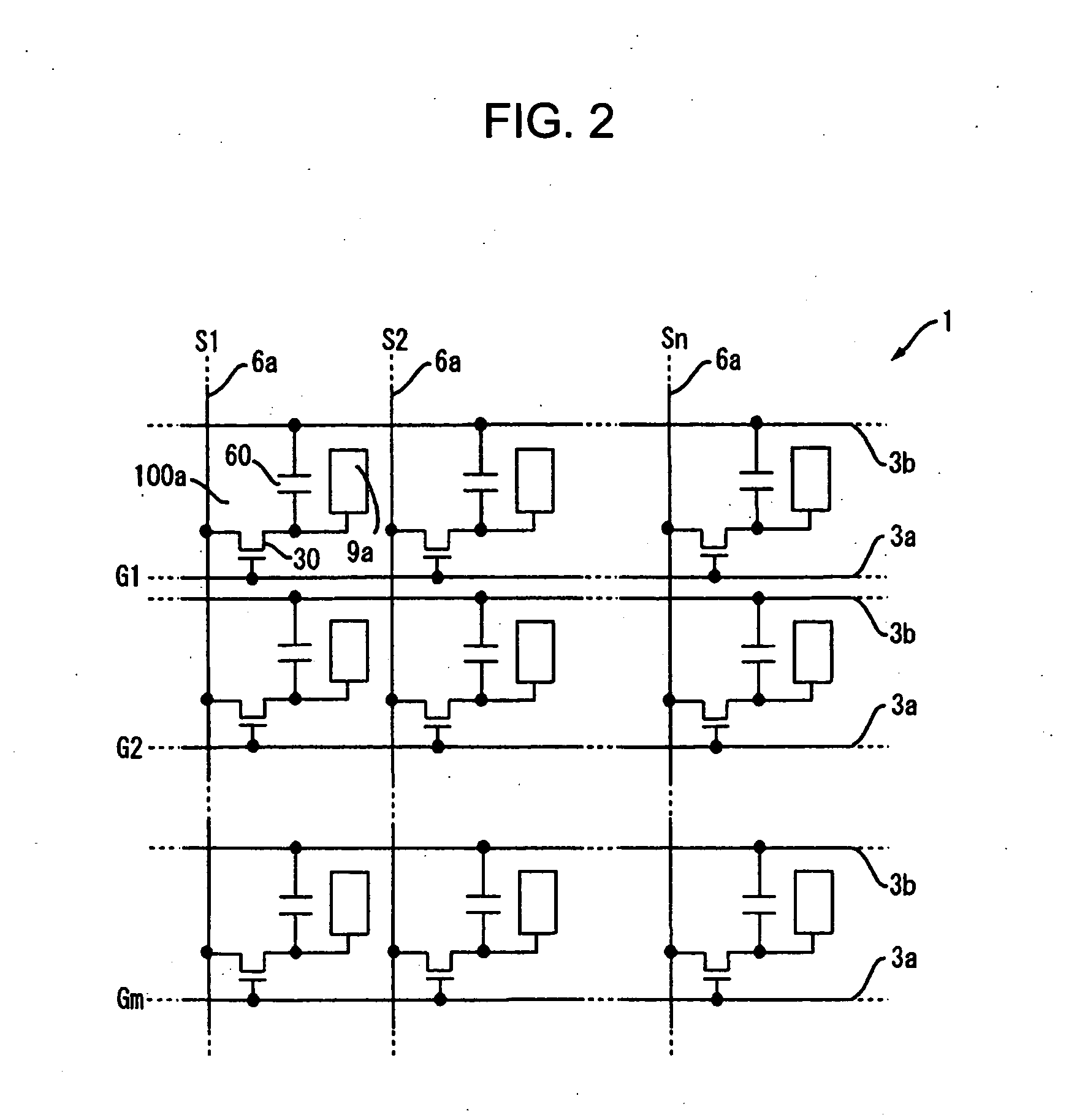

[0041]FIG. 1(A) is a view illustrating the structure of an electro-optical device according to the present invention as seen from the counter substrate side, and FIG. 1(B) is a cross-sectional view thereof. FIG. 2 is an equivalent circuit diagram for various elements and wiring lines of a plurality of pixels that is arranged in a matrix in an image display region of the electro-optical device. In the drawings used for explaining the present invention, since each layer or each member is scaled to be recognizable in the drawings, the reduced scale of each layer or each member differs from the actual scale thereof.

[0042] In FIGS. 1(A) and 1(B), an electro-optical device 1 according to the first embodiment comprises a transmissive or transflective active matrix liquid crystal panel 100. In the liquid crystal panel 100, liquid crystal 50, which is an electro-optical material, is held between a TFT array substrate 10 (an electro-optical device...

second embodiment

[0062]FIG. 5 is a cross-sectional view illustrating the structure of an electro-optical device according to the second embodiment of the present invention. In the present embodiment and other embodiments to be described later, since their basic structures are the same as that in the first embodiment, components having the same function are represented by the same reference numeral, and thus a description thereof will be omitted.

[0063] In FIG. 5, the structure of an electro-optical device 1 according to the present embodiment is equal to that in the first embodiment, except that the side of the base 210 is used as a display surface. In the electro-optical device 1 having such a structure, when the liquid crystal panel 100 is a transmissive type, light (which is indicated by arrow L2) emitted from a backlight unit is optically modulated in the liquid crystal panel 100, and then exits therefrom as display light (which is indicated by arrow L10). On the other side, when the liquid crys...

third embodiment

[0064] In the first embodiment, the spacers 260 and 270 are respectively arranged between the liquid crystal panel 100 and the first and second polarizing plates 140 and 150. However, in the present embodiment, as described below, sheets having unevenness thereon are used instead of the spacers 260 and 270 in order to prevent the generation of Newton's ring.

[0065]FIG. 6 is a cross-sectional view illustrating the structure of an electro-optical device according to the third embodiment of the present invention.

[0066] As shown in FIG. 6, in an electro-optical device 1 of the present embodiment, a base 210 having a curved surface 220, a first polarizing plate 140, a liquid crystal panel 100, ard a second polarizing plate 150 having an area larger than that of the liquid crystal panel 100 are superposed in this order. In addition, a first sheet 160 having unevenness is arranged between the first polarizing plate 140 and the liquid crystal panel 100, and a second sheet 170 having uneven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com