Patents

Literature

729results about How to "Does not fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol soluble polyacrylate resin and preparation method and application thereof

The invention discloses an alcohol soluble polyacrylate resin and a preparation method and an application thereof; the preparation method comprises the following steps: taking 260-800 parts of alcohols solvent, adding the solvent in a reaction kettle with a mixer, a reflux condenser, a heating jacket and a nitrogen covering layer, then heating the system to 70-150 DEG C, mixing the mixture for 10-30min; adding acrylic ester used as hard monomers, acrylic ester used as soft monomers, polar functional group monomers, organosilane monomers and initiator to react for 4-7h and obtain alcohol soluble polyacrylate resin. The alcohol soluble polyacrylate resin prepared by the method of the invention has no excitant odour, the number-average molar mass is 10,000-200,000, the molecular weight distribution is 1.1-4 and the Brookfield viscosity of the resin system is 100-5000cp. The coating which is prepared by mixing the resin with other pigments, fillers and assistants can be applied in glass, aluminium coil and polypropylene plastic for surface decoration and protective function.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous binding agent and preparation method thereof

ActiveCN101880512AGood storage stabilityEasy to storeMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesHot stampingEmulsion

The invention provides an aqueous binding agent which has washing resistance and is used for electrochemical aluminium hot stamping, and a preparation method thereof, belonging to a binding agent composition. The aqueous binding agent comprises 40-80 parts by weight of acrylic resin emulsion (with the solid content of 40-55%), 20-40 parts by weight of acrylic resin powder and 5-20 parts by weight of ethylene-vinyl acetate copolymer (EVA) emulsion (with the solid content of 40-60%). The binding agent does not contain organic volatile component, is harmless for the human body, is an environment-friendly electrochemical aluminium hot stamping binding agent, and is especially suitable for fabric which is needed to be printed and frequently washed.

Owner:浙江德尚化工科技有限公司

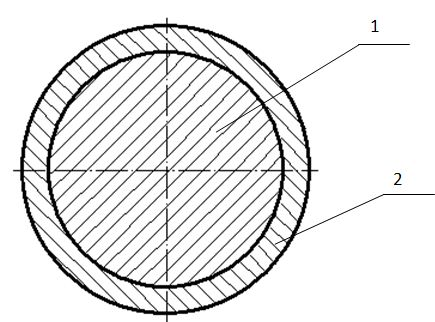

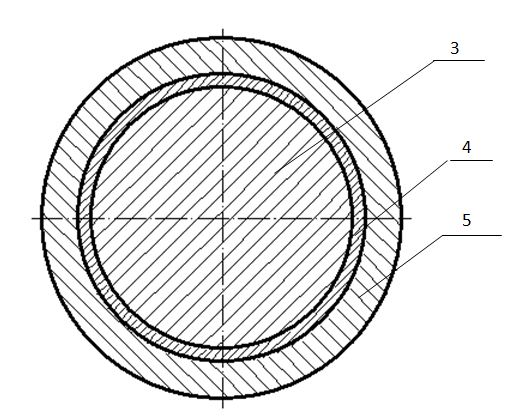

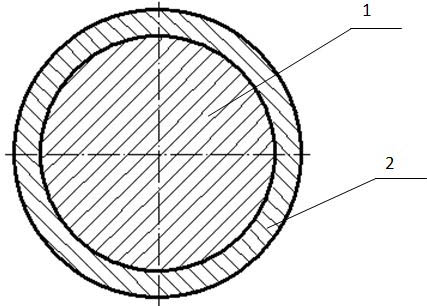

Stainless steel composite corrosion-resisting reinforcement bar and preparation method thereof

The invention relates to a stainless steel composite corrosion-resisting reinforcement bar and a preparation method thereof. By using the method, the reinforcement bar which has the advantages of good corrosion resistance, low cost, and capability of being produced in batches can be prepared. The diameter of the prepared reinforcement bar is 6 to 40mm, and the reinforcement bar mainly comprises a core metal and a stainless steel alloy layer, wherein the periphery of the core metal is coated with the stainless steel alloy layer along the length direction of the core metal, the core metal and the stainless steel alloy layer are combined in a metallurgical mode, and the thickness of the stainless steel alloy layer is 1 to 10mm.

Owner:HUNAN 3T NEW MATERIAL

High-temperature steam endurance ink for spraying code and printing

The invention relates to high-temperature steam endurance ink for spraying code and printing, containing one or more organic solvents, resin and coloring agents. In addition, the consistency of the ink is 2.8-6.2CP / 25DEG C, the conductivity is 500-1,500muS and the surface tension is 27-30Dyn / cm. The high-temperature steam endurance ink for spraying code and printing can be applied to the surfaces of various packaged objects required to be treated at high temperature. The mark and the substrate adopting the high-temperature steam endurance ink have strong adhesive force and favorable adhesiveness and cannot fade, fall off, permeate and shift after being subjected to high-temperature digestion. The dried mark can be also scraped by a cleaning agent.

Owner:北京赛腾标识系统股份公司

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Waterborne inorganic slurry interior wall putty and preparation method thereof

ActiveCN103408986AImprove water resistanceImprove heat resistanceFilling pastesCalcium silicateSlurry

The invention discloses waterborne inorganic slurry interior wall putty, which is composed of such components as silica sol, styrene acrylic latex, a silicone coupling agent, quartz powder, fillers, an assistant and water. The invention further discloses a preparation method of the waterborne inorganic slurry interior wall putty. The waterborne inorganic slurry interior wall putty has the advantages that the fine particles of the silica sol have strong seepage force on a basement layer, so that the fine particles can seep into the basement layer through capillary tubes and can react with calcium hydroxide in the basement layer of a cement wall to generate calcium silicate so as to provide strong adhesive force to the putty layer; the water resistance and heat resistance are obviously better than those of white latex or acrylic emulsion type organic putty, thereby preventing the film from dropping and saltpetering and prolonging the service life of the wall surface coating engineering, the waterborne inorganic slurry interior wall putty is low in cost, environment-friendly and non-toxic, and is capable of saving the coating cost, thereby having important practical value and environmental protection value.

Owner:广东嘉宝莉科技材料有限公司 +1

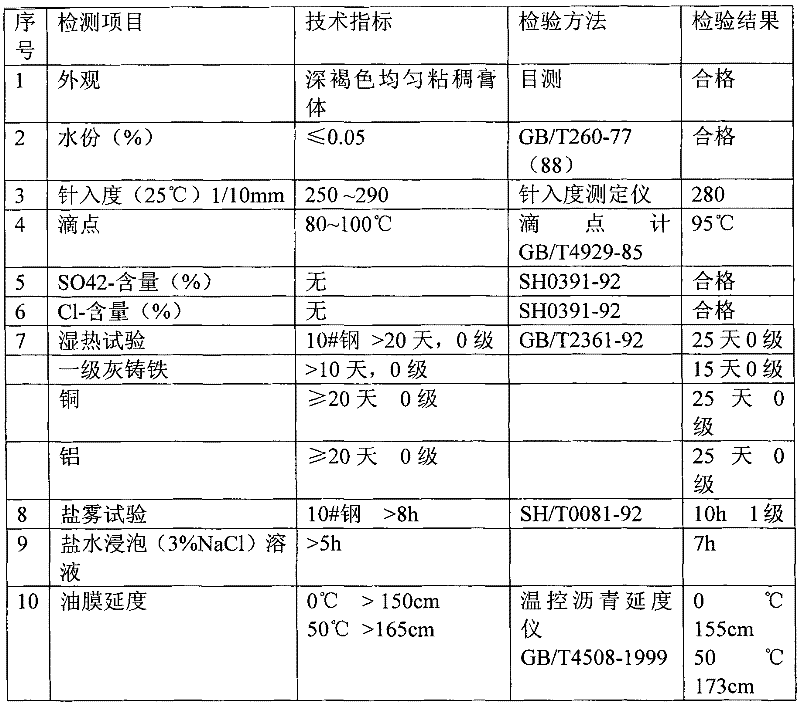

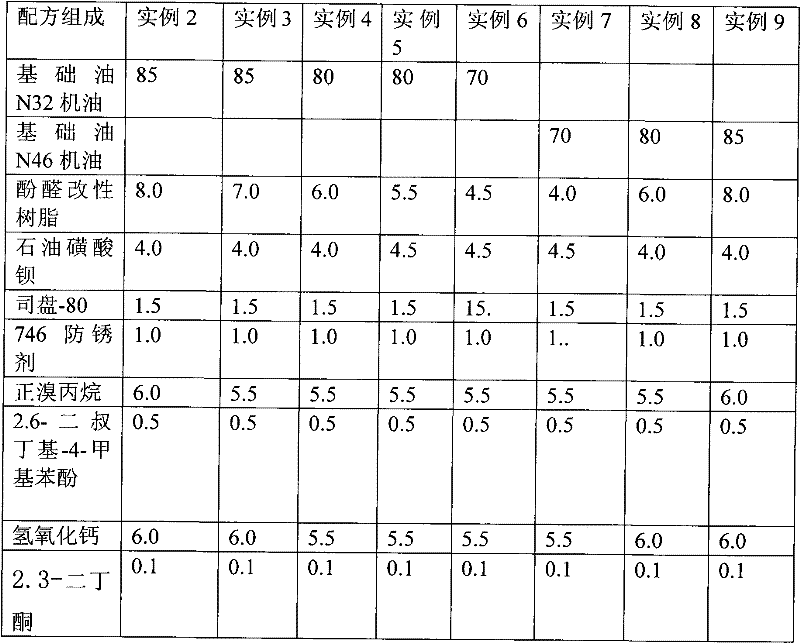

Long-acting antirust grease and preparation method thereof

ActiveCN102229845AImprove physical stabilityGood chemical stabilityLubricant compositionEngineeringFilm-forming agent

The invention belongs to the field of chemistry and relates to long-acting antirust grease and a preparation method thereof. The long-acting antirust grease mainly comprises the following components ( by weight): 70 to 90 parts of base oil, 3 to 6 parts of thickening agent, 4.5 to 8 parts of antirust additive, 4 to 8 parts of film-forming agent, 0.5 to 1 part of antioxidant, and 3 to 6 parts of assistant. The antirust grease has the characteristics that: the application of the grease is easy; the durability is high; the detachment of fasteners at next time is easy; the application range is wide; and the like. The long-acting antirust grease is suitable for outdoor steel fasteners which require anti-corrosion treatment and cannot be coated with paint.

Owner:麻城天安化工股份有限公司

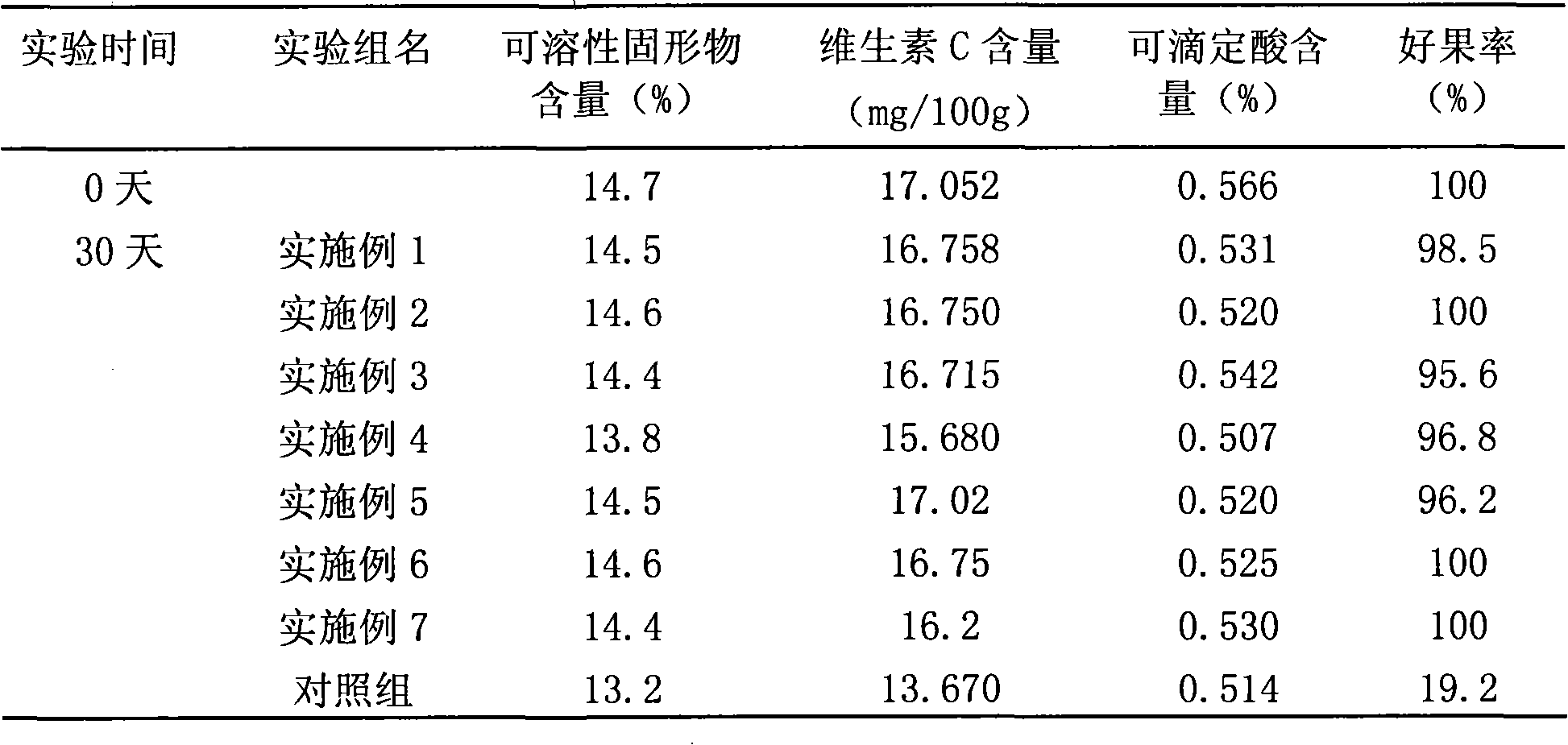

Composite antistaling agent for citrus shatangju

InactiveCN101263837ANon-perishableReduced vitamin C contentFruit and vegetables preservationVitamin CTitratable acid

The invention relates to a compound fresh-keeping agent for a Shatang orange, which comprises: one of from 0.2% to 4% of film agent of shell lac, chitosan, and wool lanline, a mixture of two or three of from 0.1% to 0.15% of antiseptic prochloraz, iprodione, pyrimethanil, fludioxonil, azoxystrobin and tecto, from 0.02% to 0.05% of the surface-active material of alkyl sodium sulfonate or a sucrose fatty acid ester, from 0.02% to 0.05% of potentiating agent of diethyl aminoethyl hexanoate or pine needle essential oil, and allowance water. The compound fresh-keeping agent has the advantages that the Shatang orange processed by the agent of the invention is not easy to rot during storage and transportation, the base and leaves of the fruit are kept, and the leaves are kept green, qualified fruit rate is over 95%, the content of vitamin C, titrable acid and dissolvable solid content is not distinctly lowered, which improves the economic value of Shatang orange.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI +1

Crystal color ceramic, crystal color glass, composite material for crystal color illuminating layer and technical method thereof

The invention discloses a crystal colorized ceramic and crystal colorized glass, substantially composite materials and process method of crystal colorized decorative layer, which comprises the following weight materials: dry-powder glaze 6-60, bond 15-50, additive 0-70, glass micro-ball 20-90; in the invention the surfaces of the ceramic and glass product adopt the crystal colorized materials and then are ornamented with patterns, and then sintered for a plurality of times at 400-860 DEG C so as to form a crystal colorized decorative layer. The product has the advantages of brocade-like straight light, wool-like side light, light-shift color-change, and special optical effect with strong solid feeling.

Owner:邓念东 +1

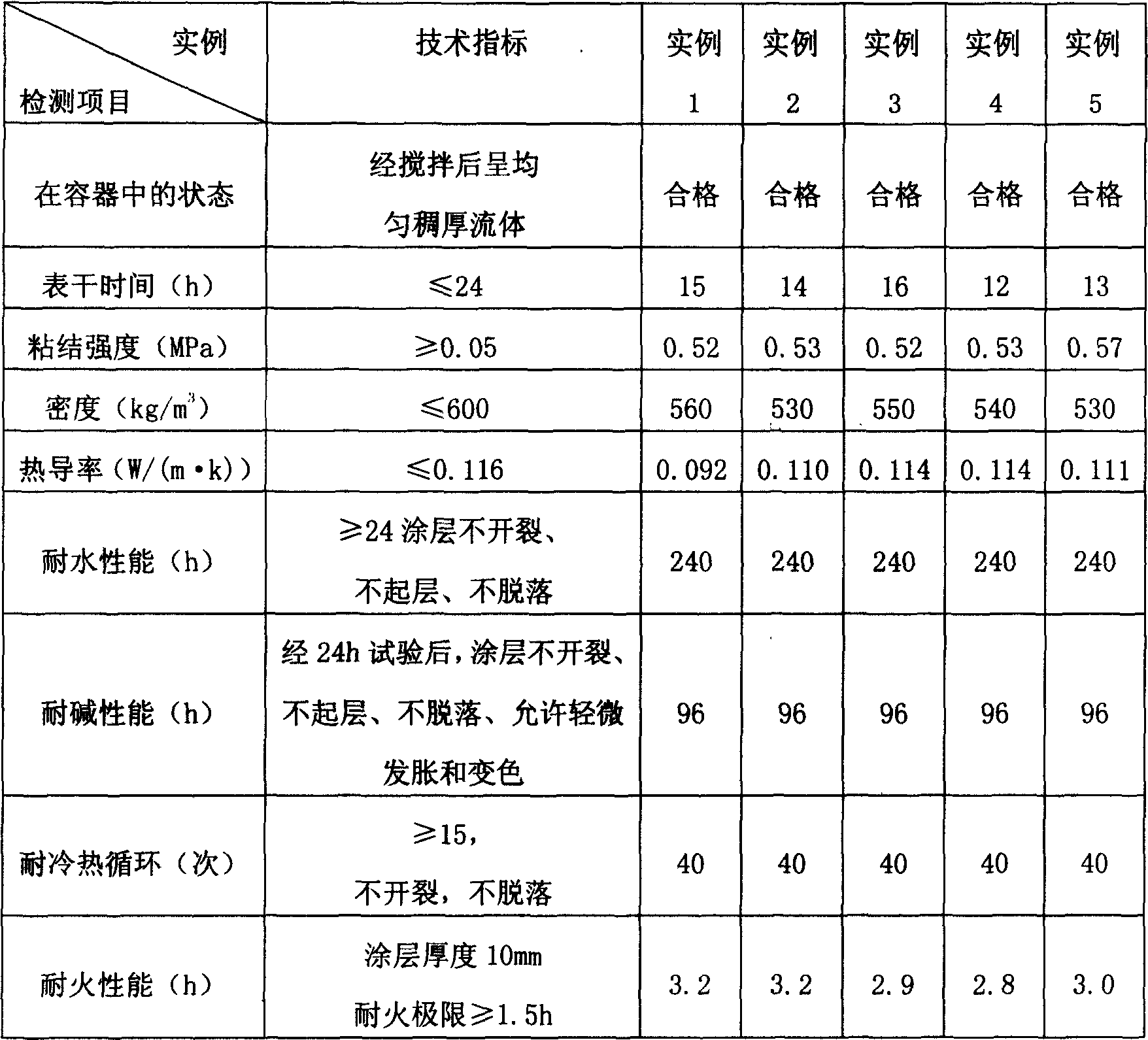

Tunnel fire retardant coating and preparation process and construction process thereof

InactiveCN101880145ASimple processImprove water retentionSolid waste managementPortland cementAluminum silicate

The invention provides a powdery mixture of a multi-component tunnel fire retardant coating, which is prepared from 582 resin, Portland cement, sepiolite, ammonium dichromate, light calcium carbonate, aluminum silicate, fly ash hollow floating beads, wollastonite powder, argil, cellulose ether, a concrete expanding agent, tin oxide and polypropylene fiber. The powdery mixture is prepared by throwing the fire retardant coating into a V-shaped forced mixer according to the proportion of the components; stirring the mixture for 10 to 15 minutes to prepare the powdery mixture; stirring water and the fire retardant coating powder in a weight ratio of 0.8-0.85 into thick paste; and spraying a tunnel from the waist to the top with spray painting equipment to reach the predetermined thickness.

Owner:成都威邦科技有限公司

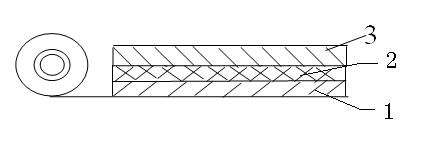

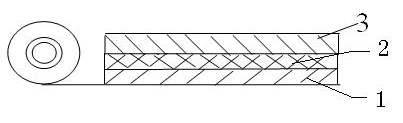

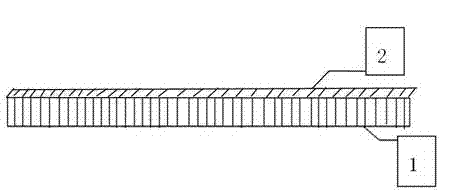

PET (polyethylene terephthalate) protective film for preparing flat-panel display

InactiveCN102134458AReduce polarityImprove cohesionFilm/foil adhesivesSynthetic resin layered productsTectorial membranePolyethylene terephthalate glycol

The invention discloses a PET (polyethylene terephthalate) protective film for preparing a flat-panel display, which is characterized by comprising an optical-level PET protective film base material and low-polarity pressure-sensitive adhesive, wherein the low-polarity pressure-sensitive adhesive is coated on the upper surface of the optical-level PET protective film base material. Since the pressure-sensitive adhesive has the characteristics of low polarity and high cohesive force, is inert, and can be instantaneously attached to the surface of the glass material of the flat-panel display, the protective film prepared from the pressure-sensitive adhesive, optical-level PET protective film and the like has the characteristics of no shedding, easy stripping after coating by vaporization, no adhesive residue, no pollution, high temperature resistance and static resistance, and can effectively avoid damaging the glass lens in the stripping process.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Wood wax oil and preparation technology thereof

The invention discloses wood wax oil for maintenance and decoration of buildings, furniture and the like and preparation technology thereof. The wood wax oil contains wood oil, linseed oil, catalpa oil, perilla oil, pine oil, castor oil, rosin modified resin, bee wax or wood wax and turpentine oil, wherein the content of each component is 5 to 10 percent; and each component is a pure natural extract. The preparation technology for the wood wax oil comprises the following steps: polymerizing the wood oil, the linseed oil, the catalpa oil, the perilla oil, the pine oil, the castor oil, the rosin modified resin and the bee wax or the wood wax at a high temperature of between 290 and 300 DEG; adding the turpentine oil into the polymerized product to dilute; filtering the mixture; and adding a drier into the filtered product to adjust. The wood wax oil has the advantages of natural health, good durability and permeability, and recoverability.

Owner:董学明

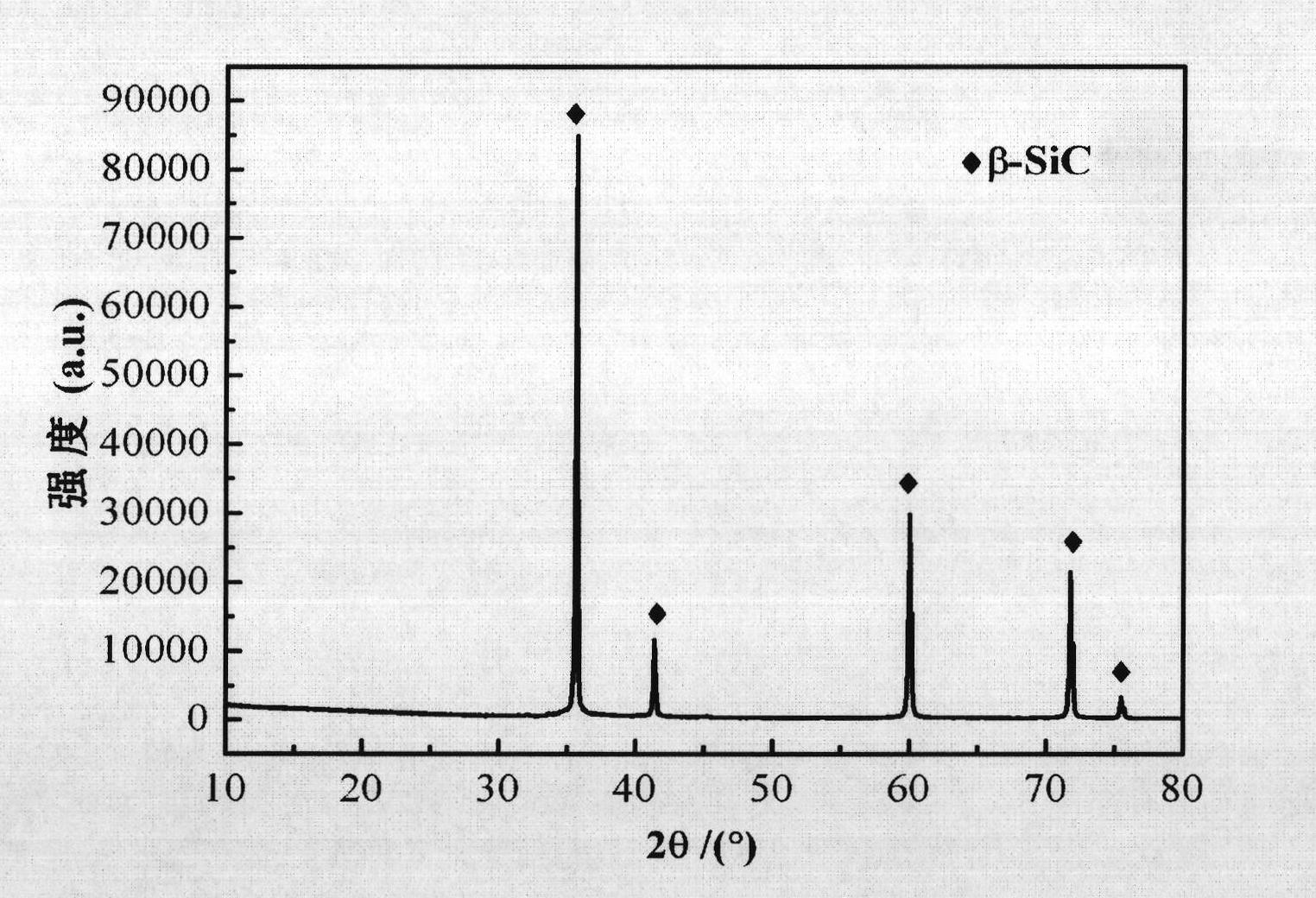

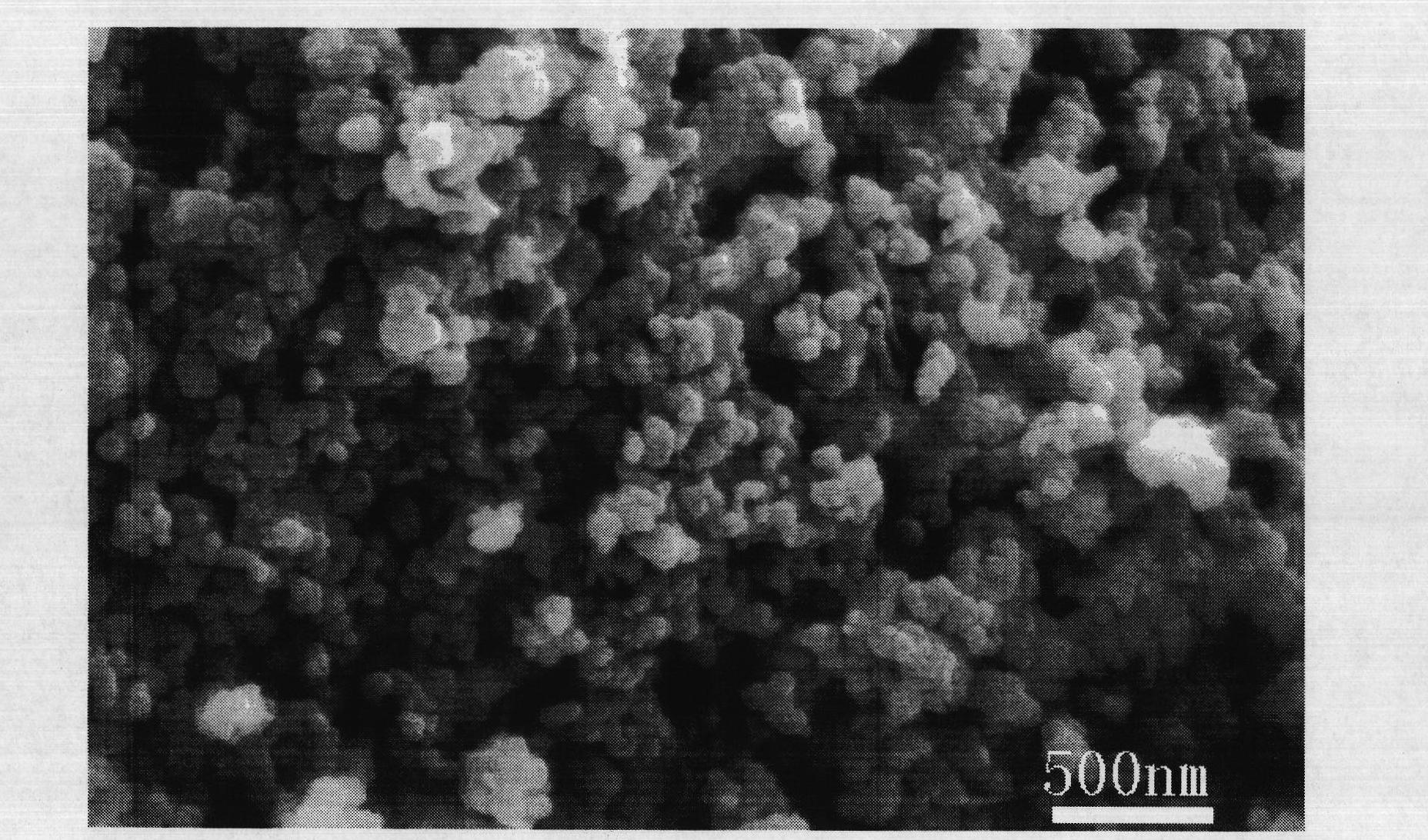

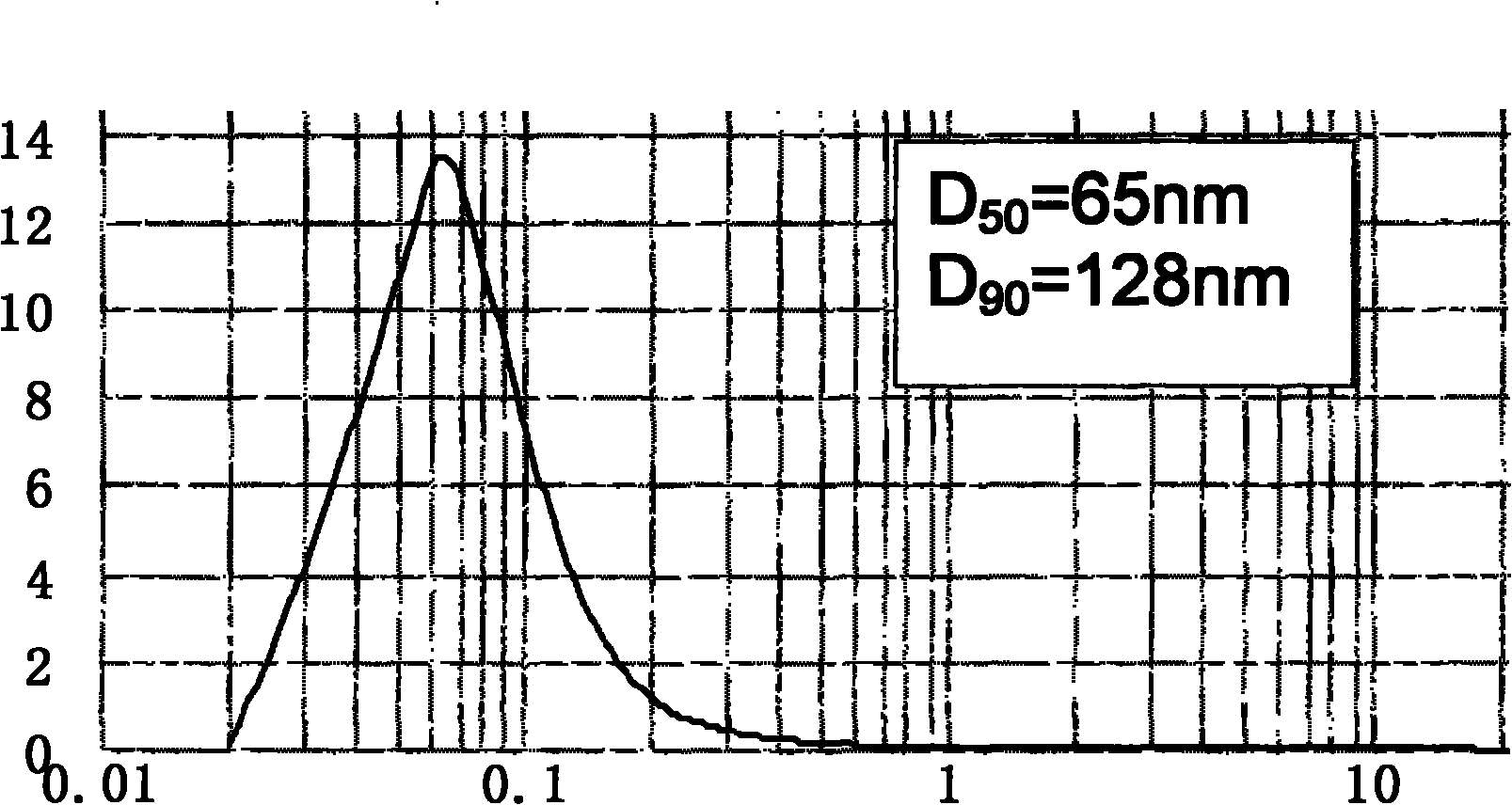

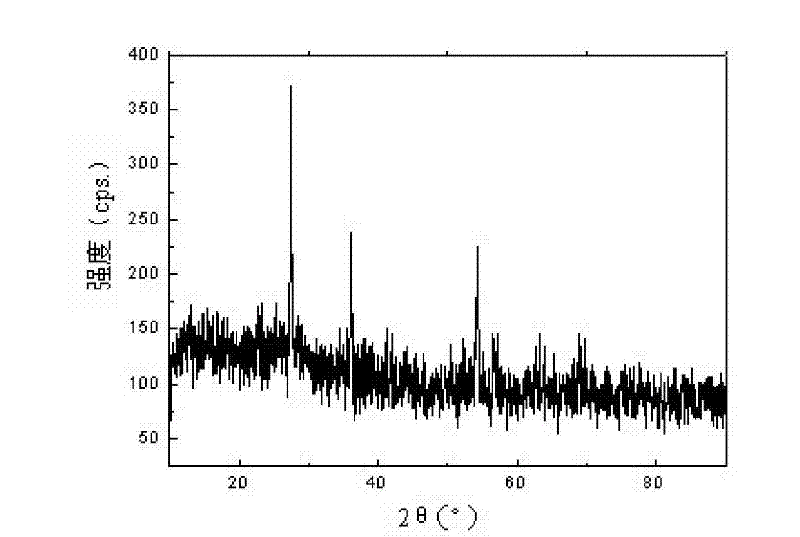

Nanometer silicon carbide-series infrared radiation coating and preparation method thereof

The invention belongs to the field of far infrared energy-saving coating used for a high-temperature industrial furnace, which particularly relates to a nanometer silicon carbide-series infrared radiation coating and a preparation method thereof. The coating is composed of a powder radiation material, a binding material, a slurry accessory ingredient and water, wherein the mass ratio of the waterto the powder radiation material is (0.5-2):1; the binding material is 10-30% of the total mass of powder radiation material; the slurry accessory ingredient is 0.1-3% of the total mass of powder radiation material; and the powder radiation material is composed of nanometer silicon carbide powder, zirconia powder, chromium hemitrioxide powder, ferric oxide powder, nickel oxide powder, bentonite powder and siliceous dust powder. The infrared energy-saving radiation coating disclosed by the invention has the advantages of high radiation coefficient and excellent thermal shock resistance. After high-temperature sintering, a sintering layer is formed on a refractory brick or cellucotton, the sintering layer can be firmly adhered on the surface of the lining of a kiln to perform the energy-saving effect on increasing radiant heat utilization and reducing heat loss.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Single system and composite fire retardant coating for tunnel

InactiveCN1687254AAvoid self-strength lossImprove performanceFireproof paintsCement coatingsAdhesiveUltimate tensile strength

The present invention relates to a production method of single system compounded tunnel fire-resisting paint. Its composition includes (by weight portion) 20.0-50.0 portions of adhesive formed from redispersible latex powder and aluminous cement, 55.0-85.0 portions of inorganic heat-insulating filler and 0.1-5.0 portions of adjuvant. Said fire-resisting paint not only has good fire-resisting property, but also has good water-proof and sound-insulating properties.

Owner:SICHUAN UNIV

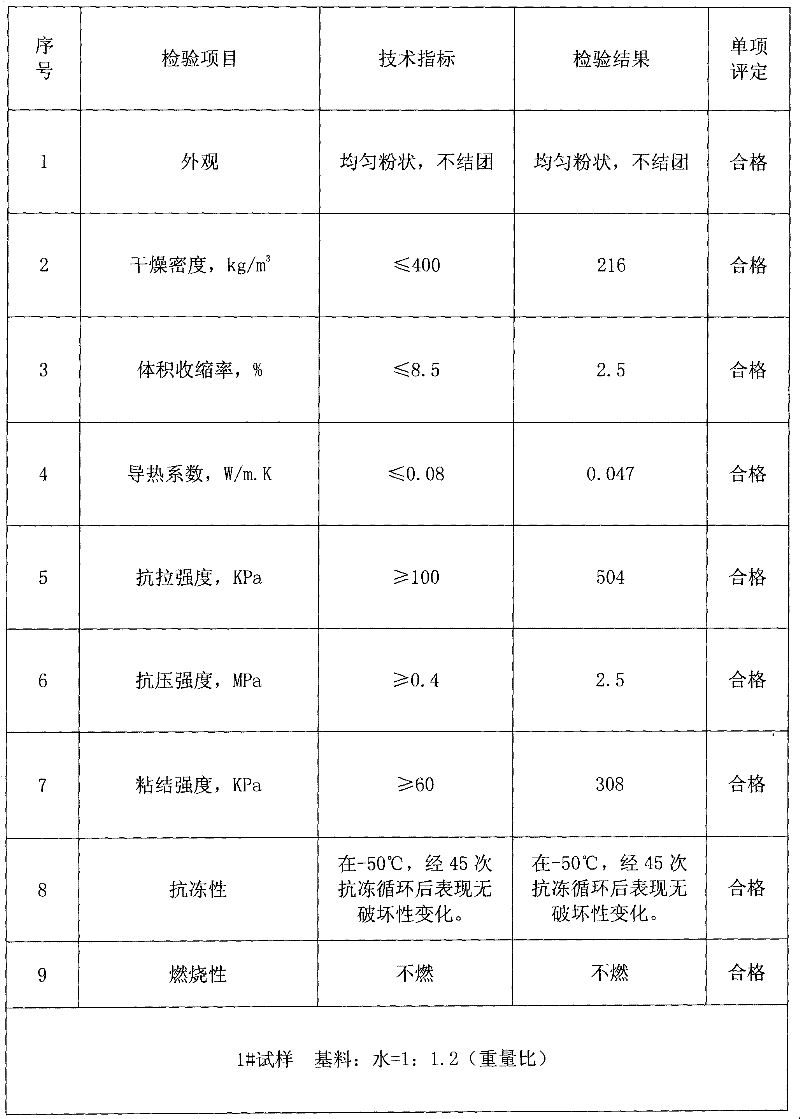

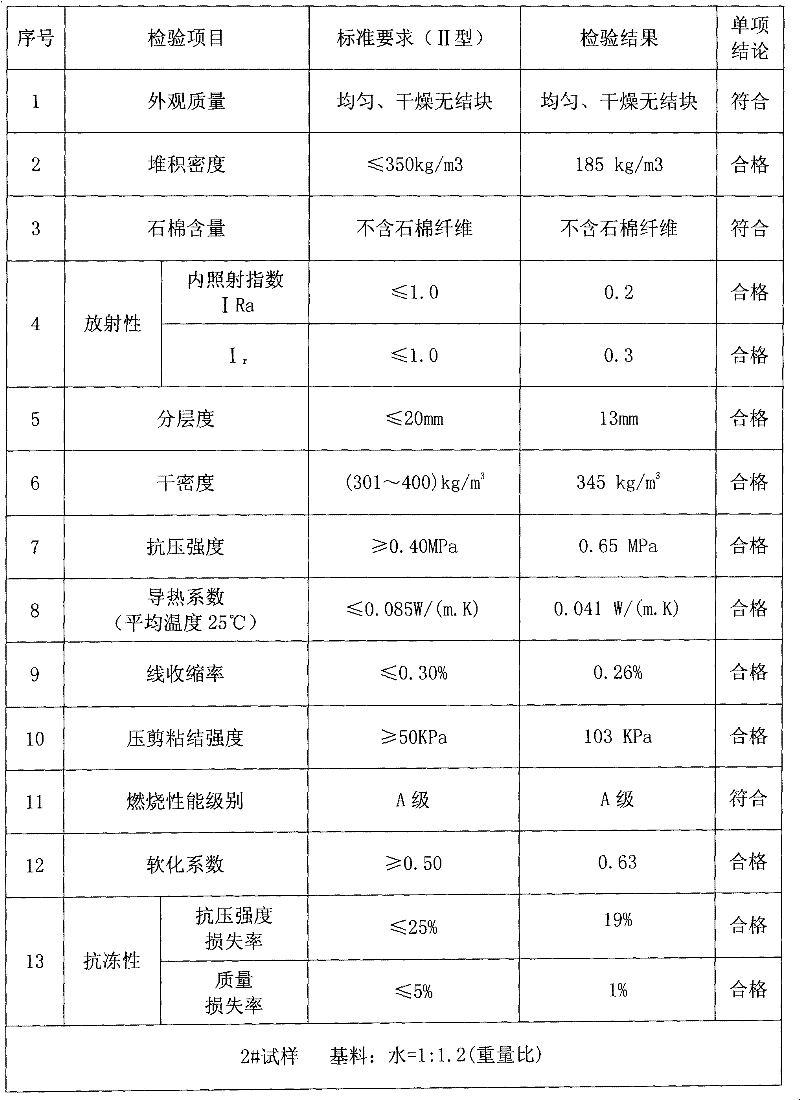

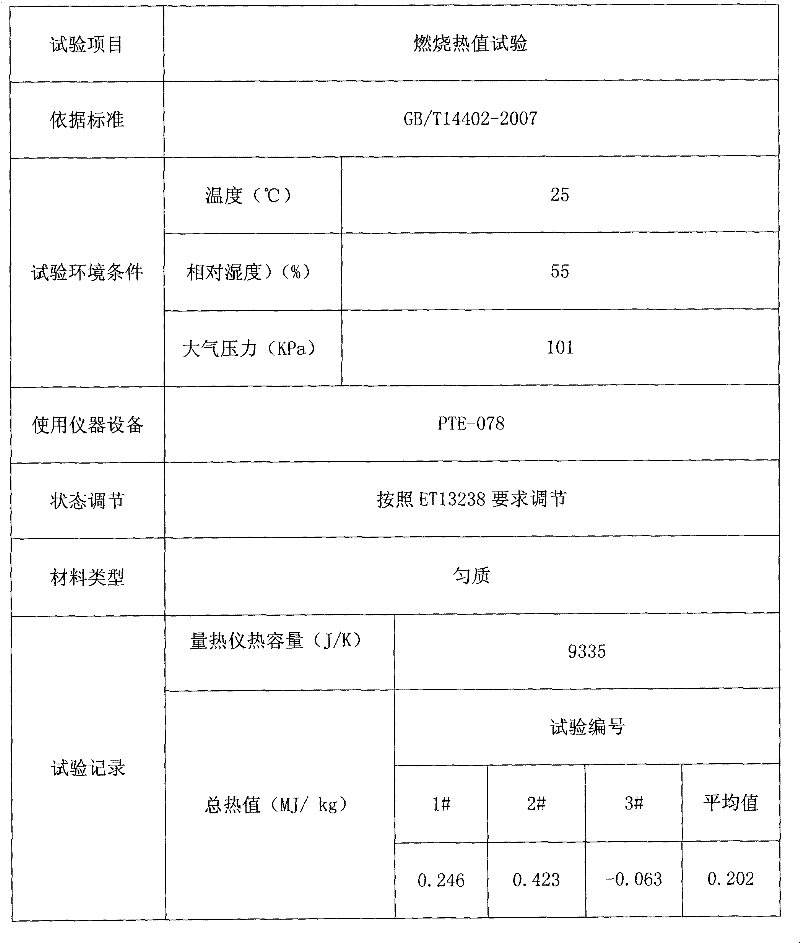

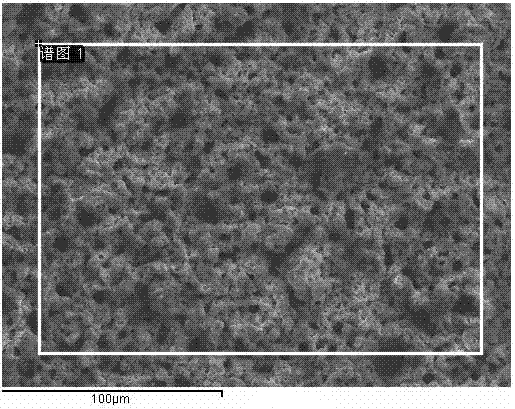

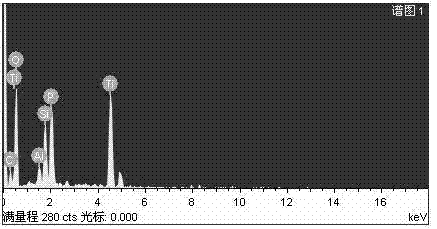

Siliceous heat-insulation composite material for wall

The invention relates to a siliceous heat-insulation composite material for a wall, which comprises base materials and water. The base materials mainly comprise closed-cell expanded perlite, cement, building gypsum, inorganic mineral substance fibers, high-viscosity attapulgite clay, redispersible rubber powder, hydroxypropyl methyl cellulose auxiliaries and a water repellent, wherein the inorganic mineral substance fibers comprise alumina silicate fibers, brucite fibers, mineral cotton fibers and the like, and when the material is used, the weight ratio of the base materials to the water is 1:1.2-1.3. The material as an amorphous powdery heat-insulation material is excellent in energy conservation, heat insulation, sound absorption, flame retardance reaching level A1, fireproofing, seismic resistance, crack control, flexibility and weatherability, does not chemically react with the wall, is high in strength and ageing resistance, avoids deformation, crack, hollowing, shedding and is the same as the wall in service life in use. The material is green, environment-friendly and non-toxic, is applicable to heat insulation of an inner wall and an outer wall made of various wall base materials, a splitting wall and heat-insulation energy-saving projects such as roofs, basements, garages, stairs, corridors, fire-fighting accesses and the like.

Owner:建平县德鑫外墙保温材料有限责任公司

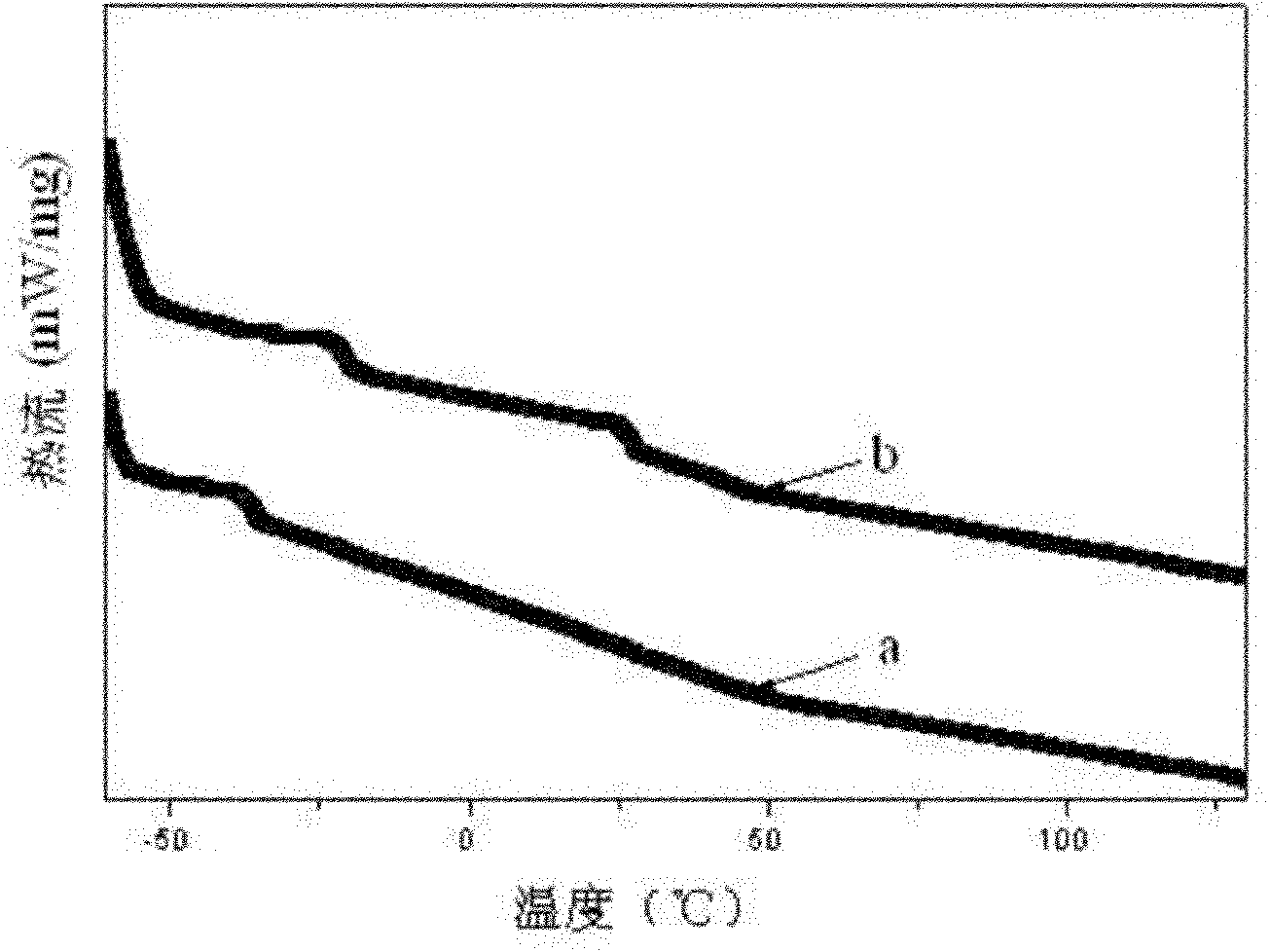

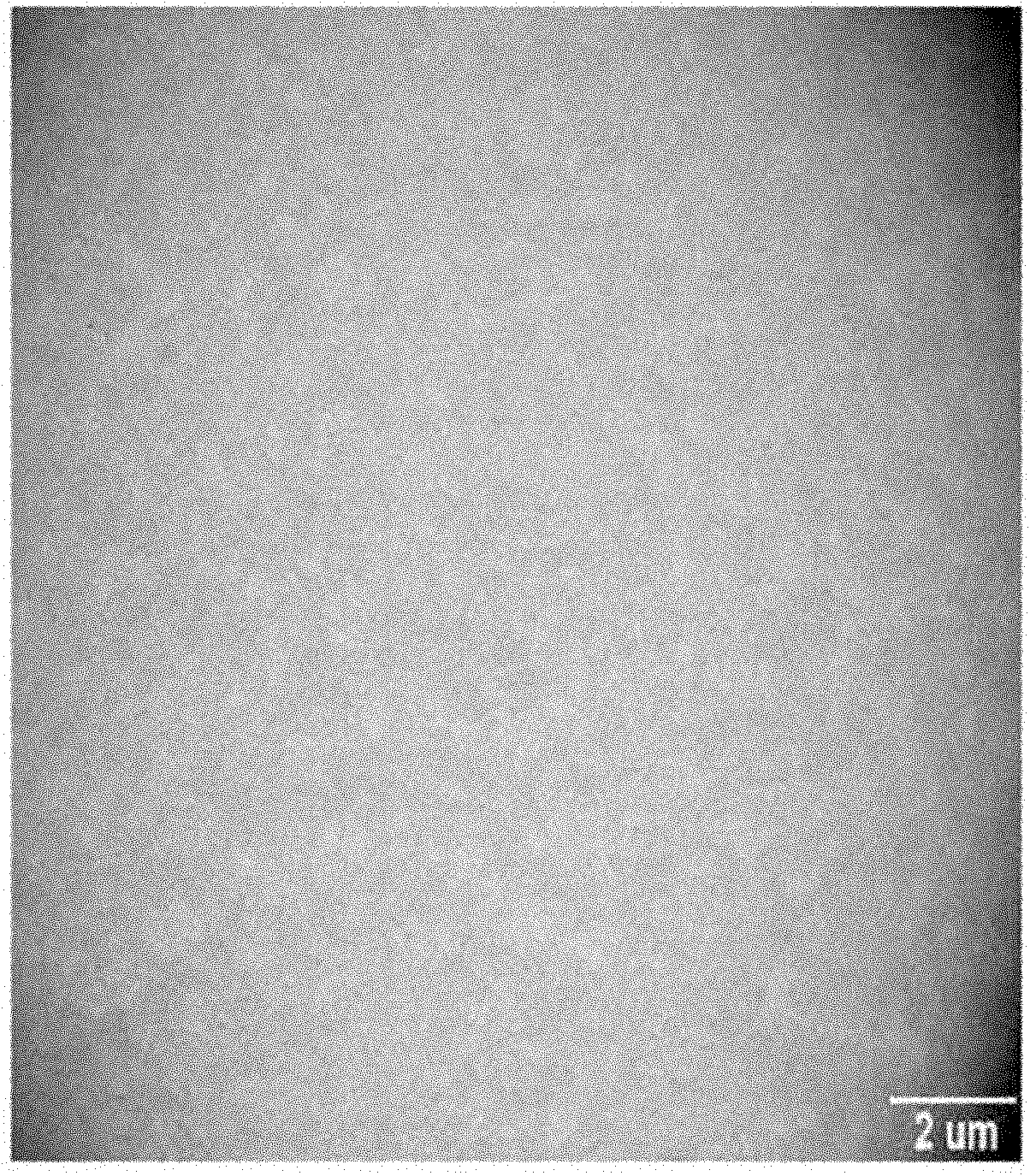

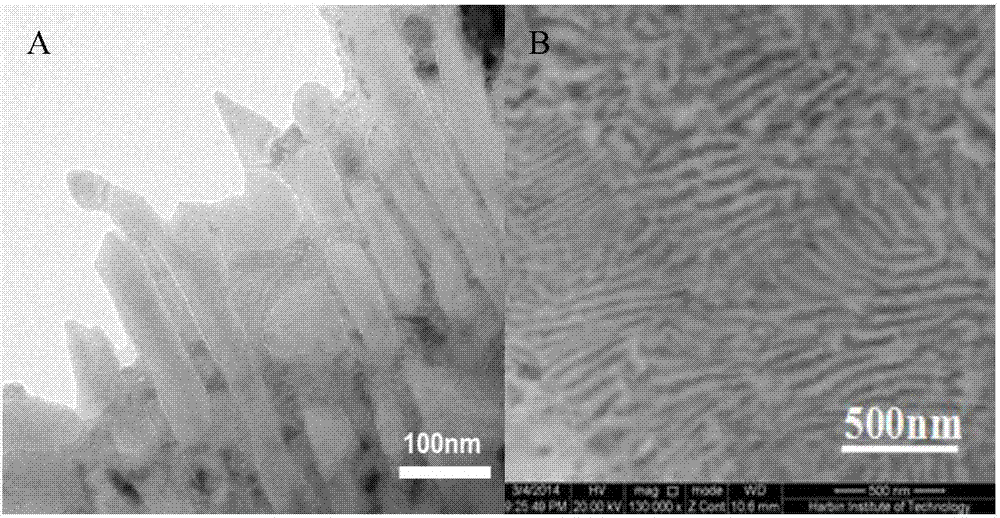

Method for preparing coating with thermostability and high emissivity on titanium alloy substrate

InactiveCN101748465AImprove bindingImprove high temperature resistanceSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a method for preparing a coating with thermostability and high emissivity on a titanium alloy substrate, relating to a method for preparing a coating on the titanium alloy substrate and solving the problems of low binding force and poor thermal shock performance of a coating with high emissivity on a titanium alloy surface in the prior art. The method comprises the following steps: firstly, grinding and cleaning the titanium alloy; secondly, preparing a major salt, a dispersing agent and an additive into colloid electrolyte; and thirdly, placing the titanium alloy in a stainless steel trough body filled with the electrolyte, and preparing the coating with thermostability and high emissivity on the titanium alloy substrate under the action of a pulse microarc oxidation power supply by using the titanium alloy as an anode and the trough body as a cathode. For the coating prepared by the invention, the emissivity is 0.8-1.0 under the temperature of 700 DEG C, the binding force between the coating and the substrate is good, the tensile strength of the coating is no less than 30 MPa, and the shear strength of the coating is 15 MPa-25 MPa. The coating can not fall off when hot shock circulation is carried out for 100 times under the testing condition that the temperature is 700 DEG C to room temperature, thereby the coating can be used as a thermal protection layer of an outer skin of a hypersonic velocity aerocraft.

Owner:HARBIN INST OF TECH

Method for preparing high-strength heat-resistant silicon resin modified acrylic ester pressure-sensitive adhesive

InactiveCN101979454ANot curlyDoes not fall offFilm/foil adhesivesPolyureas/polyurethane adhesivesCross-linkPolymer science

The invention discloses a method for preparing a high-strength heat-resistant silicon resin modified acrylic ester pressure-sensitive adhesive and relates to a method for preparing a modified acrylic ester pressure-sensitive adhesive. The method solves the problems of low peel strength and low temperature resistance of the conventional organic silicon modified acrylic ester pressure-sensitive adhesive. The method may comprise the following steps of: adding part of dibenzoyl peroxide, part of solvents, part of soft monomers and part of hard monomers into a reaction kettle to react; mixing MQ silicon resin, the residual soft monomers, the residual hard monomers, the residual dibenzoyl peroxide and the residual solvents uniformly and adding the mixture into the reaction kettle to react; coating the obtained adhesive solution on a base material; and drying. The method may also comprise the following steps of: adding part of solvents, part of dibenzoyl peroxide, part of soft monomers and part of hard monomers into the reaction kettle to react; mixing a functional monomer, hydroxyl-containing SQ silicon resin, the residual soft monomers, the residual hard monomers, the residual dibenzoyl peroxide and the residual solvents uniformly and adding the mixture into the reaction kettle to react; mixing the obtained adhesive solution and a cross-linking agent uniformly and coating the mixture on the base material; and drying. The high-strength heat-resistant silicon resin modified acrylic ester pressure-sensitive adhesive has the peel strength of 14 to 18 N / 25mm and is applied in the fields of high temperature of 200 DEG C.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Low temperature fast curing adhesive for mounting chip element and device

The low temperature fast curing adhesive for mounting chip element and device is compounded with liquid epoxy resin 30-60 wt%, diluent 5-15 wt%, curing agent 8-20 wt%, promoter 2-10 wt%, thixotropic agent 4-12 wt%, plasticizer 5-10 wt%, pigment 1-3 wt% and inorganic filler 0-20 wt%. It has curing period of 80 sec at 120 deg.c and 180 sec at 100 deg.c, adhesion strength of 10-20 MPa, absolute resistivity high than 1013 Ohm. cm, water absorption less than 0.5 %, storage life over 2 months at 20 deg.c, and zero rolling. It is used in the surface mounting of electronic elements and device.

Owner:三友(天津)高分子技术有限公司

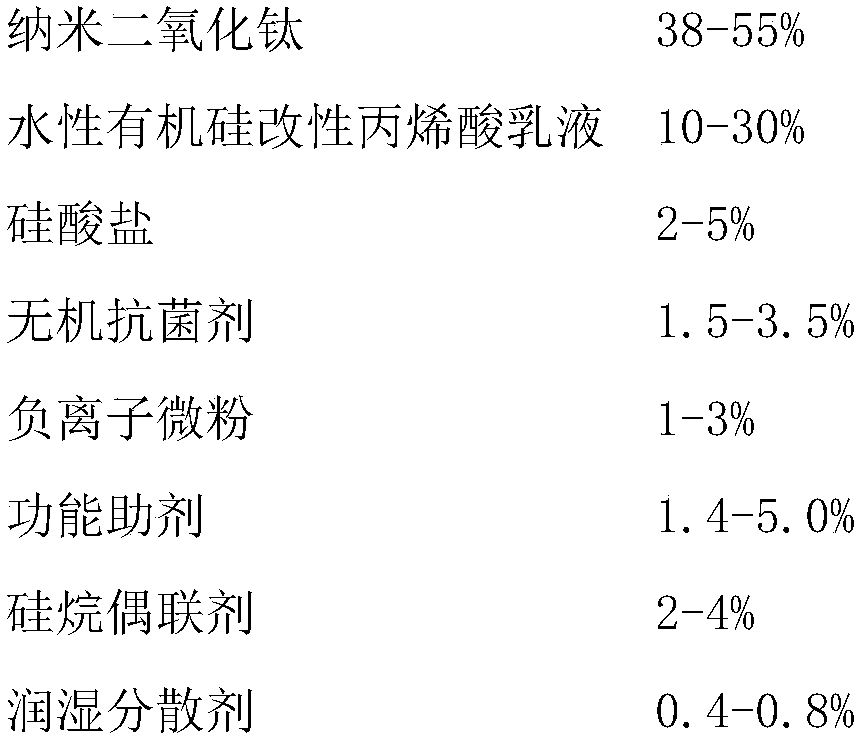

Water-based nanometer titanium dioxide photocatalytic sterilization purification coating and preparation method thereof

InactiveCN108485441APurifying airPrevent mildewAntifouling/underwater paintsPaints with biocidesWater basedCement mortar

The invention discloses a water-based nanometer titanium dioxide photocatalytic sterilization purification coating and a preparation method thereof. The coating is prepared from 38-55 wt% of nanometertitanium dioxide, 10-30 wt% of a waterborne organosilicone modified acrylic emulsion, 2-5 wt% of silicate, 1.5-3.5 wt% of an inorganic antibacterial agent, 1-3 wt% of negative ion micro-powder, 1.4-5.0 wt% of a functional assistant, 2-4 wt% of a silane coupling agent, 0.4-0.8 wt% of a wetting dispersant, and the balance of water. The coating has air purifying and bacterium killing effects, is green and environmentally friendly, has excellent anti-aging property, scrub resistance, cohesiveness, corrosion resistance and the like, can directly replace putty powder and a latex paint, and can be directly firmly bonded with a cement mortar wall without peeling, shedding or cracking.

Owner:合肥易美特建材有限公司

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

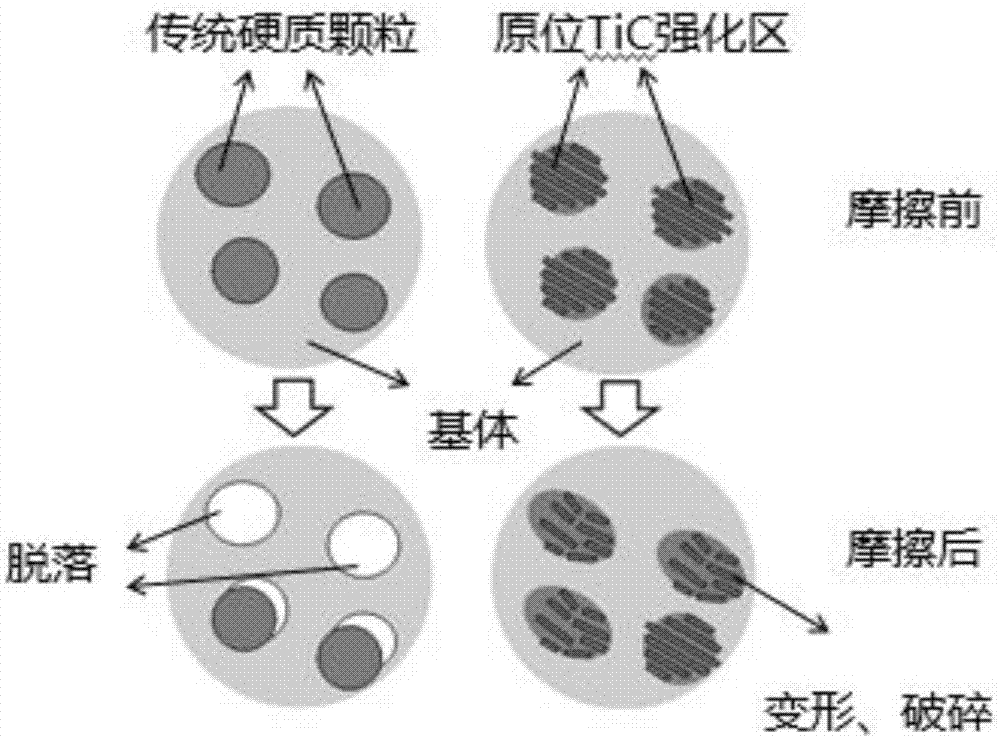

Brake pad material for high-speed railway passenger train and preparing method thereof

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

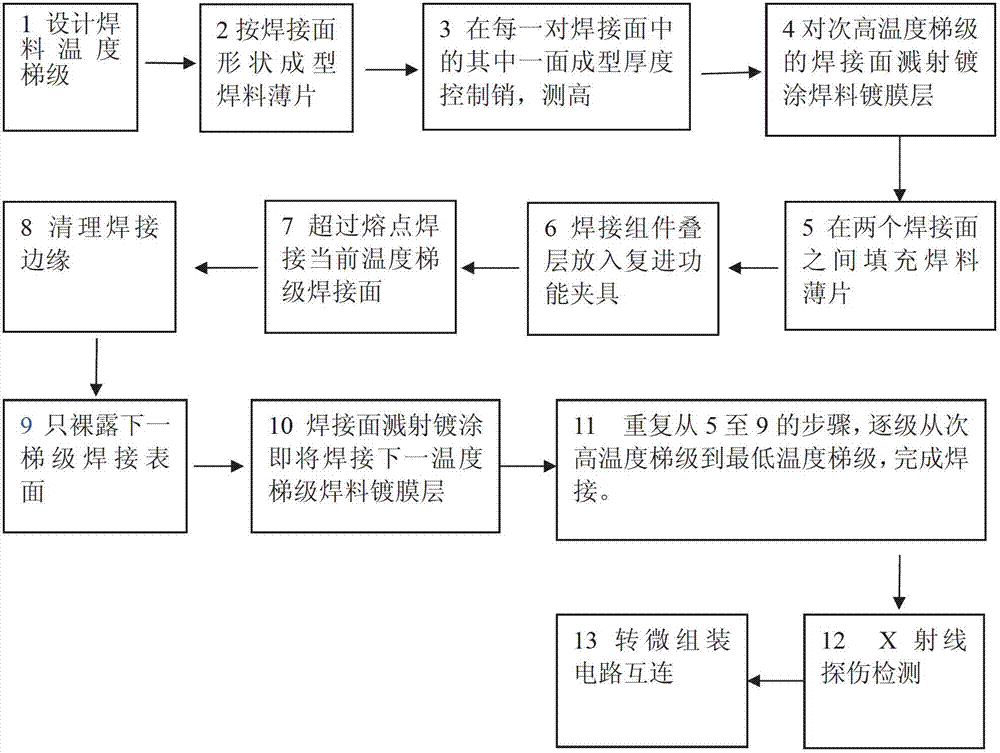

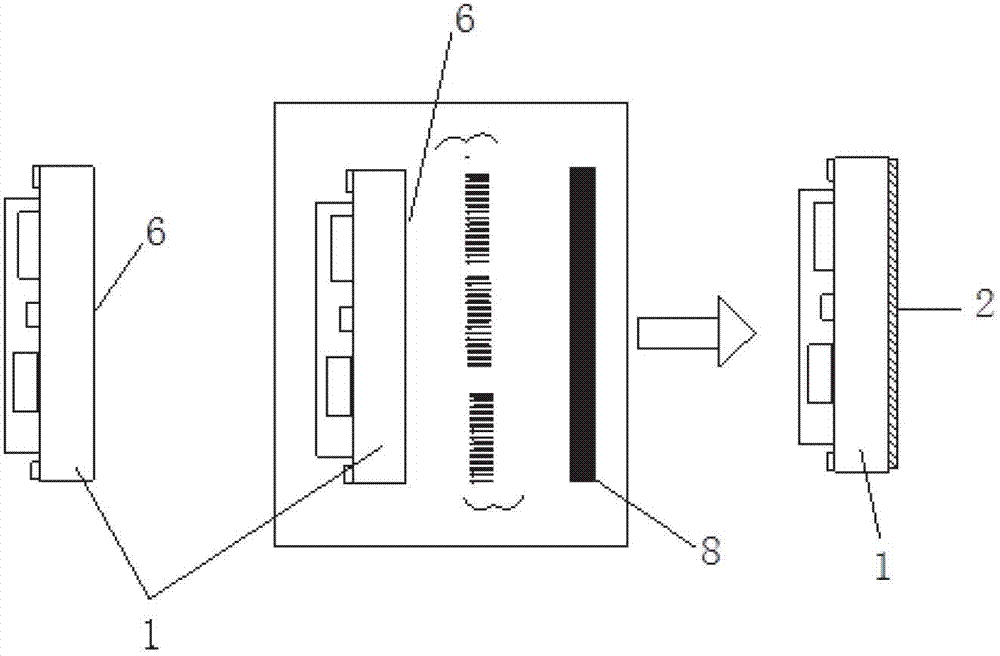

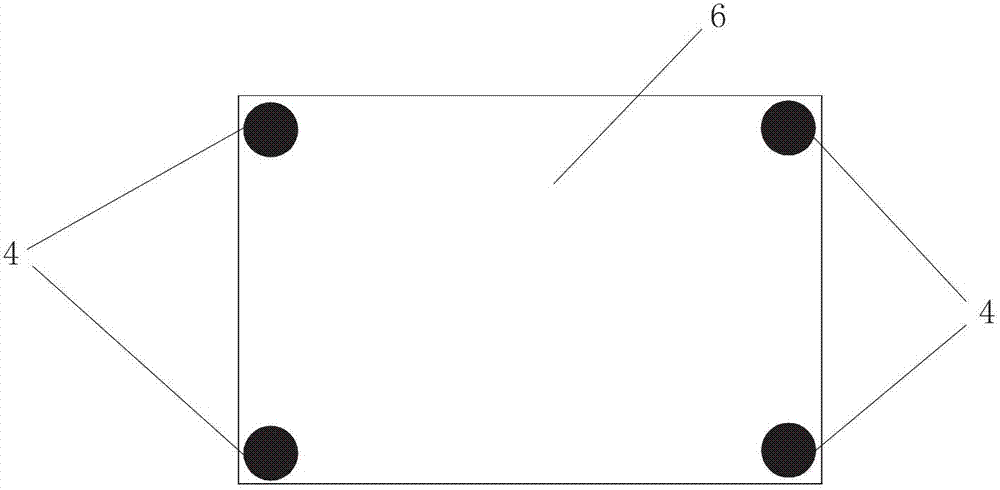

Process for welding electronic microcomponents based on multi-temperature gradient

InactiveCN102950350AEfficient removalNo discharge restrictionsSoldering apparatusElectronic componentRecoil pressure

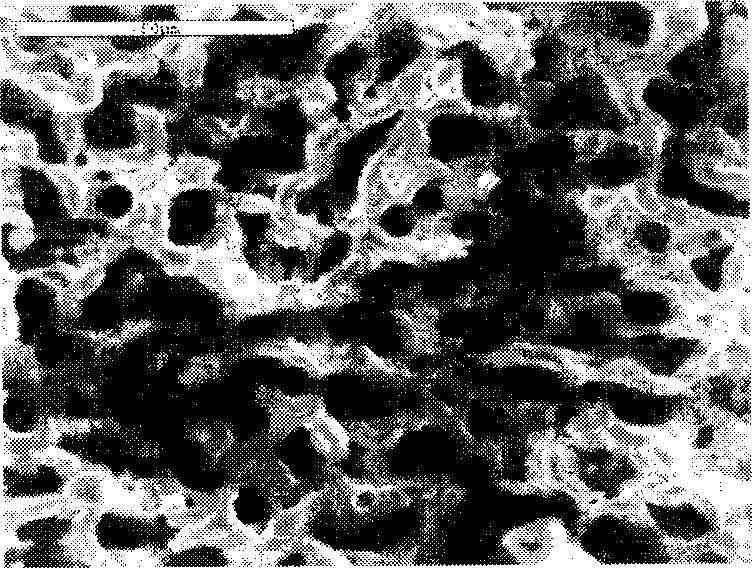

The invention discloses a process for welding electronic microcomponents based on a multi-temperature gradient. The process is simple, convenient, efficient, stable and reliable in processing quality, good in welding flowability and little in welding hollows. The process is realized by the following technical scheme: designing the temperature gradient of welding fluxes according to melting points of different welding fluxes and respectively manufacturing welding flux slices at different temperature gradients from a secondary high temperature to a minimum temperature; dividing a function substrate and a transition parent plate on each electronic microcomponent into welding surfaces of the welding fluxes at different temperature gradients and coating a welding flux film coating layer on the welding surfaces directly and respectively by sputter coating; arranging welding flux thickness control pins at more points on the welding surfaces of the electronic component; laminating the electronic microcomponents (1), the welding flux slices (3) and the substrate component (5) sequentially, putting into a clamp with a counter-recoil pressure holding mechanism and putting the clamp into a furnace for vacuum welding; firstly completing the welding at a high temperature gradient, and then protecting other surfaces, which are not used for the welding at the next temperature gradient, of the substrate component, and coating one welding flux film coating layer on the welding surfaces respectively by the sputter coating at the next temperature gradient.

Owner:10TH RES INST OF CETC

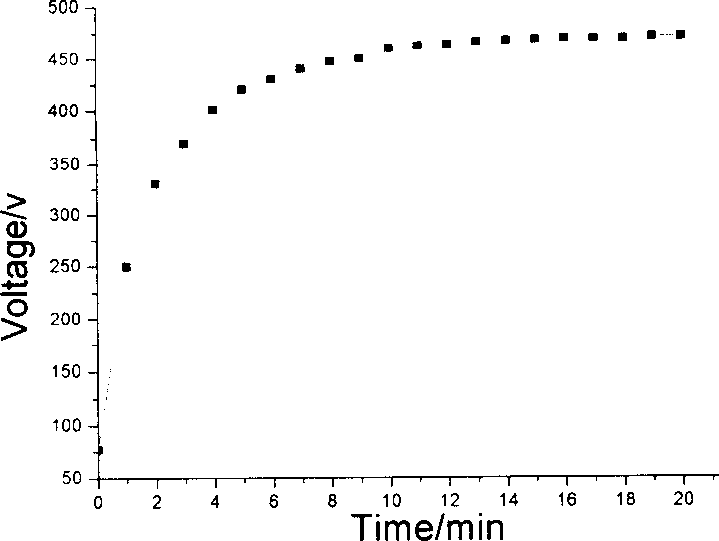

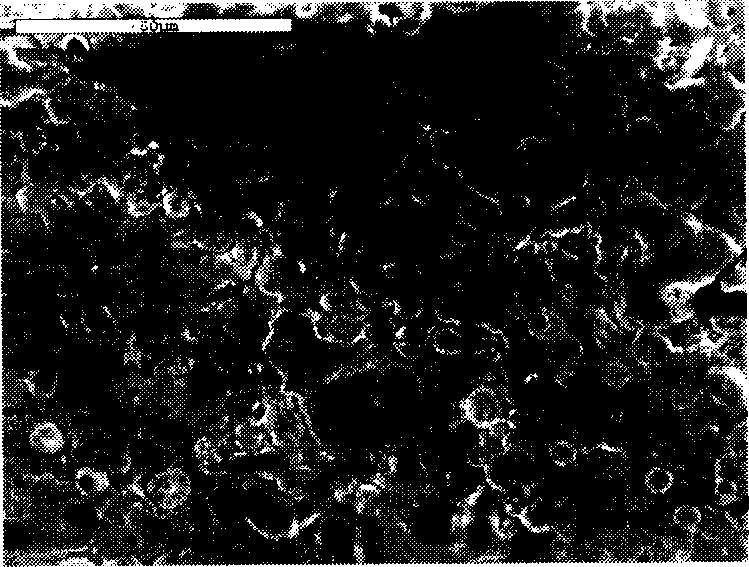

Electrolytic solution for differential arc oxidization surface treatment of magnesium aluminum alloy in aluminates system

InactiveCN1737210ABroad marketHigh electrochemical impedanceAnodisationElectrolysisPlasma electrolytic oxidation

The invention relates to an electrolytic solution used to oxygenize surface of aluminum-magnesium alloy work-piece by differential arc. Said electrolytic solution comprises 4-40g / L of sodium aluminate, 0-10g / L of caustic soda and other assistants. The invention can generate a ceramic film with smooth surface, strong resistance to soiling, corrosion resistance and great mechanical behavior.

Owner:JILIN UNIV

Method for preparing anticorrosive paint for directly-buried thermal power pipeline insulating layer

InactiveCN102775863ALow thermal conductivityImprove protectionAnti-corrosive paintsFiberInsulation layer

The invention discloses a method for preparing an anticorrosive paint for a directly-buried thermal power pipeline insulating layer. The anticorrosive paint comprises deionized water, propylene glycol, a dispersing agent, a wetting agent, an antifoaming agent, a corrosion inhibitor, a coupling agent, a ceramic fiber, a needle-shaped crystal whisker, titanium dioxide, heat insulation powder, platy fillers, modified water-dilutable resin emulsion, a film-forming addictive, a hollow microsphere, a flatting agent and a thickening agent. The method comprises the following steps of: putting the materials into a dispersing tank in several times and in batch; and stirring the mixture at different rotation speeds so as to prepare the anticorrosive paint. The anticorrosive paint does not crack or drop for a long time at the temperature of 150 DEG C when heat conduction coefficient is up to 0.040W / m.k and a hemisphere emissivity is up to 0.87-0.89. The anticorrosive paint is high in physical and mechanical properties of infrared radiation capability, fracture elongation ratio, adhesive force and the like, is good in water resisting property and is low in water absorption ratio, so that moisture absorption and water seepage are prevented under the underground environment, corrosion of pipelines is avoided, and the requirement of the insulating layer in the directly-buried laying thermal insulation technology is met.

Owner:洛阳双瑞防腐工程技术有限公司

Coated slow-release urea containing double inhibitors and preparation method thereof

InactiveCN101580444ADoes not fall offHigh organic contentAgriculture gas emission reductionUrea compound fertilisersHuskNitrogen

The invention provides a method for preparing mushroom culturing material. The mushroom culturing material comprises the following compositions by weight percentage: 35 to 55 percent of cotton seed hulls, 25 to 45 percent of rice bran, 10 to 16 percent of bran, 1.5 to 2 percent of bean cakes, 0.5 to 1 percent of lees, 0.5 to 1 percent of peanut shells, 0.5 to 1 percent of gypsum, 1.5 to 2 percent of sorghum husks, 0.1 to 0.3 percent of Sanmate, 0.1 to 0.3 percent of nitrogen phospho potash complex fertilizer, 0.1 to 0.3 percent of oxygenation powder, and 0.5 to 0.8 percent of corn meal. The method comprises the following steps: combining the cotton seed hulls, the rice bran, the bran and the bean cakes together according to the proportion; pouring the mixture into a crushing mill to be crushed into particles with about 120 meshes; adding the lees, the peanut shells, the gypsum, the sorghum husks, the Sanmate, the nitrogen phsopho potash complex fertilizer, the oxygenation powder and the corn meal into the particles according to the proportion after the particles are taken out; and pouring the mixture into a mixer to be mixed for 60 minutes and taken out, adding water according to the proportion of 1:1.3-1:1.5 into the mixture to be evenly piled and fermented for 6 hours to produce a qualified culturing material.

Owner:PANJIN STRONG FERTILIZER +1

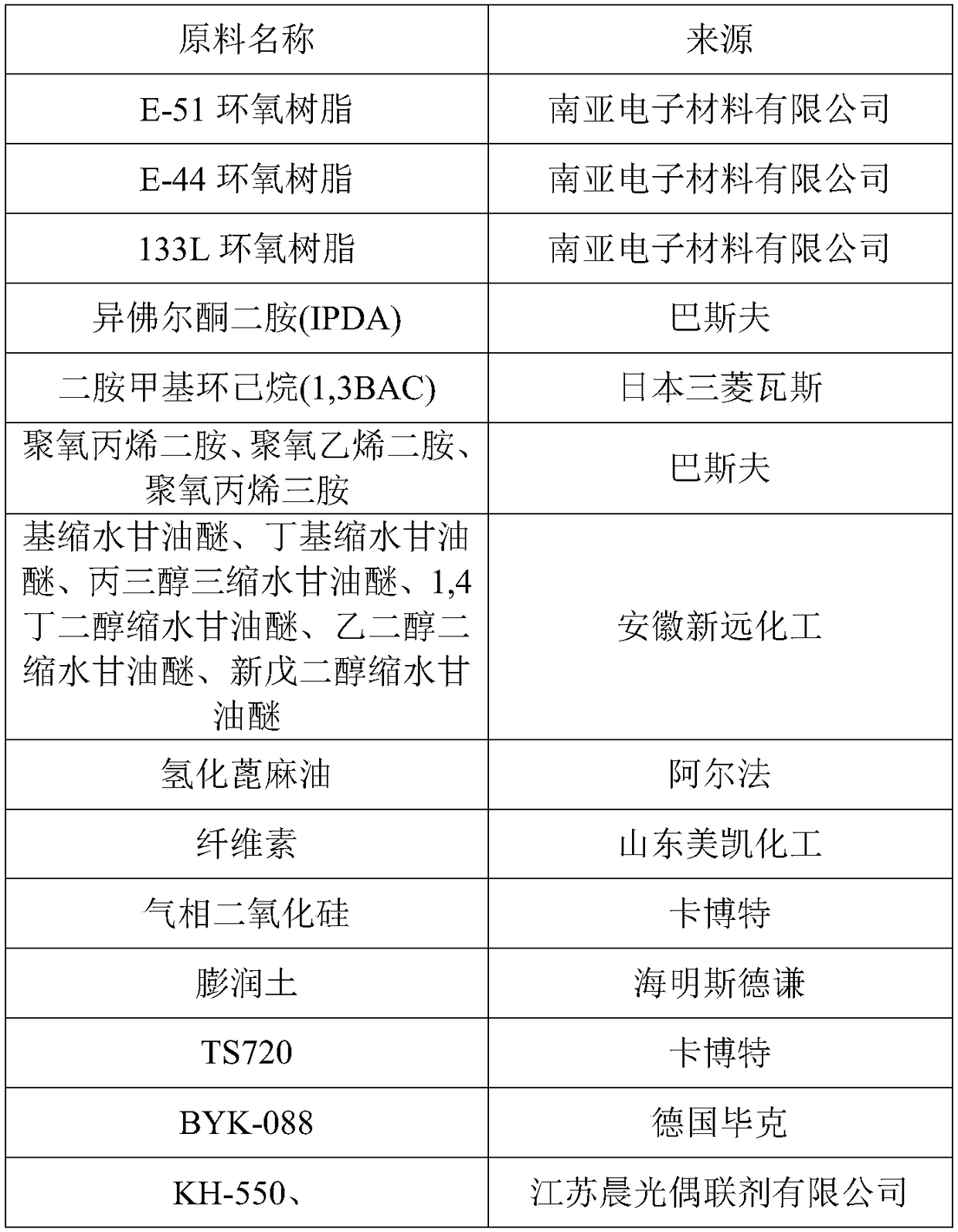

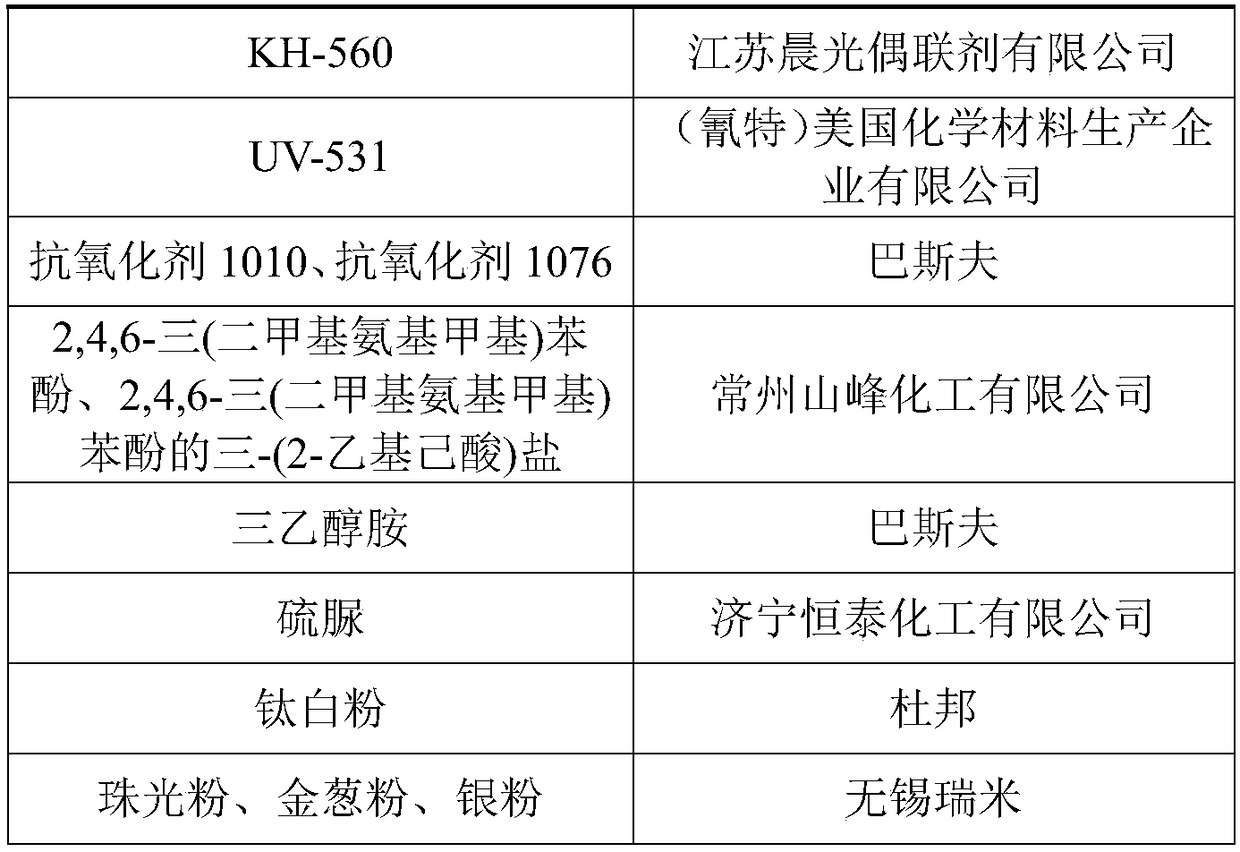

Two-component sealant sewing agent and method for preparing same

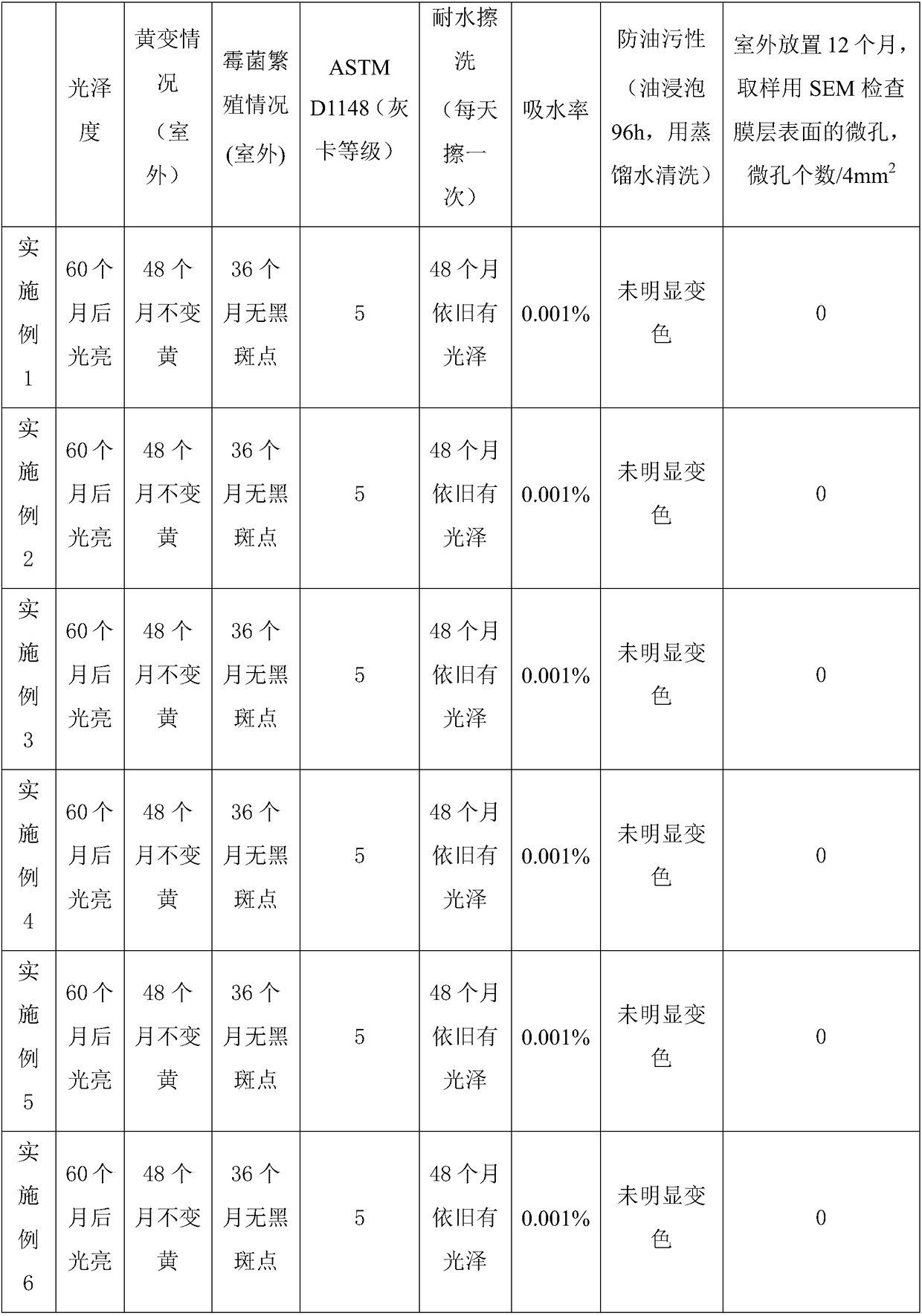

ActiveCN109486460AImprove room temperature curing performanceOvercome the problem of easy curing at room temperatureNon-macromolecular adhesive additivesEpoxy resin adhesivesAntioxidantUltraviolet

The invention discloses a two-component sealant sewing agent. The two-component sealant sewing agent comprises a component A and a component B. The component A comprises, by weight, 30-100 parts of E-51 epoxy resin, 0.1-20 parts of E-44 epoxy resin, 1-50 parts of 133L epoxy resin, 1-20 parts of reactive diluents, 1-15 parts of thixotropic agents, 0.01-1 part of defoaming agents, 0-10 parts of coupling agents, 0.05-3 parts of ultraviolet absorbents, 0.001-1 part of purple blue-phase toner and 0.05-1 part of antioxidants; the component B comprises, by weight, 50-100 parts of curing agents, 0.1-20 parts of accelerators, 1-15 parts of thixotropic agents, 1-15 parts of body pigment and 3-20 parts of coupling agents. The two-component sealant sewing agent has the advantages that the prepared two-component sealant sewing agent is free of water absorption, blackening and mildew, is easy to clean and high in strength and brightness and is scrub-resistant, and oil pollution can be prevented by the two-component sealant sewing agent; the toughness of materials can be greatly enhanced, and the two-component sealant sewing agent is an environment-friendly edge sealing material with enhanced adhesive effects and the enhanced adhesive performance.

Owner:HUNAN KOSEN NEW MATERIAL

Hot curing solder resistant printing-ink composition

The invention relates a hot-set solder resisting ink composition for production of printed circuit board which is prepared by combining some of heat hardening resin 30-70% (weight ratio), curing agent 2-8%, deflocculating agent 5-30% and filler 0-30%. The printed circuit board made from the hot-set solder resisting ink composition provided by the invention possesses good heat-proof quality, fast adherence, high degree of glossiness, and less odor.

Owner:DAHUA GROUP

Double-curing vacuum plating UV (Ultraviolet) coating finish

ActiveCN102925052AImprove permeabilityHigh glossPolyurea/polyurethane coatingsUrethane acrylateSolvent

The invention relates to double-curing vacuum plating UV (Ultraviolet) coating finish. Hydroxyl polyurethane acrylate with a high functional group and hydroxyl polyurethane acrylate with a low functional group are used as main components, a photoinitiator and isocyanate are used as curing agents, a wetting dispersant and a flatting agent are used as auxiliary materials, inorganic fillers are mixed, a solvent is used as a viscosity modifier, and all the components are mixed to prepare the double-curing vacuum plating UV coating finish. The product is widely applied to adornment of goods including plastic electronic products such as mobile phones and electrical equipment, as well as cosmetic boxes, automobile lamp cups and the like.

Owner:深圳市深赛尔股份有限公司

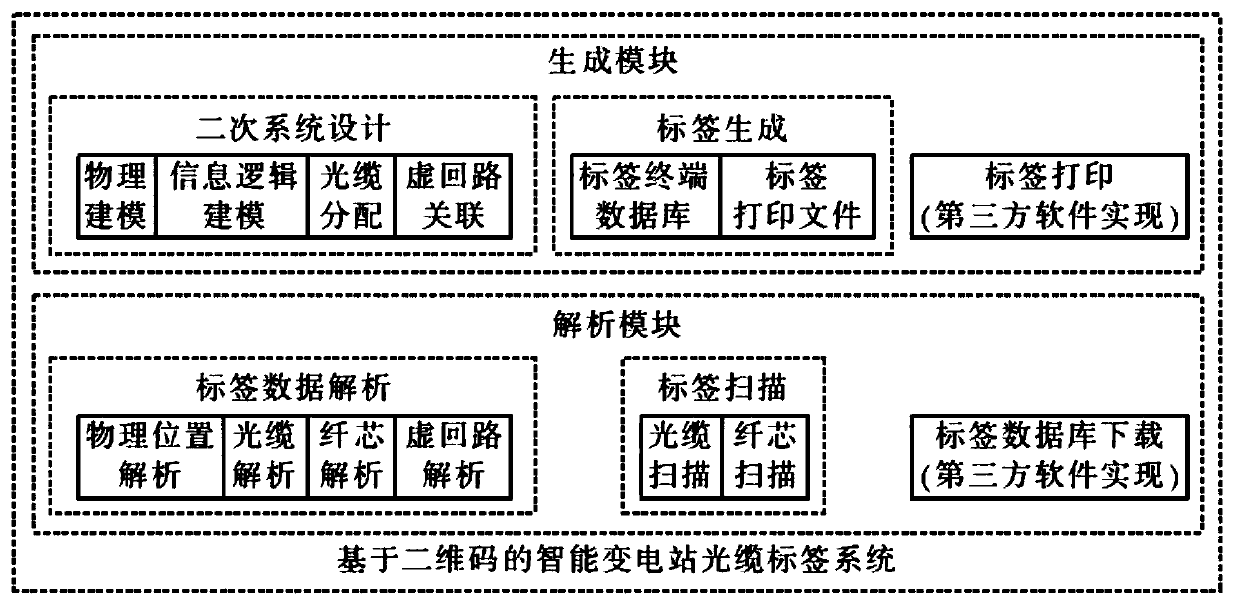

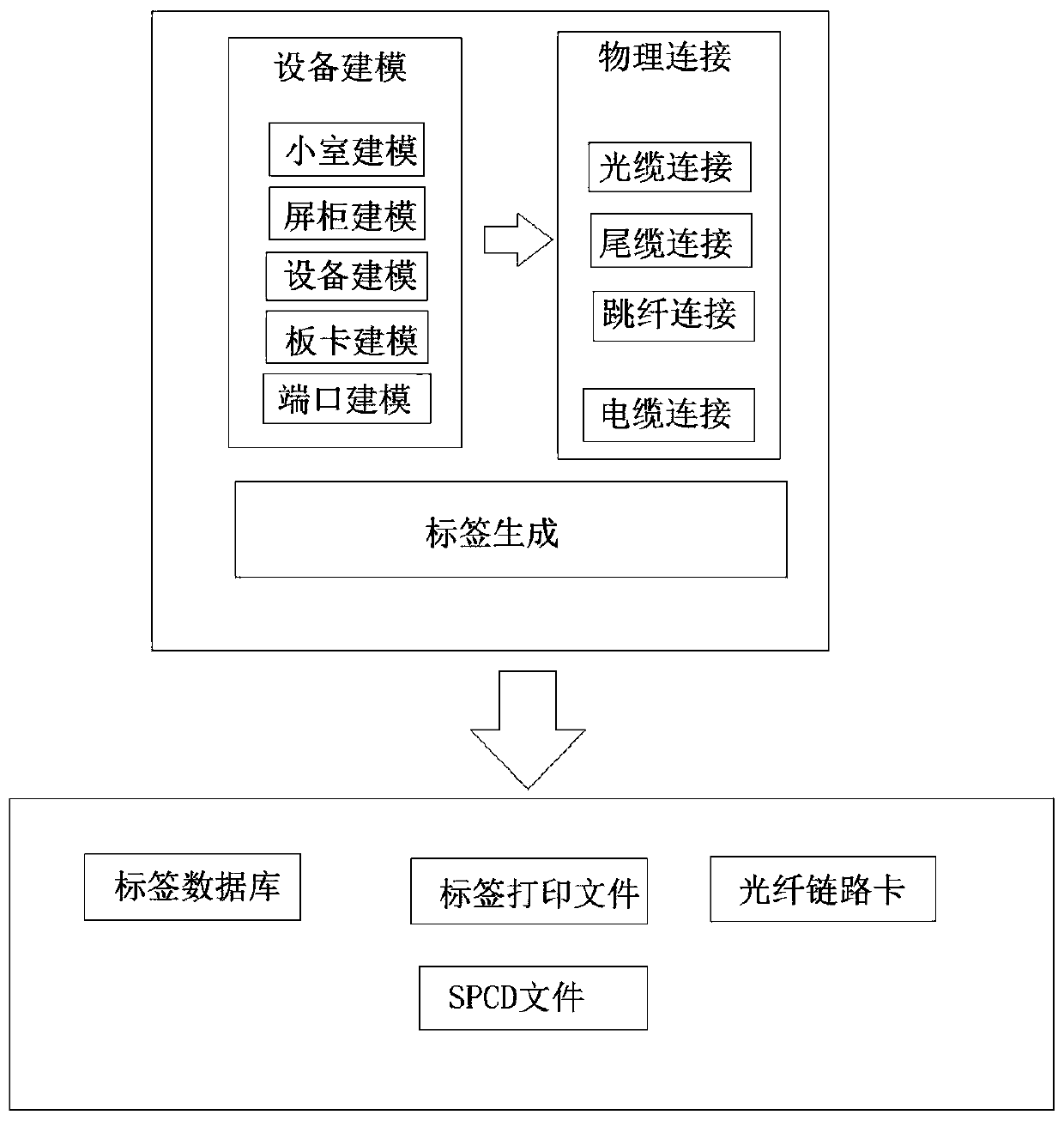

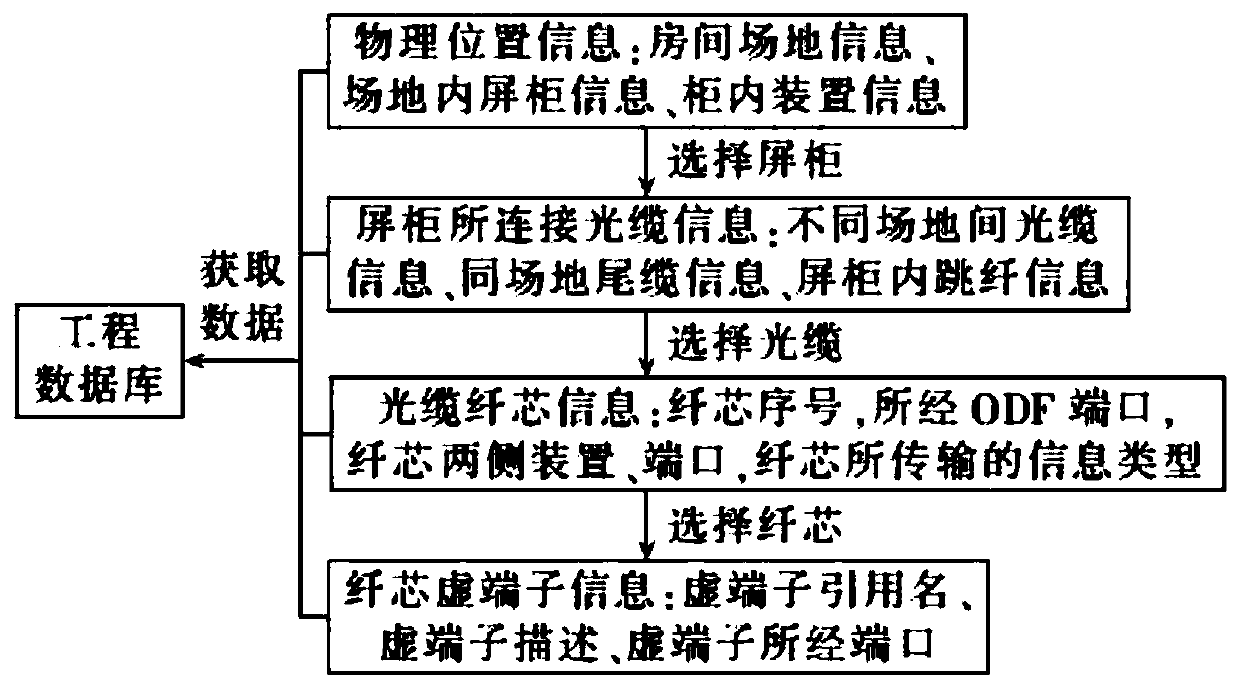

Intelligent label system

PendingCN110782047AImprove debugging efficiencyImprove operation and maintenance efficiencyStampsData processing applicationsComputer hardwareSmart substation

The invention discloses an intelligent label system. The intelligent label system comprises a generation module and an analysis module, the generation module stores designed secondary circuit physicalinformation and logic information into a database, generates a label file and prints a two-dimensional code label; the analysis module takes a two-dimensional code as an entrance, the connection information of the optical cable and the virtual loop information transmitted in the optical cable are rapidly displayed through a handheld terminal in a field scanning mode, the signal searching time isshortened from several minutes to several seconds, and scanning and watching are achieved. By scanning the two-dimensional code on the optical cable label, the physical connection information of the optical cable fiber core and the virtual loop information transmitted in the fiber core can be quickly positioned, and the debugging, operation and maintenance efficiency is improved. The advantage ofdigitization of the secondary circuit design of the intelligent substation is fully utilized, the problem that secondary circuit principle information cannot be visually obtained in field work of theintelligent substation can be effectively solved, and virtual-real correspondence of a process layer physical circuit and a logic circuit is accurately achieved.

Owner:小波科技有限公司

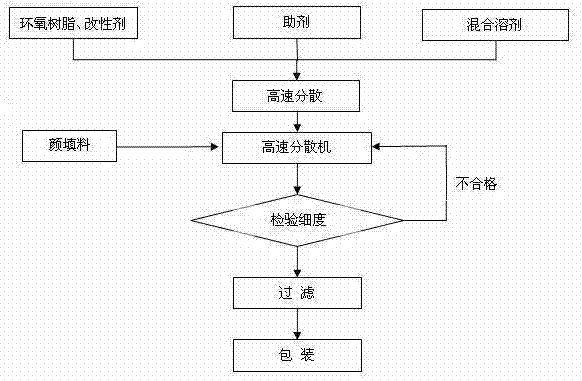

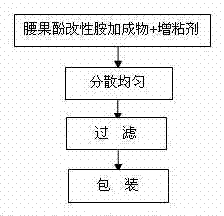

High-performance high-solid general modified epoxy antirust paint and preparation method thereof

ActiveCN102363690AHas acid and alkali resistanceNo acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsLife ProlongationSlurry

The invention discloses a general modified epoxy antirust paint with high performances and high solids and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises 10-20 parts of an E44 epoxy resin, 10-20 parts of an NPPN-631 epoxy resin, 5-15 parts of a terpene resin, 4-18 parts of a cumarone resin, 0.1-1.0 parts of a BYK antifoaming agent, 0.1-1.0 part of an HX leveling agent, 0.1-1.5 parts of a rheological assistant, 5-20 parts of active silica, 10-20 parts of a mixed solvent and 10-30 parts of a pigment-filler; and the component B comprises 10-40 parts of cardanol modified amine and 0.5-3 parts of a modified silane coupling agent. The antirust paint of the invention has the advantages of compact coating, low viscosity, good compatibility and fast curing of a curing agent, high tough strength and strong adhesion of the coating, coating number reduction during the thick slurry curing, construction efficiency improvement, construction cost reduction, and anticorrosion life prolongation.

Owner:XIAMEN SUNRUI SHIP COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com