Water-based nanometer titanium dioxide photocatalytic sterilization purification coating and preparation method thereof

A nano-titanium dioxide, photocatalytic technology, applied in the field of coatings, can solve the problems of inability to meet the living environment, purifying the air, limited ability to kill bacteria, selective killing of bacteria by nano-titanium dioxide and weak antibacterial effect, etc., to expand the application. range, excellent ageing resistance, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

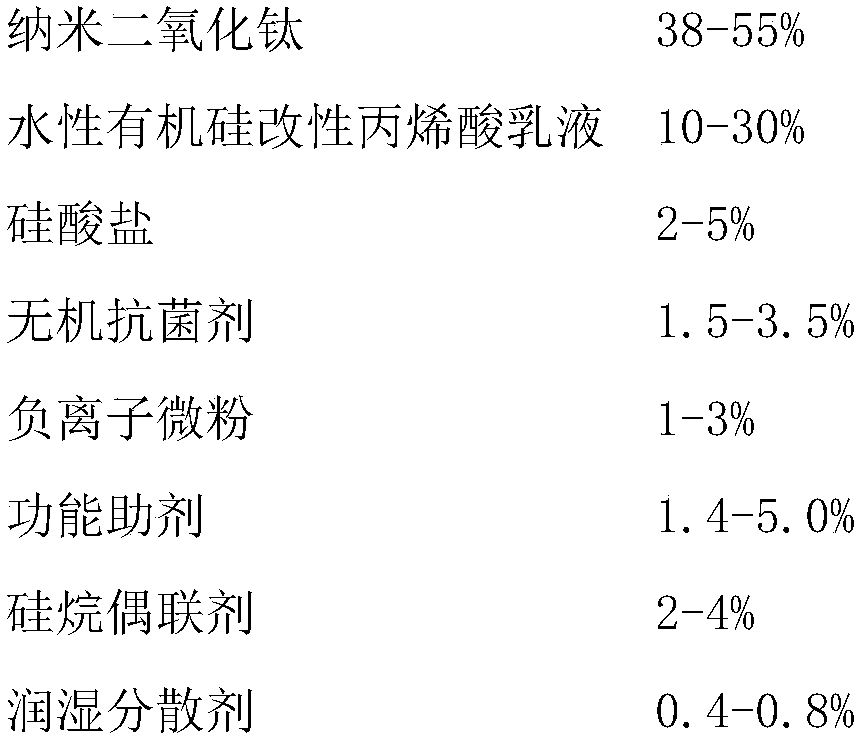

[0033] This implements water-based nano-titanium dioxide photocatalytic sterilization and purification coating, and the raw material components comprising the following mass percentages are shown in Table 1:

[0034] The raw material of the water-based nano-titanium dioxide photocatalytic sterilization purification coating of table 1 embodiment 1

[0035]

[0036] The specific preparation steps of the water-based nano-titanium dioxide photocatalytic sterilization and purification coating of the present embodiment are as follows:

[0037] (1) Mix nano-titanium dioxide, 1 / 3 water and silane coupling agent evenly, then reflux reaction in a water bath at 60°C for 5 hours, then cool down to room temperature, and the product is centrifuged and washed to obtain nano-nanometer titanium dioxide modified by silane coupling agent ;

[0038] (2) Inorganic antibacterial agent and anion micropowder are added successively in the water-based organosilicon modified acrylic emulsion, under ...

Embodiment 2

[0041] This implements water-based nano-titanium dioxide photocatalytic sterilization and purification coating, and the raw material components comprising the following mass percentages are shown in Table 2:

[0042] The raw material of the water-based nano-titanium dioxide photocatalytic sterilization purification coating of table 2 embodiment 2

[0043]

[0044] The specific preparation method of the water-based nano-titanium dioxide photocatalytic sterilization and purification coating of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0046] This implements water-based nano-titanium dioxide photocatalytic sterilization and purification coating, and the raw material components comprising the following mass percentages are shown in Table 3:

[0047] The raw material of the water-based nano-titanium dioxide photocatalytic sterilization purification coating of table 3 embodiment 3

[0048]

[0049]

[0050] The specific preparation method of the water-based nano-titanium dioxide photocatalytic bactericidal purification coating of the present embodiment is the same as in Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com