Patents

Literature

413results about How to "Less smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-smoke halogen-free flame retardant PC/ABS alloy and preparation method thereof

InactiveCN101591468AImprove flame retardant performanceImprove mechanical propertiesAcrylonitrileAlloy

The invention relates to a low-smoke halogen-free flame retardant PC / ABS alloy and a preparation method thereof. 40-75 polycarbonate (PC), 10-40 acrylonitrile-butadiene-styrol copolymer (ABS), 10-15 compound flame retardant, 0.2-2 compound smoke suppression agent, 2-16 compatilizer, 1-6 low-smoke promoter, 0.1-0.5 stabilizer and 0.1-0.6 lubricant are taken in percentage by weight and are put in a high-speed mixer for mixing for 1-15min, and then the mixture is put in a screw extruder for extrusion granulation. Compared with the prior art, the invention has the advantages of low smoke, halogen-free flaming retardation, excellent comprehensive performance, and the like.

Owner:SHANGHAI KELING INDS

Low-smoke FDY (Fully Drawn Yarn) oiling agent and preparation method thereof

The invention discloses a low-smoke FDY (Fully Drawn Yarn) oiling agent and a preparation method thereof. The low-smoke FDY oiling agent comprises the following materials in percentage by weight: 50-60% of emulsifying agent, 10-30% of smoothing agent, 6-10% of antistatic agent, 1-3% of beam concentrating agent, 9-11% of moisture, and 0.1-0.2% of preservative. The low-smoke FFY oiling agent provided by the invention has such functions of lubricating fiber, concentrating beam, preventing static electricity and the like in a production process of FDY, has the characteristics of reducing broken yarns, broken filaments, reducing dyeing and the like in a pre-spinning process, and further has the characteristics of reducing broken yarns, broken filaments, static electricity and the like in a post-processing (weaving) process, and is an important auxiliary ingredient which is essential in the production process of chemical fiber.

Owner:ZHEJIANG TIANSHENG HLDG GROUP

Flame-retardant wood-plastic composite and preparation method thereof

The invention provides a flame-retardant wood-plastic composite and a preparation method thereof, which relates to a wood-plastic composite and the preparation method thereof. The invention solves the problems that the halogen-containing flame retardant in the existing flame-retardant wood-plastic composite releases a great amount of smoke, ammonium polyphosphate as the main body of the flame retardant is unsuitable for preparing the wood-plastic composite with the requirement of high temperature for contour machining, and the wood-plastic composite prepared has poor mechanical properties. The flame-retardant wood-plastic composite is made of modified waste plastic, wood fiber, intumescent flame retardant, lubricant and auxiliary agent. The preparation method of the flame-retardant wood-plastic composite comprises the following steps of: 1. weighing raw materials; 2. pretreating the wood fiber; 3. obtaining premix compound by mixing the raw materials; 4. preparing wood-plastic composite fusant by the melting compounding of the premix compound; 5. obtaining the flame-retardant wood-plastic composite by extrusion, injection, and thermocompression or compression molding. The intumescent flame retardant of the invention is suitable for preparing the wood-plastic composite with the requirement of high machining temperature. The flame-retardant wood-plastic composite has the advantages of good flame retardancy and mechanical properties, and little smoke release.

Owner:JIANGSU KENTIER WOOD

Composition to reduce or quit smoking addiction

InactiveUS20050241658A1Reduce slowly tobacco smoking addictionAbate smoking related harmTobacco treatmentConfectioneryBuccal useFood grade

A method and composition to help persons reduce or quit smoking is disclosed, employing raw tobacco leaves, or tobacco fluid extract, or food grade tobacco like flavor and aroma, and Antioxidants, with or without and SAMe and caffeine. All ingredients can be in a micro-powdered or liquid form, for buccal administration. The composition can be in a tablet or capsule that is intended to be slowly sucked and dissolved in the mouth, and that delivers the nicotine, caffeine or SAMe, proved to be effective in alleviating smoking withdrawal symptoms. The composition can also be embedded inside a soft squeezable plastic cigarette for simulated smoking, providing additional periodic doses of nicotine, caffeine and SAMe to satisfy cravings for cigarettes.

Owner:LLOYDS INT CREDIT

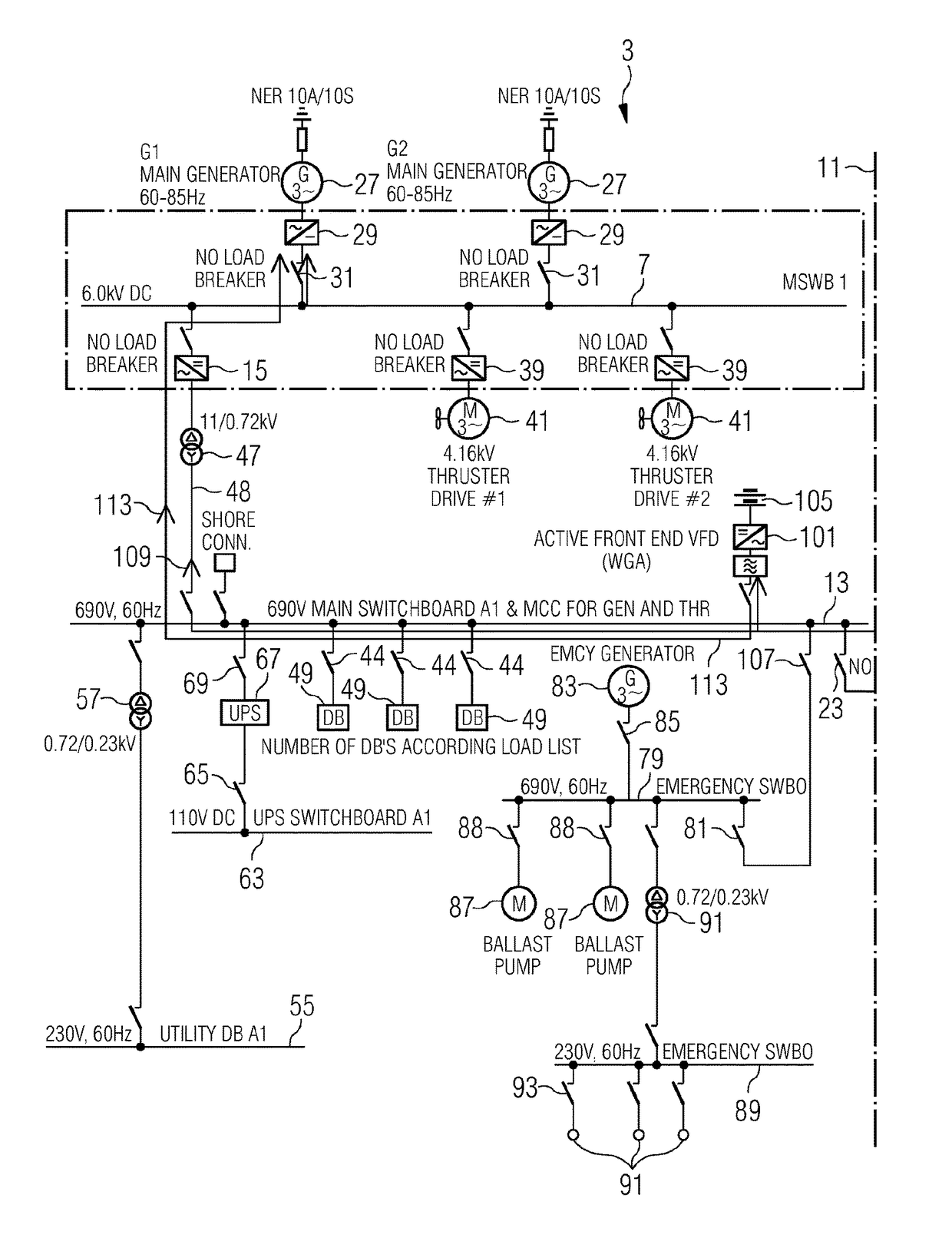

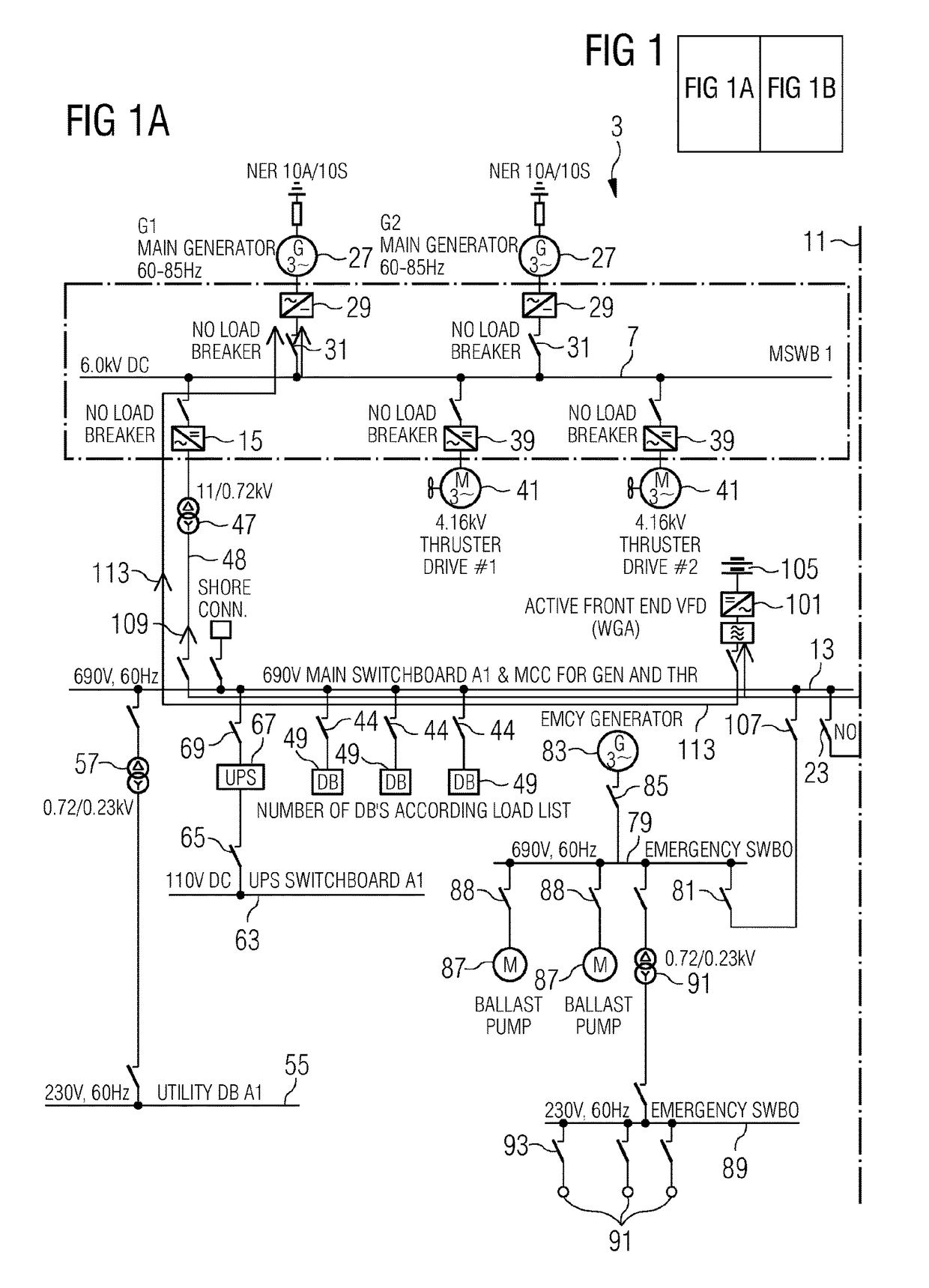

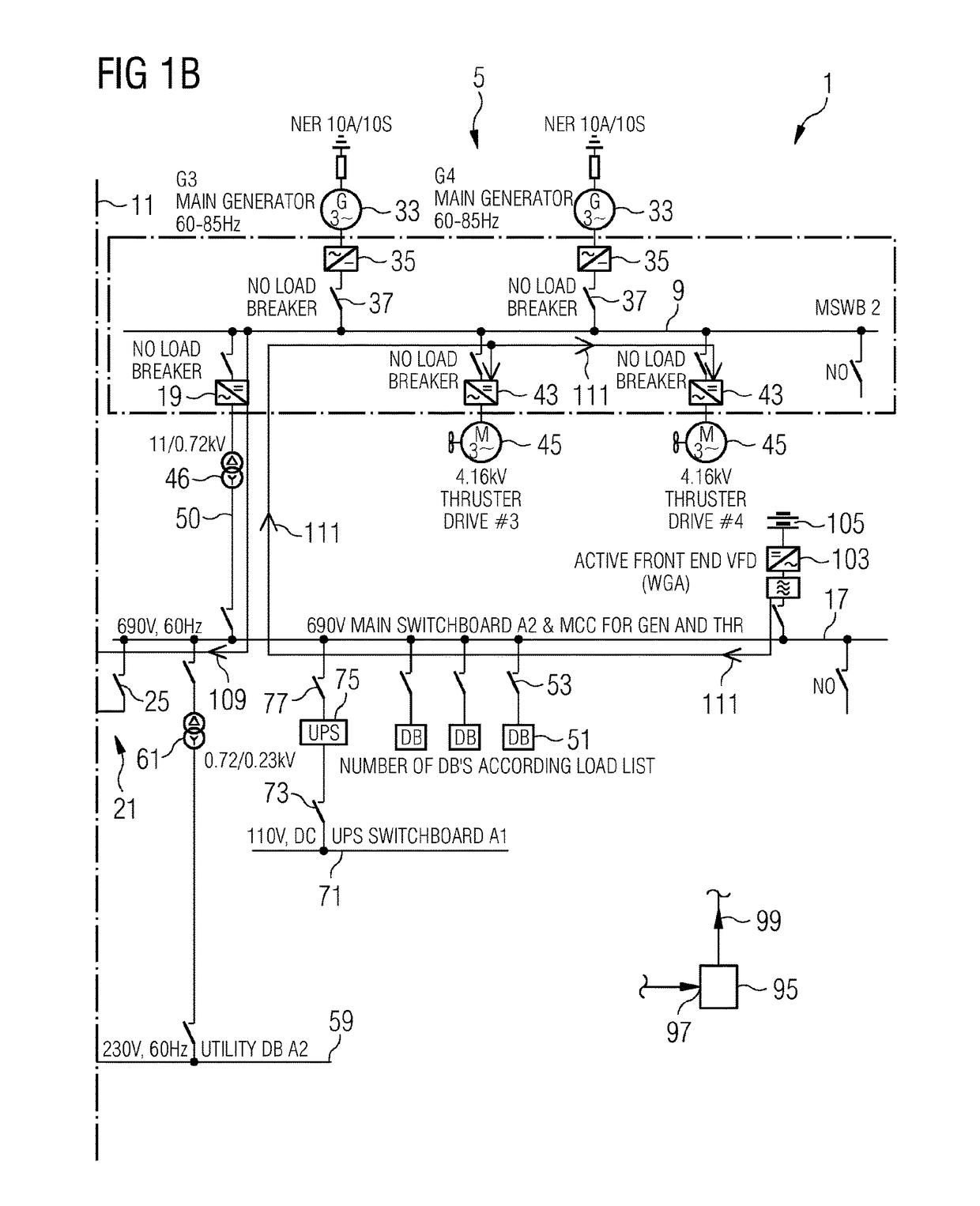

Power distribution on a vessel

ActiveUS20170373502A1Reduce size and cross-sectional sizeLow costPropulsion power plantsSingle network parallel feeding arrangementsPower flowLow voltage

An arrangement for power distribution on a vessel, having: a first DC bus operating at a first medium voltage; at least one second DC bus operating at a second medium voltage and having no direct connection with the first DC bus; a first AC bus operating at a low voltage; a first inverter coupled between the first DC bus and the first AC bus for allowing power flow from the first DC bus to the first AC bus in a first operation mode; a second AC bus operating at the low voltage; a second inverter coupled between the second DC bus and the second AC bus for allowing power flow from the second DC bus to the second AC bus in the first operation mode; a low voltage connection system for selectively connecting or disconnecting the first AC bus and the second AC bus.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG +1

Flameproof polyacrylonitrile fibre and method for preparing same

ActiveCN1566421AGood physical and mechanical propertiesImprove flame retardant performanceMonocomponent synthetic polymer artificial filamentArtifical filament manufactureSolventSilane coupling

The invention discloses a flame-proof polyacrylonitrile fiber and its manufacturing method. Said fiber comprises at least 5%-25% by polyacrylonitrile weight of APP flame retardant, or APP flame retardant treated by silane coupler or titanate coupler, furthmore, comprises pentaerythritol, bi-pentaerythritol and like polyhydric alcohol compound, which has a APP-to-polyhydric alcohol ratio ranging from 2 to 3.8 by wt / wt. The method for manufacturing said fiber includes: crossblending the flame retardant with the inorganic solvent spinning dope of polyacrylonitrile, which is obtained by one-step method or two-step method to prepare crossblending spinning dope, then spinning, washing, drafting and thermal sizing by using current technique of making acrylon with inorganic solvent spinning line. The invention applies cheap, non-poisonous and high efficient inorganic additive flame retardant APP to spin flame retardant acrylon, as a result, crossblending spinning dope with good spinnability and fiber with high flame retardancy is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +2

Low-smoke flame-retardant PVC (polyvinyl chloride) cable material and preparation method thereof

ActiveCN103319802AImprove flame retardant performanceHigh dielectric strengthPlastic/resin/waxes insulatorsOxalatePlasticizer

The invention discloses a low-smoke flame-retardant PVC (polyvinyl chloride) cable material which comprises the following components in parts by mass: 100 parts of PVC, 2-80 parts of a plasticizer, 0.3-15 parts of a heat stabilizer, 0.25-25 parts of a lubricant, 4-60 parts of a flame retardant, 0.5-60 parts of a toughener, 1-5 parts of dicyclopentadienyl iron, 0.5-1.5 parts of magnesia, 0.5-1.5 parts of copper oxalate and 10-20 parts of pottery clay. The oxygen index of the product is up to 55% which is greatly improved compared with the oxygen index (41%) of a product which is obtained in the prior art, the flame-retardant effect is more excellent, and the maximum smoke density is 280; the dielectric strength is up to 30KV / mm which is higher than the dielectric strength (27KV / mm) of the existing product; the tensile strength is 20MPa, the elongation at break is 330-350%, and the brittle temperature is -50 DEG C; the volume resistivity at 20 DEG C is 4*10<14> Ohms.cm, and the volume resistivity at 0 DEG C is 2*10<13> Ohms.cm; and the product is excellent in flame-retardant effect, less in smoke generation, resistant to ultraviolet aging and good in insulation effect and tenacity, does not generate molten drops, can be produced in a large scale, and can be used for replacing the existing material continuously.

Owner:OPTA POLYMER JIANGSU

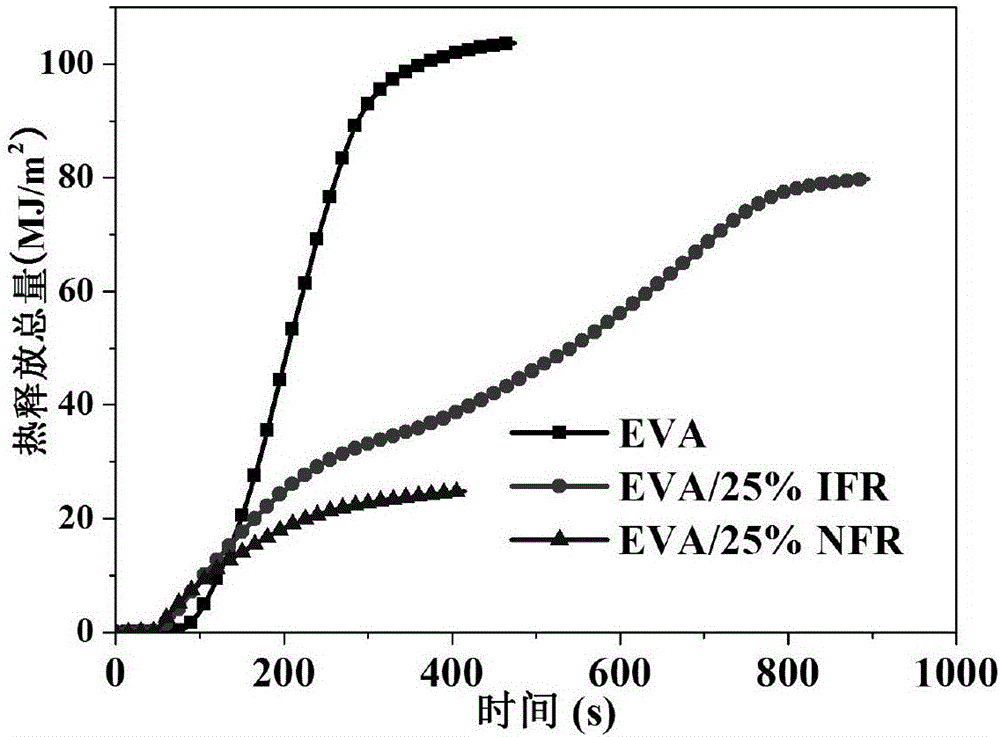

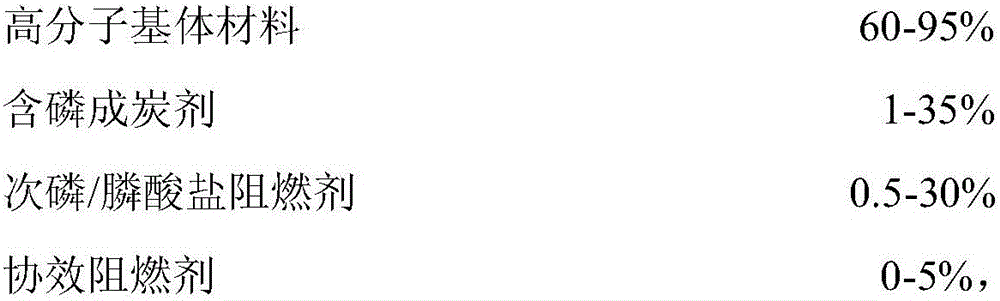

Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

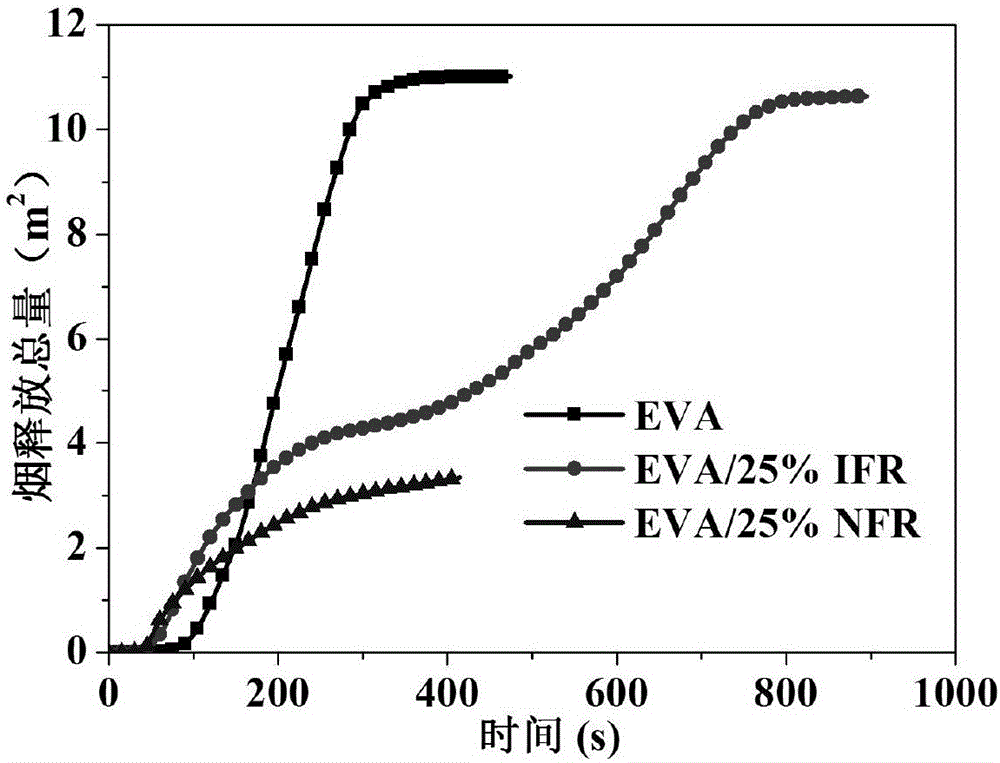

ActiveCN106496729AHigh flame retardant efficiencyGood char formationPolymer scienceLimiting oxygen index

The invention discloses a flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite / phosphonate. The flame-retardant high polymer material is formed by blending, in weight percentage, 60-95% of high polymer base materials, 1-35% of phosphorus containing char-forming agents, 0.5-30% of hypophosphite / phosphonate and 0-5% of synergistic flame retardants. The compound main flame retardants used in the material have double char-forming functions, the material has excellent flame-retardant and smoke suppression properties, limit oxygen index reaches up to 27.0-49.5%, vertical burning test level ranges from UL-94V-1 to V-0, the total heat release of the material in cone calorimeter is reduced by 48.2-90.5% as compared with that of a pure base material, and total smoke release is reduced by 41.6-88.5%. Besides, the flame retardants used in the flame-retardant high polymer material have excellent water resistance, so that the material also has excellent water resistance, after the material is soaked in 70 DEG C for 168 hours and then dried, the vertical burning test level is unchanged, and the oxygen index is only reduced by 0-0.5%.

Owner:SICHUAN UNIV

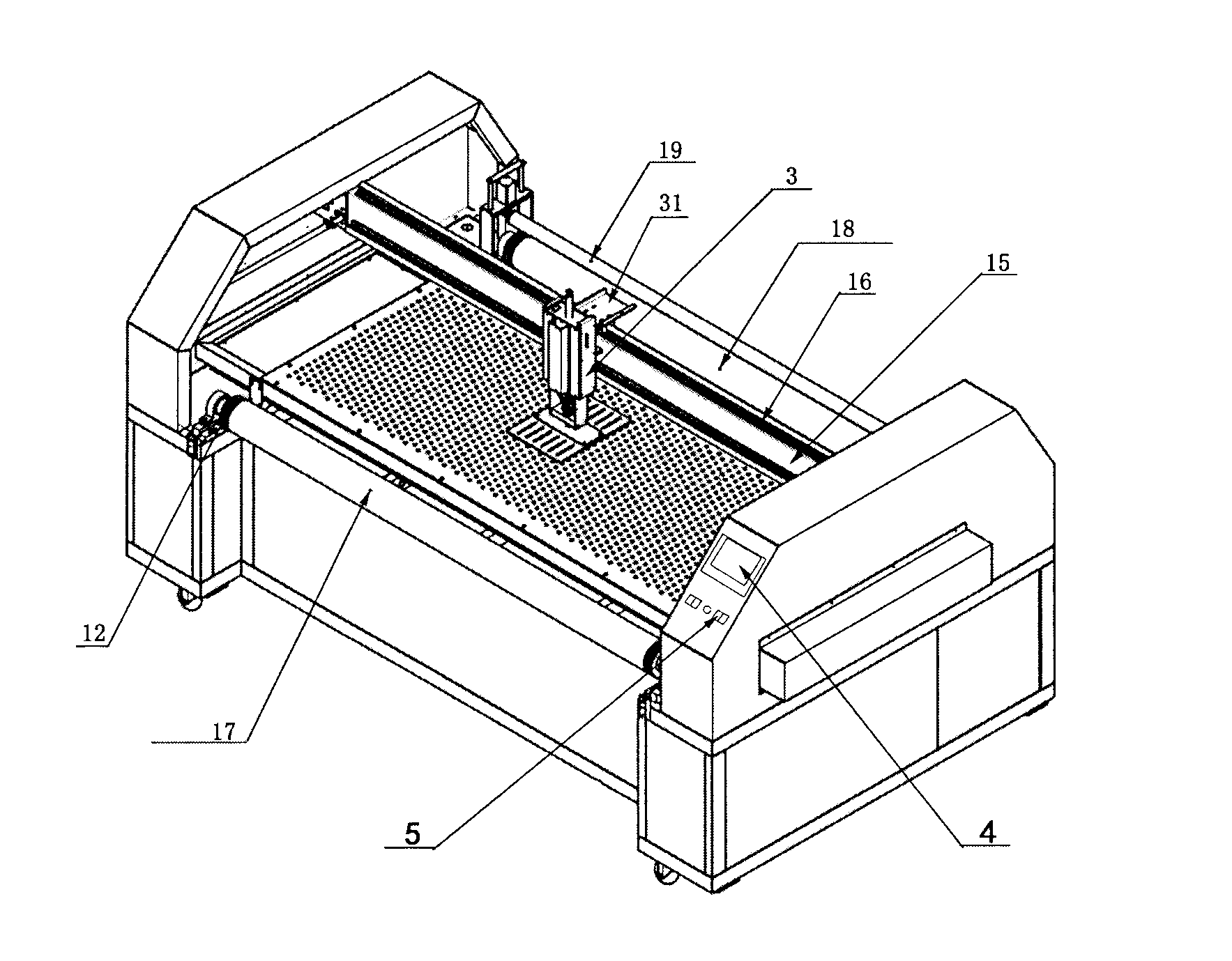

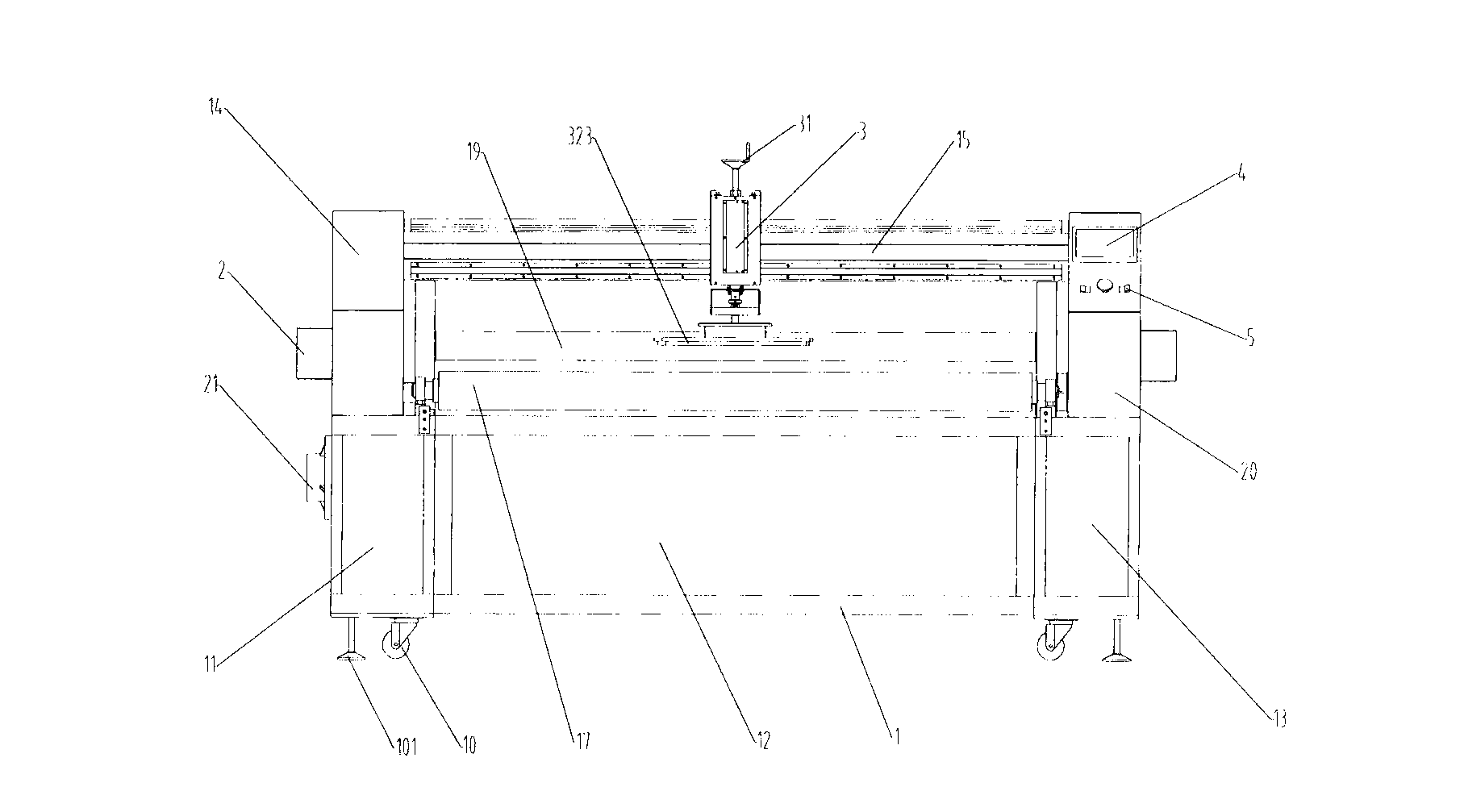

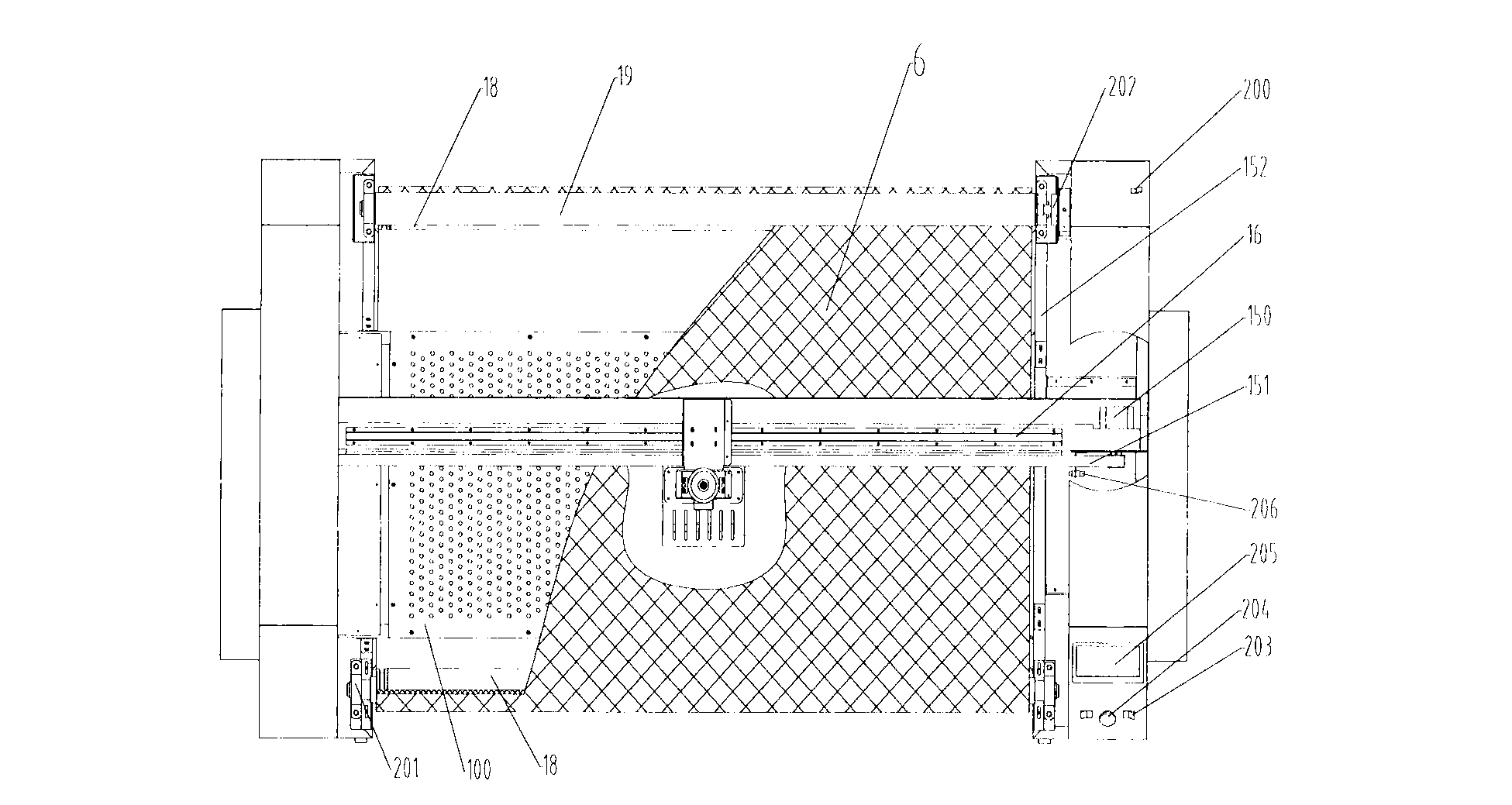

Intelligent electricity-scalding cutting device

InactiveCN103161063AImprove operational safetyImprove cutting efficiencyLeather clicking/perforating/clickingSevering textilesElectricityDrive shaft

The invention discloses an intelligent electricity-scalding cutting device and belongs to the filed of electric cutting devices. The main structure of the intelligent electricity-scalding cutting device comprises a transmission mechanism, a tool mechanism, a pneumatic mechanism, a control mechanism, trundles, a main framework and a power source. A motor, the power source, a control unit, an operation panel and a control switch are arranged on a box on one side of the main framework. The trundles are arranged at the lower end of the main framework. The tool mechanism is movably arranged on a sliding rail of a cross beam between a left support and a right support. A motor output shaft is connected with the transmission mechanism through a transmission shaft. Multi-shaft motor control is adopted in the intelligent electricity-scalding cutting device, an operator can set cutting process and monitor cutting states through terminal software arranged on a machine tool, and therefore full-automatic feeding and cutting can be achieved. In the process of actual production, the intelligent electricity-scalding cutting device can improve cutting efficiency, save labor cost and cutting materials and greatly increase operation safety coefficients of operation workers.

Owner:上海谦羽智能科技有限公司

Flame retardant fiber and preparation method thereof

ActiveCN104018243AImprove flame retardant performanceLess smokeFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsCelluloseHigh concentration

The invention relates to a flame retardant fiber and a preparation method thereof. The preparation method comprises the following steps: mixing cellulose or polyacrylonitrile and a flame retardant high polymer according to a ratio, dissolving at high temperature to prepare a high concentration spinning solution, filtering, cooling, pressurizing for extruding, uniformly mixing two components in the spinning solution through a shearing effect generated by pressure, and performing multiple stretching, thereby forming the blended fiber of polyacrylonitrile or cellulose with the phase domain size of less than 50nm. The flame retardant fiber, namely the blended fiber, is prepared by directly spinning, the problem of mixing uniformity is solved, and the flame retardant fiber has the excellent characteristics of good flame retardant performance, high flame retardant durability, zero halogen and phosphorus, low toxicity, comfort and the like and has significance for developing flame retardant fibers which are not toxic, less in smoke and environmentally friendly.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Biomass fuel oil and preparation method thereof

InactiveCN101831326AImprove combustion efficiencyLess smokeBiofuelsLiquid carbonaceous fuelsSolventChemistry

The invention relates to biomass fuel oil. The biomass fuel oil comprises the following components in percentage by weight: 10 to 15 percent of vegetable oil, 10 to 40 percent of bio-alcohol, 5 to 15 percent of bio-diesel, 0 to 5 percent of fatty acid, 5 to 15 percent of mutual solvent, 0 to 10 percent of combustion accelerant, 0.1 to 1 percent of solid base catalyst, 0.1 to 1 percent of combustion improver, 0.1 to 0.5 percent of oxygenate and 0.1 to 0.5 percent of detergent. A preparation method of the biomass fuel oil comprises the following steps of: a, adding and uniformly stirring the vegetable oil, the bio-alcohol and the mutual solvent in a reaction kettle, adding the solid base catalyst into the mixture and stirring the mixture to form suspension; and b, heating the suspension to 50 to 70 DEG C, making the suspension flow back through a condenser, stirring the obtained product for 10 to 90 minutes, cooling the product to the room temperature, filtering off the solid base catalyst, then sequentially adding the bio-diesel, the fatty acid, the combustion accelerant, the combustion improver, the oxygenate and the detergent and stirring and reacting the mixture for 20 to 30 minutes to obtain the biomass fuel oil. The biomass fuel oil provided by the invention has the advantages of high combustion value, high lubricating property and high flash point.

Owner:杭州绿洲能源科技有限公司

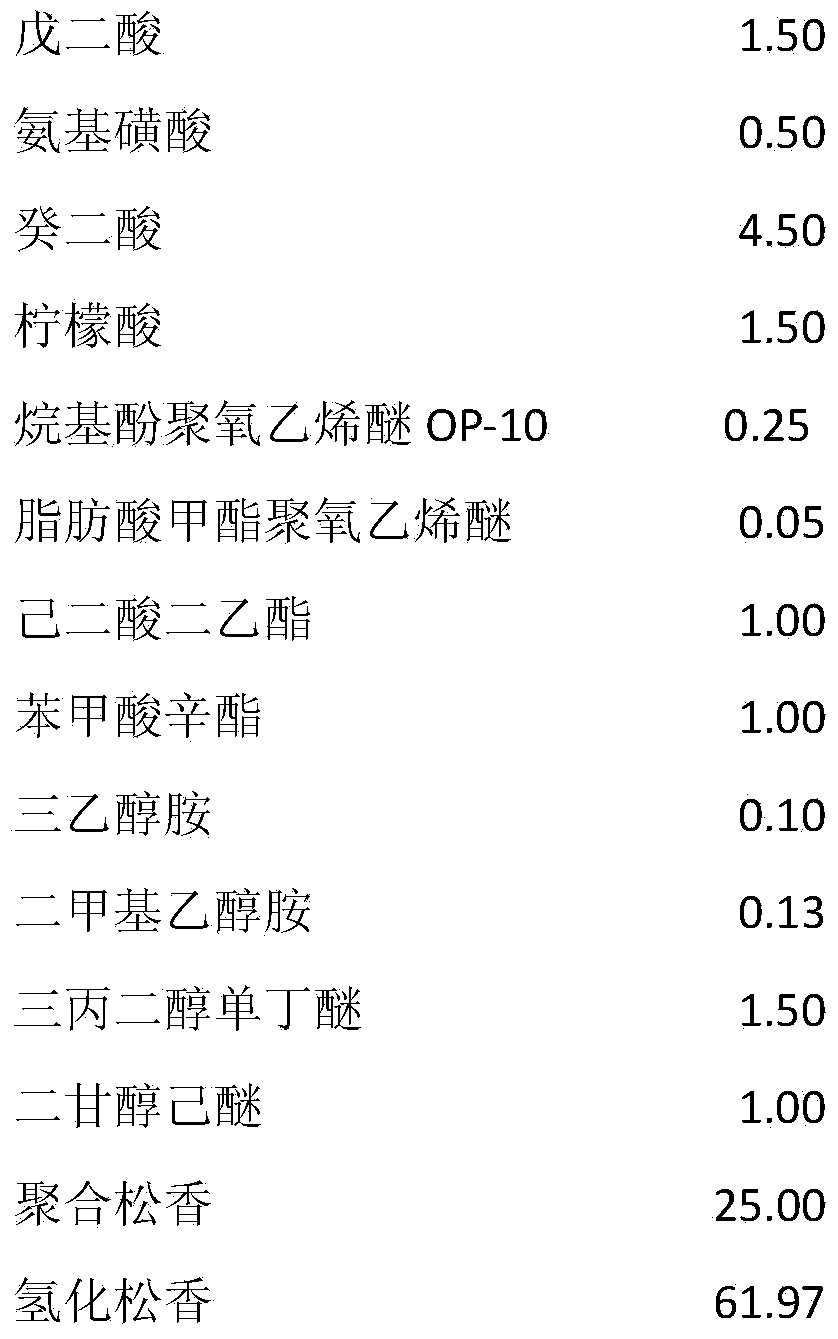

Scaling powder for lead-free solder wire

InactiveCN103128461AReduce contentReduce harmWelding/cutting media/materialsSoldering mediaOrganic acidSurface-active agents

The invention relates to scaling powder for a lead-free solder wire. The content of the scaling powder includes, by weight, 30-45% of rosin resin, 1-12% of organic acid activating agents, 0-1% of activating agent fortifier, 5-18% of protective agents, 0.1-1% of surface active agent, 0.5-1% of corrosion inhibitor, and the balance solvents. According to the scaling powder, smog is little, pungent smells do not exist, welding residues are few, washing is easy, and good welding effects are achieved.

Owner:郴州金箭焊料有限公司

Washing-free high temperature dip soldering flux

ActiveCN102029488AReduce physical impactDip soldering process is simpleWelding/cutting media/materialsSoldering mediaDip solderingBoiling point

The invention discloses a washing-free high temperature dip soldering flux, and belongs to the technical field of fluxes. The invention aims to solve the problems in the prior art, and provides a flux which has better depainting property and welding assistance property and wider operating temperature window and meets the requirement of environmental protection. The washing-free high temperature dip soldering flux comprises the following components in percentage by weight: 1.0 to 2.0 percent of active substance, 1.0 to 3.0 percent of resin, 0.05 to 0.10 percent of surfactant, 0.2 to 1.0 percent of high boiling solvent and the balance of solvent. The flux is particularly suitable for a high temperature dip soldering process for coating tin on enameled wires with the diameter of less than 0.5mm. The dip soldering process is simple, and convenient to operate; the operating temperature window is as wide as 290-480 DEG C; the flux is clean in depainting and better in coating the tin, has little residue after welding and does not require cleaning; and during operation, the smog generated by the flux is small so as to influence the body of the operators little.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

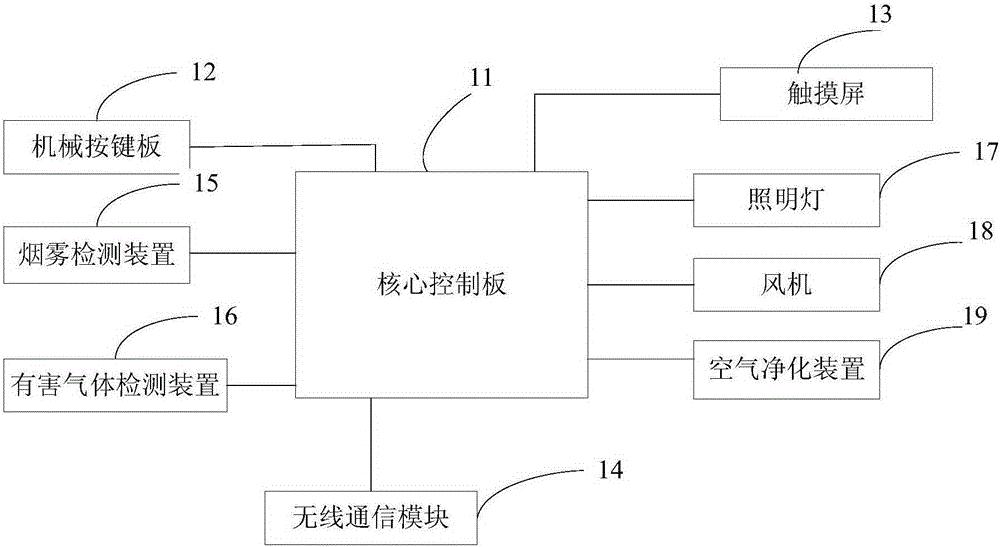

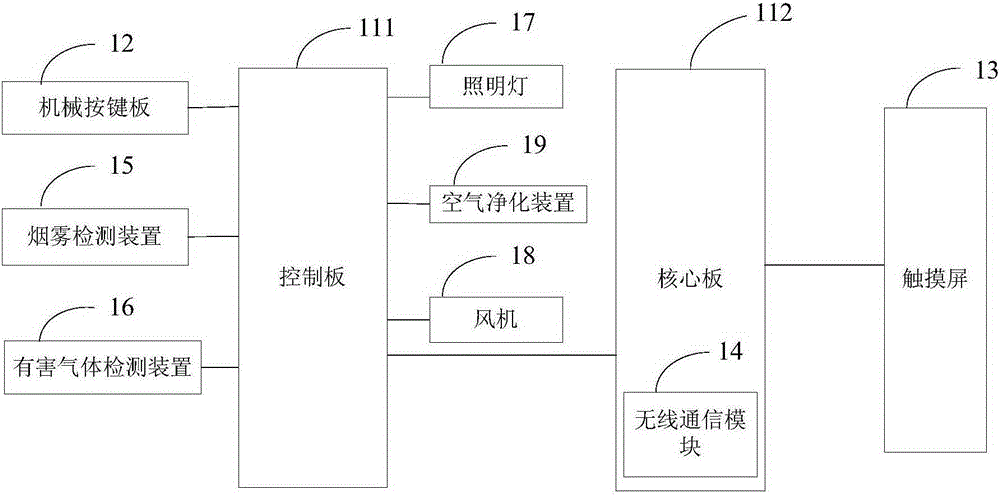

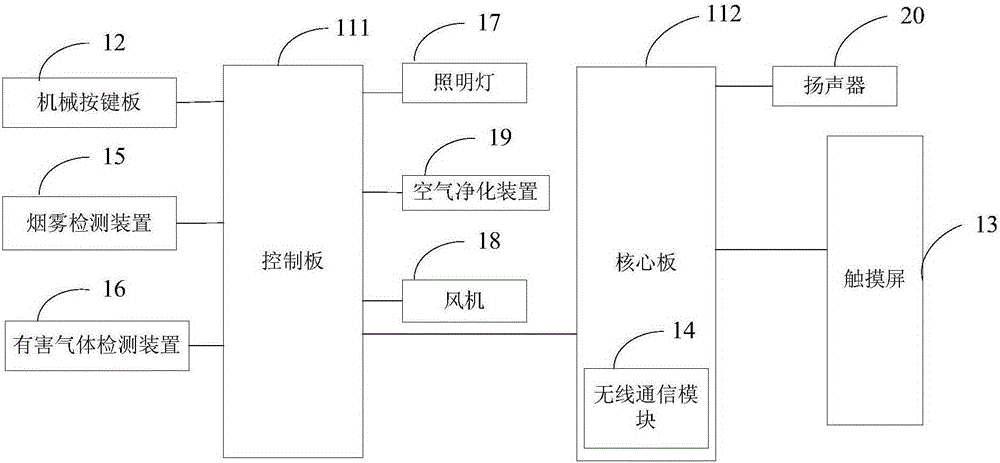

Extractor hood and control method thereof

InactiveCN105276648ALess smokePurifying airDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke

The invention discloses an extractor hood and a control method of the extractor hood. The extractor hood comprises a core control panel, a mechanical key plate, a touch screen, a wireless communication module, a smoke detection device, a harmful gas detection device, an illumination lamp, a draught fan and an air purifying device, wherein the mechanical key plate, the touch screen, the wireless communication module, the smoke detection device, the harmful gas detection device, the illumination lamp, the draught fan the and the air purifying device are connected with the core control panel. The wireless communication module is connected with a mobile terminal in a wireless communication manner to receive control signals sent by the movable terminal. The core control panel is used for controlling one or more of the illumination lamp, the draught fan and the air purifying device through control signals input by one or more of the mechanical key plate, the touch screen and the wireless communication module and transmitting smoke and harmful gas concentration information collected by the smoke detection device and harmful gas detection device to the touch screen or transmitting the smoke and harmful gas concentration information to the mobile terminal for display. Due to the adoption of the extractor hood and the control method, air in a kitchen can be purified during cooking, health of users is guaranteed, and operation intelligence of the extractor hood is achieved.

Owner:SHENYANG YINGLINTE ELECTRICAL APPLIANCE CO LTD

High-toughness halogen-free flame-retardanting reclaimed polycarbonate compound and preparation method thereof

InactiveCN101709142AIn line with the development trend of non-halogenated flame retardantImprove flame retardant performanceAntioxidantUltraviolet

The invention relates to a high-toughness halogen-free flame-retardanting reclaimed polycarbonate compound and a preparation method thereof, belonging to the field of reclaimed plastic flame-retardanting and toughening-modified products. The invention aims to provide a high-toughness halogen-free flame-retardanting reclaimed polycarbonate compound which uses reclaimed polycarbonate as a matrix. The invention is characterized in that the compound comprises the following components by weight percent: 81.0-93.4% of reclaimed polycarbonate, 3.0-10.0% of latex particles of core-shell silicon rubber, 1.0-7.0% of bulking agent, 0.1-0.5% of antioxidant, 0.1-0.5% of light stabilizer, 0.1-0.5% of ultra-violet absorber, 0.8-1.2% of heat barrier and 0.3-0.5% of anti-dripping agent. The preparation method of the compound comprises the following steps: evenly mixing the components, melting the components on a double-screw extruder, blending, extruding, cooling and pelleting the melted components to prepare the reclaimed polycarbonate compound. The compound has the advantages of good anti-impact properties, retardanting level of UL94 V-0 and low cost, thereby meeting the requirements of industries such as electronic and electric products and the like on the high-property polycarbonate engineering plastics.

Owner:BEIJING UNIV OF CHEM TECH

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

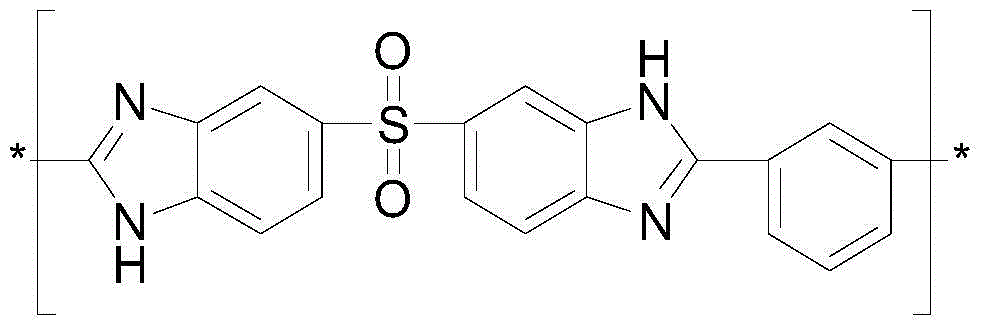

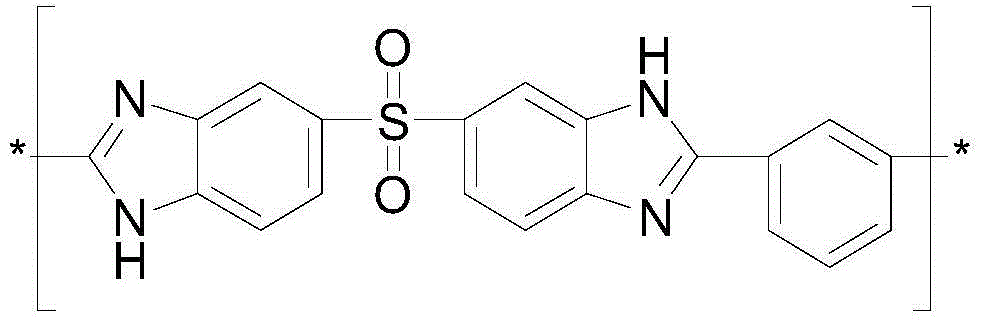

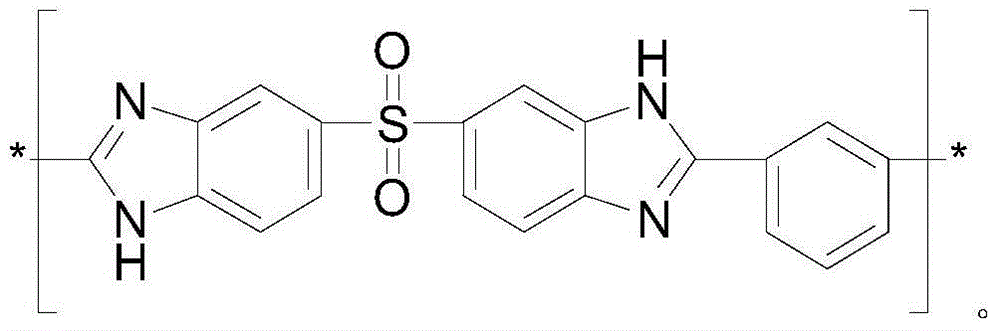

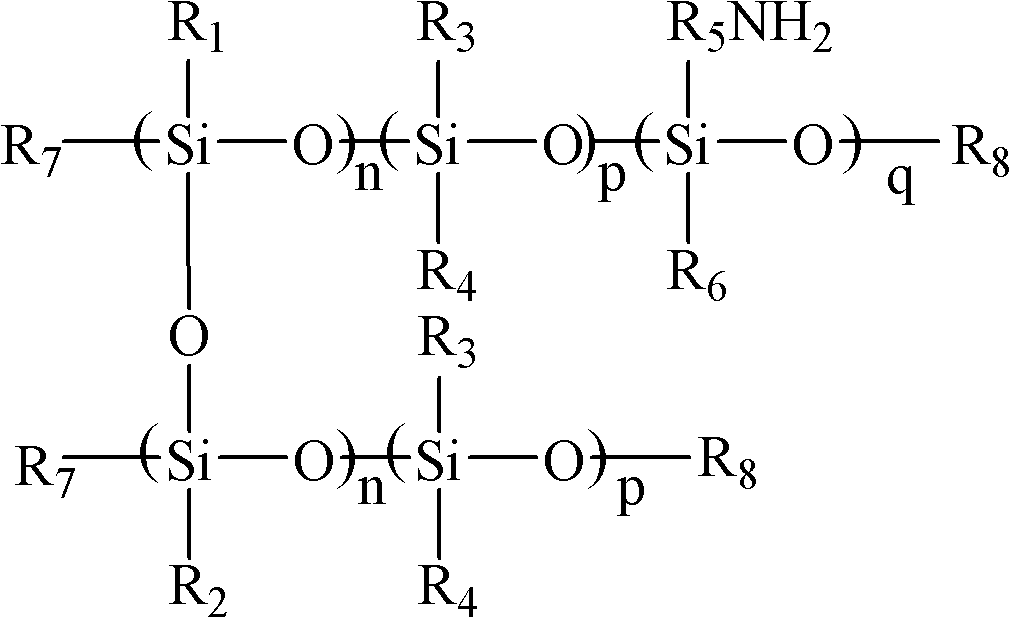

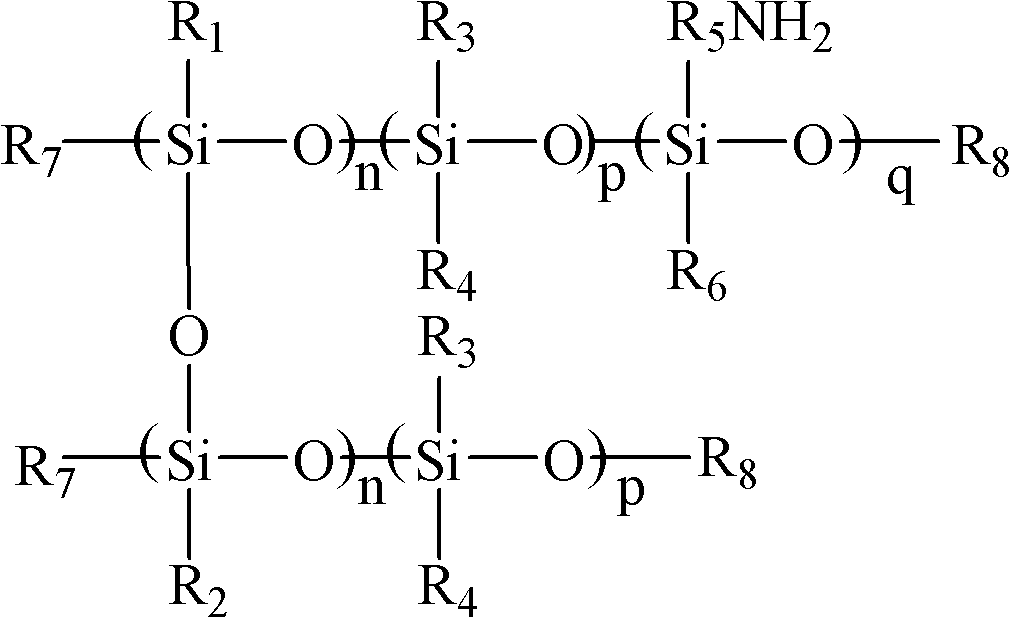

Amino-containing organic silicon resin fire retardant and preparation method thereof

The invention discloses an amino-containing organic silicon resin fire retardant and a preparation method thereof. The preparation method comprises the steps of: with amino silane and trialkoxysilane as raw materials or with amino silane, dialkoxysilane and trialkoxysilane as the raw materials, adding water or a mixed solvent of water and an organic solvent, carrying out hydrolytic polycondensation under the action of a catalyst, finally adding blocking agent to block the end, adding a neutralizer to neutralize before the reaction is finished, and then filtering, washing and drying to obtain the amino-containing organic silicon resin fire retardant. The fire retardant contains two fire-retardant elements of nitrogen and silicon, has with high efficiency and low toxicity and is an environment-friendly macromolecular fire retardant; the chemical structure is shown as follows: wherein R1, R2, R3, R4, and R6 are H, CH3 or C6H5; R5 is CH2, CH2CH2, CH2CH2CH2, CH2NHCH2CH2 or C6H5; R7 and R8 are CH3, C2H5 or C6H5; and n, p, q are integers of 1-50.

Owner:QINGDAO UNIV OF SCI & TECH +1

Halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material and preparation method thereof

ActiveCN104479339ALess smokeImprove flame retardant performanceLow smoke zero halogenPolymer science

The invention belongs to the technical filed of thermoplastic polyurethane elastomer materials, and particularly relates to a halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material which comprises the following components in percentage by weight: 70-85% of thermoplastic polyurethane elastomer, 10-28% of halogen-free nitrogen and phosphorus flame retardant, 1-5% of smoke suppressor, 0.1-1% of antioxidant and 0.1-1% of lubricant. The halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material prepared by the invention produces a small amount of smoke in the combustion process, has excellent flame retardancy and excellent mechanical property, and can be used as a low-smoke halogen-free flame-retardant cable coating material. Besides, the invention also discloses a preparation method of the halogen-free flame-retardant smoke-suppressing thermoplastic polyurethane elastomer cable material.

Owner:ANGREEN DONGGUAN NEW MATERIALS TECH

Modified TPE hybrid material for charging pile cables of electric vehicles and preparation method thereof

The invention relates to a modified TPE hybrid material for charging pile cables of electric vehicles. The modified TPE hybrid material comprises the following components in parts by weight: 50-70 parts of thermoplastic elastomer, 10-20 parts of reinforcing agent, 25-55 parts of flame retardant, 0.2-0.5 part of lubricant, 0.1-0.3 part of coupling agent, and 0.1-0.3 part of antioxidant. The modified TPE hybrid material disclosed by the invention has the advantages of high elasticity, bending resistance, high strength, tearing resistance, flame resistance, environmental friendliness, and the like, and is applicable to charging pile cables of electric vehicles.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

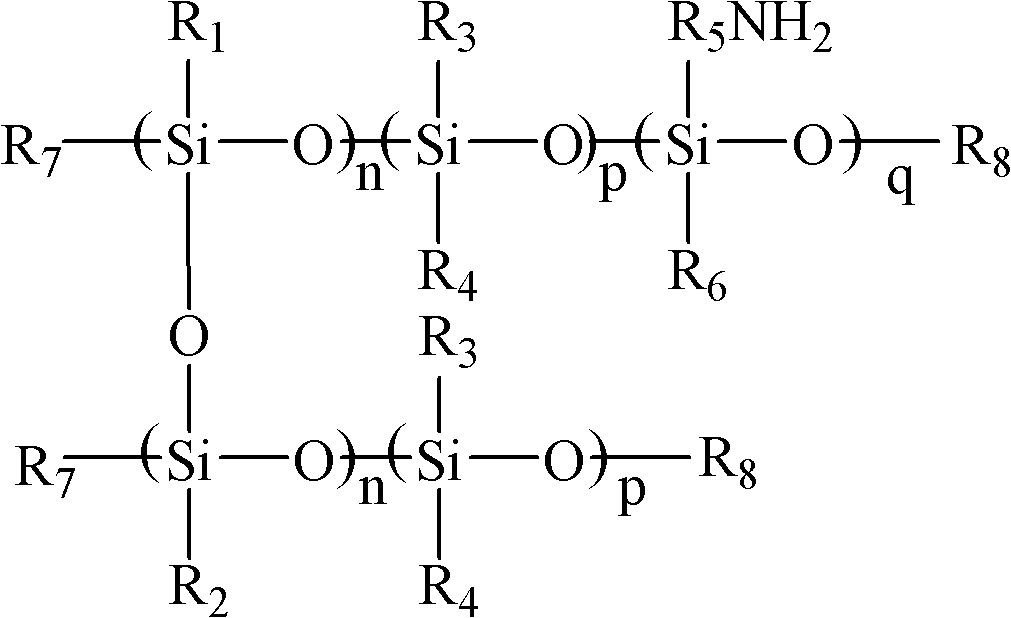

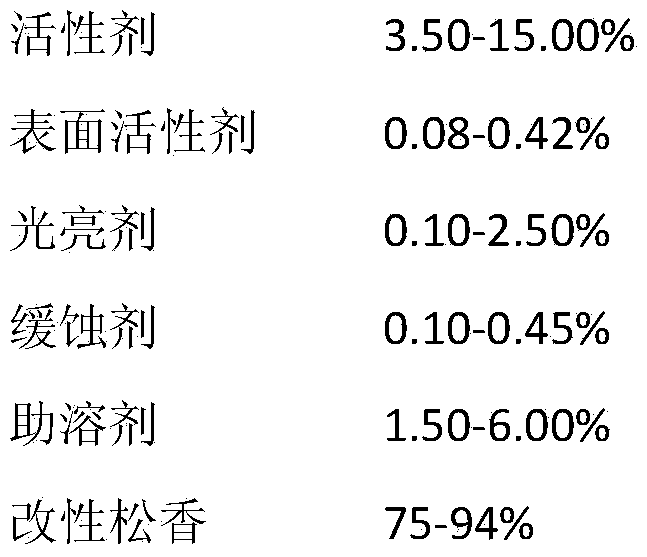

Abietyl-based soldering flux for halogen-free no-clean bright solder wire and preparation method thereof

InactiveCN104070308AIncrease brightnessGood specular reflection abilityWelding/cutting media/materialsSoldering mediaTinningElectricity

The invention discloses an abietyl-based soldering flux for a halogen-free no-clean bright solder wire and a preparation method thereof. The abietyl-based soldering flux comprises, by mass, raw materials including active agent 3.50-15.00%, surface active agent 0.08-0.42%, brightener 0.10-2.50%, corrosion inhibitor 0.10-0.45%, cosolvent 1.50-6.00% and the balance modified rosin. The ingredient proportion in the abietyl-based soldering flux is suitable for manufacture of lead-free solder wires containing the soldering flux in cores, and the soldering flux can be used for automatic welding or manual soldering iron welding. When the solder wire welding is adopted, the process stability is good, tinning speed is high, the splashing amount is small, the defects including continuous tinning, solder skips, insufficient solder, icicles and the like in the welding process can be decreased, welding spots are bright and full after welding, residues are few, the corrosivity is low, cleaning is not needed, and the surface electrical insulation property is excellent after the welded solder wires are placed for a long period of time.

Owner:SOUTH CHINA UNIV OF TECH

Methanol gasoline

InactiveCN102796574ANormal startImprove anti-corrosion performanceLiquid carbonaceous fuelsLiquid fuelFuel oil

Provided is methanol gasoline. The invention relates to the technical field of energy, and specifically relates to a methanol gasoline formula. The methanol gasoline formula includes adding a methanol gasoline compound additive to methanol by weight ratio of 0.05% for denaturation, and mixing 15-65 parts of methanol, 20-30 parts of 90 # gasoline, 10-30 parts of light aromatic hydrocarbons, and 10 parts of naphtha by weight after denaturation. The methanol gasoline is good in corrosion resistance, and generates chemical and physical adsorption to resist corrosion by inhibiting basic groups of molecules. The methanol gasoline is powerful in dynamic property, high in octane value, good in antiknock property, low in fuel consumption, and safe and reliable in use. The method makes alcohol and gasoline dissolve organically, and helps to enhance the stability without delamination and emulsification. The methanol gasoline can be used with ordinary gasoline by mixing or crossing. By using the methanol gasoline, motors are easy to start under the low temperature condition of -35 DEG C, and have no air resistance at high temperature, thereby being started normally. The methanol gasoline is suitable for gasoline and liquid fuels, and can help to save 10-25% of the fuel oil, to reduce the amount of smoke and exhaust gases, and to reduce pollution.

Owner:张伯义 +2

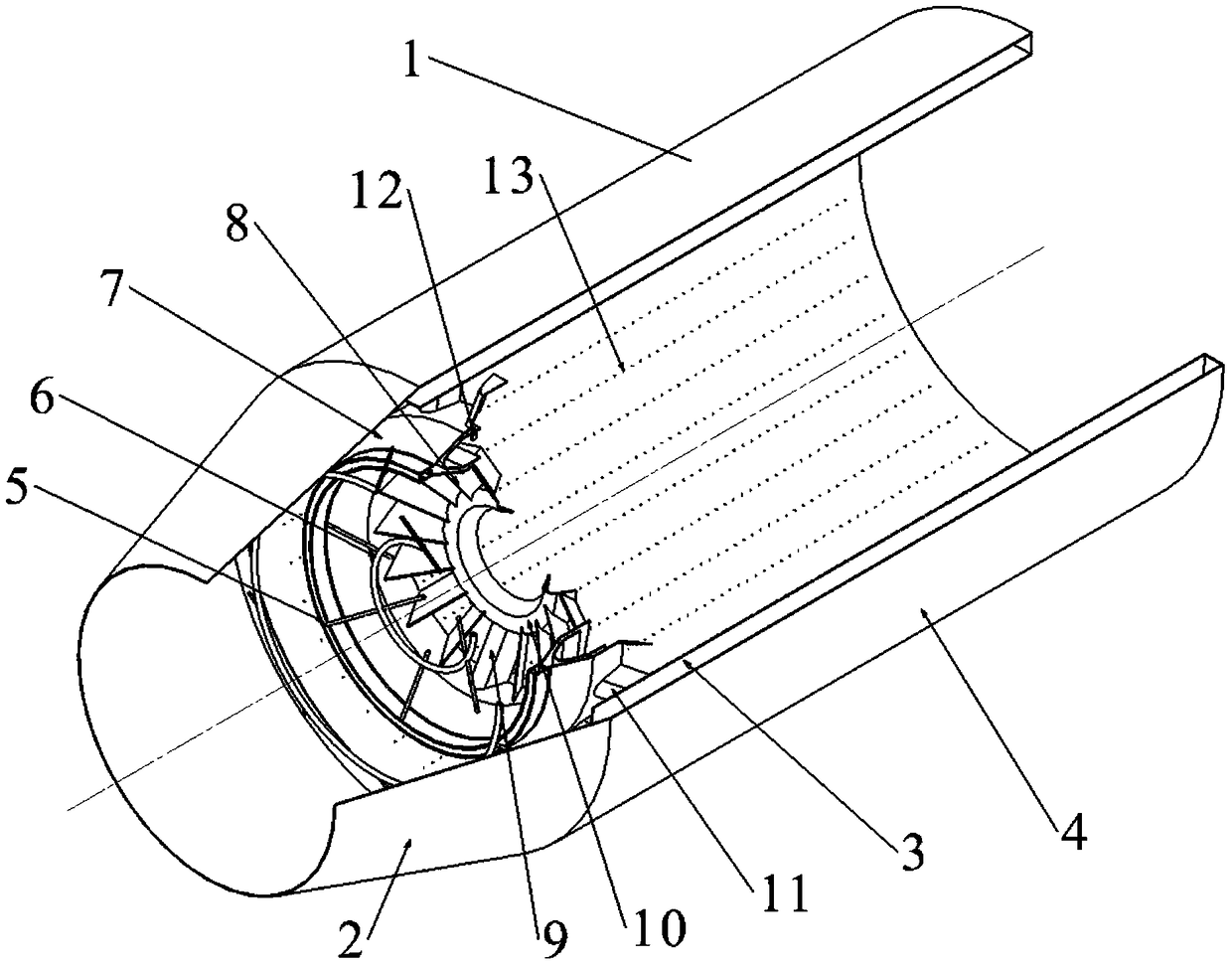

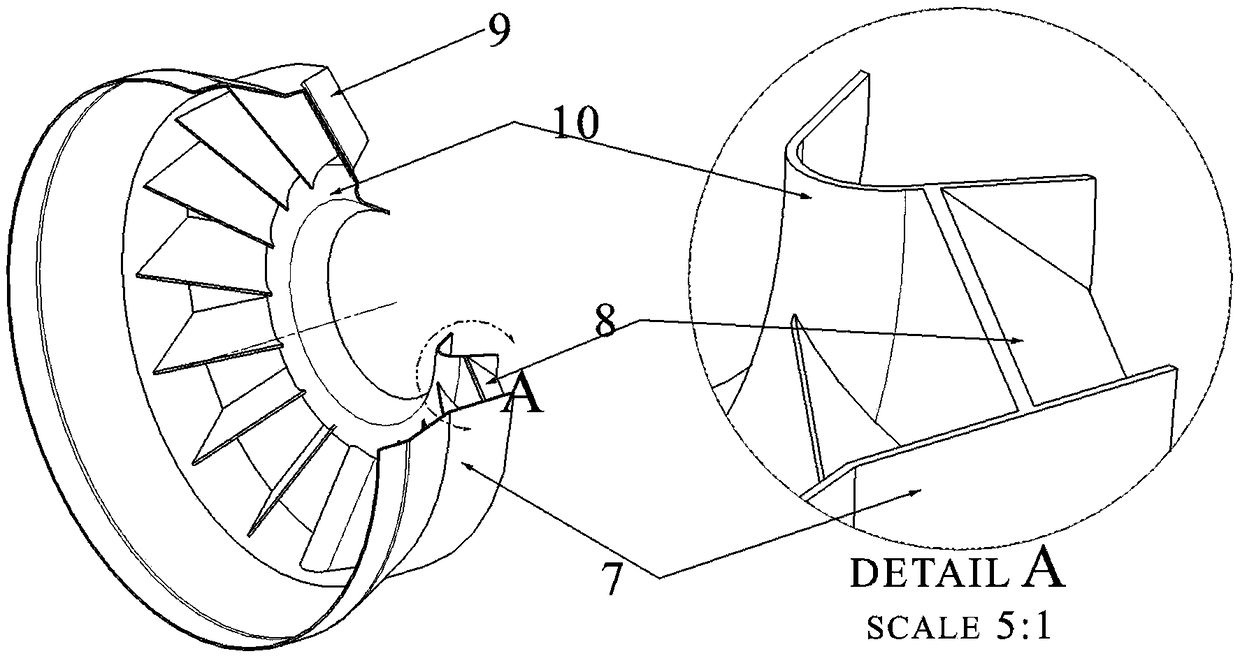

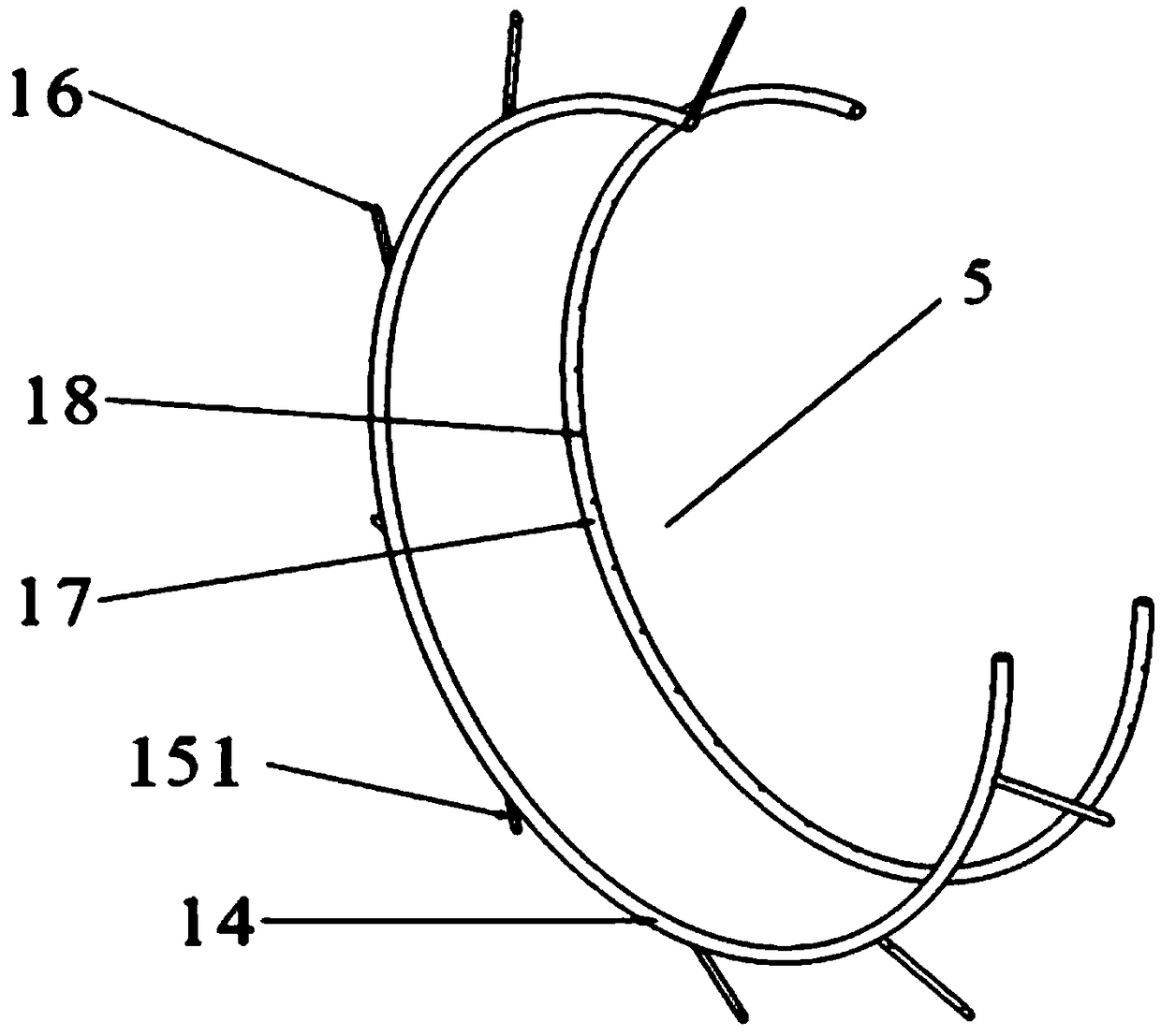

Rotational flow stress application/stamping combustion chamber

ActiveCN108800205AIncrease the propagation speedImprove performanceContinuous combustion chamberFlame propagationCombustor

The invention discloses a rotational flow stress application / stamping combustion chamber and belongs to the technical field of rotational flow combustion of new concept aero-engines. In the structureof the combustion chamber, a diffuser carries out speed reduction and pressurization on airflow; a thermal insulating screen divides the incoming flow of a diffuser pipe into a main airflow and an outer duct airflow for cooling; a plurality of cooling holes are formed in the thermal insulating screen; a flame stabilizer transmits and stabilizes flame; a rotational flow blade is positioned in the flame stabilizer and forms a set included angle with the main airflow to rotate the downstream airflow; and an oil supply system comprises on-duty level oil supply, outer ring oil supply of a radial stabilizer and main combustion level oil supply and adopts the oil supply manners of combination of a direct-injection type fuel spray nozzle and an annular oil pipe, and a radial oil pipe of a main oilpipe. Compared with a traditional combustor, as the rotational flow combustion manner is adopted, the flame propagation velocity is not affected by pressure; in addition, the subregion oil supply manner is adopted, so that the oil and gas are mixed more fully, combustion is more efficient and stable, and pollution is less; and moreover, the flame transferring device of the flame stabilizer is eliminated, so that the structure of the combustion chamber is simplified, the length of the combustion chamber is shortened and the weight of the combustion chamber is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

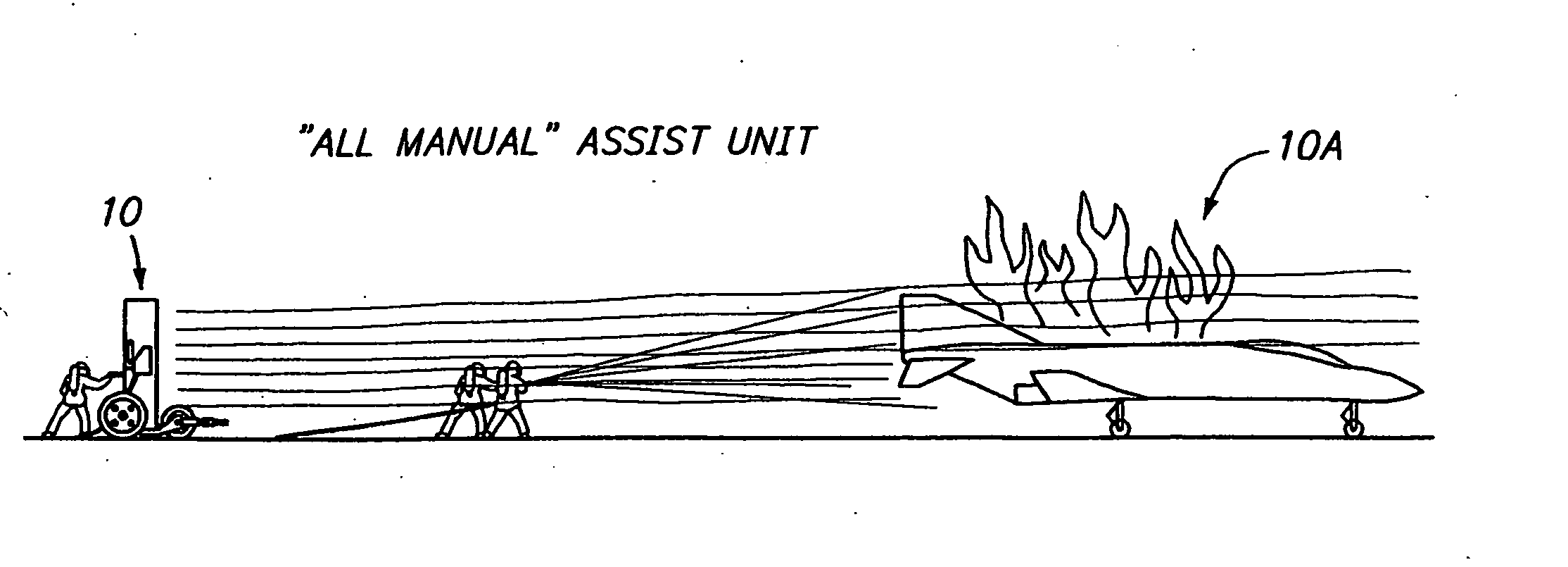

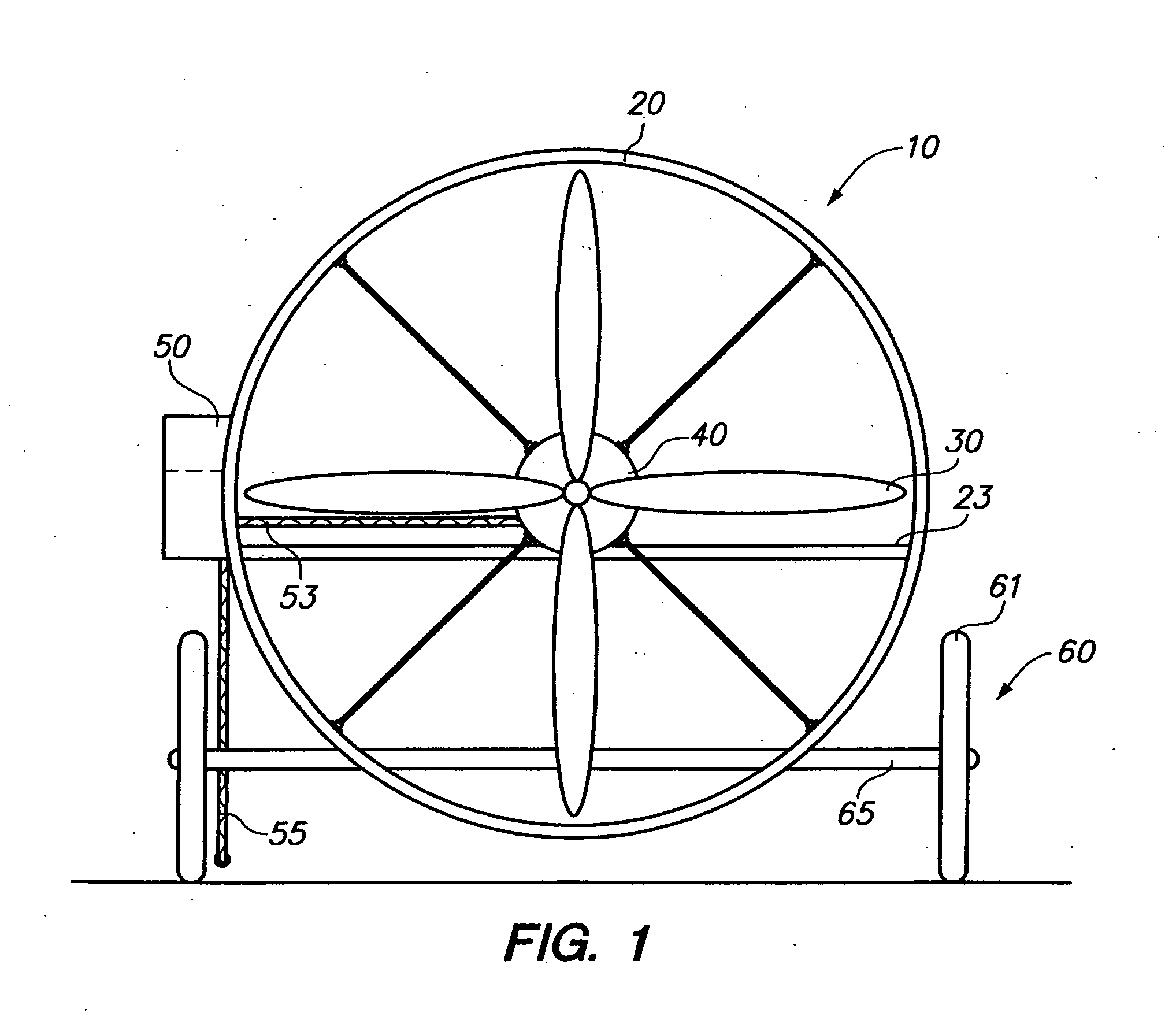

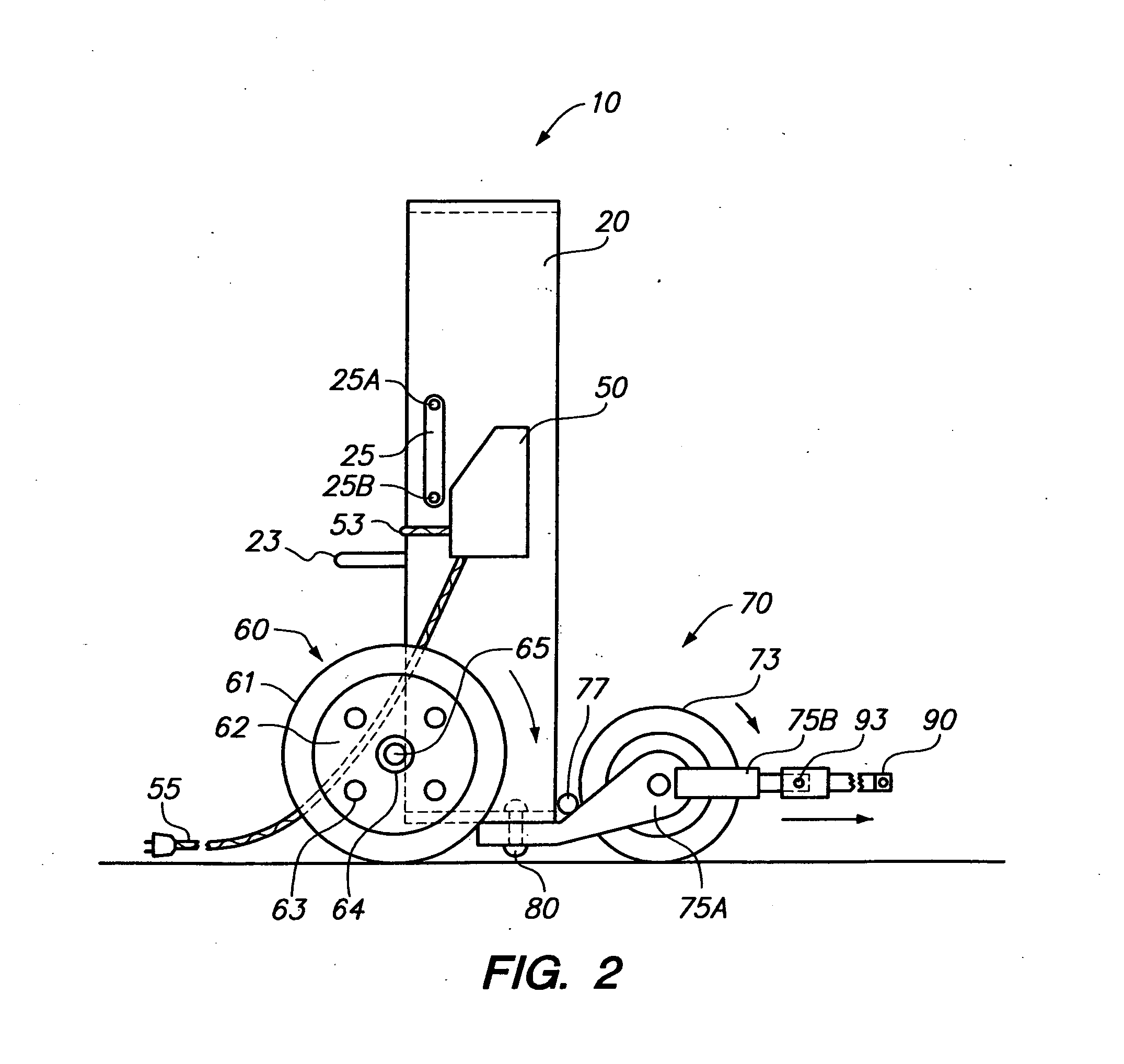

Assist unit for large outdoor fires background of the invention

The invention is designed to be used for the large outdoor fires such as fires on the U.S. Navy's aircraft carriers, in forests and grasslands and at airports and chemical plants. The operators of an “assist unit” should always be behind the firefighters. At long range it can blow fire suppressors into a fire and smother it. The suppressors can be water or chemicals by the firefighters. Soot, ashes, dirt or sand around a fire itself are good suppressors. The “assist unit” will blow them into the fire and it blows away the smoke and fumes as well. There are two versions of the “assist unit”: the ALL MANUAL one and the VEHICLE MOUNTED one.

Owner:LEWIS NATHANIAL HENRY

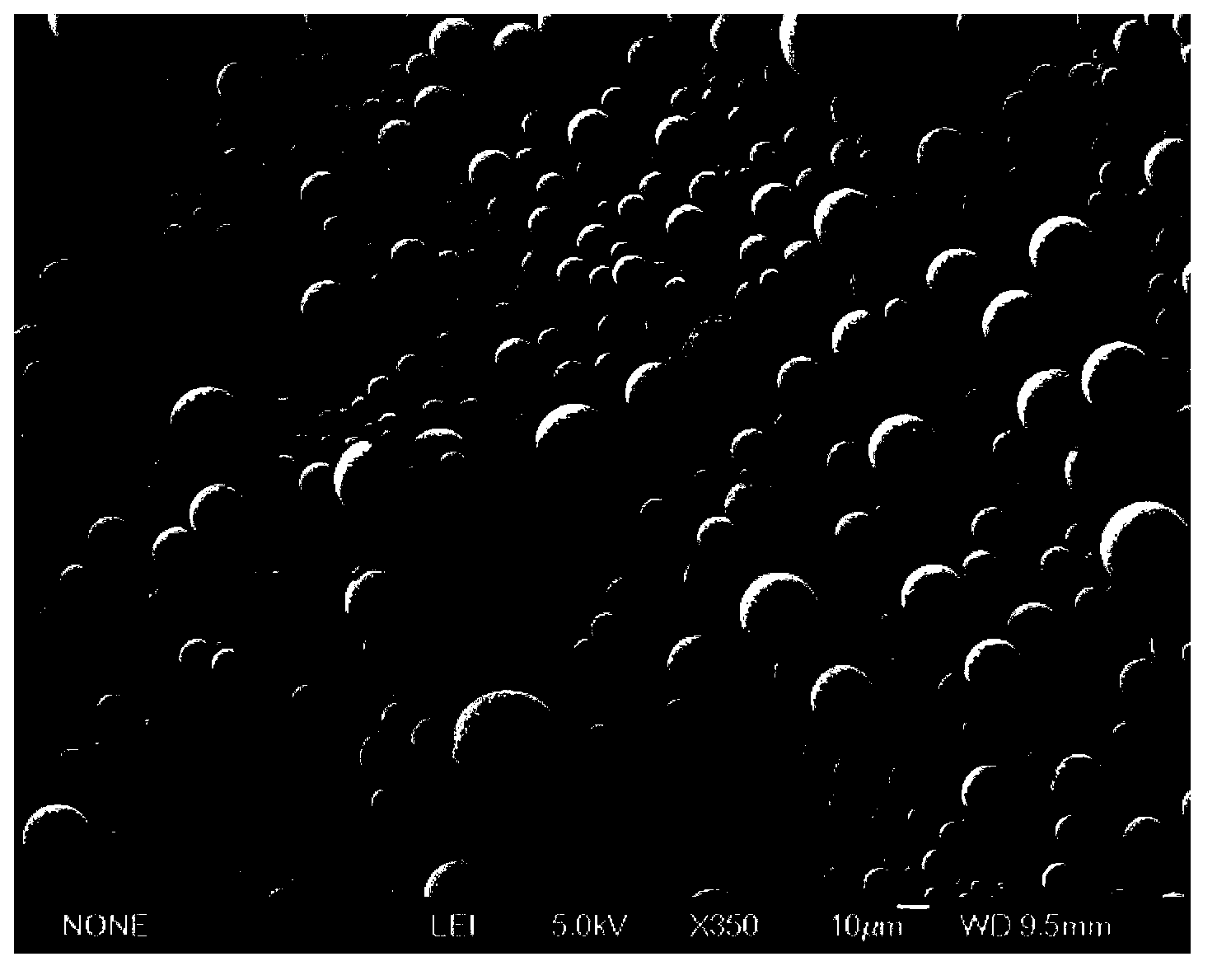

Phenolic resin hollow bead, and preparation method and application thereof

The invention provides a phenolic resin hollow bead and a preparation method and application thereof, relating to the field of plastics. The interior of the phenolic resin hollow bead is of a hollow structure, and the particle size of the bead is in a range of 5 to 100 mu m. The preparation method for the bead comprises the following steps: adding a water-soluble phenolic resin into water, carrying out stirring so as to form uniform slurry and selectively adding a foaming agent into the slurry; and subjecting the slurry to spray drying so as to allow the water-soluble phenolic resin to be cured and carrying out granulation so as to obtain the phenolic resin hollow bead. The phenolic resin hollow bead prepared in the invention has a small particle size and controllable particle size distribution and can be well applied in fields like petroleum drilling fluid; the preparation method for the bead is simple, takes a short period of time for preparation of the bead and can be easily industrialized.

Owner:CHINA PETROLEUM & CHEM CORP +2

Oil agent used for polyester industrial filament

This invention discloses a kind of oil applied to the polyester industry, its characteristic is that the oil is composed of the following component: (A) 5 ~ 70 weight % refining mineral oil; (B) 10 ~ 85 weight % polyatomic alcohol fatty acid esters; (C) 5 ~ 55 weight % copolymerizations ether; (D) 2 ~ 40 weight % fatty acid polyoxyethylene ester; (E) 1 ~ 15 weight % antistat; (F) 0.1 ~ 10%'s adhesion function improver. The oil can solve these defects of the present oil that both the heat resistance and the gluing function are bad. Since the heat resistance and the flatness are good, the smoke is few, the carbon build-up is few , waste thread rates is low in spinning handicraft; original silk brute force and modulus are good, maintained extension, breaking extension are low; The brute force loss in back handicraft processing is low , there is no color difference in the dyeing process.

Owner:CHINA PETROCHEMICAL CORP +1

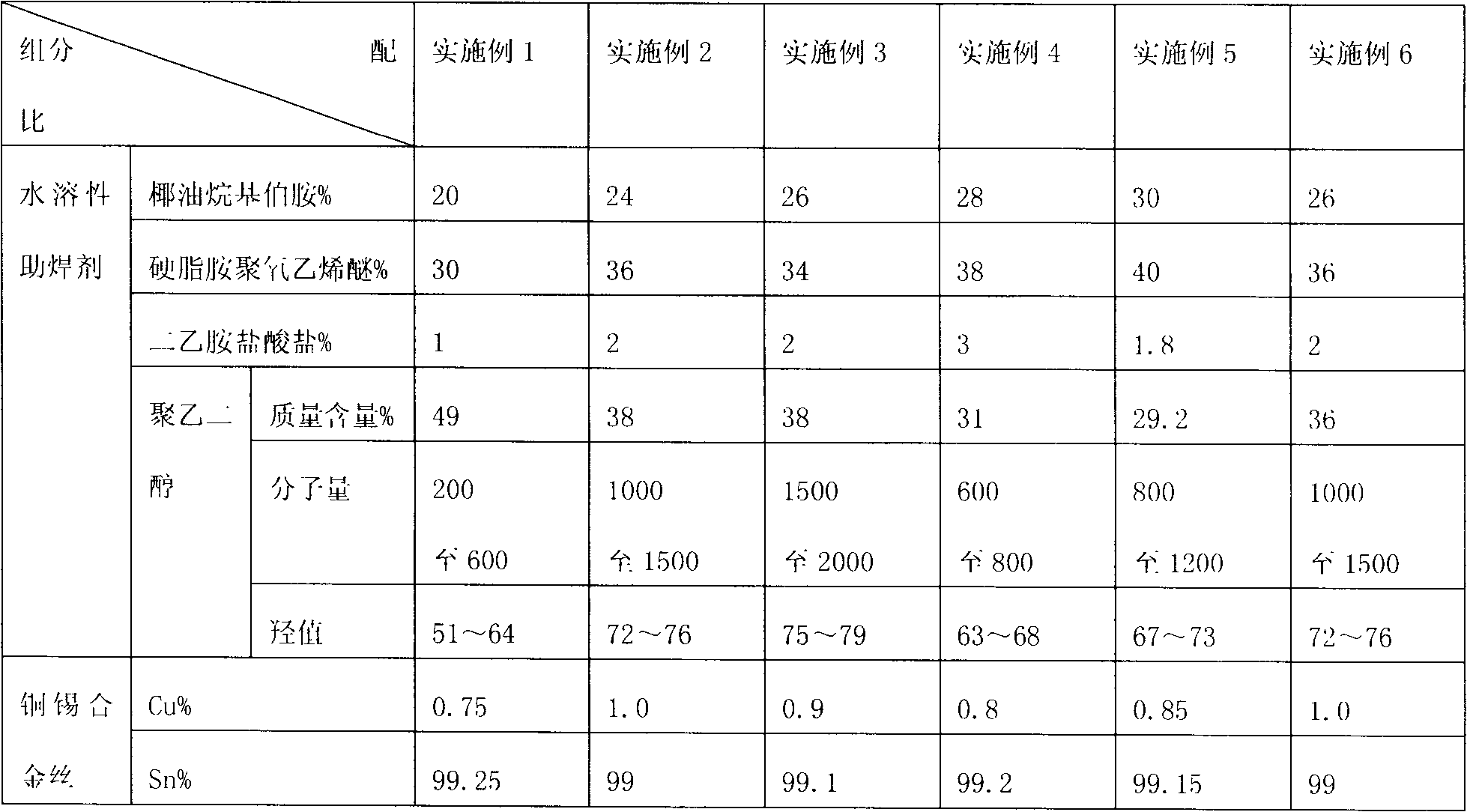

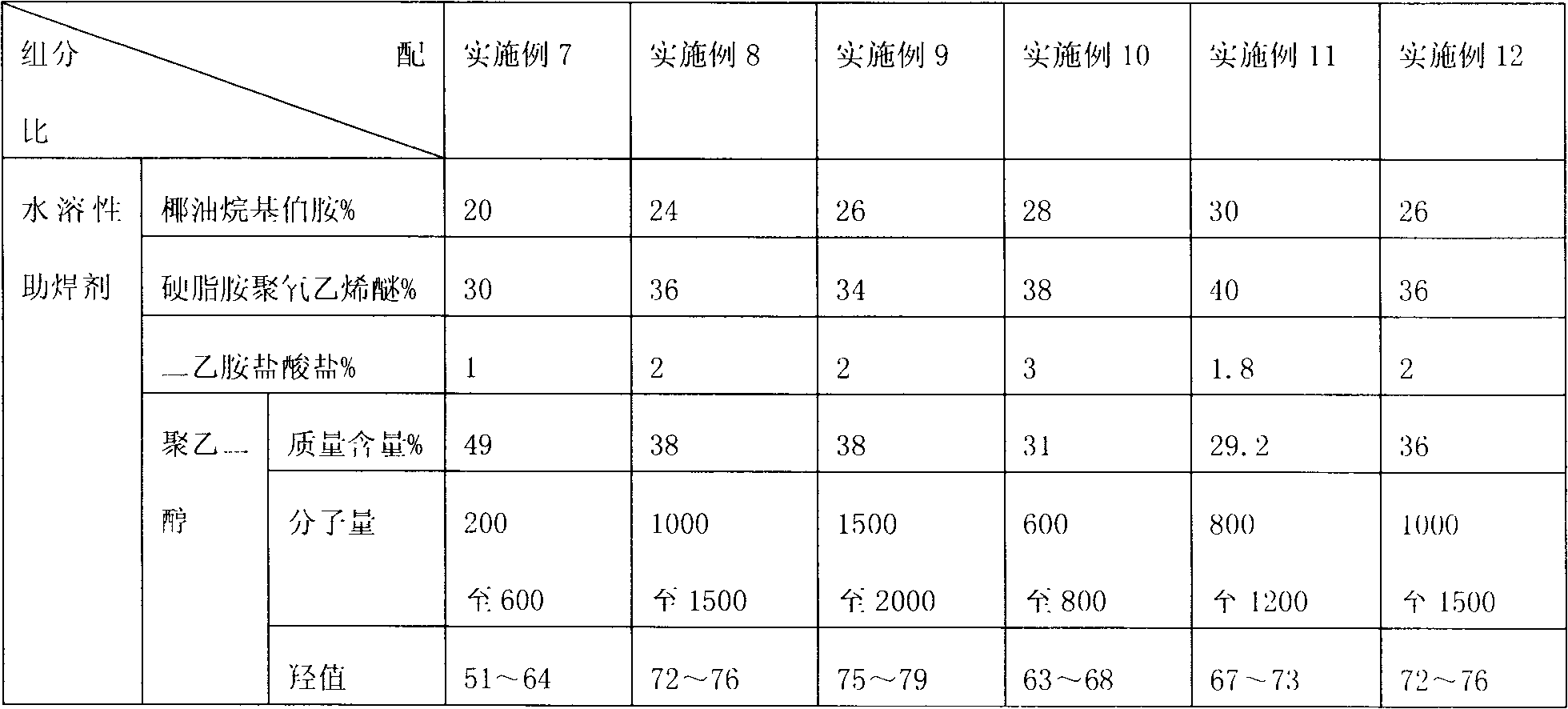

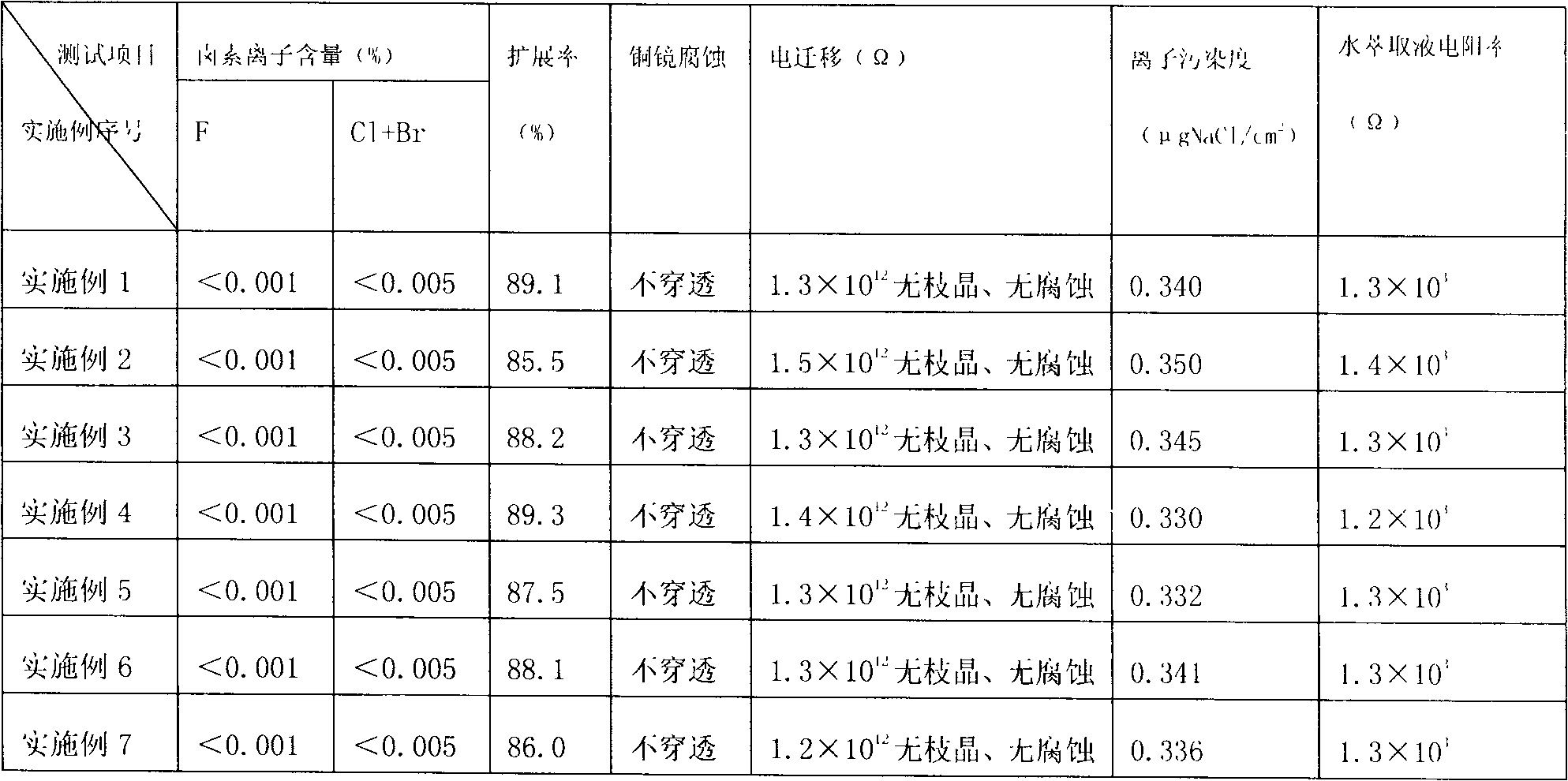

Lead-free welding tin wire and water-soluble welding flux used by same

ActiveCN102161135AReduce pollutionReduce interfacial tensionWelding/cutting media/materialsSoldering mediaPolyethylene glycolAlloy

The invention discloses a lead-free welding tin wire and a water-soluble welding flux used by the same. The lead-free welding tin wire comprises a copper-tin alloy wire provided with a hole cavity and the water-soluble welding flux arranged in the hole cavity; the proportion of the copper-tin alloy wire and the water-soluble welding flux is as follows: 2.0-2.2wt% of the water-soluble welding fluxand the balance of the copper-tin alloy wire, wherein the copper-tin alloy wire comprises the following components: 0.75-1.0wt% of Cu and the balance of Sn; the water-soluble welding flux comprises the following components: 20-30wt% of coconut oil alkyl carbinamine, 30-40wt% of octadecyl amine polyoxyethylene ether, 1-3wt% of diethylammonium chloride and the balance of water-soluble macromoleclarpolymer; the ammonium salt halogenide is diethylammonium chloride; and the water-soluble macromoleclar polymer is polyethylene glycol with the molecular weight of 200-2000. The lead-free welding tin wire provided by the invention has better welding performance and the water-soluble welding flux provided by the invention has better wettability.

Owner:浙江强力控股有限公司

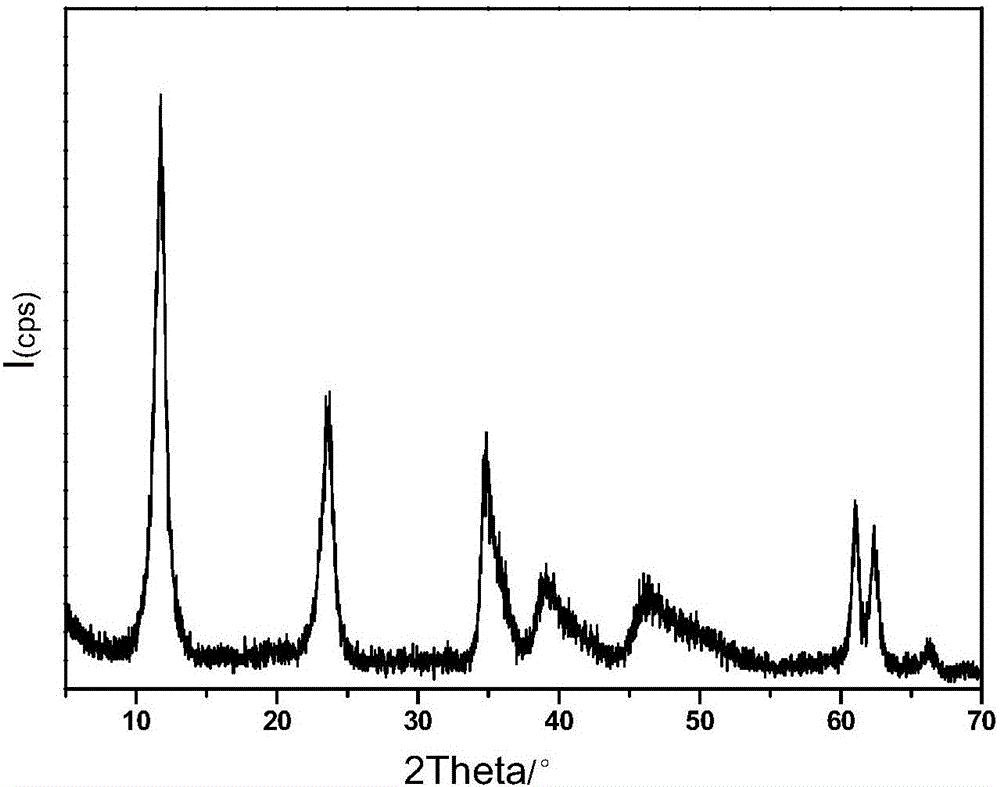

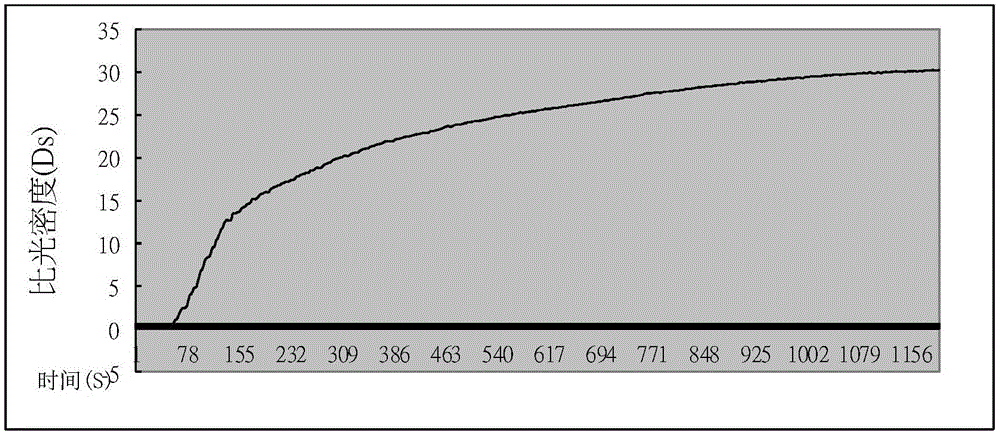

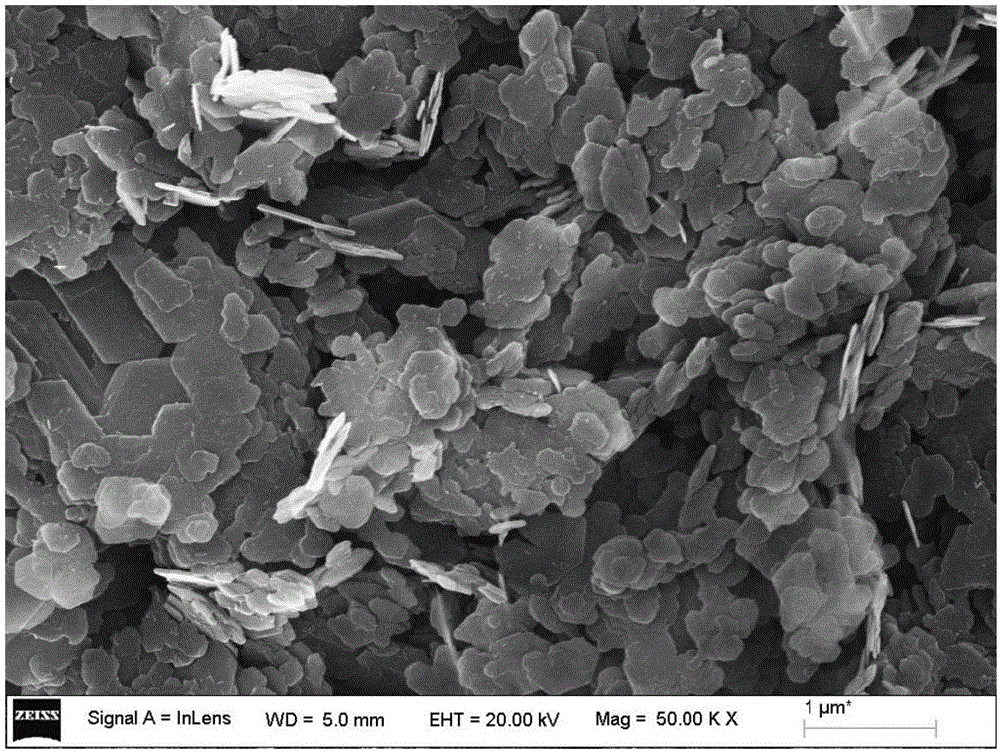

Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

The invention discloses an intercalated layered double hydroxide smoke inhibitor and a preparation method thereof. The smoke inhibitor is a layered structural material formed by assembling a laminated sheet consisting of metal cations and interlayer anions, wherein a specific composition general formula of the smoke inhibitor is M<2+>1-xM<3+>x(OH)2(A<n->)n / 2.mH2O. According to the preparation method disclosed by the invention, the intercalated layered double hydroxide smoke inhibitor is prepared by adopting a one-step coprecipitation method or a clean hydrothermal reaction at one step; the preparation method is simple and practical; according to the obtained intercalated layered double hydroxide smoke inhibitor, smoke inhibiting groups such as molybdate anions, an octamolybdate radical, a cuprate radical and a stannate radical are arranged at an interlayer, and smoke inhibiting elements such as iron and copper are introduced into the laminated sheet, so that a good carbon forming effect is realized, the smoke generating amount can be reduced, and the smoke inhibiting effect is synergically enhanced; meanwhile, a layered double hydroxide laminated sheet forms an alkaline porous substance at high temperature; the alkaline porous substance has greater specific surface area and can effectively adsorb smog; the prepared intercalated layered double hydroxide smoke inhibitor is applied to an ordinary rubber-plastic product and a high-temperature rubber-plastic product; the maximum density (Ds, max) at low additive amount (1phr) can be reduced by 87.3 percent; the intercalated layered double hydroxide smoke inhibitor is remarkable in smoke inhibiting effect and is a smoke inhibitor material with excellent performance.

Owner:BEIJING UNIV OF CHEM TECH

Fireproof paint

The invention discloses a fireproof paint prepared by the following raw materials by the weight: 25-45% of acrylic emulsion, 10-20% of dipentaerythritol, 5-15% of expanded graphite, 5-15% of melamine, 2-10% of ammonium polyphosphate, 3-10% of aluminium hydroxide, 2-5% of zinc oxide, 1-5% of silica, 4-10% of carbon fiber, 5-10% of silicon nitride fiber and the balance of water. The fireproof paint is the water paint; organic solvent is not needed in the preparation process; and the formula does not include halogen, so the fireproof paint does not release toxic or harmful gases containing the halogen, therefore, the fireproof pain has the advantages of security, low pollution and environmental protection, and is widely applied to various steel structure buildings.

Owner:SHANDONG CHANGXING GROUP

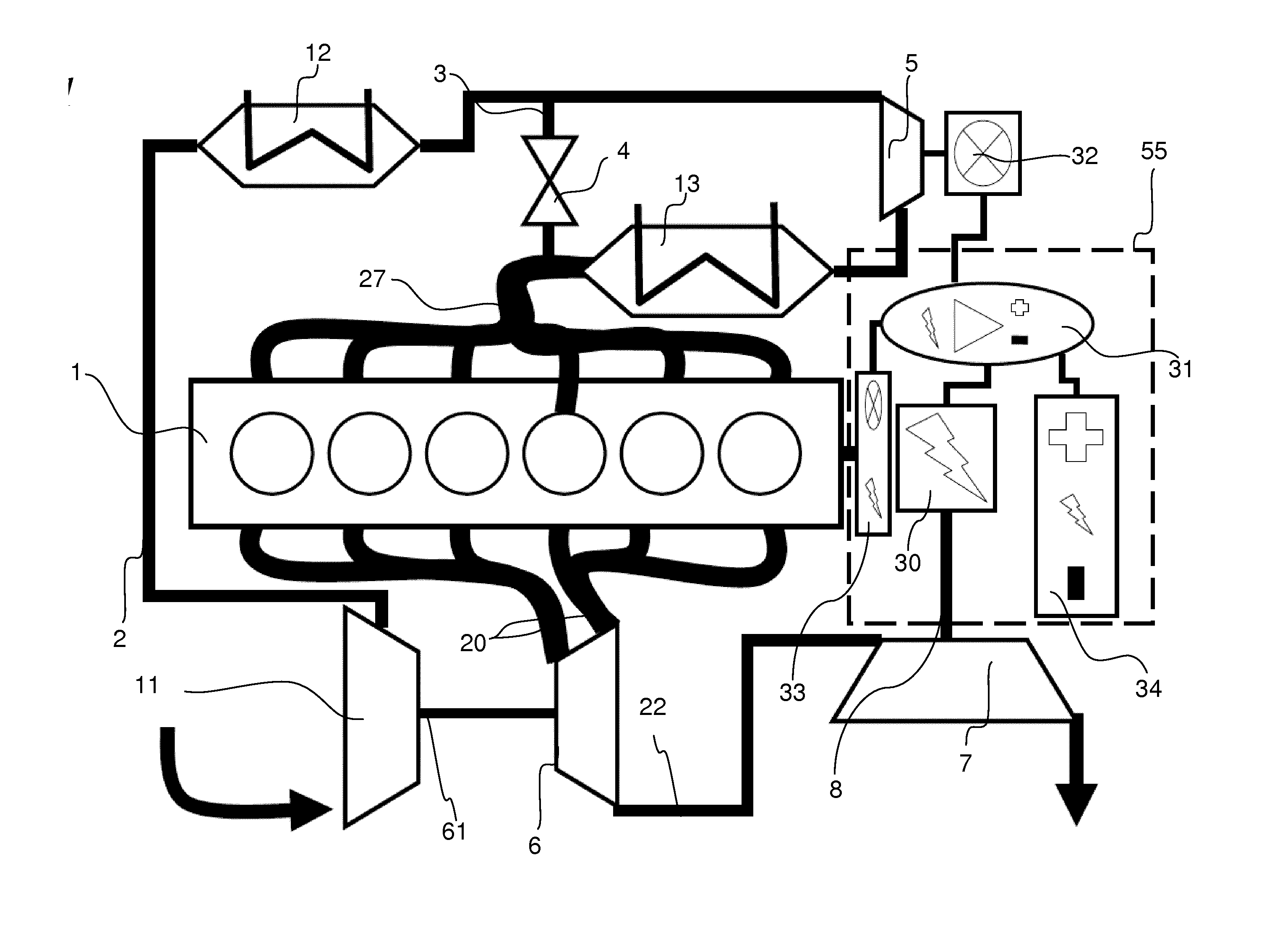

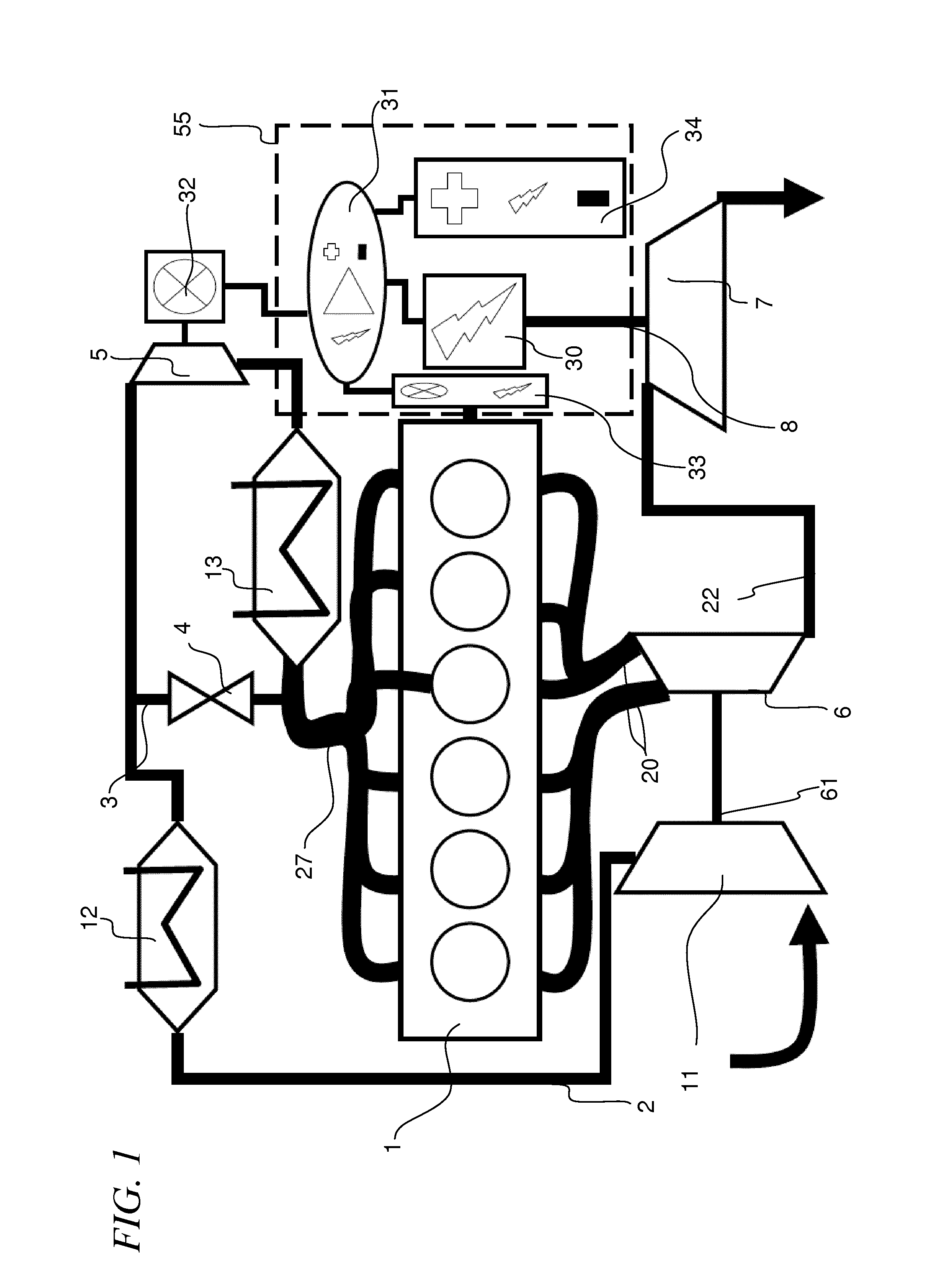

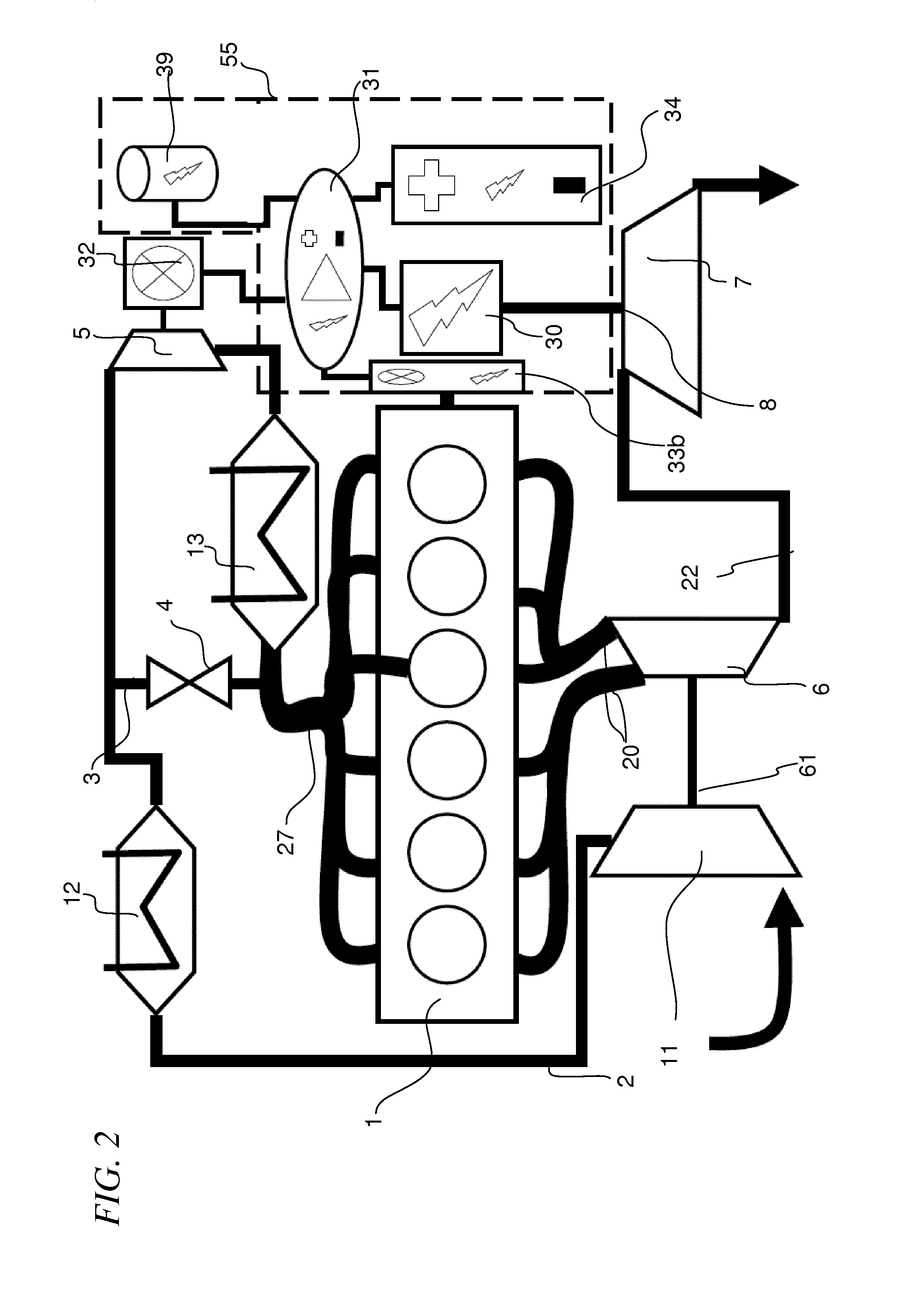

Supercharged turbocompound hybrid engine apparatus

ActiveUS20140195134A1Improve power densityLess smokeHybrid vehiclesAnalogue computers for vehiclesElectric energyElectric generator

The present invention is relative to a engine apparatus comprising a combustion engine, a low pressure compressor connected to a high pressure turbine. The apparatus also comprises a low pressure turbine and a high pressure compressor. The engine apparatus according to the invention comprises an electrical torque converter comprising at least an electric generator connected so as to be driven by said low pressure turbine and a first electric motor connected so as to drive said high pressure compressor. The torque converter also comprises electronic conversion means suitable to convert the electric energy produce by said electric generator and to power supply and control at least said first electric motor.

Owner:FPT MOTORENFORSCHUNG

Polyvinyl chloride (PVC) cable sheath material and preparation method thereof

InactiveCN102250435AExcellent low temperature/high temperature performanceIncrease char formationPlastic/resin/waxes insulatorsInsulated cablesAluminium hydroxidePolyvinyl chloride

The invention discloses a polyvinyl chloride (PVC) cable sheath material and a preparation method thereof. The PVC cable sheath material comprises 100 parts of PVC resin, 30-50 parts of plasticizer, 3-7 parts of compound stabilizer, 20-40 parts of active calcium carbonate, 5-15 parts of kaolin, 5-15 parts of aluminum hydroxide, 3-6 parts of antimony trioxide, 3-5 parts of zinc borate and 0.5-1.5 parts of aromatizer. In the cable sheath rubber disclosed by the invention, through the optimal combination of aluminum hydroxide, antimony trioxide and zinc borate, the carbonization amount is improved by approximate 50%; the smoke generation amount during naked flame combustion is reduced by 30-50%, and the limiting oxygen index (LOI) is improved to 33; by selecting a proper plasticizer, the material has excellent low-temperature and high-temperature resistance at the same time, and the use temperature of the material is (-30)-90 DEG C; and a mint-flavored essential oil aromatizer is added to the material, so that the obtained product has aromatic odor and has the actions of eliminating nausea, nervousness and tension headache and dispelling mosquito.

Owner:WUXI MINGZHU CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com