Patents

Literature

57results about How to "Reduce yarn breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-smoke FDY (Fully Drawn Yarn) oiling agent and preparation method thereof

The invention discloses a low-smoke FDY (Fully Drawn Yarn) oiling agent and a preparation method thereof. The low-smoke FDY oiling agent comprises the following materials in percentage by weight: 50-60% of emulsifying agent, 10-30% of smoothing agent, 6-10% of antistatic agent, 1-3% of beam concentrating agent, 9-11% of moisture, and 0.1-0.2% of preservative. The low-smoke FFY oiling agent provided by the invention has such functions of lubricating fiber, concentrating beam, preventing static electricity and the like in a production process of FDY, has the characteristics of reducing broken yarns, broken filaments, reducing dyeing and the like in a pre-spinning process, and further has the characteristics of reducing broken yarns, broken filaments, static electricity and the like in a post-processing (weaving) process, and is an important auxiliary ingredient which is essential in the production process of chemical fiber.

Owner:ZHEJIANG TIANSHENG HLDG GROUP

Antistatic blended yarn and application thereof

The invention provides an antistatic blended yarn, which is prepared from 20 to 45 percent of polyester fiber, 35 to 70 percent of cotton fiber and 10 to 30 percent of stainless steel fiber by weight percentage through blended spinning. The invention also provides an antistatic sweater produced by adopting the antistatic blended yarn and a method for producing the same. The product of the antistatic blended yarn has antistatic and electromagnetic shielding functions, does not have special requirement on washing, is not influenced by the environment, has complete colors and solid texture, is sweat-resistant and corrosion-resistant, can be applied to special industries such as anti-microwave clothes and radiation-resistant clothes, can effectively prevent human body from being radiated by computers and the like, and particularly protect pregnant women. The antistatic blended yarn can be processed into clothes worn in spring, autumn and winter and the clothes are comfortable to wear with excellent performance.

Owner:JIANGYIN XIANGFEI APPAREL

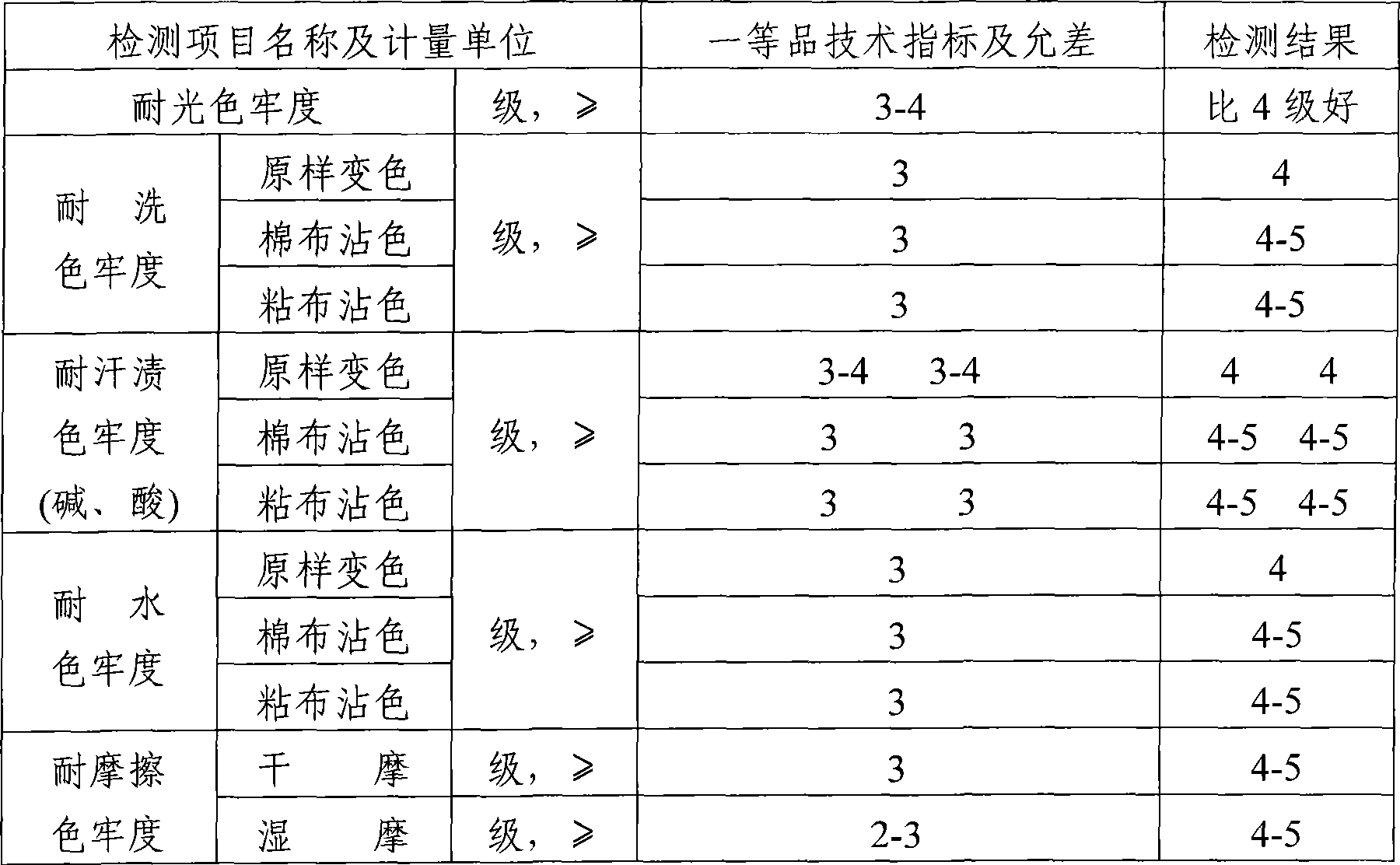

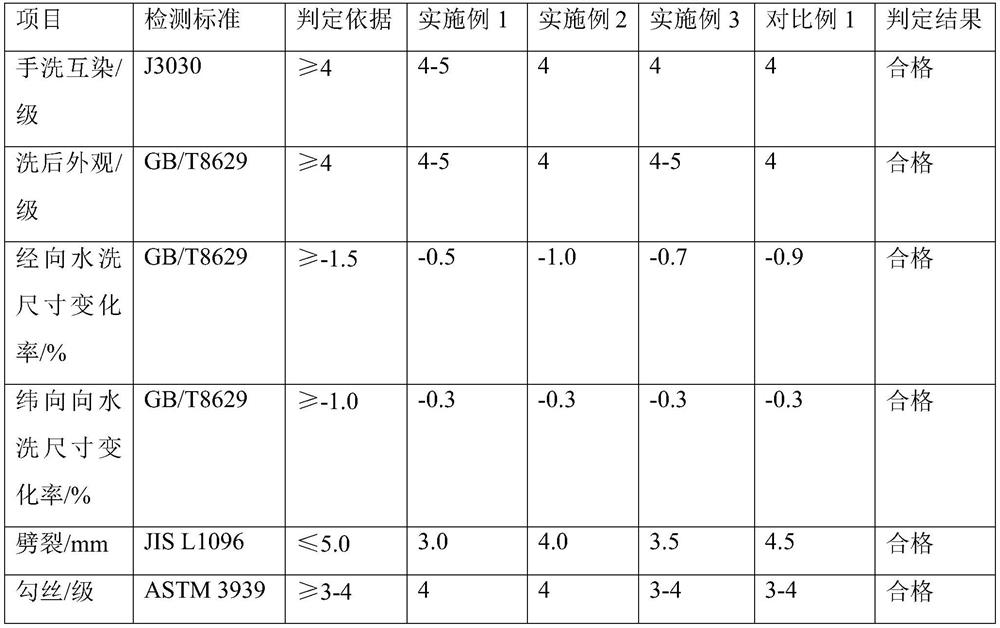

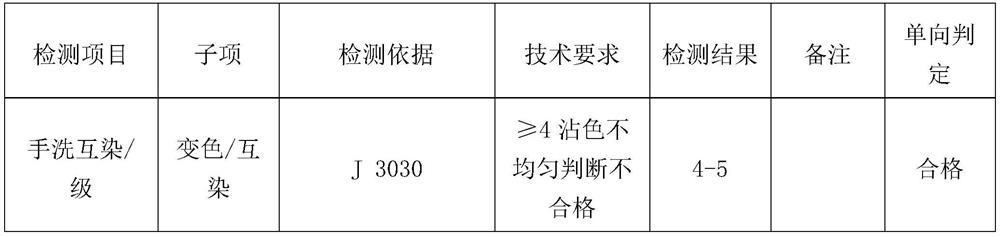

Manufacturing process of polyester cotton yarn-dyed fabric

InactiveCN107869077ALow staticReduce the probability of static electricitySingeingHeating/cooling textile fabricsYarnPolyester

The invention discloses a manufacturing process of a polyester cotton yarn-dyed fabric. The manufacturing process comprises the following technological steps: selecting a polyester cotton blended yarn; sequentially performing scouring, blanching, dyeing, soap-boiling, water washing and drying, wherein beam dyeing is adopted, and in the dyeing process, the winding density of a warp of a warping machine is 0.46-0.48 g / cm<3>; before dyeing, adding 0.2-0.4 g / L sodium sulfate into water required by dyeing, performing stirring for 8-10 min; adding sodium carbonate first at the water temperature of 35-40 DEG C; after 12-15 min, adding sodium sulfate for 12-15 min; and maintaining for 42-46 min when the temperature rises to 62 DEG C. According to the manufacturing process, the dyeing effect is improved, more uniform dyeing is achieved, the dyeing freshness is guaranteed, the static property of a spun polyester thread is reduced by an anti-static agent, the static ratio of the polyester cottonyarn-dyed fabric which is woven is favorably reduced on the whole, in addition, triple-jump, yarn breakage and yarn sinking are reduced, and the sizing percentage is increased.

Owner:JIANGSU MINGYUAN TEXTILE

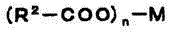

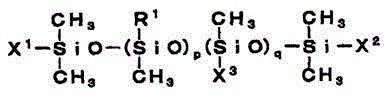

A processing agent for polyurethane elastomer fiber, a method of processing of polyurethane elastomer fiber and a polyurethane elastomer fiber

ActiveCN105178033AExcellent processing gradeImprove dispersion stabilityMonocomponent polyurethanes artificial filamentFibre treatmentChemistryFiber

The invention provides a processing agent for polyurethane elastomer fiber, a method of processing of polyurethane elastomer fiber and a polyurethane elastomer fiber, wherein the processing agent for polyurethane elastomer fiber has excellent dispersion stability,allows less scum and soft sides in post processing, and can adapt recent tendency of high level requirements of excellent production of polyurethane elastomer fibers. A composition comprising a specific slipping agent, specific amino modified silicone, and specific higher aliphatic acid salt, can be the processing agent for polyurethane elastomer fibers.

Owner:TAKEMOTO YUSHI KK

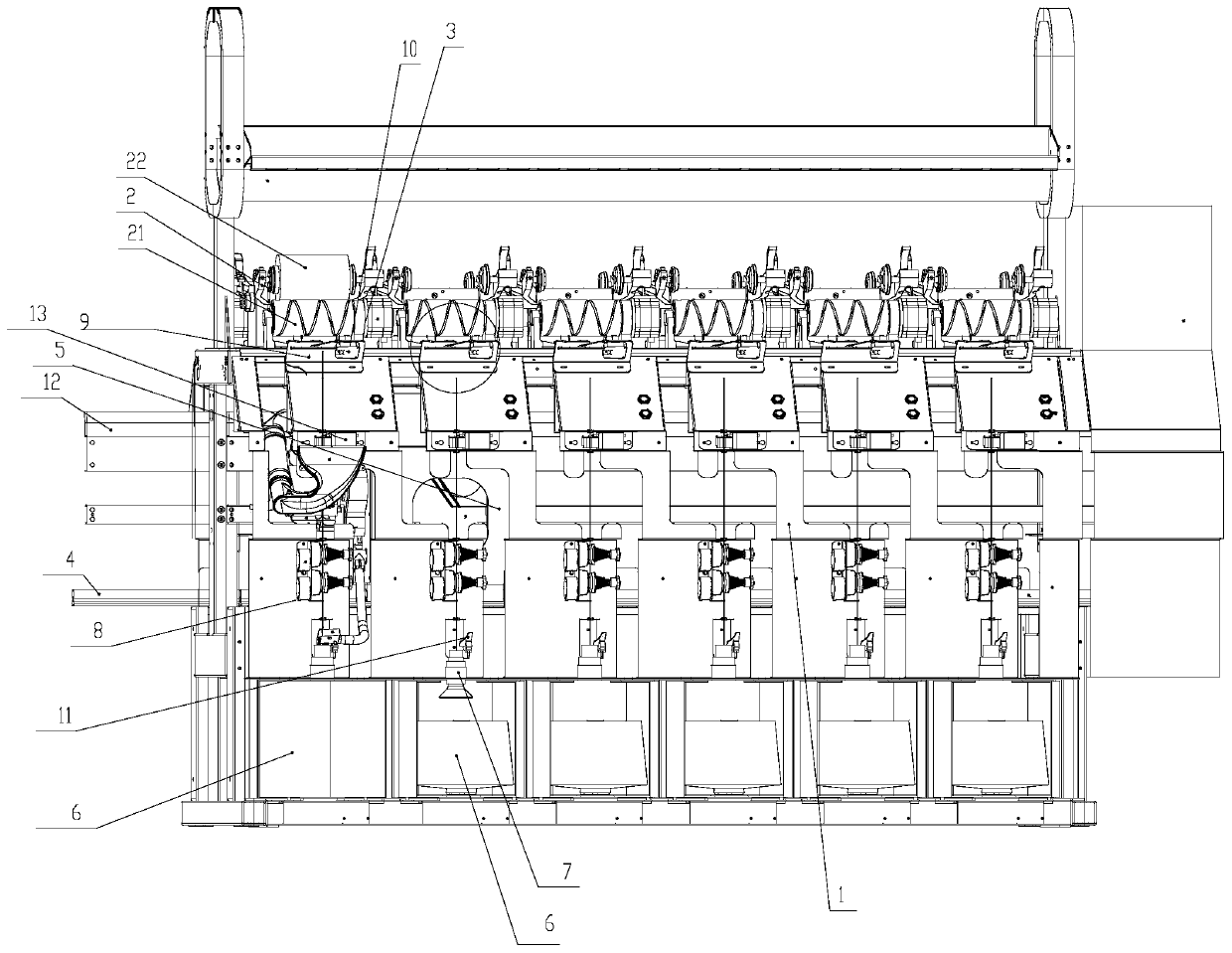

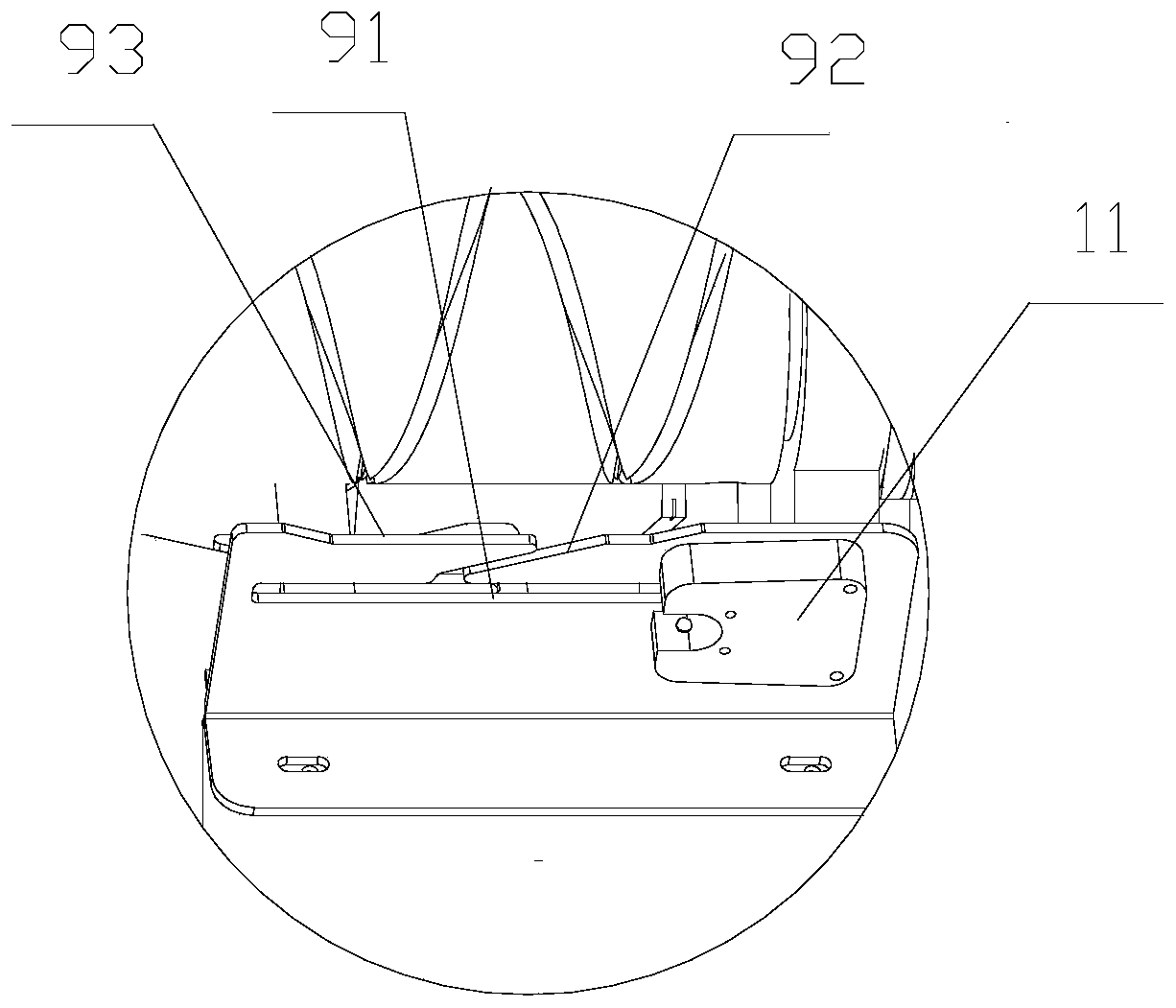

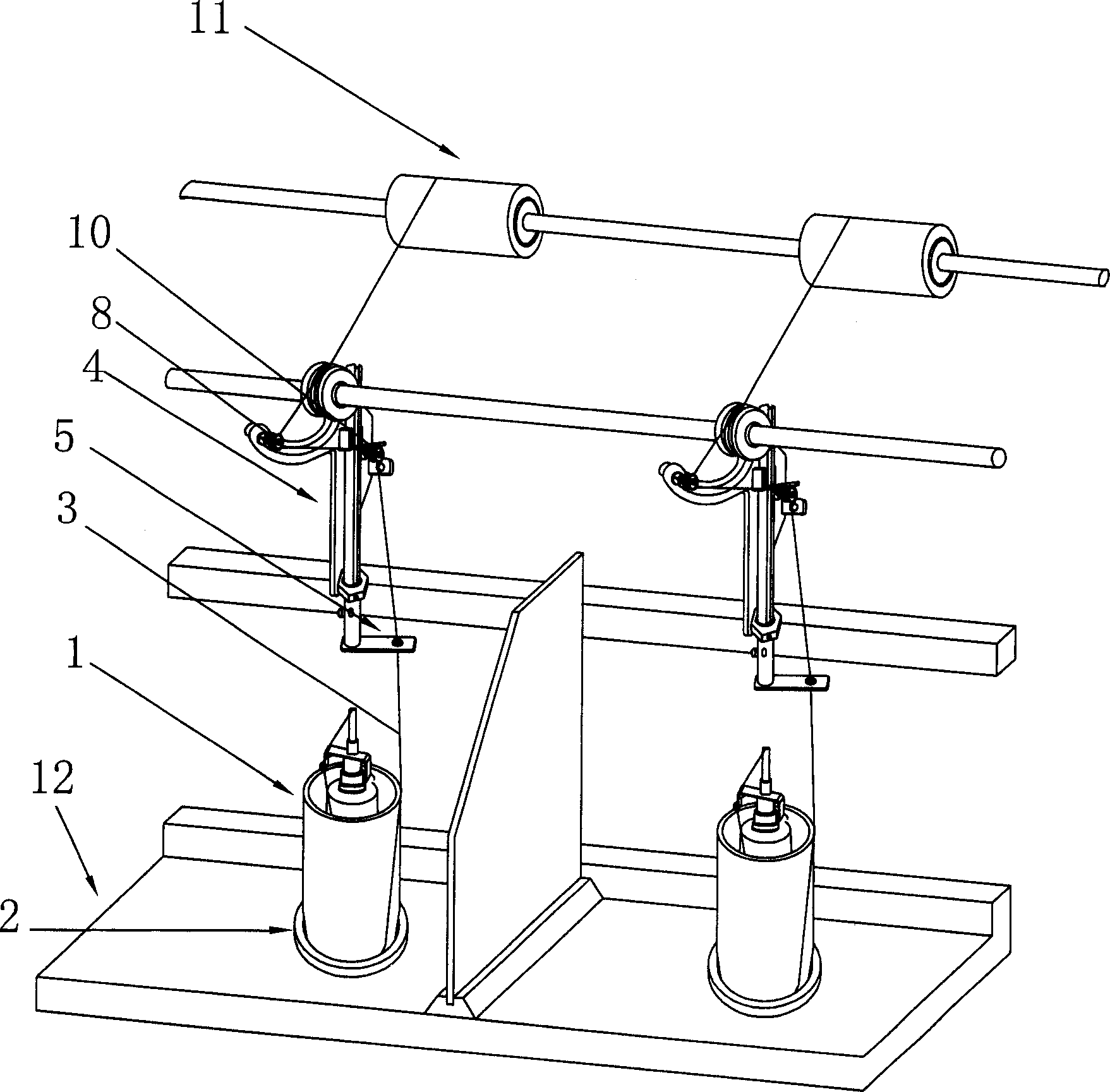

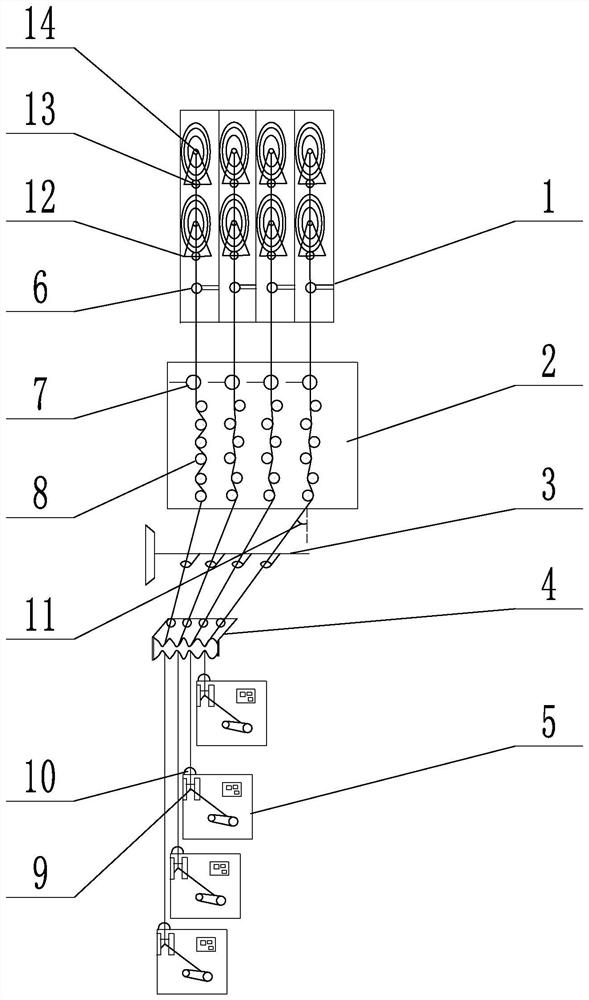

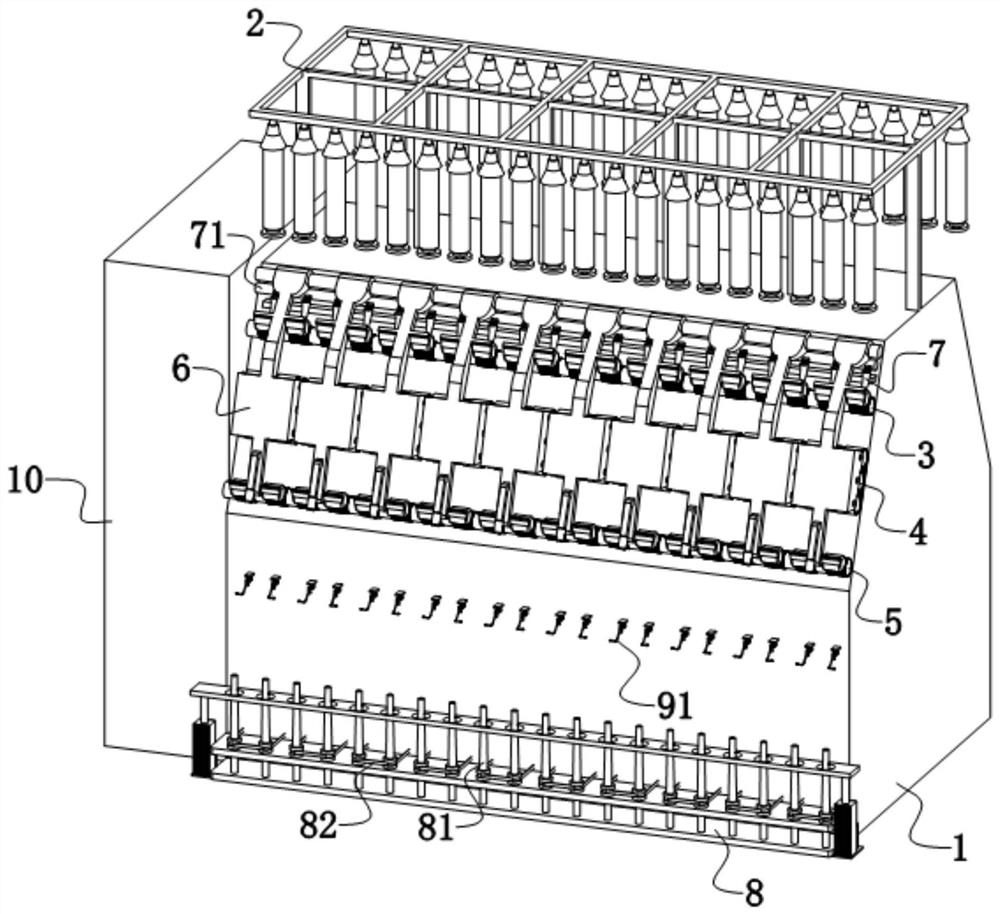

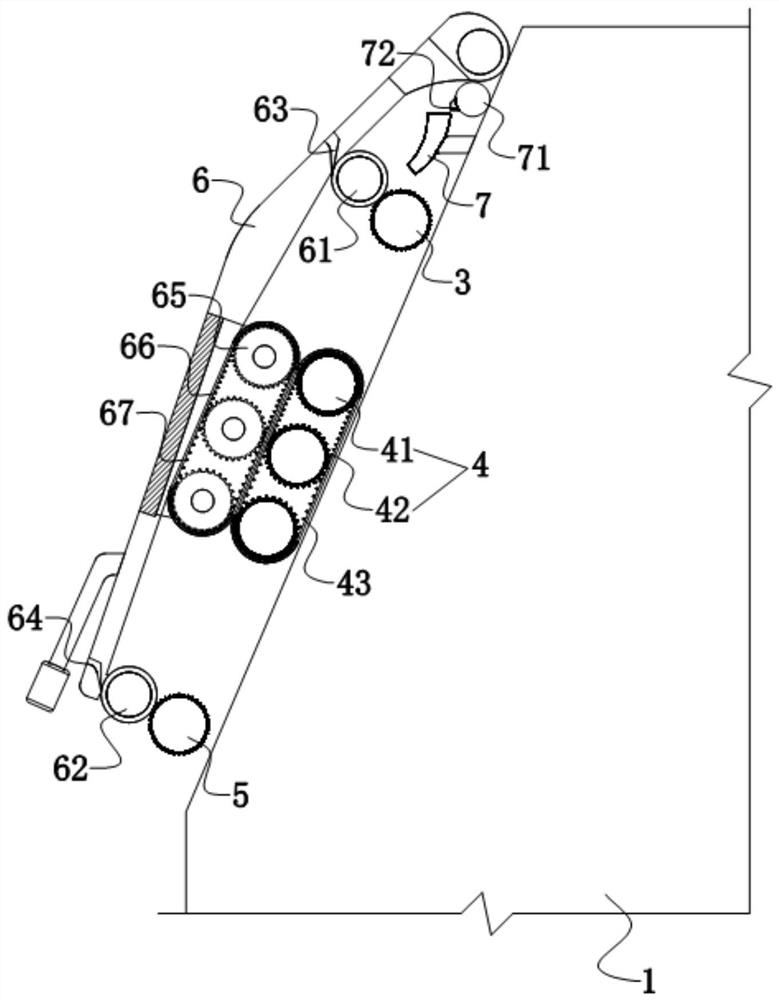

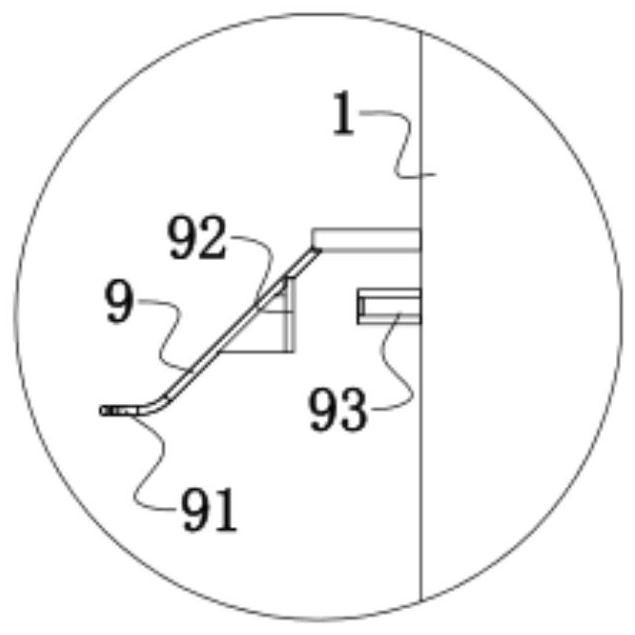

Automatic winding machine

The invention discloses an automatic winding machine. The automatic winding machine comprises a frame; the frame is provided with multiple winding modules and a winding motor for driving the winding modules; the frame is provided with electronic yarn cleaners under all the winding modules; the frame is provided with horizontal lower slide rails under the electronic yarn cleaners; knotting box modules are slidingly arranged on the horizontal lower slide rails; multiple yarn supply devices corresponding to all the winding modules are arranged at the lower part of the frame; the frame is providedwith air sucking devices above the yarn supply devices; the winding modules comprise groove cylinders rotationally arranged on the frame; rocking frame modules are arranged on the frame above the groove cylinders; bobbins are detachably arranged on the rocking frame modules; and the frame is provided with yarn tension waxing devices above the yarn supply devices. The automatic winding machine islower in production cost and use and maintenance cost.

Owner:苏州济洋纺织机械有限公司

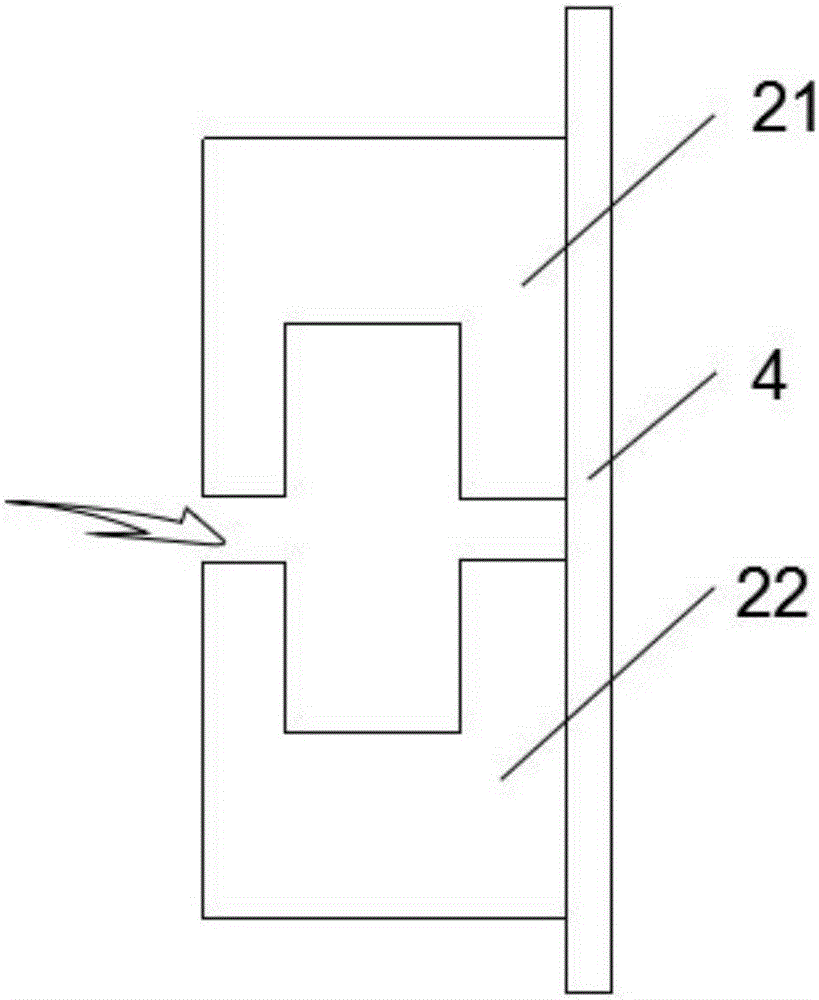

Automatic drafting machine and drafting method thereof

The invention discloses an automatic drafting machine and a drafting method thereof. The machine comprises a heddle, a rail, a crochet hook and a wallboard. The rail is half-enclosed, is composed of an upper concave block and a lower concave block which are oppositely arranged, and one side of the rail is fixed to the wallboard. The heddle is arranged on one side of the rail. A heddle eye is arranged at the position, corresponding to the position of the rail, of the heddle. After the crochet hook hooks a warp yarn, the crochet hook passes through the heddle eye and the rail, and then the drafting is completed. Nozzles are uniformly distributed in the length direction of the rail. The beneficial effects of the machine are that the nozzles are uniformly mounted in the rail through which the crochet hook passes; the nozzles are connected to an external air compression device, and the nozzles inject air in the rail; and when the crochet hook normally hooks the yarn and passes through the rail, the yarn which is attached on the surface of the rail as static electricity is generated due to friction can be blown out of the rail, so that mistakes can be reduced.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Two-for-one twisting mechanism

The double twisting framework includes the engine frame, the spindle dial running intercalated on the said engine frame, the guiding yarn setting and the winding setting intercalated on the said engine frame, the said guiding yarn is located between the storing yarn canister and the winding yarn setting, the said guiding yarn setting includes the guiding yarn bracket, the threading yarn board is located on the said guiding yarn bracket, the bearing is located on the said threading yarn board. In the practice appliance, the yarn is missive pass the spindle dial from the storing yarn canister, the spindle dial is tail-wagging, the yarn is tail-wagging drive by the spindle dial to realize the twisting and coiling handle of the yarn, when the yarn passes the guiding yarn setting, the yarn is drilled through the bearing, then the yarn is coiled the tension bearing piece, the yarn can drive the inside track of the bearing to eddy, so the tatty degree of the yarn can be depressed, the filoplume produced from the yarn is reduced to ensure the intension of the yarn and reduce the breaking yarn phenomenon.

Owner:屠建文

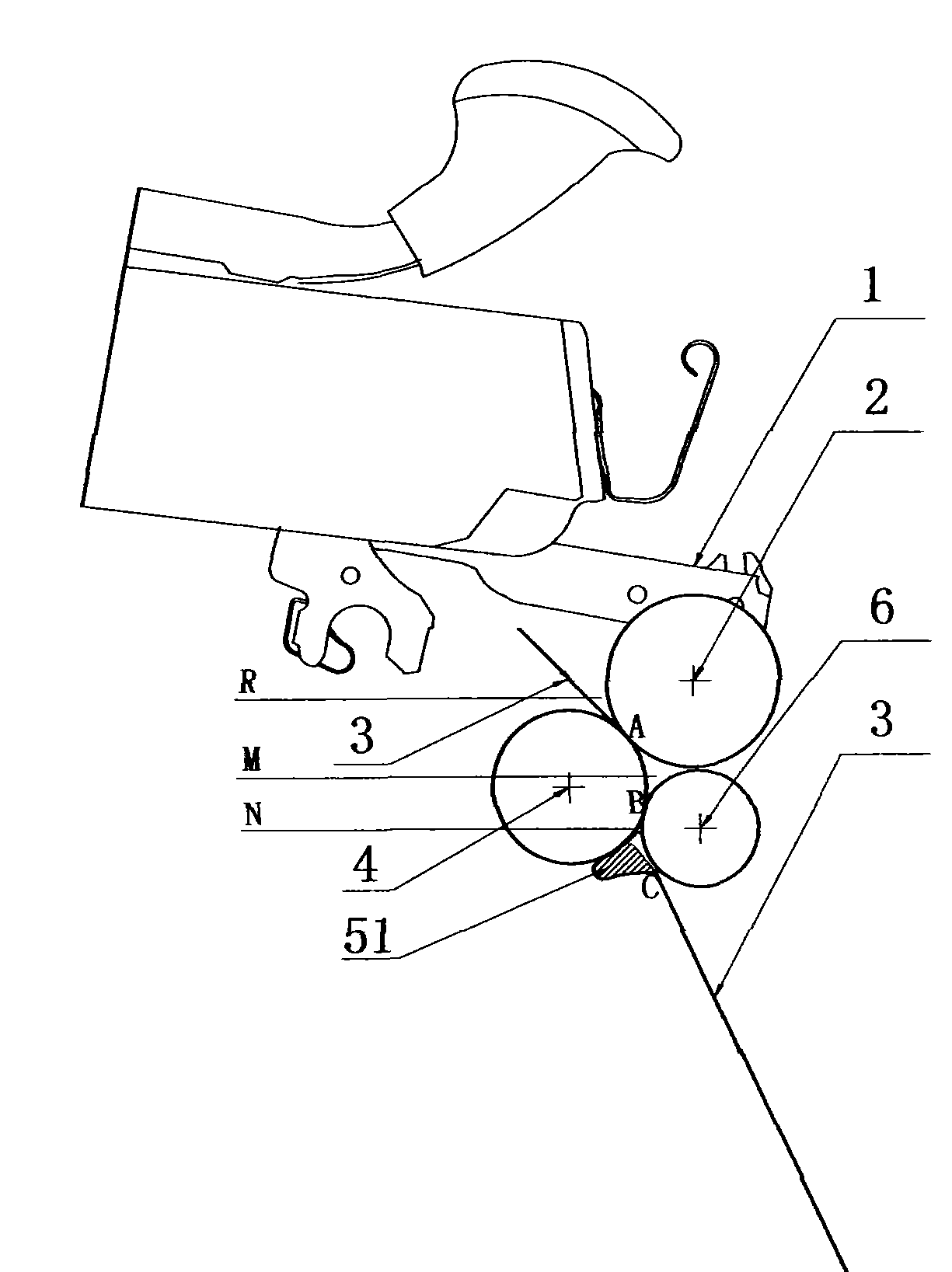

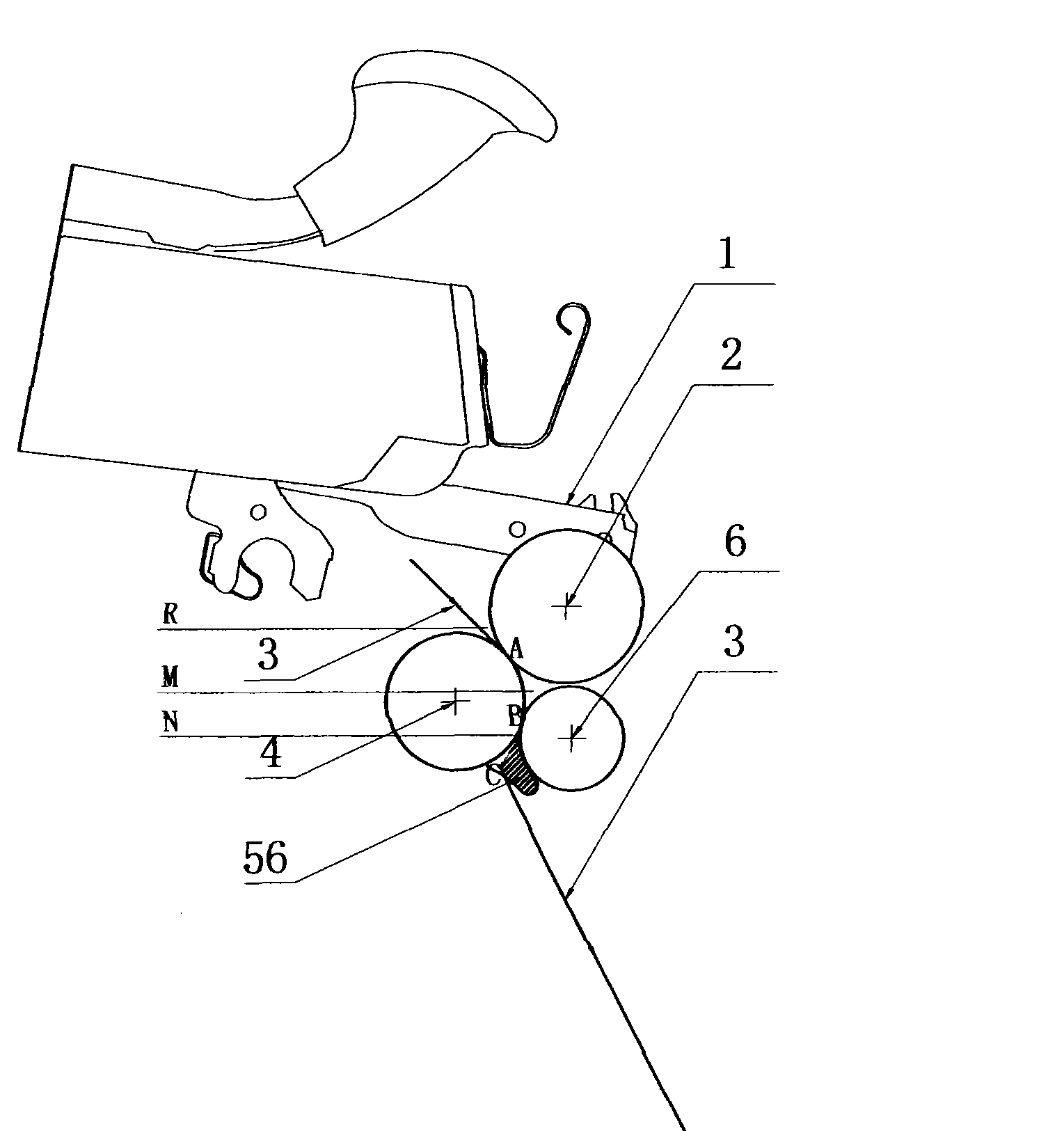

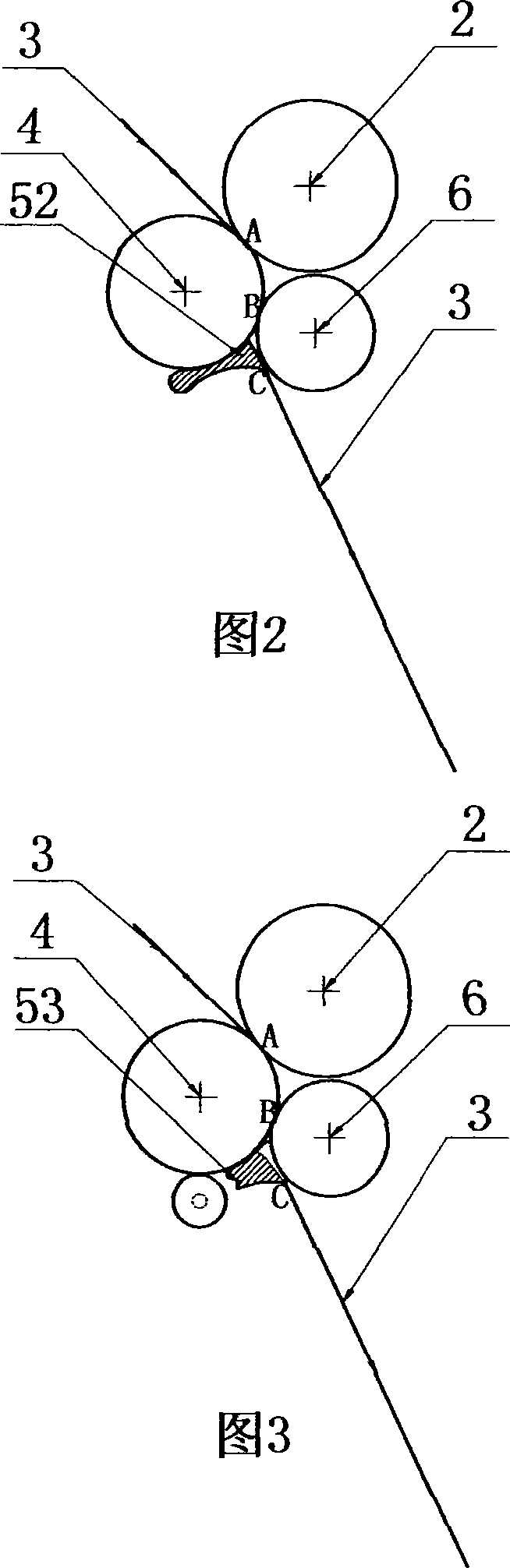

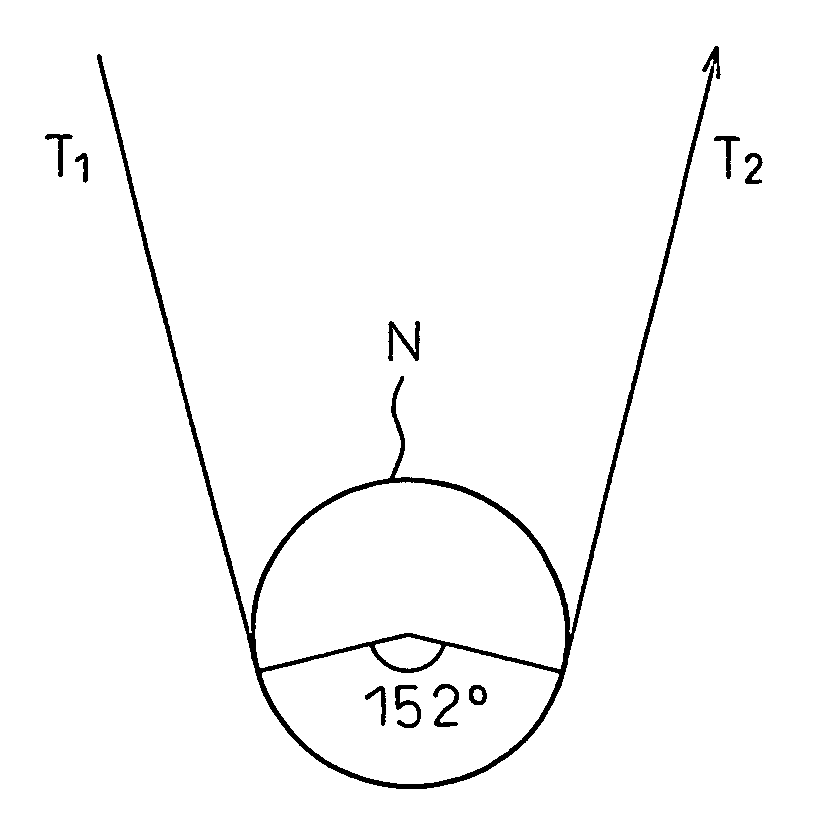

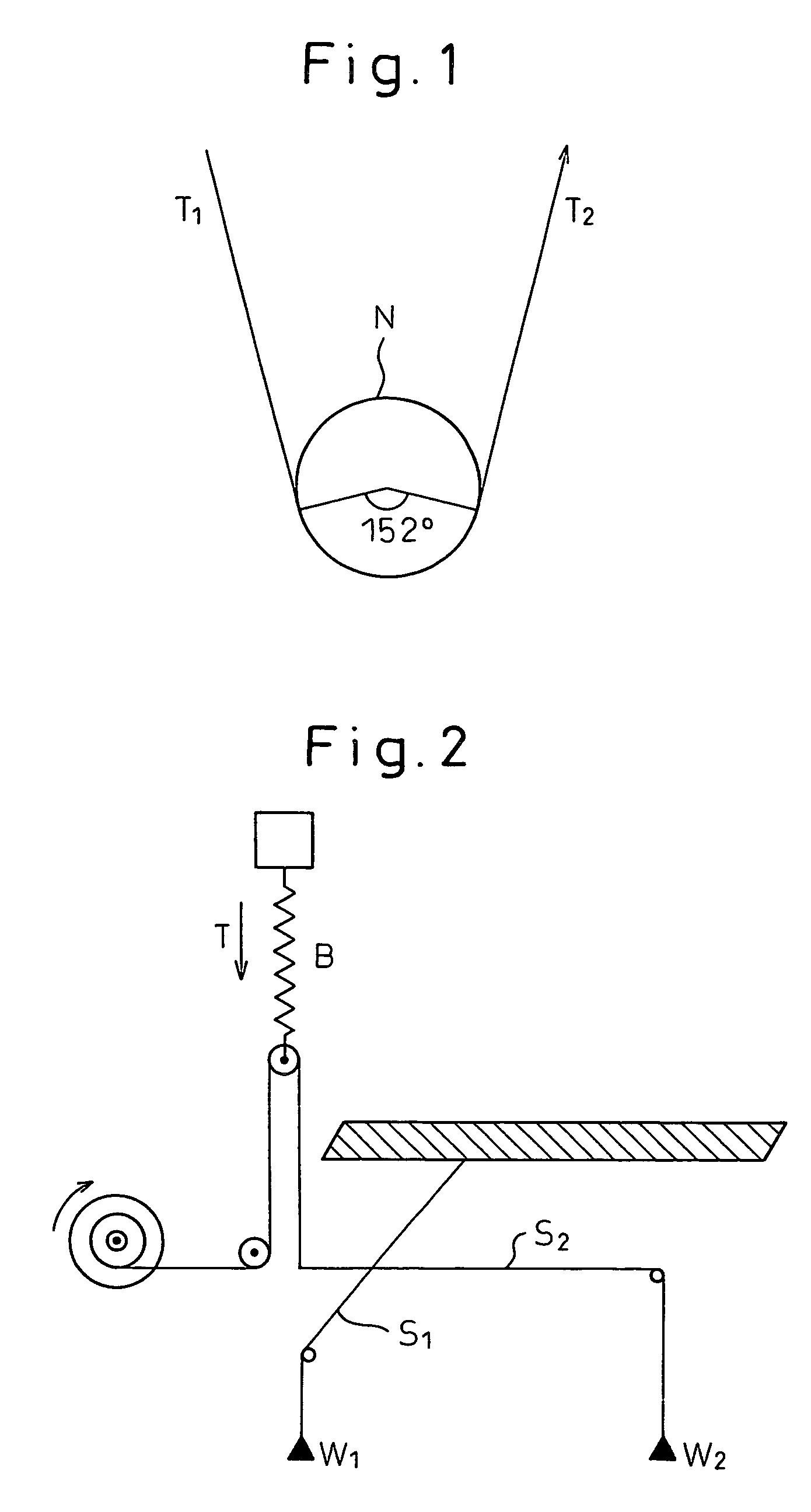

Compact spinning apparatus of spinning frame

The invention discloses a tight spinning device of a spinning machine, which belongs to the technical field of spinning mechanical technology and includes a lower leather roller mounted on a cocket centring of the spinning machine. A lower roller is mounted below the cocket centring and tightly pressed on the lower leather roller. An output compression roller is tightly pressed on the lower roller. A beaming piece is mounted in a beaming area N. The device includes a contact area A formed between the lower roller and the lower leather roller and a contact area B formed by the lower roller and the output compression roller. A yarn guide area M is formed between the contact area A and the contact area B; a beaming area N is formed by extending from the contact area B to the output end C of the beaming piece. The tight spinning device adopts a method that the yarn operation situation is adjust firstly from the yarn guide area M, then the yarn enters the beaming area N to be bunched and finally twisted by a spindle of the spinning machine through the output end C, thus greatly decreasing an inverse angle; therefore, the twist number is easy to be transferred, the yarn-off phenomena are fewer, furthermore, the beaming effect is excellent and the operation is stable.

Owner:朱爱萍

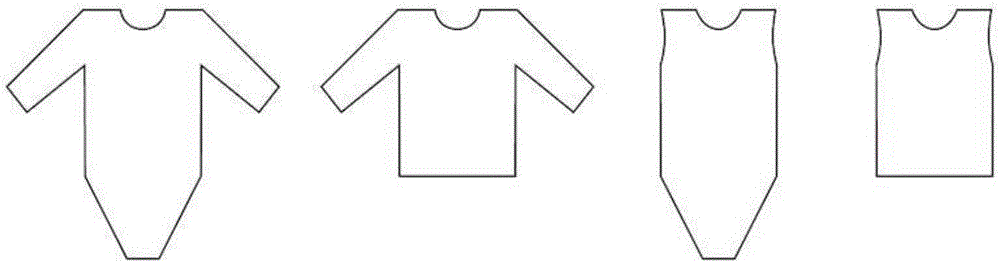

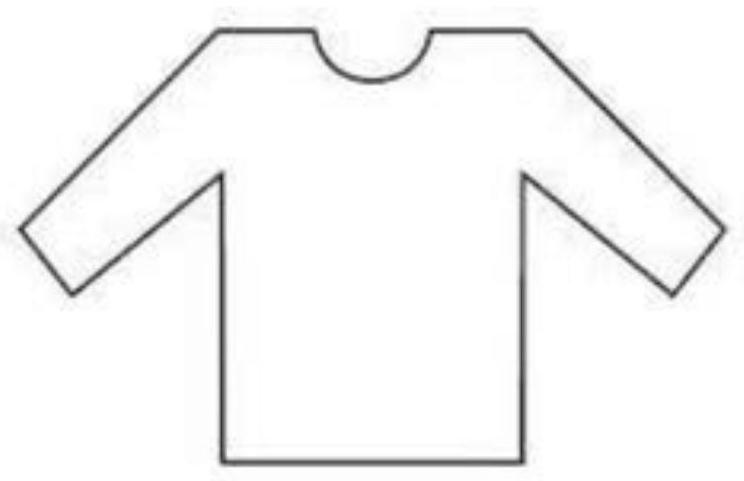

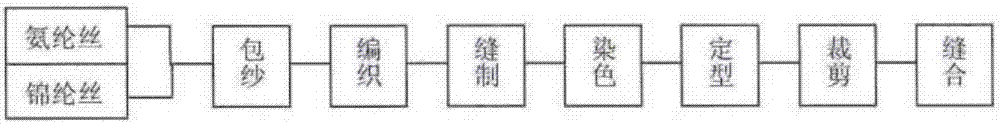

Ultra-thin run-resistant underwear produced by adopting cylinder loom and production process of ultra-thin run-resistant underwear

ActiveCN106263100AExtended service lifeCost-effectiveWeft knittingShaping/stretching tubular fabricsResistYarn

The invention provides ultra-thin run-resistant underwear produced by adopting a cylinder loom and a production process of the ultra-thin run-resistant underwear. The production process comprises the following steps: (1) wrapping by taking spandex as inner-wrapped silk and taking polyamide as outer-wrapped silk to obtain a wrapped yarn; (2) weaving: weaving the wrapped yarn by adopting the cylinder loom comprising a stocking machine to obtain a stocking blank; (3) sewing: cutting and sewing the socking blank to obtain stockings, so as to facilitate subsequent dyeing and sizing; (4) dyeing: bagging and dyeing the stockings to obtain colorful stockings; (5) sizing: sizing the colorful stockings by adopting an underwear sizing plate and endowing the colorful stockings with run-resist functions; (6) cutting: cutting the sized stockings according to a sample plate and cutting each of the stockings into two sleeveless underwear bodies; (7) sewing. In addition, the invention further provides the underwear produced by the production process. On the premise of not increasing the novel equipment investment, an ordinary cylinder loom (comprising the stocking machine) is directly adopted for producing the underwear, so that high quality and inexpensiveness are realized.

Owner:深圳市润薇服饰有限公司

Improved technology for cone yarn dyeing aftertreatment

InactiveCN107237189AAvoid hydrolysisIncreased diffusion rateDyeing processYarnPulp and paper industry

The invention discloses an improved technology for cone yarn dyeing aftertreatment. The improved technology comprises the following steps: firstly washing a cone yarn for 8 minutes with water at the temperature of 80 DEG C, then discharging the water out a dyeing machine, continuously washing for 8 minutes again with water neutralized by HAC, maintaining water temperature to be 60 DEG C, then discharging the water again, then washing for 8 minutes with the water at the temperature of 80 DEG C, then discharging the water, then adding a saponifying agent into water at the temperature of 98 DEG C, carrying out high temperature soap boiling for 16 minutes twice, discharging liquid once the soap boiling is finished, then sequentially washing for 16 minutes with the water at the temperature of 98 DEG C, washing for 8 minutes with the water at the temperature of 80 DEG C, washing for 8 minutes with water at the temperature of 60 DEG C, and washing for 8 minutes with water at the temperature of 45 DEG C, finally adding a color fixing agent, a softening agent and a smoothing agent into the water at the temperature of 45 DEG C, and carrying out softening treatment for 32 minutes. High temperature soaping is carried out twice for treating the cone yarn, so that salt, alkali and unfixed dyes can be removed.

Owner:WUHU FUCHUN DYEING & WEAVING

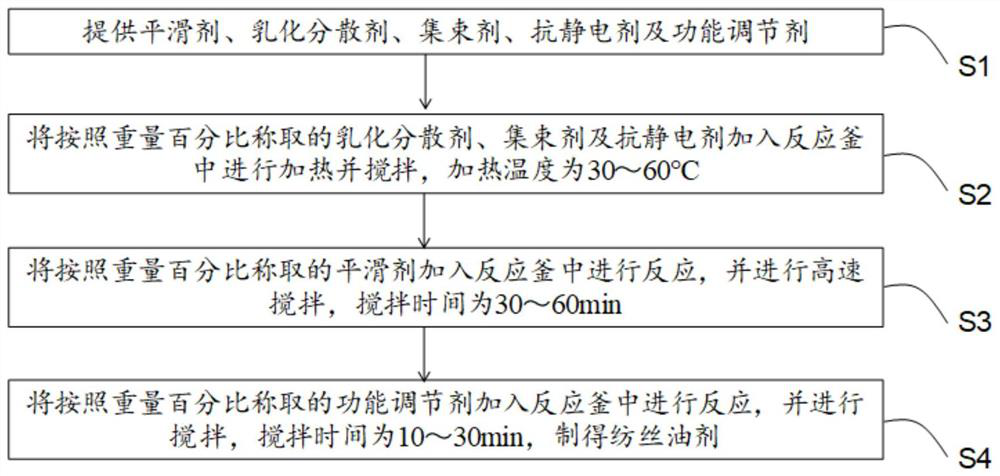

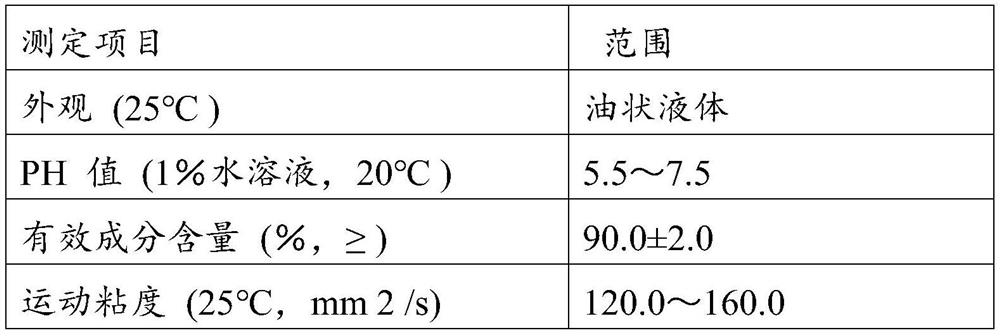

Antistatic spinning oil agent and preparation method thereof

InactiveCN111851073AEasy to useStable storageFibre typesSynthetic polymer filament chemical after-treatmentYarnPhosphoric Acid Esters

The invention discloses an antistatic spinning oil agent. The antistatic spinning oil agent is composed of a smoothing agent, an emulsifying and dispersing agent, a bundling agent, an antistatic agentand a function regulating agent, wherein the antistatic agent is composed of fatty alcohol polyoxyethylene ether phosphate salt and superfine antistatic powder; the antistatic agent adopts an anionicsurfactant and is capable of causing corrosion to an instrument in the production process of the antistatic agent; in addition, the function regulating agent is added into the antistatic spinning oilagent, stable usage and storage of the spinning oil agent can be ensured; the oil agent surface tension is reduced; the emulsion stability is improved; the function regulating agent is also capable of solving the problem that the spinning oil agent is easily adhered to a thread guide roller when false twisting and reducing fluffing and yarn breakage.

Owner:科凯精细化工(上海)有限公司

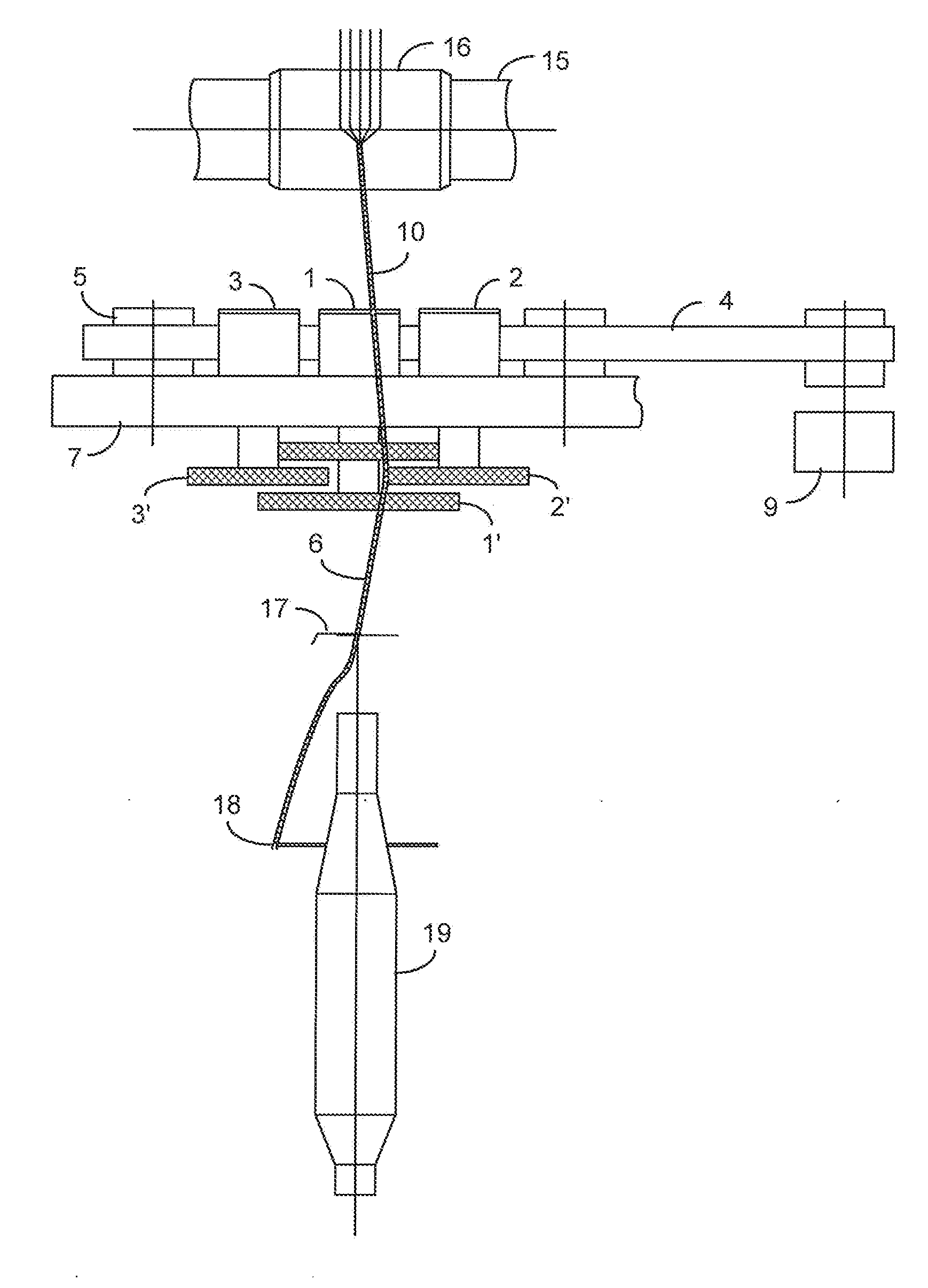

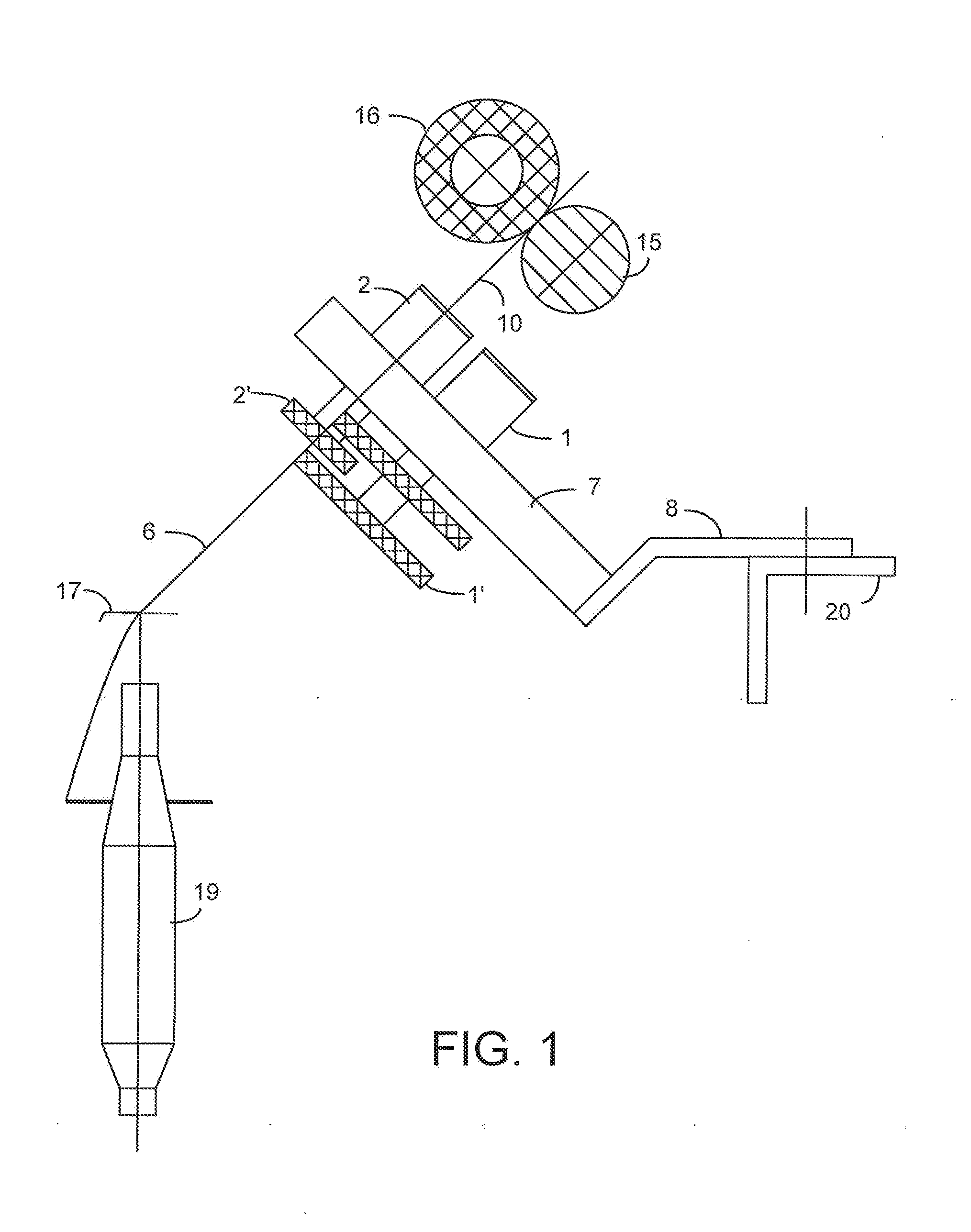

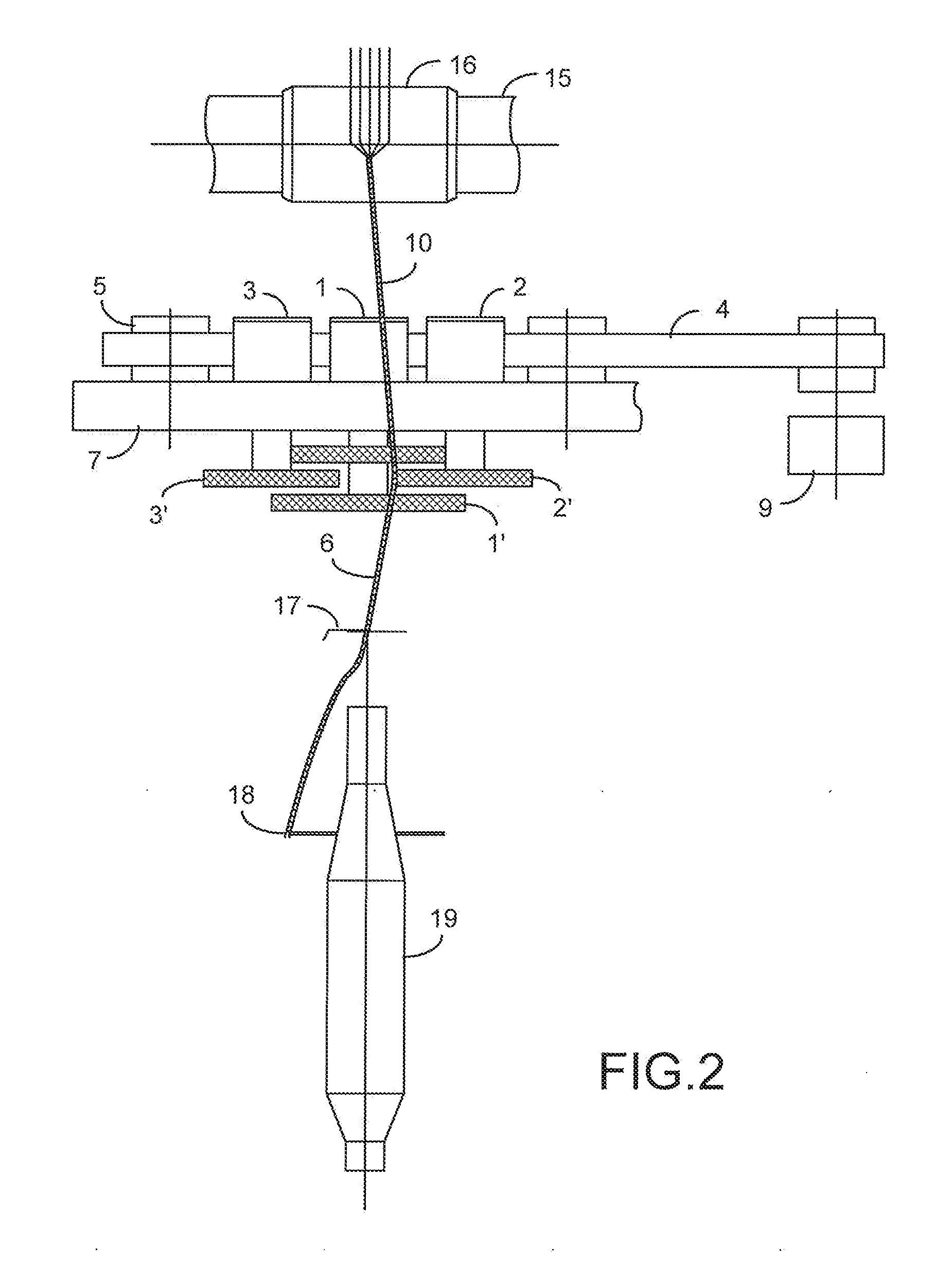

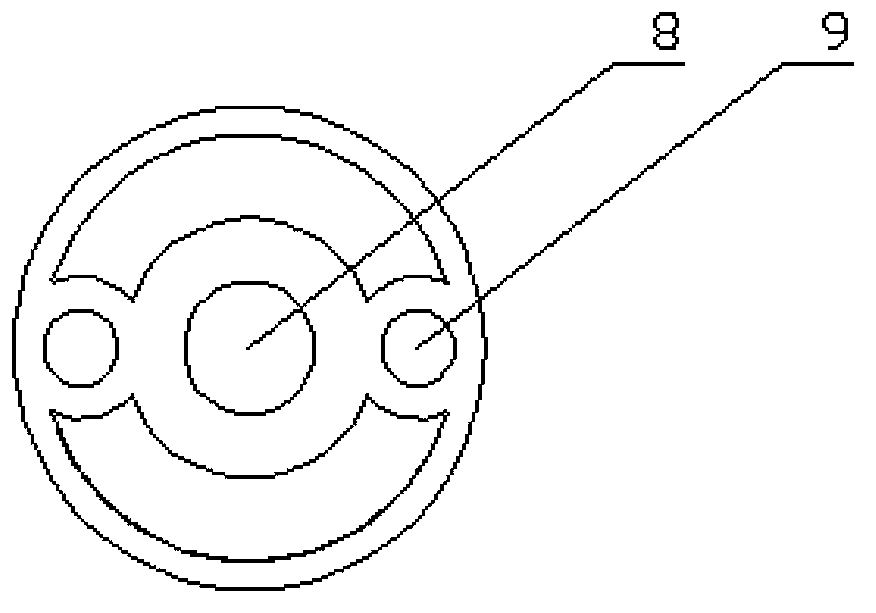

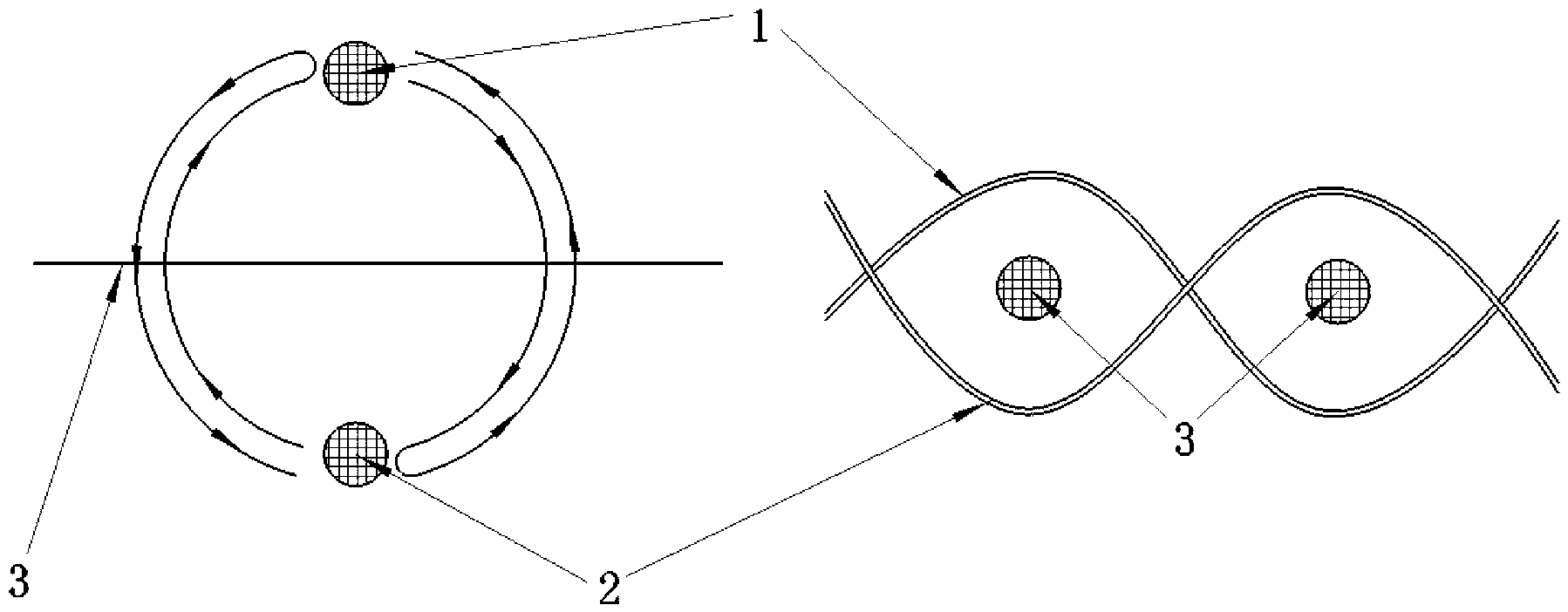

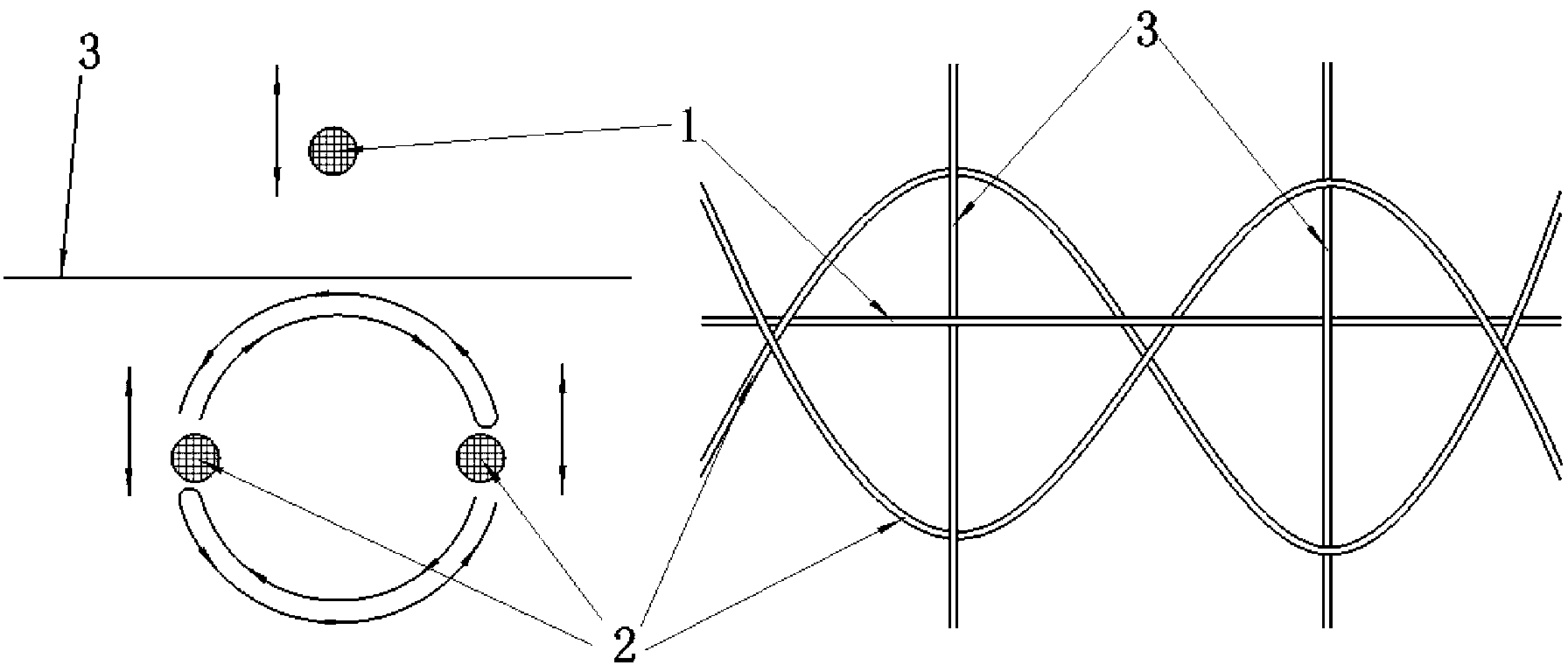

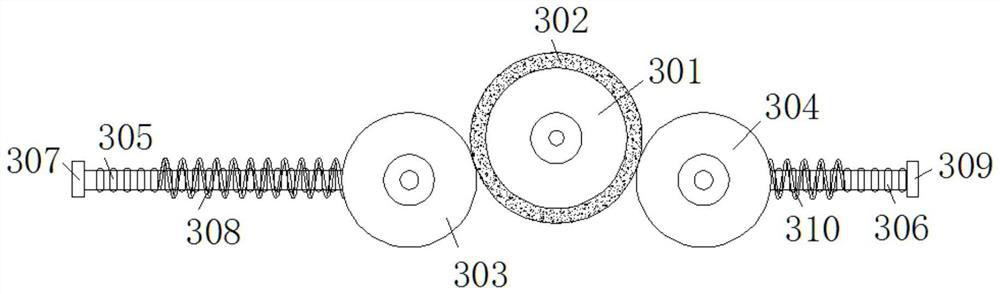

Combined frictional false twisting device for ring spinning frame

InactiveUS20150128555A1Reduce the overall heightImprove yarn strengthContinuous wound-up machinesYarnYarnEngineering

A frictional false twister is disclosed. The twister has a plurality of rotating friction plates located between the nip of the front rollers and the yarn guide. The friction plates are staggeringly arranged for rubbing a twisted yarn. The spinning direction of the twisted yarn is opposite to the rotating direction of the friction plates. Through the action of the frictional false twister, the twist of the yarn between the false twisting device to the front nip can be increased, shortening the twisting triangle height, and increasing the spinning strength. As the yarn and the outer surface of the friction plate make relative sliding and rubbing, the friction damping force correspondingly reduces the spinning tension in the twisting triangle.

Owner:INST OF WOOL & HEMP TEXTILE SCI SHANGHAI

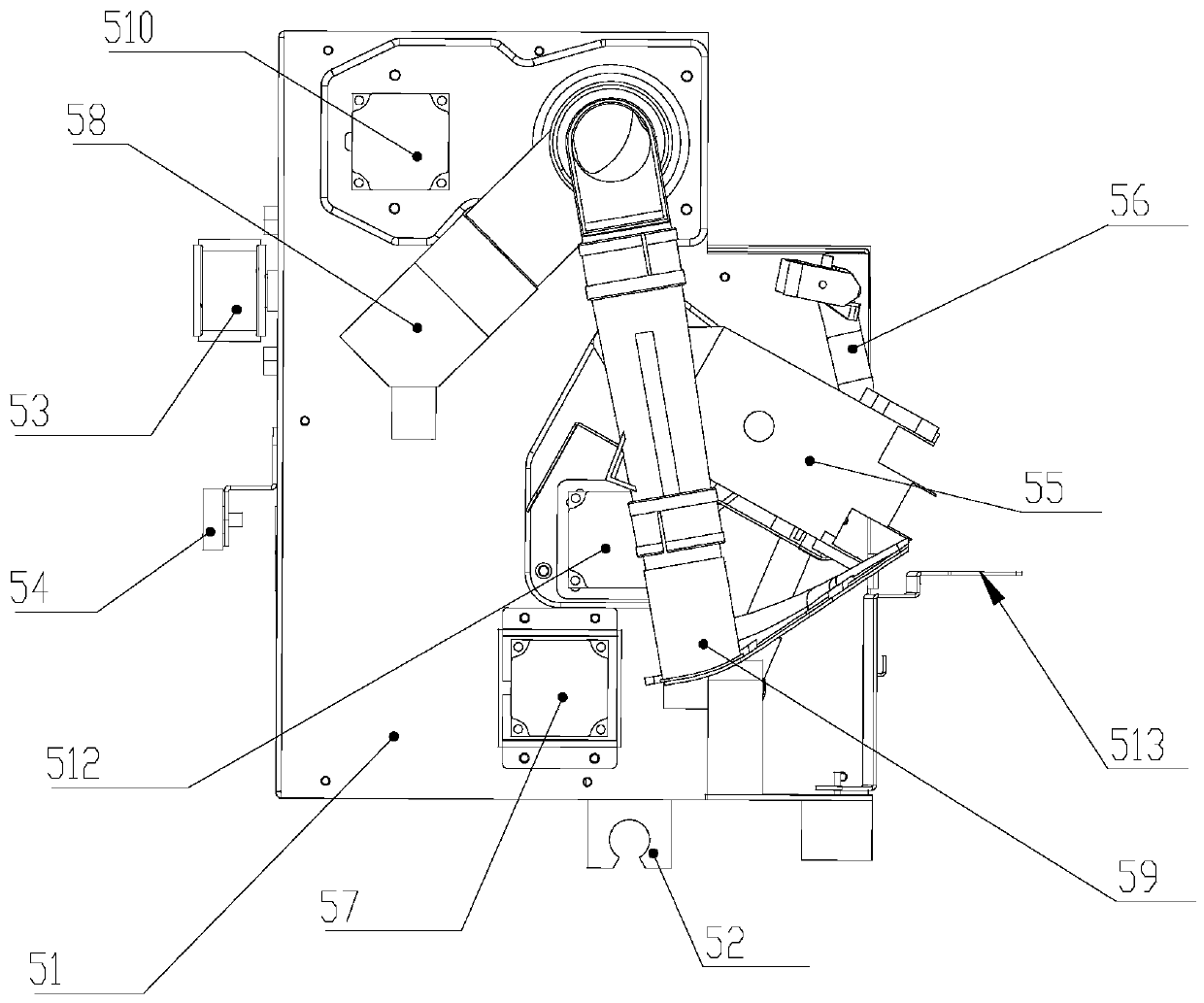

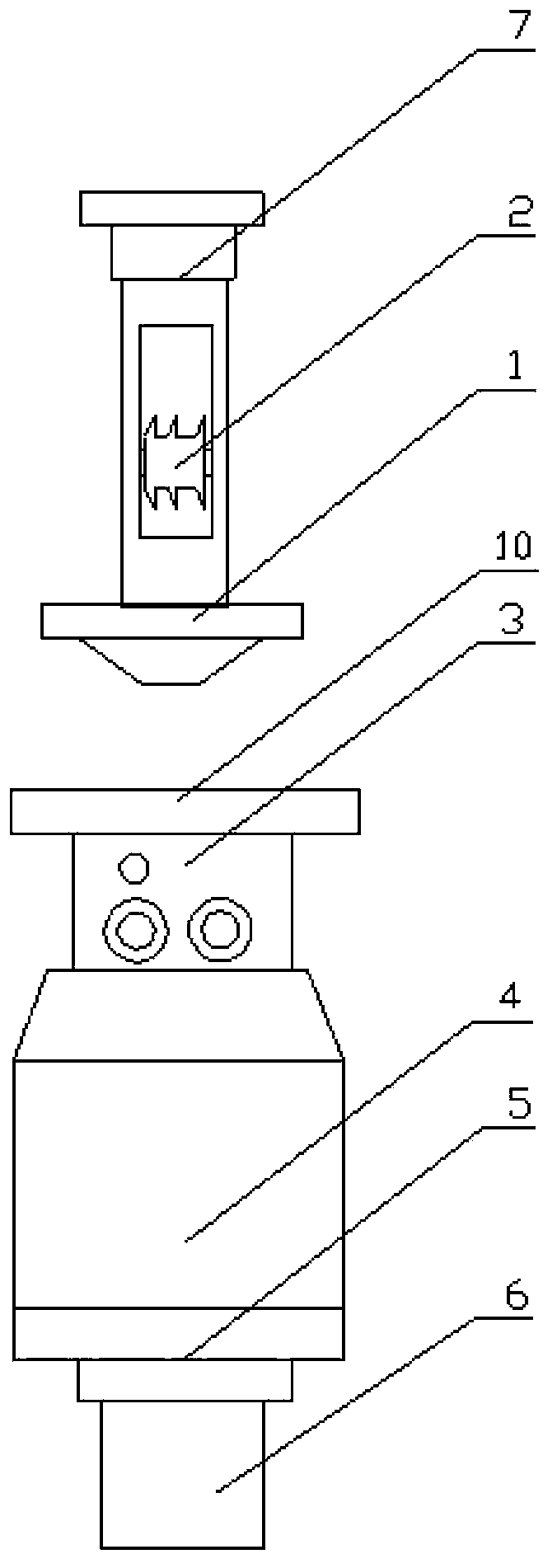

Twisting device of direct twisting machine

The invention relates to a twisting device of a direct twisting machine. The twisting device comprises a uniform twisting device, a guide wheel, an inner yarn tensioning device, a spindle tank, a spindle and an electric spindle motor, wherein the middle part of the uniform twisting device is of a hollow structure and the upper part of the uniform twisting device is provided with a light-weight shock absorption connection device; the uniform twisting device is fixedly connected with a wall plate above the twisting device of the direct twisting machine through the shock absorption connection device. The stress of the electric spindle motor is alleviated by changing the mounting position of the uniform twisting device; the structure of the guide wheel is changed, so that the clamping phenomenon of the guide wheel is avoided and the service life of the electric spindle motor is prolonged; furthermore, a top cover made of a wear-resisting material of the inner yarn tensioning device is additionally arranged, so that a yarn breaking phenomenon is effectively reduced.

Owner:ZHANGJIAGANG JUNMA POLYESTER PROD

Method for preventing yarn breakage

ActiveCN101932759AFewer tangling and yarn breaksSimplified spinning and washing/neutralization processesArtificial filament washing/dryingMonocomponent polyamides artificial filamentEngineeringBobbin

The invention pertains to the use of a multifilament yarn spinning process comprising individually washing each filament of a multifilament yarn and, if neutralized, individually neutralizing each filament of the multifilament yarn, for preventing yarn breakage during the spinning process, the spinning process comprising spinning of a polymer through a spinneret to obtain the multifilament yarn, washing the yarn, and optionally neutralizing and / or drying the yarn and winding the yarn onto a bobbin Preferably the yarn is washed with jet washers.

Owner:TEIJIN ARAMID BV

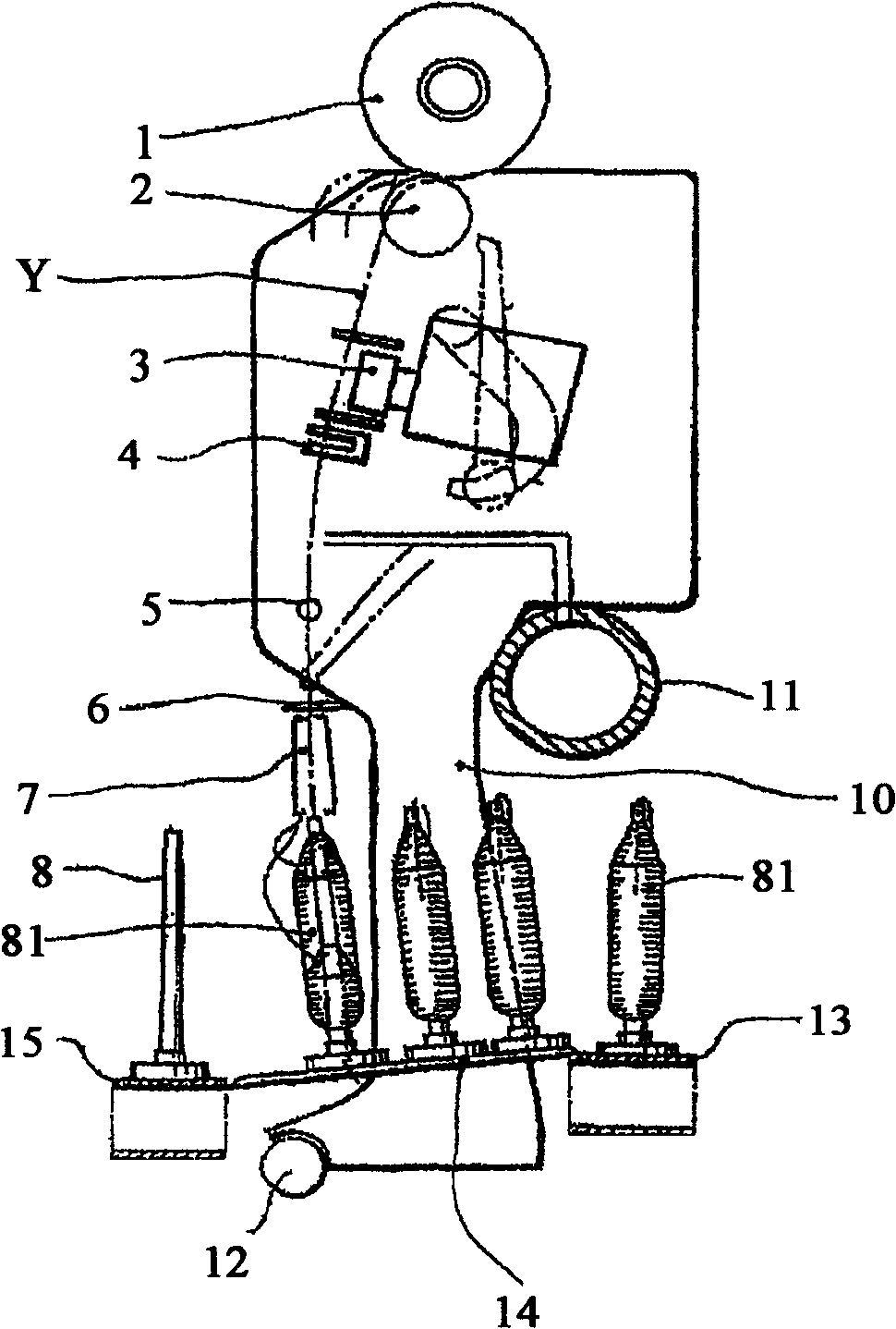

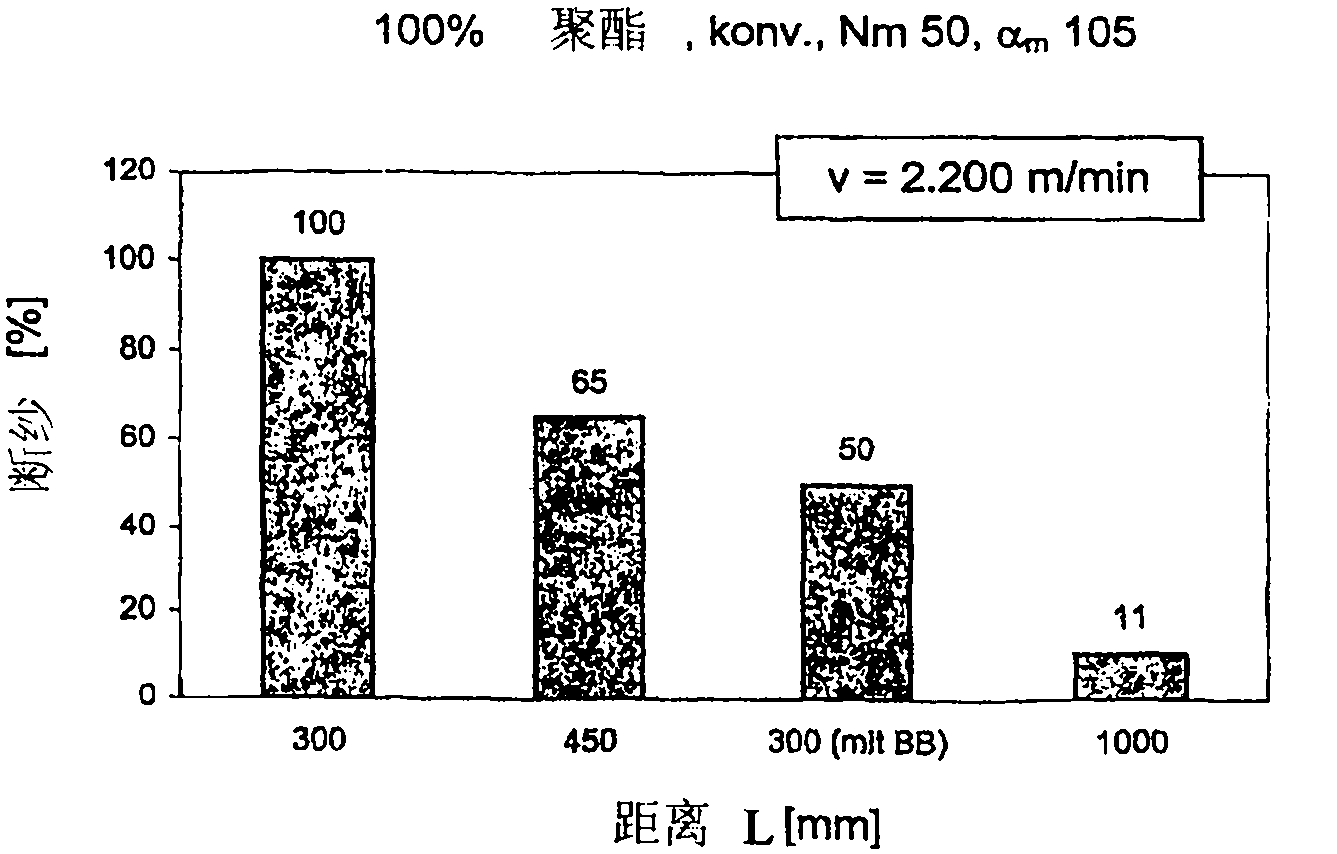

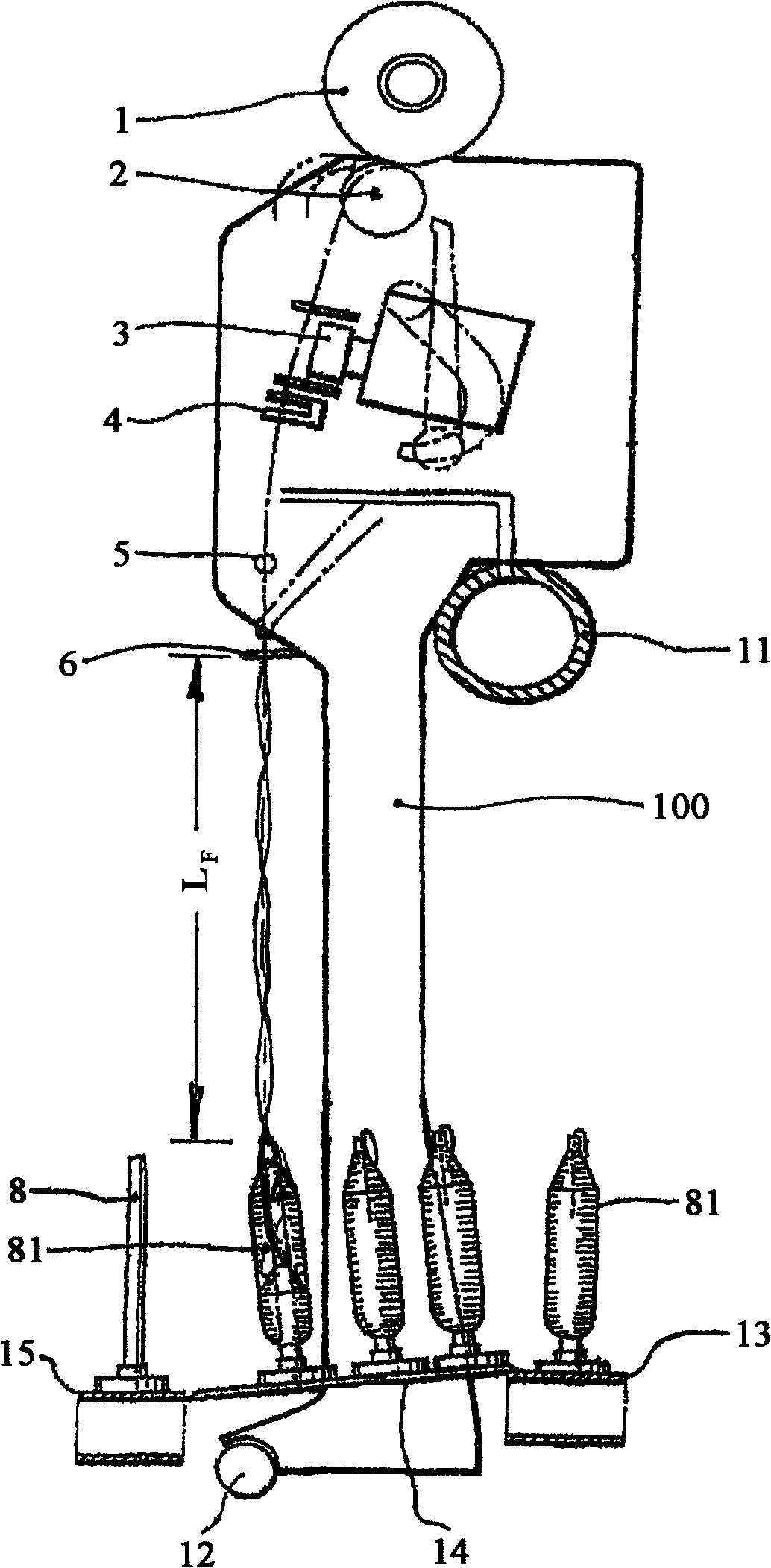

Process and device for rewinding feed spools

Owner:邓肯多夫德国纺织纤维研究所

Preparation method of superfine-denier nylon fibers and ultra-light fabric, and ultra-light coat

ActiveCN112301441AStrongHigh strengthElectroconductive/antistatic filament manufactureOvergarmentsPolymer sciencePhosphite salt

The invention discloses a preparation method of superfine-denier nylon fibers. The preparation method comprises the following steps that (1) the following components are weighed in parts by weight: 96-99 parts of nylon 66 chips, 0.35-2 parts of TiO2 extinction master batch, 0.05-1 part of a phosphite antioxidant, 0.05-0.5 part of fatty alcohol phosphate and 0.05-0.5 part of a polyethylene glycol antistatic agent, wherein the model of the nylon 66 chips is CM3006, the relative molecular weight is 25000-30000, and the viscosity is 2.8-2.9; (2) the raw materials weighed in the step (1) are prepared into nylon fibers with the filament number being 0.3-0.5 dtex through a melt spinning method, wherein in the melt spinning process, the melting temperature is 260-290 DEG C, the number of holes ofa spinneret plate is 5-30, the hole diameter is 0.1-0.2 mm, the winding speed is 300-500 m / min, the winding temperature is 18-19 DEG C, and the finished product ratio is 92% or above. The invention meanwhile provides a preparation method of a ultra-light fabric and an ultra-light coat. According to the preparation method of the superfine-denier nylon fibers, the superfine-denier nylon fibers can be prepared, and the finished product ratio can be guaranteed to be 92% or above.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

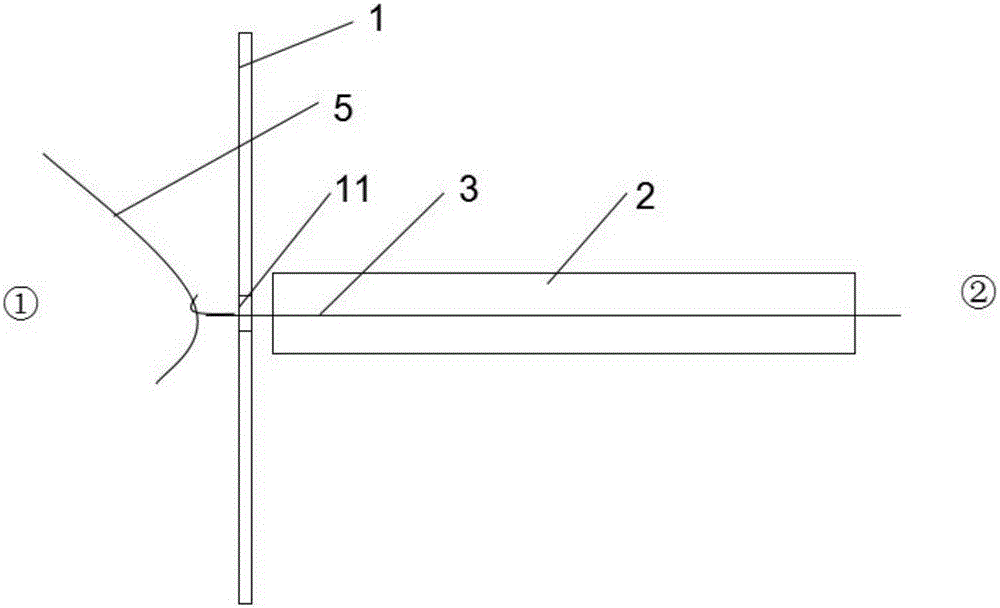

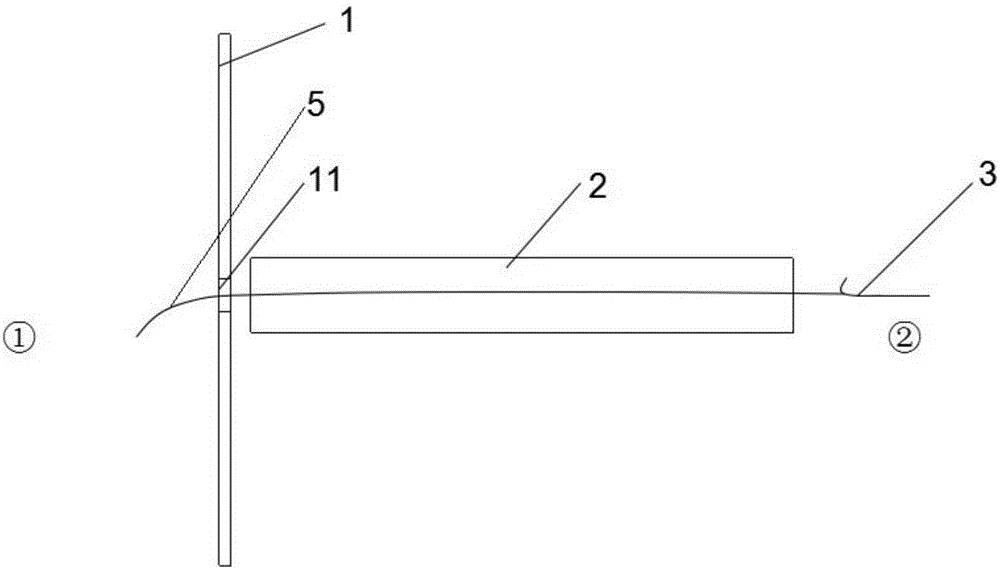

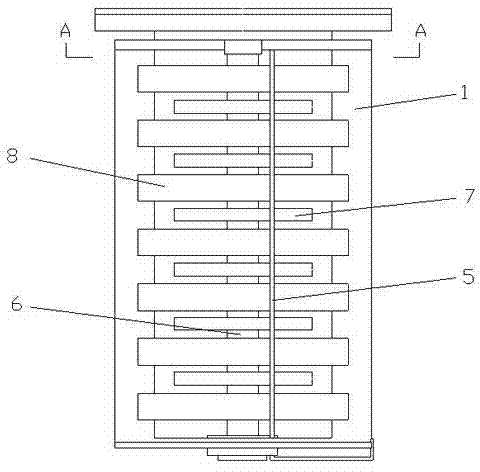

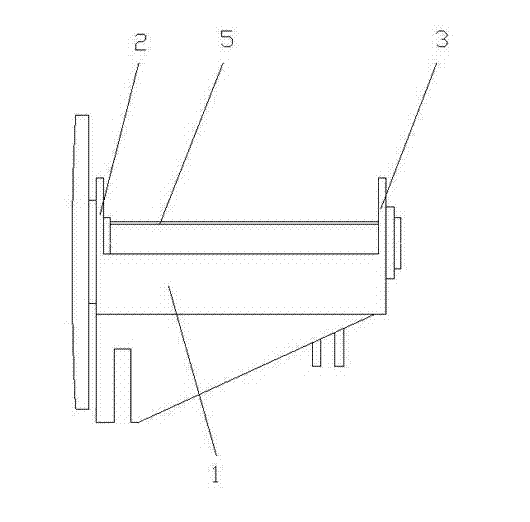

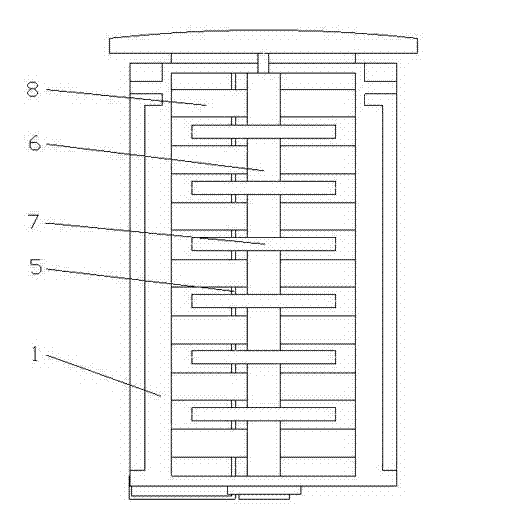

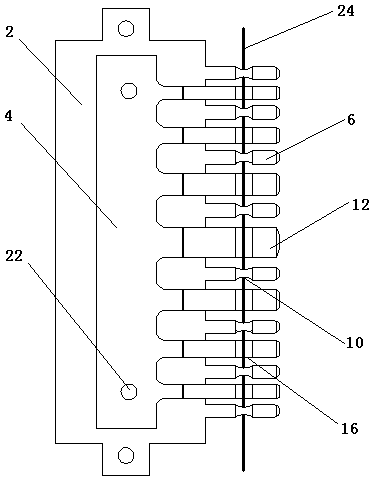

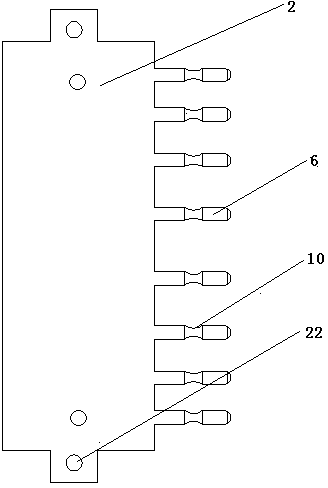

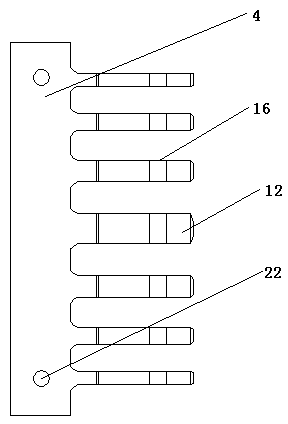

Tension balancer

InactiveCN102888708AReduce tension fluctuationsReduce yarn breakageWarp knittingYarnBiochemical engineering

The invention discloses a tension balancer, comprising a yarn guide base, wherein the yarn guide base is provided with a first side plate and a second side plate; yarn guide holes are correspondingly arranged on the first side plate and the second side plate; a yarn guide rod is arranged on the yarn guide base; one end of the yarn guide rod is crossed through the second side plate to be contacted with the first side plate; the other end of the yarn guide rod is arranged on the second side plate; a lead rail is arranged on the yarn guide base; a plurality of yarn guide rings are arranged on the lead rail; a plurality of yarn guide rollers are adaptively installed on the yarn guide base; and the lower part of the first side plate is provided with a supporting plate. With the adoption of the tension balancer, and through the method, the tension fluctuation of cotton yarns can be reduced and the relative constant of the cotton tension is kept, so that the cotton yarn has good knitting performance, therefore, the breaking yarn of the cotton yarn is effectively reduced, and the production efficiency and the product quality are improved.

Owner:CHANGZHOU SHENDA WARP KNITTING

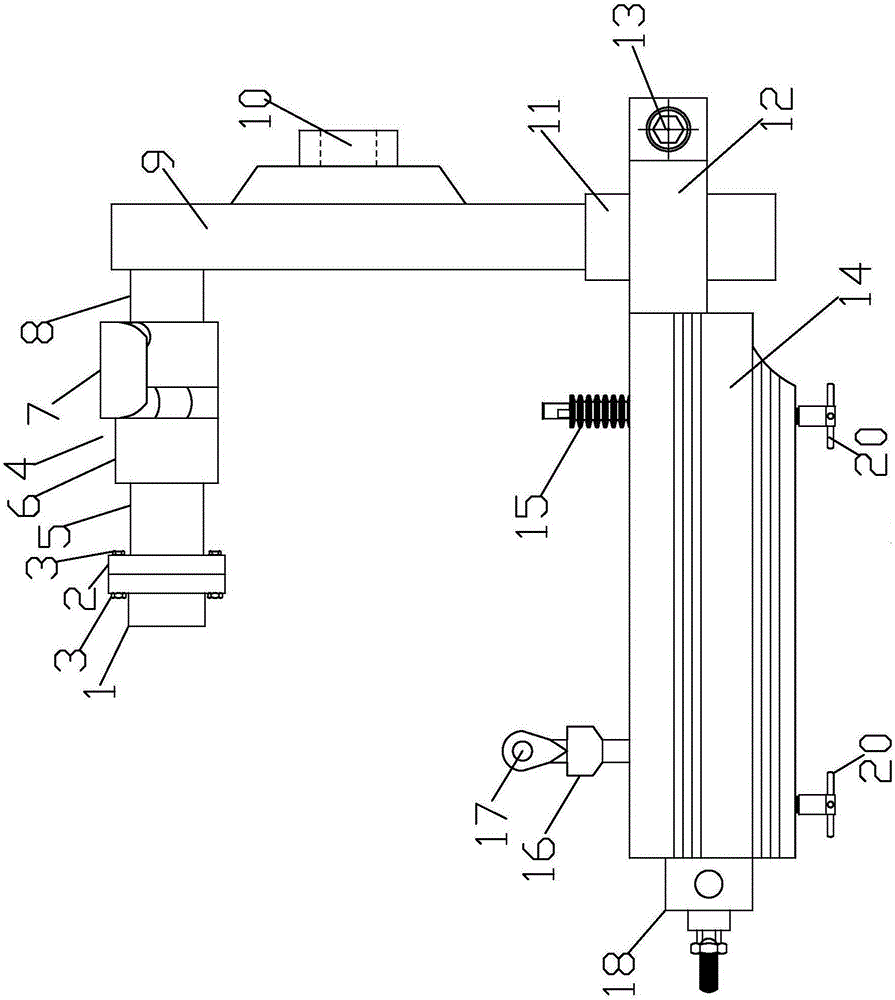

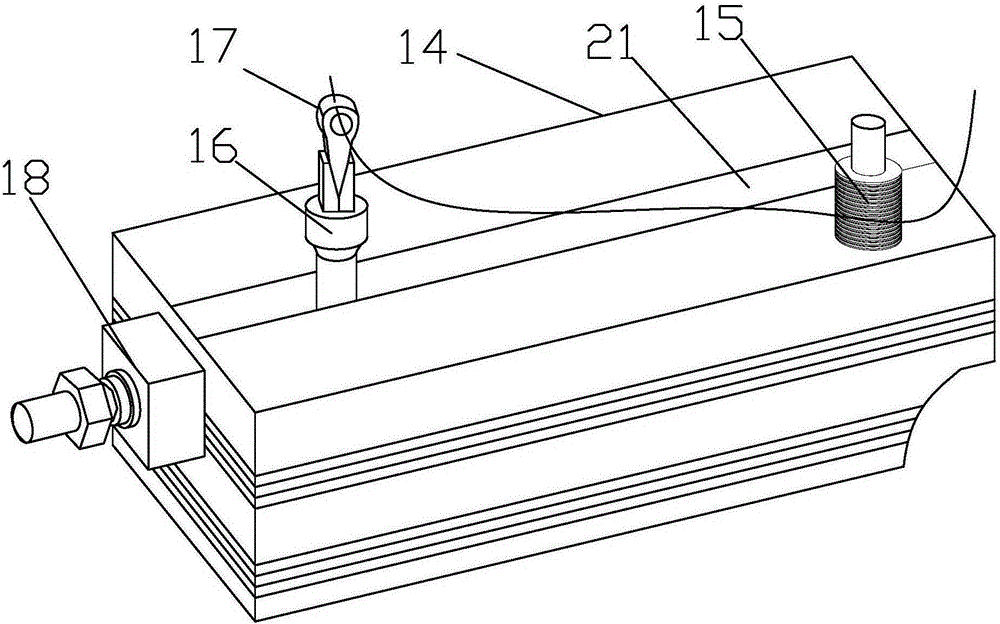

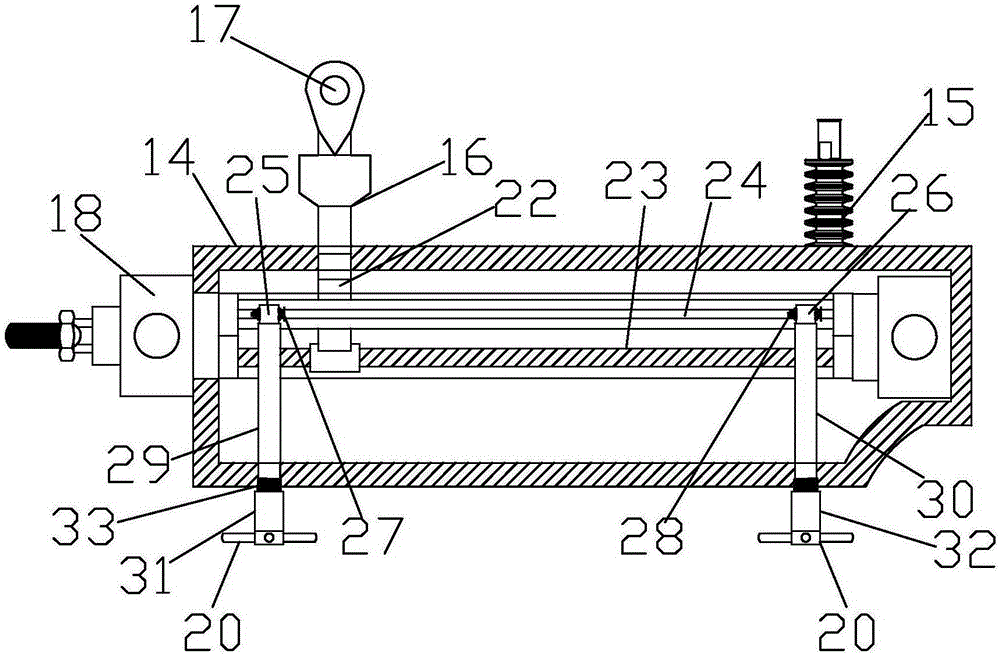

Yarn winding adjustment device applied to weft accumulator

ActiveCN105177842AReduce friction damageIncrease the actual yarn storage capacityAuxillary apparatusPulp and paper industryPiston rod

The invention discloses a yarn winding adjustment device applied to a weft accumulator. The yarn winding adjustment device comprises an installing mechanism and an adjusting mechanism. The installing mechanism comprises an electromagnet sucker, a telescopic rod and a yarn feeding plate. The electromagnet sucker is connected to the left end of the telescopic rod, and the yarn feeding plate is connected to the right end of the telescopic rod. A yarn feeding opening is formed in the yarn feeding plate. A wire distributing wheel and a yarn guide rod are connected to the upper end of a machine body. A yarn guide ceramic ring is arranged on the yarn guide rod. An air cylinder is installed in the machine body. A piston rod is arranged in the air cylinder and connected with the yarn guide rod. A sliding rail is installed in the air cylinder. Sliding blocks are connected to the left side and the right side of the sliding rail respectively. Pressure sensors are installed on the sliding blocks and matched with the yarn guide rod. As the yarn guide ceramic ring and the air cylinder are additionally arranged, with the help of the air cylinder, the yarn guide ceramic ring conveys weft yarns to the yarn storage drum uniformly, mutual knotting is avoided, the probability of yarn breaking is remarkably reduced, friction damage to the yarn storage drum is minimum, the service life of the yarn storage drum can be prolonged, and the actual yarn storage amount of the yarn storage drum can be increased.

Owner:苏州卓米纺织科技有限公司

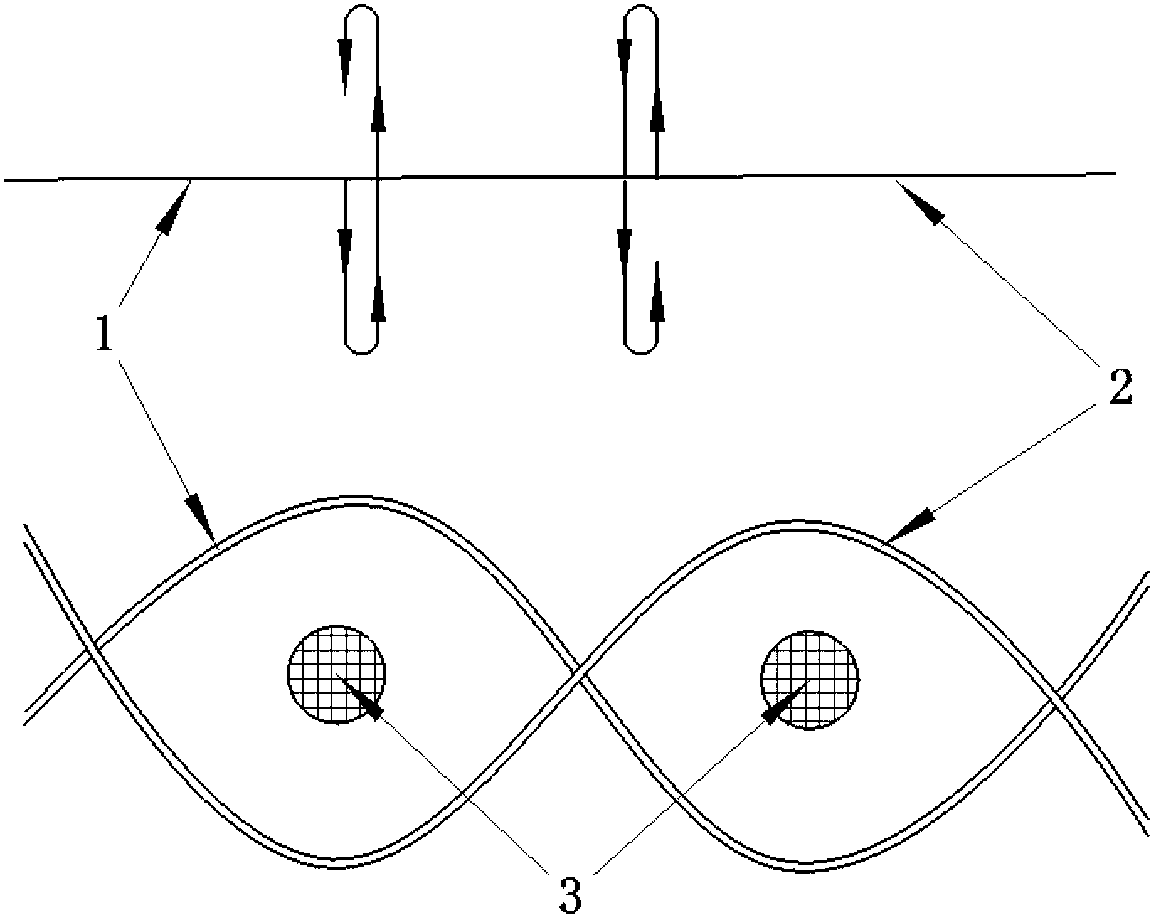

Edge weaving method of weaving machine

InactiveCN103243458AShort path of motionIncrease exerciseGauze-woven fabricsLeno-woven fabricsYarnEngineering

The invention relates to an edge weaving method of a weaving machine. The edge weaving method is characterized in that a cloth fell is formed through horizontally transverse swinging and vertically up-and-down motion of a lower hank yarn and vertically up-and-down motion of an upper hank yarn, and accordingly the function of weaving edges of the two hank yarns is achieved. By adopting the edge weaving method, the hank yarns have short motion paths, tension of the hank yarns can be controlled easily, and yarn breaking is reduced. In addition, the hank yarns are simple in motion, good in stability, suitable for a new generation of water spray high-speed weaving machine and capable of meeting market demands.

Owner:SUZHOU HUAYI MACHINE

Spinning machine drafting zone cleaning mechanism and cleaning method

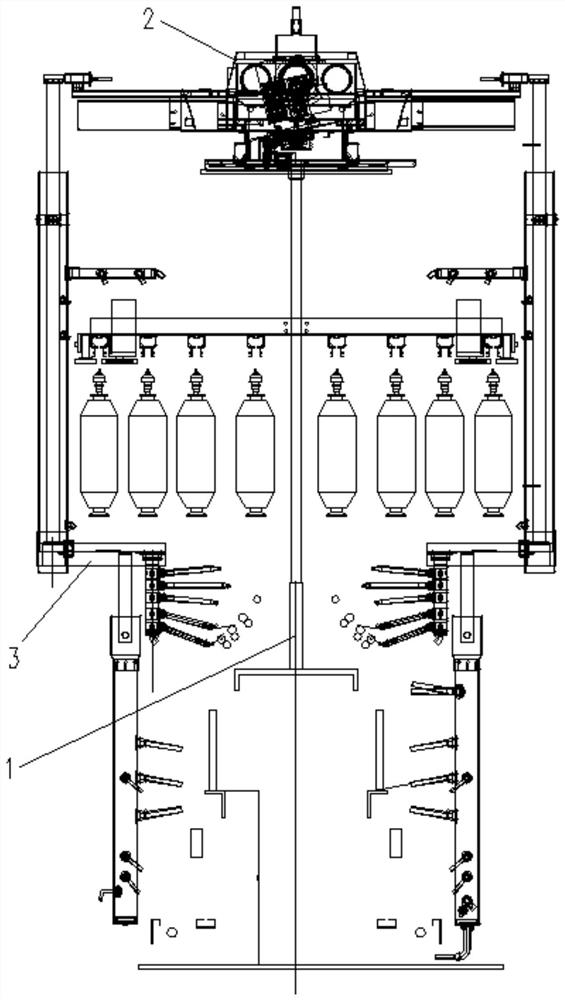

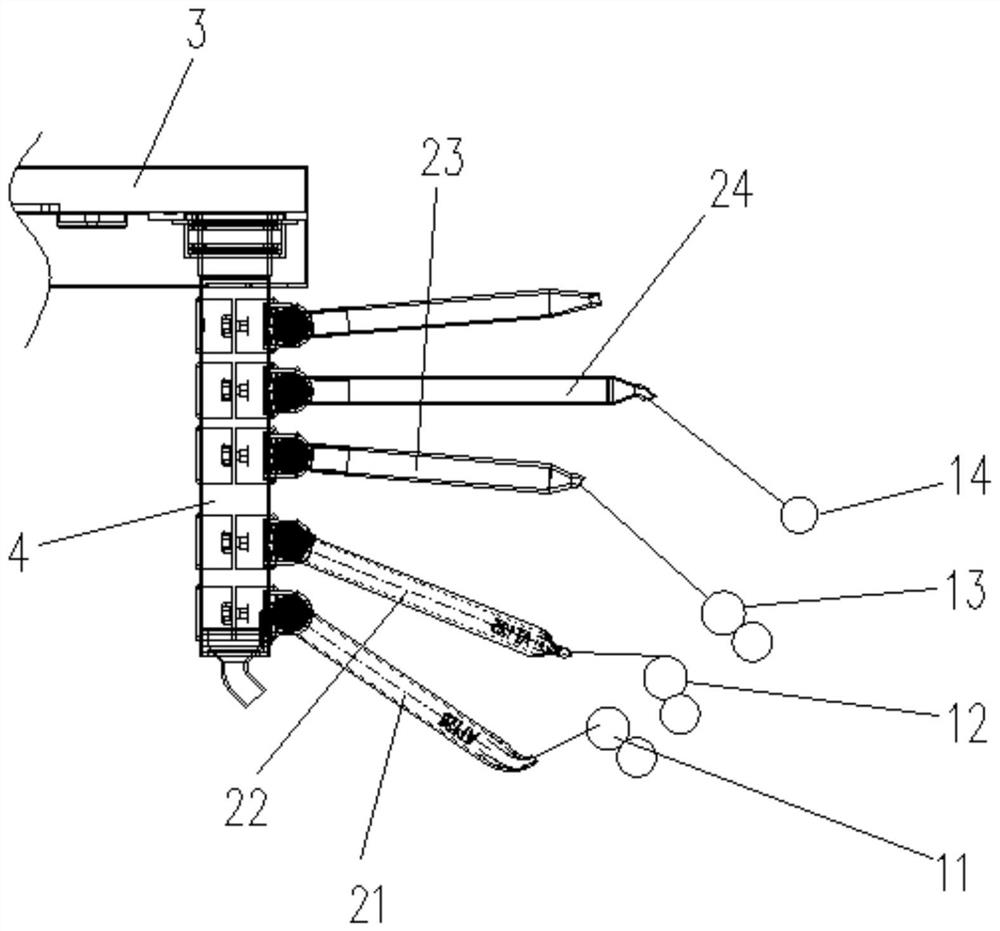

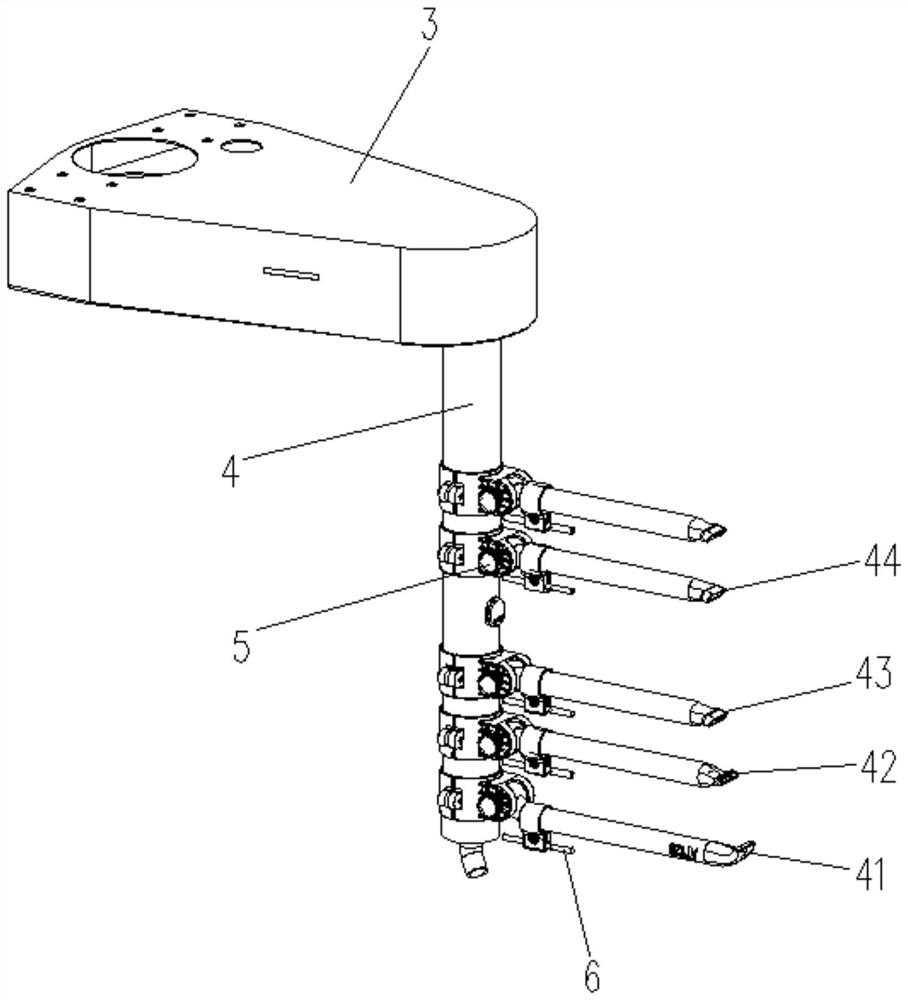

ActiveCN113231397AHigh cleaning accuracyHigh blow range utilizationTextile disintegration and recoveryCleaning using gasesYarnEngineering

The invention discloses a spinning machine drafting zone cleaning mechanism and a cleaning method. The spinning machine drafting zone cleaning mechanism comprises a main machine, the main machine is provided with a blowing main pipe extending to the side face of a spinning machine, the blowing main pipe is connected with a relatively vertical blowing branch pipe, and the blowing branch pipe is provided with at least four blowing pipes; the at least four blowing pipes are a first blowing pipe, a second blowing pipe, a third blowing pipe and a fourth blowing pipe in sequence from bottom to top, and blowing openings of the first blowing pipe and the second blowing pipe are flat openings; the blowing opening of the first blowing pipe is bent upwards, an included angle between the air outlet direction of the blowing opening of the first blowing pipe and a pipe body of the first blowing pipe is 45-135 degrees, and a blowing point of the first blowing pipe is located in a quarter area of the outer side of a first leather roller bearing; and the included angle between the air outlet direction of the blowing opening of the second blowing pipe and a pipe body of the second blowing pipe is 110-180 degrees, and the blowing point of the second blowing pipe is located on the right side of the top of a second leather roller bearing. The cleaning precision is high, the blowing range utilization degree is high, the cleaning effect is relatively ideal, and the situation that yarn breaking or yarn faults occur in a drafting zone is effectively reduced.

Owner:XINCHANG AOTAI MACHINERY MFG

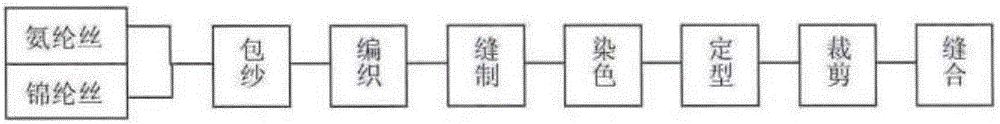

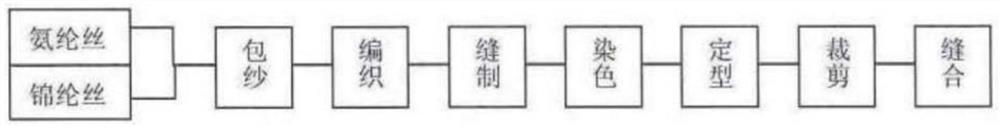

Production process of run-resistant anti-snagging underwear, and seamless underwear

InactiveCN111809299AExtended service lifeCost-effectiveWeft knittingGirdlesEngineeringMechanical engineering

The invention relates to a production process for producing a run-resistant anti-snagging underwear by adopting a cylinder loom. The production process comprises the following steps of covering yarns;weaving; sewing; dyeing; shaping; clipping and stitching. According to the production process provided by the invention, without increasing the input of novel equipment, the underwear is produced bydirectly adopting a common cylinder loom; and in accordance with the principle of attractiveness in price and quality, the breathable and warm underwear capable of being worn for all seasons, coveringthe body wrinkles and spots, and tightening skin can be manufactured. Secondly, the underwear gives the body light shape and balances the body curve. Again, the underwear has anti-snagging and run-resistant functions, the service life of the underwear is prolonged, and the cost performance of the underwear is further improved.

Owner:浙江艾恋针织服饰有限公司

Polyurethane elastic fiber and process for producing same

ActiveUS7485364B2Improve stabilityLess stainingMonocomponent polyurethanes artificial filamentOther chemical processesFiberInorganic compound

A polyurethane elastic fiber, containing inorganic compound particles that have an average particle size of 0.5 to 5 mm and that show a refractive index of 1.4 to 1.6, having at least one protruded portion that has a maximum width of 0.5 to 5 μm, in the fiber surface, per 120-μm length in the fiber axis direction.

Owner:ASAHI KASEI FIBERS CORPORATION

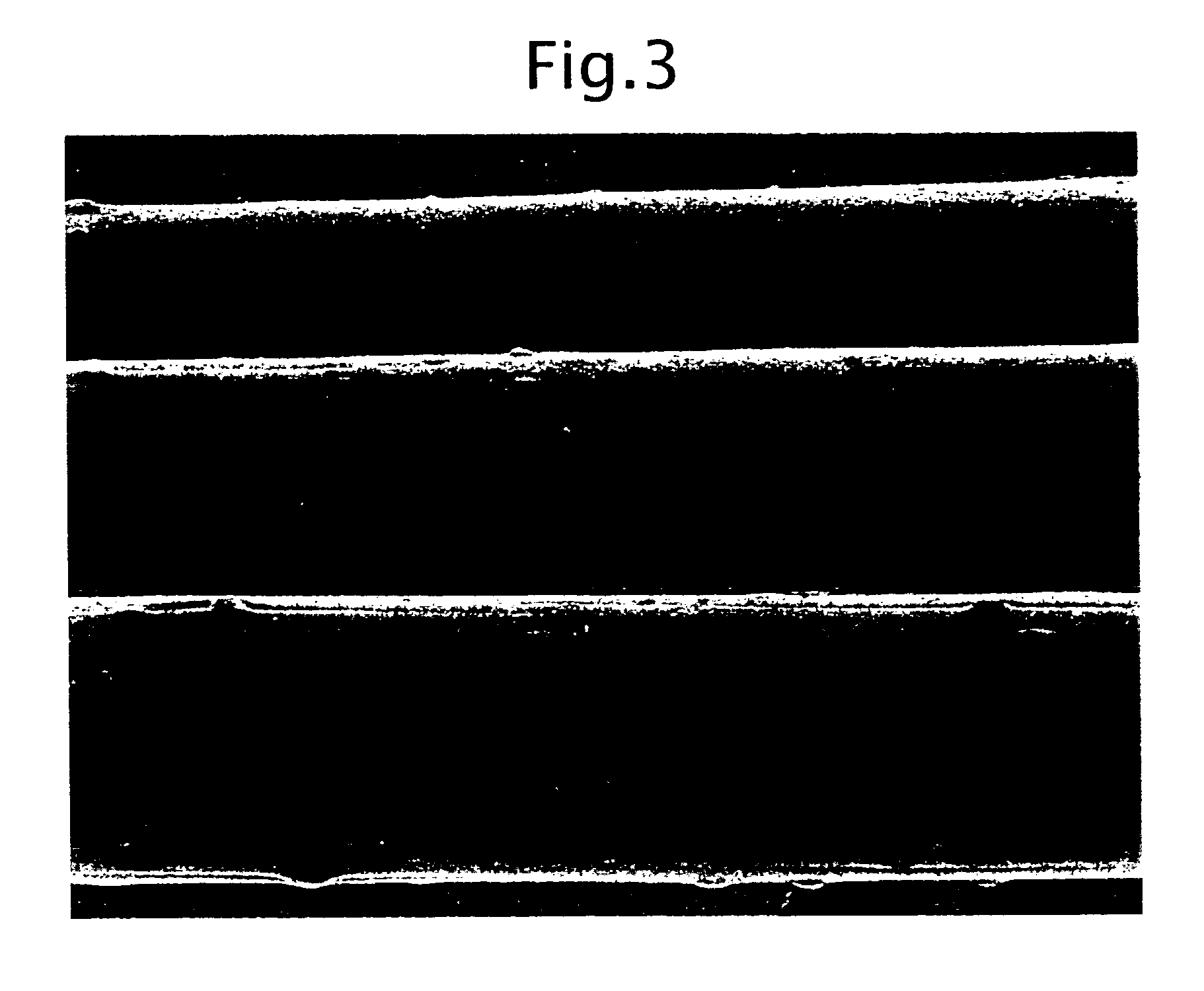

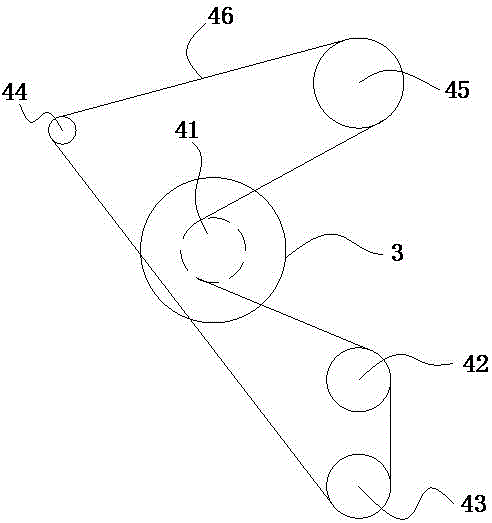

Method of spinning frame synchronous frequency converter and rare-earth permanent magnetic synchronous motor

The invention relates to a method of a spinning frame synchronous frequency converter and a rare-earth permanent magnetic synchronous motor. The method comprises the steps of supplying working voltage to the synchronous frequency converter and the rare-earth permanent magnetic synchronous motor by a power supply; controlling the rare-earth permanent magnetic synchronous motor to run by controlling the synchronous frequency converter; controlling the rare-earth permanent magnetic synchronous motor to drive a spinning frame main shaft to rotate. By adopting the synchronous frequency converter and the rare-earth permanent magnetic synchronous motor, motor inversion and shaking caused by a transmission device after the motor is started can be effectively avoided, broken yarns in the spinning process can be reduced, the yarn quality is improved, and an energy-saving purpose is realized by utilizing the characteristic of the permanent magnetic motor.

Owner:JINGWEI TEXTILE MASCH CO LTD

A kind of ultra-thin anti-off underwear produced by cylinder loom and its production process

ActiveCN106263100BExtended service lifeCost-effectiveWeft knittingShaping/stretching tubular fabricsYarnResist

The invention provides ultra-thin run-resistant underwear produced by adopting a cylinder loom and a production process of the ultra-thin run-resistant underwear. The production process comprises the following steps: (1) wrapping by taking spandex as inner-wrapped silk and taking polyamide as outer-wrapped silk to obtain a wrapped yarn; (2) weaving: weaving the wrapped yarn by adopting the cylinder loom comprising a stocking machine to obtain a stocking blank; (3) sewing: cutting and sewing the socking blank to obtain stockings, so as to facilitate subsequent dyeing and sizing; (4) dyeing: bagging and dyeing the stockings to obtain colorful stockings; (5) sizing: sizing the colorful stockings by adopting an underwear sizing plate and endowing the colorful stockings with run-resist functions; (6) cutting: cutting the sized stockings according to a sample plate and cutting each of the stockings into two sleeveless underwear bodies; (7) sewing. In addition, the invention further provides the underwear produced by the production process. On the premise of not increasing the novel equipment investment, an ordinary cylinder loom (comprising the stocking machine) is directly adopted for producing the underwear, so that high quality and inexpensiveness are realized.

Owner:深圳市润薇服饰有限公司

Reducing comb-type yarn controller

The invention relates to a reducing comb-type yarn controller which comprises a fixed comb and a plug-type comb, wherein the fixed comb and the plug-type comb are fixed together in parallel. The yarn controller is characterized in that one side of the fixed comb is provided with a plurality of first comb teeth, the side, the same as the fixed comb, of the plug-type comb is provided with a plurality of rubber connectors, the rubber connectors are inserted into second comb teeth, the radiuses of the first comb teeth are equal, and the radiuses of the second comb teeth are unequal. The reducing comb-type yarn controller overcomes defects in the prior art, due to the fact that the fixed comb is matched with the plug-type comb in use, large holding force is exerted on yarns, meanwhile, fluctuation of tension can be buffered through toothed sleeves installed on the comb teeth, broken yarns can be reduced, by inserting and pulling out the second comb teeth of different quantities and different radiuses, the holding force of the yarn controller on the yarns can be adjusted at will, the yarn controller is convenient to use and angles can be flexibly adjusted.

Owner:WUJIANG MINGJIA WEAVING

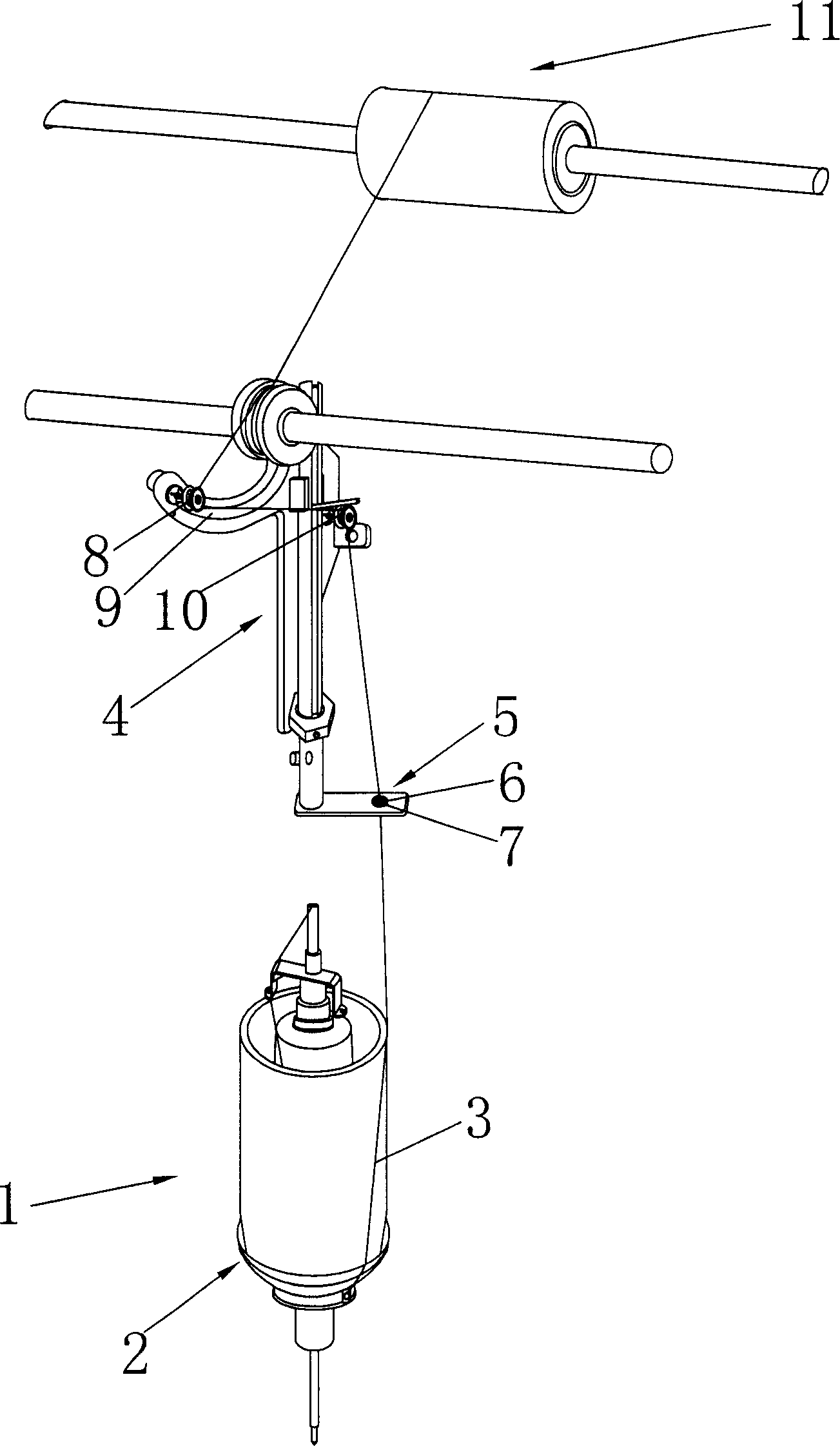

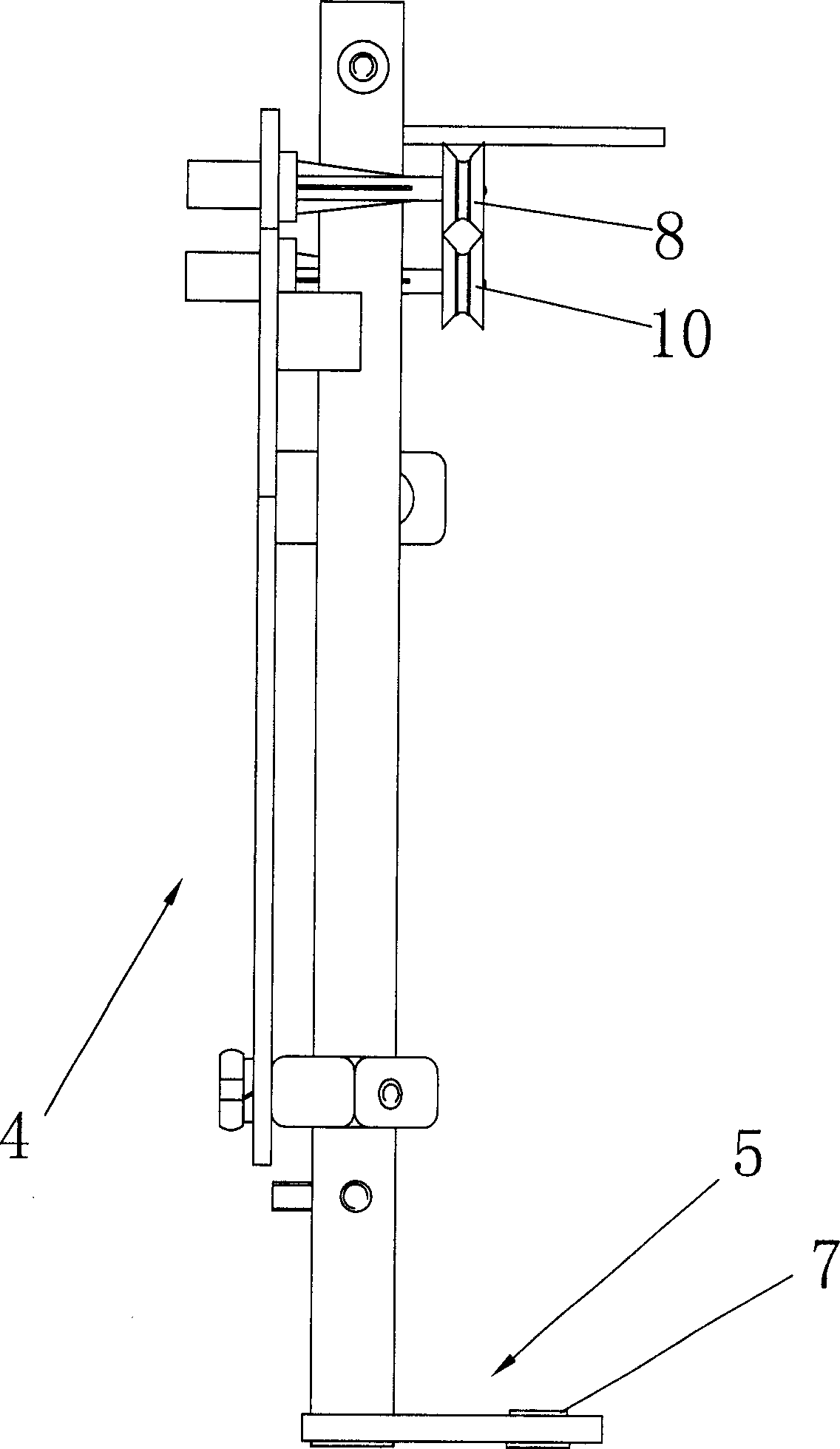

Production device and technological method of twisted yarn for ground retreating

ActiveCN114481394ARaw silk is goodReduce the probability of trippingTextile disintegration and recoveryYarnYarnIndustrial engineering

The invention relates to the technical field of plied yarn processes, in particular to a production device and process method of plied yarn for ground retreating. The production process method of the plied yarn for external retreating on the ground comprises the following steps: rotating a raw yarn cake to a creel, firstly passing through a probe yarn guide eye on the creel, then passing through a yarn guide bar on a suspension yarn regulator, continuously passing through a stand column yarn guide eye, then passing through a yarn guide eye beam splitting wheel on the ground, and finally passing through a yarn guide eye of a winder and a V-shaped guide wheel in the horizontal direction to enter the winder; plied yarns are obtained; and the yarn enters the winder at an angle of 42 degrees through the V-shaped guide wheel. According to the production process method for the ground twisted yarn for external retreating, the use efficiency of the twisted yarn product for external retreating is improved, and the quality requirement of customers for the product is guaranteed. The invention also provides a production device.

Owner:TAISHAN FIBERGLASS ZOUCHENG

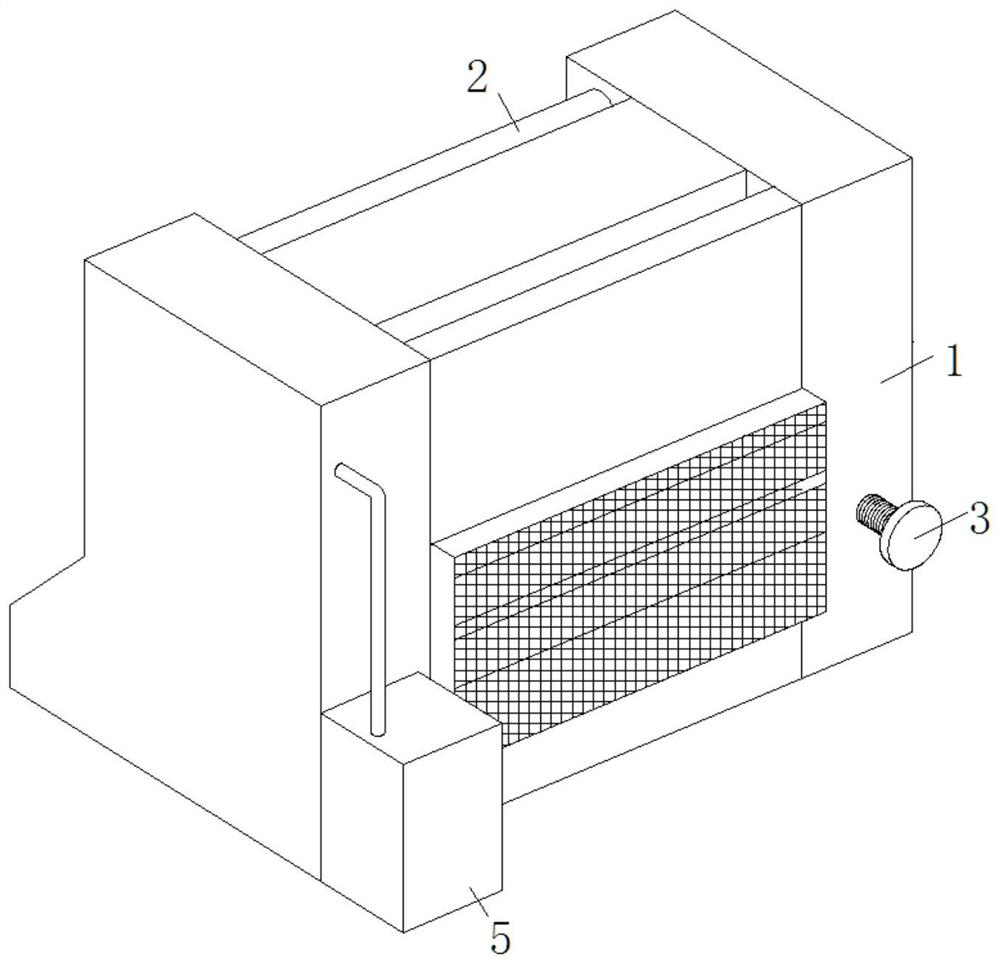

Structure for reducing broken yarns of machine table in production of glass fabric

PendingCN114507957AReduce frictionReduce wear rateLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsYarnThreaded rod

The invention relates to the technical field of sizing machines, and discloses a structure for reducing machine table yarn breakage in glass fabric production, which comprises a sizing machine body, a yarn feeding mechanism, a first tension adjusting mechanism, a second tension adjusting mechanism and a grouting mechanism, the first tension adjusting mechanism is located below the yarn feeding mechanism, the second tension adjusting mechanism is located on the rear side of the interior of the sizing machine body, and the grouting mechanisms are located on the inner side and the outer side of the sizing machine body. According to the structure for reducing the broken yarn of the machine table in the glass fabric production, the adjusting wheel is arranged, the hand wheel is rotated to drive the threaded rod to rotate, and therefore the adjusting wheel can be driven to move front and back, the distance and pressure between the adjusting wheel and the damping wheel are adjusted, and when the distance is large, the friction force between the adjusting wheel and the glass fabric and the friction force between the damping wheel and the glass fabric are reduced; the abrasion rate of the damping wheel and the pressing piece can be effectively reduced, the service life of the pressing piece is prolonged, the surface of the pressing piece is smooth, and therefore friction force is smaller.

Owner:台嘉成都玻纤有限公司

Treatment agent for synthetic fiber and its application

Owner:MATSUMOTO YUSHI SEIYAKU

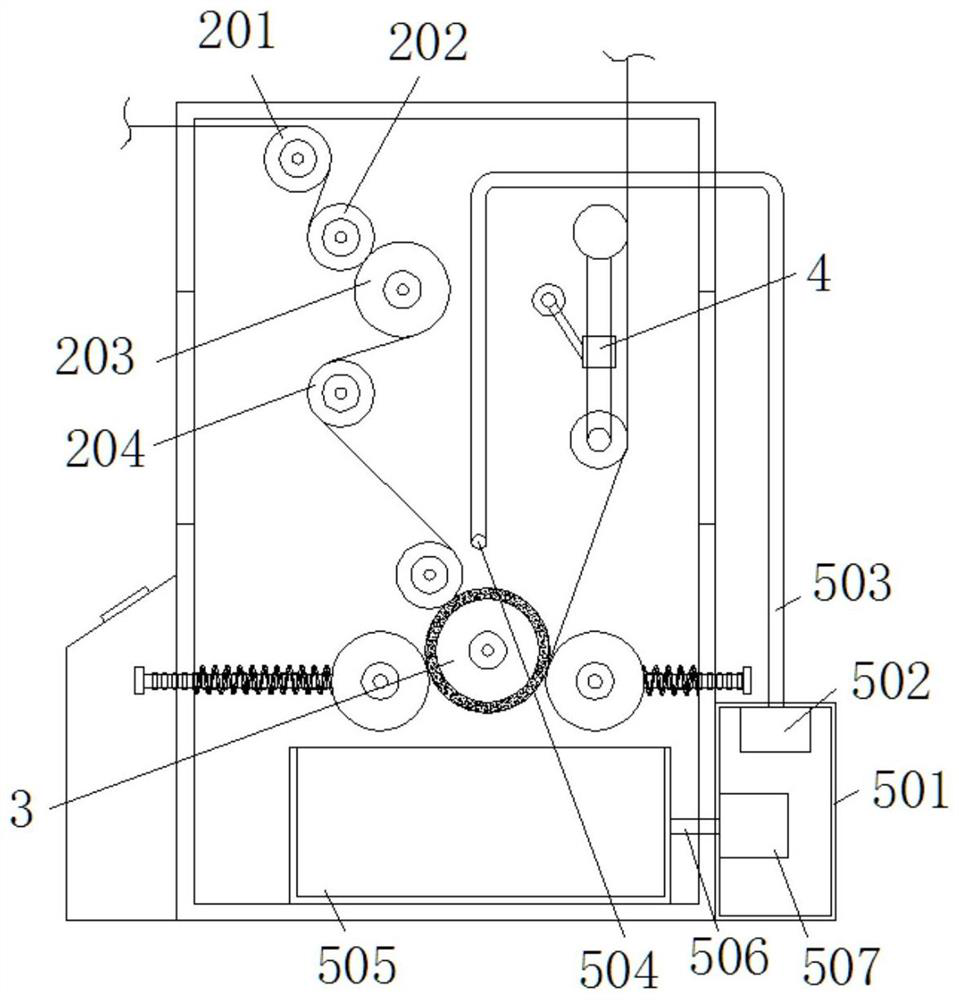

A Spinning Machine Not Easy to Break the Yarn

The invention discloses a spinning frame which is not easy to break the yarn, which comprises a frame. The upper end of the frame is provided with a roving frame. The components include a plurality of first traction gears which are arranged inclined from top to bottom in turn, and a first traction apron covering all the first traction gears; the upper end of the frame is rotatably connected with a cradle, and the left and right sides of the cradle are rotatably connected There are upper rubber rollers and lower rubber rollers. The middle part of the cradle is rotatably connected with multiple second traction gears. The left and right sides of the cradle are provided with second traction aprons covering all the second traction gears; A yarn guide bell is installed above the top roller, and the frame is horizontally provided with a flower suction tube above the yarn guide bell. The invention pulls the roving evenly in the middle section, prevents yarn breakage caused by excessive tension, and effectively prevents yarn breakage caused by flower accumulation at the bell mouth.

Owner:襄樊富仕纺织服饰有限公司

Method for preventing yarn breakage

ActiveCN101932759BDoes not increase breakageReduce tanglingArtificial filament washing/dryingWet spinning methodsYarnJet washer

The invention pertains to the use of a multifilament yarn spinning process comprising individually washing each filament of a multifilament yarn and, if neutralized, individually neutralizing each filament of the multifilament yarn, for preventing yarn breakage during the spinning process, the spinning process comprising spinning of a polymer through a spinneret to obtain the multifilament yarn, washing the yarn, and optionally neutralizing and / or drying the yarn and winding the yarn onto a bobbin Preferably the yarn is washed with jet washers.

Owner:TEIJIN ARAMID BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com