Patents

Literature

53results about How to "Reduced antistatic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

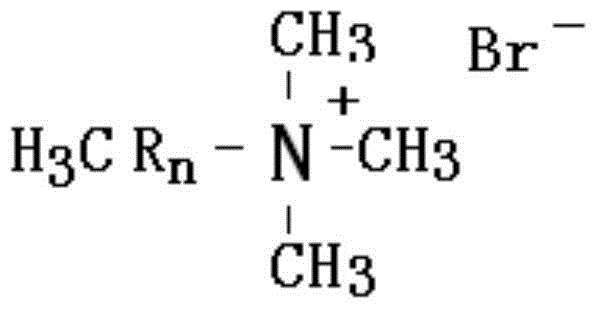

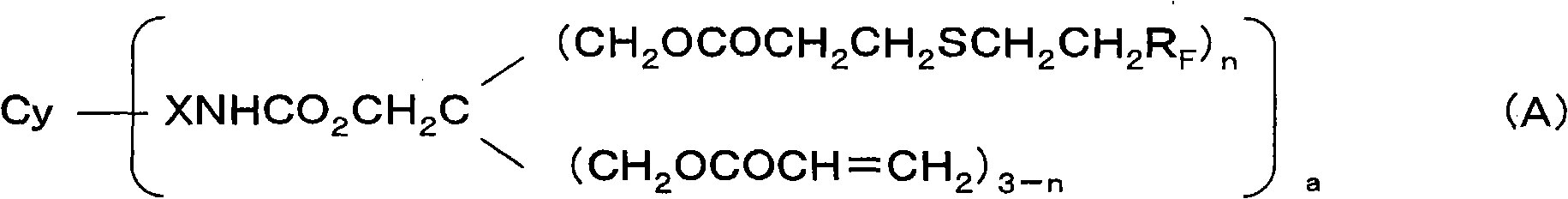

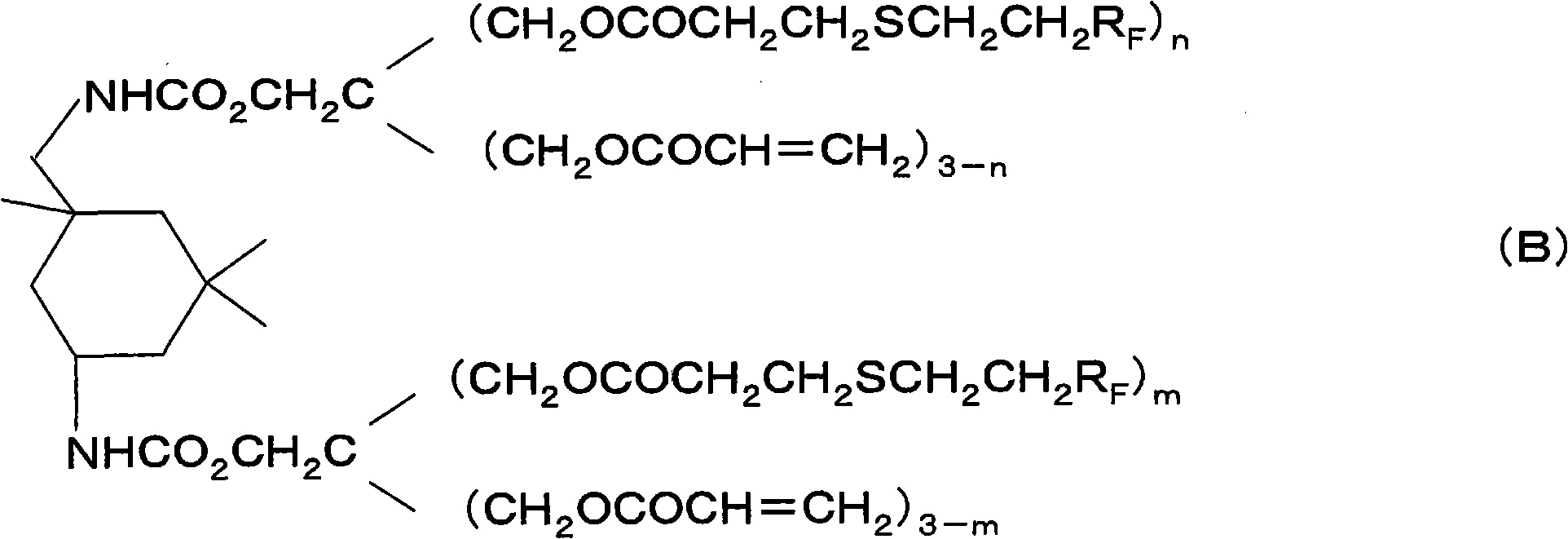

Quaternary amino cation modified polysiloxane softening agent and preparation method thereof

ActiveCN101565896AReduce hydrophobicityReduced antistatic propertiesFibre treatmentOrganic acidAminosilochrome

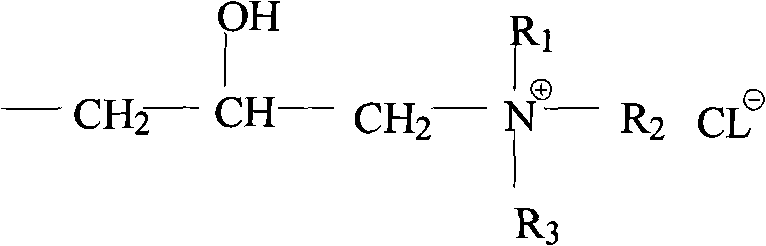

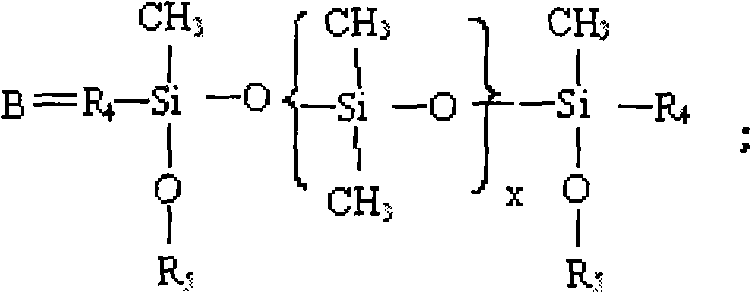

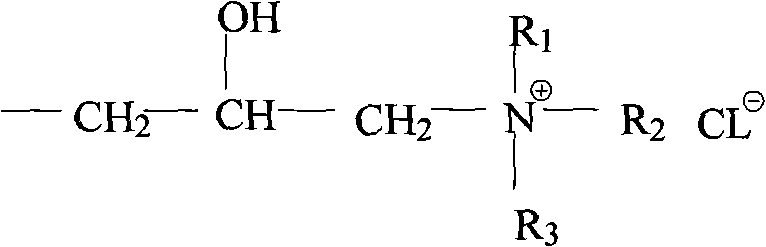

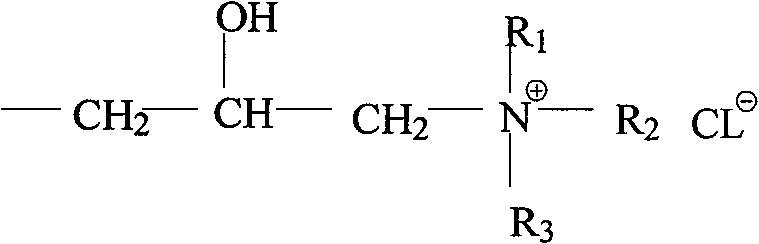

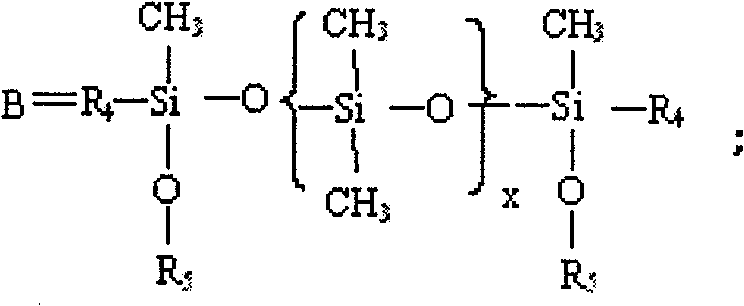

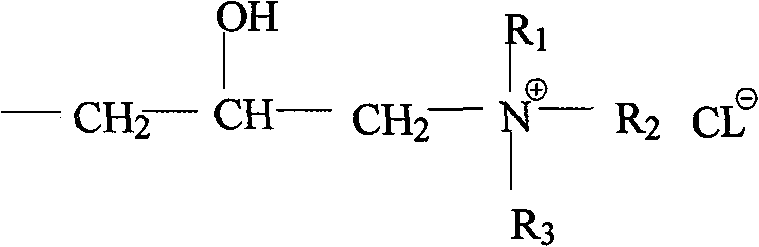

The invention relates to a quaternary amino cation modified polysiloxane softening agent and a preparation method thereof. The structural formula of the softening agent is A1BA2. The preparation method comprises the following steps: (1) mixing hydroxy silicone oil and silane coupling agent according to a molar ratio of 1:1-1:4, and carrying out reaction on the mixture for 4 to 24 hours at the temperature of between 25 and 105 DEG C to obtain an amino terminated siloxane intermediate; (2) carrying out reaction on the amino terminated siloxane intermediate and epoxy quaternary ammonium salt for 2 to 10 hours in a solvent under the protection of nitrogen during the whole reaction, and finally vacuumizing the mixture and removing partial solvent to obtain a sticky transparent modified polysiloxane product; and (3) diluting the modified polysiloxane product by water and organic acid to obtain transparent emulsion, and adding an emulsifying agent which is 5 to 10 percent of weight of the emulsion into the emulsion to obtain a product. Compared with the prior art, the softening agent has the advantages of good softness, fluffy feeling, hydrophilicity, extremely low yellowing property, and the like.

Owner:上海氟聚化学产品股份有限公司

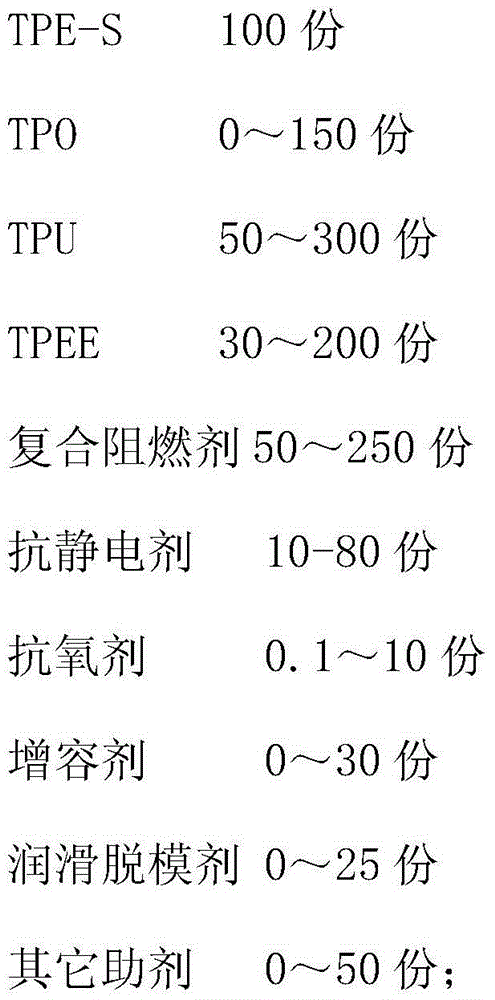

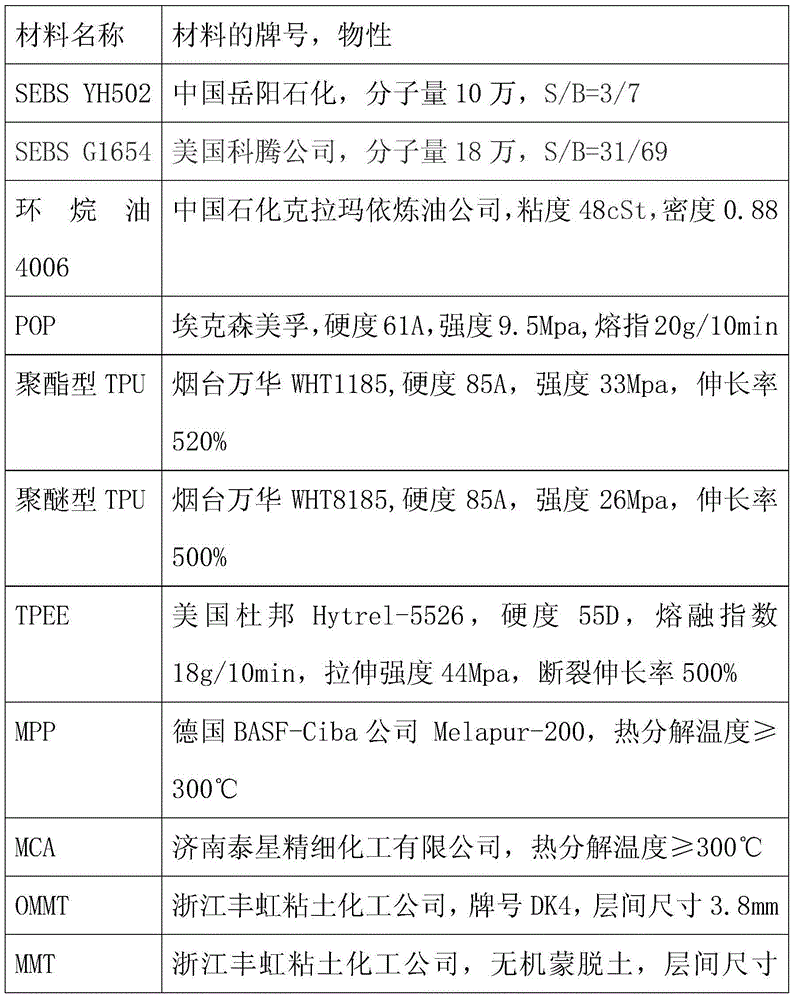

TPE flame resistant material for coating plastic and preparing method of TPE flame resistant material

The invention discloses a TPE flame resistant material for coating plastic and preparing method of the TPE flame resistant material. The TPE flame resistant material is composed of TPE-S, TPO, TPU, TPEE, a composite flame retardant, an antistatic agent, an antioxidant, a compatibilizer, a lubrication release agent and other auxiliaries. The prepared TPE flame resistant material coating plastic is good in fluidity, simple in processing technology, convenient to process and capable of being processed and formed by using an injection molding machine at the temperature between 180 DEG C and 210 DEG C, and production efficiency is high. The processing temperature is lower than 200 DEG C, processing can be conducted at 190 DEG C, energy consumption is lowered due to the low processing temperature, and energy resources are saved.

Owner:NANTONG POLYMAX ELASTOMER TECH

Antistatic blended yarn and application thereof

The invention provides an antistatic blended yarn, which is prepared from 20 to 45 percent of polyester fiber, 35 to 70 percent of cotton fiber and 10 to 30 percent of stainless steel fiber by weight percentage through blended spinning. The invention also provides an antistatic sweater produced by adopting the antistatic blended yarn and a method for producing the same. The product of the antistatic blended yarn has antistatic and electromagnetic shielding functions, does not have special requirement on washing, is not influenced by the environment, has complete colors and solid texture, is sweat-resistant and corrosion-resistant, can be applied to special industries such as anti-microwave clothes and radiation-resistant clothes, can effectively prevent human body from being radiated by computers and the like, and particularly protect pregnant women. The antistatic blended yarn can be processed into clothes worn in spring, autumn and winter and the clothes are comfortable to wear with excellent performance.

Owner:JIANGYIN XIANGFEI APPAREL

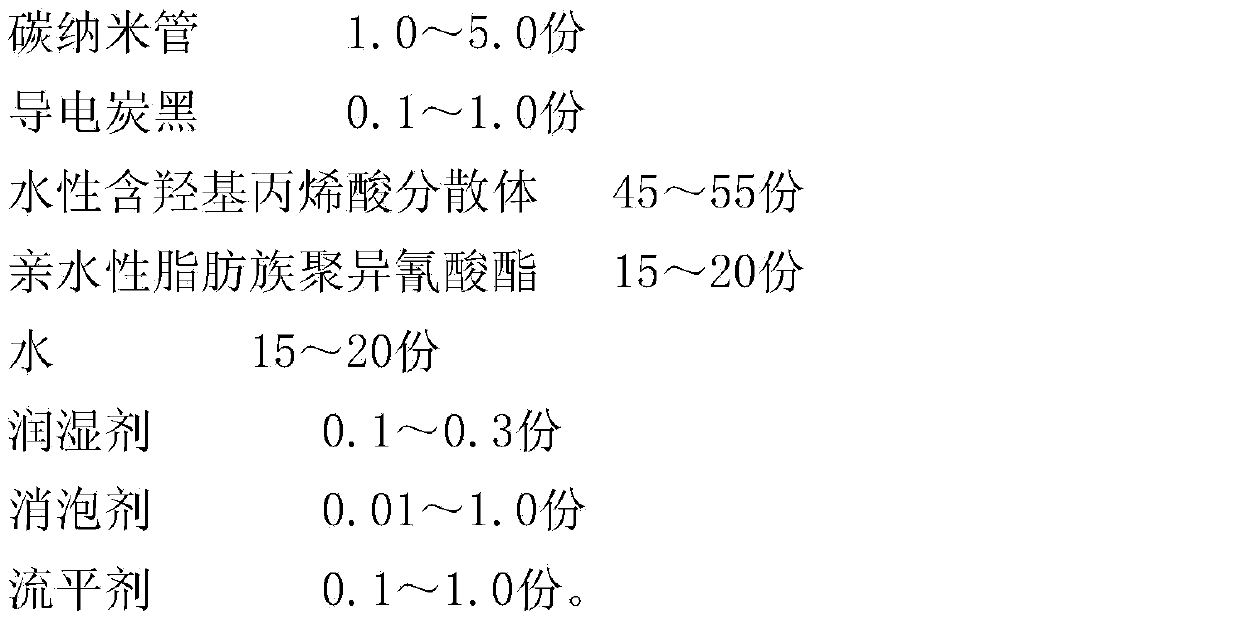

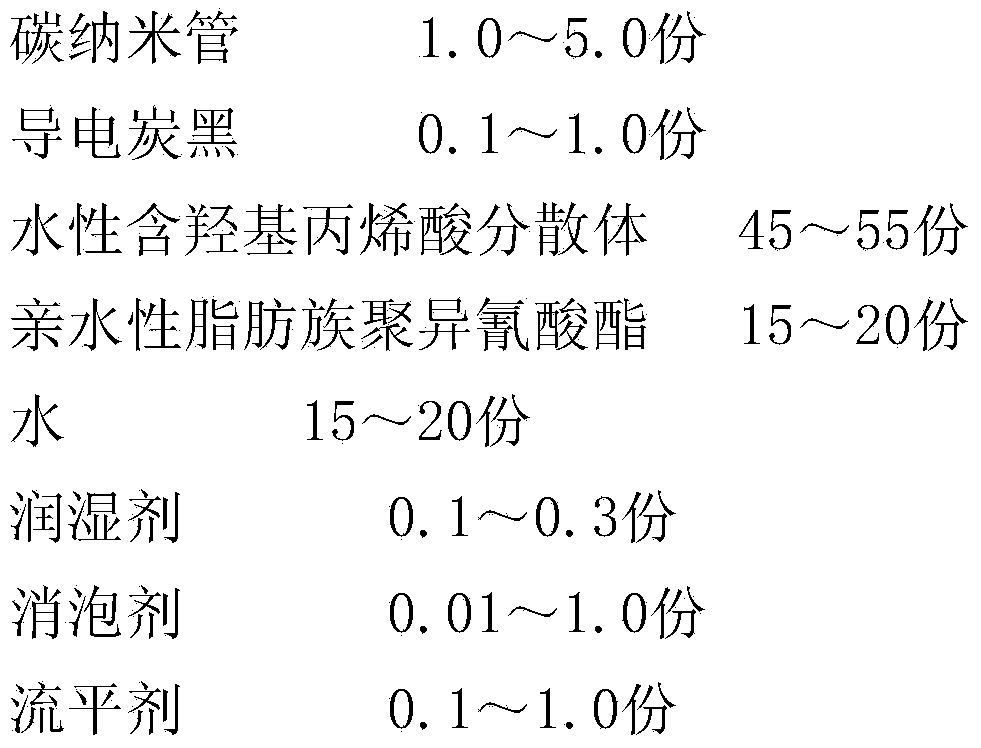

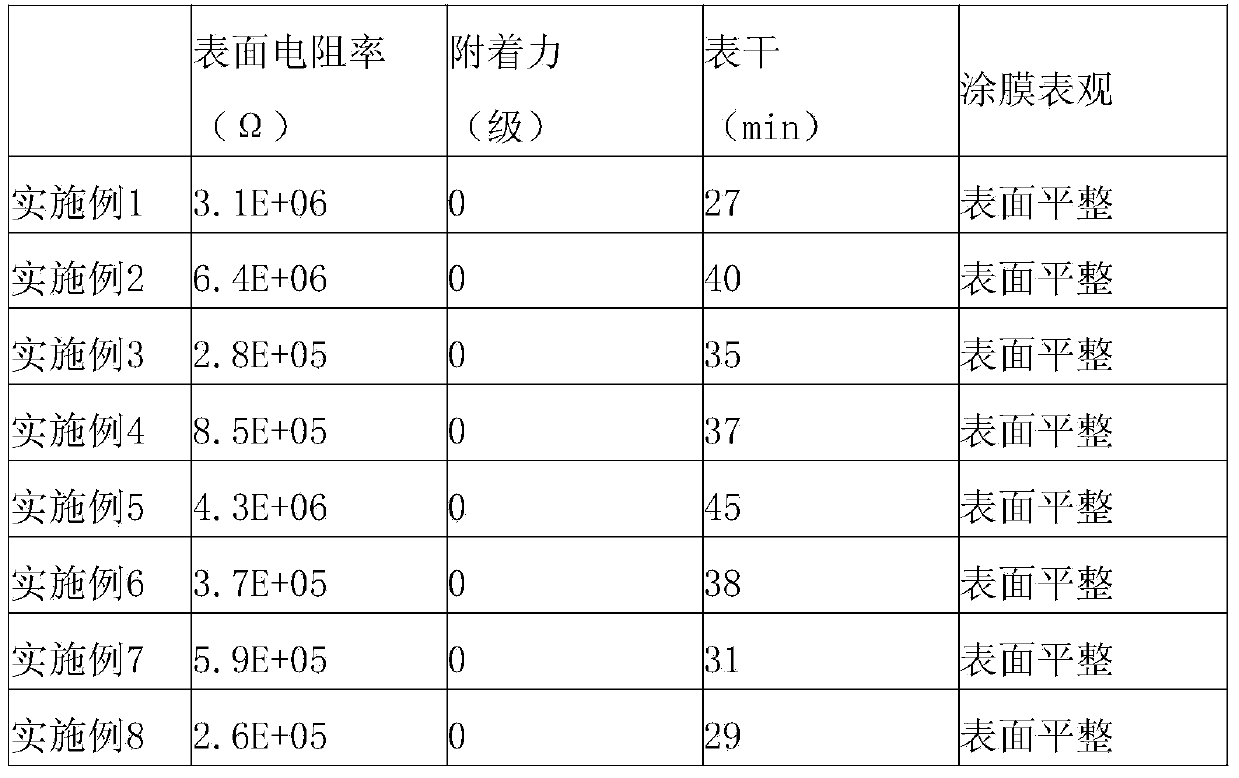

Antistatic waterborne polyurethane coating and preparation method thereof

ActiveCN103740252ASimple operation processReduced antistatic propertiesPolyurea/polyurethane coatingsElectrically-conductive paintsDefoamerChemistry

The invention belongs to the technical fields of a polymer composite material and a preparation method thereof, and particularly relates to an antistatic waterborne polyurethane coating and a preparation method thereof. The antistatic waterborne polyurethane coating comprises the following components in parts by weight: 1.0-5.0 parts of carbon nano tube, 0.1-1.0 part of conductive carbon black, 45-55 parts of waterborne hydroxyl-containing acrylic dispersion, 15-20 parts of hydrophilic aliphatic polyisocyanate, 15-20 parts of water, 0.1-0.3 part of wetting agent, 0.01-1.0 part of defoamer, and 0.1-1.0 part of flatting agent. The waterborne polyurethane coating prepared by the method has good anti-static performance, can be applied to a few of electronic equipment and elements, and effectively prevents electrostatic aggregation.

Owner:AODA KOALA PAINT HUIZHOU

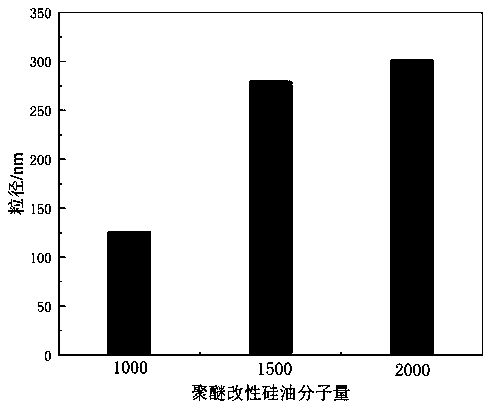

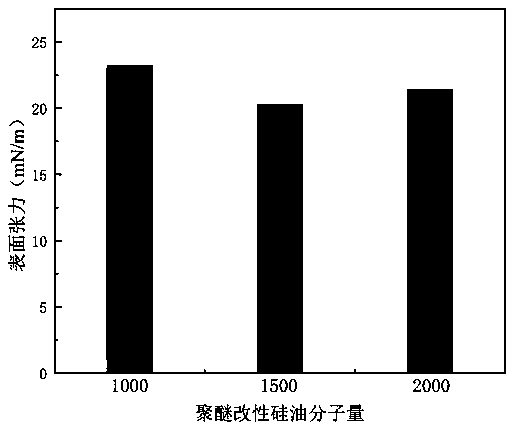

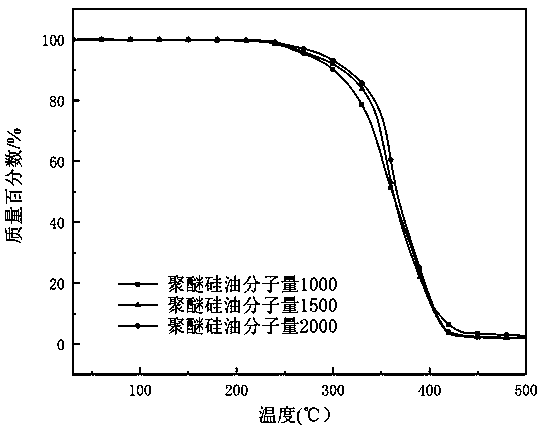

Preparation method of isocyanate modified polyether silicone oil nonionic emulsion and product and application thereof

ActiveCN110042667ASolve yieldSolve problems such as purification difficultiesCarbon fibresFiberCarbon fibers

The invention provides a preparation method of an isocyanate modified polyether silicone oil nonionic emulsion and a product and application thereof. The method comprises the steps of synthesizing double-end containing hydrogen silicone oil, synthesizing double-end hydroxyl modified silicone oil, synthesizing isocyanate modified polyether silicone oil, adding a proper amount of water for emulsifying, performing co-emulsifying with cationic amino modified epoxy silicone oil, and performing compounding to prepare a carbon fiber precursor oil agent. The technical problems met during an addition reaction of polyether modified silicone oil and high molecular weight polyethylene glycol monoallyl ether through containing hydrogen silicone oil that the reaction is difficult, the yield is low, theseparation purification is hard, and the color is dark are solved, and meanwhile the problems that the storage stability of amino modified silicone oil in the weak acid water phase is poor, compounding with cationic amino modified epoxy silicone oil is performed to prepare the carbon fiber precursor oil agent, after oiling, the carbon fiber precursor is stuck to rollers in the high-temperature drying and rolling process are solved.

Owner:吉林乾仁新材料有限公司

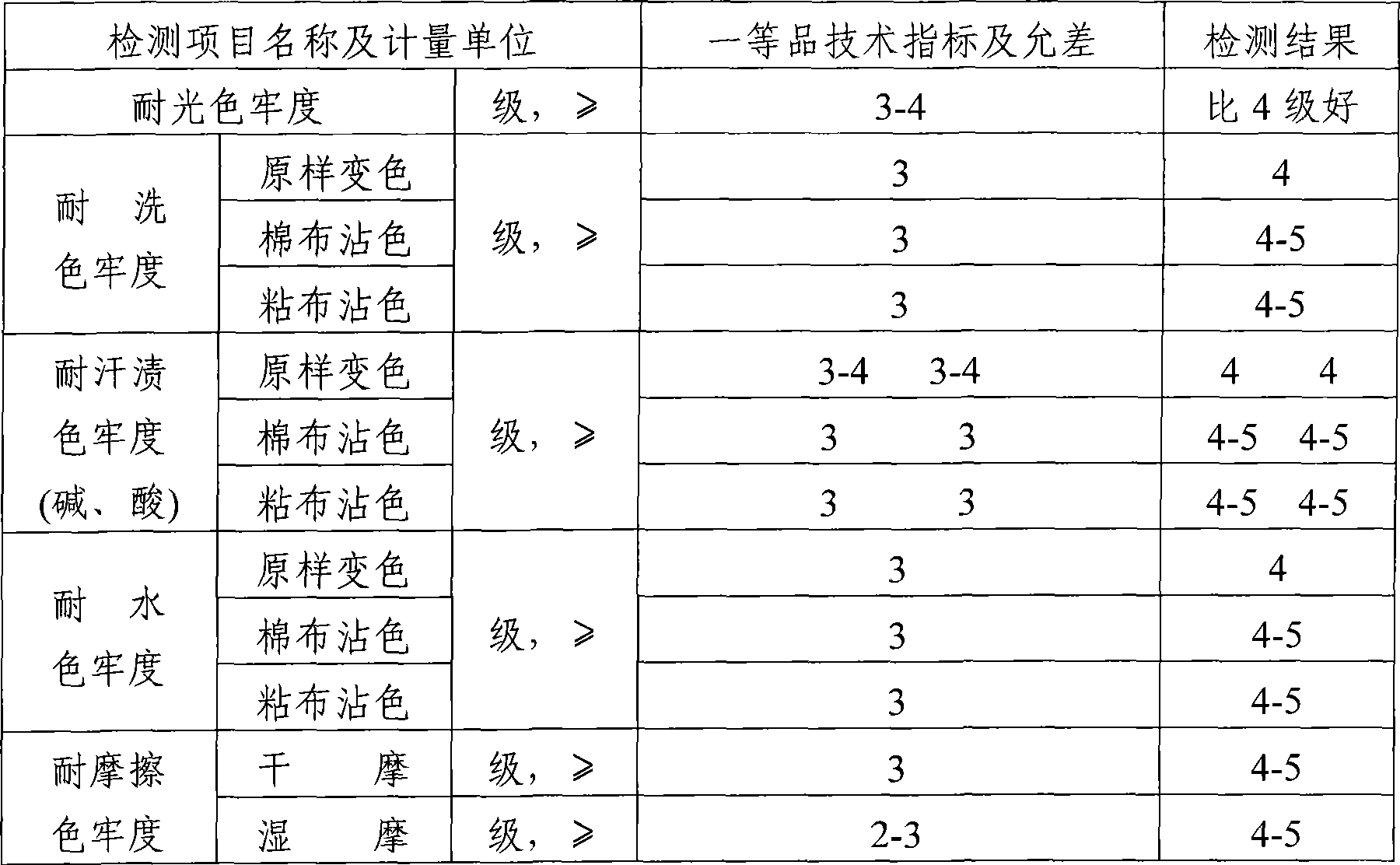

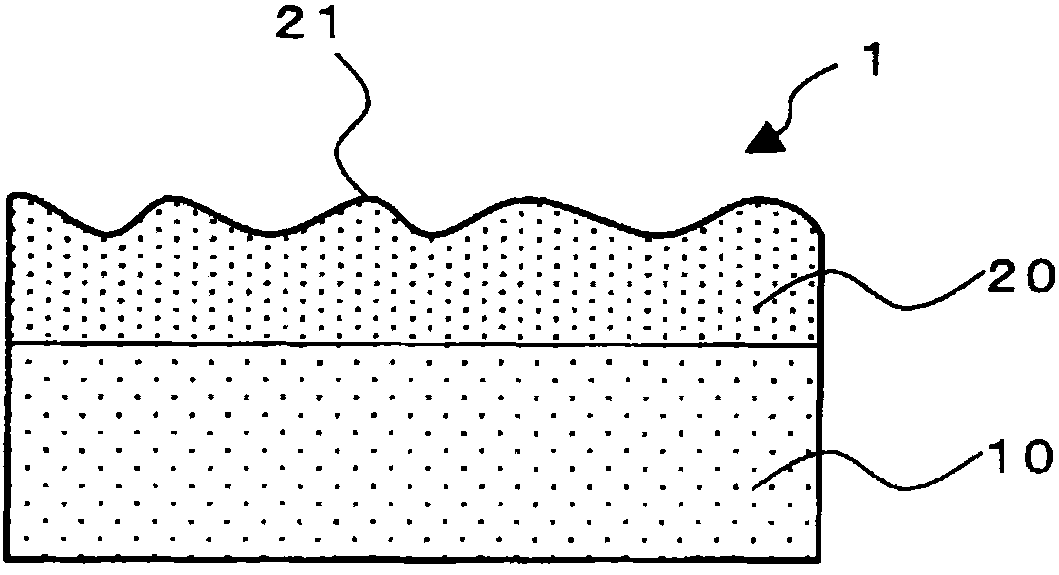

Optical laminate, polarizing plate, and display apparatus using the same

ActiveCN102012532AImprove antistatic performanceGood light fastnessSynthetic resin layered productsPolarising elementsSquare MillimeterSurface resistivity

The present invention provides an optical laminate which has excellent antistatic performance, high saponification resistance and excellent scratch resistance just through a one-layer structure. The invention also provides a polarizing plate and a display device with the same. The optical laminate of the invention is characterized in that: a light-penetrable substrate is at least provided with an optical functional layer directly or through a mode of being spaced by other layer; the optical functional layer at least comprises a conductive material; the surface resistivity at the surface of the optical laminate after carbon arc type light fastness test is less than 1.0*10<12>omega / square millimeter in a length of one meter; and furthermore, the surface resistivity ratio between the surface resistivity before the carbon arc type light fastness test and that after the carbon arc type light fastness test, namely R2 / R1 is less than 10<4>, wherein, R1 is the surface resistivity before the carbon arc type light fastness test, and R2 is the surface resistivity after the carbon arc type light fastness test.

Owner:TOMOEGAWA PAPER CO LTD

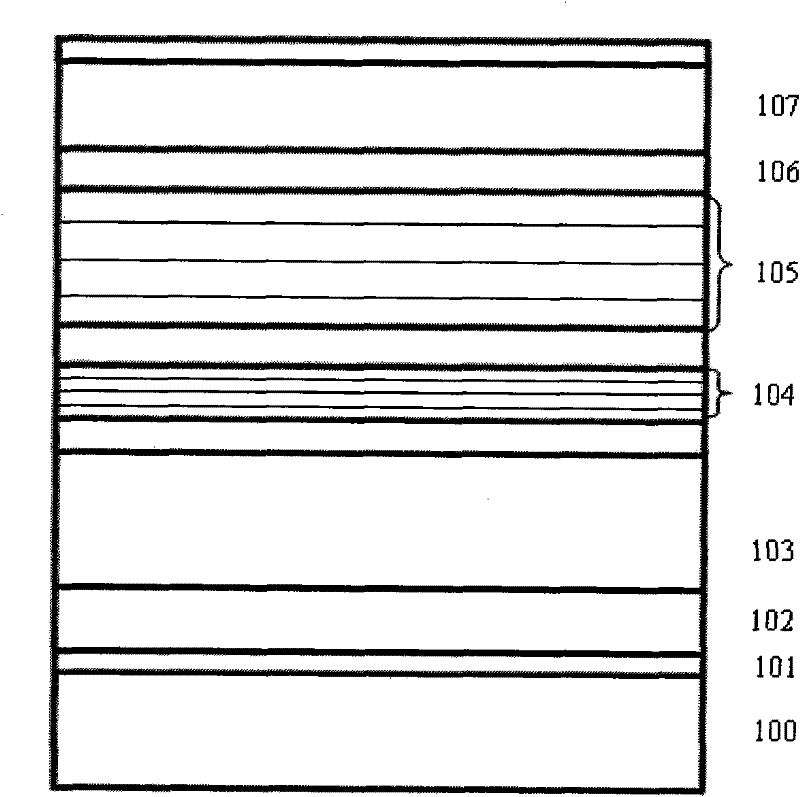

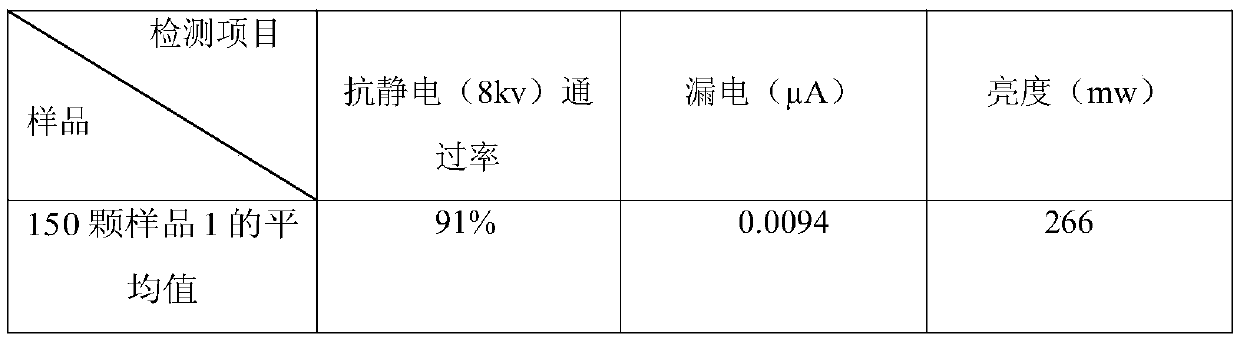

GaN-based LED epitaxial wafer and growing method thereof

InactiveCN102332517ACushion the shockReduced luminous efficiencyChemical vapor deposition coatingSemiconductor devicesQuantum wellEndurance capacity

The invention introduces a GaN-based LED epitaxial wafer and a growing method thereof. At least one cyclic n type defect blocking layer is introduced after an n type GaN layer. Due to the introduction of the n type defect blocking layer, on one hand, a defect that is generated by heteroepitaxy or n type doping can be blocked, thereby improving a growing quality of a crystal; on the other hand, a current can be expanded and an impact of static electricity on a GaN-based LED is softened, thereby enhancing an endurance capacity of the LED to the static electricity; moreover, electrons can access a quantum well effectively and an injection efficiency of the electrons into the quantum well can be increased, so that a brightness of the LED can be enhanced. According to the invention, a chip with an area of 300 * 300 square microns is manufactured according to a standard chip technology; an ESD with 4, 000 V (human body mode) is enhanced from 70% to over 90% and a brightness is raised from 14 mW to over 16 mW.

Owner:DALIAN MEIMING EPITAXIAL WAFER TECH

Preparation method for anti-static modified plastic

The invention provides a preparation method for an anti-static modified plastic and relates to the technical field of production of the anti-static plastic. The preparation method comprises the following steps: adding an organosilicone modified ethyl orthosilicate pre-condensed precursor into a quickly stirred mixed system of graphene microchip and carbon nano tube in the manner of spraying, and then fully mixing with plastic particles, extruding and pelletizing, thereby acquiring a synergic anti-static modified plastic. According to the invention, the gathering problem of graphene microchip and carbon nano tube is solved, the introduction of organic groups in OM-SiO2P can endow the carbon nano tube and the plastic substrate with the interface bonding force, the goal of low filling volume required for reaching the anti-static performance index is achieved and the acquired nanometer composite material has ideal mechanical, thermodynamic and wear-resisting properties.

Owner:扬州市维纳复合材料科技有限公司

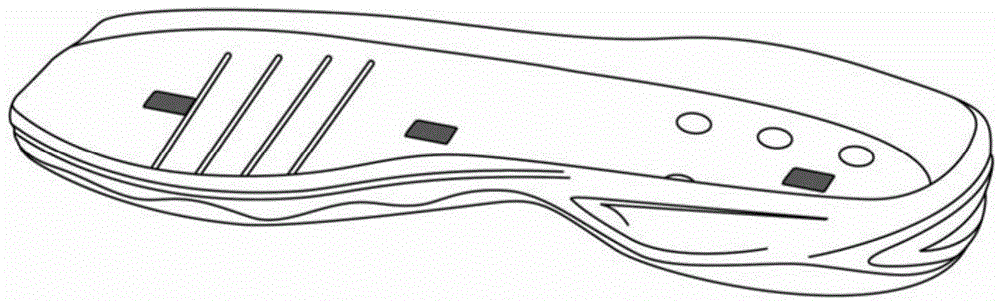

Oil-resistant anti-static-electricity rubber/EVA (ethylene-vinyl acetate copolymer) sole recipe as well as preparing method and application thereof

ActiveCN104544720AGood oil resistanceImprove antistatic performanceSolesDomestic footwearWear resistanceEthylene-vinyl acetate

The invention discloses an oil-resistant anti-static-electricity rubber / EVA (ethylene-vinyl acetate copolymer) combined sole, which is formed by combining an oil-resistant anti-static-electricity rubber outer sole and an anti-static-electricity foam EVA mid sole through being brushed with anti-static-electricity glue water. The prepared sole has the advantages that on the basis of the advantages of oil resistance, anti-static-electricity performance, wear resistance and the like, the advantages of light weight of the sole, good elasticity, comfortable wearing feeling and the like are also realized, and the sole is applicable to the shoe sole worn in work occasions with oil stain and with anti-static-electricity requirements.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Polyester fluffy softening finishing method

The invention discloses a polyester fluffy softening finishing method which comprises finishing-agent finishing and antistatic-agent finishing. The finishing-agent finishing particularly adopts the following method: finishing polyester by using a water dispersion polyester derivative product as a polyester fluffy softening finishing agent. In the antistatic-agent finishing, a finishing agent has concentration of 3 percent (o.W.f) and has a bath ratio of 1:10; polyester is soaked in the finishing agent for 20min, the temperature of the finishing agent is kept into 60 DEG C, then the polyester is taken out to be subjected to centrifugal dewatering, the polyester is dried for 10min under the temperature condition of 110 DEG C and finally, the polyester is ironed for 60S to 120S under the temperature condition of 180 DEG C to be sized, wherein a liquid carrying rate is 70 percent to 75 percent. According to the polyester fluffy softening finishing method, crosslinking is carried out on the surface of a fabric to form a film; a cohesive force of fibers is increased; fluff of yarns is reduced; scratchiness is eliminated; a water dispersion polyester component contained in the polyester fluffy softening finishing agent can effectively improve hydrophilicity and antistatic property.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

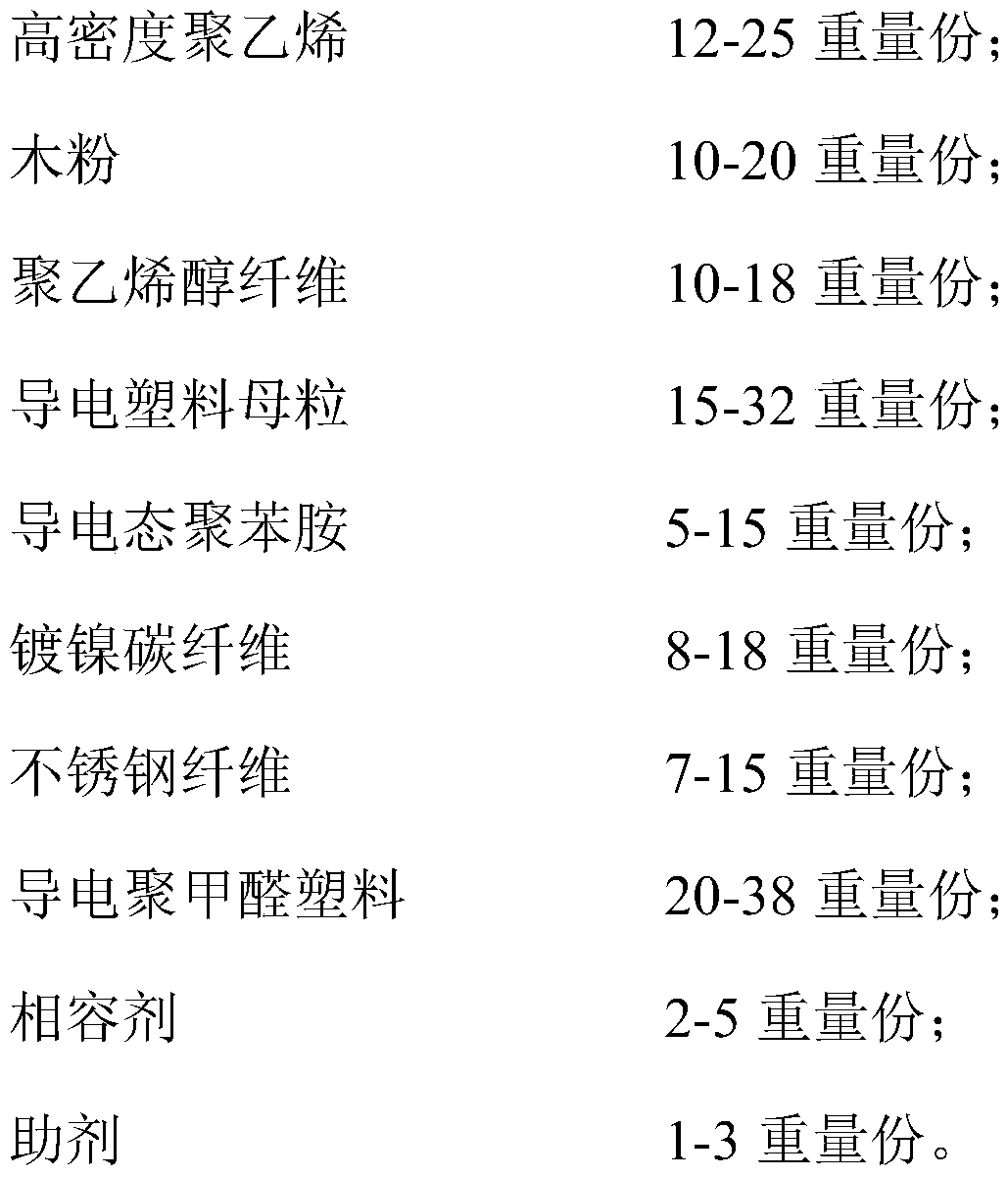

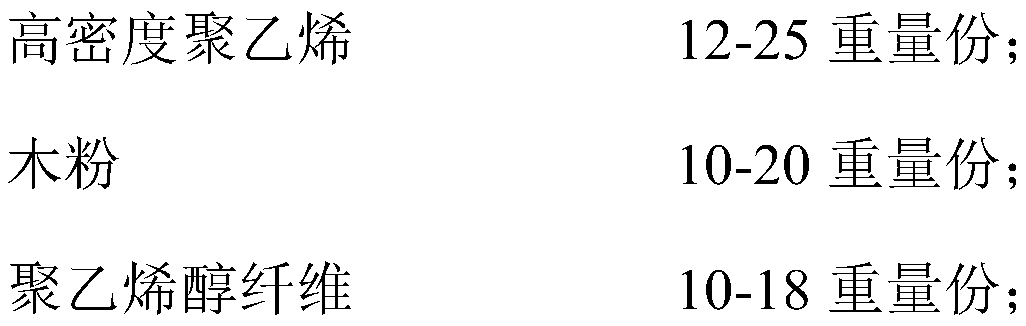

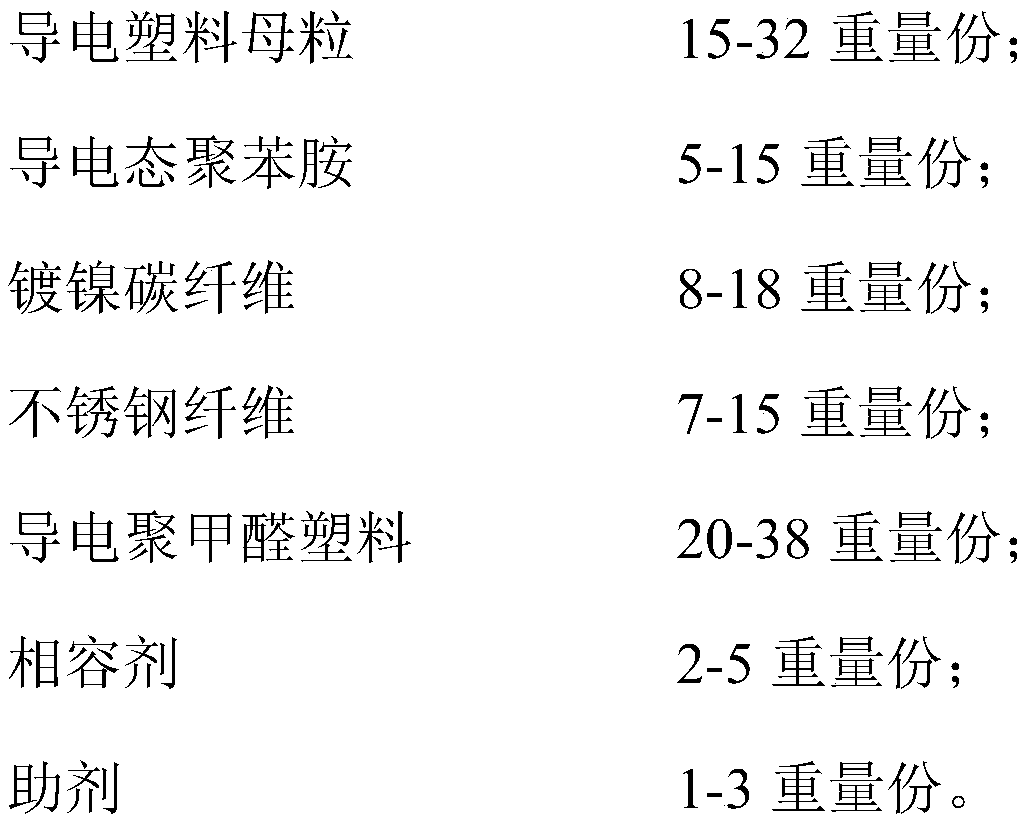

Anti-bending, anti-slip and anti-static type plastic-wood composite material and preparation method thereof

InactiveCN110283420AHigh mechanical strengthImprove antistatic performanceCarbon fibersPolyvinyl alcohol

The invention belongs to the technical field of functional plastic-wood materials, specifically relates to an anti-bending, anti-slip and anti-static type plastic-wood composite material, and further discloses a preparation method thereof. According to the anti-bending, anti-slip and anti-static type plastic-wood composite material disclosed by the invention, high-density polyethylene, wood powder, high-strength and high-modulus polyvinyl alcohol fibers, conductive plastic masterbatches, conductive-state polyaniline, nickel coated carbon fibers, 304 stainless steel fibers, conductive polyformaldehyde plastic, a compatibilizer, and auxiliaries such as a coupling agent, a lubricant, and an ultraviolet absorbent are taken as raw materials, and a product is obtained through extrusion pelleting, molding, and surface brush grinding and coarsen treatment through a wire brush. The plastic-wood composite material provided by the invention integrates outstanding anti-bending, surface anti-slip and anti-static properties, and has significant application value.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD

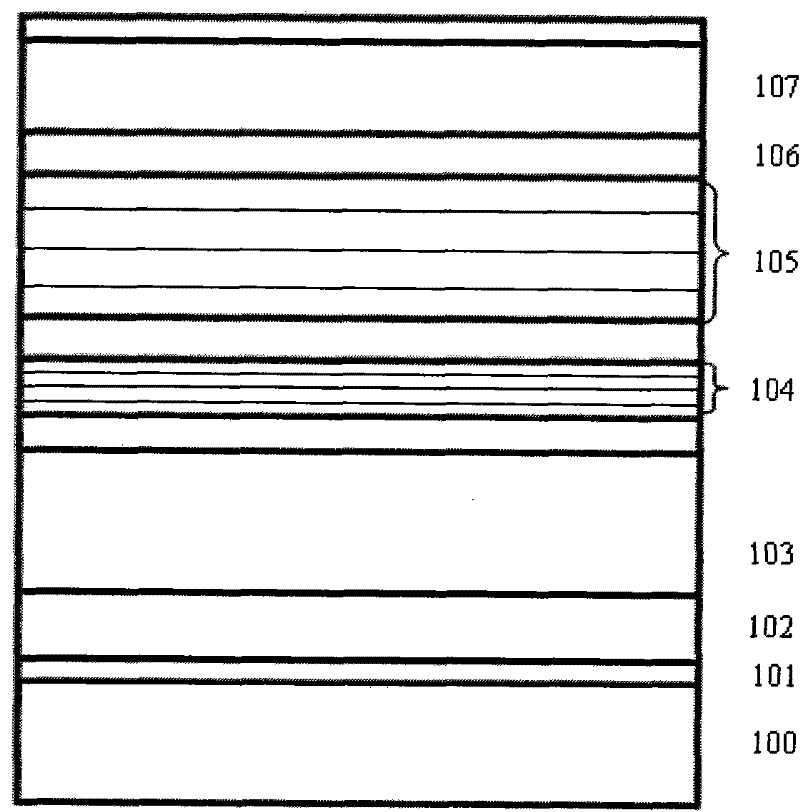

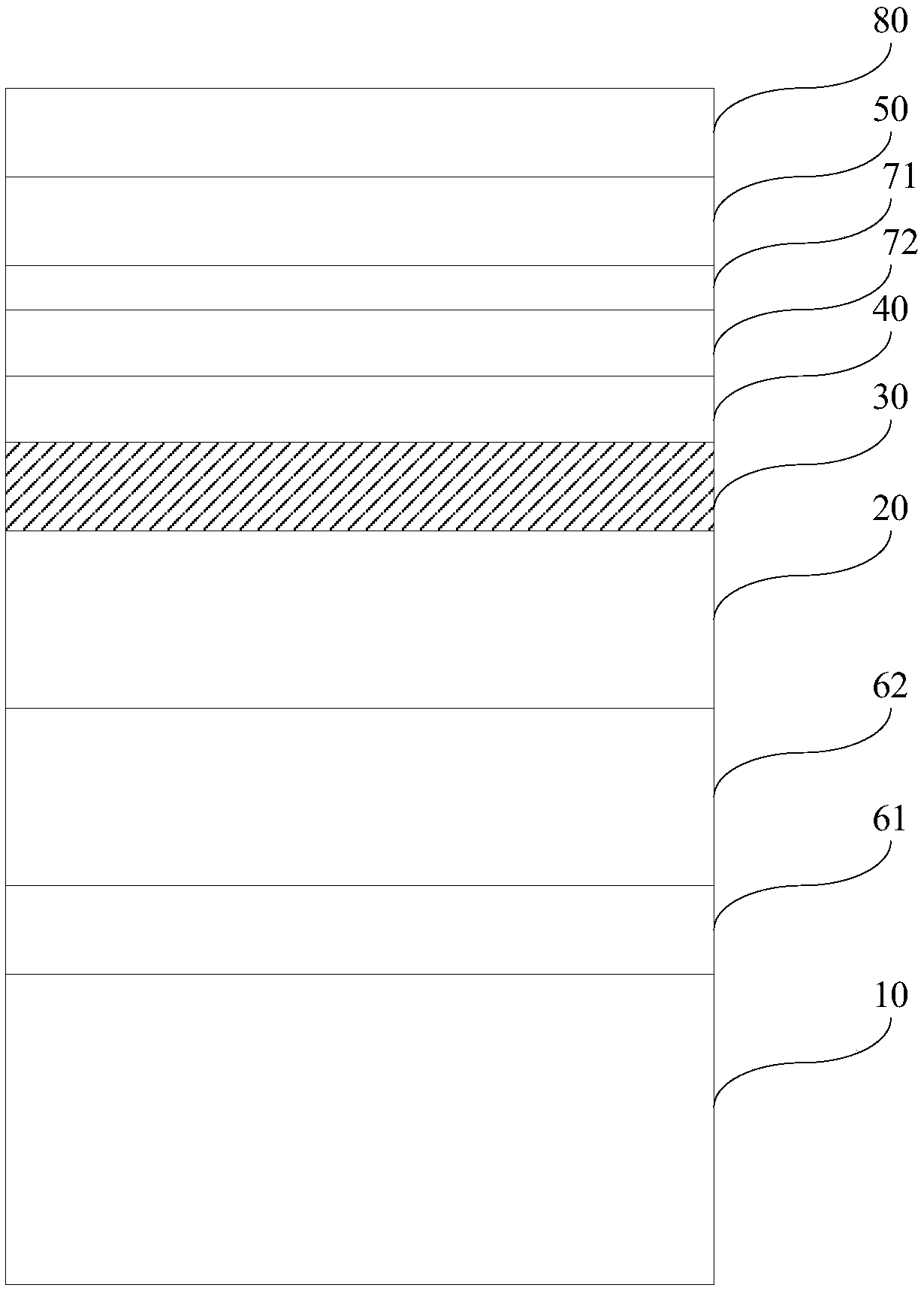

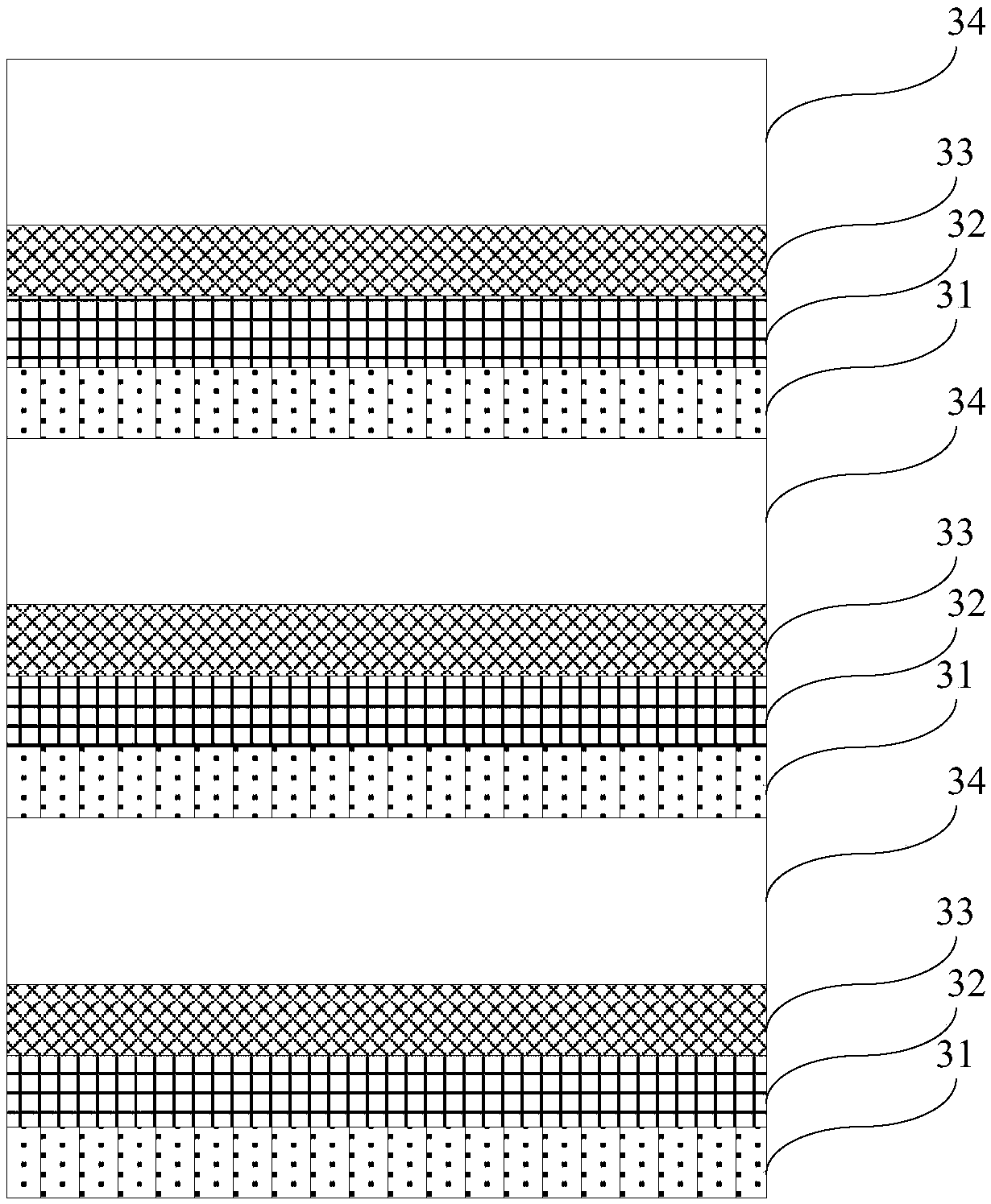

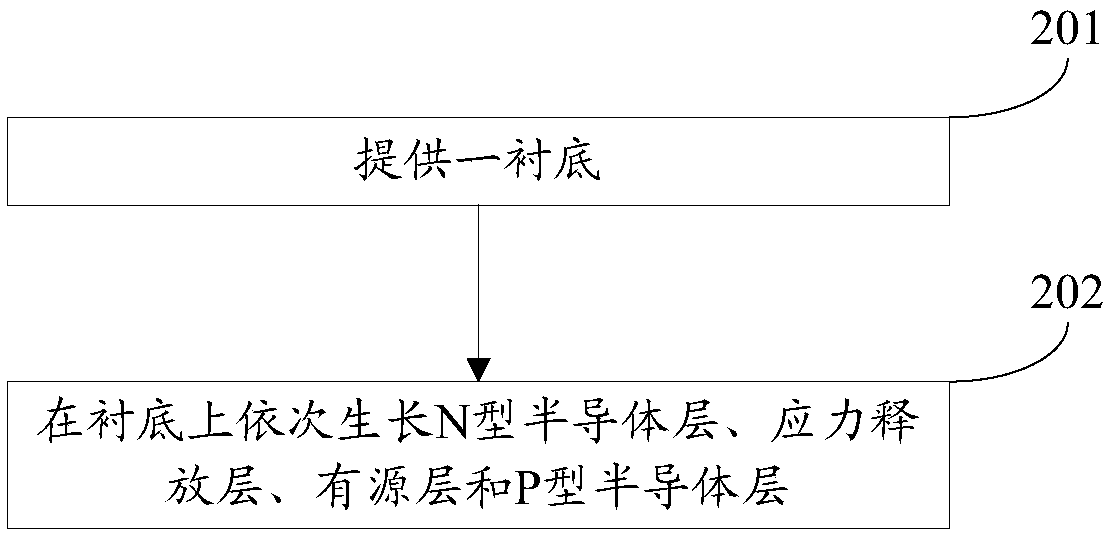

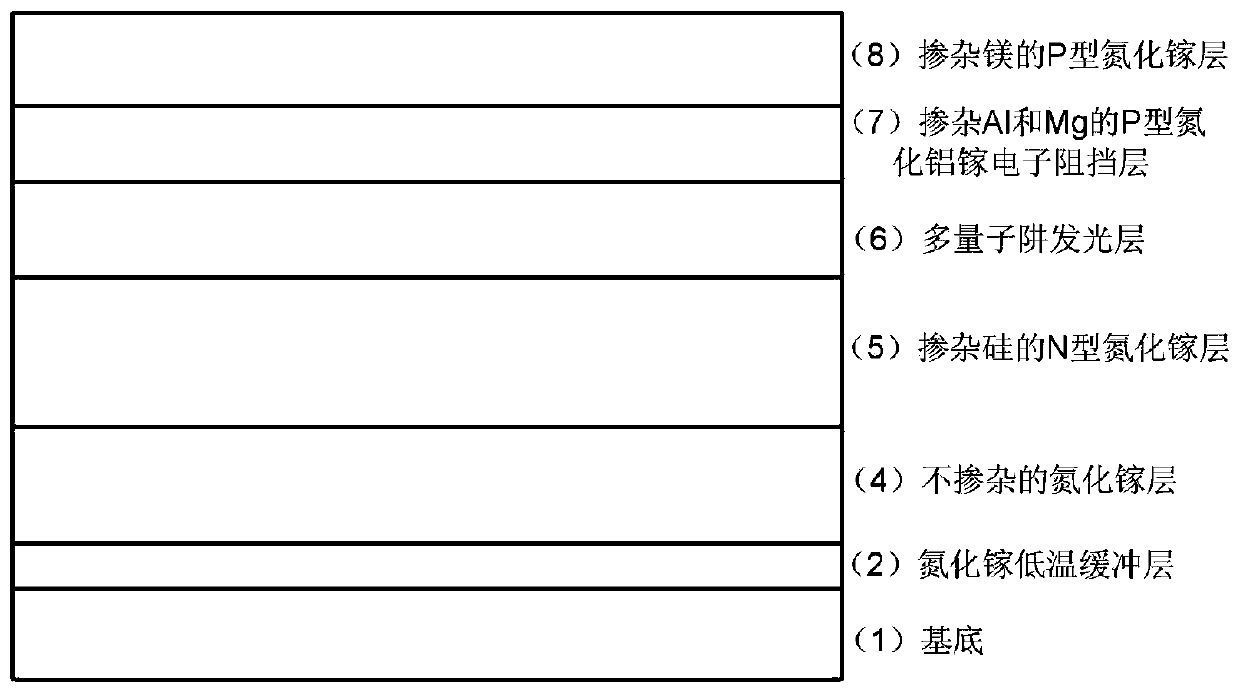

Light emitting diode epitaxial wafer and preparation method thereof,

ActiveCN109346568AImproved current spreadLow growth temperatureSemiconductor devicesGallium nitrideActive layer

The invention discloses a light emitting diode epitaxial wafer and a preparation method thereof, and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprises a substrate, an N-type semiconductor layer, a stress release layer, an active layer and a P-type semiconductor layer, wherein the N-type semiconductor layer, the stress release layer, the active layer and the P-type semiconductor layer are sequentially stacked on the substrate; the stress release layer comprises a plurality of composite structures which are stacked in sequence, wherein each composite structure comprises a first sub-layer, a second sub-layer, a third sub-layer and a fourth sub-layer which are stacked in sequence; the first sub-layer is made of non-doped indium gallium nitride, the second sub-layer is made of non-doped aluminum nitride, the third sub-layer is made of silicon nitride, and the fourth sub-layer is made of non-doped gallium nitride. According to the light-emitting diode epitaxial wafer, the photoelectric property of the LED is finally improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

High-strength, flame-retardant and antistatic polyolefin pipeline and preparation method thereof

The invention discloses a high-strength, flame-retardant and antistatic polyolefin pipeline which is mainly prepared from the following components in parts by weight: polyethylene, a modifier, a co-modifier, a peroxide initiator, short glass fibers, a surface coupling agent, red phosphorus, carbon black and a compound stabilizer. The preparation method comprises the following steps: weighing raw materials; performing surface coupling treatment on the short glass fibers; mixing the red phosphorus, carbon black and one part of polyethylene, extruding, and granulating, thereby obtaining a flame-retardant master batch; mixing the residual polyethylene, the modifier and the co-modifier, adding benzoyl peroxide and the compound stabilizer, mixing, adding the short glass fibers subjected to surface treatment and flame-retardant master batch, and performing melt extrusion molding, thereby obtaining the product. The pipeline prepared by the invention is excellent in ring stiffness and tensile strength and has excellent corrosion resistance, static resistance and flame resistance, and the preparation method is simple, high in operability, low in production cost, high in production efficiency and suitable for industrial production, popularization and application.

Owner:侯连龙

Method for making electrostatic-resisting knitted dress

InactiveCN1483880AImprove antistatic performanceReduce consumptionCircular knitting machinesYarn tensionEngineering

The method for producing anti-electrostatic knitted includes the following steps: (a) raw material selection; general fibre uses polyester / cotton blended yarn, and conductive fibre uses carbon black type polyester matrix bicomponent fibre; and (b) knitting process; basic stitch is weft plain stitch, knitting the conductive fibre into tuck and float combined stitch, the space distance of conductive fibre is 1.5-2.0 cm, and the yarn tension; polyester / cotton yarn tension is 5-9 cN, and the conductive fibre tension is 3-5 cN, and stitch length: polyester / cotton yarn is 2.5-3.8 mm, and the conductive fibre average stitch length is 1.0-1.8mm.

Owner:JIANGNAN UNIV

Flame-retardant antistatic two-component waterborne polyurethane coating and preparation method thereof

InactiveCN110283525AIncrease resistanceIncrease the number ofFireproof paintsPolyurea/polyurethane coatingsPotassium persulfateNitrocellulose

The invention discloses a flame-retardant antistatic two-component waterborne polyurethane coating and a preparation method thereof. The flame-retardant antistatic two-component waterborne polyurethane coating comprises a component A and a component B, wherein the mass ratio of the component A to the component B is (8:1) to (10:1); the component A is prepared from the following raw materials in parts by weight: 50-70 parts of methyl methacrylate, 30-40 parts of butyl acrylate, 10-14 parts of methacrylic acid, 5-7 parts of sodium dodecyl sulfate, 10-16 parts of polythiophene antistatic liquid, 2-4 parts of composite conductive mica powder, 5-6 parts of ultrafine carbon black, 4-8 parts of an emulsifier, 2-4 parts of potassium persulfate, 6-8 parts of polysiloxane, 10-12 parts of nano calcium carbonate, and 50-60 parts of water; the component B is prepared from the following raw materials in parts by weight: 6-8 parts of waterborne nitrocellulose, 1-3 parts of modified nano-alumina, and 2-4 parts of a surfactant. The flame-retardant antistatic two-component waterborne polyurethane coating disclosed by the invention is high in environmental protection safety, excellent in flame-retardant and antistatic effects, stronger in adhesion and better in water resistance.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Flame-retardant wood-plastic compound material tray

The invention relates to the technical field of plastic product production, and particularly discloses a flame-retardant wood-plastic compound material tray. The tray is prepared from the following raw materials in parts by weight: 50-70 parts of bamboo powder, 45-60 parts of high-density polyethylene, 1-4 parts of silane coupler KH550, 0.3-2 parts of maleic anhydride grafted polyethylene, 0.5-2 parts of sodium stearate, 1-2 parts of polyethylene wax, 0.5-1 part of azodiisobutyronitrile, 3-7 parts of muscovite, 0.2-1 part of p-phenylenediamine, 0.2-1 part of antioxidant 1076, 1-2 parts of black masterbatch, 9-13 parts of compound flame retardant and 6-10 parts of modified carbon black. The flame-retardant wood-plastic compound material tray has excellent electrostatic resistance and flameretardance.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

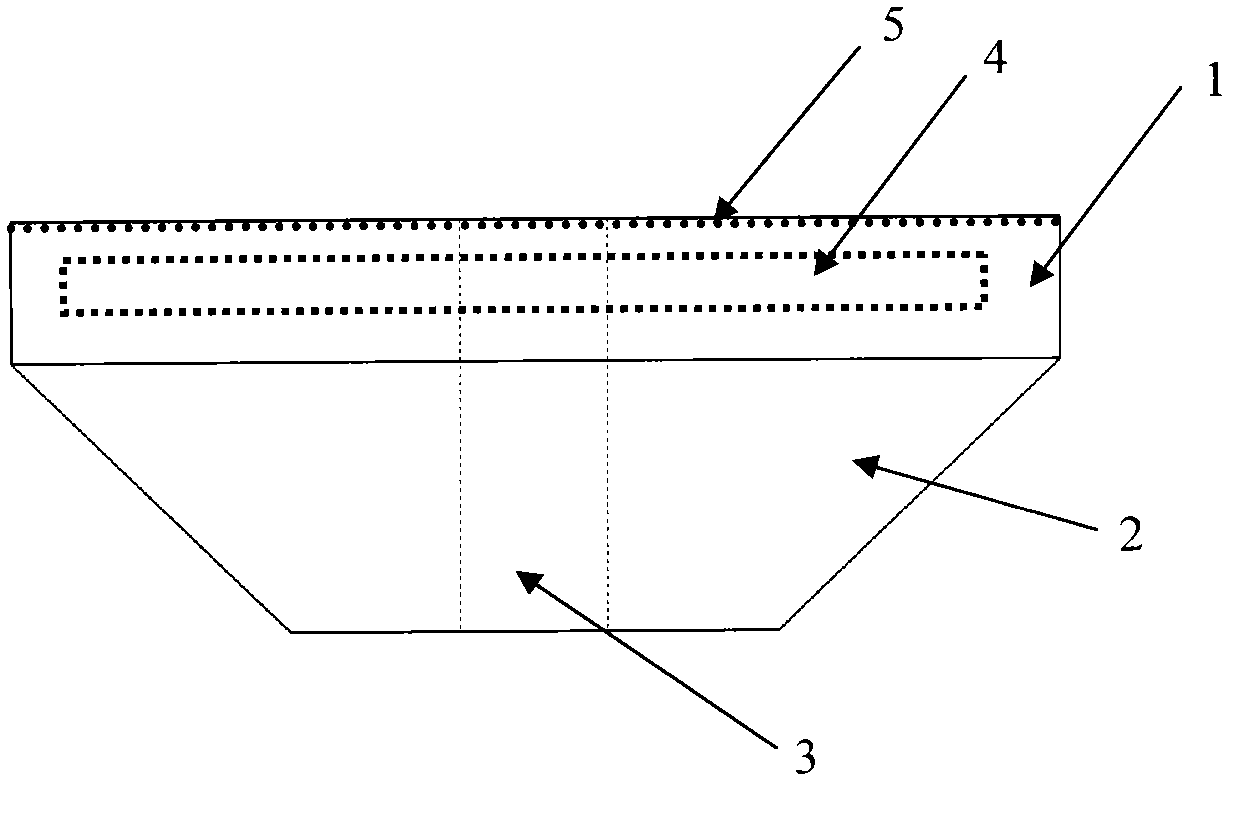

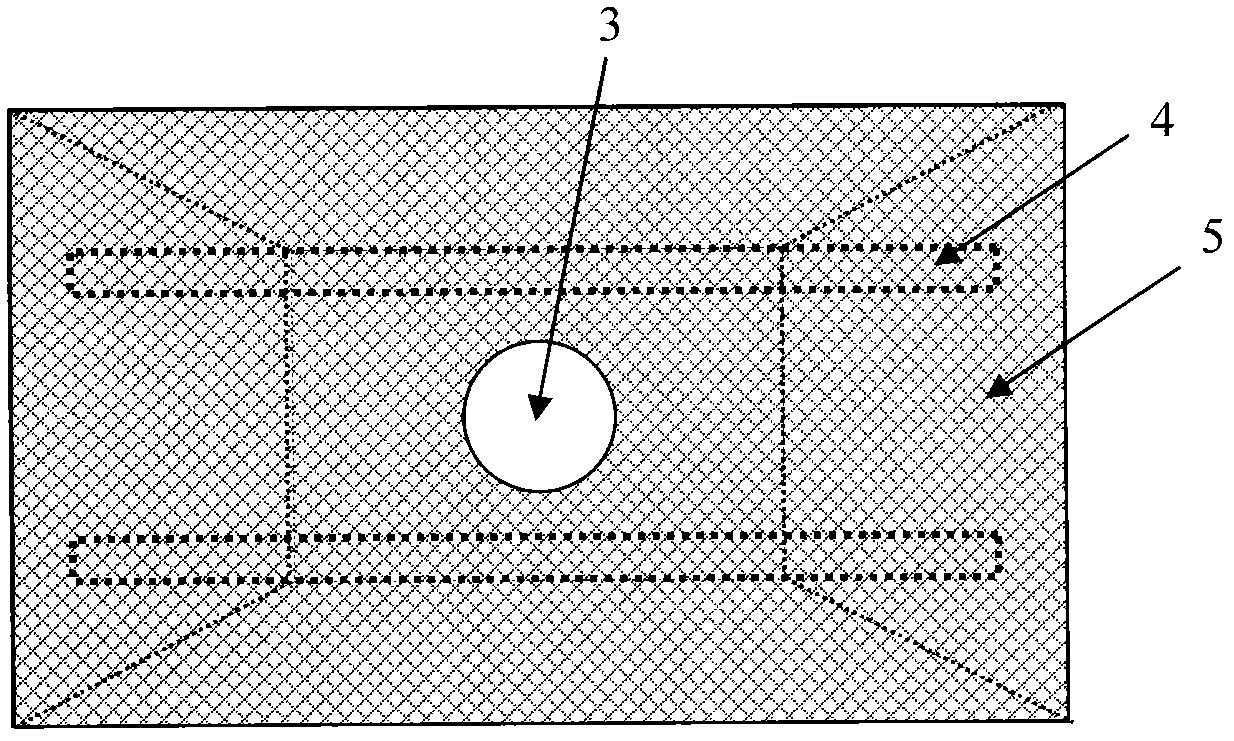

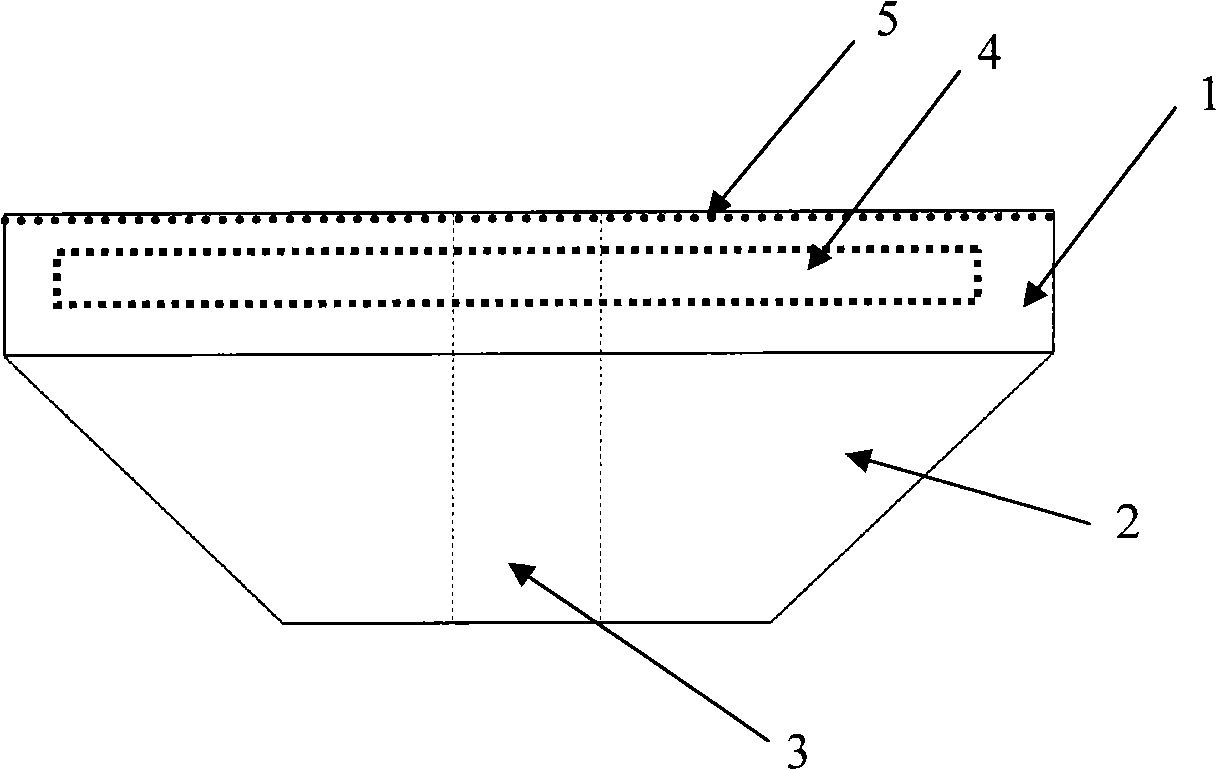

Manufacturing method of compound material supporting plate

InactiveCN102108198ASimple preparation processHigh strengthAnchoring boltsFilling materialsMixed materials

The invention provides a manufacturing method of a compound material supporting plate, relating to a supporting plate for mine shafts and solving the problems of complicated technical process, low product strength, short service life and poor safety in the prior art. The manufacturing method comprises the following process steps: fully mixing 40-55% of short glass fiber, 30-45% of resin, 2-3% of mesotherm compound initiator, 1-3% of combined accelerator, 4-8% of defoamer and 5-15% of filling material in mass percentage with a mixer; loading the mixed materials in a die; spotting, and pressurizing and preserving heat; and opening the die, and ejecting out the compound material supporting plate. The compound material supporting plate is suitable for mine shaft and tunnel supporting, is simple to manufacture and has the advantages of high product strength, safe support and the like.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

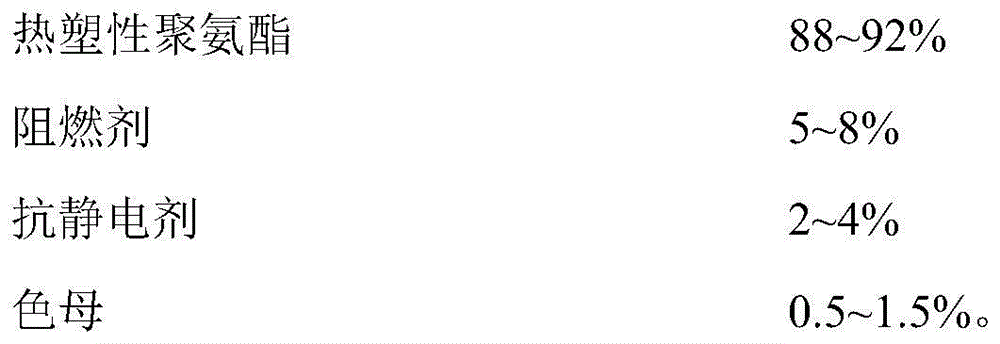

Material of elastic coupling for mining machinery and method for preparing material of elastic coupling for mining machinery

InactiveCN104893280AImprove antistatic performanceImprove flame retardant performanceCoatingsAntistatic agentCoupling

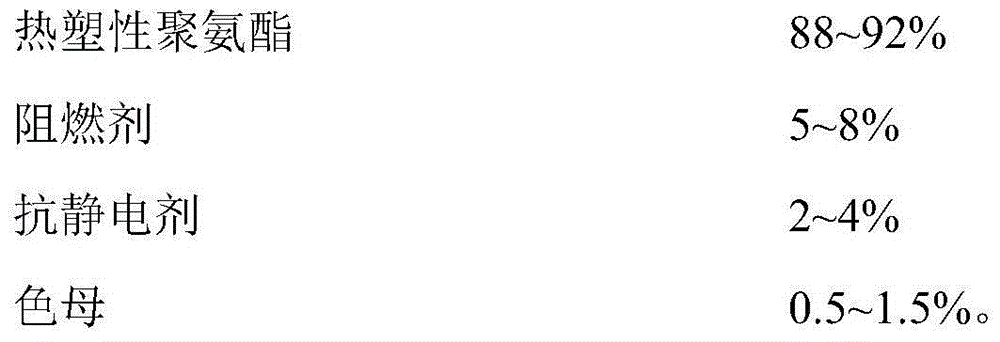

The invention belongs to the technical field of coupling materials and preparation methods thereof and discloses a material of an elastic coupling for mining machinery and a method for preparing the material of the elastic coupling for the mining machinery. The material of the elastic coupling for the mining machinery is composed of, by weight, 88-92% of thermoplastic polyurethane, 5-8% of flame retardant, 2-4% of antistatic agent and 0.5-1.5% of color masterbatch. The method includes the steps of premixing of ingredients, extruding, granulating, drying and injection molding. On the basis that intrinsic mechanical performances of high hardness, high strength, high toughness, high abrasion resistance and the like, the material of the elastic coupling has excellent flame retardant and static resistance performances and is capable of meeting the utilization requirements of the mining machinery. Moreover, since the static resistance performance of the material of the elastic coupling is perpetual, probability of dust explosion in mines is greatly reduced.

Owner:南京金三力橡塑有限公司

Quaternary amino cation modified polysiloxane softening agent and preparation method thereof

ActiveCN101565896BReduce hydrophobicityReduced antistatic propertiesFibre treatmentOrganic acidAminosilochrome

Owner:上海氟聚化学产品股份有限公司

Polyester viscose blended fabric

The invention discloses a polyester viscose blended fabric which is prepared from the following raw materials in parts by weight: 60 to 70 parts of polyester filaments, 10 to 15 parts of polyester staple fibers, 12 to 15 parts of viscose, 8 to 13 parts of selenite fibers, 5 to 9 parts of modified polyacrylonitrile fibers, 2 to 5 parts of bamboo carbon fibers, 3 to 5 parts of acetate fibers, 0.5 to 2 parts of soybean protein fibers, 1 to 3 parts of graphene oxide, 0.3 to 0.5 part of epsilon-polylysine, 2 to 5 parts of nano titanium dioxide, 5 to 8 parts of carboxymethylcellulose, 0.1 to 0.5 part of Arabic gum and 1 to 4 parts of sodium tetraborate. The polyester viscose blended fabric is high in strength, crease-resistant, anti-wear, less prone to pilling, high in moisture absorption performance and good in non-ironing property.

Owner:QINGDAO TOPLINK INFORMATION TECH

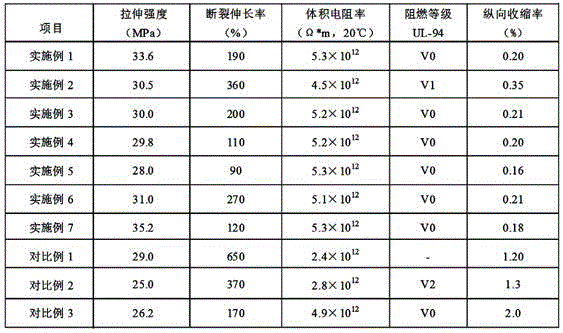

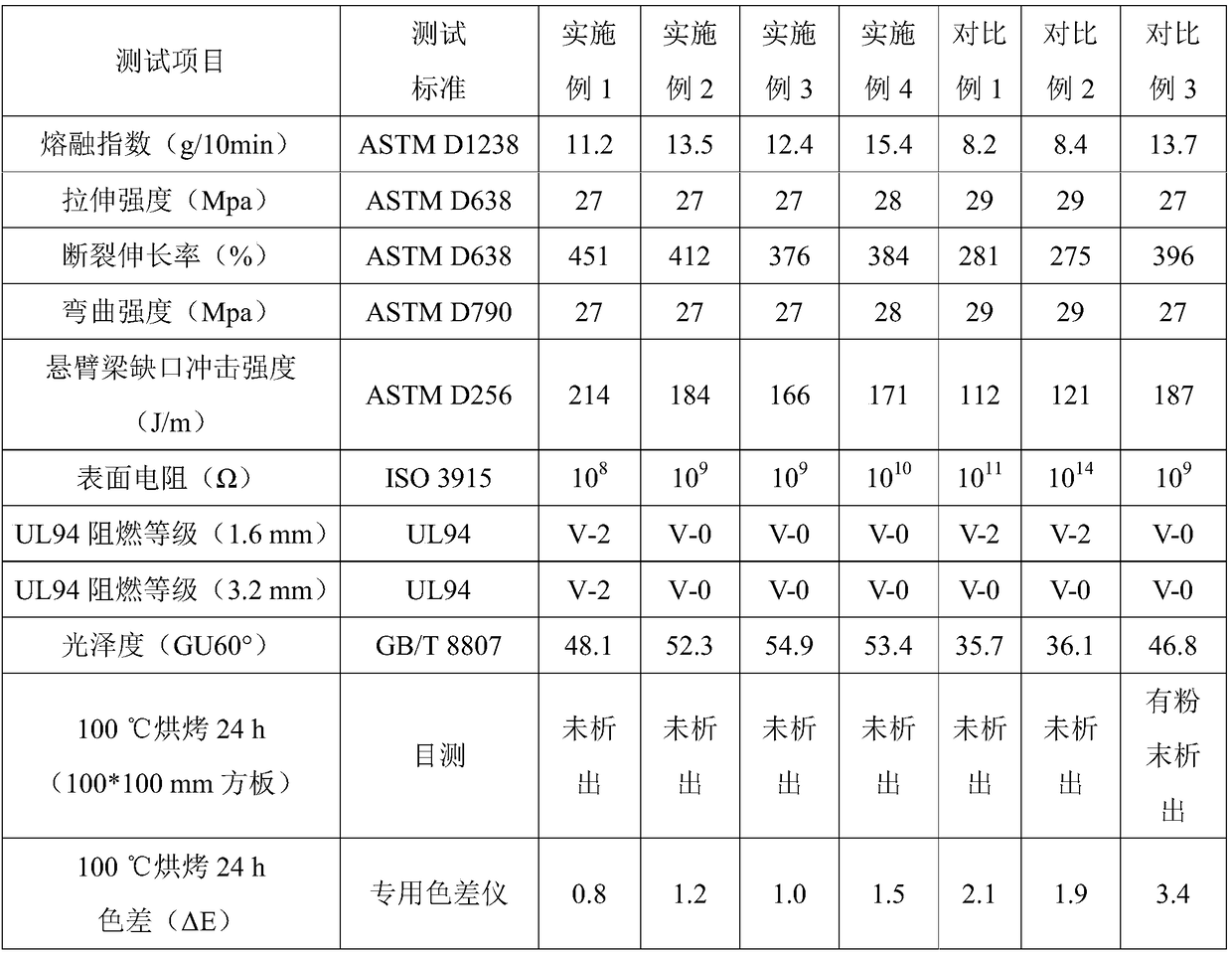

Flame-retardant polypropylene material as well as preparation method and application thereof

The invention discloses a flame-retardant polypropylene material as well as a preparation method and application thereof. The flame-retardant polypropylene material is prepared from the following rawmaterials in terms of 100 parts by mass: 72-85 parts of copolymerization polypropylene resin, 8-15 parts of brominated flame retardant-antioxidant 1010 compound, 3-6 parts of antimonic flame retardant, 1-3 parts of titanium dioxide, 0.5-1.2 parts of lubricant, 1-2 parts of antistatic agent, 0.5-1.2 parts of antioxidant and 0.3-1 part of antibacterial agent. The flame-retardant polypropylene has agood antistatic effect, has a surface resistance of 108-109 omegas, is high in glossiness, does not produce flame retardant precipitate, has a flame retardant rating of UL94V-0, and has the advantagesof being capable of inhibiting bacterial growth for a long time, being good in antibacterial effect and the like. The preparation method is simple and efficient, easily guarantees flame retardance and high-brightness white color of the material, and is high in production efficiency.

Owner:GUANGDONG JUSHI CHEM CO LTD

Antistatic shading PET film and preparation method thereof

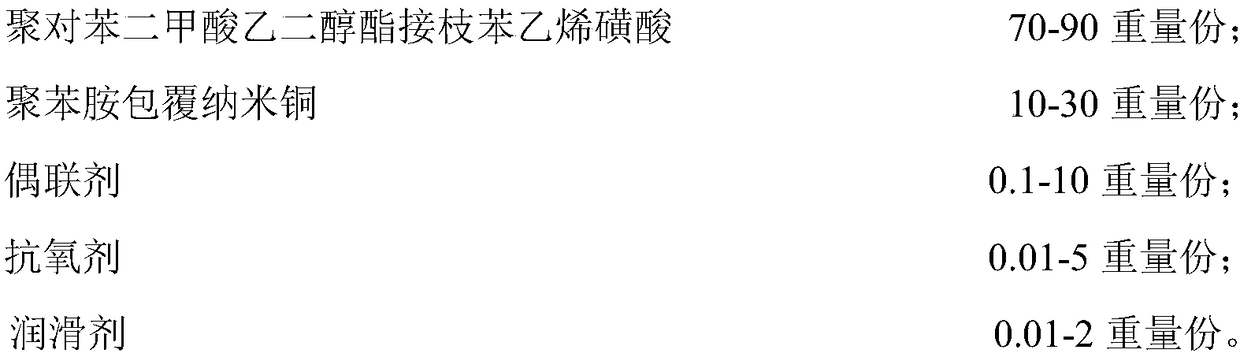

The invention provides an antistatic shading PET film and a preparation method thereof. The film takes PET-grafted styrene sulfonic acid, polyaniline coated nano-copper, a coupling agent, an antioxidant and a lubricating agent as raw materials. Compared with the prior art, the antistatic shading PET film disclosed by the invention has the advantages that the conductivity of the polyaniline is greatly improved by taking a sulfonic acid group of the PET-grafted styrene sulfonic acid as a doping agent, and due to existence of the styrene sulfonic acid group, the rigidity of the PET chain is weakened, the processing and melting temperature of the PET is lowered, and the compatibility of the PET and polyaniline microspheres is further improved. Furthermore, nano copper particles of the polyaniline coated nano-copper have excellent conductivity, and since conductive polyaniline exists on the surface of the polyaniline coated nano-copper, the compatibility of the film and the matrix is greatly improved, and the antistatic property of the film is not reduced.

Owner:天津得丰光电材料技术有限公司

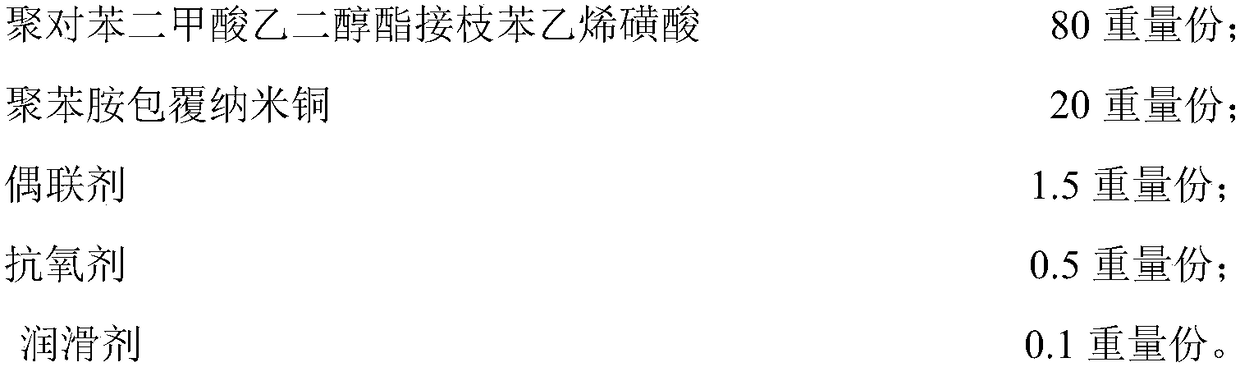

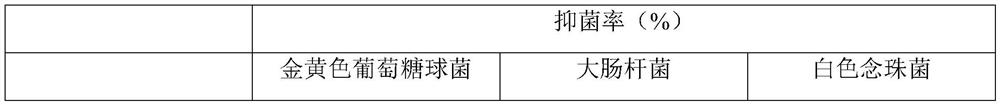

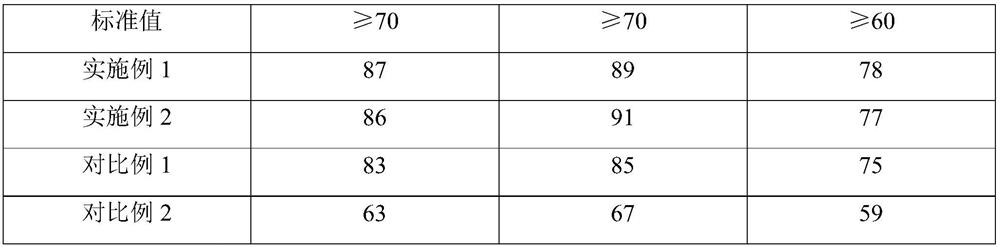

Antistatic bacteriostatic ultra-high molecular weight polyethylene fiber and preparation method thereof

PendingCN112663162AGood antibacterial effectSmall mechanical propertiesElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberPolymer science

The invention belongs to the technical field of ultra-high molecular weight polyethylene fibers, and particularly relates to an antistatic antibacterial ultra-high molecular weight polyethylene fiber. The antistatic antibacterial ultra-high molecular weight polyethylene fiber is composed of the following components of, in parts by weight, 100-200 parts of ultra-high molecular weight polyethylene, 1-3 parts of an antioxidant, 3-5 parts of an antistatic agent, 20-50 parts of an antibacterial agent, 1-10 parts of a macromolecular compatilizer, 0.2-1.4 parts of a coupling agent, 4-8 parts of a surfactant, 0.1-1 part of a synergist and 450-1,000 parts of a solvent. According to the antistatic bacteriostatic ultra-high molecular weight polyethylene fiber and the preparation method thereof, a reasonable formula is selected, and all the components have a synergistic effect, so that the overall performance of the UHMWPE fiber is effectively improved, particularly, the UHMWPE fiber has stronger antistatic and antibacterial properties, excellent mechanical properties of the material can be maintained, the stability is high, the service life of the UHMWPE fiber is prolonged, and the use cost is reduced.

Owner:九江中科鑫星新材料有限公司

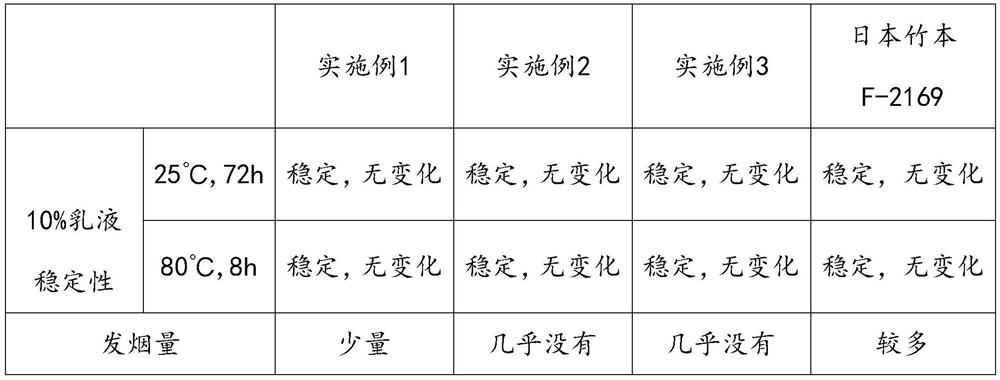

Spinning oil for polyester staple fibers and preparation method of spinning oil

ActiveCN113308765AHigh flash pointImprove smoothnessSynthetic polymer filament chemical after-treatmentPolyesterPolymer science

The invention relates to the technical field of oil for synthetic fiber processing, and provides spinning oil for polyester staple fibers and a preparation method of the spinning oil. The spinning oil comprises the following raw materials in parts by weight of 6-12 parts of dodecylamine polyoxyethylene ether, 4-8 parts of decyl monomethylol dimethyl ammonium chloride, 6-12 parts of iso-tridecanol, 64-76 parts of castor oil polyoxyethylene ether, 1.2-1.6 parts of a coupling agent, 5-10 parts of octyl stearate, 2-4 parts of an anti-splashing agent, 12-20 parts of an emulsifier and 2-4 parts of a penetrant. The problems that in the prior art, spinning oil is poor in heat resistance and splashing resistance are solved.

Owner:福建合利新材料科技有限公司

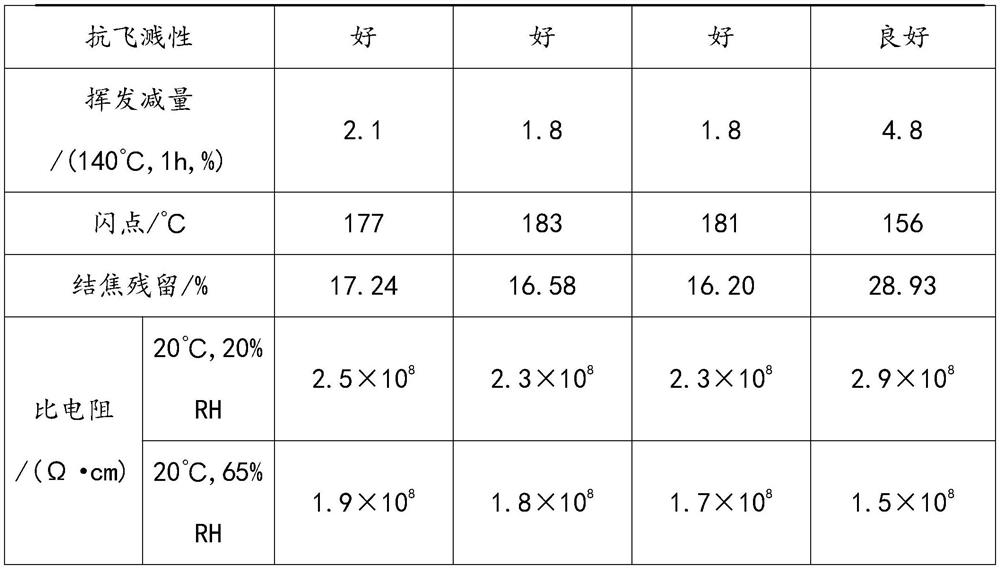

Antistatic optical release film for polaroid and preparation method of antistatic optical release film

PendingCN113308007AStable release forceQuick Peel LowElectrically-conductive paintsPtru catalystDimethyl siloxane

The invention discloses an antistatic optical release film for a polaroid. The antistatic optical release film comprises a release layer, a base material layer and an antistatic layer from top to bottom, and the release layer comprises the following components in parts by weight: 20-40 parts of vinyl polydimethylsiloxane, 3-8 parts of hydrogen-containing polysiloxane, 0.5-1.5 parts of an anchoring agent, 0.05-0.2 part of chemically modified inorganic particles, 3-8 parts of fluorine modified organic silicon resin, 2-4 parts of a platinum catalyst and 130 parts of an organic solvent. The release film has the characteristics of stable release force, low quick release force, antistatic property, high light transmittance, high residual adhesion rate and the like, is mainly used for protecting and transporting pressure-sensitive adhesive layers of polaroid products, does not generate static electricity to adsorb dust in polaroid transportation and downstream production, does not generate bad bubbles in use, and the release film cannot be quickly stripped in the downstream manufacturing process to cause poor stripping and influence the yield.

Owner:浙江日久新材料科技有限公司

Antistatic graphene coating and preparation method thereof

InactiveCN111303679AReduce surface resistanceGood antistatic propertiesPolyurea/polyurethane coatingsElectrically-conductive paintsGraphene coatingCetyl alcohol

The invention belongs to the technical field of graphene coatings, in particular to an antistatic graphene coating and a preparation method thereof, and in particular to the antistatic graphene coating which is prepared from the following components in parts by weight: 7-15 parts of graphene powder; 24-32 parts of terpene resin; 16 to 28 parts of epoxy-terminated modified polyurethane resin; 4-9 parts of sodium polyphosphate; 2-5 parts of zirconium silicate; 3-6 parts of vanadium diboride; 2-5 parts of Arabic gum; 2-6 parts of cyclodextrin; 1-5 parts of cetyl alcohol, 3-6 parts of sodium benzoate, 4-8 parts of nano attapulgite, 1-4 parts of dimethyl dimercaptoacetic acid isooctyl ester tin, 3-7 parts of magnesium sulfate, 4-9 parts of butylated hydroxyanisole, 1-5 parts of an isobutyltriethoxysilane coupling agent, 2-6 parts of gamma-mercaptopropyltrimethoxysilane, 4-7 parts of leveling agent and 60-100 parts of a solvent. The surface resistance of the graphene coating is lower than 8* 10 < 3 > ohm, and the graphene coating is good in antistatic property, high in hardness, strong in adhesive force, high in impact strength, scratch-resistant, long in service life and good in comprehensive performance; meanwhile, the preparation process is simple, low in manufacturing cost and suitable for general application and popularization.

Owner:上海碳源汇谷新材料科技有限公司

Moisturizing type hand sanitizer and preparation method thereof

InactiveCN109431947AFine foamLess irritatingCosmetic preparationsToilet preparationsBetaineHand sanitizer

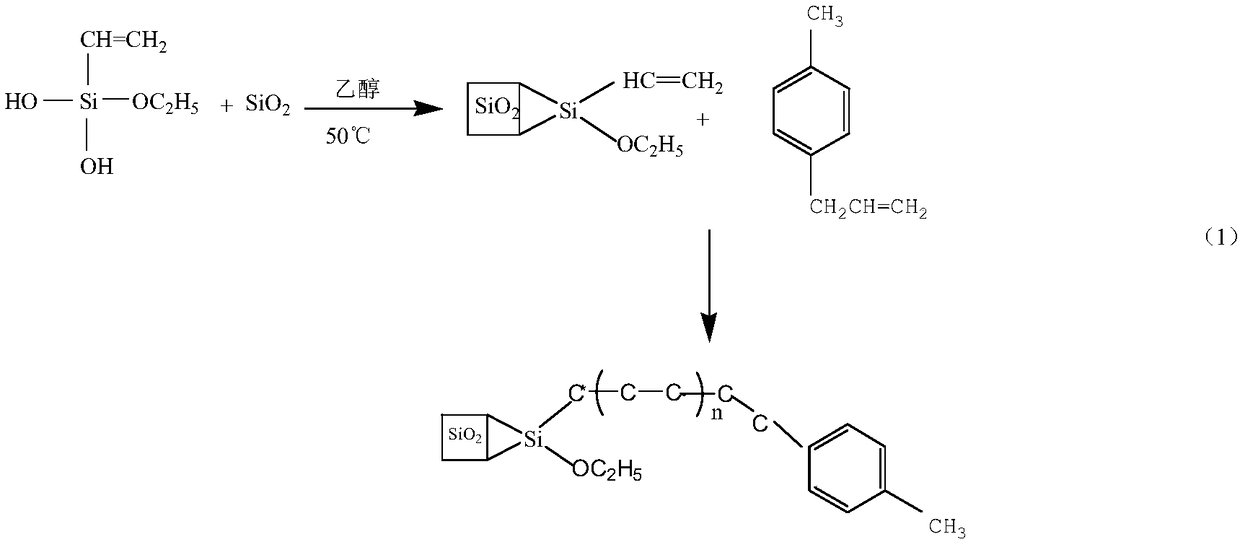

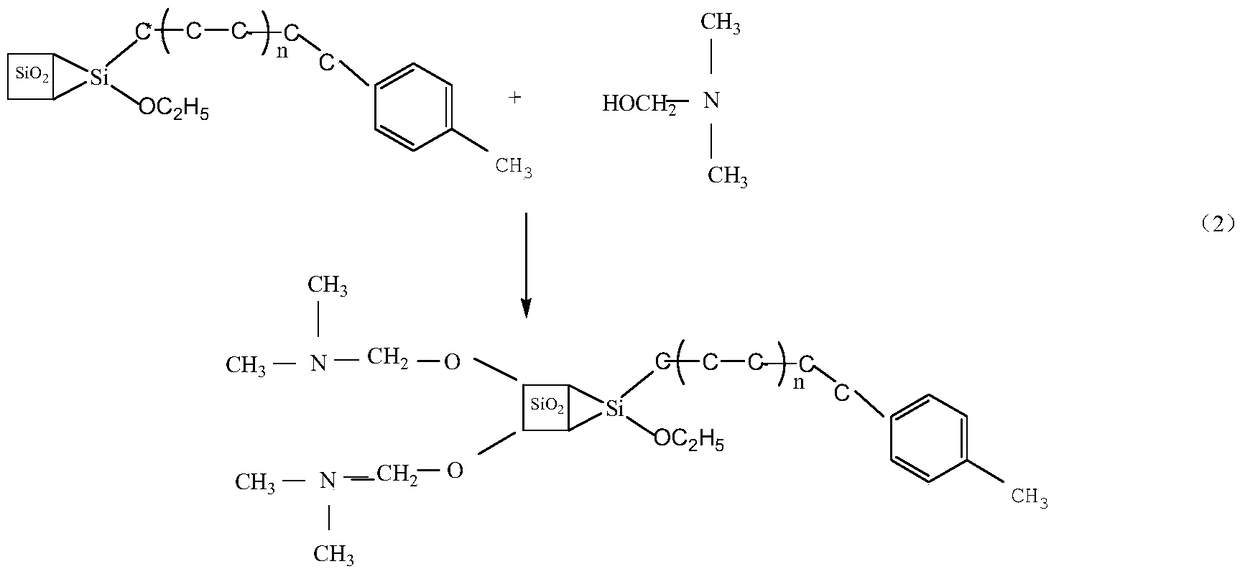

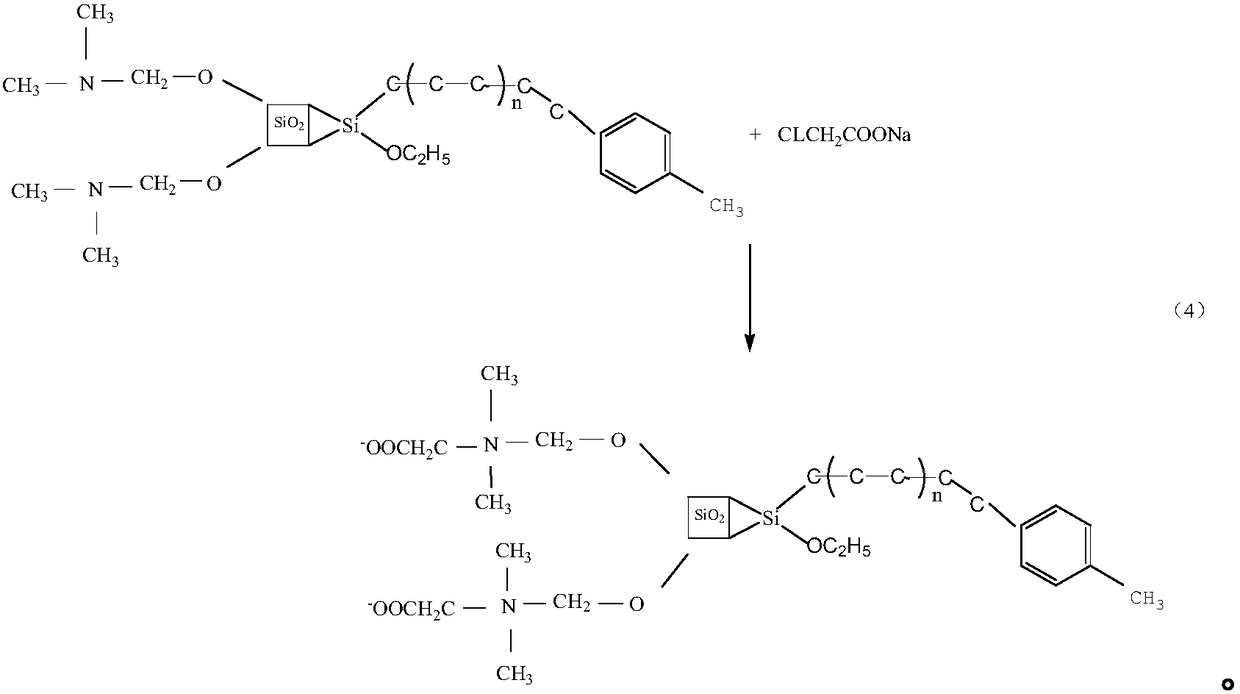

The invention provides a moisturizing type hand sanitizer and a preparation method thereof. The moisturizing type hand sanitizer is prepared from the following components in percentage by weight: 20 to 35 percent of silica supported 1-allyl-4-methyl benzene and vinyl triethoxysilane copolymer and betaine, 5 to 15 percent of emulsified olive oil, 5 to 15 percent of hyaluronic acid, 0.5 to 1.5 percent of a natural plant extract, 0.1 to 0.5 percent of a wetting agent, 0.1 to 1.0 percent of sodium chloride, 0.1 to 0.5 percent of a traditional Chinese medicine extract and the balance of small-molecular group deionized water. The moisturizing type hand sanitizer provided by the invention is slightly acidic, degreasing cannot be caused while sterilizing and decontaminating are carried out, moisturizing and nourishing functions are also obtained, and the moisturizing type hand sanitizer is strong in decontaminating capacity, is easy to flush, is non-toxic and harmless and is safe and environmental-friendly.

Owner:广州精点高分子材料制品有限公司

Antistatic rubber compound and antistatic tire

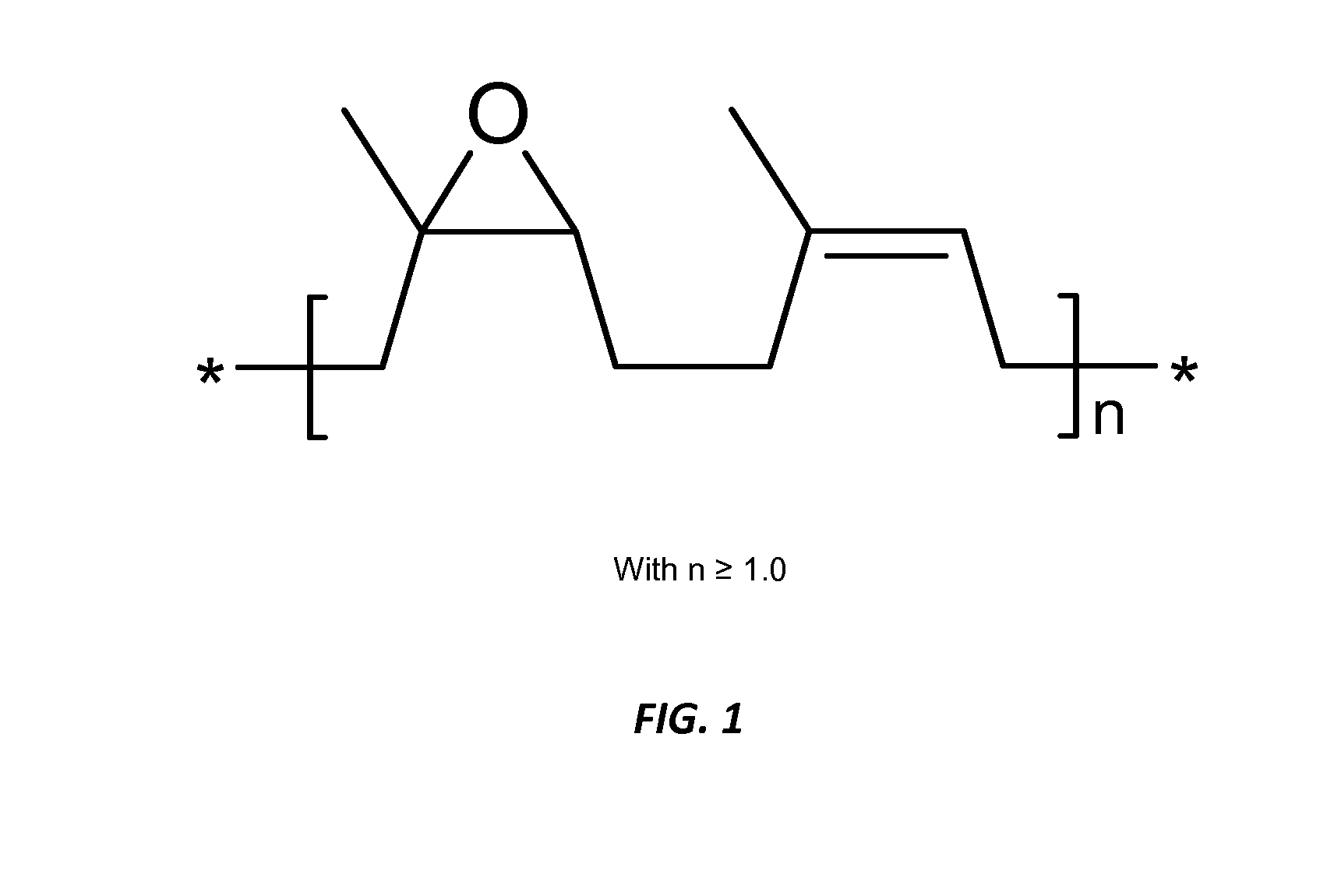

InactiveUS20150087744A1Reduce rolling resistanceReduced antistatic propertiesSpecial tyresRolling resistance optimizationRolling resistanceVulcanization

A rubber compound for the manufacture of antistatic tires used in vehicles comprising a rubber component derived from epoxidized natural rubber, a white filler component for reducing rolling resistance of said tire, an electrically conductive filler component, and a vulcanization agent. An antistatic tire for vehicles comprising a body and a tread wherein said tread is produced from said rubber compound above.

Owner:LEMBAGA GETAH MALAYSIA

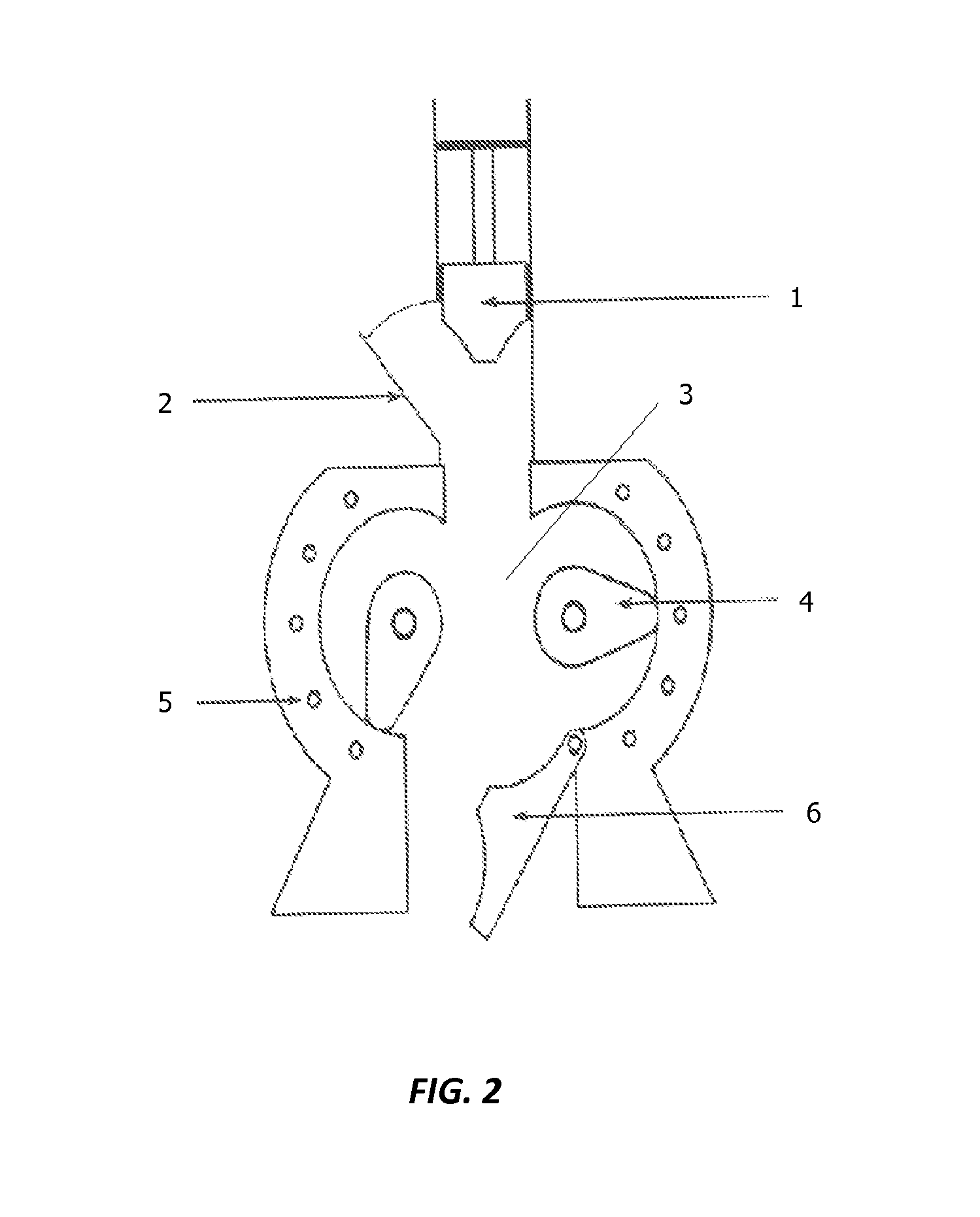

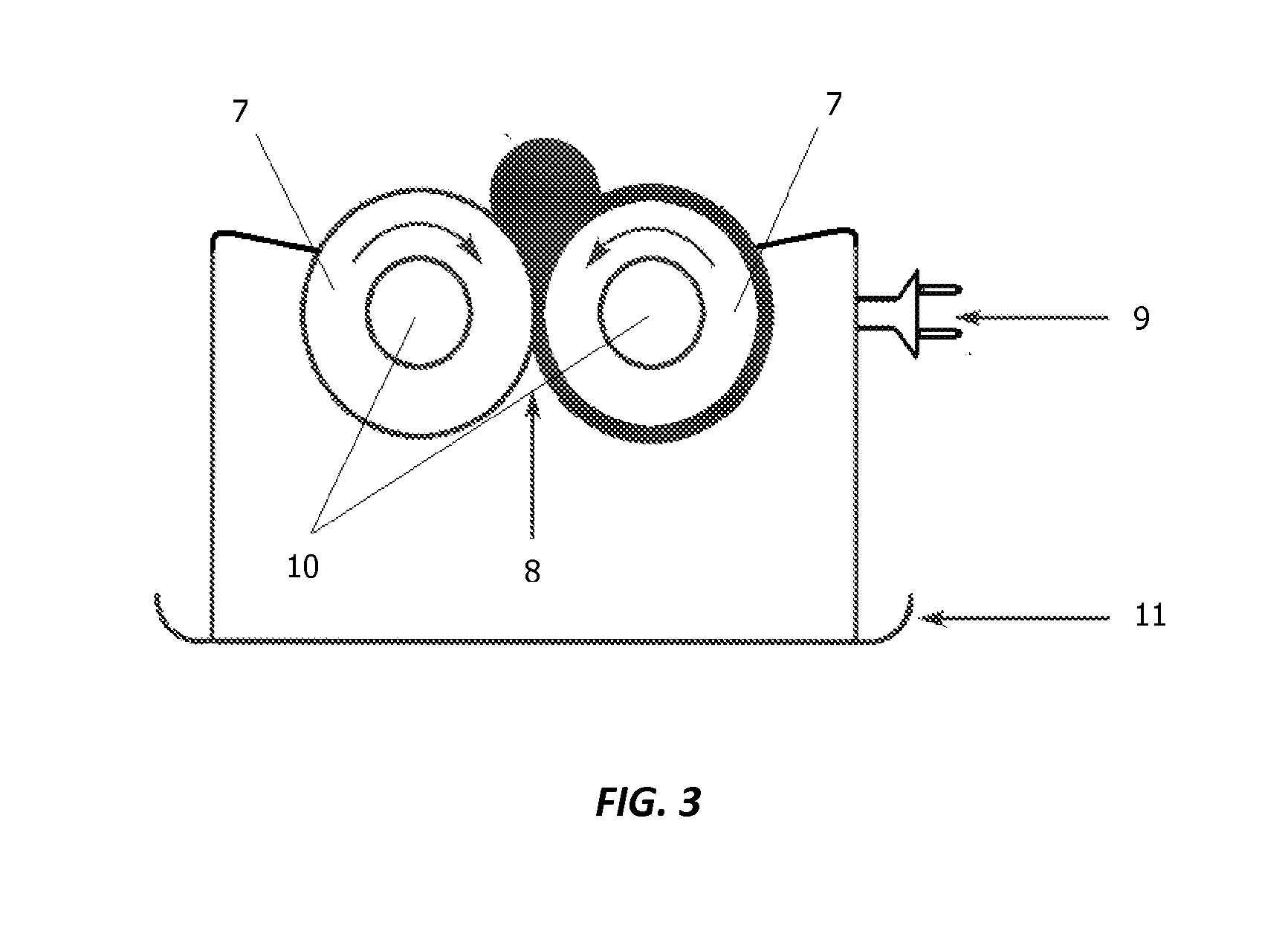

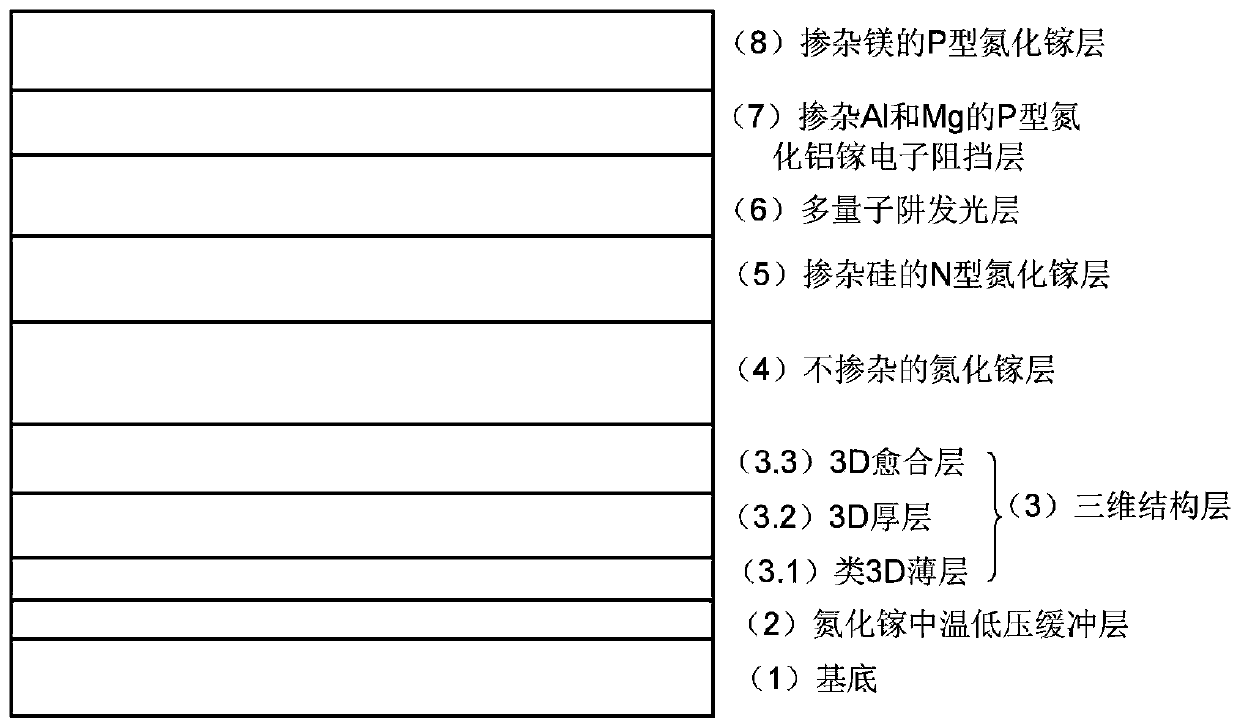

Method for growing LED epitaxial structure

InactiveCN110098290AImprove Bottom WarpingRelease bottom stressSemiconductor devicesLattice mismatchGallium nitride

The invention provides a method for growing an LED epitaxial structure, which includes the process of growing a GaN medium-temperature low-pressure buffer layer and a three-dimensional structure layer. The method specifically includes the following steps: S2, growing a GaN medium-temperature low-pressure buffer layer; and S3, growing a three-dimensional structure layer. The three-dimensional structure layer includes a 3D-like thin layer, a 3D thick layer and a 3D healing layer grown in turn from bottom to top. The step S3 of growing a three-dimensional structure layer includes the following sub-steps: S3.1, growing a 3D-like thin layer; S3.2, growing a 3D thick layer, which is a silicon-doped GaN layer; and S3.3, growing a 3D healing layer. The lattice mismatch can be improved, the dislocation defect can be reduced, and the light output power, anti-aging ability and anti-static ability of LED devices can be improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Super-hydrophobic flame-retardant anti-cutting stab-resistant fabric and production method thereof

InactiveCN112757728AGood antibacterial effectGuaranteed breathabilitySynthetic resin layered productsFilament manufacturePolyesterGlass fiber

The invention belongs to the field of production of textiles for safety protection, and relates to a super-hydrophobic flame-retardant cut-resistant stab-resistant fabric and a production method thereof. The super-hydrophobic flame-retardant cut-resistant stab-resistant fabric comprises an antibacterial warm-keeping fabric layer and a hydrophobic flame-retardant fabric layer arranged on the outer side of the antibacterial warm-keeping fabric layer; the antibacterial warm-keeping fabric layer is formed by mixing and weaving ultra-high molecular weight polyethylene curled short fibers, cotton fibers and antibacterial polyester fibers according to the mass fraction ratio of 6: 3: 1, and the hydrophobic flame-retardant fabric layer is formed by mixing and weaving ultra-high molecular weight polyethylene curled short fibers, cotton fibers and glass fibers according to the mass fraction ratio of 5: 3: 1. the ultra-high molecular weight polyethylene curled short fibers and the glass fibers are soaked in a hydrophobic solution and dried before being woven, and the problem that the use range of an existing cut-resistant and stab-resistant fabric is affected due to poor water resistance and air permeability is solved.

Owner:石磊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com