Flame-retardant polypropylene material as well as preparation method and application thereof

The technology of flame-retardant polypropylene and copolymerized polypropylene is applied in the field of flame-retardant polypropylene material and its preparation, which can solve the problems of easy adhesion of dust to finished products, large input of raw materials, obvious electrostatic effect, etc., and achieves a simple and efficient preparation method. High-gloss, high-gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

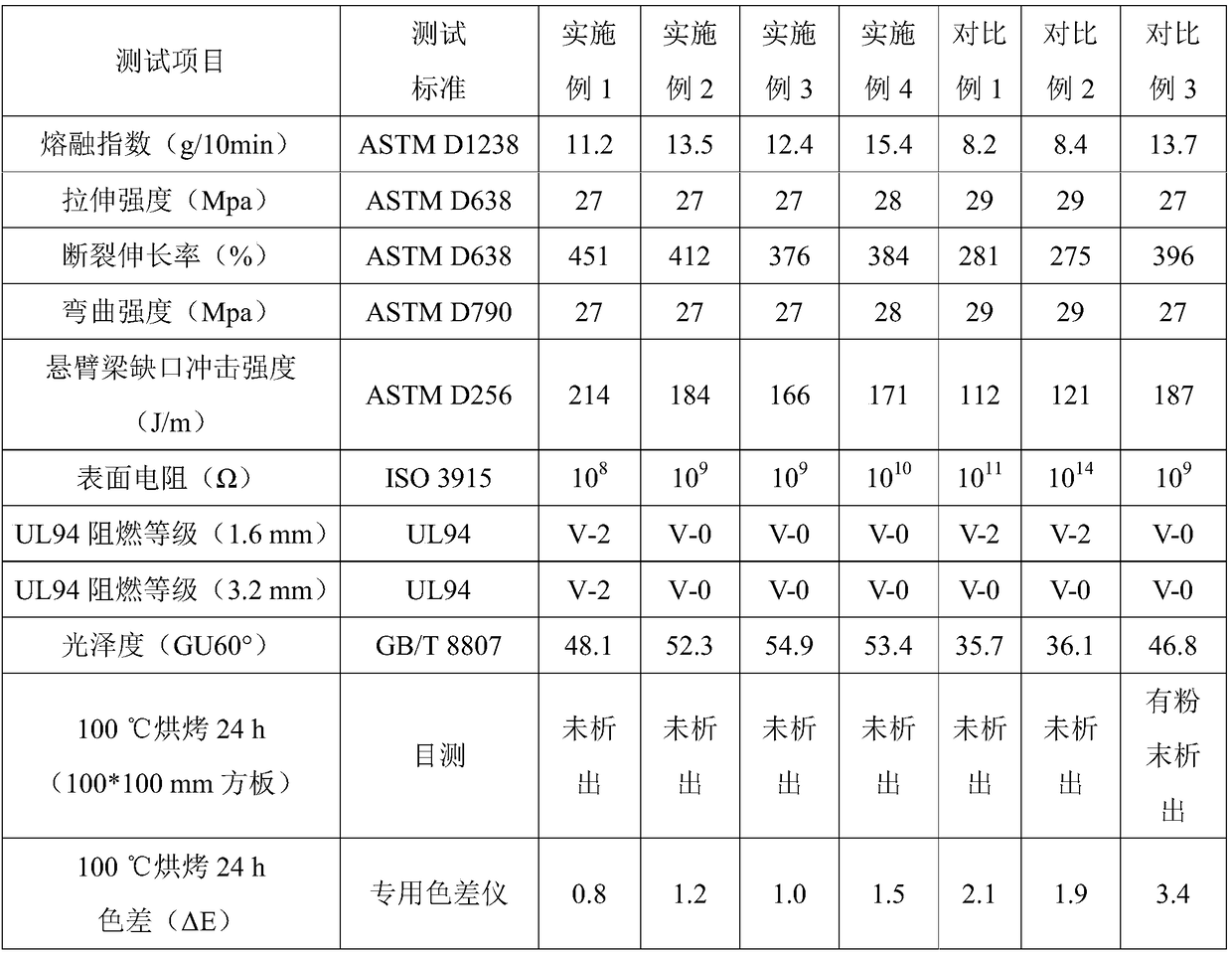

Examples

Embodiment 1

[0056] A flame-retardant polypropylene material, raw materials and mass parts thereof are as follows:

[0057] 84.4 parts of copolymerized polypropylene resin, 8 parts of octabromobisphenol S ether-antioxidant 1010 compound (the mass ratio of octabromobisphenol S ether to antioxidant 1010 is 98:2), 3 parts of antimony trioxide, 1 part of titanium dioxide, 0.8 part of lubricant (a mixture of calcium stearate and polyethylene wax compounded at a mass ratio of 3:1), 1.5 parts of sorbitan monofatty acid ester, 0.8 part of antioxidant (antioxidant Agent 626 and antioxidant 1010 are compounded at a mass ratio of 2:4), 0.5 parts of inorganic silver-zinc composite antibacterial agent.

[0058] A preparation method of a flame-retardant polypropylene material, comprising the steps of:

[0059] 1) Stir the brominated flame retardant, antimony trioxide, titanium dioxide, lubricant, antioxidant, and inorganic antibacterial agent at 50°C for 2 minutes at high speed according to the above m...

Embodiment 2

[0064] A flame-retardant polypropylene material, raw materials and mass parts thereof are as follows:

[0065] 79.4 parts of copolymerized polypropylene resin, 12 parts of octabromobisphenol S ether-antioxidant 1010 compound (the mass ratio of octabromobisphenol S ether to antioxidant 1010 is 98:2), 4 parts of antimony trioxide, 1 part of titanium dioxide, 0.8 part of lubricant (a mixture of calcium stearate and polyethylene wax compounded at a mass ratio of 3:1), 1.5 parts of sorbitan monofatty acid ester, 0.8 part of antioxidant (antioxidant Agent 626 and antioxidant 1010 are compounded at a mass ratio of 2:4), 0.5 parts of inorganic silver-zinc composite antibacterial agent.

[0066] The preparation method is the same as in Example 1, except that the mass parts of each raw material are added according to Example 2.

Embodiment 3

[0068] A flame-retardant polypropylene material, raw materials and mass parts thereof are as follows:

[0069] 77.4 parts of copolymerized polypropylene resin, 12 parts of octabromobisphenol S ether-antioxidant 1010 compound (the mass ratio of octabromobisphenol S ether to antioxidant 1010 is 98:2), 4 parts of antimony trioxide, 3 parts of titanium dioxide, 0.8 parts of lubricant (a mixture of calcium stearate and polyethylene wax compounded at a mass ratio of 3:1), 1.5 parts of sorbitan monofatty acid ester, 0.8 parts of antioxidant (antioxidant Agent 626 and antioxidant 1010 are compounded at a mass ratio of 2:4), 0.5 parts of inorganic silver-zinc composite antibacterial agent.

[0070] The preparation method is the same as in Example 1, except that the mass parts of each raw material are added according to Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com