Patents

Literature

530results about How to "Guaranteed flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-proof combustion-resistant ABS resin and its preparation method

The invention discloses a heat resistant flame-proof ABS type resin and its preparing process, wherein the constituents include (by mass portions) ABS type resin 100 parts, flame retardant 2-30 parts, heat-proof modifier 5-20 parts, flexibilizer 1-10 parts, optical-thermal stabilizing agent 0.2-2 parts, and fabrication auxiliary agent 1-5 parts. The resin can substitute engineering plastics to be applied to situations for high requirement of flame-proof and heat resistance properties.

Owner:SHANGHAI KINGFA SCI & TECH +1

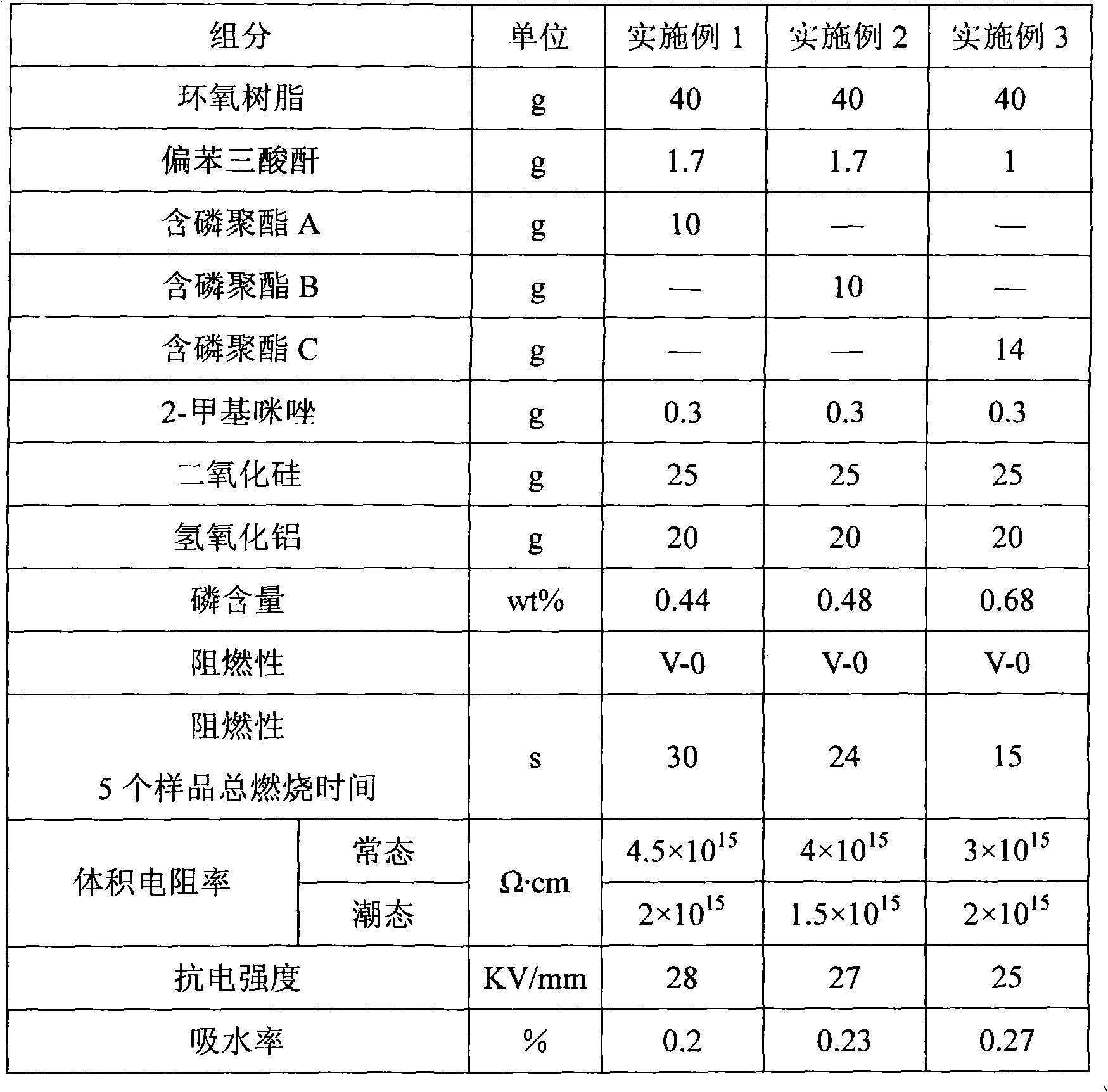

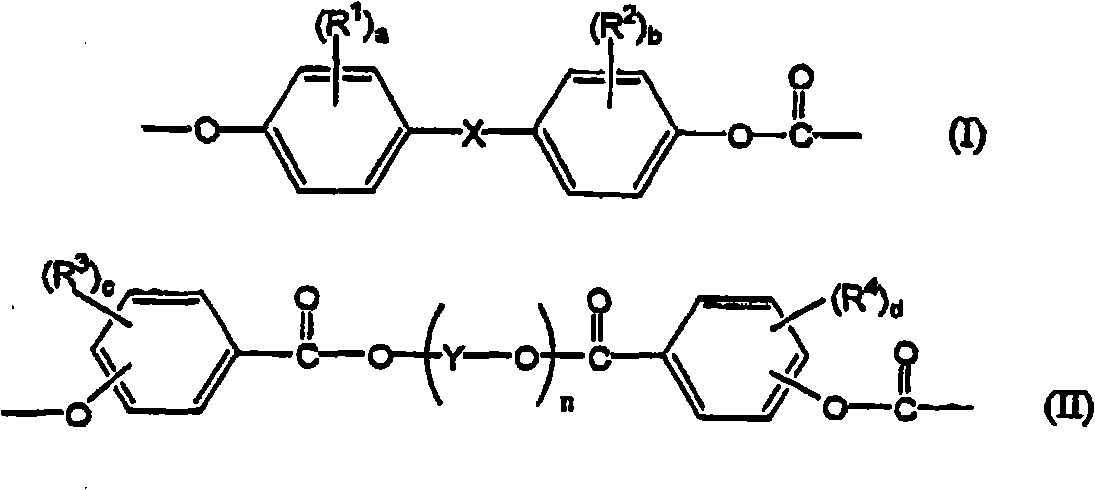

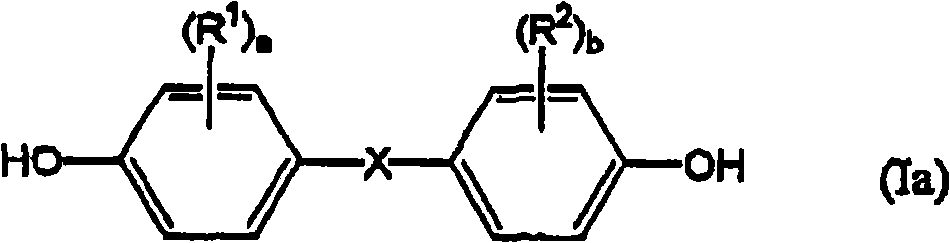

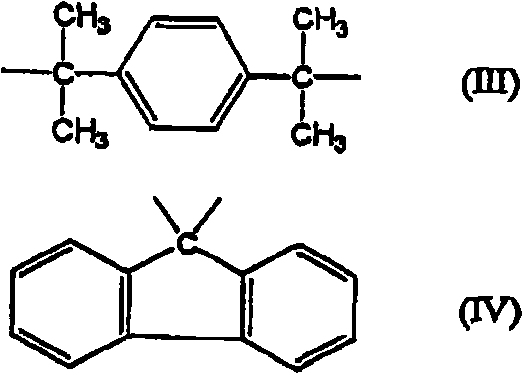

Phosphorus-containing polyester fire retardant epoxy resin composition

InactiveCN101307171AThe synthesis process is simpleStable productionOther chemical processesPolyesterEpoxy

The invention relates to a phosphoric polyester fire-retardant epoxy resin composition. The compositions by mass portion of the phosphoric polyester fire-retardant epoxy resin composition are: 20 to 40 portions of epoxy resin, 5 to 20 portions of phosphoric polyester, 0 to 10 portions of other curing agent, 0.1 to 0.3 portion of curing accelerator and 30 to 70 portions of inorganic filler. The phosphoric polyester fire-retardant epoxy resin composition does not contain harmful substances such as halogen, antimony trioxide and so on; the fire resistance can reach the fire-retardant standard of UL94 V-0; and the phosphoric polyester fire-retardant epoxy resin composition has good fire resistance and electric property.

Owner:天津凯华绝缘材料股份有限公司

Flame retardant polycarbonate resin composition and light reflection member

InactiveCN101585961AAchieve high concentration mixingGuaranteed flame retardant performanceMirrorsMass ratioPolycarbonate

Provided is a flame retardant polycarbonate resin composition, a light reflecting plate formed from the same and peripheral members thereof. The flame retardant polycarbonate resin composition is characterized by comprising (a) aromatic polycarbonate resin, (b) white pigment and (c) talcum treated by the alkali neutralizing treatment and the surface treating of a silane coupling agent, the sum of the (a), (b) and (c) is 100 mass parts, wherein the mass ratio of the (a) to (b) to (C) is (91 to 40) to (4 to 40) to (4 to 20). The formed product has no combustion inhibitor containing halogen or phosphor, with high light reflectivity and fire-retardancy, as well as favorable appearance and light index of reflection, shading performance, thermal conductivity (exothermicity ), mechanical characteristic(rigidity) and dimension stability.

Owner:IDEMITSU KOSAN CO LTD

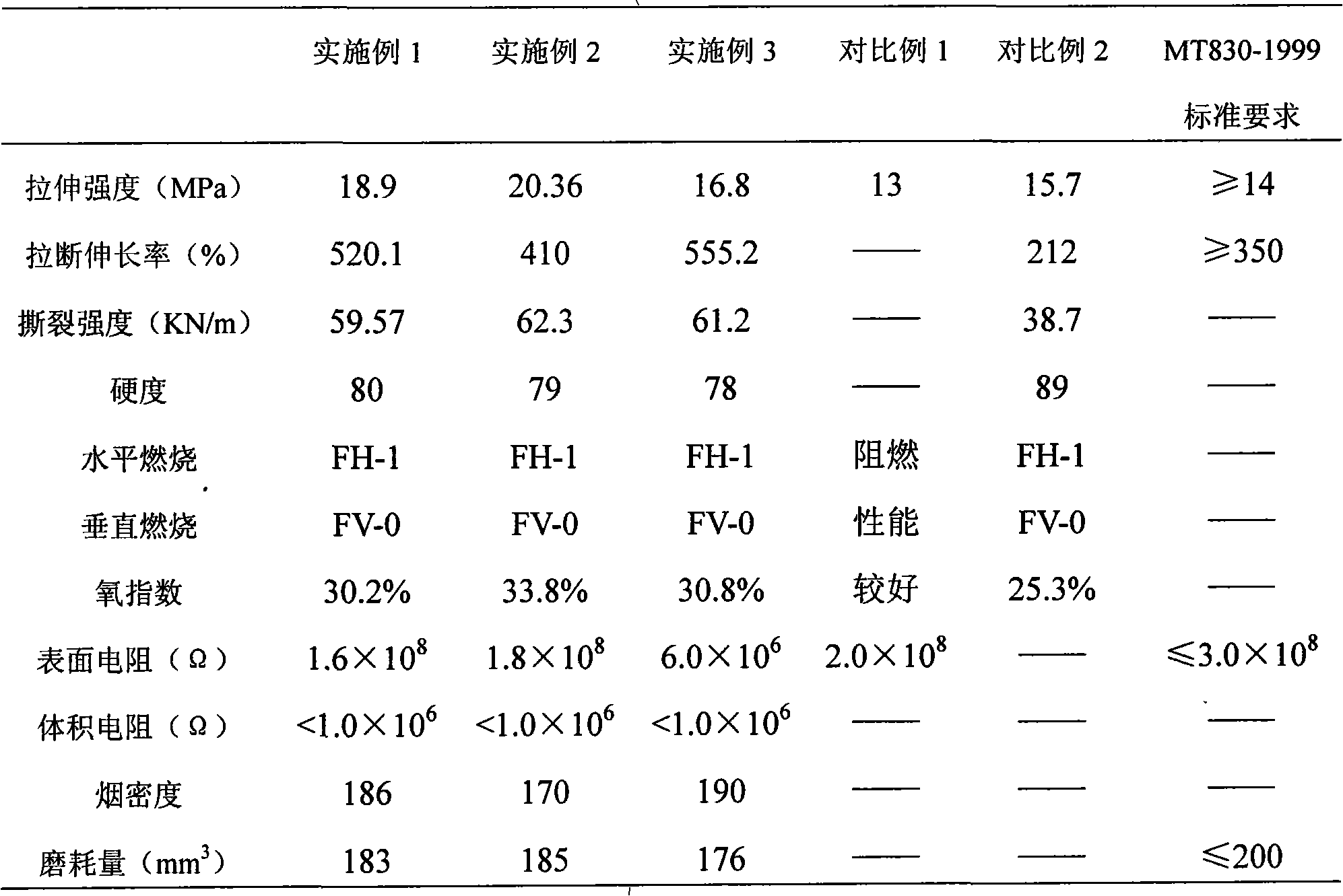

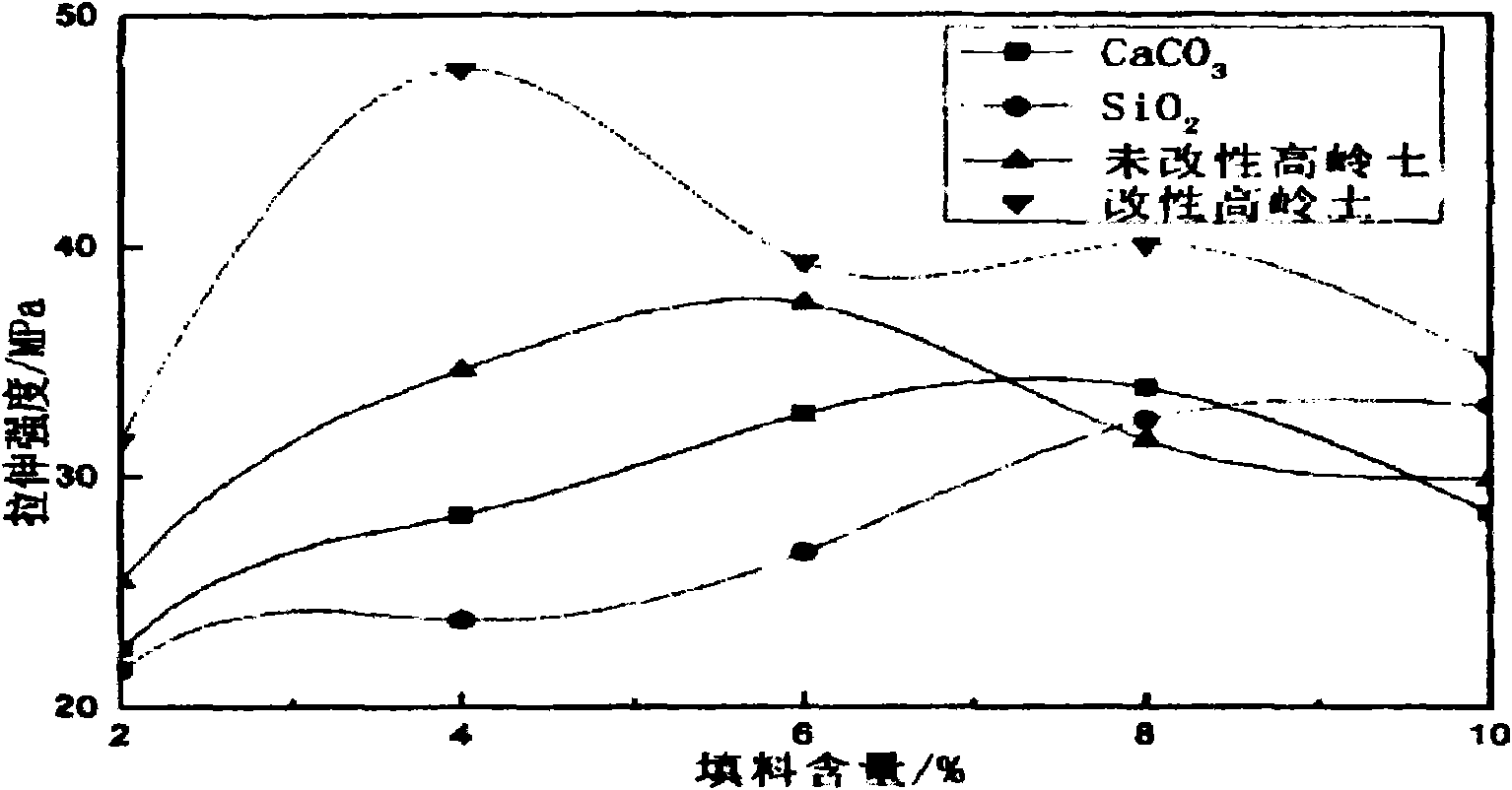

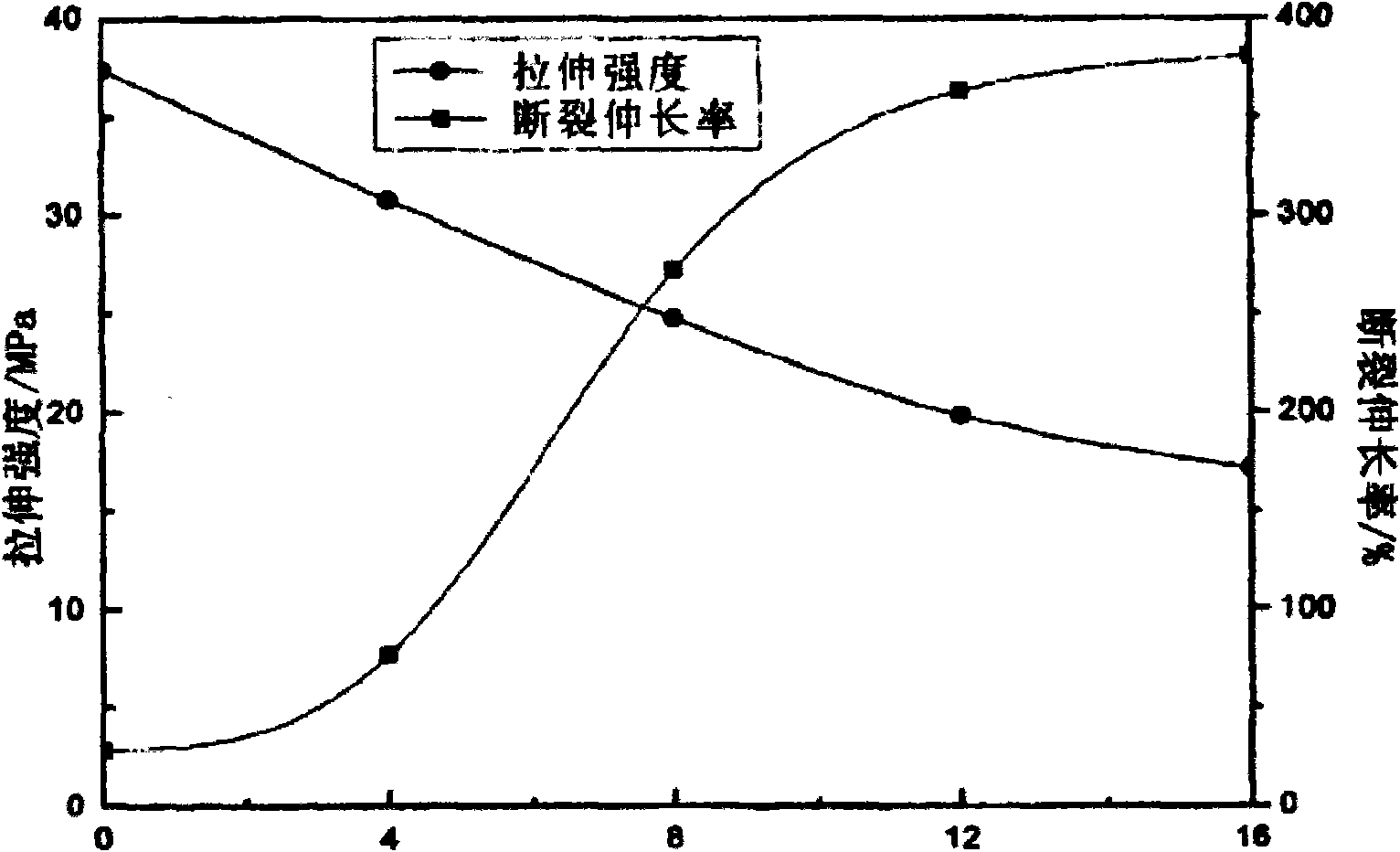

Low-smoke and halogen-free fire-retardant rubber material for covering layer of conveyor belt and preparation method thereof

InactiveCN101585934AGuaranteed flame retardant performanceGuaranteed smoke suppression effectConveyorsFlat articlesSurface modificationCoal

The invention relates to a low-smoke and halogen-free fire-retardant rubber material for a covering layer of a conveyor belt and a preparation method thereof. The preparation method comprises the following steps: filling a rubber system by adopting nano hydroxid, carrying out surface modification on nano hydroxid, matching proper fire-retardant synergist and antistatic plasticizer, and obtaining the low-smoke and halogen-free fire-retardant rubber material. The fire retardant property, the mechanical property and the antistatic property of the low-smoke and halogen-free fire-retardant rubber material all meet the requirement of a low-smoke and halogen-free fire-retardant conveyor belt covering rubber material used for underground coal mines.

Owner:BEIJING UNIV OF CHEM TECH

Preparation process, product and application of new plastic

ActiveCN101982495AImprove thermal stabilityImprove toughnessInsulated cablesInsulated conductorsTemperature controlHigh resistance

The invention provides a process for preparing a new plastic, which comprises the following steps: (1) preparing raw materials; (2) weighing and proportioning the raw materials; (3) mixing PVC powder, stabilizers, packing, plasticizers and other additives, then carrying out high-speed kneading on the obtained mixture, and preplasticizing the mixture so as to obtain a pre-plasticized mixture; (4) mixing the pre-plasticized mixture with TPU particles, carrying out banbury mixing on the obtained mixture under the condition of gradient temperature control so as to obtain colloidal products; (5) carrying out double-screw granulation on the obtained colloidal products; and (6) carrying out sorting, dehydration and packing on the granular products obtained in step 5 so as to obtain the new plastic. The process is simple, the conditions of the process are easy to control, and the process is suitable for large-scale production. The invention also provides a new plastic, which has the characteristics of high resistance to wear and scrape, high elasticity, easy recovery, high flame retardance, ultraviolet resistance, freezing damage (caused by low temperature in the north) resistance, environmental protection, soft handfeel and stick resistance, and the like; and the new plastic can be applicable to wire and cable compound.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

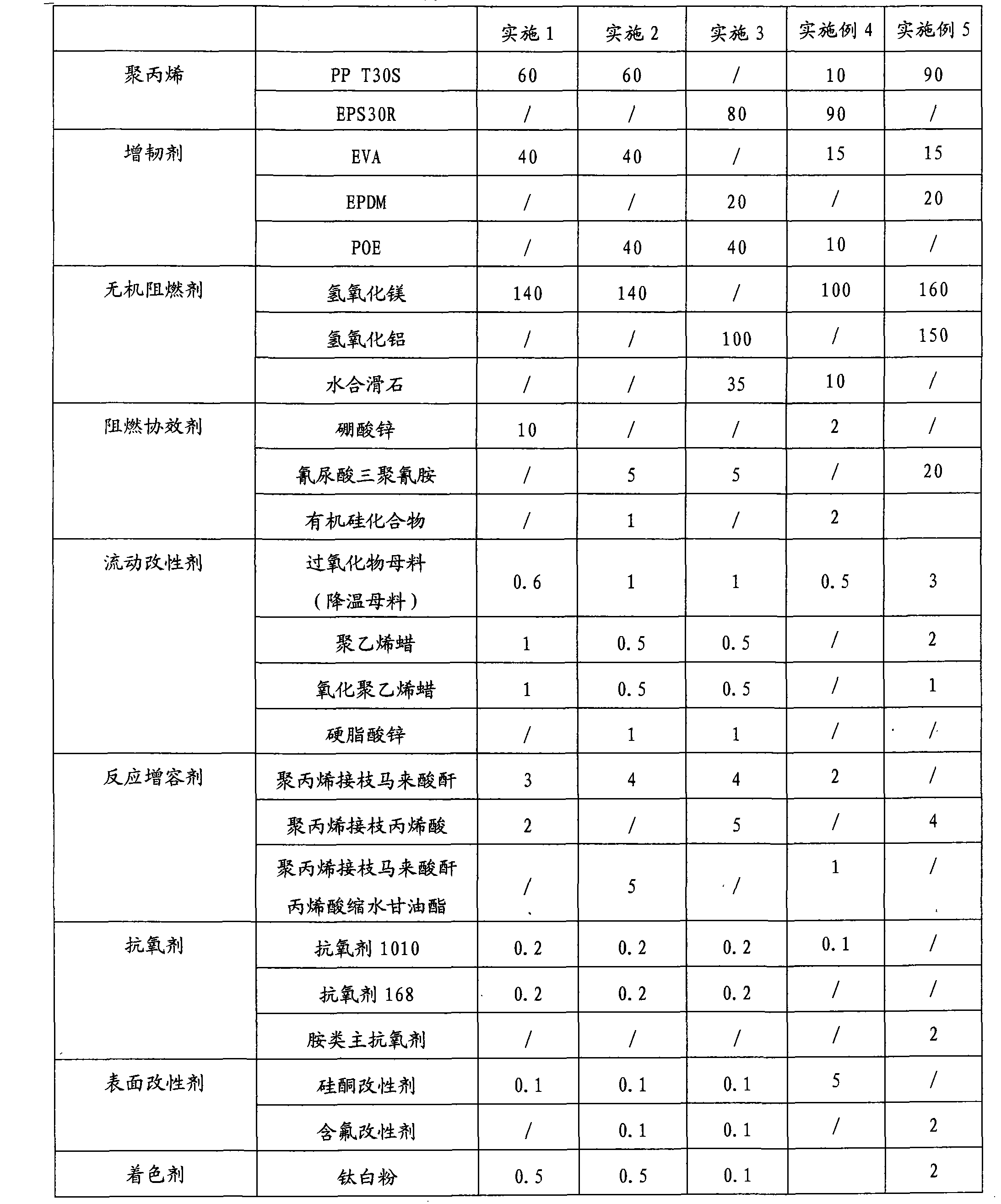

High tenacity low smoke zero halogen flame retardant polypropylene and preparation method thereof

The invention discloses a high tenacity low smoke zero halogen flame retardant polypropylene and a preparation method thereof and the polypropylene comprises the following components according to the parts by weight; 10-90 parts of polypropylene, 10-90 parts of flexibilizer, 100-160 parts of inorganic flame retardant, 2-20 parts of flame-retardant synergist, 2-5 parts of reactive compatibilizer, 0.1-2 parts of antioxidant, 0.5-5 parts of flow modifier, 0.1-5 parts of surface modifier and a defined amount of coloring agent. The low smoke zero halogen flame retardant polypropylene has the advantage of good mechanical properties, good flame resistance (the vertical flame test of the polypropylene passes UL94V-0 level), low smoke density which is not more than 20%, good aging resistance and low cost, and can meet the processing demands for injection and extrusion molding.

Owner:内蒙古睿达鑫科技有限责任公司

Fire retardant composite material of nano-aluminium hydroxide, clay and ethylene-vinyl acetate copolymer

A composite flame-retarding material is proportionally prepared from the surface-modified aluminium hydroxide nanoparticles, organic montmorillonite nanoparticles, zinc borate, ethene-vinyl acetate copolymer, and maleic anhydride grafted ethene-vinyl acetate copolymer. Its advantages are high flame-retarding effect, mechanical performance, flowability and machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

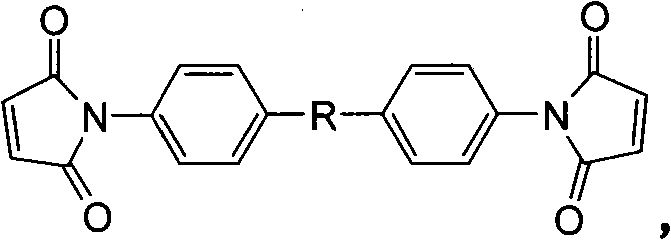

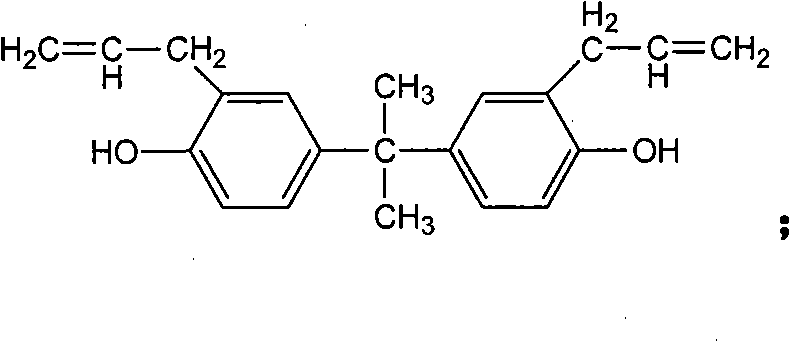

Preparation method of copper clad plate

ActiveCN101652026AGuaranteed performanceGuaranteed flame retardant performanceLaminationLamination apparatusEpoxyCopper foil

The invention discloses a preparation method of copper clad plate and the method comprises the following steps: (1) adopting bismaleimide resin and allyl compound in a weight ratio of 100:40-100 to react at 110-160 DEG C for 10-120min and obtain prepolymer, cooling to room temperature after finishing the reaction, using acetone to prepare prepolymer solution; (2) adding 15-150 parts of epoxy resinwith phosphorous, 10-100 parts of compound curing agent and 0-5 parts of curing accelerator in the solution obtained in the step 1, stirring evenly to obtain a glue solution, selecting a flat E-glassfibic cloth, coating the glue solution evenly on the glassfibic cloth, then roasting to prepare B-stage prepreg; (3) cutting the B-stage prepreg to proper size according to the size of a pressing machine, overlying five prepregs while placing two high impact copper foils with the same size separately on the top and bottom of the prepregs, placing the prepregs with copper foils in a vacuum hot pressing machine to press and obtaining the copper clad plate. The obtained copper clad plate can meet the demand for halogen-free and flame resistance, the heat resistance and humidity resistance are excellent, and the low dielectric loss and pressing toughness are good.

Owner:SHENGYI TECH SUZHOU

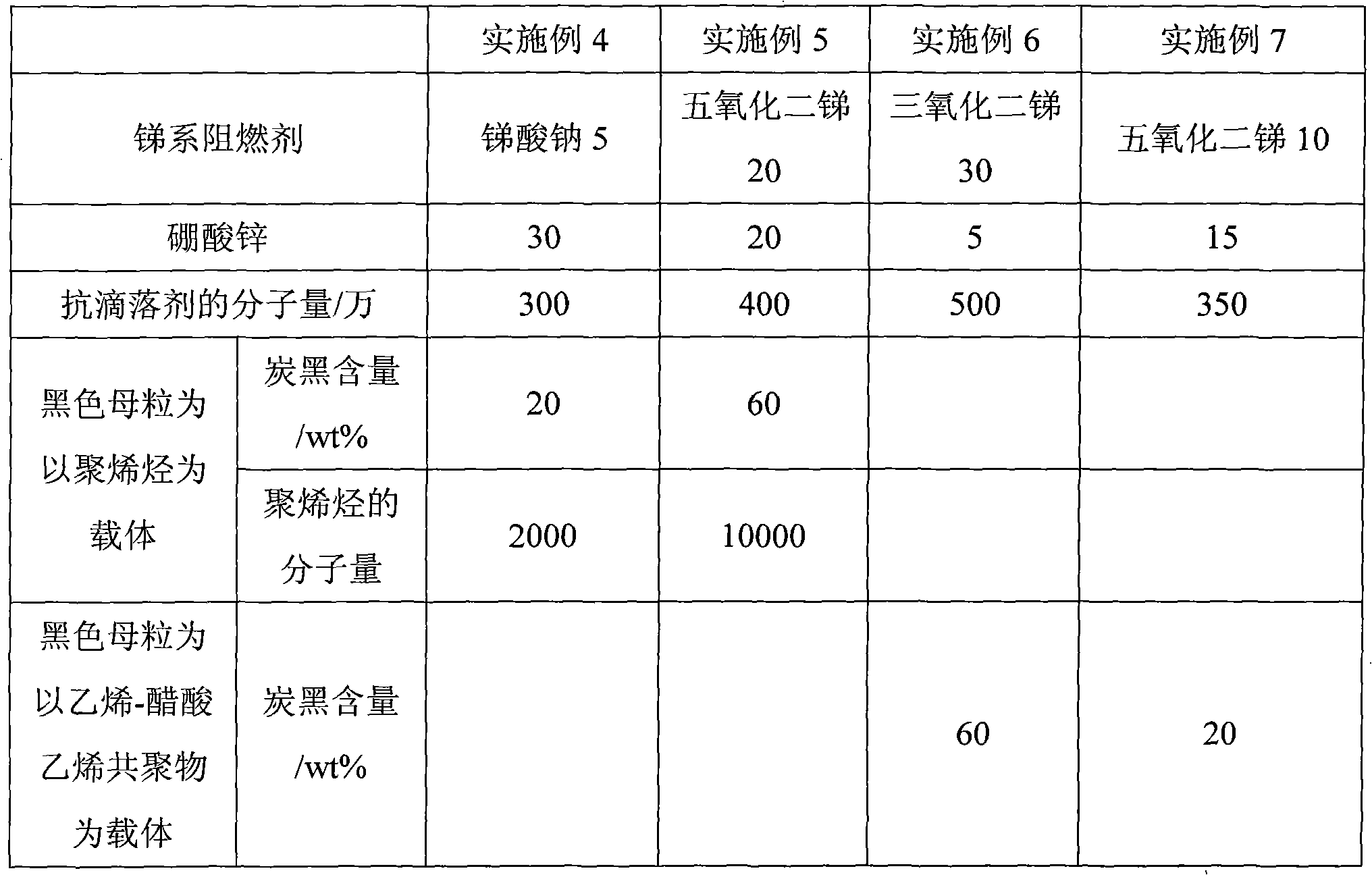

Low-L value inflaming retarding ABS modified resin and preparation method thereof

The invention relates to a low-L value (less than 27) inflaming retarding ABS modified resin and a preparation method thereof. The resin comprises the components with the content (based on parts by weight): 100 parts of ABS resin, 10-25 parts of brominated flame retardant, 20-40 parts of inorganic inflaming retarding master batch, 0.1-0.5 part of anti-dripping agent, 0.2-1 part of antioxidant, 0.1-0.5 part of light stabilizer, 1-3 parts of lubricating agent and 1-4 parts of black master batch. Compared with the prior art, the invention has reasonable technique, overcomes the defect of high L value (namely, low degree of blackness) of the existing inflaming retarding ABS resin, and adopts the novel high-efficiency inflaming retarding synergistic effect technology. The invention leads the resin has higher degree of blackness by reasonably selecting the grain diameter of antimony trioxide, a carbon black lubricating dispersion system and the processing technique of a master batch method on the basis of maintaining the excellent performance of the inflaming retarding ABS resin, and has wide application prospect in the field of the requirement of high degree of blackness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Flame-retardant cold-resistant PVC/ABS alloy and preparation method thereof

The invention belongs to the technical field of polymer alloy, and relates to polyvinyl chloride / acrylonitrile-styrene-butadiene copolymer alloy and a preparation method thereof; the polyvinyl chloride / acrylonitrile-styrene-butadiene copolymer alloy comprises the following components by weight: 100 parts of polyvinyl chloride, 30-100 parts of acrylonitrile-styrene-butadiene copolymer, 10-50 parts of a cold-resistant plasticizer, 15-30 parts of a fire retardant, 6-20 parts of a compatilizer, 1-10 parts of a heat stabilizer, 0.2-2 parts of an anti-oxidant, and 0.2-10 parts of an processing additive. The PVC / ABS alloy of the invention has a short process flow, has both maintained PVC flame retardancy and increased product cold resistance, and has enlarged product application scope.

Owner:HEFEI GENIUS NEW MATERIALS

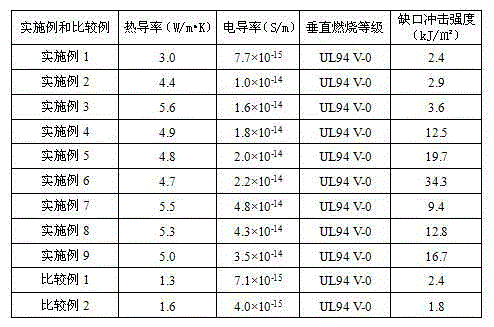

Multifunctional polypropylene composite material and preparation method thereof

ActiveCN104629187AGood mechanical propertiesGuaranteed flame retardant performancePolypropylene compositesProcedure Agents

The invention relates to a multifunctional polypropylene composite material and a preparation method thereof. The composite material is prepared from a thermoplastic polypropylene resin matrix, inorganic particles, thermal conducting fillers or a halogen-free flame retardant, carbon-based thermal conducting fillers, toughening fillers and other processing additives, the highest heat conductivity coefficient of the composite material is larger than 5.0 W / m.K, the insulating property is excellent, the vertical flammability is UL94 V-0, and the mechanical properties are excellent. The operation is simple, the cost is low, the multifunctional composite material with excellent comprehensive performance can be prepared in one step, industrialized production is easy to achieve, and the multifunctional polypropylene composite material can be widely used in such fields as heat exchangers, instrument shells, circuit components, automobiles, chemical energy and aviation, etc.

Owner:BEIJING UNIV OF CHEM TECH

Weatherproof and wear-resisting cable sheath material

InactiveCN104231600AImprove wear resistanceImprove mechanical propertiesInsulated cablesInsulated conductorsEpoxyCopper oxide

The invention discloses a weatherproof and wear-resisting cable sheath material which comprises the following raw materials in parts by weight: 40-60 parts of thermoplastic polyurethane elastomer, 20-30 parts of chloroprene rubber, 20-30 parts of chlorinated polyethylene, 30-45 parts of nano-titanium dioxide / graphene oxide, 10-15 parts of modified nano talcum powder, 20-35 parts of coupling-agent-modified attapulgite, 3-5 parts of activated zinc oxide, 4-9 parts of stearic acid, 10-18 parts of expansible graphite, 3-7 parts of copper oxide, 5-12 parts of ferric oxide, 5-9 parts of coupling-agent-modified ammonium polyphosphate, 3-6 parts of sulfur, 2-3.5 parts of tricresyl phosphate, 0.5-2 parts of oxidic polyethylene, 3.5-4.5 parts of an accelerant TMDT, 2-5 parts of an anti-aging agent, 1-2.8 parts of epoxy flaxseed oil and 1-1.8 parts of triethyl O-acetylcitrate. The weatherproof and wear-resisting cable sheath pipe has the advantages of good weather resistance, high wear resistance, good mechanical property and long service life.

Owner:无为县华祥电缆材料有限公司

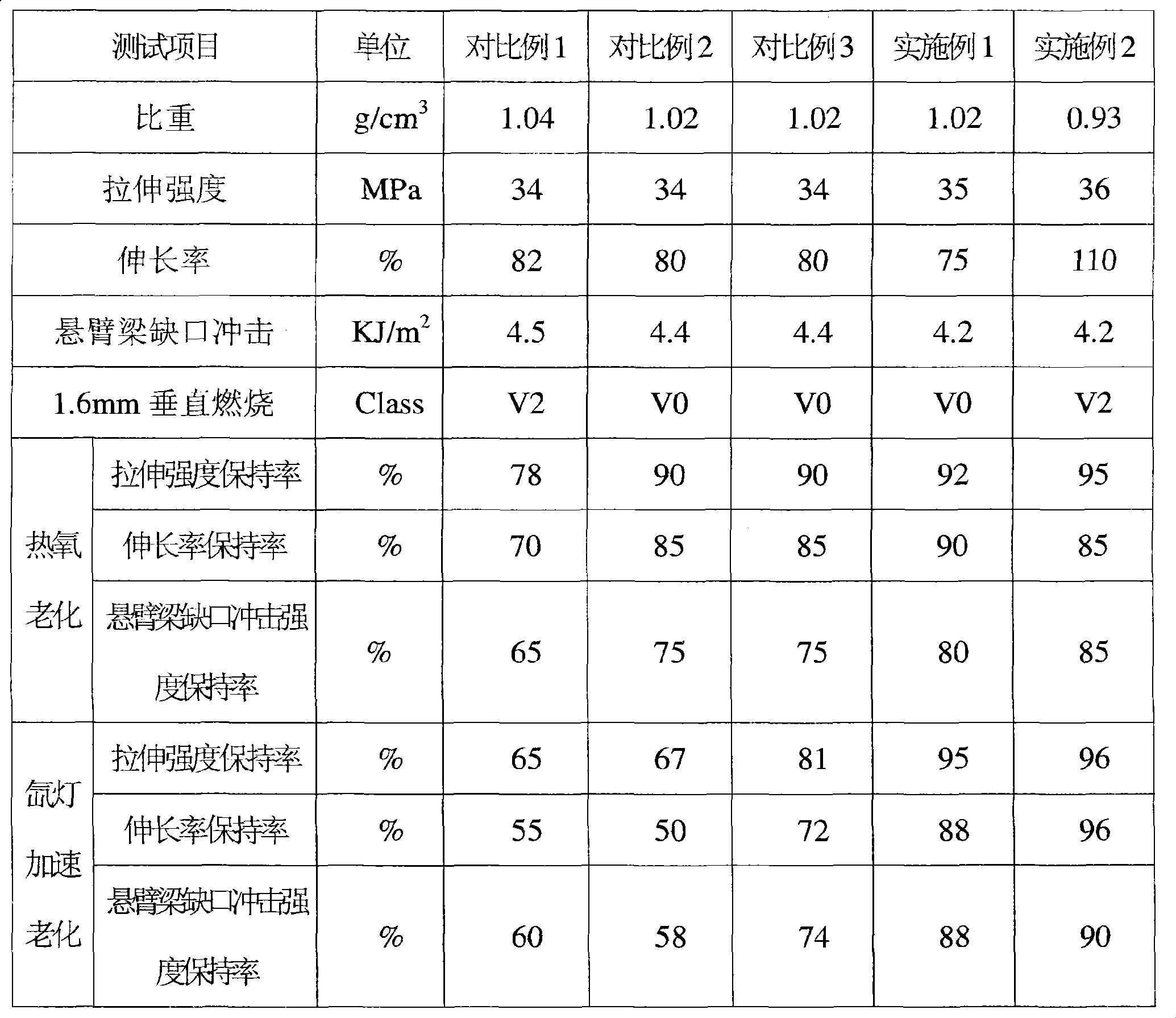

High-strength, thermo-oxidative-aging-resistant and insulating silicone rubber and preparation method thereof

The invention provides high-strength, thermo-oxidative-aging-resistant and insulating silicone rubber and a preparation method thereof. The preparation method includes the following steps of aluminum hydroxide modification, wherein aluminum hydroxide of different grain diameters is mixed according to a certain proportion, and then surfactant is added for modification; calcium carbonate modification; fumed silica modification; mixing; discharging, remilling and straining to complete preparation of the high-strength, thermo-oxidative-aging-resistant and insulating silicone rubber. Aluminum hydroxide of different grain diameters is mixed, a better filling effect is achieved on gaps between molecular chains of silicone rubber raw rubber, cost is lower, the compatibility is further improved through modification, clustering is reduced, and the electrical insulation property and the flame-retardant property of the silicone rubber are guaranteed; nano calcium carbonate and fumed silica are modified, the silicone rubber has a better dispersion effect, the filling effect is improved accordingly, the mechanical performance and thermo-oxidative-aging-resistant performance of the silicone rubber are remarkably improved, the modification process is simple, and cost is low.

Owner:YICHANG XINGZHIXIN PLASTIC ELECTRONICS TECH CO LTD

Method for preparing halogen-free smoke-suppressant and flame-retardant plastic optical fiber sheath

ActiveCN101950044AGuaranteed flame retardant performanceSmall mechanical propertiesCladded optical fibreOptical waveguide light guideTwo stepPlastic optical fiber

The invention discloses a method for preparing a halogen-free smoke-suppressant and flame-retardant plastic optical fiber sheath, which is characterized by comprising the following steps of: (1) modifying magnesium hydroxide; and (2) preparing a flame-retardant plastic optical fiber. The method has the advantages that: by modifying a magnesium hydroxide flame retardant by two steps, the affinity of the magnesium hydroxide flame retardant with a polyethylene matrix is greatly improved, a flame-retardant accelerant and a synergist are added, the reduction of the mechanical properties of the prepared flame-retardant plastic optical fiber sheath is a little under the condition of ensuring the flame retardance, and the mechanical demand of the product can be met.

Owner:江西大圣塑料光纤有限公司

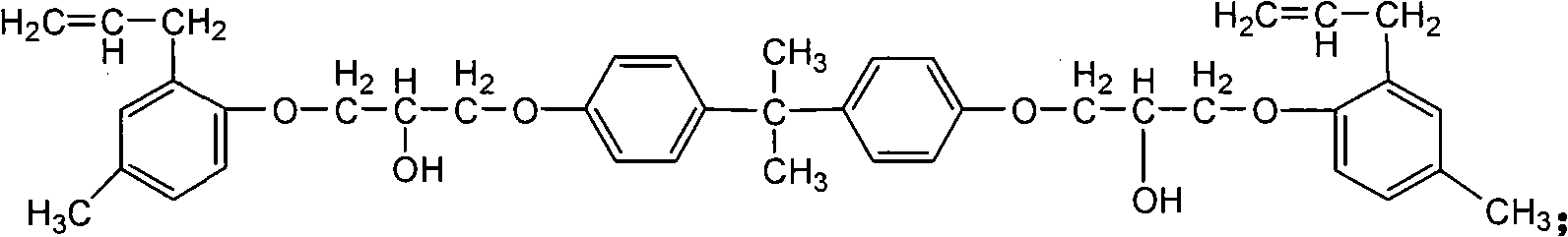

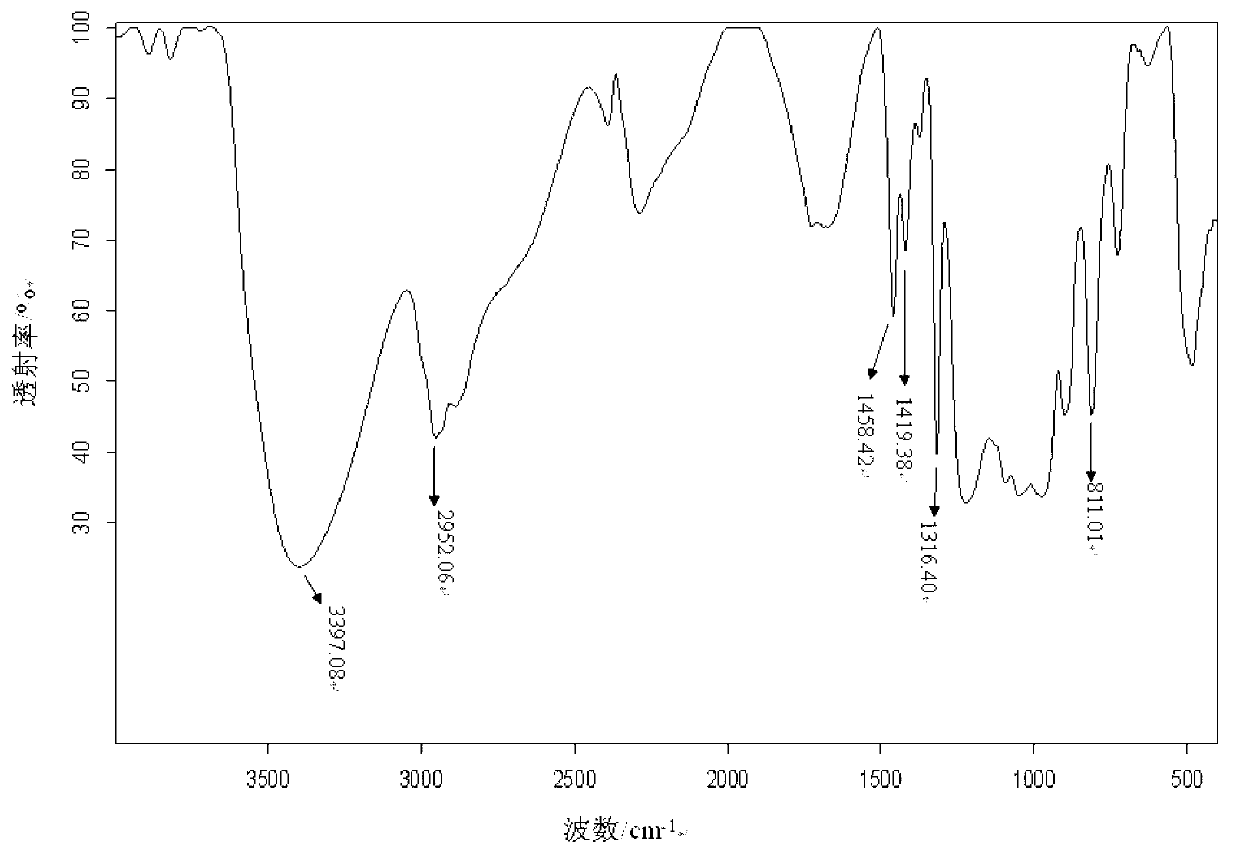

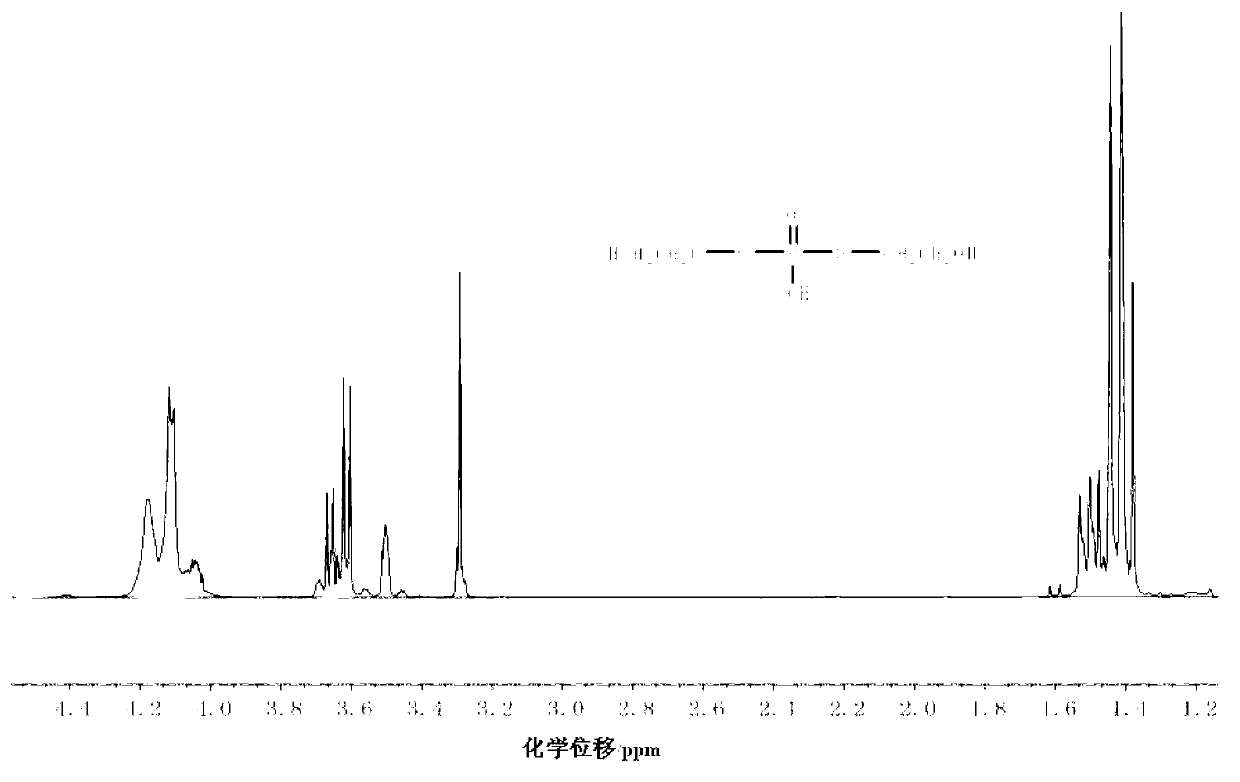

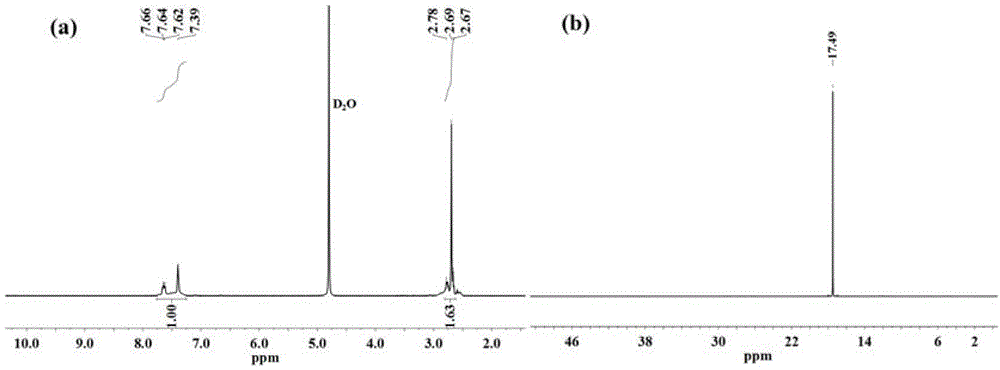

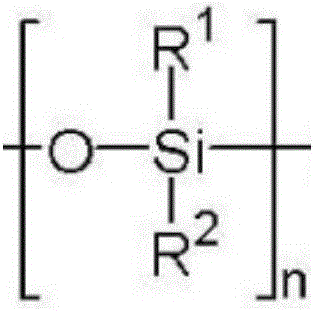

Phosphorus-containing polyol, preparation method thereof and flame-retardant polyurethane containing same

ActiveCN103102490AOvercome the shortcomings of greatly reduced mechanical propertiesImprove mechanical propertiesGroup 5/15 element organic compoundsPolyesterAryl

The invention discloses a phosphorus-containing polyol, a preparation method thereof and flame-retardant polyurethane containing the same, wherein the phosphorus-containing polyol has the structural formula as shown in formula (1), in the formula (1), R is methyl, ethyl or phenyl; R2 is alkyl or aryl; and n is an integer from 1 to 20, and when n is more than 1, R2 in all the groups can be same or different. The phosphorus-containing polyol is the macromolecular phosphorus-containing polyol with a linear structure, the molecular weight of the phosphorus-containing polyol is similar to that of a polyether polyol or a polyester polyol used in the preparation process of polyurethane resin, and the phosphorus-containing polyol contains a reactive functional group and can be used as the polyol for preparing the polyurethane resin; and furthermore, the volatility of the phosphorus-containing polyol is lower, when the phosphorus-containing polyol is used, the soft-hard section ratio in the polyurethane resin during preparation can not be damaged, the flame retardance is further ensured, and the mechanical properties of the prepared polyurethane resin are simultaneously improved.

Owner:山东海思蓝高分子材料有限公司

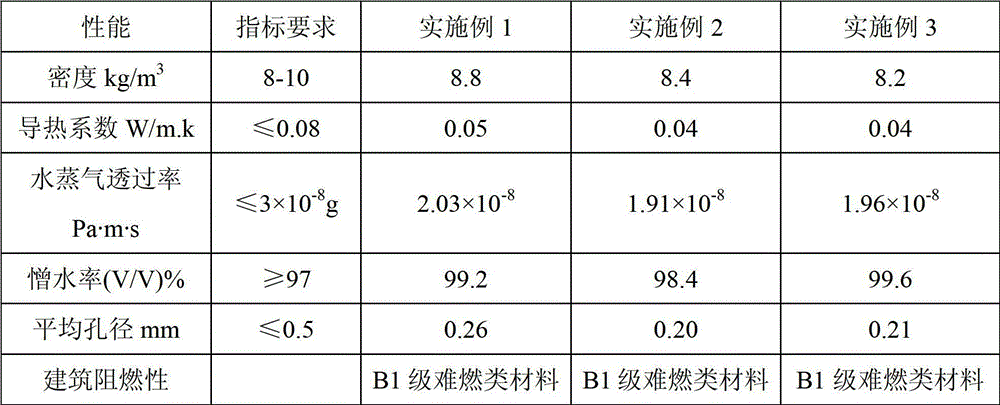

Full-water-based low-density soft polyurethane spraying composite polyether and preparation method thereof

ActiveCN102942676ANo damageTo achieve the purpose of thermal insulationPolyurea/polyurethane coatingsChemical synthesisWater based

The invention belongs to the field of chemical synthesis, and particularly relates to a full-water-based low-density soft polyurethane spraying composite polyether and a preparation method thereof. The composite polyether is composed of a component A and a component B in a weight ratio of 100:(100-105), wherein the component A is composed of polyether glycol A, polyether glycol B, polyester polyol, a crosslinking agent, a surfactant, a foaming agent, a catalyst, a flame retardant and an emulsifier; and the component B is polymethyl polyphenyl polyisocyanate or diphenylmethane diisocyanate. The preparation method comprises the following steps: adding the polyether glycol A, polyether glycol B and polyester polyol into a reaction kettle; adding the other raw materials in the component A, mixing, and barrelling to complete the production of the component A; and adding the component B, evenly mixing, atomizing, foaming, and forming and aging the foam to obtain the product. By using water as the foaming agent, the composite polyether provided by the invention achieves the goals of thermal insulation and heat preservation, and achieves the international standards in the aspects of elasticity, flame retardancy and sound insulation effect.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Flame-retardant fabric

The invention relates to a flame-retardant fabric, which is made of fiber materials, and specially comprises fiber materials in a weaving, knitting or non-woven form. The flame-retardant fabric is prepared by using a flame-retardant process, and the main ingredients of the flame-retardant fabric include a low molecular pre-shrinking body of tetrakis hydroxymethyl phosphonium sulfate (THPS) and amide, a surfactant, a flame-retardant finishing liquid of high-concentration polyethylene, so that the flame-retardant fabric has a durable flame retardant performance, and the flame retardant performance is not reduced with the increasing of the number of washing times; the flame-retardant finishing does not change the original features of the fabric fibers, so that the fabric is soft in handfeel, and small in strength loss, and the comfortableness and durability of the fabric are basically kept, therefore, the flame-retardant fabric has a characteristic that the fabric is carbonized after meeting fire and self-extinguished after leaving fire, and the spread of flames is effectively prevented; and the protective clothing prepared by using the fabric can prevent flames from causing harm to the human body.

Owner:魏延杰 +1

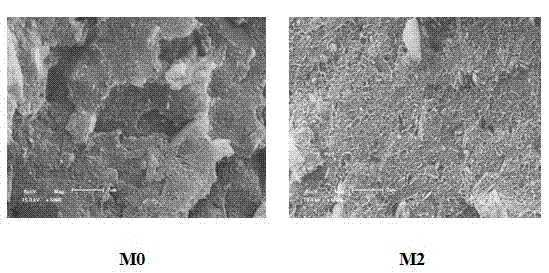

Modified magnesium hydroxide fire retardant and high impact polystyrene composite inflaming-retarding material formed by modified magnesium hydroxide fire retardant and manufacturing method

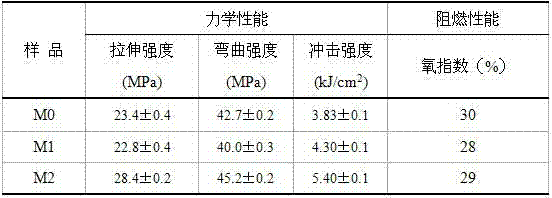

InactiveCN102219929AImprove mechanical propertiesGood compatibilityPigment treatment with macromolecular organic compoundsMagnesiumFlexural strength

The invention relates to a modified magnesium hydroxide fire retardant which is a magnesium hydroxide fire retardant which is formed in a way that sulfonation high-impact polystyrene surface treatment is carried out on magnesium hydroxide powder with average grain diameters of 1-100mum and 0.5-20m2 / g of BET (runauer, emmertt and teller) specific surface area, the sulfonation high-impact polystyrene has 5-80 percent of sulfonating degree, and the weight of the sulfonation high-impact polystyrene is 1-20 percent of that of the magnesium hydroxide. The invention also relates to a high-impact polystyrene composite inflaming-retarding material formed by modified magnesium hydroxide fire retardants, which is prepared by the following ingredients by mass ratio: 50-80 percent of high impact polystyrene, 10-40 percent of improved magnesium hydroxide fire retardants and 5-20 percent of common auxiliaries for other polystyrenes. The composite inflaming-retarding material has 28MPa of tensile strength, 45MPa of bending strength, 5.4kj / cm2 of impact strength and 29 percent of oxygen index. The invention also discloses a manufacturing method of the high impact polystyrene composite inflaming-retarding material.

Owner:NANJING UNIV +1

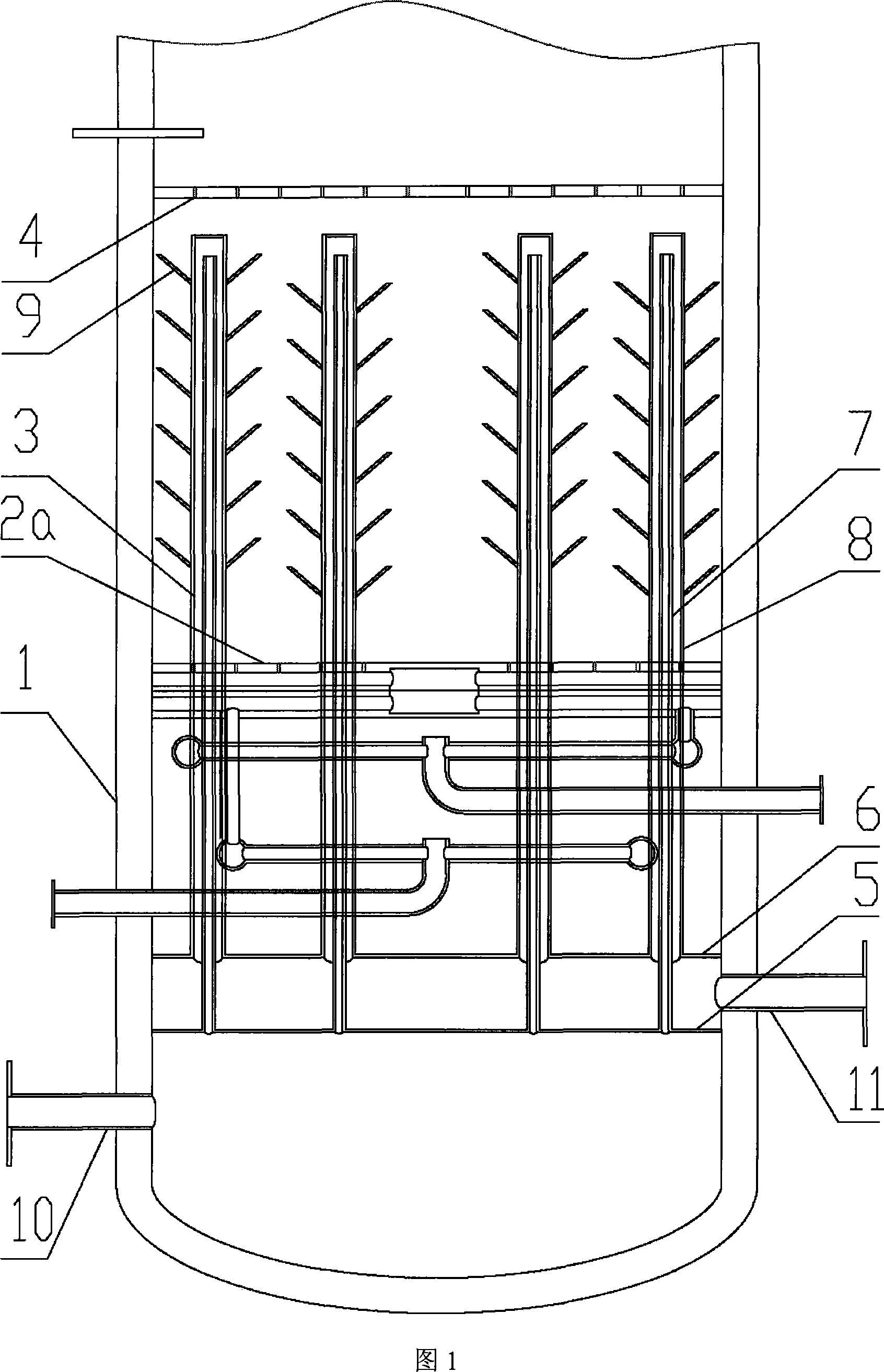

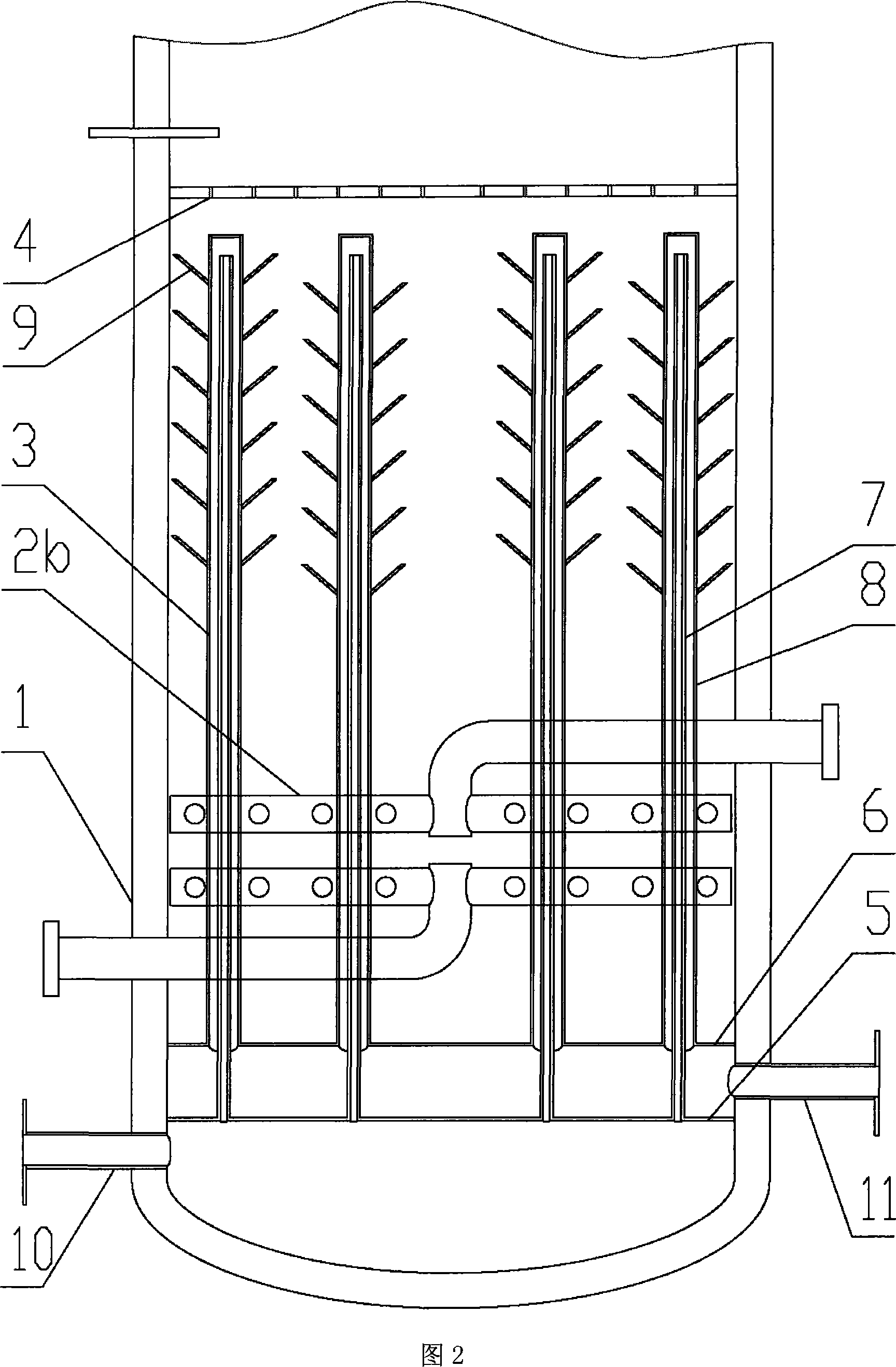

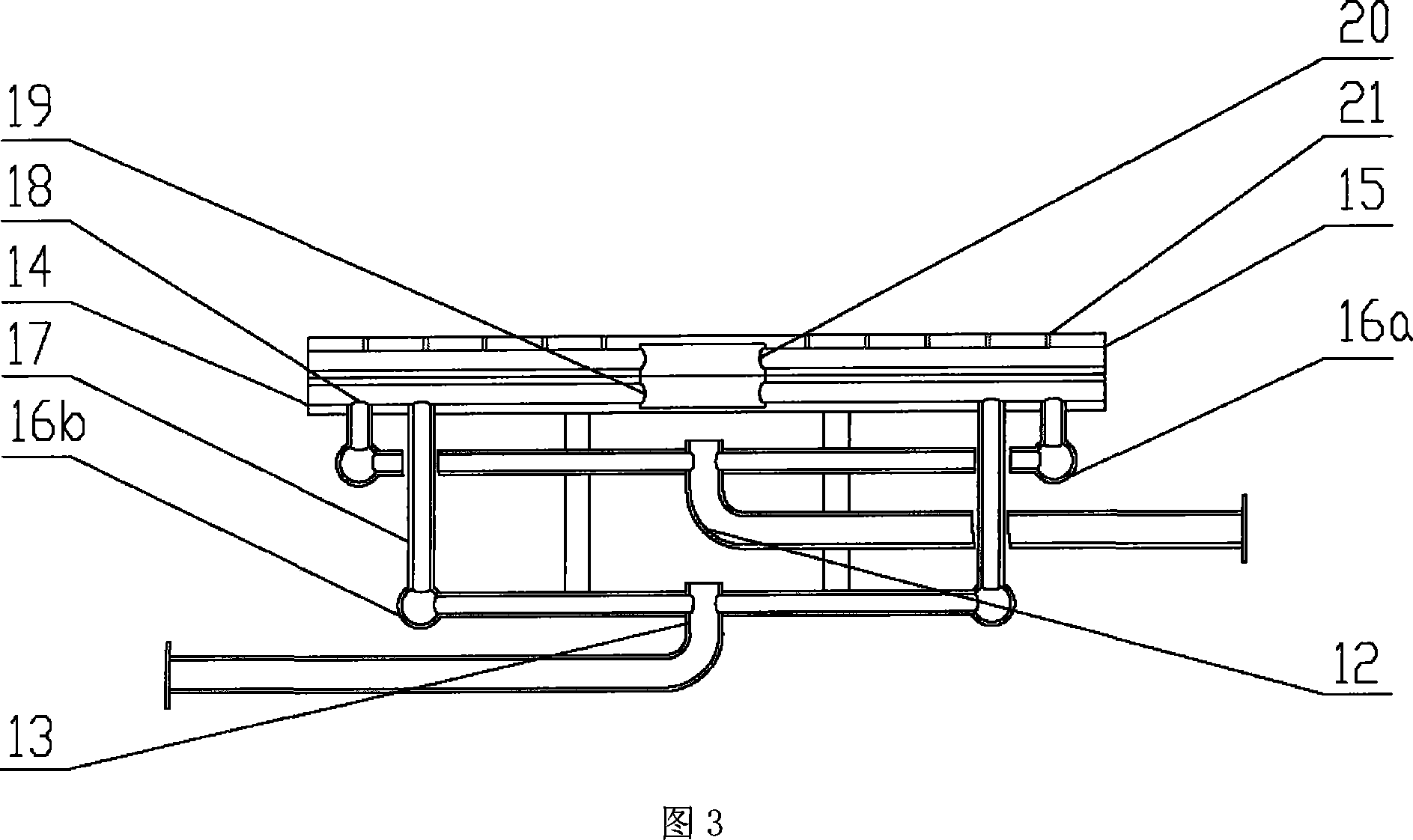

Methane and oxygen pre-mixer

InactiveCN101125282AEvenly distributedRemove in timeHydrogenFlow mixersNuclear engineeringPartial oxidation

The present invention relates to a methane and oxygen pre-mix device, mainly consists of a casing, a gas distributed system, a heat exchange system and a multiorifice gas distribution plate; the gas distributed system adopts the rotational flow or the circular flow gas distributed system; the rotational flow gas distributed system consists of a methane air intake system, an oxygen air intake system, an upper distributor and a lower distributor; the circular flow gas distributed system consists of center feed pipes, cross feed pipes and ring gas distributor of the methane and the oxygen; the heat exchange system consists of an upper separator, a lower separator, a centre internal pipe, an external pipe, a metal fin, a heat exchange medium inlet pipe and a heat exchange medium outlet pipe; via the gas distributed system, the methane and the oxygen have a preliminary mixture in a smaller space, then by the stimulant fluidized bed consisting of the centre internal pipe, the external pipe and the metal fin, circuitously flowing upwards, achieving a molecular level mixture at the exit. The present invention effectively increases the pre-mix effect and guarantees the inflaming retarding and explosion prevention of the pre-mix chamber, having a good function in the industry of methane partial oxidation to syngas.

Owner:TSINGHUA UNIV

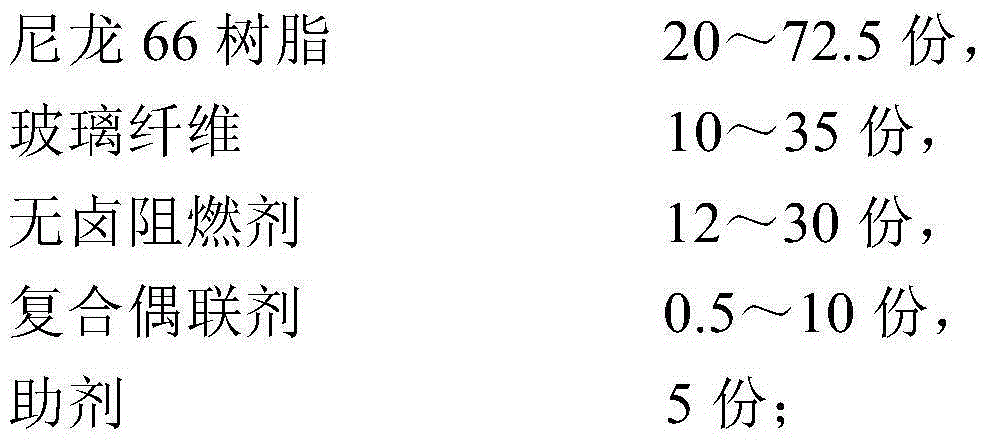

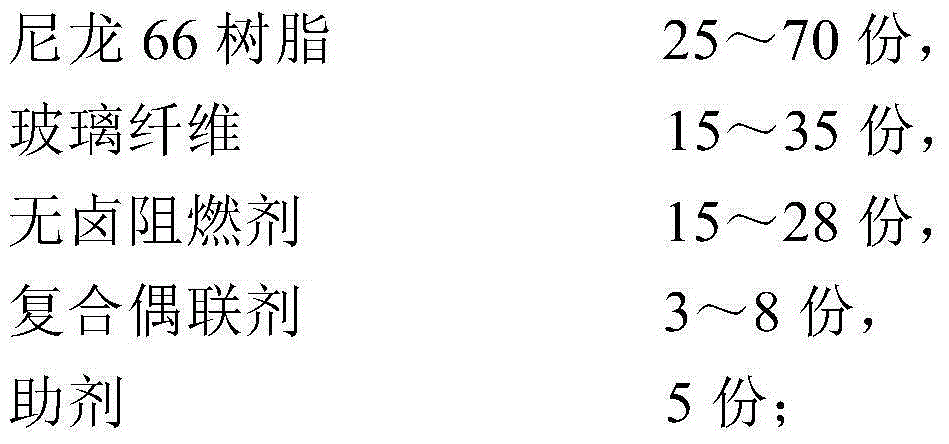

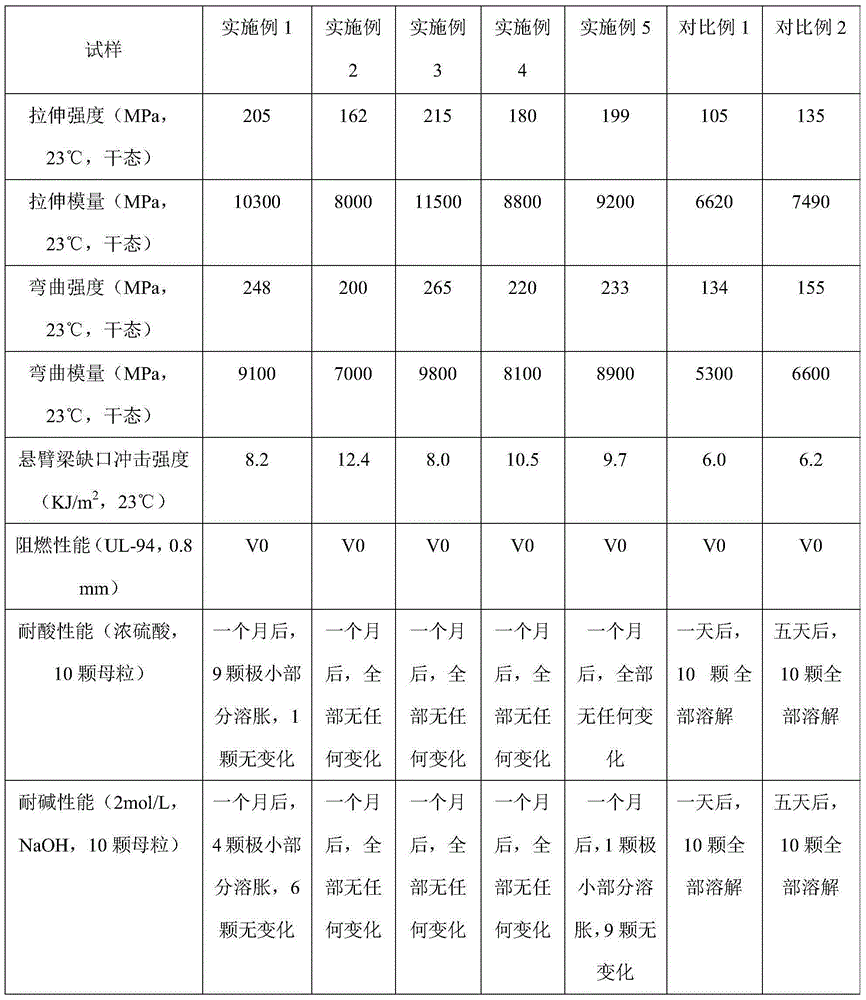

Halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance and preparation method of PA66 composite material

InactiveCN105062050AGood acid and alkali resistanceStrong acid and alkali resistanceEpoxyGlass fiber

The invention discloses a halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance. The PA66 composite material comprises raw materials in parts by weight as follows: 20-72.5 parts of PA66 resin, 10-35 parts of glass fiber, 12-30 parts of a halogen-free flame retardant, 0.5-10 parts of a composite coupling agent and 5 parts of an auxiliary, wherein the composite coupling agent is selected from a mixture formed by mixing gamma-aminopropyl triethoxysilane with gamma-epoxy propoxy propyl trimethoxysilane or epoxy resin in the weight ratio being 1: (1-50). The composite material has higher acid and alkali resistance, good processing fluidity as well as excellent mechanical properties, heat resistance and flame retardation, the problem of insufficient acid and alkali resistance of PA products in the prior art is particularly solved, the acid and alkali resistance is improved remarkably, and the composite material has broad market prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Flame retardant polypropylene resin blend and preparation method thereof

The invention discloses a flame retarding polypropylene resin blend and a preparation method thereof. The flame retarding polypropylene resin blend is prepared according to a weight ratio by 56-90 percent of polypropylene resin, 3-18 percent of flame retardant, 3-6 percent of auxiliary flame retardant, 1-6 percent of flame retarding synergist, 2-8 percent of compatibilizer, 0.5-5 percent of melt strength regulator, 0.1-0.5 percent of antioxidant, 0.1-0.5 percent of heat stabilizer, and 0.3-0.5 percent of light stabilizer. The components are mixed in a high-speed mixer for 2-5 minutes, then extruded by a twin-screw extruder and finally granulated. The flame retarding polypropylene resin blend of the invention can maintain a flame retarding property, and at the same time, has the advantages of low proportion, excellent mechanical property, long thermo oxidative aging, excellent lightfast aging capability, and reduced flame retardant migrating, etc.

Owner:KINGFA SCI & TECH CO LTD +1

Production process of flame retardant trim cow leather

ActiveCN104032048AProper firmnessImprove uniformityTanning treatmentPolyurea/polyurethane coatingsEngineeringWear resistance

The invention relates to a production process of flame retardant trim cow leather. The production process comprises the steps of fleshing, deliming, softening, tanning, shaving, retanning, dyeing, stuffing, drying, milling and finishing, wherein the step of tanning comprises the successive procedures of salting, pickling and chrome powder tanning; and the retanning, the dyeing, the stuffing, the low-temperature airing drying and the finishing adopt characteristic processes. The flame retardant trim cow leather is compact and uniform in body, is excellent in toughness, is good in resilience and is excellent in flame retardance, and the quality can be controlled easily in the production process; after the leather is stretched in a seat or is used, the seat can be kept in an optimal form and comfort because of excellent resilience of the leather; and under the precondition of guaranteeing the softness and flame retardance, the water resistance, the sweat resistance, the color fastness to rubbing and the wear resistance of a coating layer are effectively improved.

Owner:浙江富邦汽车内饰科技有限公司

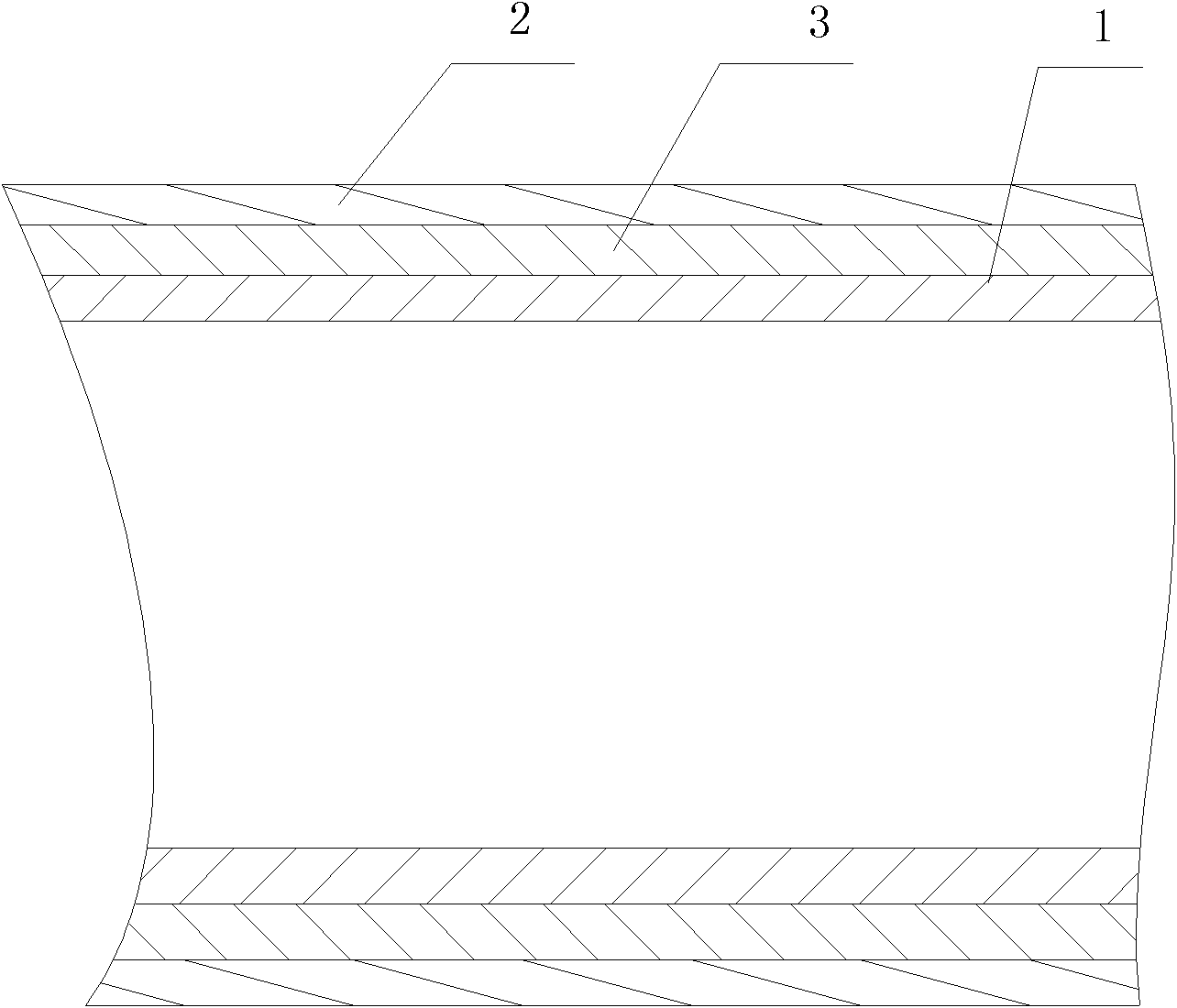

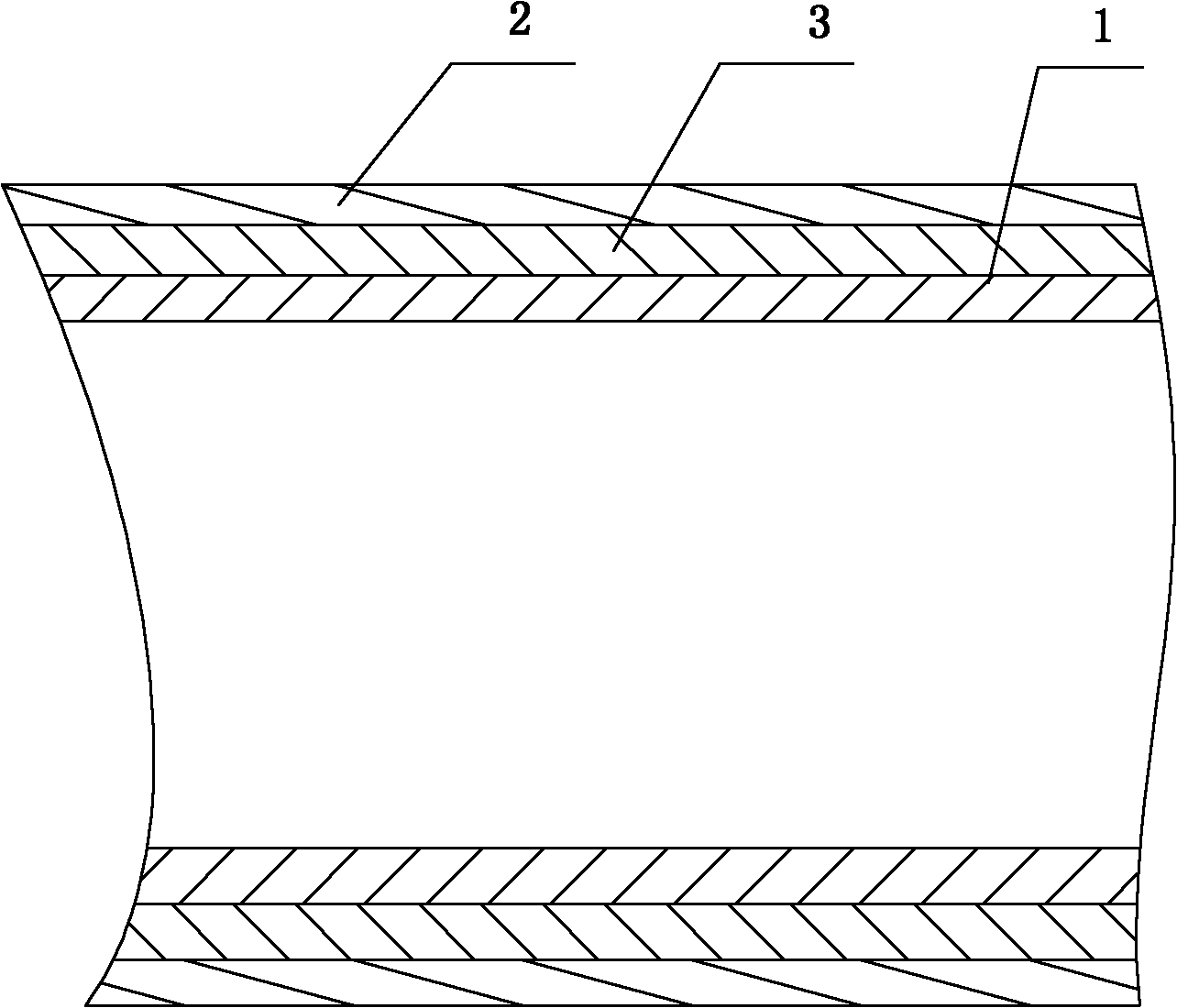

Fiber reinforced pipe for mine and production method thereof

InactiveCN102011897AImprove flame retardant performanceImprove antistatic performanceSynthetic resin layered productsRigid pipesFire resistanceMechanical engineering

The invention provides a fiber reinforced pipe for a mine and a production method thereof. The fiber reinforced pipe comprises a lined pipe, wherein the lined pipe is made of an antiflaming and antistatic special polyethylene material, so that the fire resistance and anti-static electricity performance of a pipe are improved; therefore, the safety of the pipe is improved; the weight of the polyethylene is light, so that the pipe can be conveniently installed and transported; moreover, the fiber reinforced pipe has a simple structure and can be processed conveniently; and the processing method of the fiber reinforced pipe is easy to operate, and can improve the fire resistance of the fiber reinforced pipe.

Owner:江苏金波新材料科技有限公司

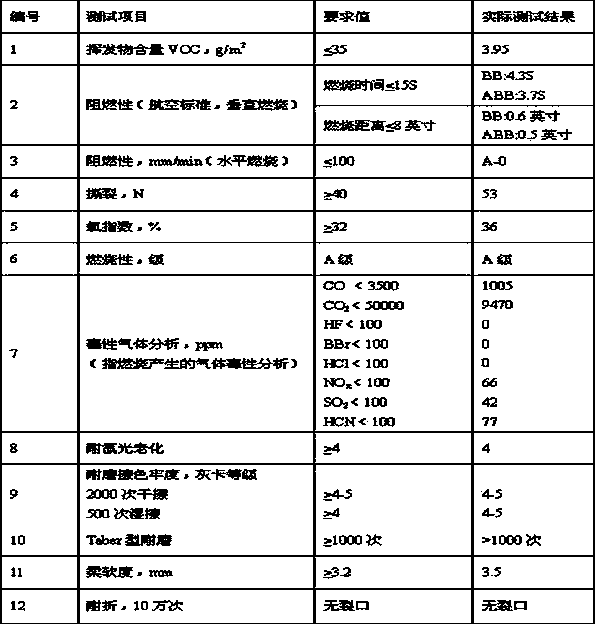

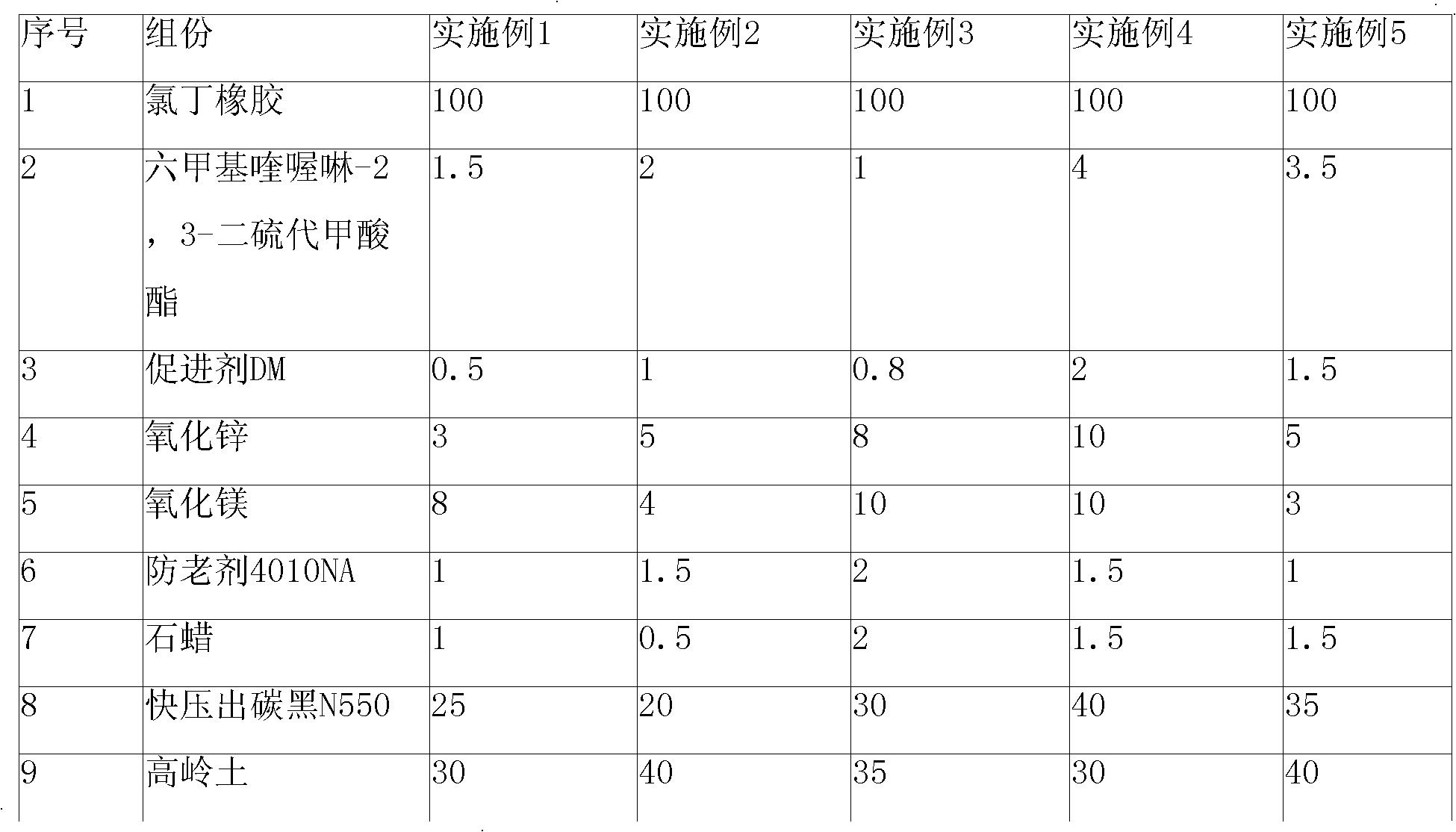

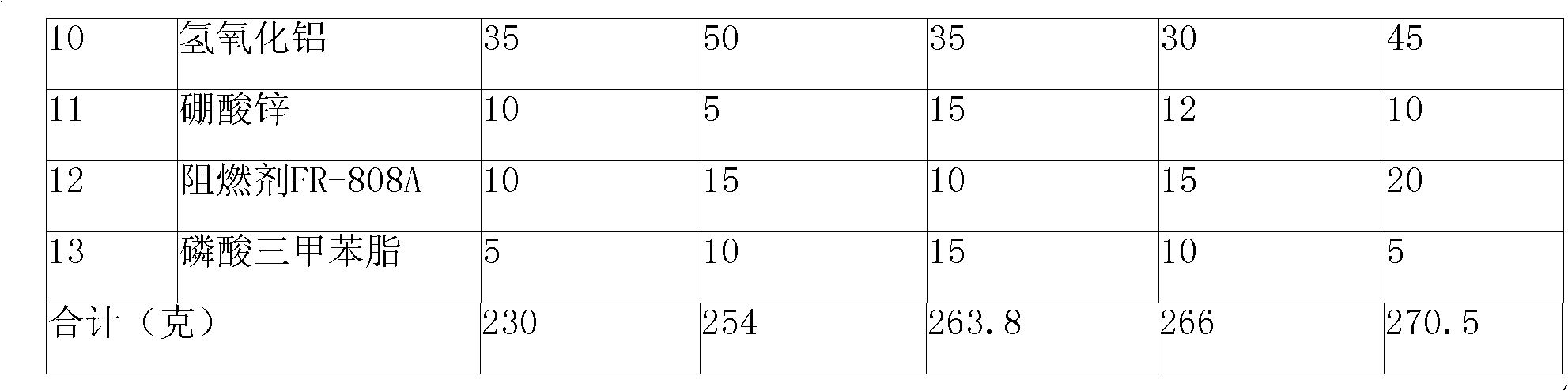

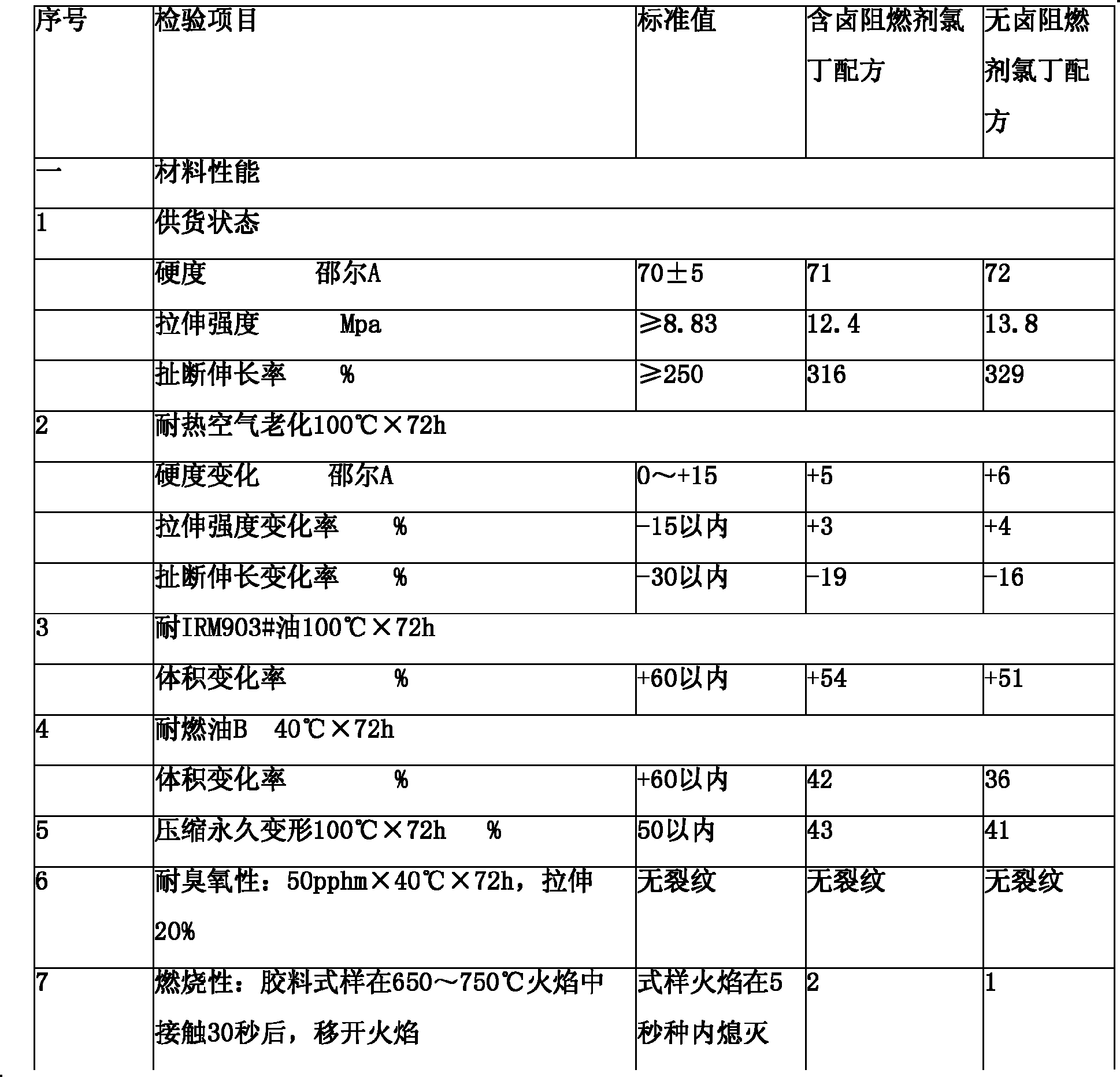

Formula of environment-friendly flame-retardant chloroprene rubber

The invention relates to the formula of environment-friendly flame-retardant chloroprene rubber. The flame-retardant chloroprene rubber, according to the formula thereof, comprises the following components by weight part: 100 parts of chloroprene rubber, 1 to 4 parts of hexamethyl-quinoxaline-2,3-dithioformate, 1 to 2 parts of DM as accelerator, 3 to 10 parts of zinc oxide, 3 to 10 parts of magnesium oxide, 1 to 2 parts of 4010NA as anti-ager, 0.5 to 2 parts of paraffin, 20 to 40 parts of FEF (fast-extruding furnace) carbon black (N550), 30 to 40 parts of kaolin, 30 to 50 parts of aluminum hydroxide, 5 to 15 parts of zinc borate, 10 to 20 parts of FR-808A and 5 to 15 parts of tricresyl phosphate. According to the comparative analysis on the performance of the chloroprene formula using halogen-containing flame retardant and the chloroprene rubber formula using halogen-free flame retardant, the performance of the formula using the halogen-free flame retardant in the invention can fully satisfy the requirements of standards, thus substituting for the chloroprene formula using the halogen-containing flame retardant; and based on the chloroprene rubber formula, the invention can meet the requirements of the flame-retardant application, and the materials of the formula are environment friendly and safe for human bodies.

Owner:TIANJIN PENGYI GRP CO LTD

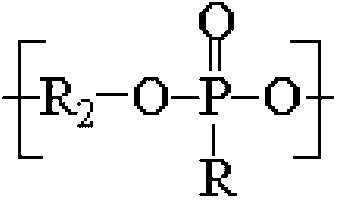

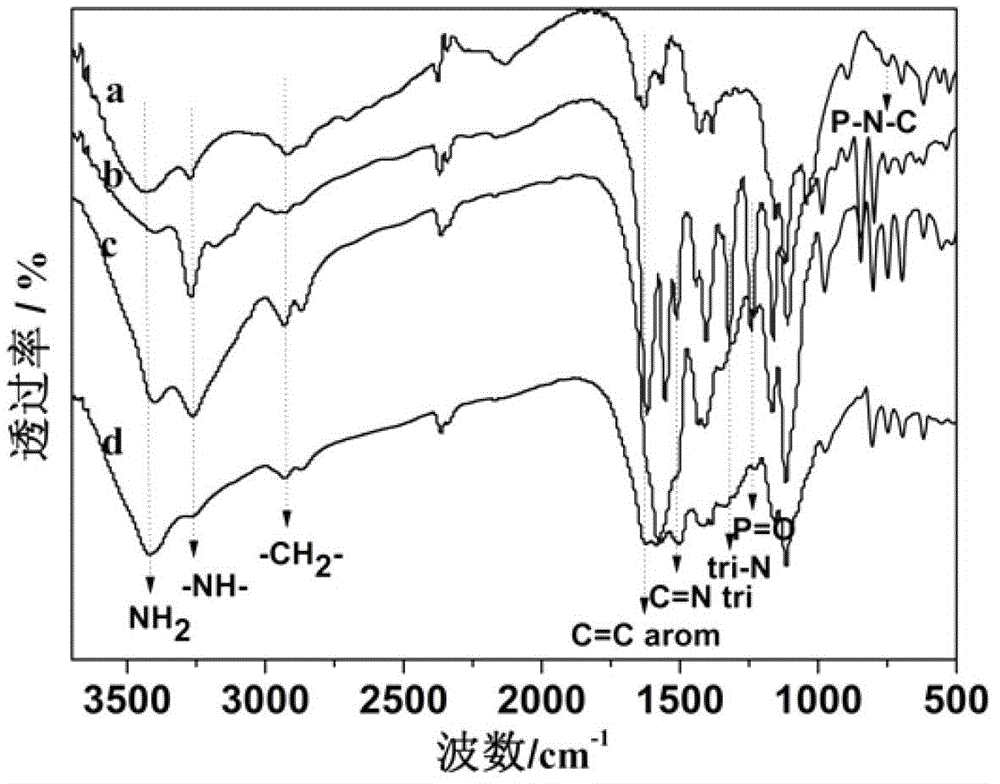

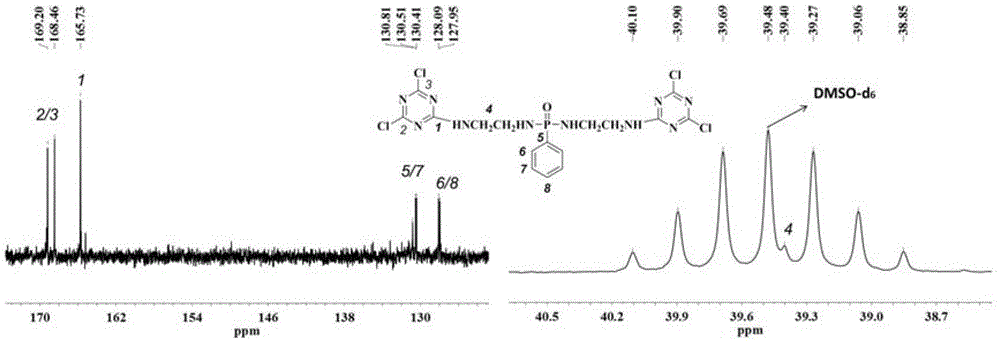

Phosphorus-containing macromolecule intumescent flame retardant char forming agent as well as preparation method thereof and intumescent flame retardant formed by char forming agent

ActiveCN103333493AImproved water resistance and migration resistanceReduce moisture absorptionGroup 5/15 element organic compoundsFire retardantAniline

The invention discloses a phosphorus-containing macromolecule intumescent flame retardant char forming agent. The structural general formula of the phosphorus-containing macromolecule intumescent flame retardant char forming agent is as shown in descriptions, wherein in the formula, X is -NH-R-NH-, Y is -NH-R1-OH or -NH-R1-NH2, Z is phenyl, phenoxy, methoxy or anilino group, m is in the range from 1-25, n is the range from 1-25, and m+2 is greater than or equal to 2. The invention discloses a preparation method of the phosphorus-containing macromolecule intumescent flame retardant char forming agent and an intumescent flame retardant formed by the char forming agent, an acid source and a flame retardant synergist. The char forming agent provided by the invention has good heat stability and char forming property as well as excellent water resistance and mobility resistance in a polymer system; the preparation method of the char forming agent is simple and practicable, easy to control and convenient for the realization of industrial production.

Owner:SICHUAN UNIV

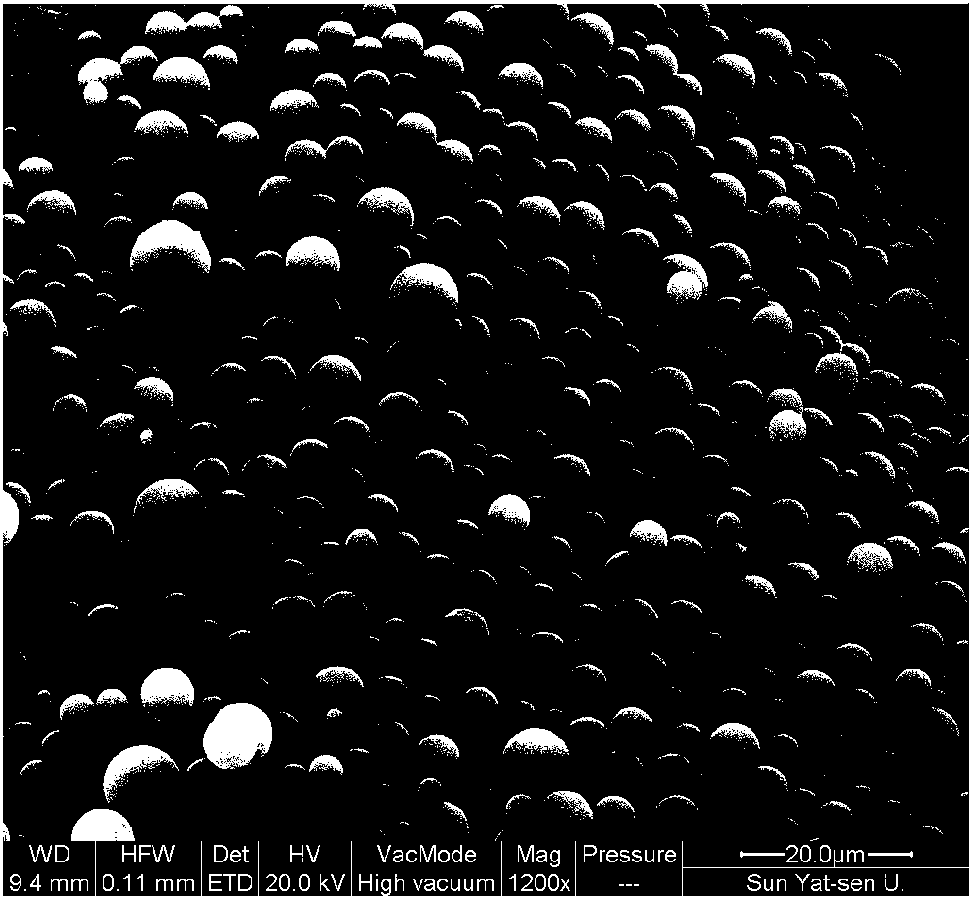

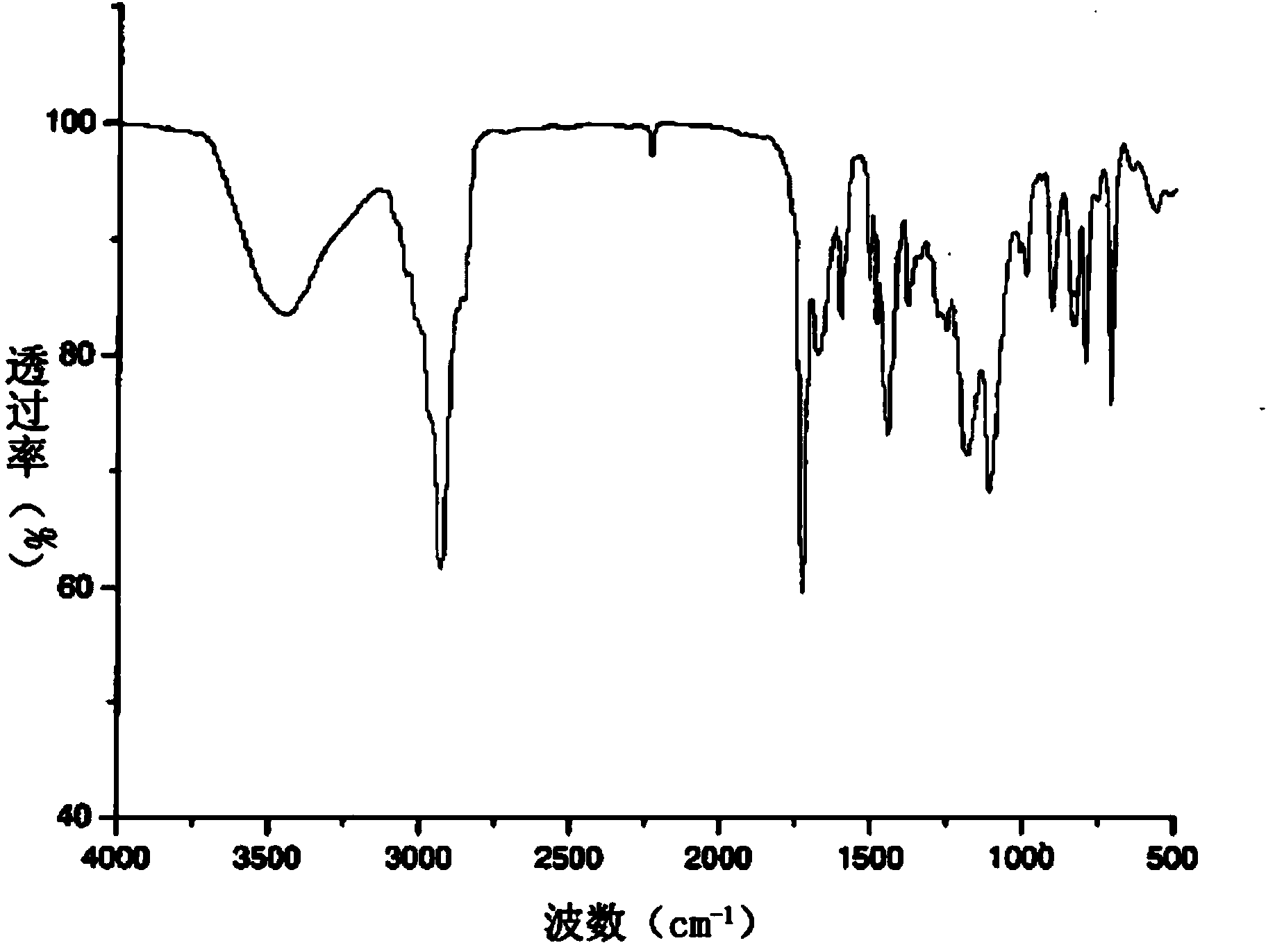

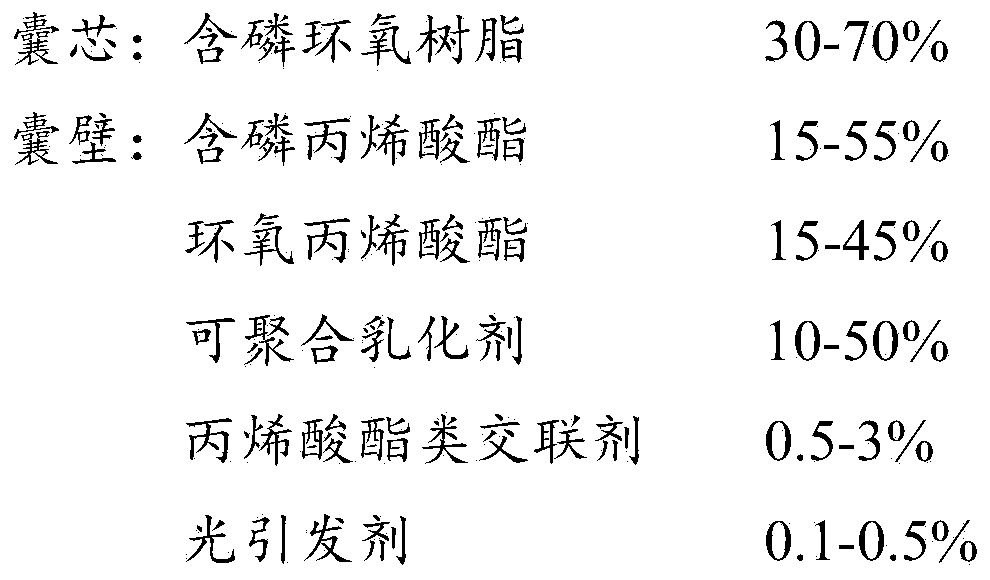

Reaction-type flame-retardant epoxy resin microcapsule and preparation method thereof

ActiveCN104226216AWith self-healing functionEnsure self-healing capabilitiesMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

The invention discloses a reaction-type flame-retardant epoxy resin microcapsule. The reaction-type flame-retardant epoxy resin microcapsule comprises a capsule core and a capsule wall, wherein the capsule core is 30 to 70 percent by mass of phosphorus-containing epoxy resin, and the capsule wall consists of the following ingredients by mass percent: 15 to 55 percent of phosphorus-containing acrylate, 15 to 45 percent of epoxy acrylate, 10 to 50 percent of a polymerizable emulsifier, 0.5 to 3 percent of an acrylate crosslink agent and 0.1 to 0.5 percent of a photoinitiator. The invention also discloses a method for preparing the microcapsule. The microcapsule has the following advantages that the flame resistance and self-repairing function are good, so that the microcapsule can be widely applied to the fields such as thermosetting self-repairing resin-based composite materials and coatings. The method for preparing the microcapsule adopts an ultraviolet interface in-situ polymerization method, so that not only is the process simple and less time consumed, but also the method is controllable, the safety of the prepared composite material can be improved, and the service life of the composite material can be prolonged.

Owner:广东润昌南星新材料有限公司

Formulation of military sole

The invention relates to a formulation of a sole, in particular to formulation of a military sole, comprising the formulations for forming an outer bottom and a middle layer of the sole, wherein the formulation of the outer bottom based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.7-0.9 part of vulcanizing agent S-80, 2.4-2.6 parts of accelerating agent, 1.9-2.1 parts of magnesium oxide, 4.5-5.5 parts of zinc oxide, 4.5-5.5 parts of antimony oxide, 1.9-2.1 parts of stearic acid, 1.9-2.1 parts of zinc stearate, 20-24 parts of high wear resistance carbon black, 2-4 parts of engine oil 46#, 6-8 parts of dibutyl ester, 1.4-1.6 parts of anti-aging agent, 0.8-1.2 parts of paraffin wax and the like; and the formulation of the middle layer based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.9-1.1 parts of sulphur, 2.5-2.7 parts of accelerating agent, 4.5-5.5 parts of zinc oxide, 1.9-2.1 parts of magnesium oxide, 3.8-4 parts of antimony oxide, 6.3-6.7 parts of decabromodiphenyl oxide, 1.9-2.1 parts of stearic acid and the like. The sole prepared by the formulation has good wear resistance and folding resistance, and has the performances of oil resistance, acid-base resistance, inflaming retarding, static electricity prevention and the like, thus meeting the military requirements.

Owner:JIHUA 3513 IND

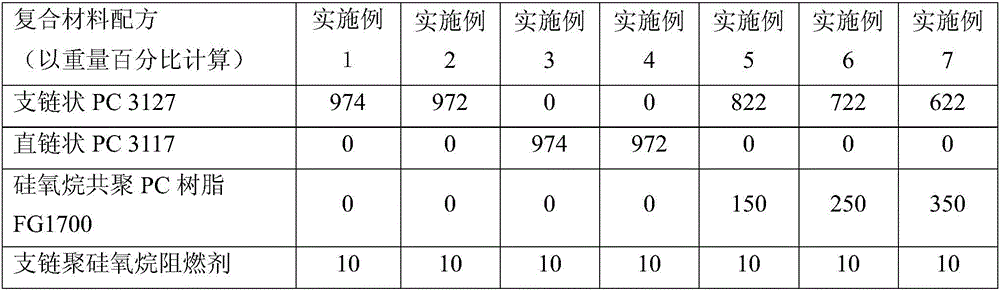

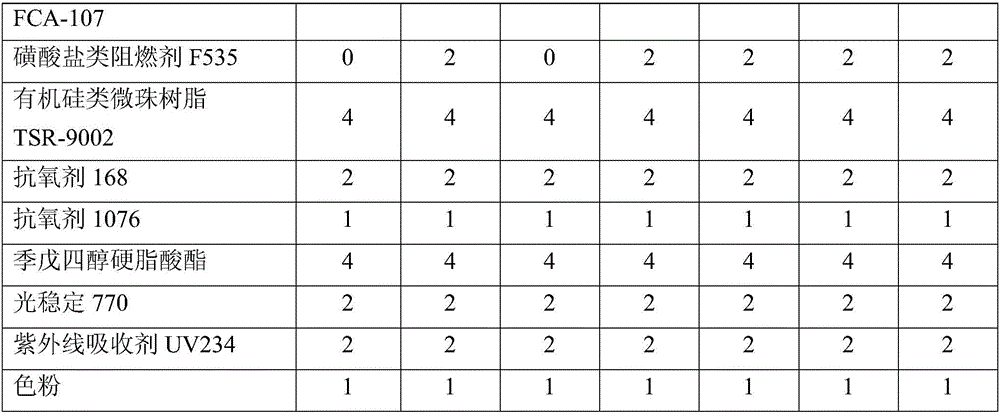

Low-temperature-resistant low-smoke inflaming-retarding light-diffusing polycarbonate composite material

The invention relates to the field of high molecular composite materials, and particularly discloses a transparent low-temperature-resistant halogen-free low-smoke inflaming-retarding polycarbonate composite material, which is prepared from the following components in percentage by weight: 45 to 90 percent of branch-chain-shaped polycarbonate resin, 5 to 50 percent of siloxane copolymeric PC (Polycarbonate) resin, 0.1 to 1 percent of sulfonate inflaming retarding agent, 0.05 to 1 percent of polysiloxane inflaming retarding agent, 0.1 to 2 percent of light diffusant and 0.5 to 1.5 percent of aid. The transparent low-temperature-resistant halogen-free low-smoke inflaming-retarding polycarbonate composite material has the advantages that the light-diffusing PC composite material provided by the invention also has the characteristics of being resistant to low temperature, low in smoke density, halogen-free and inflaming-retarding besides having the basic optical property of light-diffusing PC; higher inflaming retarding class and lower smoke density can be achieved.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Halogen-free fire-retardant polyphenyl ether composition capable of improving low-temperature toughness and preparation method thereof

The invention discloses a halogen-free fire-retardant polyphenyl ether composition capable of improving low-temperature toughness and a preparation method thereof. The composition comprises the following components in parts by weight: 70 to 90 parts of polyphenyl ether resin, 10 to 30 parts of high impact polystyrene resin, 3 to 8 parts of elastic body, 5 to 10 parts of main fire retardant, 2 to 5 parts of assistant fire retardant, 0.1 to 1 part of antioxidant, and 0.05 to 0.5 part of anti-dripping agent. The polyphenyl ether composition is prepared after the components are subjected to pre-mixing, double-screw extruder plasticization and mixing. The polyphenyl ether composition has the advantages of fire retardance, high mechanical performance, good low-temperature toughness, high heat resistance, high flowability, outstanding weather resistance and the like, and is applicable in the fields of electronic appliance, office equipment, vehicles and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

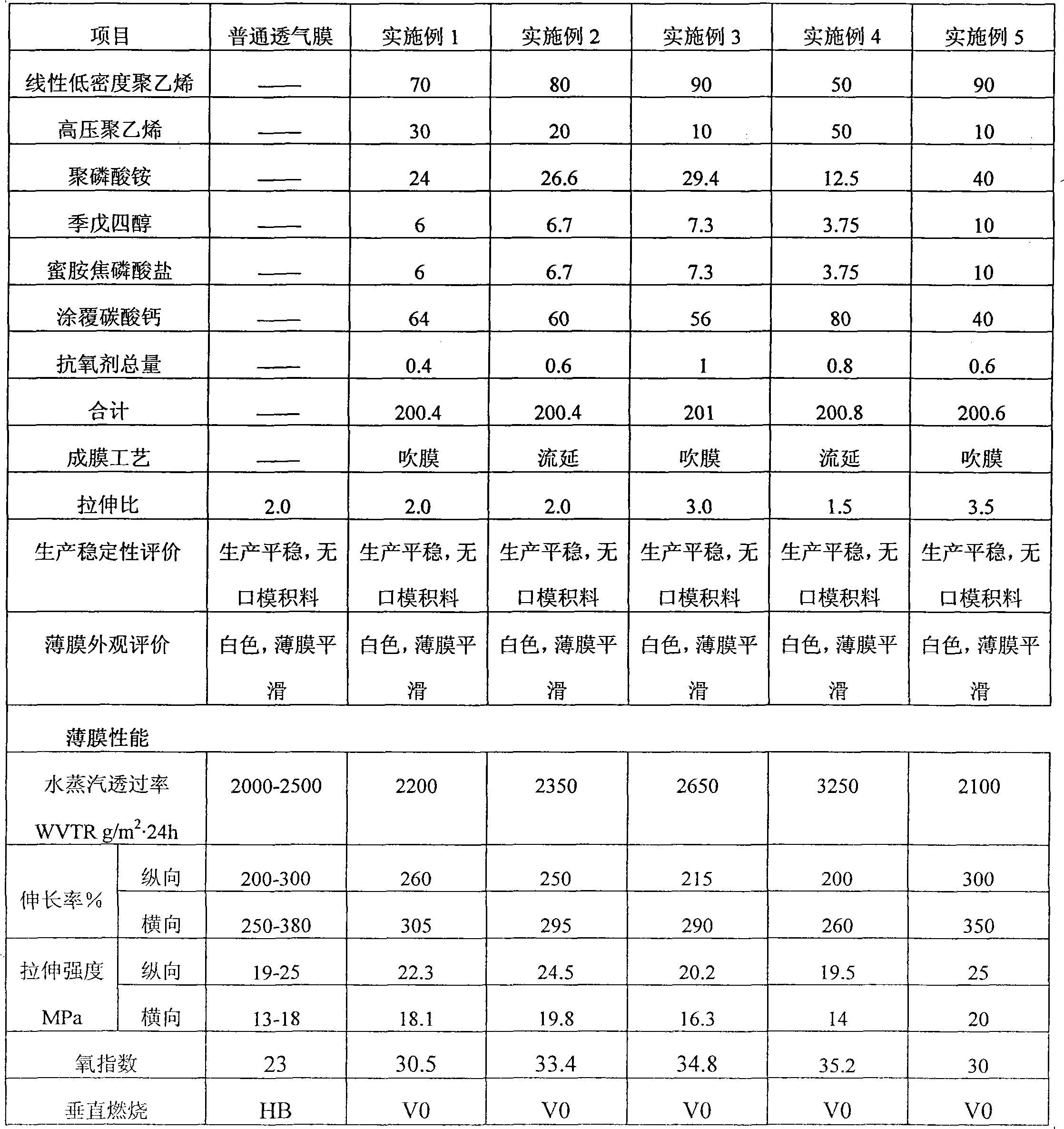

Zero halogen flame resistance polyethylene breathable film and preparation method and application thereof

ActiveCN101629006AGuaranteed flame retardant performanceDoes not affect processing performanceFlexible coversWrappersPolymer scienceHalogen

The invention discloses a zero halogen flame resistance polyethylene breathable film and a preparation method and an application thereof. The preparation method adopts surface modifier to treat calcium carbonate so as to promote the dispersion of calcium carbonate in a polyethylene resin system; then zero halogen fire retardant and polyethylene are treated by grafting treatment to have polar group and nonpolar macromolecular chain so that the dispersion of the zero halogen fire retardant in polyethylene is easier and the formed chemical bonds can effectively solve the problem that the mechanical properties of the breathable film are reduced; after the grafting treatment, the zero halogen fire retardant and the polyethylene both have the function of macromolecular coupling agent so as to further improve the dispersion of calcium carbonate in the polyethylene resin system and reduce the affect of calcium carbonate on the performance of the film. The zero halogen flame resistance polyethylene breathable film prepared by the invention not only ensures the gas permeability and mechanical properties of the polyethylene breathable film, but also improves the fire resistance of the film and does not affect the processing properties of the product. The product of the invention has both gas permeability and fire resistance, thus having wide application scope.

Owner:合诚技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com