Low-smoke and halogen-free fire-retardant rubber material for covering layer of conveyor belt and preparation method thereof

A technology of flame-retardant rubber and covering layer, which is applied in the field of low-smoke halogen-free flame-retardant rubber material for conveyor belt covering layer and its preparation, which can solve the problems of affecting the conveying efficiency of the conveyor belt, the difficulty of reducing the resistance, and the increase of smoke concentration. Achieve excellent surface modification, improve dispersion, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

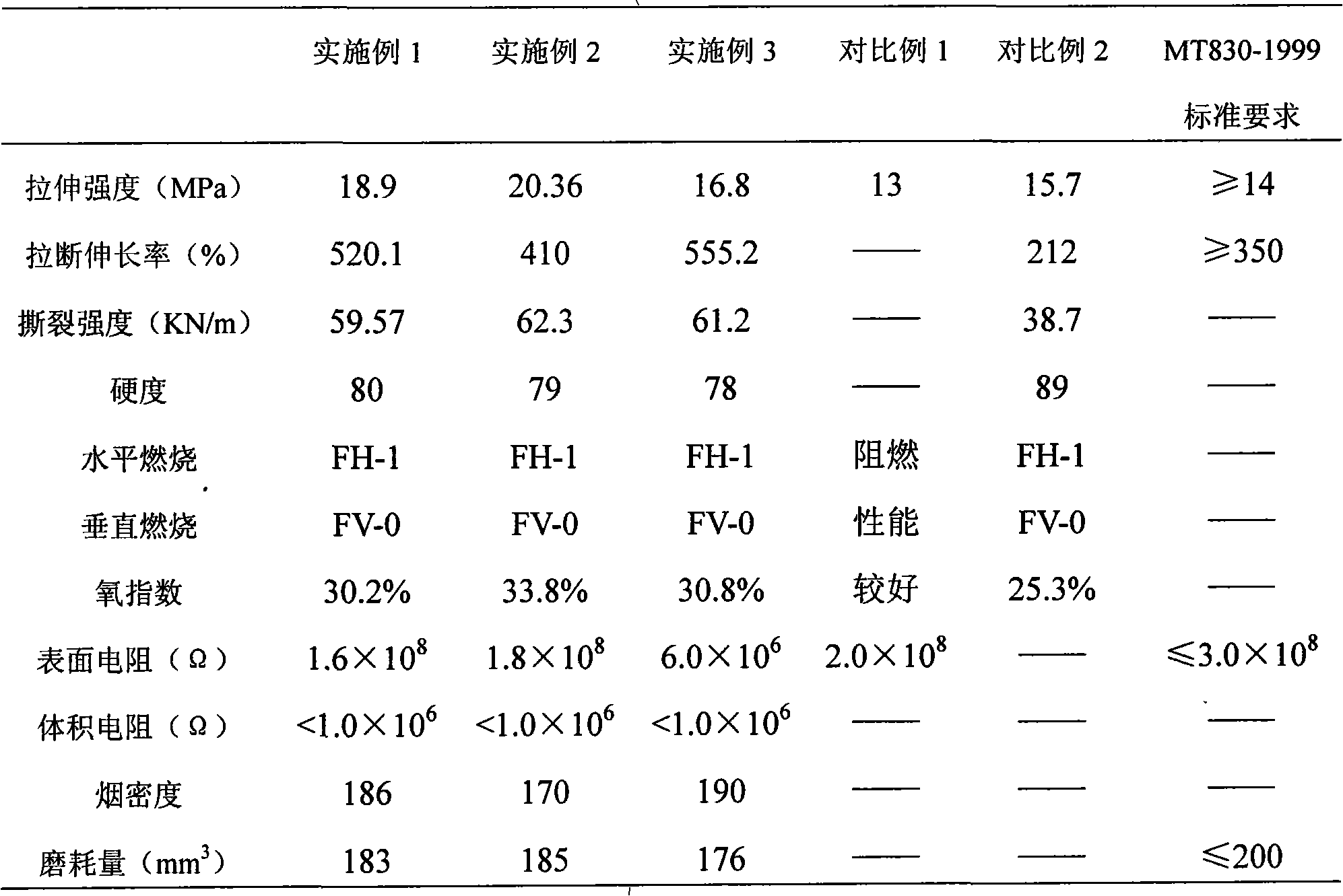

Examples

Embodiment 1

[0032] The formulation system is as follows:

[0033] Raw rubber matrix: nitrile rubber (230S) 100

[0034] Nano-inorganic filler: nano-magnesium hydroxide (particle size 150-200 nm) 90

[0035] Modifier: Silane KH-845-4 5

[0036] Flame Retardant Synergist: Red Phosphorus 6

[0037] Expandable graphite (commercially available) 3.5

[0038] Antistatic plasticizer: conductive carbon black (commercially available) 5

[0039] TP-90B 20

[0040] Vulcanizing agent: Sulfur 1.5

[0041] Activator: Zinc Oxide 5

[0042] stearic acid 2

[0043] Vulcanization accelerator: CZ 1.2

[0044] DM 1

[0045] Antiaging agent: RD 1

[0046] 4010NA 2

[0047] The nano-magnesium hydroxide modification method is to dilute the silane KH-845-4 with 3 times the mass of acetone, mix it with nano-magnesium hydroxide, stir evenly, and then dry.

[0048] On the 6-inch open-type rubber mixing machine, adjust the roll distance...

Embodiment 2

[0050] The formulation system is as follows:

[0051] Raw rubber matrix: EP-35 100

[0052] Nano-inorganic filler: nano-magnesium hydroxide (particle size 150-200 nm) 130

[0053] Modifier: Si69 10

[0054] Flame Retardant Synergist: Red Phosphorus 7

[0055] Expandable graphite 3

[0056] Antistatic Plasticizer: Conductive Carbon Black 5

[0057] TP-90B 40

[0058] Vulcanizing agent: Sulfur 1.5

[0059] Activator: Zinc Oxide 5

[0060] stearic acid 2

[0061] Vulcanization Accelerator: CZ 2

[0062] DM 1.5

[0063] Antiaging agent: RD 1

[0064] MC 2.5

[0065] The modification method of nano-magnesium hydroxide is to dilute Si69 with 3 times the mass of acetone, mix it with nano-magnesium hydroxide, stir it evenly, and then dry it.

[0066] On the 6-inch open-type rubber mixing machine, adjust the roll distance to be less than 0.2mm and pass three times, then increase the roll distance to about 3mm, and th...

Embodiment 3

[0068] The formulation system is as follows:

[0069] Raw rubber matrix: nitrile rubber (220S) 100

[0070] Nano-inorganic filler: nano-aluminum hydroxide (particle size 150-200 nm) 60

[0071] Modifier: Si69 10

[0072] Flame Retardant Synergist: Red Phosphorus 10

[0073] Expandable graphite 2

[0074] Antistatic Plasticizer: Conductive Carbon Black 15

[0075] TP-90B 20

[0076] Vulcanizing agent: Sulfur 1.5

[0077] Activator: Zinc Oxide 5

[0078] stearic acid 2

[0079] Vulcanization Accelerator: CZ 2

[0080] DM 1

[0081] Antiaging agent RD 1.5

[0082] 4010 2

[0083] The above nano-aluminum hydroxide modification method is to dilute Si69 with 3 times the mass of acetone and mix it with nano-aluminum hydroxide, stir evenly and then dry.

[0084] On the 6-inch open-type rubber mixing machine, adjust the roll distance to be less than 0.2mm and pass three times, then increase the roll dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com