Zero halogen flame resistance polyethylene breathable film and preparation method and application thereof

A technology of flame-retardant polyethylene and breathable film, applied in the field of plastic modification, can solve problems such as droplet phenomenon, affecting pore formation, and low compatibility, so as to solve the problem of flame-retardant non-halogenation, meet applicable requirements, The effect of meeting production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

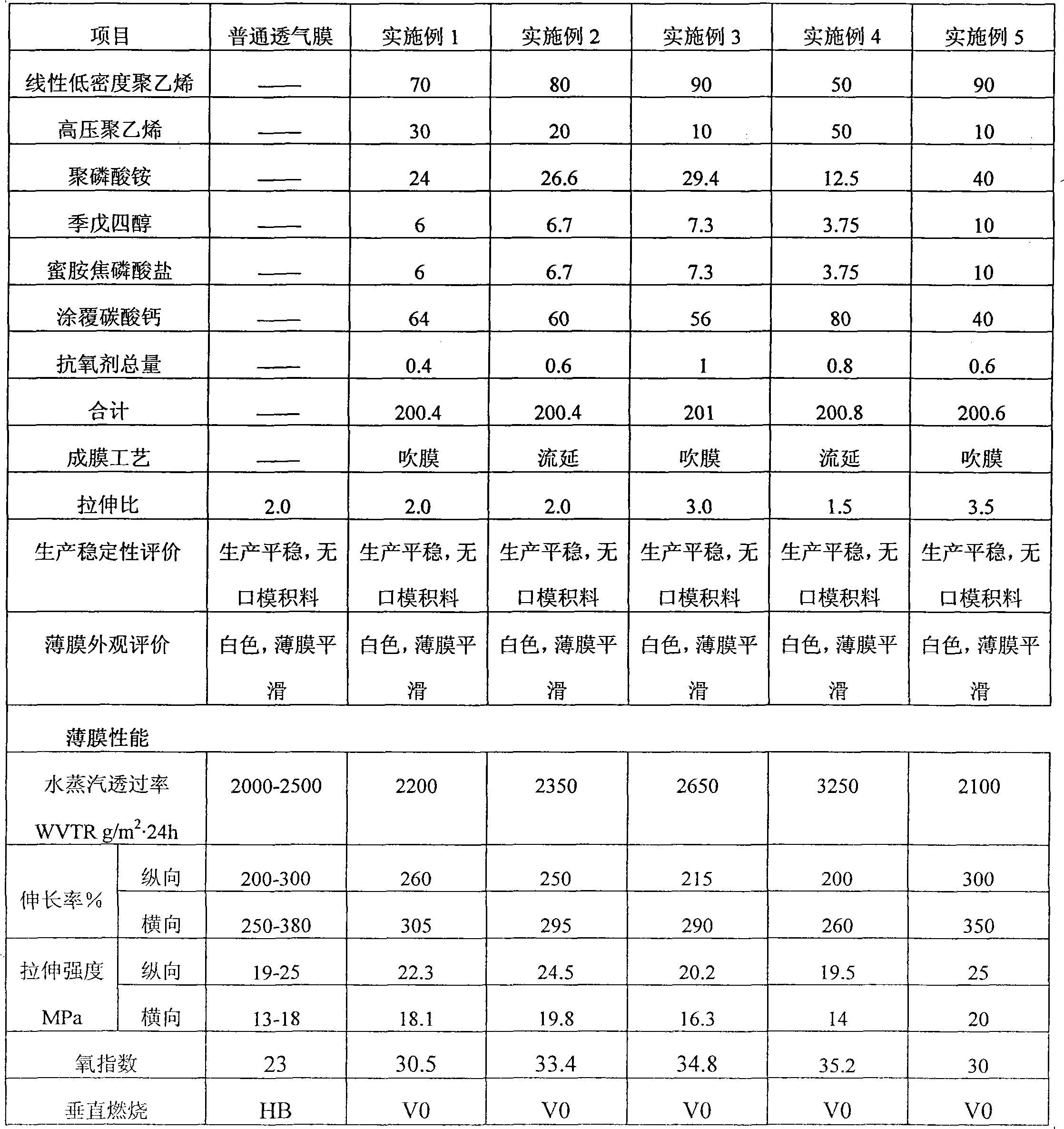

Examples

Embodiment 1

[0046] (1) Carry out surface coating treatment to calcium carbonate (particle diameter is 5.0 μ m) with surface modifier stearic acid in high-speed mixer and obtain coating calcium carbonate, the consumption of surface modifier is 2.0 of the total amount of calcium carbonate % (percentage by weight). The treatment process conditions are as follows: the rotation speed is 3000 rpm, the treatment temperature is 100° C., and the treatment time is 20 minutes.

[0047] (2) 70 parts by weight of linear low density polyethylene (its melt index is 1.0g / 10min and density is 0.915g / cm2) copolymerized with ethylene and octene (C8) 3 , molecular weight distribution is 3), 30 parts by weight of high pressure polyethylene (melt index is 2.0g / 10min, density is 0.920g / cm 3 ), 36 parts by weight of halogen-free flame retardant (density of 1.38, obtained by mixing MPP / PER / APP in a mass ratio of 6:6:24) and 0.5 parts by weight of maleic anhydride in 0.2 parts by weight of dicumyl peroxidation U...

Embodiment 2

[0050] (1) calcium carbonate (particle diameter is 0.5 μ m) is carried out surface coating treatment with surface modifier isopropyl tris (dioctyl phosphate acyloxy) titanate in high-speed mixer to obtain coated calcium carbonate, The amount of the surface modifier is 1.5% (percentage by weight) of the total amount of calcium carbonate. The treatment process conditions are as follows: the rotation speed is 3000 rpm, the treatment temperature is 90° C., and the treatment time is 30 minutes.

[0051] (2) 80 parts by weight of linear low density polyethylene (melt index is 4.0g / 10min, density is 0.918g / cm2) copolymerized with ethylene and hexene (C6) 3 , molecular weight distribution is 5), 20 parts by weight of high pressure polyethylene (melt index is 5.0g / 10min, density is 0.916g / cm 3 ), 40 parts by weight of a halogen-free flame retardant (density of 1.42, obtained by mixing MPP / PER / APP in a mass ratio of 6.7:6.7:26.6) and 0.2 parts by weight of maleic anhydride in 0.1 parts...

Embodiment 3

[0054] (1) Using the surface modifier isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate to perform surface coating treatment on calcium carbonate (particle size: 5.0 μm) in a high-speed mixer to obtain Coating calcium carbonate, the consumption of surface modifier is 0.5% (percentage by weight) of the total amount of calcium carbonate. The treatment process conditions are as follows: the rotation speed is 1500r / min, the treatment temperature is 130°C, and the treatment time is 10min.

[0055] (2) 90 parts by weight of linear low-density polyethylene copolymerized with ethylene and butene (C4) (its melt index is 8.0g / 10min, density is 0.925g / cm 3 , molecular weight distribution is 8), 20 parts by weight of high pressure polyethylene (melt index is 7.0g / 10min, density is 0.913g / cm 3 ), 44 parts by weight of halogen-free flame retardant (density of 1.52, obtained by mixing MPP / PER / APP in a mass ratio of 7.3:7.3:29.4) and 2 parts by weight of maleic anhydride in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com