Patents

Literature

674results about How to "High oxygen index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aminosilane coupling agent modifying ammonium polyphosphate

InactiveCN101235221AHigh flame retardant efficiencyReduce solubilityFireproof paintsFibre treatmentSolubilityPolyolefin

The invention discloses a preparation process of modifying ammonium polyphosphate with amino silane coupling agent, relating to the flame-retardant technology in chemical field. The invention provides a surface organic modified technology which can significantly reduce the water-solubility of ammonium polyphosphate, increases the compatibility of ammonium polyphosphate expansion flame-proof macromolecule material and the flame-proof efficiency, aiming to the problems existing the current ammonium polyphosphate flame-retardant that the current ammonium polyphosphate flame-retardant has higher dissolvability in water, and serious mechanical loss after applied on flame-proof plastic. The invention is conducted through two steps that firstly mixing amino silane coupling agent with deionized water according to weight ratio to hydrolyze, and secondly conducting surface organic modifying processing for ammonium polyphosphate (II type) with hydrolyzed amino silane coupling agent, which makes the dissolvability of II type ammonium polyphosphate in water be reduced to 0.43g / 100mL H2O from 1.101g / 100mL H2O, and respectively increases elongation at break and tension strength by 39.4% and 8.0% through applying modified ammonium polyphosphate on expansion flame-proof polypropylene. The modified ammonium polyphosphate can be extensively applied on the expansion flame-proof of polyolefins plastic, textile, lumber, paper and painting.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

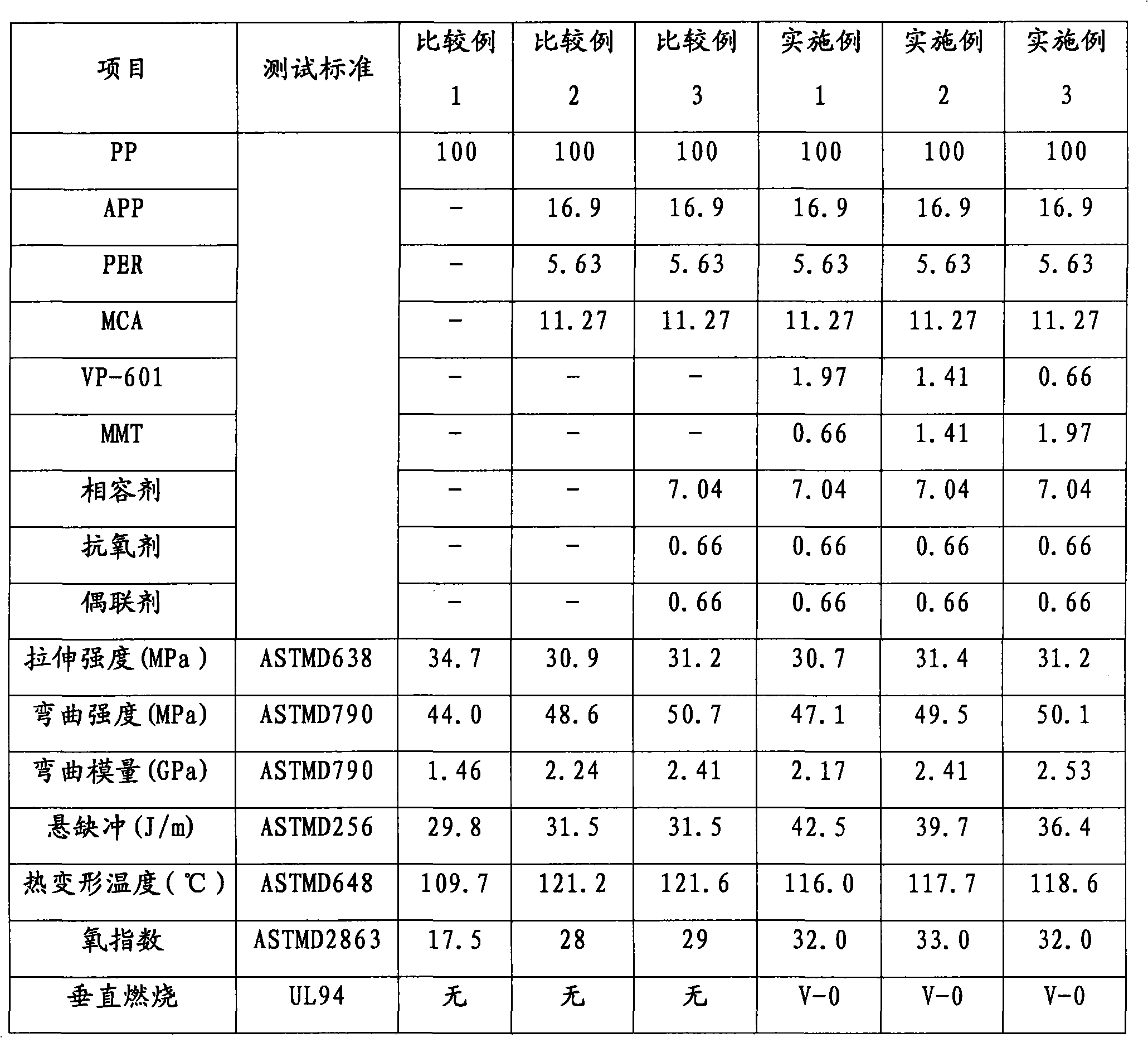

Expansion flame-proof polypropelene composition and preparation method thereof

The invention relates to an expansive flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 3.3-10 weight parts of pentaerythritol, 6.6-20 weight parts of melamine cyanurate, 0.5-5 weight parts of silicone rubber and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning the components according to the weight parts, melting, mixing, extruding, and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

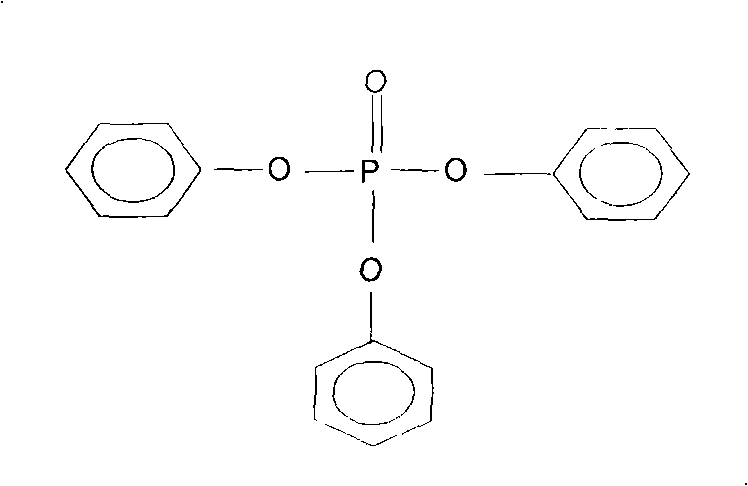

Reaction-type transparent halogen-free flameproof unsaturated polyester and preparation method thereof

The invention discloses a method for preparing a reaction type transparent halogen-free flame retardation unsaturated polyester. A program temperature control melting polycondensation reaction method is adopted; C2-6 dihydric alcohol, C3-8 saturated binary acid or anhydride, C4 unsaturated binary acid or anhydride, and a difunctional reactivity phosphatic flame retardant are used to synthesize an unsaturated polyester oligomer; styrene is taken as a crosslinking agent to prepare the unsaturated polyester which can be solidified at room temperature with transparent appearance, moderate viscosity and lower cost. After solidification, no added dissociated flame retardant component is contained in the cross linked network of the unsaturated polyester. The mechanical property, the flame retardation property and the electricity property of the product can be stable in a long period, the oxygen index of the product can be increased from 19 to 29 percent, and the product can pass the vertical firing UL94-V0 level. The reaction type transparent halogen-free flame retardation unsaturated polyester can be applied to the field of electronic and electric appliance insulating materials with higher performance requirements, construction flame retardation coating, ship-building material, flame retardation fiber glass reinforced plastics, and the like.

Owner:SOUTH CHINA UNIV OF TECH

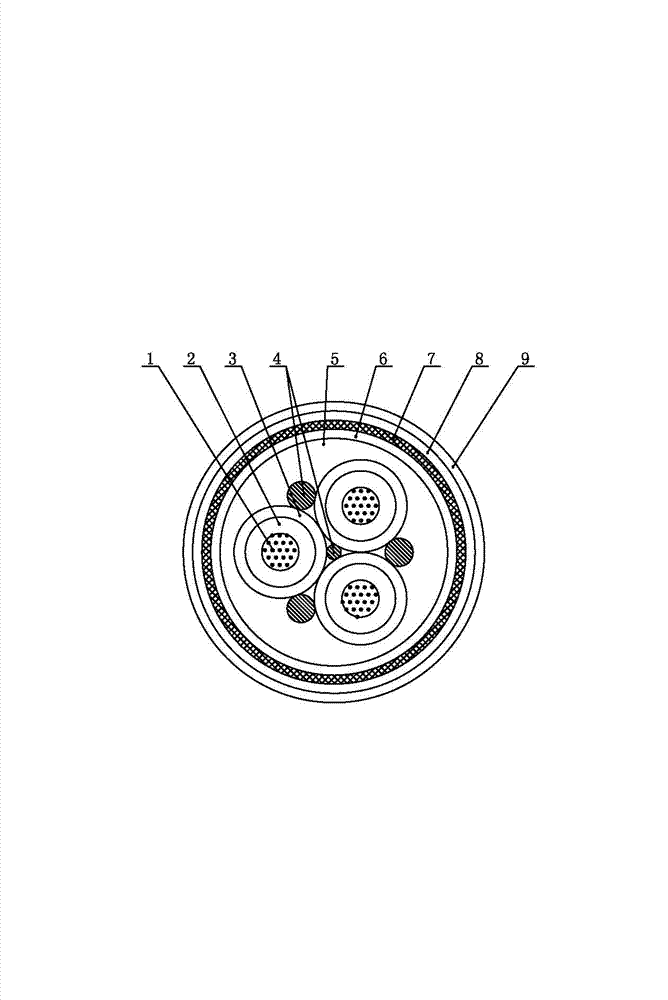

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

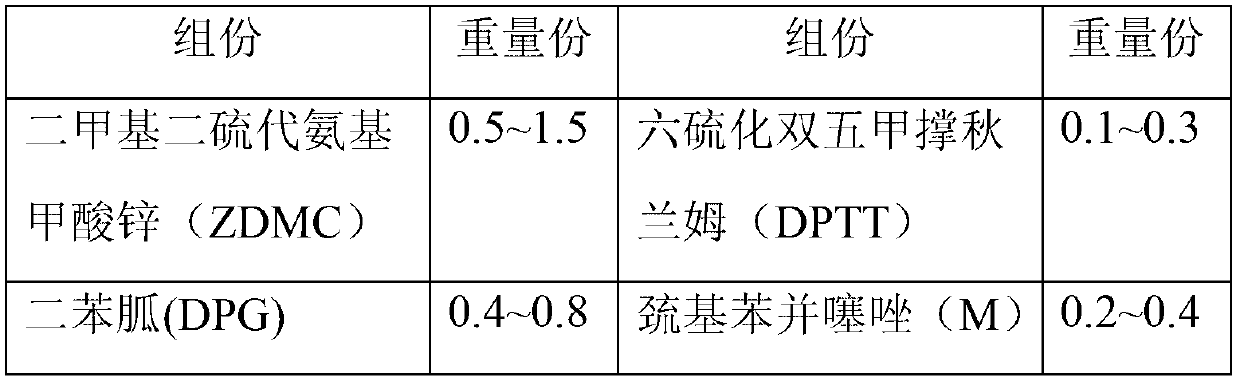

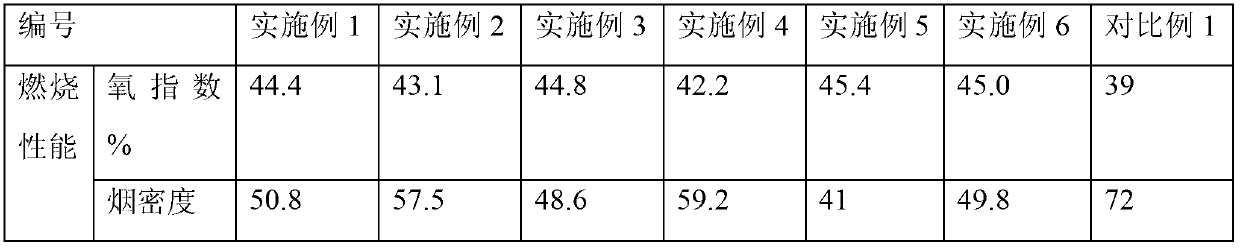

High flame retardancy type soft foam plastic insulation product and preparation method thereof

ActiveCN103102533AHigh oxygen indexImprove flame retardant performancePolyvinyl chloridePolyethylene glycol

The invention provides a high flame retardancy type soft foam plastic insulation product and a preparation method thereof. The product comprises the following components in parts by weight: 12 to 15 parts of nitrile rubber, 8 to 10 parts of talcum powder, 0.5 to 0.8 parts of polyethylene glycol, 0.2 to 0.4 parts of antiager 4020, 15 to 20 parts of chlorinated paraffin, 0.6 to 0.9 parts of paraffin, 1 to 2 parts of epoxidized soybean oil, 0.1 to 0.3 parts of antiager RD, 0.4 to 0.7 parts of carbon black, 7 to 10 parts of polrvinyl chloride, 26 to 36 parts of fire retardant based on the total amount, 2 to 5 parts of dioctyl ester, 8 to 12 parts of azodicarbonamide, 0.2 to 0.5 parts of stearic acid, 0.4 to 0.7 parts of zinc oxide, 0.4 to 0.7 parts of sulphur, and 1.3 to 1.8 parts of accelerant based on the total amount. By adopting the high flame retardancy type soft foam plastic insulation product, the technical problem that the oxygen index and the smoke density are mutually conflicted in the technological manufacture is solved, and the bottleneck due to mutual limitation is broken through.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

Aluminium hydroxide composite anti-flaming density fiber board and preparation method thereof

The invention relates to an aluminium hydroxide composite anti-flaming density fiber board and a preparation method thereof; according to the prepared anti-flaming density fiber board, the needed characteristic substances are as follows by mass parts: 100 parts of wood fiber, 20-30 parts of aluminium hydroxide, 0-10 parts of flame retardant synergists, 1-3 parts of coupling agents, 12-18 parts of adhesives, 1-3 parts of curing agents and 1-3 parts of waterproof agents; the composite flame retardant has low cost and no precipitation and is environmental-friendly and has no toxicity, and has good anti-flaming effect on density fiber board, oxygen index can each 36 percent and the vertical burning level is UL-94V-0.

Owner:BEIJING UNIV OF CHEM TECH

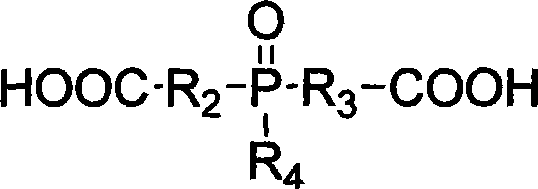

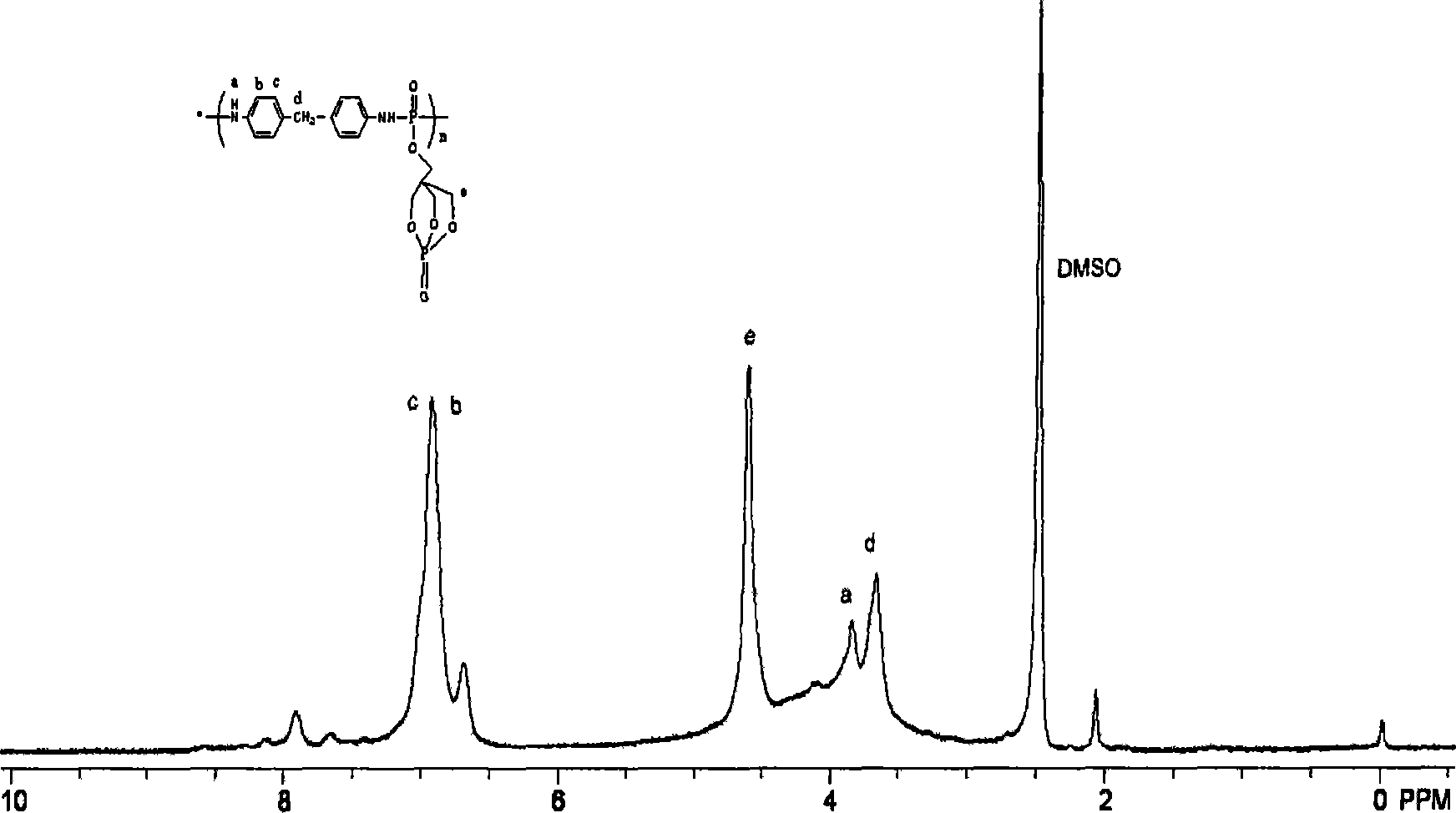

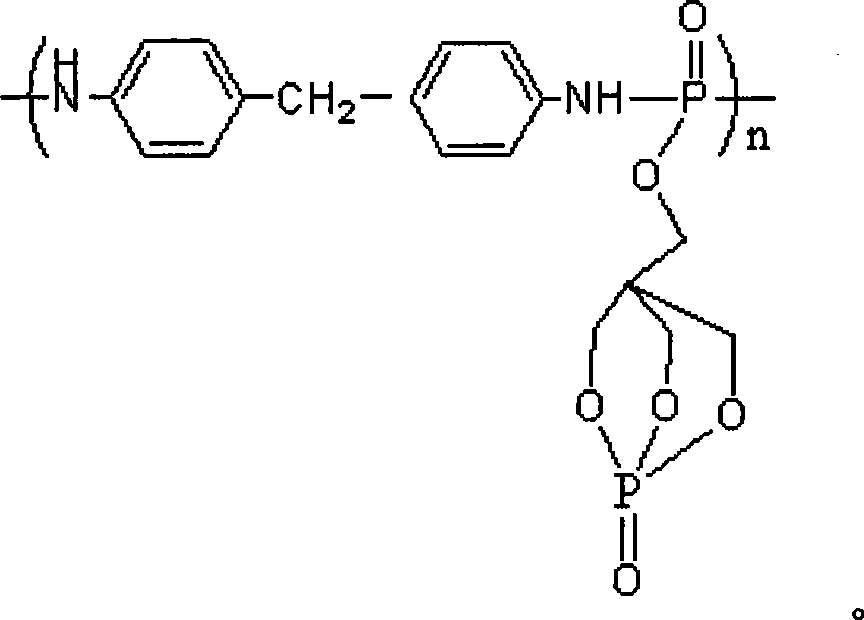

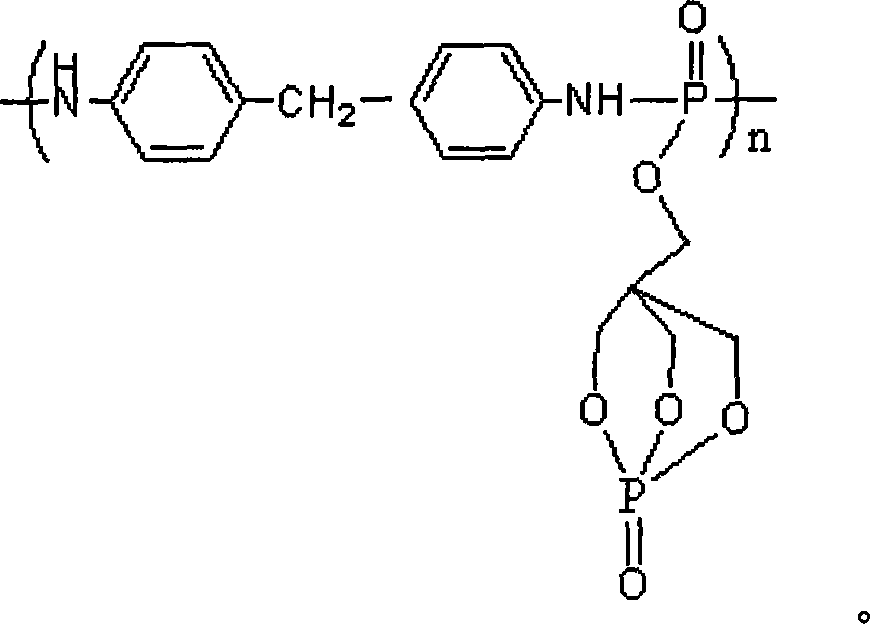

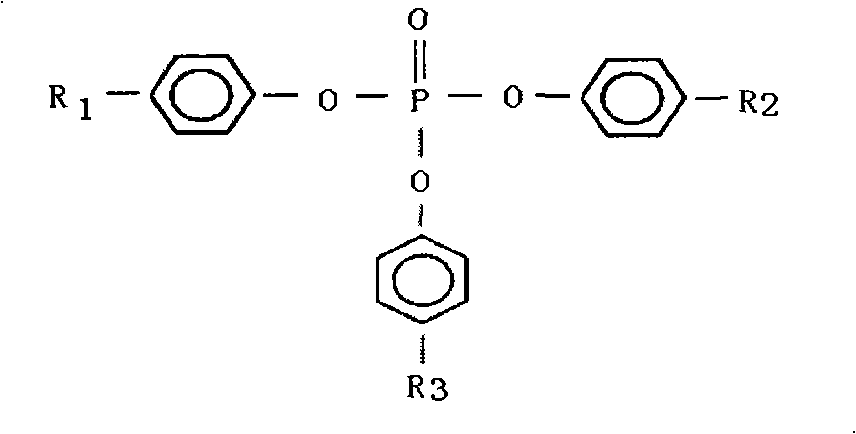

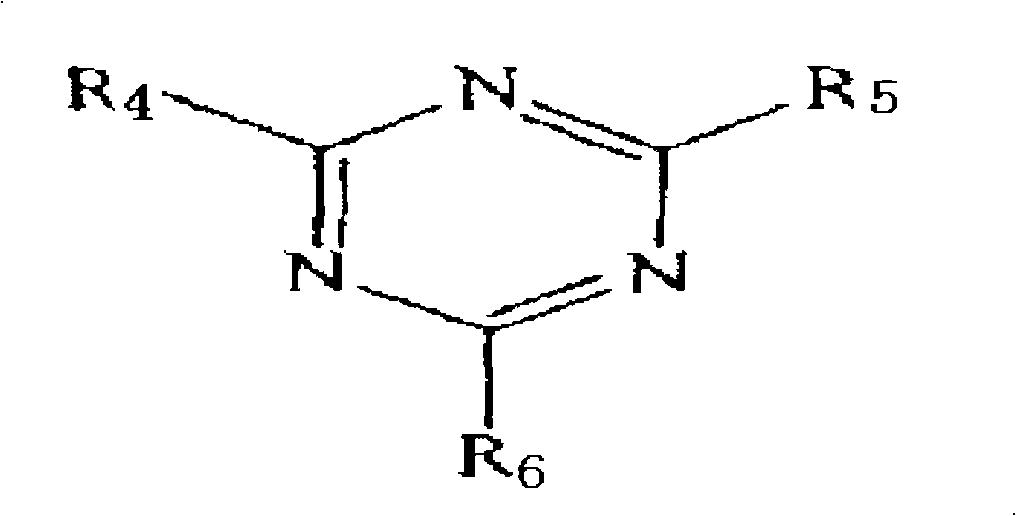

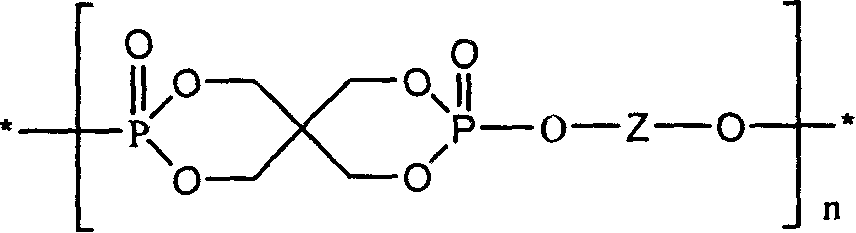

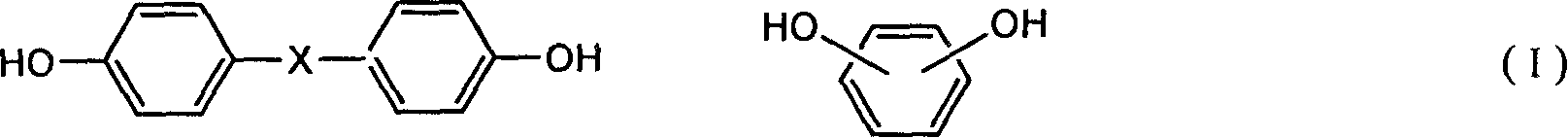

Buckling flame retardant containing phosphor-nitrogen macromolecule and preparation method thereof

InactiveCN101225310AGood application prospectImprove thermal stabilityFireproof paintsSolventDiamine

The invention relates to a macromolecular intumescent flame retardant with phosphorus and nitrogen, which is characterized in that: the chemical composition is poly (2, 6 and 7-trioxy-1-phosphorous dicyclic-[2, 2 and 2]-octane-1-anisyl) organic phosphate 4 and 4'-diaminodiphenylmethane; the preparation process is that: 2, 6 and 7-trioxy-1-phosphorous dicyclic-[2, 2 and 2]-octane-1-anisyl is put into the solvent of acetonitrile and dissolved after heating and stirring, and then diamine compound and catalyst are added into the solution, and a temperature reaction is processed under the protection of nitrogen; the solution is filtered when reaction is over to obtain the filter mass after being rinsed and dried. The macromolecular intumescent flame retardant with phosphorus and nitrogen has the advantages of being halogen-free and environment-friendly, big molecular weight, basically solving transplantation, separation, volatilization or other problems on the machineshaping of the flame retardant and the polymer substrate, simple preparation method and operation and higher productive rate of the product.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

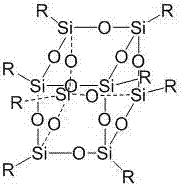

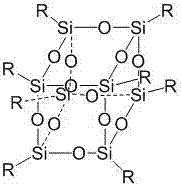

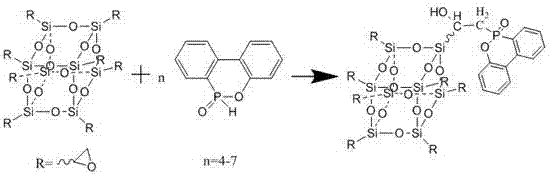

Silsesquioxane cross-linked silicon nitrogen phosphor synergic anti-flaming water-borne epoxy resin and preparation method thereof

ActiveCN107057517AImprove flame retardant performancePromote formationFireproof paintsAnti-corrosive paintsEpoxyCross-link

The invention discloses a silsesquioxane cross-linked silicon nitrogen phosphor synergic anti-flaming water-borne epoxy resin and a preparation method thereof. The water-borne epoxy resin is prepared from 40-80wt% of epoxy resin base stock, 2-12wt% of silicon nitrogen phosphor containing silsesquioxane epoxy resin curing agent, 0.5-2wt% of curing accelerator, 5-20wt% of foaming agent, 5-20wt% of charring agent, 3-20% of charring catalyst, 2-12wt% of pigment filler and 0.1-2.5wt% of flatting agent, and the sum of the content of the components is 100%. According to the invention, the silicon nitrogen phosphor containing silsesquioxane epoxy resin curing agent is taken as a curing agent and is synergic with the charring agent, the foaming agent and the charring catalyst so as to obviously improve the flame retardant property of the water-borne epoxy resin; the acquired water-borne epoxy resin has high bonding force with the metal surface, has high heat resistance and has an oxygen index of above 32; the preparation method is simple, safe and low-cost; the water-borne epoxy resin has an excellent application prospect.

Owner:广东一通科技股份有限公司

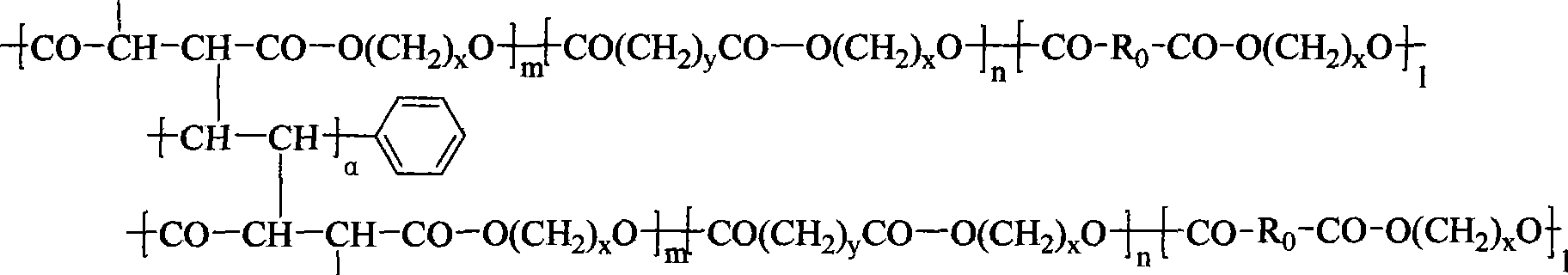

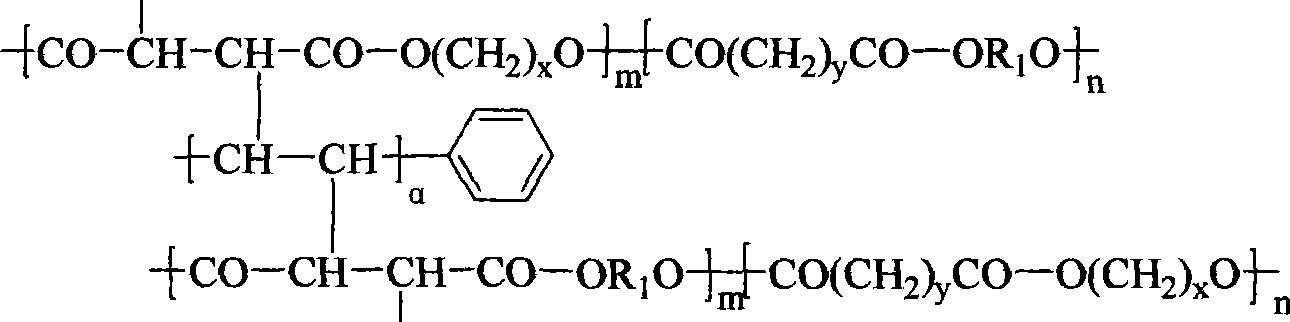

Flame-retardant anti-dropping resin composition

InactiveCN101348603AExcellent and durable flame retardantLittle impact on mechanical propertiesPolyesterFiber

The invention discloses a flame-retardant anti-dripping resin compound, consisting of 100 weight portions of thermoplastic resin, 0.01-5 weight portions of modified polytetrafluoroethylene anti-dripping agents and 20 to 40 weight portions of environment-friendly flame retardant containing phosphorus and / or nitrogen. The resin compound has strong anti-dripping effect and heat resisting performance, is level and smooth in exterior appearance, and can endow polyester fiber products with excellent enduring flame retardancy without using halogen (Cl and Br) flame retardant. The resin compound has the advantages of high oxygen index, droplet resistance, low heat release rate, no halogen, little toxicity, low smoke dust emission, little influence on the mechanical properties of base materials, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Phase-change energy-storage polyurethane foam and preparation method thereof

The invention discloses a phase-change polyurethane foam and a preparation method thereof. The foam is prepared by subjecting a polyurethane foam raw material to processes of reacting, foaming, and curing; wherein the polyurethane foam raw material comprises polyether, polymethylene polyphenyl isocyanate, silicone oil, and methyl chloride; the reactions are carrier out after the mixing of a phase-change energy-storage microcapsule and the polyurethane foam raw material, the phase-change energy-storage microcapsule is composed of a capsule wall made of polyurethane-polysiloxane and a capsule core made of an organic phase-change material, and polycarbodiimide is taken as the cross-linking agent. The phase-change energy-storage microcapsule integrates the advantages of organic materials and inorganic materials together, namely has the organic materials' advantages of flexibility and elasticity, also has the inorganic materials' advantages of excellent mechanical performance and fire-retardant performance, and overcomes the shortage of easy separation between the conventional microcapsule and the foam substrate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing damping porous denoise tunnel asphalt covering material

ActiveCN101173104AExcellent structural performanceImprove skid resistanceBuilding insulationsFiberSurface layer

The invention relates to a preparation method of a tunnel asphalt surface layer material. A preparation method for damping porous noise-reducing tunnel asphalt pavement material is characterized in that it comprises the following steps: 1) preparation of high-viscosity and high-elasticity modified asphalt: base asphalt according to the mass ratio of each component: modifier SBS : Activated rubber powder: Viscosifying compatibilizer: Antioxidant: Stabilizer=100: 6.0~18.3: 20.2~45.7: 1.2~3.7: 0.2~1.4: 0.4~1.9, select; obtain high viscosity and high elasticity modification Asphalt; 2) Add flame retardant to high-viscosity and high-elasticity modified asphalt, heat and melt high-viscosity and high-elasticity modified asphalt to add flame retardant, stir for 3-9 minutes, and stand at 150-170°C for 15-30 minutes to obtain Flame-retardant high-viscosity high-elasticity modified asphalt; 3) according to the mass ratio, mineral material: flame-retardant high-viscosity high-elasticity modified asphalt: fiber stabilizer = 100: 3.6~5.2: 0.1~0.4, choose; noise tunnel asphalt surface material. The invention has the functions of noise reduction, flame retardancy and anti-skid.

Owner:WUHAN MUNICIPAL CONSTR GROUP

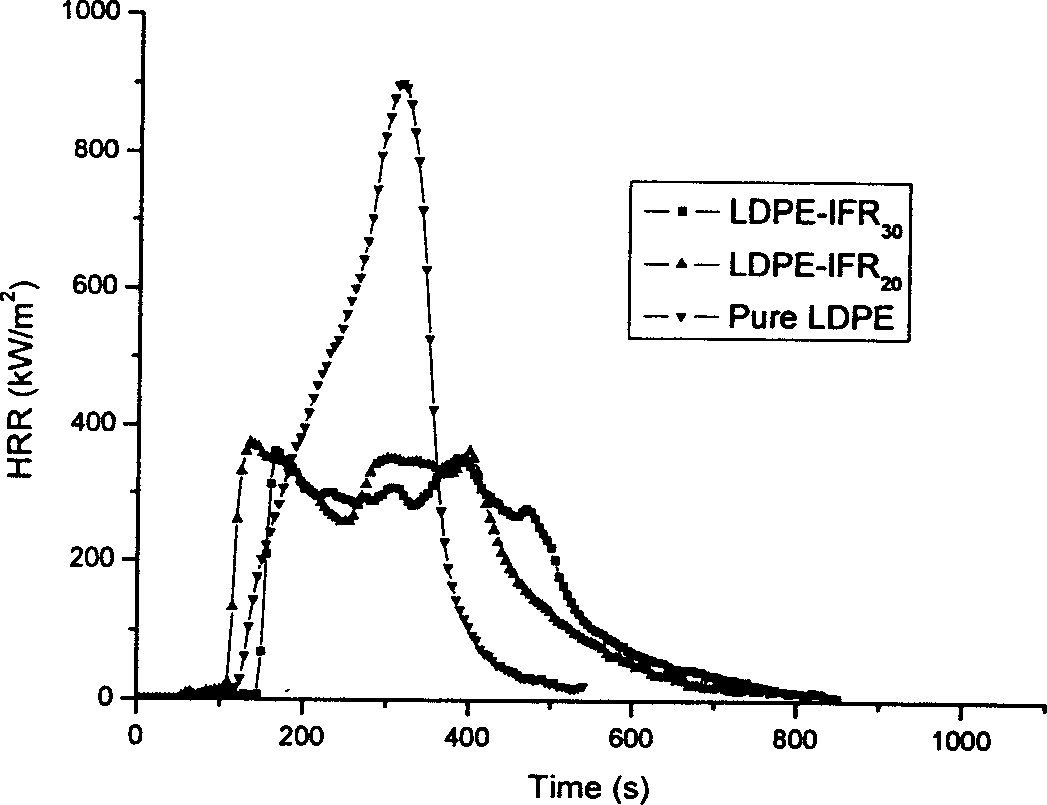

Halogon-free expansion flame-retarded polyolefin complex substance

The invention discloses a kind of non-halogen inflating fire-retarding polyolefine composition, which includes 50 - 90 weight shares of thermosplasticity polyolefine basic material and 10 - 50 weight shares of non-halogen inflating fire retarder. The non-halogen inflating fire retarder is comprised of non-halogen charcoal becoming fire retarder, non-halogen nitrous fire retarder and APP, weight proportions of which are 1 - 6 : 0.5 - 2 : 0.5 - 2. The compound has high oxygen index, melting drops resistance, low heat emitting velocity, no halogen, low toxicity, low smoke emission and small effect to dynam performance of basic material. It can be used in various fire retarding fields, and is especially suitable to be used in electrical wire cable, communications cable, shipping and auto industries.

Owner:SICHUAN UNIV

Organic-inorganic composite nanometer heat-insulating fire-retardant coating and preparation method thereof

ActiveCN104177965AImprove adhesionImprove anti-corrosion performanceFireproof paintsEpoxy resin coatingsEpoxyOrganic film

The invention discloses an organic-inorganic composite nanometer heat-insulating fire-retardant coating and a preparation method thereof. The organic-inorganic composite nanometer heat-insulating fire-retardant coating is prepared by mixing organic film-forming substance acrylic ester emulsions or styrene-acrylate emulsions, epoxide resin, organic intumescent fire-retardant system pentaerythritol, melamine and ammonium polyphosphate with inorganic fire retardant nanometer aluminum hydroxide, nanometer magnesium hydroxide, filler nanometer titanium dioxide, ceramic hollow microspheres, glass hollow microspheres and a part of auxiliary agents. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention not only has excellent facing property and fire-retardant property, but also achieves reflection effect on solar radiation and certain heat-insulating and heat-preserving property on a substrate, also has good adhesivity, mechanical property and hydrophobic effect, can be formed through spray coating or brush coating before being solidified, and is a novel water-based multifunctional fire-retardant material. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention can not only be used as a general building wall body fire-retardant coating, but also be suitable for the fire prevention of building and ornament materials, heat-insulating materials, steel structure supports, beam columns, metal roofs and the like.

Owner:山西省建筑科学研究院集团有限公司

PVC cable material and preparation method thereof

ActiveCN103275427AHigh oxygen indexExcellent flexibility and electrical insulationPlastic/resin/waxes insulatorsThermal ageingPlasticizer

The invention discloses a PVC (polyvinyl chloride) cable material which comprises the following components by mass: 100 parts of PVC, 5-15 parts of heat stabilizer, 10-60 parts of plasticizer, 1-15 parts of lubricant, 0.1-1 part of antioxygen, 2-10 parts of fire retardant, 5-10 parts of calcined clay, 10-40 parts of calcium carbonate, and 0.1-0.5 part of UV-329; the oxygen index of the PVC cable material reaches up to be 33%, the dielectric constant is 4.2, the smoke density per the unit mass of smoke is 10-12 g, thermal ageing quality loss is 15-18 g / m<2>, the volume resistivity is 8*1015 omega / cm at the temperature of 20 DEG C, the volume resistivity is 6*1015 omega / cm at the temperature of 70 DEG C, the tensile strength is 18-19 MPa, the tensile strength retention rate is 99%, and the PVC cable material resists is heat-resistant and cold-resistant, is difficult to volatilize, is pumping-resistant and excellent in flexibility and electric insulation property, can be widely produced and can replace the conventional material continuously.

Owner:DAISHAN POWER SUPPLY CO STATE GRID ZHEJIANG ELECTRIC POWER CO +1

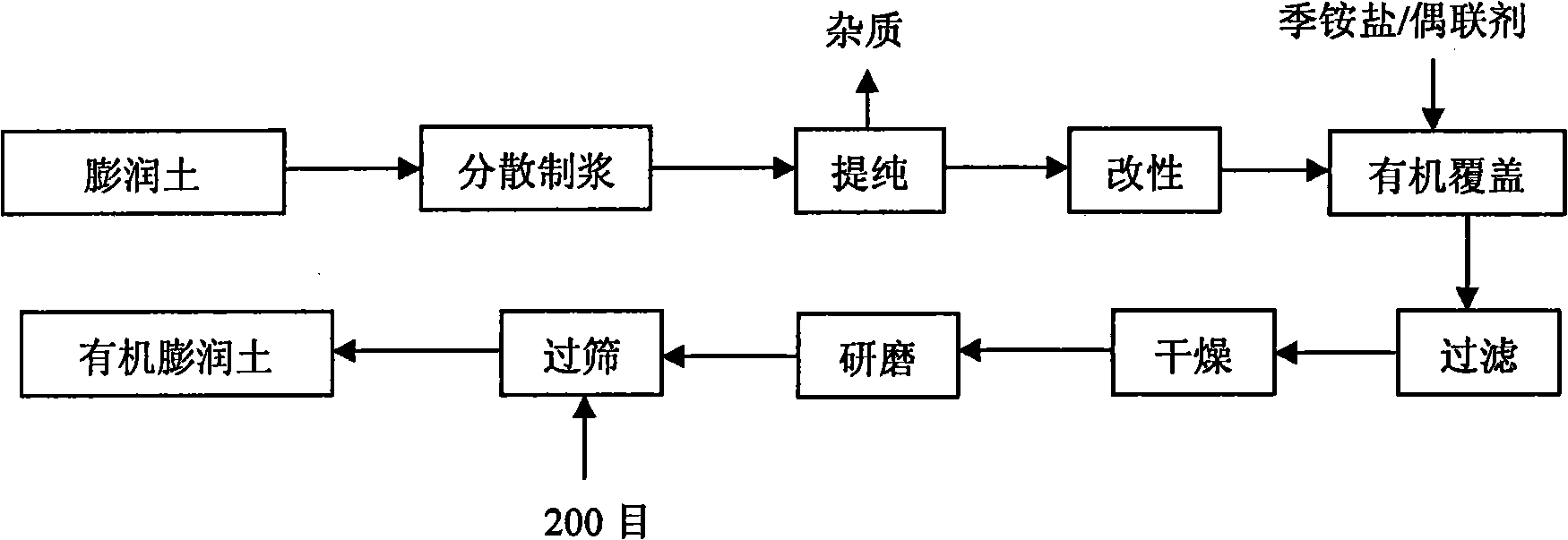

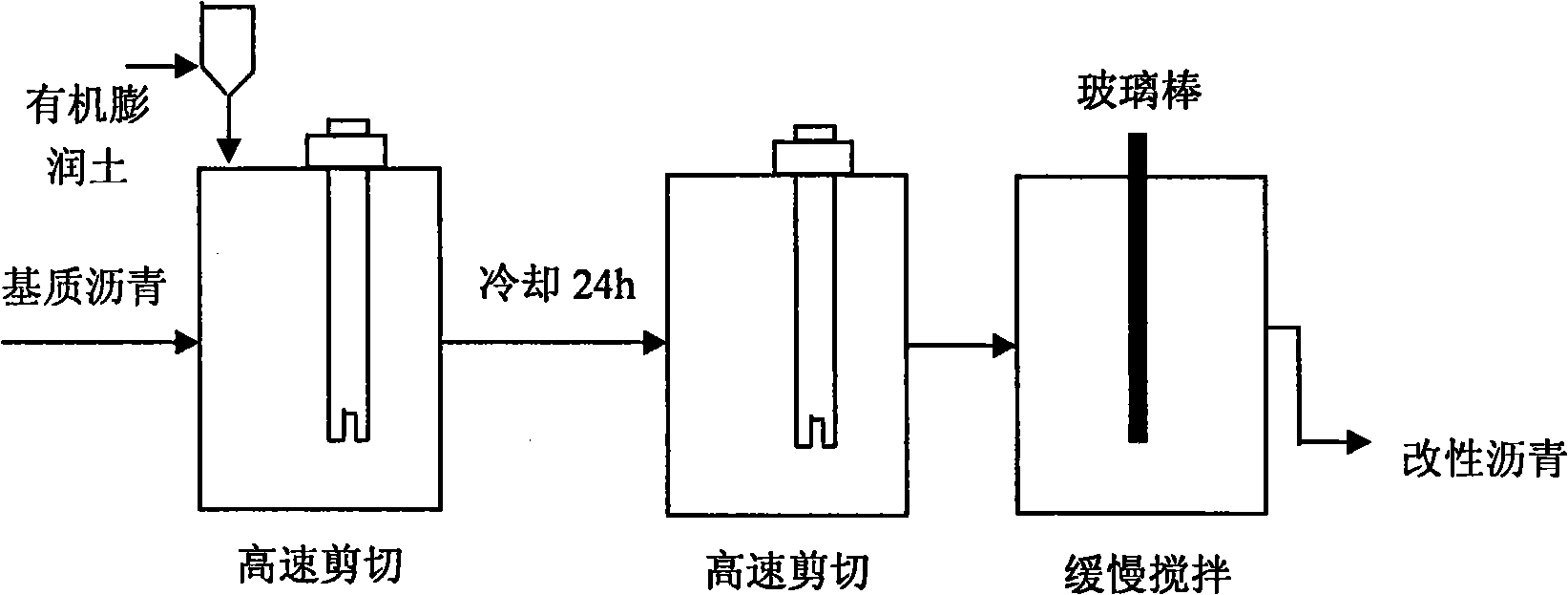

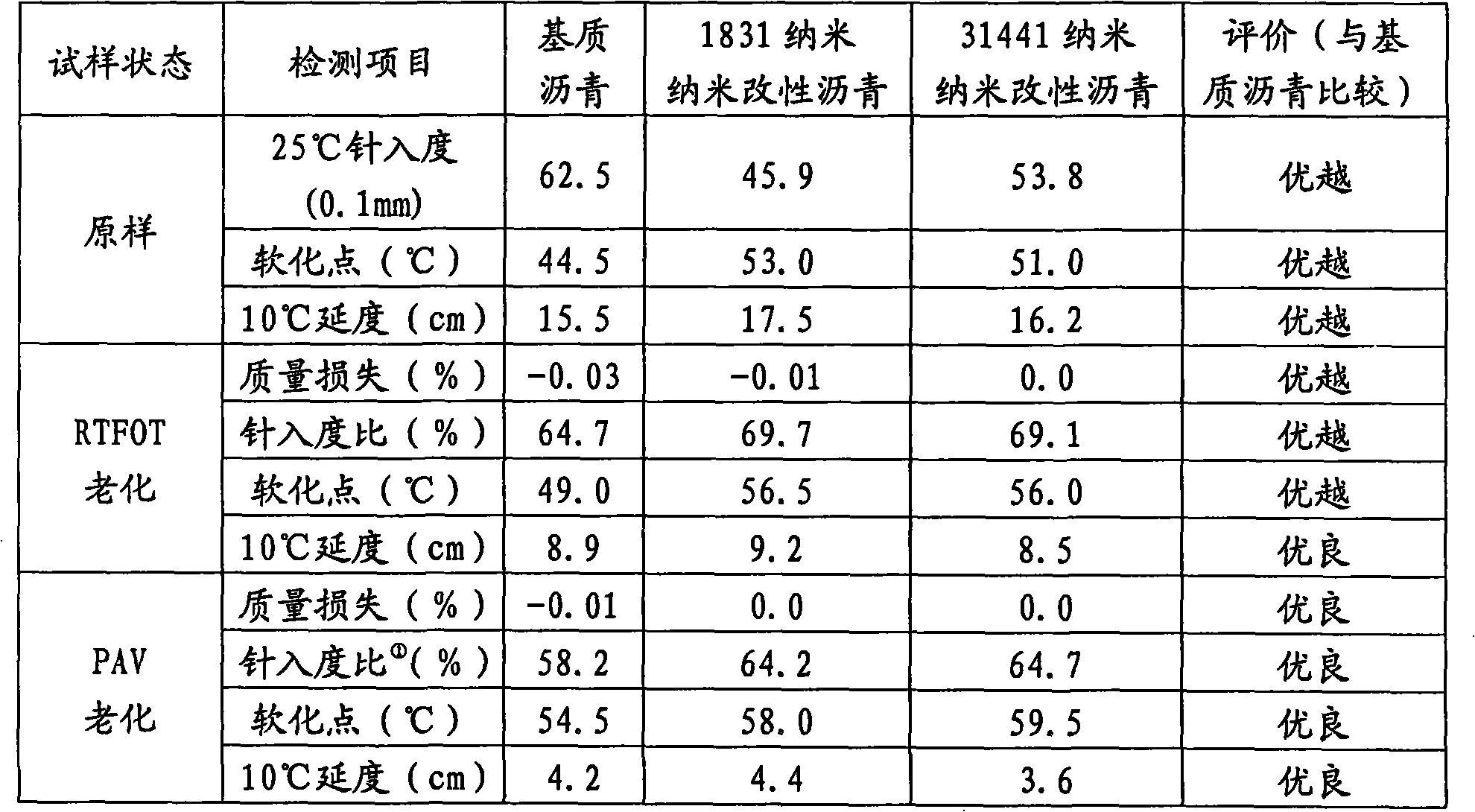

Phyllosilicate nano modified asphalt by dual processing of intercalation and coupling and preparation method thereof

InactiveCN101525492AImprove high temperature stabilityEnhanced toughening effectBuilding insulationsOrganificationCoupling

The invention adopts organic cation intercalator and coupling agent to carry out organification intercalation processing on laminated clay silicate, so as to prepare organification laminated clay silicate and mix the silicate with liquated road asphalt to form the modified asphalt. The invention also relates to the preparation process of the modified asphalt. The modified asphalt of the invention not only has better road performance than that of matrix asphalt but also prevents premature failure of asphalt road surface and lengthens service life of the road surface; in addition, the cost of materials and processing devices is far lower than the cost of polymer nano modified asphalt.

Owner:CHONGQING JIAOTONG UNIVERSITY

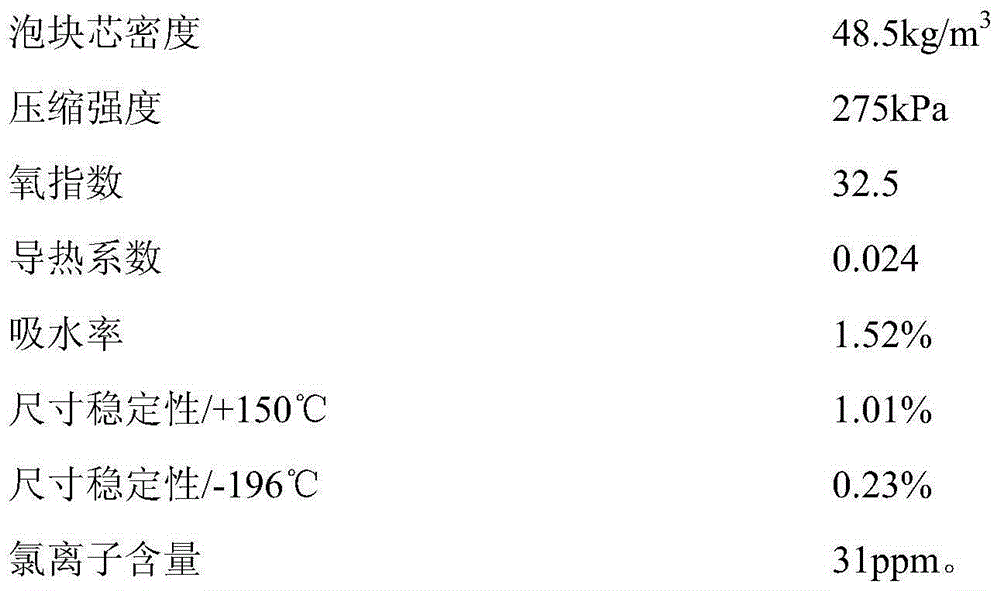

Preparation method of expansible graphite modified high-flame-retardant rigid polyurethane foam

The invention discloses a preparation method of expansible graphite modified high-flame-retardant rigid polyurethane foam. The preparation method includes the steps that firstly, white materials are prepared, wherein polyester polyol, polyether polyol, structural flame retardant polyether polyol, foam homogenizing agents, liquid fire retardant, fermentation catalysts, gel type catalysts, trimerization catalysts and water are evenly mixed, then graphite is added, foaming agents are added to the evenly mixed mixture, and the white materials are obtained; the prepared white materials are mixed with black materials according to the mass ratio of 1:1.5-1.8, the mixture is stirred and injected into a constant-temperature die for foam aging, and the rigid polyurethane foam is obtained, wherein the black materials are polyisocyanates. By means of the preparation method of the expansible graphite modified high-flame-retardant rigid polyurethane foam, the oxygen index of the rigid polyurethane foam is raised, the combustion performance can reach the non-combustible level, the mechanical strength and size stability are good, and the heat conductivity coefficient is low; compared with a similar product in the market, a great price advantage is achieved, and machining and forming are easy; the added fire retardant is free of volatility, not prone to being separated out, low in toxicity and durable in flame retardant effect.

Owner:JINAGSU SUNPOWER PIPELINE ENG TECH CO LTD

Auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process

The invention discloses auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methyl-2-pyrrolidinone is 0.93-1.15 to 1.00-1.28 to 1.98-2.98 to 1.18 to 1.48. The industrial synthetic process mainly comprises the following steps: firstly, in a sodium hydrosulfide dehydration treatment stage, a pipeline filter is adopted to filtrate a sodium hydrosulfide solution to treat mechanical impurities in the solution, then a sodium hydroxide solution with the concentration 84 mol percent is added in the formula for chemical treatment on the sodium hydrosulfide; secondly, in the condensation polymerization stage, anaerobic deionized water is added to further appropriately adjust the molecular weight and molecular weight distribution coefficient of synthesized polyphenylene sulfide resin; thirdly, deionized water is adopted for repeatedly scrubbing for 3 to 6 times, and finally, the target product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process provided by the invention is obtained. The resin in the obtained product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is low in polydispersity index and high in oxygen index, and has an excellent electrical insulation property.

Owner:周洪

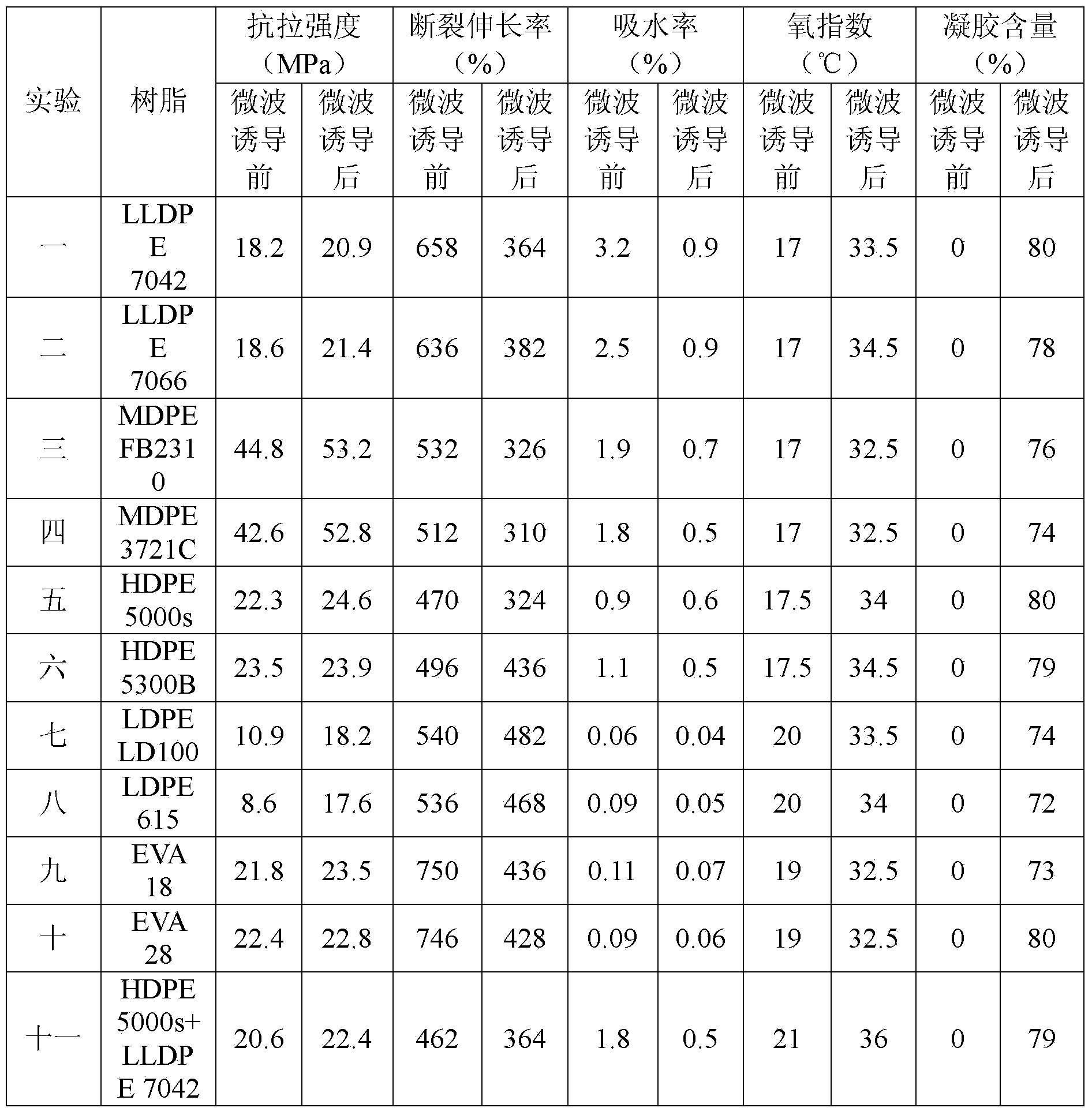

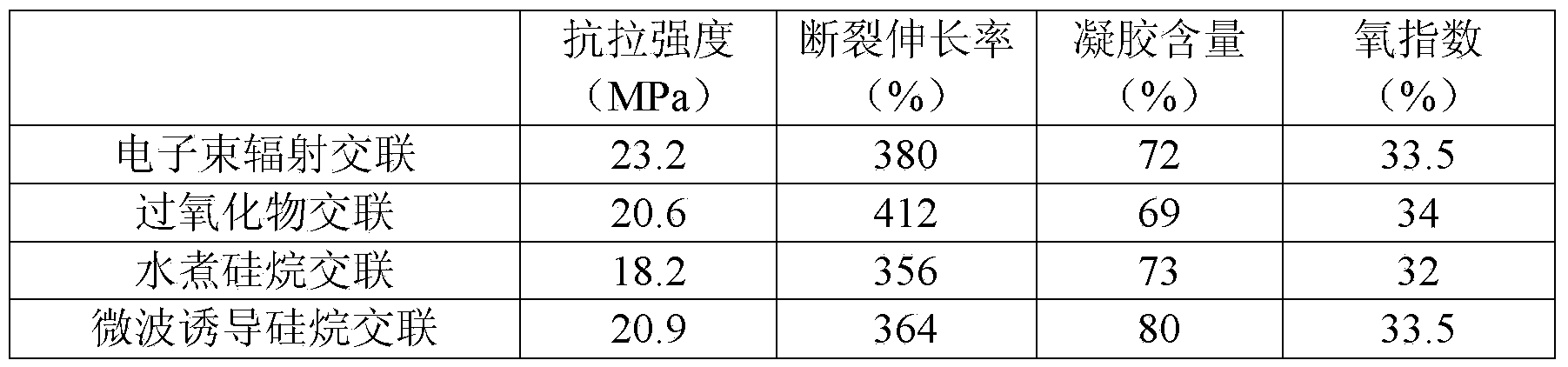

Microwave induced intumescent flame-retardant silane crosslinked polyolefin sheath material for cables and preparation method thereof

InactiveCN103435897ALow costImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesPolyolefinPolymer science

The invention relates to a sheath material and a preparation method thereof and provides a microwave induced intumescent flame-retardant silane crosslinked polyolefin sheath material for cables and a preparation method thereof for solving such technical problems in the existing preparation method of flame-retardant silane crosslinked sheath materials as long-time boiling with water is required, the stability and flame retardant effect of the product are poor. The material is prepared from a polyolefin resin, an intumescent flame retardant, a silane coupling agent, a microwave absorbent, a water bringing agent, a polyfunctional group crosslinking agent, a crosslinking accelerant and an antioxidant. The preparation method comprises the steps of carrying out melt mixing on the polyolefin resin, the intumescent flame retardant, the silane coupling agent, the microwave absorbent, the water bringing agent, the polyfunctional group crosslinking agent, the crosslinking accelerant and the antioxidant, carrying out granulation and tabletting, then carrying out microwave induced crosslinking and putting the product at room temperature, thus preparing the material. The mechanical property of the material prepared by the preparation method is obviously increased, the tensile strength is improved by nearly 20% and the oxygen index is improved by more than 70%. The material and the preparation method belong to the field of preparation of polyolefin sheath materials.

Owner:HONGLONGJIANG ORIENT SCI & TECH

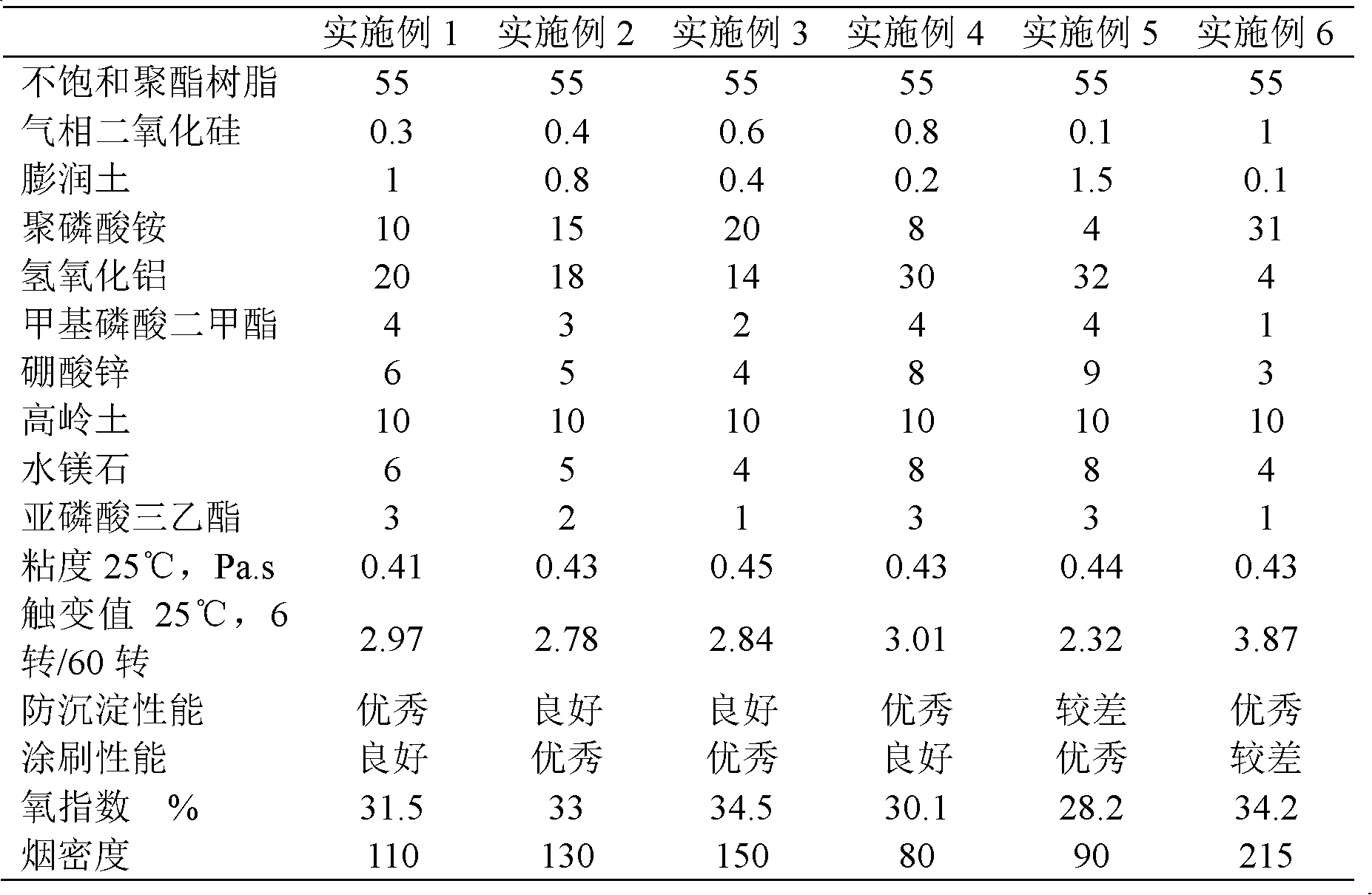

Low-smoke density additive-type flame retardant resin and application thereof

The invention discloses a low-smoke density additive-type flame retardant resin which comprises 45-70 parts of unsaturated polyester resins by mass, 0.5-10 parts of mixtures of fumed silica and bentonite by mass, 4-8 parts of zinc borate by mass, 5-30 parts of aluminum hydroxide by mass and 5-30 parts of ammonium polyphosphate flame retardants by mass. The ammonium polyphosphate, the zinc borate and the aluminum hydroxide are combined and added to the unsaturated polyester resins to prepare the low-smoke density additive-type flame retardant resin which has the characteristics of low smoke density during burning, good mechanical performance and the like. Through the synergistic effect of the fumed silica and the bentonite, resin settlement can be prevented and the storage stability of the resin can be improved. The low-smoke density additive-type flame retardant resin provided by the invention is mainly applicable to the fields such as traffic vehicles, buildings, shipbuilding, chemical equipment, electronics, sports equipment, daily equipment and the like.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

Highly flame-resistant external wall heat preservation material and process for producing same

InactiveCN101748811ALow water absorptionLow smoke densityHeat proofingEngineeringVolumetric Mass Density

The invention discloses a highly flame-resistant external wall heat preservation material and a process for producing the same, which are mainly used for the construction of isolation belts and the heat preservation of high-rise buildings and building bodies with relatively higher requirement on fire-protection rating. According to the process, the highly flame-resistant external wall heat preservation material is produced by taking modified phenol aldehyde resin with low hydroxyl content as a raw material and performing low-acid curing on the modified phenol aldehyde resin. The modified phenol aldehyde resin with the low hydroxyl content is prepared by heating phenol, formaldehyde, a modifier and chopped glass fiber firstly under an acidic condition and then under an alkali condition and then performing copolymerization and condensation on the phenol, the formaldehyde, the modifier and the chopped glass fiber. The modified phenol aldehyde resin with the low hydroxyl content, a surfactant, a gas foaming agent, a modified moisture repel and an organic acid catalytic system are cured and molded on a continuous line. The highly flame-resistant external wall heat preservation material has the following advantages that: a terminal hydroxyl group of the adopted phenol aldehyde resin is closed, so the water absorbing capacity of the material is reduced; the cured molding material has high strength and low acidity; the service life of the material is prolonged and simultaneously convenience is provided for construction; the highly flame-resistant external wall heat preservation material has excellent flame resistance, lower smoke density and a higher oxygen index; and fire protecting safety property in a construction and use process is greatly improved due to the non-smoldering property of the highly flame-resistant external wall heat preservation material.

Owner:滕州市华海新型保温材料有限公司

Low-smoke halogen-free coal mine electric cable material and preparation method thereof

InactiveCN104371199AGood flexibilityMeet the laying conditionsRubber insulatorsPlastic/resin/waxes insulatorsCrack resistanceEngineering

The present invention discloses a low-smoke halogen-free coal mine electric cable material and a preparation method thereof. The raw materials of the low-smoke halogen-free coal mine electric cable material comprise an ethylene propylene diene monomer, an ethylene-vinyl acetate rubber, a fire retardation agent, a reinforcing agent, an anti-hydrolysis agent and a peroxide cross-linking agent. The low-smoke halogen-free coal mine electric cable material of the present invention is a thermosetting electric cable material, has low smoke during burning, has advantages of high temperature-low temperature (-40-120 DEG C) resistance, cracking resistance, corrosion resistance, ozone resistance and the like, meets environmental protection requirements, and does not contain any halogen-containing components. According to the present invention, with the combination of the ethylene propylene diene monomer and the ethylene-vinyl acetate rubber, the dispersion uniformity of other materials in the electric cable material is increased, and the molecular structure is improved, such that the softness of the electric cable material is good, the conditions such as the laying under the -40 DEG C low temperature environment and the like can be met for a long time, and the oxygen index and the good fire retardation are provided; and the low-smoke halogen-free coal mine electric cable material is suitable for the underground mine or the occasion of the special work environment having high security.

Owner:TEBIAN ELECTRIC APP CO LTD

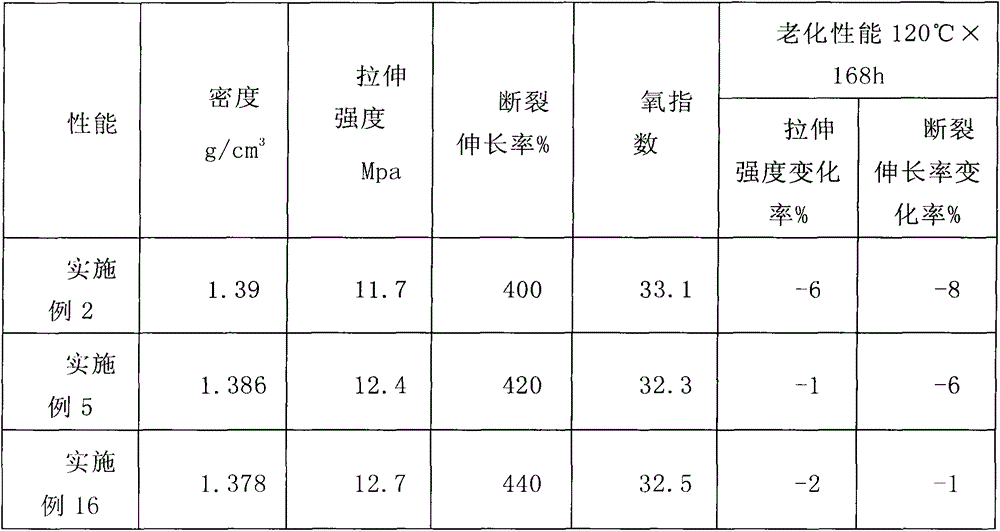

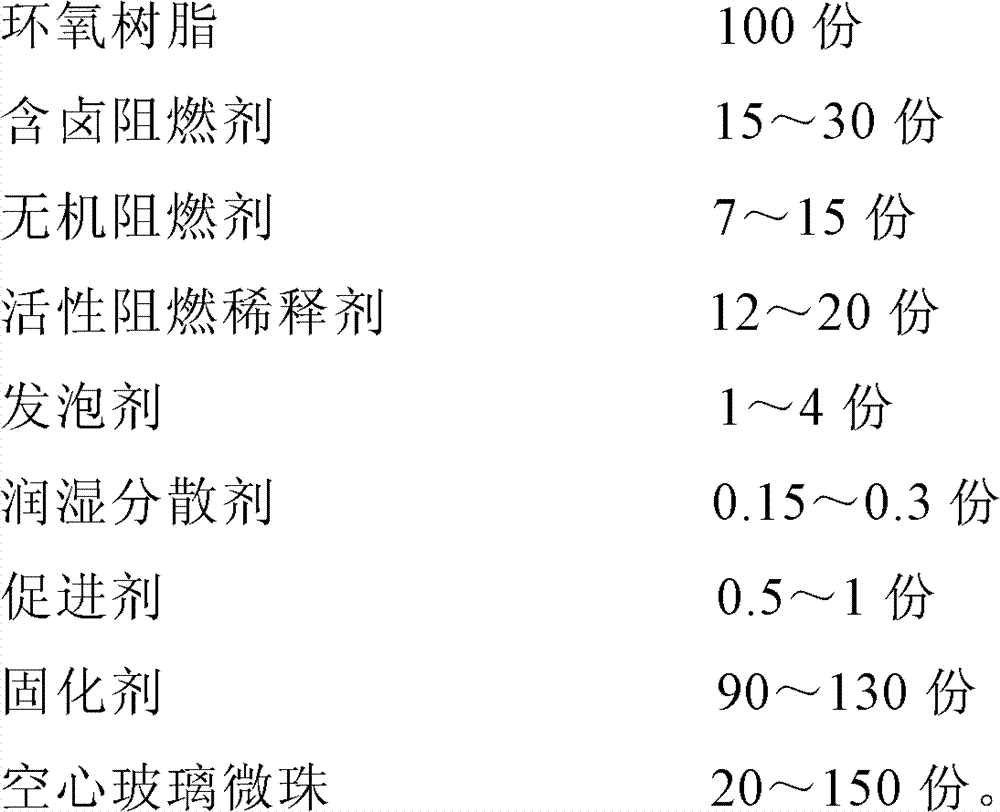

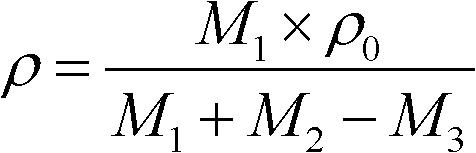

Flame retardant solid buoyancy material and preparation method thereof

ActiveCN102775727AOvercoming Flame Retardancy RequirementsNo loss of net buoyancyHalogenFire retardant

The invention relates to the technical field of a solid buoyancy material used in a marine environment and specifically to a flame retardant solid buoyancy material and a preparation method thereof. The flame retardant solid buoyancy material comprises, by mass, 100 parts of an epoxy resin, 15 to 30 parts of a halogen-containing fire retardant, 7 to 15 parts of an inorganic fire retardant, 12 to 20 parts of an active flame retardant diluent, 1 to 4 parts of a foaming agent, 0.15 to 0.3 part of a wetting dispersant, 0.5 to 1 part of an accelerator, 90 to 130 parts of a curing agent and 20 to 150 parts of hollow glass beads. The flame retardant solid buoyancy material provided in the invention has the characteristic of flame retardation, can be used in deep sea, is free of loss of net buoyancy and is processable.

Owner:MARINE CHEM RES INST

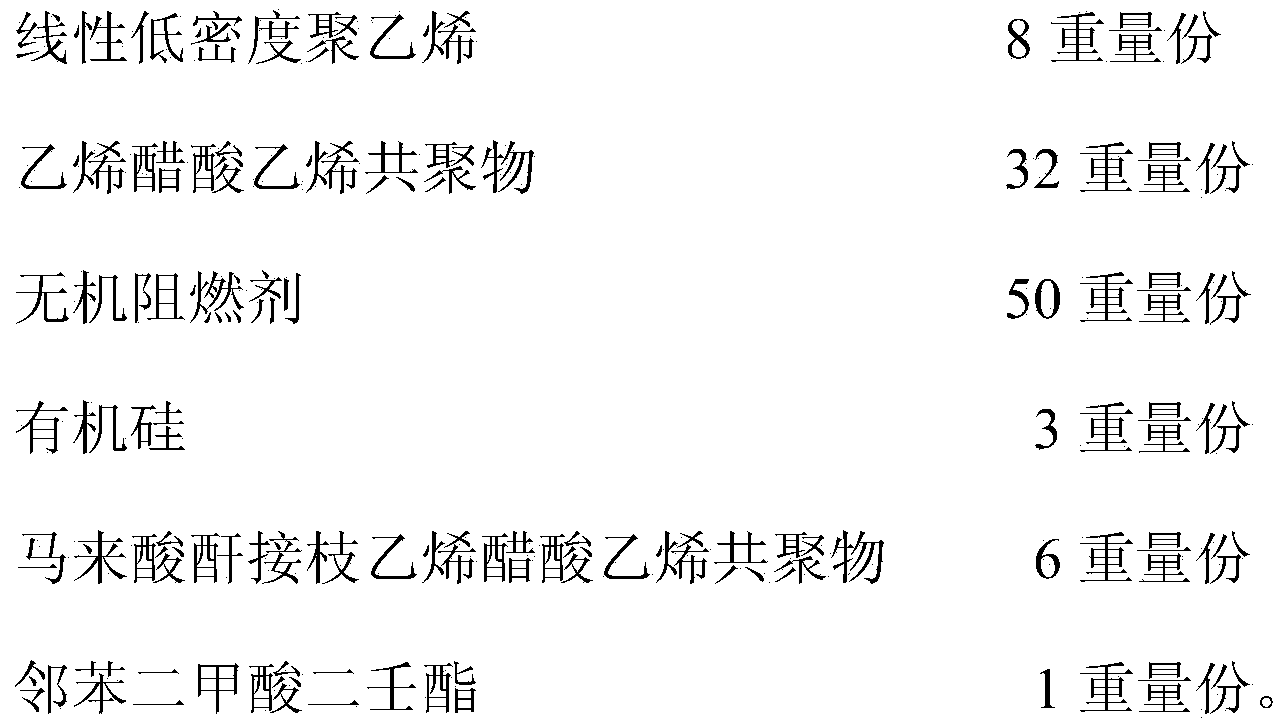

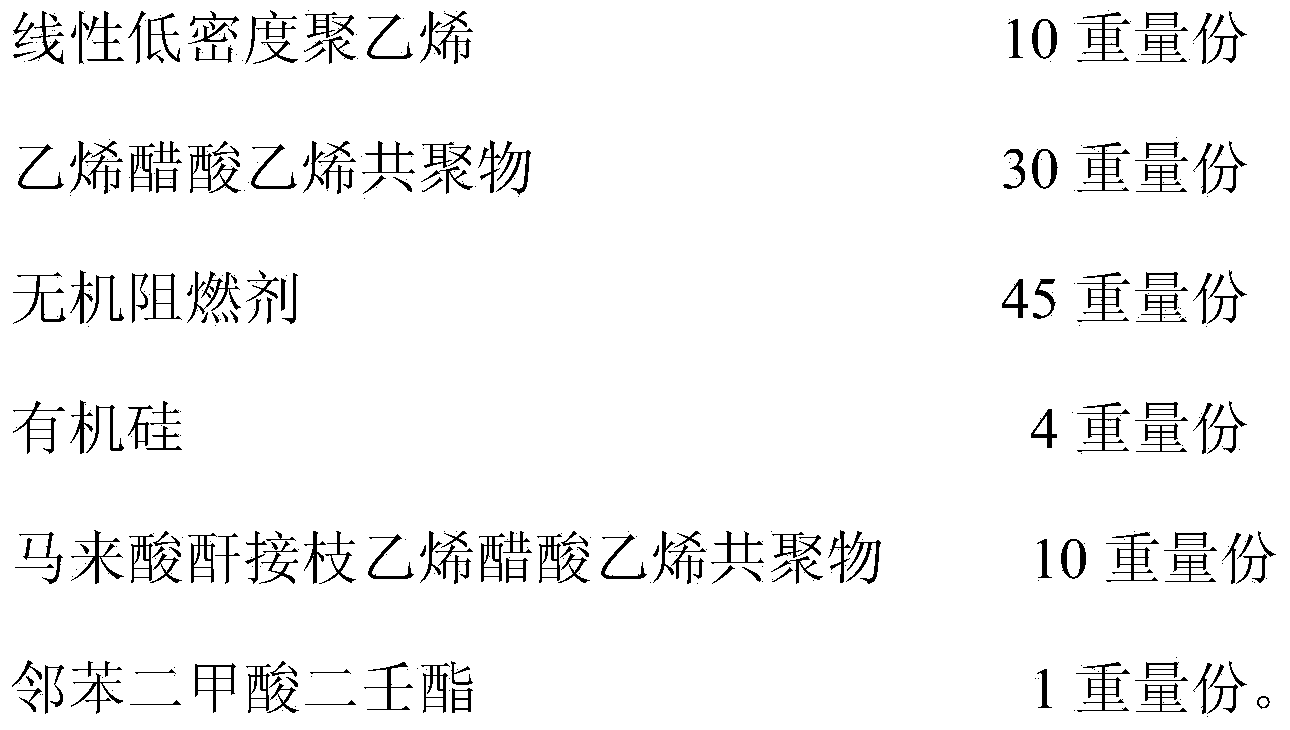

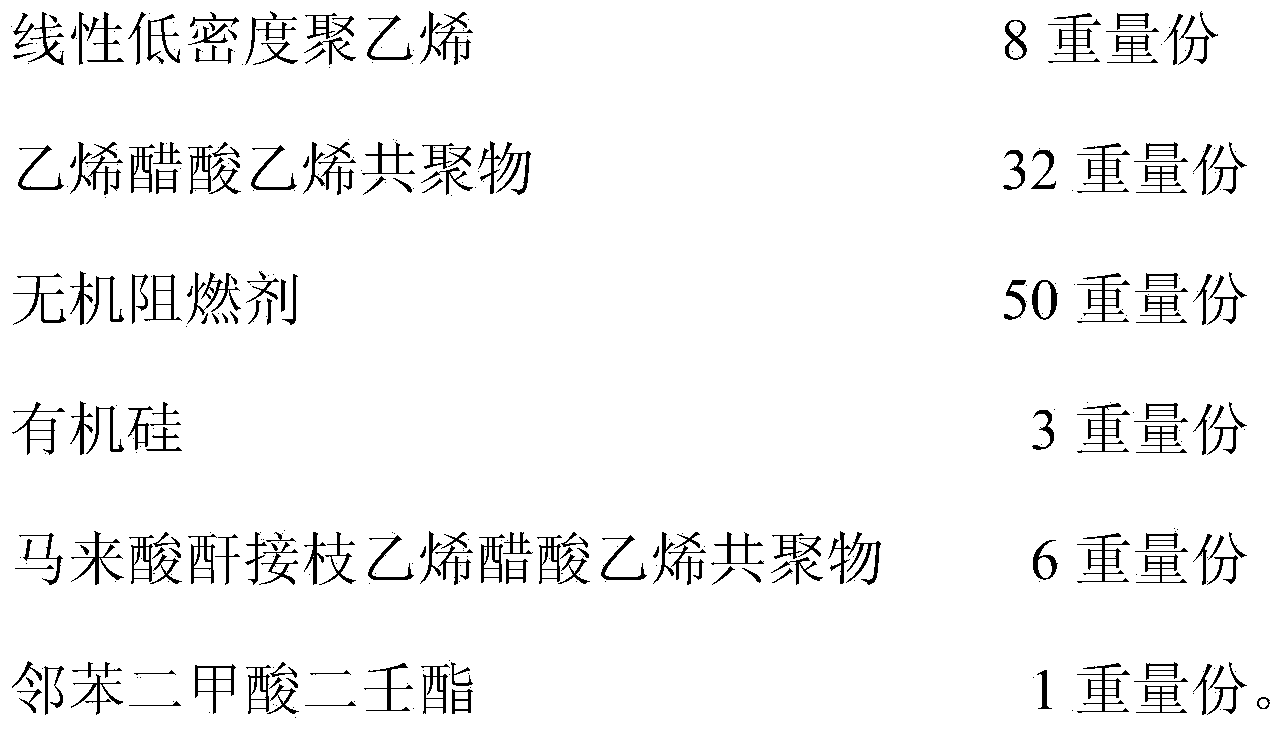

Crosslinked halogen-free flame-retardant cable material

InactiveCN104177695AGood dispersionImprove mechanical propertiesPlastic/resin/waxes insulatorsLinear low-density polyethyleneCombustion

The invention discloses a crosslinked halogen-free flame-retardant cable material which comprises linear low density polyethylene, ethylene-vinyl acetate copolymer, an inorganic flame retardant, a flame-retardant synergist, maleic anhydride grafted ethylene-vinyl acetate copolymer and a crosslinking agent. The crosslinked halogen-free flame-retardant cable material has the advantages of higher oxygen index during combustion, excellent workability, excellent mechanical properties and excellent flame retardancy.

Owner:朱忠良

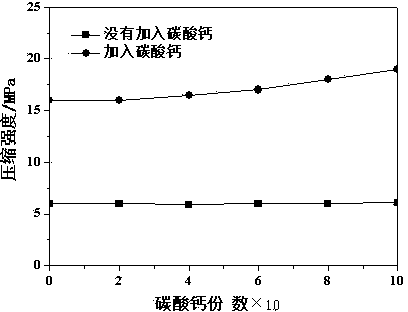

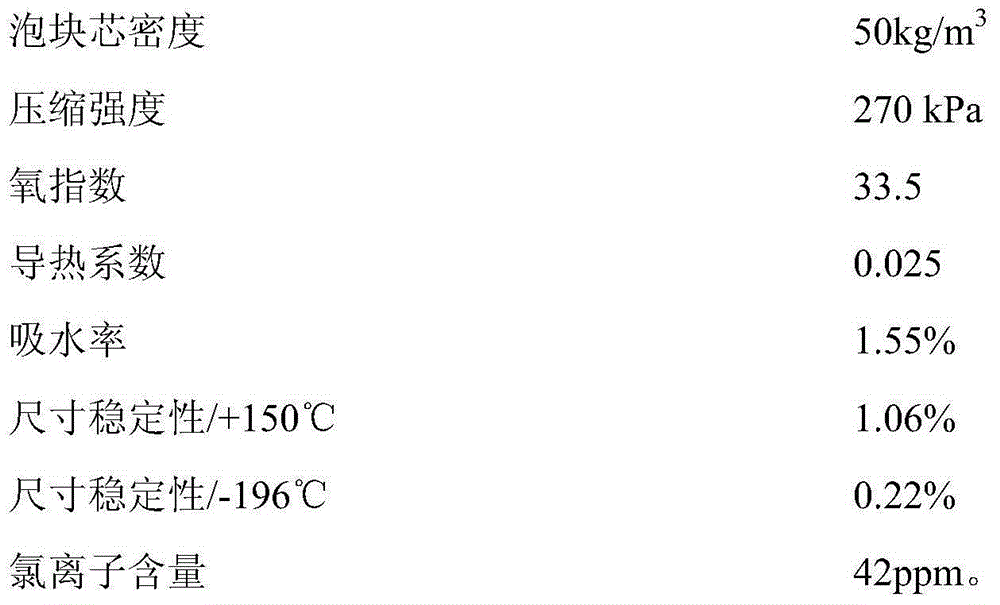

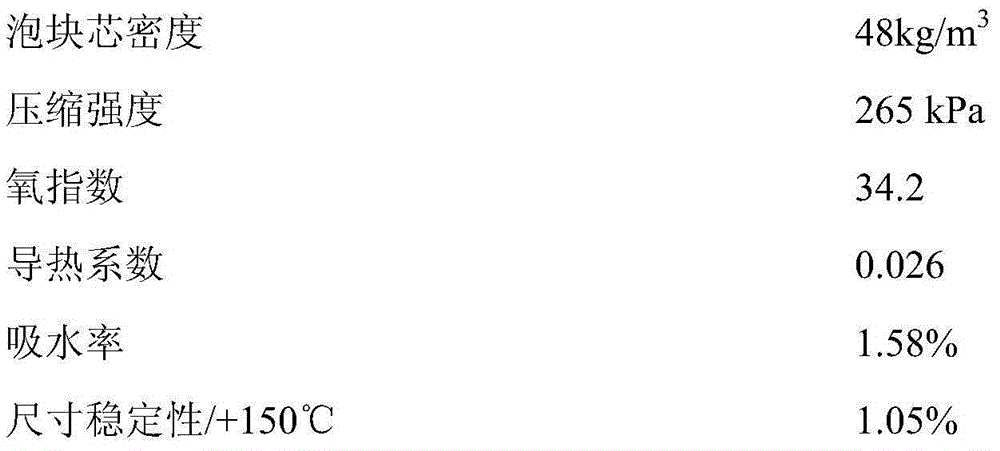

Modified polyurethane rigid foam material and preparation method thereof

InactiveCN102898607AMaintaining and Improving Technical Parameters of Physical ExperimentsHigh hardnessPolyesterCombustion

The invention relates to a modified polyurethane rigid foam material and a preparation method thereof. The method comprises the following steps of: selecting an isocyanate liquid state material as a black material, selecting a polyether polyol liquid state material or a combined liquid state material of polyether polyol and polyester polyol as a white material, and mixing inorganic powder in the black material or mixing the inorganic powder in the white material or mixing the inorganic powder in the black material and the white material simultaneously; mixing the black material and the white material which are mixed with the inorganic powder; and performing polymerization reaction of the mixture in a mode of injecting the mixture into a die or a mode of foaming freely to obtain the modified polyurethane rigid foam material. According to the modified polyurethane rigid foam material, isocyanate and the polyether polyol or the combined material of the polyether polyol and the polyester polyol are mixed with the inorganic powder of different types; after the inorganic powder is mixed with polyurethane raw materials, the expression of the inorganic powder is stable, and a cell structure of polyurethane rigid foam is not destroyed after reaction is finished, so that oxygen indexes and combustion residual amount which are directly relevant with combustion resistance are improved obviously, and the hardness of the material is improved.

Owner:汤燕 +1

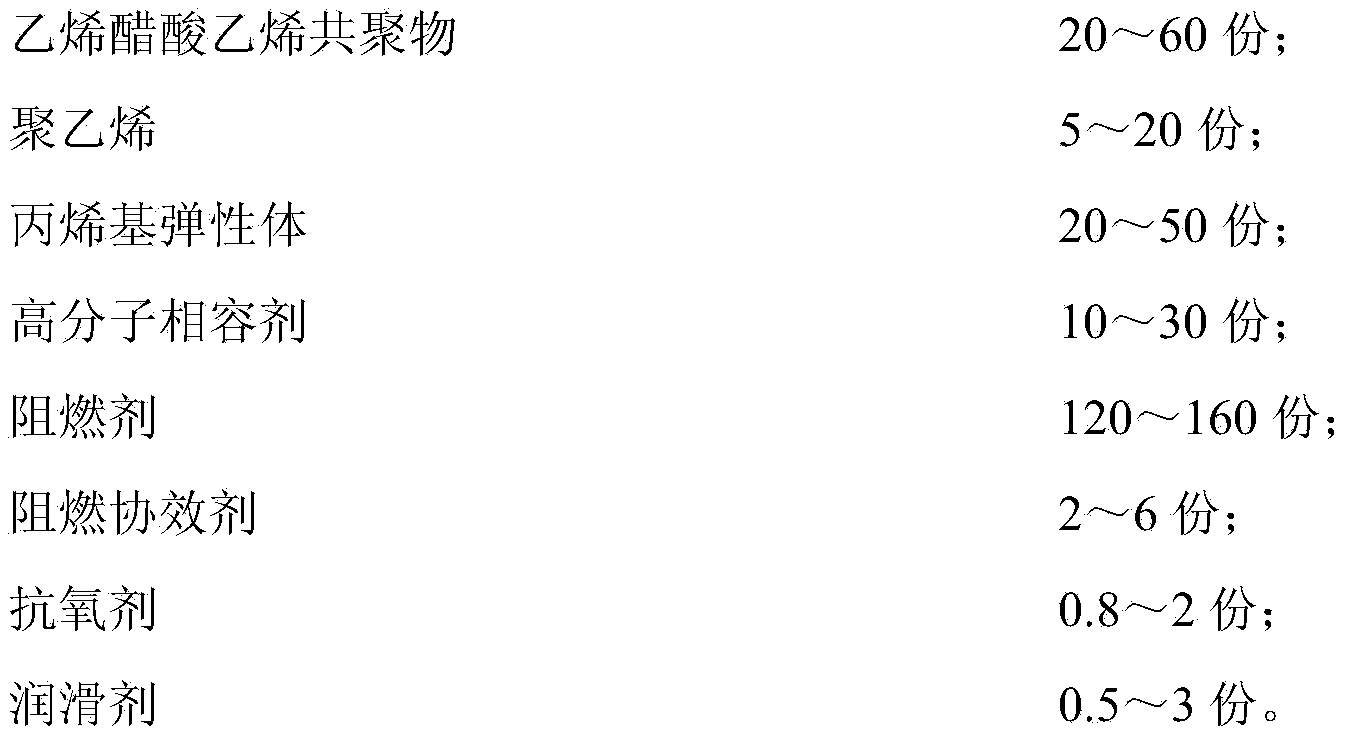

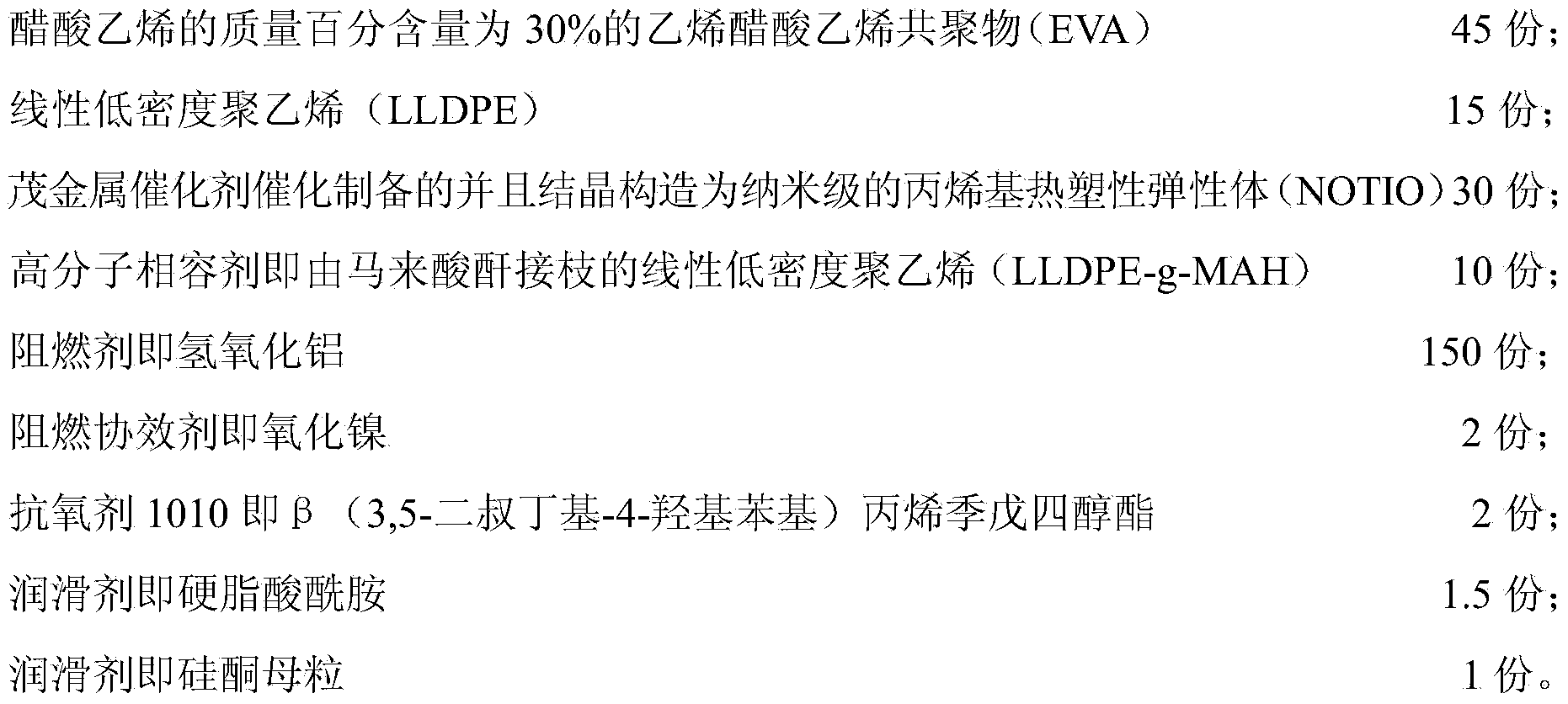

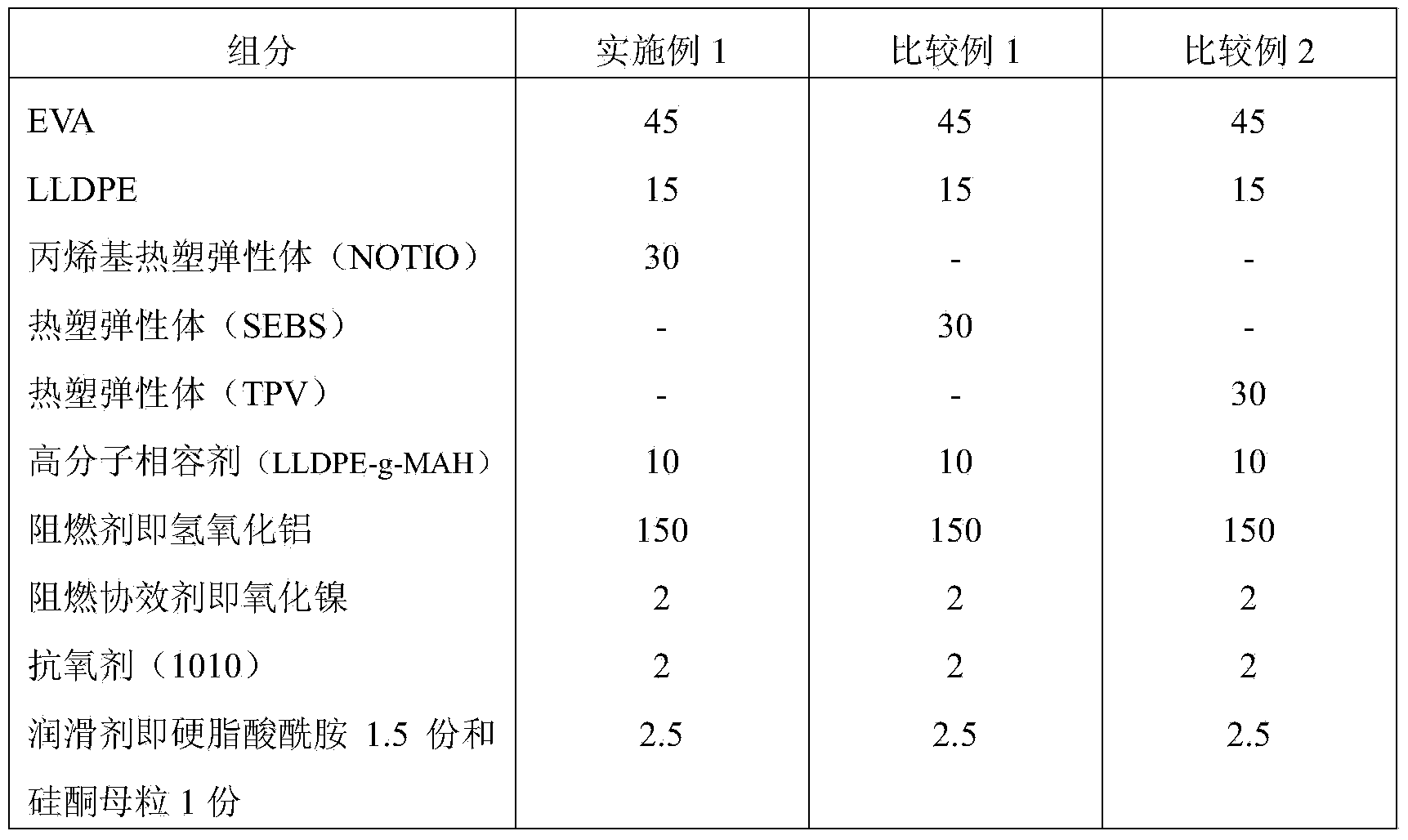

Heat-resisting thermoplastic halogen-free low-smoke flame retardant polyolefin plastic for wire and cable

ActiveCN103524869AReasonable ratioExcellent heat deformation resistancePlastic/resin/waxes insulatorsInsulated cablesSmokeEthylene-vinyl acetate

A heat-resisting thermoplastic halogen-free low-smoke flame retardant polyolefin plastic for wire and cable belongs to the technical field of insulation or sheath material for wire and cable in industrial high molecular material. The polyolefin plastic is composed of the following raw materials by weight: 20-60 parts of an ethylene vinyl acetate copolymer, 5-20 parts of polyethylene, 20-50 parts of a propylene based elastomer, 10-30 parts of a polymer compatibilizer, 120-160 parts of a flame retardant, 2-6 parts of a flame retardant synergistic agent, 0.8-2 parts of an antioxidant and 0.5-3 parts of a lubricant. The invention has the following advantages: the polyolefin plastic has excellent heat deformation resistance and heat aging resistance, and can meet the property requirements of wire and cable insulation and sheath material with usage temperature at 90-105 DEG C; and the polyolefin plastic gains better compatibility and crack resistance, has good flexibility, avoids the problem of thermal stress cracking, and can improve the flame retardant performance and oxygen index of flame retardant materials.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

Material for reinforcement of coal and rock and preparation process and application thereof

InactiveCN101747524ADoes not affect admissibilityImprove adhesionMine roof capsCeramicwareOrganic acidPlasticizer

The invention relates to a material for reinforcement of coal and rock and a preparation process and application thereof. In the technical scheme, resol, a plasticizer, fire-resistance polyether and methanol are used as raw materials and are heated under alkaline conditions to form modified phenolic resin with an inter-penetrating structure through copolymerization and condensation, the modified phenolic resin is then mixed with an organic acid catalyst system by a pump, and the mixture is then poured into a broken coal and rock to be cured and to be closely combined with the coal and rock. The preparation process comprises preparation of the modified phenolic and preparation of the coal and rock curing material. The modified phenolic resin has low viscosity and can infiltrate into tiny cracks. The cured phenolic material has excellent bounding capacity and can achieve strong viscosity with the formation. Due to the excellent flexibility properties, the material can withstand the subsequent formation movement without retardant fire, thereby improving the safety of underground operation. Moreover, the material can not affect the mineability of coal, and can be easily planed and cut, thereby realizing the easy breakage of large coal lumps bonded together.

Owner:滕州市华海新型保温材料有限公司

Halogen-free roadfire-resistant asphalt

InactiveCN1935903AHigh oxygen indexReduce pollutionIn situ pavingsBuilding insulationsMelamine phosphateRoad surface

The invention relates to no halogen type road using inflaming retarding asphalt whose components part by weight are as follows: heavy traffic road petroleum asphalt 50-70, melamine phosphate 9-15, zinc borate 2-7, antimony trioxide 2-7, magnesium hydroxide 4-10, aluminum hydroxide 4-10, tempering agent 2-3.5, modifier 0.5-1.5, coupling agent 0.3-0.8. While burning it has high oxygen index to form stable charring layer to arise self extinguishing, little lamp black and no halogen hydride harmful gas to reduce environment pollution. Thus it has wide application prospect, good socioeconomic performance. The preparing method is simple, effective, economic, convenient, and widely used.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

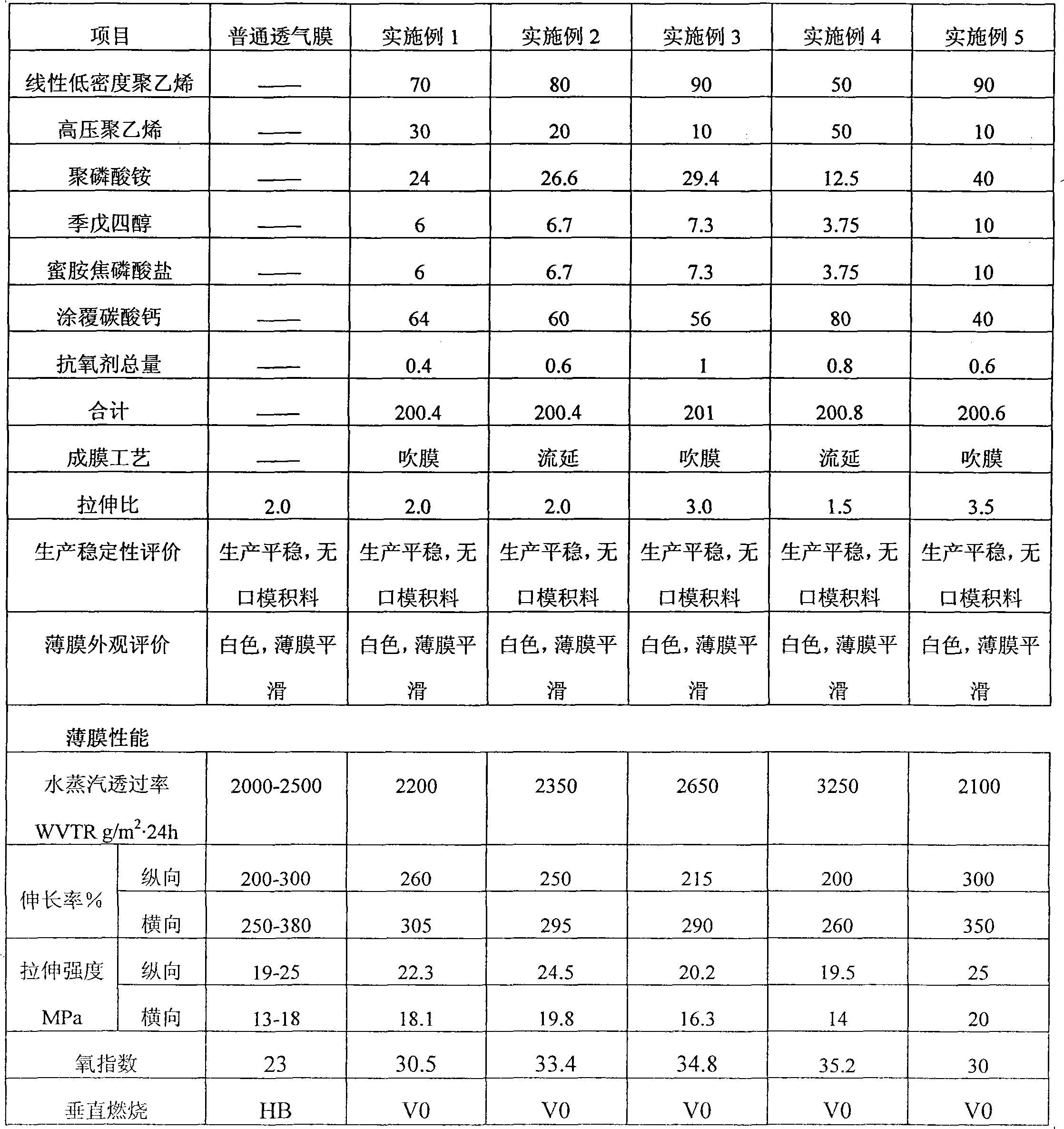

Zero halogen flame resistance polyethylene breathable film and preparation method and application thereof

ActiveCN101629006AGuaranteed flame retardant performanceDoes not affect processing performanceFlexible coversWrappersPolymer scienceHalogen

The invention discloses a zero halogen flame resistance polyethylene breathable film and a preparation method and an application thereof. The preparation method adopts surface modifier to treat calcium carbonate so as to promote the dispersion of calcium carbonate in a polyethylene resin system; then zero halogen fire retardant and polyethylene are treated by grafting treatment to have polar group and nonpolar macromolecular chain so that the dispersion of the zero halogen fire retardant in polyethylene is easier and the formed chemical bonds can effectively solve the problem that the mechanical properties of the breathable film are reduced; after the grafting treatment, the zero halogen fire retardant and the polyethylene both have the function of macromolecular coupling agent so as to further improve the dispersion of calcium carbonate in the polyethylene resin system and reduce the affect of calcium carbonate on the performance of the film. The zero halogen flame resistance polyethylene breathable film prepared by the invention not only ensures the gas permeability and mechanical properties of the polyethylene breathable film, but also improves the fire resistance of the film and does not affect the processing properties of the product. The product of the invention has both gas permeability and fire resistance, thus having wide application scope.

Owner:合诚技术股份有限公司

Method for preparing fire retardant modification timber

InactiveCN101602214AImprove mechanical propertiesMaintain flame retardant propertiesWood treatment detailsPressure impregnationVacuum pressureMineralogy

The invention discloses a method for preparing a fire retardant modification timber. The method comprises the following steps of: (1) adding a fire retardant into a urea formaldehyde resin concentrate to obtain a timber impregnation liquid after the fire retardant is completely dissolved; (2) making the impregnation treatment of the timber to be treated by using the vacuum pressure method and the timber impregnation liquid obtained in the step (1); and (3) drying the timber to be treated to obtain the fire retardant modification timber. In the method, the fire retardant is directly added into the urea formaldehyde resin concentrate to form the impregnation liquid, so that by one-time impregnation treatment, the use performance of the timber is improved, the fire retardant effect is enhanced, the process for modifying the timber is simplified, and other steps which are needed after the timber modification to realize the fire retardant function are saved. The method has the advantages of simple process and unnecessary complex equipment; and when the method is adopted to treat the timber, the size stability of the treated timber is obviously improved, the physical and mechanical properties are obviously improved, the weight gain rate of the timber is between 25 and 50 percent, and the oxygen index is increased by 40 to 80 percent.

Owner:EVERFIRST WISEFUND TECH BEIJING

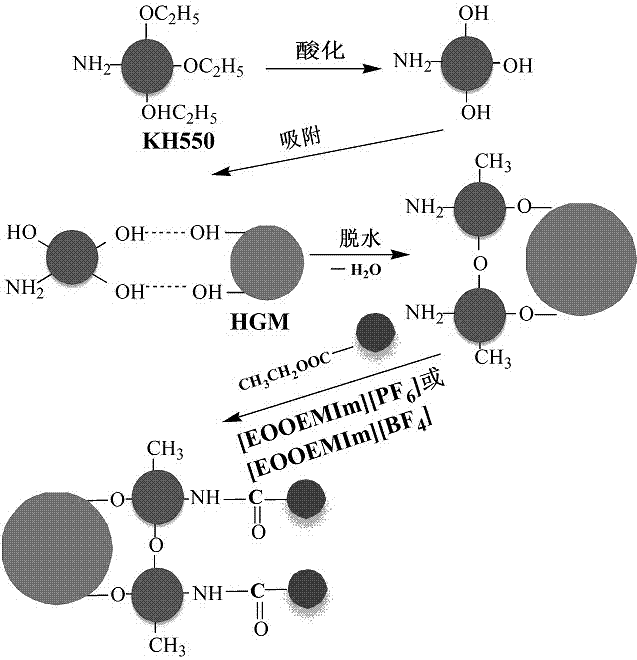

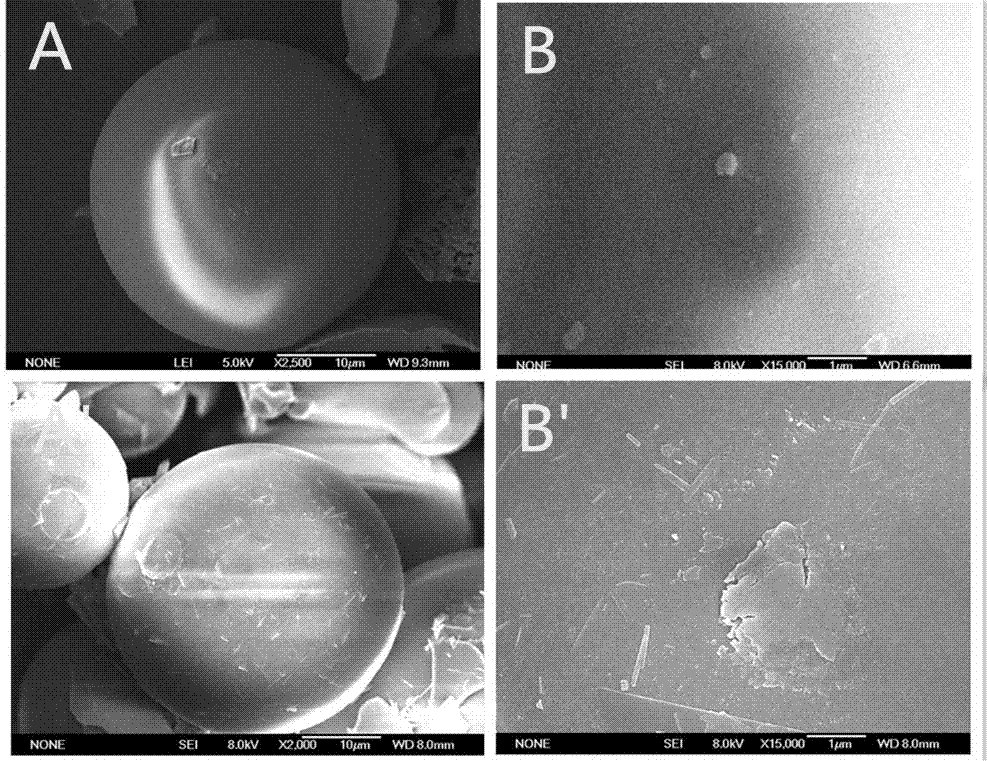

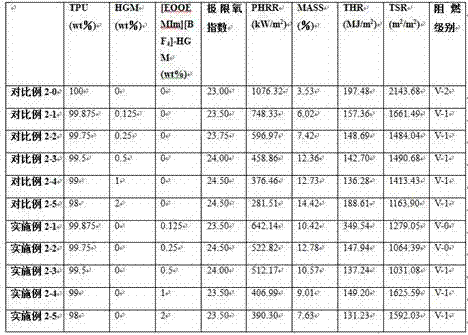

Method of modifying hollow glass microbeads with ionic liquid and flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as flame retardant

The invention discloses a method of modifying hollow glass microbeads with an ionic liquid and a flame-retarding thermoplastic polyurethane elastomer with the modified hollow glass microbeads as a flame retardant. The method includes the steps of: 1) treating the hollow glass microbeads with a hydrochloric acid solution; 2) after the acid treatment, repeatedly washing and drying the hollow glass microbeads; 3) activating the hollow glass microbeads, adding a silane coupling agent, and performing mechanical stirring reflux; 4) stopping the reaction and cooling the reaction product to room temperature, and performing suction filtration with acetonitrile, ethanol and deionized water and drying the reaction product; 5) adding the ionic liquid to the silanized hollow glass microbeads and performing mechanical stirring reflux; 6) stopping the reaction and cooling the reaction product to room temperature, performing suction filtration successively with ethanol, a mixed solution of ethanol and deionized water, and ethanol, and drying the reaction product. By means of the hollow glass microbeads modified with the ionic liquid as the flame retardant for preparing flame-retarding thermoplastic polyurethane (TPU) elastomer, not only is oxygen index of the composite material improved, but also the vertical combustion performance, which reflects melt-dripping resistance, is improved, so that heat release rate is reduced and smoke is significantly inhibited.

Owner:JIANGSU STERRIC CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com