Patents

Literature

31results about How to "Excellent heat deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

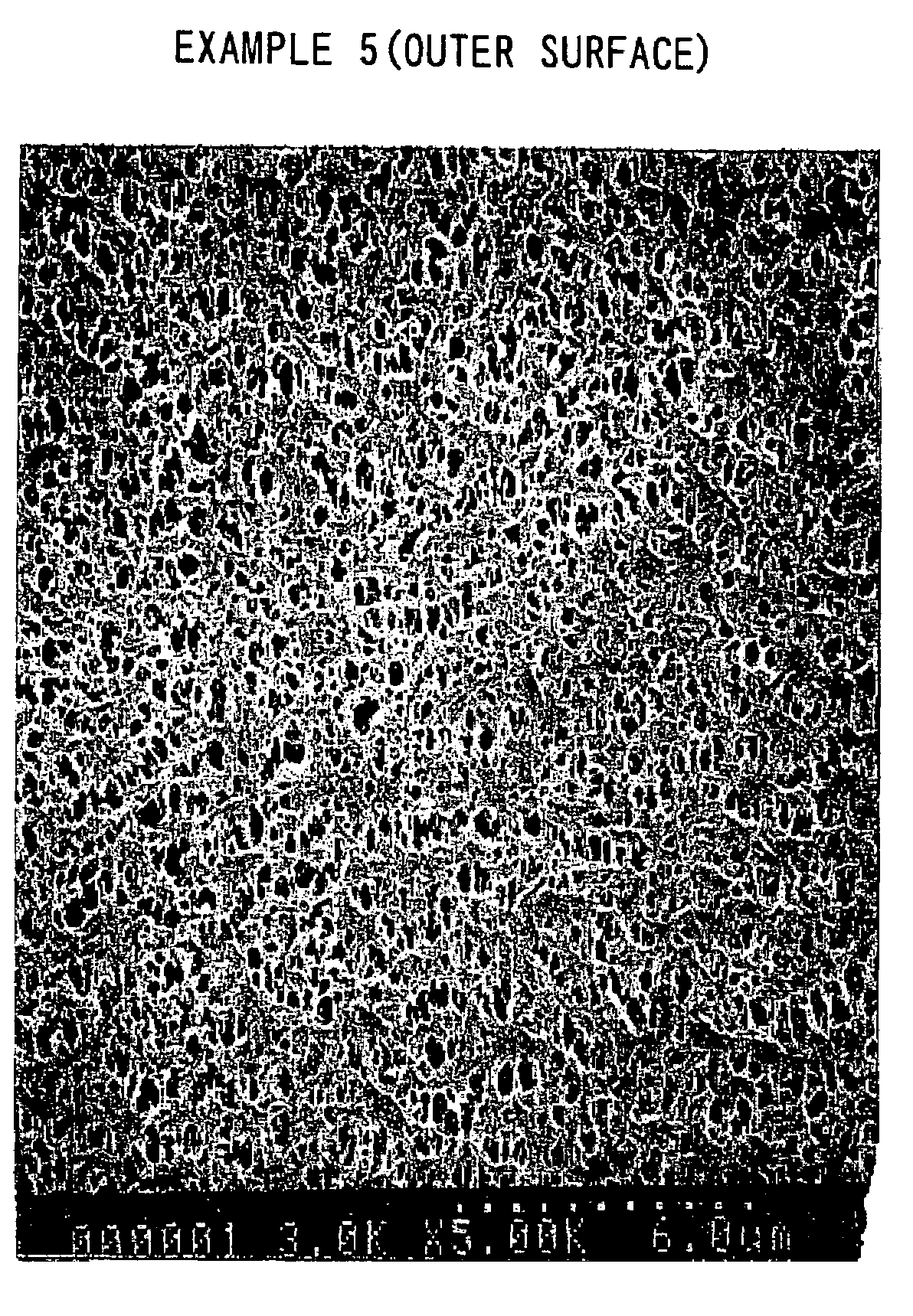

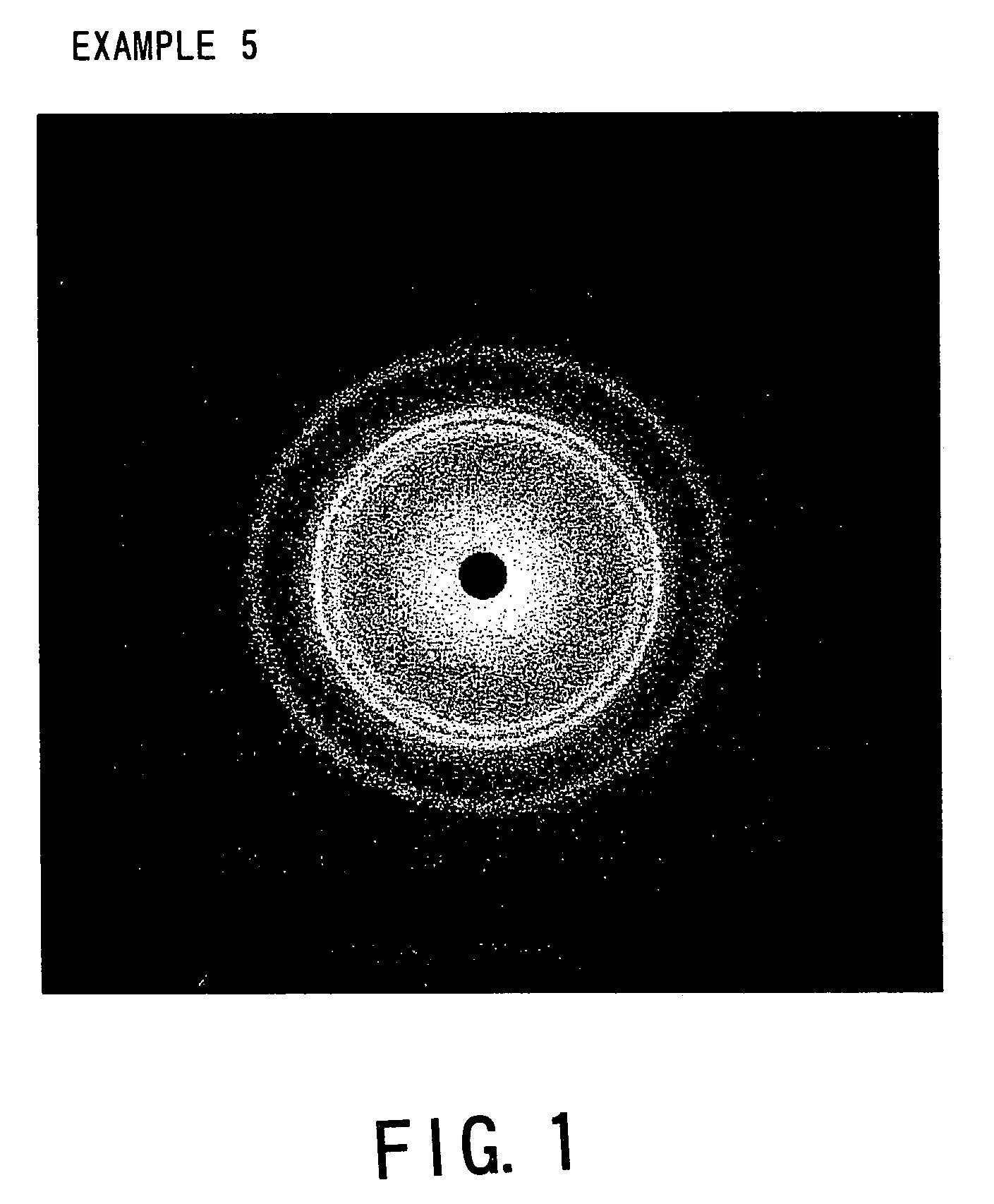

Porous membrane of vinylidene fluoride resin and process for producing the same

ActiveUS20060178480A1Improve heat distortion resistanceFacilitate stretchingSemi-permeable membranesMembranesSolventPorous membrane

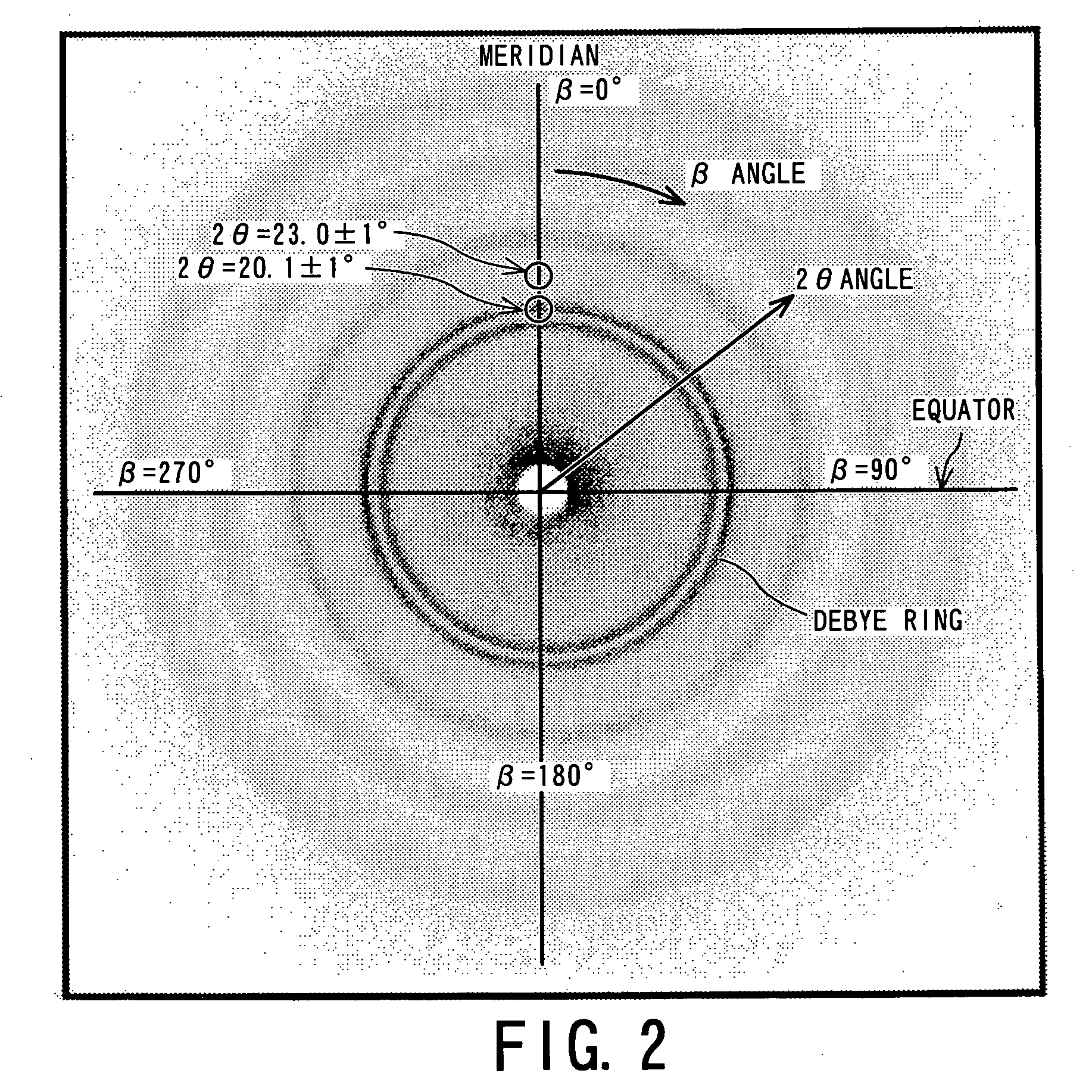

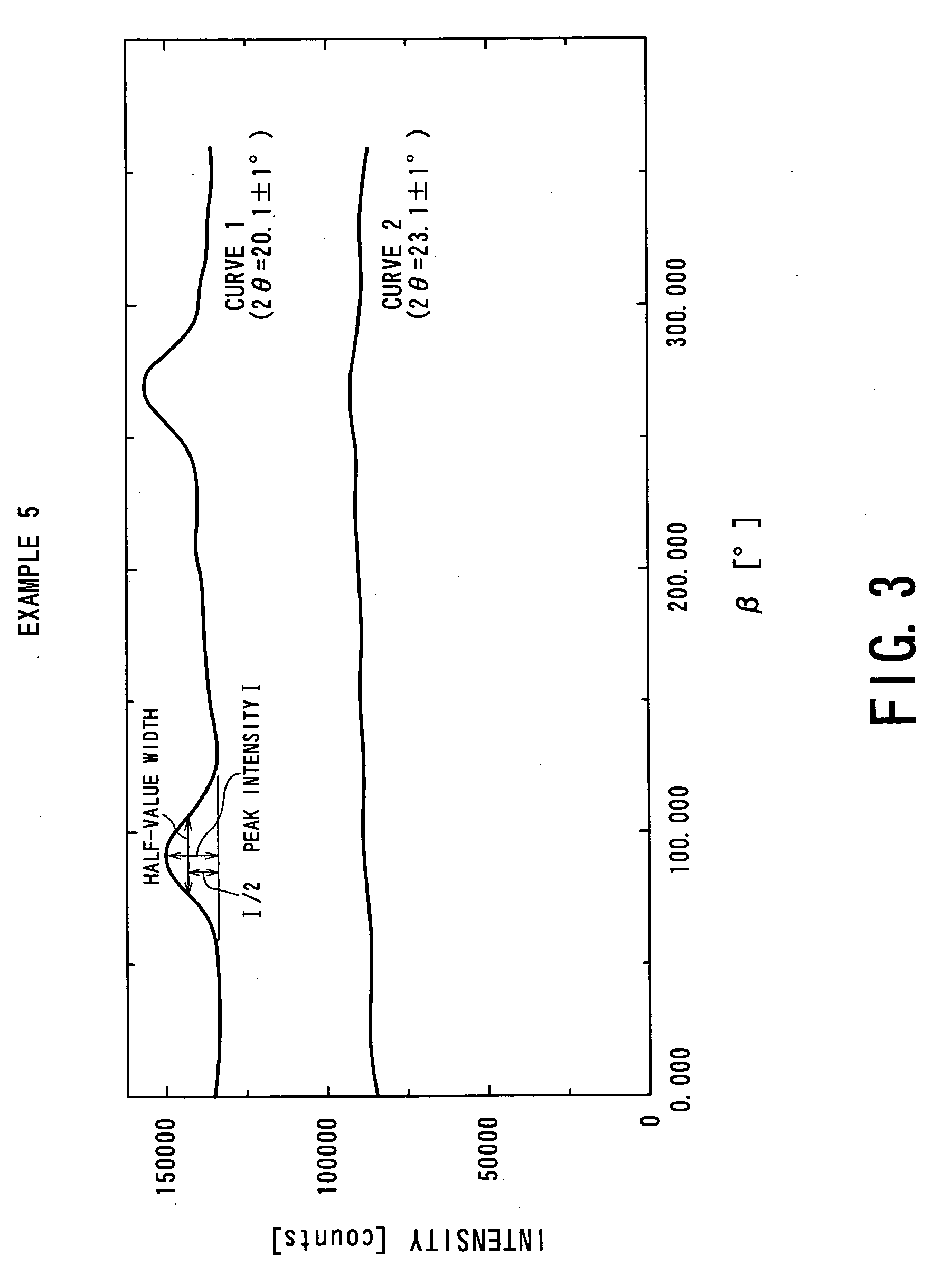

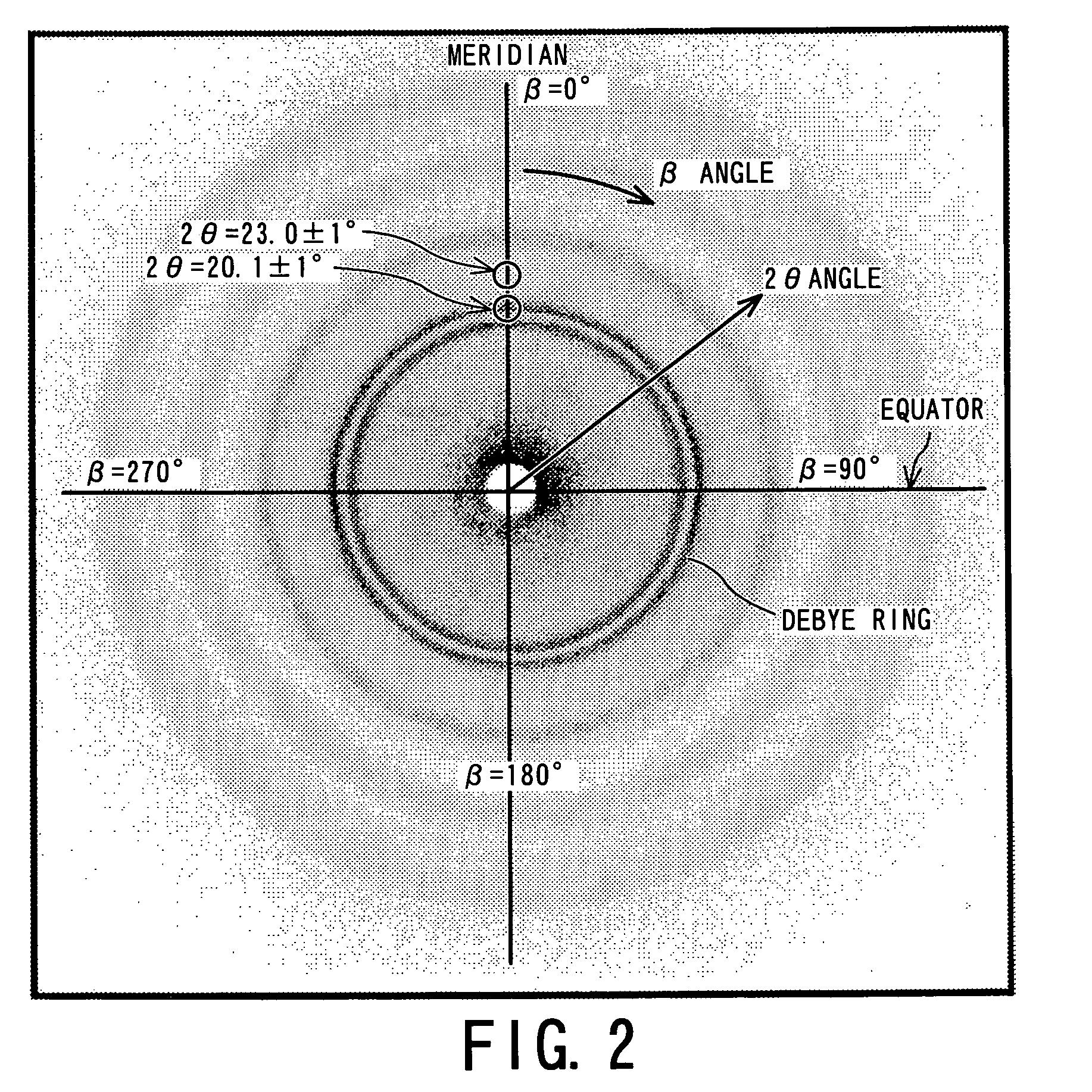

There is provided a porous membrane of vinylidene fluoride resin which has pores of appropriate size and distribution and also excellent mechanical strength represented by tensile strength and elongation at break and is useful as a microfiltration membrane or a separator for batteries. The porous membrane of vinylidene fluoride resin is characterized by the presence in mixture of a crystalline oriented portion and a crystalline non-oriented portion as confirmed by X-ray diffraction, and is produced by subjecting a melt-extruded composition obtained by mixing a vinylidene fluoride resin having a molecular weight distribution which is appropriately broad and high as a whole with a plasticizer and a good solvent for vinylidene fluoride resin, to cooling for solidification from one surface, extraction of the plasticizer and stretching.

Owner:KUREHA KAGAKU KOGYO KK

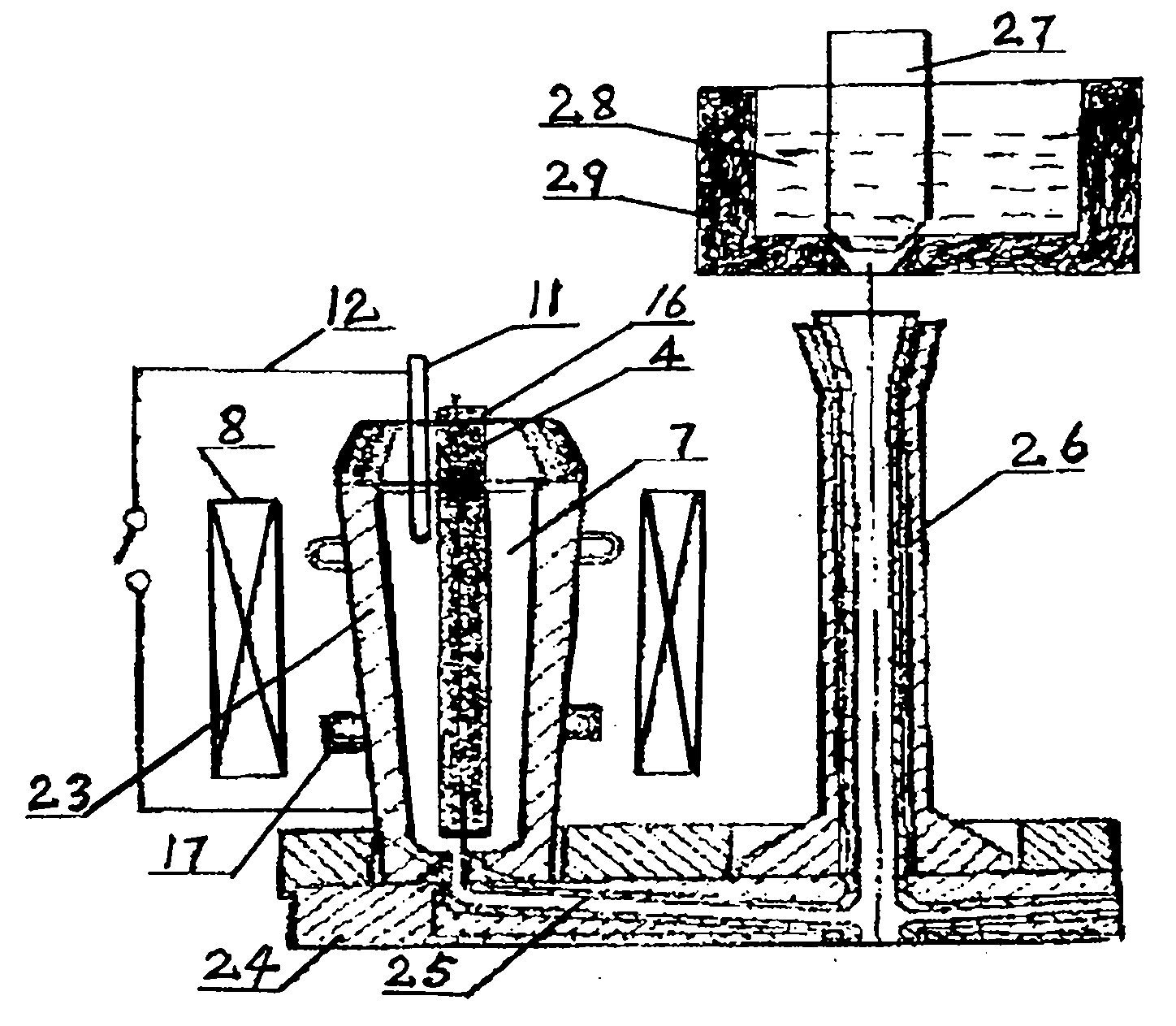

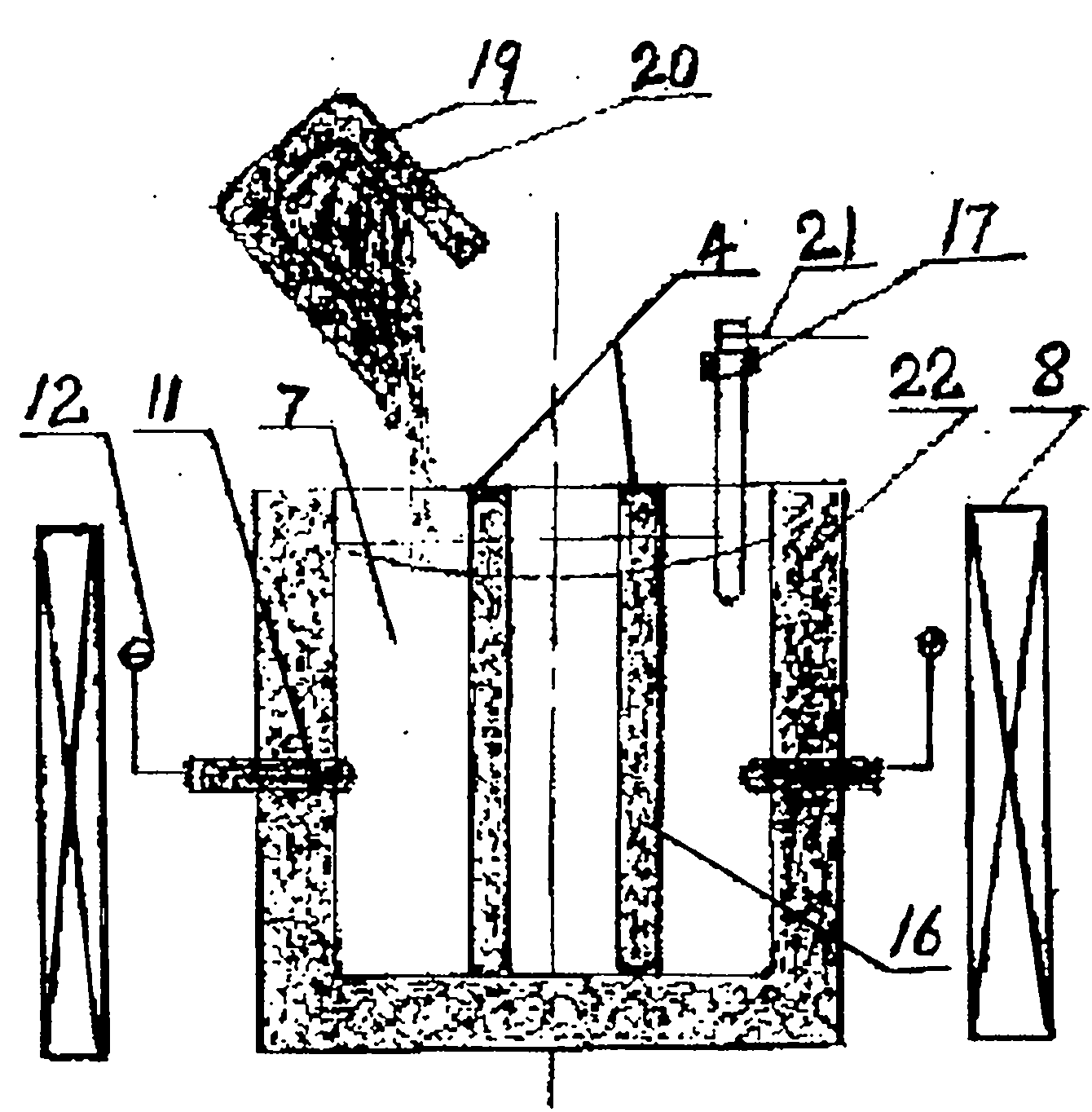

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

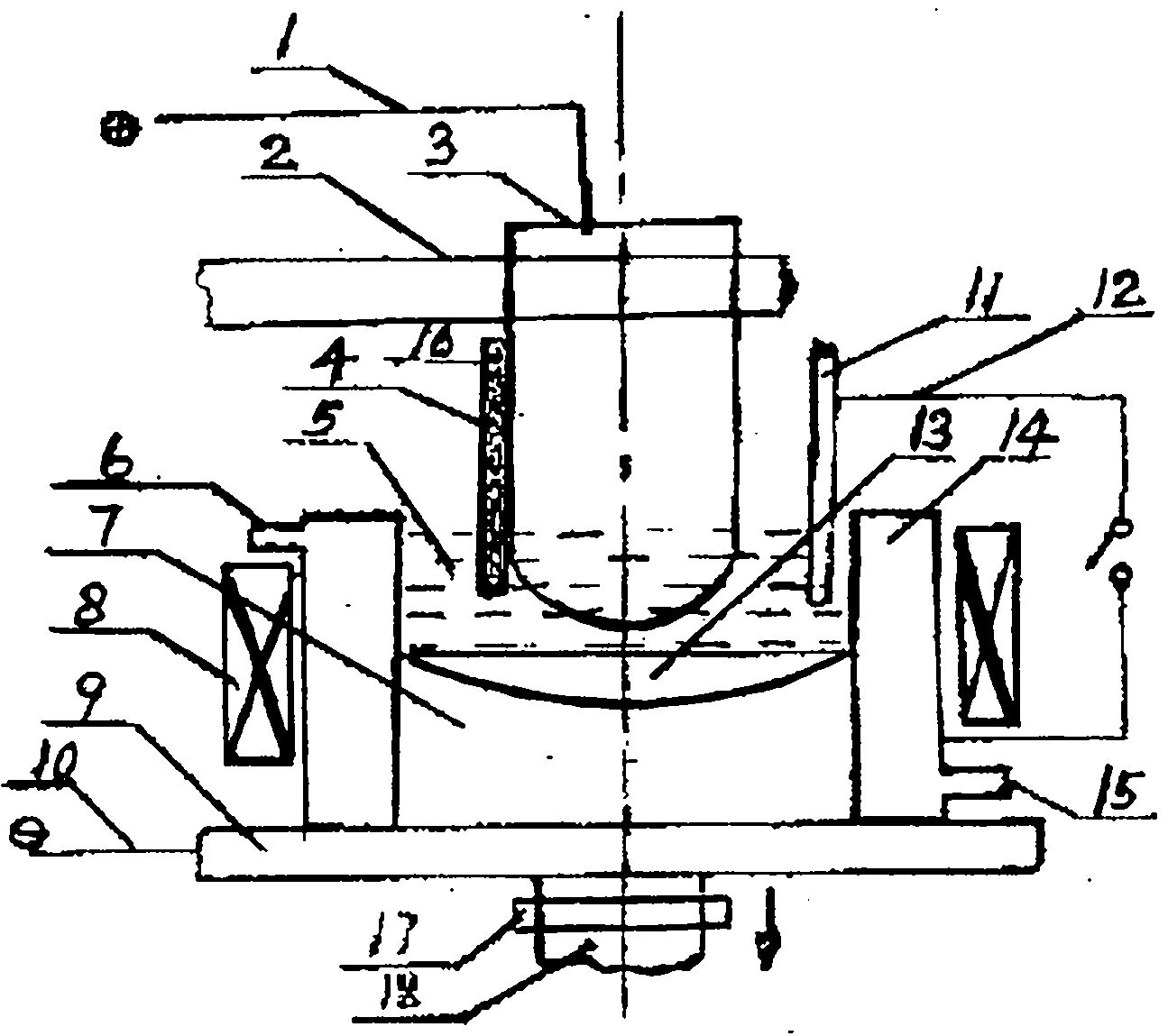

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

Porous membrane of vinylidene fluoride resin and process for producing the same

There is provided a porous membrane of vinylidene fluoride resin which has pores of appropriate size and distribution and also excellent mechanical strength represented by tensile strength and elongation at break and is useful as a microfiltration membrane or a separator for batteries. The porous membrane of vinylidene fluoride resin is characterized by the presence in mixture of a crystalline oriented portion and a crystalline non-oriented portion as confirmed by X-ray diffraction, and is produced by subjecting a melt-extruded composition obtained by mixing a vinylidene fluoride resin having a molecular weight distribution which is appropriately broad and high as a whole with a plasticizer and a good solvent for vinylidene fluoride resin, to cooling for solidification from one surface, extraction of the plasticizer and stretching.

Owner:KUREHA KAGAKU KOGYO KK

Foamed polystyrene curtain plate sheet and manufacturing method thereof

ActiveCN102070853AExcellent heat deformation resistanceSimple manufacturing methodCurtainsDraperiesLow latitudeFoaming agent

The invention discloses a foamed polystyrene curtain plate sheet and a manufacturing method thereof. The foamed polystyrene curtain plate sheet consists of the following components in part by weight: 100 parts of polystyrene, 1 to 50 parts of blended resin, 1 to 50 parts of filler, 0.1 to 20 parts of compatilizer, 0 to 1 part of antioxidant, 0 to 5 parts of processing aid, 0.1 to 10 parts of foaming agent and 0.1 to 10 parts of cross-linking agent. The foamed polystyrene curtain plate sheet manufactured according to a formula of the invention has light weight, aging resistance, corrosion resistance, heat insulation and insulating property, and the most outstanding advantage of high thermal deformation resistance, and can adapt to direct sunlight under a hot weather condition in summer in low-latitude regions. The manufacturing method of the foamed polystyrene curtain plate sheet is simple and practical, and has wide application prospect.

Owner:广东波斯科技股份有限公司

Heat-resisting thermoplastic halogen-free low-smoke flame retardant polyolefin plastic for wire and cable

ActiveCN103524869AReasonable ratioExcellent heat deformation resistancePlastic/resin/waxes insulatorsInsulated cablesSmokeEthylene-vinyl acetate

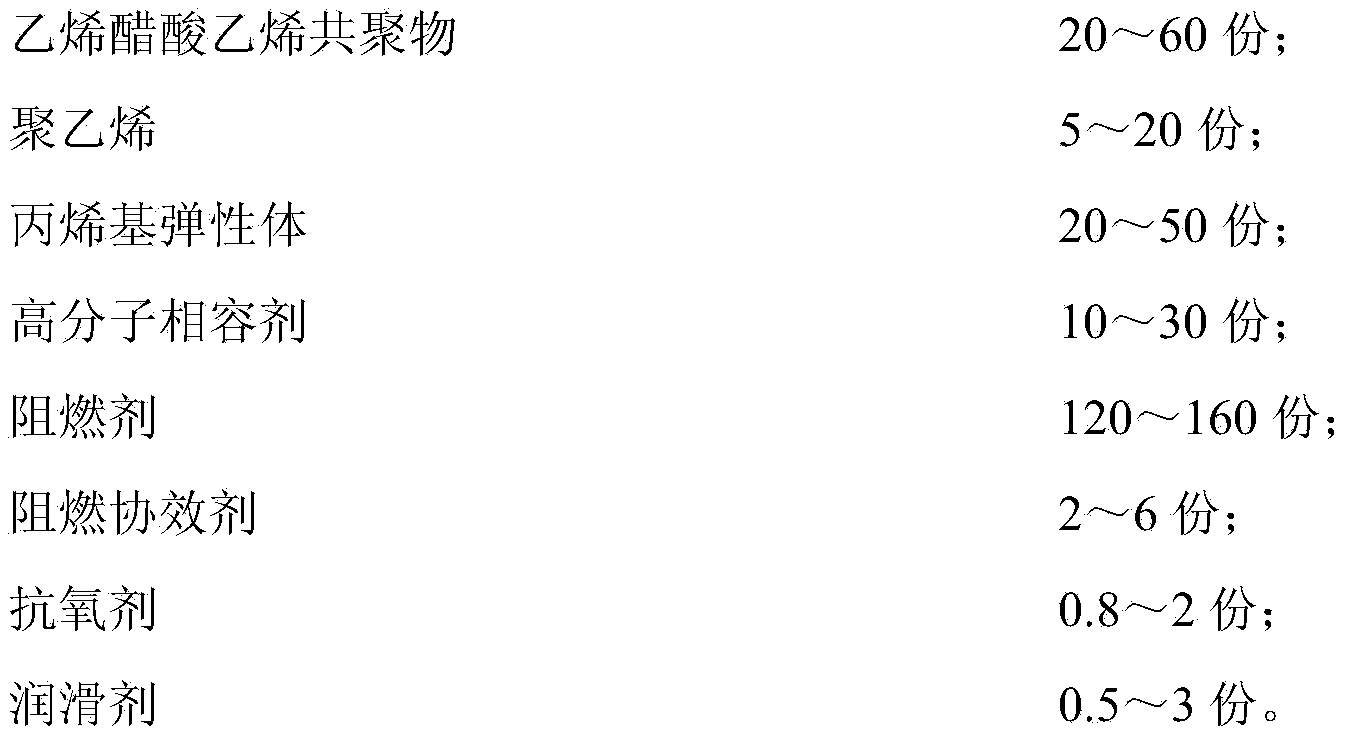

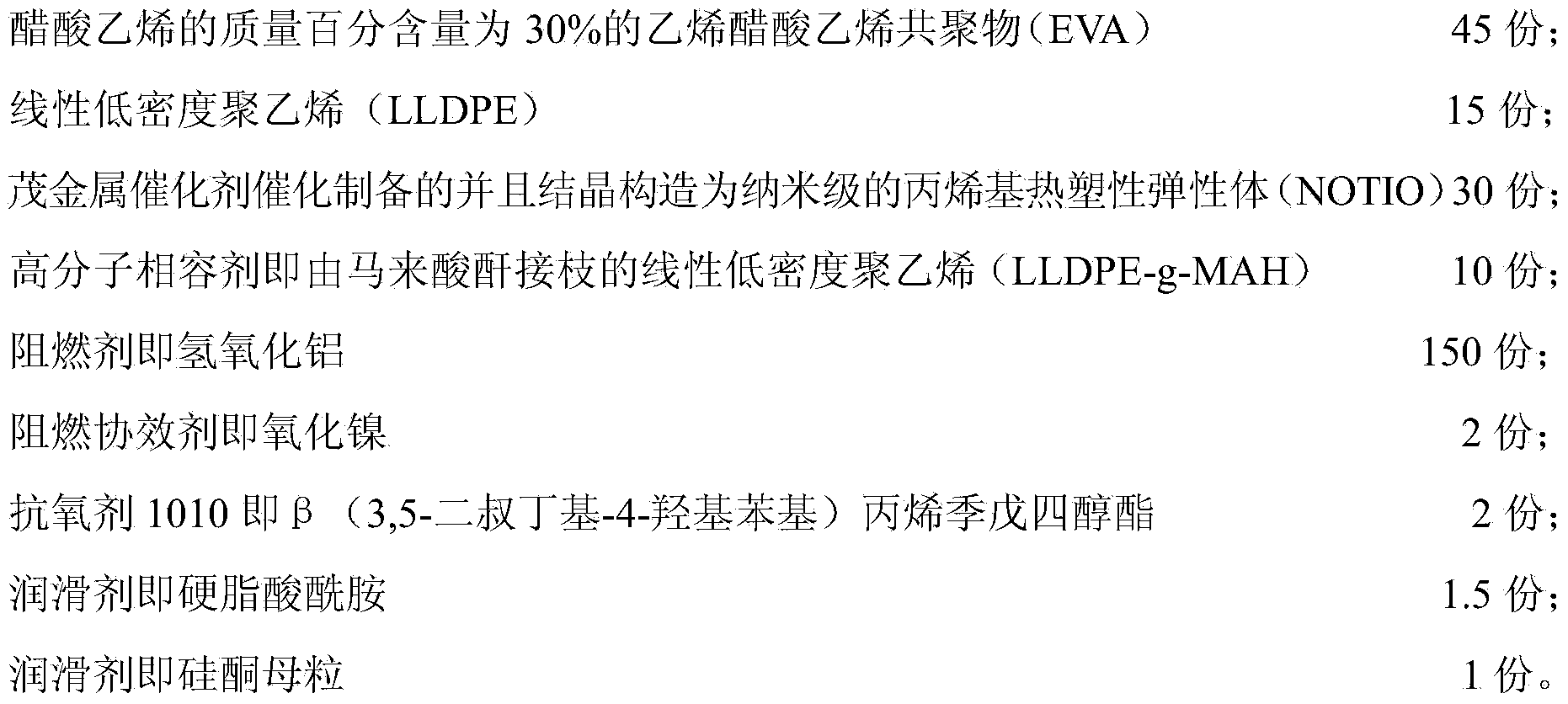

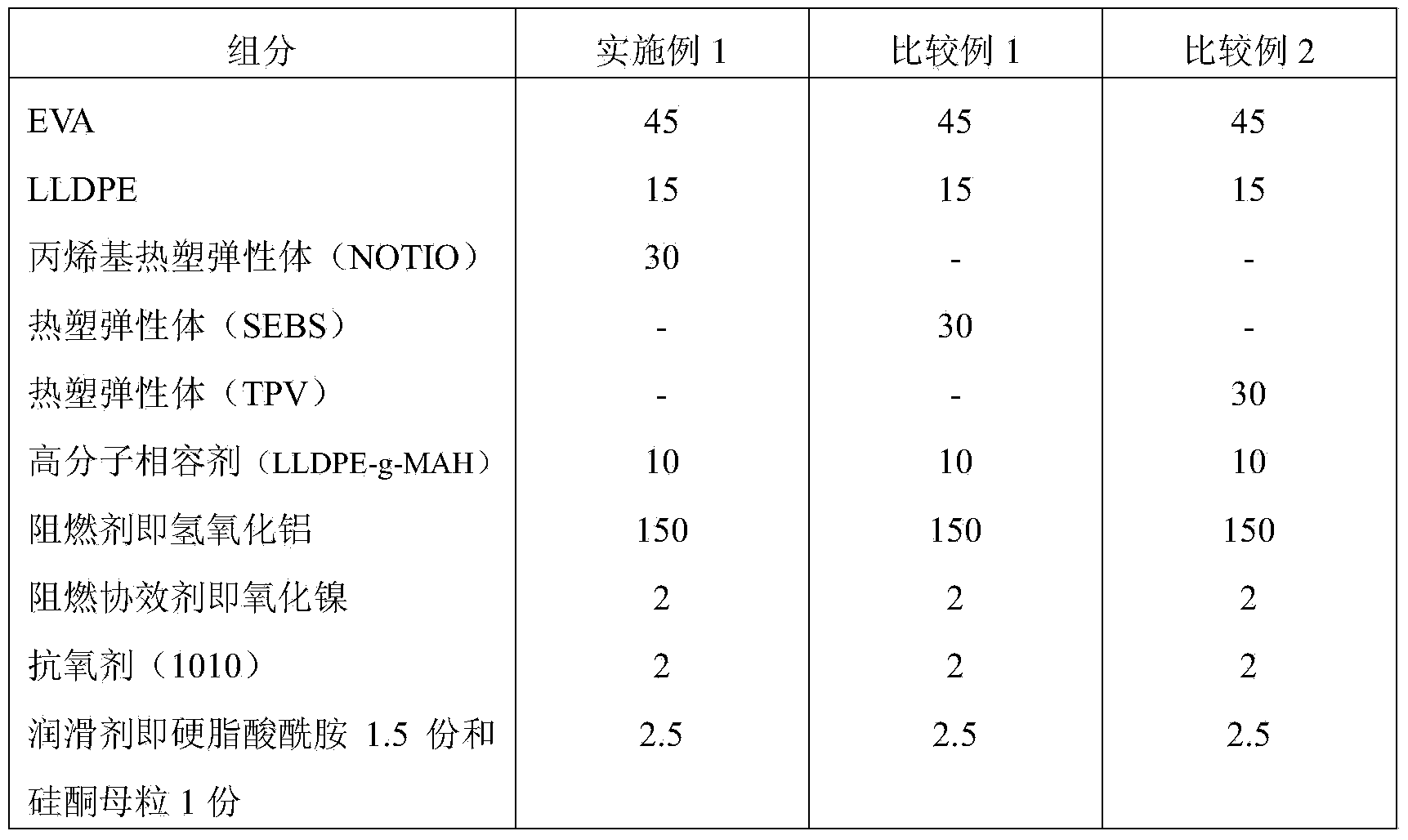

A heat-resisting thermoplastic halogen-free low-smoke flame retardant polyolefin plastic for wire and cable belongs to the technical field of insulation or sheath material for wire and cable in industrial high molecular material. The polyolefin plastic is composed of the following raw materials by weight: 20-60 parts of an ethylene vinyl acetate copolymer, 5-20 parts of polyethylene, 20-50 parts of a propylene based elastomer, 10-30 parts of a polymer compatibilizer, 120-160 parts of a flame retardant, 2-6 parts of a flame retardant synergistic agent, 0.8-2 parts of an antioxidant and 0.5-3 parts of a lubricant. The invention has the following advantages: the polyolefin plastic has excellent heat deformation resistance and heat aging resistance, and can meet the property requirements of wire and cable insulation and sheath material with usage temperature at 90-105 DEG C; and the polyolefin plastic gains better compatibility and crack resistance, has good flexibility, avoids the problem of thermal stress cracking, and can improve the flame retardant performance and oxygen index of flame retardant materials.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

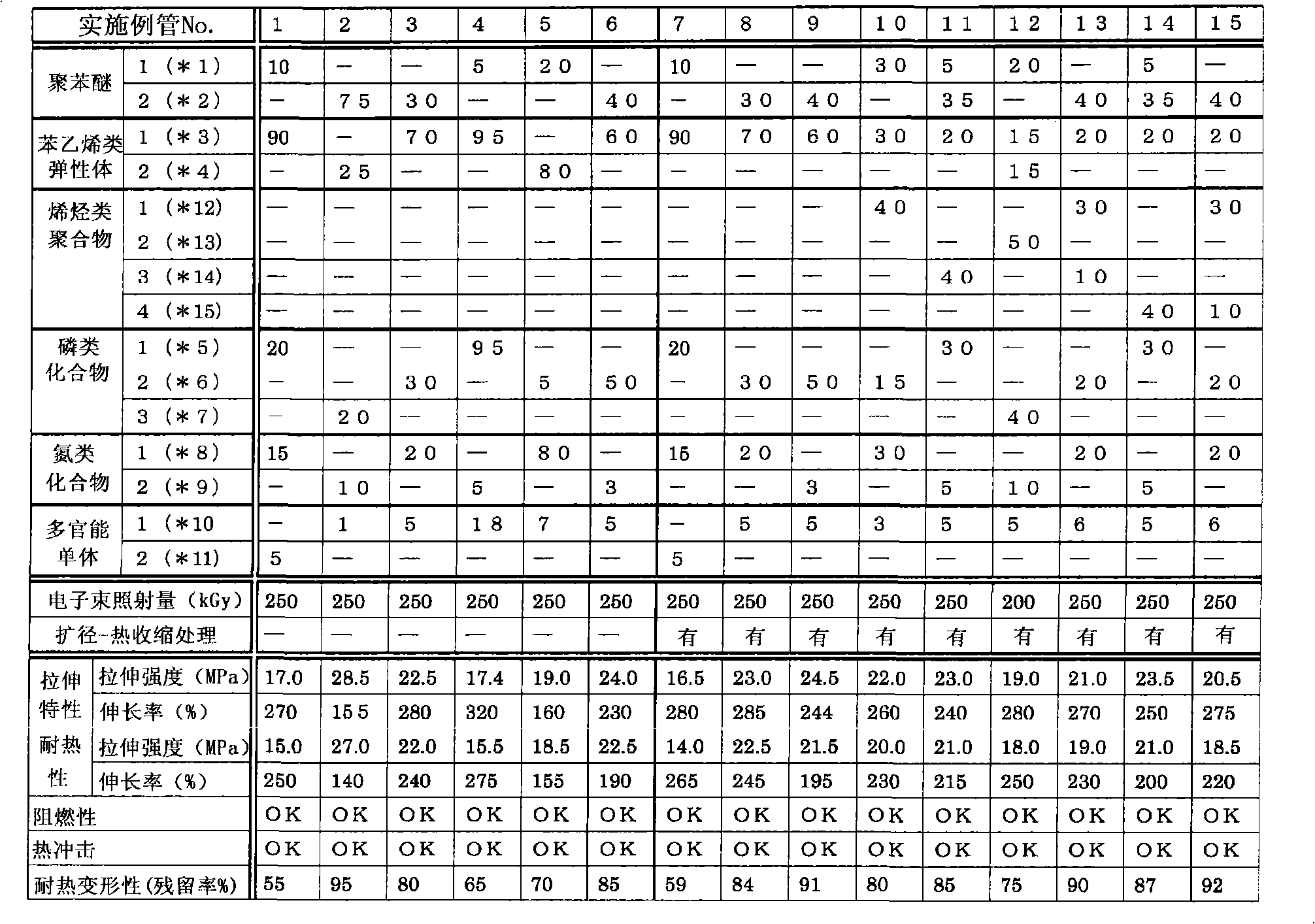

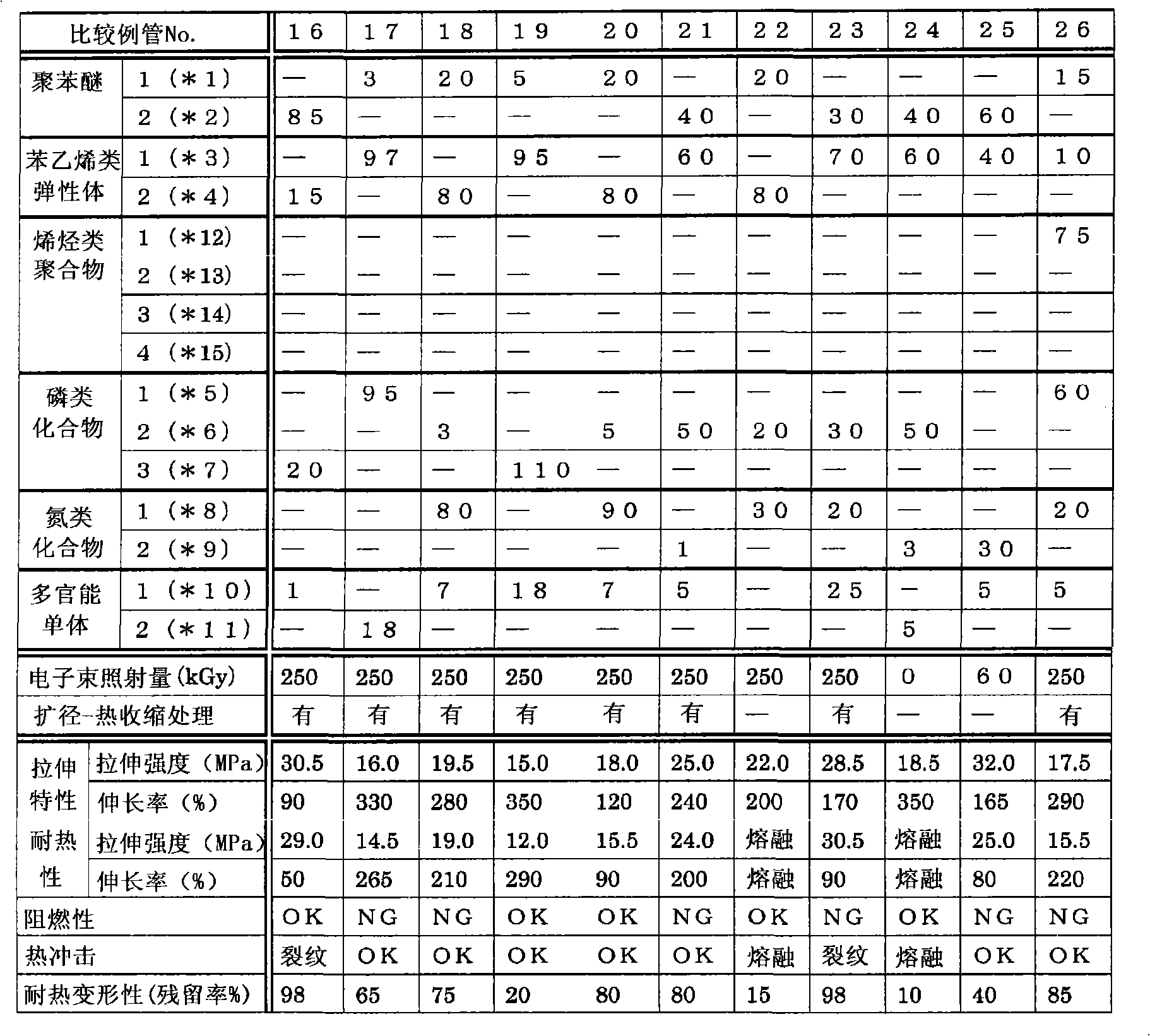

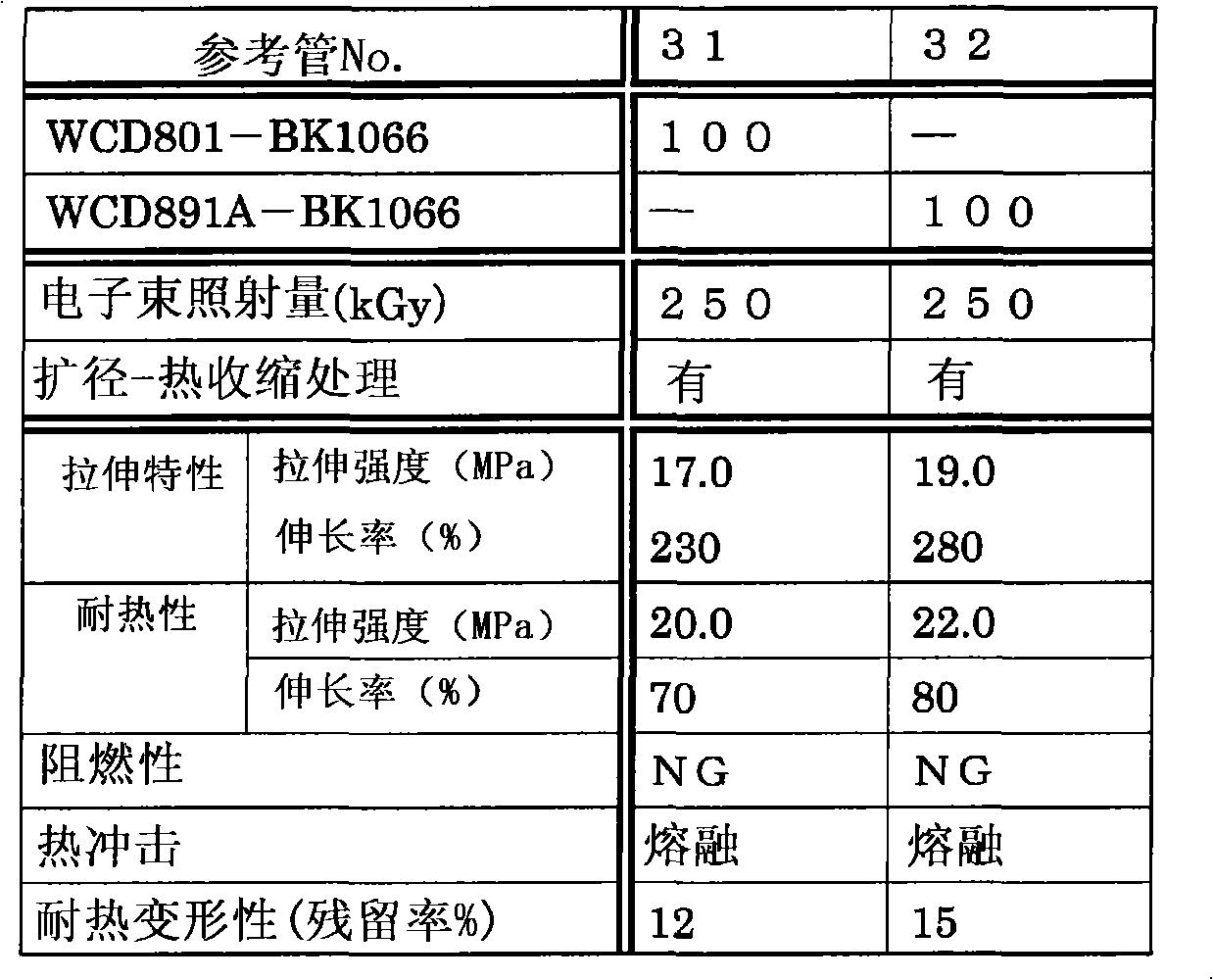

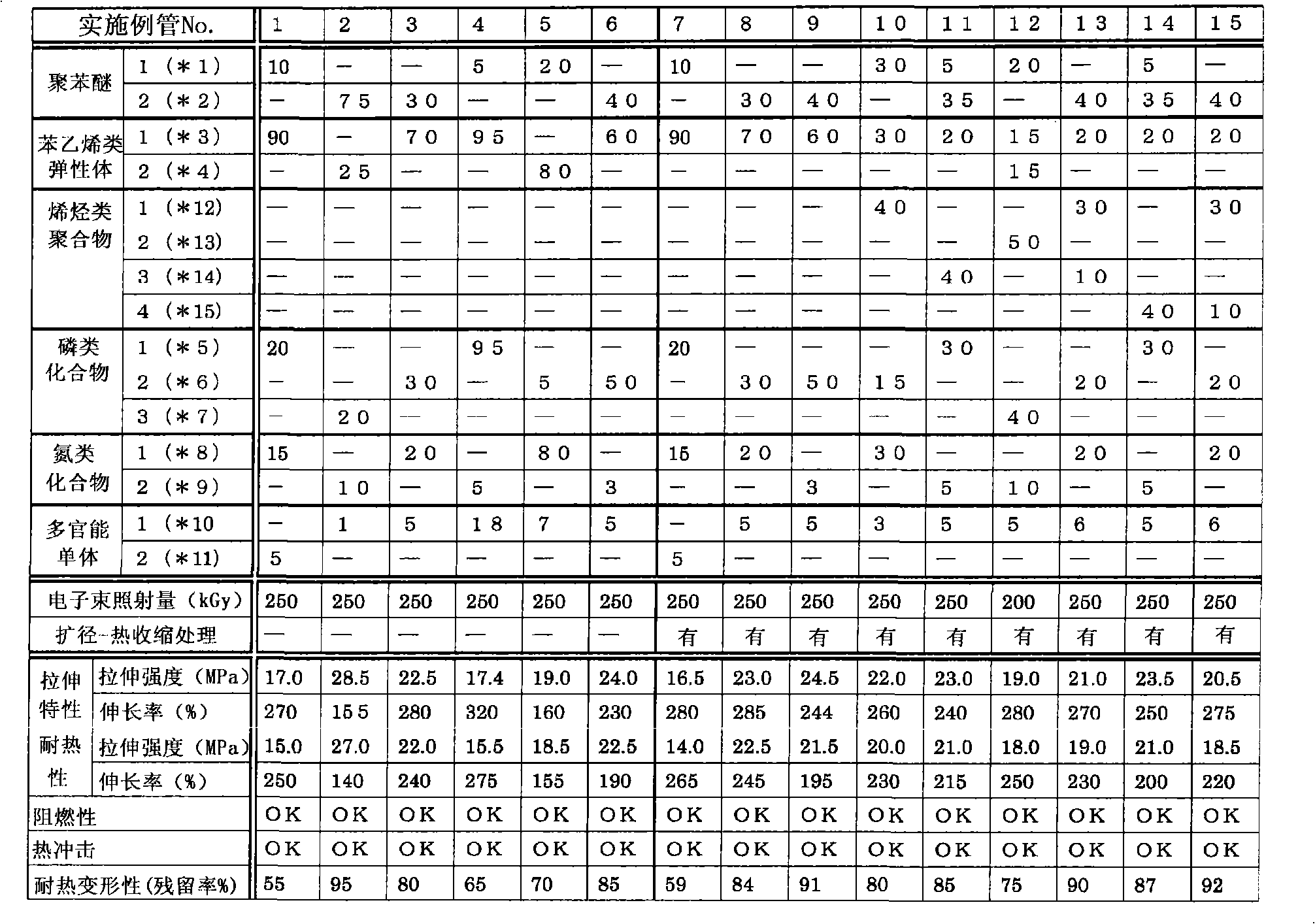

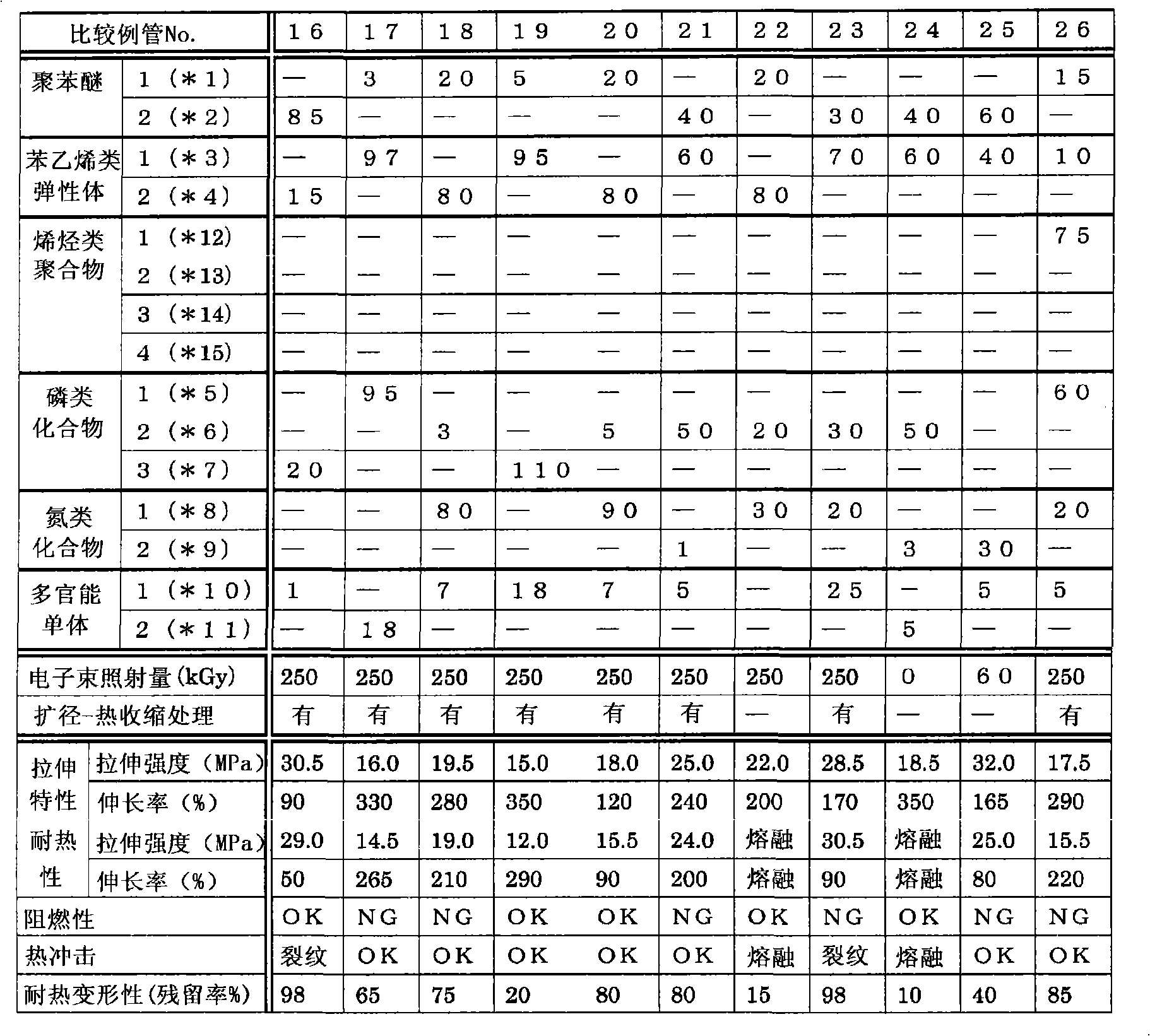

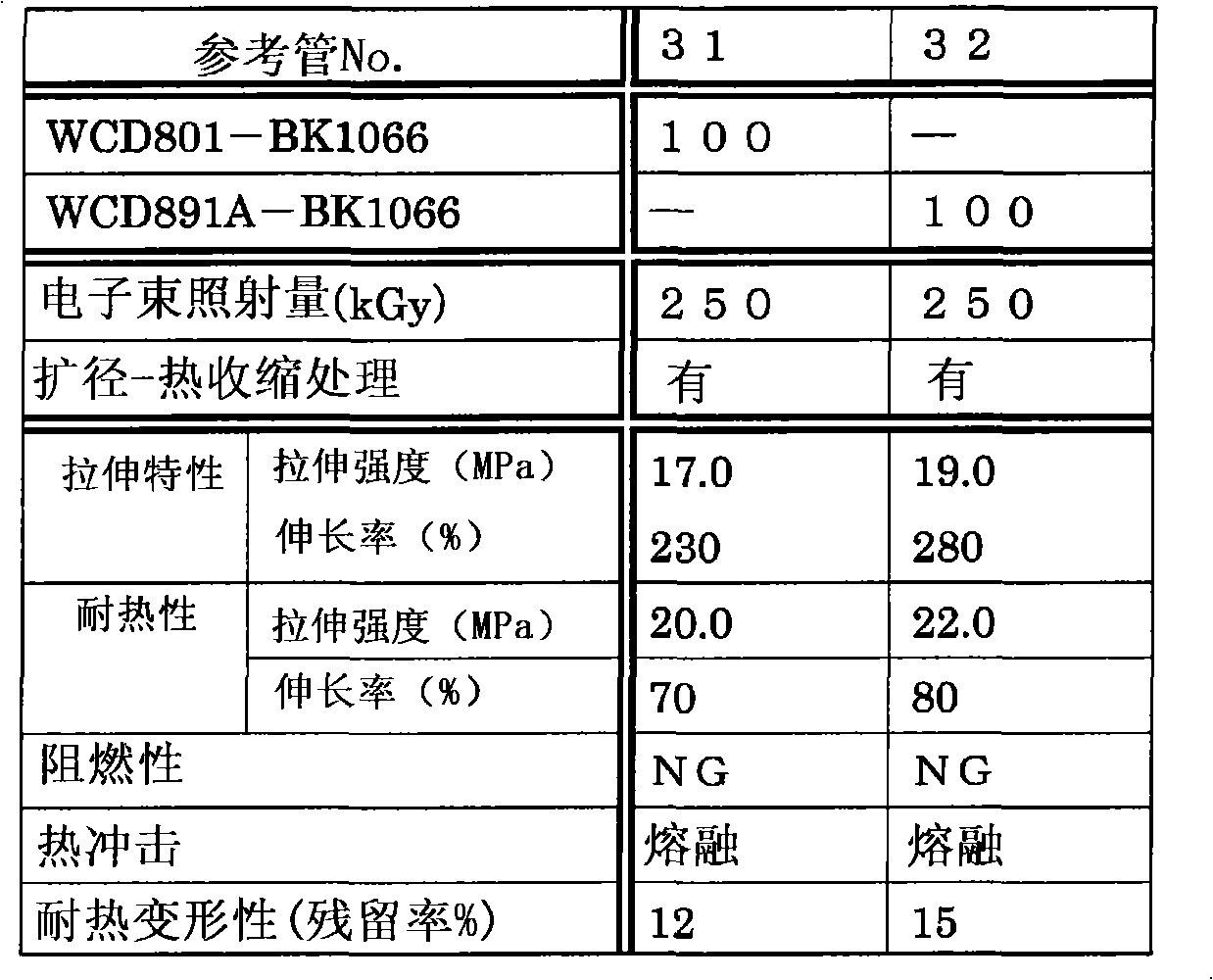

Flame-retardant tube and heat-shrinkable tube made by using the same

A non-halogen type flame-retardant tube which exhibits satisfactory flame retardance, tensile characteristics under high temperature, and heat deformation resistance; and a heat -shrinkable tube, more specifically, a flame-retardant tube produced by molding a flame-retardant resin composition which comprises 100 parts by mass of a base polymer comprising 5 to 80mass% of polyphenylene ether, 20 to95mass% of a styrenic thermoplastic elastomer, and 0 to 70mass% of an olefinic polymer, 5 to 100 parts by mass of a phosphorus-containing flame retardant, 3 to 80 parts by mass of a nitrogenous organic compound, and 1 to 20 parts by mass of a polyfunctional monomer into a tube and irradiating the tube with an electron beam; and a heat-shrinkable tube produced by subjecting the tube to diameter expansion under heating and then setting the tube by cooling.

Owner:SUMITOMO ELECTRIC IND LTD +1

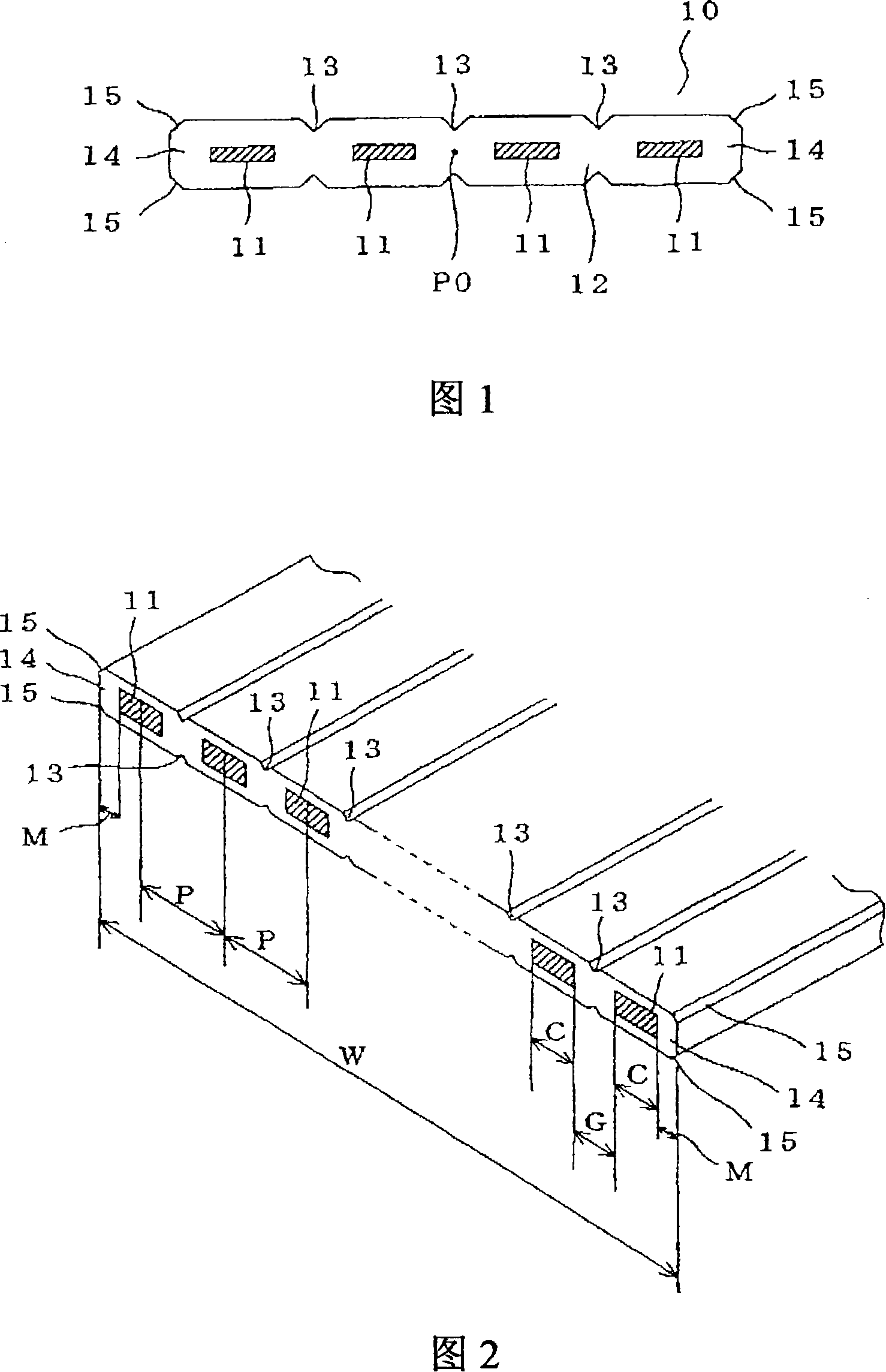

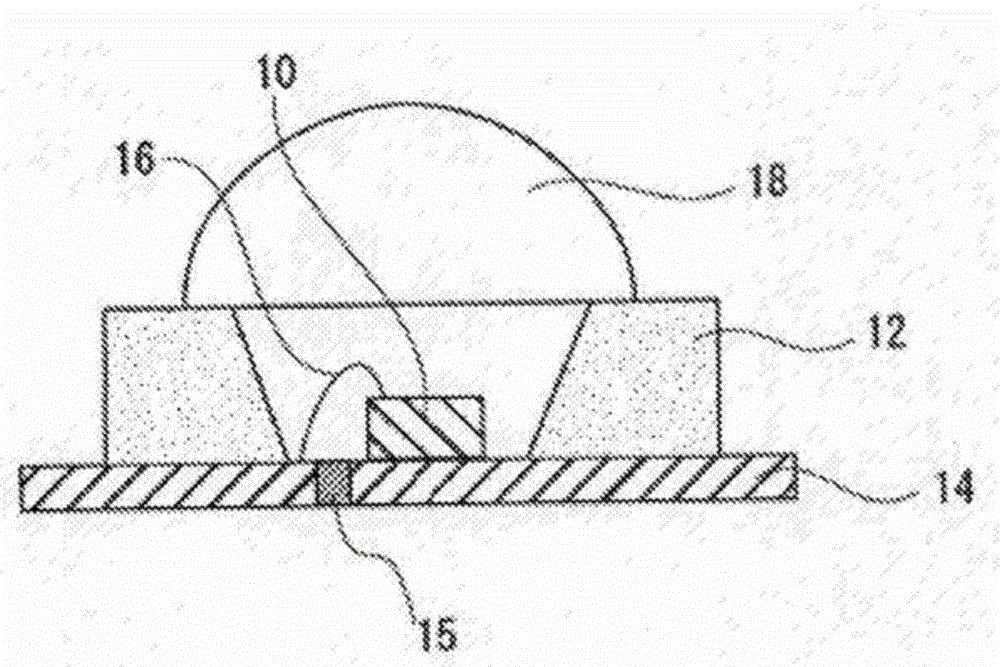

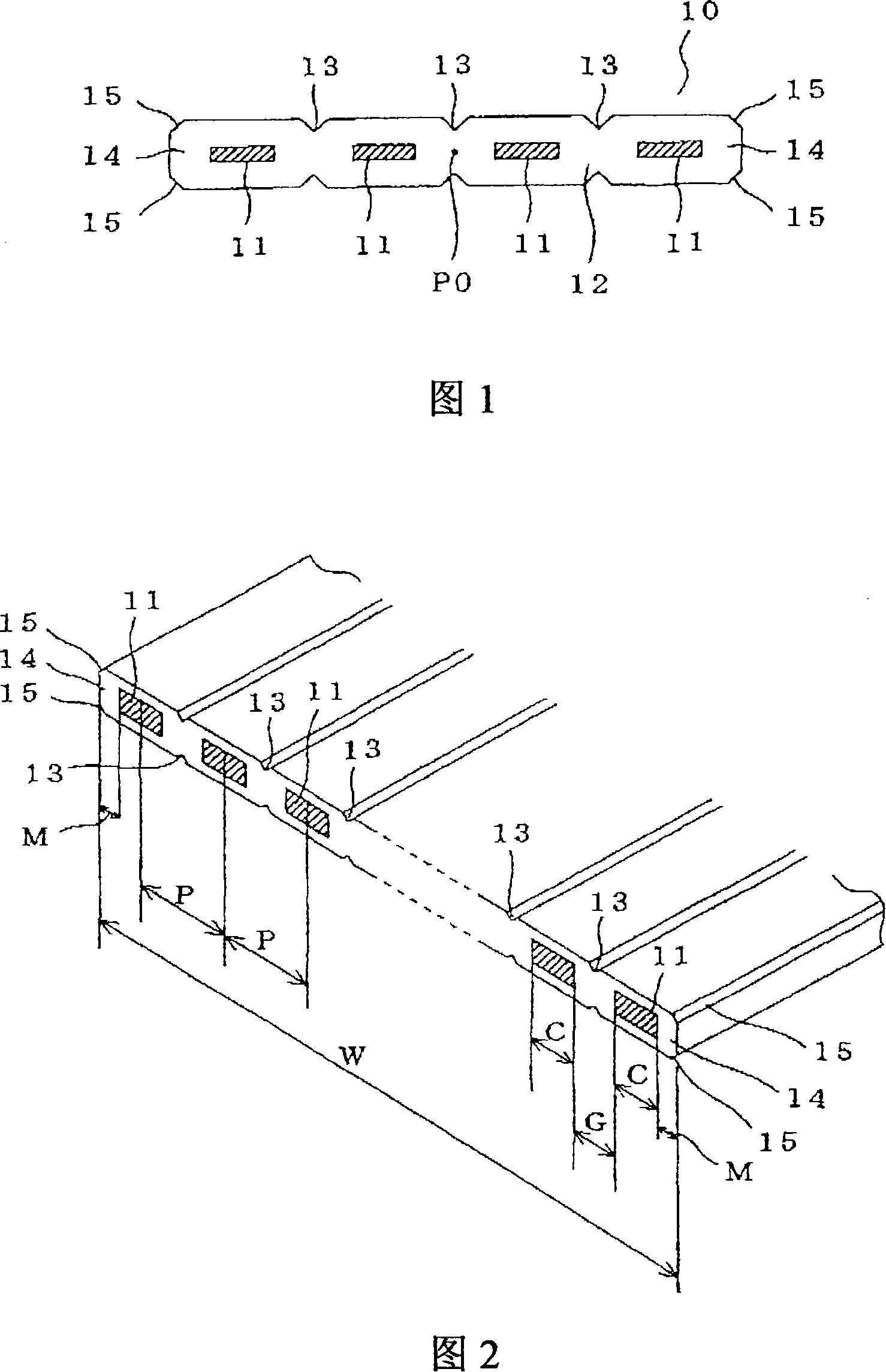

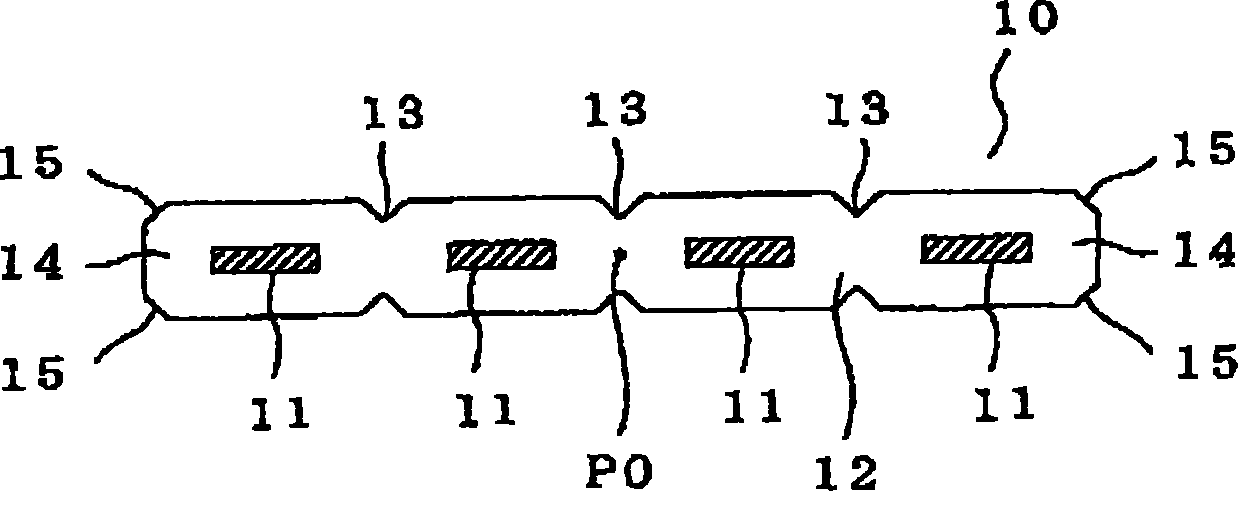

Flexible flat cable

InactiveCN101174491AImprove flame retardant performanceImprove flexibilityPlastic/resin/waxes insulatorsFlat/ribbon cablesElectrical conductorHeat resistance

A flexible flat cable is provided to facilitate division or branching into a plurality flexible flat cables with a predetermined number of straight angle conductors by including cutting grooves on both surfaces of an insulating coating along a longitudinal direction. A flexible flat cable(10) is formed by insulating coating of a plurality of straight angle conductors(11) arranged in parallel with an insulating coating material(12) at once. The insulating coating material is composed of a flame-retardance resin composition including a resin component 100 parts by weight and a metal hydroxide 40~250 parts by weight. The resin component includes a thermoplastic polyurethane elastomer with a JIS hardness of below A97 measured according to JIS K 7311 and an ethylene acetic vinyl copolymer with an acetic vinyl unit 50~90 wt% at a ratio of 40:60 to 90:10.

Owner:SUMITOMO ELECTRIC IND LTD

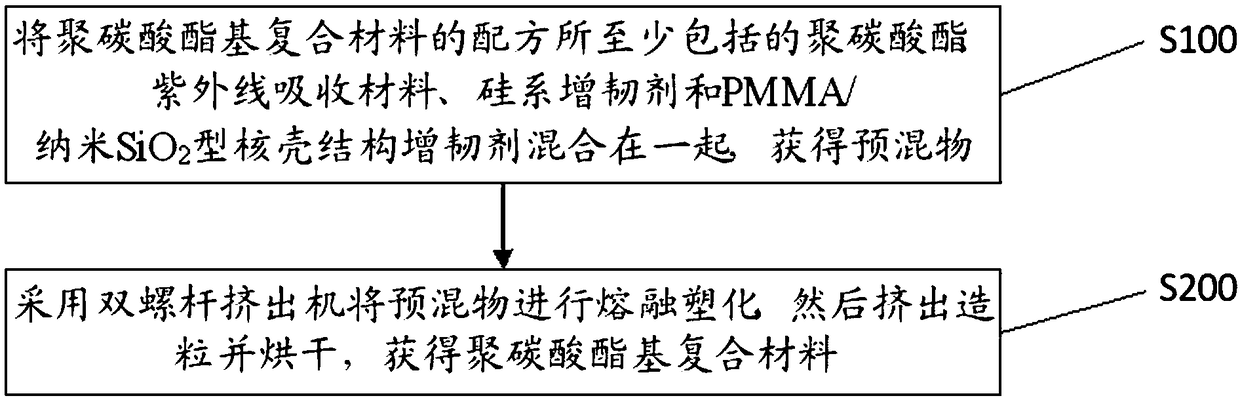

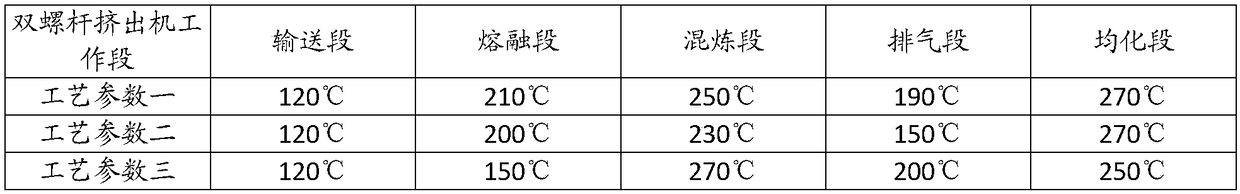

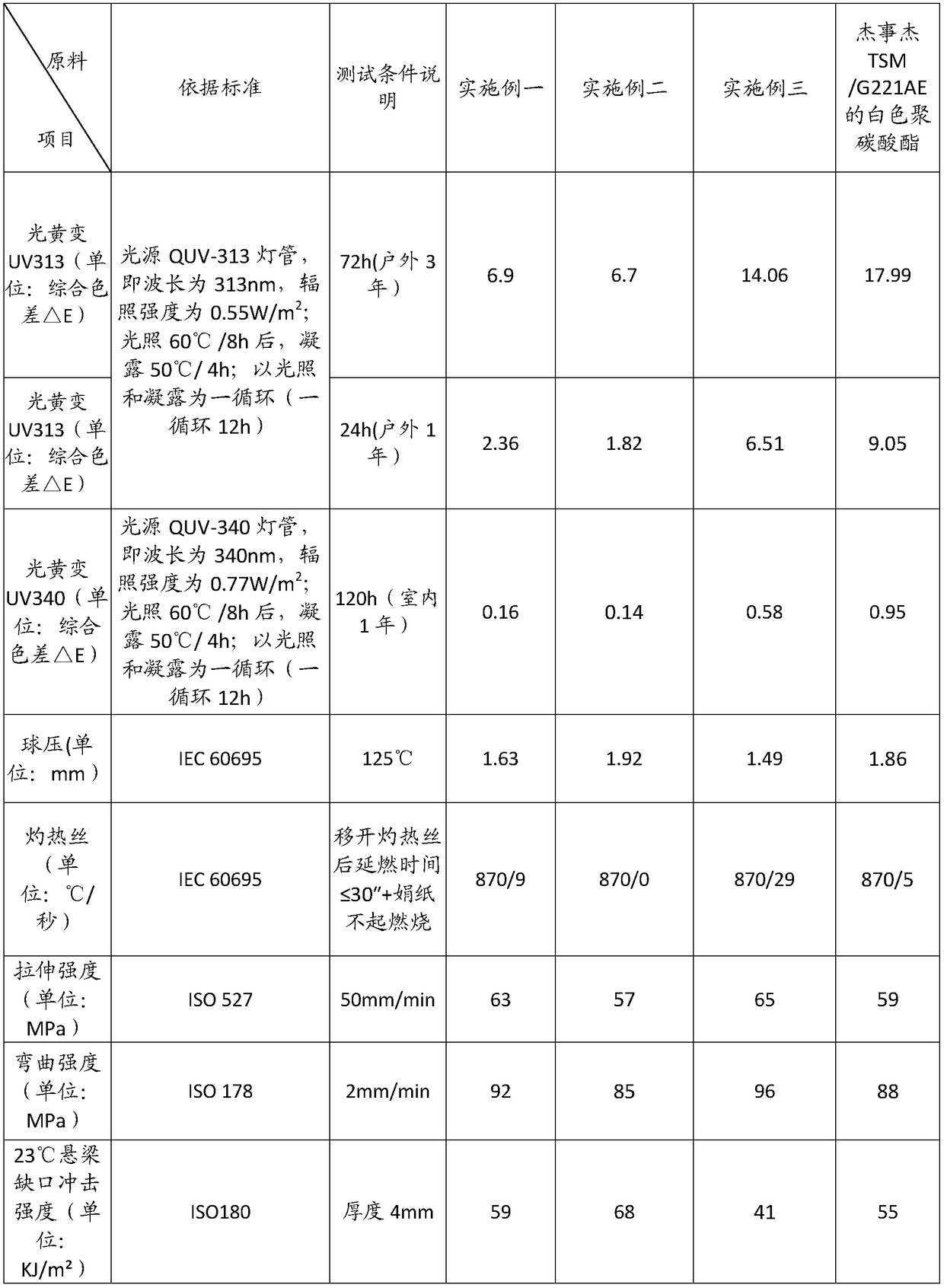

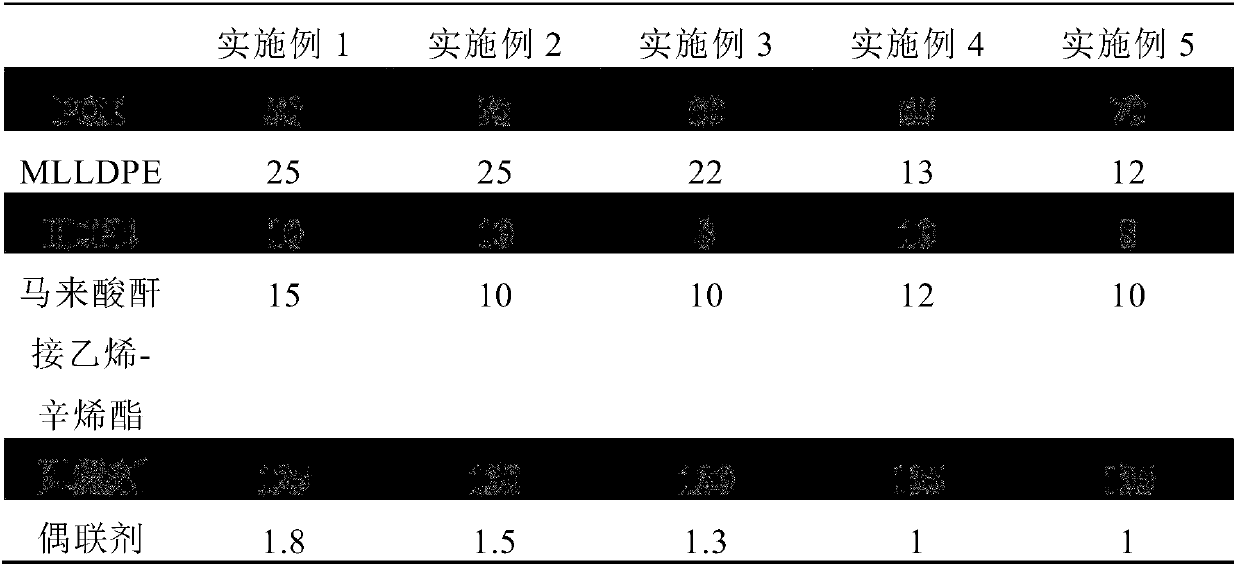

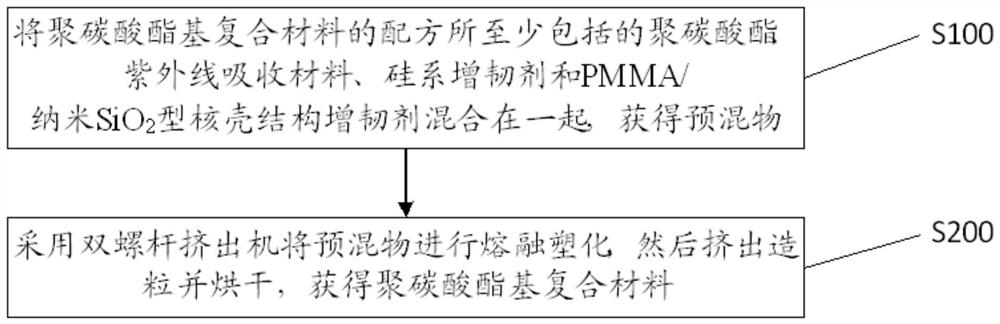

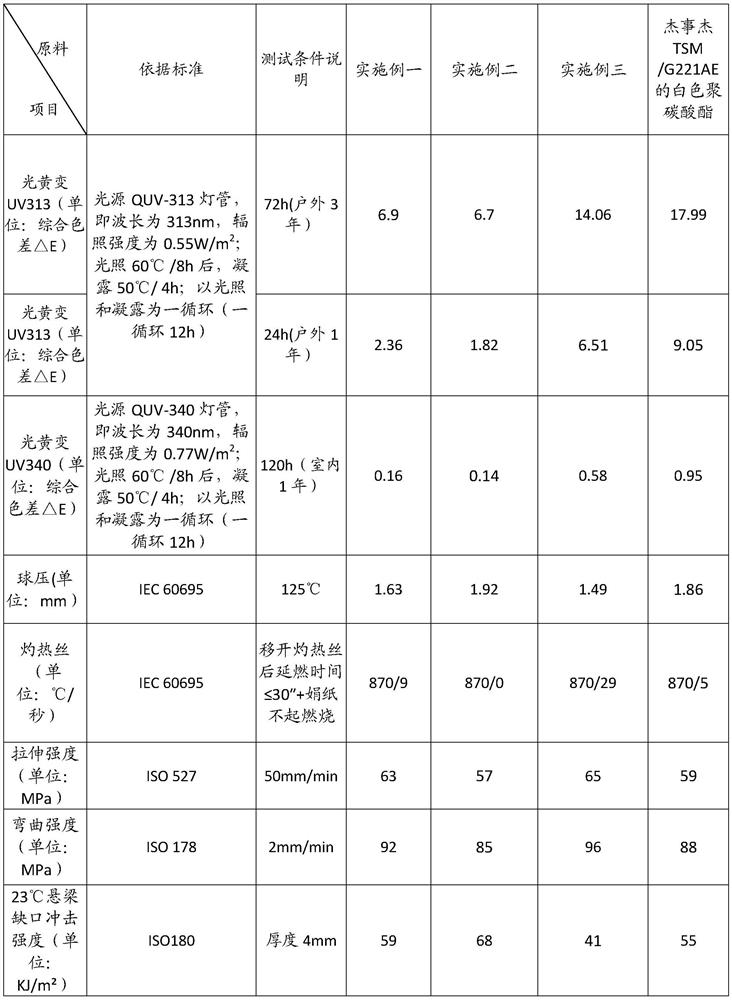

Polycarbonate-based composite material and preparation method and application thereof

ActiveCN109251502AImprove low temperature toughnessImprove light yellowing resistanceNano sio2Ultraviolet lights

The invention discloses a polycarbonate-based composite material and a preparation method and application thereof, and relates to the technical field of material modification, in order to improve thelight yellowing resistance, low temperature toughness and structural strength of plastic parts made of polycarbonate in a long-term ultraviolet light environment and maintain good thermal deformationresistance of a PC material. The polycarbonate-based composite material is prepared by using the following formula: the formula at least includes polycarbonate, an ultraviolet light absorber, a silicon-based flexibilizer, and a PMMA / nano-SiO2-type core-shell structured flexibilizer. The method for preparing the polycarbonate-based composite material is used for preparing the above polycarbonate-based composite material. The polycarbonate-based composite material provided by the invention and the preparation method thereof are applied to anti-yellowing plastic parts.

Owner:BULL GRP CO LTD

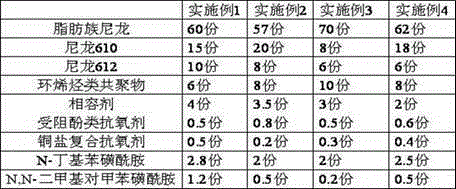

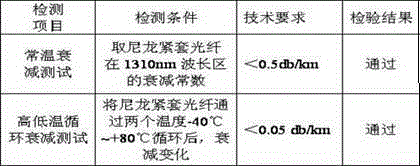

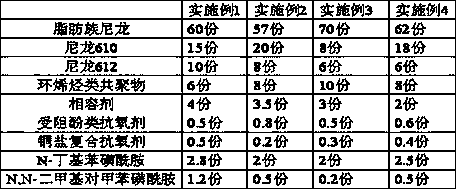

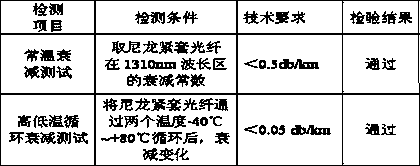

High/low temperature-resistant nylon composite material and preparation method thereof

The invention discloses a high / low temperature-resistant nylon composite material and a preparation method thereof. The high / low temperature-resistant nylon composite material comprises the following components: 55-85 parts of aliphatic nylon 12, 5-25 parts of nylon 610, 5-10 parts of nylon 612, 1-15 parts of a cycloolefin copolymer, 0.5-5 parts of a compatilizer, 0.1-1 part of a hindered phenol antioxidant, 0.1-0.5 part of a copper salt compound antioxidant, 2-3 parts of N-butylbenzene sulfonamide and 0.2-1 part of N,N-dimethyl-p-toluenesulfonamide, wherein the relative viscosities of the aliphatic nylon 12, the nylon 610 and the nylon 612 are below 2.7; the cycloolefin copolymer is selected from ethylene with density of 1.01+ / -0.01 g / cm<3> and a norbornene copolymer TOPAS resin; the compatilizer is selected from maleic anhydride grafted amorphous polyolefin. The high / low temperature-resistant nylon composite material is difficult to crystallize, high in transparency and low in coefficient of thermal expansion, and has the advantages of greatly improving the problem of high optical attenuation loss and further improving the mechanical strength of the material.

Owner:中广核三角洲(江苏)塑化有限公司

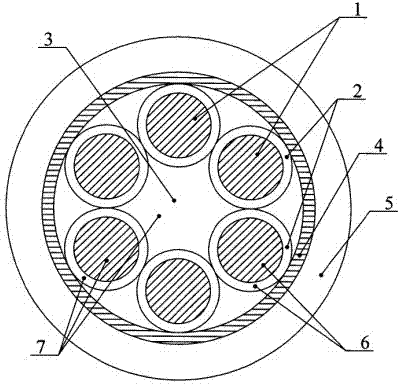

Flexing-resistant multi-core control cable

InactiveCN102956296AEven by forceSimple structureNon-insulated conductorsClimate change adaptationCopper conductorElectric cables

The invention belongs to the technical field of cable application and relates to a multi-core control cable, in particular to a flexing-resistant multi-core control cable which is applicable to rated voltage of 450V / 750V and particularly applicable to electric welding machines. The technical scheme includes that the flexing-resistant multi-core control cable comprises copper conductors (1) and insulating layers (2), the copper conductors (1) and the insulating layers (2) form a plurality of core wires (6), the core wires in monolayer arrangement and packing (3) among the core wires are stranded into a cable core (7), and a lapped covering (4) is arranged outside the cable core (7) and wrapped by a sheath (5) in an extruded manner. After the technical scheme is adopted, the cable core is uniform in stress, and the cable becomes flexible, good in flexibility and flexing-resistant.

Owner:JIANGSUSNGSHANG CABLE GROUP

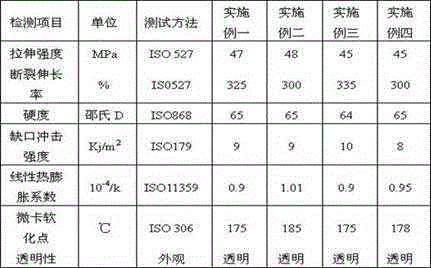

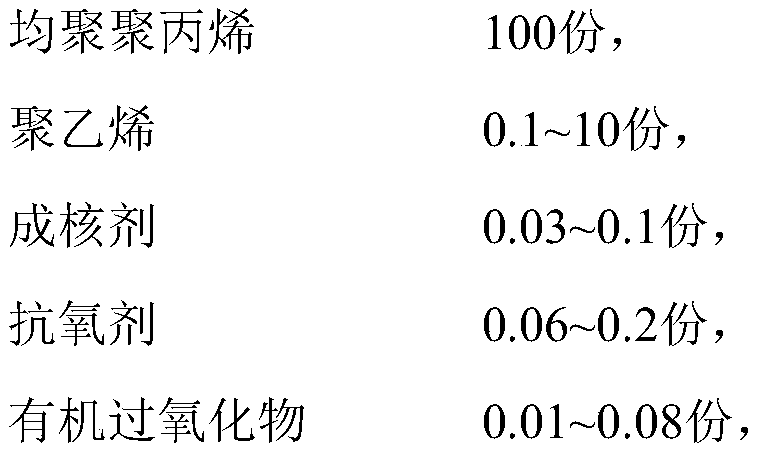

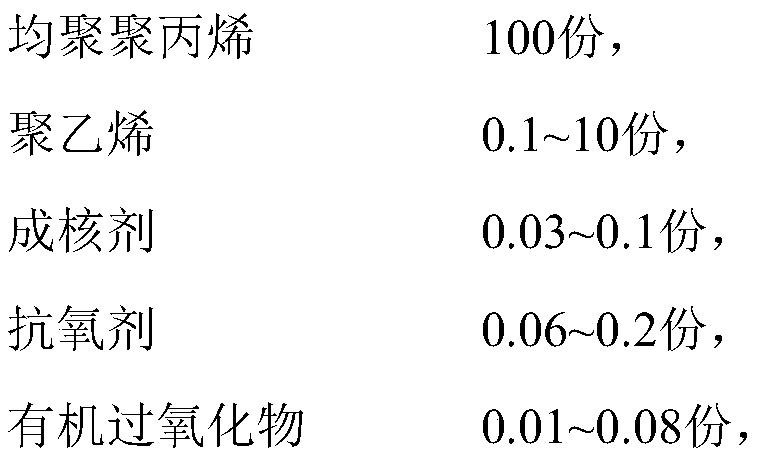

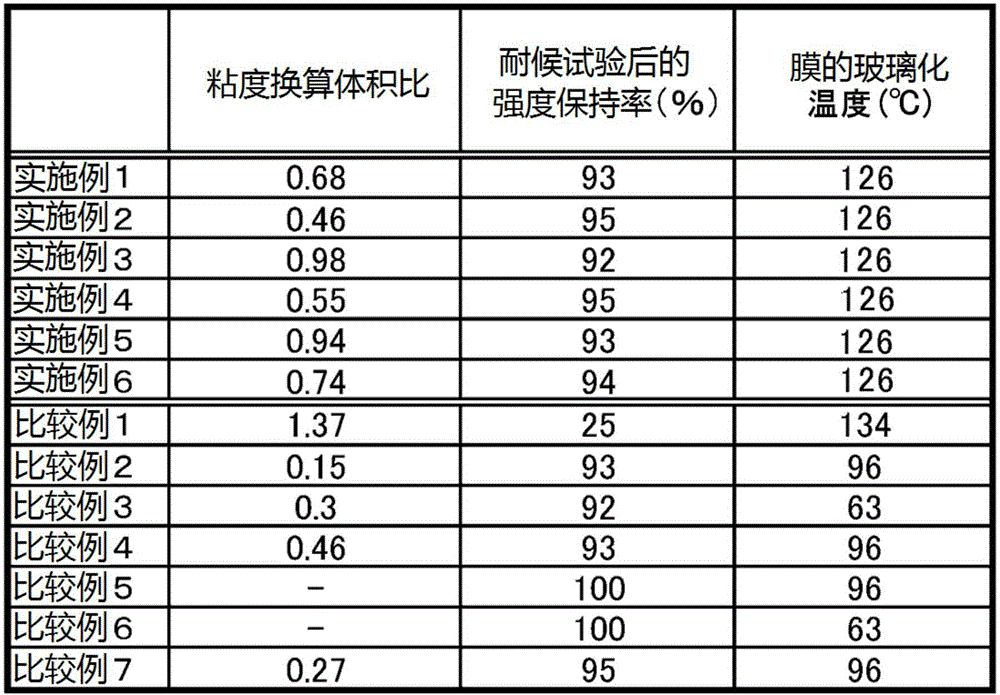

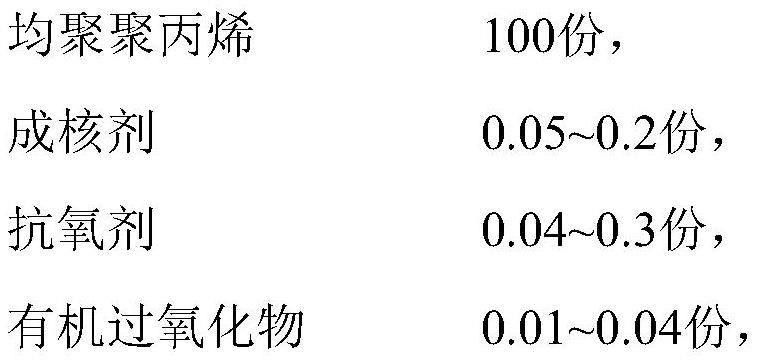

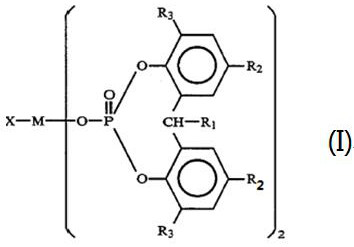

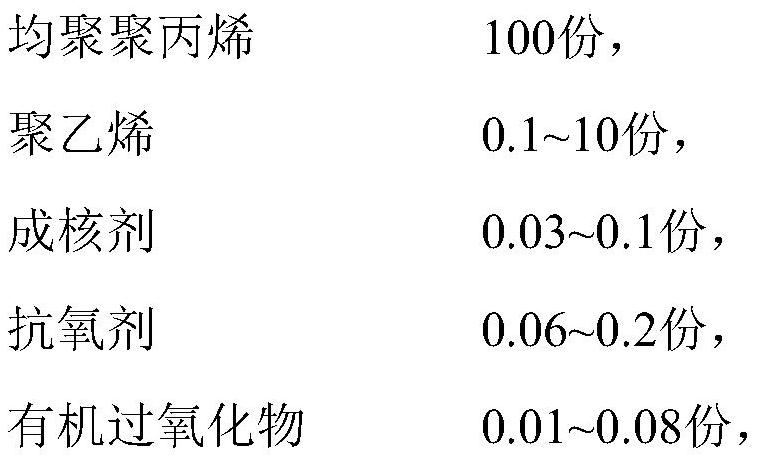

Toughening polypropylene material and preparation method thereof

ActiveCN109851913ALower crystallization temperature and longer crystallization timeIncrease production costPolypropyleneCrystallite

The invention discloses a toughening polypropylene material, comprising the following components in parts by weight: 100 parts of homo-polypropylene, 0.1-10 parts of polyethylene, 0.05-0.2 part of nucleating agent, 0.04-0.3 part of antioxygen, and 0.01-0.04 part of organic peroxide. The invention also discloses a preparation method of the toughening polypropylene material, and the preparation method includes the following steps: adding homo-polypropylene, polyethylene, a nucleating agent, an antioxygen and an organic peroxide into a high speed mixer for mixing, and conducting melting blendingextruding pelletizing on the uniformly mixed premix by a twin screw extruder, so as to obtain the final product. According to the invention, a low proportion of polyethylene is added into the formulacomponents and is used as a toughening agent of polypropylene, thereby realizing impact modification of polypropylene, refining grain size of polypropylene crystal, increasing impact resistance of thepolypropylene material, enhancing low-temperature resistance, and decreasing the melting point of the polypropylene material, decreasing the processing temperature and correspondingly reducing energyconsumption.

Owner:东华能源(宁波)新材料有限公司 +2

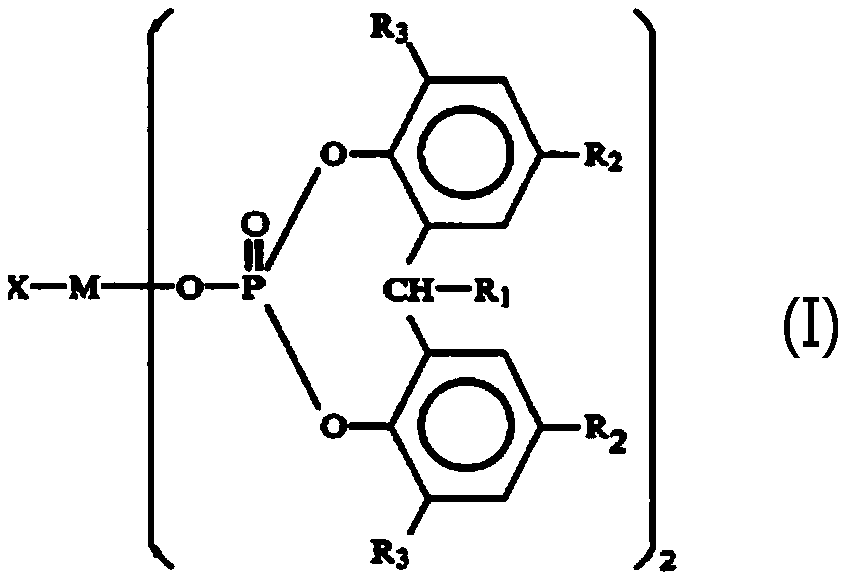

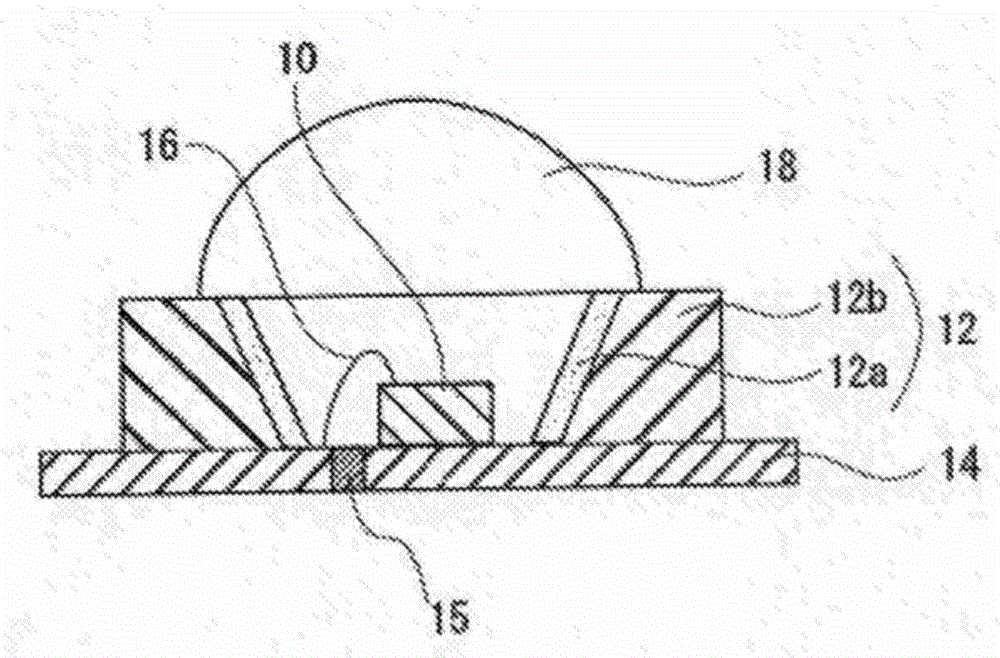

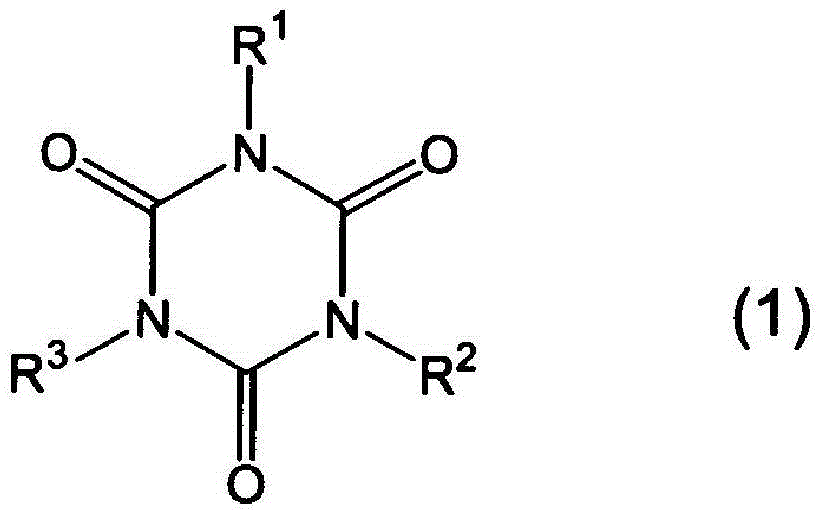

Electron beam curable resin composition, reflector resin frame, reflector, semiconductor light-emitting device, and molded article production method

InactiveCN104968724AExcellent heat deformation resistanceSolid-state devicesSemiconductor devicesLight emitting deviceSemiconductor

The present invention involves an electron beam curable resin composition containing an olefin resin and a crosslinking agent. The crosslinking agent has a saturated or unsaturated ring structure, and at least one of the atoms forming at least one ring is bonded to an allylic substituent of any of an allyl group, a metallyl group, a linking group-mediated allyl group, and a linking group-mediated metallyl group. The electron beam curable resin composition is obtained by blending in more than 15 parts by mass to 40 parts by mass of the crosslinking agent with respect to 100 parts by mass of the olefin resin. The present invention further involves a reflector resin frame that uses the resin composition, a reflector, a semiconductor light-emitting device, and a molding method in which the resin composition is used.

Owner:DAI NIPPON PRINTING CO LTD

Fiber reinforcing polymer composite and articles made therefrom

ActiveUS20190283372A1Excellent processing speedExcellent heat distortion resistanceSynthetic resin layered productsPolymer compositesPultrusion

Pultruded fiber reinforced polymer composite is disclosed, having a blend of conventional pultrusion resins and a rigidsol. The replacement of some of the conventional pultrusion resin with the rigidsol does not adversely affect mechanical properties but does enhance affinity of the pultruded part to a polyvinyl chloride-containing capstock.

Owner:AVIENT CORP

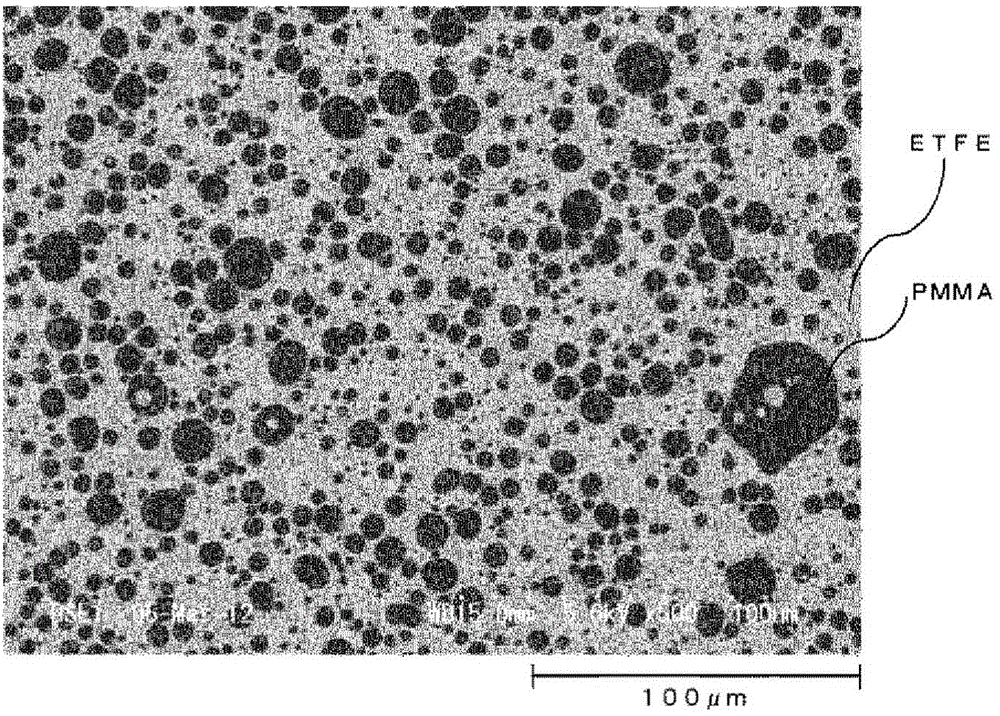

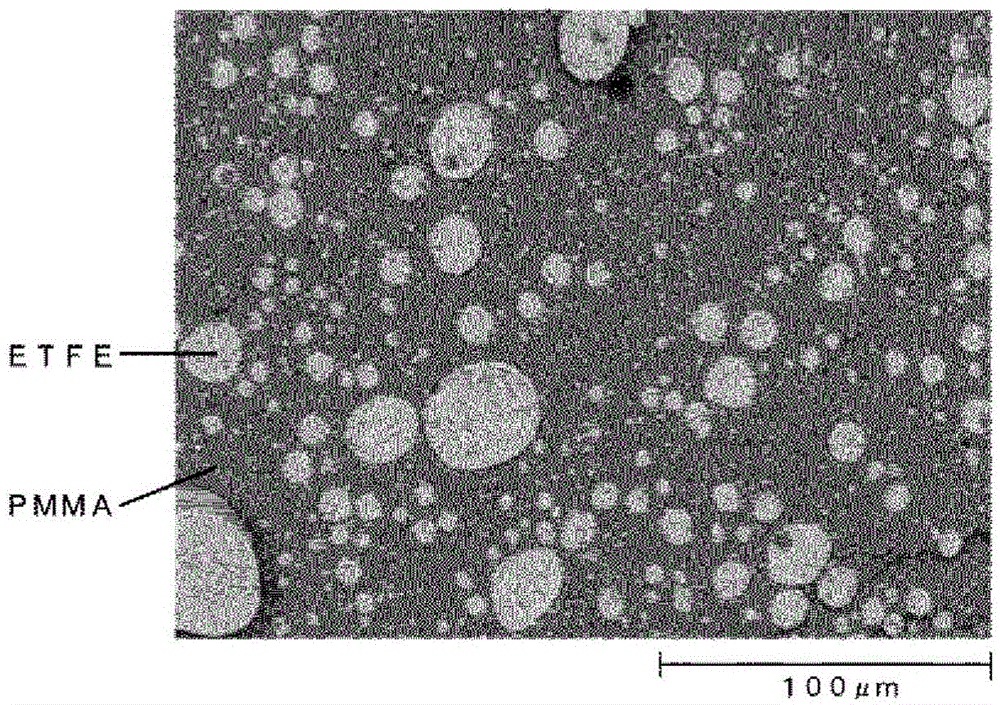

Blend polymer containing ethylene/tetrafluoroethylene copolymer, molded body of said blend polymer, back sheet for solar cells, and method for producing said molded body

InactiveCN104884527AGood weather resistanceHigh heat distortion temperaturePhotovoltaic energy generationSemiconductor devicesHeat deflection temperatureTetrafluoroethylene

To provide a blended polymer containing an ethylene / tetrafluoroethylene copolymer, which is excellent in weather resistance and has a high thermal deformation temperature, a molded product such as a film thereof, a back sheet for a solar cell provided with such a film, etc., and a method for producing such a molded product. A blended polymer which comprises an ethylene / tetrafluoroethylene copolymer and a polymethyl methacrylate, wherein the mass ratio of the ethylene / tetrafluoroethylene copolymer to the total mass of the ethylene / tetrafluoroethylene copolymer and the polymethyl methacrylate, is from 50 to 75%, and which has a microphase-separated structure wherein the continuous phase is the ethylene / tetrafluoroethylene copolymer, and the dispersed phase is the polymethyl methacrylate.

Owner:AGC INC

Polyamide moulding composition for extrusion blow moulding

Thermoplastic moulding composition consisting of(A) 51 to 69.9 wt % of polyamide elastomer;(B) 15 to 38 wt % of ethylene-α-olefin copolymer;(C) 3 to 25 wt % of polyamide selected from the group consisting of: PA6, PA66, PA6 / 66, PA610, PA612, PA614, PA616, PA6 / 610, PA66 / 610 or mixtures thereof;(D) 0.1 to 2.0 wt % of heat stabilizers based on copper and / or iodide, organic stabilizers or a mixture thereof;(E) 0 to 5.0 wt % of additives, different from (A) to (D);where the sum of (A) to (E) makes 100 wt % of the total moulding composition, and with the proviso that the sum of (B) and (C) is in the range from 30 to 48 wt % based on the total moulding composition.

Owner:EMS PATENT AG

pvc building plastic formwork and preparation method

The invention provides a PVC (Polyvinyl Chloride) building plastic template and a manufacturing method thereof. The building plastic template comprises the following raw materials: polyvinyl chloride, chlorinated polyethylene, calcium powder, talcum powder, wood flour, tribasic lead sulfate, calcium stearate, oxidized polyethlene wax, PE (Polyethylene) wax, resin chloroprene rubber, a polypropylene grafted butyl acrylate copolymer, calcium stearate, an antioxidant, glass fibers, an ultraviolet light absorber, azodicarbonamide and sodium hydrogen carbonate. The manufacturing method of the building plastic template comprises the following steps: heating a blender mixer to 90 DEG C; adding calcium powder and wood flour, and then adding chlorinated polyethylene, and finally adding various assistants and filler; gradually heating to 140 DEG C for mixing for 10-20 minutes, and cooling to 30-45 DEG C; extruding by a twin-screw extruder and plastifying to form colloid; and manufacturing in a moulding press die.

Owner:SHANDONG JINHUA CONSTR GRP

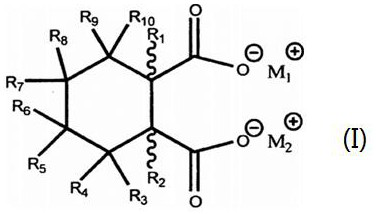

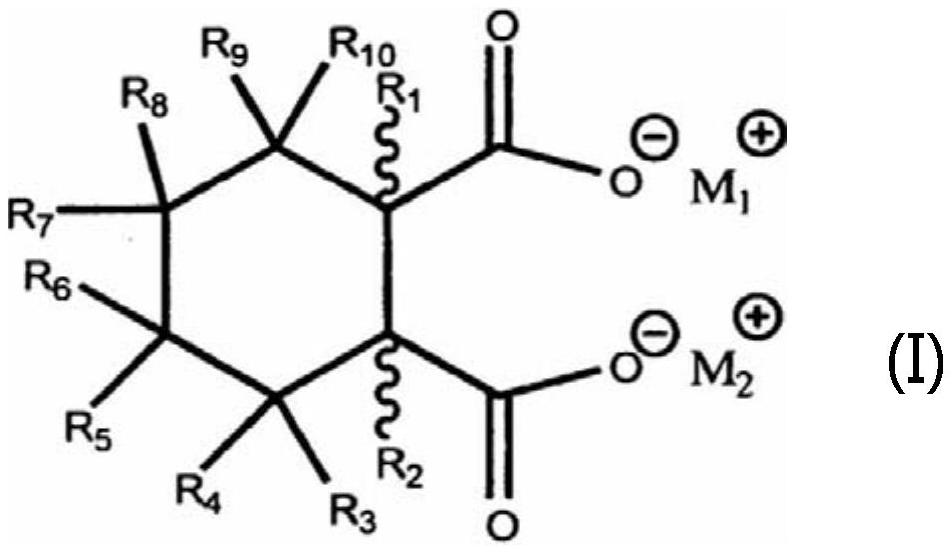

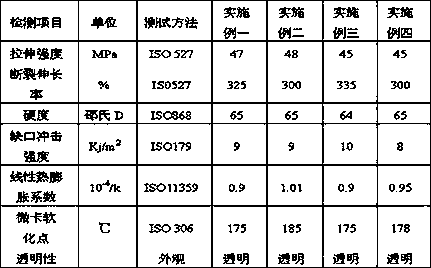

A kind of transparent polypropylene material and preparation method thereof

The invention discloses a transparent polypropylene material, which comprises the following components in parts by weight: 100 parts of homopolypropylene, 0.05-0.2 parts of nucleating agent, 0.04-0.3 parts of antioxidant, and 0.01-0.04 parts of organic peroxide share. The invention also discloses a preparation method of transparent polypropylene material, comprising the following steps: mixing and dispersing homopolypropylene, nucleating agent, antioxidant and organic peroxide in a high-speed mixer, heating, melting and extruding The polypropylene material is obtained by granulation, wherein the homopolypropylene is obtained by the hydrogen modulation method, and after being degraded by adding an organic peroxide, it is finally obtained at 230°C and under a load of 2.16kg. Polypropylene material with a melt flow rate of 10min. The transparent polypropylene material prepared by the invention exhibits good processing fluidity, balance between rigidity and toughness, dimensional stability, thermal deformation resistance, and optical performance of low haze.

Owner:东华能源(张家港)新材料有限公司 +2

Flexible flat cable

InactiveCN101174491BImprove flame retardant performanceImprove flexibilityPlastic/resin/waxes insulatorsFlat/ribbon cablesThermoplasticElectrical conductor

The invention provides a flexible flat cable which utilizes an insulation wrapping material without the content of a combing halogenous atom or a flame retardant of the halogen family and has the advantages of the high flame retardant capability which meets the UL specification, flexibility, mechanical property, heat tolerance, resistance against the aging in high temperature, resistance against the deformation during heating, a property of low temperature, electric insulation, etc. The flexible flat cable of the invention comes into being through the wrapping of a plurality of flat conductors into a whole with the insulation wrapping material. The insulation wrapping material is a flame retardant resin compound with a content of a metal hydroxide with a weight proportion of 40 to 250 in the 100 weight shares of the following resin ingredients. The resin ingredients contains a thermoplastic PU elastomer, the JIS hardness of which is measure to be less than or equal to A97 according to the JIS-K-7311, and an ethylene- vinyl acetate copolymer which contains an acetic ethylene unit with a weight percentage of 50-90%.

Owner:SUMITOMO ELECTRIC IND LTD

A kind of toughened polypropylene material and preparation method thereof

The invention discloses a toughened polypropylene material, which comprises the following components in parts by weight: 100 parts of homopolypropylene, 0.1-10 parts of polyethylene, 0.05-0.2 parts of nucleating agent, and 0.04-0.3 parts of antioxidant , 0.01~0.04 parts of organic peroxide. The invention also discloses a preparation method of toughened polypropylene material, comprising the following steps: adding homopolypropylene, polyethylene, nucleating agent, antioxidant and organic peroxide into a high-speed mixer and mixing, mixing The homogeneous premixed material is made by melting, blending, extruding and granulating with a twin-screw extruder. In the present invention, by adding a low proportion of polyethylene into the formula components, as a toughening agent for polypropylene, the impact modification of polypropylene is realized, the crystal grain size of polypropylene is refined, and the polypropylene material is increased. The impact resistance and low temperature resistance are enhanced, and the melting point of polypropylene material is lowered, so that the processing temperature is lowered, and the energy consumption is also reduced.

Owner:东华能源(宁波)新材料有限公司 +2

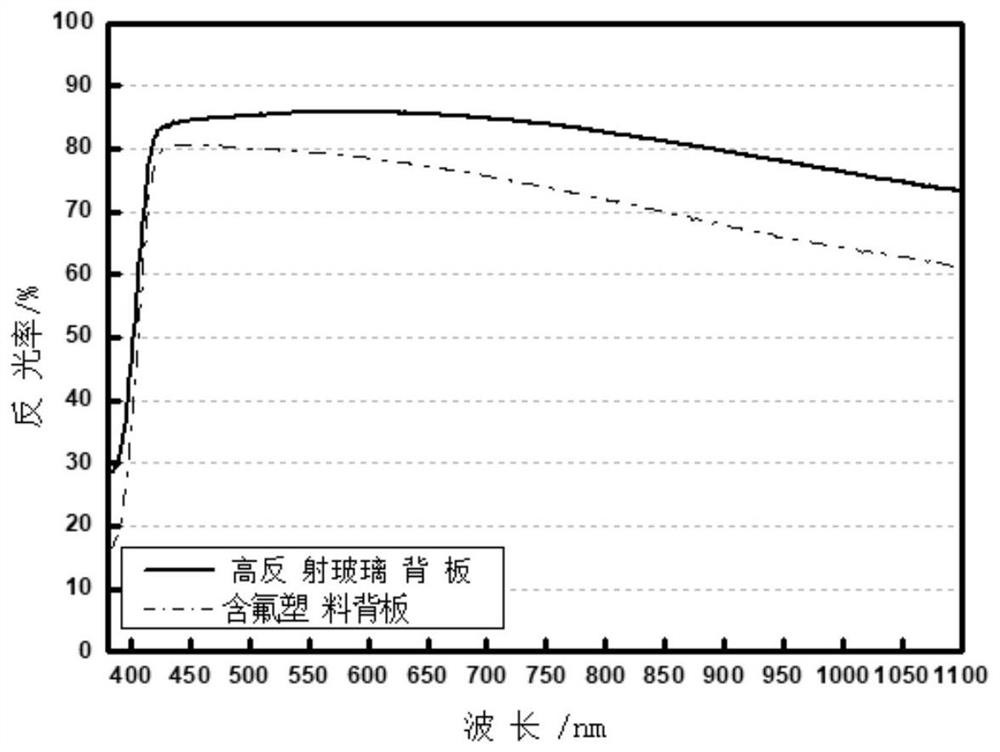

A kind of white ink and coated glass backplane, its preparation method and application, and double-glass solar photovoltaic module

ActiveCN110358443BGood adhesionStrong adhesionPhotovoltaic energy generationReflecting/signal paintsPolymer resinWeather resistance

The invention belongs to the field of solar cells, and discloses a white ink and glass back plate, a preparation method thereof, and a solar photovoltaic module. White ink is composed of the following components: 45-70% of high-reflection inorganic fillers, 10-40% of inorganic sintering agents, 2%-18% of polymer resins, 12%-28% of solvents, 0-3% of additives; The filler is selected from TiO 2 , BaSO 4 、BaCO 3 、Al 2 o 3 , CaCO 3 , CaSO 4 , ZrO 2 At least one of , lithopone, mica, lead white and talcum powder; the inorganic sintering agent contains Bi 2 o 3 , SiO 2 and / or B 2 o 3 , MgO and ZnO, and based on the total weight of the inorganic sintering agent, Bi 2 o 3 The content of SiO is 20-60wt%. 2 and B 2 o 3 The total content of MgO is 25-50wt%, the content of MgO is 0.5-10wt%, and the content of ZnO is 5-20wt%. The preparation method of the glass backplane includes S1, coating film preparation; S2, pre-cured coating film; S3, tempered coating film. The glass back plate provided by the invention has good weather resistance, strong adhesive force and strong adhesion, and can be used for preparing double-glass solar photovoltaic modules.

Owner:厦门威亮光学涂层技术有限公司

Heat-resistant, high-strength, low-smoke, halogen-free and flame-retardant sheathing material for optical cables, and preparation method of sheathing material

InactiveCN109535539AHigh strengthExcellent heat deformation resistanceElastomerLinear low-density polyethylene

Owner:上海至正新材料有限公司

A kind of polycarbonate base composite material and its preparation method and application

ActiveCN109251502BImprove low temperature toughnessImprove light yellowing resistanceUltraviolet lightsThermal deformation

The invention discloses a polycarbonate-based composite material and its preparation method and application, and relates to the technical field of material modification to improve the light yellowing resistance, low-temperature toughness and toughness of plastic parts made of polycarbonate in long-term ultraviolet light environments. Structural strength and maintain good thermal deformation resistance of PC materials. The polycarbonate-based composite material is prepared using the following formula; the formula includes at least polycarbonate, ultraviolet absorber, silicon-based toughening agent and PMMA / nanometer SiO 2 Toughener for core-shell structure. The preparation method of the polycarbonate-based composite material is used to prepare the above-mentioned polycarbonate-based composite material. The polycarbonate-based composite material provided by the invention and its preparation method and application in anti-yellowing plastic parts.

Owner:BULL GRP CO LTD

High and low temperature resistant nylon composite material and preparation method thereof

Owner:中广核三角洲(江苏)塑化有限公司

Fiber reinforcing polymer composite and articles made therefrom

ActiveUS10899115B2Good bonding and affinity characteristicExcellent heat deformation resistanceSynthetic resin layered productsPolymer sciencePolyvinyl chloride

Pultruded fiber reinforced polymer composite is disclosed, having a blend of conventional pultrusion resins and a rigidsol. The replacement of some of the conventional pultrusion resin with the rigidsol does not adversely affect mechanical properties but does enhance affinity of the pultruded part to a polyvinyl chloride-containing capstock.

Owner:AVIENT CORP

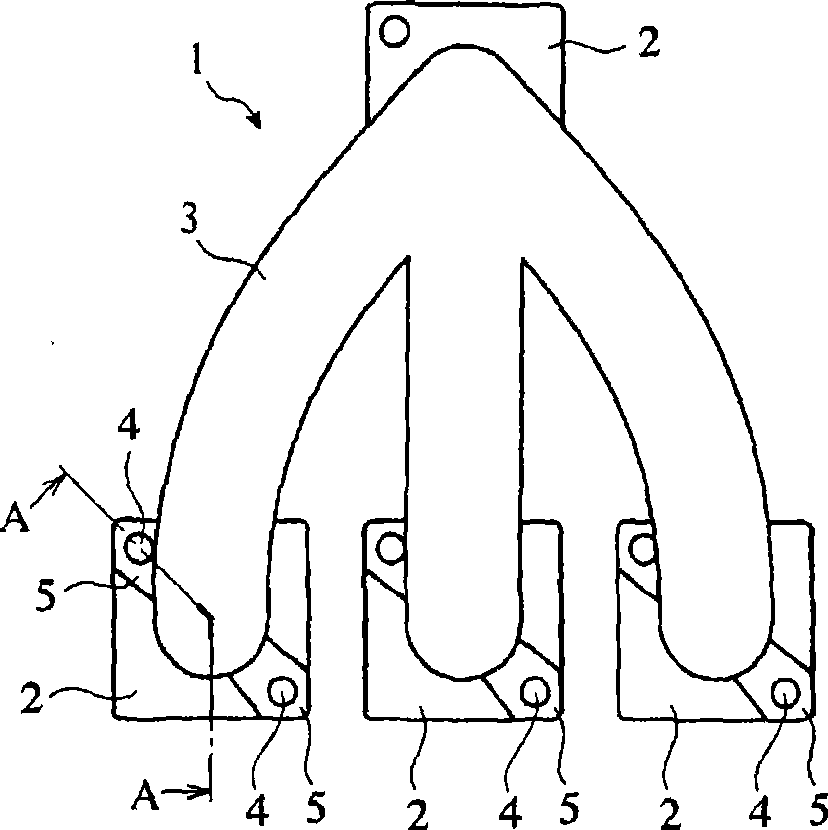

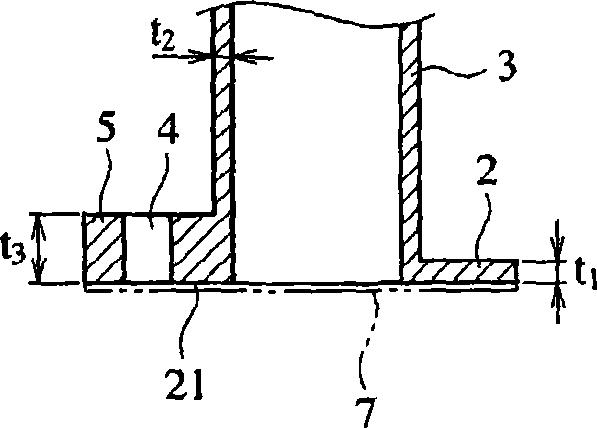

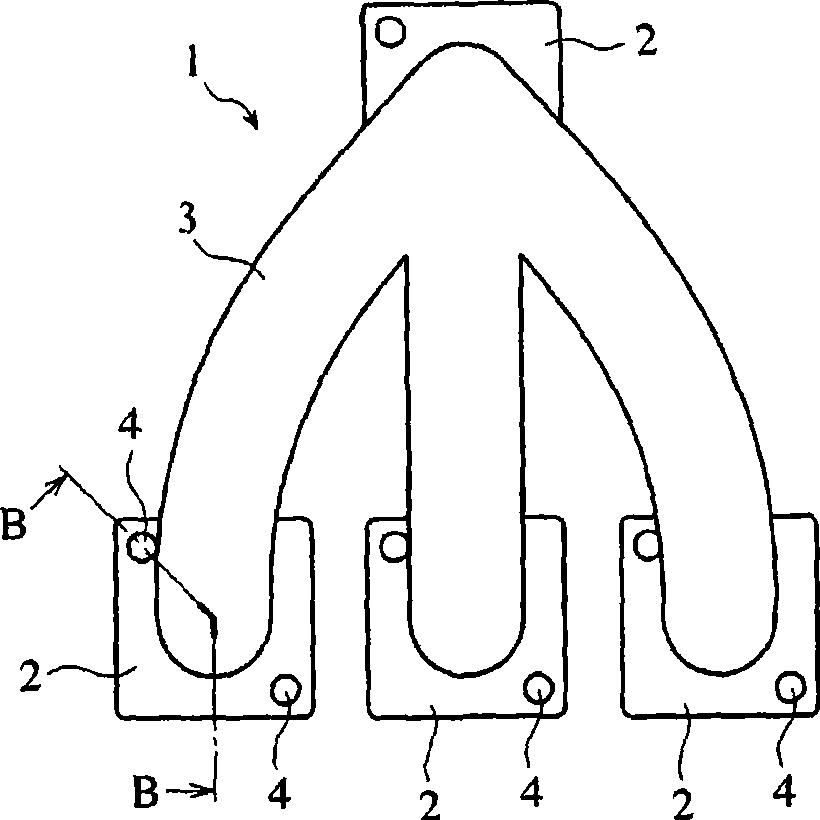

Heat-resistant cast steel exhaust manifold

InactiveCN101384803ALess man-hour yieldEfficient preparationFoundry mouldsSilencing apparatusCylinder headEngineering

Provided is a heat-resistant cast steel exhaust manifold includes: a plurality of flange portions having a hole for connection by a bolt to an exhaust port of an engine cylinder head; a plurality of port portions connected to the flange portions; and a confluence portion where the port portions are collected. The flange portion has a thickness equal to 80 to 150% of the thickness of the port portion.

Owner:HITACHI METALS LTD

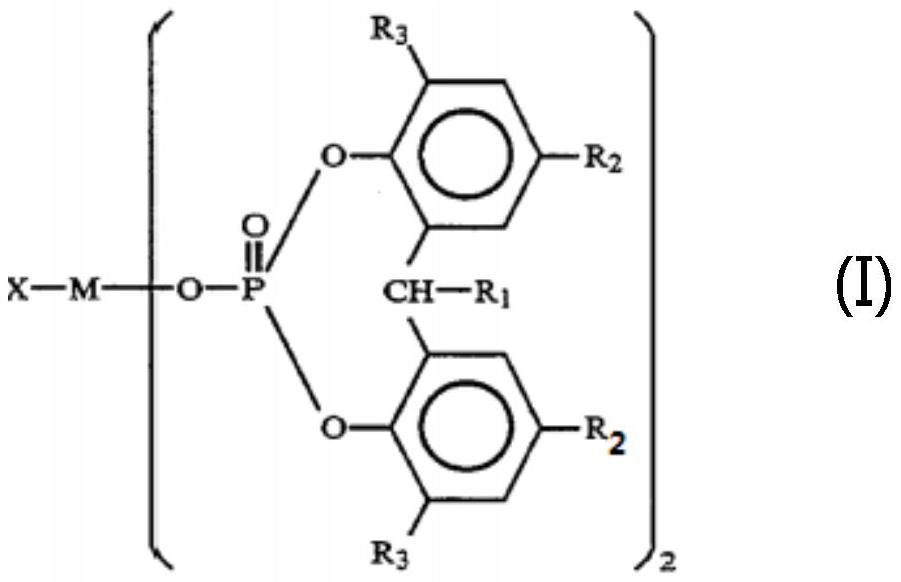

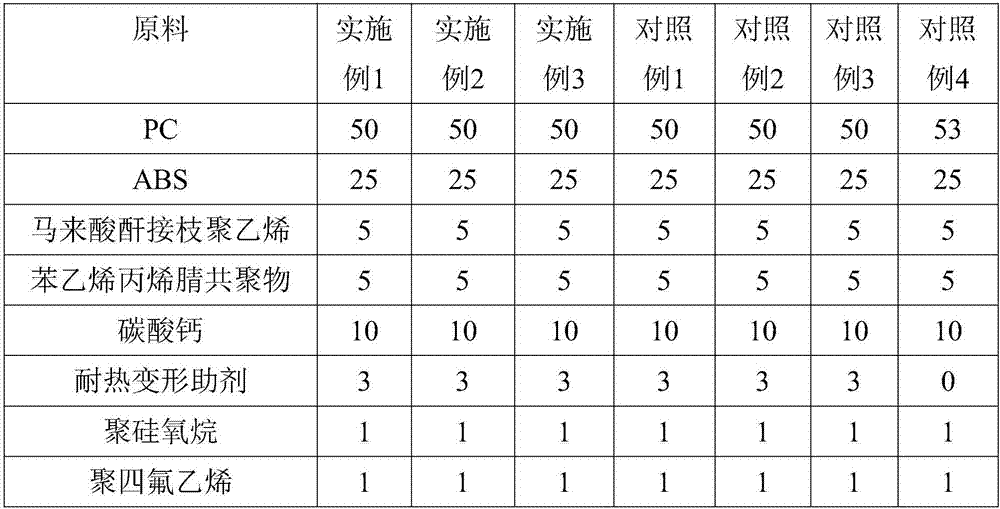

Thermal deformation resisting assistant for injection molding processing of laptop computer case

InactiveCN107474319AGive full play to heat deformation resistanceImprove blend compatibilityDiphenylmethaneThermal deformation

The invention discloses a thermal deformation resisting assistant for injection molding processing of a laptop computer case, and relates to the technical field of injection molding processing. The thermal deformation resisting assistant is prepared from the following raw materials in parts by weight: 15 to 25 parts of superfine silica aerogel, 5 to 10 parts of triallyl cyanurate, 5 to 10 parts of zinc dimethacrylate, 5 to 10 parts of superfine magnesium oxide, 1 to 5 parts of molecular sieve micro powder, 1 to 5 parts of diphenylmethane bismaleimide, 0.5 to 3 parts of asbestos wool, 0.5 to 3 parts of a titanate coupling agent and 50 to 100 parts of absolute ethanol. The thermal deformation resisting assistant disclosed by the invention is suitable for the injection molding processing of the laptop computer case, the thermal deformation performance of the laptop computer case can be remarkably enhanced when the mass adding amount of the thermal deformation resisting assistant is up to 3 percent, and thermal deformation temperature under 2MPa is increased to be 120 DEG C or more.

Owner:ANHUI SHENGLI PRECISION MFG TECH CO LTD

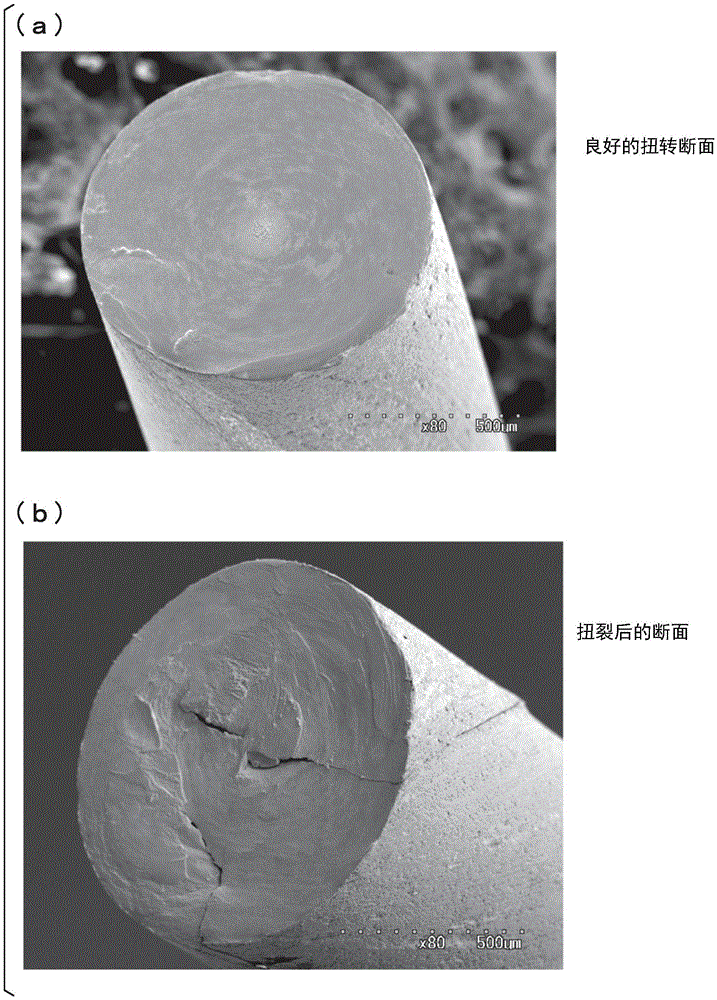

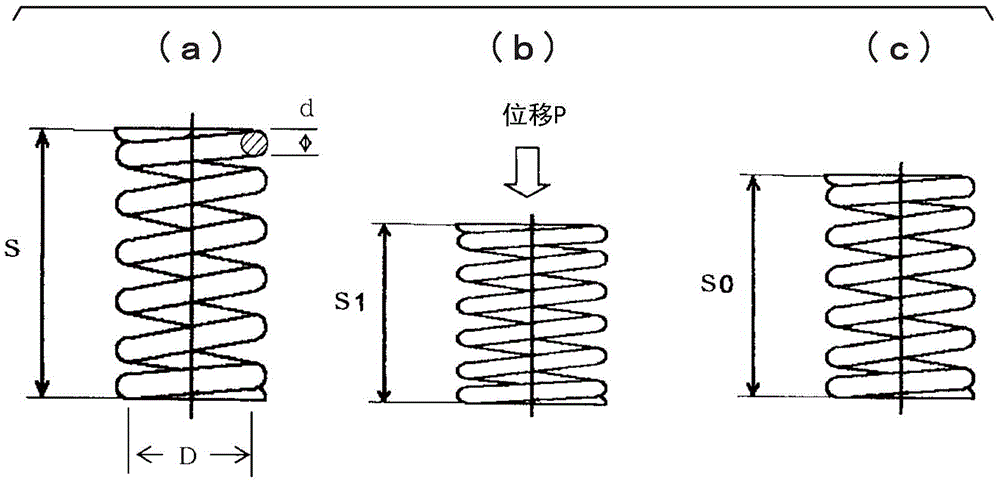

High-strength stainless steel wire excellent in thermal deformation resistance, high-strength spring, and manufacturing method thereof

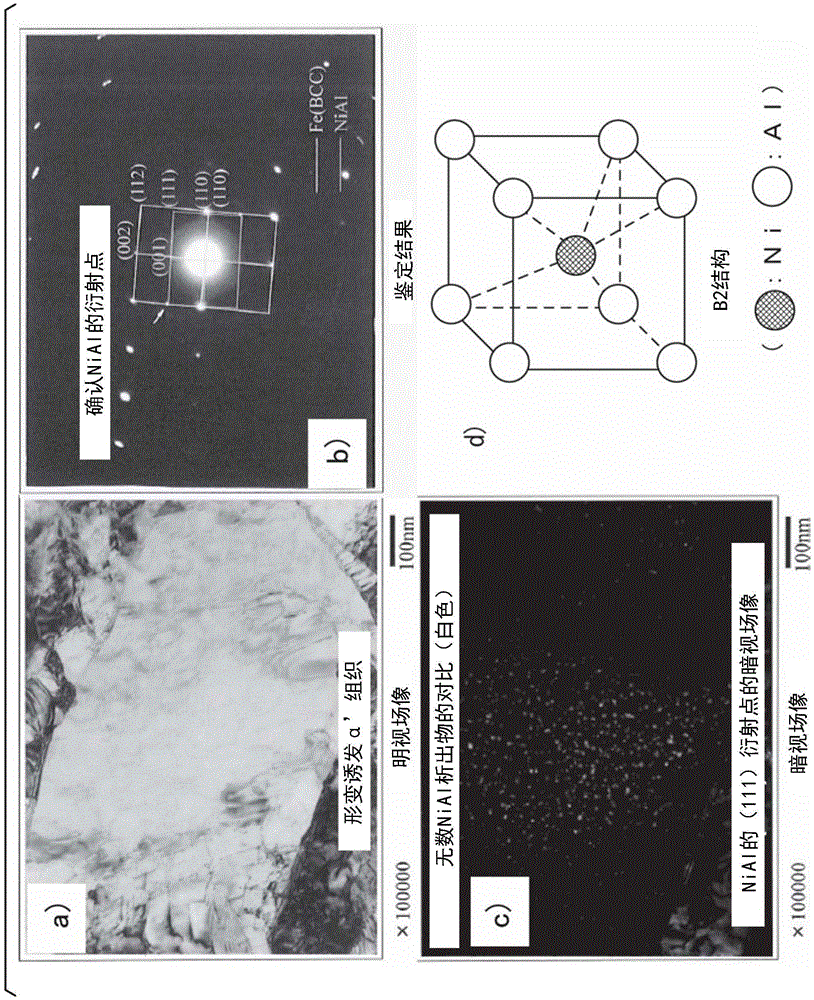

ActiveCN104136645BPromote precipitationExcellent heat deformation resistanceFurnace typesHeat treatment furnacesMetallurgyMartensite

A high-strength stainless steel wire includes, by mass%, C: 0.02% to 0.12%, N: 0.005% to 0.03%, Si: 0.1% to 2.0%, Mn: 0.1% to 2.0%, Ni: 6.8% to 9.0%, Cr: 12.0% to 14.4%, Mo: 1.0% to 3.0%, Al: 0.5% to 2.0%, and a balance consisting of Fe and unavoidable impurities, in which an amount of C and N is controlled in a range of 0.05% ‰¤ (C + N) ‰¤ 0.13%, a deformation induced martensite formation index MdS value is 15 to 60, an amount of deformation induced martensite is 80 vol% to 99 vol%, and a tensile strength is 1800 MPa to 2200 MPa. MdS = 551 - 462 �¢ C + N - 9.2 �¢ Si - 8.1 �¢ Mn - 29 �¢ Ni + Cu - 13.7 �¢ Cr - 18.5 �¢ Mo

Owner:NIPPON STEEL STAINLESS STEEL CORP +1

A water wood grain craft

InactiveCN110435350BImprove anti-corrosion performancePromote infiltrationNatural patternsWood treatment detailsCarbonizationThermal deformation

The invention provides a wood grain process. The process comprises steps of base plate dipping and drying pre-treatment, surface carbonization, double layer wood grain drawing treatment and surface protection layer treatment, so that the corrosion resistance, the deformation resistance and the surface wear resistance of a product are improved. The wood grain-drawn base material prepared by the process has excellent corrosion resistance, insect damage resistance, thermal deformation resistance, anti-falling property, fire resistance and moisture resistance, and can be repeatedly scrubbed without fading.

Owner:WENZHOU KULE DINING TABLE ARTICLES CO LTD

Flame-retardant tube and heat-shrinkable tube made by using the same

ActiveCN101679720BImprove heat resistanceExcellent heat deformation resistanceSimple Organic CompoundsPolymer science

A non-halogen type flame-retardant tube which exhibits satisfactory flame retardance, tensile characteristics under high temperature, and heat deformation resistance; and a heat -shrinkable tube, more specifically, a flame-retardant tube produced by molding a flame-retardant resin composition which comprises 100 parts by mass of a base polymer comprising 5 to 80mass% of polyphenylene ether, 20 to 95mass% of a styrenic thermoplastic elastomer, and 0 to 70mass% of an olefinic polymer, 5 to 100 parts by mass of a phosphorus-containing flame retardant, 3 to 80 parts by mass of a nitrogenous organic compound, and 1 to 20 parts by mass of a polyfunctional monomer into a tube and irradiating the tube with an electron beam; and a heat-shrinkable tube produced by subjecting the tube to diameter expansion under heating and then setting the tube by cooling.

Owner:SUMITOMO ELECTRIC IND LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com