Patents

Literature

124results about How to "Improve blend compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

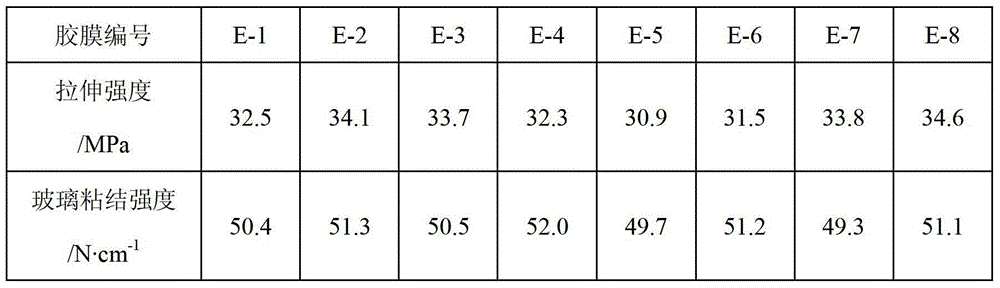

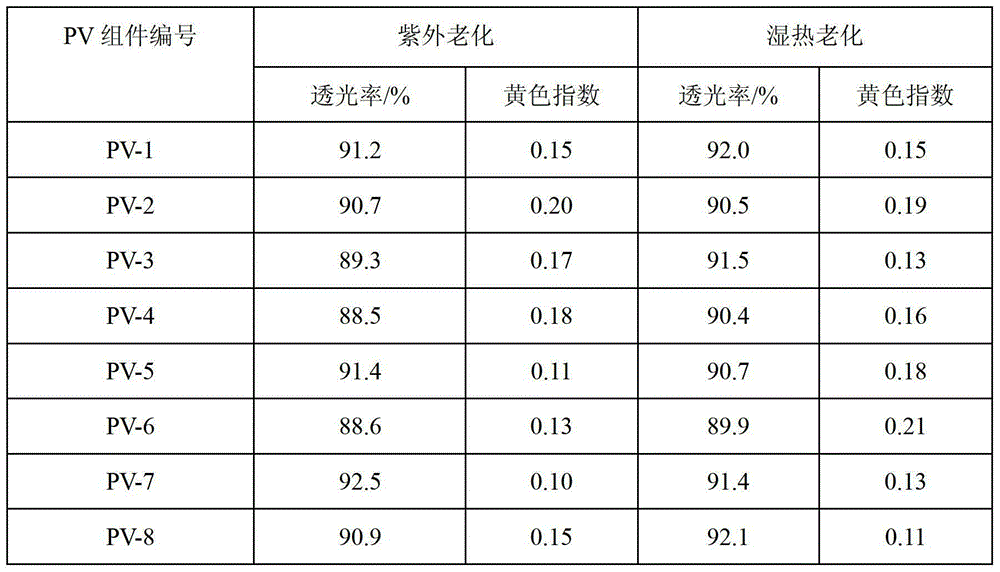

Production processes of packaging adhesive film with ultra-low ionic mobility and photovoltaic component

InactiveCN103342968AImprove insulation performanceImprove the phenomenon of poor mechanical propertiesFilm/foil adhesivesOrganic non-macromolecular adhesiveElastomerPolyolefin

The invention relates to a solar cell packaging adhesive film having low ionic mobility and belongs to the technical field of photovoltaic power generation fittings. The solar cell packaging adhesive film with low ionic mobility is formed by compounding a bonding layer adhesive film with an ion isolation layer in a certain proportion; the thickness proportion of the bonding layer to the ion isolation layer is (1:1)-(1:5); the thickness of the packaging adhesive film is 0.5-0.8 mm. According to the invention, the ion isolation layer is innovatively introduced; on one hand, the isolation layer has high insulativity of polyolefin elastomers, such as POE (Polyolefin Elastomer) and EPDM (Ethylene-Propylene-Diene Monomer); on the other hand, because of a hydrogen bond in a siloxane structure, the blending compatibility of the packaging adhesive film with other high-molecular polymers is greatly increased; meanwhile polymer linear polysiloxane is modified by using an ethylene-acrylate polymer; the poor mechanical property phenomenon of polysiloxane can be greatly improved.

Owner:CHANGZHOU UNIV +1

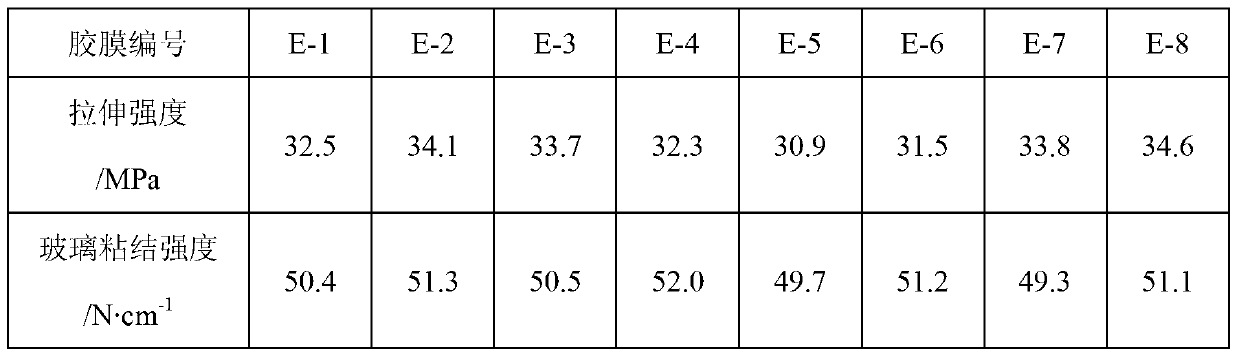

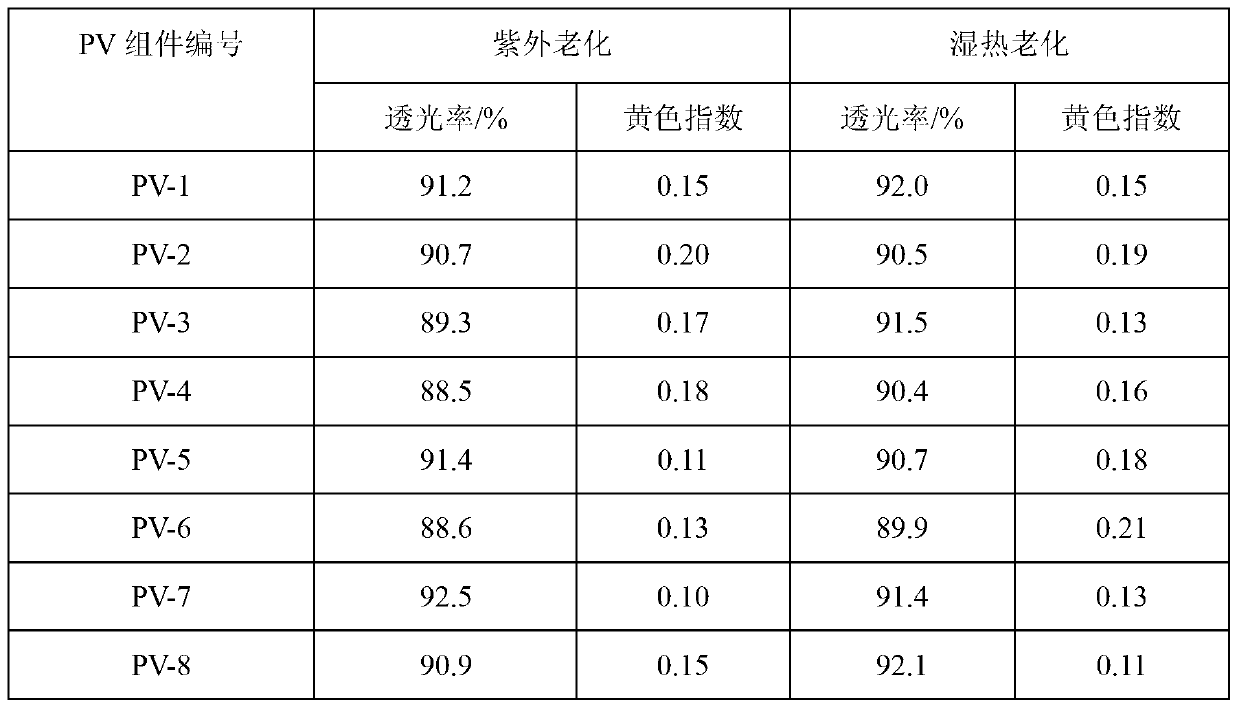

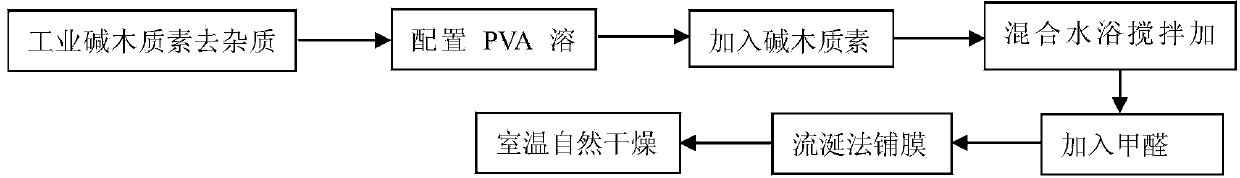

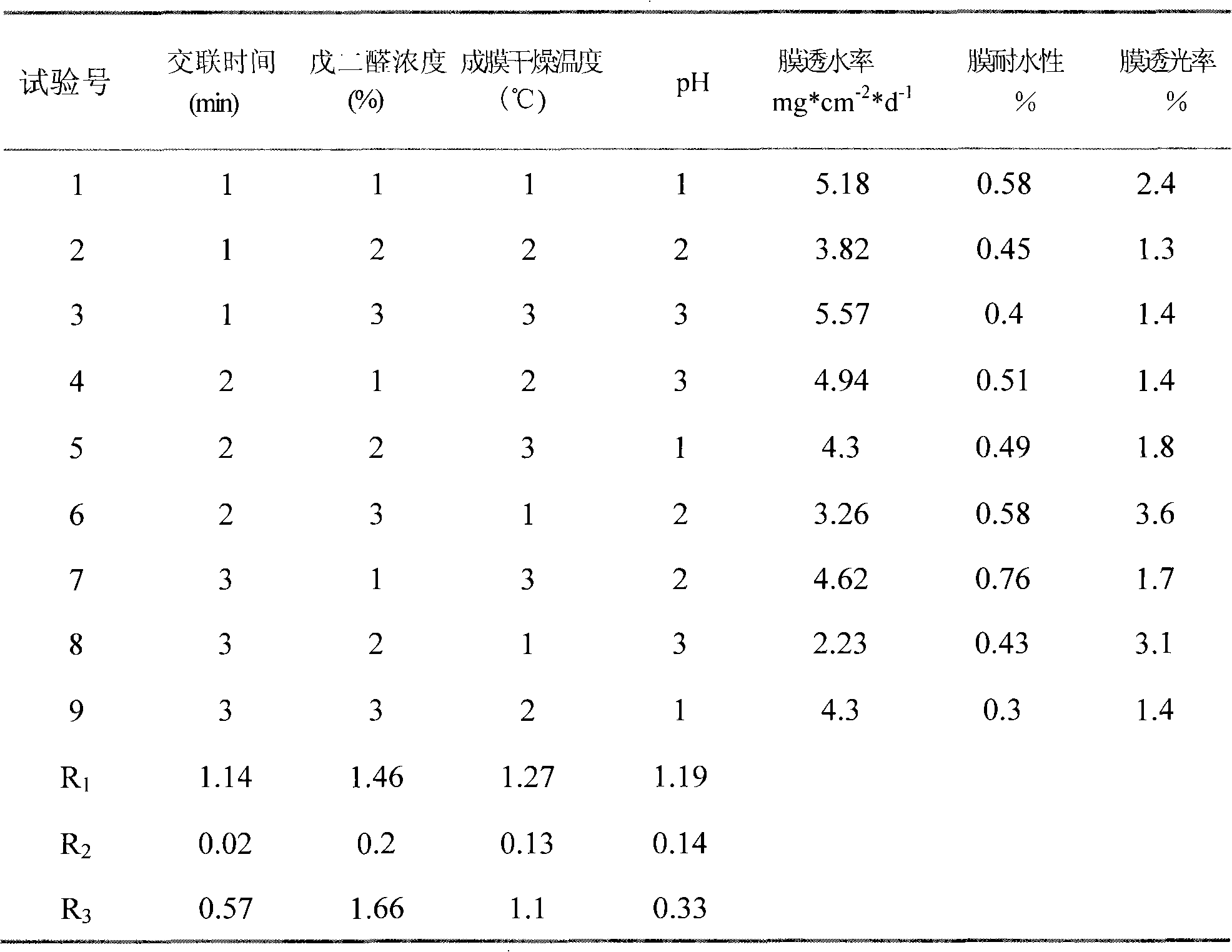

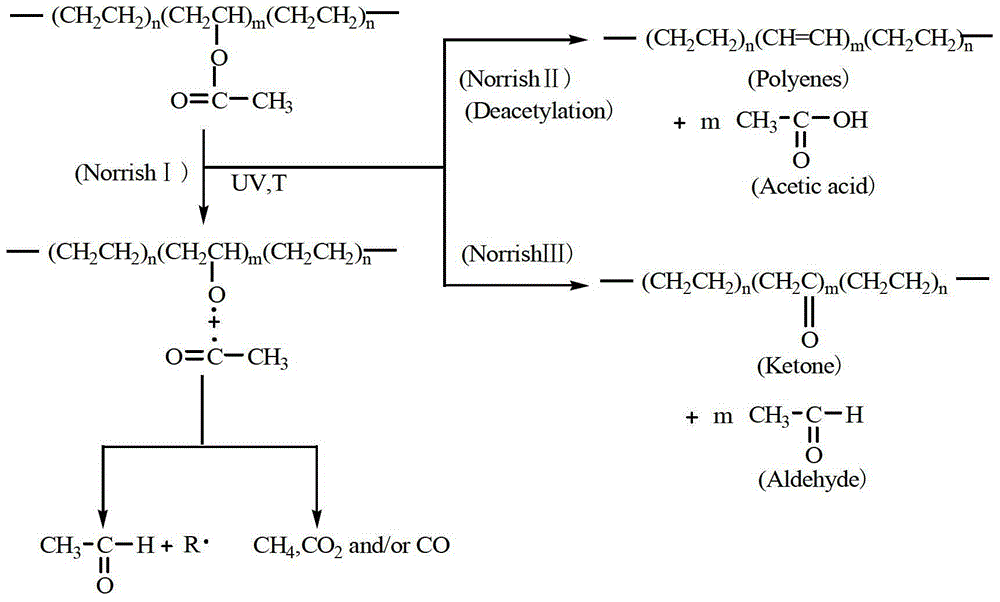

Preparation method of industrial alkali lignin/polyvinyl alcohol cross-linked thin film

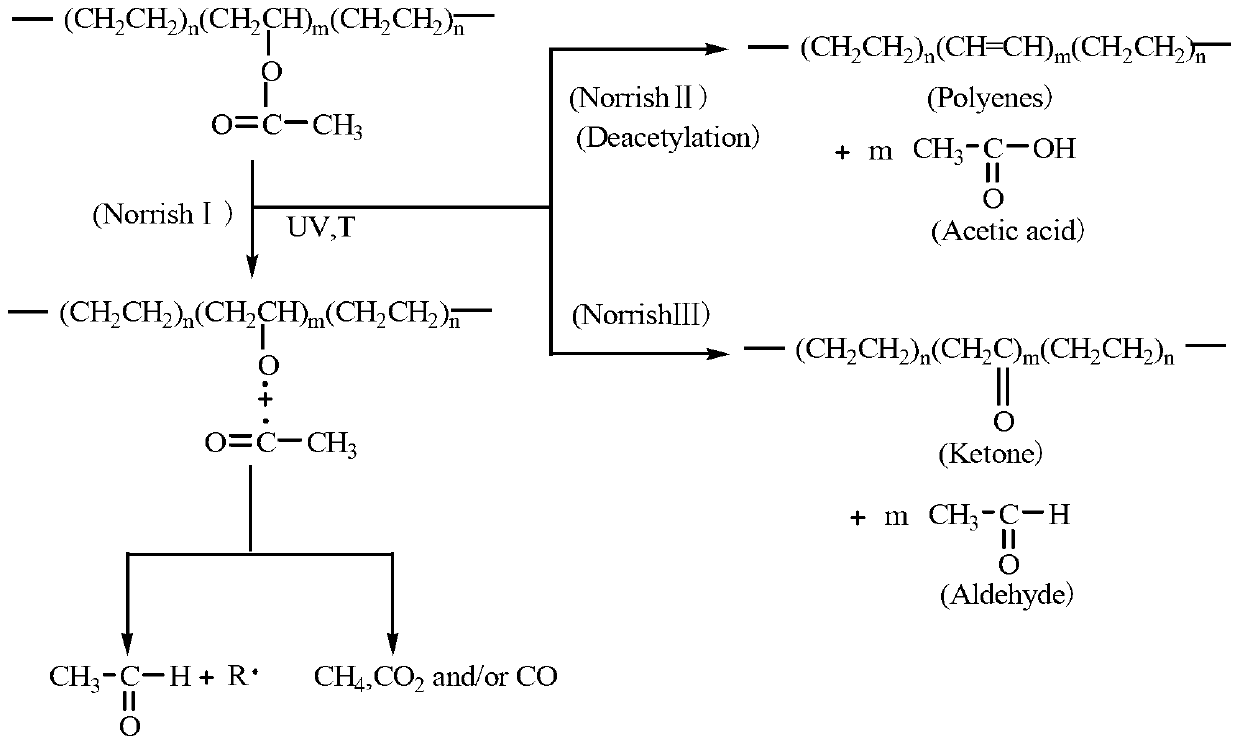

InactiveCN103467759AImprove thermal stabilityLower glass transition temperaturePolyvinyl alcoholUltraviolet lights

Alkali lignin is a main by-product of the papermaking industry of our country, and sever environmental pollution will be caused by direct discharge of alkali lignin. The invention discloses a preparation method of an industrial alkali lignin / polyvinyl alcohol cross-linked thin film, so as to increase utilization ratio of lignin, reduce environmental pollution and ease the resource crisis. The industrial alkali lignin / polyvinyl alcohol cross-linked thin film is prepared by following steps, industrial alkali lignin and polyvinyl alcohol (PVA) are taken as raw materials, and are crosslinked by a cross-linking agent; and then the mixture is subjected to tape casting so as to obtain the alkali lignin / polyvinyl alcohol cross-linked thin film. An optimized preparation technology is obtained based on mechanical properties. The mechanical properties of the industrial alkali lignin / polyvinyl alcohol cross-linked thin film are better than that of industrial polyvinyl alcohol films; absorption rate on ultraviolet light is about 100%; and transmittance is reduced to a certain degree. Blending compatibility of alkali lignin and PVA is excellent; the surfaces of alkali lignin and polyvinyl alcohol thin films, which are prepared by blending or crosslinking, are smooth; and phase separation is not caused. Thermal stability of the industrial alkali lignin / PVA cross-linked thin film is increased. The industrial alkali lignin / PVA cross-linked thin film can be used as an excellent ultraviolet absorption material, and it is possible to develop a novel specific packaging material or mulching film.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

Grafted copolymer of polyisobutene and polyisoprene and preparation method thereof

The invention relates to the field of grafted copolymers, and provides a grafted copolymer of polyisobutene and polyisoprene and a preparation method thereof. According to the grafted copolymer, isocrotyl polymer chain segments are adopted as a main chain, polyisoprene chain segments are adopted as a branch chain, and the main chain and the branch chain are bonded in a grafted mode. The absolute weight-average molecular weight Mw of the grafted copolymer ranges from 200 kg / mol to 3000 kg / mol, and the polydispersity index ranges from 1.3 to 4.0. On the basis that the total mass of the grafted copolymer is 100%, the mass content of polyisoprene chain segments ranges from 3% to 40%; the absolute weight-average molecular weight of the isocrotyl polymer chain segments as the main chain ranges from 100 kg / mol to 2000 kg / mol. By means of the method, grafted copolymer materials with different branch chain numbers and branch chain lengths are synthesized, and the problems that in isoprene cationic polymerization, the polymer molecular weight is low, and cyclizing isomerization is serious are effectively solved.

Owner:BEIJING UNIV OF CHEM TECH

High temperature-resistant nylon/thermotropic liquid crystal polymer blend and preparation method for blend

ActiveCN102585488AOvercome the disadvantages of poor fluidity and low processing performanceIncrease usageNylon materialPolymer science

The invention discloses a high temperature-resistant nylon / thermotropic liquid crystal polymer blend and a preparation method for the blend. The blend comprises the following components in parts by weight: 70-90 parts of high temperature-resistant nylon, 5-10 parts of thermotropic liquid crystal polymer, 5-10 parts of compatilizer, 0.2-1.0 part of antioxygen and 0.2-0.8 part of lubricant. The novel copolymer material provided by the invention not only has the characteristics of high strength and high rigidity of the high temperature-resistant nylon but also has excellent flame retardant property and high liquidity of the liquid crystal polymer. The material production process is simple; the operation of the method is simple and convenient; and very high industrial economic benefits can be obtained.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Biodegradable material containing aliphatic polycarbonate, and preparation method and application thereof

The invention relates to a biodegradable material containing aliphatic polycarbonate, and a preparation method and an application thereof. The biodegradable material is obtained by the following steps of mixing 20-90 parts by weight of aliphatic polycarbonate, 10-80 parts by weight of aliphatic polyester, 0.01-1 part by weight of an organic peroxide, 0.05-1 part by weight of a cross-linking agent, 3-15 parts by weight of a compatilizer, 0.3-5 parts by weight of a plasticizer, 0.1-5 parts by weight of a heat stabilizer and 0.01-1 part by weight of an auxiliary agent uniformly; adding the above mixture in a double-screw extruder for melt blending, stretching the blended mixture into strips; pelletizing the strips to obtain granular mixing resin slices; and vacuum drying the slices and removing water from the slices. The biodegradable material can be used for preparing completely biodegradable film which has various excellent performances of conventional films, can keep relatively good transparency, has relatively high tensile strength, can provide high toughness and tearing strength, and has good thermal stability, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Heat conductive plastic pipe

InactiveCN101666397AMaintain solderabilityImprove thermal conductivityRigid pipesChemical industryCorrosion

A heat conductive plastic pipe is characterized by melt-mixing and modifying a pipe-grade thermoplastic resin with good corrosion resistance and micro powder of a heat conductive material with good corrosion resistance and high heat conductivity and then obtaining a tubing by extrusion molding, wherein, the heat conductivity is 150%-300% of the pipe-grade thermoplastic resin. The tubing can be directly applied to a ground source heat pump, a water source heat pump system and a floor radiant heating system as the heat-exchanging pipe, thus improving heat transfer capability of the system; and the tubing can be machined into heat exchangers with different styles and different structures by welding, and can be applied to the manufacturing processes of chemical industry, foods and medicine.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

Composite board produced from modified phosphorus slag and waste plastics and production method thereof

ActiveCN103351530AReduce pollutionAccelerate the process of resource utilizationProcess engineeringComposite slab

The invention discloses a composite board produced from modified phosphorus slag and waste plastics and a production method thereof. According to the invention, waste polypropylene or polyethylene plastics and industrial waste phosphorus slag are taken as major raw materials, and formed into high strength composite board by an appropriate preparation method; as a result, pollution on environment caused by the waste plastics and phosphorus slag is reduced and a new material is added to the constructional engineering; the new material is capable of substituting for bamboo plywoods and wood building templates which are widely used in building operations. Furthermore, a coupling agent isopropyl trioctylpyrophosphatotitanate or isopropyl trioleyl titanate is utilized to modify the surface of the phosphorus slag so that the surface property of the phosphorus slag is changed from hydrophily into lipophilicity; the modified phosphorus slag has excellent dispersing performance in an organic phase, so that the blending compatibility and combinability of the modified phosphorus slag with the waste plastics are greatly improved; consequently, the performance of the composite board is improved.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

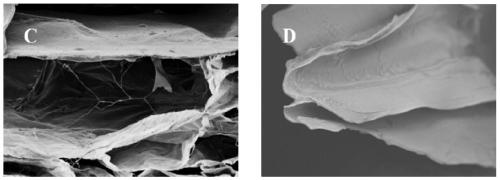

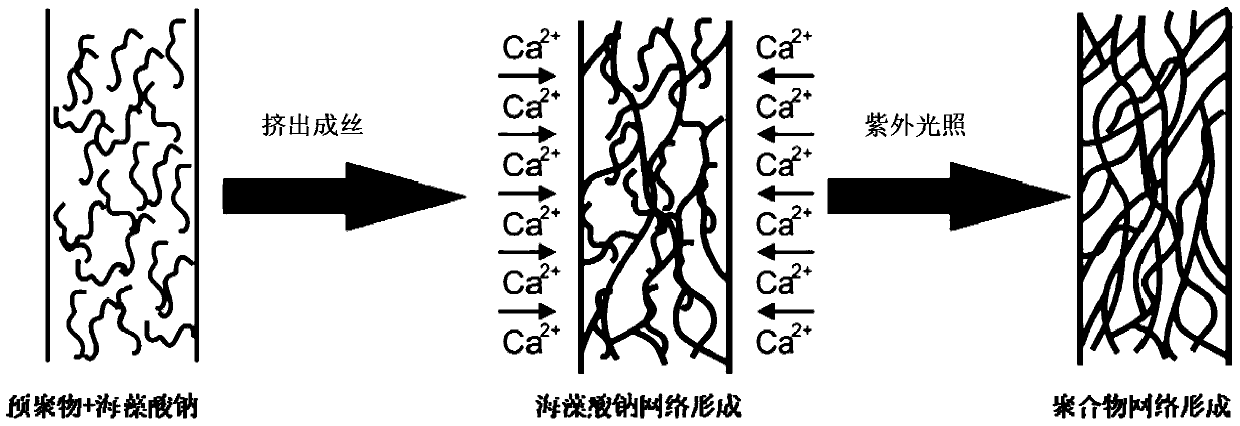

Konjac glucomannan glycosyl antibacterial hydrogel fiber and preparation method thereof

ActiveCN110067042AUniform structureStrong water absorptionConjugated artificial filamentsArtifical filament manufactureFiberBiocompatibility Testing

The invention discloses a konjac glucomannan glycosyl antibacterial hydrogel fiber and a preparation method thereof. The fiber comprises the following raw material components in parts by weight: 50-100 parts of konjac glucomannan polymerizable monomers, 100-800 parts of alginate, 10-20 parts of organic guanidine salt polymerizable monomers, 10000-40000 parts of deionized water and 0.1-5 parts of an initiator. The preparation method comprises the following steps: (1) preparing modified konjac glucomannan with double bonds on side groups and the organic guanidine salt polymerizable monomer; (2)preparing a spinning liquid; and (3) preparing a hydrogel fiber by using a two-step crosslinking method. The preparation method disclosed by the invention is simple and safe, low in cost, rich in material and good in experiment repeatability; no high-voltage electric field is used in the preparation process, no organic solvent is used, no pollution can be caused, cell damage can be avoided, and cell packaging can be achieved; the prepared hydrogel is not only uniform, controllable in size, high in mechanical property and good in water absorption performance, but also good in biocompatibility,and has an excellent antibacterial property and a wide application prospect, particularly in the field of sanitary materials.

Owner:DONGHUA UNIV

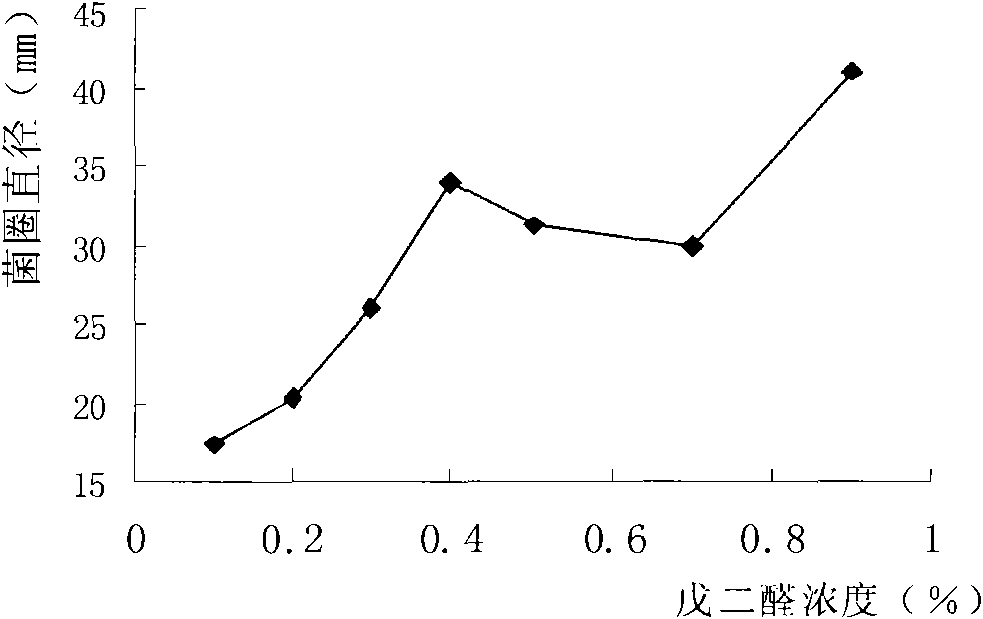

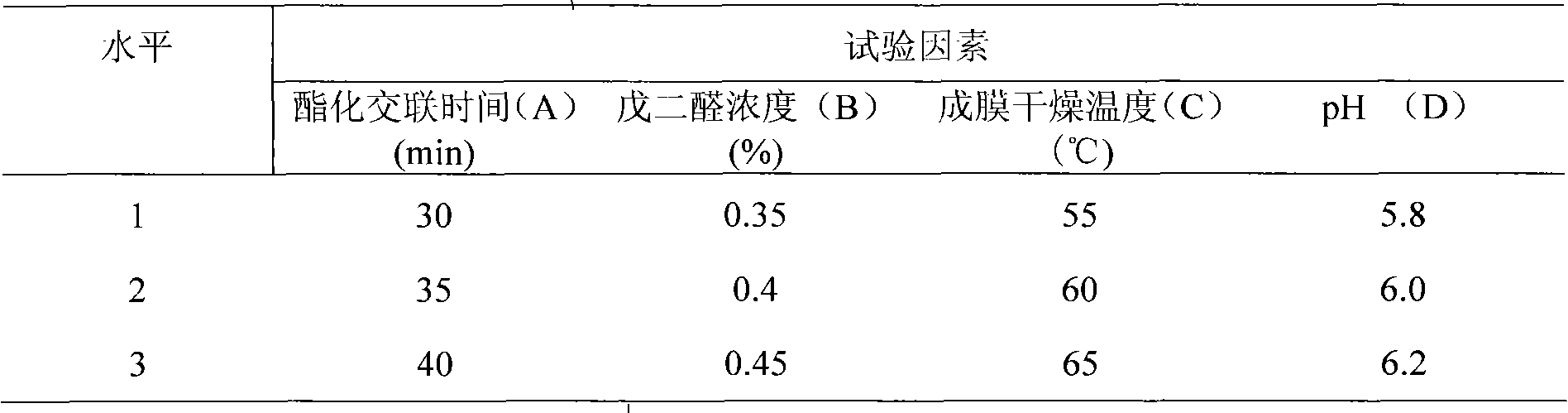

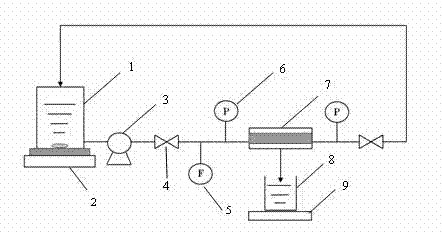

Novel PVA-based preserving and packaging coating material and preparation process thereof

InactiveCN101565482AImprove water resistanceImprove film formationFlexible coversWrappersStearic acidFood packaging

The invention relates to a process for preparing a novel PVA-based preserving and packaging coating material, and belongs to the field of food packaging materials. The process comprises the following steps: mixing the new materials according to the following concentration: 3 to 8 percent of PVA and water, 1 to 3 percent of stearic acid and water, and 0.35 to 0.45 percent of glutaric dialdehyde and water; soaking the PVA for 2 hours at a normal temperature, heating and dissolving the PVC; dissolving the stearic acid in 95 percent ethanol, heating and dissolving the stearic acid; when the temperature of the PVA and the stearic acid reaches over 85 DEG C, mixing and reacting the PVA and the stearic acid for 3 to 10 minutes; adding the glutaric dialdehyde into the mixture, and reacting the mixture and the glutaric dialdehyde for 30 to 50 minutes at the temperature of 85 DEG C; and adjusting the pH value of the obtained product to between 4 and 6.5, and preparing the PVA-based preserving composite coating material. The process adopts the glutaric dialdehyde as a crosslinking agent of the stearic acid and a PVA diatomic substrate, and the novel PVA-based preserving and packaging coating material obtained by crosslinking reaction can obviously reduce the water permeability of the PVA substrate after film-forming, improve the water resistance, and generate strong antibacterial property.

Owner:CHANGSHU YIHAO FOOD PACKAGING MATERIAL TECH +1

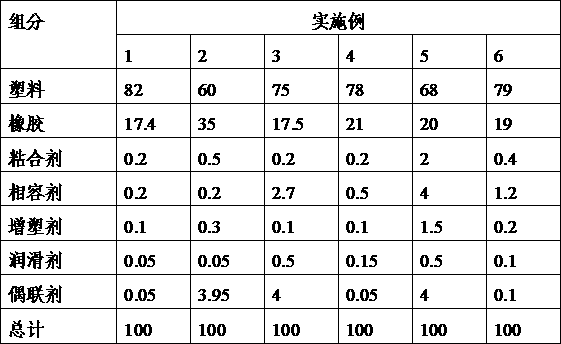

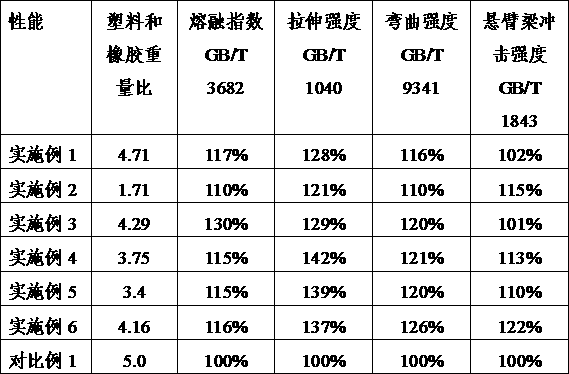

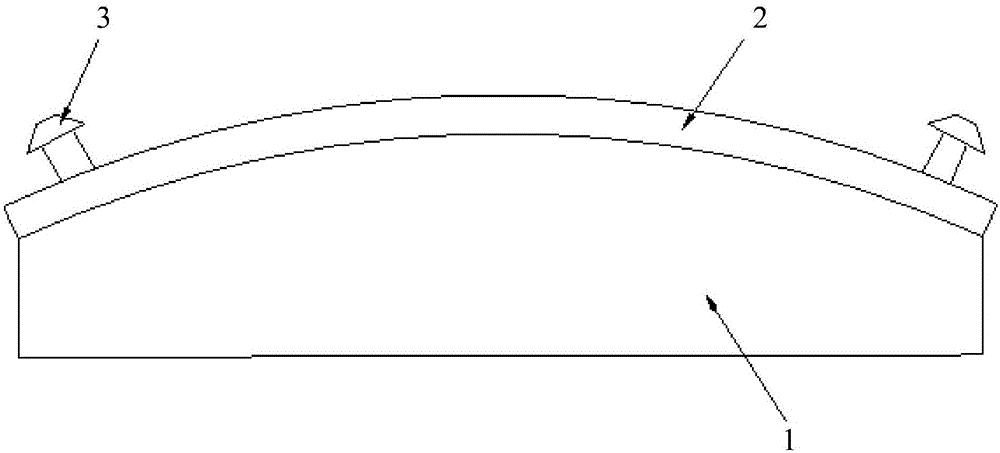

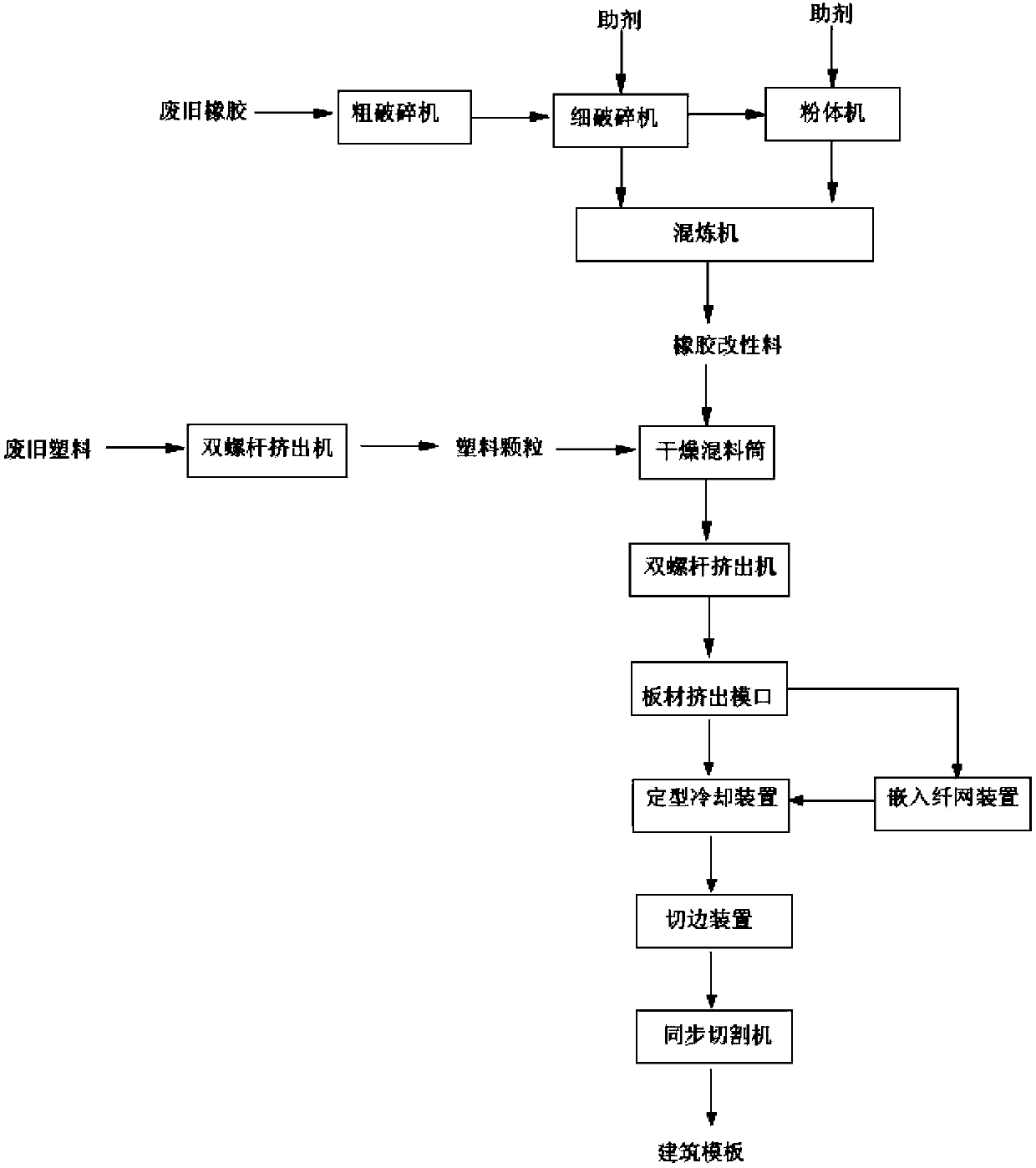

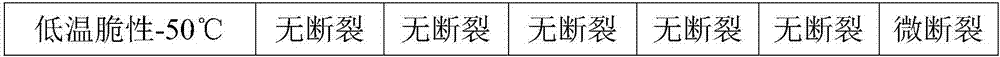

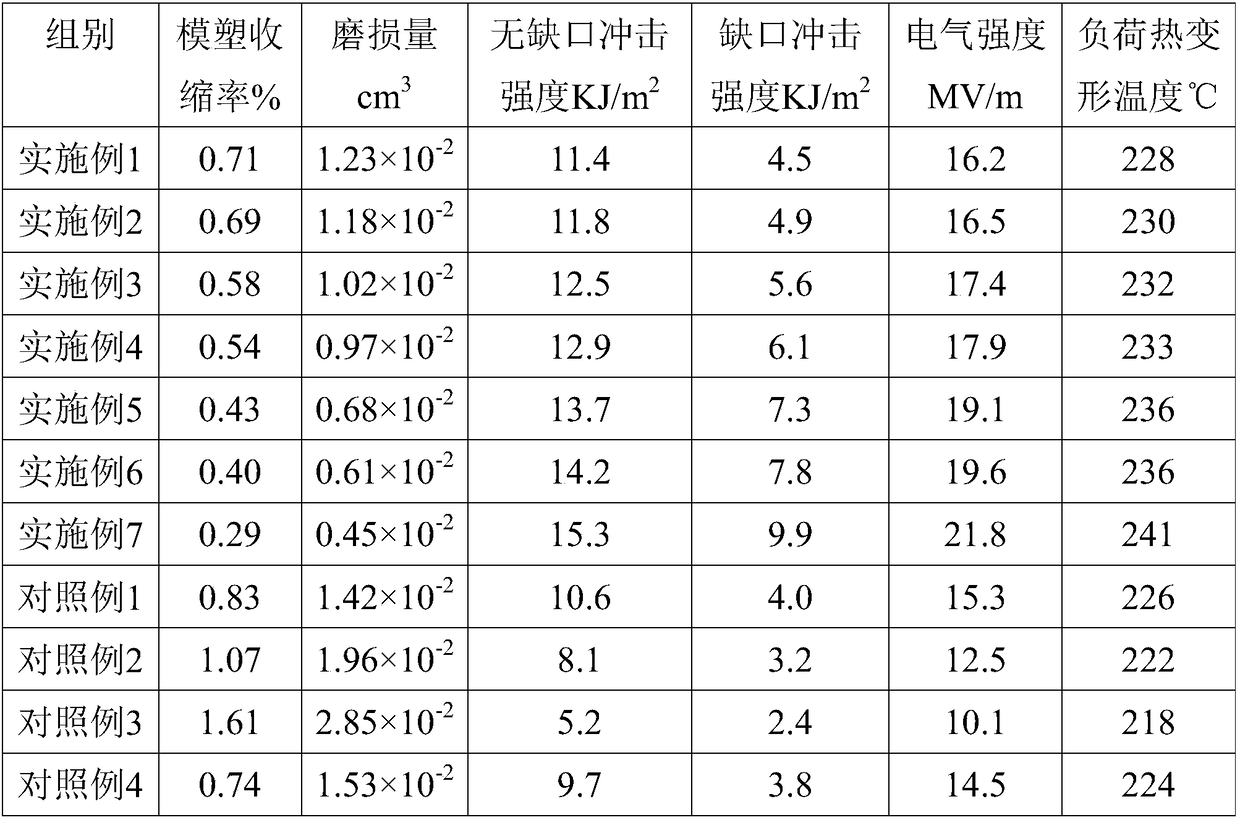

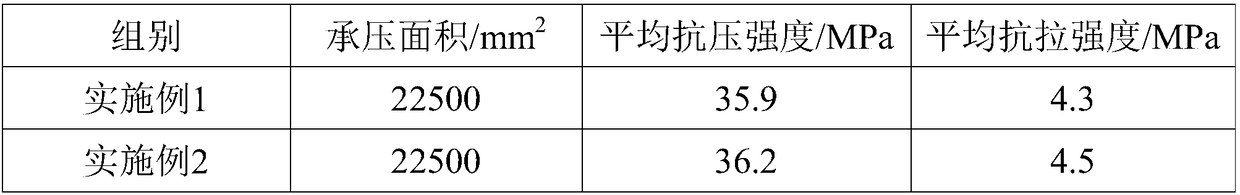

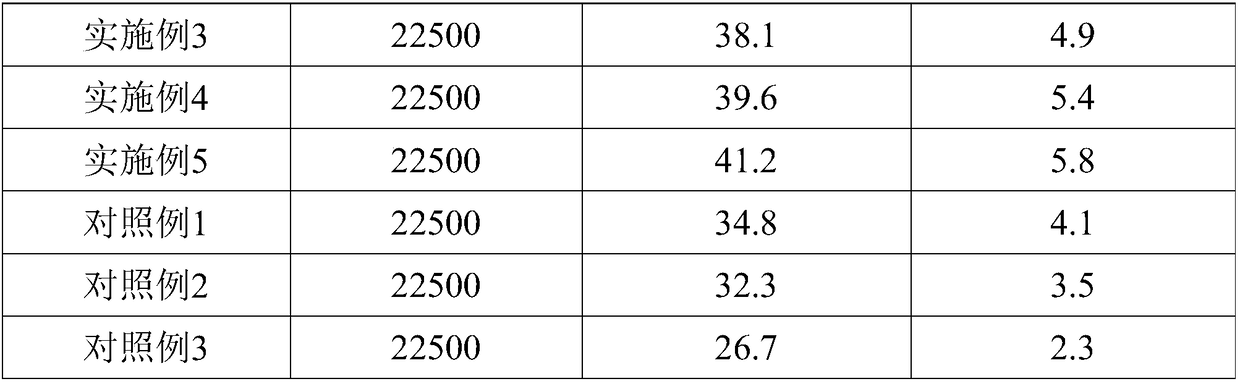

High-strength and high-tenacity plastic building template

InactiveCN103291069AImprove toughnessExtended service lifeForming/stuttering elementsFiberState of art

The invention relates to a high-strength and high-tenacity plastic building template. On one hand, the mixed material of plastics and rubber serves as the main material of the building template, the weight ratio of the rubber to the plastics is higher than that of rubber and plastics in the prior art, and a specific accessory ingredient system is adopted to improve the tenacity of the building template. On the other hand, common chopped fiber is replaced by a reinforced fiber net which serves as a reinforcing body of the building template, the rigidity of the plastic building template is improved accordingly, the reinforcing fiber net is embedded into a single plastic plate to be fixed with the plastic plate rather than be fixed with the plastic plate through splicing and other methods, so that the two sides of the reinforcing fiber net are made of the same material, and the problem that boundary is separated easily due to the fact that the reinforcing fiber net is fixed through a traditional splicing method is avoided. According to the high-strength and high-tenacity plastic building template, three aspects including tenacity improvement, rigidity improvement and boundary separation prevention are taken into consideration, and therefore the service life of the plastic building template is comprehensively prolonged. In addition, recycled plastics and / or rubber is used as the main raw material of the plastic building template, so that production cost is reduced.

Owner:江阴市佳宝建筑节能模板有限公司

Non-transfer organic silicon modified acrylate parting agent and preparation method thereof

ActiveCN106381084AImprove blend compatibilityPrevent hypoallergenic adhesive layer transferFilm/foil adhesivesCoatingsPressure sensitiveAcrylate

The invention discloses a non-transfer organic silicon modified acrylate parting agent. The non-transfer organic silicon modified acrylate parting agent is prepared from the following raw materials of 89 to 99.8wt% of organic silicon modified acrylate, 0.1 to 1wt% of interface modifier, and 0.1 to 10wt% of dispersion stabilizer. The non-transfer organic silicon modified acrylate parting agent has the advantages that by introducing an organic silicon molecular chain into a acrylate molecular chain through a chemical bonding manner, and adding the interface modifier and the dispersion stabilizer, the acrylate parting agent without silicon transfer in the use process is obtained; the acrylate parting agent can be used as a parting coating for the back side of a substrate of an electronic protective film, and be widely applied into the field of protective films; in the use process, the silicon-containing parting agent is not transferred to the adhesive layer side of the protective film; the adhesion force of pressure-sensitive adhesive in the 6 month or above protective film is maintained 99% or above.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

Corrosion-resistant and weatherproof paint specially used for pop can

ActiveCN105385265AGood blending compatibilityPerformance synergyAnti-corrosive paintsEpoxy resin coatingsBrown iron oxideEmulsion

The invention discloses corrosion-resistant and weatherproof paint specially used for a pop can. Raw materials of the corrosion-resistant and weatherproof paint specially used for the pop can are as follows in parts by weight: 100 parts of acrylic emulsion, 20-35 parts of epoxy resin emulsion, 2-10 parts of waterborne polyaniline solution, 3-8 parts of terpene resin, 10-25 parts of titanium dioxide, 10-20 parts of talcum powder, 15-20 parts of light calcium carbonate, 2-8 parts of precipitated barium sulphate, 2-10 parts of mica powder, 3-15 parts of zinc oxide, 2-10 parts of nanosilicon dioxide, 10-25 parts of modified graphene oxide, 1-5 parts of zinc phosphate, 3-10 parts of iron oxide red, 1-2 parts of a dispersing agent, 0.5-1.5 parts of a thickening agent, 3-10 parts of a coalescing agent, 0.5-2 parts of 2-amino-2-methyl-1-propanol and 20-50 parts of water. The corrosion-resistant and weatherproof paint specially used for the pop can, disclosed by the invention, has good weatherproof property and excellent corrosion resistance and also has certain antibacterial property.

Owner:合肥市易远新材料有限公司

Hydrophilic polyaryletherketone blended hollow fiber ultrafilter membrane and preparation method thereof

ActiveCN103071402AImprove heat resistanceImprove mechanical propertiesSemi-permeable membranesFatty/oily/floating substances removal devicesFiberHollow fibre

The invention discloses a hydrophilic polyaryletherketone blended hollow fiber ultrafilter membrane and a preparation method thereof. The preparation method comprises that phenolphthalein polyaryl ether ketone and high-molecular weight polyvinylpyrrolidone are used as main membrane-preparation materials; a membrane casting liquid is prepared by a solution blending method; a hollow fiber ultrafilter membrane is prepared by a dry-wet phase inversion technology; and the hydrophilic polyaryletherketone blended hollow fiber ultrafilter membrane having lasting hydrophily is prepared by hydrophilic effect-persistence aftertreatment. The preparation method has simple processes, is convenient for operation, does not need special equipment and is conducive to industrial production and application. The hydrophilic polyaryletherketone blended hollow fiber ultrafilter membrane obtained by the preparation method has high temperature resistance, chemical solvent resistance, acid and basic corrosion resistance, and lasting, stable and excellent hydrophily. In oil-containing waste water treatment, the hydrophilic polyaryletherketone blended hollow fiber ultrafilter membrane has high membrane flux, obvious oil removal effects and strong oil pollution resistance and is suitable for high-efficiency treatment on oil-containing waste water.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

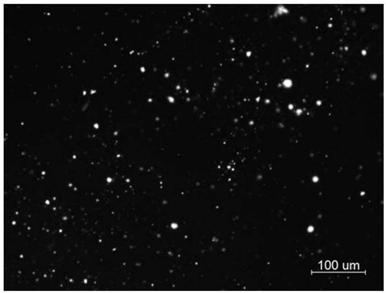

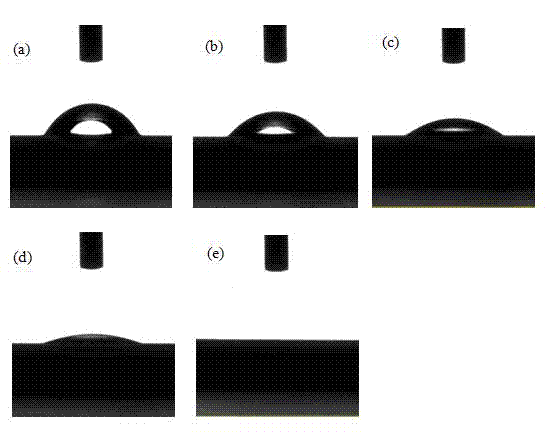

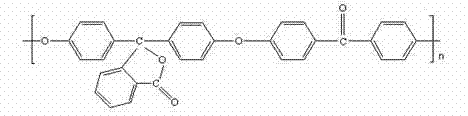

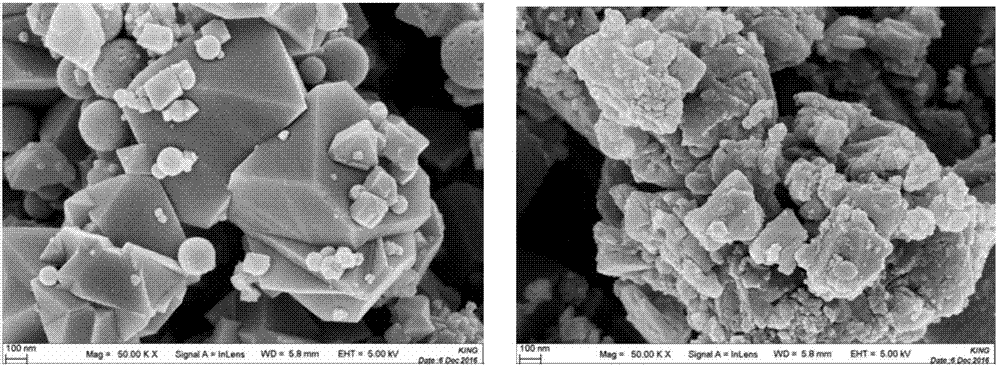

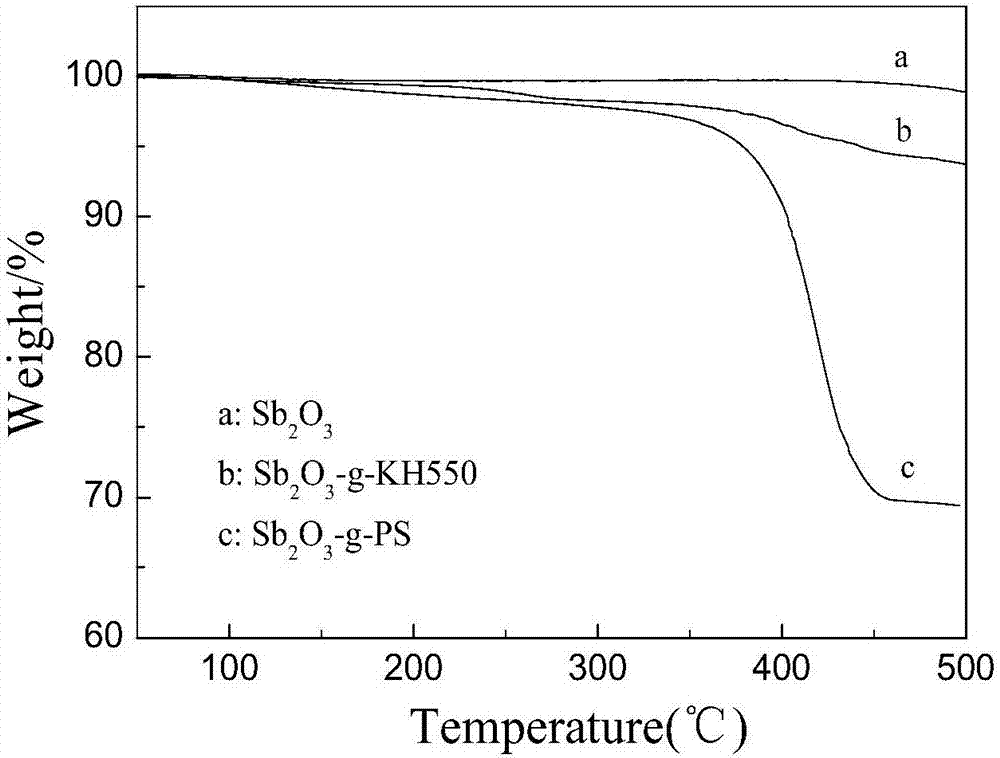

Polymer chemically-modified inorganic oxide particles and preparation method thereof, and applications of polymer chemically-modified inorganic oxide particles in laser sensitive materials

The present invention relates to the field of laser sensitive materials and polymer composite materials, more particularly to polymer chemically-modified inorganic oxide particles and a preparation method thereof, and applications of the polymer chemically-modified inorganic oxide particles in laser sensitive materials. The preparation method comprises: grafting a polymer chain having controlled molecular weight and controlled sequence structure on the surface of inorganic laser sensitive oxide particles (P) through active atom transfer radical polymerization, wherein the polymer chain comprises a chain segment (A) with characteristics of easy carbon forming and high residual carbon content and a chain segment (B) with an effect of interface compatibilization; and adding the modified inorganic oxide particles to polyolefin or a polyolefin blending material with poor laser energy sensitivity to prepare the laser sensitive material. According to the present invention, with the application of neodymium-yttrium-aluminum-doped garnet (Nd:YAG) laser device having a wavelength of 1064 nm to carry out laser labeling on the laser sensitive material, the results show that the modified inorganic oxide particles can improve the laser sensitivity of the polyolefin material, and have excellent mechanical properties.

Owner:CHANGZHOU UNIV

Oil fume resistant polycarbonate material, preparation method and application thereof

The invention discloses an oil fume resistant polycarbonate material, a preparation method and application thereof. The oil fume resistant polycarbonate material is prepared from the following components by mass: 70-90% of polycarbonate; 5-20% of modified nitrile butadiene rubber; 4-15% of a flame retardant; 0.3-3% of an antioxidant, and 0.4%-3% of a lubricating agent. The modified nitrile butadiene rubber is prepared from nitrile butadiene rubber and an ethylene-methyl acrylate copolymer in a mass ratio of 2-5:1. The material has excellent impact toughness, good flame retardant properties and electrical insulation properties, also has well improved oil fume cracking resistance, and is very suitable for preparation of kitchen wall switches and other products. The preparation method of the oil fume resistant polycarbonate material disclosed in the invention adopts existing equipment, the preparation is simple and is easy for industrial production, thus having broad application prospects.

Owner:中广核俊尔(浙江)新材料有限公司 +2

Anti-aging and wear-resistant rubber material for tire

The invention discloses an anti-aging and wear-resistant rubber material for a tire. The anti-aging and wear-resistant rubber material for the tire is prepared from, by weight, 15-35 parts of natural rubber, 25-35 parts of 320 type chloroprene rubber, 25-35 parts of neoprene, 20-50 parts of modified kaolinite, 0.5-1.5 parts of 616 antiager, 0.2-0.8 part of phosphite, 0.5-1.2 parts of tetramethyl thiuram disulfide, 0.5-1.5 parts of zinc oxide, 1-3 parts of magnesium oxide, 5-15 parts of pumice, 10-18 parts of zinc borate, 1-2 parts of aluminum borate whiskers, 12-18 parts of sodium antimonite, 5-15 parts of aluminum phosphate, 10-20 parts of carbon black, 0.2-0.8 part of polyepoxy soybean oil, 0.1-0.9 part of hydroxyl silicone oil, 1-2 parts of white oil, 1-3 parts of pine tar, 0.2-0.8 part of fatty acid, 0.5-1.5 part of stearic acid and 1-2 parts of 3-aminopropyltrimethoxysilane. The anti-aging and wear-resistant rubber material for the tire is good in wear-resistant and anti-tear performance and excellent in anti-aging performance.

Owner:DELUN RUBBER

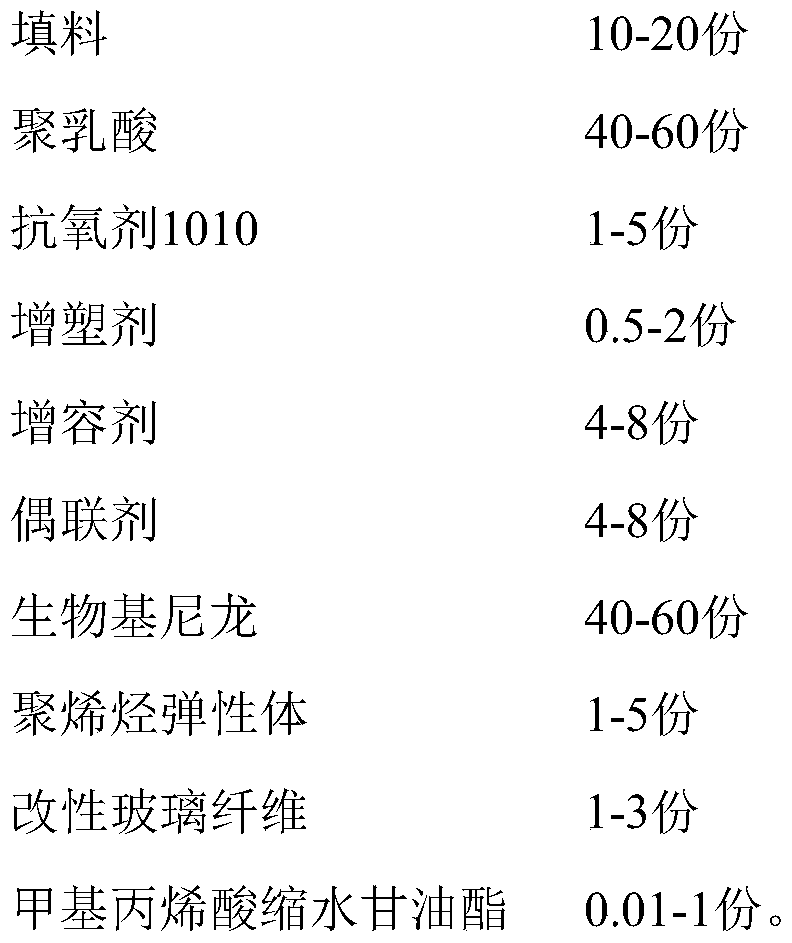

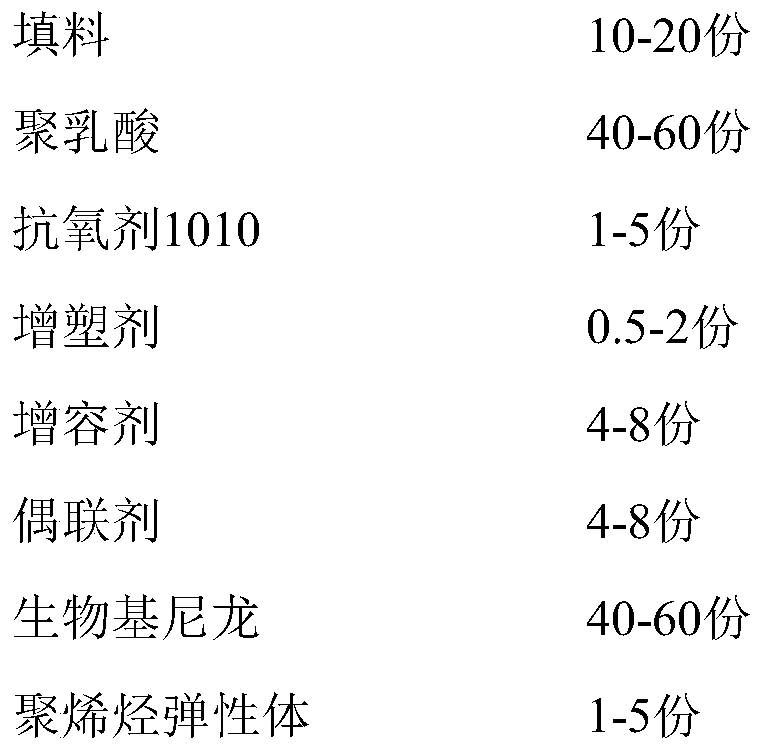

Bio-based nylon composite PLA material and preparation method thereof

ActiveCN110467804AProtects against thermo-oxidative degradationHigh mechanical strengthElastomerGlycidyl methacrylate

The invention relates to the technical field of biomaterials, particularly to a bio-based nylon composite PLA material and a preparation method thereof, wherein the raw materials comprise, by weight,10-20 parts of a filler, 40-60 parts of polylactic acid, 1-5 parts of an antioxidant1010, 0.5-2 parts of a plasticizer, 4-8 parts of a compatibilizer, 4-8 parts of a coupling agent, 40-60 parts of a bio-based nylon, 1-5 parts of a polyolefin elastomer, 1-3 parts of modified glass fiber, and 0.01-1 part of glycidyl methacrylate. According to the present invention, the mechanical strength and the size stability of the PLA material are improved by filling the modified glass fiber with the bio-based nylon and the polylactic acid while the bio-based nylon and polylactic acid compounding process isfilled and grafted by using the filler and the high-toughness grafting agent glycidyl methacrylate, such that the bio-based nylon composite PLA material meets the performance requirements of engineering plastics and has good degradability.

Owner:DONGGUAN ZHONGYI NEW MATERIAL TECH CO LTD

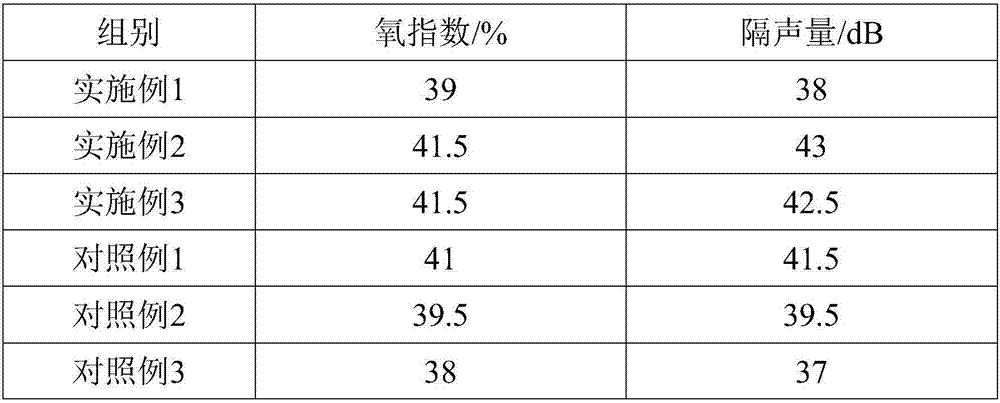

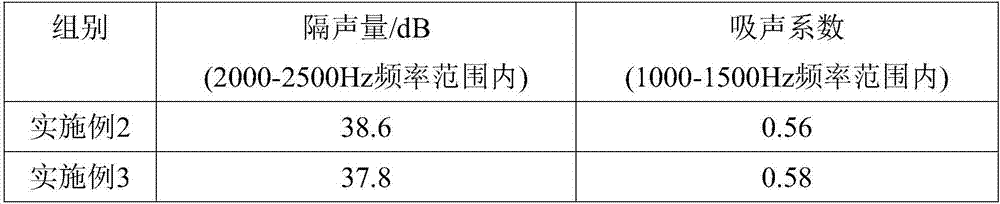

Light flame-retardant and sound-proof material for architectural decoration

InactiveCN107474536AImprove blend compatibilityImprove flame retardant performanceFiberChlorinated polyethylene

The invention discloses a light flame-retardant and sound-proof material for architectural decoration and relates to the technical field of decoration materials. The light flame-retardant and sound-proof material is prepared from the following raw materials in parts by weight: 75-85 parts of polyphenylene sulfide particles, 30-40 parts of polycarbonate particles, 10-20 parts of fly ash, 10-20 parts of agricultural filling waste, 5-10 parts of asbestos wool, 5-10 parts of chlorinated polyethylene, 5-10 parts of sepiolite fiber, 1-5 parts of bisphenol A type epoxy resin / polyasparaginic acid, 1-5 parts of ceramic micro powder, 0.5-2 parts of trimethylolpropane triacrylate and 0.5-2 parts of hexakis(methoxymethyl)melamine. The material prepared by the invention can be processed into a wall barrier that is applied to decoration of the places such as offices, KTVs and hotels, and meets the using requirements.

Owner:ANHUI ZHIBO NEW MATERIAL TECH CO LTD

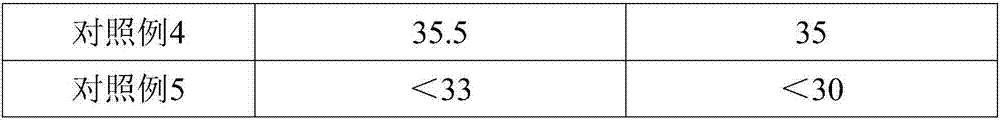

Sound insulation and noise reduction type composite bamboo fiberboard

ActiveCN107877624AImprove sound insulation and noise reductionGuaranteed physical and mechanical performanceLaminationLamination apparatusFiberNoise reduction

The invention discloses a sound insulation and noise reduction type composite bamboo fiberboard, and relates to the technical field of bamboo fiberboard processing. The sound insulation and noise reduction type composite bamboo fiberboard is composed of three layer structures of a bamboo fiber bottom board, a sound insulation and noise reduction layer and a bamboo fiber panel, and the sound insulation and noise reduction layer is arranged between the bamboo fiber bottom board and the bamboo fiber panel and is made of an asbestos wool-foamed aluminum-magnesium composite. According to the soundinsulation and noise reduction type composite bamboo fiberboard, the asbestos wool-foamed aluminum-magnesium composite serves as the sound insulation and noise reduction layer, so that the manufactured composite bamboo fiberboard has excellent sound insulation and noise reduction performance; and the sound insulation and noise reduction performance of the manufactured composite bamboo fiberboard is further enhanced by using the self-made bamboo fiber bottom board or bamboo fiber panel, meanwhile, physical and mechanical using performance of the composite bamboo fiberboard is ensured, and construction requirements of building decoration are met accordingly.

Owner:广西平乐爱森新材料有限公司

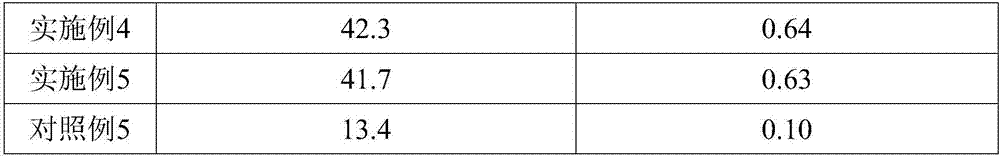

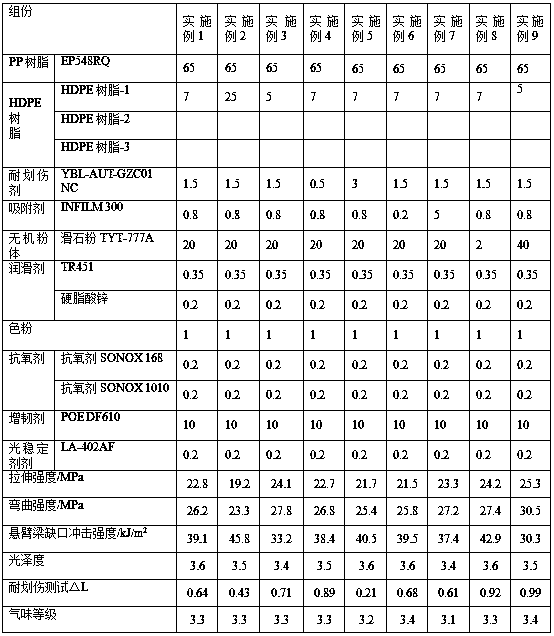

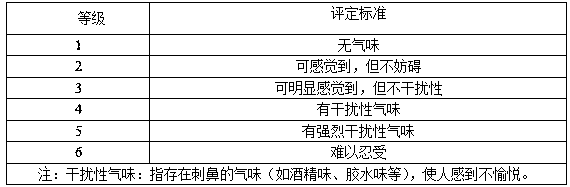

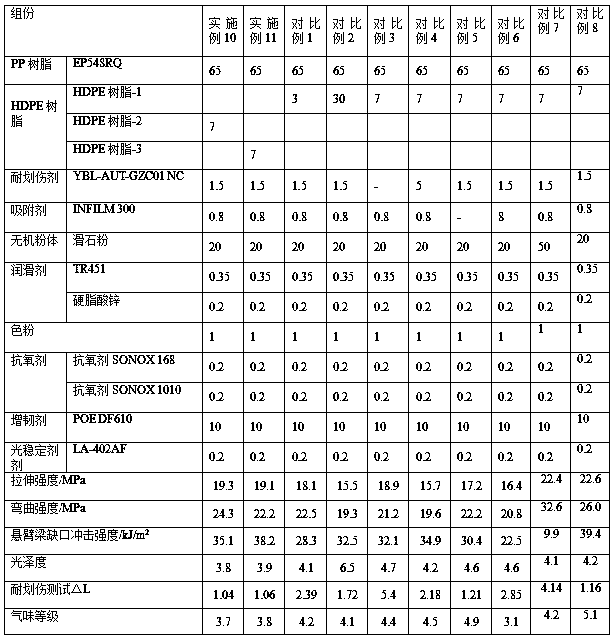

Polypropylene composite material with characteristics of low odor, scratch resistance and low gloss, and preparation method thereof

ActiveCN109021380AImprove blend compatibilityImproved scratch resistanceIndustrial scalePolypropylene composites

The invention discloses a polypropylene composite material with characteristics of low odor, scratch resistance and low gloss, and a preparation method thereof, wherein the polypropylene composite material comprises 50-90 parts of a PP resin, 5-25 parts of a HDPE resin, 0.5-3 parts of a scratch-resistant agent, 0.2-5 parts of an adsorbent, and 2-40 parts of inorganic powder. According to the present invention, the blending compatibility is increased by adding the HDPE, the co-action is achieved with the scratch-resistant agent so as to improve the scratch resistance, the low odor of the composite material is further improved by adding the water injection / drying process and the adsorbent, and the gloss of the composite material is reduced by filling with the inorganic powder, such that thepolypropylene composite material having the balance among the low odor, the scratch resistance and the low gloss can be achieved under the premise of the substantially unchanged mechanical properties;the composite material has the excellent comprehensive performance, and can be suitable for the production of vehicle interior decoration parts; and the preparation method has characteristics of simple and easily-controlled preparation process, low production cost and stable product performance, and is suitable for industrial scale production.

Owner:WUHAN JINFA TECH CO LTD +1

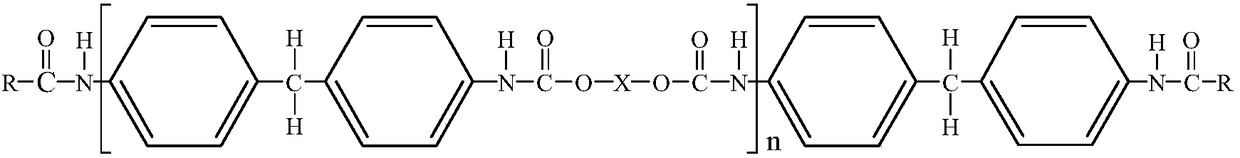

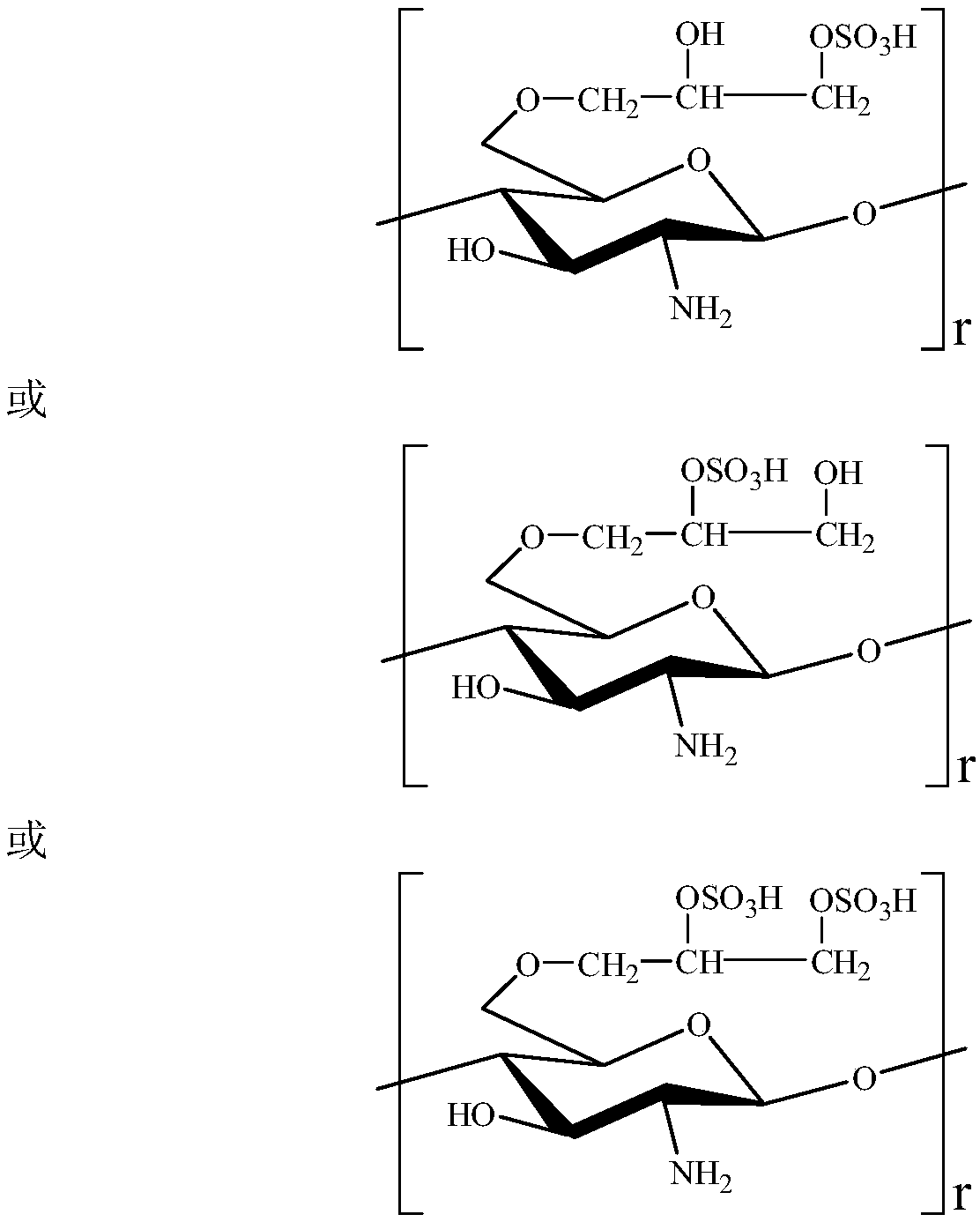

Heparan modified polyurethane/polyethersulfone blended hollow fiber membrane and preparation method thereof

InactiveCN109316982AReduced compatibilityReduce the amount of adsorptionSemi-permeable membranesHollow fibre membraneHydroxypropyl Chitosan

The invention provides a heparan modified polyurethane / polyethersulfone blended hollow fiber membrane and a preparation method thereof. According to the heparan modified polyurethane / polyethersulfoneblended hollow fiber membrane, heparan modified polyurethane is sulfonated dihydroxypropyl chitosan modified polyurethane; the preparation method comprises the following steps: adding 1 to 10 percentof the sulfonated dihydroxypropyl chitosan modified polyurethane, 8 to 20 percent of polyethersulfone and 80 to 90 percent of a solvent into a dissolving kettle; controlling the temperature to be 70 to 90 DEG C and stirring for 2 to 20 h; after the components are completely dissolved, standing for 10 to 20 h to finish de-foaming, so as to obtain a membrane solution; then preparing the sulfonated dihydroxypropyl chitosan modified polyurethane / polyethersulfone blended hollow fiber membrane by adopting a dry-wet process spinning method. The blended hollow fiber membrane provided by the inventionhas good anticoagulation performance and physicochemical stability; a preparation technology is simple and conditions are moderate and controllable.

Owner:CENT SOUTH UNIV

Method for making disposable tableware by blending modified inorganic powder material and polypropylene

InactiveCN1730266AIncrease the amount of participationLow costDomestic articlesInjection mouldingPolypropylene

A method for disposable tableware by blending modified inorganic powder material and polypropylene, including modifying inorganic powder material with modifier, blending them with polypropylene, and extrusion pelleting, injection molding or by extruding sheet, stamping or plastic uptake molding to get disposable tableware. Because the inorganic powder material modified before blending with polypropylene to produce disposable tableware, not only the quantity of the inorganic powder material increases largely, reduced the cost dramatically, but also the tableware meets the settled hygienic standard, to make such tableware to be of utility type and quite well competitive. The method provided is simple, reasonable, controllable, and the leftover bits and pieces of industrial material produced during the process can be reprocessed.

Owner:SICHUAN UNIV

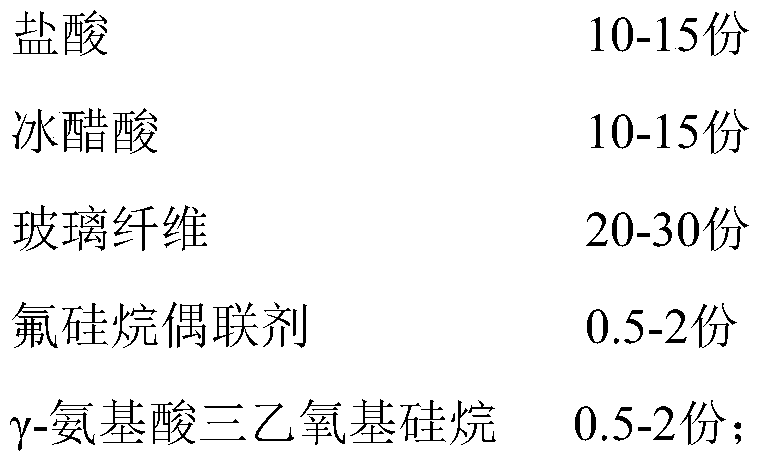

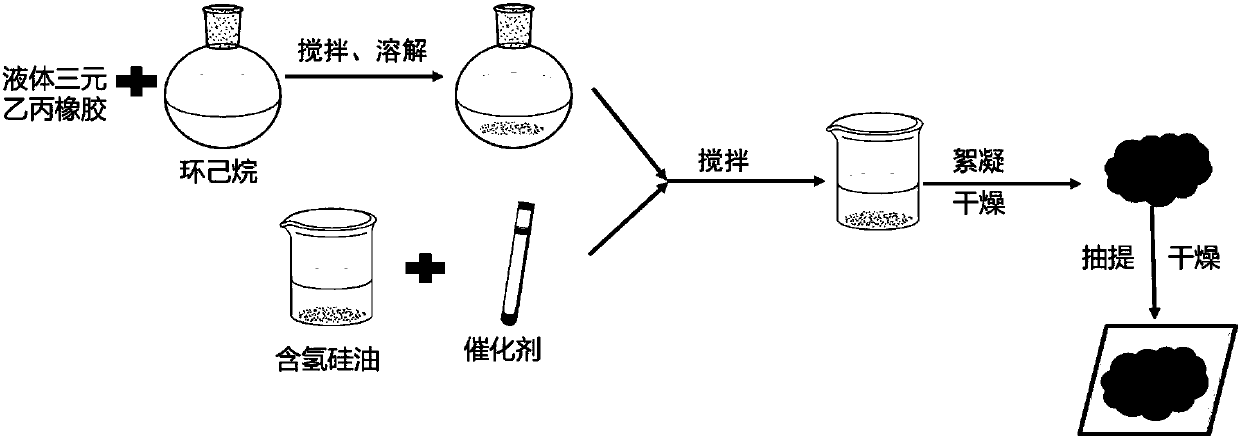

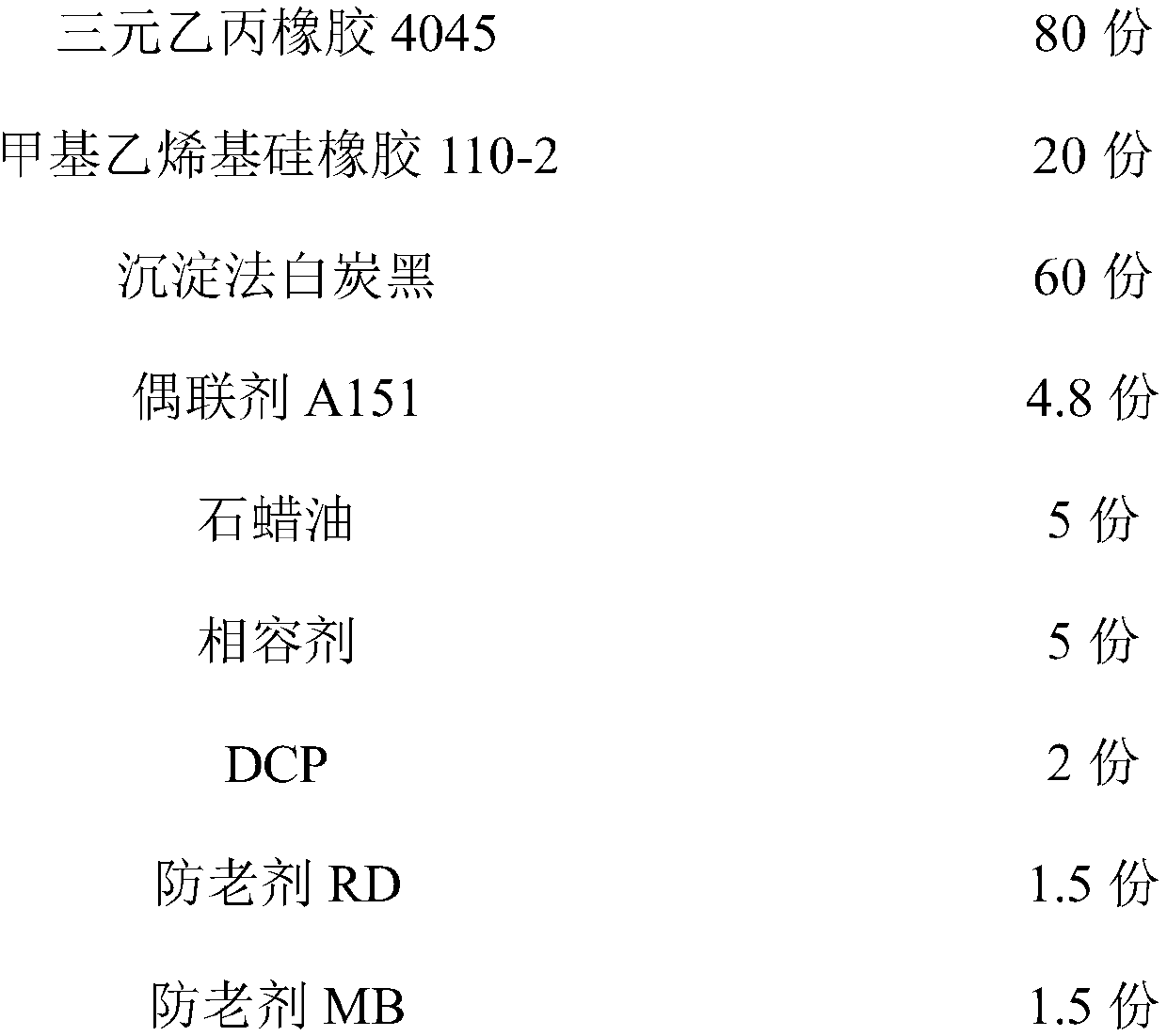

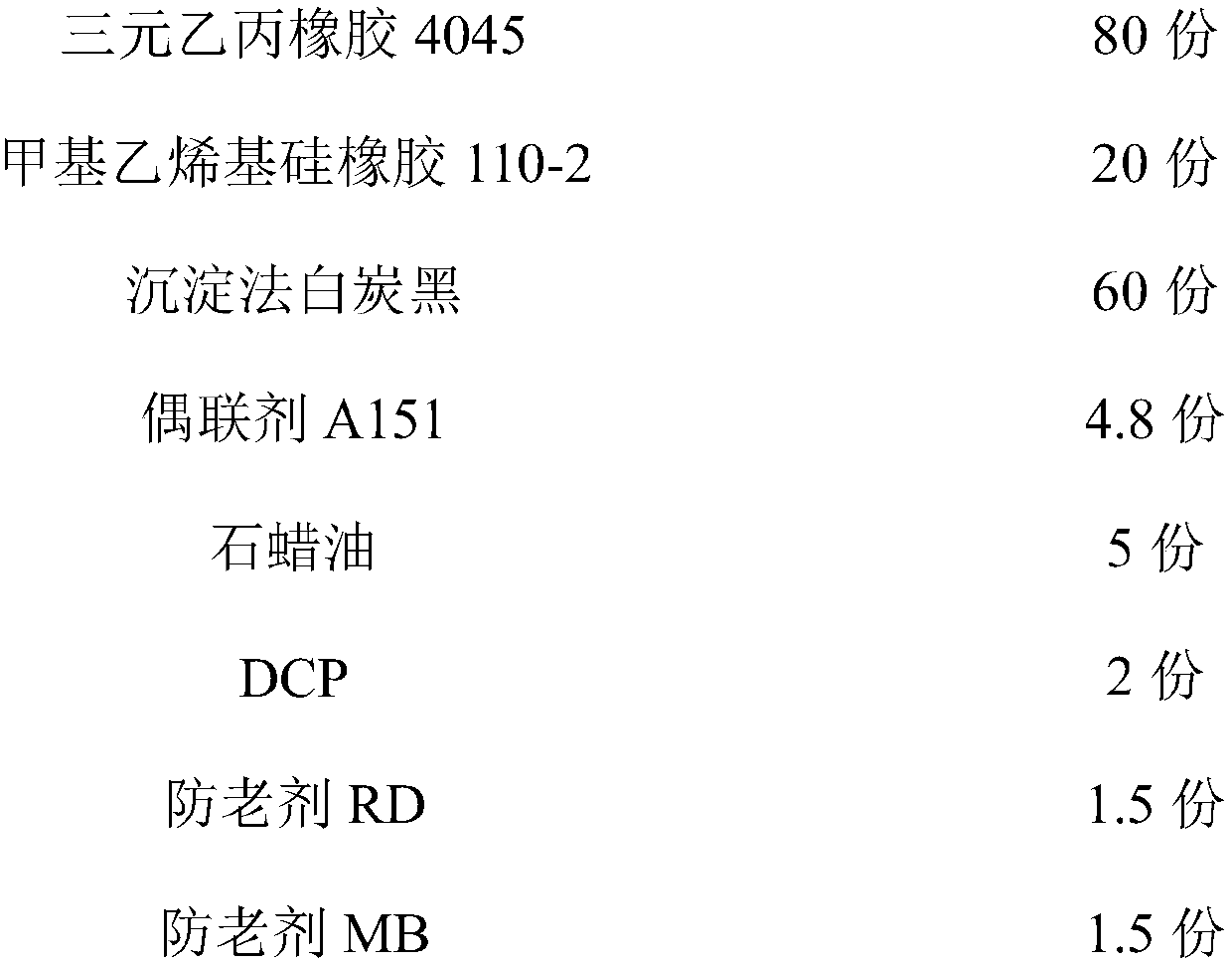

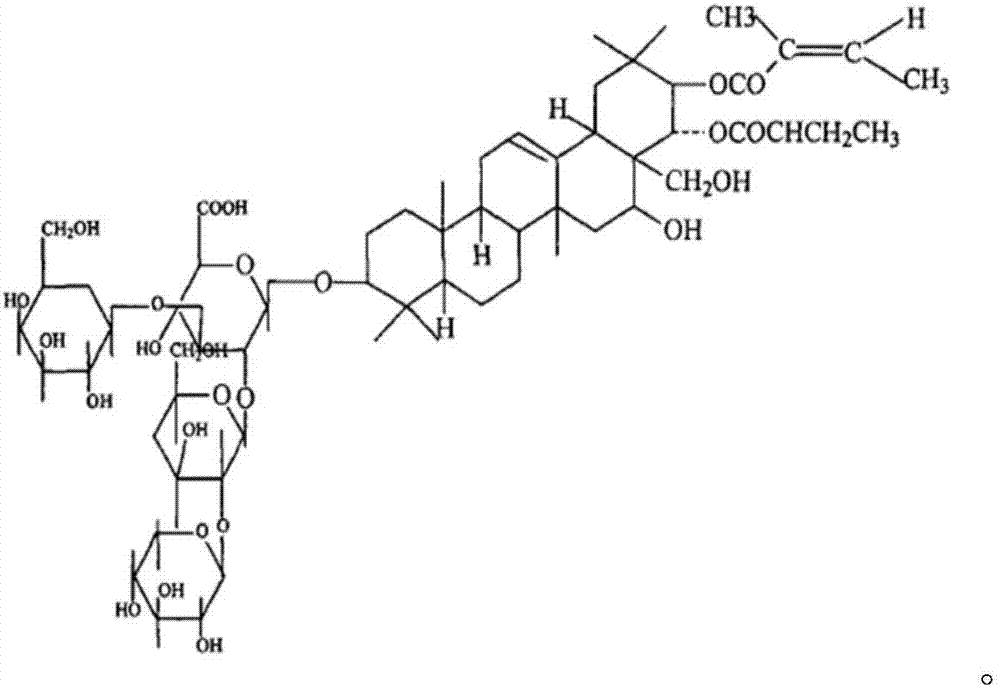

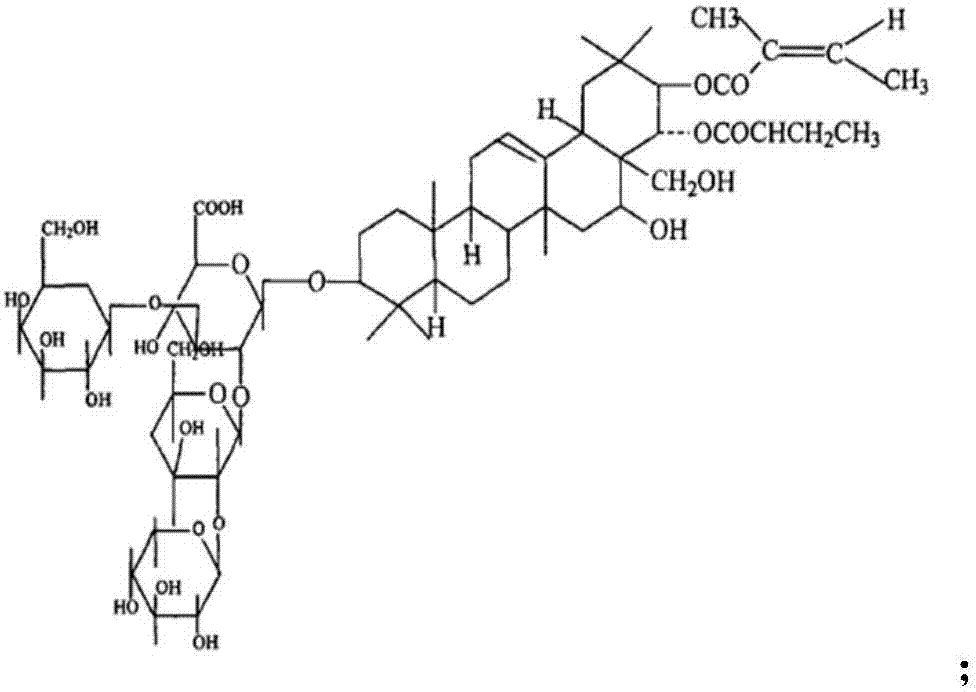

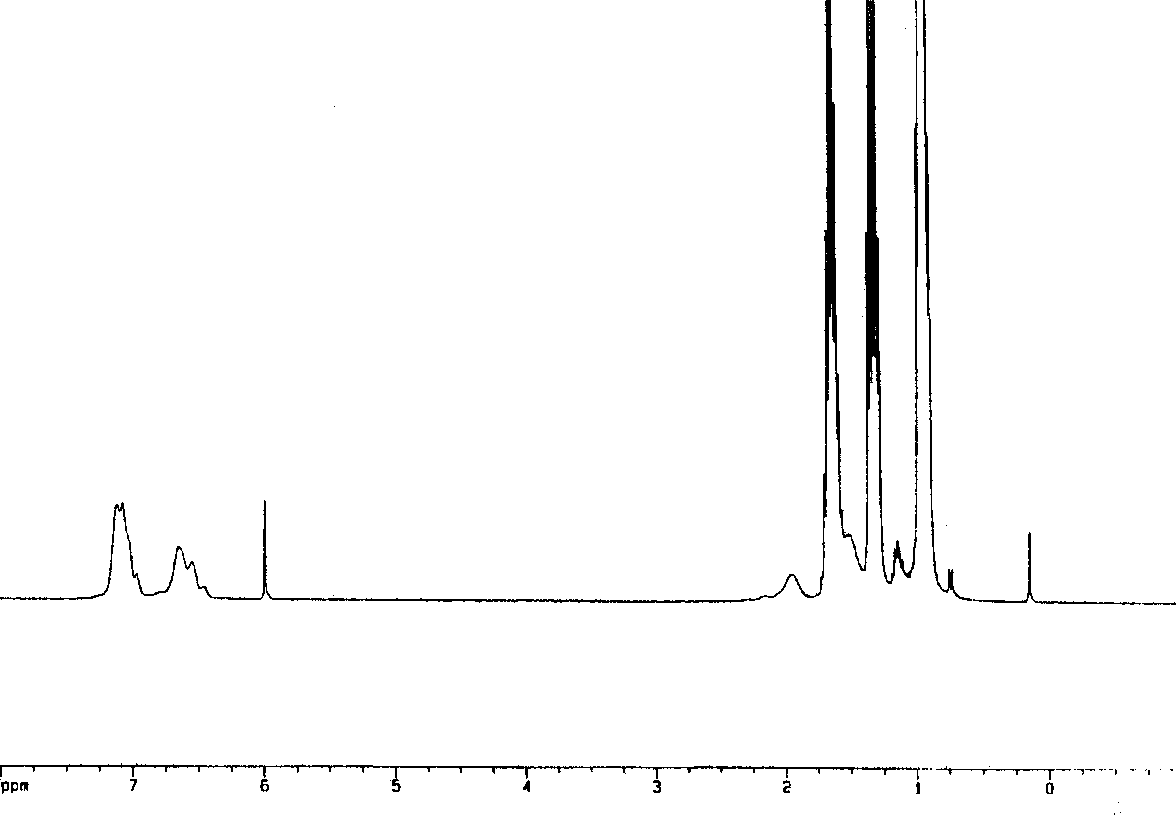

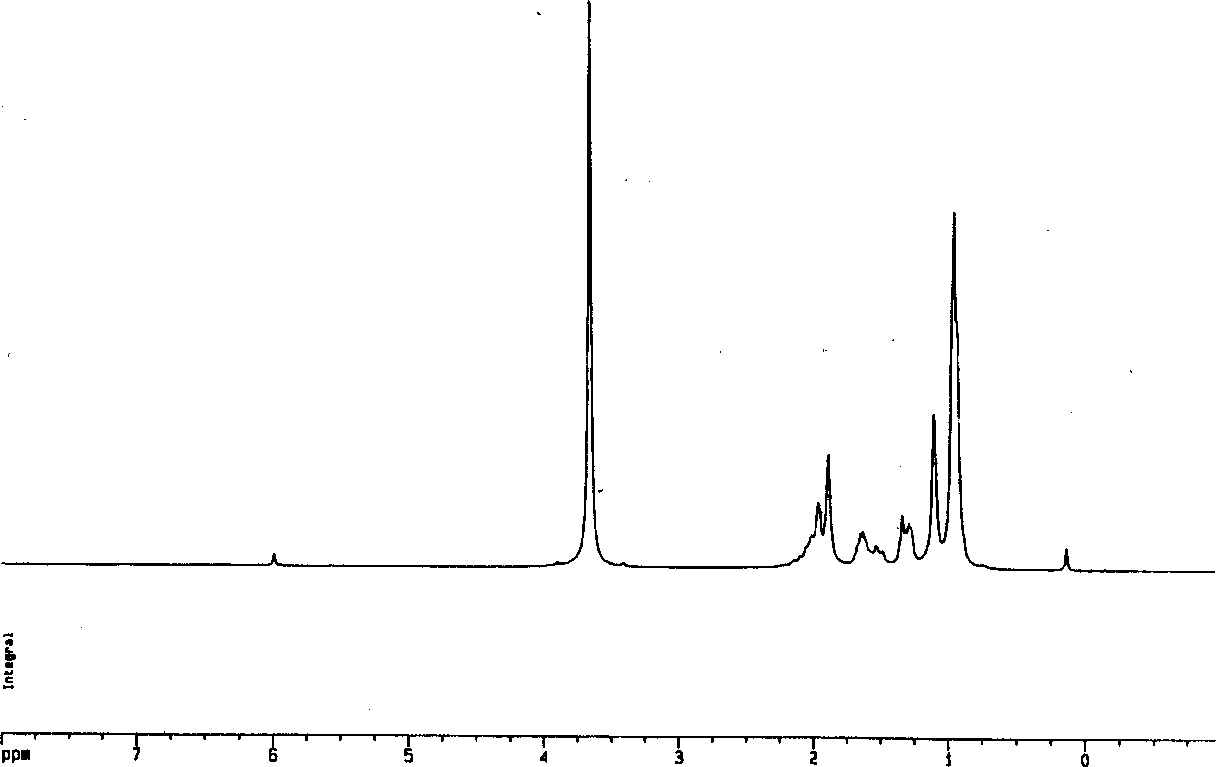

Compatilizer for improving blending compatibility of ethylene propylene diene monomer with silicone rubber and preparation method of compatilizer

InactiveCN109867789AImprove blend compatibilityImproved thermo-oxidative aging performanceChemical effectsHydrosilylation

The invention relates to a compatilizer for improving blending compatibility of ethylene propylene diene monomer with silicone rubber. The compatilizer comprises 100 parts of liquid ethylene propylenediene monomer, 30-50 parts of hydrogen-containing silicone oil and 0.5-1 part of a catalyst. The preparation method comprises the following steps: firstly, dissolving the liquid ethylene propylene diene monomer, then adding the hydrogen-containing silicone oil and the catalyst, and carrying out a hydrosilylation reaction to graft the hydrogen-containing silicone oil onto the liquid ethylene propylene diene monomer to prepare the compatilizer. The novel compatilizer can be enriched at the interface of two phases in a blending process of ethylene propylene diene monomer with methyl vinyl silicone rubber, and surface tension of the two phases is reduced through physical or chemical effects generated by the compatilizer with a two-phase polymer component, so that an effect of improving compatibility of the two components is achieved, and performance of blended rubber is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

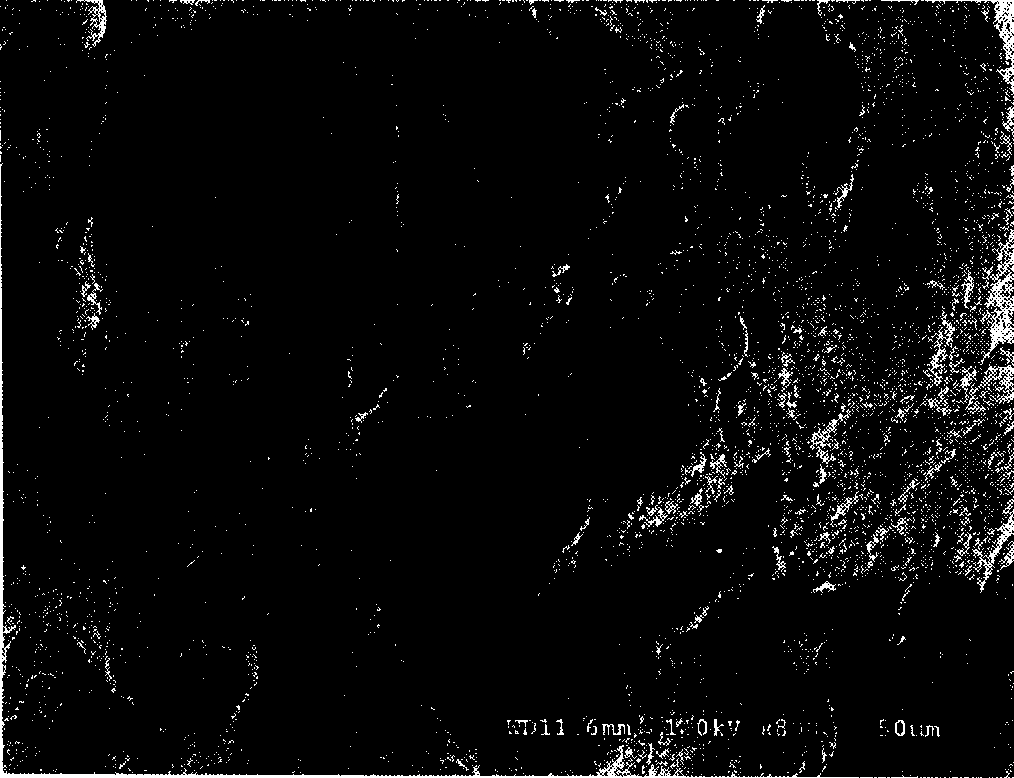

Tea saponin modified electrolytic manganese residues and compound flooring tile prepared from tea saponin modified electrolytic manganese residues and waste plastics

The invention discloses tea saponin modified electrolytic manganese residues. The tea saponin modified electrolytic manganese residues are characterized by comprising 5wt%-7wt% of tea saponin, 2wt%-5wt% of NaOH and 88wt%-93wt% of electrolytic manganese residues. The tea saponin modified electrolytic manganese residues are prepared through the following steps: the electrolytic manganese residues and NaOH are added to a high-speed mixer at 25 DEG C and stirred for 6-7 min, tea saponin is added when the temperature reaches 65 DEG C, the mixture is heated and stirred for 5-6 min, and the tea saponin modified electrolytic manganese residues are obtained. A compound flooring tile prepared from the tea saponin modified electrolytic manganese residues and waste plastics is prepared from raw materials in parts by weight as follows: 20-30 parts of waste polyvinyl chloride plastics and 70-80 parts of the tea saponin modified electrolytic manganese residues through stirring, plastication into sheets, die pressing and cutting into sheets. The surface property of the modified electrolytic manganese residues is changed from hydrophilicity to lipophilicity by means of tea saponin, blending compatibility and binding performance of the modified electrolytic manganese residues with waste polyvinyl chloride are improved greatly, the performance of the compound flooring tile is improved greatly, filling parts of the electrolytic manganese residues in the compound flooring tile are increased, and product cost is reduced effectively.

Owner:GUIZHOU UNIV

Polypropylene graft copolymer, its production and use

A polypropylene graft copolymer, its production and use are disclosed. In the molecular formula, n is integer between 50-100000, k is integer between 10-5000, L is integer between 4-10, R is alkyl, R1 is H or methyl, R2 is phenyl, p-methyl, -OCOCH3, -CONH2, -CN or -COOR3, and R3 is alkyl. It can adjust graft density and length, and maintain polypropylene excellent performances and blending compatibility. It can be used for blending compatilizer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Production method for high-toughness building template

InactiveCN104228022AReduce manufacturing costImprove processing fluidityFlat articlesPolymer scienceLiquid state

The invention relates to a production method for a high-toughness building template. According to the production method, the building template is prepared from recycled regenerated plastic and / or rubber serving as a main raw material, so that the production cost of the building template is lowered; in the production method, a mixture of rubber and an auxiliary is blended and granulated to obtain a rubber modified material, and the rubber modified material and plastic particles are fused and blended, so that the auxiliary, in spite of a liquid state or a solid state, can be effectively mixed with the rubber during blending and can enter the rubber; therefore, a network structure in the rubber can be released, and the processing flowability, the compatibility and the dispersion uniformity of the rubber and the plastic particles during fusing and blending are improved, and the toughness of the building template is also enhanced; furthermore, the rubber modified material is of a large particle shape, so that the environment friendliness of the technology is high. The production method has another advantage that after being rejected, the building template can be recycled to serve as a raw material for processing a new building template, so that resource recycling is realized.

Owner:JIANGYIN DATIAN TECH SERVICE

Dust-resistant weather-proof additive for processing rubber sealing strips of aluminum alloy doors and windows

InactiveCN107245212AGuaranteed dustproof effectGuaranteed weather resistancePolyglutamic acidRaw material

The invention discloses a dust-resistant weather-proof additive for processing rubber sealing strips of aluminum alloy doors and windows, relating to the technical field of the aluminum alloy doors and windows. The additive is prepared from the following raw materials in parts by weight: 5-10 parts of chlorinated polyvinyl chloride, 1-5 parts of polyglutamic acid, 1-5 parts of molecular sieve raw powder, 1-5 parts of pentaerythritol ester of hydogenated rosin, 0.5-1 part of polyether-modified silicone oil, 0.5-1 part of glass fiber powder, 0.1-0.5 part of polyaluminium chloride, 0.05-0.1 part of N-isopropylacrylamide, 0.05-0.1 part of vulcanized lard and 0.01-0.02 part of ferrocene. By using the dust-resistant weather-proof additive prepared by the invention, the dust-resistant property and the weather-proof property of the sealing strips can be obviously improved, so that the quality of the sealing strips in use is guaranteed, and the service life of the sealing strips is prolonged.

Owner:安徽兰天大诚门窗幕墙有限公司

Processing method of self-lubrication wear-proof unsaturated polyester molding compound

The invention discloses a processing method of a self-lubrication wear-proof unsaturated polyester molding compound and relates to the technical field of thermosetting molding compounds. The processing method comprises the following steps of: (1) batching, (2) mixing and (3) granulation. The method prepares the self-lubrication wear-proof unsaturated polyester molding compound by taking solid unsaturated polyester resin as a main material, kaoline as filling and C5 hydrogenated petroleum resin and chlorinated polyethylene rubber as forming assistants, a lubricant, a releasing agent, a cross-linking agent, an initiator, a pigment, a polymerization inhibitor as functional assistants, can significantly reduce a wear extent and therefore prolongs a service life when the molding compound is applied to a moving component of an electric appliance product.

Owner:马斌祥

Production processes of packaging adhesive film with ultra-low ionic mobility and photovoltaic component

InactiveCN103342968BImprove insulation performanceImprove the phenomenon of poor mechanical propertiesFilm/foil adhesivesOrganic non-macromolecular adhesiveElastomerPolyolefin

The invention relates to a solar cell packaging adhesive film having low ionic mobility and belongs to the technical field of photovoltaic power generation fittings. The solar cell packaging adhesive film with low ionic mobility is formed by compounding a bonding layer adhesive film with an ion isolation layer in a certain proportion; the thickness proportion of the bonding layer to the ion isolation layer is (1:1)-(1:5); the thickness of the packaging adhesive film is 0.5-0.8 mm. According to the invention, the ion isolation layer is innovatively introduced; on one hand, the isolation layer has high insulativity of polyolefin elastomers, such as POE (Polyolefin Elastomer) and EPDM (Ethylene-Propylene-Diene Monomer); on the other hand, because of a hydrogen bond in a siloxane structure, the blending compatibility of the packaging adhesive film with other high-molecular polymers is greatly increased; meanwhile polymer linear polysiloxane is modified by using an ethylene-acrylate polymer; the poor mechanical property phenomenon of polysiloxane can be greatly improved.

Owner:CHANGZHOU UNIV +1

Road traffic stone processed and prepared from solid wastes of blast furnace slag and pulverized fuel ash

The invention discloses a road traffic stone processed and prepared from solid wastes of a blast furnace slag and a pulverized fuel ash, and relates to the technical field of processing of the road traffic stone. The road traffic stone comprises the following raw materials by weight: 40-50 parts of blast furnace slag, 25-35 parts of pulverized fuel ash, 20-30 parts of fine sand, 15-25 parts of Portland cement, 10-15 parts of ceramic waste micro-powder, 5-10 parts of a gelling agent, 3-8 parts of asbestos wool, 1-5 parts of petroleum coke micro-powder, 1-5 parts of polyaluminium sulfate, and 0.5-2 parts of polyborosiloxane. Due to the use of the gelling agent, the solid wastes of the blast furnace slag and the pulverized fuel ash have certain gelling property so as to be favorable for the recycling of the blast furnace slag and the pulverized fuel ash as the main materials of concrete, the blending compatibility between the preparation materials of the concrete is strengthened, the evendispersion of the raw material is guaranteed, the environmental pollution caused by the wasted blast furnace slag and the wasted pulverized fuel ash is avoided, and meanwhile, the mechanical use performance of the prepared road traffic stone is improved.

Owner:FENGYANG FENGCHENG JIANAN PREFABTED FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com