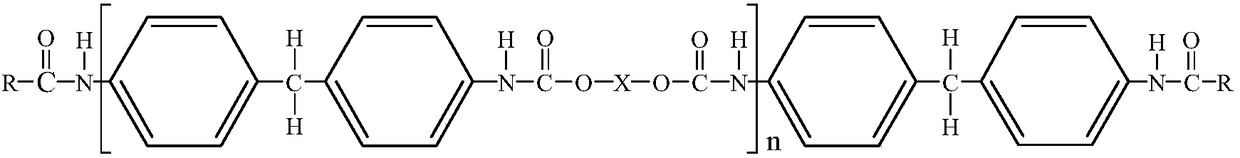

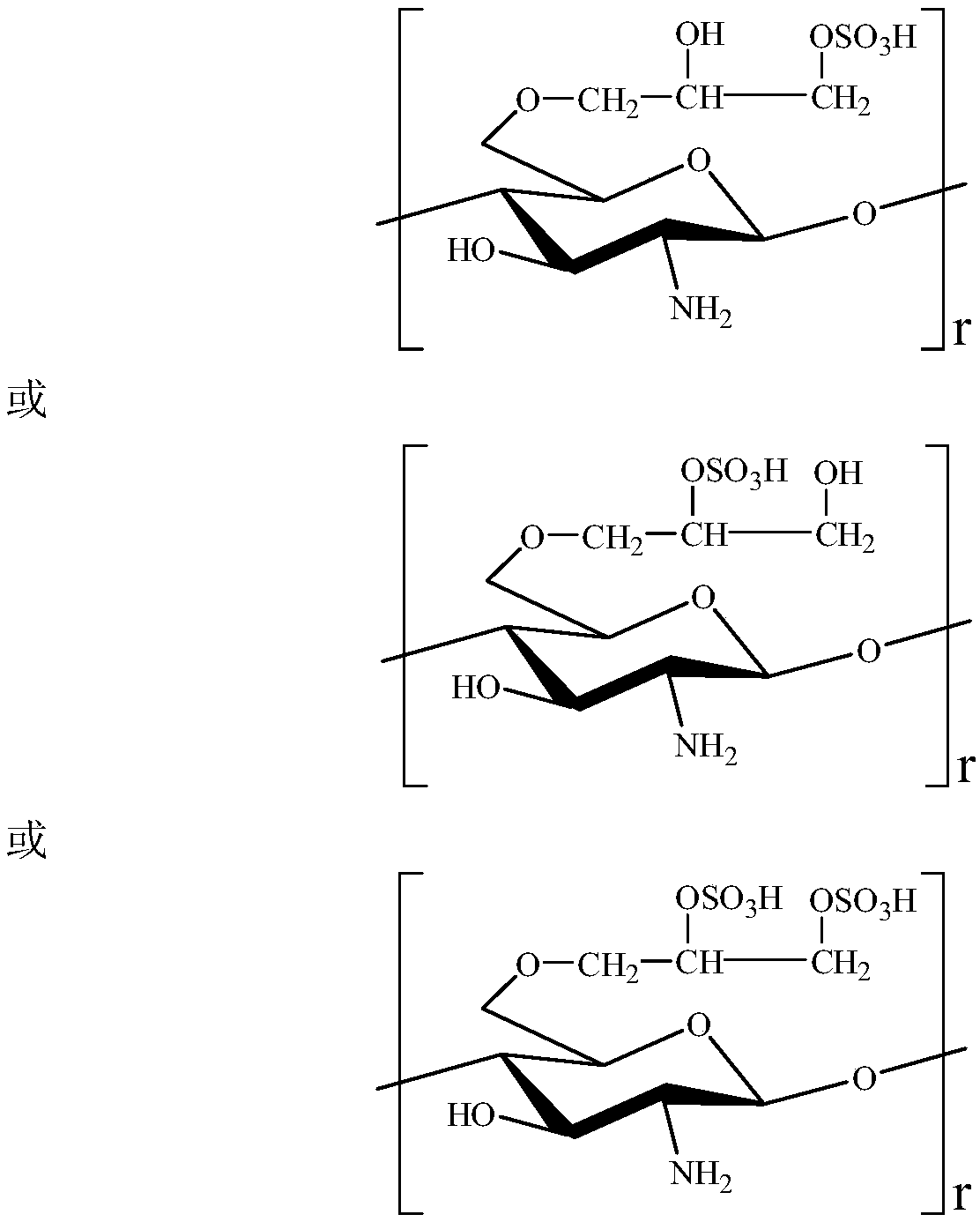

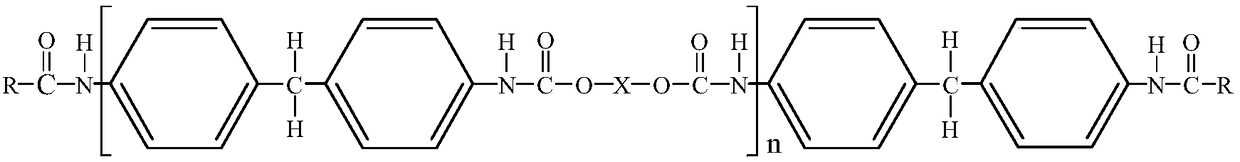

Heparan modified polyurethane/polyethersulfone blended hollow fiber membrane and preparation method thereof

A technology of polyurethane and polyethersulfone, which is applied in the field of heparan-modified polyurethane/polyethersulfone blended hollow fiber membrane and its preparation, which can solve the problems of expensive modified substances, insignificant anticoagulant effect, and complicated preparation process, etc. problem, to achieve the effect of improving blood compatibility, simple preparation method, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 1% of sulfonated dihydroxypropyl chitosan-modified polyurethane, 17% of polyethersulfone, and 82% of N,N-dimethylformamide into a dissolution kettle equipped with a thermometer, agitator and reflux condensing device, Control the temperature at 70-90°C and stir for 2-20 hours; after the dissolution is complete, let it stand for 10-20 hours to complete the defoaming and obtain the membrane liquid;

[0023] Open the nitrogen valve, control the pressure of the raw material kettle to 0.08MPa, press-filter the spinning, pump the core liquid into the inner hole of the spinneret through the metering pump and extrude it, control the core liquid flow rate to 1.2mL / min, and stabilize the core liquid flow rate , start spinning; control the spinning speed of 1.5mL / min, the film liquid is pressed into the spinneret and extruded from the ring gap, after passing through the air distance of 25cm, it enters the coagulation water bath with a temperature of 30°C to cool and solidify, an...

Embodiment 2

[0025] Add 2% of sulfonated dihydroxypropyl chitosan-modified polyurethane, 18% of polyethersulfone, and 82% of N,N-dimethylformamide into a dissolution kettle equipped with a thermometer, agitator and reflux condensing device, Control the temperature at 70-90°C and stir for 2-20 hours; after the dissolution is complete, let it stand for 10-20 hours to complete the defoaming and obtain the membrane liquid;

[0026] Open the nitrogen valve, control the pressure of the raw material kettle to 0.10MPa, filter the spinning, pump the core liquid into the inner hole of the spinneret through the metering pump and extrude it, control the core liquid flow rate to 1.2mL / min, and stabilize the core liquid flow rate , start spinning; control the spinning speed of 1.3mL / min, the film liquid is pressed into the spinneret and extruded from the ring gap, after passing through the air distance of 25cm, it enters the coagulation water bath with a temperature of 30°C to cool and solidify, and then...

Embodiment 3

[0028] Add 2% of sulfonated dihydroxypropyl chitosan-modified polyurethane, 17% of polyethersulfone, and 81% of N,N-dimethylacetamide into a dissolution kettle equipped with a thermometer, agitator and reflux condensing device, Control the temperature at 70-90°C and stir for 2-20 hours; after the dissolution is complete, let it stand for 10-20 hours to complete the defoaming and obtain the membrane liquid;

[0029] Open the nitrogen valve, control the pressure of the raw material kettle to 0.06MPa, filter the spinning, pump the core liquid into the inner hole of the spinneret through the metering pump and extrude it, control the core liquid flow rate to 1.2mL / min, and stabilize the core liquid flow , start spinning; control the spinning speed of 1.5mL / min, the film liquid is pressed into the spinneret and extruded from the ring gap, after passing through the air distance of 20cm, it enters the coagulation water bath with a temperature of 30°C to cool and solidify, and then wrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com