Patents

Literature

447results about How to "Reduce the amount of adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mud resisting and slump retaining type polycarboxylic acids water reducer and preparation method thereof

ActiveCN105110687ASimple preparation processNo pollution in the processFunctional monomerCross linker

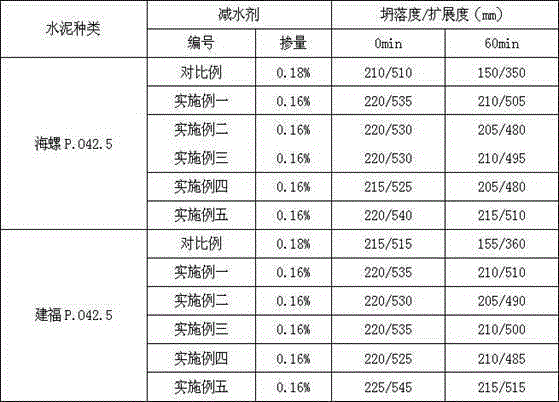

The invention discloses a mud resisting and slump retaining type polycarboxylic acids water reducer and a preparation method thereof. The mud resisting and slump retaining type polycarboxylic acids water reducer comprises, by weight, unsaturated polyoxyethylene ether 32.5% to 33.6%, unsaturated carboxylic acid 1.7% to 2.5%, functional monomer 3.25% to 3.36%, cross-linking agent 0.08% to 0.13%, oxidizing agent 0.12% to 0.32%, reducing agent 0.09% to 0.17%, chain transferring agent 0.03% to 0.06%, alkalinity modifier 0.86% to 1.22%, and water 60%. The water reducer in the invention has quite strong adaptability for sandstone with high silt content, good effect on mud resisting, large initial dispersibility, low cost and good slump retaining performance. Moreover, the preparation method in the invention reacts at normal temperature; has short reaction time, low energy consumption, low cost, high security coefficient, and no need to control the temperature in the whole production process; and is simple, without pollution, and suitable for commercial production.

Owner:厦门路桥翔通建材科技有限公司

Novel lepidolite flotation method

InactiveCN103240185AEfficient separationLarge adsorption capacityFlotationCoconut oilCharge compensation

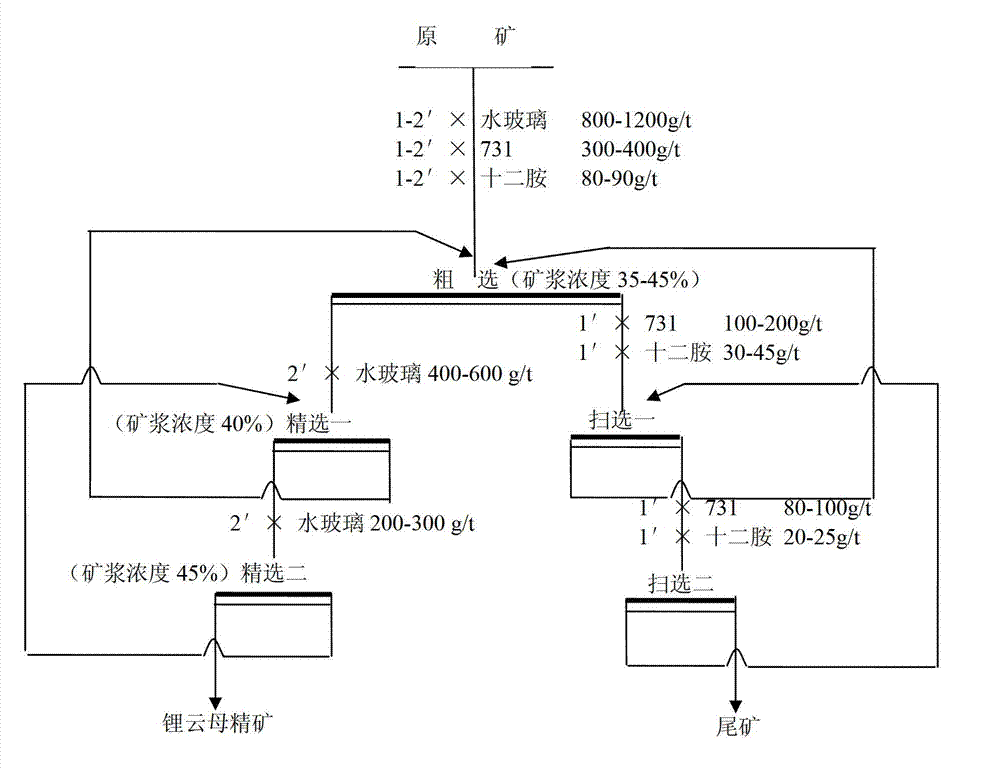

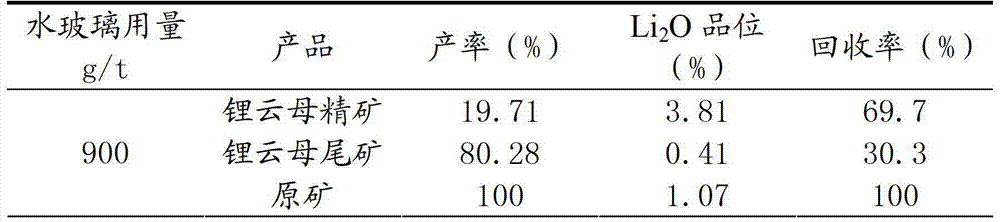

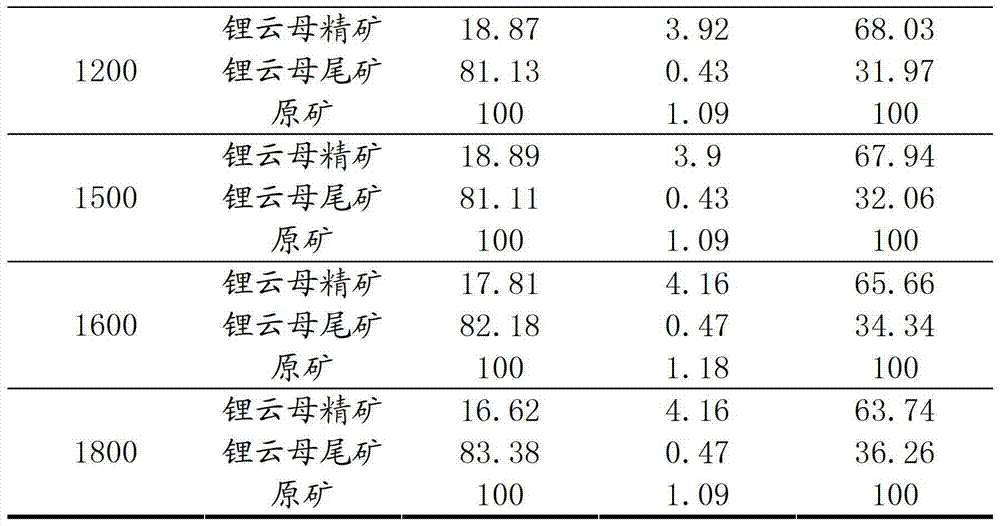

The invention discloses a novel lepidolite flotation method including primary rough selection, secondary fine selection and secondary scavenging. During the flotation, sodium silicate is added as an inhibitor with the amount ranging from 1400g / t to 1900g / t; an anionic collector is sodium oleate or oxyparaffin soap 731 with the amount ranging from 480g / t to 700g / t; and a cationic collector is dodecylamine or coconut oil amine with the amount ranging from 130g / t to 160g / t. The adding sequence of collectors is the anionic collector first and the cationic collector second, or the anionic collector and the cationic collector are added together. By the method, the lepidolite is selected through the combination of the anionic and the cationic, good flotation effect can be realized, flotation efficiency is high, and meanwhile, the synergistic effect is generated between the anionic collector and the cationic collector, and results from joint action of three mechanisms of coadsorption, charge compensation and function complementation.

Owner:JIANGXI UNIV OF SCI & TECH

Additive agent selectively reducing aldehydes matter in cigarette flue gas, production method and application thereof

ActiveCN101194755AReduce the amount of adsorptionExtended reaction timeTobacco smoke filtersPigment treatment with non-polymer organic compoundsCrotonaldehydeChemical compound

The invention discloses an additive to selectively lower the aldehydes substances in cigarette smoke, which uses the silica gel with thick holes as the carrier and introduces the functional group through modification to coat a layer of chemical compounds provided with amidogen, carbamido or amide and capable of reacting with aldehydes substances on the carrier surface and the hole channel surface, wherein the modified carrier is applied in the cigarette filter up and can selectively lower the contents of the aldehyde substances in the cigarette smoke, such as formaldehyde, aldehyde, propanal, acrylic aldehyde, crotonaldehyde and the like.

Owner:CHINA TOBACCO HUNAN INDAL CORP

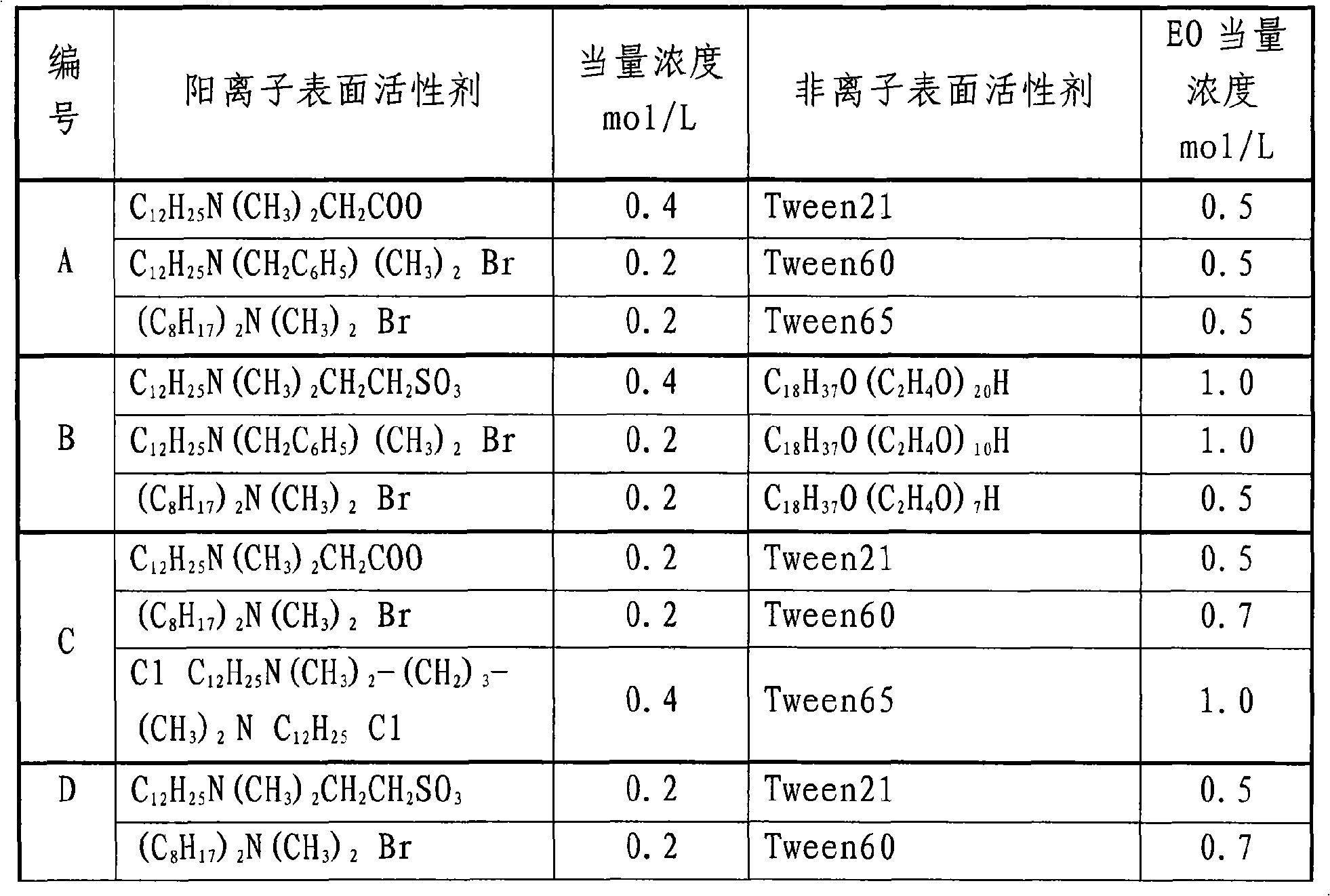

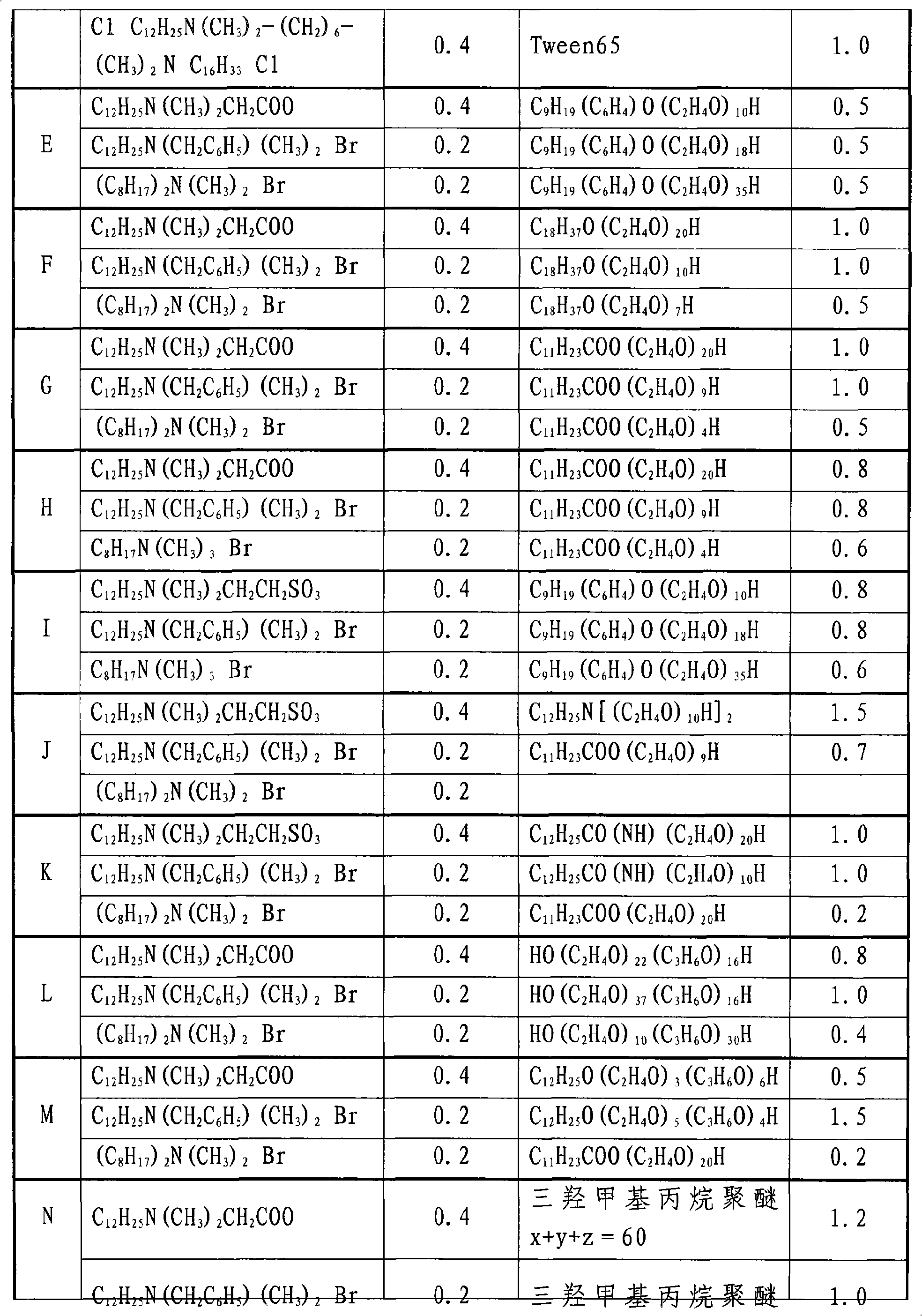

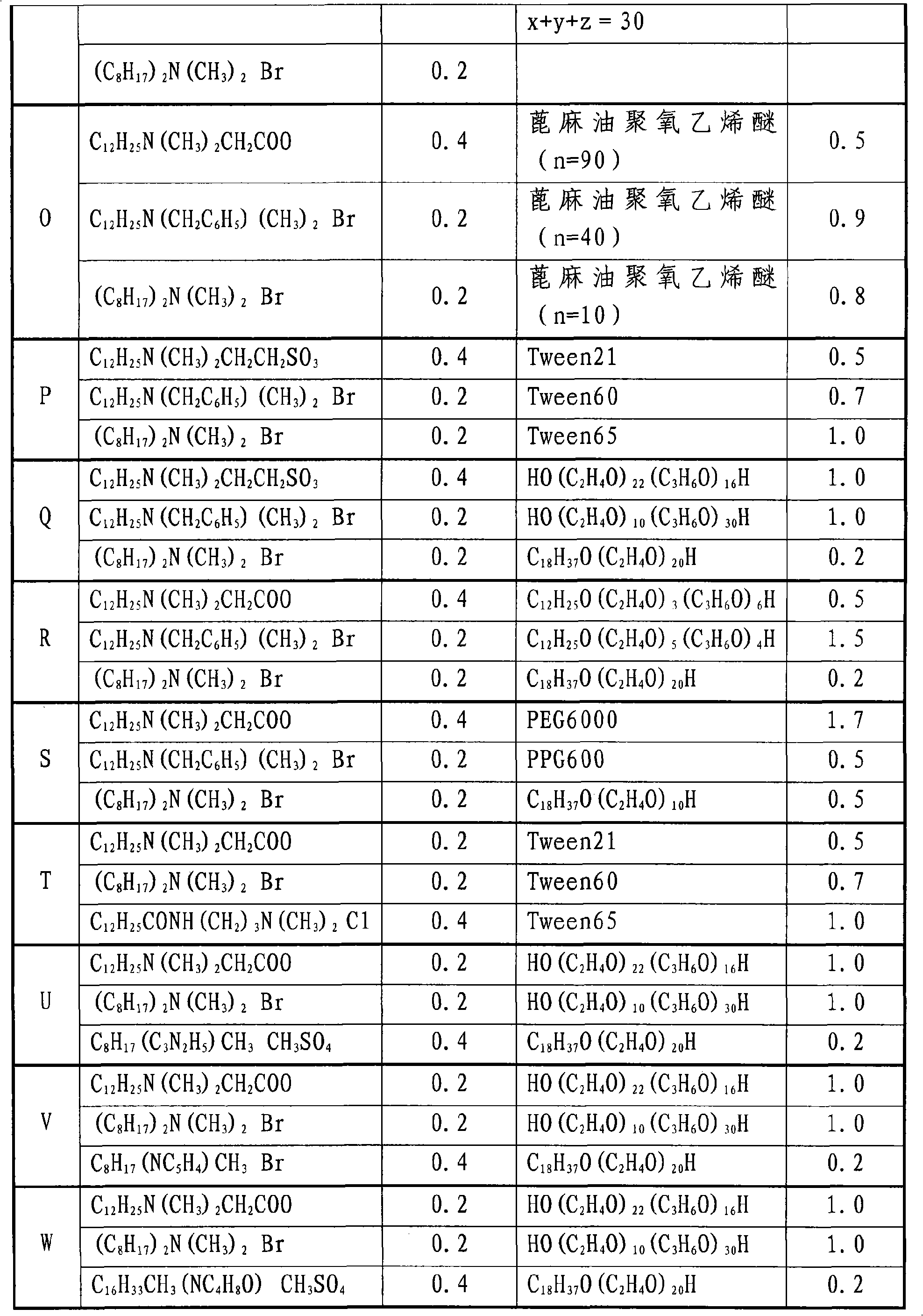

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

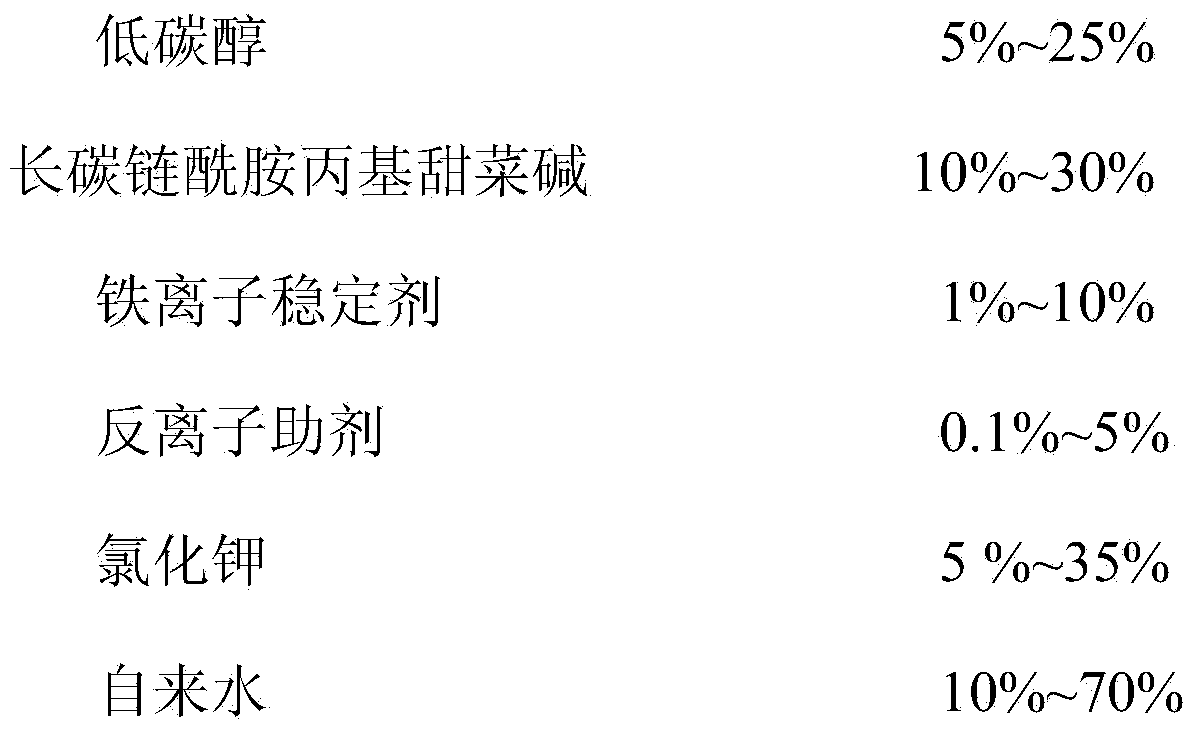

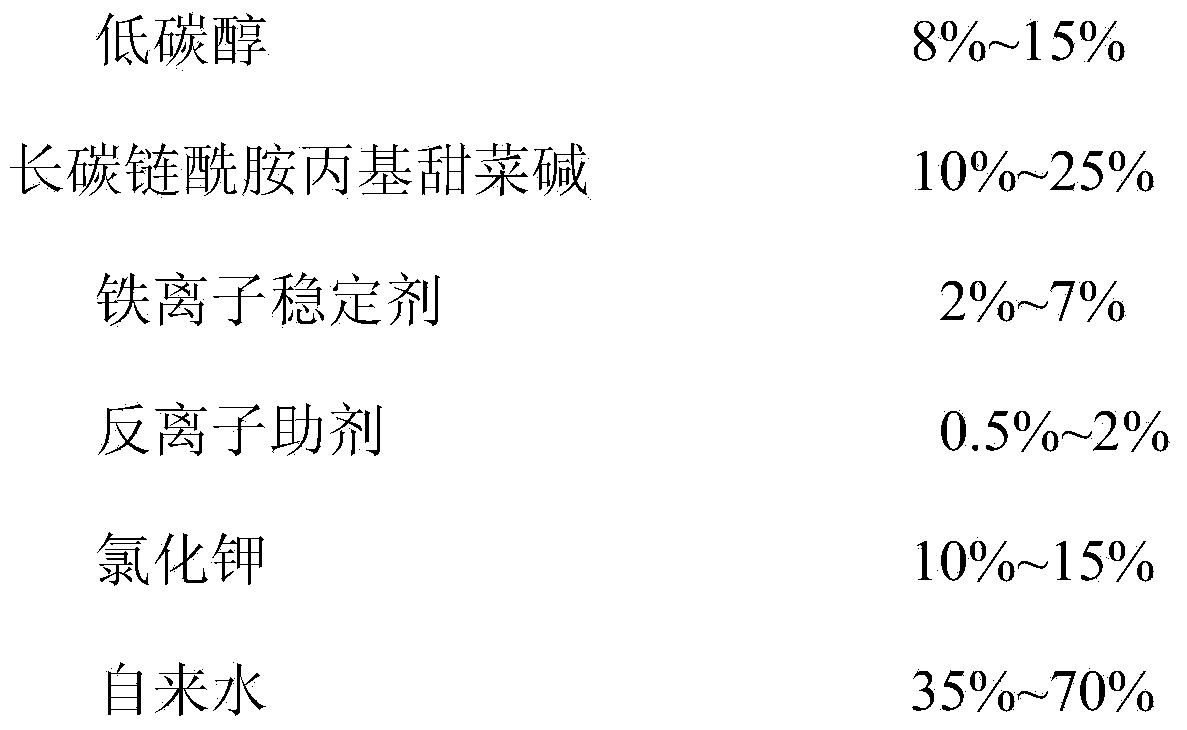

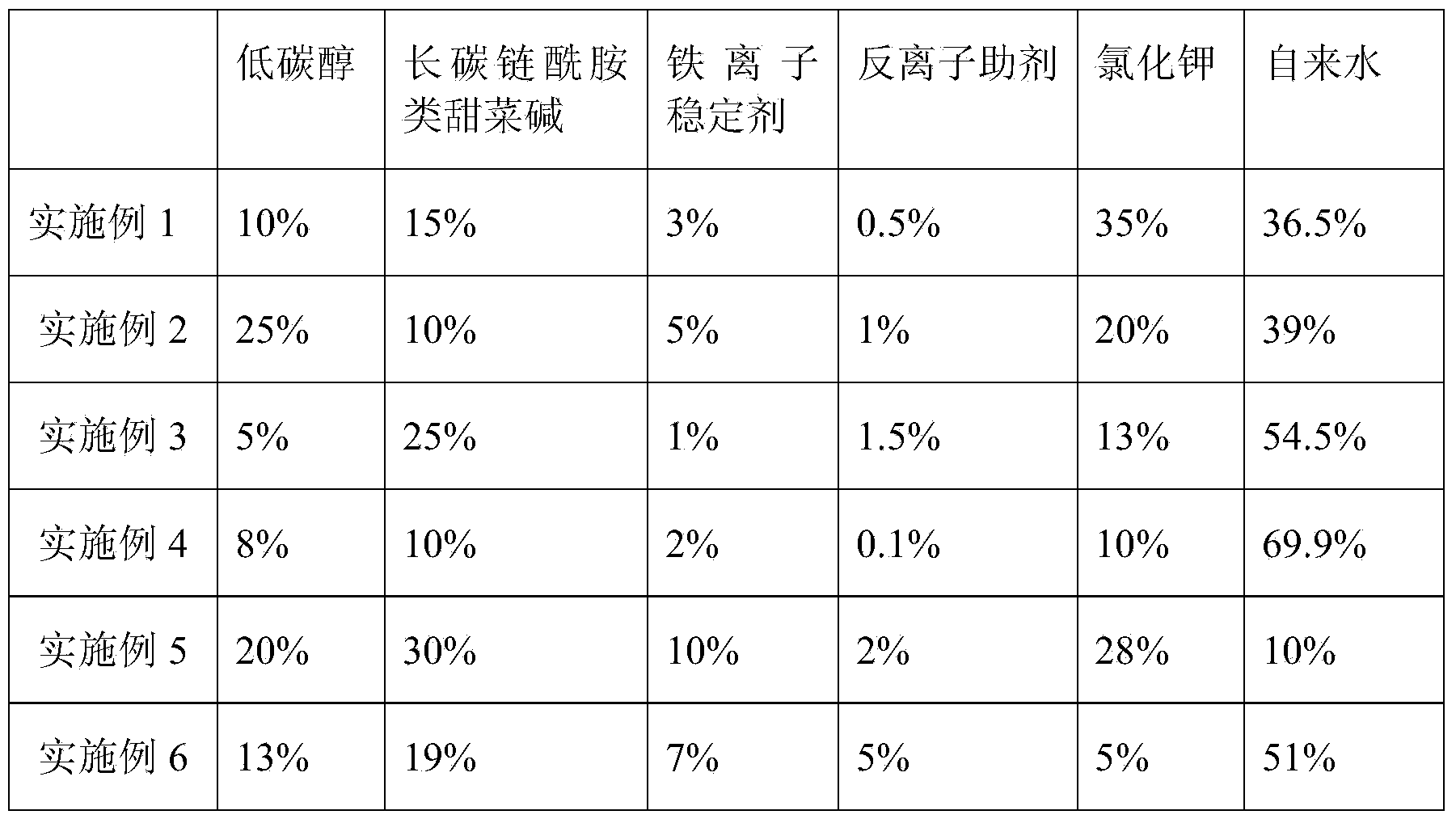

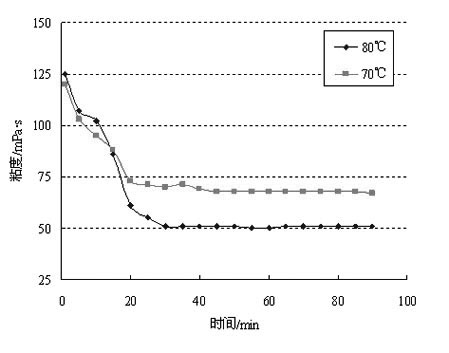

Long-carbon-chain amide glycine betaine clean fracturing fluid and preparation method thereof

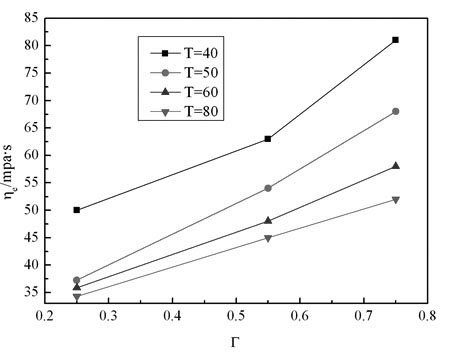

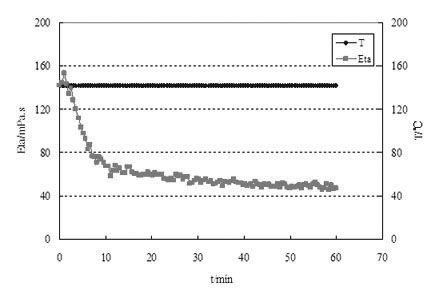

The invention relates to long-carbon-chain amide glycine betaine clean fracturing fluid and a preparation method thereof. The glycine betaine amphiprotic surface active agent long-carbon-chain (more than 18 carbons) amide glycine betaine is used as a main agent, the carbon chain of the glycine betaine is long, the glycine betaine is dissolved in the water and is likely to form gel after being stirred, so that the fracturing fluid is good in viscosity. In addition, the clean fracturing fluid by adopting the long-carbon-chain (more than 18) amide glycine betaine as the main agent adsorbs less rock stratum, the consumption of the surface active agent is effectively reduced, the calcium resistance is strong, the gel is thorough to break, no residue exists, and the harm on the stratum is small. The prepared long-carbon-chain amide propyl glycine betaine clean fracturing fluid can be well applied to an oil field and plays an important role in increasing the yield of the oil-gas field.

Owner:XI'AN PETROLEUM UNIVERSITY

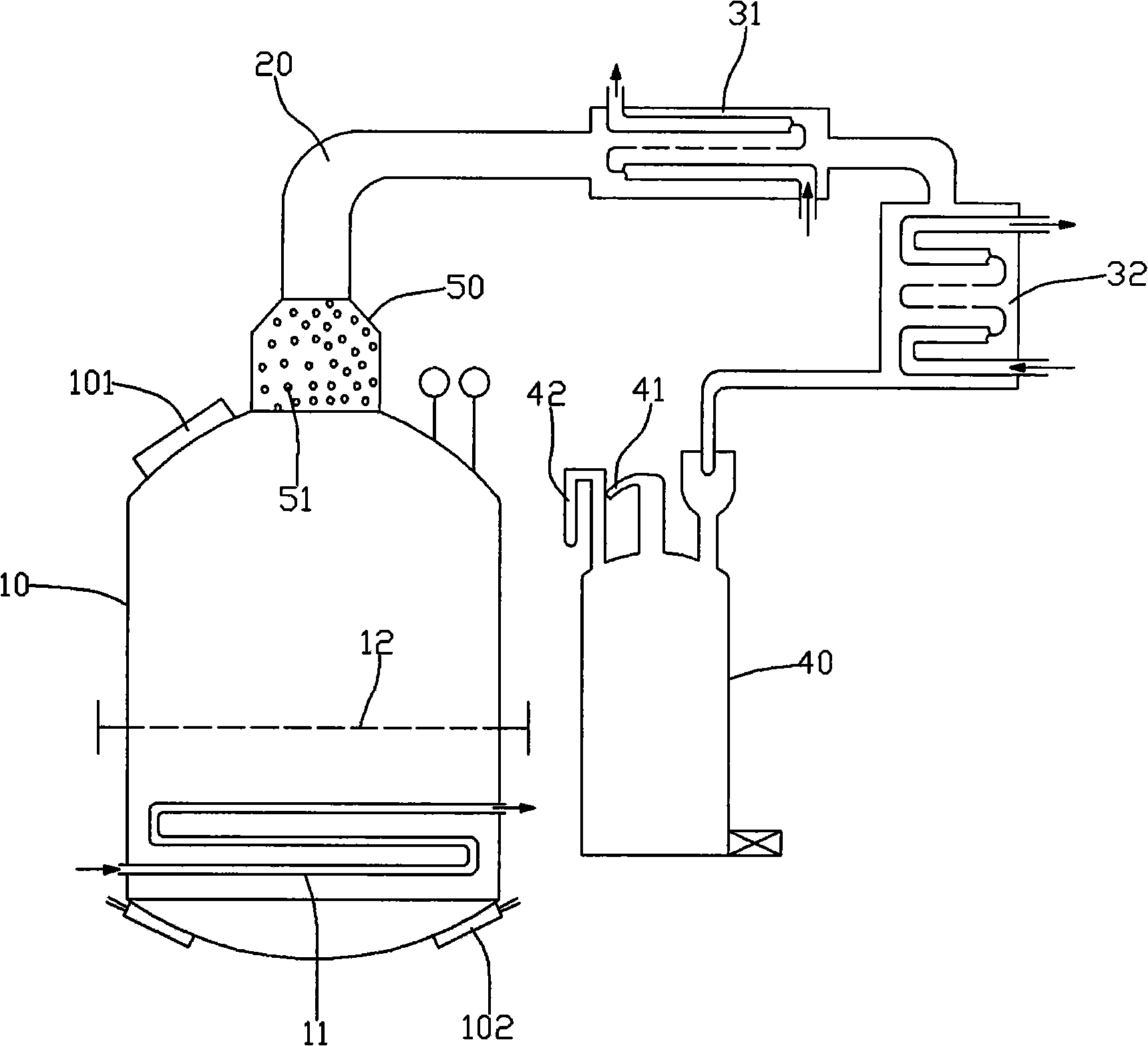

Rose essential oil and rose pure dew extraction equipment

InactiveCN101353611AAvoid direct accessInhibition of dissolutionEssential-oils/perfumesDistillationEngineering

The invention discloses extraction equipment for rose essential oil and rose hydrosol which mainly includes a distillation still, a steam conduit, a condenser and an oil-water separator, wherein, the distillation still is connected with the oil-water separator by the steam conduit and the condenser; the lower end of the interior of the distillation still is provided with a steam heating coil; and the upper part of the steam heating coil is provided with a transverse plate sieve which can be opened freely. An adsorption plant is arranged between the top of the distillation still and the steam conduit and internally filled with active ceramic rings serving as an absorbent. The extraction equipment of the invention has the advantages of simple operation, convenient use and high production efficiency, and can greatly enhance the quality of the rose essential oil and the rose hydrosol.

Owner:许向梅

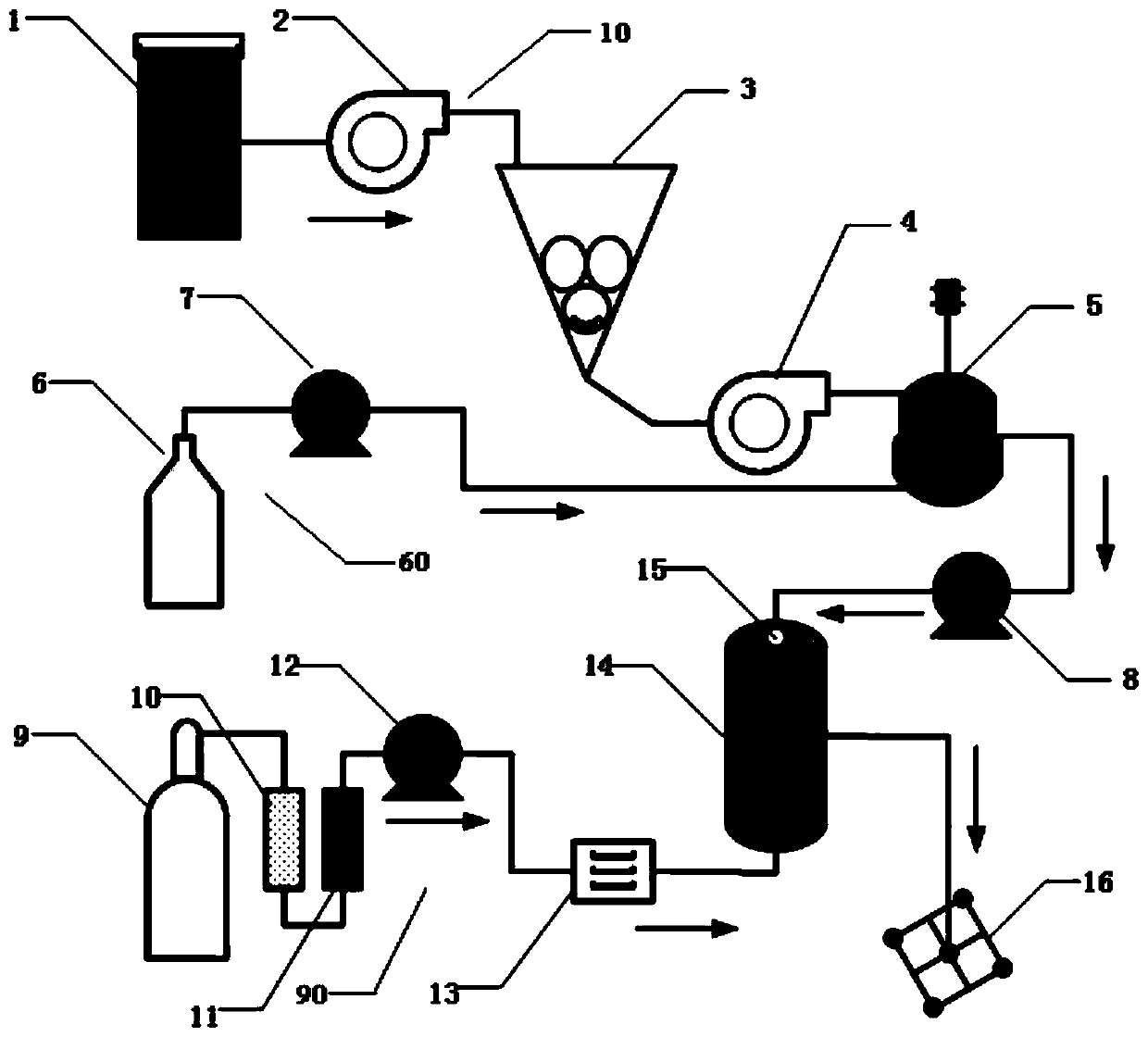

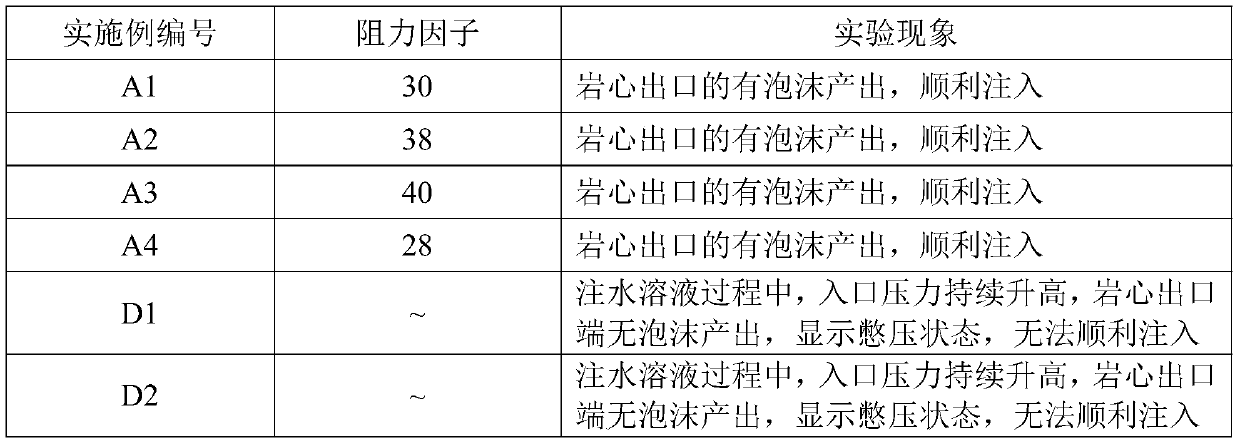

Fracturing fluid system of CO2 cleaning foam

The invention relates to a fracturing fluid system used in an oil and gas field, in particular to a fracturing fluid system of CO2 cleaning foam. The fracturing fluid system comprises the following components in percentage by weight: 0.3-0.8 percent of water-soluble hydrophobic association polymer, 0.25-0.55 percent of rheological auxiliary agent, 0.5-3.0 percent of clay stabilizer, 0.1-0.5 percent of foaming agent, 0.01-0.2 percent of gel breaker, 30.0-80.0 percent of liquid CO2 and the balance of water. Compared with the prior art, in the fracturing fluid system of the CO2 cleaning foam, a cross-linking agent is not needed, the foamability is good, the foam stability is high, the sand-carrying capability is strong, gel breaking is easy to control, no residue is generated after gel breaking, the superficial / interfacial tension of gel-breaking liquid is low, and the damage to the formation is less, and therefore, the fracturing fluid system can be used for fracturing modification of hypoisotonic, low-pressure and water-sensitive storage layers at the temperature of 60-140 DEG C.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

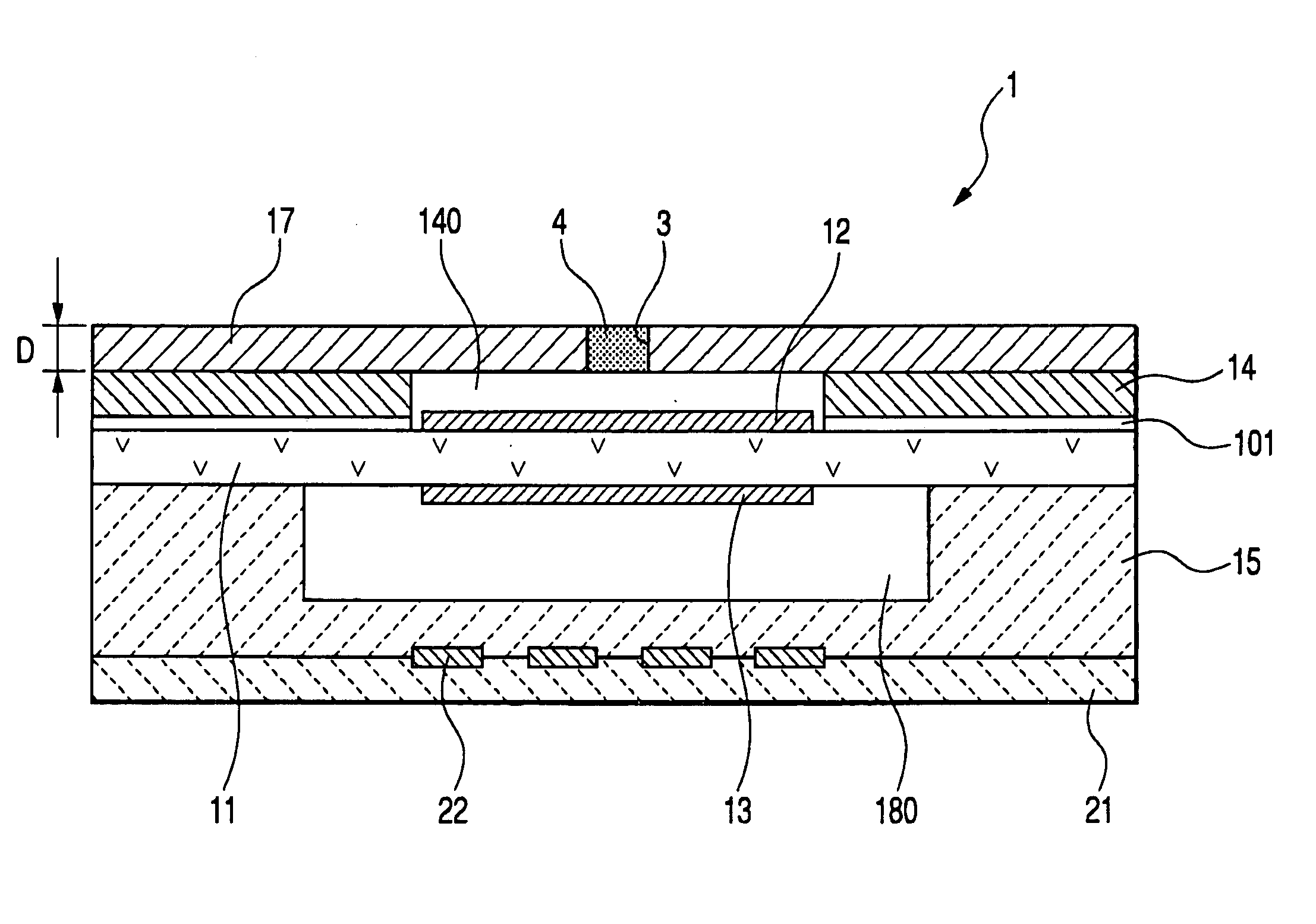

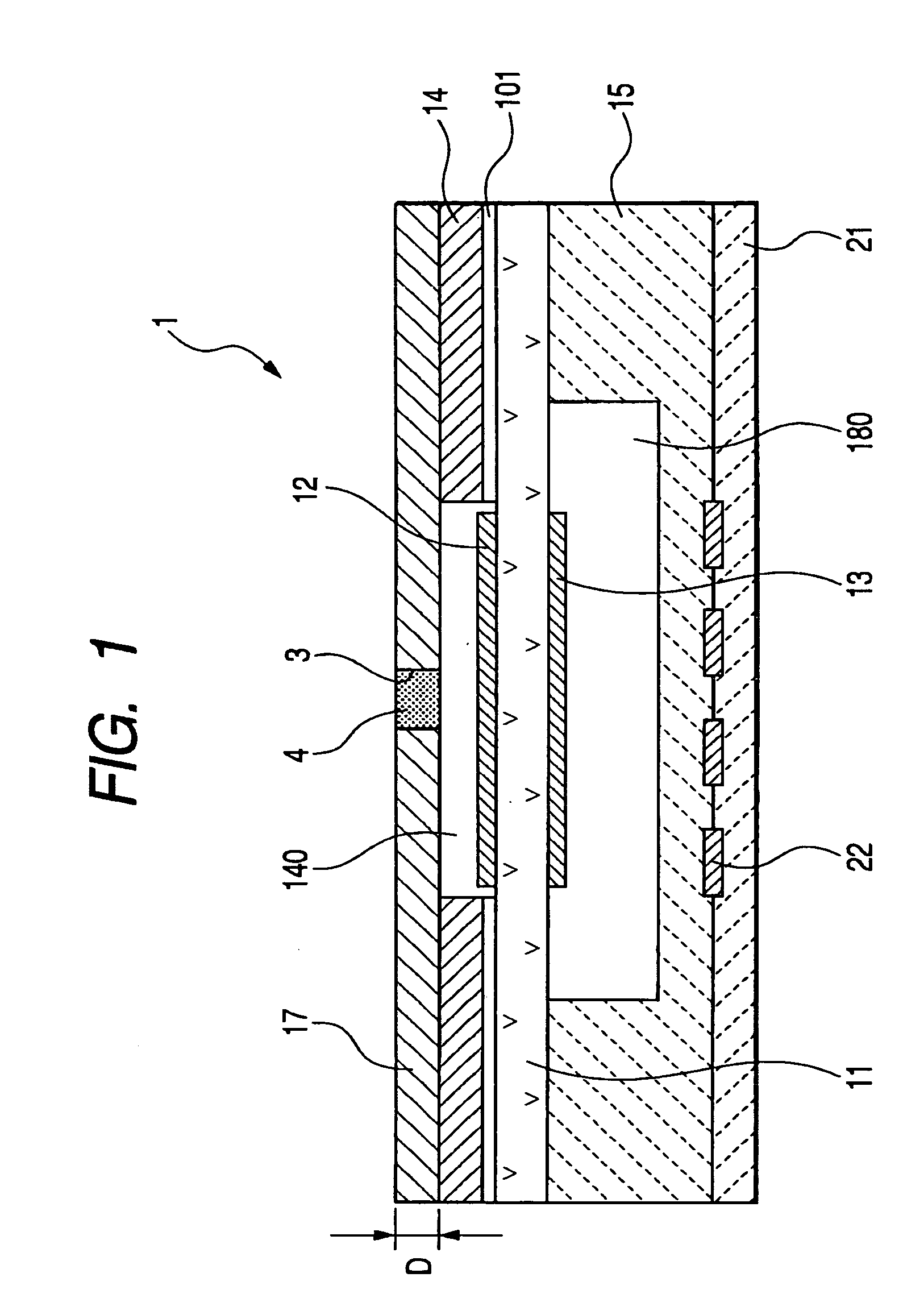

Gas sensing element

InactiveUS20050274615A1Reduce resistanceEasy dischargeMaterial electrochemical variablesElectricityOxygen ions

A gas sensing element includes a solid electrolyte body having oxygen ionic conductivity, a measured gas side electrode provided on one surface of the solid electrolyte body, and a reference gas side electrode provided on the other surface of the solid electrolyte body. The measured gas side electrode is positioned in a chamber space. The gas sensing element has an introducing hole connecting the chamber space to a measured gas atmosphere outside of the gas sensing element. The introducing hole is filled with a porous member having an average pore diameter of 2 to 30 μm.

Owner:DENSO CORP +1

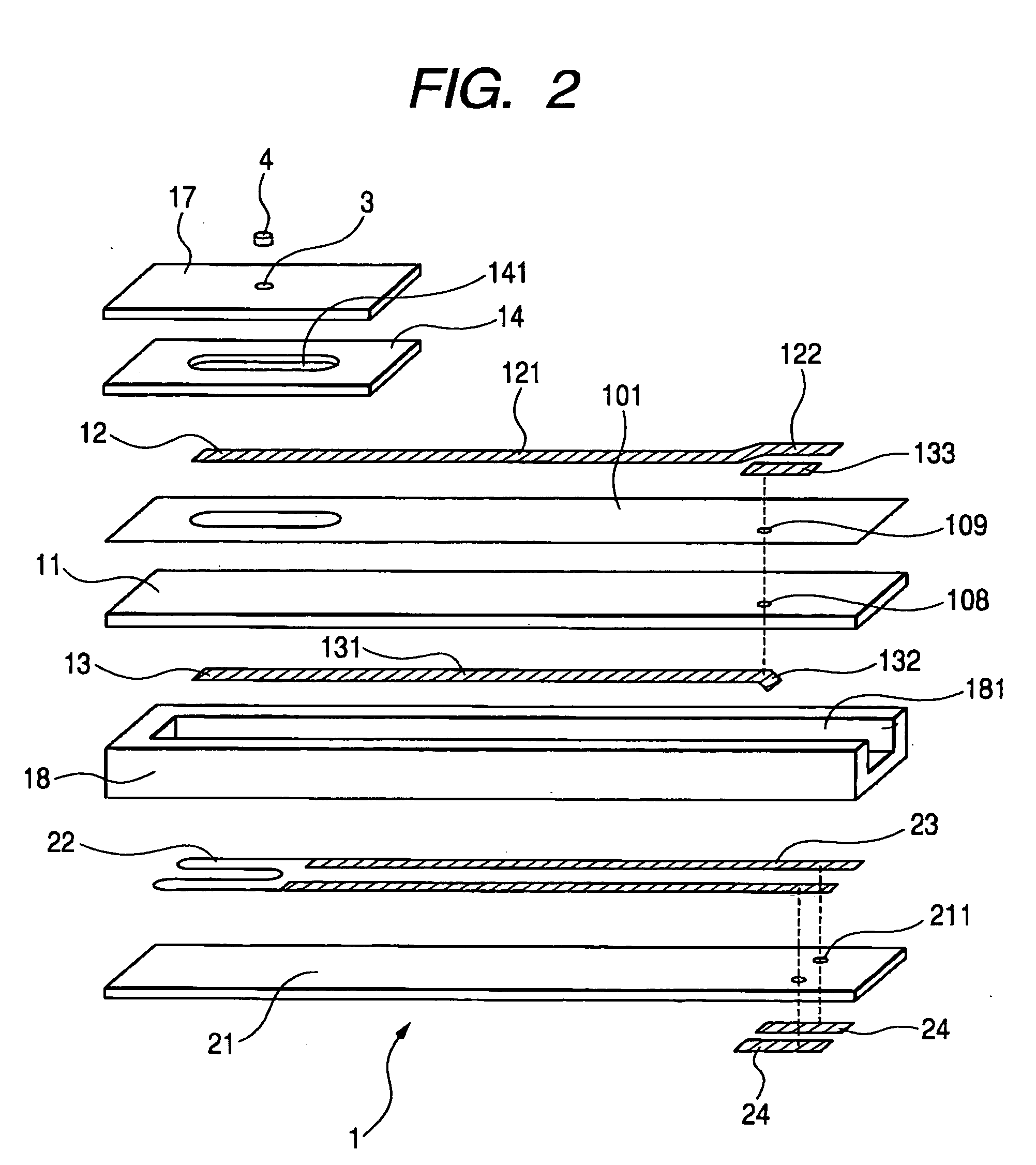

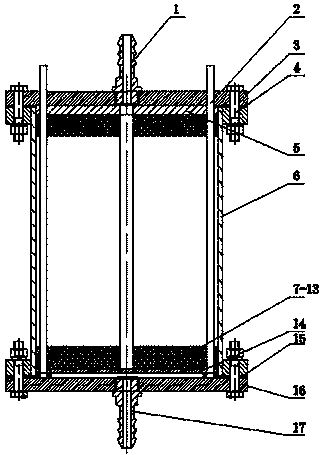

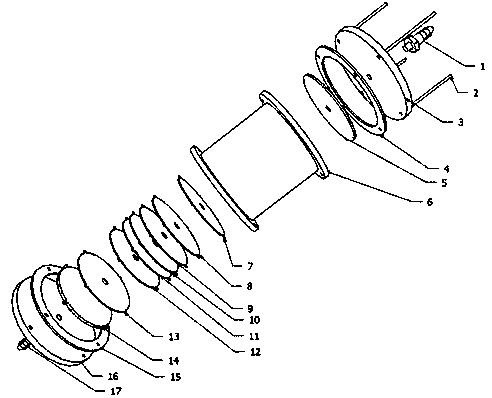

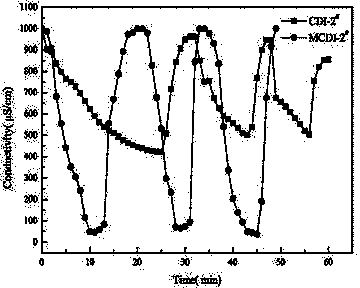

Continuous wastewater treatment device utilizing membrane capacitive deionization

ActiveCN103991937ALower resistanceLarge capacityDispersed particle separationWater/sewage treatment by ion-exchangeCapacitanceProcess module

The invention relates to a continuous wastewater treatment device utilizing membrane capacitive deionization. An upper cover plate and a lower cover plate are coaxially installed at the upper end and the lower end of a cylindrical shell, a water inlet nozzle and a water outlet nozzle which are communicated with the interior of the shell are respectively formed in the axis part of the upper cover plate and the axis part of the lower cover plate, a water collecting plate is coaxially installed on the upper cover plate in the shell, conducting rods are uniformly and axially distributed on the periphery of the shell at intervals, a lower distribution board and an upper distribution board are coaxially installed in the shell between the water collecting plate and a water distributing plate and are of a pair of metal boards, and a plurality of groups of processing module components are coaxially installed between the two distribution boards, wherein each group of processing module component comprises an upper current collecting plate, a membrane carbon positive electrode, a diaphragm, a membrane carbon negative electrode and a lower current collecting plate. According to the continuous wastewater treatment device, the membrane electrode is integral and is prepared by a carbon electrode and an ion membrane through spraying a cation exchange coating on a cathode and spraying an anion exchange coating on an anode, the thickness of the ion exchange layer is less than 10mu, and the membrane electrode has small resistance and large capacitance compared with those of a membrane electrode on which an ion membrane is directly added.

Owner:BEIJING HUA YAN BANG SCI & TECH +1

Preparation method of silanization-modified molecular sieve

ActiveCN104477933AReduce static and dynamic water adsorptionImprove hydrophobicityPentasil aluminosilicate zeoliteMolecular sieveNitrogen

The invention belongs to the field of synthesis and application of molecular sieves, and discloses a preparation method of a silanization-modified molecular sieve. The method comprises the following steps: transferring a molecular sieve subjected to acid-alkali alternate treatment, an accelerator and a silanization reagent dissolved in an organic solvent into a reactor, carrying out silanization modification on the molecular sieve in a nitrogen protective sealed environment under the conditions of certain temperature and high pressure, filtering, washing, and drying to obtain the silanization-modified molecular sieve. The preparation method disclosed by the invention can effectively enhance the silanization efficiency, does not have great influence on the pore structure of the molecular sieve, and has the advantages of low cost, simple technique and high silanization degree.

Owner:杭州富阳奥玛德科技有限公司

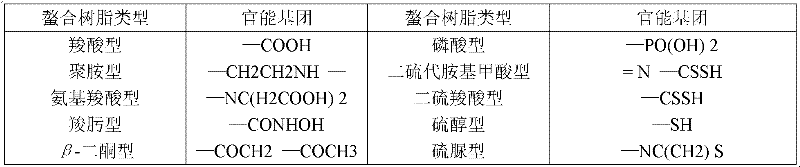

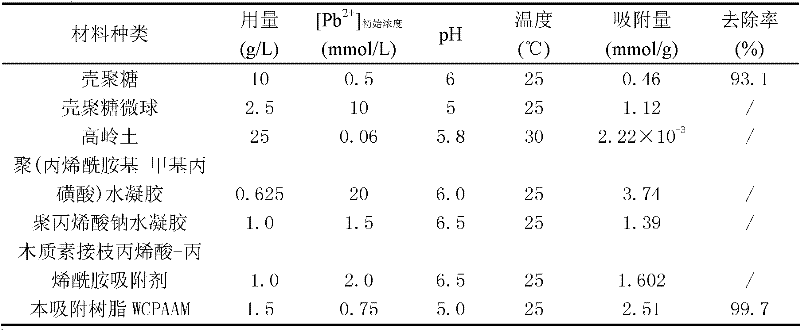

Heavy metal ion adsorption resin and preparation method thereof

InactiveCN102675540AHigh gel strengthAvoid dissolution lossOther chemical processesChemistryIon adsorption

The invention belongs to the technical field of preparation of functional high polymer materials, and particularly relates to a natural high polymer material modified adsorption resin for the adsorption of heavy metal ions and a preparation method for the adsorption resin. The heavy metal ion adsorption resin comprises the following components in percentage by weight: 10.0 to 15.0 percent of chitosan (Chit), 25.0 to 50.0 percent of acrylic acid (AA), 20 to 45 percent of acrylamide (AM), 0.1 to 0.4 percent of N,N-methylene-bisacrylamide (NMBA), 1.0 to 3.0 percent of potassium persulfate (KPS) and 0.0 to 15.0 percent of wood meal. By the heavy metal ion adsorption resin, Pb2+ can be efficiently adsorbed and separated, the cost of a chitosan modified adsorption resin can be lowered, adsorption capacity can be improved, the number of reuse times can be increased, and the adsorptive selectivity of the resin can be improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

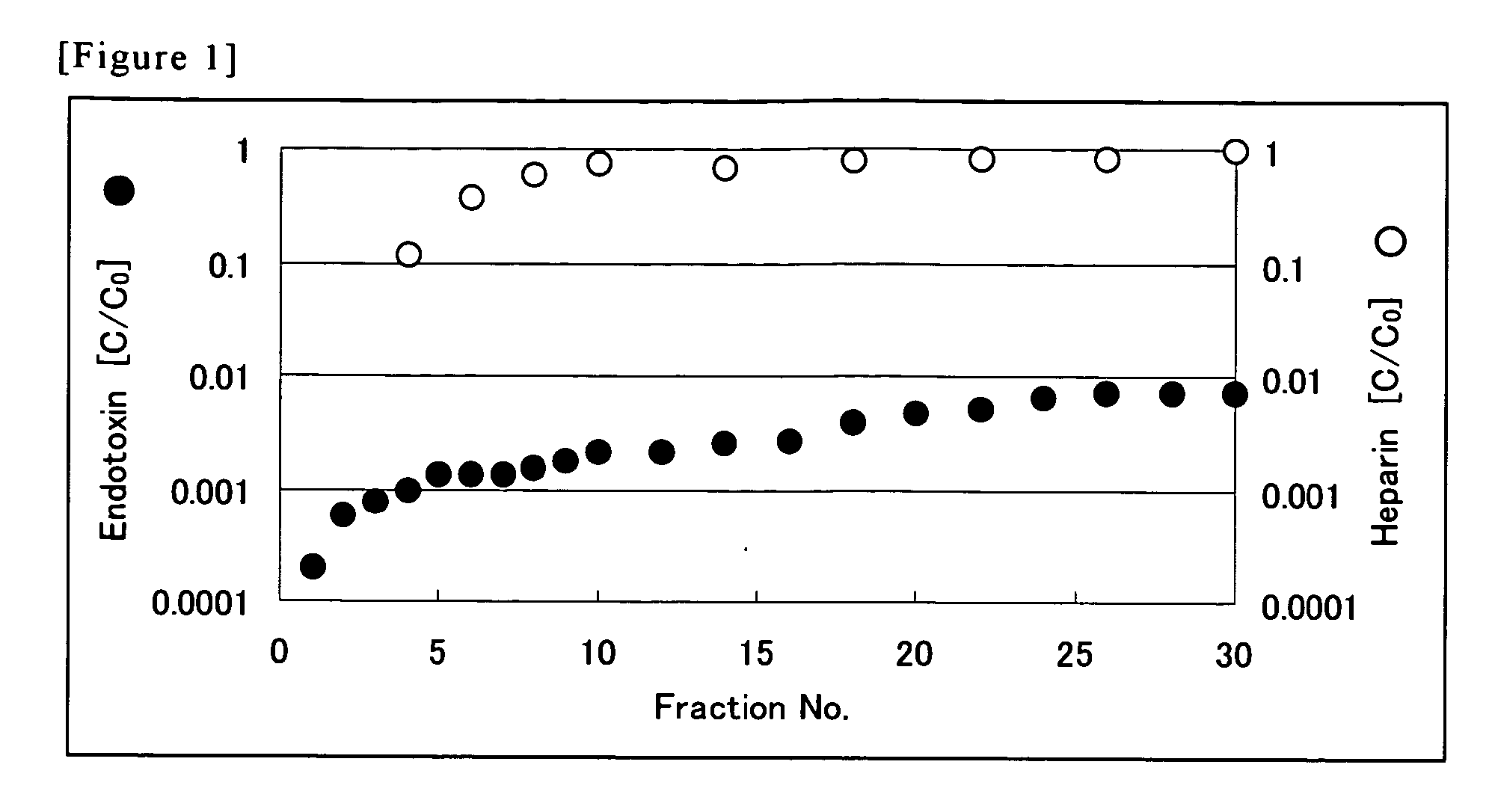

Endotoxin adsorbent, and method for removing endotoxin using the same

InactiveUS20070213258A1Decrease amount of adsorptionReduce the amount of adsorptionBiocideOrganic active ingredientsToxinEndotoxin removal

[OBJECT] The present invention provides a method for selecting and eliminating endotoxin selectively from a solution where a highly acidic substance such as heparin co-exists, and an adsorbent used therefor. [MEANS FOR SOLVING] The present invention also provides a method for providing the endotoxin adsorbent, which comprises partially modifying amino groups contained within an amino group-containing molecule used as a ligand of the endotoxin adsorbent, with a molecule that is capable of reacting with an amino group.

Owner:JNC CORP

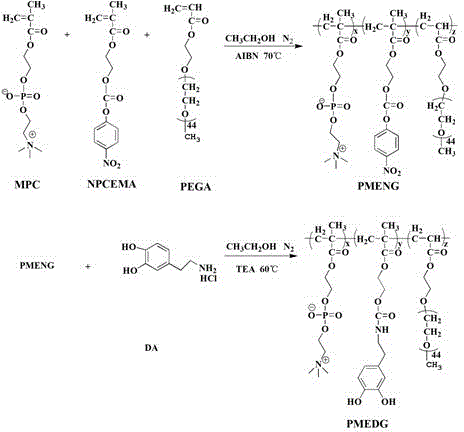

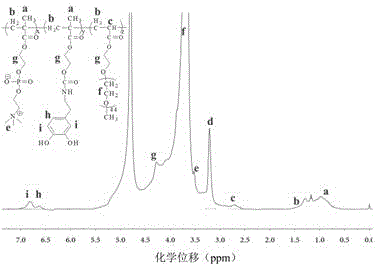

Functional polymer containing phosphorylcholine and PEG and method for forming anti-pollution coating with functional polymer

ActiveCN104610516AReduce the amount of adsorptionReduce adhesionAntifouling/underwater paintsPretreated surfacesPhosphorylcholineSide chain

The invention discloses a functional polymer containing phosphorylcholine and PEG and a method for forming a biological pollution resistant interface. The polymer is a functional polymer that contains multiple function groups on a side chain and has a controllable proportion; a PEG flexible chain with larger steric hindrance and outer cell membrane phosphorylcholine hydrophilic group interact to achieve good anti-pollution effect; the polymer contains less than 10% of catechol group, and can be strongly combined with surfaces of various polydopamine-mediated base materials to form a stable hydrophilic monomolecular coating, so that the functional modification of material surfaces is implemented. The method for forming coatings is simple; the coatings can exist on the surface of any base material, so that the ability of resisting adhesion and pollution of multiple biological ingredients of the material surface is improved.

Owner:NORTHWEST UNIV(CN)

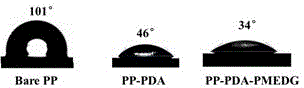

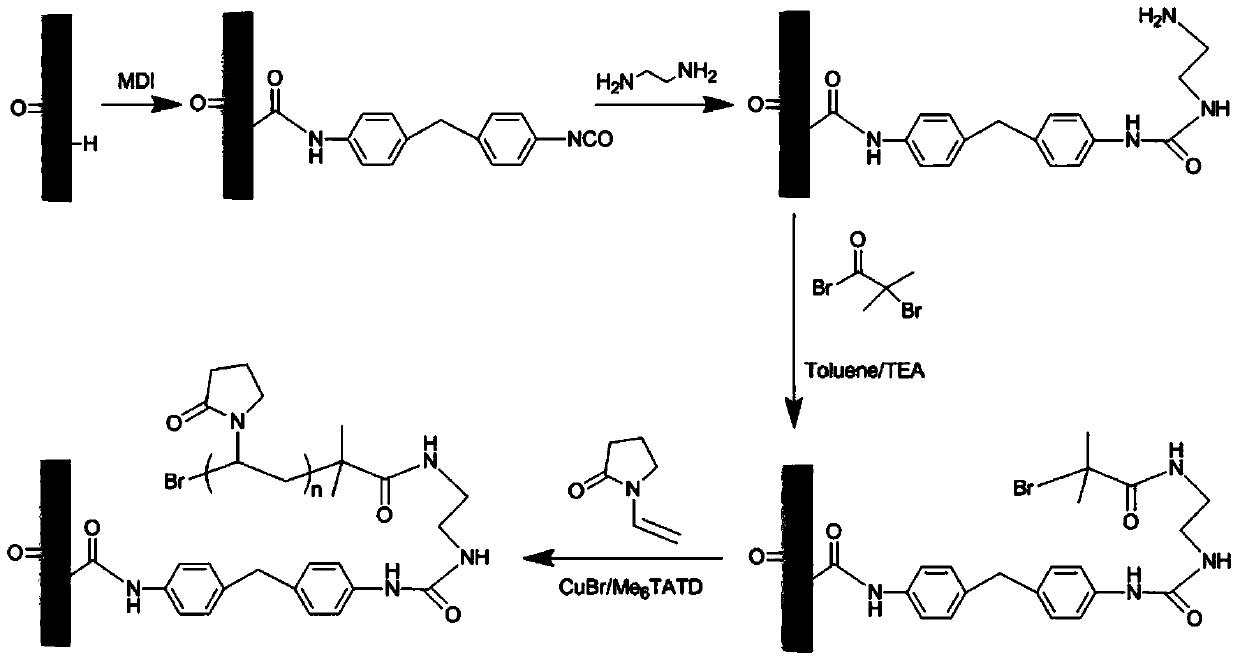

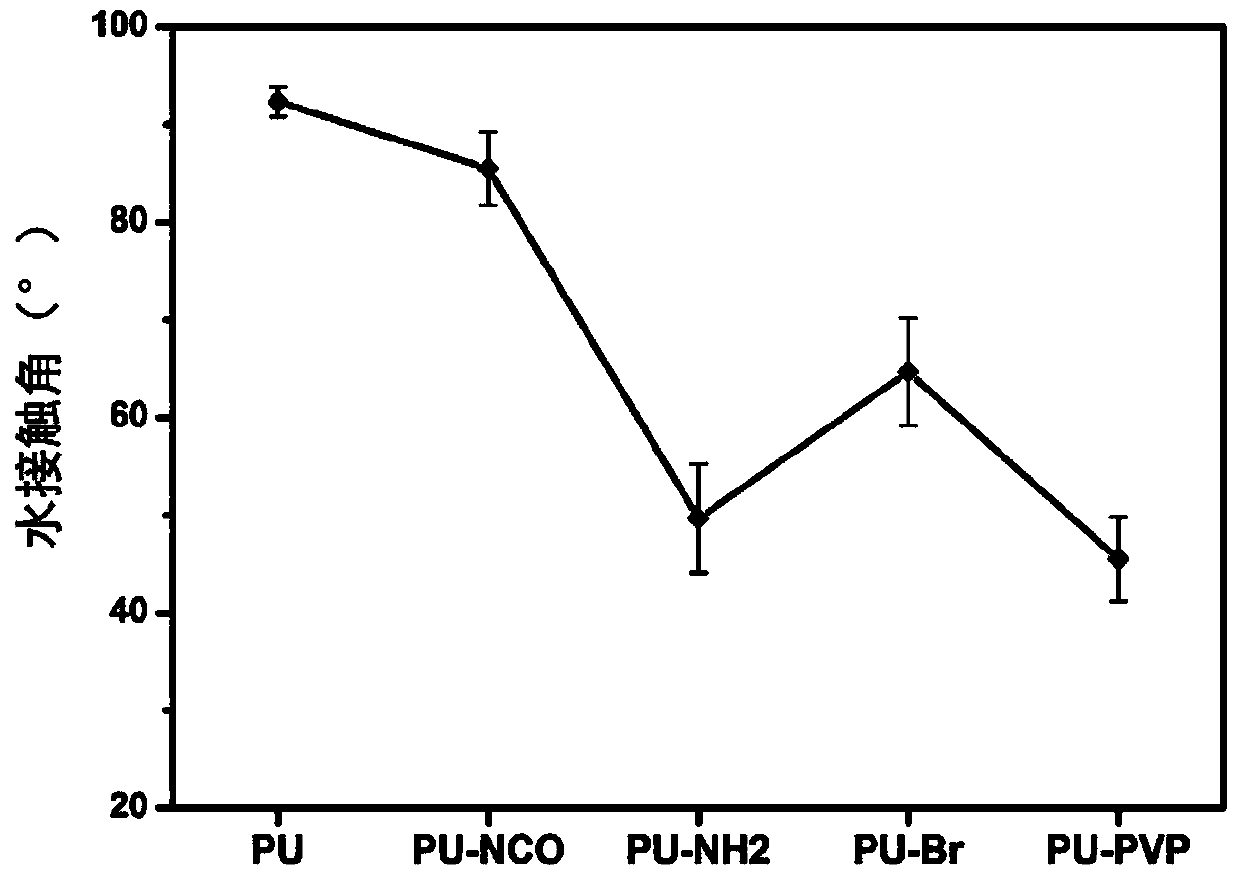

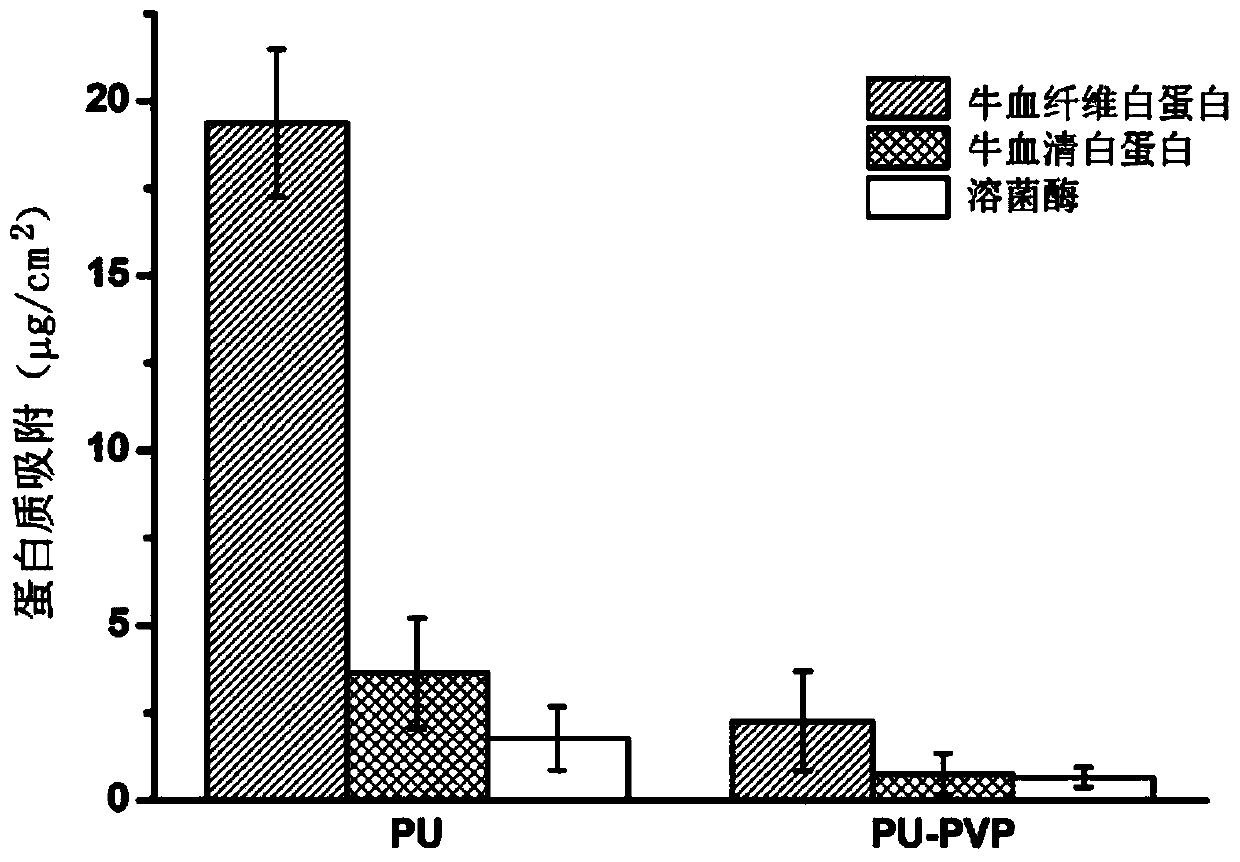

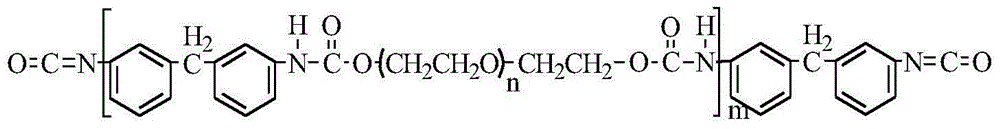

Polyurethane material with protein adsorption resistance and cell adhesion resistance and preparing method thereof

ActiveCN104262668AImprove hydrophilicityAnti-protein non-specific adsorption functionCatheterFiberCell adhesion

The invention relates to a polyurethane material with protein adsorption resistance and cell adhesion resistance and a preparing method thereof. The material comprises a substrate and a modification layer. The substrate is made of polyurethane. The modification layer is obtained by polymerizing a vinyl pyrrolidone monomer on the surface of the substrate by utilization of an atom transfer radical polymerization technology. The material is prepared by steps of: subjecting the polyurethane to isocyanic acid esterification, performing amination, fixing a bromine initiator, and initiating graft polymerization of the vinyl pyrrolidone on the surface of the material. The surface of the polyurethane material prepared by the method has good hydrophilicity, good resistance to bovine serum fibrinogen adsorption, bovine serum albumin adsorption and lysozyme adsorption, and a function of resisting cell adhesion of mouse fibroblast cells (L-929), so that the polyurethane material is suitable for preparing biomedical catheter materials with complex shape structures.

Owner:EAST CHINA UNIV OF SCI & TECH

Special effect boron adsorption resin and synthetic method and application thereof

InactiveCN102336856AReduce the amount of adsorptionOther chemical processesAlkali metal oxides/hydroxidesSpecial effectsIsopropylene glycol

The invention relates to a special effect boron adsorption resin and a synthetic method and application thereof, belonging to the fields of high molecules and waste water treatment. The general structural formula of the resin is shown in the specifications, wherein n=1,000-2,000. The method comprises the following steps of: (1) preparing 2-amino-1,3-propylene glycol; (2) preparing chloromethylated styrene-divinylbenzene copolymerized spheres; and (3) preparing the special effect boron adsorption resin from the 2-amino-1,3-propylene glycol and the chloromethylated styrene-divinylbenzene copolymerized spheres. The special effect boron adsorption resin can be used for extracting and recovering boric acid from an acid aqueous solution. In the invention, the special effect boron adsorption resin which is suitable for a strongly acid environment is synthesized by taking 1,3-propylene glycol as a functional group.

Owner:CHANGZHOU UNIV

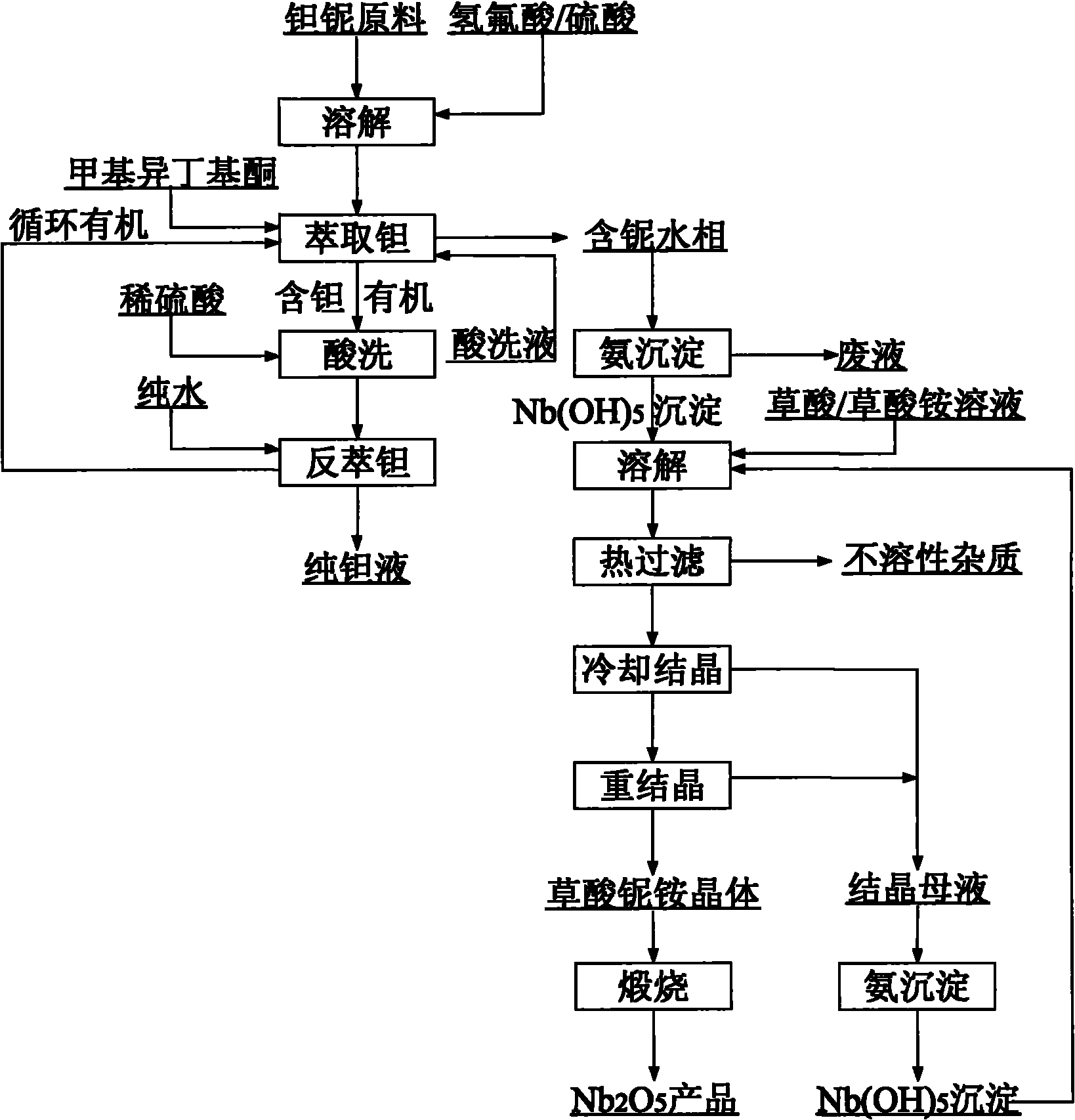

Method for separating tantalum and niobium

InactiveCN101955228AReduce concentrationReduce productionTantalum compoundsNiobium compoundsCoordination complexAmmonium oxalate

The invention relates to a method for separating tantalum and niobium from a raw material containing the tantalum and the niobium, comprising the following steps: dissolving the raw material containing the tantalum and the niobium by utilizing hydrofluoric acid or the mixing solution of the hydrofluoric acid and sulfuric acid to obtain the solution containing tantalum and niobium fluorine coordination compounds; extracting the tantalum by utilizing methyl isobutyl ketone to obtain a tantalum-containing organic phase and a niobium-containing aqueous phase; washing the tantalum-containing organic phase by dilute sulphuric acid, and performing back-extracting by pure water to obtain the pure tantalum liquid; precipitating the niobium-containing aqueous phase to obtain the Nb (OH)5 precipitation; dissolving the obtained Nb (OH)5 precipitation by utilizing an oxalic acid and ammonium oxalate mixing solution to obtain an oxalic acid niobium ammonium solution; carrying out hot filtering, crystallizing, and recrystallizing process to obtain the oxalic acid niobium ammonium crystal; and calcining the crystal to obtain the pure niobium pentaoxide. The method can realize extraction and separation of the tantalum and the niobium at low hydrofluoric acid concentration, and solves the problems that a large amount of fluorine-containing waste liquid and waste residue are generated in the extracting and separating process at the high hydrofluoric acid concentration, and F content in the final product is higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

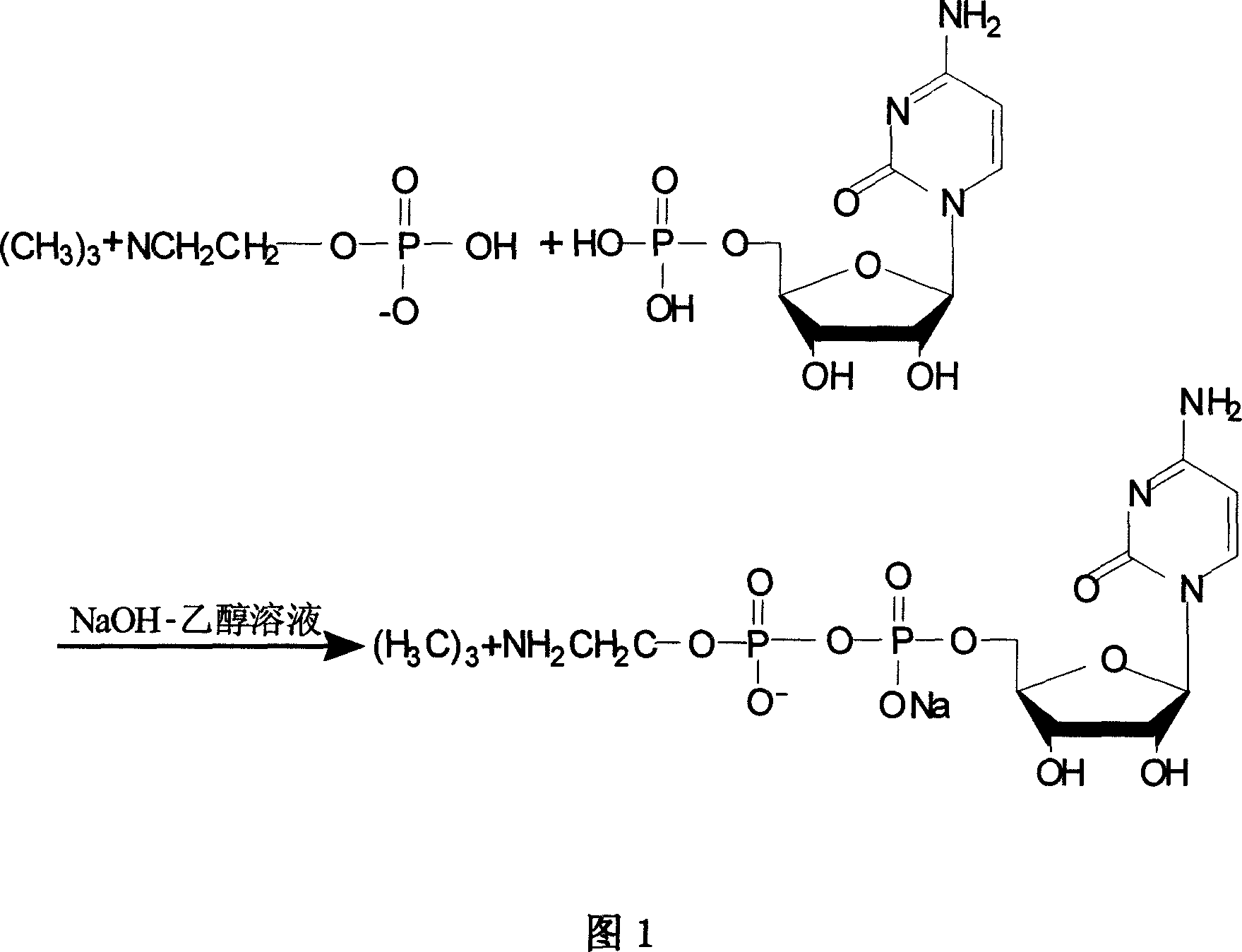

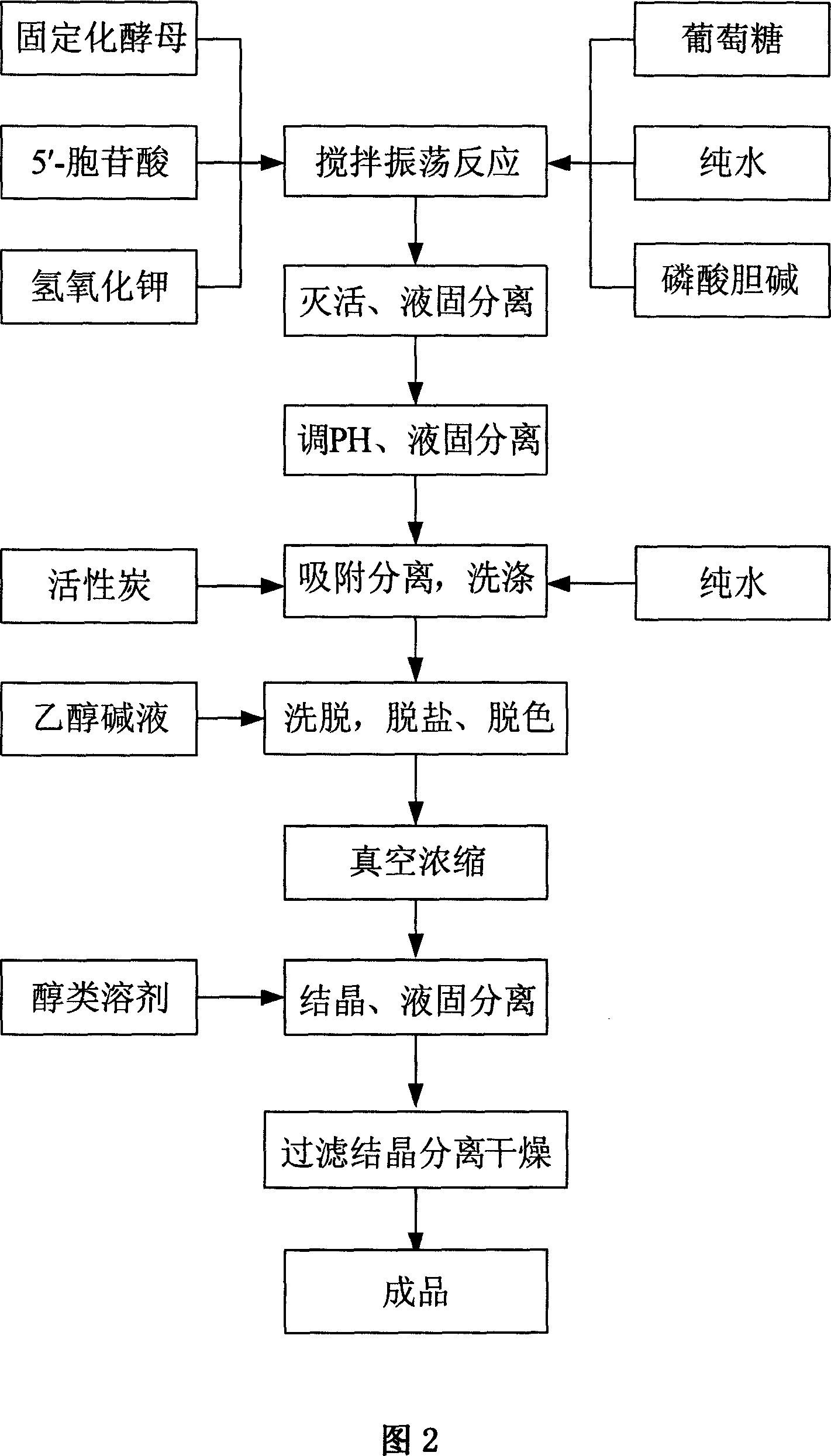

Process for preparing citicoline sodium

The present invention is process of preparing citicoline sodium. The preparation process includes the biotransformation of material including 5'-cytidylate, phosphorylcholine, potassium hydroxide and glucose with yeast as the biocatalyst; extraction and separation with active carbon as the adsorbing carrier, Cl- type ion exchange resin as the separating carrier and re-compounded water-alcohol mixture as the analyzing reagent; and product purification with alcohol solvent as the crystallizing solvent. Compared with available technology, the present invention has the advantages of high product yield and high product purity.

Owner:苏州正济药业有限公司

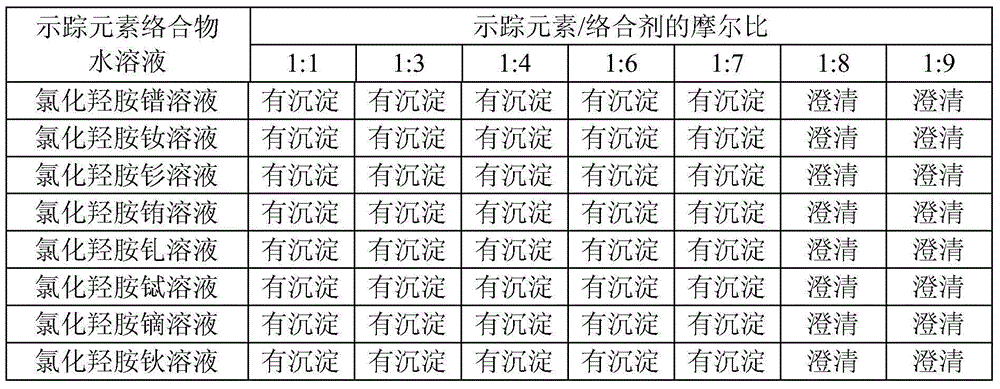

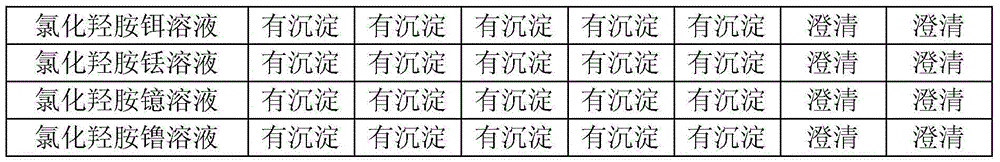

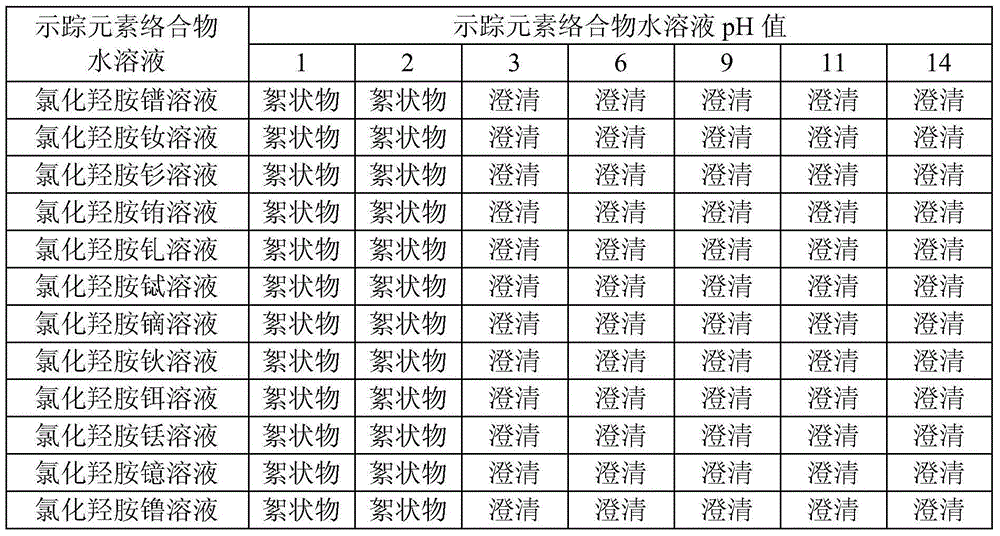

Tracer for monitoring multistage fracturing flow-back fluid and monitoring method

The invention provides a tracer for monitoring multistage fracturing flow-back fluid and a monitoring method. The tracer comprises twelve tracer element complex water solution formed by respectively mixing twelve tracer elements with complexing agents, the twelve tracer elements include praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium. The monitoring method is a method for monitoring the multistage fracturing flow-back fluid by the aid of the tracer. The tracer is fine in compatibility with fracturing fluid, small in formation adsorption quantity, fine in stability and high in analytical precision, the twelve tracer elements are not mutually interfered, and the fracturing flow-back fluid in layers in the multistage fracturing process of an oilfield can be monitored.

Owner:PETROCHINA CO LTD

Mesoporous adsorbent resin with uniform pore size and large specific surface area and preparation method and application thereof

InactiveCN102600810ALarge specific surface areaExcellent adsorption kinetic propertiesOther chemical processesSolid sorbent liquid separationBenzoyl peroxideDivinylbenzene

The invention relates to mesoporous adsorbent resin with a uniform pore size and a large specific surface area, which has a brown spherical structure. The particle size is 0.3-1.0mm, and the pore size is 5-10nm. The preparation method comprises the steps of: dissolving polyvinyl alcohol in water to prepare an aqueous phase; mixing benzoyl peroxide as an initiator, a total monomer phase made via mixing of styrene and divinylbenzene as a crosslinking agent, a pore making agent with mixture of methyl cyclohexane and toluene to prepare an oil phase; and adding the aqueous phase into the oil phase to prepare matrix resin; adding xylene dichloride (XDC) and ferric chloride for reaction after swelling, filtering to obtain resin, cleaning and drying to obtain the target product. The invention has the advantages that: the specific surface area of the adsorbent resin is large, the pore size is concentrated in the mesoporous area, resin holes are distributed uniformly and have the single peak characteristics, the capacity for adsorption of relatively large dye molecules is high, and the equilibrium of adsorption can be achieved faster. The process of the preparation method is simple, the cost is low, and the preparation method has broad prospects for application in dye wastewater treatment.

Owner:NANKAI UNIV

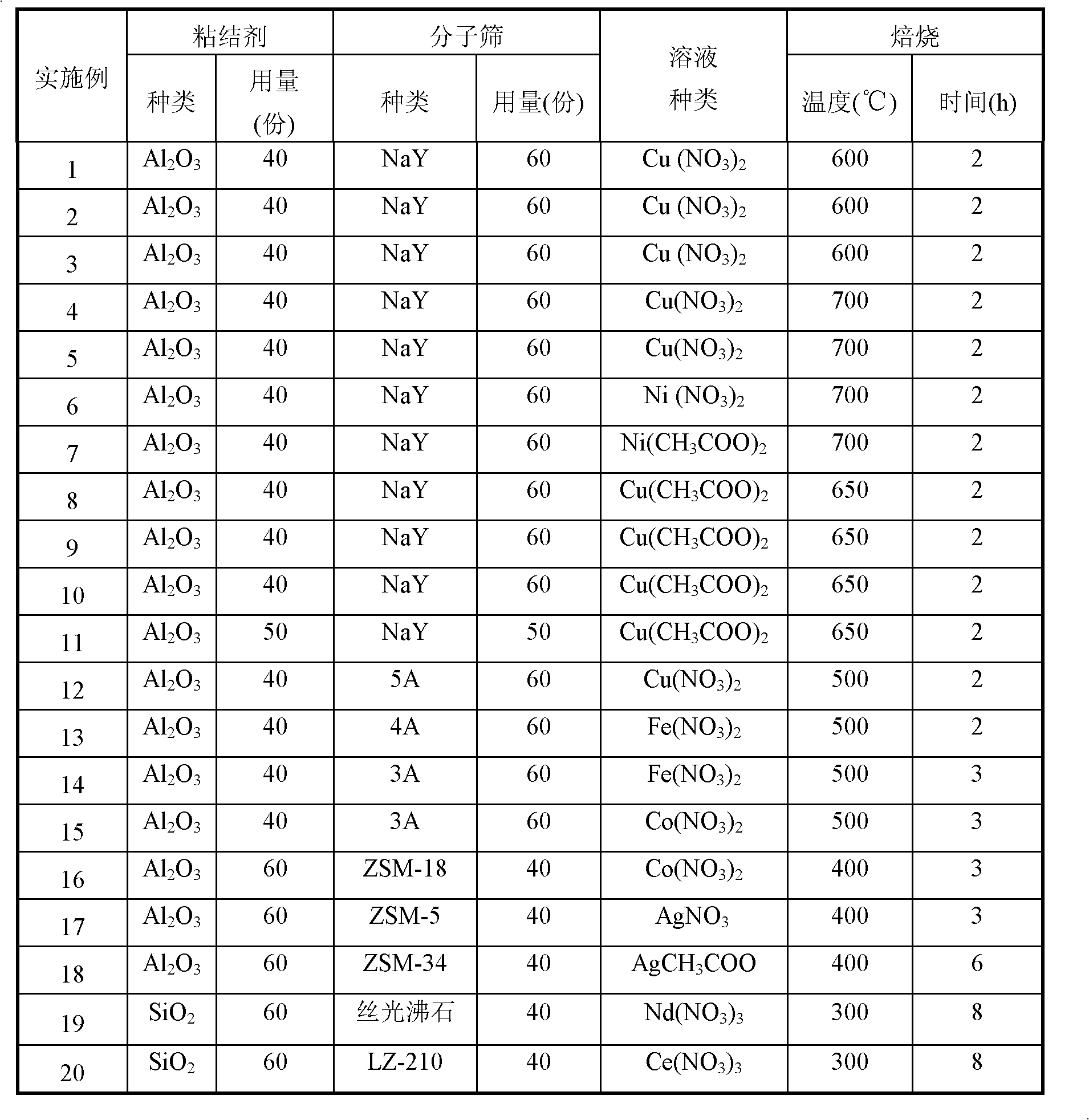

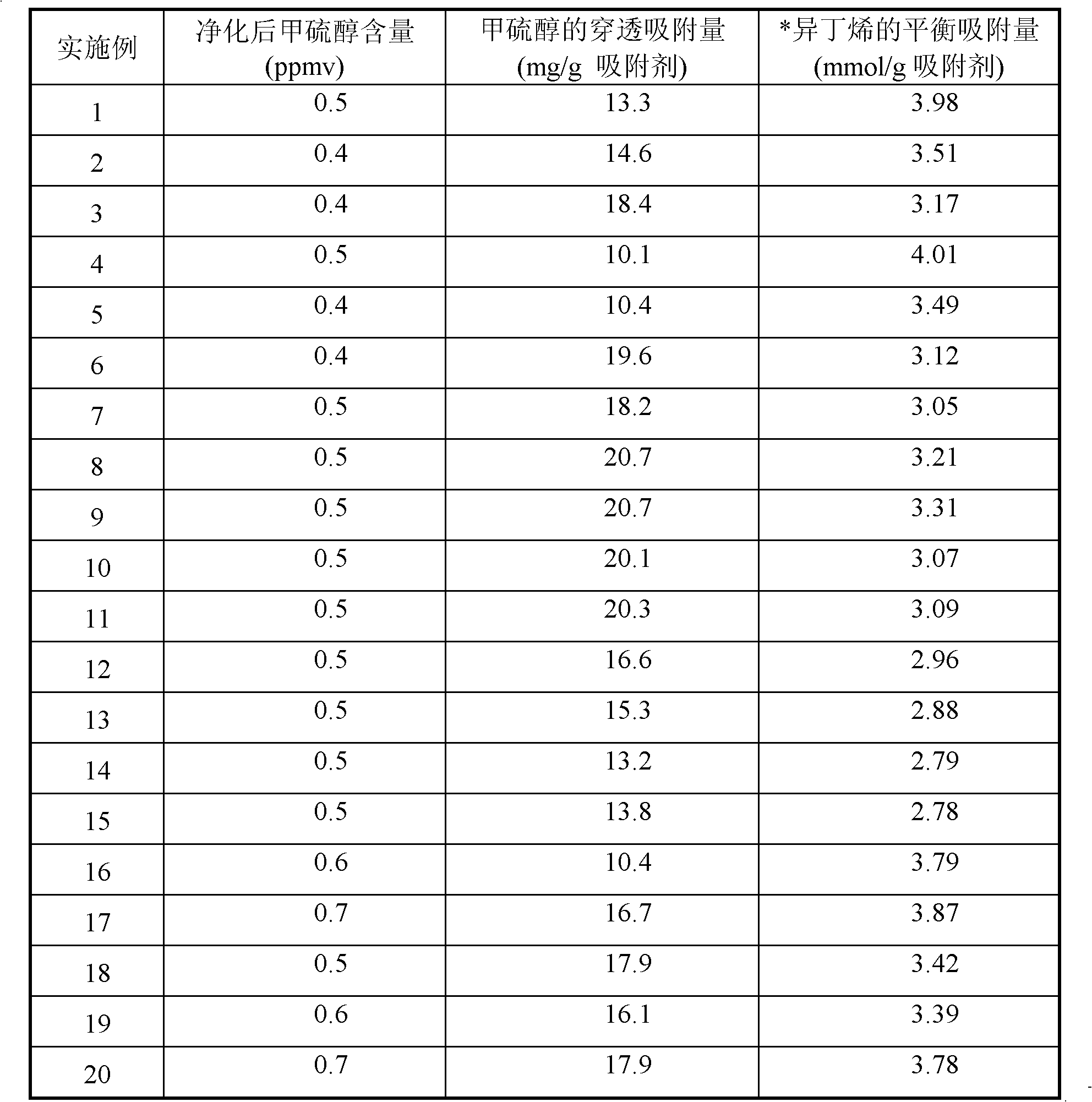

Solid desulfuration adsorbent and preparation method and application thereof

ActiveCN103120929AIncreased breakthrough adsorption capacityLow Equilibrium Adsorption CapacityOther chemical processesAdsorption purification/separationSorbentAdhesive

The invention relates to solid desulfuration adsorbent and a preparation method and application thereof and mainly solves the problems of low adsorptive purification depth, low sulfur capacity and poor desulfuration selectivity in the prior art. The solid desulfuration adsorbent comprises, by weight, 20-80 parts of at least one adhesive of aluminum oxide or silicon oxide, and 20-80 parts of ion-exchange-modified molecular sieve. The ion-exchange-modified molecular sieve comprises, by weight, 1-20 parts of at least one metal cation of Ag+, Fe2+, Co2+,Ni2+, Cu2+, Zn2+, Nd3+, Ce3+ or Ga3+, and 80-99 parts of at least one A-type, X-type, Y-type, L-type, mordenite, ZSM zeolite, Al-MCM-41 or beta molecular sieves. The problem is solved well by the application of the technical scheme. The solid desulfuration adsorbent is applicable to industrial adsorptive purification of removing silicon compounds in various alkene materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-activity mud adsorbent and its production

InactiveCN1981921ALarge adsorption capacityReduce the amount of adsorptionOther chemical processesSilicon compoundsWater bathsRed mud

A high-activity red mud adsorbent used for treating the P contained sewage is prepared from the red mud rejected in preparing alumina through proportionally mixing it with acid solution, heating by water bath while reacting to generate solid product, water washing, filtering and baking. It has high adsorptive volume.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

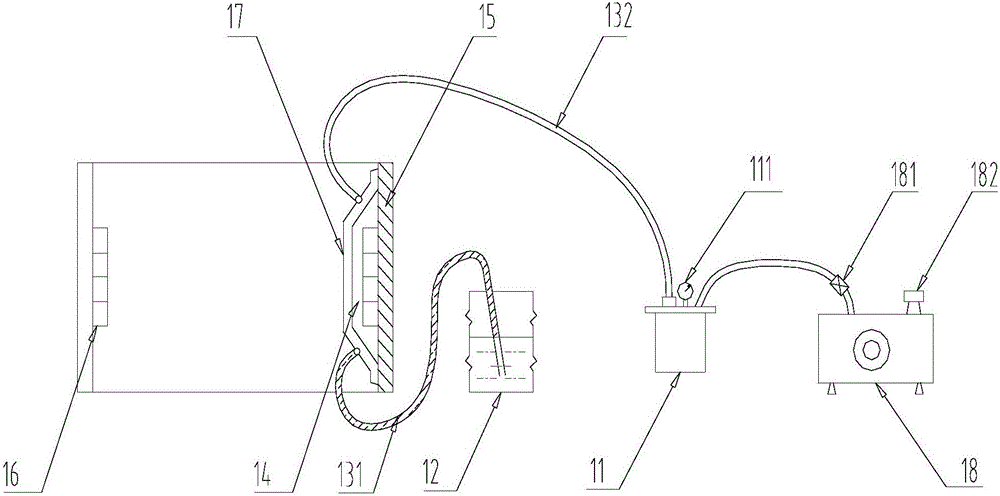

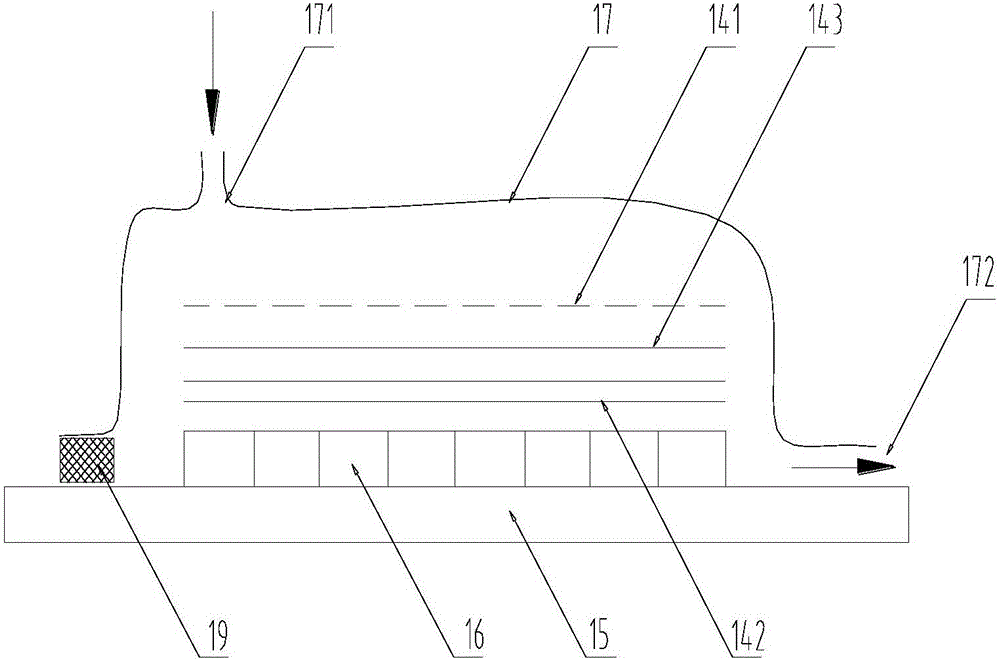

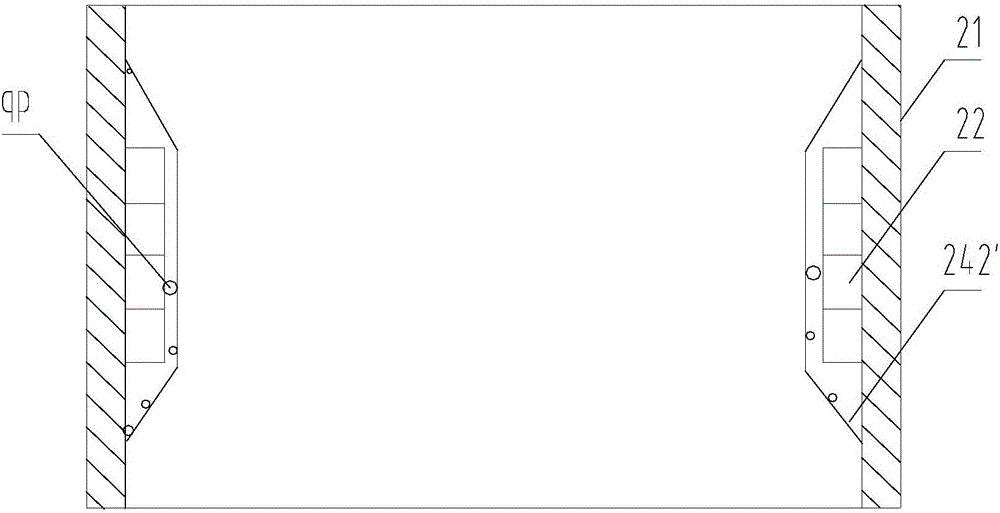

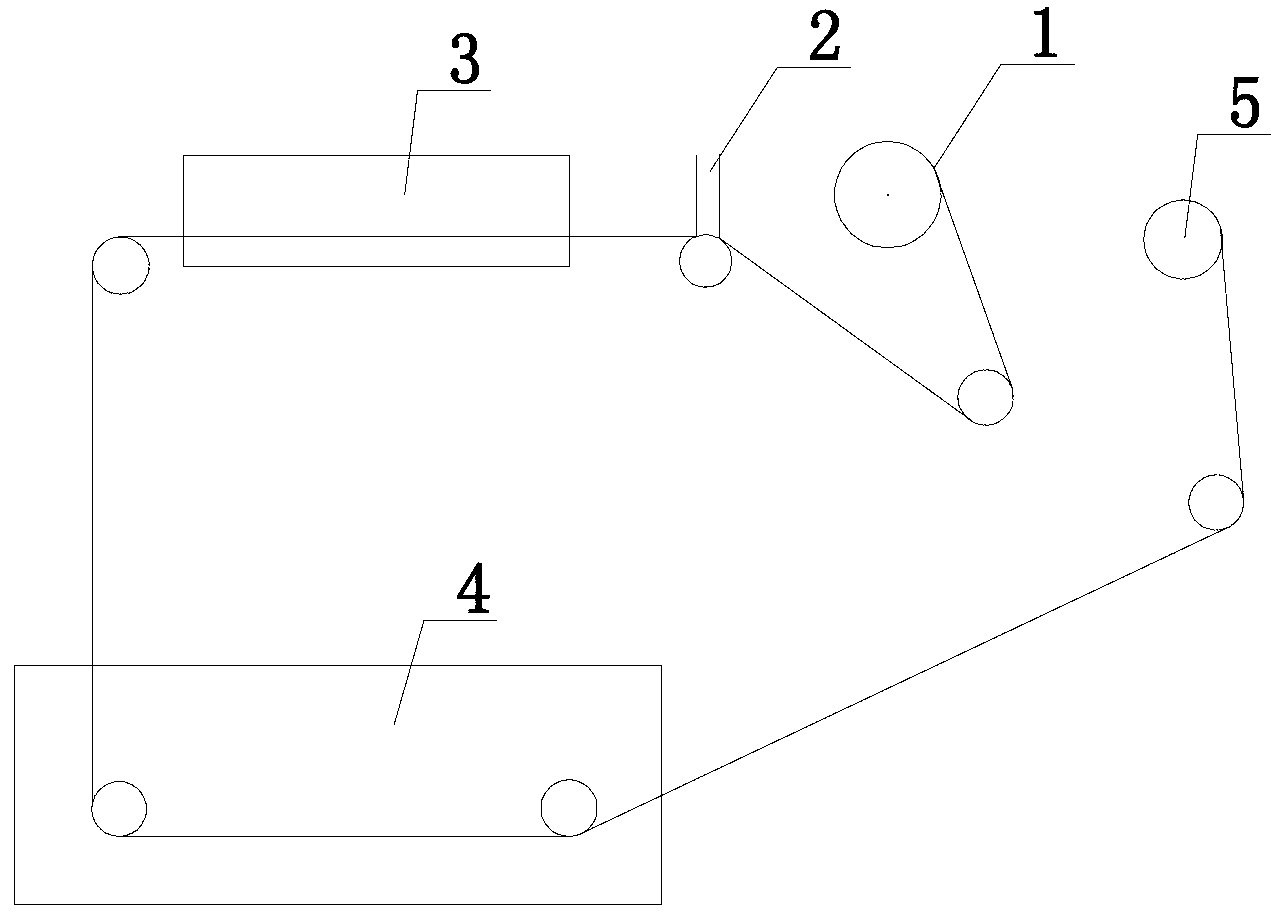

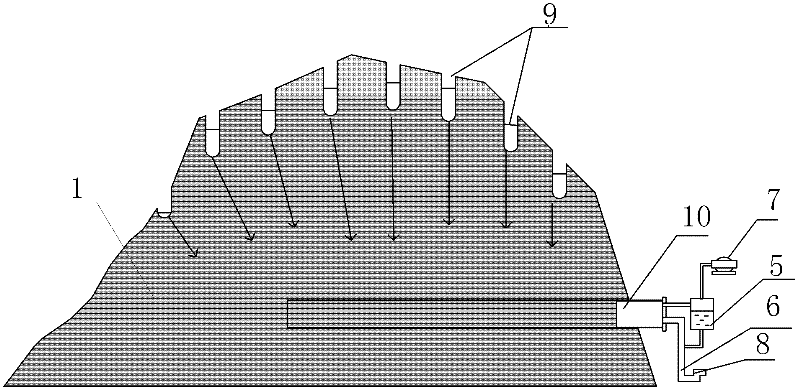

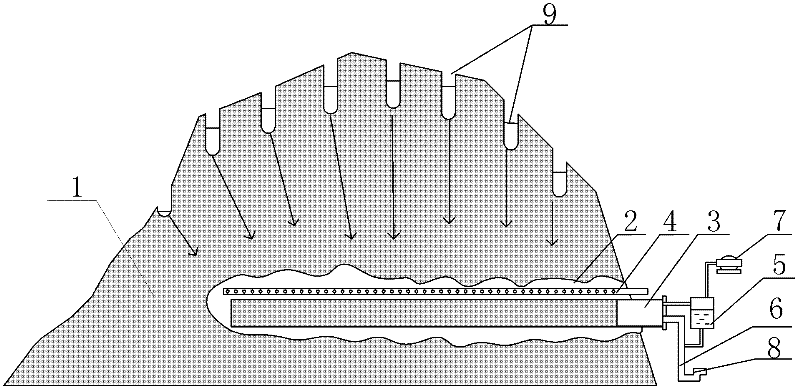

Magnetic pole protective layer flexible molding process and system

ActiveCN106426978AReduce hole positionExcellent impregnationManufacturing stator/rotor bodiesDomestic articlesMagnetic polesUltrasonic vibration

The invention discloses a magnetic pole protective layer flexible molding process and system; the process comprises: fitting magnet steel to corresponding position of one side wall of a magnet yoke, applying reinforcing material and a vacuum bag sequentially to the sidewall of the magnet steel and magnet yoke, such that the vacuum bag, along with the sidewall of the magnet steel and magnet yoke, forms a closed system; impregnating, to be specific, evacuating the closed system to inject an impregnating liquid to the closed system to implement wetting and impregnating; heating and / or transmitting ultrasonic to the closed system during impregnating; after impregnating, carrying out curing, to be specific curing the impregnating liquid to form a protective layer. By heating, it is possible to reduce the angle of contact; by ultrasonic vibration, mechanical wave is transmitted to the impregnating liquid; both facilitates full wetting and impregnating of the impregnating liquid; therefore, holes in the formed protective layer are decreased.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Preparation method of low-pressure high-flux nanofiltration membrane

InactiveCN103055726AStrong anti-pollutionImprove separation efficiencySemi-permeable membranesOrganic solventFoaming agent

The invention belongs to the technical field of membrane separation, and particularly relates to a preparation method of a low-pressure high-flux nanofiltration membrane. The method comprises the steps of pouring a certain amount of mould liquid into a trough, wherein the mould liquid contains polyether sulfone, a pore-foaming agent and an organic solvent; a non-woven fabric passes through the trough under the drive of a motor, the mould liquid is scraped onto the non-woven fabric through controlling a scraper in the trough, the relative humidity of a membrane room is 45-50%, and the temperature of the membrane room is 25-30 DEG C; then enabling the mould liquid to pass through a dryer with the temperature of 80-100 DEG C, evaporating a solvent for 0.2-2min in the dryer, and finally solidifying into a membrane through a gel trough, wherein the evaporating of the solvent and the solidifying into membrane are automatically and continuously carried out. The membrane prepared by adopting the preparation method has the advantages of strong anti-pollution capacity, high separating efficiency and large water flux, and can be used for concentrating and desalting of dye in industry.

Owner:LISHUI UNIV

Method for extracting general flavone from herba desmodii styracifolii

InactiveCN102232993AReduce distractionsIncrease throughputNervous disorderUrinary disorderAlcoholUltrafiltration

The invention relates to a method for extracting general flavone from herba desmodii styracifolii, in particular to a preparation process for extracting the purified general flavone from the herba desmodii styracifolii. The method comprises the following process steps of: taking herba desmodii styracifolii medicinal materials, adding low-carbon alcohols into the herba desmodii styracifolii medicinal materials for reflowing and extracting; condensing an extraction solution to be small volume; standing and removing precipitation; removing water-soluble macromolecules by using an ultrafiltration membrane; feeding macroporous resin and adsorbing; and eluting with an alcohol solution and collecting the general flavone of the herba desmodii styracifoli. The method has the advantages of simpleness in operation, low requirement for equipment, higher purity of the obtained product, and the like.

Owner:NANJING ZELANG MEDICAL TECH

Foaming agent and acidic cross-linking foam breakdown fluid

The invention relates to a novel fracturing fluid of foaming agent and acidic cross bonding foams for fracturing, wherein the foaming agent comprises ampholytic surface active agent e.g. alkyl dimethyl acetate, anionic surface active agent e.g. alkyl sodium sulfonate and low molecular alcohol e.g. ethanol, it solves the problems of poor foamability and difficult acidic coupling of the single component foaming agent, thus is a foaming agent and fracturing fluid architecture suitable for oil field CO2 foam fracturing.

Owner:PETROCHINA CO LTD

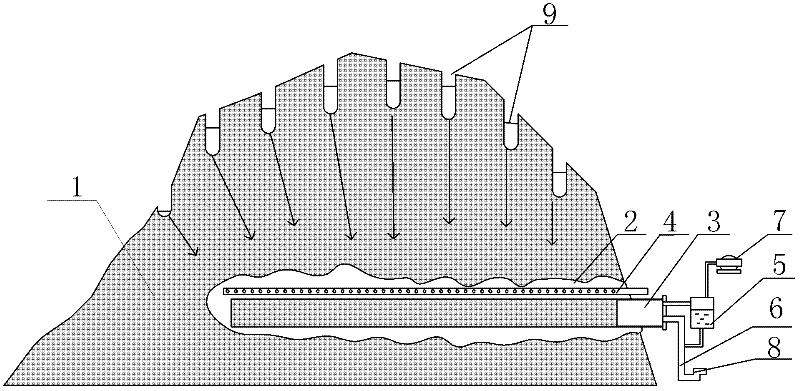

Method and system of in-situ ore leaching and leachate discharge of ion adsorption type ore

ActiveCN102392129AAvoid enteringReduce energy consumptionProcess efficiency improvementPregnant leach solutionDischarge efficiency

The invention relates to a method of in-situ ore leaching and leachate discharge of ion adsorption type ore; the leachate is collected in a vacuum mode; a porous capillary leachate-guiding layer is disposed between the ore body and a vacuum leachate outlet and has the function of obstructing air; the leachate is transferred from the ore body to the vacuum leachate outlet under the vacuum pressure conducted by capillary action. The invention also provides a system for realizing the method. The method and system of the invention facilitate the improvement of vacuum leachate discharge area and system vacuum degree, greatly decrease the energy consumption required for maintaining vacuum, thus reduce the moisture capacity of the ore layer, enlarge the control range, and increase the leachate discharge efficiency.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

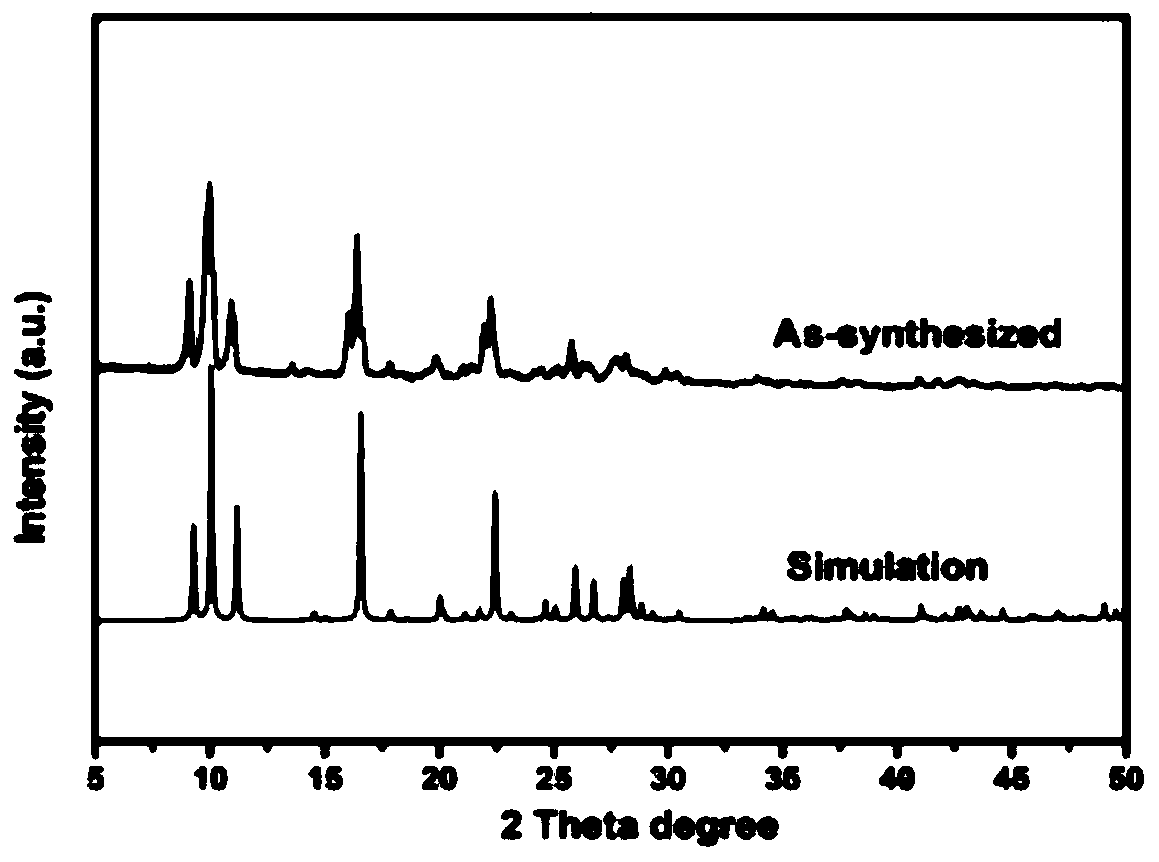

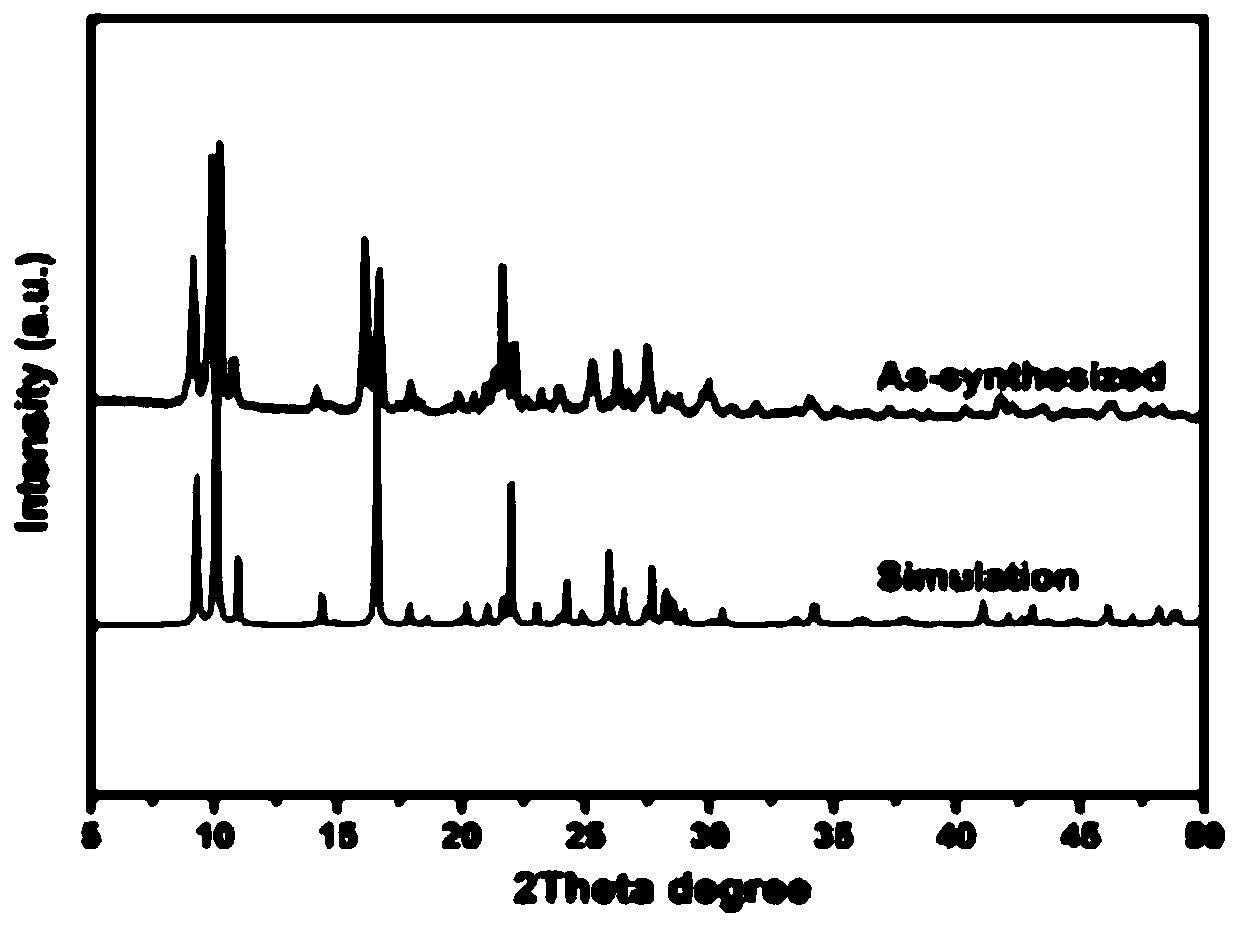

Metal organic framework material as well as preparation method and application thereof

ActiveCN110483794ALarge adsorption capacityReduce the amount of adsorptionOther chemical processesDispersed particle separationCarbon dioxideMetal-organic framework

The invention relates to the field of metal organic framework materials, and provides a metal organic framework material and a preparation method and application thereof. The chemical formula of the metal organic framework material provided by the invention is [Cu(dps)2(SiF6)].6H2O or [Cu(dps)2(GeF6)].6H2O, wherein the dps is bipyridine sulfur. The metal organic framework material provided by theinvention contains fluorine adsorption sites, so that the metal organic framework material can adsorb a large amount of acetylene, but has very small adsorption capacity on other gases with similar sizes, such as ethylene, carbon dioxide and ethane, so that the metal organic framework material provided by the invention can be used for high-selectivity adsorption of acetylene. Results of embodiments show that the adsorption capacity of the metal organic framework material provided by the invention to acetylene under the same condition is far greater than that to ethylene, carbon dioxide and ethane.

Owner:NANCHANG UNIV

Equipment and method for preparing supercritical carbon dioxide microemulsion and fly ash particle compound dispersion

ActiveCN109943313AReduce reunionReduce exposureDrilling compositionBulk chemical productionEmulsionProduct gas

The invention relates to the technical field of oil-gas field development and oil extraction engineering, and discloses equipment and method for preparing a supercritical carbon dioxide microemulsionand fly ash particle compound dispersion. When the supercritical carbon dioxide microemulsion and fly ash particle compounded dispersion prepared by the equipment and the method flows in an oil reservoir stratum, due to the fact that the fly ash particles are solubilized in the dispersed phase the probability of contact between the fly ash particles and a pore throat wall surface of the stratum can be greatly reduced, the adsorption amount is reduced, and the utilization efficiency is improved; when the dispersion is in contact with stratum water in the stratum, reverse microemulsion of water-in-carbon dioxide can be converted into dioxide-in-water carbon emulsion, namely carbon dioxide foam, and in the conversion process, the fly ash nano particles can be adsorbed on a gas-liquid interface to hinder gas diffusion among bubbles, so that the strength of a bubble liquid film is improved, the stability of the foam is enhanced, the carbon dioxide fluidity is controlled, and the crude oil recovery is enhanced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

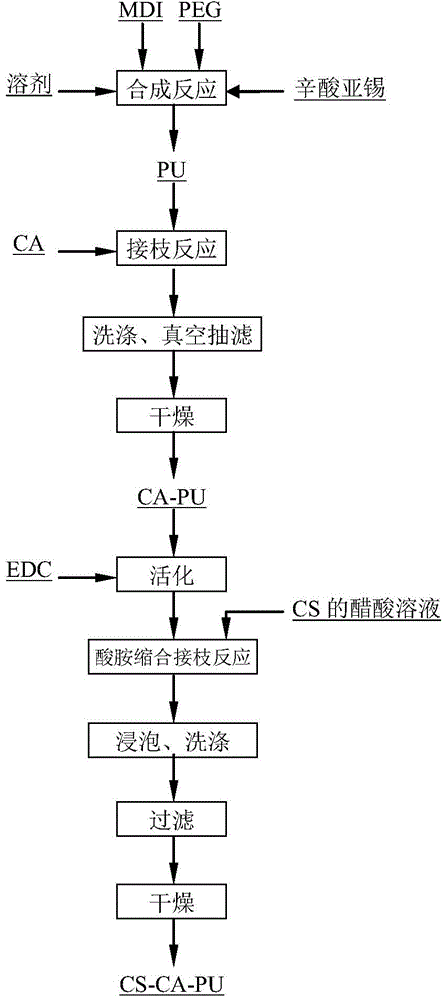

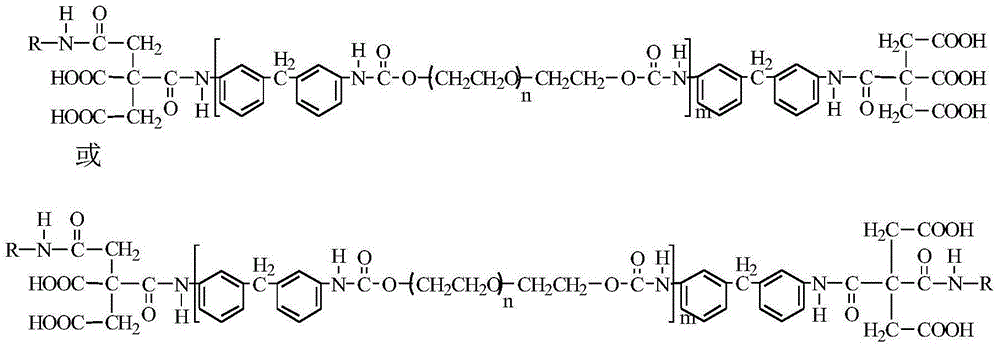

Citric acid and chitosan modified biocompatible polyurethane and preparation method thereof

The invention discloses a citric acid and chitosan modified biocompatible polyurethane and a preparation method thereof. A main chain of the polyurethane disclosed by the invention is a polyurethane long chain, the two ends of the long chain are respectively an anticoagulative citric acid structure covalently grafted with the long chain, and a chitosan structure is selectively grafted on the citric acid structure. The preparation method comprises the following steps: firstly, adding isocyanate, polyethylene glycol and a catalyst into a reactor, and carrying out stirring reaction for 2-5 h in the presence of nitrogen; then, adding a citric acid, and heating for reacting for 12-18 h, so that a citric acid modified polyurethane is obtained; and activating the citric acid modified polyurethane by using carbodiimide, and soaking the obtained object into a chitosan-acetic acid solution to carry out acid-amide condensation reaction, so that the modified biocompatible polyurethane is obtained. According to the citric acid and chitosan modified biocompatible polyurethane disclosed by the invention, the citric acid structures with biocompatibility and the chitosan structure are covalently bonded in the polyurethane long chain, so that the polyurethane has good chemical stability and biocompatibility, and can be used as a biomedical material; and the preparation method has the advantages of simple and easily-controlled process, low cost, and the like.

Owner:CENT SOUTH UNIV

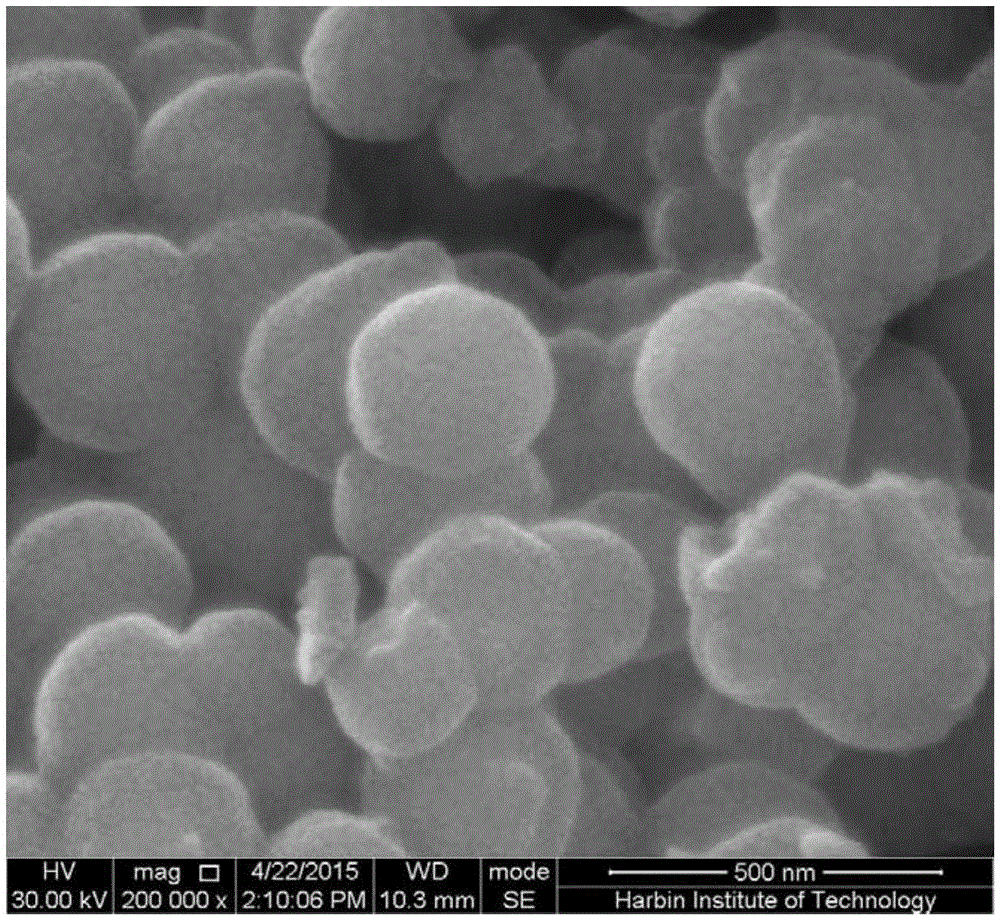

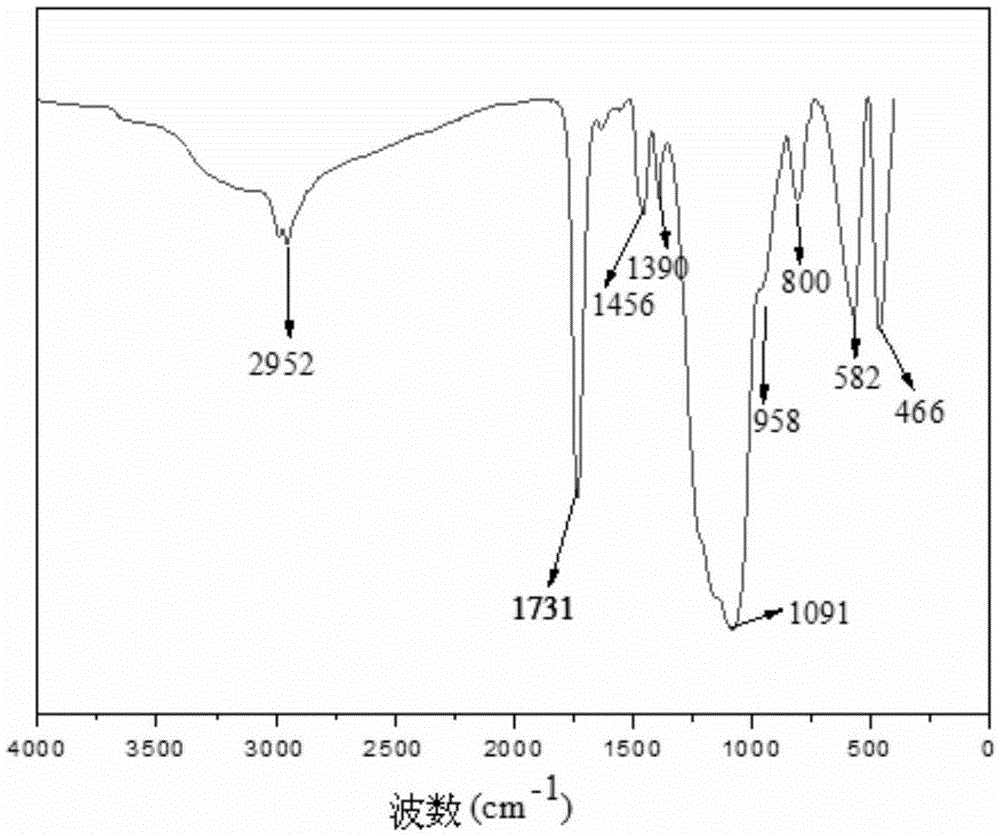

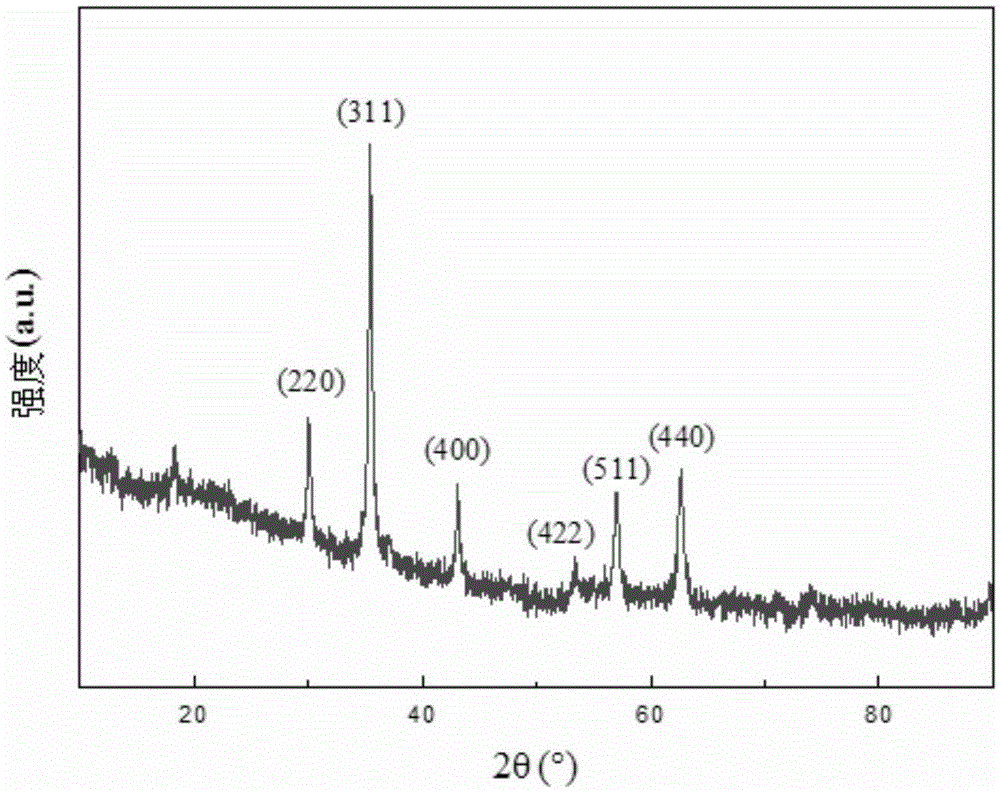

Preparation method of magnetic nano molecularly imprinted polymer for separating nicotinic pesticide IPP

ActiveCN105254827AImprove adsorption efficiencyReduce the amount of adsorptionOther chemical processesAlkali metal oxides/hydroxidesMicroparticleDouble bond

The invention provides a preparation method of a magnetic nano molecularly imprinted polymer for separating a nicotinic pesticide IPP, aiming to solve the problem that methods for preparing magnetic nano molecularly imprinted polymers capable of separating the nicotinic pesticide IPP do not exist at present. The preparation method comprises the following steps: I. preparation of Fe3O4 magnetic nanoparticles; II. modification of the Fe3O4 magnetic nanoparticles; III. silanization of the Fe3O4 magnetic nanoparticles; IV. preparation of double bond modified Fe3O4@SiO2 particles; and V. preparation of the magnetic nano molecularly imprinted polymer for separating the nicotinic pesticide IPP. The preparation method has the beneficial effects that the maximum saturation adsorption quantity of the product towards IPP is 17.305+ / -0.403mg / g and is 2.0 times that of a non-molecularly imprinted polymer; the adsorption quantity is still kept at about 85.3% after five-time repeated adsorption; and the repeated utilization rate is high.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com