Tracer for monitoring multistage fracturing flow-back fluid and monitoring method

A fracturing flowback fluid and tracer technology, applied in construction and other directions, can solve the problems of good fracturing fluid compatibility, small adsorption capacity in formation, and high analysis accuracy, and achieve good stability, small adsorption capacity, and high analysis accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a tracer for monitoring multi-stage fracturing flowback fluid, which includes 12 kinds of tracer element complex aqueous solutions mixed with 12 kinds of tracer elements and ammonium hydrogen chloride (complexing agent) , respectively: praseodymium and hydroxylamine chloride mixed in a molar ratio of 1:8, a praseodymium chloride aqueous solution with a mass concentration of 3%-5%, and neodymium and hydroxylamine chloride mixed in a molar ratio of 1:8 Hydroxylamine chloride aqueous solution of neodymium chloride with a mass concentration of 3%-5%, samarium and hydroxylamine chloride in a molar ratio of 1:8 to form a mass concentration of 3%-5% aqueous solution of hydroxylamine chloride samarium, europium and chlorine The mass concentration of hydroxylamine chloride mixed with hydroxylamine in a molar ratio of 1:8 is 3%-5%. 5% hydroxylamine chloride gadolinium aqueous solution, terbium and hydroxylamine chloride are mixed in a molar ratio of 1:8 t...

Embodiment 2

[0034] This embodiment provides a method for monitoring multi-stage fracturing flowback fluid, which is a method for monitoring multi-stage fracturing flowback fluid using the tracer in Example 1, comprising the following steps: using the described method for monitoring The tracer layers (12 layers) of the multi-stage fracturing flowback fluid are added to the oil wells implementing the multi-stage fracturing measures, and each layer is added with a different kind of tracer element complex aqueous solution (tracer low-cost tracers in layers with large doses), during the fracturing fluid flowback process, the fracturing flowback fluid was sampled every 12 hours, and various tracer element complexes in the samples were collected. The content of the tracer element complex is detected at the same time, and the monitoring of the multi-stage fracturing flowback fluid is realized according to the detected content of the tracer element complex in each layer.

[0035] The content of th...

Embodiment 3

[0038] This example provides various performance tests of the tracer of the present invention.

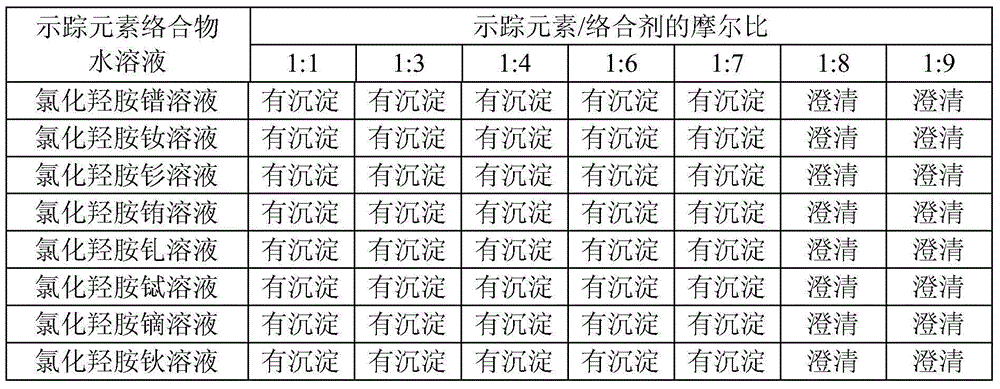

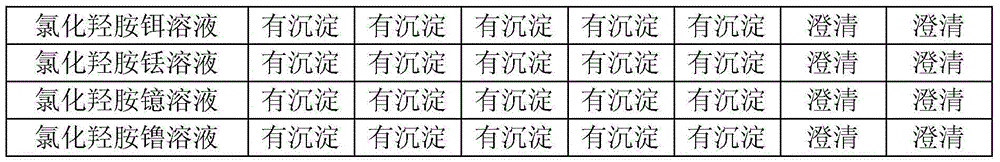

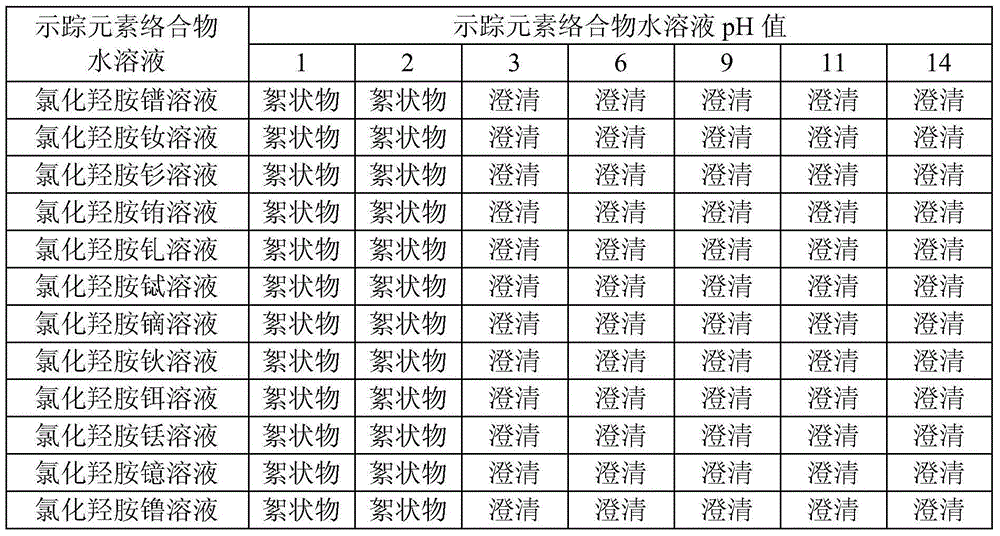

[0039] (1) Thermal stability experiment

[0040] The thermal stability test is used to evaluate the thermal stability of the tracer of the present invention. The method of the thermal stability experiment includes the following steps: each of the 12 tracer elements (praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium) Prepared with complexing agent (hydroxylamine chloride) in molar ratios of 1:1, 1:2, 1:3, 1:4, 1:5, 1:6, 1:7, 1:8 and 1:9 A mass concentration of 1% tracer element complex aqueous solution (the preparation method of these tracer element complex aqueous solutions is the same as the preparation method of the tracer element complex aqueous solution in Example 1), and a total of 84 tracer element complexes were obtained. Element complex aqueous solution, the 84 kinds of tracer element complex aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com