Process for preparing citicoline sodium

A technology of citicoline sodium and phosphorylcholine, which is applied in the field of preparation of citicoline sodium, can solve the problems of high synthesis price, difficult condensation agent separation, and unsuitable products for medicinal use, and achieve high enzyme activation and reduce Adsorption capacity, effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

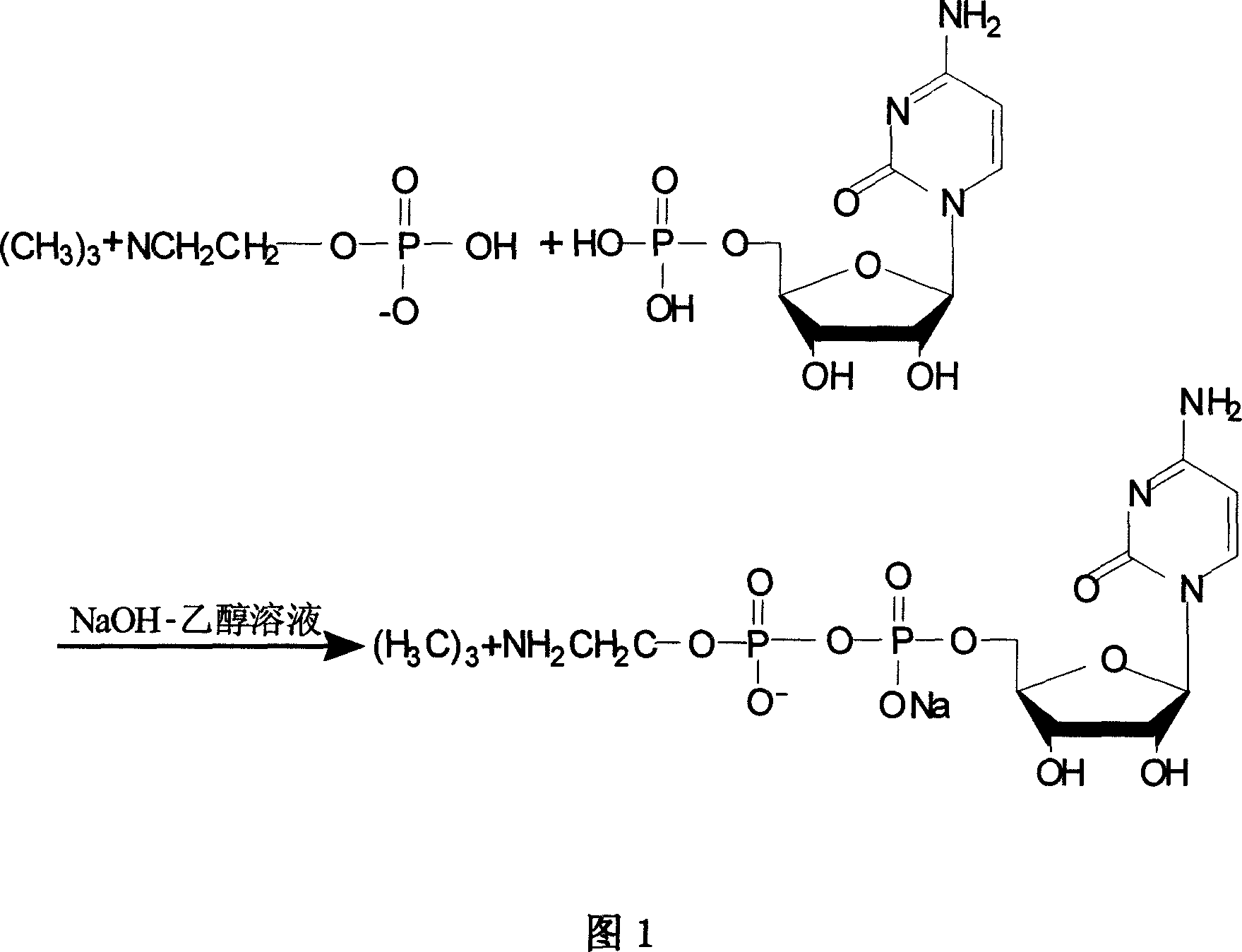

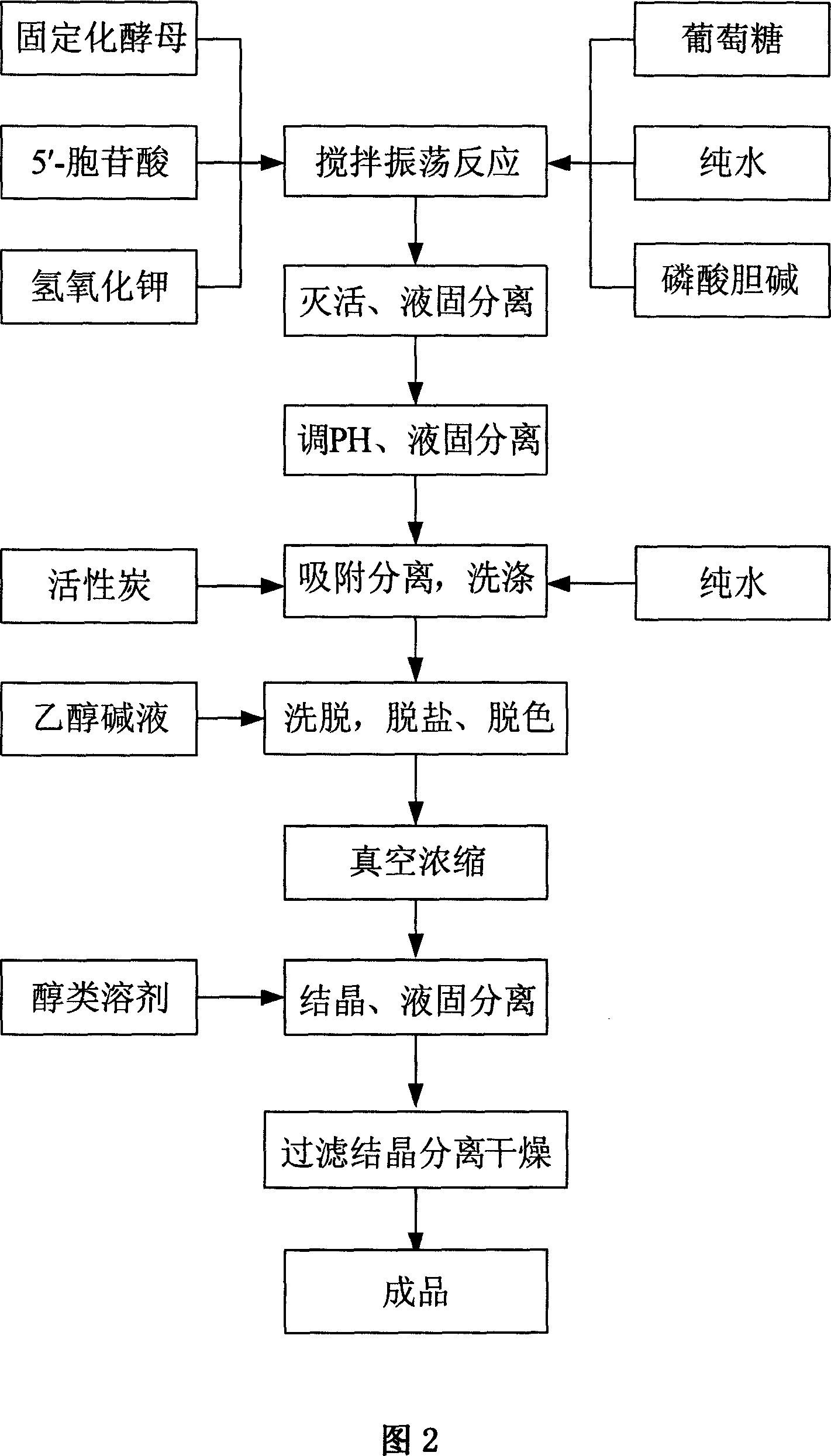

[0031] The main reaction formula of the preparation method of Citicoline Sodium of the present invention is as shown in Figure 1. The present invention uses yeast enzyme as the reaction carrier, and uses 5'-cytidylic acid, phosphorylcholine, potassium hydroxide, and glucose as the main raw materials to carry out the production mode of biotransformation, uses activated carbon as the adsorption carrier, and uses Cl - Type ion exchange resin is used as the separation carrier for extraction and separation. The acidic pH is used as the adsorption condition, and the pH is between 2 and 6 for adsorption. The compound reagent with alcohol is used as the analysis reagent to extract and separate the analysis solution, and the alcohol solvent is used as the crystallization solvent to refine the finished product. As shown in Figure 2, the preparation method of citicoline sodium includes the following steps: ① Mix yeast, glucose, potassium hydroxide, phosphorylcholine, 5′-cytidylic acid an...

Embodiment 1

[0035] Mix 30 kg of quick-frozen yeast, 3 kg of phosphorylcholine, 1 kg of 5′-cytidylic acid, 10 kg of glucose, 2 kg of potassium hydroxide, and 800 kg of water, then adjust the temperature to 25°C, pH=6, and perform 65 rpm Stir the reaction for 6 hours to make it fully react; raise the temperature of the reaction solution to 50°C to inactivate, and perform liquid-solid separation; adjust the pH to 8.0, precipitate some basic proteins and nucleic acids, perform liquid-solid separation, and then adjust the pH to 2.5, Precipitate the acidic protein, carry out liquid-solid separation, and separate the precipitate; use activated carbon to adsorb and separate, PH=2.5, and wash with pure water; use ethanol alkali-soluble reagent for elution, and the eluate is desalted and decolorized, and the liquid is collected; wash Deliquification and vacuum concentration; add 2 times ethanol to the concentrated solution, crystallize, and separate the liquid and solid to obtain the crude product; ...

Embodiment 2

[0037] Mix 80 kg of quick-frozen yeast, 4 kg of phosphorylcholine, 4 kg of 5′-cytidylic acid, 16 kg of glucose, 4 kg of potassium hydroxide, and 1100 kg of water, adjust the temperature to 30°C, and add 0.5 kg of MgSO 4 Solution, PH=6, carry out stirring reaction at 120 rpm for 8 hours to make it fully react; heat the reaction solution to 70°C to inactivate, and carry out liquid-solid separation; adjust PH=10, part of the basic protein and nucleic acid precipitation, carry out Solid separation, and then adjust PH=4 to precipitate acidic protein, carry out liquid-solid separation, and separate precipitate; use activated carbon for adsorption separation, PH=4, wash with pure water; elute with ethanol alkaline reagent, eluent Carry out desalting and decolorization treatment, collect the liquid; eluate is concentrated in vacuum; add 2 times methanol to the concentrated solution, crystallize, and separate the liquid and solid to obtain the crude product; dissolve the crude product, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com