Patents

Literature

280results about How to "Diffusion is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

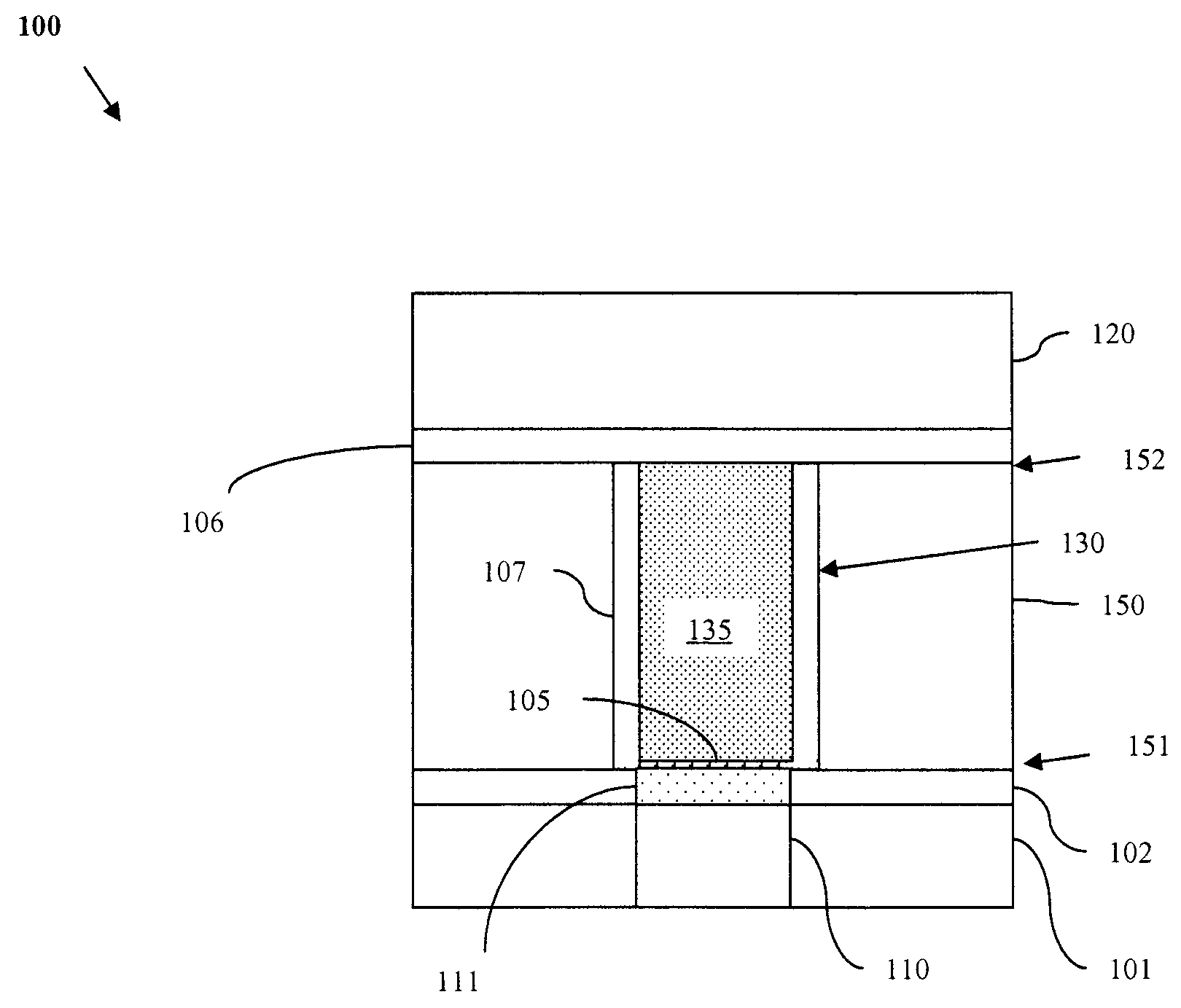

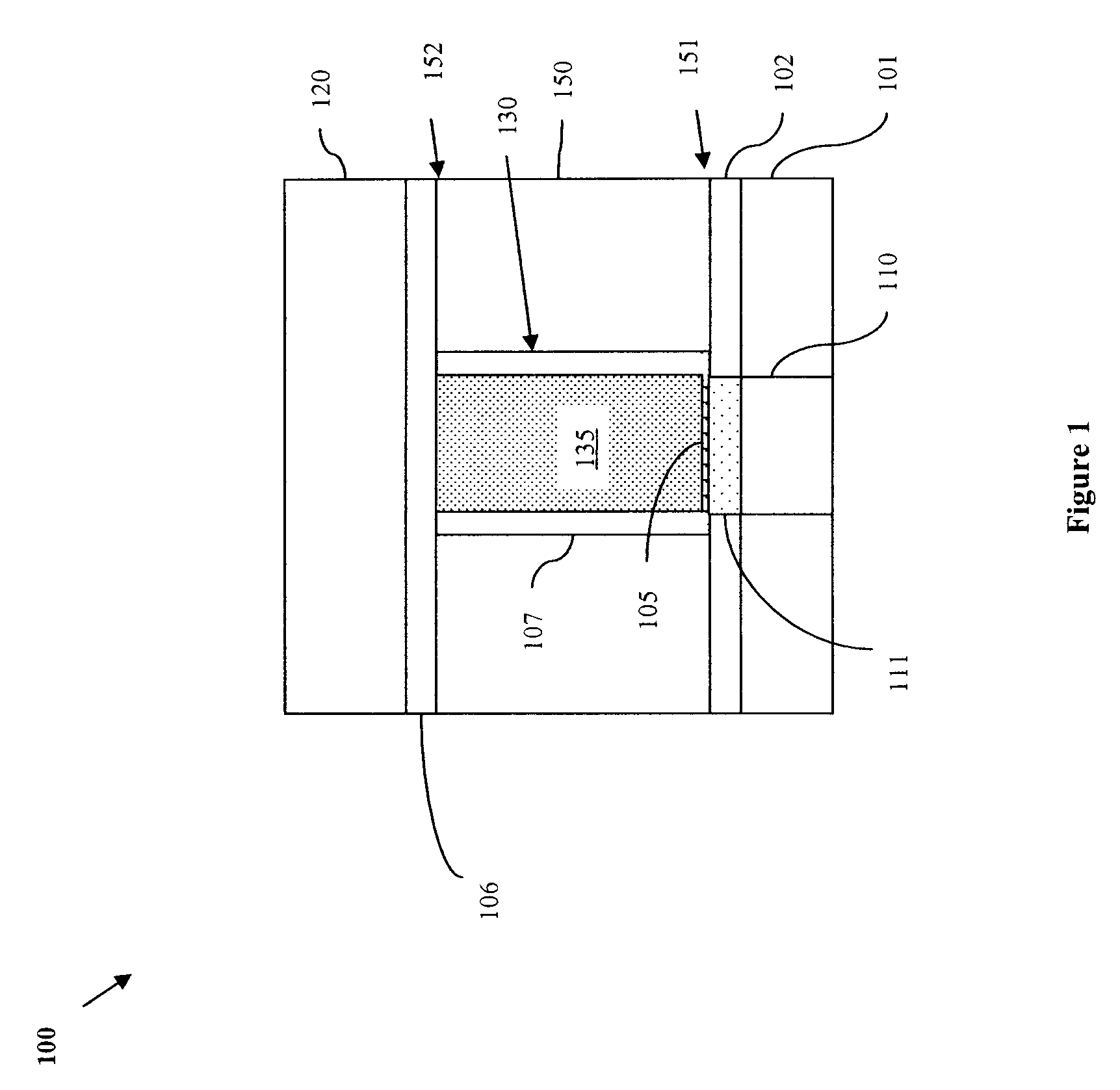

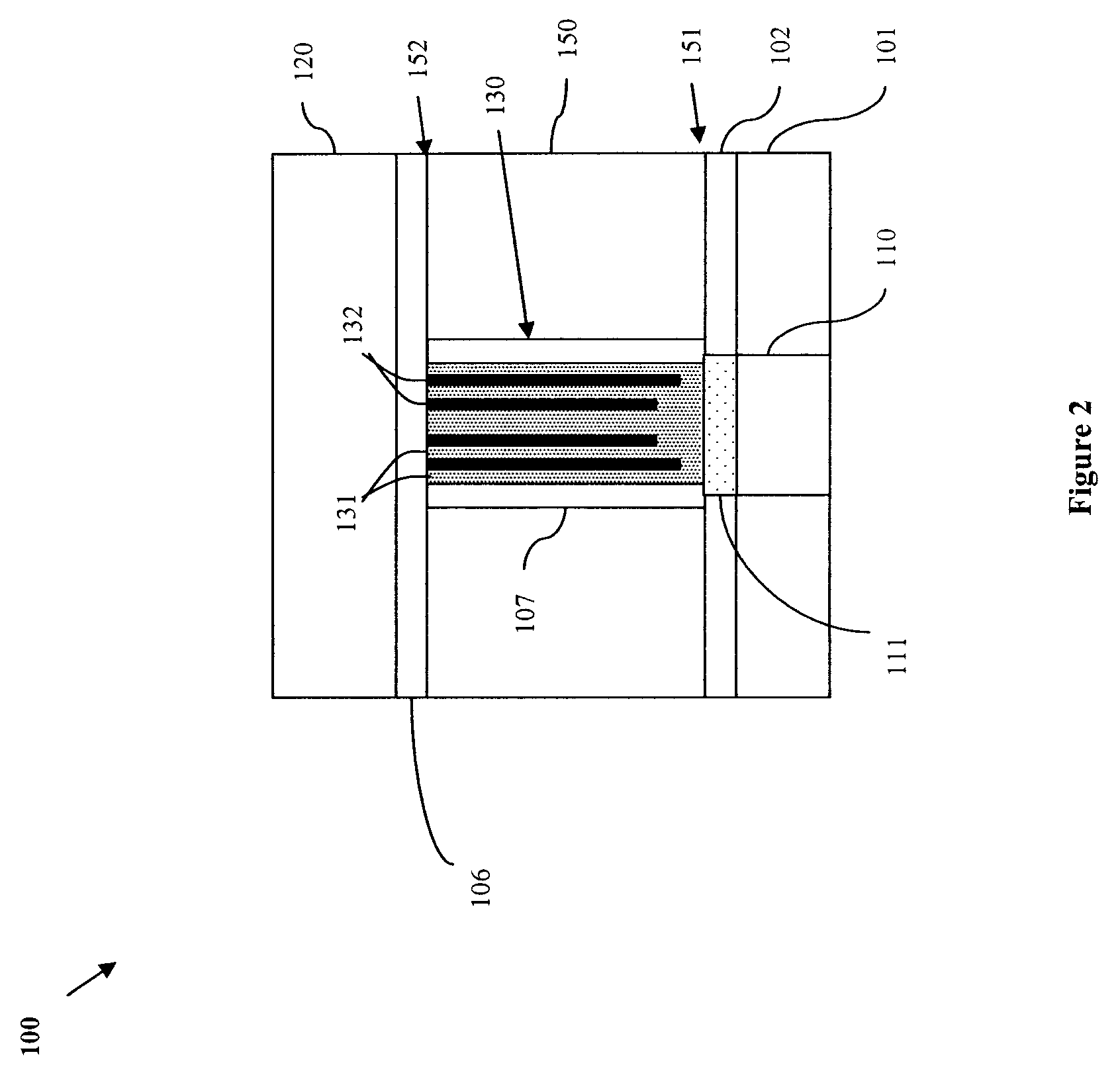

Programmable resistor, switch or vertical memory cell

InactiveUS20080173975A1Decrease resistivity and hence resistanceSimple processSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceMetal electrodes

Disclosed are embodiments of a device and method of forming the device that utilize metal ion migration under controllable conditions. The device embodiments comprise two metal electrodes separated by one or more different dielectric materials. One electrode is sealed from the dielectric material, the other is not. The device is adapted to allow controlled migration of embedded metal ions from the unsealed electrode into dielectric material to form a conductive path under field between the electrodes and, thereby, to decrease the resistance of the dielectric material. Reversing the field causes the metal ions to reverse their migration, to break the conductive metallic path between the electrodes and, thereby, to increase the resistance of the dielectric material. Thus, the device can comprise a simple switch or programmable resistor. Additionally, by monitoring the resistance change, a two-state, two-terminal, silicon technology-compatible, flash memory device with a very simple tuning process can be created.

Owner:INFINEON TECH AG +1

Activated carbon materials for high energy density ultracapacitors

ActiveUS8318356B2Simple designLow costCarbon compoundsHybrid capacitor electrodesCelluloseActivated carbon

Owner:CORNING INC

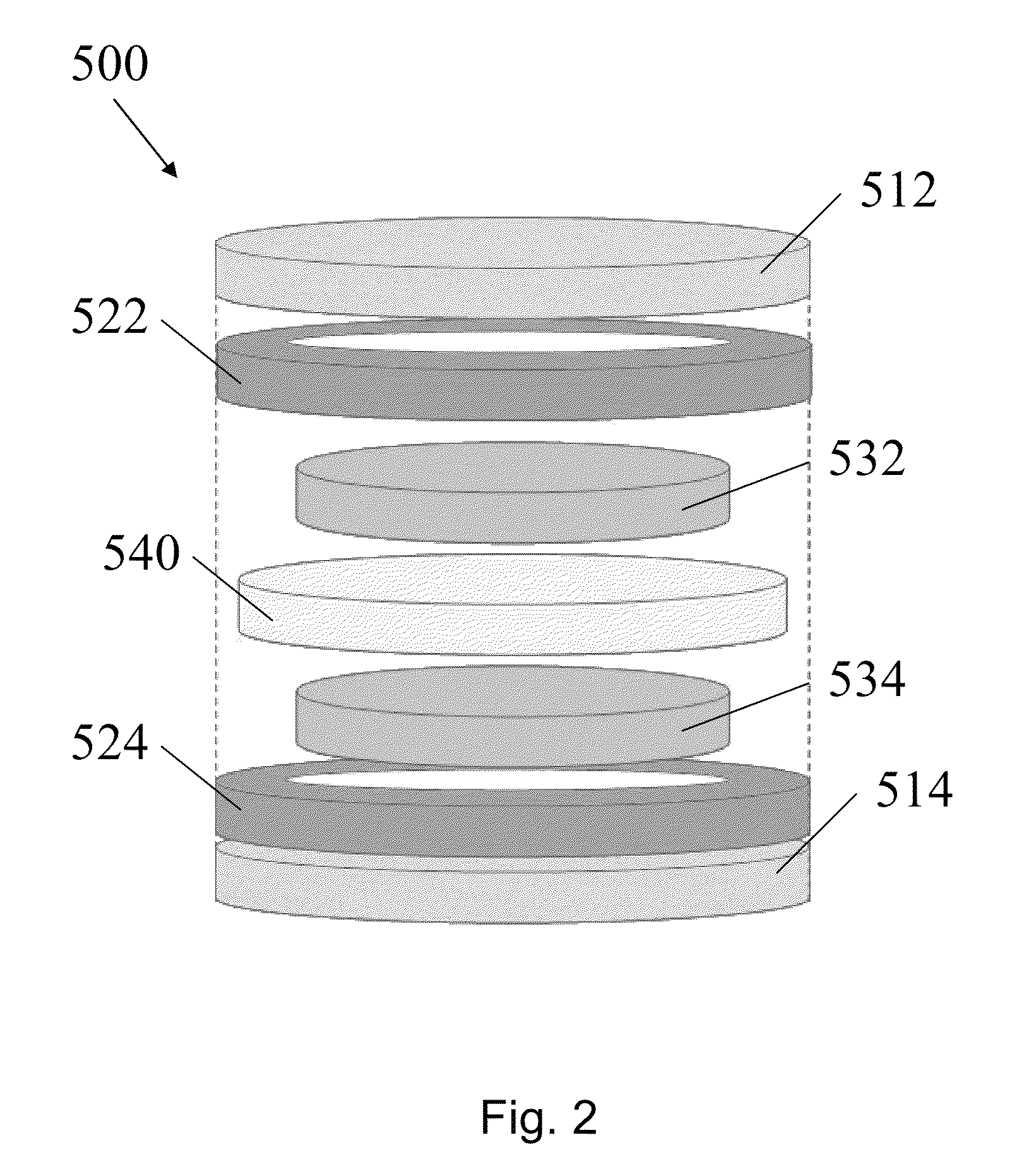

Hybrid capacitor-battery and supercapacitor with active bi-functional electrolyte

InactiveUS20140065447A1High densityHigh pulse currentCapacitor and primary/secondary cellsHybrid capacitor electrodesSupercapacitorCapacitor

An electrode includes a substrate having a carbon nanostructure (CNS) disposed thereon and a coating including an active material conformally disposed about the carbon nanostructure and the substrate. The electrode is used in a hybrid capacitor-battery having a bifunctional electrolyte capable of energy storage.

Owner:GOOGLE LLC +1

Activated Carbon Materials For High Energy Density Ultracapacitors

ActiveUS20100151328A1Inexpensive materialsHigh energy density deviceCarbon compoundsHybrid capacitor electrodesActivated carbonCellulose

An activated carbon material derived, for example, by carbonizing and activating a non-lignocellulosic carbon precursor has a structural order ratio less than or equal to 0.08, and a nitrogen content greater than 0.2 wt. %. The activated carbon material can also have a volumetric capacitance greater than or equal to 70 F / cm3, an area-specific resistance less than or equal to 0.1 ohm-cm2 and / or a specific surface area greater than 300 m2 / g, and is suitable to form improved carbon-based electrodes for use in high energy density devices.

Owner:CORNING INC

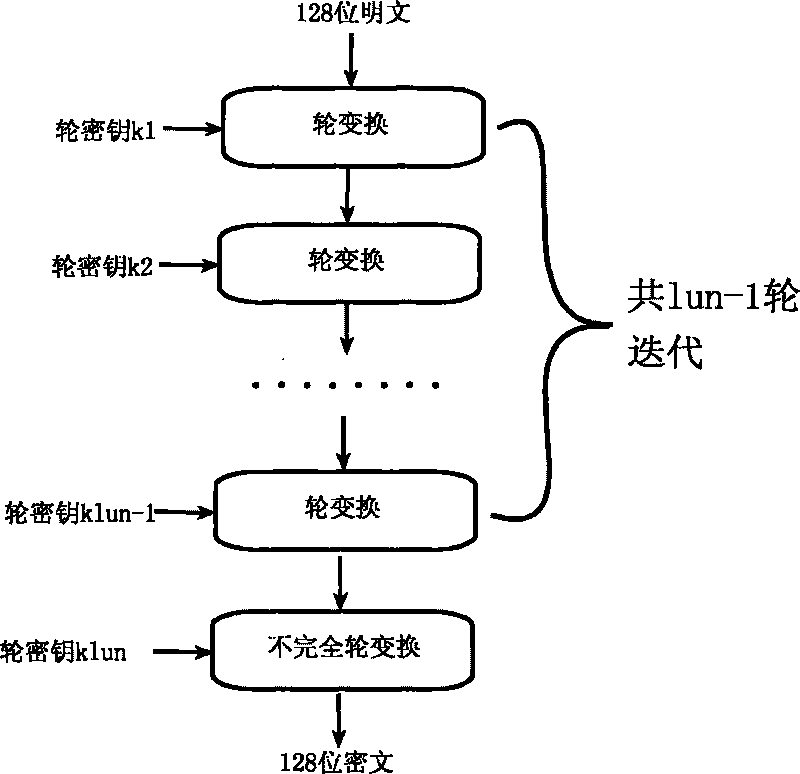

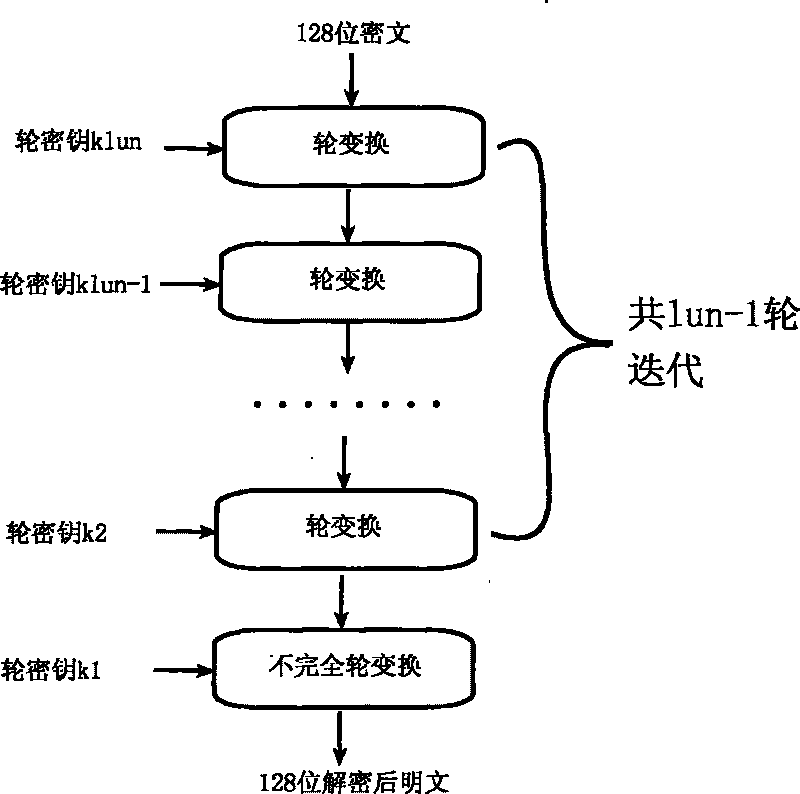

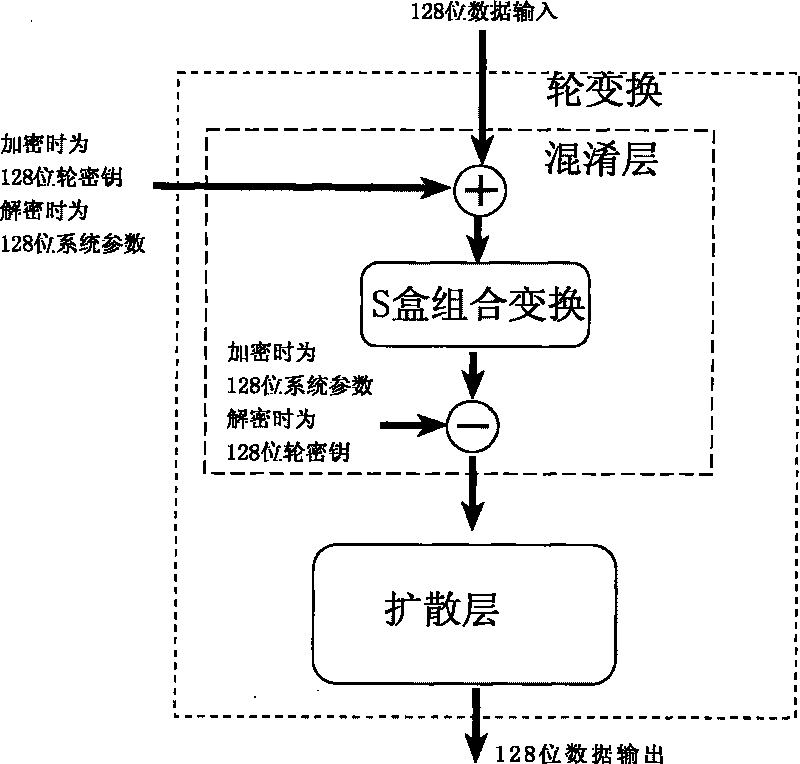

Encryption method for network and information security

ActiveCN101764686AHigh speedDiffusion is fastKey distribution for secure communicationEncryption apparatus with shift registers/memoriesComputer hardwareKey size

The invention relates to an encryption method for network and information security; the adopted packet length and key length are 128 bits, and a 128-bit system parameter is added; encryption algorithm comprises a plurality of rounds of round transform iteration consisting of mixed layers and diffusion layers, wherein the last round is incomplete round transformation, and the incomplete round transformation consists of the mixed layer; the mixed layer comprises key plus, S box portfolio transform and system parameter minus; the S box portfolio transform comprises 8-input 8-output reversible S box transform and inverse S box transform in the same number which are output by parity exchange; the diffusion layer can construct linear transformation with a reversible re-model polynomial matrix; an encryption round key is generated by an encryption key through encryption round transformation; and decryption algorithm is the inverse transformation of encryption algorithm. The encryption methodfor network and information security has the advantages of high diffusion speed, good security strength, hardware resource saving, and very high speed when being realized by hardware and on a software platform.

Owner:INST OF APPLIED MATHEMATICS HEBEI ACADEMY OF SCI

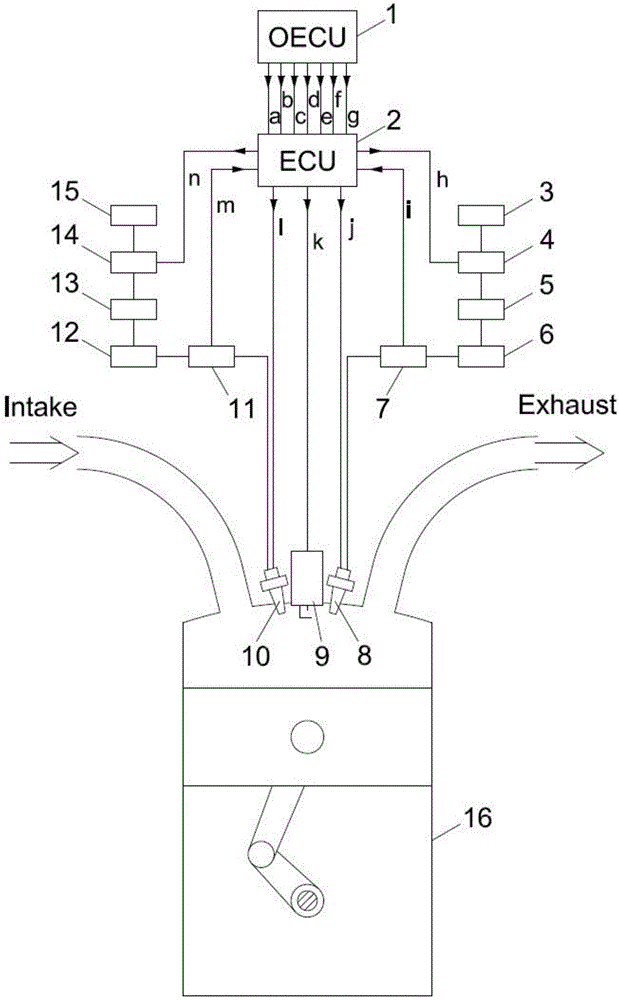

Double-nozzle gas/liquid dual-fuel in-cylinder direct injection internal combustion engine and control method

ActiveCN106499531AImprove powerImprove featuresElectrical controlInternal combustion piston enginesMass ratioLubrication Problem

The invention provides a double-nozzle gas / liquid dual-fuel in-cylinder direct injection internal combustion engine and a control method, and belongs to the field of internal combustion engine control. According to the system, on the basis of still using an ignition type internal combustion engine body, a double-nozzle gas / liquid dual-fuel ignition type internal combustion engine in-cylinder direct injection device and a fuel injection and ignition electronic control unit are additionally arranged, and the double-nozzle gas / liquid dual-fuel ignition type internal combustion engine in-cylinder direct injection device comprises a gas fuel flow sensor, a gas fuel control valve, a gas fuel pressure stabilizer, a liquid fuel flow sensor, a liquid fuel control valve and the like. The fuel injection and ignition electronic control unit adjusts injection time and injection pulse width of a gas fuel nozzle and a liquid fuel nozzle, and therefore in-cylinder injection of gas / liquid dual fuels in any ratio is achieved; the injection mass ratio of the gas / liquid dual fuels is adjusted in real time according to working conditions, and therefore the starting speed and accelerating response speed of the internal combustion engine are increased, and fuel consumption and pollutant emission are reduced; and the heat dissipation and lubrication problems caused by long-time use of the internal combustion engine are relieved by decreasing the using frequency of the gas-fuel high pressure nozzle.

Owner:BEIJING UNIV OF TECH

Dechlorination agent and preparation method thereof

ActiveCN103386244AImprove adsorption efficiencyHigh dechlorination precisionDispersed particle separationHigh concentrationChemical reaction

Owner:康健科技(山东)有限公司

Electrical Connecting Element and Method for Manufacturing the Same

InactiveUS20140217593A1Improve adhesionAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesCopperMetal

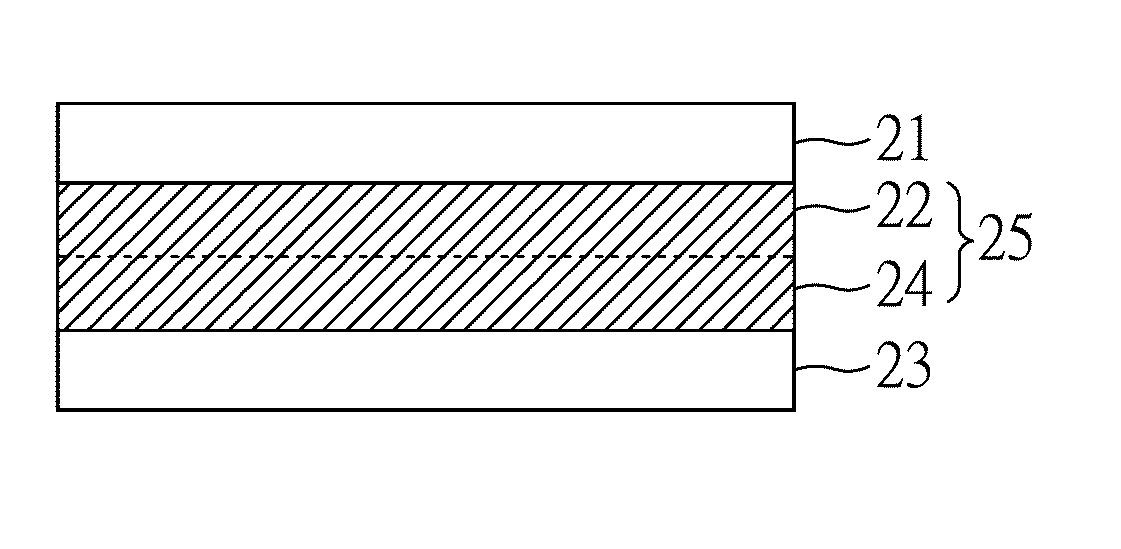

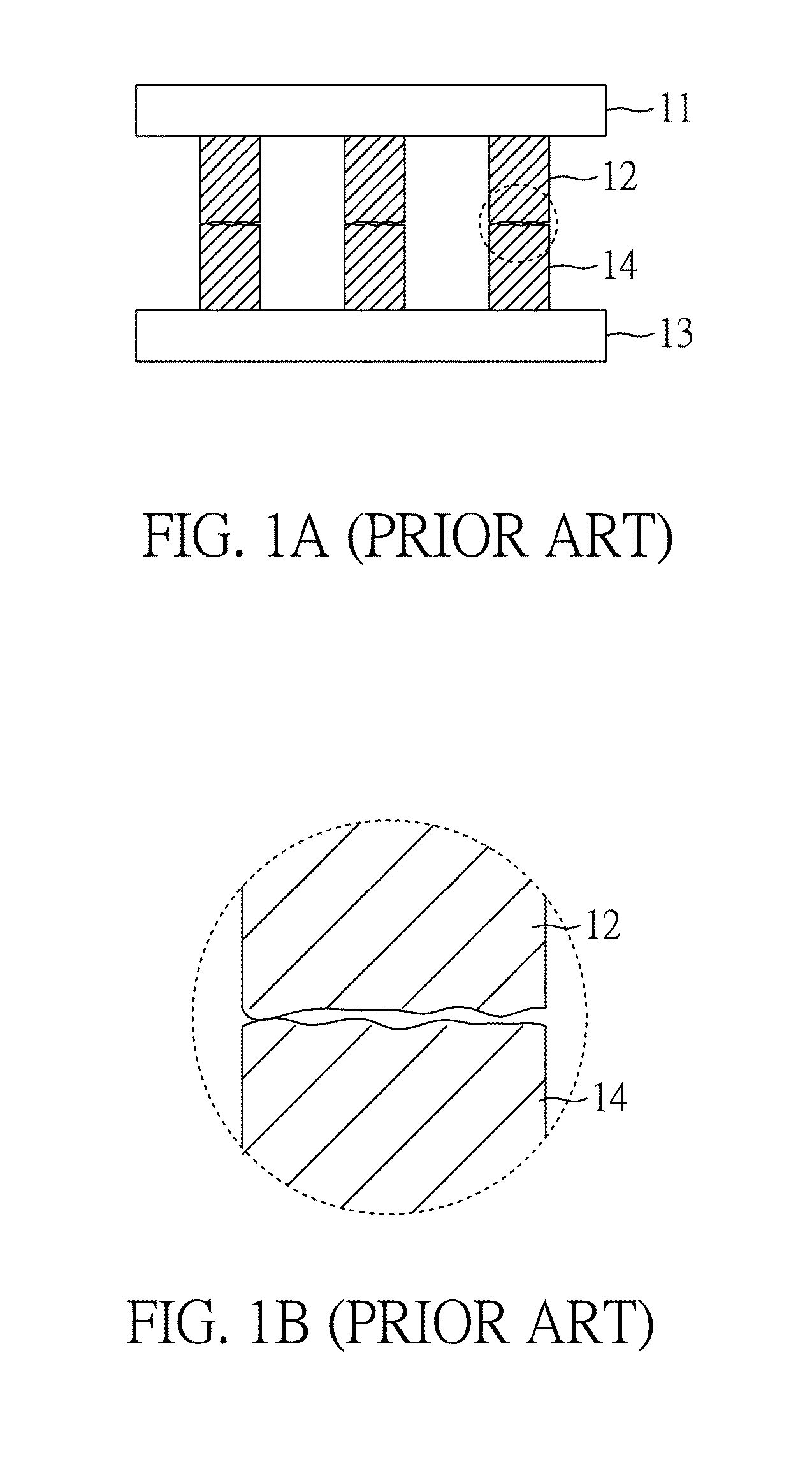

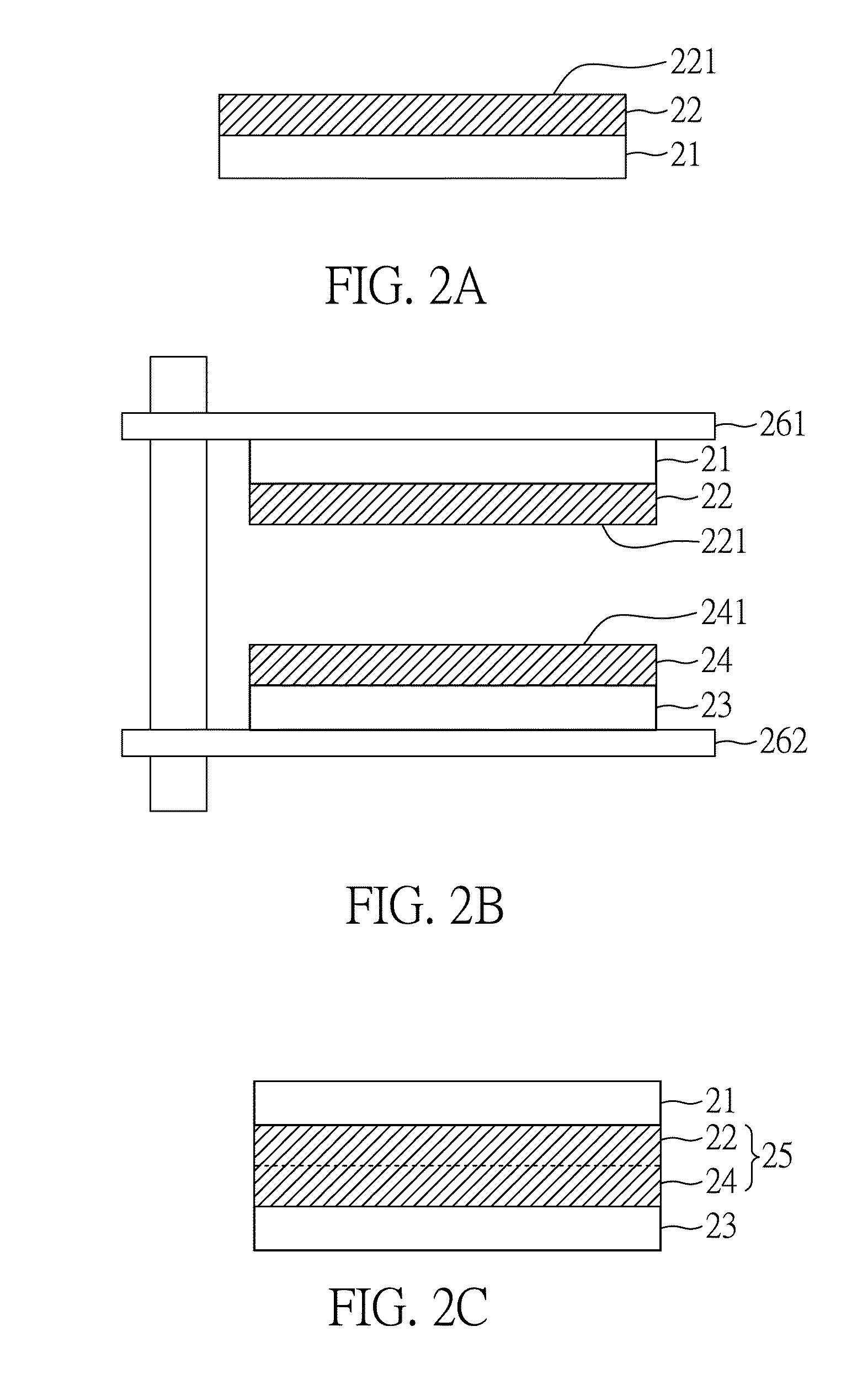

An electrical connecting element for connecting a first substrate and a second substrate and a method for manufacturing the same are disclosed. The method of the present invention comprises: (A) providing a first substrate and a second substrate, wherein a first copper film is formed on the first substrate, a first metal film is formed on the second substrate, a first connecting surface of the first copper film has a (111)-containing surface, and the first metal film has a second connecting surface; and (B) connecting the first copper film and the first metal film to form an interconnect, wherein the first connecting surface of the first copper film is faced to the second connecting surface of the first metal film.

Owner:NAT CHIAO TUNG UNIV

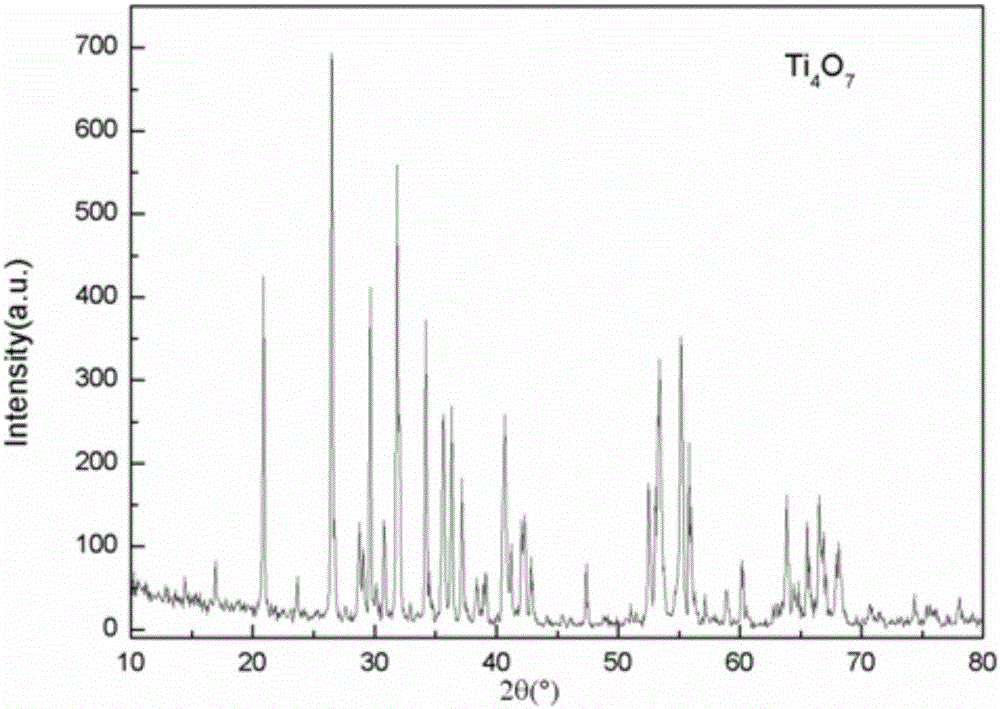

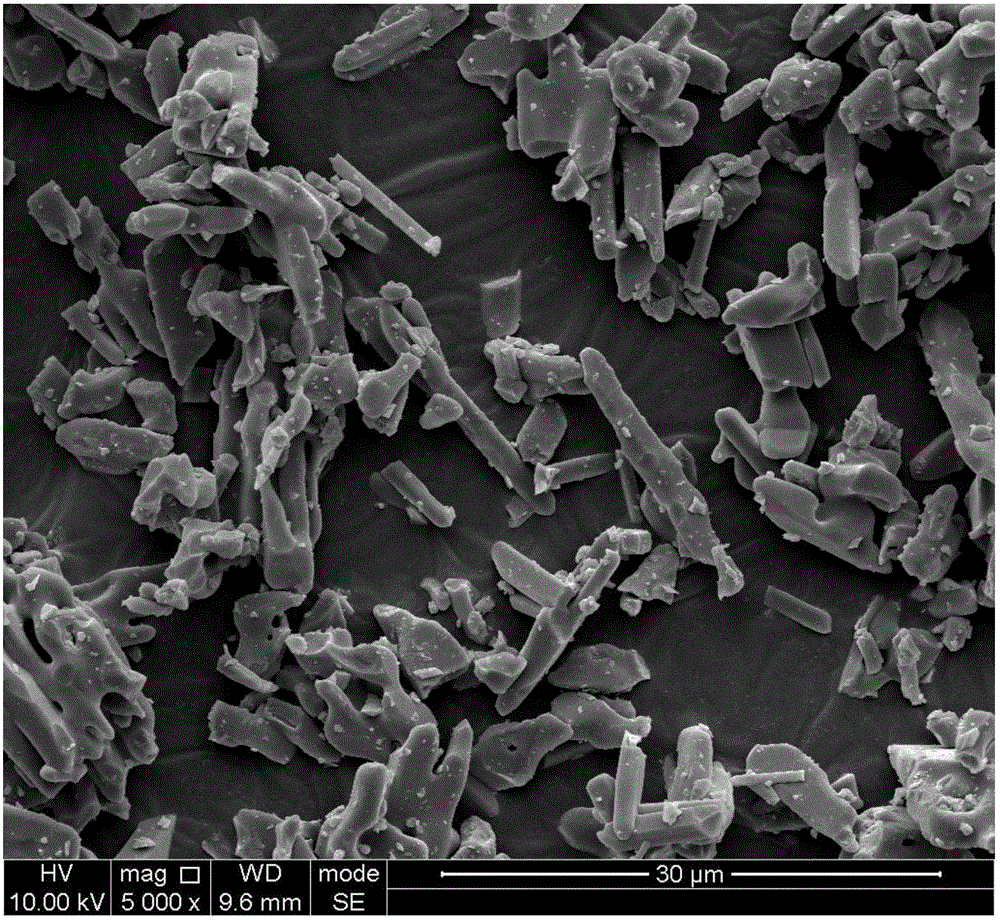

Rod-like titanium protoxide powder and preparation method thereof

The invention relates to a rod-like titanium protoxide powder and a preparation method thereof, wherein the titanium protoxide powder is Ti3O5 powder, Ti4O7 powder, Ti5O9 powder, Ti6O11 powder, Ti7O13 powder, Ti8O15 powder or Ti9O17 powder. The preparation method comprises: (1) material preparing, wherein raw materials comprise titanium dioxide powder, a carbon reducing agent and a chlorine salt, and according to the chemical formulas of each titanium protoxide powder and the chemical reactions among the used raw materials, the mold ratios of the raw materials for preparing various titanium protoxide powders are calculated; (2) material mixing and drying; (3) sintering, wherein the mixed powder obtained in the step (2) is loaded into a heating furnace, heating is performed at a heating speed of 5-15 DEG C / min under a flowing inert gas to achieve a temperature of 700-1300 DEG C, a reduction reaction is performed for 2-8 h at the temperature of 700-1300 DEG C, and cooling is performed along with the furnace to a room temperature after the reduction time is achieved; and (4) washing and drying, wherein the titanium protoxide-salt mixed powder obtained in the step (3) is washed with deionized water 3-10 times, and then drying is performed to obtain the rod-like titanium protoxide powder.

Owner:SICHUAN UNIV

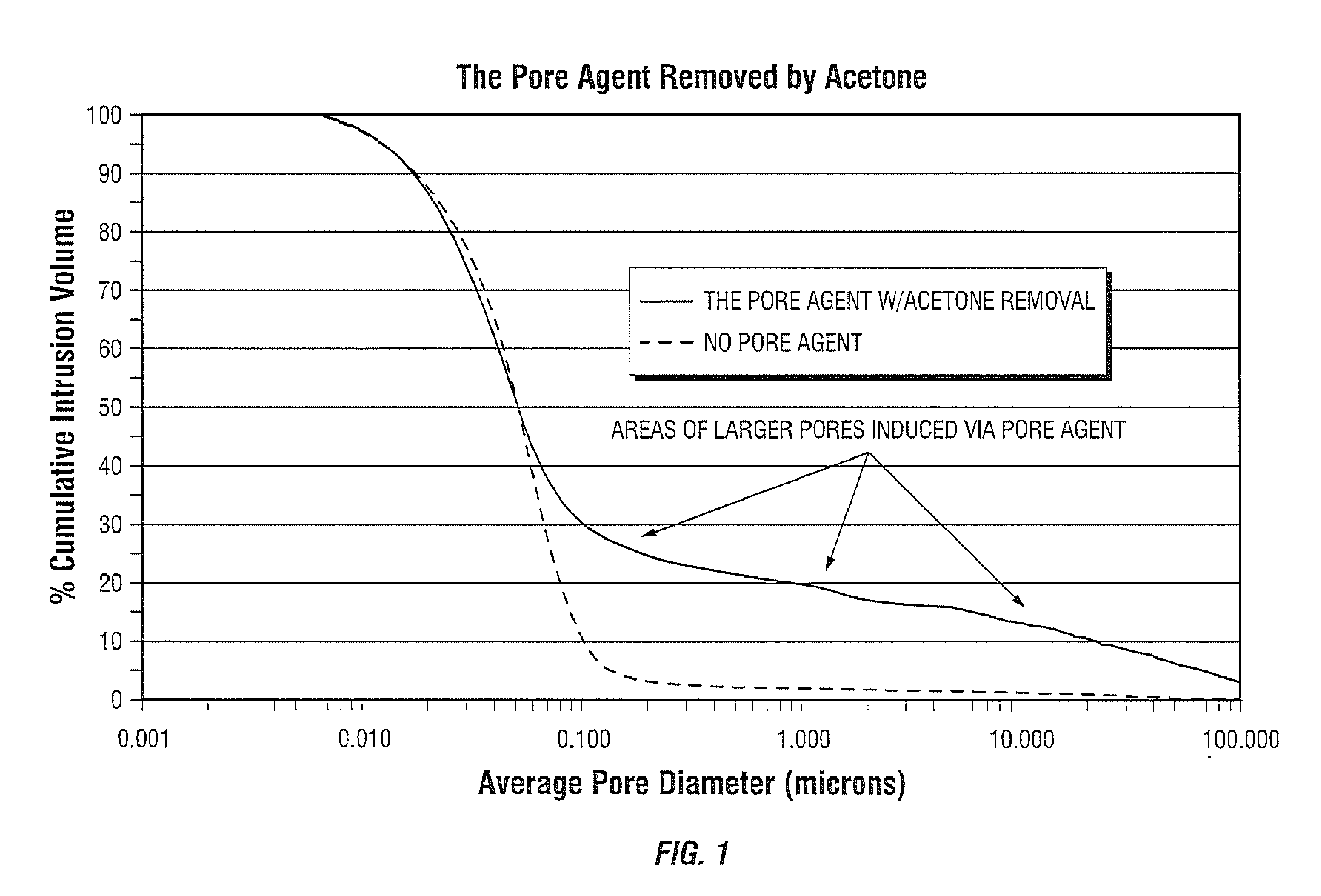

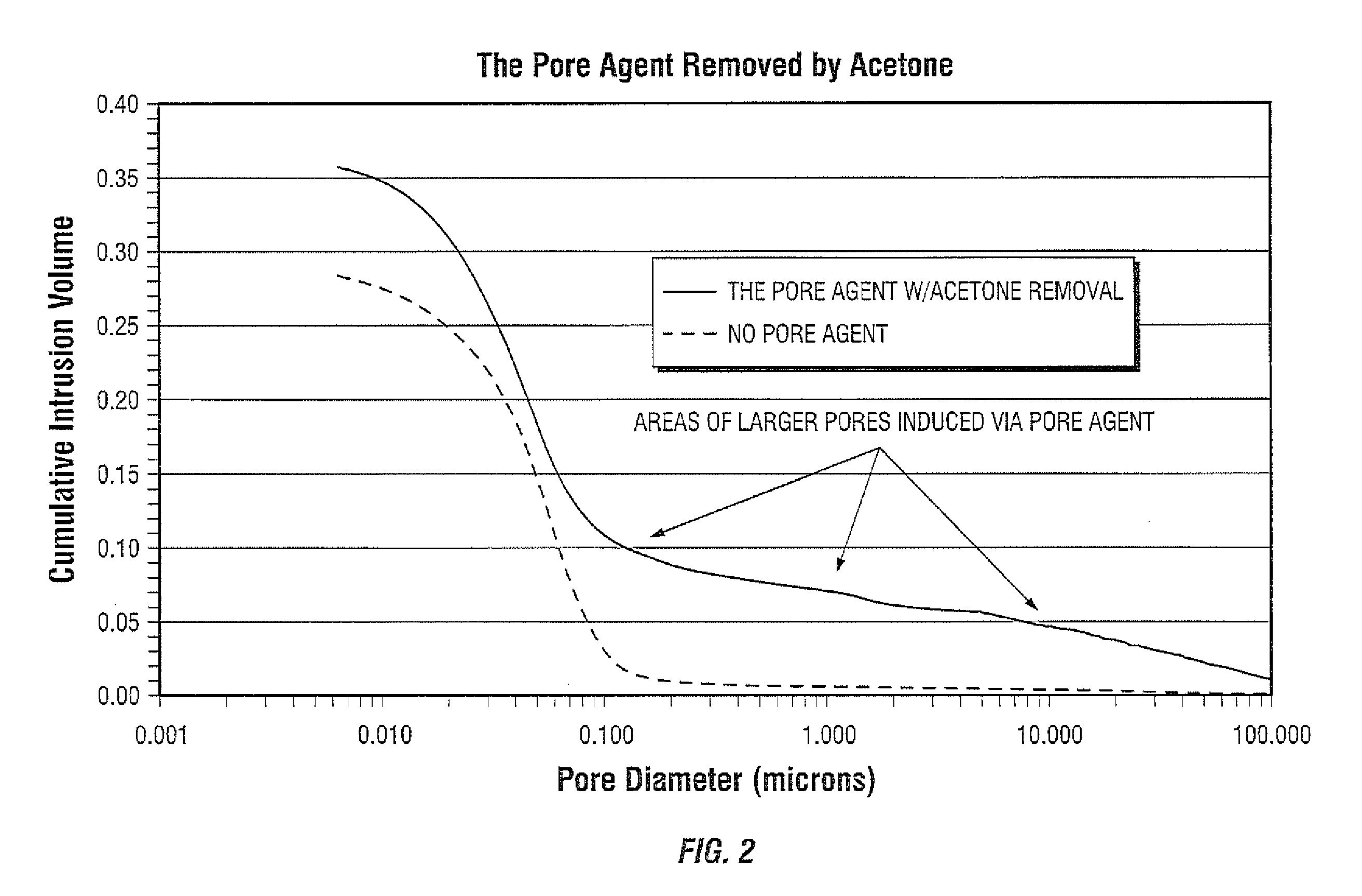

Alginate hard capsule disintegrable at different positions in gastrointestinal tract

ActiveCN102657869AGood heat and humidity stabilityEasy to preparePharmaceutical non-active ingredientsCapsule deliveryHard CapsuleMedicine

Disclosed is an alginate hard capsule disintegrable at different positions in gastrointestinal tract. Processing steps include preparing glue solution, glue solution dipping, solidifying, drying, drawing out, cutting, fastening, optical testing and sterilizing of glue solution and capsule filling. The glue solution is prepared by dissolving univalent alginate, plasticizer and pore former in water, wherein the pore former is a polymer film-forming material, glycerin and sorbitol serve as the plasticizer; the solidifying is that dipped gel solution is made into alginate gel capsule by means of ionic cross-linking or acidulating, wherein solidifying solution is multivalent metal ion water solution or acid solution; and finally active ingredients and disintegrating accelerator are filled in hard capsule shells to obtain finished products, wherein the disintegrating accelerator is a substance which can be in precipitation reaction or complexation with multivalent metal ions. The alginate hard capsule is widely applied to different disintegrating environments in the gastrointestinal tract and disintegrable in vivo at different speeds to release the active ingredients and has the advantages of high hydrothermal stability, simple preparation method and low cost.

Owner:南京健辉生物科技有限公司

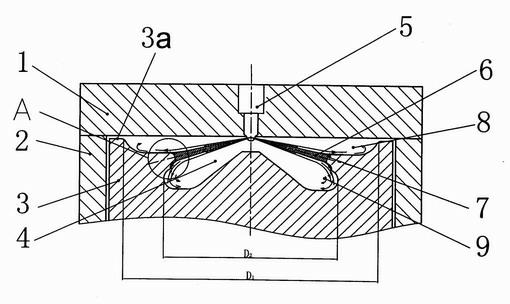

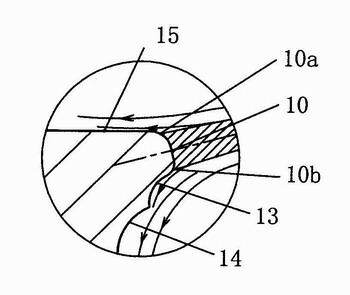

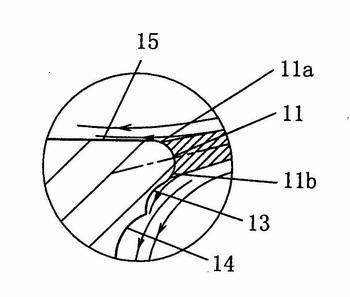

Double-layer split-flow burning system of direct-injection diesel engine

ActiveCN102661193APromote combustionReduce accumulationInternal combustion piston enginesFuel re-atomisation/homogenisationCombustion systemCombustion chamber

Owner:隆成利达(大连)科技有限公司

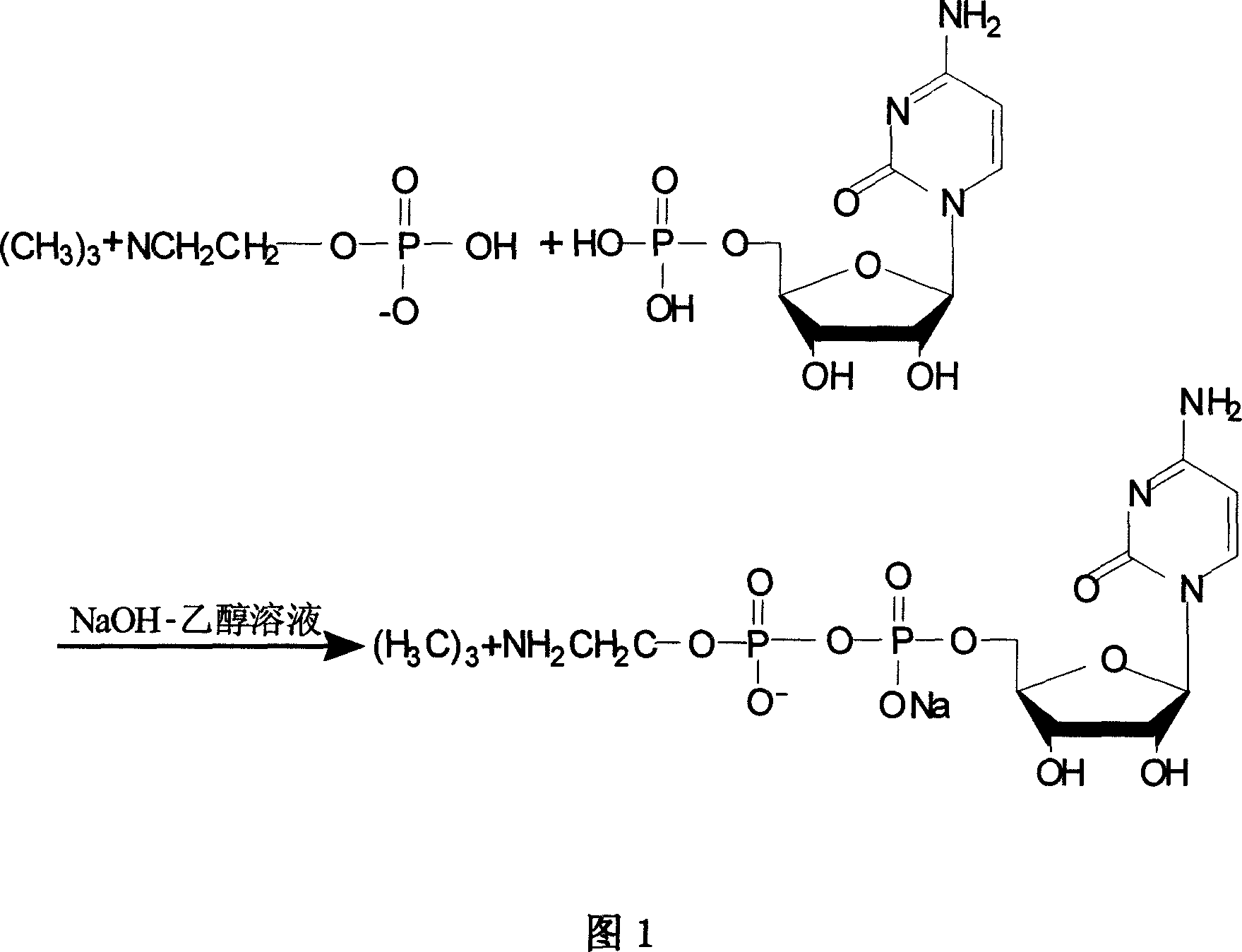

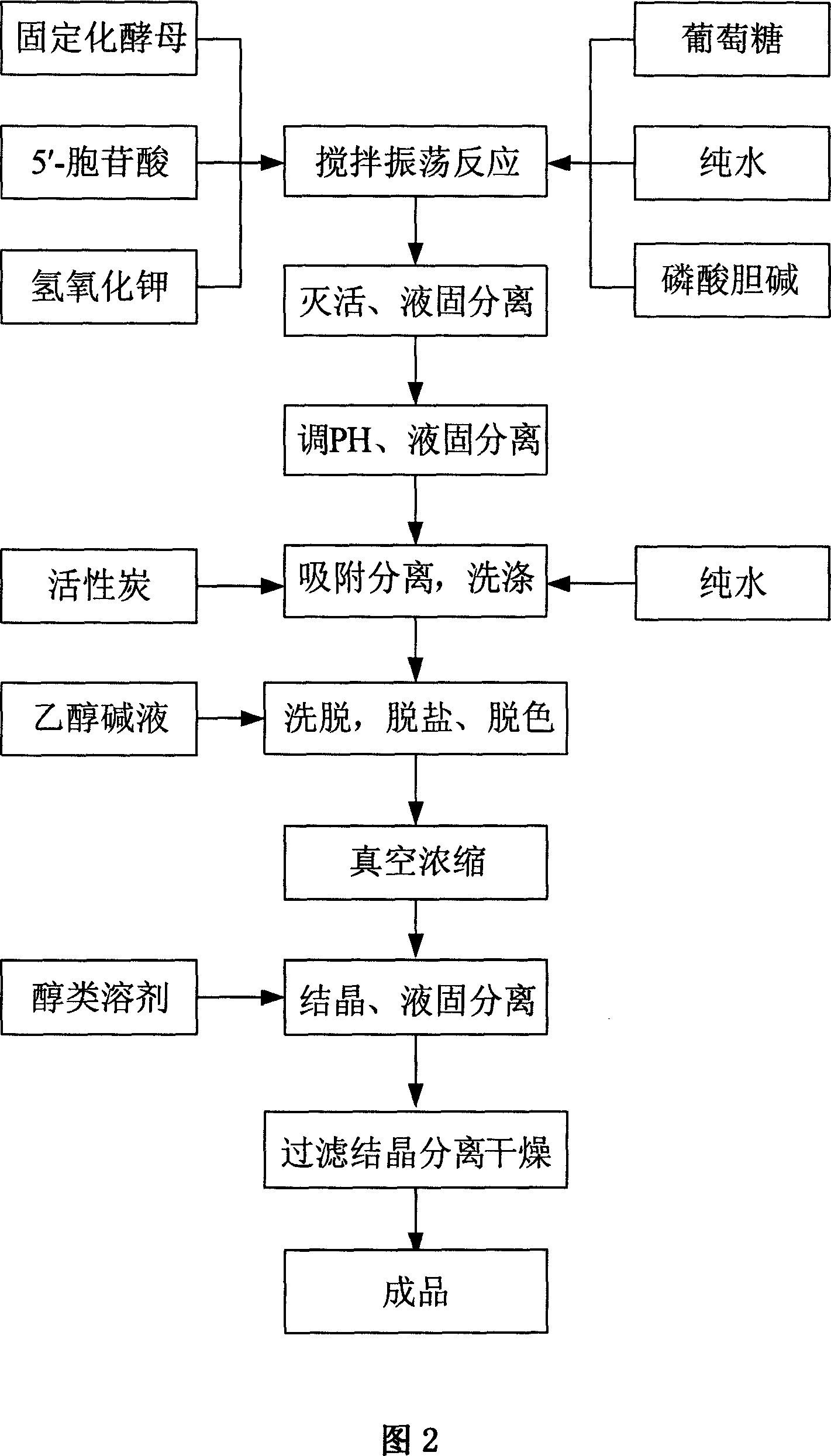

Process for preparing citicoline sodium

The present invention is process of preparing citicoline sodium. The preparation process includes the biotransformation of material including 5'-cytidylate, phosphorylcholine, potassium hydroxide and glucose with yeast as the biocatalyst; extraction and separation with active carbon as the adsorbing carrier, Cl- type ion exchange resin as the separating carrier and re-compounded water-alcohol mixture as the analyzing reagent; and product purification with alcohol solvent as the crystallizing solvent. Compared with available technology, the present invention has the advantages of high product yield and high product purity.

Owner:苏州正济药业有限公司

Method for reinforcing soft soil foundation by using calescence type vacuum preloading way

InactiveCN103255761AImprove bearing capacityDrain fastSoil preservationVacuum extractionVacuum pressure

The invention relates to a method for reinforcing a soft soil foundation by using a calescence type vacuum preloading way. The method comprises the steps of: introducing a foundation heating system on the basis of a regular vacuum preloading way; and keeping an under-film vacuum pressure and a temperature of shallow-layer soft soil in a reinforcing region respectively above 80 kPa and 62 DEG C within a period of time of a reinforcing period so as to rapidly vaporize pore water of foundation soil and pump the vaporized pore water by vacuum extraction equipment to cause sedimentation of the foundation. Compared with the prior art, the method for reinforcing the soft soil foundation by using the calescence type vacuum preloading way has the advantages of shorting the construction period, improving reinforcing effects, reducing settlement after the construction, increasing the bearing capacity of foundation soil and the like.

Owner:TONGJI UNIV

Fertilizer for coating paddy seeds

ActiveCN101665383AIncrease profitDiffusion is fastPlant growth regulatorsBiocideAdditive ingredientPotassium

The invention relates to a fertilizer for coating paddy seeds. The fertilizer is prepared by grinding active ingredients such as nitrogenous fertilizers, phosphate fertilizers, potash fertilizers andother macroelement fertilizers, zinc fertilizers and other trace element fertilizers, compound sodium nitrophenolate as a plant growth regulator and the like, and inactive ingredients such as acid-soluble chitosan as a compound film former, coloring matters, addition agents and the like. The invention relates to a novel fertilizer used for coating paddy seeds. The quality ratio of the fertilizersand the seeds ranges from 1:25 to 1:50. When coated, the surface of the seed can form a fertilizer film with compact film pores, and the fertilizer nutrient can be released slowly through the film pores with a lasting period up to 45-60 days. The invention is applicable to coating various paddy seeds under different ecological conditions, and raising seedlings on a watered bed, raising seedlings on a dry bed, transplanting seedlings or direct seeding can accelerate the growth of the seedlings, improve the resistance of the seedlings, increase the seedling establishment percentage by 8.3%-13.7%, save the fertilizers by 19.5%-27.3%, and save the seeds by 8.1%-13.2%. The invention has the advantages of simple production, low cost and convenient use, and has obvious economical, social and ecological benefits.

Owner:HUNAN AGRICULTURAL UNIV

Method for quickly and efficiently testing liquid absorptivity of pole piece

InactiveCN106814004AHigh flash pointHydrophobicWeighing by absorbing componentObservational errorPole piece

The invention relates to a method for quickly and efficiently testing liquid absorptivity of a pole piece. The method comprises the following steps: cutting a pole piece sample, and weighing the pole piece sample to obtain the mass M0; putting the weighed pole piece sample into a container; pouring a soaking solution into the container, and immersing the pole piece sample; putting the container into a vacuum drying oven, and keeping for 15-20 minutes; taking out the pole piece, wiping the free soaking solution on the surface of the pole piece sample by using filter paper, and weighing the pole piece sample to obtain the mass M1; and calculating the liquid absorptivity epsilon=(M1-M0) / M0 and the electrolyte maintenance dose M=epsilon*M0*rho1 / rho2, wherein rho1 is the electrolyte concentration, and rho2 is the density of the soaking solution. The used octadecane has the advantages of high stability, high flash point and low volatility, is hydrophobic, and thus, is suitable to be used as a solvent for soaking the pole piece. The method overcomes the defects of long time consumption, big measurement errors, great environmental pollution caused by the electrolyte and potential hazards to the operating personnel when the electrolyte is used for soaking the pole piece and testing the liquid absorptivity in the past.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

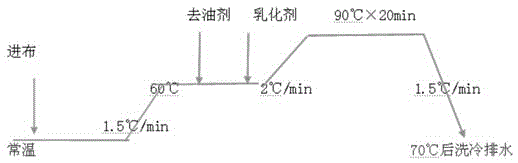

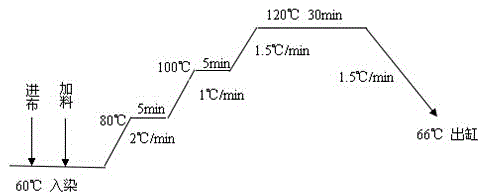

Processing method of multifunctional double-side bicolor knitted fabric

InactiveCN104452069ADurableImprove product added valueWeft knittingHeating/cooling textile fabricsDisperse dyeSewage

The invention discloses a processing method of multifunctional double-side bicolor knitted fabric. The processing method includes steps of preparing gray fabric, pre-treating, dyeing, dewatering, sectioning, shaping, inspecting and packaging. By adopting two different kinds of functional fabric and a double-side knitting method, the fabric has four functions of being hygroscopic and sweat releasing, antibiosis, static prevention and pilling resistance integrated and is durable. By adopting low-temperature disperse dye and cationic dye-one-bathing-one-stage method, dyeing temperature is lowered, sewage discharge is reduced, and influence on nano-silver fiber antibiosis performance by high temperature is prevented. Cationic modification polyester is adopted on the front side, and the fabric is bright in color, soft in hand feeling, good in hygroscopic performance and conductivity and pilling resistance and overcomes the defect of poor wearability of common polyester. Nano-silver hygroscopic and sweat-releasing profile polyester fibers are adopted on the back side, so the close-fitting side of the fabric is hygroscopic and sweat-releasing, anti-microbial and odor resistant, and clothes manufactured by the fabric are healthy, environment friendly and comfortable and have the double-side bicolor effect.

Owner:IANGSU COLLEGE OF ENG & TECH

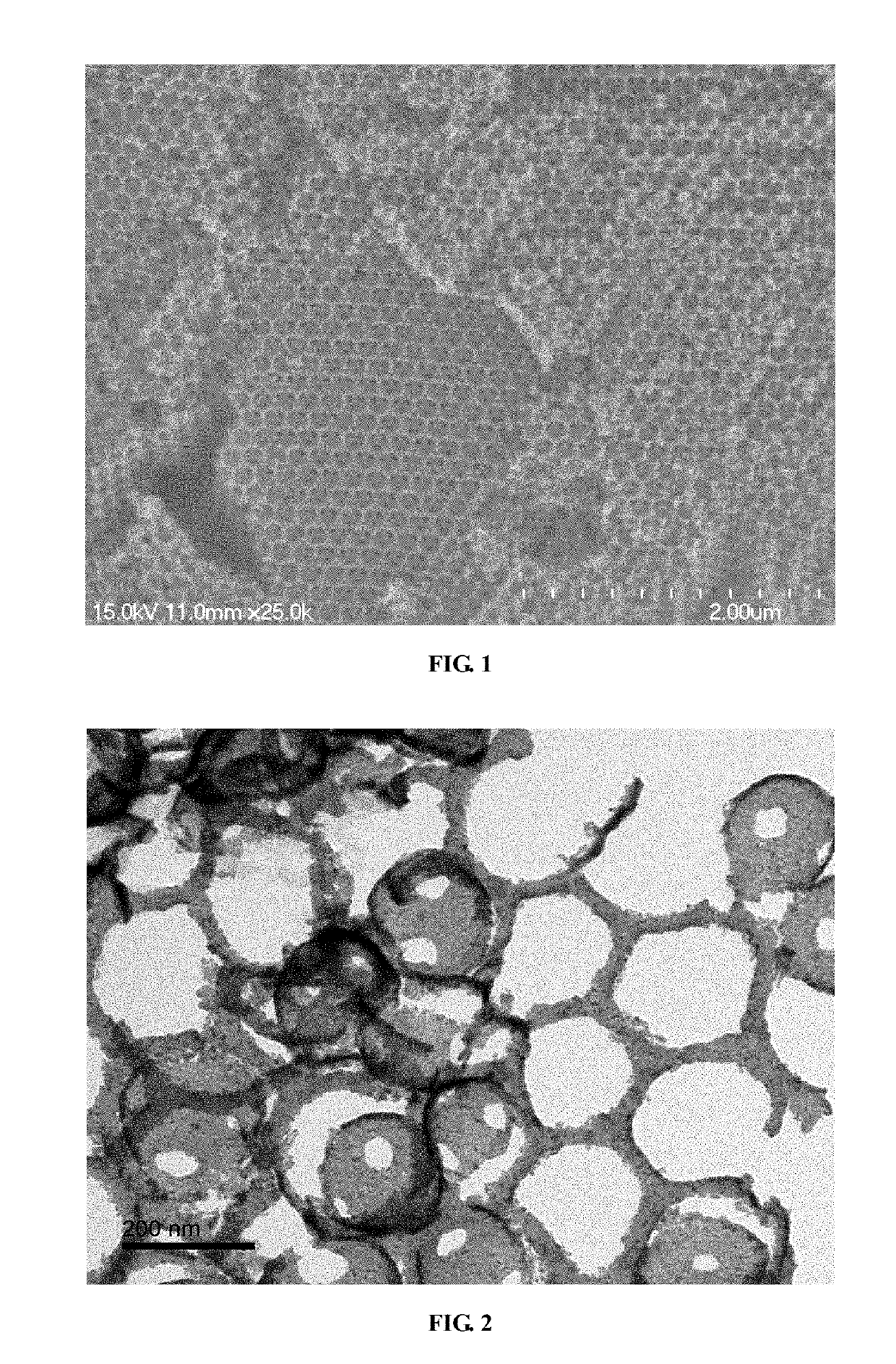

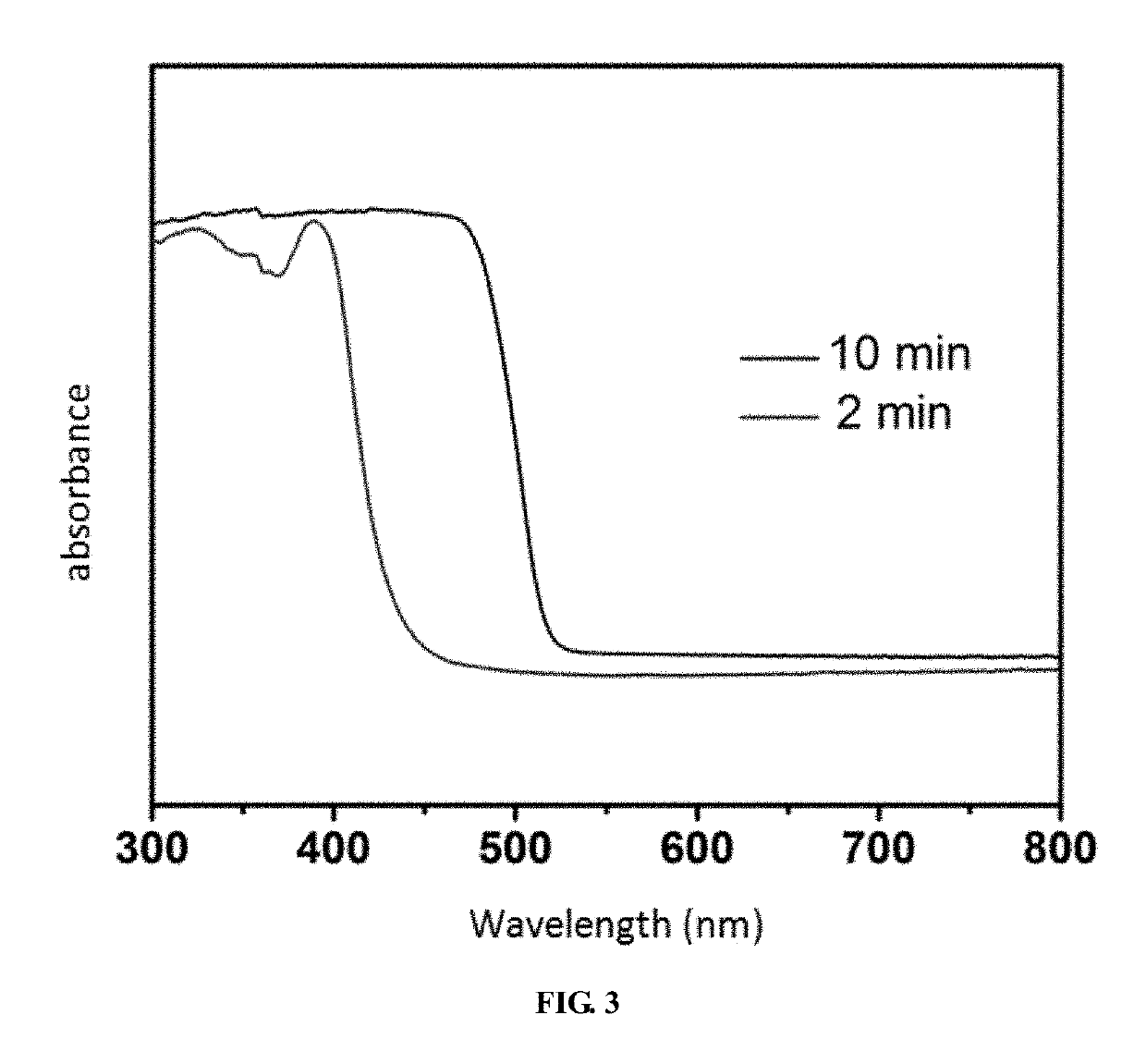

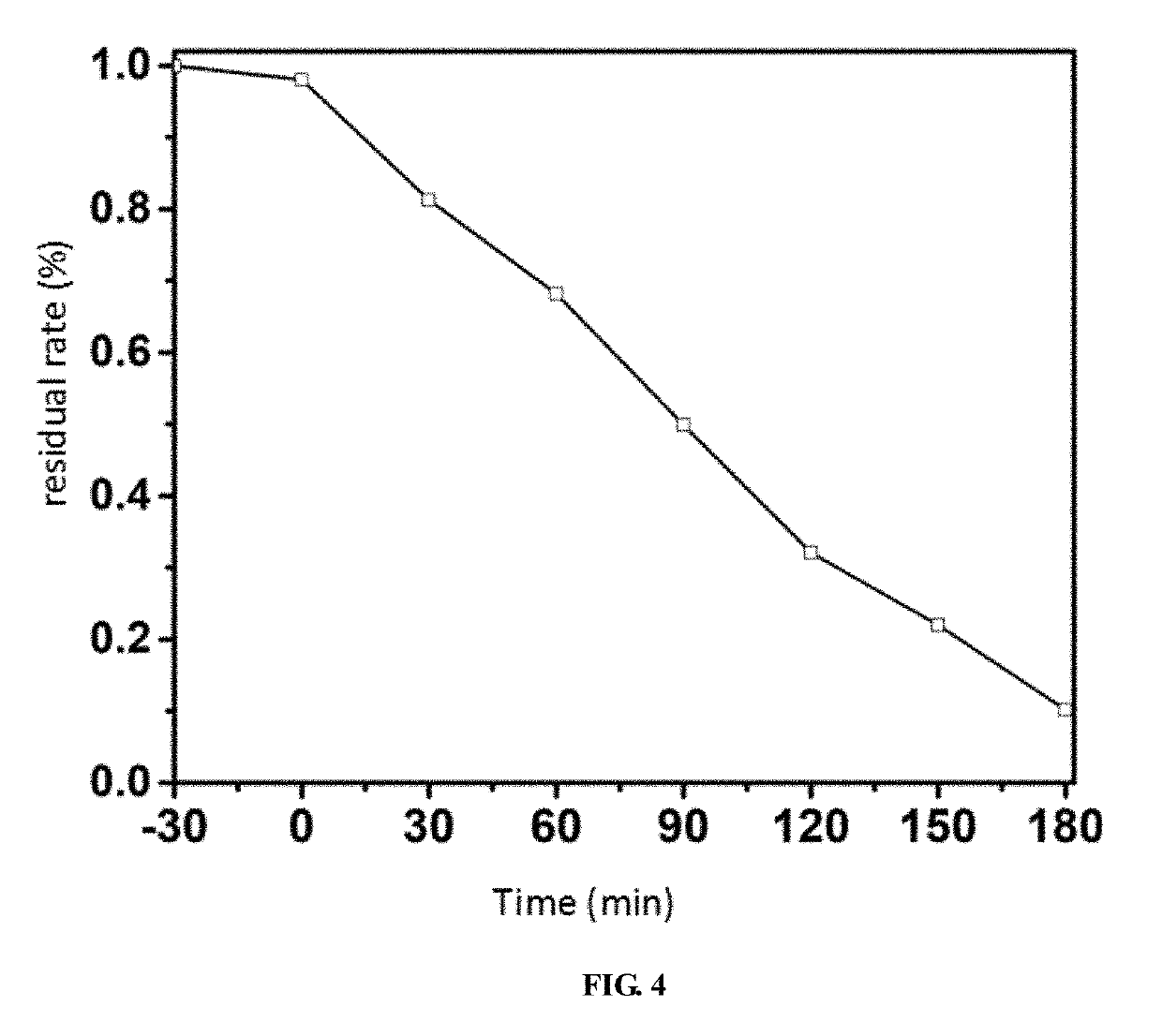

Three-dimensional composite material, preparation method thereof and application thereof in removal of water pollutants by visible light catalytic degrading

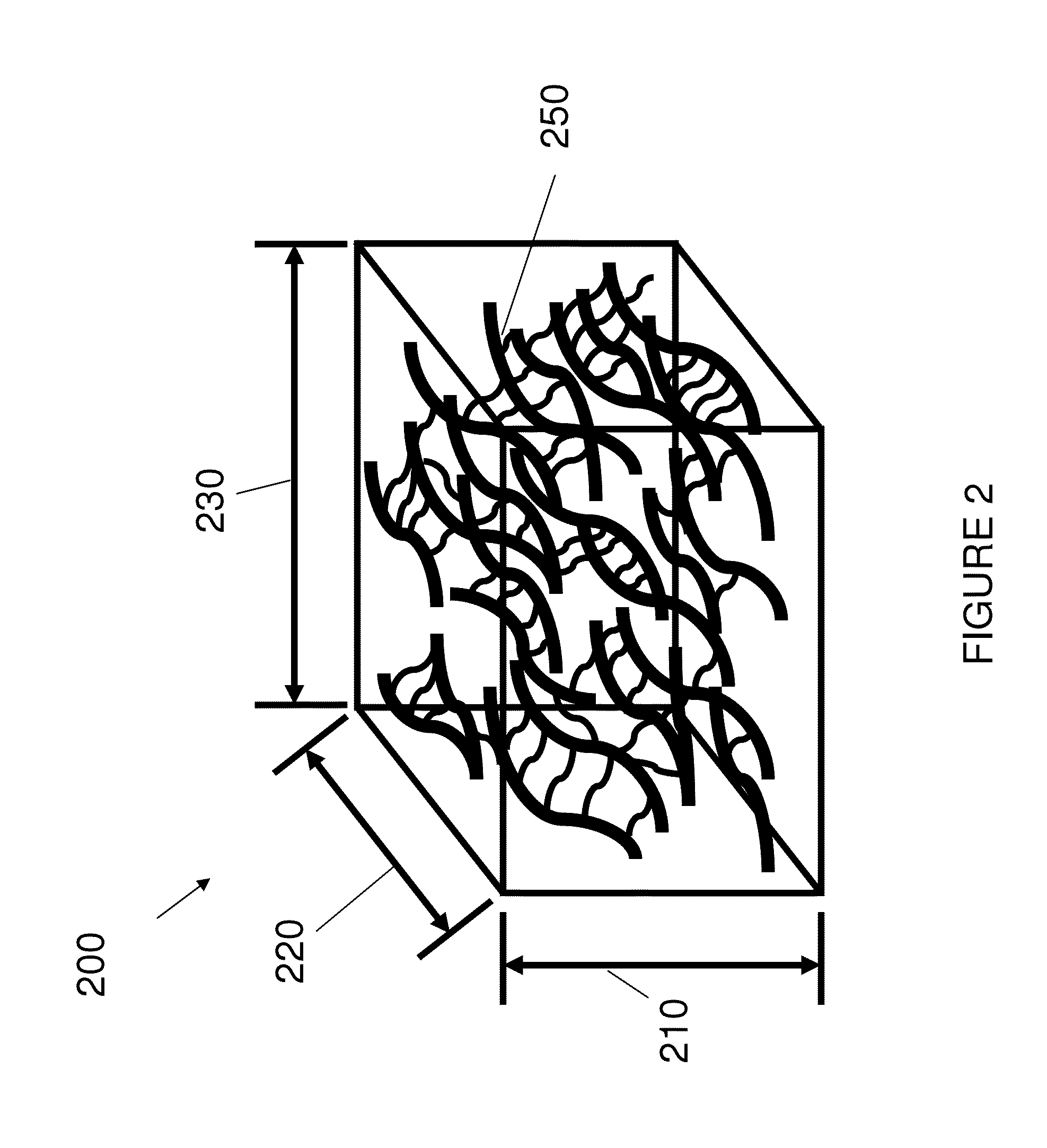

ActiveUS20190329233A1Efficient separationImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsMOPSPolystyrene

A method of preparing a three-dimensional composite material includes the following steps: preparing polystyrene by soap-free emulsion polymerizing, obtaining polystyrene opal by a vertical deposition method, synthesizing MoP IO (molybdenum phosphide inverse opal), and compounding with quantum points CdS, so as to obtain a novel inorganic composite material, namely cadmium sulfide quantum dot-compounded MoP IO. The preparation method has the advantages that the MoP IO is prepared first, and the MoP IO is of a three-dimensional cyclic pore structure and has the photonic band gap feature, so that the MoP IO has better catalysis effect in light catalysis in comparison with that of common porous material; the MoP IO is compounded with the cadmium sulfide quantum dots, so that the light absorbing ability is enhanced, and the composite material capable of absorbing the visible light is obtained.

Owner:SUZHOU UNIV

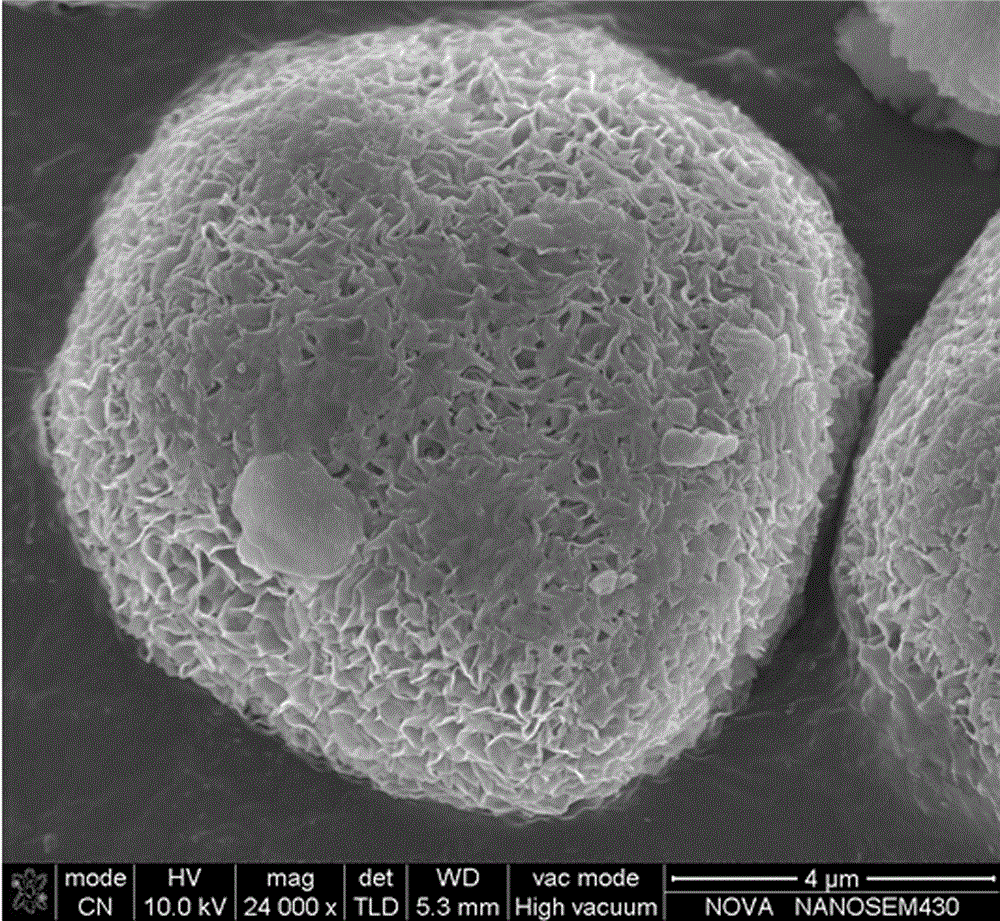

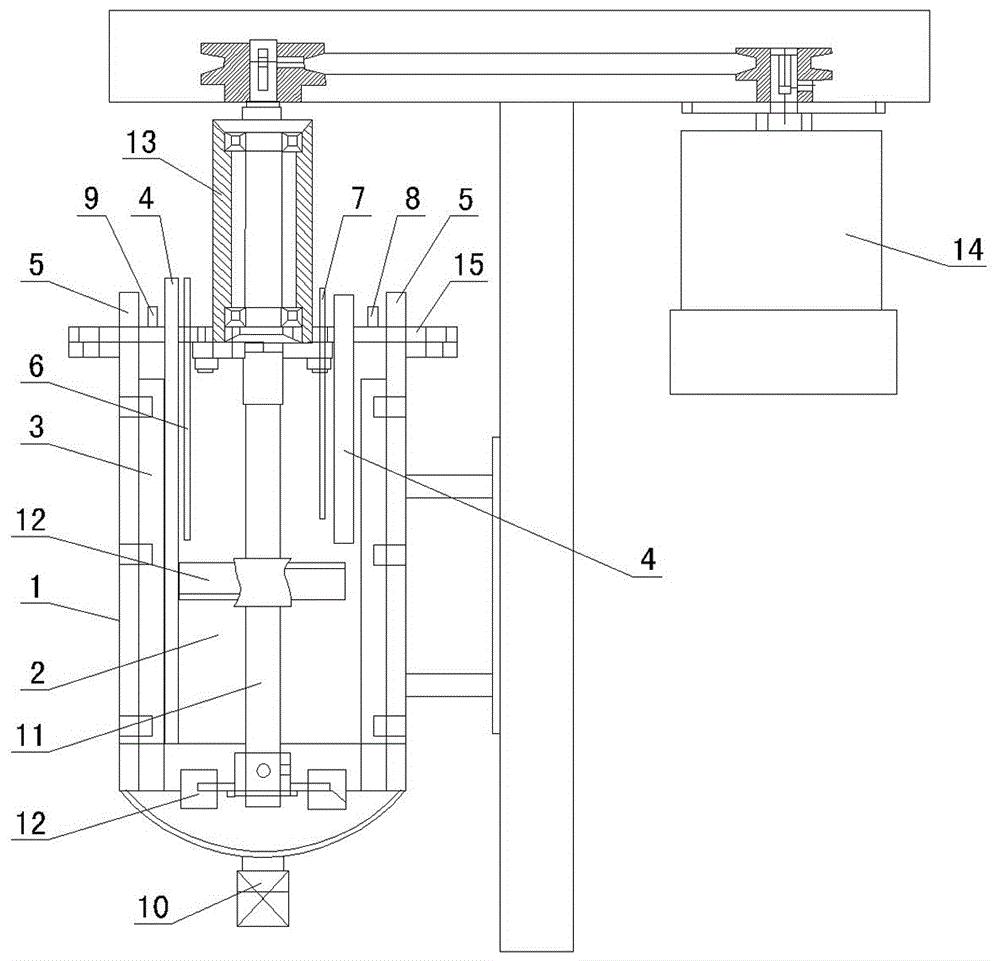

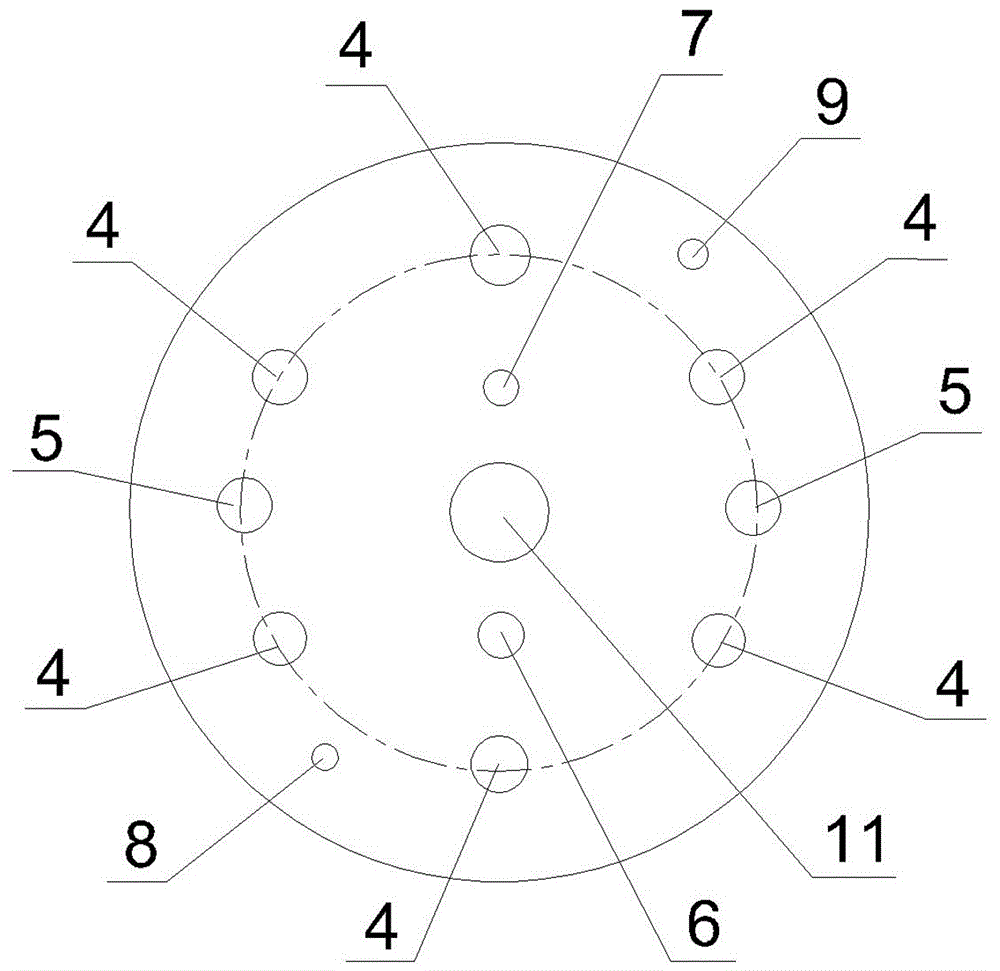

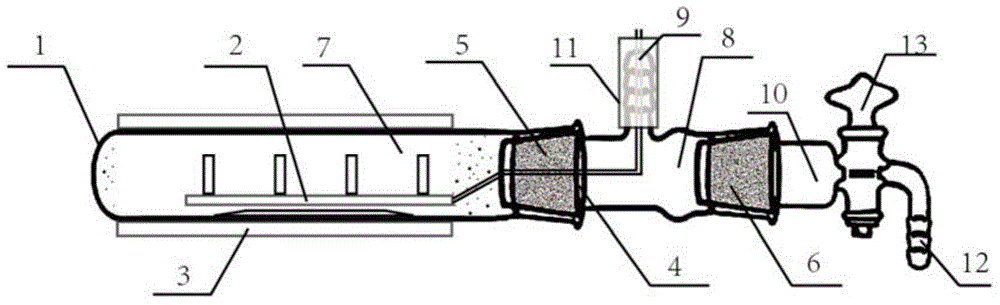

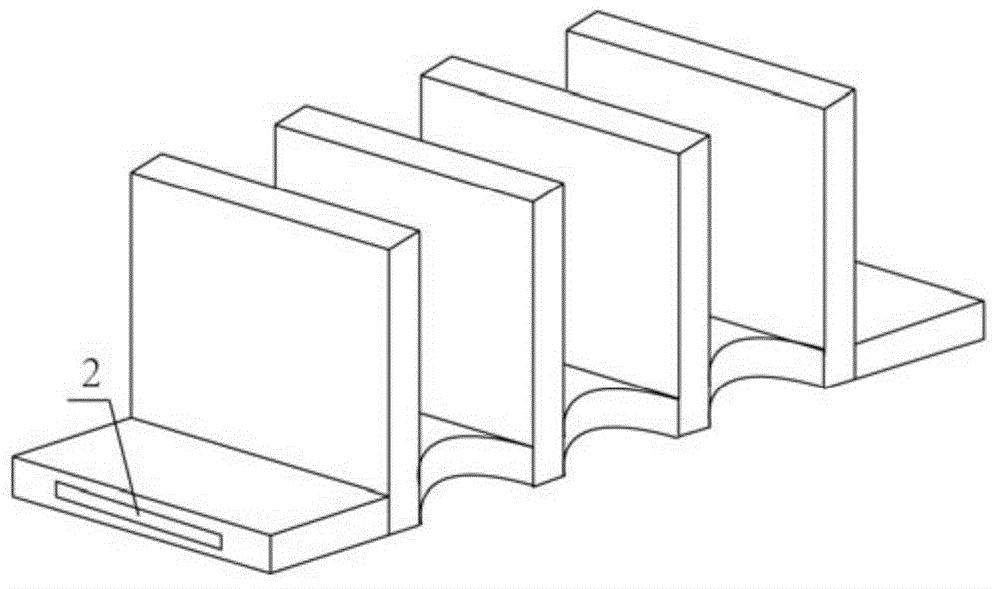

Preparation method and device of nickel-cobalt-aluminum anode material precursor

InactiveCN106058244ACo-precipitated evenlyCo-precipitation realizationCell electrodesAluminum IonAluminum anode

The invention discloses a preparation method and a preparation device of a nickel-cobalt-aluminum anode material precursor. The preparation method is characterized by comprising the following steps: preparing a nickel-cobalt-aluminum mixed salt solution containing a complexing agent and a strong base solution containing ammonia water; combining the nickel-cobalt-aluminum mixed salt solution with the strong base solution at a uniform flowing speed and synchronously filling into a reaction kettle with a base solution for co-precipitation reaction; after the nickel-cobalt-aluminum mixed salt solution is filled, stopping adding the strong base solution, and after the reaction is completed, aging the slurry, and further performing liquid-solid separation, thereby obtaining the nickel-cobalt-aluminum anode material precursor. According to the preparation method and the device, the complexing agent is directly added into an aluminum solution, and the complexing agent is complexed with aluminum ions before the co-precipitation reaction, so that aluminum can be prevented from nucleating and precipitating immediately after entering the reaction system; meanwhile, a mixed salt solution is prepared from nickel, cobalt and aluminum together, so that the ratio of nickel and cobalt to aluminum in the formed precursor is accordant with that of an expected nickel-cobalt-lithium aluminate material at any moment, nickel, cobalt and aluminum can be subjected to uniform co-precipitation reaction, and the nickel-cobalt-aluminum anode material precursor of which indexes such as the morphology, the granularity and the density are all higher than those of similar products can be prepared.

Owner:GUANGDONG INST OF RARE METALS

Deep softening method of thick oil sewage

ActiveCN102815765ASolving the scaling problem of boilers reused in thermal recoveryAvoid badWater/sewage treatment by ion-exchangeWater qualitySewage

The invention relates to a deep softening method of thick oil sewage, which comprises the following steps: preterating thick oil sewage to remove impurities in the thick oil sewage, and carrying out preliminary softening treatment with a macroporous weak acid resin until the pH value of the thick oil sewage reaches 7-9 and the temperature reaches 57-80 DEG C; passing the pretreated thick oil sewage through an adsorption tower or adsorption column filled with a chelating resin at the flow rate of 20-30 BV / h to carry out adsorption treatment; and when the adsorption reaches the leakage point, obtaining the thick oil sewage subjected to deep softening. The method provided by the invention is a treatment process capable of efficiently softening thick oil sewage according to the water quality characteristic of the thick oil sewage; and the method provided by the invention can still be used repeatedly in a thermal recovery boiler without generating scales after saving the silicon removal system.

Owner:PETROCHINA CO LTD

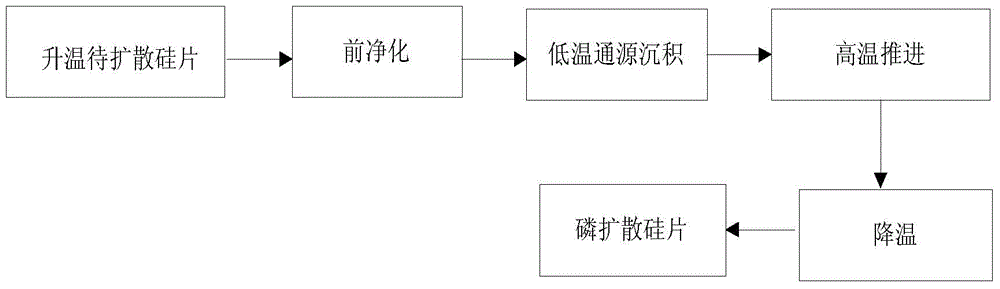

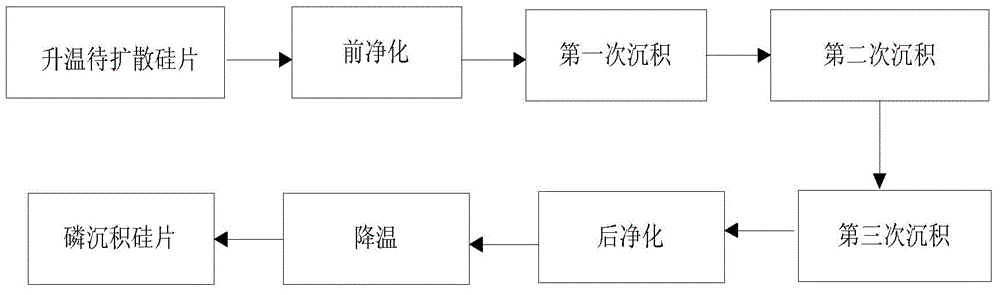

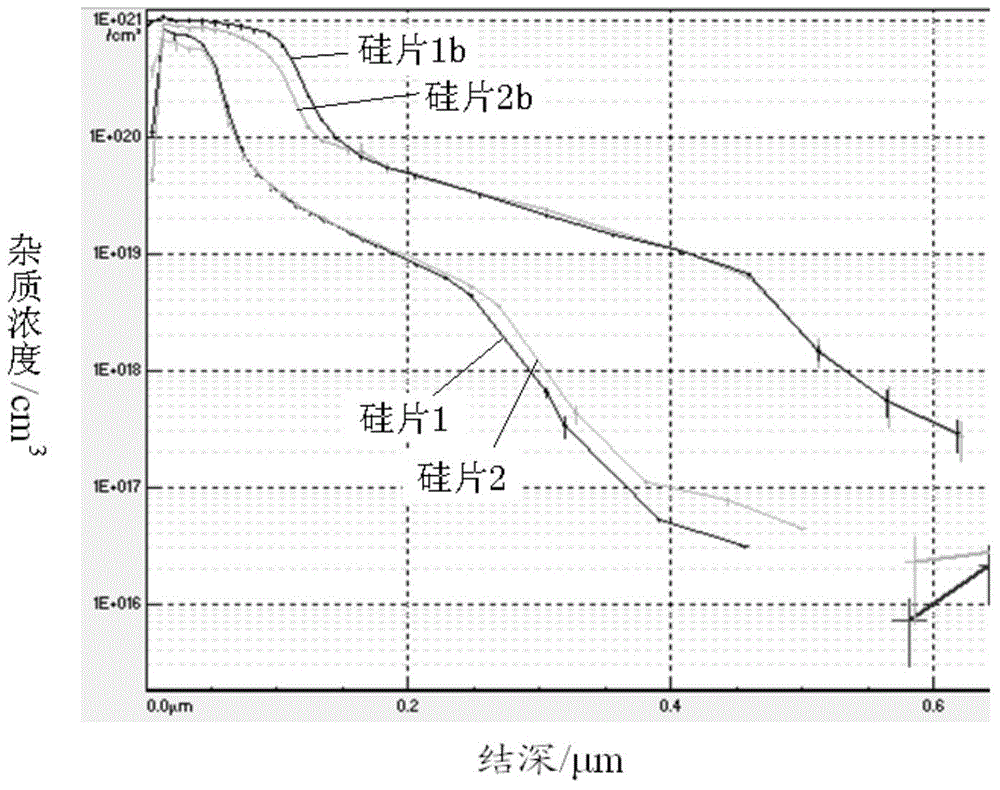

Phosphorus doping silicon wafer, manufacturing method of phosphorus doping silicon wafer, solar cell and manufacturing method of solar cell

ActiveCN103606596AGood electrical parametersImprove conversion efficiencyFinal product manufactureDiffusion/dopingConcentration gradientSolar cell

The invention discloses a phosphorus doping silicon wafer, a manufacturing method of the phosphorus doping silicon wafer, a solar cell and a manufacturing method of the solar cell. The manufacturing method of the phosphorus doping silicon wafer includes the steps of warming of a silicon wafer to be doped, prepurification, phosphorus deposition and diffusion and cooling. In the phosphorus deposition and diffusion step, POC13 is used as a phosphorous source and reacts with O2 for step-by-step deposition diffusion, and in the step-by-step deposition and diffusion step, the volume ratio of POC13 to O2 is decreased progressively. By the adoption of the step-by-step deposition diffusion process, the diffusion speed is high in the initial stage, phosphorus on the surface of the silicon wafer diffused into the interior of a substrate of the silicon wafer, the concentration of phosphorus on the surface of the silicon wafer is gradually reduced, in the follow-up process, the amount of phosphorus deposited on the surface of the substrate of the silicon wafer is reduced along with reduction of the concentration of the phosphorous source, and the concentration of phosphorus distributed on the surface and the interior of the substrate of the silicon wafer is larger than the impurity concentration gradient under the condition that the phosphorous source POC13 with large concentration is continuously supplemented in the current deposition and diffusion process. Good electric parameters are acquired, and conversion efficiency of the solar cell is improved.

Owner:YINGLI GRP

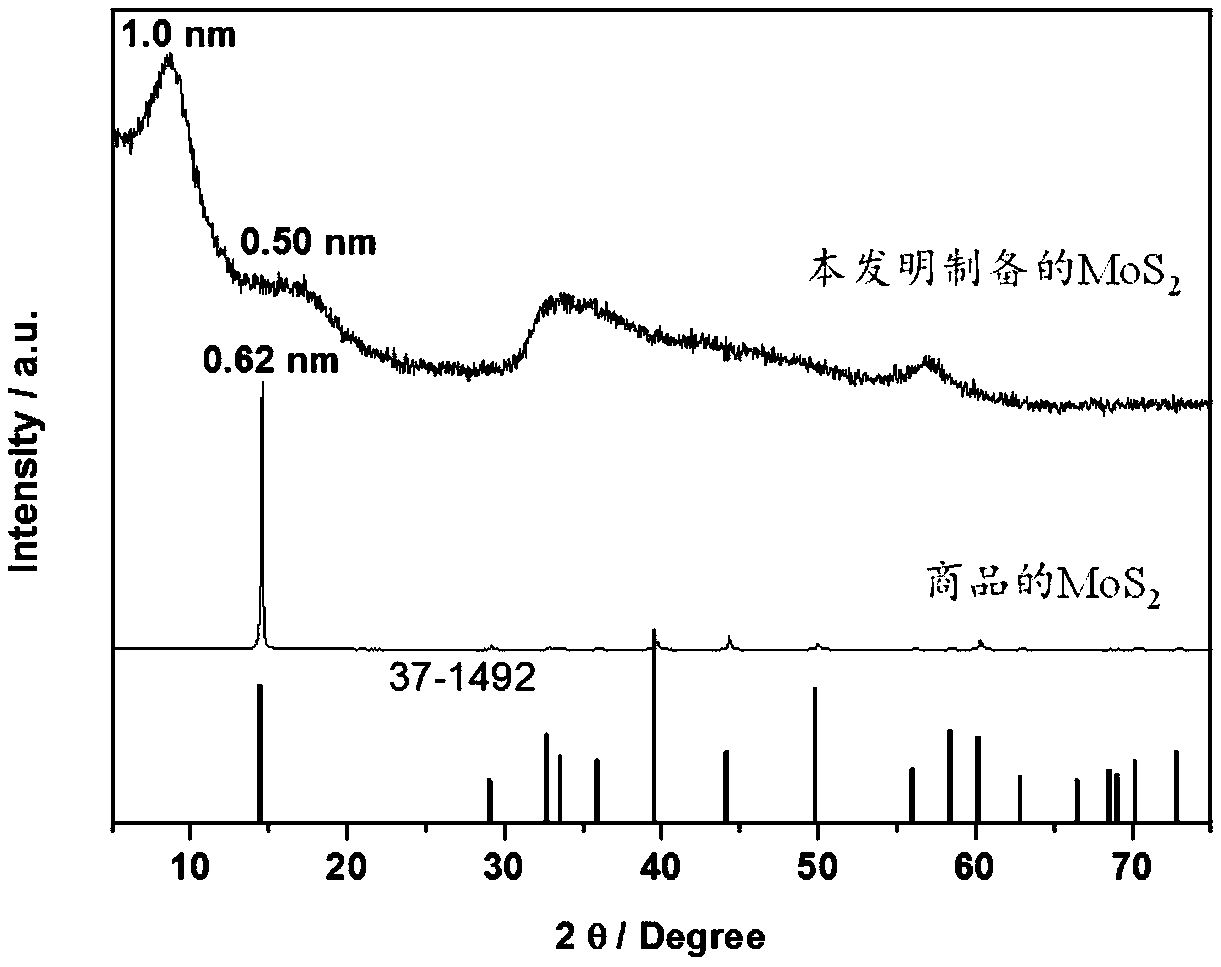

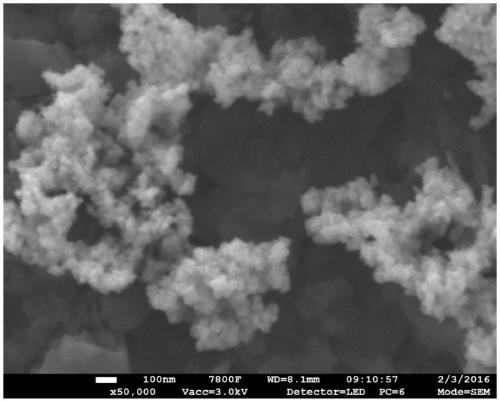

Preparation method of high-activity molybdenum sulfide hydrogenation catalyst

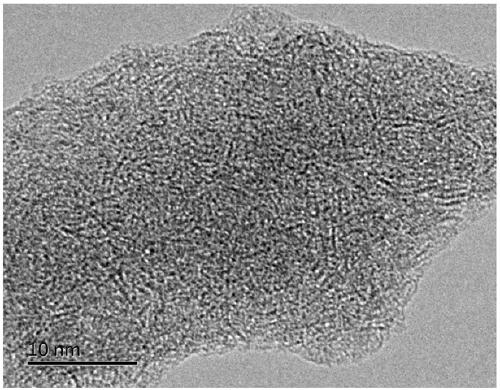

InactiveCN111229258AAvoid reunionAvoid accumulationCatalyst activation/preparationHydrocarbon oils refiningPtru catalystReaction temperature

The invention discloses a preparation method of a high-activity molybdenum disulfide (MoS2) hydrogenation catalyst. The method comprises the following steps: dissolving or dispersing a certain amountof molybdenum source and reductive sulfur source in a high-viscosity solution, and adding a reducing agent to obtain a solution or turbid liquid; regulating and controlling the types of the molybdenumsource, the sulfur source and a solvent; putting the prepared solution or turbid liquid into a closed stainless steel reaction kettle, and controlling the reaction temperature to be 120-220 DEG C andthe reaction time to be 3-72 hours; and after the reaction is finished, cooling, separating, washing and drying to obtain the high-activity MoS2 hydrogenation catalyst. The synthesis method disclosedby the invention has the advantages of low temperature, low pressure, no need of adding an additional reducing agent and the like, and the prepared MoS2 hydrogenation catalyst has the advantages thatthe interlayer spacing is enlarged, the accumulation degree is less than 3 layers, and the lamellar length is shorter than 10nm, so that the highest hydrogenation active site exposure rate is achieved. The high-activity exposed nano MoS2 hydrogenation catalyst synthesized by the method disclosed by the invention has extremely high catalytic hydrogenation activity in the field of catalytic hydrogenation of oil products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Diaphragm, method for preparing diaphragm and secondary battery comprising diaphragm

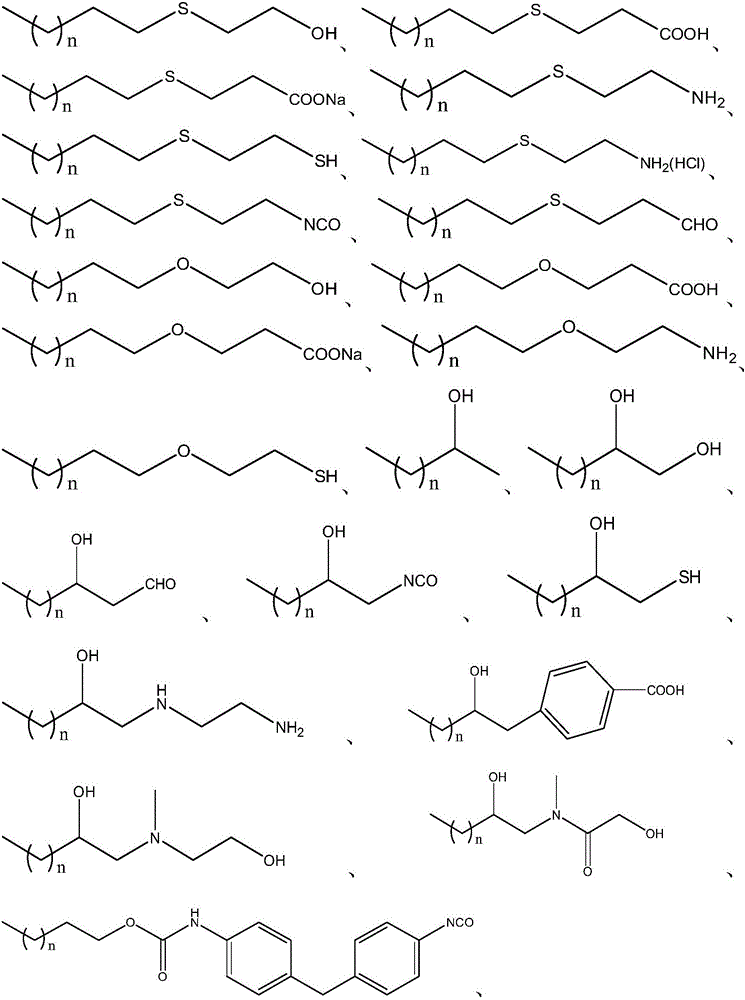

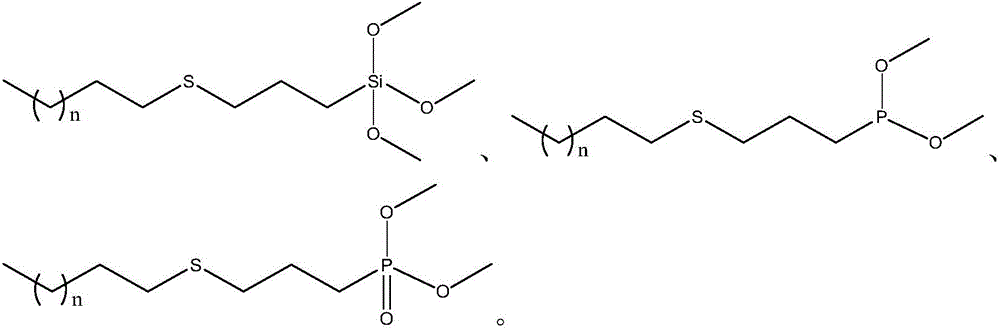

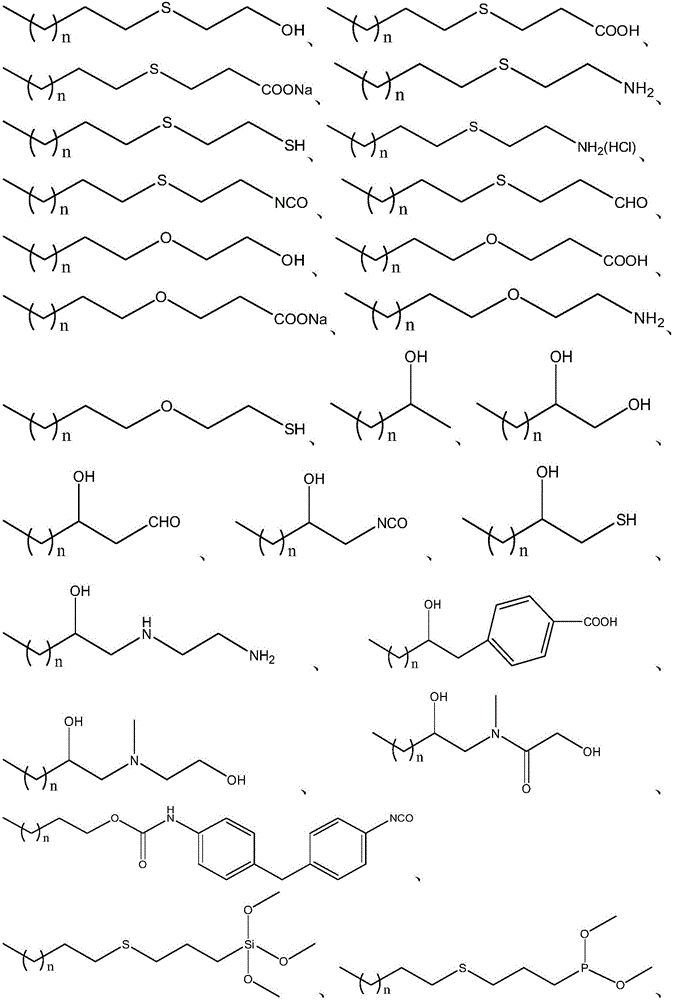

InactiveCN105789538AGood electrophilic performanceImprove hydrophilicityCell component detailsPolyvinyl butyralPolyolefin

The invention relates to the field of secondary batteries, in particular to a diaphragm, a method for preparing the diaphragm and a secondary battery comprising the diaphragm. The diaphragm comprises a base material and a modification layer arranged on the surface of the base material, wherein the modification layer contains amphiphilic polymers which are at least one of polyvinyl butyral, amphiphilic segmented copolymer and polyolefin with a functional end group, and the functional end group at least contains a hydrophilic group. The diaphragm has high electrolyte loving property and water loving property, so that the diffusion rate of electrolyte in a prepared lithium ion battery is high, infiltration time is shortened, and the charge-discharge rate of the battery is increased; besides, the standing time of a naked battery cell after injection can be shortened, and then efficiency is improved and cost is reduced.

Owner:CONTEMPORARY AMPEREX TECH CO

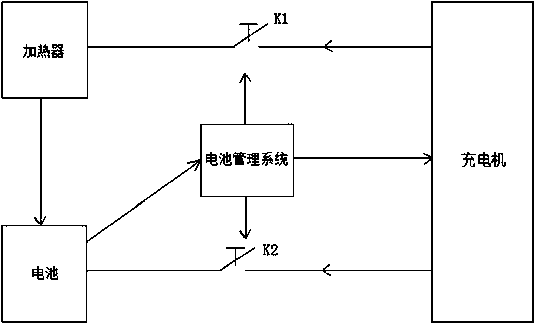

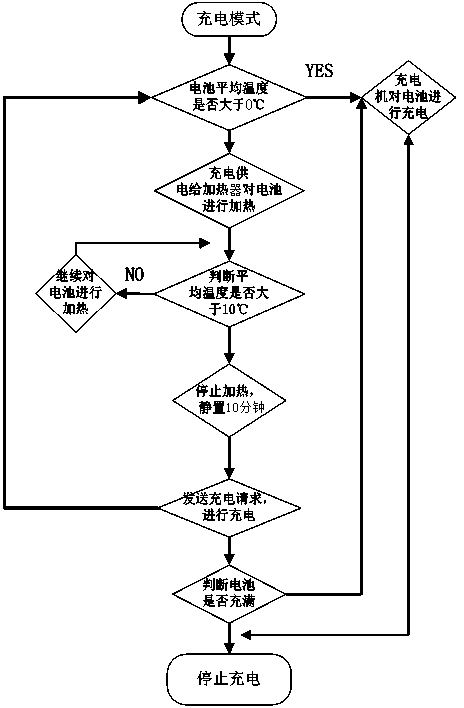

Method for controlling battery heating in charging mode

InactiveCN103682525AImprove conductivityAvoid damageSecondary cells charging/dischargingBatteriesStable stateIonic diffusion

The invention discloses a method for controlling battery heating in a charging mode. A charging system is employed and comprises a charger, a battery management system and a heater, wherein the charger comprises a first output end and a second output end; the first output end is connected with a charged battery by a charge relay; and the second output end is connected with the heater by a heating relay. According to the method, a specific temperature value is set; when the mean temperature of the battery is in different temperature intervals, the charger changes working states flexibly, so that the battery is charged only under the conditions of the appropriate temperature and the stable state; the heating is required to be controlled at the too low temperature; and the battery is charged after cooled for a period of time at the excess temperature. The strong conductivity of the battery can be maintained, the ionic diffusion speed is high, so that the damage to the battery caused by charging at the low temperature is reduced, and the influence on the battery charging when the state of the battery is unstable can be avoided.

Owner:HUIZHOU EPOWER ELECTRONICS

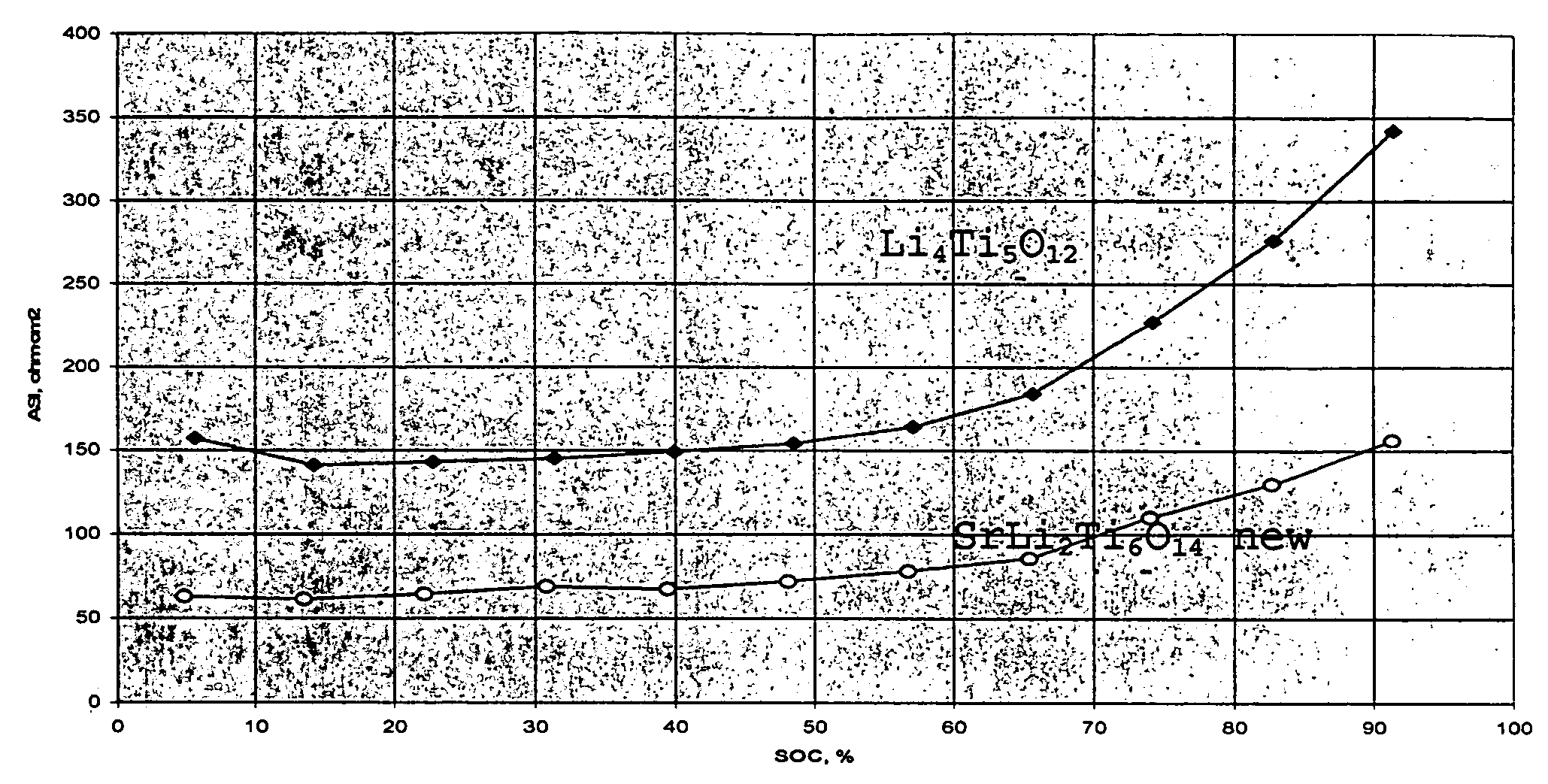

Anode material for lithium batteries

ActiveUS7390594B2Good ionicImprove abilitiesNegative electrodesTitanatesPolymer electrolytesLithium metal

Primary and secondary Li-ion and lithium-metal based electrochemical cell system. The suppression of gas generation is achieved through the addition of an additive or additives to the electrolyte system of respective cell, or to the cell itself whether it be a liquid, a solid- or plastized polymer electrolyte system. The gas suppression additives are primarily based on unsaturated hydrocarbons.

Owner:CHICAGO UNIV OF THE +1

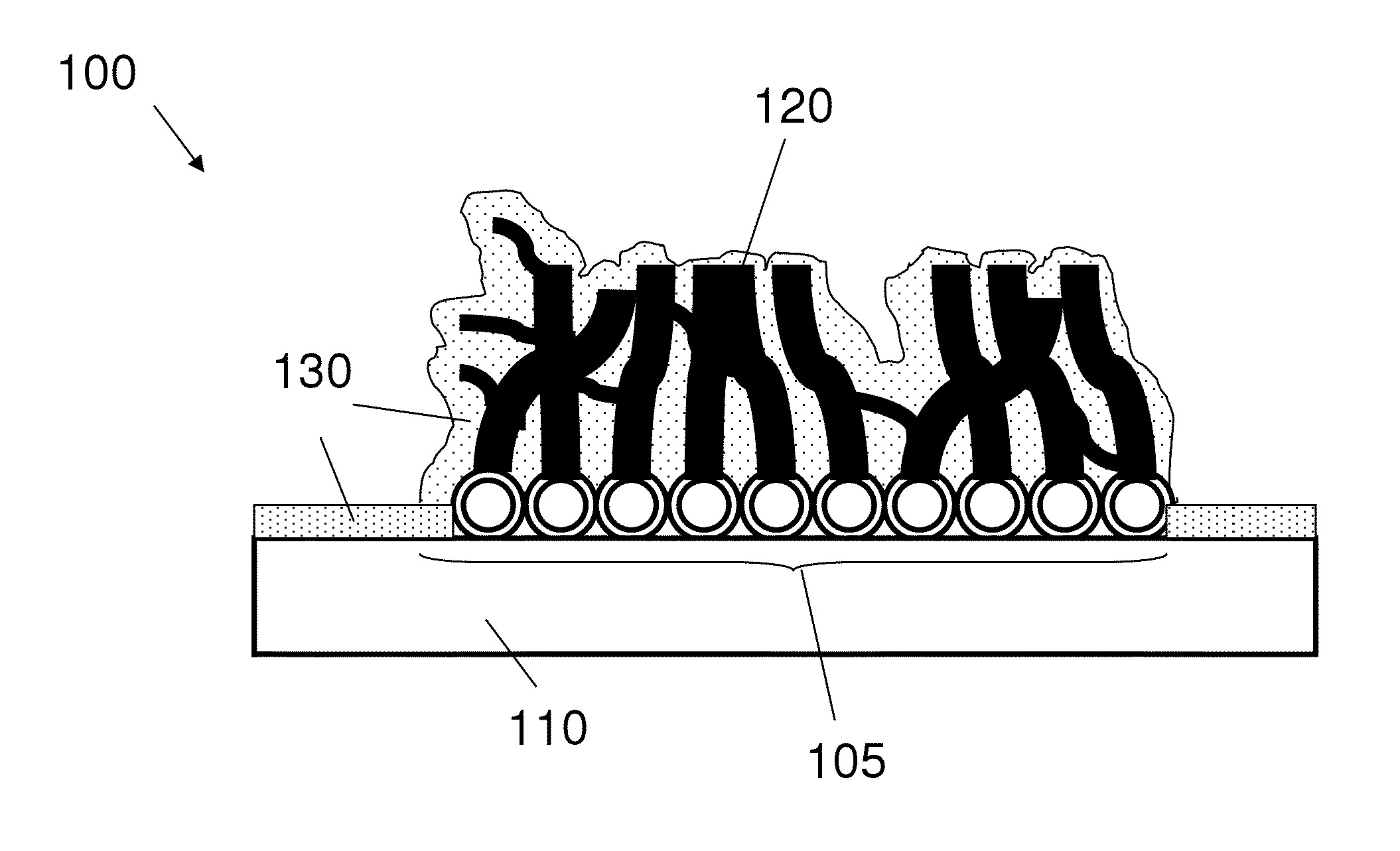

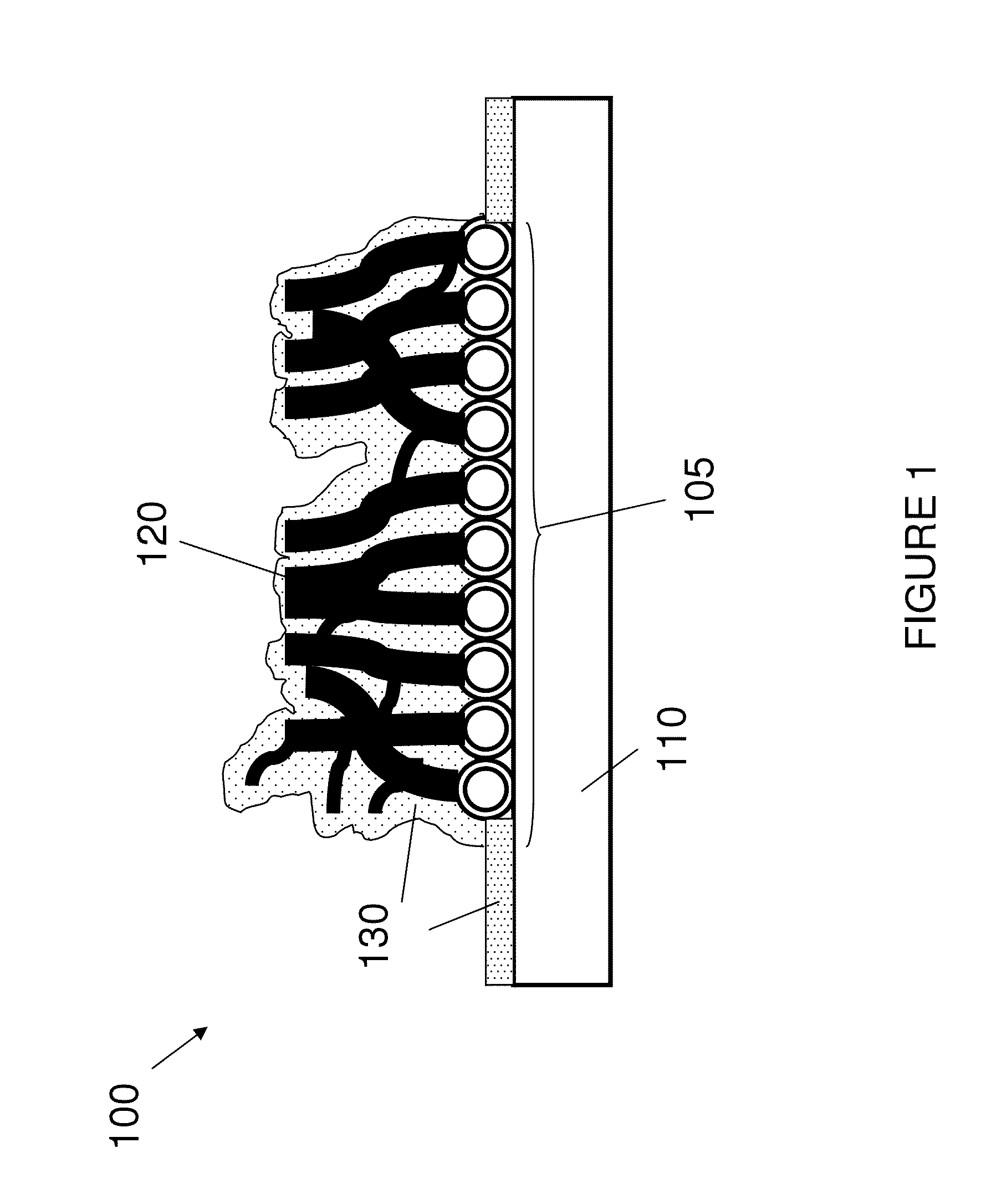

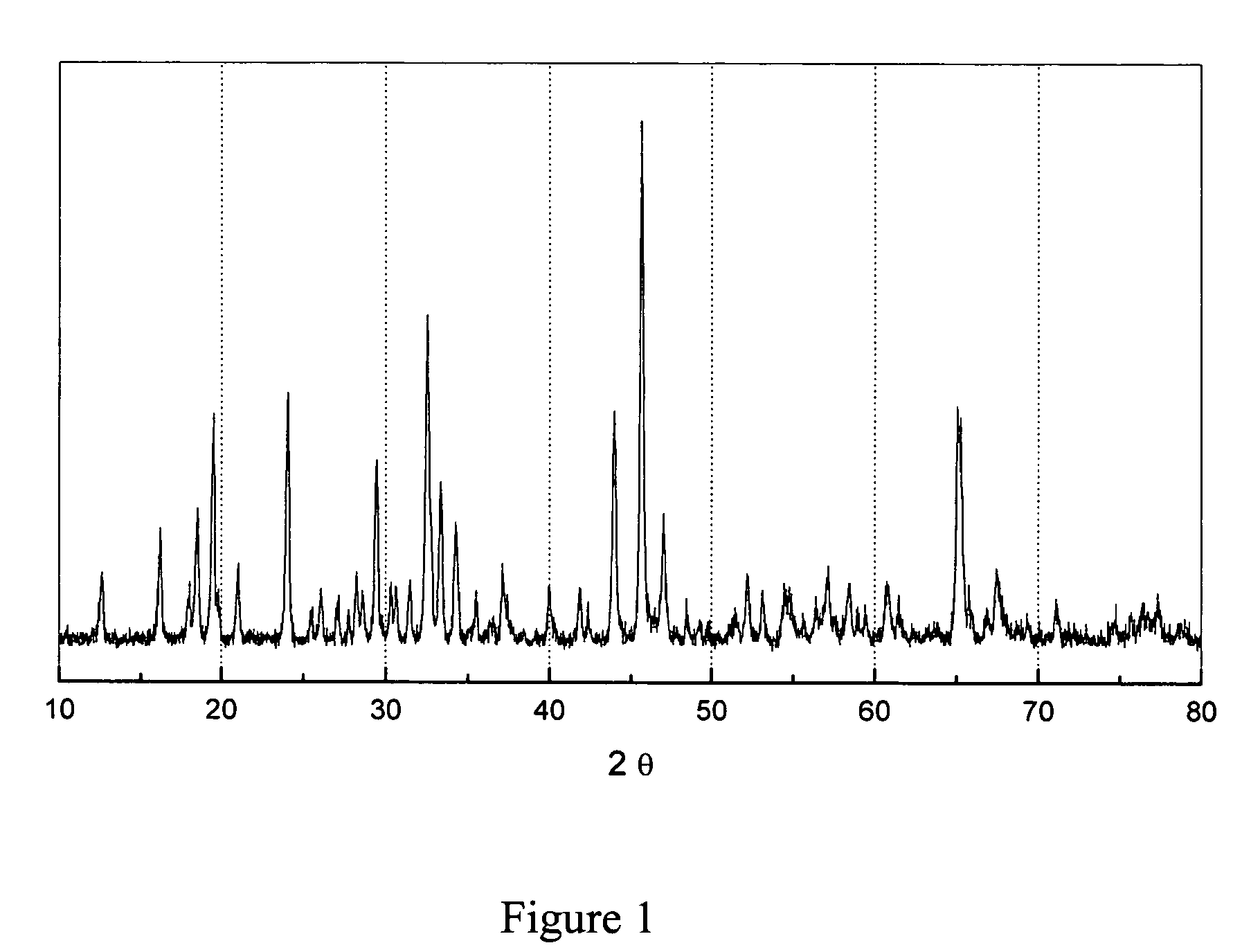

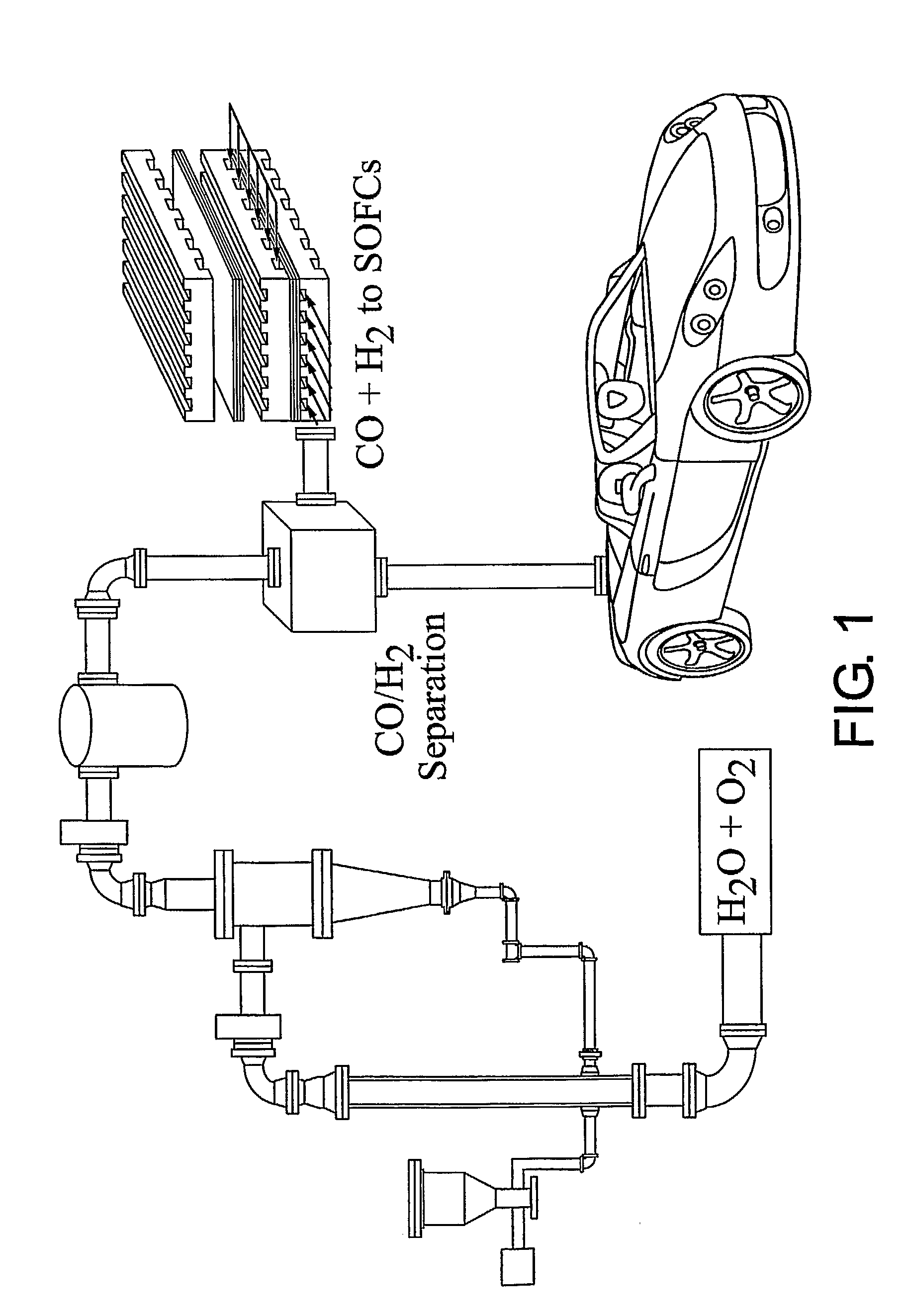

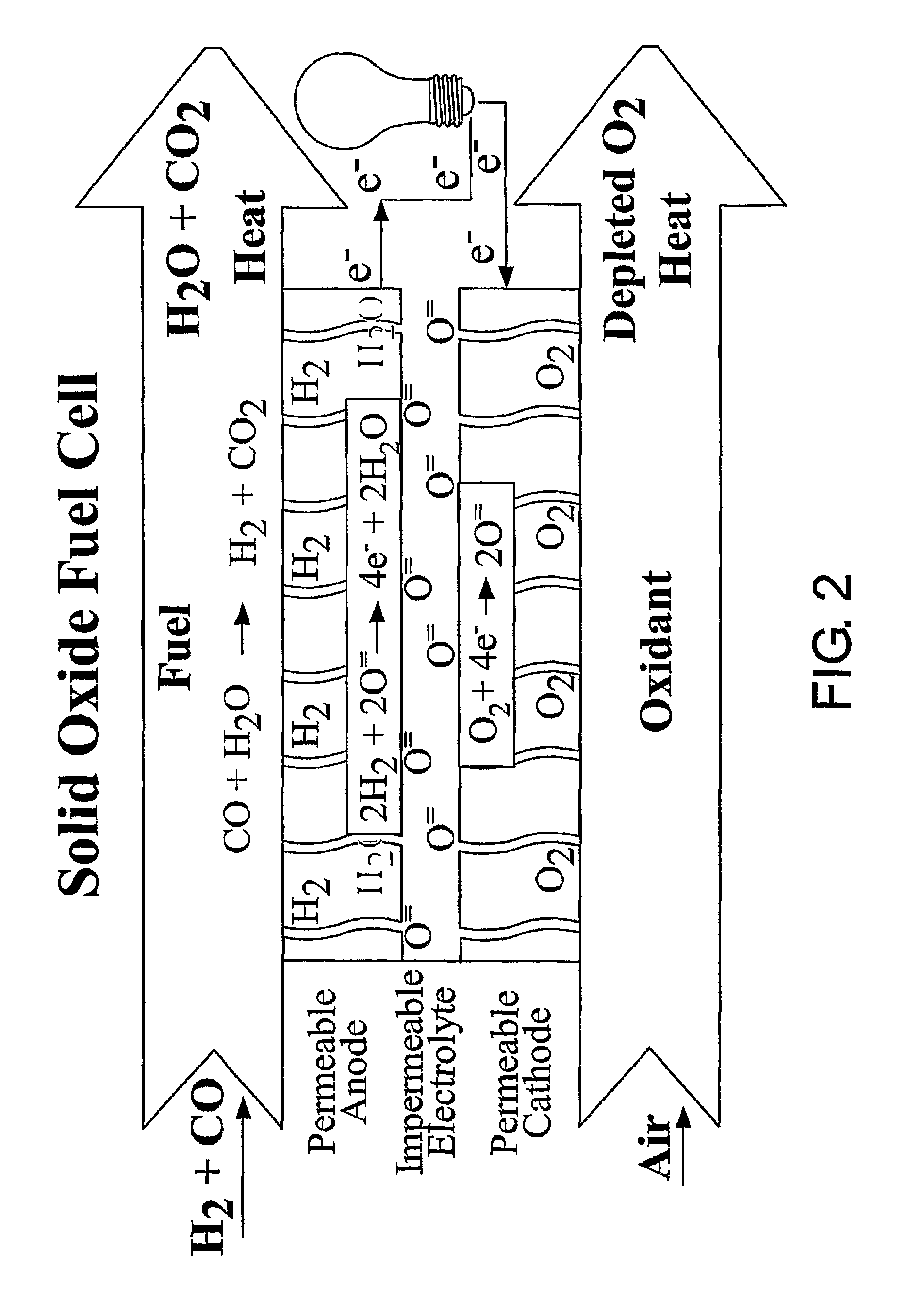

Sulphur-Tolerant Anode For Solid Oxide Fuel Cell

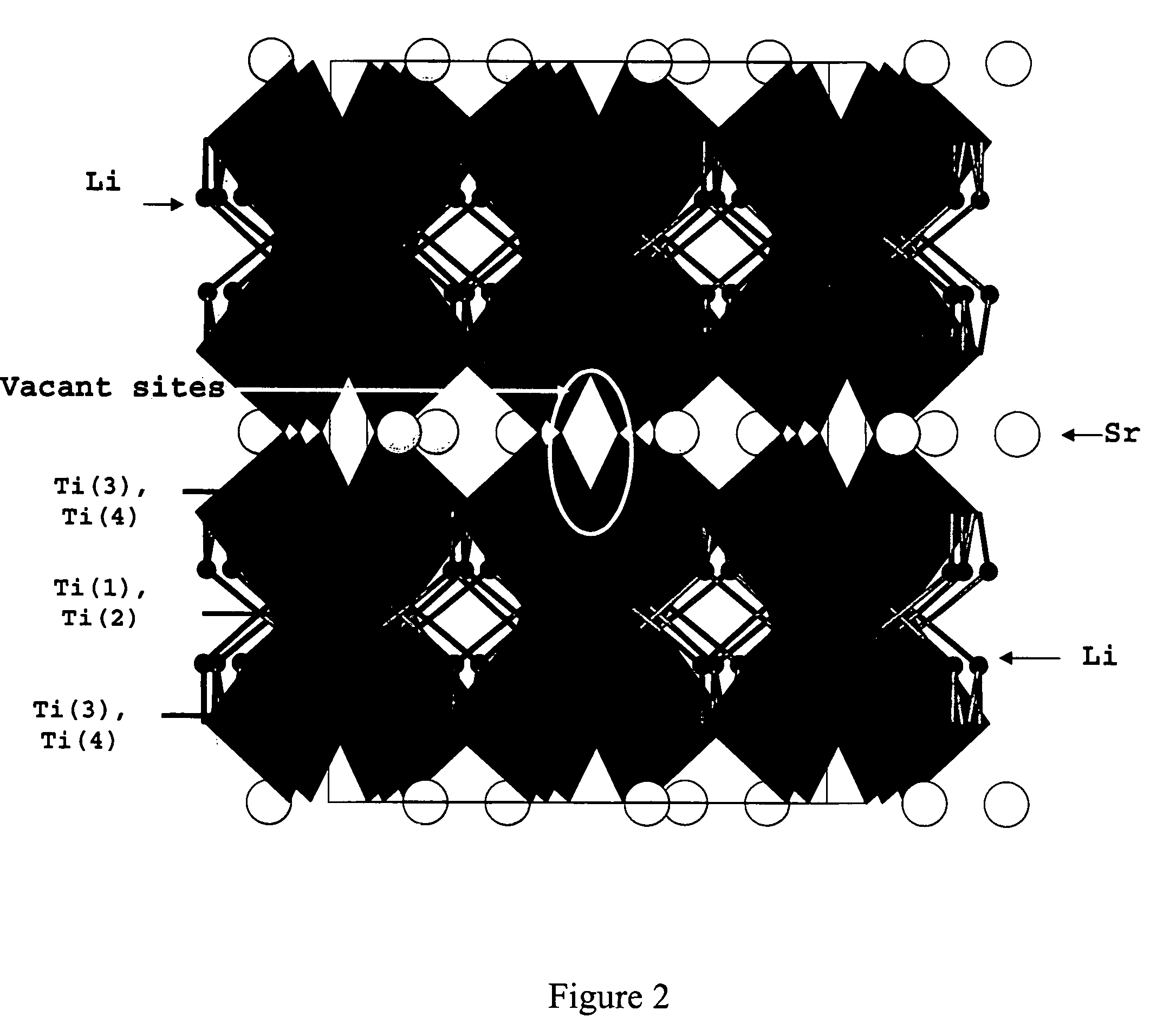

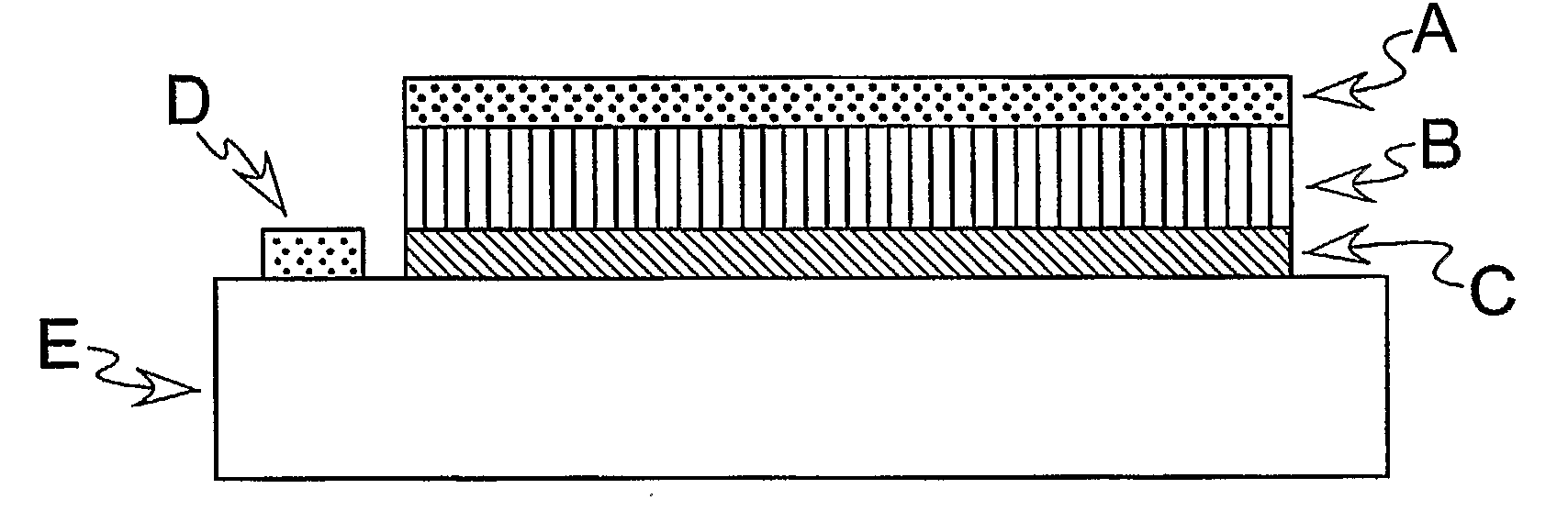

InactiveUS20080138669A1Efficiently oxidizedHigh densityFuel cell auxillariesNegative electrodesStrontium titanateLanthanum

An anode for a solid oxide fuel cell. The anode is not harmed by sulfur-containing compounds, nor is its resistance increased thereby. The anode has two layers, including a “protective” layer (A) and a layer (B) that oxidizes molecular hydrogen The protective layer has a diffusion rate for molecular hydrogen that exceeds its diffusion rate for sulfur-containing compounds, and has an oxidation rate for sulfur-containing compounds that exceeds its oxidation rate for molecular hydrogen. The first anode layer can be selected fro the group of Lanthanum Strontium Titanate (LST) and Lanthanum Strontium Vanadate (LSV), and the second anode layer is made of Gadolinium Doped Cerium oxide (GDC) and nickel. The first layer can include Yttria Stabilized Ziroonia (YSZ), and the second layer can include YSZ interspersed throughout the layer as a separate phase.

Owner:OHIO UNIV

Hard carbon-metal oxide-soft carbon composite material and preparation method and application thereof

ActiveCN107240680AHigh specific capacitySmall specific surface areaCell electrodesSecondary cellsCarbon compositesSodium-ion battery

The invention discloses a hard carbon-metal oxide-soft carbon composite material and a preparation method and application thereof. The preparation method comprises the steps of firstly, performing a hydrothermal method on hydrocarbon in a reaction kettle to prepare a hard carbon precursor; secondly, pre-coating the hard carbon precursor and a titanium salt, placing asphalt in a muffle furnace for low-temperature pyrolysis reaction to obtain a soft carbon precursor; and finally, fully mixing the pre-coated hard carbon precursor and the soft carbon precursor, and performing high-temperature pyrolysis reaction under protection of an inert gas to obtain the product, wherein the product is the hard carbon-metal oxide-soft carbon composite material. The material can be used as a negative active material of a sodium ion battery. The preparation method is wide in raw material source and low in cost, and the prepared hard carbon-metal oxide-soft carbon composite material has the advantages of large reversible capacity, high initial charge-discharge coulombic efficiency, good cycle property and the like in the sodium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing organic ammonium metal halide film

InactiveCN104404478AImprove diffractionStrenuous exerciseChemical vapor deposition coatingChemical reactionCharge carrier mobility

The invention discloses a method for preparing an organic ammonium metal halide film. A half-closed type carrier gas free hot wall type low-pressure chemical vapor deposition method process is adopted to prepare the organic ammonium metal halide film. The method comprises the following steps: firstly, preparing a metal halide (MX2) film on a quartz substrate by using a dry method or a wet method, and transferring the metal halide (MX2) film into a glass tube for annealing, wherein one end of the glass tube is sealed and the other end is grounded; secondly, transferring the energy to organic ammonium (AX) powder inside the glass tube through a hot wall, forming steam blocks through self-diffusion of AX steam in low vacuum, performing chemical reaction on MX2 with a hot substrate to generate the film which is uniform in thickness, good in appearance, high in light absorption rate and smooth in surface, and performing in-situ annealing so as to generate the AMX3 film which is dense in structure and high in crystallinity degree. The method has the advantages that in-situ annealing can be performed in the film formation process, continuous vacuuming is not needed, the preparation time is shortened, the energy consumption is reduced, the filming efficiency is high, the charge capture trap in the film is reduced, and the carrier mobility is increased.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

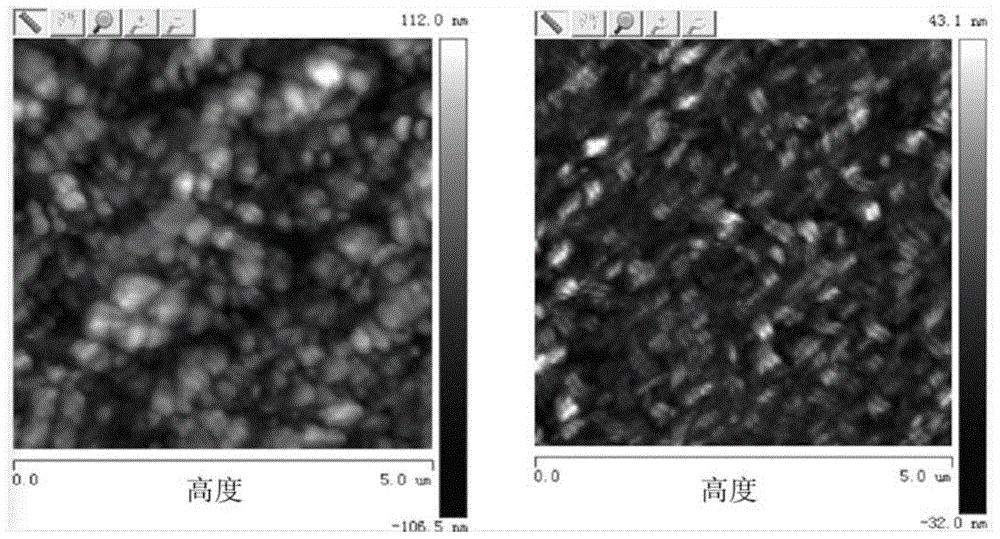

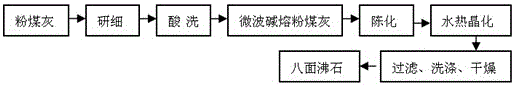

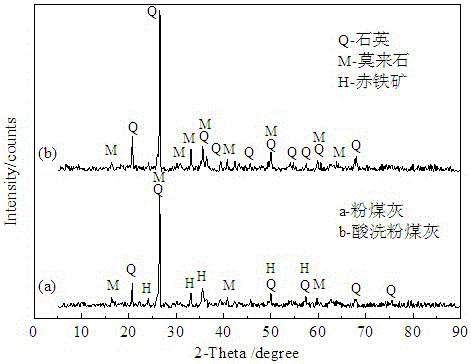

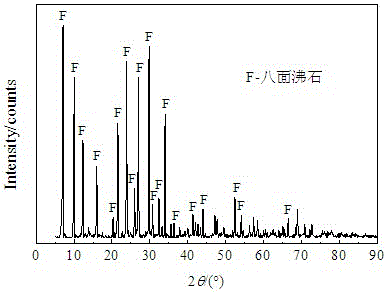

Method for making coal ash into faujasite through microwave alkali fusion-hydro-thermal synthesis

InactiveCN106276960AReduce the temperatureShort firing timeFaujasite aluminosilicate zeoliteFaujasiteCalcination

The invention discloses a method for making coal ash into faujasite through microwave alkali fusion-hydro-thermal synthesis. Solid waste of coal ash is used as raw materials; sodium hydroxide is used as an activating agent; the microwave alkali fusion-hydro-thermal synthesis is used for making the faujasite. The method comprises the following steps of (1) grinding the coal ash into -75mum; removing iron impurities in the coal ash by hydrochloric acid; (2) uniformly mixing the coal ash subjected to iron removal with sodium hydroxide; then, performing calcination in a microwave box type high-temperature reactor; performing fine grinding after a alkali fusion product is cooled; (3) mixing and stirring alkali fusion coal ash and deionized water for a certain time; heating the material to 90 to 100 DEG C for still standing and crystallization for 12 to 16h; (4) filtering and washing reaction products to a neutral state, and performing drying to obtain faujasite products. A conventional calcination mode is changed; the microwave alkali fusion coal ash is used; the advantages of low calcination temperature, short calcination and crystallization time, low energy consumption, cleanness, environment protection, high coal ash conversion rate, low cost and the like are realized; the possibility is provided for the industrial production of preparing faujasite from the coal ash.

Owner:GUIZHOU UNIV

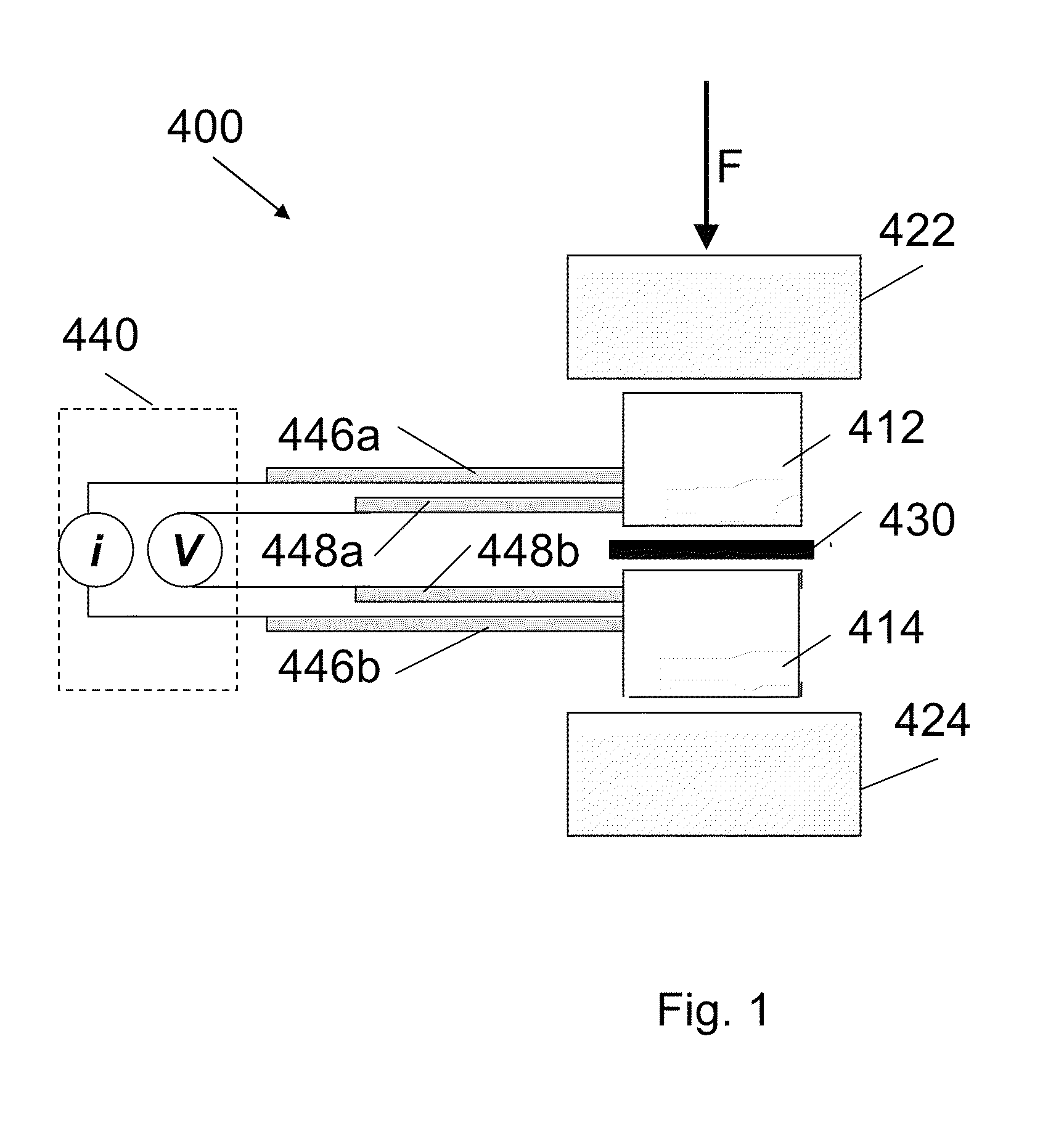

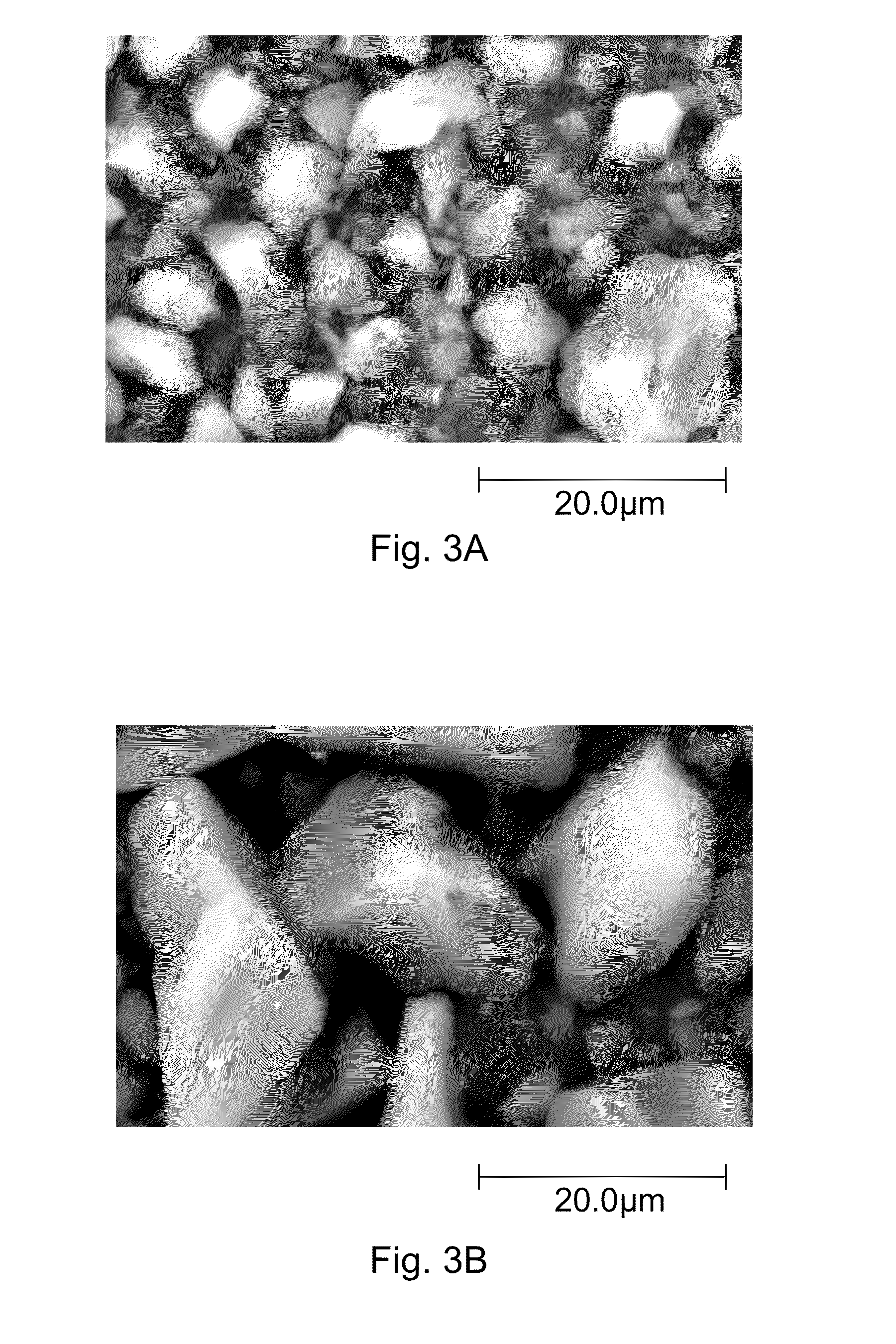

Maleic anhydride catalyst and method for its preparation

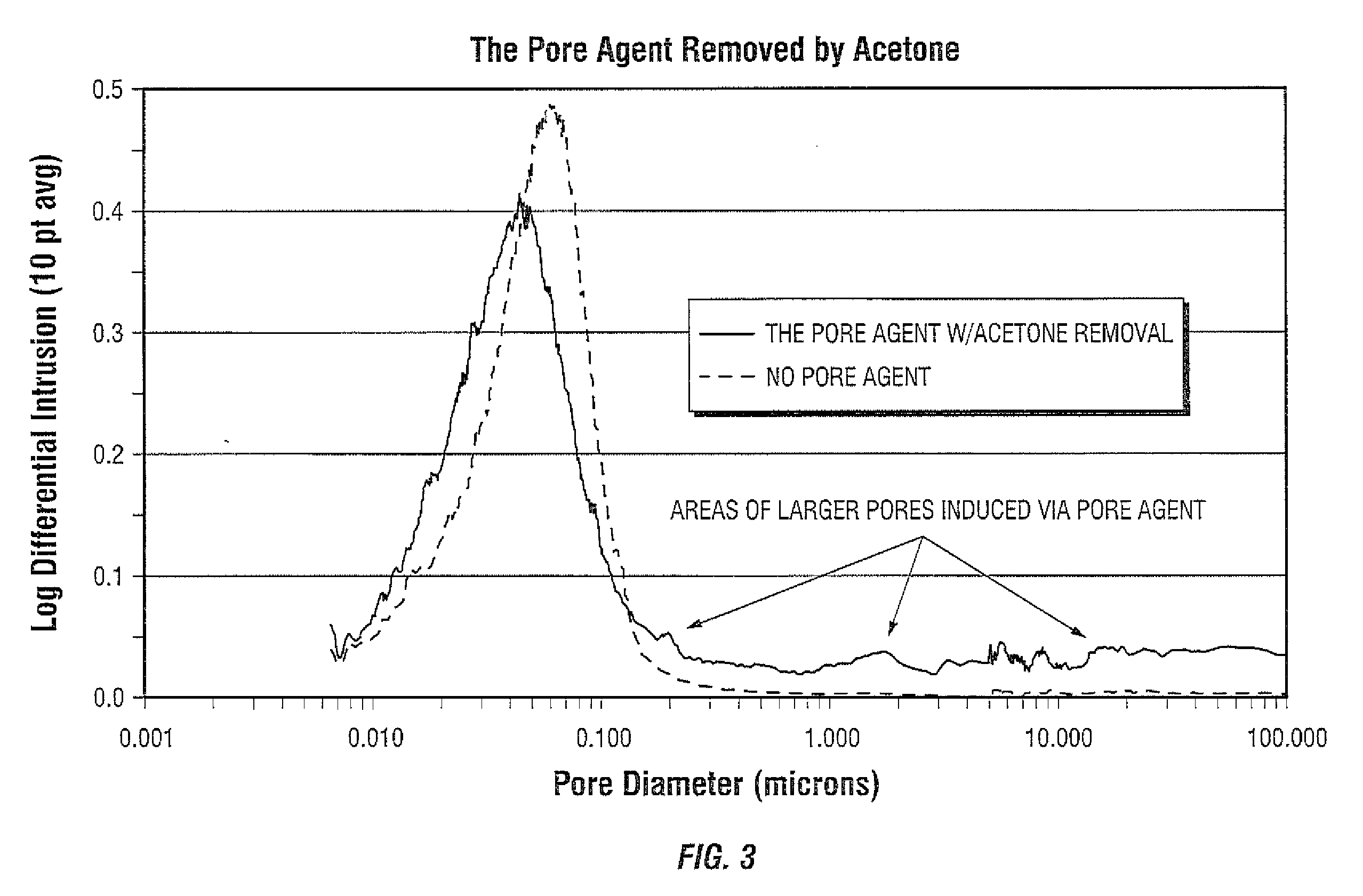

ActiveUS20100016644A1Rapid external diffusionRapid internal diffusionOrganic compound preparationHeterogenous catalyst chemical elementsCatalytic oxidationAccelerant

The present invention provides a process for producing a vanadium / phosphorus oxide catalyst by (i) preparing a catalyst precursor powder containing vanadium, phosphorus and an optional promoter element; (ii) converting the catalyst precursor powder into an activated catalyst by heat treatment; (iii) and compressing the activated catalyst into a desired shape to form the vanadium / phosphorus oxide catalyst. The vanadium / phosphorus oxide catalyst may be used in the production of maleic anhydride by the catalytic oxidation of hydrocarbon feed streams.

Owner:HUNTSMAN PETROCHEMICAL LLC

High-voltage direct-current thermal fuse

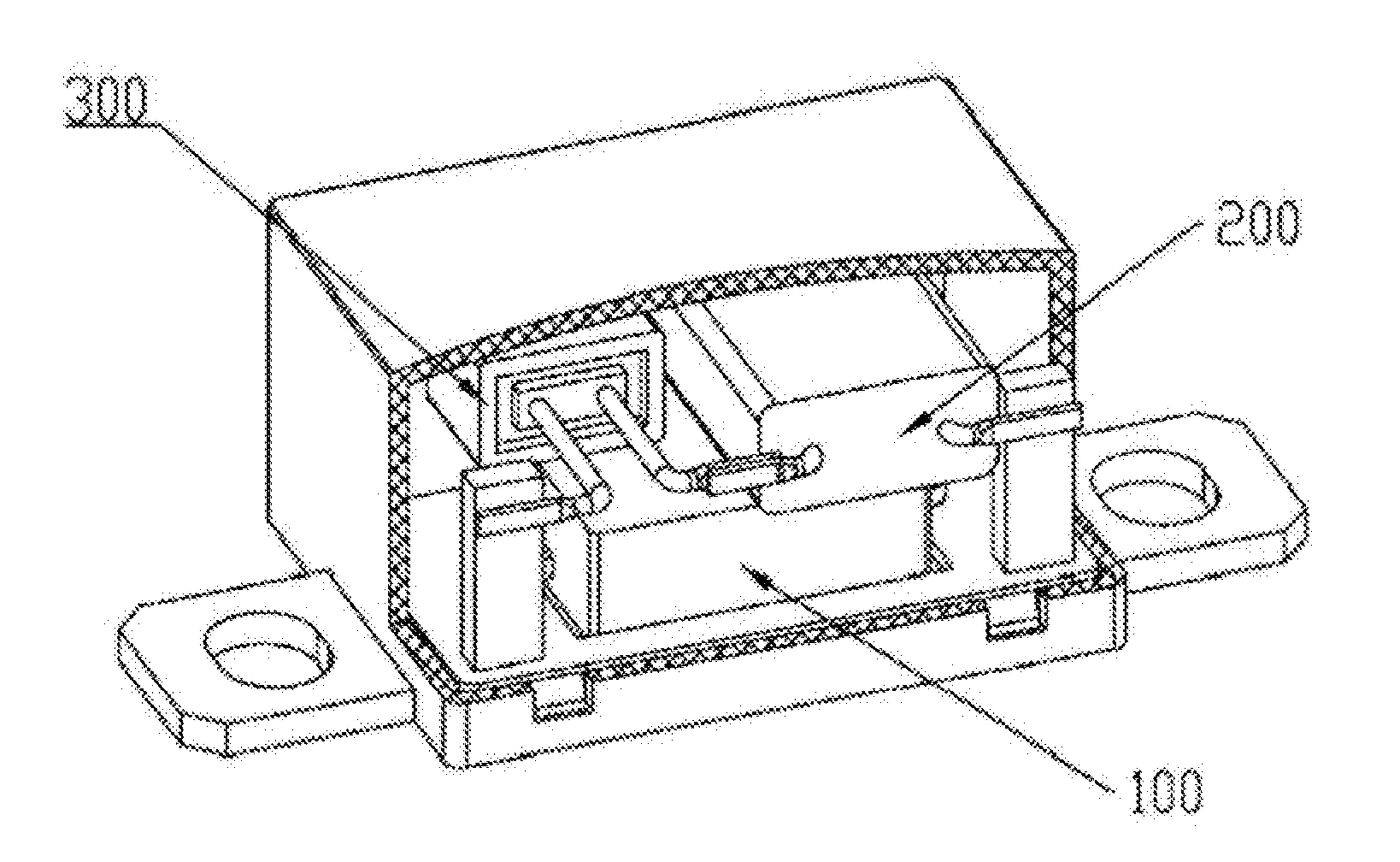

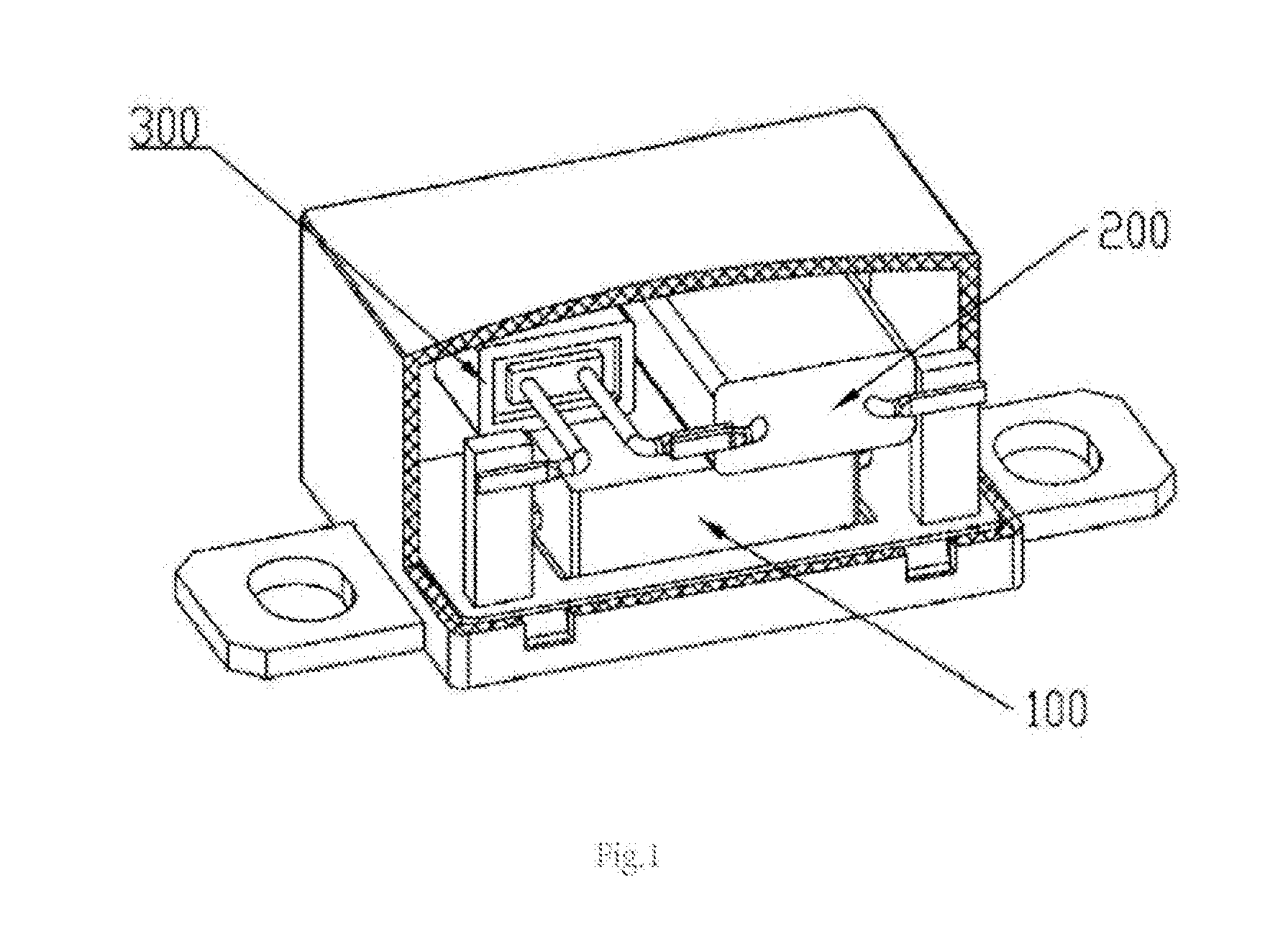

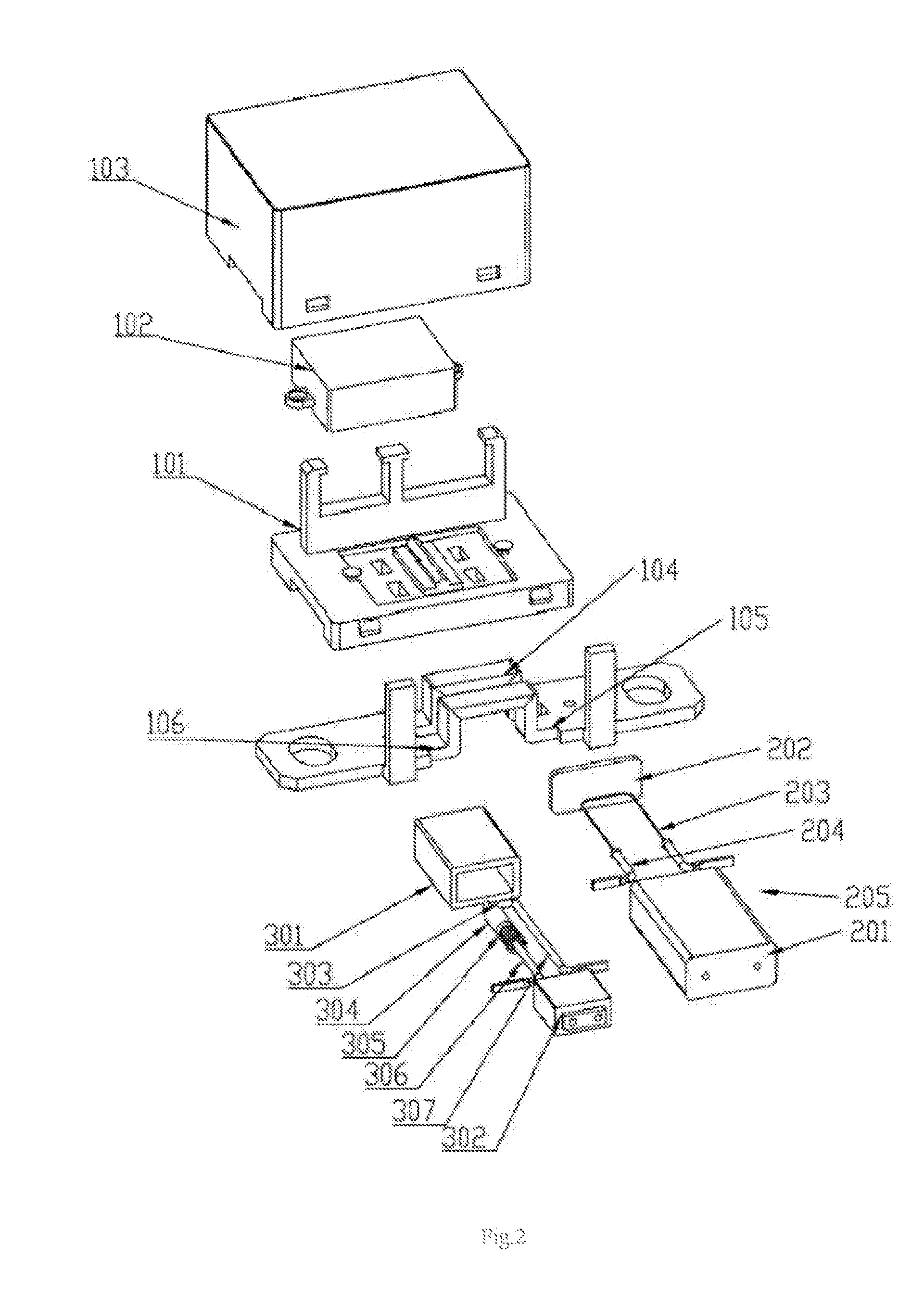

ActiveUS20170004947A1Simple internal structureUse directlyHeating/cooling contact switchesThermal switch detailsHigh-voltage direct currentAlloy

A high-voltage direct-current thermal fuse comprising a high-voltage low-current thermal fuse connected to a high-voltage direct-current circuit. The high-voltage low-current thermal fuse comprises a casing, fusible alloy wires, wherein the fusible alloy wires are connected between the two leads. One of the leads is sequentially sleeved with an arc extinguishing sleeve and a spring. One end of the arc extinguishing sleeve is in contact with the fusible alloy wires; and the other end of the arc extinguishing sleeve is in contact with the spring. One end of the spring is connected to the inner end face of the casing; and the spring is in a compressed state. The high-voltage direct-current thermal fuse further comprises a conventional thermal fuse; or further comprises a current. The high-voltage direct-current thermal fuse solves the problem of timely arc cutting-off and can be directly applied to a high-voltage direct-current circuit.

Owner:XIAMEN SET ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com