Patents

Literature

96 results about "Citicoline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

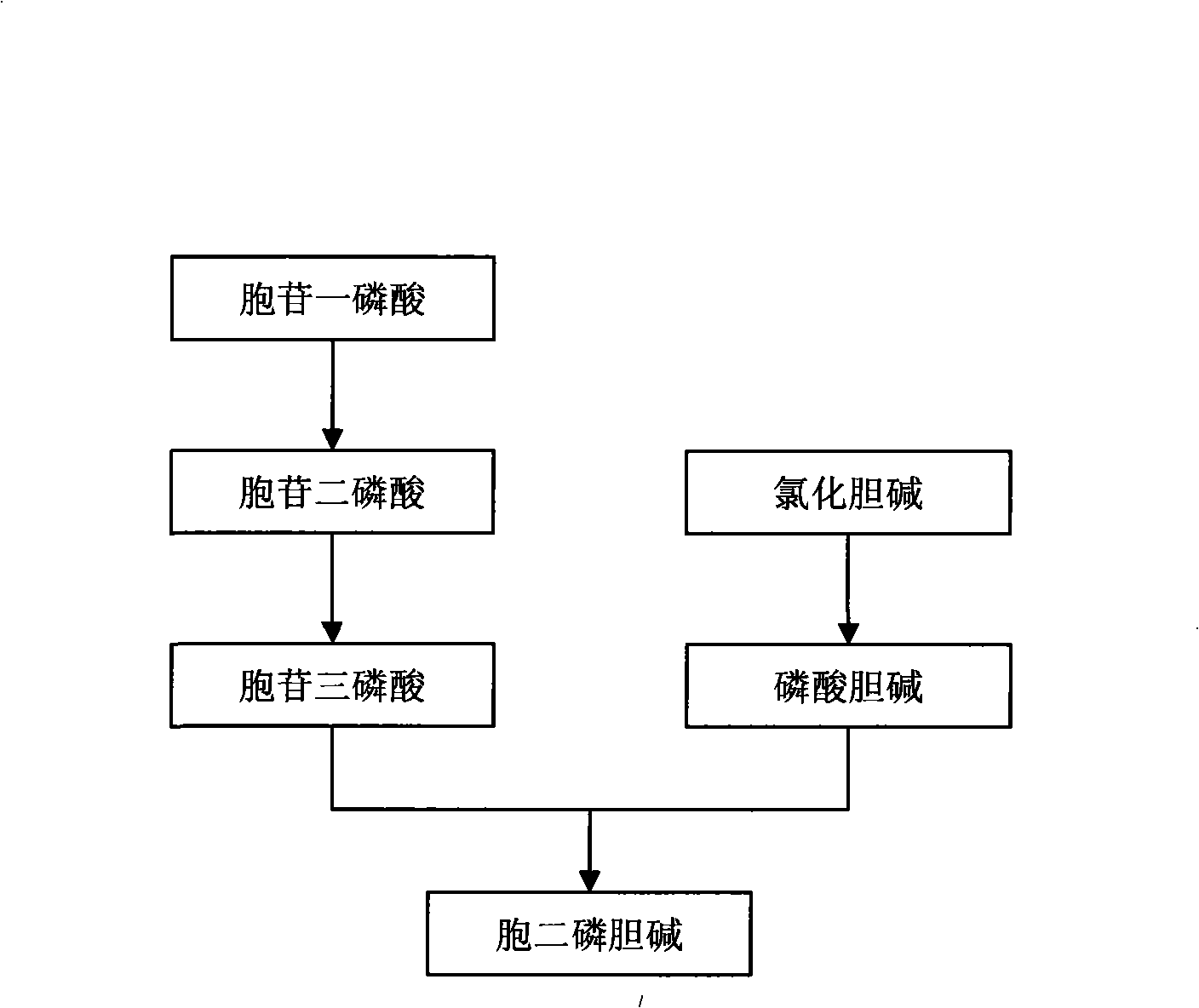

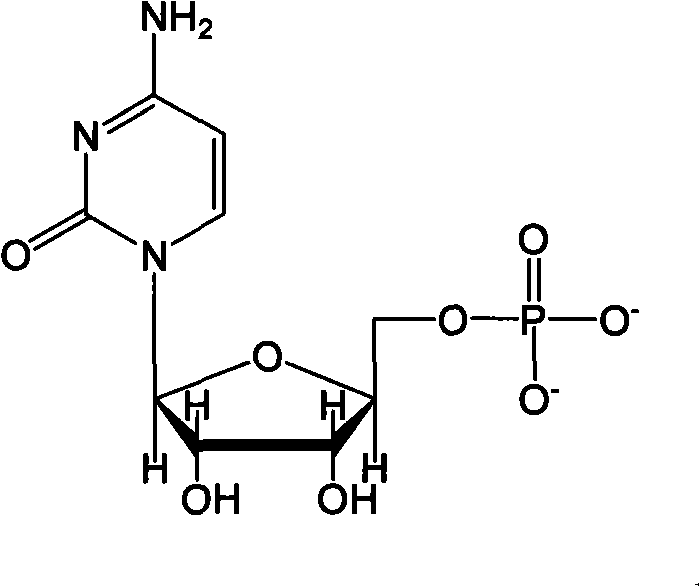

Citicoline (INN), also known as cytidine diphosphate-choline (CDP-Choline) or cytidine 5'-diphosphocholine is an intermediate in the generation of phosphatidylcholine from choline, a common biochemical process in cell membranes. Citicoline is naturally occurring in the cells of human and animal tissue, in particular the organs.

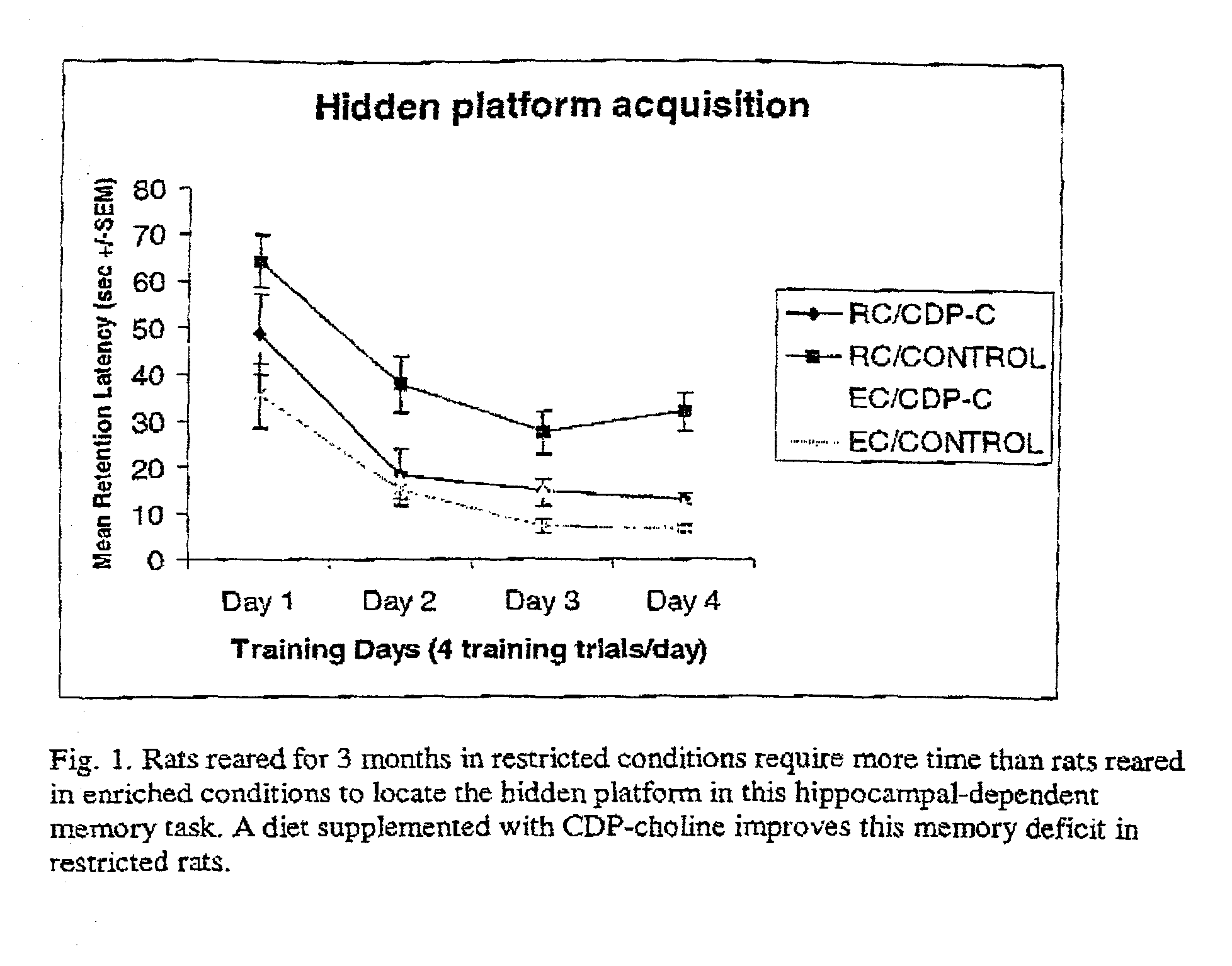

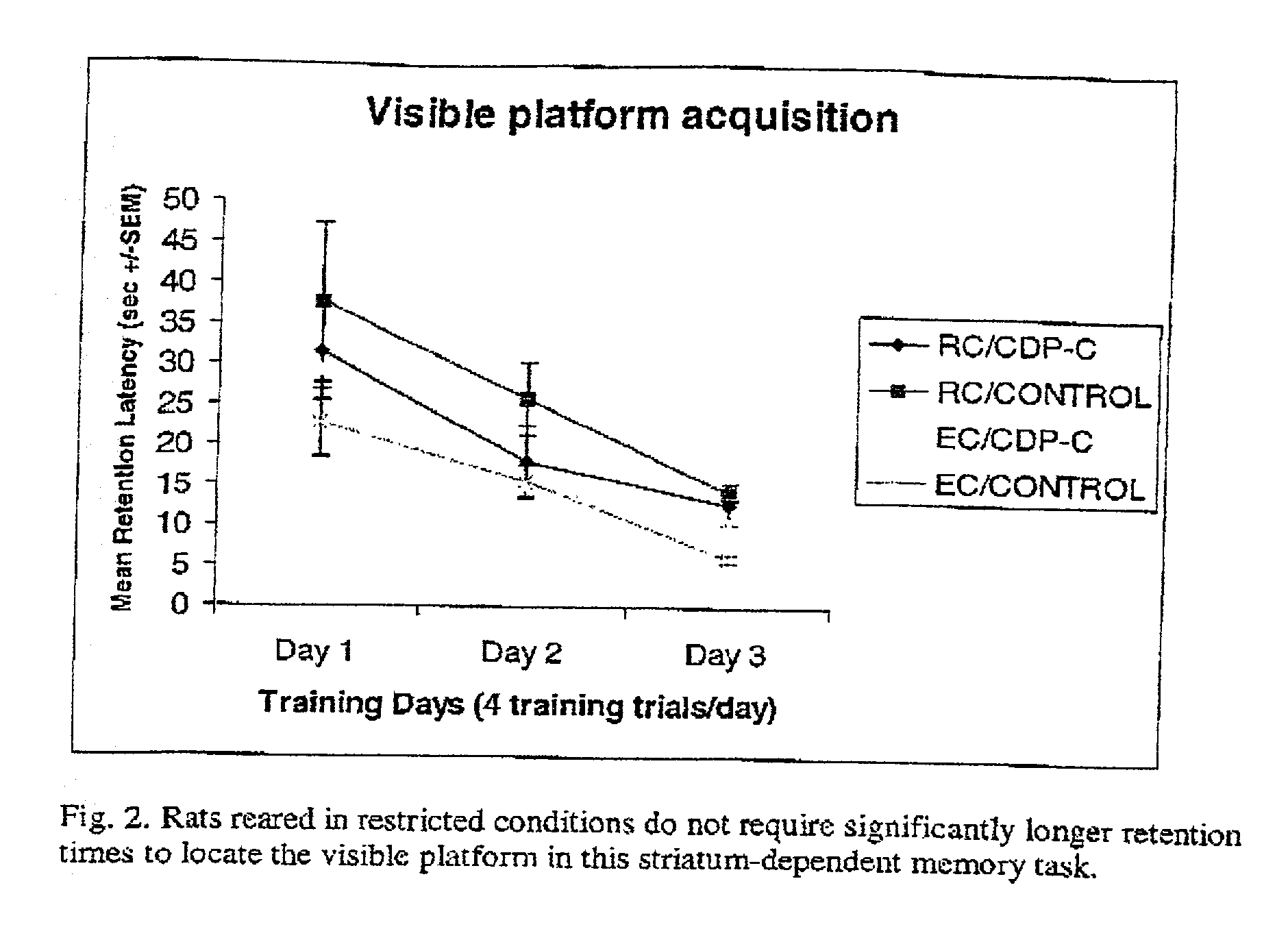

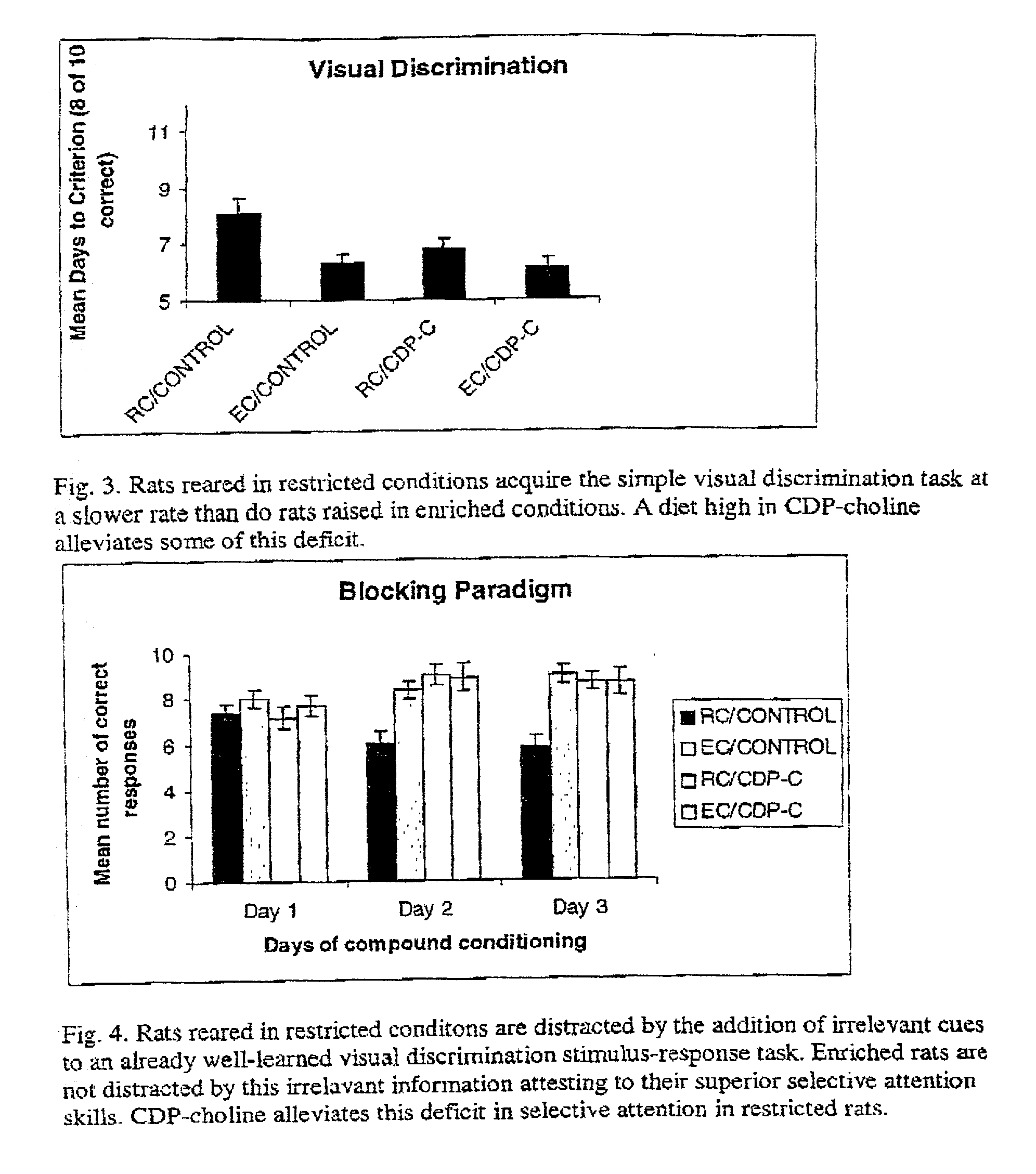

Compositions and methods for treating and preventing memory impairment using citicoline

InactiveUS20030114415A1Low toxicityAvoid damageBiocideCarbohydrate active ingredientsMemory disorderCiticoline

This invention relates to compositions and methods for preventing and treating cognitive dysfunction or memory impairment. The compositions include an effective amount of citicoline, or pharmaceutically-acceptable salts thereof, and one or more of the compounds selected from the group consisting of linoleic acid and linolenic acid. Other compositions of this invention include an effective amount of citicoline, or pharmaceutically-acceptable salt thereof, wherein said citicoline is metabolized to form at least one of cytidine, uridine, and choline. Still other compositions of this invention include effective amounts of choline, cytidine, and / or uridine, or their pharmaceutically-acceptable salts. This invention also encompasses methods for preparing these compositions.

Owner:MASSACHUSETTS INST OF TECH

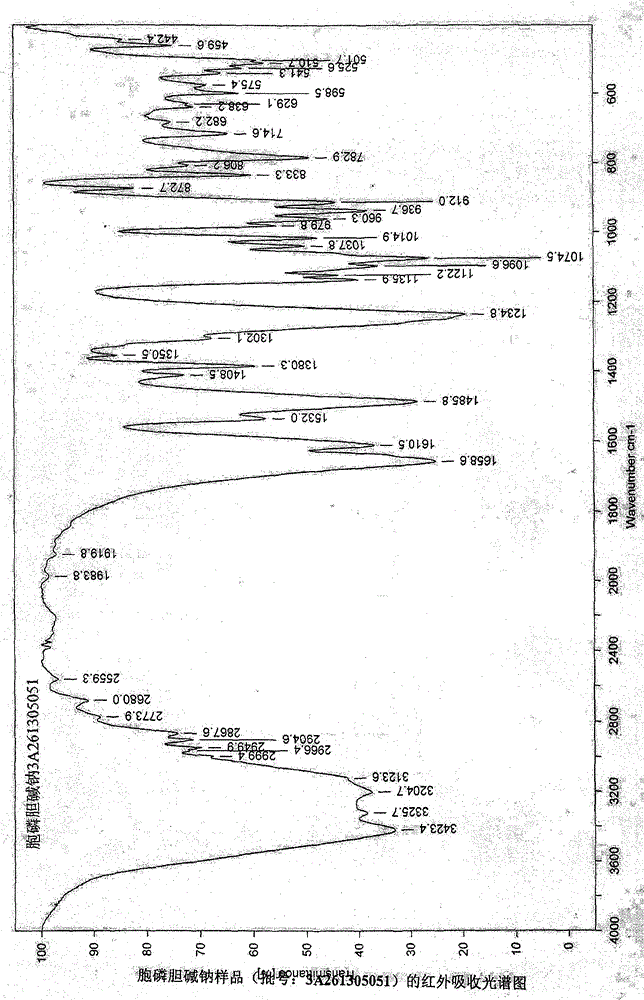

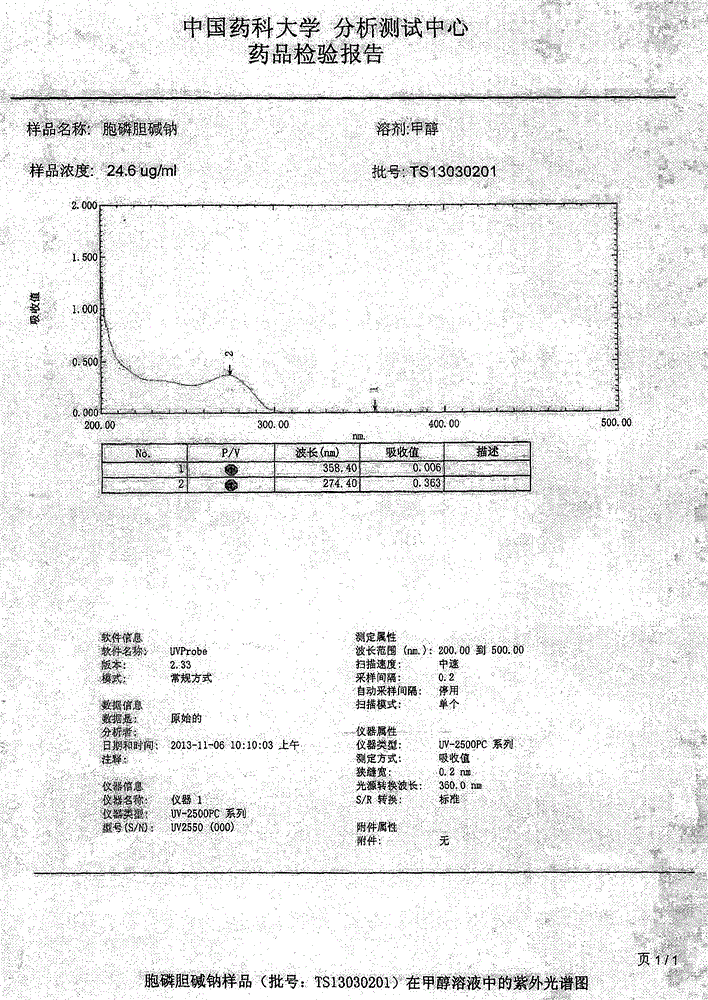

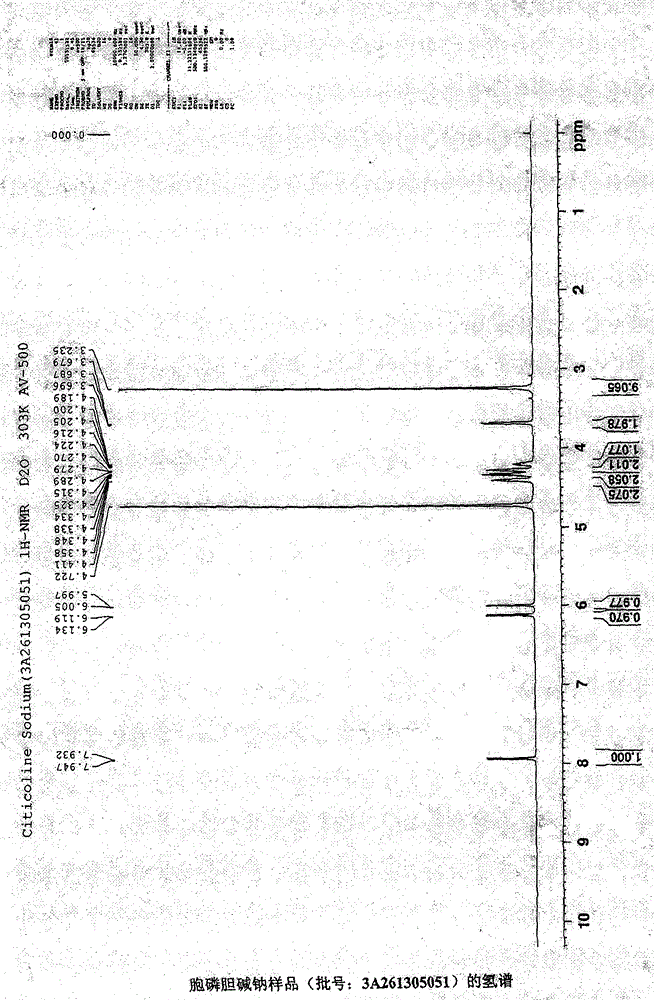

Salting-out and solvating-out crystallization method for citicoline

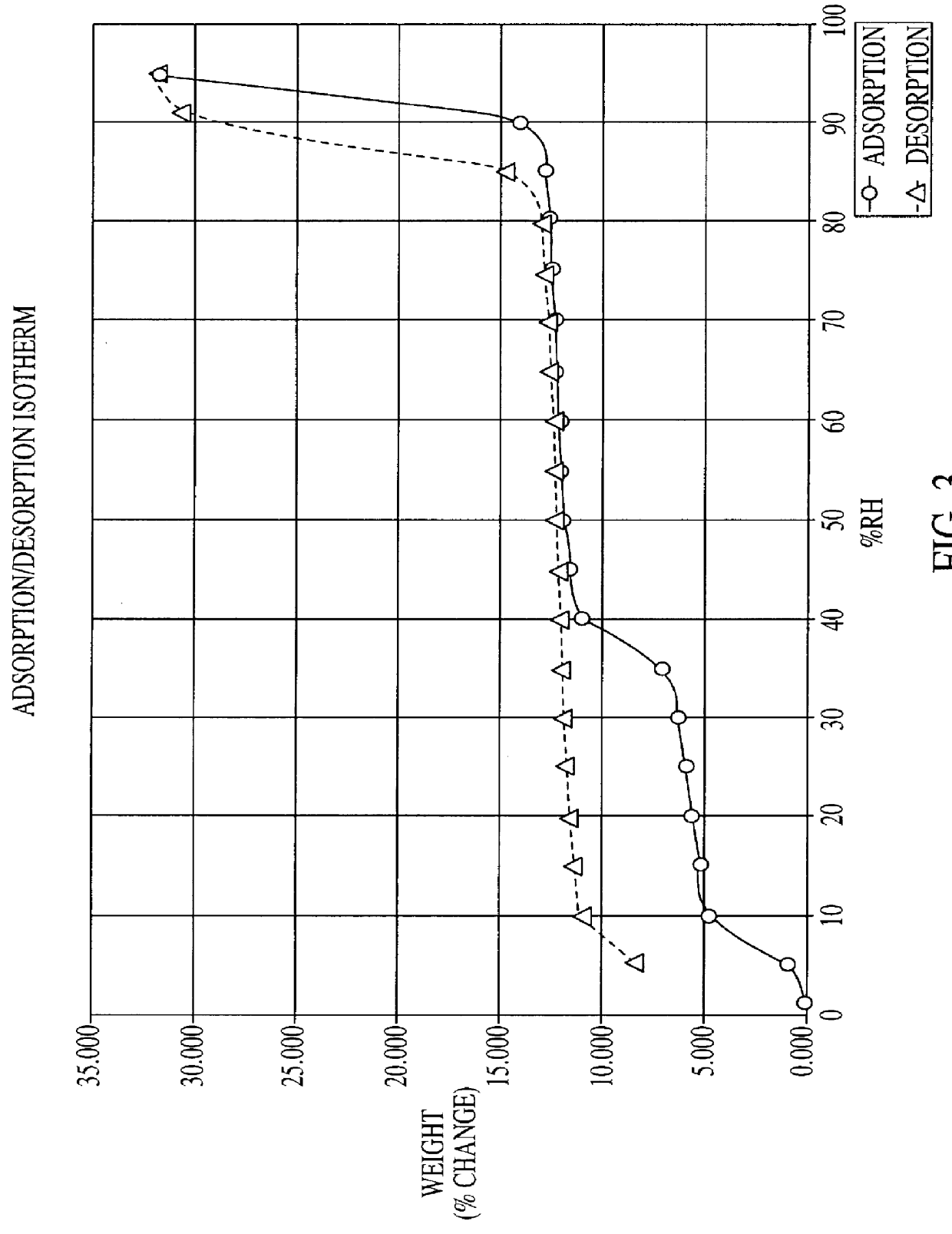

ActiveCN101538300AHigh yieldGood hygroscopicitySugar derivativesCardiovascular disorderFiltrationSalting out

The invention discloses a salting-out and solvating-out crystallization method for citicoline. The method comprises the following steps: adding inorganic sodium salt which accounts for 1 to 20 percent of citicoline and a solvating agent which is 1.0 to 4.0 times the volume of a staring citicoline aqueous solution to a citicoline aqueous solution with a pH value between 5.0 and 8.0 and a concentration between 10 and 400 g / L; stirring the materials at a rotating speed controlled between 20 and 230 rpm at a temperature of between 10 and 40 DEG C; performing pumping filtration after complete crystallization; washing the obtained product with ethanol; drying the obtained product in vacuum; and obtaining the citicoline sodium salt crystals with the purity higher than 99 percent. The method has the advantages that the method obviously improves the quality of final products, raises crystallization yield stability, can control the particle size of the crystals by changing crystallization temperature or the states of a flow field, and is simple to operate, good in repeatability and suitable for the industrial production of the citicoline.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

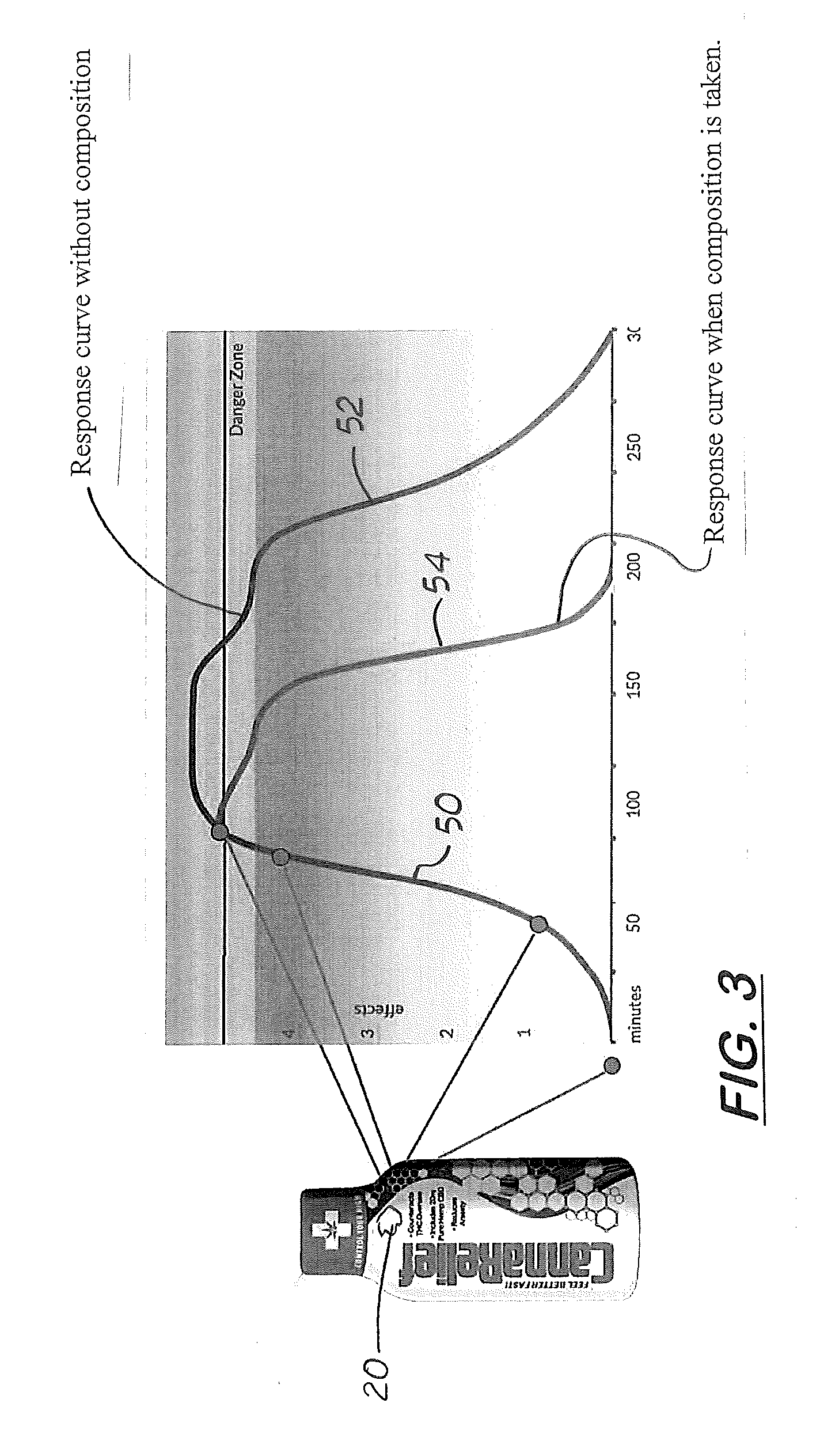

Composition, Commericial Product and Method for Treating Cannabis Toxicity

InactiveUS20160213624A1Alleviate toxicity symptomReduce riskDispersion deliveryHydroxy compound active ingredientsHemp plantVitamin C

The present invention provides a novel emulsion composition in a stable, fast acting emulsion that contains cannabidiol in an aqueous vehicle. The cannibidiol is extracted using CO2 from an industrial hemp plant that produces cannibiodiol molecules surrounded by less fats and waxes making it more hydrophilic. A little emulsifying agent, such as polysorbate 80, is mixed with cannabidiol oil to create a stable first emulsion mixture. A batch mixture is then prepared containing water, food preservatives, sugar, a sufficient amount of CBD Premix that contains citicoline and masker A for Reb A. Both mixtures are then mixed in water with ginger, Vitamin C, Vitamin B6, Vitamin B12, and sugar. The final mixture is then distributed in 60 ml bottles and consumers are instructed to take an initial loading dose of 15 ml (equal to approximately 5 mg of cannabidiol) either before a THC containing product is in consumed or smoke, shortly after a THC containing consuming or smoking or when the first signs of anxiety are perceived.

Owner:LINDEMAN TOM

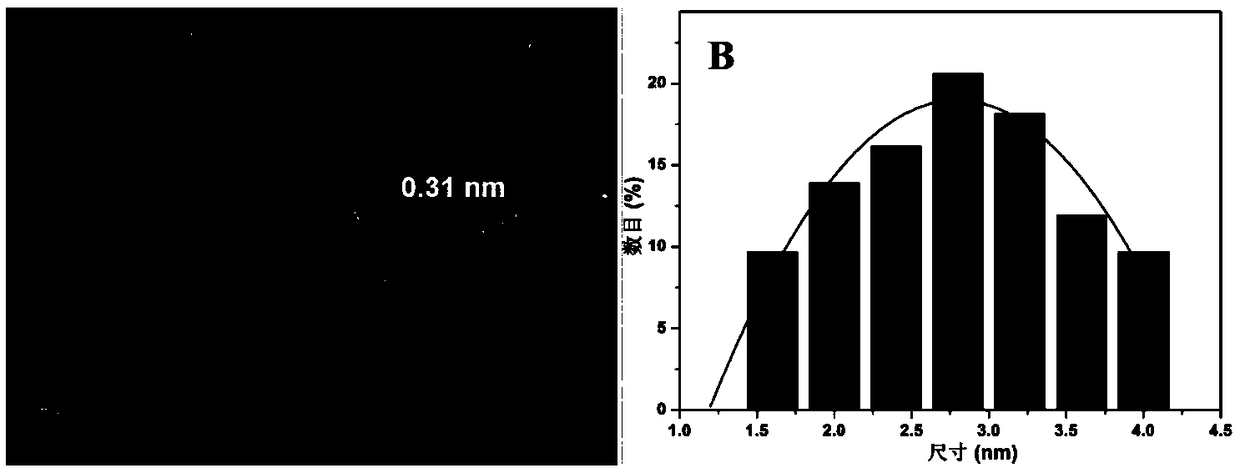

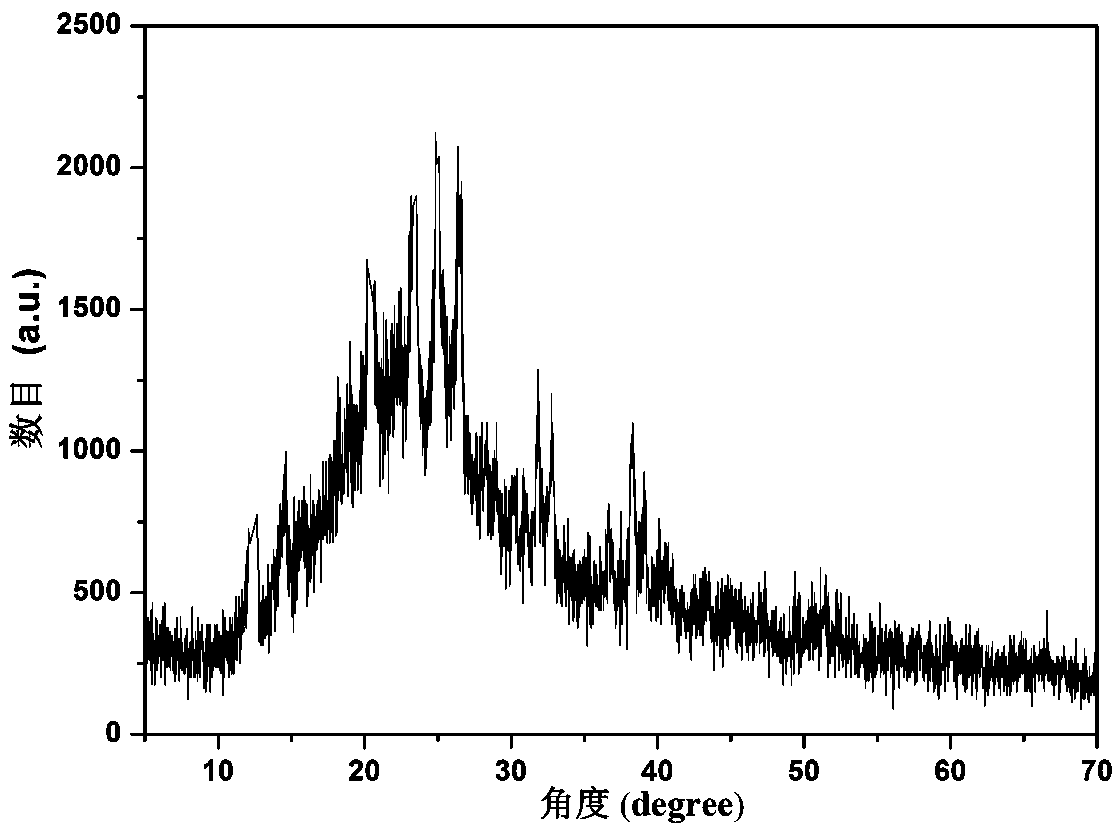

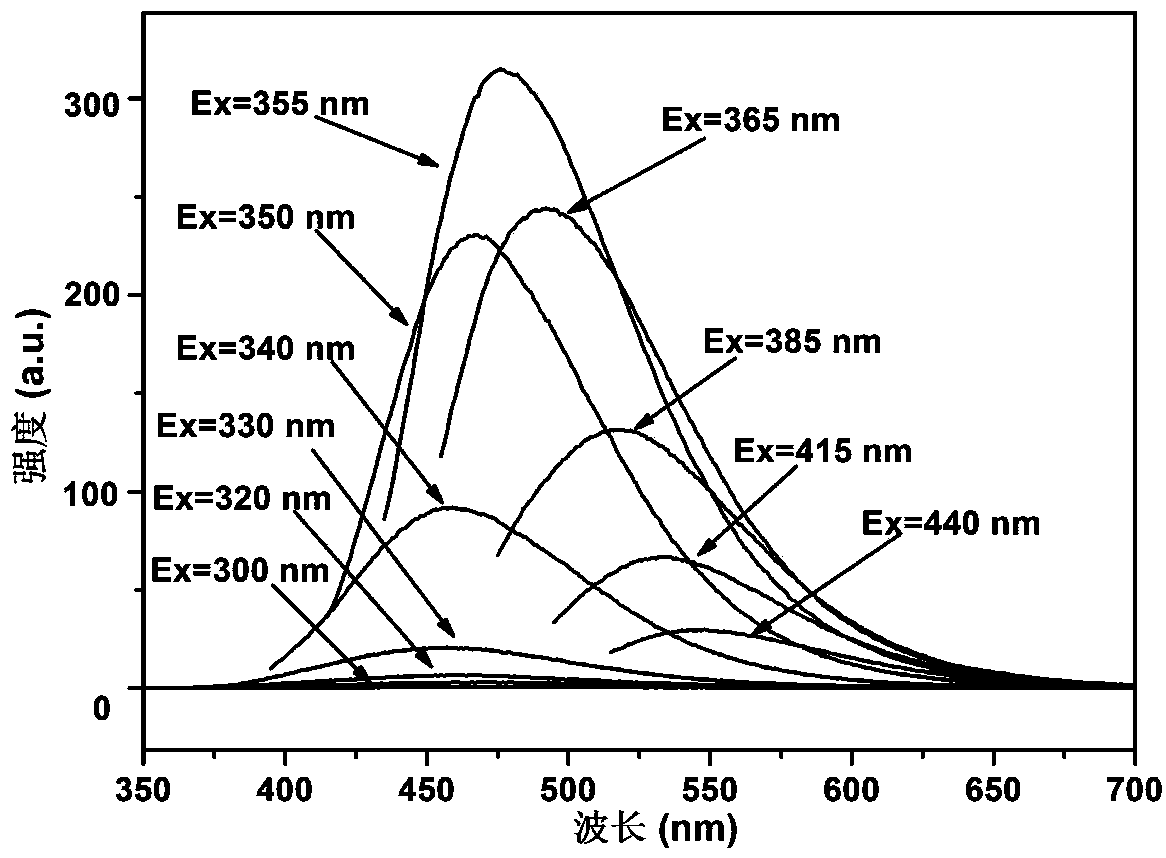

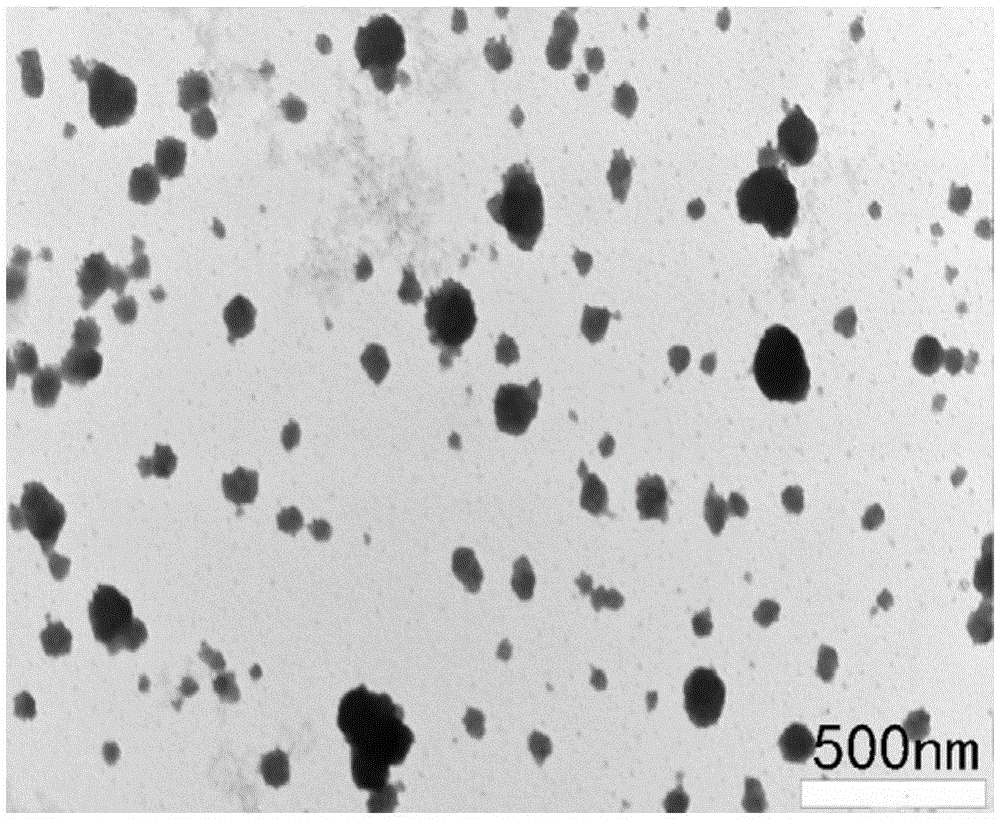

N, P doped carbon quantum dots as well as preparation method and application thereof

ActiveCN108865124AEasy to prepareSmall sizeNanoopticsFluorescence/phosphorescenceEthylenediamineNitrogen

The invention provides N, P doped carbon quantum dots as well as a preparation method and application thereof. The preparation method of the N, P doped carbon quantum dots is simple, and the obtainedN, P doped carbon quantum dots can be sensitively used for cobalt ion detection. The preparation method comprises the following steps of by taking citicoline as a carbon source, performing hydrothermal reaction on citicoline and ethylenediamine, and performing purification on a reaction product to obtain the N, P doped carbon quantum dots. The N, P doped carbon quantum dots are prepared from the following components: 47-49 percent of carbon, 27-29 percent of oxygen, 17-19 percent of nitrogen and 3-5 percent of phosphorus, preferably, for the N, P doped carbon quantum dots, the average grain diameter is 2.1-3.4nm, the interlayer spacing is 0.25-0.35nm, and the average fluorescence lifetime is 3.4-4.0ns. The preparation method provided by the invention prepares the N, P doped carbon quantumdots with one step by using citicoline as the carbon source and is simple; and the N, P doped carbon quantum dots can perform detection on cobalt ions in a solution with the limit of detection reaching 53.0nM.

Owner:NANJING UNIV

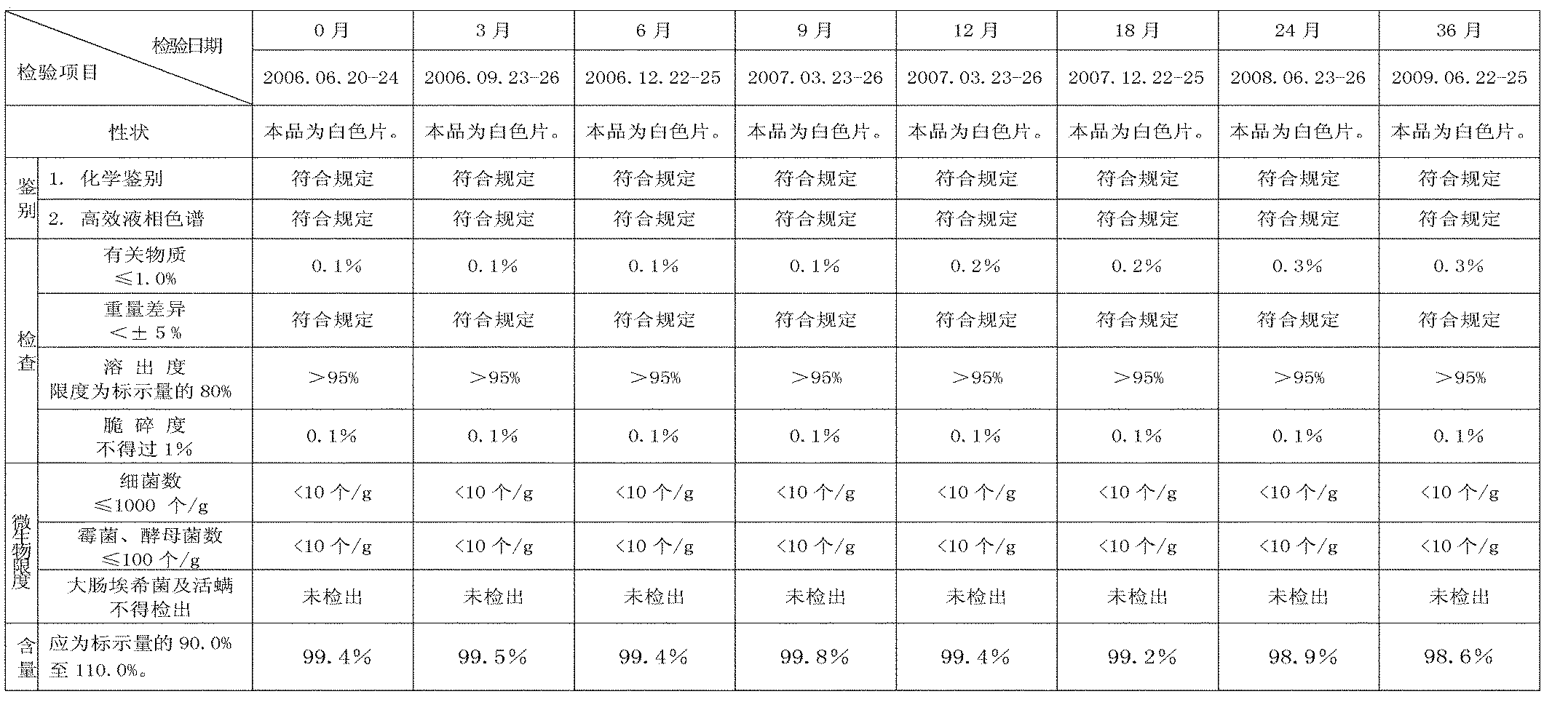

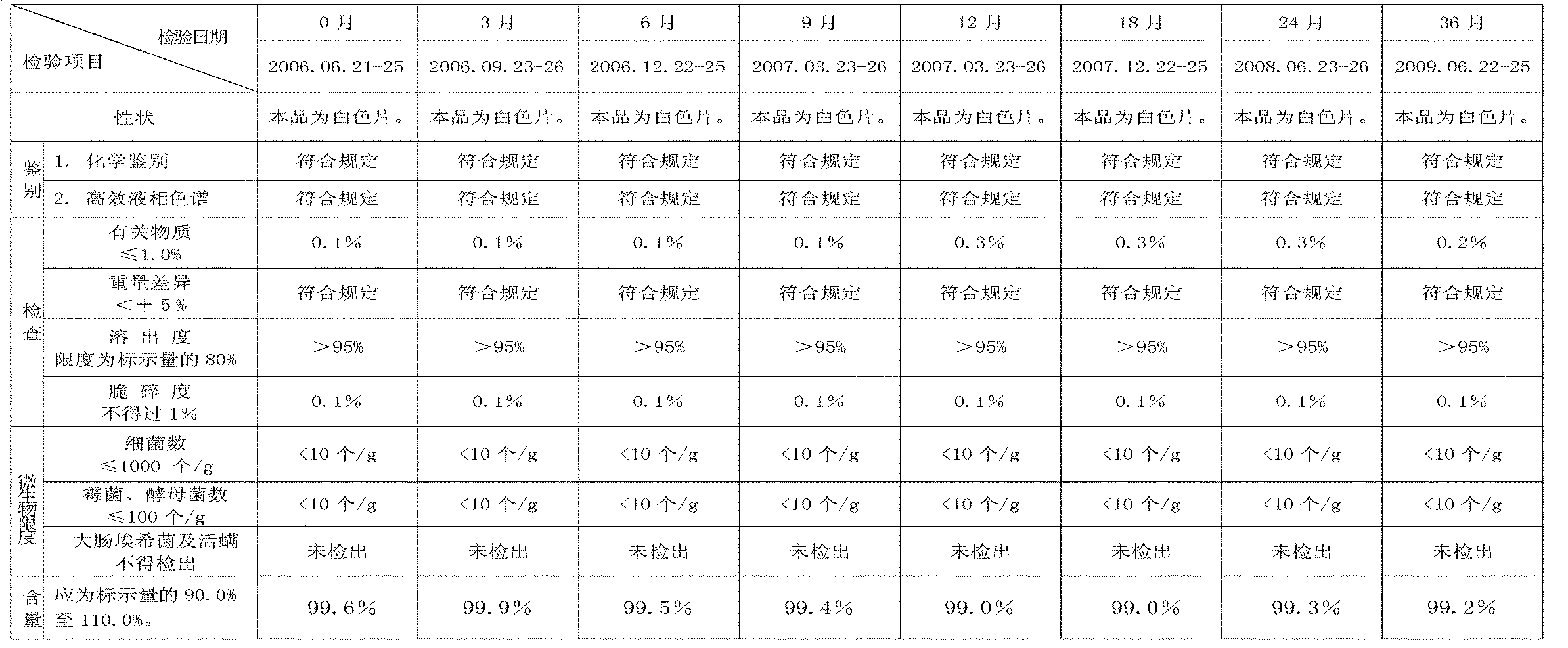

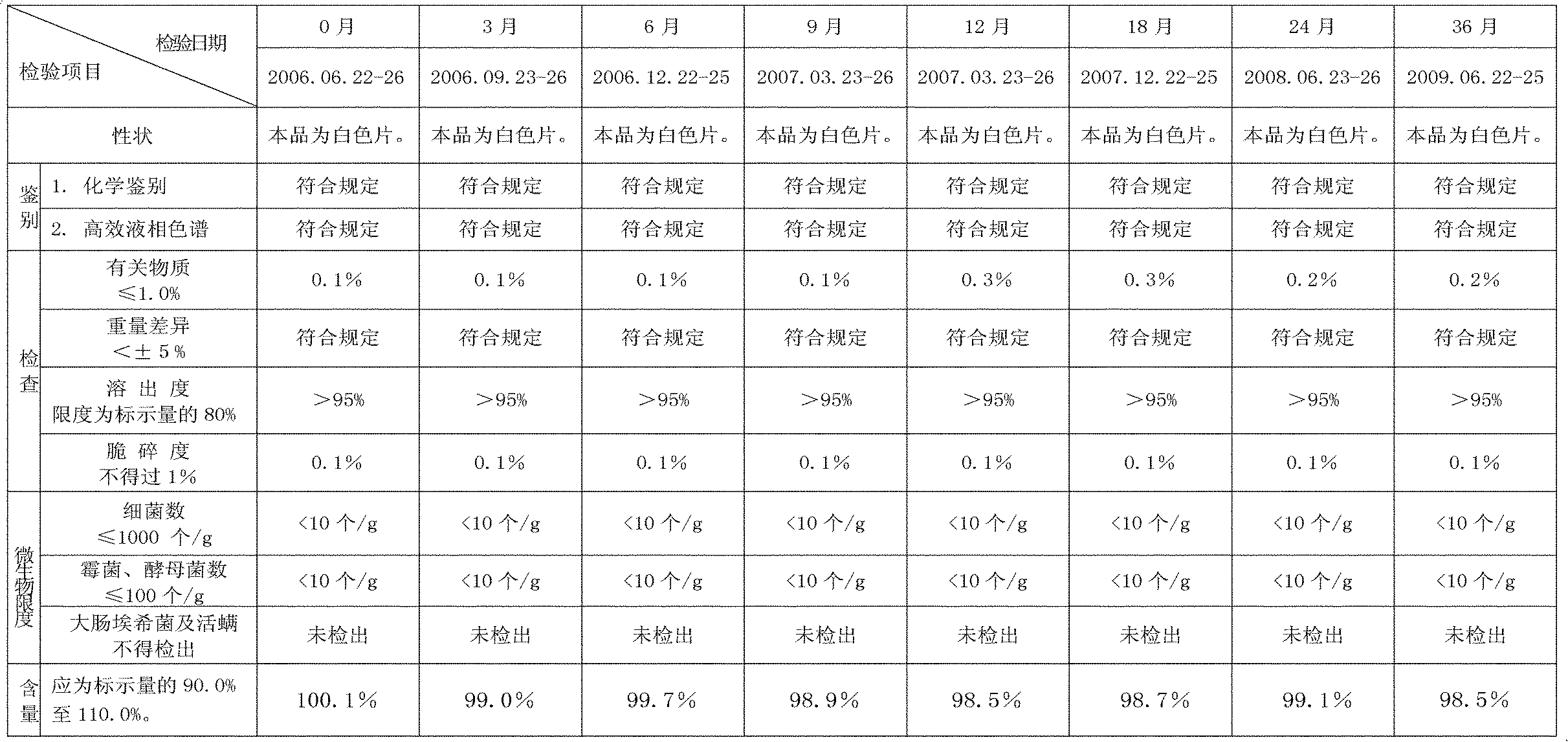

Citicoline sodium tablets and preparation method thereof

ActiveCN102028664AIncrease productionLow costOrganic active ingredientsNervous disorderNervous systemCiticoline sodium

The invention provides citicoline sodium tablets which are medicinal preparations for treating sequela of a nervous system caused by a craniocerebral injury or a cerebrovascular accident, and a preparation method thereof. Every 1,000 tablets comprise 100.0 to 300.0g of citicoline sodium, 20.0 to 70.0g of starch, 50.0 to 160.0g of microcrystalline cellulose, 0.6 to 3g of hydroxypropyl methyl cellulose, 1.7 to 5.5g of magnesium stearate, 0 to 10g of sodium starch glycolate and 0 to 6.0g of pregelatinized starch. The preparation method of the citicoline sodium tablets mainly comprises the steps of sieving, weighing, proportioning, premixing, preparing a soft material, preparing wet granules, drying, granulating, mixing, tabletting, performing aluminum-plastic-aluminum packaging and outer packaging and the like. The tablets prepared by the method have the advantages of high yield, low cost, accurate divided dose, relatively stable medicinal physicochemical property and longer storage period and are convenient to carry and use.

Owner:四川梓橦宫药业股份有限公司

Ubelin manufacturing technique

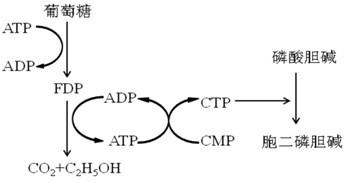

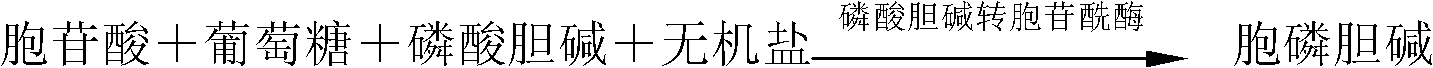

InactiveCN101130797ASolve pollutionHigh activityMicroorganism based processesFermentationUltrafiltrationCholine Phosphate

The present invention relates to a production process of citicoline. It is characterized by that said production process includes the following steps: firstly, adding water and glucose into a reaction tank, then adding yeast, making fermentation, after fermentation adding inorganic salt and choline phosphate, the adding cytidine monophosphate solution, an adding cane sugar, heating, then quickly-cooling by using water, pressing reaction liquid, washing by using water, removing salt from obtained clear liquor; then pressing said clear liquor and making said clear liquor be fed into a carbon column, rinsing said carbon column by using pure water, then using ethyl alcohol solution to make elution, collecting citicoline sodium; then vaporizing and concentrating eluent, diluting concentrate and making it be fed into a macroporous ion exchange resin column, then washing said column by using water and making elution, concentrating eluent, heating the collected citicoline sodium solution, removing impurity by utilizing ultrafiltration device, decolouring, adding ethyl alcohol and stirring them, storing the above-mentioned material in a refrigeration house and staying overnight; then making crystal solution undergo the processes of centrifugal separation, vacuum drying, bagging, weighing, sealing and dry-storage.

Owner:张剑

Citicoline enteric coated preparation and its preparation method

InactiveCN101053572APrevent moisture absorptionImprove stabilityOrganic active ingredientsPill deliveryMedicineMedical prescription

The invention relates to an intestines dissolved preparation comprising citicoline and preparation method thereof. In the present invention, the recipe amount of citicoline and routine auxiliary materials are prepared to be intestines dissolved preparation in preparation processing. Compared with other preparation, the invention is characterized in non-disintegration in the stomach, small dissolving-out speed, reduced stimulation to the stomach, high dissolving-out speed in the intestinal tract, convenient oral-taken, low production cost, without needing special apparatus, convenience in taking-along, transportation and oral-taken and stability.

Owner:NAT INST OF PHARMA R & D CO LTD

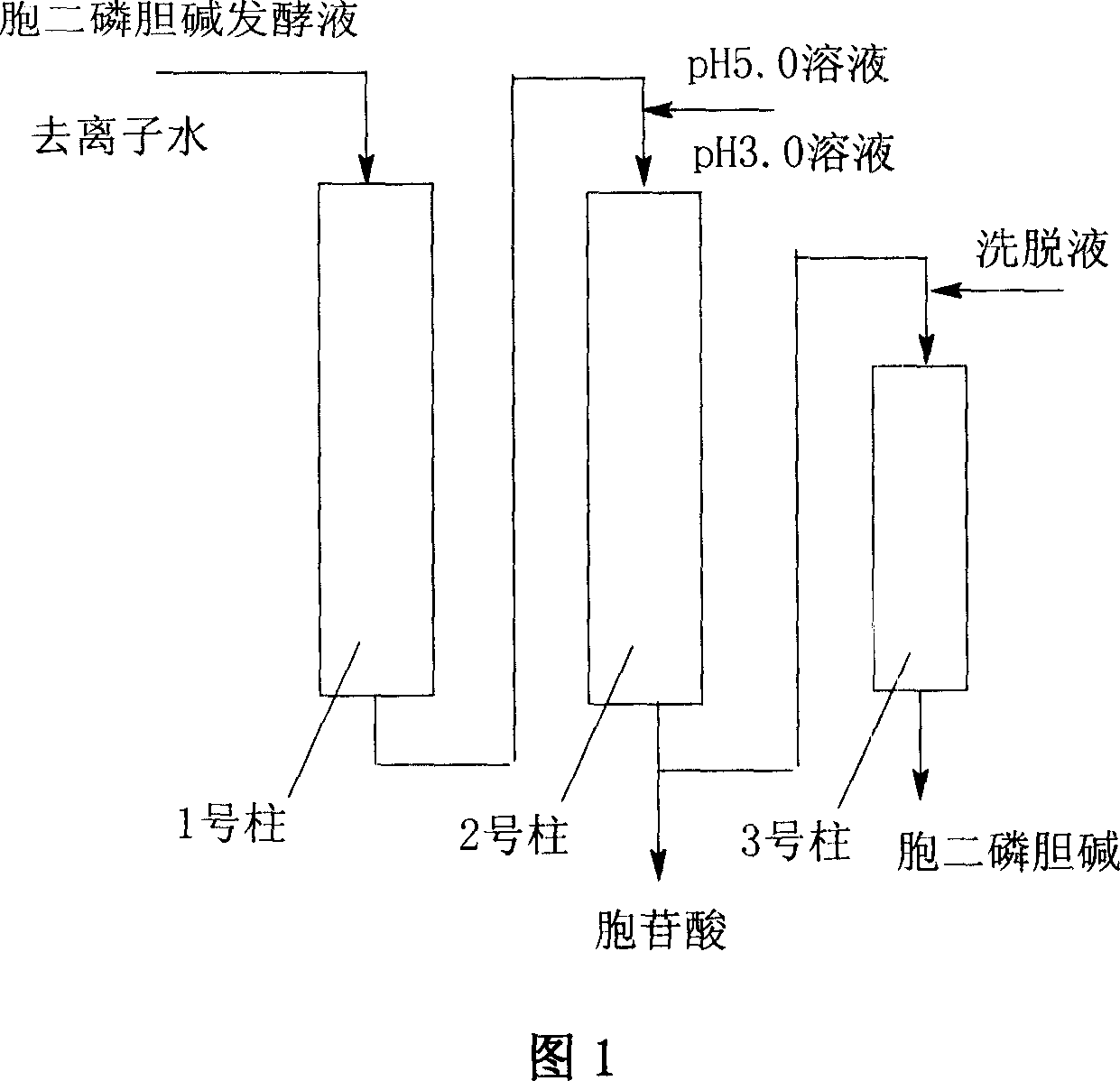

Method for purifying citicoline from biotransformation or multienzyme reaction liquid

ActiveCN101096380ASimple and fast operationHigh rate of returnSugar derivativesSugar derivatives preparationState of artHigh density

The invention discloses a separating method of CDP-C from biological conversion or polyzyme reacting liquid in the biochemical technical domain, which is characterized by the following: passing the CDP-C reacting liquid into cation exchange column 1, anion exchange column 2 and anion exchange column 3; washing the columns 1-3 through deionized water; washing the anion exchange column 2 and anion exchange column 3 through solution with pH value at 5.0; eluting CDP-C from anion exchange column 3 through high-density salt and alcaine to obtain high-density CDP-C solution; using the solution with pH value at 3.0 to elute CMP on the anion exchange column 2. The invention shortens the separating time with water consumption over 60%, which improves the receiving rate of CDP-C with easy crystallization and recycles most of non-reacted CMP.

Owner:NANTONG QIUZHIYOU BIOSCI & BIOTECH

Method for preparing citicoline through biological enzyme catalysis

The invention discloses a method for preparing citicoline through biological enzyme catalysis. The method is characterized by comprising the steps that a single artificially-transformed gene engineering strain is used as an enzyme source, an ammonium chloride catalyst, orotic acid, choline phosphate and other chemical substances are subjected to a reaction to generate citicoline, and then the citicoline is extracted from the reaction solution. Compared with the prior art, single strain is adopted for fermentation, the production technology is simple, the production period is short, the production cost is low, and the method for preparing citicoline through biological enzyme catalysis can be widely applied to industrial production of citicoline.

Owner:苏州正济药业有限公司

A strain of Issakia orientalis and its whole cell transformation method for producing citicoline

InactiveCN102286386AEfficient preparationIncrease regeneration rateFungiMicroorganism based processesCholine PhosphateManganese

The invention relates to Issatchenkia orientalis and a method for producing citicoline by whole cell conversion of Issatchenkia orientalis, belonging to the technical field of biological pharmacy. In the method provided by the invention, the whole cells of Issatchenkia orientalis Z1, namely CCTCC (China Center for Type Culture Collection) NO: M2011272 are utilized to prepare citicoline, choline phosphate and 5'-cytidylic acid are used as substrates, glucose is used as an energy donor, and the ATP (adenosine triphosphate) regeneration efficiency is improved by adding inorganic ions; glucose is used as the energy donor, so that the energy requirement of the strain is provided and ATP is provided for a citicoline synthesis enzyme system; one or more of potassium ion, magnesium ion and manganese ion are added to change the metabolism flow direction and improve the ATP regeneration rate, so that the ATP regeneration rate is matched with the rate of the citicoline enzyme synthesis system and the high-efficiency preparation of citicoline is achieved; and the whole cells of Issatchenkia orientalis are used, and toluene is added to an aqueous solution during the preparation process so as to improve the cell permeability, so that the rate of the citicoline enzyme synthesis system is improved.

Owner:江苏华晟知识产权运营有限公司

Method for preparing citicoline

InactiveCN101538598AIncrease profitAvoid investmentMicroorganism based processesFermentationPhosphate ionPhosphorylation

The invention discloses a method for preparing citicoline. The method comprises the following steps of taking choline chloride, phosphate ions and cytidine monophosphate or a precursor thereof as substrates, taking glucose, fructose, sucrose or maltose as an energy donor, adding a small-molecule chemical effect substance and utilizing the yeast-cell whole cells with permeability to catalyze and prepare the citicoline. By building a metabolic network model and metabolic flow analysis, adopting the small-molecule chemical effect substance to regulate and control metabolic flow so as to improve the efficiency of energy self-coupling and choline phosphorylation and utilizing the yeast cells with permeability to efficiently prepare the citicoline, the method has the advantages of greatly increasing product concentration and raising the utilization ratio of the substrates.

Owner:NANJING UNIV OF TECH

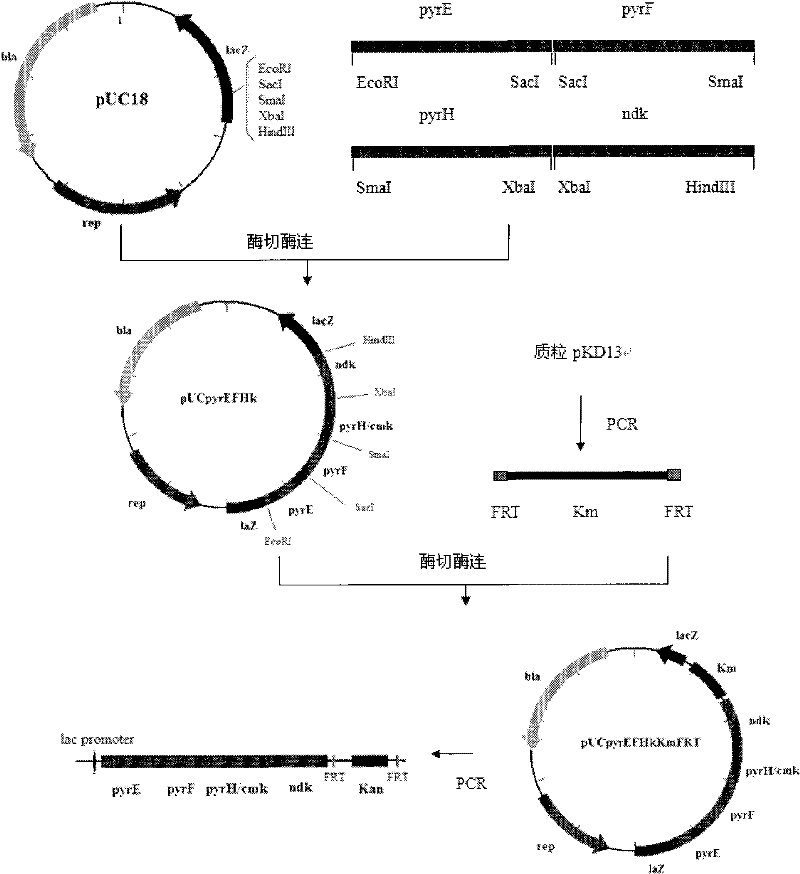

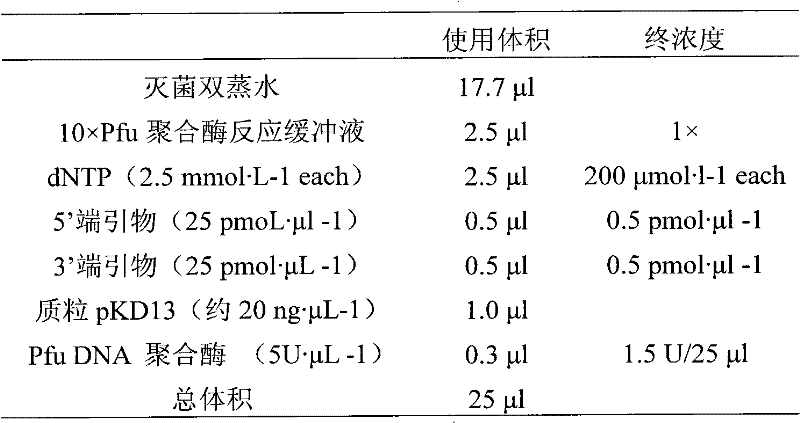

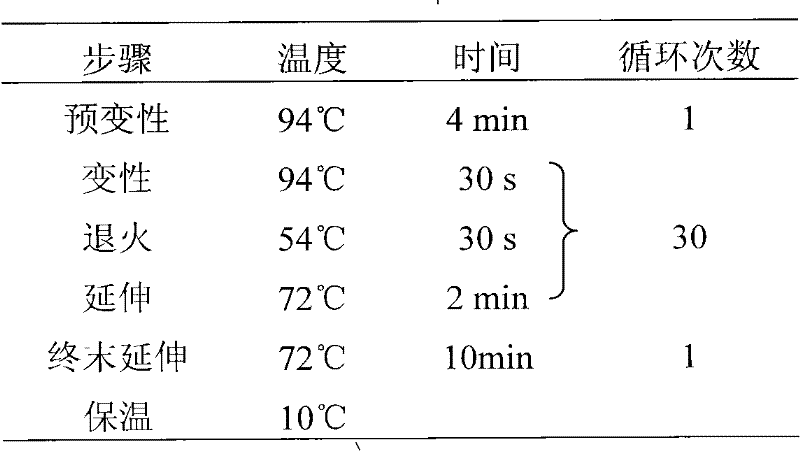

Bioengineering method for synthesis of citicoline

InactiveCN102605025AImprove responseAchieve separationBacteriaTransferasesEscherichia coliCholine Phosphate

The invention provides a bioengineering method for synthesis of citicoline. The method comprises the following steps: constructing an escherichia coli engineering strain containing choline phosphate cytidylyltransferase by recombination through a genetic engineering method; utilizing the engineering strain to perform large-scale high-density culture as well as separation and purification, thereby obtaining the choline phosphate cytidylyltransferase with high purity and high activity; utilizing the choline phosphate cytidylyltransferase to perform enzymatic catalysis synthesis under appropriate conditions to obtain the citicoline; and adding cation exchange resin into a system of the enzymatic catalysis synthesis of the citicoline to enable the citicoline to be constantly adsorbed on the resin in the synthesis process, thereby realizing coupling of reaction and separation of the citicoline. The bioengineering method has the advantages that the substrate utilization rate is high, the product recovery rate is high, reaction conditions are mild, the reaction time is short, the environment pollution is small, the cost is low, and the like, thus being suitable for industrial mass production.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES +1

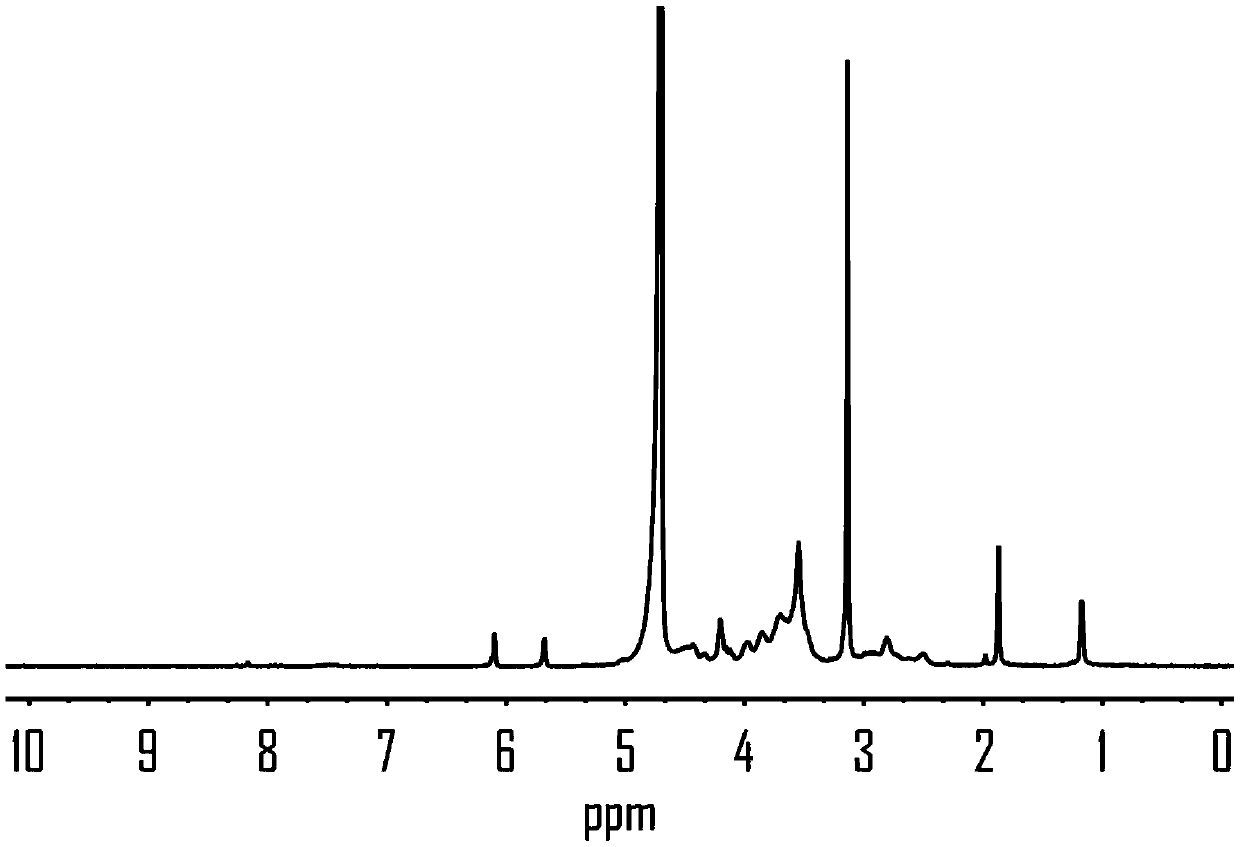

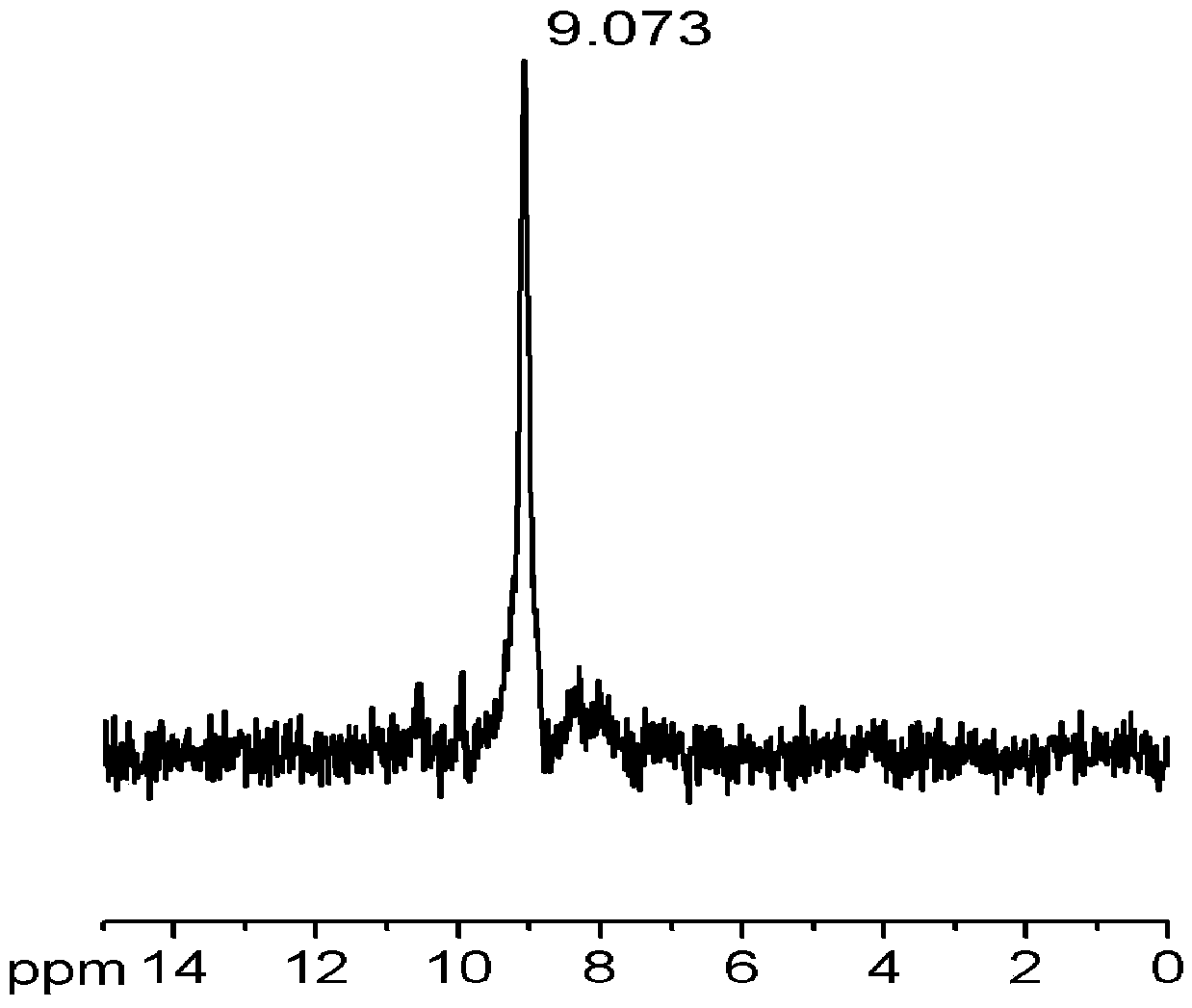

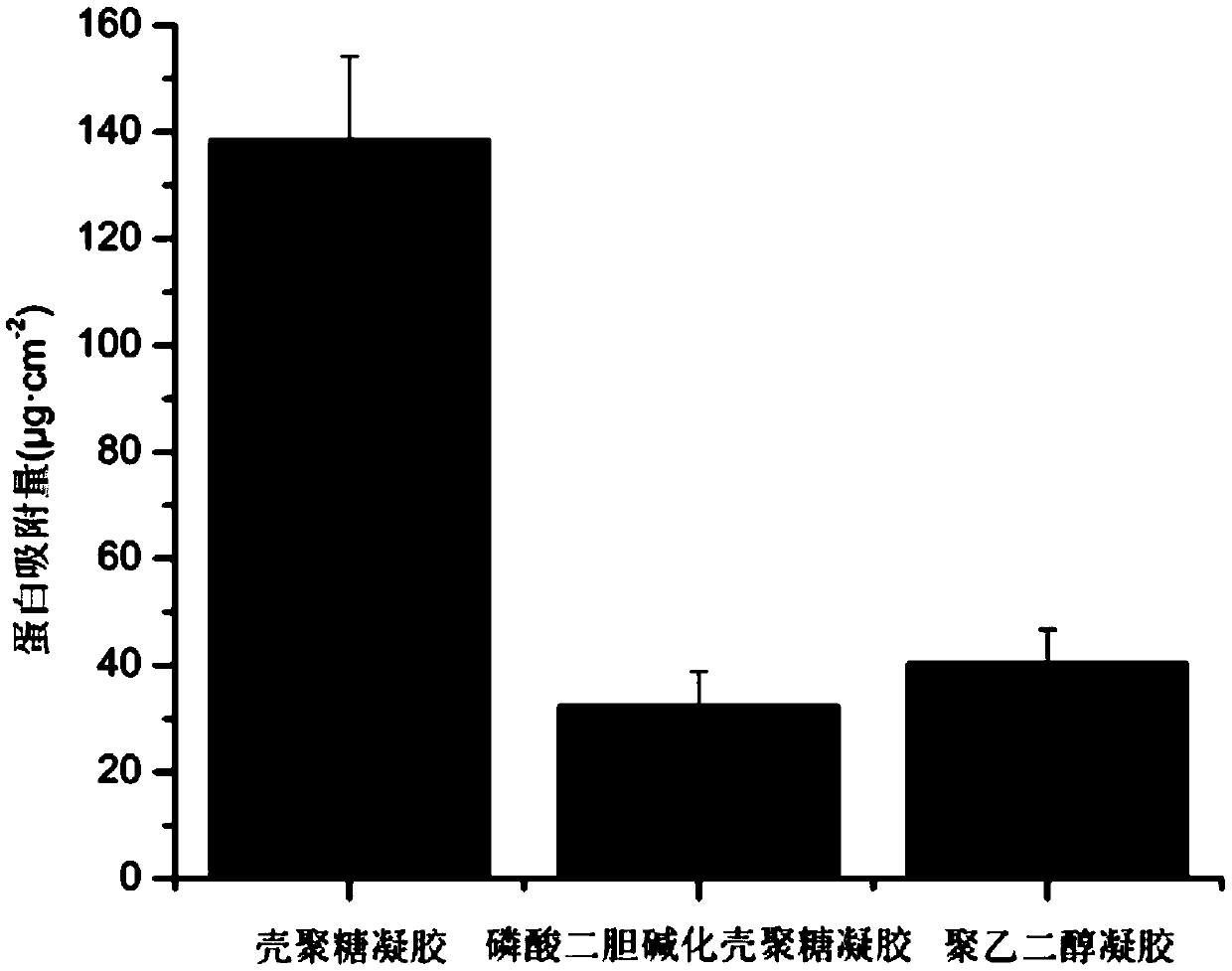

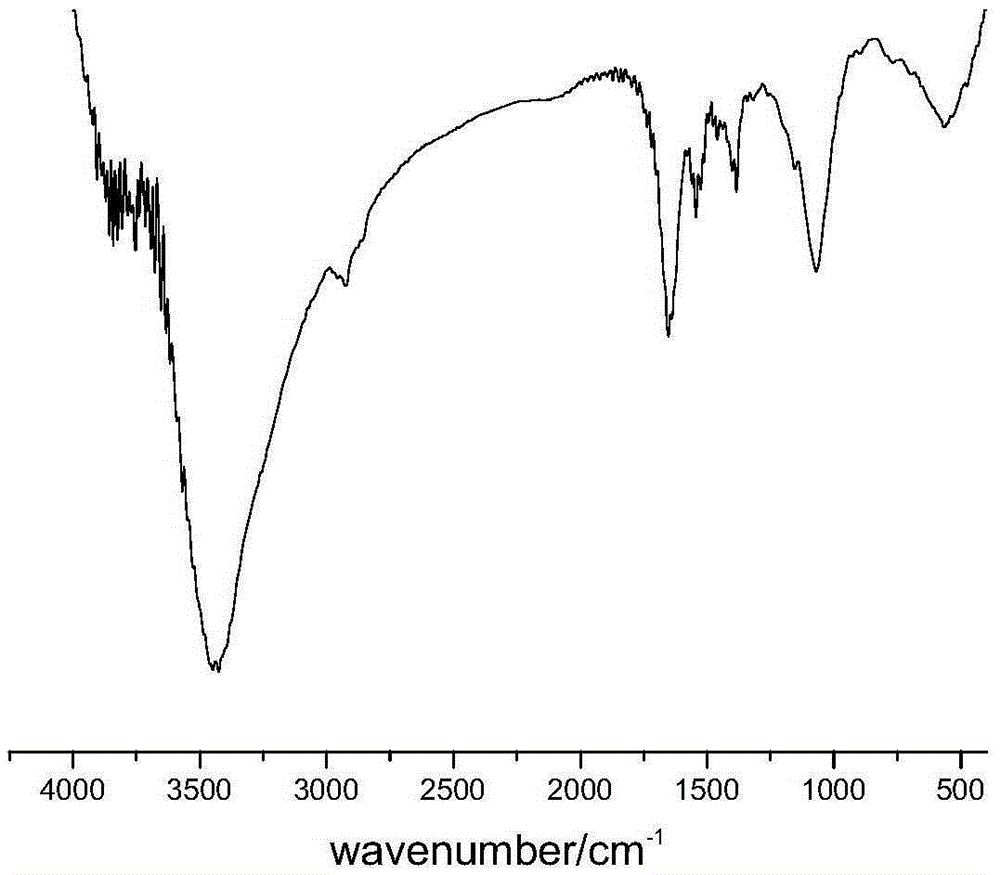

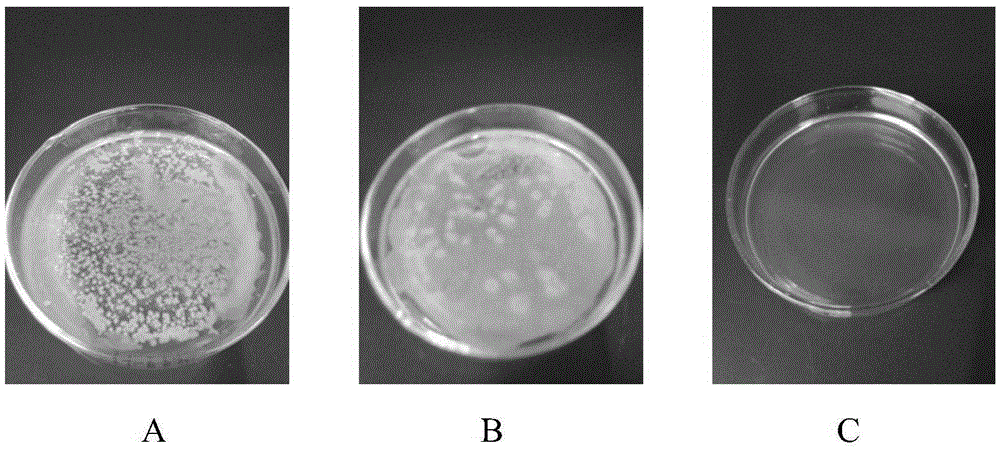

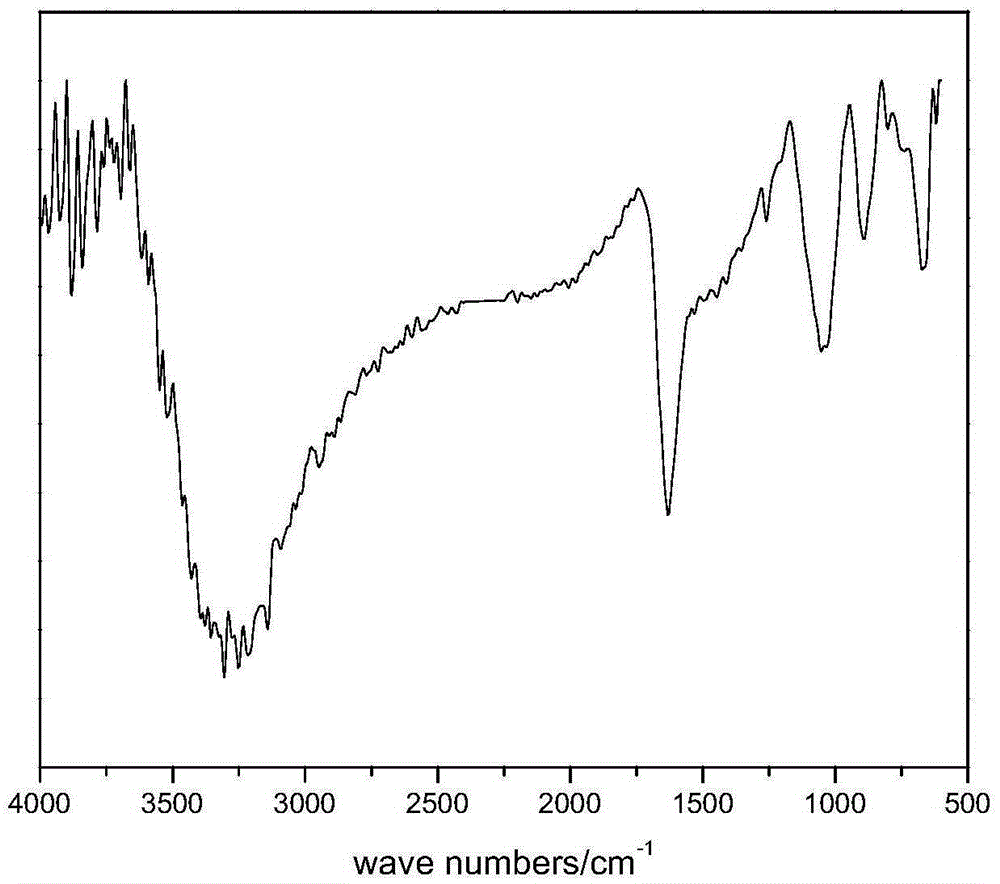

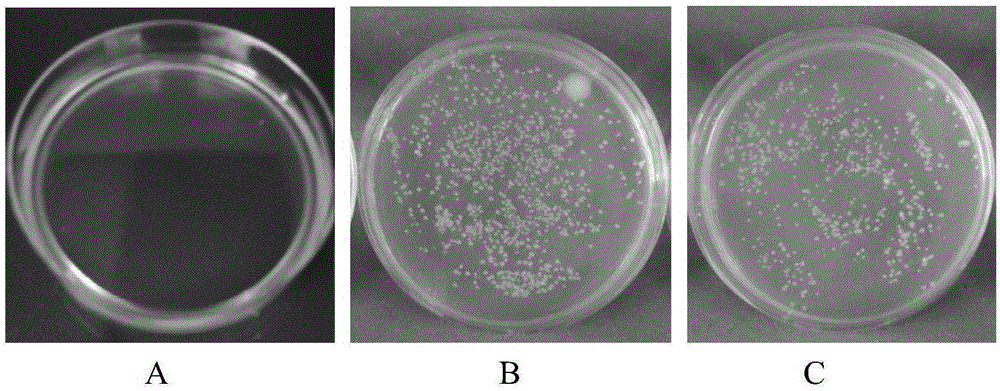

Photo-crosslinking bionic hydrogel and preparation and application thereof

ActiveCN105504190AFast forming conditionsMild molding conditionsSurgeryAbsorbent padsGlycidyl methacrylateCytotoxicity

The invention discloses a photo-crosslinking bionic hydrogel and preparation and application thereof. The monomer of the photo-crosslinking bionic hydrogel is glycidyl methacrylate-citicoline alkalization chitosan hydrochloride. The preparation method comprises the three steps of synthesis of citicoline alkalization chitosan hydrochloride, synthesis of glycidyl methacrylate-citicoline alkalization chitosan hydrochloride and addition of a photoinitiator to obtain the glycidyl methacrylate-citicoline alkalization chitosan hydrochloride hydrogel. The photo-crosslinking bionic hydrogel molding conditions are rapid and mild, a citicoline basic group of a local area branch dual-positive-charge structure can improve hydrophilia, cytotoxicity, antibacterial property and protein adsorption restraining, the obtained bionic hydrogel has the remarkable broad-spectrum antibacterial effect on the physiological environment condition, is non-toxic for normal cells, can restrain protein adsorption, and has the great application value in the biological medical fields of medical treatment, healthcare and the like.

Owner:广州佰斯伦医疗器械有限公司

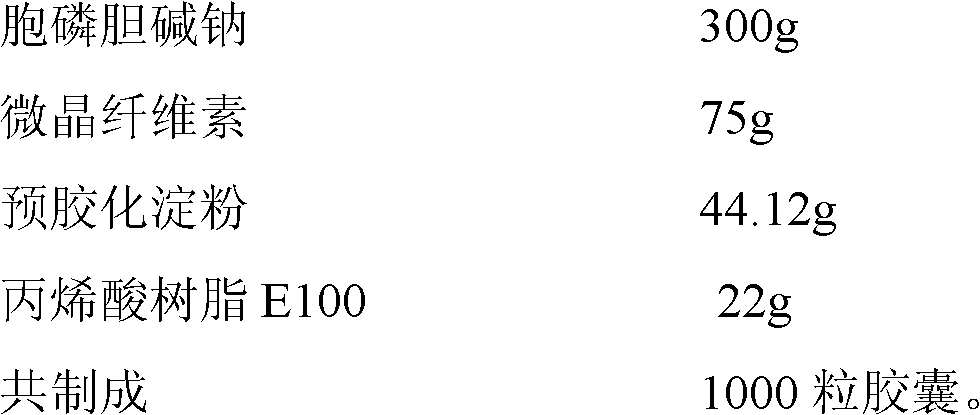

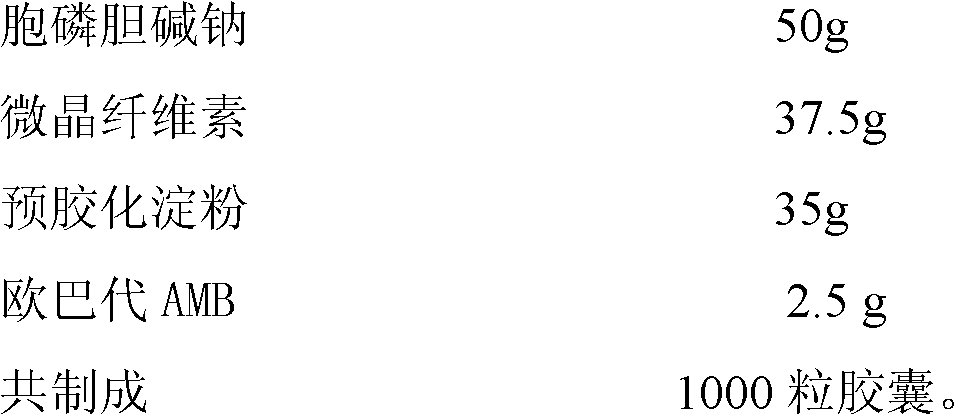

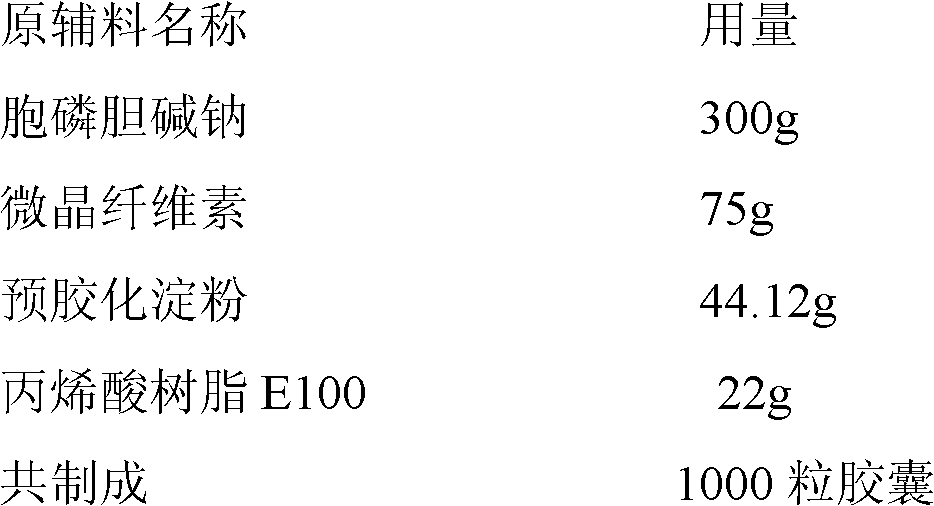

Moisture-proof coating citicoline sodium capsule and preparation method thereof

ActiveCN102525997AGood granularityGood disintegrationOrganic active ingredientsNervous disorderCiticoline sodiumMoisture absorption

The invention provides a moisture-proof coating citicoline sodium capsule and a preparation method thereof. The citicoline sodium capsule is composed of a capsule casing and quick-release moisture-proof micro pills or granules. All components in each capsule containing citicoline sodium quick-release moisture-proof micro pills or granules by percentage are 40% to 70% of citicoline sodium, 10% to 30% of microcrystalline cellulose, 10% to 30% of pregelatinized starch and 2% to 10% of moisture-proof coatings. The moisture-proof micro pills or granules are obtained by being extruded and rounded or pressed and granulated to be coated with moisture-proof coatings. The citicoline sodium capsule is good in moisture-proof function and resolves the problems that the capsule is prone to absorb waterdue to the fact that citicoline sodium is strong in moisture absorption, the capsule casing is prone to be fragile, and the like.

Owner:QILU PHARMA CO LTD

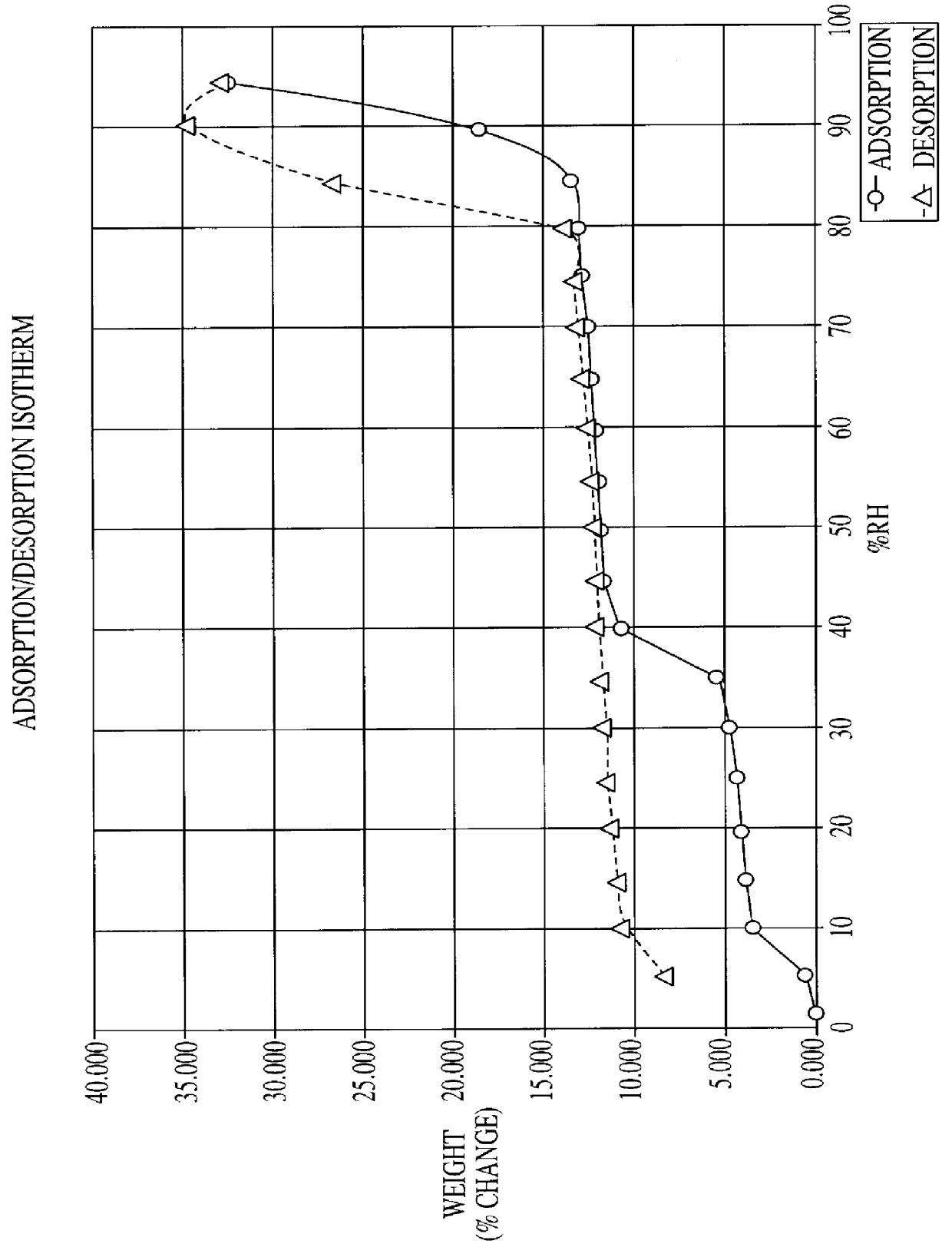

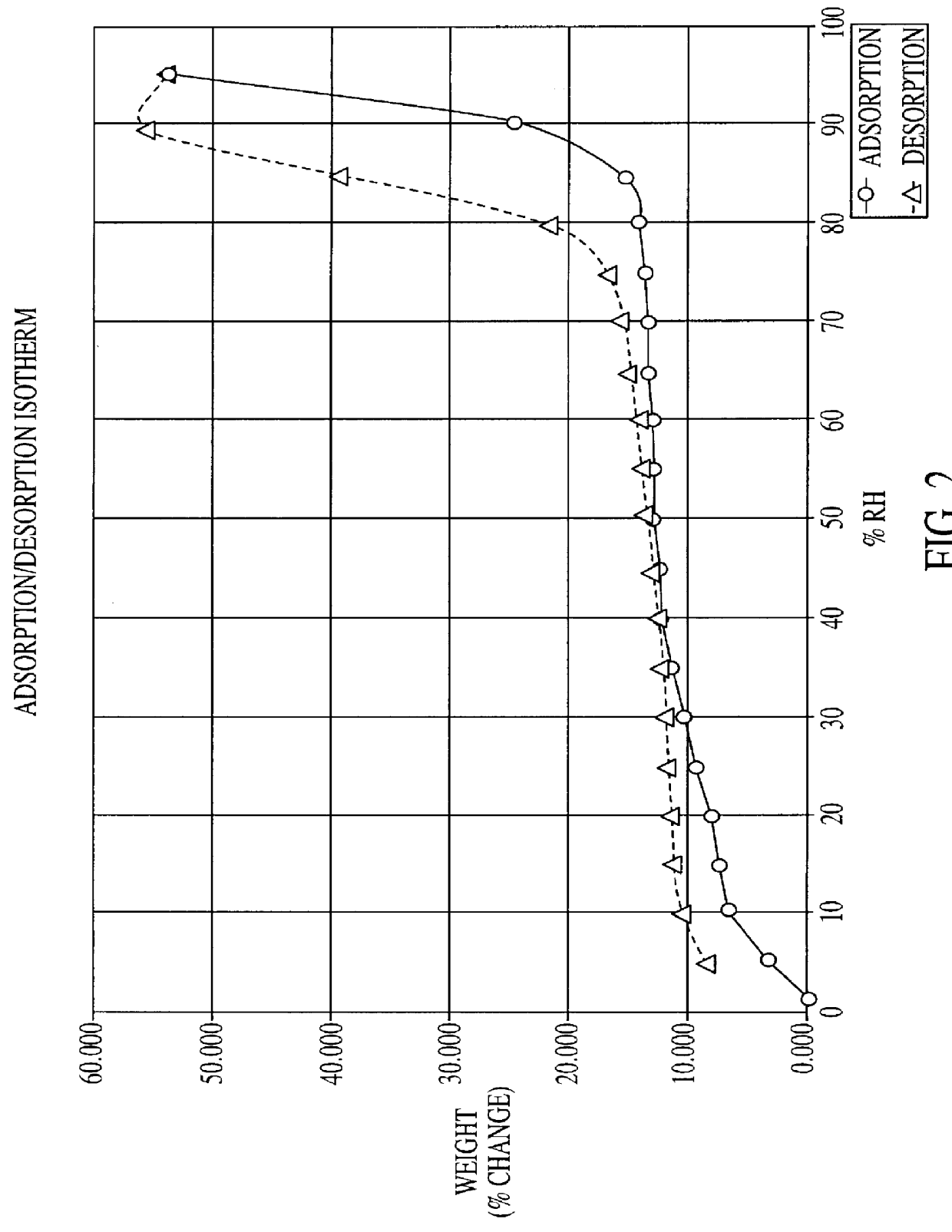

Hyperhydrated citicoline, process and use

A hyperhydrated form of citicoline and its formulations, which exhibits desirable characteristics, including crystal formation, moisture resistance, improved storage stability, and formulation versatility, is disclosed. Methods of preparing the citicoline hyperhydrate and its use in the manufacture of stable pharmaceutical dosage forms are also described.

Owner:FERRER INT SA

Microsphere injection for treating ophthalmopathy

The microballoon injection for treating eye diseases has medicine containing microballoons comprising medicine and microballoon forming material. The medicine is musk, citicoline and Chinese medicine vasodilator or their composition; and the microballoon forming material consists of medicinal polymer material. The microballoon injection may be used in treating several kinds of eye disease, as well as central nerve disease, cardiac vascular diseases, local nerve functional disorder and damage, and ischemic diseases. The present invention has the preferable embodiment of preparing microballoon injection or microballoon powder for injection through an optimized emulsifying-solvent volatilizing process and freeze drying process.

Owner:段亚东

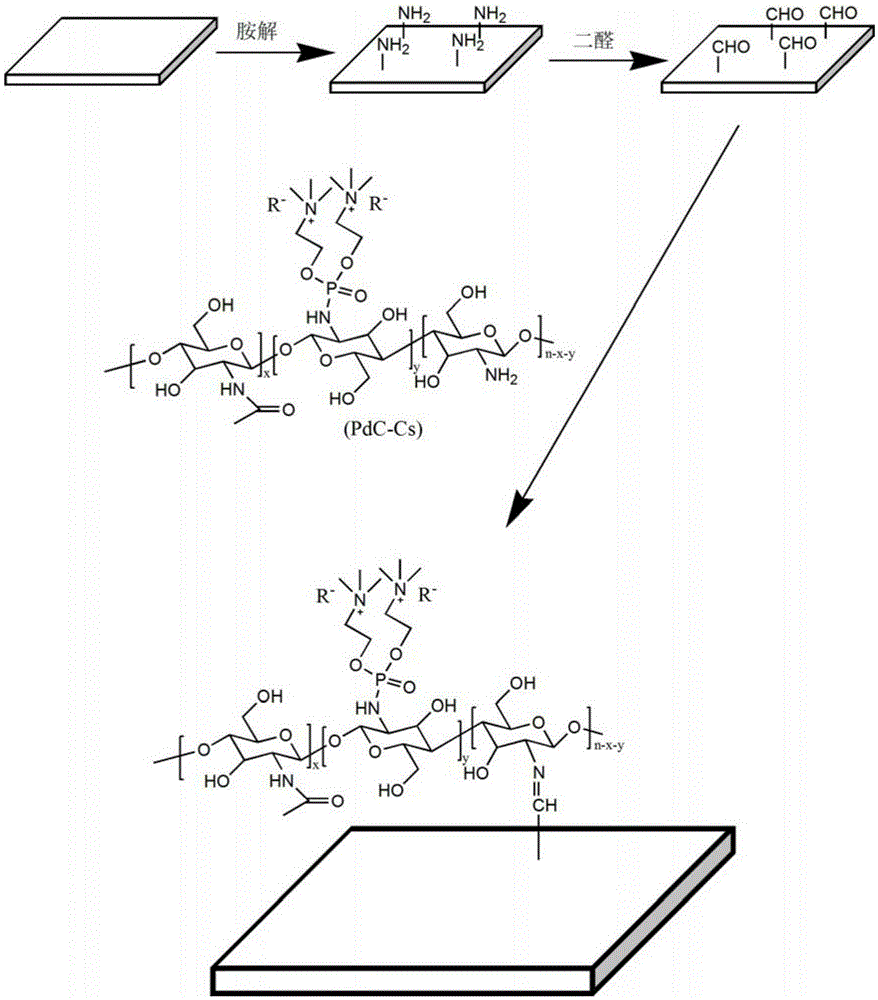

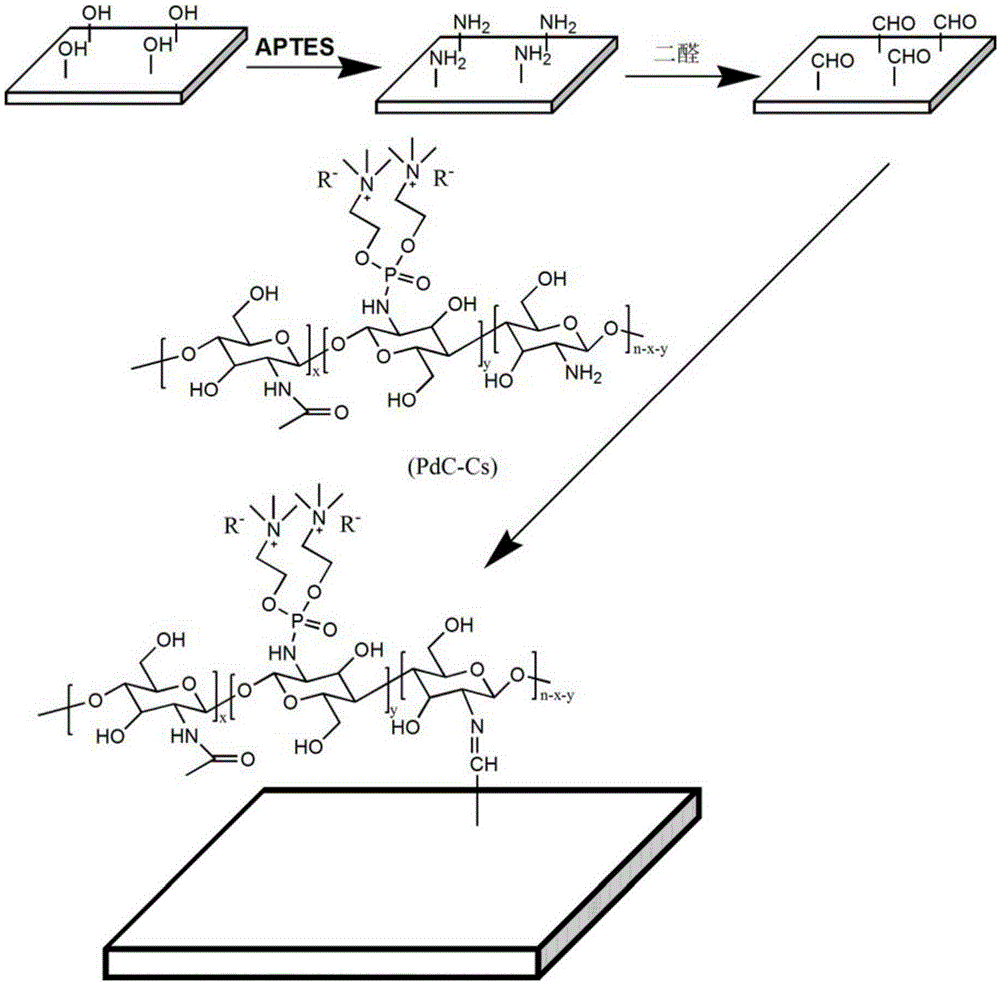

Polyester material with antibacterial and biocompatible surface and preparing method and application thereof

The invention discloses a polyester material with an antibacterial and biocompatible surface and a preparing method and application thereof. The method comprises the steps that amination of the surface of a polyester material is achieved by means of aminolysis or the plasma technique, so that a surface-aminated polyester material is obtained; the obtained surface-aminated polyester material is made to react with dialdehyde to achieve formylation of the surface of the polyester material, so that a surface-formylated polyester material is obtained; the obtained surface-formylated polyester material is made to react with citicoline chitosan salt to achieve citicoline chitosan salt immobilization of the surface of the polyester material, and washing is conducted to obtain the polyester material with the antibacterial and biocompatible surface. The adopted citicoline chitosan salt has high cytocompatibility, blood compatibility and broad-spectrum antibacterial property in the physiological environment and can be fixed to the surface of the polyester material under a mild condition, operation is easy, the polyester material with the antibacterial and biocompatible surface can be obtained, and the polyester material is suitable for implantable and interventional medical devices.

Owner:JINAN UNIVERSITY

Preparation method of citicoline

InactiveCN102199643AReduce manufacturing costReaction conditions are easy to controlMicroorganism based processesChemical recyclingCiticolinePhosphocholine

The invention discloses a preparation method of citicoline. The method comprises the following steps: the culture of a single gene engineering bacterium or the treatment material of the culture is used as enzyme source to catalyze the reaction of a substrate comprising ammonium chloride, orotic acid and phosphocholine and ensure that citicoline is generated and accumulated in the reaction solution, and citicoline is extracted from the reaction solution. The invention has the following beneficial effects: (1) the single microorganism is utilized to catalyze the reaction, reaction conditions are easy to control; (2) the cost of the substrate is lower so that the production cost of citicoline is lower; and (3) the reaction is fast and the conversion rate is higher. The method can be widely used in the preparation of citicoline.

Owner:苏州天马医药集团天吉生物制药有限公司

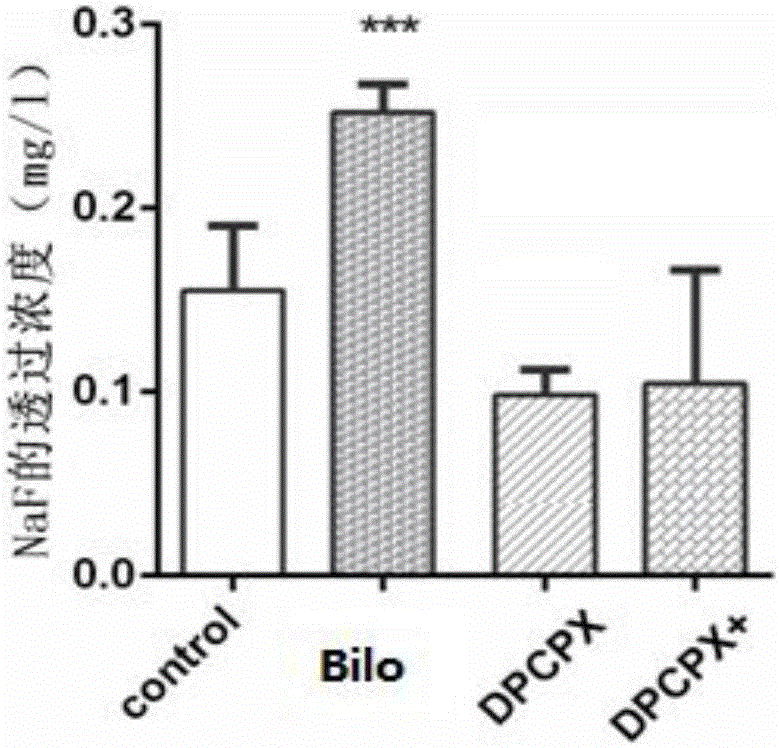

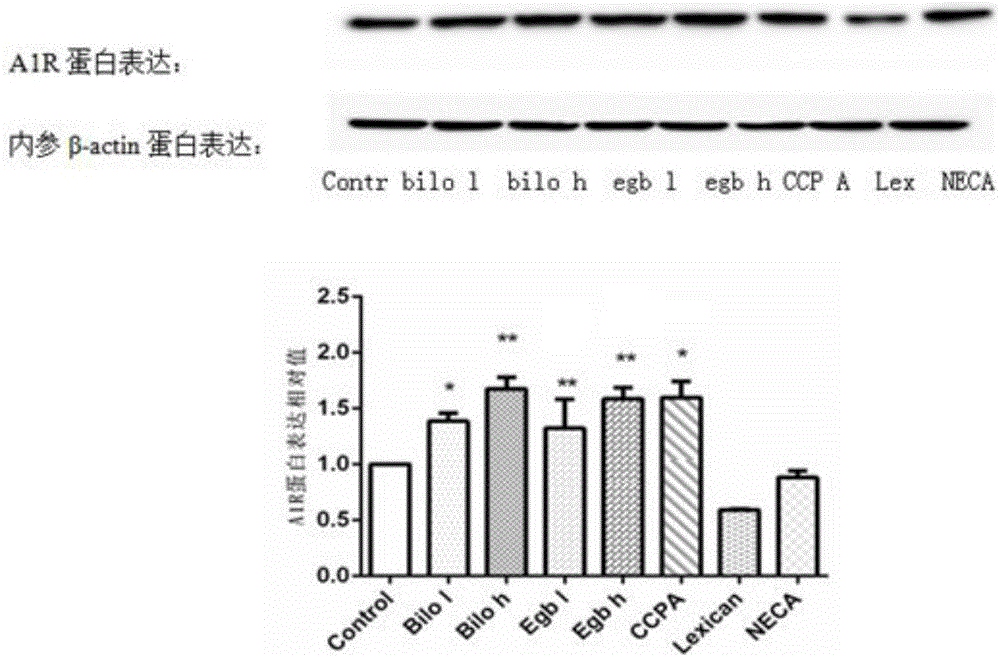

Application of bilobalide as synergist in preparation of drug for preventing cranial nerve injury diseases

InactiveCN106727501AActive ingredient clearQuality improvementNervous disorderHydroxy compound active ingredientsDiseaseSide effect

The present invention discloses application of bilobalide as a synergist in preparation of a drug or a heath product for preventing cranial nerve injury diseases. An inventor discovers that compounds of bilobalides, particularly bilobalide, bilobalide extracts, and hydroxyl derivatives of bilobalides, particularly glucoside derivatives, ester derivatives and ether derivatives can well promote drug molecules with a treating or health care function on cranial nerve injury diseases to enter brain tissues, wherein the drug molecules comprise ginsenoside, stibene glucoside, resveratrol, levodopa, edaravone, vinpocetine, nicergoline, citicoline, oxiracetam and the like; under the conditions of not increasing drug concentration in blood, the concentration of bilobalide can be increased to a large extent in the brain tissues, so that the efficacy of the drug can be improved, and side effects and adverse reactions of the drug can be reduced.

Owner:GUANGDONG PHARMA UNIV

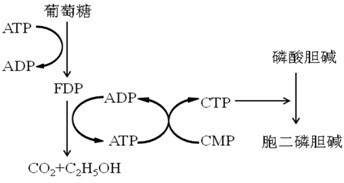

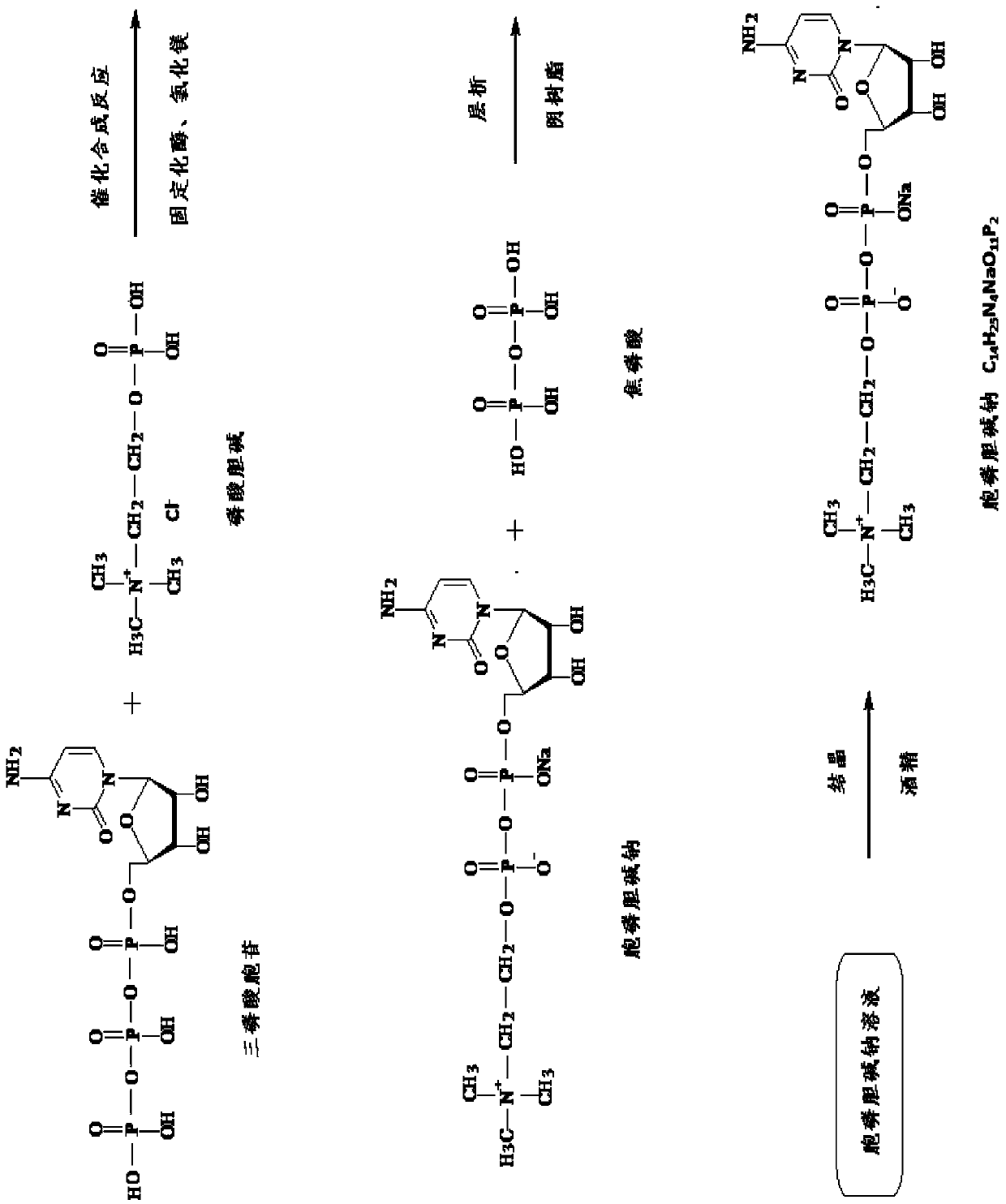

Process for preparing cytidine diphosphate choline

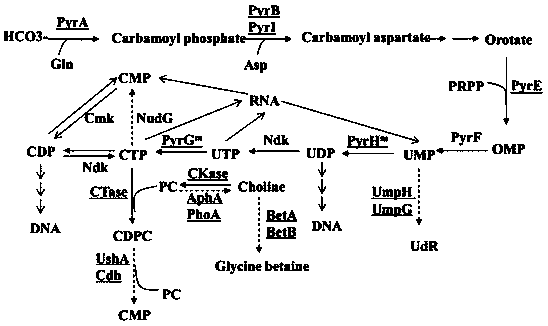

ActiveCN102586383AFast metabolismReduce manufacturing costMicroorganism based processesFermentationMicroorganismPh control

The invention relates to a process for preparing cytidine diphosphate choline. According to the method, denovo synthesis of pyrimidine is utilized as a basic reaction and choline materials are subjected to a reaction at the reaction temperature ranging from 20 DEG C to 38 DEG C for 10 to 72 hours with pH controlled at 5 to 7.5 in the presence of culture solution of microorganism A or further in the presence of culture solution of microorganism B or treatment so as to accumulatively produce cytidine diphosphate choline. Simple starting materials of carbon and nitrogen sources are utilized, in culture solution containing the choline materials, precursor of the cytidine diphosphate choline, namely cytidine monophosphate is synthesized by means of metabolic process, and cytidine diphosphate choline is cumulatively produced in the reaction solution. According to the method, expensive cytidine monophosphate or the precursor materials are avoided so that the preparing cost of the cytidine diphosphate choline is greatly reduced.

Owner:QILU PHARMA HAINAN +1

Method for catalytically producing citicoline sodium with immobilized enzyme

ActiveCN103849666AAvoid pollutionAvoid processing powerTransferasesMicroorganism based processesEscherichia coliPhosphorylcholine

The invention provides a method for catalytically producing citicoline sodium with an immobilized enzyme. The method comprises the following steps: by utilizing engineered escherichia coli of a molecularly cloned cytidine phosphotransferase gene for fermentation, preparing cytidine phosphotransferase, and preparing cytidine phosphotransferase liquid through purification; immobilizing cytidine phosphotransferase; by using phosphorylcholine and cytidine disodium triphosphate as raw materials, catalytically generating citicoline with immobilized cytidine phosphotransferase. The method is simple in production process, short in production cycle and low in production cost and can be widely applied to industrial production of citicoline.

Owner:KAIPING GENUINE BIOCHEM PHARMA

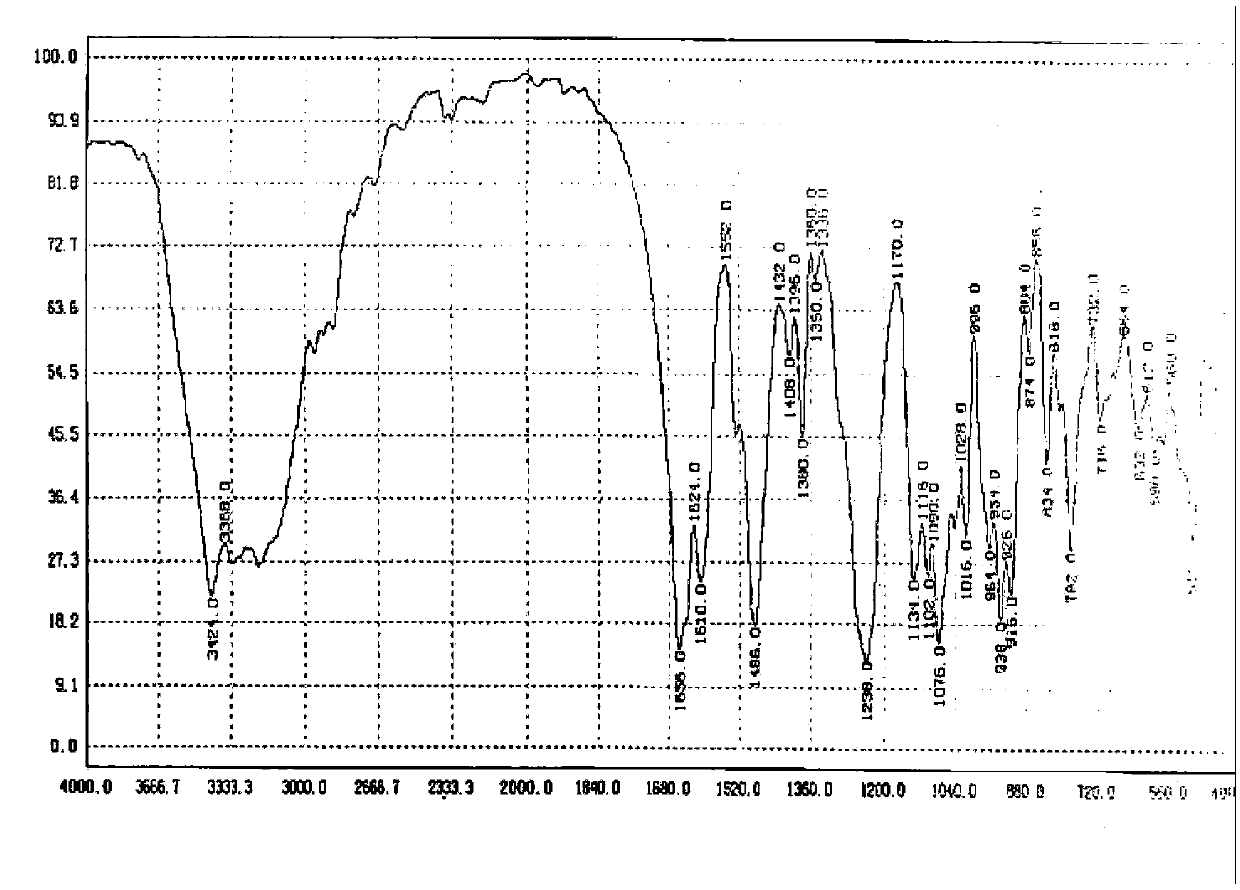

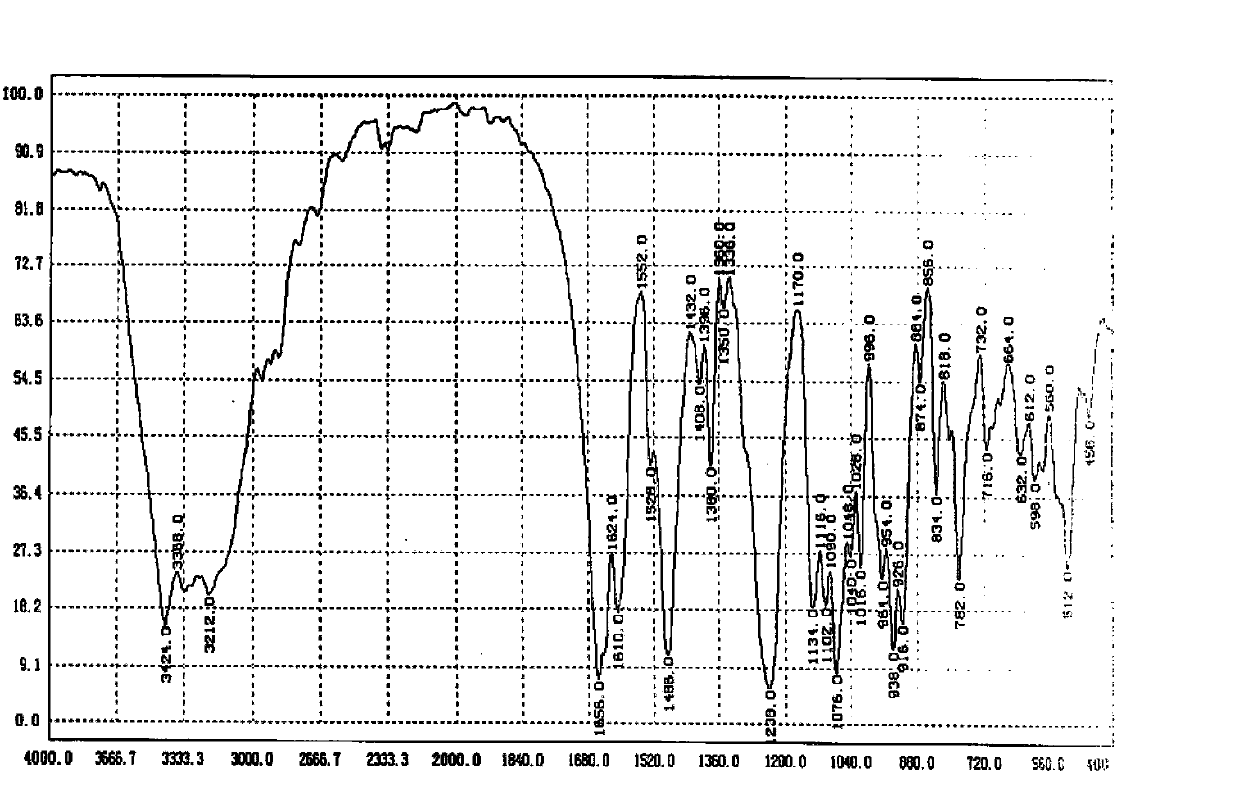

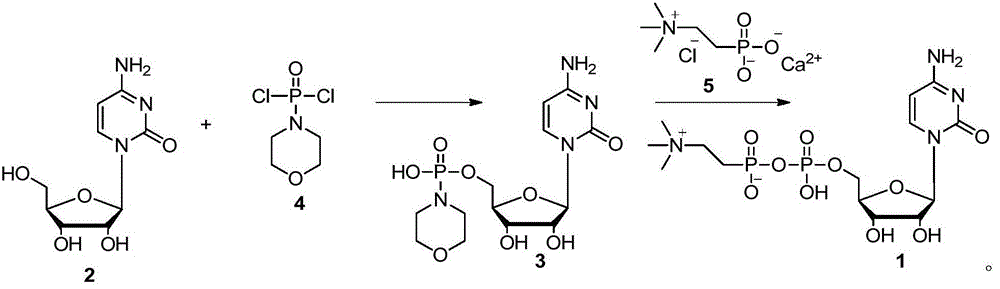

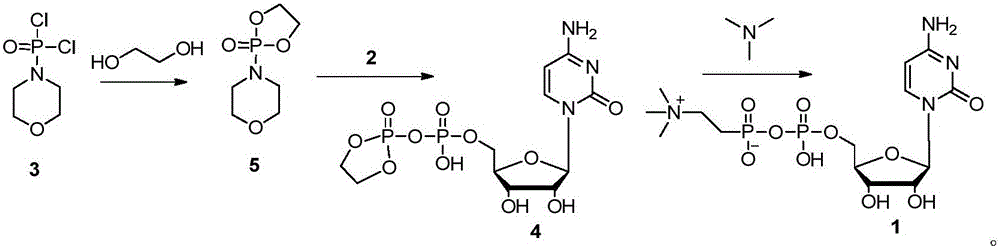

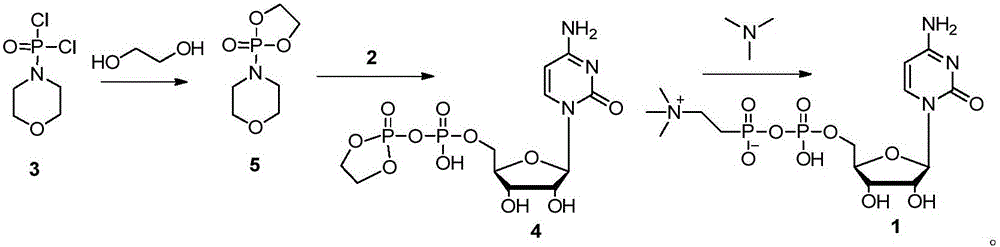

Citicoline and synthetic method thereof

InactiveCN105732752AHigh yieldLess side effectsSugar derivativesSugar derivatives preparationMorpholineChloride

The invention discloses citicoline and a synthetic method thereof.The synthetic method includes subjecting cheap and easily available cytidine, serving as a raw material, and dichlorophosphoryl morpholine to condensation at a 5' position highly selectively so as to obtain 5'-phosphorylmorpholinylcytidine; subjecting the 5'-phosphorylmorpholinylcytidine and phosphocholine chloride calcium to condensation in solvents so as to obtain the citicoline.Total yield is up to 58% only by the two steps.The synthetic method is cheap in and easily available to raw materials, expensive cytidine monophosphate is unused, operation steps are simplified, and reaction scale can be expanded to synthesize 500 g of citicoline.The synthetic method has a potential application prospect by providing a novel citicoline synthetic route.

Owner:XINXIANG UNIV

A recombinant microorganism for producing citicoline and a method for producing citicoline

ActiveCN109207415ALow costRealize large-scale industrial productionBacteriaHydrolasesCholine kinasePhosphorylcholine

The invention provides a recombinant microorganism for producing citicoline and a method for producing citicoline by using the recombinant microorganism, which knocks out the degradation and utilization genes of citicoline, choline and phosphorylcholine, and knocks out the 5-hydroxyl-CTP bisphosphatase encoded by the CTP degradation gene, thus blocking the shunt of CTP, the precursor of CDP. The key enzymes involved in citicoline synthesis are expressed in appropriate amounts, including choline kinase which phosphorylates choline chloride to phosphorylcholine, and choline phosphocytidyltransferase, which catalyzes the reaction of phosphorylcholine with CDP to produce citicoline. In addition, the pyrimidine nucleoside pathway was genetically engineered to remove the feedback inhibition of the synthesis pathway. The recombinant strain could produce more than 20g / L citicoline in a 5-liter fermentor by biological fermentation, and the production cost of citicoline is low, the pollution islittle and the environment is green, so it had high value of popularization and application.

Owner:SUZHOU BIOSYNTHETICA CO LTD

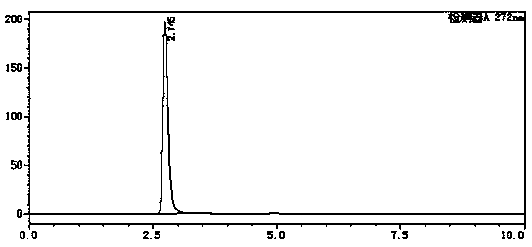

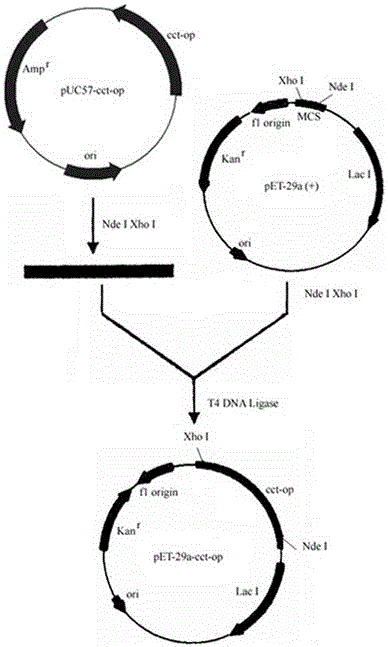

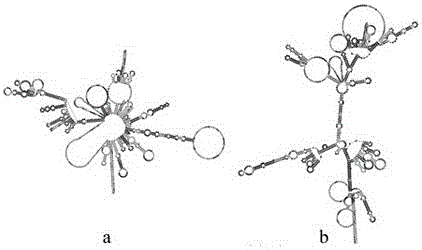

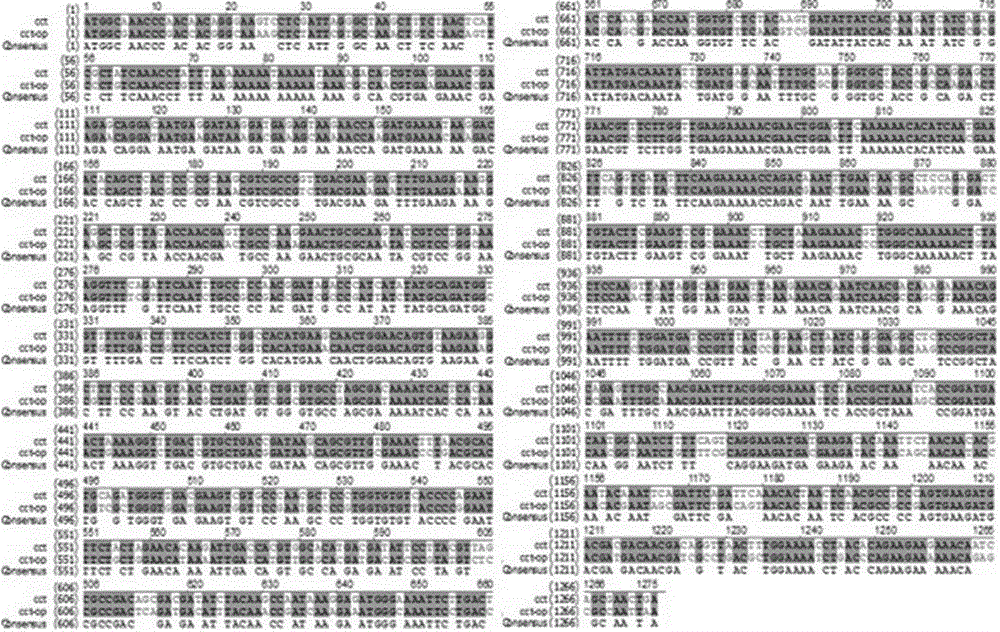

Codon optimized phosphocholine cytidylyltransferase gene and expression thereof

ActiveCN105039366AHigh crude enzyme activityIncrease enzyme activityBacteriaMicroorganism based processesEscherichia coliCytidyl Transferase

The invention relates to a codon optimized phosphocholine cytidylyltransferase cct gene and expression thereof, wherein the cct gene is constructed on the basis of escherichia coli codon preference. The optimized cct gene is obtained through a total synthesis method, the nucleotide sequence of the gene is represented by SEQ ID No.1, and the sequence of coding amino acid is represented by SEQ ID No.2. The length of the gene is 1275 bp, and encodes 424 amino acids. The homology between optimized cct gene and wild cct gene is 76.6%; the optimized cct gene is connected to a carrier pET-29a(+) to obtain a recombinant carrier pET-29a-cct-op, and the recombinant carrier is converted to escherichia coli. After IPTG inducible expression and enzyme activity detection, an engineering bacterium strain, which has been modified by preference and can efficiently express phosphocholine cytidylyltransferase, is obtained. The invention has the advantages that brewer's yeast cct gene is redesigned according to the preference of escherichia coli codon so as to improve the efficiency of escherichia coli on expressing phosphocholine cytidylyltransferase, the gene can be used to produce phosphocholine, the industrial output can be increased, and the economic profits for enterprises are increased.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

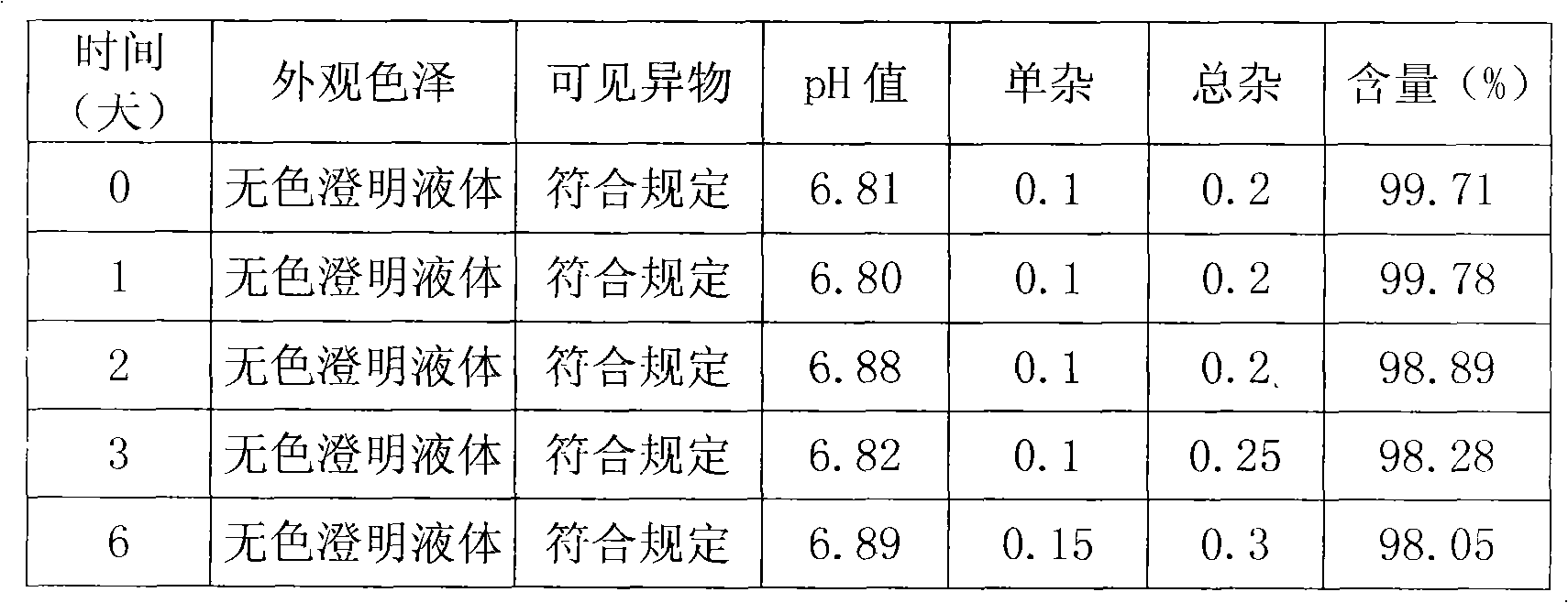

Citicoline sodium injection and preparation method thereof

ActiveCN102462659APollution controlControl Endotoxin LevelsOrganic active ingredientsSenses disorderCiticoline sodiumCiticoline

The invention discloses a citieoline sodium injection with good quality and low cost, and provides a method for preparing the injection simultaneously. The citieoline sodium injection provided by the invention is prepared from 1,000-5,000g of citieoline sodium, 5g of versene disodium and 20,000ml of water for injection, and is 2-5ml per tube. The preparation method comprises the following steps of: weighing each component; heating the water for injection to 28-30 DEG C, adding 0.02-0.05 percent of injection active carbon, adsorbing for 20-30 minutes, and filtering; and heating a feed liquid to 60-65 DEG C, preserving heat for 8-10 minutes, adding 0.02 percent of injection active carbon, stirring, dissolving, decarburizing, filtering, lowering temperature of the feed liquid to be below 40 DEG C, and performing split charging. Due to the adoption of the method, the pollution levels and endotoxin levels of relevant substances of a product and microorganisms are effectively controlled, and the stability and light inspection yield of the product are increased.

Owner:NORTH CHINA PHARMA COMPANY

Implant agent for treating ophthalmopathy

InactiveCN1745850AUnique formulaFormulation InnovationSenses disorderPeptide/protein ingredientsAtrophyNeurotrophic factors

An implant for treating retinosis and optic atrophy is composed of the carrier and the medicine chosen from the Chinese-medicinal vascular dilating medicine, neurotrophic factor and citicoline.

Owner:段亚东

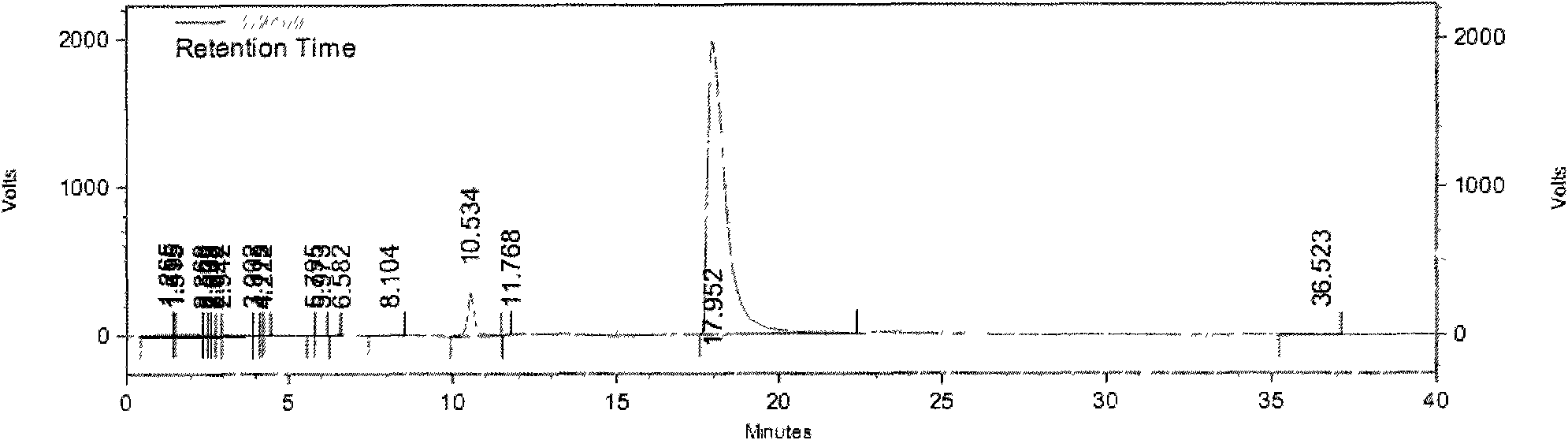

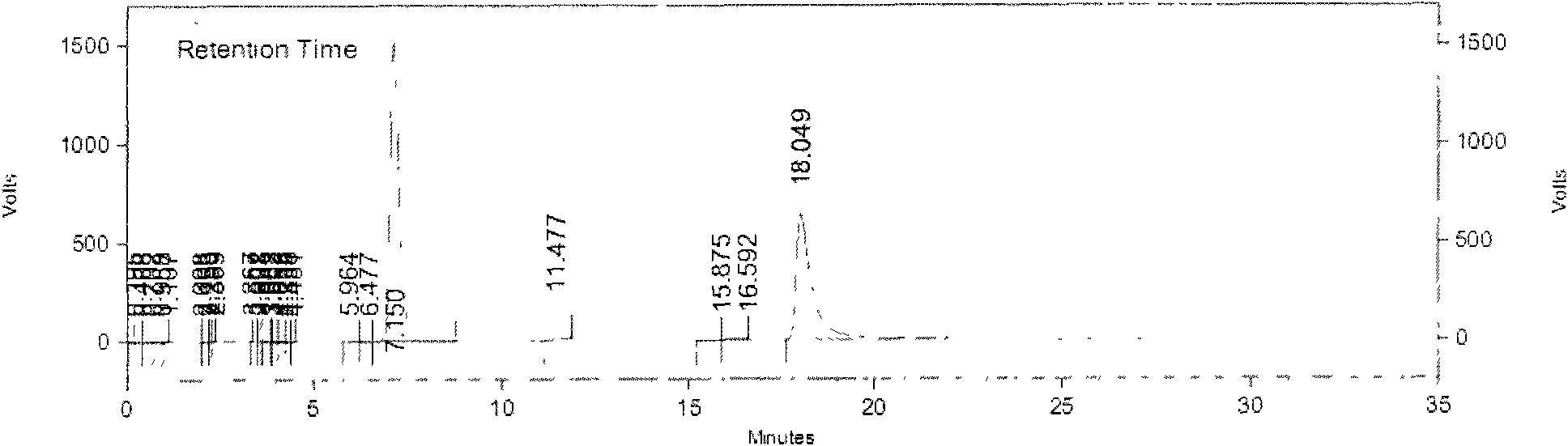

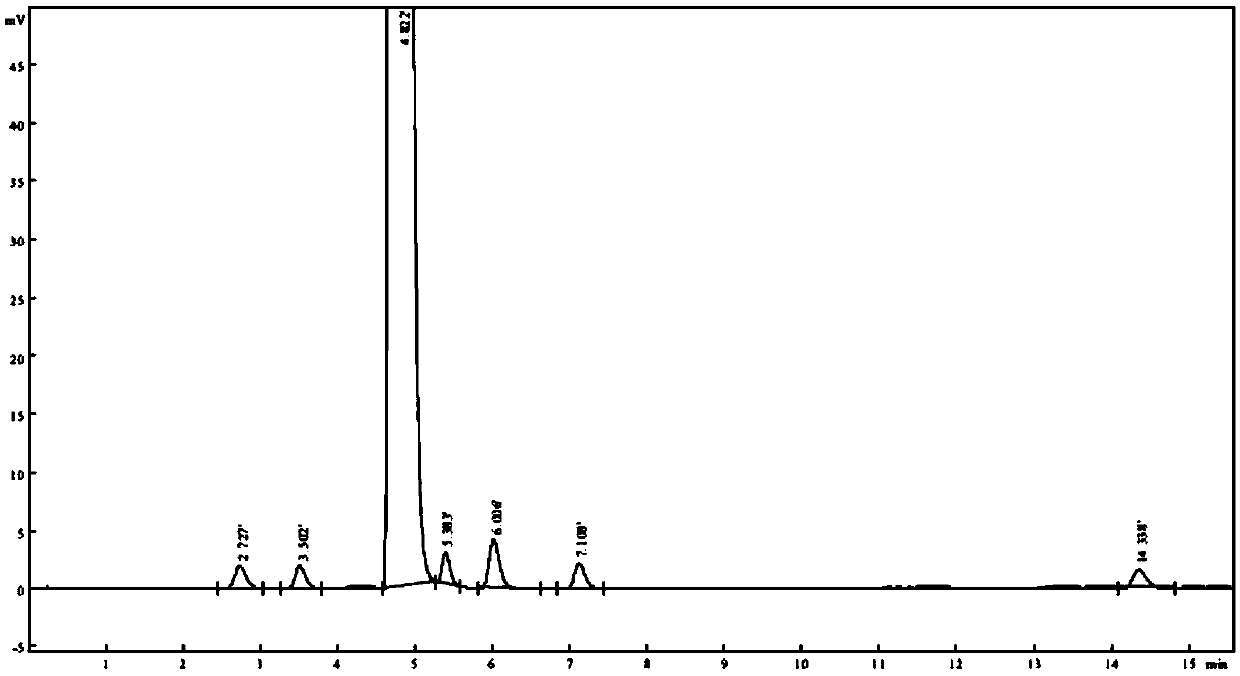

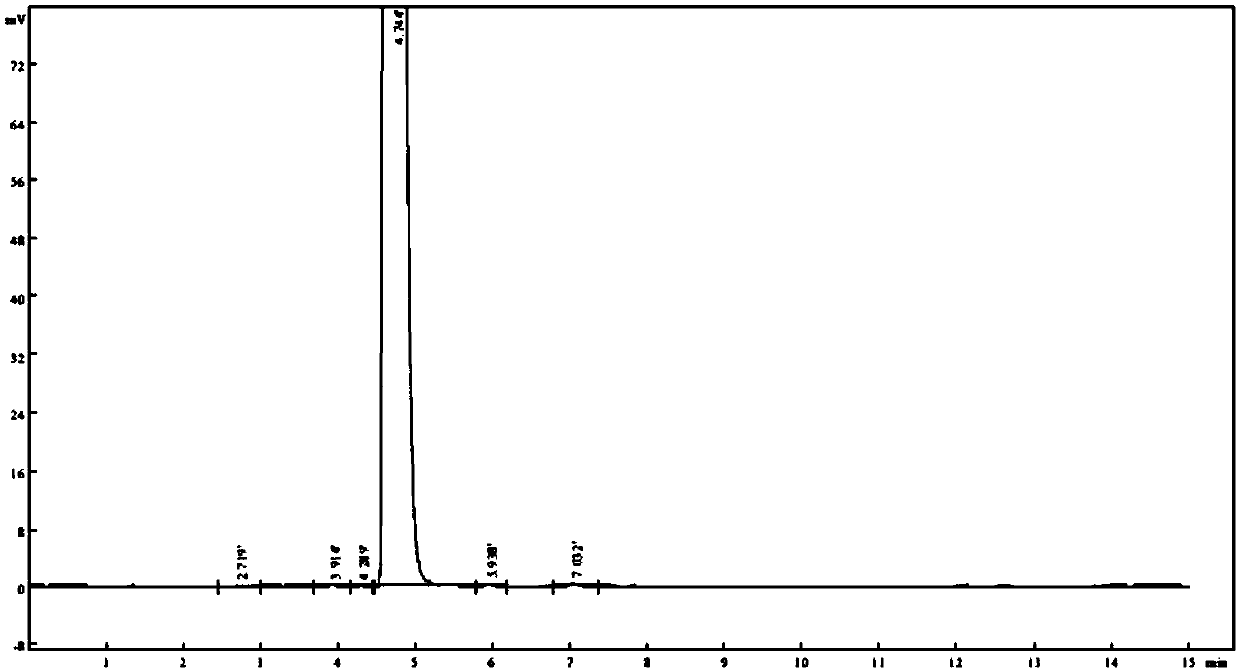

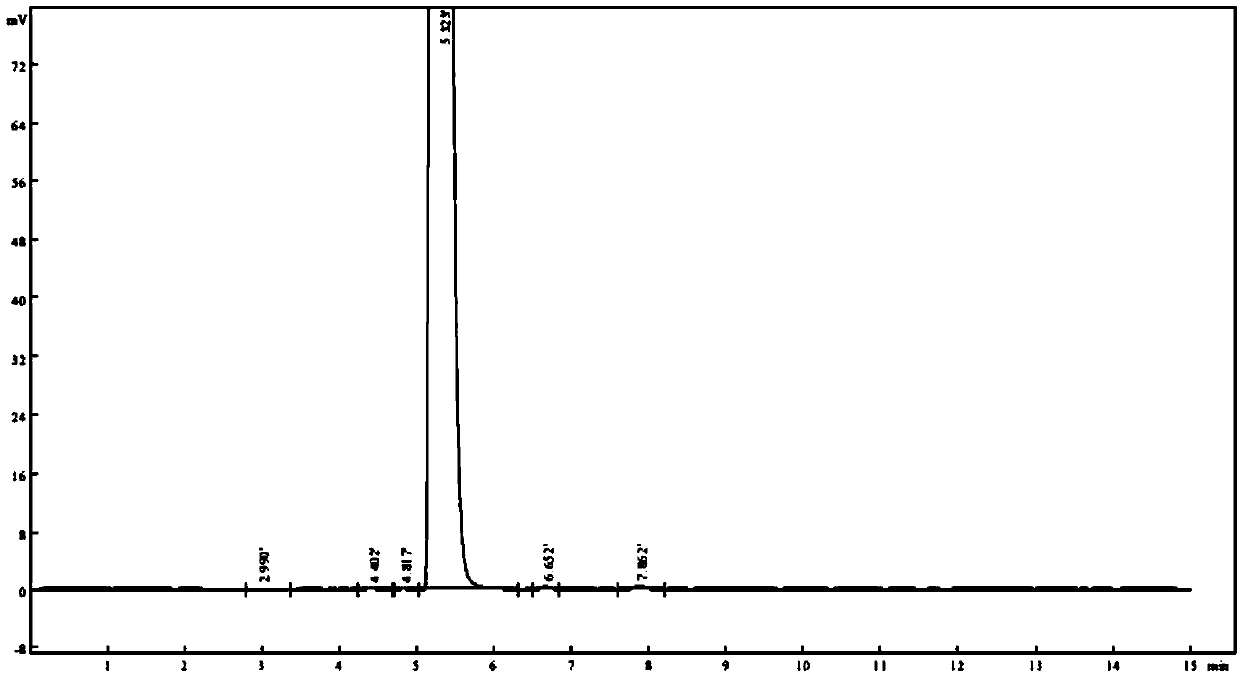

Method for detecting related substances in pharmaceutical preparation containing citicoline sodium

InactiveCN109580834AEfficient separationImprove applicabilityComponent separationTheoretical plateRetention time

The invention relates to a method for detecting related substances in a pharmaceutical preparation containing citicoline sodium. High performance liquid chromatography is adopted to analyze a system applicability solution, and the separation degree and theoretical plate number of citicoline sodium peak among the citicoline sodium peak and adjacent impurities and each known impurity in a chromatogram are recorded; the separation degree among citicoline sodium and adjacent impurities and each known impurity is greater than 1.5, when the theoretical plate number of the citicoline peak is greaterthan 2000, then a test solution and a contrast solution are analyzed and detected, the chromatogram is recorded for three times of the retention time of a main component peak, and the impurity number,type, relative percentage content, peak area and separation degree between the peaks are read and calculated from the recorded chromatogram; and the peak area in the chromatogram is calculated to obtain the content of each impurity. Compared with the prior art, the method for detecting the related substances in the pharmaceutical preparation containing citicoline sodium is simple and convenient,quick and good in durability, the impurities in the citicoline sodium can be effectively detected, and the method for detecting the related substances in the pharmaceutical preparation containing citicoline sodium is good in applicability, and high in accuracy and precision.

Owner:CISEN PHARMA

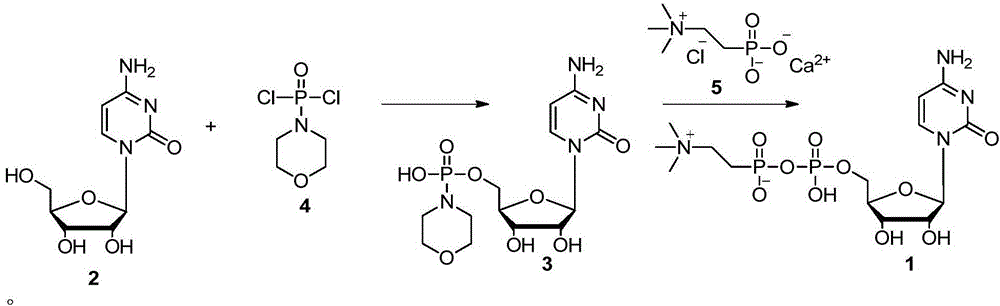

Citicoline and synthesizing method of citicoline not using phosphocholine chloride calcium

InactiveCN105693798AReduce usageMild reaction conditionsSugar derivativesSugar derivatives preparationMorpholineChloride

The invention discloses a method for synthesizing citicoline and citicoline without using calcium phosphorylcholine chloride. Acylmorpholine is used as raw material, reacts with ethylene glycol to obtain ethylene glycol ester phosphoromorpholine, and then directly condenses with cytidylic acid to obtain ethylene glycol ester phosphoryl cytidylic acid, and finally tributylamine to ethylene glycol ester The ethylene glycol ester of phosphoromorpholine is ring-opened to give citicoline. There are three steps in the reaction, and the total yield is 78%. The method has cheap and easy-to-obtain raw materials, avoids the use of expensive and toxic DCC and calcium phosphorylcholine chloride, and the yield does not decrease significantly when the reaction scale is expanded to a scale of 500 g. The application of the present invention provides a new synthesis route for the synthesis of citicoline, and has potential application prospects.

Owner:XINXIANG UNIV

Material with antibacterial and biocompatible surface and preparing method and application thereof

ActiveCN105251051AGood cell compatibilityGood blood compatibilitySurgeryCoatingsCiticolineMedical device

The invention discloses a material with an antibacterial and biocompatible surface and a preparing method and application thereof. The preparing method comprises the steps that amination of the surface of a material is achieved with an amino silane coupling agent, so that a surface-aminated material is obtained; the obtained surface-aminated material is made to react with dialdehyde to achieve formylation of the surface of the material, so that a surface-formylated material is obtained; the obtained surface-formylated material is made to react with citicoline chitosan salt to achieve citicoline chitosan salt immobilization of the surface of the material, and washing is conducted to obtain the material with the antibacterial and biocompatible surface. The adopted citicoline chitosan salt has high cytocompatibility, blood compatibility and broad-spectrum antibacterial property in the physiological environment and is biodegradable; furthermore, the citicoline chitosan salt can be fixed to the surface of the material under a mild condition to generate the material with the antibacterial and biocompatible surface, and the material is suitable for implantable and interventional medical devices.

Owner:广州佰斯伦生物技术有限公司

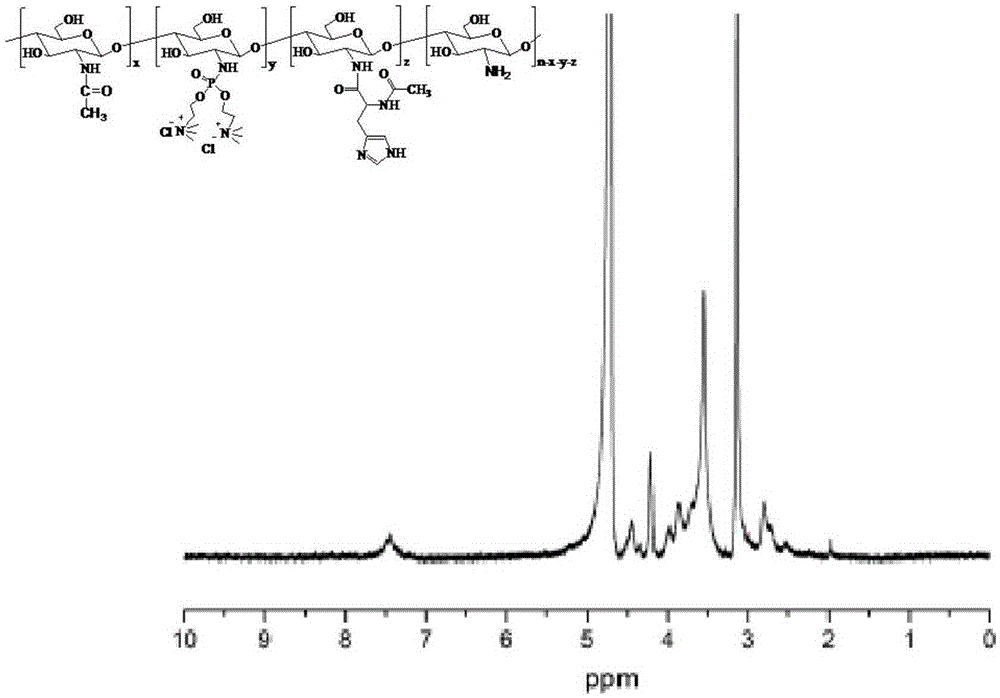

Cation-type chitosan bionic derivative and application thereof

ActiveCN105254780AGood for maintaining conformationPromote escapePeptide/protein ingredientsPharmaceutical non-active ingredientsSolubilityBiocompatibility Testing

The invention discloses a cation-type chitosan bionic derivative and application thereof and belongs to the technical field of biomedical polymer materials. The cation-type chitosan bionic derivative contains citicoline groups (PdC) provided with a locally branched dual positive charge structure, and acetyl histidine groups with pH sensitivity, wherein water solubility, cell toxicity and blood compatibility are also taken into consideration, and protein conformation is kept easily; endosomal escape in carrier system cells can be promoted, and the acetyl histidine groups and PdC cooperate with each other to improve intracellular transmission efficiency of protein medicine. The derivative and the protein medicine can be automatically assembled through a simple technology under moderate conditions to form a nano composite system, good biocompatibility and endocytosis efficiency are presented, activity of protein can be maintained, and the derivative is used for protein medicine conveying.

Owner:浙江梅迪维斯生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com