Patents

Literature

563results about How to "Prevent moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

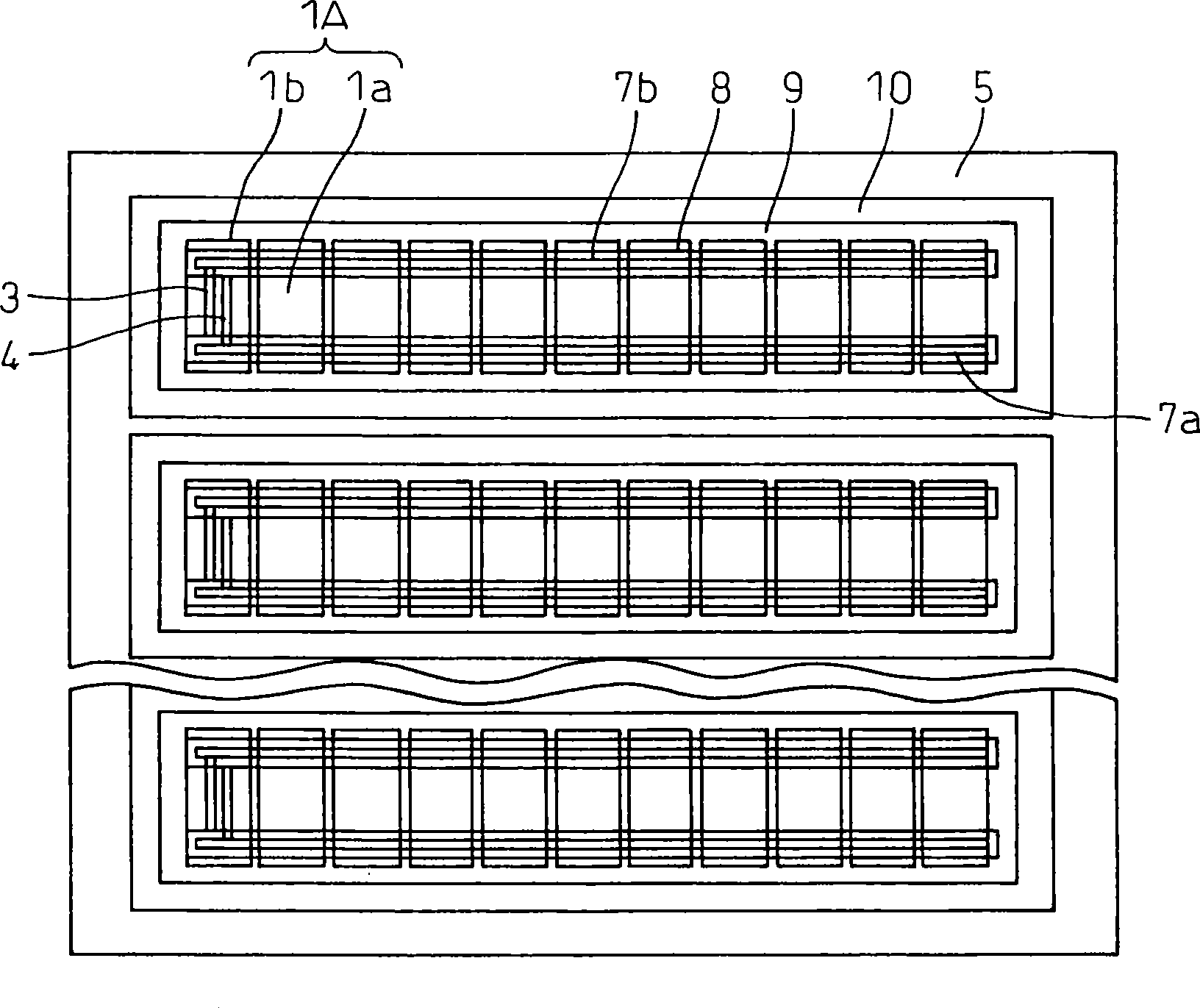

Flexible film-like solar cell composite layer

InactiveCN101465386APrevent moisture absorptionFully flexiblePhotovoltaicsPhotovoltaic energy generationEngineeringMoisture absorption

The invention provides a flexibility water proof membrane solar cell compound layer body capable of preventing a conductive section moisture absorption and power output from reducing, wherein a solar cell layer (1) is jointed on a flexibility water proof support membrane material (5), a flexibility adhesive resin layer (9) and a flexibility surface protective membrane layer (10) are covered on the solar cell layer in turn, and further extend outward, thereby jointing on the support membrane material (5). The solar cell layer is sealed. An anode and a cathode conductive sections in the solar cell layer are covered directly by a conductive section damp course or indirectly by the resin layer (9), and a crosslinking resin layer (6) formed between the resin layer (9) and the membrane layer (10) according to demands.

Owner:TAKASHIMA & CO LTD +1

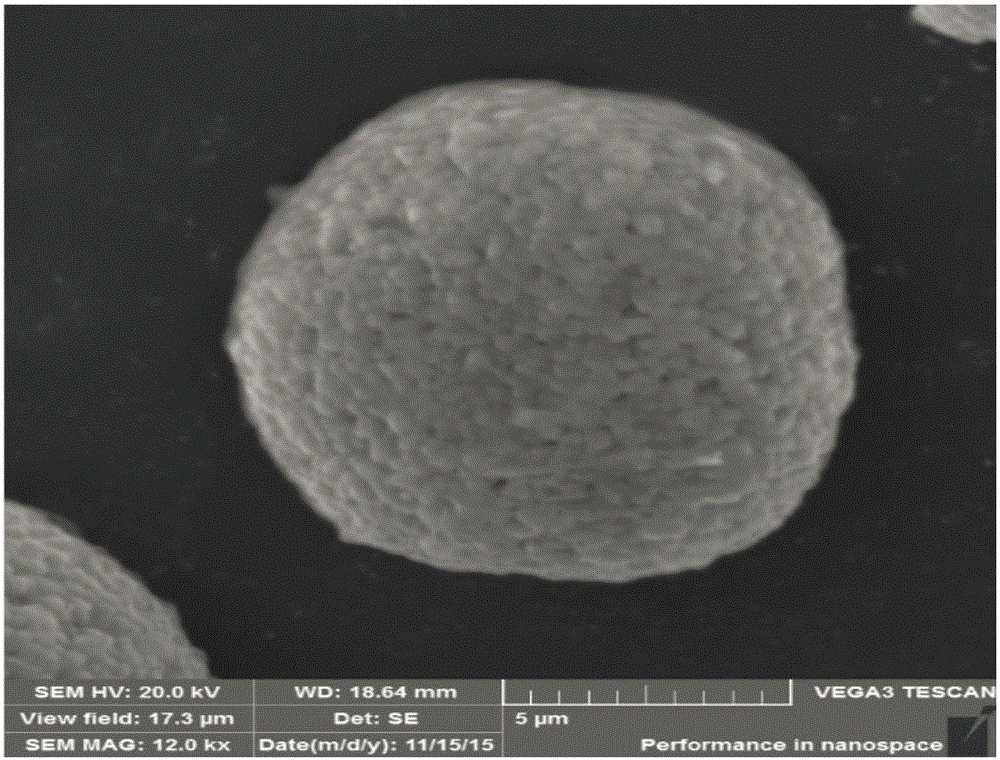

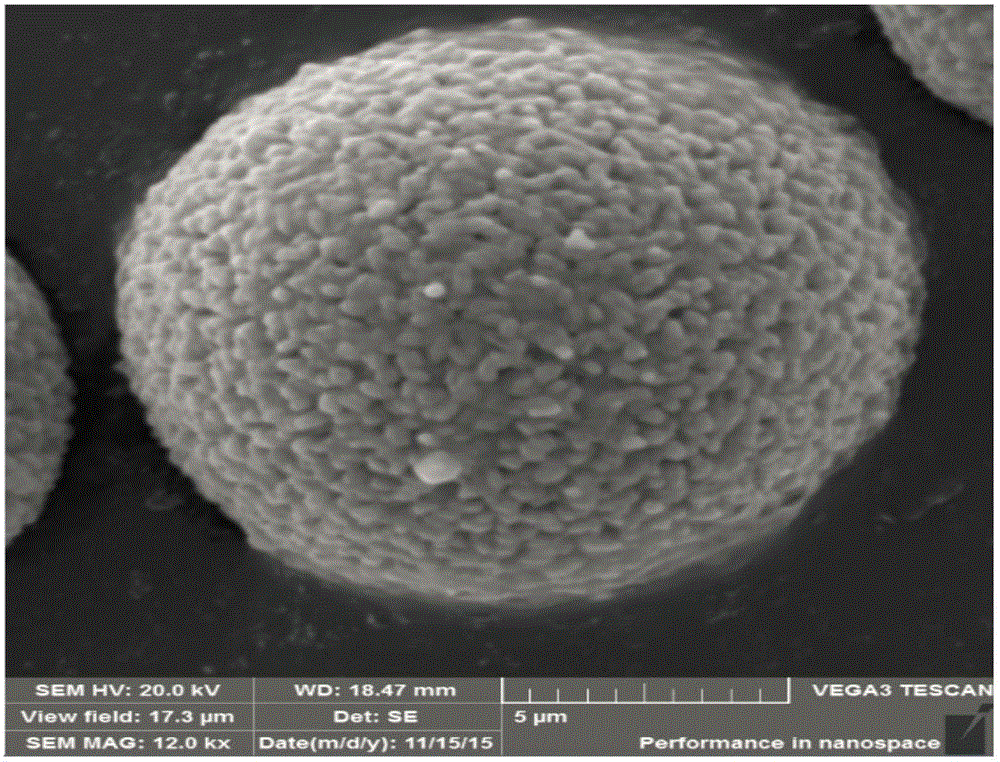

Beta-carotene microcapsule and preparation technology thereof

ActiveCN104719894AUnique emulsificationImprove stabilityNatural dyesFood shapingVegetable oilOrganosolv

The invention relates to a beta-carotene microcapsule and a preparation technology thereof. The technology comprises the following steps: mixing corn starch which contains beta-carotene crystals and microhole ocentyl succinic anhydride and serves as a core material, an oil phase consisting of plant oil, an antioxidant and the like and a water phase consisting of a wall material, an antioxidant, a dispersant, water and the like according to a ratio, homogenizing to prepare microemulsion, and performing spray drying to prepare beta-carotene microcapsule powder. In a preparation process, no organic solvent needs to be added, and an obtained product keeps the bioactivity, is stable to the photo-thermal property and is extremely high dissolvability in cold water; processing, transportation and storage are facilitated; the safety, the flowability, the taste and the water solubility of the product are greatly improved; the beta-carotene microcapsule is a high-quality health food and food pigment raw material. The yield of the beta-carotene microcapsule prepared by the technology is high, and the preparation method is suitable for batch preparation of the beta-carotene microcapsules; continuous large-scale production is realized.

Owner:武汉志邦化学技术有限公司

Water-based environment-friendly porcelain glaze-like plastic coating and preparation method thereof

The invention discloses water-based environment-friendly porcelain glaze-like plastic coating and a preparation method thereof. The water-based environment-friendly porcelain glaze-like plastic coating adopts a formula comprising the following materials by mass: 20 to 40 percent of a water-based acrylic emulsion, 10 to 20 percent of water-based silica sol, 35 to 50 percent of water-based inorganic silicon dioxide nanodispersion, 0.1 to 0.3 percent of a wetting dispersant, 1 to 5 percent of silane, 0.1 to 0.5 percent of an amine neutralizing agent, 5 to 10 percent of lead-free pigment, 0.5 to 2.5 percent of a film-forming additive, and 5 to 25 percent of deionized water. The water-based environment-friendly porcelain glaze-like plastic coating can be coated on the surfaces of various materials in the form of porcelain glaze, and can be applied on the surfaces of the materials of various shapes through roller-applied coating, shower coating, spraying, blade coating, brush coating, dip coating and the like; moreover, the formed porcelain glaze coating is unique and free from hydrolysis, and cannot be melted at a certain temperature, so that a base material can be effectively protected from corrosion, abrasion, scraping, acid-alkali, impact, inflaming and fire.

Owner:吕标

Method for producing preserved low-sugar blueberry fruit

The invention discloses a method for producing preserved low-sugar blueberry fruit. The method comprises the steps of selection of raw materials, cleaning, draining, freezing, thawing, color protection, hardening, rinsing and draining, ultrasonic-assisted sugar-permeating, draining, drying, production of finished products and the like. The preserved low-sugar blueberry fruit produced by the method provided by the invention keeps the original taste and nutrition of blueberry fruit well, and has full shape, bright color, good taste and good quality; and moreover, the shelf life of blueberry fruit is prolonged.

Owner:徐静

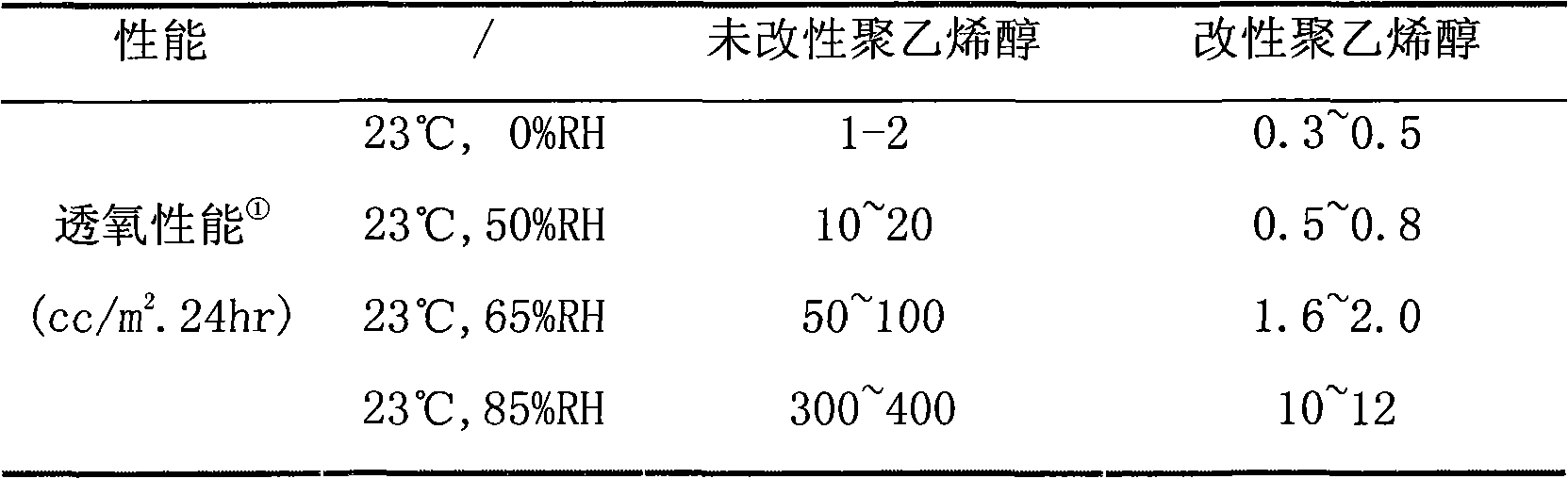

Water-tolerant blocking polyvinyl alcohol coating for coating and preparation method thereof

ActiveCN102304314AImprove sensitivityImprove oxygen barrier performanceCoatingsLayered structureDefoaming Agents

The invention provides a water-tolerant blocking polyvinyl alcohol coating for coating and a preparation method thereof; the coating is prepared from the following raw materials in percentage by weight: 5-7% of polyving akohol, 0.01-0.05% of nanometer montmorillonite, 0.5-1% amino resin, 0.01-0.3% of catalytic agent, 0.01-0.1% of defoaming agent and 91-94% of deionized water; by adding the nanometer montmorillonite in the polyvinyl alcohol coating, after the modified coating is coated, the nanometer montmorillonite is dispersed in a polyving akohol coating in a layered structure so as to block gases such as oxygen and the like from flowing and diffusing so as to further increase the oxygen blocking performance of a polyving akohol coating membrane; and the coating is stable, has good coating adaptability, is simple in process and is suitable for industrial production.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

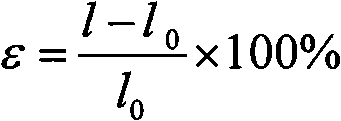

Light masonry mortar with heat insulation and preservation

InactiveCN101643349AImprove insulation effectAvoid "Cold Bridge" PhenomenonSolid waste managementFiberSlag

The invention discloses a light masonry mortar with heat insulation and preservation, comprising the following components by weight percent: 20 percent to 65 percent of portland cement, 5 percent to 50 percent of fly ashes, 0 percent to 50 percent of furnace bottom slag, 0 percent to 55 percent of slag, 10 percent to 23 percent of vitrified microspheres, 0.1 percent to 1.0 percent of water retention and thickening materials, 0.1 percent to 0.5 percent of lignocellulose and 0.1 percent to 1.0 percent of water reducing agent. The mortar has the dry density of 750 to 1000 kg / m<3>, the thermal conductivity of 0.15 to 0.20 w / m k, the lowest compressive strength of 5 Mpa and the liner shrinkage rate of less than 0.1 percent, satisfies the requirements of heat insulation and preservation of an energy-saving building, has the advantages of favorable heat insulation and preservation performance, favorable water retention, favorable workability, high adhesion strength of a wall body, simple construction, energy saving, environmental protection and the like, completely avoids the occurrence of the phenomenon of cold bridge, and efficiently prevents dry-shrinkage cracking and the phenomenon ofmoisture absorption of the wall surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

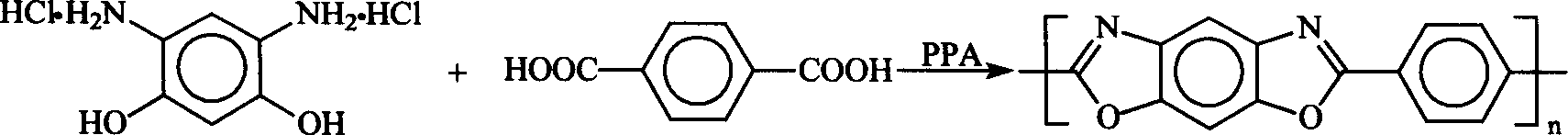

Preparation of poly-p-phenylene benzodioxazole fibers

InactiveCN1644772AEasy to transportPrevent moisture absorptionMonocomponent synthetic polymer artificial filamentFiberPolymer science

A process for preparing poly-p-phenylene benzdioxazole (PBO) fibres includes such steps as prepolymerizing by adding part (90-99%) of terephthalic acid to obtain low-viscosity prepolymer, mixing the rest of terephthalic acid with polyphosphoric acid (PPA) to obtain slurry, mixing it with prepolymer and polycondensating in a dual-screw extruder, and liquid-crystal spinning.

Owner:DONGHUA UNIV

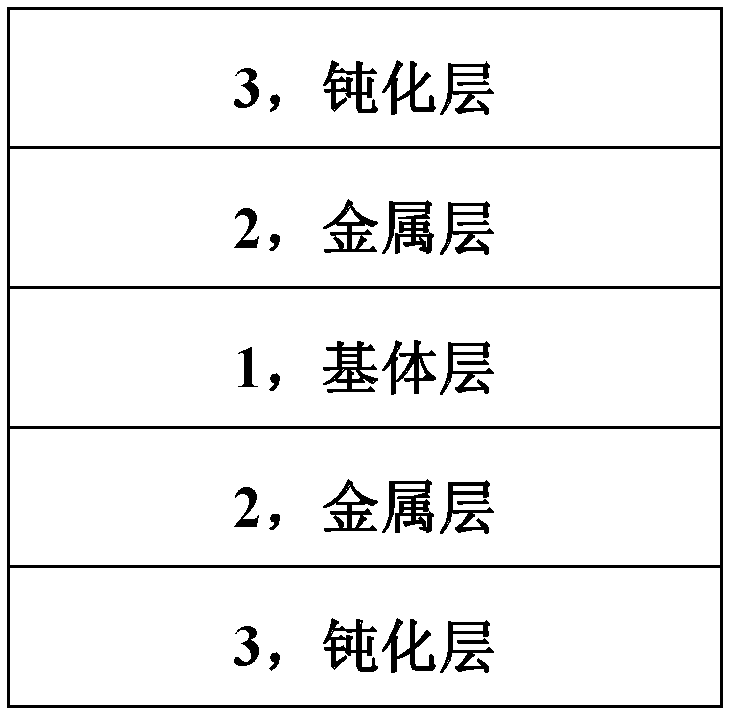

Soft board base material without glue and preparation method thereof

ActiveCN103167731AHigh composite strengthImprove reliabilityPrinted circuit manufactureCircuit susbtrate materialsHeat resistanceHigh intensity

A functional soft board base material without glue is composed of a metal layer, a basal layer and a metal passivation layer which are superimposed. The manufacturing method includes that (1), polyimide is used to make a basal body, and surface treatment is performed for two faces (or one face) of the basal body; (2), a physical vapor deposition (PVD) method is adopted to deposit and form a metal membrane layer on a product improve (PI) face of a treated face; and (3), passivation treatment is performed for the metal membrane layer. The soft board base material without the glue has high-strength tensile performance, excellent chemical resistance, heat resistance, dimensional stability, peel strength, compactness, uniform consistency, and mechanical machining performance, is strong in shielding function, and can be used for manufacturing printed circuit boards (PCB), flexible printed circuits (FPC), soft and hard combination plate, special function (shielding function) material and the like, the PVD method is adopted to deposit the metal layer, the thickness of the metal layer is enabled to be adjustable, achievement of superfine precision circuit is enabled to be possible, and the soft board base material without glue is low in cost, environment-friendly, good in bending performance and easy for technical processing.

Owner:英德宏庆电子有限公司

Anti-powdering and anti-caking agent for urea

InactiveCN1648110APrevent moisture absorptionHigh strengthUrea compound fertilisersFertilizer mixturesDefoaming AgentsChemistry

The present invention relates to powdering and caking resisting agent for urea. The powdering and caking resisting agent for urea consists of polymer 1-20 wt%, surfactant 2-25 wt%, viscosity regulator 2-25 wt%, defoaming agent 0.05-1 wt%, preservative 0.05-1 wt% and water 50-90 wt%. The powdering and caking resisting agent for urea can prevent urea from caking and powdering effectively, has small use amount, and has no harm to soil, plant, animal and environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Production process of color functional industrial polyester fiber

ActiveCN101021016ALower melting temperatureShort stayElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberPolyester

The production process of color functional industrial polyester fiber includes the following steps: 1. drying agglomerate and smelting the agglomerate to form agglomerate melt; 2 pumping the agglomerate melt into the spinning metering pump and mixing the agglomerate melt with conventional high viscosity melt prepared in the static mixer; and 3. conveying the mixture melt to a spinning assembly and spinning. The process injects the agglomerate melt to lower its temperature and to decrease its degradation, so as to maintain excellent physical performance during spinning.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

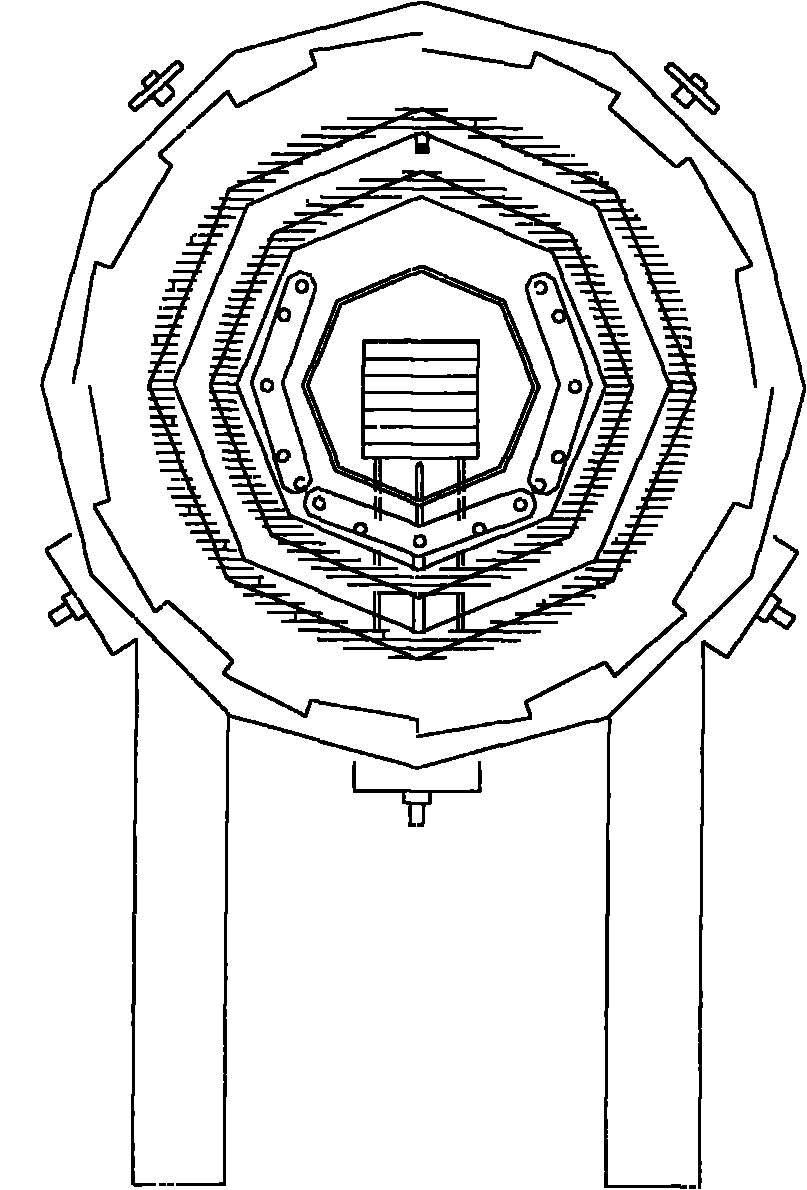

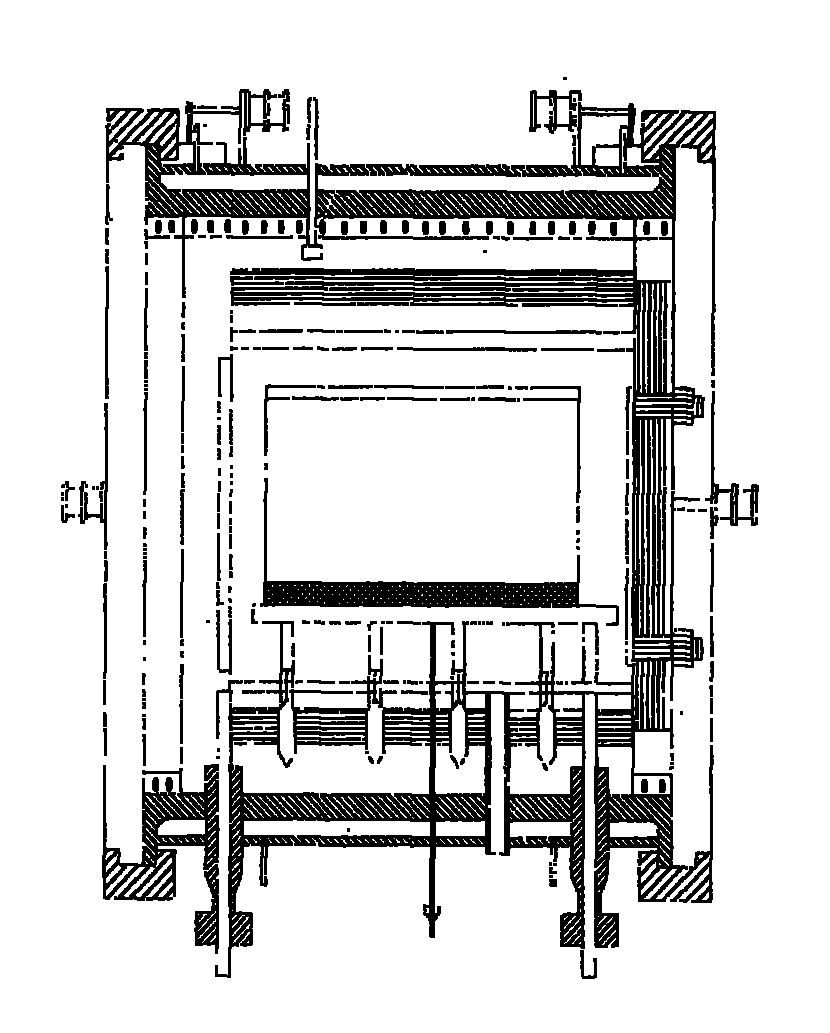

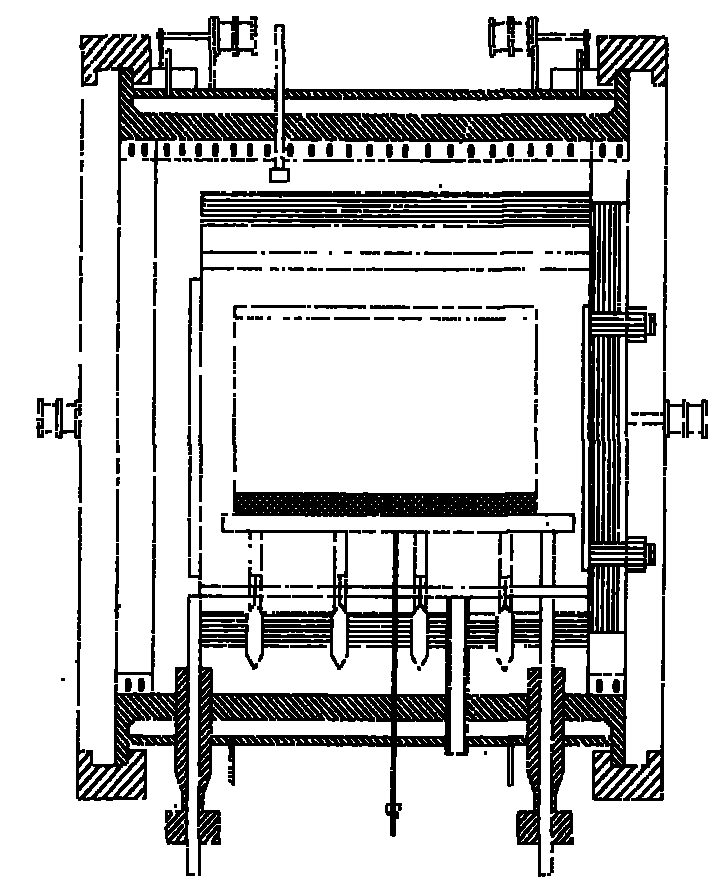

Pressure sintering furnace

InactiveCN101788226AAchieve elastic compressionSolve elastic compression problemsFurnace componentsMuffle furnacesCouplingDistribution system

The invention relates to a pressure sintering furnace used for producing hard alloys. The pressure sintering furnace comprises a furnace shell, a vacuum system, an air distribution system, a heating and thermal-insulating device, a compression system, a cooling system and a decompression device. The pressure sintering furnace is characterized in that the furnace shell is a horizontal cylinder provided with a double-wall water jacket, the furnace door on the furnace shell has a quick-opening hydraulic side-rotating structure, the furnace door of the furnace shell comprises a thermal-insulating door on the external layer of the furnace and a graphite door on the internal side of the furnace, the opening of the furnace door is controlled by a hydraulic locking device with a door-closing air cylinder, the door-closing air cylinder is provided with an elastic coupling device, and the thermal-insulating door of the furnace door is a boss thermal-insulating door. The pressure sintering furnace has stable performance and low cost and safety production can be realized by using the pressure sintering furnace, thus the uniformity of temperature field distribution in the furnace can be effectively improved and the qualification rate of products can be more than 90%.

Owner:ZHUZHOU CEMENTED CARBIDE EQUIP

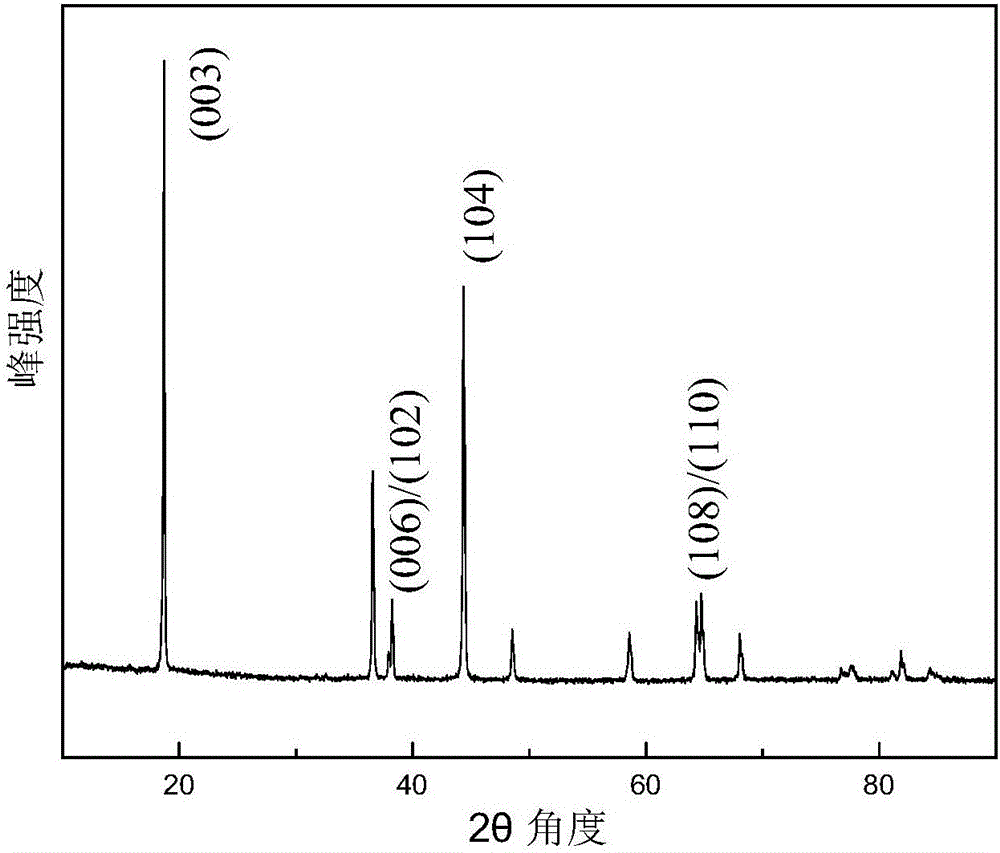

Lithium ion battery anode material with surface hydrophobicity and preparation method of lithium ion battery anode material

InactiveCN106299299APrevent delithiationNot corrodedCell electrodesSecondary cellsOrganic solventTwo temperature

The invention discloses a lithium ion battery anode material with surface hydrophobicity and a preparation method of the lithium ion battery anode material, relates to a lithium ion battery anode material prepared according to a surface modification technology and a preparation method thereof, and aims to solve the problems that the conventional anode material is poor in recycling performance, storage performance and compatibility with an electrolyte. The lithium ion battery anode material with the surface hydrophobicity has an organic hydrophobic layer on the surface, wherein the hydrophobic layer has the thickness of 0.5-20nm and the mass content of 0.1-10%; the preparation method of the lithium ion battery anode material with the surface hydrophobicity comprises the following steps: uniformly mixing an organic matter with hydrophobicity and an organic solvent, stirring together with an anode material at 30-80 DEG C, carrying out a reaction to obtain a mixture, filtering the mixture to obtain a solid filter cake, and treating the solid filter cake according to two temperature gradients to obtain the lithium ion battery anode material with the surface hydrophobicity. The lithium ion battery anode material with the surface hydrophobicity, prepared by the preparation method provided by the invention, is applied to a lithium ion battery.

Owner:HARBIN INST OF TECH

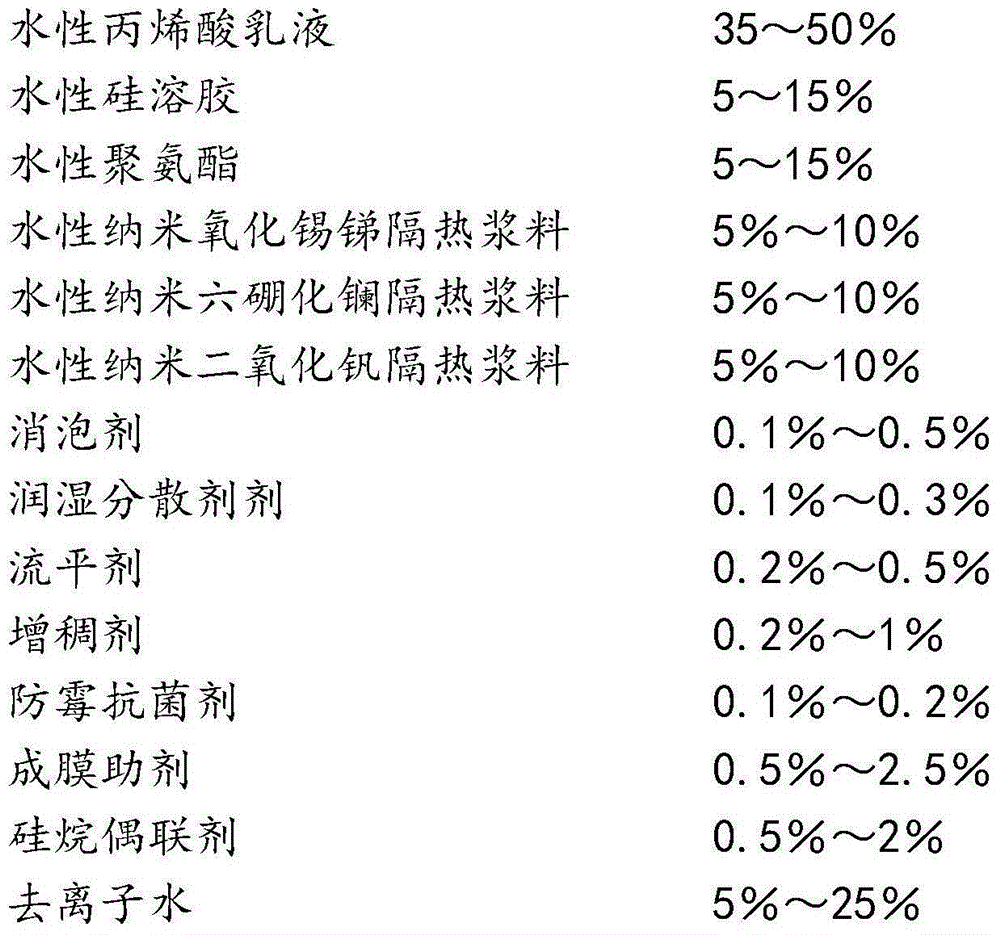

Water glass transparent reflecting heat-insulation coating material and preparation method thereof

InactiveCN106167657AAchieve a closed effectImprove lighting effectsPolyurea/polyurethane coatingsReflecting/signal paintsVanadium dioxideSlurry

The invention discloses a water glass transparent reflecting heat-insulation coating material and a preparation method thereof, wherein the water glass transparent reflecting heat-insulation coating material comprises, by mass, 35-50% of an aqueous acrylic emulsion, 5-15% of an aqueous silica sol, 5-15% of an aqueous polyurethane, 5-10% of an aqueous nanometer antimony tin oxide heat-insulation slurry, 5-10% of an aqueous nanometer lanthanum hexaboride heat-insulation slurry, 5-10% of an aqueous nanometer vanadium dioxide heat-insulation slurry, 0.1-0.5% of an anti-foaming agent, 0.1-0.3% of a wetting dispersing agent, 0.2-0.5% of a leveling agent, 0.2-1% of a thickening agent, 0.1-0.2% of an anti-mildew antibacterial agent, 0.5-2.5% of a film forming auxiliary agent, 0.5-2% of a silane coupling agent, and 5-25% of deionized water.

Owner:刘生金

Method for preparing melamine phosphate (borate) fire retardant

InactiveCN101143876AHarm reductionAvoid corrosionGroup 3/13 element organic compoundsPhosphorus organic compoundsPhosphateMelamine phosphate

The present invention discloses a method which can prepare a phosphate (borate) melamine salt flame retardant by a dry process. According to the molar ratio of 1:2 to 4, small molecular polyol and inorganic acid containing phosphor or boron are uniformly mixed with lewis acid catalyst with one to one point five percent of the weight of the small molecular polyol, the temperature of the produced solution is raised to 100 to 150 DEG C, reaction lasts two to five hours, after melamine with the molar ratio of 1:1.5 to 2.5 of inorganic acid containing phosphor or boron is added, the produced solid is smashed into fine powder which can pass through a sieve with one hundred and twenty meshes, under a reaction temperature between 180 DEG C and 230 DEG C, reaction lasts one point five to four hours, and after the generated product is washed until the filtrate is neutral, the phosphate (borate) melamine salt flame retardant is produced by filtration, drying and smash. Because the dry process is applied, the present invention avoids the problem that the organic solvents used by the prior art harm environment and erode equipment, reduces energy consumption and production cost and avoids the problem of the hydrolysis of phosphate, which is caused by a reaction under the water phase; moreover, the present invention has the advantages of simple technique and convenient operation and is suitable for industrialized production.

Owner:应急管理部四川消防研究所

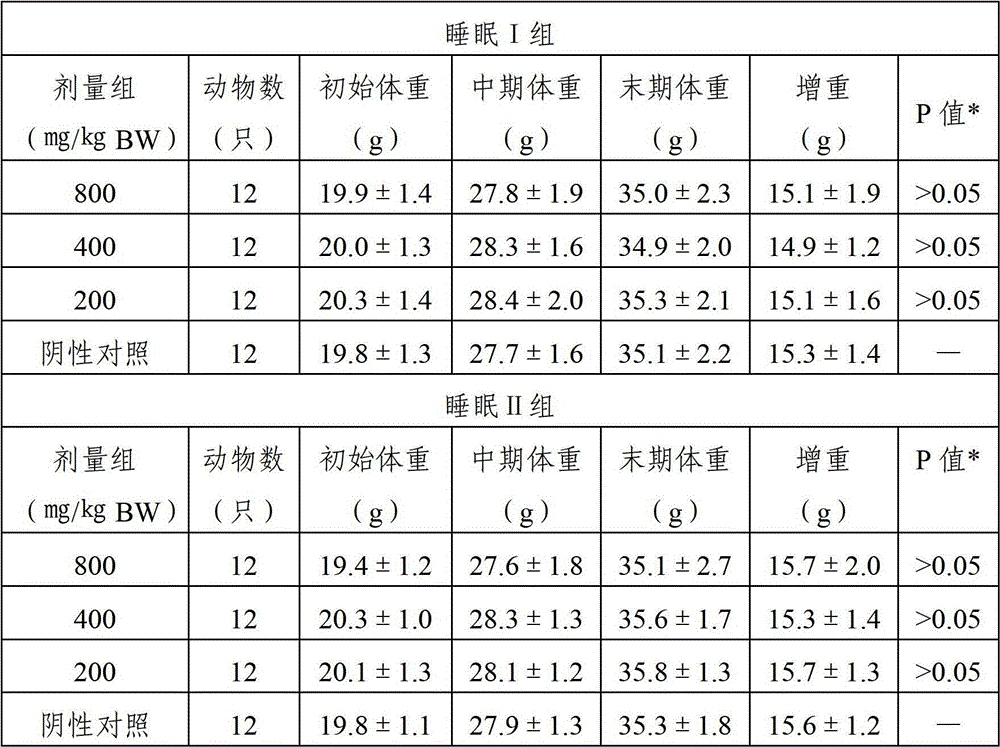

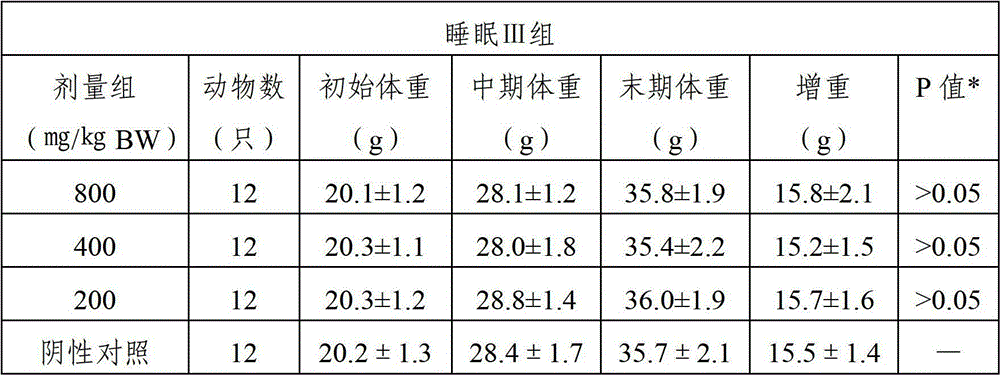

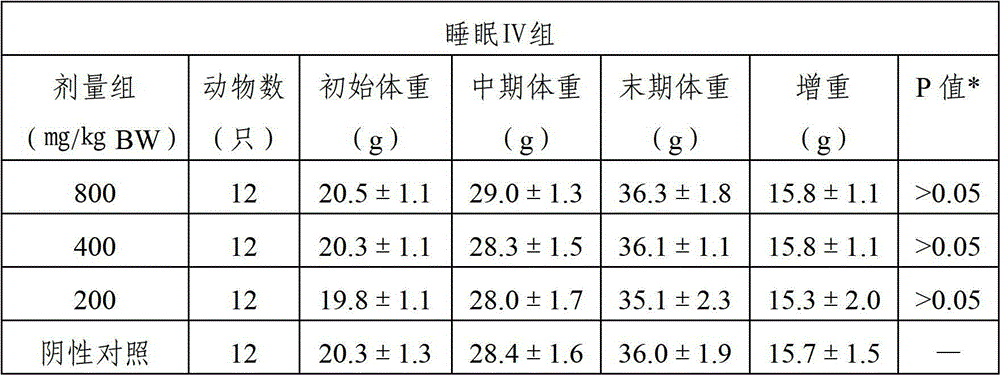

Composition for improving sleep and preparation method and application thereof

ActiveCN102940768AImprove sleep rateGood sedative and hypnotic effectNervous disorderFood preparationMedicineCurative effect

The invention relates to a composition for improving sleep and a preparation method and application thereof. The composition comprises the following components in parts by weight: 400 to 700 parts of tuckahoe, 350 to 650 parts of seed of wild jujube, 250 to 550 parts of lily, 100 to 250 parts of ginseng and 40 to 200 parts of schisandra. The five gouts of Chinese medicament raw materials are reasonably matched, and the raw materials achieve a good synergistic effect according to the given component proportion, namely each Chinese medicament exerts the effect; the composition has a remarkable effect on the aspect of improving the sleep and is superior to the prior art, namely the formula is optimal, the process is reasonable, the active ingredients are extracted completely, and the treatment effect of the composition is well exerted; the composition does not have adverse response and is high in safety; and the equipment is simple, the cost is low, and industrialized production can be realized.

Owner:吉林一正药业集团有限公司

Method for preparing lanthanum-doped alloy molybdenum powder

The invention discloses a method for preparing lanthanum-doped alloy molybdenum powder. The method includes the steps of selecting raw materials, preparing MoO2 powder, preparing initial mixed materials, preparing lanthanum-doped MoO2 pre-mixing material matrixes, preparing lanthanum-doped MoO2 and preparing the lanthanum-doped alloy molybdenum powder. The method solves the problems that nitric oxides like NO and NO2 can be generated in the process of preparing the lanthanum-doped alloy molybdenum powder in an existing solid-liquid doping method and an existing liquid-liquid doping method, environment can be polluted and production cost is increased. The method is combined with advantages of a solid-solid doping method and a water spraying method, and the nitric oxides will not be generated; La2O3 xH2O powder is used as additives, the uniformity of La contents of products is improved, and the phenomenon of moisture absorption is prevented; a great number of lanthanum-doped MoO2 pre-mixing material matrixes can be prepared at a time and used for preparing the lanthanum-doped MoO2 in batches, and therefore errors of the La contents among batches are reduced; different types of lanthanum-doped MoO2 can be prepared by adjusting the added amount of the pre-mixing material matrixes, and finally the La contents in the products can be changed.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Preparation method of effervescent tablets

InactiveCN105663078AImprove molding rateFast disintegrationDispersion deliveryPill deliveryOrganic filmPolymer science

The invention discloses a preparation method of effervescent tablets. Polyethylene glycol is heated and melted and then is diluted with ethanol, a polyethylene glycol-ethanol solution is formed and then coats an acid source and an alkaline source, and accordingly, acid-source granules coated with polyethylene glycol film layers and alkaline-source granules coated with polyethylene glycol film layers are formed; the acid-source granules and the alkaline-source granules are sufficiently mixed and stirred, a mixture is formed, an ethanol solution of polyvinylpyrrolidone K30 is added to the mixture for secondary coating, a product is crushed after being dried, and effervescent granules coated with double organic film layers are obtained after uniform mixing; main medicine ingredients of a medicine and other acceptable excipients used for preparation of the effervescent tablets are added to the effervescent granules, and the effervescent tablet preparations are obtained through tableting after sufficient mixing. The prepared effervescent tablets are not prone to moisture absorption and deterioration and have good flowability; the forming rate is high, and sticking is avoided; the disintegration is fast. According to the method, adopted raw materials are cheap and easy to obtain, the method is simple, pollution-free and harmless to a human body, has low requirements for equipment and has good application prospect, and industrial production is easily realized.

Owner:CENT SOUTH UNIV

Processing method for drying, dehydrating and conditioning lettuce slices by hot air

InactiveCN101623025APrevent browningImprove organizationFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationThree stageSulfite salt

The invention relates to a processing method for drying, dehydrating and conditioning lettuce slices by hot air, which comprises the following steps: A. selecting raw materials; B. conditioning; C. cleaning; D. cutting; E. blanching, wherein the pH value of blanching water is adjusted to be 7.0-8.0 by using pure alkali; F. cooling; G. waterlogging; H. protecting color: placing the raw materials into prepared color-protecting liquid for soaking, wherein the color-protecting liquid is a mixed solution of sodium sulfite and zinc acetate; I. centrifugally dehydrating; J. adding accessories: adding glucose, lactose, and salt; K, standing; L. drying by hot air in three stages; and M. cooling and taking the materials out of the pot. The invention provides a processing method for massively drying, dehydrating and conditioning the lettuce slices by hot air for dehydrating intensive processing, and intensive processed dehydrated lettuce slices with high quality can be obtained by the method.

Owner:海通食品集团余姚有限公司

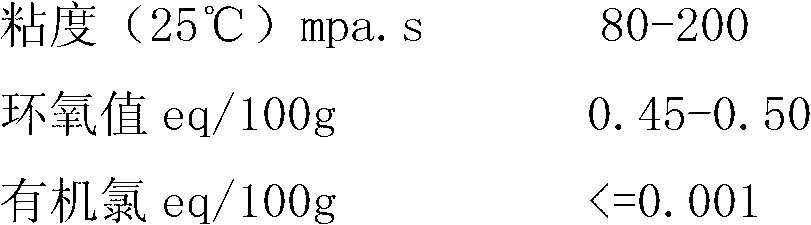

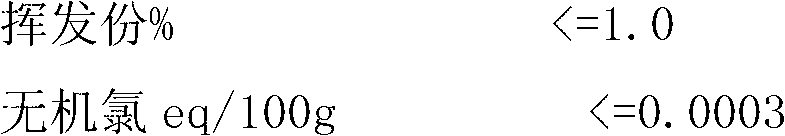

Dry outdoor type electric power complete equipment insulation casting material and preparation method thereof

The present invention discloses a dry outdoor type electric power complete equipment insulation casting material, which comprises the following raw materials, by weight, 100 parts of an EHL-55A modified high purity and flexibility alicyclic epoxy resin, 80-85 parts of an EHLS-60 modified methylhexahydrophthalic anhydride, 17-20 parts of an EHLP-200 reactive toughener, 0.2-0.3 part of a N,N-benzyldimethylamine accelerator, 300-350 parts of EHLA-400 coupling silicon micropowder, and 1-3 parts of an LA epoxy resin colorant. The invention further discloses a preparation method for the dry outdoor type electric power complete equipment insulation casting material. The dry outdoor type electric power complete equipment insulation casting material has characteristics of good outdoor weathering resistance, excellent mechanical performance, excellent dielectric performance and excellent heat resistance, can not deform and crack under high temperature impact and low temperature impact (-40 to 125 DEG C), and has high insulation and mechanical properties.

Owner:TAICANG LIANAN NEW INSULATION MATERIAL MFG WORKS

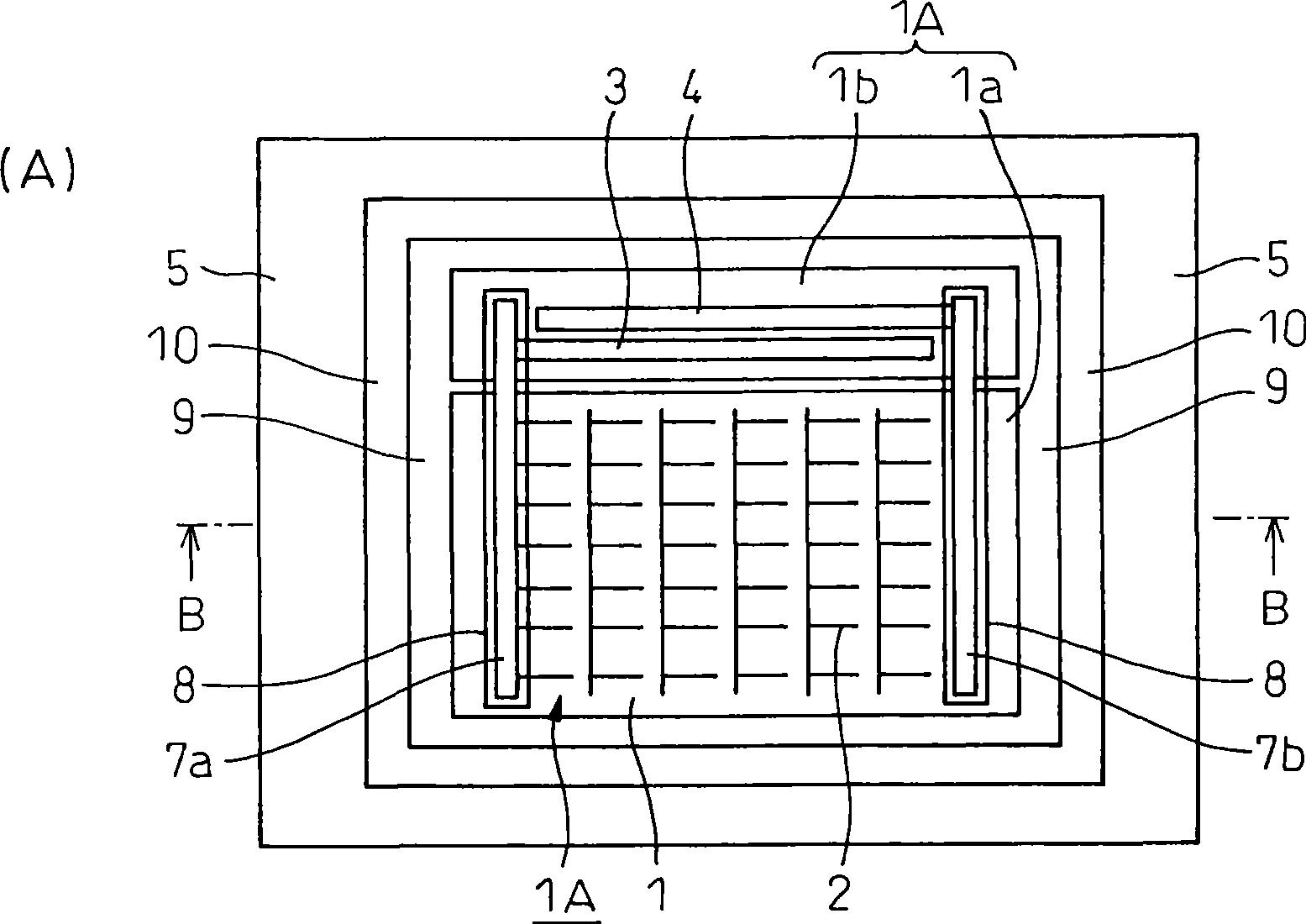

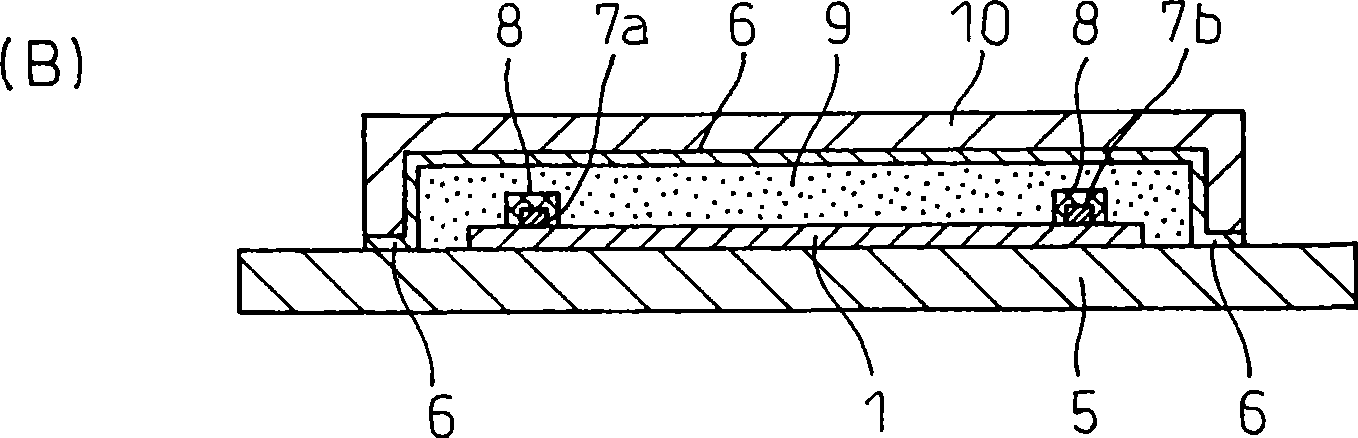

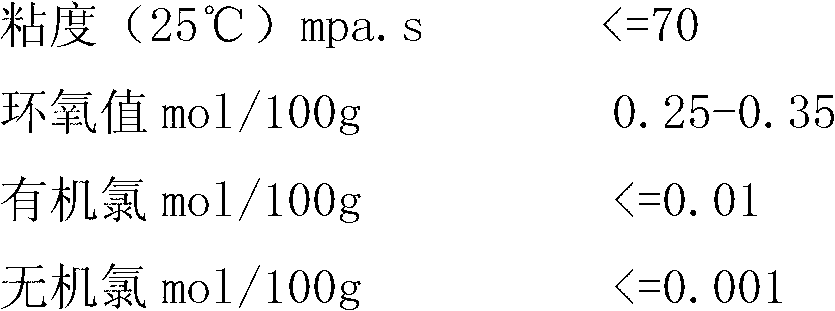

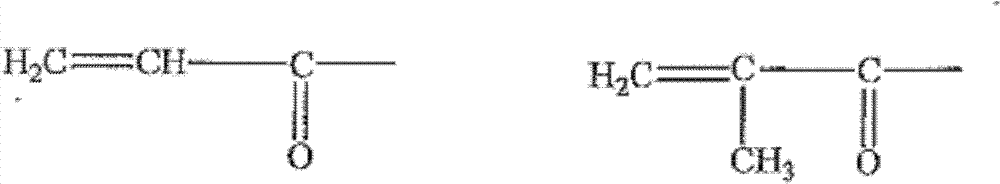

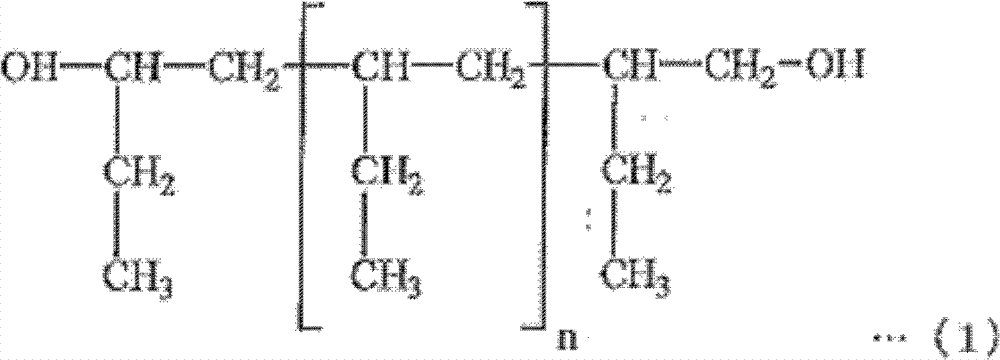

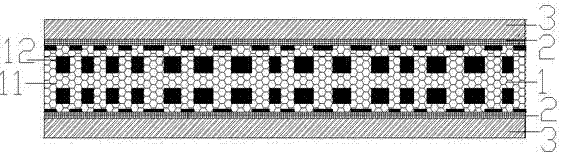

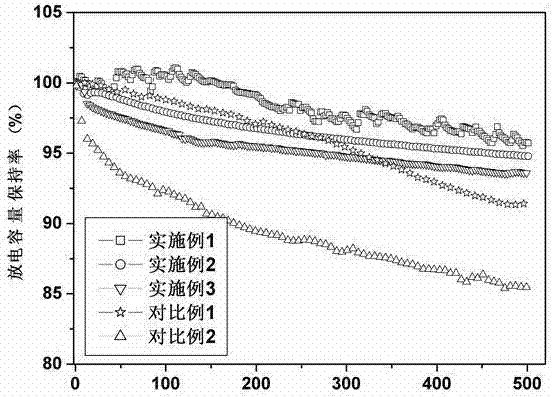

Dye-sensitized solar cell, and seal member to be used for the dye-sensitized solar cell

InactiveCN102737848AGood adhesionIncreased durabilityLight-sensitive devicesFinal product manufactureElastomerPolymer resin

A dye-sensitized solar cell of a polymer resin type is provided, which is excellent in sealability. A counter electrode substrate (1) provided with an electrically conductive transparent electrode layer (5) and a working electrode substrate (1') provided with an electrically conductive transparent electrode layer (5') are opposed to each other with the electrode layers (5, 5') facing inward. A space defined between the substrates (1, 1') is sealed with a seal member (4) disposed along peripheries of inner surfaces of the substrates (1, 1'). An electrolyte solution is filled in the sealed space. The substrates (1, 1') are each made of a polymer resin material. Inorganic layers (2, 2' , 3, 3') are provided between the substrates (1, 1') and the electrode layers (5, 5'). The seal member (4) is composed of a material obtained by curing a photopolymerizable composition essentially comprising a specific hydrogenated elastomer derivative. The inorganic layers (3,3') each have a portion coated with a (meth)acryloxyalkylsilane silage coupling agent in contact with the seal member (4).

Owner:NITTO DENKO CORP

Lithium ion battery with high energy density

PendingCN106960949AImprove compactnessEasy to controlSecondary cellsManufacture by sprayingCarbon compositesElectrical battery

The invention belongs to the field of preparation of a lithium ion battery, and particularly relates to a lithium ion battery with high energy density. The lithium ion battery comprises a ternary positive electrode material, a hard carbon composite negative pole plate, a ceramic separator and a functional electrolyte, wherein the preparation method of the hard carbon composite negative pole plate comprises the steps of depositing a lithium salt on a surface of a hard carbon electrode, preparing a hard carbon / lithium salt composite pole plate, coating a surface of the hard carbon / lithium salt composite pole plate with an organic polymer, and preparing a hard carbon composite pole plate containing the lithium salt and the polymer coating layer. Lithium supplementary is performed on the surface of the hard carbon pole plate by an electrochemical method, the initial efficiency of hard carbon can be substantially improved, the transmission quantity of lithium ions during the charge-discharge process is increased, and the rate performance of the lithium ion battery is improved; and meanwhile, a shell is coated with a special polymer material, the lithium salt on a surface of the material is prevented from being in contact with outside air, and the processability and the safety of the material are improved.

Owner:江苏元景锂粉工业有限公司

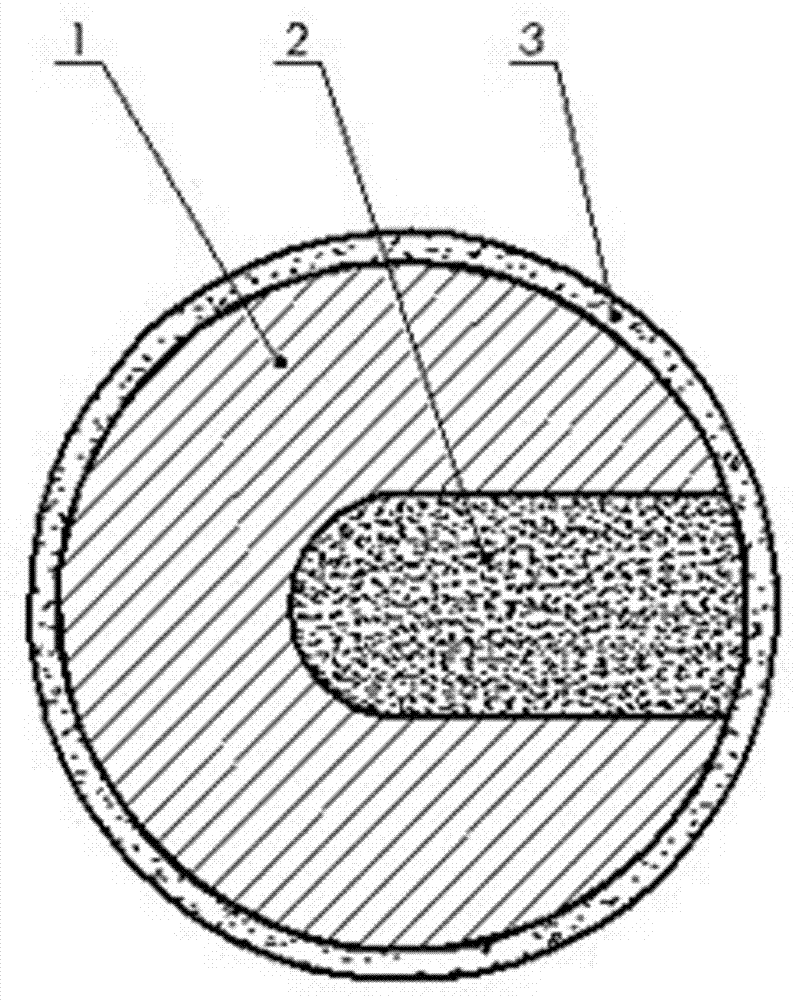

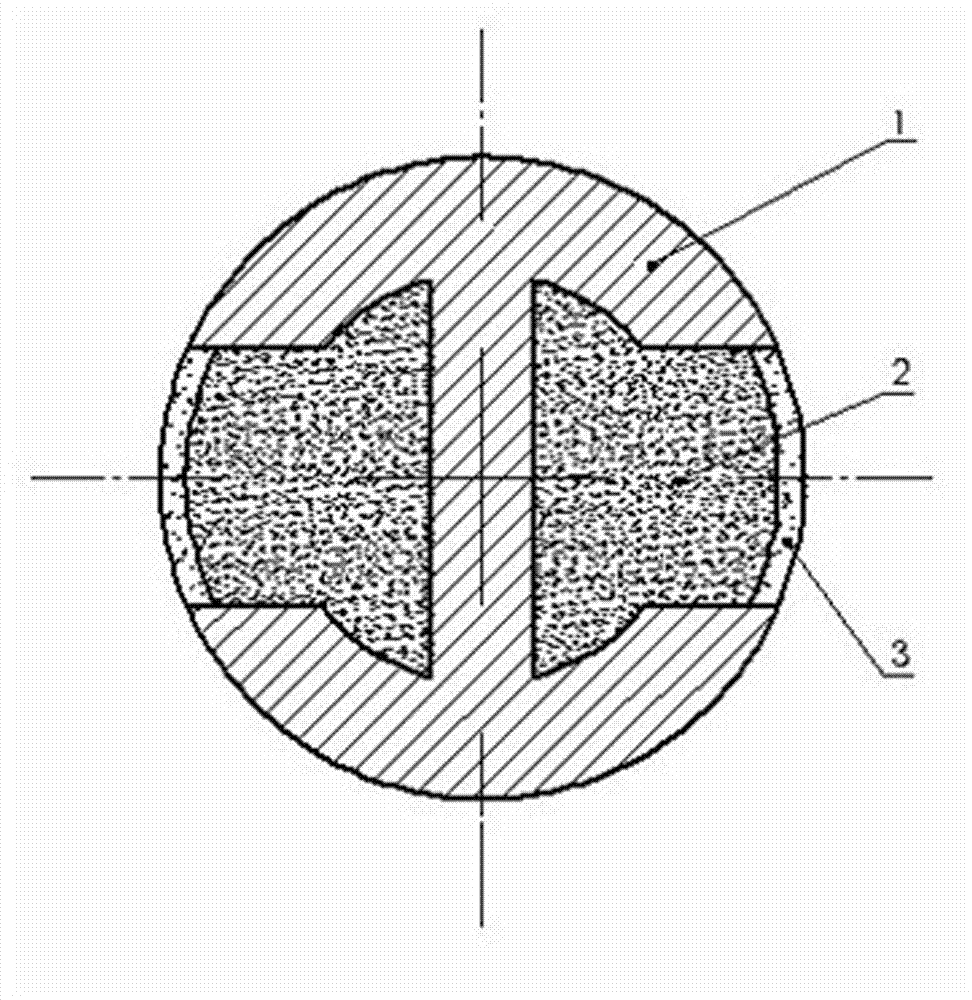

Composite aluminum-base brazing wire for continuously brazing aluminum alloy and method for manufacturing composite aluminum-base brazing wire

InactiveCN103203560AReasonable structureThe joint performance is stable and goodWelding/cutting media/materialsSoldering mediaFiller metalSilicon

The invention discloses a composite aluminum-base brazing wire for continuously brazing aluminum alloy and a method for manufacturing the composite aluminum-base brazing wire. The aluminum-base brazing wire comprises a section of aluminum-base brazing filler metal, non-corrosive brazing fluxes for aluminum and silicon powder coating layers; the section of the aluminum-base brazing filler metal is provided with grooves, the non-corrosive brazing fluxes for the aluminum are composited in the grooves of the section, and the silicon powder coating layers are coated on surfaces of the brazing fluxes; and the section side of the section of the brazing filler metal can be provided with one groove or two grooves or three grooves. The method includes smelting and casting the brazing filler metal of the brazing wire during manufacture and squeezing a blank which is a rod; manufacturing the section of the brazing filler metal of the brazing wire by means of rolling and squeezing; compositing the section of the brazing filler metal with the non-corrosive brazing fluxes for the aluminum; and coating the silicon powder coating layers on the surfaces of the composite brazing fluxes. The composite aluminum-base brazing wire and the method have the advantages that the local composite aluminum-base brazing wire for continuously brazing the aluminum alloy is suitable for intelligent brazing equipment provided with a laser brazing system, so that the intelligent brazing equipment can be used for continuously brazing various medium and large aluminum alloy structural parts with over-burning temperatures higher than 580 DEG C, the quality of brazing seams is stable, and the efficiency is high.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

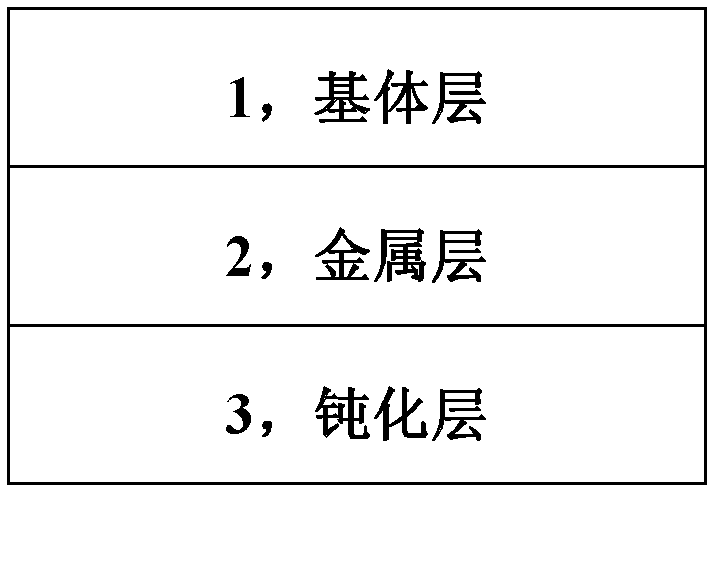

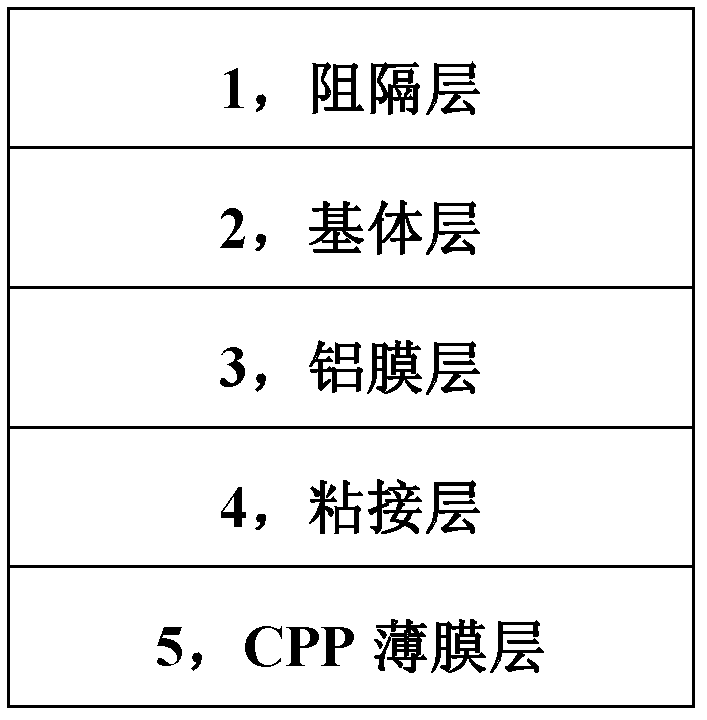

Aluminium-plastic film and preparation method for same

ActiveCN103158298AHighly corrosiveStrong acid and alkali resistanceMetal layered productsPre treatmentPlastic film

The invention discloses an aluminium-plastic film and a preparation method for the same. The aluminium-plastic film is composed of a blocking layer, a matrix layer, an aluminium film layer, an adhesive film layer and a CPP (castpolypropylene) film layer which are sequentially stacked. The preparation method for the aluminium-plastic film comprises the following steps of: 1) using polyimide (PI) for preparing a matrix, and performing pre-treatment on the surface of the matrix; 2) coating a blocking coating on one surface of the preheated PI matrix; 3) forming the aluminium film layer on the other surface of the PI matrix by a PVD (physical vapour deposition) method; 4) coating the adhesive layer on the aluminium film layer; and 5) compounding the CPP film on the adhesive layer. The aluminium-plastic film disclosed by the invention provides a coloured matrix film layer, as well as is extremely high in strength, air tightness, blocking property, acid-base resistance and electrolyte resistance, and convenient to identify; the aluminium film layer generated by virtue of the PVD method is extremely high in peeling strength with the matrix layer; and the functional aluminium-plastic film prepared by the method is excellent in machining performance, shielding effectiveness, blocking performance and the like, and capable of being used for external packaging for lithium batteries and high-performance batteries. Moreover, the aluminium-plastic film is low in cost, excellent in bending and tensile property, environment-friendly, and easy in technical processing.

Owner:英德宏庆电子有限公司

Preparation of flexible high-resistance multi-layer transparent conductive film

InactiveCN101476109AExtended service lifeDense filmConductive layers on insulating-supportsLayered productsHigh energy particleOxide

The invention provides a method for preparing a flexible high resistance multi-layer transparent conductive film which includes steps as follows: forming a titanium dioxide layer, a silicon dioxide layer, an indium tin oxide layer, a zinc-aluminium oxide layer or zinc-gallium oxide layer continuously and orderly on one surface of a flexible base material PET polyester film by using a mid-frequency magnetron sputtering technique; temperature reaching to 120 DEG C or more by using heat energy generated by bombardment continuously and deposition of the high-energy particle on the PET polyester film, and controlling oxide-indium atom ratio between 1.26-1.29 for obtaining the indium tin oxide layer with crystal structure; adhibiting another side of the PET polyester with one side of the second layer PET polyester, setting a hard coating on another side of the second layer PET polyester; forming the titanium dioxide layer and the silicon dioxide layer continuously and orderly on the hard coating by using mid-frequency magnetron sputtering technique. The product has better resistance stability and durability, has advantages of short production flow, high efficiency and low cost. The product is not easy to warp in follow processing flow.

Owner:甘国工

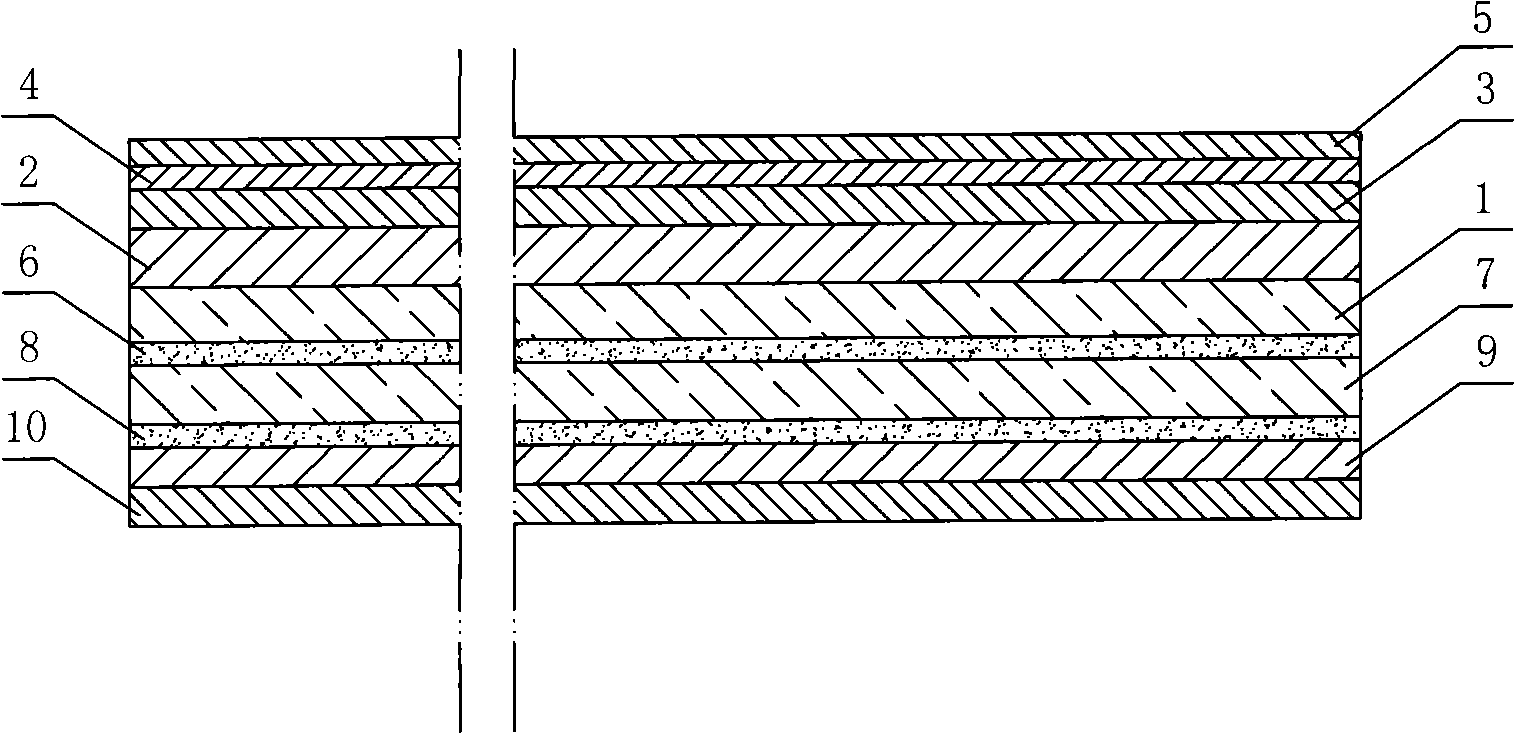

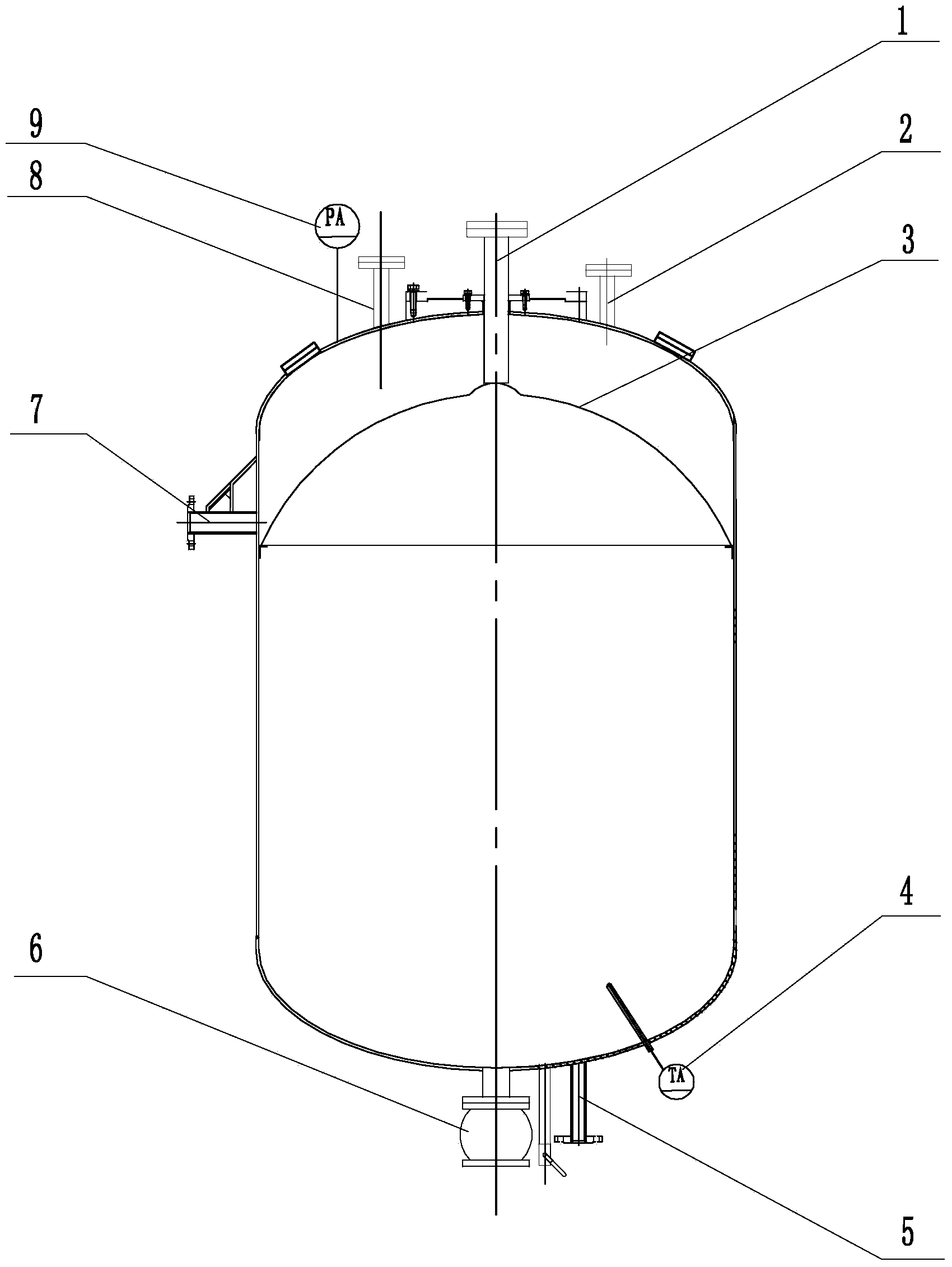

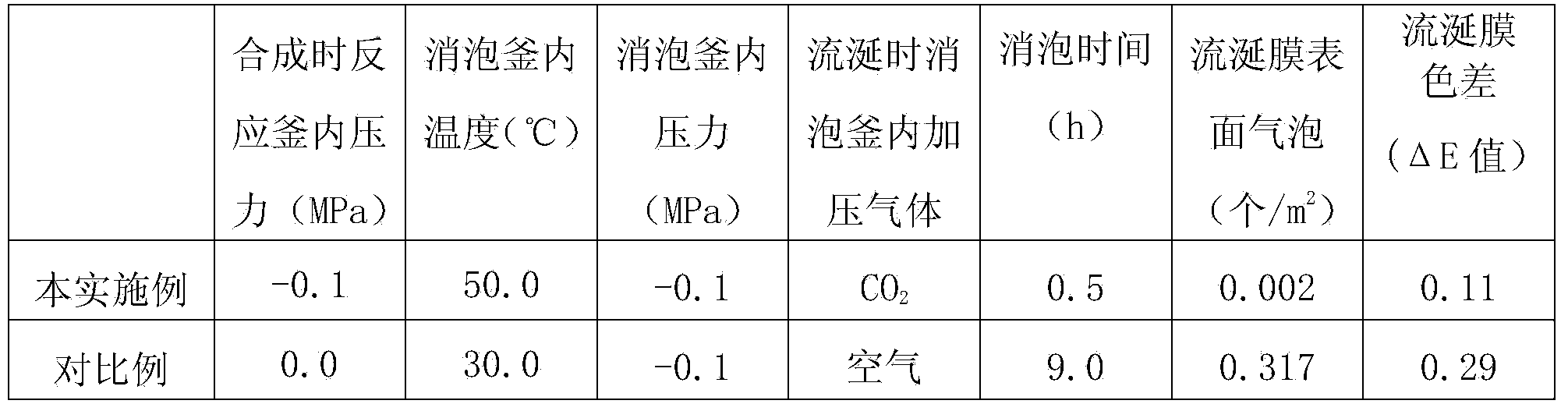

Defoaming kettle and defoaming method for preparing polyamide acid resin

ActiveCN104107565APrevent oxidationPrevent moisture absorptionFoam dispersion/preventionThin layerEngineering

The invention discloses a defoaming kettle and a defoaming method for preparing polyamide acid resin. A thin layer distributor with an arch rotary curve surface is fixedly installed in a defoaming kettle tank body; the distance from the curve surface arch top of the thin layer distributor to the lower end opening of a feeding pipe ranges from 0.01mm to 1 / 3 of the height of the tank body; the clearance between the lower edge of the curve surface of the thin layer distributor and the inner wall of the tank body is 0.01mm-10mm; the rotary curve surface of the thin layer distributor is a spherical surface; a resin conveying pipeline between a reaction kettle and the defoaming kettle is provided with a metering pump; the tank body is provided with a sandwiched sleeve, and an heat conduction medium inlet and outlet are formed at the top and bottom of the tank body. The defoaming method comprises the step that resin entering the defoaming kettle falls on the arch top of the curve surface of the thin layer distributor, and disperses and flows downward along the curve surface of the thin layer distributor to form a thin layer which results in bubble breakage. The metering pump is used for adjusting the flow rate of resin so as to keep that the thickness of the resin solution layer on the thin layer distributor is less than 5mm. Defoaming is completed immediately when resin is conveyed completely, and then pressurization is carried out for discharging. During defoaming, a heat conduction medium is introduced for warming, and negative pressure is kept in the tank body. According to the invention, defoaming is complete, and the defoaming time is shortened greatly so as to guarantee subsequent continuous film preparation. The defoaming kettle is simple in structure and convenient to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

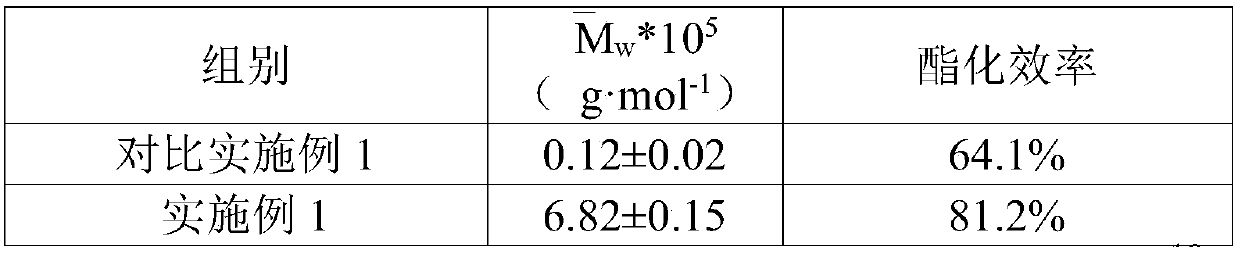

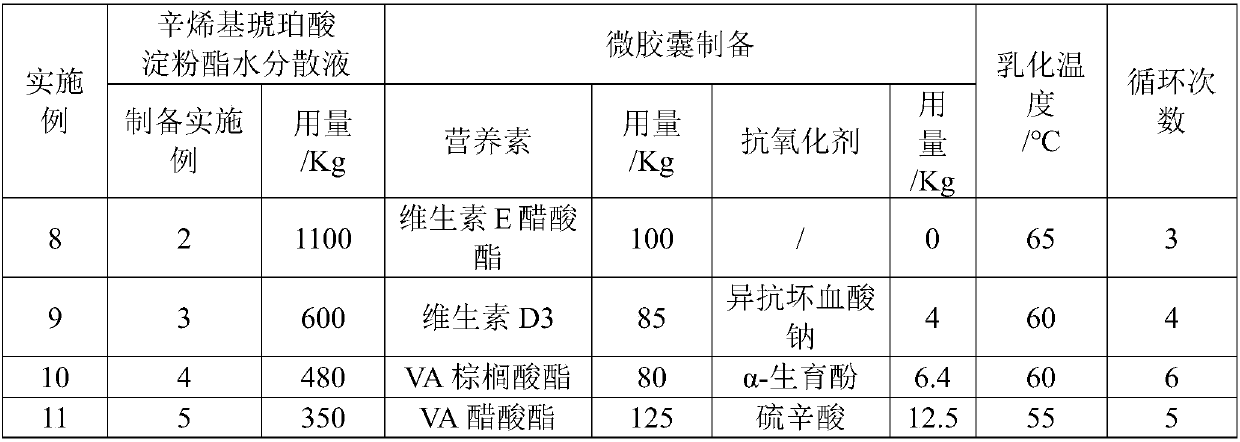

Octenyl succinic acid starch ester, lipid-soluble nutrient microcapsule as well as preparation method application of lipid-soluble nutrient microcapsule

ActiveCN109517080AHigh esterification rateGood emulsifying effectAccessory food factorsFood ingredientsChain lengthSuccinic acid

The invention relates to octenyl succinic acid starch ester, a lipid-soluble nutrient microcapsule as well as a preparation method application of the lipid-soluble nutrient microcapsule. A preparationmethod of octenyl succinic acid starch ester comprises the step of carrying out esterification reaction on gelatinized starch and octenyl succinic anhydride in a cavitation emulsification process, soas to obtain octenyl succinic acid starch ester. According to the preparation method, the esterification reaction is promoted and intensified by virtue of the cavitation emulsification process, remarkably substitution occurs in a crystallization region and an amorphous region of the starch through the molecular collision of the collision between gelatinized starch and octenyl succinic anhydride,so that the esterification rate of prepared octenyl succinic acid starch ester is increased, and the emulsifying property is greatly improved. The method is rapid and efficient, and a hydrolysis stepis omitted after the esterification, so that the problems that molecular chains are damaged in different degrees due to the hydrolysis, the chain length and content of amylose are remarkably decreased, the compactness of a film formed by octenyl succinic acid starch ester is decreased, and the film easily absorbs moisture and conducts heat and is crispy are avoided, and the application performanceof octenyl succinic acid starch ester is improved.

Owner:ZHEJIANG UNIV +2

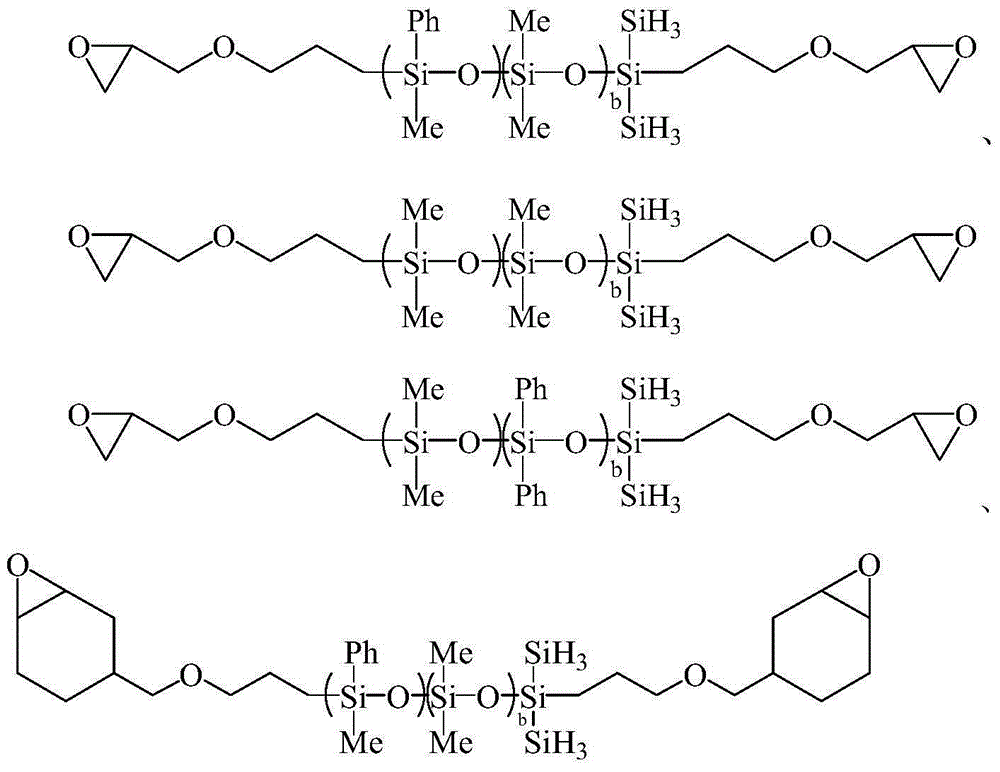

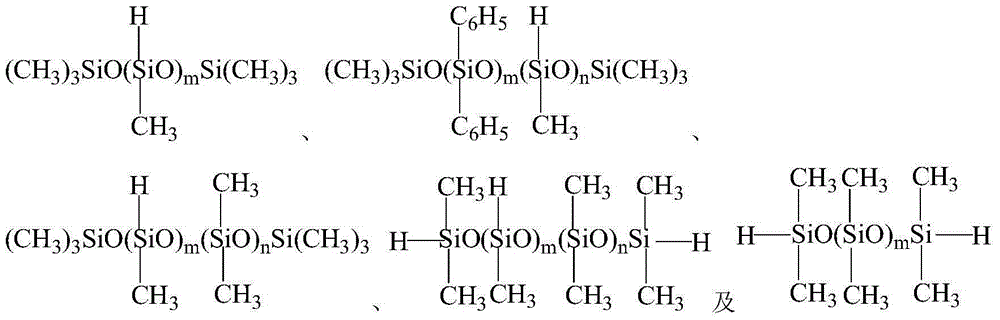

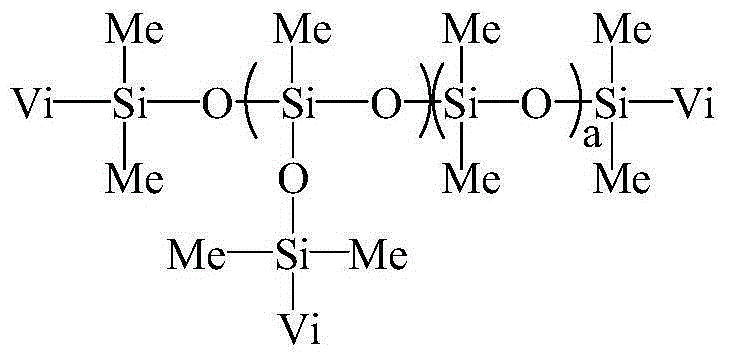

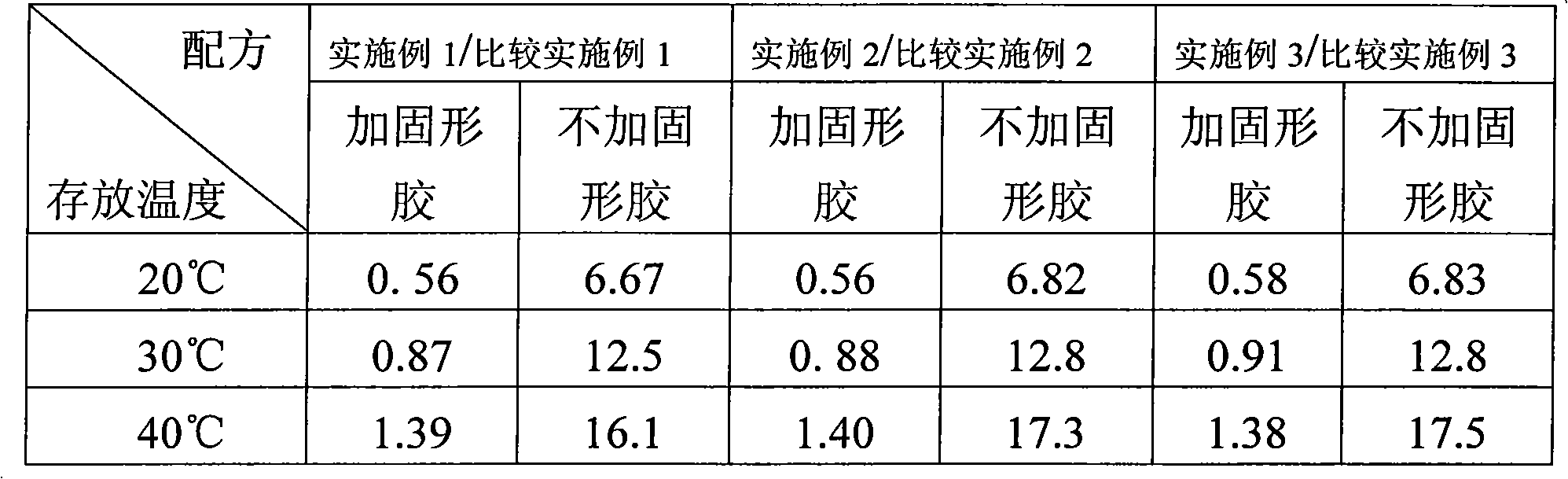

Organosilicon composite material and preparation method thereof

The invention discloses an organosilicon composite material and a preparation method thereof. The composite material is prepared from alkylene-containing polysiloxane, hydrogen-containing polysiloxane, epoxide group polysiloxane, a heat-conduction filling material, a hydrosilation catalyst, a reaction inhibitor and the like through mixing and curing. The prepared organosilicon composite material has the characteristics of low content of volatile compounds, resistance to high and low temperature, high heat conduction, light weight, high strength, good cementability, electrical insulating properties, etc., can meet development demands of functional assemblies for large power, microminiaturization, lightweight and high reliability, and is applicable as a badly-needed high-performance heat-conducting insulating material in military fields like aviation, spaceflight and weapons and in fields related to people's livelihood, e.g., an LED illumination system and an electronic circuit integration system.

Owner:HUNAN BOOM NEW MATERIALS

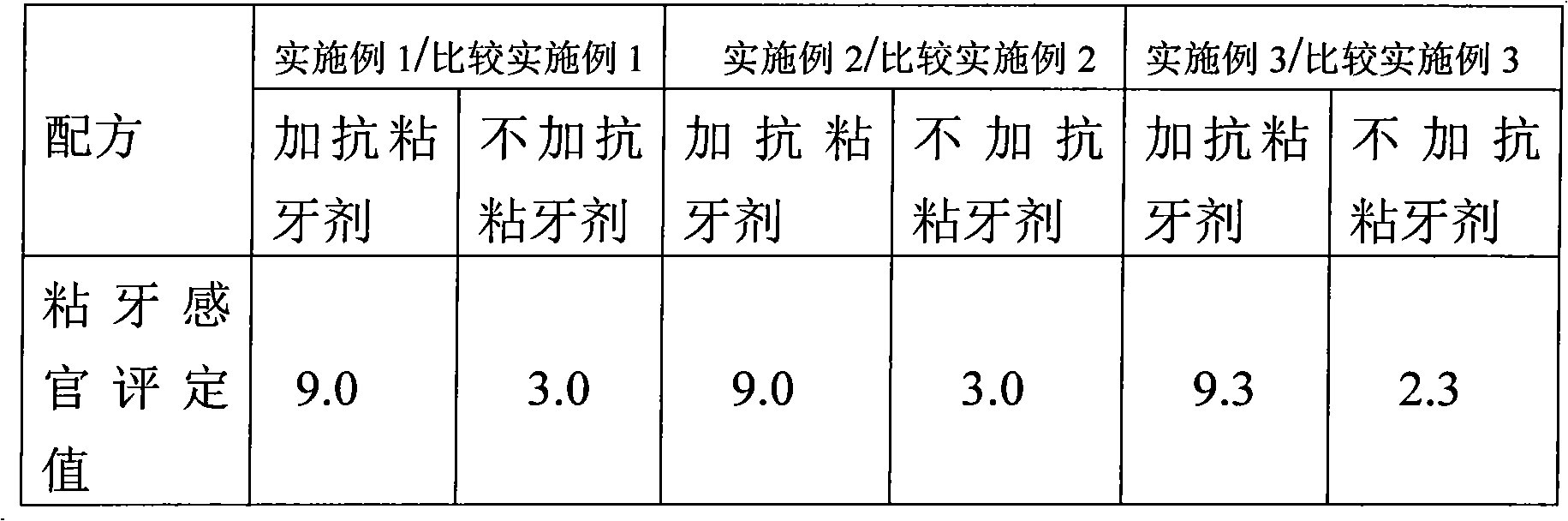

Solid honey candy and preparation method thereof

InactiveCN102058004AChange the curing characteristicsImprove product valueConfectionerySweetmeatsSucroseMicrowave

The invention relates to a solid honey candy and a preparation method thereof. The solid honey candy comprises the following components in percentage by weight: 100 percent of liquid pure honey, 3 to 6 percent of edible solid gum and 0.7 to 3 percent of teeth stick-resisting agent, wherein the edible solid gum is selected from arabic gum, konjac gum and pectin, and the teeth stick-resisting agentis selected from lecithin, sucrose fatty acid ester and water-soluble glycerol monostearate. The preparation method of the solid honey candy comprises the following steps of: weighing the components in a weight ratio, dissolving the edible solid gum and the teeth stick-resisting agent in hot water, adding the solution into the liquid pure honey, dehydrating the obtained mixed liquid by a vacuum microwave heating method to ensure that water content is below 3 percent, performing cast molding at the temperature of between 60 and 70 DEG C, cooling and demolding to obtain the solid honey candy. The honey content of the solid honey candy is above 90 percent; the color, aroma, taste and nutrients of the original liquid honey are basically not changed; a solid shape can be kept at room temperature; and the edible teeth stick-resisting agent is added into the formula, so that the solid honey candy is not sticky to teeth and has good mouthfeel during chewing. The preparation method is easy.

Owner:JIANGNAN UNIV

Lycopene microcapsule granules and preparation process thereof

InactiveCN104431690AImprove liquidityAvoid the problem of exceeding the standardFood preservationFood ingredientsBiotechnologyStarch corn

The invention relates to lycopene microcapsule granules and a preparation process thereof. Lycopene crystal powder, sunflower oil or corn oil, porous starch, oxidized starch, modified cassava starch, corn syrup, trehalose, natural VE oil are used as main raw materials, a process is reasonably improved and optimized to be used for greatly shortening the production time, the entire production process is controlled, the drying is carried out layer by layer and the recycling is carried out step by step. Obtained products are spherical, the surfaces of the products are smooth and trim, the biological activity of the products is kept, the products can be well solved in cold water, the use, storage and transportation are relatively well facilitated, no organic solvent or harmful substance is left, the safety, liquidity, taste and water solubility of the products are greatly improved, and resource waste is reduced. By adopting the process, the yield of the lycopene microcapsule granules is high, and the process is suitable for being used for large scale preparation of the lycopene microcapsule granules, and is used for achieving the continuous mass production and reducing the production cost.

Owner:武汉志邦化学技术有限公司

Polynutrient anti-blocking synergy urea and preparation method

InactiveCN101591207APromote growthMeet needsUrea compound fertilisersFertilizer mixturesDecompositionCaking

The invention discloses polynutrient anti-blocking synergy urea which contains large particle urea and a film coating composition, wherein the film coating composition comprises the following components in proportion by weight: 60-95 magnesium sulfate, 2-15 polyacrylamide, 0.5-4 sodium carboxymethyl cellulose, 0.5-4 dodecyl benzene sulphonic acid, 378-1770 water, 5-15 compound sodium nitrophenolate and 5-15 alpha-pimacol; and the weight ratio of the film coating composition to the large particle urea is 1:100-500. The film coating composition forms a coating film on the surface of the large particle urea so as to have good effects of anti-caking and anti-chalking. The components of the polynutrient anti-blocking synergy urea mutually cooperate to ensure that the decomposition velocity of nitrogen is consistent with the demand for nitrogen of crops and can improve the utilization rate of the nitrogen in the urea, promote the growth of plants and meet the requirement on magnesium of the crops, thus the product is polynutrient anti-blocking high-efficiency urea which has simple process and low cost and is suitable for popularization.

Owner:乔山峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com