Patents

Literature

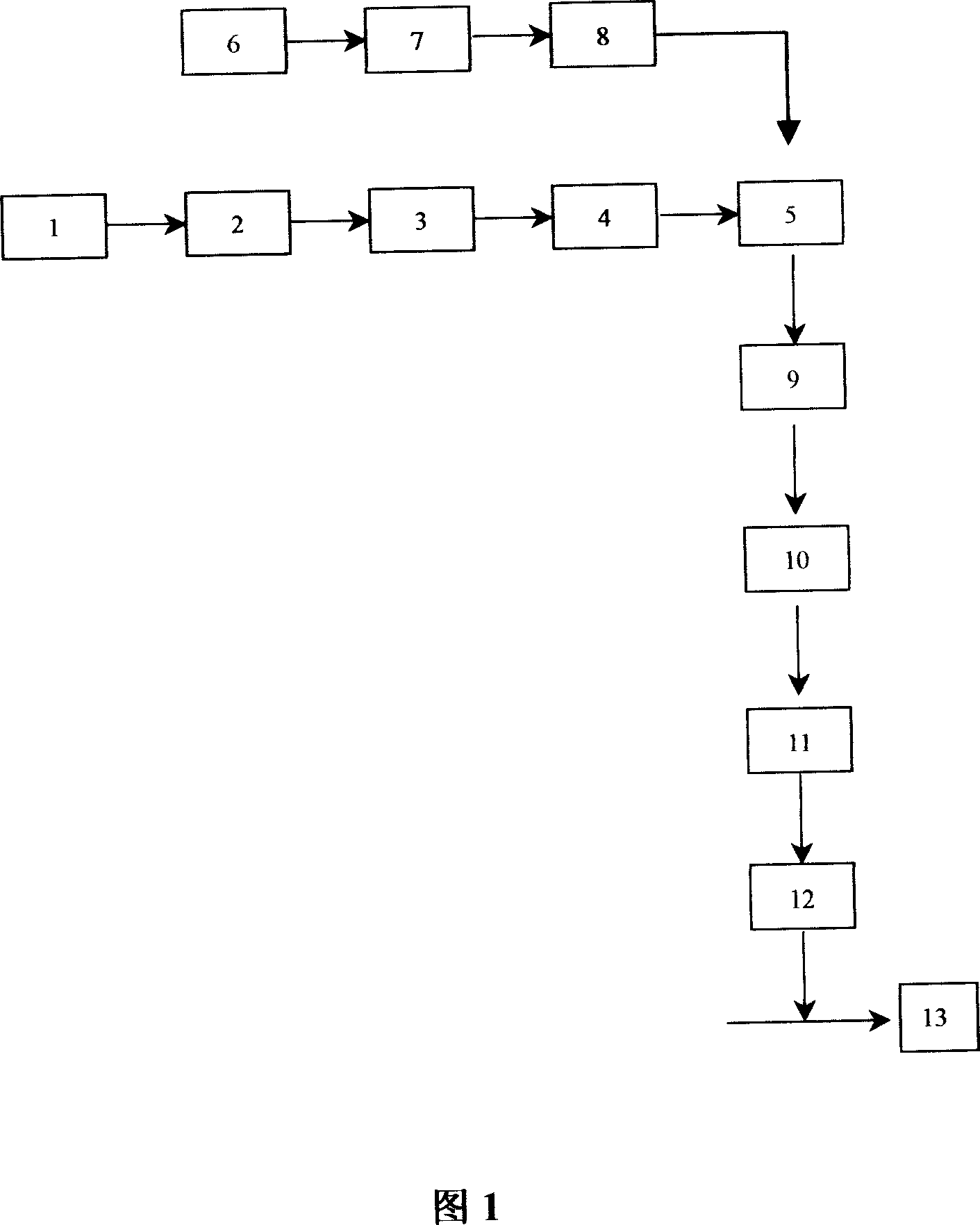

792results about How to "Improve molding rate" patented technology

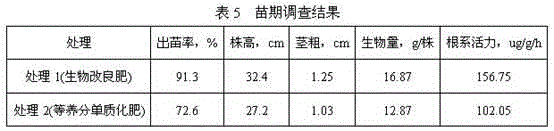

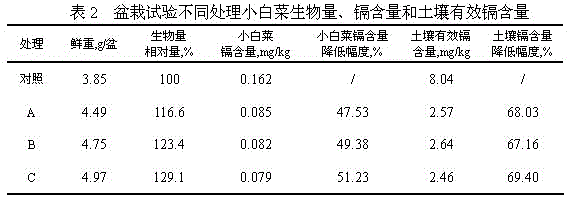

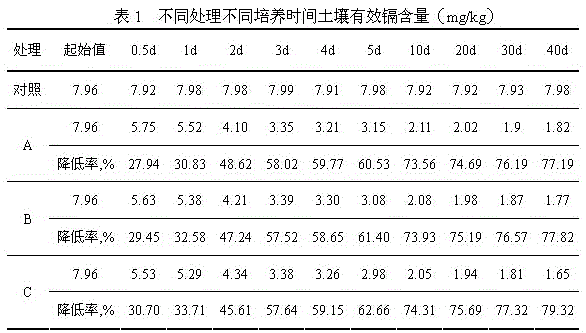

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

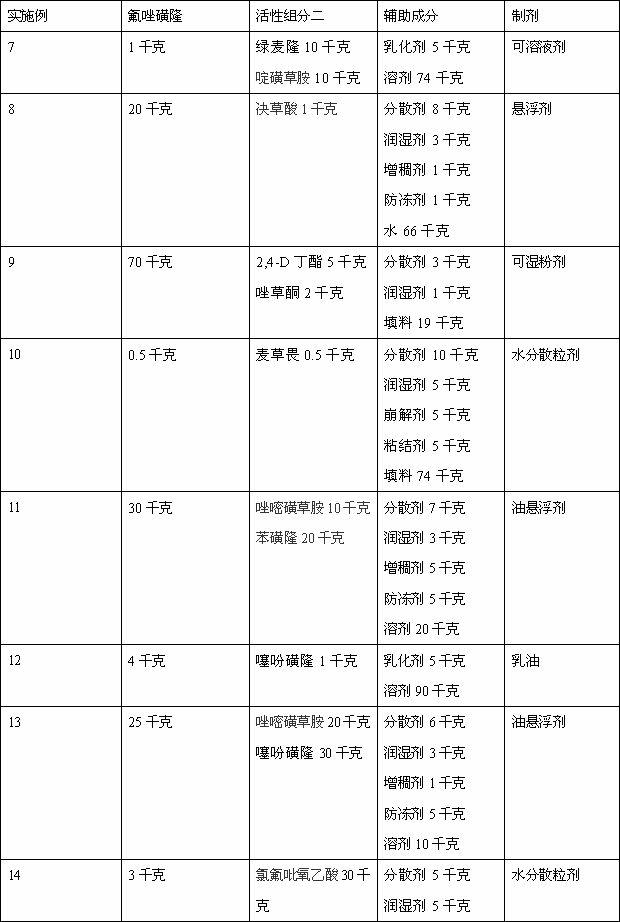

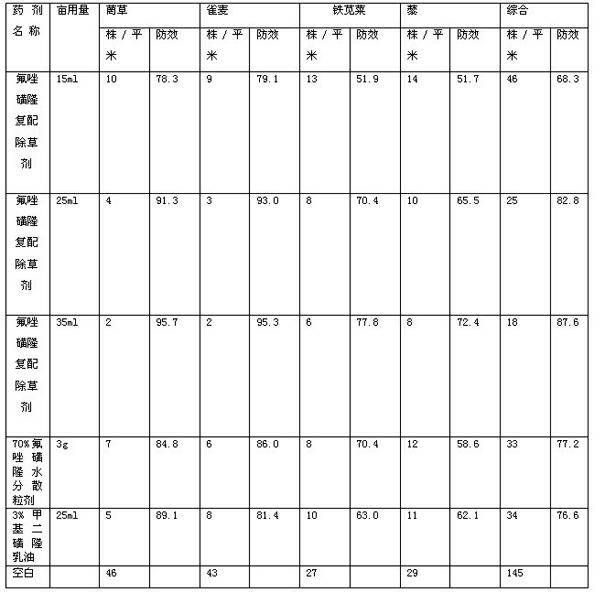

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

Honeycomb activated carbon, preparation method thereof, and air purifier prepared from honeycomb activated carbon

ActiveCN102489250AImprove adsorption capacityHigh strengthBiocideOther chemical processesParticulatesHEPA

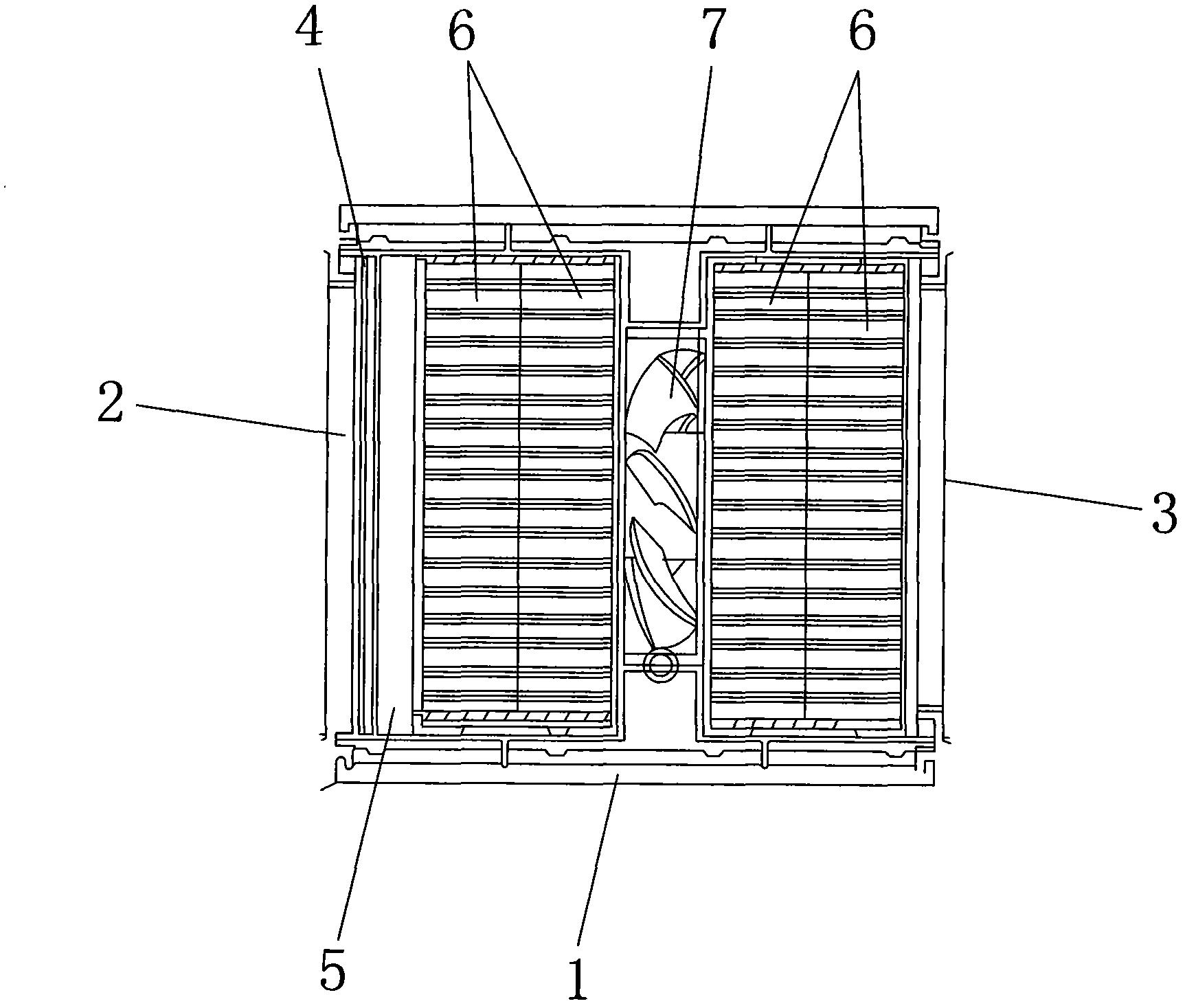

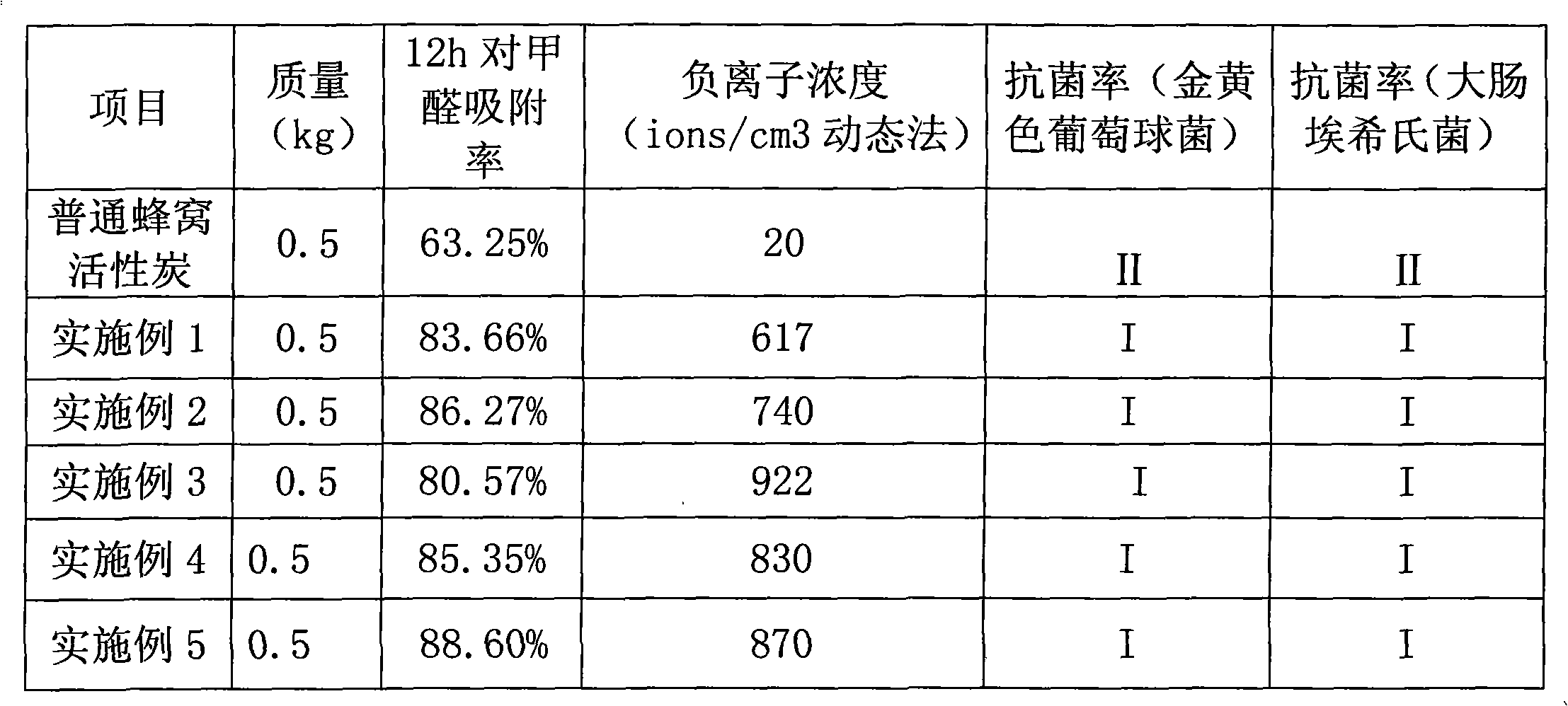

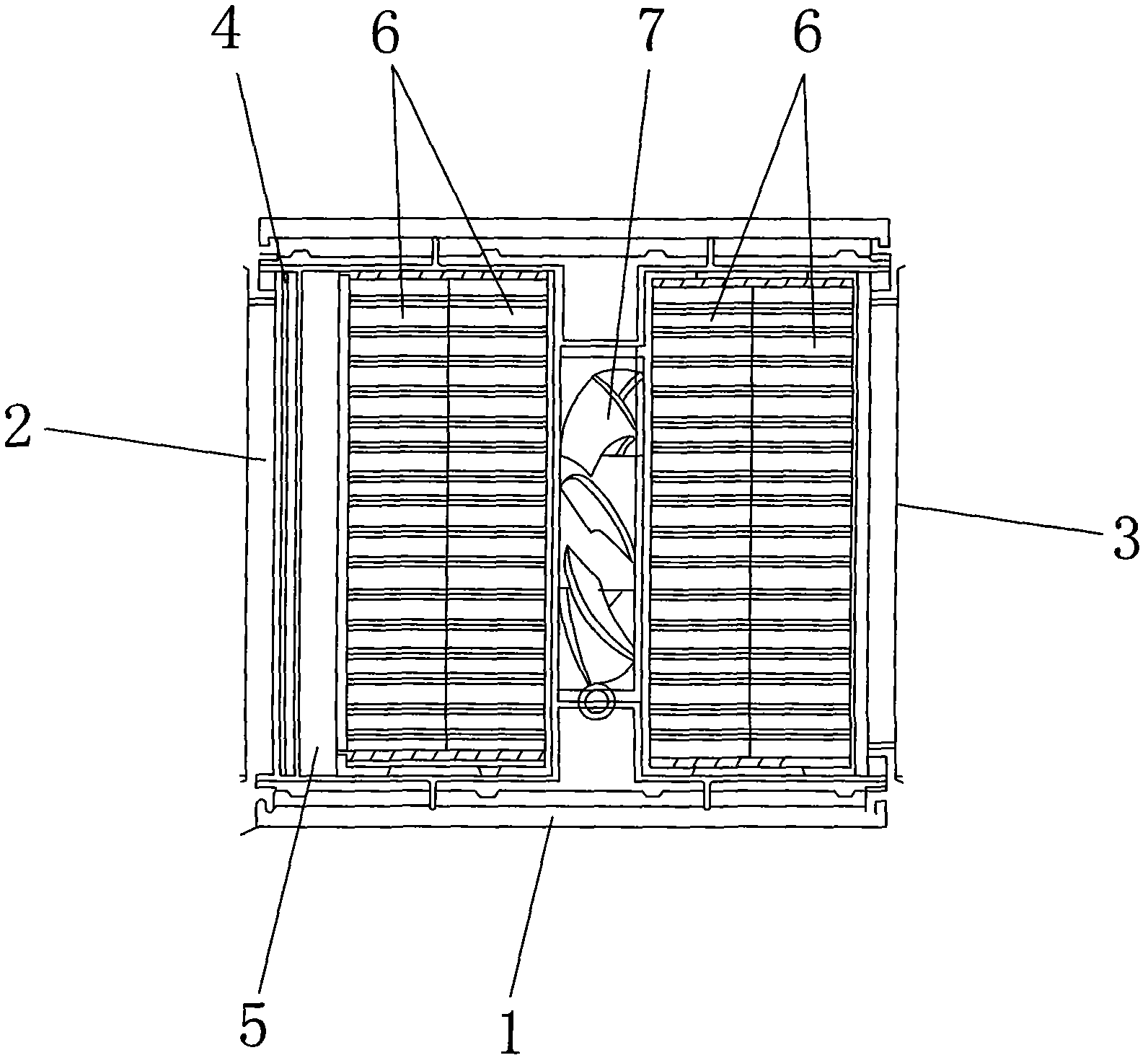

The invention provides honeycomb activated carbon with a good purification function. The honeycomb activated carbon is characterized by consisting of the following components in percentage by weight: 50 to 75 percent of activated carbon, 20 to 40 percent of silicate, 3 to 15 percent of negative ion powder, and 1 to 5 percent of nano TiO2 powder. The activated carbon is prepared by the steps of mixing, ball-milling, filter-pressing and drying, pugging, performing extrusion molding, drying and calcining. An air purifier which is prepared from the activated carbon comprises a shell; two ends of the shell are provided with an air inlet and an air outlet; the air purifier is characterized in that: three plane filter plates, namely primary filter cotton, a high-efficiency particulate air (HEPA) high-efficiency filter element, and a cellular activated carbon sieve are sequentially arranged in the shell from the air inlet to the air outlet; and the three plane filter plates are parallel to the planes of the air inlet and the air outlet; and a fan is fixed on a support arranged in the shell, and a rotation shaft of the fan is vertical to the plane filter plates.

Owner:湖南文象炭基环保材料股份有限公司

High-temperature pressure sensor and production method thereof

ActiveCN103115704AAvoid it happening againHigh sensitivityPrecision positioning equipmentLamination ancillary operationsCapacitanceSpiral inductor

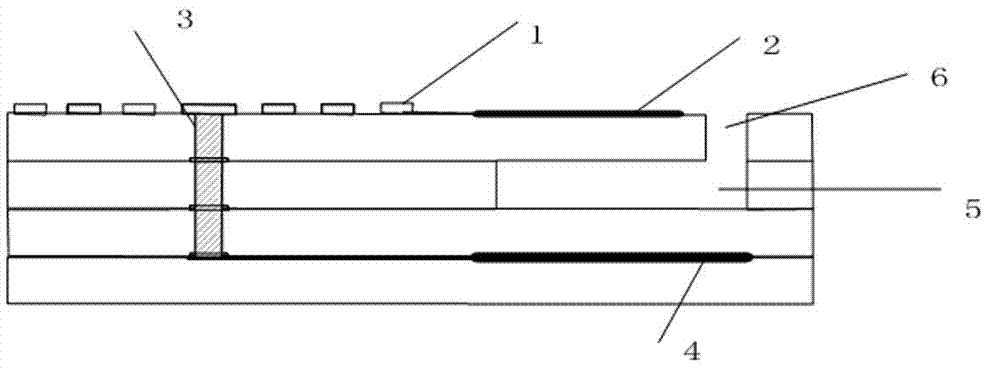

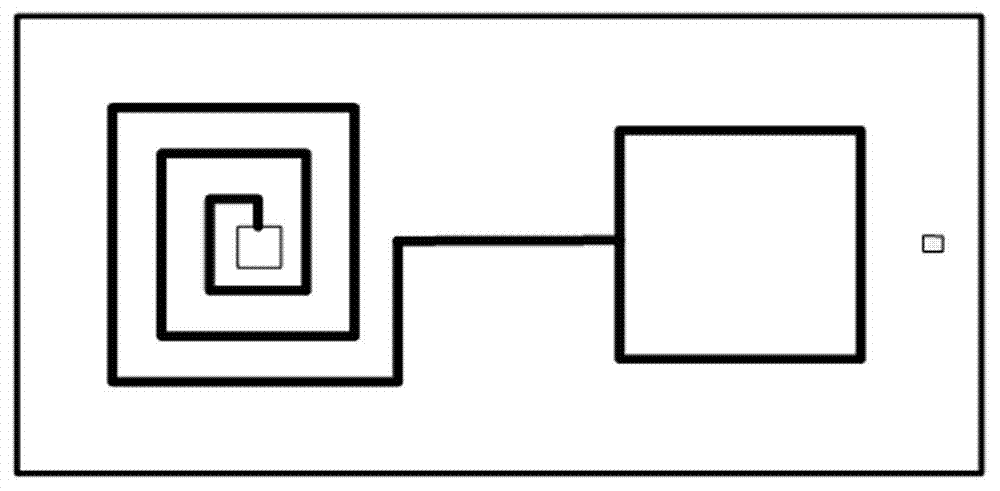

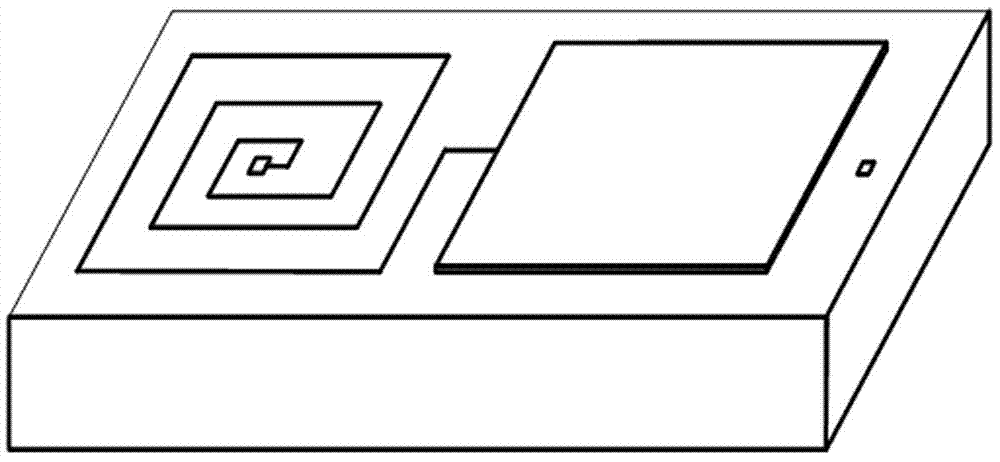

The invention belongs to the technical field of pressure sensors, particularly relates to a high-temperature pressure sensor and a production method thereof and solves the problem that the existing pressure sensor fails to operate normally in environments of high temperature, moistness and the like due to the insufficiently reasonable design. The high-temperature pressure sensor comprises four layers. A planar square spiral inductor and a capacitor upper electrode are made on the first layer by pasting; a sealed pressure cavity is arranged on the second layer; a capacitor electrode is made on the fourth layer by pasting and is connected with an inner circular core of the top planar square spiral inductor. The production method includes filling the pressure cavity with carbon paste; subjecting the laminated structure to high-temperature sintering to volatilize carbon from air holes so as to form a complete cavity; and after sintering, placing glass beads at the air holes to allow for secondary sintering sealing. The high-temperature pressure sensor is capable of operating at normal temperature and high temperature more than 400 DEG C, and is simple in structure, small in size, simple in manufacture process and easy for industrial production.

Owner:ZHONGBEI UNIV

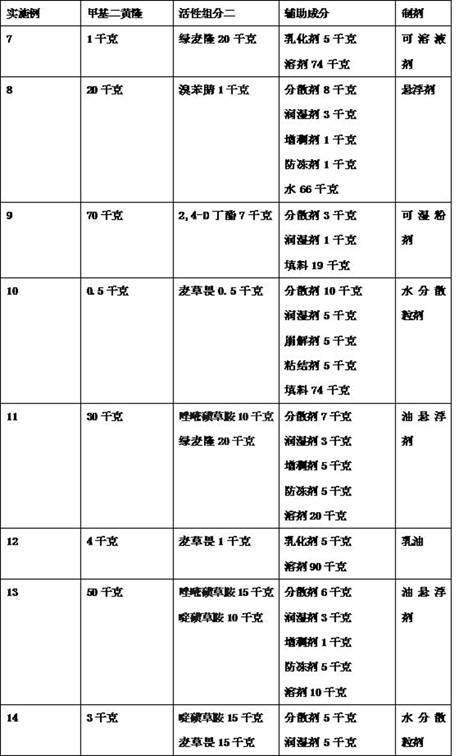

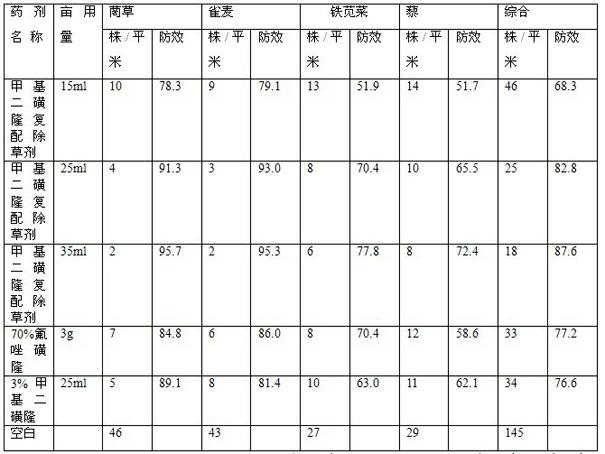

Mesosulfuron-methyl compound herbicide

InactiveCN102550585APrevent flocculationAvoid layeringBiocideAnimal repellantsAdjuvantAdditive ingredient

The invention discloses a mesosulfuron-methyl compound herbicide which consists of mesosulfuron-methyl as active ingredient I, active ingredient II and auxiliary ingredients; the active ingredient II is the combination of one or more of flucarbazone-Na, isoproturon, chlortoluron, pyroxsulam, 2-methyl-4-chlorophenoxy acetic acid, 2,4-D butyl ester, dicamba, bromoxynil, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary ingredients consists of adjuvant and one of filler and solvent, and the adjuvant is the combination of one or more of emulsifying agent, dispersing agent, wetting agent, disintegrant, binding agent, antifreezing agent and thickening agent; the sum of the weight of the mesosulfuron-methyl as the active ingredient I and the weight of the active ingredient II is 1 to 85 percent of the total weight of the mesosulfuron-methyl compound herbicide; and the weight ratio of the active ingredient I to the active ingredient II is 1:20 to 20:1. The mesosulfuron-methyl mixed herbicide is novel herbicide for wheatlands.

Owner:河北博嘉农业有限公司

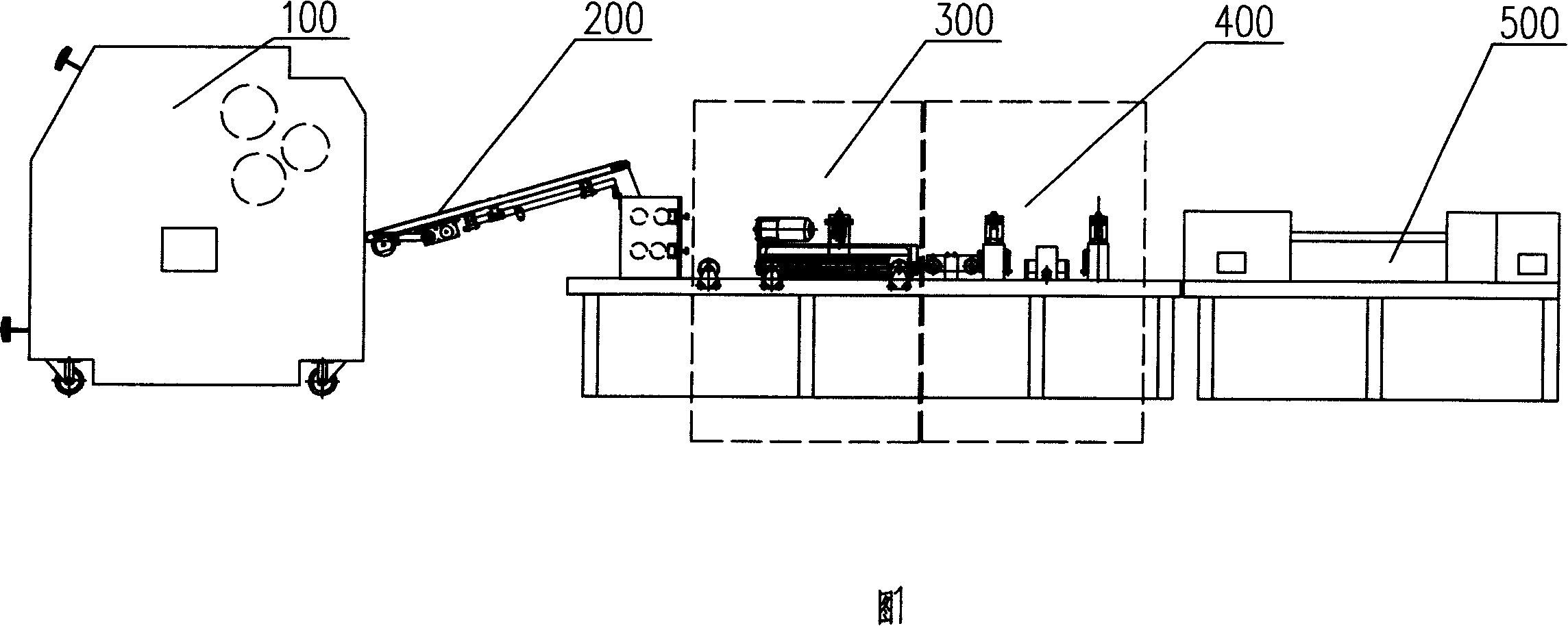

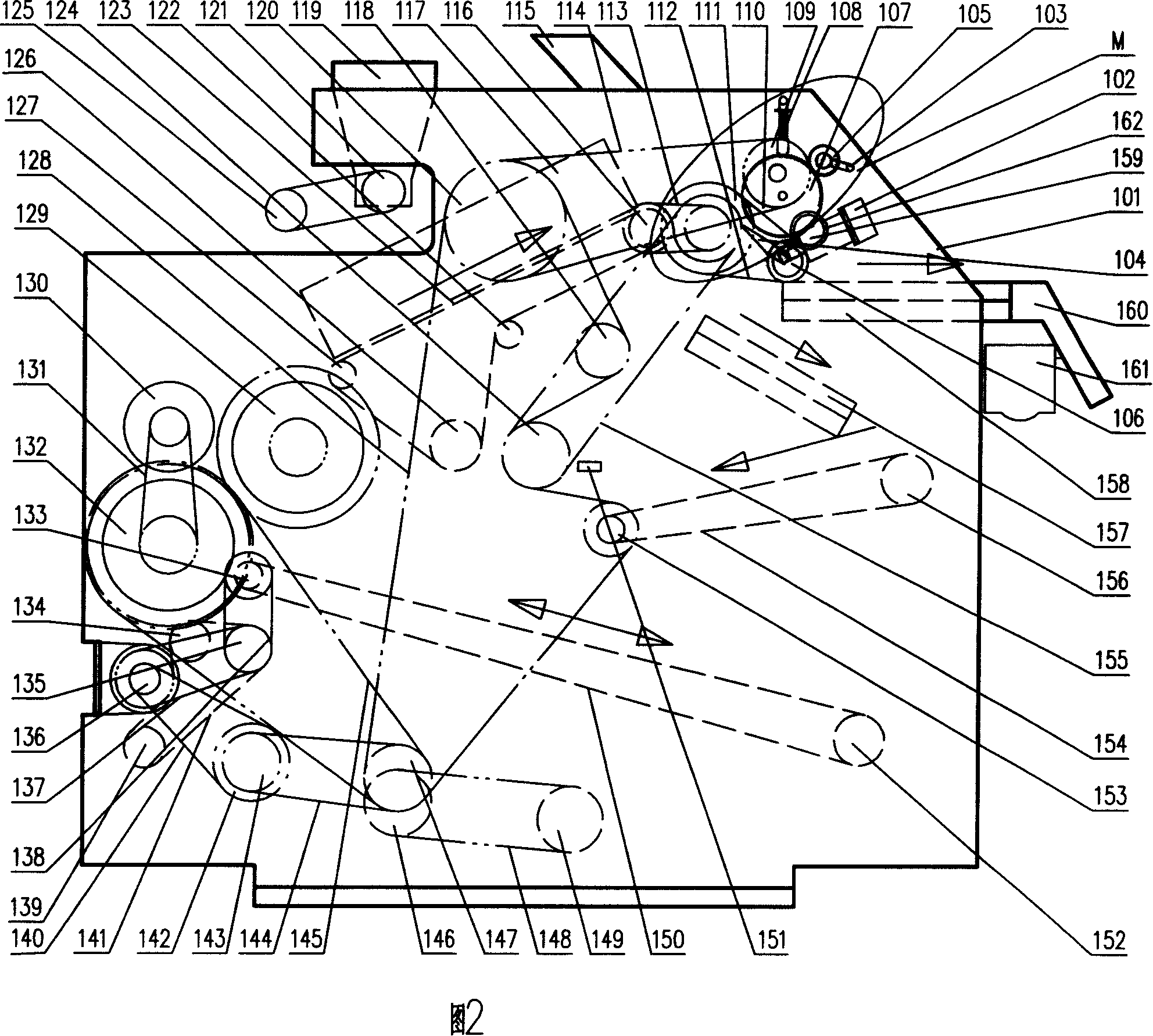

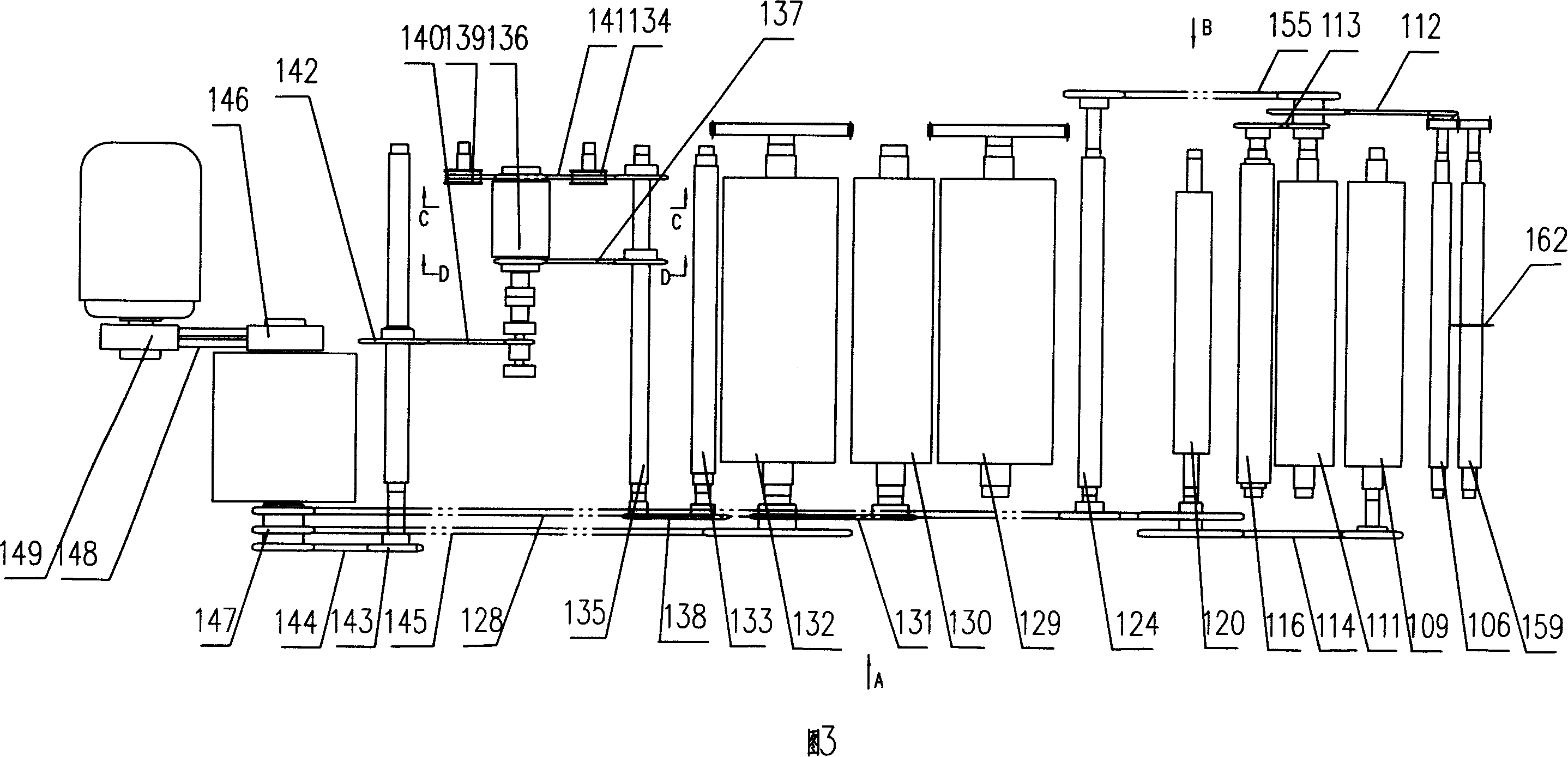

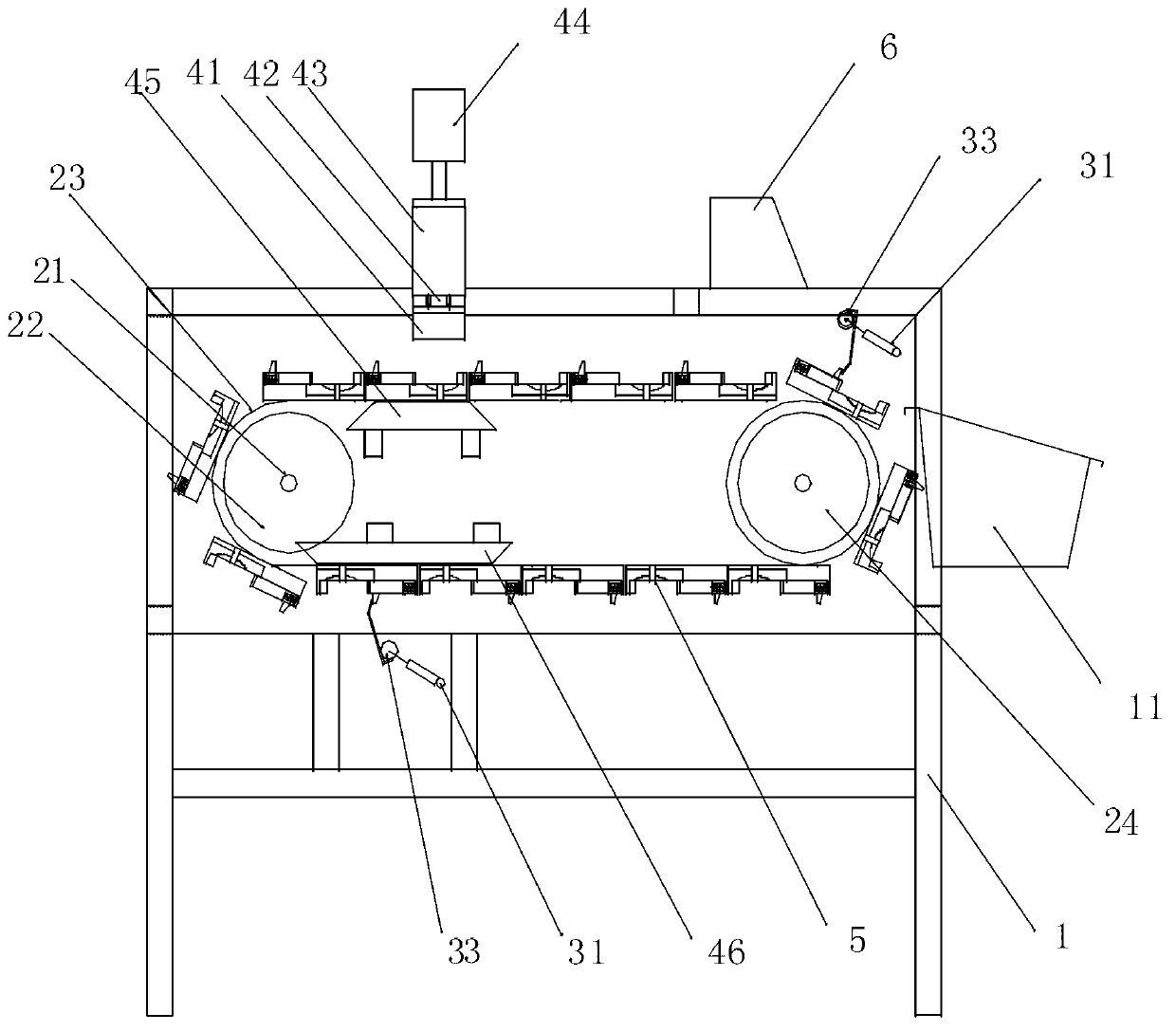

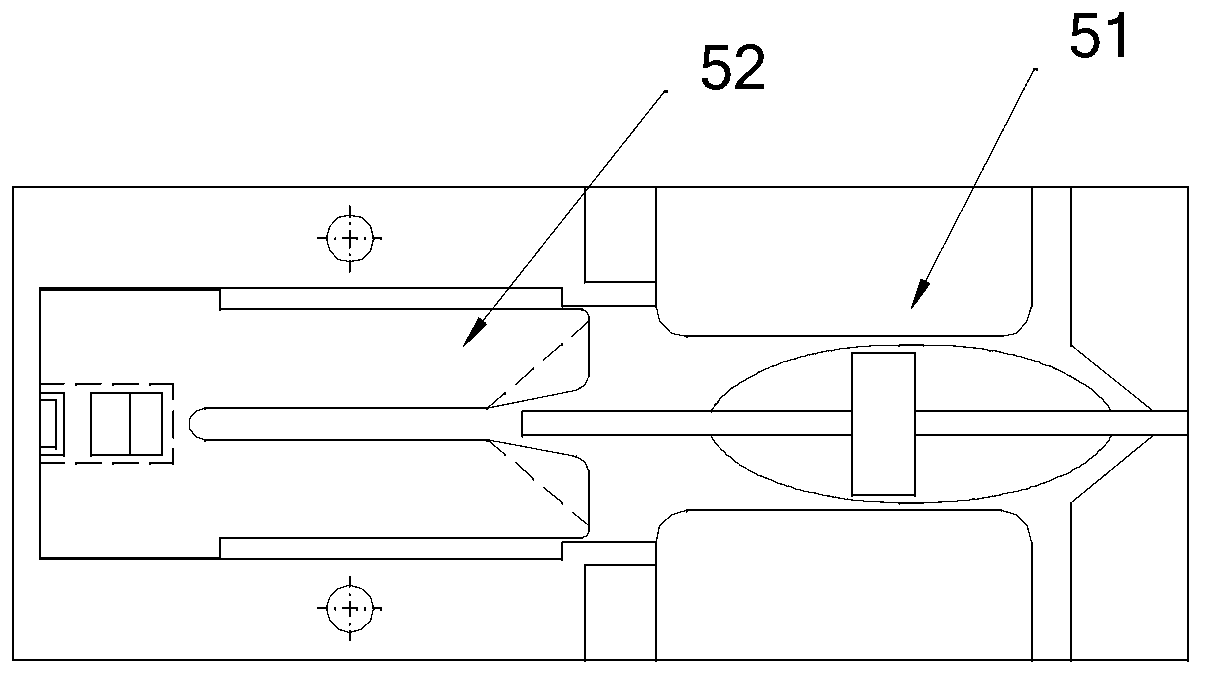

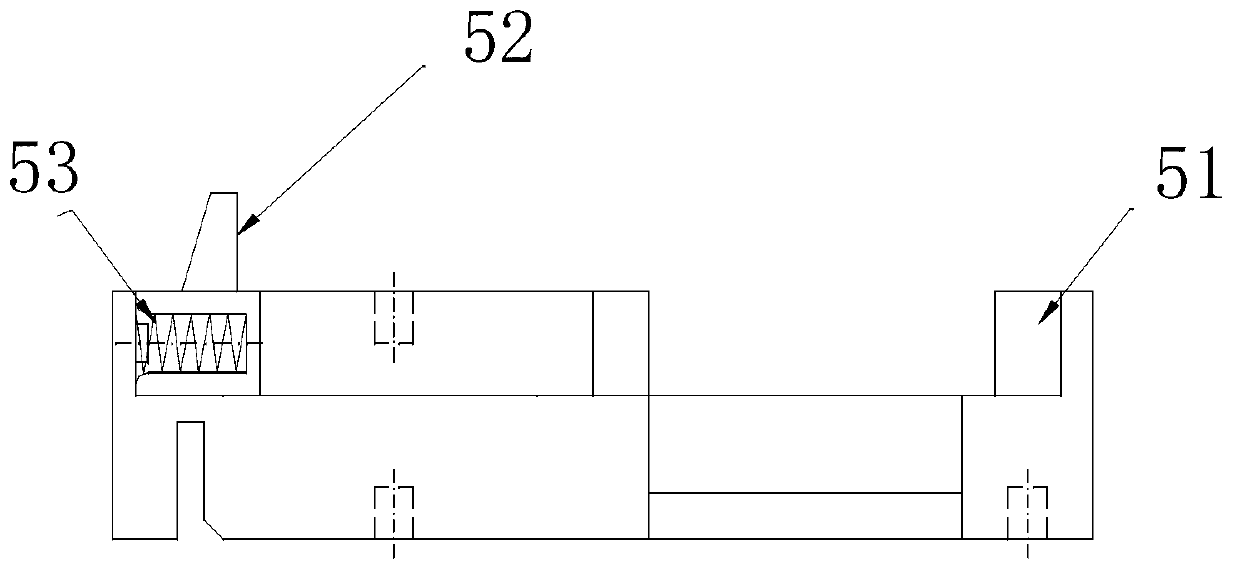

Equipment for producing round steamed bread

ActiveCN101112202AImprove skin brightnessClear internal structureDough-sheeters/rolling-machines/rolling-pinsForming processesFood products

The invention pertains to the technical field of food machinery and relates to producing equipment of round steamed bread. The equipment is provided with the following settings from front to back in sequence: a squash device (100), an incline plane transportation device (200), a winding device (300), a cutting device (400) and a molding device (500). Each device is connected by conveying belt. The squash, winding and cutting devices are added before the molding process. The process steps are as follows: paste is squashed into dough sheet; dough roll is made of the dough sheet through the winding device; then the dough roll is cut, molded to form a clear inner structure layer and improve the brightness of the steamed bread surface and enable the steamed bread to be tasted puckering. The molding process of the invention simulates manual entwisting molding process, which enables the steamed bread inner structure to be difficult to be torn and broken, maintains the sourdough network completely and evenly, has high molding efficiency, and at the same time improves the appearance quality of the dough.

Owner:郑州多福多食品有限公司

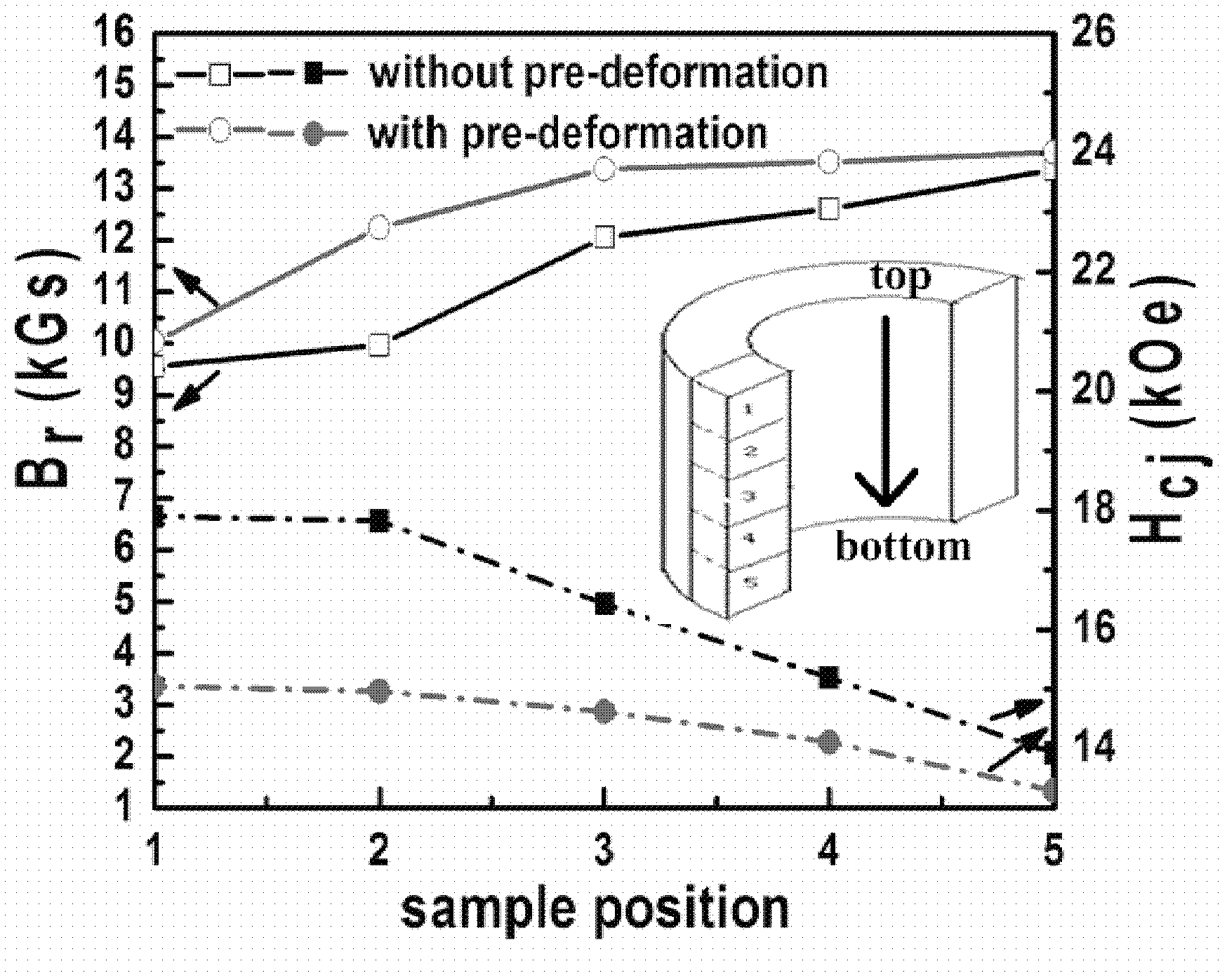

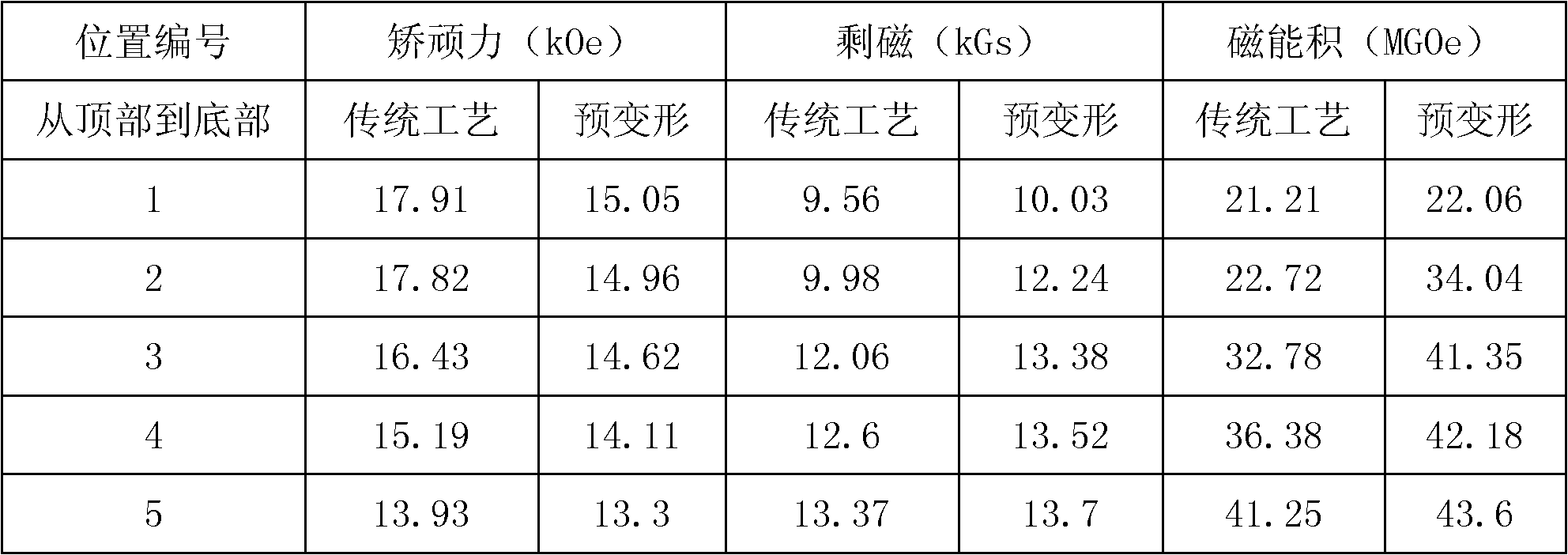

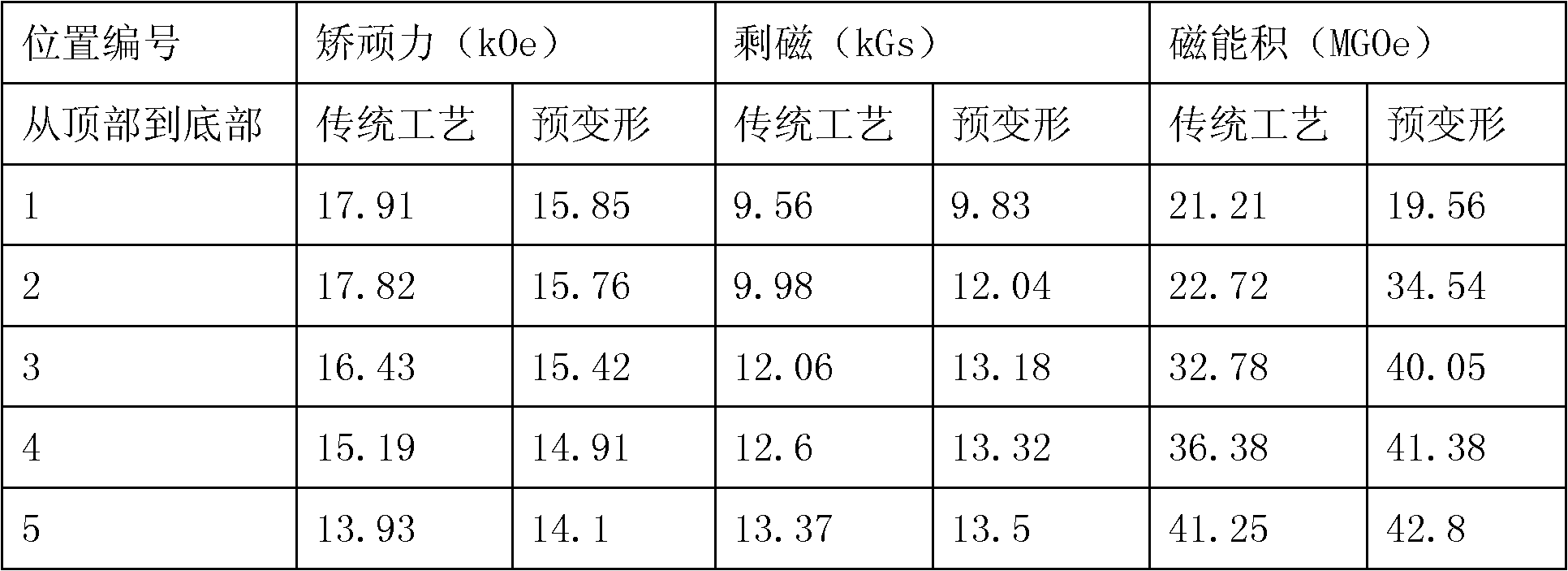

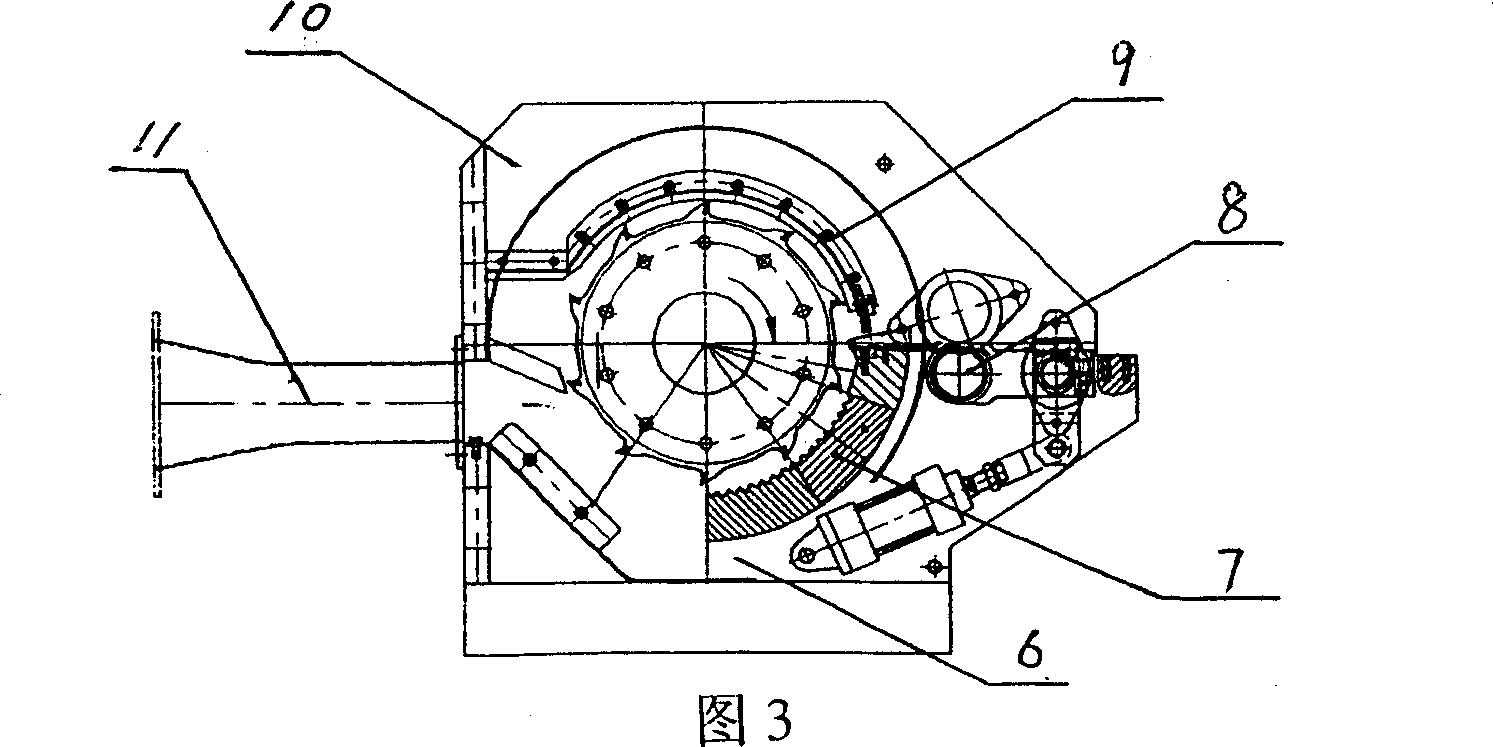

Method for improving performance of thermal compression or thermal deformation radiation orientation neodymium iron boron permanent magnet ring and axial uniformity thereof

ActiveCN103123862AImprove performanceImprove uniformityPermanent magnetsInductances/transformers/magnets manufactureThermal deformationDigital recording

The invention relates to a method for improving the performance of thermal compression or thermal deformation radiation orientation neodymium iron boron permanent magnet ring and the axial uniformity of the thermal compression or thermal deformation radiation orientation neodymium iron boron permanent magnet ring. The method for improving the performance of the thermal compression or thermal deformation radiation orientation neodymium iron boron permanent magnet ring comprises the following steps: (1) conducting thermal compression on rapid quenching magnetic powder which has a nanocrystalline structure or high density digital recording (HDDR) magnetic powder in a vacuum inductive thermal compressor to form an isotropous magnetic body by utilization of a thermal compression technology; (2) conducting thermal deformation on the isotropous magnetic body through cutting or replacement of a series of molds with different internal diameters to obtain an anisotropy magnetic body with different predeformation amounts; and (3) preparing the above predeformation anisotropyv magnetic body through a back extrusion technology to form a radiation orientation permanent magnet ring; by means of the predeformation technology, blank of the prepared radiation orientation magnet ring is enabled to have a certain degree of orientation and texture. In the process of preparation of the radiation orientation ring, the radiation orientation is benefited to be formed, thus under the condition that coercive force is not significantly reduced, the performance and the uniformity of the radiation orientation magnet ring are improved, the ratio of briquetting of the magnet ring can be greatly improved in the process of preparation of the magnet ring, energy consumption is reduced, and cost is saved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

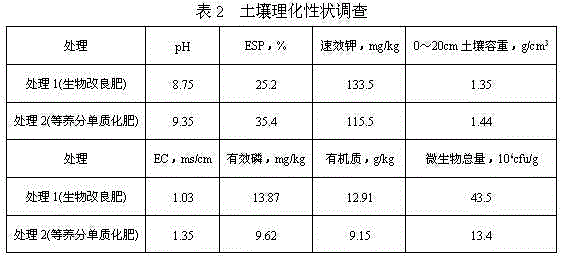

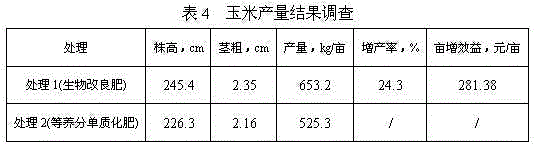

Saline-alkali soil biological improved fertilizer based on high-sulfur gangue and preparation method thereof

ActiveCN104788265ABreak the lattice structureIncrease the areaFertilizer mixturesThiobacillus ferrooxidansEcological environment

The invention discloses a saline-alkali soil biological improved fertilizer based on high-sulfur gangue. The saline-alkali soil biological improved fertilizer is prepared from the following components in parts by weight: 50-60 parts of high-sulfur gangue microbial fermentation product, 20-30 parts of compost cow manure or chicken manure, 1-2 parts of citric acid, 1-2 parts of oxalic acid, 2-4 parts of urea, 2-4 parts of ammonium sulfate, 2-4 parts of monoammonium phosphate, 1-3 parts of potassium sulphate, 2-5 parts of ferrous sulfate, 1-2 parts of zinc sulfate, 1-2 parts of manganese sulfate and 1-10 parts of bentonite, wherein the high-sulfur gangue microbial fermentation product is a product obtained by performing activating treatment on the high-sulfur gangue by a compound microorganism bacterium solution composed of thiobacillus thiooxidans, bacillus subtilis, bacillus megatherium, bacillus mucilaginosus and enterococcus faecalis. The resource utilization of the high-sulfur gangue is realized, the improvement of the inland saline land can be promoted, the crop yield can be increased and the entironment can be improved.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Composite compact type biomass fuel and preparation method thereof

The invention discloses a composite compact type biomass fuel and a preparation method thereof. The fuel comprises the following components in parts by weight: 15-70 parts of domestic garbage, 5-40 parts of restaurant garbage, 10-80 parts of drain sludge, 10-30 parts of human and poultry excrement and 10-30 parts of agriculture and forestry wastes, preferably, 25-35 parts of domestic garbage, 5-20 parts of restaurant garbage, 15-25 parts of drain sludge, 15-25 parts of human and poultry excrement and 15-25 parts of agriculture and forestry wastes. The obtained composite compact type biomass fuel can simultaneously treat the domestic garbage, the restaurant garbage, the agriculture and forestry wastes, the drain sludge and the human and poultry excrement and can be produced by a wet method at room temperature and normal pressure on a large scale without loss of heat value. In addition, the invention also provides the preparation method of the biomass fuel. The method is simple, practicable, clean and environment-friendly, is low in investment and operation cost, and has extremely obvious economic and environment-friendly benefits.

Owner:北京新日月环能科技有限公司

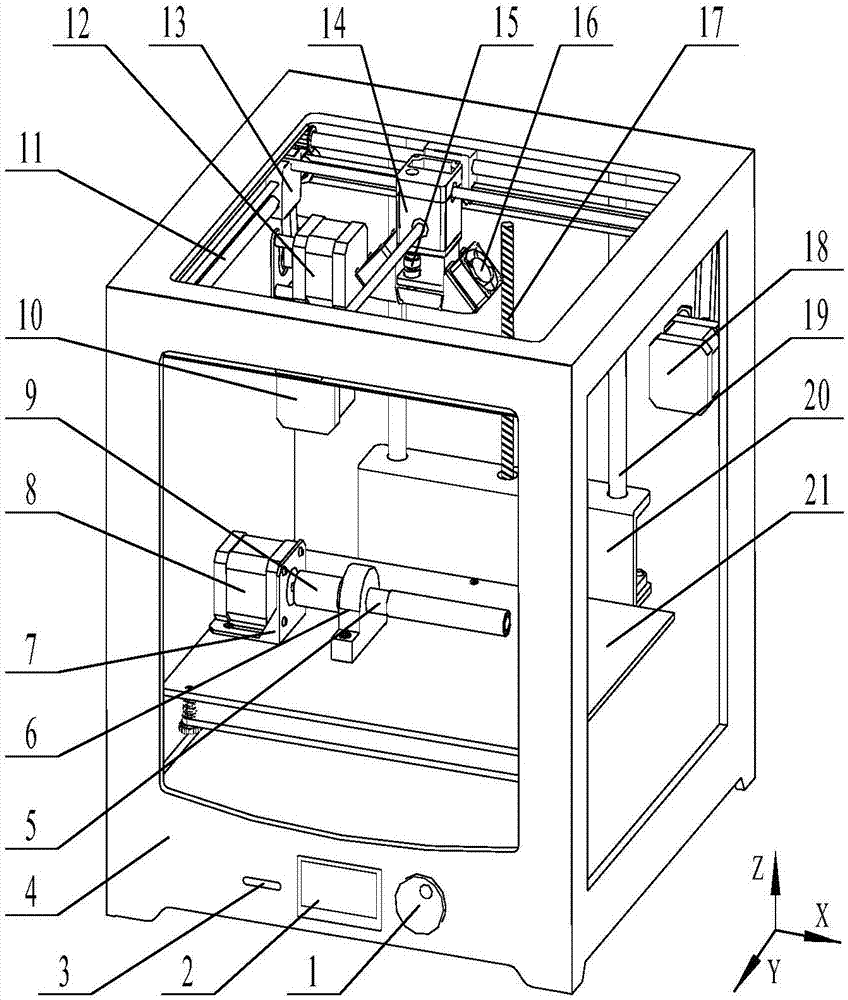

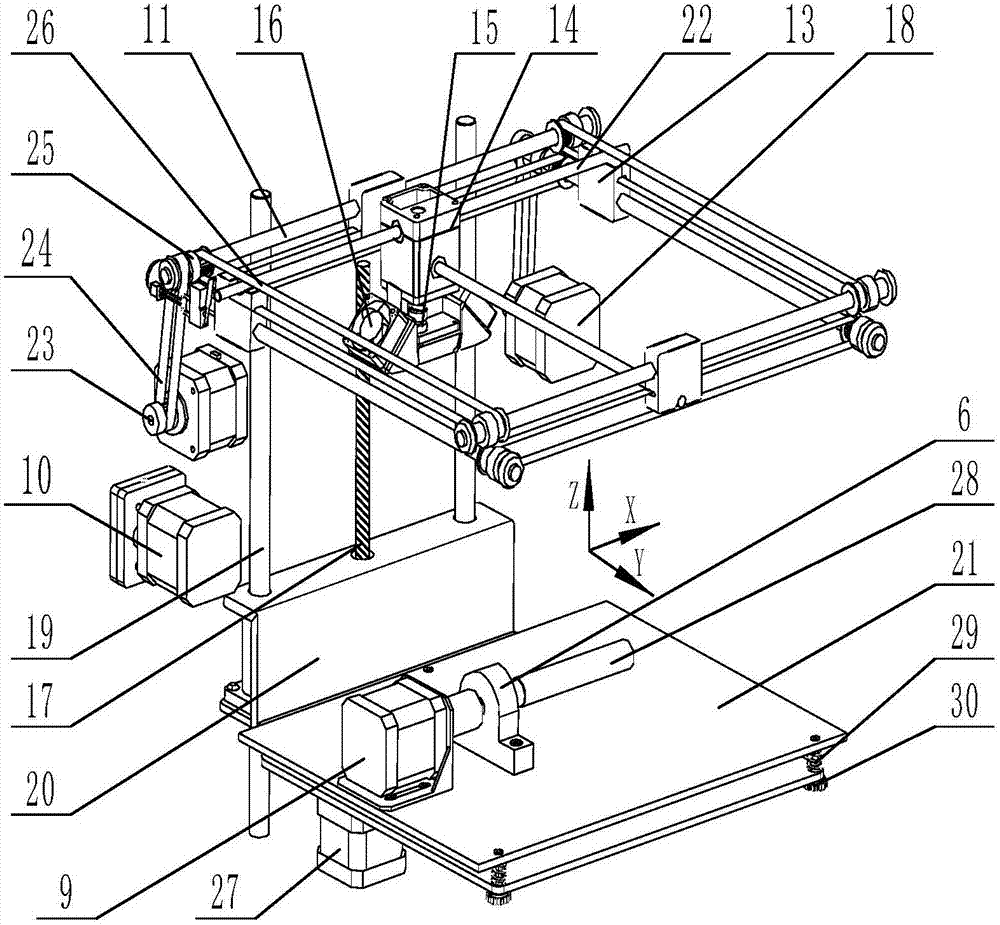

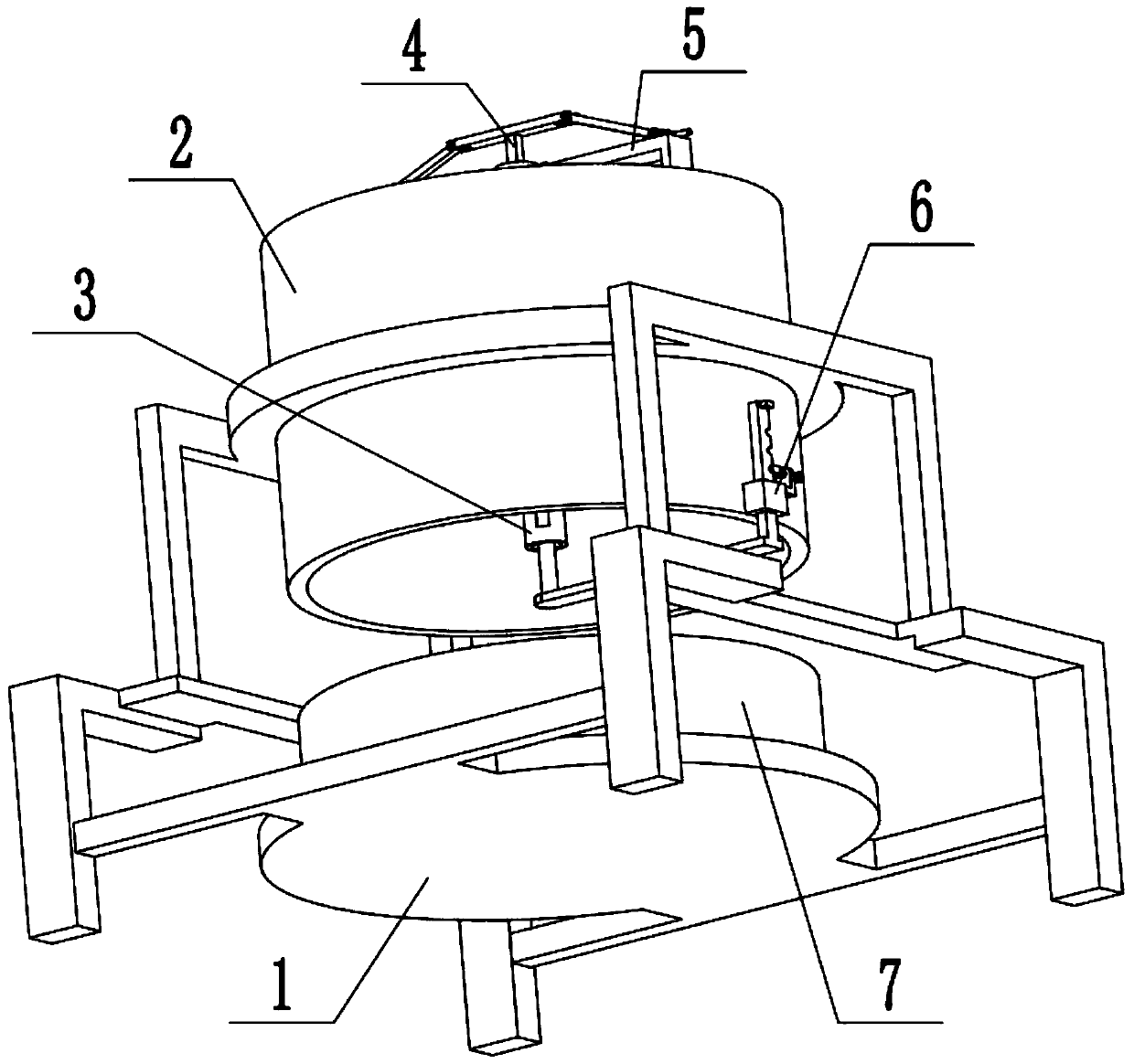

Four-axis linkage 3D printing device based on fusion deposition principle

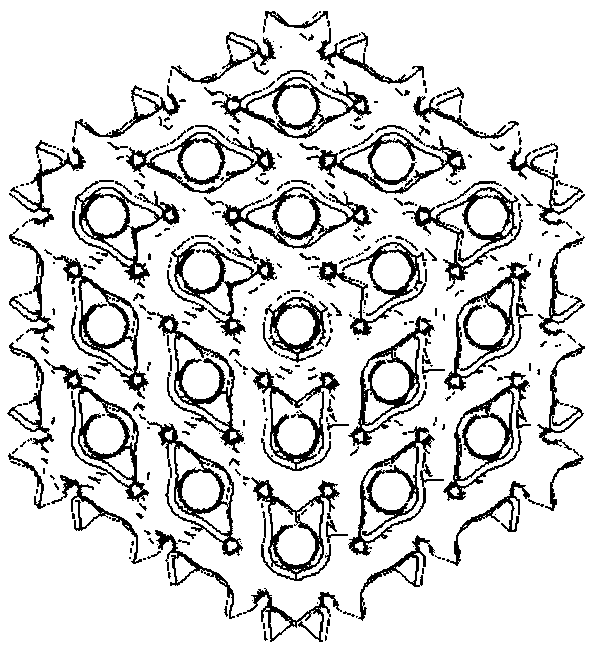

InactiveCN106985379AEasy to manufactureImprove molding rateManufacturing driving means3D object support structuresSprayerSurface mass

The invention discloses a four-axis linkage 3D printing device based on the fusion deposition principle, belongs to the field of 3D printing and manufacturing, and relates to the four-axis linkage 3D printing device based on the fusion deposition principle. The printing device is composed of a rack, a printing sprayer assembly, a control assembly, an X-axis drive assembly, a Y-axis drive assembly, a Z-axis drive assembly and an A-axis drive assembly. A shaft sleeve of the A-axis drive assembly can be detached and replaced, a series of shaft sleeves the same in inner diameter but different in outer diameter can be selected, and forming and manufacturing of pipe-shaped structure models different in inner diameter are conveniently achieved. By means of the printing device, a thin-wall pipe net-shaped structure can be conveniently prepared, any auxiliary supporting structure does not need to be additionally arranged in the printing process, the posttreatment and other complex operation processes are simplified, printing materials are saved, and the forming rate and surface quality of test piece printing are effectively improved. The A-axis drive assembly is flexible in control and easy and convenient to mount and dismount, a series of inner diameter test pieces can be formed by replacing the shaft sleeves of different outer diameters, and the four-axis linkage 3D printing device is simple, practical and easy to operate and popularize.

Owner:DALIAN UNIV OF TECH

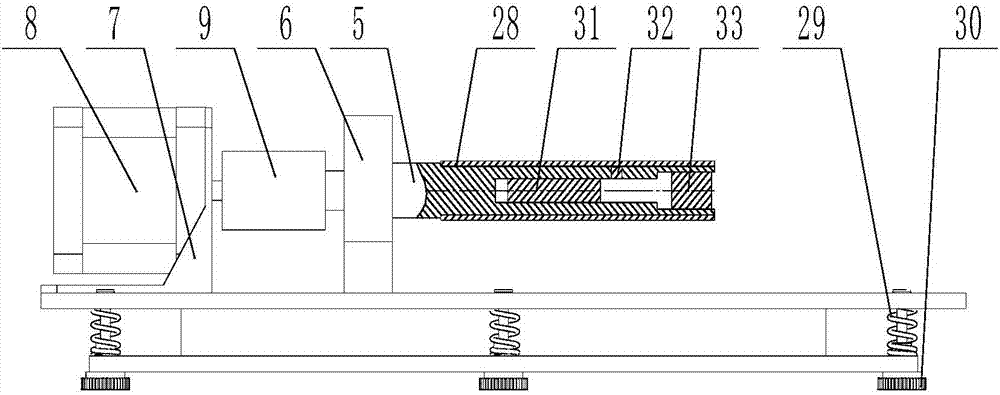

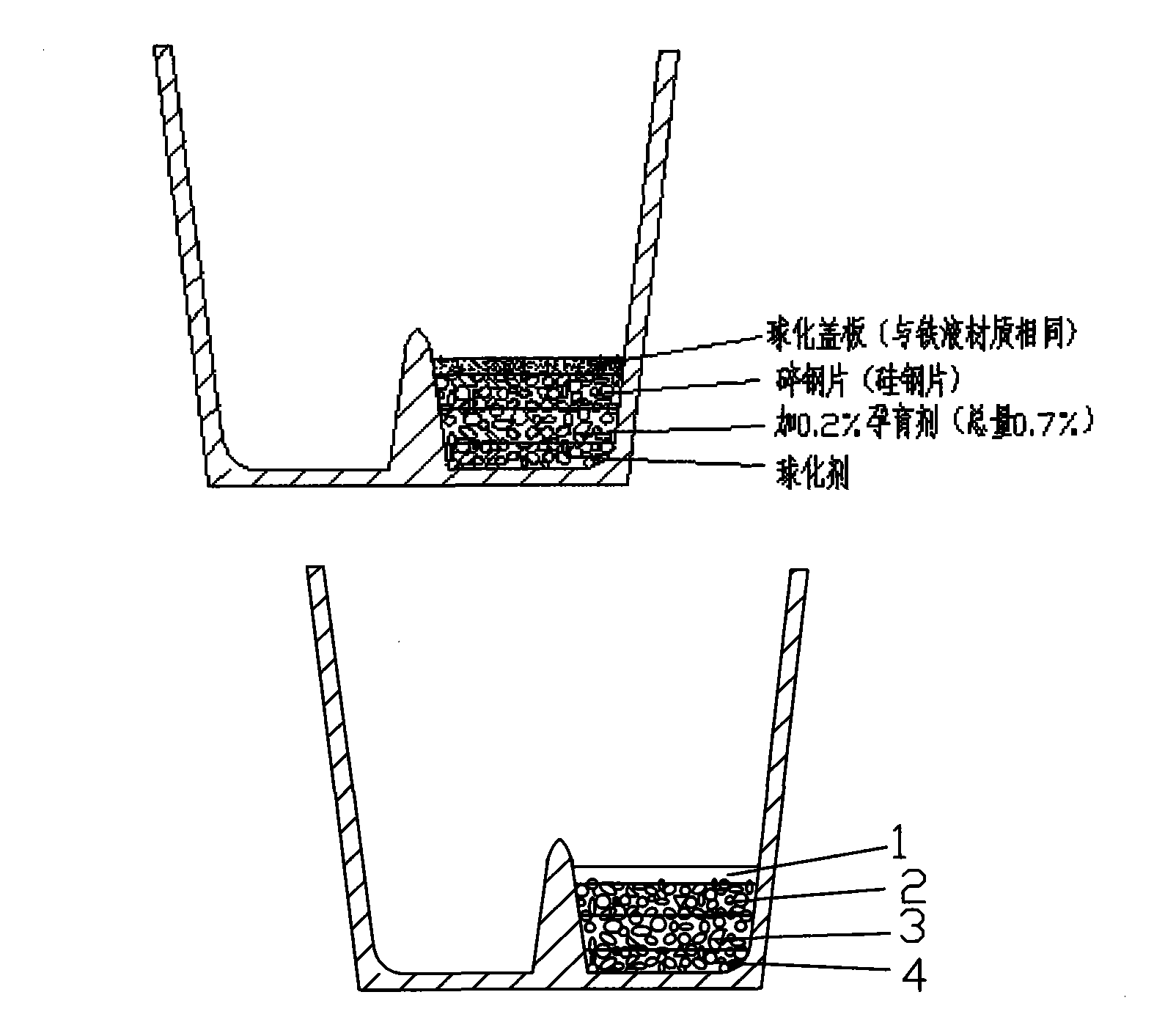

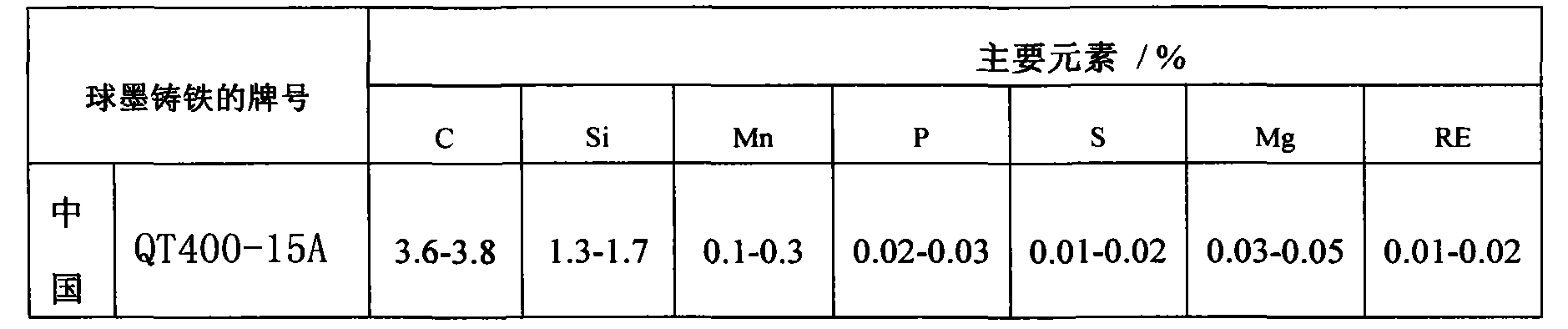

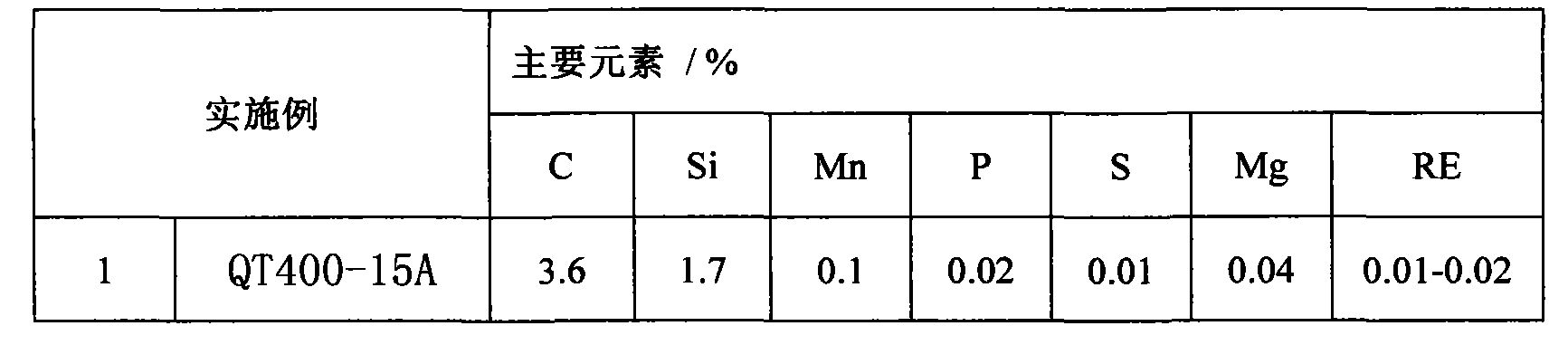

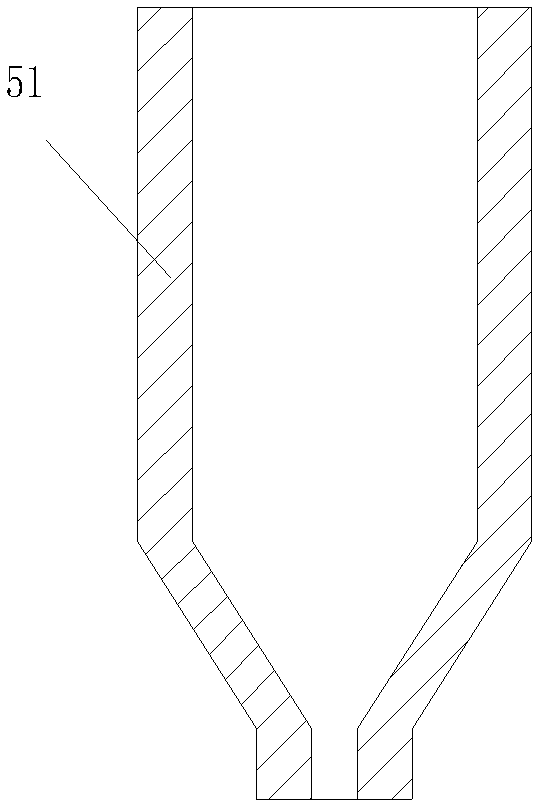

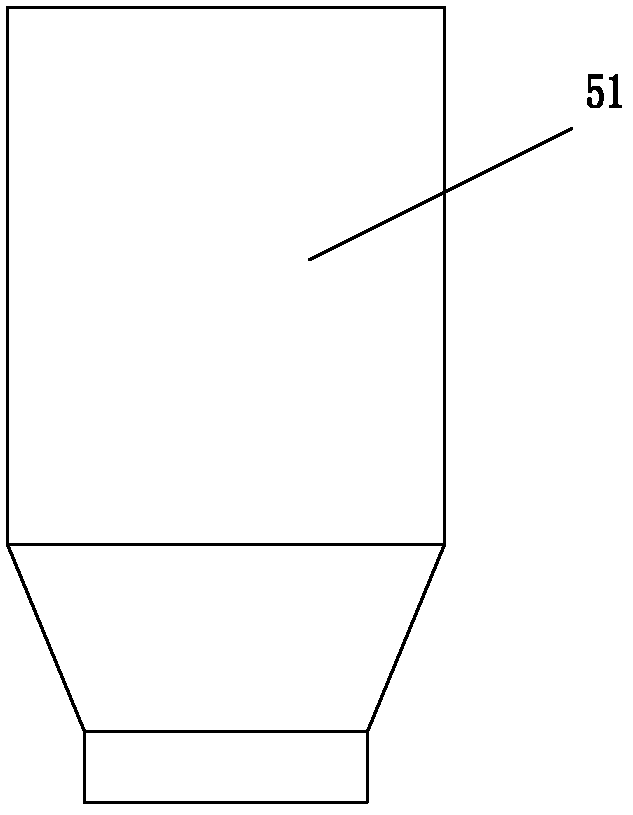

Method for integrally casting large-sized V-shaped diesel engine body by utilizing nodular cast iron

The invention discloses a method for integrally casting a more-than-25-ton large-sized diesel engine V-shaped body by utilizing nodular cast iron. The method comprises the following steps of A1, smelting the nodular cast iron in a smelting furnace, and adding bariumsili and metallurgical carborundum pretreatment agent after the smelting; A2, placing a spheroidizing agent into a bottommost layer of a dam-type spheroidizing ladle, utilizing a nucleating agent to cover a second layer, and utilizing a low-maganese low-alloy broken steel sheet to completely cover and compact a third layer; A3, adding a calcium-barium nucleating agent, charging the melted iron in one step to carry out the tapping metal-stream inoculation, realizing the nucleating effect while carrying out the spheroidizing treatment on charged melted iron, and carrying out the pouring pretreatment on the melted iron in the ladle; A4, placing the metal-stream inoculation agent into a funnel to carry out the pouring metal-stream inoculation; and A5, finally pouring the melted iron with the temperature being more than or equal to 1400 DEG C into a sand box, forming a cast by mold filling and solidifying the melted iron under the feeding of the feeder head liquid metal, and carrying out the heat treatment by utilizing the waste heat of the cast.

Owner:宜宾普什联动科技有限公司

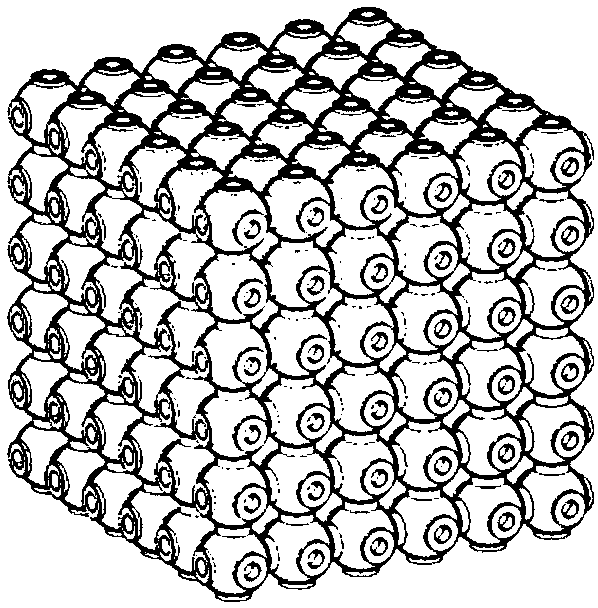

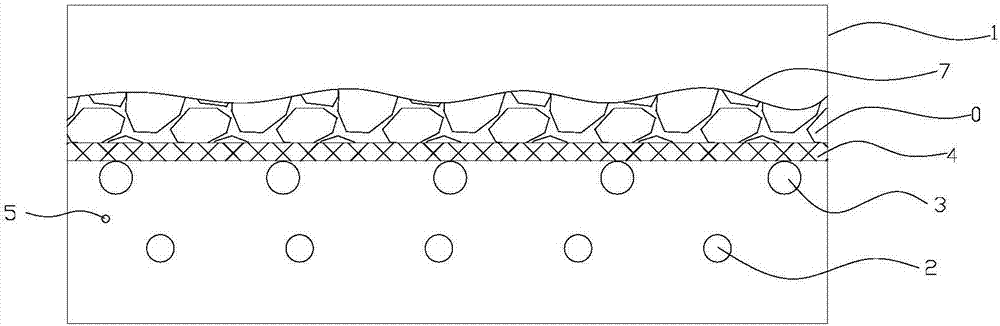

Preparation method of porous extremely small curved structure aluminum oxide ceramics based on 3D printing

InactiveCN109665819ALow integration costAccurateAdditive manufacturing apparatusCeramicwareSlurryHigh intensity

The invention relates to a preparation method of porous extremely small curved structure aluminum oxide ceramics based on 3D printing, which belongs to the field of 3D printing technology as well as porous ceramics, filtering, thermoengineering and the like. The DLP (digital photocuring ) 3D printing technology has the advantages of high forming speed, high printing model precision and low cost. The preparation method provided by the invention is implemented by virtue of the following software and devices. A three-dimensional model is designed and optimized by using rhinoceros and grasshopper,Q3DP software is guided into the model to perform the slicing, the slurry is prepared according to a specific ratio to perform the ball milling, the slurry is poured into a BESK printer resin tank tostart printing, a printed blank is degreased and sintered in a medium-sized furnace according to specific parameters, and finally the porous extremely small curved surface structure aluminum oxide ceramics with high strength, uniformity in arrangement, uniformity in aperture, stable performance and high orderliness can be obtained.

Owner:BEIJING UNIV OF TECH

1100-O state aluminum alloy strip for capacitor housing and production method thereof

The invention discloses a 1100-O state aluminum alloy strip for a capacitor housing and a production method thereof. The production method comprises the steps that firstly, various alloy components are prepared according to the composition ratios of the 1100-O state aluminum alloy strip, then the alloy components are sequentially smelted, statically refined and degassed, a grain refiner is added,filtration is carried out, then semi-continuous casting carried out to obtain ingots, the obtained ingots are sequentially subjected to homogenization heat treatment, hot rolling, cold rolling, intermediate annealing, cold rolling again to the thickness of a finished product, stretch bending straightening and cleaning, plate form stretching and slitting, and finally finished product annealing, inspection and packaging are carried out. The product obtained by using the technical scheme is high in dimensional accuracy, good in isotropy, high in molding rate, fine in surface crystal grain and fine and smooth in surface after deep drawing, and has less than or equal to 2.5% of ear-making rate. Therefore, the use requirements of the current market for high precision capacitor housings can be completely met.

Owner:河南明晟新材料科技有限公司

Chemical repairing agent for farmland soil Cd pollution

ActiveCN105567249ALow toxicityReduce absorptionAgriculture tools and machinesContaminated soil reclamationAmmonium sulfateHumic acid

The invention discloses a chemical repairing agent for farmland soil Cd pollution. The chemical repairing agent is prepared from the following raw materials of 10 to 30 parts of humic acid, 10 to 30 parts of ammonium sulfate, 10 to 30 parts of potassium dihydrogen phosphate, 10 to 15 parts of citric acid, 5 to 15 parts of disodium dihydrogen pyrophosphate, 5 to 10 parts of biosurfactant, 5 to 10 parts of Cd chemical antidote and 5 to 10 parts of bentonite in a mixing way. The chemical repairing agent disclosed by the invention can be uniformly applied into soil along with soil tillage, the application amount per mu is 40 kg to 50 kg, and then water can be irrigated after the soil is uniformly raked. Cd in the soil is enabled to form a more stable chelation state of enabling the Cd not easy to absorb and utilize by a plant through activation, chelation and adsorption, the Cd in the soil can be changed from small molecules into big molecules, passivation of the Cd in the soil is realized, the toxicity of the Cd is reduced, and the chemical repairing agent is suitable for Cd pollution chemical repairing of limy farmland soil.

Owner:山西大地民基生态环境股份有限公司 +1

Preparation method of effervescent tablets

InactiveCN105663078AImprove molding rateFast disintegrationDispersion deliveryPill deliveryOrganic filmPolymer science

The invention discloses a preparation method of effervescent tablets. Polyethylene glycol is heated and melted and then is diluted with ethanol, a polyethylene glycol-ethanol solution is formed and then coats an acid source and an alkaline source, and accordingly, acid-source granules coated with polyethylene glycol film layers and alkaline-source granules coated with polyethylene glycol film layers are formed; the acid-source granules and the alkaline-source granules are sufficiently mixed and stirred, a mixture is formed, an ethanol solution of polyvinylpyrrolidone K30 is added to the mixture for secondary coating, a product is crushed after being dried, and effervescent granules coated with double organic film layers are obtained after uniform mixing; main medicine ingredients of a medicine and other acceptable excipients used for preparation of the effervescent tablets are added to the effervescent granules, and the effervescent tablet preparations are obtained through tableting after sufficient mixing. The prepared effervescent tablets are not prone to moisture absorption and deterioration and have good flowability; the forming rate is high, and sticking is avoided; the disintegration is fast. According to the method, adopted raw materials are cheap and easy to obtain, the method is simple, pollution-free and harmless to a human body, has low requirements for equipment and has good application prospect, and industrial production is easily realized.

Owner:CENT SOUTH UNIV

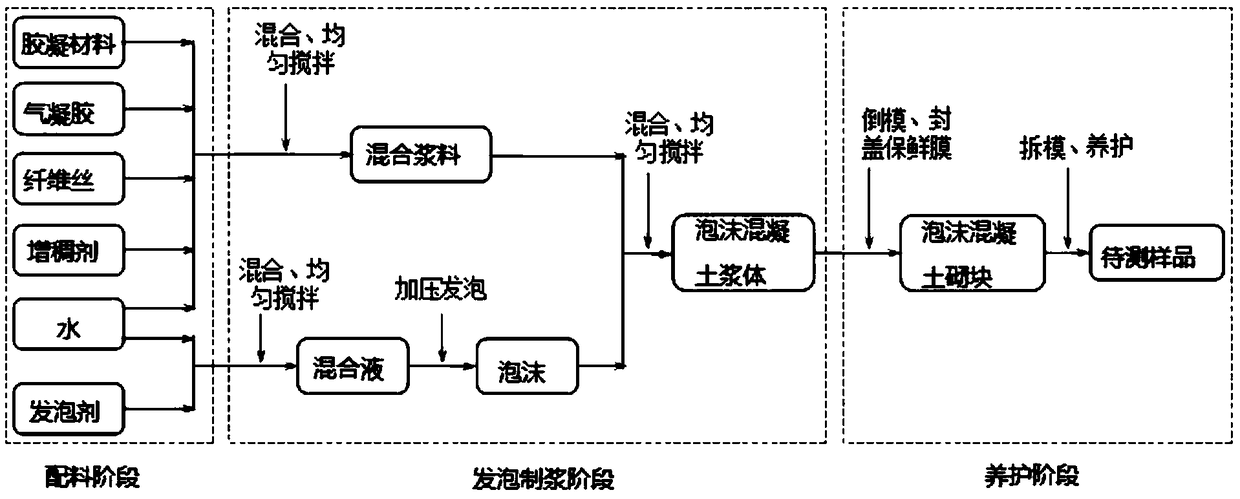

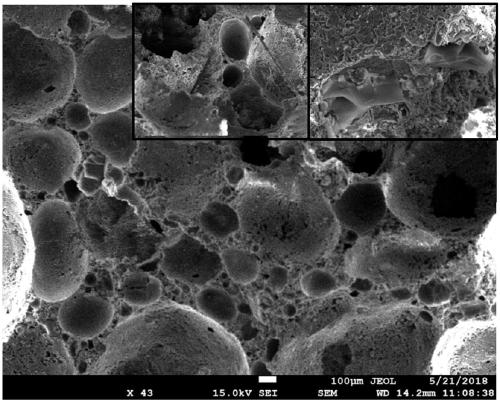

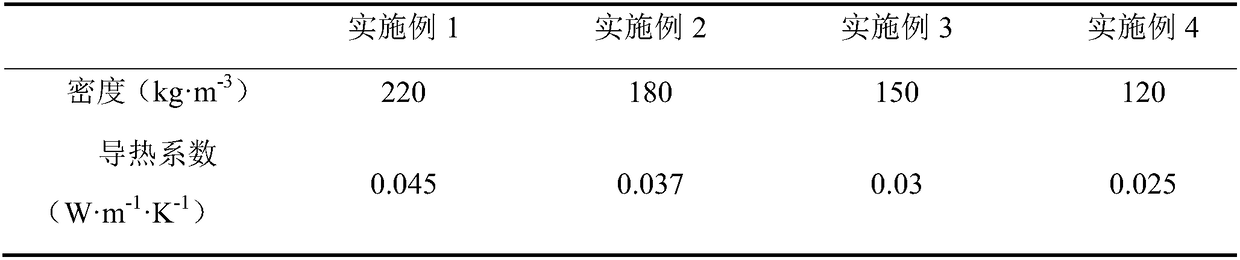

Fiber aerogel foam concrete, preparation method and application thereof

InactiveCN109231910AImproved stomatal distributionImprove mechanical propertiesCeramicwareFoam concreteFiber

The invention discloses fiber aerogel foam concrete, a preparation method and application thereof. The fiber aerogel foam concrete disclosed by the invention comprises the following raw materials: binding materials, aerogel powder, cellosilk, viscous water, a foaming agent and water, wherein the mass ratio of the binding materials to aerogel powder to cellosilk to viscous water is 1: (0.01-0.3):(0.001-0.01):(0.35-1); the particle size of the aerogel powder is smaller than 250 microns, the porosity is 80-99%, and the pore diameter is 10-50nm; the cellosilk is uniformly distributed, and the diameter is 10-50 microns. The fiber aerogel foam concrete disclosed by the invention has the advantages of ultralow density, ultralow heat conductivity and excellent thermal insulation, can be applied tothe fields of thermal insulation of building walls, road filling, barrier sound insulation, and has wide application prospect.

Owner:GUANGZHOU UNIVERSITY

Granular fuel with crop straw and production thereof

InactiveCN1746274AWide range of materialsSimple processSolid fuelsWaste based fuelHigh densityEngineering

A crop straw particle fuel and its production are disclosed. The fuel is prepared by drying crop or plant waste under moisture content 16%, crushing them into powder with grain size under 8mm from side-rub multifunctional crusher, mixing one material or several materials with water, steam vaporizing, compression forming from special straw granulating flat die machine, cooling, and packing into particle fuel of which grain size is 6-9mm, length is 20-30mm and moisture content <=14wt%. Its advantages include low cost, high density, heat value and forming rate, simple process and no environmental pollution.

Owner:张建超

Method for improving formability of high-strength aluminum alloy powder for 3D printing

InactiveCN111360257AHigh strengthLow costAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingLaser scanning

The invention discloses a method for improving formability of high-strength aluminum alloy powder for 3D printing. The method comprises the following steps that the Al-Mg-Sc-series high-strength aluminum alloy powder is prepared by using a gas atomization method in a selective laser melting forming device, wherein alloy comprises the following components of, in percentage by mass, 3%-6% of Mg, 0.1%-2% of Sc, 0.1%-0.8% of Zr, 0.2%-1% of Mn, and the balance Al. By optimizing the forming process, that is, adjusting the sintering strategy, the single-layer sintering energy density is reduced, andthe sheet layer thickness is increased to 0.04-0.07 mm; and by adopting a layer-by-layer independent sintering mode, that is, performing two-time laser scanning on single-layer alloy powder, and through second laser scanning, the alloy surface solidified after first laser scanning can be remelted, so that the non-penetration phenomenon caused by single scanning is avoided, holes and cracks in a formed part are effectively reduced, the forming rate of a workpiece is improved, and finally, the high-strength aluminum alloy workpiece with excellent comprehensive performance is obtained.

Owner:COMAC +1

Green-shell egg layer ecological culture method

InactiveCN106212374AImprove body immunityIncrease egg productionFood processingBiofuelsNutrient contentEgg laying

The invention relates to the farm animal husbandry culture field, and especially relates to a green-shell egg layer ecological culture method characterized by comprising the following steps: 1, baby chick selection and brood chamber management; 2, breeding management; 3, egg laying house management; 4, egg laying period feeding management; 5, epidemic prevention health management; 6, chicken manure recovery utilization. The method raises egg layers in a grassplot and a Chinese herbal medicine plot in turns, thus providing rich nutrition components for green-shell egg layers, and realizing large scale ecological farming; the farmed green-shell egg layer is rich in nutrients, high in egg yield, and the egg is rich in nutrient compositions; in addition, the method can realize low carbon processing of chicken manure so as to prepare biomass fuels, thus realizing cycle utilization of the chicken manure, and reducing farming cost.

Owner:广西陆川县润润养殖有限公司

Areca nut cutter

InactiveCN103009413AWon't cutIncrease productivityMetal working apparatusStructural engineeringMechanical engineering

The invention provides an areca nut cutter. A corresponding areca nut gripper is disposed on a gripper base plate which is disposed on a chain. A base comprises a movable block arranging part and an areca nut arranging part. The movable block arranging part is a square groove. A lengthened retainer is on the inner wall of each two sides of the right end of the square groove. The areca nut arranging part is a semi-ellipsoidal groove, a cutter groove which transversely penetrates the semi-ellipsoidal groove is reserved on the semi-ellipsoidal groove, and a vertical through hole is reserved at the center of the semi-ellipsoidal groove. A movable block is disposed on the movable block arranging part of the base, and a spring is disposed in a left side middle hole of the movable block. Areca nuts can be placed at different angles without loosening according to different shaping requirements of different areca nut products and cut into different shapes, the shaping requirements of various products are completely satisfied, high production efficiency is achieved, cut of fingers can be avoided, and the cut areca nut is uniform, attractive and high in shaping rate.

Owner:杨支钢

Method and system of producing molded coal by coking organic castoff and weakly caking coal

The invention provides the method for producing molded coal with coking organic waste and baking coal. The method uses coking organic waste as binding agent, and then it is mixed with baking coal. The molded coal can be used as coking material. The method comprises baking coal breaker, coal dashpot, coking organic waste stirring device, coking organic waste dashpot, preliminary hybrid arrangement, homogeneous hybrid arrangement, and forming machine. The invention has the advantages of intimate mixing, high forming, solving environmental pollution, improving coke quality, save cost.

Owner:SHOUGANG CORPORATION

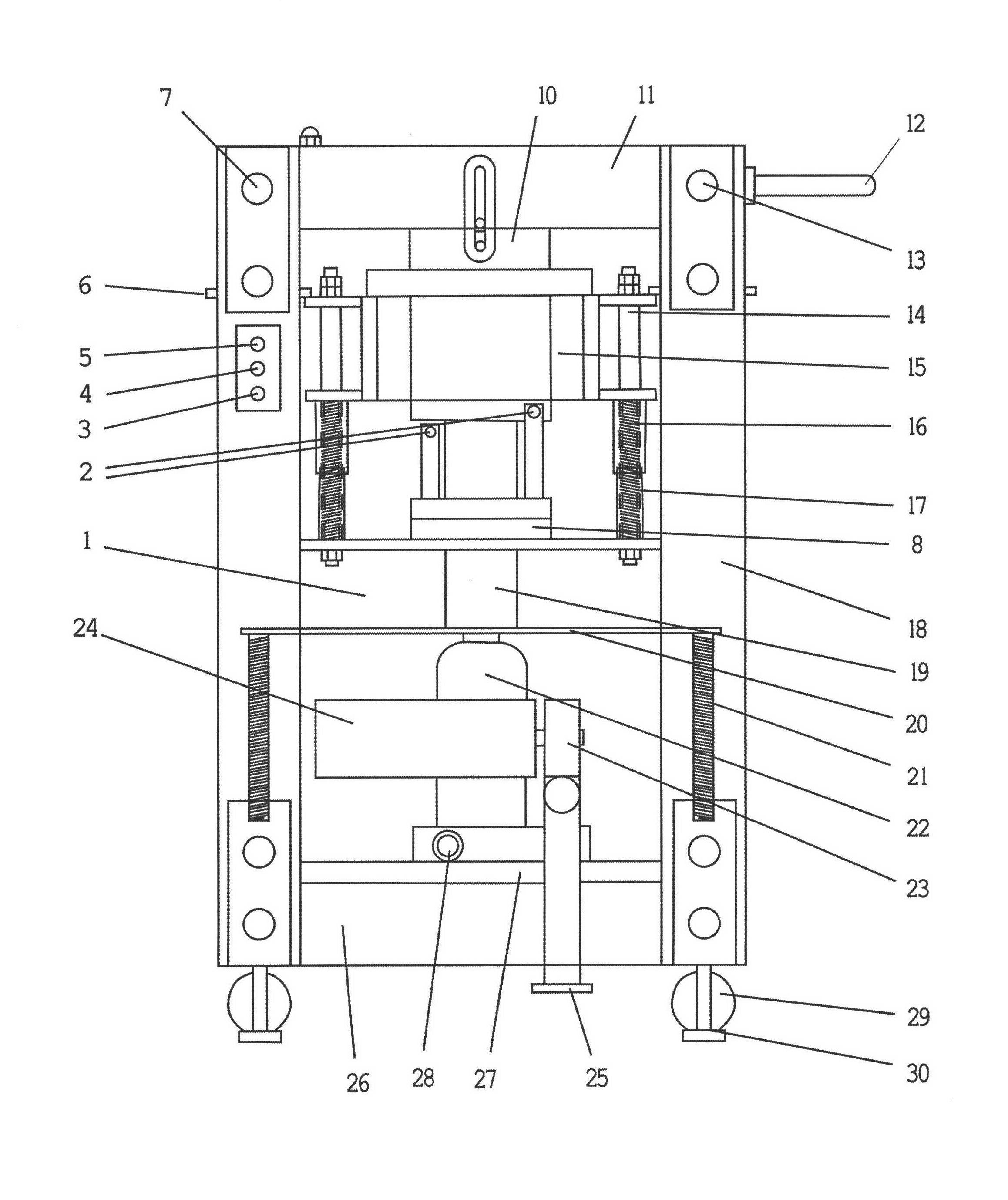

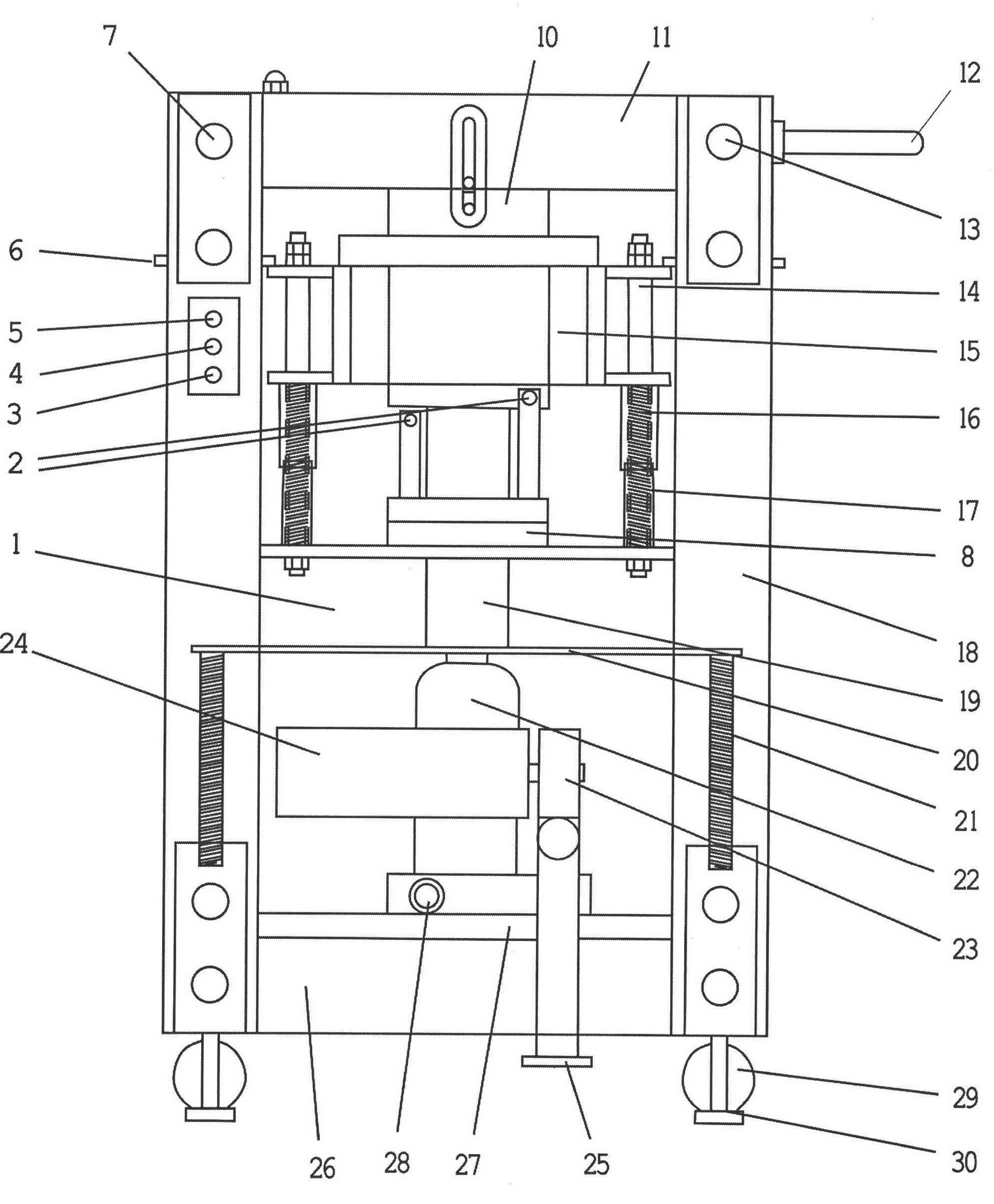

Semi-automatic tea wafer machine and tea wafering process

The invention provides a semi-automatic tea wafer machine, comprising a machine body, four columns 18, a lower principal thick bearing plate 26, a supporting plate 27, a jack 22 on the supporting plate, a motor 24 and a transmission cam 23, a pedal 25, a lift sliding panel 20, an oil-way switch 28, a draw spring 21, a lift sliding column 19, a fixed die supporting plate 9, a lift die supporting plate 8, a die slider 14, a spring 17 and a spring sleeve 16 that are arranged on the die slider, two dead levers with different heights and an inductor 2 that are arranged on the fixed die supporting plate 9, a die 15 and a spacer pin 6 that are arranged on the die slider, an upper and principal thick bearing plate 11 and a die cover press plate, etc. A tea wafering process using the semi-automatic tea wafer machine comprises steps of: installing the die; loading teas into the die; wafering a tea cake; and resetting the die. The semi-automatic tea wafer machine of the invention has a simple structure, easy operation, uniform pressure, good wafering effect and high moulding rate and is capable of wafering high-quality tea cakes.

Owner:GUANGXI WUZHOU MAOSHENG TEA IND

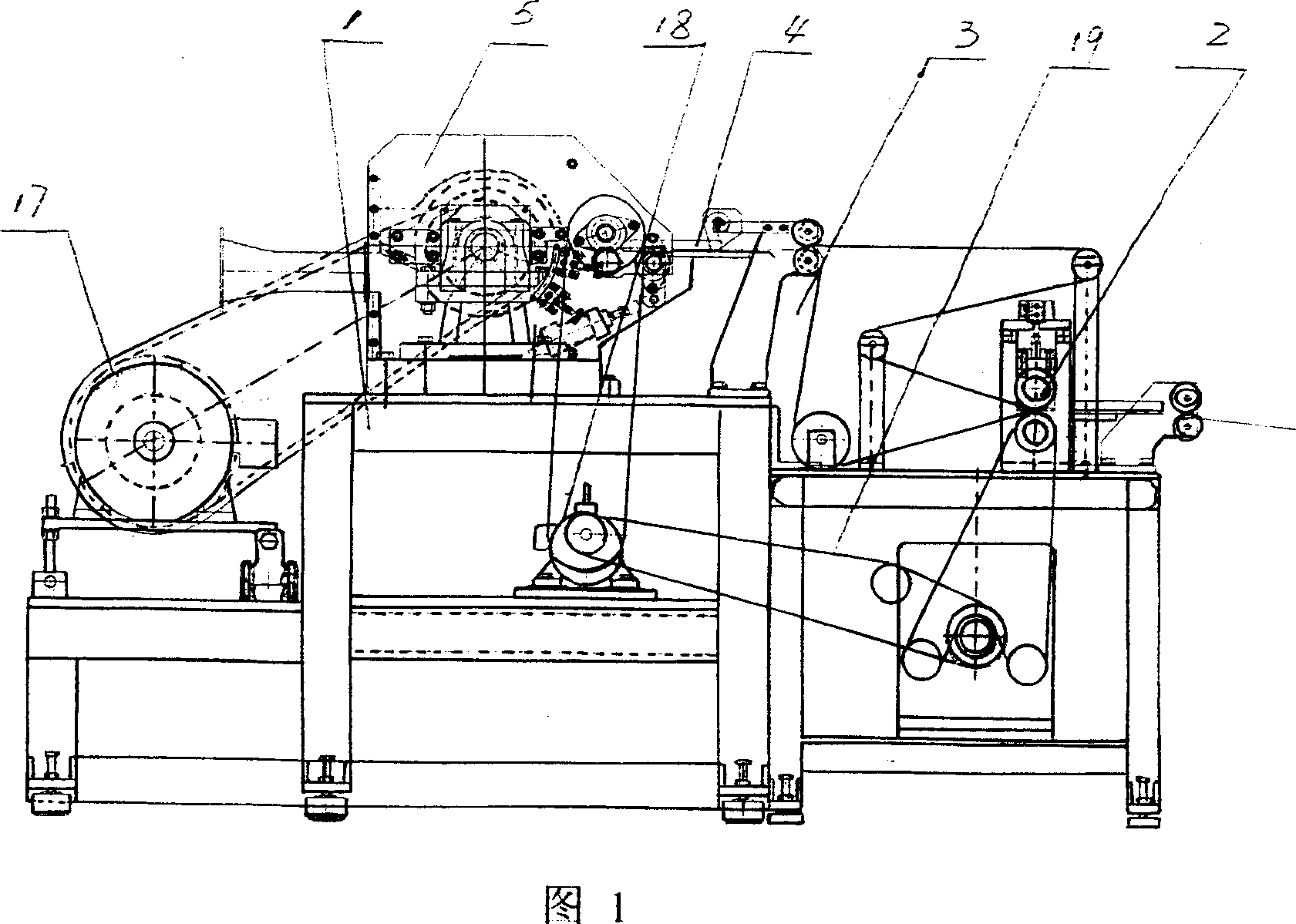

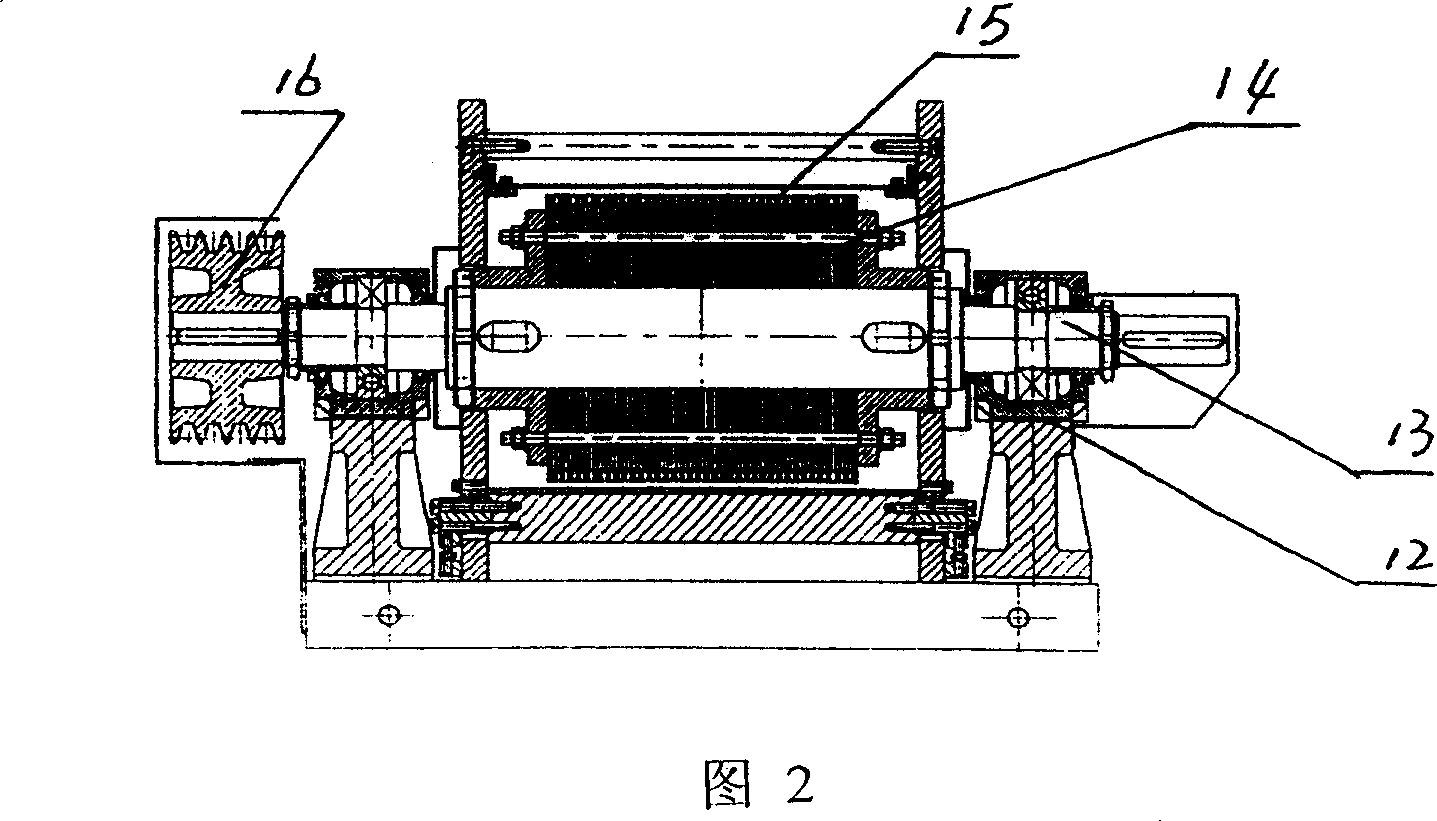

Fibre decomposite and fibre de-composition apparatus

This invention relates to fiber solute body and its machine for producing treatment, half treatment and un-treatment pulp slurry. The fiber solute body is on the materials shelf, pulpboard folding agencies is in the front of double feed month, slitting knife assembly is in the in the front of pulpboard folding agencies, both the slitting knife assembly and pulpboard folding agencies are on the materials shelf. The motor in slitting knife assembly is driven by transportation agency, the knife in slitting knife assembly is driven by Drive agency, the slitting plate is sent to pulpboard folding agencies by the transportation agencies, and then to be made into a double-decker by pulpboard folding agencies, finally be sent to the fiber solute body by feeding assembly to solute fiber. The advantages are as follows: Firstly, effectively reduce dust pollution to achieve the purpose of environmental protection; secondly, not only reduce the volume of fiber, and greatly reduced the consumption of electric power; thirdly, not only improve its crushing capacity, but also significantly reduces vibration noise, raise its forming rate.

Owner:HANGZHOU XINYUHONG INTELLIGENT EQUIP CO LTD

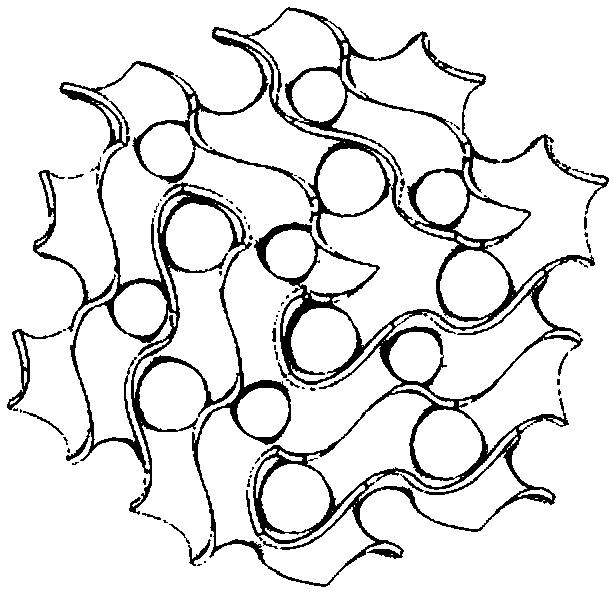

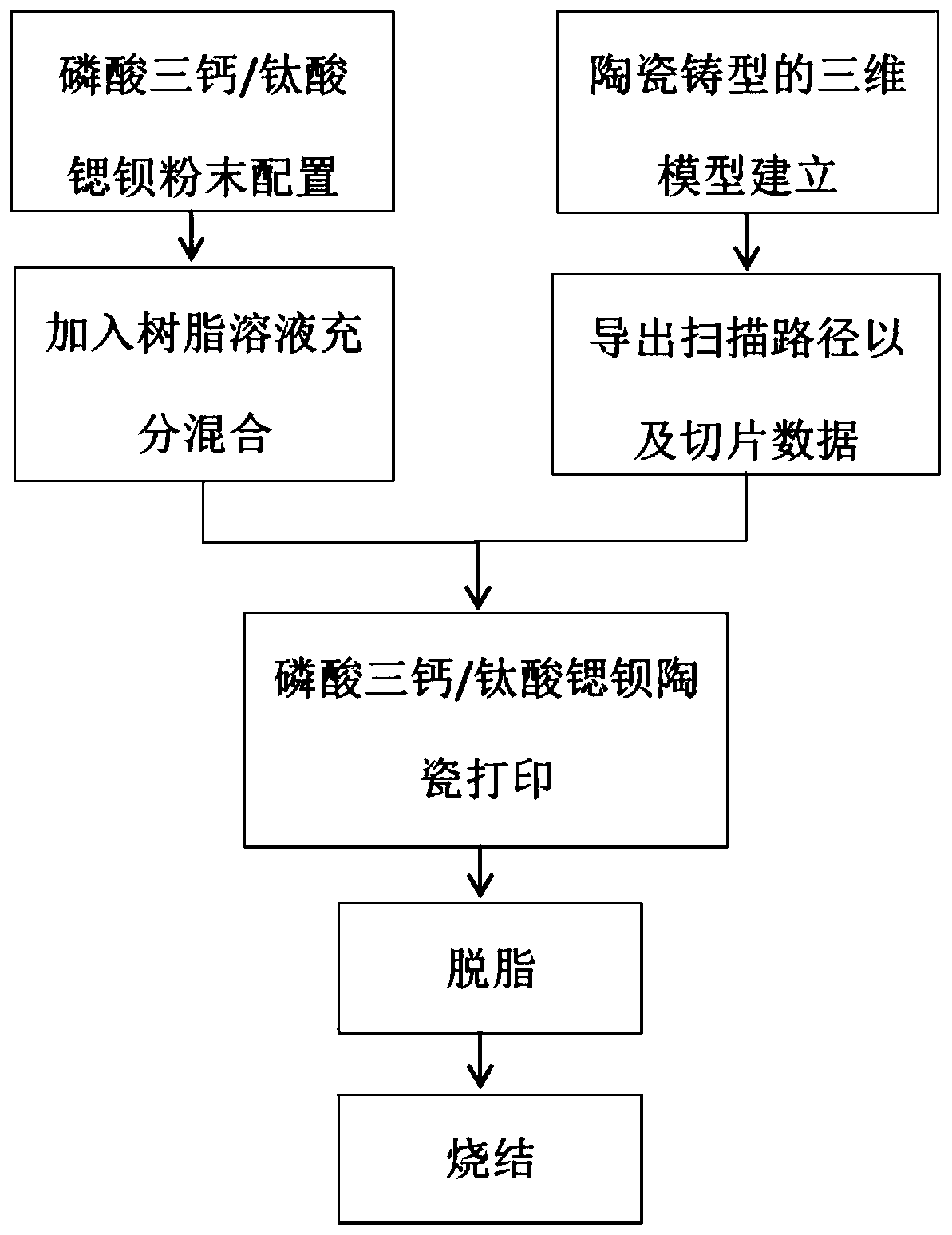

Method for preparing tricalcium phosphate/barium strontium titanate composite biological ceramic with minimum curved surface structures on basis of 3D (three-dimensional) printing technologies

ActiveCN109734434AImprove high temperature stabilityImprove antioxidant capacityAdditive manufacturing apparatusCeramic shaping apparatusBarium strontium titanatePhosphate

The invention discloses a method for preparing tricalcium phosphate / barium strontium titanate composite ceramic with minimum curved surface structures by means of 3D (three-dimensional) printing, andbelongs to the field of 3D printing technologies and biological ceramic. Compositions for the tricalcium phosphate / barium strontium titanate composite ceramic mainly include 35-70 vol% of tricalcium phosphate / barium strontium titanate composite ceramic powder and 30-65 vol% of photosensitive resin premixed liquid. The method has the advantages that DLP (digital light processing) (digital light curing) 3D printing technologies are high in forming speed and printing model precision and low in cost; Rhino software designs are used, minimum curved surface models are optimized, models are importedinto Q3DP software, scanning data are sliced and exported, slurry is prepared according to certain proportions, ball-milling is carried out, the slurry is led into resin grooves of BESK printers, printing is started, printed bodies are further placed into medium-sized furnaces to be degreased and sintered, accordingly, the tricalcium phosphate / barium strontium titanate composite ceramic with the stable structure, excellent mechanical properties, piezoelectric properties and biocompatibility can be ultimately obtained, and the like.

Owner:BEIJING UNIV OF TECH

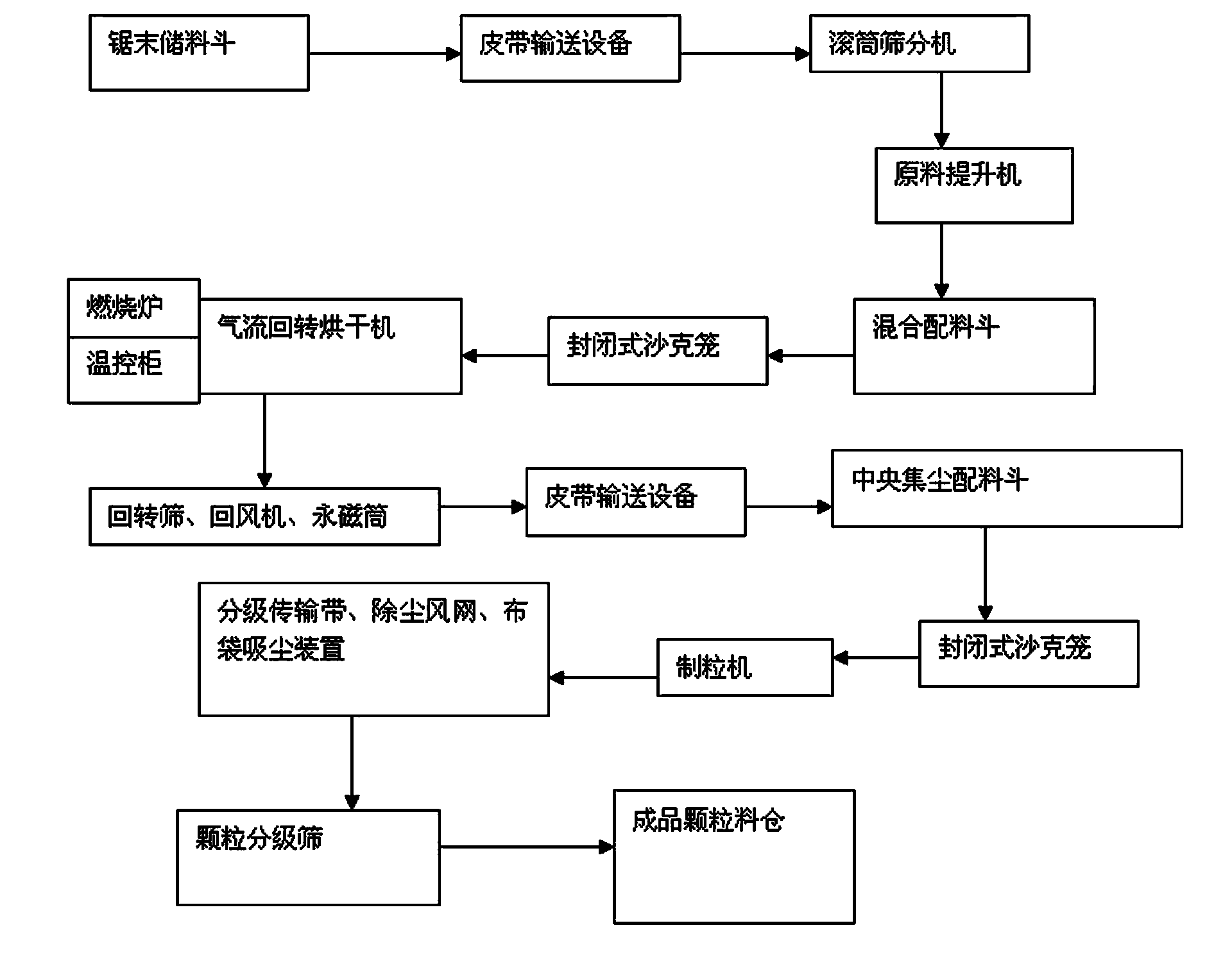

Production technique of pure cedar biomass granular fuel

The invention relates to a production technique of a pure cedar biomass granular fuel, which comprises the following steps: screening cedar sawdust, mixing materials, drying, cooling, carrying out secondary mixing on the mixture and cedar shavings, and granulating to obtain the finished product. The technique provided by the invention has the advantages of simpleness, less generated dust, high forming ratio and high yield; and the prepared biomass granular fuel has the advantages of high heating value, low slagging tendency, wide raw material resources and low production cost.

Owner:蓬溪县天桥木业有限公司

Pre-pressing forming and intensified sintering method of fine iron ore concentrate

The invention relates to a pre-pressing forming and intensified sintering method of fine iron ore concentrate. The pre-pressing forming and intensified sintering method comprises the following steps of: firstly, mixing fine iron ore concentrate with calcined lime uniformly, and forming into cylindrical material particles through pre-pressing by a high pressure roller forming machine; then, mixing the cylindrical material particles with other sintering raw materials to form a mixture, and arranging, igniting and sintering sintering material particles after the sintering material particles are prepared inside a cylindrical nodulizer so as to obtain agglomerate. The key of the method is as follows: the iron ore concentrate is processed through pre-pressing forming, material difficult to pelletize is forced to be formed through strong external force effect, the size composition of the mixture is improved, and the mixture is palletized together with other mixtures so as to improve the air permeability of sintering material layer; the sintering performance and metallurgical performance of the fine iron ore concentrate are improved so as to intensify the sintering; and under the condition of keeping the quality of sintering ore, the sintering ore yield and iron grade are improved, the energy consumption is reduced, and charging material with good quality is provided for intensifying blast furnace process.

Owner:CENT SOUTH UNIV

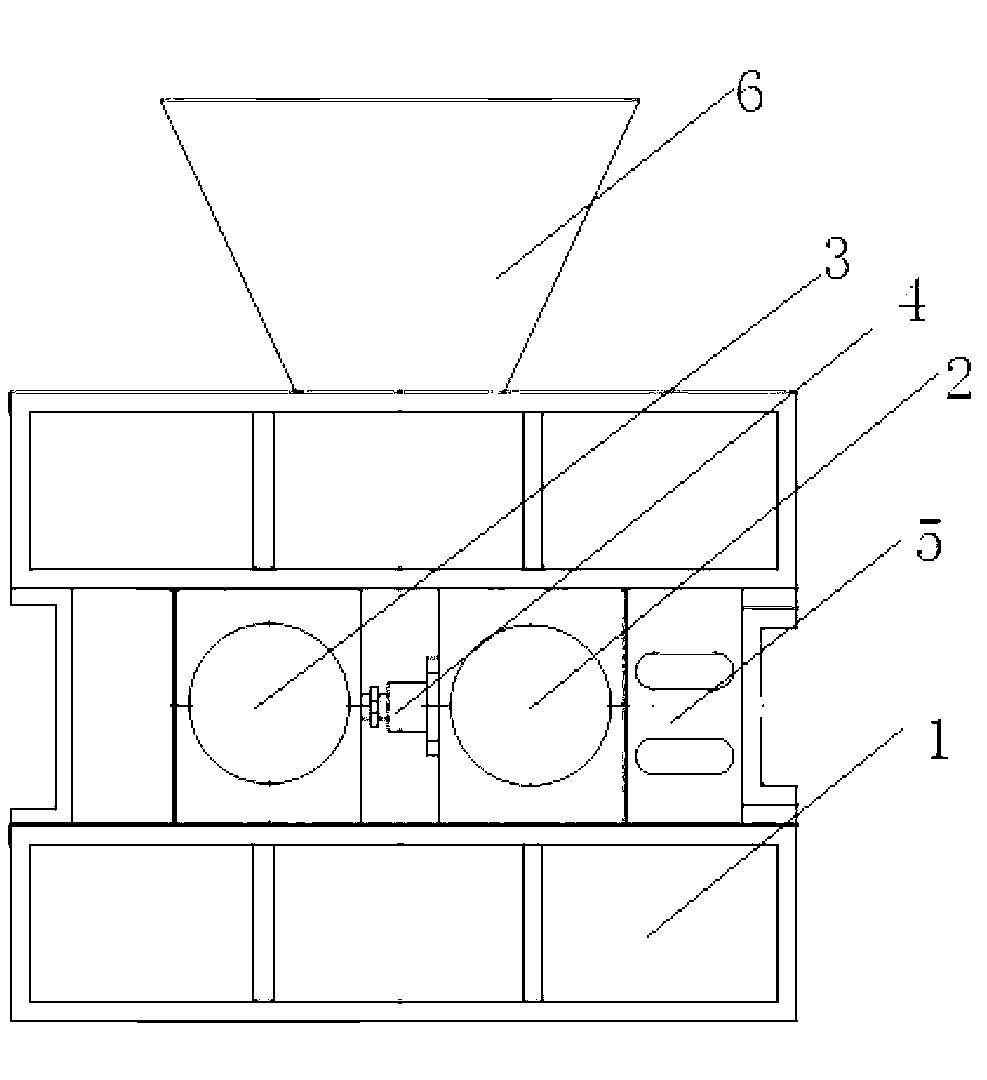

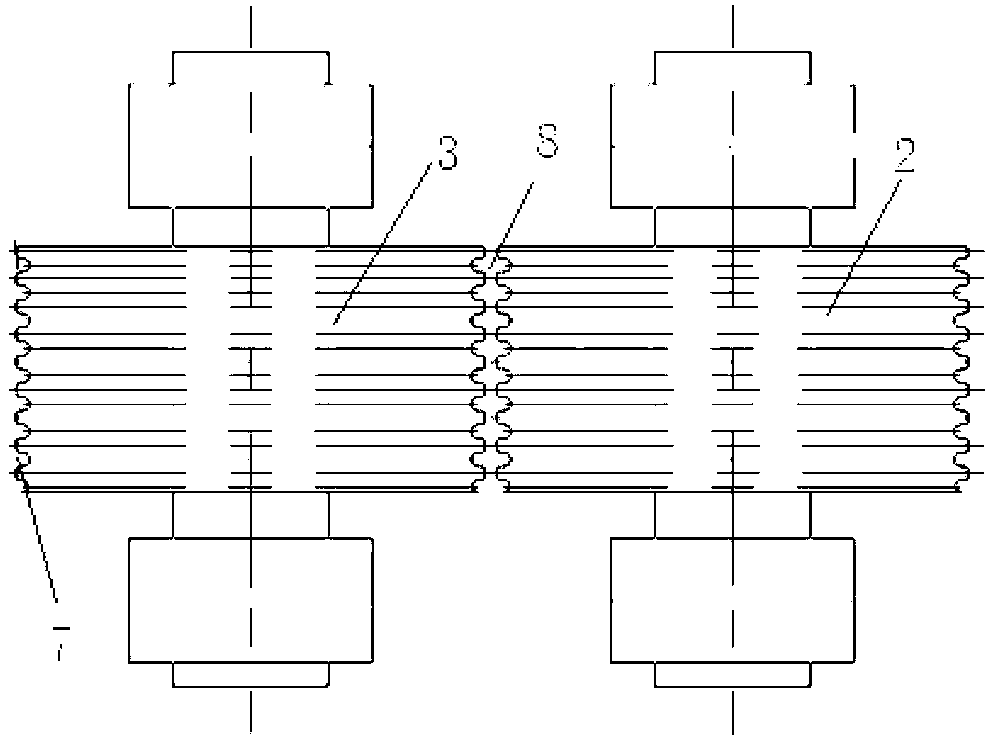

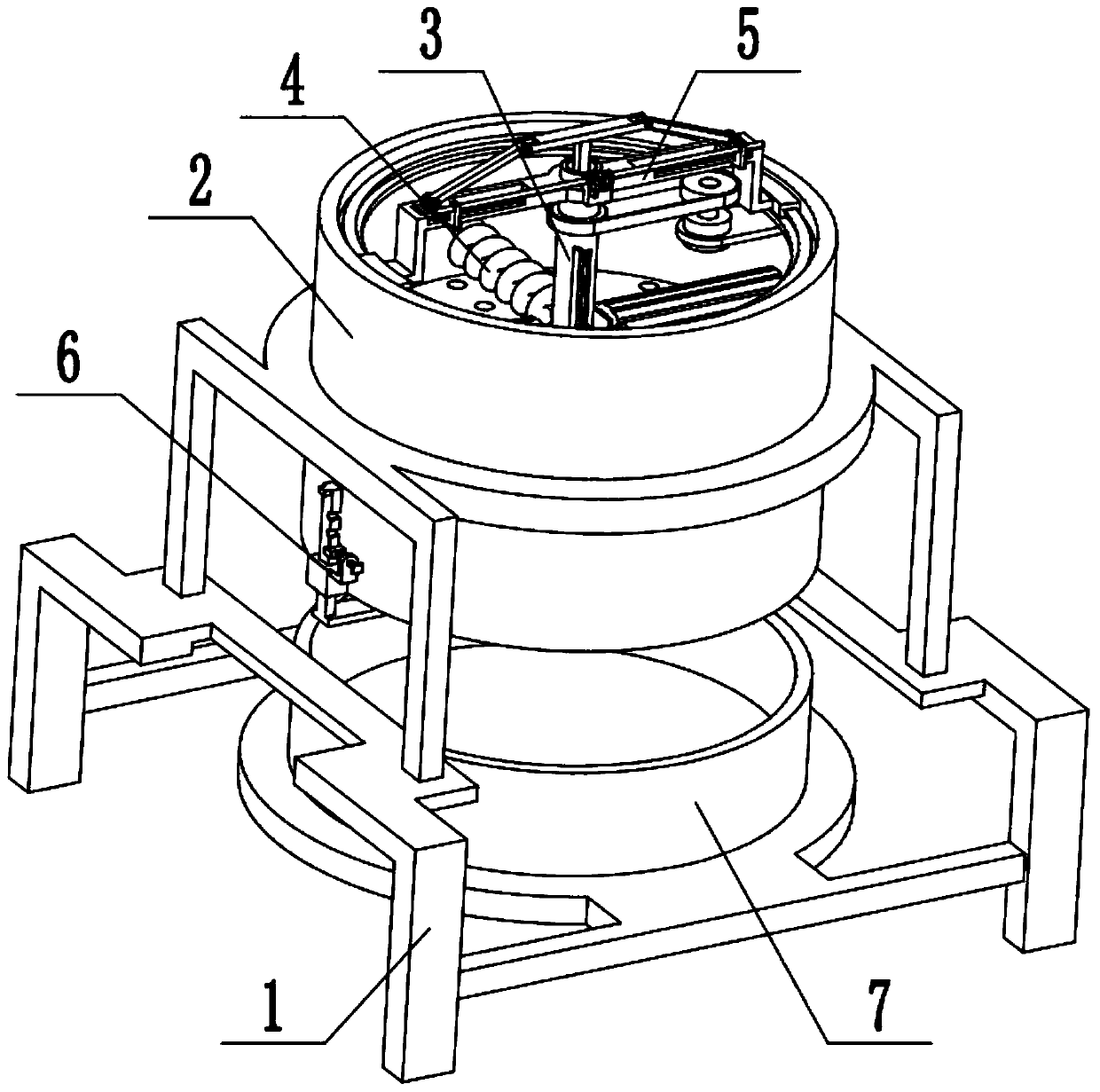

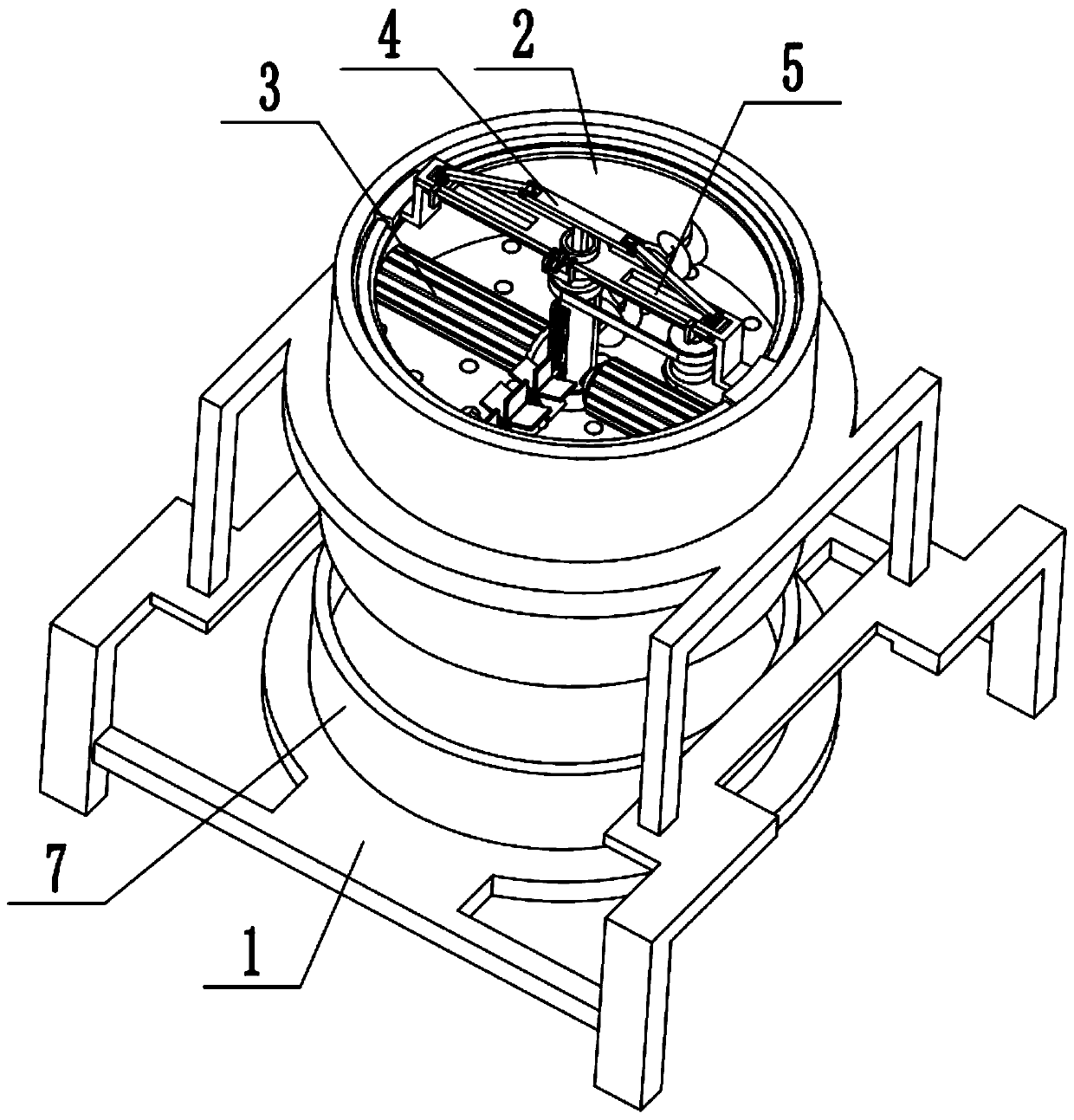

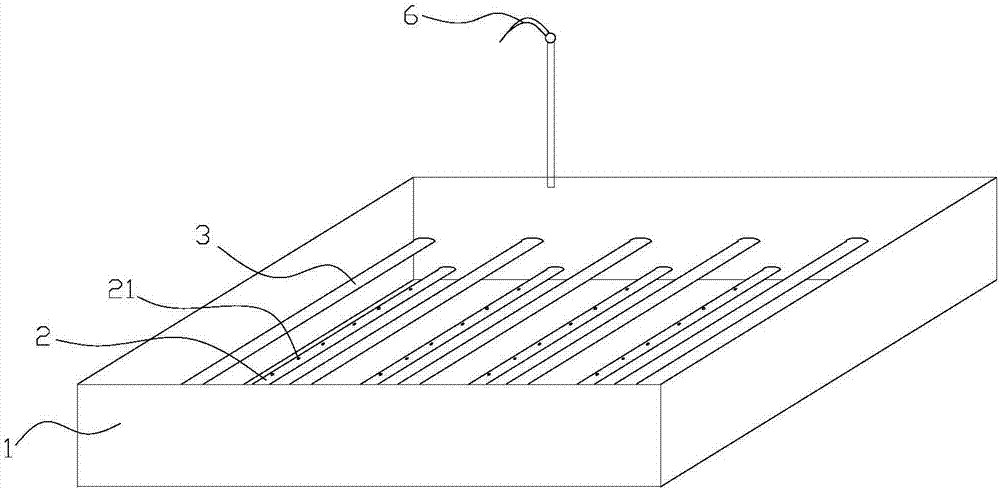

Biomass fuel particle and processing device and method thereof

ActiveCN110791349APrevent coagulationImprove the suppression effectShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to a biomass fuel particle and a processing device and method thereof. The biomass fuel particle is prepared from the components: 15 parts of rice husks, 25 parts of straw, 10 parts of wood scraps, 3 parts of corn cobs, 35 parts of rice and wheatgrass, 5 parts of tree roots, 35 parts of wood chips, 10 parts of bagasse, 5 parts of cottonseed shells, 3 parts of a dehydrator, 1part of pecan shells and 1 part of bamboo chips. The processing method includes the following steps that step 1, biomass fuel is put into a fuel processing cylinder; step 2, a reciprocating drive assembly starts to drive a stirring plate and a spiral stirring blade move up and down in a reciprocating mode, and the biomass fuel is rotated and stirred up and down in a reciprocating mode; step 3, a particle processing driving part starts to drive two pressing rollers to rotate, and the two pressing rollers extrude the biomass fuel from a circular through hole by the cooperation with a round holeseat plate; step 4, the particle processing driving part drives a cutting knife mechanism to rotate, and the rotary cutting knife mechanism cuts the extruded column-shaped biomass fuel into grain shape; and step 5, biomass fuel particles fall into a material receiving box to be collected.

Owner:吉林省尚心能源有限责任公司

Traditional Chinese medicine prescription granule preparation by melted extrusion method

InactiveCN101669974AImprove molding rateImprove liquidityGranular deliveryOil/fats/waxes non-active ingredientsPrillCompressibility

The invention relates to a melted extrusion method for preparing traditional Chinese medicine prescription granules, comprising the following steps: using an auxiliary material with a low melting point as a binding agent and evenly mixing with traditional Chinese medicine extract powder according to a certain ratio; placing the mixture in an extrusion pelletiser to prepare into granules in the extrusion process; straightening granules after cooling to obtain the traditional Chinese medicine prescription granules, wherein 40-70 DEG C is preferably used as the melting point or melting range of the low melting point auxiliary material; and the dosage ratio of the auxiliary material accounts for 10-40% of the total weight of the auxiliary material to the traditional Chinese medicine extract powder. The invention has higher molding efficiency, avoids the phenomena such as change of medicine tincture and active ingredients caused by repeated extrusion, weakened dissolubility and the like, thus especially being suitable for traditional Chinese medicine extract powder with poor viscosity and varieties such as fruit and seeds containing high fatty oil and starch, roots and tubers, parts offlowers and plants, leather and the like. The granules prepared by the invention have fine mobility, compressibility and dissolubility, and the granules prepared by using hydrophobic auxiliary materials have lower hygroscopicity.

Owner:JIANGYIN TIANJIANG PHARMA

Processing method and device for decoction pieces of dried roots of Changium smyrnioides Wolff

The invention discloses a processing method for decoction pieces of dried roots of Changium smyrnioides Wolff. The processing method comprises the steps of cleaning; sprinkle-moistening: putting dried roots of Changium smyrnioides Wolff on a partition plate with meshes and spraying water for sprinkle-moistening; steaming and moistening: carrying out steaming and moistening on the dried roots of Changium smyrnioides Wolff treated in the sprinkle-moistening step through steam at 40-60 DEG C and keeping for 2-4h; slicing: cutting the dried roots of Changium smyrnioides Wolff into pieces when being hot; and drying. By adopting a mode of combining sprinkle-moistening and steaming and moistening, the first-grade product molding rate is greatly improved and the decoction pieces are better in quality. The invention further provides a processing device for the decoction pieces of dried roots of Changium smyrnioides Wolff. According to the device, the first-grade product molding rate of the decoction pieces of dried roots of Changium smyrnioides Wolff can be effectively improved.

Owner:KANGMEI PHARMA

Method for preparing biomass pellet fuel by mulberry branch fermentation wastes

InactiveCN104845696AGood technical effectImprove molding rateBiofuelsSolid fuelsWoody plantCaloric values

The invention discloses a method for preparing biomass pellet fuel by mulberry branch fermentation wastes. The method comprises the following steps of crushing the mulberry branch fermentation wastes into 1 to 3mm, and crushing the woody plant leftovers into 3 to 6mm; uniformly stirring and mixing 5 to 40 parts of mulberry branch fermentation waste powder and 60 to 95 parts of woody plant leftover powder, heating and drying to the 14 to 25% of water content, and sending the dried material into a press roll type annular die to form. The method has the advantages that by mixing the mulberry branch fermentation wastes with low caloric value and the woody plant leftovers with high caloric value, the biomass raw material can be formed under the condition of lower aperture and length ratio of the annular die, the abrasion of the annular die is reduced, and the forming rate, product density, durability and lower caloric value of the pellet fuel can be effectively improved.

Owner:GUANGXI ACAD OF SCI +1

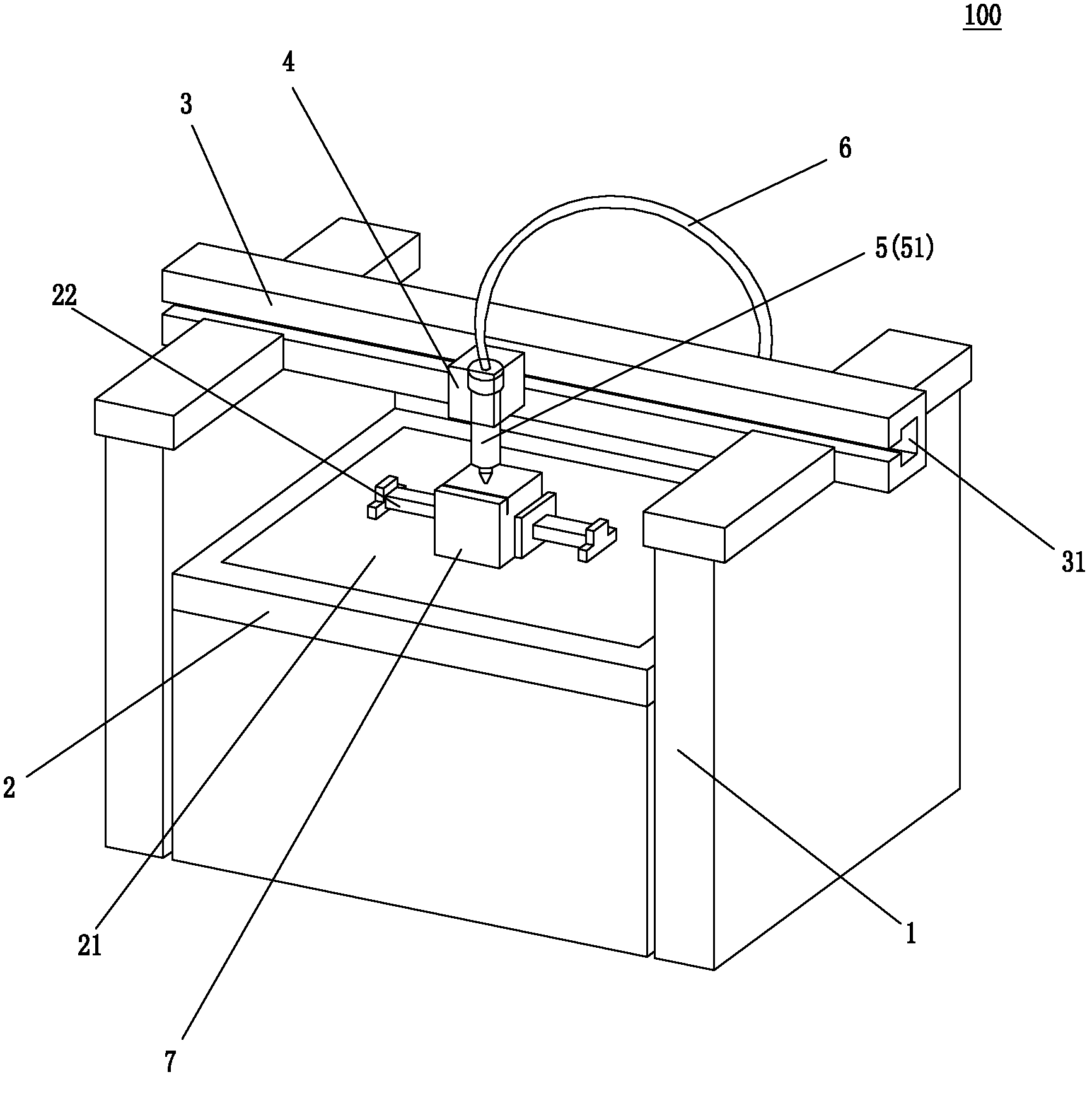

Coal sample preparation device for true three-dimensional permeability determination

InactiveCN102519769AReduced risk of breakageImprove molding ratePreparing sample for investigationStress concentrationJet flow

The invention relates to a coal sample preparation device for the true three-dimensional permeability determination. The preparation device comprises a fixed support, the fixed support is provided with a sample loading bench, and the sample loading bench is formed by a loading plane and a sample holder arranged on the loading plane; and a sliding guide rail is arranged over the sample loading bench, the sliding guide rail is slidingly provided with a sliding block, the sliding block is provided with a vertically downward jet nozzle, the jet nozzle is a flat seam nozzle, the flat seam of the flat seam nozzle and the sliding guide rail are arranged in a longitudinal parallel mode. The coal sample preparation device for the true three-dimensional permeability determination adopts the flat seam nozzle, so a jet flow jetted by the flat seam nozzle forms a plane type jet flow, and a stress concentration problem caused by the strong heterogeneity of the internal structure of coal can be maximally reduced, so the coal sample fragmentation risk is reduced, and the coal sample molding rate is improved; coal sample cutting is carried out in a plane type jet mode, so the cutting speed of a water jet flow is improved, thereby cutting surfaces are flattened, and the cutting effect is good.

Owner:CHINA UNITED COALBED METHANE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com