High-temperature pressure sensor and production method thereof

A pressure sensor, high temperature technology, used in chemical instruments and methods, lamination, instruments, etc., can solve problems such as pressure sensors not working properly, and achieve the effects of preventing cavity collapse, improving sensitivity, and improving molding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

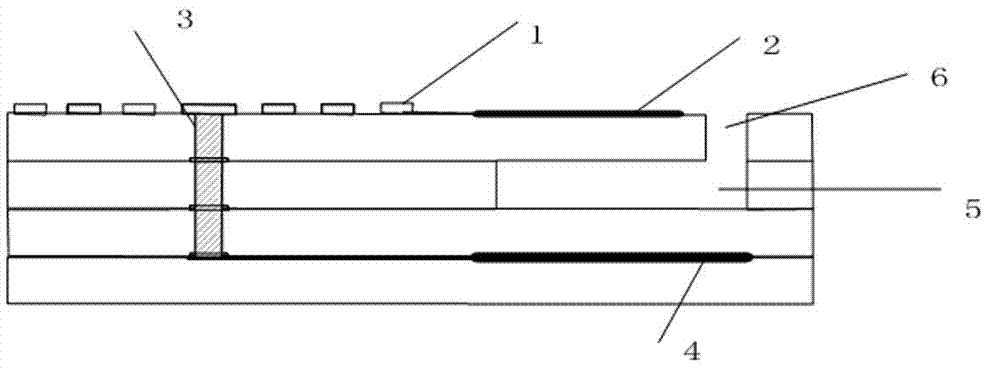

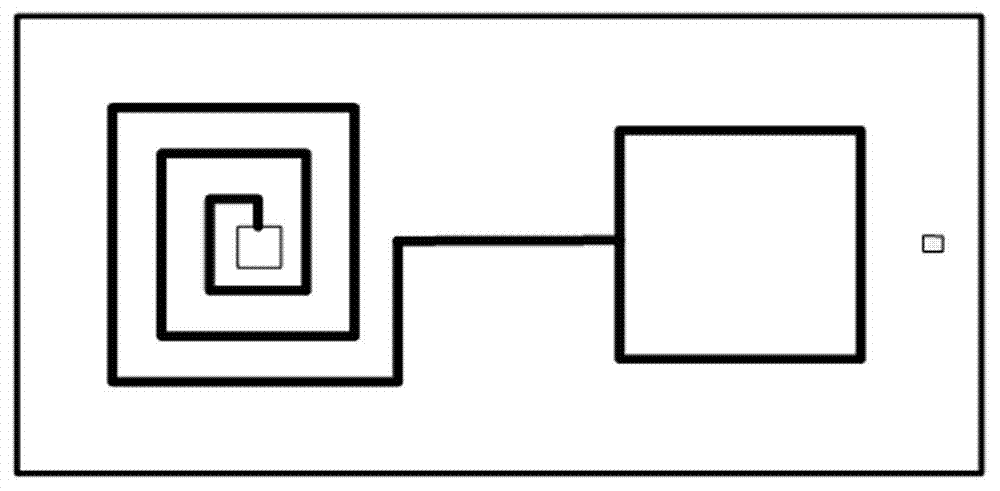

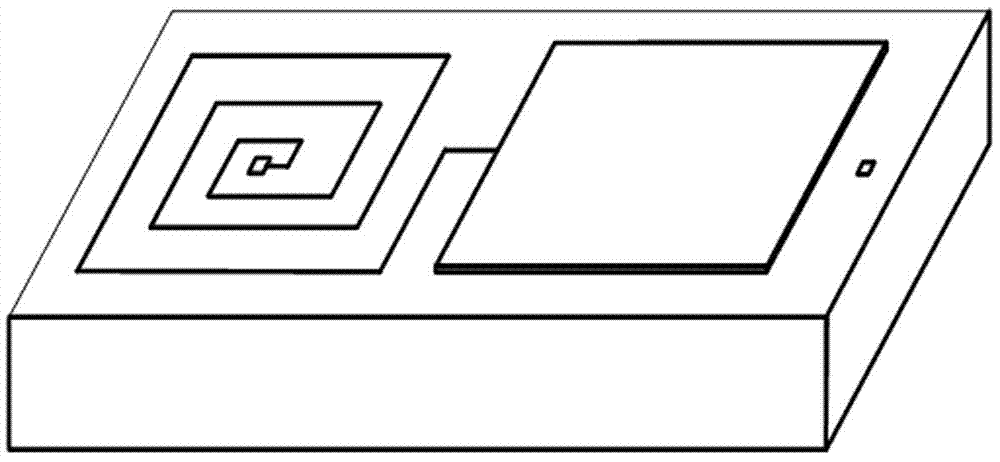

[0027] like figure 1 As shown, the high-temperature pressure sensor includes four layers from top to bottom. The first layer, that is, the upper surface of the top layer is brushed with a plane square spiral inductor, and the other side of the top layer is brushed with a capacitor upper plate. It is connected in series with the outer ring of the planar square spiral inductor; the second layer is provided with a sealed pressure cavity, and the third layer covers the upper surface of the fourth layer to separate the lower plate of the capacitor from the pressure cavity; the fourth layer is the upper surface of the bottom layer The lower plate of the capacitor is brushed, and the lower plate of the capacitor is connected to the inner ring center of the top planar square spiral inductor through a via hole filled with silver paste. Each layer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com