Patents

Literature

229results about How to "Improve the suppression effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

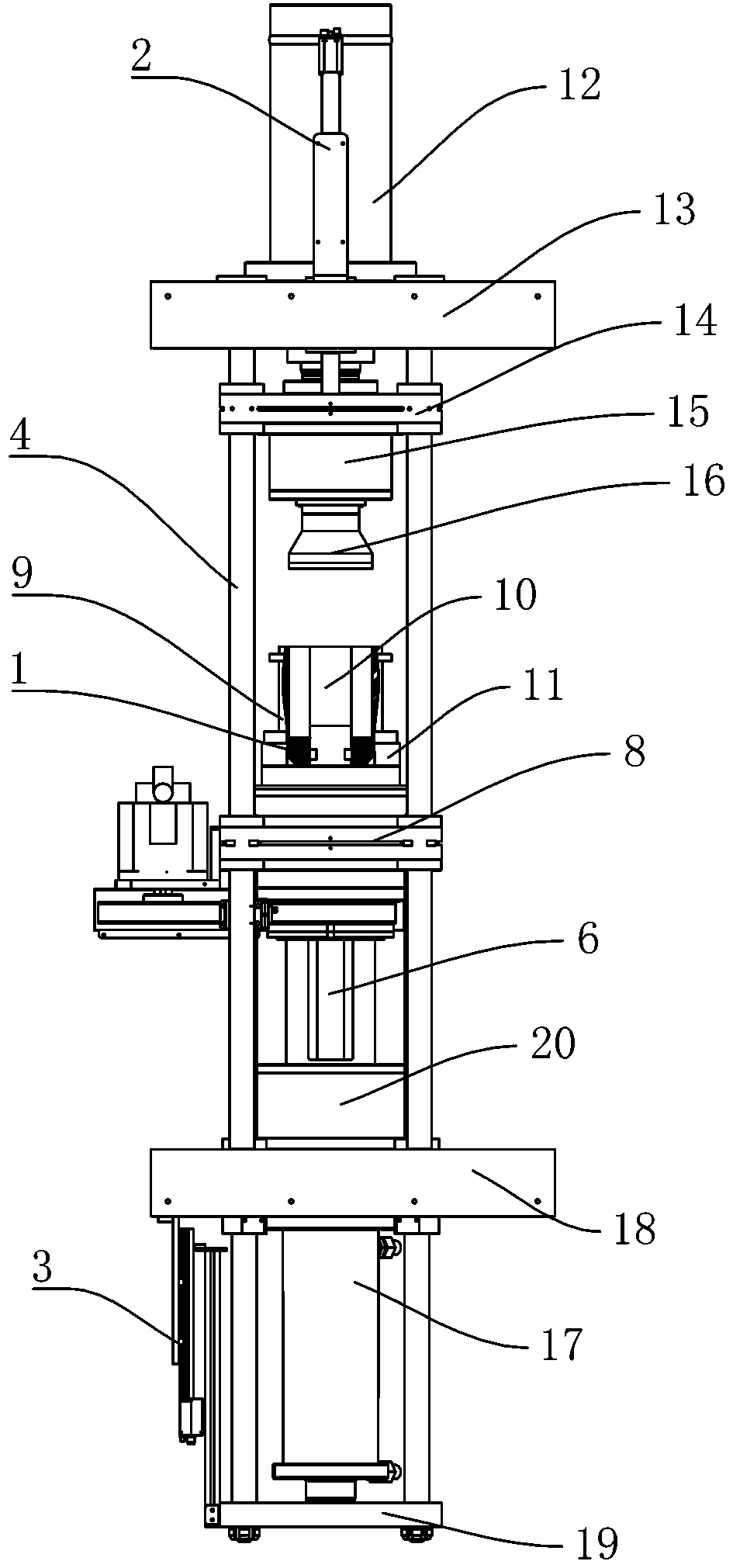

Servo electrohydraulic composite pressure method and press machine thereof

InactiveCN101927578AImprove performanceReduce energy consumptionPress ramNumerical controlPunch press

The invention discloses a servo electrohydraulic composite pressure method, comprising the following steps: 1) arranging a stander; 2) arranging an upper hydraulic device on the stander, 3) arranging a closed ring servo electrohydraulic control system, wherein the closed ring servo electrohydraulic control system is connected with the upper hydraulic device, and controls the work situation of the upper hydraulic device; the invention further discloses a press machine which implements the method; the method provided by the invention uses a servo electrohydraulic technology to replace the traditional electrohydraulic control technology, which has simple manufacturing, high efficiency, little power consumption and high control precision; the position control precision can reach to 0.01 to 0.02 millimeters; the pressing, the tensioning, the de-molding, the full deciding and other functions can be realized simultaneously, so the method has a comparatively high processing flexibility; the press machine provided by the invention is rational in structure, little in volume, stable in work, high in capacity, little in noise, and wide in application range. The advantages of a mechanical punching machine, a hydraulic punching machine and a numerical control are integrated, so the press machine has the advantages of multi-function, low cost, large pressure tonnage, etc.

Owner:东莞市得力仕机械科技有限公司

Method for preparing high-density iron-base powder metallurgy parts

The invention provides a method for preparing high-density iron-base powder metallurgy parts, and belongs to the technical field of powder metallurgy molding. The compaction density of iron-base powder can be increased by utilizing the special stratified structure, the low friction factor and the good lubricating property of MoS2 (molybdenum disulfide). The method comprises the following steps: uniformly mixing the iron powder with MoS2 powder, carrying out annealing treatment, and causing MoS2 to be uniformly distributed on the surface of the iron powder; and uniformly mixing annealed mixed powder with a certain amount of metal powder, graphite powder and the like, and pressing and sintering to obtain the high-density iron-base parts. In the pressing process, the friction force among powder particles is reduced and the friction state among the powder particles is improved through the MoS2, the pressing performance is increased, and the iron-base powder metallurgy parts with the density of 7.2g / cm3-7.5g / cm3 can be obtained. The method has the advantages that the pressing performance of the iron-base powder is improved; the high-density iron-base powder metallurgy parts is obtained on the premise of cost reducing; the friction factor is reduced, the loss of abrasive tools is decreased, and meanwhile, the adverse influence of sulphur on the iron-base parts does not exist; and the process is simple and suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

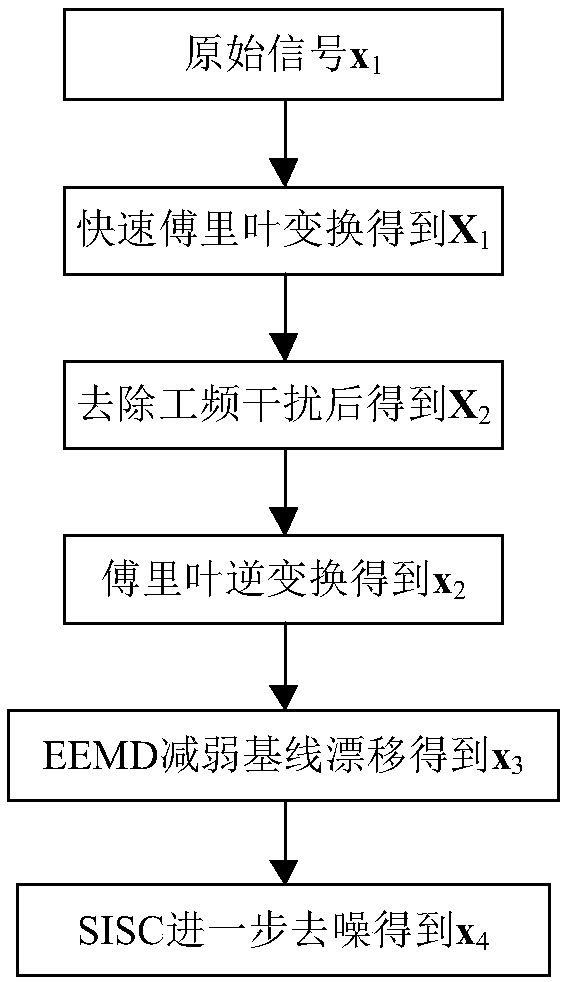

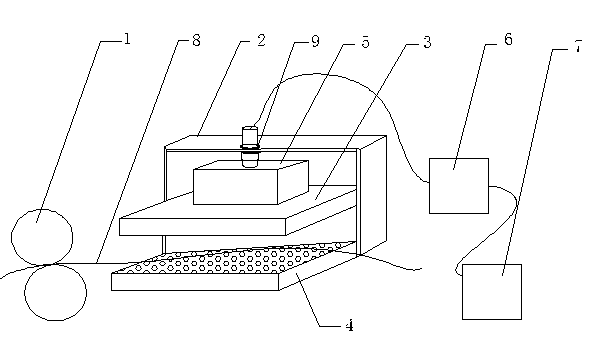

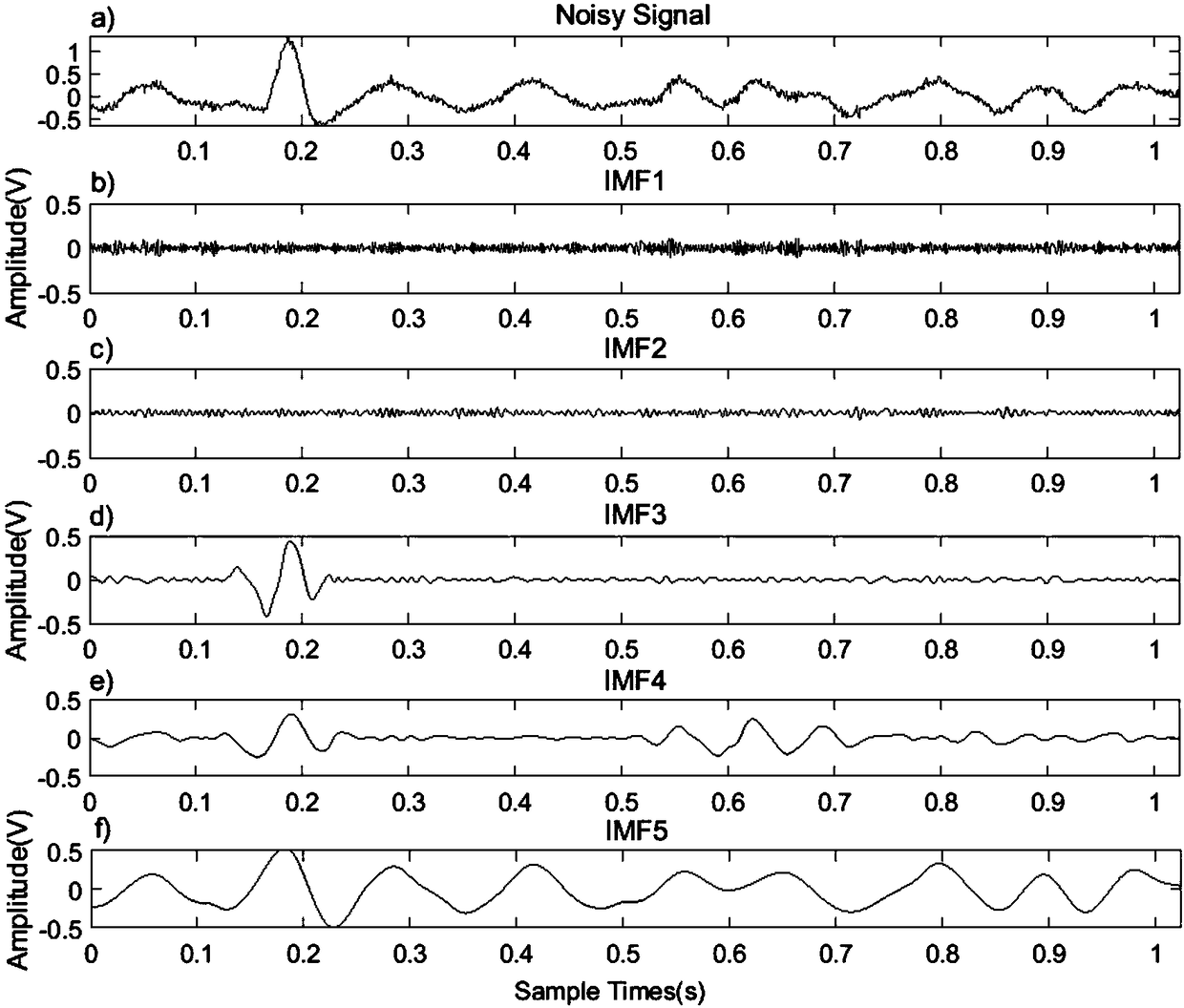

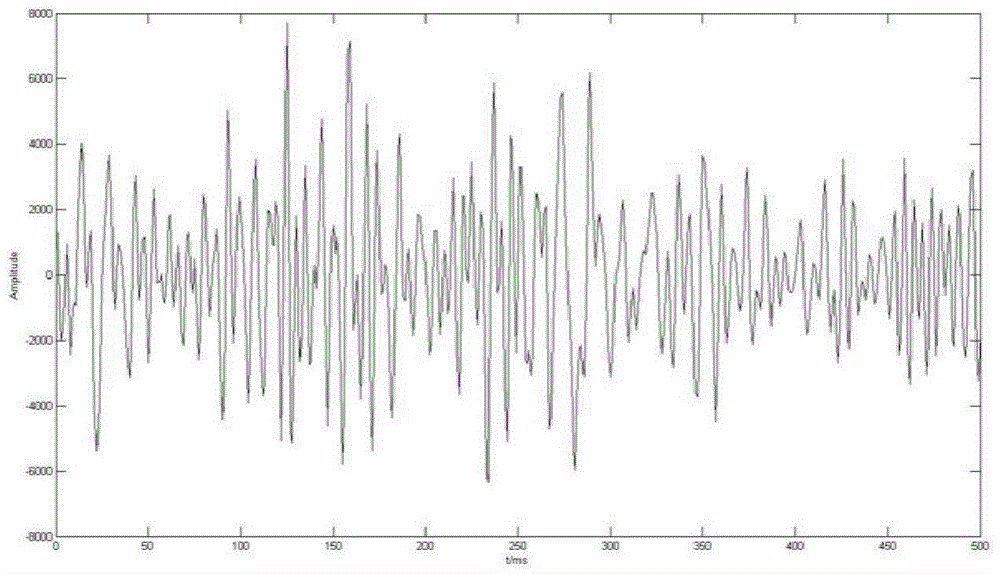

Denoising method of observation signal of artificial-source electromagnetic-method

ActiveCN108399368AReduce Construction BarriersAccurate separationCharacter and pattern recognitionMachine learningFast Fourier transformTime domain

The invention discloses a denoising method of an observation signal of an artificial-source electromagnetic-method. The method includes: firstly, carrying out fast Fourier transform (FFT) on the noised signal, removing power-frequency interference in a frequency-domain signal, and returning to a time domain after inverse Fourier transform; then carrying out EEMD (Ensemble Empirical Mode Decomposition) on a time-domain signal after removing the power-frequency interference, and attenuating signal baseline drift; and finally, further correcting the baseline drift of the signal on the basis of shift-invariant sparse coding (SISC), and removing other human noises. According to the method, power-frequency interference noises, baseline drift noises and the human noises of pulses and the like ofwhich amplitude is much larger than that of a useful signal can be effectively removed on the premise of not losing the useful signal, the strong noises are allowed to exist in an entire process fromobservation starting to ending, and thus the artificial-source electromagnetic-method is enabled to be used for observation under an environment of continuous and strong interference.

Owner:CENT SOUTH UNIV

Composite thermal-shock-resisting high-aluminum refractory brick and preparation method thereof

The invention relates to a composite thermal-shock-resisting high-aluminum refractory brick for steel smelting blast furnace hot blast stoves and a preparation method of the brick. The refractory brick is prepared by mixing and evenly grinding homogeneous material, sillimanite, andalusite, alpha-aluminum oxide, zirconium oxide, soft clay powder and water, forming via a machine and firing at a temperature of 1475-1500 DEG C. According to the composite thermal-shock-resisting high-aluminum refractory brick and the preparation method, the formula is reasonable, the cost is relatively low, the preparation method is simple, the operation is easy, the thermal shock resistance of the fired refractory brick is greatly enhanced, the service life of the hot blast stoves is prolonged and the economic benefit of the enterprises is improved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

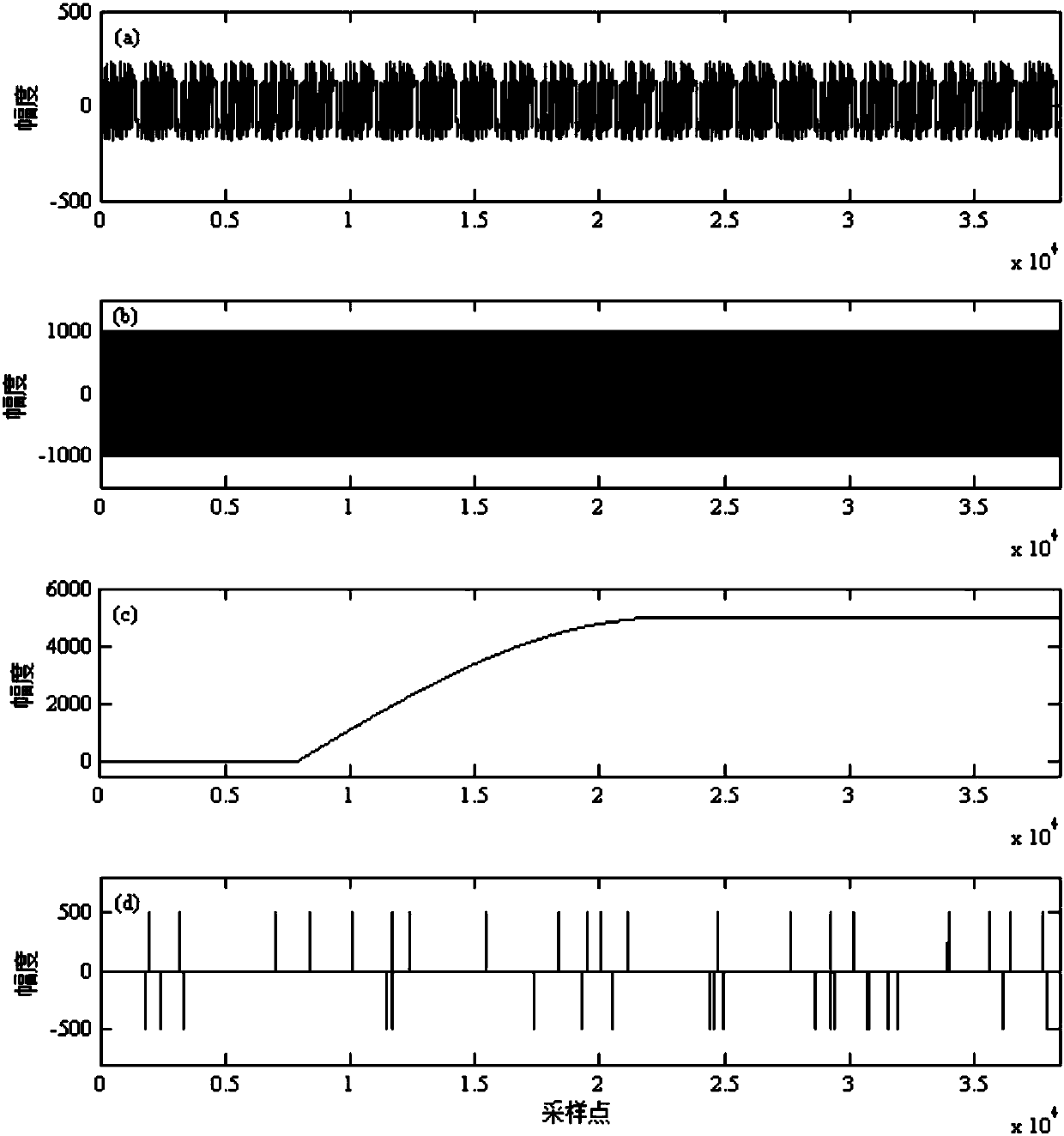

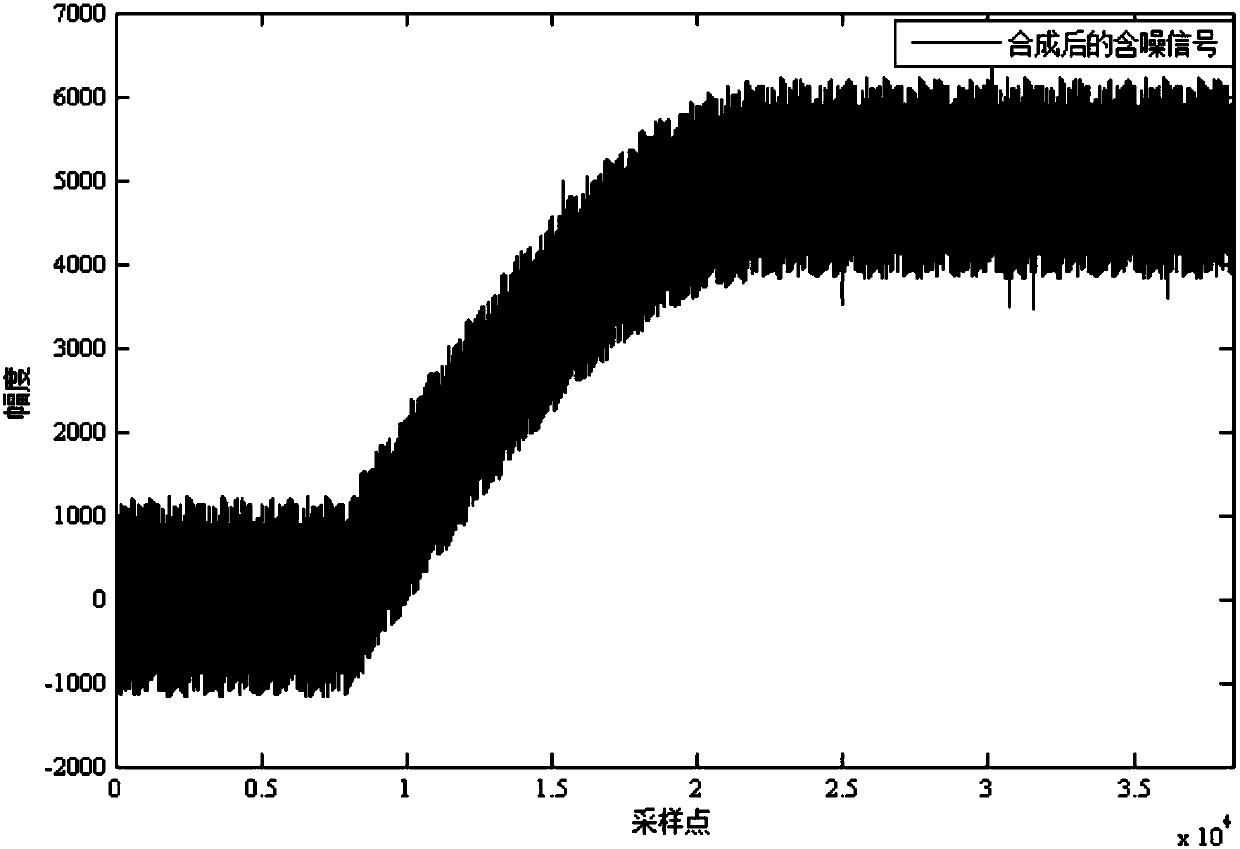

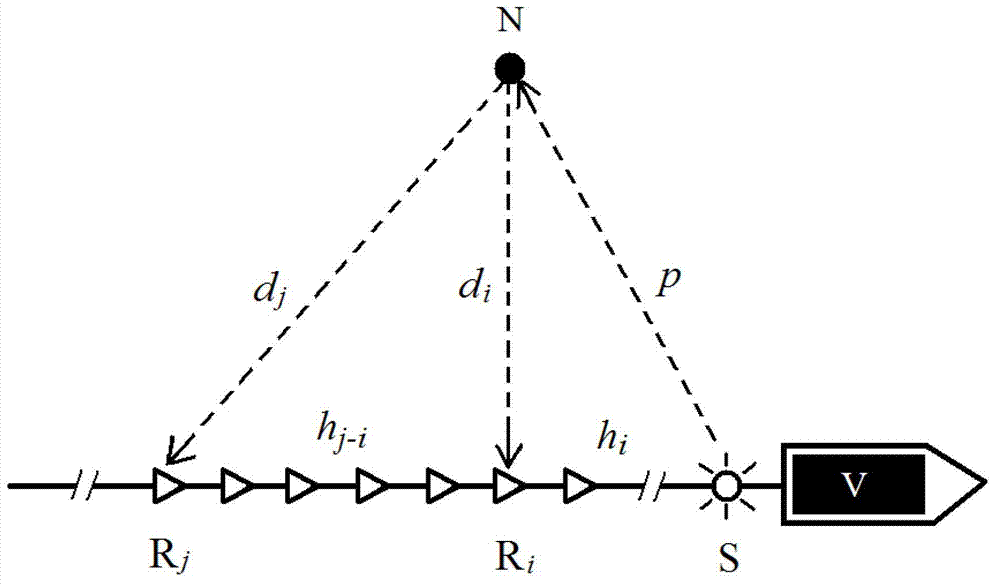

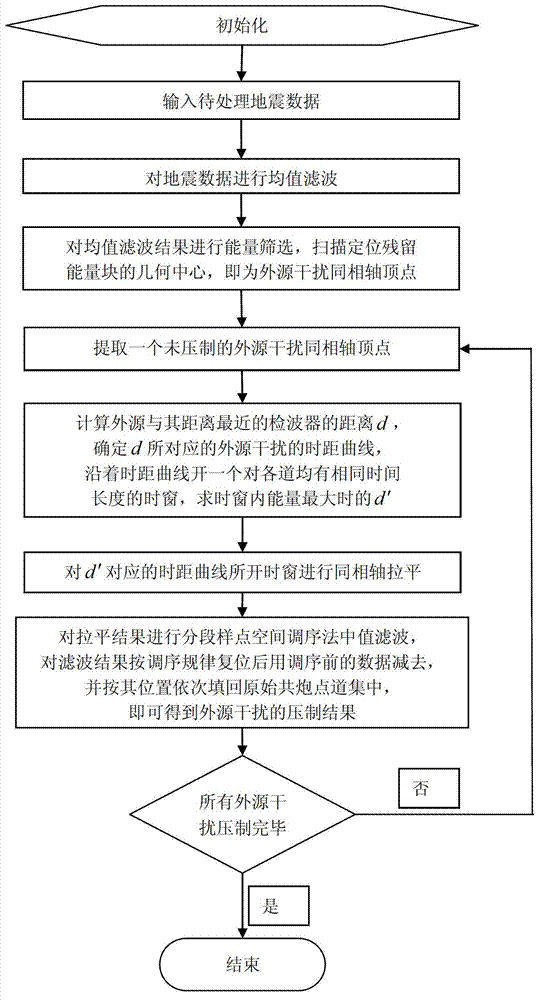

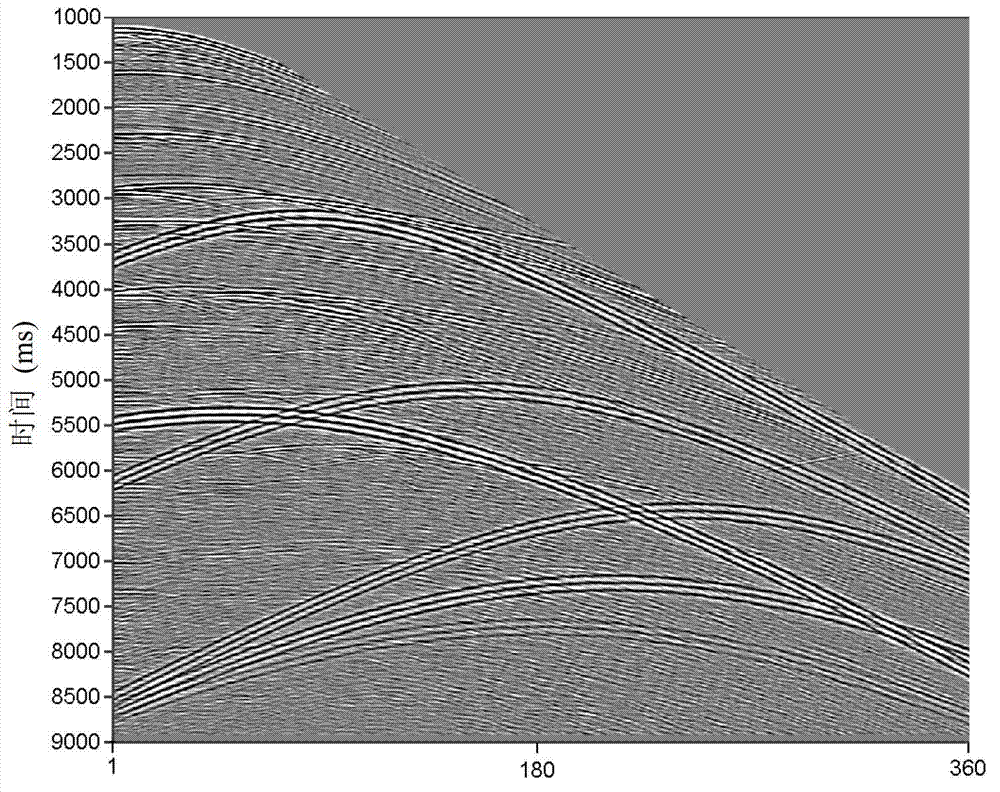

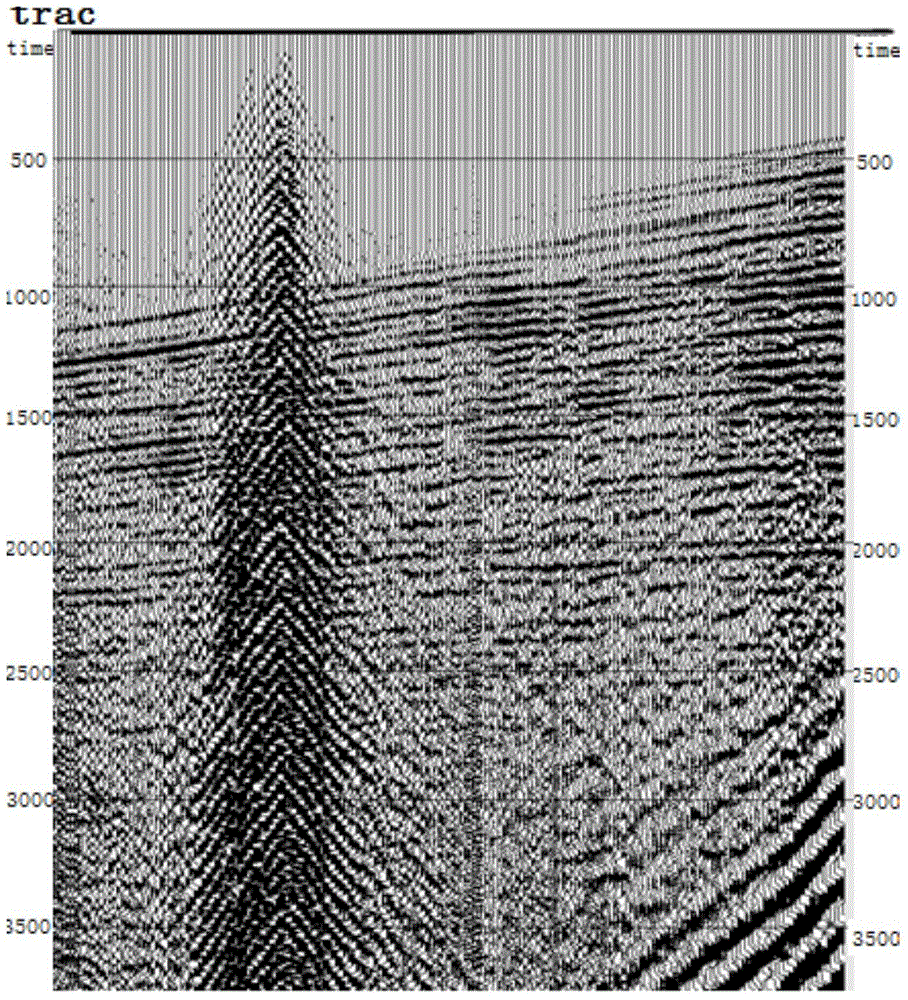

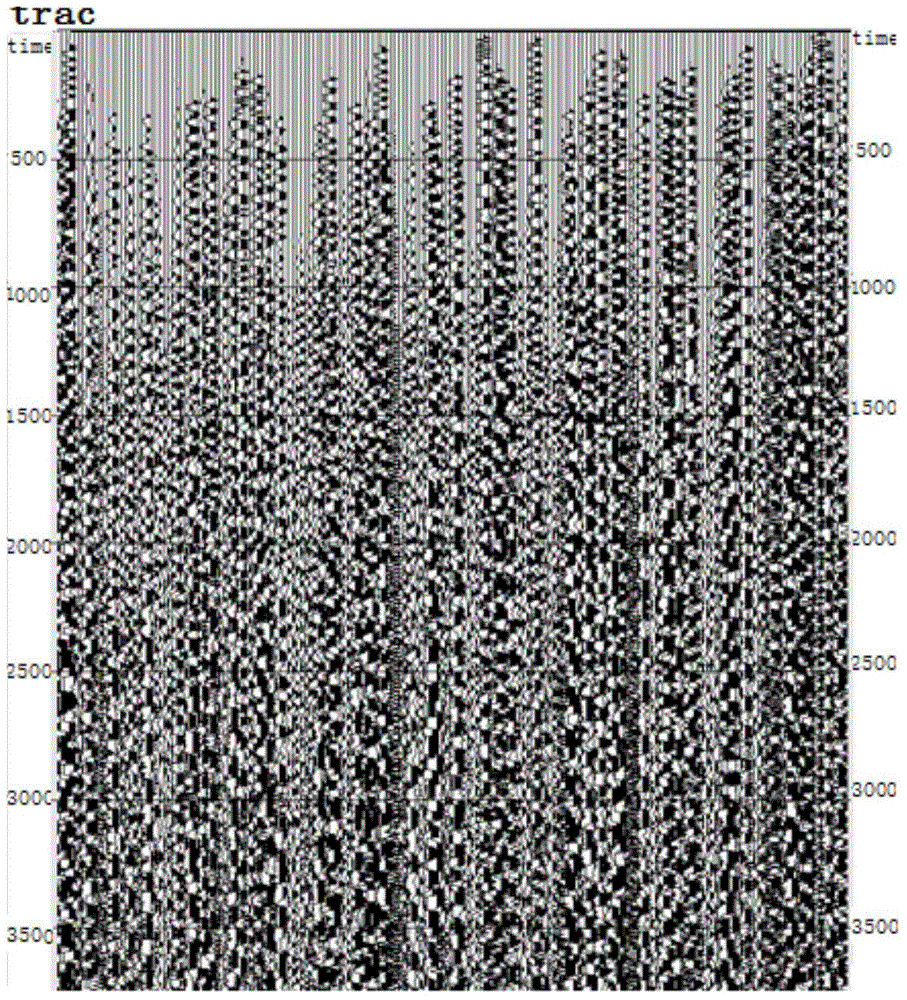

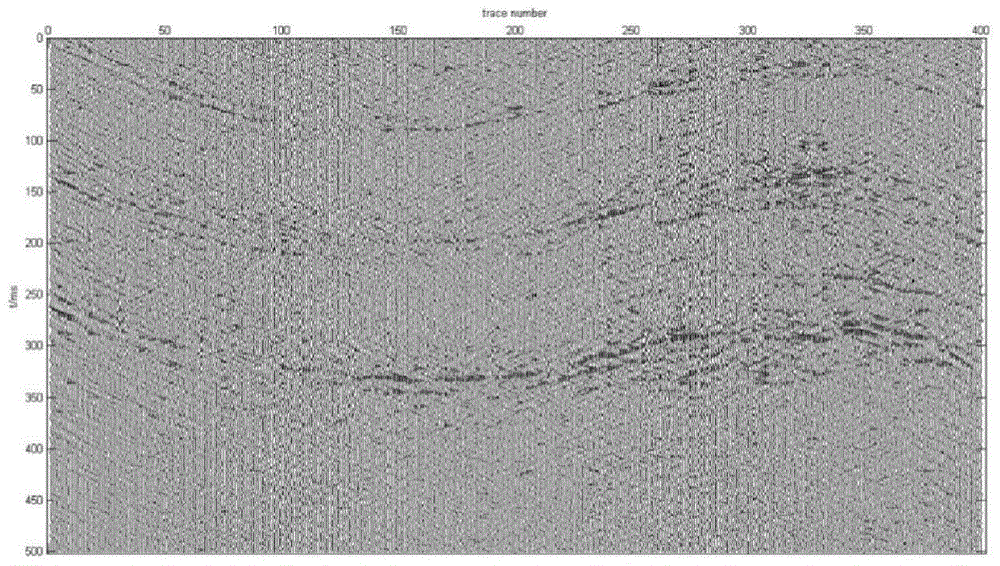

Self-adapting suppressing method for external source interference in seismic data

ActiveCN102890291AEfficient processingImprove the suppression effectSeismic signal processingSeismology for water-covered areasSelf adaptiveData information

The invention relates to a self-adapting suppressing method for external source interference in seismic data. The self-adapting suppressing method comprises the steps of: firstly, performing mean filtering to the seismic data, performing self-adapting location to the peak of each external source interference time distance curve; then, orderly performing the following steps to each peak: according to a mechanism model generated by the external source interference, scanning the external source interference time distance curve to obtain a relative distance of each external source interference and a detector; after performing same-phase alignment to the corresponding time distance curve, using median filtering to process the result after the same-phase alignment by segmented sampling point space sequence adjustment method, using data before sequence adjustment to subtract the filtering result after resetting according to the sequence adjustment rule, and orderly filling back to primary common-source point for gathering according to positions to finish external source interference suppression. The self-adapting suppressing method has self-adaptability; and compared with a conventional external source interference suppression algorithm, the self-adapting suppressing method has the advantages that the seismic data information with vast quantity of data is processed with high efficiency and the suppression effect is improved effectively. The self-adapting suppressing method can be widely applied to the technical field of seismic exploration to process the seismic data with complicatedly distributed external source interferences.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Biomass fuel particle and processing device and method thereof

ActiveCN110791349APrevent coagulationImprove the suppression effectShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to a biomass fuel particle and a processing device and method thereof. The biomass fuel particle is prepared from the components: 15 parts of rice husks, 25 parts of straw, 10 parts of wood scraps, 3 parts of corn cobs, 35 parts of rice and wheatgrass, 5 parts of tree roots, 35 parts of wood chips, 10 parts of bagasse, 5 parts of cottonseed shells, 3 parts of a dehydrator, 1part of pecan shells and 1 part of bamboo chips. The processing method includes the following steps that step 1, biomass fuel is put into a fuel processing cylinder; step 2, a reciprocating drive assembly starts to drive a stirring plate and a spiral stirring blade move up and down in a reciprocating mode, and the biomass fuel is rotated and stirred up and down in a reciprocating mode; step 3, a particle processing driving part starts to drive two pressing rollers to rotate, and the two pressing rollers extrude the biomass fuel from a circular through hole by the cooperation with a round holeseat plate; step 4, the particle processing driving part drives a cutting knife mechanism to rotate, and the rotary cutting knife mechanism cuts the extruded column-shaped biomass fuel into grain shape; and step 5, biomass fuel particles fall into a material receiving box to be collected.

Owner:吉林省尚心能源有限责任公司

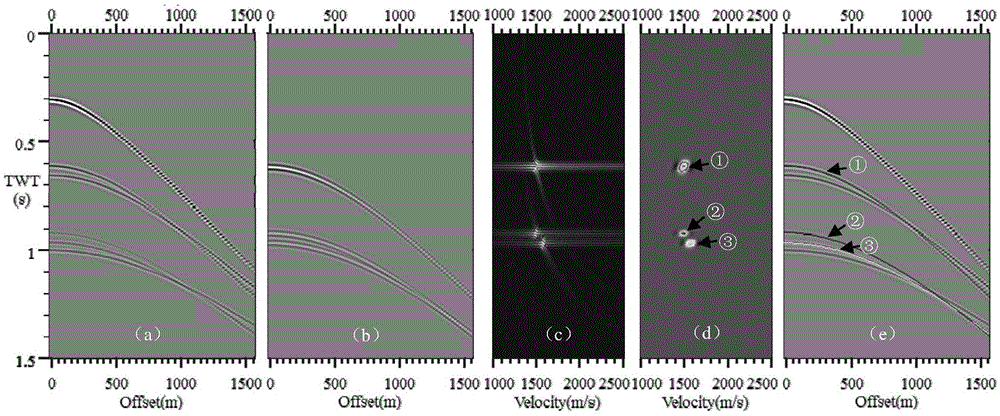

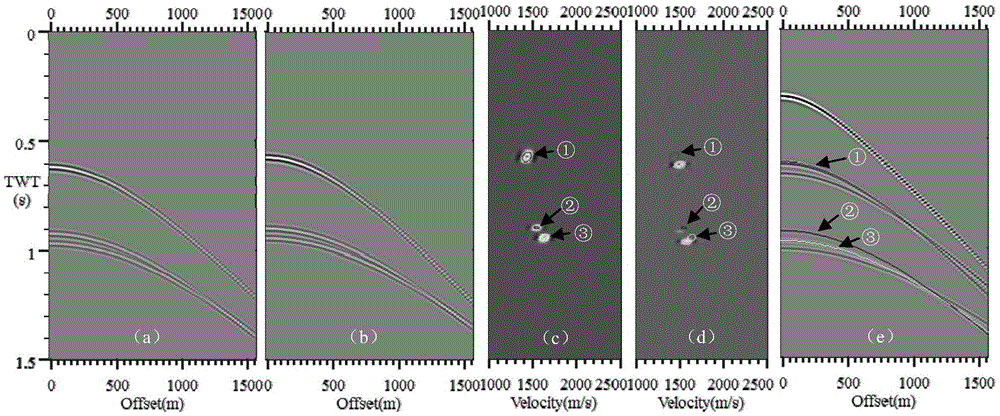

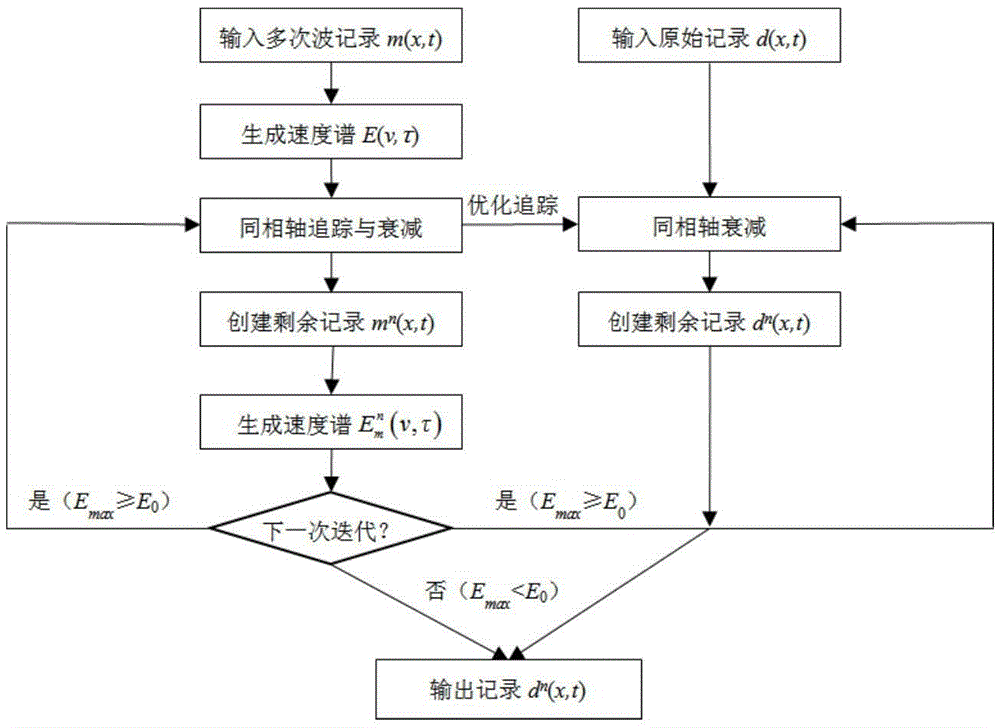

Multiple wave matching attenuation method based on optimized phase axis tracking

ActiveCN105676291AImprove the suppression effectAdaptive Multiple Rejection ProcessingSeismic signal processingUltrasound attenuationVelocity spectrum

A multiple wave matching attenuation method based on optimized phase axis tracking belongs to the field of seismic multiple wave attenuation. The method comprises the following steps: firstly, giving the phase axis density Nm and the spectrum energy threshold E0; then applying a surface-related multiple prediction (SRMP) method to an original record to obtain a multiple wave record as an initial record; using optimized phase axis tracking technology and a short time window FK fan filtering method to iteratively extract and attenuate a multiple wave phase axis until the amplitude maximum of a residual multiple wave stacking velocity spectrum is less than E0; and thereby obtaining a primary wave record after multiple wave attenuation. The method carries out matching attenuation according to the direction of the multiple wave phase axis, is not affected by the predicted multiple wave signal amplitude difference and waveform change, can more or less overcome the defect that Wiener filtering methods are likely to damage a primary signal, and can significantly improve the attenuation effect of far-offset channel multiple wave signals.

Owner:OCEAN UNIV OF CHINA

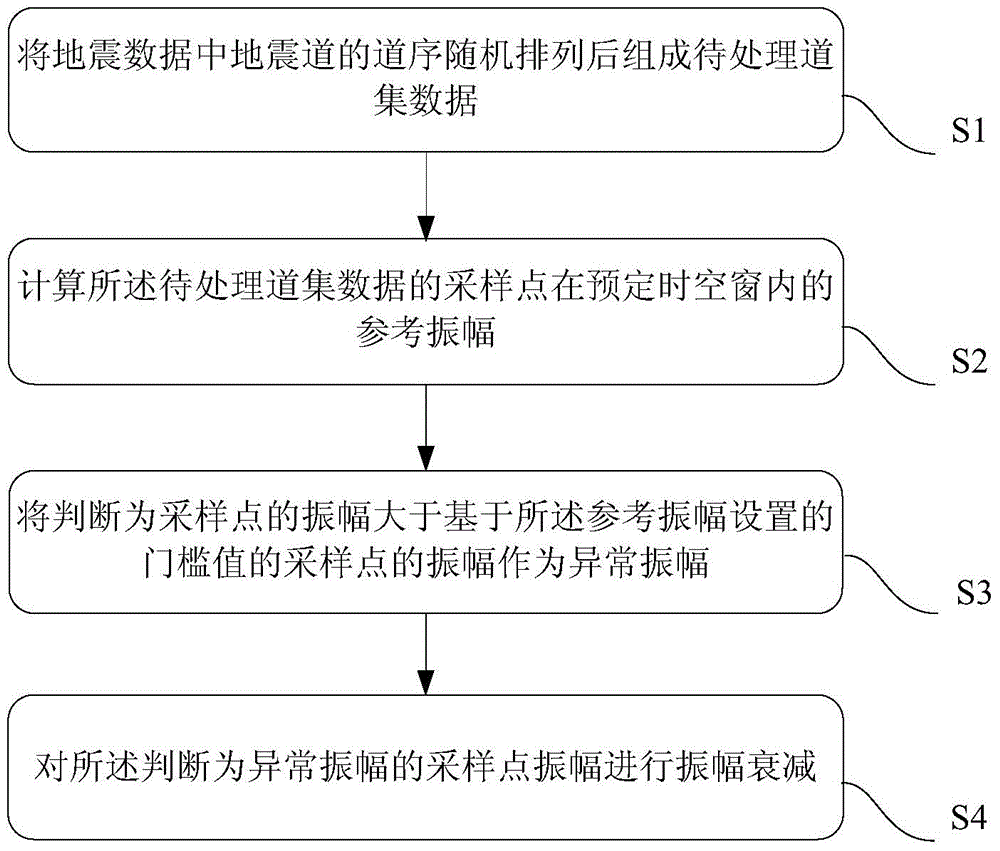

Anomalous amplitude suppression method and apparatus

ActiveCN104932017AEffective attenuationImprove the suppression effectSeismic signal processingSignal-to-noise ratio (imaging)Ultrasound attenuation

The invention provides an anomalous amplitude suppression method and an apparatus. The method includes: making random arrangement of trace sequence of seismic traces in seismic data and forming to-be-processed trace gather data; calculating the reference amplitude of sampling points of the to-be-processed trace gather data in a predetermined space-time window; comparing the amplitude of the sampling point with the reference amplitude and determining whether the amplitude of the sampling point is greater than the threshold value set based on the reference amplitude; regarding the amplitude of the sampling point whose determination result is yes as the anomalous amplitude; moving the predetermined space-time window to the next sampling point and determining whether the amplitude of the next sampling point is the anomaly amplitude; and performing amplitude attenuation of the amplitude of the sampling point which is determined to be anomalous amplitude. By employing the embodiments, the interferences of the anomalous amplitude in the seismic data can be effectively suppressed, and the data signal to noise ratio is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

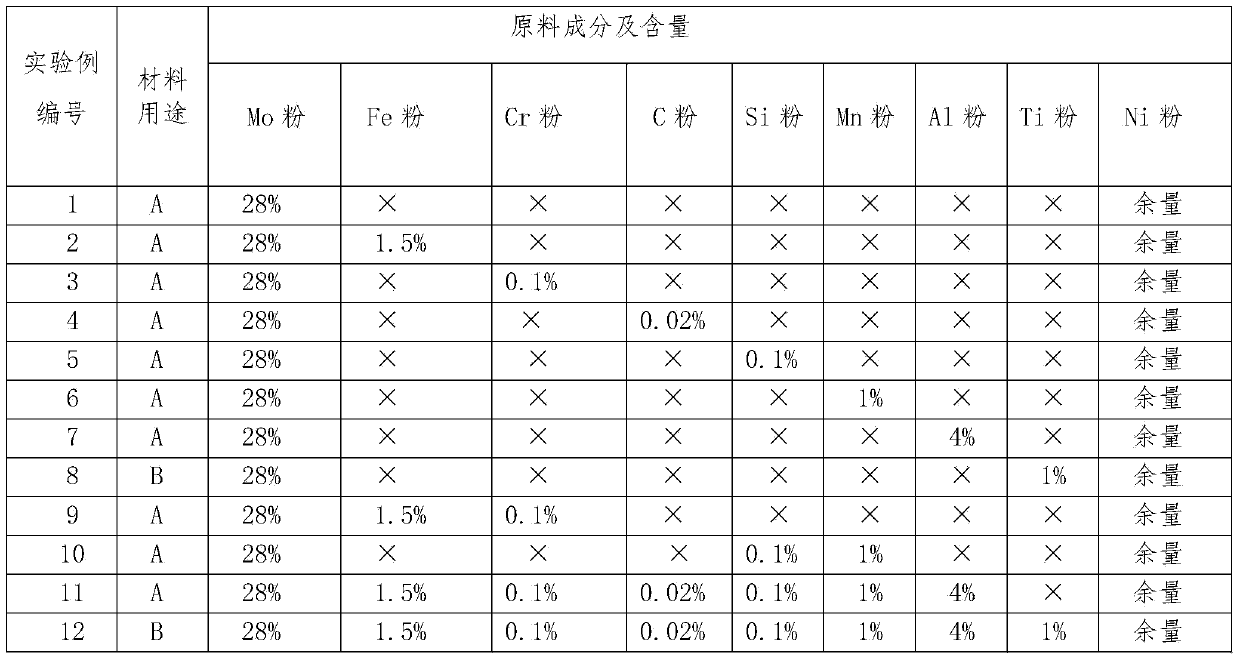

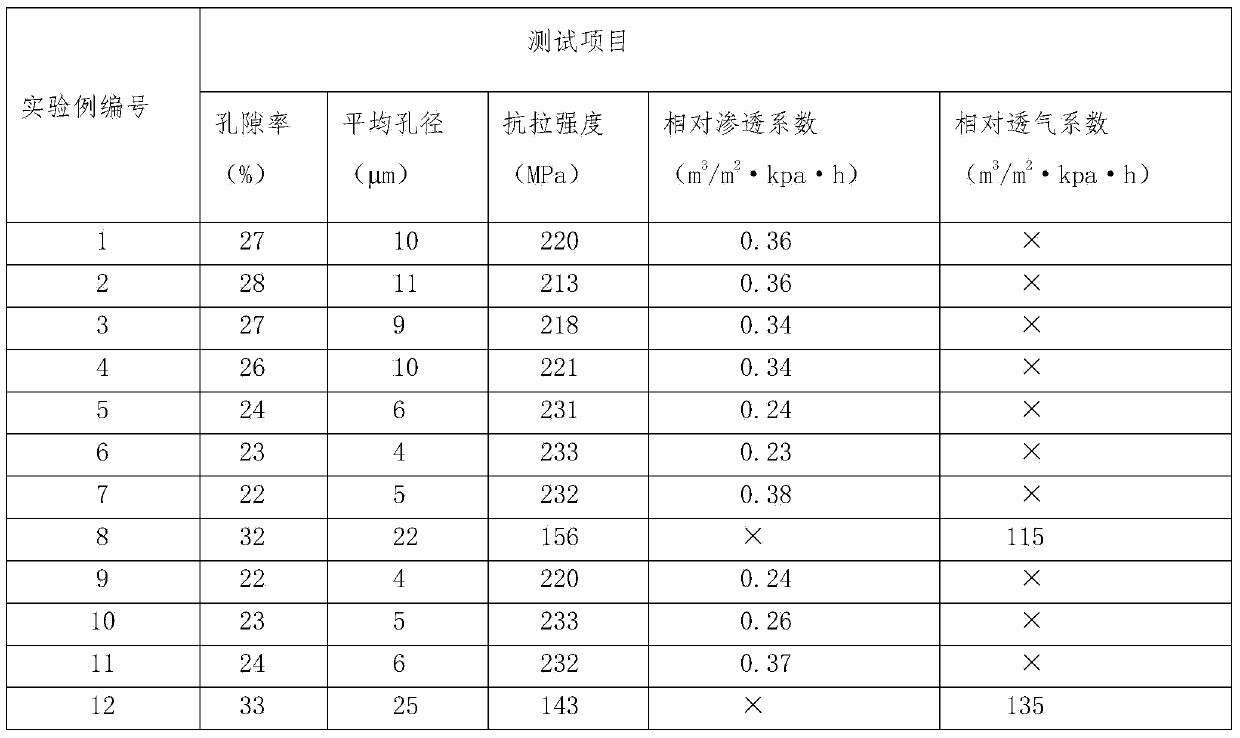

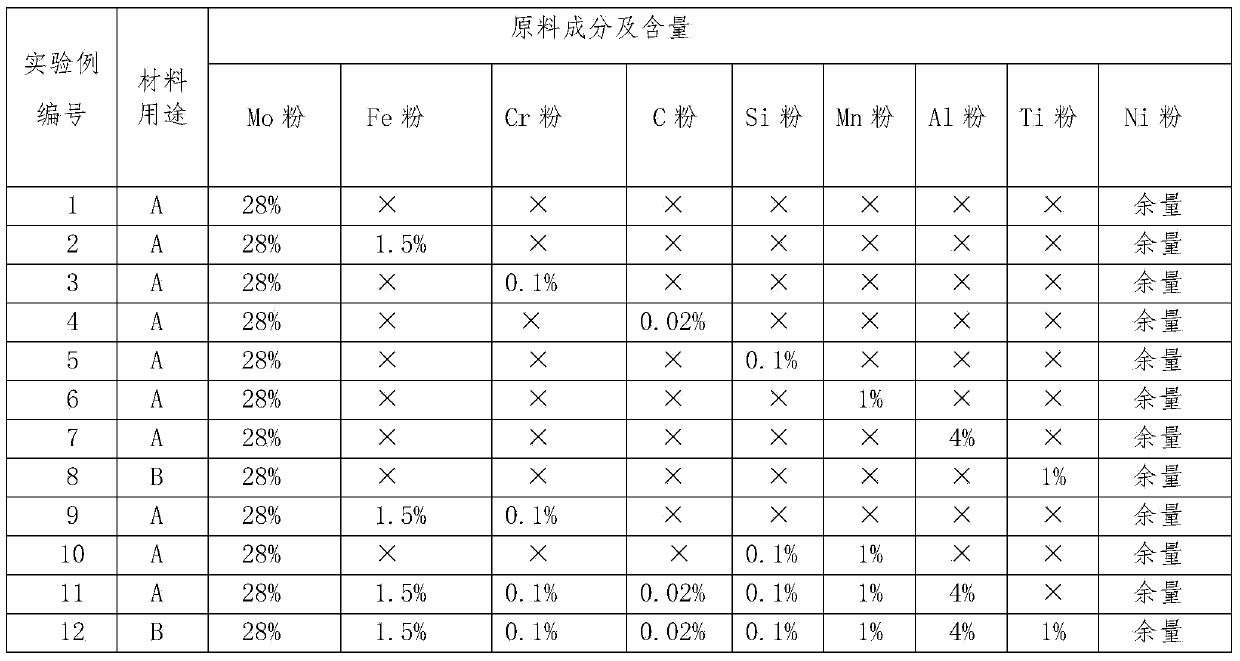

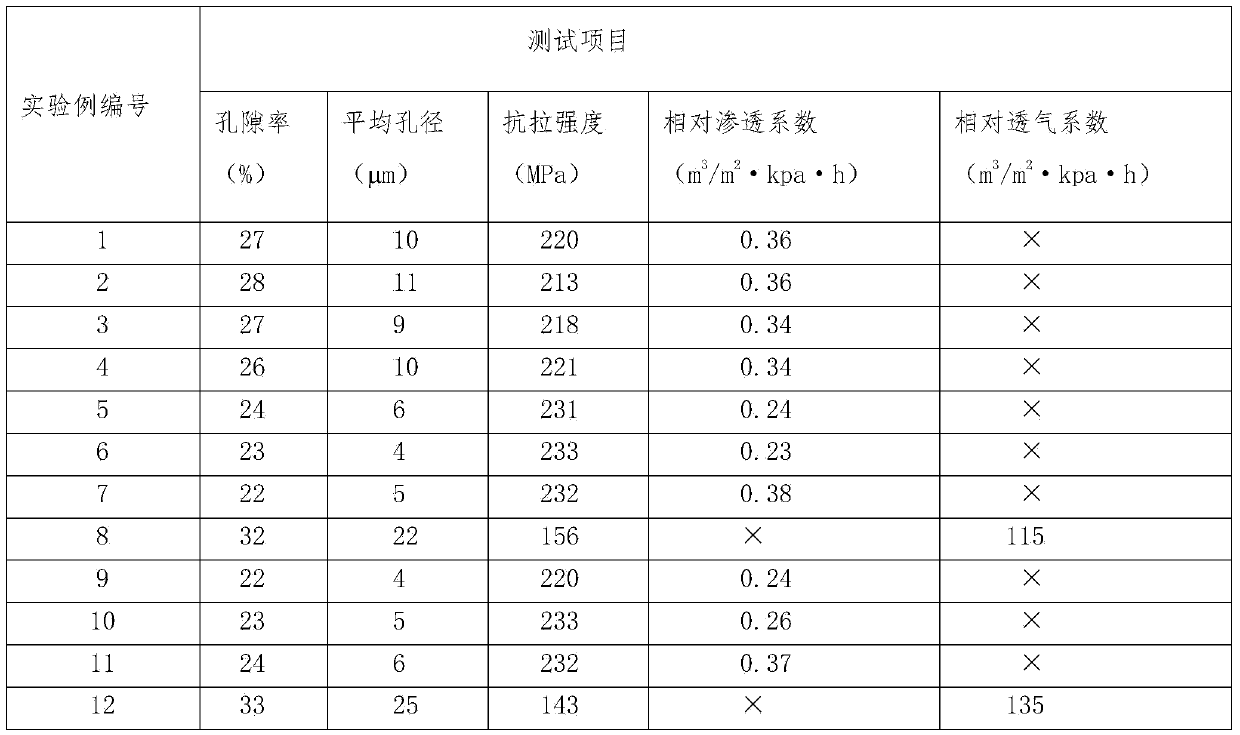

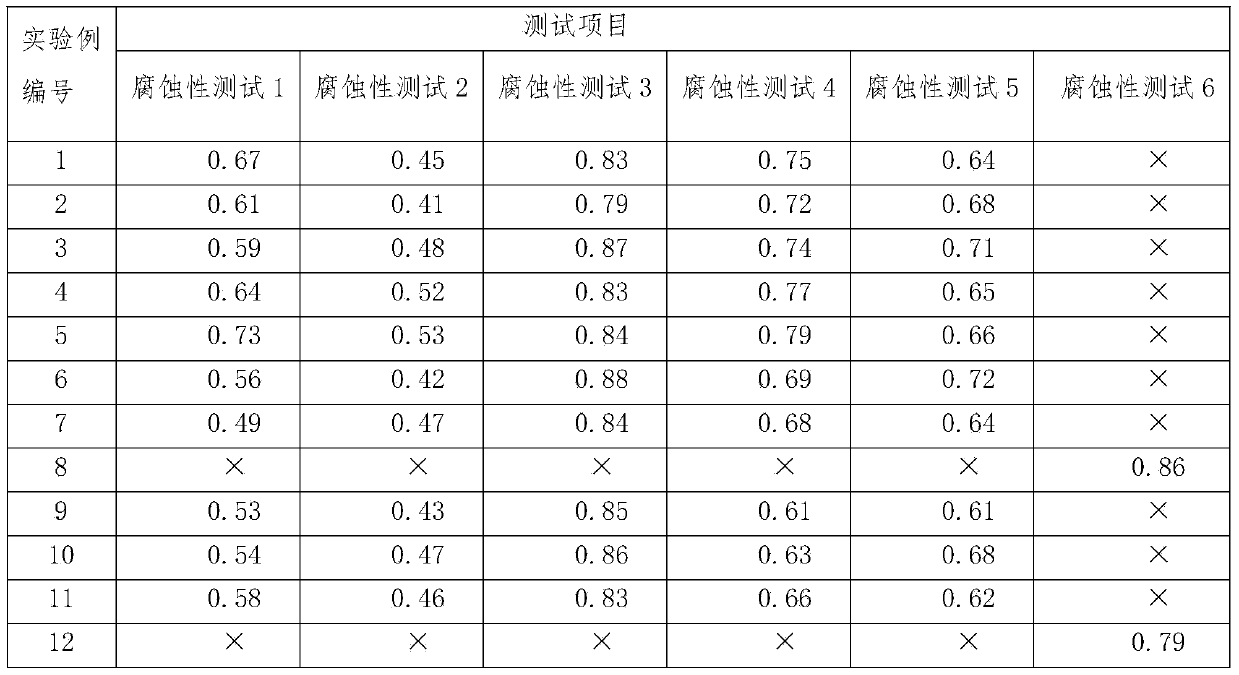

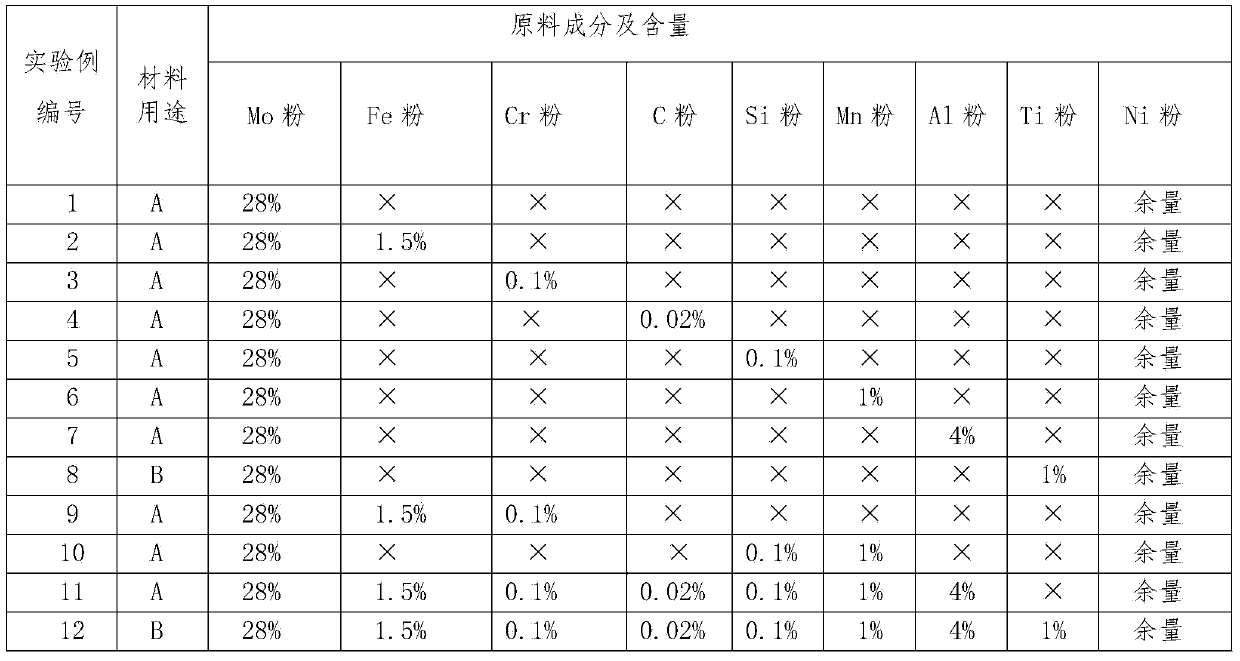

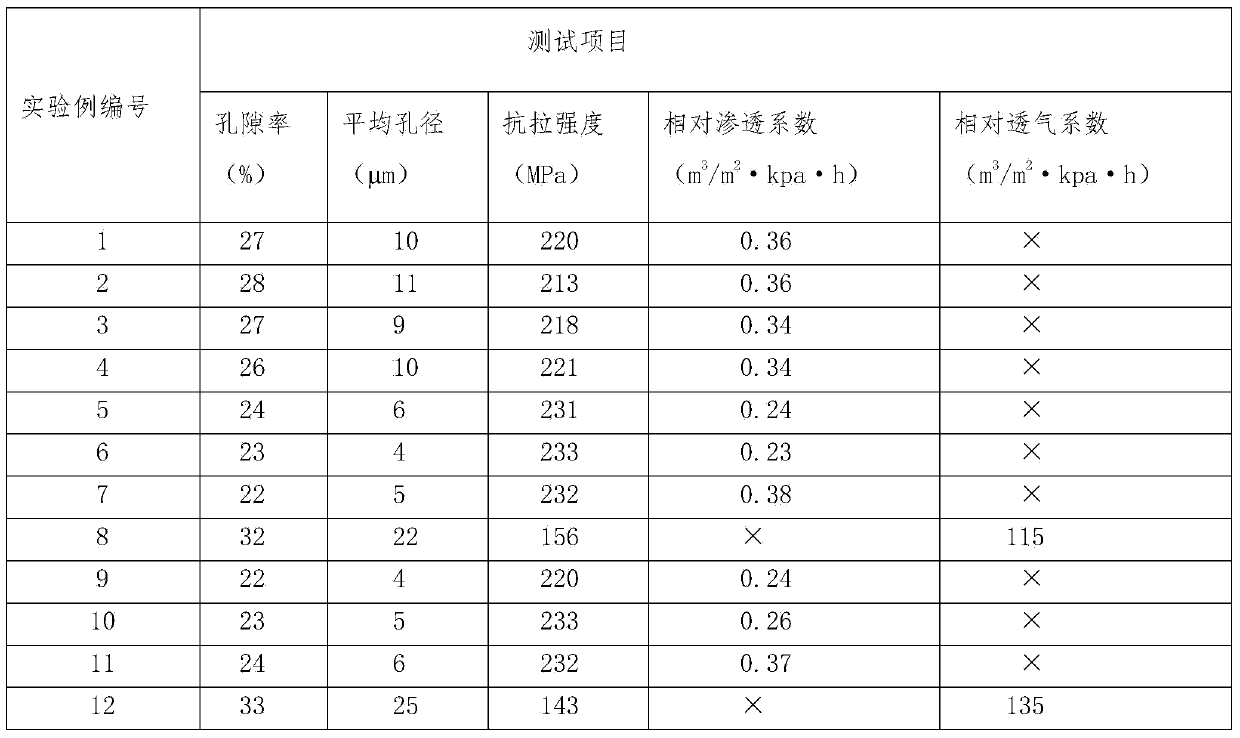

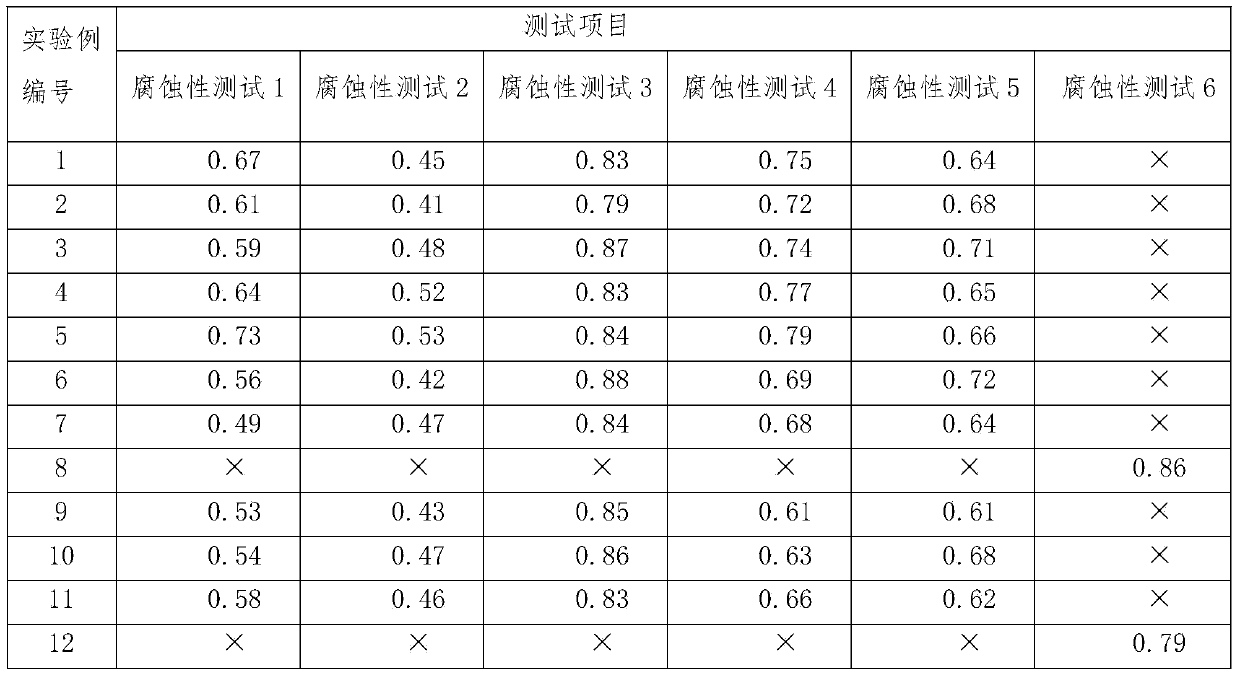

Powder sintered porous filter alloy, preparation method thereof and pre-compression molded body

The invention discloses a powder sintered porous filter alloy, a preparation method of the alloy and a pre-compression molded body for preparing the alloy. The alloy is basically prepared from the ingredients in percentage by mass: 14-17% of Cr, 15-17% of Mo, 0-7% of Fe, 0-4.5% of W, 0-2.5% of Co, 0-0.08% of C, 0-1% of Si, 0-1% of Mn, 0-0.35% of V, 0-0.04% of P, 0-0.03% of S, 0-5% of Al, 0-1.5% of Ti and the balance of Ni; when the alloy is used for filtering liquid, the average pore size is not greater than 20 microns, and the relative coefficient of permeability is not smaller than 0.2m<3> / m<2>.kPa.h; when the alloy is used for filtering gas, the average pore size is not greater than 60 microns, and the relative coefficient of gas permeability is not smaller than 80m<3> / m<2>.kPa.h. The alloy shows superior corrosion resistance in both an oxidizing system and a reducing system; secondly, the alloy is mainly resistant to wet chlorine, various oxidizing chlorides, chloride salt solutions, sulfuric acid and oxidizing salts. The alloy is suitable for being applied to the industrial fields of chemical industry, petrochemical industry, flue gas desulfurization, pulp and paper making, environmental protection and the like.

Owner:CHENGDU INTERMENT TECH

Method for controlling spartina alterniflora

ActiveCN110235666APrevent regenerationHigh density of forestationClimate change adaptationAfforestationMangroveHigh density

The invention relates to the field of the forestry, and discloses a method for controlling spartina alterniflora. The method comprises the steps of (1) root overturning, wherein the overground parts of the spartina alterniflora are cut off, stubbles with the heights of 3-8 centimeters are reserved, and the overground parts of the spartina alterniflora are overturned and buried in silt; (2) planting of a mangrove forest, wherein nursery stocks of the mangrove forest are planted in an area after root overturning in the density greater than or equal to 1000 plants per mu. The method for controlling the spartina alterniflora has the advantages that through the synergistic effect of a specific root overturning technology and a super-high density afforestation mode, the regeneration of the spartina alterniflora can be effectively inhibited; the spartina alterniflora is controlled by adopting the mode provided by the method, and an indigenous plant mangrove is utilized to replace the spartina alterniflora, so no ecological risk exists, and the problem of the biggest defect, namely, re-invasion of the spartina alterniflora of an existing spartina alterniflora prevention and control technology is completely eradicated.

Owner:XIAMEN UNIV +1

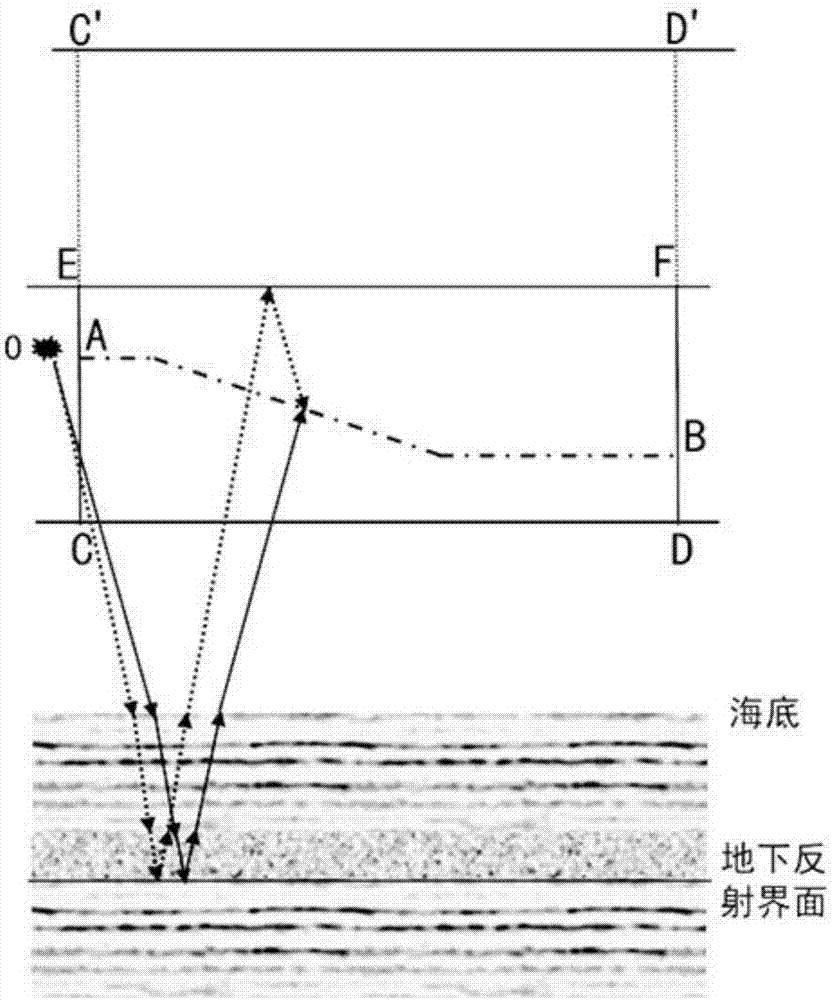

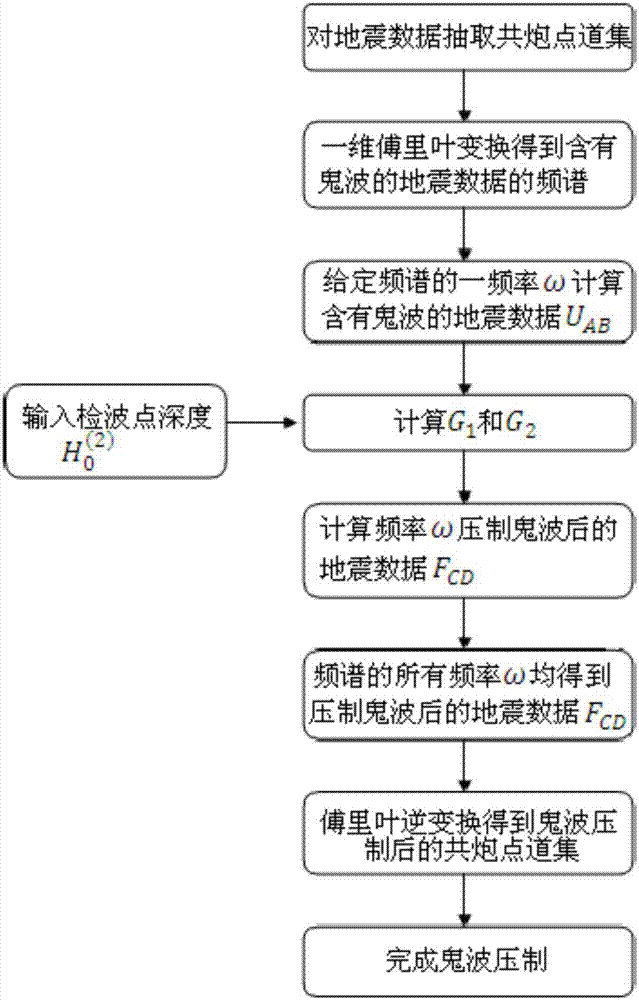

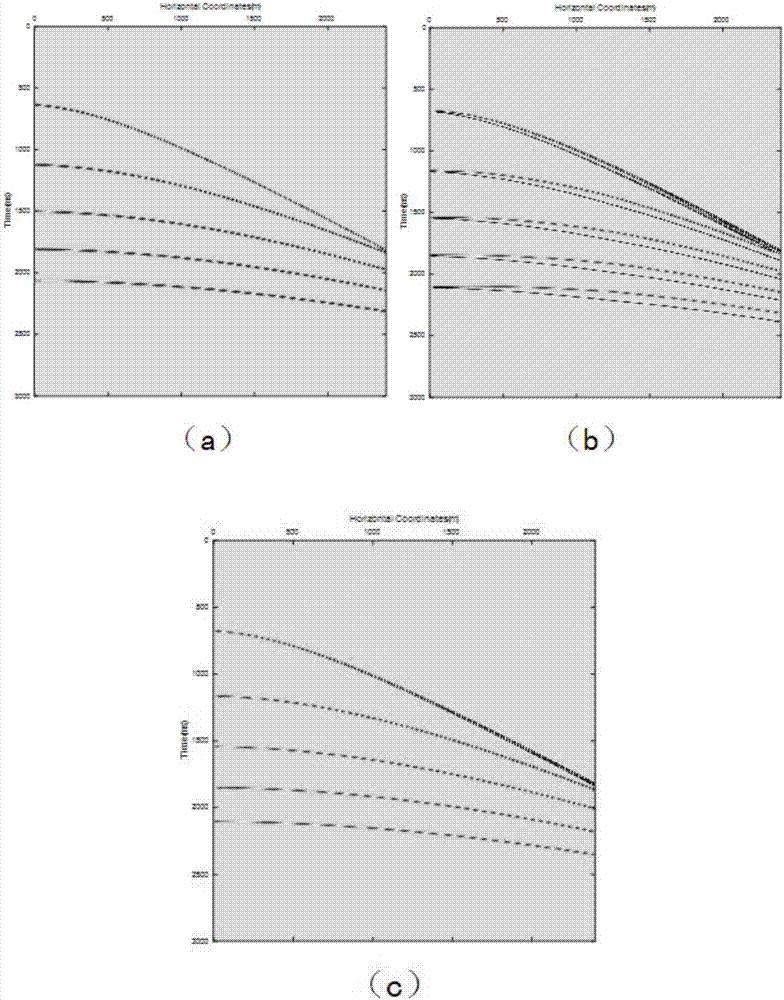

Variable-depth cable ghost wave suppression method based on wave equation boundary value inversion

ActiveCN106896409ASolve the problem of suppressionImprove the suppression effectSeismic signal processingFrequency spectrumBoundary values

The invention relates to a variable-depth cable ghost wave suppression method based on wave equation boundary value inversion. The method includes the following steps: 1) extracting a common-shot-point gather from seismic data collected by a variable-depth cable; 2) performing one-dimensional Fourier transform on the seismic data of a certain shot of the common-shot-point gather to obtain a frequency spectrum containing ghost wave seismic data; 3) calculating frequency domain seismic data U<AB> containing ghost waves corresponding to a certain frequency omega in the frequency spectrum; 4) calculating G1 and G2 according to detection point depth H<0><(2)>; 5) calculating frequency domain seismic data F<CD> after ghost wave suppression which are corresponding to the frequency omega according to U<AB>, G1 and G2; 6) performing steps 3) to 5) on all frequencies omega on the frequency spectrum in the common-shot-point gather to obtain frequency domain seismic data after ghost wave suppression; 7) performing steps 2) to 6) on other shots in the common-shot-point gather to obtain frequency domain seismic data after ghost wave suppression; and 8) performing inverse Fourier transform on frequency domain seismic data F<CD> after ghost wave suppression to obtain a common-shot-point gather after ghost wave suppression. The variable-depth cable ghost wave suppression method based on wave equation boundary value inversion can be used in the processing process of seismic data collected by a maritime variable-depth cable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

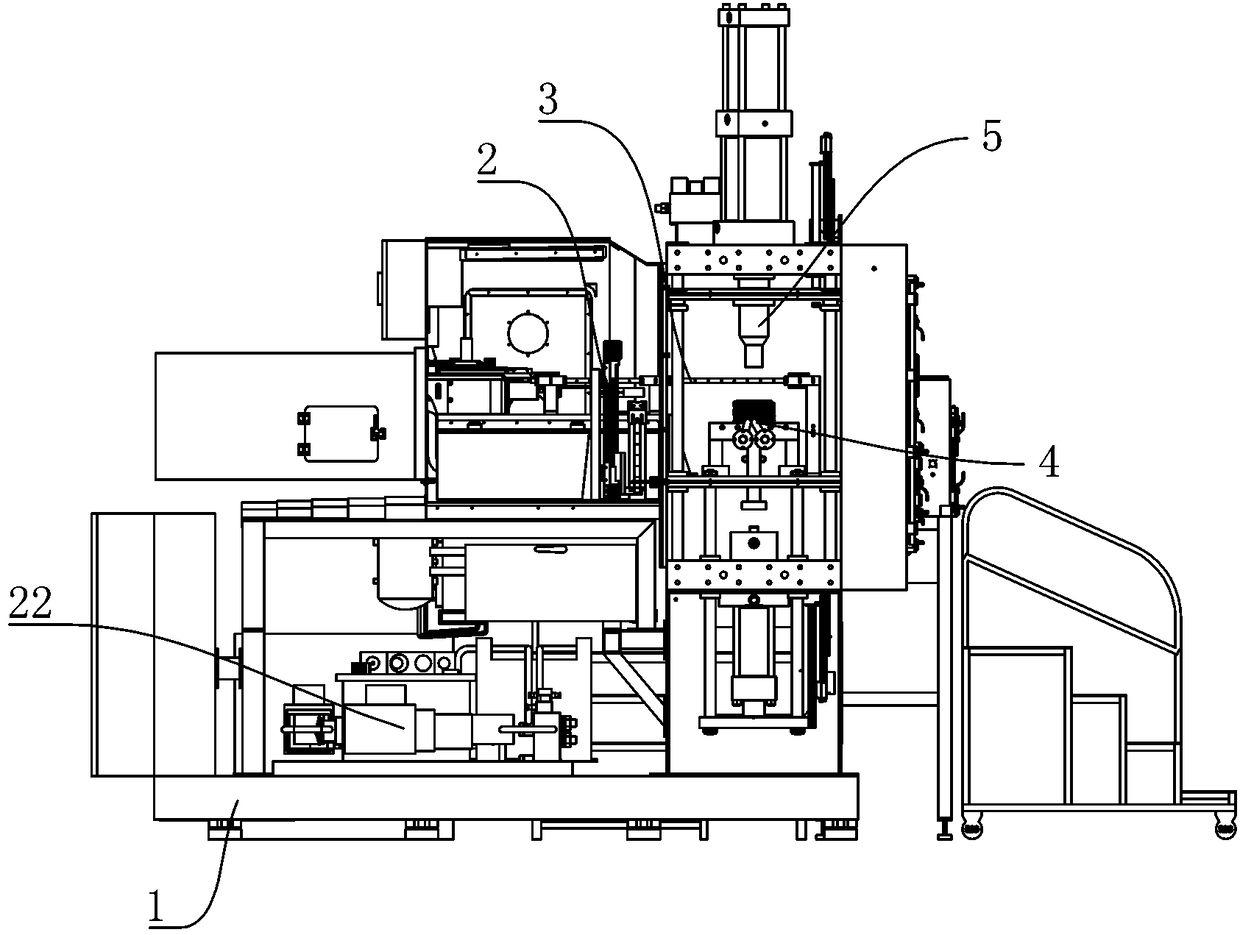

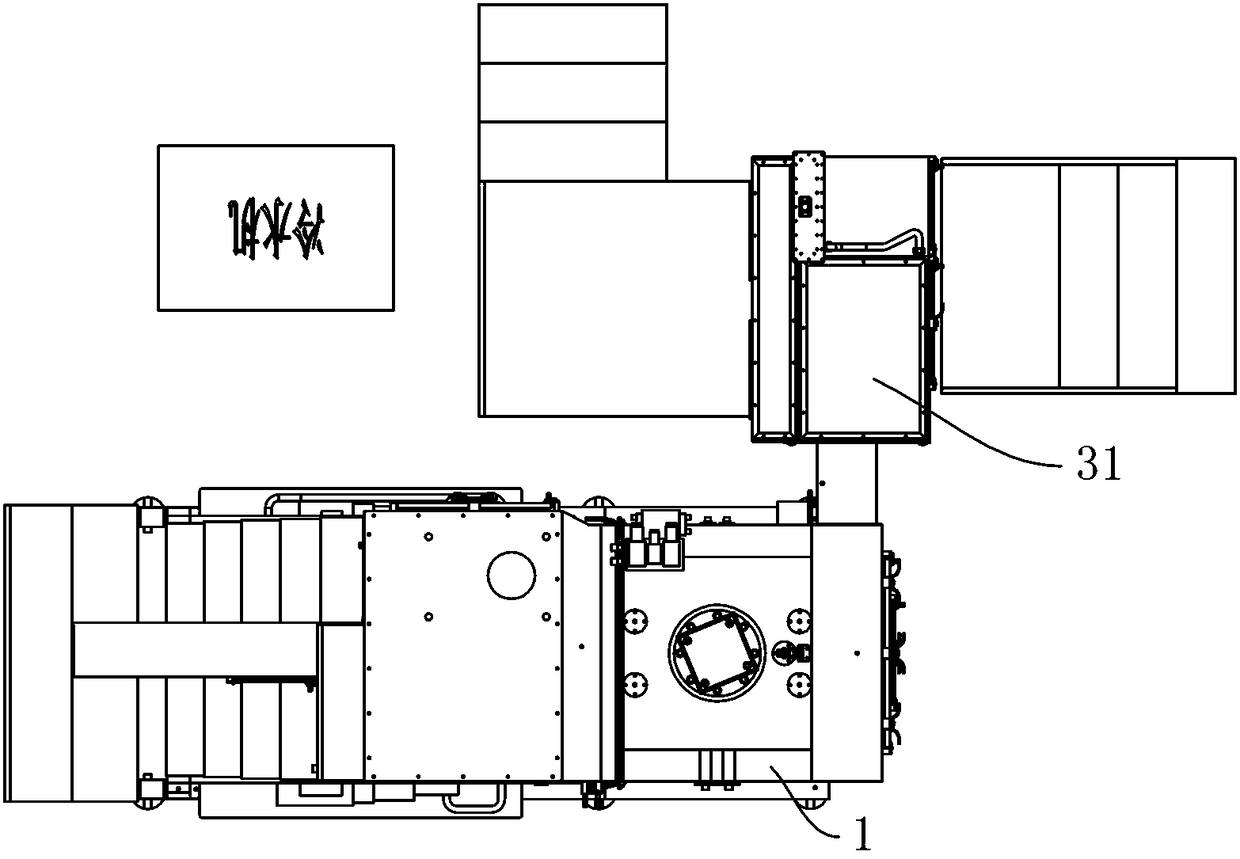

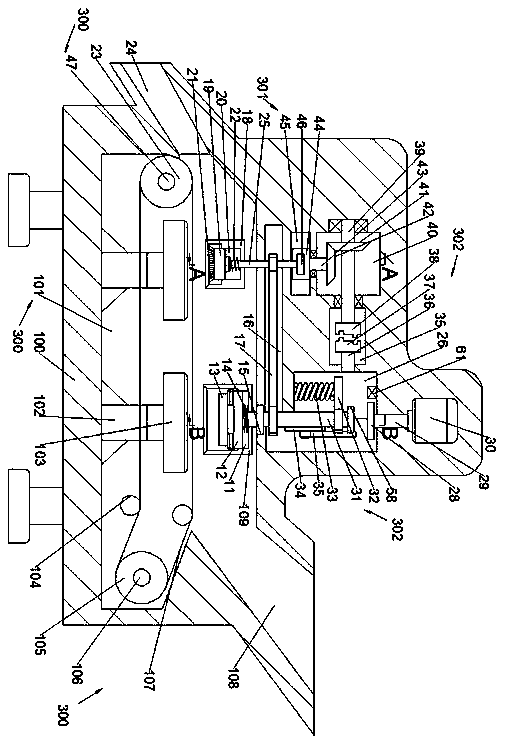

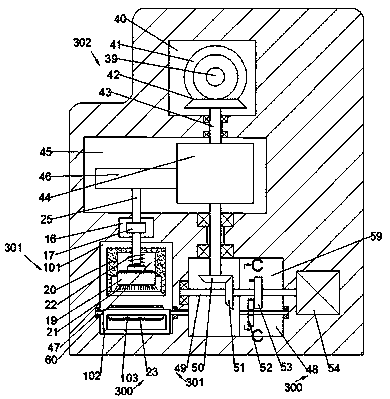

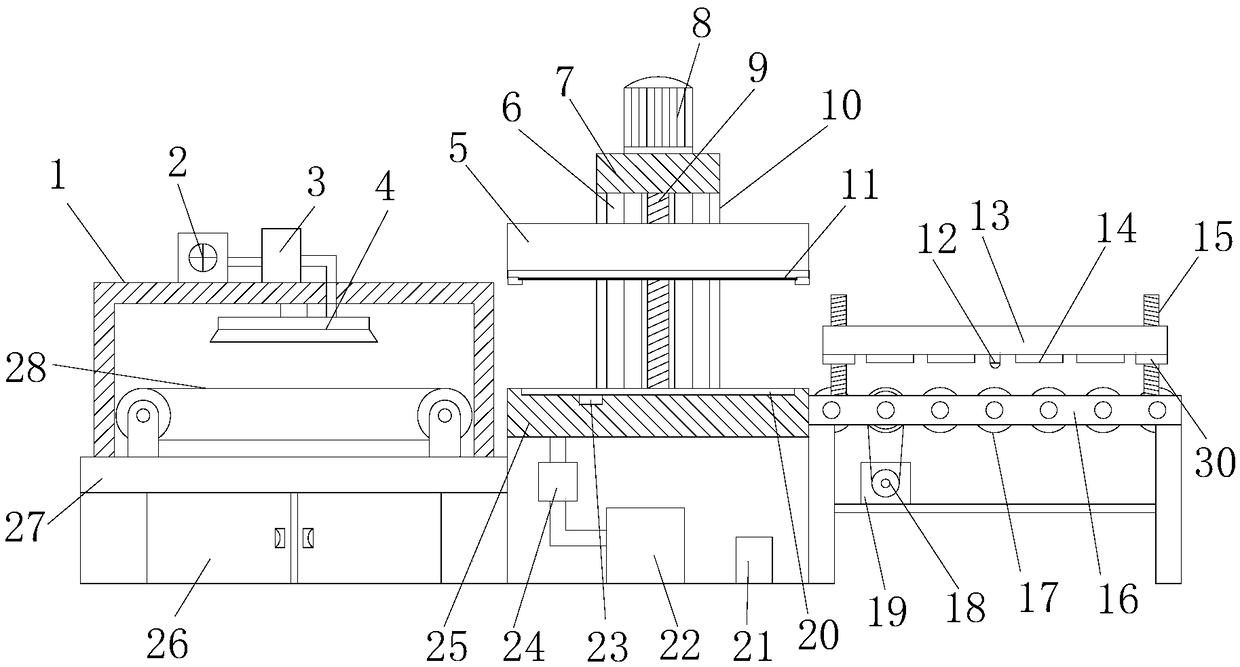

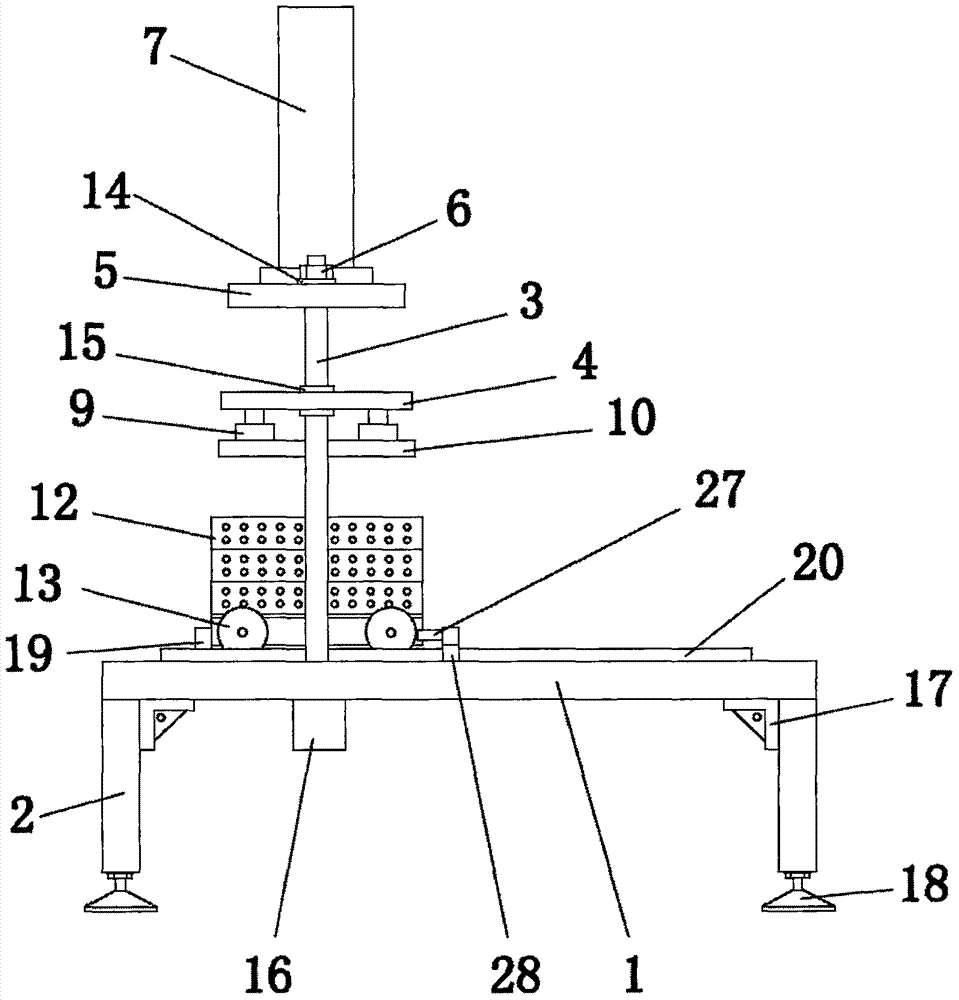

Full-automatic floating type hot-press forming press

The invention discloses a full-automatic floating type hot-press forming press which comprises a seal protective cover. A framework is arranged in the seal protective cover, a feed device, a conveyingdevice, a heating device and a forming device are arranged on the framework, the feed device, the conveying device and the heating device are transversely sequentially arranged, the forming device isarranged at the upper end and the lower end of the heating device, a balance system is arranged below the conveying device, a precision control box for controlling the balance system is arranged beside the balance system, the heating device comprises a forming die and a heating coil, the forming die is connected with the conveying device, and the heating coil is wound outside the forming die. Thefull-automatic floating type hot-press forming press has the advantages that the structure of the forming device is improved, accordingly, excellent pressing effects can be realized, the full-automatic floating type hot-press forming press is low in rejection rate, the automation degree can be upgraded, and the work efficiency can be improved; blanks can be continuously and stably added into theforming die in pressing procedures, and accordingly the machining efficiency can be guaranteed.

Owner:BAIQIDA INTELLIGENT TECH NINGBO CO LTD

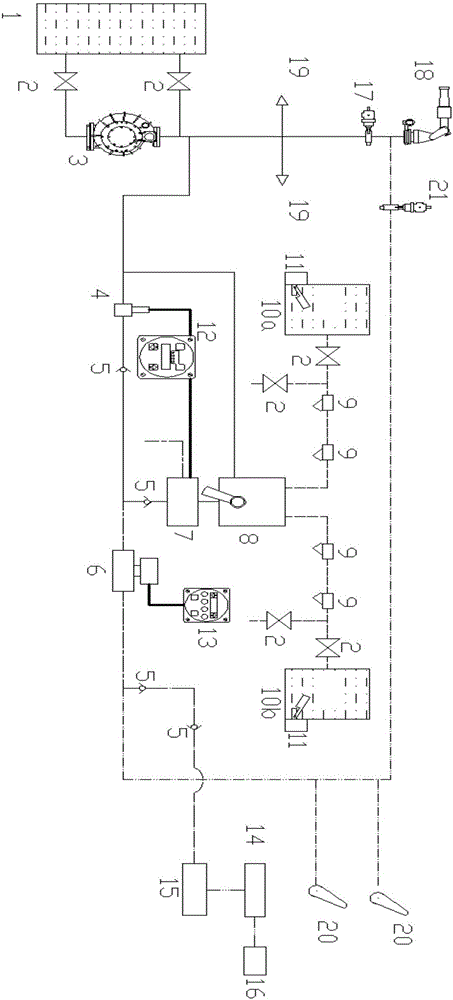

Compressed nitrogen and foam fire-extinguishing system

InactiveCN105879269AEliminate oxygen combustionImprove the isolation effectFire rescueCombustionNitrogen

The invention discloses a compressed nitrogen and foam fire-extinguishing system. The compressed nitrogen and foam fire-extinguishing system comprises a fire-extinguishing foam tanker and a nitrogen tanker, wherein the fire-extinguishing foam tanker is basically equal to a fire-extinguishing foam tanker in the prior art, the nitrogen tanker is provided with a compressed nitrogen system, the nitrogen system comprises a nitrogen generating device and a nitrogen delivery pipeline, and the nitrogen outlet end of the nitrogen generating device is connected with a water-foam mixing pipeline on the fire-extinguishing foam tanker to form a compressed nitrogen and foam liquid pipeline. The compressed nitrogen and foam fire-extinguishing system has the technical advantages that oxygen supported combustion in the air is completely eradicated, a foam insulation effect is improved, and the fire disaster suppressing capability is strengthened. The nitrogen generating device serves as an independent unit to constantly supply nitrogen, accordingly the operating capability of the whole fire-extinguishing system is improved, and the fire-extinguishing system is especially suitable for large fire disaster handling.

Owner:四川川消消防车辆制造有限公司

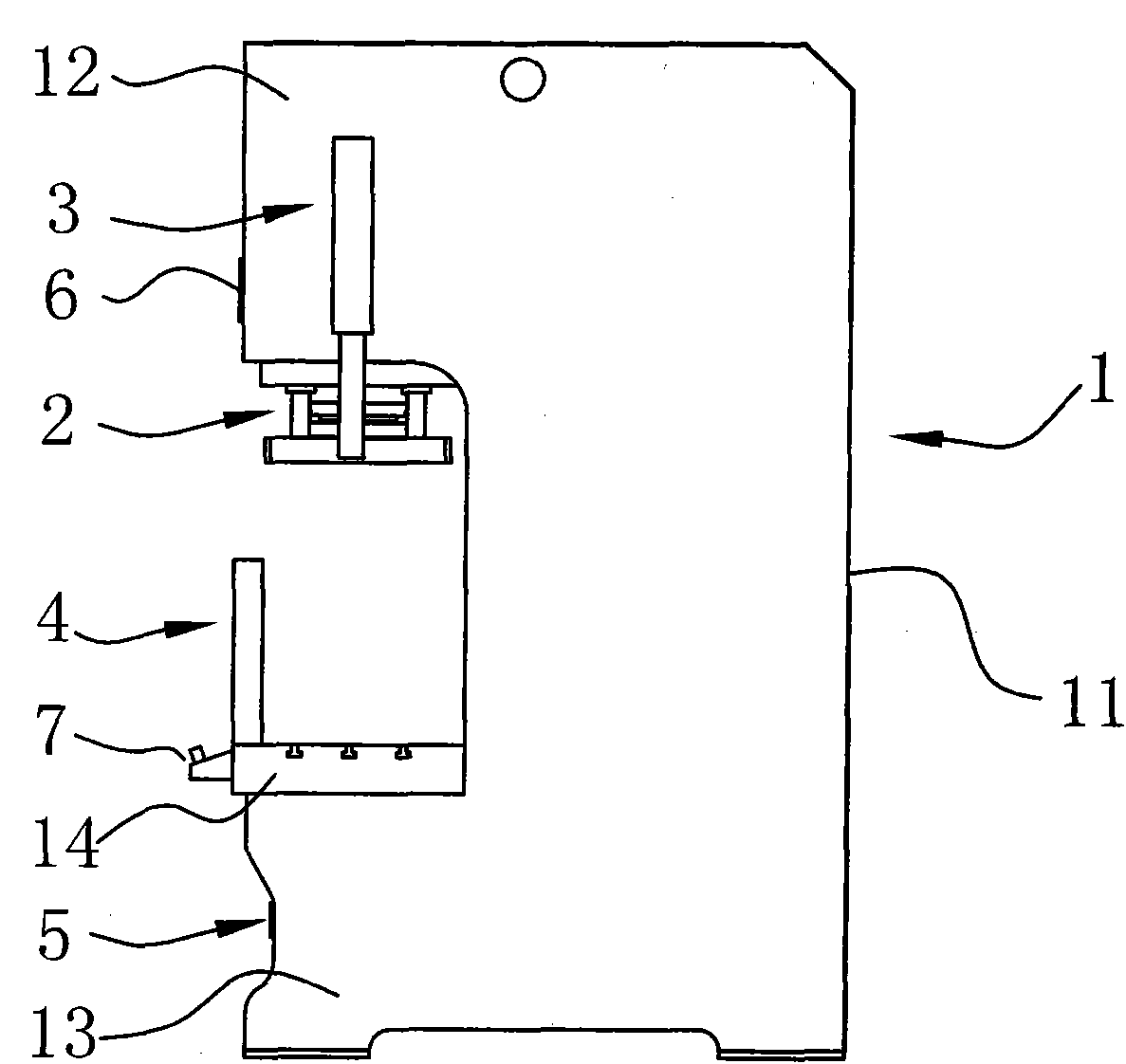

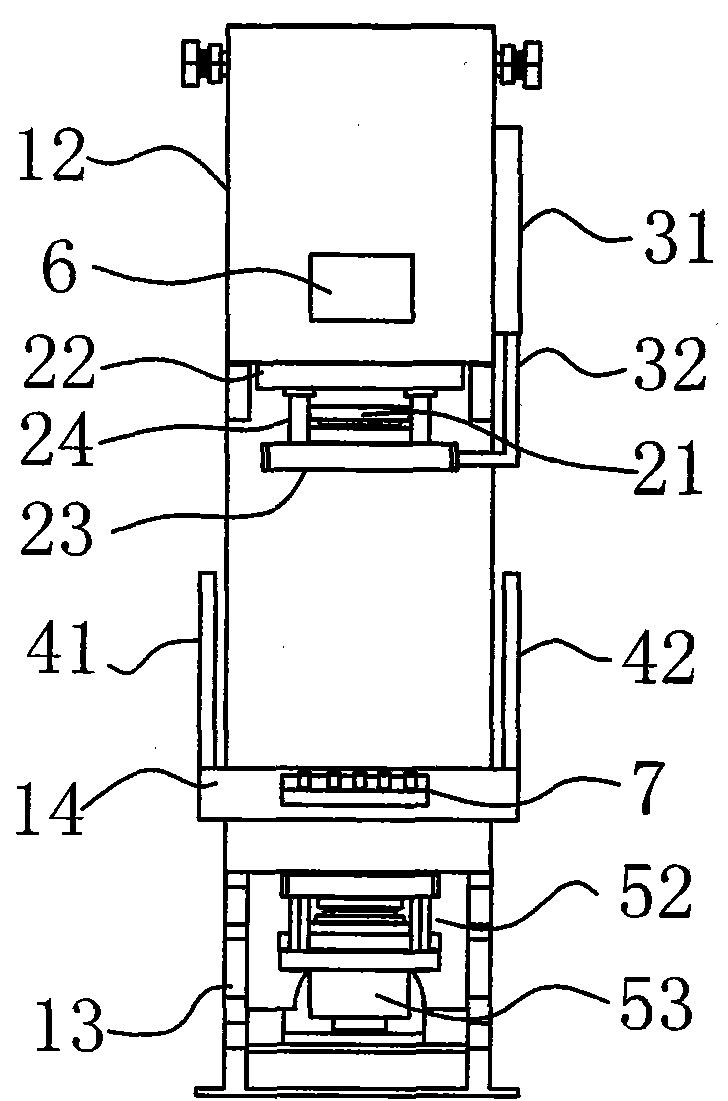

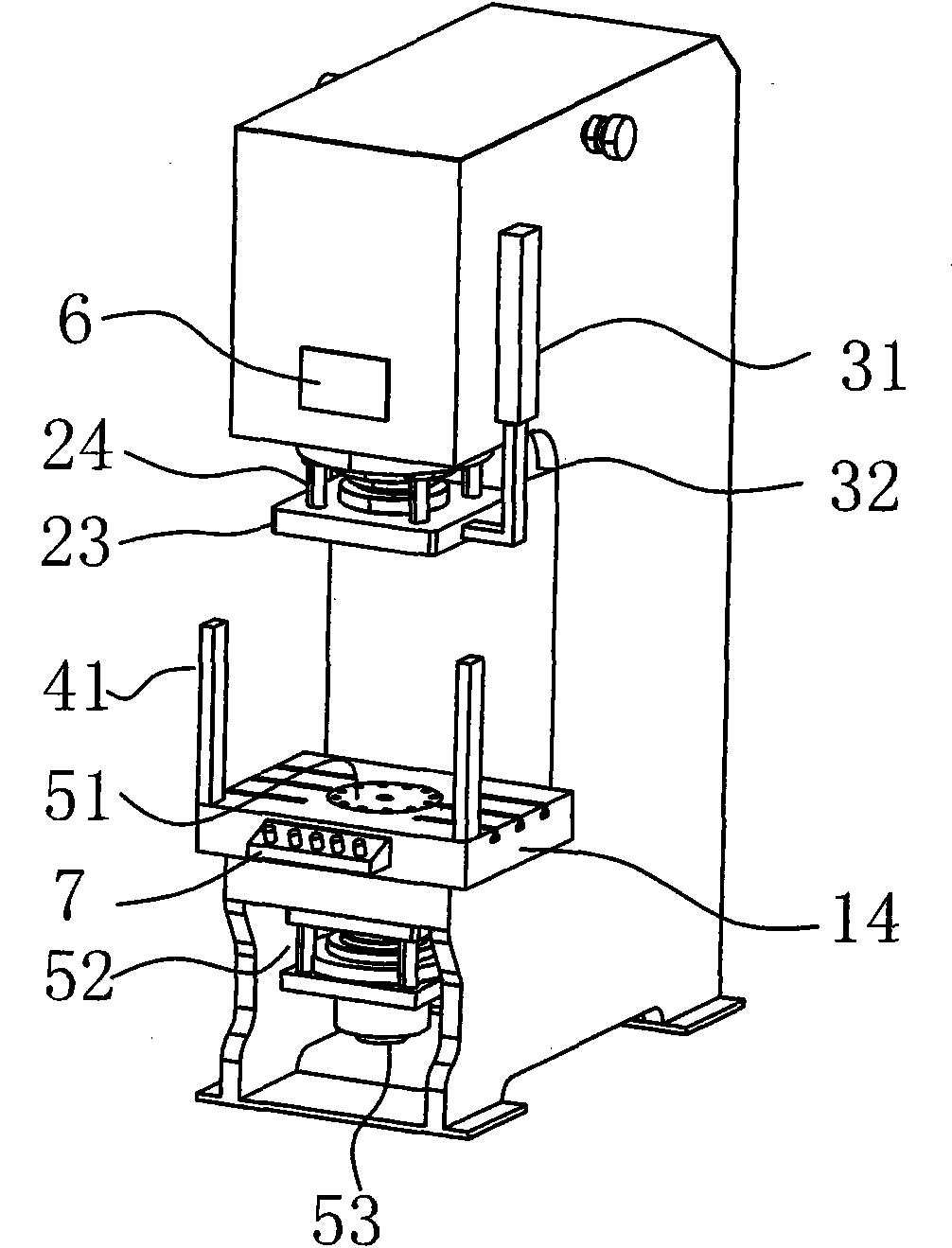

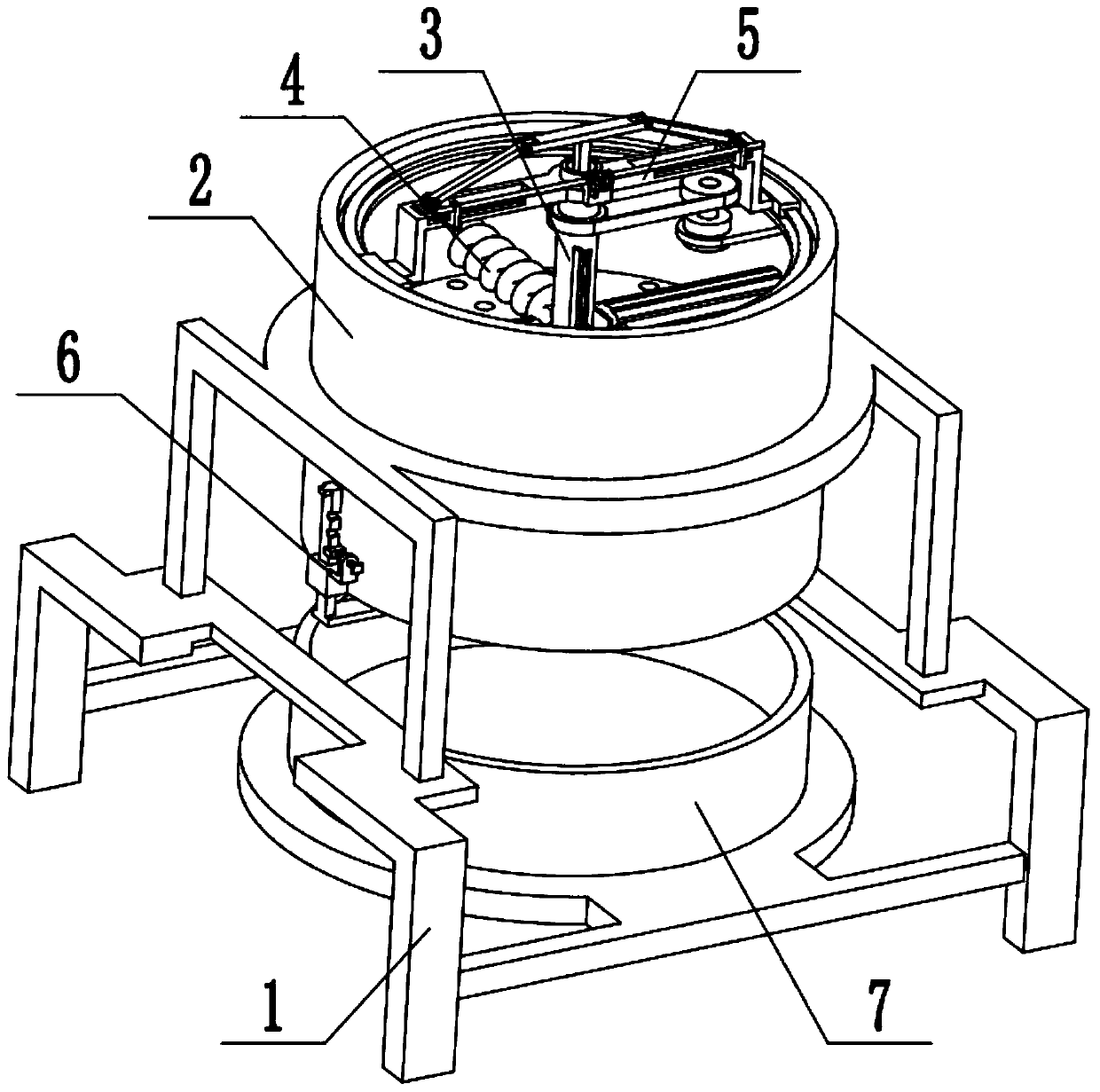

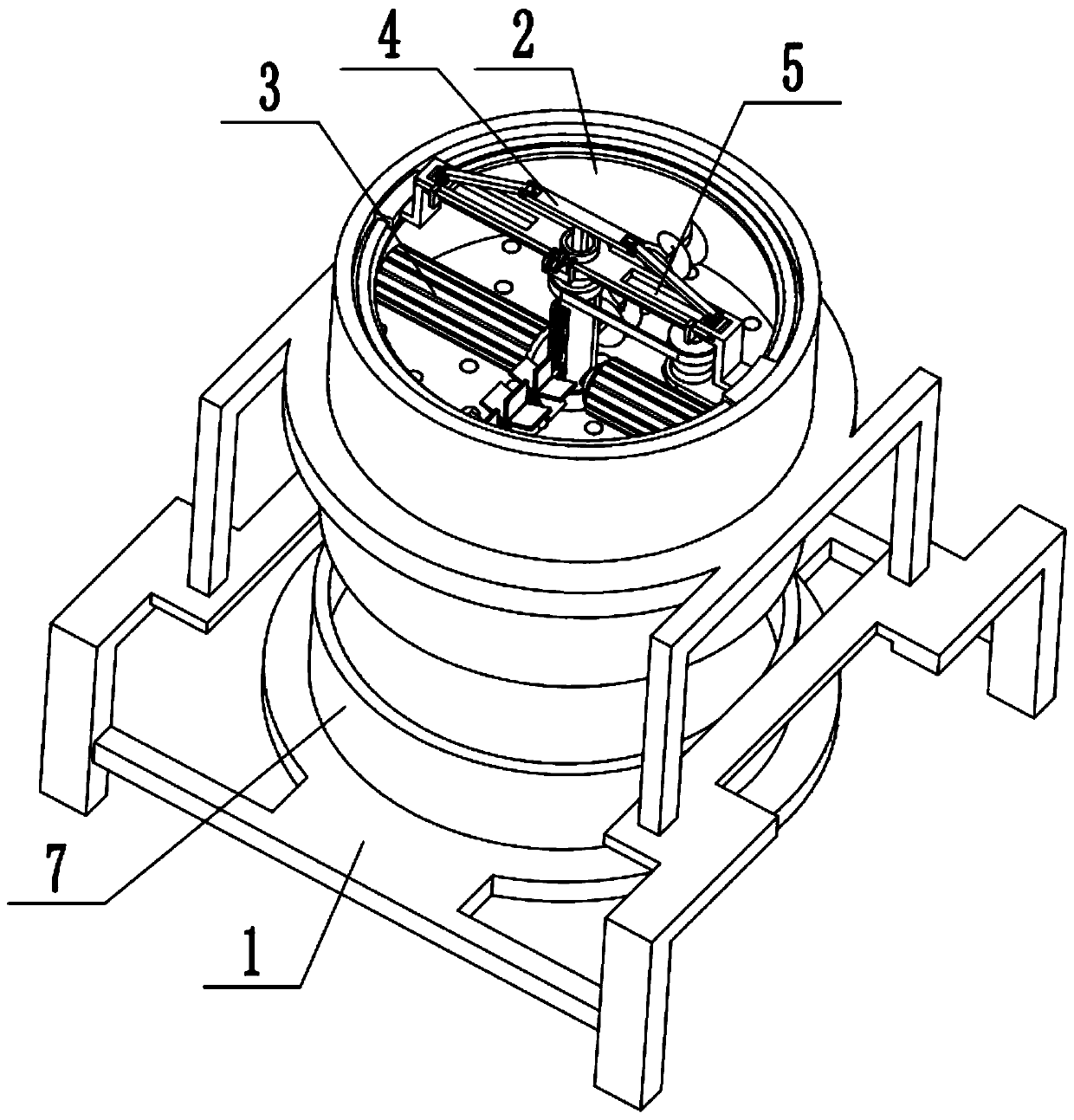

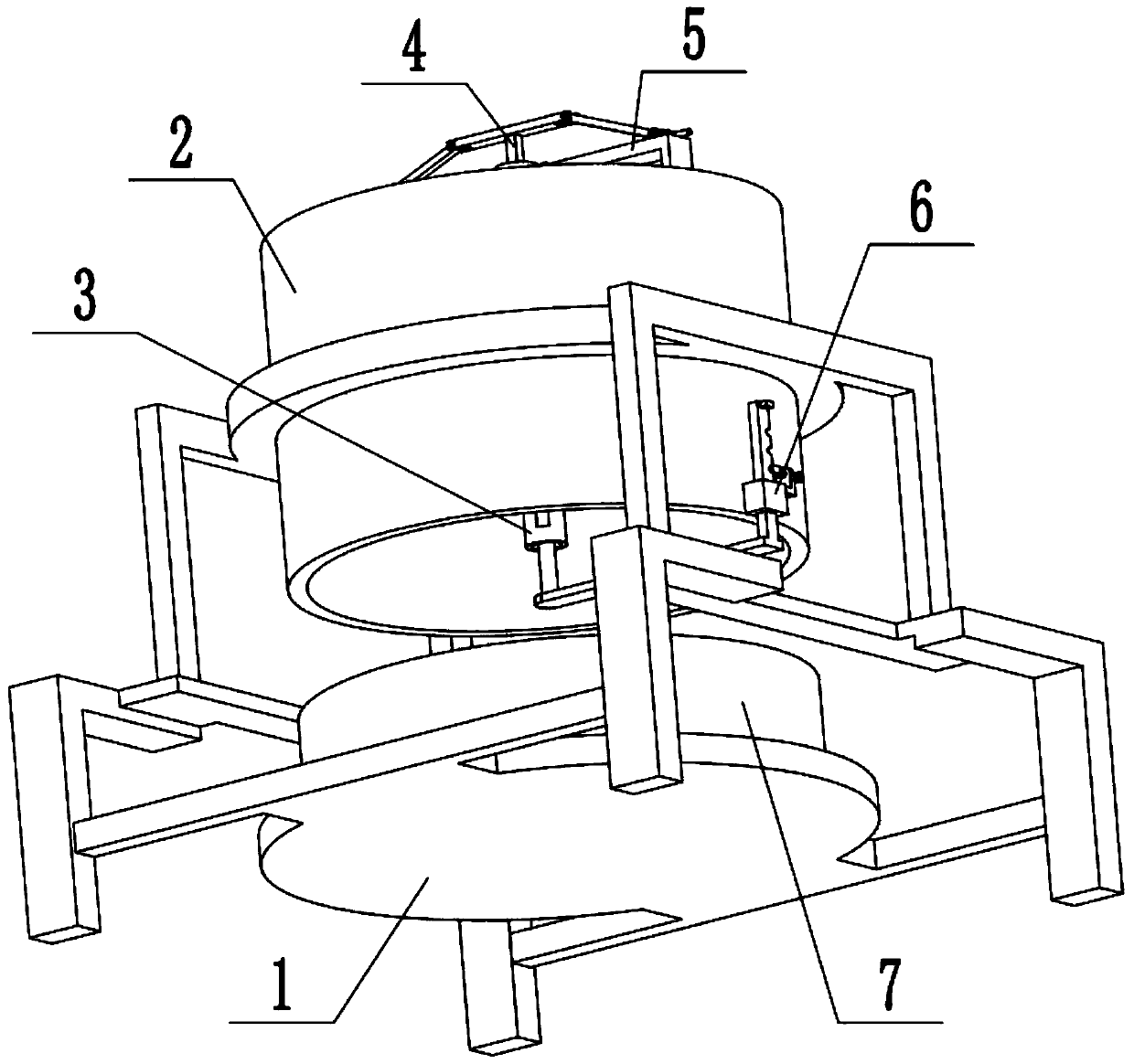

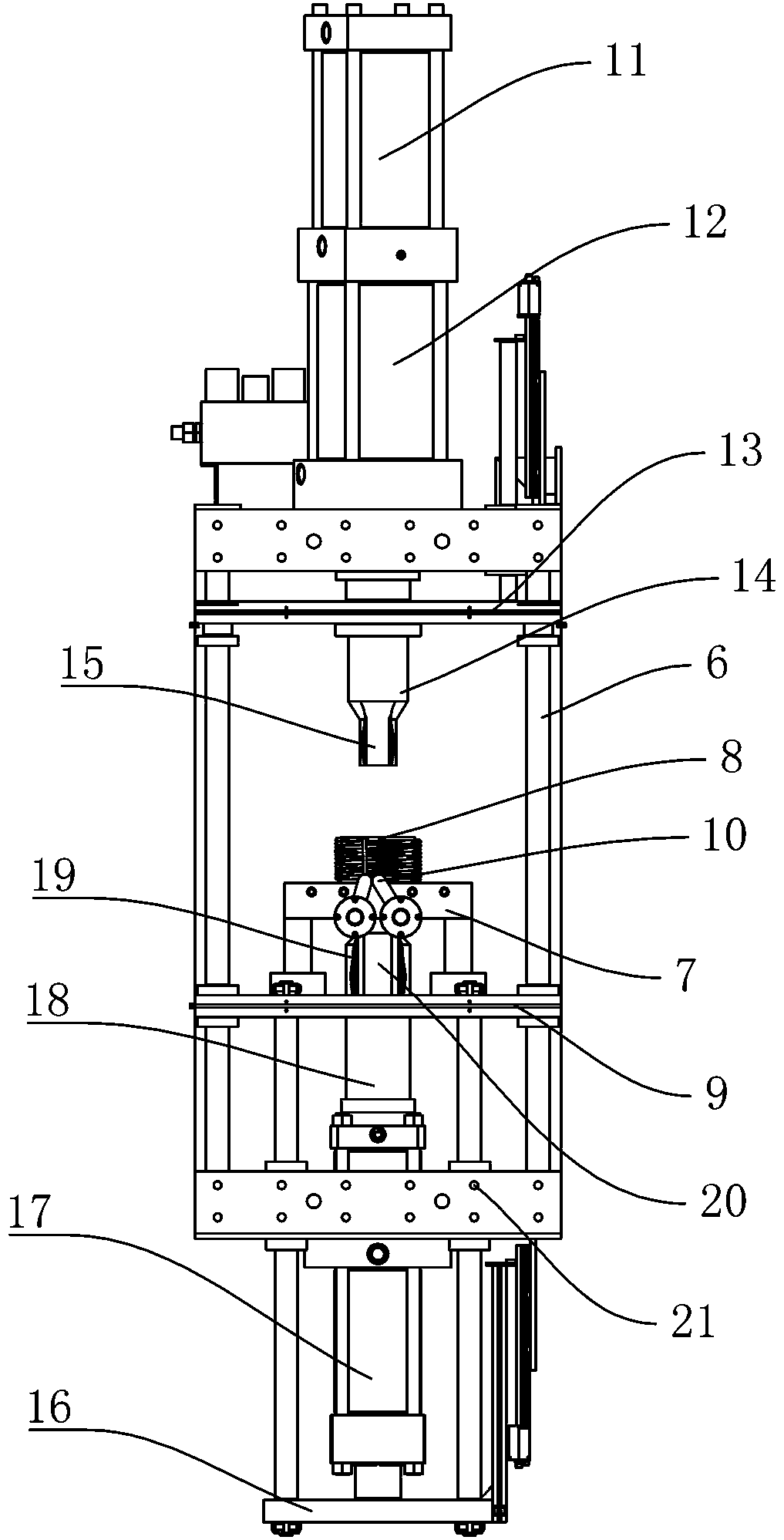

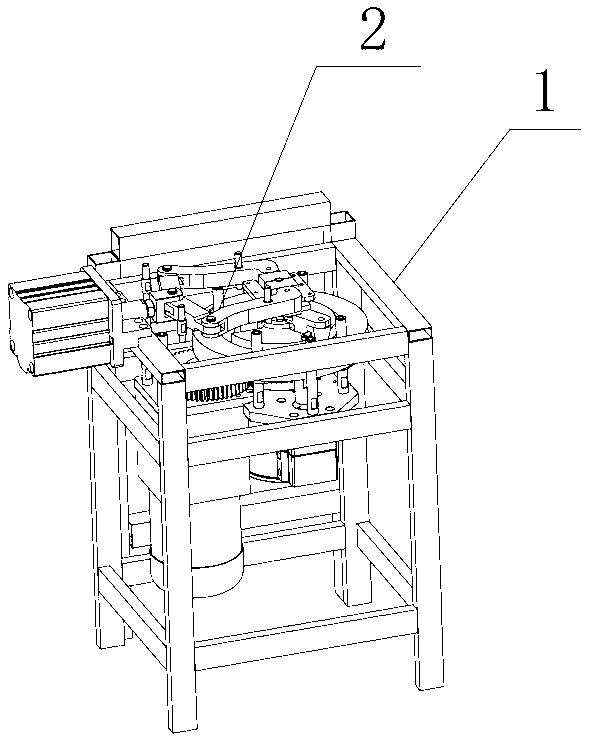

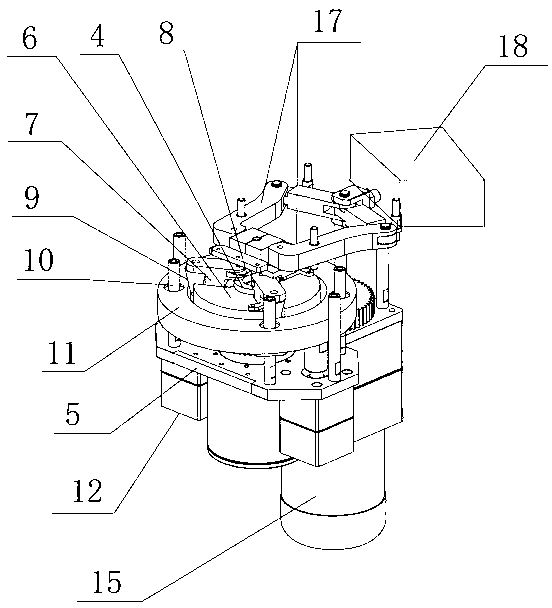

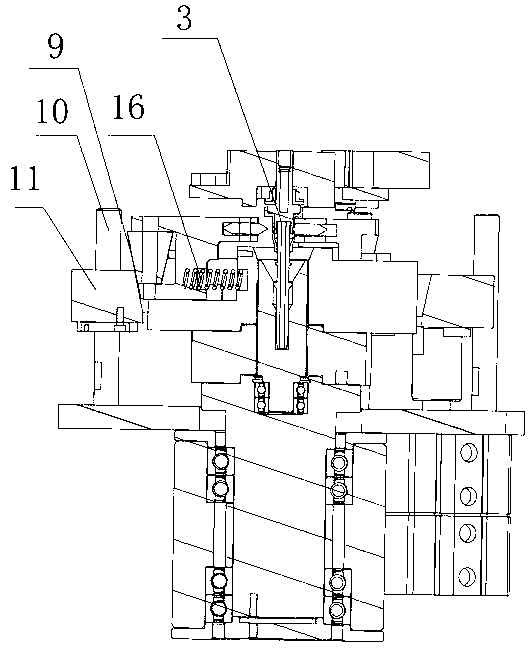

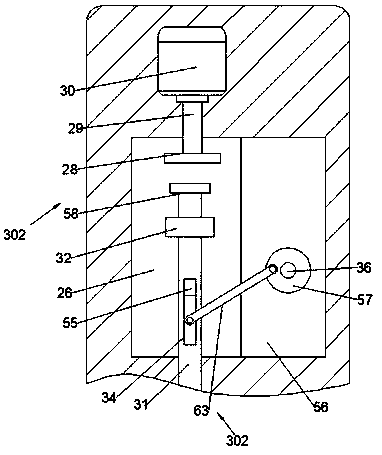

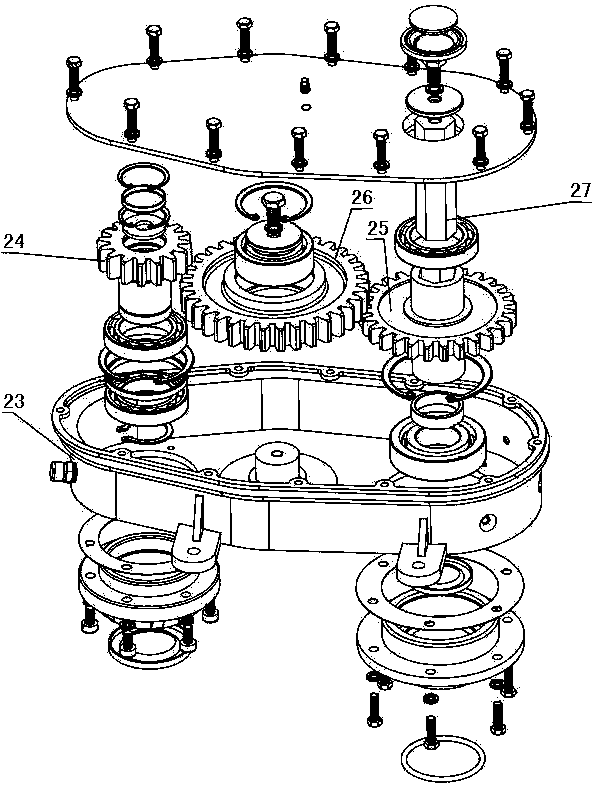

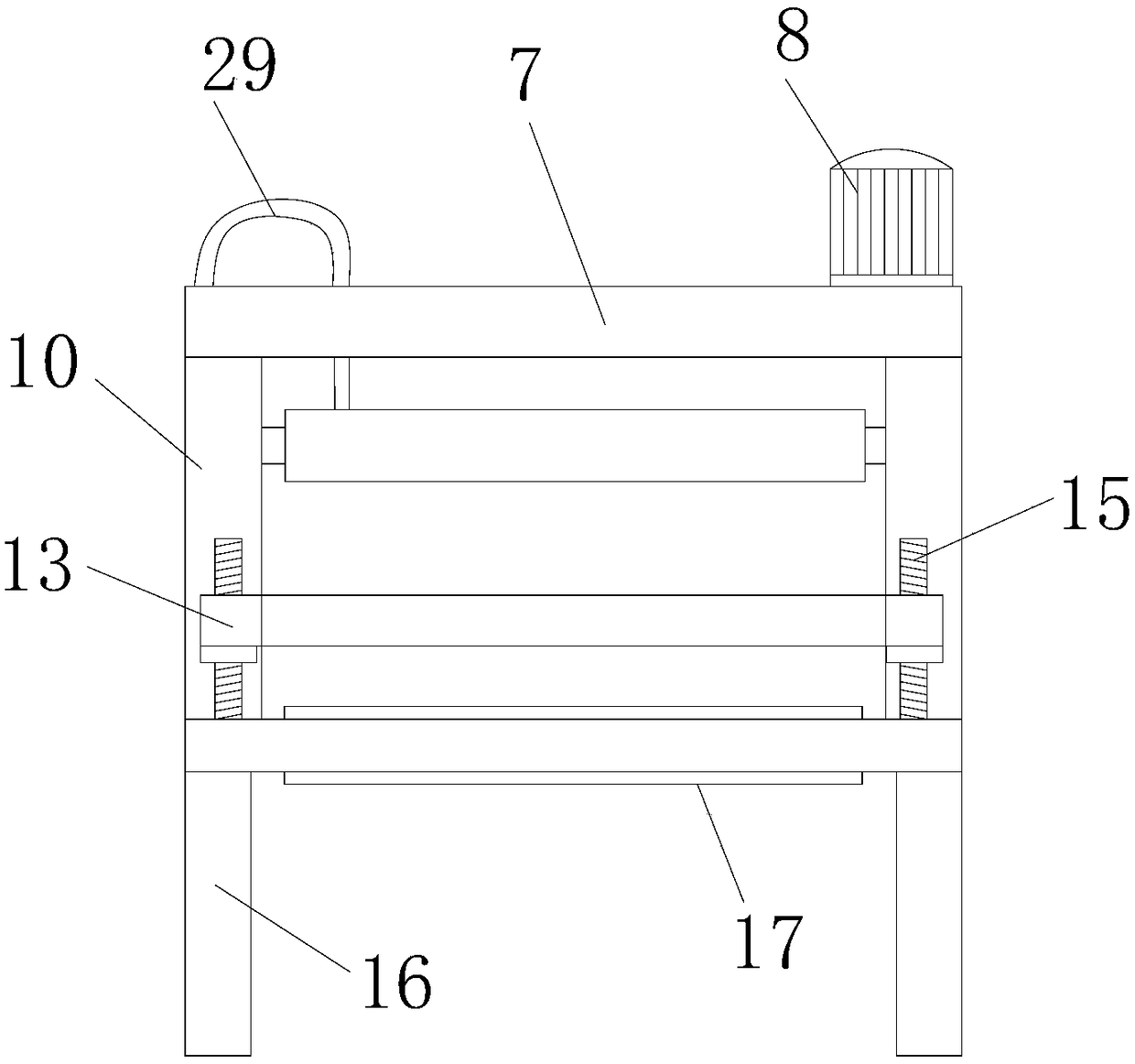

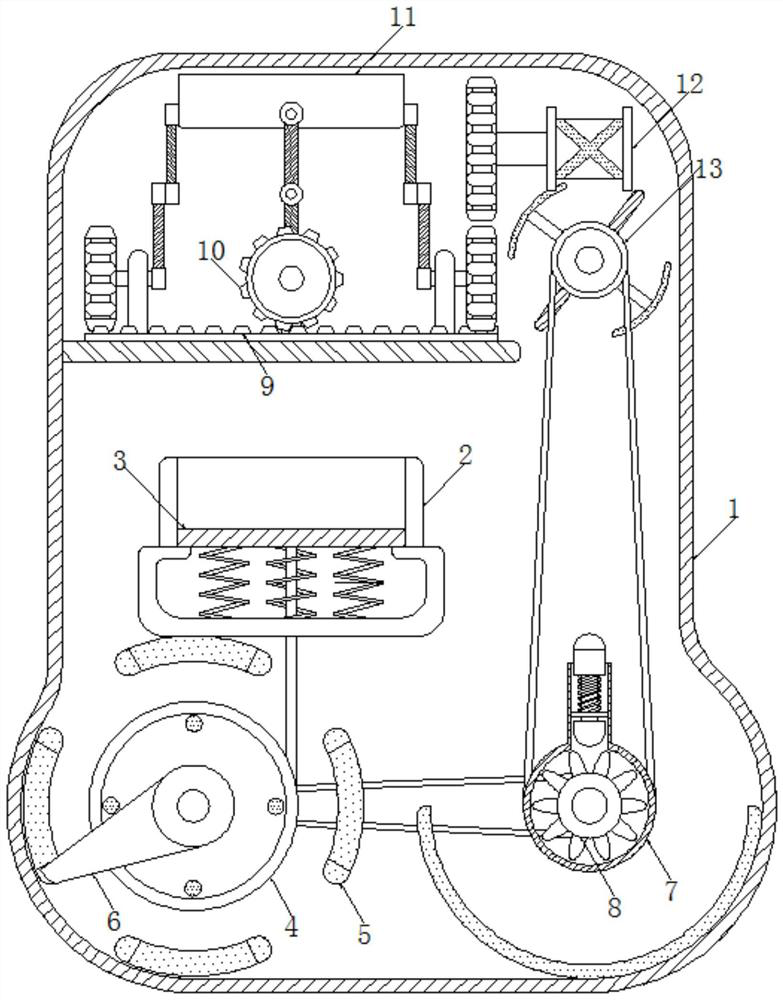

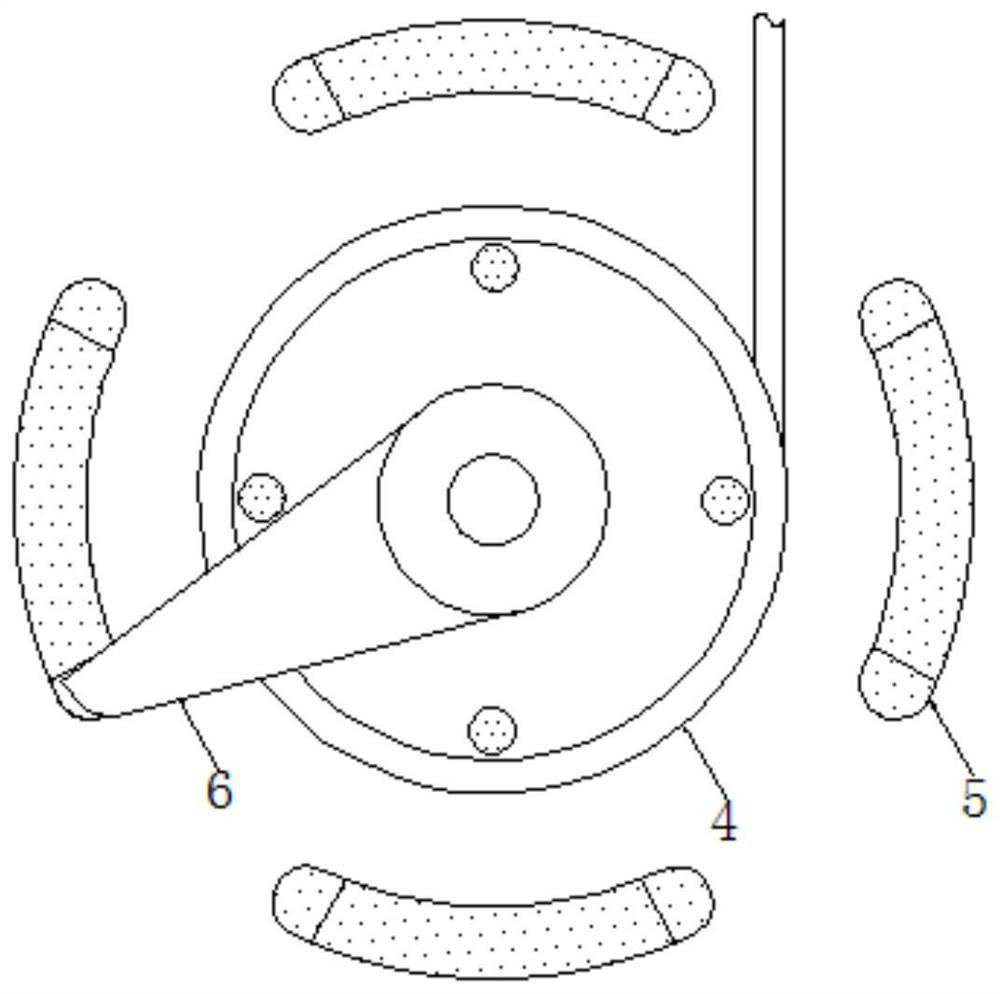

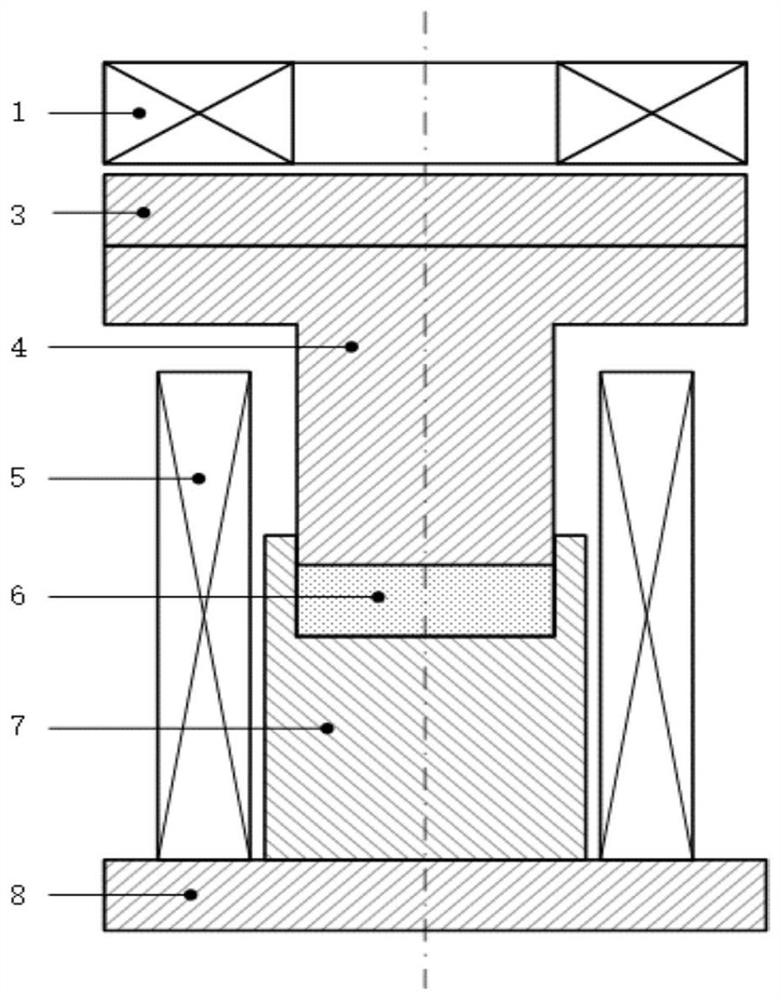

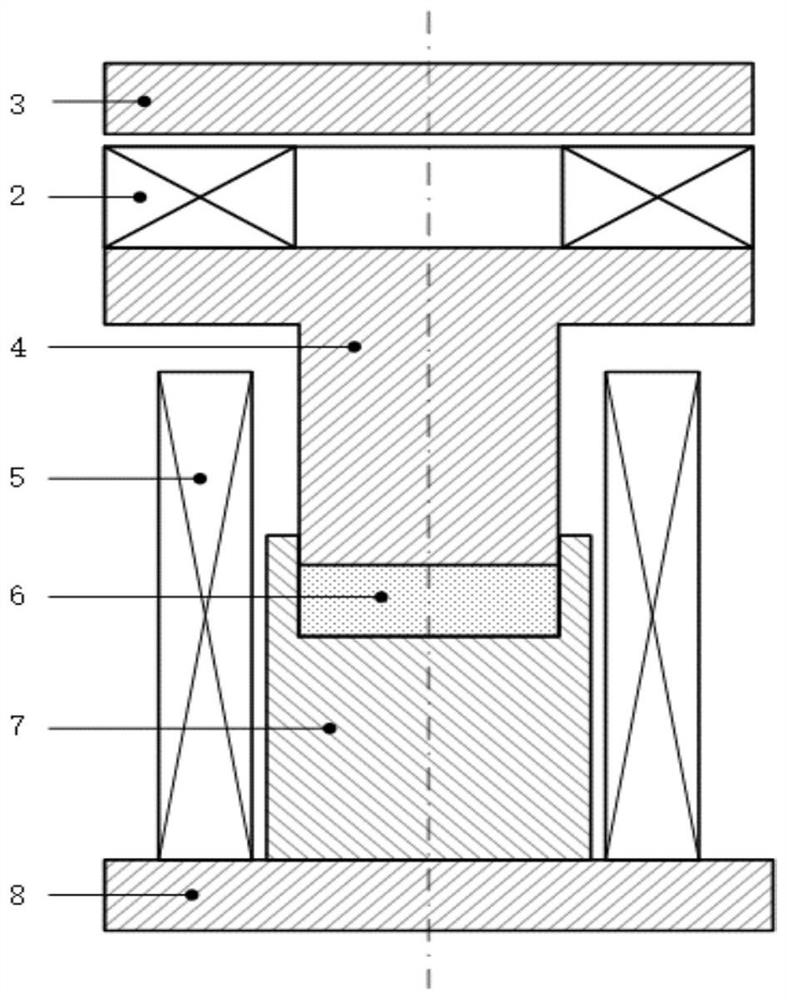

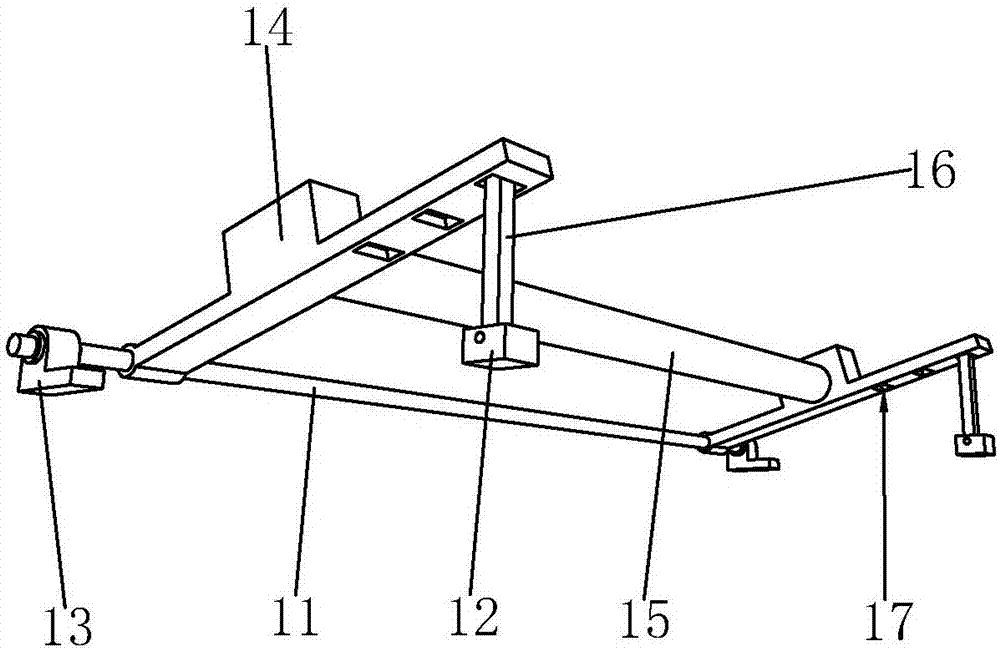

Forming device of full-automatic radiation ring floating type magnetic field forming press

PendingCN108145155AUniform density distributionGood suppression effectCompression moldingEngineering

The invention discloses a forming device of a full-automatic radiation ring floating type magnetic field forming press. The forming device comprises a forming device body which comprises a guide column, a middle guide plate, forming molds, a mold frame, an upper punch, a lower punch and a magnetic field coil, wherein the middle guide plate is arranged on the guide column, and the mold frame is rotationally arranged on the middle guide plate; the forming molds are installed on the mold frame, a core rod is arranged in the forming molds, and the core rod is installed on the mold frame; the upperpunch and the lower punch are located at the upper ends and the lower ends of the forming molds respectively, and the magnetic field coil is located beside the forming molds; the upper punch comprises an upper cylinder, a top plate, an upper guide plate and an upper mold; the lower punch comprises a lower cylinder, a bottom plate, a lower guide plate, a lower mold connecting base and a lower moldfixing base. By improving the structure of the forming device, neodymium iron boron powder is subjected to compression molding, and the forming molds can move relative to each other, so that densitydistribution of the neodymium iron boron powder in mold cavities of the forming molds is uniform, the pressing effect is good, and the rejection rate is low.

Owner:BAIQIDA INTELLIGENT TECH NINGBO CO LTD

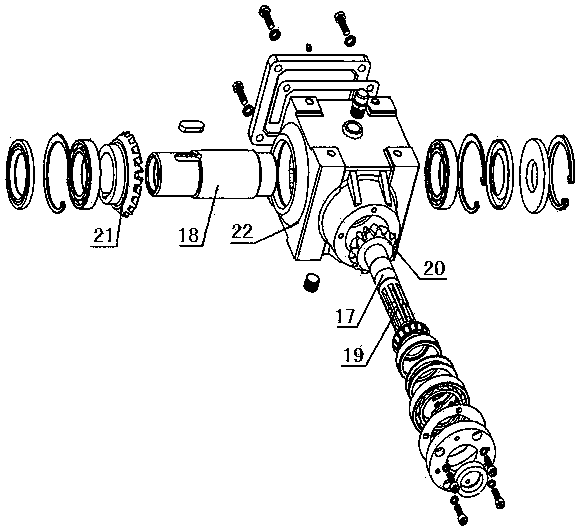

Riveting press for automobile automatic gear-shifting cable heads

InactiveCN103008482AImprove consistencyImprove the suppression effectEngineeringMechanical engineering

Owner:NINGBO AUTO CABLE CONTROLS

Wallet surface treatment device

InactiveCN110271269AEasy to useImprove aestheticsCylinder pressesPlaten pressesEngineeringDrive motor

The invention discloses a wallet surface treatment device. The wallet surface treatment device comprises a device box. A drive motor is started; the drive motor drives a shifting wheel and a driving bevel gear to rotate; the shifting wheel rotates to drive a grooved wheel to rotate intermittently; the intermittent rotation of the grooved wheel drives a transmission roller to rotate intermittently; wallets are fed into a working space to be processed through a conveying mechanism; burrs, generated by pressing or production, of the wallets are removed through a burr removing mechanism; and the patterns of the wallets are pressed through a pressing mechanism. Aiming at different materials, pressing is carried out, steel seals are heated, and the pressing effect is guaranteed, so that the pressing effect is improved, and the using hand feeling and the beautiful degree of the wallets are improved.

Owner:义乌市玉刚箱包有限公司

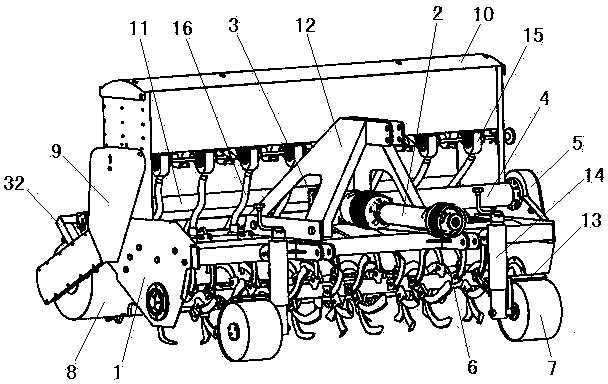

Novel rotary-tillage fertilizing seeder

InactiveCN103749018AEasy to disassemble and maintainConvenient tillage depth adjustmentSpadesAgricultural machinesSeederDrive shaft

The invention relates to a novel rotary-tillage fertilizing seeder which comprises a frame. A central transmission case which is in transmission connection with a tractor power output shaft through a transmission shaft is arranged in the middle front portion of the frame; a side transmission case which is in transmission connection with the central transmission case through a hexagon input shaft is arranged on one side of the frame; a rotary tillage cutter shaft assembly driven through the hexagon input shaft of the side transmission case is disposed on the lower front side of the frame; two depth-limited wheel assemblies are symmetrically disposed in the front of the frame, a suppression wheel assembly is disposed in the rear of the frame, a sprocket-wheel case in transmission connection with the suppression wheel assembly is arranged on the other side of the frame, and a seed fertilizer case in transmission connection with the sprocket-wheel case is arranged in the rear of the frame. The novel rotary-tillage fertilizing seeder has the advantages of simple structure, manufacture easiness, convenience in installation, no leakage, good suppression effect, high transmission efficiency, long service life and the like.

Owner:黄宗筹

Paper embossing machine

InactiveCN103182799ASimple structureEasy to pressMechanical working/deformationHydraulic pumpPulp and paper industry

The invention discloses a paper embossing machine which comprises a flattening device, a bracket, a pressing plate, a pattern plate, a hydraulic rod, a fixing member, a hydraulic pump and a control cabinet, wherein the section of the bracket is in a square shape; the flattening device consists of double rotary shafts; the pressing plate is movably connected with the left and right sides of the bracket; the pattern plate is fixedly mounted at the bottom of the bracket; one end of the hydraulic rod is fixed above the pressing plate through the fixing member, and the other end is fixed at the top of the bracket through a nut; the hydraulic rod is connected with the hydraulic pump; and the hydraulic pump is connected with the control cabinet. The paper embossing machine disclosed by the invention embosses paper through a mechanical embossing mode, can emboss the pattern of the pattern plate on the paper through the lifting of the pressing plate, realizes a good embossing effect and is beneficial for popularization and application.

Owner:KUNSHAN DACHANG MACHINERY MFR

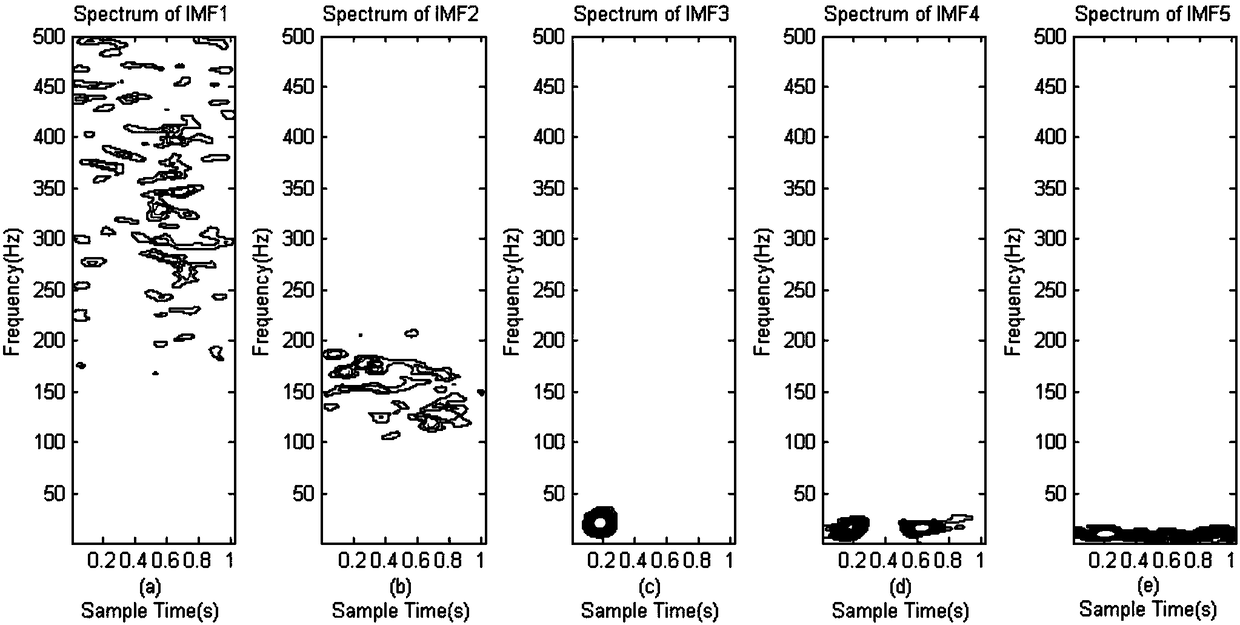

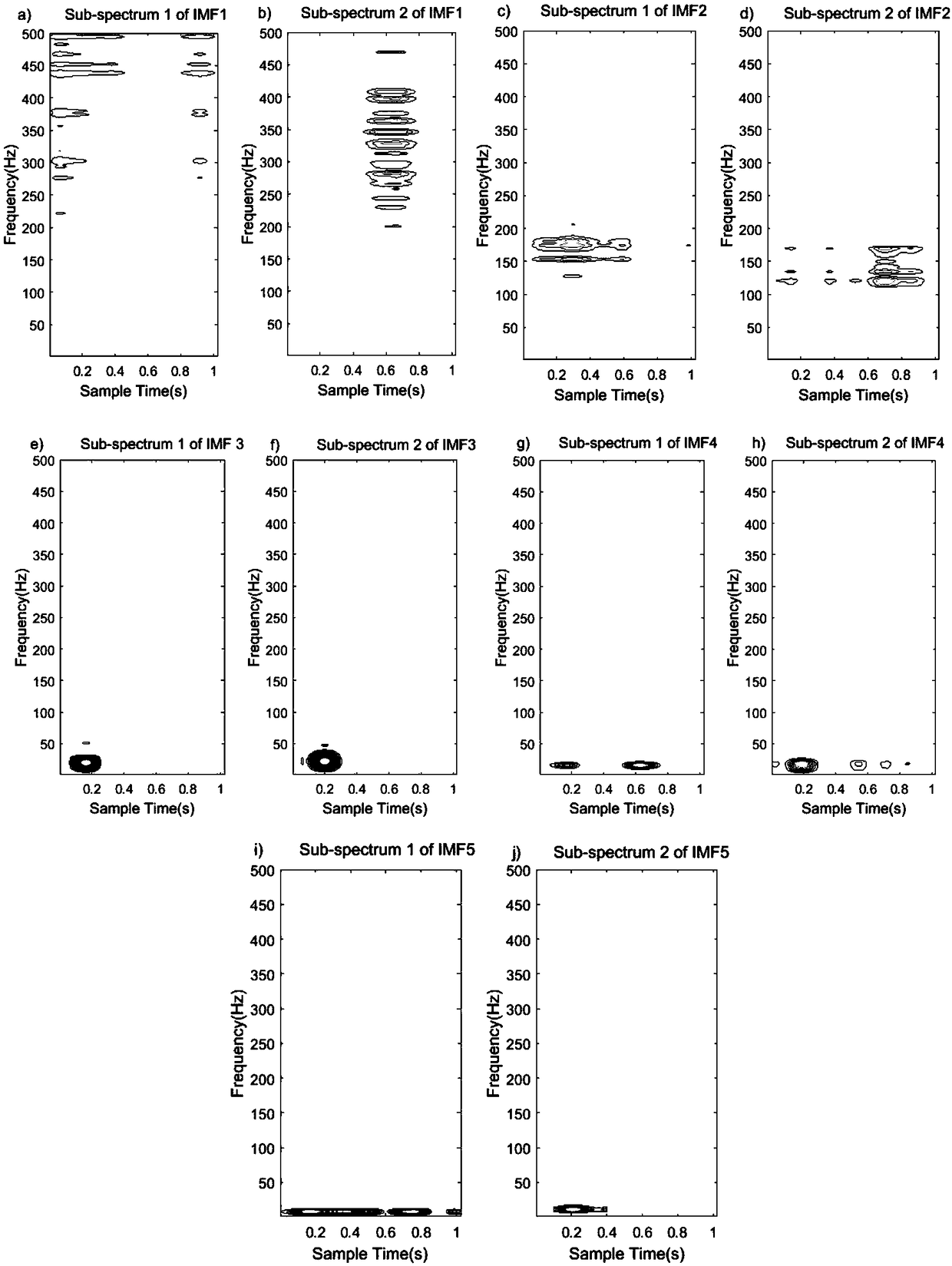

SNMF-2D time-frequency spectrum separation based desert low-frequency noise reduction method

InactiveCN108227001AImprove the suppression effectReduce mixSeismic signal processingFrequency spectrumDecomposition

The invention provides an SNMF-2D time-frequency spectrum separation based desert low-frequency noise reduction method. decomposing a noise-containing seismic record into multiple sub-signals with different frequency bands; performing spectrum separation of the time-frequency spectra of the sub-signals with different frequency bands based on a SNMF-2D (two-dimensional sparse non-negative matrix factorization) algorithm, so as to sufficiently reduce the mixing degree of effective signal component and noise component; and performing inverse transformation of each separated sub-spectrum to obtaincorresponding sub-signal, and gathering the signal component-containing sub-signals into a signal class by using a clustering algorithm, so as to obtain an effective signal component. The comparisonresult between empirical mode decomposition EMD and time-frequency peak filtering TFPF verifies the effectiveness of the method provided by the invention in the aspects of suppressing desert low-frequency random noise and maintaining the reverse side of the effective component.

Owner:JILIN UNIV

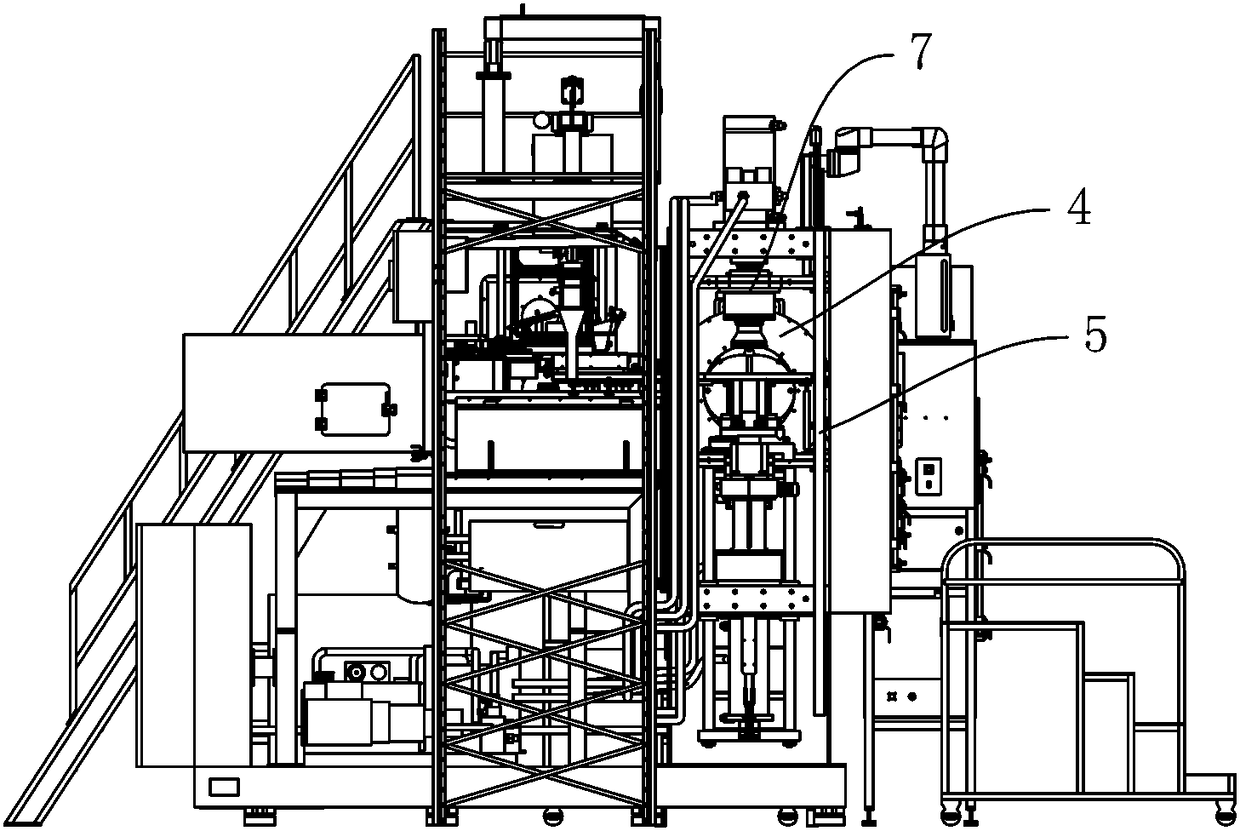

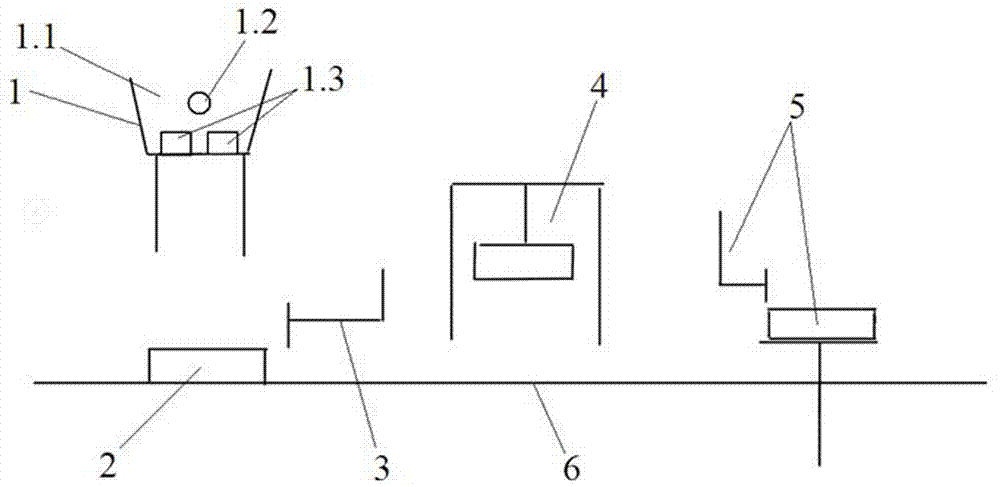

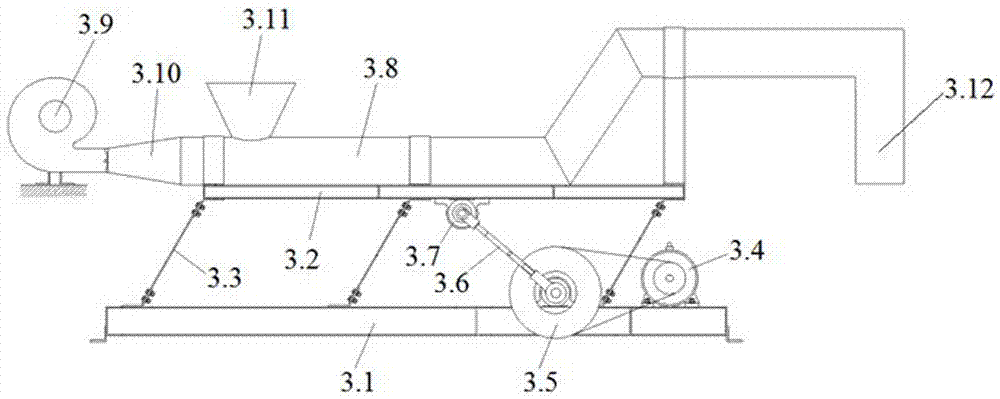

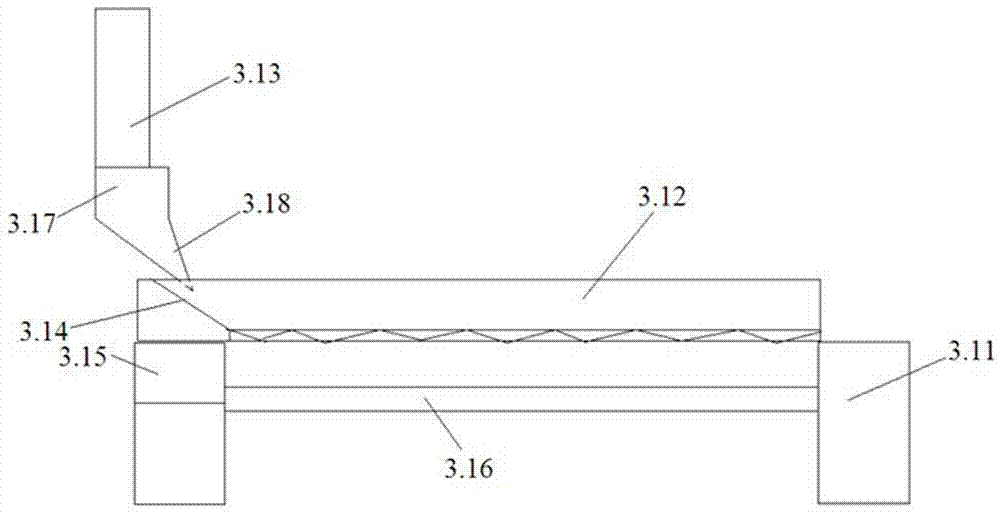

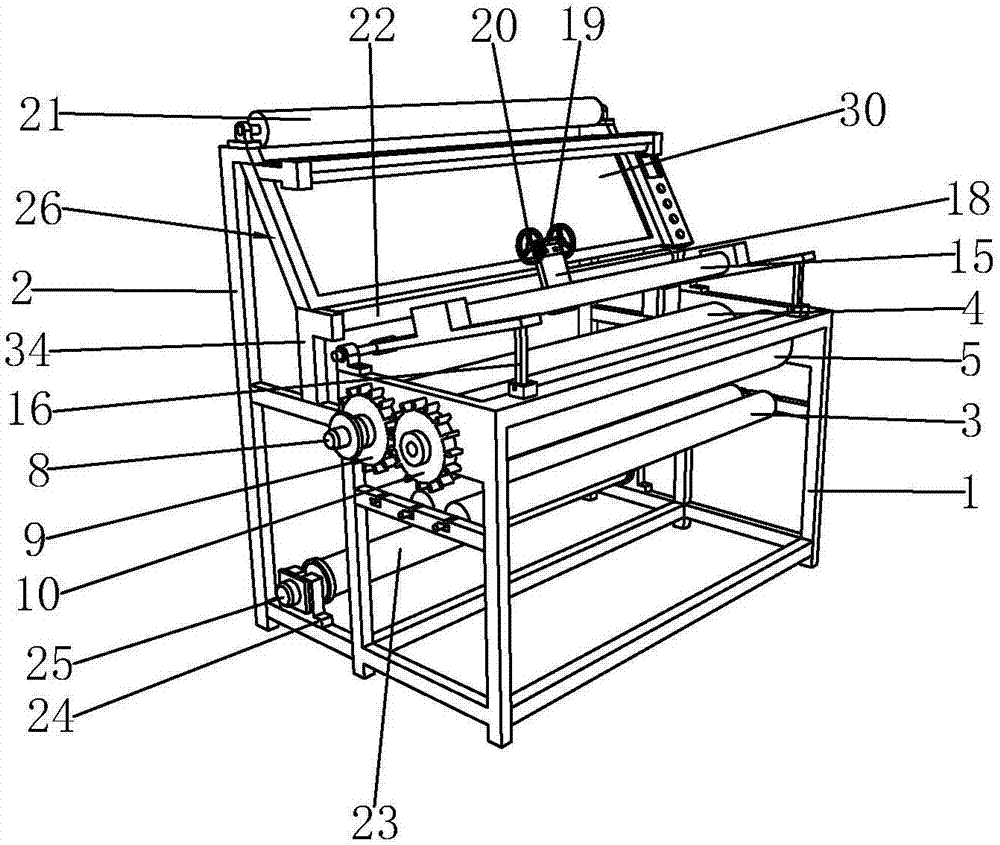

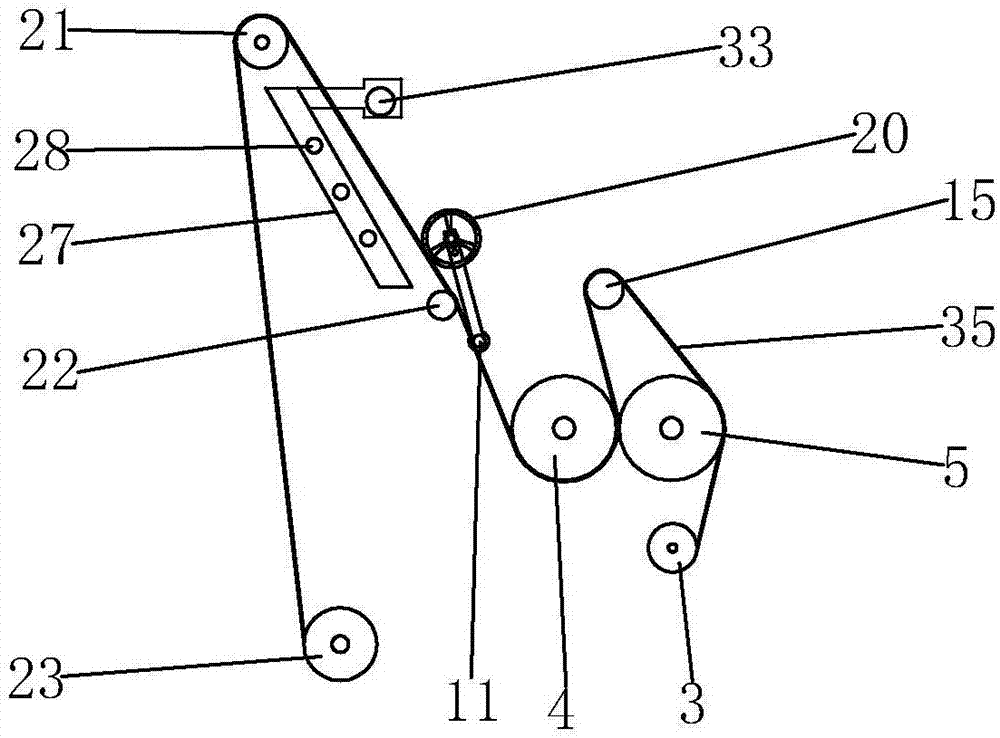

Mechanized tea brick production system

ActiveCN107494801AImprove air delivery efficiencySolve easy blockagePre-extraction tea treatmentBrickAgricultural engineering

The invention relates to a mechanized tea brick production system. The system comprises a raw tea leaf feeding device, a tea leaf pressing mold, a tea-leaf-conveying, dust-removing and surface-smoothing device, a hydraulic tea leaf pressing device, a tea brick pushing-off device and a circulating conveyer belt, wherein the raw tea leaf feeding device, the tea leaf pressing mold and the tea-leaf-conveying, dust-removing and surface-smoothing device are arranged on the front section of the circulating conveyer belt; the raw tea leaf feeding device is arranged on the upper part of the tea leaf pressing mold; the tea leaf pressing mold is arranged on the circulating conveyer belt; the tea-leaf-conveying, dust-removing and surface-smoothing device is arranged on one side of the tea leaf pressing mold; the hydraulic tea leaf pressing device is arranged on the middle section of the circulating conveyer belt; the tea brick pushing-off device is arranged on the back section of the circulating conveyer belt; and one side of the tea-leaf-conveying, dust-removing and surface-smoothing device is provided with a tea leaf returning conveyer belt. The system provided by the invention basically realizes mechanization and automation of tea processing, greatly enhances processing efficiency, and powerfully guarantees production of sanitary tea products conforming to a unified standard.

Owner:普洱市布朗茶业有限公司

Highly-efficient laminating machine used for production of solar cell panel

InactiveCN108608713AReduce replacementLow costDispersed particle filtrationControlling laminationEngineeringWorkbench

The invention discloses a highly-efficient laminating machine used for production of a solar cell panel. The highly-efficient laminating machine comprises a preheating device, a laminating device anda cooling device, wherein the preheating device comprises a support and a preheating platform; a plurality of driving rollers are arranged in the middle of the support; the driving rollers are in engaged connection through gears; a first driving device used for driving the driving rollers is arranged in the lower part of the support; the left and right sides of the upper part of the support are respectively provided with a thread guide pillar; the upper part of each thread guiding pillar is provided with a nut seat; the preheating platform is slidably arranged at the upper parts of thread guide pillars through the nut seats; the left side of the preheating device is provided with the laminating device; the laminating device comprises a sealing pressure head and a workbench; baffle plates are respectively and fixedly arranged above two sides of the workbench; the upper ends of baffle plates are fixedly connected with a cross beam; and the sealing pressure head is slidably arranged between the baffle plates. The highly-efficient laminating machine provided by the invention has the advantages of simple structure, diversified functions, high degree of automation, high production efficiency, high product yield and easy promotion.

Owner:ZHANGJIAGANG GUOLONG SOLAR TECH CO LTD

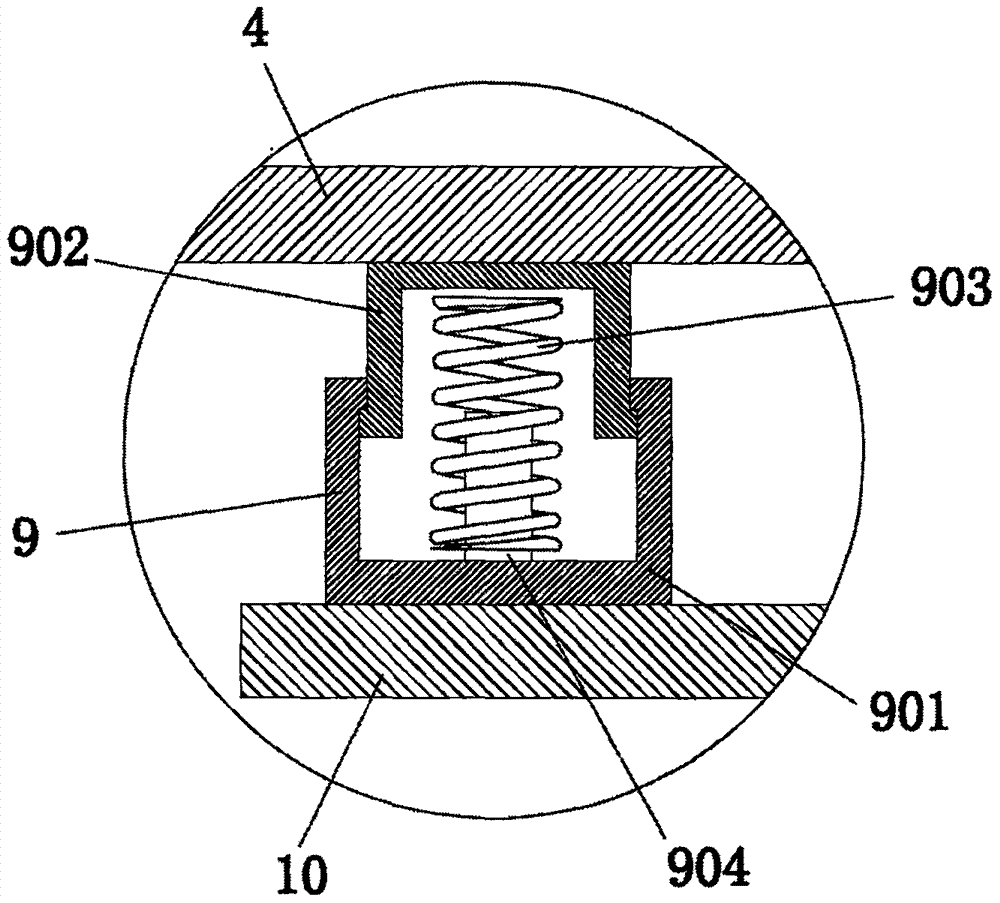

Dried beancurd hydraulic machine

InactiveCN107415299AEven by forceImprove the suppression effectCheese manufacturePressesHydraulic cylinderClassical mechanics

The invention discloses a dried beancurd hydraulic machine. The dried beancurd hydraulic machine comprises a platform. The left side and the right side of the upper surface of the platform are both provided with guide pillars, the top ends of the outer walls of the guide pillars are provided with a top plate, the center of the upper surface of the top plate is provided with a hydraulic cylinder, and the bottom end of the hydraulic cylinder is provided with a piston rod. The bottom end of a sliding plate is provided with a pressing plate, a supporting plate is placed above the platform, and dried beancurd dies are arranged on the upper surface of the supporting plate. According to cooperation among the dried beancurd dies, the pressing plate and the supporting plate, the piston rod drives the sliding plate to move downwards, the sliding plate drives the pressing plate to move downwards to press uncongealed beancurd, the stress of the uncongealed beancurd can be uniform through the elastic action of tcompression springs, the pressing effect is better, and the quality of the dried beancurd is improved; and after pressing is finished, the pressing plate is moved upwards to be separated from the dried beancurd dies, the supporting plate is pulled forwards, the dried beancurd dies are taken down, the dried beancurd dies are convenient to store and take out, work efficiency is improved, and the use requirements of users can be met.

Owner:张志通

Flattening device for tea processing for improving pressing effect by utilizing vibration effect

InactiveCN111631279AImprove the suppression effectIncrease linkagePre-extraction tea treatmentEngineeringMechanical engineering

The invention relates to the technical field of tea processing, and discloses a flattening device for tea processing for improving the pressing effect by utilizing the vibration effect. The flatteningdevice comprises a shell, and a limiting frame is fixedly connected to the interior of the shell; a rotating frame rotates to enable a rotating plate to intermittently rotate by 360 degrees, a powersource is provided for subsequent vibration operation, the rotating plate rotates to enable a first rotating disc to intermittently rotate in a reciprocating manner, a vibration plate continuously moves up and down, and the tea leaves on the vibration plate are vibrated and are uniformly spread so as to avoid the condition that: because of uneven distribution of the tea leaves, the tea leaves arenot uniformly pressed, some regions are too loose, other regions are too compact, and the tea leaf pressing quality is poor. A second rotary disc rotates to enable a second gear to intermittently rotate by 360 degrees, a power source is provided for subsequent pressing operation, the second gear rotates to enable a pressing plate to move up and down, the pressing plate moves downwards to get closeto the vibration plate, the evenly-distributed tea leaves are automatically pressed, and the high automation degree is achieved.

Owner:陶雪

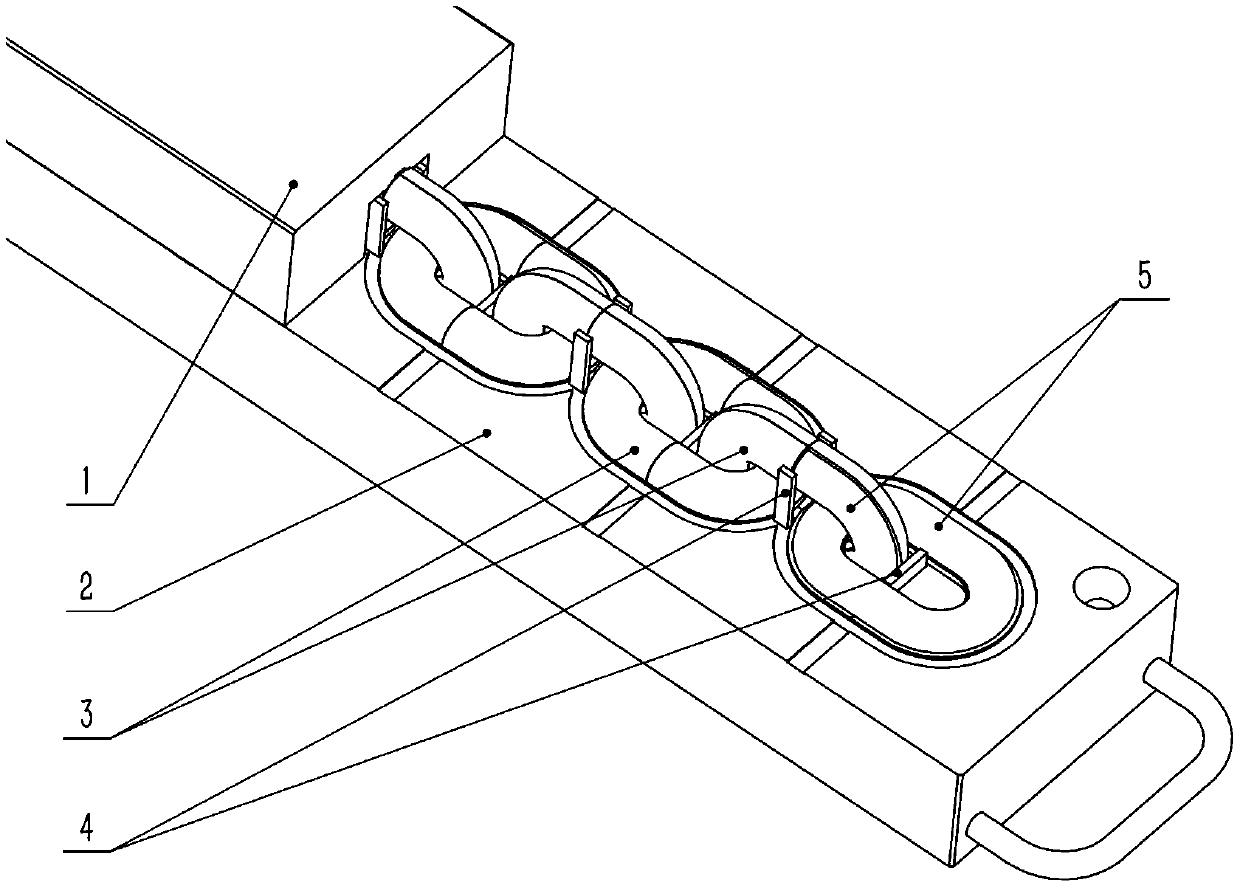

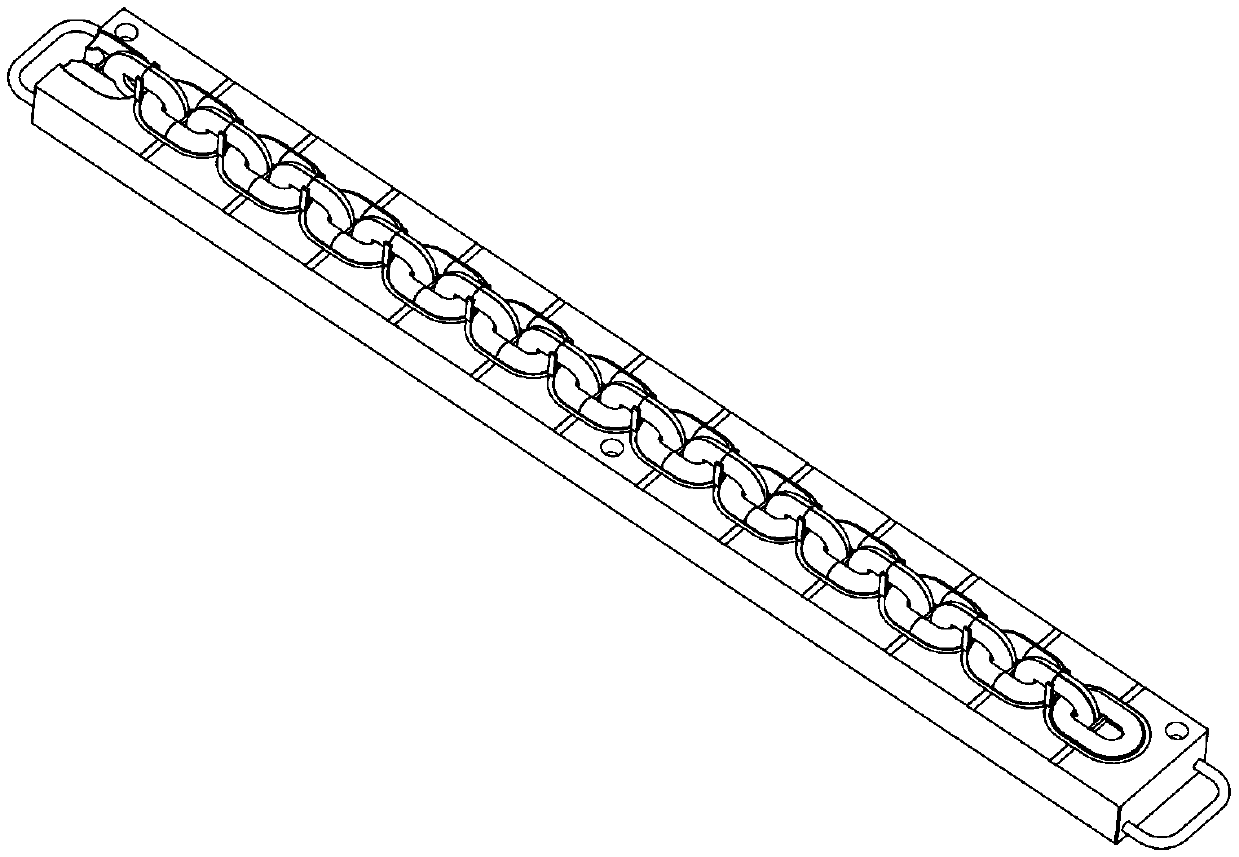

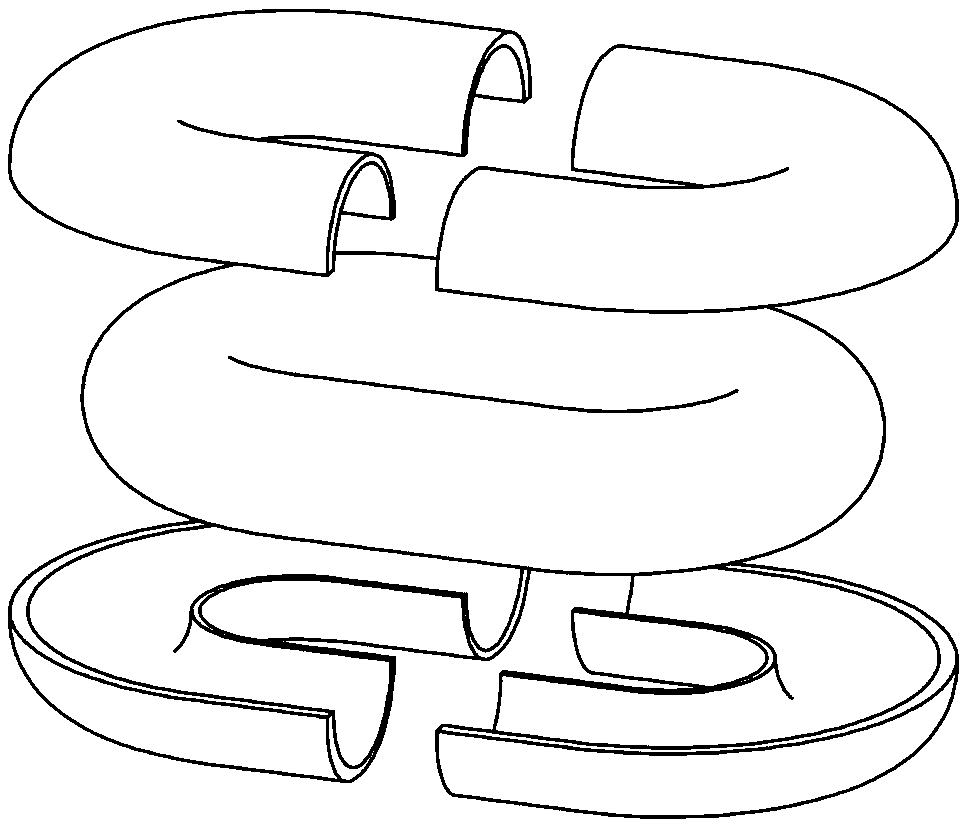

Composite round-link chain forming mold

PendingCN111572063AImprove the suppression effectFast integrated productionDomestic articlesChain linkIndustrial engineering

A composite round-link chain forming mold mainly consists of an upper mold body, a lower mold body, round-link chain section mold sleeves and auxiliary positioning pieces. Round-link chain sections which are connected in series after being preformed are sleeved with the round-link chain section mold sleeves, and each round-link chain section is matched with four round-link chain section mold sleeves. Then, each round-link chain section sleeved with the corresponding round-link chain section mold sleeves is placed into a corresponding position of the lower mold body, and the auxiliary positioning pieces are welded to the lower mold body and have a certain gap away from the round-link chain section mold sleeves, so that the round-link chain section mold sleeves can be effectively separated;and through the positioning of the auxiliary positioning pieces and the covering of the upper mold body, after hot press molding and cooling, a long composite round-link chain can be obtained. The mold can perform integral forming to form the long composite round-link chain, thoroughly solves the problem of difficulty of closed-loop series-connection forming of the composite round-link chain and meanwhile greatly improves the production efficiency of the composite round-link chain due to the forming simplicity and chain length controllability of the round-link chain.

Owner:衡阳五行复合材料有限公司

Manufacturing method for porous powder sintered body and preloading molded body for manufacturing sintered body

ActiveCN104190935AAccelerated corrosionImprove corrosion resistanceCompression moldingMaterials preparation

The invention discloses a manufacturing method for a porous powder sintered body and a preloading molded body for manufacturing the sintered body. According to the method, the aperture size of the porous powder sintered body can be controlled easily and effectively, and the breakage probability of the molded body during compression molding can be lowered. The method comprises the steps of material preparation, molding and sintering. During material preparation, according to basic raw material powder for manufacturing the porous body, first powder and second powder are used, wherein the first powder and the second powder are different in shape and size, compared with the second powder, the granularity of the first powder is smaller, the compactibility of the first powder during molding is better, and the first powder accounts for 10 percent-90 percent of the total mass of the basic raw material powder. The first powder has the characteristics of being better in compactibility and smaller in sintered aperture size, the second powder has the characteristic of being larger in sintered aperture size, in this way, after the first powder is fully mixed with the second powder, gaps formed in the second powder can be filled with the first powder, on one hand, the effect of controlling the aperture size of the sintered material is achieved, and on the other hand, the compactibility of the mixed powder is improved.

Owner:CHENGDU INTERMENT TECH

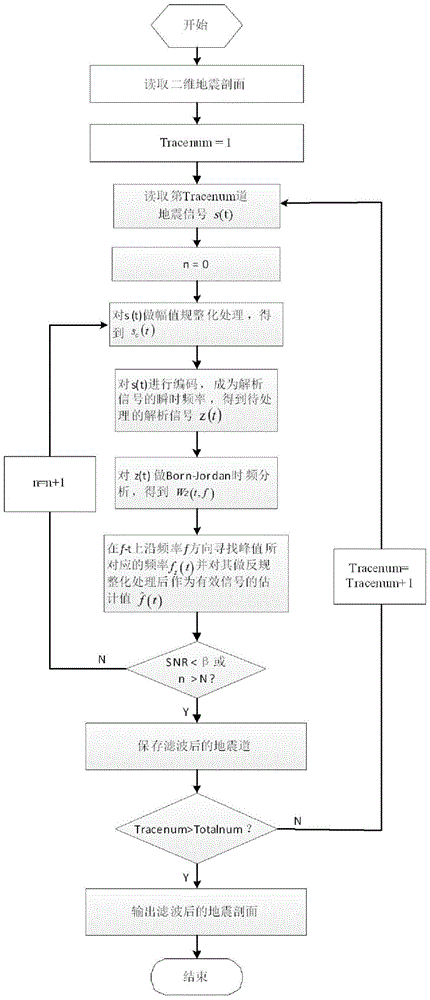

Seismic signal time frequency peak value filtering method based on Born-Jordan time frequency distribution

ActiveCN105700019AImprove the suppression effectEliminate ringingSeismic signal processingFilter algorithmPeak value

The invention provides a time frequency peak value filtering algorithm based on Born-Jordan time frequency distribution aiming at increasing the linearity of seismic signals in time windows, suppressing noise at a greater degree, and increasing the precision of signal reconstruction and signal to noise ratio of seismic data after filtering. The method comprises following steps: first, inputting a noise-containing original seismic profile to be processed; performing amplitude standardization process to each seismic record of the noise-containing profile; coding each seismic record after standardization process as instantaneous frequency of a unit amplitude analytic signal to obtain analytic signals to be processed; performing Born-Jordan time frequency analysis to the analytic signals to obtain a time frequency distribution; finding the frequency of an analytic signal corresponding to the peak value of the time frequency distribution in the frequency direction on the time frequency distribution, and performing amplitude de-standardization process to the found frequency to obtain an estimation value of effective signals; repeatedly performing step 2 to step 5 to each seismic record, and obtaining an estimation value of the whole seismic profile after de-standardization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Soil pressing roller with adjustable pressing force and manufacturing method thereof

The invention provides a soil pressing roller with adjustable pressing force and a manufacturing method of the soil pressing roller, belongs to the technical field of agriculture, agricultural engineering, machinery and materials, and particularly relates to the technical field of agricultural machinery. The soil pressing roller comprises a roller body and is characterized in that the roller body is a plastic roller body or a rubber roller body, the roller body is of a hollow cylindrical structure, a water injection hole is formed in the end face of the roller body, and a sealing cover is arranged at the opening of the water injection hole to seal the water injection hole. Traction shafts are arranged on the two end faces of the roller body respectively. When the soil pressing roller is used, water is injected in the roller body, a good pressing effect is achieved, and when the soil pressing roller is not used, water is discharged, and the soil pressing roller is light in weight and convenient to transport. The weight of the soil pressing roller can be regulated by controlling the liquid injection amount, so that the soil pressing roller of different weights is formed so as to adapt to different soil moisture states and different soil pressing force requirements after crops are planted.

Owner:YANGZHOU UNIV

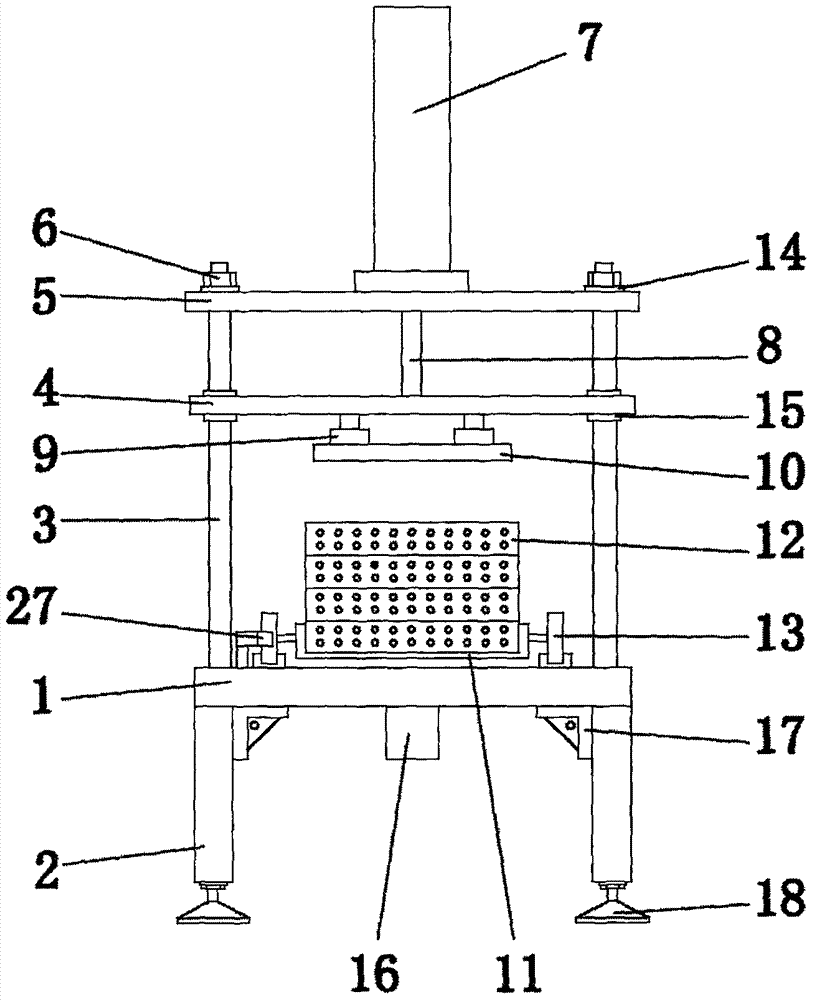

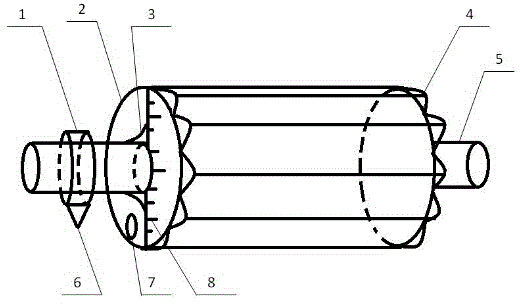

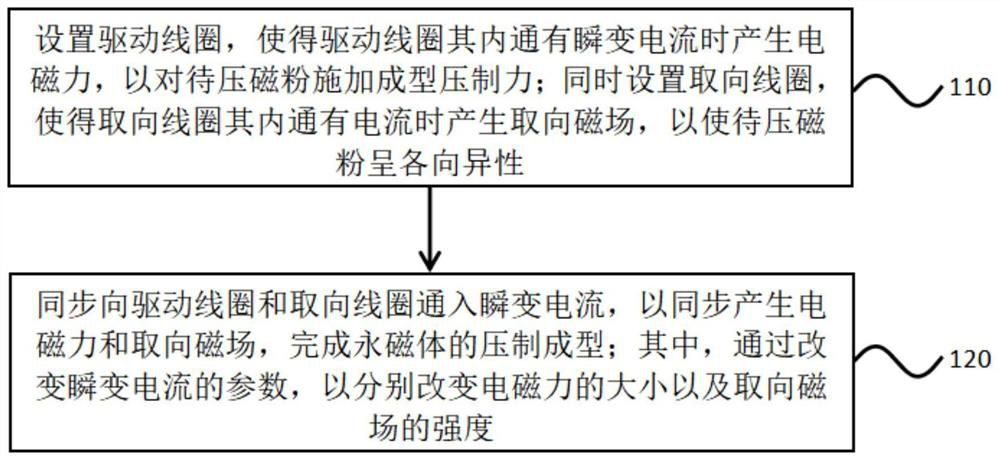

Permanent magnet compression molding method and device

ActiveCN111640552AGood orientationImprove magnetismMagnetic bodiesInductances/transformers/magnets manufactureCompression moldingCondensed matter physics

Owner:HUAZHONG UNIV OF SCI & TECH

Cloth inspecting machine for textile cloth

InactiveCN106958133AImprove stabilityPracticalInspecting textilesWebs handlingPulp and paper industryTextile

The invention discloses a cloth inspecting machine for textile fabrics, which comprises a frame and a support frame. The frame is respectively provided with a cloth releasing roller, a main pressing roller and a secondary pressing roller, the main pressing roller is connected with the secondary pressing roller, and the frame The cloth guide roller and the fixed base are respectively arranged on the top of the cloth guide roller, and the swing plate is arranged on the cloth guide roller, and the tension roller is movably connected between the swing plates, and the tension roller is located above the main pressure roller and the secondary pressure roller. Connected with a support rod, the bottom of the swing plate is evenly distributed with card slots, the card slots are connected to the support rod, a mounting plate is provided on the fabric guide roller, a coder is provided on the mounting plate, and step wheels are connected to both sides of the coder , There are cloth guide rollers, cloth passing rollers and cloth receiving rollers respectively between the supporting frames. The invention is compact in structure, flexible in connection, integrates cloth inspection, cloth rolling, and code counting, has wide applicability, strong practicability, and convenient adjustment. By adjusting the tension of winding cloth, it can meet the requirements of different materials, and improve the cloth's efficiency. flatness and quality.

Owner:嵊州市靖洁纺织机械有限公司

Powder sintering porous filter alloy, preparation method thereof and pre-pressing molding body for preparing powder sintering porous filter alloy

ActiveCN104190918AAccelerated corrosionImprove corrosion resistanceFiltration separationFiltrationMicrometer

The invention discloses powder sintering porous filter alloy, a preparation method thereof and a pre-pressing molding body for preparing the powder sintering porous filter alloy. The powder sintering porous filter alloy is basically composed of, by mass, 14%-17% of Cr, 6%-10% of Fe, 0%-0.15% of C, 0%-0.5% of Si, 0%-1% of Mn, 0%-0.05% of Cu, 0%-5% of Al, 0%-1.5% of Ti and the balance Ni. The average pore size of the alloy is not larger than 60 micrometers, the relative permeability coefficient of the alloy is not smaller than 80 m<3> / m<2> kpa h. The powder sintering porous filter alloy has good chlorine corrosion resistance and good hydrogen chloride gas corrosion resistance (especially under high temperature), and is especially suitable for gas-solid separation and filtration under a high-temperature chlorine and hydrogen chloride system.

Owner:CHENGDU INTERMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com