Patents

Literature

108 results about "Breakage probability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Usually, the breakage probability distribution can be found by means of stress or energy approach. The first one uses the stress to calculate the breakage probability distribution. The second approach uses the mass-related work done to break the particle.

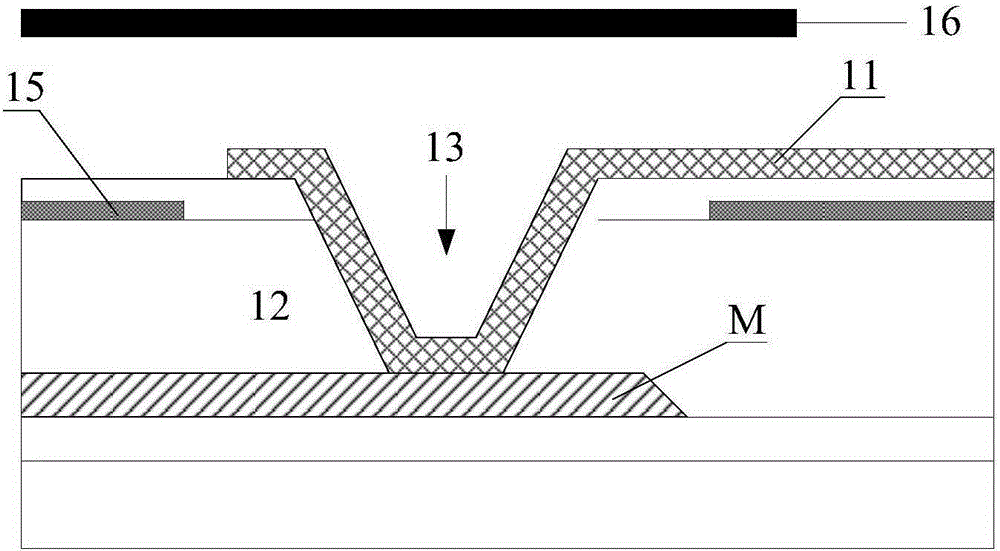

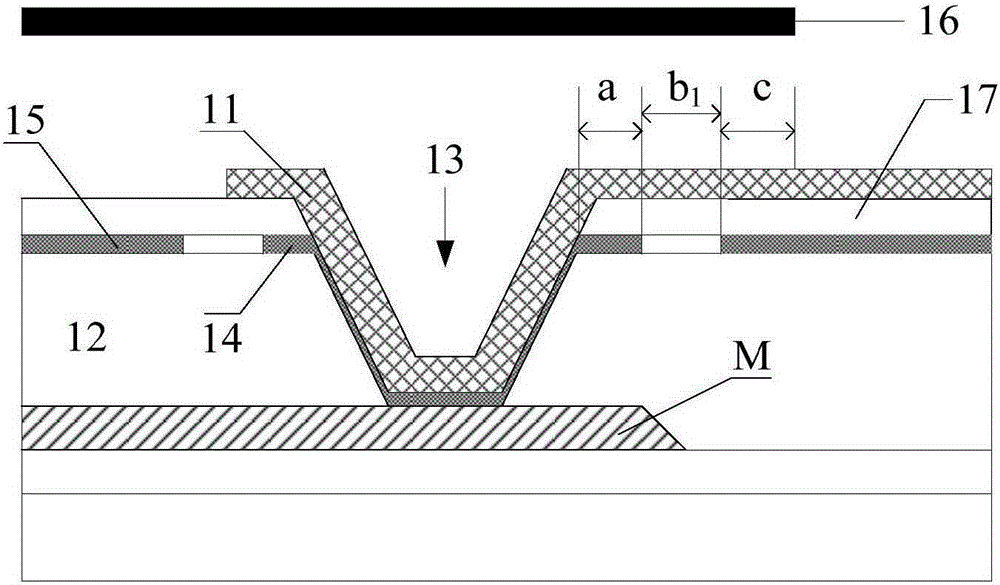

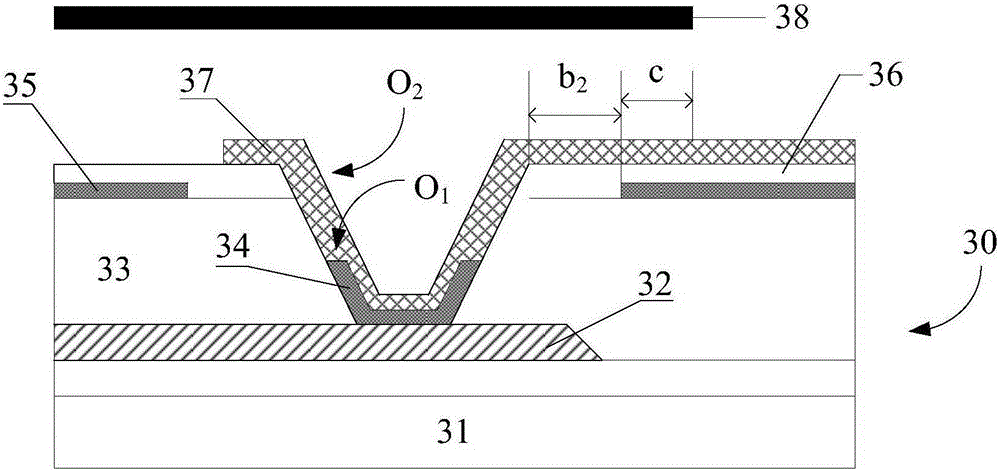

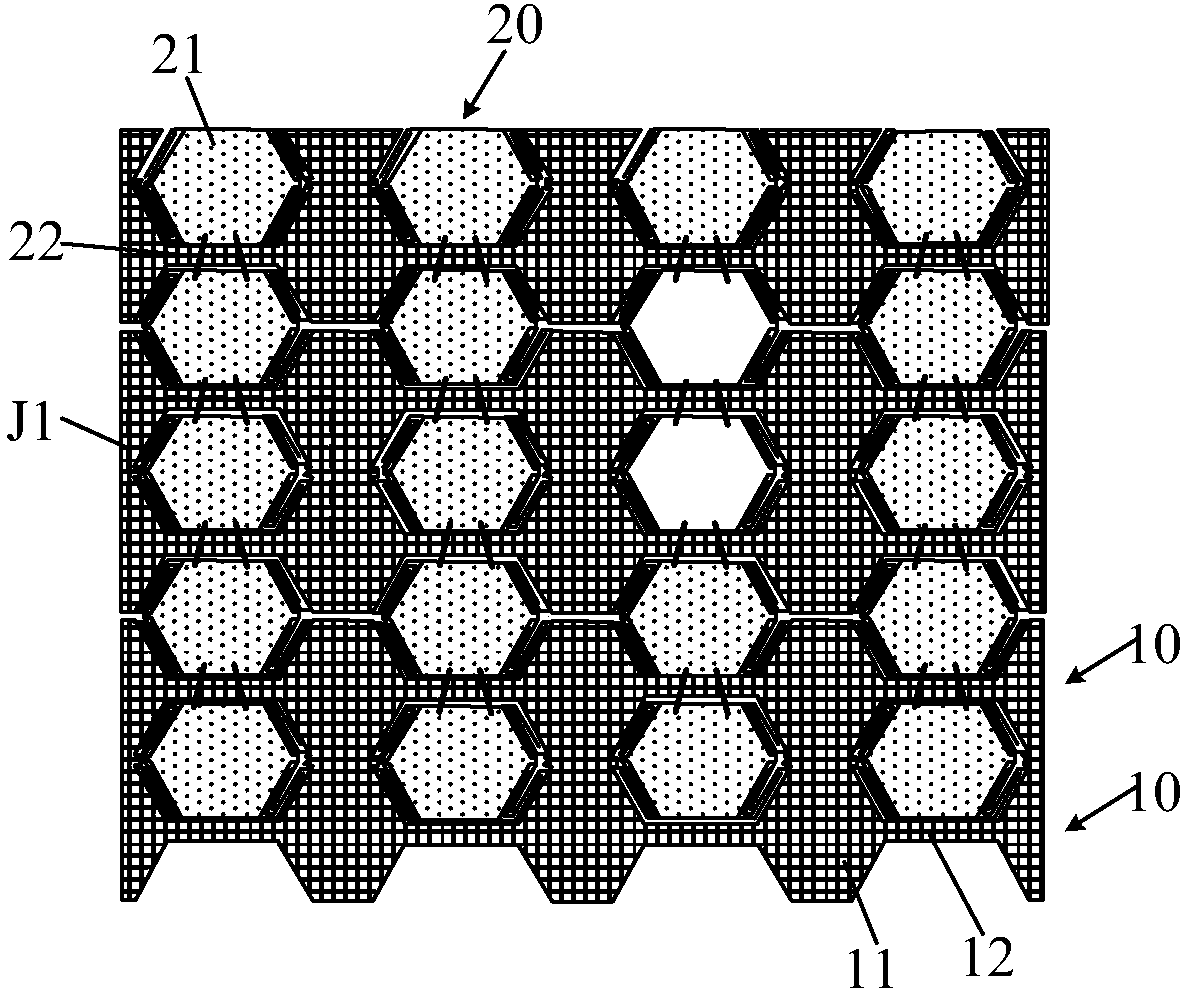

Liquid crystal display panel, array substrate and manufacturing method of array substrate

ActiveCN105116655AReduce the chance of membrane ruptureSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingBreakage probabilityElectrical resistance and conductance

The invention provides an array substrate. A floating electrode layer is additionally arranged in a contact hole enabling electric connection of a TFT metal layer and a pixel electrode layer to be achieved, so that the pixel electrode layer is electrically connected with the metal layer again through the bridging of the floating electrode layer. Resistance at the contact hole and the film breakage probability of the pixel electrode layer in the contact hole can be reduced. In addition, the edge of the floating electrode layer is located in the contact hole, the dimension of a corresponding black matrix layer can be reduced, and the pixel aperture opening ratio can be increased. The invention further provides a method for manufacturing the array substrate and a liquid crystal display panel with the array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

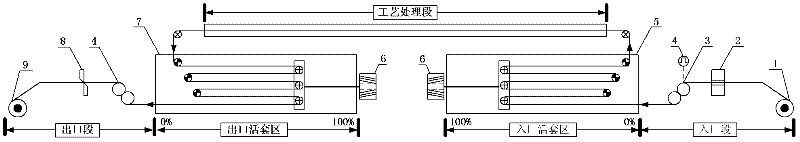

Automatic dynamic adjustment method for synchronous extension of loop of cold rolling continuous processing line

ActiveCN102553948AThere is no need to dynamically adjust the set value of synchronous setsPrevent deviationFlexible work arrangmentsMetal rolling arrangementsBreakage probabilityExtension set

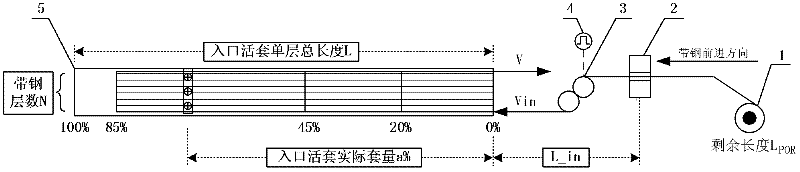

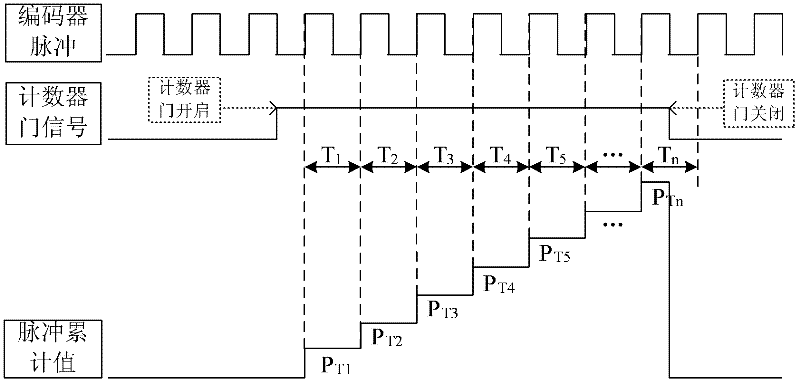

The invention relates to an automatic dynamic adjustment method for synchronous extension of a loop of a cold rolling continuous processing line. The automatic dynamic adjustment method specifically comprises the following steps of: at a non-drift stage of an uncoiling machine, acquiring a pulse encoder signal on an inlet tension roller, calculating the actual traveling distance of strip steel and thereby judging the relative position of a weld joint and the loop, and automatically adjusting a synchronous extension set value of the loop; at a drift stage of the uncoiling machine, calculating length of strip steel to be replenished according to a target set value and a current actual value for the synchronous extension of the loop, comparing the length of the strip steel with that of the remaining strip steel on the inlet uncoiling machine, and automatically adjusting the synchronous extension set value of the loop; and finally, arranging a functional module in a cold rolling continuous processing line control system to realize an undisturbed automatic switching function of the synchronous extension set value of the loop. According to the automatic dynamic adjustment method, deviation of the strip steel in the loop can be prevented, and the strip breakage probability of the strip steel in the loop is reduced; the production efficiency of the processing line can be increased and the working intensity of operation personnel is reduced; and the disposal difficulty for strip breakage accidents in the loop can be reduced and the accident recovery time is shortened.

Owner:WISDRI WUHAN AUTOMATION

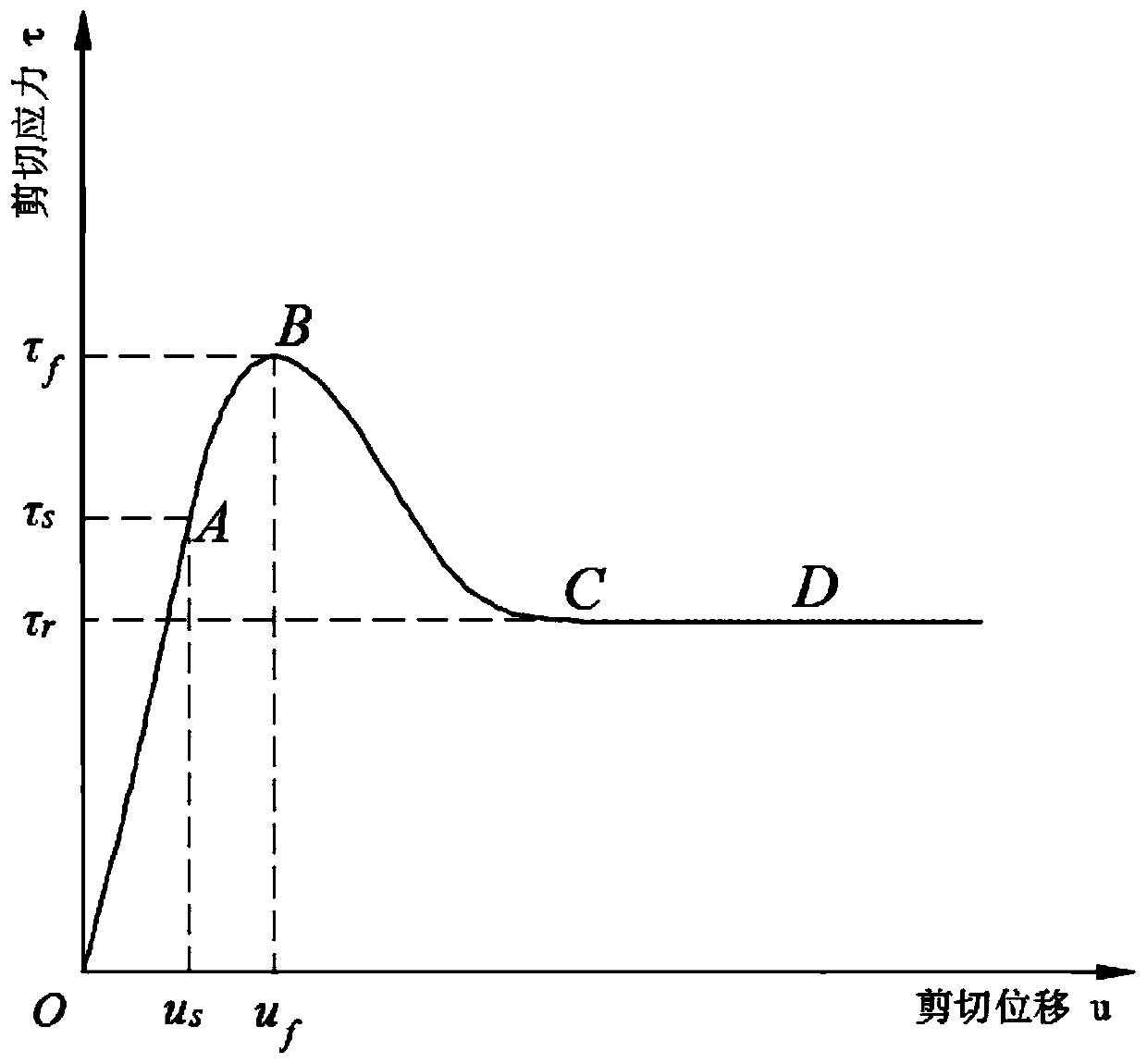

Joint shearing whole-process damage constitutive model for determining a yield point based on a stress difference

ActiveCN109885980AWell formedThe physical meaning of the parameter is clearSpecial data processing applicationsBreakage probabilityThin layer

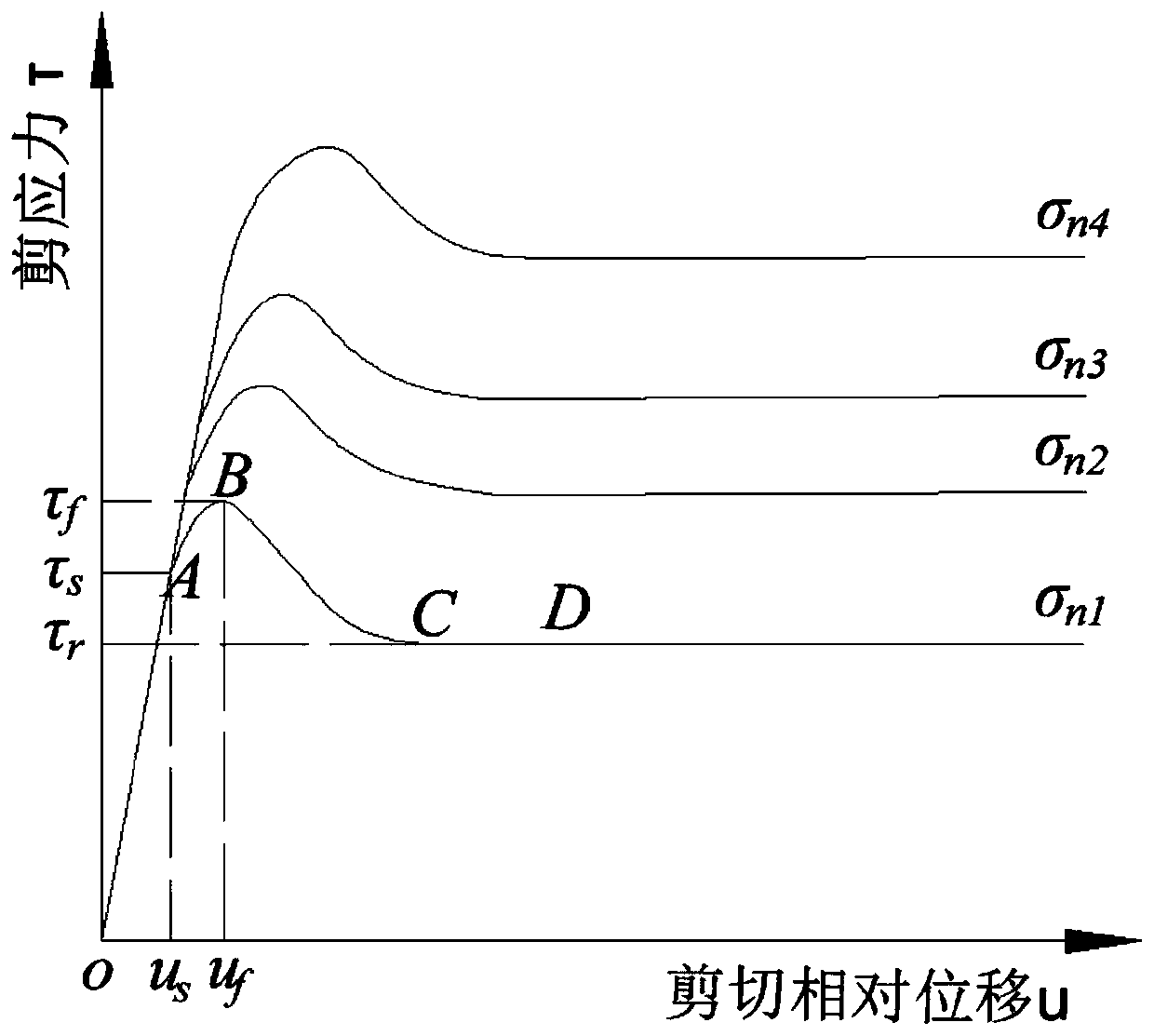

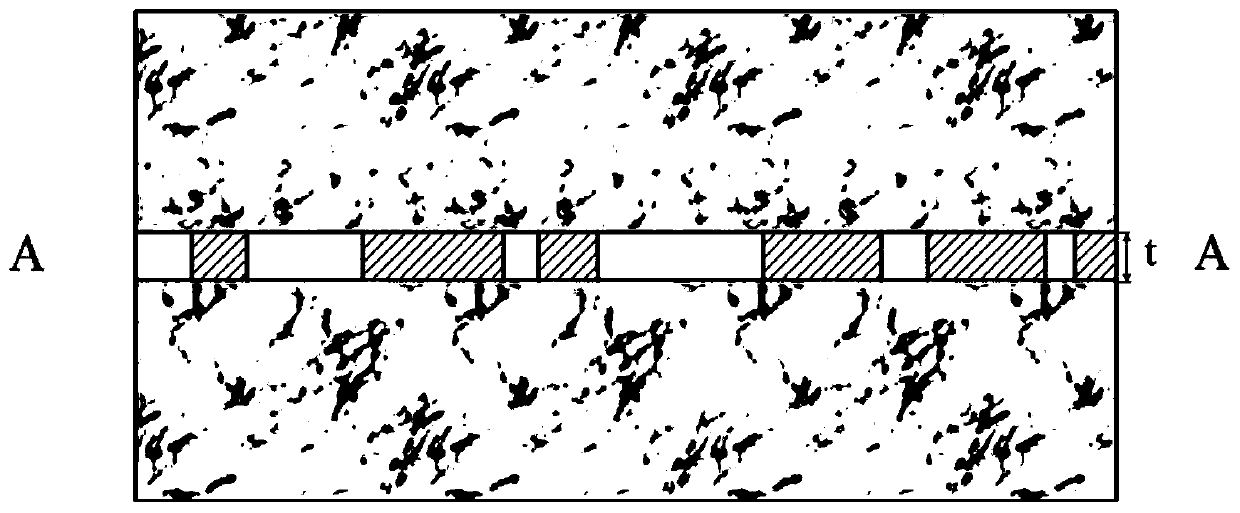

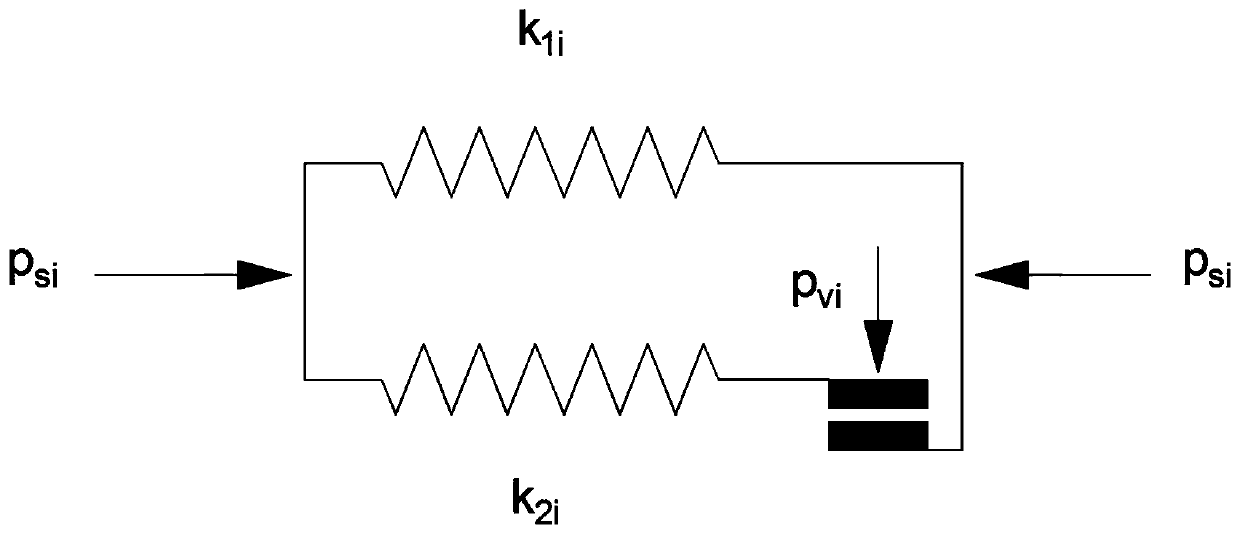

The invention discloses a joint shearing whole-process damage constitutive model for determining a yield point based on a stress difference. The method comprises the steps that S1, setting a joint thin-layer microscopic unit body to be loaded and then enters a linear elasticity stage, the joint thin-layer microscopic unit body is an isotropic continuous medium, the microscopic unit body is instantaneously completed when being converted from a lossless state to a lossy state, and the process is irreversible; S2, defining an external load threshold F * based on a Weibull distribution function toobtain a damage probability density function of the mesoscopic unit body; S3, based on a rheological model mechanical element, simulating the load condition of a mesoscopic unit body by adopting thecombination of a spring and a friction plate to obtain a statistical damage constitutive model of the joints under the shearing action; S4, determining an external load threshold F * according to twoparts, namely damage and non-damage, of the rock and soil material after being subjected to load damage, and obtaining a damage evolution model and a joint shear deformation damage constitutive modelof the joint in the shear deformation process; S5, determining parameters m, u0 and us of the joint shear deformation damage constitutive model; and S6, verifying the correctness of the constitutive model.

Owner:CENT SOUTH UNIV

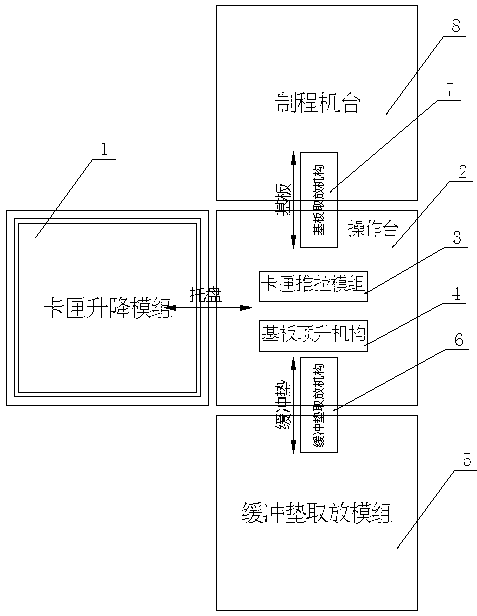

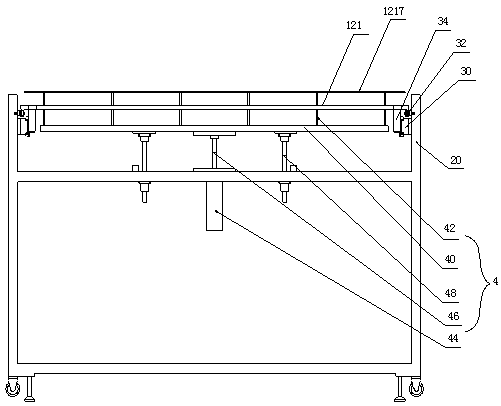

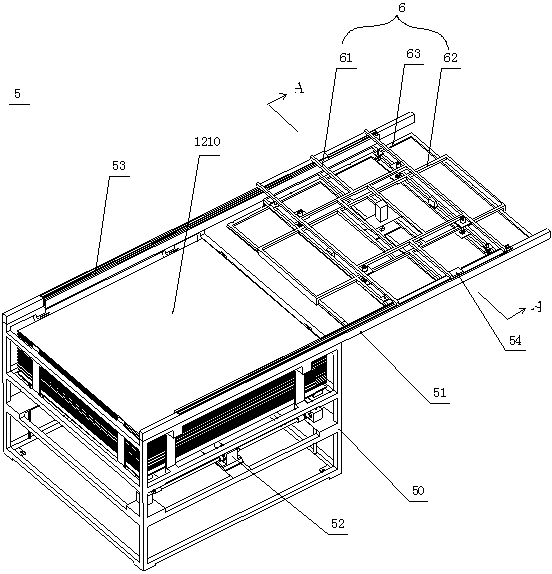

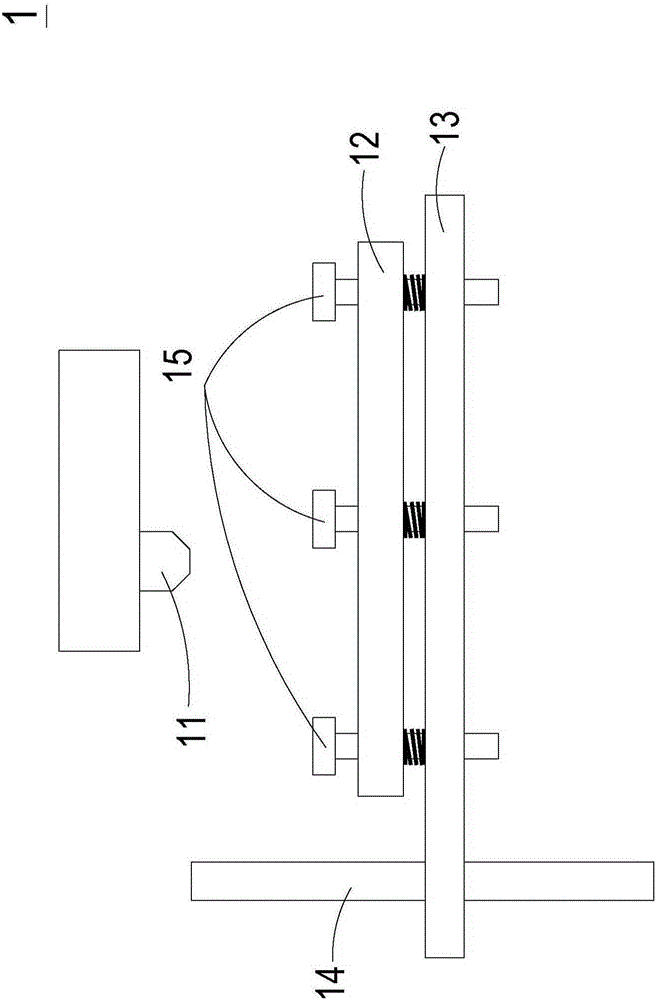

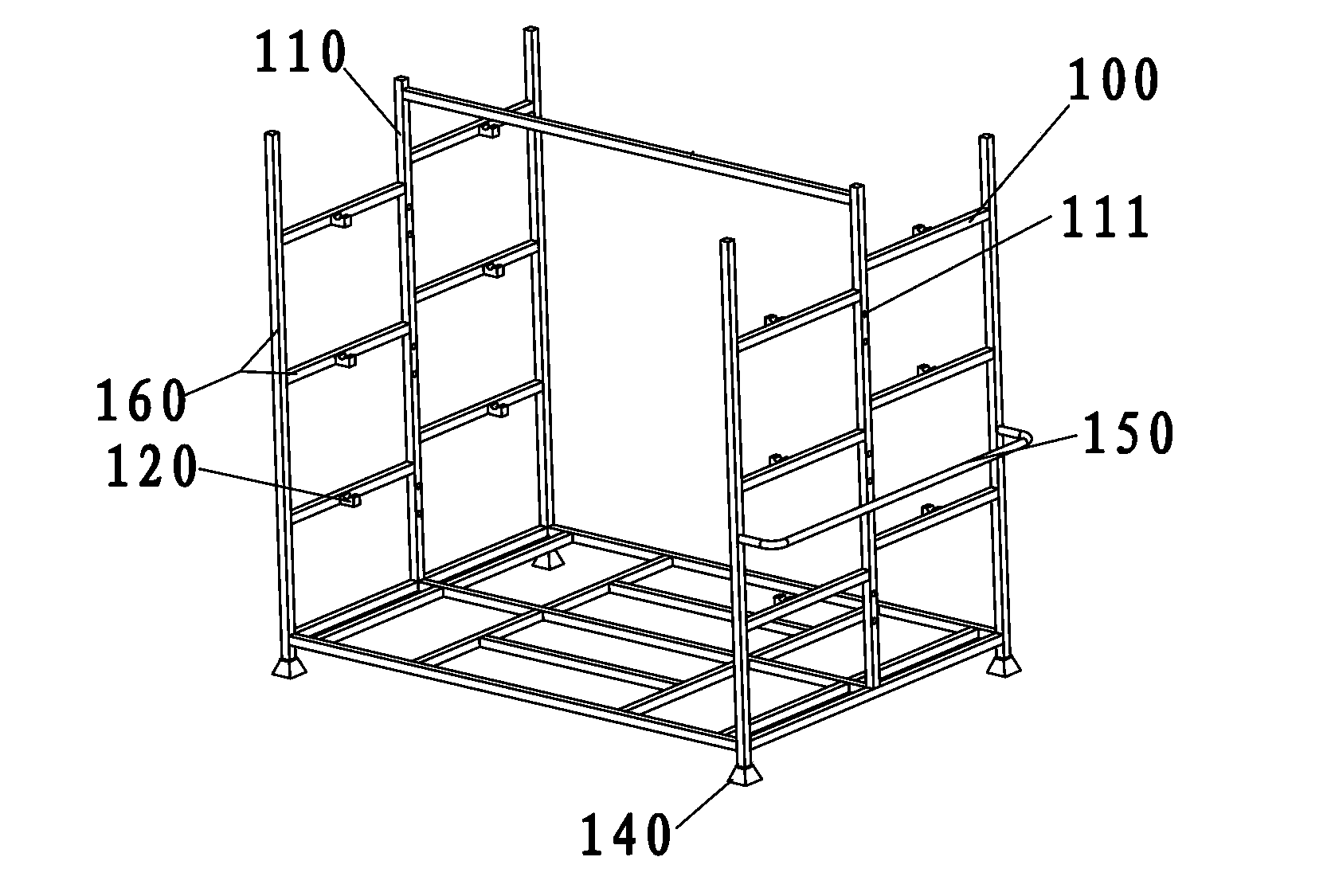

Automation equipment for picking and placing large-sized liquid crystal substrate

ActiveCN103303676AAutomatic movingImprove securitySemiconductor/solid-state device manufacturingCharge manipulationPush and pullBreakage probability

The embodiment of the invention discloses automation equipment for picking and placing a large-sized liquid crystal substrate, which comprises a cartridge lifting module, a cartridge pushing and pulling module, a cushion pick-and-place module and a substrate jacking mechanism. According to the embodiment of the invention, the large-sized liquid crystal substrate can be picked and placed automatically, so that the manpower is saved, the productivity is increased, and breakage probability of the liquid crystal substrate is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

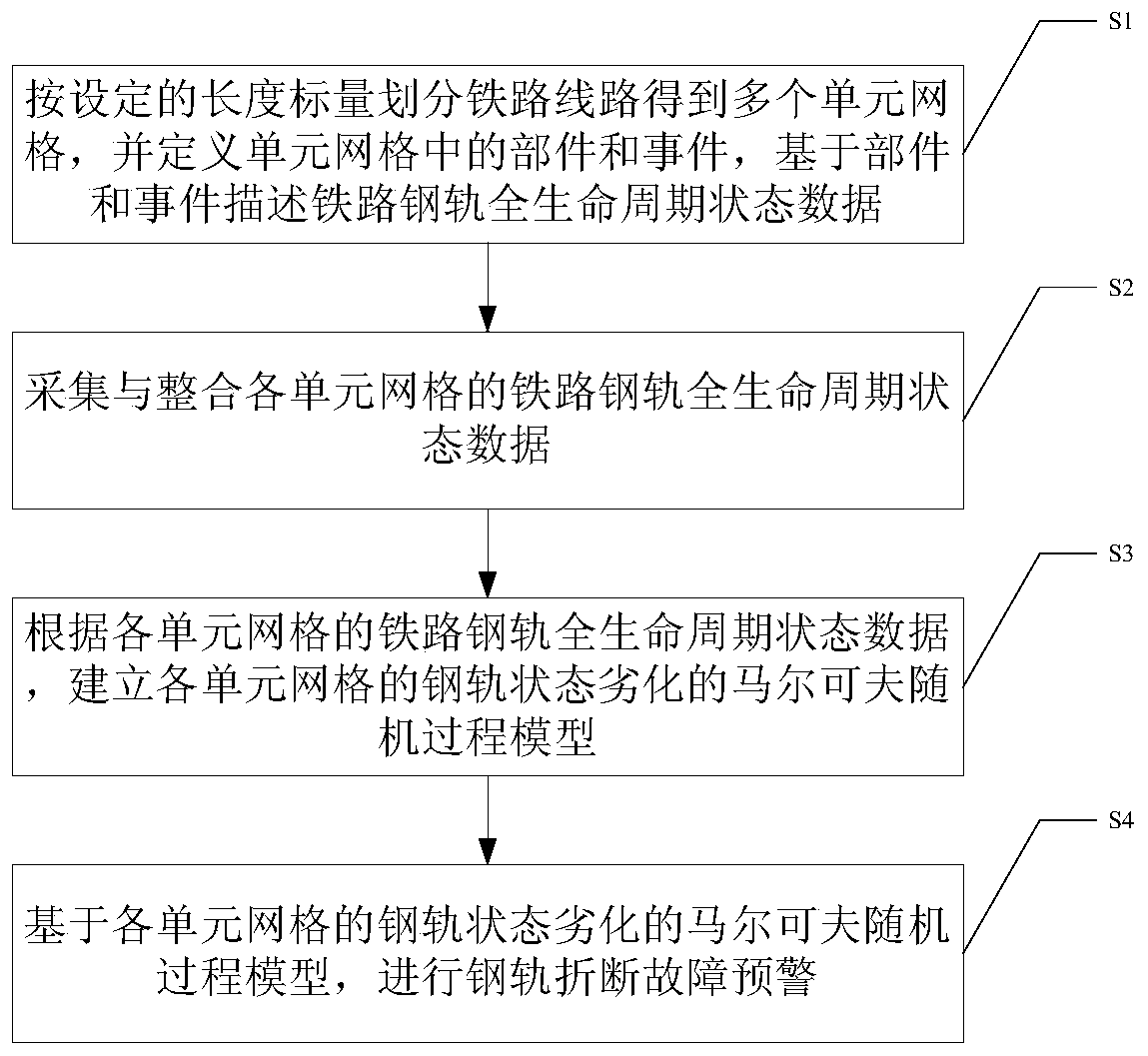

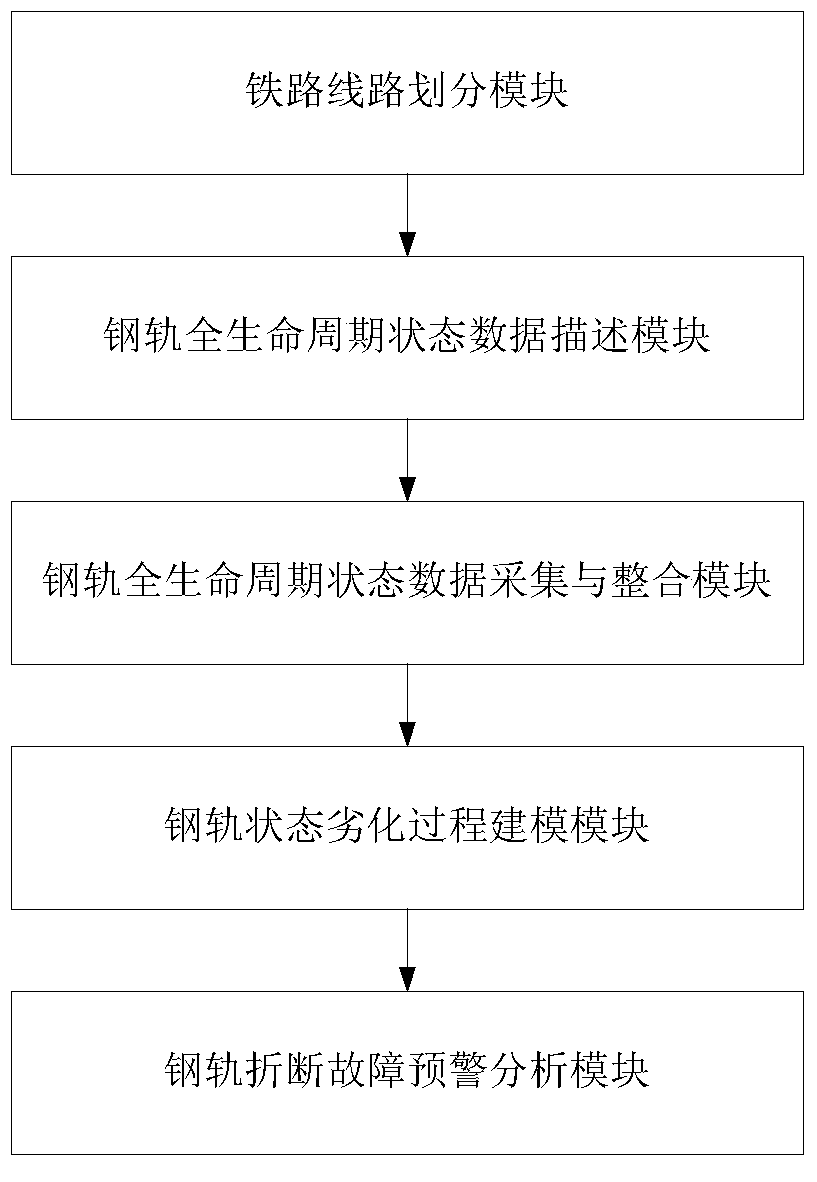

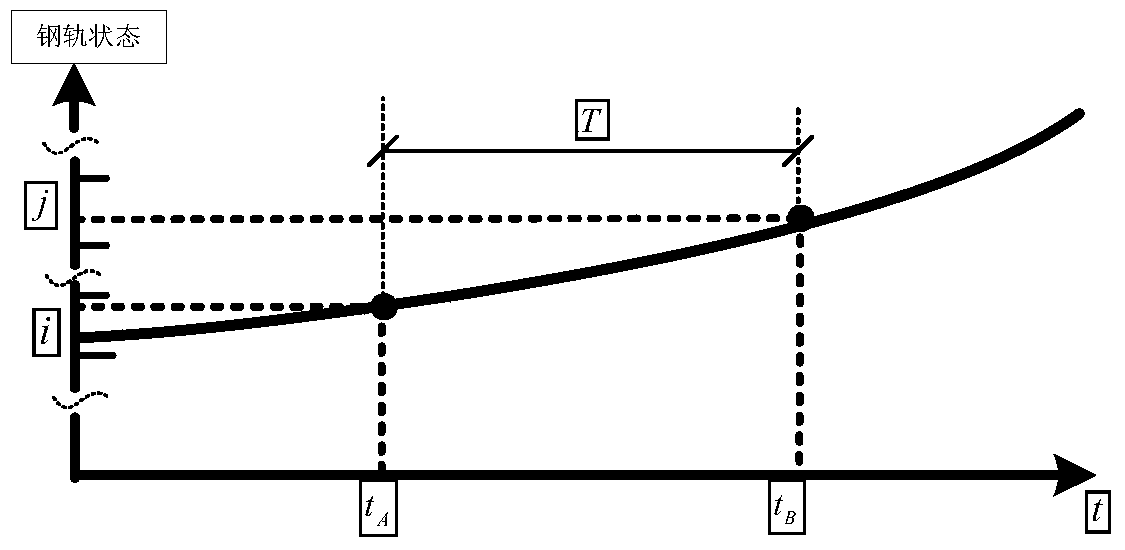

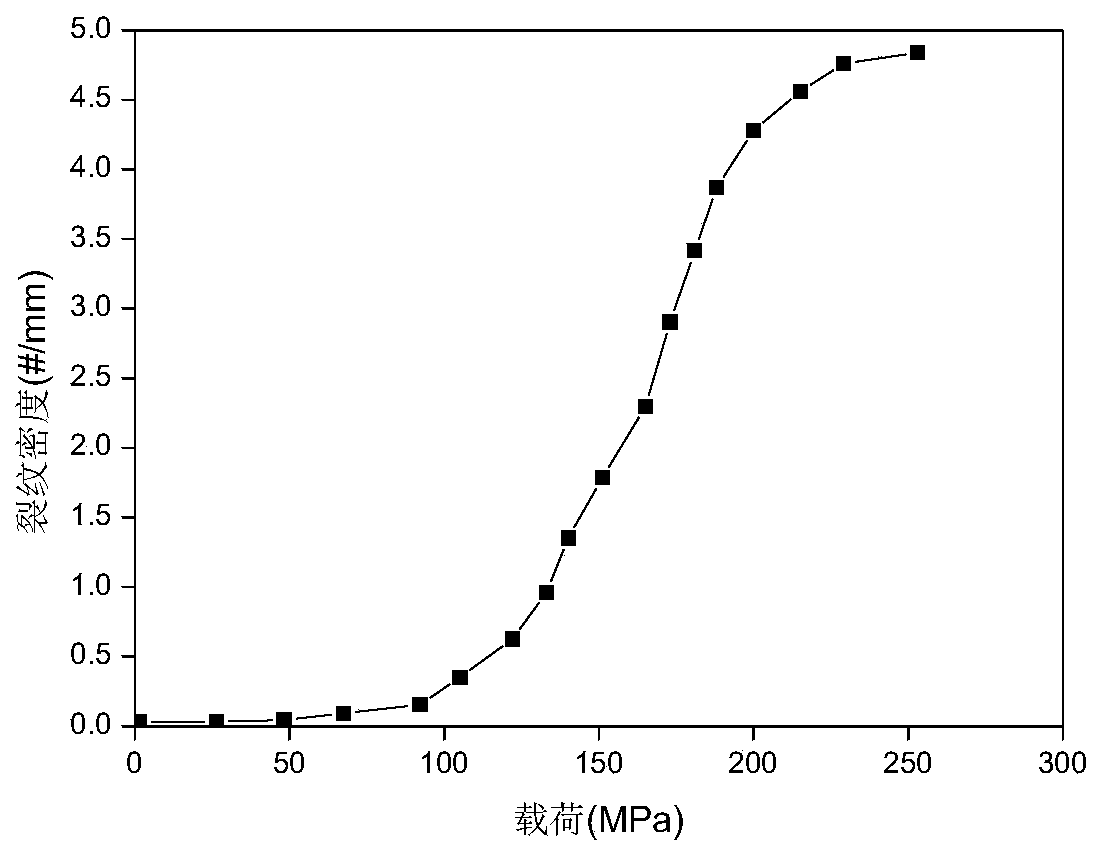

Steel railroad rail breakage fault analyzing and warning method and steel railroad rail breakage fault analyzing and warning system

ActiveCN104850748ASimplify computing scaleImprove calculation accuracySpecial data processing applicationsBreakage probabilityFault analysis

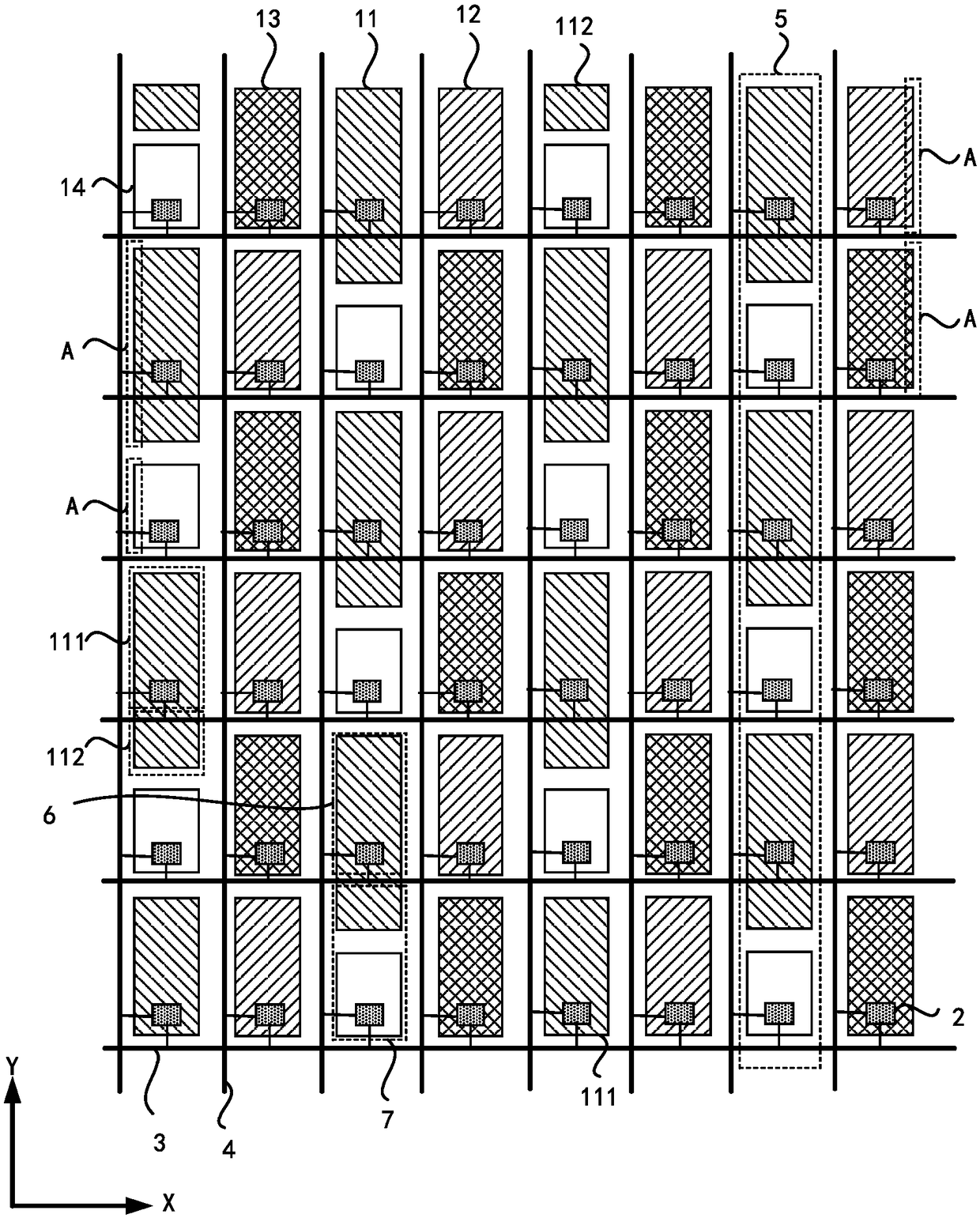

The invention discloses a steel railroad rail breakage fault analyzing and warning method and a steel railroad rail breakage fault analyzing and warning system. The steel railroad rail breakage fault analyzing and warning method includes the steps of dividing a railroad line into a plurality of unit grids according to a length scaler, defining parts and events of each unit grid, and describing full-life-circle status data of a steel rail on the basis of the parts and the events; collecting and integrating the full-life-circle status data of the steel rails in each unit grid; establishing a steel rail status degradation Markov random process model for each unit grid according to the full-life-circle status data of the steel rail of each unit grid; calculating steel rail breakage probability of each unit grid in the next steel status detecting period on the basis of Markov random process model for each unit grid, assigning different threshold values to the steel rail, and warning a steel breakage fault. The steel railroad rail breakage fault analyzing and warning method and the steel railroad rail breakage fault analyzing and warning system have the advantages that by the aid of the technical scheme, calculation scale for steel rail breakage fault analyzing and warning is reduced, calculating precision is improved, and specific position and time of the steel rail breakage fault can be analyzed and warned.

Owner:BEIJING JIAOTONG UNIV +1

Method for predicting residual tensile strength of ceramic-based composite material in stress oxidation environment

ActiveCN109992850AAccurate Prediction of Tensile StrengthAccurate prediction of residual tensile strengthDesign optimisation/simulationSpecial data processing applicationsBreakage probabilityResidual strength

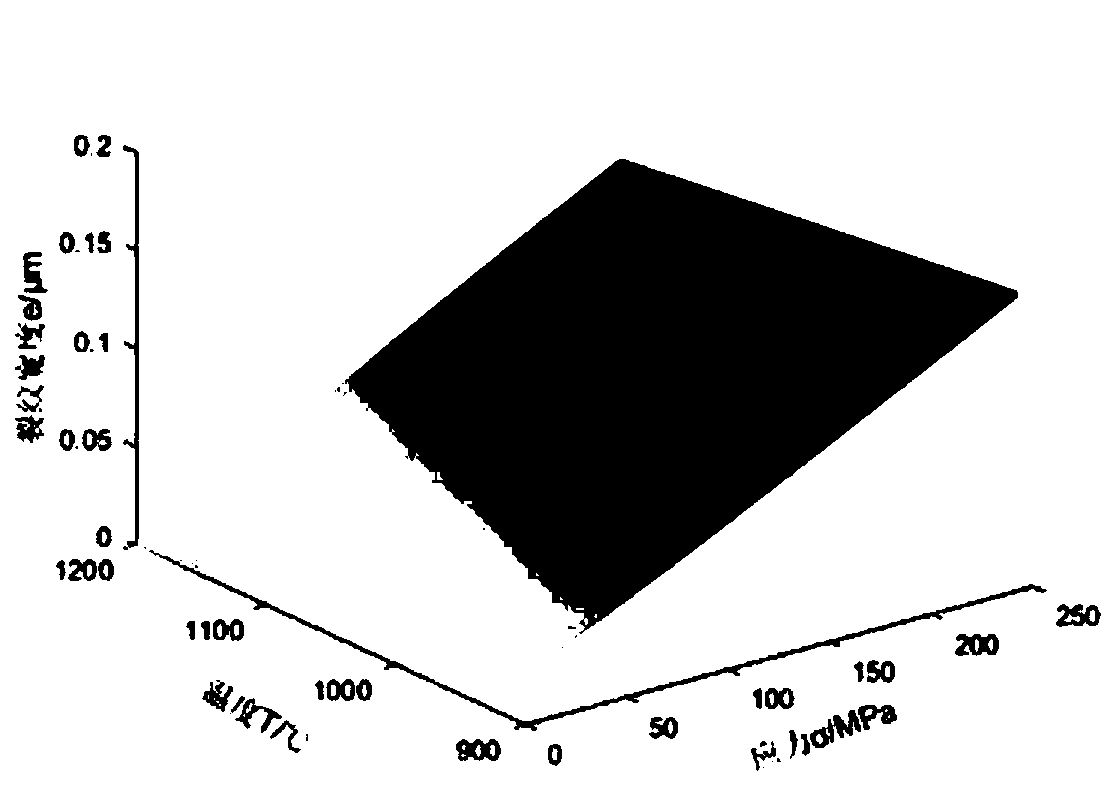

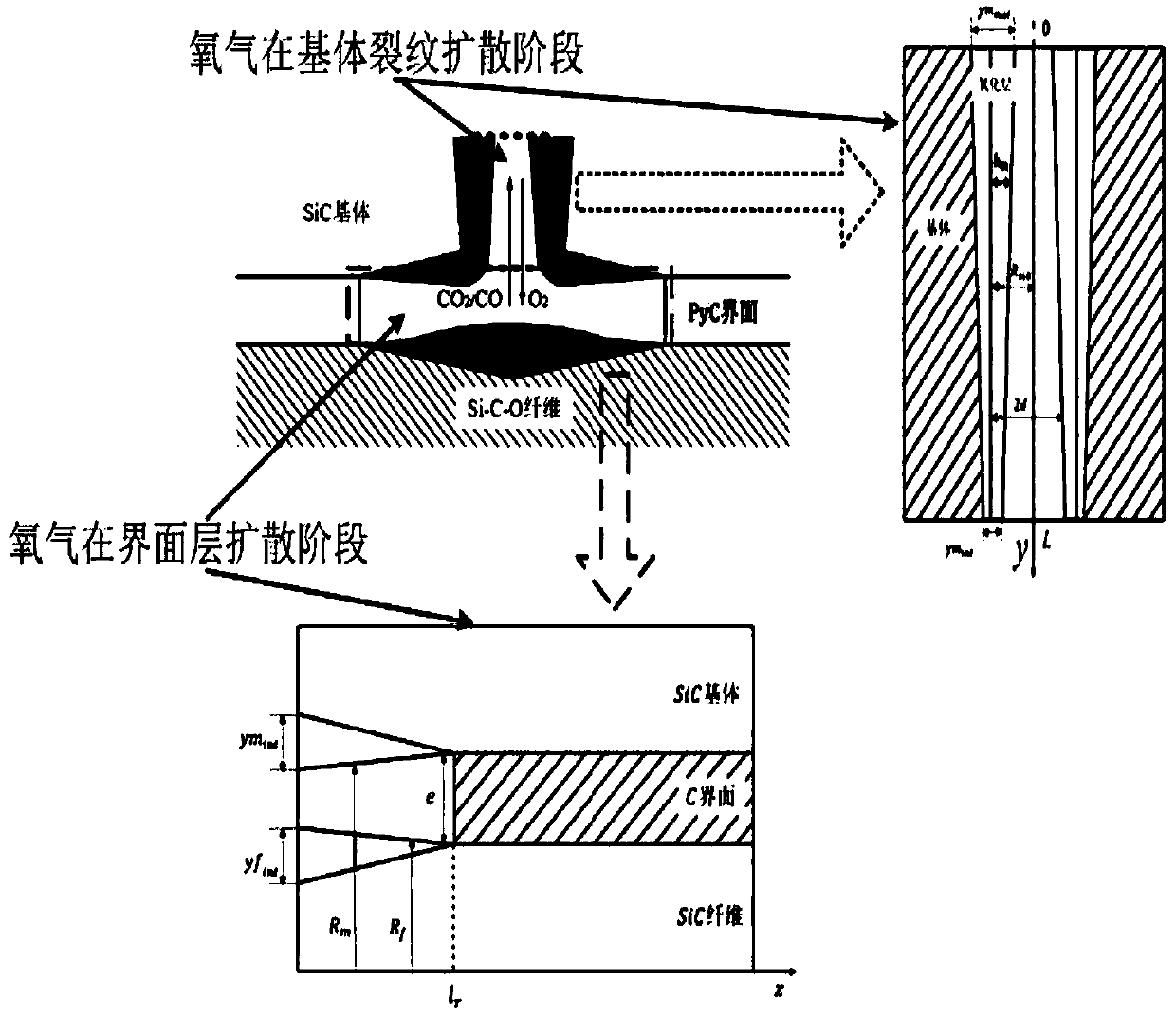

The invention discloses a method for predicting the residual tensile strength of a ceramic-based composite material in a stress oxidation environment. The method comprises the following steps: determining a change rule of a one-way SiC / SiC composite material SiC matrix saturated crack spacing and a SiC matrix crack average spacing along with stress; determining the change rule of the SiC matrix crack width along with the stress and the temperature; acquiring oxygen concentrations at different positions in the material at different moments and solving the change rule of the interface consumption length and the thickness of the surface oxide layer of the SiC fiber at the crack along with stress, temperature and time; obtaining the axial stress distribution of the SiC fiber; determining the size of oxidation defects on the surface of the SiC fiber; deducing a SiC fiber characteristic strength distribution expression; deducing a SiC fiber breakage probability expression; acquiring the maximum stress in the bridging SiC fiber; solving the SiC fiber fracture probability under certain temperature, stress and oxidation time; obtaining the residual strength of the material. According to themethod, the residual tensile strength of the unidirectional SiC / SiC composite material at each moment, each temperature and the tensile stress level can be accurately predicted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

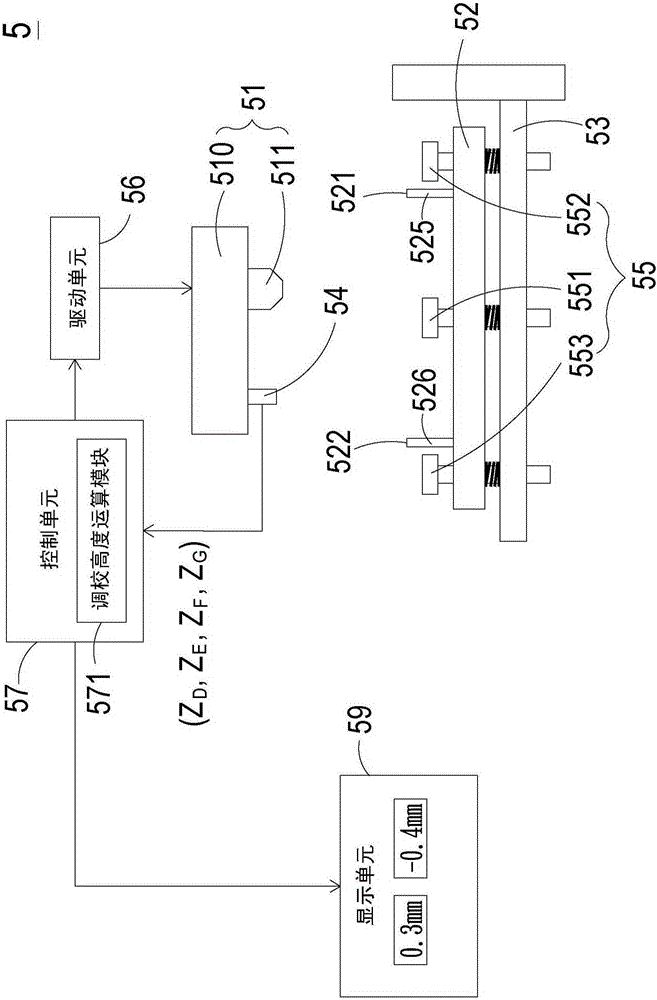

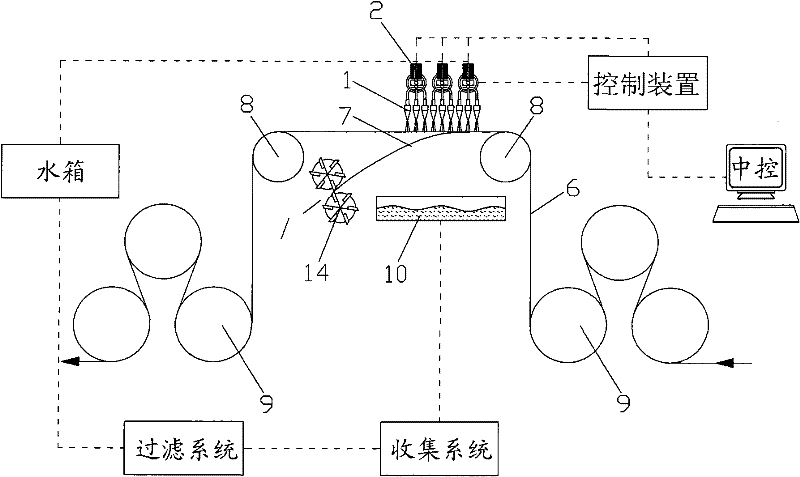

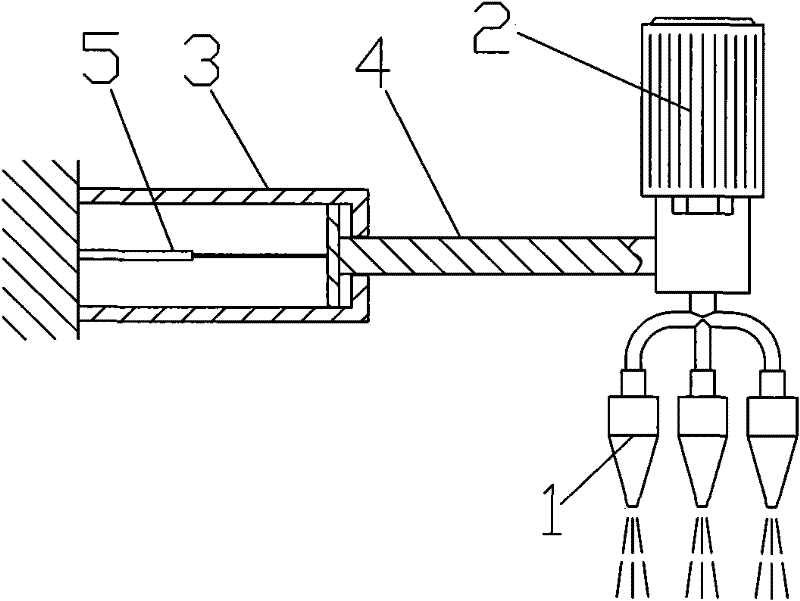

Adjustment system and adjustment method thereof for printing platform

InactiveCN106476278AReduce the chance of damageImprove qualityManufacturing platforms/substratesBreakage probabilityDistance detection

The invention discloses an adjustment system and an adjustment method for a printing platform of a three-dimensional printer. The system comprises a jet head unit, a printing platform supporting frame, the printing platform, a drive unit, a distance detector, a control unit and a parallelism adjusting assembly; the printing platform is arranged on the printing platform supporting frame and is provided with a plurality of detection points; the drive unit drives a jet head of the jet head unit to move; the distance detector is arranged on the jet head unit and detects multiple vertical detection height values between the jet head and the multiple detection points; the control unit controls the drive unit to move, receives the multiple vertical detection height values of the distance detector and converts the multiple vertical detection height values into a plurality of vertical adjustment height values; and the parallelism adjusting assembly comprises a plurality of adjusting and locking units, and the printing platform is adjusted to be parallel with a horizontal displacement surface of the jet head according to the multiple vertical adjustment height values. According to the adjustment system and the adjustment method, the adjustment operation can be simplified, the adjustment time can be shortened, the adjustment accuracy can be improved, the breakage probability of the jet head can be lowered, and the printing forming quality can be improved.

Owner:TECO IMAGE SYST

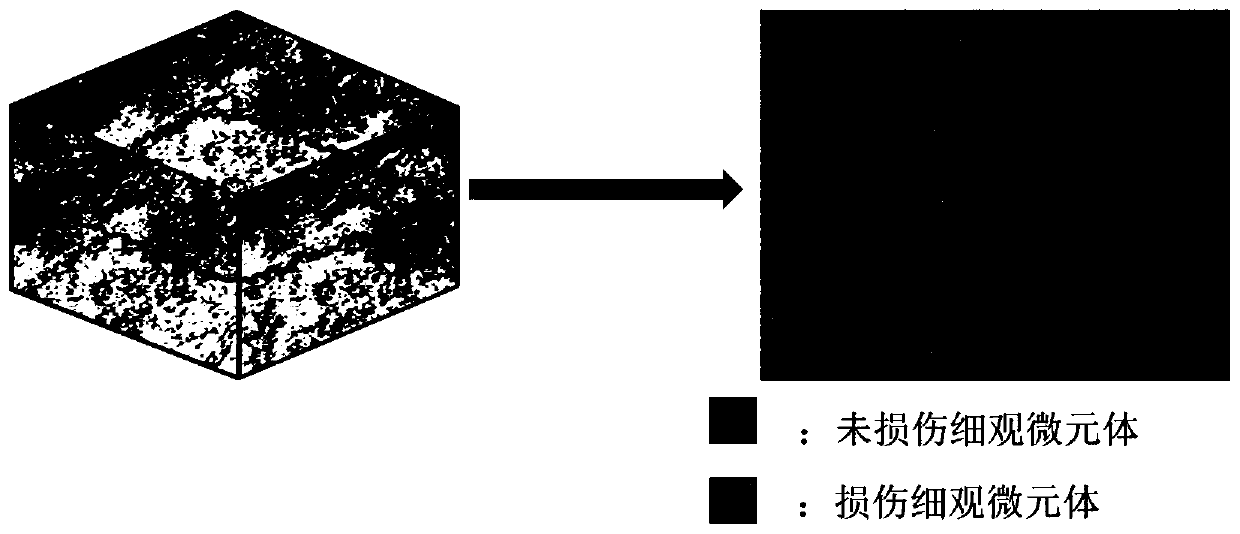

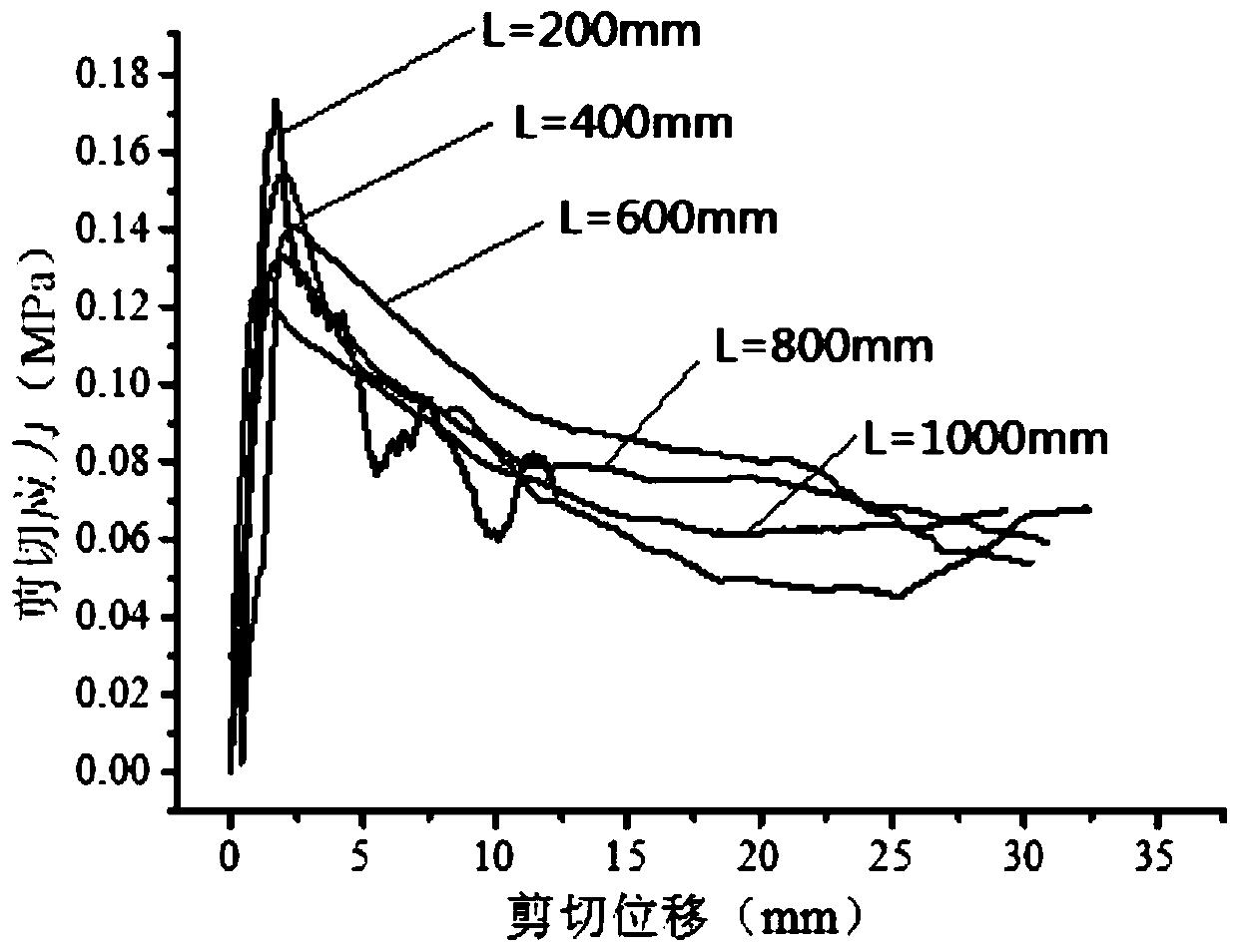

Construction method of rock structural plane damage statistical constitutive model considering size effect

PendingCN110135113AVerify correctnessWell formedDesign optimisation/simulationSpecial data processing applicationsBreakage probabilityShear stress

The invention discloses a construction method of a rock structural plane damage statistical constitutive model considering a size effect, which comprises the following steps of: firstly, simplifying astructural plane into an equivalent thin layer, and determining damage variables according to the number of damaged mesoscopic microelements and the total number of the mesoscopic microelements in the thin layer; secondly, obtaining a damage probability density function of the mesoscopic unit body; then, determining a reasonable damage initial stage, simulating the structural plane load condition, and obtaining a statistical damage constitutive model of the structural plane under the shearing effect; secondly, according to stress balance in the shearing process, determining the relation amongnominal shearing stress, effective shearing stress borne by the undamaged infinitesimal body and shearing stress borne by the damaged infinitesimal body, and obtaining a damage evolution model and astructural surface shearing deformation damage constitutive model of the structural surface in the shearing deformation process; determining parameters m and u0 of the structural plane shear deformation damage constitutive model, and establishing a structural plane shear constitutive model considering the size effect based on the nonlinear relationship between the parameters and the size; finallyverifying the correctness.

Owner:CENT SOUTH UNIV

Preparation process of tempered glass

InactiveCN104045229AReduce the chance of self-explosionGood anti-fog performanceGlass tempering apparatusSurface stressBreakage probability

The invention relates to the glass processing field and specifically discloses a preparation process of tempered glass. The preparation process of the tempered glass comprises the steps of thermally tempering glass, and then coating the tempered glass with an anti-fog layer so that the tempered glass has an excellent anti-fog effect; besides, the tempered glass has the advantages of even surface stress distribution, high flatness, low spontaneous breakage probability in a cooling process, and the like.

Owner:FUJIAN GANGDA GLASS PROD

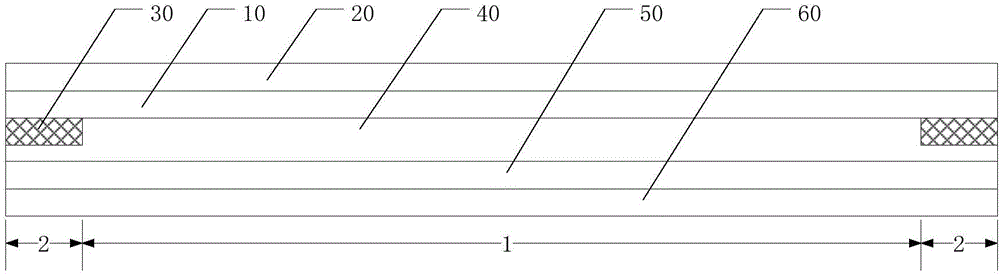

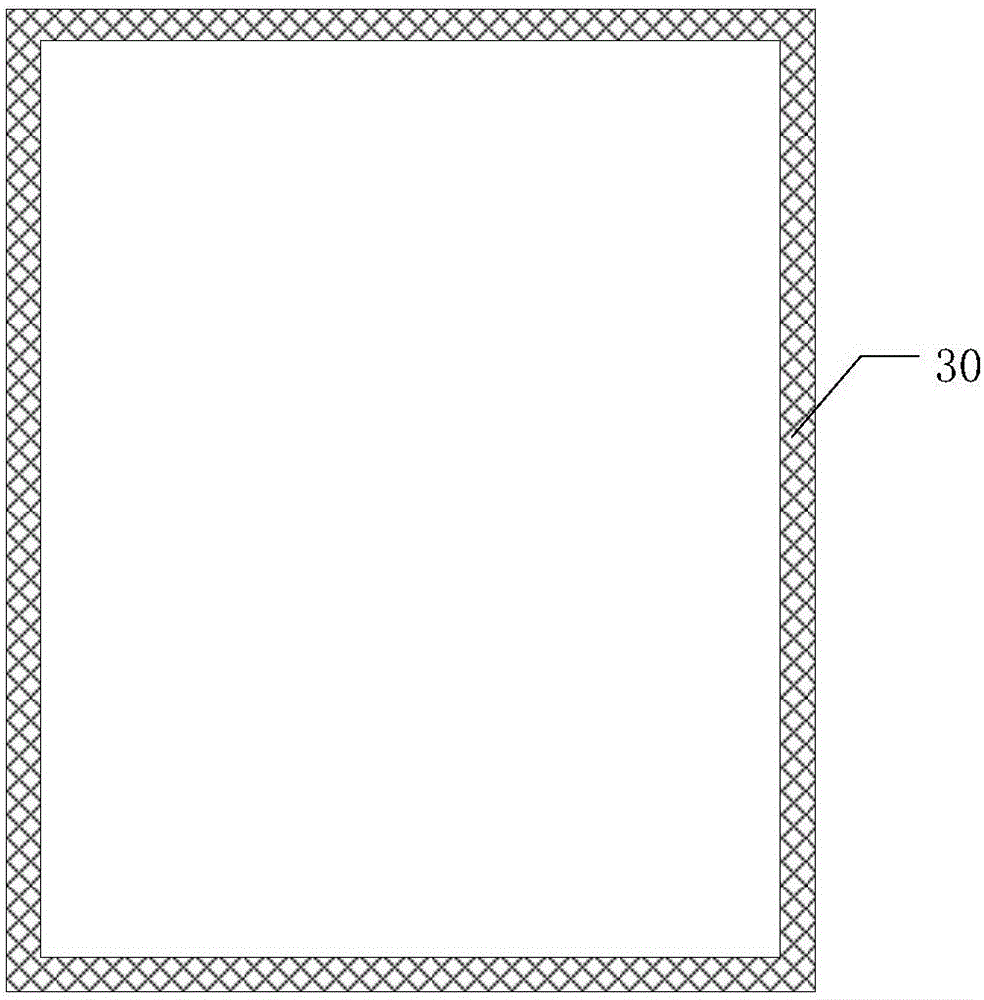

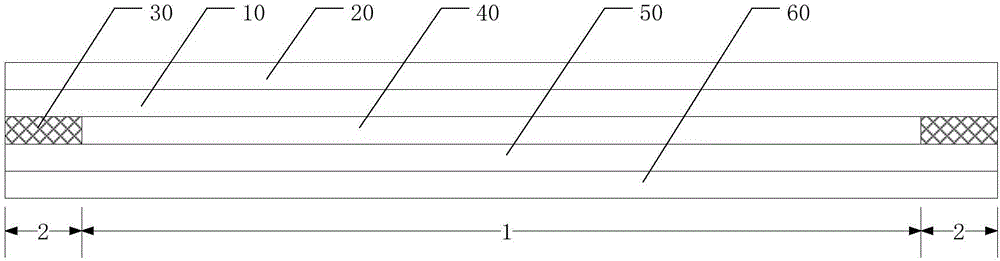

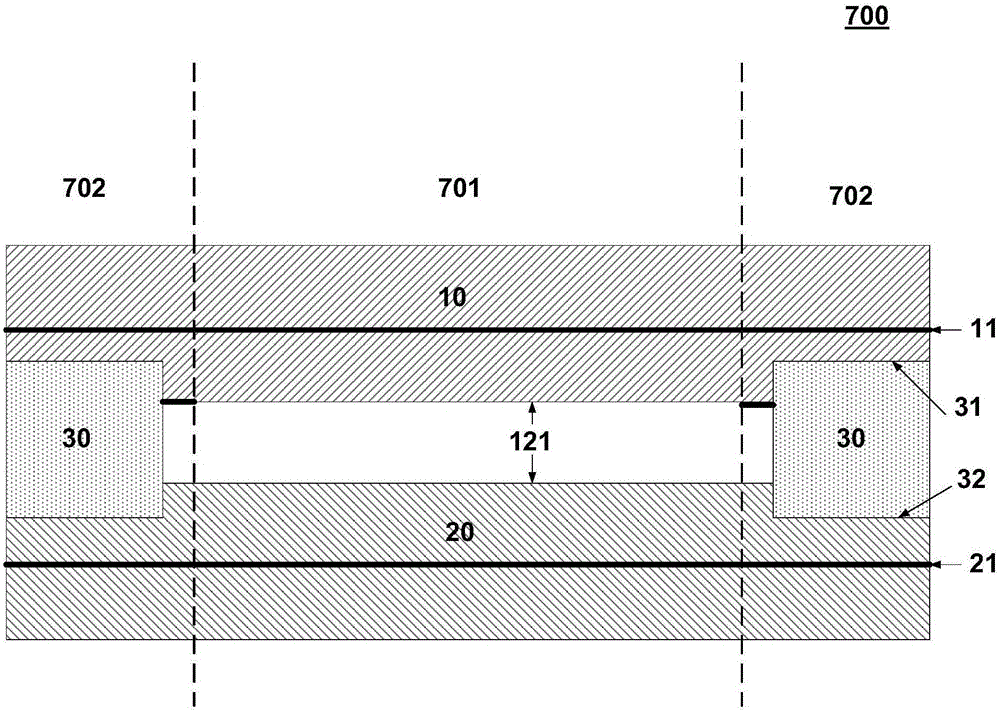

Rupture membrane and manufacturing method thereof, touch screen and display device

InactiveCN105807994AGood optical performanceReduce thicknessDigital data processing detailsGlass/slag layered productsBreakage probabilityDisplay device

The invention provides a rupture membrane and a manufacturing method thereof, a touch screen and a display device. The rupture membrane comprises a transparent substrate, the transparent substrate comprises an intermediate region and an edge region located on the periphery of the intermediate region, and a shielding layer is arranged on the edge region. The rupture membrane provided by the invention can be used on an OGS touch screen, as the shielding layer is arranged additionally on the edge region of the transparent substrate, the optical effect of the touch screen can be improved by the shielding layer, so the thickness of a light resistance frame in the touch screen can be decreased, and the light resistance frame in the touch screen can be even omitted, accordingly the line breakage probability of a signal line in the OGS touch screen in a climbing process can be reduced.

Owner:BOE TECH GRP CO LTD +1

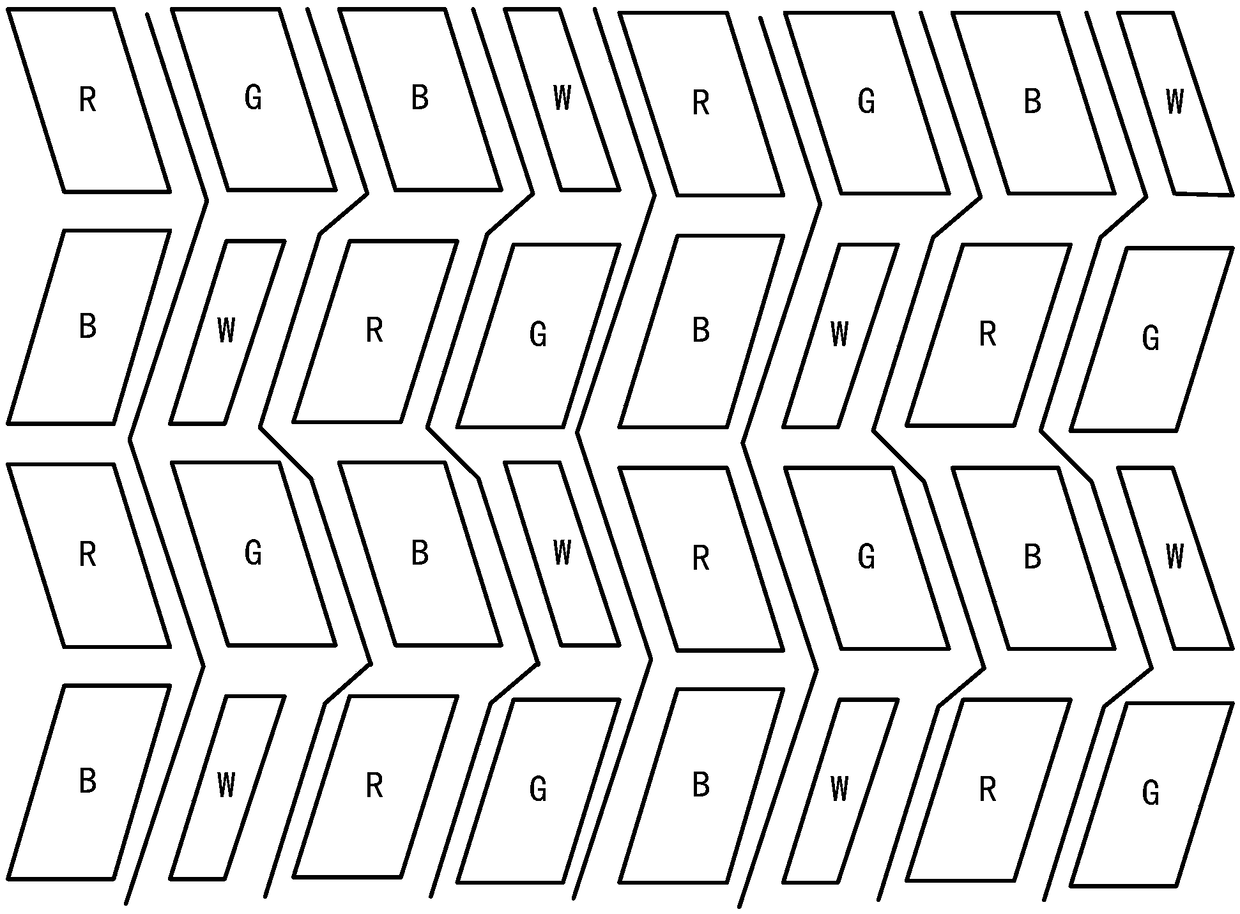

Display panel and display device

ActiveCN108227267ASimple arrangementReduce disconnection rateNon-linear opticsBreakage probabilityDisplay device

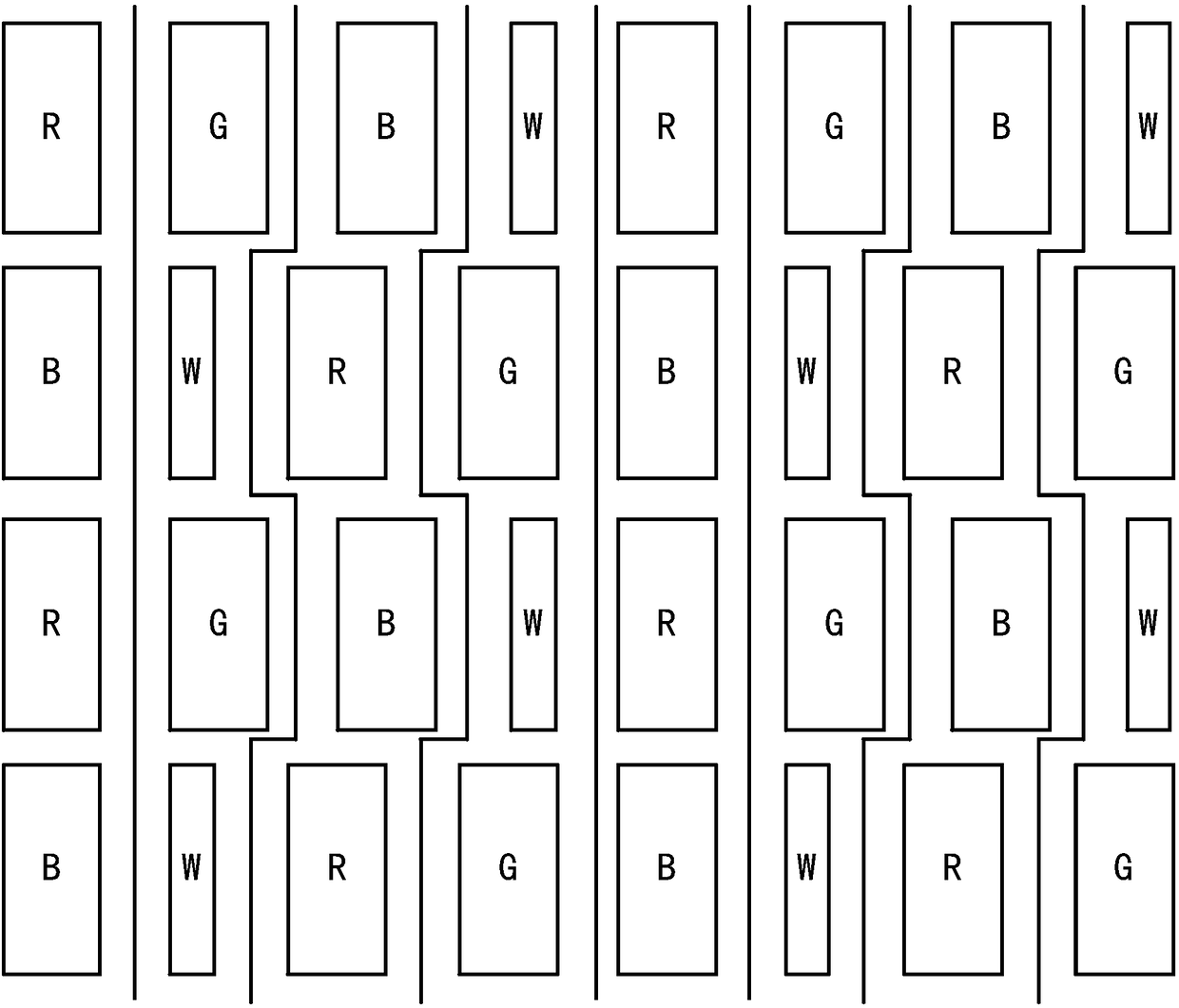

An embodiment of the invention provides a display panel and a display device. The display panel comprises white sub-pixel units, first sub-pixel units, second sub-pixel units and third sub-pixel units. Thin film transistors which correspond to the white sub-pixel units, the first sub-pixel units, the second sub-pixel units and the third sub-pixel units among each row of sub-pixel units are positioned on the same straight line; the widths of the white sub-pixel units are equal to those of the first sub-pixel units in row directions, the white sub-pixel units and the first sub-pixel units are alternately arranged in column directions, and the opening areas of the first sub-pixel units are larger than those of the white sub-pixel units. Compared with the prior art, the display panel and the display device in the embodiment of the invention have the advantage that the display panel and the display device in the designs are favorable for reducing the bending frequencies of partial data cables and accordingly are favorable for reducing the breakage probability of data cables in manufacturing procedures.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Axial-flow fan blade handling vehicle

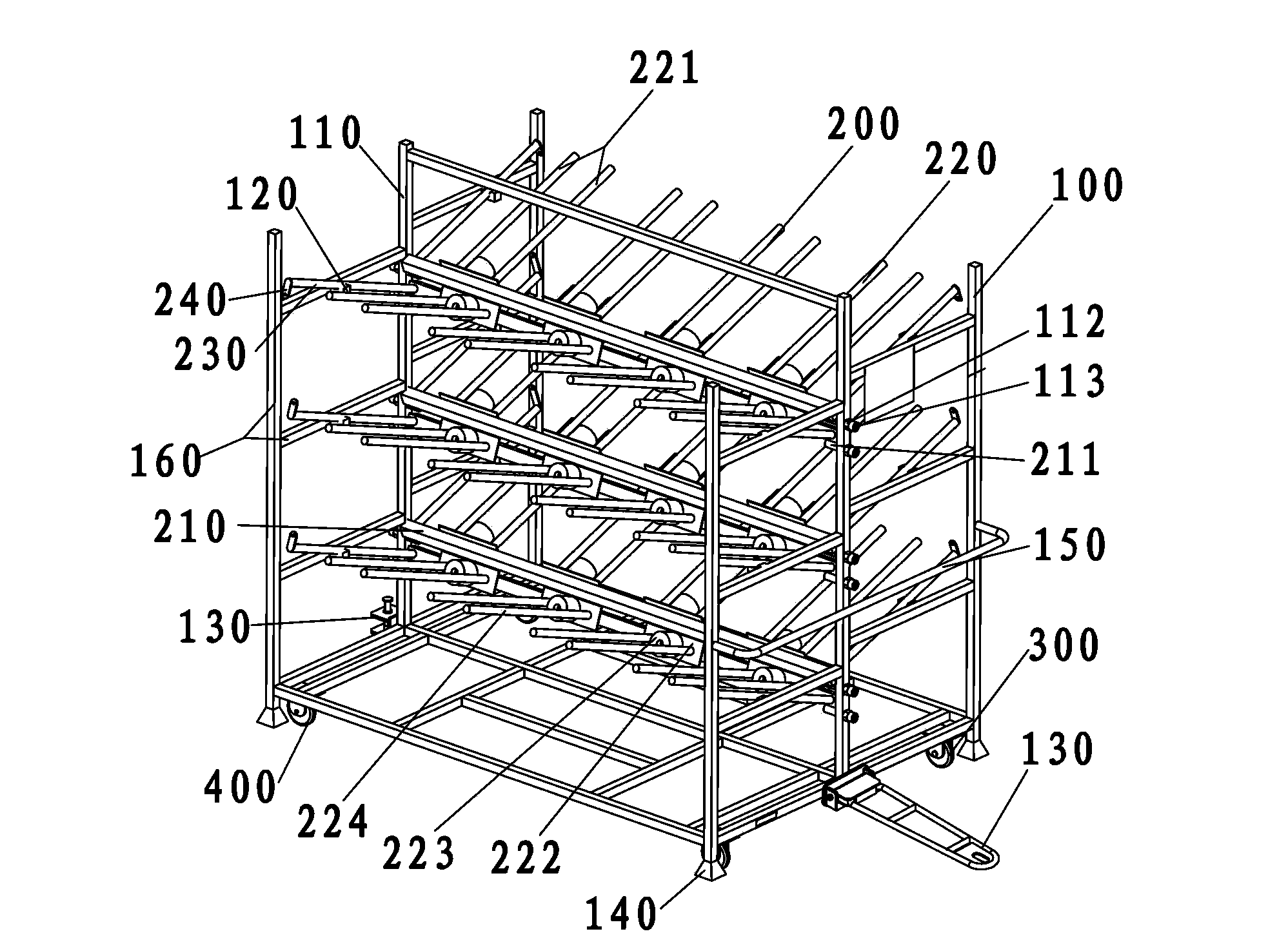

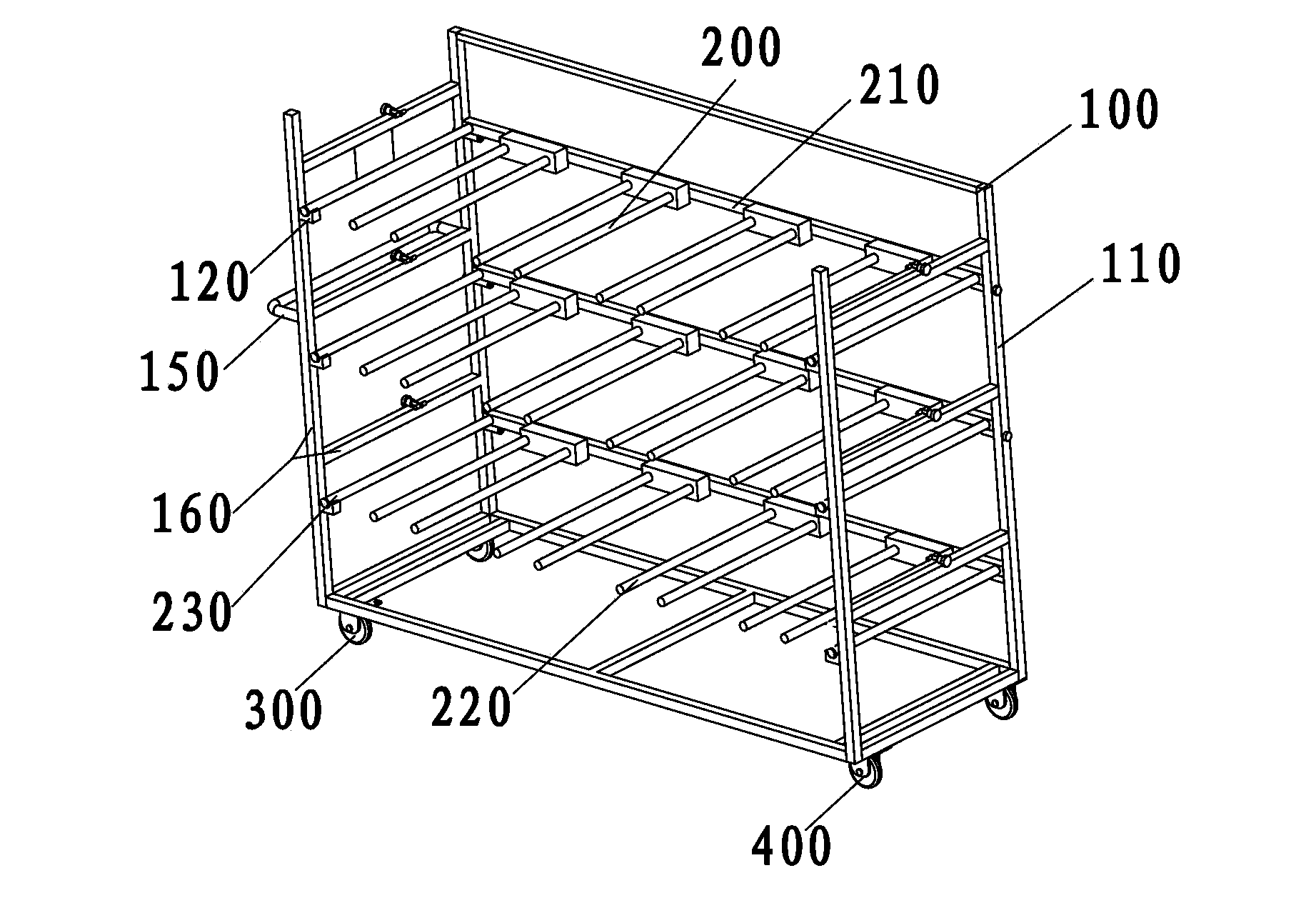

ActiveCN103420029AQuality assuranceImprove work efficiencyExternal framesContainers to prevent mechanical damageBreakage probabilityPack material

The invention discloses an axial-flow fan blade handling vehicle which comprises a main frame and at least one interlayer frame. Each interlayer frame comprises a connecting rod and at least one group of axial-flow fan blade storage racks fixed on the connecting rod which is connected on the main frame, and each axial-flow fan blade storage rack comprises at least two storage rods fixed on the connecting rod. By the axial-flow fan blade handling vehicle, occupied storage space is reduced, site utilization rate is increased, and space is effectively saved; collision among axial-flow fan blades and between the axial-flow fan blades and packed articles is prevented, hidden breakage probability is lowered, and quality of the axial-flow fan blades is guaranteed; packing materials are not needed, so that cost is saved; packing and unpacking processes are not needed, convenience in use is realized, labor intensity is lowered, manpower cost is saved, and working efficiency of the axial-flow fan blades is improved.

Owner:GREE ELECTRIC APPLIANCES INC

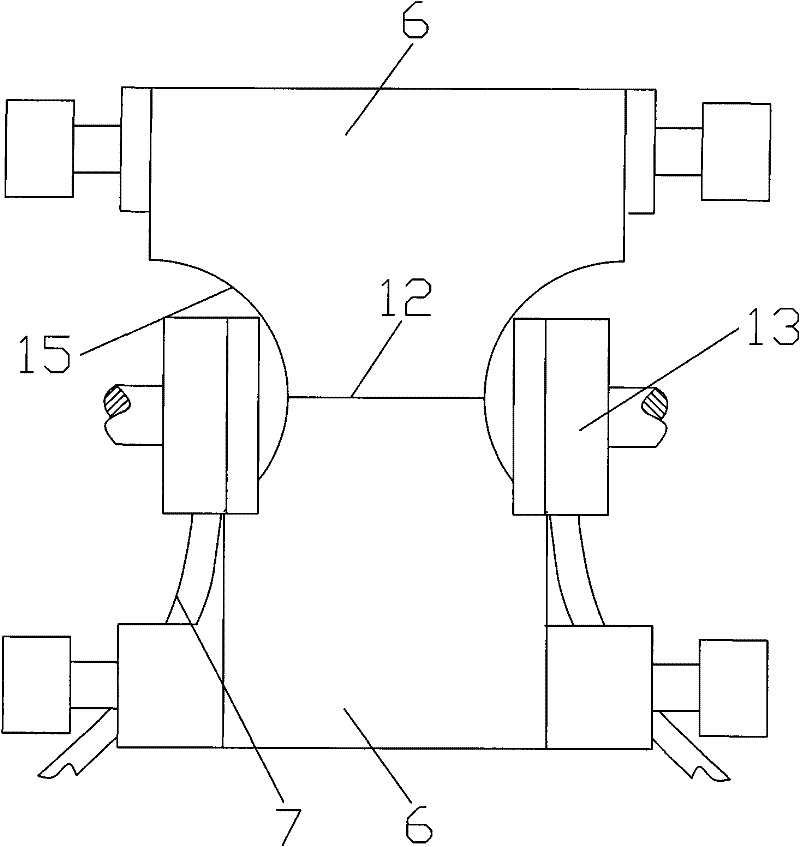

Fixed-width trimming device and method for cold-state strip steel

ActiveCN102189404AProtection reliabilityUniform stress distributionOther manufacturing equipments/toolsGrinding/polishing apparatusBreakage probabilitySpray nozzle

The invention relates to the field of strip steel rolling production, in particular to a fixed-width trimming device and method for cold-state strip steel. The fixed-width trimming device for cold-state strip steel comprises two rows of high-pressure spray nozzles, a turning roll, a tensioning unit, a scrap cutter and a control device, wherein the two rows of high-pressure spray nozzles are arranged at the two sides of strip steel respectively in a direction consistent with the moving direction of the strip steel. The fixed-width trimming method for cold-state strip steel comprises the following steps: tensioning strip steel so that the surface of the strip steel is flat and straight and has stable tension; preparing the mixed solution for spray cutting, wherein the high-pressure spray nozzles adopt the mixed solution of industrial pure water and abrasive; and finally controlling the high-pressure spray nozzles to perform trimming by the control device. Based on the high-pressure abrasive jet cutting technology, the device and method provided by the invention realize combination of high-speed cutting and good cutting quality; and smooth-transition tracking cutting is adopted in width specification switch of the strip steel, an S-shaped track is obtained, and the breakage probability of the welded seam area is effectively reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

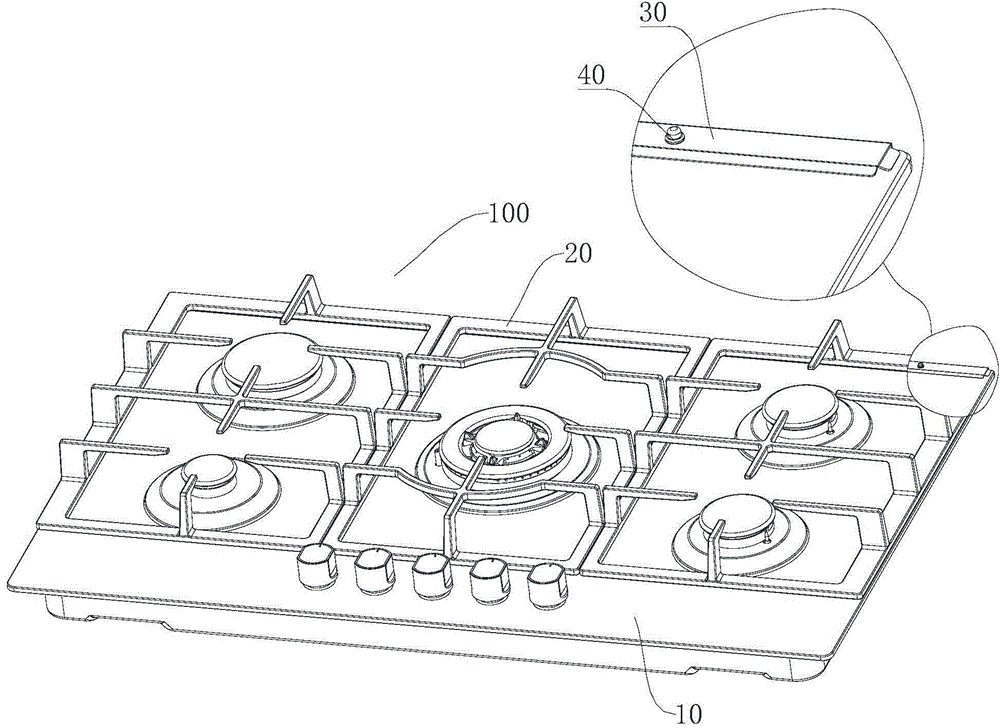

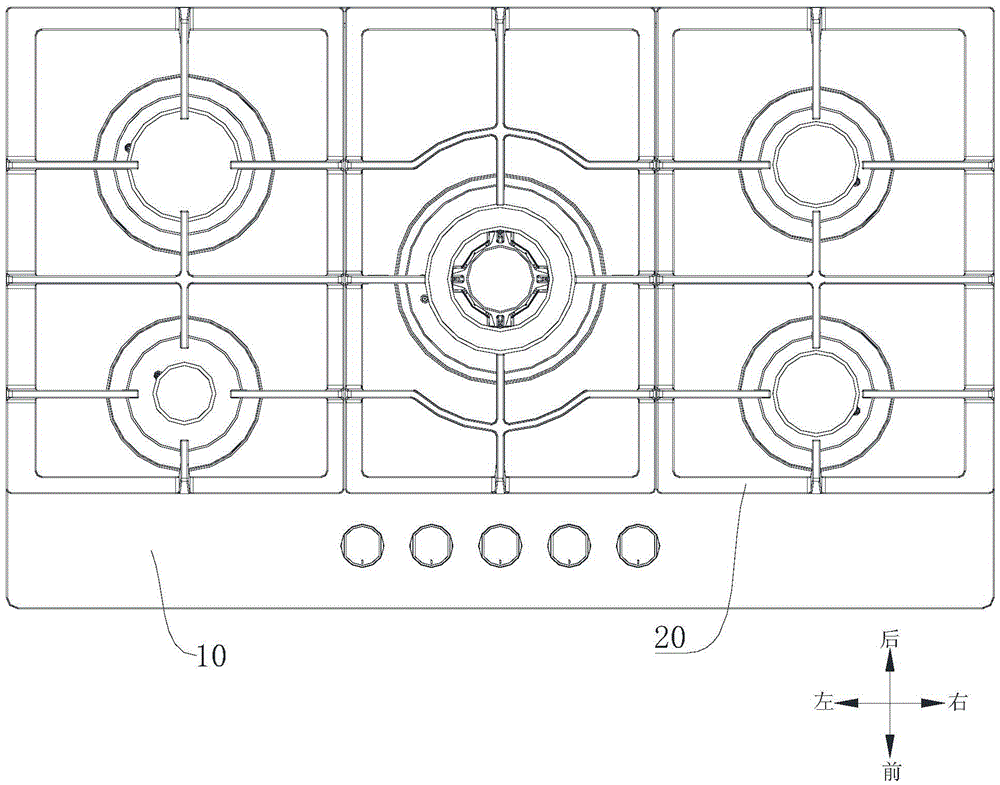

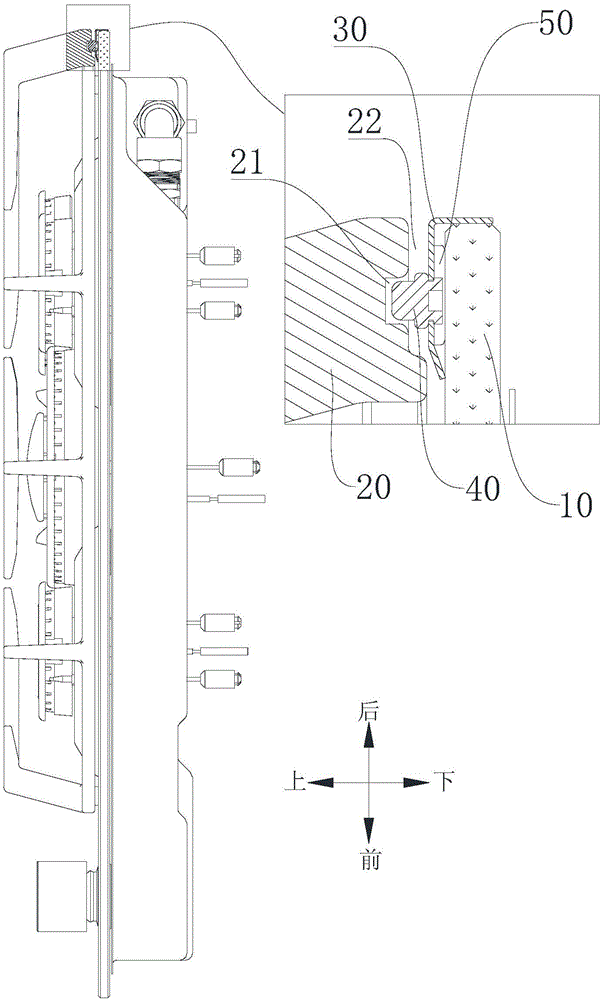

Gas stove

ActiveCN104654365ALower quality requirementsImprove structural stabilityDomestic stoves or rangesStoves/ranges shelves or racksBreakage probabilityTemperature difference

The invention discloses a gas stove. The gas stove comprises a panel, a pot frame, a decoration strip and a connecting piece, wherein the pot frame is arranged on the upper side of the panel, the lower part of the pot frame is provided with a positioning hole, and the decoration strip is arranged between the panel and the pot frame; the decoration strip is connected with the panel, one end of the connecting piece is connected with the decoration strip, and the other end of the connecting piece is detachably embedded in the positioning hole. According to the gas stove disclosed by the embodiment of the invention, the positioning and fixing of the pot frame on the panel are realized through the connecting piece and the decoration strip, holes used for positioning are not formed in the panel due to the positioning way, so that the quality requirements of the panel are lowered, a trepanning process is not needed, the manufacturing costs is lowered, meanwhile the whole structure stability of the panel is improved, the abnormal breakage is observably lowered, and the ultimate temperature difference borne by the panel is obviously increased. The structure is reliable, simple and efficient, and the gas stove is capable of effectively reducing the panel breakage probability and improving the product quality.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

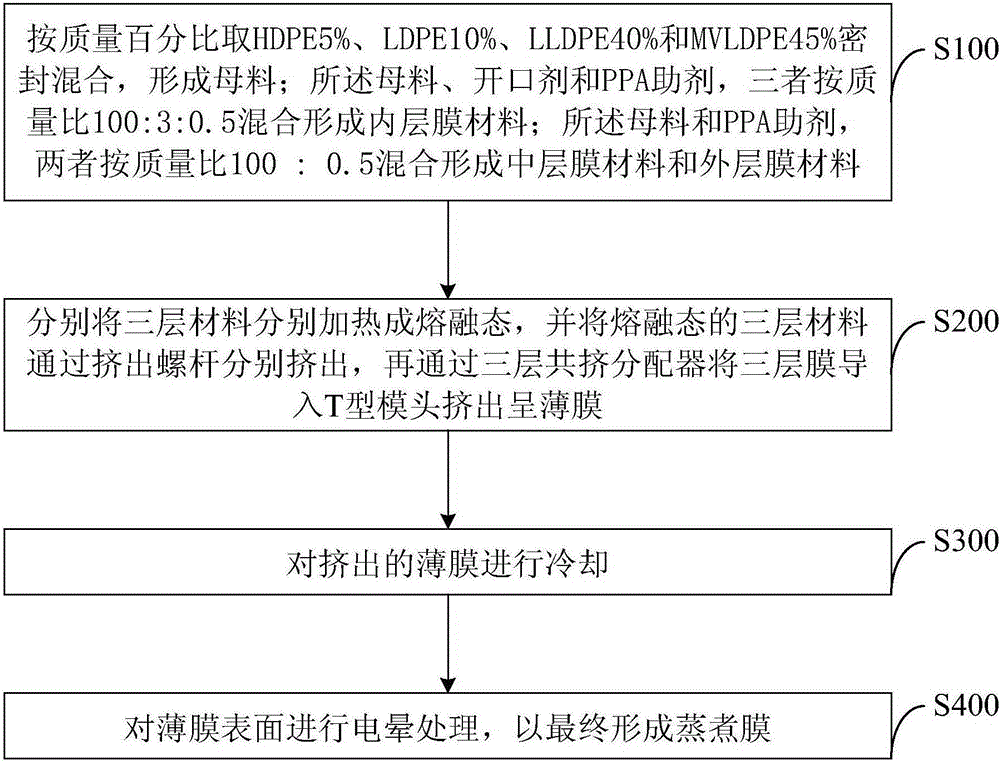

Cooling film and manufacturing method thereof

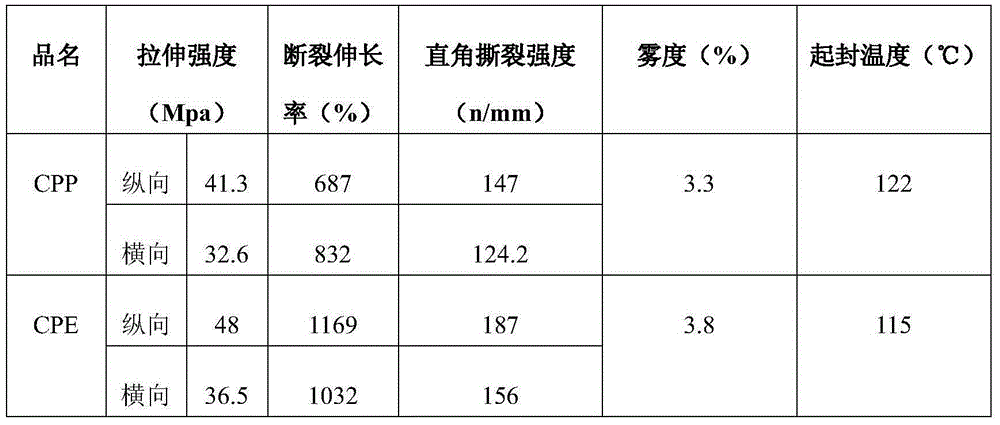

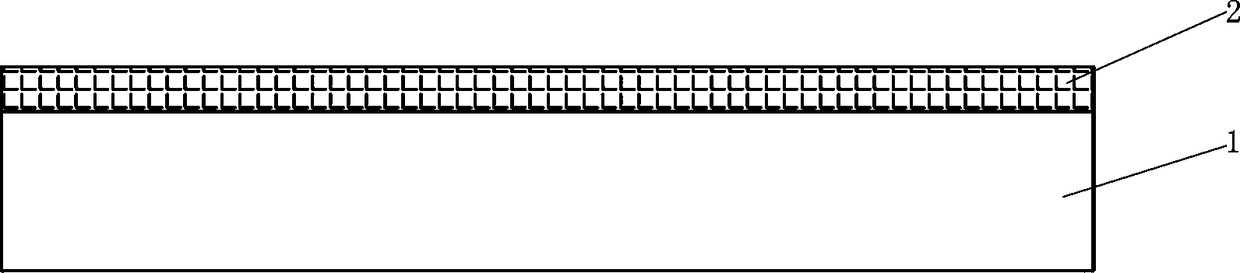

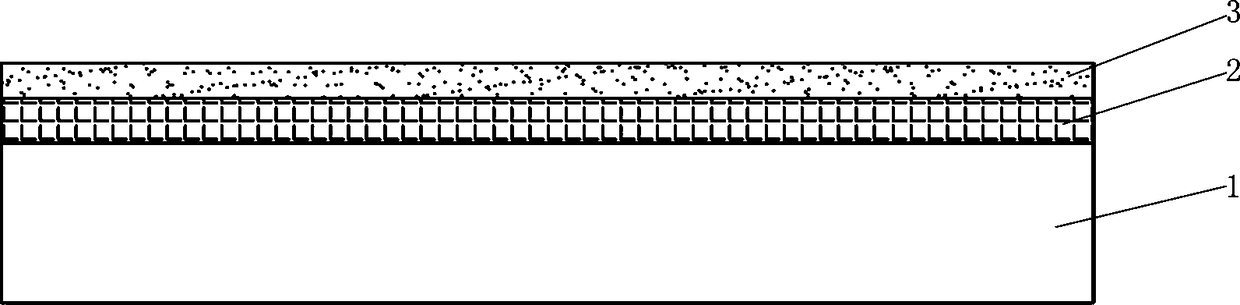

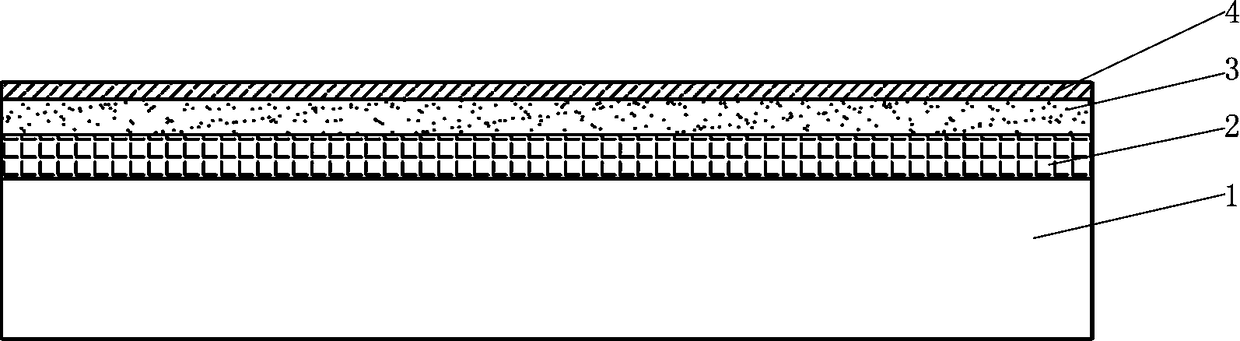

InactiveCN105172299AImprove hot and cold physical propertiesReduce the chance of bag breakageLamination ancillary operationsSynthetic resin layered productsBreakage probabilityMass ratio

The invention relates to the technical field of food packaging materials and discloses a cooking film. The cooking film comprises an inner-layer film, a middle-layer film and an outer-layer film. The inner-layer film comprises a master batch, an antiblocking agent and a PPA assistant. The master batch, the antiblocking agent and the PPA assistant are mixed according to the mass ratio of 100:3:0.5. The middle-layer film and the outer-layer film each comprise a master batch and a PPA assistant, wherein the master batch and the PPA assistant are mixed according to the mass ratio of 100:0.5. The master batches of the inner-layer film, the middle-layer film and the outer-layer film each comprise HDPE, LDPE, LLDPE and MVLDPE, wherein HDPE, LDPE, LLDPE and MVLDPE are mixed according to the mass percentage of 5%:10%:40%:45%. The cooking film comprises the special material components. The cold and hot physical performance of the cooking film is improved, and the bag breakage probability in the refrigeration or high-temperature heat-seal process is greatly reduced.

Owner:重庆松尚久德新材料有限公司

Manufacturing method for ultrathin capacitive touch screen

InactiveCN108319403AReduce the chance of breakageReduce generationInput/output processes for data processingCapacitanceBreakage probability

The invention discloses a manufacturing method for an ultrathin capacitive touch screen. The method comprises the steps of coating a carrier plate with stripping glue; attaching a thin glass sheet tothe carrier plate through the stripping glue; making a touch circuit layer on the thin glass sheet; performing lacerating and precision carving on a combined body of the carrier plate and the thin glass sheet; and soaking lacerated units in an etching chemical liquid for performing chemical polishing. Through cooperation of two aspects of reducing the probability of generating thin and small cracks and controlling a spreading trend of the thin and small cracks, the breakage probability of the thin glass sheet is greatly reduced in the thin glass sheet making process, so that the manufacturingyield of the capacitive touch screen is greatly increased.

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD

Display device

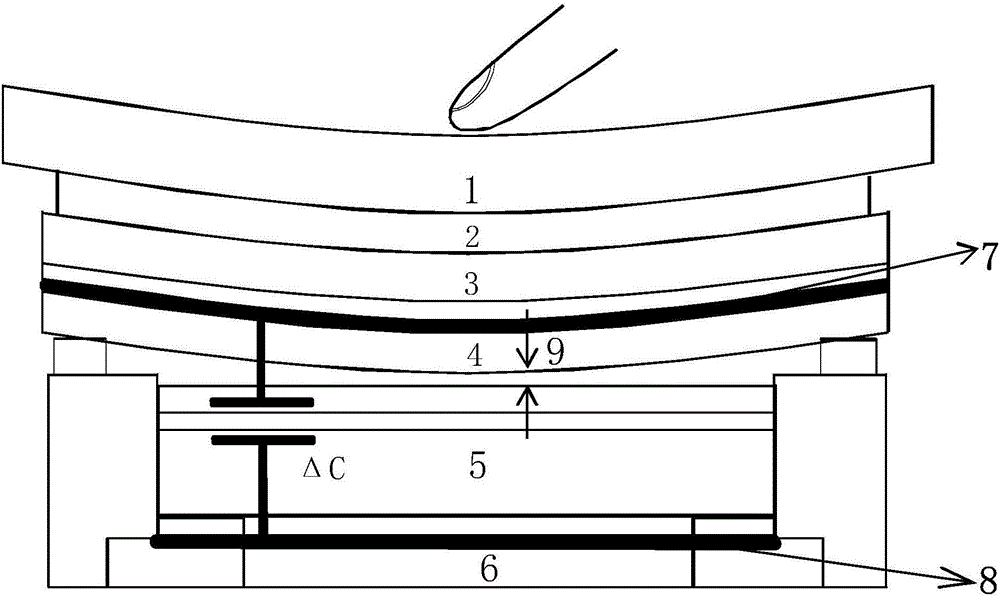

ActiveCN106547408AReduce deformation requirementsReduce the probability of broken screenNon-linear opticsInput/output processes for data processingBreakage probabilityCapacitance

The invention discloses a display device. The display device comprises a first pressure sensing module, a second pressure sensing module opposite to the first pressure sensing module and an elastic component, wherein the elastic component comprises a first end face and a second end face opposite to the first end face; and the first end face is in contact with the first pressure sensing module and the second end face is in contact with the second pressure sensing module to ensure that the elastic component is compressed when the display device is pressed, and then the distance between a first pressure sensing layer and a second pressure sensing layer changes to realize pressure detection. According to the display device disclosed by the invention, the pressing deformation of a display panel in a capacitance change dependence module in the prior art is converted to deformation of the elastic component to be realized, so that the deformation requirement for the display panel is relatively low, or pressure detection also can be carried out on the display panel without deformation, so that the screen breakage probability of a display screen is reduced, the clearance deformation becomes uniform, and the influence on the display is decreased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

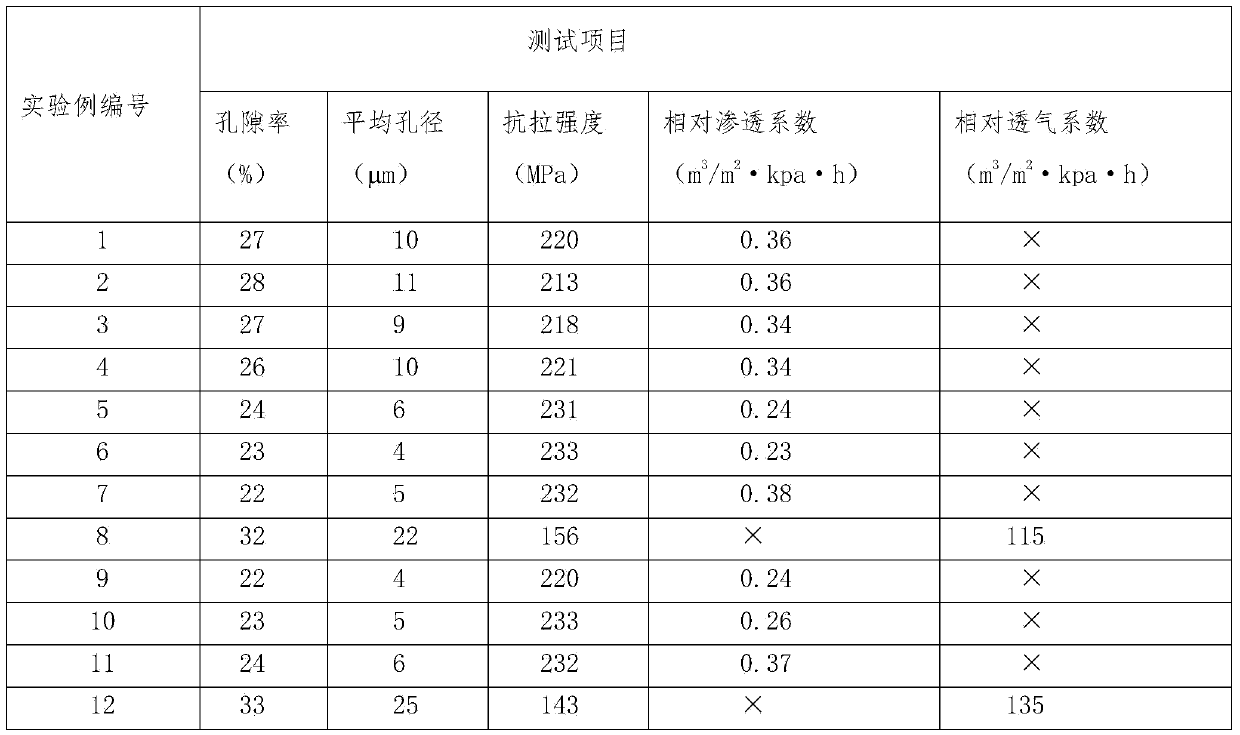

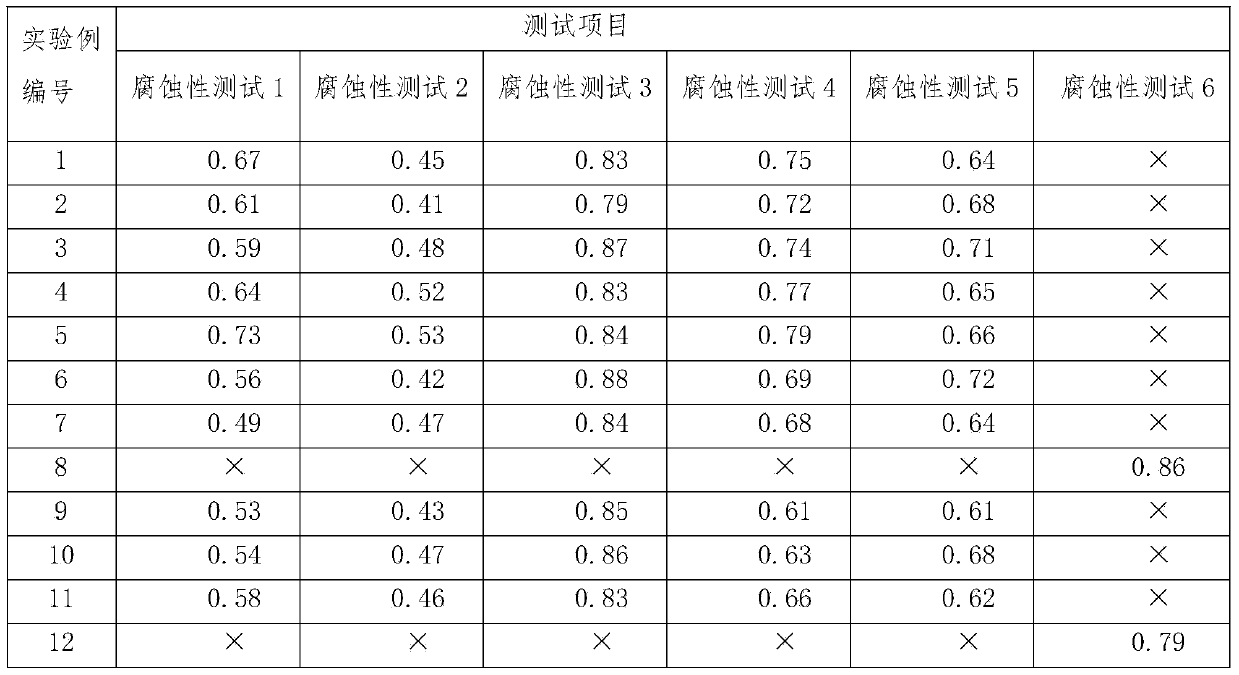

Manufacturing method for porous powder sintered body and preloading molded body for manufacturing sintered body

ActiveCN104190935AAccelerated corrosionImprove corrosion resistanceCompression moldingMaterials preparation

The invention discloses a manufacturing method for a porous powder sintered body and a preloading molded body for manufacturing the sintered body. According to the method, the aperture size of the porous powder sintered body can be controlled easily and effectively, and the breakage probability of the molded body during compression molding can be lowered. The method comprises the steps of material preparation, molding and sintering. During material preparation, according to basic raw material powder for manufacturing the porous body, first powder and second powder are used, wherein the first powder and the second powder are different in shape and size, compared with the second powder, the granularity of the first powder is smaller, the compactibility of the first powder during molding is better, and the first powder accounts for 10 percent-90 percent of the total mass of the basic raw material powder. The first powder has the characteristics of being better in compactibility and smaller in sintered aperture size, the second powder has the characteristic of being larger in sintered aperture size, in this way, after the first powder is fully mixed with the second powder, gaps formed in the second powder can be filled with the first powder, on one hand, the effect of controlling the aperture size of the sintered material is achieved, and on the other hand, the compactibility of the mixed powder is improved.

Owner:CHENGDU INTERMENT TECH

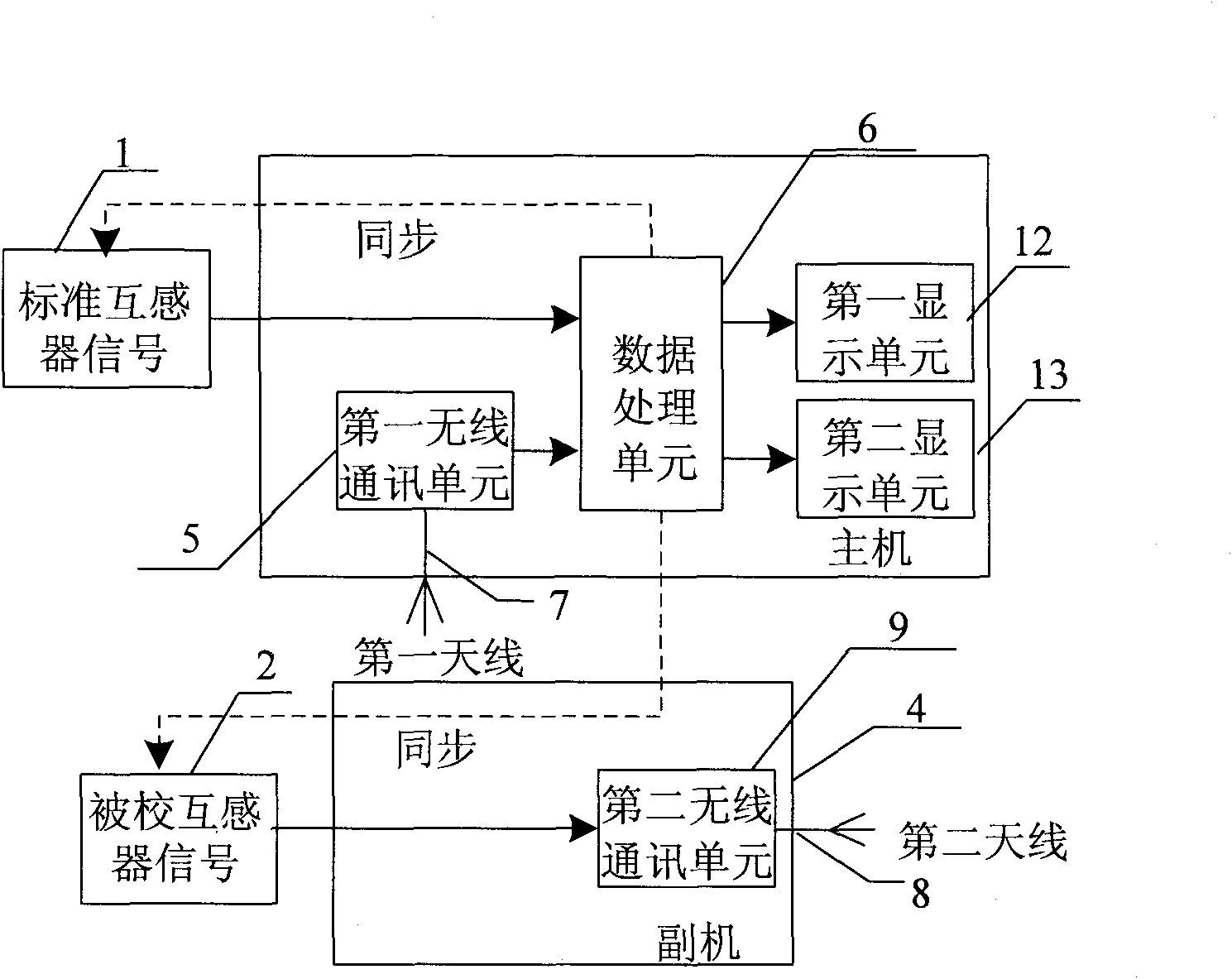

Mutual inductor calibration instrument

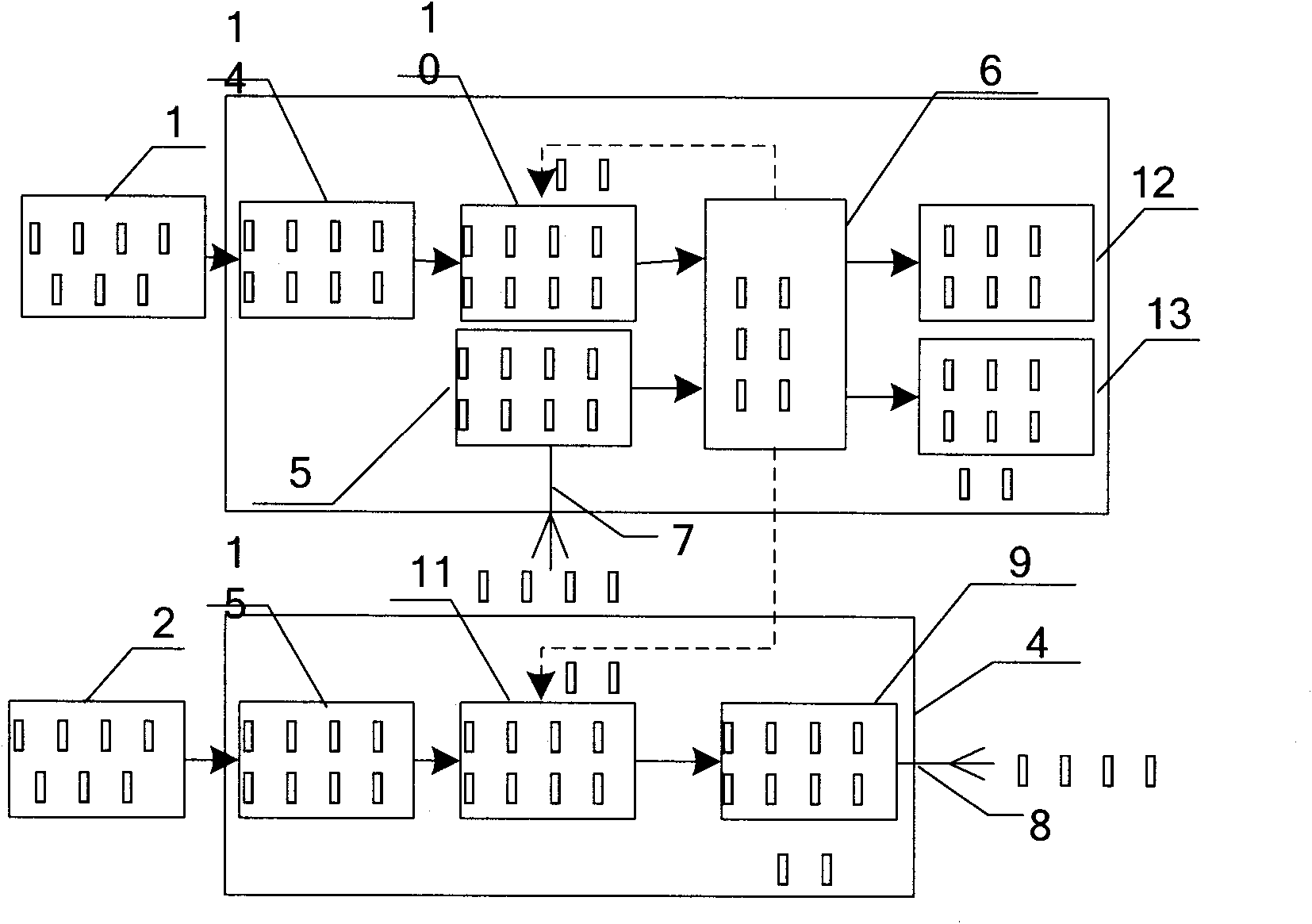

InactiveCN101819265AReduce the chance of breakageImprove securityElectrical measurementsBreakage probabilityMain processing unit

The embodiment of the invention discloses a mutual inductor calibration instrument which comprises a host machine and an auxiliary machine, wherein the host machine comprises a first wireless communication unit, a data processing unit and a first display unit; and the auxiliary machine comprises a second wireless communication unit and a second display unit. The host machine is used for conditioning, acquiring and converting signals of a mutual inductor, and the auxiliary machine is used for conditioning, acquiring and converting the signals of the mutual inductor and then transmitting the signals to the host machine through wireless communication. A ratio difference and a phase difference after the signals are compared are obtained by data operation processing of the data processing unit of the host machine. The mutual inductor calibration instrument has no need of connecting a secondary test lead, thereby reducing false wiring and lead breakage probability, improving the test safety and reliability, relieving the site workload, and improving the working efficiency and the quality.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST

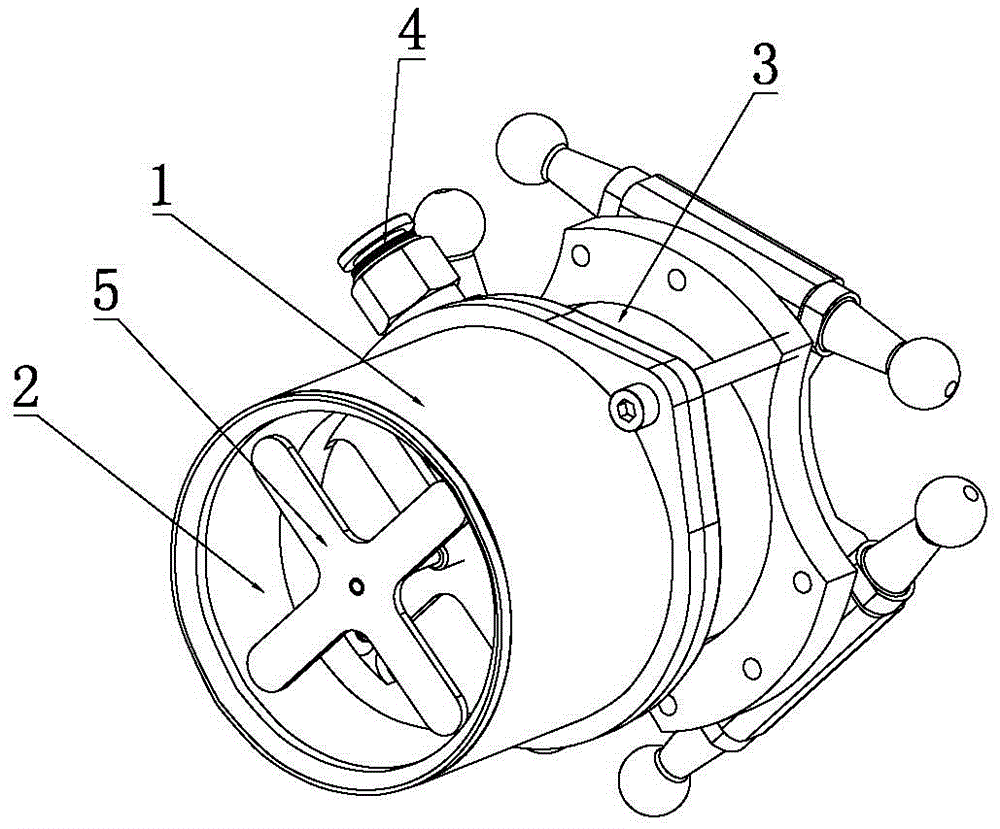

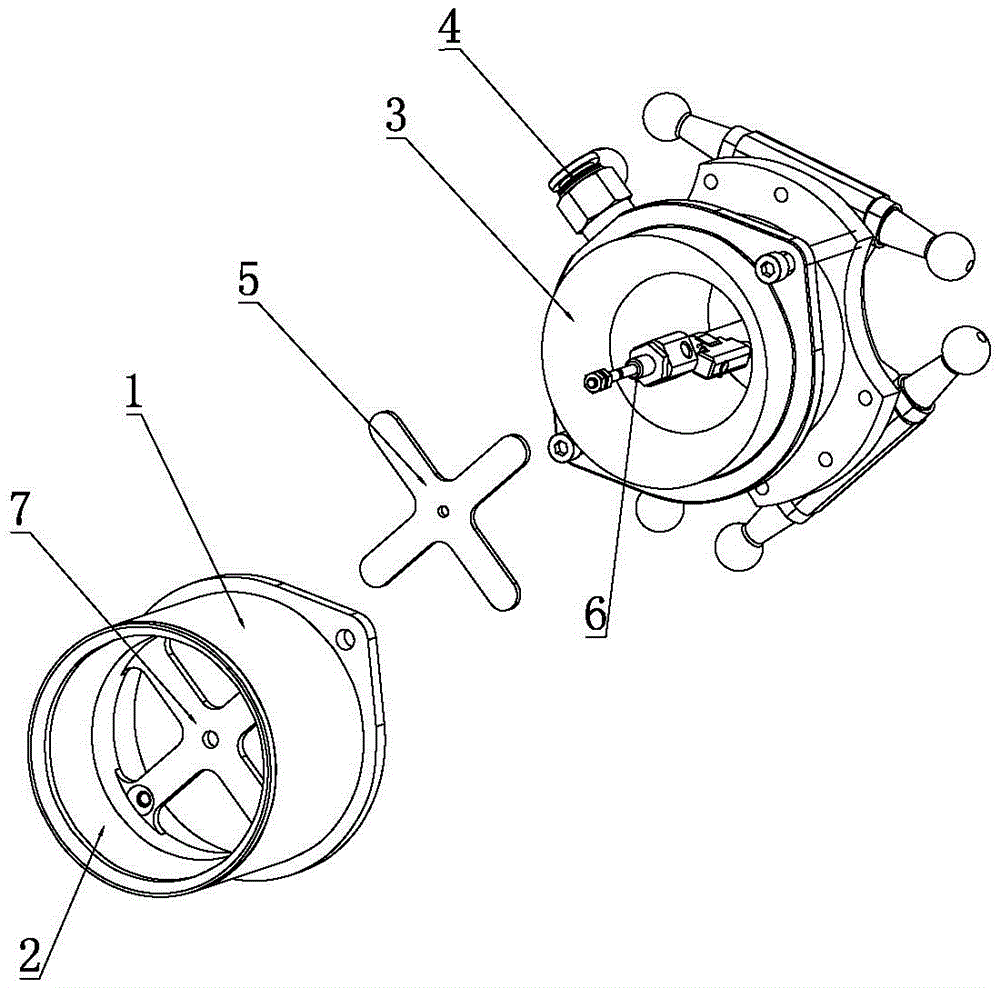

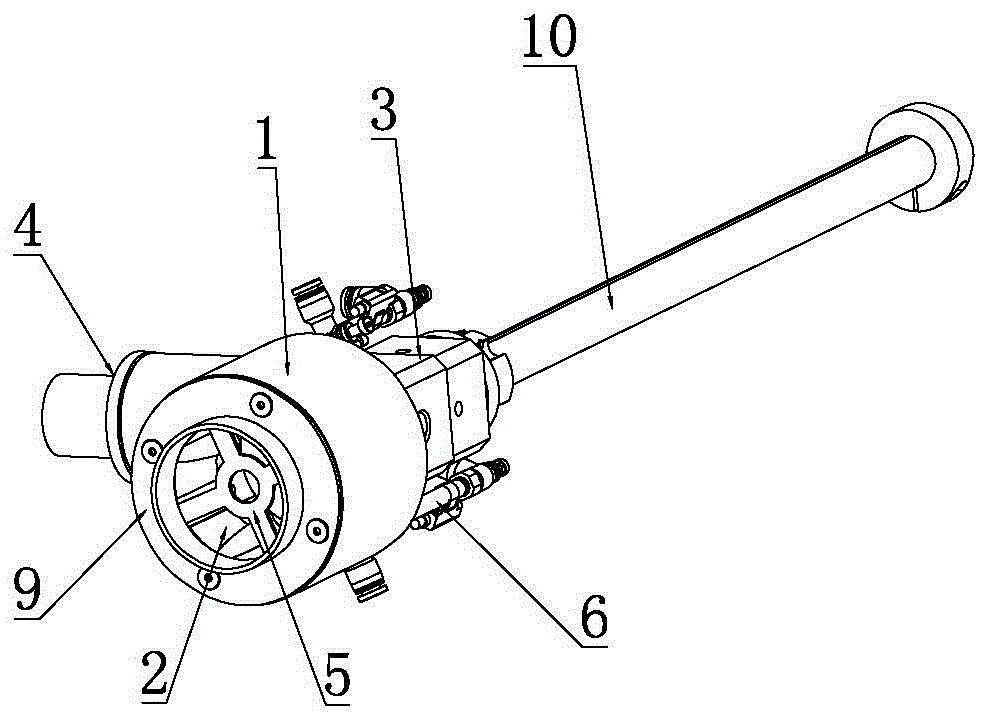

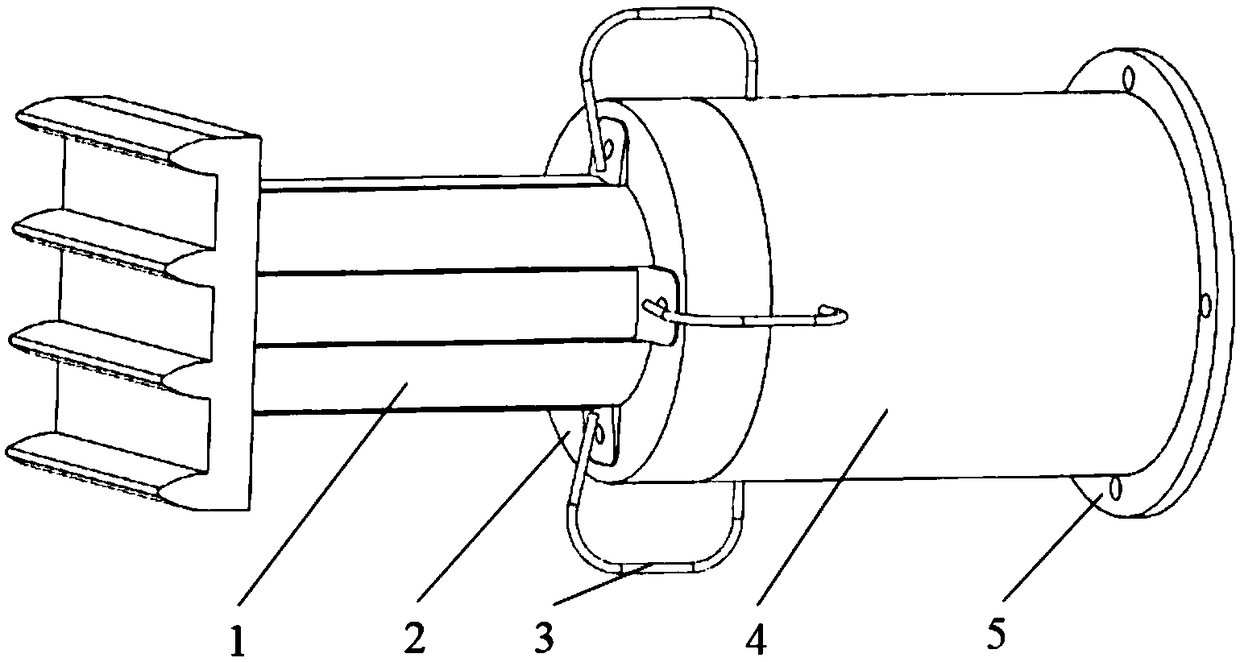

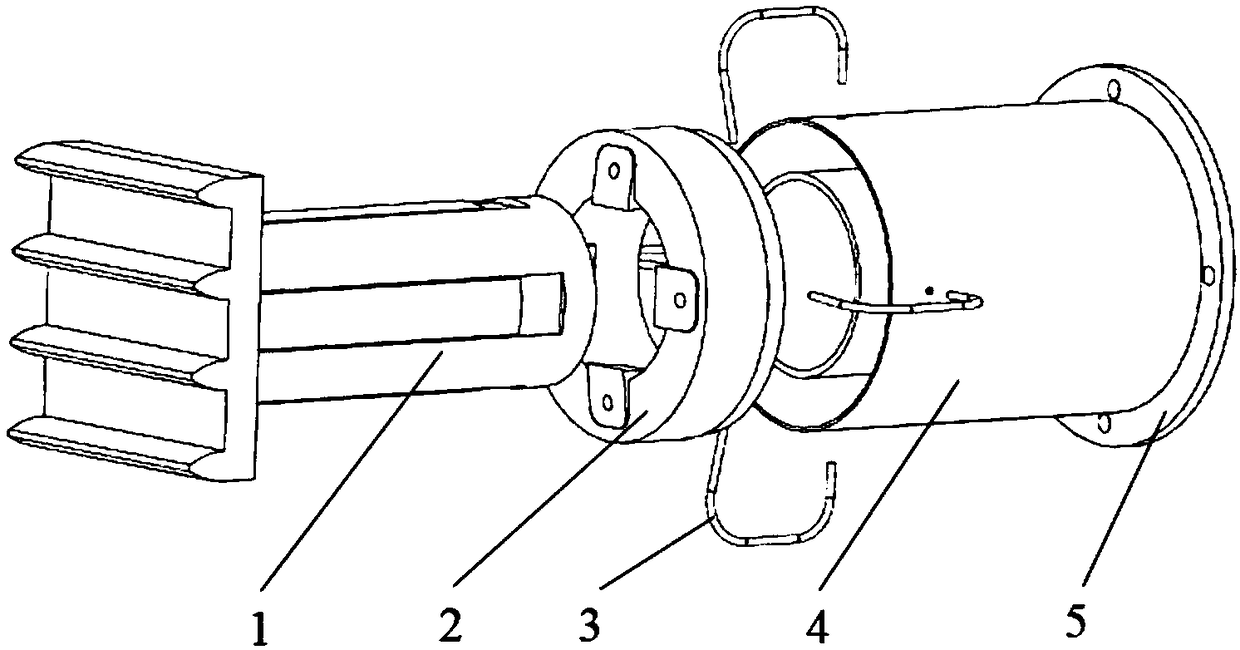

Sliced food sucking device

The invention discloses a sliced food sucking device and relates to the technical field of food packaging equipment. The sliced food sucking device structurally comprises a sucking head with a containing cavity. Due to the fact that a sliding buffer part is arranged in the containing cavity, the buffer part gets close to a sucking port of the sucking head before food is sucked, in this way, the first slice of food can be tightly attached to the buffer part by moving a quite small distance when food is sucked, side turning of the first slice of food can be prevented, smooth sucking of follow-up food is ensured, collision between the first slice of food and the buffer part is reduced, and then the food breakage probability is reduced. Meanwhile, due to the fact that the buffer part is moved towards the bottom of the containing cavity by the distance of the thickness of at least one slice of food every time the sucking head sucks one slice of food, side turning of follow-up sucked food can be prevented, collision between food can be reduced, and the food breakage probability is further reduced. In the discharge process, the buffer part pushes all food in the sucking head together, and rapid and smooth discharge is achieved.

Owner:QKM TECH (DONG GUAN) CO LTD

Wafer thinning method

InactiveCN109346403AReduce internal stressAvoid pollutionSemiconductor/solid-state device manufacturingBreakage probabilityEtching

The invention discloses a wafer thinning method. The wafer thinning method is characterized by comprising the steps of providing a wafer to be thinned, trimming a wafer edge by laser, and removing a part of material at a round angle to form an arc chamfer angle; preparing a coating liquid, uniformly coating the coating liquid on a front surface of the wafer and the chamfer angle of the edge, baking and hardening to form a coverage layer, and fixing the front surface of the wafer and a substrate; performing first-time grinding on a back surface of the wafer, and performing first-time wet etching on the back surface of the wafer; performing second-time grinding on the back surface of the wafer; and performing second-time wet etching on the back surface of the wafer, making the wafer and thesubstrate separated, removing the coverage layer of the wafer, thereby obtaining the thinned wafer. The wafer thinning method employs a special protection process, the internal stress of the device generated during the wafer thinning process can be reduced, the front surface of the wafer can be prevented from being polluted by a mixture of particle generated during the wafer thinning process and cooling wafer, the breakage probability is reduced, the finished rate is improved, and the production cost is reduced.

Owner:广西桂芯半导体科技有限公司

Transfer box for cleaning of silicon wafers

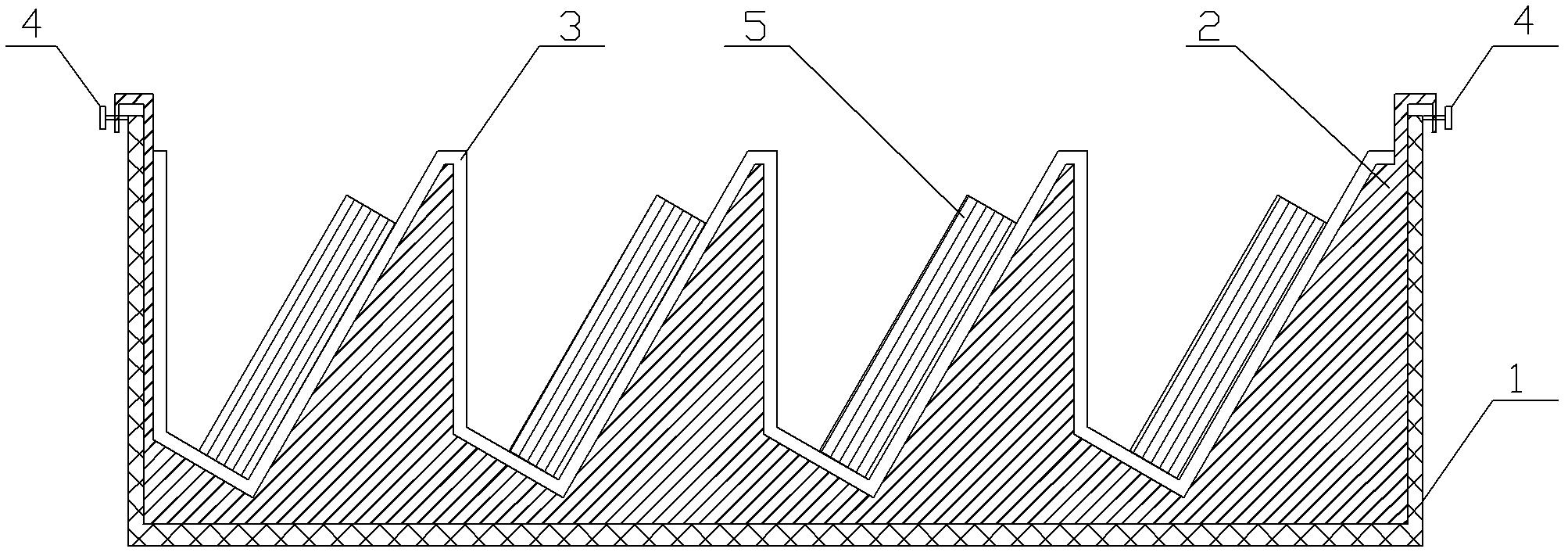

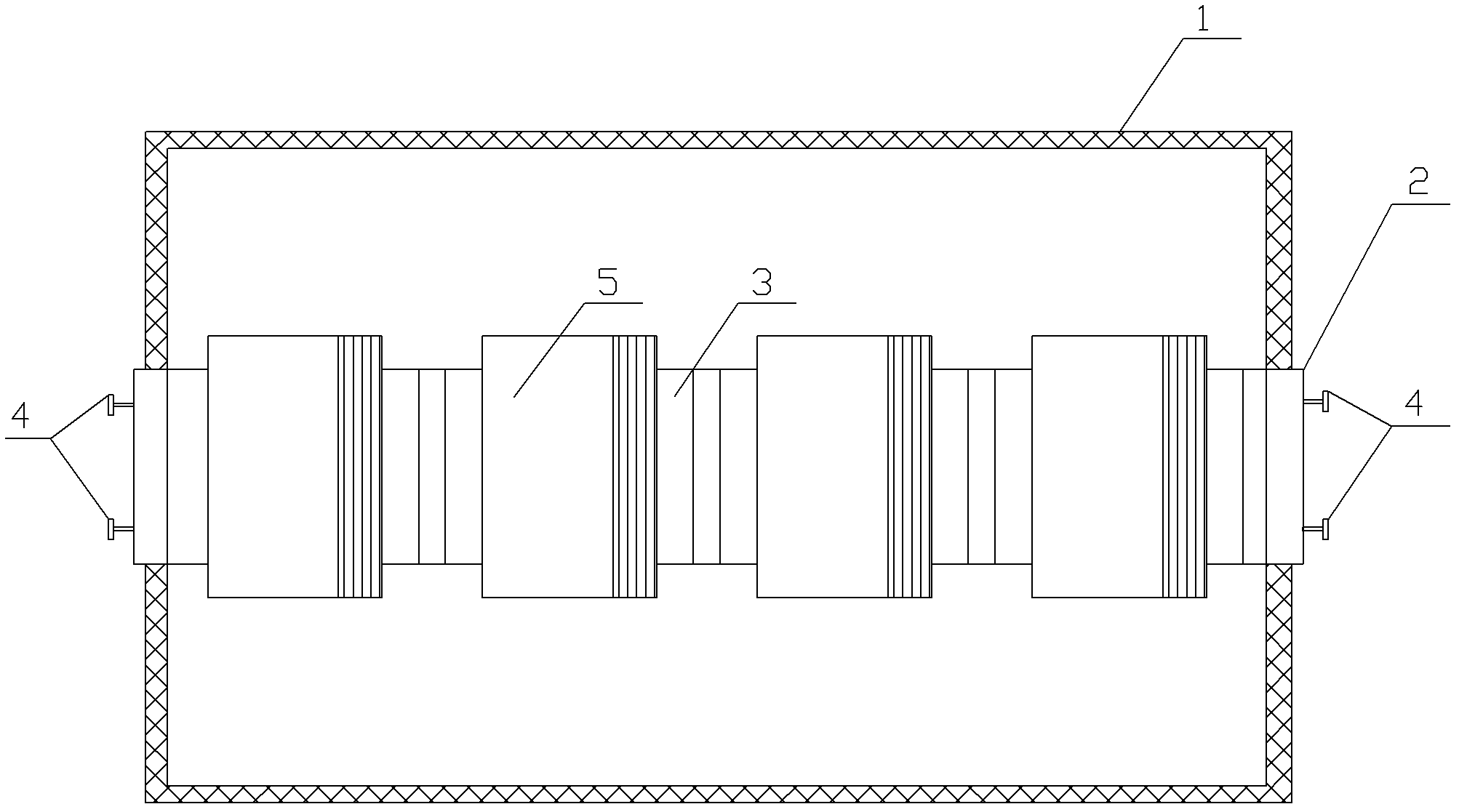

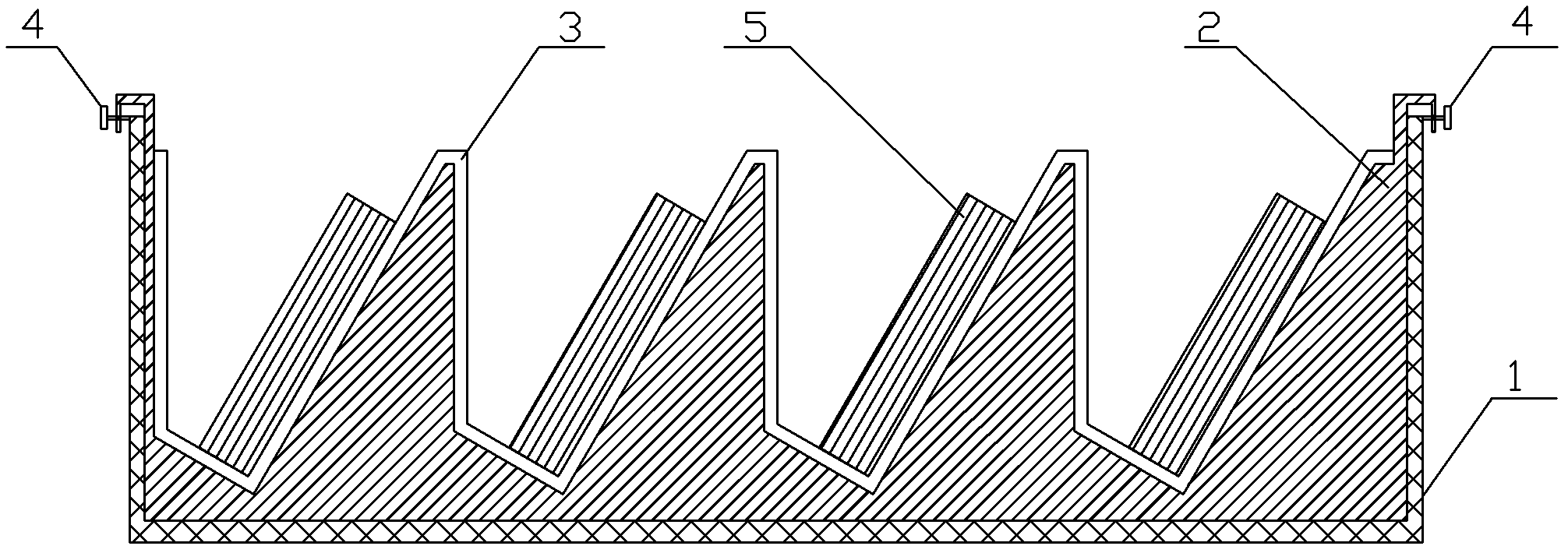

InactiveCN102553874AEasy to pick and placeReduce impactCleaning processes and apparatusBreakage probabilityEngineering

The invention discloses a transfer box for cleaning of silicon wafers, which comprises a box body. A support is arranged in the box body and provided with at least one V-shaped groove for holding silicon wafers. By the aid of the transfer box for cleaning of silicon wafers, the silicon wafers can be stored and picked conveniently. A rubber pad covering the surface of the support is capable of reducing impact and pressure subjected by the silicon wafers when the silicon wafers are stored and picked, and sliding of the silicon wafers is avoided effectively and the breakage probability of the silicon wafers is lowered due to the design of the V-shaped grooves on the support. The width of the support is smaller than that of the silicon wafers and gripping spaces can be reserved on two sides of silicon wafers on the support, so that the silicon wafers can be stored and picked conveniently. In addition, due to the fact that the support is detachable, silicon dust left on the surface of the support can be cleaned directly without changing of water in the box body, then damages to the edges of the silicon wafers caused by silicon chips can be reduced, and high work efficiency can be achieved.

Owner:KONCA SOLAR CELL

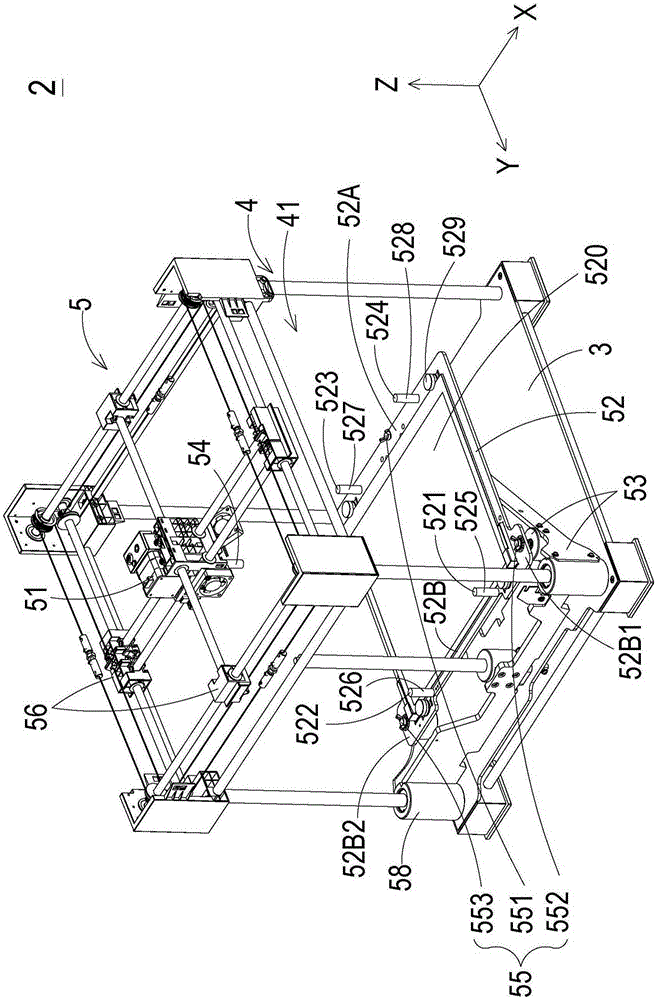

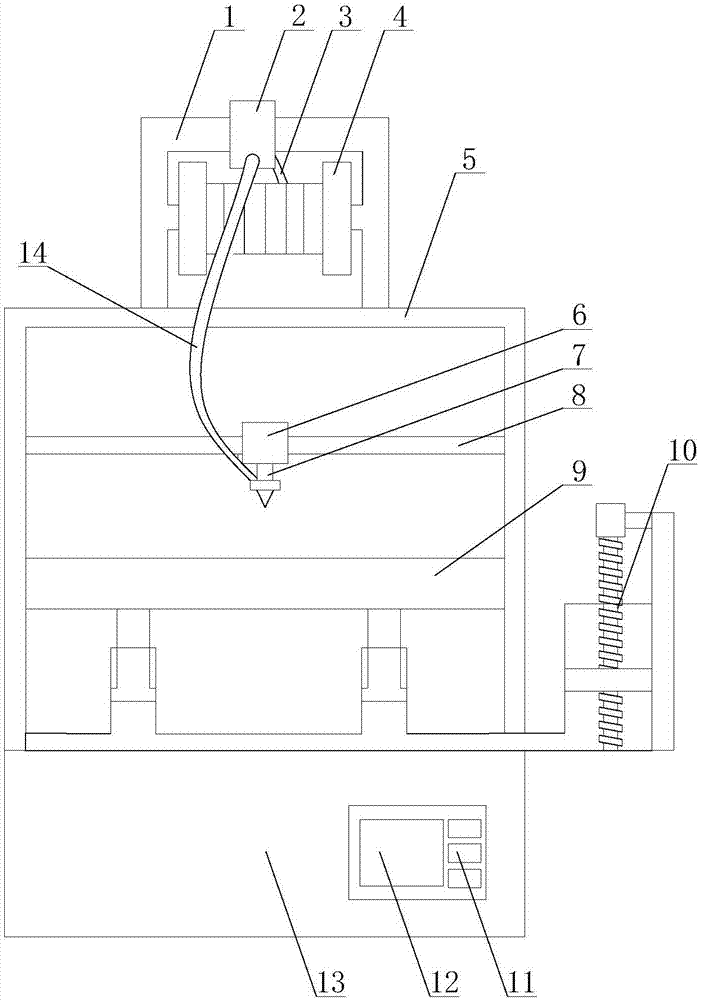

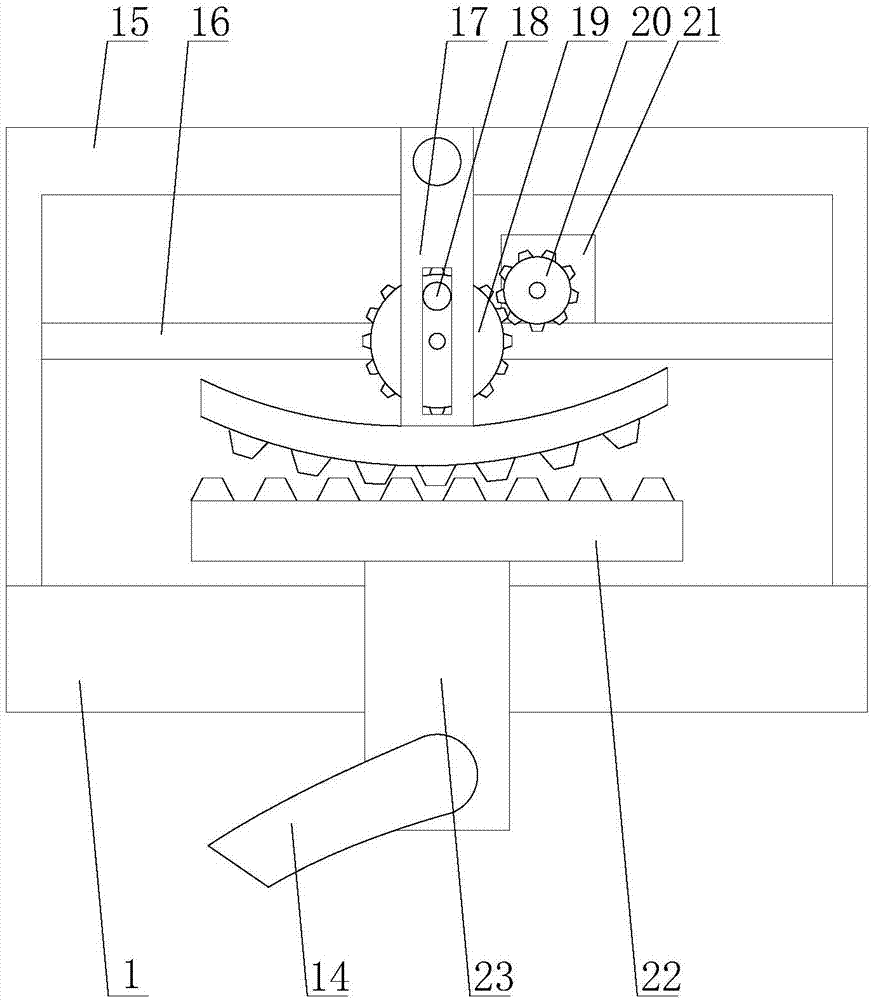

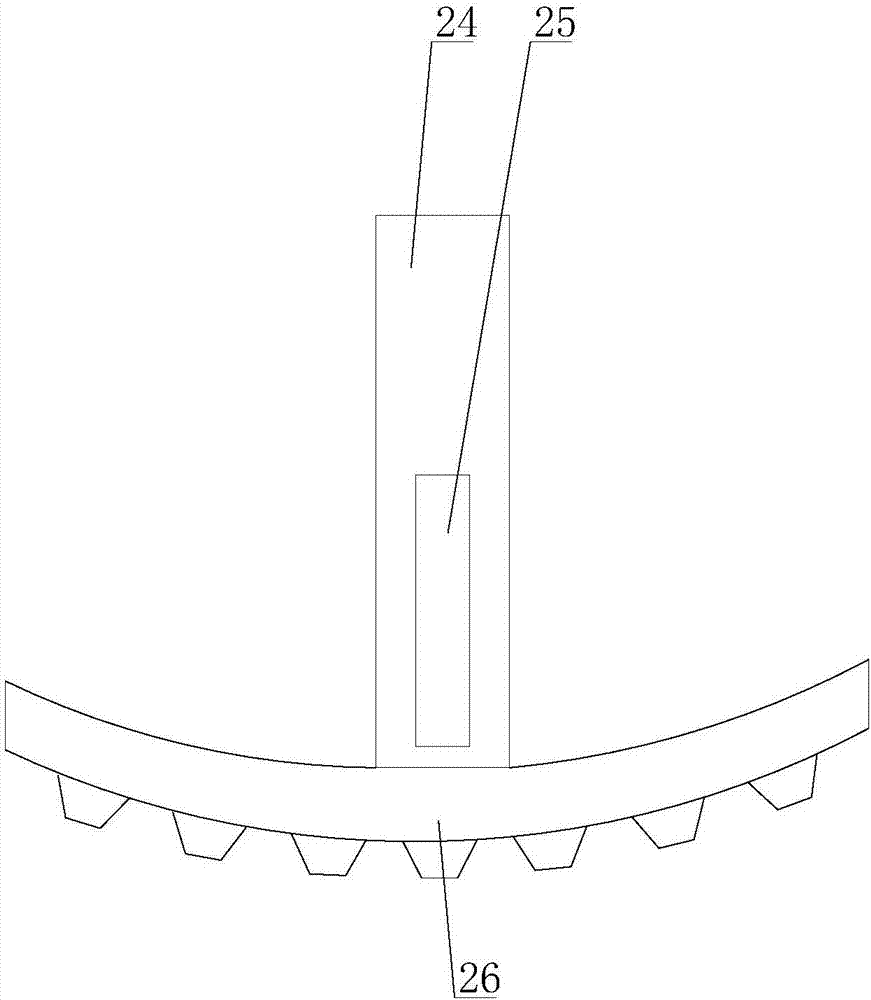

Intelligent 3D printer with material wire guiding function

ActiveCN107127964ARealize moving up and downImprove calibration efficiencyManufacturing driving means3D object support structuresBreakage probabilityDrive shaft

The invention relates to an intelligent 3D printer with a material wire guiding function. The intelligent 3D printer comprises a first support, a guide mechanism, a feeding mechanism, a shell, a moving mechanism, a tray, a correcting mechanism and a base. The guide mechanism comprises a driving assembly, a guide assembly, a second support, a first supporting rod and a moving assembly. The driving assembly comprises a first gear, a second gear, a first motor and a limiting block. The guide assembly comprises a guide rod, a second driving rod and an open groove. The moving assembly comprises a first driving rod, a second sliding block and a guide pipe. The correcting mechanism comprises lifting rods, a second motor, a driving shaft, a second supporting rod, a third sliding block, an oil storage groove and a pipeline. According to the intelligent 3D printer with a waste material monitoring function, abrasion of material wires is reduced through the guide mechanism, the breakage probability of the material wires is lowered, and printing efficiency of the 3D printer is improved; and due to arrangement of the correcting mechanism, the tray can be corrected automatically, correcting efficiency and precision of the tray are improved, and quality of 3D printer finished products is improved.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

Cutting type railway vehicle energy absorption anticreeper

PendingCN109367561AReduce the chance of meltingImprove reliabilityRailway wheel guards/bumpersBreakage probabilityEnergy absorption

The invention discloses a cutting type railway vehicle energy absorption anticreeper. The cutting type railway vehicle energy absorption anticreeper comprises a piston rod, a cylinder body, an inner sleeve, a flange and a cooling pipe. The inner sleeve and the cylinder body are internally provided with cooling liquid. The inner sleeve and one end of the cylinder body are each connected with one side of the flange. The flange is provided with a guiding hole, wherein the piston rod is connected with the guiding hole in a sliding manner, and the guiding hole is aligned with the inner sleeve. A cutting tool is mounted at the other side of the flange and extends into a guiding groove in the piston rod. The cooling pipe unidirectionally extends to the mounting position of the cutting tool in a communicating manner from the interior of the cylinder body. The end, away from the flange, of the inner sleeve is provided with a damping hole, wherein the damping hole communicates with the cylinderbody. According to the cutting type railway vehicle energy absorption anticreeper, the mode that the tool is cooled through the cooling liquid is adopted; the probability that the tool is molten in the cutting process is lowered; reliability of the cutting tool is improved; meanwhile, after cutting, a cutting portion pushes a piston to extrude the cooling liquid in the cylinder body, and when vehicle collision occurs, part of kinetic energy can be converted into kinetic energy and pressure energy of the cooling liquid; and the breakage probability of the tool is lowered.

Owner:CENT SOUTH UNIV

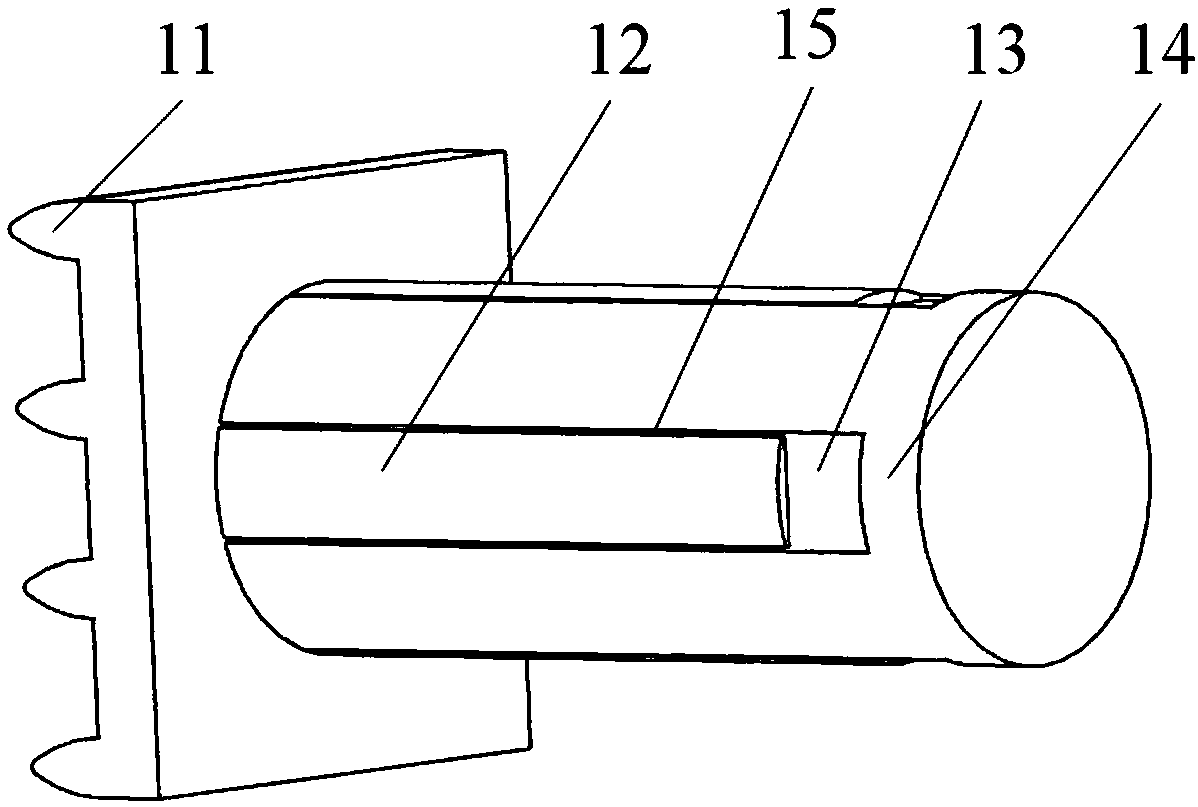

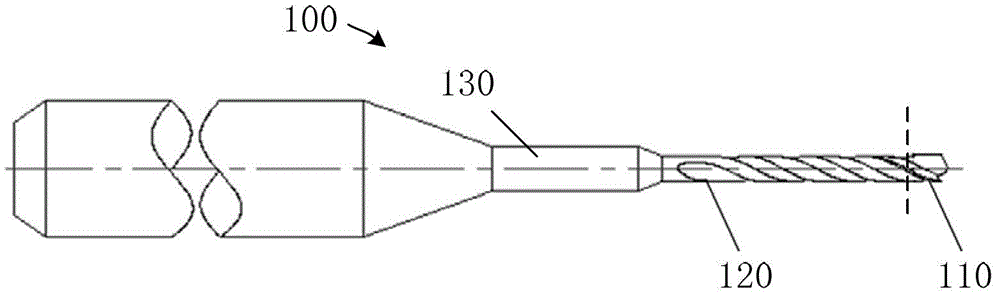

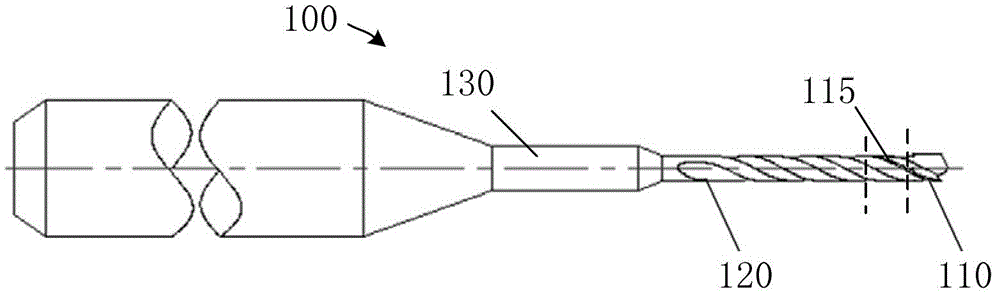

Substrate for processing cutter and manufacturing method of substrate and drill bit using substrate

InactiveCN102974871AImprove wear resistanceExtended service lifeTwist drillsBreakage probabilityAlloy

The invention discloses a substrate for processing a cutter and a manufacturing method of substrate and a drill bit using the substrate; the substrate is a hard alloy material; the substrate is provided with at least two alloy sections with different hardness; and the substrate is formed by integrally pressing and sintering a plurality of sections. The drill bit comprises a drill tip section and a drill body section, and the hardness of the drill tip section is more than that of the drill body section. According to the substrate for processing the cutter and the manufacturing method thereof and the drill bit using the substrate, because the substrate for processing the cutter is provided with a plurality of alloy sections with different hardness, the alloy sections with higher hardness can be used for manufacturing the cutting part of the cutter, such as the drill tip of the drill bit. In such a manner, the wear resistance of the drill bit and the drill tip can be improved, and the service life of the cutter is prolonged. The alloy sections with lower hardness can be used for manufacturing the cutter body of the cutter, such as the drill body of the drill bit. The drill body is provided with a spiral groove and bear the drilling pressure and torque, so that the toughness of the drill body can be improved by the alloy sections with lower hardness, so that the drill breakage probability of the drill bit is reduced.

Owner:SHENZHEN JINZHOU PRECISION TECH

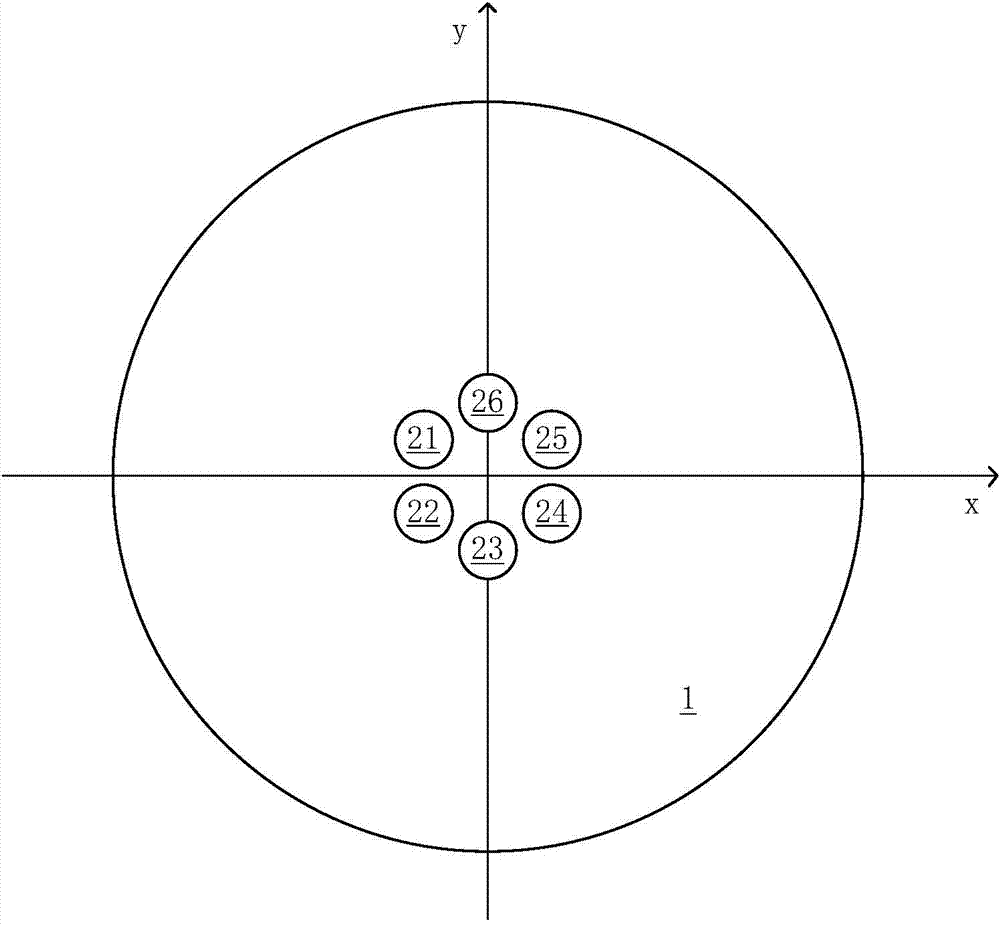

Semiconductor film thickness measurement calibration standard sheet and manufacturing method thereof

ActiveCN104716125ACutting costsImprove work efficiencySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsBreakage probabilityState of art

The invention discloses a semiconductor film thickness measurement calibration standard sheet and a manufacturing method thereof. The calibration standard sheet comprises a wafer substrate and at least two pattern regions which are located on the surface of the wafer substrate and are of different film thickness levels. Due to the fact that the pattern regions of the different thickness levels are formed on the same standard sheet, the same standard sheet can be adopted for calibrating multiple thickness levels. Compared with the prior art, the expense for purchasing the standard sheet can be saved, the measurement use rate of a film thickness measurement table used for a product is increased, the work efficiency of operators is improved, and meanwhile the wafer breakage probability and the management and control efficiency of a wafer of the standard sheet are reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Tear-resistant absorption nano-modified rubber and preparation method thereof

The invention discloses tear-resistant absorption nano-modified rubber and a preparation method thereof. The tear-resistant absorption nano-modified rubber comprises the following raw materials: chlorohydrin rubber, nitrile-butadiene rubber, acrylonitrile-butadiene copolymer rubber, diene rubber, styrene-butadiene rubber and regenerated rubber. By the matched use of the chlorohydrin rubber, the nitrile-butadiene rubber, the acrylonitrile-butadiene copolymer rubber, the diene rubber, the styrene-butadiene rubber and the regenerated rubber as main materials, the material toughness is greatly improved, the problem of high breakage probability of a conveying belt is effectively solved, and meanwhile, gas harmful to a human body cannot be generated at a higher temperature; high temperature resistance, tear resistance and other properties are perfectly integrated, so that the tear-resistant absorption nano-modified rubber disclosed by the invention can be applied to various harsh conditions. Adopted chitosan can absorb negatively-charged bacteria as molecules are positively-charged, so that a bactericidal function is achieved; structurally, fiber membrane layers with different diameters and pores are prepared; by means of nano grapheme between a bonding layer and a layer, the porosity and the specific surface area of a composite absorption membrane are improved, and the effect is enhanced.

Owner:SUZHOU RUI TE JIE CHEM PROD CO LTD

Touch substrate and display device

ActiveCN107908319AImprove stabilityImprove touch performanceInput/output processes for data processingBreakage probabilityDisplay device

The invention provides a touch substrate. The touch substrate comprises a touch layer; the touch layer comprises multiple first electrodes and multiple second electrodes; the first electrodes and thesecond electrodes are insulated and crossed; the first electrodes comprise multiple first electrode units, which are arranged along the row direction and connected in sequence; the second electrodes comprise multiple second electrode units, which are arranged along the column direction and connected in sequence; the multiple first electrodes are divided into multiple first electrode sets arrangedalong the column direction; each first electrode set comprises multiple first electrodes; in each first electrode set, the first electrode units in the same column are connected in sequence; and / or, the multiple second electrodes are divided into multiple second electrode sets arranged along the row direction; each second electrode set comprises multiple second electrodes; and, in each second electrode set, the second electrode units in the same row are connected in sequence. The invention further provides a display device. By means of the touch substrate and the display device provided by theinvention, the electrode breakage probability in a touch product can be reduced; and the product stability can be improved.

Owner:BOE TECH GRP CO LTD +1

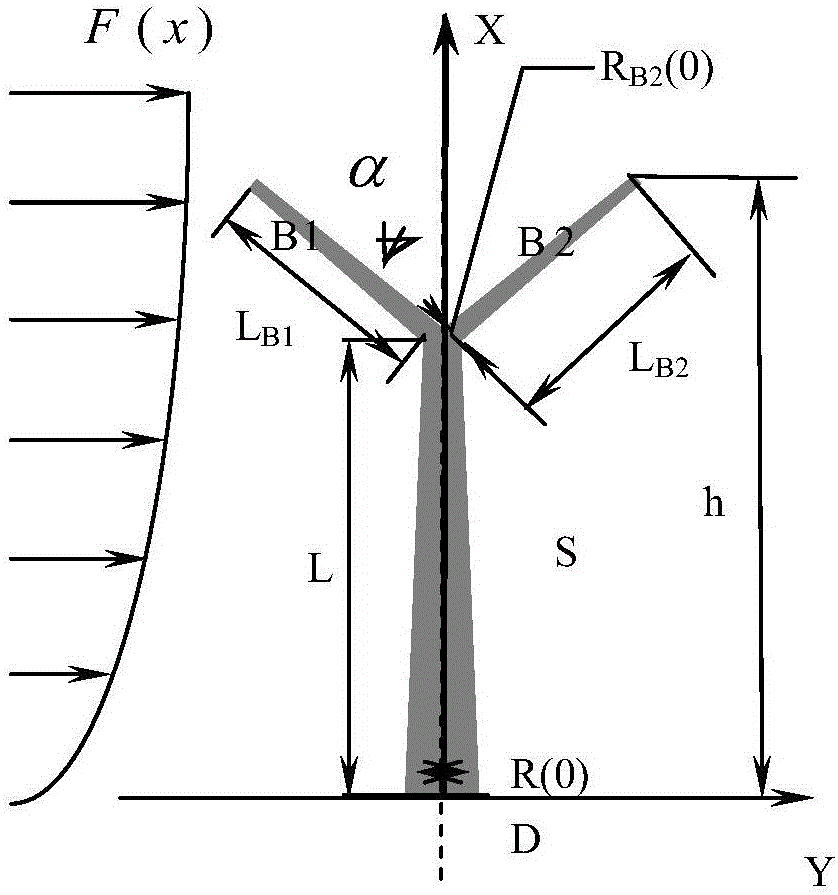

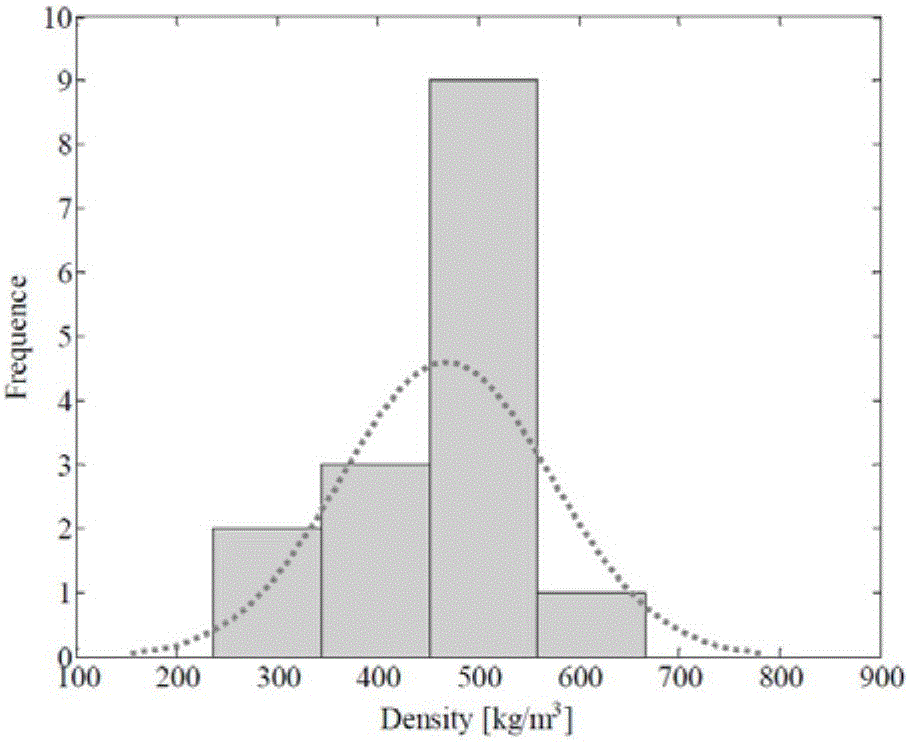

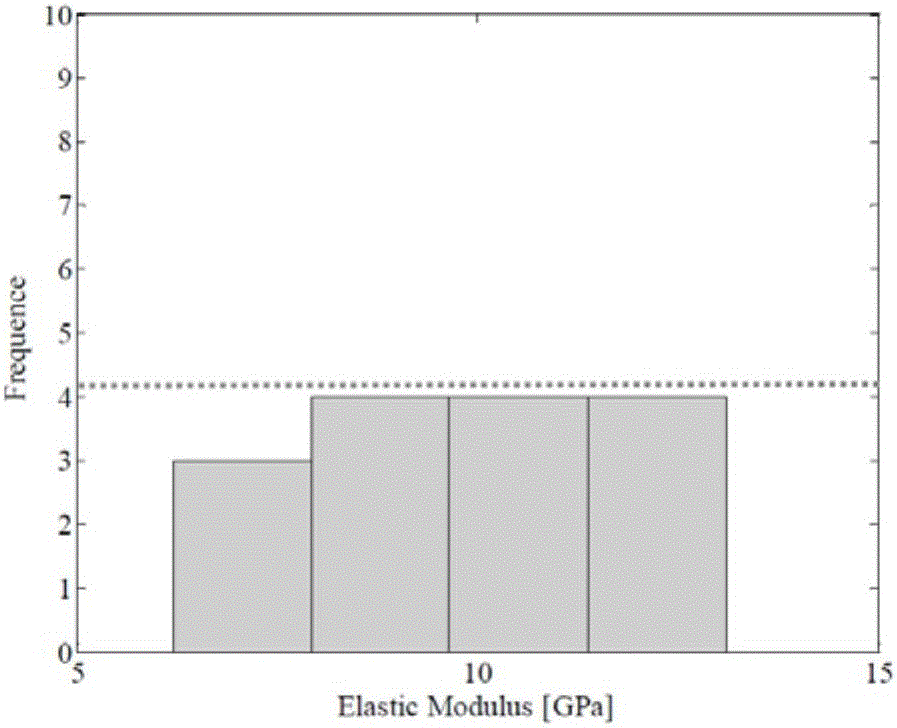

Street tree wind-caused damage rapid evaluation method

InactiveCN105956753AReduce the workload of solvingSimulation solution is accurateResourcesBreakage probabilityAlgorithm

A rapid assessment method for wind-induced damage to urban street trees. A simplified model of wind-induced damage to street trees is established. According to the finite element theory and assuming that the tree materials are isotropic and uniform, the material physical parameters that affect the individual dynamic behavior of trees are abstracted; at the same time, considering Due to the different tree species and growth conditions, as well as the large differences in individual tree shapes and traits, the material physical parameters in the wind-induced damage model of street trees are regarded as random variables; the input fluctuating wind speed is taken as the Davenport spectrum, and the virtual excitation method is used for rapid wind-induced response of street trees. calculate. On this basis, a wind-induced damage criterion for street trees based on flexural strength is defined, and Monte Carlo simulation is used to quickly evaluate the damage probability of street trees under different wind load levels. The invention is beneficial to more accurately and effectively predicting wind disaster damage to street trees in urban areas, and has practical significance for formulating corresponding defense measures.

Owner:TONGJI UNIV

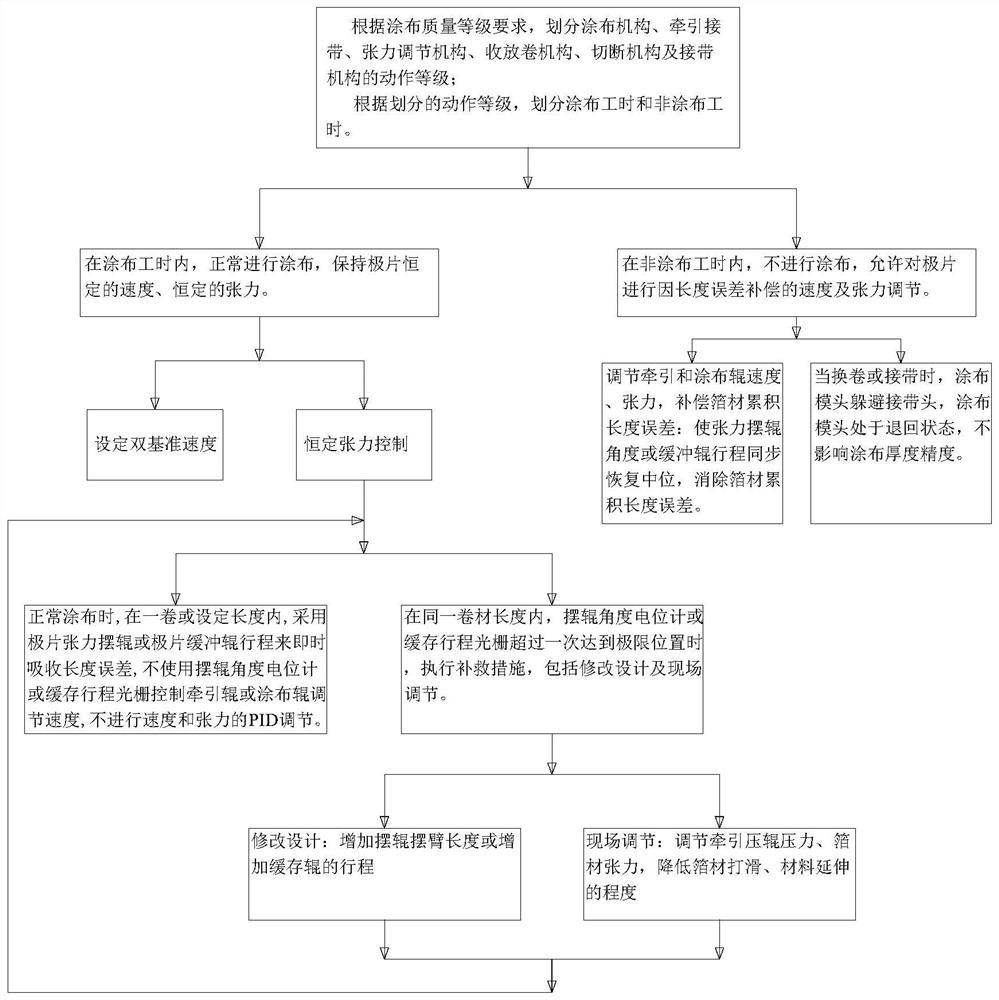

Speed and tension control method for eliminating pole piece slipping or extension accumulative errors

PendingCN113460768AAvoid broken beltImprove production efficiencyLiquid surface applicatorsElectrode manufacturing processesBreakage probabilityControl engineering

The invention discloses a speed and tension control method for eliminating pole piece slipping or extension accumulative errors. The method comprises the following steps that action grades of a coating mechanism, a traction spliced belt, a tension adjusting mechanism, a winding and unwinding mechanism, a cutoff mechanism and a belt splicing mechanism are divided according to coating quality grade requirements; coating working time and non-coating working time are divided according to the divided action grades, and within the coating working time, coating is normally carried out, and the constant speed and constant tension of a pole piece are kept; and within the non-coating working time, coating is not carried out, and speed and tension adjustment of length error compensation is allowed to be carried out on the pole piece. According to the speed and tension control method for eliminating the pole piece slipping or extension accumulative errors, the coating quality cannot be affected, pole piece tension fluctuation is reduced, the pole piece belt breakage probability is reduced, the belt splicing time is saved, and the production efficiency and the production benefit are improved.

Owner:SHENZHEN NEW KATOP AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com