Manufacturing method for ultrathin capacitive touch screen

A technology of capacitive touch screen and manufacturing method, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of low manufacturing yield and easy cracking of ultra-thin glass substrates, and reduce the probability of cracking , reduce the probability, improve the effect of manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

[0026] The manufacturing method of this ultra-thin capacitive touch screen comprises the following steps:

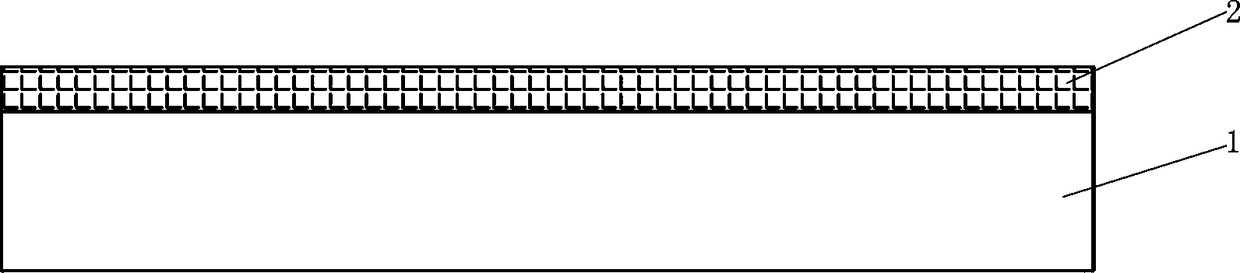

[0027] (1) if Figure 1-a As shown, a peeling glue 2 is coated on the carrier 1, and the peeling glue 2 is an ultraviolet decomposing glue, such as a glue mixed with an acrylic resin with a reactive group and a multifunctional photosensitive resin.

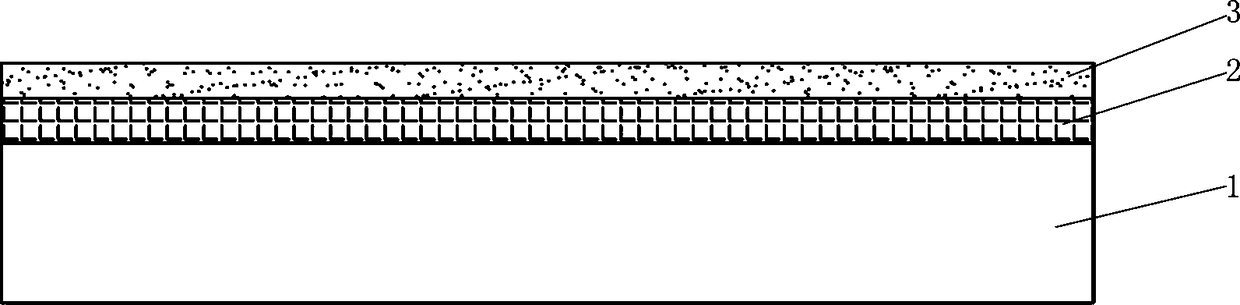

[0028] (2) if Figure 1-b As shown, the thin glass sheet 3 is attached on the carrier plate 1 through the peeling glue 2;

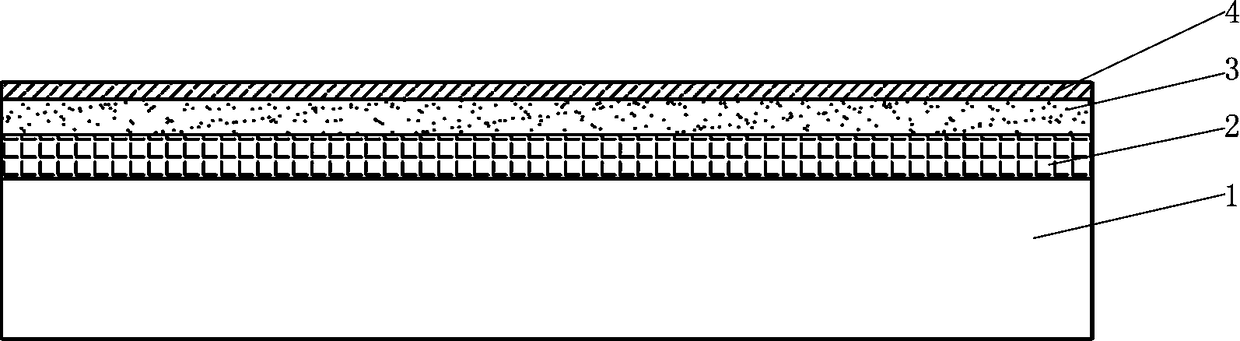

[0029] (3) if Figure 1-c As shown, the touch circuit layer 4 is made on the thin glass sheet 3, and a protective layer can be further coated on the touch circuit layer 4, only the external port of the touch circuit layer 4 is exposed, and the protective layer can be transparent. The photosensitive resin coating can also be a non-transparent insulating lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com