Patents

Literature

1029results about How to "Reduce the chance of breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

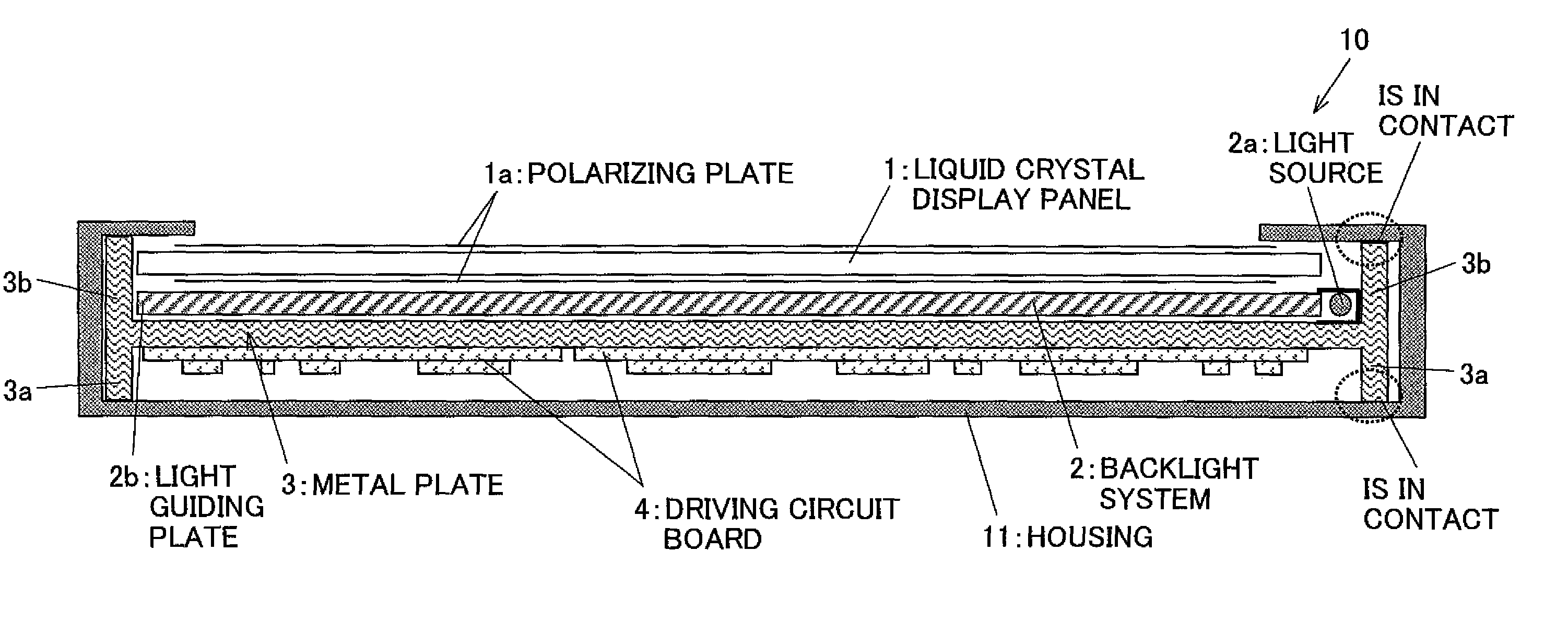

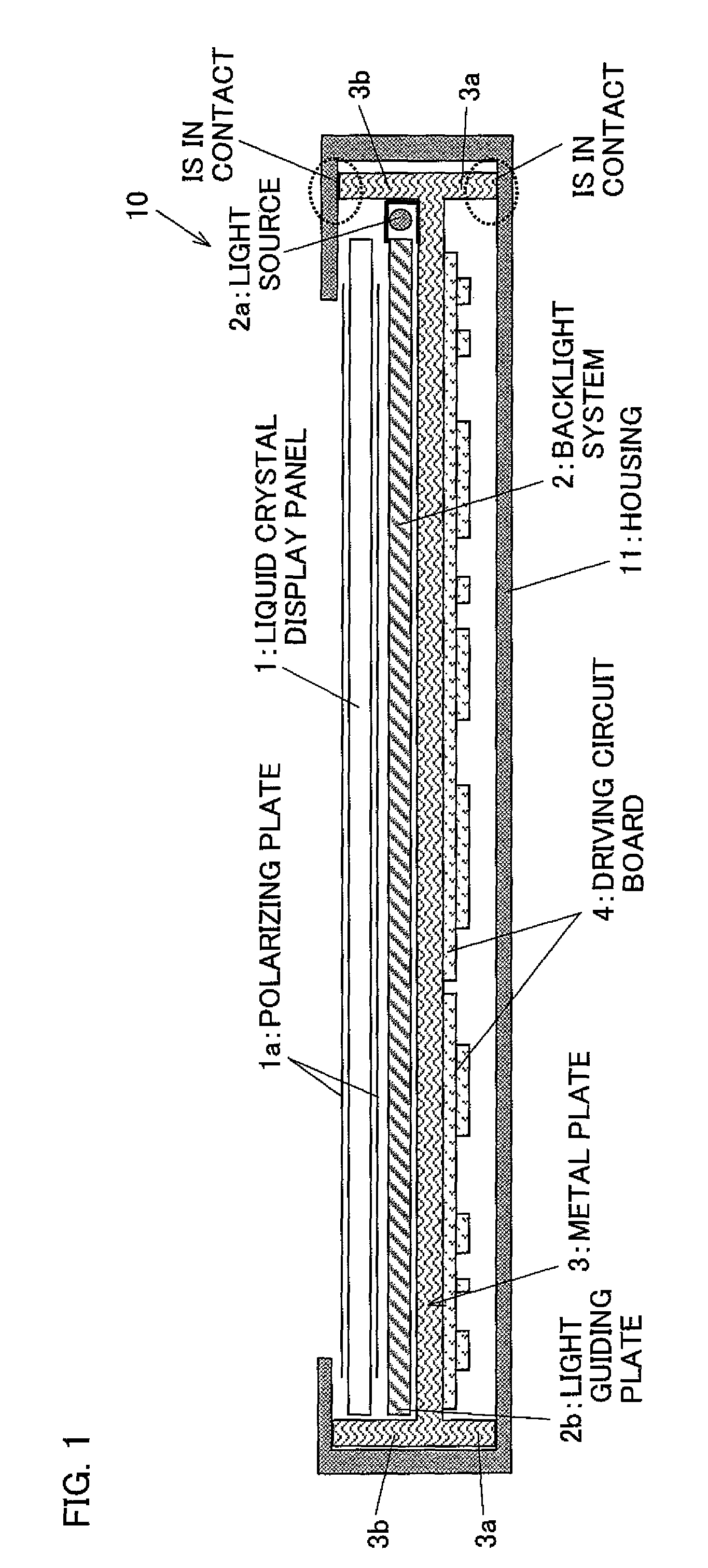

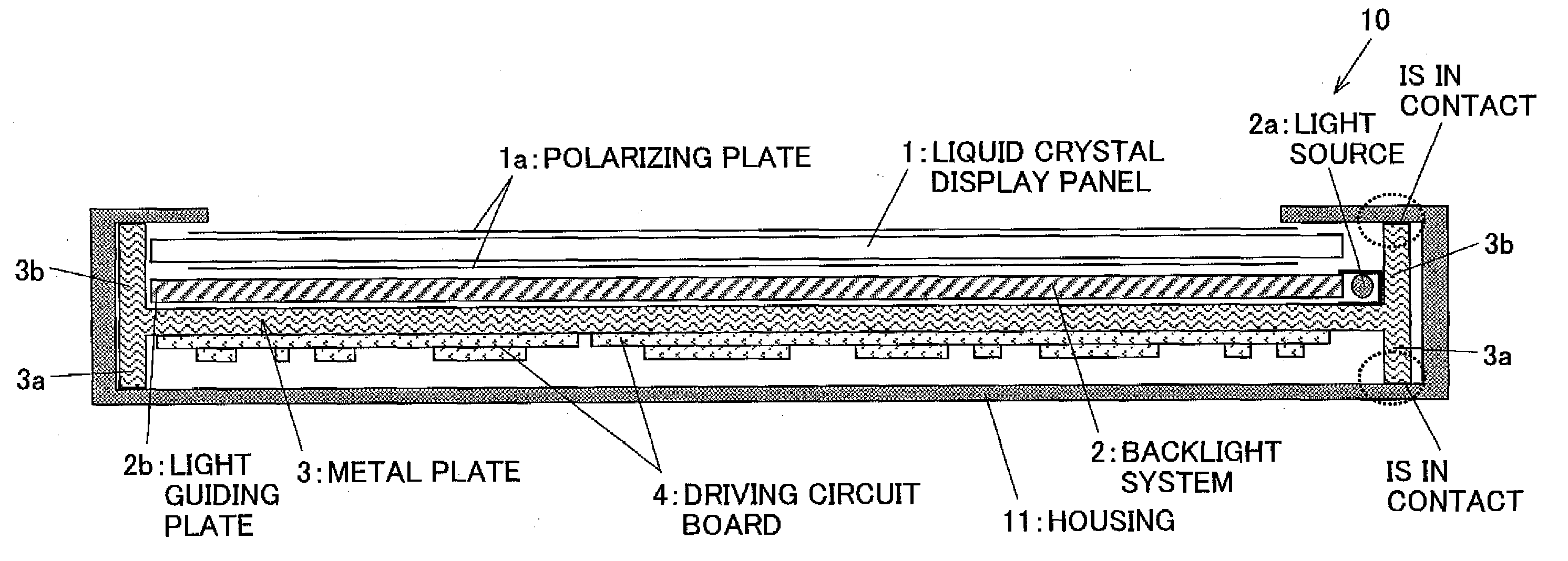

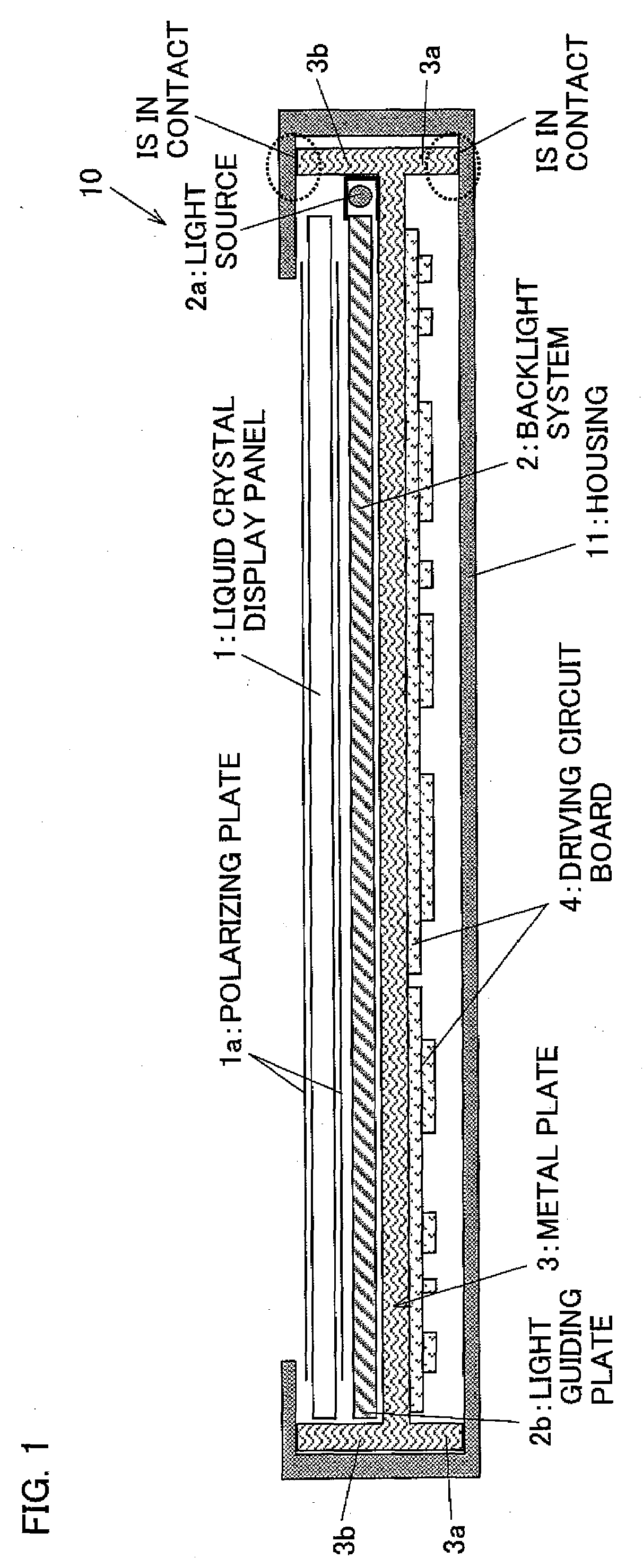

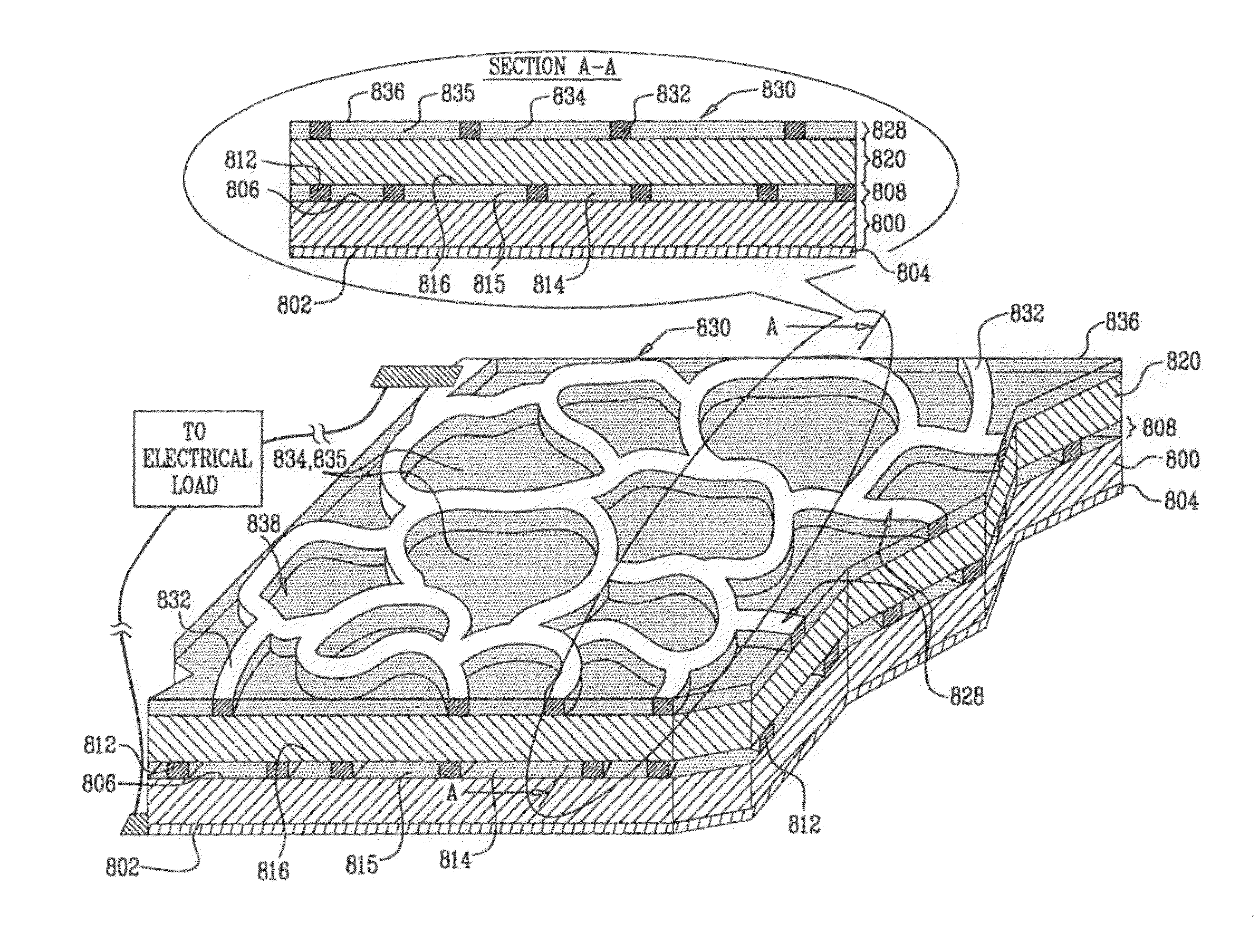

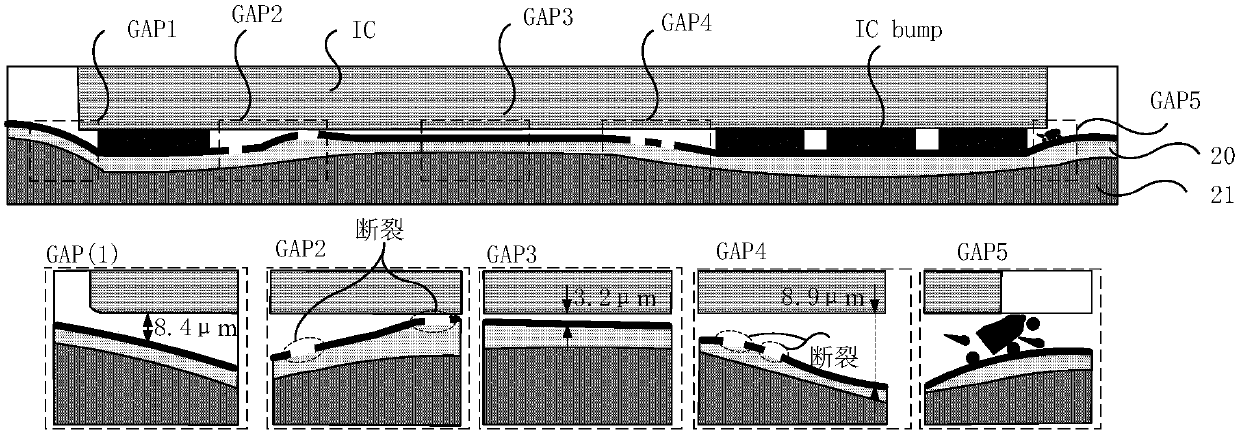

Liquid crystal display device and electronic apparatus provided with same

InactiveUS7944520B2Reduce the chance of breakageSubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksLiquid-crystal displayEngineering

Owner:SHARP KK

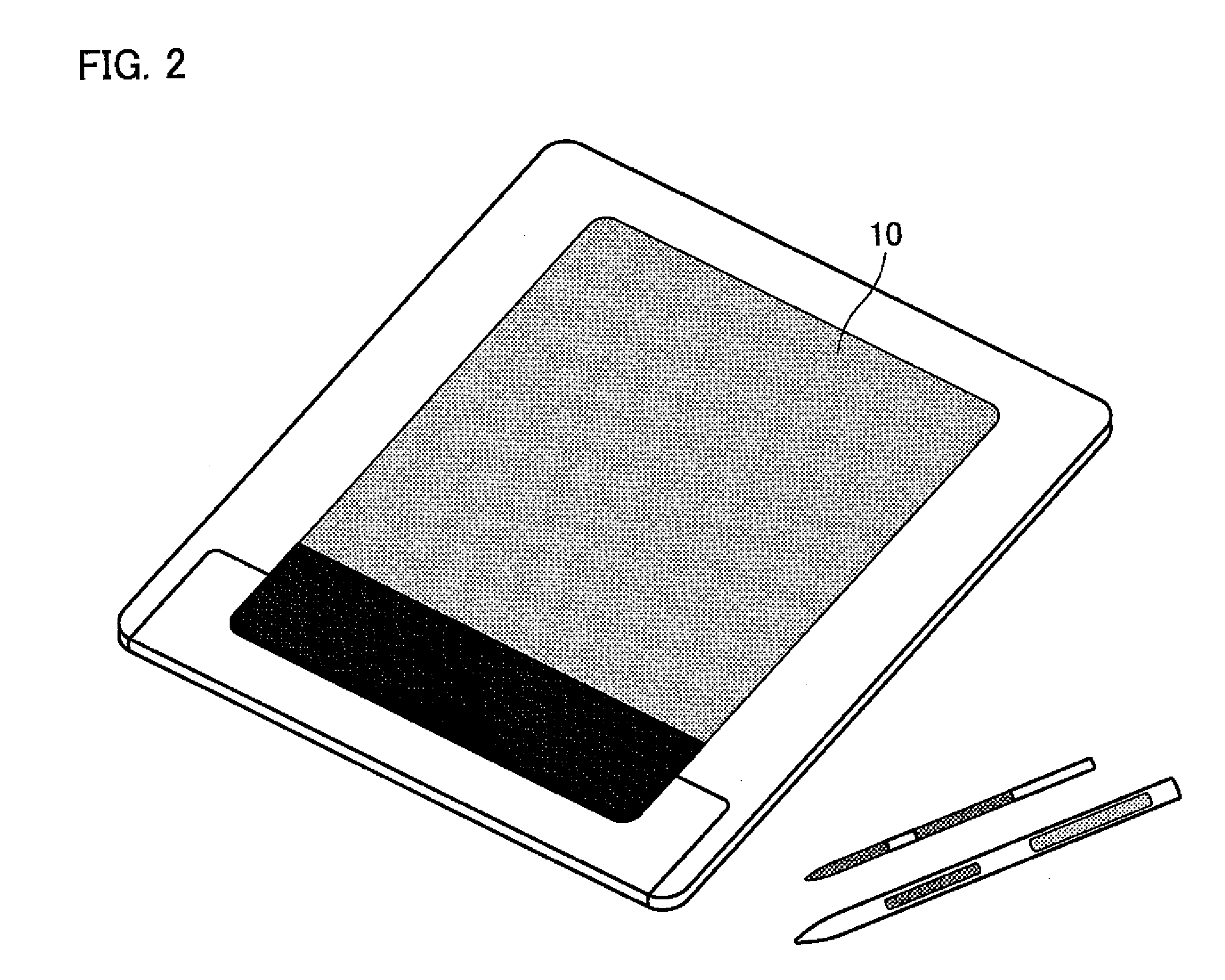

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

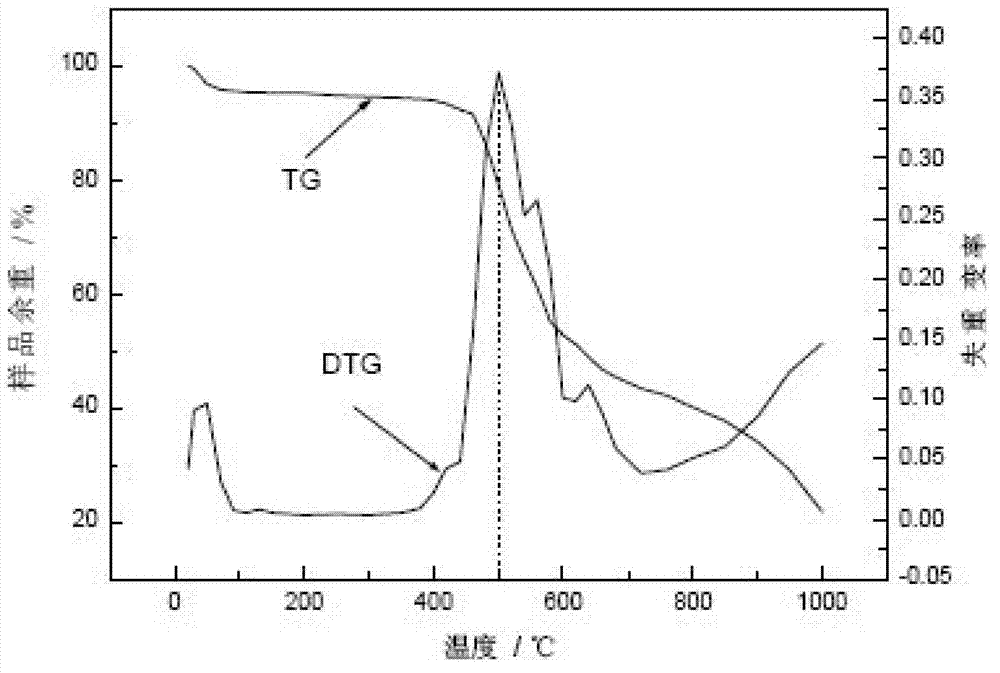

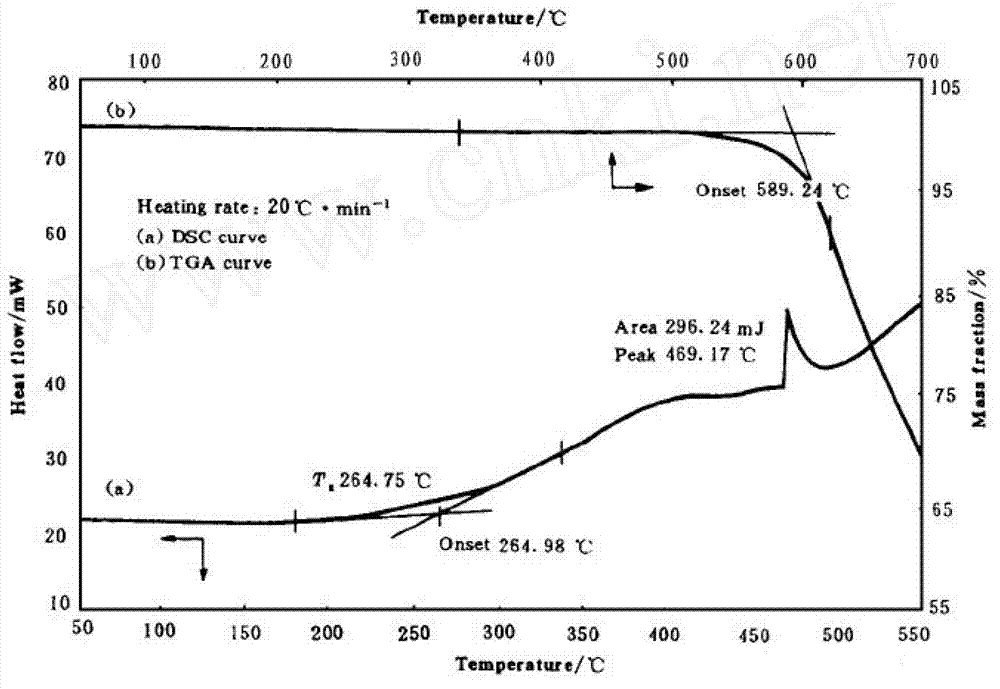

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

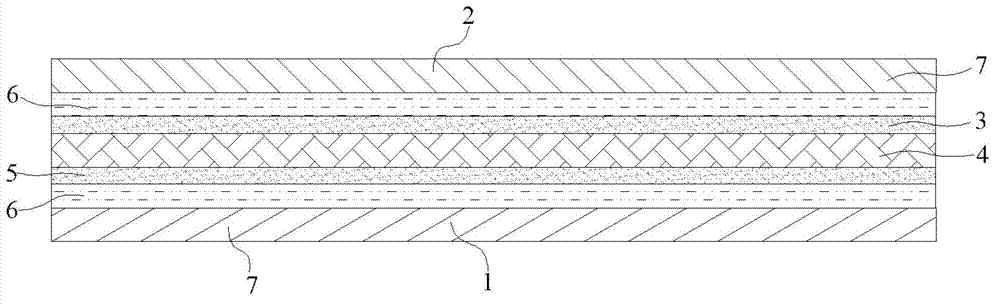

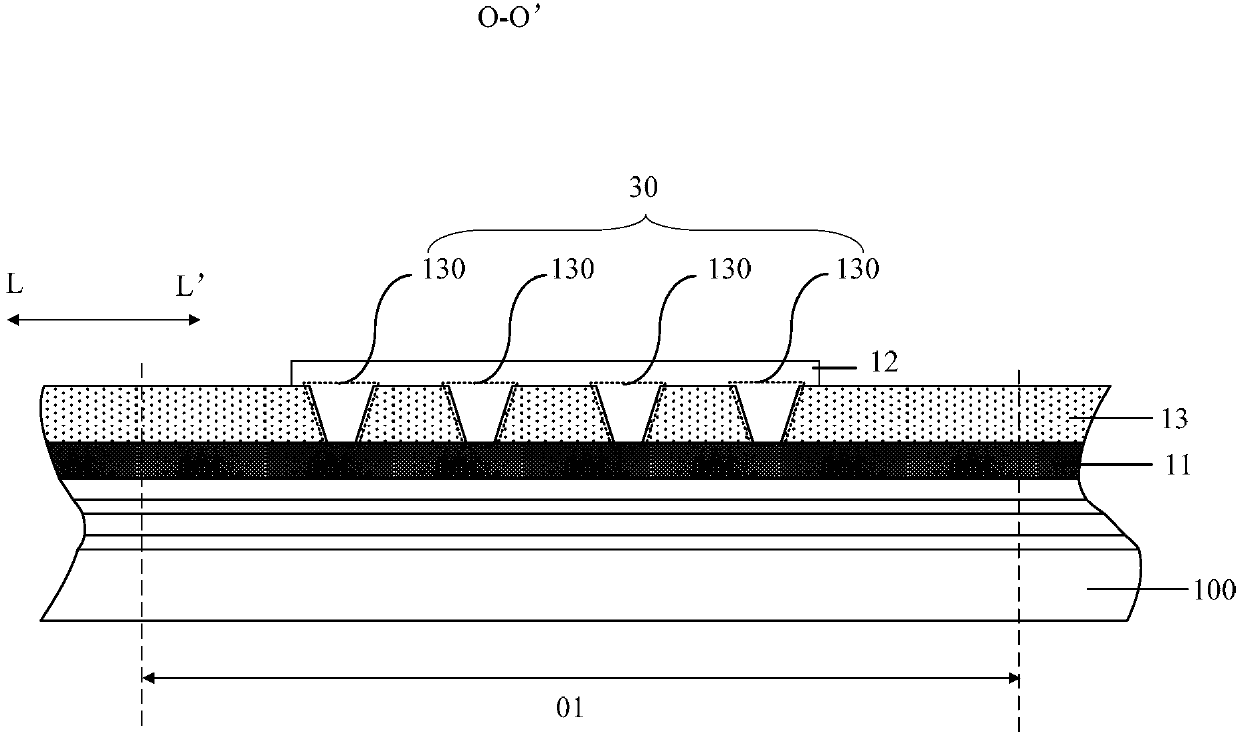

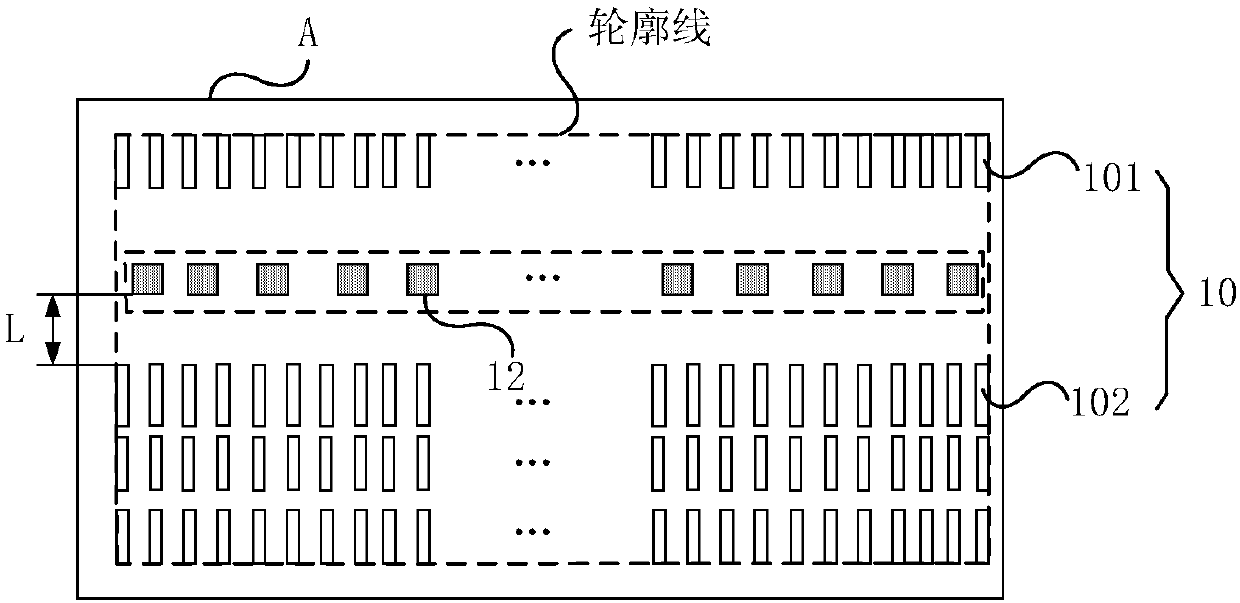

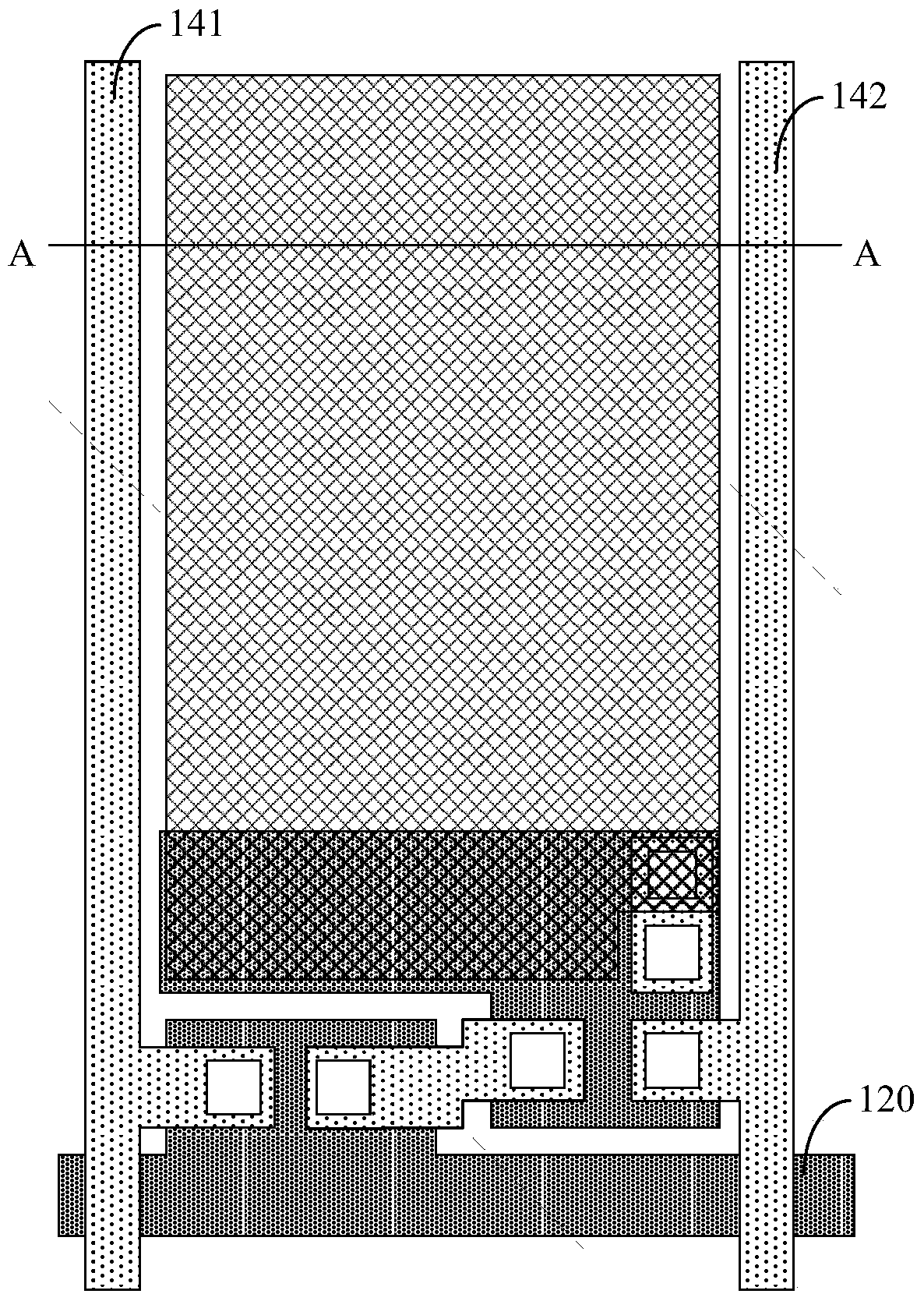

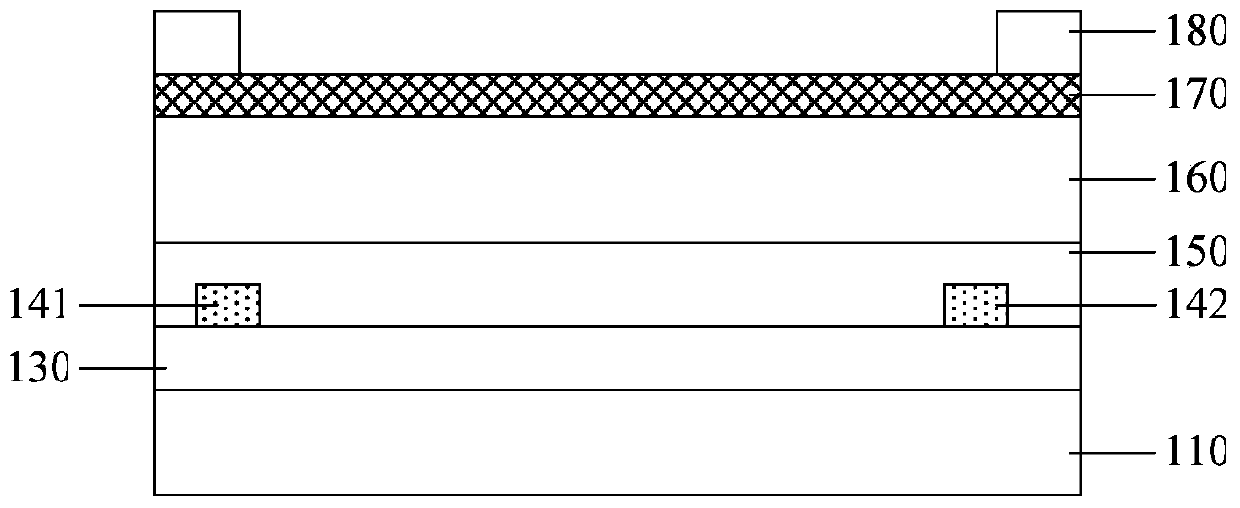

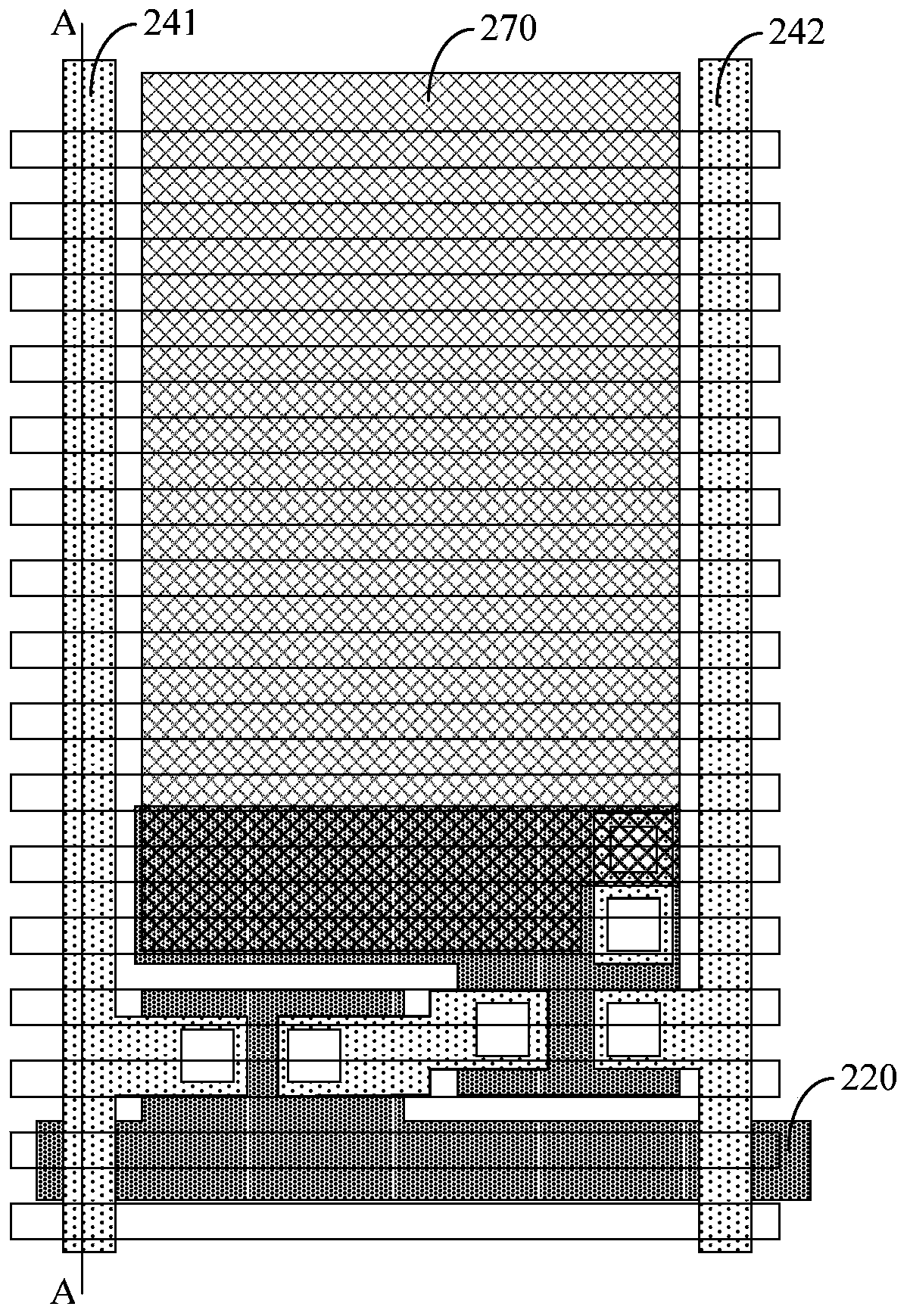

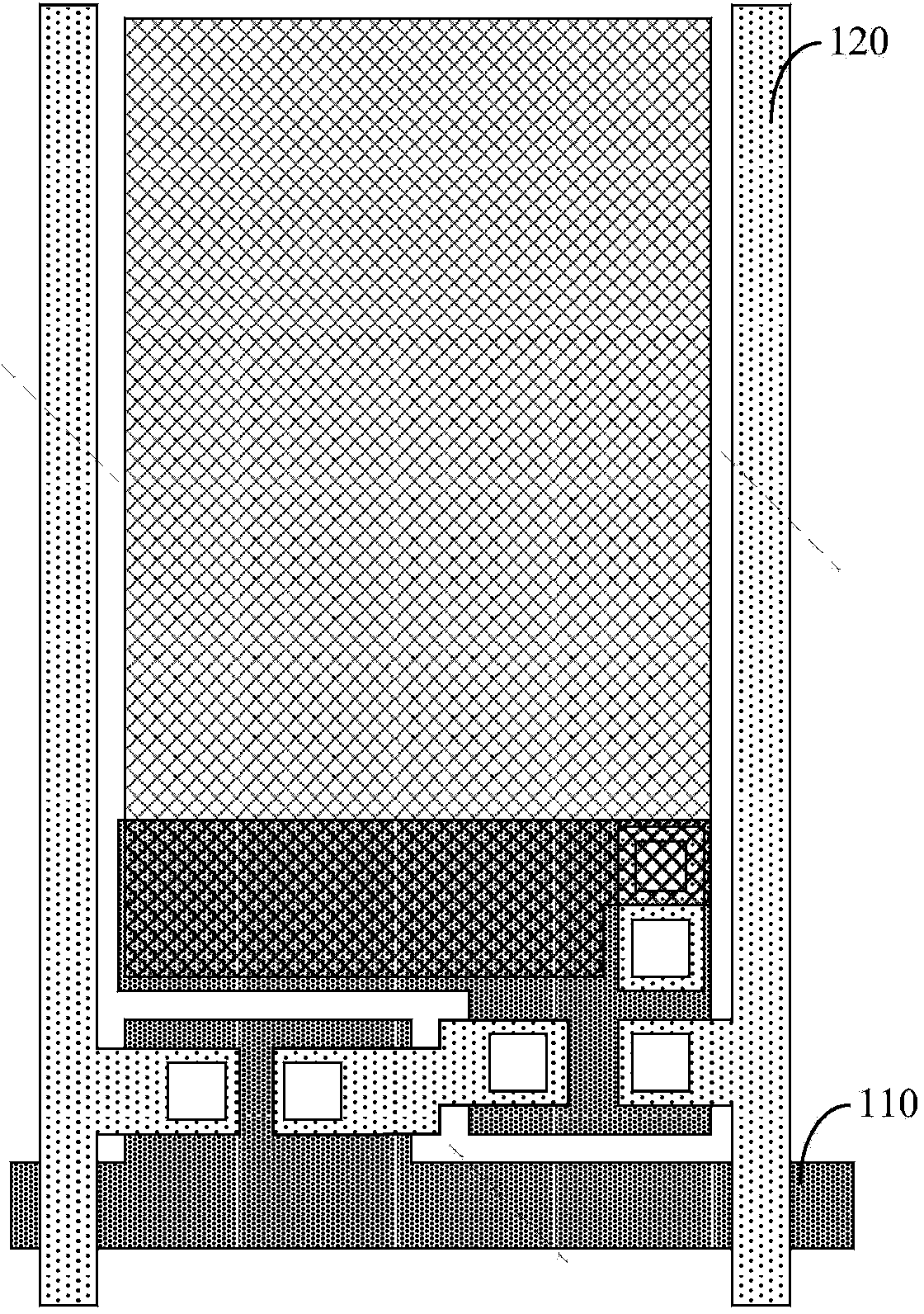

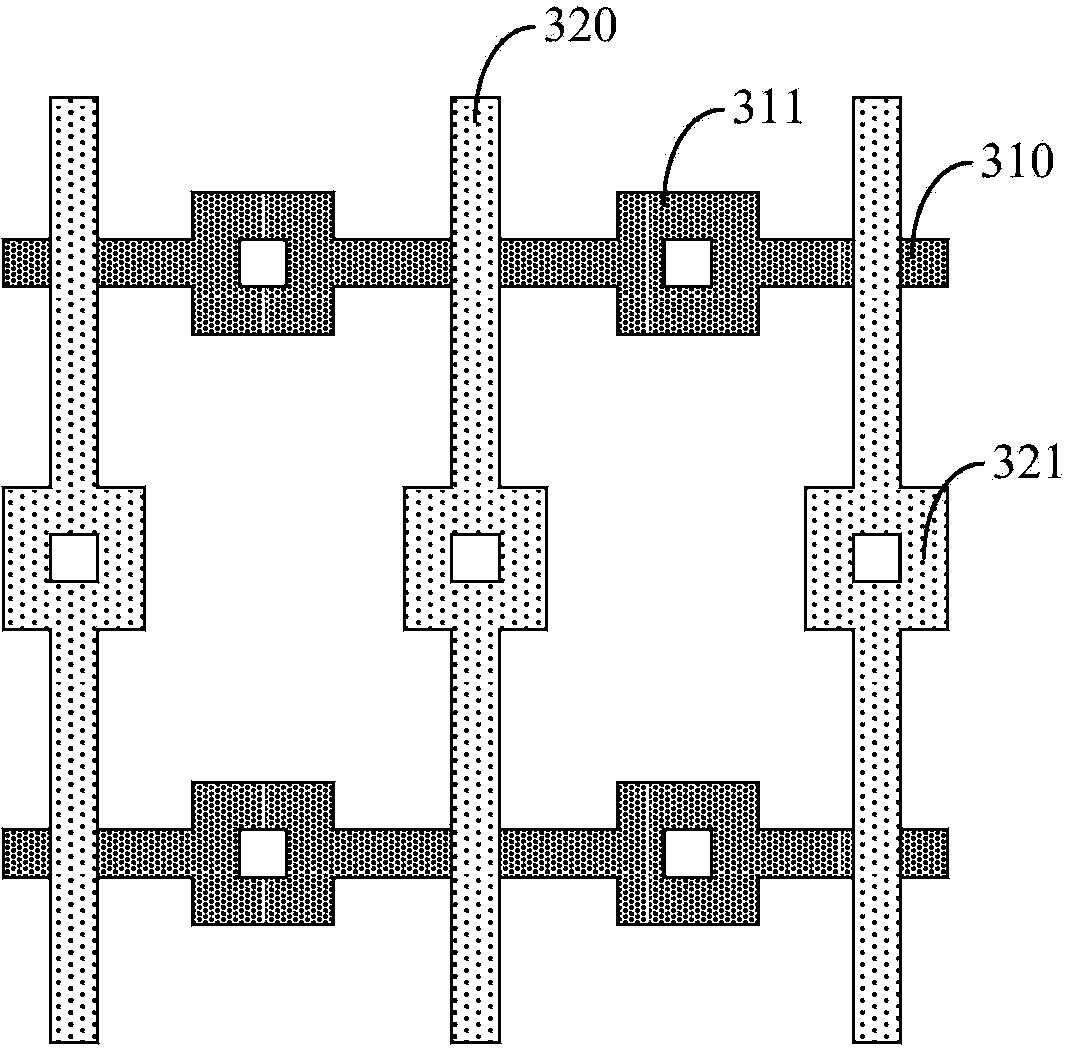

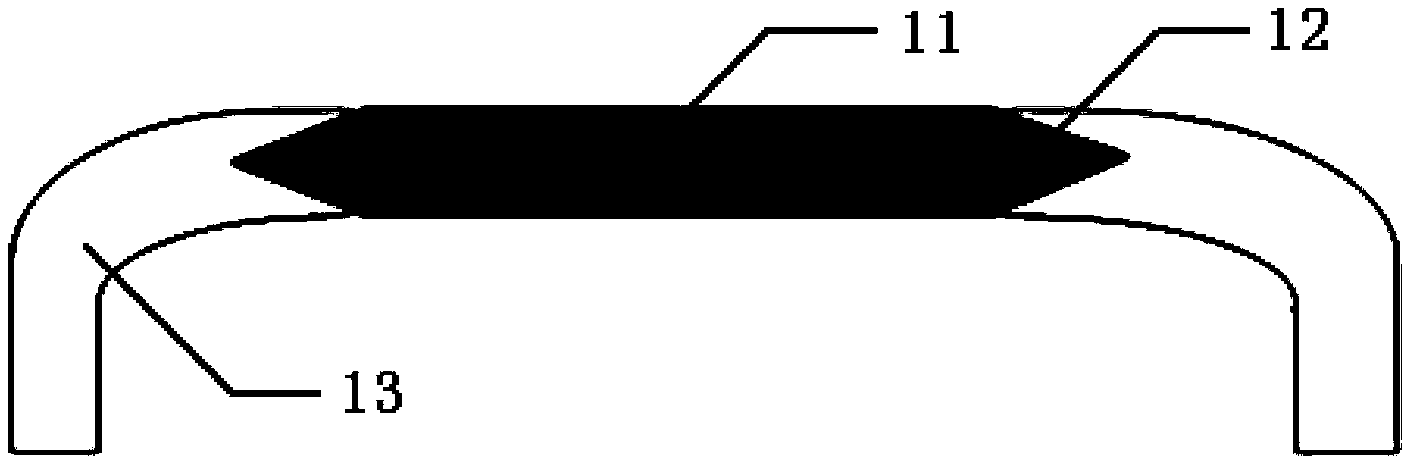

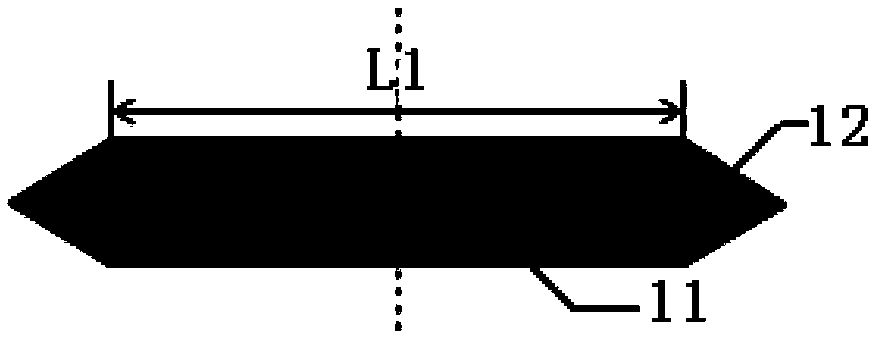

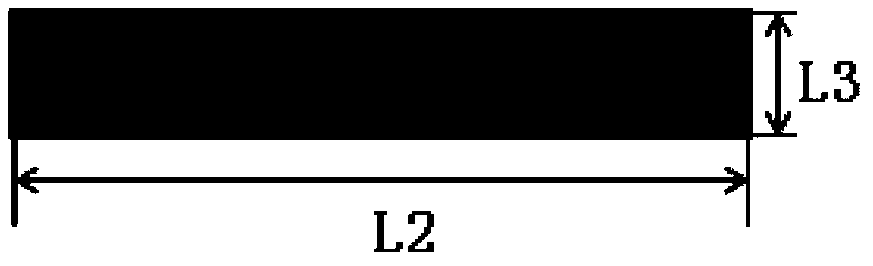

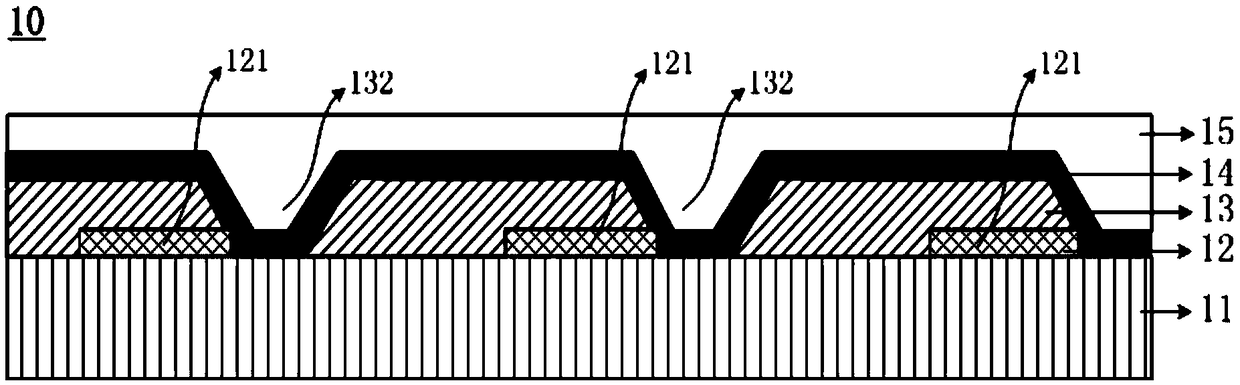

Flexible array substrate and preparation method thereof, display substrate and display device

ActiveCN107946317AReduce bending stressReduce the chance of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

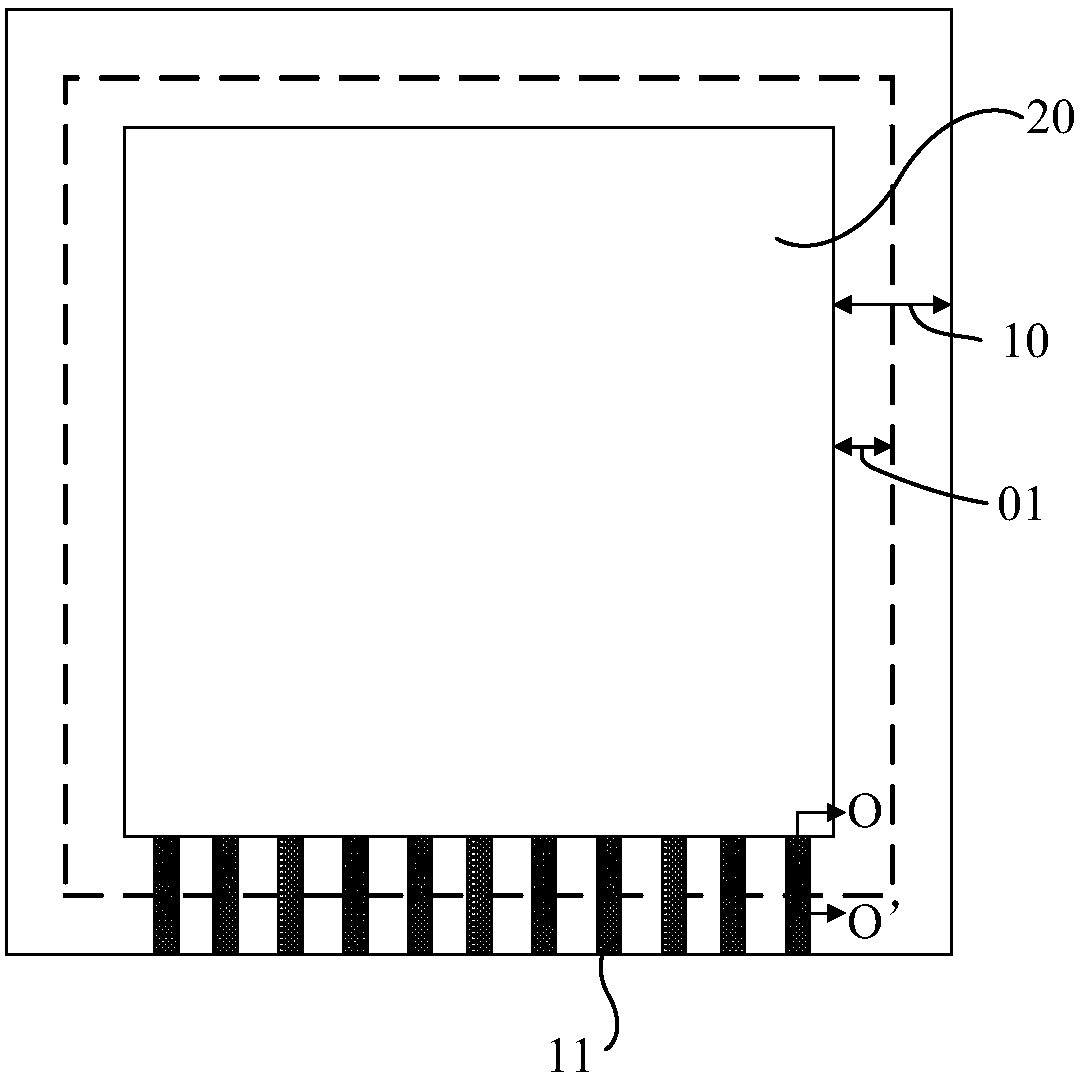

The embodiment of the invention provides a flexible array substrate and a preparation method thereof, a display substrate and a display device, and relates the technical field of display. The probability of fracture of the signal lines in the bonding area caused by bonding can be reduced. The flexible array substrate comprises a display area and a non-display area. The non-display area comprises the bonding area adjacent to the display area. The bonding area comprises the signal lines and auxiliary lines which are arranged on the underlying substrate, and the auxiliary lines are arranged on one side back to the underlying substrate of the signal lines. The area of the insulating layer in which the bonding area is overlapped with different signal lines is provided with different concave part groups formed by multiple concave parts which are arranged along the extension direction of different signal lines, and the auxiliary lines cover the concave part groups.

Owner:BOE TECH GRP CO LTD

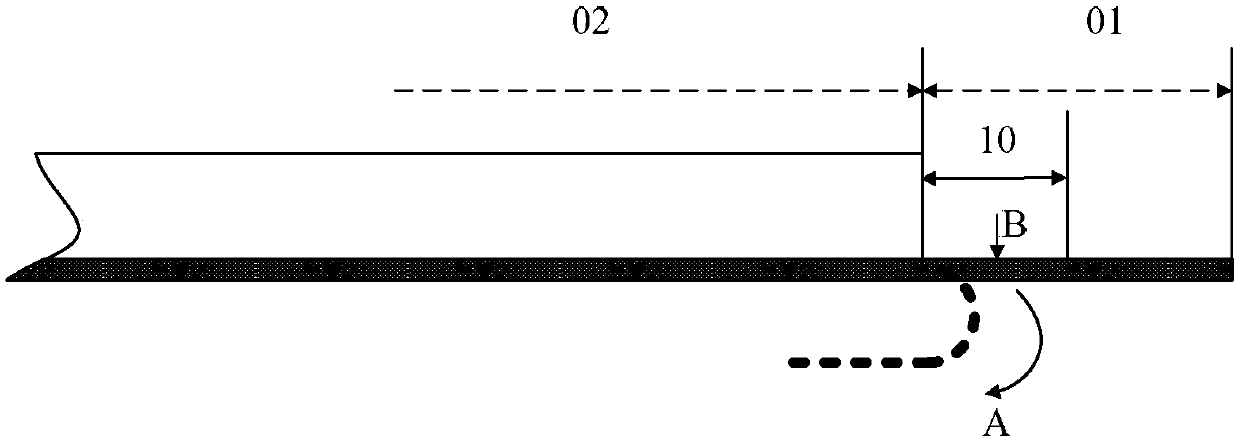

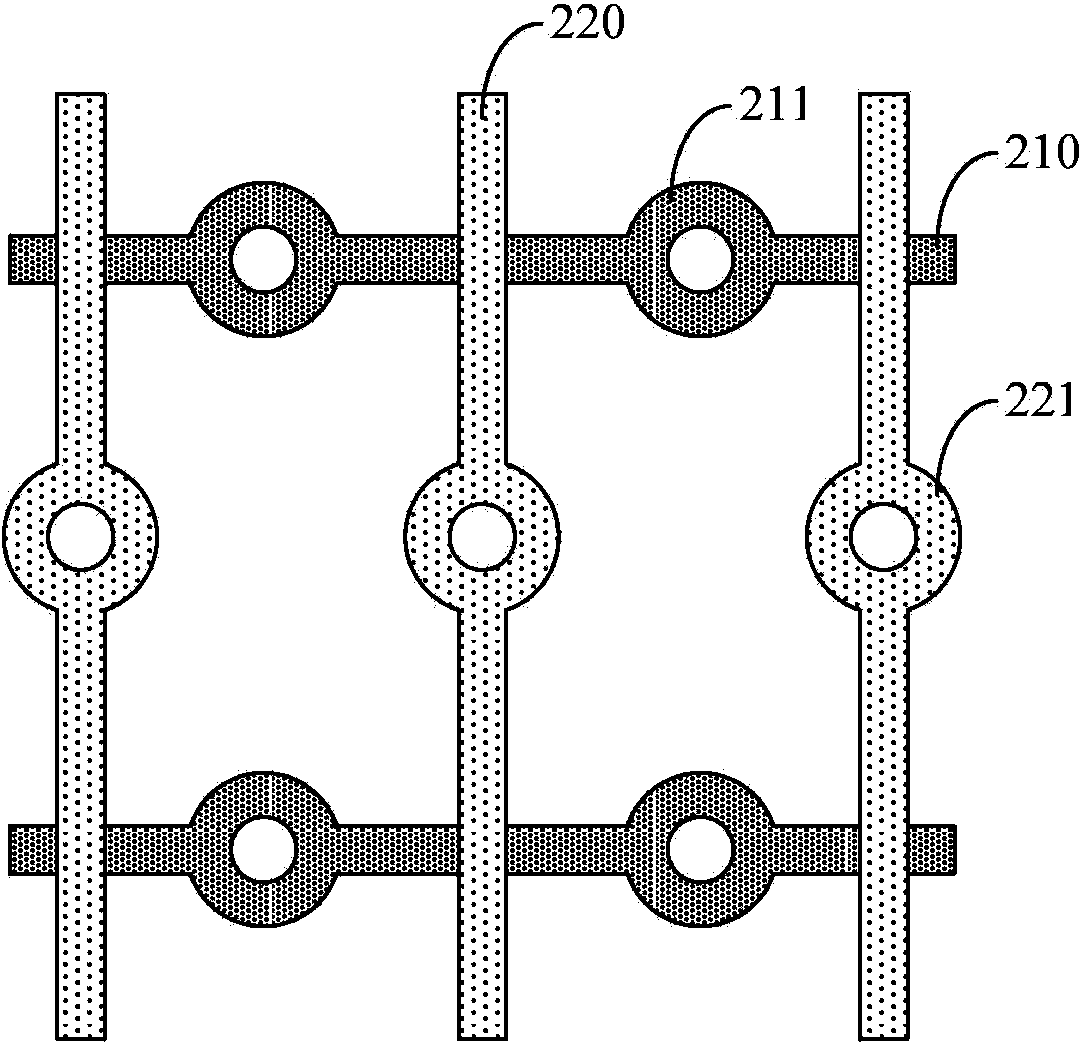

Flexible array substrate and preparation method thereof and display device

ActiveCN107634086AImprove stress uniformityReduce the chance of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

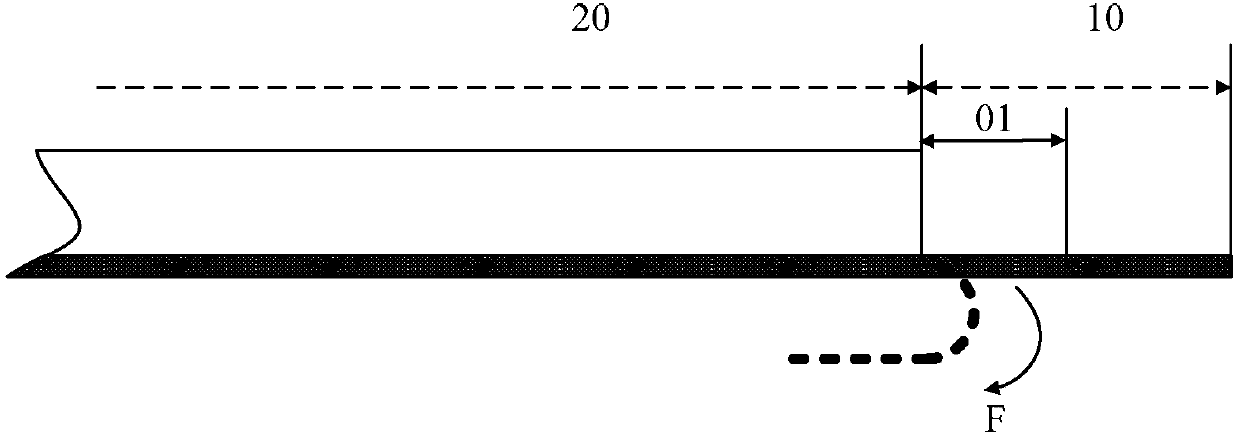

An embodiment of the invention provides a flexible array substrate and a preparation method thereof and a display device and relates to the display technical field. The probability of breakage of signal lines in a bending region due to bending can be reduced. The flexible array substrate comprises a display region and a wiring region. The wiring region comprises a bending region adjacent to the display region. The bending region comprises signal lines arranged on a substrate and a protection layer. The protection layer is arranged at one side, away from the substrate, of the signal lines; andthe orthographic projection of the protection layer on the substrate and the orthographic projection of the signal lines on the substrate have an overlapped region, and Young modulus of the protectionlayer is larger than or equal to Young modulus of the signal lines.

Owner:BOE TECH GRP CO LTD +1

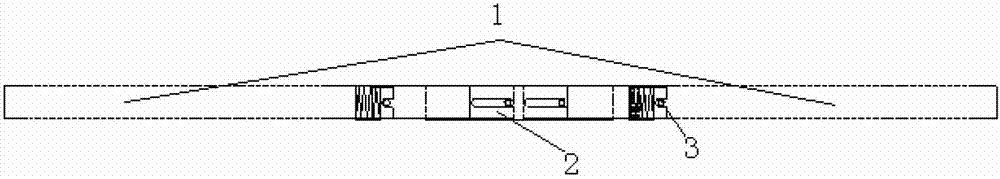

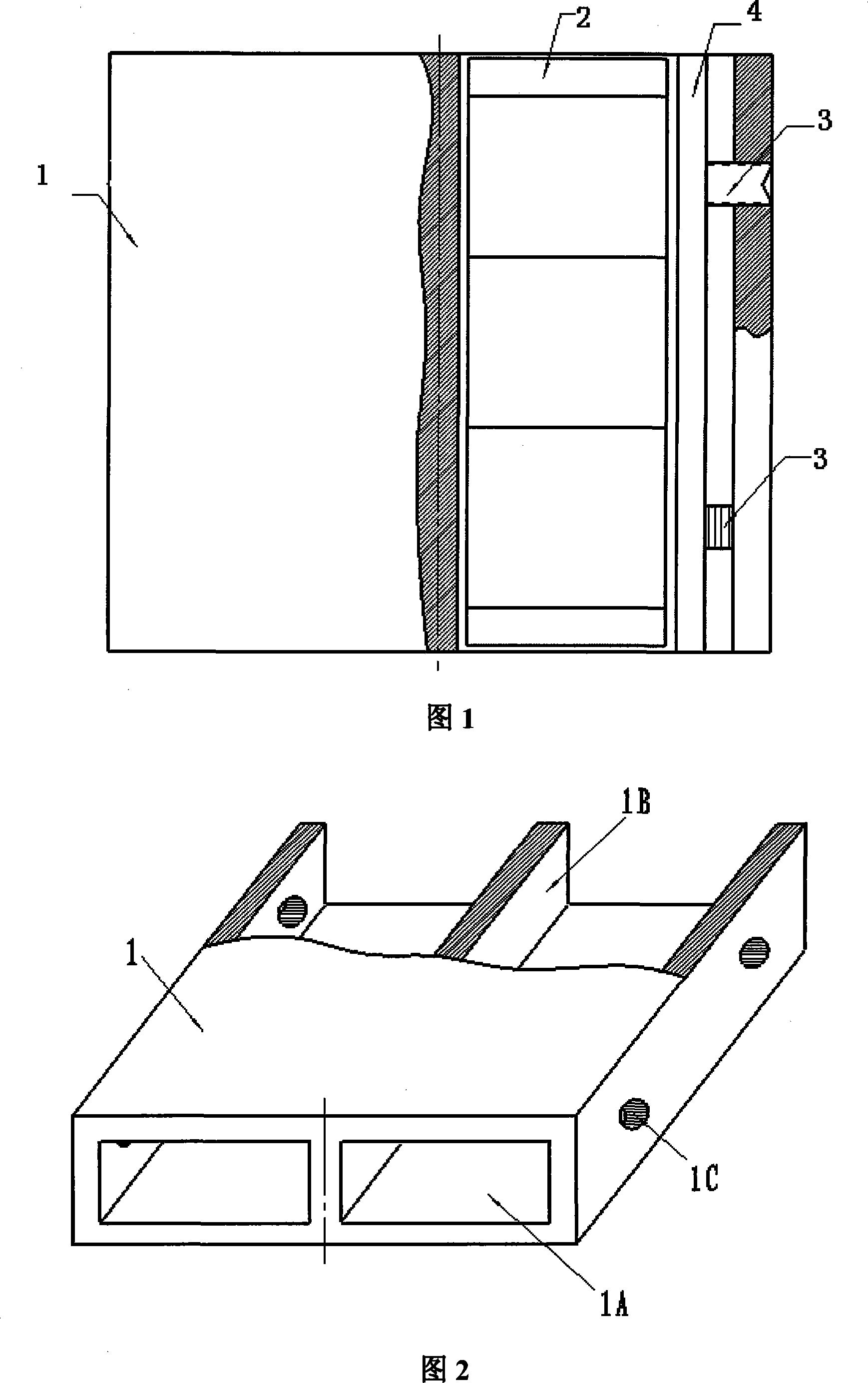

Liquid crystal display device and electronic apparatus provided with same

InactiveUS20090290089A1Reduce the chance of breakageSubstation/switching arrangement casingsSubstation/switching arrangement boards/panels/desksLiquid-crystal displayEngineering

A liquid crystal display apparatus includes a liquid crystal display panel, a backlight system, a driving circuit board for driving the liquid crystal display panel and the backlight system, and a housing for housing the foregoing members. A metal plate is provided between the backlight system and the driving circuit board, which metal plate has a plane surface on a front and back surface which is broader than the backlight system and the driving circuit board. On at least a pair of opposed edges of the metal plate, at least one of a falling portion and a rising portion is provided along the edges of the metal plate. Further, a bezel is provided between the housing and at least one of the falling portion and rising portion, which bezel is arranged so as to integrally support the metal plate and at least the liquid crystal display panel and the backlight system. Hence, a liquid crystal display apparatus and an electronic apparatus including same are provided, which liquid crystal display apparatus is capable of reducing a possibility of breakage due to load placed on a display surface of the liquid crystal display panel or an impact when dropped.

Owner:SHARP KK

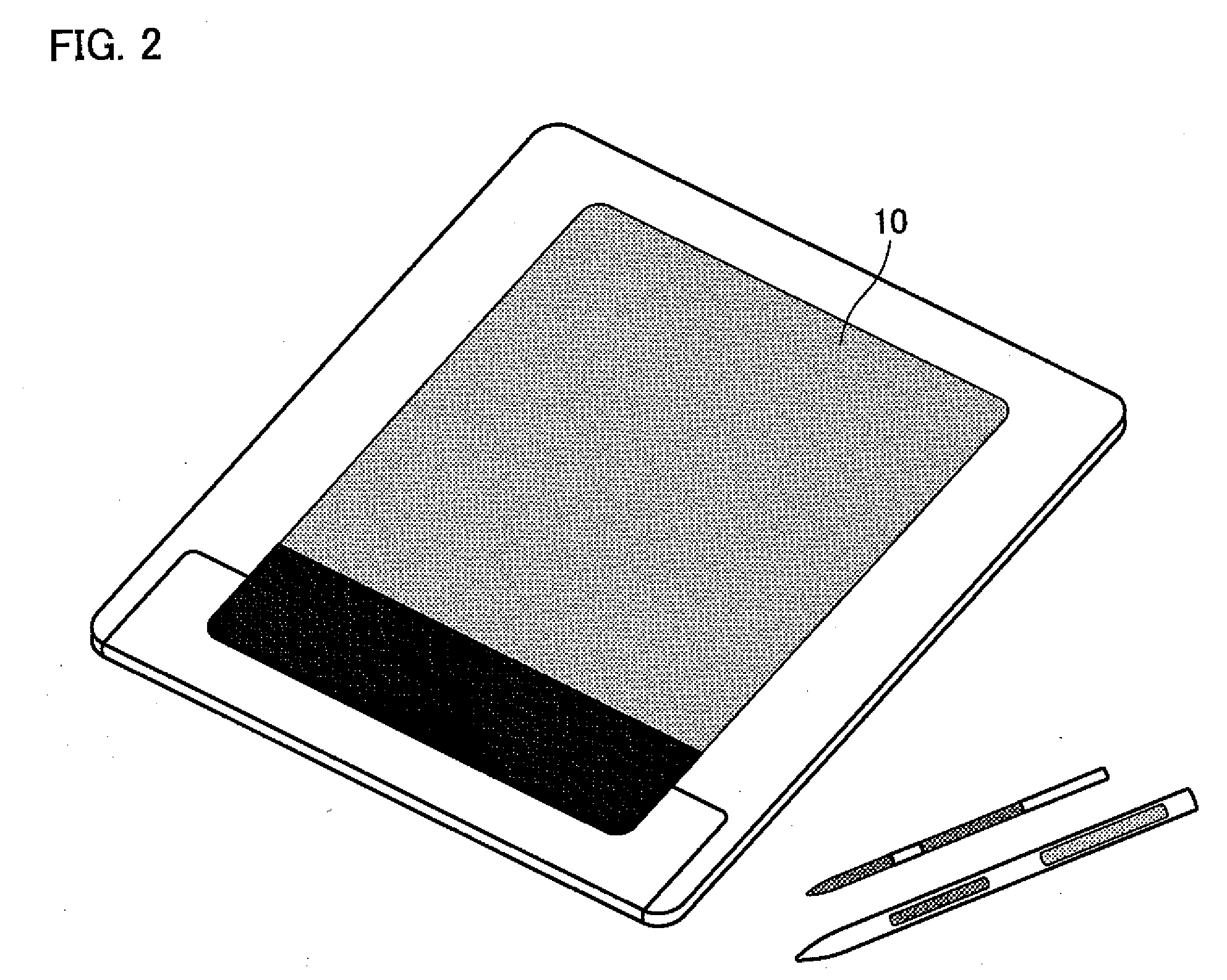

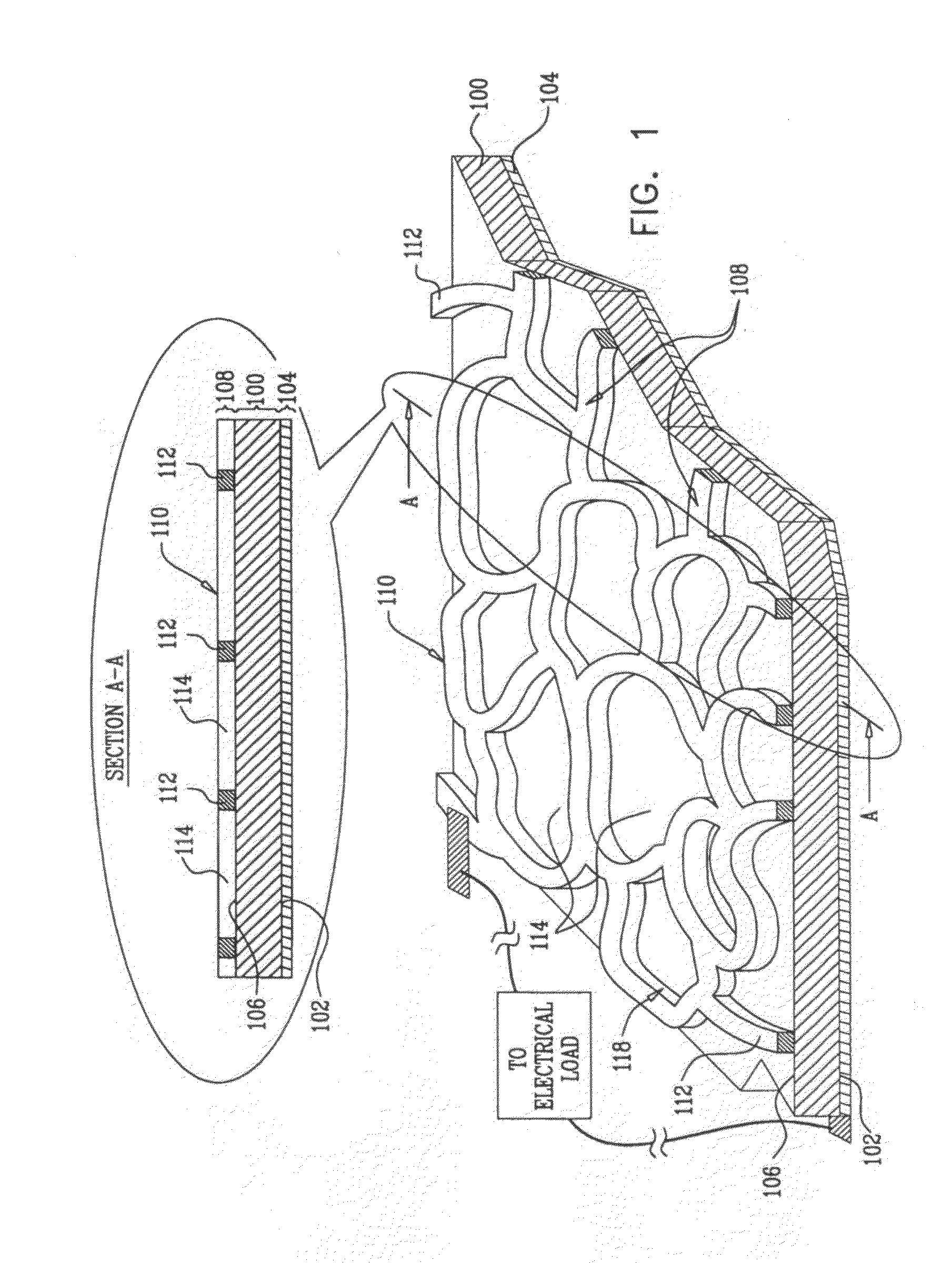

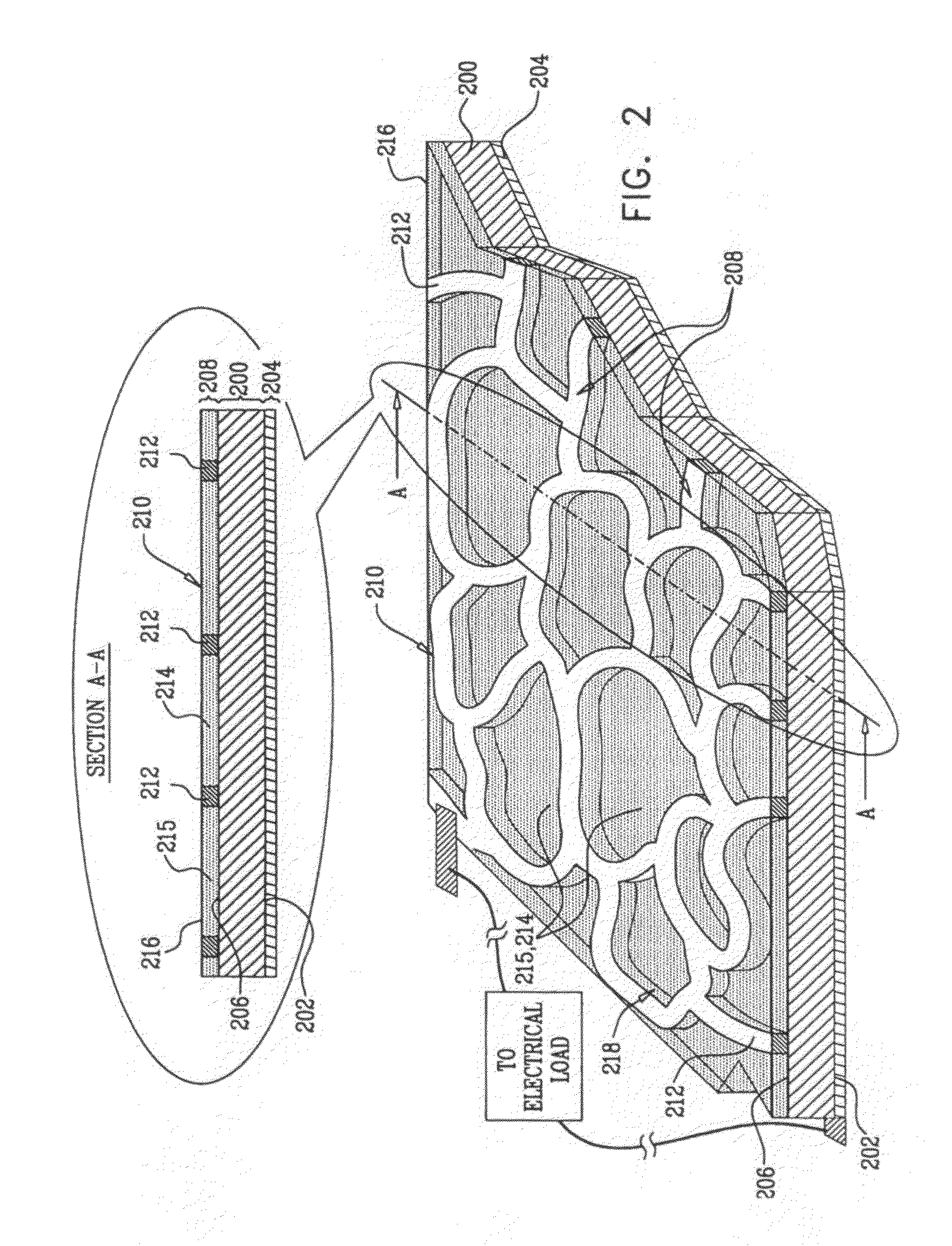

Photovoltaic device having transparent electrode formed with nanoparticles

InactiveUS20110175065A1Reduce the chance of breakageCost-effectiveElectroluminescent light sourcesSolid-state devicesEmulsionNanoparticle

A photovoltaic device is disclosed that includes a transparent front electrode formed by the self-assembly of conductive nanoparticles from an emulsion coated onto a substrate and dried. The nanoparticles self-assemble into a network-like pattern of conductive traces that define randomly-shaped transparent cells. The cells may be filled with various transparent filler materials and additional layers may be present in the device in addition to conventional components. Processes for forming the transparent electrode are also disclosed.

Owner:CIMA NANOTECH ISRAEL

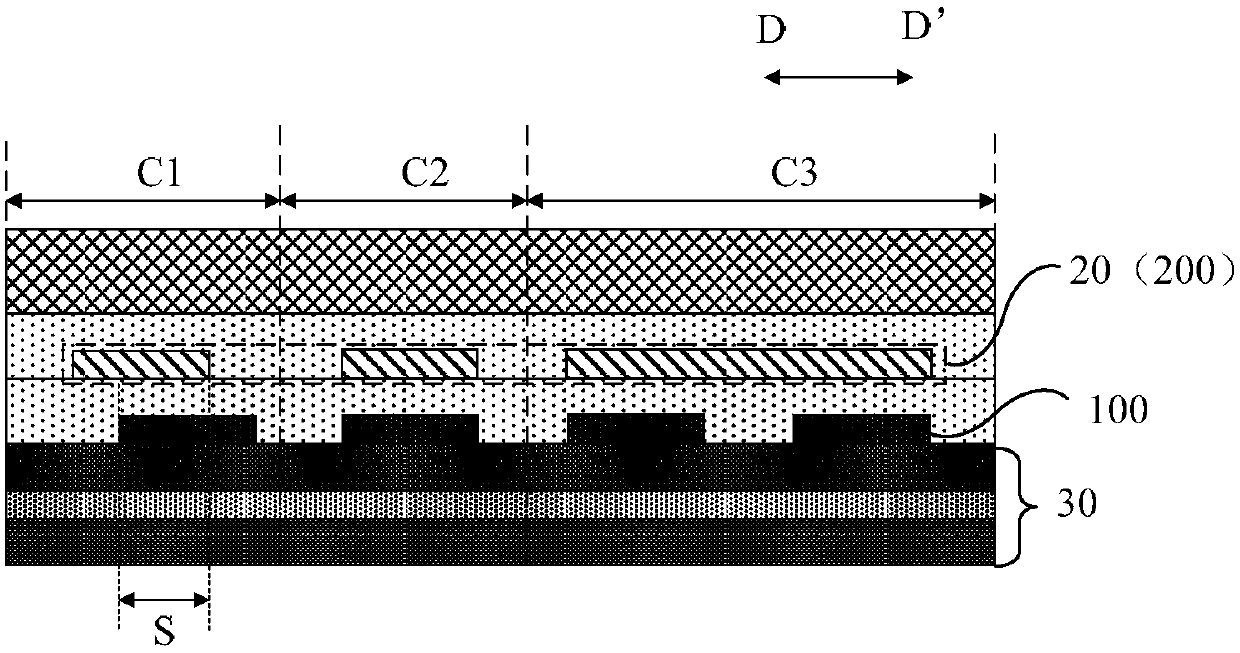

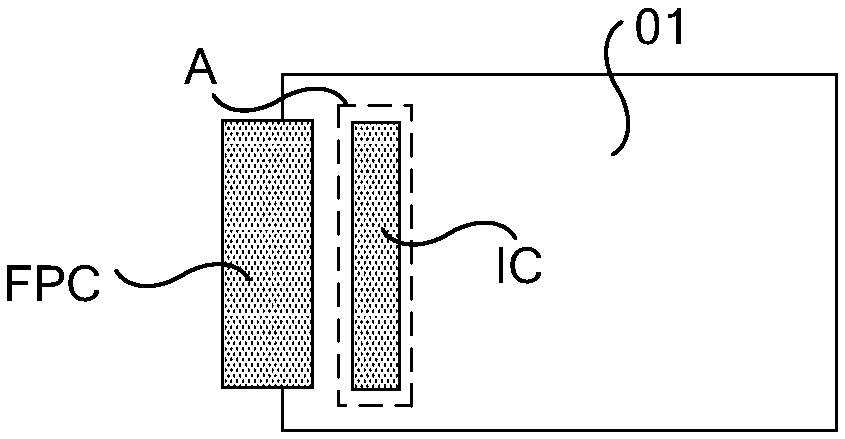

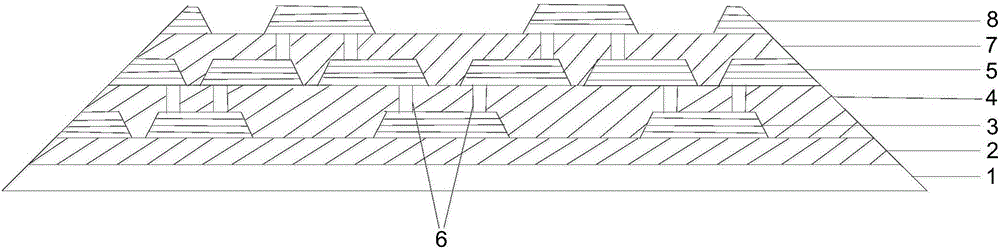

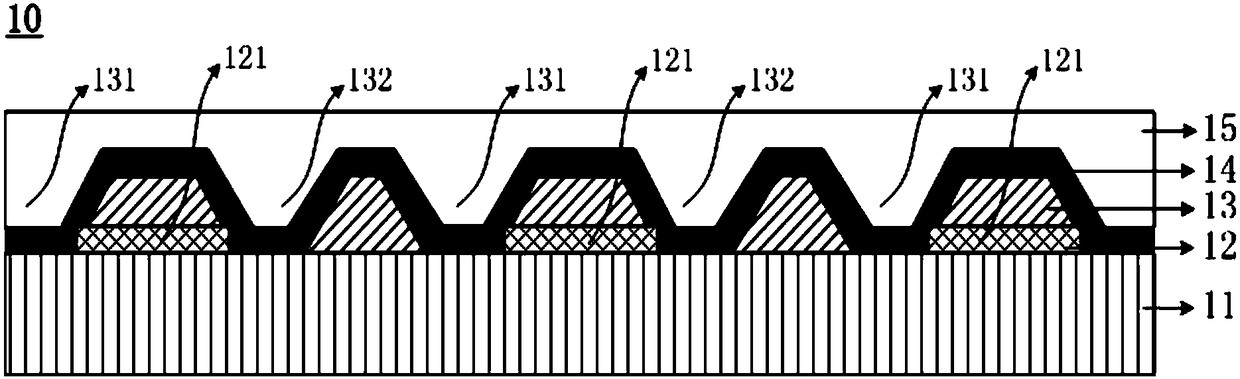

Array substrate and preparation method thereof, flexible display device

ActiveCN107564923APlay a supporting roleAvoid contactSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlexible display

An embodiment of the invention provides an array substrate and a preparation method thereof, and a flexible display device, relates to the technical field of flexible display and is used for solving aproblem of proneness of circuit breakage and short circuit when an IC is bound to the flexible display panel directly. The array substrate including a binding area and a plurality of binding bondingpad arranged in the binding area of the flexible substrate. The array substrate also includes an insulation support part disposed in the binding area and in a position without the binding bonding pad.The upper surface of the insulation support part protrudes from the upper surface of the binding bonding pad. The array substrate is used for forming the flexible display device.

Owner:BOE TECH GRP CO LTD

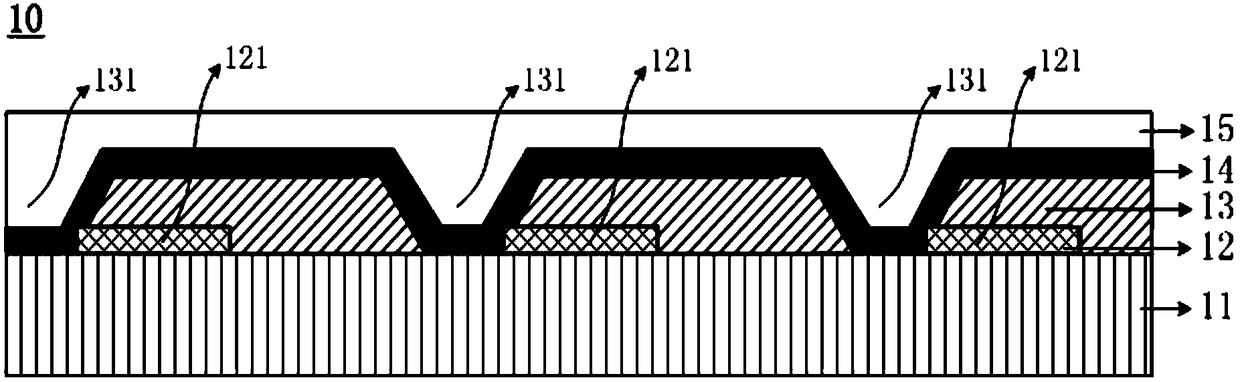

Flexible display substrate and preparing method thereof

ActiveCN106206613AReduce the chance of breakagePrevent agingSemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

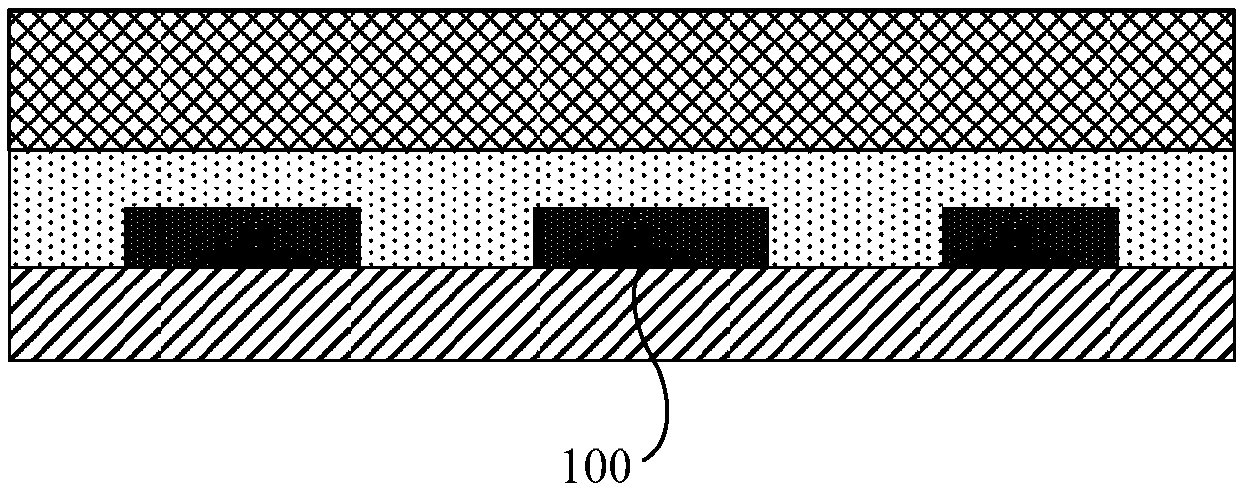

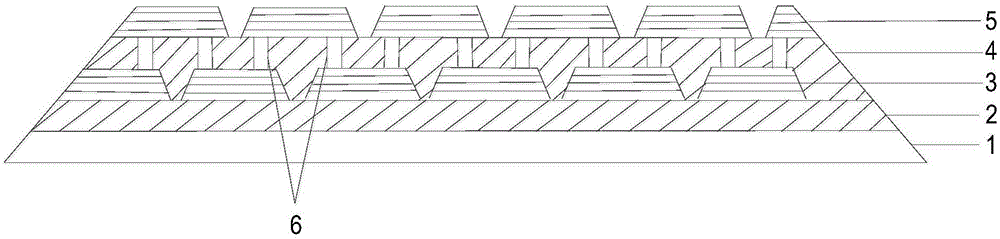

Array substrate and display device

ActiveCN103700322AReduce the chance of gate line or data line breakageReduce the chance of breakageIdentification meansData linesMechanical engineering

The invention relates to the technical field of displaying and discloses an array substrate which comprises a grid line formed on an underlay substrate, a grid insulating layer and a data line. A plurality of first concave-convex structures are formed on the surface, away from the underlay substrate, of the grid insulating layer. The invention further discloses a display device comprising the array substrate. By enabling the surface of the grid insulating layer to form a graph of a concave-convex structure, the grid or the data line formed on the surface of the grid insulating layer is enabled to form a graph of a concave-convex structure, and the graph of the concave-convex structure can enable a tension portion to be dispersed when a flexible display device bends, so that breaking probability of the grid line or the data line when the flexible display device bends is reduced, and the flexible display device is ensured to be capable of normally displaying.

Owner:BOE TECH GRP CO LTD

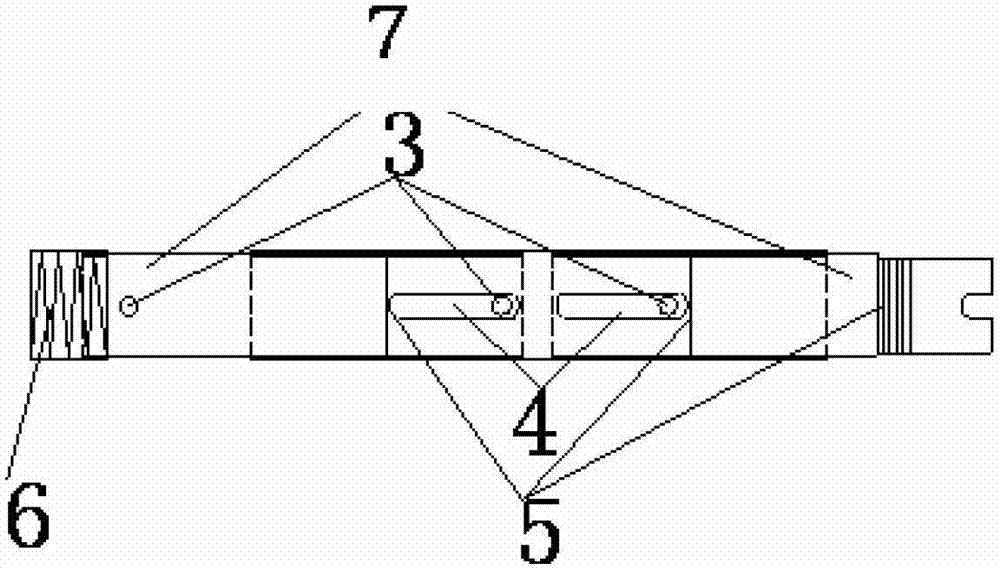

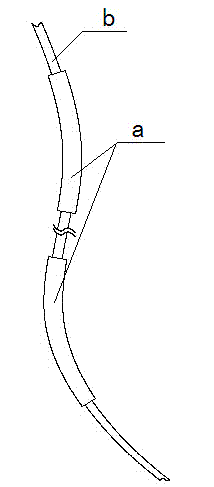

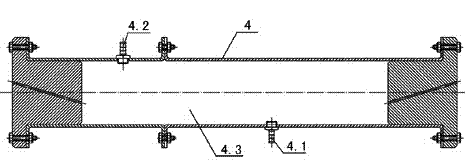

Extensible settlement and incline measuring pipe for measuring settlement and horizontal displacement and mounting method thereof

ActiveCN103195043AEasy to installEasy to processFoundation testingIn situ soil foundationEngineeringSediment

An extensible settlement and incline measuring pipe for measuring settlement and horizontal displacement is composed of a settlement measuring pipe, an incline measuring pipe, a bottom cover and a joint pipe and is characterized in that the joint pipe is an freely-extensible connection sleeve pipe which is composed of two secondary pipes and a main pipe, the external walls of the two secondary pipes are provided with sliding grooves, and fixing pins arranged on the internal wall of the main pipe are snapped with the sliding grooves of the secondary pipes; and both ends of each secondary pipe are respectively connected with the screws of the settlement measuring pipe and the incline measuring pipe through locating pins. The extensible settlement and inline measuring pipe for measuring the settlement and the horizontal displacement can guarantee the settlement measuring pipe and the inline measuring pipe not to be deformed along with a large-displacement deformation of a soil body, thereby reducing the interaction force between the settlement measuring pipe of the inline measuring pipe and the surrounding soil body and reducing the probability of pipe blocking or pipe breaking; sediment and water can be effectively prevented from entering among every parts; and the freely-extensible joint pipe, the settlement measuring pipe and the incline measuring pipe can be mounted through direct screwing. Therefore, the extensible settlement and inline measuring pipe for measuring the settlement and the horizontal displacement is convenient to build in and mount, has low technical requirements for mounting personnel, can largely reduce the mounting time, and is easy to process and achieve.

Owner:NANJING HYDRAULIC RES INST +1

Quick-frozen black sesame rice ball and preparation method thereof

InactiveCN103005275AIncrease viscosityImprove compactnessFood preparationGlucose polymersMaltodextrin

The invention discloses a quick-frozen black sesame rice ball. The quick-frozen black sesame rice ball comprises the following raw materials in part by weight: 55-65 parts of glutinous rice, 10-12 parts of cream, 4-6 parts of glucose, 3-5 parts of maltodextrin, 5-7 parts of black sesame, 4-6 parts of peanut, 1-3 parts of starch, 0.8-1 part of dried rose, 0.6-0.8 parts of matcha powder, 0.6-0.8 parts of salad oil, 0.5-0.8 parts of fried barley flour and a proper amount of water. A proper amount of starch, maltodextrin and fried barley flour is added in a stuffing making process, so that the emulsifying stability is improved, the stickiness and the compactness of stuffing are improved, the impact of the stuffing on a wrapper is reduced and the breakage opportunity of the wrapper is also reduced; the added matcha powder and rose improves the taste and the mouthfeel of the rice ball; and the quick-frozen black sesame rice ball is soaked by a Chinese herbal extract, so that the health-care value of the quick-frozen black sesame rice ball is improved.

Owner:凤台县康志食品有限责任公司

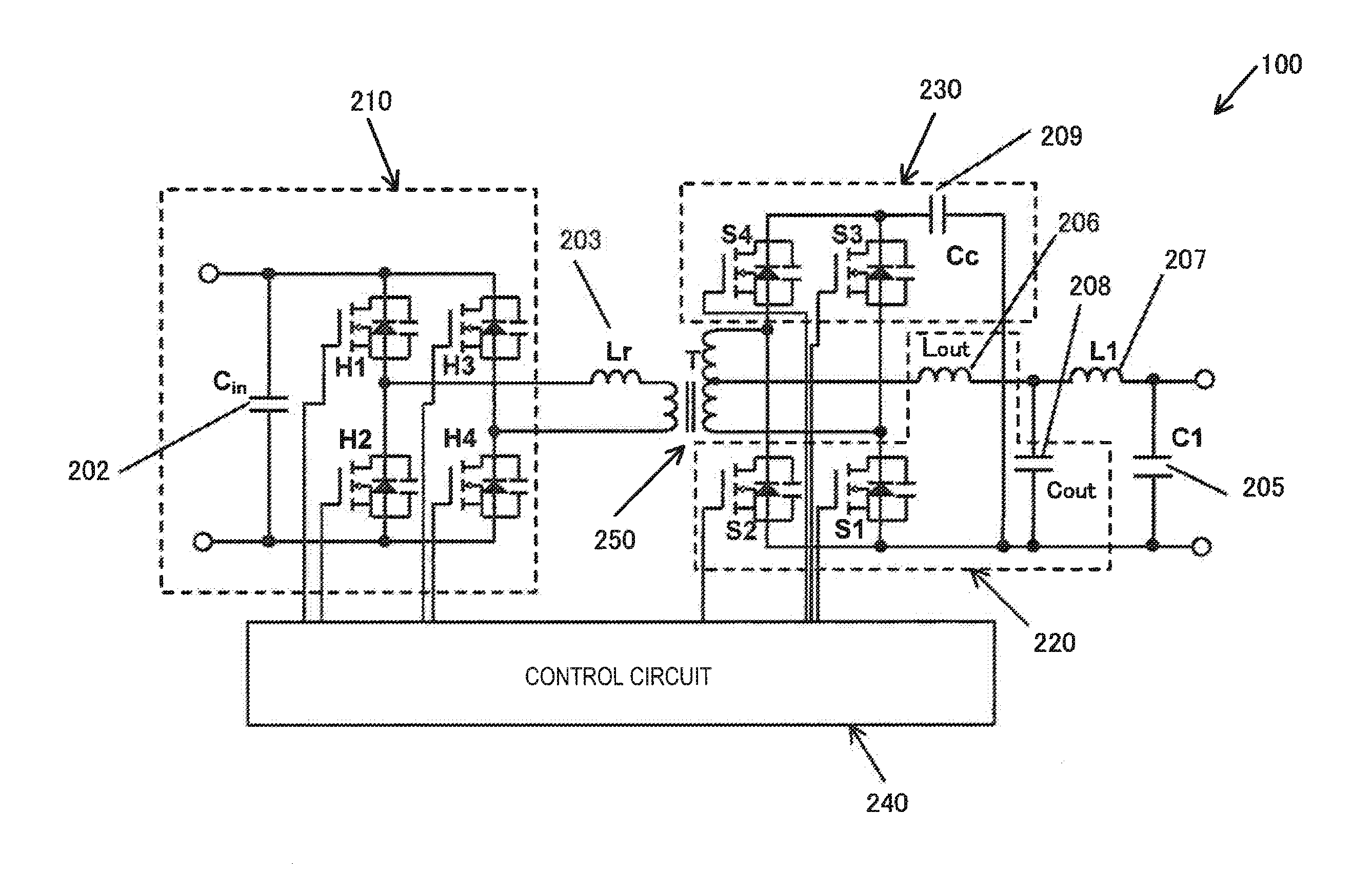

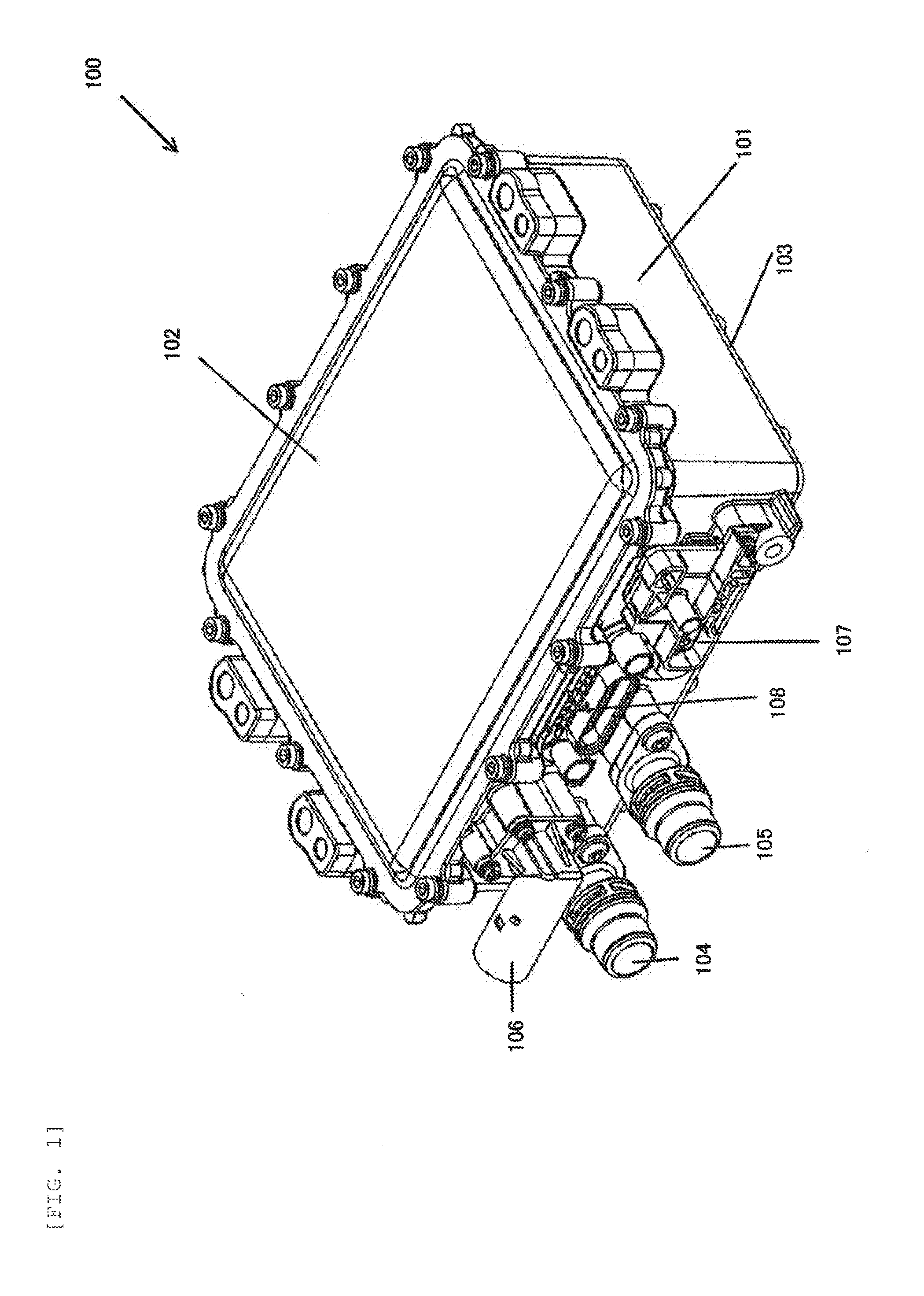

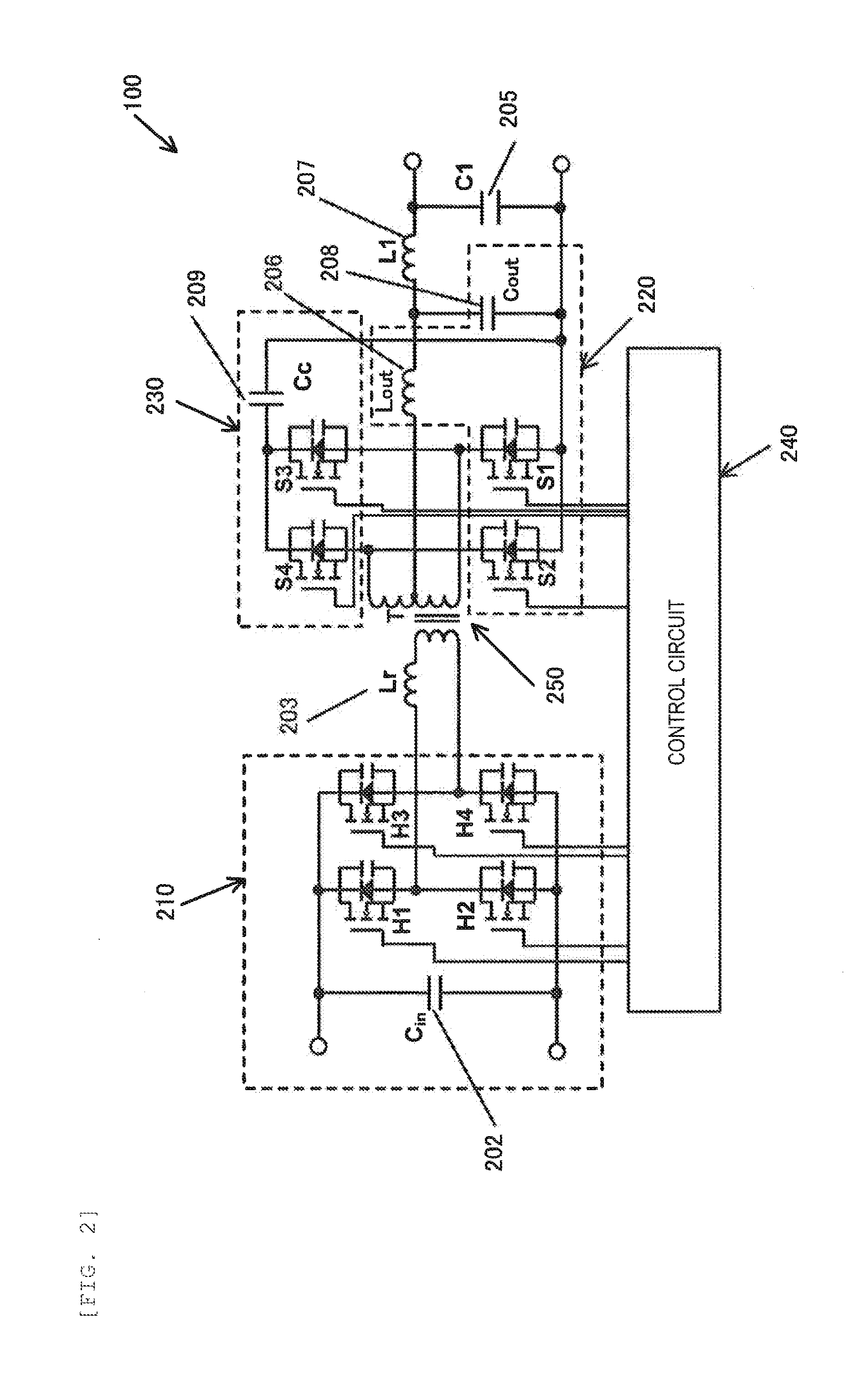

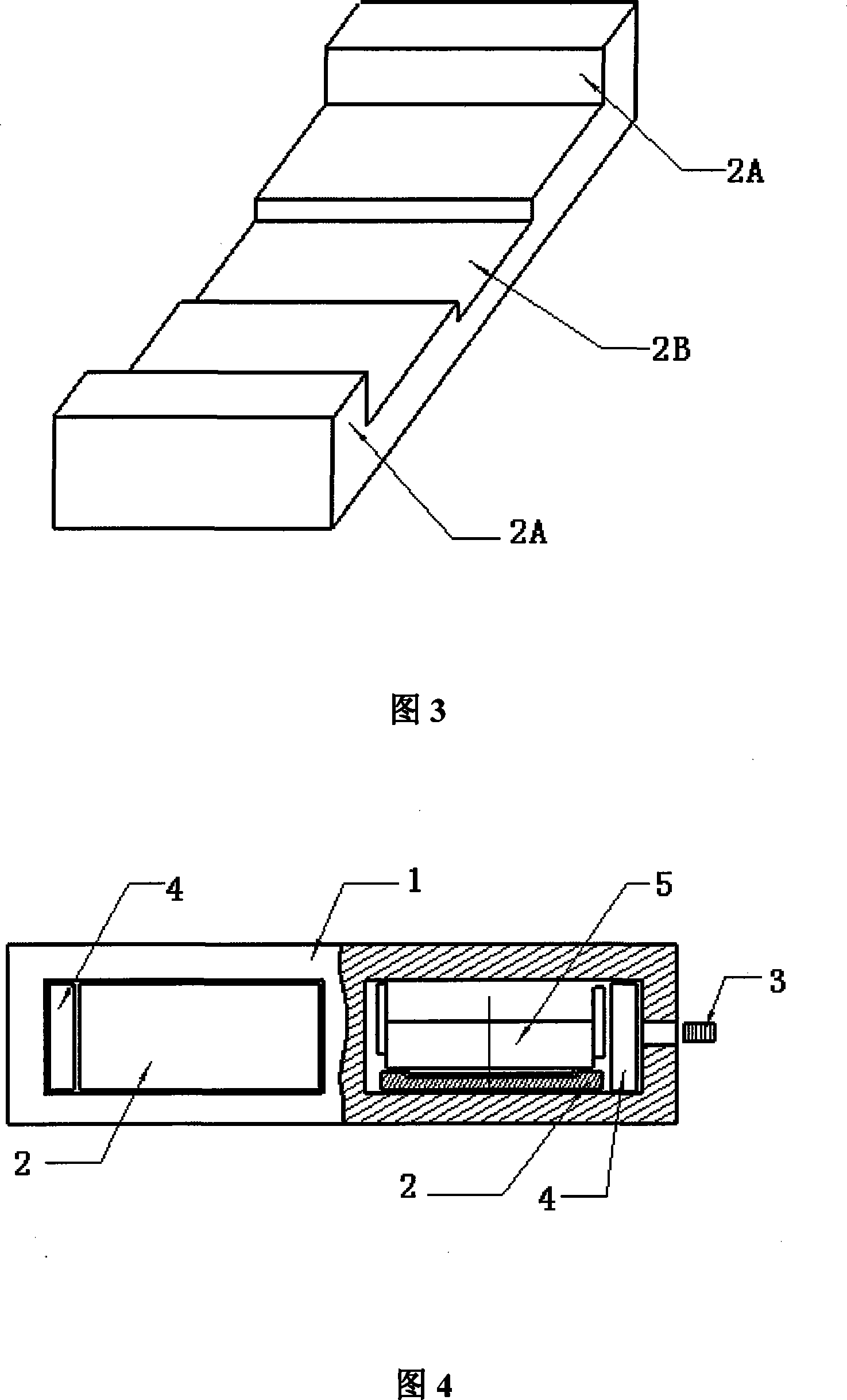

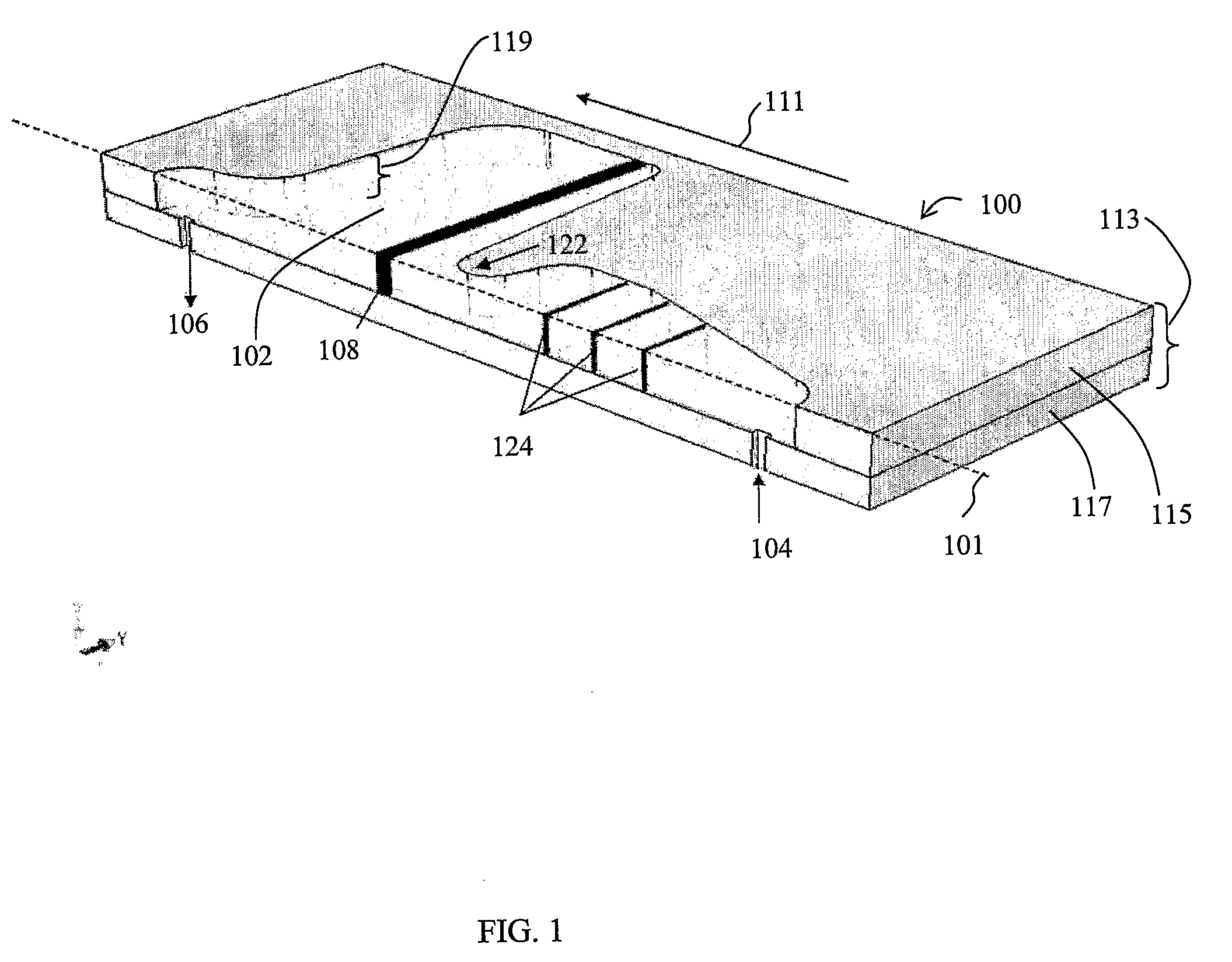

DC-DC Converter Apparatus

ActiveUS20150357923A1Reduce the chance of breakagePrinted circuit board receptaclesApparatus with intermediate ac conversionElectromagnetic noiseMechanical engineering

Objects of the invention are not to receive influence of an electromagnetic noise from a transformer and to reduce a possibility of breakage caused by shock or vibration. In a DC-DC converter apparatus of the invention, a shielding metal frame 300 is placed between a transformer 250 and a control circuit board assembly 240A housed in a case 101. A plate spring 311 attached to the metal frame 300 is pressed to cores 251 of the transformer 250 to fix the transformer 250 to a bottom portion 101a of the case 101. Heat generated from the transformer 250 is transmitted to the metal frame 300 and the bottom portion 101a of the case 101 and is then radiated.

Owner:HITACHI ASTEMO LTD

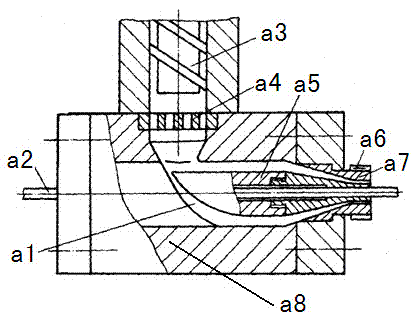

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

ActiveCN103075112AAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Method for preparing transmission electron microscope sample of soft brittle phototransistor

InactiveCN102023111AProtection from being brokenAvoid breakingPreparing sample for investigationAdhesiveProtection layer

The invention belongs to the technical field of the preparation of transmission electron microscope samples of soft brittle phototransistors, and relates to a method for preparing a transmission electron microscope sample of a soft brittle phototransistor, in particular to a method for preparing a transmission electron microscope sample of a soft brittle photo semiconducting transistor. The method is characterized in that a hard brittle semiconductor with micro Vickers hardness of over 8 GPa is used as a protective layer of the soft brittle phototransistor, wherein the roughness Ra of the ultra-smooth surface of the protective layer is below 1 nanometer, and the thickness is below 650 micrometers; sand paper of 120 to 800 meshes is adopted in the coarse grinding stage, and a membrane is ground by adopting diamond of between 0.1 and 30 micrometers in the accurate grinding stage; the protective layer is bonded with the sample by adopting a hot setting adhesive which is insoluble in an organic solvent, and a first surface of the ground transmission electron microscope sample is bonded with a substrate by adopting a hot setting adhesive which is soluble in the organic solvent; and in the final stage of accurate grinding, the transmission sample and a thin area of the protective layer are obtained by a stress-free grinding method. The method has the advantages that the preparation of the transmission electron microscope sample of the soft brittle phototransistor is realized, and high-resolution transmission electron microscope atomic images are obtained.

Owner:DALIAN UNIV OF TECH

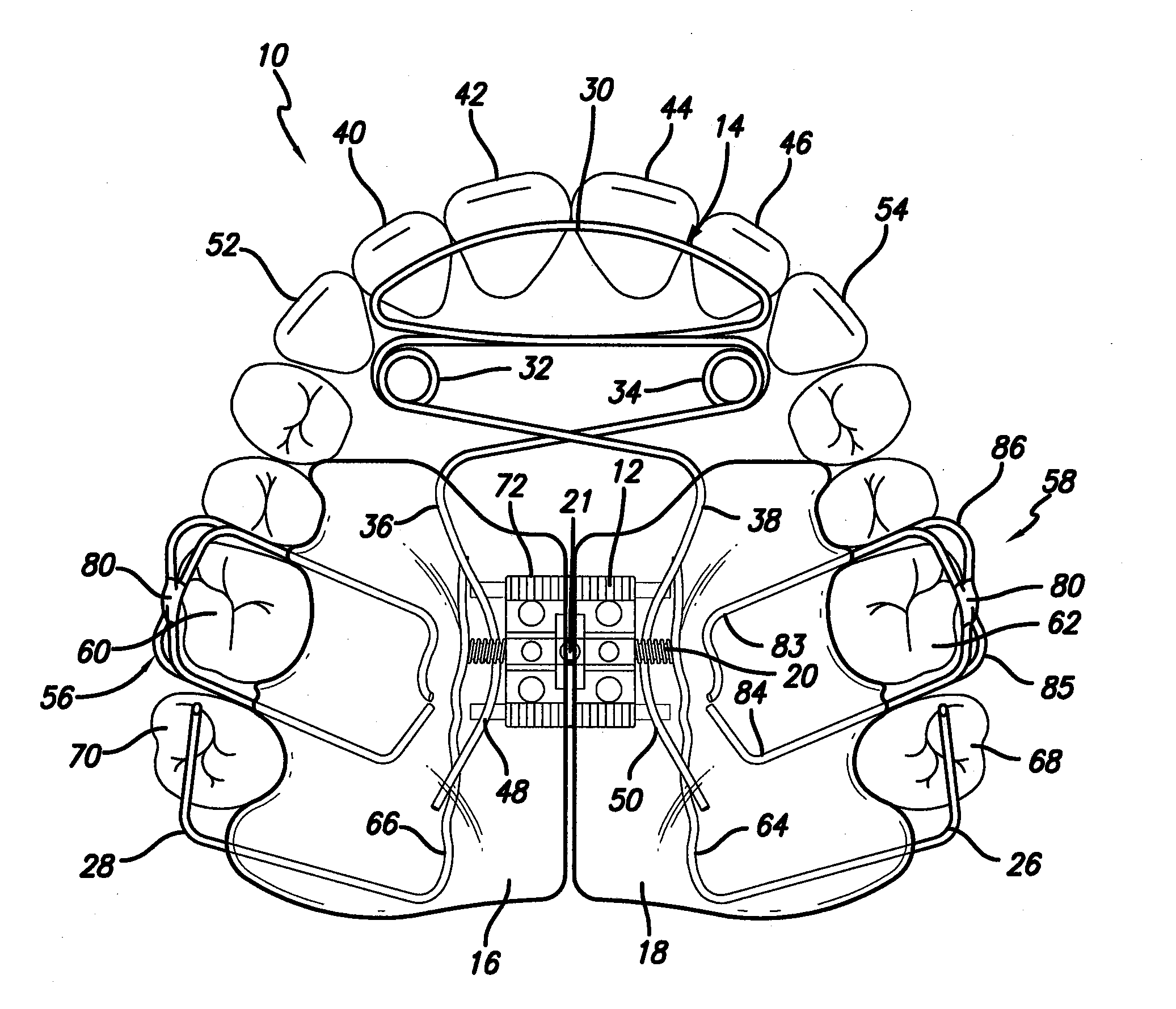

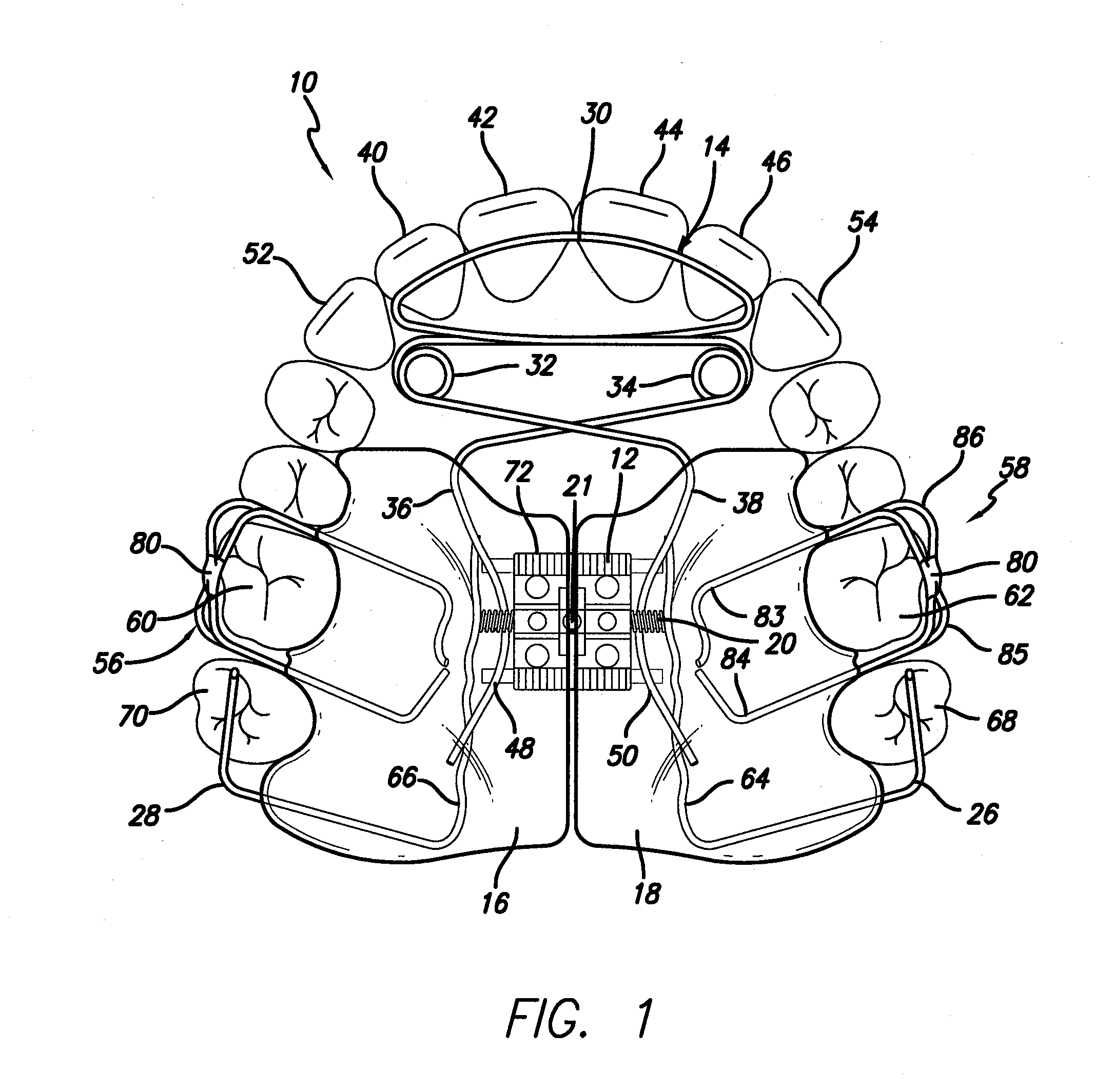

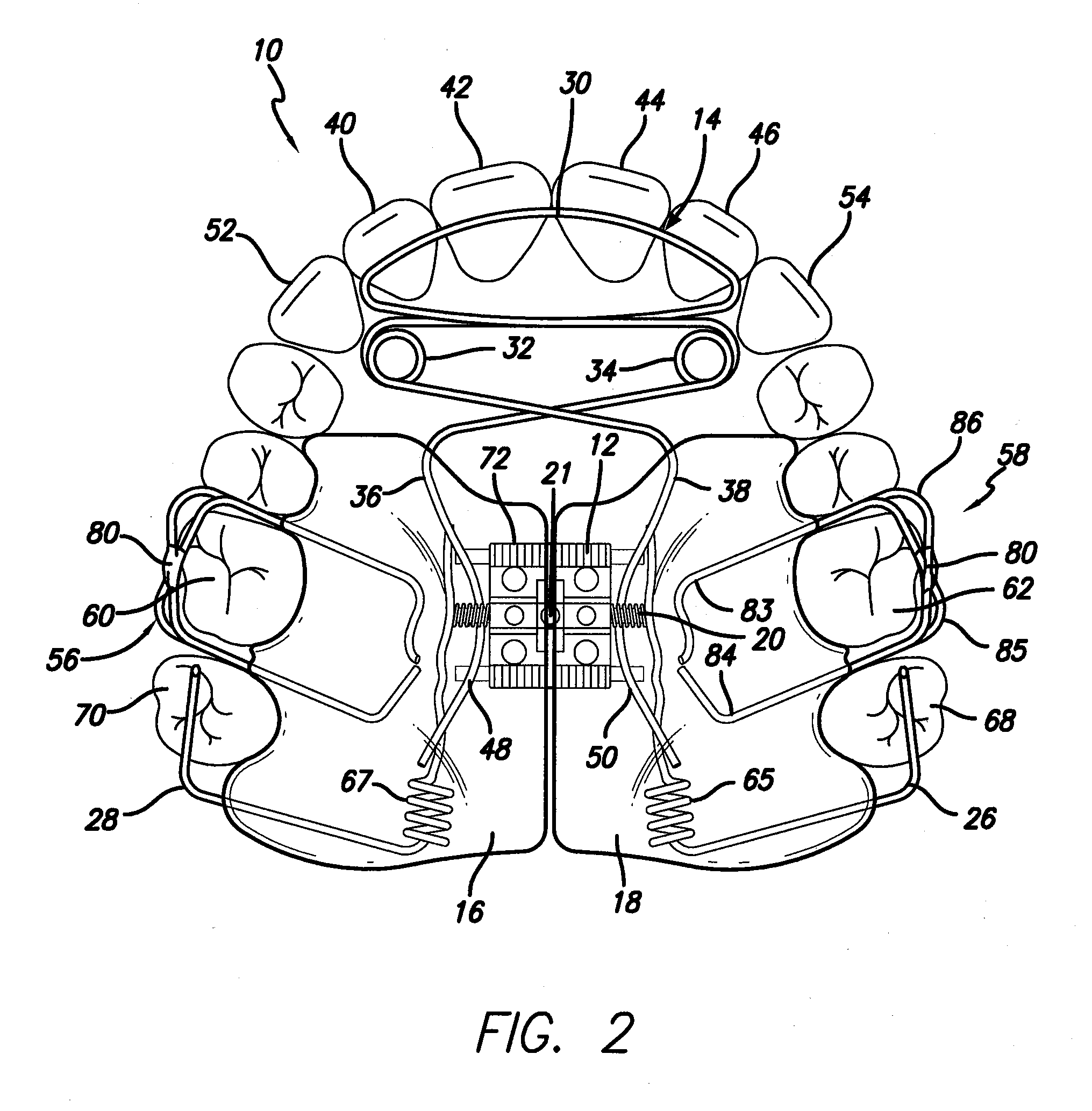

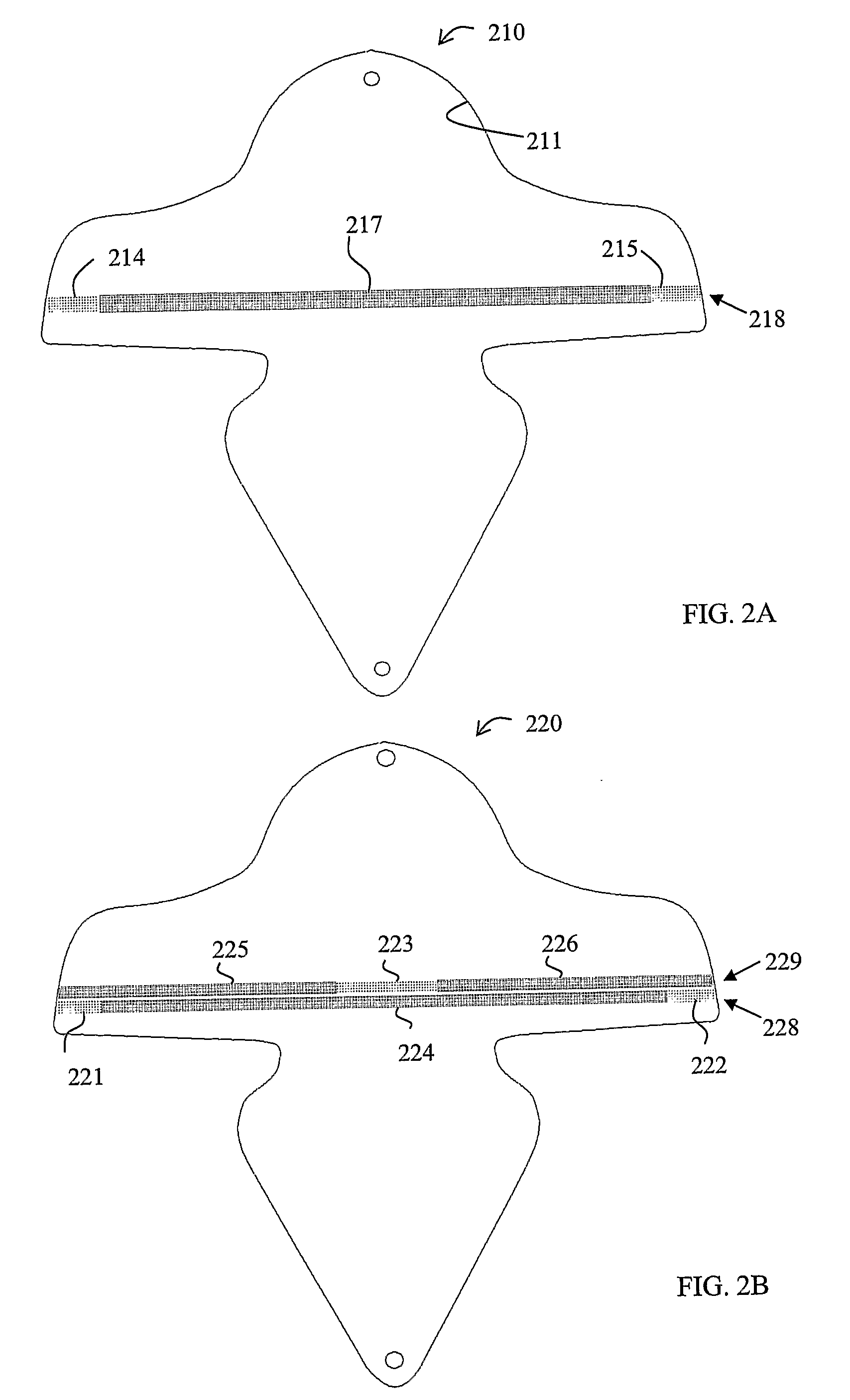

Orthodontic appliance

InactiveUS20110236847A1Effectively and efficiently combineUseful and effective to accomplish craniofacial modificationOthrodonticsDental toolsOrthodonticsMaxillary arch

A palatal expansion orthodontic appliance comprising, an advancer for advancing the upper front teeth, an expansion screw for controlling the expansion of two acrylic halves that each contain a Hang Clasp and optionally a molar intrusion wire. The two acrylic halves share and anchor the wire ends of the advancer, the Hang clasps and any molar intrusion wires. The orthodontic appliance simultaneously expands the maxillary arch and advances the upper front teeth. Methods of manufacture, including kits for the manufacture of the orthodontic appliance are also included.

Owner:HANG WILLIAM M

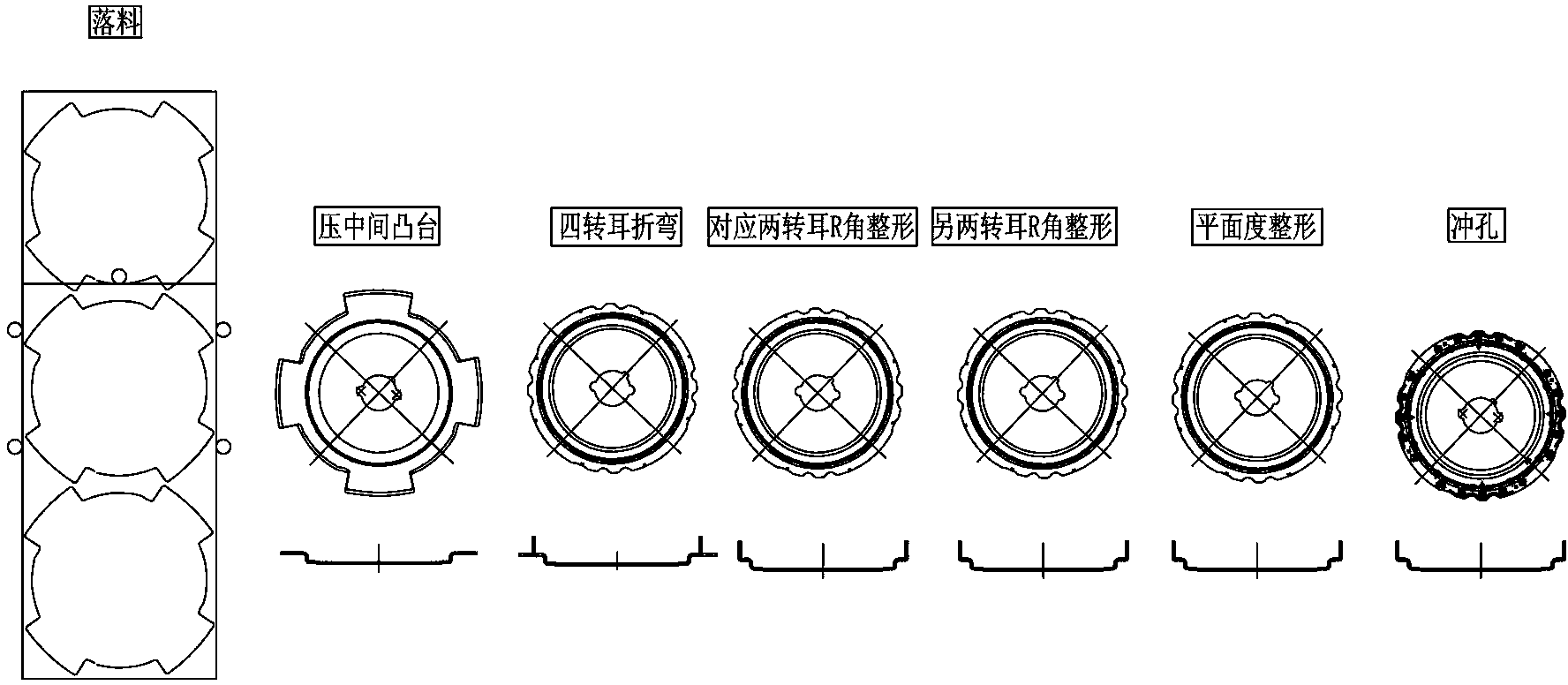

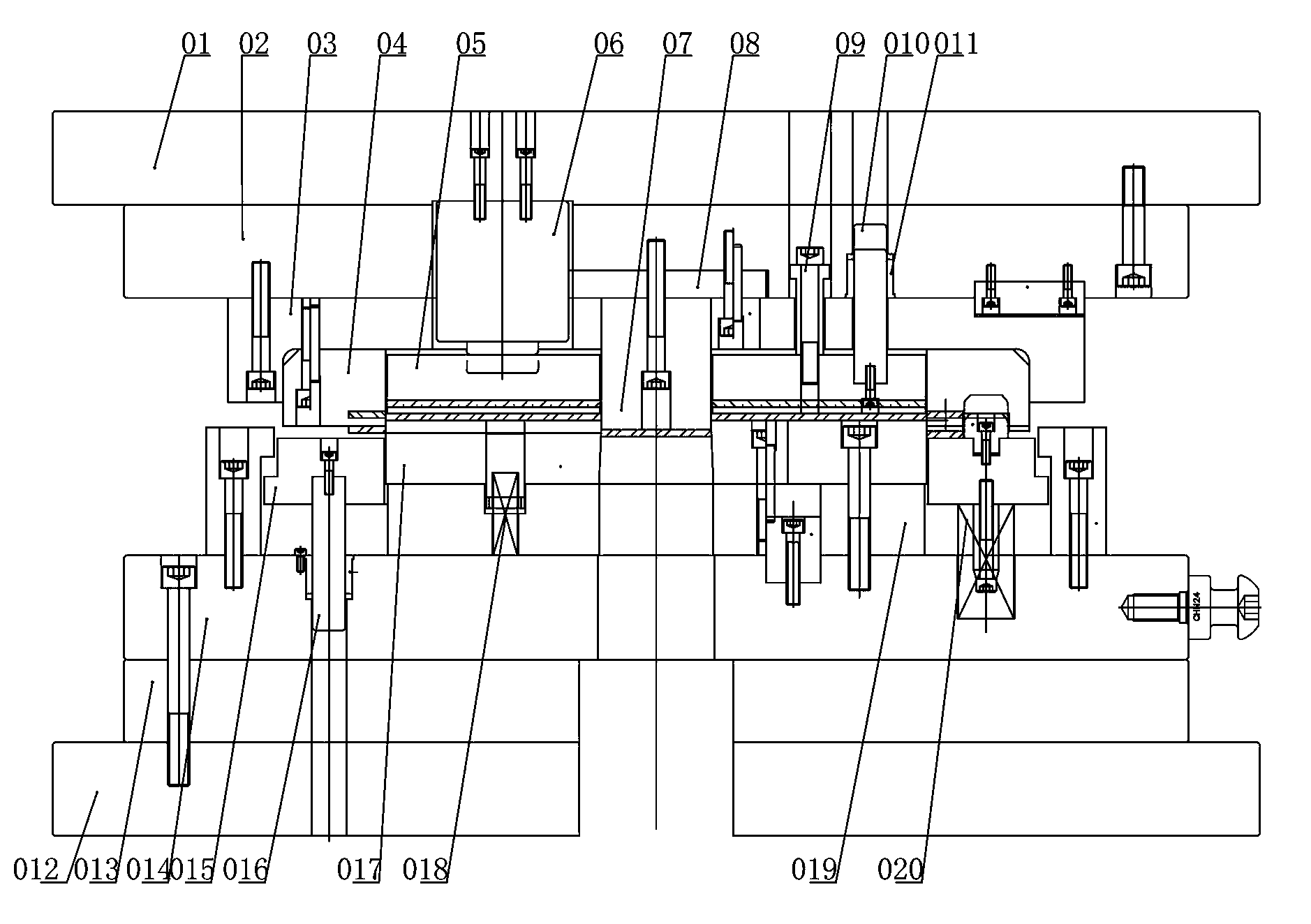

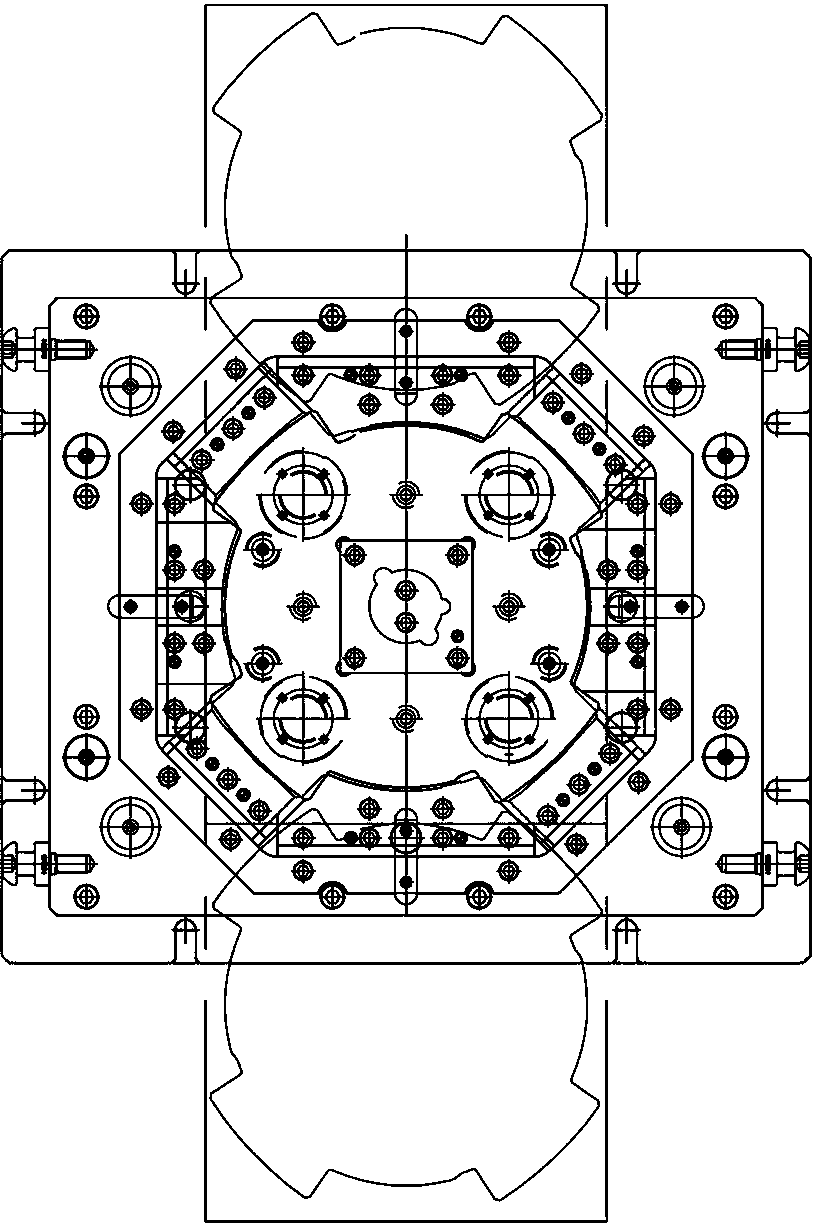

Clutch cap forming process and forming equipment thereof

The invention discloses a clutch cap forming process. The clutch cap forming process is characterized by including the following steps of (a) blanking, (b) pressing a middle boss, (c) bending four rotating lugs, (d) angle R shaping of two corresponding rotating lugs, (e) angle R shaping of the other two rotating lugs, (f) shaping flatness, and (g) punching. The invention further discloses clutch cap forming equipment which comprises a blanking die, a stretching die, a bending die, a first shaping die, a second shaping die and a punching die. According to the clutch cap forming process and the forming equipment thereof, the mode that pulling is carried out first and then folding is carried out is adopted, the thickness of a clutch can reach 6.35 mm, and the obtained bearing force of the clutch can reach 100000 newtons; meanwhile, a bending mode with an angle R is adopted, the probability that materials break during bending is reduced, and the bending success rate reaches 99.3%; angle R shaping of the rotating lugs is carried out twice, the angle R is eliminated, an assembling hole is convenient to form, and the best shaping effect is achieved; a flatness shaping procedure is arranged, accuracy of the formed hole is guaranteed, and meanwhile, a cap of the clutch and the clutch are accurately assembled.

Owner:RAINBOW METAL TECH

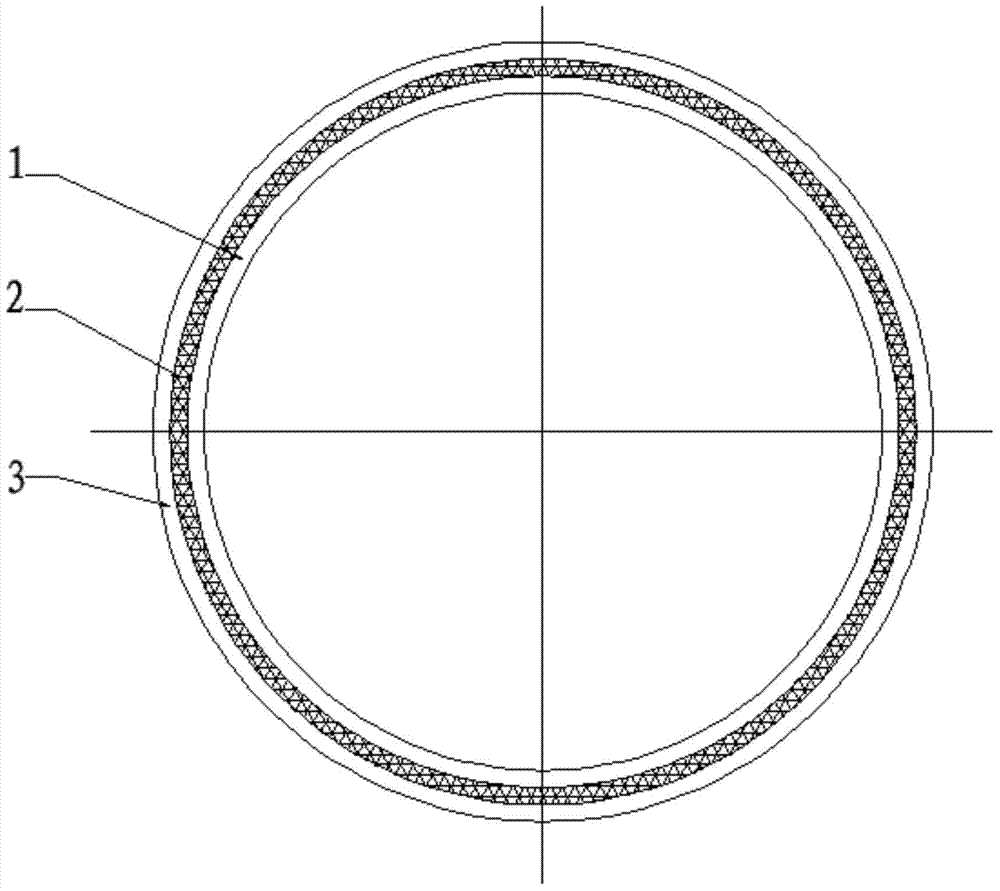

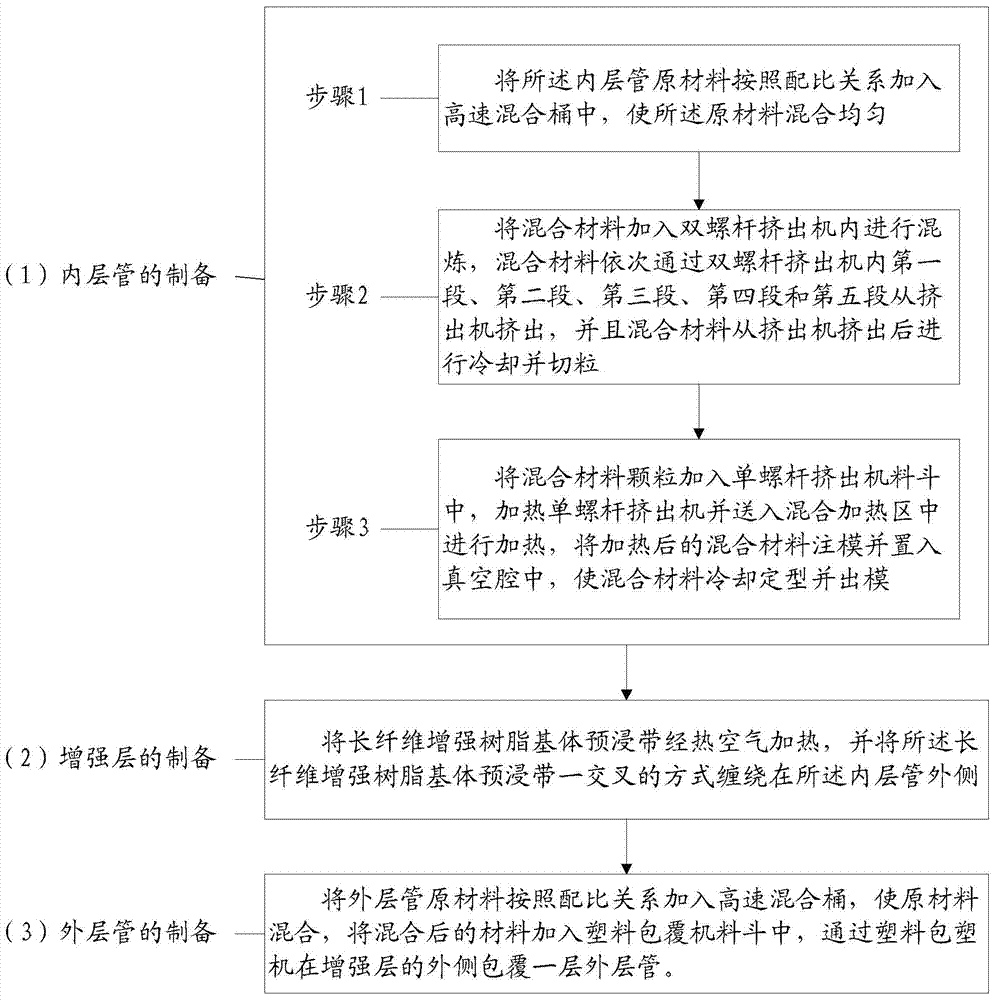

Flexible composite tube and manufacturing method thereof

ActiveCN103498979AImprove stress toleranceReduce the chance of breakageFlexible pipesPolyvinylidene fluorideMaleic anhydride

The invention discloses a flexible composite tube and a manufacturing method thereof, and belongs to the technical field of pipelines. The flexible composite tube comprises an inner layer tube, a reinforcing layer and an outer layer tube. The inner layer tube is made of polyvinylidene difluoride, polyethylene, polyethylene stem grafting difluoro maleic anhydride, ethylene-propylene polymer and antioxygen. The reinforcing layer is made of long-fiber reinforced resin matrix prepreg tapes. The outer layer tube is made of polyethylene or polypropylene. The manufacturing method for the flexible composite tube comprises the step of manufacturing the inner layer tube, the step of manufacturing the reinforcing layer and the step of manufacturing the outer layer tube. The inner layer tube made of the polyvinylidene difluoride, the polyethylene, the polyethylene stem grafting difluoro maleic anhydride, the ethylene-propylene polymer and the antioxygen is adopted, so that the flexible composite tube has a good high-temperature resistant property, a good barrier property and a good anti-swelling property. The creep deformation of the inner layer tube can be effectively avoided, the long-fiber reinforced resin matrix prepreg tapes adopted in the reinforcing layer have a good binding capability with the inner layer tube, and the layering of a pipeline can be effectively avoided. Meanwhile, the flexible composite tube has the advantages of being simple in structure, low in cost, simple in manufacturing method and the like, and has wide application prospects.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

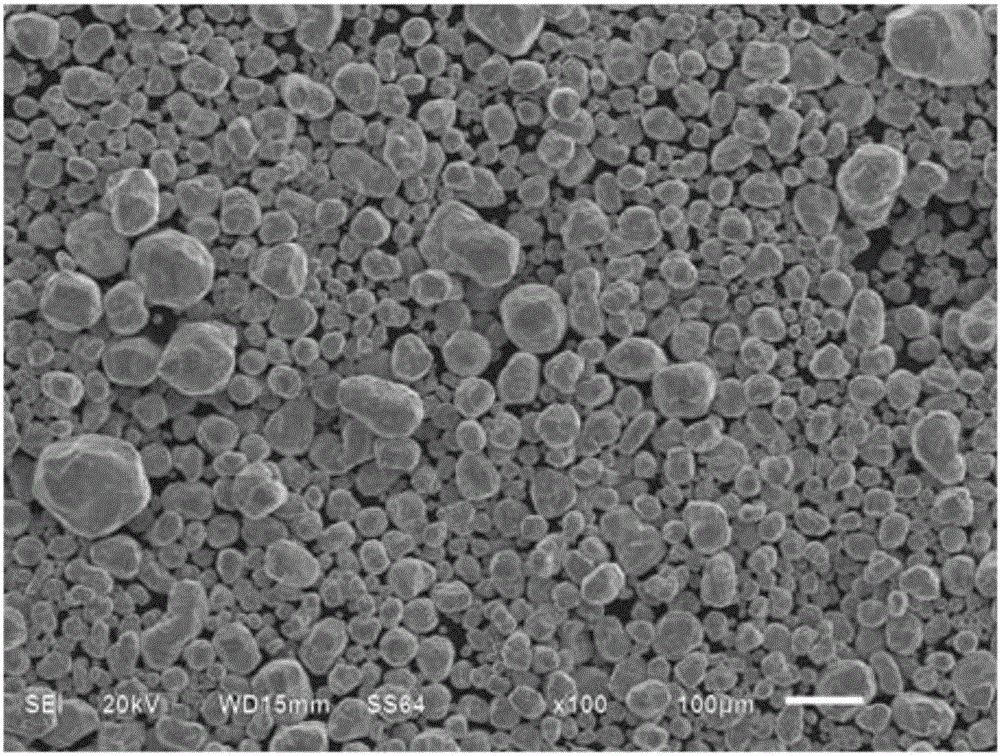

Preparing method for ball-like metal magnetically soft alloy powder

ActiveCN105710378ALow impurity contentGood formability and magnetic propertiesTransportation and packagingMetal-working apparatusForming processesSingle crystal

The invention relates to a preparing method for ball-like metal magnetically soft alloy powder, and belongs to the technical field of powder preparing. The method comprises the steps that raw materials of a metal magnetically soft alloy are weighed and mixed according to the weight ratio, intermediate-frequency induction smelting is adopted, and the molten alloy is prepared into an alloy casting strip through a thin-strip continuous casting technology; the alloy casting strip is placed into a crushing device, and the alloy casting strip is crushed into particle powder under the inert gas shielding condition; the crushed powder is placed into a shaping treatment device to be shaped, ball-like powder with the regular shape is obtained, the powder is subjected to annealing heat treatment, and fine powder is prepared through screening and collecting. According to the method, the uniformity of alloy powder components can be obviously improved, meanwhile, the powder wrapping insulating and pressing forming are facilitated through the prepared ball-like single-crystal particle powder, the uniformity degree of a soft magnetism powder core pressing insulating layer and the mechanical strength obtained after pressing forming can be obviously improved, the probability of damage of the insulating layer in the powder pressing forming process is greatly reduced, and accordingly the application field of the soft magnetism powder core is greatly enlarged.

Owner:有研增材技术有限公司

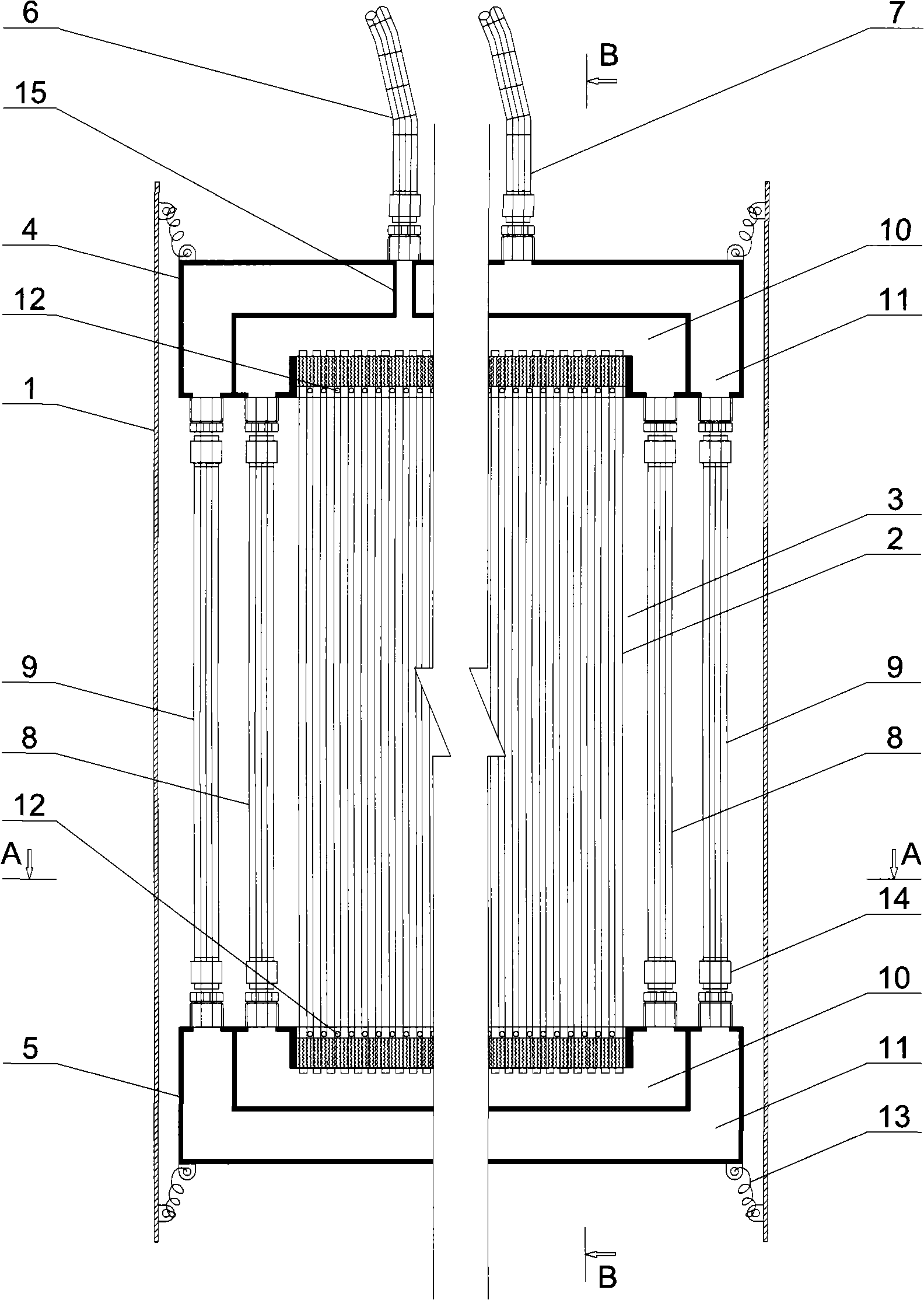

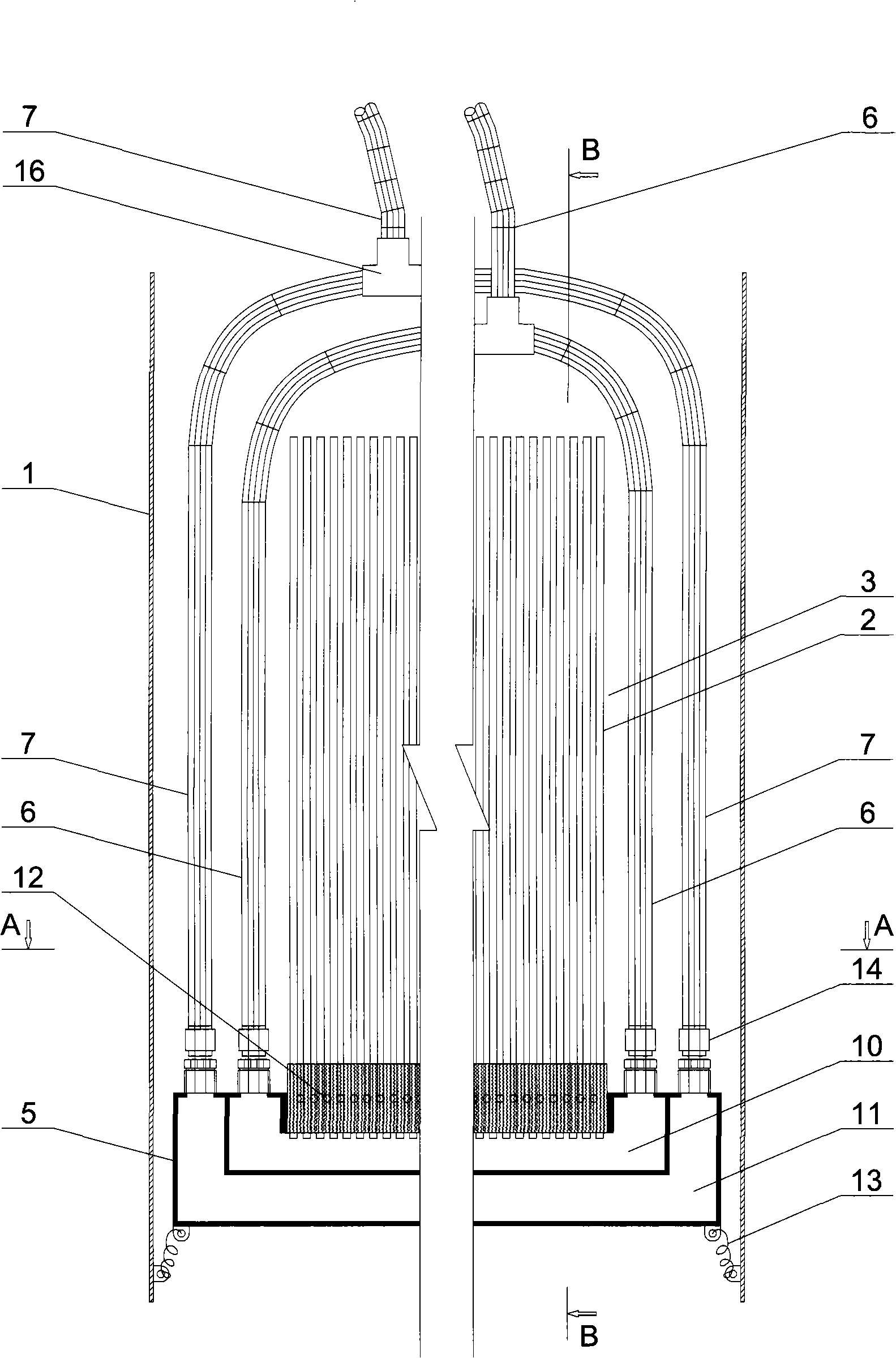

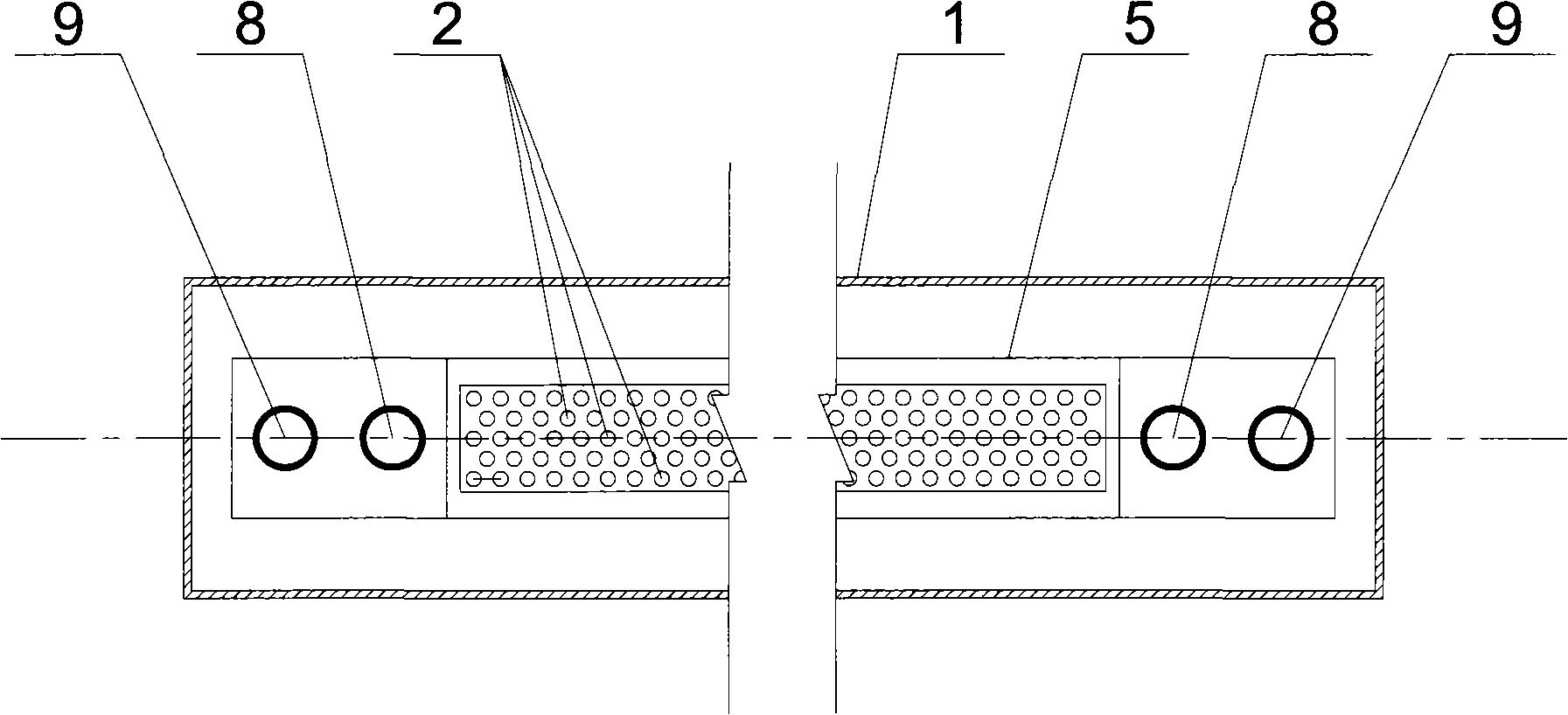

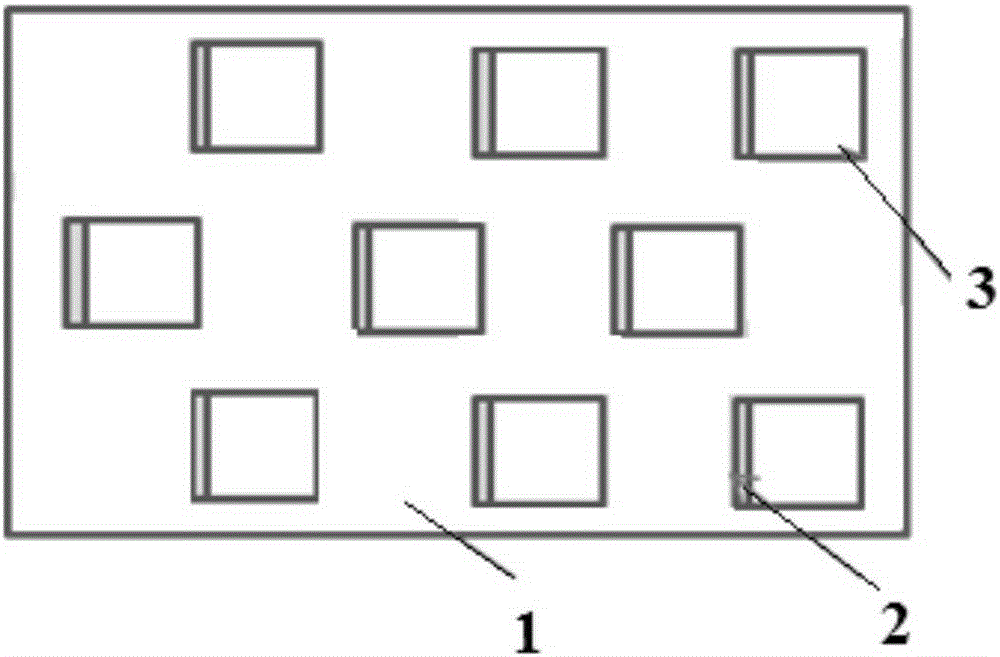

Hollow fiber curtain type film assembly

ActiveCN101254978AImprove anti-pollution performanceExtended service lifeWater/sewage treatment bu osmosis/dialysisSustainable biological treatmentHollow fibreEngineering

The invention discloses a hollow fiber curtain-type membrane component, which comprises a hollow fiber membrane bundle composed of a plurality of hollow fibrous membrane threads, the end head(s) at one end or the both ends of the hollow fiber membrane bundle, an air inlet pipe and a water producing pipe. The end presents a strip shape, an air distribution device with an air distribution hole is arranged at least one end, the air distribution device is communicated with the air inlet pipe, and the hole opening of the air distribution hole is opened towards the top part of the hollow membrane fiber; the end head(s) at one end or the both ends of the hollow fiber membrane bundle refers that the end head(s) is (are) provided at one end or the both ends of the hollow fiber membrane bundle. The invention also discloses a membrane bioreactor utilizing the hollow fiber membrane component and water treatment equipment. The hollow fiber membrane component disclosed by the invention has the structural characteristics that the anti pollution performance of the hollow fiber membrane component is enhanced, particularly the anti pollution performance of the root of the hollow fiber membrane is enhanced, the effective filtering areas of the hollow fibrous membrane threads are ensured, the service life of the hollow fiber membrane component is prolonged, and the processing, the assembly, the installation and the reparation of the hollow fiber membrane component are very convenient.

Owner:BEIJING ECOJOY WATER TECH

Ceramic double arrange packaging device high accelerate centrifugation experiment cramping apparatus

InactiveCN101135636AEven by forceAvoid deformationUsing mechanical meansCentrifugesCentrifugationEngineering

The fixture comprises a mother fixture, a daughter fixture used for placing the test piece, a fastening used for fastening the test piece and a fastening clamp plate. Said mother fixture has a through slot used for mounting the said daughter fixture by using a drawer way; on the side wall of the mother fixture there are screw type locking components.

Owner:NO 24 RES INST OF CETC

Mobile phone cover glass main printing technology

The invention relates to the technical field of mobile phone cover glass printing, in particular to a mobile phone cover glass main printing technology. The mobile phone cover glass main printing technology comprises the steps of (1) primary mirror-like silver printing, wherein a mirror-like silver layer is printed on the lower surface of clear glass in a blade coating mode by means of the screen printing technique; (2) secondary bluish violet printing, wherein a second bluish violet layer is printed on the lower surface of the clear glass in a blade coating mode by means of the screen printing technique; (3) tertiary pearl white printing, wherein a pearl white layer is printed on the lower surface of the clear glass in a blade coating mode by means of the screen printing technique. According to the mobile phone cover glass main printing technology, by means of the composite printing technology conducted on the clear glass and combining the primary mirror-like silver printing, the secondary bluish violet printing and the tertiary pearl white printing, printed patterns are stereoscopic, and natural transition is achieved between different ink layers. The mobile phone cover glass main printing technology has the advantages that operation is simple and convenient to control, quality is stable, production efficiency is high, and large-scale industrial production can be achieved.

Owner:广东星弛光电科技有限公司

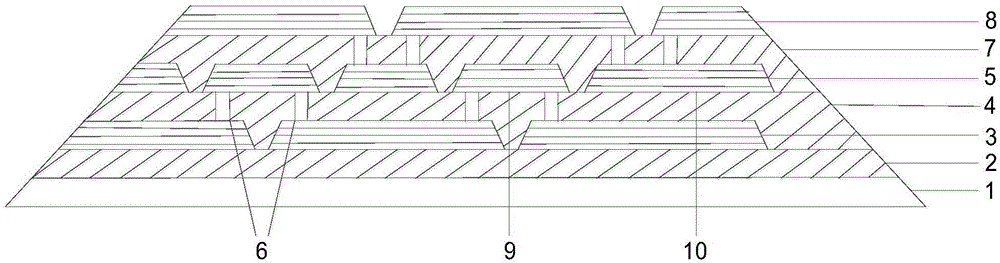

Array substrate and display device

InactiveCN103730476AReduce the chance of breakageGuaranteed display effectSolid-state devicesSemiconductor devicesDisplay deviceFlexible display

The invention relates to the technical field of display and discloses an array substrate. The array substrate comprises grid lines, data lines and a plurality of pixel units which are defined by intersection of the grid lines and the data lines, wherein a first anti-fracture structure is formed on each grid line, and / or a second anti-fracture structure is formed on each data line. According to the array substrate, due to the fact that the anti-fracture structures are formed on patterns of the grid lines and / or the data lines, when a flexible display device is bent, part of tension can be dispersed through the anti-fracture structures, the probability that the grid lines and the data lines are fractured when the flexible display device is bent can be reduced, and normal display of the flexible display device can be guaranteed.

Owner:BOE TECH GRP CO LTD

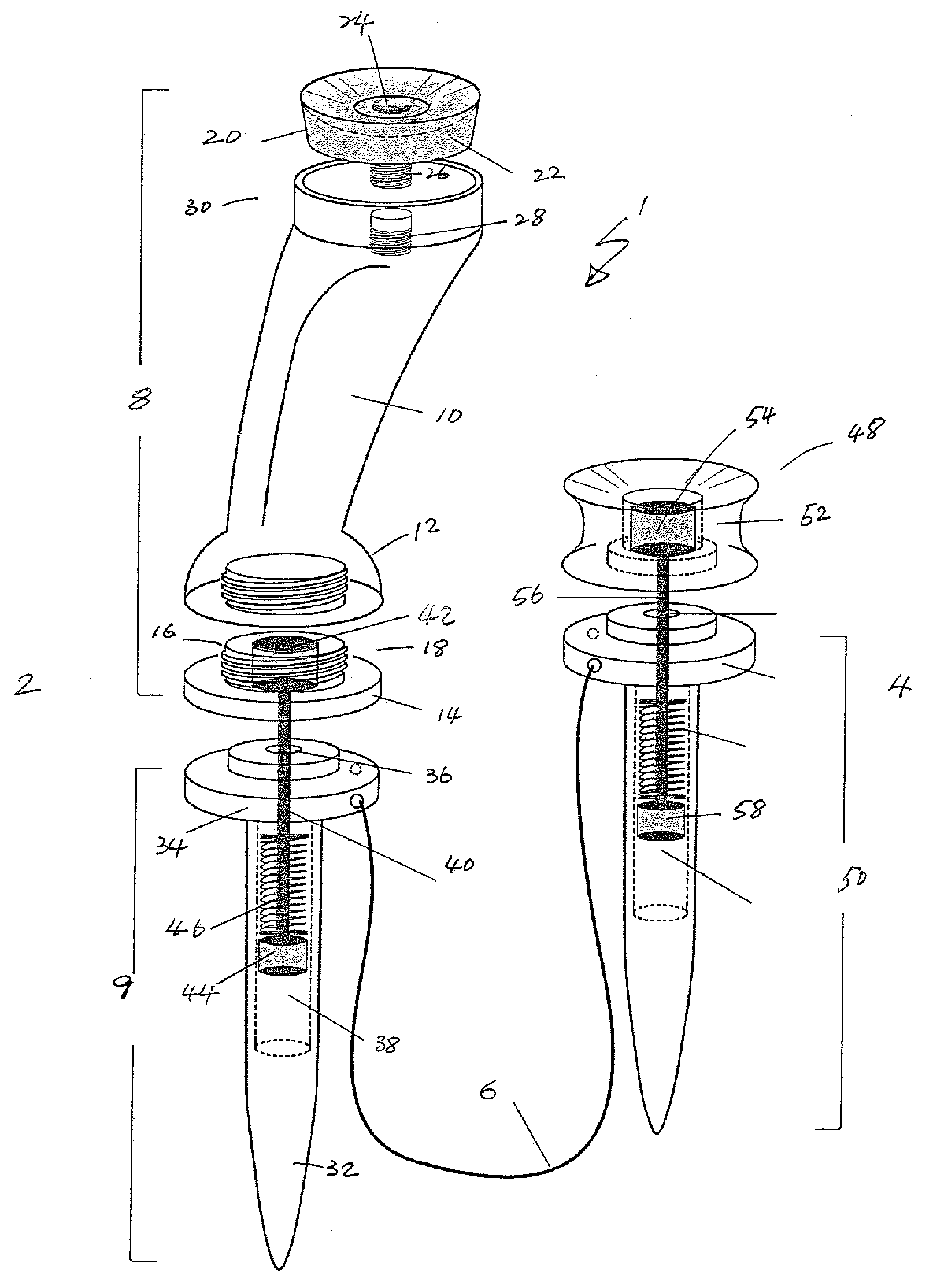

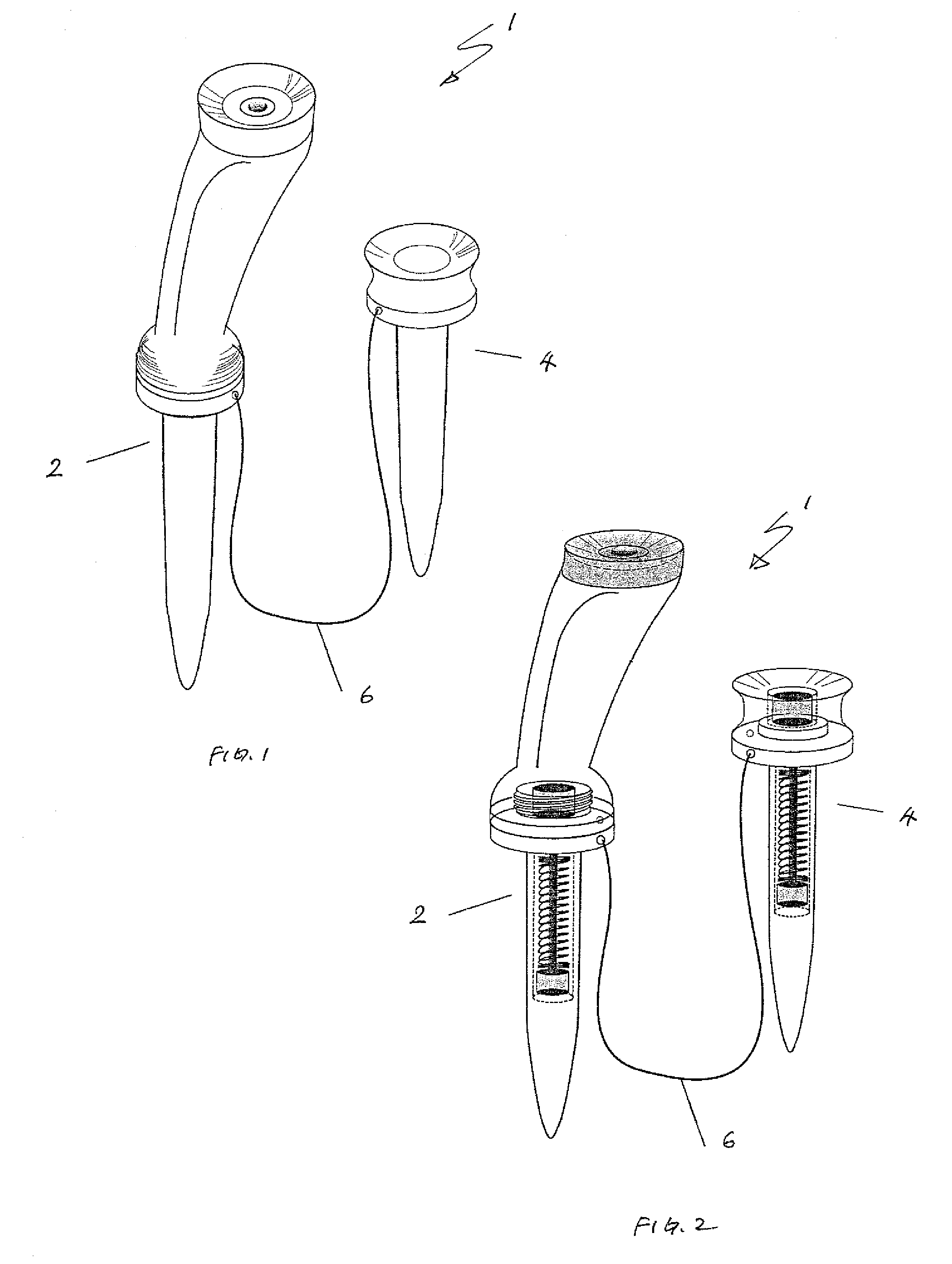

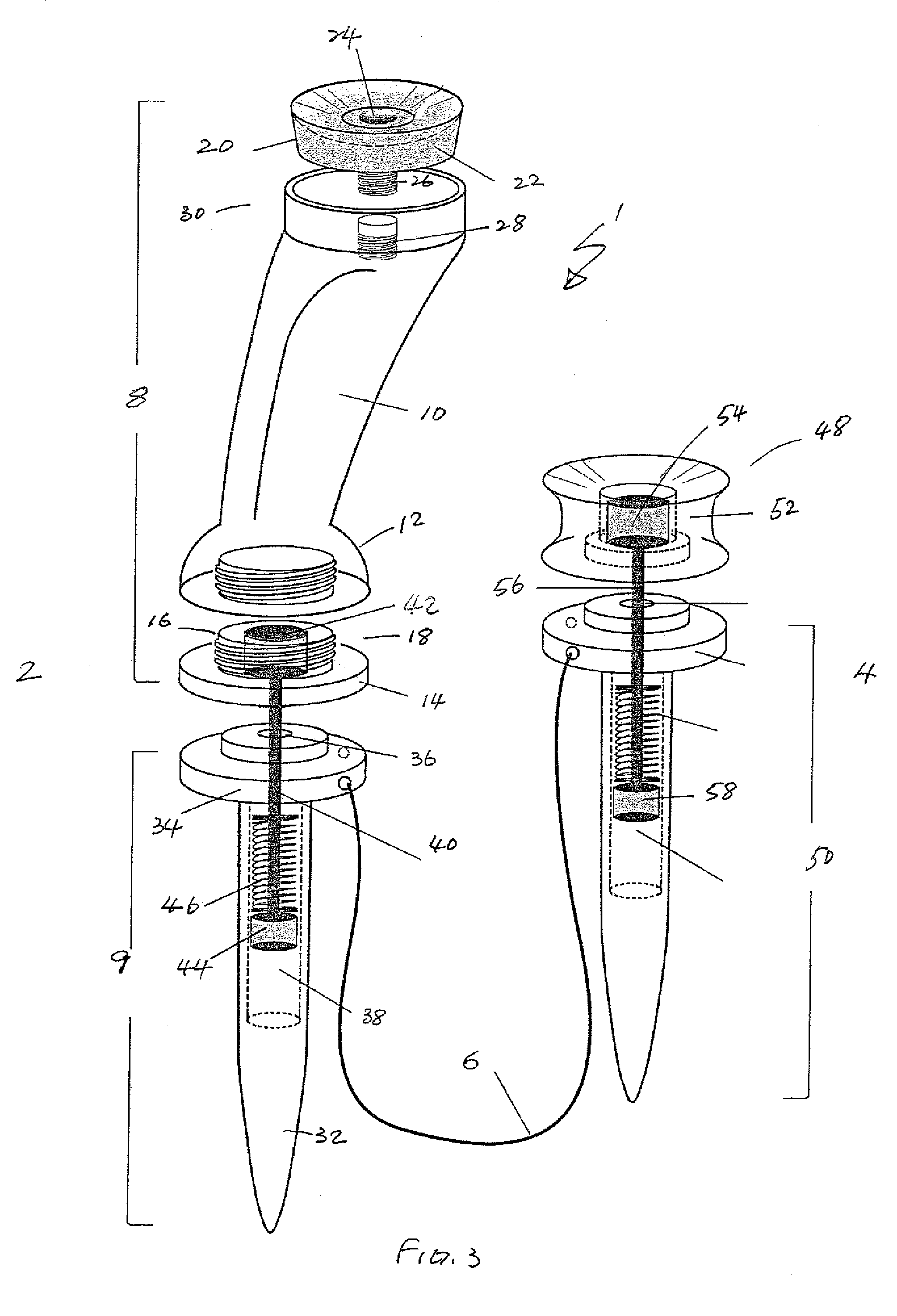

Golf accessories

InactiveUS7374501B2Reduce the chance of breakageReduce absorptionGolf teesRacket sportsEngineeringGolf Ball

There is provided a golf tee comprising a ground-engaging portion provided with a cavity therein, a golf ball supporting portion releasably engageable with the ground-engaging portion, means for connecting the ground-engaging portion and the golf ball supporting portion, and spring means for urging said golf ball supporting portion to the ground-engaging portion, wherein the spring means resides and is movable in the cavity.

Owner:LU LI HAN EDEN

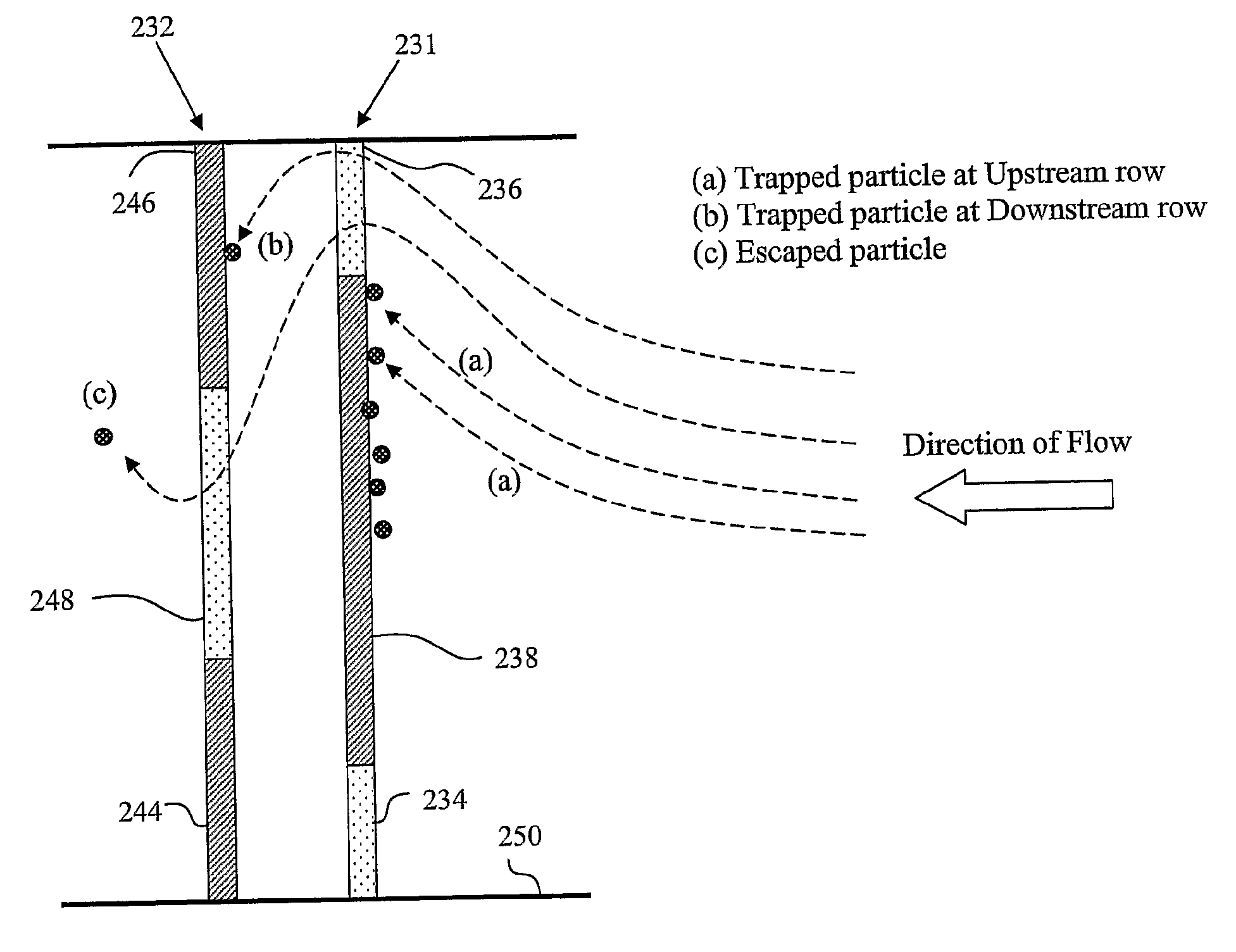

Microfluidic filtration unit, device and methods thereof

InactiveUS20100288689A1Reduce flow of fluidLess sensitiveSamplingFixed microstructural devicesFiltrationNominal size

A microfluidic filtration unit for trapping particles of a predetermined nominal size present in a fluid is provided. The unit comprises a fluid chamber connected to an inlet for introducing the fluid to be filtered and an outlet for discharging filtered fluid, a filtration barrier arranged within the fluid chamber, said filtration barrier comprising a plurality of pillars arranged substantially perpendicular to the path of fluid flow when fluid is introduced into the fluid chamber, said pillars being aligned to form at least one row extending across said path of fluid flow, wherein each of said at least one row of pillars in the filtration barrier comprises at least one fine filtration section comprising a group of pillars that are spaced apart to prevent particles to be filtered from the fluid from moving between adjacent pillars, and at least one coarse filtration section comprising a group of pillars that are spaced apart to permit the movement of particles between adjacent pillars.

Owner:AGENCY FOR SCI TECH & RES

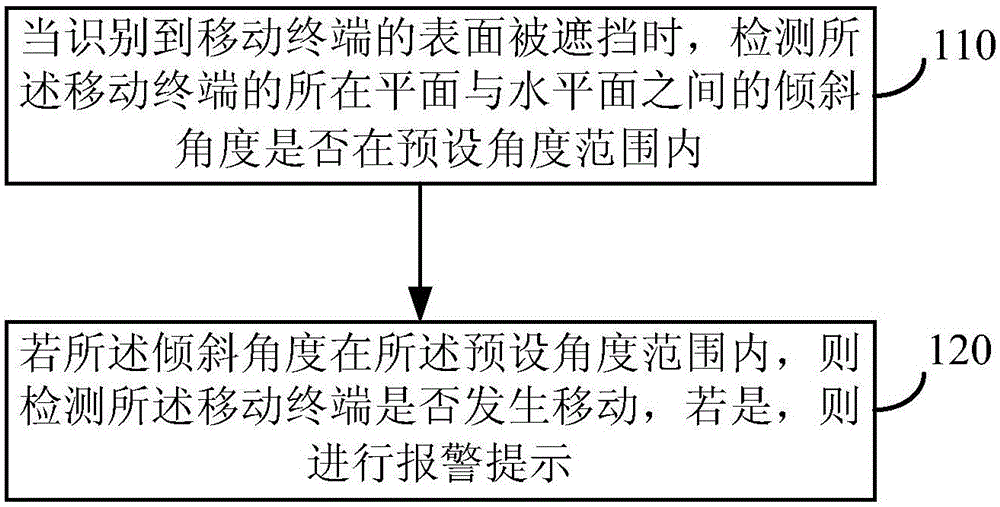

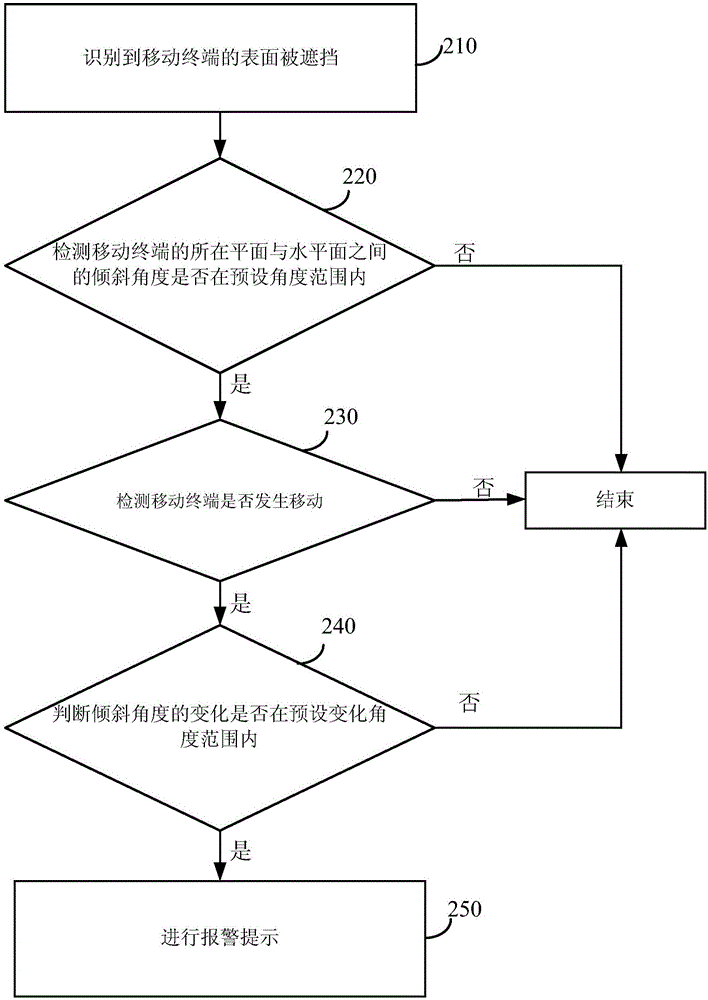

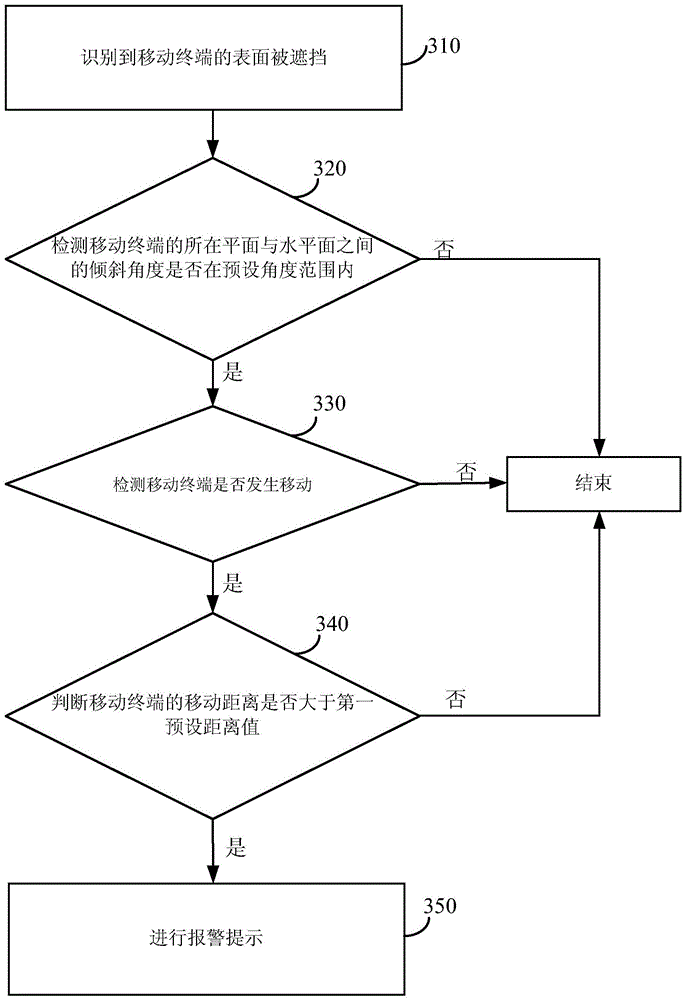

Sliding alarm method and device of mobile terminal

InactiveCN105141779AReduce the chance of breakageSubstation equipmentAlarmsComputer terminalComputer science

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

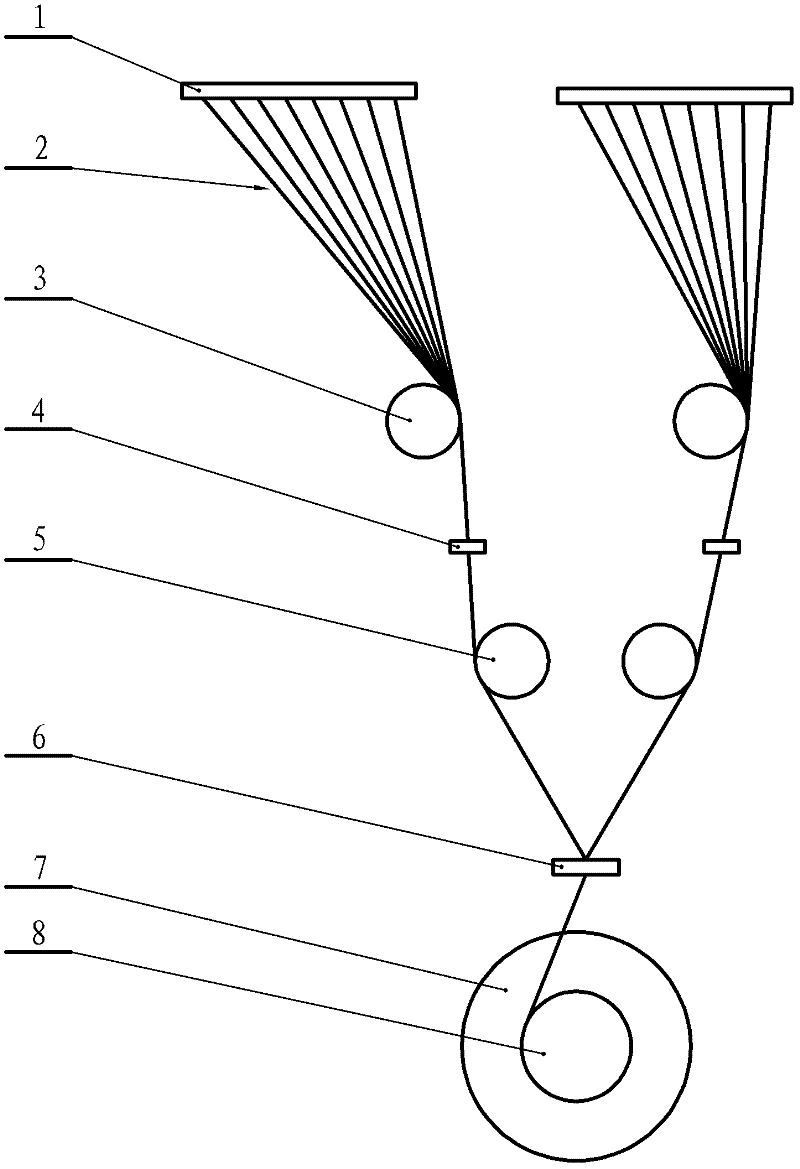

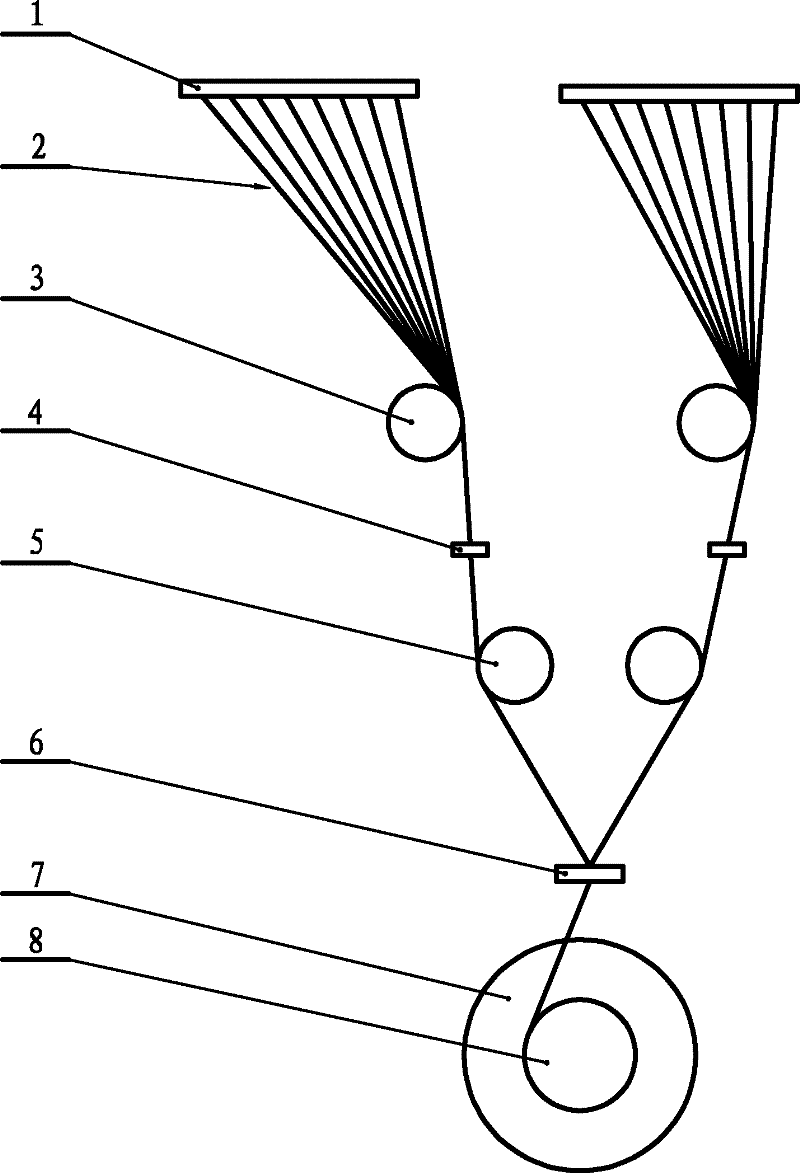

Multi-bushing plate merging wiredrawing technology and multi-bushing plate wiredrawing device employing it

ActiveCN102515504ASimplify temperature controlReduce manufacturing costGlass making apparatusGlass fiberEngineering

The invention provides a multi-bushing plate merging wiredrawing technology. Specifically, 2 or more bushing plates are employed, and each bushing plate is provided with a plurality of leaks. Molten glass flows through each leak of each bushing plate and is cooled, and then a plurality of glass fibers can be obtained through wiredrawing molding respectively. Pulled by a wiredrawing machine driven wire cylinder, the glass fibers respectively pass through multiple upper bunchers and are neatened and gathered into glass fiber bundles, which are then neatened and gathered by a gathering buncher into a complete glass fiber bundle that is then wound on the wire cylinder into a finished glass fiber bundle. A multi-bushing plate wiredrawing device is provided with 2 or more bushing plates, each of which is equipped with a plurality of leaks. An upper buncher is installed behind each bushing plate respectively, a gathering buncher is arranged behind each upper buncher, the wiredrawing machine is disposed behind the gathering buncher, the wire cylinder is positioned on the gathering buncher, and the wire cylinder and the wiredrawing machine are in driving rotary connection. With the technology and device provided in the invention, the manufacturing cost of a bushing plate for a glass fiber bundle with a great weight of per unit length can be reduced, the band forming property of the glass fiber bundle can be improved, and the effect can be obvious.

Owner:CHONGQING POLYCOMP INT

Ceramic shell structure member and preparation method thereof, and mobile phone

ActiveCN104068595AReduce the chance of breakageImprove drop resistanceOther accessoriesTelephone set constructionsMetal matrix compositeCeramic

Embodiments in the invention provide a ceramic shell structure member, comprising a ceramic shell and a frame equipped with a recessed part, wherein the ceramic shell comprises a ceramic flat plate and a ceramic protruding member outwardly protruding from the side surface of the ceramic flat plate, the ceramic protruding member is arranged in the recessed part of the frame so as to allow the ceramic shell to be compactly jointed with the frame, the upper surface of the joint of the frame and the ceramic protruding member is aligned with the upper surface of the ceramic flat plate along the thickness direction of the ceramic flat plate, and the frame covers the side surfaces of the ceramic shell or the side and bottom surfaces of the ceramic shell and is made of an alloy, a metal-based composite or plastic. According to the invention, the frame can protect the edges of the ceramic shell from direct collision with other objects, the ceramic protruding member can increase the bonding force between the ceramic shell and the frame, so the integral anti-breaking capability of the ceramic shell structure member is improved and the application scope of the ceramic shell structure member is broadened. The embodiments in the invention further provide a preparation method for the ceramic shell structure member and a mobile phone. The mobile phone comprises the ceramic shell structure member.

Owner:HUAWEI TECH CO LTD

Method for manufacturing electric plating diamond burr

InactiveCN101423968AStrong impact resistanceReduce the chance of breakingElectrolytic coatingsDental toolsMetallic NickelTitanium alloy

The invention provides a method for manufacturing a plated diamond needle, which takes nickel-titanium alloy as a substrate of the needle, and comprises the following steps: firstly, the nickel-titanium alloy substrate of the needle is processed; secondly, the nickel-titanium alloy substrate of the needle and diamond particles are subjected to electroplating pre-treatment; thirdly, a composite diamond clad layer is coated on the head of the needle by means of direct-current electroplating; and fourthly, the diamond needle prepared is subjected to vacuum heat-treatment after electroplating. The method has the advantages that: firstly, the nickel-titanium alloy substrate of the needle has strong impact resistance, and the fracture probability of the substrate of the needle under the actuation of impulsive load is reduced, so that the fracture accident of the substrate of the needle can be effectively prevented; and secondly, due to adoption of the nickel-titanium alloy substrate of the needle and the heat-treatment technology after electroplating, a diffused layer is formed on an interface between the nickel-titanium alloy substrate of the needle and a metallic nickel clad layer, and metallic nickel in the clad layer and titanium in the nickel-titanium alloy substrate of the needle form intermetallic compounds, so that the bonding force of the clad layer is greatly reinforced, and the service life of the diamond needle is further improved.

Owner:HARBIN ENG UNIV

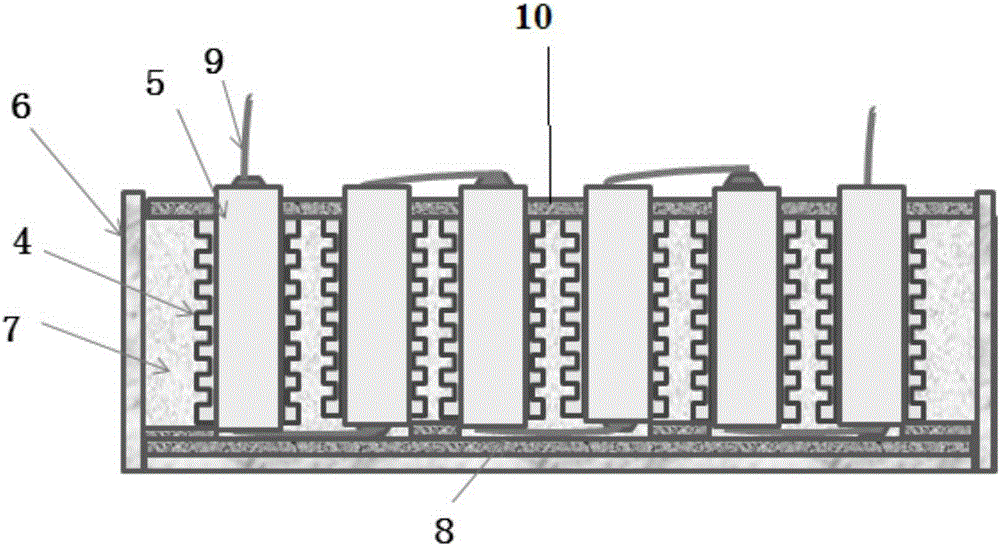

Flexible display panel and preparation method thereof, and flexible display device

InactiveCN109309111AReduce stressReduce the chance of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFlexible display

The invention discloses a flexible display panel and a preparation method thereof, and a flexible display device. As a partial metal routing section in a bending area of the flexible display panel isa double layer structure, the routing of a second metal layer can adopt a design of wavy routing, so that stresses on metal routing during bending can be reduced, the probability of the cracking of the metal routing in the bending area of a flexible display can be decreased, and the stabilization of the resistance value of the metal routing can be ensured; and the effect of enhancing reliability can be achieved through the connection part of the routing of a first metal layer and the routing of the second metal layer, and therefore, the probability of abnormal display caused by the cracking ofthe metal routing can be reduced, and normal signal transmission can be ensured.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Heat-conducting ring band with scale-like fins and composite heat dissipating device with heat-conducting ring band

InactiveCN105226215AReduce impact strengthReduce the chance of breakageSecondary cellsCell component detailsEngineeringPhase-change material

The invention relates to a heat-conducting ring band with scale-like fins and a composite heat dissipating device with the heat-conducting ring band. The heat-conducting ring band is used for reinforcing the heat dissipating ability of a heat generating device to the external environment. The heat-conducting ring band comprises a heat-conducting ring band base body wrapping the heat generating device. The heat-conducting ring band base body is provided with the multiple scale-like fins stamped in an integrally-formed mode. The composite heat dissipating device comprises the heat-conducting ring band wrapping a cell monomer, and a housing box arranged outside the heat-conducting ring in a sleeving mode. The portion between the housing box and the heat-conducting ring band is filled with a phase-change material, so that a heat conducting channel of the cell monomer, the heat-conducting ring band, the fins and the phase-change material is formed. Compared with the prior art, the heat-conducting ring band has the advantages of being excellent in heat transfer reinforcing effect, good in impact buffering effect, low in weight, small in size and low in cost, few materials are used, and the heat dissipating performance of the composite heat dissipating device is excellent.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com