Patents

Literature

822results about How to "Improve drop resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

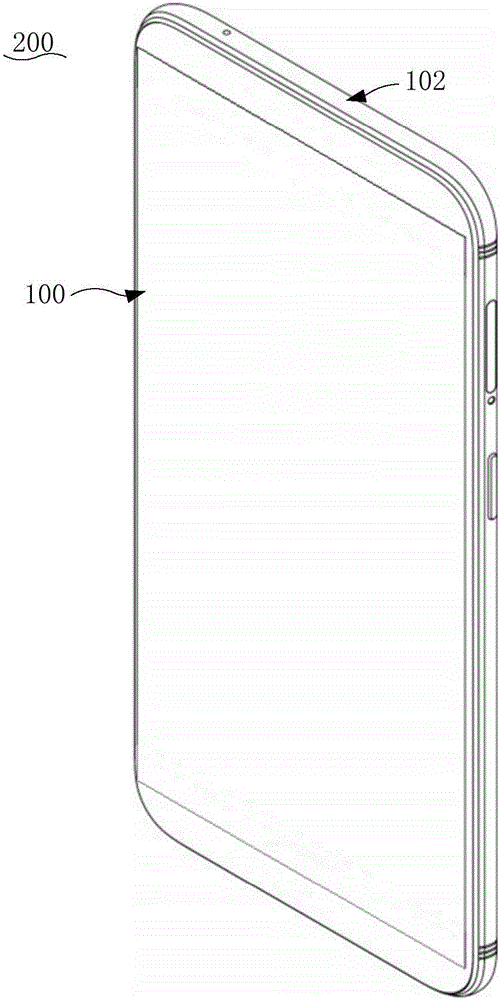

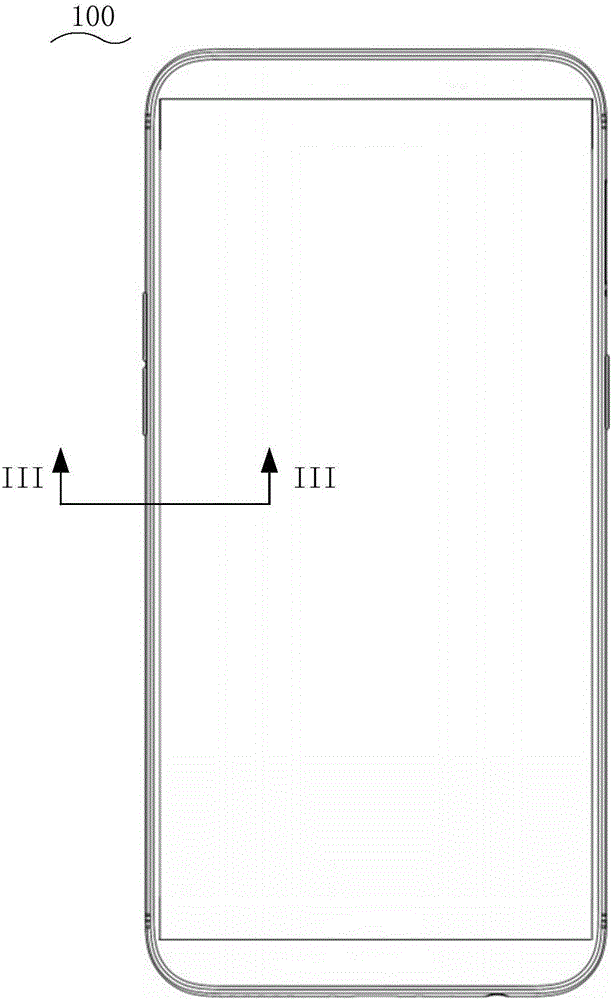

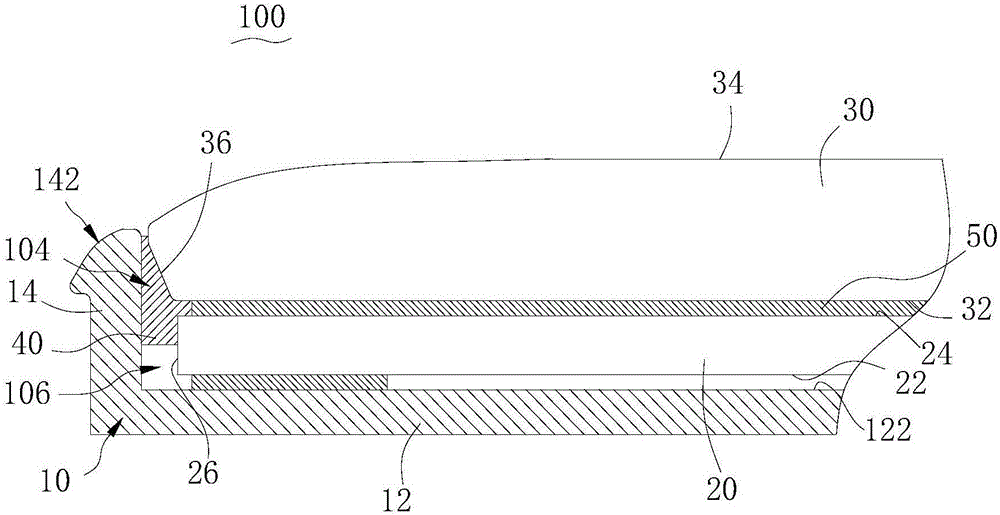

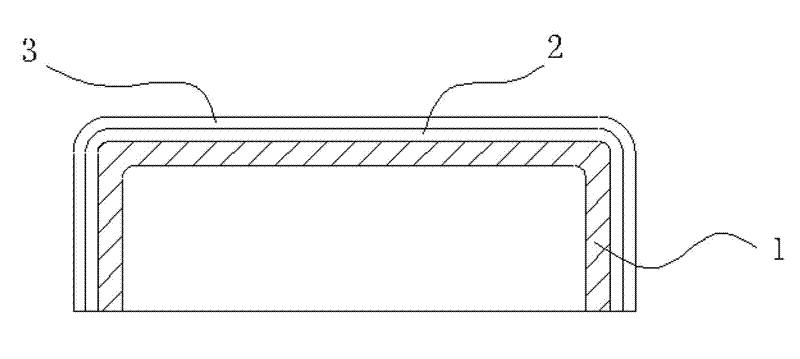

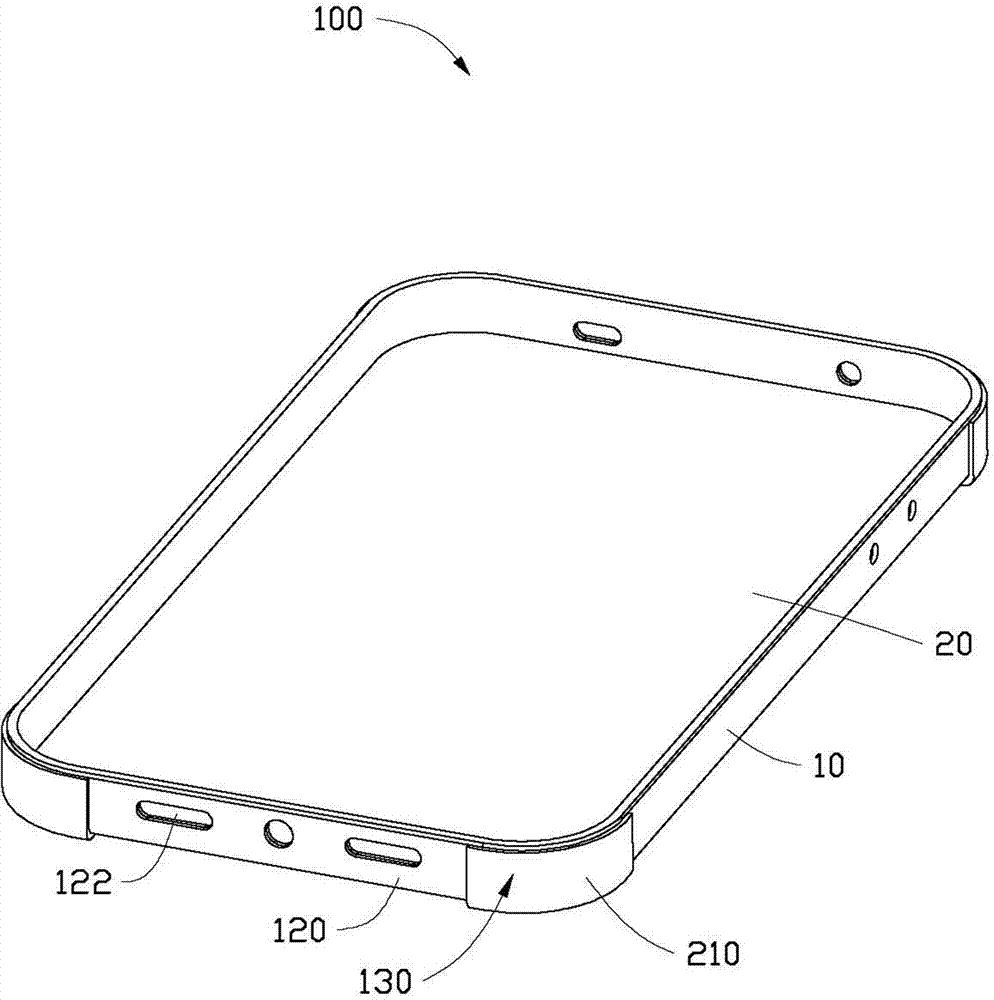

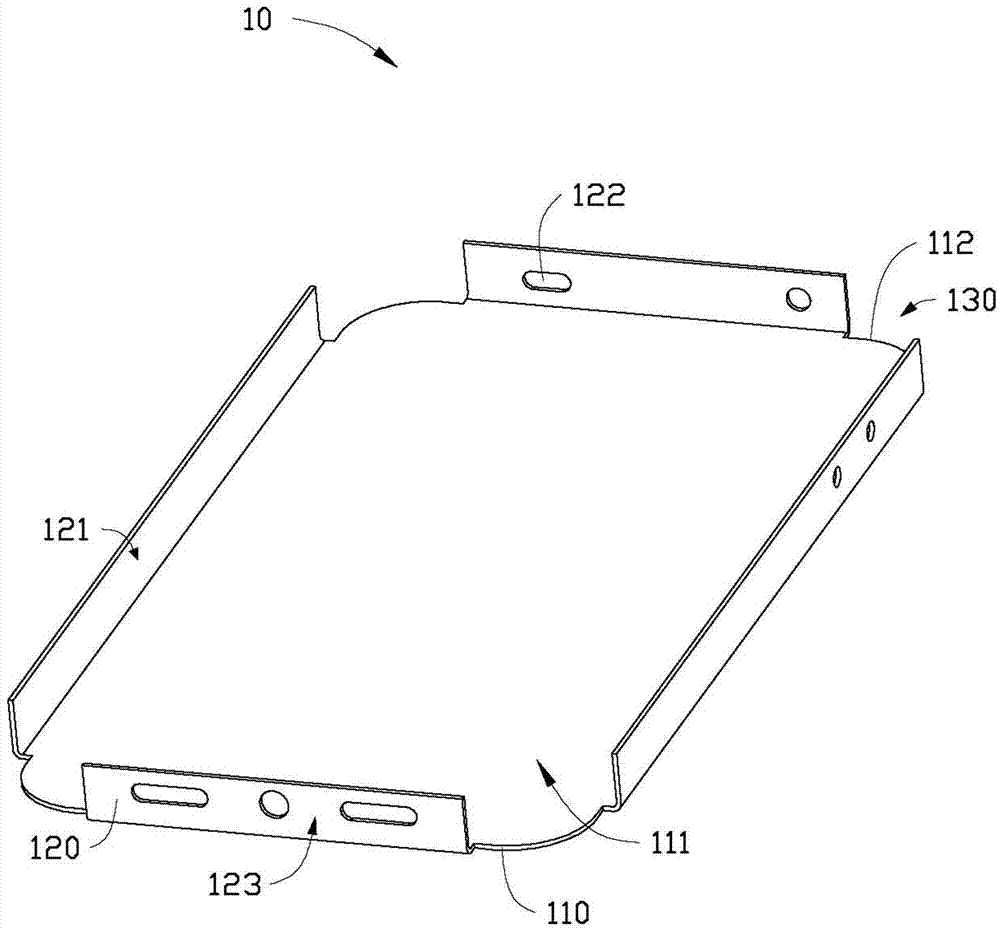

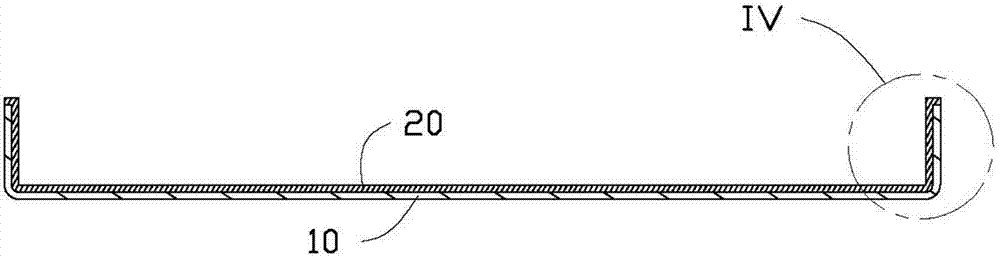

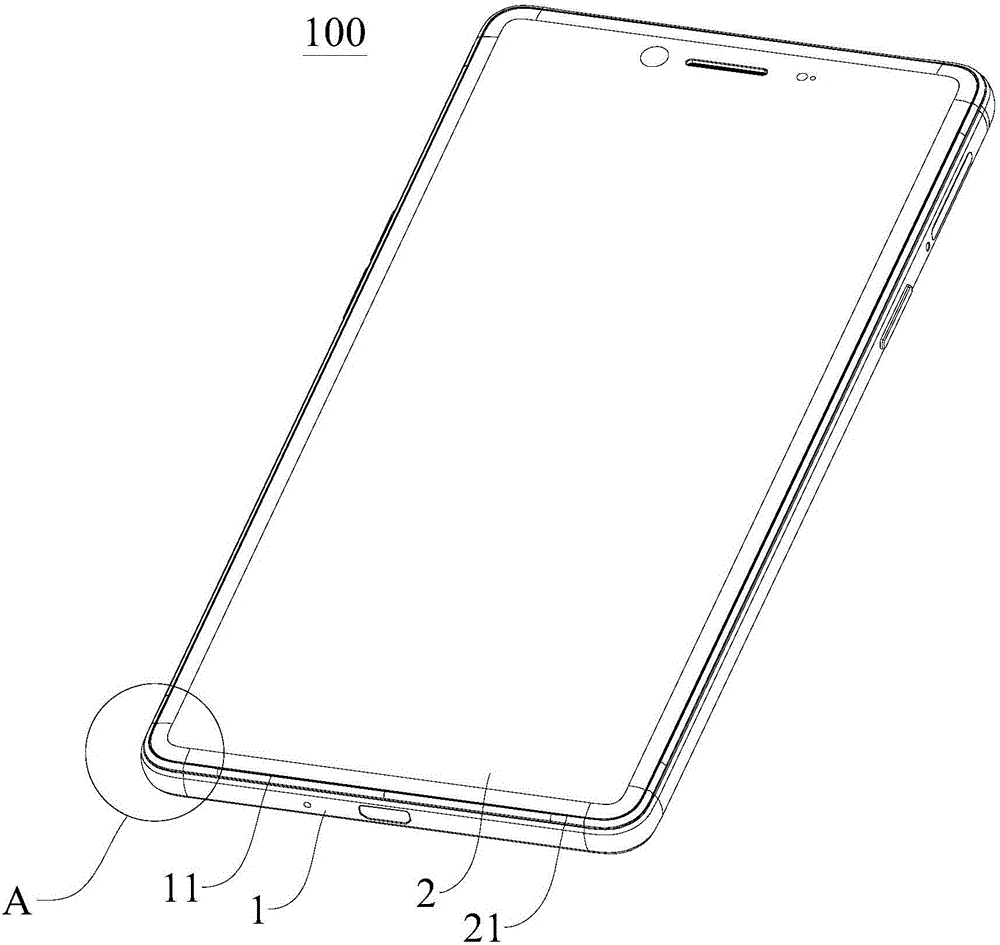

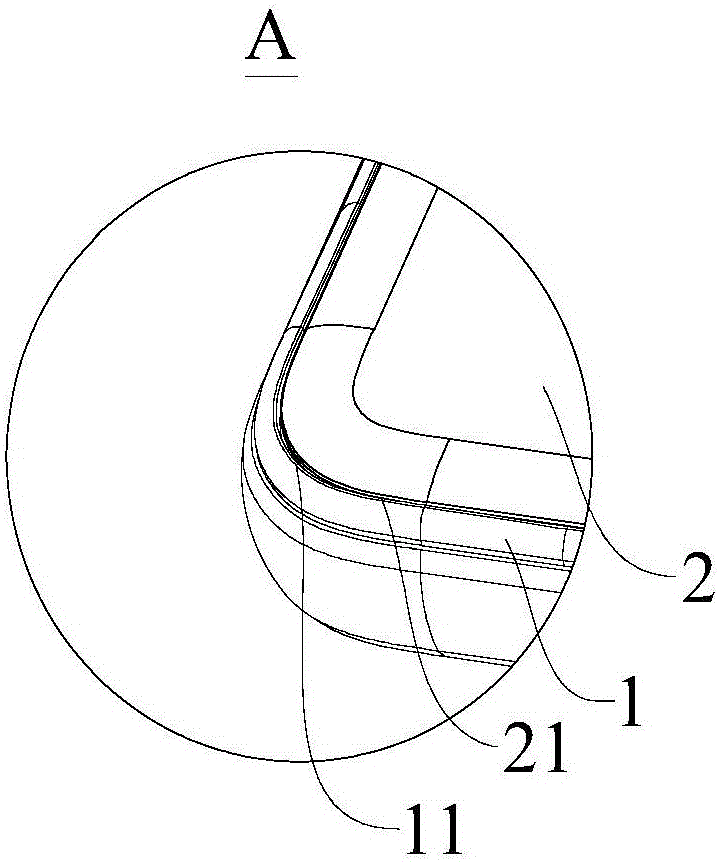

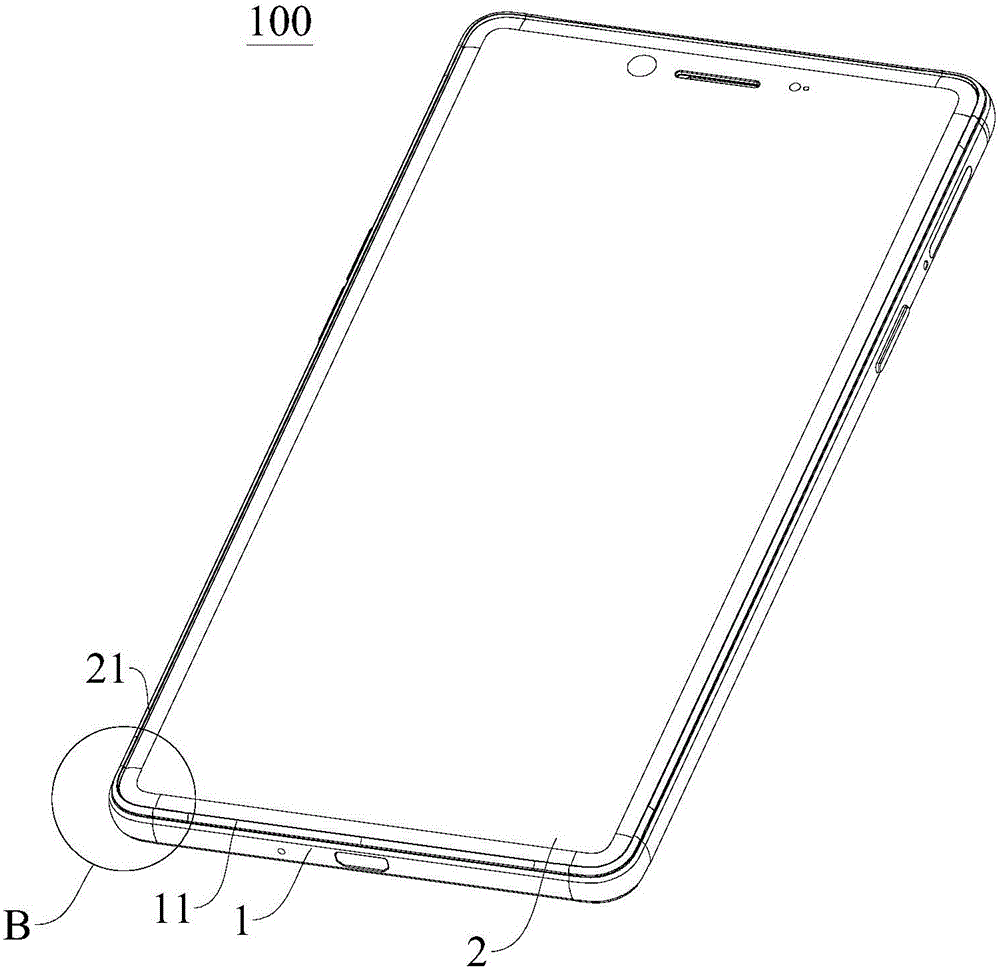

Display screen module, electronic device and making method of display screen module

ActiveCN106843390AReduce non-display bordersImprove drop resistanceFinal product manufactureDigital data processing detailsEngineering

The invention discloses a display screen module, an electronic device and a making method of the display screen module. The display screen module comprises a front shell component, a display screen, a cover plate and viscose. The front shell component comprises a bottom wall and side walls extending around from the bottom wall. The bottom surface of the display screen is fixedly arranged on the top face of the bottom wall. The cover plate is fixedly arranged on the top face of the display screen, the side walls surround the cover plate and the display screen, and a first gap is formed between each side wall and the corresponding side face of the cover plate; in the direction of approaching to the bottom wall, the width of the first gaps is gradually increased. The first gaps are filled so that the side walls and the side faces of the cover can be combined. In the implementation of the display screen module, the electronic device and the making method of the display screen module, the side faces of the cover plate and the side walls of the front shell component are combined through viscose, while the area of a non-display frame of the display screen module is easily reduced, the cover plate can be prevented from pulling the flexible screen when the electronic device falls off, therefore, the anti-falling performance of the electronic device is improved, and the service life of the electronic device is prolonged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

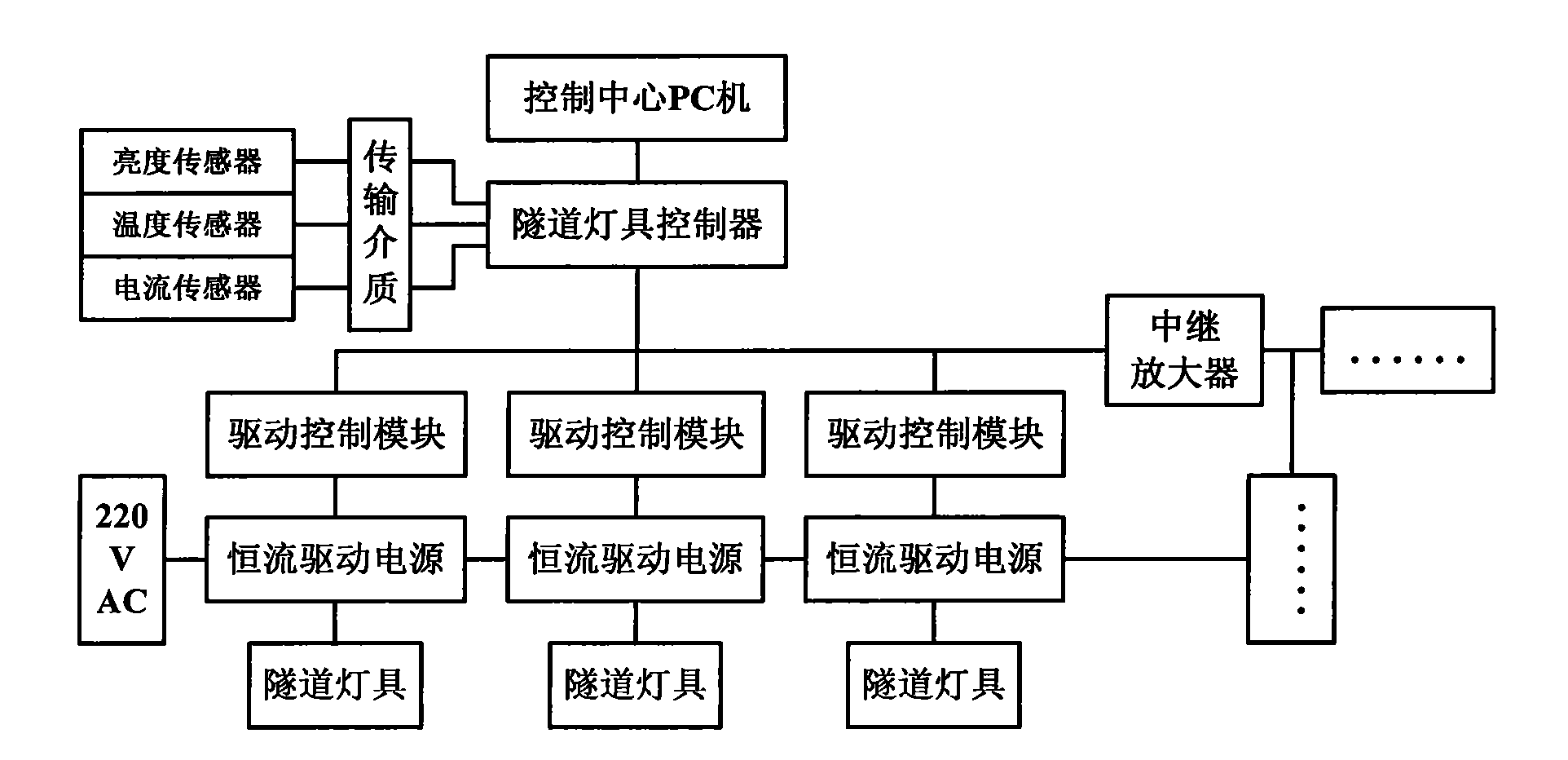

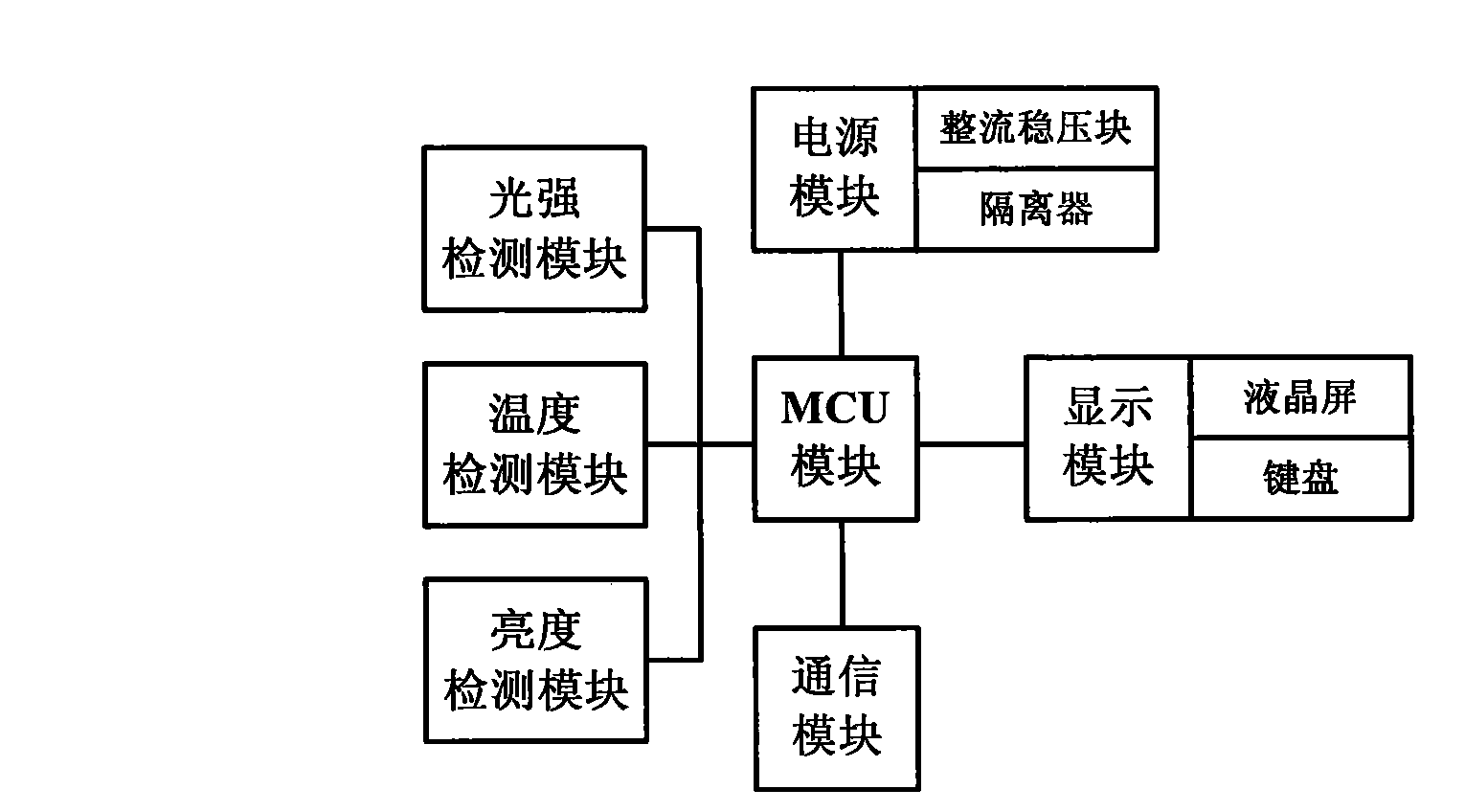

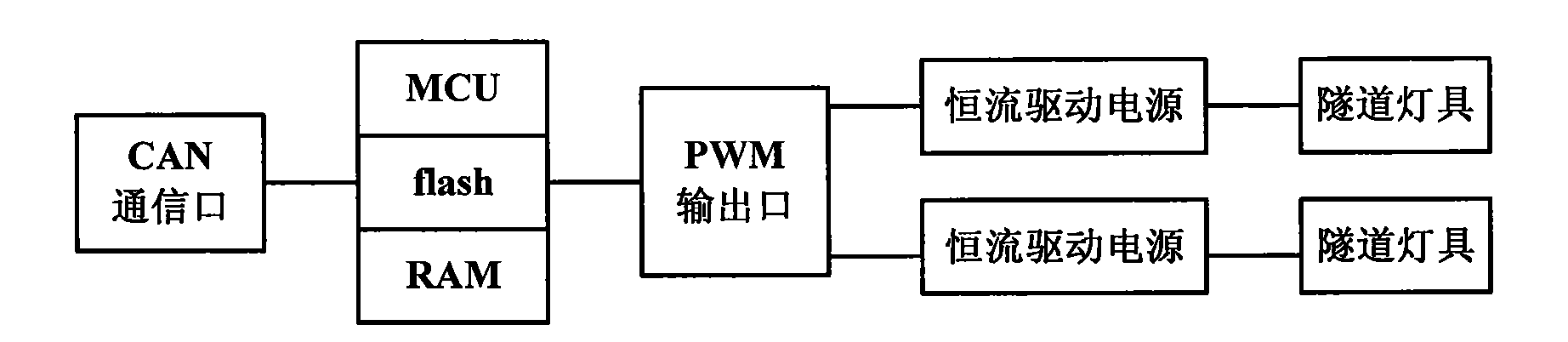

Intelligent control system for LED tunnel lamps and method for controlling LED tunnel lamps

InactiveCN101662863ARealize stepless intelligent controlOptimal control methodElectronic switchingElectric light circuit arrangementCurrent sensorEngineering

The invention provides an intelligent control system for LED tunnel lamps and a method for controlling the LED tunnel lamps. The system comprises a control center PC computer, a tunnel lamp controllerand lamps, wherein a brightness / temperature / current sensor is connected with the controller via a transmission medium; the control center PC computer is connected with a plurality of drive control modules via the controller and a bus structure; and each drive control module is connected with a constant-current driving power supply of each LED tunnel lamp. Therefore, the system detects the intensity and weakness of light at the entrance and exit of a tunnel in real time via optical detectors distributed in the tunnel by applying highly accurate intelligent detection measure based on an advanced RISC microprocessor, and feeds processed data back to a control center; the control center processes the data and controls various tunnel lamps at different positions so as to control the brightnessof the LED tunnel lamps at different positions and finally achieve the aim of saving energy source.

Owner:NANJING HANDSON SCI & TECH CORP

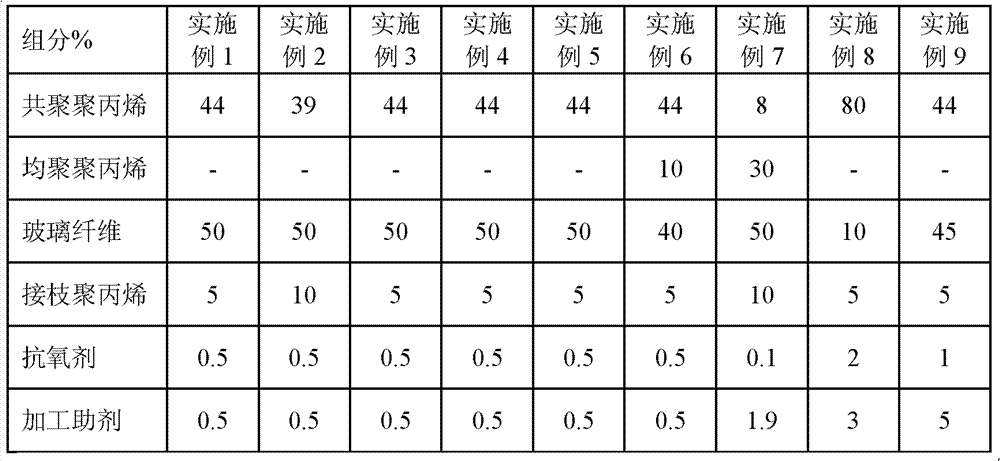

High-impact-resistance less-fiber-floating long glass fiber reinforced polypropylene material

The invention discloses a high-impact-resistance less-fiber-floating long glass fiber reinforced polypropylene material which is prepared from the following components in parts by weight: 10-80% of long glass fiber reinforced polypropylene master batch and 20-90% of high-impact-resistance less-fiber-floating master batch. The long glass fiber reinforced polypropylene master batch is prepared from 8-80% of polypropylene copolymer, 0-80% of polypropylene homopolymer, 10-60% of glass fiber, 1-10% of grafted polypropylene, 0.1-2% of antioxidant and 0.2-2% of processing aid. The high-impact-resistance less-fiber-floating master batch is prepared from 20-80% of polypropylene copolymer, 0-50% of glass fiber, 0-30% of elastomer, 0-30% of grafted elastomer, 0-10% of low-viscosity polyamide resin, 0.1-2% of antioxidant and 0.2-5% of processing aid. The polypropylene material disclosed by the invention has the advantages of high glossiness and less fiber floatings; and the finished product made of the polypropylene material has the advantages of good drop resistance and processability, and can be used for replacing the parts made of engineering plastics.

Owner:WUHAN JINFA TECH CO LTD

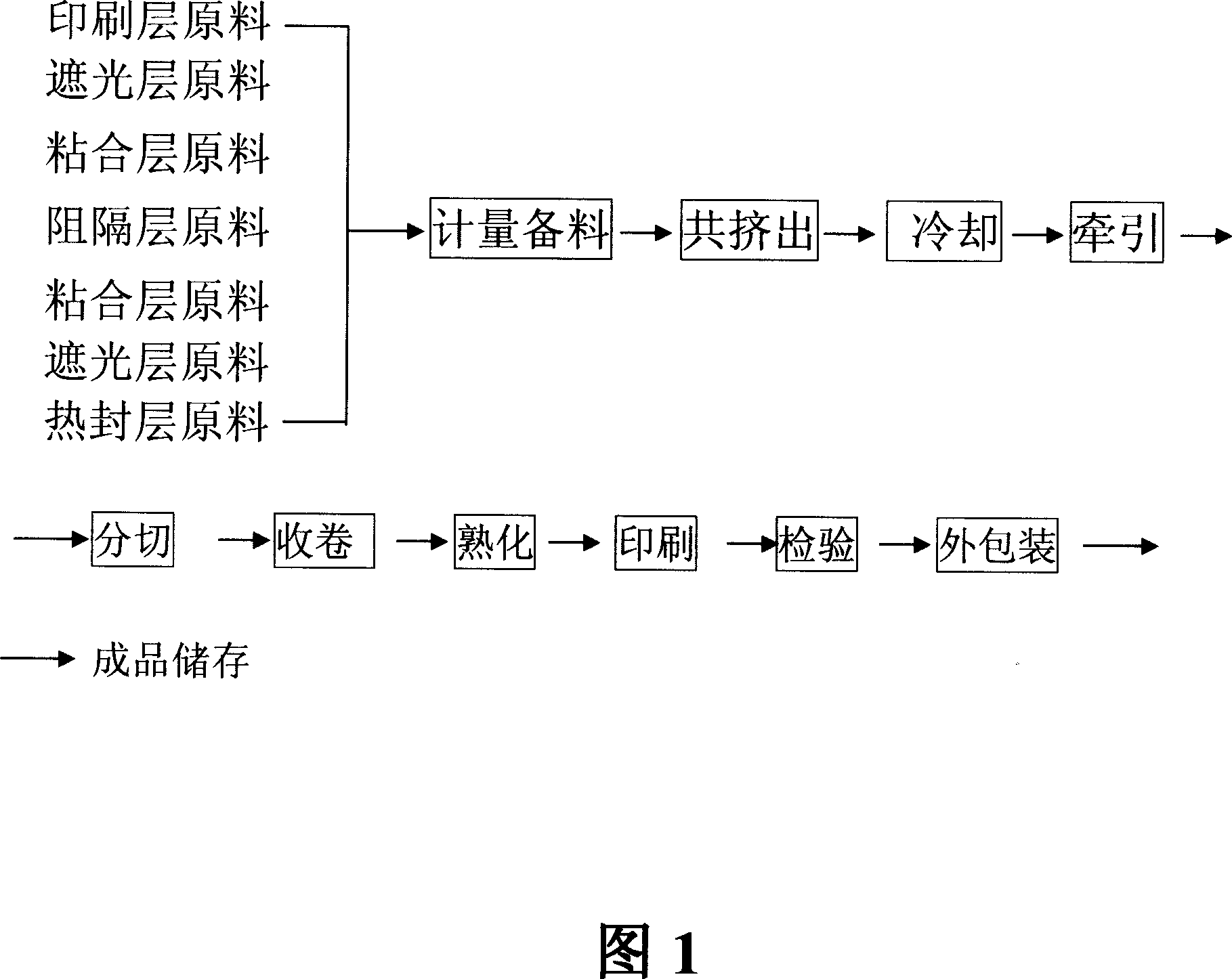

Seven-layer co-extrusion high-isolating packaging film

The seven layer high obstruct packing film includes the first printing layer made of LLDPE, LDPE and FSU; the second shading layer made of white color, LLDPE and LDPE; the third adhering layer of adhesive Tie; the fourth obstructing layer comprising EVOH; the fifth adhering layer of adhesive Tie; the sixth shading layer made of black color, LLDPE and LDPE; and the seventh thermal sealing layer made of LLDP, LDPE and FSU. The present invention possesses the advantages of non-toxicity, high humidity resistance, high oxygen resistance, high heat resistance, high flexibility, high cold resistance and high thermal sealing strength, and is used in packing milk without need of adding preservative and being cold stored.

Owner:郭瑞林

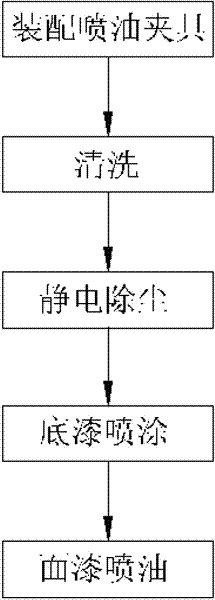

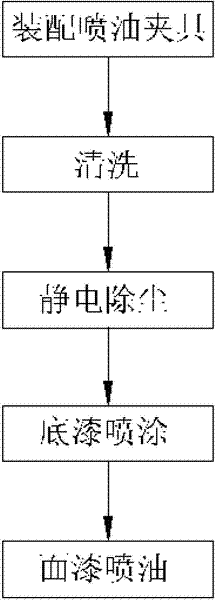

Process for spraying plastic parts of mobile phone and mobile phone shell made by adopting process

InactiveCN102671844AReduce consumptionImprove drop resistancePretreated surfacesCoatingsColor effectEngineering

The invention discloses a process for spraying plastic parts of a mobile phone. The process comprises the following steps of (1) assembly of an oil injection clamp; (2) cleaning; (3) electrostatic dust collection; (4) spraying of primer; and (5) oil injection on finishing paint. The invention also discloses a mobile phone shell made by adopting the process. The process is easy to operate, the primer of a corresponding color is selected according to the required color effect, the spraying frequency is lowered, the consumption of the pigments is reduced, and the production efficiency is improved, the production cost is lowered; and due to the adoption of the steps of cleaning and electrostatic dust collection, the adhesive force of the primer and the finishing paint is improved, the spraying effect is effectively improved, and the product quality is guaranteed. The mobile phone shell has a reasonable structure; due to the combination of the primer and the finishing paint, the primer is used for showing the required color effect, the finishing paint is used for improving the crash resistance and the wear resistance of the mobile phone shell, and the service life is prolonged. The spraying process is simple, low in cost and convenient to produce, and large-area popularization and application are facilitated.

Owner:DONGGUAN XUTONGDA MOLD PLASTIC +2

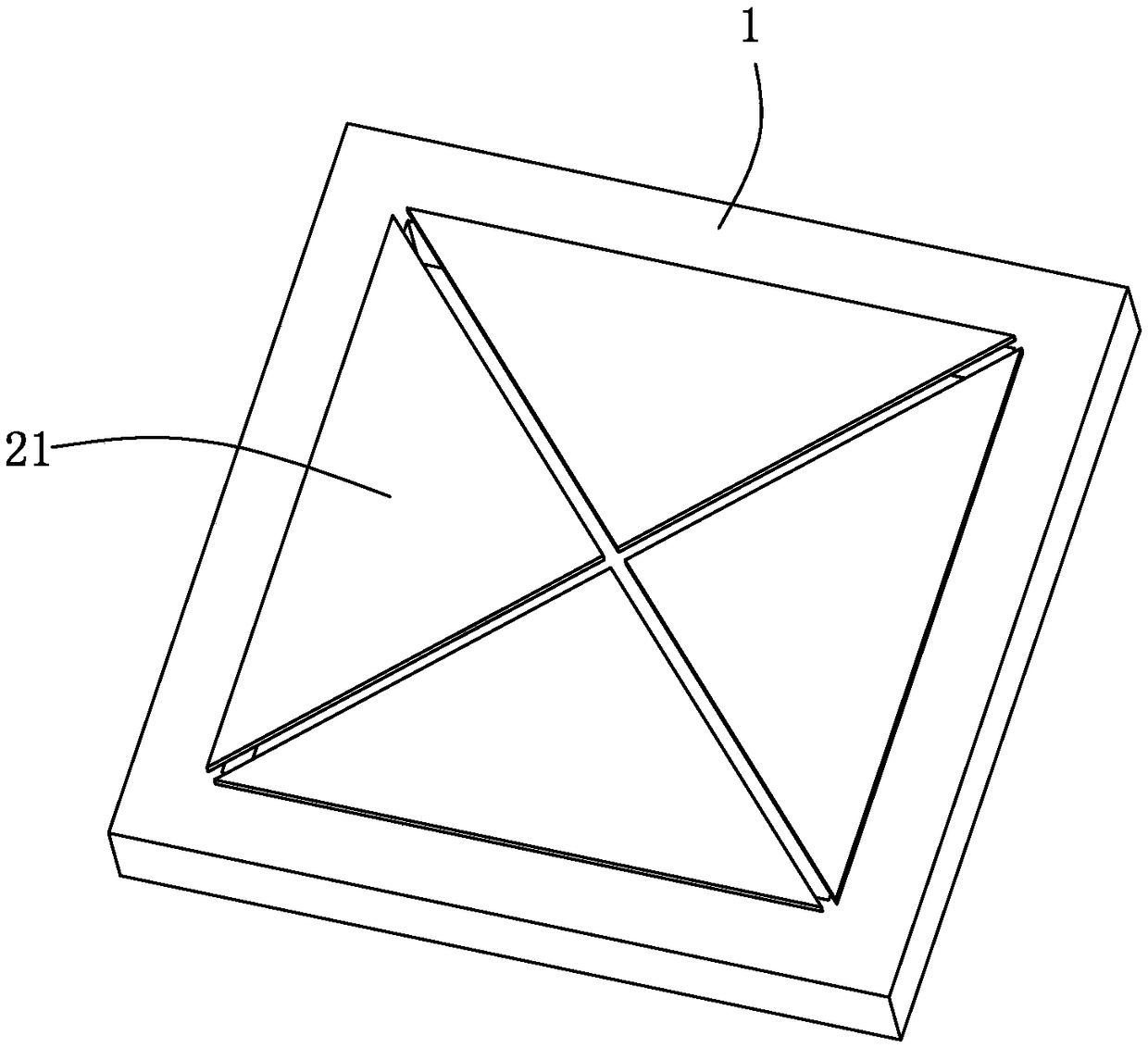

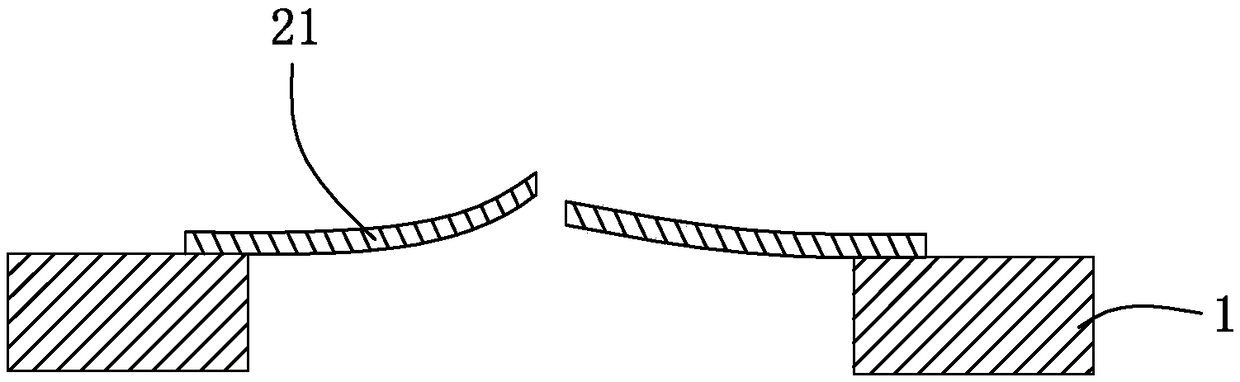

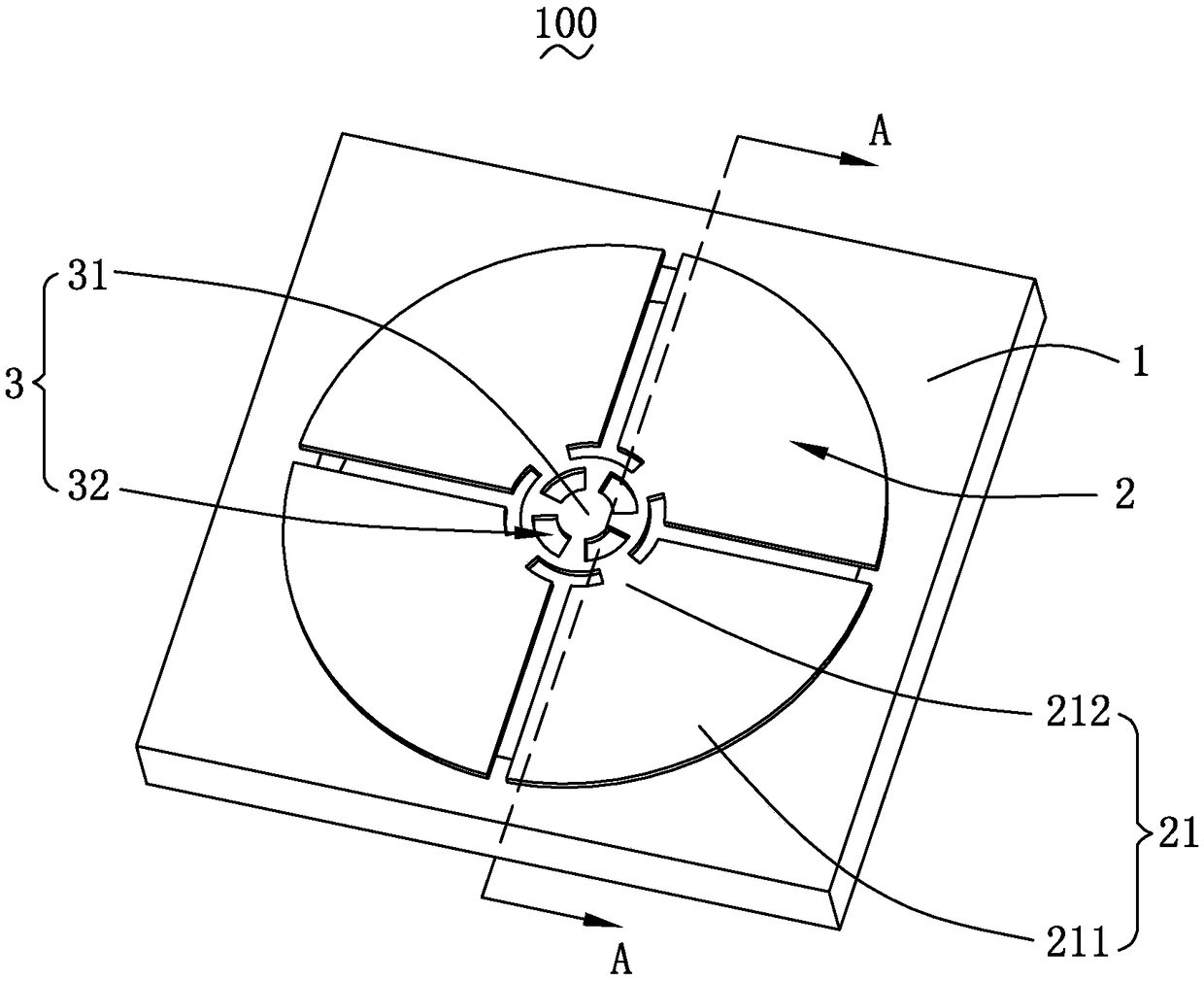

Piezoelectric MEMS microphone

ActiveCN109495829AImprove drop resistanceStructural difference is smallPiezoelectric/electrostrictive microphonesMicrophonesPiezoelectric memsEngineering

The invention provides a piezoelectric MEMS microphone, comprising a substrate having a rear cavity, and a piezoelectric diaphragm disposed on the substrate. The piezoelectric diaphragm comprises a plurality of diaphragms, each of the diaphragms comprises a fixed end connected to the substrate and a free end connected to the fixed end and suspended above the rear cavity, and adjacent two of the diaphragms are spaced or in contact with each other. The piezoelectric EMES microphone further comprises a constraining structure at a central region of the piezoelectric diaphragm, and free ends of atleast two of the diaphragms are connected to the constraining structure. Compared with the related art, the piezoelectric MEMS microphone limits the free ends of the diaphragms in the same plane by the constraining structure, thereby improving the uniformity of product performance and the anti-drop performance.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

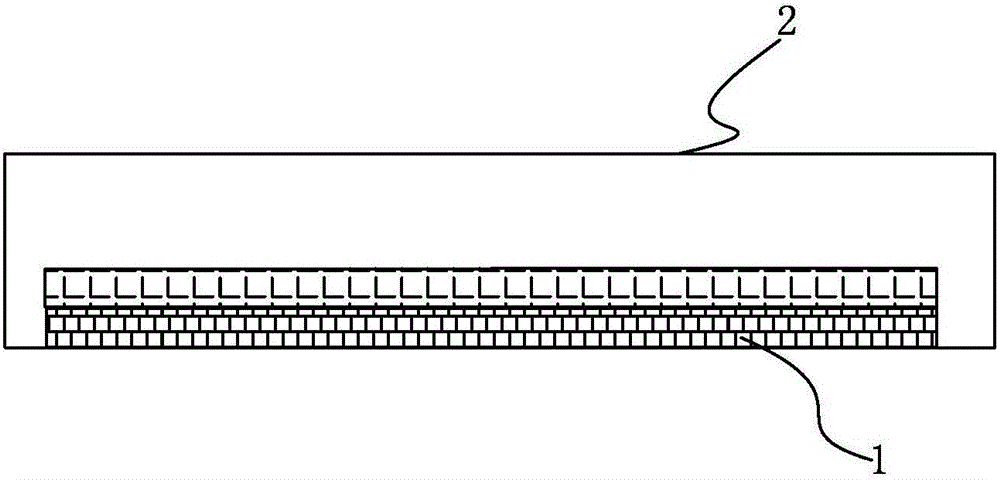

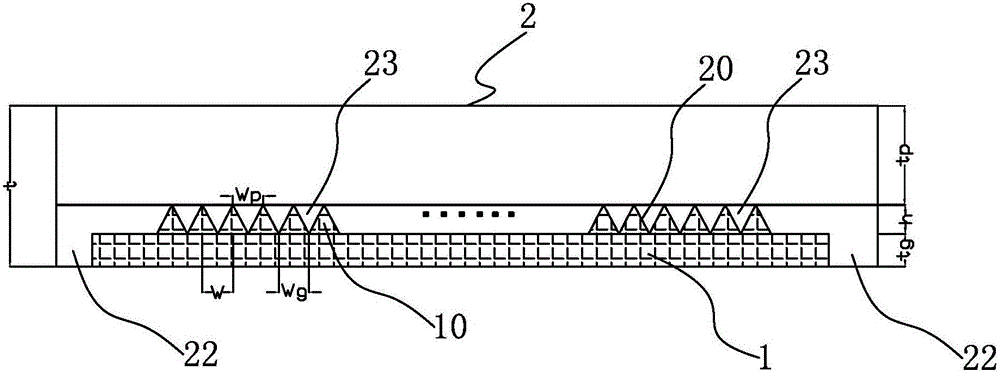

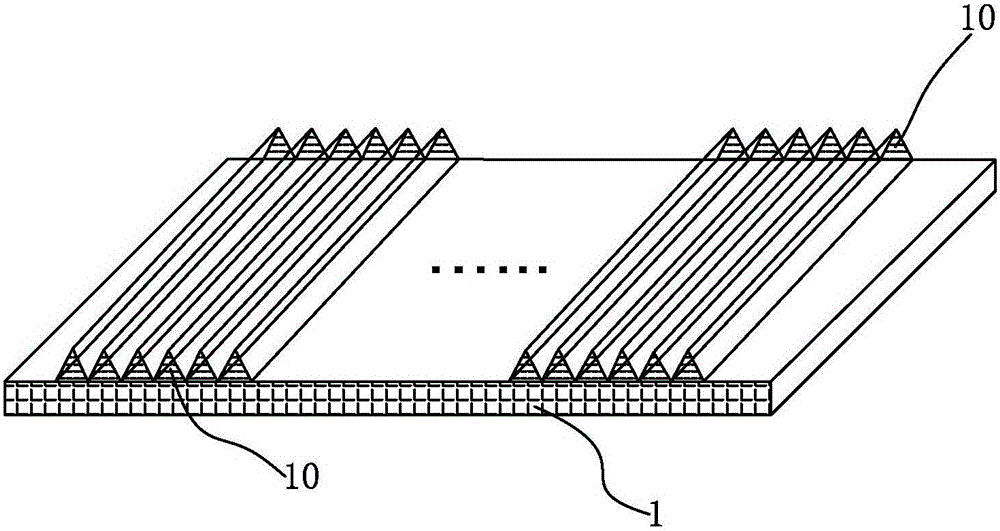

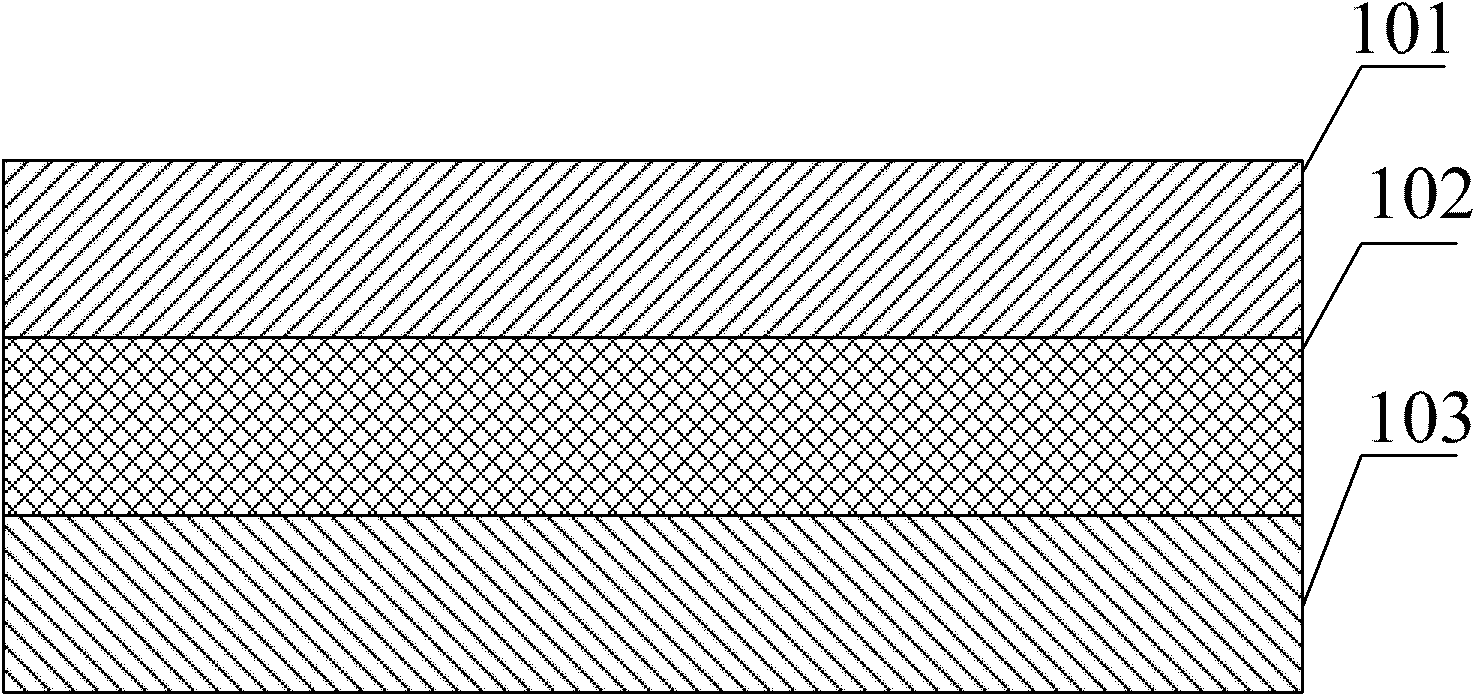

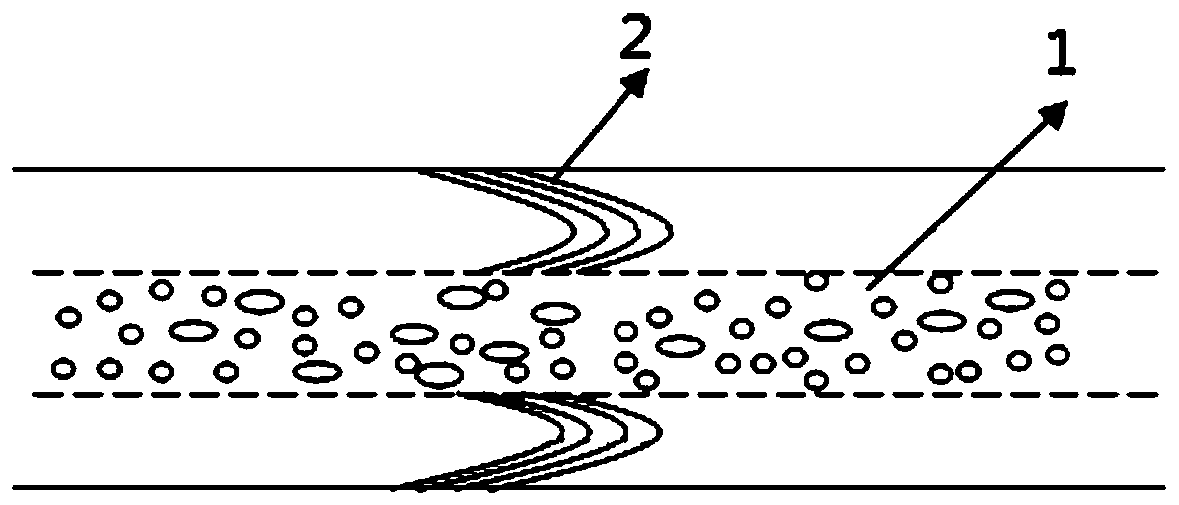

Flexible display substrate thin film and manufacturing method therefor, and display apparatus

ActiveCN105679774AExcellent gas barrier performanceImprove impact resistanceSynthetic resin layered productsSolid-state devicesThermal impactMechanical impact

The invention discloses a flexible display substrate thin film and a manufacturing method therefor, and a display apparatus. The flexible display substrate thin film comprises a glass thin film and a plastic thin film for coating the glass thin film, wherein multiple convex parts are arranged on the upper surface of the glass thin film; multiple concave parts for accommodating the convex parts are arranged on the lower surface of the plastic thin film; and the multiple convex parts are arranged transversely, vertically or in an array manner on the glass thin film. The flexible display substrate thin film has simple manufacturing process and excellent gas barrier property; for avoiding glass thin film fracture or cracks caused by mechanical impact or thermal impact, the weight of the flexible display substrate thin film can be lowered, and the buffering shock absorption function of the plastic thin film can be utilized, so that the anti-fall-off performance and impact-resistance of the flexible display substrate thin film are greatly improved.

Owner:DALIAN DKE LCD CO LTD

Polyethylene (PE) film and preparation method thereof

ActiveCN102179985AImprove mechanical propertiesGood solvent resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene (PE) film and a preparation method thereof. The PE film sequentially comprises a composite layer, an intermediate layer and a heat-seal layer, wherein the composite layer comprises 25 to 40 weight percent of low-density PE, 25 to 40 weight percent of linear low-density PE and 33 to 45 weight percent of modified metallocene linear low-density PE; the intermediate layer comprises 25 to 50 weight percent of the low-density PE and 50 to 75 weight percent of the linear low-density PE; and the heat-seal layer comprises 28 to 35 weight percent of the low-density PE and 65 to 72 weight percent of the linear low-density PE. The invention also provides a cleaning solution packaging composite film and a cleaning solution packaging bag, wherein the cleaning solution packaging composite film is prepared from the PE film. Correspondingly, the invention also provides a preparation method of the cleaning solution packaging composite film which is prepared from the PE film. A product is packaged by the PE film provided by the invention, so the packaging bag has certain solvent resistance and excellent heat-seal performance, the relatively high sealing property and tensile strength of a material subjected to heat sealing are guaranteed, and the leakage resistance and falling resistance of the composite film which is prepared by the material are further improved.

Owner:HUANGSHAN NOVEL

Mobile terminal casing and manufacturing method thereof

InactiveCN104754897AIncrease storage spaceAvoid breakingCasings/cabinets/drawers detailsPortable casingsEngineeringMechanical engineering

Owner:FUTAIHUA PRECISION ELECTRONICS ZHENGZHOU +1

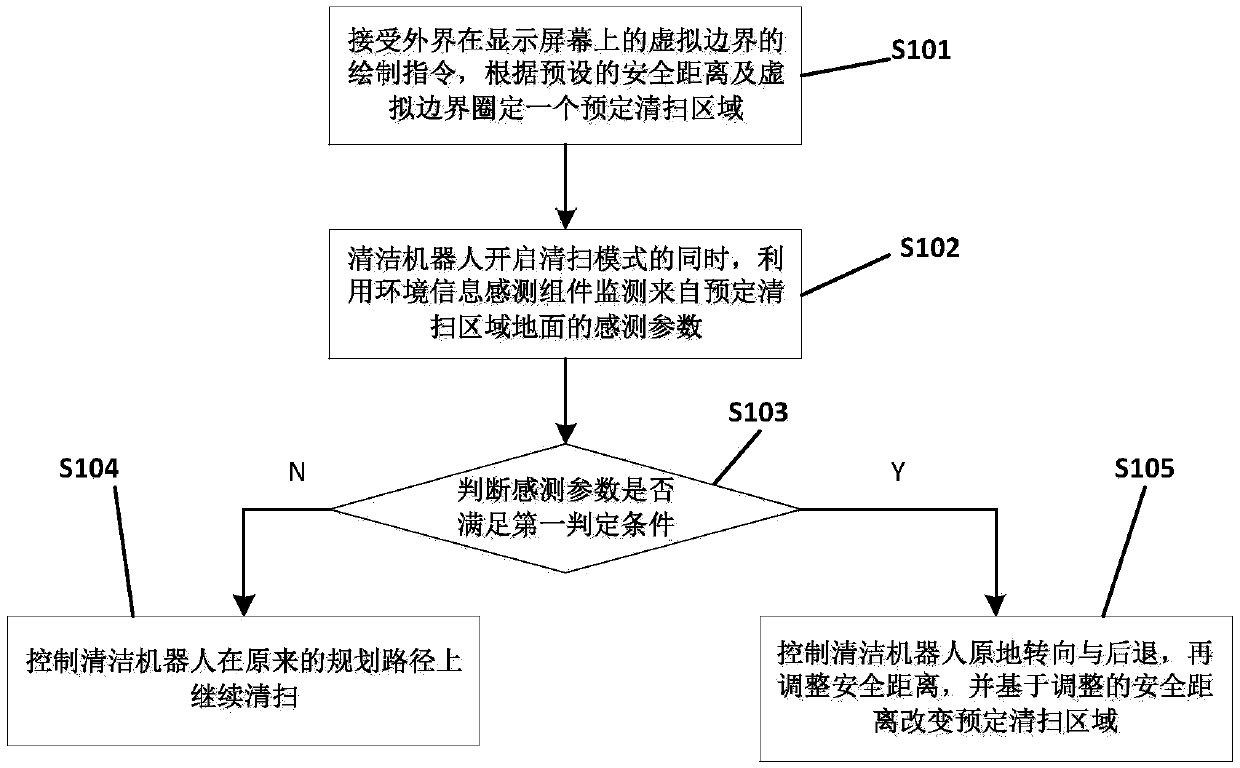

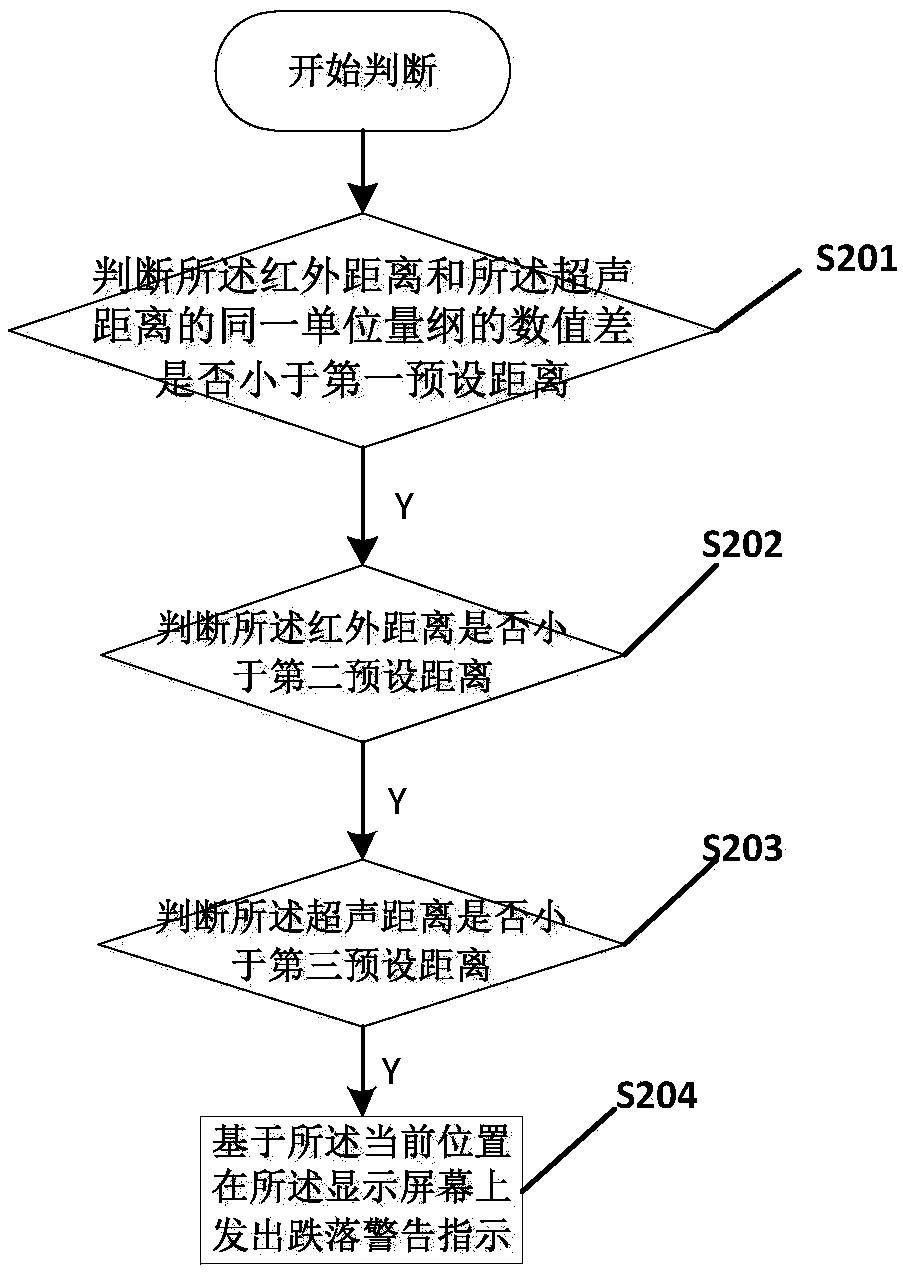

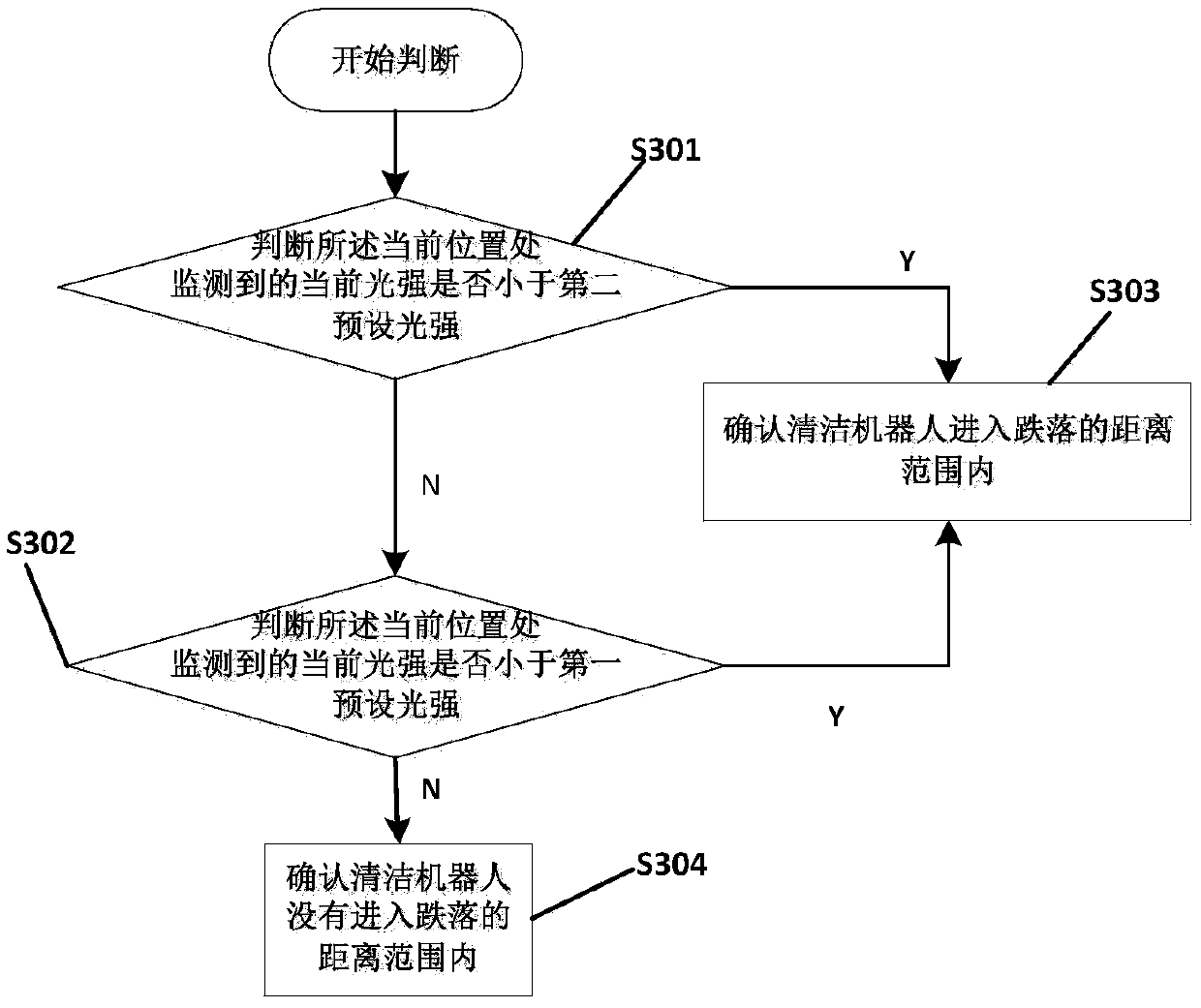

Cleaning robot drop control method and chip based on virtual boundary

ActiveCN109602341AImprove accuracyImprove drop resistanceAutomatic obstacle detectionTravelling automatic controlSimulationRobot

The invention discloses a cleaning robot drop control method and a chip based on a virtual boundary. A cleaning robot is provided with an environmental information sensing component. The cleaning robot drop control method comprises the following steps: accepting an external drawing instruction of a virtual boundary on a display screen, setting a virtual boundary according to a preset safety distance, and delineating a predetermined cleaning area based on the virtual boundary; monitoring a sensing parameter from the ground of the predetermined cleaning area by utilizing the environmental information sensing component while the cleaning robot starts a cleaning mode; when the sensing parameter does not satisfy a first determination condition, controlling the cleaning robot to continue the original planned cleaning in the predetermined cleaning area; when the sensing parameter satisfies the first determination condition, controlling the cleaning robot to turn and retreat in situ, then adjusting the safety distance, and changing the predetermined cleaning area based on the adjusted safety distance. By adopting the method provided by the invention, the detection ability and the work efficiency of the cleaning robot anti-drop stability are improved, and the damage degree of the robot is reduced.

Owner:AMICRO SEMICON CORP

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

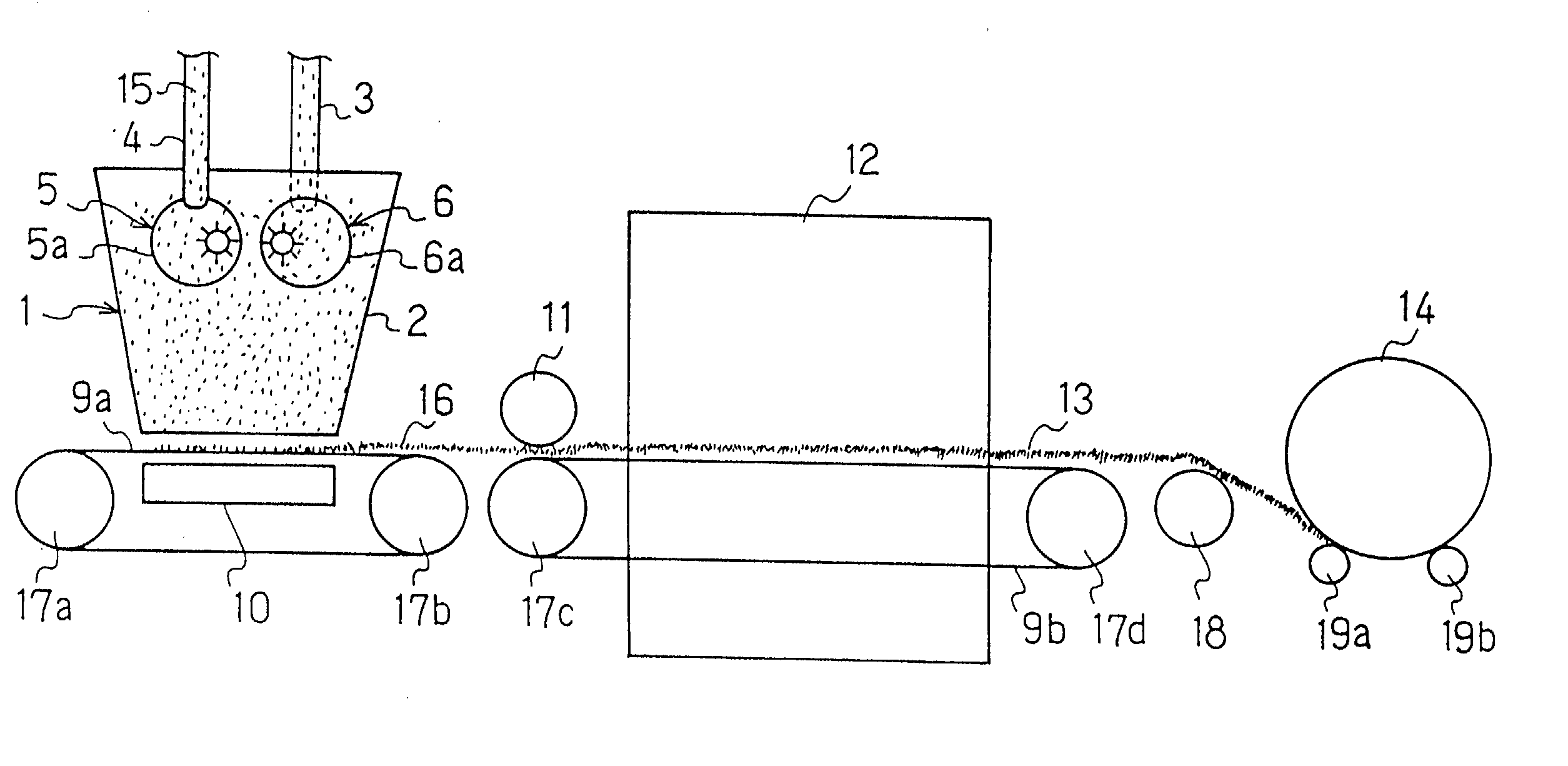

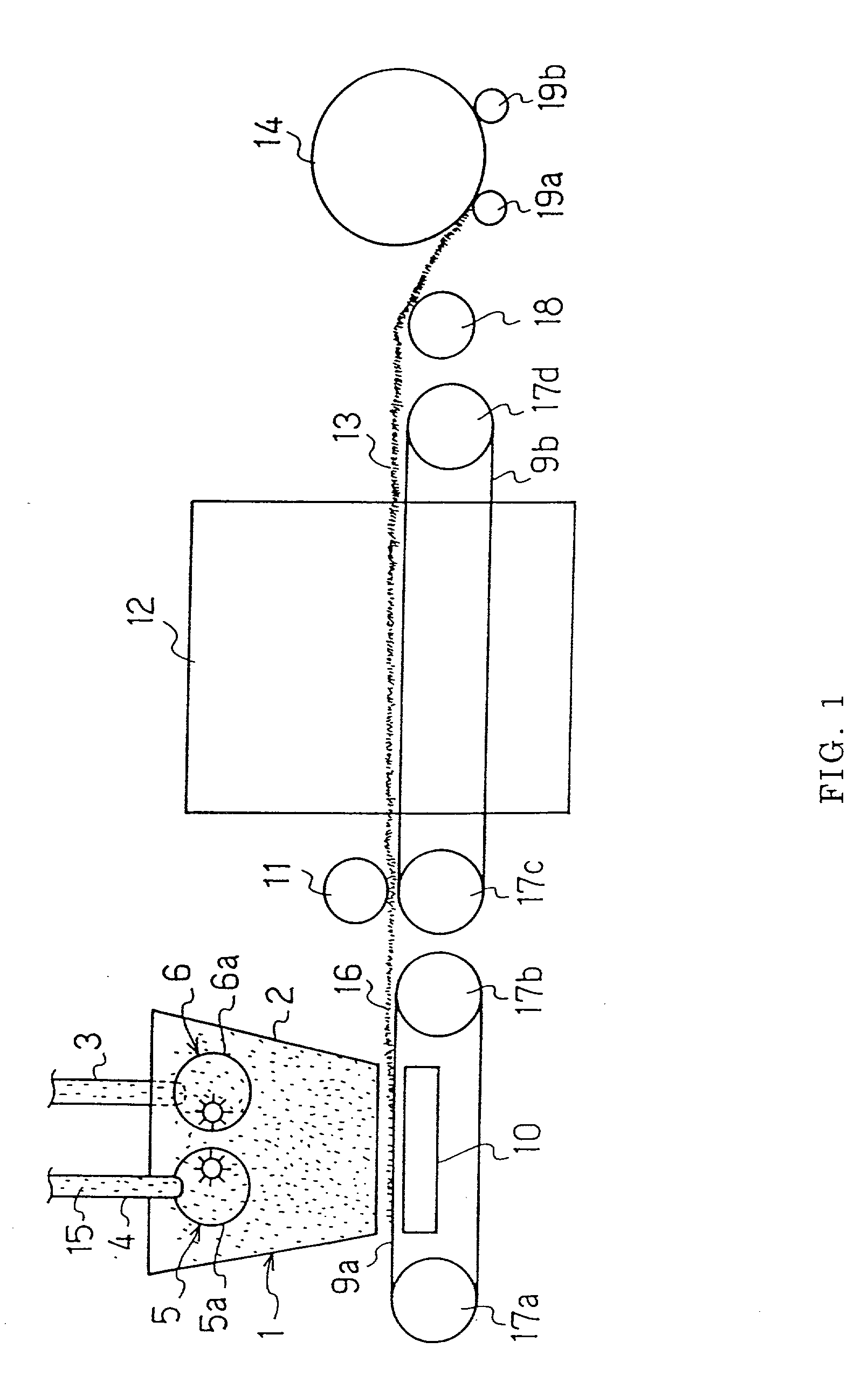

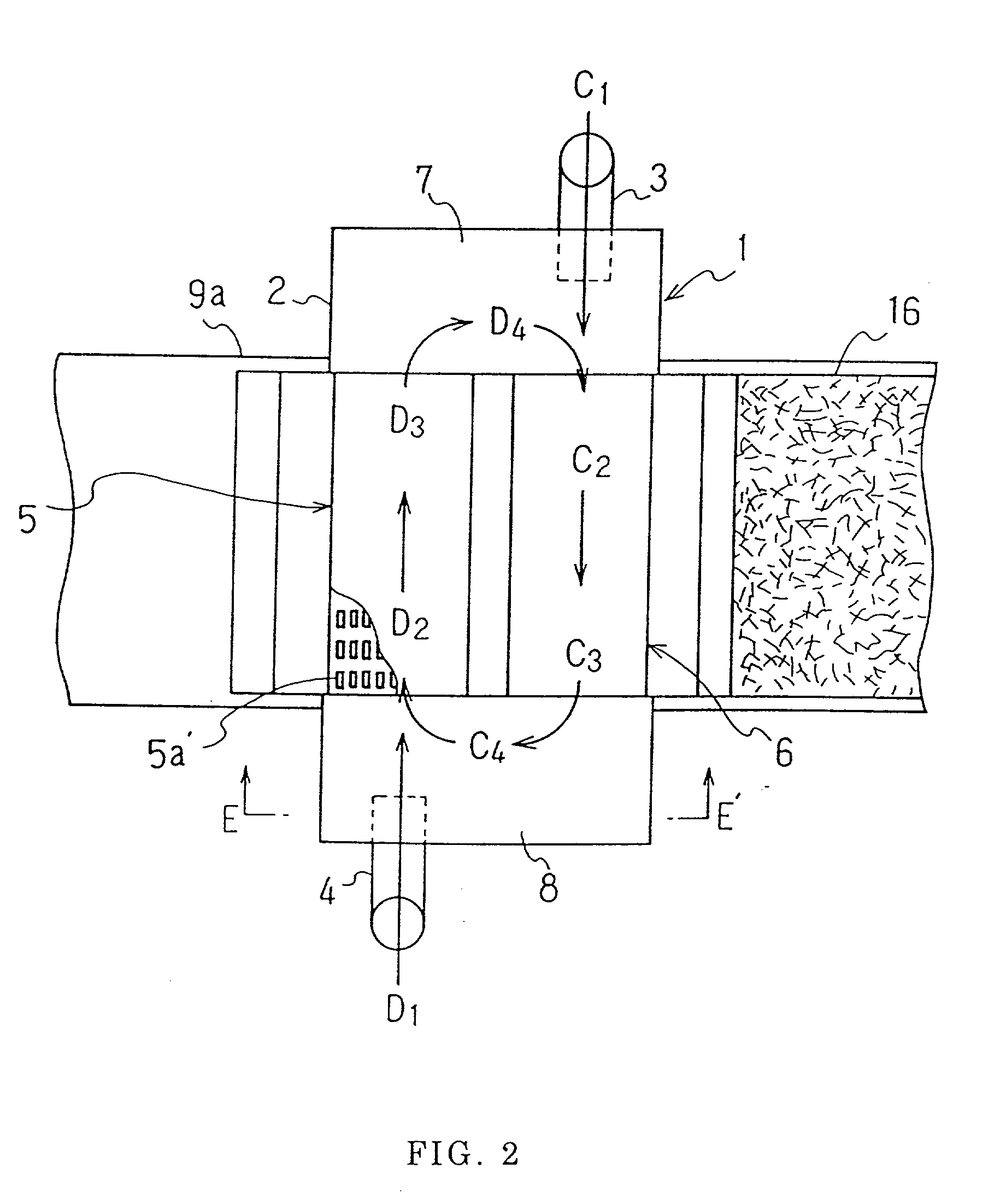

Non-woven fabric comprising staple fibers and an absorbent article using the same

InactiveUS20020016120A1High densityHigh strengthLap-winding devicesLap forming devicesPolymer scienceSingle fiber

A non-woven fabric comprising staple fibers, having a fiber length of 3 to 25 mm and a single fiber fineness of 1 to 100 denier, and is produced by the fibers being dropped while being dispersed to be accumulated and adhered at the intersection point of the staple fibers. The non-woven fabric has a specific volume of 40 to 200 cm3 / g, and the number of fiber lumps having a volume of not less than 1 mm3 is not more than 5 lumps per 20 g of the non-woven fabric. The bulky non-woven fabric of the present invention in which the sufficient contribution to bulkiness by fibers is exhibited is suitable for sanitary materials, such as disposable diapers, sanitary napkins, incontinence pads, nursing pads or the like, or wipes etc.

Owner:CHISSO CORP

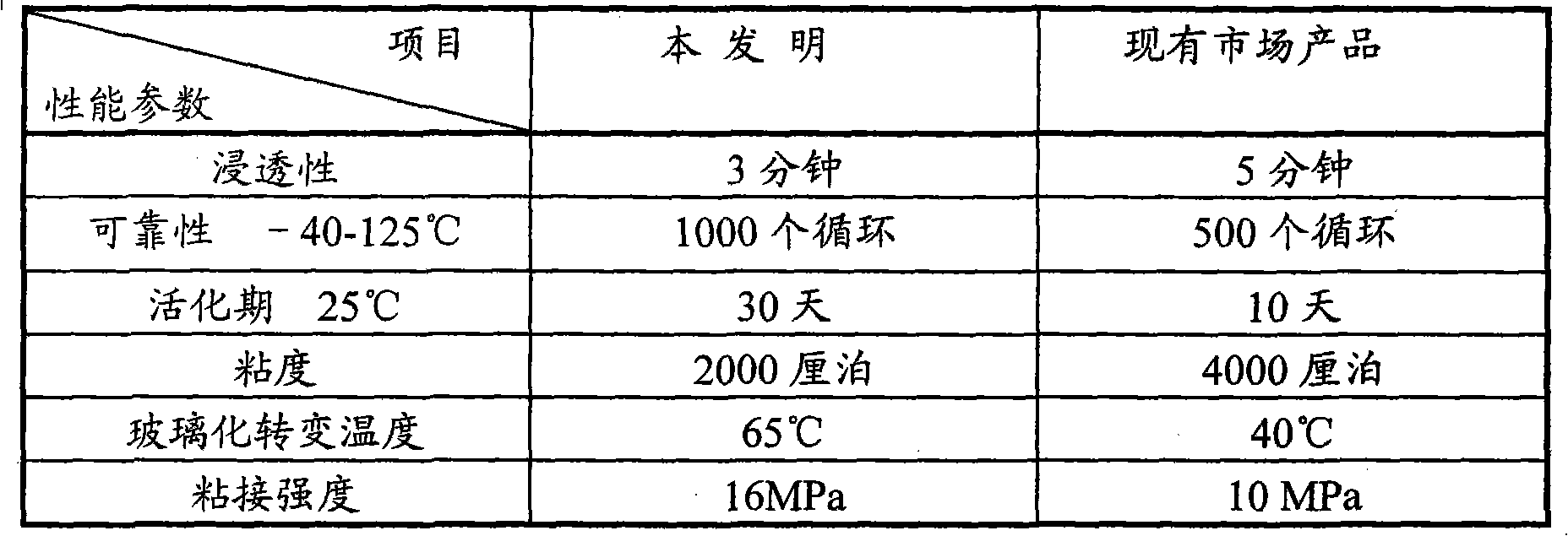

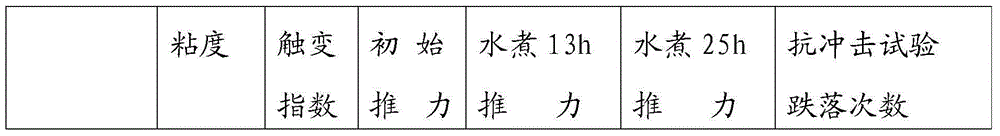

High-reliability and low-viscosity underfill

InactiveCN101880515ALow viscosityImprove drop resistanceNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsFilling materialsViscosity

The invention discloses a high-reliability and low-viscosity underfill for packaging a semiconductor device and a substrate, which comprises the following raw materials by weight percent: 0-12.8% of bisphenol-type epoxy resin, 11.4-62.5% of alicyclic epoxy resin, 0.44-13% of multi-functional epoxy resin, 11.4-62.5% of curing agent, 0.86-5.7% of curing accelerator, 11.6-51.1% of inorganic filler, 00.4-4.2% of silane coupling agent and 0-4.2% of carbon black. The invention uses the bisphenol type epoxy resin, the inorganic filler material and the silane coupling agent with molecular weight of more than 400 as necessary components, and has good mobility and thermal cycling stability and high reliability.

Owner:深圳市库泰克电子材料技术有限公司

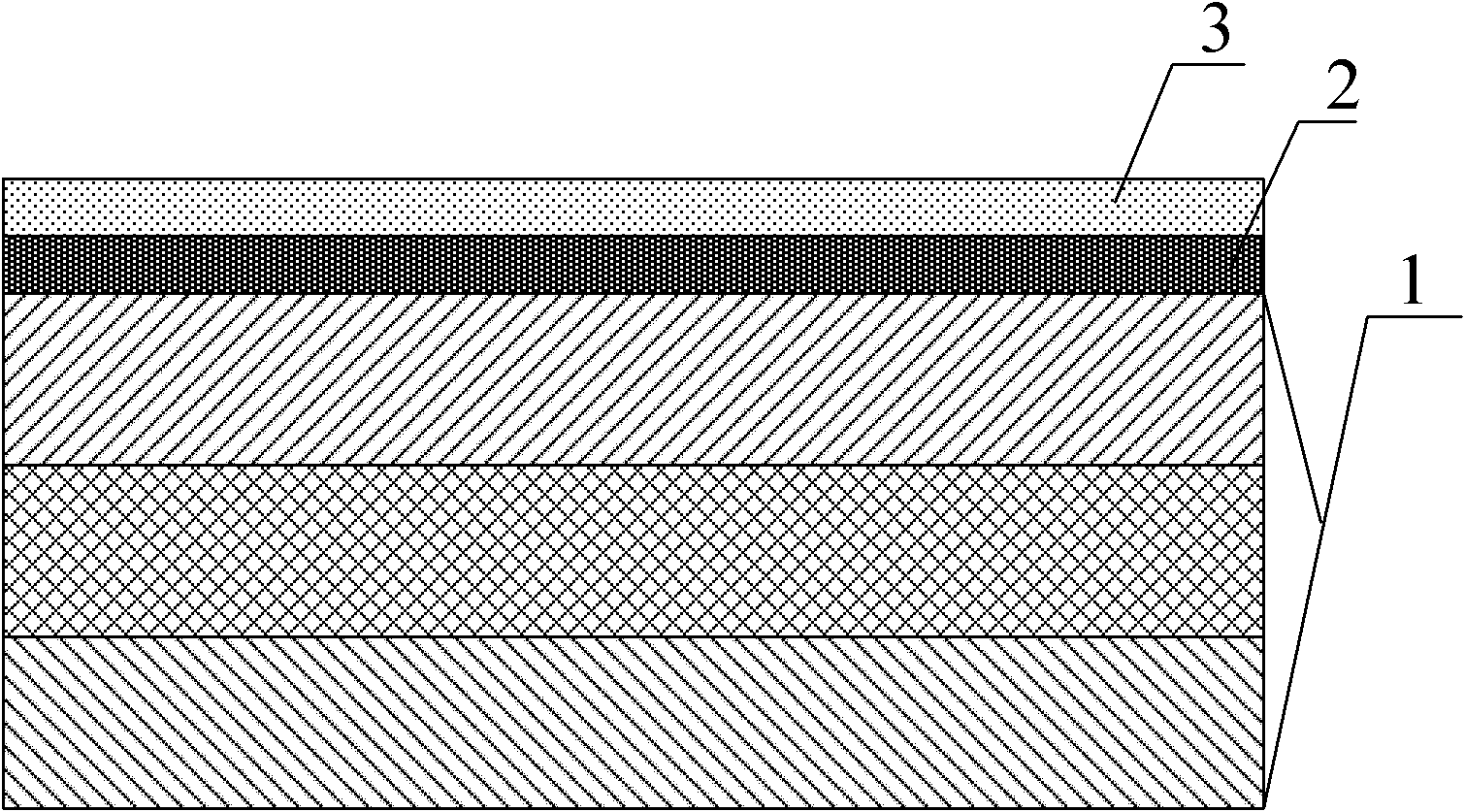

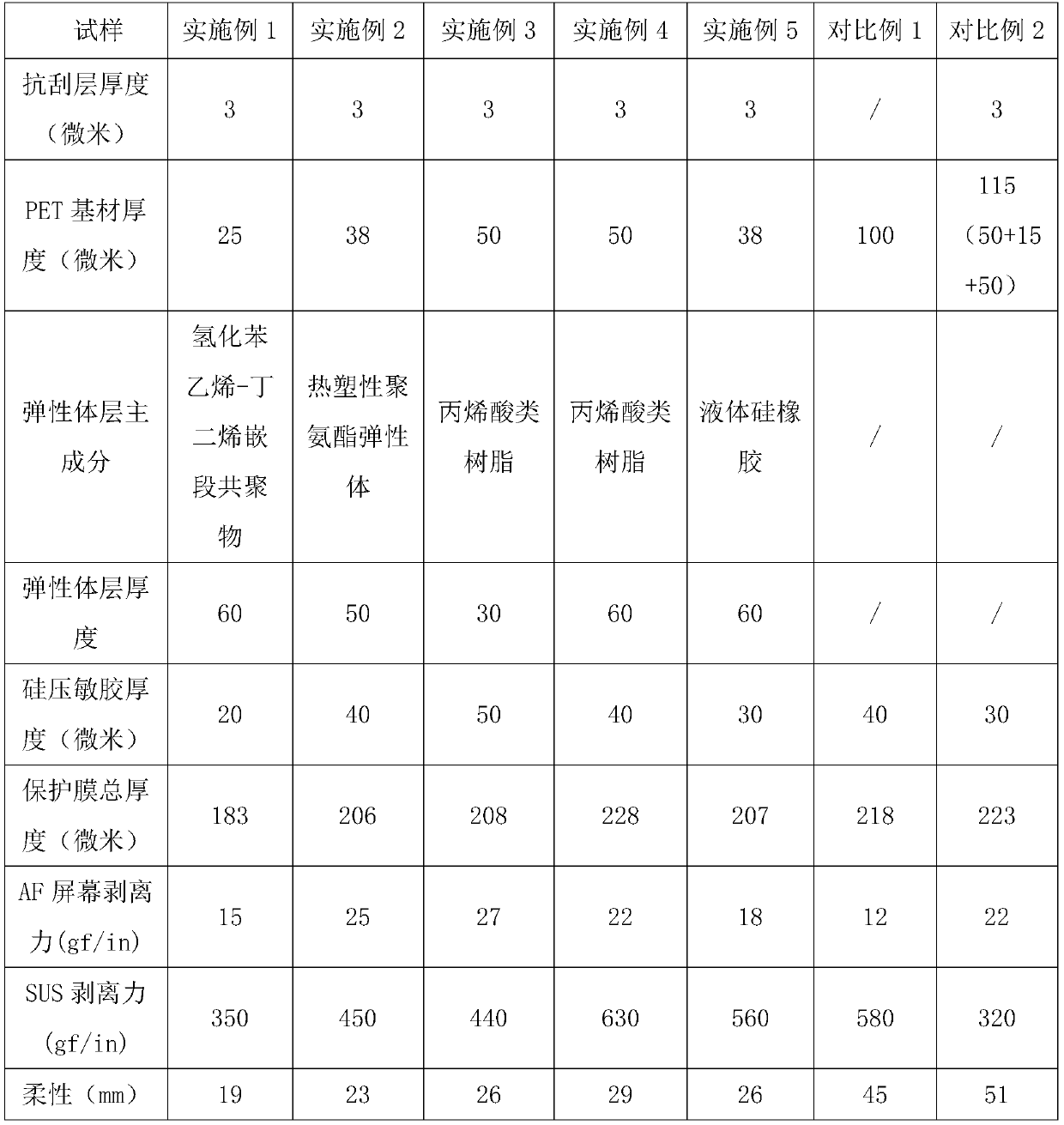

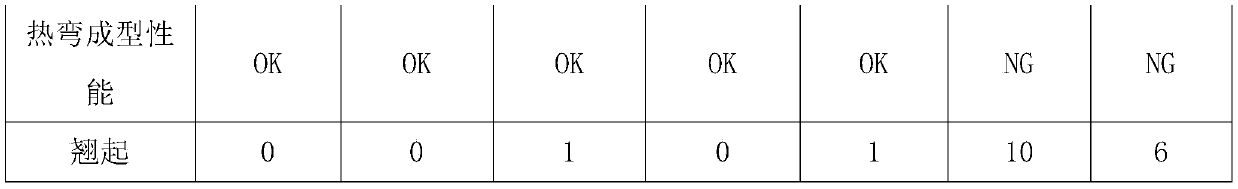

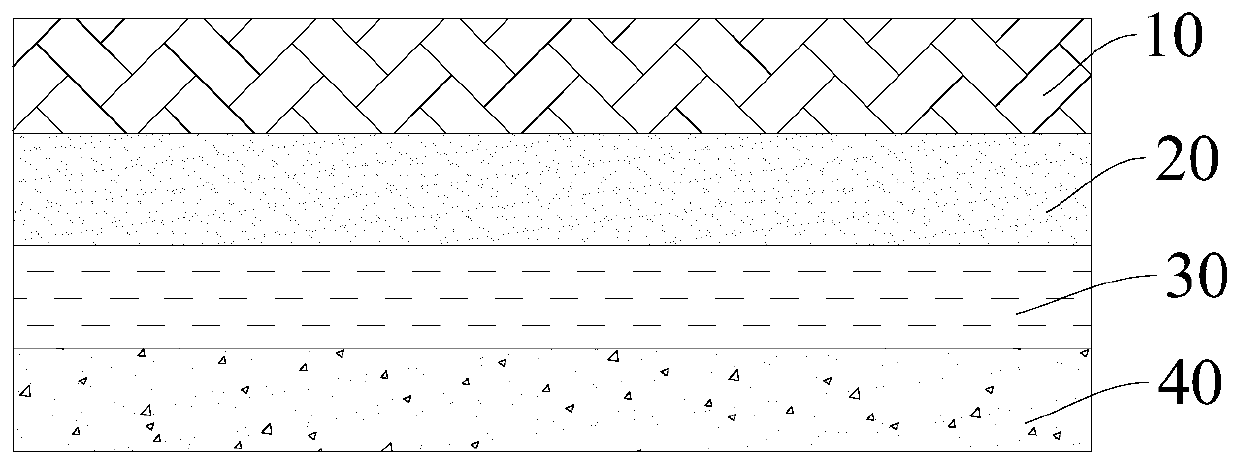

Curved screen protection film and preparation method thereof

ActiveCN110105896AImprove bendabilityImprove impact performanceFilm/foil adhesive primer layersPolyurea/polyurethane coatingsElastomerTectorial membrane

The invention relates to the technical field of curved screen protection films, in particular to a screen protection film for protecting curved liquid crystal screens and a manufacturing method of thescreen protection film. The curved screen protection film structurally comprises an anti-scratching layer, a PET base material, an elastomer layer, a silica gel layer and a fluorine release film which are sequentially arranged. According to the protection film, the arranged elastomer layer is beneficial to improving the bending property and drop resistance of the protection film, and under cooperation with the silica gel layer arranged on a protection film body, improvement of the fixing and fitting property of the protection film is facilitated, so that the problem of edge warping is effectively solved, and the protection film is suitable for the design of large angles and radians of the edge positions of mobile phone screens. Through the reasonable arrangement of the structure and thickness of each layer, the protection film has the basic performance of a PET screen protection film, and meanwhile, the flexibility, drop resistance and edge warping resistance of the protection film are further improved.

Owner:佛山固泰明科技有限公司

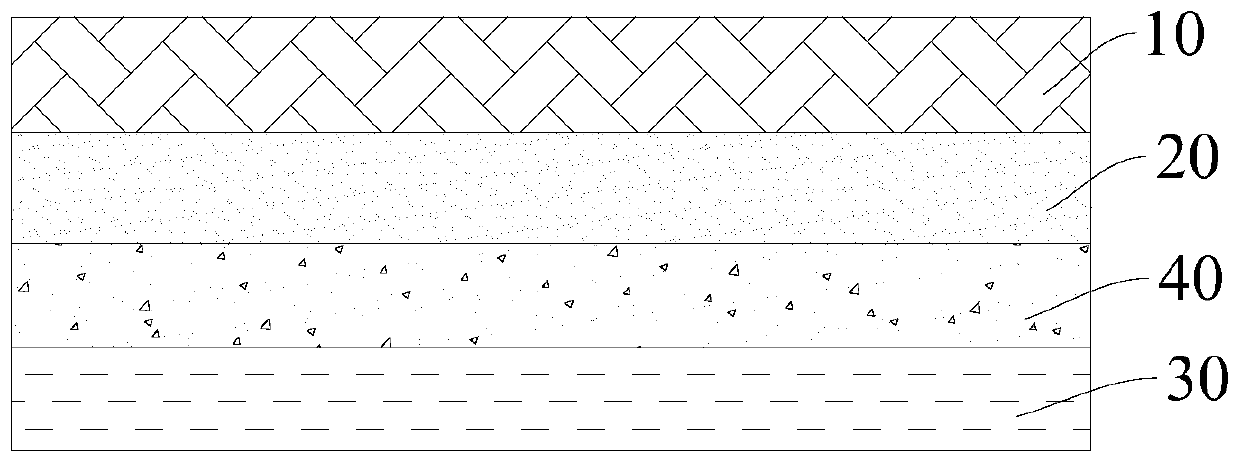

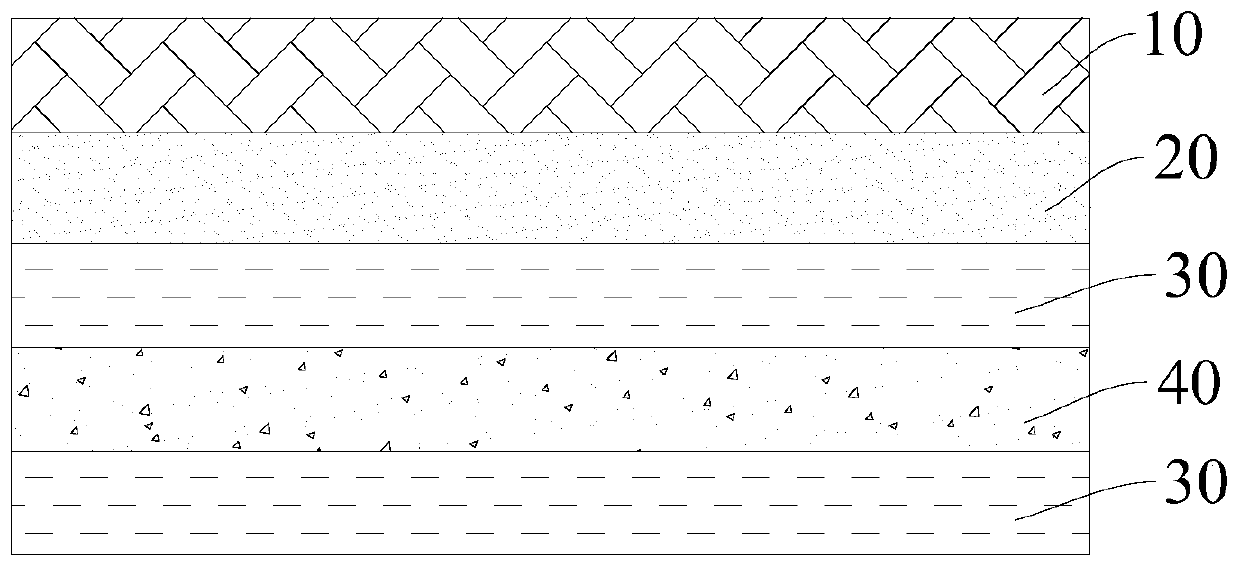

Shell, and preparation method thereof, and electronic equipment

InactiveCN109874253AImprove drop resistanceSynthetic resin layered productsCasings/cabinets/drawers detailsElectric equipmentElectronic equipment

The application provides a shell, and a preparation method thereof and electronic equipment. The shell comprises a substrate; a UV texture layer arranged at one side of the substrate; a base color inklayer arranged at one side, far away from the substrate, of the UV texture layer; a tenacious membrane layer arranged at one side, far away from the substrate, of the base color ink layer, and / or arranged between the UV texture layer and the base color ink layer. Therefore, the UV texture layer, the base color ink layer and like fragile membrane layers can be effectively protected through the arrangement of the tenacious membrane layer and the arrangement way, thereby preventing the UV texture layer and the base color ink layer from cracking when the shell falls off and improving the anti-falling performance of the shell, the condition that the cracking of the UV texture layer and the base color ink layer influences the appearance effect of the shell is avoided; the service life of the shell and the service life of the electronic equipment using the shell can be prolonged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

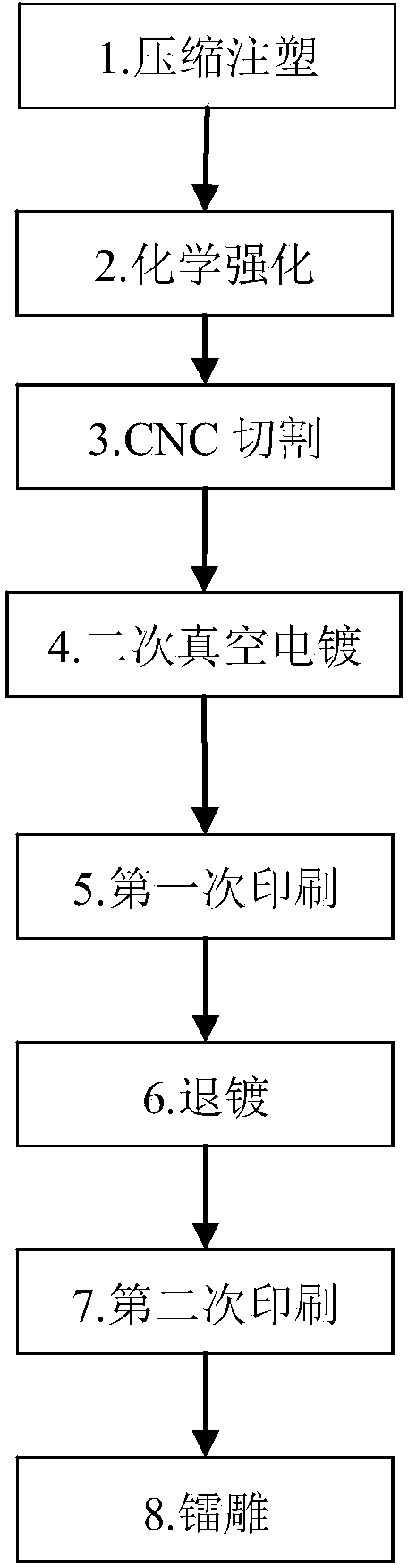

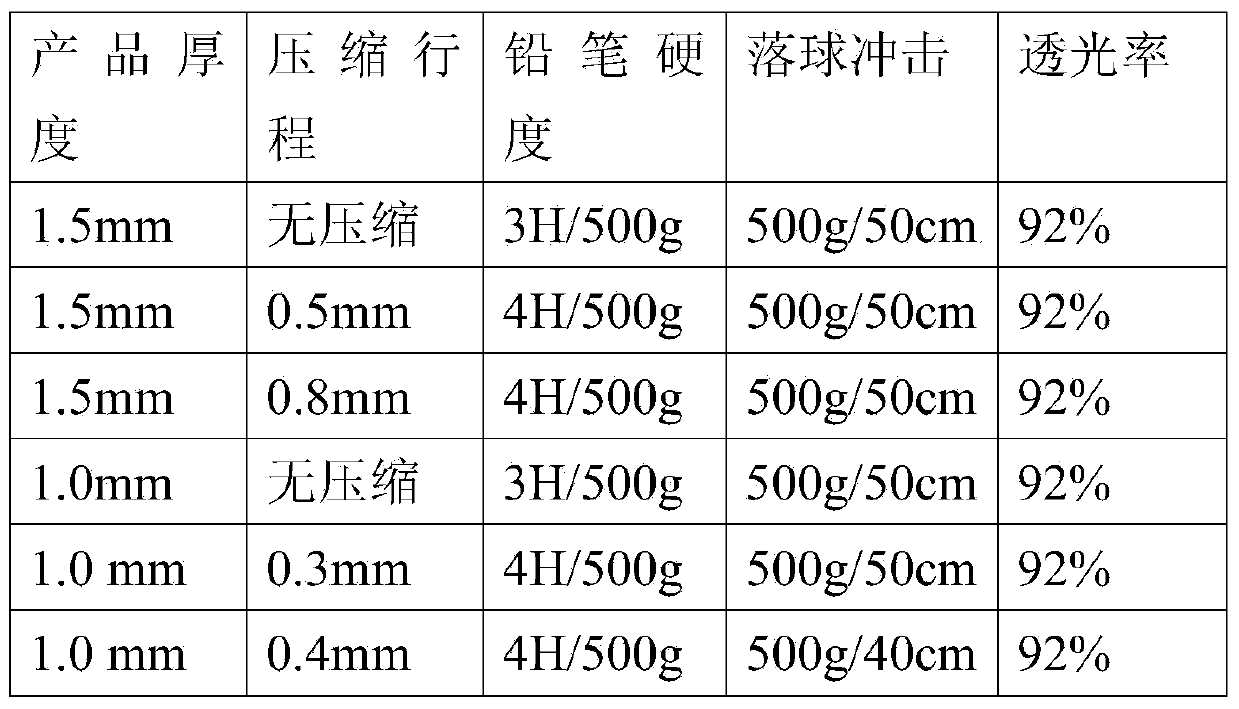

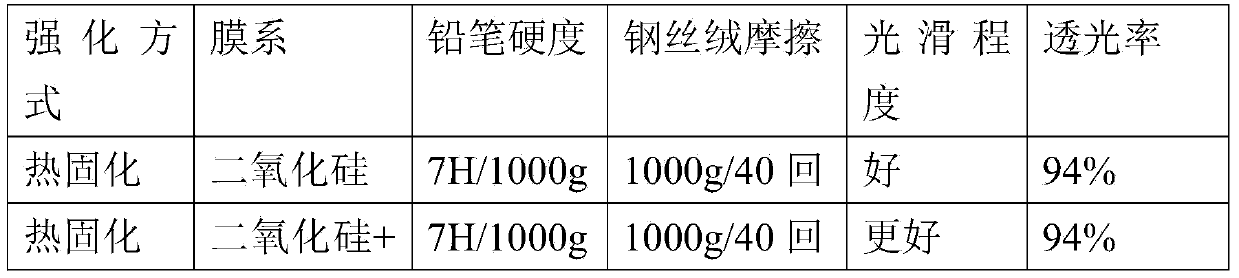

Strengthened organic glass window for cellphone and manufacture method of window

ActiveCN103738008AHigh hardnessHigh light transmittanceGlass/slag layered productsTelephone set constructionsTransmittanceHardness

The invention discloses a strengthened organic glass window for a cellphone. The strengthening organic glass window comprises an organic glass lens, wherein the organic glass lens comprises a base plate and a strengthening layer which is used for carrying out chemical strengthening treatment on the outer surface of the base plate; the inner surface of the base plate is coated with a decorating layer, and the outer surface of the strengthening layer is coated with a first vacuum electroplated layer. The invention also discloses a manufacture method of the strengthening organic glass window for the cellphone. The strengthening organic glass window disclosed by the invention has the advantages that the outer surface of a window lens strengthening layer is coated with the vacuum electroplated layer, and the hardness, smooth degree and light transmittance of the surface of the window can be effectively improved.

Owner:DONGGUAN HUAQING OPTICAL TECH

Polyether-type urethane acrylate UV-cured adhesive and preparation method thereof

ActiveCN104531041AGood flexibilityExcellent heat and humidity resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveShock resistance

The invention belongs to the technical field of adhesives and relates to a polyether-type urethane acrylate UV-cured adhesive and a preparation method thereof. The polyether-type urethane acrylate UV-cured adhesive comprises, by weight, 20-70 parts of polyether-type urethane acrylate, 10-40 parts of auxiliary resin, 5-20 parts of ethylene-acrylate rubber, 5-40 parts of an acrylate monomer, 5-35 parts of isobornyl acrylate, 1-7 parts of a photoinitiator, 1-5 parts of fumed silica and 0.5-2 parts of a silane coupling agent. Through use of the polyether-type urethane acrylate, auxiliary resin, ethylene-acrylate rubber and acrylate monomer, the polyether-type urethane acrylate UV-cured adhesive has excellent long-term high temperature resistance, low temperature resistance, high temperature and high humidity resistance, excellent shock resistance and a low cost and can be prepared by simple processes.

Owner:信泰永合(烟台)新材料有限公司

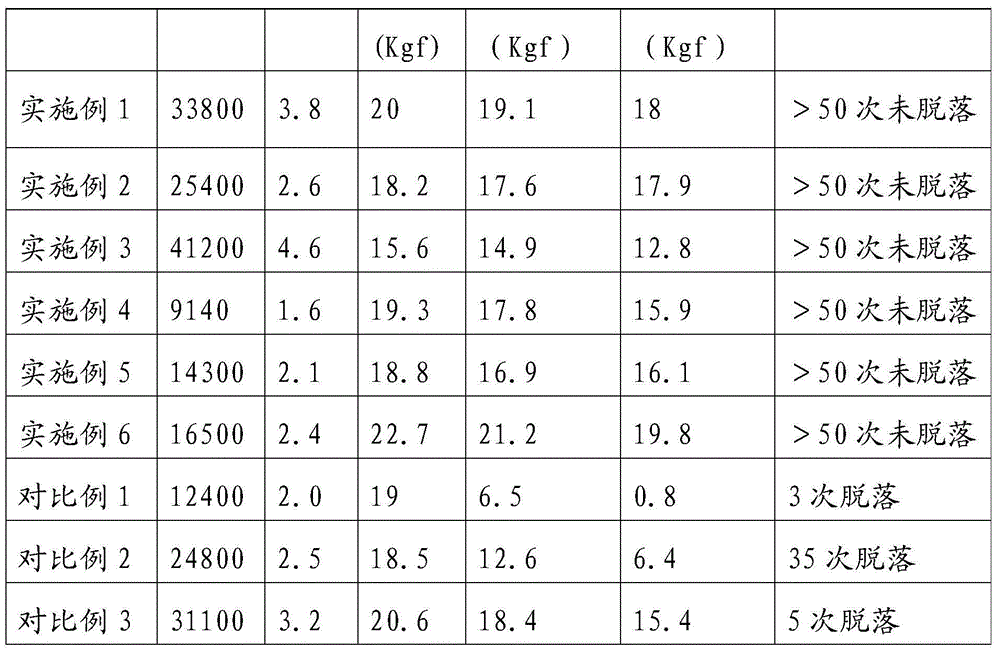

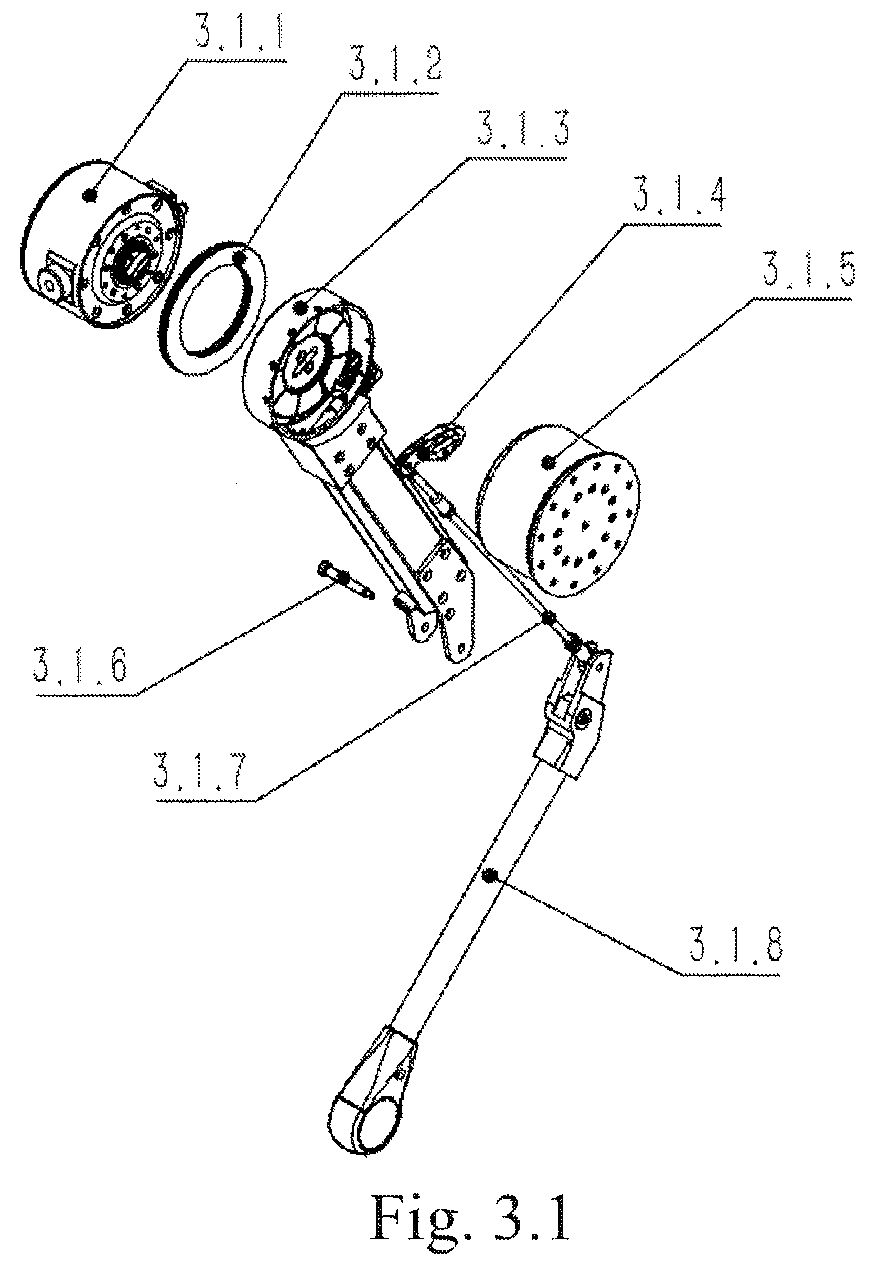

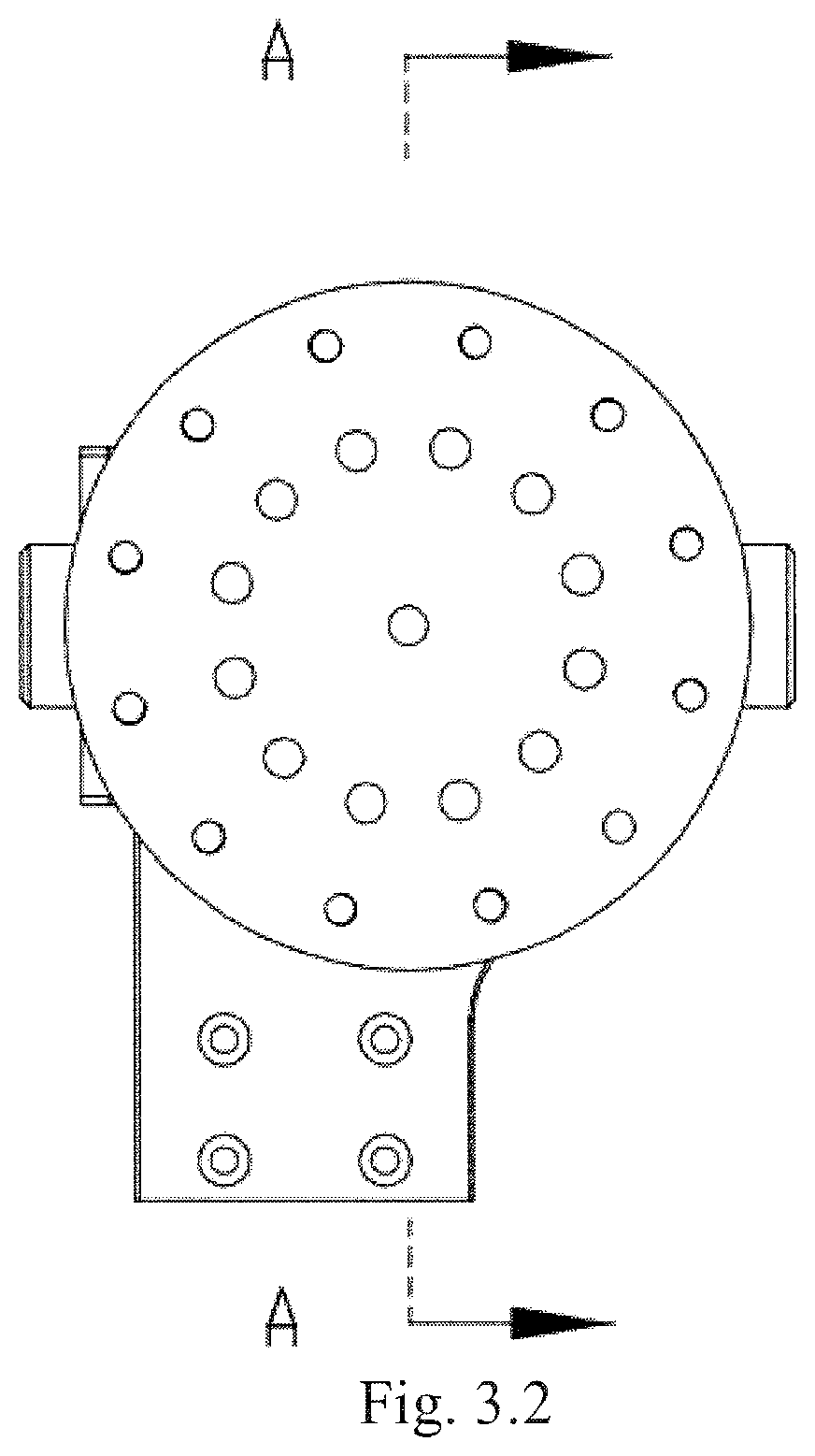

Leg power system structure of electrically driven four-legged robot

ActiveUS20200282554A1Compact structureLight weightProgramme-controlled manipulatorJointsAntiparallelogramPhysical therapy

Owner:HZ UNITREE TECHNOLOGY CO LTD

Lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and preparation method and application thereof

The invention discloses lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and a preparation method and application thereof. The molar content of oxide components contained in the lithium aluminum silicon glass satisfies the following relationship: the SiO2 content is at least 66.5 mol%, and the total amount of an alkali metal oxide usable for ion exchange is not more than 14 mol%; (Na2O+Li2O) / (SiO2+Al2O3) is 0.09-0.22; Na2O / Li2O is 0.4-1.2; MgO / SiO2 is 6%-18%; (Na2O+Li2O+0.3*MgO) / Al2O3 is 0.7-1.4; and 0.5%<P2O5+ZnO+SnO2+K2O+ZrO2+TiO2<7%. The lithium aluminum silicon chemically strengthened glass is formed by chemically strengthening the lithium aluminum silicon glass as basic glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

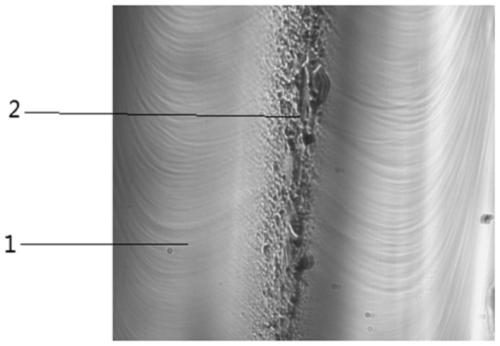

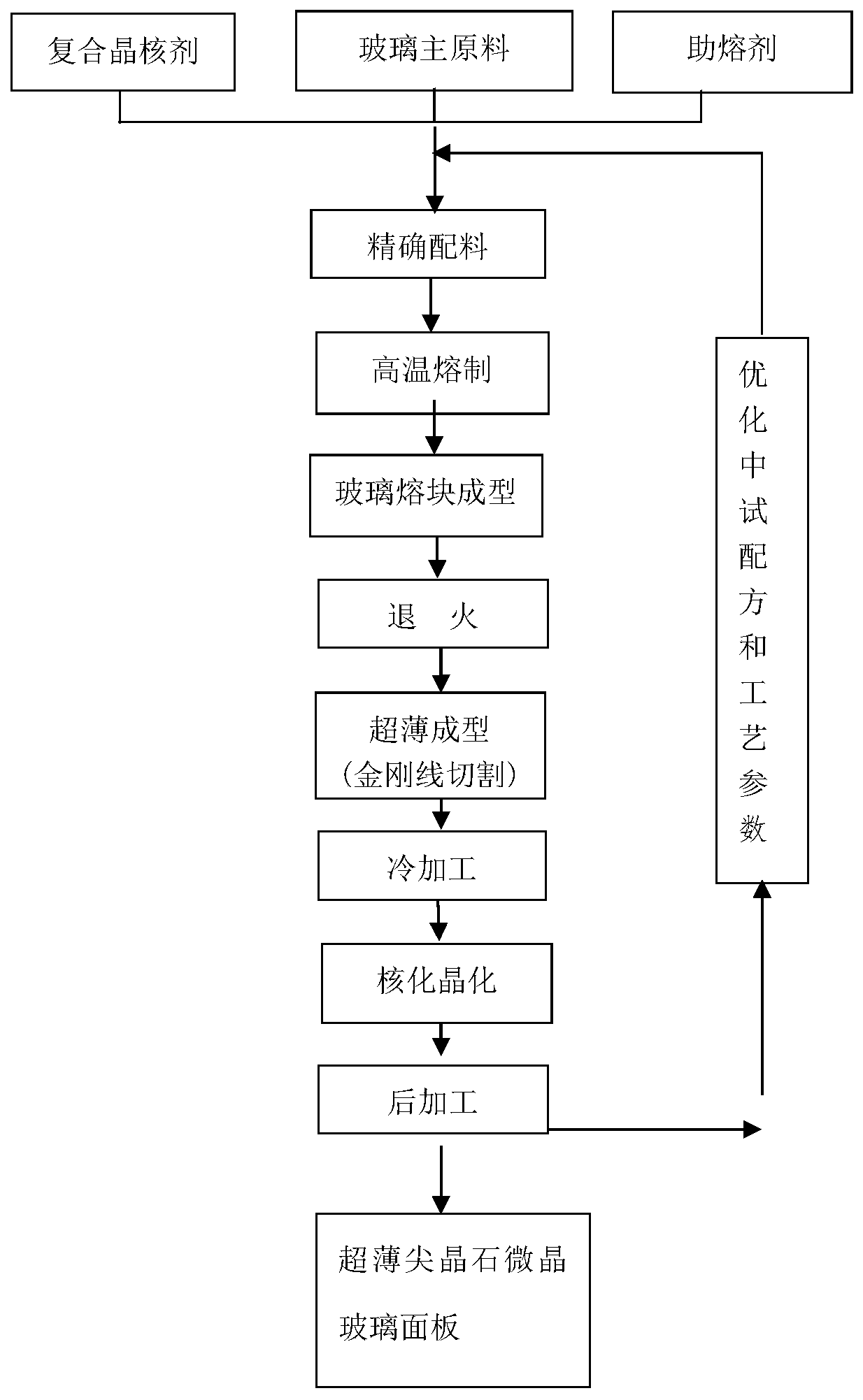

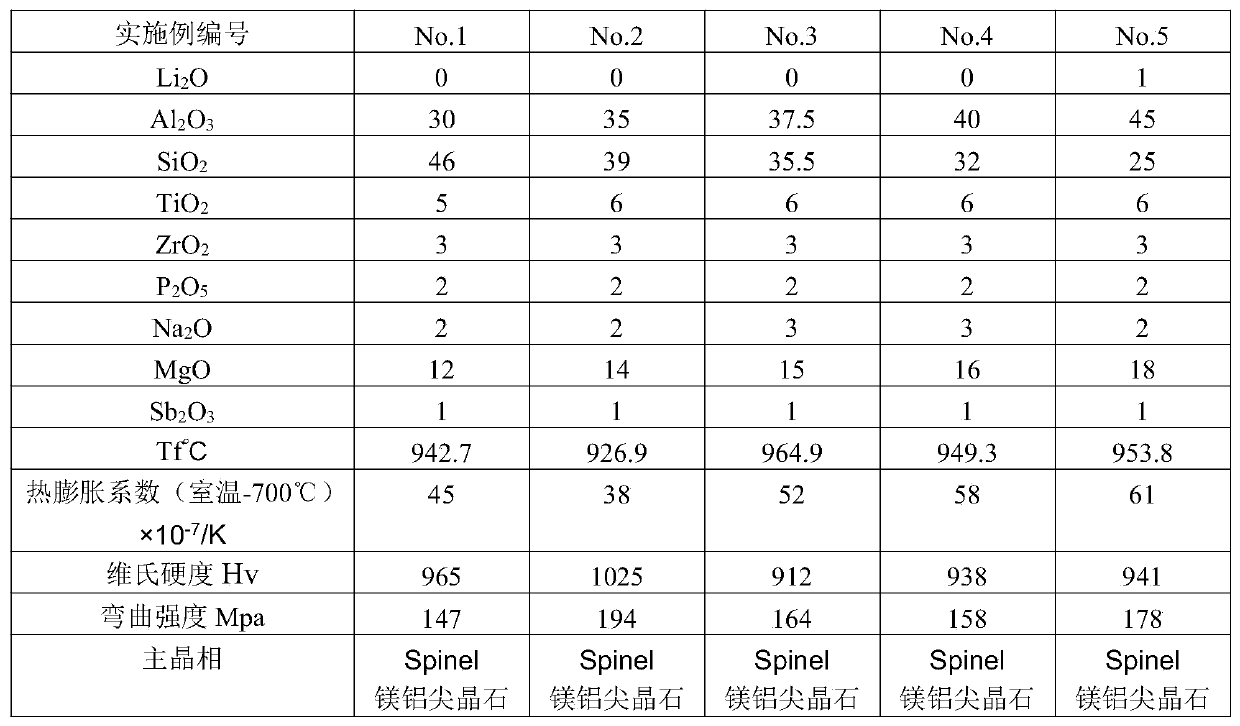

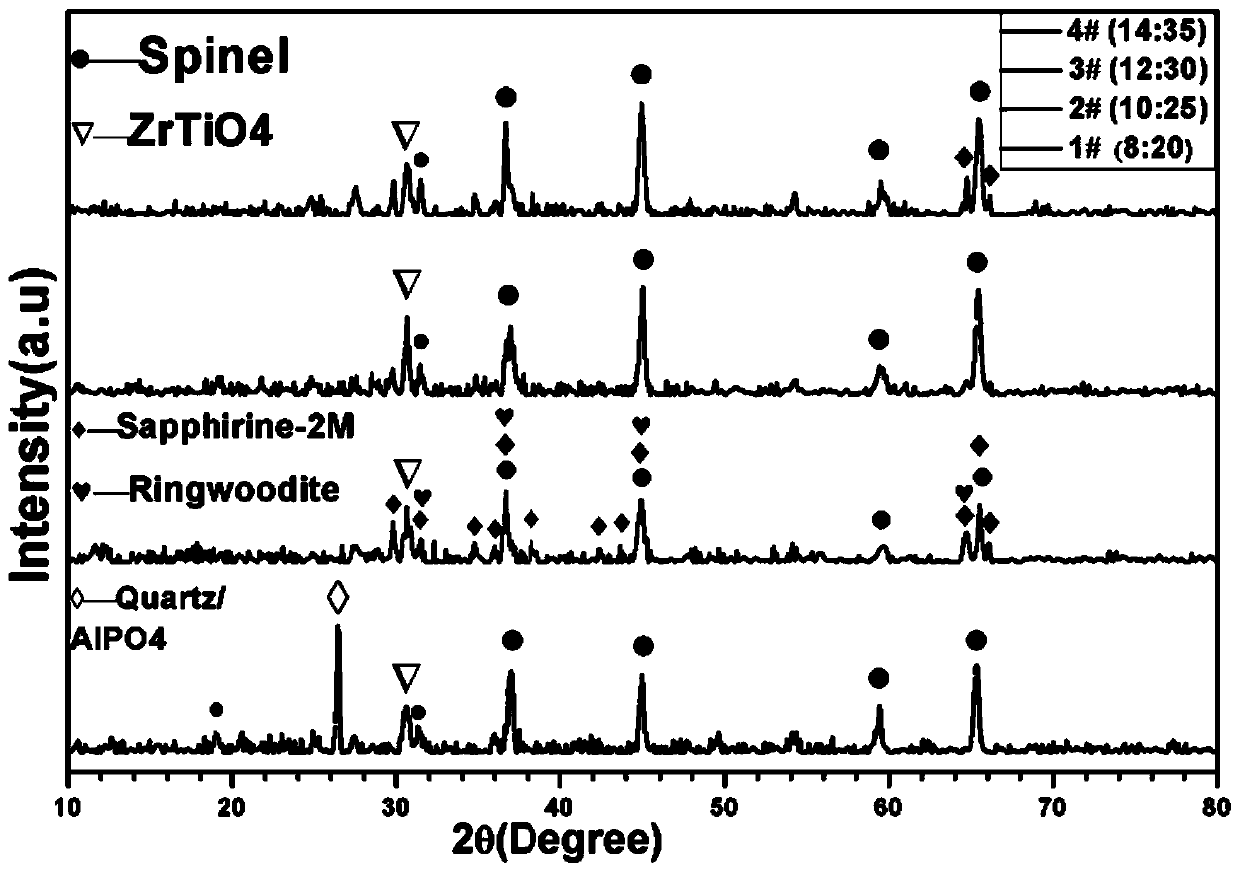

Mg-Al-Si spinelle crystallized glass

InactiveCN109809696AFlat surfaceComplete structureGlass furnace apparatusHigh intensityMaterials science

The invention provides Mg-Al-Si spinelle crystallized glass, which is prepared from the following ingredients in percentage by weight: 20 to 45 weight percent of Al2O3, 25 to 60 weight percent of SiO2, 8 to 18 weight percent of MgO, 3 to 10 weight percent of TiO2, 0 to 5 weight percent of ZrO2, 0 to 3 weight percent of P2O5, 0 to 2 weight percent of Li2O, 0 to 2 weight percent of Na2O, 0 to 2 weight percent of K2O and 0.5 to 3 weight percent of Sb2O3. The product has the characteristics of high intensity, high hardness, dropping resistance, low expansion and excellent dielectric property.

Owner:温州市康尔微晶器皿有限公司

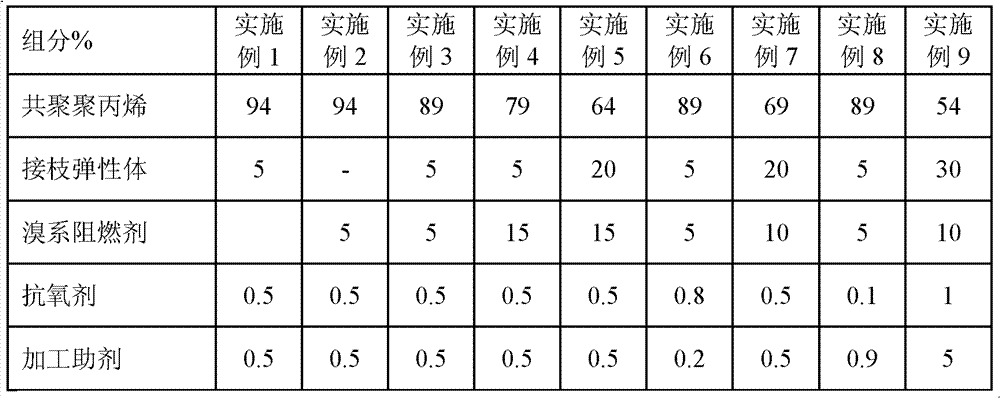

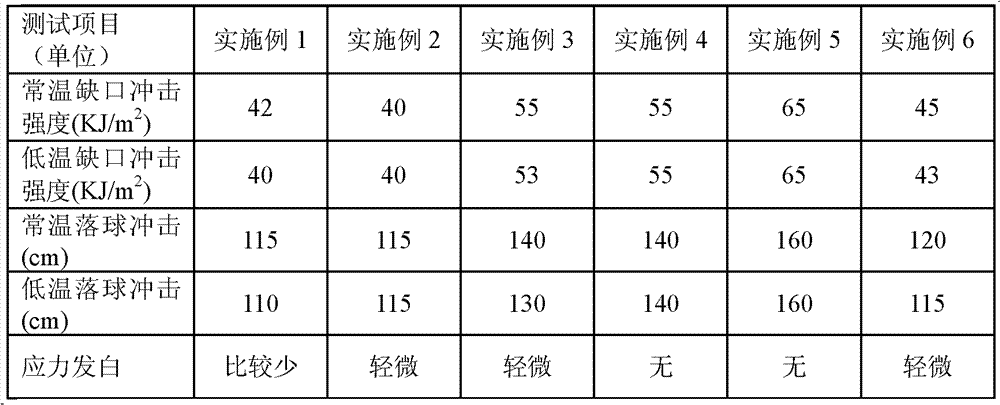

Low-temperature impact-resistant and low stress whitening-resistant long glass fiber reinforced polypropylene material, and preparation method and application thereof

ActiveCN103242586AImproved low temperature impact propertiesReduces stress whiteningBrominated flame retardantPolypropylene

The invention discloses a low-temperature impact-resistant and low stress whitening-resistant long glass fiber reinforced polypropylene material, comprising, by weight, 10%-80% of long glass fiber reinforced polypropylene masterbatches and 20% -90% of low-temperature impact-resistant and low stress whitening-resistant masterbatches, wherein the long glass fiber reinforced polypropylene masterbatches comprise, by weight, 0%-80% of co-polypropylene, 0%-80% of homo-polypropylene, 10%-60% of glass fibers, 1%-10% of grafted polypropylene, 0.1%-2% of an antioxidant and 0.2-2% of a processing agent; the low-temperature impact-resistant and low stress whitening-resistant masterbatches comprise, by weight, 50%-95% of co-polypropylene, 0-30% of a grafted elastomer, 0-20% of a brominated flame retardant, 0.1%-2% of an antioxidant and 0.2-5% of a processing agent. The polypropylene material prepared by the method improves the characteristic of low-temperature impact resistance and reduce generation of stress whitening. A finished product prepared by the material has good drop impact resistance, and can be used for workpieces such as packing cases or electric tools, etc.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Mobile terminal

PendingCN105975003AExtended service lifeReduce use costDigital data processing detailsTelephone set constructionsEngineeringComputer terminal

The invention discloses a mobile terminal. The mobile terminal comprises a frame and a screen, wherein the screen is arranged inside the frame and can move between a first position and a second position along the thickness direction of the screen relative to the frame; in the falling process of the mobile terminal, the screen moves from the first position to the interior of the frame to the second position; and when the screen is located at the second position, edge bottom surface of the screen is completely contained in the frame. According to the mobile terminal, the edge of the screen can be effectively protected, and the impact force suffered by the upper surface of the screen can be buffered, so that the screen damage probability is reduced, the anti-falling performance and reliability of the screen are effectively improved, the service life of the mobile terminal is prolonged and the use cost of the mobile terminal is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

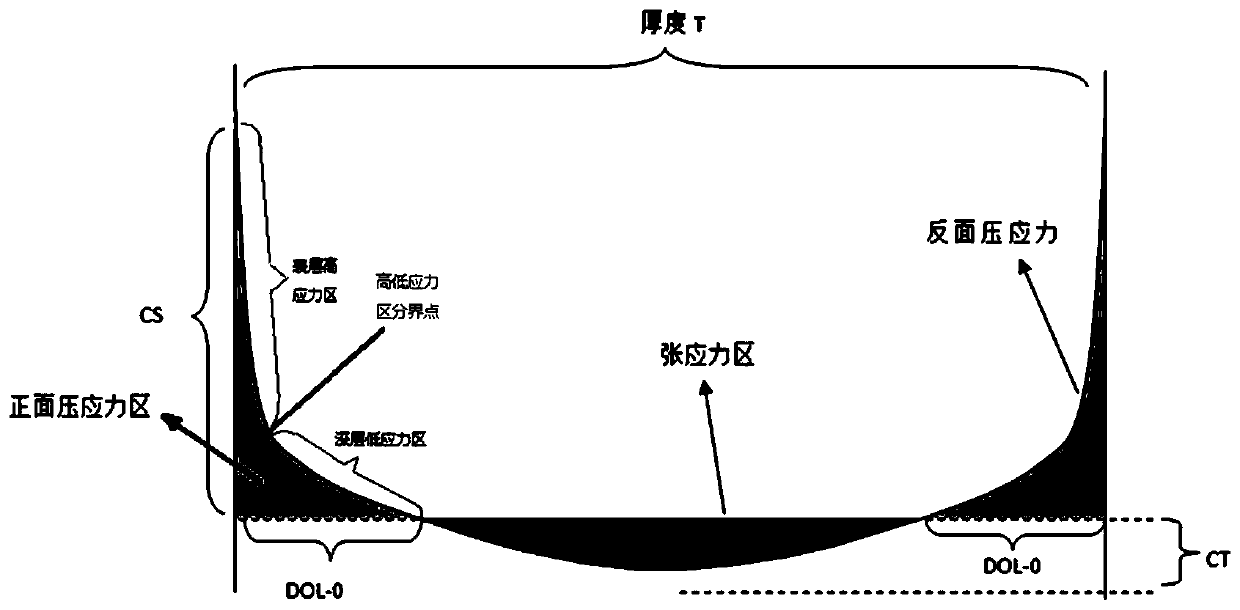

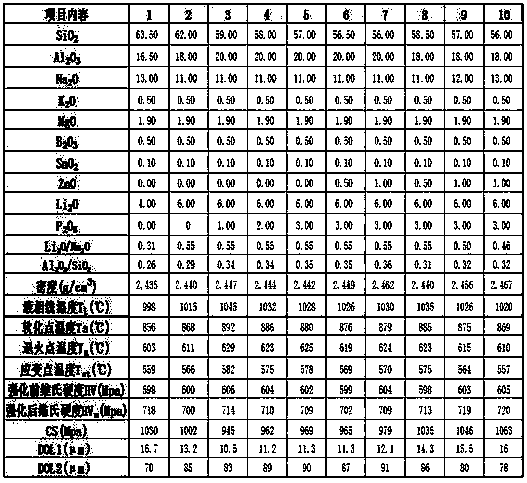

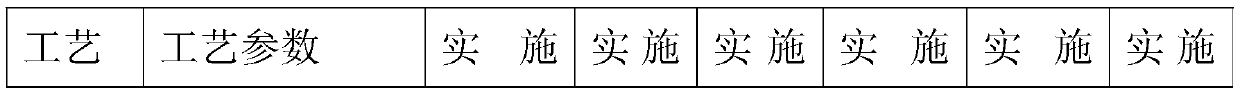

Two-step-method chemically strengthened alkali aluminosilicate glass composition and preparation method thereof

The invention belongs to the technical field of glass materials, and particularly relates to a two-step-method chemically strengthened alkali aluminosilicate glass composition and a preparation methodthereof. The two-step-method chemically strengthened alkali aluminosilicate glass composition comprises the following components in percentages by mole: 53-65% of SiO2, 16-22% of Al2O3, 0.01-0.5% ofB2O3, 4-8% of Li2O, 8-14% of Na2O, 0.01-1% of K2O, 0.01-3% of MgO, 0-1% of ZnO, 0-4% of P2O5 and 0-0.1% of SnO2. The formula of glass is optimized and lithium and phosphorus are added in the glass toobtain the composition, the composition is chemically strengthened by a two-step method, thus, glass has high surface pressure stress and a deep ion exchange layer, and the surface hardness, scratch resistance and falling resistance of the glass are improved.

Owner:KORNERSTONE MATERIALS TECH

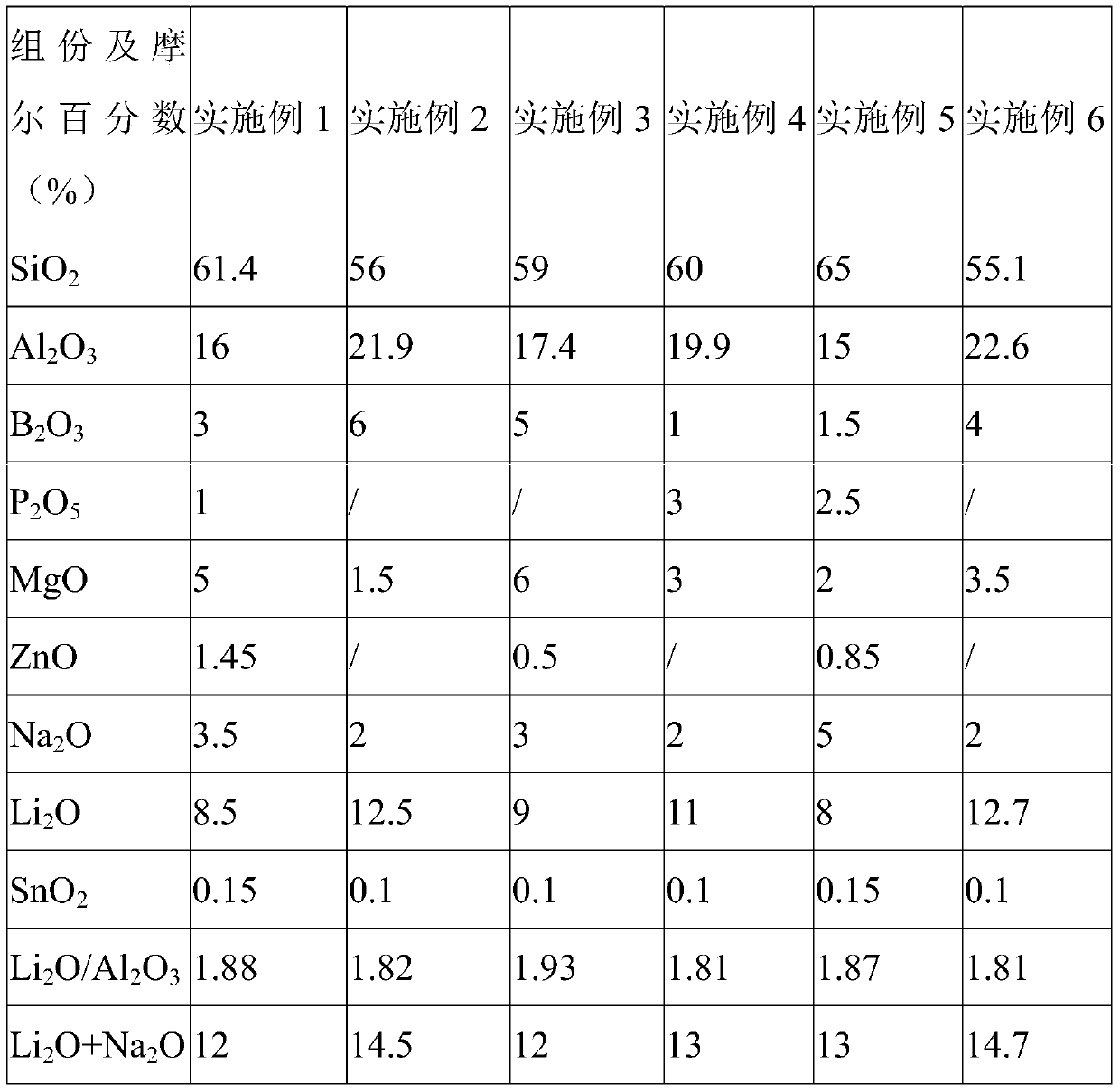

Chemically strengthenable self-crystallizing glass ceramic and preparation method thereof

ActiveCN110104955AFasten the network structureHigh mechanical strengthGlass forming apparatusGlass rolling apparatusLithiumQuartz

The invention discloses a chemically strengthenable self-crystallizing glass ceramic and a preparation method thereof. The glass ceramic has crystals with the average crystal size ranging from 5 nm to60 nm, a main crystal phase of the crystals is at least one of a beta quartz solid solution, nepheline and a nepheline solid solution, the crystals account for 30%-90% by mass of the glass ceramic, and the glass ceramic contains 8%-13% of Li2O by mole, the content ratio of Al2O3 to Li2O is greater than or equal to 1.8, the sum of the content of the Li2O and the content of the Na2O is 10% to 15%,and nucleating agents ZrO2, TiO2 and fluoride are not added in the glass ceramic. The glass ceramic has the advantages of high aluminum content, high lithium content and low sodium content in composition, and contains no nucleating agent; the high lithium content increases the crystallization tendency of the glass substrate to realize uniform crystallization; the crystal growth speed can be controlled by the high aluminum content, so that the glass ceramic network structure is firm, and the mechanical strength is improved; the low nano content can reduce the dielectric constant of the glass ceramic.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD +1

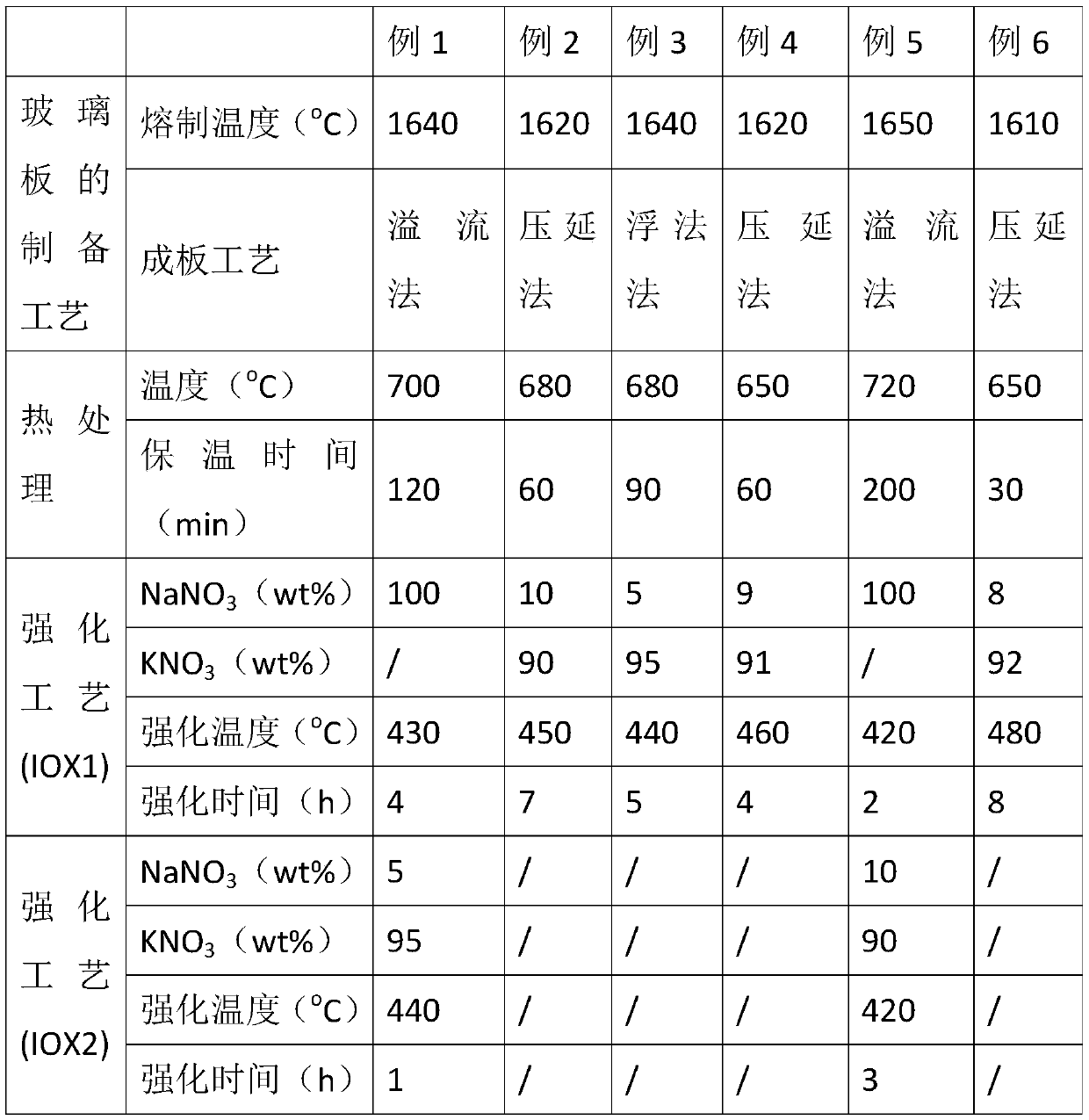

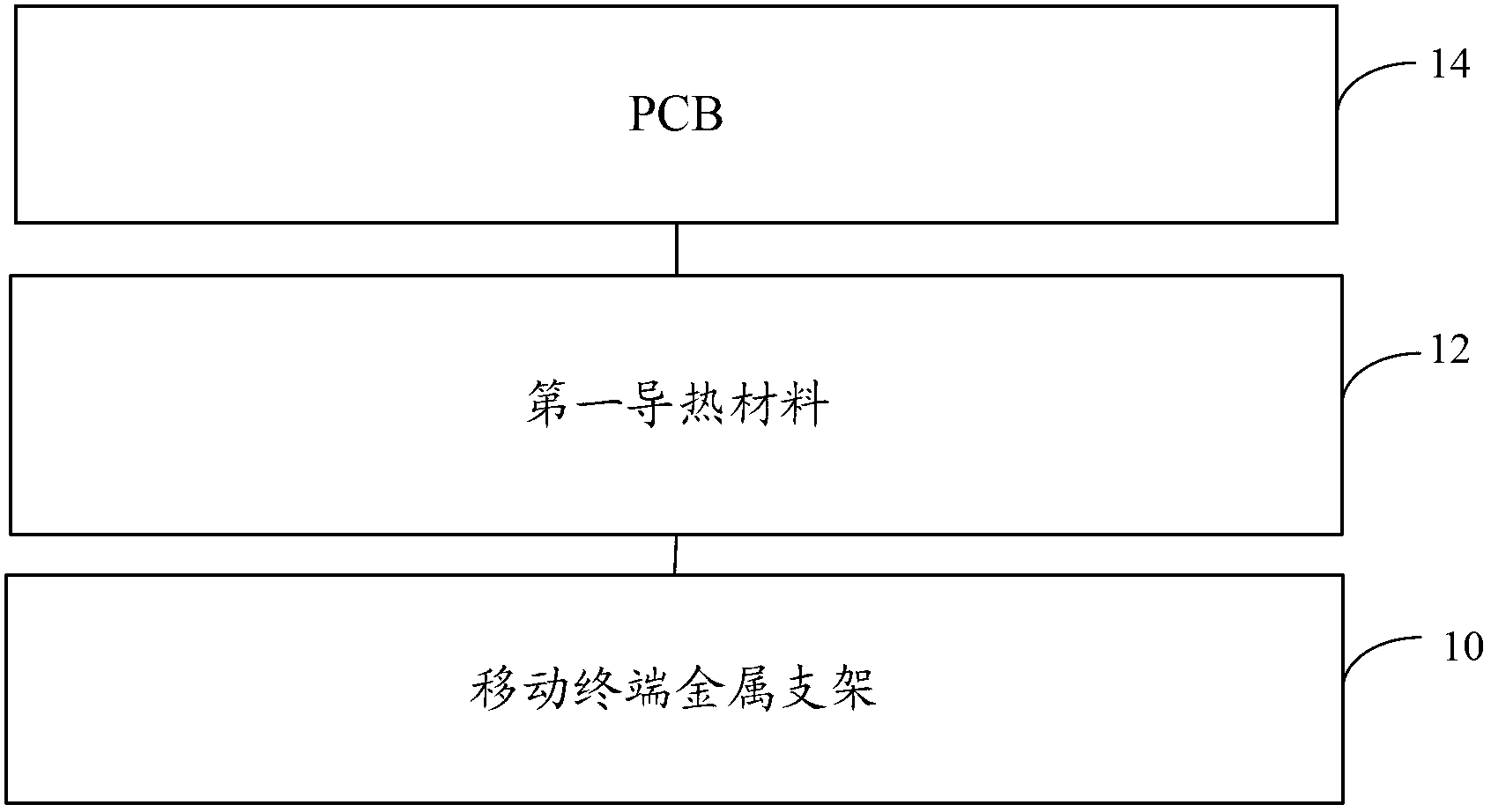

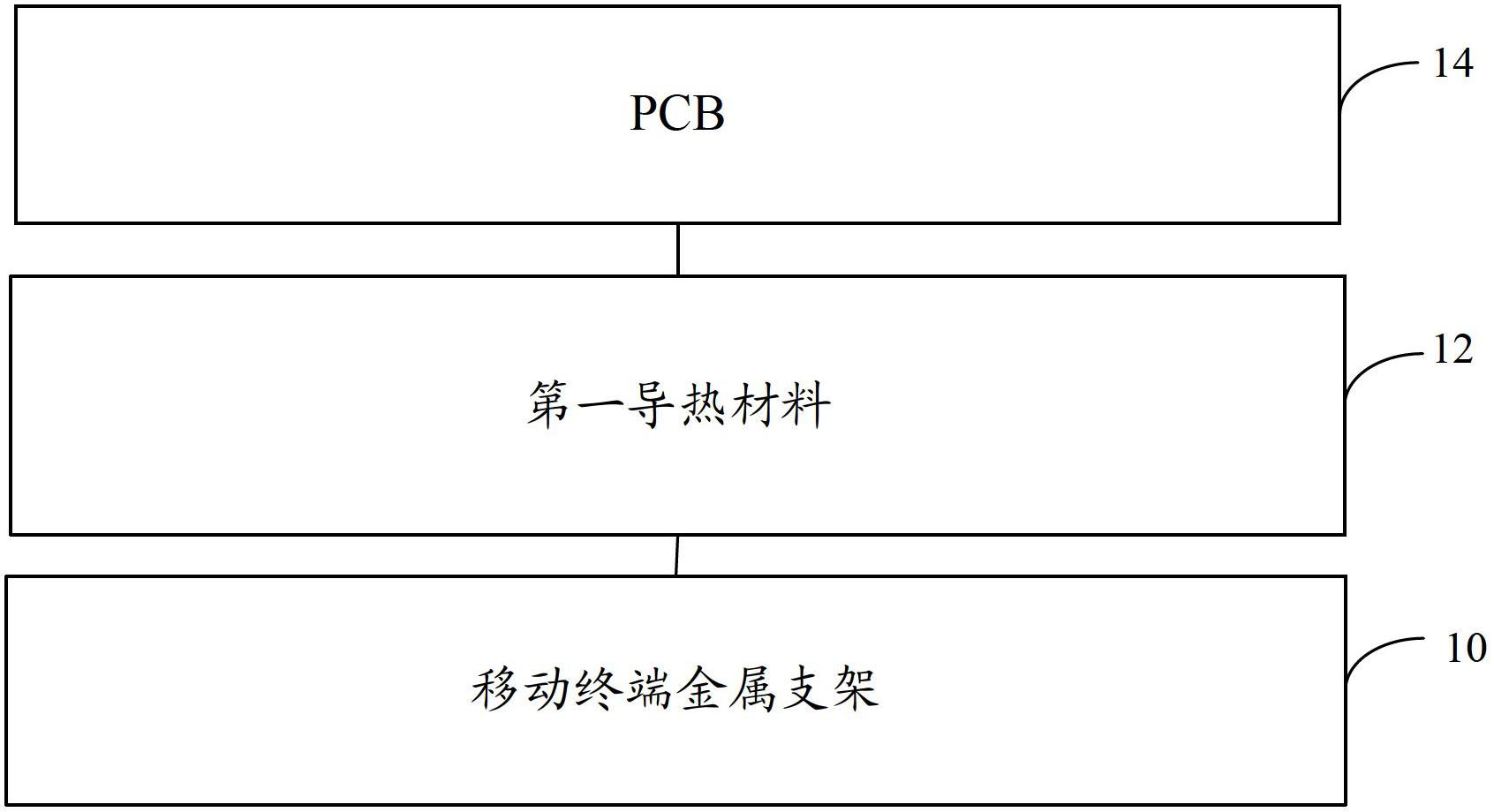

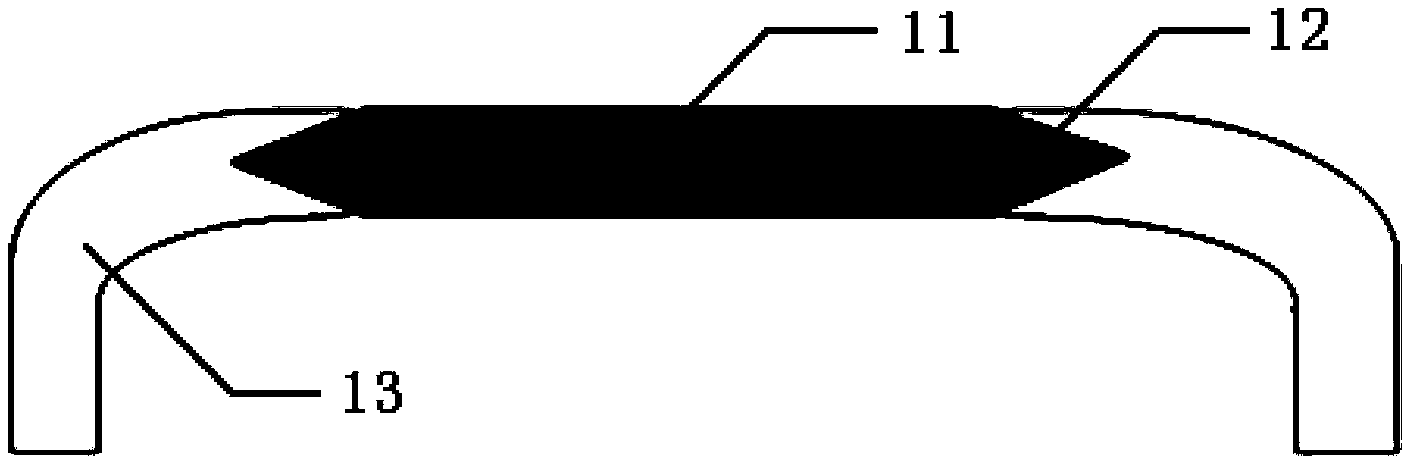

Heat dissipation processing device and mobile terminal

ActiveCN102711416AGood grounding effectImprove RF signal reception performanceMagnetic/electric field screeningCooling/ventilation/heating modificationsStructural reliabilityHeat conducting

The invention discloses a heat dissipation processing device and a mobile terminal. The device comprises a mobile terminal metal stand subjected to low-thermal-conductivity surface removal treatment, a first heat conducting material with rough surface, and a PCB (printed circuit board) with a multilayer structure, wherein the mobile terminal metal stand is located between a mobile terminal LCD (liquid crystal display) and the PCB; the space between the mobile terminal metal stand and the PCB is filled with the first heat conducting material; large-power devices on the PCB are arranged at a middle position of the device surface of the PCB, and are kept with gap between the devices; at least one layer of ground copper is arranged in the PCB; ground copper is arranged on the bottom or other positions of the large-power devices on the device surface of the PCB; and a ground hole is formed on the device surface of the PCB. Based on the technical scheme provided by the invention, the heat dissipation processing device provided by the invention can improve the overall electromagnetic compatibility index, radio frequency index and structural reliability index while the mobile terminal electronic system is subjected to the effective heat dissipation treatment.

Owner:ZTE CORP

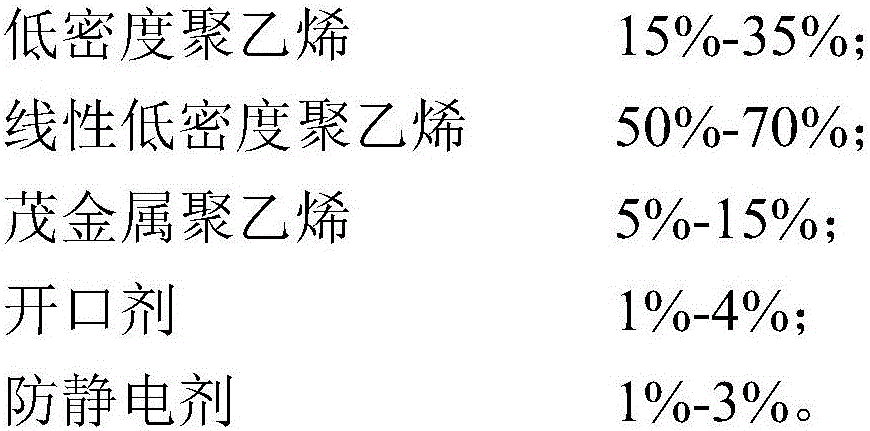

High-strength antistatic polyethylene film as well as preparation method and application thereof

InactiveCN106432888AImprove mechanical propertiesEasy to stretchBag making operationsPaper-makingLow-density polyethyleneBlow molding

The invention discloses a high-strength antistatic polyethylene film. The polyethylene film contains the following components in percentage by weight: 15-35% of low-density polyethylene, 50-70% of linear low-density polyethylene, 5-15% of metallocene polyethylene, 1-4% of an anti-blocking agent, and 1-3% of an antistatic agent. Besides, the invention also discloses a preparation method and application of the high-strength antistatic polyethylene film. The high-strength antistatic polyethylene film provided by the invention is prepared by the steps of taking the low-density polyethylene (LDPE) as a base material, adding the linear low-density polyethylene (LLDPE) and the metallocene polyethylene (MLLPE) and performing blending extrusion, granulation and blow molding, so that the polyethylene film has relatively good tensile strength and antistatic property; and a packaging bag prepared from the high-strength antistatic polyethylene film has the characteristics of good economical efficiency and mechanical property, lasting antistatic property and convenience in use.

Owner:东莞市中为包装制品有限公司

High-toughness melamine resin and preparing method thereof

The invention discloses a high-toughness melamine resin and a preparing method thereof. An elastomer is adopted to be added in melamine resin with the form of powder and emulsion, the impact strength of melamine resin is improved, and high-toughness melamine resin is prepared. The preparing method of melamine resin comprises the steps of placing 40-85 parts of melamine-formaldehyde resin prepolymer, 5-50 parts of fiber, 0.1-0.5 part of curing agent, 5-30 parts of elastomer and 0.1-1 part of flowable agent into a kneading machine at 25-80 DEG C to be subjected to kneading for 30-90 min, afterwards placing kneaded materials into a stove at 70-130 DEG C to be subjected to stoving and dehydration, and then conducting ball milling on the kneaded materials and 3-10 parts of inorganic filler in a ball mill for 4-20 h to obtain high-roughness melamine powder. The other preparing method comprises the steps of placing prepolymer, the fiber, the curing agent and the elastomer into the kneading machine to be subjected to kneading, afterwards putting the kneaded materials into the stove to be subjected to stoving and dehydration to obtain irregular blocky solid, and then conducting ball milling on the blocky solid, inorganic filler and elastomer powder in the ball mill according to matching to obtain the high-roughness melamine powder. The preparation of the high-roughness melamine material is beneficial to reducing the breakage rate of a melamine product in use, and prolonging the service life of the melamine product.

Owner:ZHEJIANG UNIV OF TECH +1

Ceramic shell structure member and preparation method thereof, and mobile phone

ActiveCN104068595AReduce the chance of breakageImprove drop resistanceOther accessoriesTelephone set constructionsMetal matrix compositeCeramic

Embodiments in the invention provide a ceramic shell structure member, comprising a ceramic shell and a frame equipped with a recessed part, wherein the ceramic shell comprises a ceramic flat plate and a ceramic protruding member outwardly protruding from the side surface of the ceramic flat plate, the ceramic protruding member is arranged in the recessed part of the frame so as to allow the ceramic shell to be compactly jointed with the frame, the upper surface of the joint of the frame and the ceramic protruding member is aligned with the upper surface of the ceramic flat plate along the thickness direction of the ceramic flat plate, and the frame covers the side surfaces of the ceramic shell or the side and bottom surfaces of the ceramic shell and is made of an alloy, a metal-based composite or plastic. According to the invention, the frame can protect the edges of the ceramic shell from direct collision with other objects, the ceramic protruding member can increase the bonding force between the ceramic shell and the frame, so the integral anti-breaking capability of the ceramic shell structure member is improved and the application scope of the ceramic shell structure member is broadened. The embodiments in the invention further provide a preparation method for the ceramic shell structure member and a mobile phone. The mobile phone comprises the ceramic shell structure member.

Owner:HUAWEI TECH CO LTD

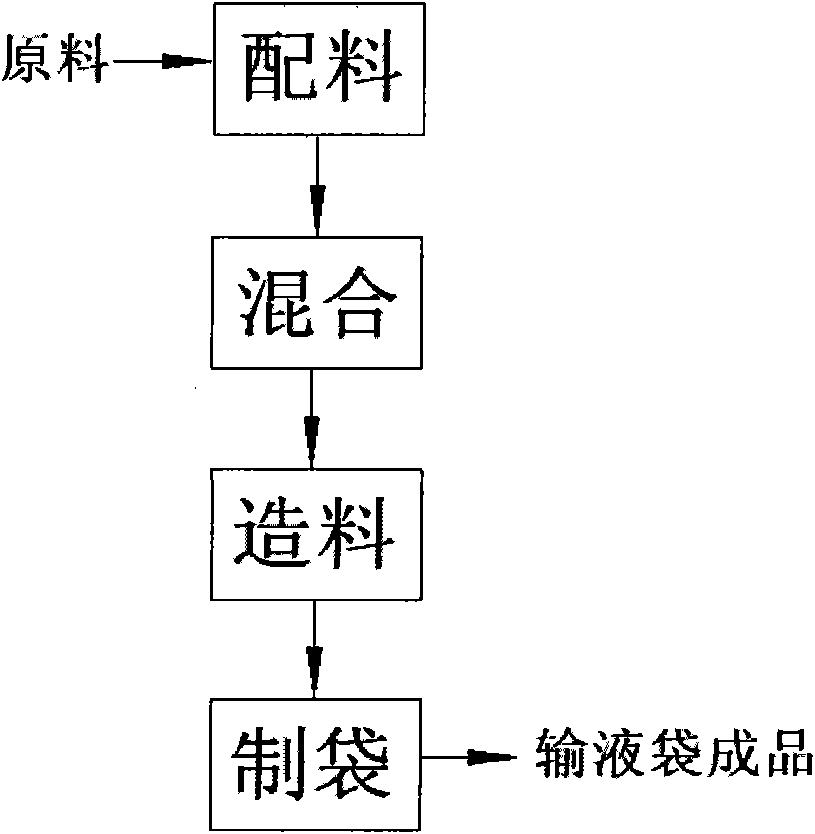

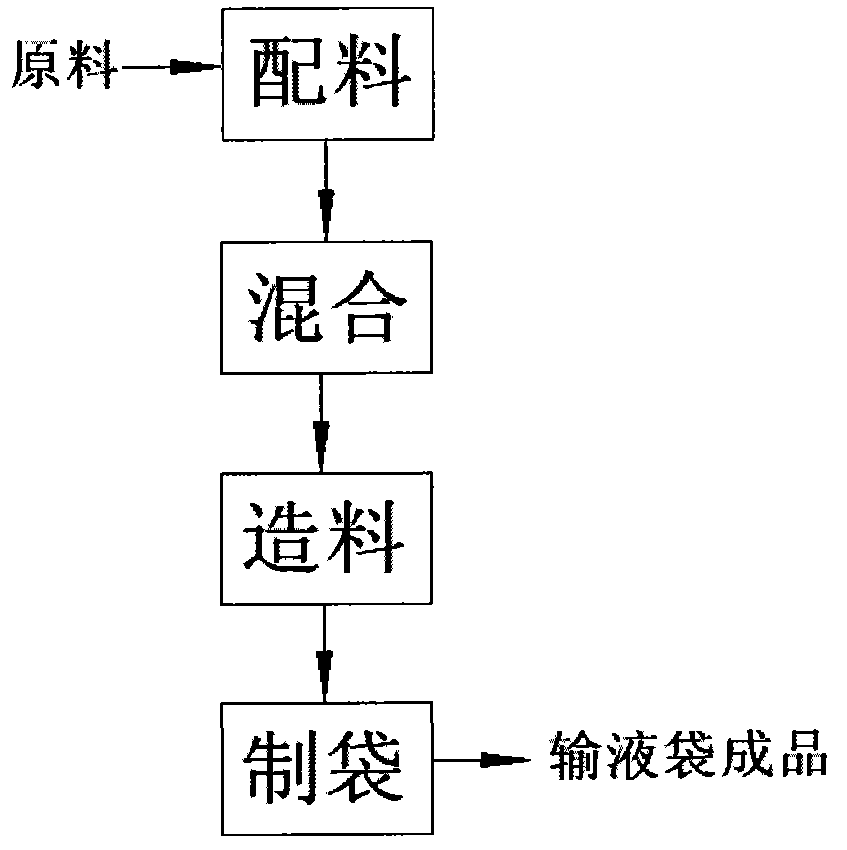

Manufacturing process and production equipment for medical infusion bags

InactiveCN101845173AImprove air tightnessImprove barrier propertiesPharmaceutical containersMedical packagingForeign matterPolypropylene

The invention discloses a medical infusion bag. The infusion bag is manufactured by using polypropylene and polyethylene and styrene-ethylene / butylene-styrene block copolymer. The infusion bag manufactured by adopting the technical scheme has the advantages that: the air-tightness and the steam resistance are excellent, the chemical stability is high, and the infusion bag is suitable to be used for manufacturing liquid medicinal products requiring high-temperature disinfection and sterilization; the transparence is high, and the detection of foreign materials when the infusion bag is produced and used is ensured; the softness is high, the falling resistance is high, the heat-sealing property is high, the high-temperature resistance is high, and the infusion bag can be sterilized at the temperature of 121 DEG C; because the infusion bag does not contain halogens, the infusion bag does not cause any environmental pollution when processed after use; and simultaneously, the barrier property is high, the chemical inertness and the biological inertness are high, the compatibility with medicaments is good, and the infusion bag can be used for packaging various kinds of common fluid, enteral nutrient fluid, parenteral nutrient fluid, dialyzate, flushing fluid, treating type large-capacity injection and the like.

Owner:ANHUI DOUBLE CRANE PHARMA

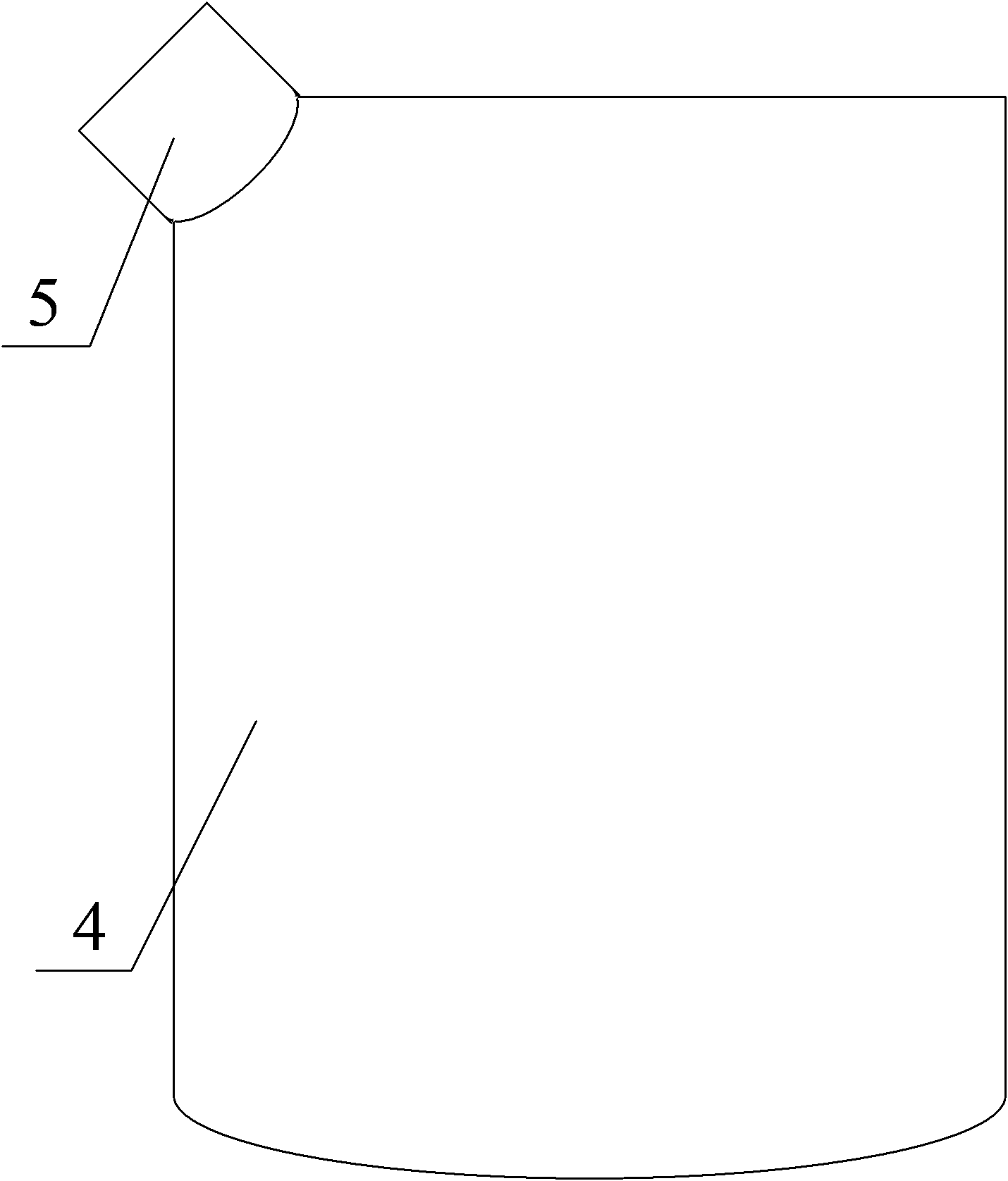

Drop-preventing terminal and terminal drop preventing method

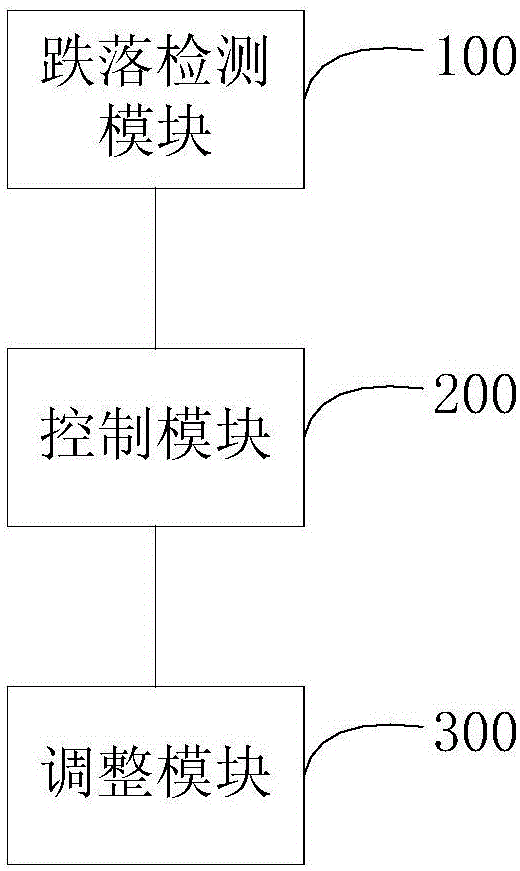

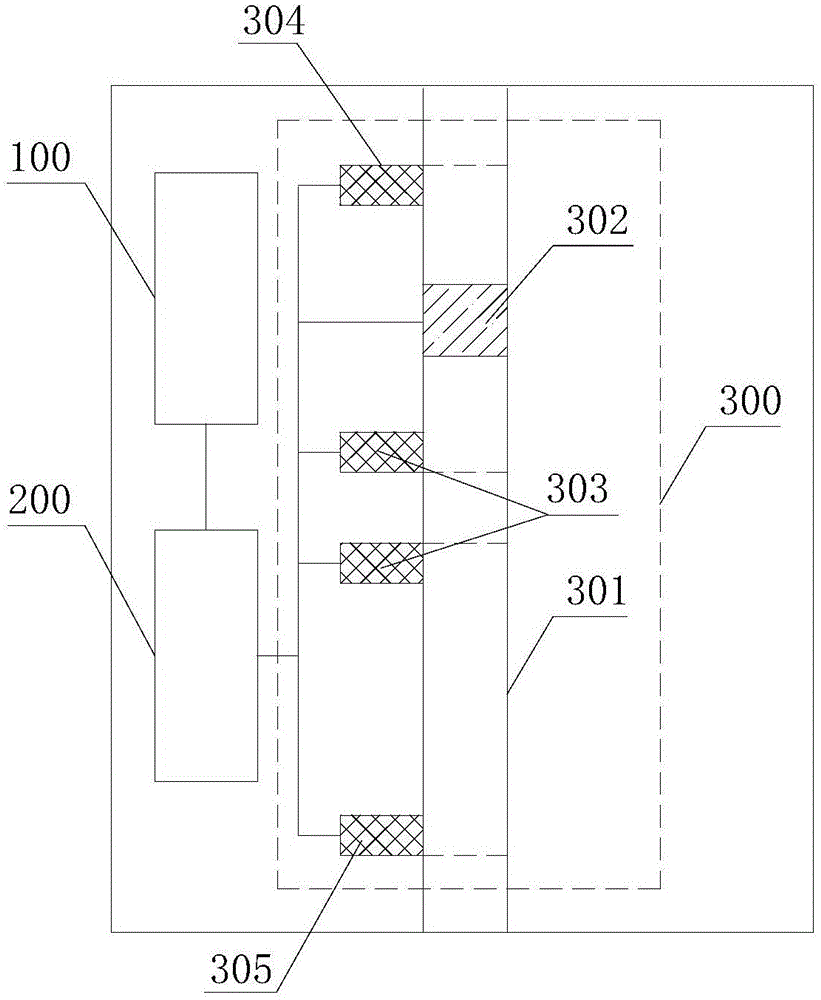

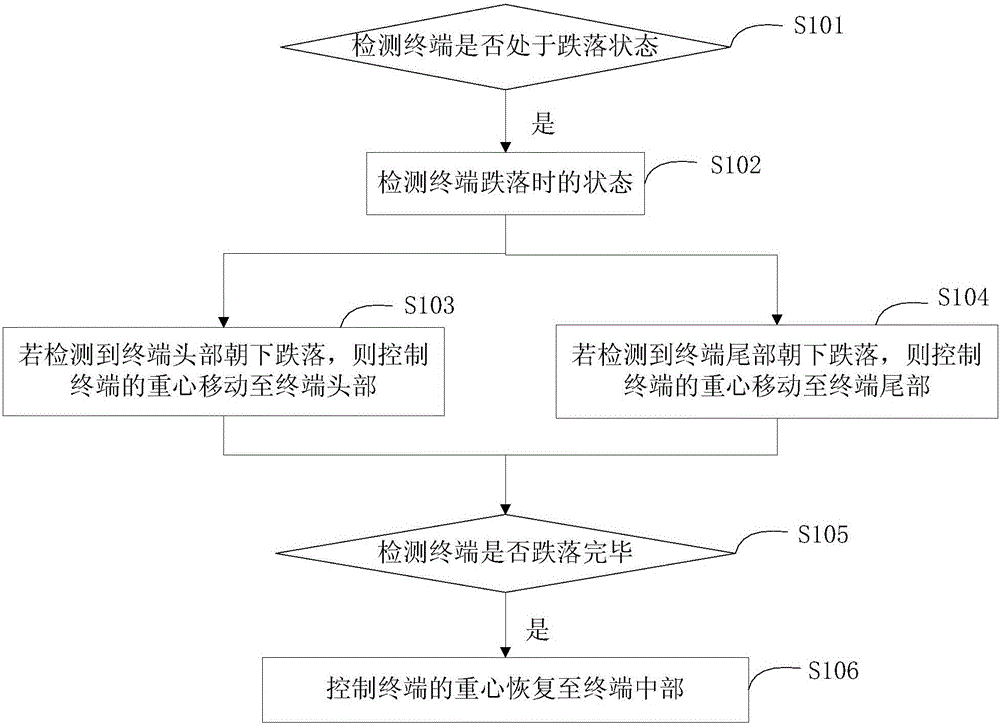

ActiveCN105162912AAvoid landingImprove drop resistanceTelephone set constructionsGravitationState control

The invention belongs to the technical field of terminals and specifically relates to a drop-preventing terminal and a terminal drop preventing method. The drop-preventing terminal comprises a terminal body, and also a drop detection module, a control module and an adjustment module; the drop detection module is used for detecting the state of the terminal while dropping; the control module is used for controlling the adjustment module according to the state; the adjusting module is used for shifting the center of gravity of the terminal according to the control of the control module. According to the drop-preventing terminal, the center of gravity of the terminal is controlled to shift according to the state of the terminal while dropping, to guide the terminal to drop vertically as much as possible, and therefore, the drop point of the terminal is guided to the head or the tail of the terminal and the side portions of the terminal are prevented from landing, and therefore, the drop prevention property of the terminal is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com