Two-step-method chemically strengthened alkali aluminosilicate glass composition and preparation method thereof

A technology of glass composition and alkali-aluminosilicate, applied in the field of glass materials, can solve the problems of insufficient Li ion and Na ion exchange capacity, difficulty in quickly obtaining high DOL value strengthened glass, etc., and achieve the effect of improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further disclose rather than limit the present invention, the present invention will be further described in detail below in conjunction with examples.

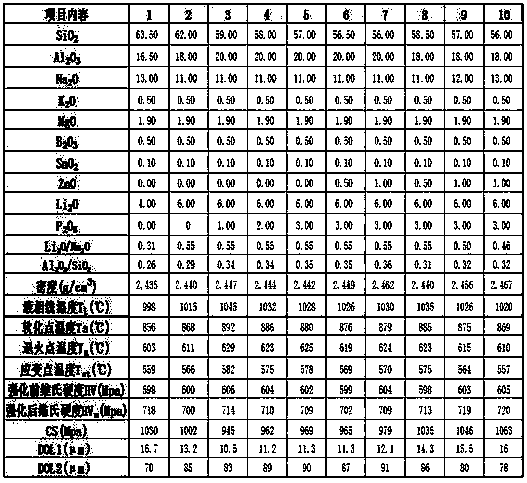

[0036] Table 1 is some examples of the present invention, according to the molar percentage of each oxide in table 1, weigh glass raw material, raw material weighs and puts into plastic bottle and mixes, to obtain uniform compound; Transfer to an 800ml platinum crucible, place the platinum crucible in a silicon-molybdenum rod high-temperature furnace, gradually raise the temperature to 1650°C, keep it warm for 4-6 hours, accelerate the discharge of glass bubbles and homogenize and eliminate the glass by stirring. After melting, pour the molten liquid into a heat-resistant stainless steel mold for molding, then take out the glass block and move it into a box-type annealing furnace for heat treatment at 600°C for 2 hours, and then lower it to 550°C at a rate of less than 1°C / min. Then naturally cool to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com