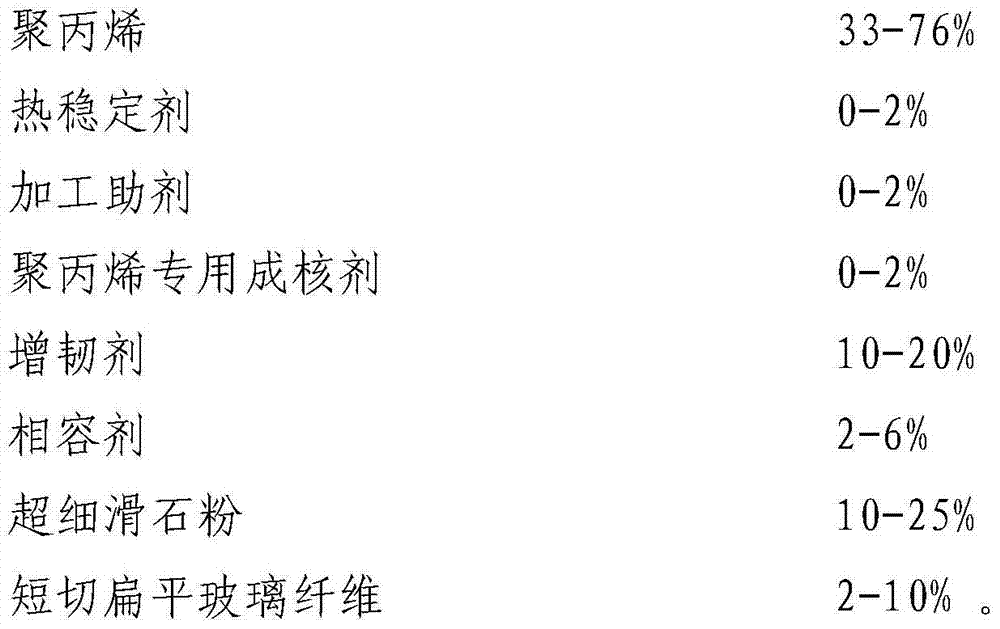

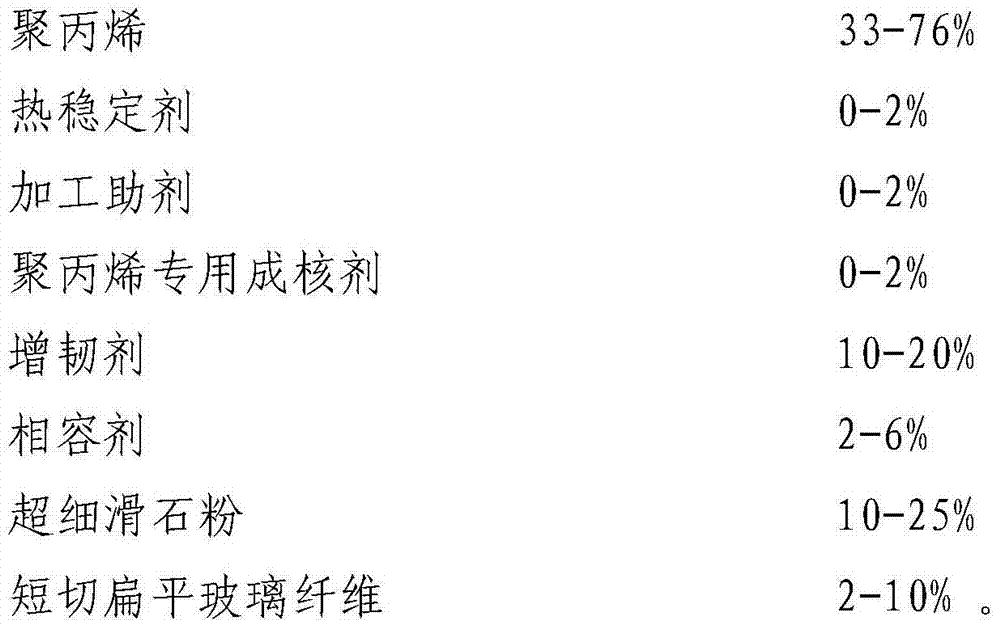

Polypropylene composite material for automobile hard plastic instrument panel and preparation method for polypropylene composite material

A composite material and polypropylene technology, which is applied in the field of polypropylene composite materials for automotive rigid plastic instrument panels and their preparation, can solve the problems of deteriorating instrument panel material odor, not meeting consumer demands, and rising material costs, and achieves excellent resistance. Scratch effect, low gloss, high dimensional stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 70 kg of polypropylene PP (BX3800), 0.2 kg of phenolic heat stabilizer 1010, 0.3 kg of phosphite heat stabilizer 168, 0.3 kg of processing aid EBS, 0.2 kg of special nucleating agent for polypropylene TMP-5, 12 One kilogram of ethylene octene copolymer POE LC670, 2 kilograms of maleic anhydride grafted polypropylene CA-100, 11 kilograms of 3000 mesh ultrafine talc powder were melt mixed and dispersed in a twin-screw extruder with an aspect ratio of 40:1;

[0029] Then 4 kg of chopped alkali-free flat glass fiber (aspect ratio = 4) is weighed by a loss-in-weight weighing scale and then accurately added from a side feeding device to finally obtain the product. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 190°C, the temperature of the second zone is 200°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone ...

Embodiment 2

[0033] 59 kg of polypropylene PP (BX3900), 0.5 kg of phenolic heat stabilizer 1010, 0.5 kg of phosphite heat stabilizer 168, 0.5 kg of processing aid EB-FF, 0.5 kg of polypropylene special nucleating agent HPN-20E , 15 kilograms of ethylene octene copolymer POE8130, 4 kilograms of maleic anhydride grafted polypropylene Bondyram1001CN, 13 kilograms of 5000 mesh superfine talcum powder are melt mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1; then 7 kg of chopped alkali-free flat glass fiber (aspect ratio = 6) is weighed by a loss-in-weight weighing scale and then accurately fed from a side feeding device to obtain the final product. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 190°C, the temperature of the second zone is 200°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zo...

Embodiment 3

[0037] 45 kg of polypropylene PP BX3920, 1 kg of phenolic heat stabilizer 1010, 1 kg of phosphite heat stabilizer 627A, 1 kg of processing aid zinc stearate, 1 kg of polypropylene special nucleating agent HTPUTRA5, 20 kg Ethylene octene copolymer POE8137, 6 kilograms of maleic anhydride grafted polypropylene Bondyram1001, 15 kilograms of 3000 mesh talc powder were melt mixed and dispersed in a twin-screw extruder with an aspect ratio of 40:1.

[0038] 10 kg of chopped non-alkali flat glass fiber (aspect ratio = 7) is accurately fed from the side feeding device through a loss-in-weight weighing scale, and finally the product is obtained. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 190°C, the temperature of the second zone is 200°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 240°C. The specific perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com