Patents

Literature

769results about How to "Improve forming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

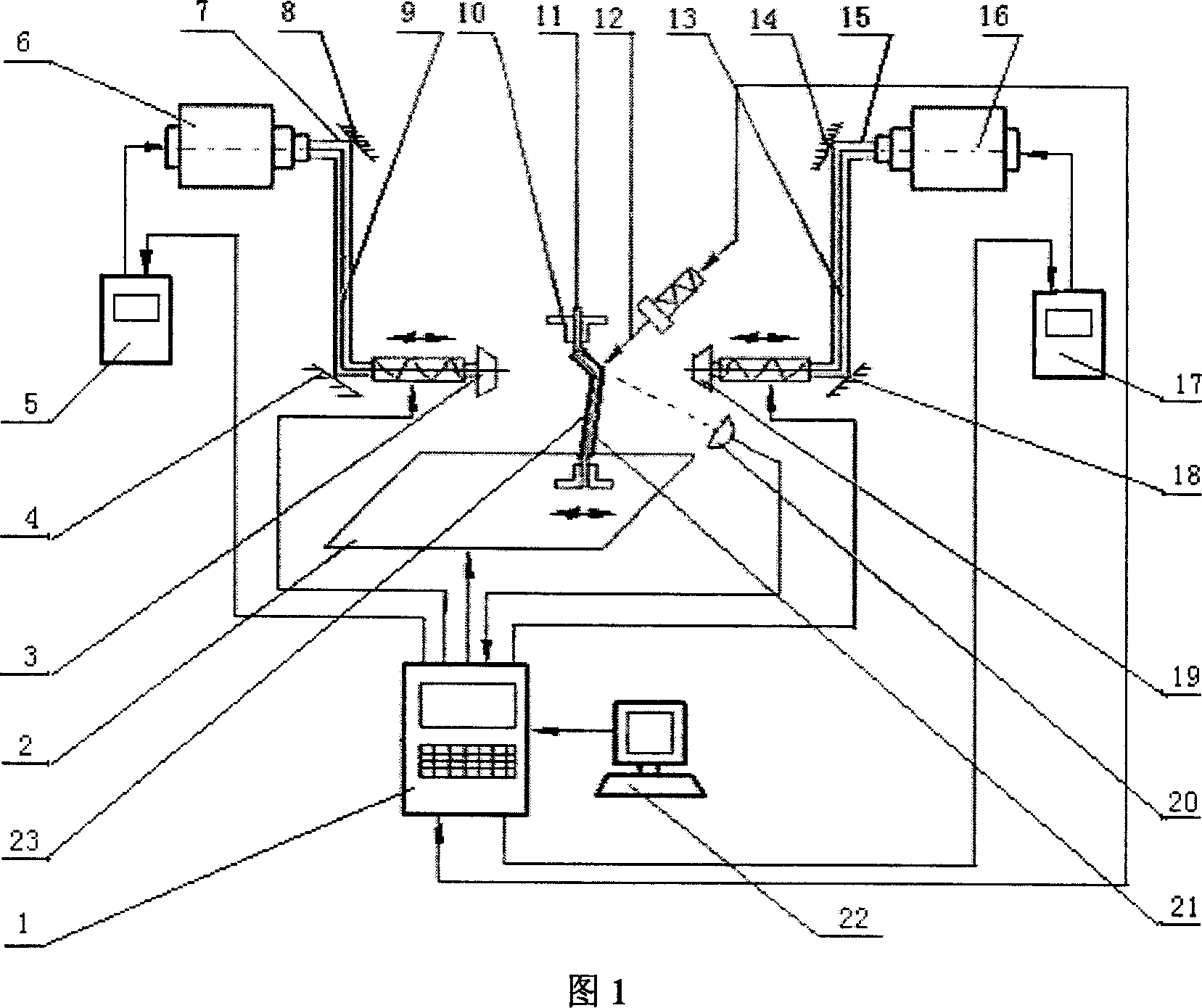

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

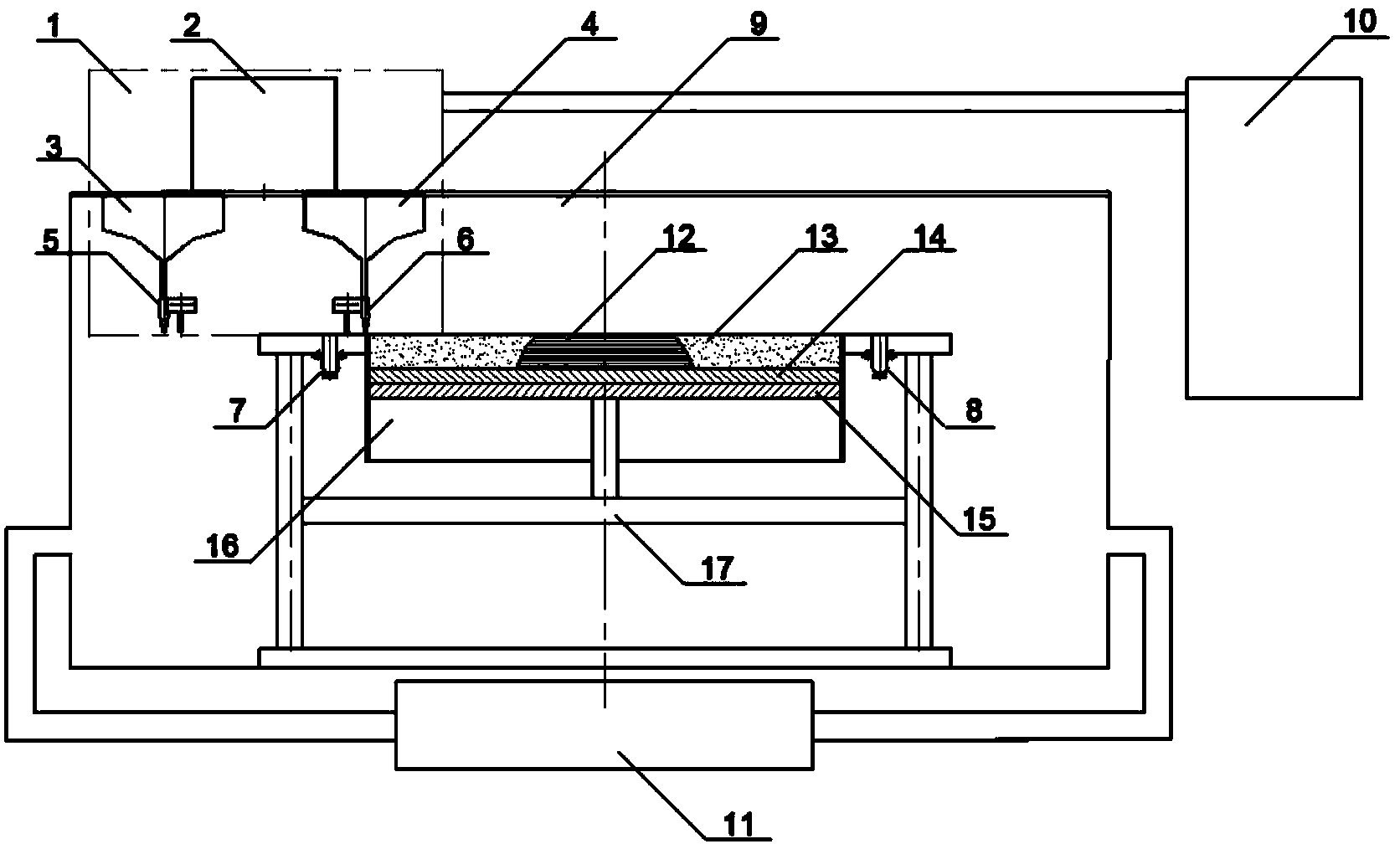

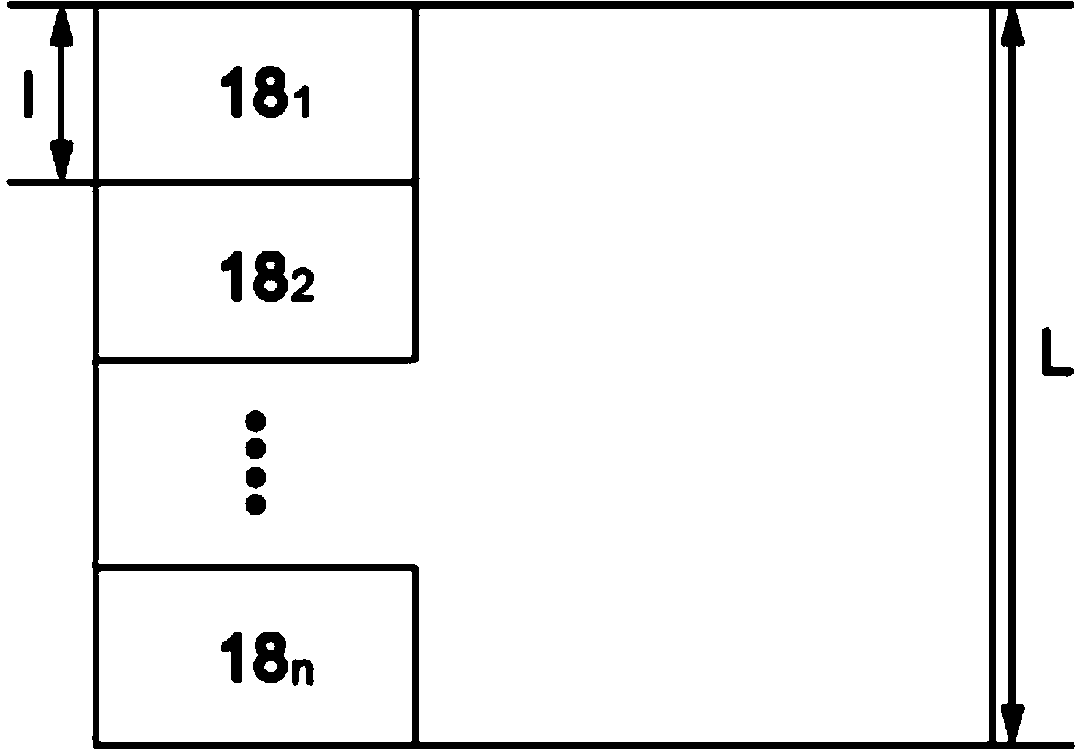

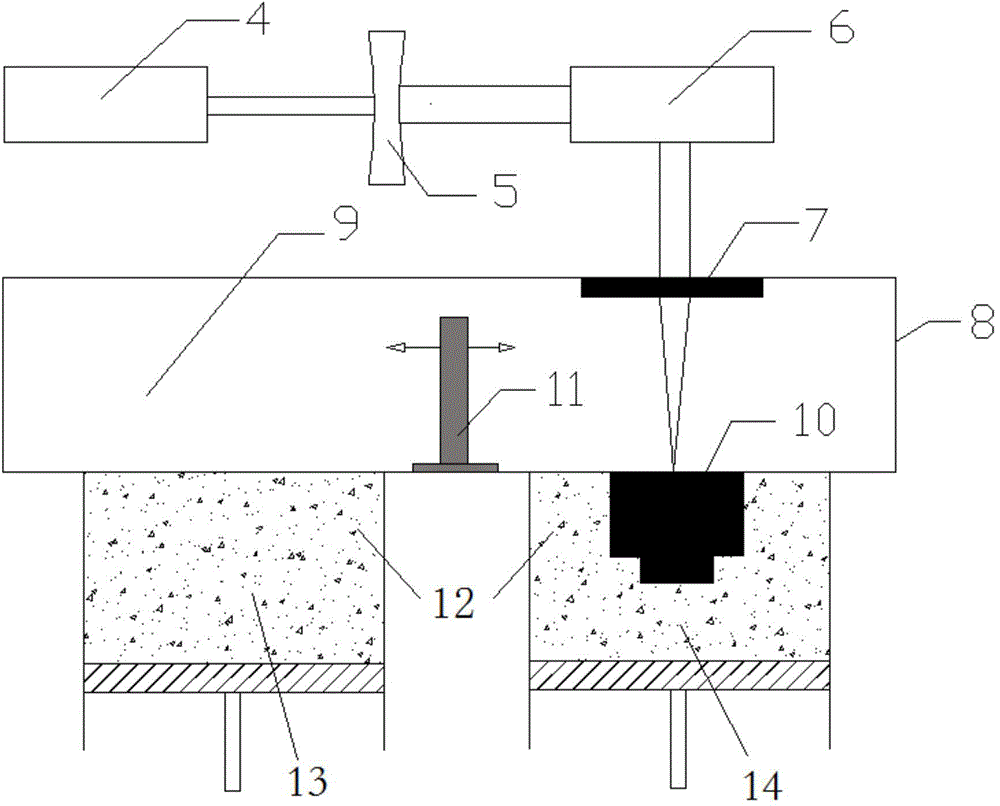

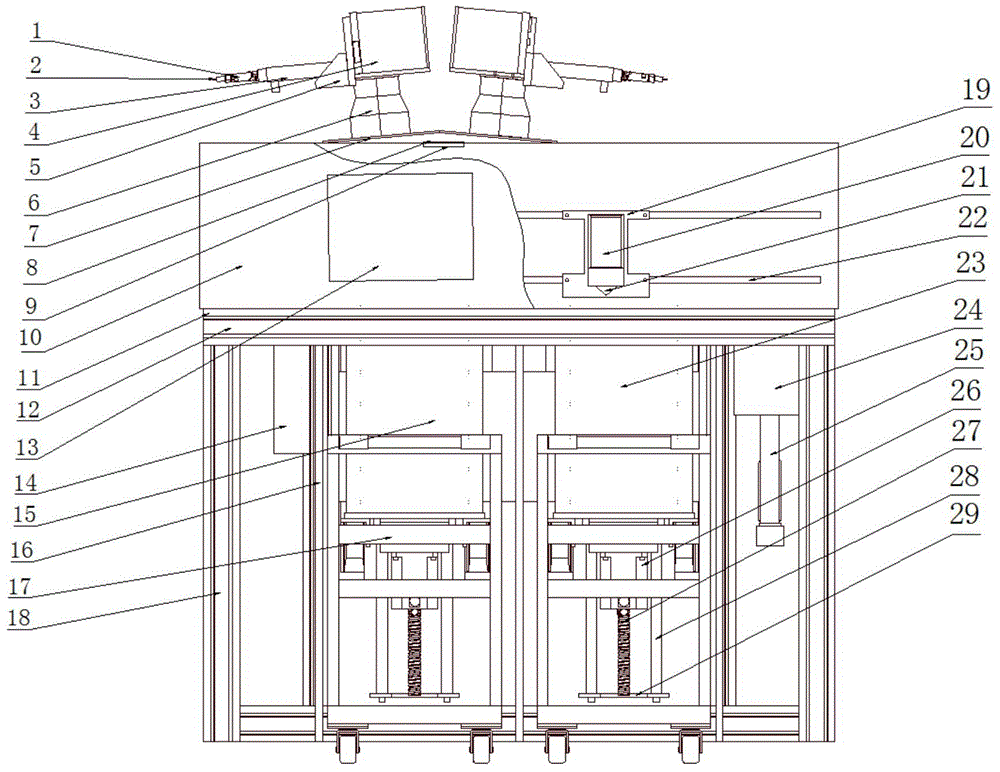

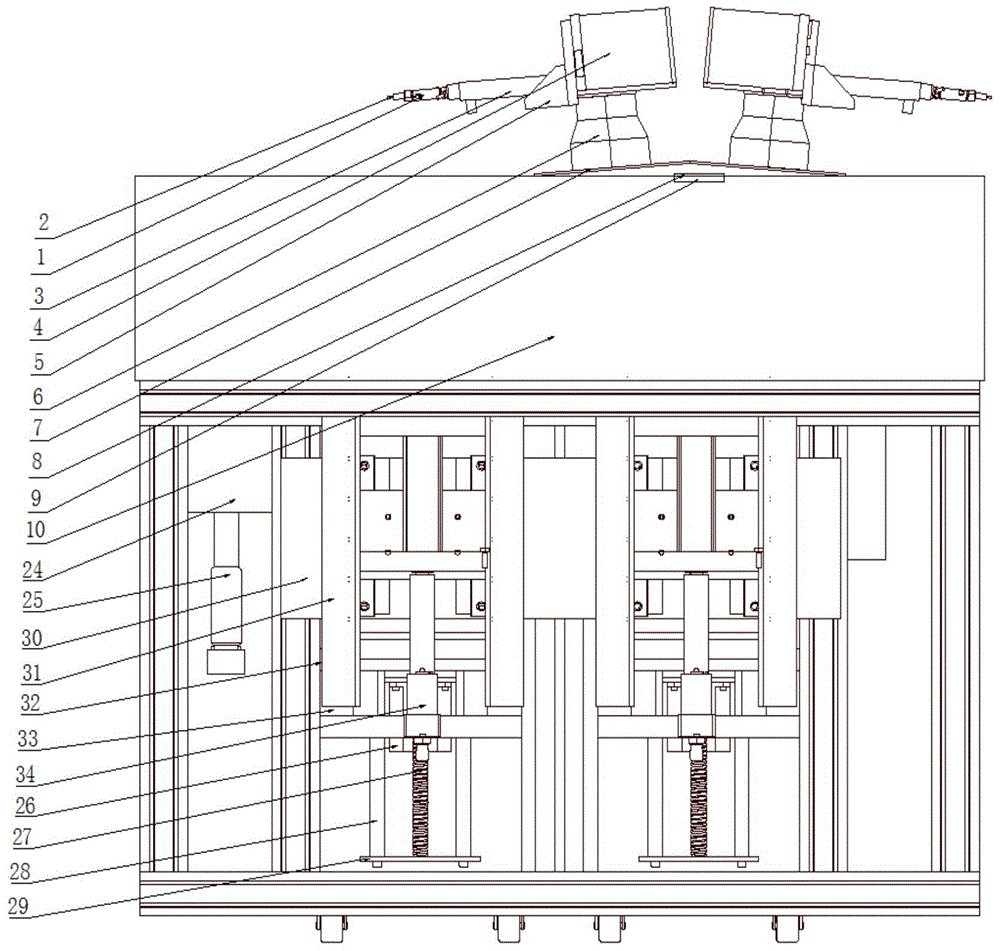

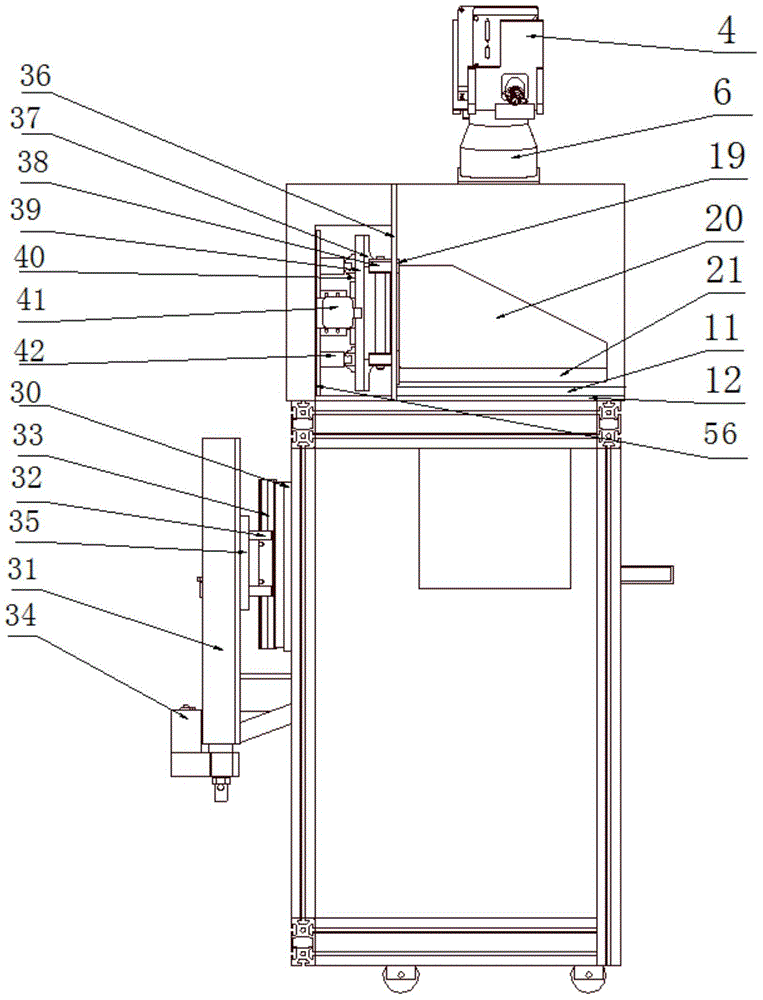

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

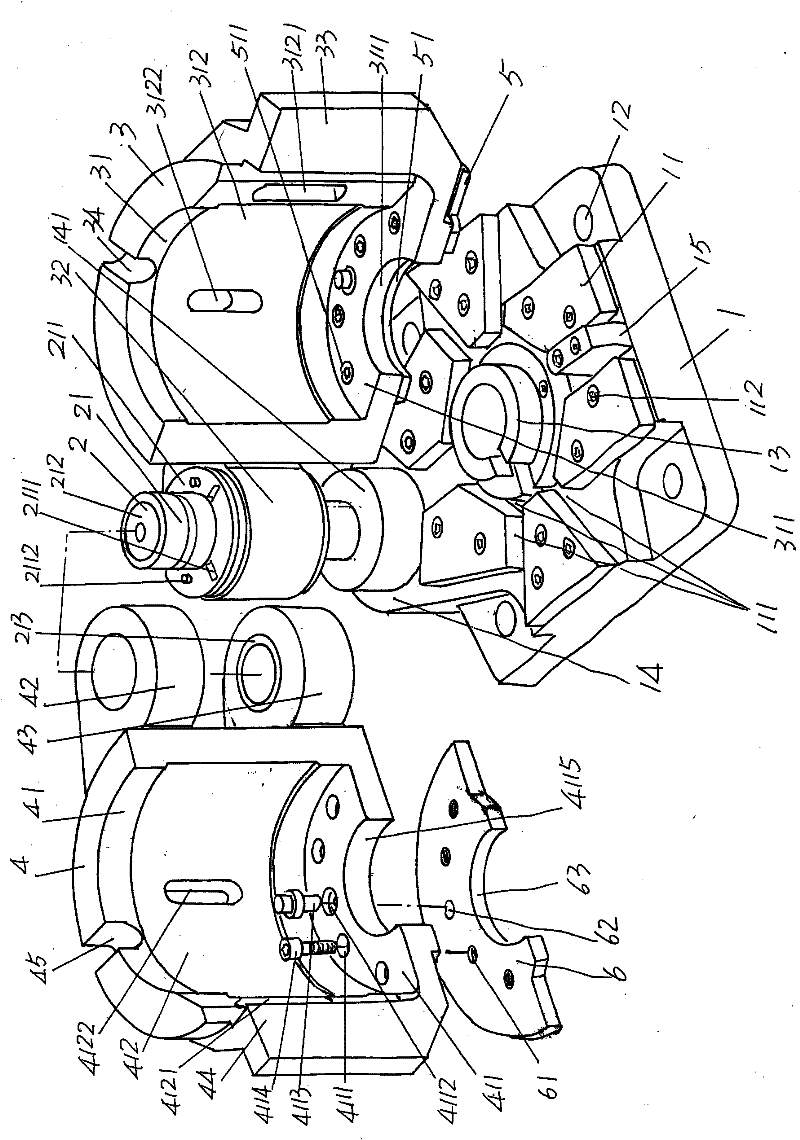

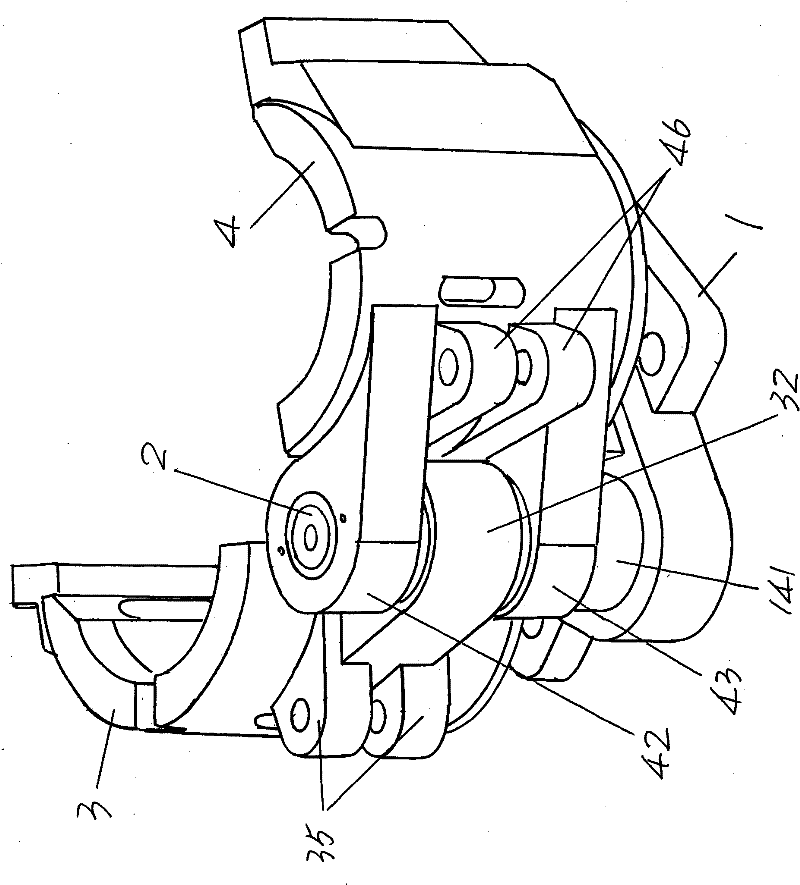

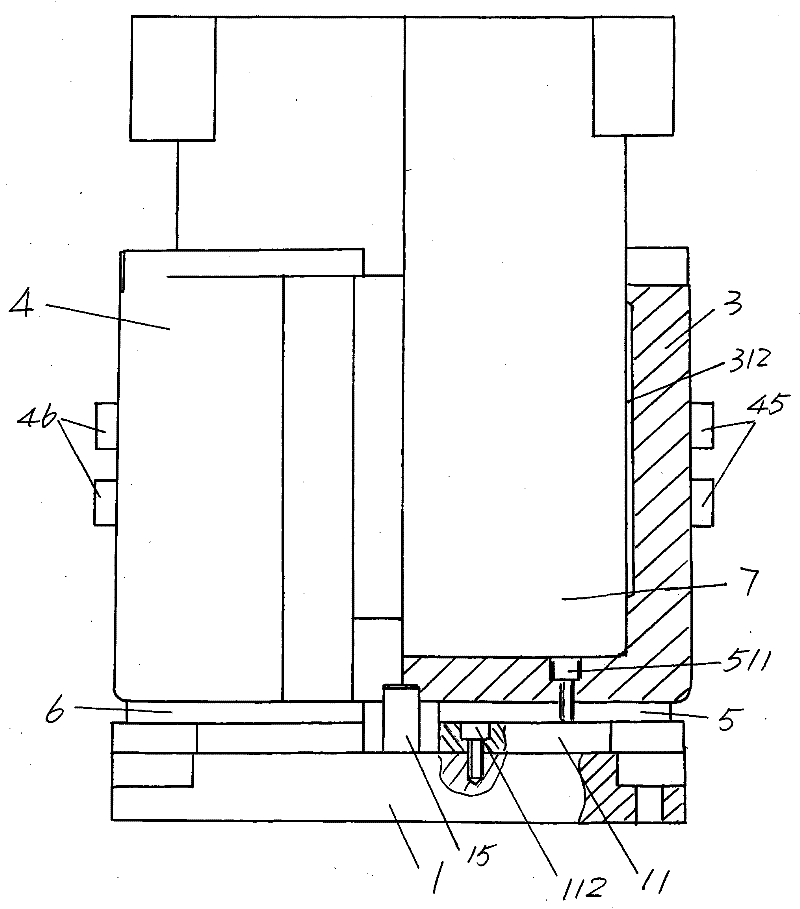

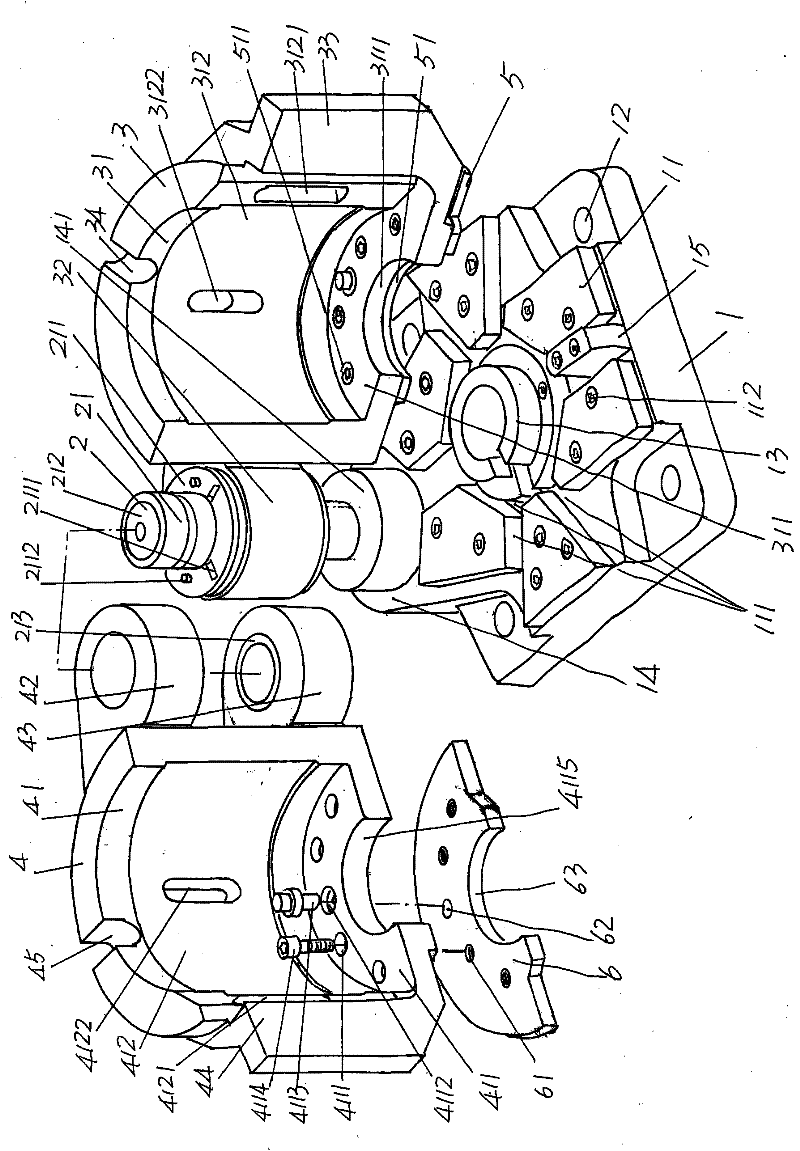

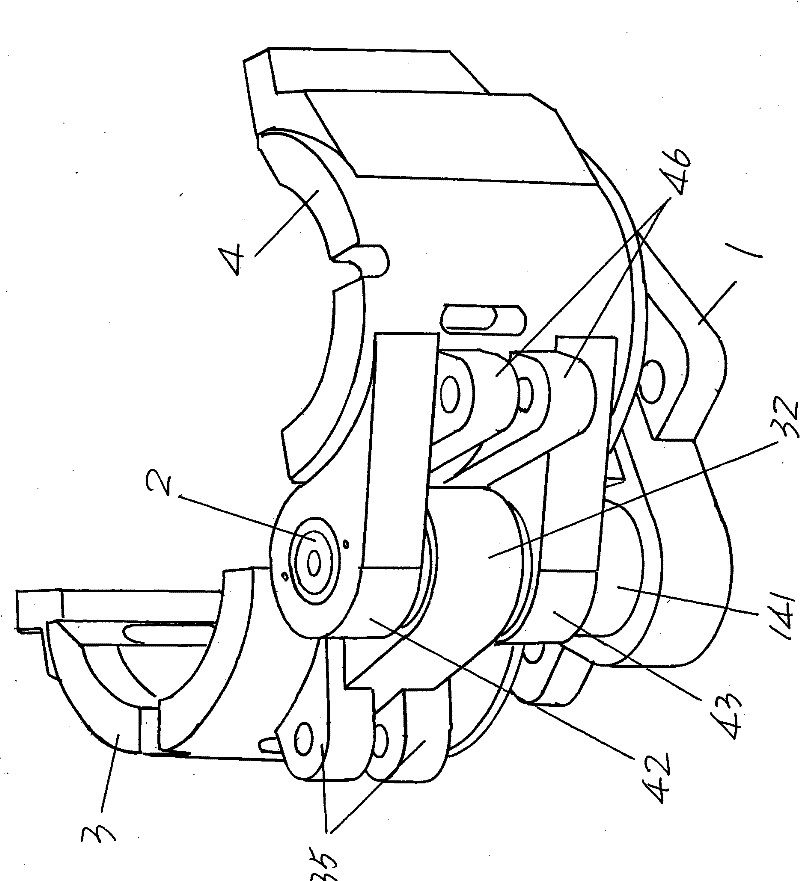

Ware mould clamp of glassware

ActiveCN101891373BAvoid direct contactReduce frictionGlass pressing apparatusMechanical engineeringEngineering

Owner:CHANGSHU JIANHUA MOLD TECH

Glassware mould fixture

ActiveCN101891372BImprove cooling effectReduce frictionGlass pressing apparatusMechanical engineering

A glassware mould fixture belongs to the technical field of glassware moulds, which comprises a base, pivot shafts, a first fixture half mould and a second fixture half mould, and is characterized in that the surface of the base, which corresponds to the first and the second fixture half moulds, is provided with a group of base splice pieces, wherein the surface of one side of a first ware half mould bottom wall of a first ware half mould cavity, which corresponds to the base, is provided with first half mould splice pieces, the surface of one side of a second ware half mould bottom wall of asecond ware half mould cavity, which corresponds to the base, is provided with second half mould splice pieces, the first and the second half mould splice pieces are matched with the base splice pieces, a cylindrical boss is formed at the center of the upward surface of the base, a chip groove is arranged on the cylindrical boss, one group of the base splice pieces are arranged around the cylindrical boss, and chip gaps are left among the base splice pieces, and are communicated with the chip groove, and are further communicated with the outside. The glassware mould fixture has the advantagesof prolonging the service lives of the base, the first and the second fixture half moulds, conveniently cleaning, improving the shaping efficiency, and protecting a first, a second and a third pivot shaft bases.

Owner:CHANGSHU JIANHUA MOLD TECH

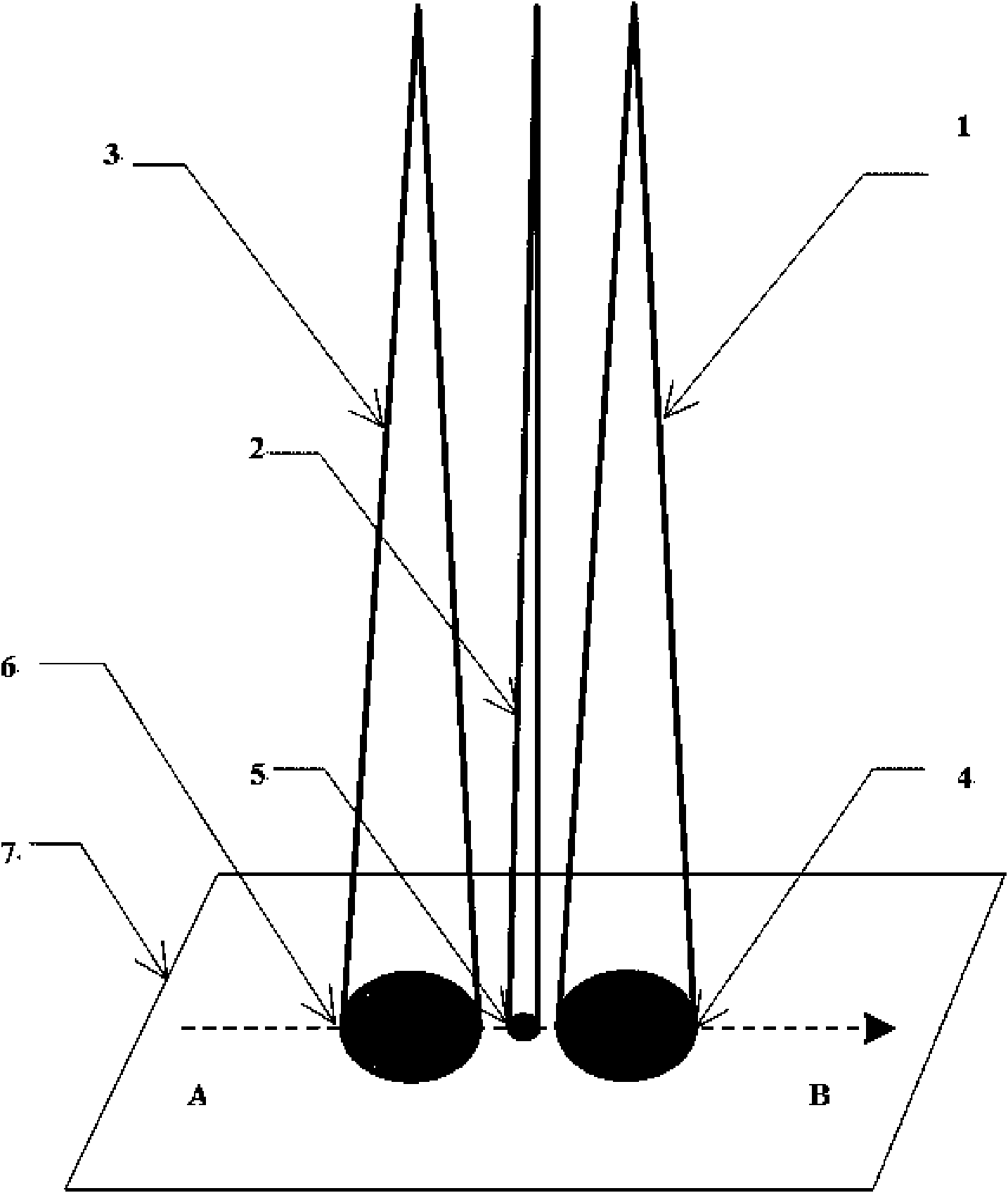

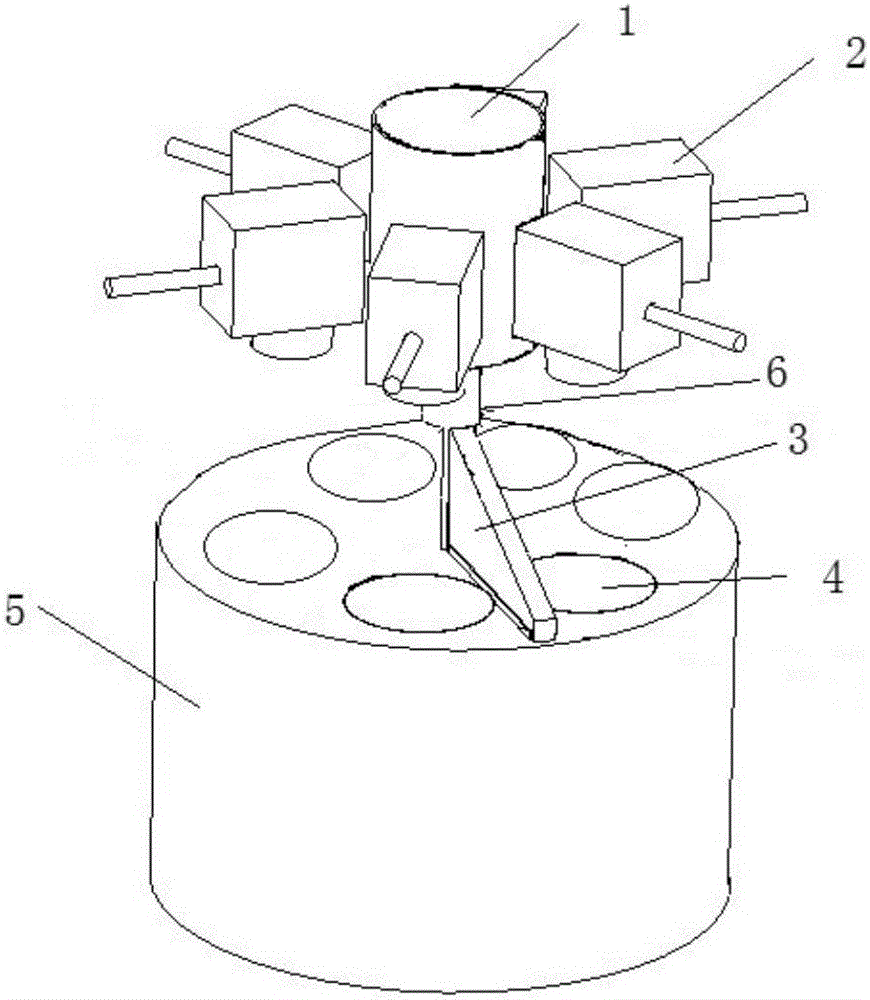

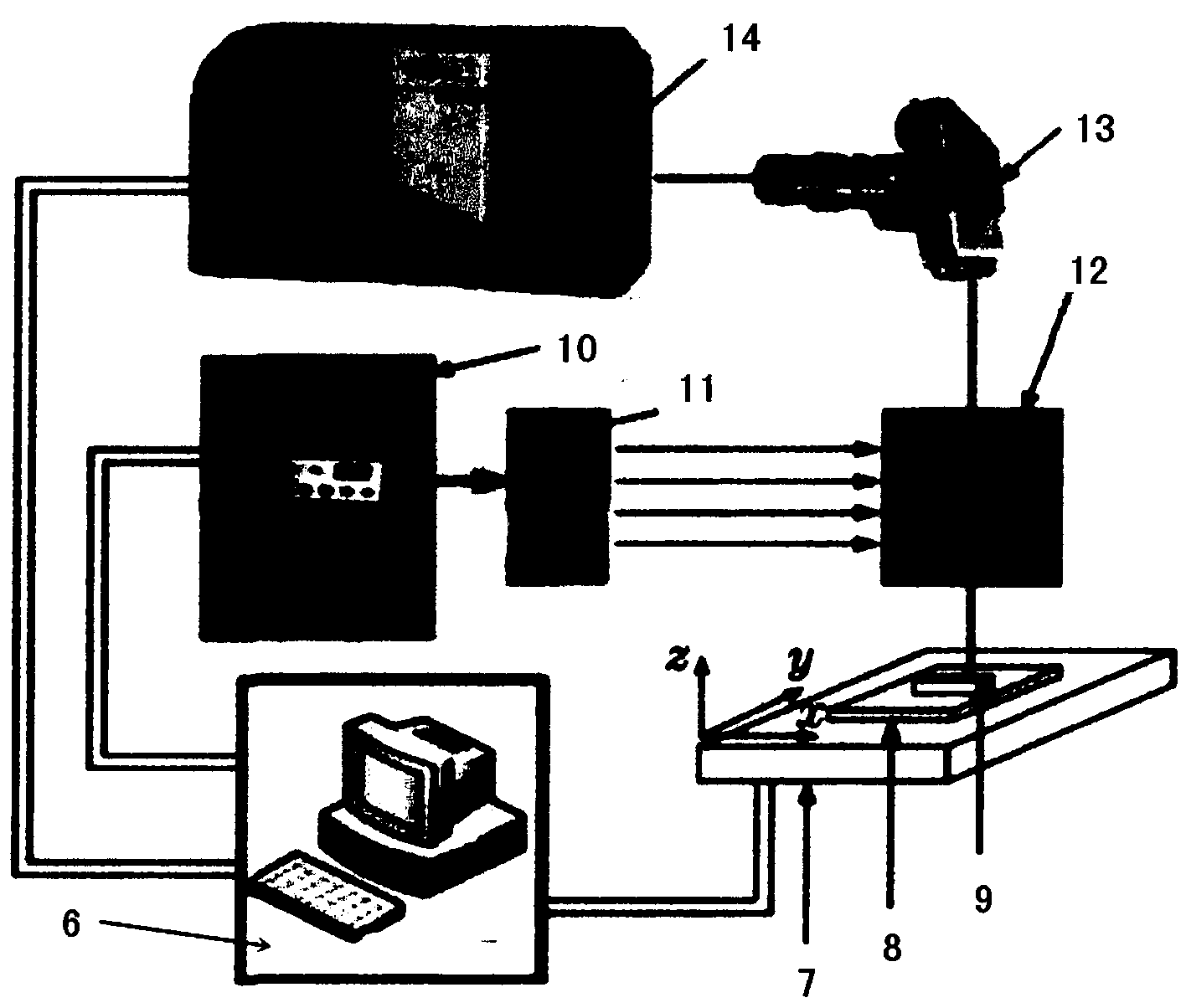

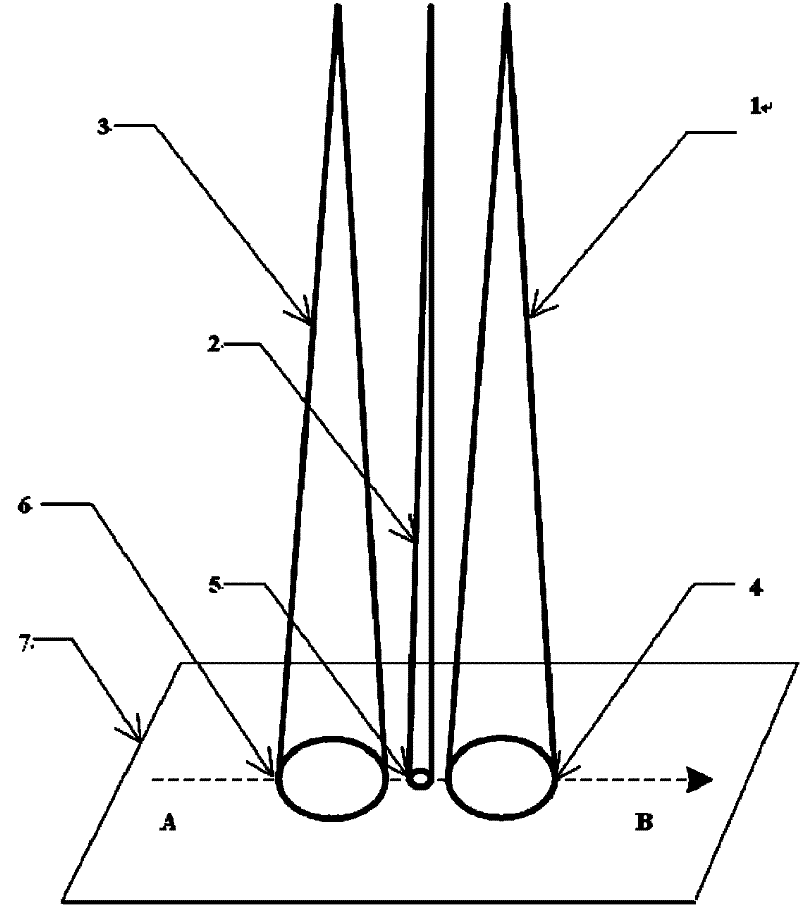

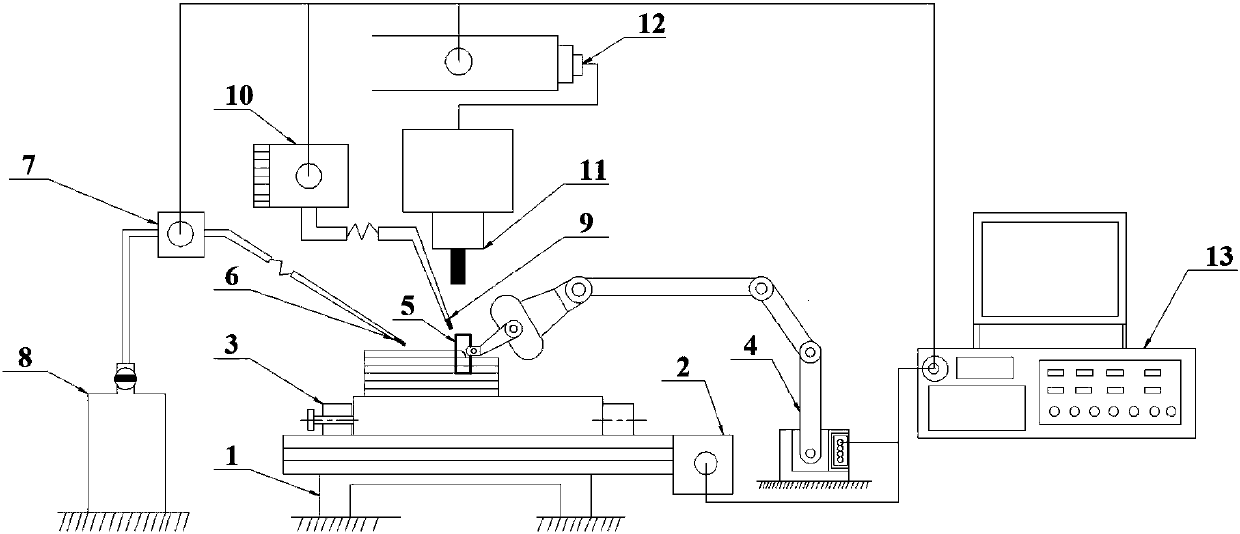

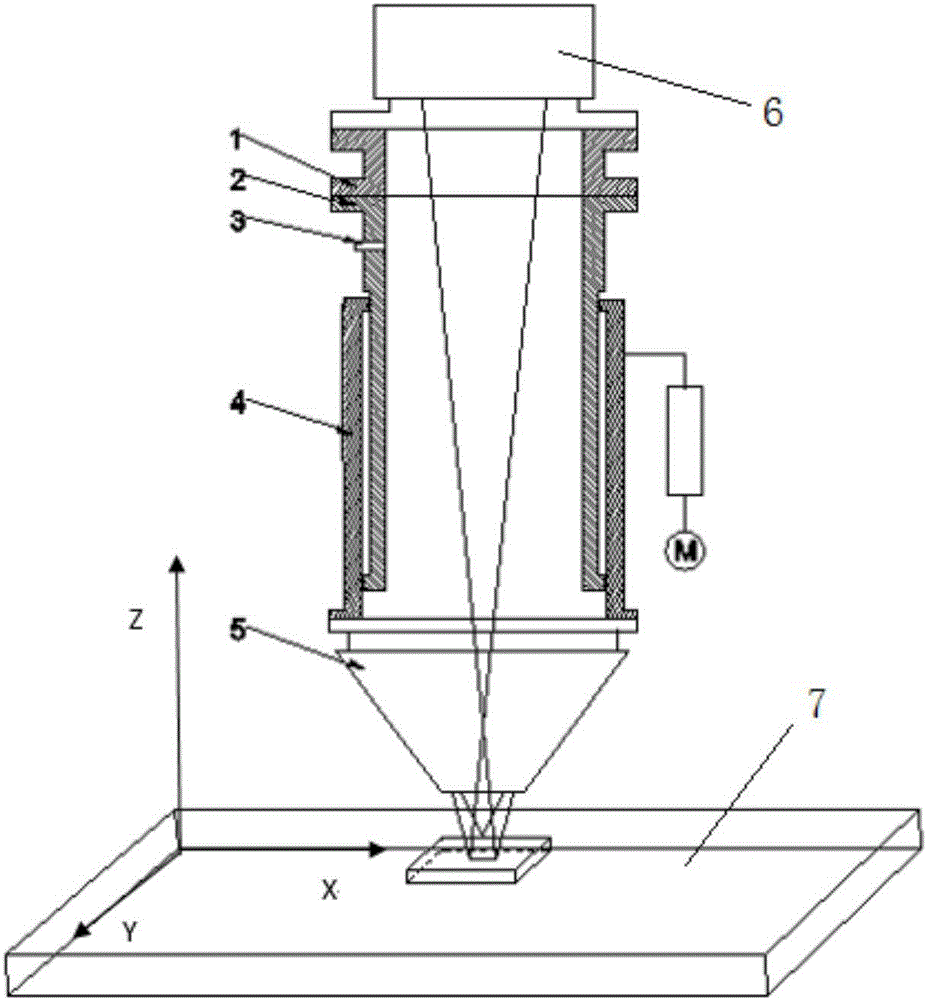

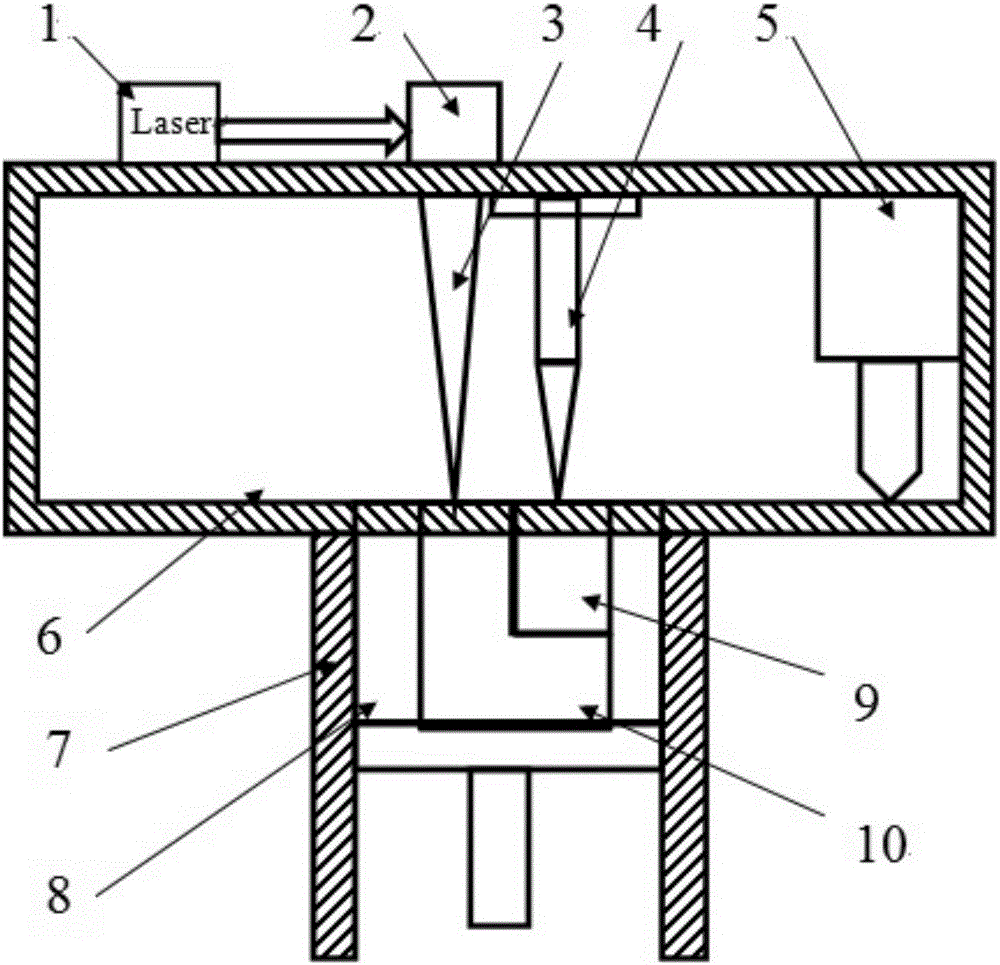

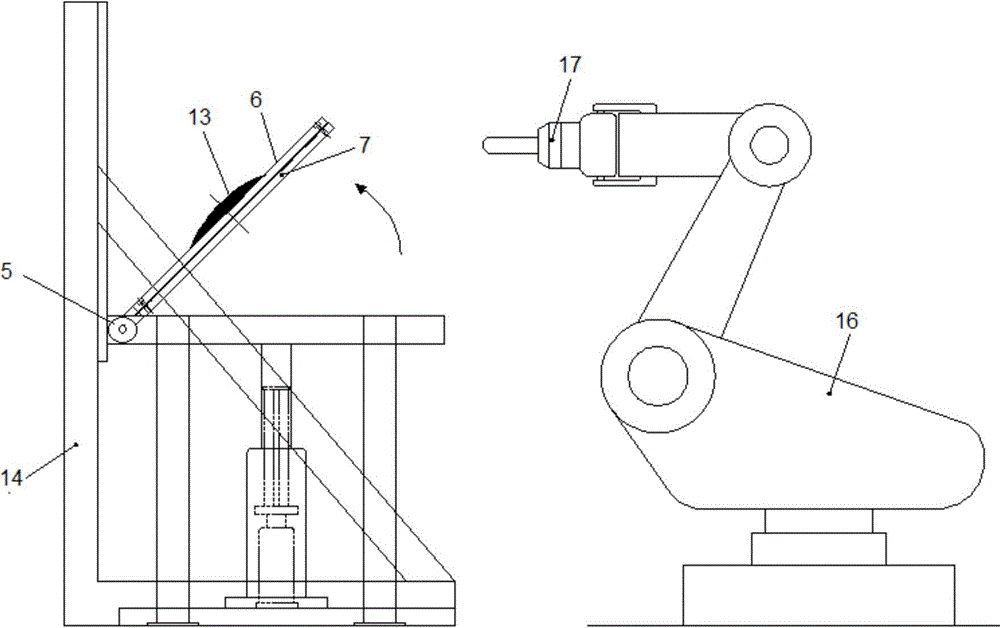

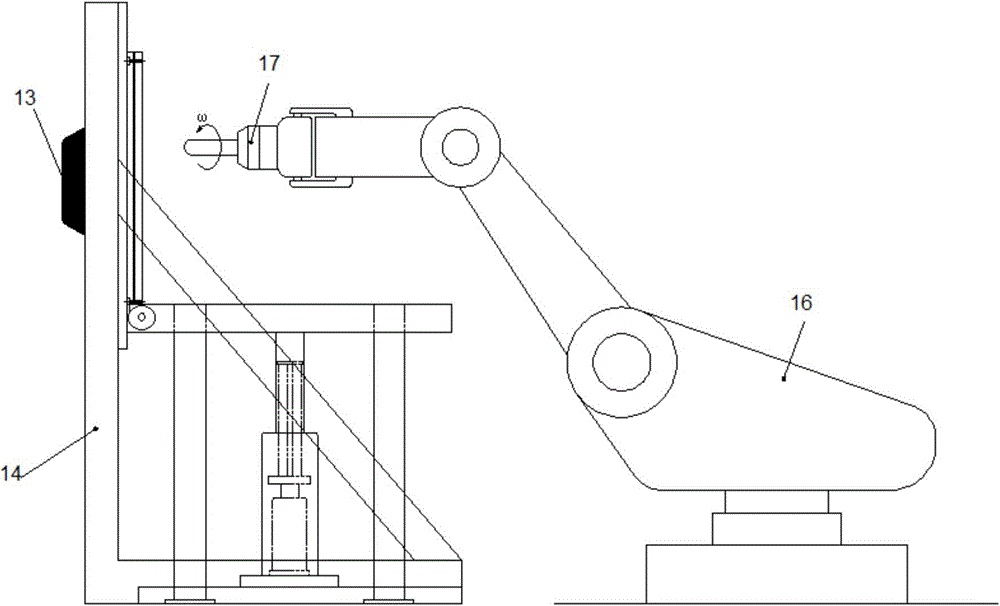

Synchronous powder feeding space laser machining and three-dimensional forming method and device

ActiveCN104190927APrecise couplingWon't flowAdditive manufacturing apparatusIncreasing energy efficiencySynchronous motorComputer module

The invention discloses a synchronous powder feeding space laser machining and three-dimensional forming method and device. A three-dimensional solid is divided into a plurality of forming units according to the form simplification and nozzle fusion covering scanning accessibility principle, each forming unit is divided into a plurality of laminates, a mode for single-beam gas-carried powder feeding in a hollow annular laser is adopted, a mechanical arm is controlled to drive an in-laser powder feeding nozzle to move for scanning in filling areas and boundary areas of the laminates according to a preset trajectory, and forming fusion covering and stacking forming of the laminates are sequentially completed, so that forming fusion covering and stacking forming of the whole unit are completed. The device comprises the in-laser powder feeding nozzle, a laser generator, the mechanical arm, a control module, a transmission optical fiber, a gas-carried powder feeder and a gas source. The control module is connected with the mechanical arm, the laser generator and the gas-carried powder feeder. The in-laser powder feeding nozzle is fixed to the front end of the mechanical arm and can make spatial motion along with the mechanical arm. Through the method and device, fusion covering and three-dimensional stacking forming on any surface of the space can be achieved, and supportless three-dimensional forming of parts with complex structures such as a hanging structure and a cavity can be achieved.

Owner:SUZHOU UNIV

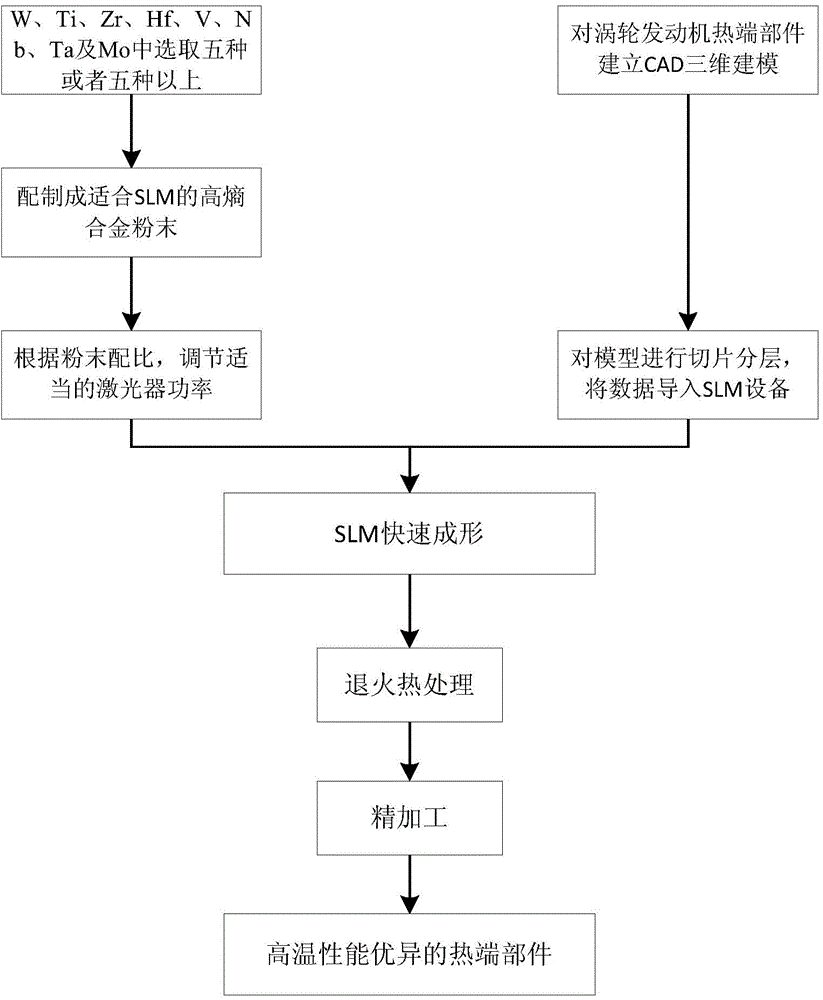

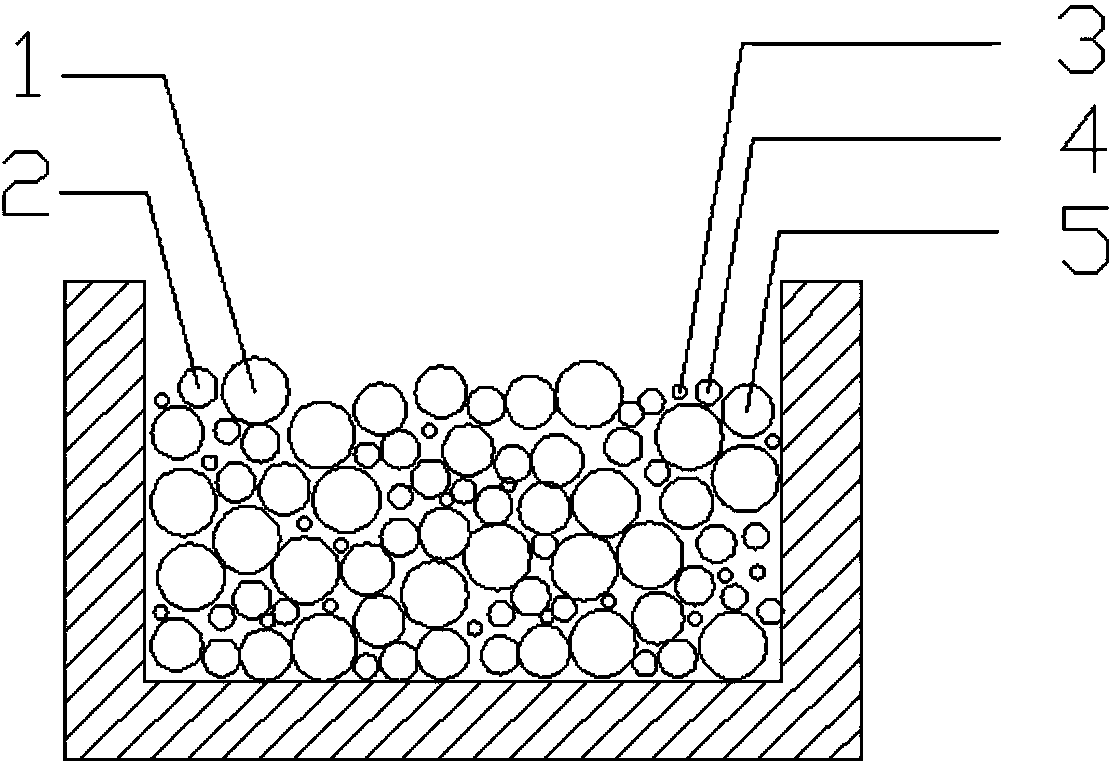

High-entropy alloy hot-end part manufacturing method of turbine engine on basis of selective laser melting

ActiveCN104308153AMeet the requirements of gas temperature to form a large thrustSatisfy the requirement of increasing the gas temperature to form a large thrustTurbinesIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a high-entropy alloy hot-end part manufacturing method of a turbine engine on the basis of selective laser melting and belongs to the technical field of manufacture of hot-end parts of the turbine engine. The high-entropy alloy hot-end part manufacturing method includes firstly selecting five or more of eight kinds of high-melting metal powder of tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum, and mixing the powder uniformly according to a certain mole ratio to obtain high-entropy alloy powder; setting up a three-dimensional solid model of a hot-end part of the turbine engine, slicing and layering by software to obtain profile data of various sections, and importing the data into a quick forming device; quickly forming a hot-end part blank of the turbine engine by the SLM technology; thermally treating and finely processing the blank to obtain the high-temperature high-entropy alloy hot-end part of the turbine engine. The formed hot-end part of the turbine engine has high compactness and excellent high temperature performance, has high forming accuracy and surface accuracy and can be quickly and accurately manufactured.

Owner:XI AN JIAOTONG UNIV

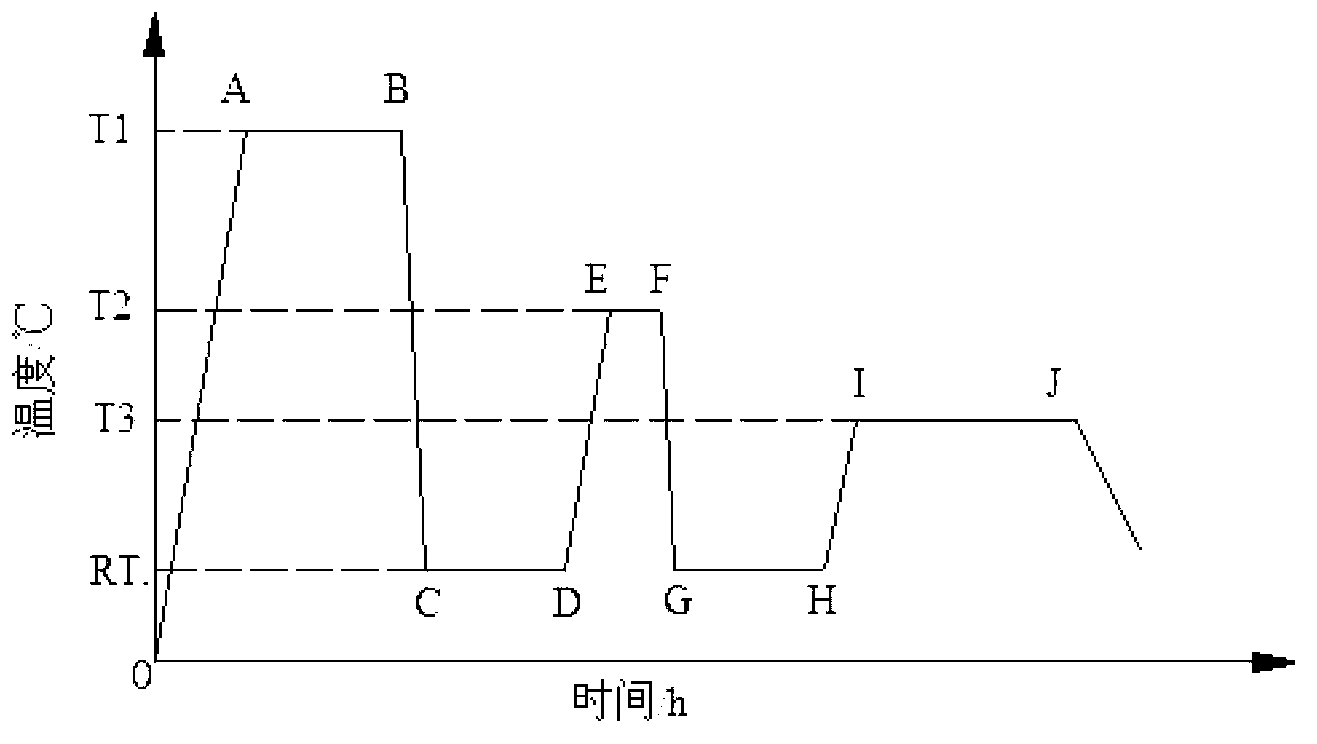

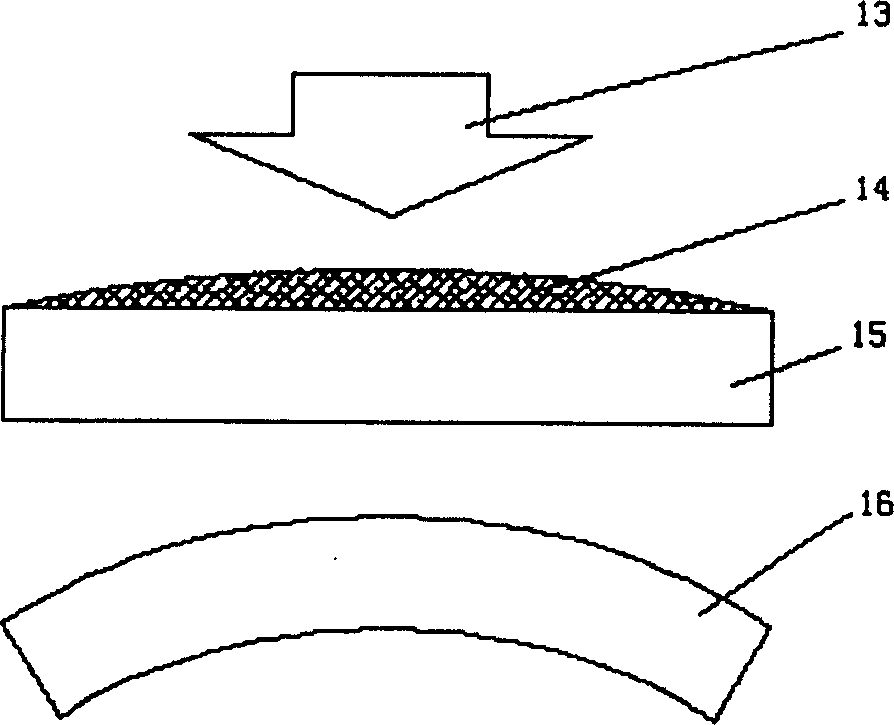

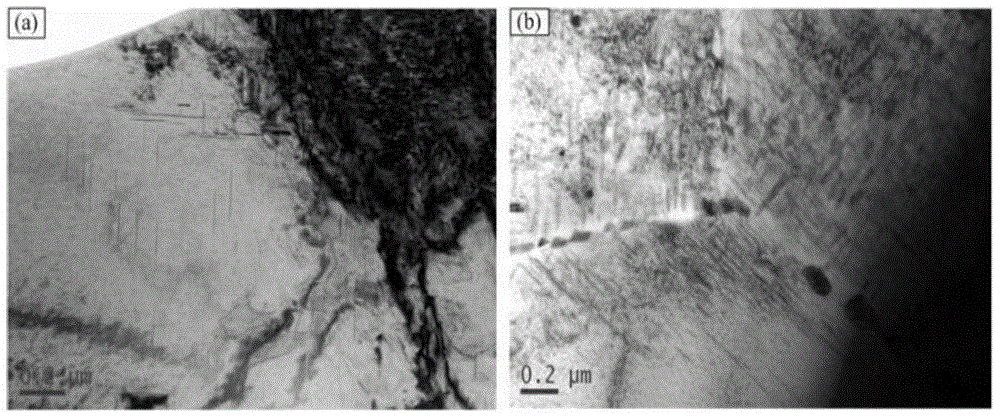

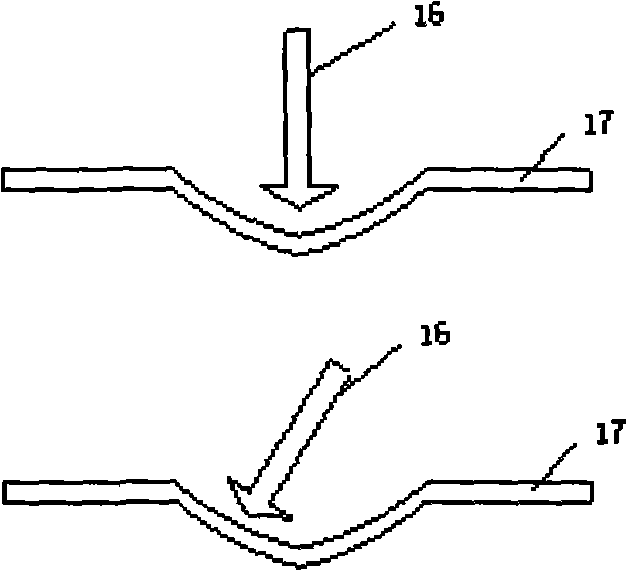

Heat forming method for aluminum alloy sheet metal part after solid solution and water quenching

InactiveCN102974675AGuaranteed shape and size accuracyAvoid quick transfersShaping toolsSize changeSupersaturated solid solution

The invention discloses a heat forming method for an aluminum alloy sheet metal part after solid solution and water quenching, relates to a heat forming method for a heat-treatable strengthening aluminum alloy sheet metal part and aims at solving the technical problems that existing heat-treatable strengthening aluminum alloy is large in shape and size change in the process of heat treatment after the heat-treatable strengthening aluminum alloy is formed first, heat melting forming and cold mold quenching technique requires transfer locating and forming to be fast, in an aluminum alloy sheet metal part cold-hot compound mold forming method, control on temperature of an aluminum alloy slab is difficult, in-mold cooling and quenching speed after forming is slow and not beneficial for obtaining a supersaturated solid solution, requirements for forming equipment are high, and the like. The forming method includes the flowing steps: carrying out the solid solution and the water quenching to the aluminum alloy slab, then, placing the aluminum alloy slab in a hot-state mold to carry out secondary heating, and carrying out aging treatment after pressing forming. According to the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching, the requirements for the forming equipment are not high, precision of shape and size of the aluminum alloy sheet metal part is high, strength is greatly improved, and the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching is suitable for the heat-treatable strengthening aluminum alloy such as 2000 series aluminum alloy, 6000 series aluminum alloy and 7000 series aluminum alloy.

Owner:HARBIN INST OF TECH

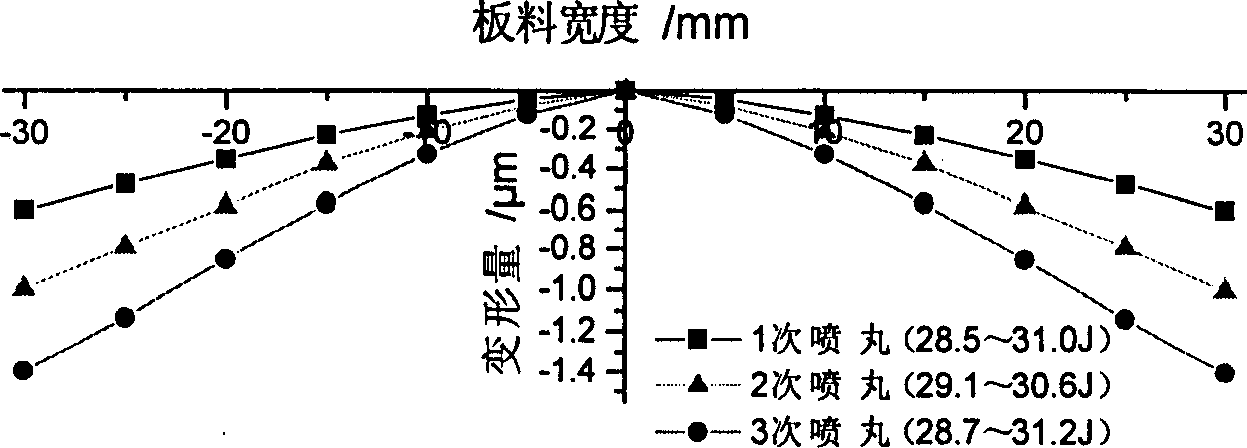

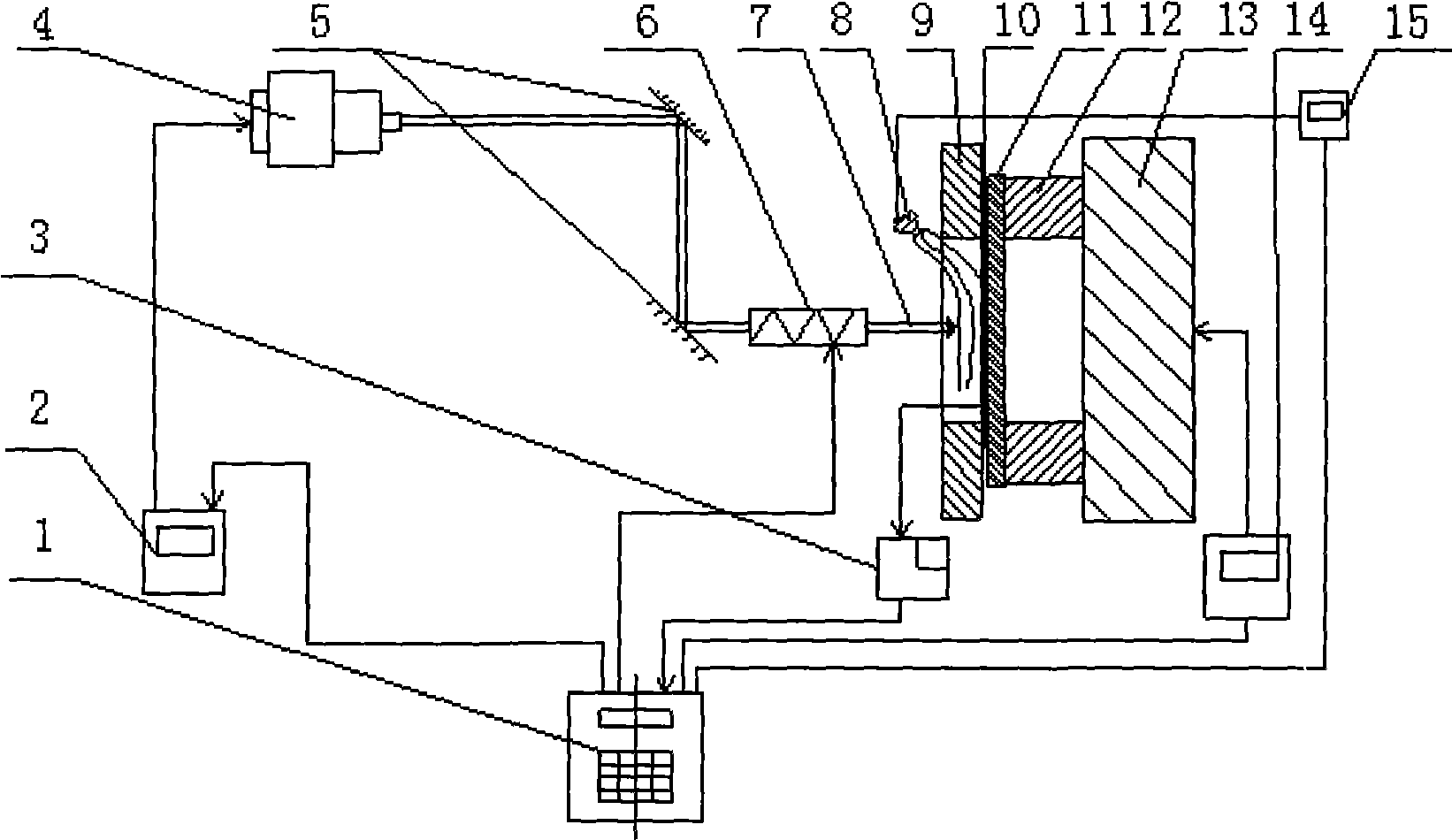

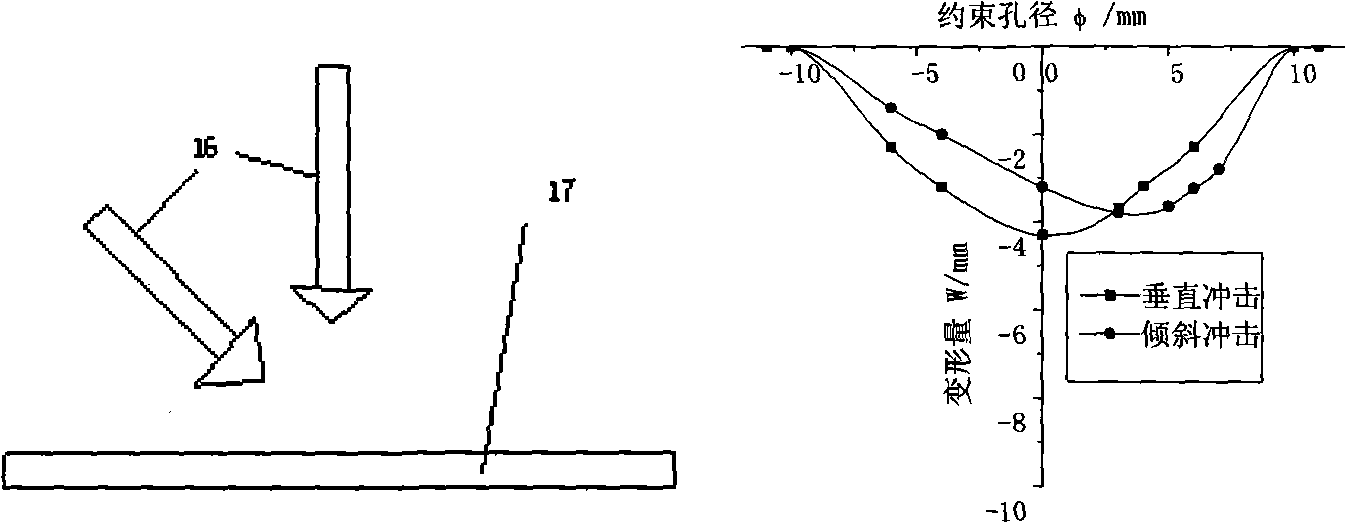

Method and equipment for forming plate of moderate thickness through laser shot blast

InactiveCN1695873AReduce surface roughness valueGood finishComputer controlNumerical controlShock waveEngineering

A laser blasting apparatus for shaping on the surface of medium-thick plate is composed of laser device, optical guide system, laser blasting head, fixture system for workpiece, and control system. Its shaping process includes computer simulation of the stress field distribution according to the curved surface shape to be processed, optimizing it to obtain the distribution of shock wave pressure and blasting tracing on the surface of plate, automatically choosing the parameters of laser pulse optical beam converte and optical mask, writing control program, generating strong short laser pulses, covering them to several pulse clusters, passing through optical mask, acting on energy converting body on the surface of workpiece to obtain shock waves, acting on the surface of workpiece for shaping.

Owner:JIANGSU UNIV

Laser-CMT welding aluminum alloy additive manufacturing method and forming system

PendingCN107283061AImprove stabilityImprove interlayer bonding performanceWelding/soldering/cutting articlesLaser beam welding apparatusSlag (welding)Molten bath

The invention discloses a laser-CMT welding aluminum alloy additive manufacturing method and a forming system. A laser and an electric arc are adopted as a composite heat source, the cold metal short circuiting transfer manner is adopted, and additive manufacturing forming for an aluminum alloy component is achieved. According to the provided laser-CMT welding additive manufacturing method, the problems that in the process of aluminum alloy component manufacturing through laser additive, the required laser power is high, and forming is difficult are solved, the problems that in the traditional process of aluminum alloy manufacturing through electric arc additive, the heat input amount is large, deformation is serious, and a molten bath is prone to overflowing or webbing are solved, and the problem that in the process of aluminum alloy manufacturing through CMT welding additive, incomplete fusion or slag inclusion or the like is likely to happen is solved; and the additive manufacturing method based on the laser-electric arc composite heat source principle is provided for additive manufacturing forming for the aluminum alloy component.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN +1

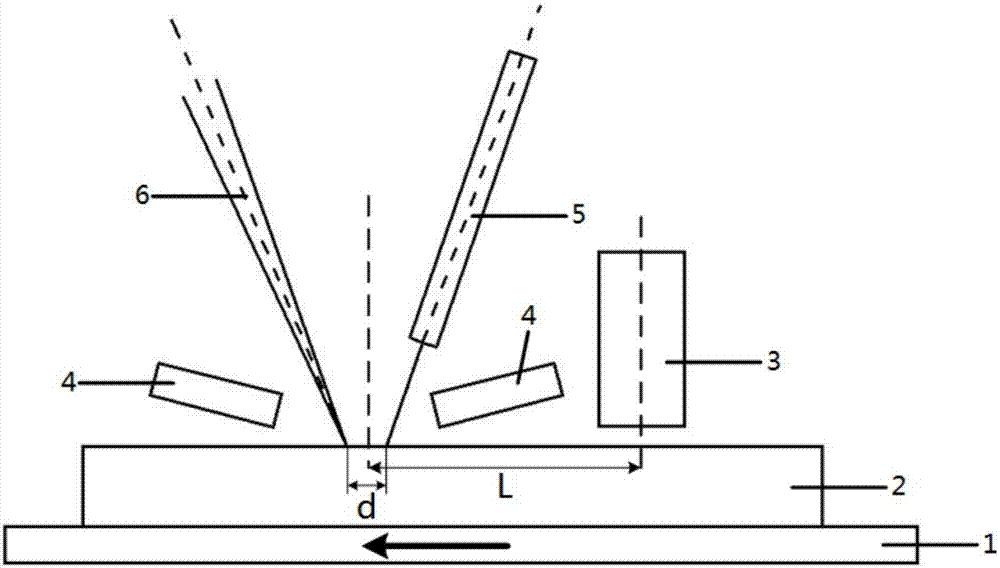

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

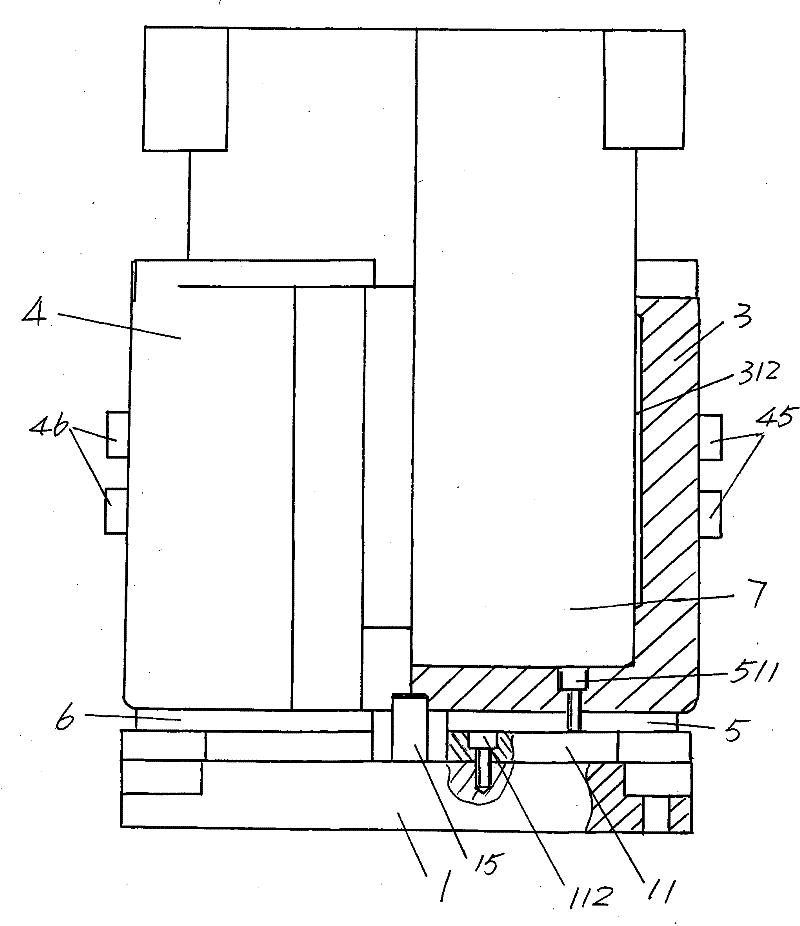

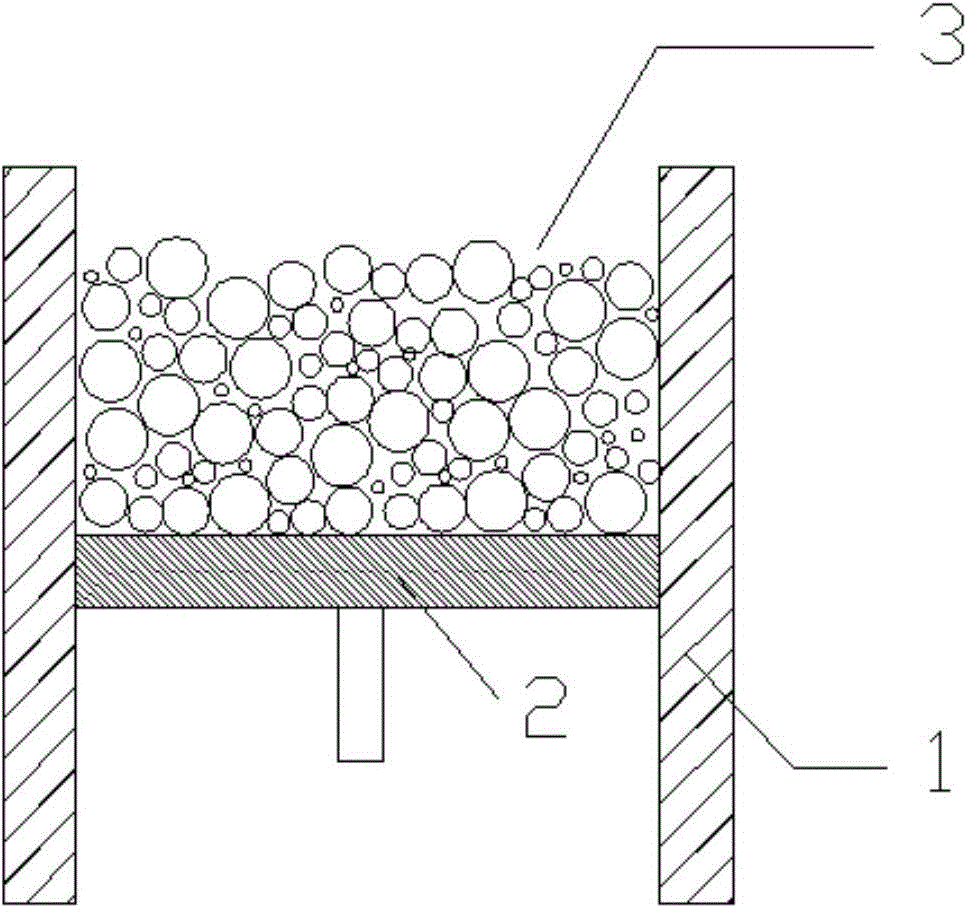

Dual-beam laser selective melting and moulding equipment with exchangeable powder cylinder

ActiveCN105039970AEasy to replaceImprove absorption rateMetallic material coating processesDual beamLight beam

The invention discloses dual-beam laser selective melting and moulding equipment with an exchangeable powder cylinder. The equipment comprises two optical systems, a frame, a workbench plate, a powder feeding cylinder, a powder storage cylinder, a moulding cylinder, a powder returning cylinder, a moulding cavity, and two first driving mechanisms, which are used to respectively drive the moulding cylinder and powder feeding cylinder to move up and down. The workbench plate is fixed on the frame, the moulding cavity is fixed on the upper surface of the workbench plate, and the powder returning cylinder, the moulding cylinder, the powder feeding cylinder, and powder storage cylinder are fixed on the lower surface of the workbench plate from left to right in sequence. A scraper is arranged in the moulding cavity, and a second driving mechanism is arranged on the frame. A substrate is arranged in the powder feeding cylinder, a substrate is arranged in the moulding cylinder, the lower ends of the powder feeding cylinder and the moulding cylinder are both provided with a cylinder end cover, and the substrates are connected to a first piston system. A second piston system is arranged in the powder storage cylinder. The provided equipment has a high moulding efficiency and is capable of effectively reducing the deformation and cracking of members.

Owner:XI AN JIAOTONG UNIV

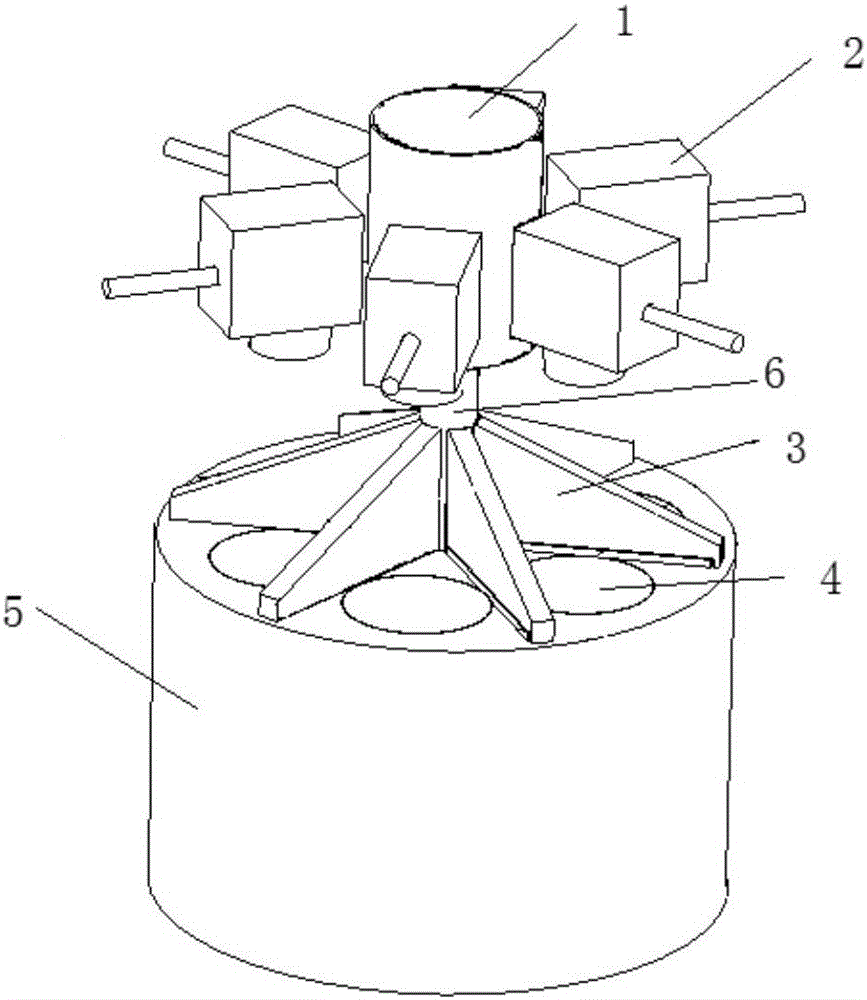

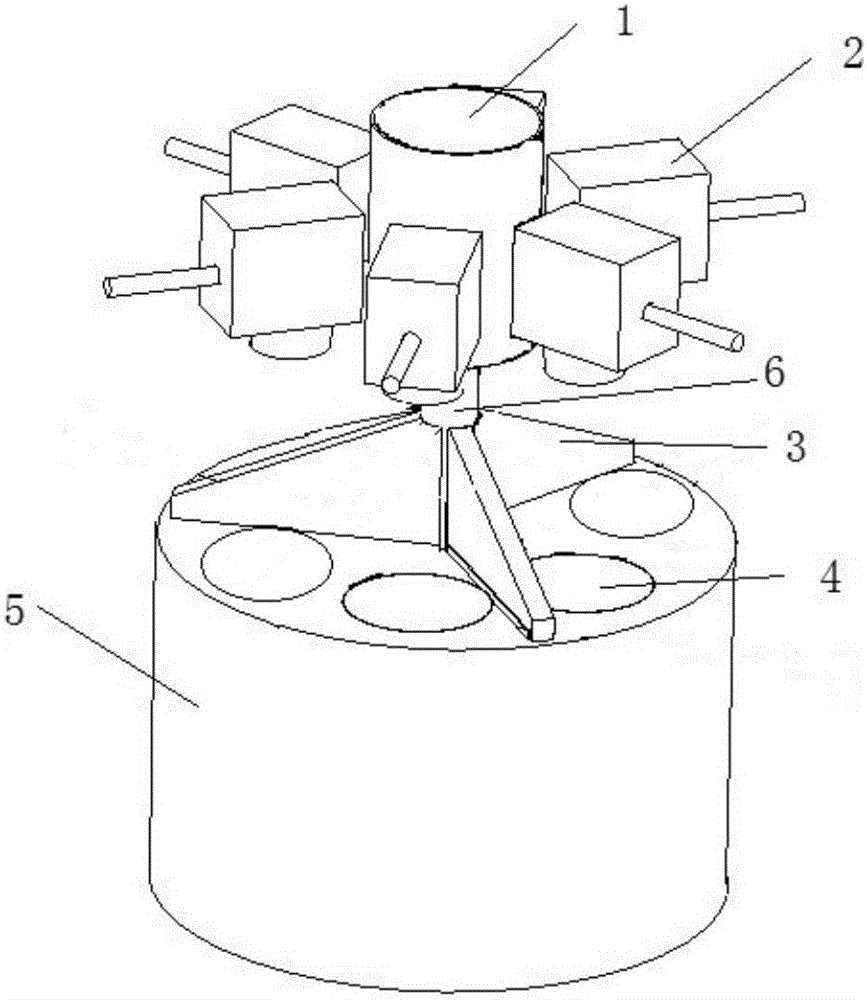

Selective laser melting forming equipment and forming method thereof

InactiveCN106077639AImprove efficiencyReduce processing costsAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMaterials science

The invention discloses selective laser melting forming equipment which comprises a chief equipment platform, lifting forming platforms, a rotatable powder supplying and paving device and laser systems. The chief equipment platform is provided with through holes which downwards extend along the upper surface of the chief equipment platform, the forming platforms are embedded in the through holes and can move up and down in the through holes, and the laser systems are located above the lifting forming platforms. The invention further discloses a forming method which specifically includes the following steps that 1, base materials are placed on the forming platforms, and the upper surfaces of the base materials are made to be aligned with the upper surface of the chief equipment platform; 2, powder is added into a powder supplying bin, a hollow rotating shaft rotates to pave the surface of each base material with a layer of powder; 3, the laser systems are started to scan the powder layers in the areas of the forming platforms; and 4, after scanning is completed, the forming platforms fall by the distance of the thickness of one layer of powder, and the second step of powder paving and the third step of scanning are repeated till forming is completed. The selective laser melting forming equipment and the forming method thereof are high in forming efficiency.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

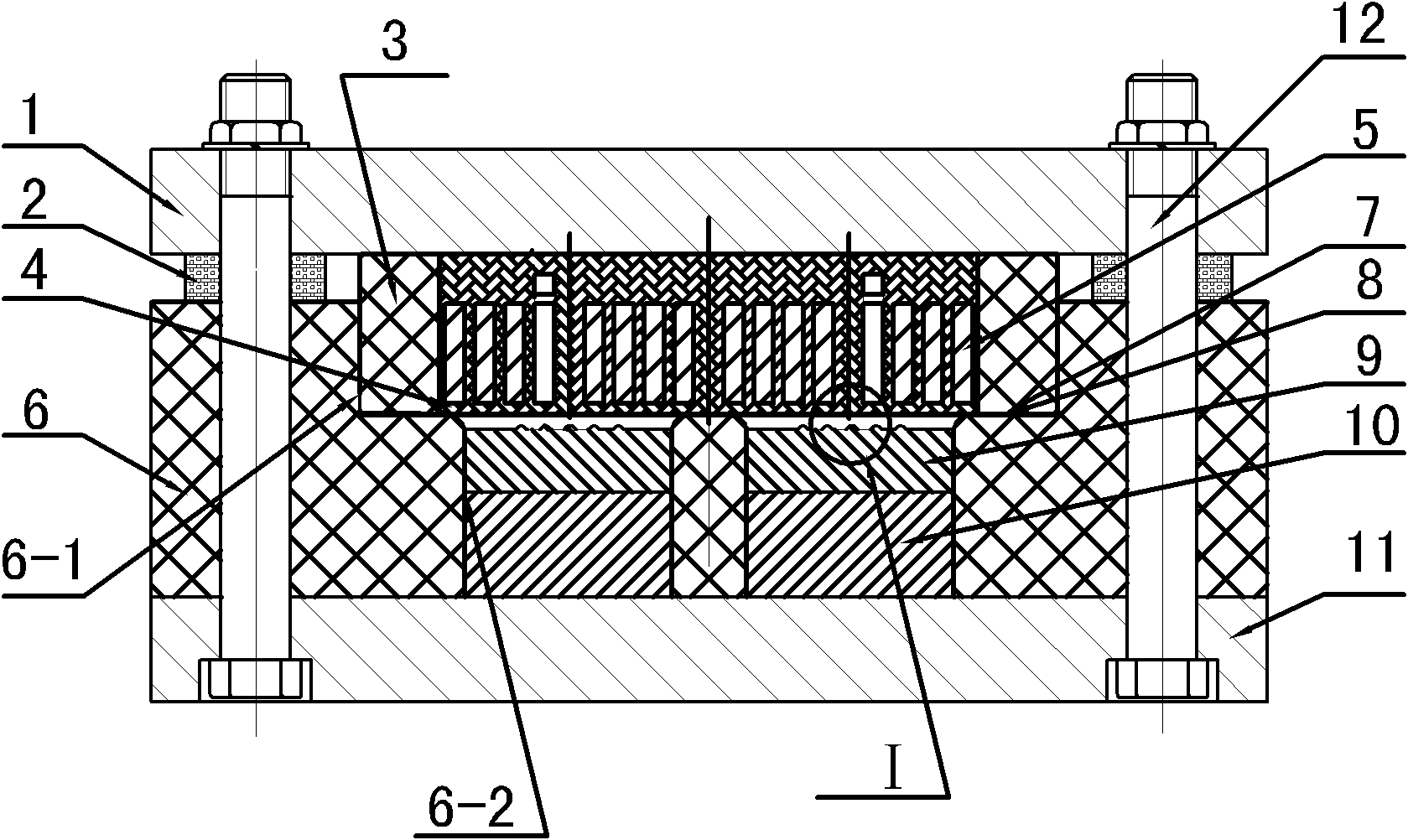

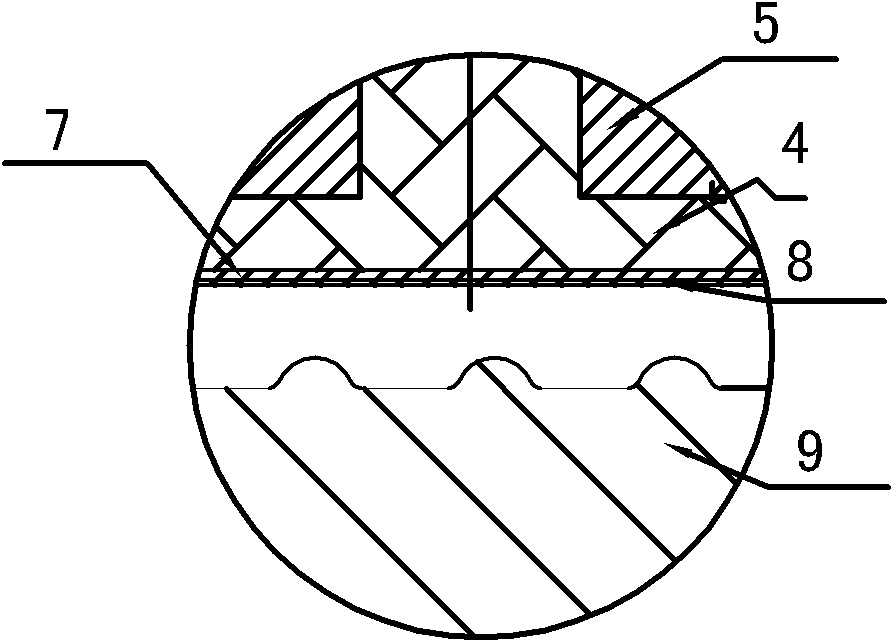

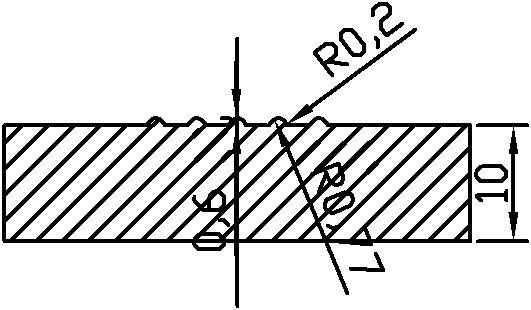

Electromagnetic forming device and method for micro fuel cell metal bipolar plate microchannel

The invention discloses an electromagnetic forming device and an electromagnetic forming method for a micro fuel cell metal bipolar plate microchannel, and relates to a micro fuel cell metal bipolar plate microchannel forming device and a micro fuel cell metal bipolar plate microchannel forming method so as to solve the problem of matching difficulty between micro male and female dies in the process of forming a microstructure on a metal thin plate based on stamping and other conventional plastic deformation means. The device comprises an upper template, a coil, a driving sheet, a die, a lower template and a fastening bolt; a groove is formed on the surface of a supporting frame so as to accommodate the coil; a circular through hole is formed in the center of the bottom of the groove so as to accommodate the die; the driving sheet is arranged above the die; and an axial lead of the coil is in upper and lower directions. The method comprises the following steps of: discharging to the coil to excite a strong pulsed magnetic field; generating induced eddy on the surface of the driving sheet so as to generate a magnetic field opposite to the magnetic field of the coil in the transient strong pulsed magnetic field; and driving a plate blank to make die attaching motion by using the driving sheet under repellent applied force between the magnetic fields. The invention is used for micro-forming.

Owner:HARBIN INST OF TECH

No-mold fusion stacking manufacture method of parts or mold

InactiveCN101362272AReduce or eliminate dropReduce or eliminate droolingWelding/cutting auxillary devicesArc welding apparatusNumerical controlMelting tank

The invention relates to a method for die-free fused deposition modeling of a part or a die, which belongs to the method of die-free modeling, and solves the problems of falling, flowing and collapsing of fusing material in the process of support-free and die-free fused deposition modeling of the existing method. The method comprises the following steps: (1) hierarchy slicing processing is performed to the three-dimensional CAD model of the part or the die; (2) a computer generates numerical control codes required by the shaping of each hierarchy according to the hierarchy slicing data and the characteristics of the slicing size and shape of each hierarchy; and (3) numerically controlled gas-shielded welding arc or laser bean is adopted to fuse and shape the fusing material on the base plate in sequence according to the numerical control codes of each hierarchy, until the requirements on the size and the surface of the part or the die are met; simultaneously, electromagnetic field acting on the fusing material in the melting bath is generated through an electromagnetic device. By adopting the method, the part or the die made of metal, intermetallic compound, metal ceramics, ceramics and functionally gradient material can be quickly obtained with low cost and high quality.

Owner:HUAZHONG UNIV OF SCI & TECH

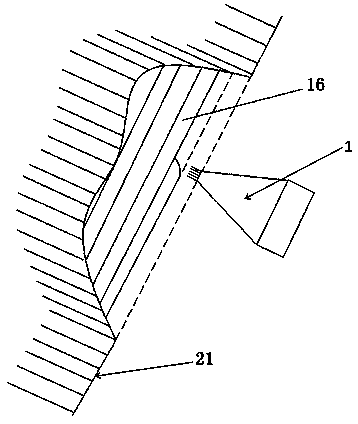

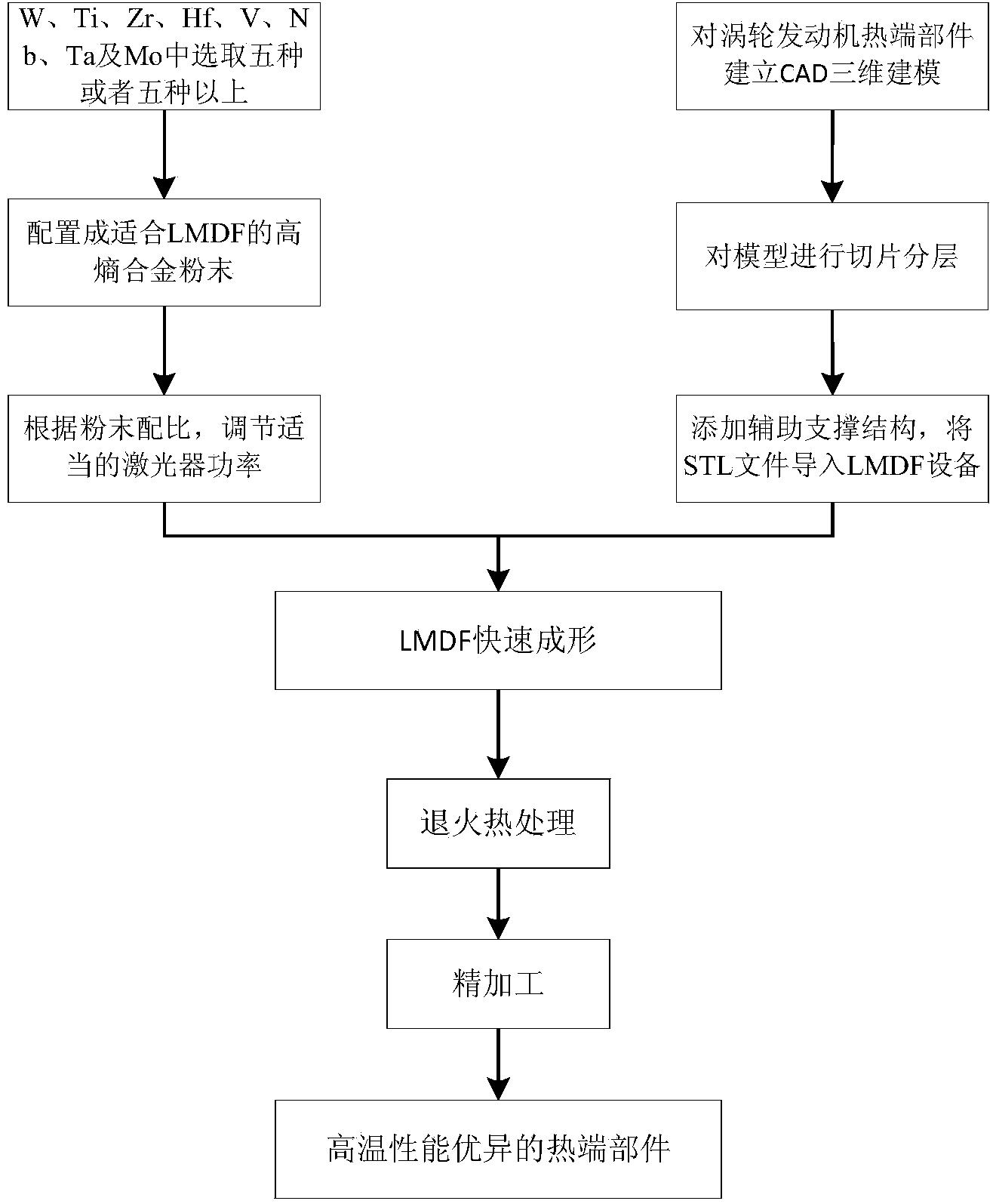

Method for directly molding high-entropy alloy turbine engine hot end component through laser metal

ActiveCN104368814AImprove efficiencyIncrease productivityIncreasing energy efficiencyHigh entropy alloysHigh density

The invention discloses a manufacturing method for directly molding a high-entropy alloy turbine engine hot end component through laser metal, and belongs to the technical field of manufacturing of turbine engine hot end components. The method includes the steps that any five or more kinds of high-melting metal powder is selected from eight kinds of high-melting metal powder, and the high-melting metal powder is evenly mixed to prepare high-entropy alloy powder; a three-dimensional solid model of the turbine engine hot end component is built, necessary auxiliary supporting structures are additionally arranged, and data files in the stl format are obtained and led into a rapid molding device; a blank of the turbine engine hot end component is rapidly molded through the LMDF technology, heat processing is carried out, then the auxiliary supporting structures are removed, abrasive particle stream finish machining and surface processing are carried out, and the high-entropy alloy turbine engine hot end component with the good high-temperature behavior is obtained. The turbine engine hot end component molded with the method has the high density and the excellent high-temperature behavior; meanwhile, the high molding precision and the high surface precision are achieved, and rapid and accurate manufacturing of the high-performance turbine engine hot end component can be achieved.

Owner:XI AN JIAOTONG UNIV

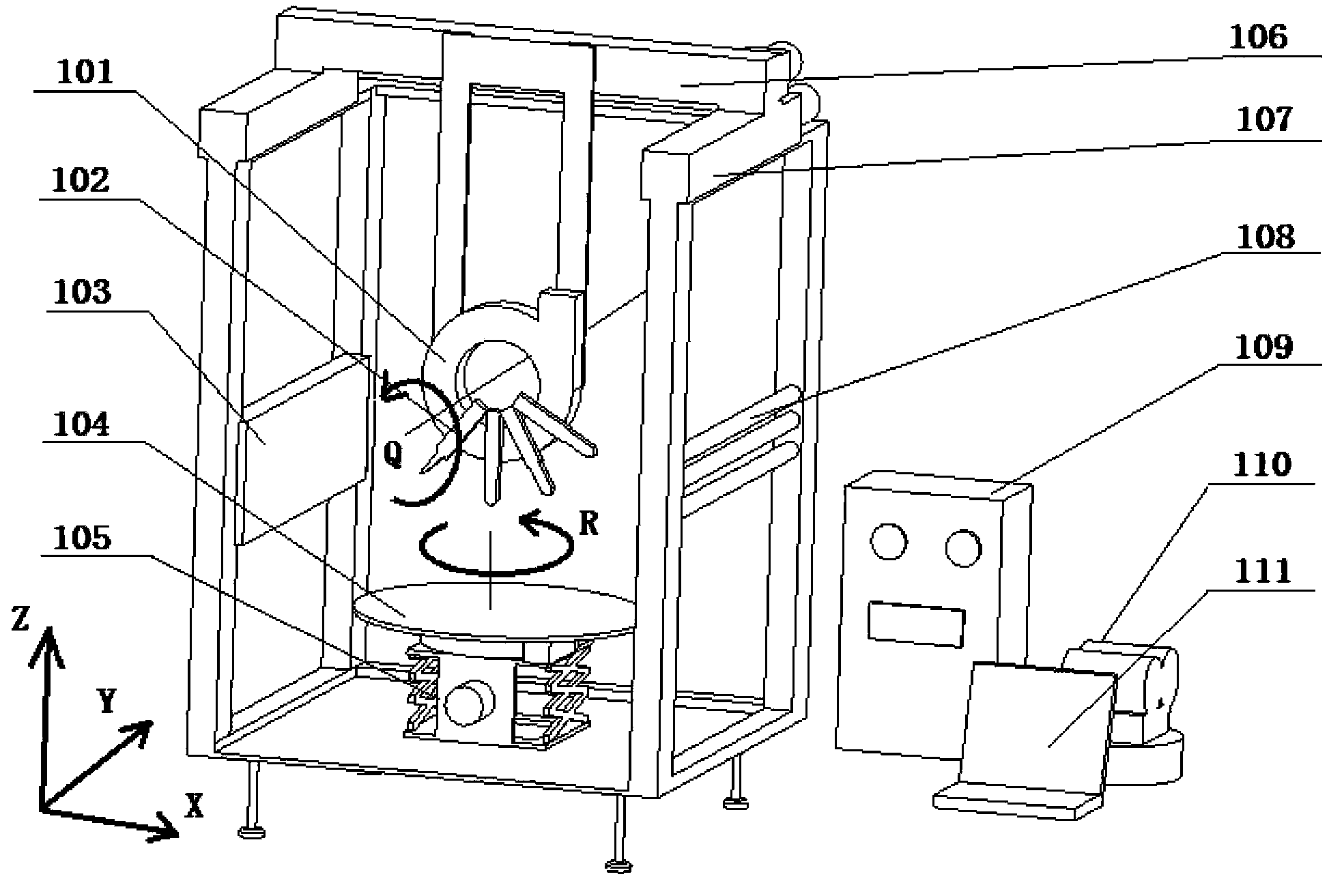

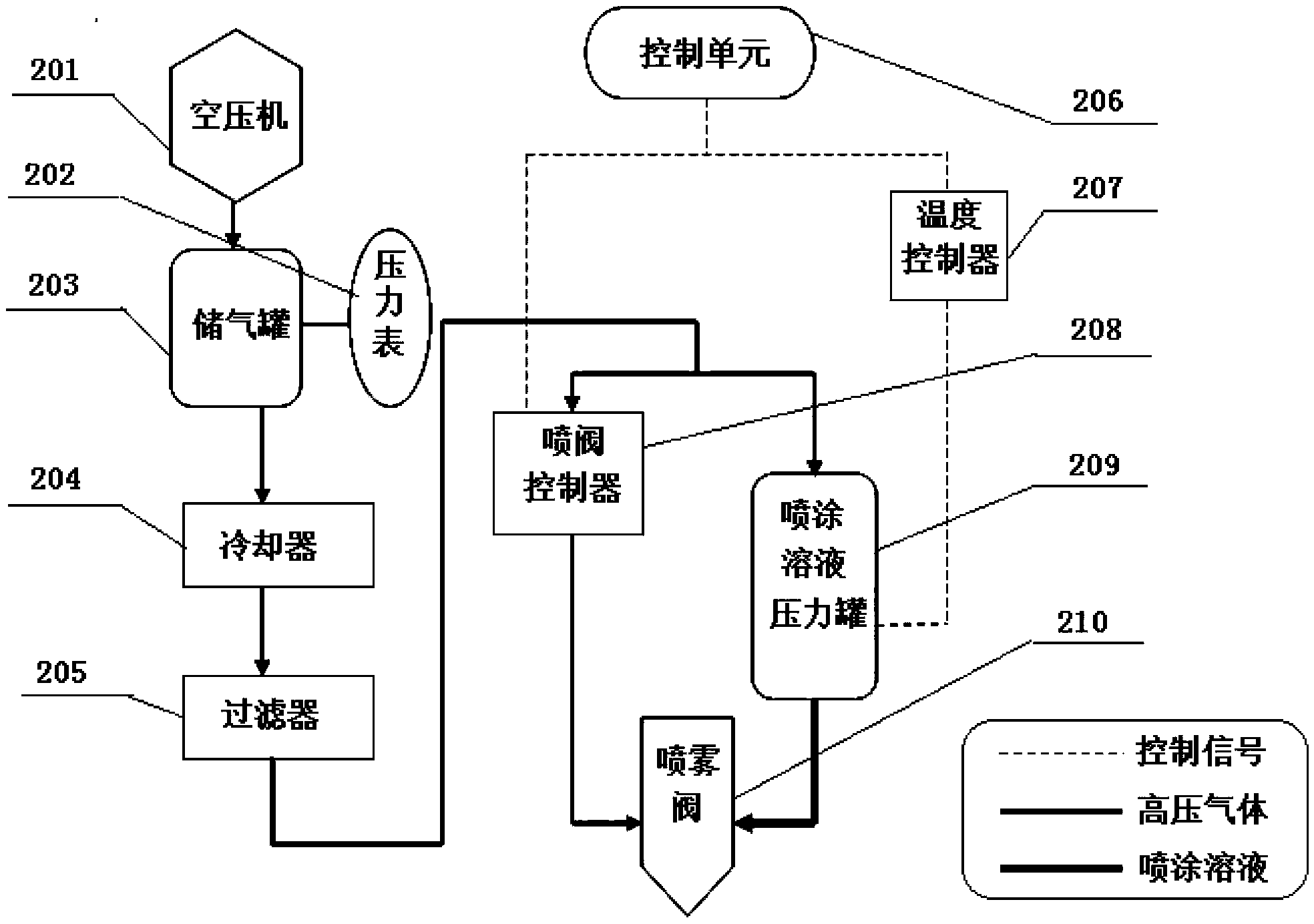

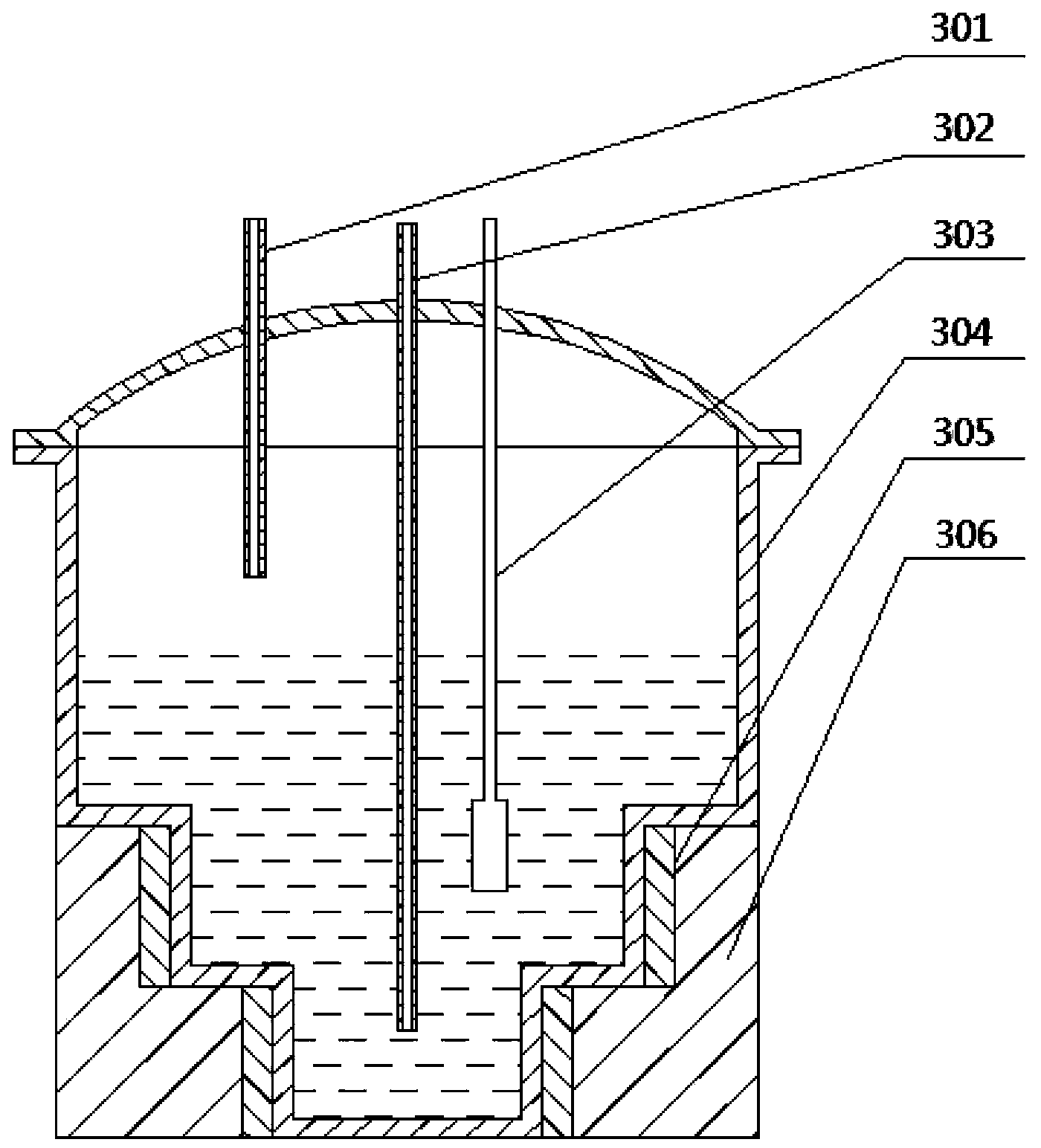

Pneumatic multi-nozzle complex tissue and organ manufacturing system with multiple degrees of freedom

InactiveCN103431925APrecise processingEasy to manufactureAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineeringIn vivo

The invention relates to a pneumatic multi-nozzle complex tissue and organ manufacturing system with multiple degrees of freedom, belonging to the field of organ manufacturing. The system comprises an X-direction movement mechanism, a Y-direction movement mechanism, a Q-direction rotation mechanism, a lifting platform, a rotary forming table, a shell, a high-pressure air source, a multi-nozzle forming unit, a spray solution pressure tank, a temperature control device, a sterilization device and a control unit. Under the control of the control unit, the multi-nozzle unit moves according to the set path and can spray according to the set sequence, so that the forming size is wide in cover range; the relative angle formed between a center shaft of a spray valve and the surface of the rotary forming table can be changed, so that a complex curved surface can be conveniently manufactured. The system enables multiple cells and support materials to be arranged at the corresponding positions for once according to the computer instruction, and various subsequent processing processes can be completed at the same time; the formed three-dimensional structure is directly connected with the corresponding circulating system in vivo, and various physiological functions of the complex tissues and organs can be rapidly realized.

Owner:TSINGHUA UNIV

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

Shape follow-up support deformation control method for selective laser melting forming of thin-walled part

ActiveCN108372298AEfficient additionAvoid complex and hard-to-remove problemsAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingDeformation control

The invention relates to a shape follow-up support deformation control method for selective laser melting forming of a thin-walled part. On the basis of existing selective laser melting forming support adding, the stress deformation behavior of the large thin-walled structural part in the forming process is analyzed and predicted, according to the molded surface structural characteristics, a design method that different shape follow-up supports are added at different positions is adopted, the problems such as cracking and deformation at the different positions such as the bottom in the selective laser melting forming process are solved through the method of supporting structure shape follow-up adding, the stability in the forming process is effectively improved, and the reliability of thequality of the formed structure part is guaranteed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

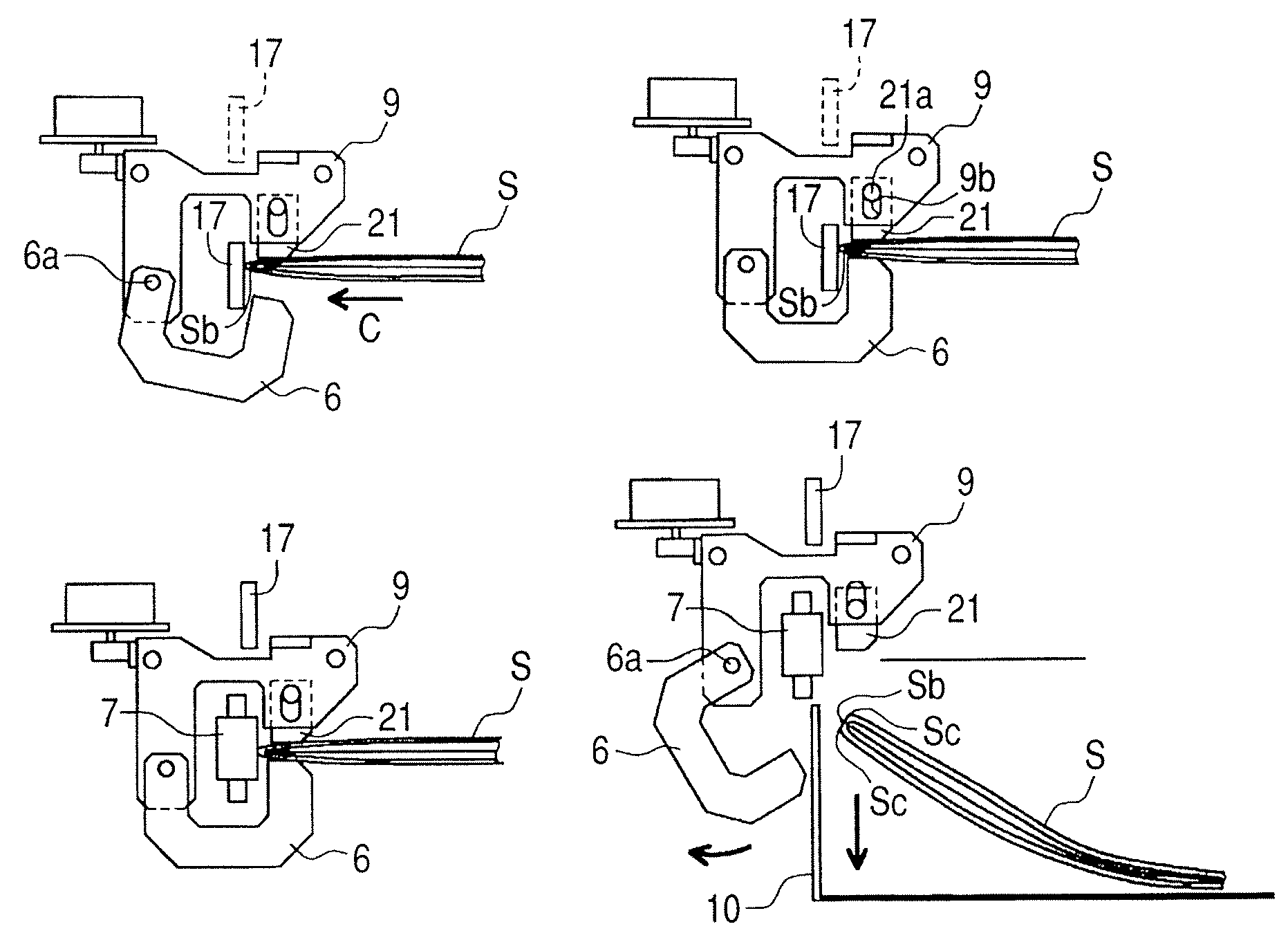

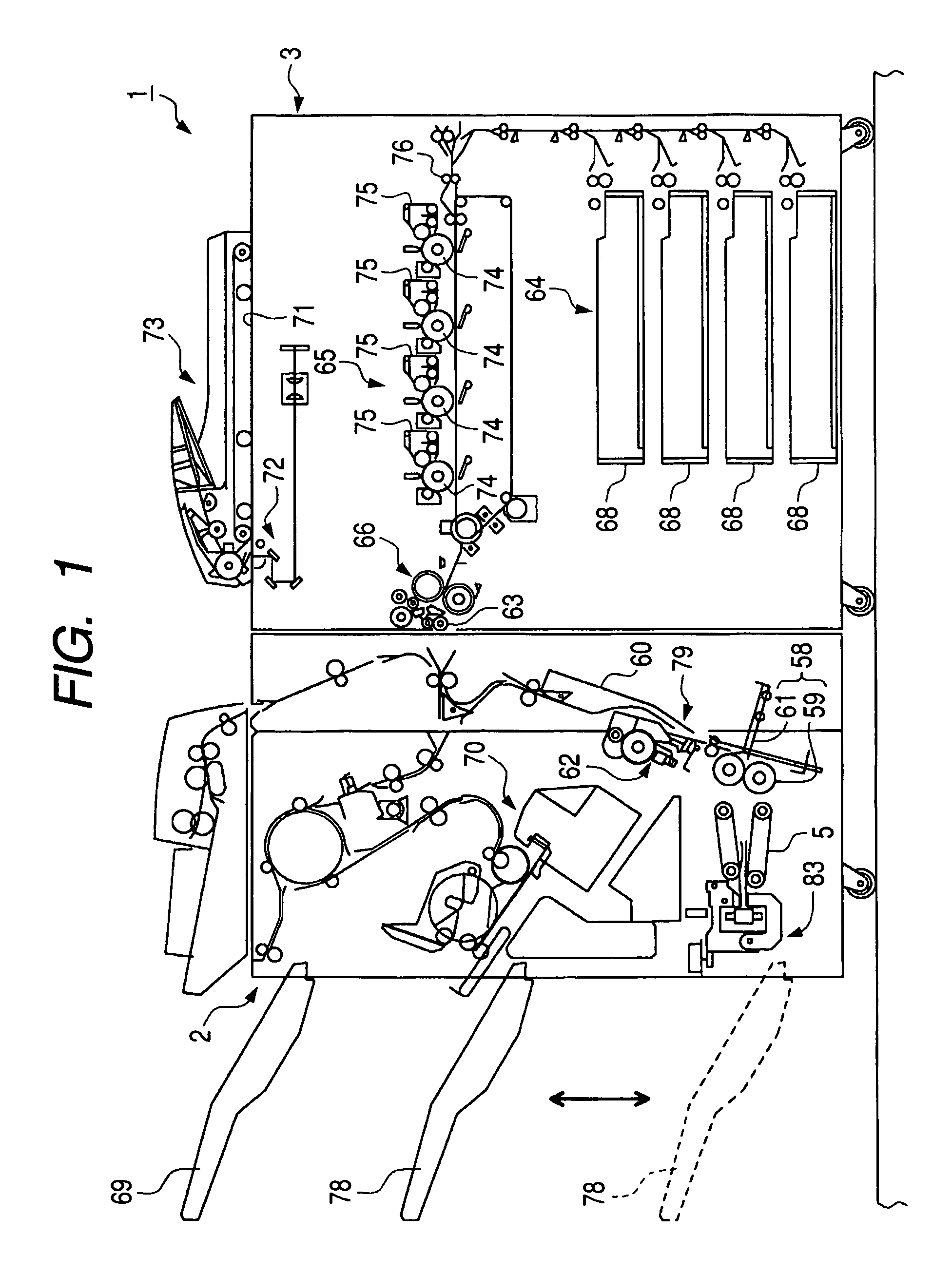

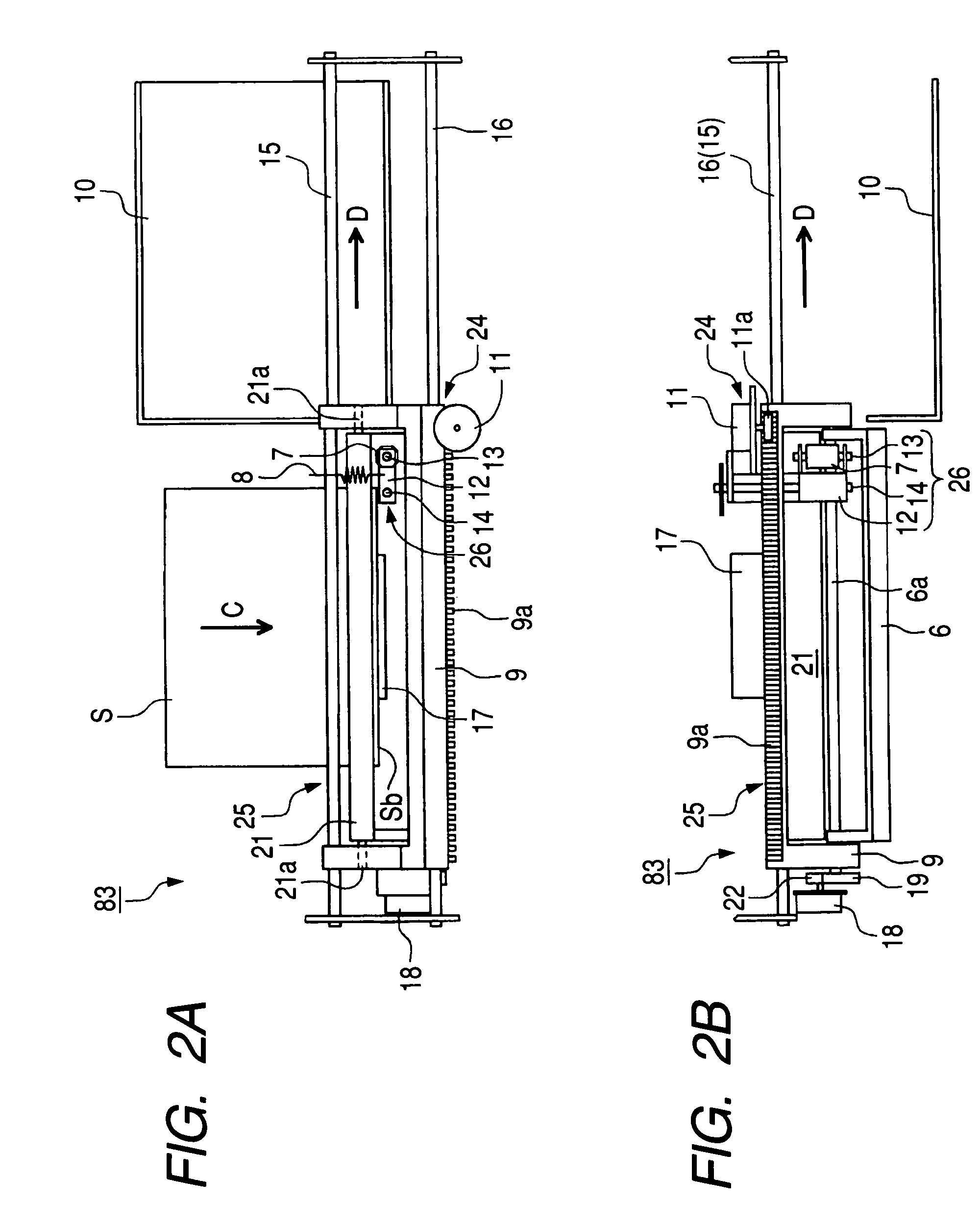

Spine folded portion flattening apparatus, sheet treating apparatus and image forming apparatus

ActiveUS7431273B2Improve processing efficiencyImprove efficiencyFolding thin materialsBook making processesSheet materialImage formation

Owner:CANON KK

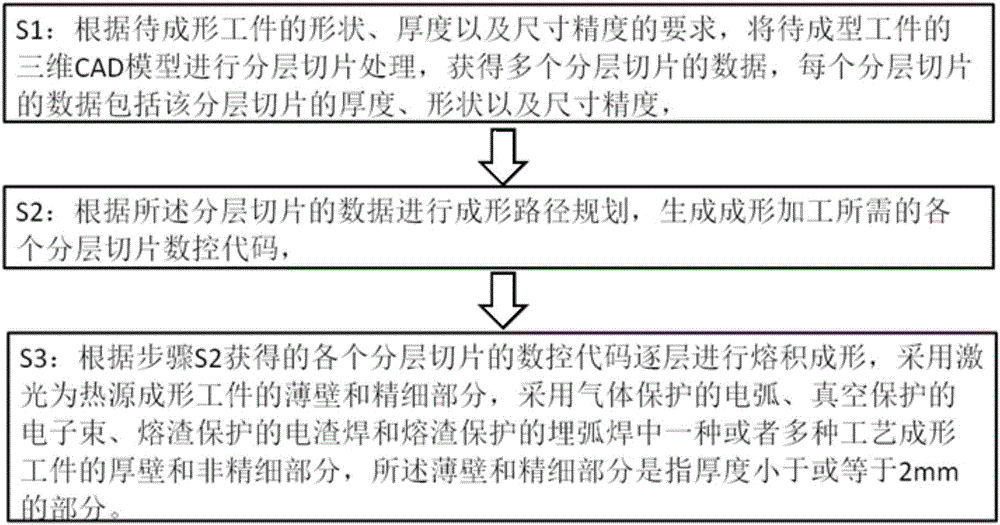

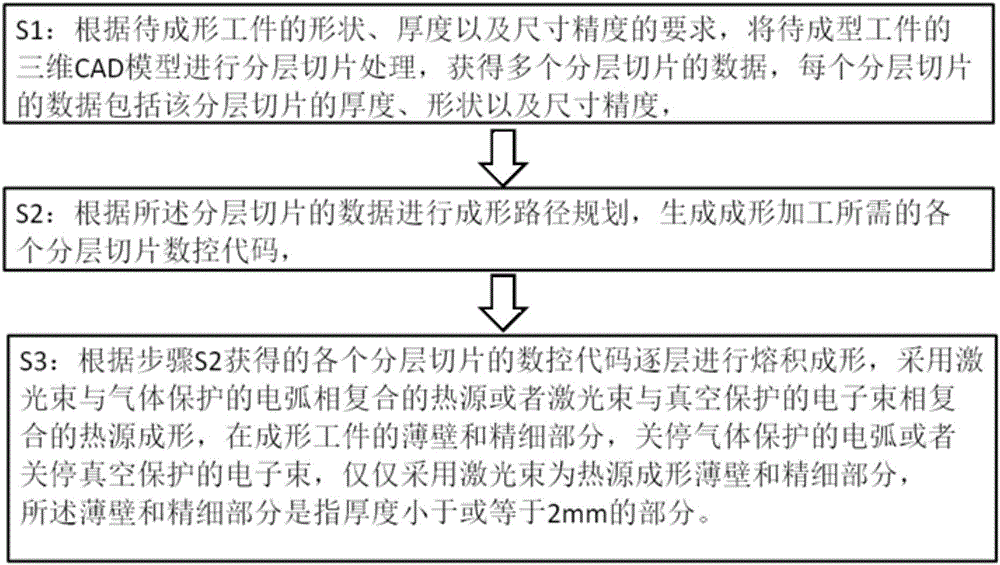

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

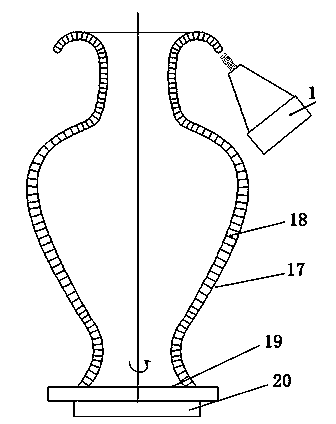

Method and device for improving forming quality of laser additive manufacturing thin-wall parts

ActiveCN107685149AStable jobOvercoming flow problemsAdditive manufacturing apparatusIncreasing energy efficiencyForming processesMetal

The invention provides a method and device for improving the forming quality of laser additive manufacturing thin-wall parts. The device comprises a movable platform system, a laser metal deposition system, an auxiliary forming system, an active cooling system and a central control system. According to the forming method, when the laser metal deposition system conducts cladding forming on the thin-wall parts, the auxiliary forming system controls the thin-wall thicknesses and the forming directions in real time; when the multiple layers of the thin-wall parts are deposited, the problem of molten pool flowing caused by interlayer stacking can be solved, and the problem that the surface roughness in the thin-wall forming process is excessively large due to interlayer stacking is solved, andthe thickness-changeable thin wall, the flat thin wall and the curved thin wall are machined; and meanwhile, the active cooling system cools deposited layers in real time. The problems that the quality of the laser cladding formed surfaces is low; during continuous multiplayer depositing, the temperature is increased, therefore, thermal stress of the deposited layers is accumulated, consequently the deposited layers are cracked, and microstructures of the deposited layers are coarse; and the forming efficiency is low due to slow cooling are solved, and high-quality and efficient forming of thecomplex thin-wall parts is achieved.

Owner:JIANGSU UNIV

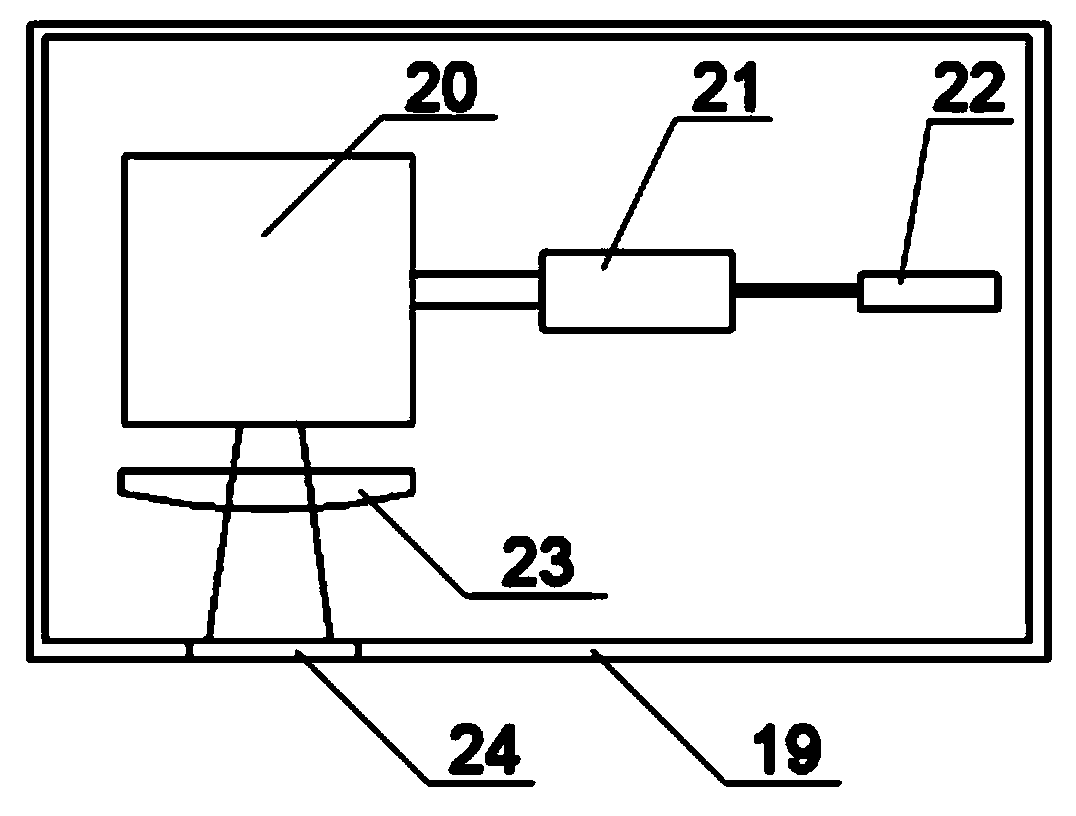

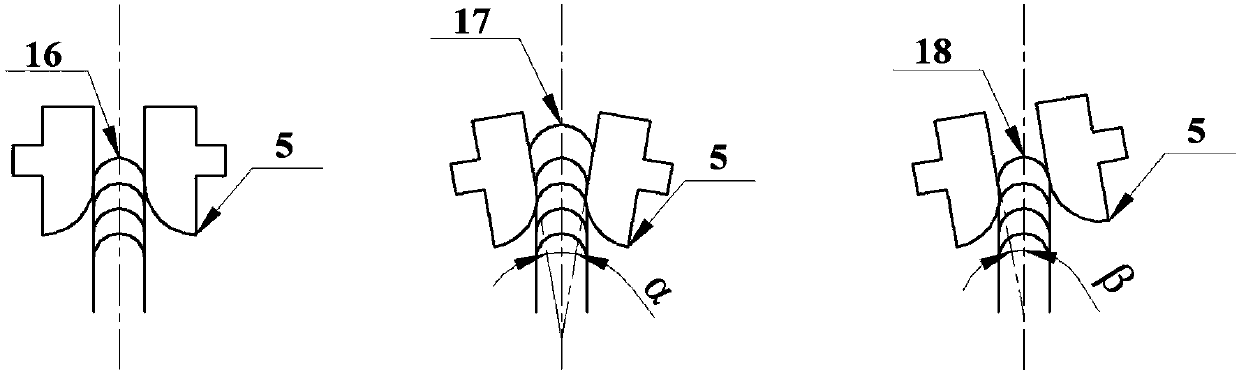

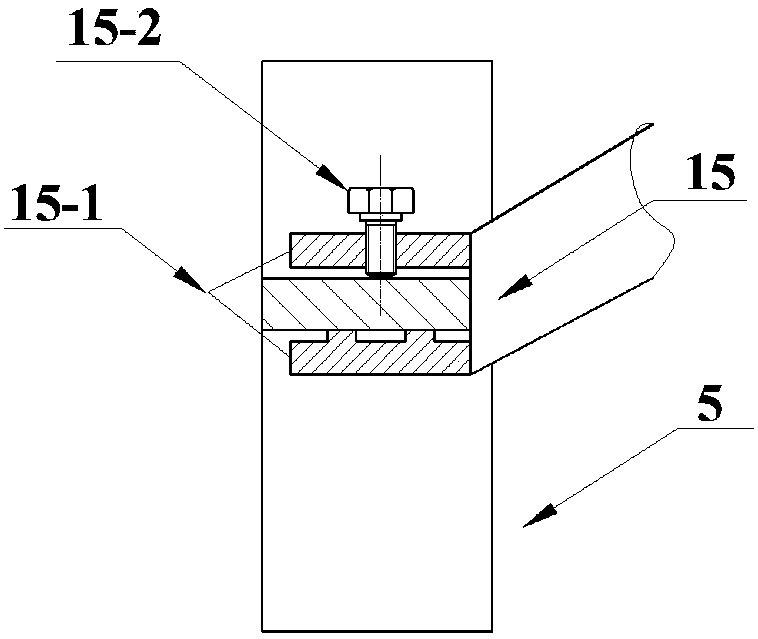

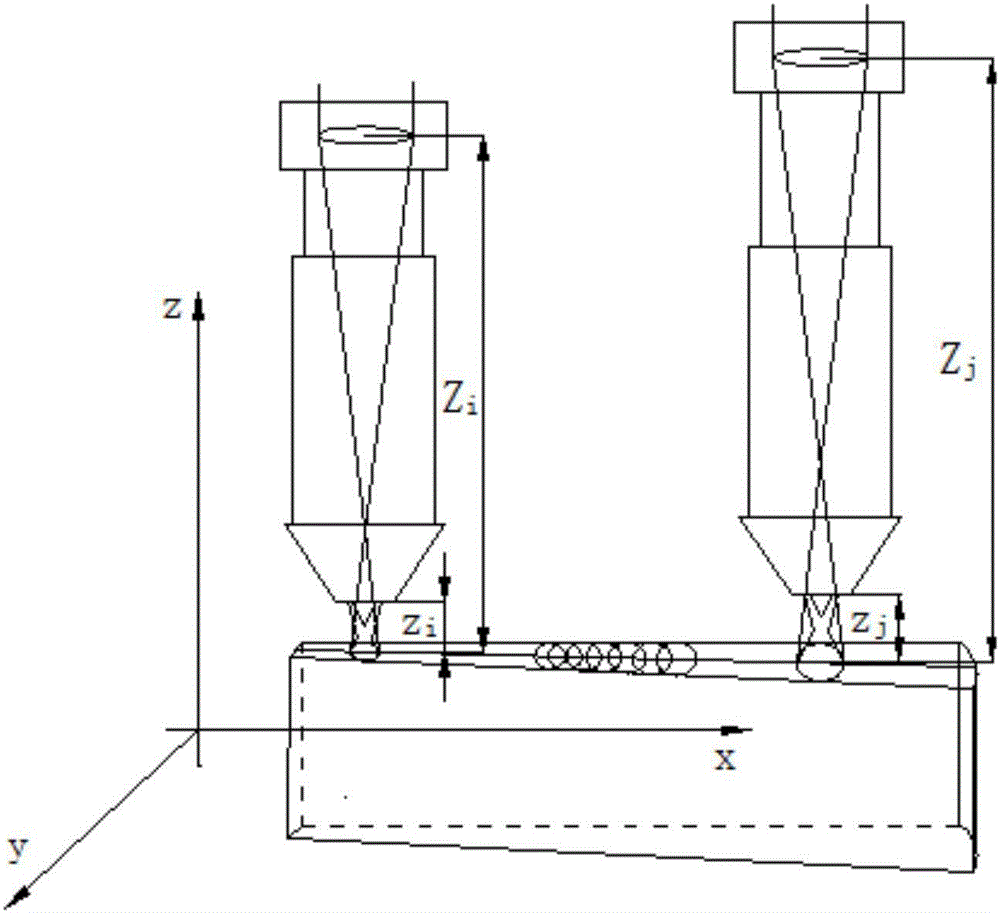

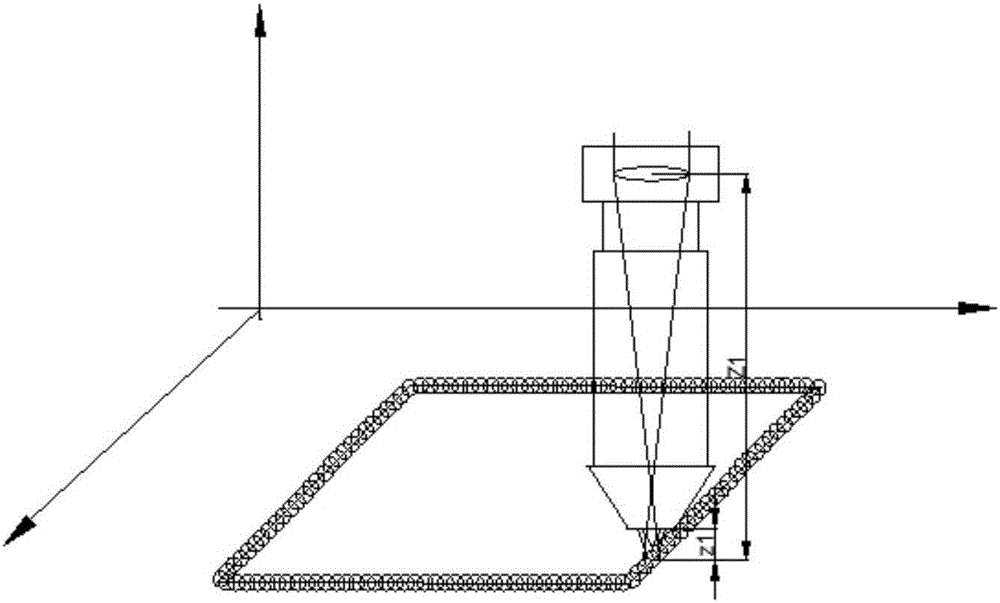

Light spot and powder spot automatic collaboration controlled laser metal added material manufacturing device and method

ActiveCN106513676AImprove matchThe cladding process is stableAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlAdditive layer manufacturing

The invention discloses a light spot and powder spot automatic collaboration controlled laser metal added material manufacturing device and a method. The device comprises a connecting joint, a laser focusing head and a sleeve respectively fixed at the upper end and the lower end of the connecting joint, a mobile sleeve slidingly coating the sleeve, a powder feeding nozzle fixed at the lower end of the mobile sleeve, and a numerical control worktable for placing workpieces; the laser focusing head is used for forming light spots on workpiece machined surfaces of a focusing mirror; the powder feeding nozzle is used for gathering powder currents to feed in a machining position to form powder spots on the workpiece machined surfaces; the centers of the light spots and the powder spots are overlapped always; the numerical control worktable is used for driving the workpieces to perform the space movement corresponding to the focusing mirror to control the out-of-focus distance; and a driving device is arranged on the mobile sleeve for driving the powder feeding nozzle to move up and down through the mobile sleeve to control the sizes of the powder spots. When the method forms thick and large workpieces with the cladding layer sizes exceeding the adjusting range, the profile scanning and filling scanning combined path formation is adopted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

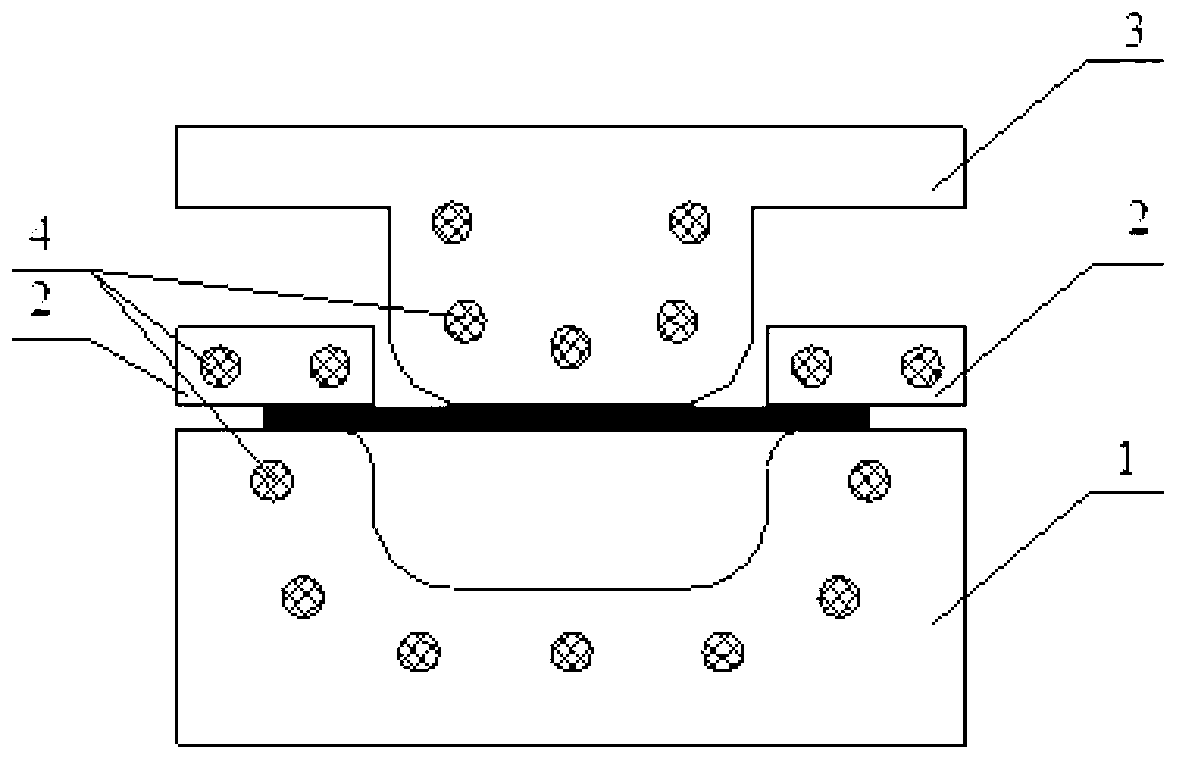

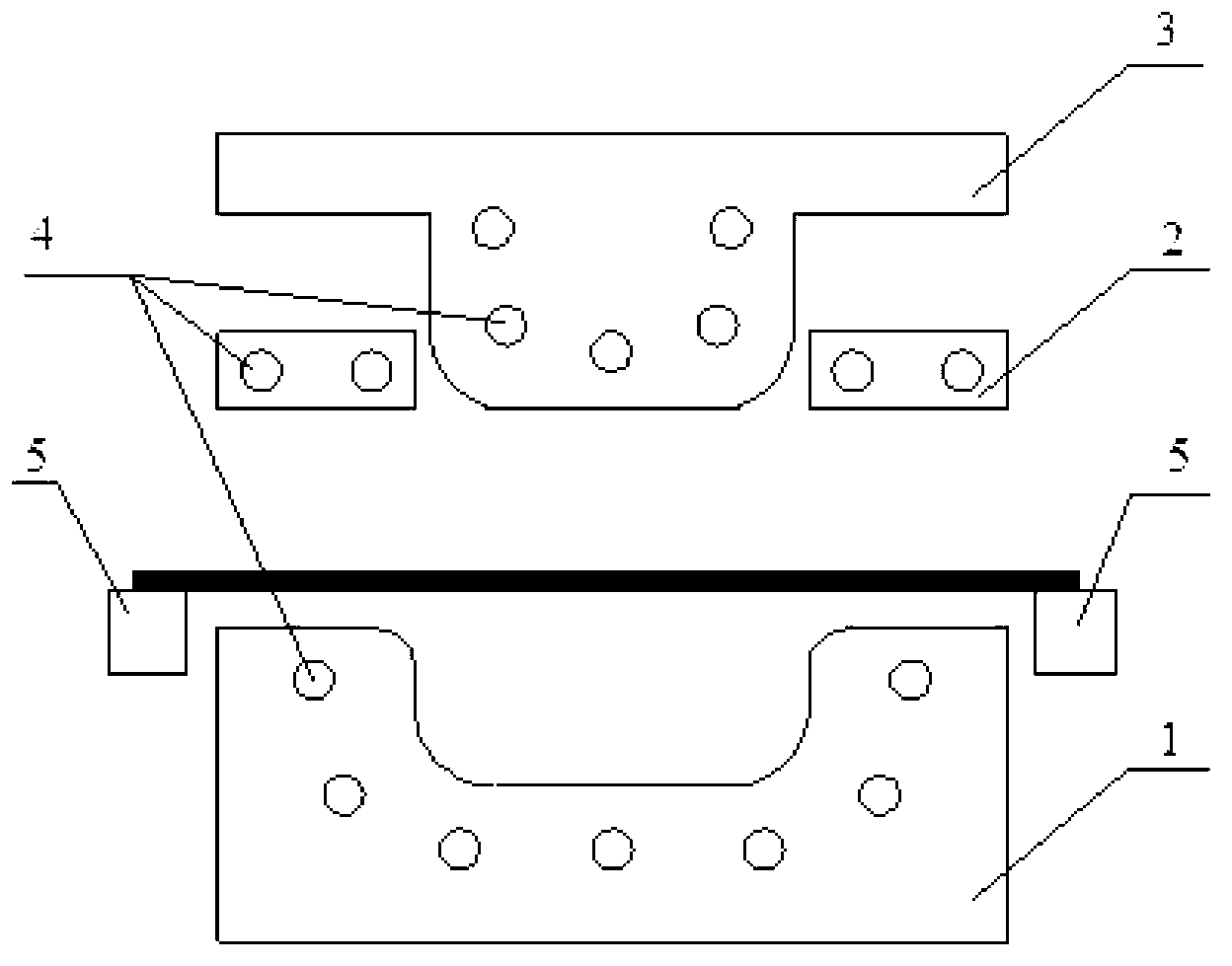

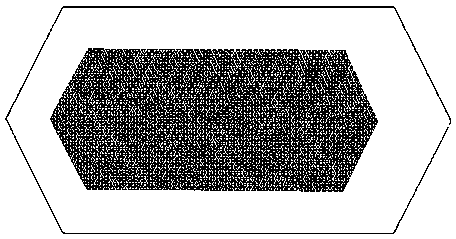

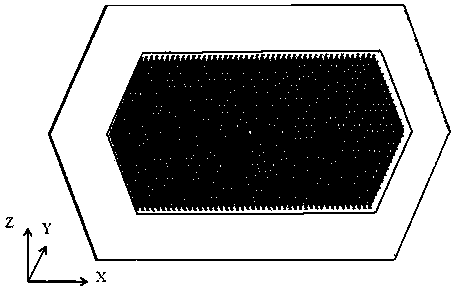

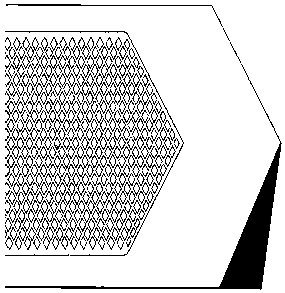

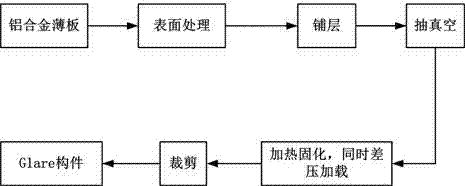

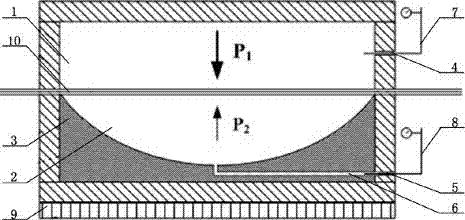

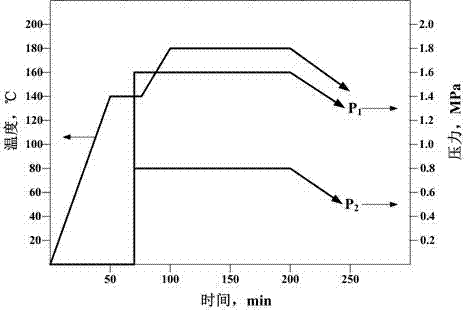

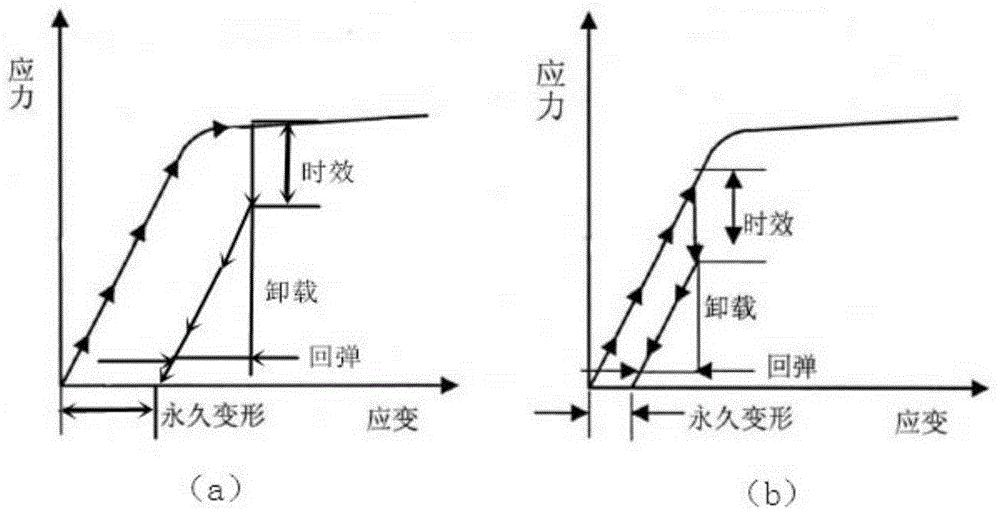

Preparation molding method of Glare component

ActiveCN103895315AImprove forming efficiencyHigh engineering application valueLaminationLamination apparatusEpoxyComposite laminates

The invention discloses a preparation molding method of a Glare component, and belongs to the field of preparation and molding of composite materials. The method comprises the following steps: treating the surface of an aluminum alloy blank; laying a composite laminate; positioning the composite laminate on a concave die of a differential-pressure molding device; treating by vacuumizing and side pressing; heating the composite laminate to reach the temperature required for realizing the synchronization of solidifying of epoxy resin and age molding of aluminum alloy; performing bidirectional differential-pressure loading on the composite laminate in the differential-pressure molding device to realize the synchronization of the solidification of the epoxy resin and age molding and strengthening of aluminum alloy, thus realizing the preparation of a Glare laminate and integral molding of the component; then clipping redundant blanks on the Glare component. The preparation molding method of the Glare component is applicable to integrated molding of the Glare components of various complex structures, is also high in molding efficiency, outstanding in accuracy, small in resilience and relatively high in engineering application value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method and device for manufacturing metal additive materials

ActiveCN105834422AGuaranteed forming qualitySimple structureAdditive manufacturing apparatusIncreasing energy efficiencyOrganic solventMetal powder

The invention discloses a method for manufacturing metal additive materials. The method includes the steps that a part structure and a supporting structure are built layer by layer, wherein the supporting structure is built by using an adhesive agent for bonding metal powder materials; and after part formation is completed, the adhesive agent is melted by high-temperature heating or dissolved by an organic solvent, and the supporting structure is removed. The invention further discloses a device for manufacturing the metal additive materials, and the device is included in the method. The device comprises a high-energy beam source, an optical unit, a forming chamber, a forming cylinder and a powder laying device, wherein the forming cylinder and the powder laying device are located in the forming chamber; the forming chamber is further provided with an adhesive spraying device which is used for providing the adhesive agent needed for building the supporting structure included in the method. The supporting structure built by the adoption of the method and device can be removed only by making the adhesive agent melted with high-temperature heating or dissolved with the organic solvent after part formation is completed, and no subsequent machining treatment is needed, so that cost for the subsequent treatment is reduced, and the forming efficiency is improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

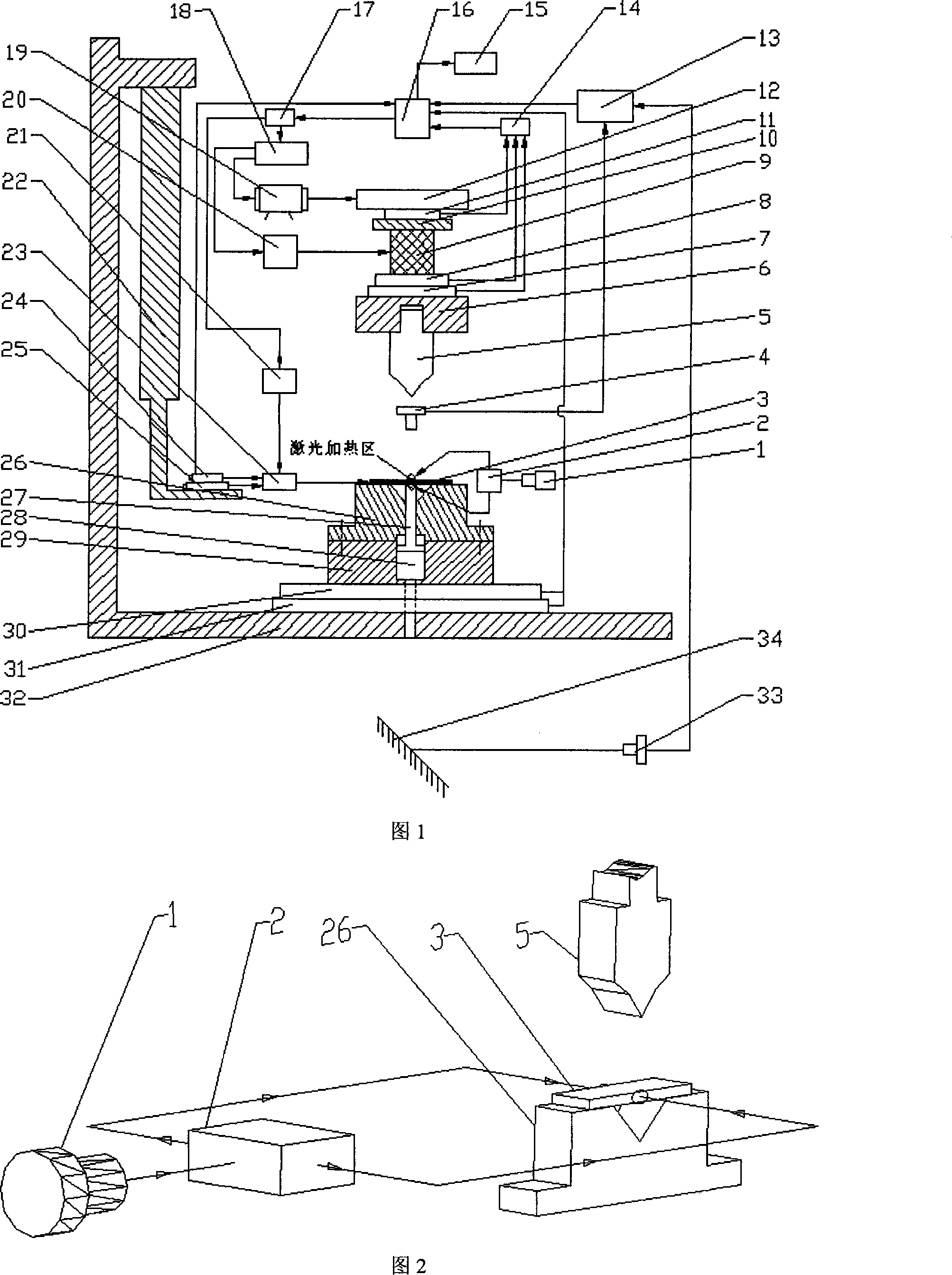

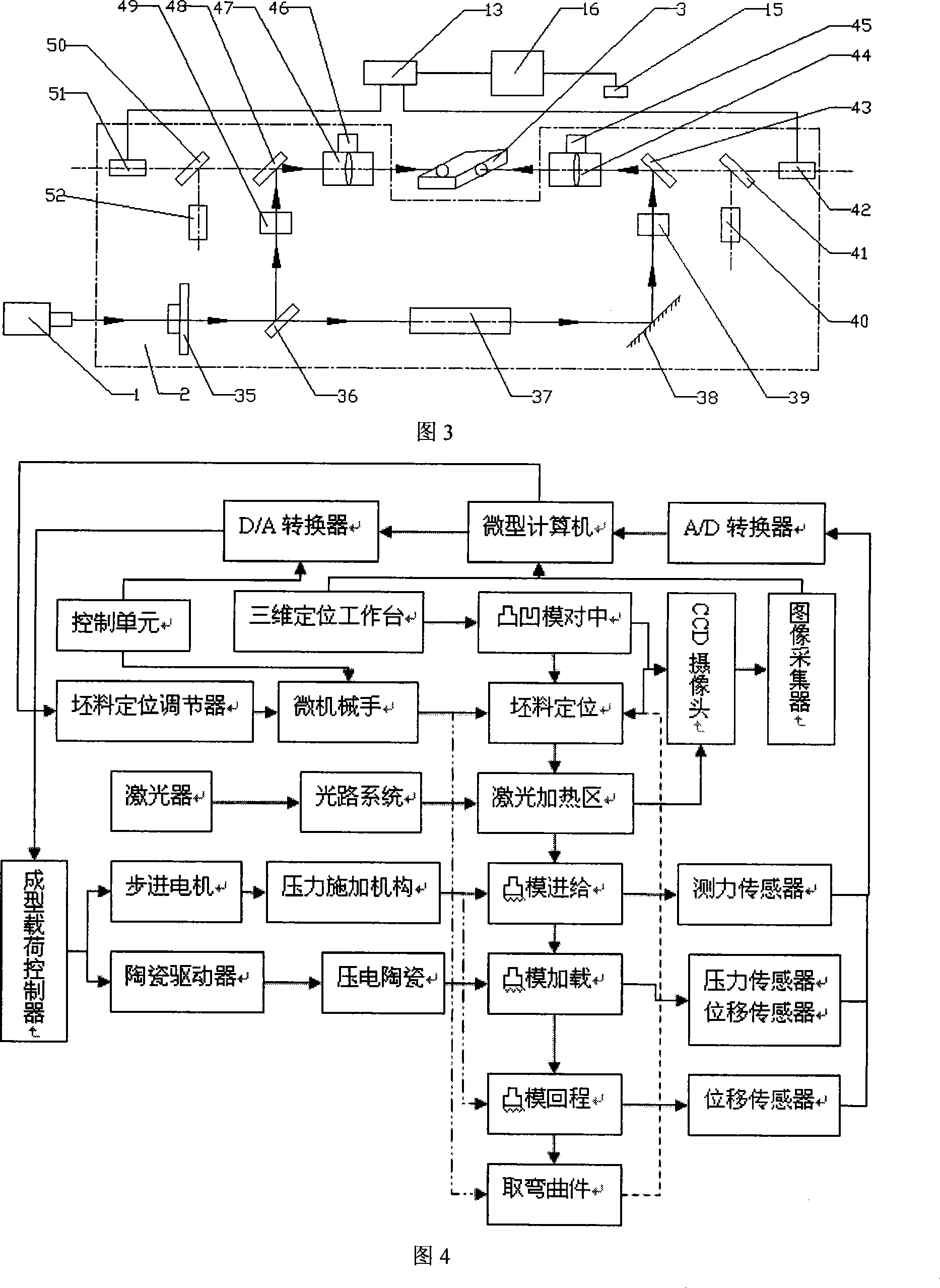

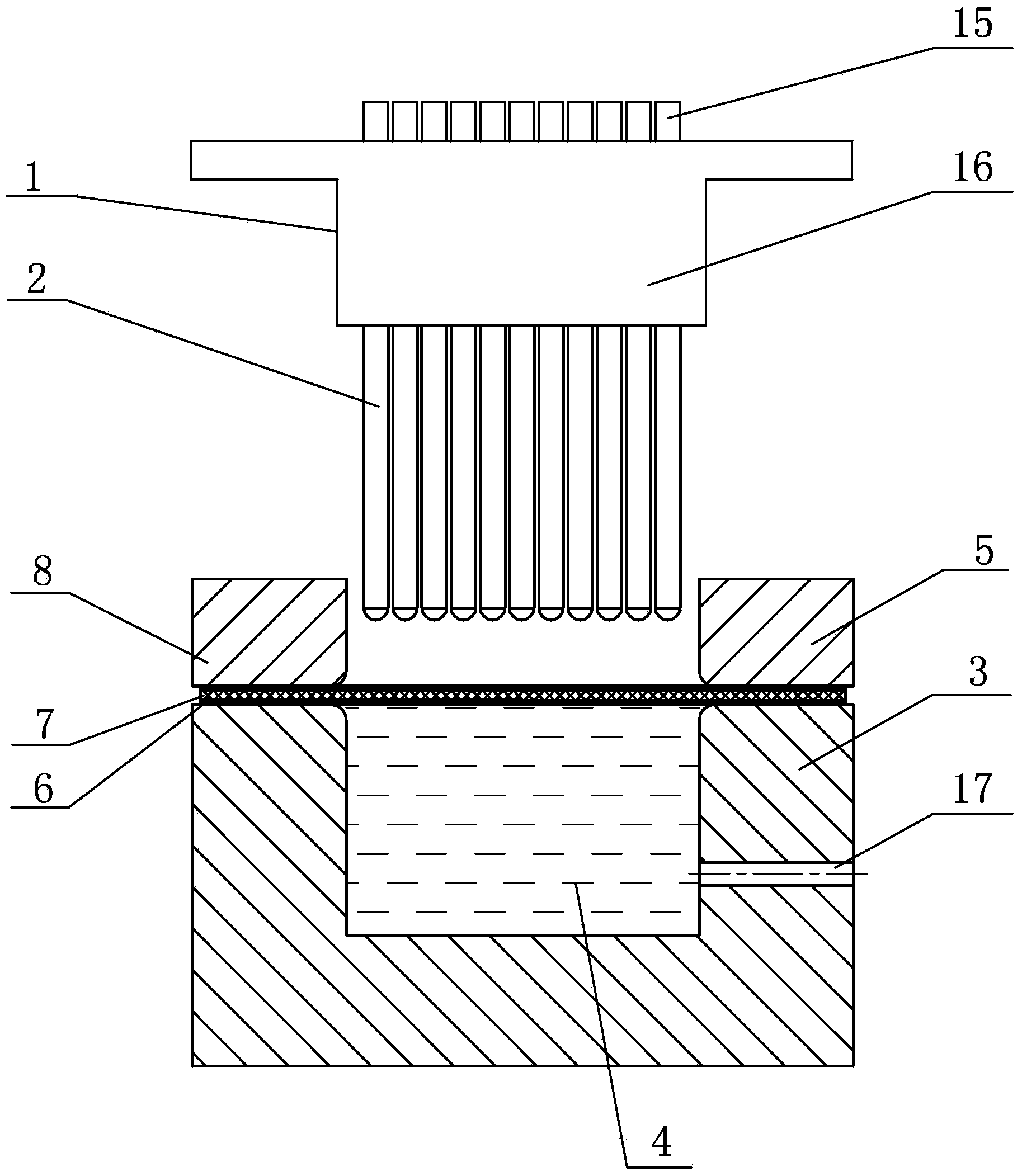

Auxiliary heating micro-device bending forming method and device based on laser

InactiveCN101177236AQuality improvementHigh forming precisionSemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesCeramicLaser assisted

Micro-device bending forming method and device based on laser-assisted heating, involving micro-device manufacturing and micro-plastic forming technology, suitable for forming materials that are difficult or impossible to form by conventional micro-bending methods. The device includes a mounting platform, punch and die alignment Components, micro-bending forming components, feeding mechanism, loading mechanism, workpiece positioning components, laser heating system and control system, the laser beam emitted by the laser passes through the external optical path system to simultaneously perform non-contact quasi-static heating on both sides of the tiny workpiece, using laser The heat conduction makes the blank reach the forming temperature range; the laser heating system is combined with the micro-bending forming component, and the feeding and return of the punch is realized by the stepping motor drive, and the punch is loaded on the workpiece by the piezoelectric ceramic micro-driver, and the micro-bend is completed. Bending of devices. The invention reduces the influence of the temperature gradient on the forming precision. The device has reasonable design, simple process and good controllability, and is suitable for industrialized production.

Owner:JIANGSU UNIV

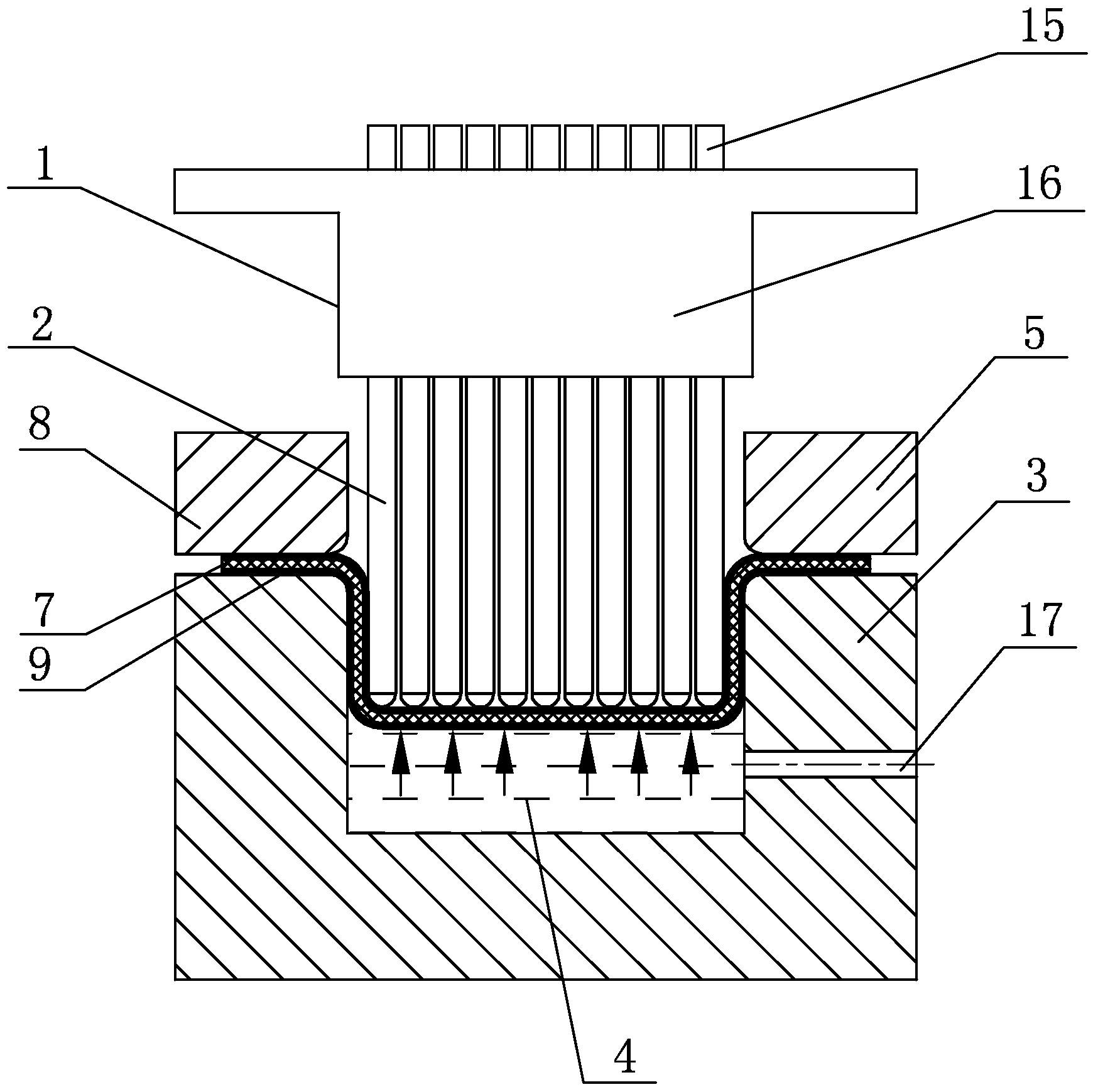

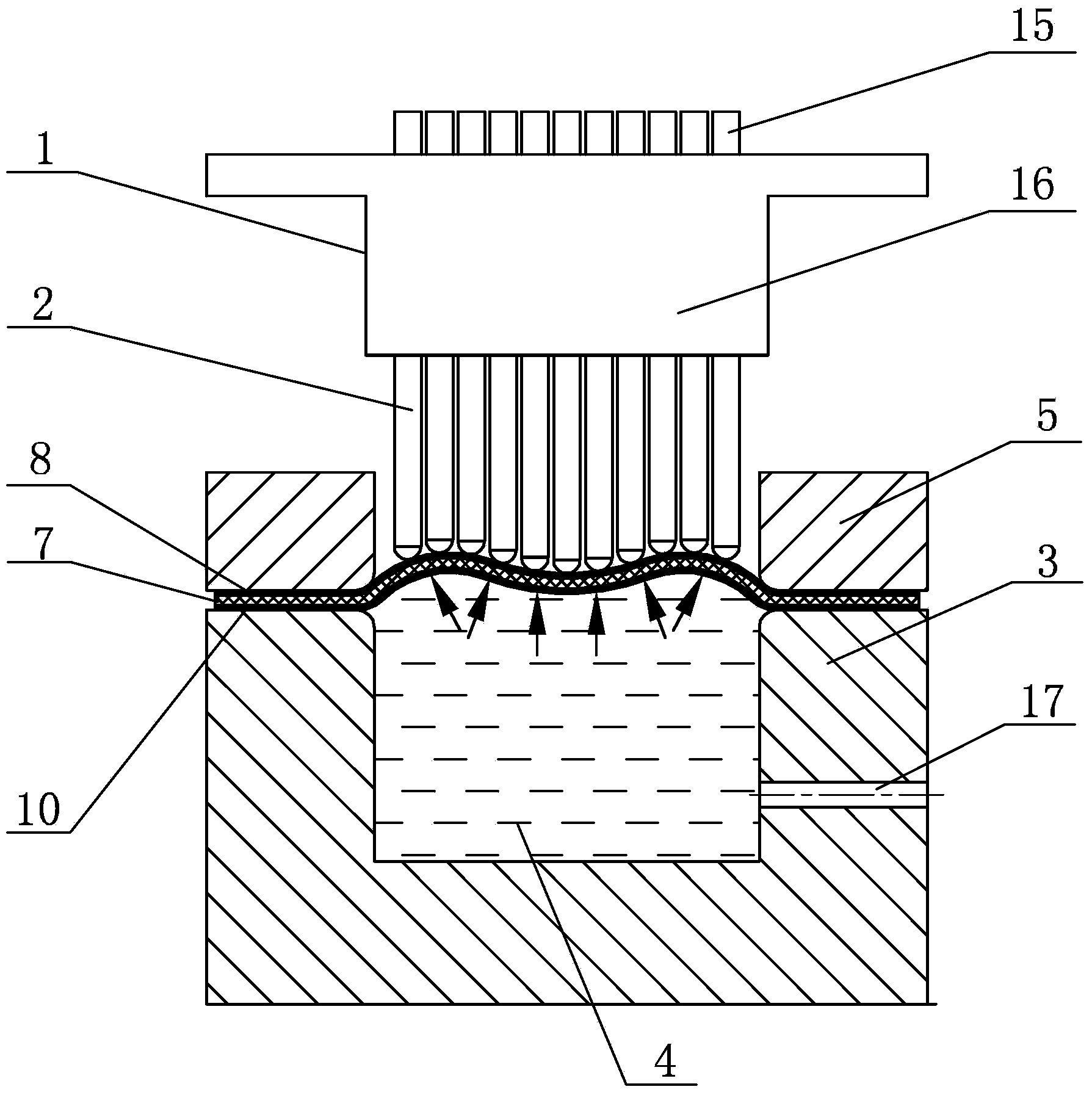

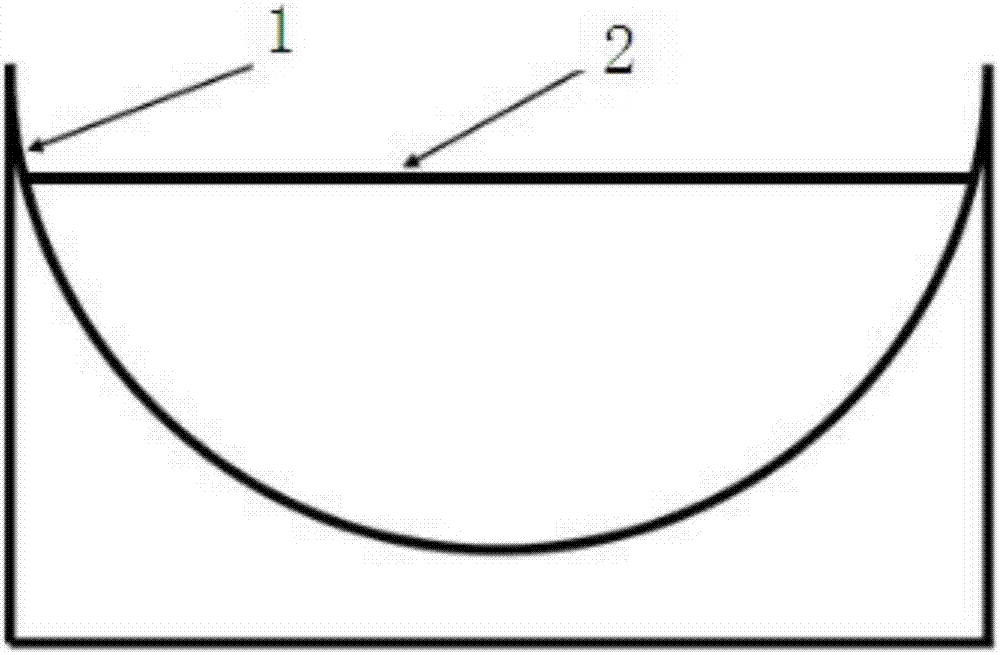

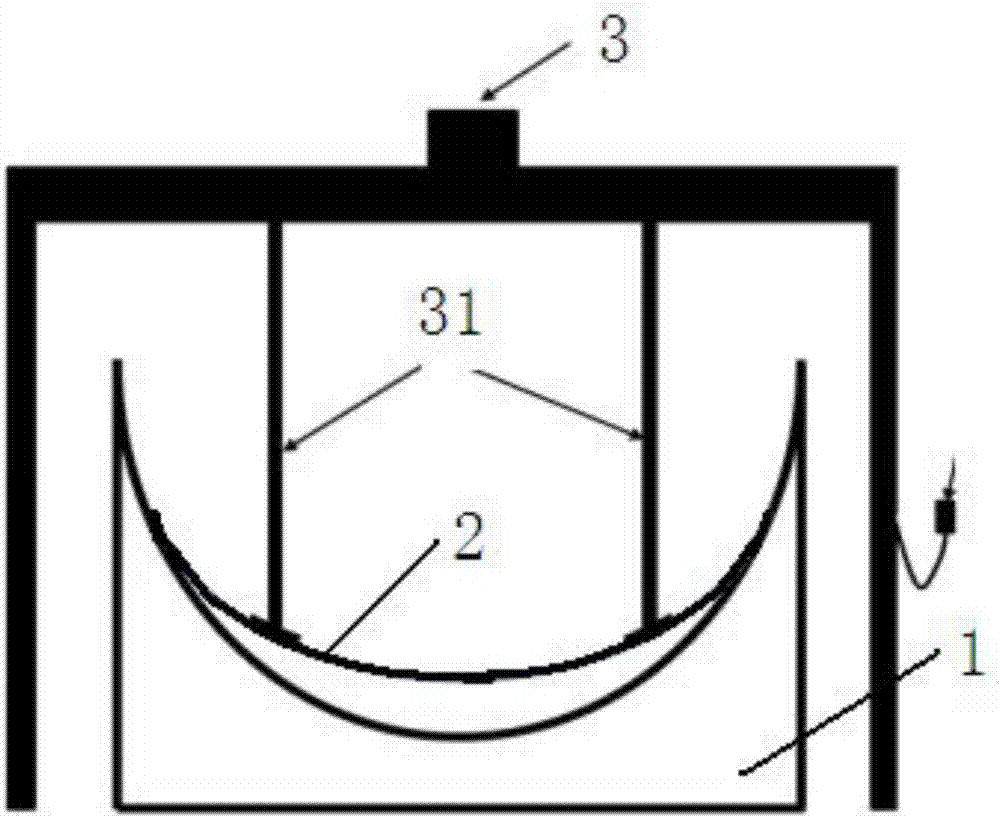

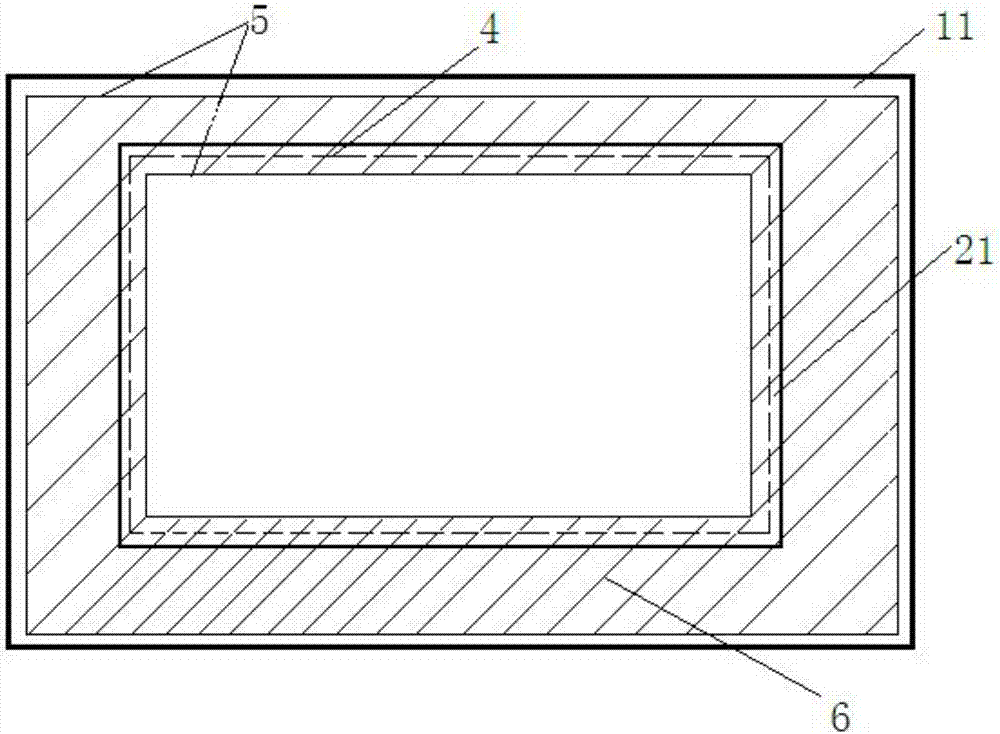

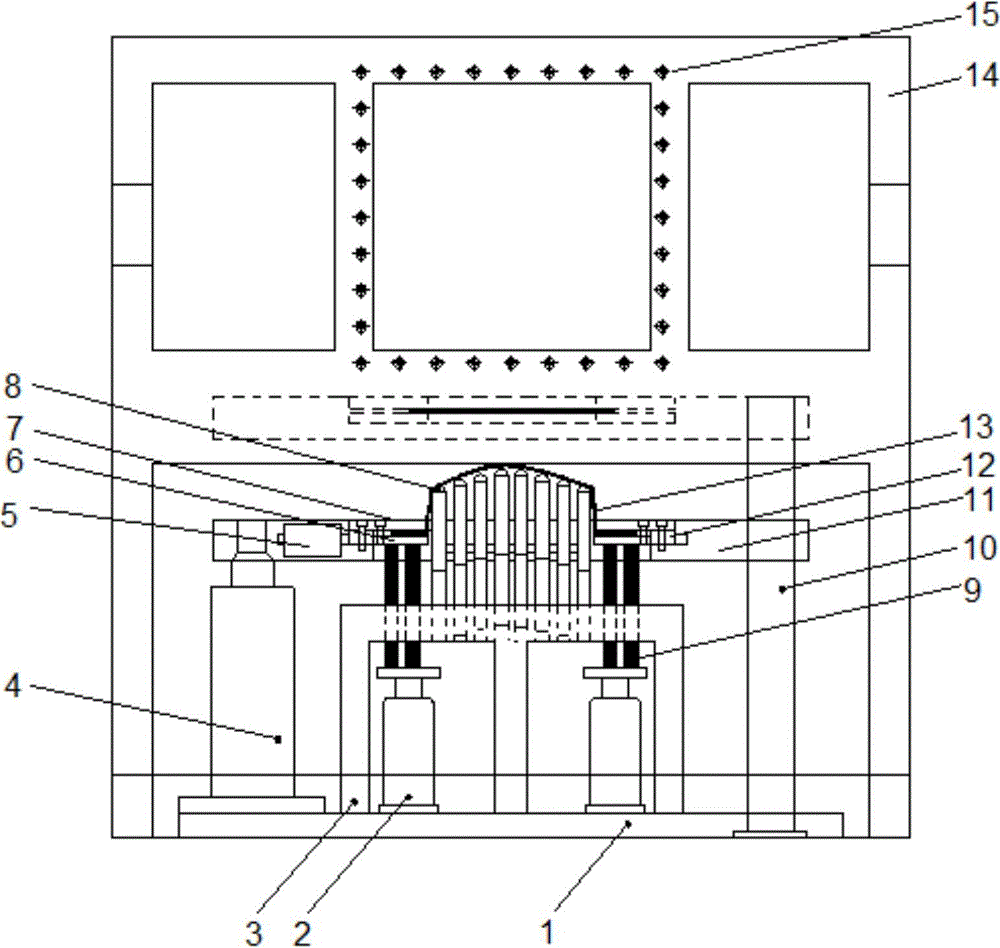

Multi-point male die liquid-filling drawing forming device and method for plate

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

Method for manufacturing large-curvature aluminum alloy integral wall board component

The invention provides a method for manufacturing a large-curvature aluminum alloy integral wall board component. The method includes the steps that A, solution hardening is conducted on a wall board; B, the wall board obtained in the step A is arranged in a sealed environment formed by a thin film covering layer and a forming die jointly, the wall board is elastically deformed and plastically deformed in sequence under the vacuumized condition, and then the deformed wall board is obtained, wherein the temperature in the sealed environment where the wall board is located ranges from 15 DEG C to 35 DEG C, the vacuum degree ranges from -0.1 MPa to -0.05 MPa, and the treatment time ranges from 5 min to 60 min; C, in-situ creep stress relaxation aging is conducted on the deformed wall board obtained in the step B, wherein creep stress relaxation aging time is more than 2 h; D, unloading operation is conducted, and then the large-curvature aluminum alloy integral wall board component is obtained. When the method is used for manufacturing the large-curvature aluminum alloy integral wall board component, the residual stress of the product is greatly reduced, the strength of the product is improved, and the product with high forming accuracy and good performance is obtained.

Owner:CENT SOUTH UNIV

Creep age forming method for aluminium alloy plate

The invention provides a creep age forming method for an aluminium alloy plate. The method comprises the steps as follows: a to-be-formed component is arranged on the molded surface of a mold firstly, and parts (the whole lower surface and the peripheral edge of the upper surface) of the component are covered with air-permeable felt; a plate is bent downwards by a mechanical loading device, and the mechanical loading device stops moving downwards after reaching the set force value; the load is unchanged, at least one circle of a sealant is sequentially bonded to the component and the edge of the mold, a vacuum bag is laid and bonded between the sealants, a closed space is formed, vacuum pumping treatment is performed, and the component is almost attached to the molded surface of the mold as far as possible or is kept to be attached to the molded surface of the mold; and then the mechanical loading device is detached, the component and the mold are placed into an autoclave for vacuum creep age forming, and the component and the mold are separated after ageing is completed. With the method, the time required for vacuum pumping is shortened, so that the forming efficiency is improved; less test materials are used, and thus the test cost is reduced; and the mold attaching error is reduced, and accordingly, the forming precision of the component is improved.

Owner:CENT SOUTH UNIV

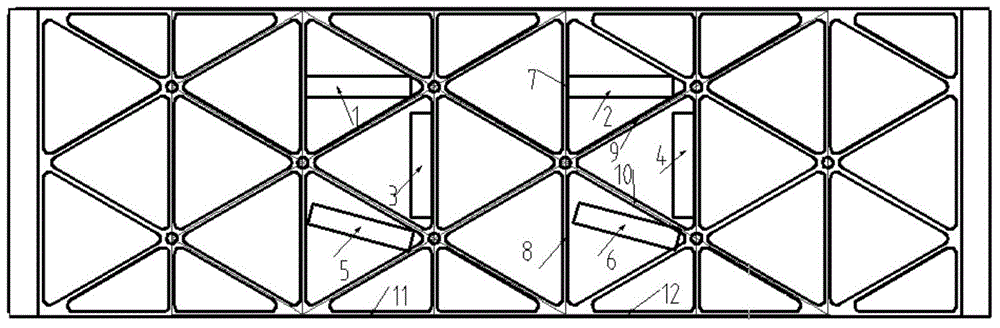

Plate material multi-point-die pre-drawing progressive compound forming method and plate material multi-point-die pre-drawing progressive compound forming device

ActiveCN103599982AOvercome the uneven distribution of sheet metal thicknessImprove forming efficiencyThree dimensional modelForm processing

The invention relates to a plate material multi-point-die pre-drawing progressive compound forming method and a plate material multi-point-die pre-drawing progressive compound forming device. The method includes that the shape of a pre-drawing multi-point die is adjusted according to the shape of a part needed to be processed; a plate material is fixed on a drawing workbench through a rotatable edge-pressing clamping structure, a lifting oil cylinder drives the drawing workbench to move downwards to set a distance, at the same time, back pressure oil cylinders provide back edge-pressing force, and the part is drawn to be in a needed shape through the pre-drawing multi-point die; the lifting oil cylinder drives the drawing workbench to move upwards to an initial position; a progressive-forming processing track is generated according to a three-dimensional model of the part needed to be processed and stored into an industrial robot; the rotatable edge-pressing clamping structure together with the plate material thereon rotate to a vertical position; a six-degree-of-freedom moving mechanism controls a tool head to perform progressive-forming processing on the plate material. Compared with the prior art, the method and the device have the advantages that die-free flexible forming of deep-cavity-type sheet metal parts can be realized, and high forming efficiency, easiness in realization of plate material progressive forming integration and the like are realized.

Owner:SHANGHAI JIAO TONG UNIV

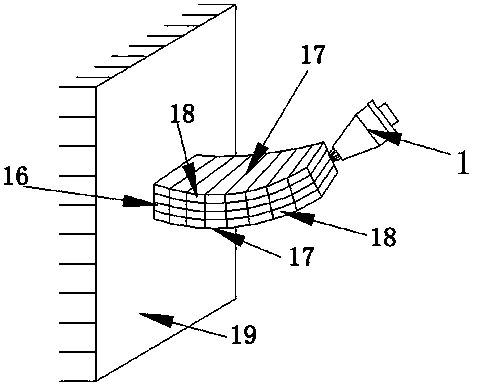

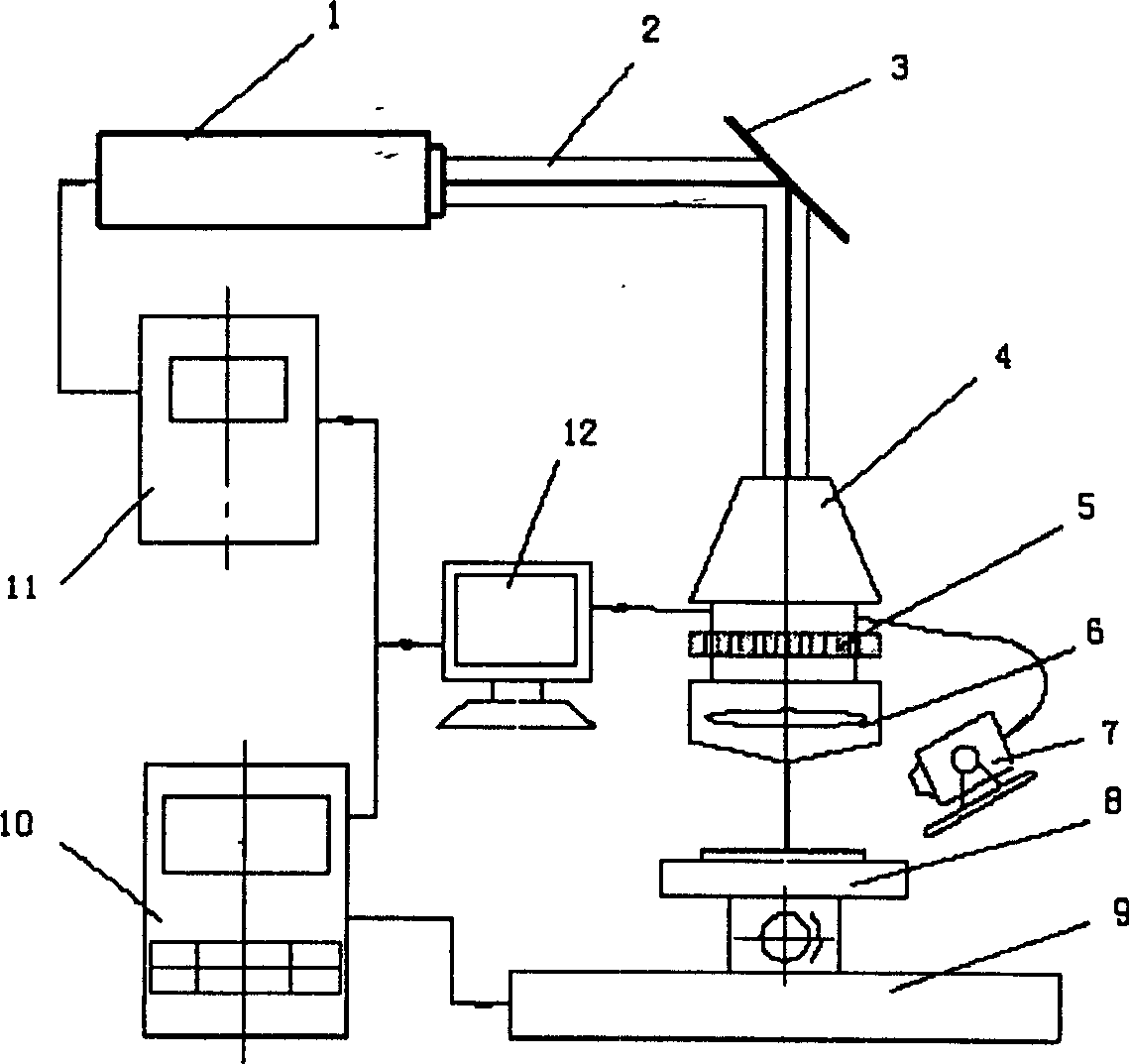

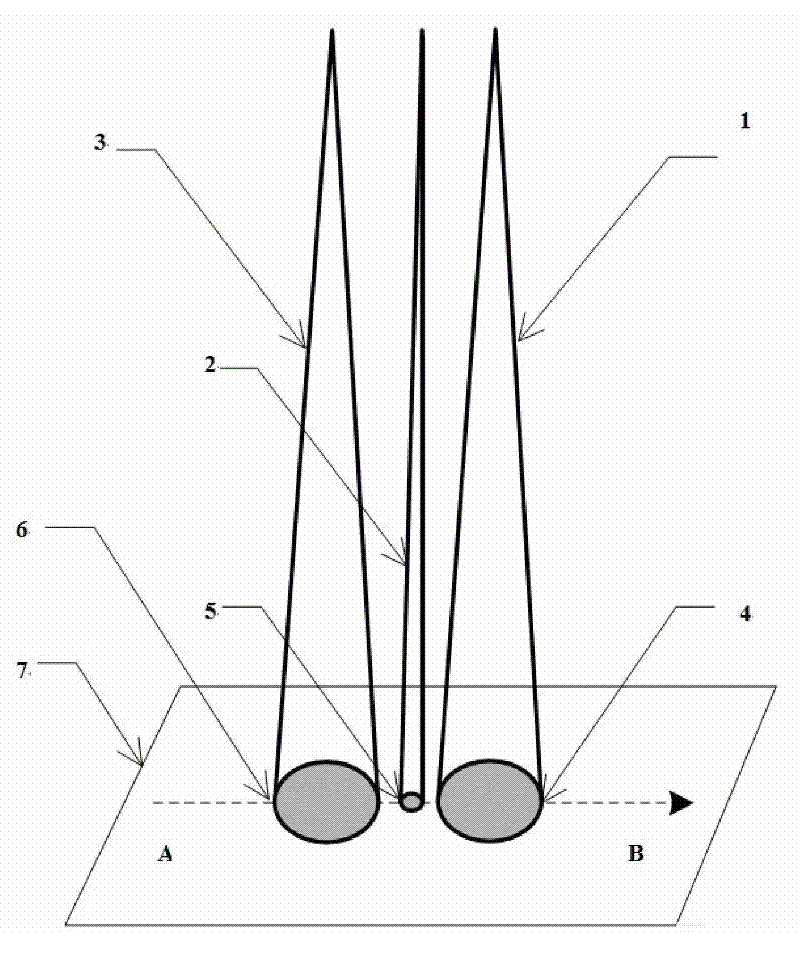

Method and device for improving laser shock forming property of metal plate material

InactiveCN101486129AImprove forming efficiencyGood formabilityLaser beam welding apparatusOptical pathComputer programming

The invention relates to the field of laser machining and manufacturing, in particular to a method and a device for improving forming performance of a metal sheet material by laser and impact to improve the forming performance of the sheet material, realize accurate forming of complex shape of the sheet material and obtain largest forming limit, and is particularly suitable for material forming which the prior method is difficult to form or cannot form basically. When the method adopts a large-power pulse laser (4) to carry out several impact on the sheet material or impact on a curved surface part by an outer optical path system, the method feeds back specific information on the sheet material shape prescanned by a feedback system device (3) to a central control processor (1); the information is input to a CAD software for carrying out curved surface modeling; the normal direction is determined; and computer programming controls the rotation of a multiaxial coordinate station (13) and ensures that the incident direction of laser beans is always consistent with the normal direction of the sheet material so as to improve the forming performance and obtain the maximal forming effect. Simultaneously, the method improves the distribution of residua stress field on the surface of the sheet material, improves the capacity for resisting stress corrosion, and prolongs fatigue life.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com