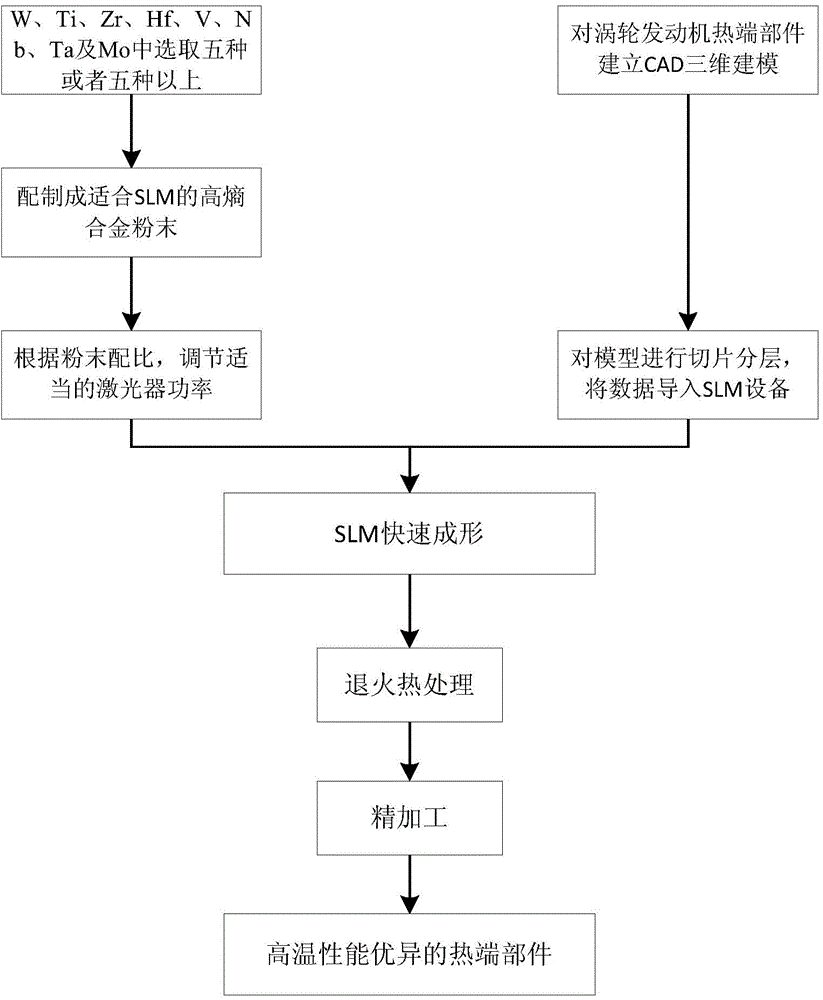

High-entropy alloy hot-end part manufacturing method of turbine engine on basis of selective laser melting

A selective laser melting and turbine engine technology, which is applied in the direction of turbines, process efficiency improvement, mechanical equipment, etc., can solve the problems of difficult to obtain high-entropy alloys, difficult processing and manufacturing, etc., to reduce manufacturing costs, meet use requirements, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

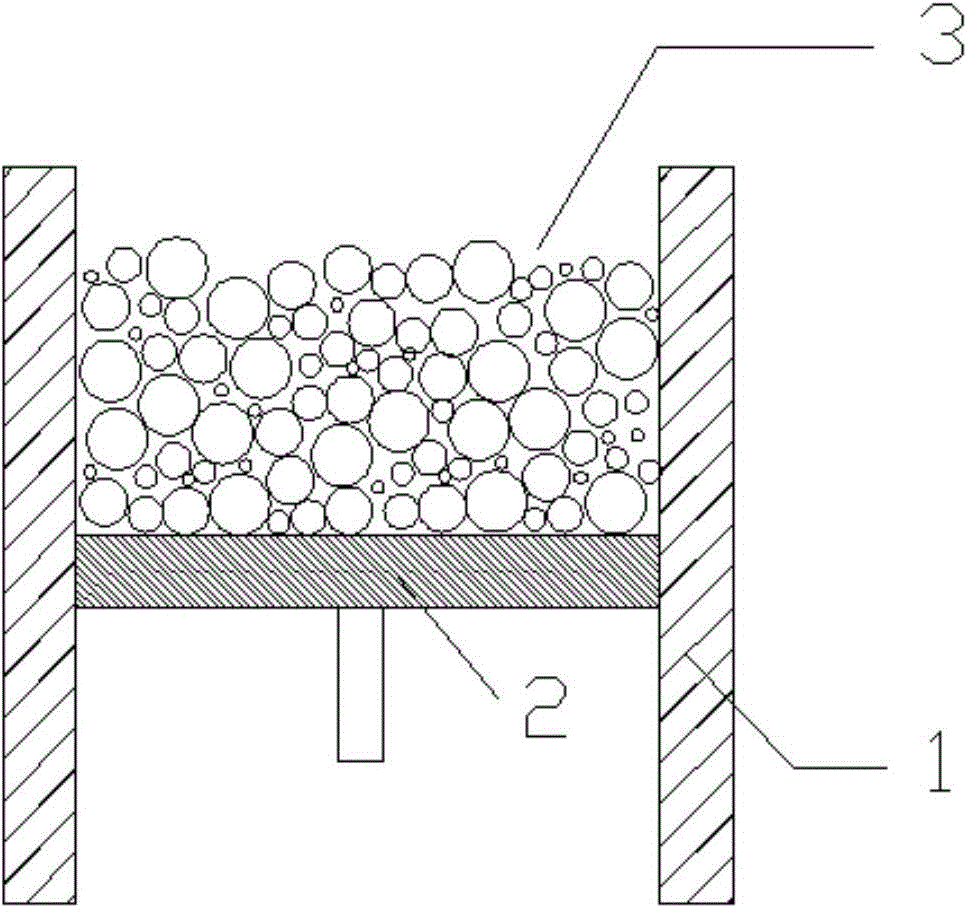

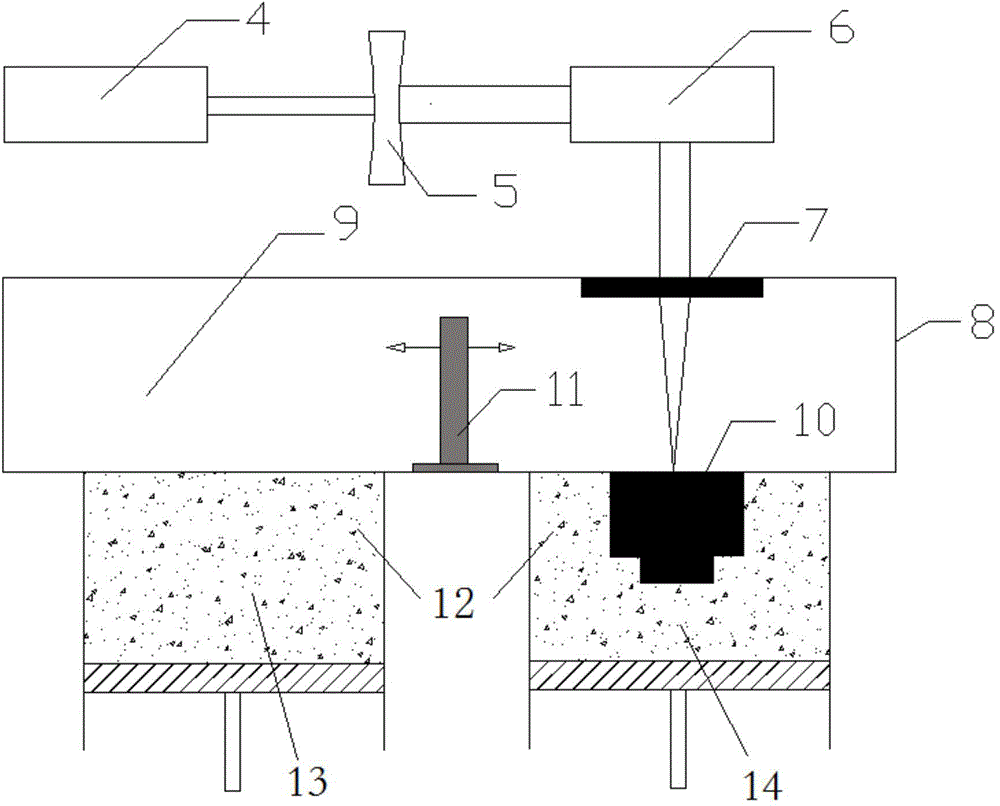

[0050] Five kinds of high-melting point metal powders, W, Ti, Zr, V, and Ta, were selected and configured into high-entropy alloy powders according to the equiatomic ratio, and placed in the material cylinder of the SLM rapid prototyping equipment. UG software is used to establish a three-dimensional CAD model of the hollow turbine blade, slice and layer it, and import the obtained data into the SLM device. According to the vapor pressure of these five different elements, the selected laser power is 200W. At the same time, because the hollow turbine blade has tiny air film holes and exhaust edge structure, and has high requirements on the surface quality and forming accuracy of the formed part, it is necessary to use a small The focal length of the lens (100mm) to obtain a fine focus spot size (30μm). Scraper type powder spreading device with pre-compacted powder. The mixed scanning path of contour + grating + partition is adopted, the scanning speed is set to 100 mm / s, and t...

Embodiment 2

[0052] Five kinds of metals, W, Ti, Zr, V, and Ta, were selected and prepared into high-entropy alloy powder according to the equiatomic ratio, and placed in the material tank of the SLM rapid prototyping equipment. UG software is used to slice and layer the established three-dimensional CAD model of the turbine disk, and import the obtained data into the SLM device. According to the vapor pressure of these five different elements, the laser power is selected as 200W. At the same time, because the turbine disk has high requirements on the forming surface quality and forming accuracy, a lens with a small focal length (100mm) is required to obtain a fine focus spot size (30μm). . Scraper type powder spreading device with pre-compacted powder. The mixed scanning path of contour + grating + partition is adopted, the scanning speed is set to 100 mm / s, and the scanning layer thickness Δh is 35 μm. Fill the forming chamber with protective gas (argon) to prevent the high-entropy all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com