Patents

Literature

330results about How to "Avoid assembly errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy hot-end part manufacturing method of turbine engine on basis of selective laser melting

ActiveCN104308153AMeet the requirements of gas temperature to form a large thrustSatisfy the requirement of increasing the gas temperature to form a large thrustTurbinesIncreasing energy efficiencySelective laser meltingSelective laser sintering

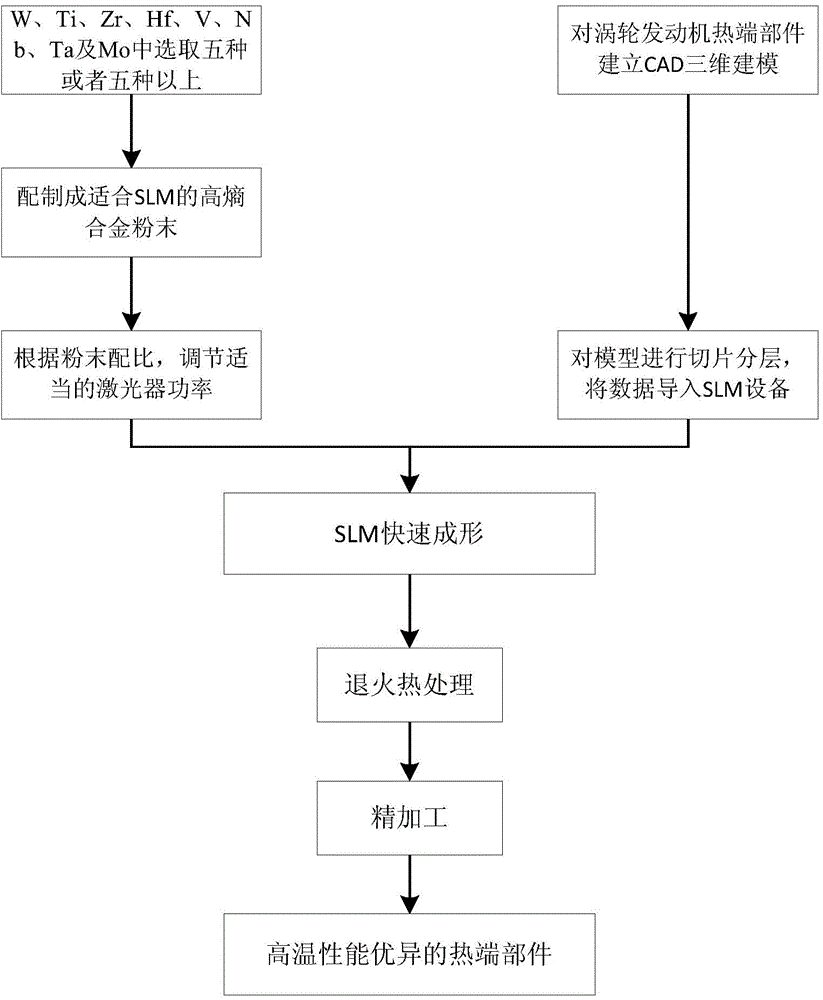

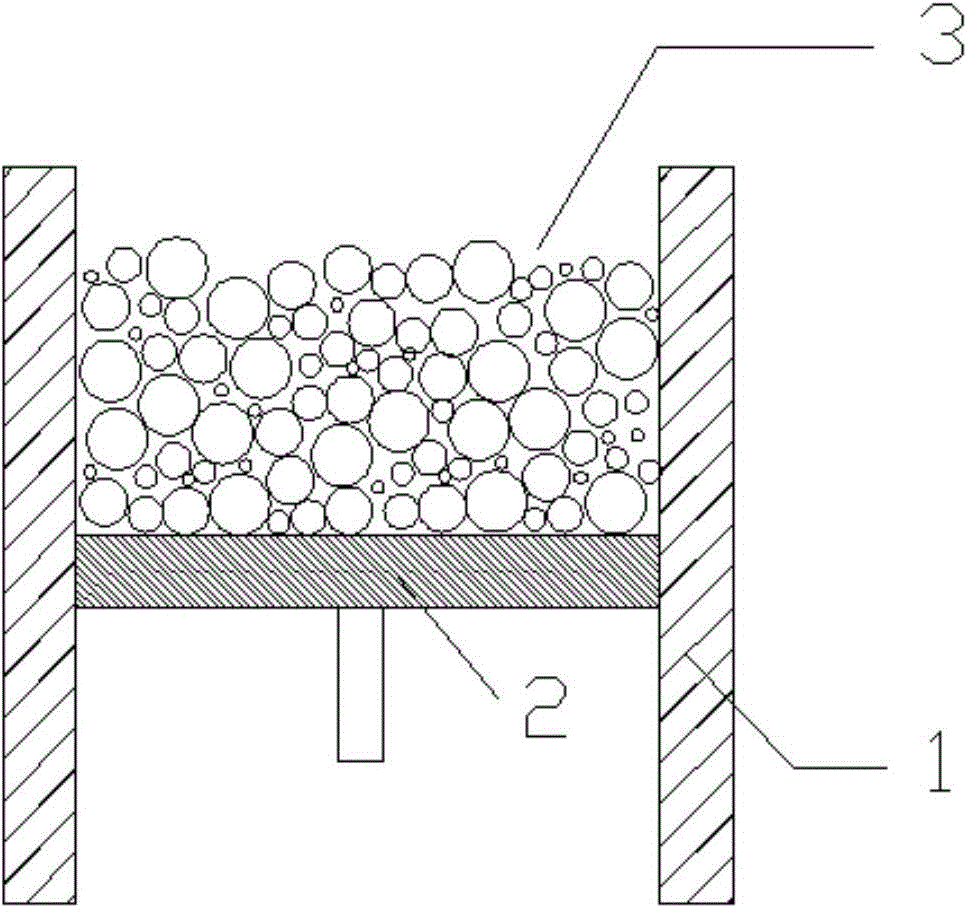

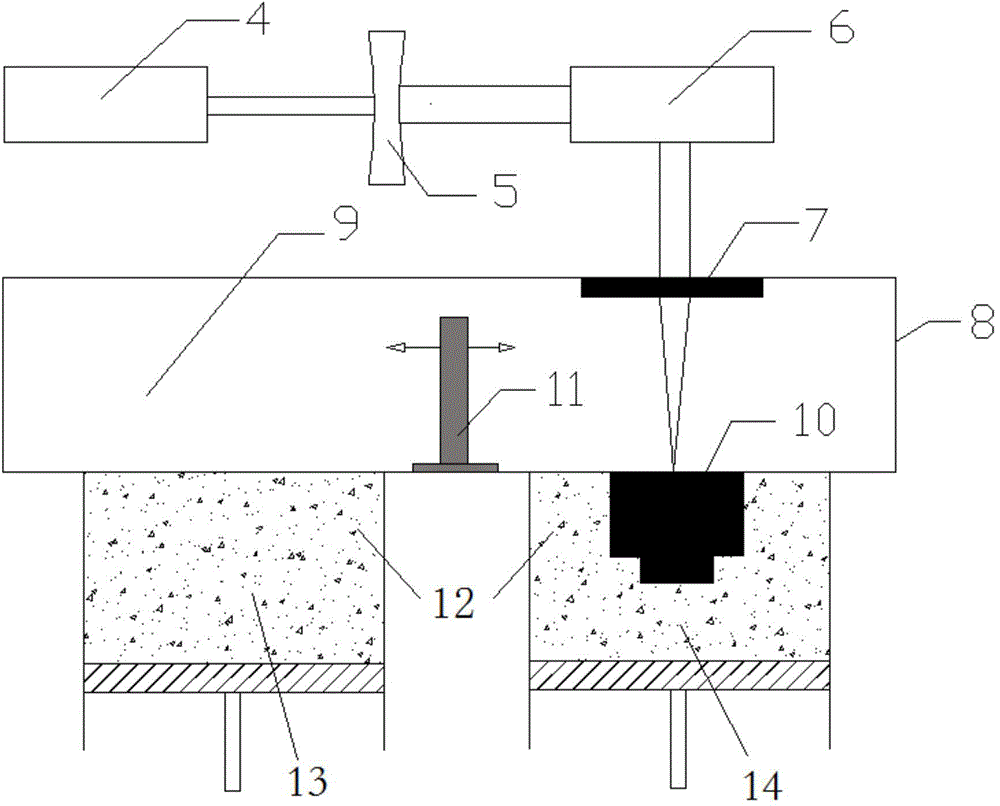

The invention discloses a high-entropy alloy hot-end part manufacturing method of a turbine engine on the basis of selective laser melting and belongs to the technical field of manufacture of hot-end parts of the turbine engine. The high-entropy alloy hot-end part manufacturing method includes firstly selecting five or more of eight kinds of high-melting metal powder of tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum, and mixing the powder uniformly according to a certain mole ratio to obtain high-entropy alloy powder; setting up a three-dimensional solid model of a hot-end part of the turbine engine, slicing and layering by software to obtain profile data of various sections, and importing the data into a quick forming device; quickly forming a hot-end part blank of the turbine engine by the SLM technology; thermally treating and finely processing the blank to obtain the high-temperature high-entropy alloy hot-end part of the turbine engine. The formed hot-end part of the turbine engine has high compactness and excellent high temperature performance, has high forming accuracy and surface accuracy and can be quickly and accurately manufactured.

Owner:XI AN JIAOTONG UNIV

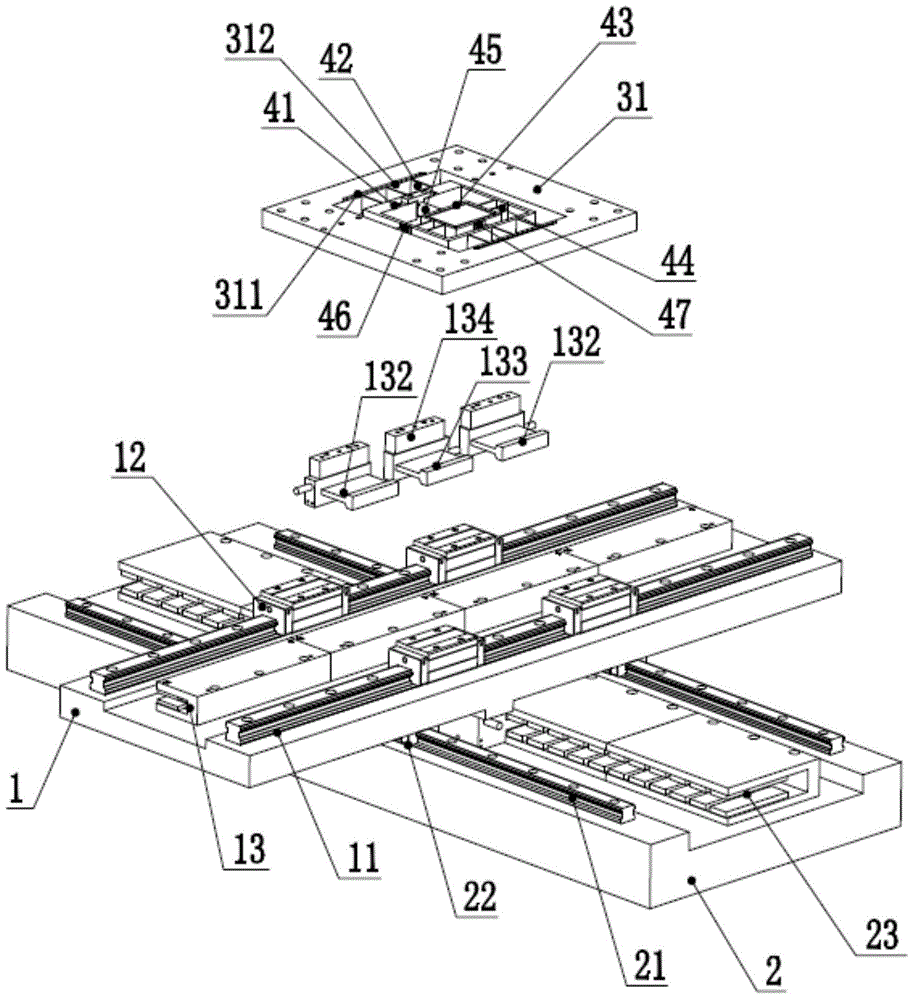

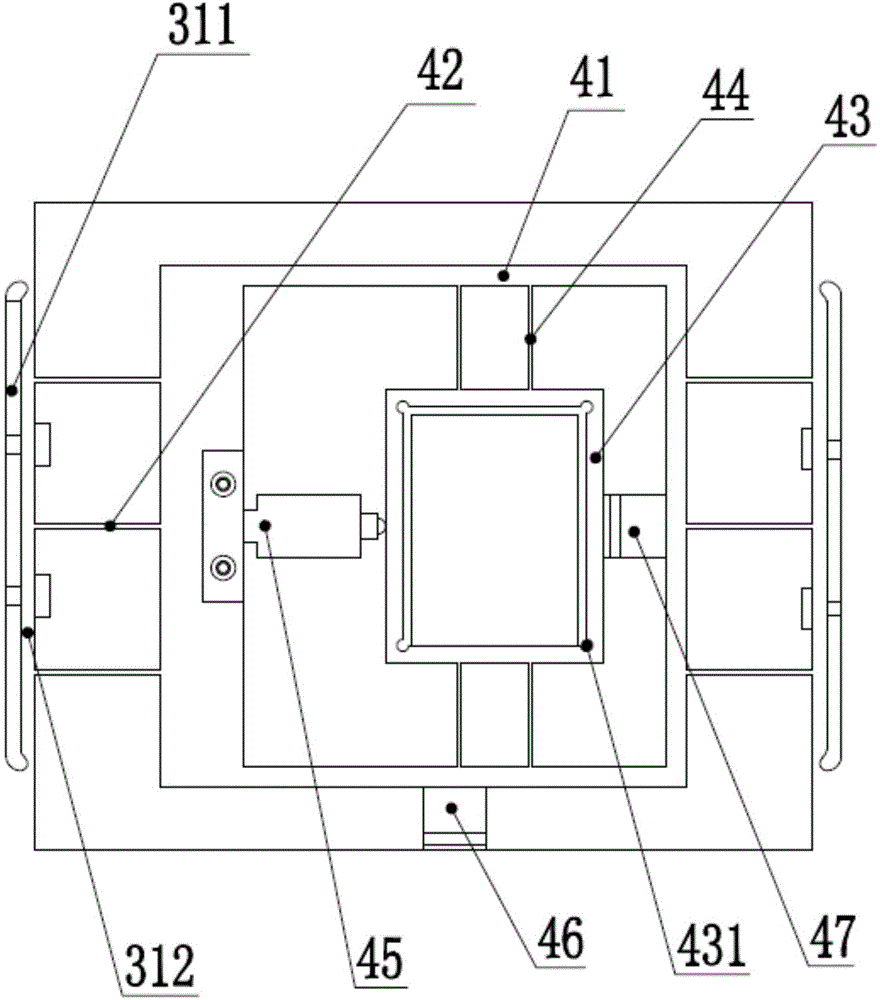

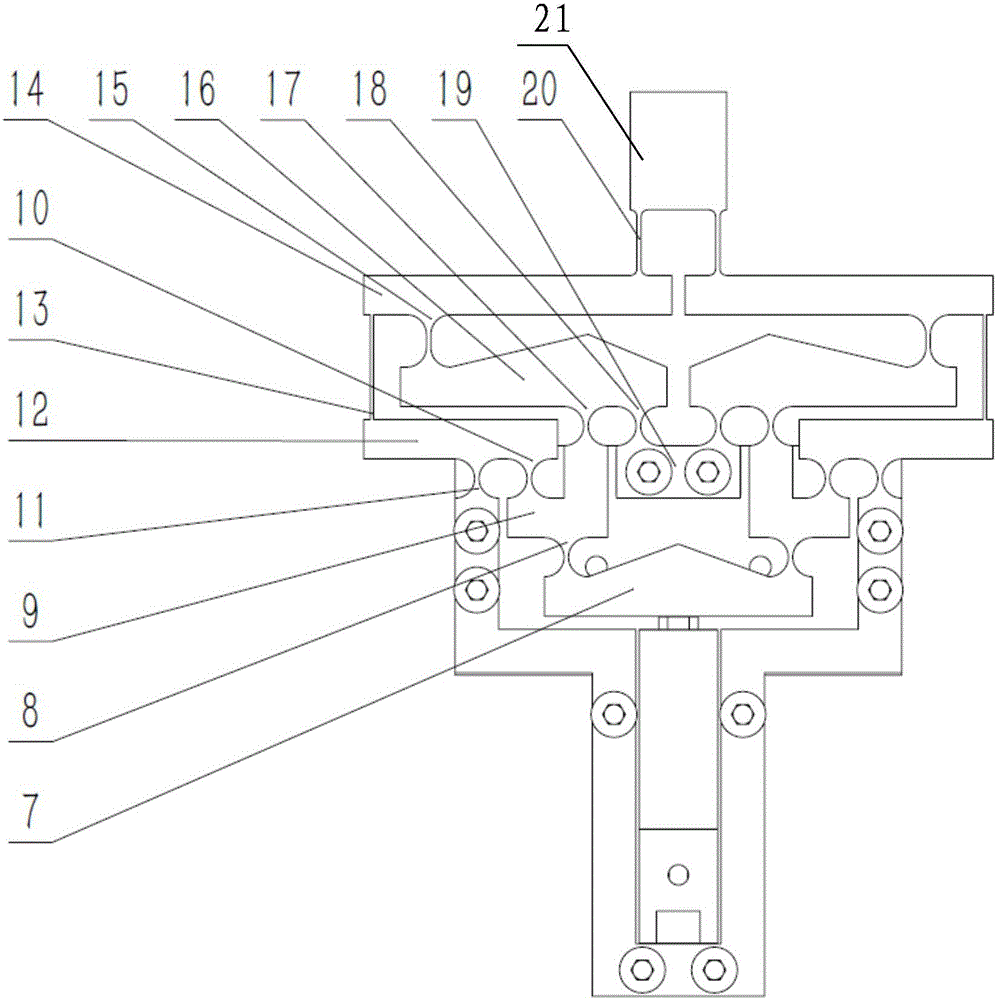

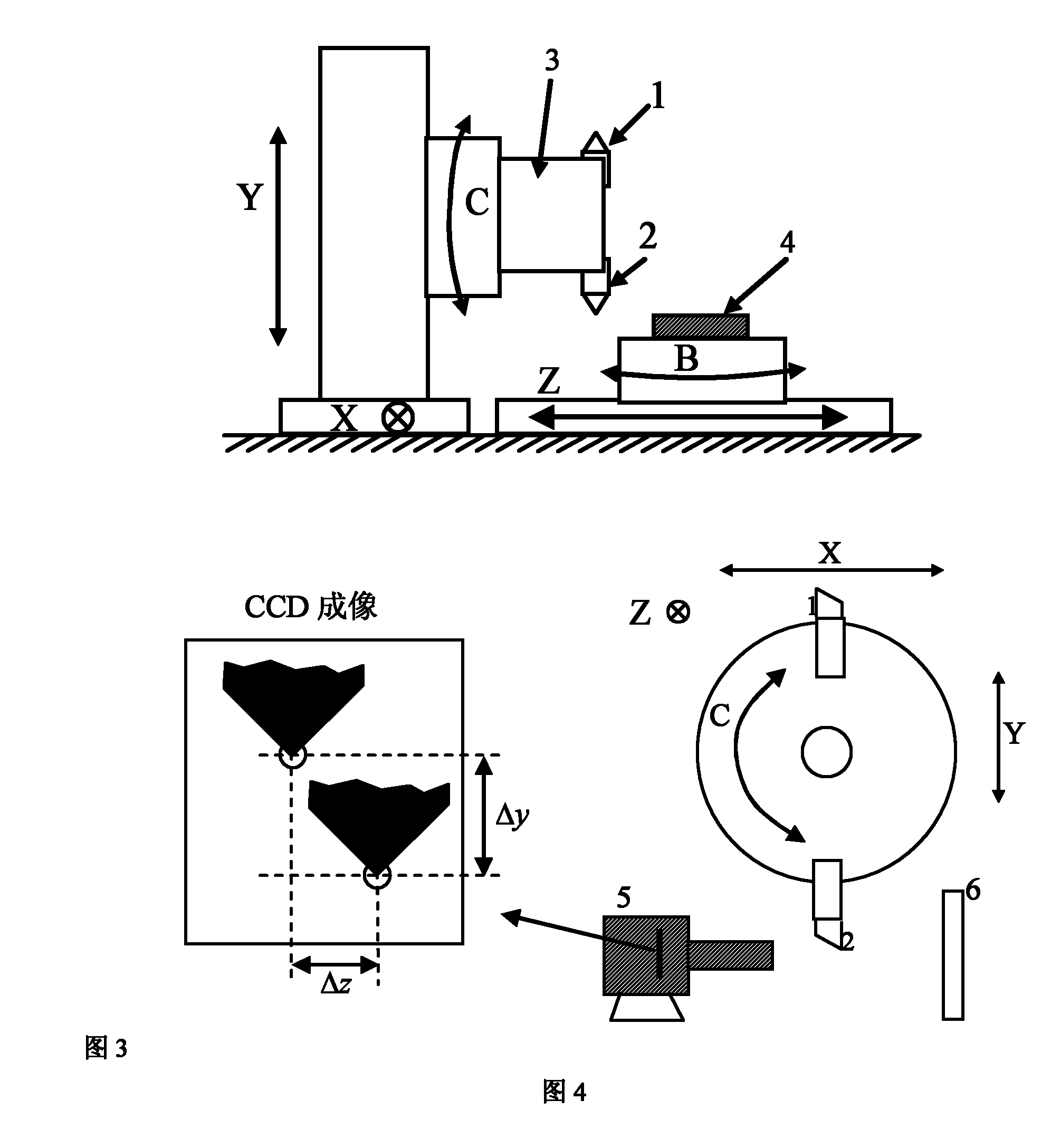

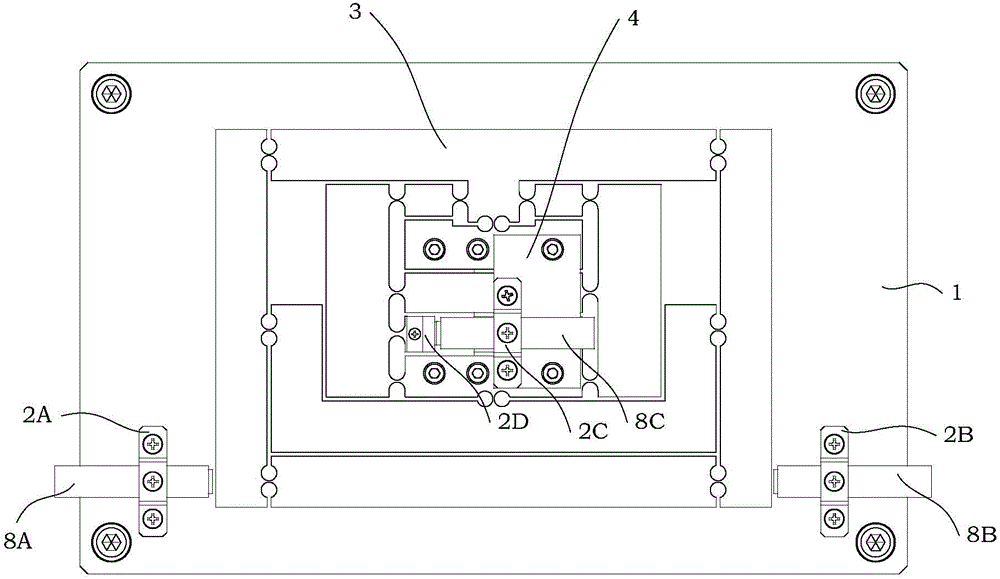

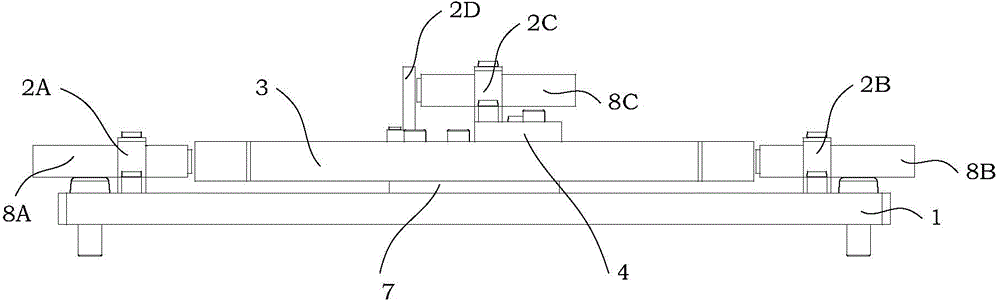

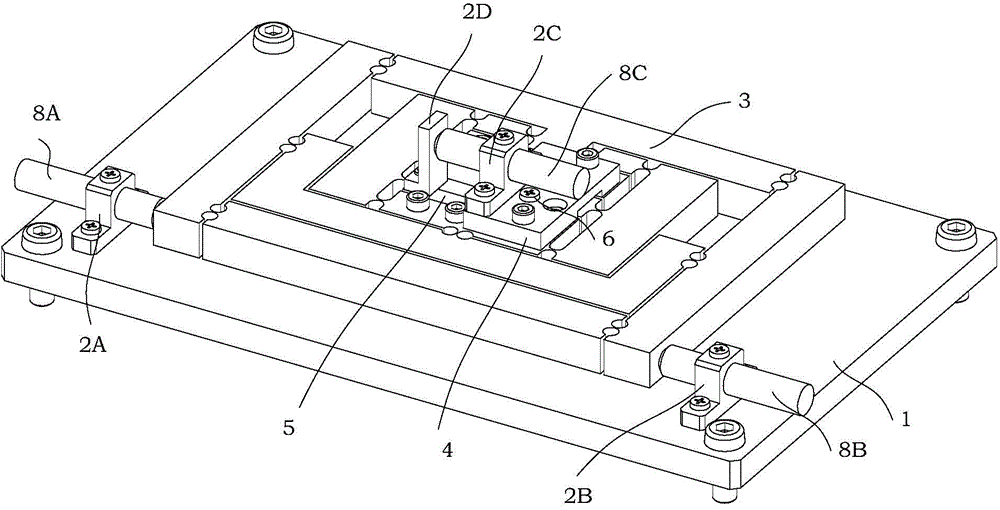

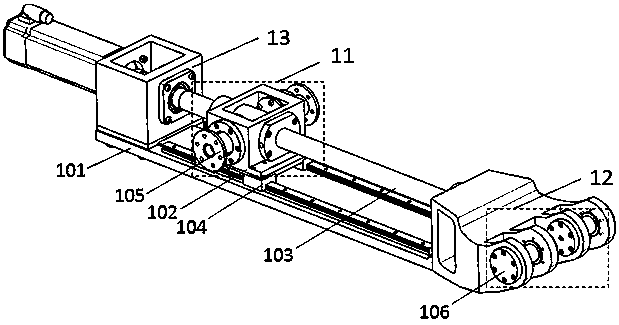

Co-stator multi-drive macro and micro integration high-speed precision movement two-dimensional platform for linear motor

ActiveCN104440344AHigh movement precisionAvoid assembly errorsFeeding apparatusEngineeringVoice coil

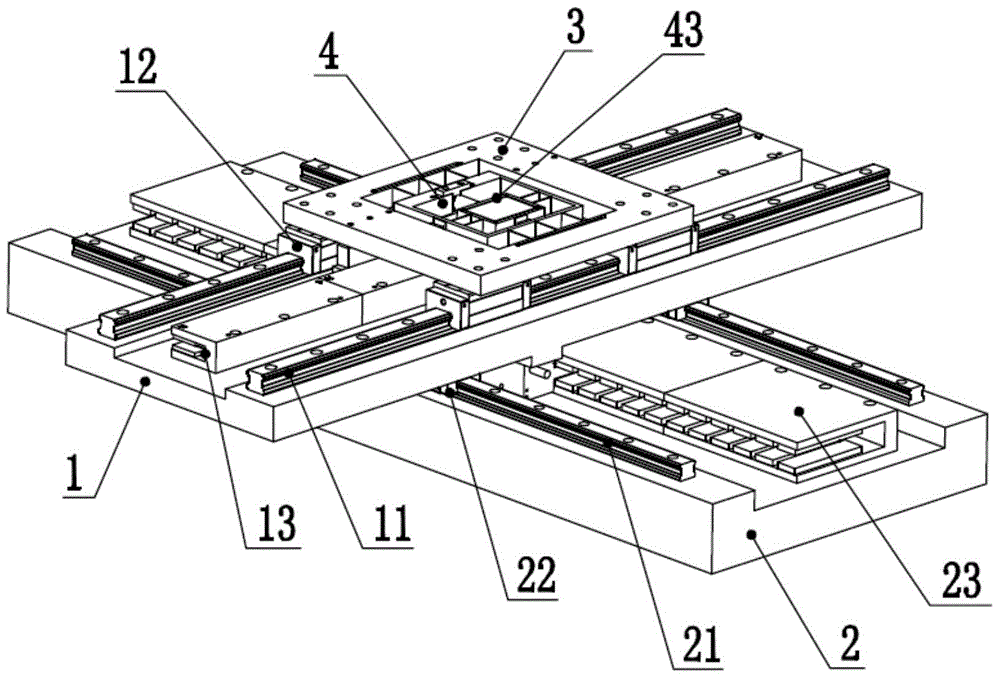

The invention provides a co-stator multi-drive macro and micro integration high-speed precision movement two-dimensional platform for a linear motor. The platform comprises X / Y-direction bases, X / Y-direction guide rails, sliders, U-shaped linear motor stators, a macro movement rotor, a micro movement rotor and a macro and micro integration platform body, wherein a macro movement platform body and a micro movement platform body are connected through an elastic component to form the integration platform body, a stator installed on the X-direction base is shared by a rotor of the macro movement platform body and a rotor for controlling the X-direction micro movement of the micro movement platform body, precision displacement compensation is performed in the Y direction through piezoelectric ceramic or a decoupling voice coil motor, and when the macro and micro rotors are driven at the same time, overall high-speed movement within a large range can be achieved; when movement deviation occurs, because the micro movement platform body is small in inertia and free of friction, precision displacement output is achieved through elastic deformation, and independent drive can be performed so that high-frequency movement deviation compensation can be achieved. Due to composite movement control, two-dimensional high-speed precision movement can be achieved, an installing and using mode is consistent with that of a traditional platform, and application and popularization are facilitated.

Owner:GUANGDONG UNIV OF TECH

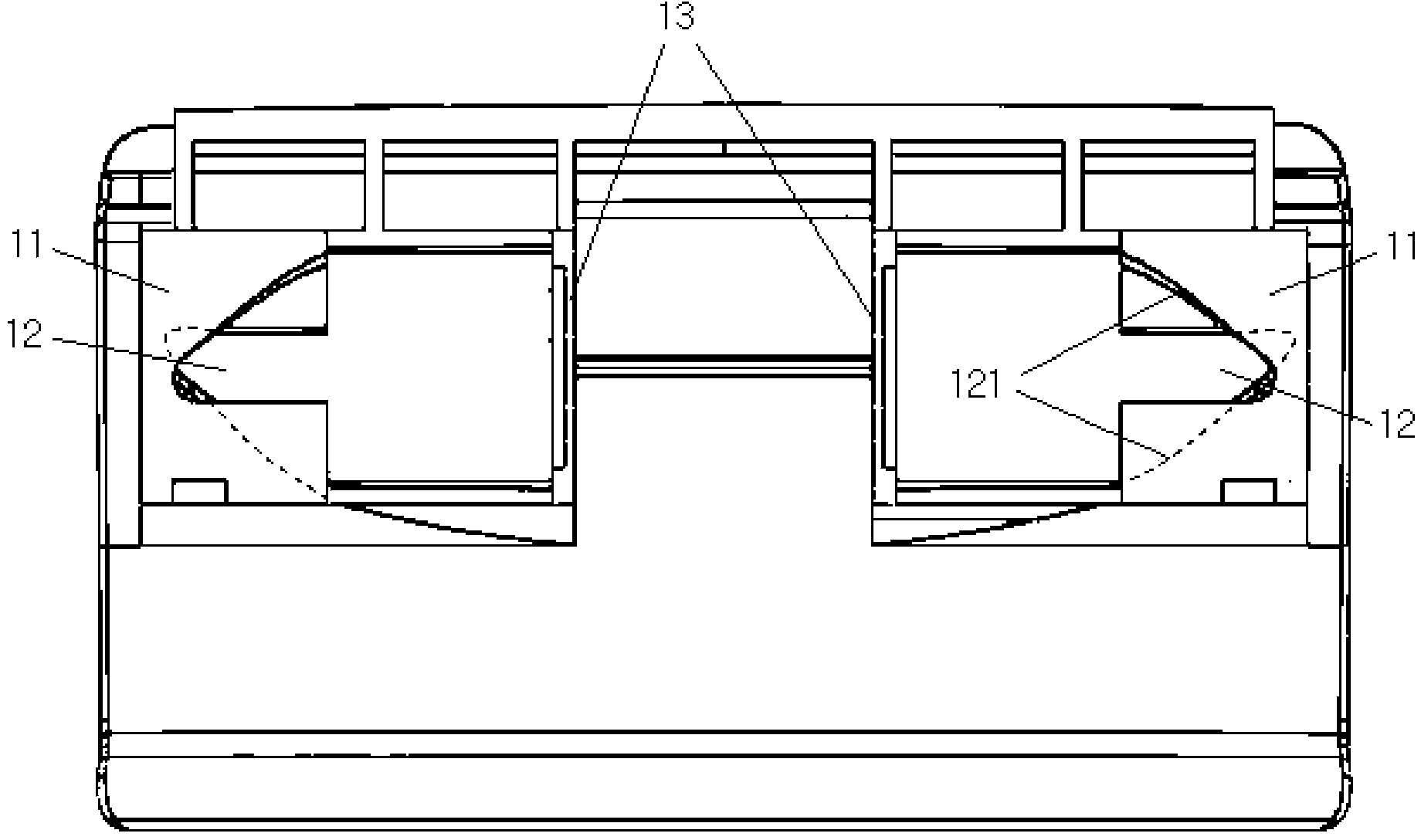

Bilateral locking device

InactiveCN103867052AEasy to disassembleAvoid damageNoise-prevention/anti-rattling lockingPulp and paper industry

The invention relates to a bilateral locking device, relates to the technical field of locksets and aims to solve to the technical problems of inconvenient maintenance and low assembling efficiency of an existing device. The device comprises an outer cover plate, a main-body part and a handle, wherein the main-body part is fixedly arranged on the outer cover plate, and the handle is pivoted with the main-body part; a left sliding-shaft barrel and a right sliding-shaft barrel are respectively and fixedly arranged at the back of the handle, a sliding shaft is arranged in each sliding-shaft barrel, and the two sliding shafts are respectively driven to extend and retract through the matching of the shaft-barrel guiding ports and the sliding-shaft pins of the two sliding-shaft barrels and the sliding shafts in the barrels; a shaft hole is formed in the clamping end of each sliding shaft, two disassembling holes are formed in the hole wall of each shaft hole, and a stop block is fixedly arranged in each shaft hole; the left side and the right side of the main-body part are respectively provided with a locking rod, the hook end of each locking rod is inserted into the shaft hole of the corresponding sliding shaft, and the stop block in each shaft hole is hooked after two elastic clamping hooks at the hook end of the corresponding locking rod penetrate through a clamping hole in the corresponding shaft hole. The device provided by the invention is suitable for being used as the box cover of an automobile glove box.

Owner:上海琦天汽车科技有限公司

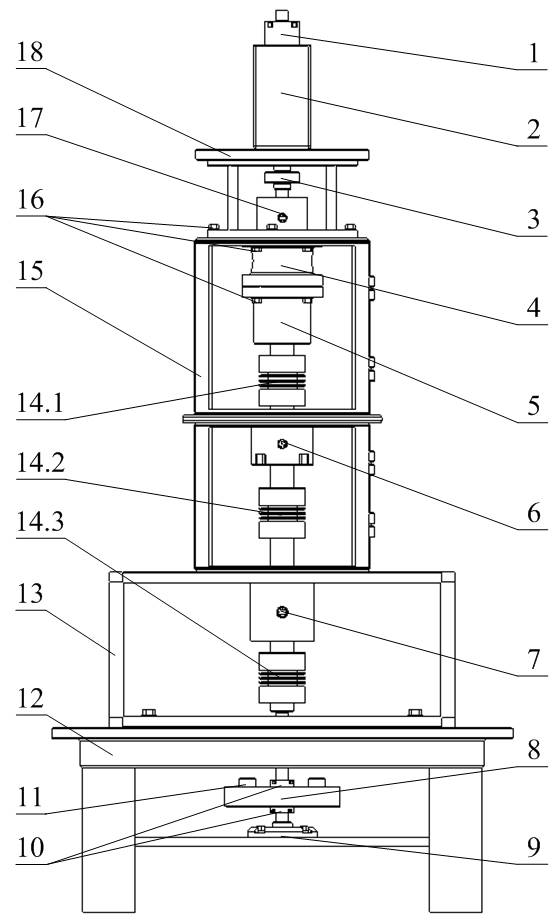

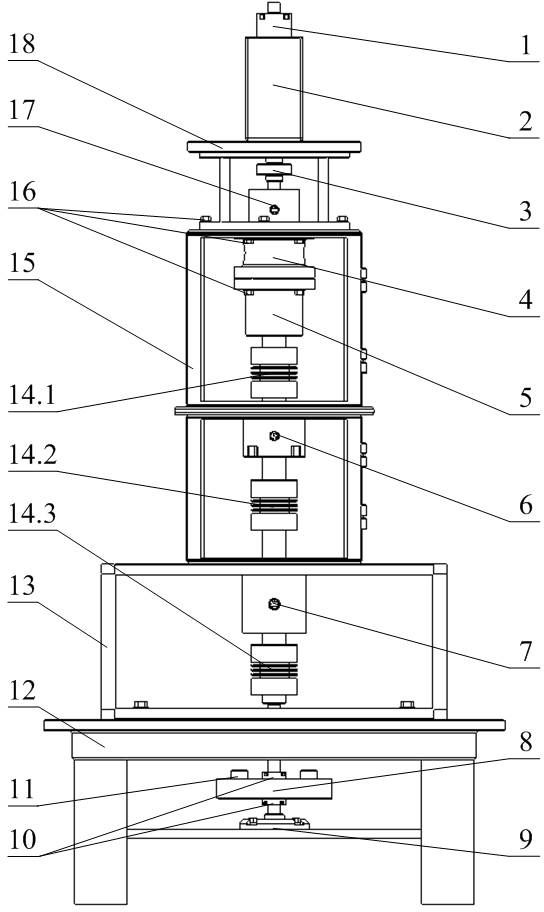

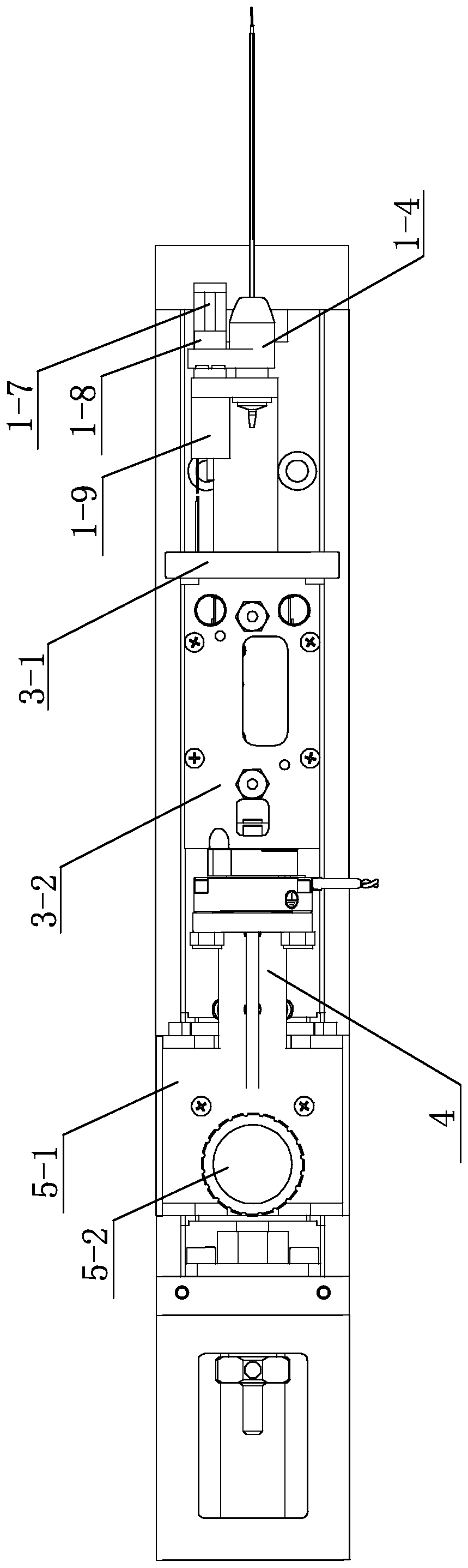

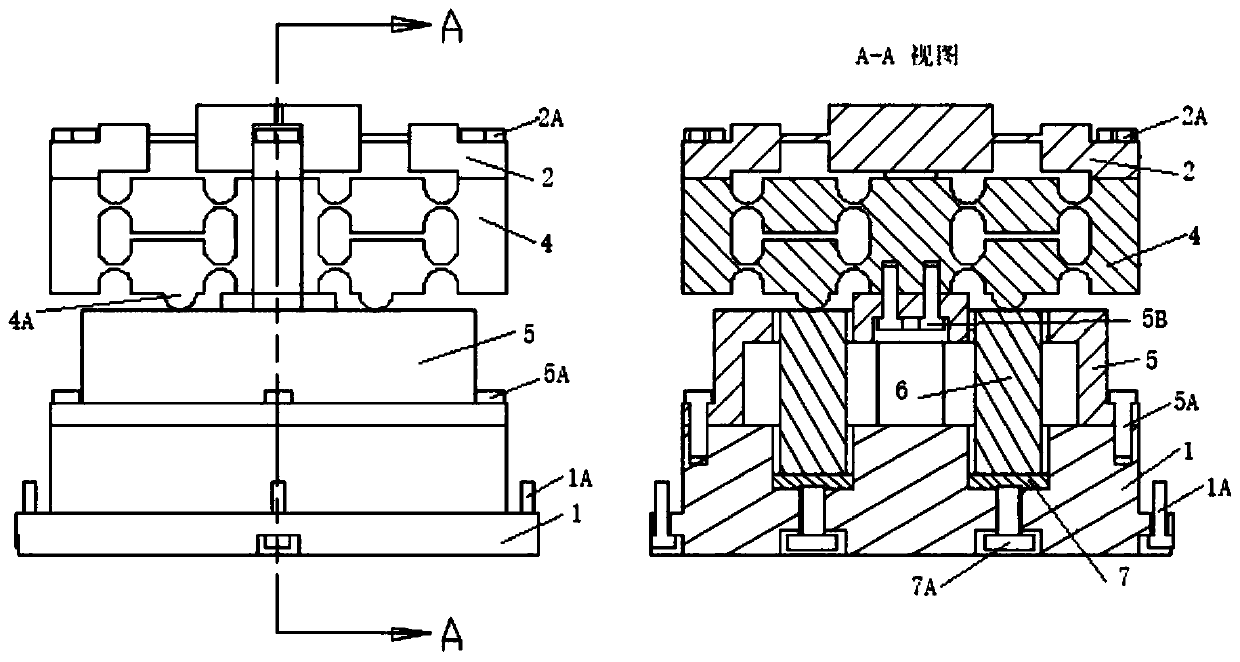

Vertical experiment table for precise performance test of small-tooth-difference planetary reducer

InactiveCN102607844AAvoid assembly errorsEasy to install and debugMachine gearing/transmission testingReduction driveCoupling

The invention discloses a vertical experiment table for a precise performance test of a small-tooth-difference planetary reducer. The vertical experiment table comprises a mounting bracket, a drive motor, an input end torque instrument, an output end angle encoder, an output end torque instrument and a thrust disc, wherein the drive motor is vertically mounted on the mounting bracket; the input end torque instrument is connected with the output shaft of the drive motor and the input shaft of the tested reducer respectively; the output end angle encoder is connected with the output shaft of the tested reducer; the output end torque instrument is connected with the output shaft of the output end angle encoder; the thrust disc is connected with the output shaft of the output end torque instrument; the drive motor is provided with a motor end angle encoder; and the drive motor and the input end torque instrument are connected through a rigid coupling. By vertically arranging the drive motor, the tested reducer, the output end angle encoder and the output end torque instrument, the vertical experiment table effectively avoids the assembly error caused by gravity, is convenient to mount and debug, is high in degree of automation, high in test precision and great in generality, and can test multiple dynamic characteristics of the tested reducer at the same time.

Owner:重庆奔腾智能装备技术有限公司

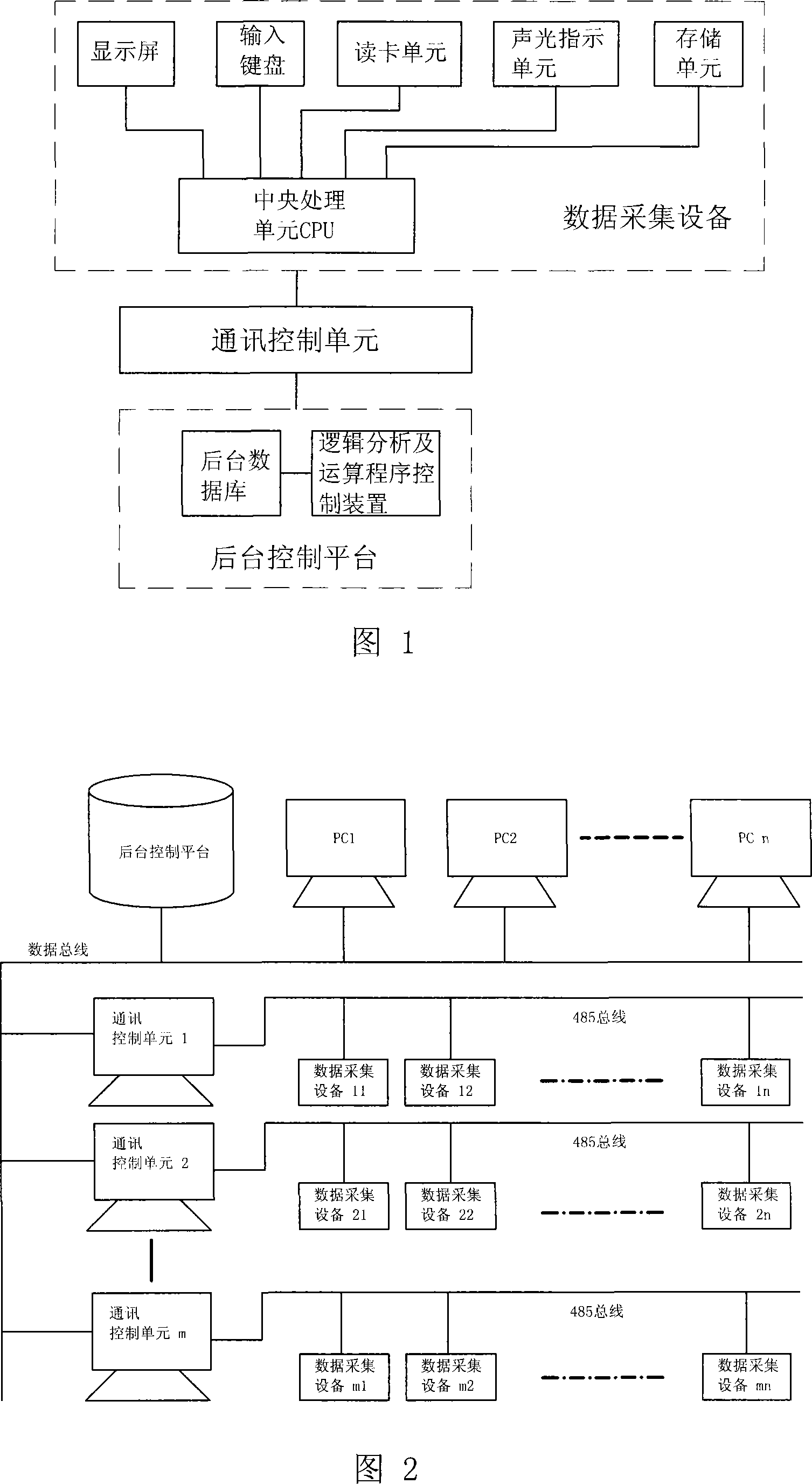

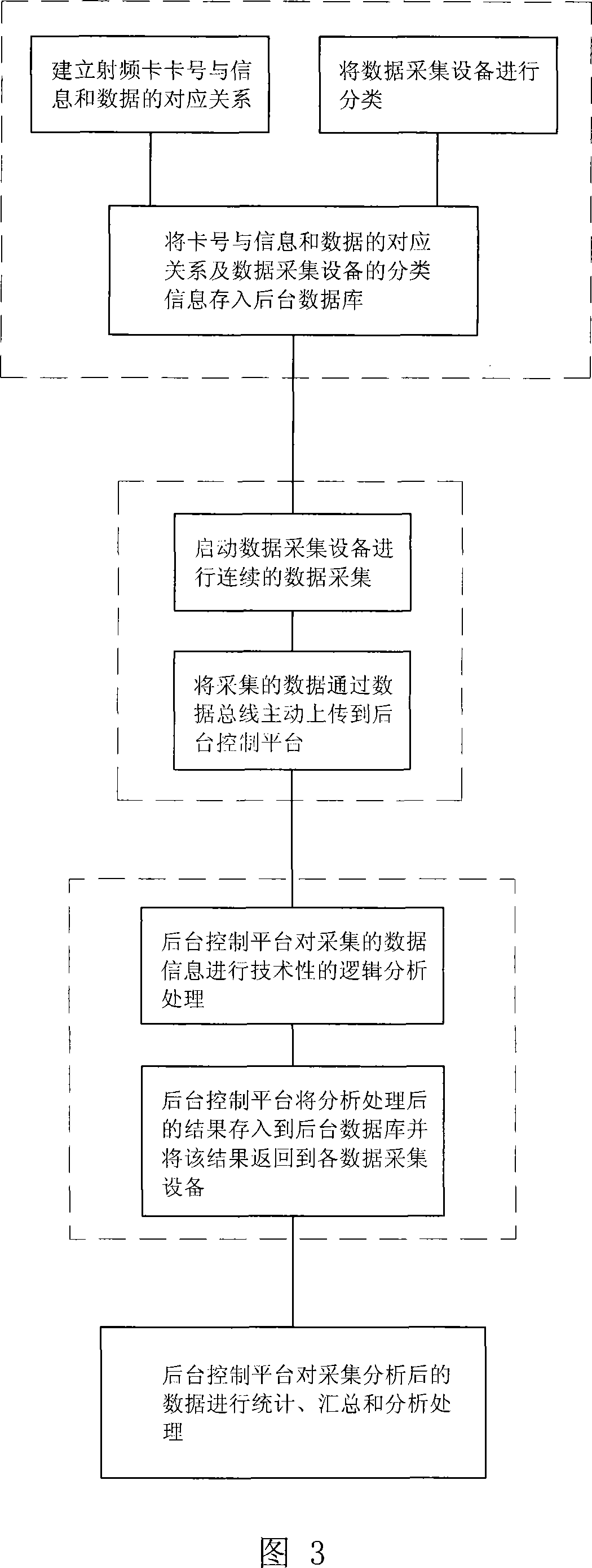

Data acquisition based on radio frequency card and processing equipment, and method thereof

InactiveCN101118655AReduce workloadReduce manufacturing costRegistering/indicating working of machinesSensing record carriersComplete dataReal-time data

The present invention provides a method and a data collecting and processing device based on a radio frequency card, and the device includes a data collecting device composed of a central processing unit CPU, a display screen, an input keyboard, a card reading unit, a sound and light indicating unit, a storage unit; and at least one communication controlling unit and a background controlling platform; wherein the central processing unit CPU uploads the data information to the background controlling platform through the corresponding communication unit, the background controlling platform processes the collected data information, and then conducts real-time data exchange with the central processing unit CPU. As the present invention uses the processing method that producs random data to solve the initiative questioning, and combines the program measure of complete data and information, solves the information-based problem of the corporation, ensures that the corporation and the manager and the worker can learn the front producing condition, the producing progress rate, the product quality and so on in the workshop, can improve the work efficiency and the managing level of the corporation, and keeps the information free.

Owner:惠州市新天健服装有限公司

One-freedom-degree flexible micro-positioning platform

ActiveCN106113022AImprove the stroke of the zoomAccurate magnificationProgramme-controlled manipulatorHinge angleDisplacement error

The invention discloses a one-freedom-degree flexible micro-positioning platform. The one-freedom-degree flexible micro-positioning platform comprises a motion input device, a flexible motion platform and a platform base used for fixing the flexible motion platform; and the flexible motion platform comprises two half motion mechanisms, and each half motion mechanism comprises a motion platform connected through flexible hinges and multi-stage differential motion levers. According to the design, displacement is amplified and can be accurately amplified on the conditions that the positions and the sizes of the flexible hinges and the levers are accurate; the design structure is simple, the occupied space is relatively small, displacement can be output stably through the symmetric structure, lateral additional displacement can be effectively removed, longitudinal coupling displacement errors of the platform can be reduced, the displacement amplification accuracy is improved, and the flexible hinges can be integrally machined easily due to the design, and assembly errors can be avoided. Displacement amplification is accurately realized in relatively-small space and at low cost, and the problem that large stroke and high accuracy of the flexible micro-positioning platform cannot be balanced is solved.

Owner:GUANGDONG UNIV OF TECH

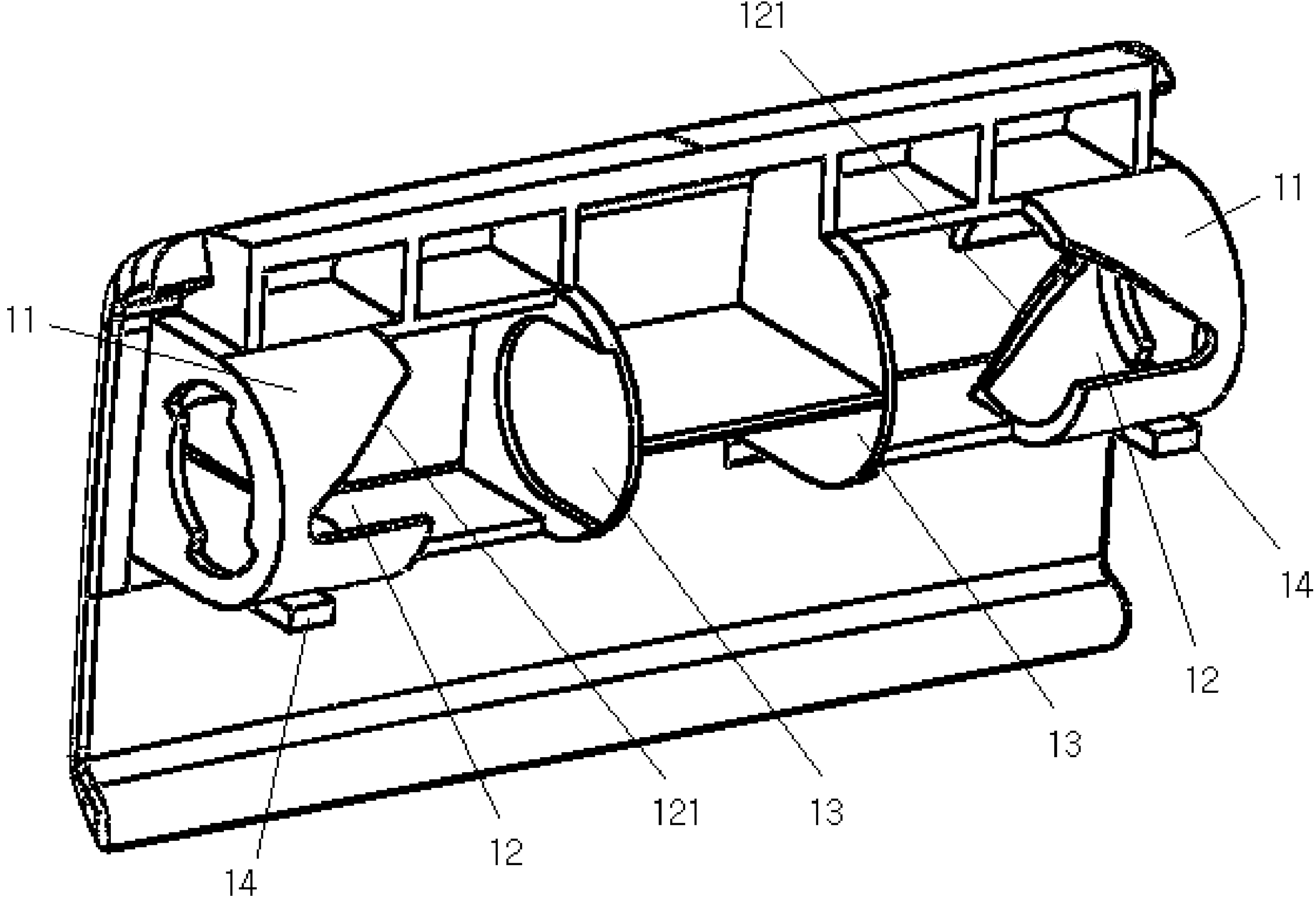

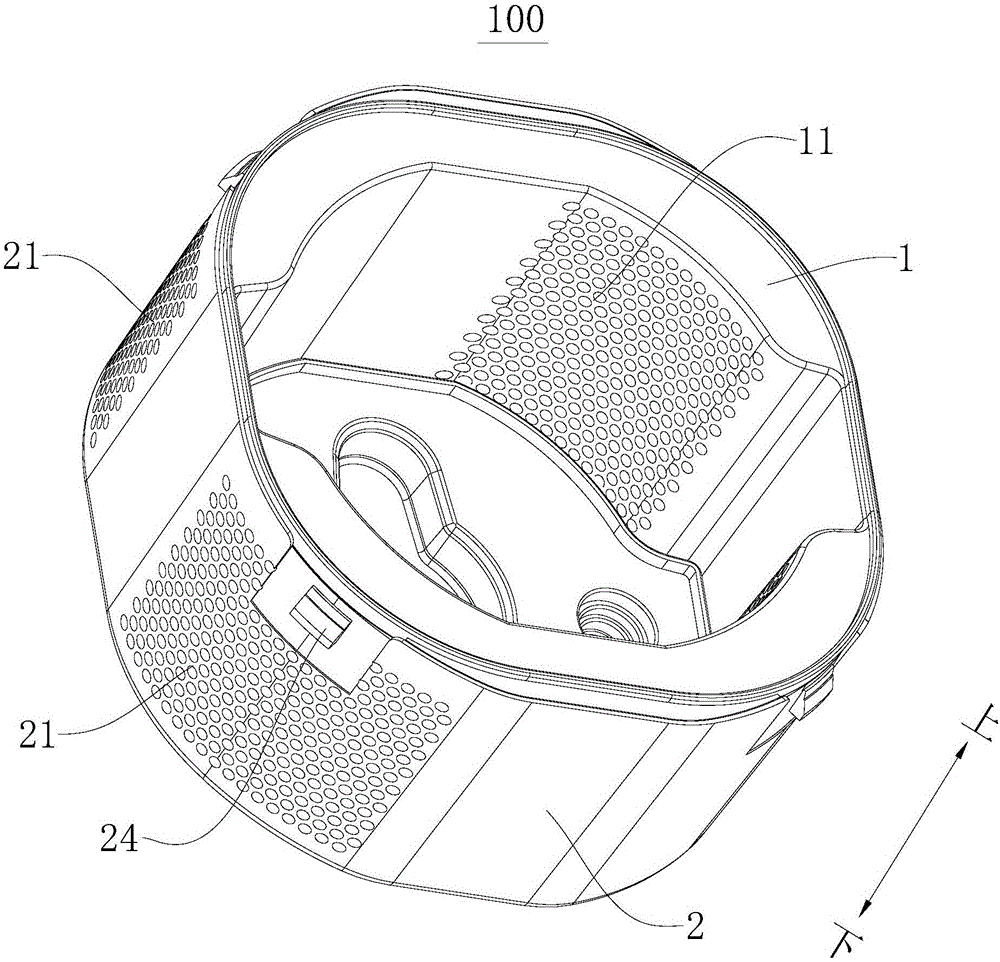

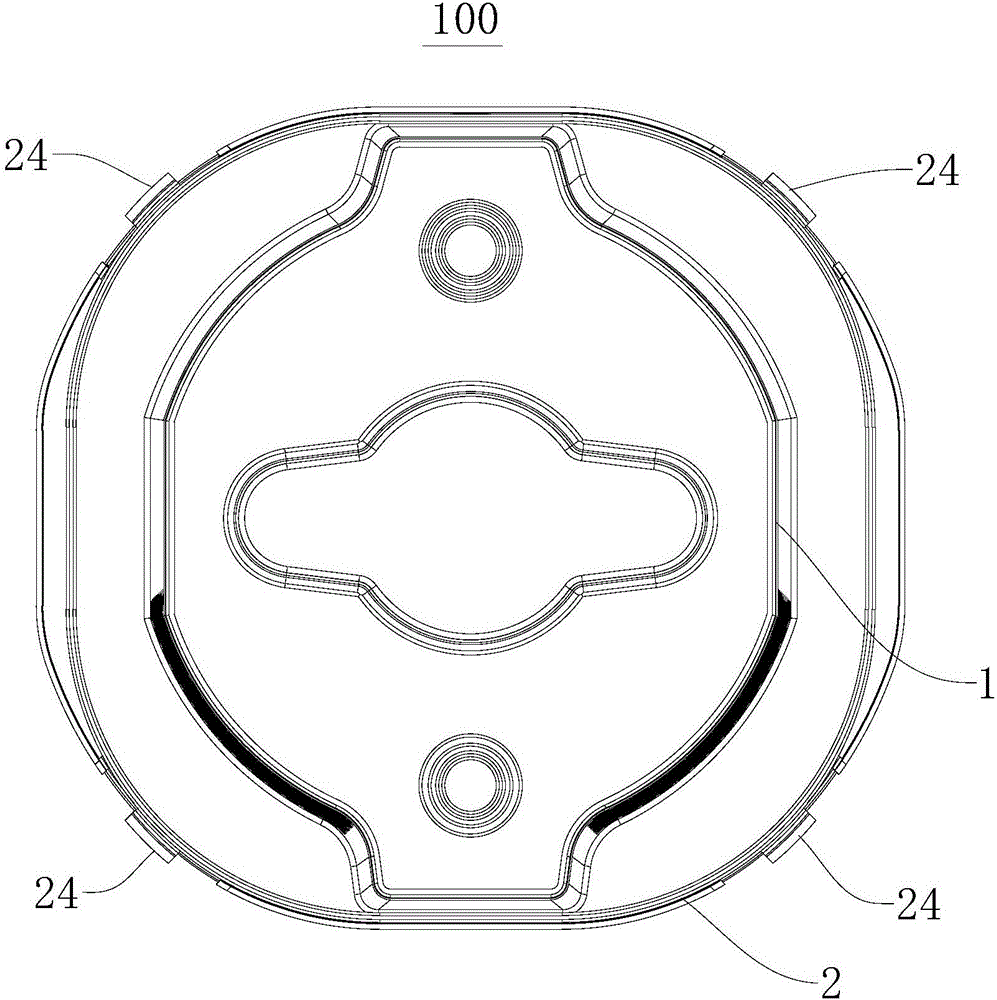

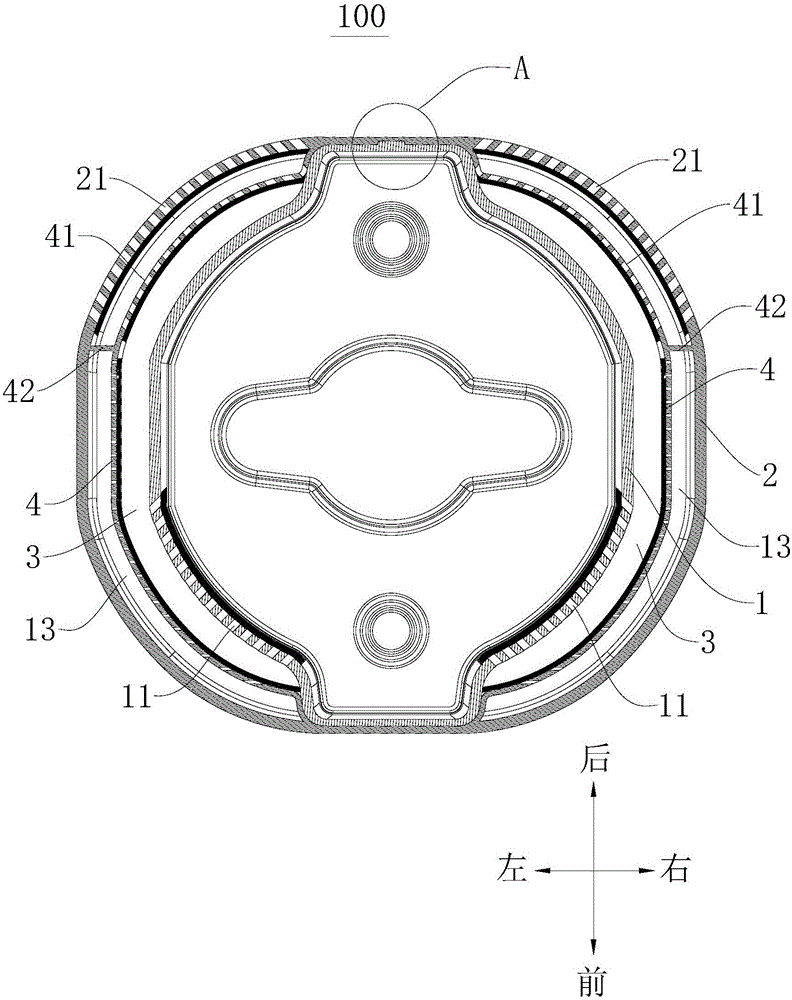

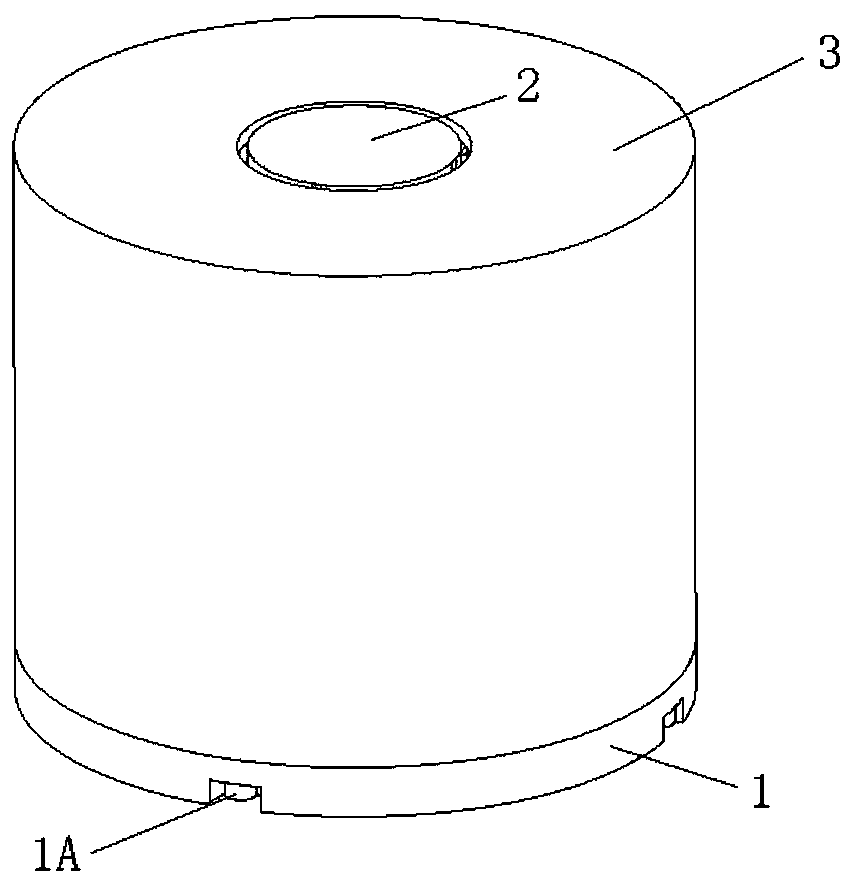

Mute motor inner cover, mute motor and dust collector provided with mute motor

InactiveCN106175584AReduce installation stepsSimple structureExhaust-air diffusionSupports/enclosures/casingsControl theoryDust collector

The invention discloses a mute motor inner cover, a mute motor and a dust collector provided with a mute motor. The mute motor inner cover for the dust collector comprises an inner housing defining an accommodating cavity for accommodating a motor body and an outer housing which is an integrally formed part, wherein a first outlet is formed in the side wall of the inner housing, the inner housing is detachably arranged in the outer housing, an airflow channel is defined between the outer housing and the inner housing, a second air outlet is formed in the outer housing, the first air outlet and the second air outlet are respectively communicated with the airflow channel, and a mute cavity is defined in the outer housing, is located between the first air outlet and the second air outlet and is communicated with the first air outlet. According to the mute motor inner cover for the dust collector, the number of parts is decreased, convenience is brought to mounting and dismounting, damage is not likely to occur, and the problem of inverse mounting can be also prevented. In addition, the mute cavity can be defined in the outer housing, and the mute effect of the motor inner cover for the dust collector can be further improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

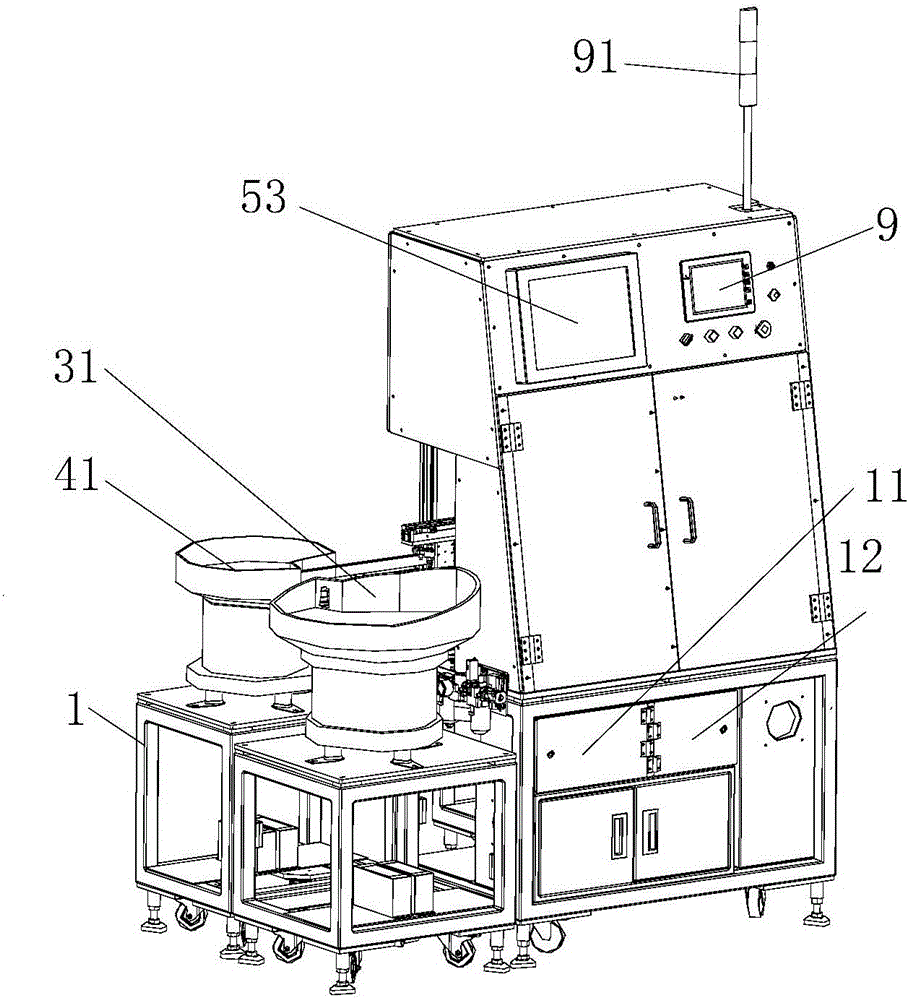

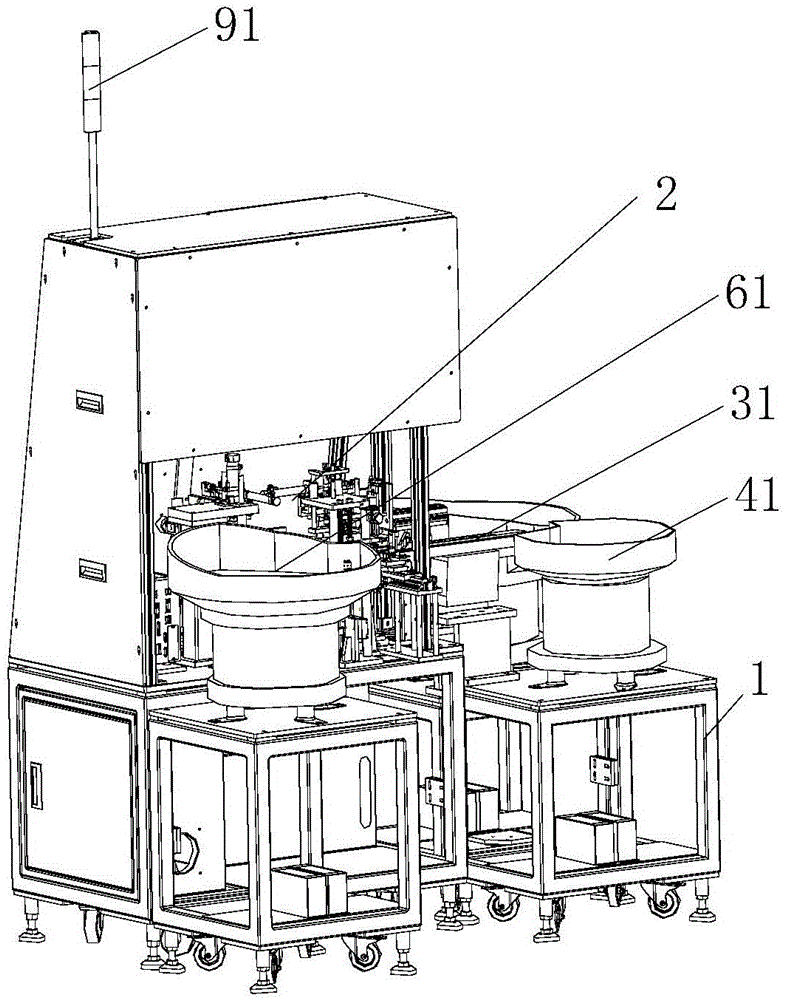

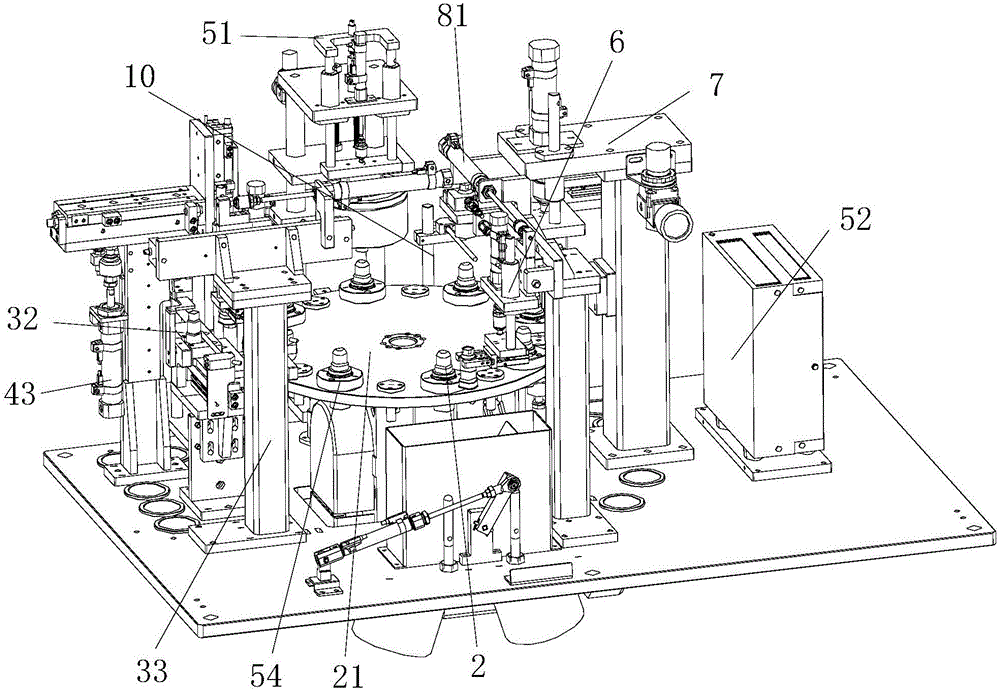

Full-automatic assembling apparatus for connector protective jackets

InactiveCN105048236ARealize automatic assemblyPrevent inflowLine/current collector detailsCircular discEngineering

The invention discloses a full-automatic assembling apparatus for connector protective jackets. The full-automatic assembling apparatus comprises a frame and an assembling apparatus assembly arranged on the frame; the assembling apparatus assembly comprises a turnplate mechanism; the turnplate mechanism comprises a disc and a disc driving mechanism for driving the disc to rotate; at least six fixtures for holding materials are arranged on the disc in the circumferential direction; the assembling apparatus assembly further comprises a lower shell loading mechanism, a protective jacket loading and assembling mechanism, an upper shell loading and assembling mechanism, an upper shell press-fitting mechanism and a discharge mechanism, all of which are connected with a controller arranged on the frame, respectively; a product receiving box is further arranged under the turnplate mechanism; automatic assembling of the connector protective jackets is realized; the assembling is more accurate; the labor is saved and the production efficiency is improved.

Owner:SUZHOU HYH AUTOMATION EQUIP CO LTD

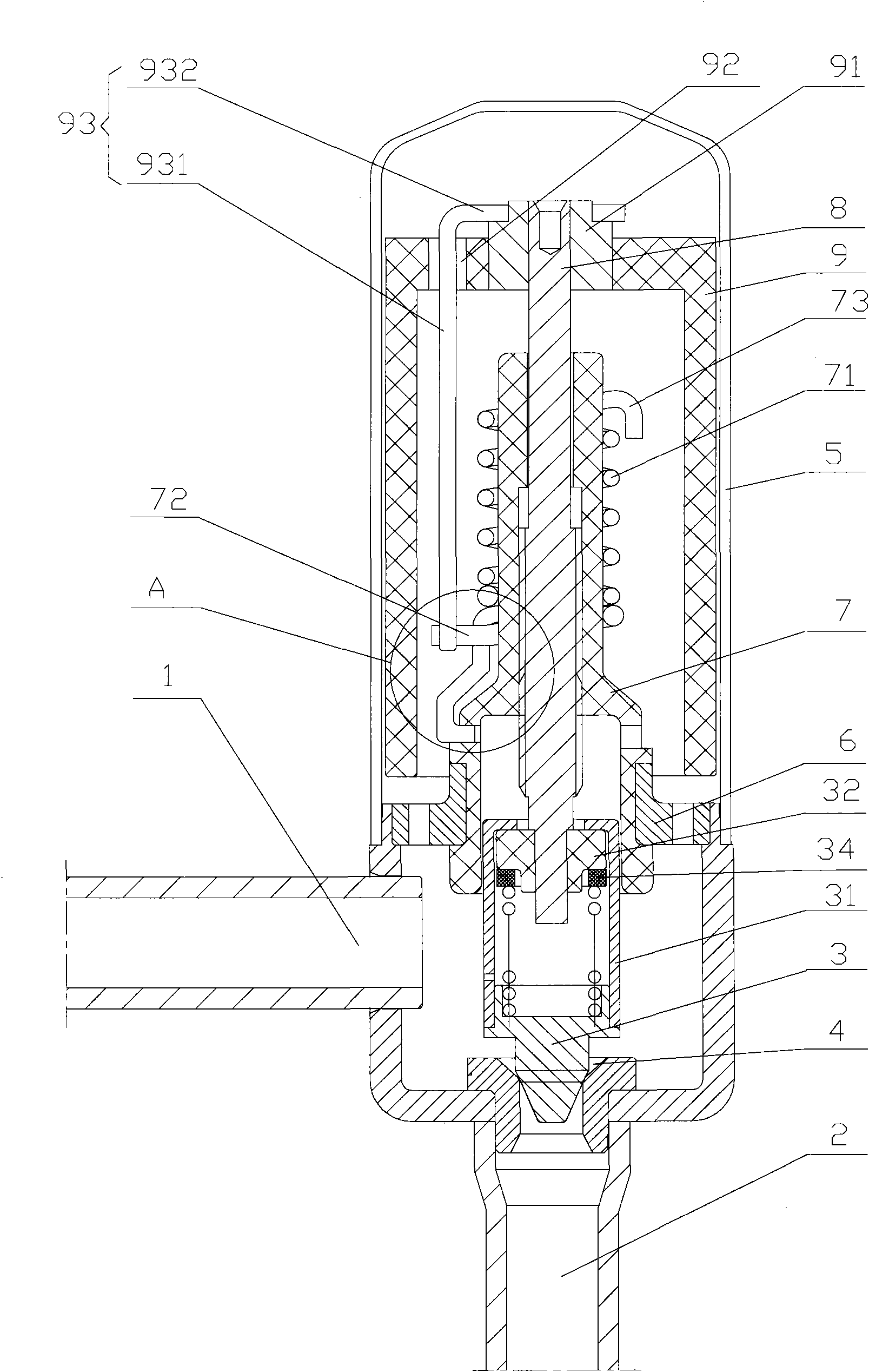

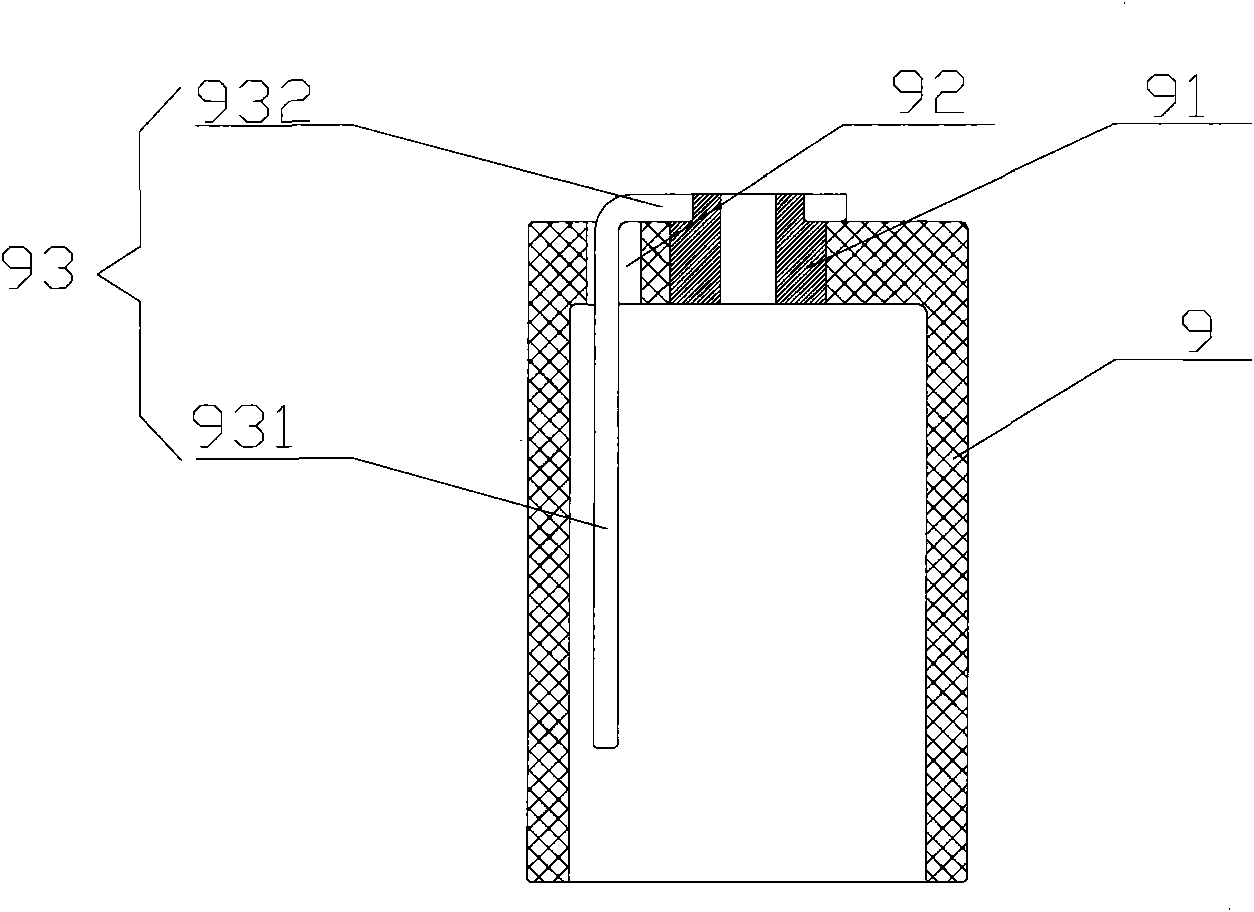

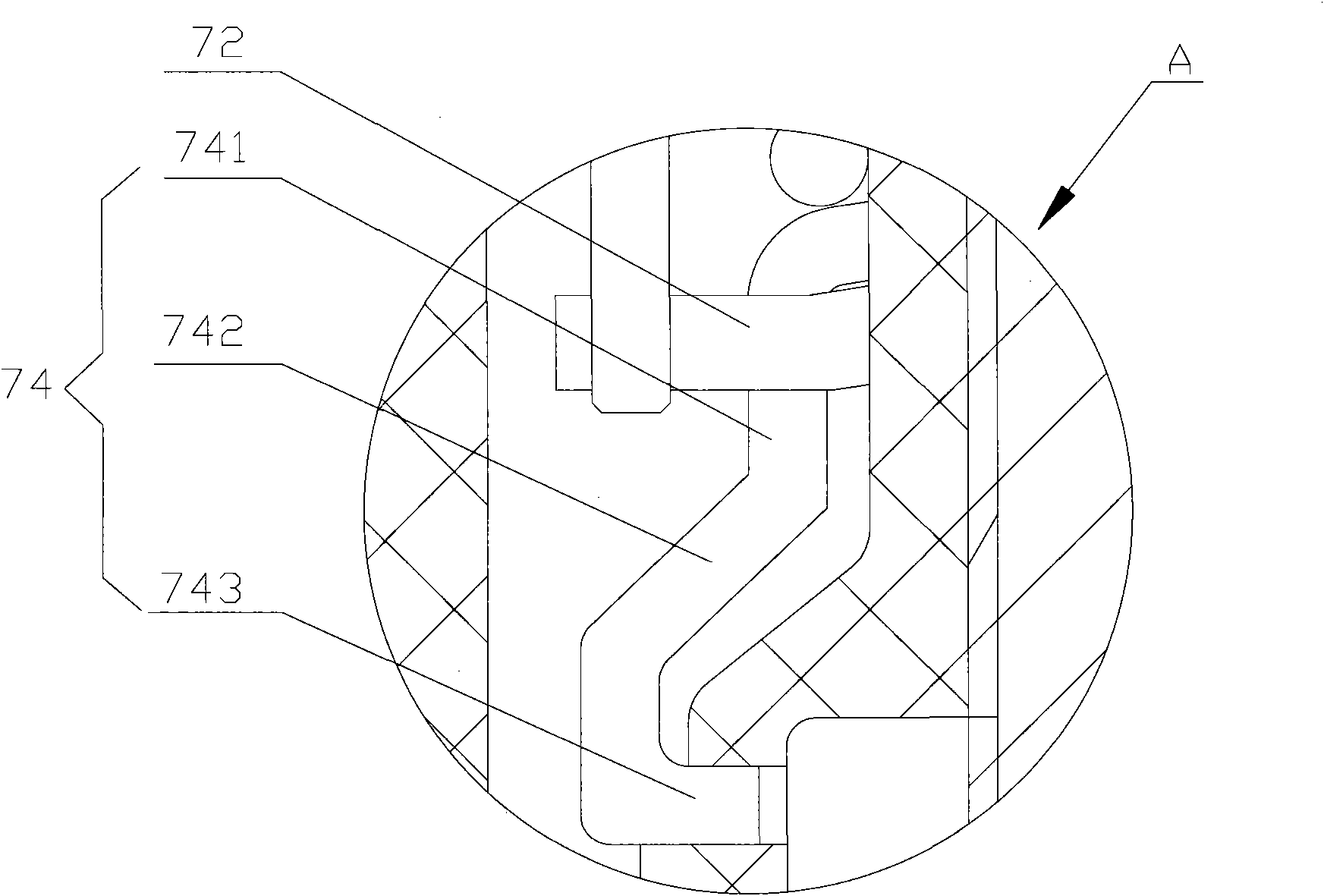

Electric control valve

ActiveCN101994839AEasy to assemblePromote repairOperating means/releasing devices for valvesLift valveEngineeringControl valves

The invention discloses an electric control valve. The inner cavity of a magnetic rotor (9) of the electric control valve is provided with a guidance supporting axle (7) fixedly connected with a casing (5) along the axial direction, and the guidance supporting axle (7) is screwed with a screw rod (8) through a central through hole of the guidance supporting axle; the outer wall of the guidance supporting axle (7) is provided with a spiral guidance structure (71) and a sliding component (72) sliding along the spiral guidance structure (71); the sliding component (72) slides or stops along with a stop component fixedly connected with the magnetic rotor (9); and the main body part of the stop component is arranged in the inner cavity of the magnetic rotor (9) and has a proper distance away from the side wall of the magnetic rotor (9). The electric control valve can effectively prevent the magnetic rotor (9) from magnetic powder pulloff due to impact, improve the reliability and safety of the electric control valve, and effectively prolong the service life of the electric valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

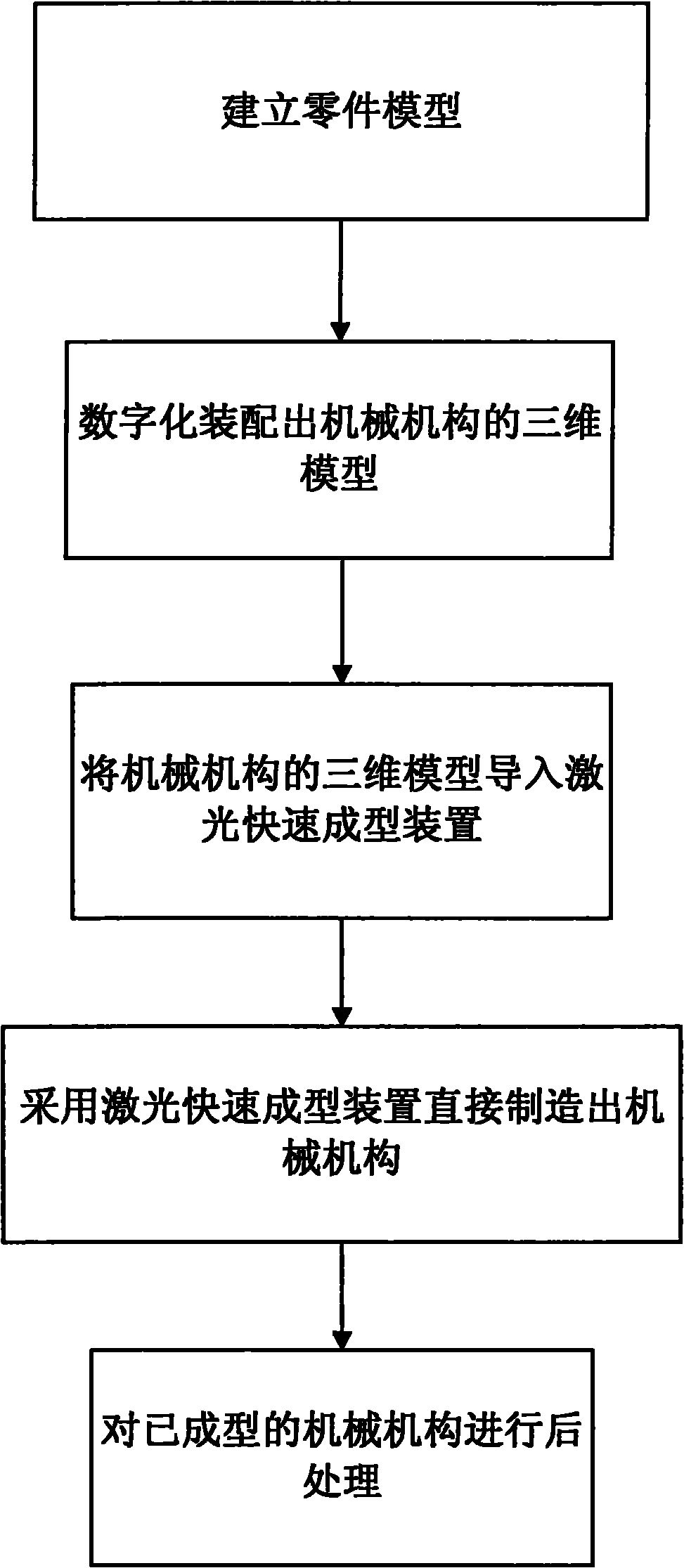

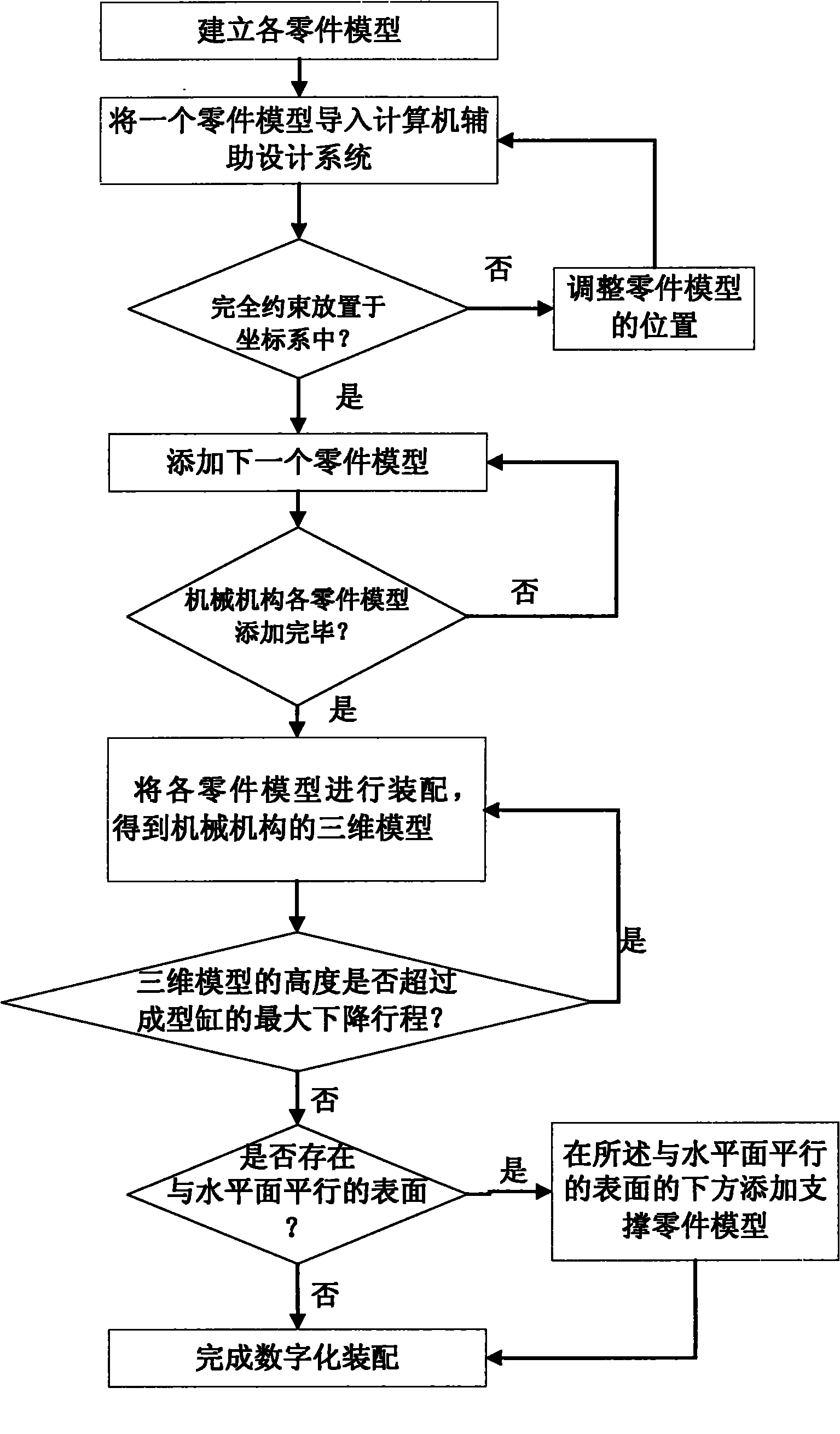

Once-forming direct making method of assembly-free mechanical mechanism and application thereof

ActiveCN101941070AShorten production timeImprove stabilityTurbinesOther manufacturing equipments/toolsBiomedical engineeringLaser

The invention provides a once-forming direct making method of an assembly-free mechanical mechanism, comprising the following steps of: establishing a three-dimensional model of each part in the mechanical mechanism, and digitally assembling each part model to obtain the three-dimensional model of the mechanical mechanism; inducing the three-dimensional model of the mechanical mechanism into a laser rapid forming device, and directly making the whole mechanical mechanism through once forming by adopting laser rapid forming; and postprocessing the formed mechanical mechanism to obtain a finished mechanical mechanism. The invention also provides application of the method. The invention breaks through traditional design and making ideas of independently processing each part and then assembling the mechanical mechanism, establishes digitalized design and assembly, and establishes a novel idea of directly making the whole mechanical mechanism through once forming, thereby not only saving the subsequent assembly process, but also not limiting the design process of the mechanical mechanism by the traditional processing method and the traditional assembly means and ensuring that the structure and the connecting mode of the mechanical mechanism are flexible and various.

Owner:SOUTH CHINA UNIV OF TECH

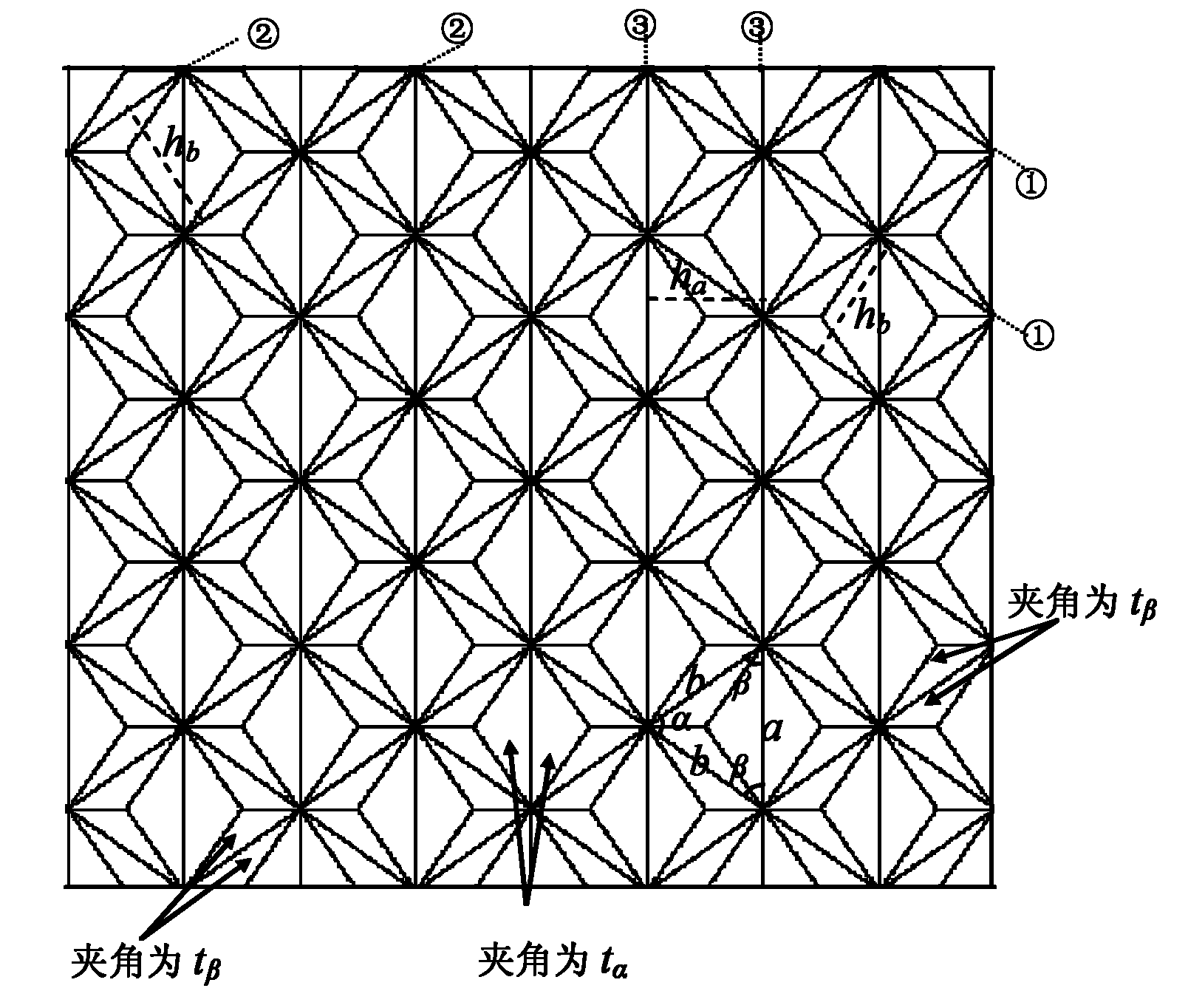

Isosceles micro prism and method for manufacturing mold

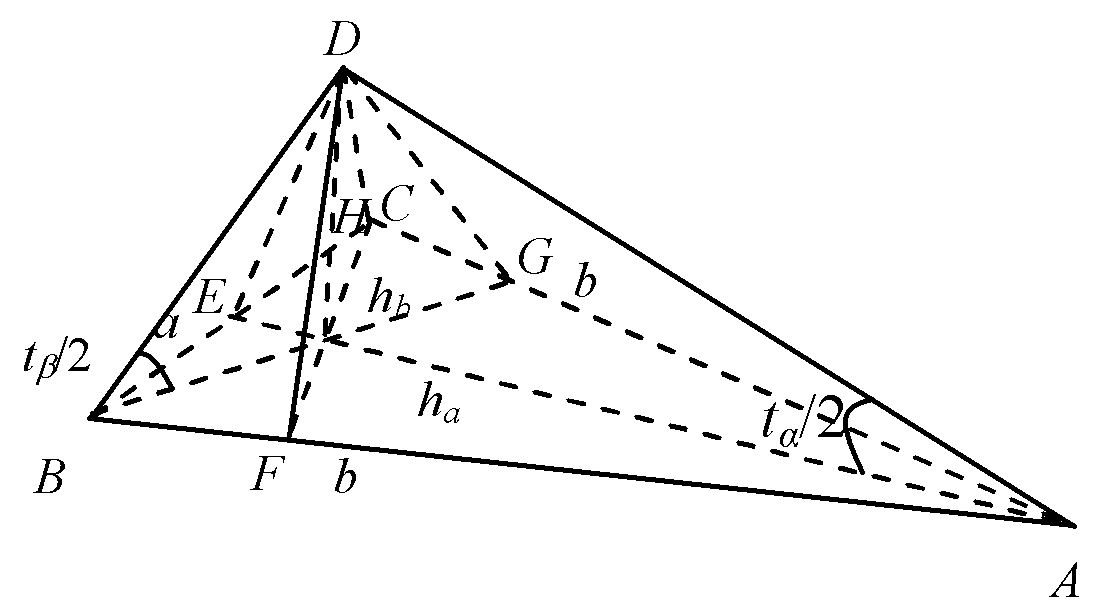

InactiveCN102156314AReduced retroreflective performanceLow retroreflective performanceMilling equipment detailsOptical elementsManufacturing technologyEngineering

The invention belongs to the technical field of retroreflective material manufacture, and relates to an isosceles micro prism. A micro prism unit constituting the isosceles micro prism is a tetrahedron; the bottom surface of the tetrahedron is an isosceles triangle; one of the three side surfaces is an isosceles triangle, the rest two side surfaces are the same hypotenuse triangles, and the three surfaces are perpendicular to one another and intersect at a structural vertex; and included angles between the side surfaces of the two hypotenuse triangles and the adjacent units are equal. The invention also provides a method for manufacturing a mold of the isosceles micro prism. By the micro prism structure provided by the invention, the retroreflective performance of the micro prism is reduced with the increase of an incidence angle.

Owner:TIANJIN UNIV

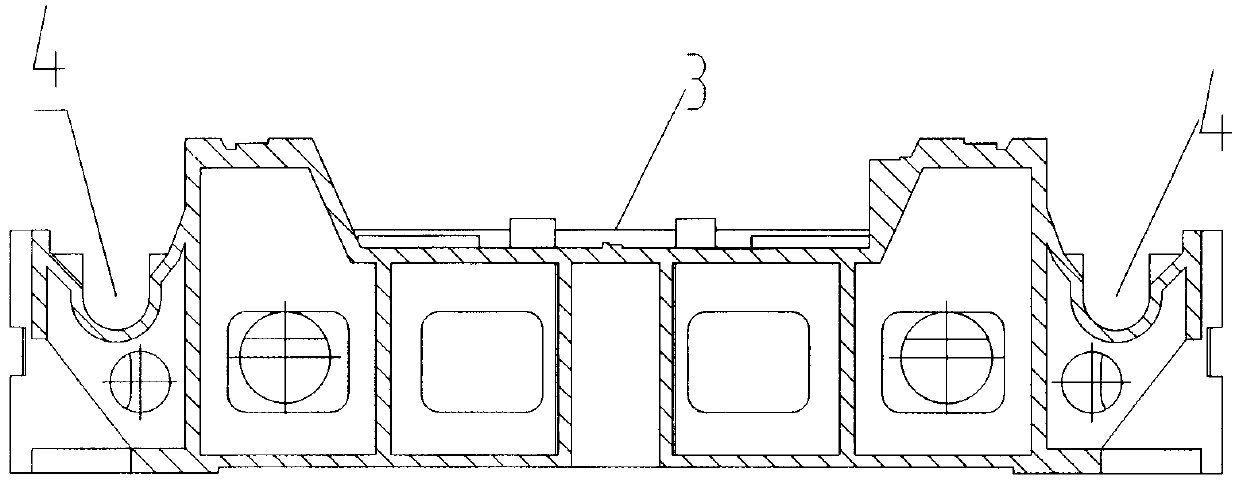

Large-duty loader hydraulic valve body casting mold and manufacturing method

ActiveCN105772646ACompact and reasonable structureStrong reliabilityFoundry mouldsFoundry coresCasting moldCasting defect

The invention discloses a large-duty loader hydraulic valve body casting mold. The large-duty loader hydraulic valve body casting mold comprises an upper shell mold body, a lower shell mold body, a sand core and a pouring and riser system. The sand core comprises a core head, a main core body and small core bodies. The main core body is composed of seven longitudinal arbors and four transverse arbors, and the longitudinal arbors and the transverse arbors are horizontally arranged in the same plane. The main core is provided with a plurality of convex blocks. Installation grooves are formed in the convex blocks. The small core bodies are fixed to the main core body through the installation grooves. The pouring and riser system comprises two exothermic and insulating risers with the diameter being 90 mm and the height being 120 mm. The large-duty loader hydraulic valve body casting mold has the advantages of being reasonable and compact in structure, high in reliability and convenient to assemble and cast, the straightness of a blank casted through a main valve hole is controlled to be smaller than 0.8 mm, assembly errors of a complex sand core are avoided, the casting defects of shrinkage cavities, shrinkage porosity, internal pores and the like of a casting piece are overcome, and the compactness of the internal structure is improved, so that leakage is avoided under a high-pressure working condition with the rated pressure being larger than or equal to 35 Mpa; and the casting qualified rate is improved greatly, and the casting cost is reduced.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

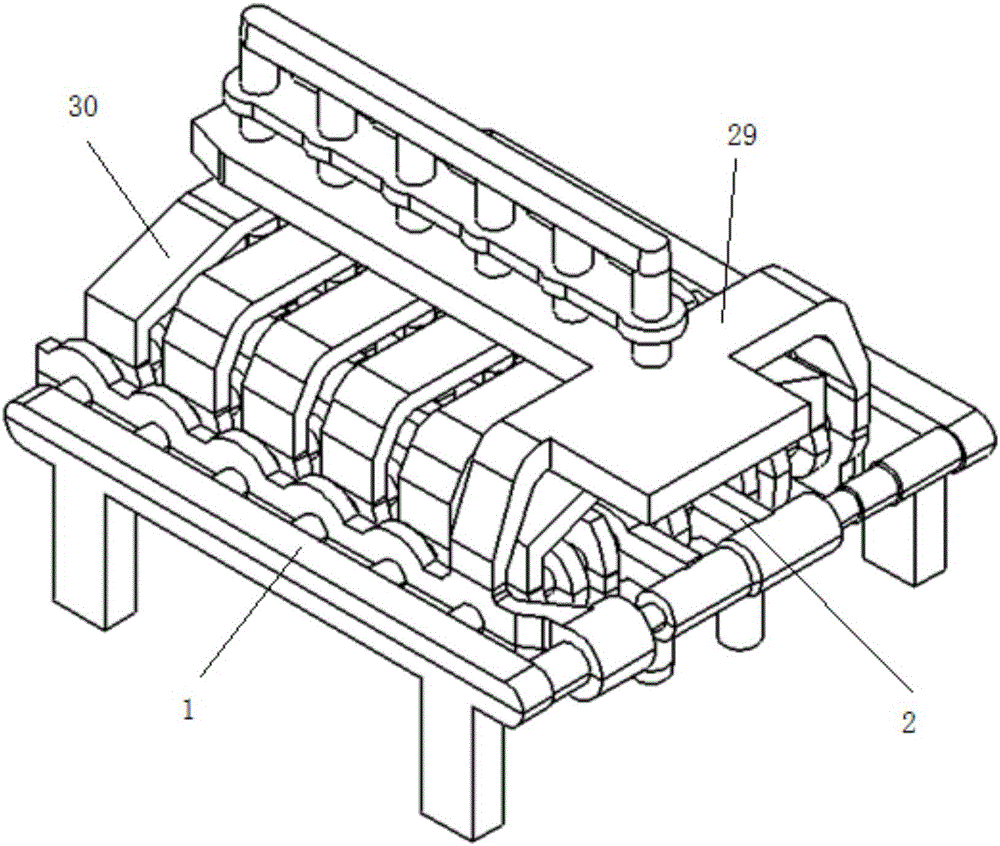

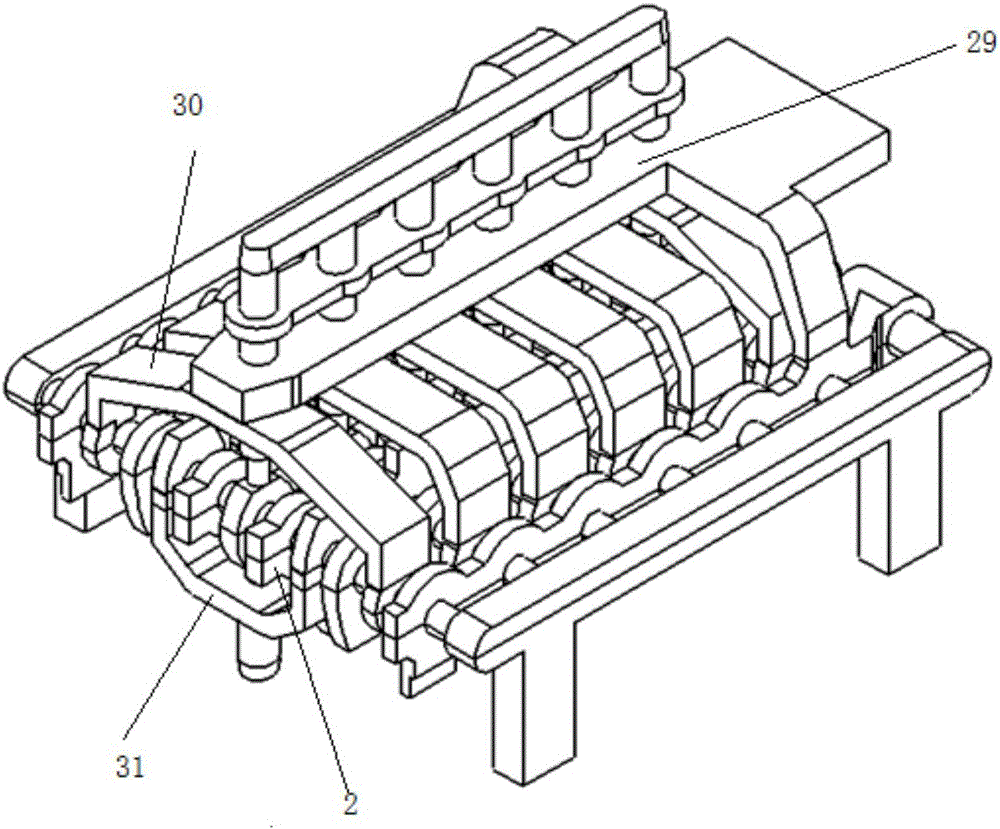

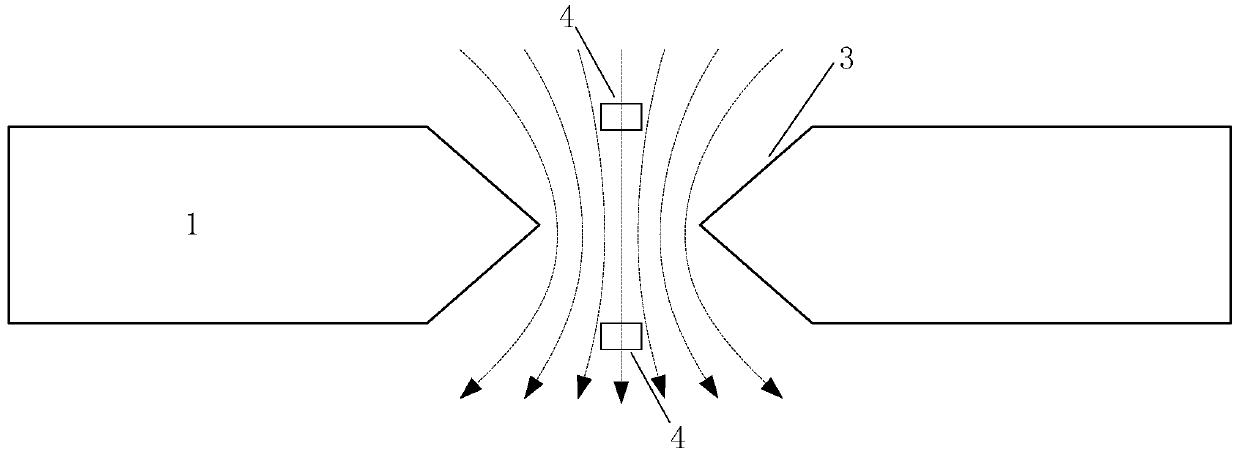

MEMS (Micro Electro Mechanical System) thermal acoustic particle vibration velocity sensor with sound field enhanced microstructure and method

ActiveCN109916501AImprove machining accuracySmall sizeSubsonic/sonic/ultrasonic wave measurementUsing electrical meansDistortionHeating temperature

The invention discloses an MEMS thermal acoustic particle vibration velocity sensor of a sound field enhancement microstructure and a method. According to the invention, the on-chip integrated sound field self-enhancement through hole is adopted, the processing of the sound field self-enhancement through hole is completed when the heating temperature measurement cross beam is processed by using the MEMS technology, a macro mechanical processing means is not required to be used for designing a sound field enhanced packaging structure, the packaging size is greatly reduced, and the application range of the sensor is broadened; due to the fact that the heating temperature measuring beam and the sound field self-enhancement through hole are all machined in a unified mode through the MEMS technology, the MEMS technology has extremely high machining precision, and therefore the method avoids the problem that in the traditional sensor assembling process, assembling errors exist between a chipprepared through the MEMS technology and a packaging structure prepared through the machining means; due to the fact that the sensor manufactured through the method is small in size, reflection and scattering of a to-be-measured sound field are small, distortion of the to-be-measured sound field cannot be caused, and single-point accurate measurement is achieved.

Owner:PEKING UNIV

Four-ridge horn antenna and processing method thereof

InactiveCN106374231AImprove performanceImprove performance indicatorsWaveguide hornsHorn antennaRidge

The invention relates to a four-ridge horn antenna and a processing method. The four-ridge horn antenna comprises a horn main body, four ridge pieces, a probe and a short-circuit board, wherein the four ridge pieces are sequentially, uniformly and circumferentially arranged on an inner cavity of the horn main body at interval, the four ridge pieces and the horn main body are of an integral forming structure, a tail part of the horn main body is connected with the probe, the probe penetrates through the horn main body in a radial direction, and the tail part of the horn main body is connected with the short-circuit board. In the four-ridge horn antenna proposed by the antenna, the four ridge pieces and the horn main body are of the integral forming structure, the four-ridge horn antenna is simple in structure, is good in quality and high in accuracy, and has favorable antenna electrical property, a processing and assembly error is effectively avoided, and the four-ridge horn antenna is applicable to application development demands of a millimeter-wave horn antenna for high performance and high reliability.

Owner:京航泰(北京)科技有限公司

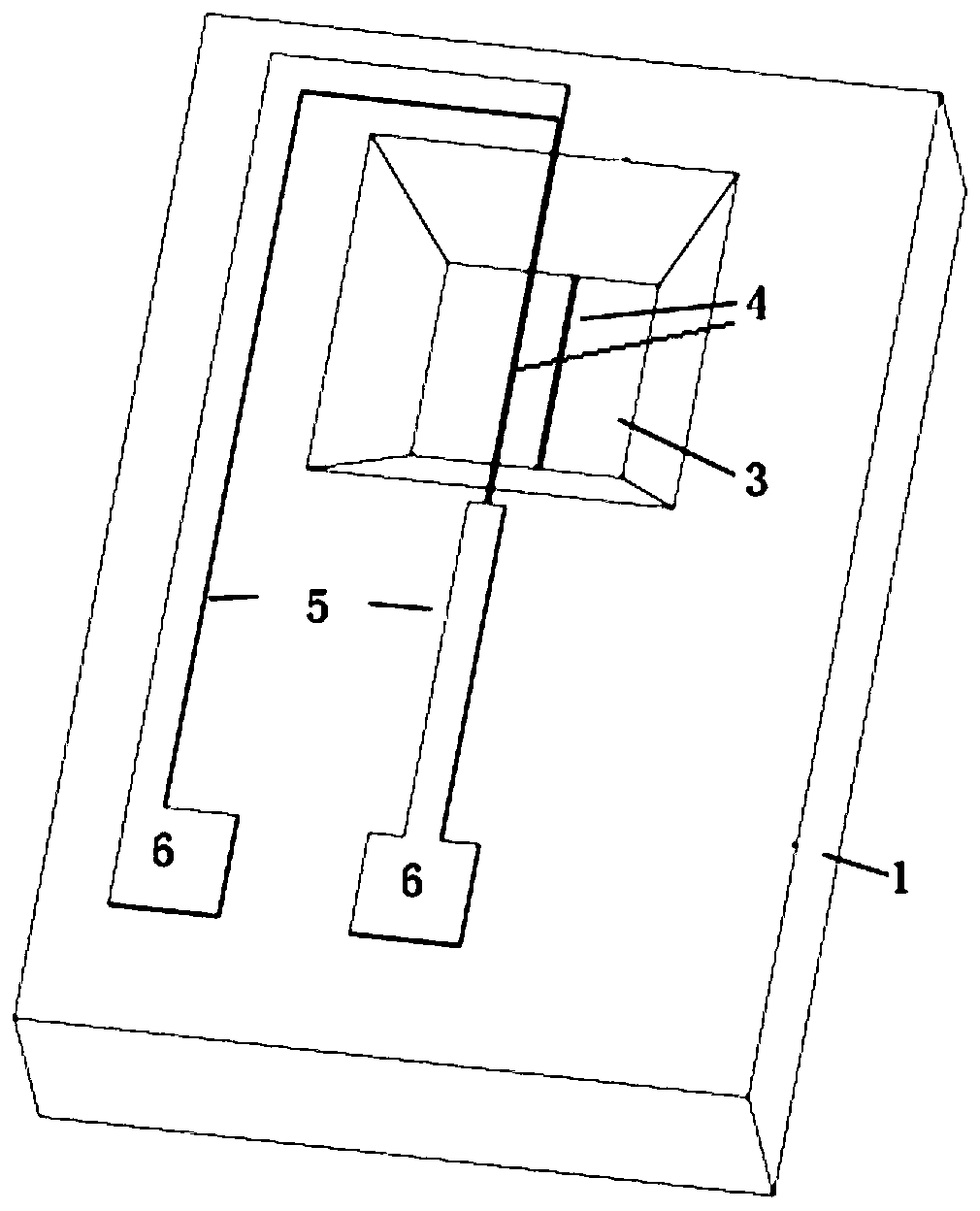

Virtual impactor and particle separation and concentration detecting device and method based on 3D printing technology

InactiveCN105651643AAvoid assembly errorsMaintain calibrationDispersed particle separationParticle suspension analysisMain channelPhotoresist

The invention discloses a virtual impactor and particle separation and concentration detecting device and method based on the 3D printing technology. The virtual impactor and particle separation and concentration detecting device comprises a virtual impactor and a quartz crystal microbalance (QCM) resonance sensor. The virtual impactor is composed of a particle inlet, a middle small-flow channel, two large-flow channels on the two sides and a QCM support, wherein the large-flow microchannels on the two sides are flat and straight, the length of the middle small-flow microchannel is 20 mm, the middle small-flow microchannel is folded back and forth six times and gradually reduced at an inlet part, the surface of the QCM resonance sensor which is arranged on the main channel on one side and composed of electrodes on the front side and the back side is coated with a photoresist layer, and thus separated particles adhere to the QCM resonance sensor. The main channels on the two sides and the secondary channel in the middle are adopted to serve as separation units, and the separation rate for particles smaller than 2.5 micrometers is 90%; the concentration of the particles is reflected through the resonance changing rate with the QCM resonance sensor, and conversion to the electric quantity from non-electric quantity is carried out; the device is simple in structure, small in size, capable of working under a room-temperature environment and easy to process in a batched mode.

Owner:ZHEJIANG UNIV

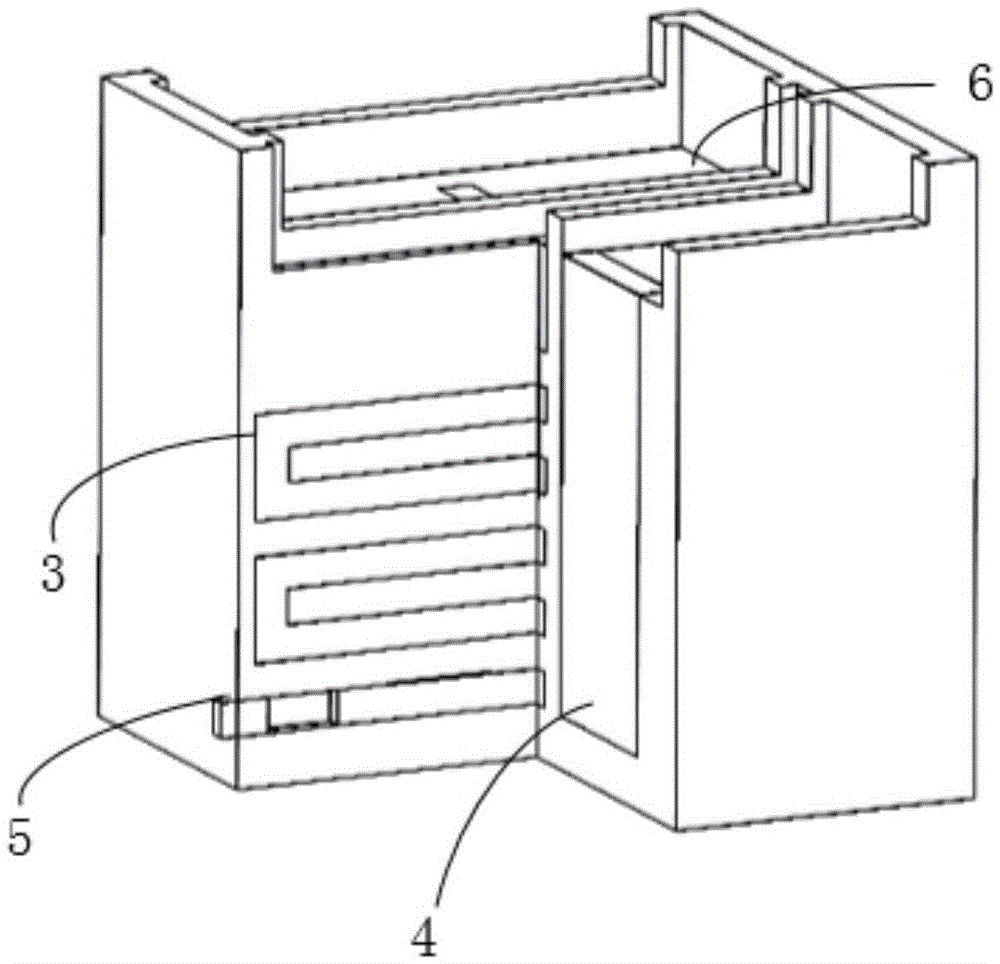

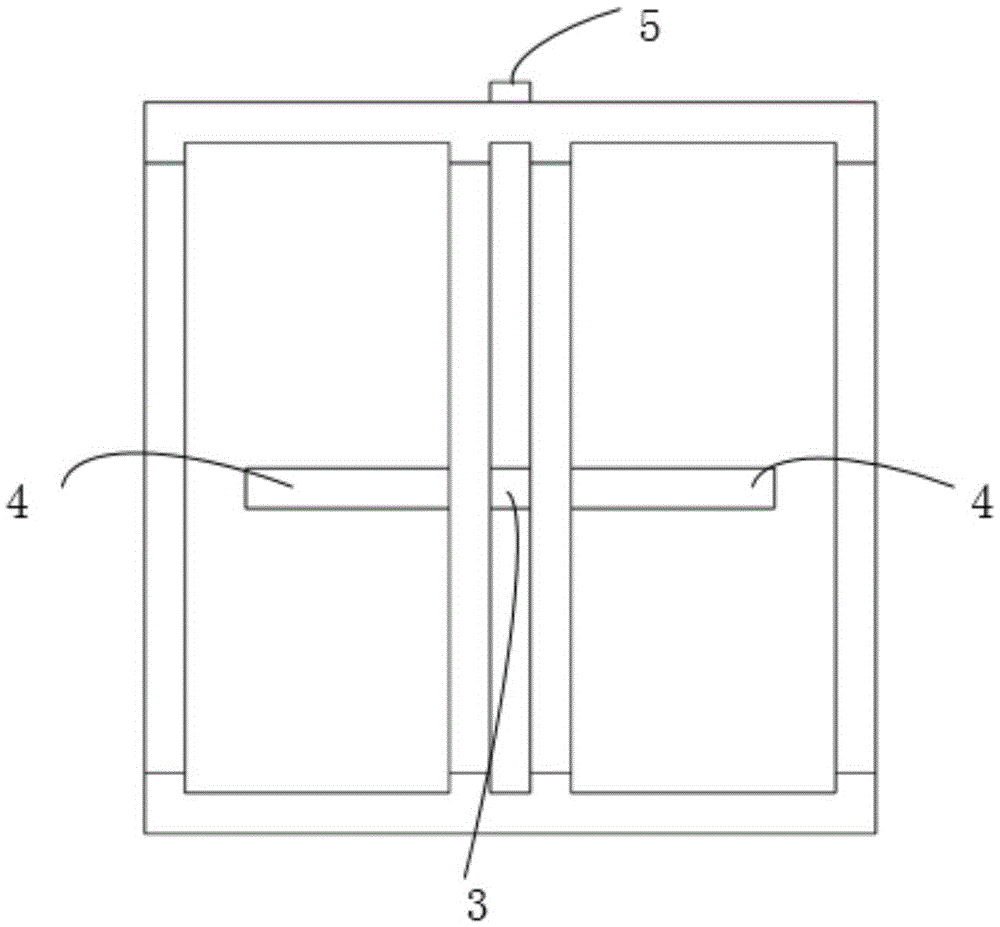

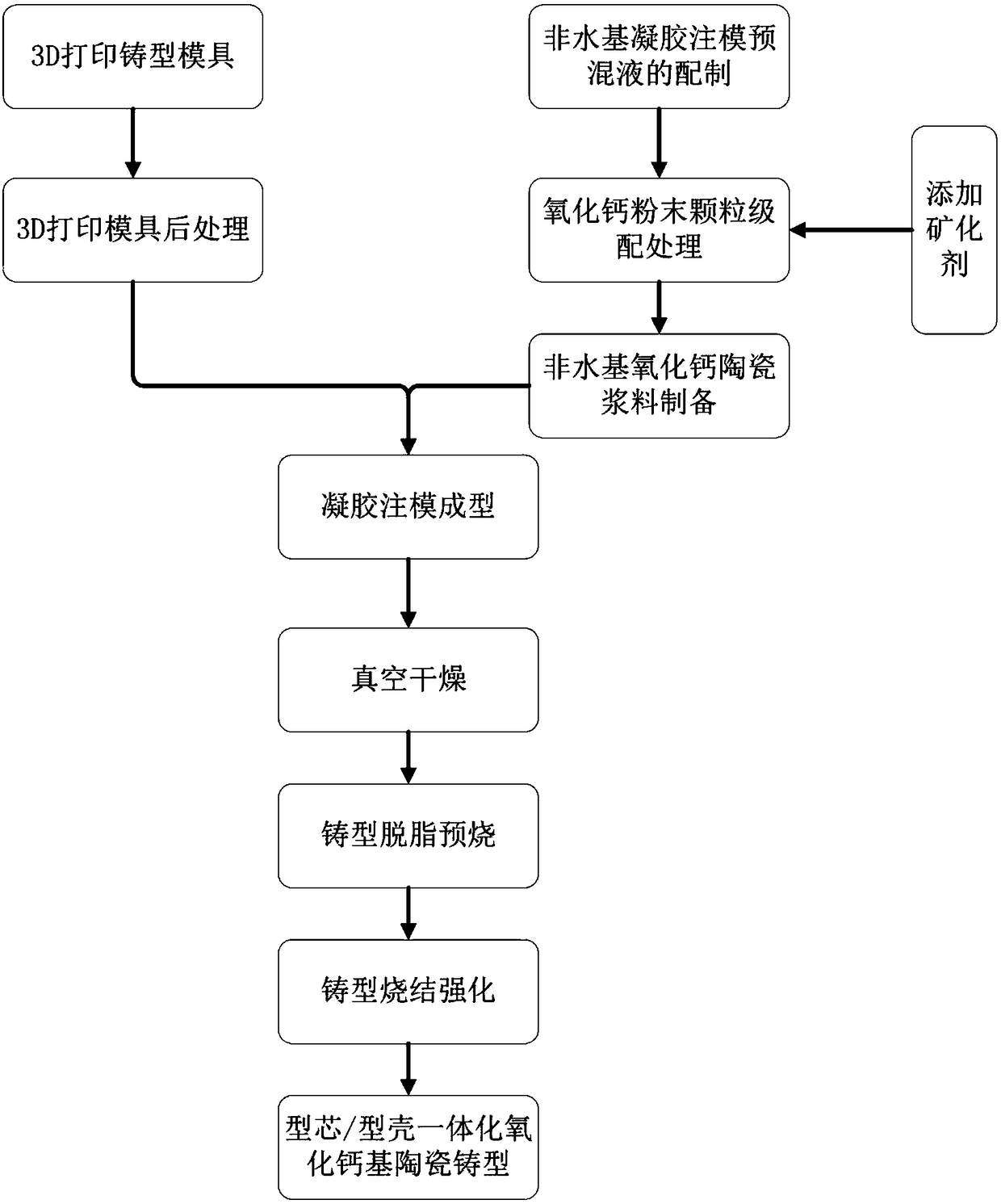

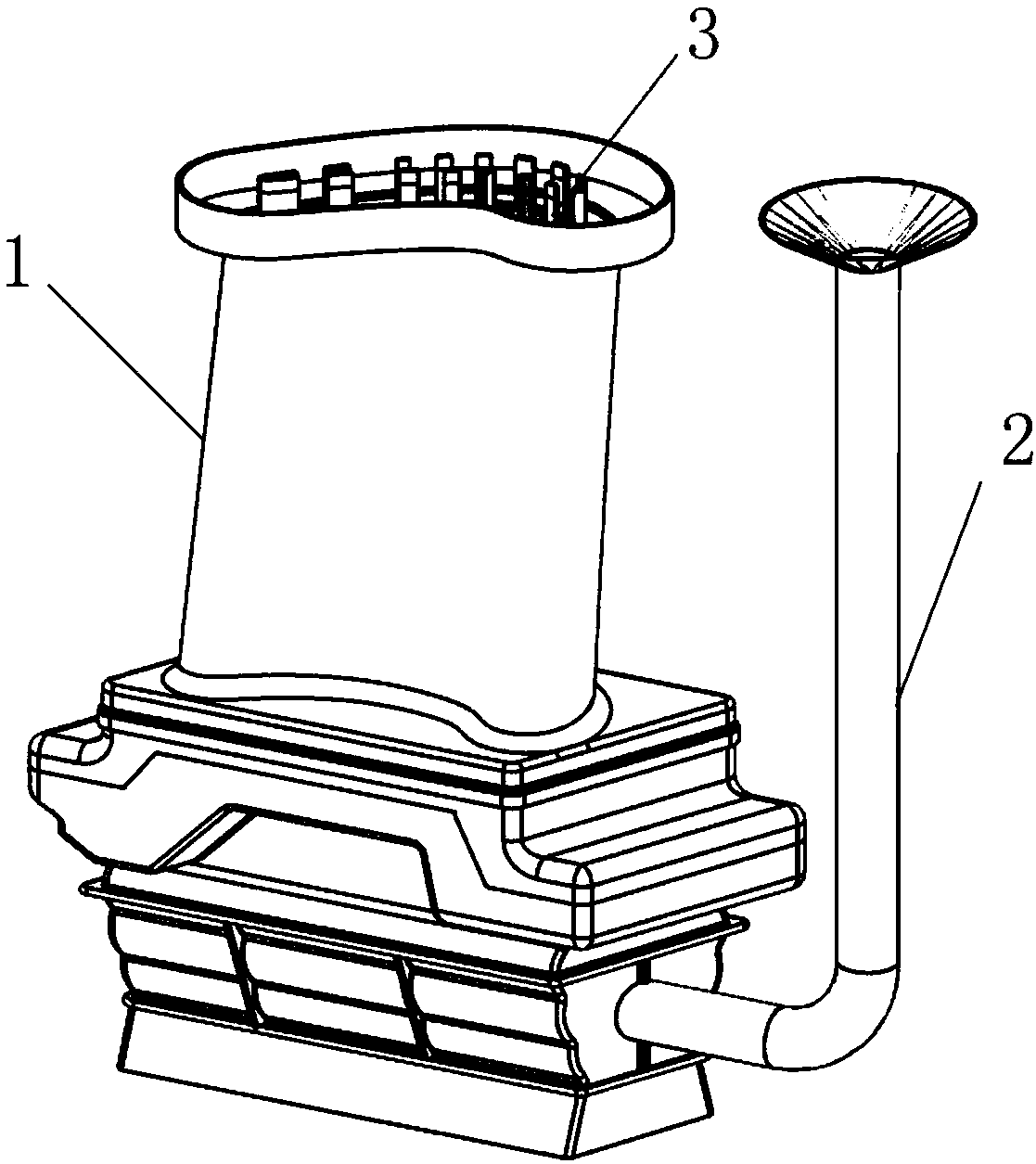

Non-water-based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and preparation method thereof

InactiveCN108059445AInhibition of hydrationImprove sintering performanceAdditive manufacturing apparatusWater basedNiobium

The invention discloses a non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and a preparation method thereof, and belongs to the technical field of rapid precision casting. The method is characterized in that a mold required for 3D printing technology rapid manufacture is used, and simultaneously a non-water-based gel injection molding technology isapplied, so that the problem of hydration of calcium oxide powder during a casting mold preparation process is effectively solved, and the method can be successfully applied to the preparation of a mold core / mold shell integrated calcium oxide-based ceramic casting mold with complex internal structural parts and components. The manufactured calcium oxide-based ceramic casting mold has good overallperformance, and can meet the casting requirements of ultrahigh-temperature alloys such as a new generation of niobium-silicon-based high-temperature alloy and active light alloys such as titanium-aluminium alloy and magnesium-aluminium alloy, and the core removal performance is extremely excellent, so that the technical problems of difficult removal and high rejection rate of silicon oxide-basedand aluminium oxide-based mold cores are solved, therefore, the non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold is a huge improvement on an existinginvestment mold precision casting and molding technology, and has broad market prospect and market value.

Owner:XI AN JIAOTONG UNIV

Hall thrustor capable of realizing self cleaning of polluted membrane of discharge channel and self cleaning method of Hall thrustor

InactiveCN102493937AAchieve cleaningConsistent vacuum conditionsHollow article cleaningMachines/enginesJet flowEngineering

The invention relates to a Hall thrustor capable of realizing self cleaning of a polluted membrane of a discharge channel and a self cleaning method of the Hall thrustor, which aim to resolve problems that an exiting method for cleaning a polluted membrane of a discharge channel of a Hall thrustor by means of opening a vacuum tank is easy to change vacuum conditions of a test device, assembly errors are easy to be caused during assembly and disassembly, and experimental results are affected greatly. An anode is arranged in the middle of the discharge channel; a cathode is arranged at an outlet of the discharge channel; an outer coil and an inner coil are symmetrically arranged on two sides of the outlet of the discharge channel; the outer coil, the inner coil and an additional coil form an excitation loop after being electrified and excited; and a self cleaning power source is added between a gas distributor and the anode to form a self cleaning preionization electric field. The cleaning method includes steps of firstly, generating self cleaning ions; and secondly, forcing out an inner wall surface or an outer wall surface by the aid of the self cleaning ions to realize self cleaning of the polluted membrane of the discharge channel. An ion jet flow direction is controlled by means of changing magnetic field configuration, so that the self cleaning method is realized, and the structure of the thrustor does not need to be changed.

Owner:HARBIN INST OF TECH

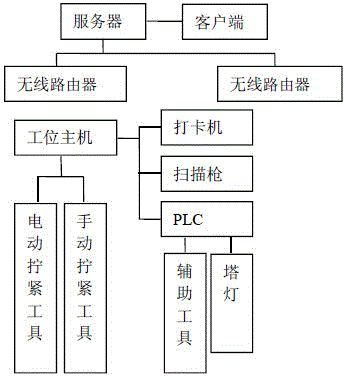

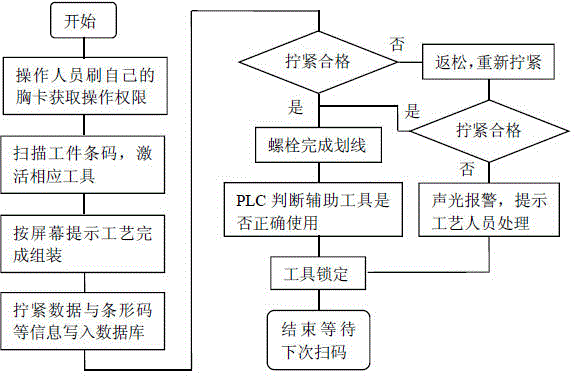

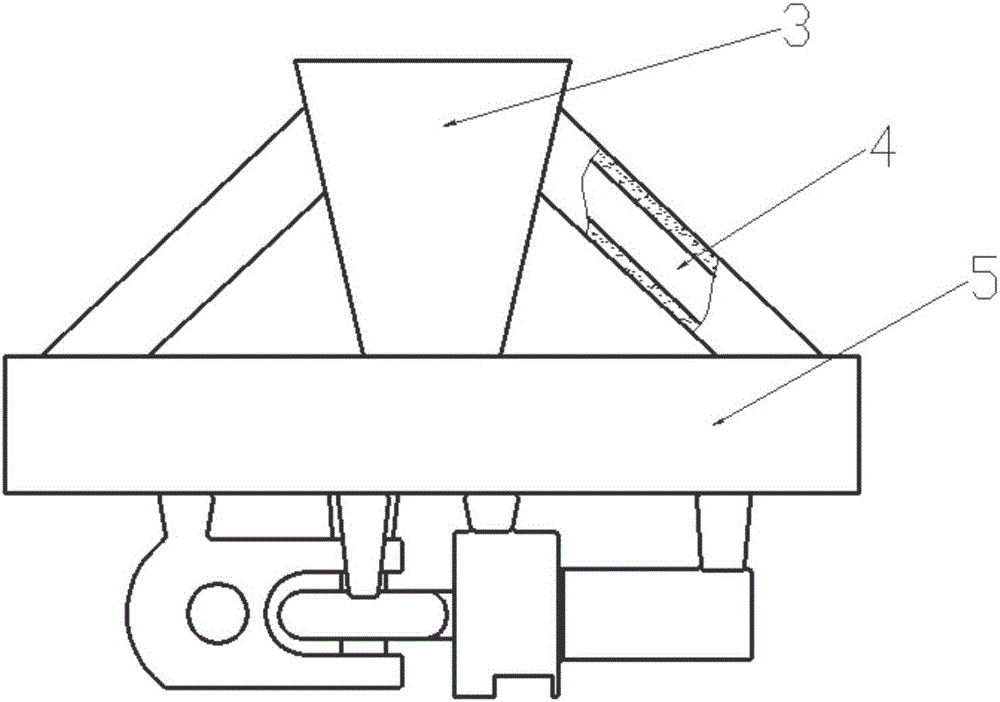

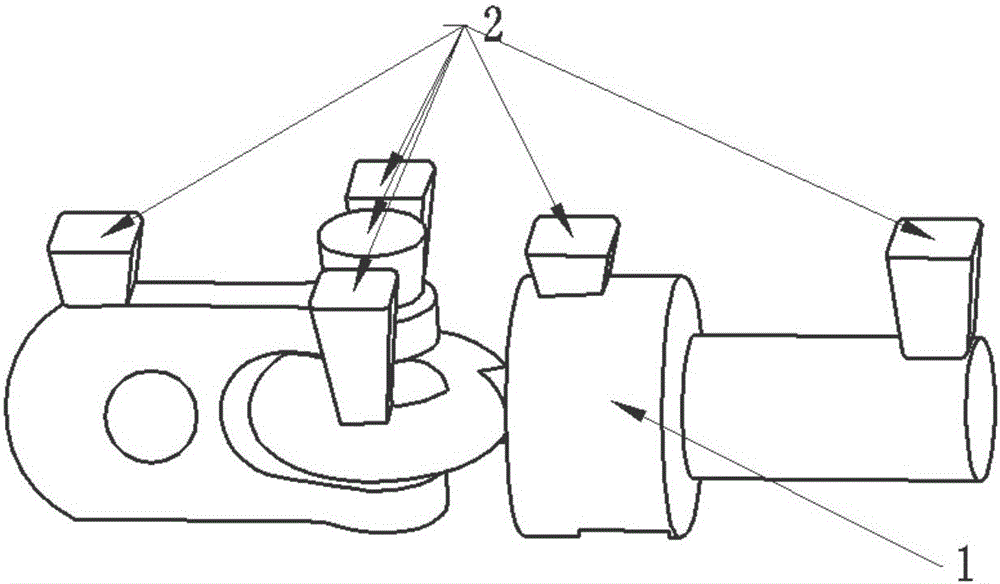

Quantized assembly and overhaul control system for locomotive

ActiveCN104950793AGuaranteed assembly qualityGuaranteed workmanshipProgramme control in sequence/logic controllersControl systemProgrammable logic controller

The invention provides a quantized assembly and overhaul control system for a locomotive. The system comprises a client, a server and an operating terminal, wherein the server is a database server; the operating terminal comprises multiple workstations; the client is connected with the server through a network; the workstations are in data interaction with the server through wireless nodes; each workstation comprises a workstation host, a card punch, a scanning gun, a PLC (programmable logic controller), an electric tightening tool, a manual tightening tool, a tower lamp and auxiliary tools, the card punch, the scanning gun and the PLC are connected with the workstation host through data lines respectively, data transmission interfaces of the electric tightening tool and the manual tightening tool are connected with the workstation host respectively, the tower lamp is connected with a PLC control port through a data line, and sensors are arranged at storage places of the auxiliary tools and connected with the PLC control port. The quantized assembly and overhaul control system for the locomotive can guarantee the tightening process and the tightening precision, effectively prevents wrong assembly, realizes whole tracing of the production process, and guarantees the assembly quality of the locomotive and a high-speed bullet train.

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

Manufacturing method of complicated structure ceramic part of gas turbine-oriented hot-end component

ActiveCN104496507AAvoid assembly errorsAvoid easy deformation of the coreManufacturing technologyMetallurgy

The invention discloses a manufacturing method of a complicated structure ceramic part of a gas turbine-oriented hot-end component. The method comprises the following steps: laminating phenolic resin on ceramic powder surface; adding a binder, and carrying out assisted forming; adding a proper amount of staple fibers to toughen; and stacking and molding the parts by using a material increase manufacturing technology. According to the method disclosed by the invention, siliconing or dipping treatment is carried out on the ceramic part; internal gaps of the part are filled by a chemical gas phase permeability technology; the compactness is improved, and thus, the manufacturing method is suitable for manufacturing of complicated structure part of the gas turbine; the manufacturing efficiency and the success rate can be greatly improved; and the method has high practical value.

Owner:XI AN JIAOTONG UNIV

Method for integrally casting electric power fitting based on 3D printing technology

InactiveCN104985122AReduce fracture failureAvoid working errorsAdditive manufacturing apparatusFoundry mouldsMolten stateRefractory

The invention discloses a method for integrally casting an electric power fitting based on the 3D printing technology. The method comprises the following steps that (1), a three-dimensional model of an electric power fitting to be manufactured is drawn, and a to-be-manufactured electric power fitting model, a plurality of casting channels, an exhaust channel, a gate stick and a gate are manufactured through a 3D printing machine according to the three-dimensional model; (2), shells are manufactured for the outer wall of the to-be-manufactured electric power fitting model, the outer walls of the casting channels, the outer wall of the exhaust channel, the outer wall of the gate stick and the outer wall of the gate, and the outer walls of the shells are wrapped with fire-resisting materials; (3), a same-pressure steam method is adopted for removing the to-be-manufactured electric power fitting model, the casting channels, the exhaust channel, the gate stick and the gate inside the shells in a melting manner; and (4), the shells are roasted, then molten metal materials are poured into the shells to be cooled, the shells are removed, and the needed electric power fitting is obtained. The assembling errors do not exist in the manufactured electric power fitting manufactured according to the method, and the internal organization and the mechanical property of the electric power fitting are coincident.

Owner:XI AN JIAOTONG UNIV

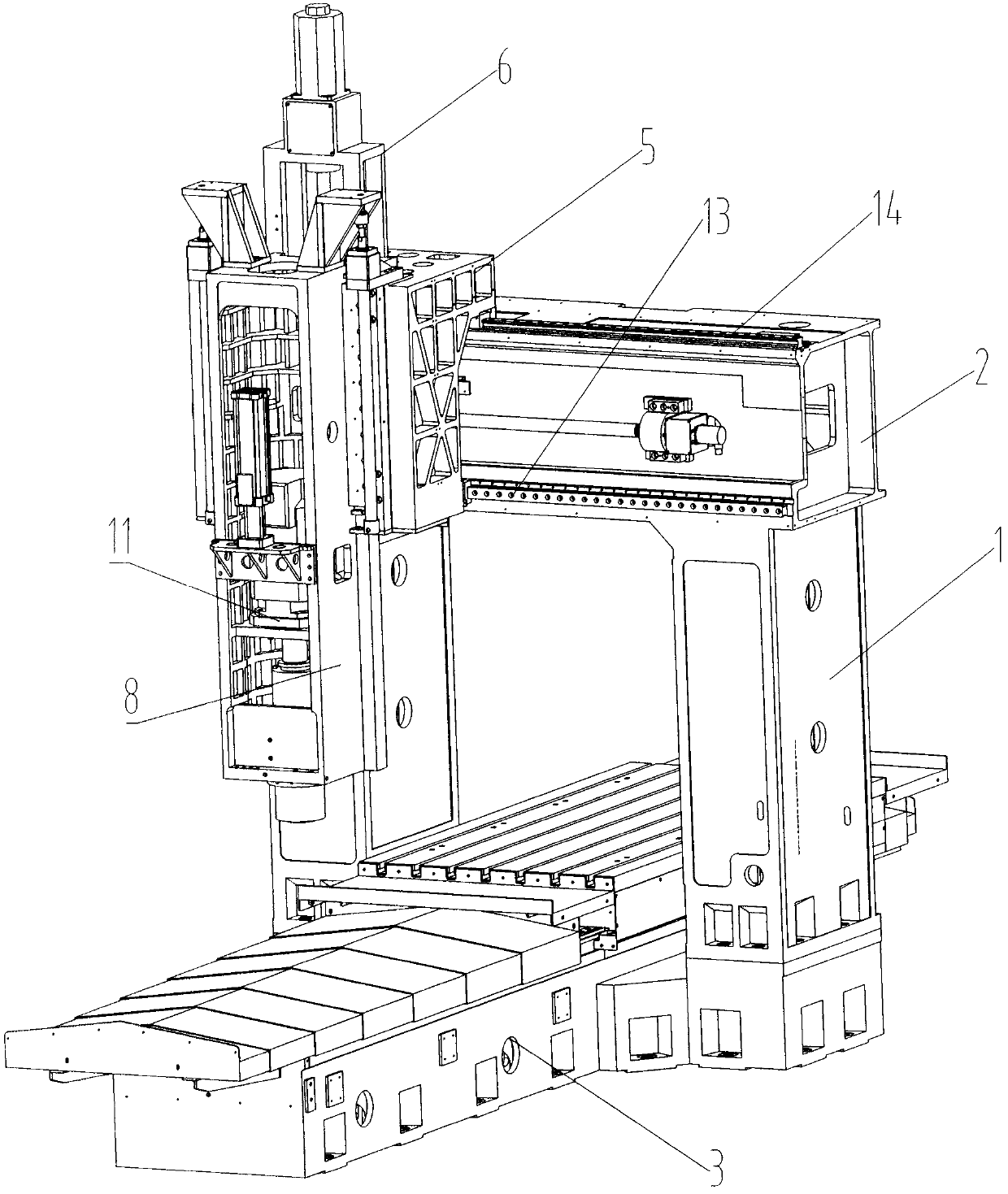

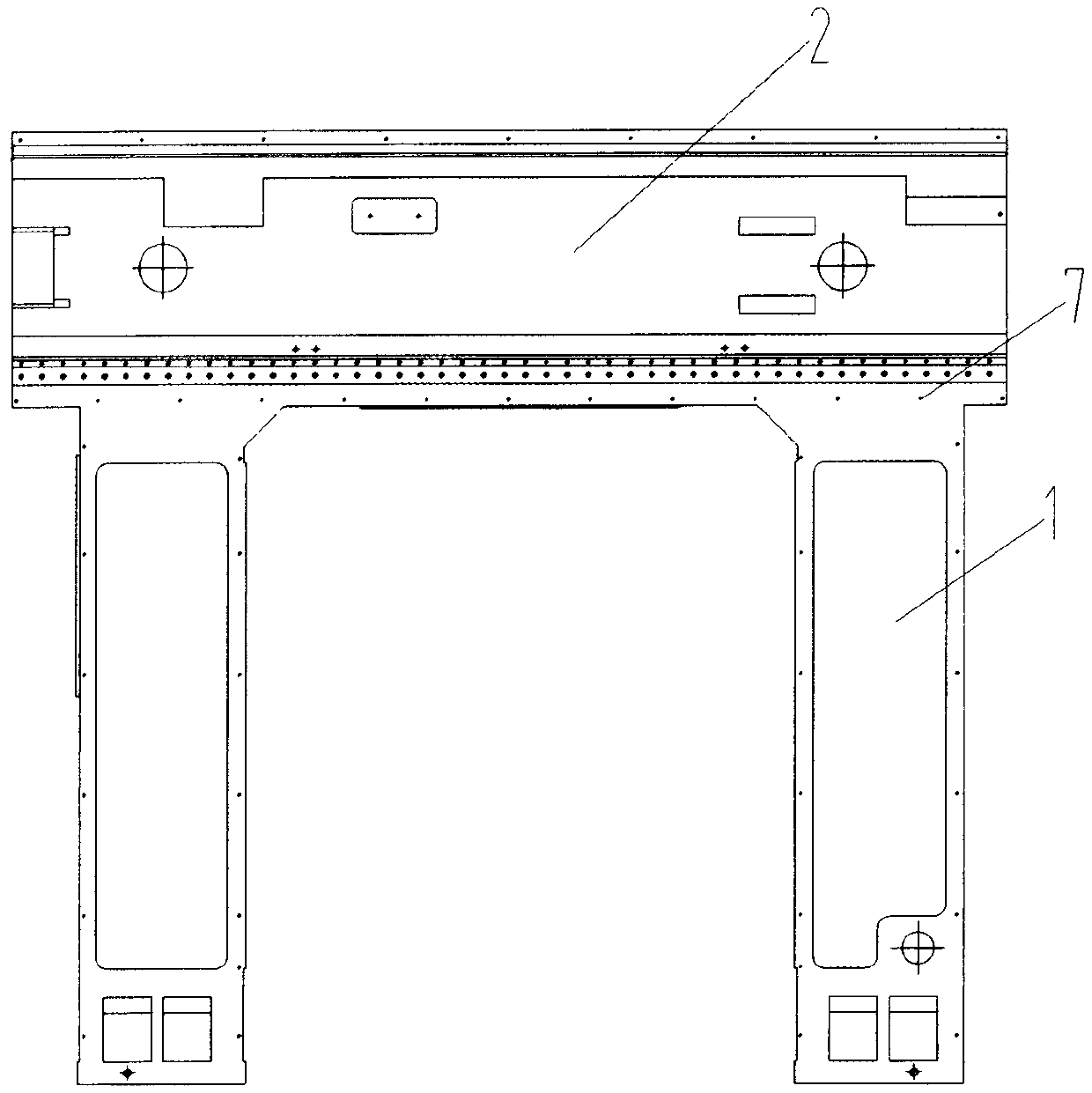

Novel gantry machining center

InactiveCN103624553AEnsure rigidityEnsure strengthLarge fixed membersDriving apparatusEngineeringUltimate tensile strength

The invention discloses a novel gantry machining center which comprises a stand column, a beam, a lathe bed body, casting chip removal device grooves, a sliding base body, a sliding base support and the like. The novel gantry machining center is characterized in that the stand column and the beam are of an integrated structure which is one-time formed by cast iron, the casting chip removal device grooves are formed in the two sides of the lathe bed body, the casting chip removal device grooves and the lathe bed body are of an integrated structure which is one-time formed by castings, the sliding base body and the sliding base support are of a split structure and are fixedly connected together through bolts. According to the novel gantry machining center, the partial integrated structure or the split structure is adopted, the rigidity and strength of the whole gantry machining center are improved, and assembling efficiency and production efficiency are improved.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

Rail vehicle wheel shaft thermal insert technique method

InactiveCN101259577AExtended service lifeAvoid assembly errorsMetal working apparatusElectrical resistance and conductanceEngineering

A hot charging technique method of wheel axles of railway vehicles comprises the steps of matching tread diameter and the diameter of the internal hole of the two wheels arranged on the same axle, confirming magnitude of interference matched with the axle, scrubbing the surface of the wheels, putting the wheels in an incubator according to the sequence of the wheel shaft on the axles after natural drying, setting temperature to be 220 to 240 DEG C and constant temperature time to be 2.5 to 3.5 hours, heating, at the moment putting the axles on a shelf in sequence, opening the incubator after 2.5 to 3.5 hours, assembling wheels according to the sequence of the wheels on the wheel shaft, at the same time detecting the wheel-position difference and the distance of inner side until being qualified, detecting the wheel-position difference and the distance of inner side again after cooling for 1 to 2 hours, starting an anti-thrust test in which testing load value is 840 to 1100 kilonewton after cooling for 24 hours, and continuing the check of resistance value and flaw inspection. Surface contact stress of the invention is zero, and 100 percent flaw inspection is qualified, thus service life is greatly prolonged and back repair rate and rejection rate are zero; the wheel-position difference can be steadied within 0.3 mm and assembly error can be completely avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

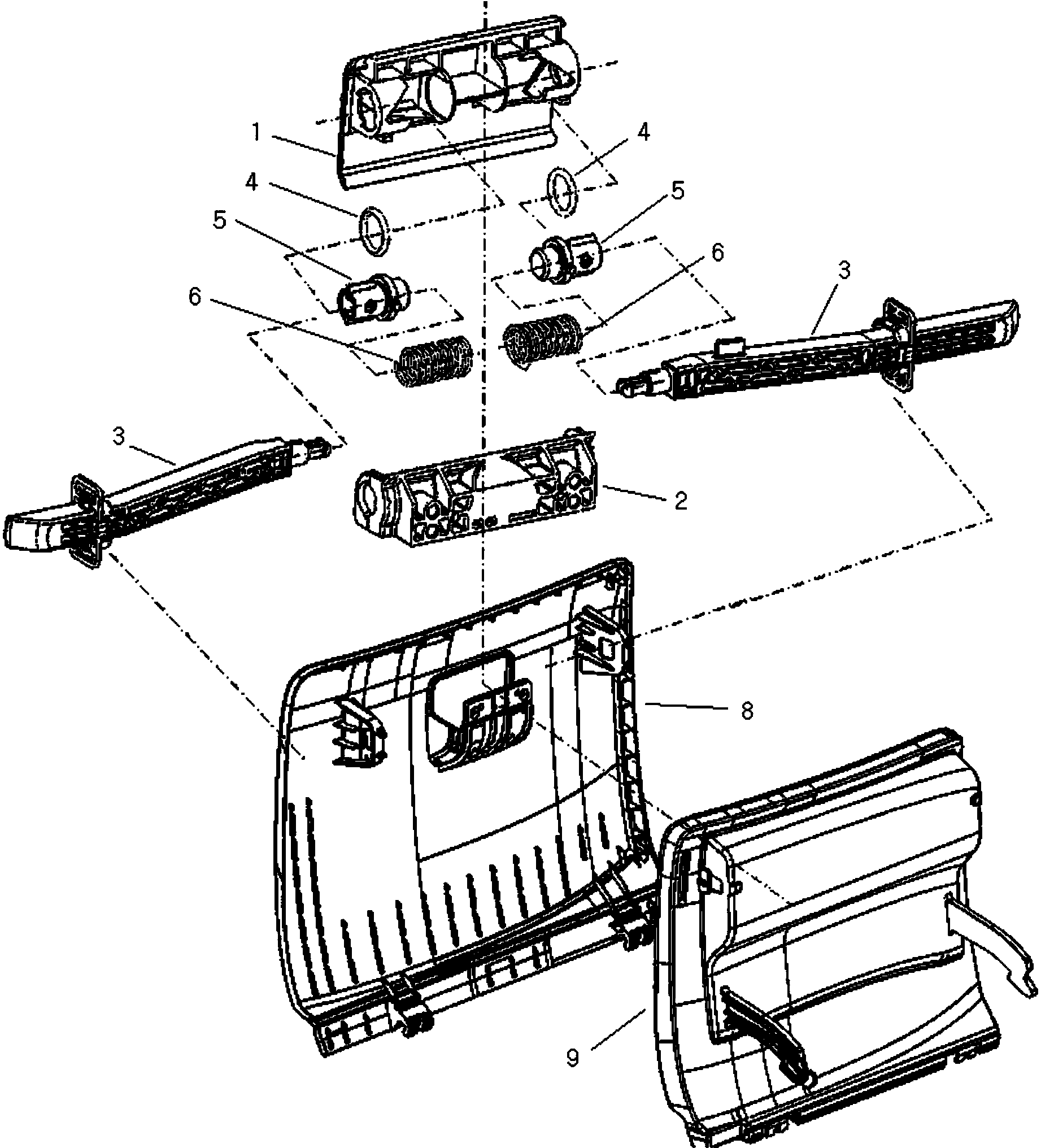

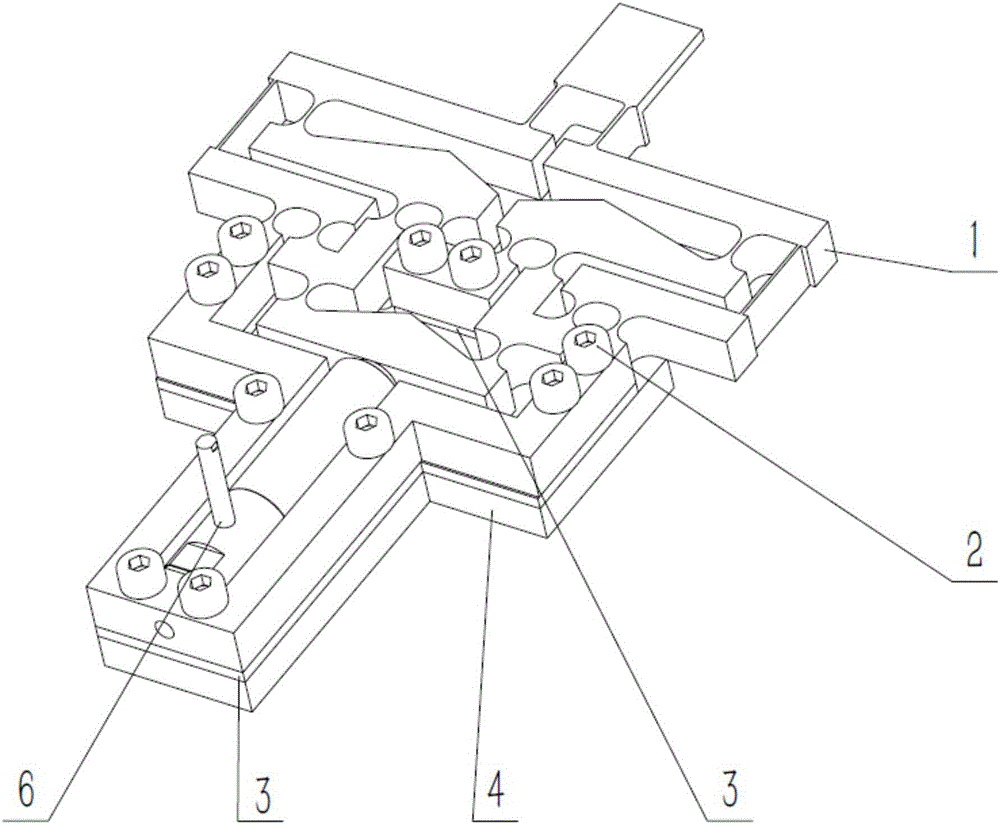

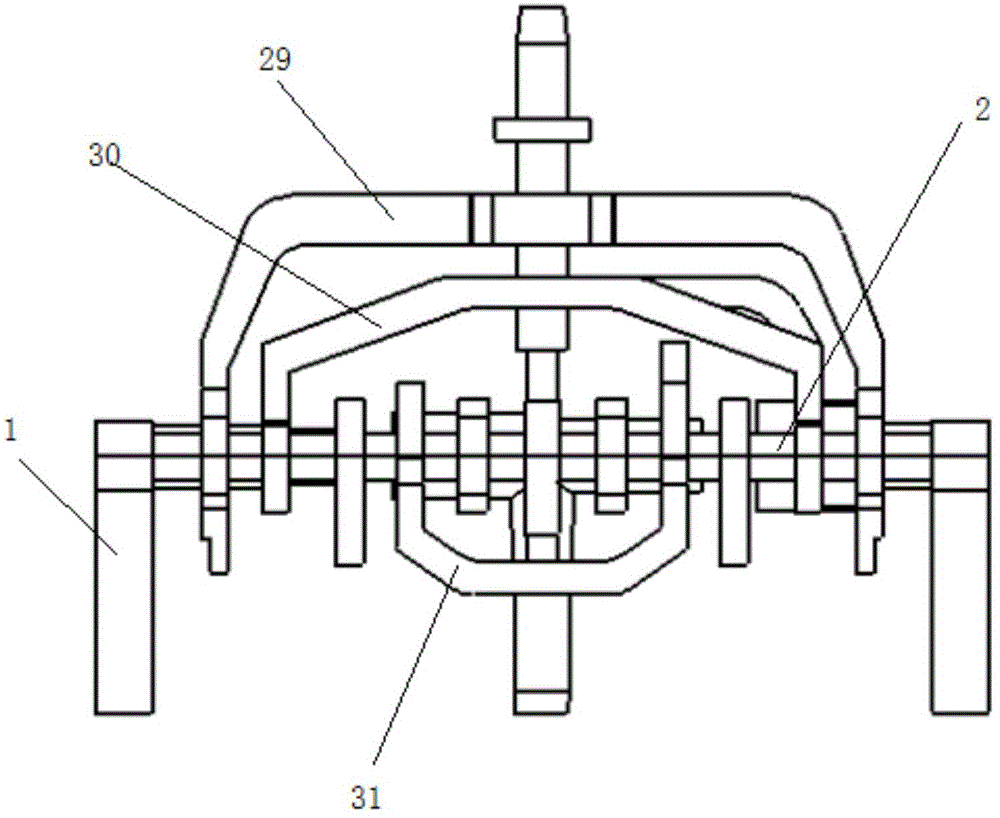

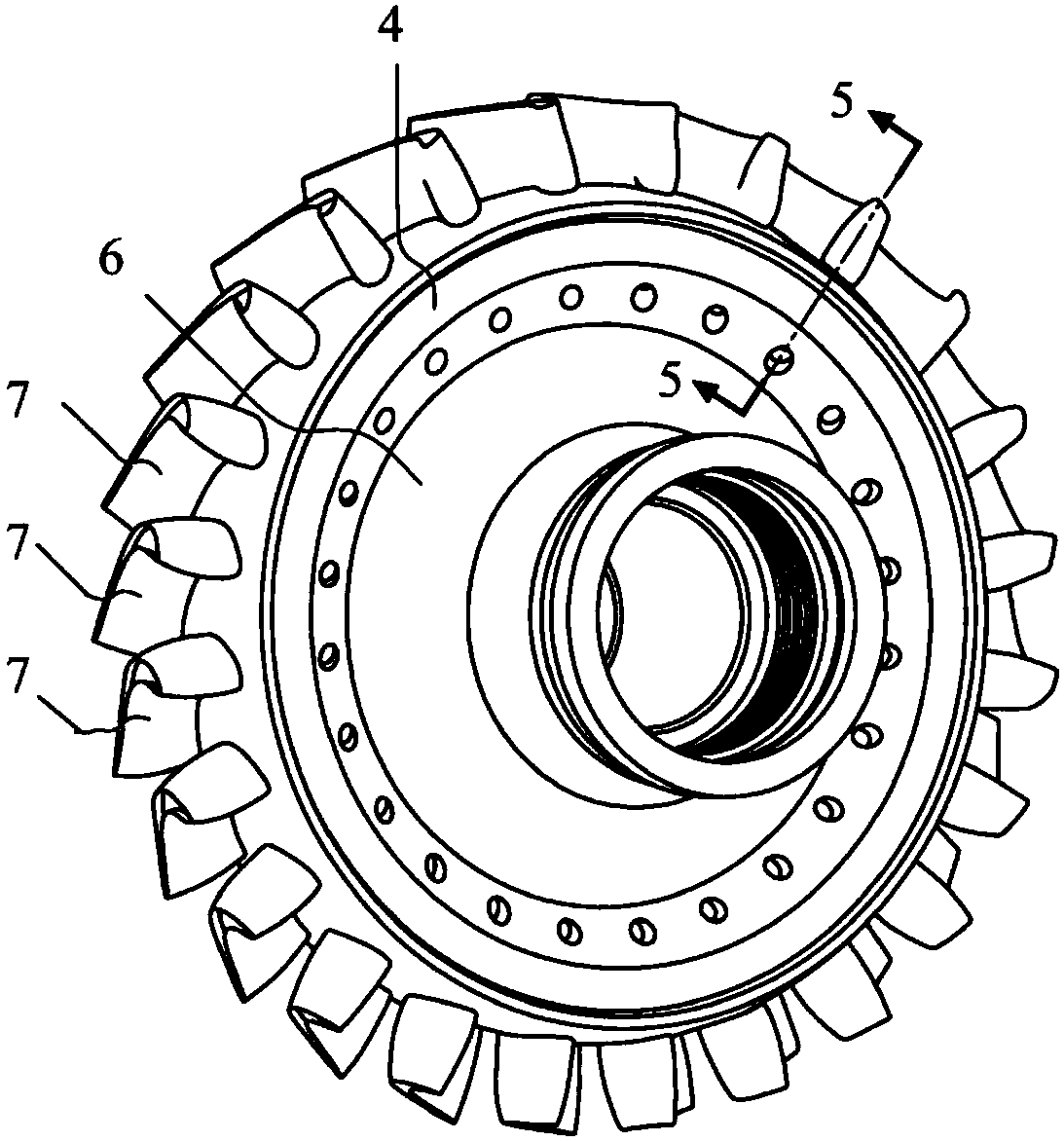

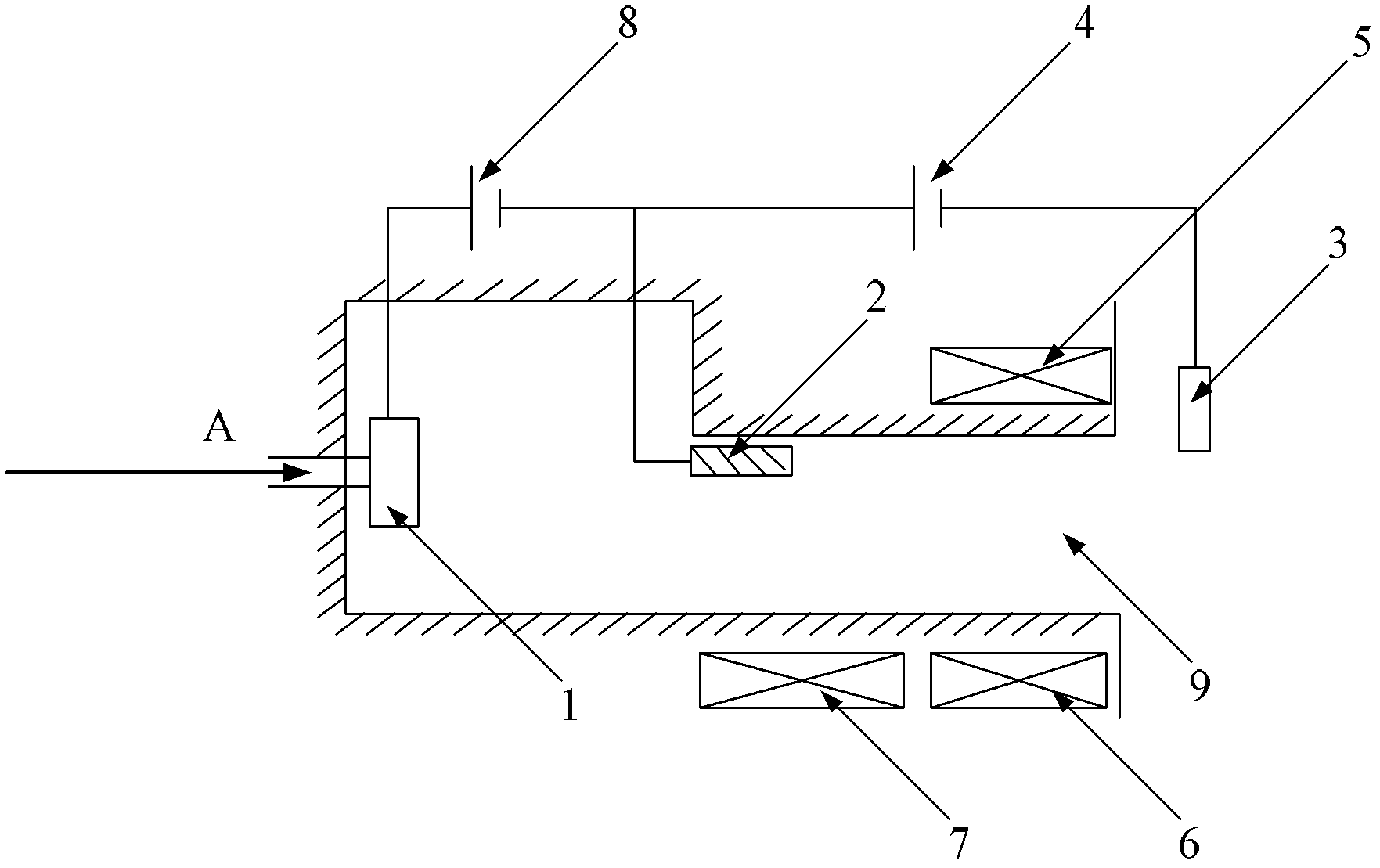

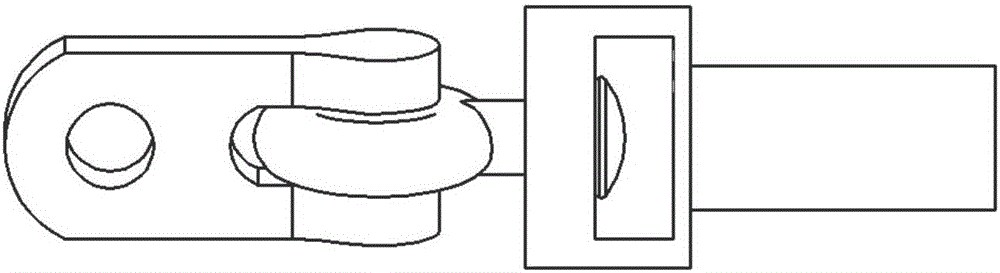

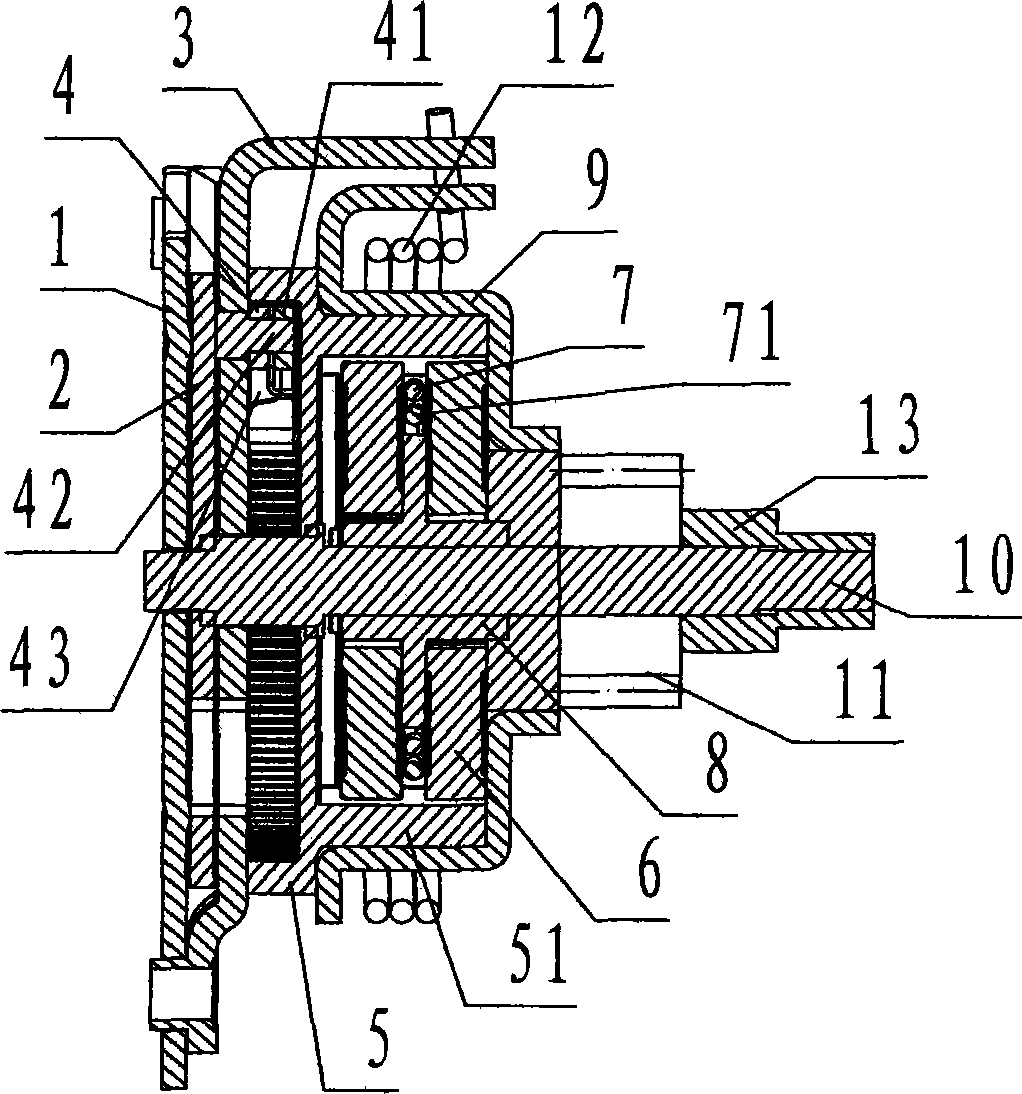

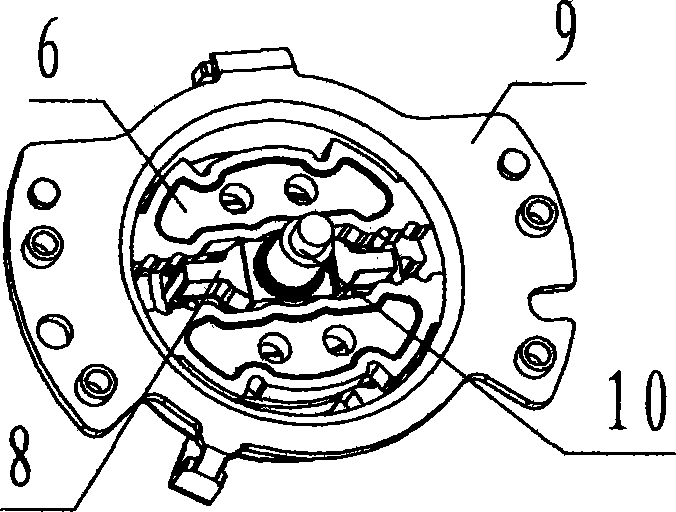

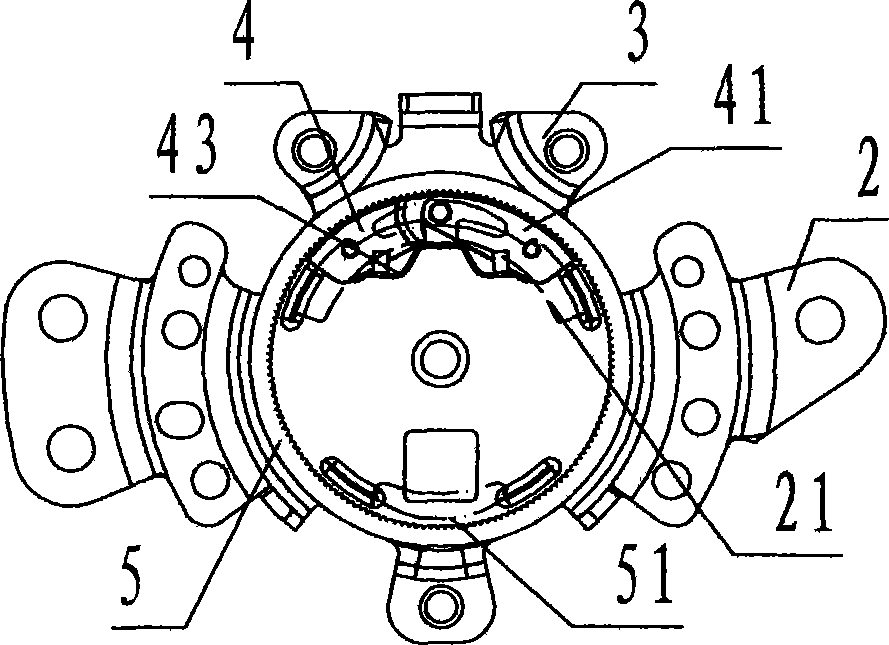

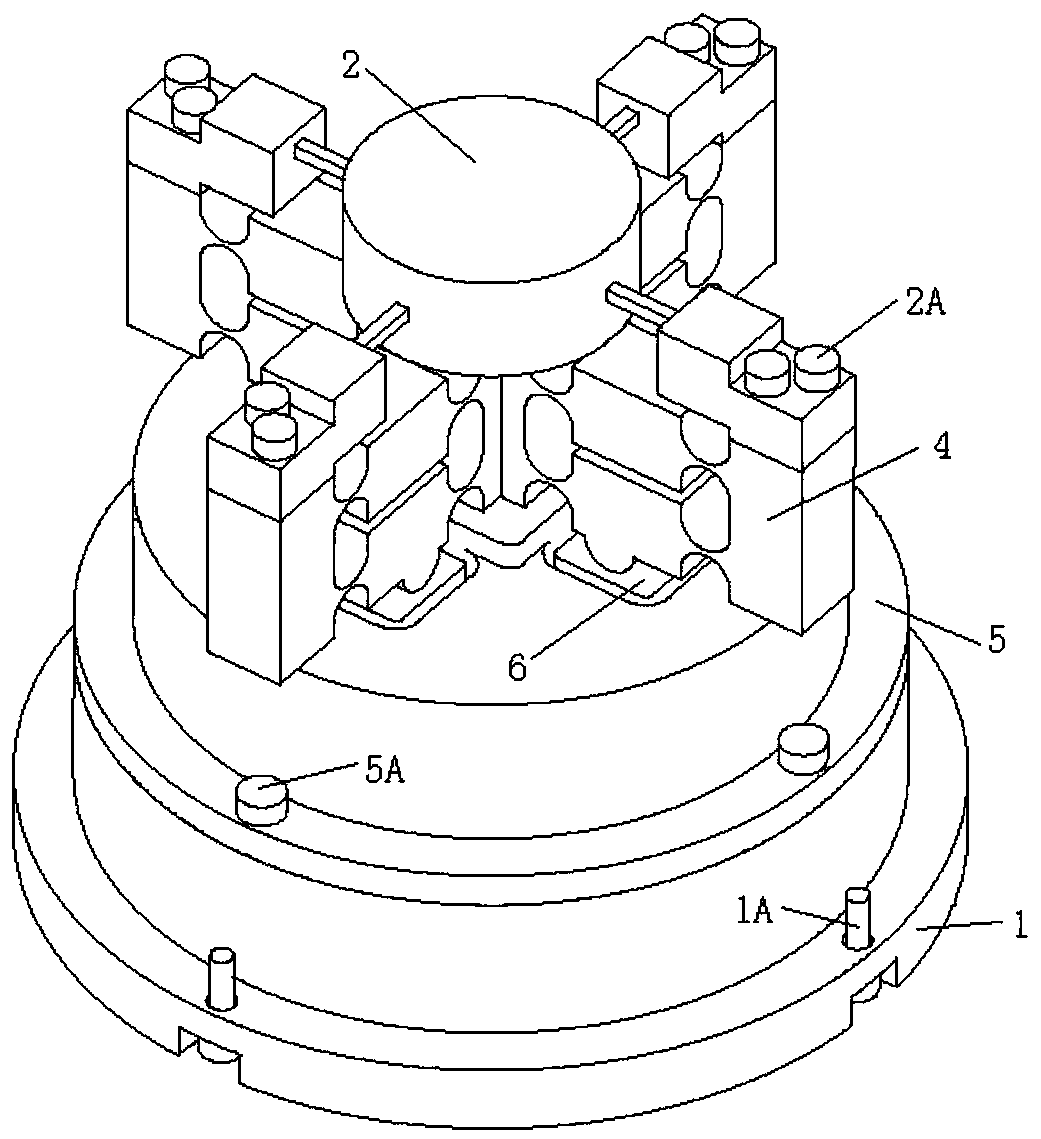

Manual lifting adjustment device with double pawl driving and brake block interchangeability

InactiveCN102837624AAvoid assembly errorsImprove product pass rateMovable seatsCamMechanical engineering

The invention discloses a manual lifting adjustment device with double pawl driving and brake block interchangeability. The manual lifting adjustment device comprises a handle plate (1), a mounting plate (2), a rotating plate (3), a left pawl (4), a right pawl (41), an inner gear driver plate (5), a brake block (6), a snap ring A (7), a snap ring B (71), a driving cam (8), a casing (9), a central shaft (10), an output gear (11), a return spring (12) and an end sleeve (13). According to the manual lifting adjustment device disclosed by the invention, by using the interchangeability of the brake block, the error of the assembly is avoided and the qualification rate of products is improved; the left pawl and the right pawl are respectively and separately in meshed connection with the inner gear driver plate to transmit the torque, so that the defect that the tooth sliding fault easily occurs in the integral pawl is overcome and the work reliability is improved, and further the manual lifting adjustment device for an automobile seat achieves the aims of improving the reliability, simplifying the structure, reducing the size and the weight and reducing the cost.

Owner:NINGBO SHUANGLIN AUTO PARTS

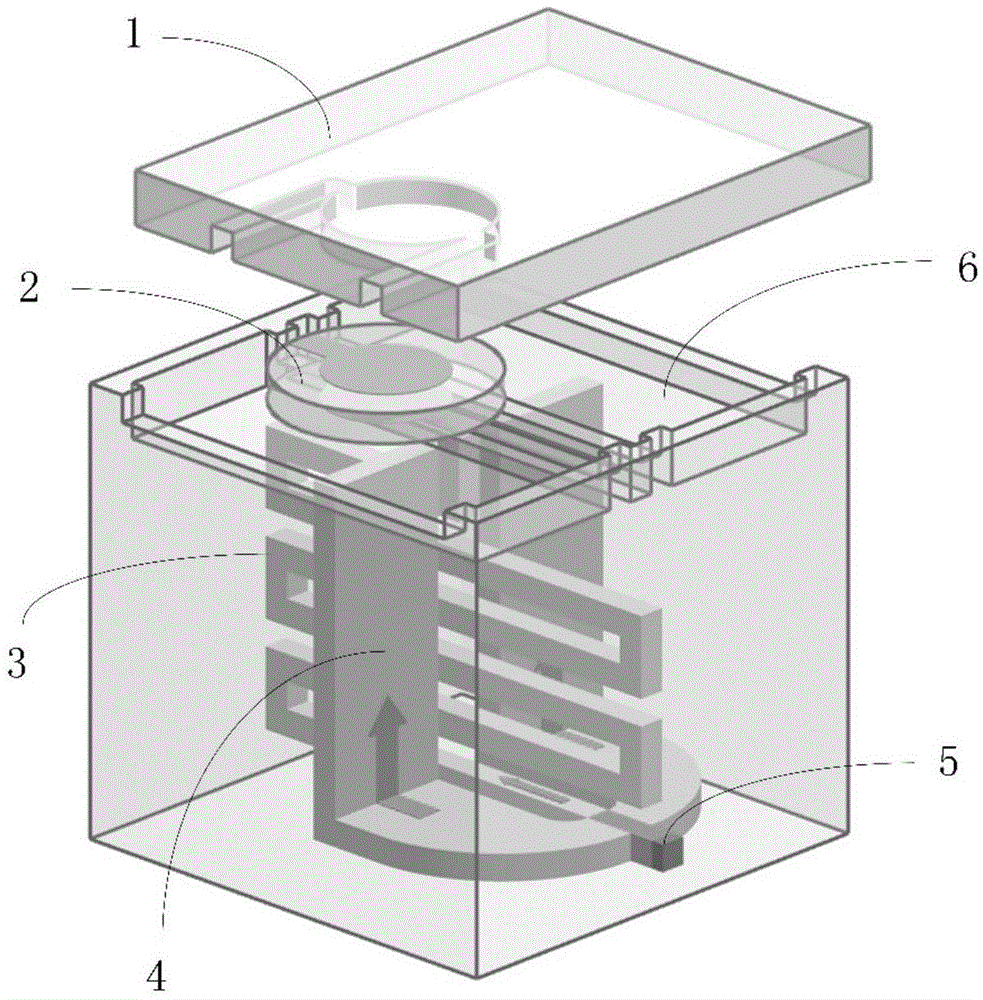

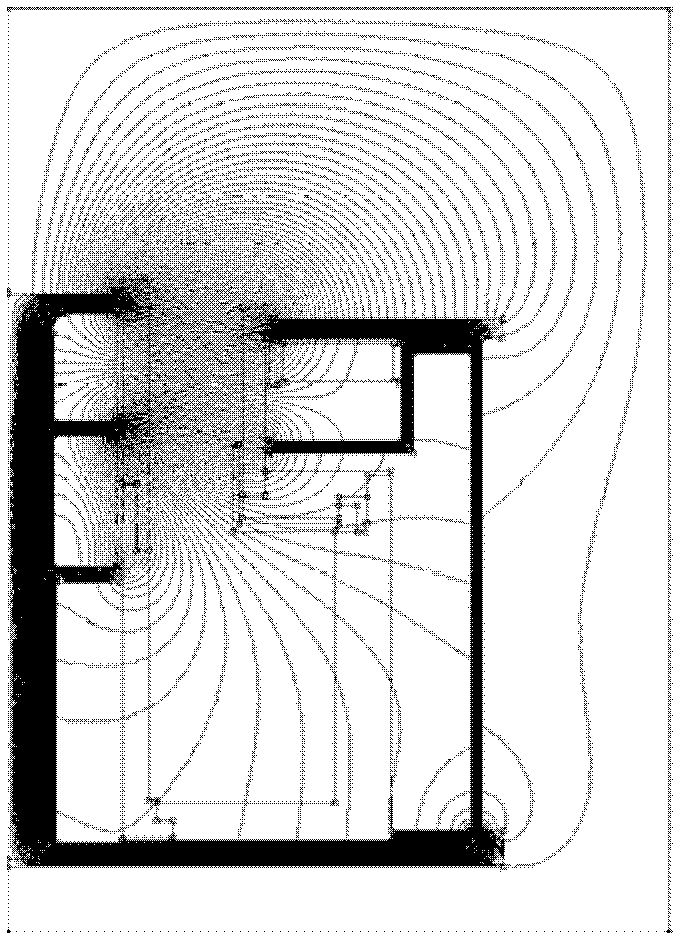

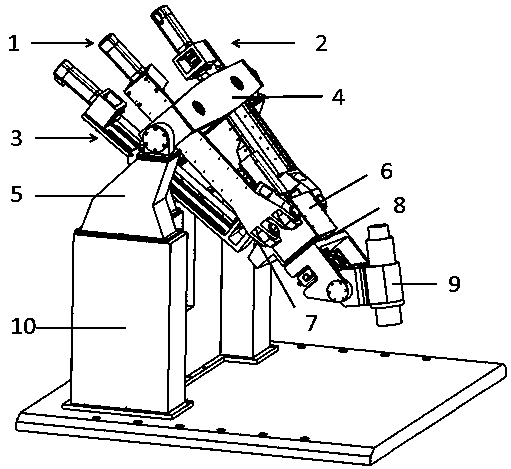

Parallel alignment platform based on flexible parallelogram mechanism and provided with remote rotating center

ActiveCN104626111AHigh rotational positioning resolutionCompact structureProgramme-controlled manipulatorElectricityEngineering

The invention discloses a parallel alignment platform based on a flexible parallelogram mechanism and provided with a remote rotating center. The parallel alignment platform comprises a base, a pre-tightening screw, a capacitive sensor, a sensor support, a cover plate, a platform base plate, a movement transmission mechanism, a piezoelectric ceramic driver and a gasket. The cover plate, the movement transmission mechanism, the platform base plate and the base are arranged in the thickness direction. The base and the movement transmission mechanism are fixedly installed through a screw. The pre-tightening screw is installed on the cover plate and makes contact with the gasket. The piezoelectric ceramic driver and the gasket are installed between the movement transmission mechanism and the platform base plate. According to the designed parallel alignment platform, through a dual-lever amplifying mechanism and a dual-parallelogram guide mechanism in the movement transmission mechanism, the parallel alignment function of rotation around a remote center can be achieved.

Owner:电科北方数字科技(山东)有限公司

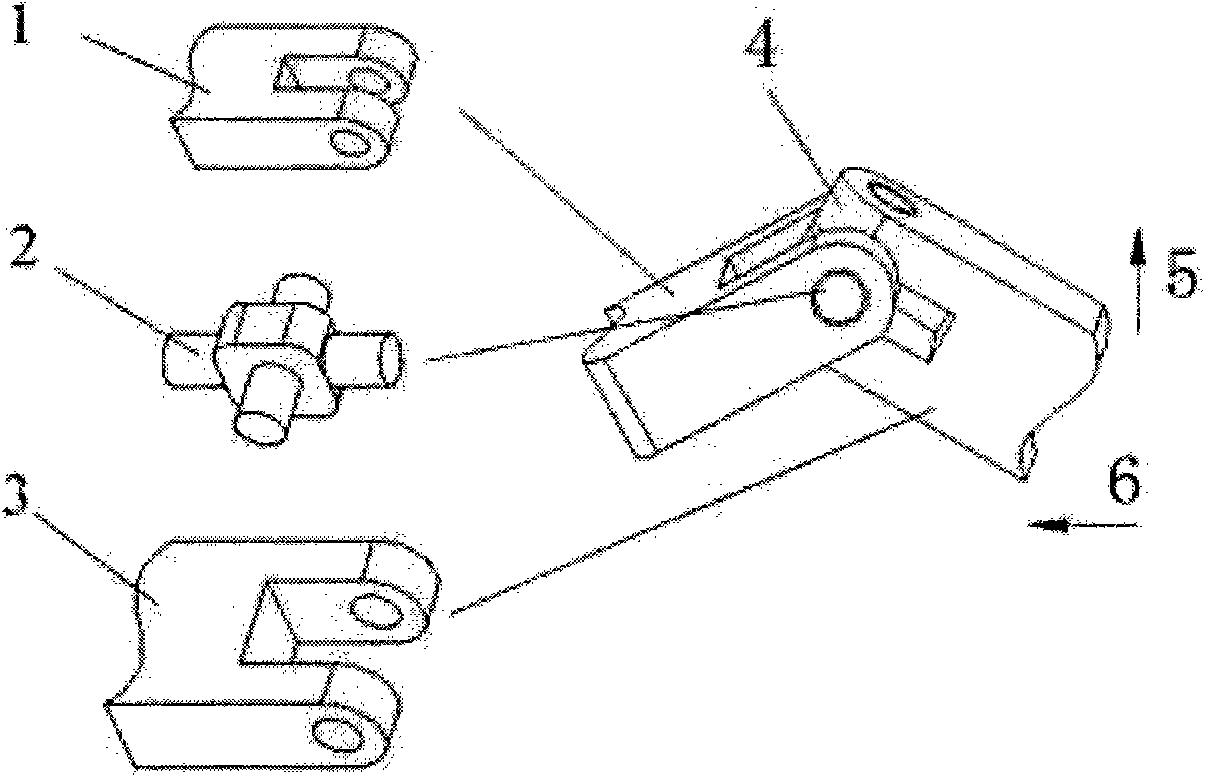

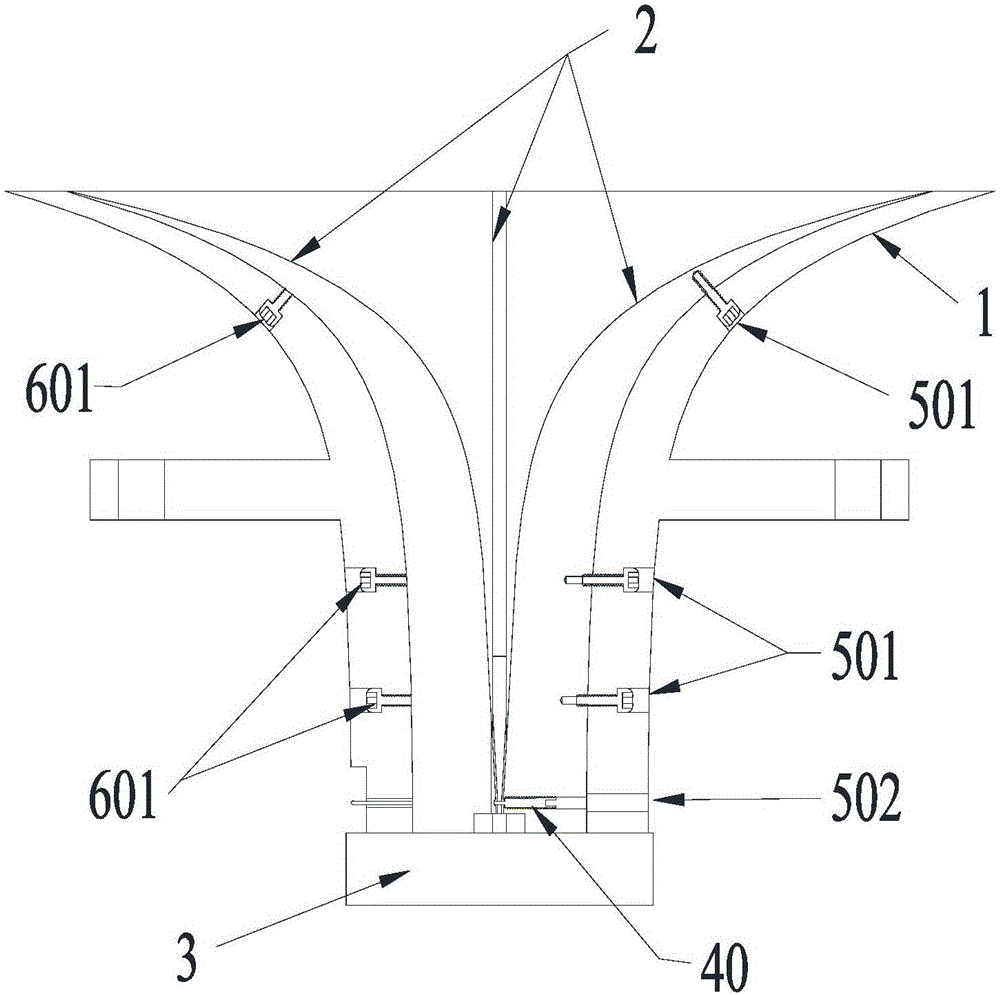

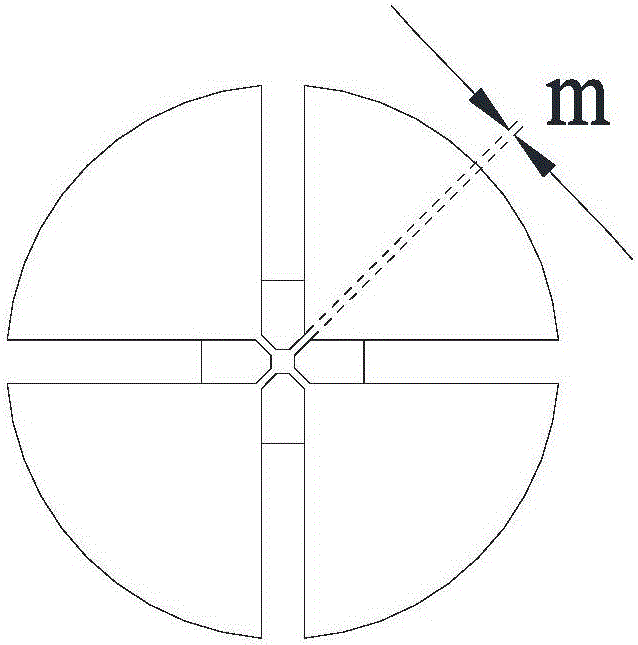

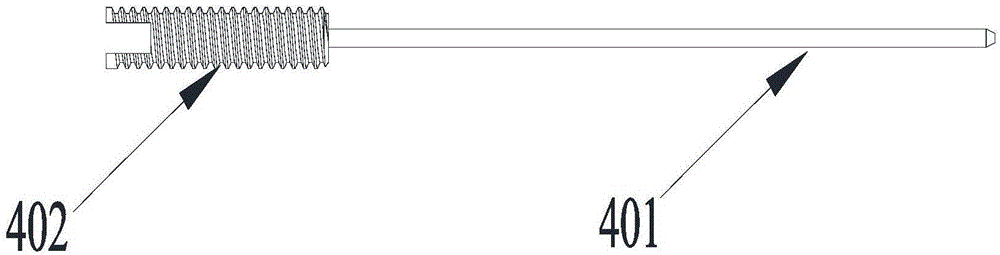

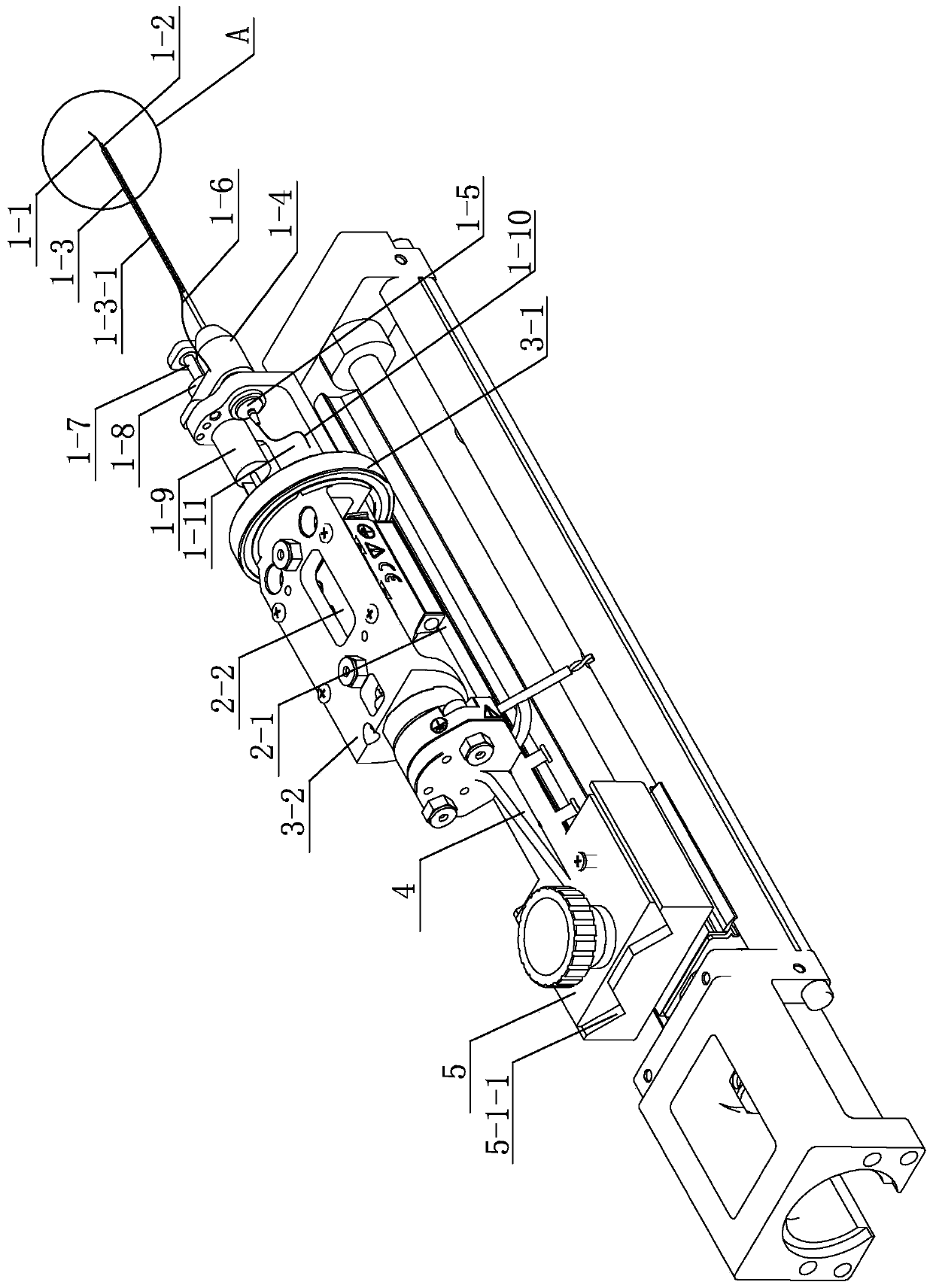

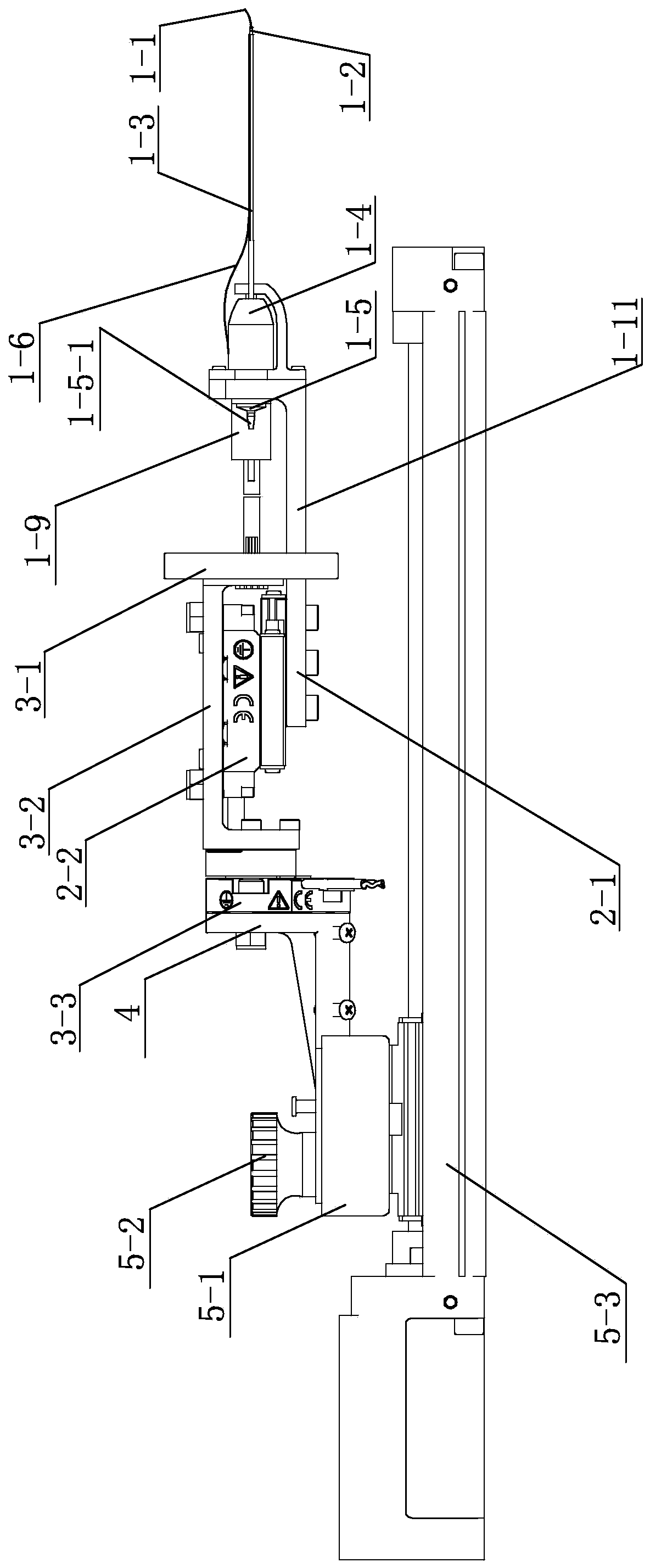

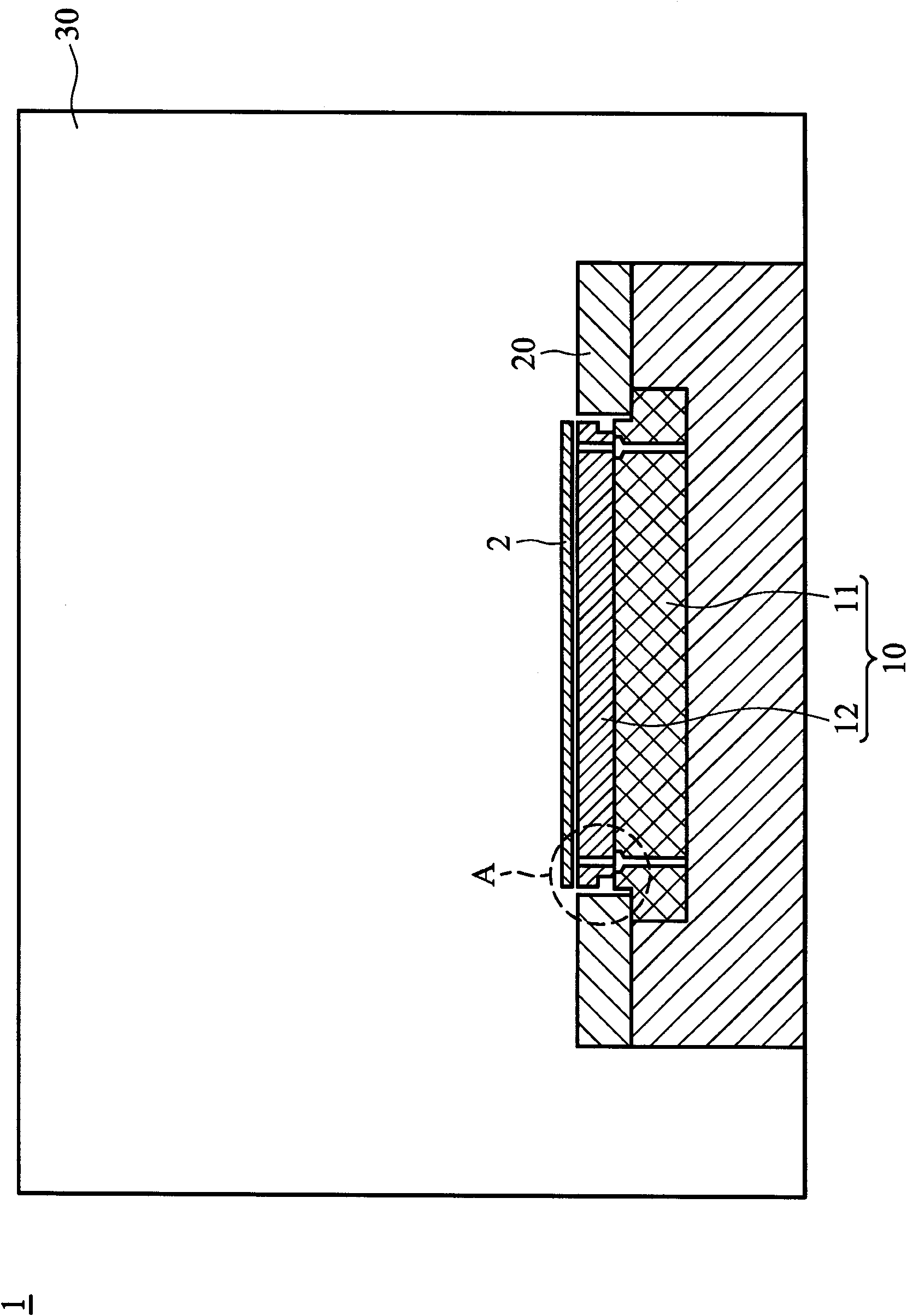

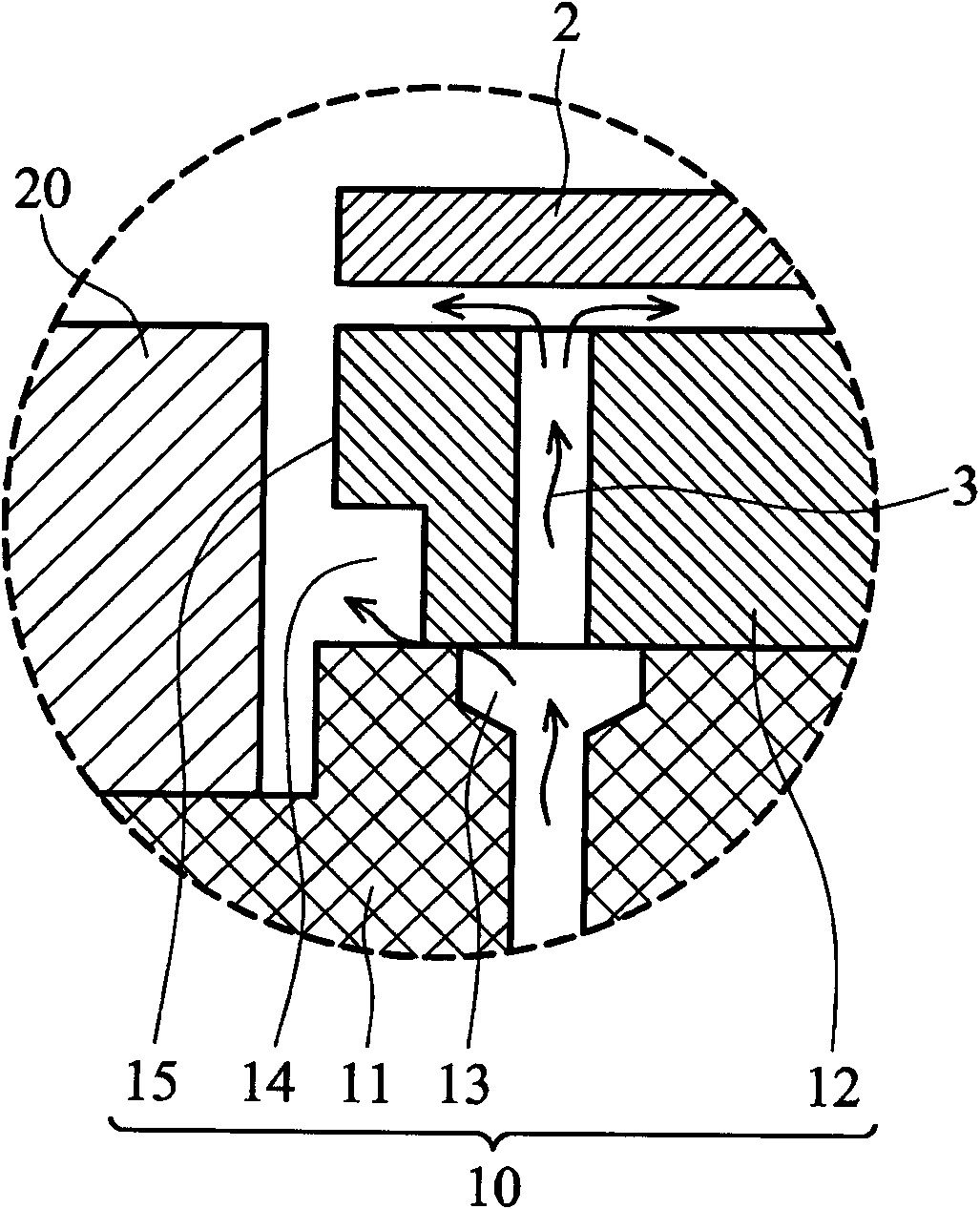

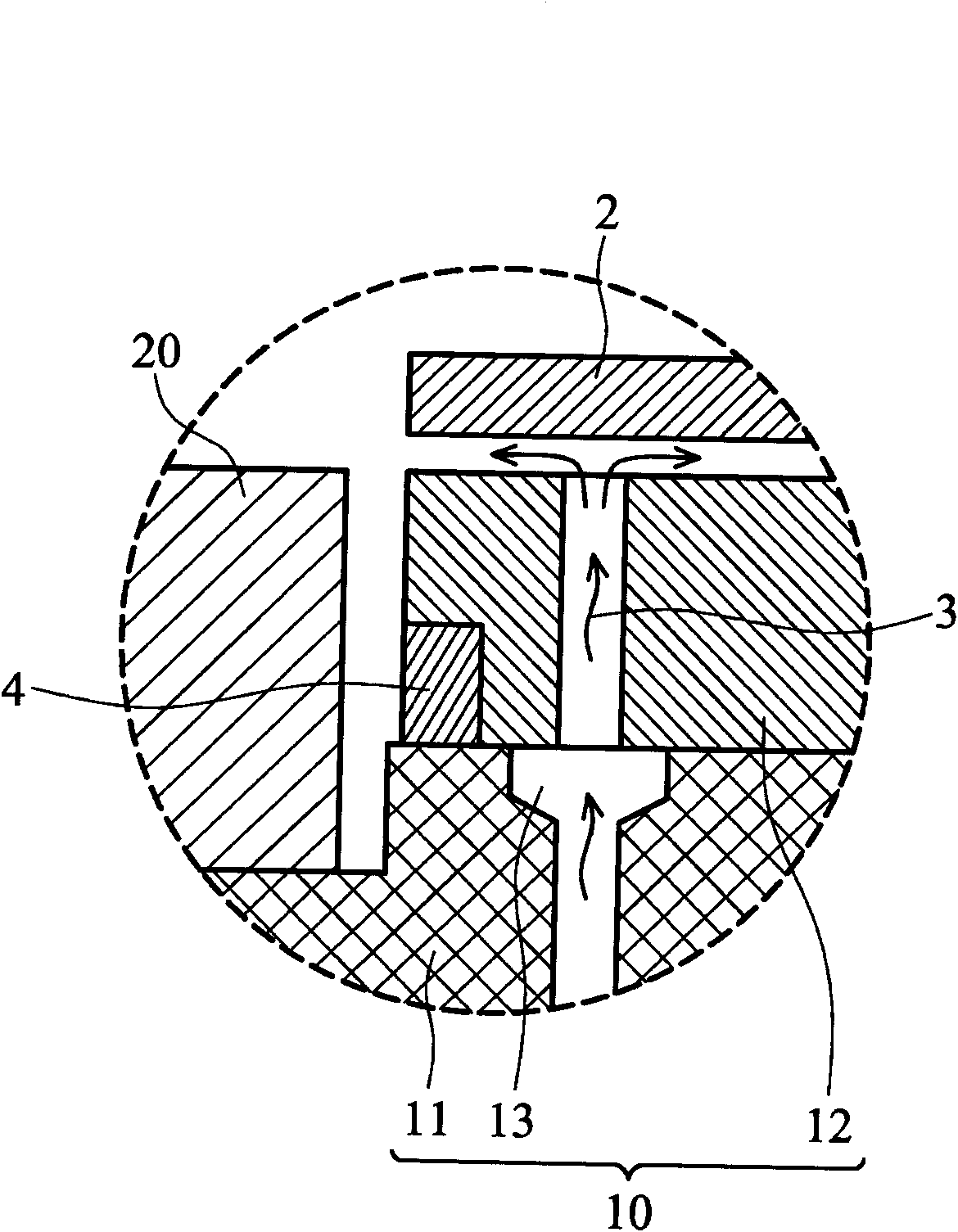

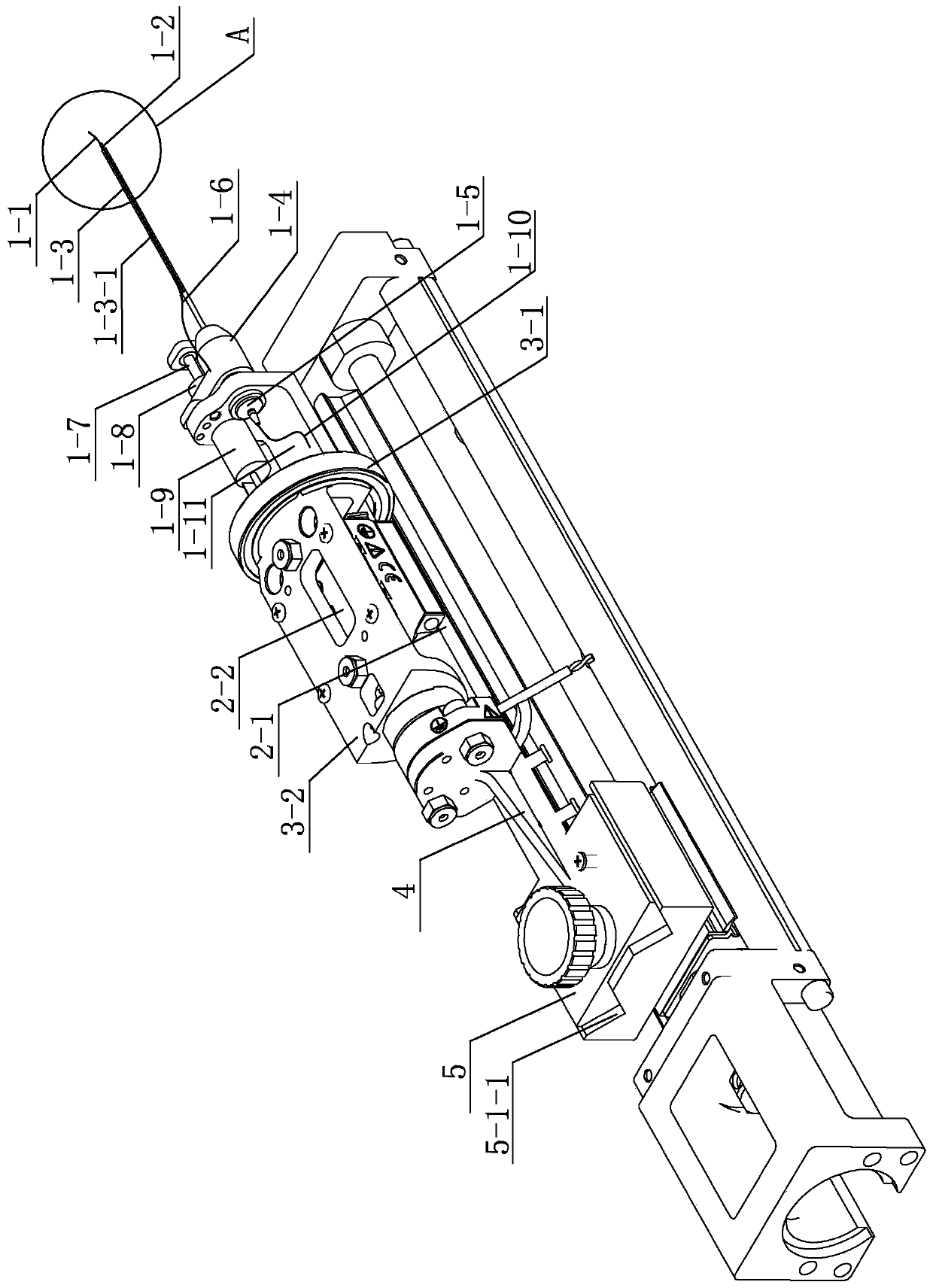

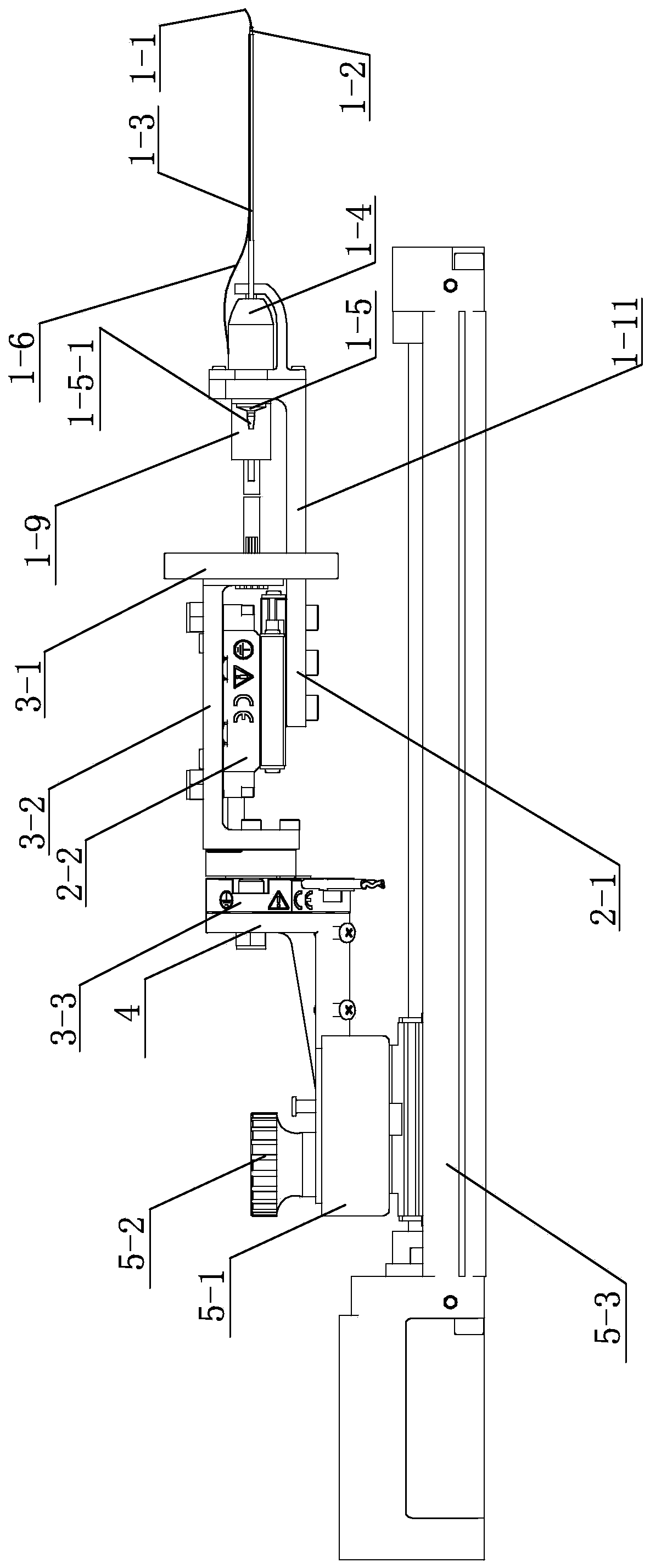

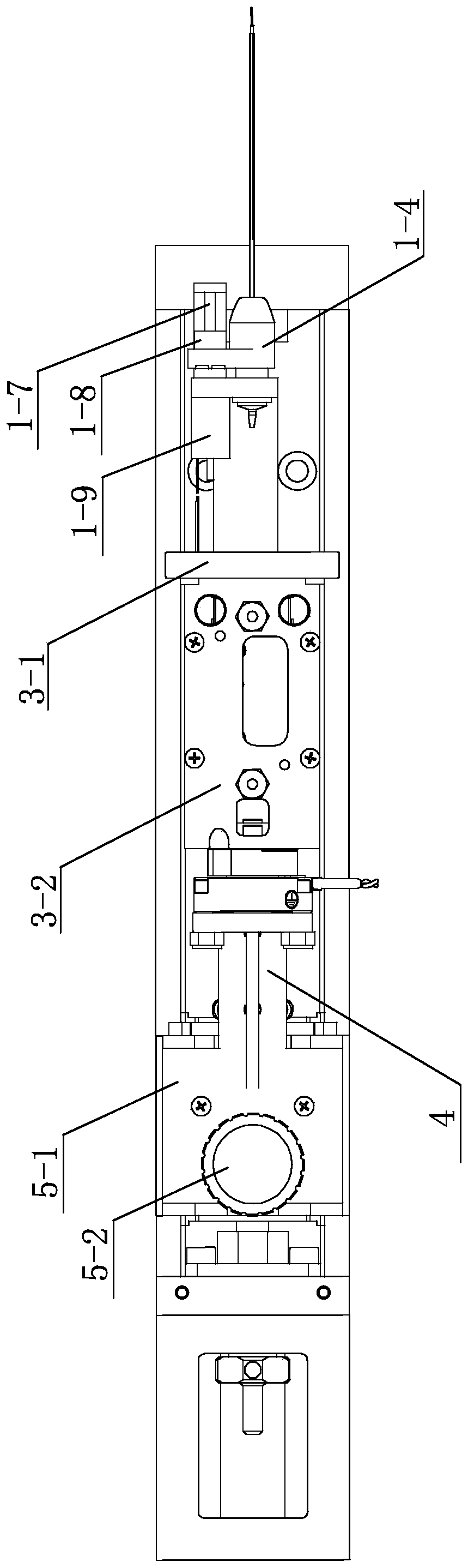

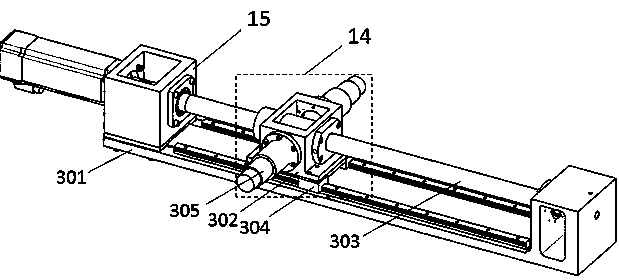

Retinal blood vessel syringe for ophthalmologic operation robot

The invention relates to a retinal blood vessel syringe, and particularly provides a retinal blood vessel syringe for an ophthalmologic operation robot. In order to solve the problems that the movement of the needle tip of an existing syringe device is limited, only linear translation and circumferential change can be achieved, consequently, a proper posture can be found by multi-time positioning,and the operation efficiency and the positioning efficiency are low, the retinal blood vessel syringe comprises an actuator fixing base (4), and further comprises a needle tube group module (1), a feeding module (2) and a rotating module (3), wherein the needle tube group module (1) is installed on the feeding module (2) and driven by the feeding module (2) to achieve feeding, the feeding module(2) is installed on the front portion of the rotating module (3), the needle tube group module (1) and the feeding module (2) are driven by the rotating module (3) to achieve rotation, and the rotating module (3) is installed on the actuator fixing base (4). The retinal blood vessel syringe is used on the ophthalmologic operation robot.

Owner:HARBIN INST OF TECH

Semiconductor process equipment and O-shaped ring thereof

InactiveCN101840849APrevent leakageImprove sealingSemiconductor/solid-state device manufacturingProcess equipmentUltimate tensile strength

Owner:TAIWAN SEMICON MFG CO LTD +1

Retina blood vessel syringe for ophthalmic operation robot and injection method thereof

The invention relates to a retina blood vessel syringe for an ophthalmic operation robot and an injection method thereof. The problems that an existing syringe device is low in operationand positioning efficiency, the device cannot be directly inserted into an eye, injection failsor secondary injury is caused are solved. The syringe comprises an actuator fixing base (4), a needle tube module (1),a feeding module (2) and a rotation module (3), the needle tube module (1) is installed on the feeding module (2) and achieves feeding under the drive of the feeding module (2), the feeding module (2)is installed on the front of the rotation module (3), the needle tube module (1) and the feeding module (2) rotate under the drive of the rotation module (3), and the rotation module (3) is installedon the actuator fixing base(4). The syringe is applied to the ophthalmic operation robot.

Owner:HARBIN INST OF TECH

Five-degree-of-freedom precise series-parallel robot with mobile platform additional constraints

InactiveCN108500953AHigh movement precisionAvoid manufacturing errorsProgramme-controlled manipulatorEngineering

The invention relates to a five-degree-of-freedom precise series-parallel robot with mobile platform additional constraints. The robot comprises a rotating platform, a base support, a mobile platform,a precise spherical hinge connection pair, a first series connection joint, a movement tail end, a base, a first rod, a second rod and a third rod, wherein the first rod and the second rod are the same in structure, and the two rods penetrate through a first hinge and are connected to the rotating platform; the third rod is connected to the base through a hinge and is located below the first rodand the second rod; and one end of the first rod and one end of the second rod are connected with the mobile platform through a second hinge, and one end of the third rod is connected with the mobileplatform through the precise spherical hinge connection pair. According to the five-degree-of-freedom precise series-parallel robot with the mobile platform additional constraints, due to the structural characteristic that the precise spherical hinge connection pair is connected between the third rod and the mobile platform, the mobile platform is subjected to the additional constraints, the motion space of the mobile platform is a plane perpendicular to the ground, the precision is relatively high, the overall structure is provided with fewer joints and parts, and machining, manufacturing andassembling are convenient.

Owner:SHANGHAI UNIV

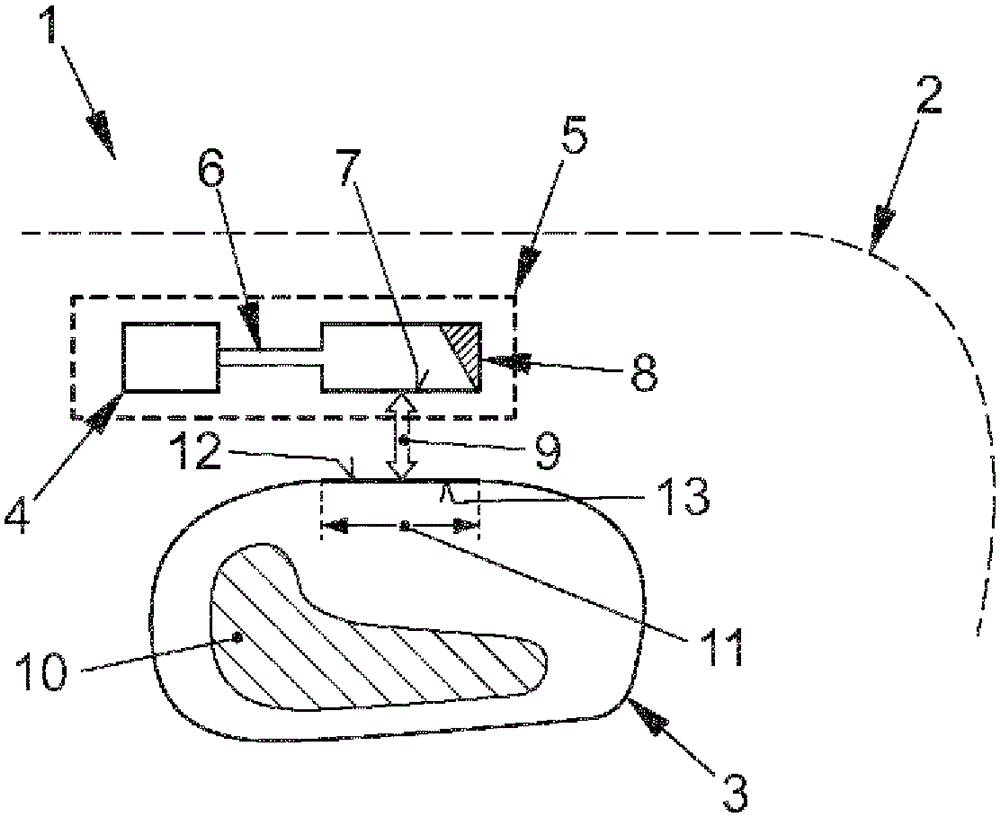

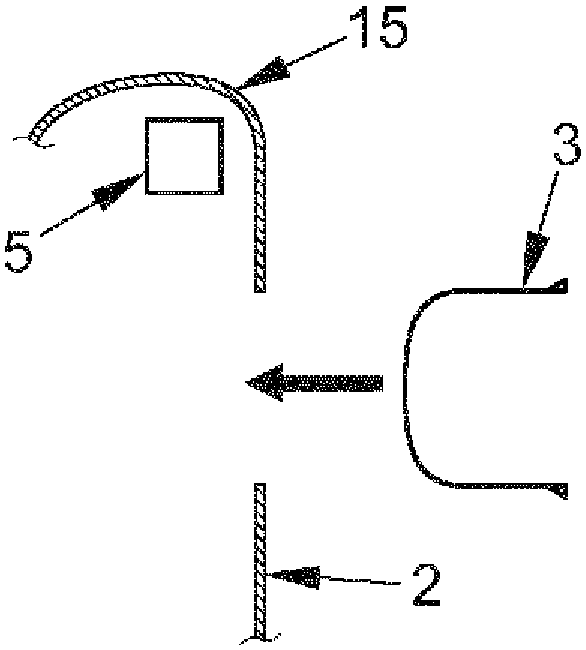

Device with a handle shell and with an illumination means for the handle shell, and a method for mounting the device

ActiveCN105121767AReduced scattering lossOmit hold functionVehicle locksVehicle interior lightingLight equipmentCoupling

The invention relates to a device (1) assigned to an interior door moulding (2) of a motor vehicle, comprising a handle shell (3) fixed on an interior door moulding (2), and an illuminating means (5), and also a mounting method therefor. The illuminating means (5) here comprises, in addition to the light source (4), an optical waveguide (6) with a directed light outlet surface (7) for the light. The light coupled into the optical waveguide (6), before being decoupled, impinges against a reflection element (8) which is arranged on the end side at an inclination in relation to the cross-sectional plane of the optical waveguide (6) and serves at the same time for shaping the emerging light beam. In particular, an undesirable scattering of the light in the region of the free distance (9) between the light outlet surface (7) and the handle shell (3) is thereby substantially reduced. The concave handle shell (3) which is intended for receiving a pivotable actuating element (10) has, for the coupling-in of light, a transmissive region (11), the light outlet surface (13) of which is designed as a diffusion lens. According to the invention, a separation of functions is achieved, making it possible, for the first time, to mount the illumination means (5) and the handle shell (3) as separate functional units and independently of each other.

Owner:VOLKSWAGEN AG

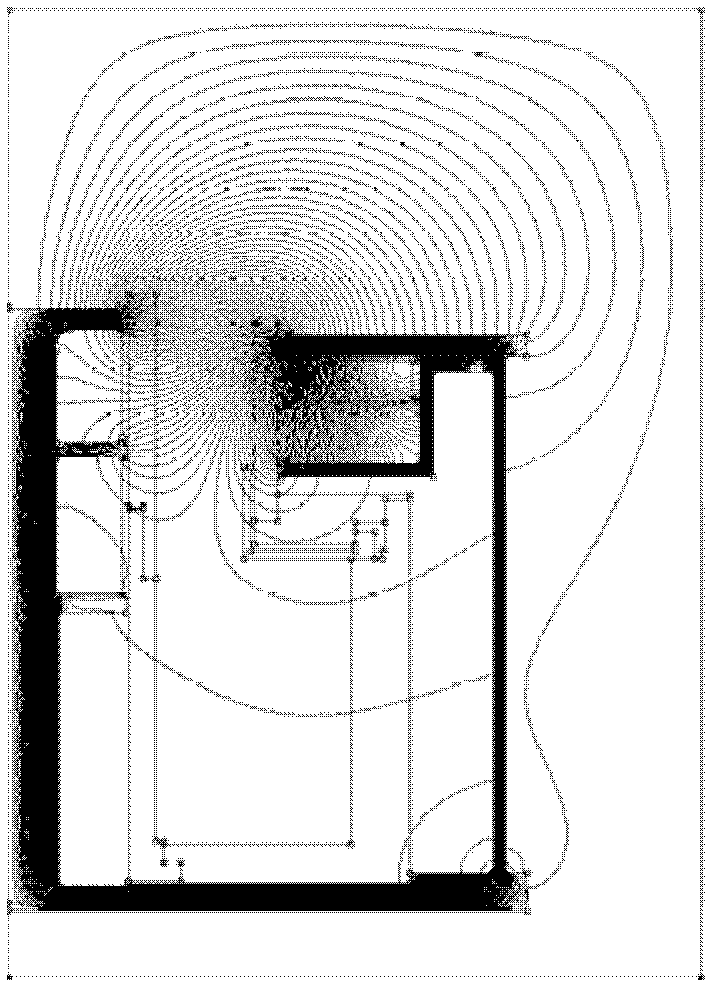

Precision pointing platform based on flexible parallelogram mechanism

ActiveCN109723945AStable Pointing AccuracyIncrease stiffnessStands/trestlesControl without using feedbackElectricityComputer science

The invention relates to a precision pointing platform based on a flexible parallelogram mechanism, belongs to the field of the precision pointing platform, and solves the problems that the existing precision flexible pointing platform lacks an effective pointing motion guiding mechanism, so that the rotation center of an output platform of the precision flexible pointing platform drifts, and a driver does not effectively isolate harmful lateral motions. The precision pointing platform based on the flexible parallelogram mechanism provided by the invention comprises a base assembly, an outputplatform assembly, an outer sleeve, a parallelogram rotation guide mechanism, an adapter assembly, a piezoelectric ceramic driver and a pretightening assembly. The precision pointing platform providedby the invention adopts the flexible parallelogram mechanism for rotary guidance, the input end is provided with a convex circular contact table, and the output platform is provided with a fixing rotation center. According to the invention, the rotation center of the output platform does not drift, so that stable pointing precision is ensured; and the convex circular contact table which is arranged at the input end can reduce the adverse effects of lateral load on the piezoelectric ceramic driver.

Owner:BEIJING MECHANICAL EQUIP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com