Co-stator multi-drive macro and micro integration high-speed precision movement two-dimensional platform for linear motor

A linear motor, precision motion technology, applied in metal processing mechanical parts, metal processing equipment, feeding devices and other directions, can solve the problems of ordinary macro motion equipment unable to meet actual needs, increased manufacturing costs, short strokes, etc., to achieve simple structure, The effect of large load capacity and avoidance of assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

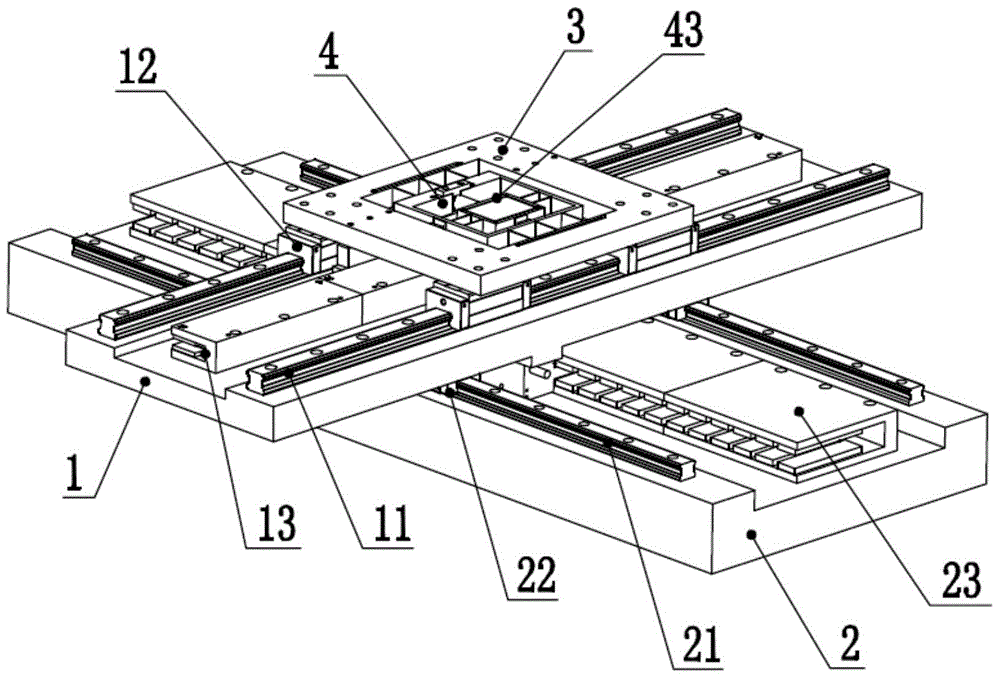

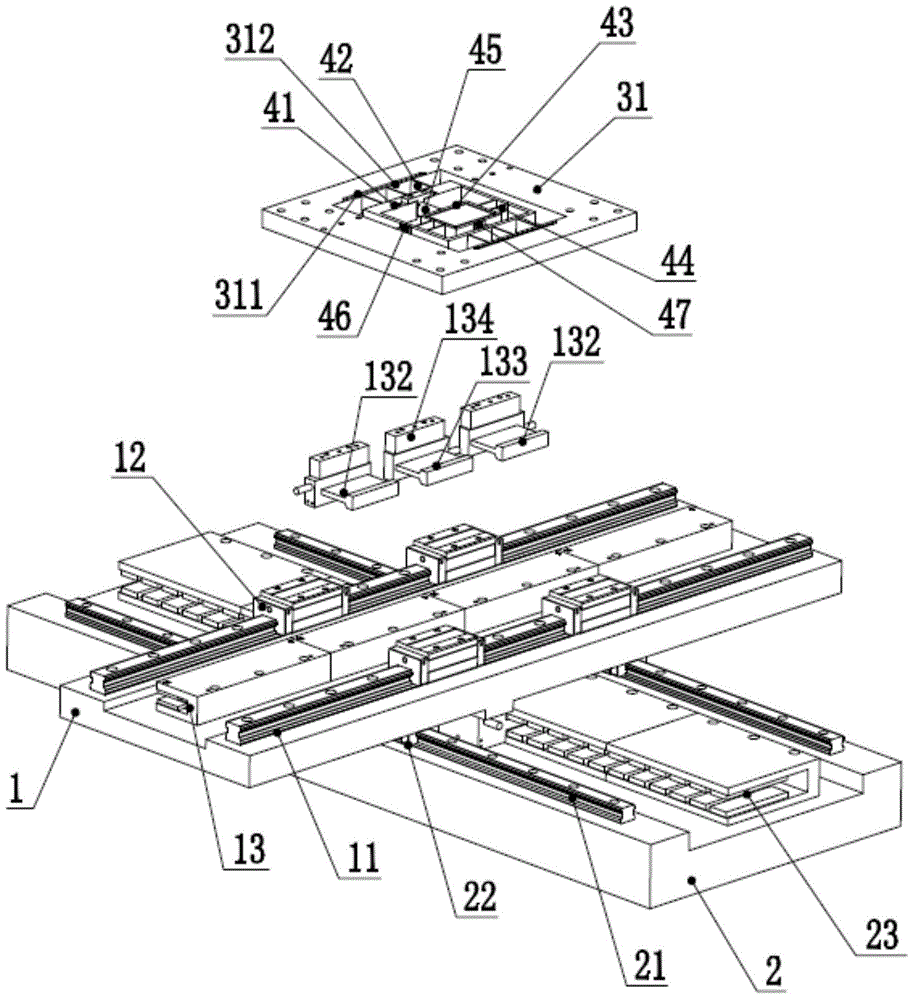

[0028] Such as figure 1 or figure 2 As shown, the linear motor common stator multi-drive macro-micro integrated high-speed precision motion two-dimensional platform includes X-direction base 1, Y-direction base 2 and integrated platform 3;

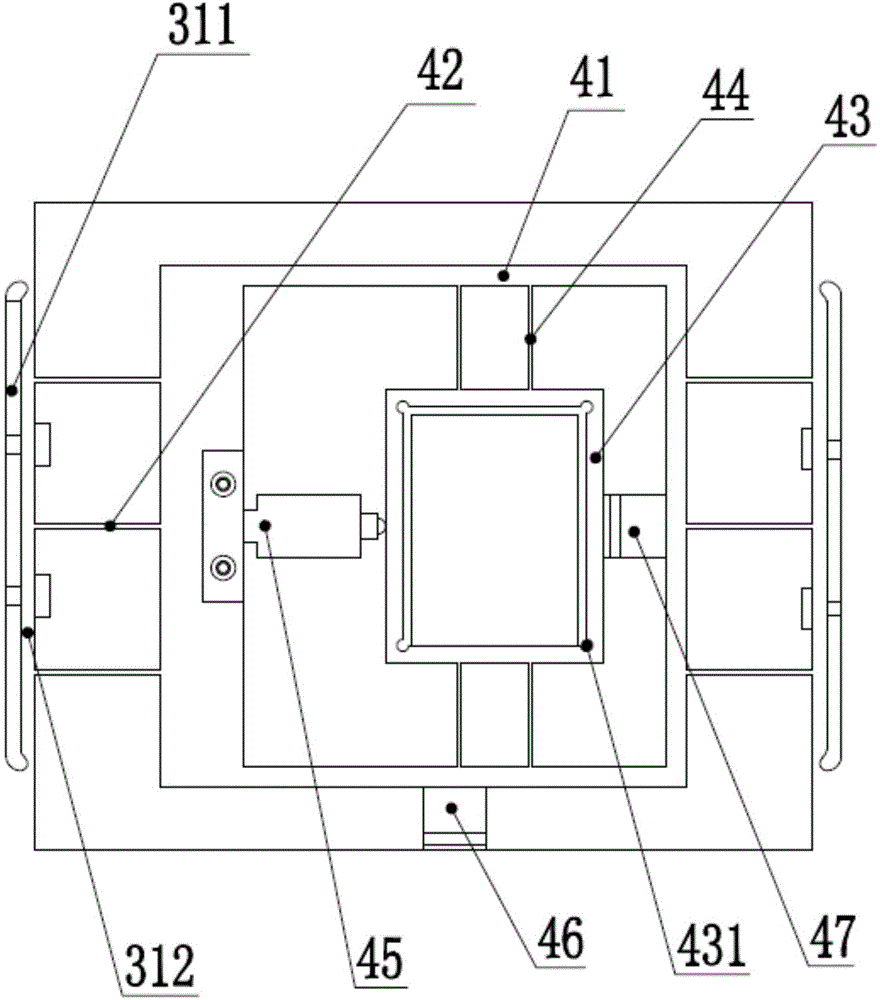

[0029] The integrated platform 3 includes a macro-moving outer frame 31 and a micro-moving platform 4, such as image 3 As shown, the micro-motion platform 4 includes an X-direction micro-platform 41, an X-direction shrapnel group 42, a Y-direction micro-platform 43, a Y-direction shrapnel group 44 and a Y-direction micro-drive 45, and the elastic X-direction shrapnel group 42 It is arranged on both sides of the X-direction micro-platform 41, one end of which is connected to the inner wall of the macro-motion outer frame 31, and the other end is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com