MEMS (Micro Electro Mechanical System) thermal acoustic particle vibration velocity sensor with sound field enhanced microstructure and method

A vibration velocity sensor and microstructure technology, which is applied to the measurement of ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of measurement result error, complicated assembly process, unavoidable reflection and scattering of the sound field to be measured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

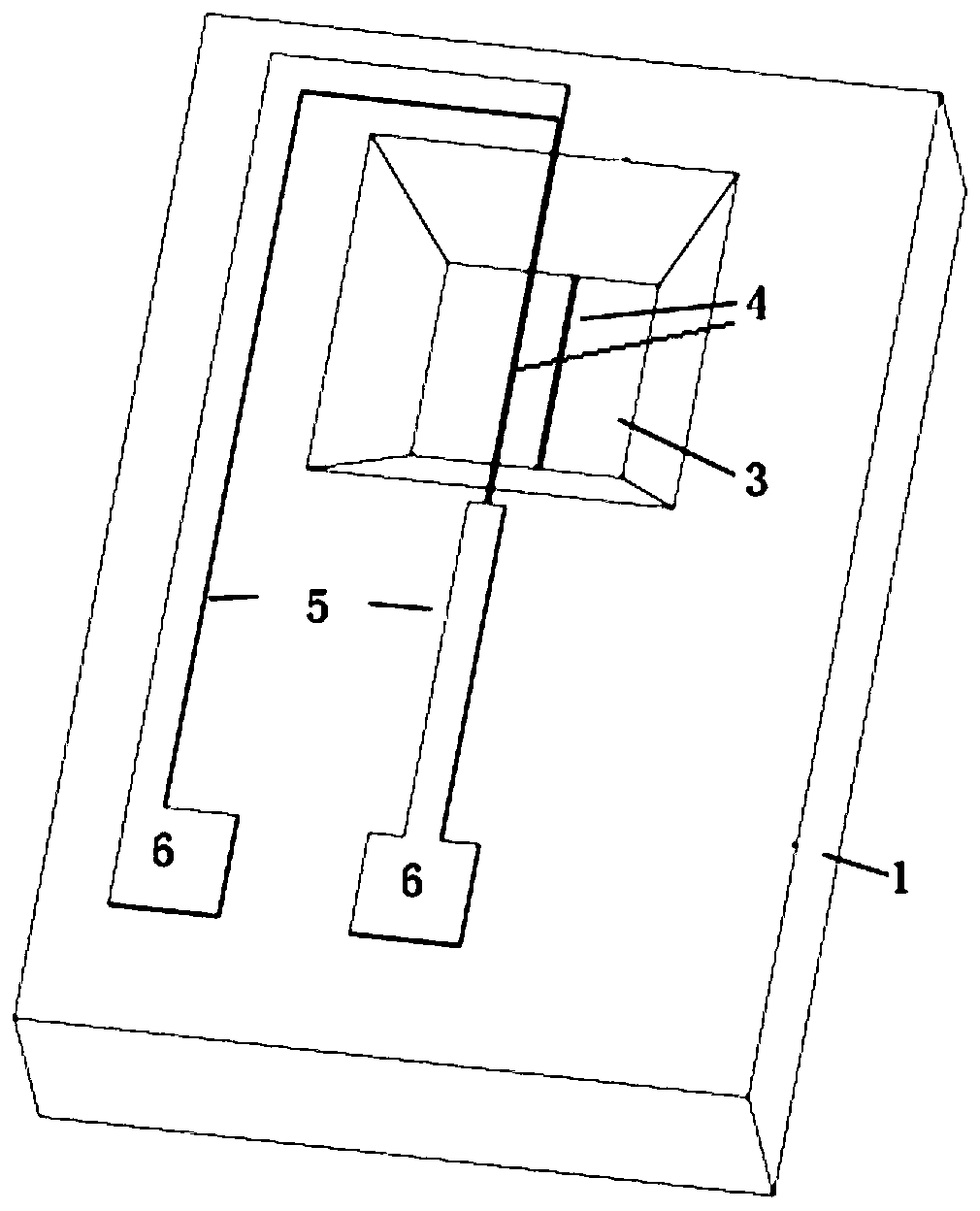

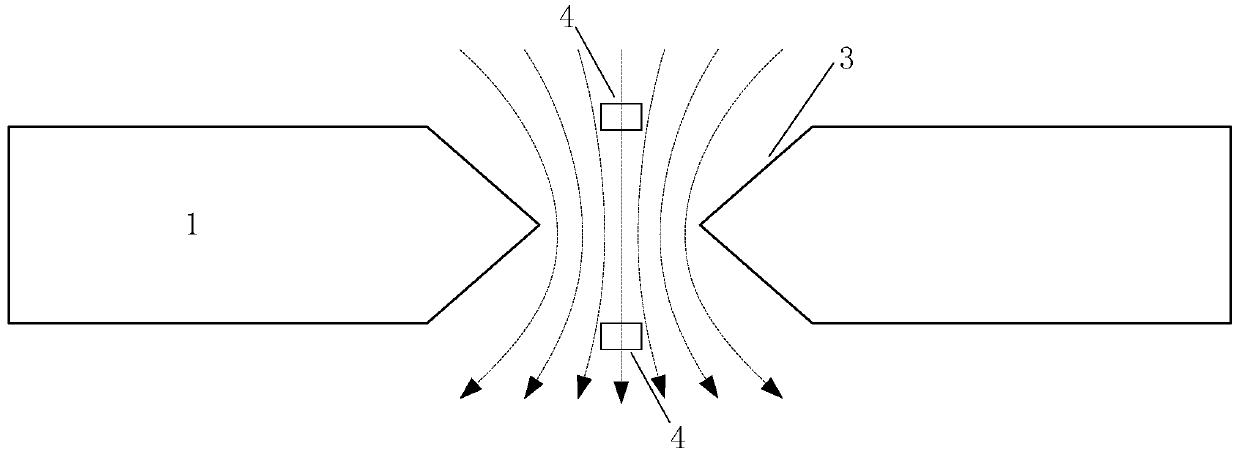

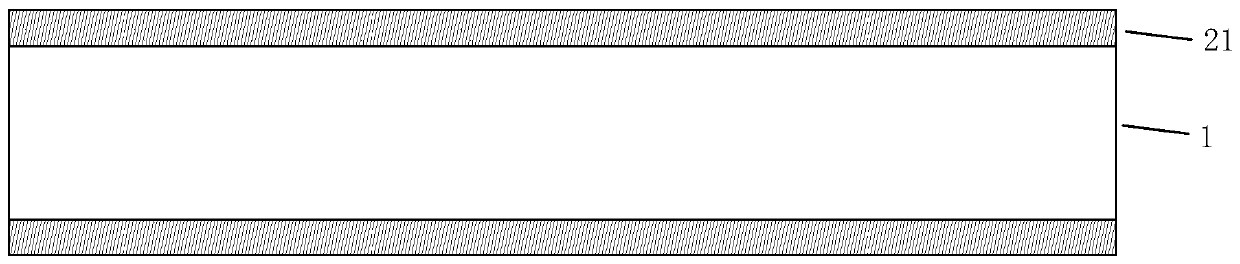

[0050] Such as figure 1 As shown, the acoustic probe of the MEMS thermal acoustic particle vibration velocity sensor based on the on-chip integrated sound field self-enhancing microstructure of the present embodiment includes: a substrate 1, an insulating layer, a sound field self-enhancing through hole 3, and a heating temperature measuring beam 4 , lead wire 5, electrode 6 and detection circuit; wherein, the upper surface and the lower surface of the substrate are respectively covered with an insulating layer to form a sandwich structure; the sound field self-enhancement through hole penetrating the upper and lower surfaces of the sandwich structure is opened on the sandwich structure, and the sound field is self-enhancement The through hole is in the shape of a bell mouth that is relatively connected, that is, it is symmetrical about th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com