Patents

Literature

85 results about "Acoustic vector sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

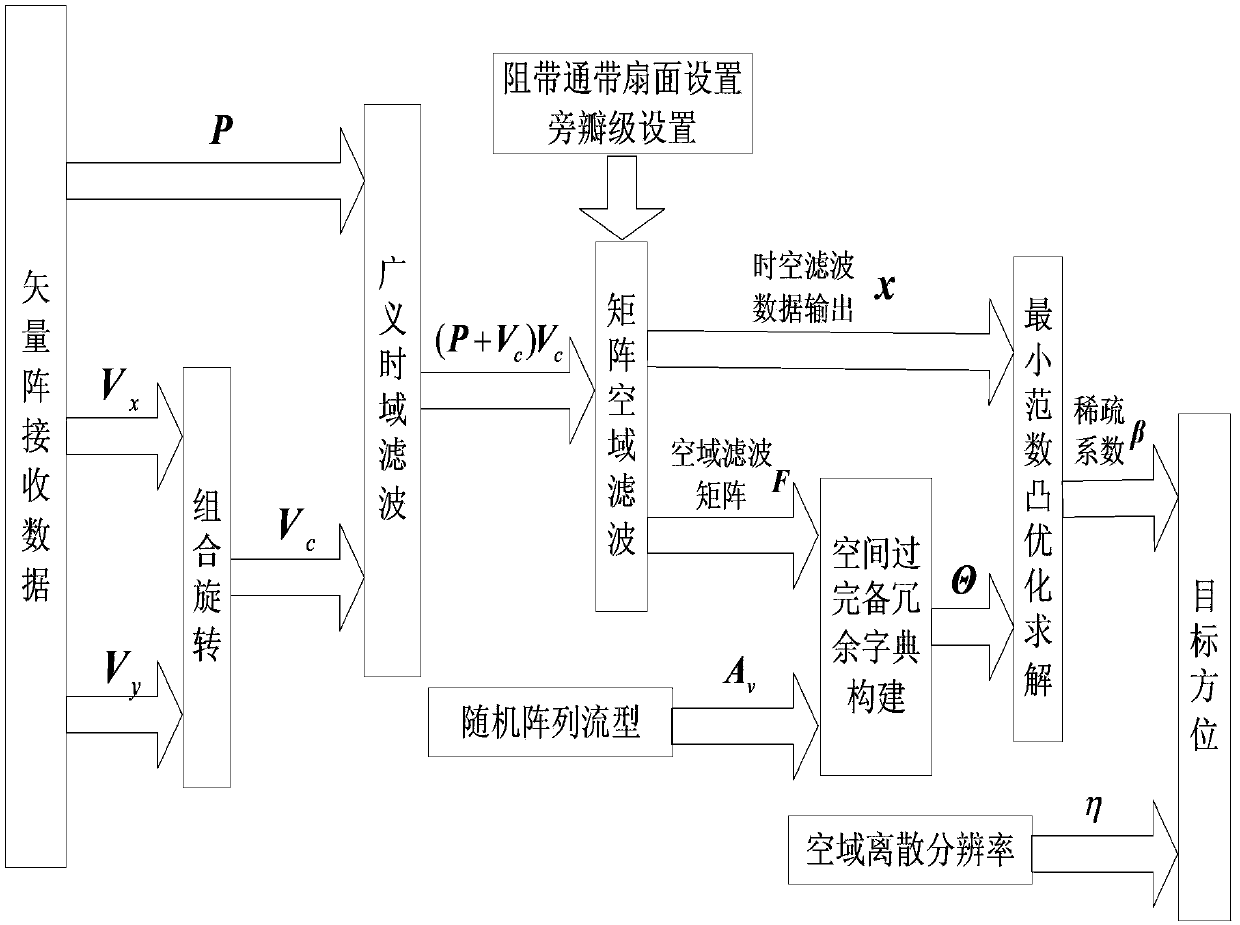

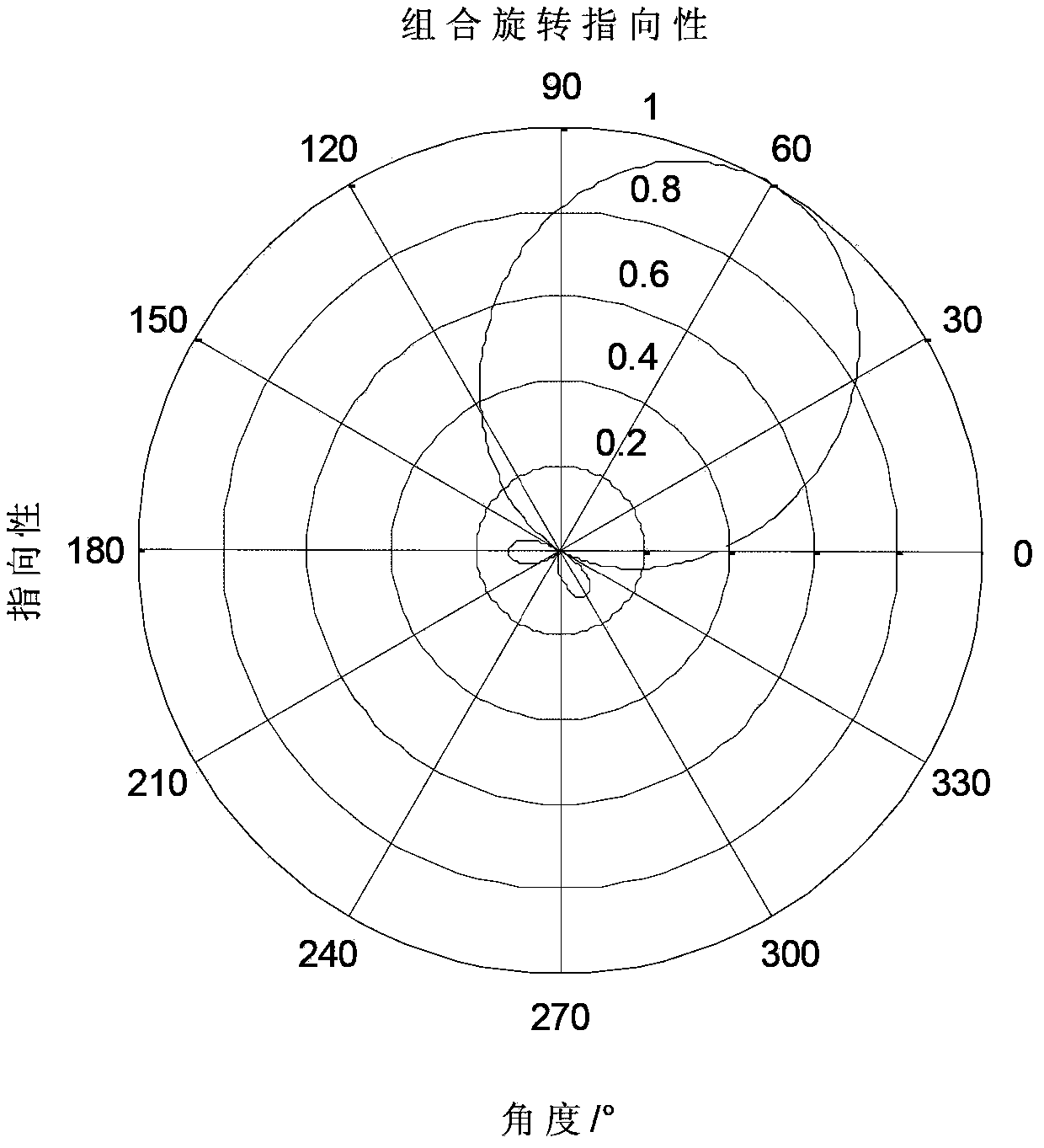

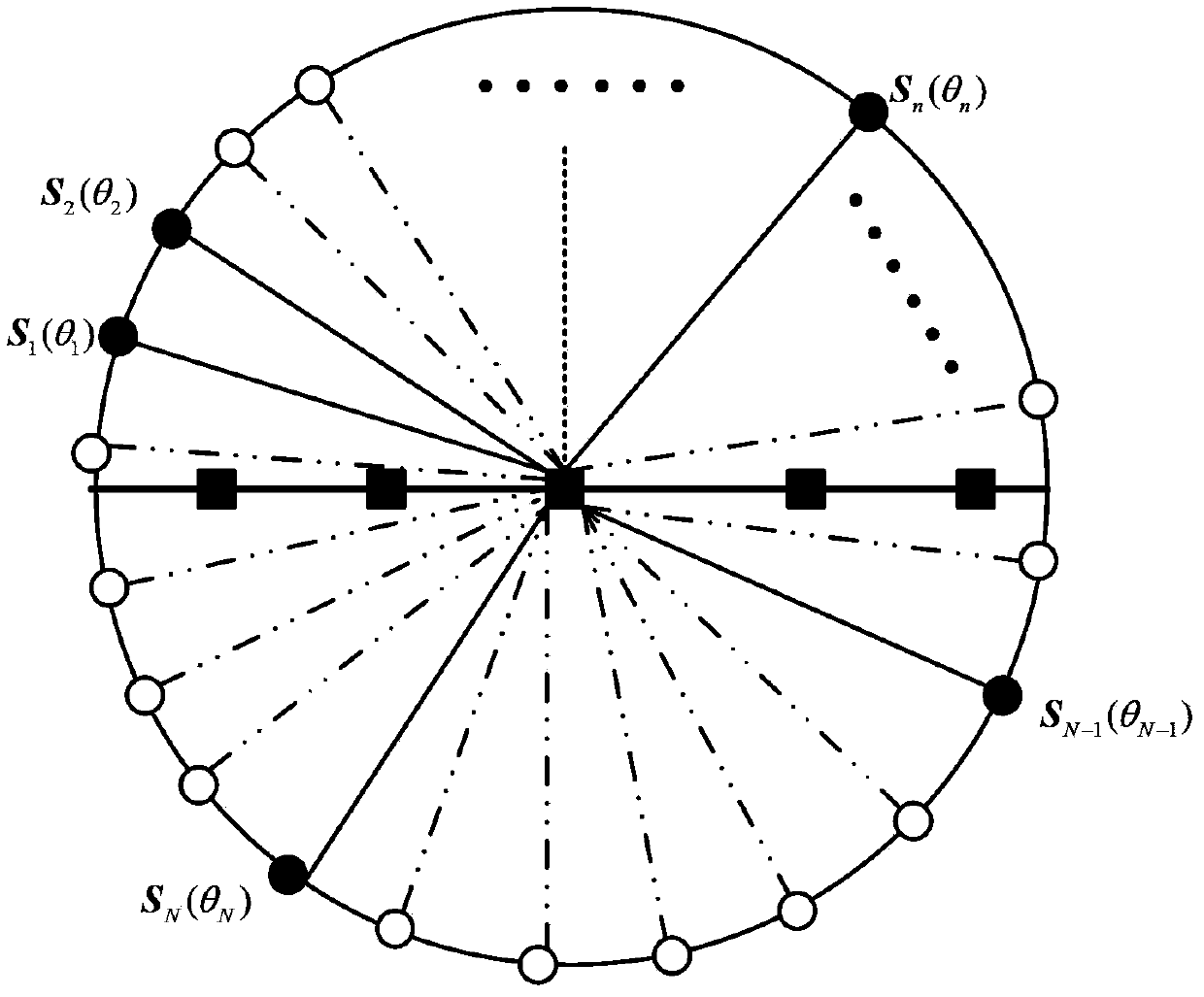

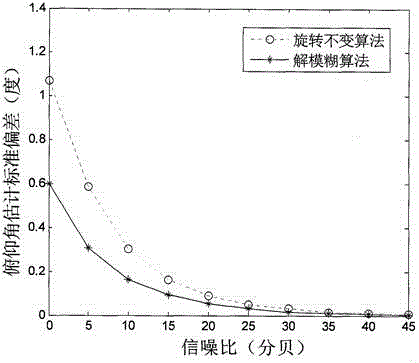

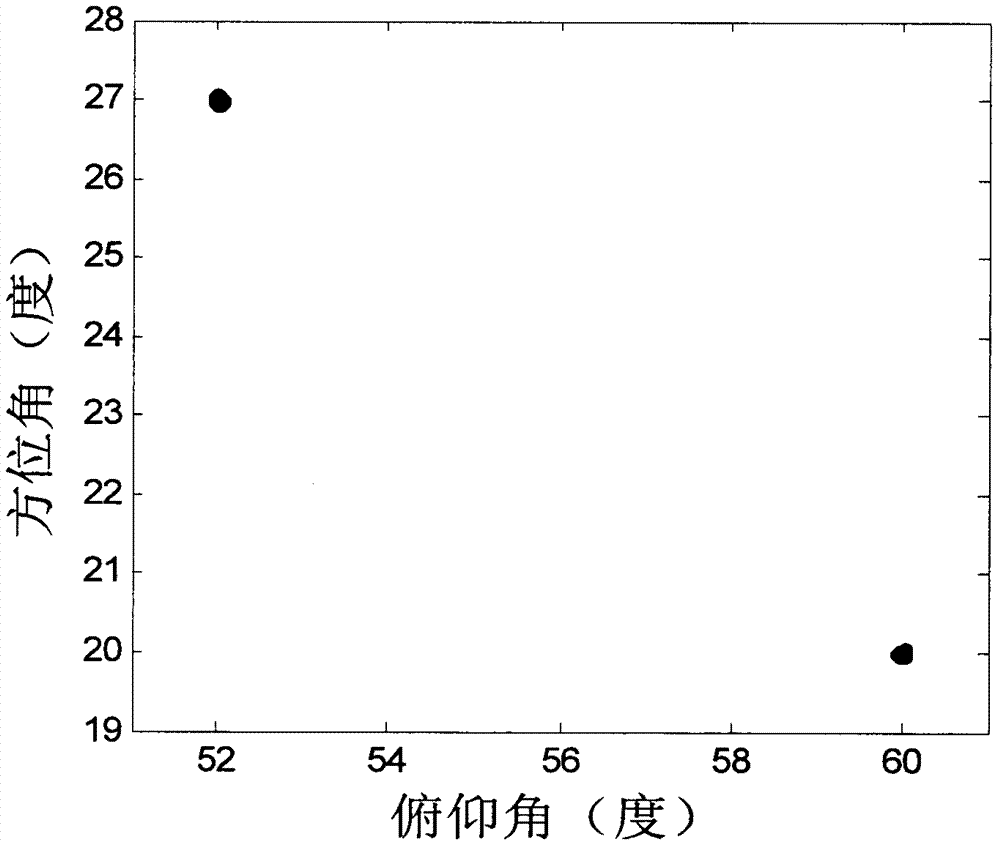

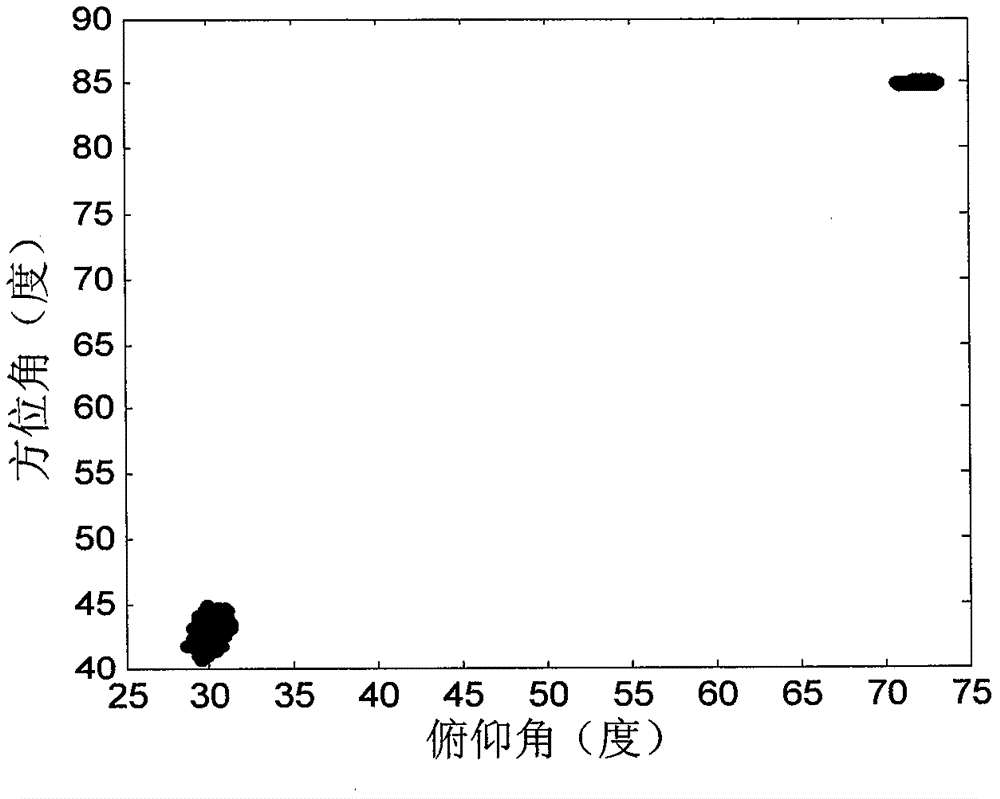

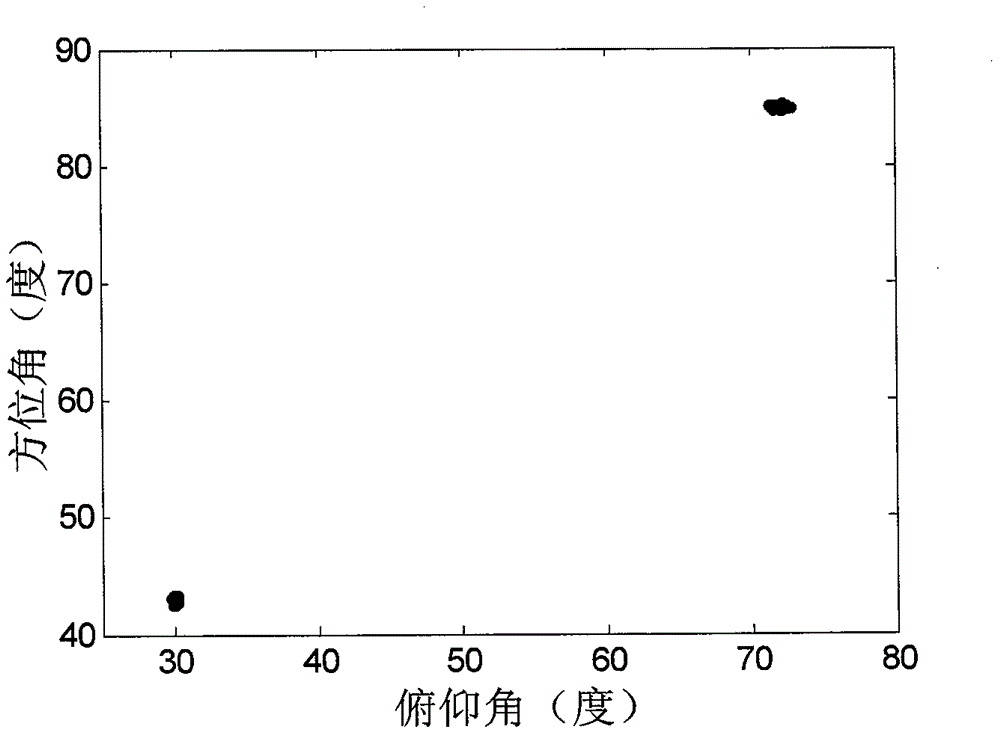

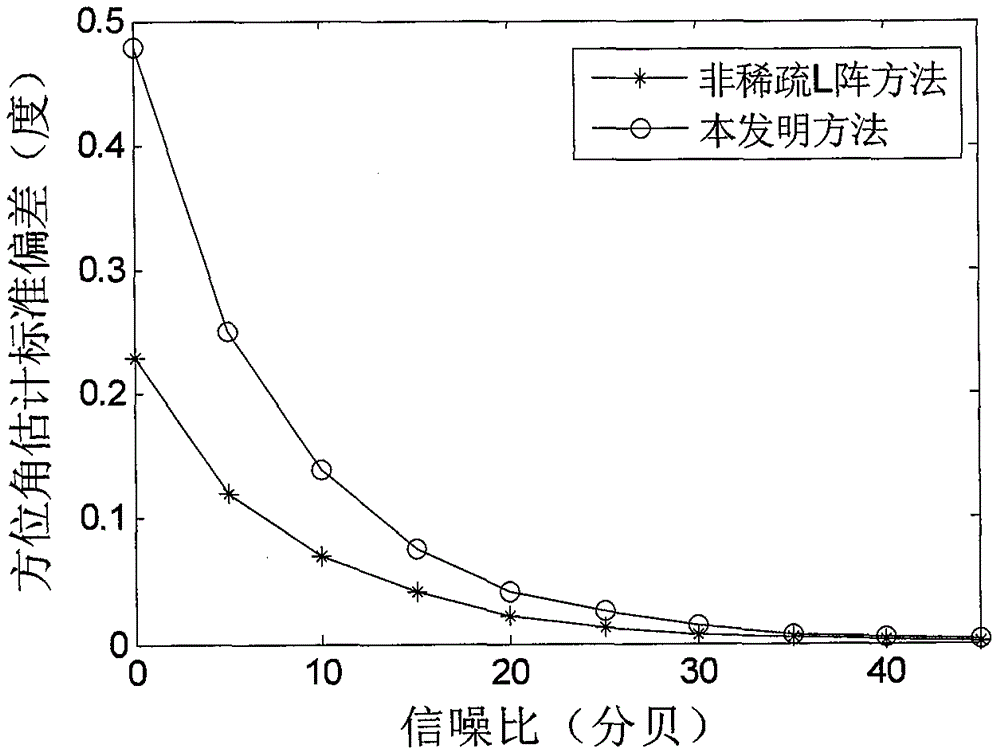

Temporal-spatial joint filtering high-resolution DOA (Direction of Arrival) estimation method based on compressed sensing technology

InactiveCN103399312ALower the input SNR thresholdEffective estimateWave based measurement systemsCompressed sensingNarrowband

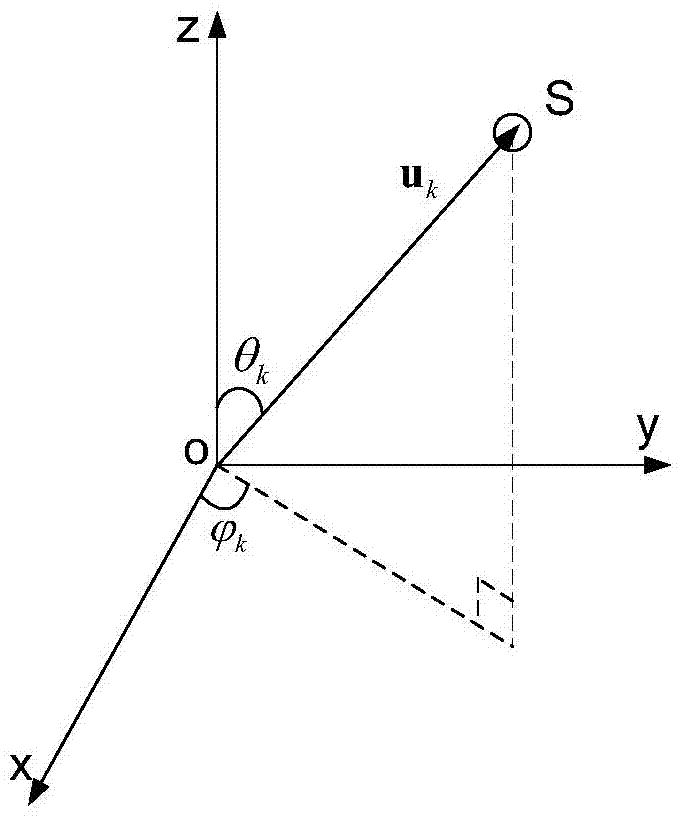

The invention provides a temporal-spatial joint filtering high-resolution DOA (Direction of Arrival) estimation method based on a compressed sensing technology. The method comprises the following steps: (1) acoustic pressure vibration velocity joint temporal filtering, to be specific, carrying out rotating combination on the data of an acoustic vector sensor, and utilizing differences in the corresponding properties of a signal and noise to carry out denoising processing; (2) matrix spatial filtering, to be specific, carrying out spatial filtering on the temporally filtered data by a matrix spatial filter of which the maximum value of the mean square error of attenuation in a stop-band and a passband is minimum; and (3) compressed sensing DOA estimation by the array of the acoustic vector sensor, to be specific, receiving data and a manually formed spatial over-complete redundance dictionary via an input array preprocessed by temporal filtering, and seeking the sparse representation of the signal to carry out vector spatial spectrum estimation. The method has great spectral resolution capability in the high-resolution DOA estimation problem of a high-speed motion target under single snapshot conditions and is insensitive to the wideband and narrowband properties and coherent properties of the signal.

Owner:HARBIN ENG UNIV

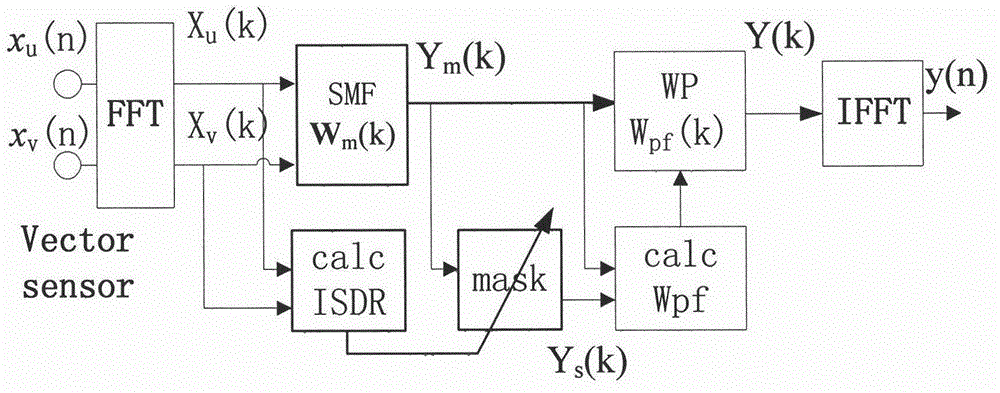

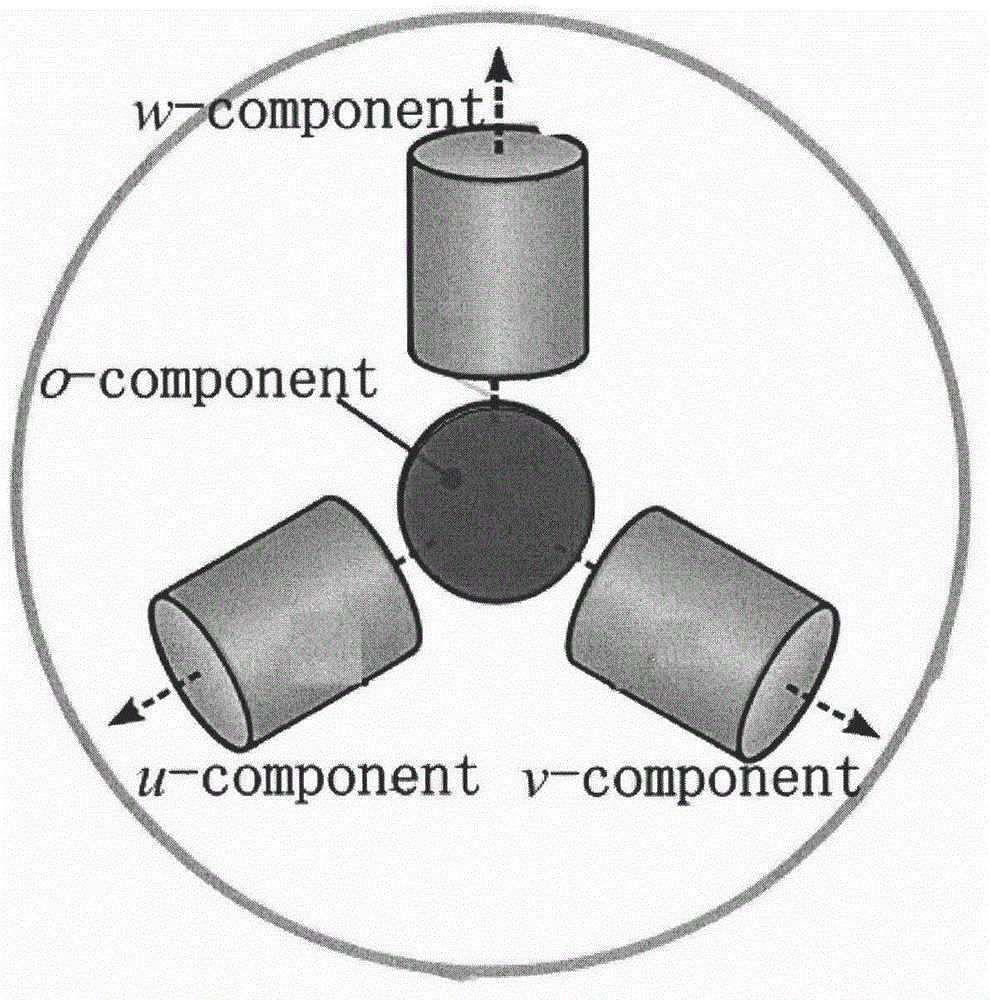

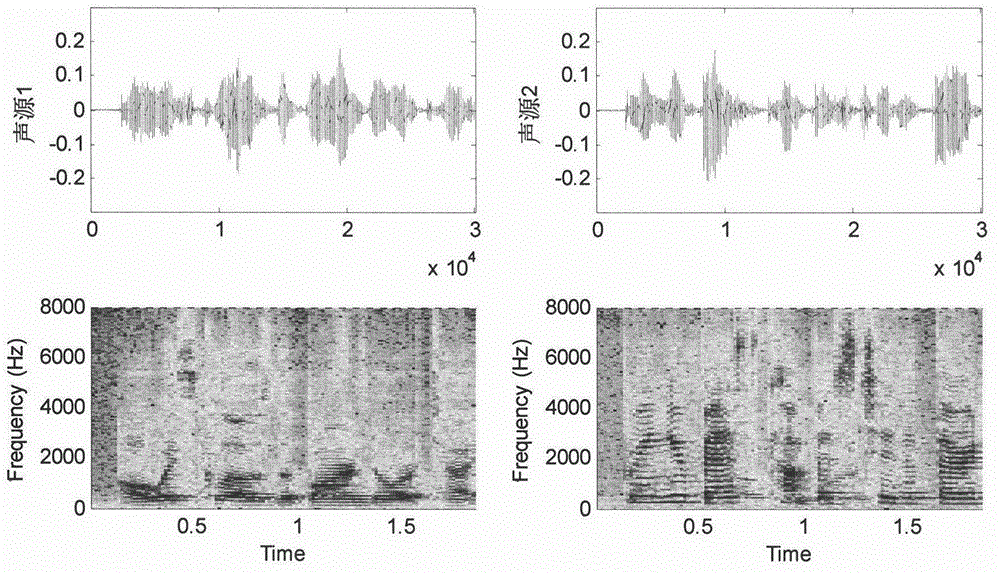

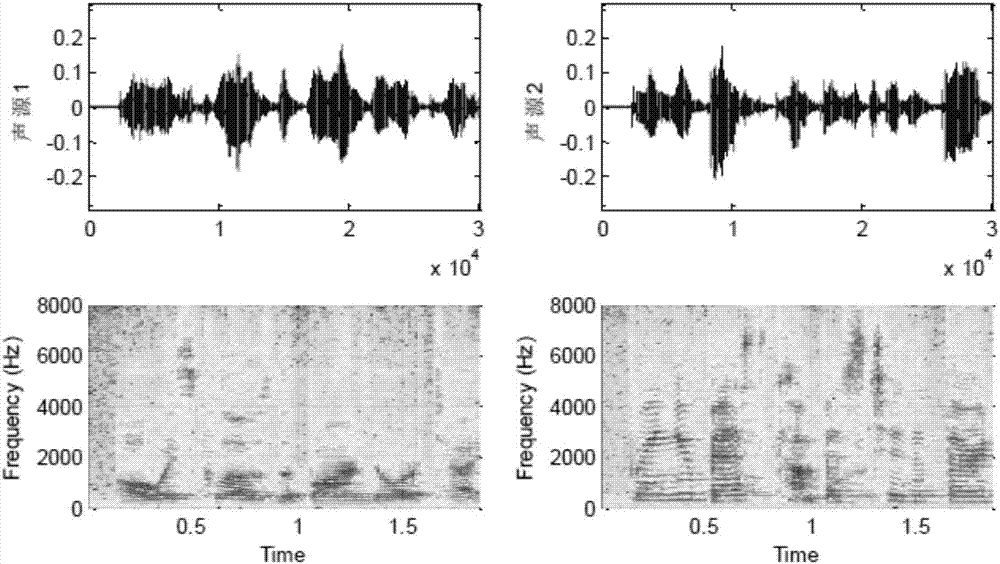

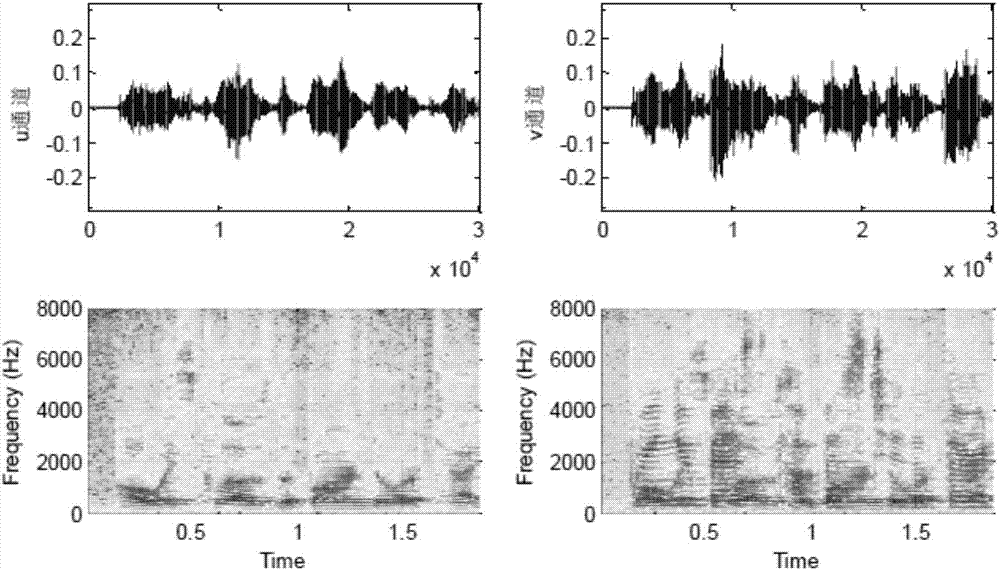

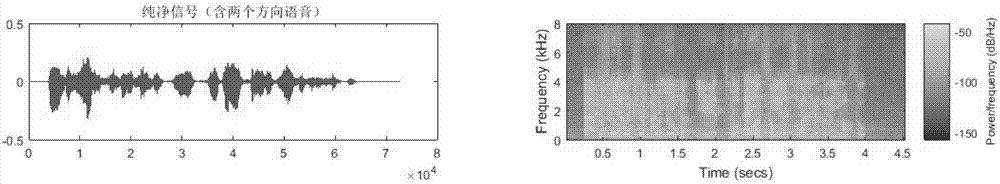

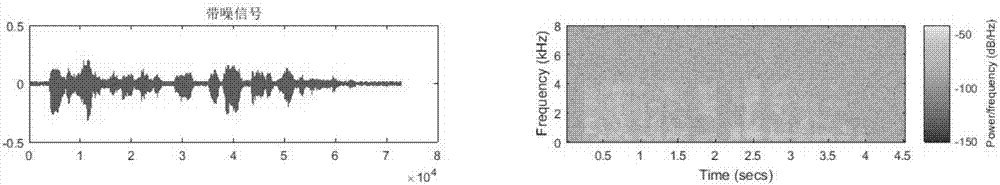

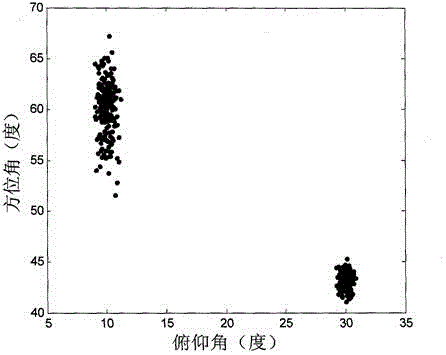

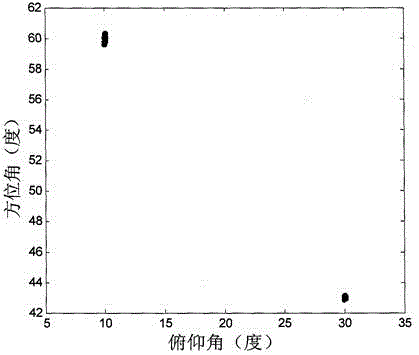

Time frequency mask-based single acoustic vector sensor (AVS) target voice enhancement method

ActiveCN104103277AReduce complexityTarget Direction Speech EnhancementSpeech analysisPoint correlationAcoustic vector sensor

The invention relates to a time frequency mask-based single acoustic vector sensor (AVS) target voice enhancement method. According to the method, the arrival angle of the target voice is known, a method of combining a fixed beam former and a post-positioned Wiener filter is adopted for realizing target voice enhancement, and calculation of the weight value of the post-positioned Wiener filter involves self-power spectrum estimation of the target voice. Time frequency sparse characteristics of a voice signal are used, the time frequency point correlation arrival angle for receiving audio signals is estimated through calculating the ISDR (Inter-sensor data ratio) of component signals outputted by two gradient sensors in the AVS, time frequency mask is designed through calculating errors between the time frequency point correlation arrival angle and a target arrival angle, and thus self-power spectrum estimation of the target voice is acquired. According to the method of the invention, any noise prior knowledge does not needed, the target voice can be effectively enhanced in a complicated environment where multiple speakers exist, and interference voice can background noise can be suppressed. In addition, the operation complexity is low, the adopted microphone array size is small (about 1cm<3>), and application on a portable device is excessively facilitated.

Owner:SHENZHEN HIAN SPEECH SCI & TECH CO LTD

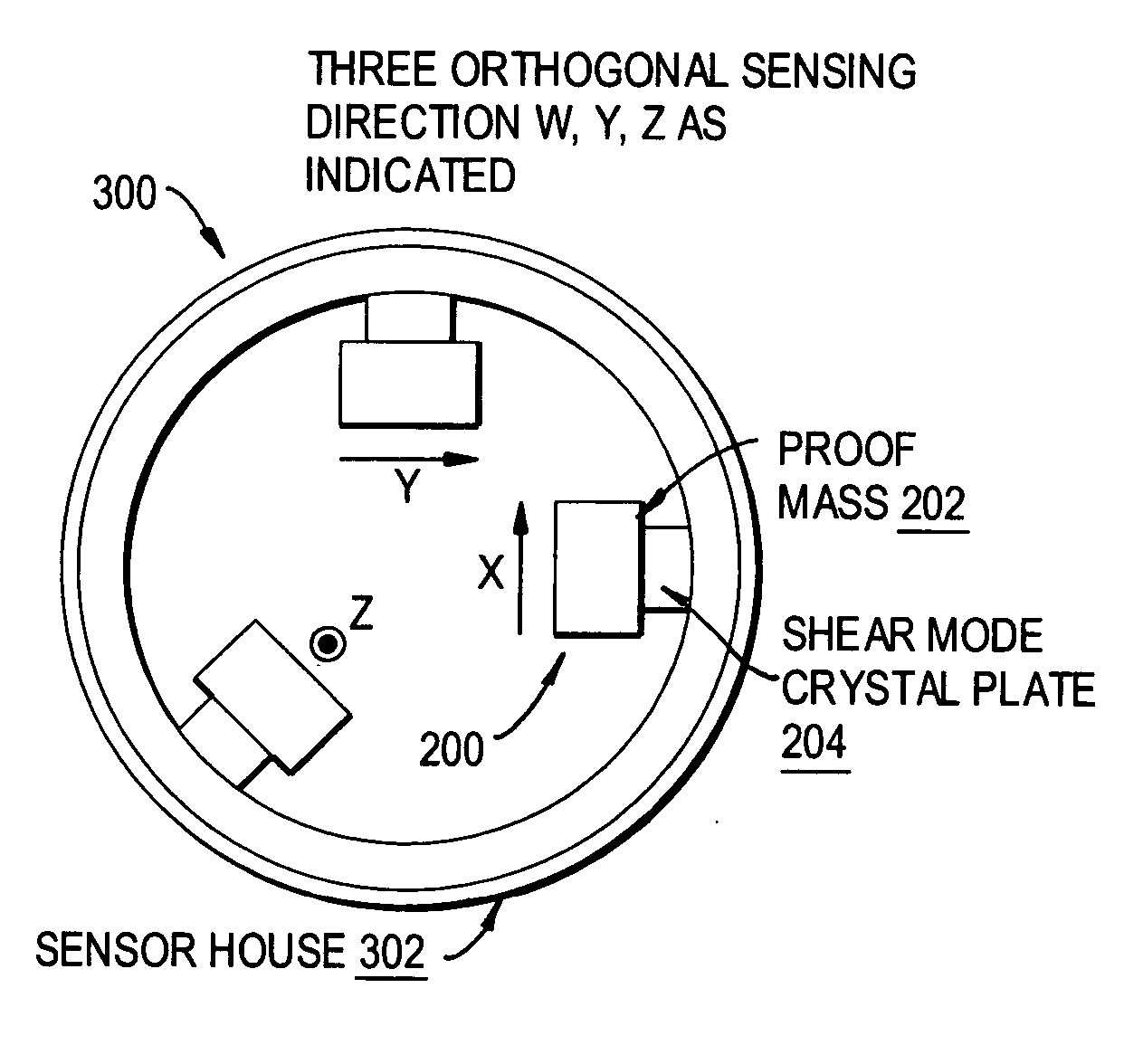

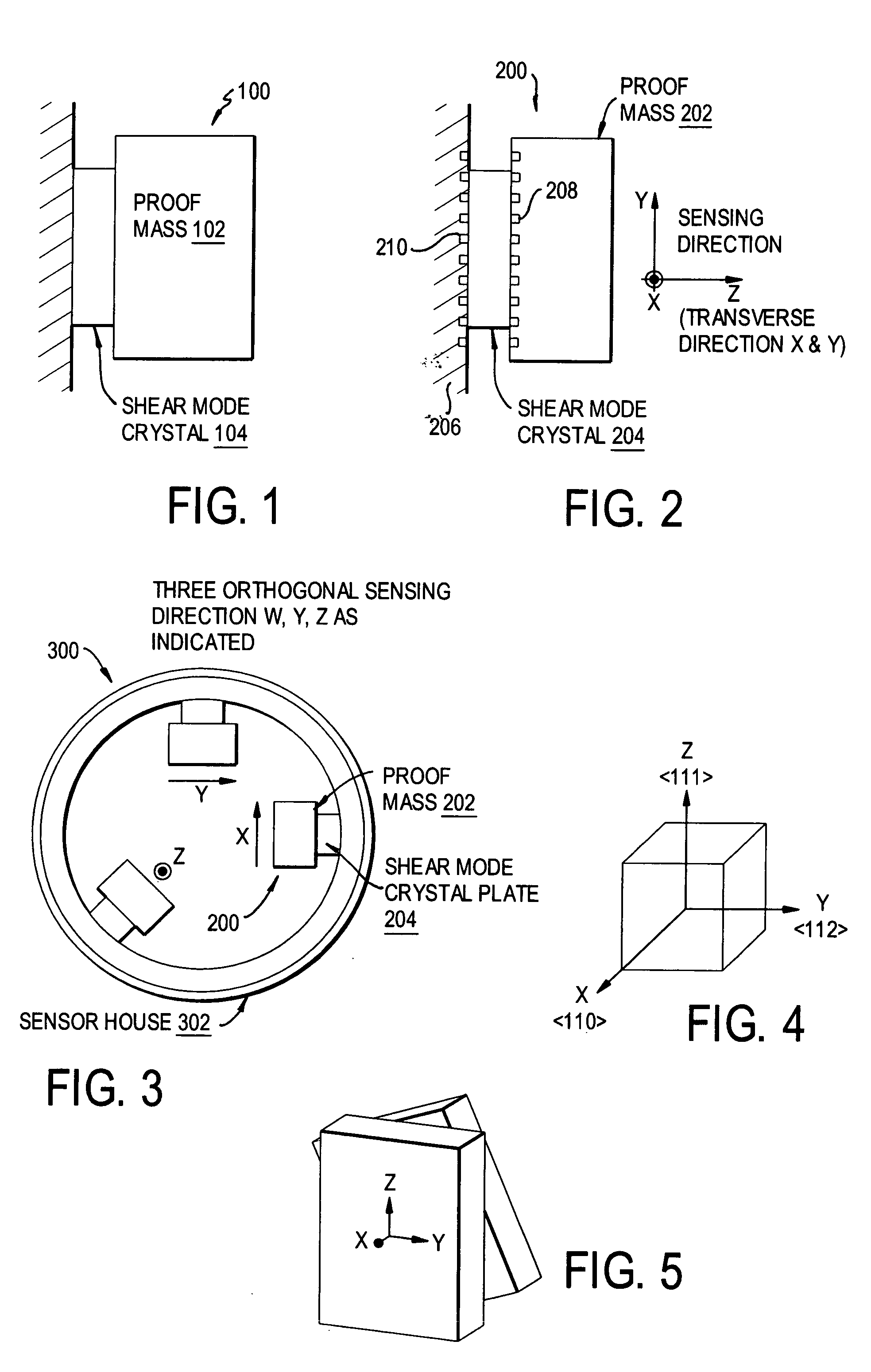

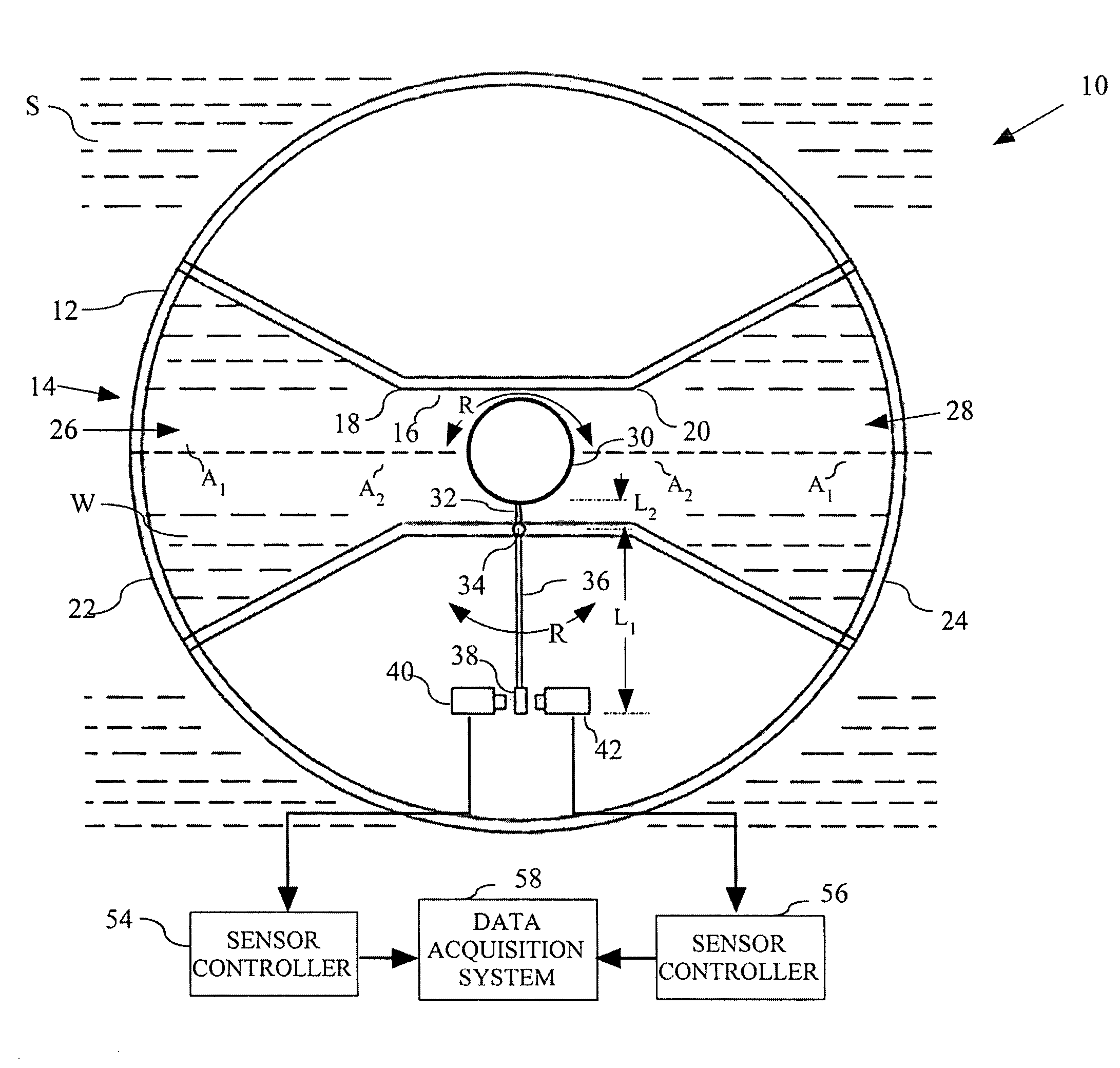

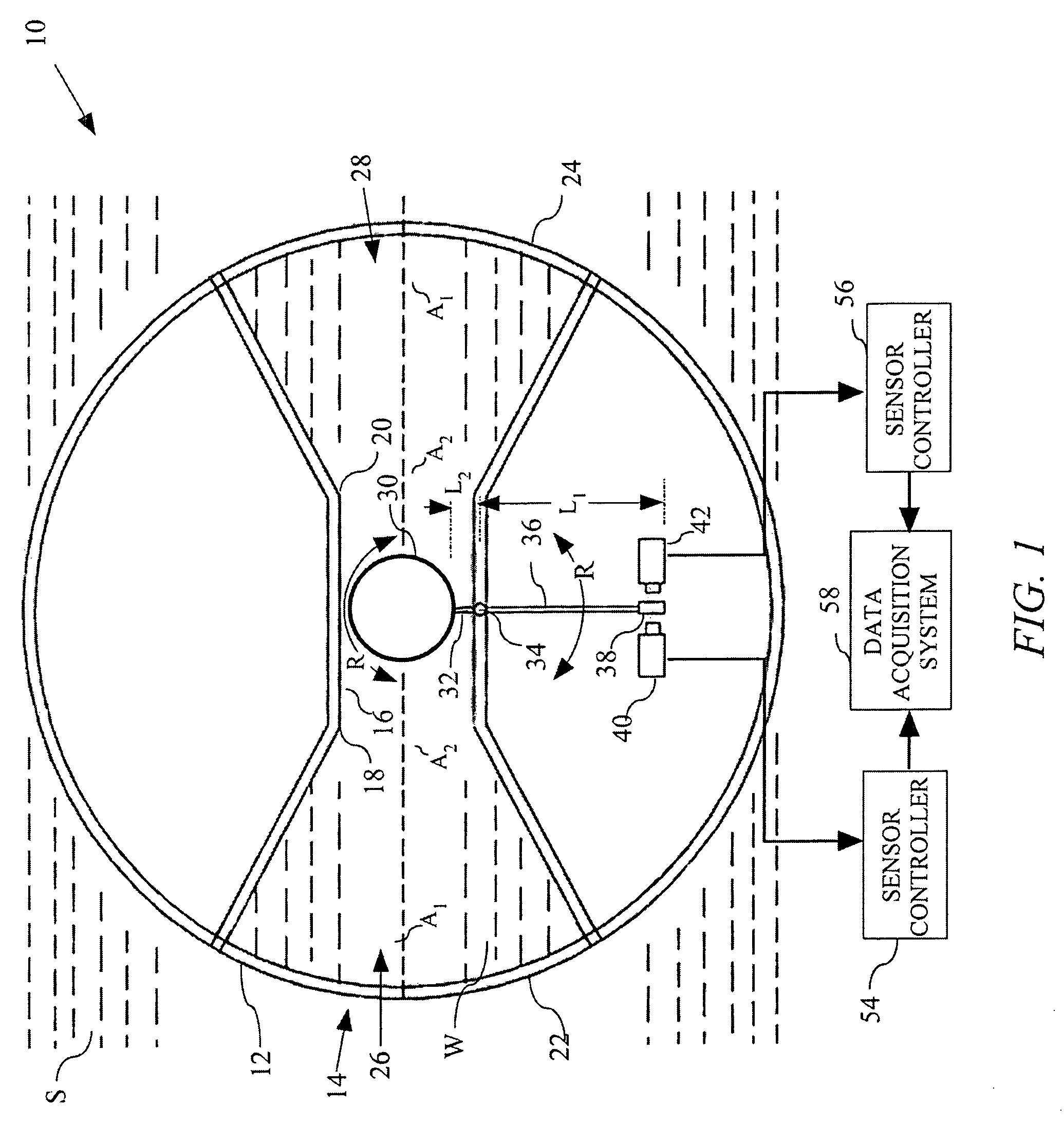

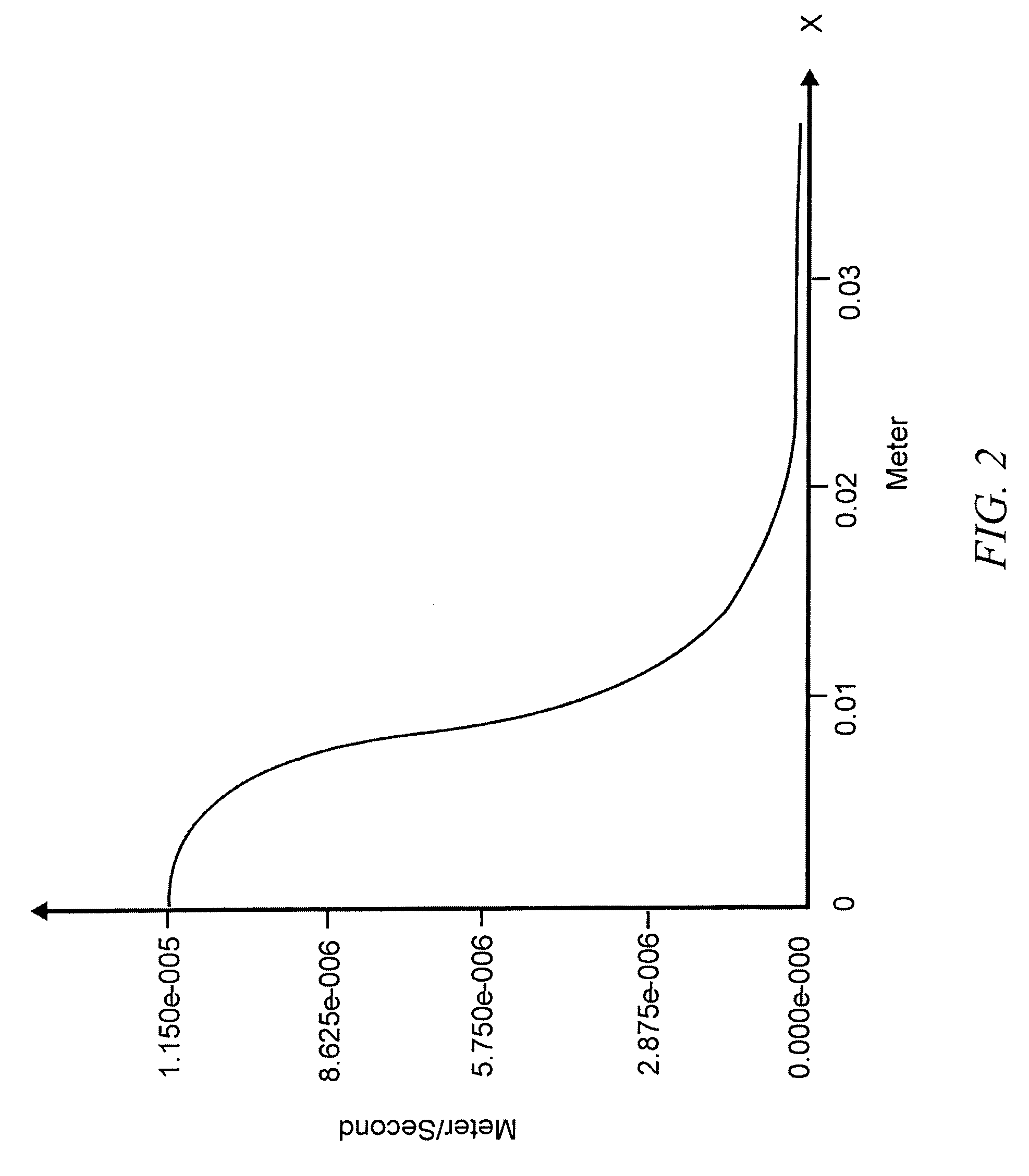

Acoustic vector sensor

InactiveUS20050034519A1Improve noise levelNarrow bandwidthAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesElectricityAcoustic energy

The present invention is directed to an acoustic vector sensor, specifically an underwater acoustic vector sensor. The acoustic vector sensor contains three piezoelectric sensors orthogonally mounted inside a rigid housing, where each of the piezoelectric sensors measures acoustic energy from one of the three different, orthogonal, axial directions (X, Y, and Z). The piezoelectric sensor contains a proof mass, a base, and a piezoelectric crystal sandwiched therebetween. The bonding surfaces of the proof mass and the base are preferably castellated; and the piezoelectric crystal is preferably a shear mode (d15) relaxor single crystal.

Owner:AMPHENOL MARYLAND INC

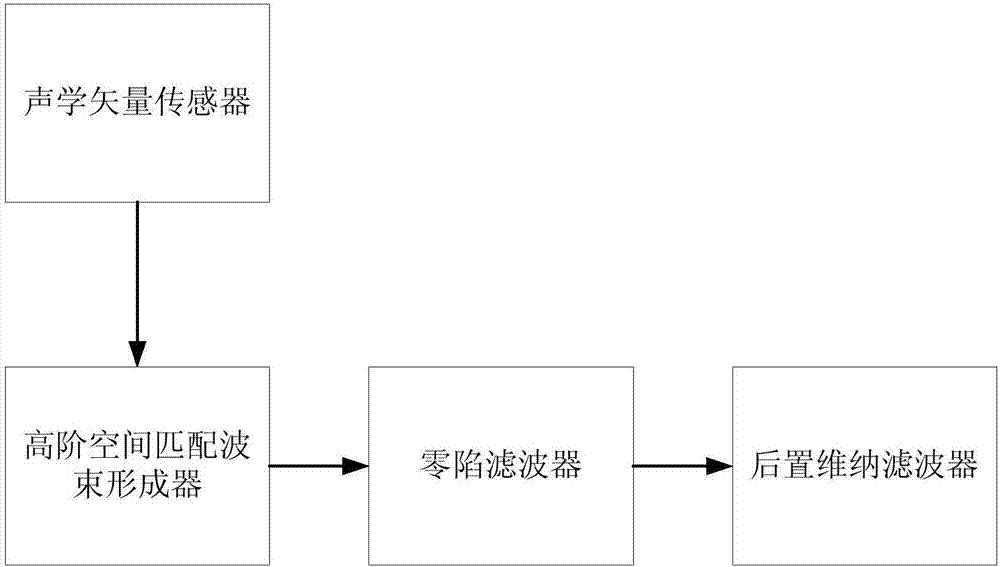

Target voice enhancement device and method

ActiveCN107221336AReduce complexityEnhance target voiceSpeech analysisComputation complexitySound sources

The invention relates to a target voice enhancement device. The device comprises an acoustic vector sensor used for acquiring an audio signal, a high-order space matching wave beam former, a nulling filter and a back Wiener filter, wherein wave beam processing on the audio signal acquired by the acoustic vector sensor is carried out through the high-order space matching wave beam former, the nulling filter and the back Wiener filter which are sequentially connected, and enhancement of a target direction voice is realized. The invention further provides a target voice enhancement method. According to the method, the sound source orientation information can be effectively utilized to inhibit a space interference source and background noise, the target direction voice can be enhanced, distortion of the target voice after enhancement is small, and a hearing perception evaluation score is relatively high. The device is advantaged in that the device has relatively low calculation complexity and has application and popularization values on micro equipment.

Owner:SHENZHEN HIAN SPEECH SCI & TECH CO LTD

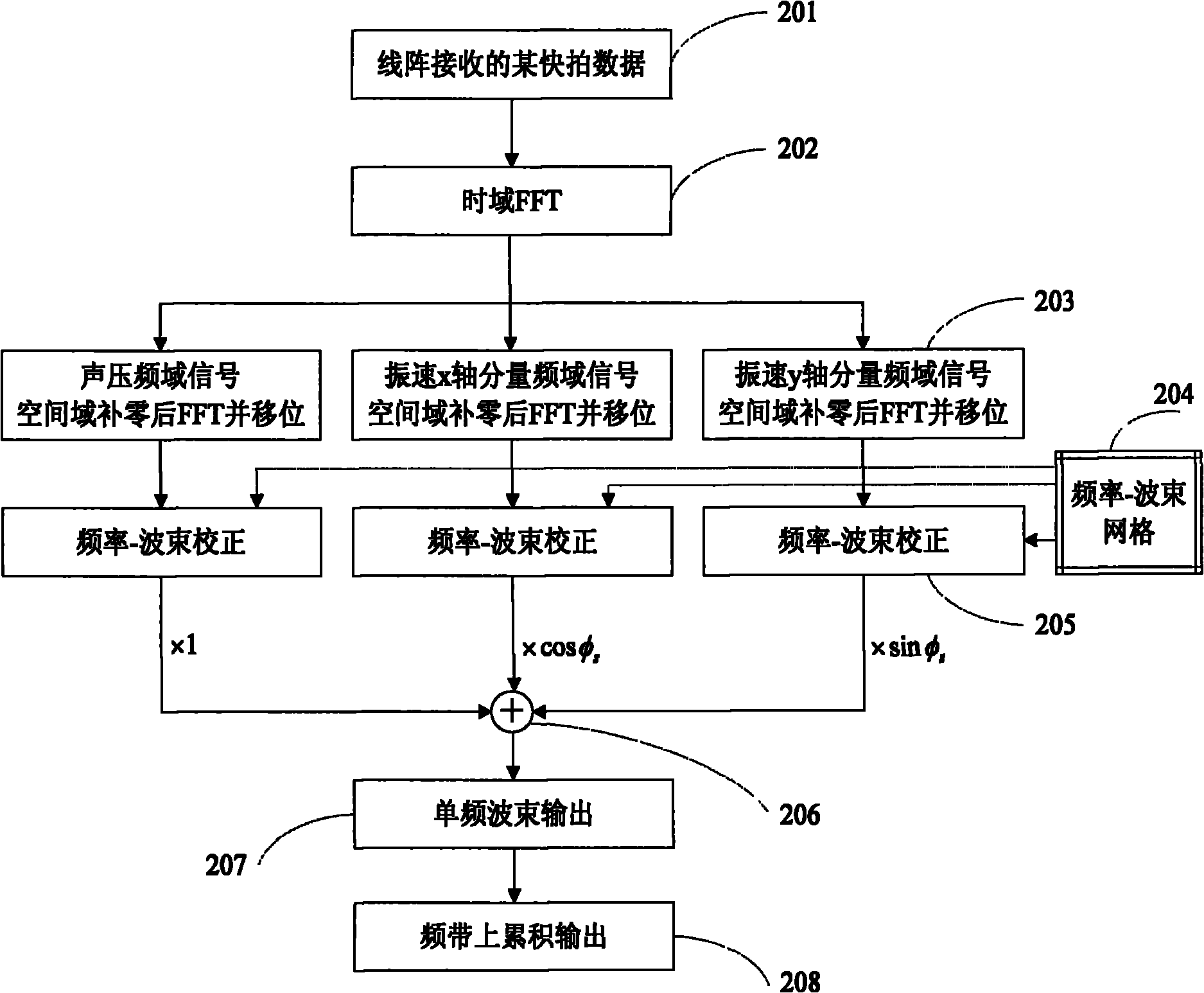

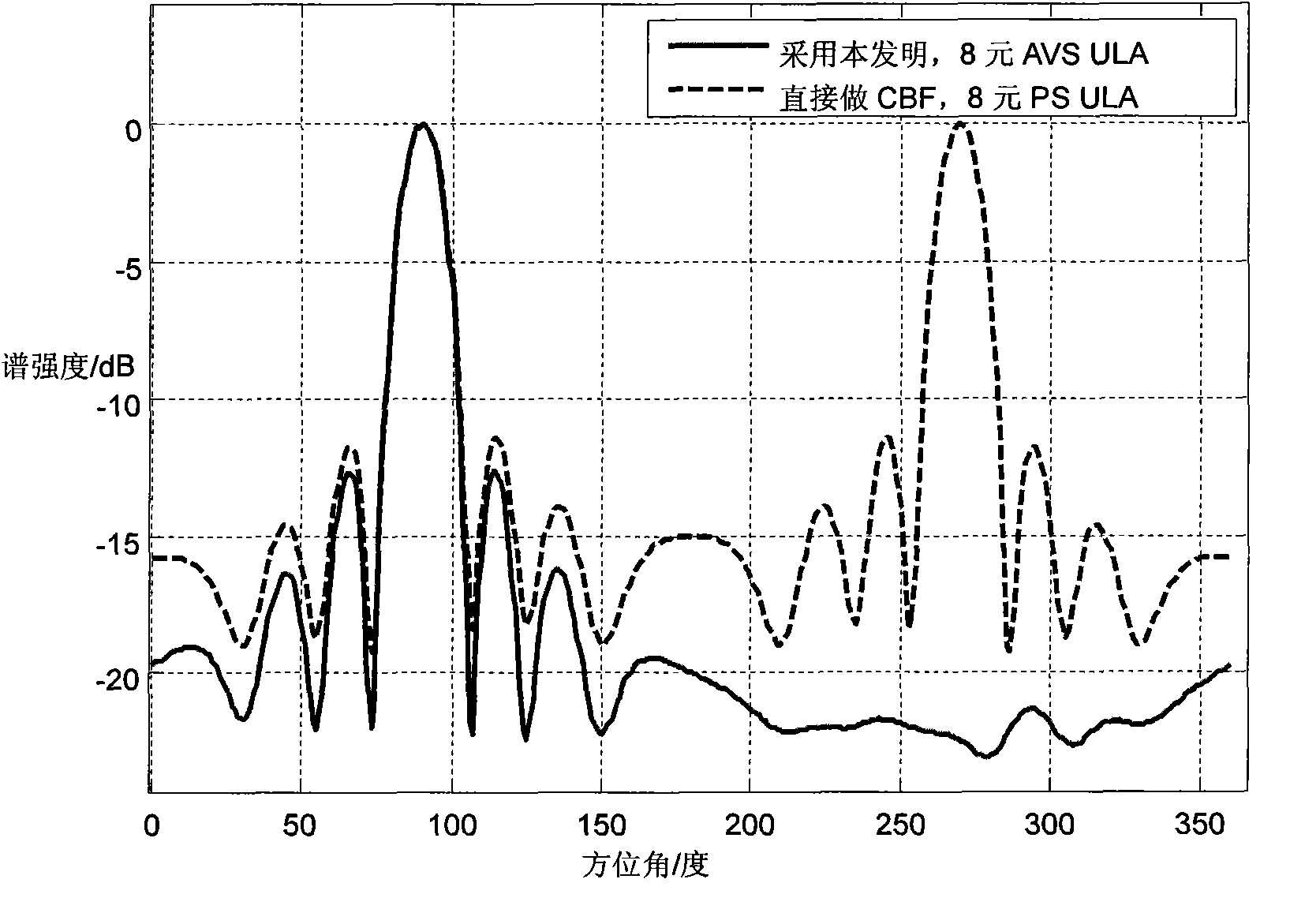

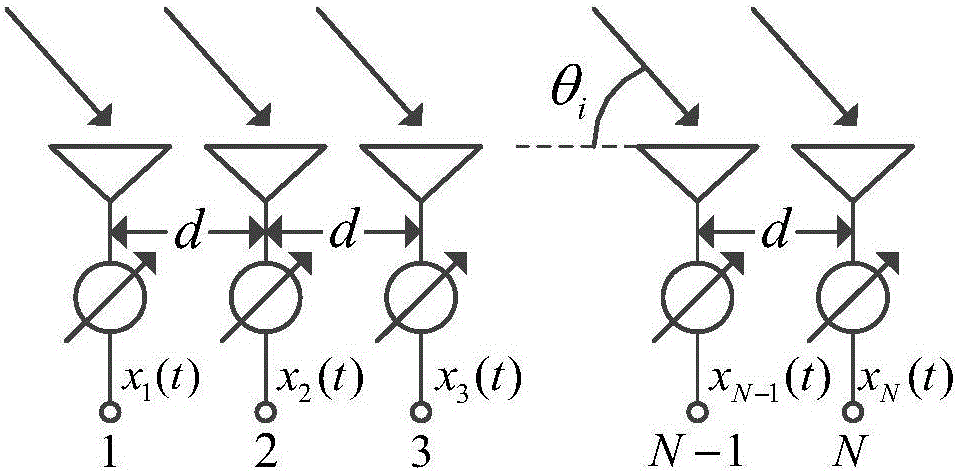

Rapid broadband frequency domain beamforming method based on acoustic vector sensor uniform linear array

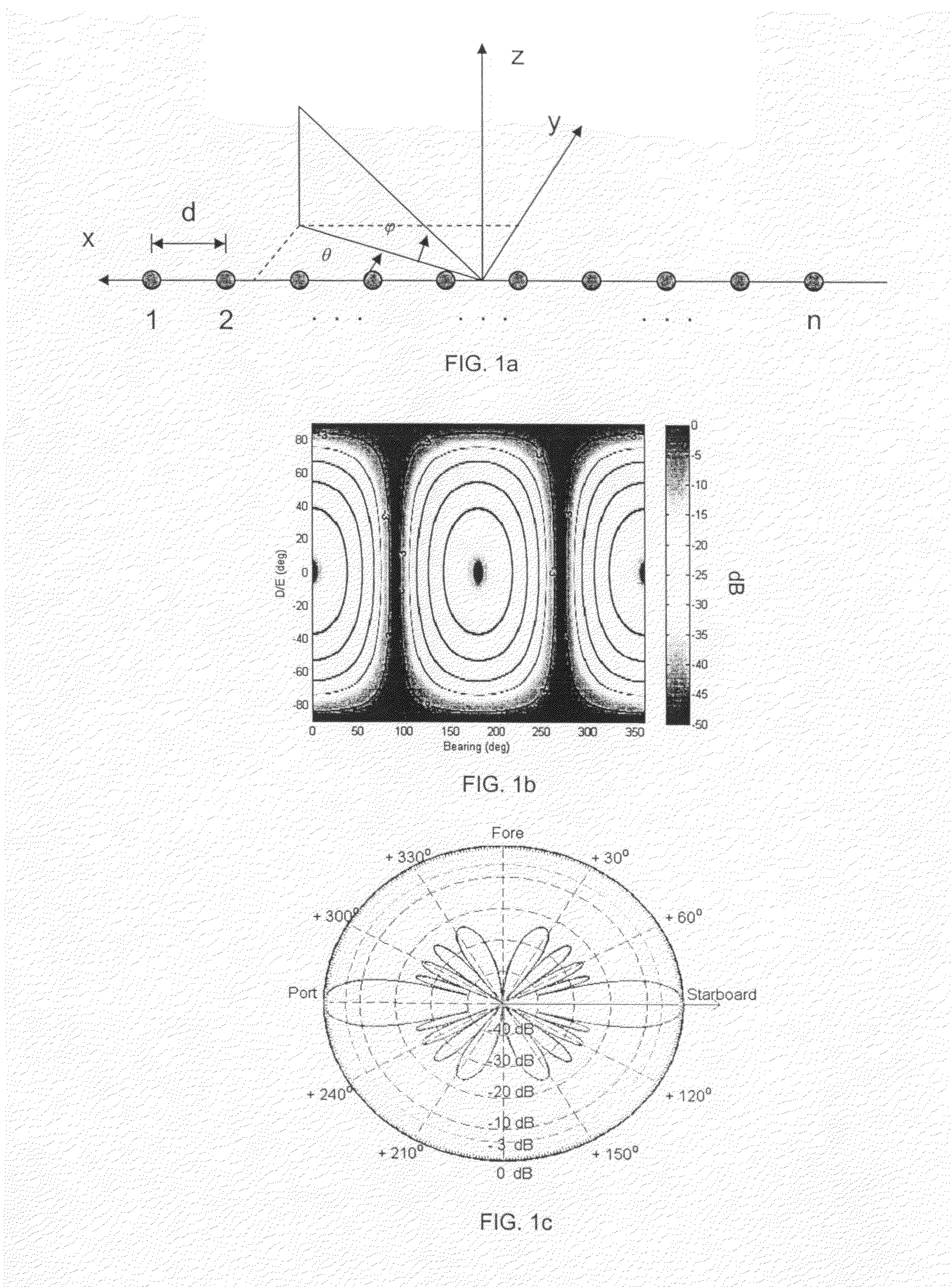

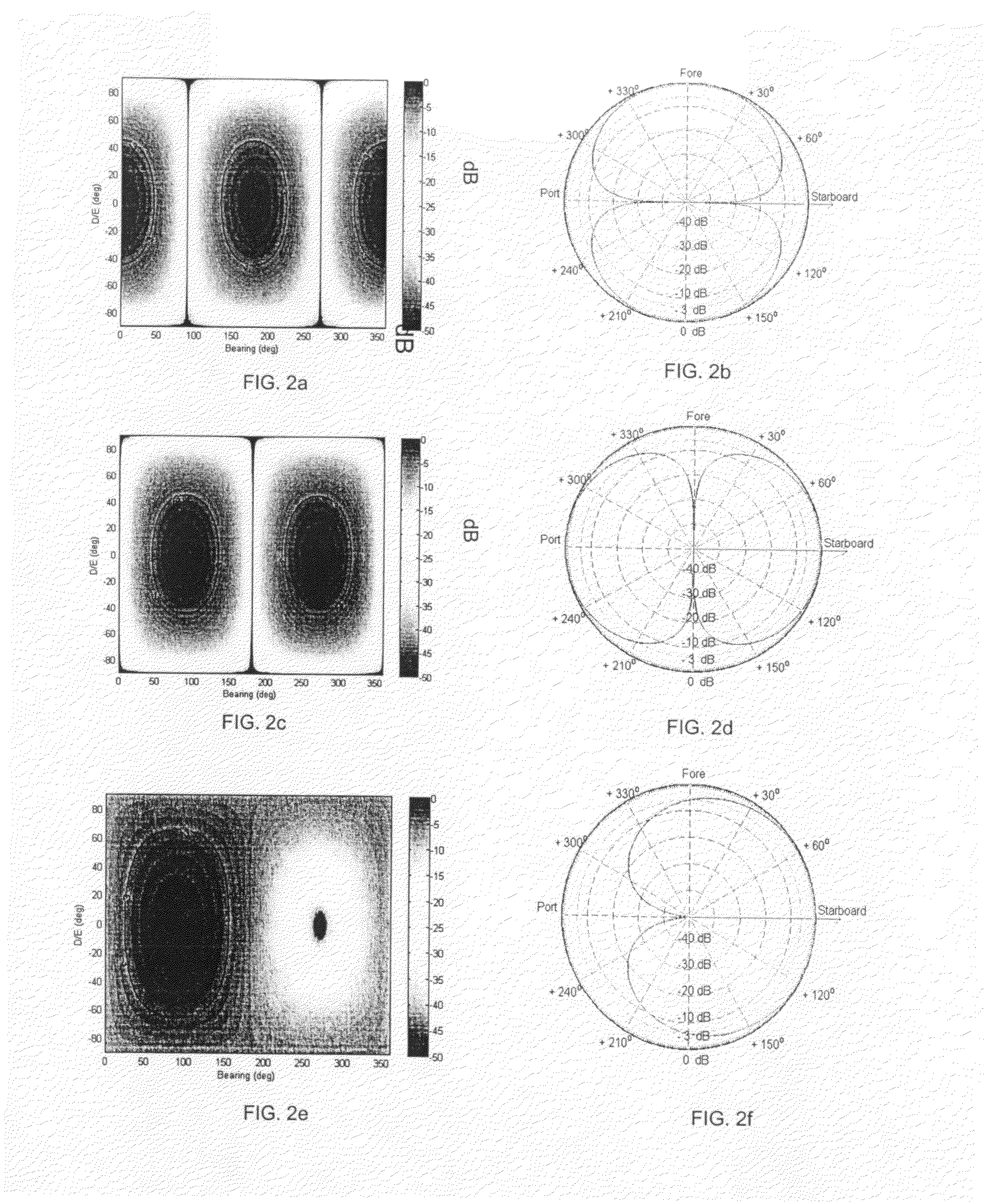

InactiveCN102043145AEasy to detectImprove robustnessWave based measurement systemsFourier transform on finite groupsArray element

The invention relates to a rapid broadband frequency domain beamforming method based on an acoustic vector sensor uniform linear array. The method comprises the following steps of: firstly, receiving spatial signals through the acoustic vector sensor uniform linear array to obtain time domain signals of all array elements, wherein the time domain signals comprise time domain acoustic pressure signals and time domain vibration velocity signals, and performing Fourier transform on snapshot data needed to be processed so as to obtain a corresponding frequency domain signal; secondly, performing zero fill on the acoustic pressure signals and the vibration velocity signals of all the array elements in a space domain according to a frequency band range needed to be processed, performing fast Fourier transform (FFT) on the signals in the space domain, and transferring a zero frequency component of the transform result to a spectrum center; thirdly, performing alignment correction and corresponding linear addition on beam and space domain Fourier results at each frequency point of bandwidth needed to be processed according to a frequency-beam grid corresponding to the acoustic pressure signals and the vibration velocity signals so as to obtain beamforming results of different frequency points; and finally, synthesizing beamforming results of different frequencies to obtain power output of a linear array spatially.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

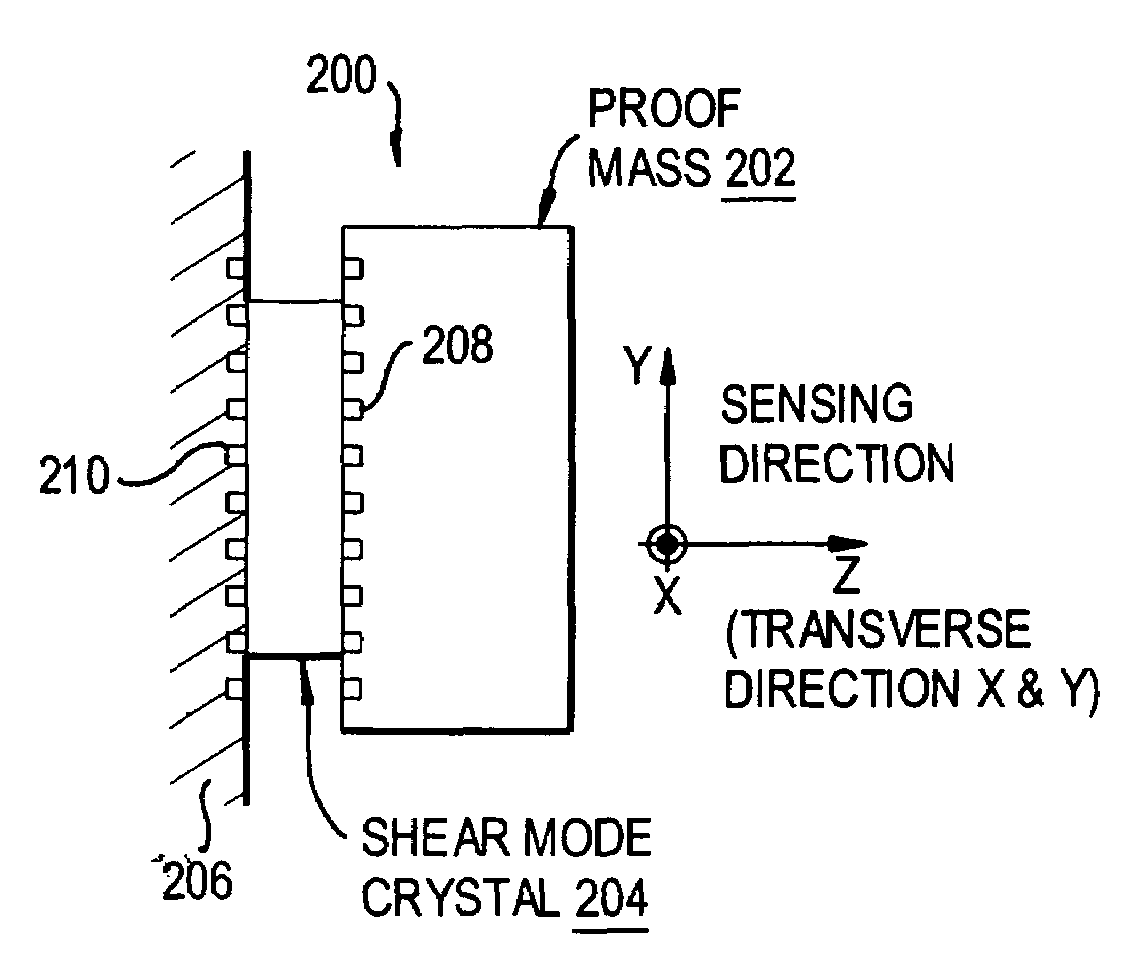

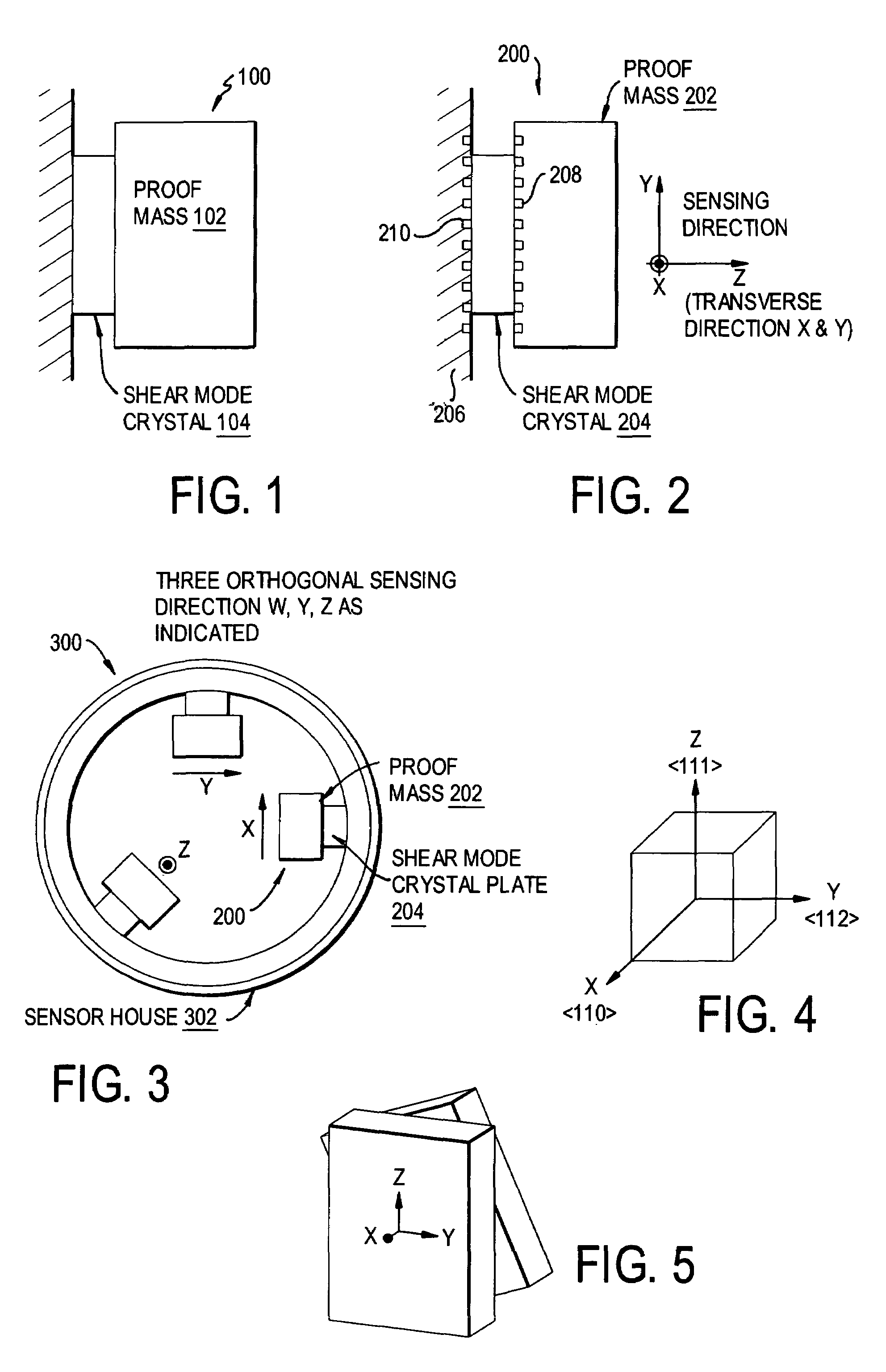

Underwater acoustic vector sensor using transverse-response free, shear mode, PMN-PT crystal

InactiveUS7066026B2Improve noise levelNarrow bandwidthAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesElectricityFree state

The present invention is directed to an acoustic vector sensor, also called particle velocity sensor. <111> direction poled, shear mode, relaxor single crystals are used as the sensing elements. In addition, these crystal plates are cut at a special orientation such that they provide zero or minimum responses in the transverse directions, but have a maximum piezoelectric response in sensing direction. The piezoelectric sensor contains a proof mass, a base, and an aforementioned relaxor crystal. Three of the sensors are mounted orthogonally with a rigid case, and they are designated to sense the acoustic particle velocity in three designated directions, say X, Y, and Z. To solve the adverse lateral constraint problem (also known as clamping effect) associated with the relaxor crystal; reduced bonding area between the proof mass and the relaxor crystal are introduced. This feature greatly reduced the percentage of the bonding area for the crystal; consequently the free-state piezoelectric properties of the relaxor crystals are preserved.

Owner:AMPHENOL MARYLAND INC

Speech enhancement method and system, computer equipment and storage medium

ActiveCN110503972AVoice enhancementReduce hardware costsSpeech analysisFrequency spectrumCollection system

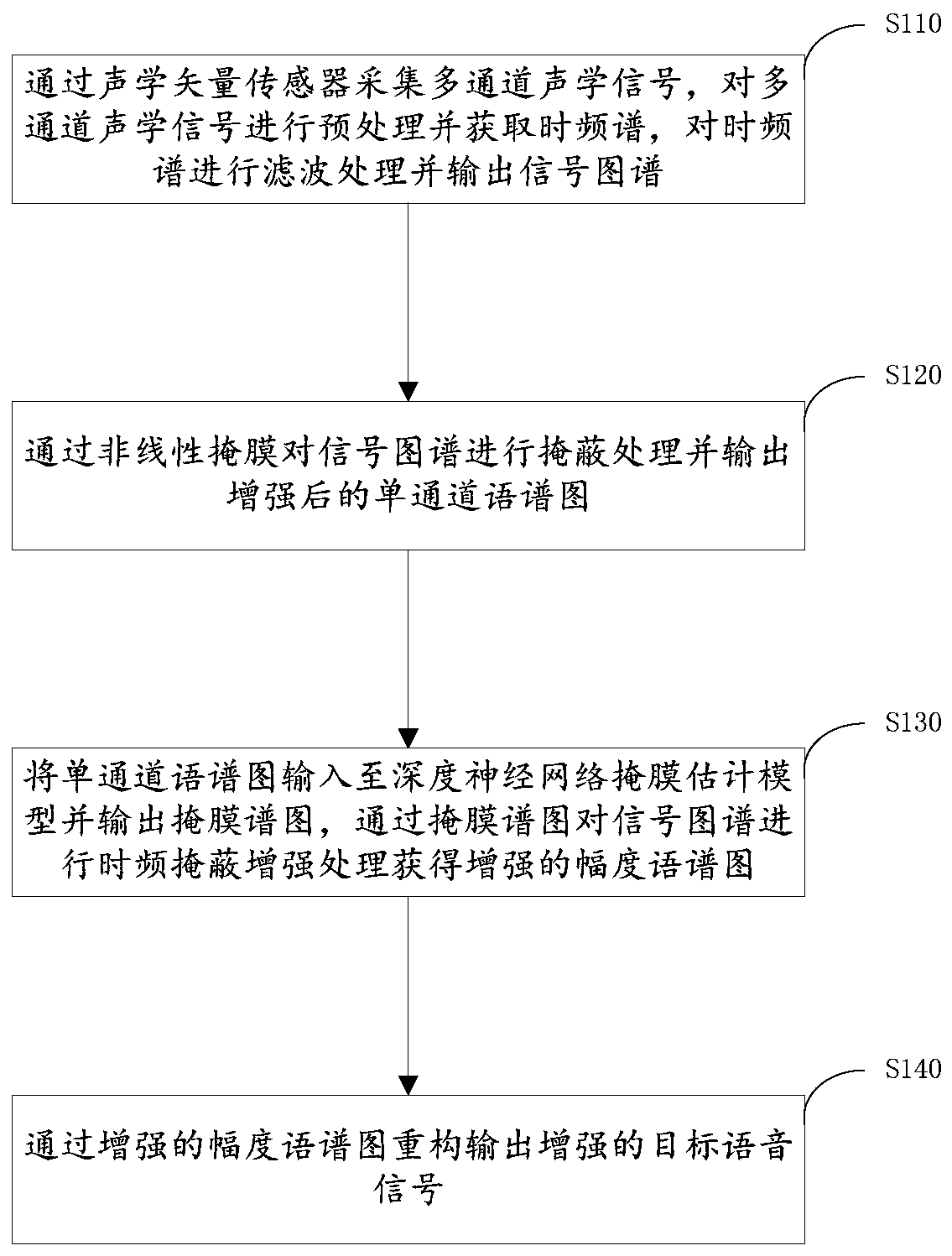

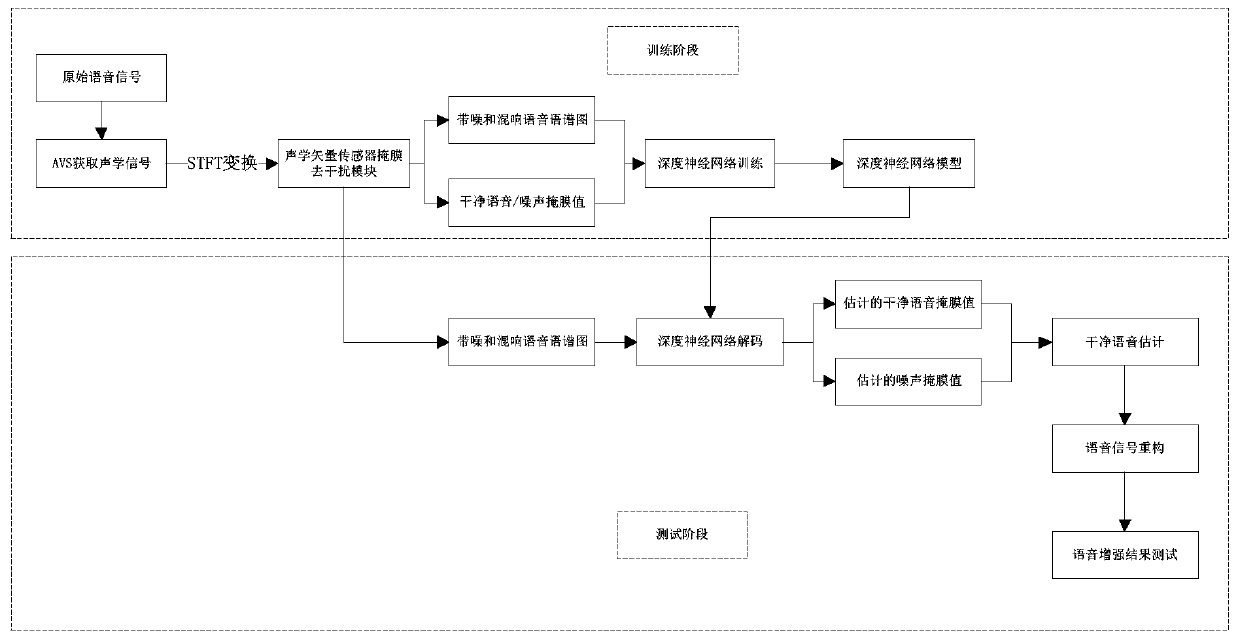

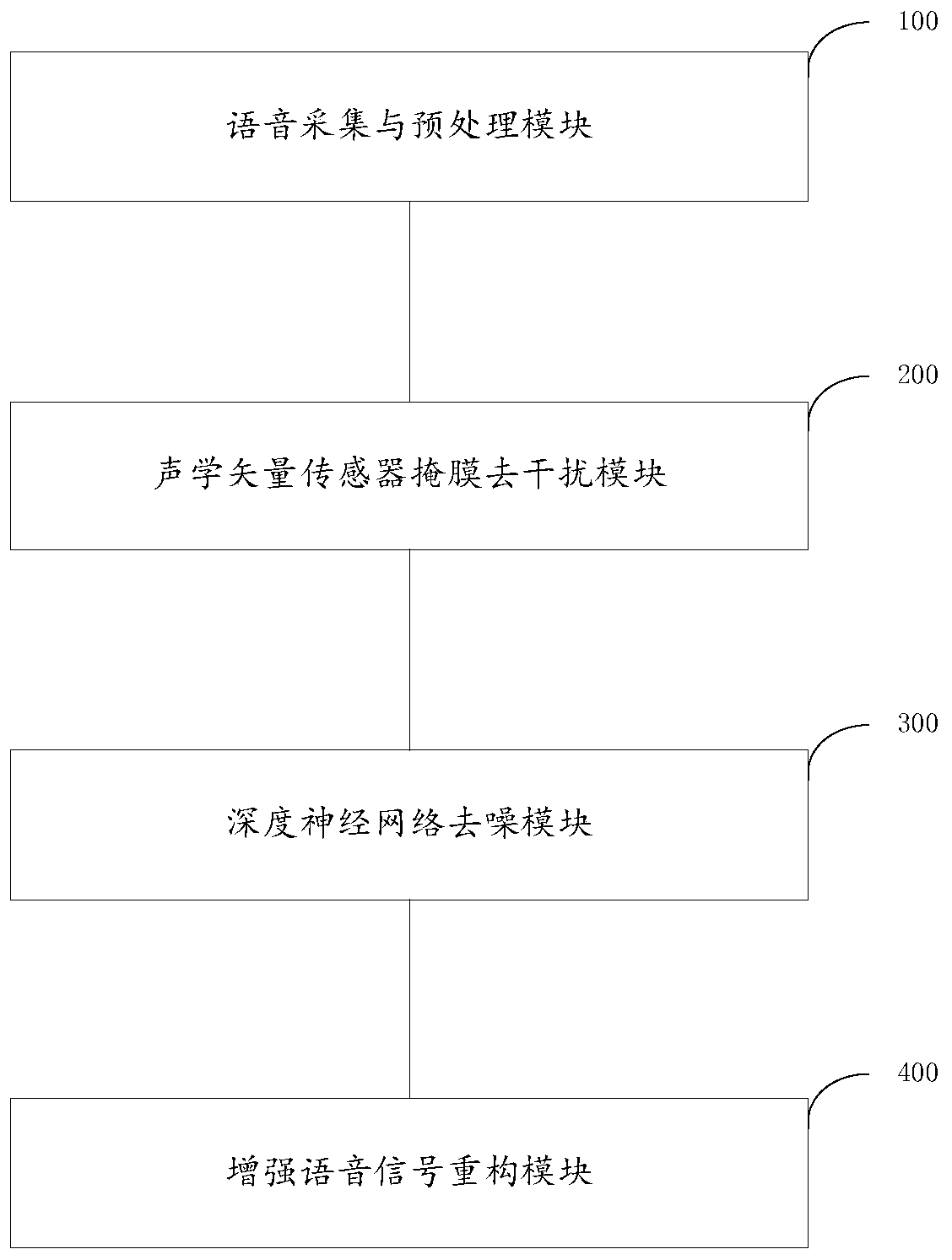

The invention provides a speech enhancement method and system, computer equipment and a storage medium, and relates to the technical field of the human-machine speech interaction. The method comprisesthe following steps: collecting multi-channel acoustic signals through an acoustic vector sensor, preprocessing the multi-channel acoustic signals and acquiring a time-frequency spectrum, filtering the time-frequency spectrum and outputting a signal atlas; performing masking processing on the signal atlas through a nonlinear mask, and outputting an enhanced single-channel speech spectrogram; inputting the single-channel spectrogram into a deep neural network mask estimation model and outputting a mask spectrogram; performing time-frequency masking enhancement on the signal atlas through the mask spectrogram to acquire enhanced amplitude speech spectrogram; reconstructing through the enhanced amplitude speech spectrogram so as to output an enhanced target speech signal. The technical problem that the multi-channel speech enhancement is high in hardware cost, large in collection system volume, and high in operation complexity is solved, and the excellent speech enhancement effect can beacquired under difference interference noise types, strengths and room reverberation conditions.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

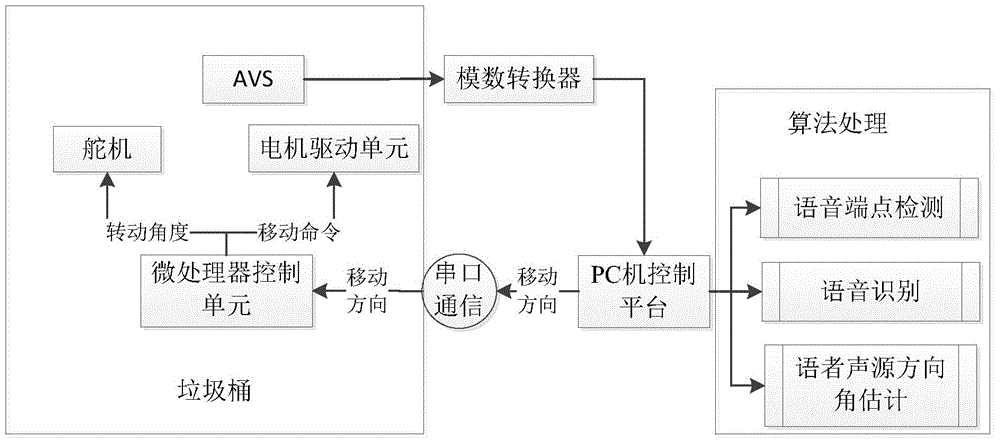

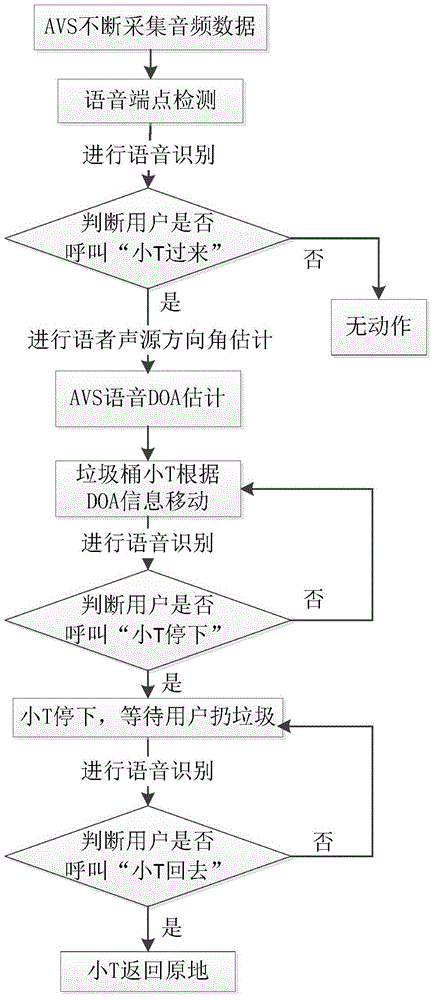

Voice control intelligent garbage can based on acoustic vector sensor

InactiveCN104309964ASolve the troubleMeet the use requirementsRefuse receptaclesTarget-seeking controlSound sourcesEngineering

The invention discloses a voice-control intelligent garbage can based on an acoustic vector sensor. The functions of the garbage can such as listening, turning and walking are realized. Listening means identifying simple command words of a user; turning means turning to an estimated azimuth angle where the user is; walking means moving to the front of the user; the voice-control intelligent garbage can belongs to the technical field of voice human-computer interaction. The garbage can is called mini T; when the user needs to throw garbage, the user only needs to say 'come here, mini T', the azimuth angle of the sound voice of the user is estimated after the user command is identified by the mini T, and the user moves towards the user according to the azimuth angle; when the user says 'stop, mini T', the mini T stops moving after the command is identified; the user says 'go back, mini T' after the garbage is thrown, the mini T returns to an original position after the command is identified. The voice control intelligent garbage can provides a friendly voice human-computer interaction mode, and the garbage can is controlled by voice, so that the using requirement for old people, the disabled and pregnant women with mobility difficulties or bedridden patients, and great convenience is brought for the application scenarios such as intelligent home and medical wisdom.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

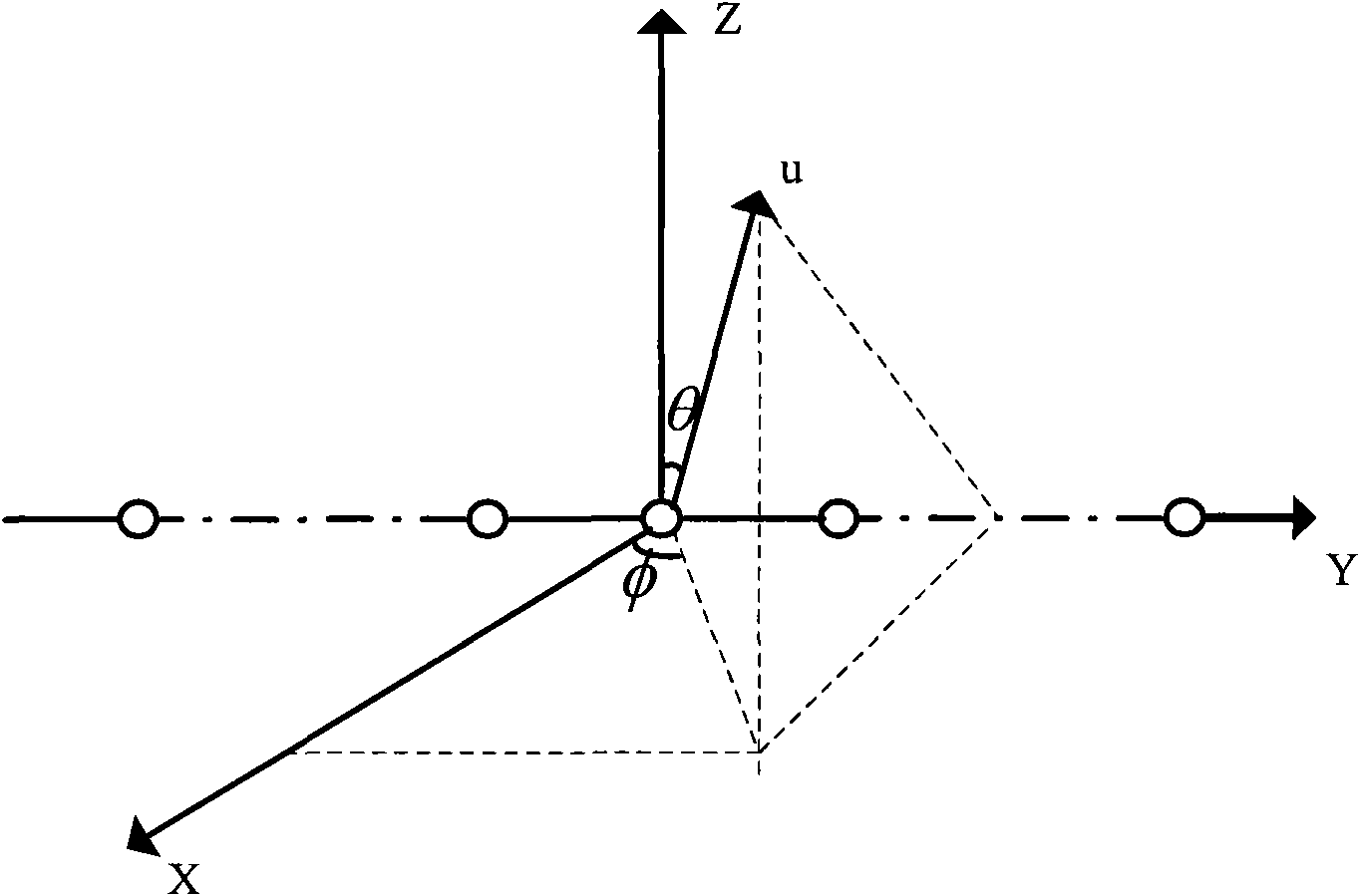

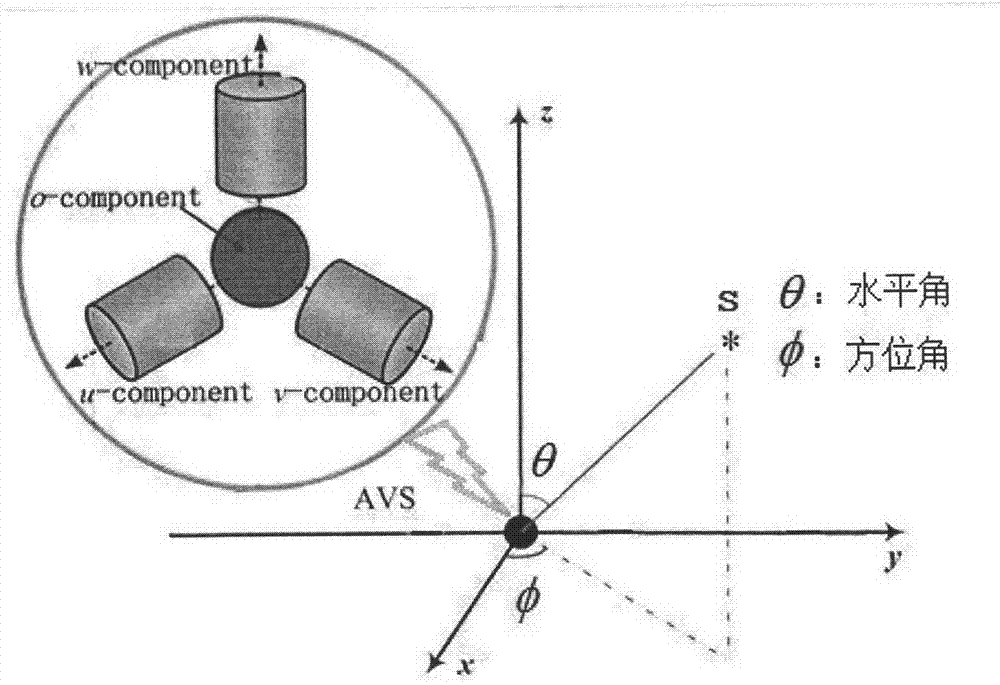

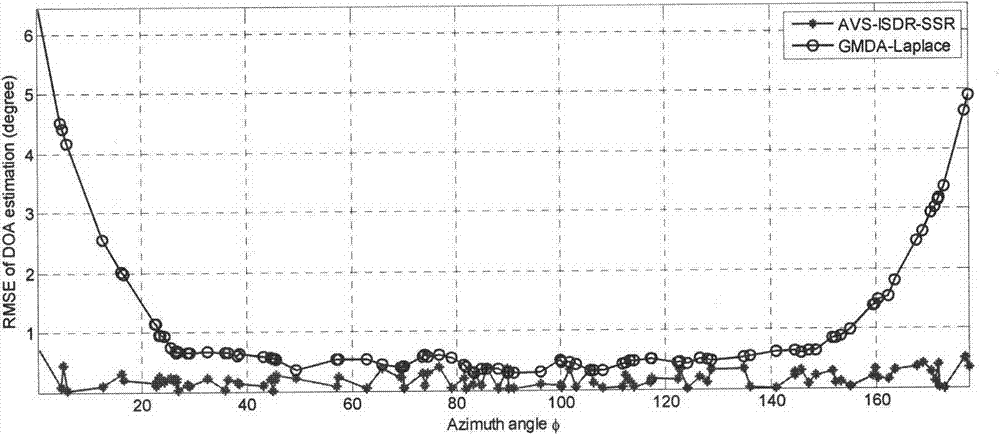

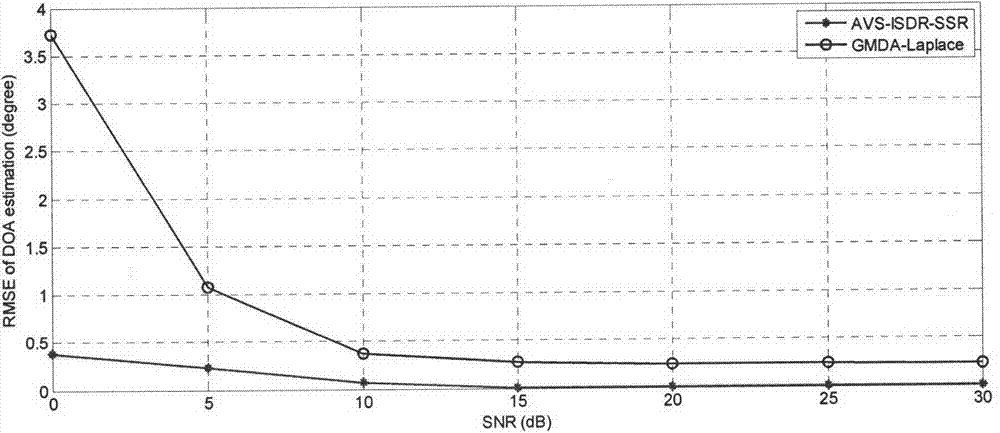

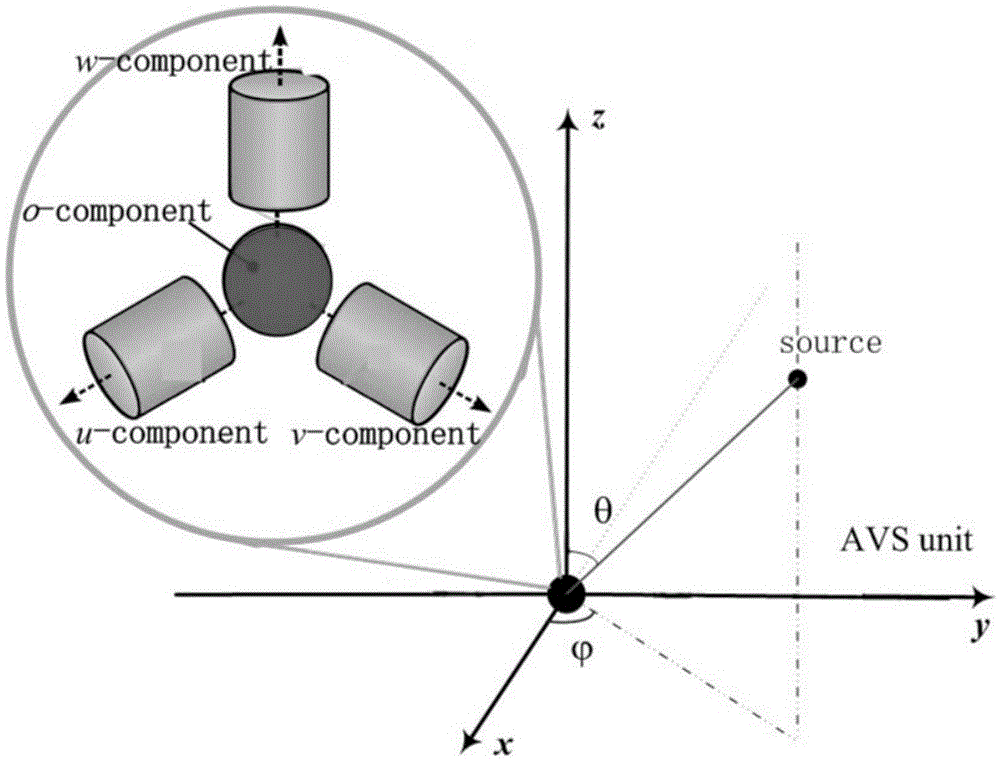

Monolingual sound source DOA estimation method based on AVS and sparse representation

ActiveCN103760520AReduce complexityEasy to integrateDirection/deviation determination systemsSound sourcesTrack algorithm

The invention provides a monolingual sound source DOA estimation method based on an AVS and sparse representation. According to the method, the acoustic vector sensor is adopted to collect audio signals, high signal-to-noise ratio time frequency points are extracted by utilizing the trigonometric function relationship between the time frequency sparse characteristic of the voice signals and the receiving component of the AVS and adopting a sine track algorithm, and the ratio of data of a pressure gradient sensor to data of an all-around pressure sensor is calculated. On the basis, an over-complete dictionary sparse representation model for the ratio of data of the sensors is acquired through the spatial sparse characteristic of a sound source, and the monolingual sound source direction-of-arrival estimation problem is converted into a sparse vector solving problem. The sparse vector is solved with the l1-SVD method, the spatial power spectrum is calculated, and the DOA of the monolingual sound source can be obtained through calculation. The DOA of the monolingual sound source can be accurately estimated under conditions of different noise intensities and room reverberations with the method. Besides, a microphone array adopted for the method is small in size and only has the area of 1 cm<3>, and thus the method is very suitable for the voice technology for portable devices.

Owner:SHENZHEN HIAN SPEECH SCI & TECH CO LTD

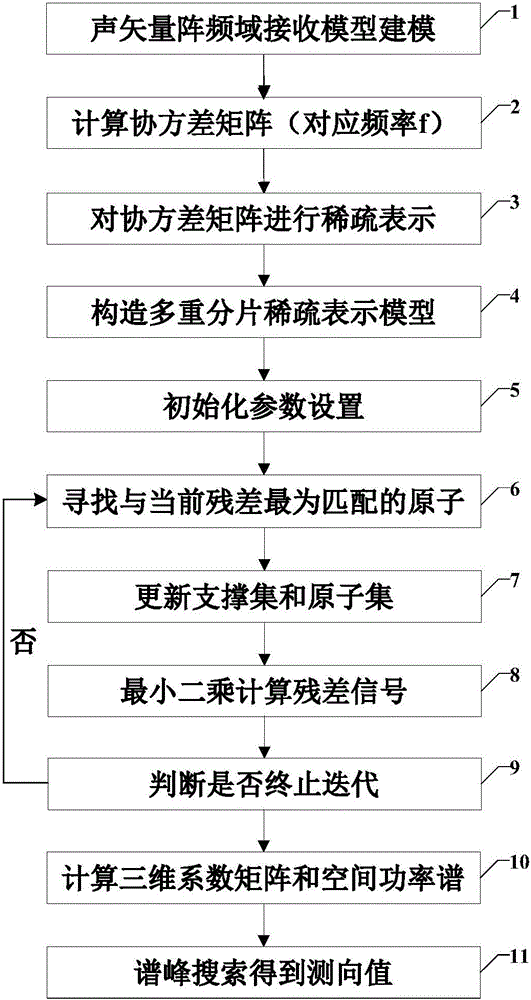

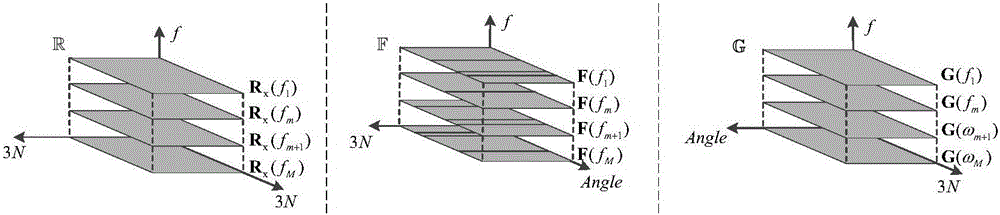

Acoustic vector array wideband direction finding method based on sparse decomposition theory

ActiveCN106093921AEasy to distinguishEasy to detectWave based measurement systemsDecompositionAmplitude noise

The invention discloses an acoustic vector array wideband direction finding method based on a sparse decomposition theory, and relates to a direction finding technique and implementation method for target broadband continuous spectrum noise in the acoustic vector sensor array detection field. The sparsification idea is introduced to an acoustic vector array direction finding system; a combined sparse constraint is established according to frequency point components in broadband continuous spectrum noise signal bandwidth; and finally, a unified airspace sparse decomposition form is obtained, thereby realizing direction finding of the broadband continuous spectrum noise. According to the method, a relatively-sharp spectrum peak and a low-amplitude noise floor can be formed; when the number of array snapshots is small, the method is stable in performance and can distinguish coherent signal sources; and when the target DOA (direction of arrival) approaches to the array axial direction, the phenomenon of noise floor fluctuations occurring under the condition of low signal-to-noise ratio of a conventional beam forming (CBF) method and a minimum variance distortionless response (MVDR) method does not exist.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Hybrid pressure and vector sensor towed array

InactiveUS7599253B1SeismologyUltrasonic/sonic/infrasonic finder detailsAmbiguityAcoustic vector sensor

The invention as disclosed is of a combined acoustic pressure and acoustic vector sensor array, where multiple acoustic pressure sensors are integrated with an acoustic vector sensor in a towed array as a means of resolving the left-right ambiguity of the multiple acoustic pressure sensors.

Owner:UNITED STATES OF AMERICA

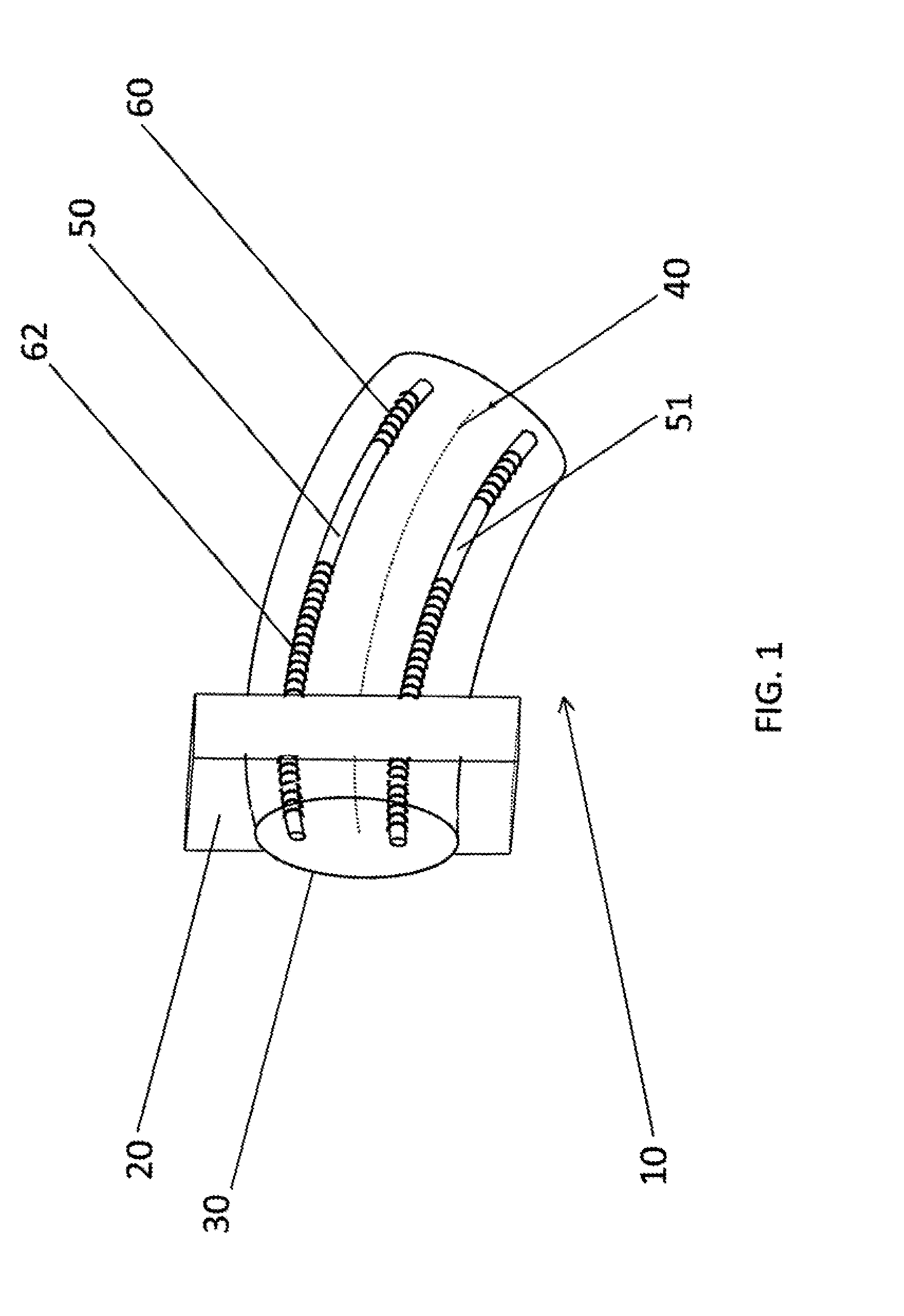

Fiber optic cantilever acoustic vector sensor

InactiveUS20130272645A1High sensitivityReduce weightSubsonic/sonic/ultrasonic wave measurementForce measurementFiberAcoustic vector sensor

A planar or cylindrical, cantilever-type apparatus including a rigid support. The apparatus further includes a first optical fiber connected to the rigid support, the first optical fiber including a first neutral axis and at least one first wave-guiding core running parallel to the first neutral axis and located at a distance from the first neutral axis, each of the at least one first wave-guiding core including at least one first reflector. The apparatus further includes a first membrane surrounding the first optical fiber; and a first liquid inside the first membrane and surrounding the first optical fiber, the first liquid including a Reynolds number less than one.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

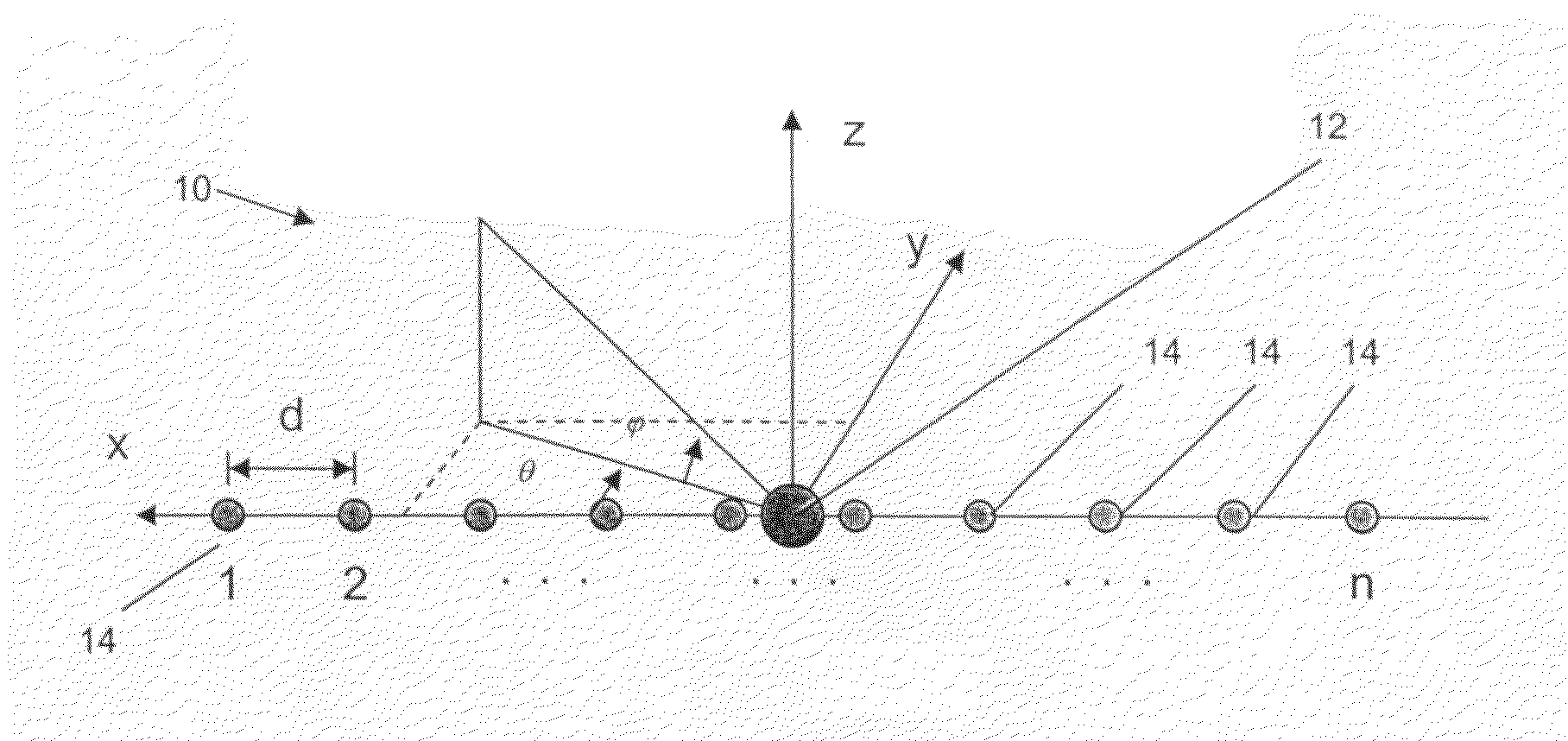

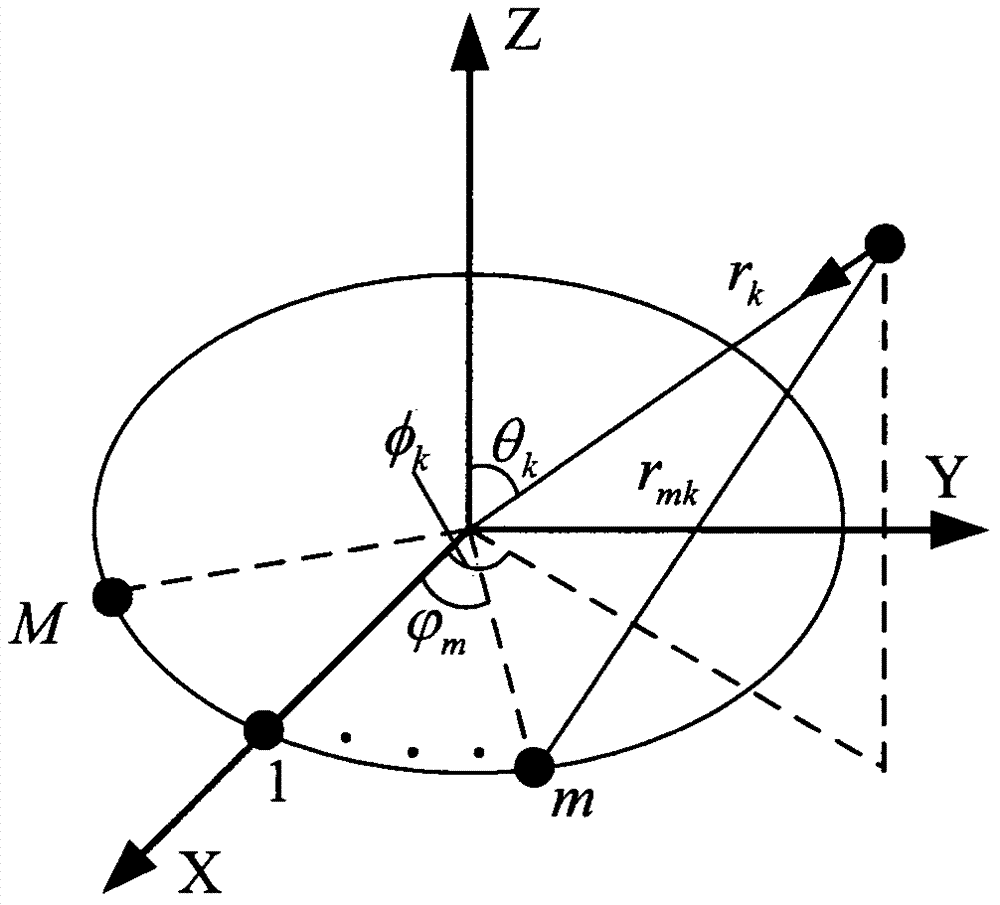

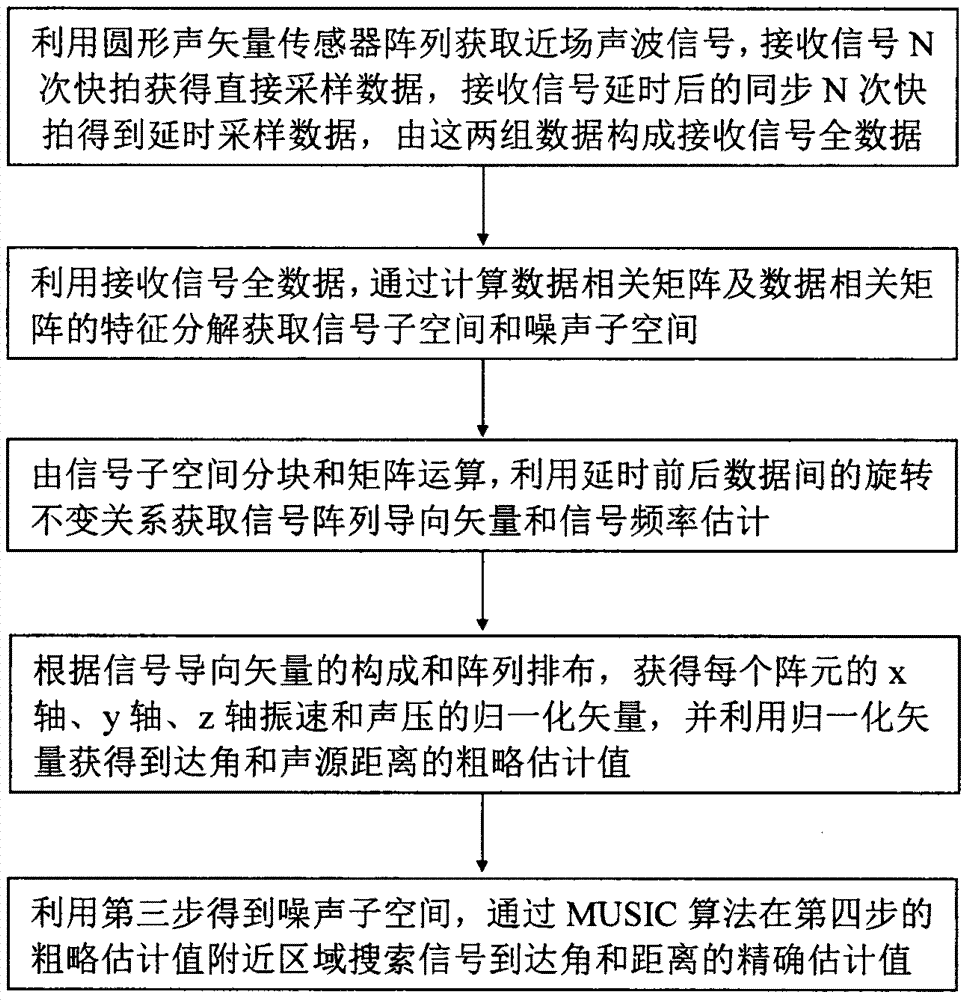

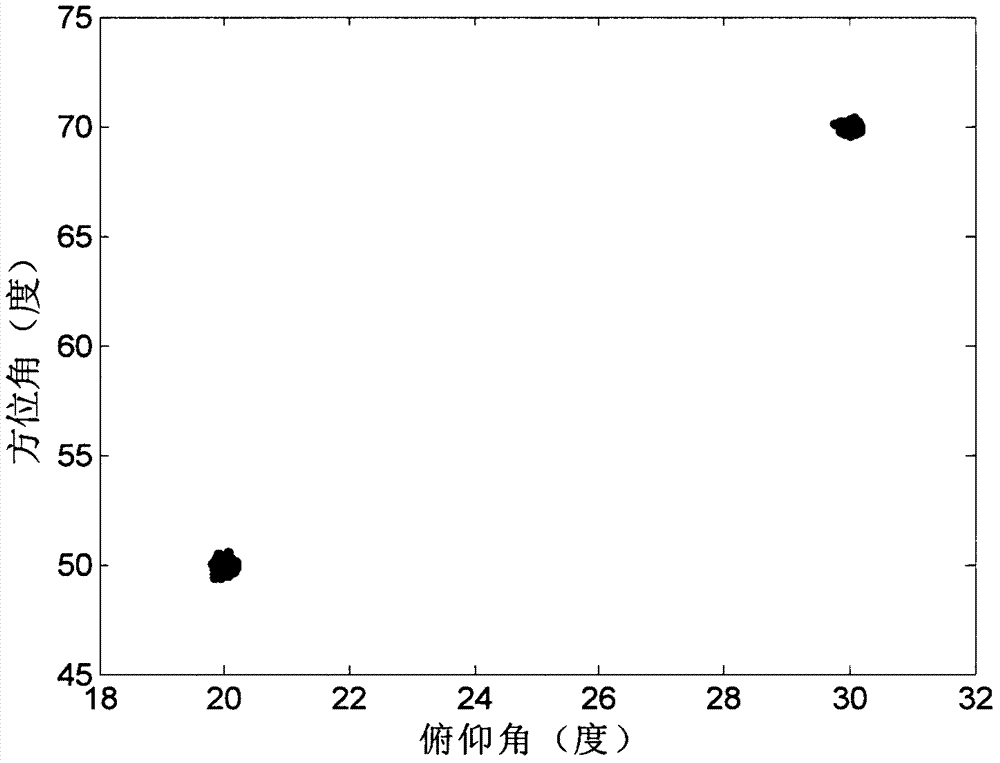

Circular acoustic vector sensor array near-field source multi-parameter estimation method

The invention relates to a circular acoustic vector sensor array near-field source multi-parameter estimation method. The method includes the following steps that: the output signals of an acoustic vector sensor array are sampled, direct sampling data and delay sampling data are adopted to form received signal whole data; a signal subspace and a noise subspace are obtained through the feature decomposing of a data correlation matrix; a signal array guidance vector and a signal frequency estimate are obtained by using a rotation invariant relationship between of data before and after time delay; the signal guidance vector is divided into four sub-array guidance vectors; the roughly estimated values of a direction of arrival and a sound source distance are obtained based on the ratios of the sub-array guidance vectors; and the accurately estimated values of the direction of arrival and distance of the signals are searched in regions in the vicinities of the roughly estimated values through the MUSIC algorithm. According to the circular acoustic vector sensor array near-field source multi-parameter estimation method of the invention, the inherent rotational invariant structure of an acoustic vector sensor is fully utilized; and the ESPRIT rough estimation algorithm and the MUSIC small-region accurate search method are combined to realize the accurate estimation of the direction of arrival and the distance. The method has the advantages of small computation amount, simple algorithms and convenient use.

Owner:深圳市晶凯斯科技有限公司

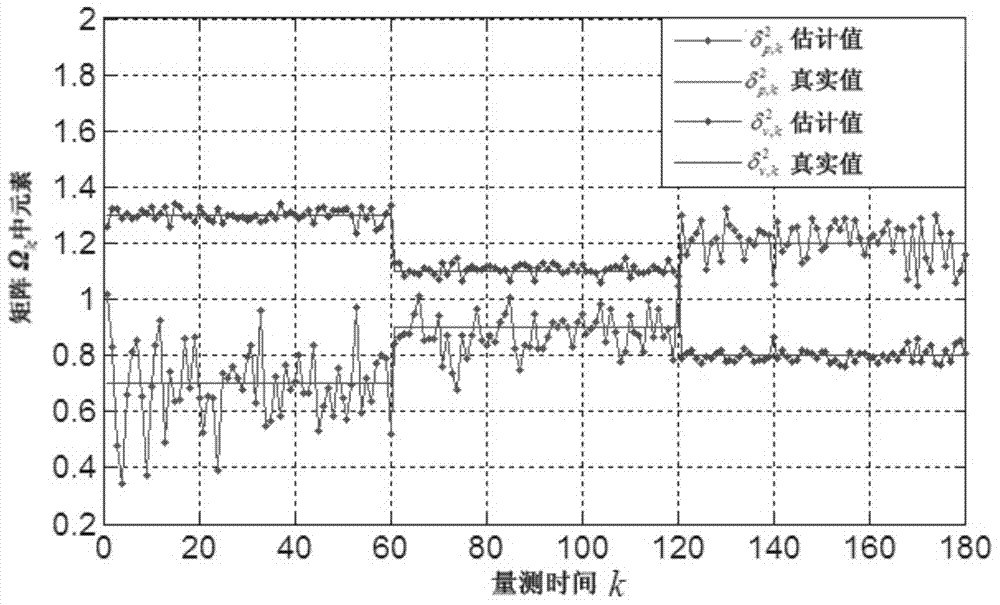

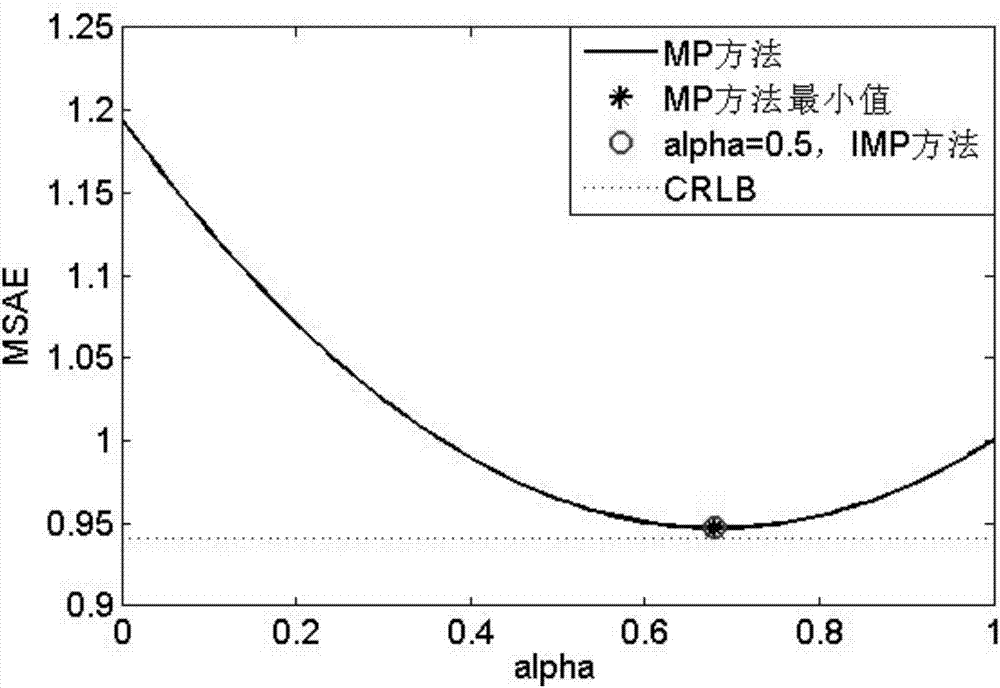

Maneuvering sound source position estimation method based on acoustic vector sensor

InactiveCN104330768AImprove estimation accuracyAvoid one-dimensional search processDirection/deviation determination systemsPrior informationMean square

The invention relates to a maneuvering sound source position estimation method based on an acoustic vector sensor and belongs to the technical field of signal processing. The method is characterized by, to begin with, estimating a spatial domain noise covariance matrix, and solidifying weighting parameters in a maximum energy positioning method through a noise-whitening method, thereby preventing the one-dimensional search process selected by the optimum weighting parameters, and improving estimation precision of the maximum energy positioning algorithm; and then, with maximum energy positioning estimation sub-output and prior information of sound source uniform motion being combined, maneuvering sound source position estimation precision is further improved by utilizing the Kalman filtering technique in a polar coordinate system. Through theoretical analysis and simulation study, the estimation precision of the maneuvering sound source position estimation and tracking method based on the acoustic vector sensor is superior to that of the original maximum energy positioning method; and the Kalman filtering technique is utilized, the mean square angle error is lower than that of the CRLB (Cramer-Rao Lower Bound) under the condition of static sound source positioning.

Owner:HENAN UNIV OF SCI & TECH

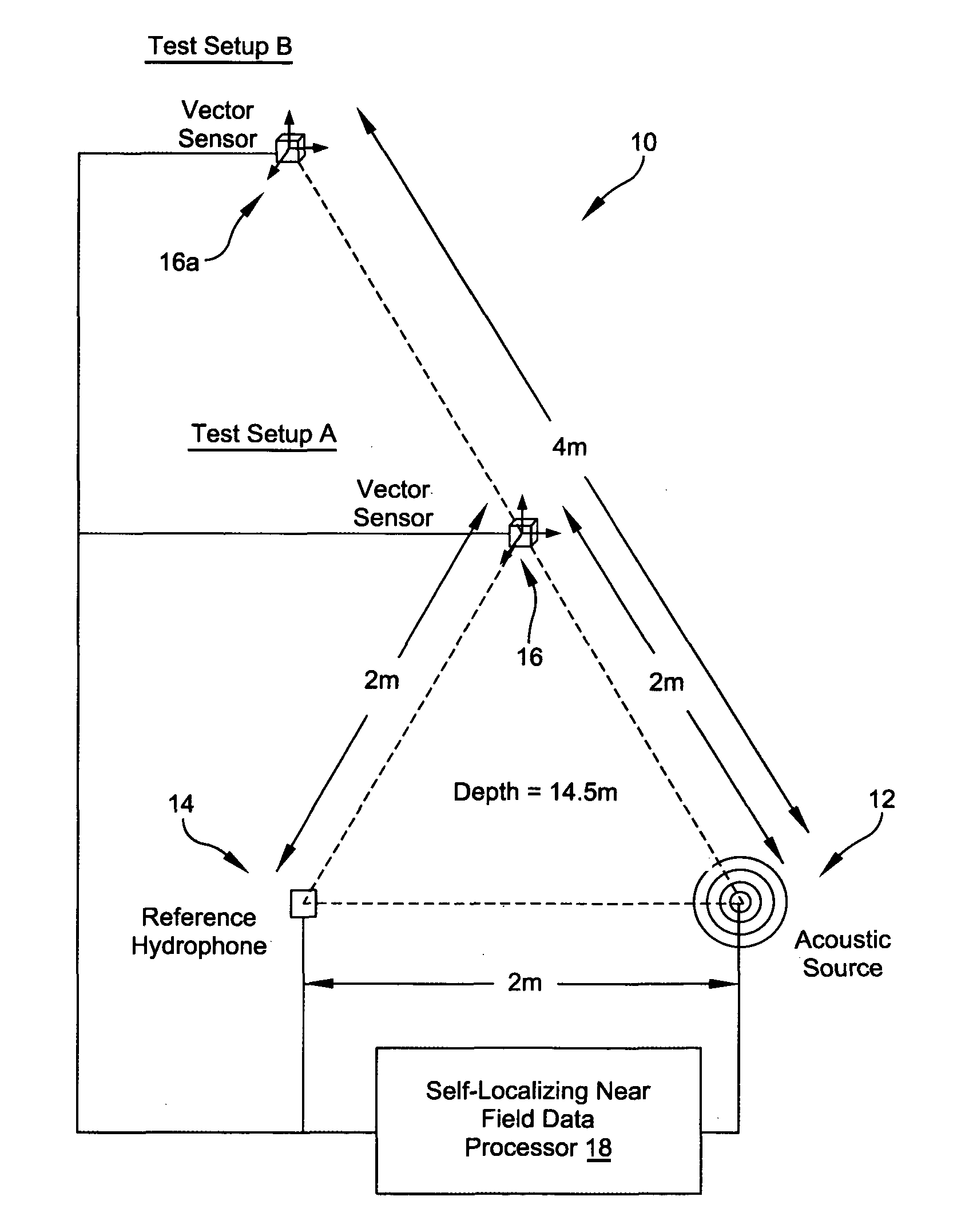

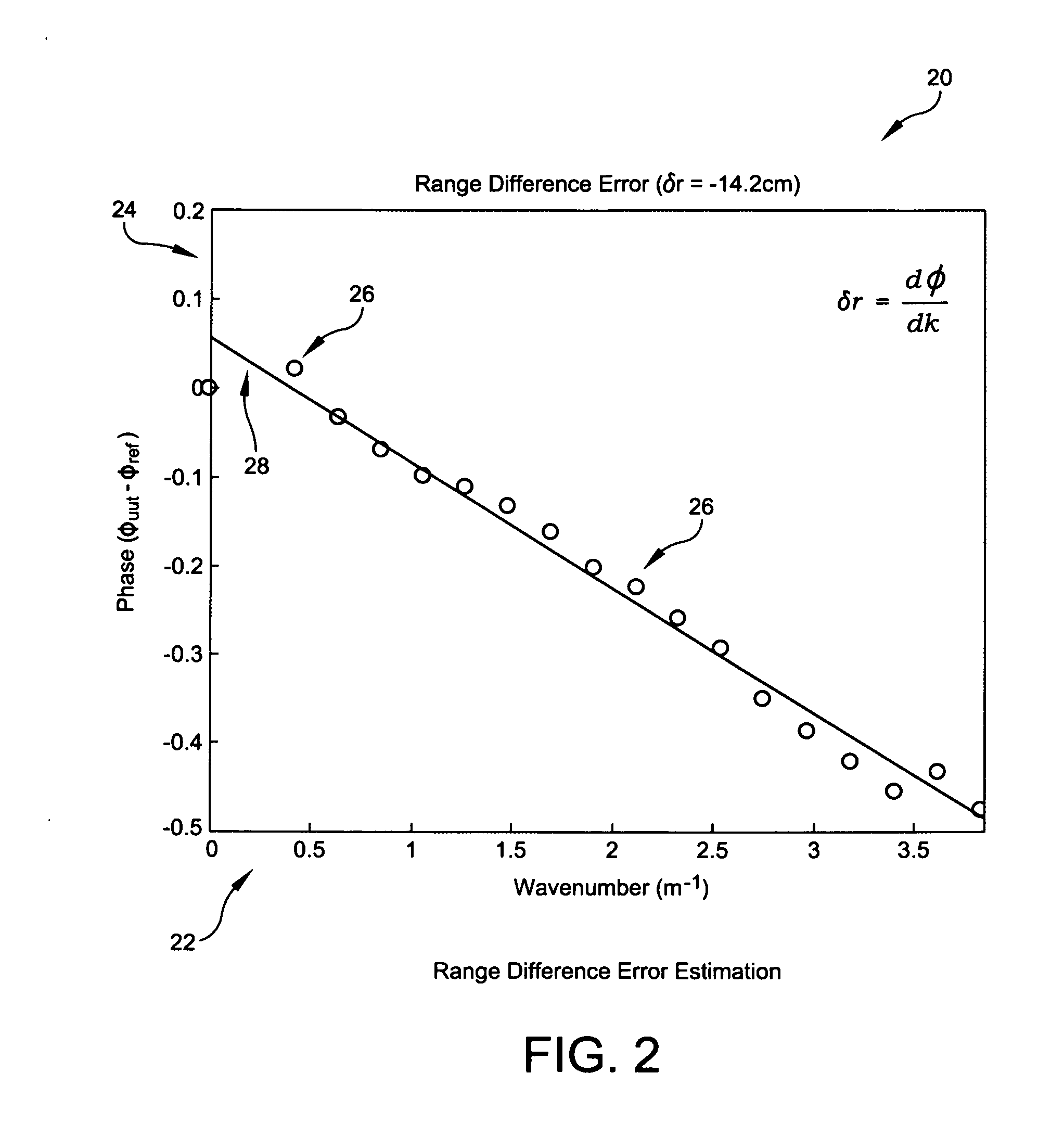

Method for calibrating a plurality of data channels in a vector sensor

InactiveUS8576657B1Improve accuracyTransmission monitoringSystems with adjusting phase/time-lag-errorsAcoustic vector sensorLength wave

A system, processor and method of use for calibration processing is provided to calibrate acoustic vector sensor data collected at comparatively close range. Vector sensor data collected at close range includes data collected with source-to-receiver separations ranging from a one-tenth to approximately two acoustic wavelengths. The calculations substantially account for the acoustic impedance of a spherically diverging wave front, where the curvature is sufficiently pronounced to cause errors in resulting measurements in the calculations. The processing uses information contained within the vector sensor data to increase the accuracy of the vector sensor data.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

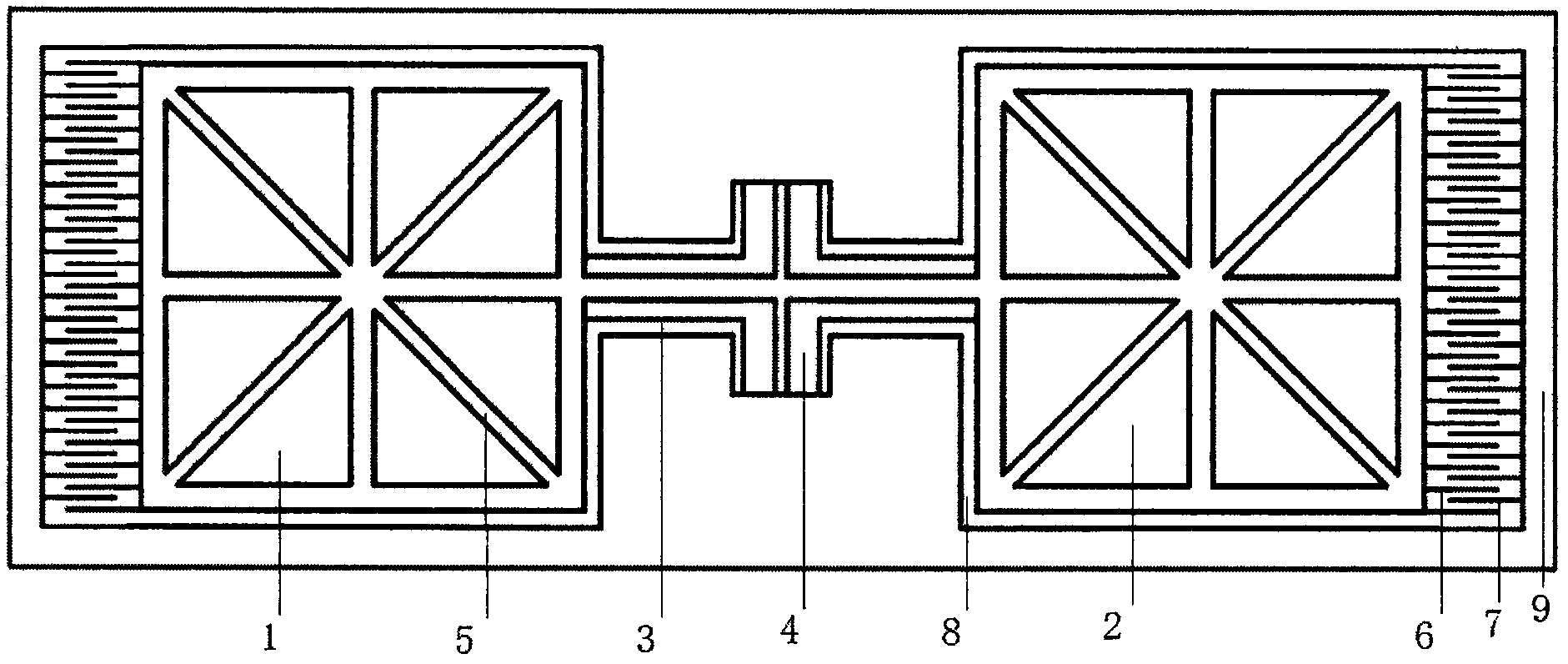

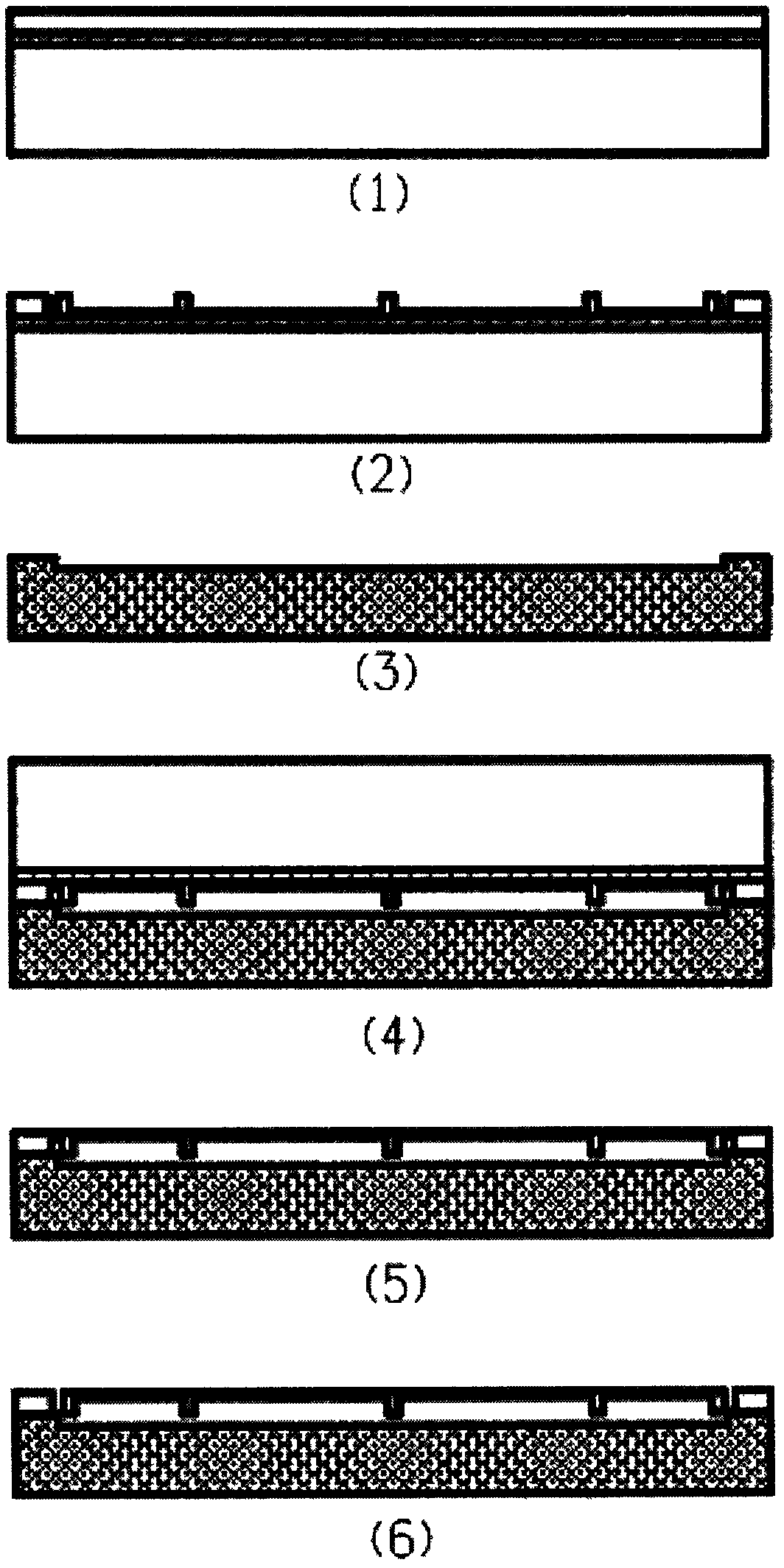

Novel MEMS (microelectromechanical systems) bionic acoustic vector sensor and manufacturing method thereof

InactiveCN102508203AAchieve positioningMake up for the shortcomings of capacitance detectionSubsonic/sonic/ultrasonic wave measurementDecorative surface effectsCapacitanceManufacturing technology

The invention discloses a novel MEMS bionic acoustic vector sensor structure, which belongs to the field of acoustics. Moveable comb teeth 6 are arranged on a left vibrating diaphragm 1 and a right vibrating diaphragm 2 of the novel MEMS bionic acoustic vector sensor structure, and form comb tooth pairs with fixed comb teeth 7 which are connected in an anchoring area 9. By adopting a comb tooth pair structure, the defect that the conventional structure cannot detect capacitance due to existence of reinforcing ribs is remedied, so that a vibrating amplitude curve can be detected by detecting the capacitance change, the amplitudes and damping of a first-order modal frequency and a second-order modal frequency can be sequentially computed, an acoustic pressure value is tested by a testing microphone beside an apparatus, and an incidence angle of sound wave is computed for positioning an acoustic source. The invention also discloses a manufacturing method for the novel MEMS bionic acoustic vector sensor structure. When an SOG technology is used for etching a fluid clearance on glass, the technology is simple and the clearance depth is controllable, so that a footing effect generated in the deeply etching process in an ICP technology is avoided, the manufacturing technology is optimized, and the structural precision and the yield rate of apparatus are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

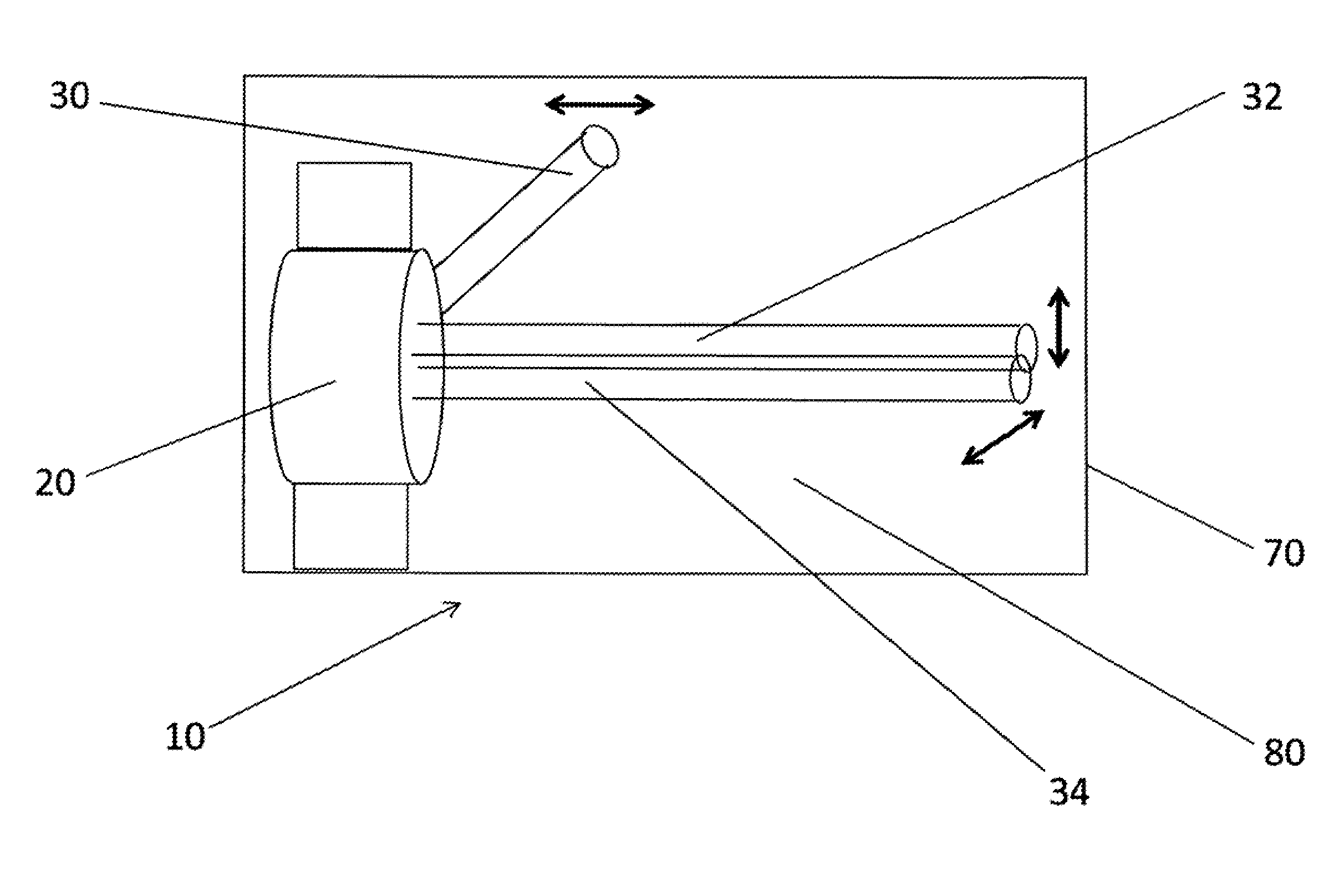

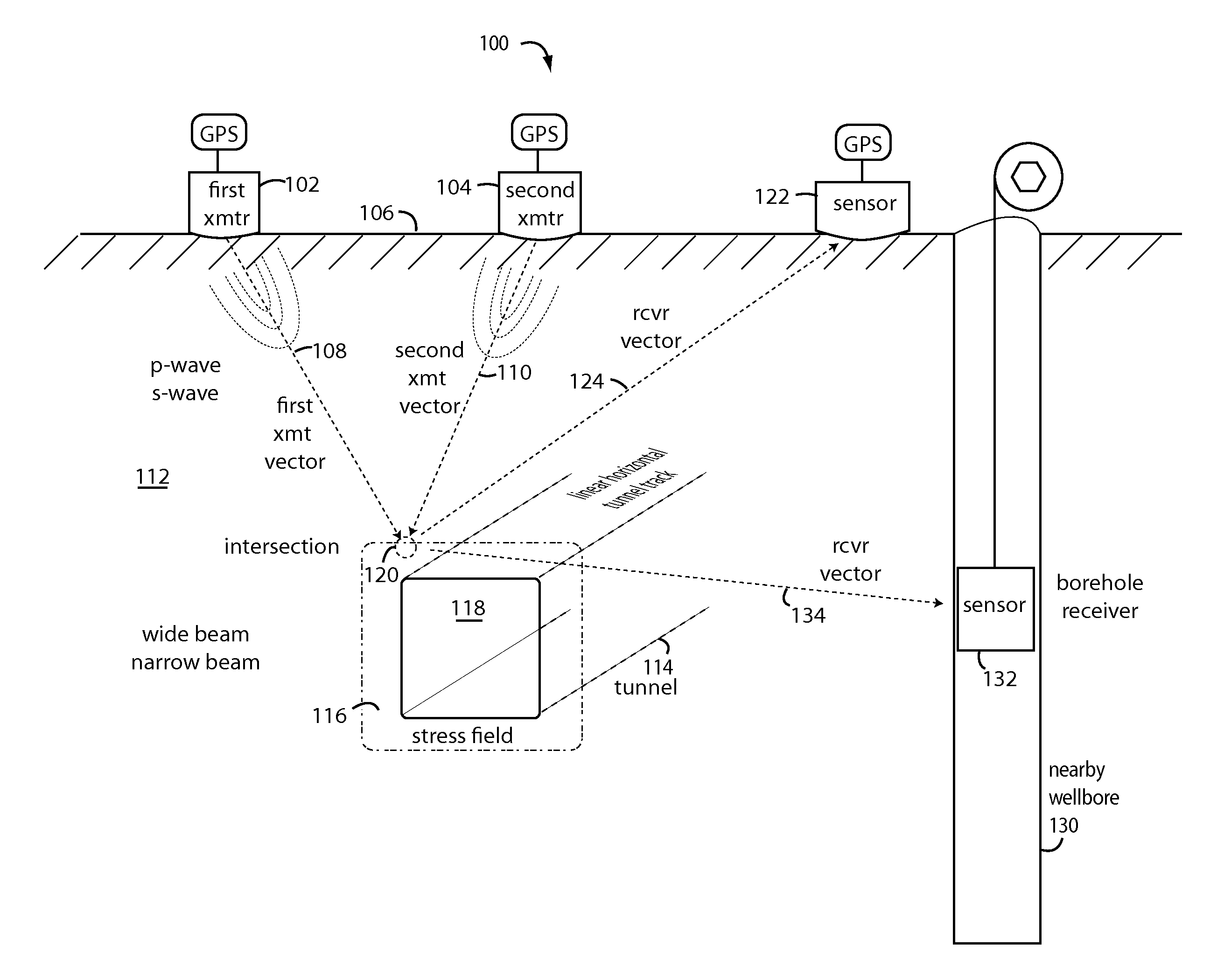

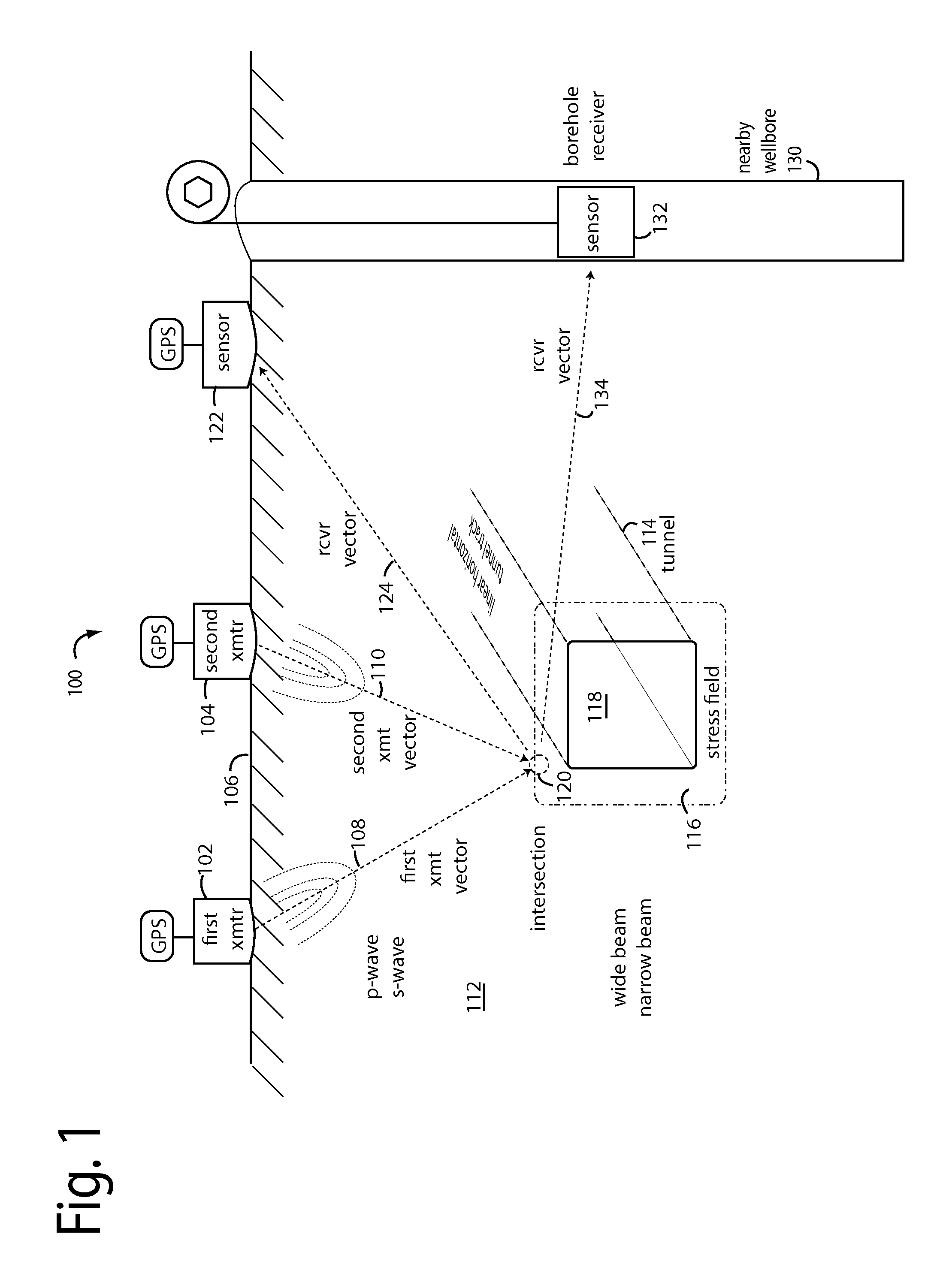

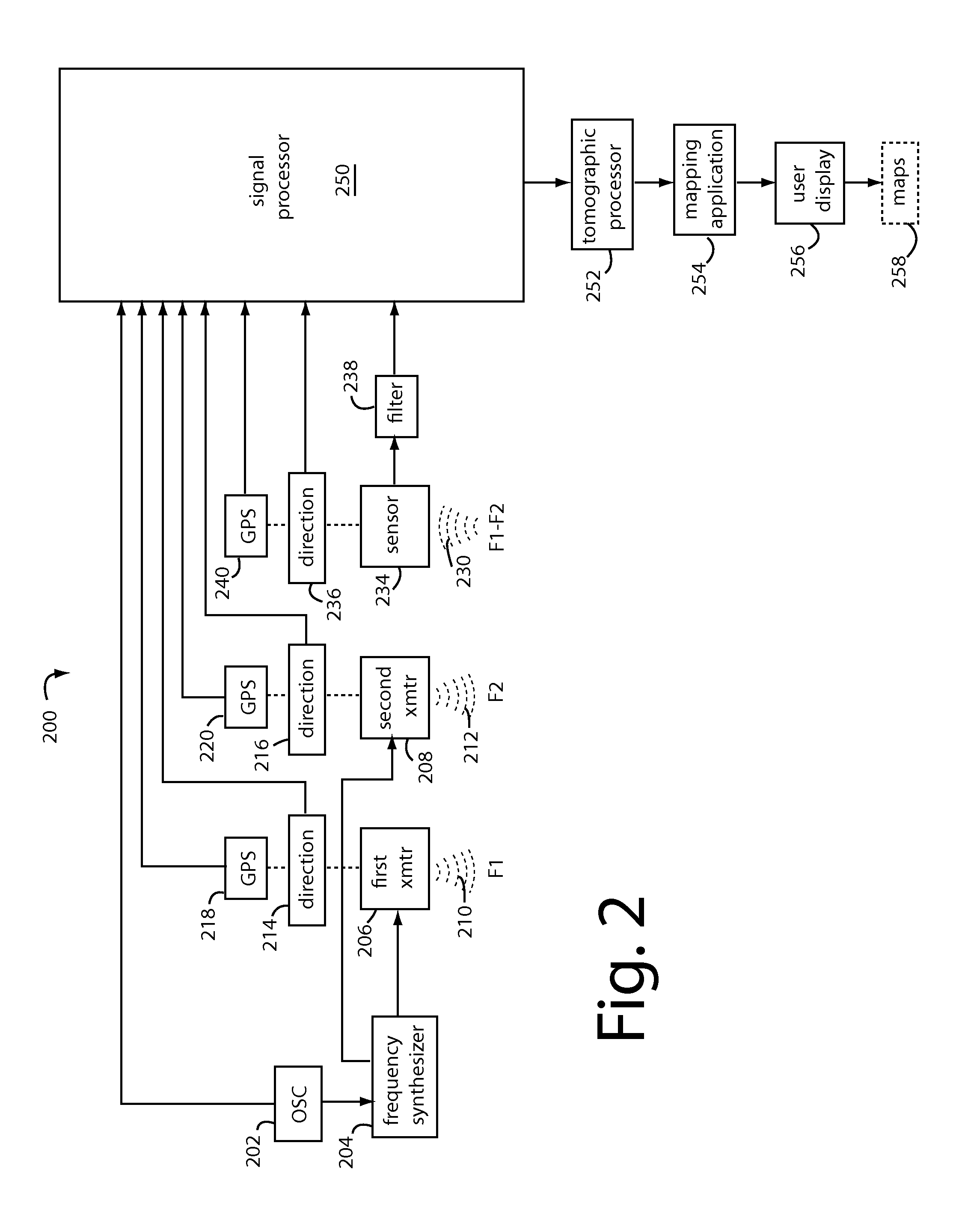

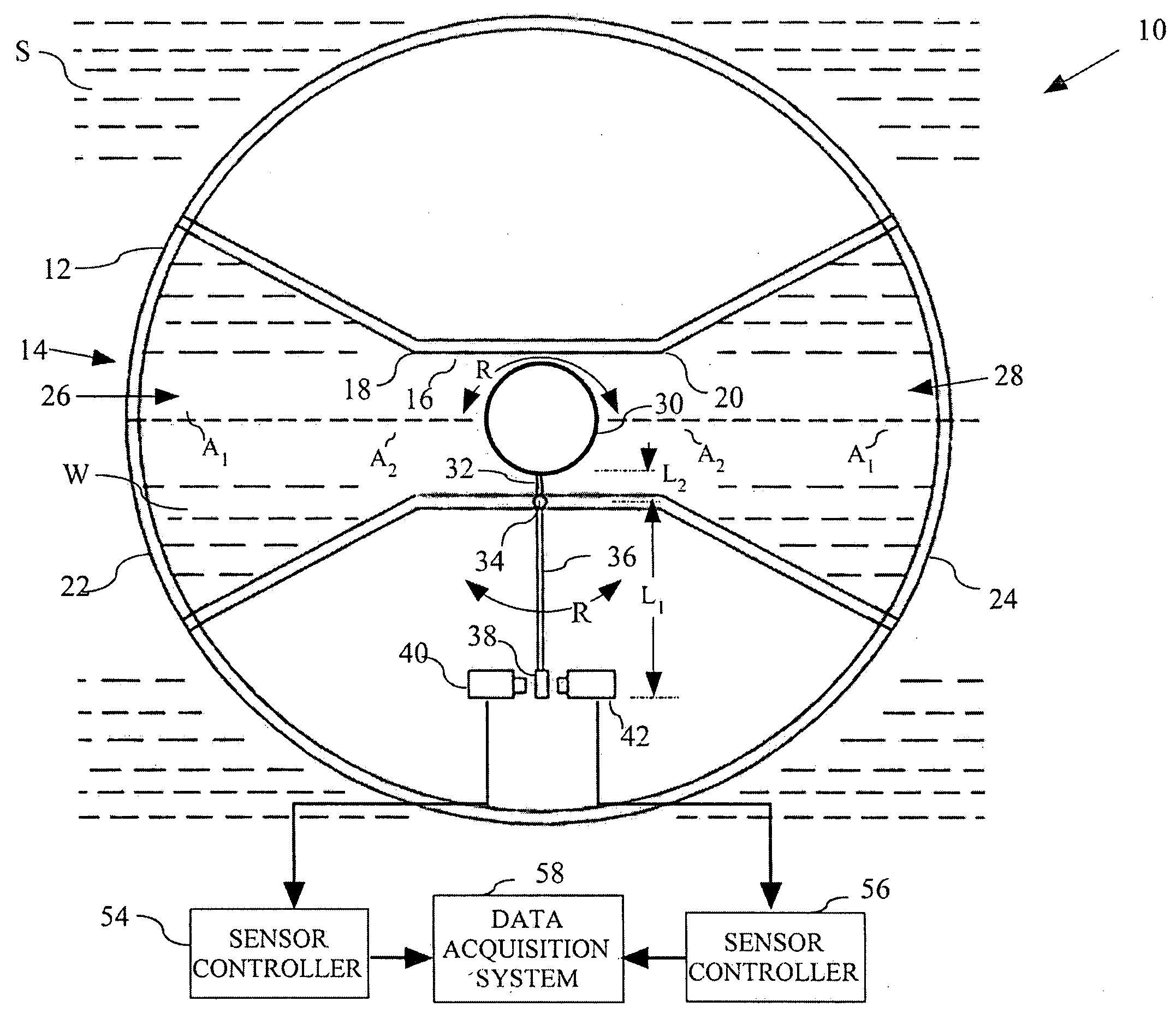

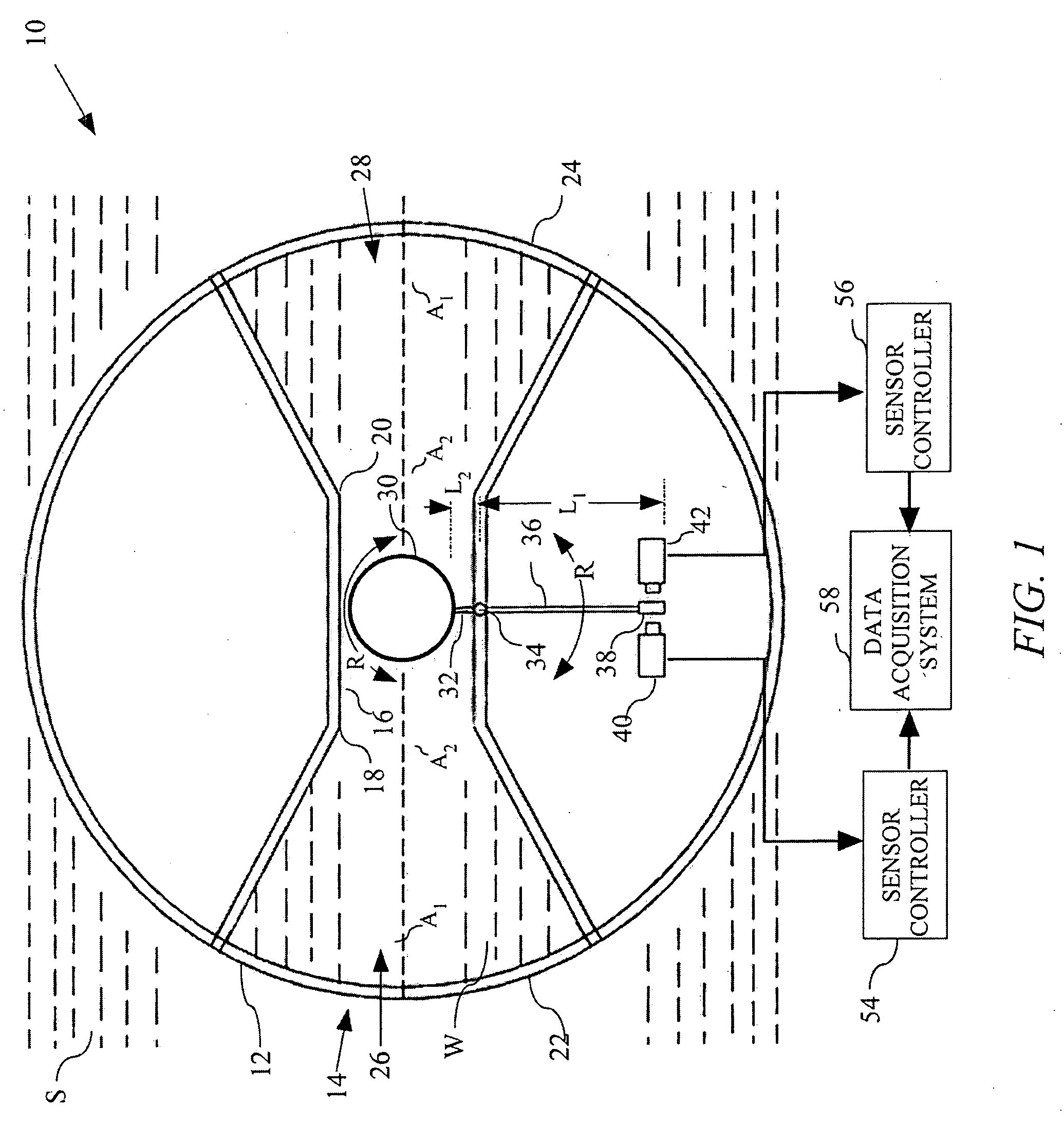

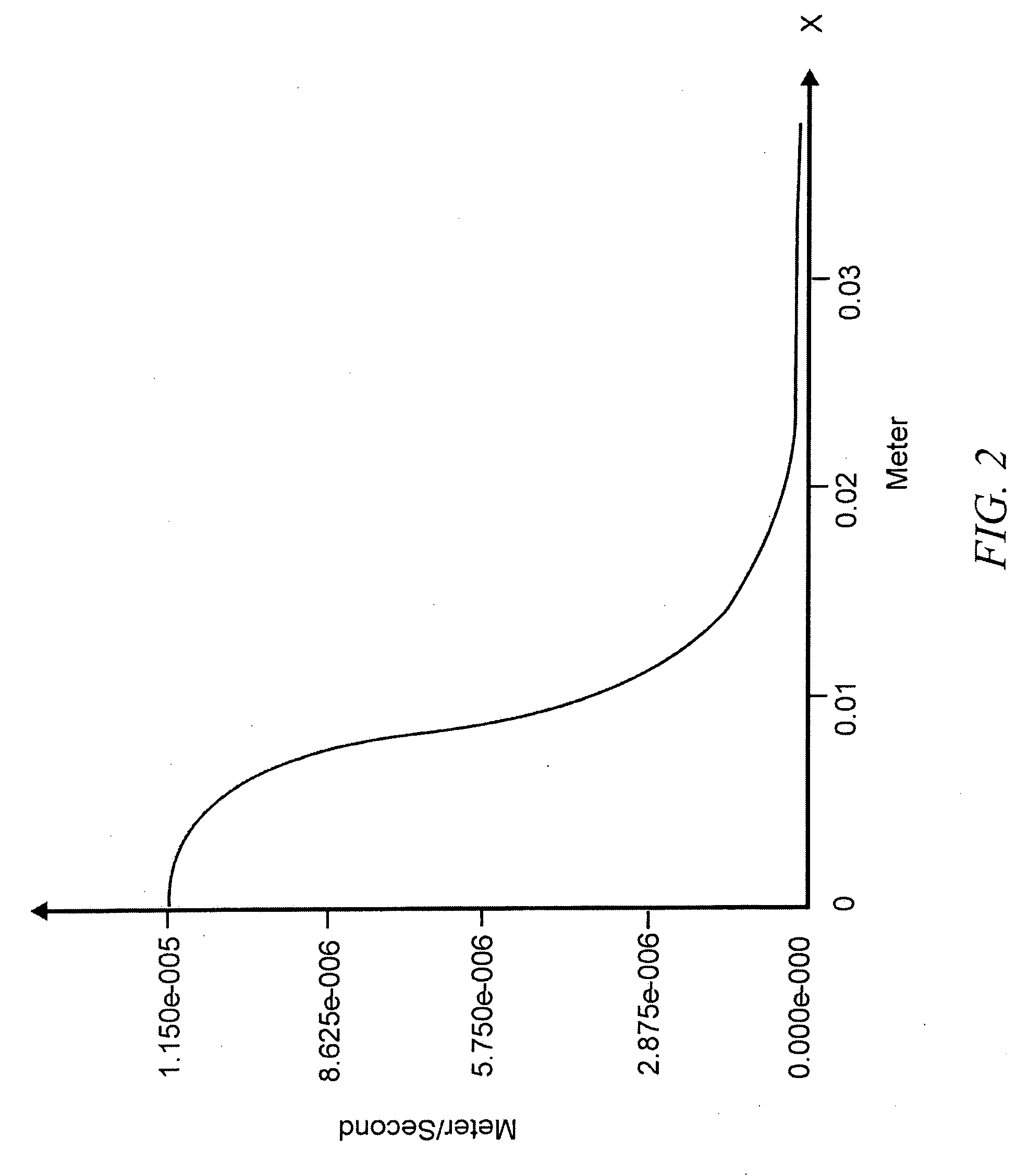

Ground-Penetrating Tunnel-Detecting Active Sonar

InactiveUS20140104979A1Good estimateEfficiently provideAcoustic wave reradiationPhotographySonarBandpass filtering

A ground-penetrating tunnel-detecting active sonar launches two different monotonic acoustic beams down into the ground from the surface. If the two separate monotonic acoustic waves arrive at a stress field, they will mix and produce a frequency difference heterodyne due to the inherent pressure nonlinearities in the solid medias. Any sonar returns are bandpass filtered so only an acoustic frequency difference heterodyne can pass through. The existence of a tunnel is revealed by the return of acoustic frequency difference heterodynes all coming from a more-or-less horizontal line of phase-delayed sources and directions. These phase differences can be derived from the vector values provided by the acoustic vector sensor. Three or more acoustic vector sensors on the surface can be used effectively to provide triangulations down to the tunnel to better estimate the tunnel track.

Owner:STOLAR

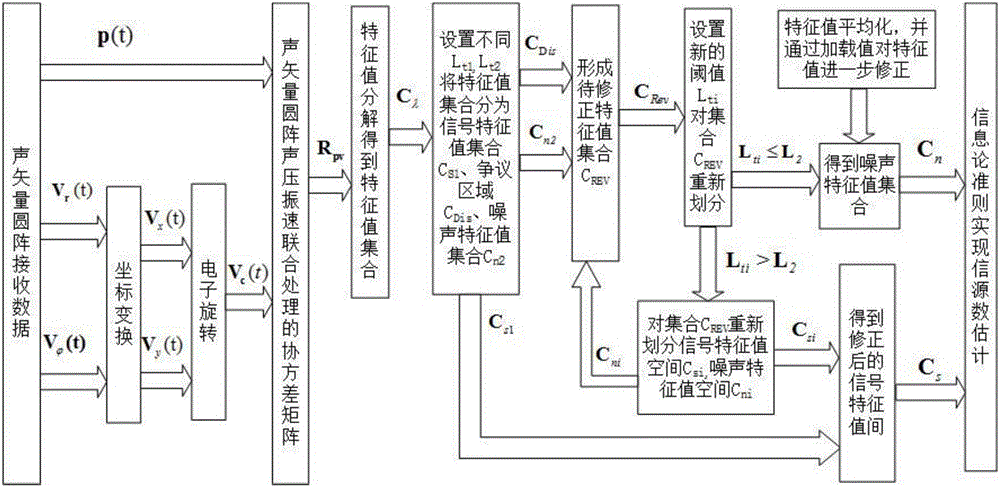

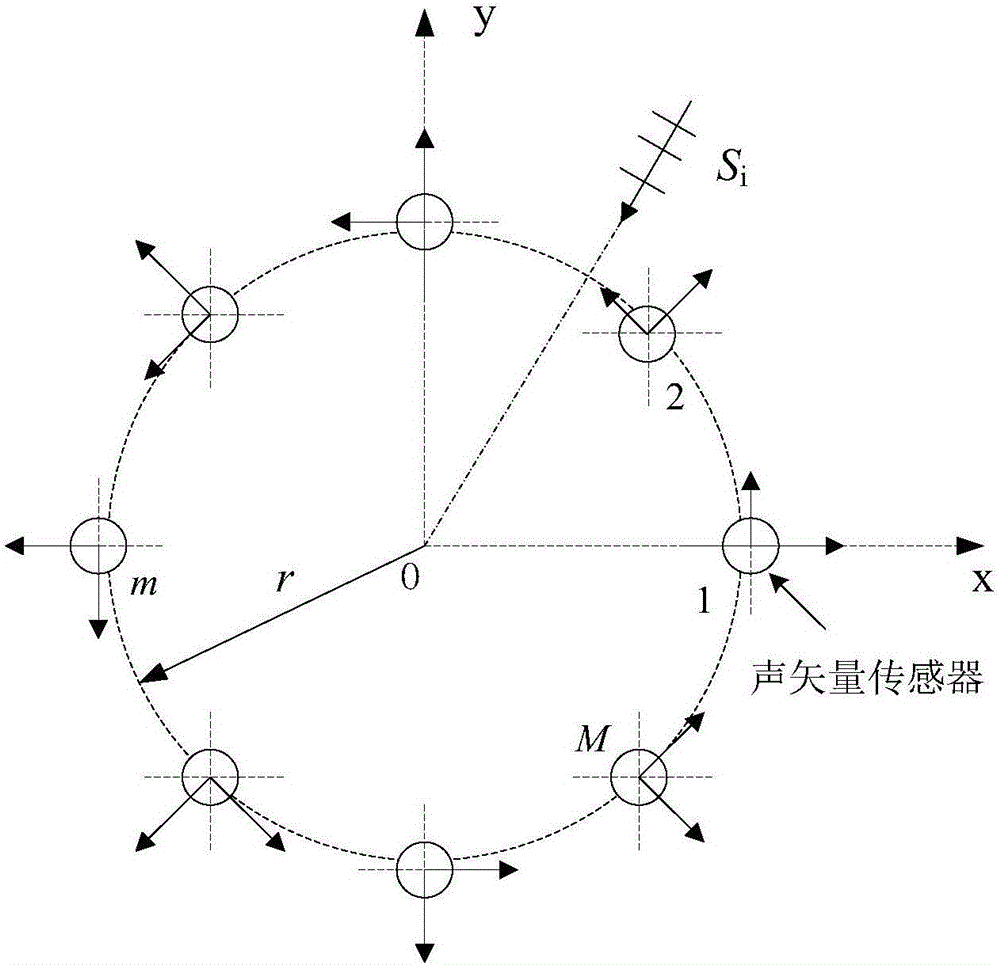

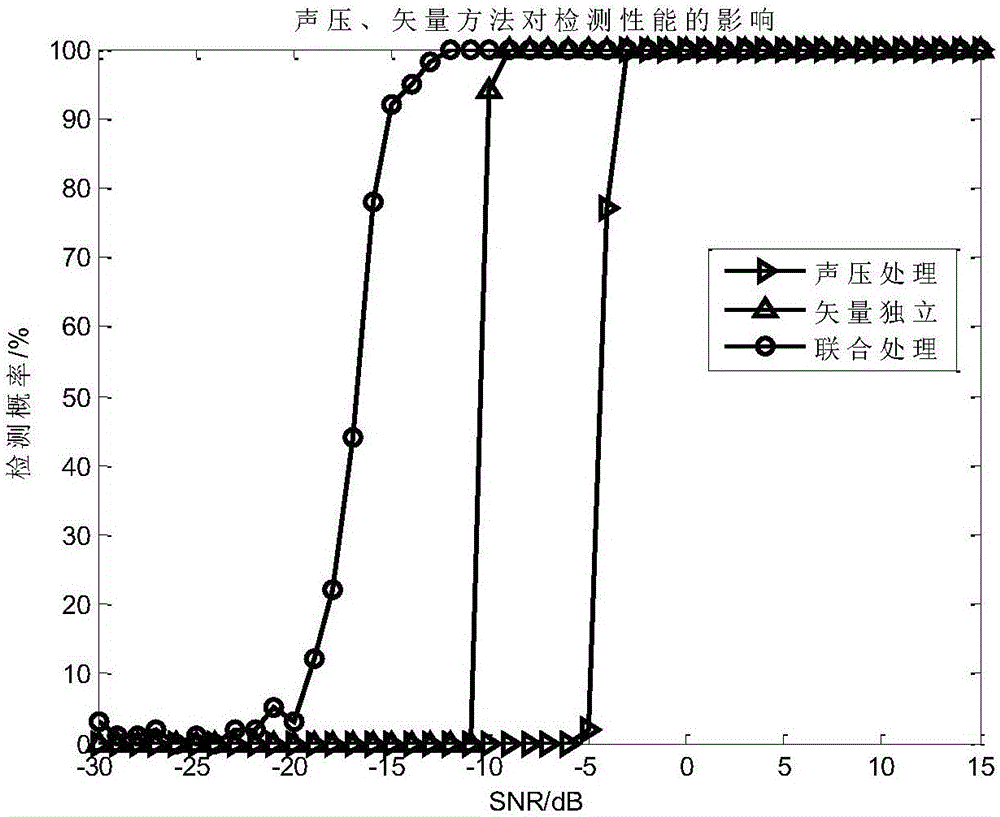

Acoustic vector circular array source number detection method based on characteristic value multiple threshold correction

ActiveCN105954709ALower SNR ThresholdImprove noise immunityDirection finders using ultrasonic/sonic/infrasonic wavesValue setCombined treatment

The invention belongs to the acoustic vector sensor array signal processing field, and more specifically relates to an acoustic vector circular array source number detection method based on characteristic value multiple threshold correction which is applied to underwater target remote passive detection. The method comprises establishing an acoustic vector circular array signal receiving model, obtaining acoustic vector circular array receiving acoustic pressure data, radial vibration velocity data and tangential vibration velocity, constructing a covariance matrix of acoustic vector circular array acoustic pressure and vibration velocity combined treatment, and decomposing characteristic values; and performing multiple threshold division treatment on a characteristic value set obtained by decomposing the covariance matrix to obtain a signal and noise corresponding characteristic value set. The method dynamically integrates an information theory detection method based on characteristic value multiple thresholds and the sound anti-noise performance of an acoustic vector circular array, obviously reduces the signal to noise ratio threshold of a detection algorithm, and overcomes the disadvantages that traditional detection methods such as MDL, diagonal loading MDL, and GDE are more sensitive to noise characteristic value change.

Owner:HARBIN ENG UNIV

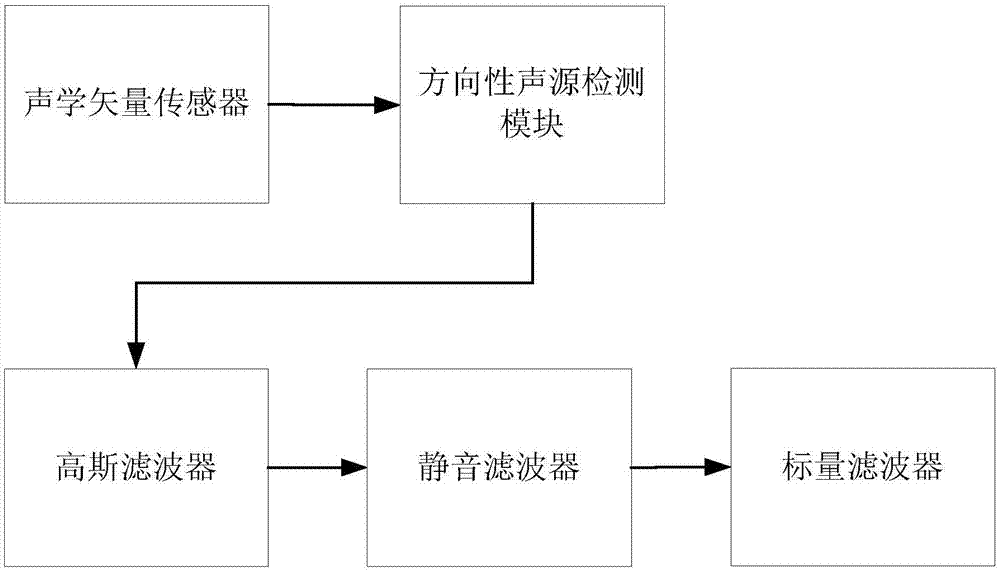

Speech enhancement device and method based on acoustic vector sensor space sharpening technique

ActiveCN107369460ASuppress background noiseReduce complexitySpeech analysisComputation complexityAcoustic vector sensor

The present invention relates to a speech enhancement device based on an acoustic vector sensor space sharpening technique comprising an acoustic vector sensor for collecting an audio signal, a directional sound source detection module, a Gaussian filter, a mute filter and a scalar filter. The audio signal collected by the acoustic vector sensor is subjected to beam processing through the directional sound source detection module, the Gaussian filter, the mute filter and the scalar filter which are sequentially connected to obtain an enhanced target direction voice. The present invention also provides a method of enhancing a target voice. By the speech enhancement device and the method, it is possible to effectively enhance all spatial directional sound sources and suppress background noise; in addition, the device has low computational complexity and is very advantageous for application and promotion on small devices.

Owner:SHENZHEN HIAN SPEECH SCI & TECH CO LTD

Quaternion ESPRIT parameter estimation method of sparse circular sound vector sensor array

ActiveCN106249225APreserve vector propertiesEmbodying OrthogonalityWave based measurement systemsQuaternionEstimation methods

Provided is a quaternion ESPRIT parameter estimation method of a sparse circular sound vector sensor array. The array receives K far-field narrowband sound signals of different frequencies and independent from one another, according to each of two groups of complex-domain data received by the array, the same sound pressure of sampling data of the array is overlapped with vibration speed data in three directions vertical to one another to form quaternion linear sampling data; characteristic decomposition and related operation are carried out on an autocorrelation matrix of full-array reception data to obtain estimated values of array guiding vectors; the estimated values of the array guiding vectors are used to reconstruct subarray guiding vectors, and the rotation-invariant relation among the subarray guiding vectors is used to obtain a roughly estimated value of the cosine in the signal direction; and the roughly estimated value of the cosine in the signal direction is used to determine a phase period fuzzy number of a spatial domain guiding vector, and a least square method is used to obtain an accurate estimated value of the arrival angle of the signal. According to the invention, orthogonal feature among components of the sound vector sensors is maintained, error robustness of a model is higher, and the problem of phase fuzziness of the sparse vector sensor circular array is solved.

Owner:HARBIN ZHONGDA KERUI ELECTRIC POWER

Ultra low frequency acoustic vector sensor

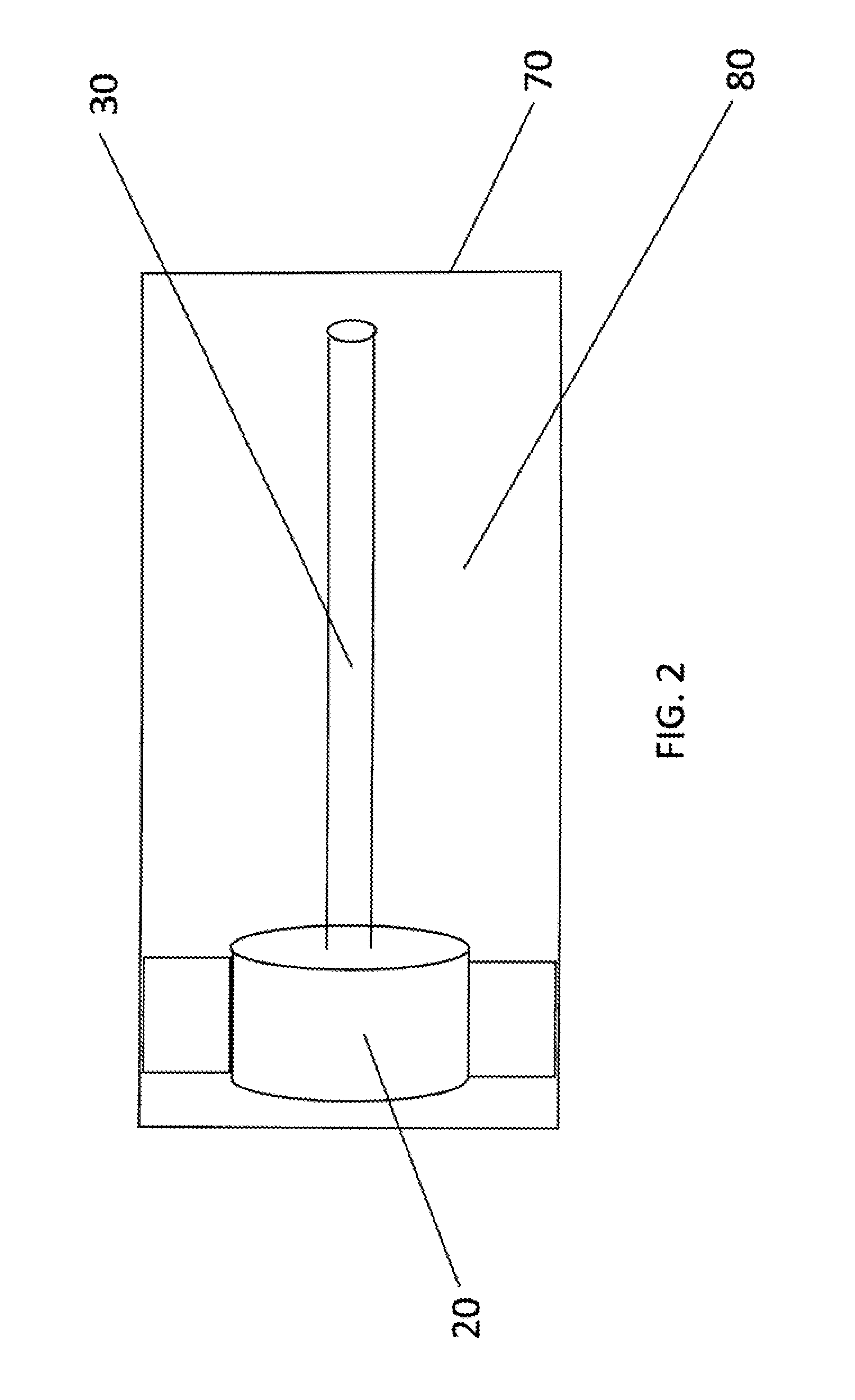

ActiveUS8085622B2Vibration measurement in fluidVolume/mass flow measurementAcoustic vector sensorAcoustic wave

An acoustic vector sensor mounted in a housing is provided for measuring ultra low frequency acoustic wave particle velocities in a liquid, comprising a horn for amplifying the acoustic wave particle velocities, and a neutrally buoyant object supported in a liquid contained in the horn. The neutrally buoyant object, in reacting to the amplified acoustic wave particle velocities, produces displacements that are sensitively measured.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

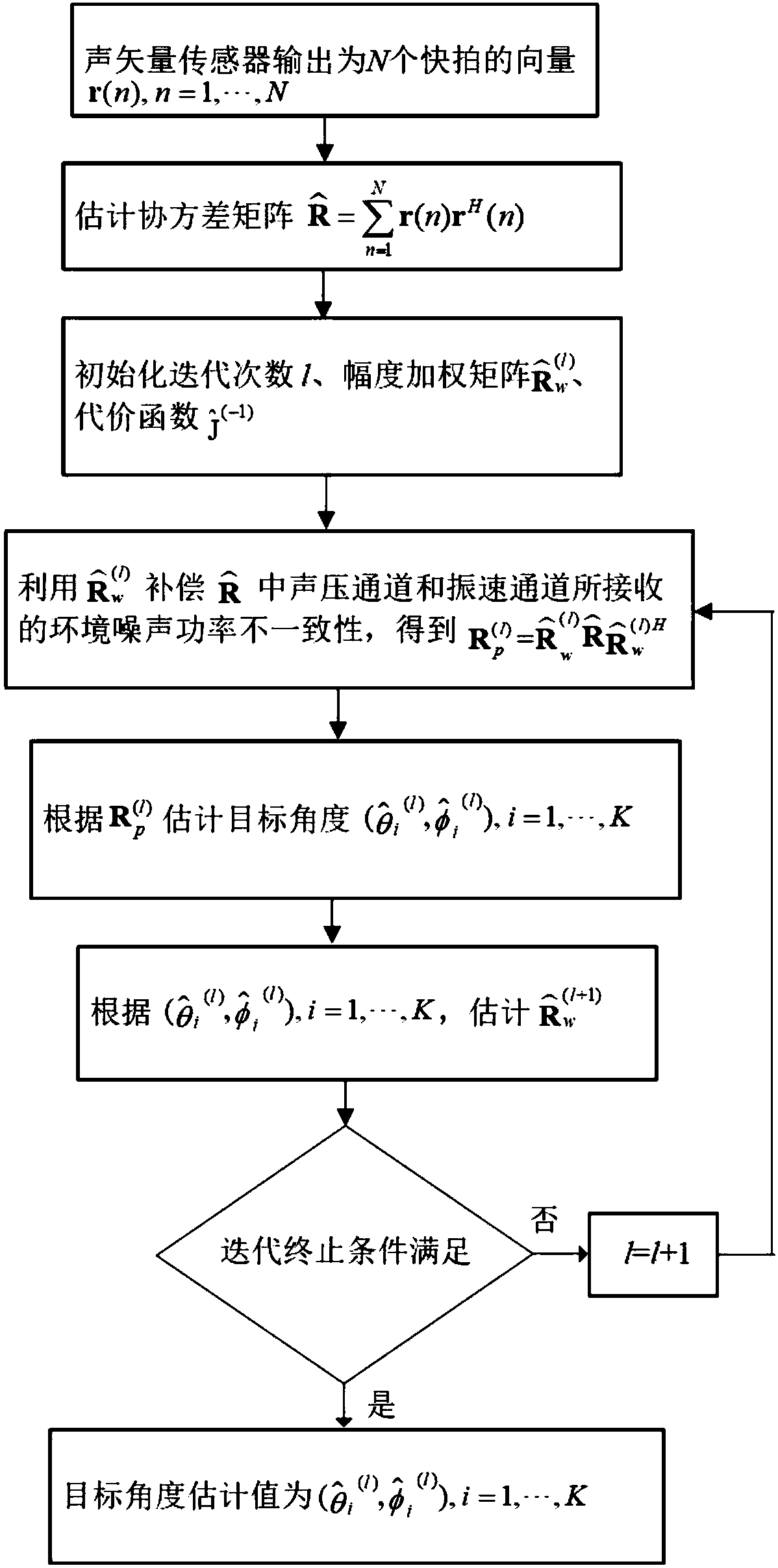

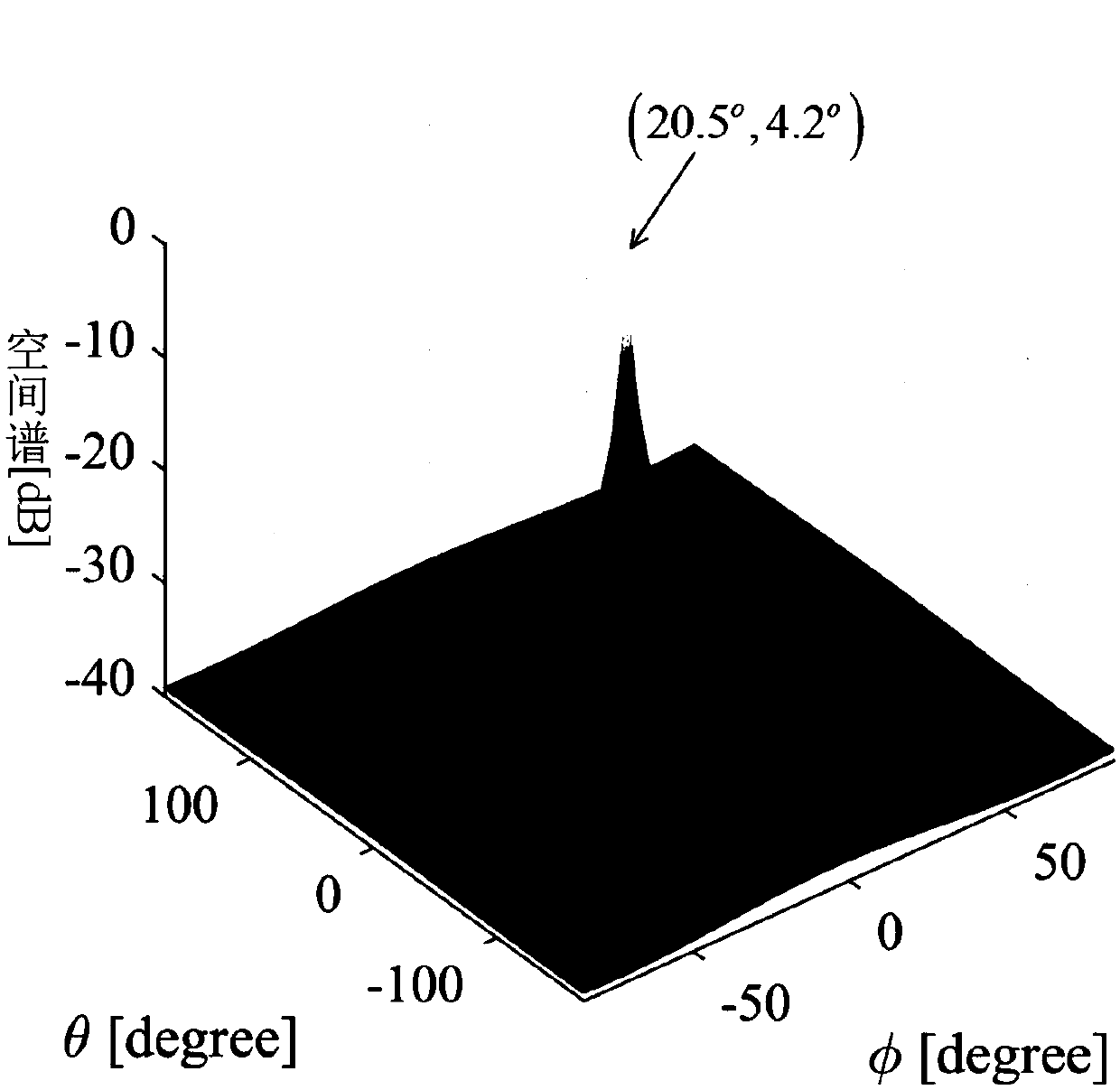

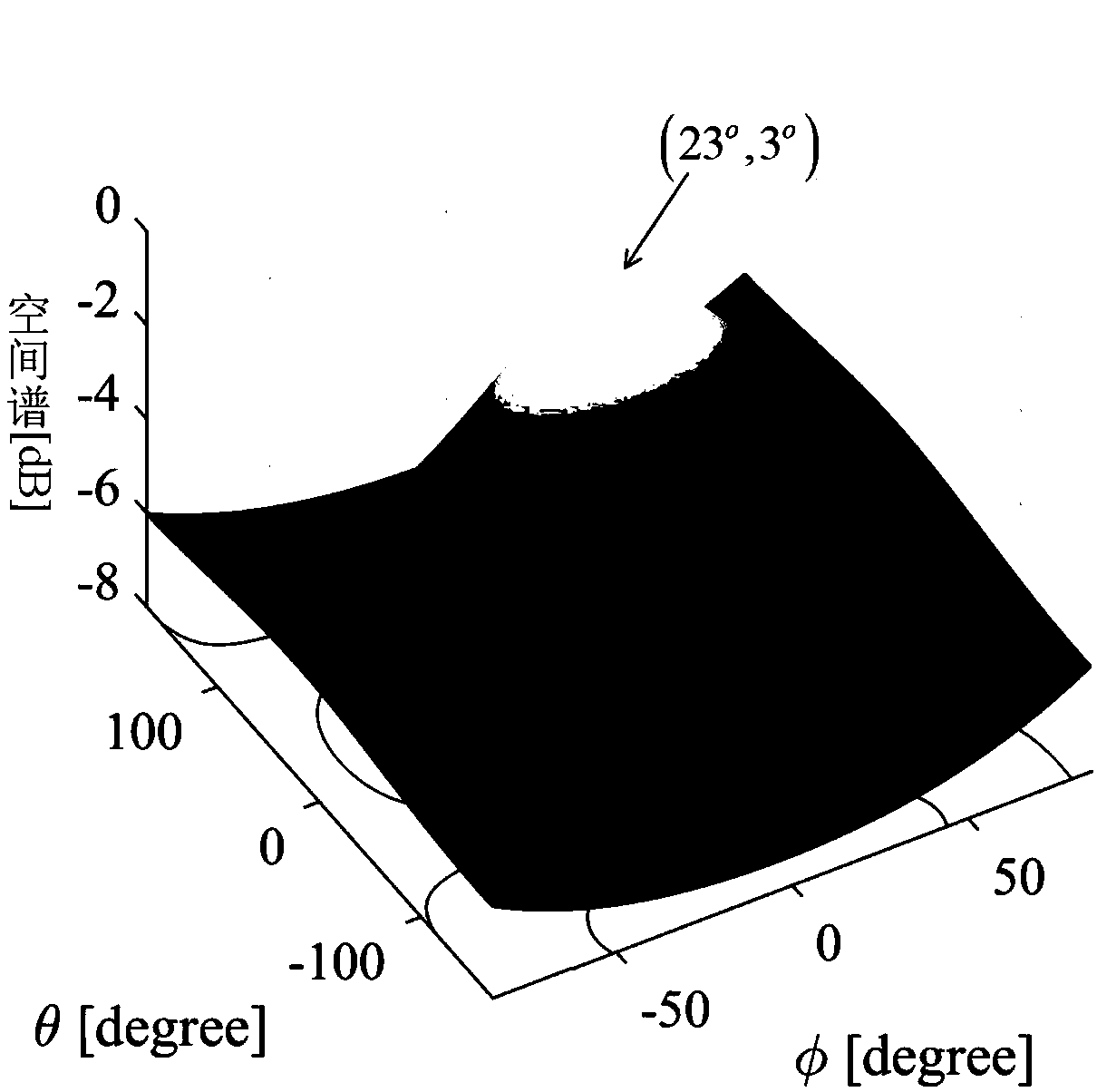

Acoustic vector sensor amplitude weight MUSIC direction finding method

ActiveCN108469599ACompensation inconsistencyImprove estimation accuracyDirection finders using ultrasonic/sonic/infrasonic wavesSignal-to-quantization-noise ratioSound pressure

The invention discloses an acoustic vector sensor amplitude weight MUSIC direction finding method, belongs to the sensor signal processing technical field, and specifically relates to a method that uses a single acoustic vector sensor to carry out target direction finding in a sea environment noise field; the method is realized via an acoustic vector sensor; the acoustic vector sensor comprises asound pressure sensor and three vibration velocity sensor in a space common point mode, and can simultaneously measure the sound pressure and three vibration velocity components in x, y and z directions. The method combines to consider target angle and sound pressure channel and vibration velocity channel ambient noise powers, compensates the sound pressure and vibration velocity channel ambient noise power non-consistency, thus ensuring high estimation precision and resolution under a low signal to noise ratio condition; the method can solve the problems that an existing MUSIC direction finding technology is high in sidelobe and fat in main lobe, and cannot distinguish two targets in the sea environment noise field; the method can be applied to solve the passive direction finding problemsof a weak target and dual-target in the sea environment noise field.

Owner:HARBIN ENG UNIV

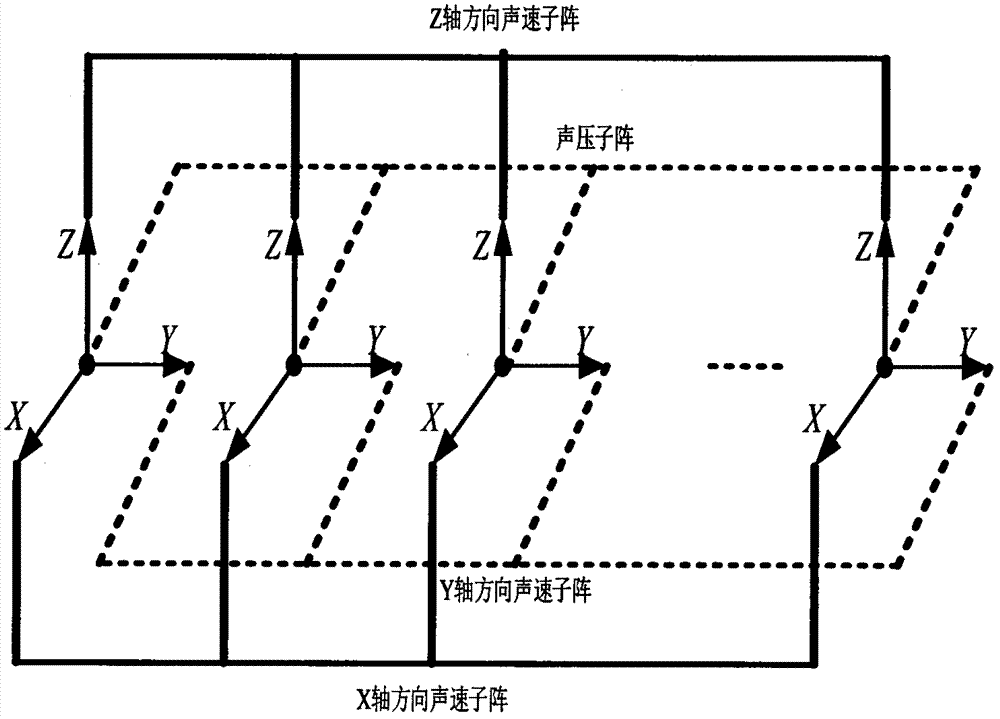

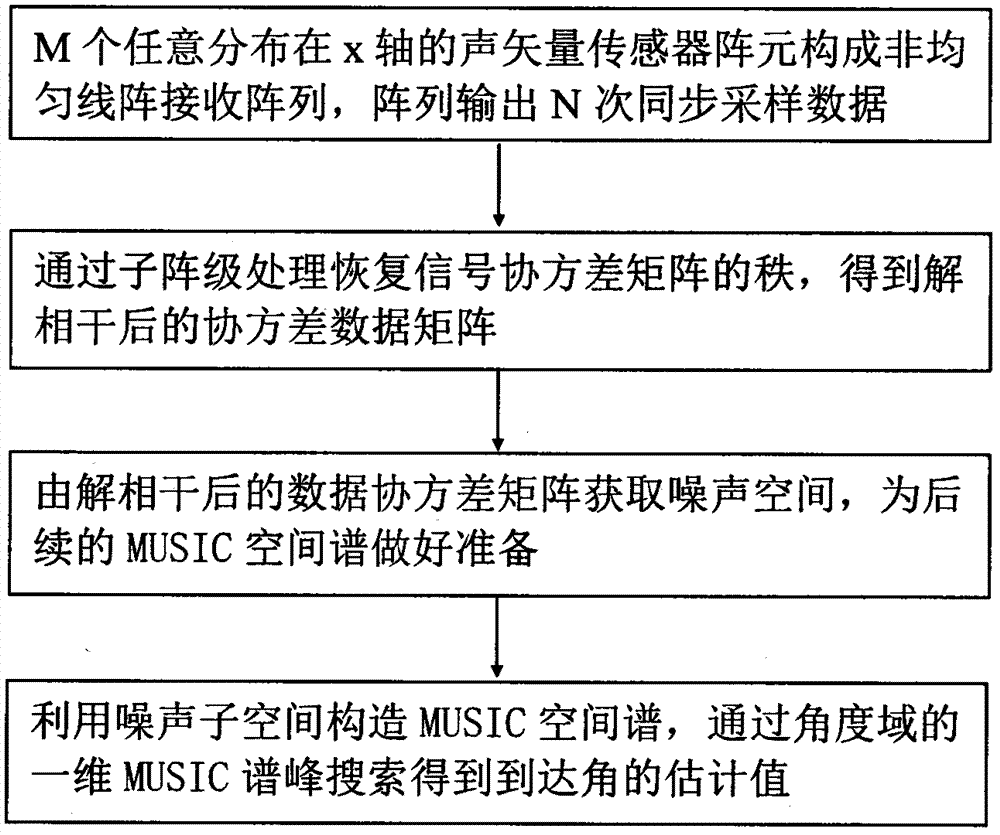

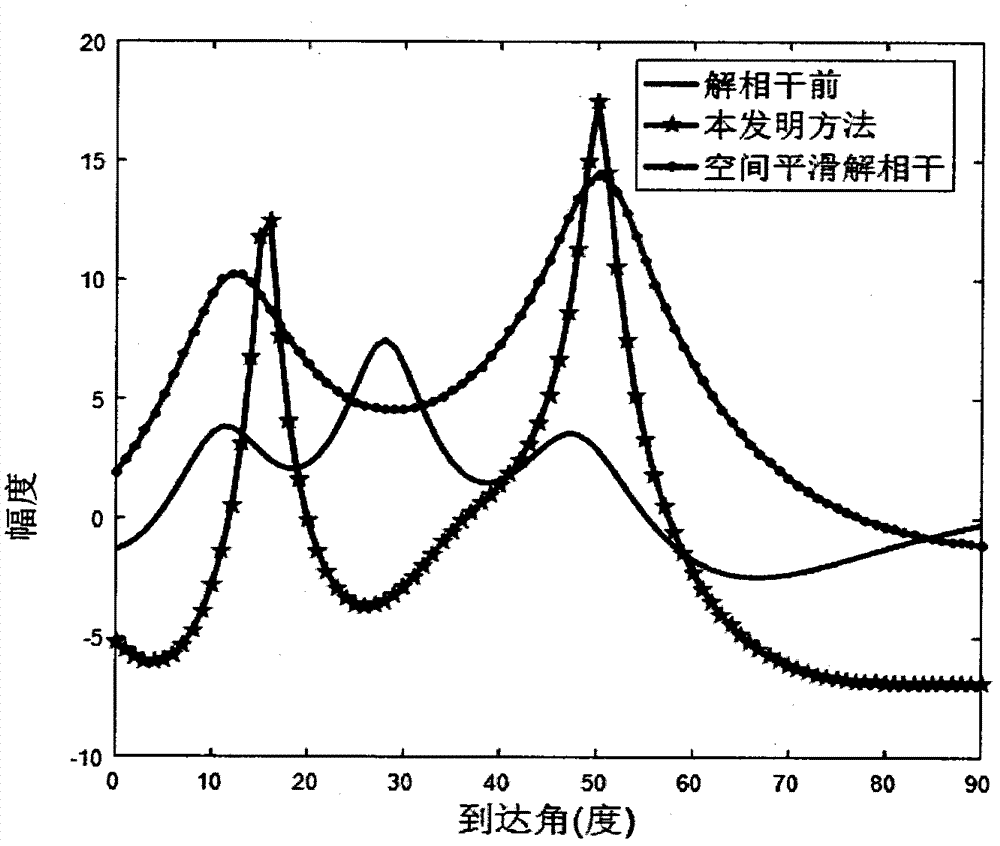

Acoustic vector sensor array space rotation solution coherence arrival angle estimation method

InactiveCN106997037ANo reduced aperture informationIncrease spaceDiversity direction findingUsing reradiationHigh spatial resolutionEstimation methods

The invention provides an acoustic vector sensor array space rotation solution coherence arrival angle estimation method. An array receives K coherence narrowbands and a stationary far-field signal. The single-shot snapshot output data of all elements are acquired through a receiving array. N-times snapshot data of the array are measured. The orthogonal vector characteristic of an acoustic vector sensor is fully used. The acoustic vector sensor array is divided into four sub-arrays of an acoustic pressure sub-array, an x-axis vibration velocity sub-array, a y-axis vibration velocity sub-array and a z-axis vibration velocity sub-array. The signal covariance matrix rank is acquired through sub-array processing, so as to acquire a data covariance matrix after solution coherence. A noise space is acquired through the data covariance matrix after solution coherence. A noise subspace is used to construct a MUSIC spatial spectrum. The estimated value of an arrival angle is acquired by searching the one-dimensional MUSIC peak of an angular domain. Compared with a spatial smooth de-coherence method, the method provided by the invention is applicable to a uniform linear array and a non-uniform linear array, is free of aperture loss, and has the advantages of higher spatial resolution, orientation accuracy and wide application range.

Owner:XIDIAN UNIV

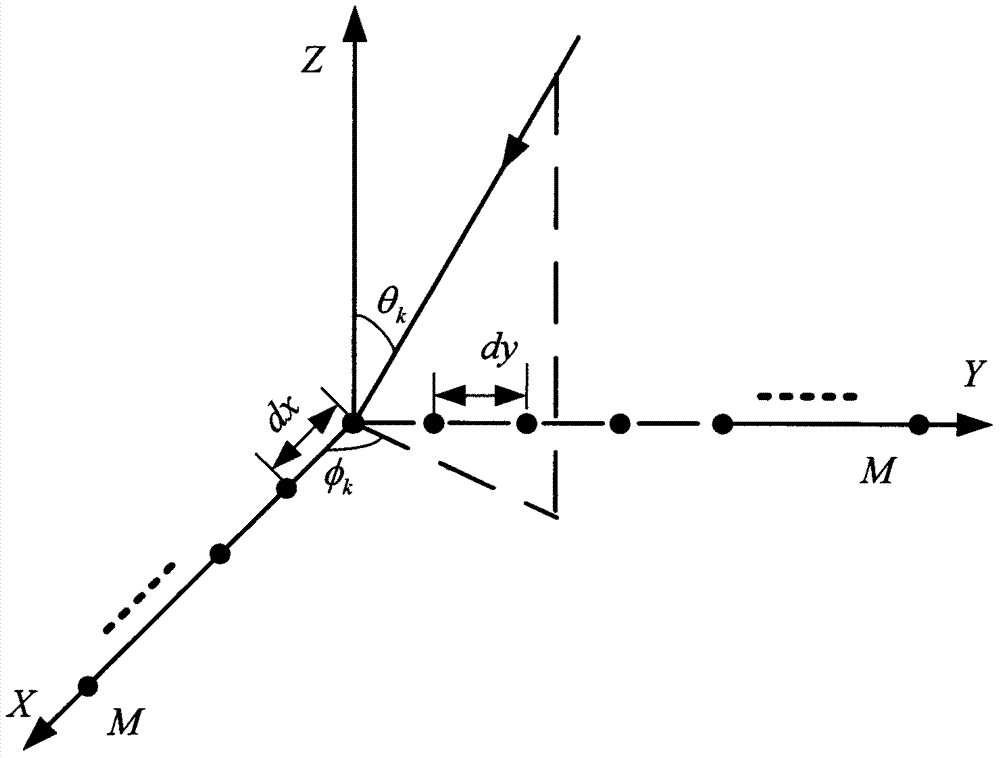

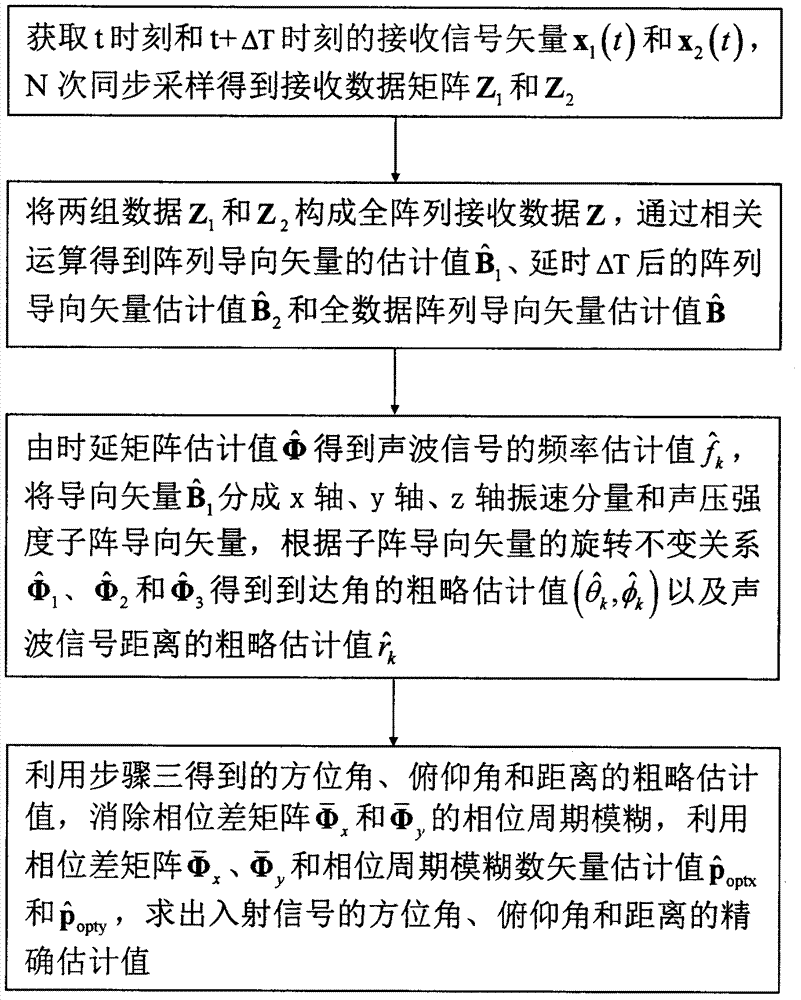

Near-field source L-type acoustic vector sensor array ambiguity-resolving multi-parameter estimation method

ActiveCN106872936ASimple algorithmSmall amount of calculationDirection finders using ultrasonic/sonic/infrasonic wavesUsing reradiationPhase differenceAmbiguity

The invention provides a near-field source L-type acoustic vector sensor array ambiguity-resolving multi-parameter estimation method. The method is characterized in that the array receives K different-frequency narrow-band independent stationary near-field signals; full array reception data z is subjected to correlation operation to obtain array steering vector estimation values, B<^>1 and B<^>2,before and after time delay respectively and a full data array steering vector estimation value B<^>; a frequency estimation value f<^>k is obtained through a delay matrix estimation value [phi]<^>, the array steering vector estimation value B<^>1 is divided into x-axis, y-axis and z-axis vibration velocity components and sound pressure intensity sub-matrix steering vector, and according to rotation invariant relation [phi]<^>1, [phi]<^>2 and [phi]<^>3 of the sub-matrix steering vector, an angle-of-arrival roughly-estimated value (theta<^>k, phi<^>k) and a distance roughly-estimated value r<^>k) are obtained; and through azimuth angle and pitch angel and the distance roughly-estimated values, phase difference matrix period fuzzy number estimation vectors p<^>optx and p<^>opty in the x-axis and y-axis directions are determined, and thus azimuth angle, pitch angel and distance accurately-estimated values of an incident signal can be obtained. The method makes full use of orthogonality of an acoustic vector sensor itself and array aperture information to carry out parameter estimation, and gives a closed-form solution of parameter estimation; and spectrum peak search is not needed, and calculation amount is small.

Owner:SHAANXI SCI TECH UNIV

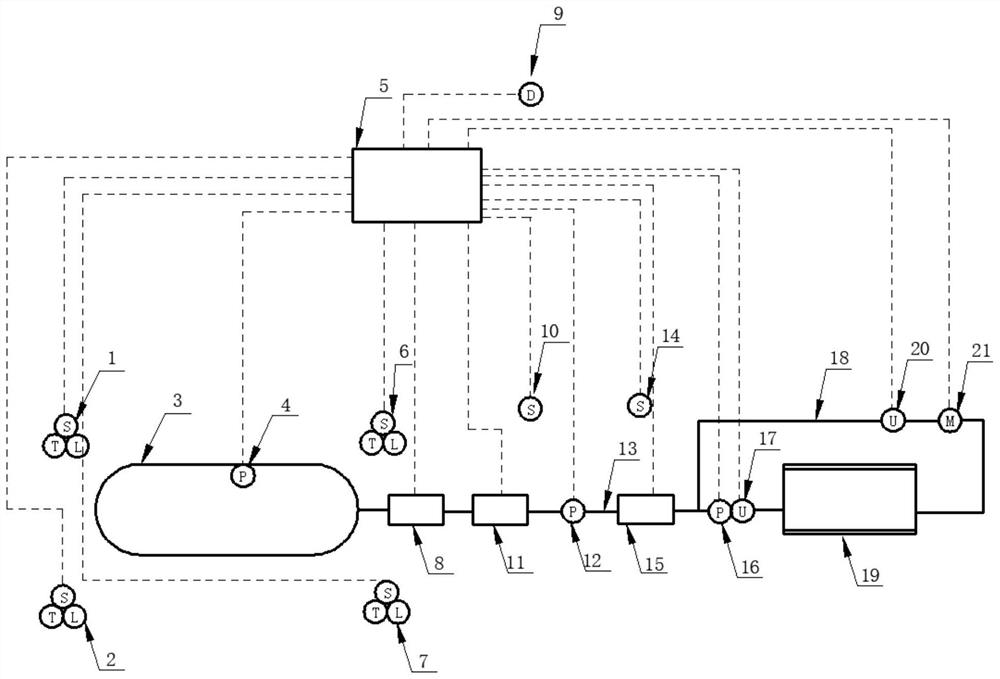

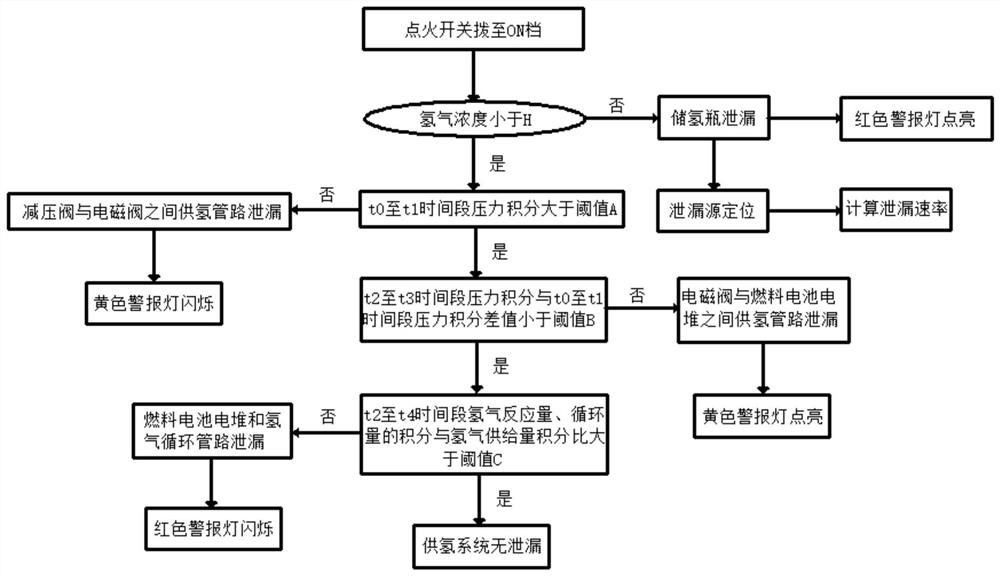

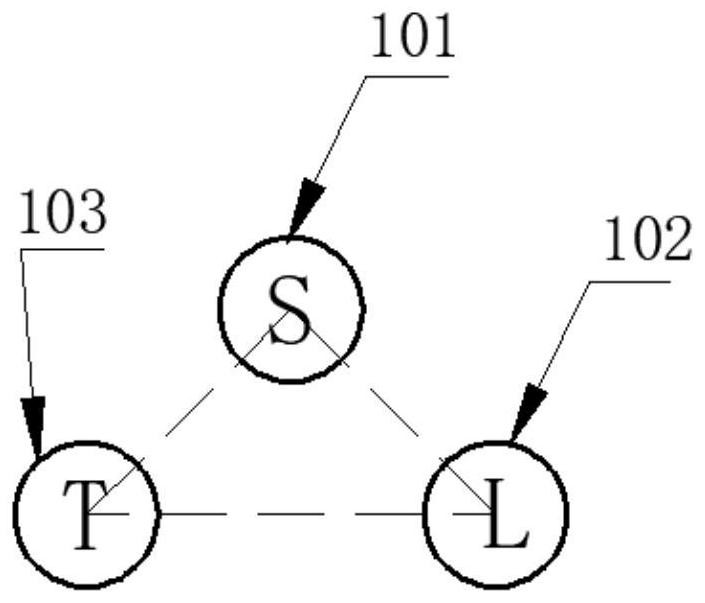

Detection system and detection method for hydrogen leakage of fuel cell vehicle

ActiveCN113720537AReduce misuseExact relative positionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateHydrogen concentrationAcoustic vector sensor

The invention provides a detection system and detection method for hydrogen leakage of a fuel cell vehicle. The method comprises the steps that: the relative position of a leakage source is determined through a signal incident angle of an acoustic vector sensor and a numerical value of a trigonometric function of the signal incident angle if the hydrogen concentration in a detection system reaches a threshold value before starting, and the relative position is converted into a distance to a reference plane through coordinates, the hydrogen leakage rate is estimated through a neural network based on error back propagation,the leakage degree is judged; and if the hydrogen concentration does not reach the threshold value, whether a hydrogen supply pipeline leaks or not is judged by comparing the integral of the pressure of the hydrogen supply pipeline to the time with the threshold value, and whether a fuel cell stack and a hydrogen circulation pipeline leak or not is determined through the hydrogen reaction and the proportion of the sum of a remaining amount to a supply amount. The position of the hydrogen leakage source can be judged and displayed, and meanwhile the leakage rate of the leakage source at a hydrogen storage bottle can be estimated.

Owner:JIANGSU YONGYA AUTOMOBILE ACCESSORY CO LTD

Ultra low frequency acoustic vector sensor

ActiveUS20090245028A1Overcome disadvantagesOvercome problemsVibration measurement in fluidVolume/mass flow measurementAcoustic vector sensorAcoustic wave

An acoustic vector sensor mounted in a housing is provided for measuring ultra low frequency acoustic wave particle velocities in a liquid, comprising a horn for amplifying the acoustic wave particle velocities, and a neutrally buoyant object supported in a liquid contained in the horn. The neutrally buoyant object, in reacting to the amplified acoustic wave particle velocities, produces displacements that are sensitively measured.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

L type simplified acoustic vector sensor array multi-parameter joint estimation quaternion method

ActiveCN106154220AGood robustness to model errorsOrthogonal characteristic embodimentDirection/deviation determination systemsDecompositionArray element

The invention relates to an L type simplified acoustic vector sensor array multi-parameter joint estimation quaternion method. According to the method, an array receives K far-field and uncorrelated narrow-band acoustic signals with different frequencies; two groups of data received by the array are superposed according to the sound pressure of the same array element as well as vibration velocities in the direction of an x axis and the direction of a y axis so as to form full-array receiving quaternion data; autocorrelation matrix feature decomposition is carried out on the data, so that the estimated value of an array steering vector is obtained; the estimation of sub-array steering vectors is reconstructed according to the estimated value of the array steering vector, and the rough estimated value of the direction cosine of the signals is obtained according to the rotation invariant relation of the sub-array steering vectors; and the translation invariant relationship matrix of sub-arrays on the x axis and the y axis can be obtained through using the translation invariant relationship of the sub-arrays on the x axis and the y axis, and the phase cycle fuzzy number of the translation invariant relationship matrix in the direction of the x axis and the direction of the y axis is determined according to the rough estimated value of the direction cosine, and therefore, the accurate estimated values of an azimuth angle and a pitch angle can be obtained. With the method of the invention adopted, the orthogonality between the components of an acoustic vector sensor can be kept, and better model error robustness can be achieved.

Owner:国骄胶粘新材料产业园管理有限公司

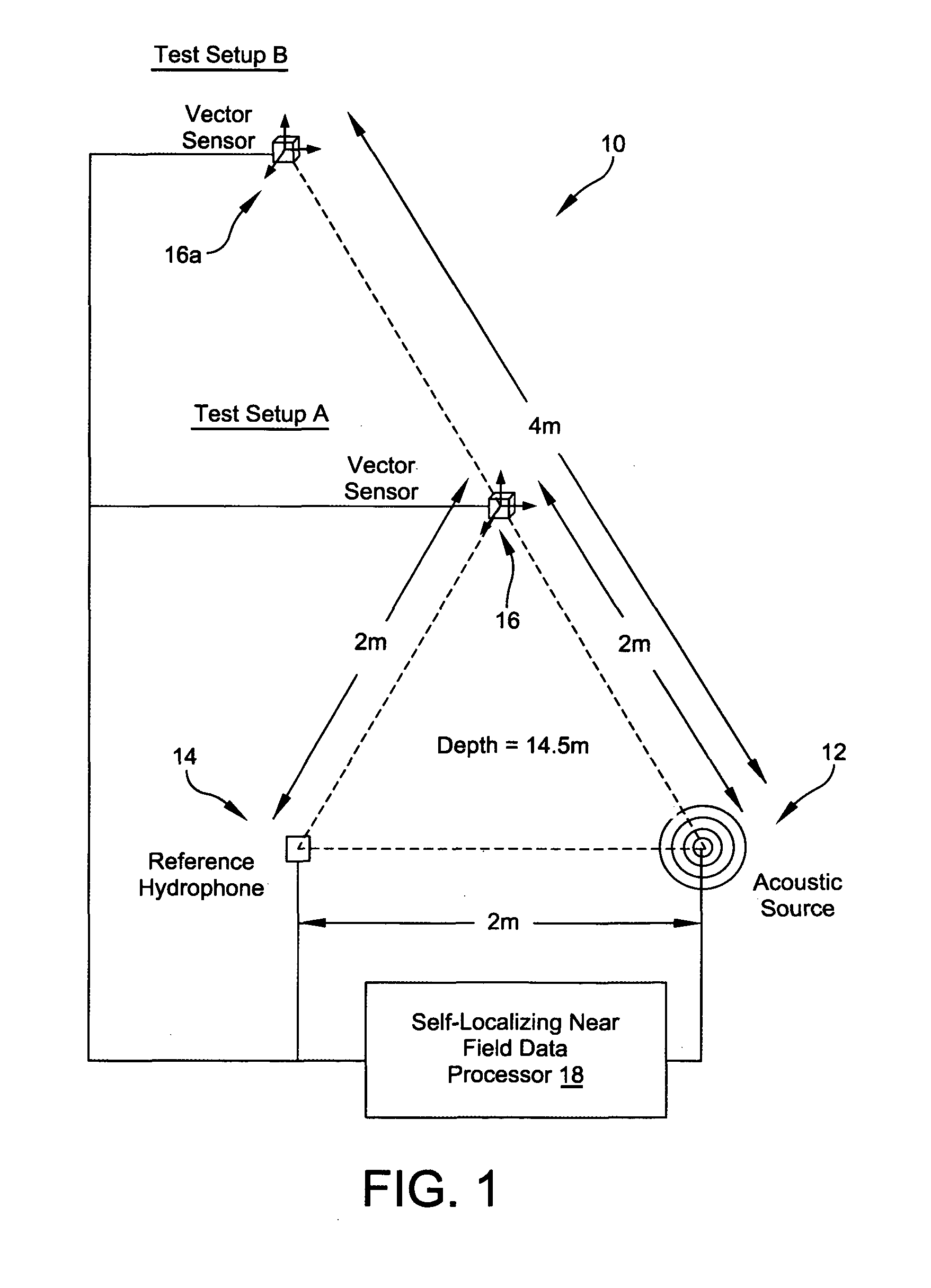

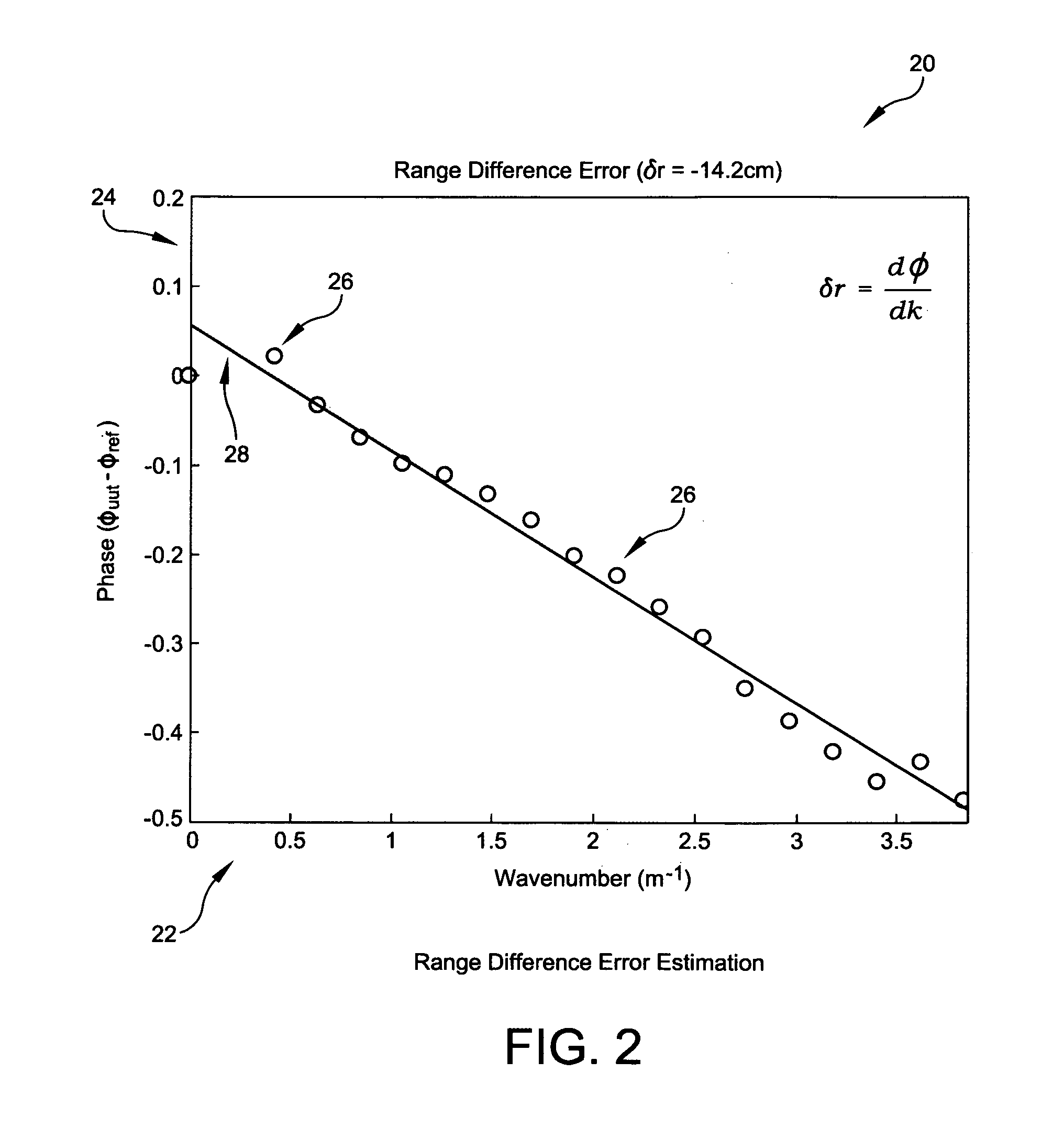

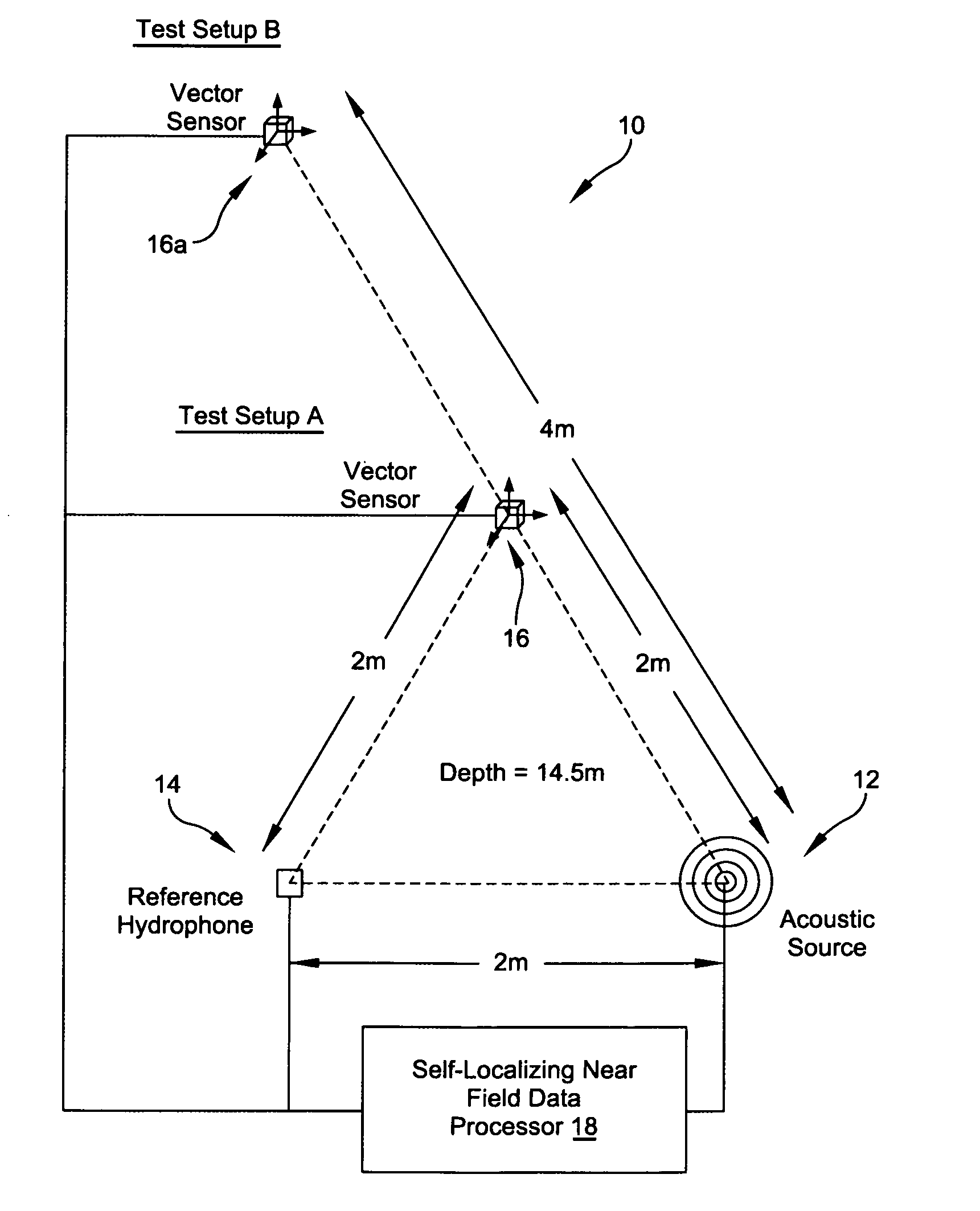

System for self-localizing near field data processing

InactiveUS9001614B1Improve accuracyTransmission monitoringDirection/deviation determination systemsAcoustic vector sensorField data

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

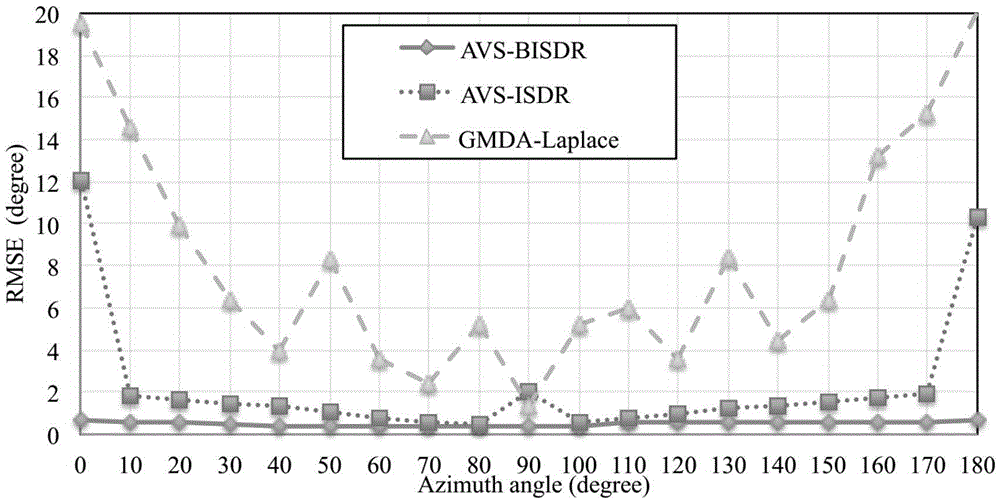

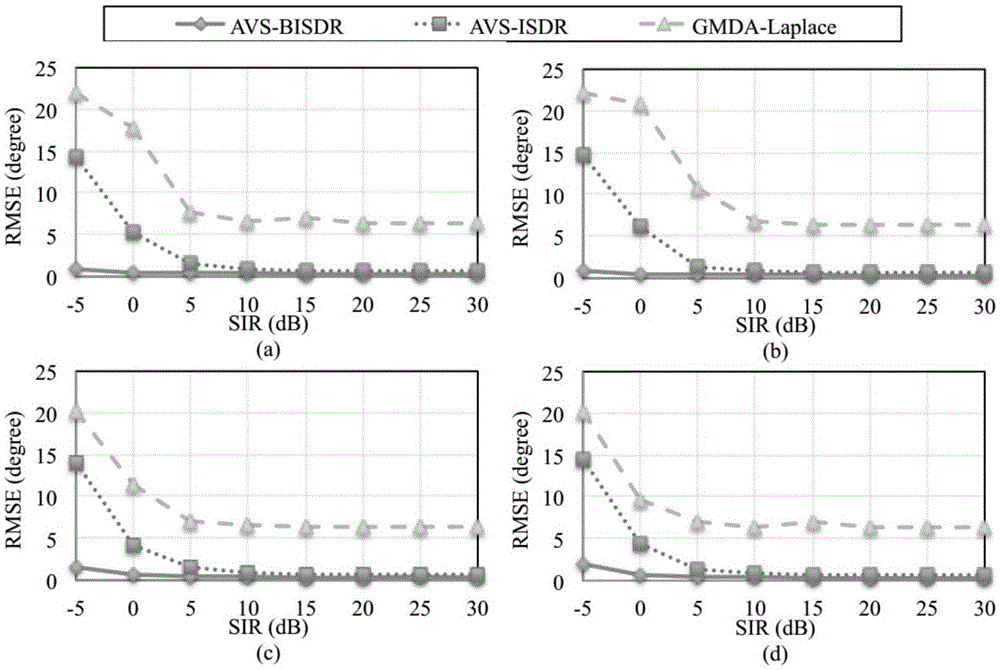

Robust monolingual sound source DOA estimation method based on acoustic vector sensor and bispectrum transformation

ActiveCN105676167AHigh precisionHigh Accuracy Monolingual Sound Source DOA EstimationDirection finders using electromagnetic wavesSound sourcesSignal acquisition

The invention provides a robust monolingual sound source DOA estimation method based on an acoustic vector sensor and bispectrum transformation. The method adopts an acoustic vector sensor (AVS), realizes four-channel voice signal acquisition, performs bispectrum transformation on collected data, and obtains corresponding bispectrum data. A trigonometric function relation between AVS receiving components on bispectrum is utilized to calculate a data ratio between AVS sensor components. A bispectrum mask spectrum is calculated, frequency points with high signal to interference ratios are extracted, a KDE method is utilized to cluster the points, and on this basis, the direction of arrival (DOA) of a voice sound source is obtained by calculation. The method provided by the invention can estimate the DOA of the monolingual sound source with high precision under the conditions of different room reverberation, interference noise types and interference noise intensity. In addition, the AVS sensor used by the method which is only 1cm3 in size is very suitable for voice technology application on a portable device.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

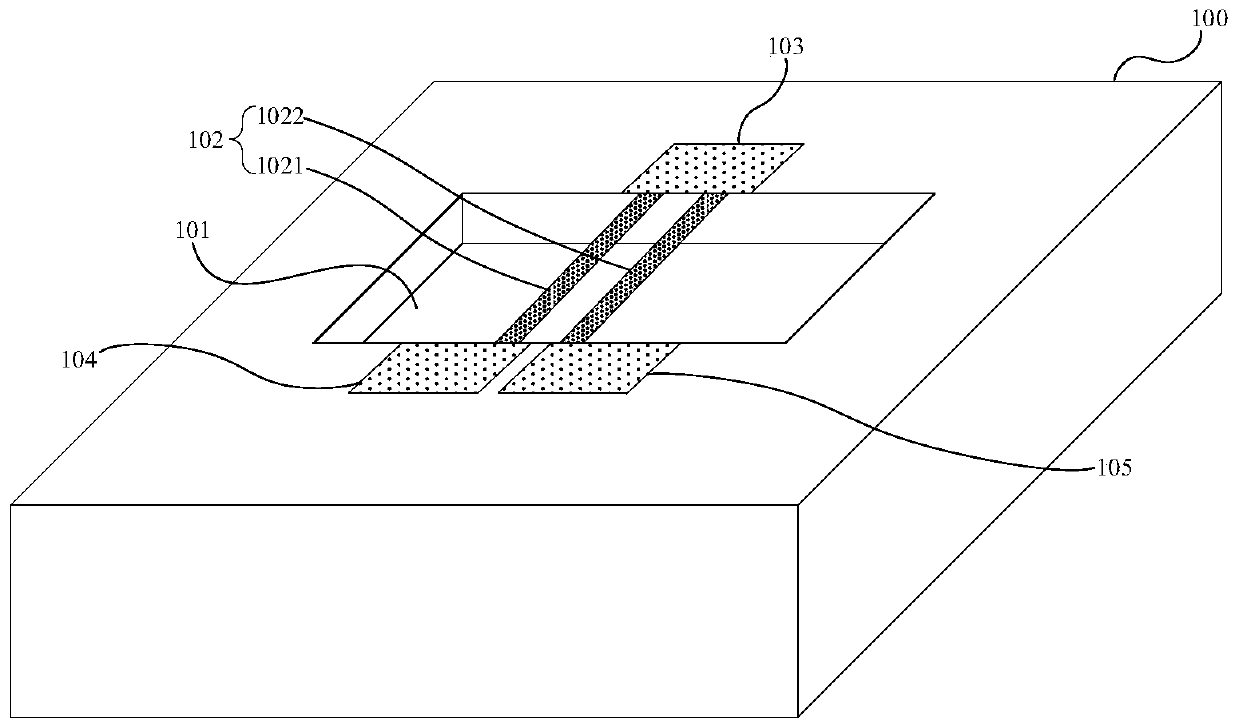

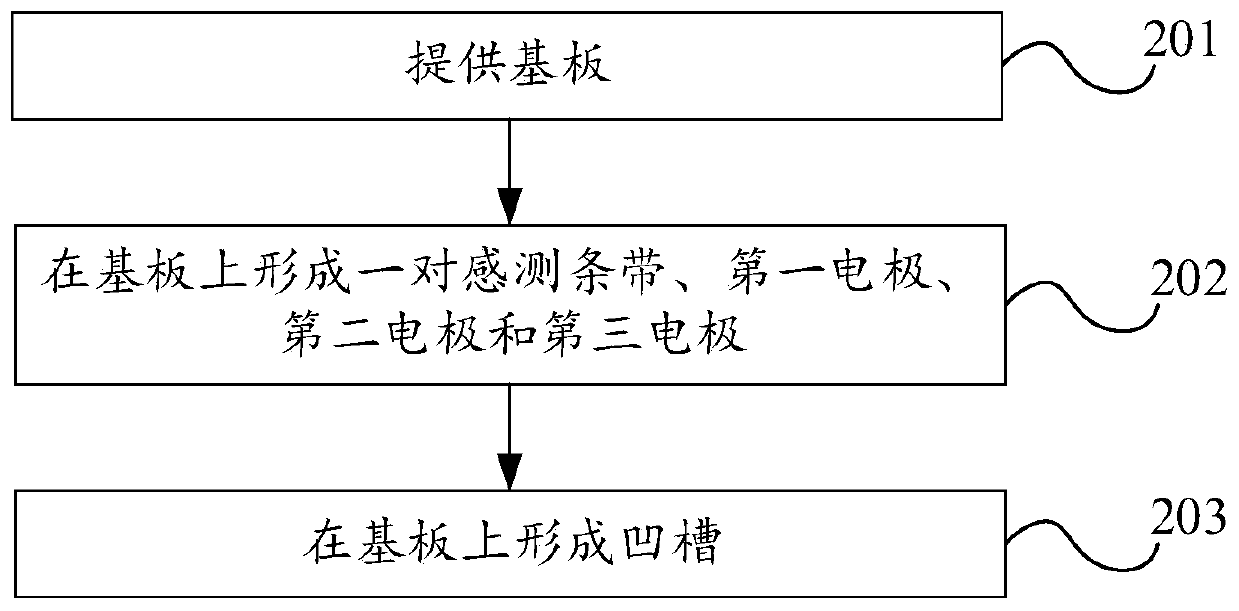

Acoustic vector sensor and production method thereof

InactiveCN109752078ARealize sensingMiniaturizationSubsonic/sonic/ultrasonic wave measurementUsing electrical meansElectrical resistance and conductancePower flow

The invention provides an acoustic vector sensor and a production method thereof and relates to the field of an acoustic sensor. The acoustic vector sensor comprises a base plate, wherein a groove isformed on the base plate; a pair of sensing bands which are set at two sides of the groove in a spanning mode and are set on the base plate, wherein the pair of sensing bands comprise bearing insulating parts and graphene film; and a first electrode, a second electrode and a third electrode which are set on the base plate. When a current is applied to the graphene film through utilization of the electrodes, heat is generated, temperature is changed resulting from the fact that air around the graphene film is disturbed due to an acoustic wave, further a resistance value of the graphene film ischanged, and through detection of the change of the resistance value, acoustic particle vibration speed can be measured, so the acoustic wave is detected. A structure of the acoustic vector sensor canbe prepared by a method compatible with a micro-electro-mechanical system technology. The structure also can be miniaturized.

Owner:南京粒子声学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com