Patents

Literature

311results about How to "Inhibition of hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

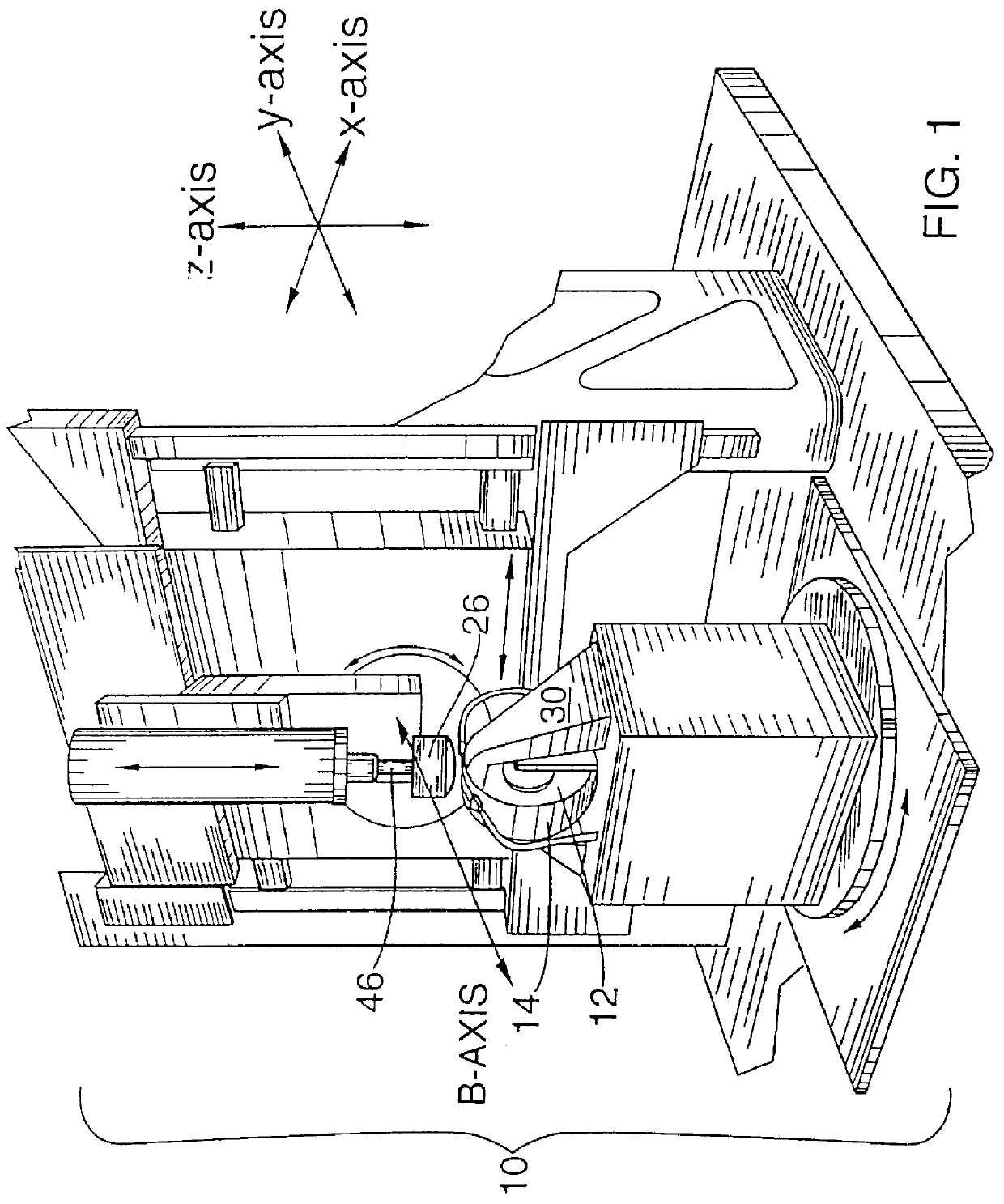

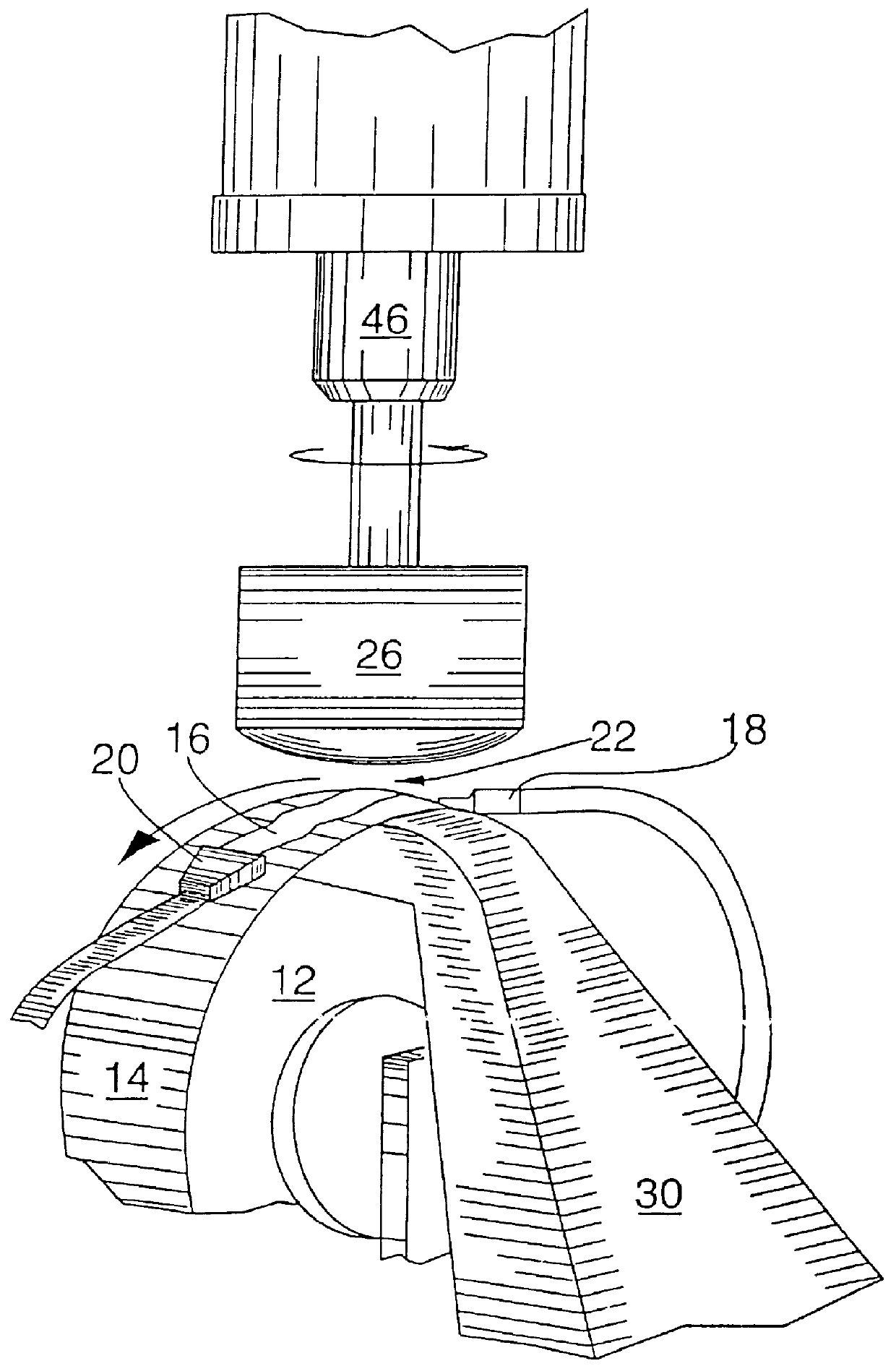

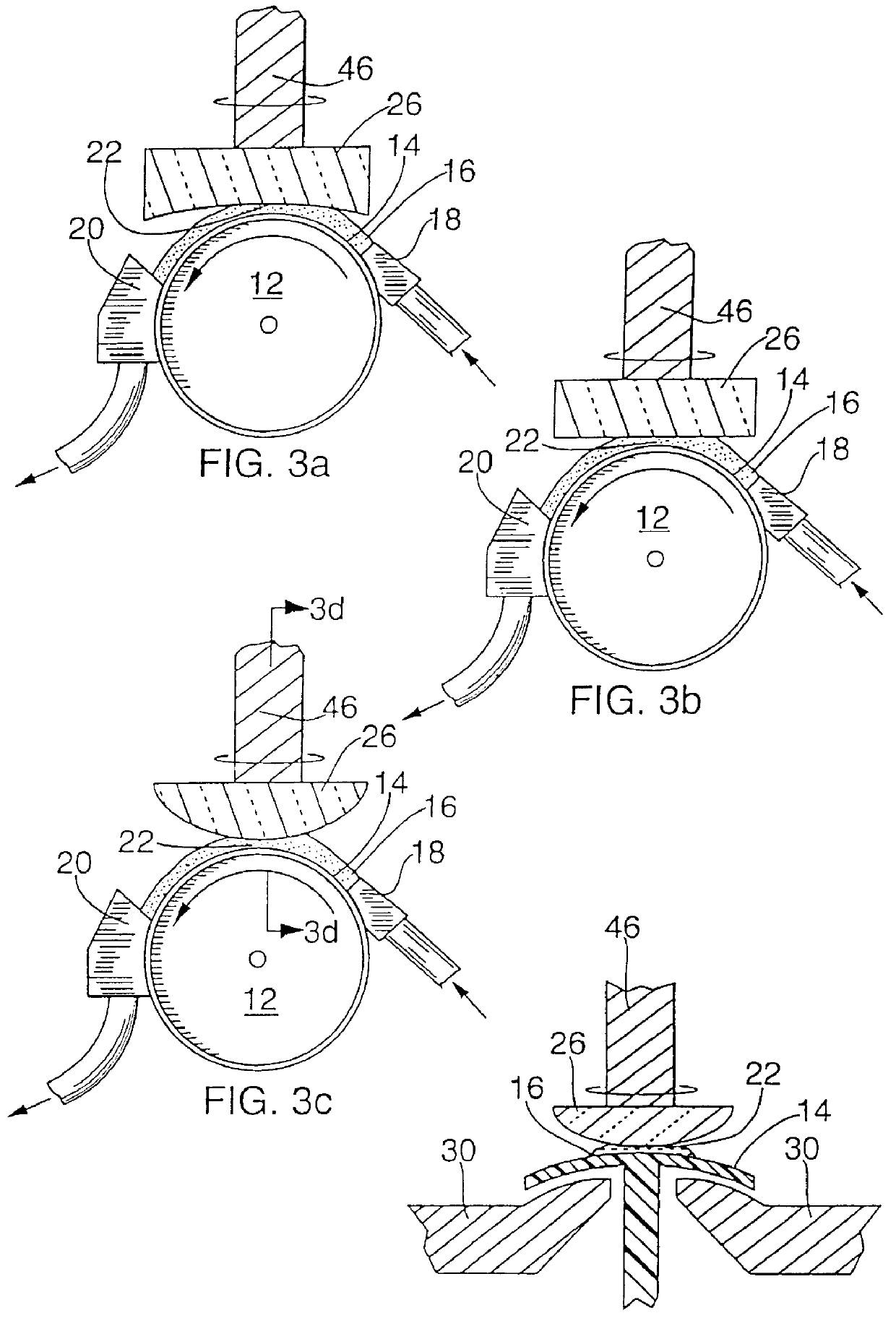

Deterministic magnetorheological finishing

InactiveUS6106380AConstantHigh viscosityEdge grinding machinesNanomagnetismMaterial removalMagnetorheological finishing

A method and apparatus for finishing a workpiece surface using MR fluid is provided wherein the workpiece is positioned near a carrier surface such that a converging gap is defined between a portion of the workpiece surface and the carrier surface; a magnetic field is applied substantially at said gap; a flow of stiffened MR fluid is introduced into said converging gap such that a work zone is created in the MR fluid to form a sub-aperture transient finishing tool for engaging and causing material removal at the portion of the workpiece surface; and the workpiece or the work zone is moved relative to the other to expose different portions of the workpiece surface to the work zone for predetermined time periods to selectively finish said portions of said workpiece surface to predetermined degrees.

Owner:QED TECH INT

A low-cost precision casting method for titanium alloy and titanium-aluminum alloy

InactiveCN102294436AIncrease contentControl quality costFoundry mouldsFoundry coresPolyvinyl alcoholTitanium alloy

The invention relates to a method for precisely casting a titanium alloy and a titanium aluminum alloy with low cost, which relates to a method for precisely casting the titanium alloy and the titanium aluminum alloy, and solves the technical problem that cast pieces have low surface quality and internal quality in the conventional method for lowering the cost of precisely casting the titanium alloy and the titanium aluminum alloy by using electrically-fused alumina and silica sol. The method comprises the following steps of: preparing a surface layer binder from zirconium sol, silica sol, a wetting agent JFC, n-octyl alcohol, polyvinyl alcohol and latex; adding calcium carbonate, alumina, titanium dioxide and zirconia to prepare a surface layer coating; preparing a shell surface layer; preparing a shell back layer by a universal method for precisely casting the titanium alloy; dewaxing and sintering to obtain a shell; and casting the titanium alloy or the titanium aluminum alloy by using the shell so as to obtain a titanium alloy cast piece or a titanium aluminum alloy cast piece. Compared with a precise casting method by purely using a zirconium-based binder and a zirconia fireproof material, the method has the advantage that raw material cost is lowered by 30 to 70 percent and the method can be used for civil titanium alloy cast pieces and titanium aluminum alloy cast pieces for common aviation.

Owner:HARBIN SHITAI NEW MATERIAL TECH & DEV

Concrete mixtures having high flowability

InactiveUS20070056480A1Improve liquidityAvoid excessive viscositySolid waste managementCeramicwarePolymer scienceViscosity modifier

A viscosity modifying agent is added to a concrete mixture to give the concrete desirable rheological properties. The viscosity modifying agent is incorporated into a foam admixture before it is mixed into the concrete. Because the viscosity modifying agent is a component of the foam admixture, the viscosity modifying agent is dispersed in the aqueous film that forms the foam bubbles. The viscosity modifier in the foam bubbles gives the foam beneficial rheological properties. The viscosity modifier performs more efficiently when included in the foam bubbles as compared to being mixed directly into the concrete. The foam bubbles containing the viscosity modifier can be stabilized using a fluorochemical stabilizer, which is included in the foam admixture. The foam bubbles can be further stabilized with respect to cement mixtures by including a hydration stabilizing in the cement mixture.

Owner:WELKER CHARLES D

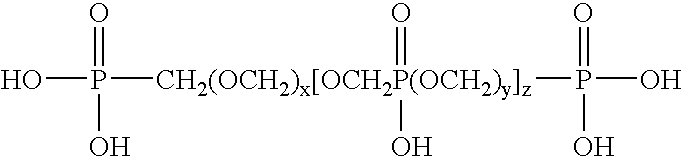

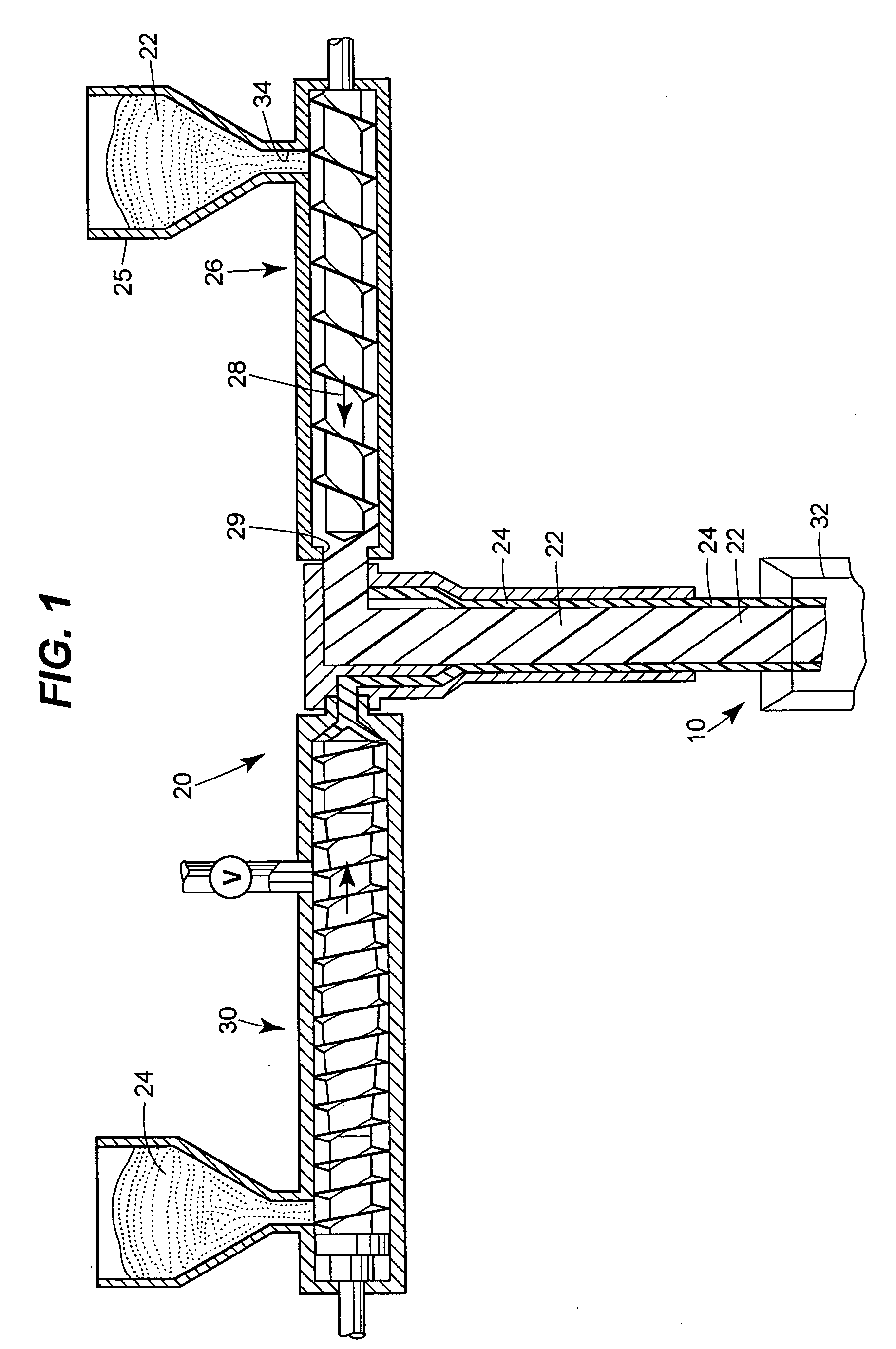

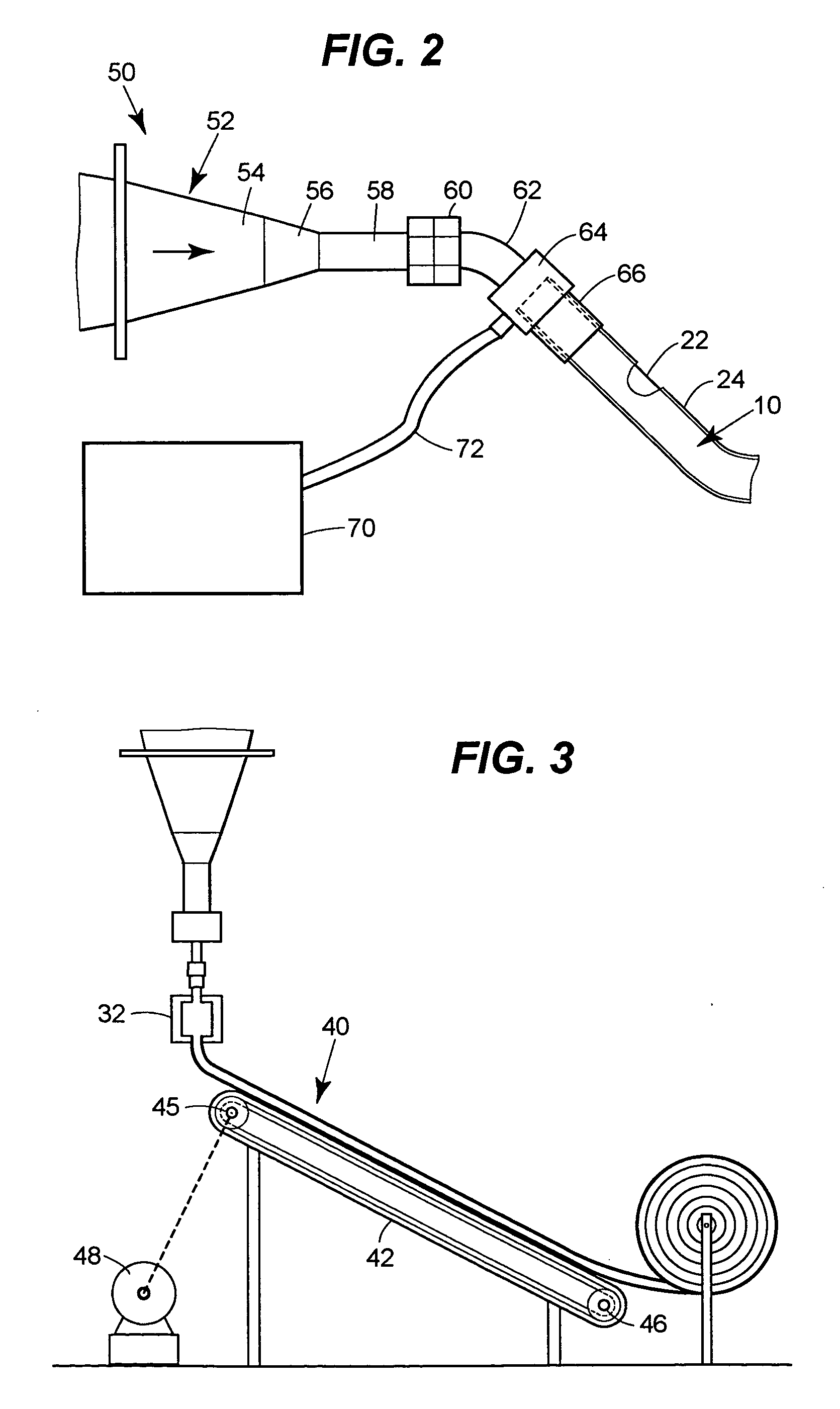

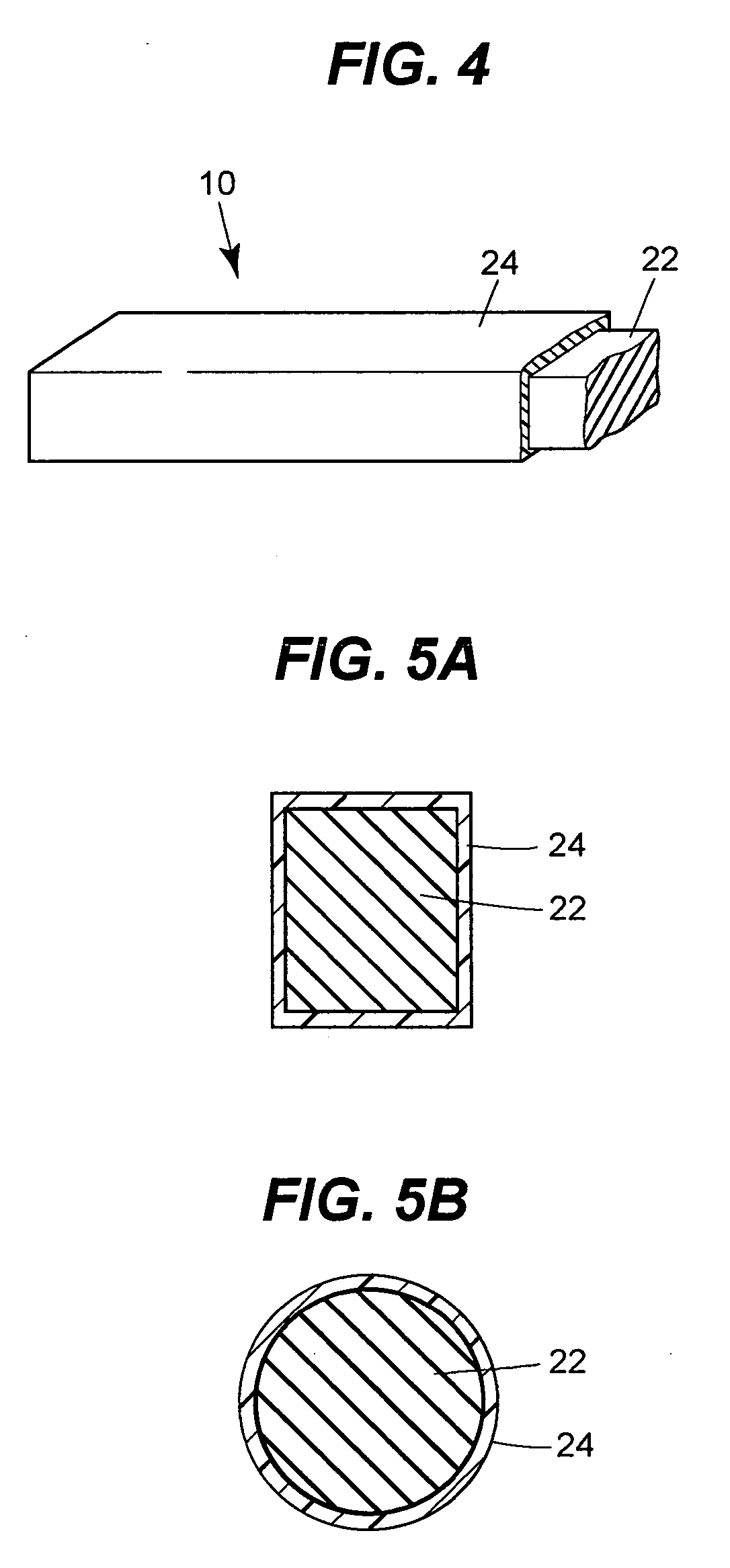

Moisture-impervious water-swellable clay-containing "water-stop" composition containing a water-penetrable coating

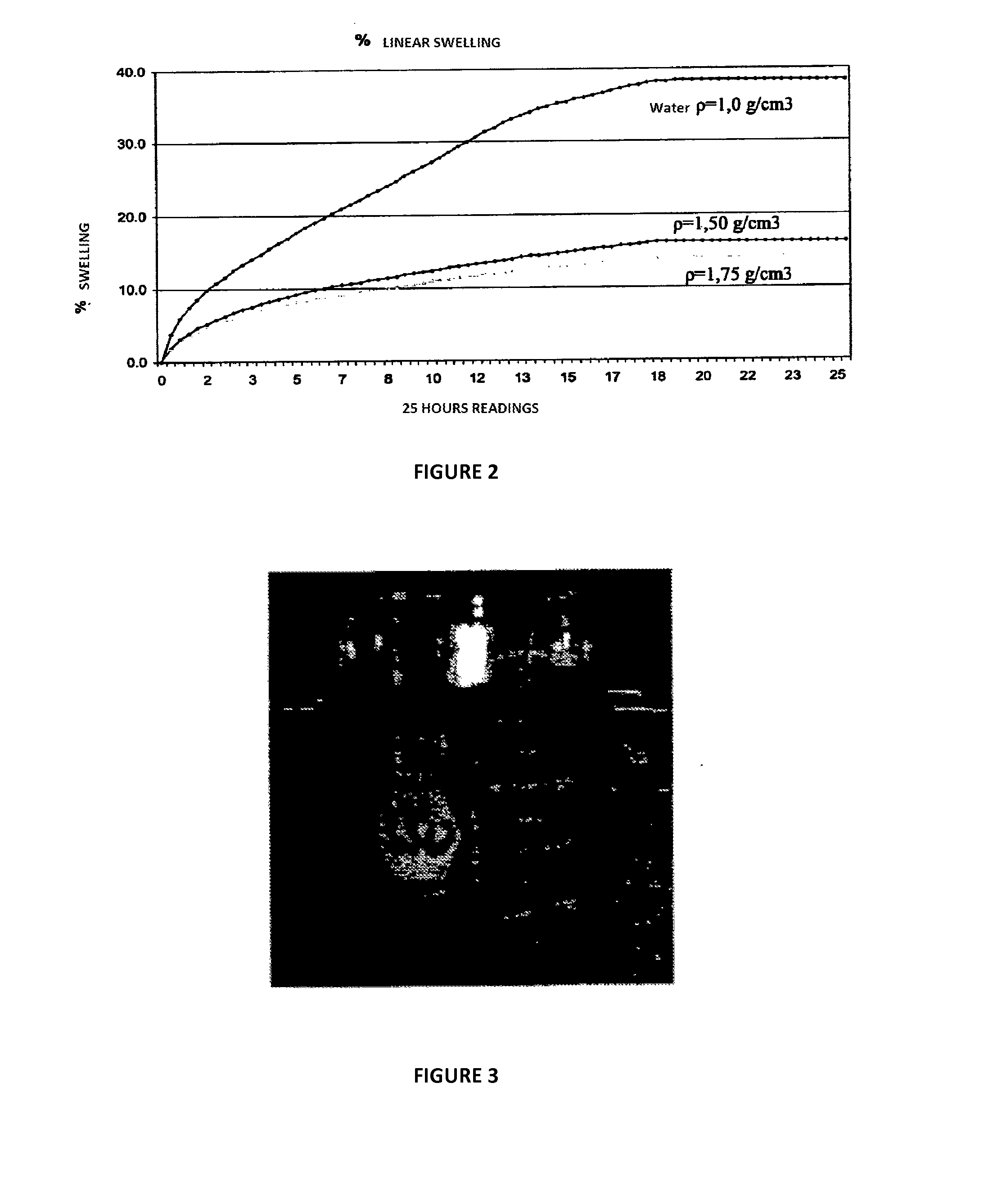

ActiveUS20050065261A1Inhibition of hydrationReduce hydrationPigmenting treatmentRoof covering using tiles/slatesSolubilityWater soluble

A waterproofing article in the form of rod-, or rope-shaped clay-containing compositions, and a method of waterproofing using the article, whereby a water-penetrable, degradable, or water-soluble film or coating forms an outer surface of the article for avoiding premature hydration of an underlying clay-containing composition. In the preferred embodiment, an inner core of a water-swellable clay-containing composition includes a coating of a water-removable or degradable material, completely encasing the major outer surfaces of the composition, having controlled, predetermined water-penetration; high pH degradability; or water-solubility so that the core of water-swellable clay-containing composition is quickly hydrated after water-penetration of the coating material, and to prevent clay hydration during installation, prior to water-penetration of the coating material.

Owner:AMCOL INTERNATIONAL CORPORATION

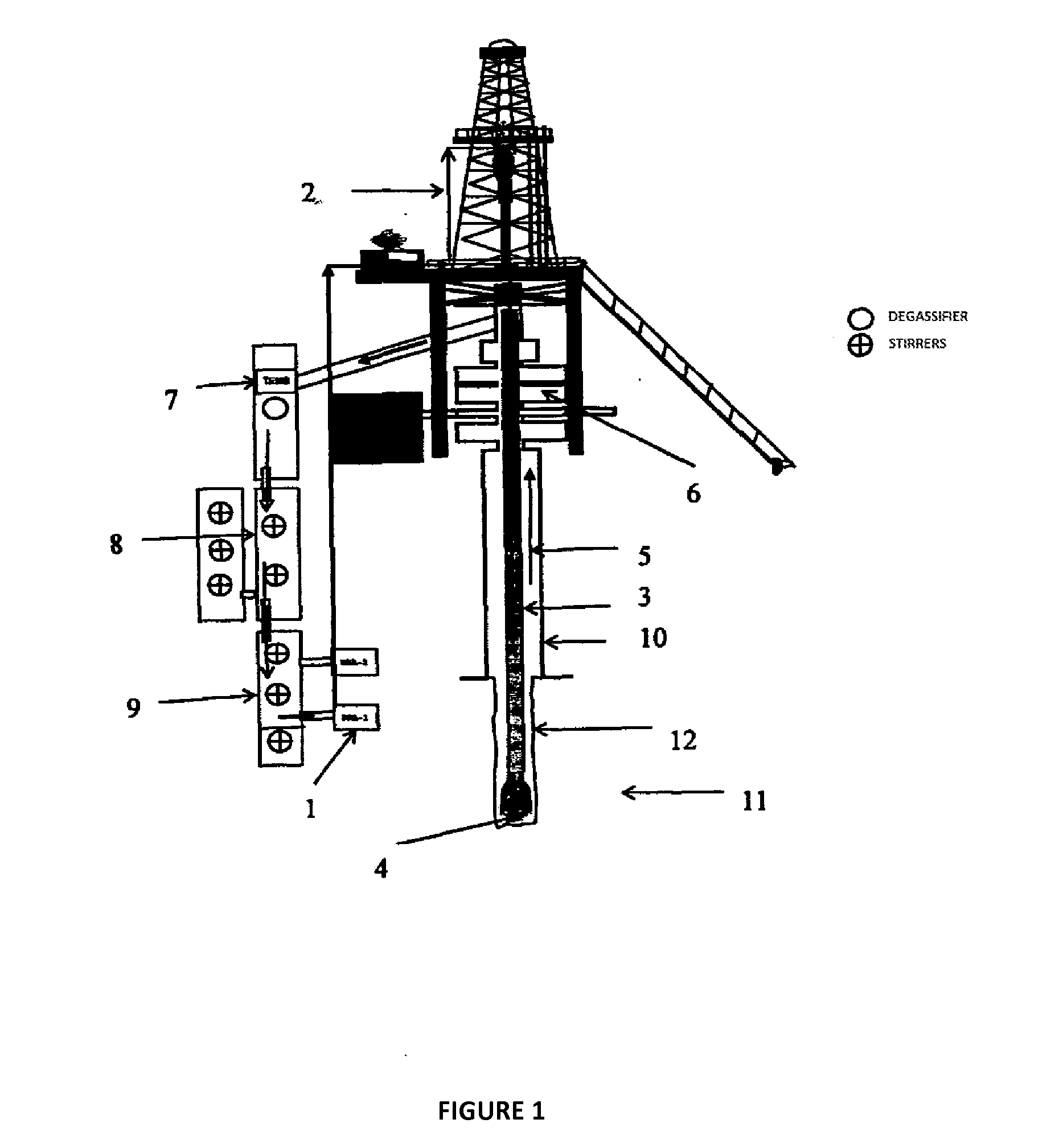

High-pressure/high-temperature solids-free fluid system for drilling, completing and repairing petroleum and gas wells

The present invention relates to the composition, preparation method and use of a solids-free drilling fluid system formulated with a mixture of divalent heavy brines, which is resistant to high pressures and high temperatures. The system has the special feature that it significantly reduces productive-formation permeability damage as it uses mixtures of different salts of water-soluble divalent metals to provide the features of density, polymers and special additives to provide the system with the physicochemical properties that any fluid for drilling, completing and repairing wells requires in order to fulfill the functions thereof and to provide heat resistance up to 200° C. A main feature of the present invention is that the composition that embeds the drilling / completing / repairing of oil wells fluid contains synthetic polymers and biopolymers that do not require large amounts of time, high shear speeds or heating for hydration thereof in divalent metal salt derived simple or binary brines.

Owner:PROTEXA S A DE

Colloidal electrolyte of lead acid batteries

InactiveCN101291002AInhibition of hydrationPrevent severe crackingLead-acid accumulatorsPhosphoric acidSilicon dioxide

The invention discloses a lead-acid accumulator colloid electrolyte. The lead-acid accumulator colloid electrolyte comprises the following compositions in percentage by mass: 30 to 45 percent of sulphuric acid, 4 to 12 percent of nanometer silicon dioxide, 0.05 to 0.5 percent of macromolecular stabilizing agent, 0.1 to 0.5 percent of superfine glass fibre, 0.1 to 0.5 percent of boric acid, 0.1 to 1 percent of phosphoric acid, 0.3 to 2.5 percent of sodium sulfate and 50 to 57 percent of water. The electrolyte is added with the macromolecular stabilizing agent and the hydrophilic superfine glass fibre and sets up a strong network structure with the sulphuric acid and water molecules; the macromolecular stabilizing agent effectively prevents the delamination of various compositions and the hydration of the colloid electrolyte; the superfine glass fibre in the colloid electrolyte forms a reinforcing rib of the colloid electrolyte, effectively prevents the colloid electrolyte from seriously crazing, strengthens the tensile strength and vibration resistance performance of the colloid and has the strong liquid absorption capacity which improves the diffusing and transmitting speed of the electrolyte. The lead-acid accumulator colloid electrolyte improves the charging and receiving capacity, thereby increasing the cycle life of an accumulator.

Owner:CHAOWEI POWER CO LTD

Modeling dough and a surface active drying agent coating composition for same

InactiveUS6767938B1Shorten drying timeGood shelf lifeOrganic detergent compounding agentsMixingChemistrySurface-active agents

This invention relates to modeling doughs comprising algin, a sugar based polysaccharide resin, water and a synthetic resin latex. Additionally disclosed are surface active coating compositions for molded compositions of the algin / sugar-based polysaccharide based modeling dough. Hardening and enhanced drying of the modeling compound articles is accomplished by a spray coating application to a finished molded article by a surface active agent coating composition comprising a Boron containing salt and polyvinylpyrrolidone.

Owner:MATTEL INC

Drilling fluid for shale hydrocarbon reservoir exploration

InactiveCN104610941AInhibition of hydrationPrevent collapseDrilling compositionWell drillingPotassium silicate

The invention provides a drilling fluid for shale hydrocarbon reservoir exploration. The drilling fluid is based on water, and comprises 4-6wt% of bentonite, 2-5wt% of potassium silicate, 0.2-0.5wt% of a coating inhibitor, 0.2-1.5wt% of a flow pattern regulator, 4-6wt% of a fluid loss additive, 2-3wt% of a shale caving inhibitor, 2-3wt% of a plugging agent, 0.5-1wt% of a filter cake surface modifier, 2-4wt% of a lubricant and 0.4-0.6wt% of a pH value regulator. The drilling fluid has the characteristics of good plugging property, strong inhibition, good lubricity and stable high temperature performances to shale hydrocarbon reservoir stratums, and is suitable for the exploration of shale hydrocarbon reservoirs.

Owner:CHINA PETROCHEMICAL CORP +1

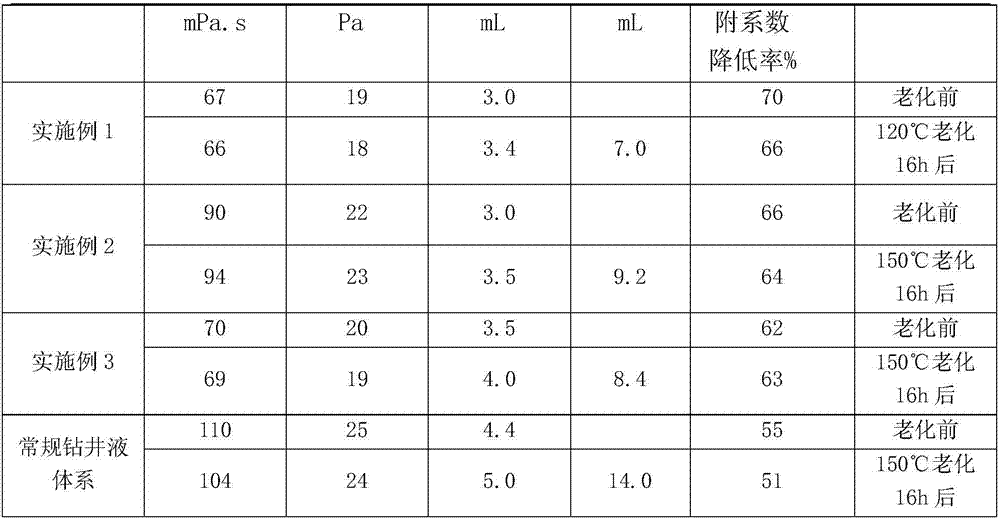

Drilling fluid and preparation method thereof

ActiveCN103773332ANo biological toxicityInhibition of hydrationDrilling compositionEpoxyPolymer science

The invention discloses a drilling fluid and a preparation method thereof. The drilling fluid comprises, by weight, 2.0 to 6.0 parts of bentonite, 0.1 to 1 part of sodium carboxymethylcellulose, 0.2 to 0.8 part of a zwitter-ion sulphonate copolymer, 0.03 to 0.4 part of sodium hydroxide, 0.1 to 0.8 of a polyamine polymer, and 100 parts of water; the polyamine polymer is a polymer of terminal diamine, a cyclic ether, and an epoxy alkyl halide. The preparation method comprises following steps: the polyamine polymer is prepared firstly, wherein the polyamine polymer is prepared via copolymerization of terminal diamine, the cyclic ether, and the epoxy alkyl halide; and then an aqueous solution containing bentonite, sodium carboxymethylcellulose, the zwitter-ion sulphonate copolymer, sodium hydroxide, the polyamine polymer, and water is prepared according to the stoichiometric ratio so as to obtain the drilling fluid. The drilling fluid is excellent in system inhibition performance and collapse resistance, and contains no sylvite, so that subsequent processing on high salt content is unnecessary.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-voltage working electrolyte and preparation method thereof

The invention provides a high-voltage working electrolyte, which comprises the following raw materials by weight portion: 5.5-11 portions of solute, 80-88 portions of composite solvent, 0.1-2.5 portions of dehydrogenating agent, 0.1-1portion of waterproof combined additive, 0-2 portions of sparking voltage improving agent, 0.5-3 portions of anti-corrosion additive and 0.5-1 portion of high temperature stabilizer. The solvent is heated to 70-100 DEG C. The invention also provides a preparation method of the electrolyte, which comprises the followings steps: adding the sparking voltage improving agent, the high temperature stabilizer and the anti-corrosion additive, and uniformly mixing; heating to 120-130 DEG C, adding the solute, the dehydrogenating agent and the waterproof combined additive, holding at a temperature of 120-130 DEG C until a mixture is completely dissolved; and cooling and then obtaining the high-voltage working electrolyte. The process is simple, and the conditions are easy to control. The high-voltage working electrolyte provided by the invention has the advantages of high sparking voltage, high temperature resistance and long service life.

Owner:东莞宏强电子有限公司

Method for desulphurizing gasoline

ActiveCN102093907AImprove stabilityIncrease the degree of exchangeOther chemical processesHydrocarbon oils refiningSorbentCerium

The invention relates to a method for desulphurizing gasoline. In the method, a beta molecular sieve serves as a carrier; a selective adsorbent is adopted to adsorb thiophene sulfides in the gasoline and remove the thiophene sulfides from the gasoline; a hydrogen type beta molecular sieve serves as the carrier of the adsorbent; the molecular sieve carries copper, silver, zinc, nickel or gallium metal ions and metal cerium ions; and the exchange amount of the metal ions is 0.001 to 15 percent based on the mass of the hydrogen type beta molecular sieve. The adsorbent is used to selectively adsorb the thiophene sulfides in the gasoline and deeply remove the thiophene sulfides from the gasoline. A result shows that: the bimetallic ions have a synergistic effect, improve the selectivity of adsorptive desulphurization and can reduce the content of the sulfides in the fluid catalytically cracked (FCC) gasoline to below 1mu g / g or zero from 200mu g / g. The reaction condition is mild; the equipment is simple; the activity of the adsorbent is high; and the adsorbent is easy to regenerate. At normal temperature and normal pressure, hydrogen is not consumed and the gasoline is finely desulphurized.

Owner:PETROCHINA CO LTD +1

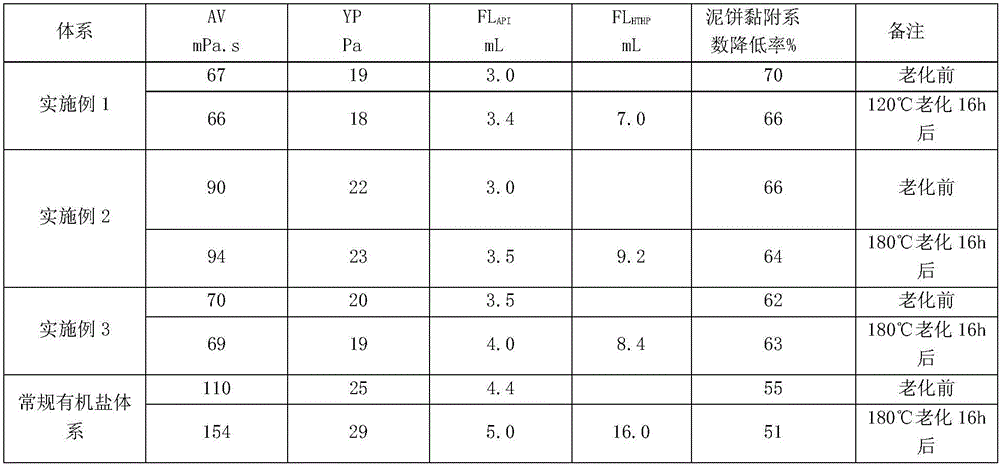

Organic salt drilling fluid applicable to extended-reach wells

ActiveCN105754563AGood thermal stabilityReduce fluid lossDrilling compositionDrilling fluidCastor oil

The invention discloses an organic salt drilling fluid applicable to extended-reach wells.The organic salt drilling fluid comprises 1-4% of bentonite, 0.3-0.5% of sodium carbonate, 0.5-1% of sodium hydroxide, 0.3-1% of xanthan gum, 2-8% of filtrate reducer, 2-5% of nanometer plugging agent, 1-4% of plugging agent, 0.5-4% of lubricant, 40-60% of organic salt and 25-250% of inert weighting agent, wherein the nanometer plugging agent is formed by copolymerization of MAPOSS, N-isopropylacrylamide and acrylamide, the plugging agent is formed by copolymerization of N-isopropylacrylamide, acrylamide and N,N'-methylene diacrylamide, and the lubricant is formed by compounding of castor oil polyoxyethylene ether, polyethylene glycol and polyvinyl pyrrolidone.The organic salt drilling fluid applicable to the extended-reach wells has the advantages of excellent plugging performance, good lubricating property and rheological property and powerful rock debris carrying capability, thereby being particularly applicable to exploitation of the extended-reach wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

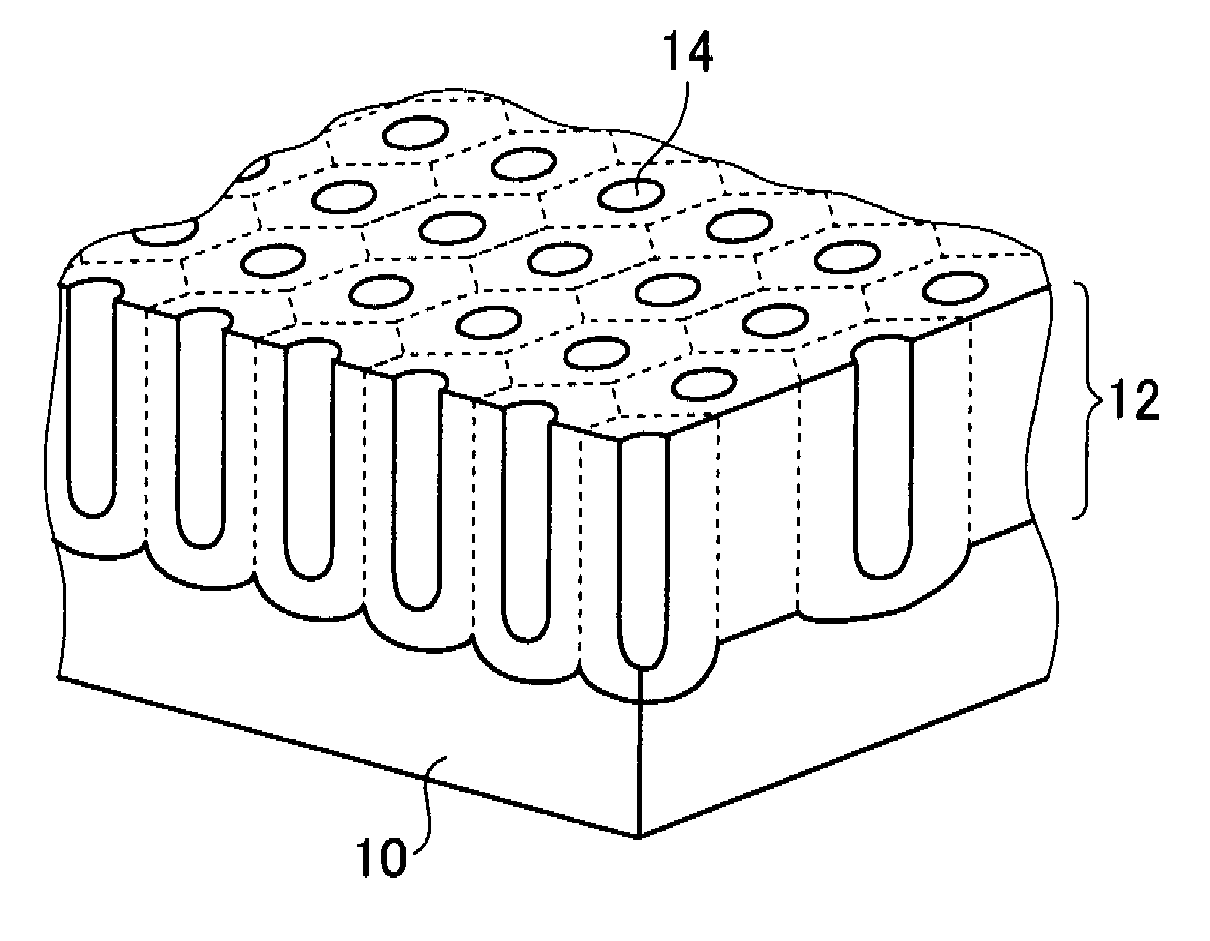

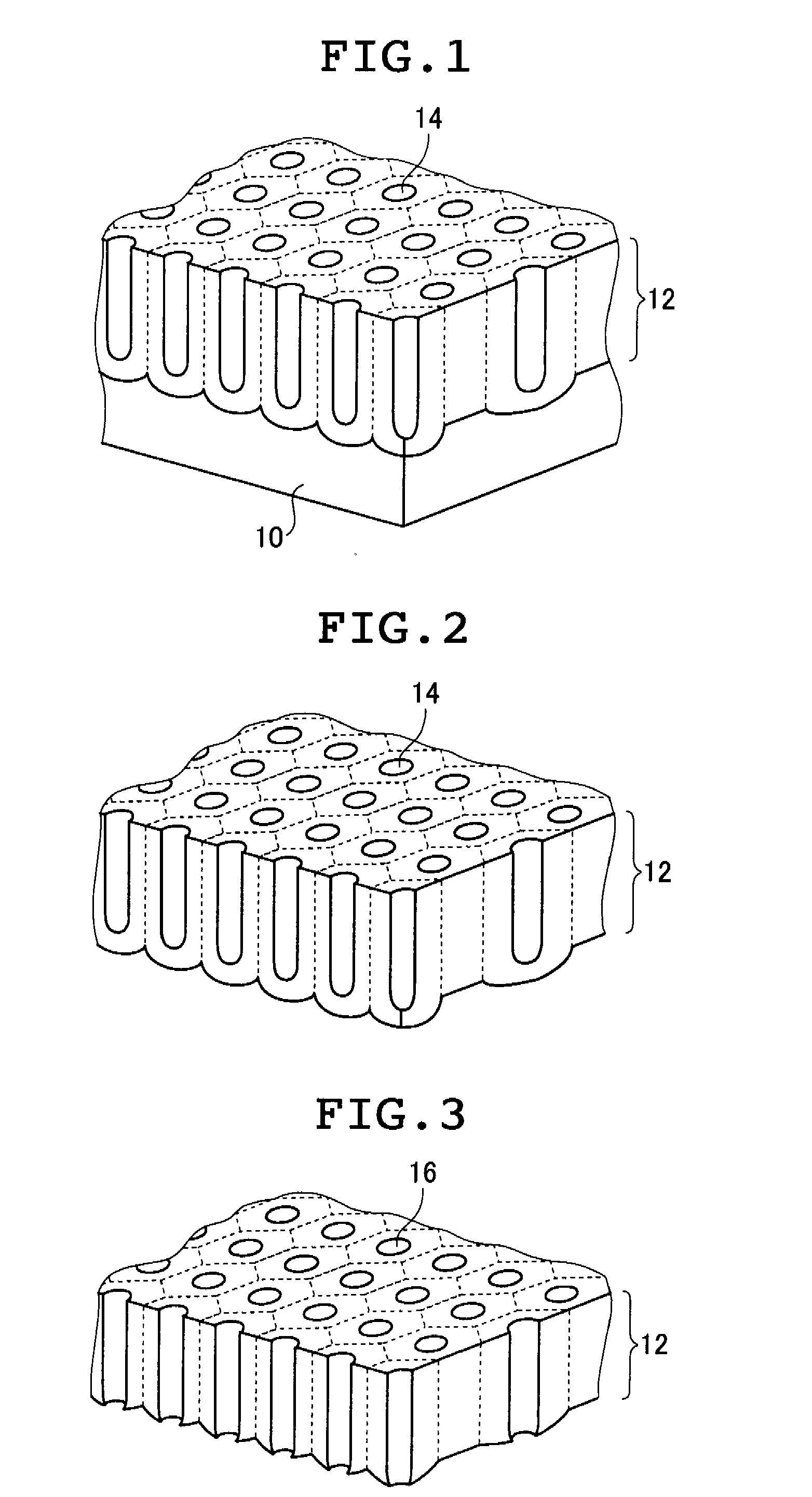

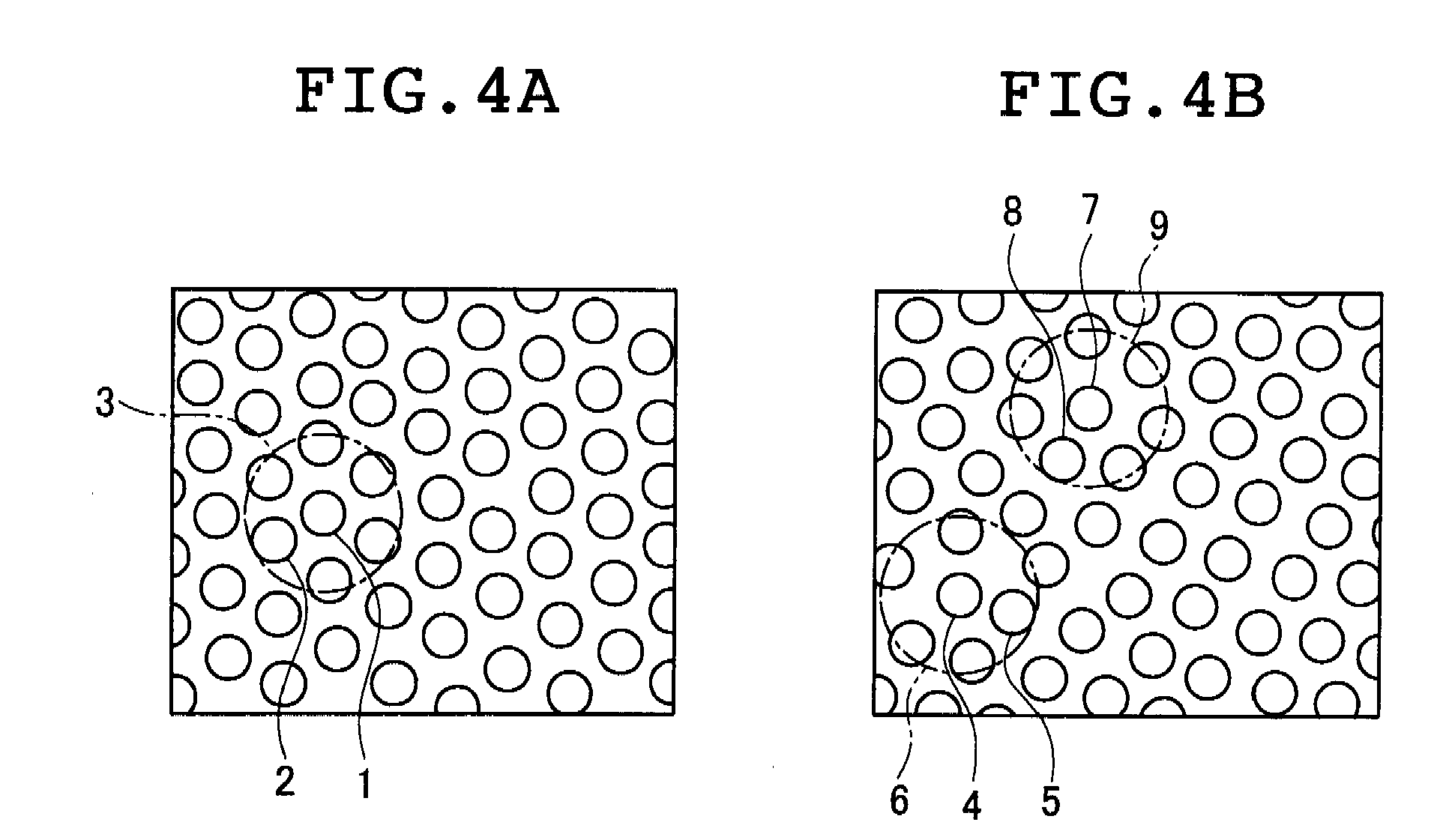

Microstructure and method of manufacturing the same

Disclosed is a microstructure comprising an aluminum anodized film bearing through micropores, wherein a surface of the microstructure is covered with a protective film for preventing hydration of the aluminum anodized film. The microstructure may be used as a porous alumina membrane filter excellent in filtration rate and its stability with time.

Owner:FUJIFILM CORP

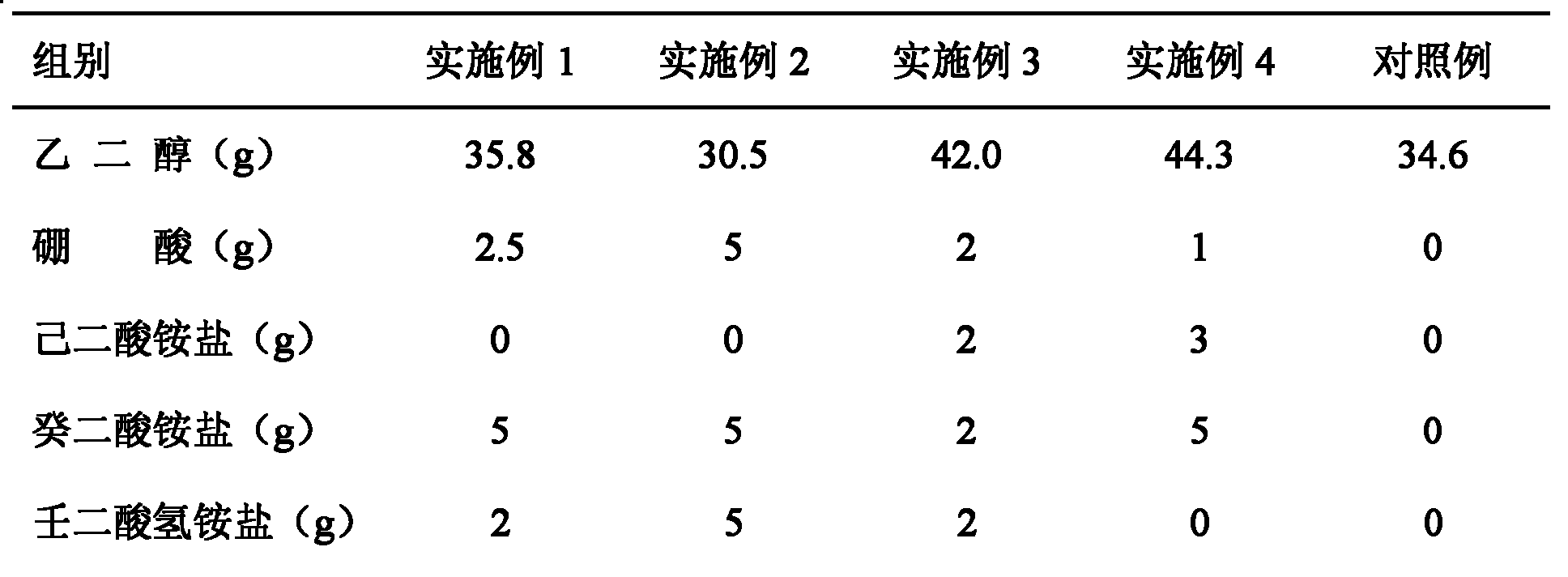

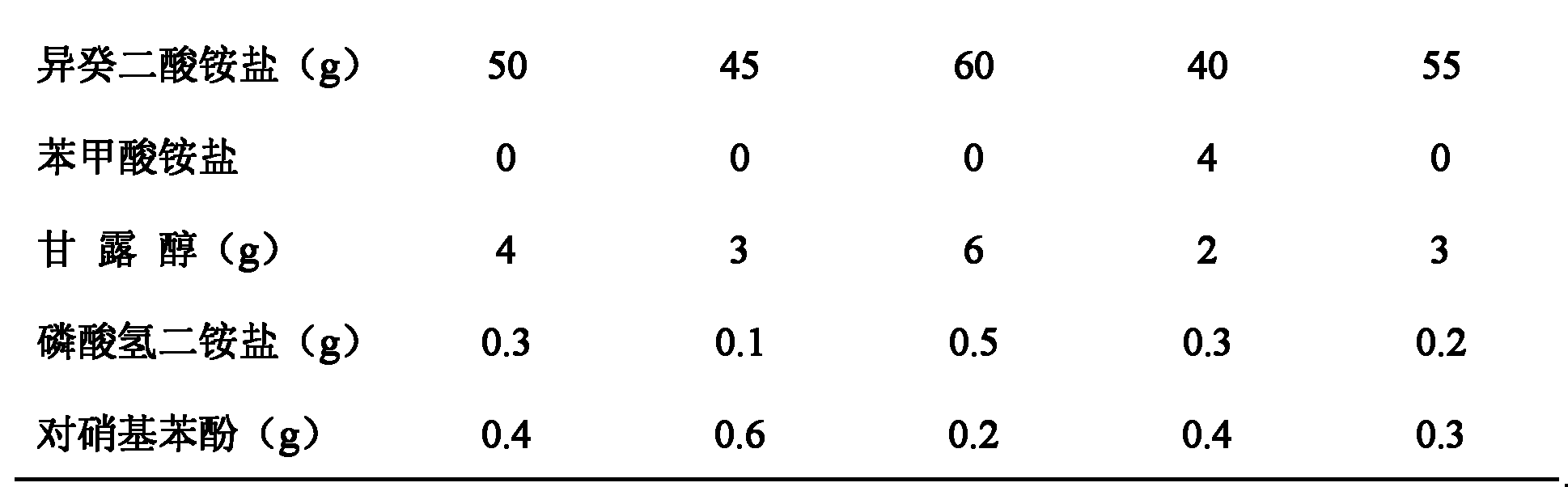

Novel electrolyte

The invention discloses a novel electrolyte, which mainly comprises the following components in parts by weight: 30-45 parts of ethylene glycol, 1-5 parts of boric acid, 4-10 parts of at least one kind of long straight-chain saturated dicarboxylic acid or ammonium salt thereof, 40-60 parts of at least one kind of long straight-chain saturated dicarboxylic acid with branched chains or ammonium salt thereof, 2-6 parts of mannitol, 0.1-0.5 part of phosphate and 0.2-0.6 part of dehydrogenation agent. Since the electrolyte uses ethylene glycol as solvent and uses long straight-chain saturated dicarboxylic acid with branched chains, long straight-chain saturated dicarboxylic acid and boric acid as solute, the invention has the advantages that the forming efficiency and the breakdown voltage of the electrolyte are improved, the solubility of the solute is increased, the electric conductivity is improved, the specific resistance is reduced and the service life of the product is improved.

Owner:FUJIAN YUNXING ELECTRONICS

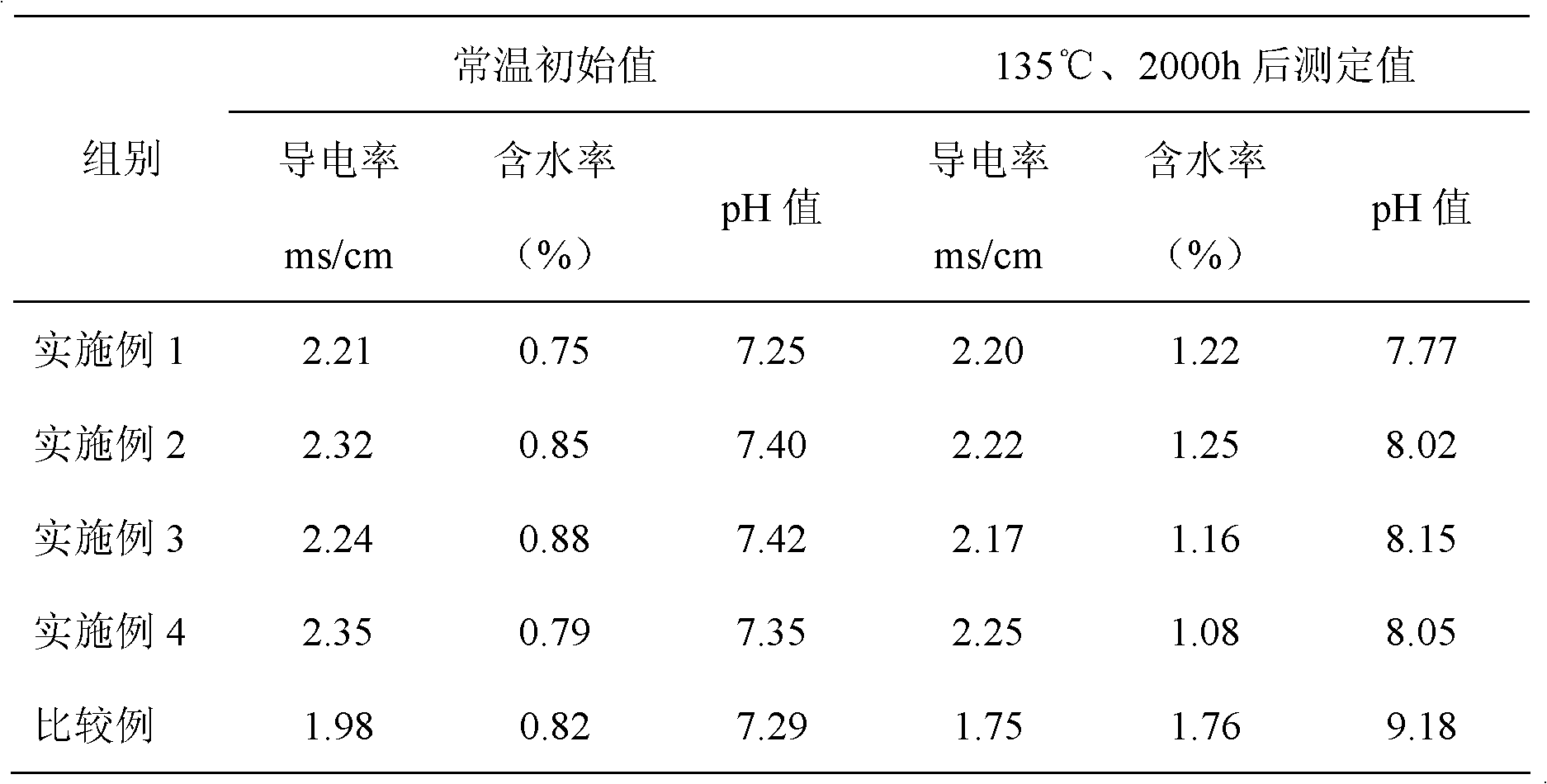

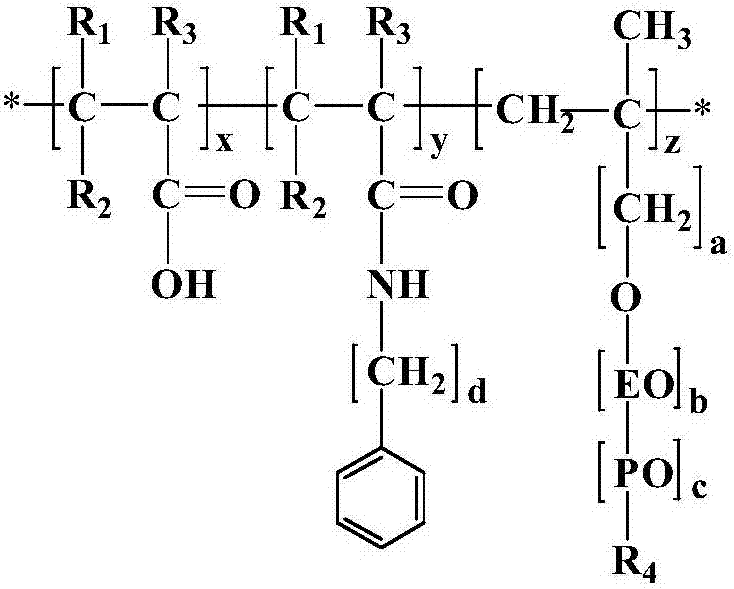

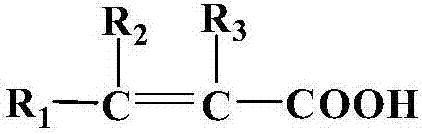

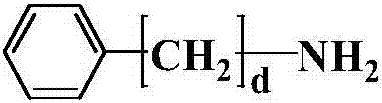

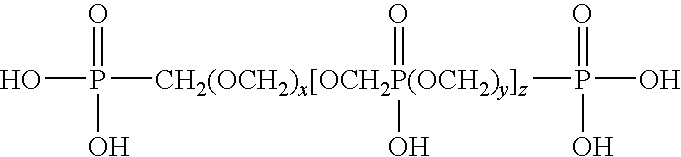

Slow-release polycarboxylate superplasticizer and preparation method thereof

The invention discloses a slow-release polycarboxylate superplasticizer and a preparation method thereof. The preparation method comprises specific steps as follows: firstly, small unsaturated carboxylic acid monomers and diphenylphosphinyl chloride are subjected to a partial reaction, and small unsaturated monomers containing phosphate ester groups are obtained; then 2-phenylethylamine and phosphate ester groups are added to a reaction system and subjected to a reaction, and small unsaturated monomers containing amide groups are obtained; the small unsaturated monomers containing the amide groups are subjected to an oxidation-reduction free radical polymerization reaction with unsaturated polyether macromonomers under the action of an initiating agent, a reducing agent and a chain transfer agent, and a copolymerization product is obtained; pH value is adjusted to 6-7 after the reaction, water is added, and the polycarboxylate superplasticizer is obtained. The amide groups containing benzene rings are introduced to side chains of the prepared polycarboxylate superplasticizer, so that the dispersibility of the polycarboxylate superplasticizer for cement is improved, the polycarboxylate superplasticizer has good slump retaining performance on the premise of water reduction, and besides, the yield of the polycarboxylate superplasticizer containing the amide groups can reach 94% or higher.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

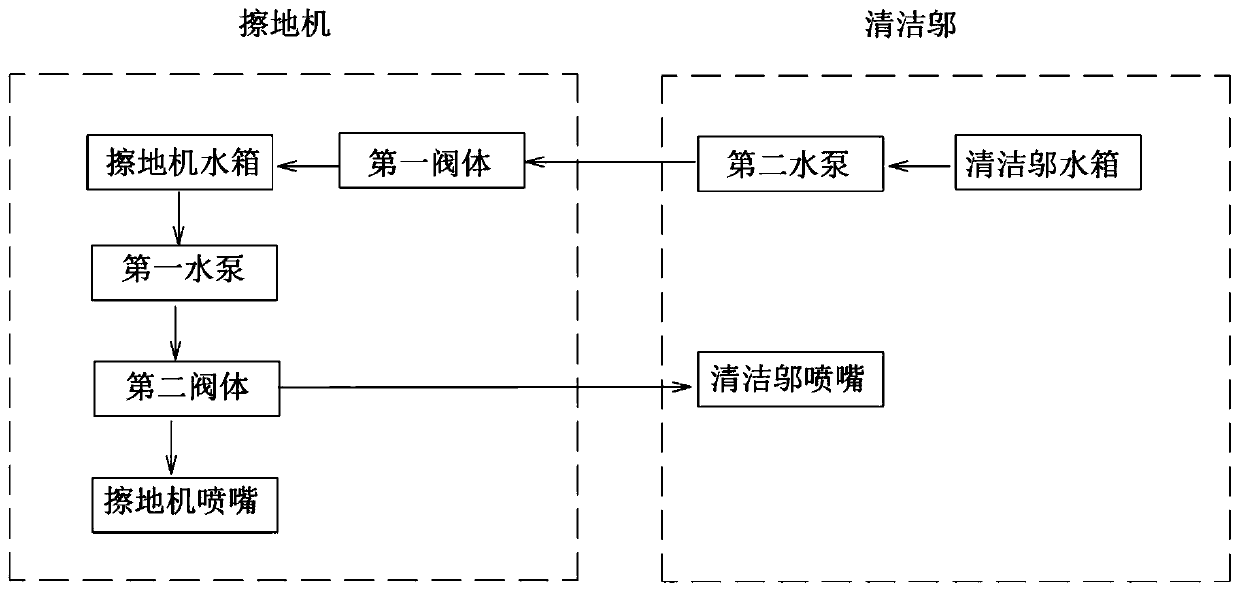

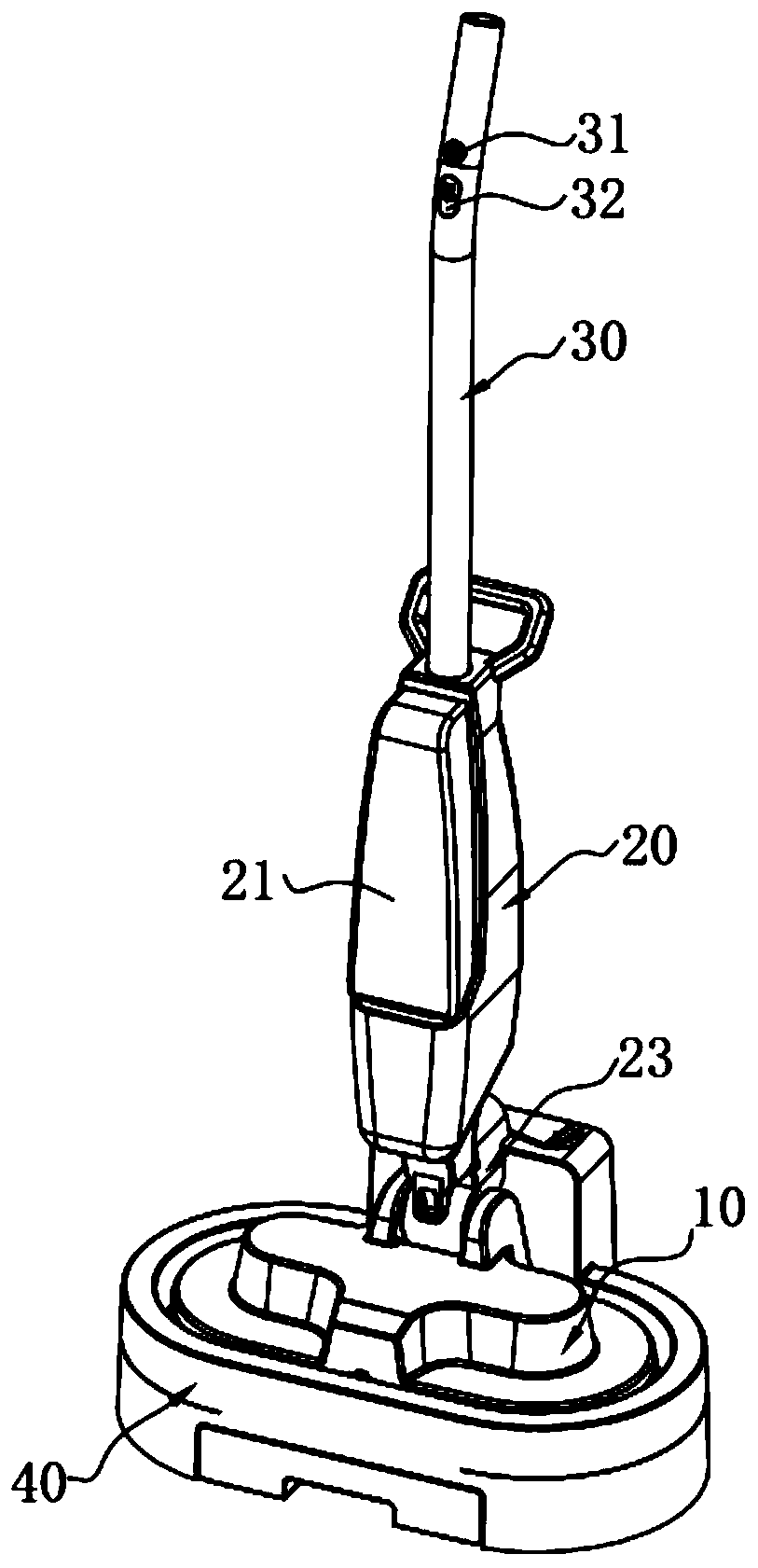

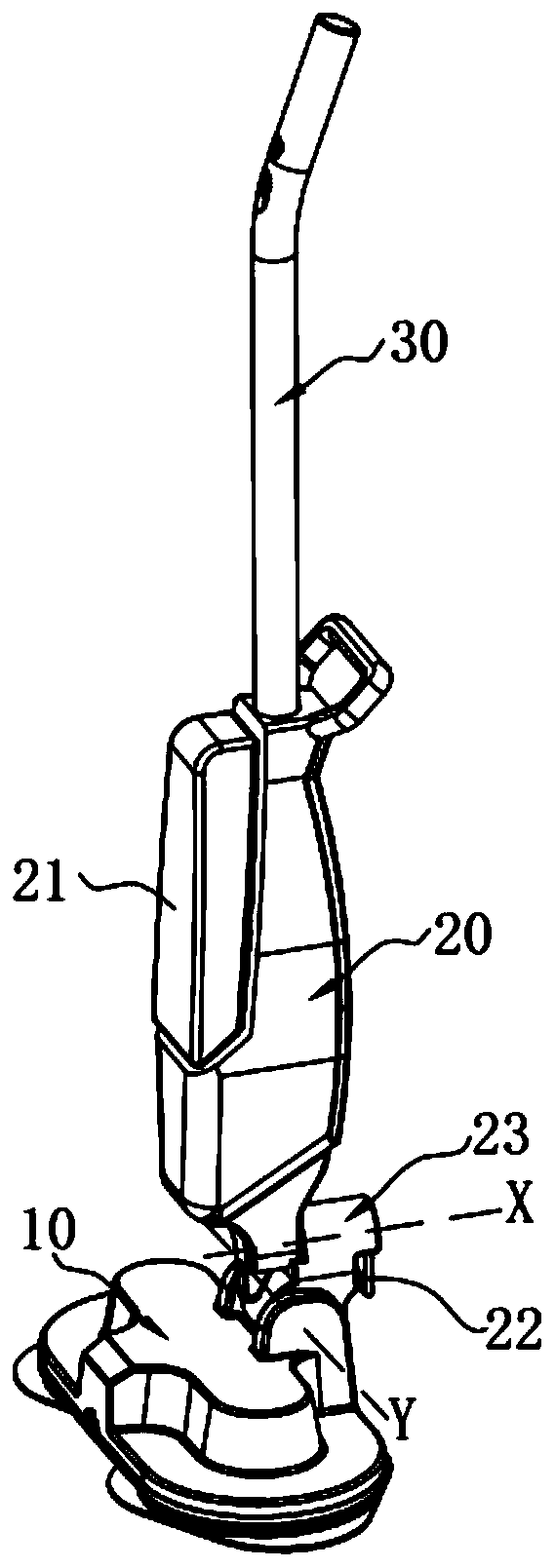

Control method for floor mopping machine, controller and floor mopping machine

ActiveCN110974092AImprove user comfortSimple structureCarpet cleanersFloor cleanersProcess engineeringManufacturing engineering

The invention discloses a control method for a floor mopping machine, a controller and the floor mopping machine. The control method comprises the steps that after a floor mopping machine water tank located on the floor mopping machine is communicated with a second connector located on a cleaning plate, a cleaning instruction is received, a first water pump of the floor mopping machine is controlled to be started according to the cleaning instruction so that a liquid in the floor mopping machine water tank can be conveyed to the cleaning plate to wet a cleaning cloth of the floor mopping machine, and after the first water pump works for a first preset time, a power device of the floor mopping machine is controlled to enable the cleaning cloth of the floor mopping machine to rotate on the cleaning plate. According to the control method for the floor mopping machine, the controller and the floor mopping machine, the problem that the cleaning cloth of the floor mopping machine is inconvenient to clean is solved, and the use comfort of a user is improved.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

Organic salt drilling fluid

ActiveCN105694830AImprove thermal stabilityReduce fluid lossDrilling compositionFiltrationPolyethylene glycol

The invention discloses organic salt drilling fluid. The organic salt drilling fluid is prepared from 1%-4% of bentonite, 0.3%-0.5% of sodium carbonate, 0.5%-1% of sodium hydroxide, 0.3%-1% of xanthan gum, 2%-8% of a filtrate loss reducer, 2%-5% of a nanometer blocking agent, 1%-4% of a blocking agent, 0.5%-4% of a lubricating agent, 40%-60% of organic salt and 25%-250% of an inert weighting agent, wherein the nanometer blocking agent is prepared by copolymerizing methacrylic acid carbomethoxy cage-like oligomeric silsesquioxane, N-isopropylacrylamide and acrylamide, and the lubricating agent is prepared by compounding castor oil polyoxyethylene ether, polyethylene glycol and polyvinyl pyrrolidone. The organic salt drilling fluid has the very good heat stability, the low filtration loss and the high blocking performance and lubricating performance and is especially suitable for shale gas well development.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

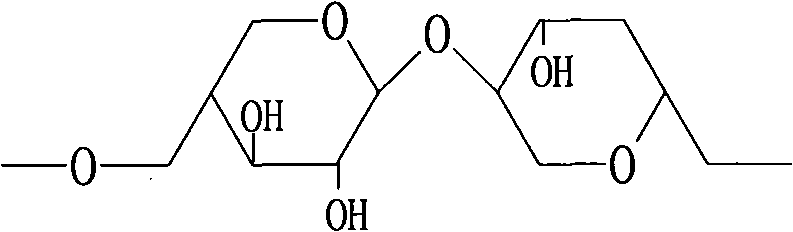

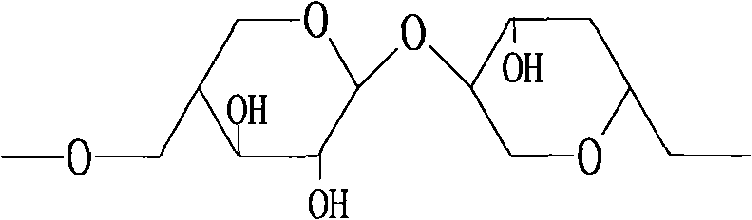

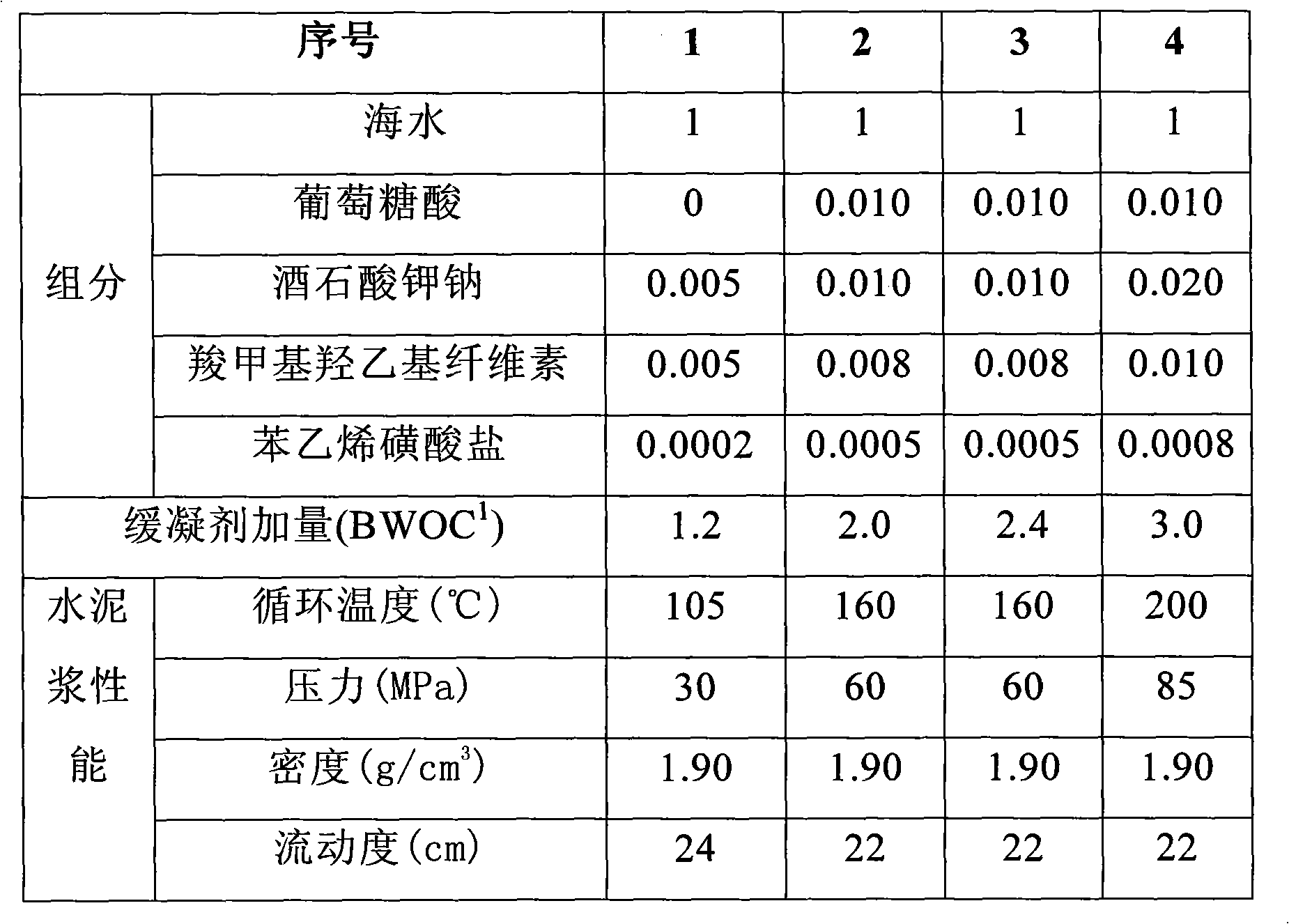

Oil well cement high temperature retarder

ActiveCN101597487ASuitable for a wide temperature rangeMeet the needs of drilling and completion engineeringDrilling compositionSulfonateWell drilling

The invention relates to an oil well cement high temperature retarder applied to the technical field of oil field well drilling and completion. The invention is characterized in that: the retarder is composed of 1 part by weight of water, 0.005-0.030 part by weight of hydroxycarboxylic acid and salt thereof, 0.005-0.010 part by weight of cellulose derivative and 0.0001-0.0010 part by weight of sulfonate. The high temperature retarder has wide applicable temperature range, can be applied to cement paste systems with various densities, has strong compatibility with a plurality of admixture systems, and does not influence the performance of cement paste. The cement paste prepared by the retarder is stable, the thickening transition time is short, and the thickening time is adjustable; the hardened cement paste has rapidly developed compression strength and is suitable for the requirement of well cementation engineering.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

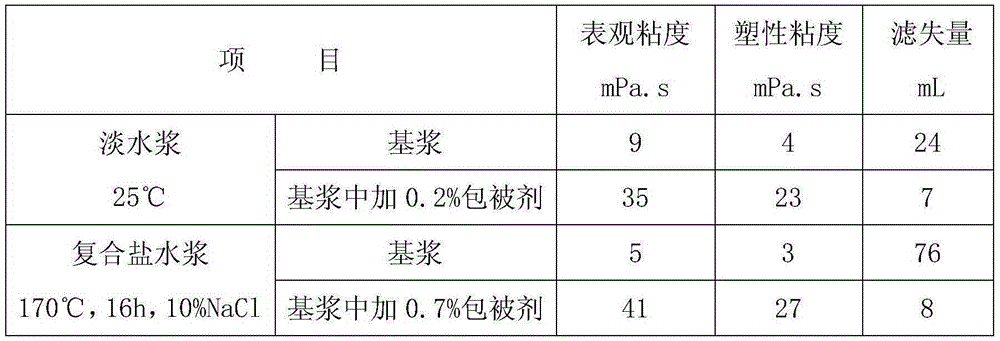

Coating agent for water-based drilling fluid

InactiveCN105294946AInhibition of hydrationPrevent collapseDrilling compositionApparent viscosityChemistry

The invention discloses a coating agent for a water-based drilling fluid. The coating agent is prepared from the following raw materials in parts by weight: 900-1100 parts of liquid polyacrylamide, 180-220 parts of AMPS, 170-190 parts of 1-methyl-2-pyrrolidinone, 75-85 parts of sodium carbonate, 180-220 parts of a co-solvent, 1.5-2.5 parts of sodium bisulfite and 1.5-2.5 parts of hydrogen peroxide. The coating agent can be added into the drilling fluid for controlling the filtration vector, and can be used in a salt water drilling fluid system for key control of the apparent viscosity, the plastic viscosity, the filtration vector and the like; drillings can be effectively coated by the coating agent, so as to protect the drillings and shale from hydration, protect a well wall from collapse, facilitate the stability of the well wall, and improve the drilling speed; meanwhile, the coating agent is capable of resisting high temperature, calcium, magnesium and salinity, has the characteristic of being good in filtrate loss effect, and is applicable to fresh water, sea water and saturated salt water slurry systems.

Owner:天津滨海新区普瑞德石油科技有限公司

Recycled concrete with high slump loss resistance and preparation method thereof

The invention discloses recycled concrete with high slump loss resistance and a preparation method thereof. The invention belongs to the field of building materials, the key points of the technical scheme comprise that the raw materials comprise 180-220 parts by weight of cement, 380-490 parts of a modified recycled coarse aggregate, 400-500 parts of gravels, 680-820 parts of natural sand, 90-130parts of fly ash, 65-98 parts of mineral powder, 156-185 parts of water, 4.2-5.8 parts of a polycarboxylate superplasticizer and 3.5-6.4 parts of a slump retaining enhancer. A treatment method of themodified recycled coarse aggregate comprises the steps: a crushed coarse aggregate is placed in a sodium silicate solution with the concentration of 3%-7% to be soaked for 4 h-9 h, then the recycled coarse aggregate is added into a mixed solution of a polyvinyl alcohol solution with the concentration of 8%-12% and a silane emulsion with the concentration of 4%-10% to be continuously soaked for 8 h-12 h, and the effect of improving the slump loss resistance of the recycled concrete is achieved.

Owner:深圳市恒星建材有限公司

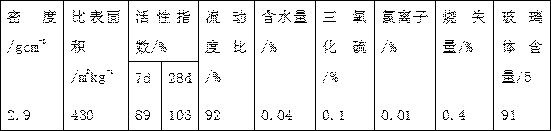

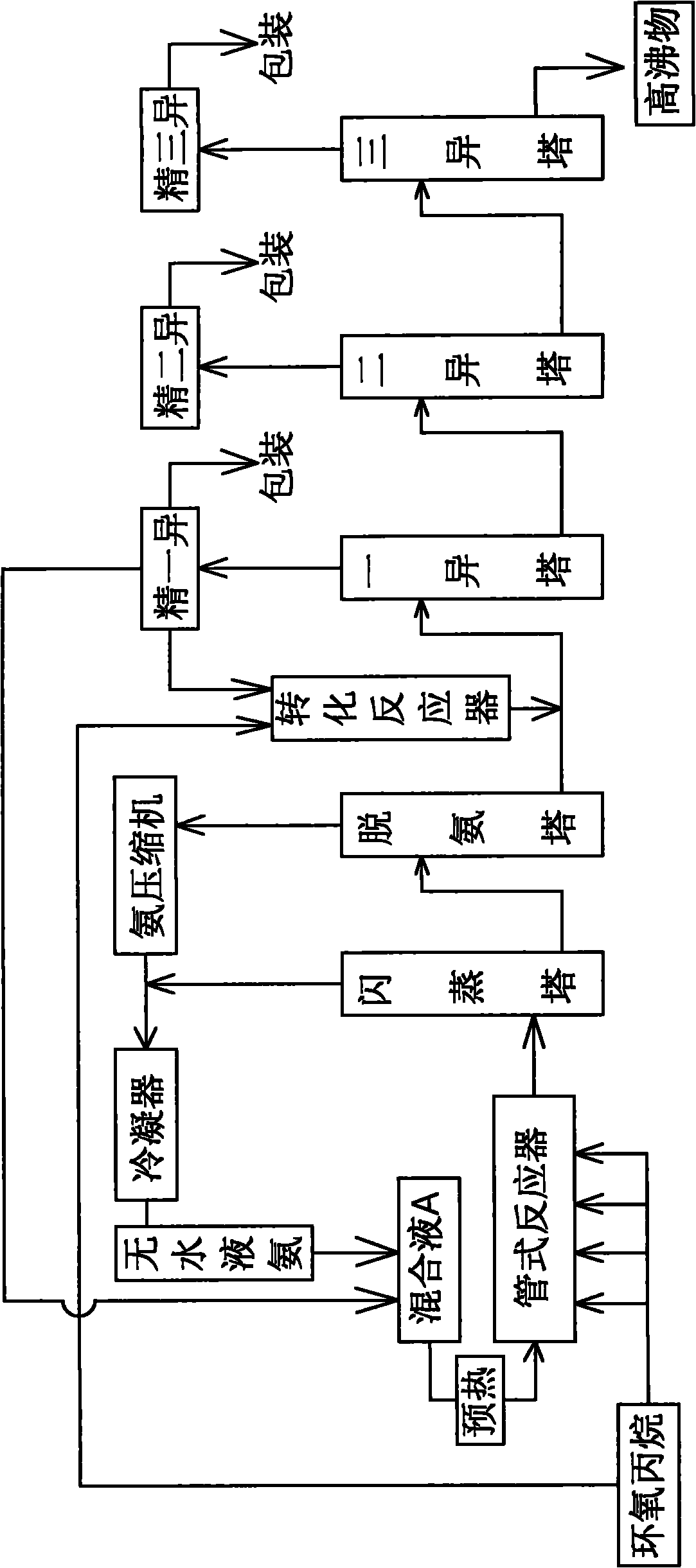

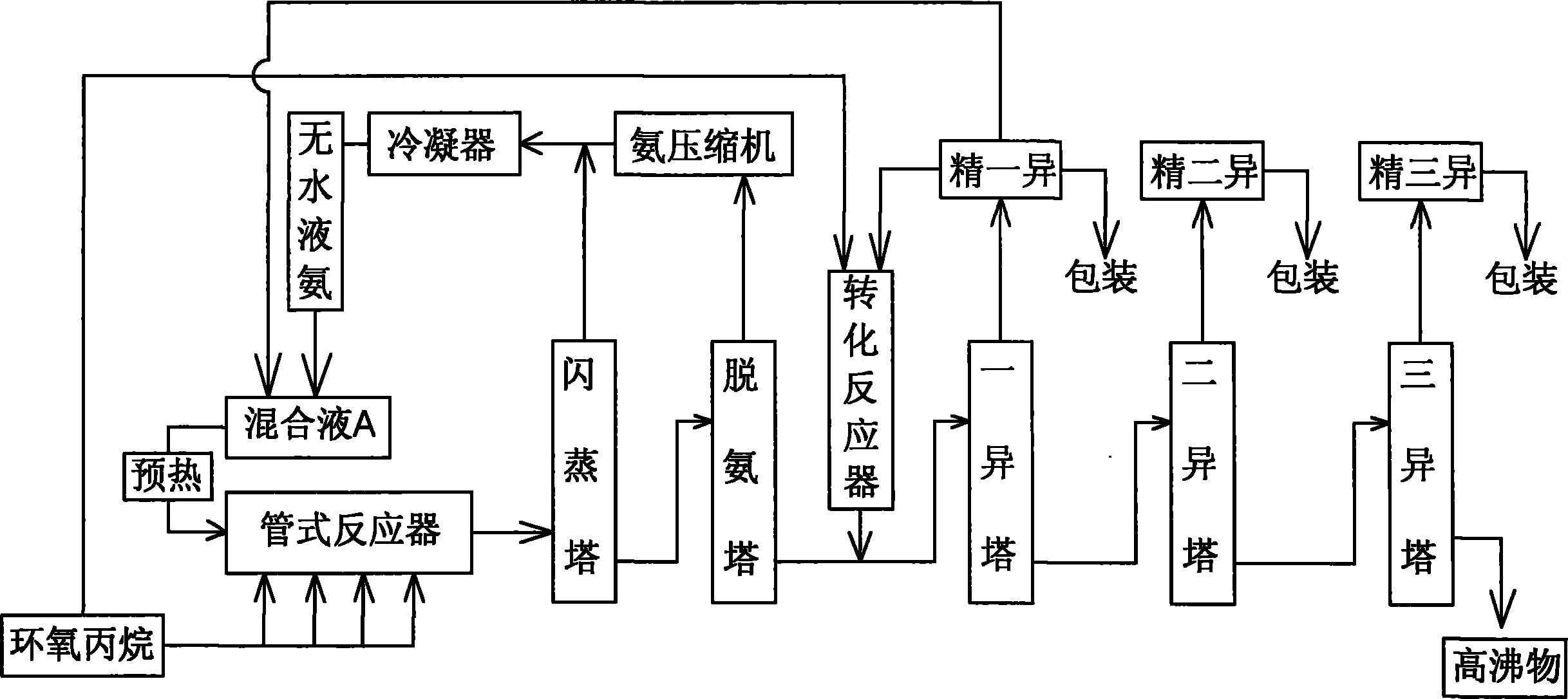

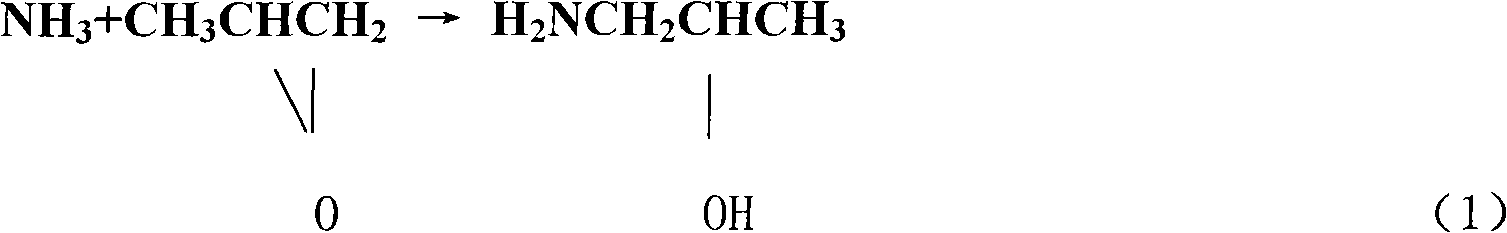

Isopropanolamine producing method

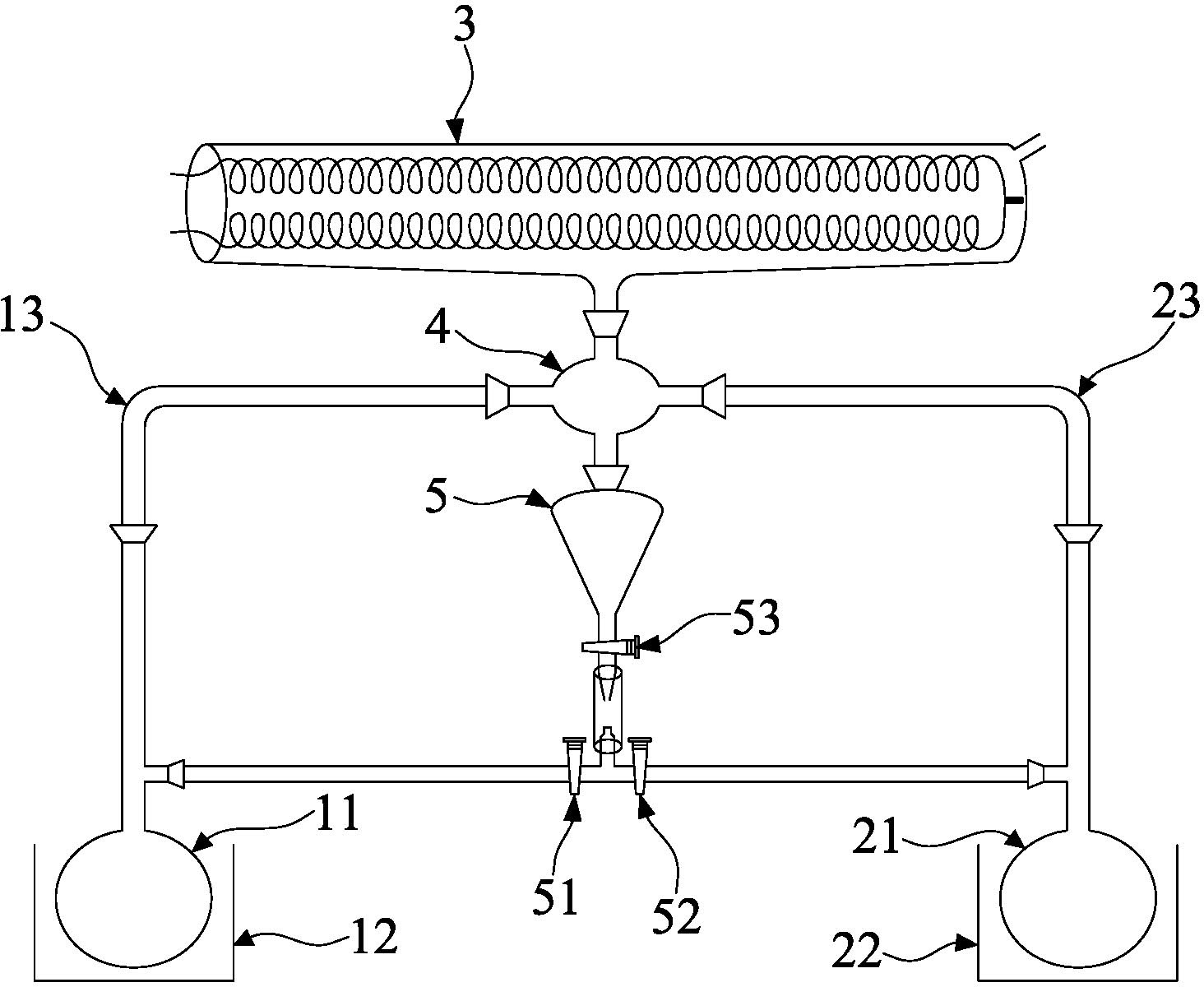

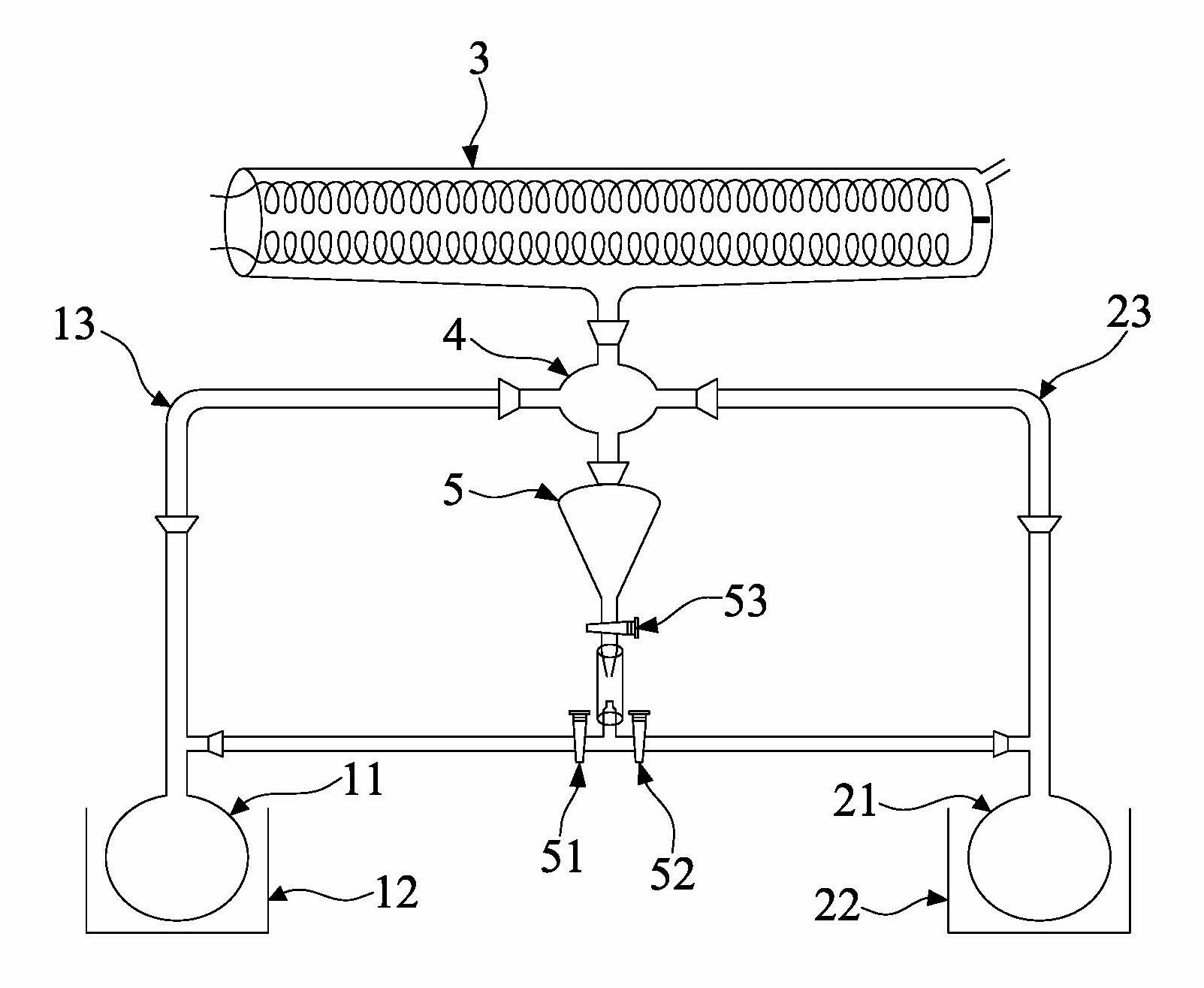

InactiveCN101786957ASave energyInhibition of hydrationOrganic compound preparationAmino-hyroxy compound preparationSide effectMonoisopropanolamine

The invention relates to an isopropanolamine producing method. As the present isopropanolamine producing method uses water as a catalyst, the energy consumption for subsequent dehydration is high and side effects can be easily caused. For this reason, the isopropanolamine producing method of the invention includes tubular reaction, flash evaporation, deamination and rectification, wherein isopropanolamine is used as the catalyst in the tubular reaction; before feeding, a liquid mixture A of anhydrous liquid ammonia and the catalyst is prepared according to the weight ratio of 96-99:1-4; finally, the liquid mixture A and propylene oxide are added according to the feeding speed ratio of 85-340:58. The isopropanolamine producing method realizes low energy consumption and less byproducts in the subsequent dehydration. The invention is applicable to producing the isopropanolamine.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

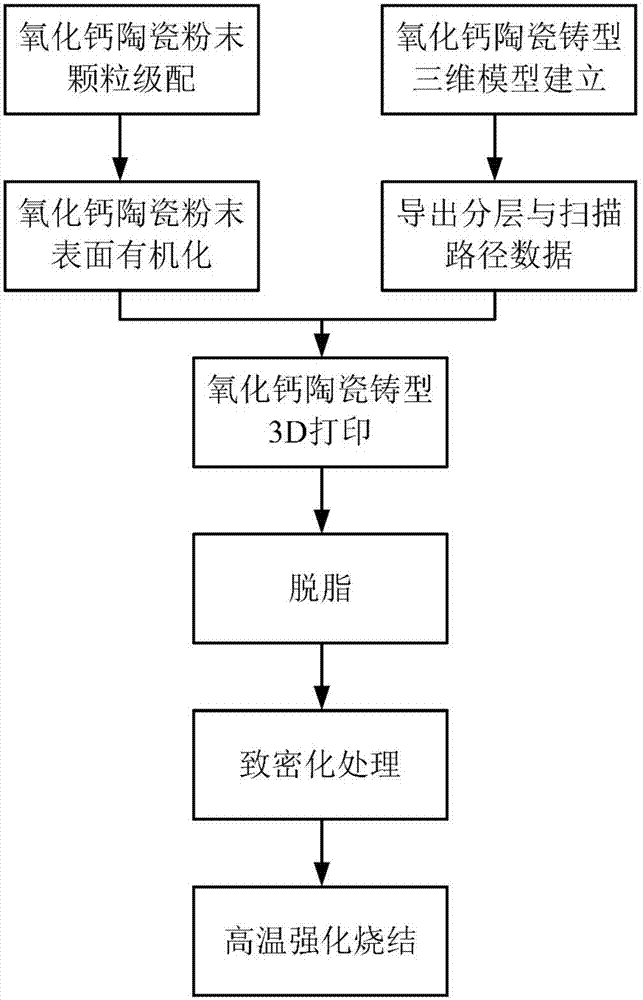

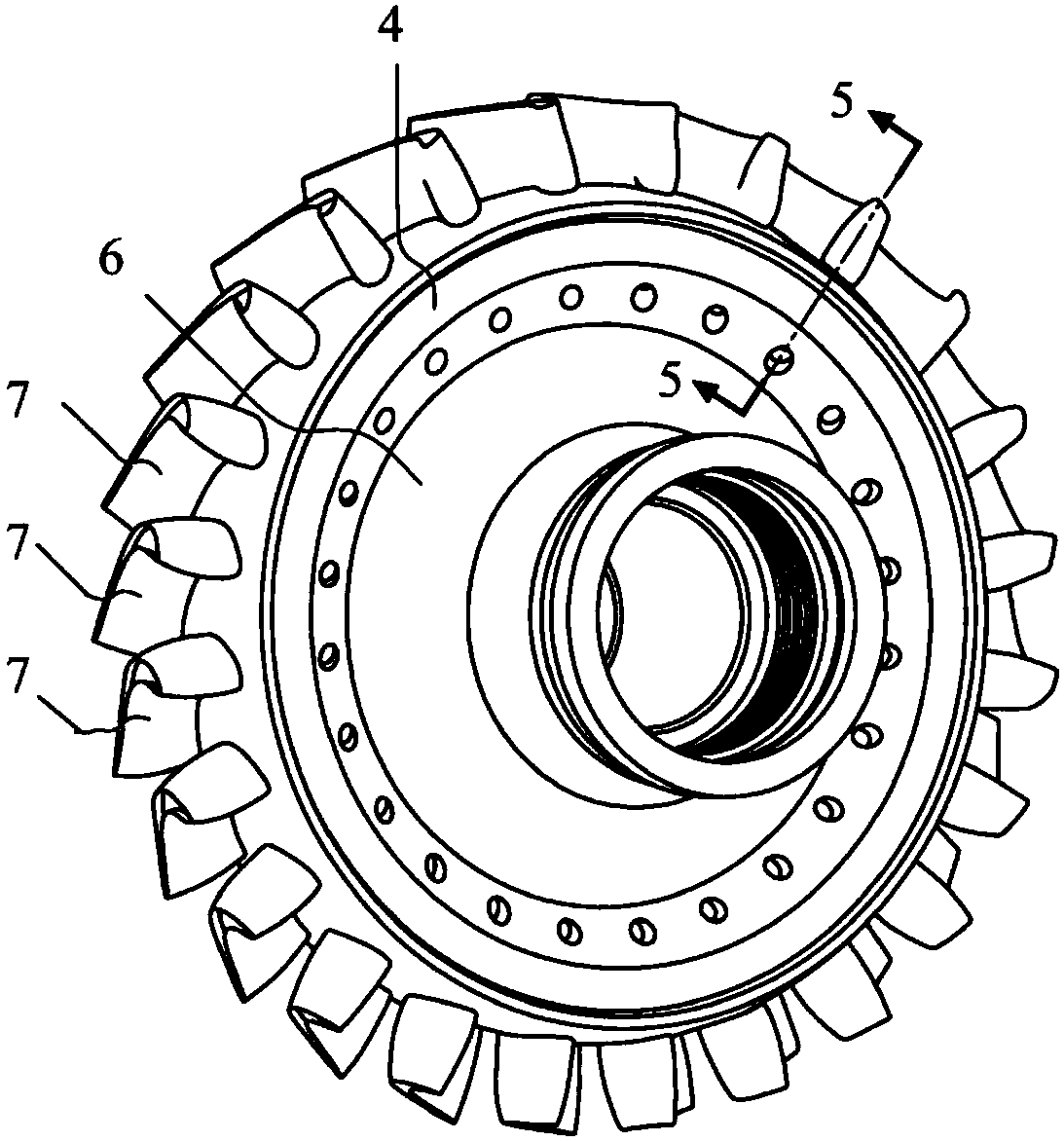

Calcium oxide-based ceramic mold manufacturing method based on 3D (Three Dimensional) printing technology

ActiveCN107021771AGuaranteed dimensional accuracyInhibition of hydrationAdditive manufacturing apparatusFiberHigh intensity

The invention a calcium oxide-based ceramic mold manufacturing method based on a 3D (Three Dimensional) printing technology. The method comprises the following steps: after carrying out organic treatment on calcium oxide ceramic powder subjected to grain size gradation, adding a proper amount of an sintering auxiliary agent and enhanced short fibers and uniformly mixing to prepare calcium oxide-based ceramic powder for 3D printing; carrying out the 3D printing by utilizing a photo-cured adhesive and the calcium oxide-based ceramic powder subjected to the organic treatment, so as to form a calcium oxide-based ceramic mold green body; carrying out degreasing, reactive melt infiltration and high-temperature intensified sintering on the calcium oxide-based ceramic mold to finally obtain a high-strength calcium oxide-based ceramic mold; carrying out surface hydration-proof treatment on the prepared ceramic mold. By adopting the method, the hydration resistance of the calcium oxide-based ceramic mold is improved; the calcium oxide-based ceramic mold prepared by the method has a good high-temperature comprehensive performance and can meet casting requirements of an alloy with higher temperature and (B2) metal with active high-temprature chemical properties, and a mold core is easy to remove.

Owner:XI AN JIAOTONG UNIV

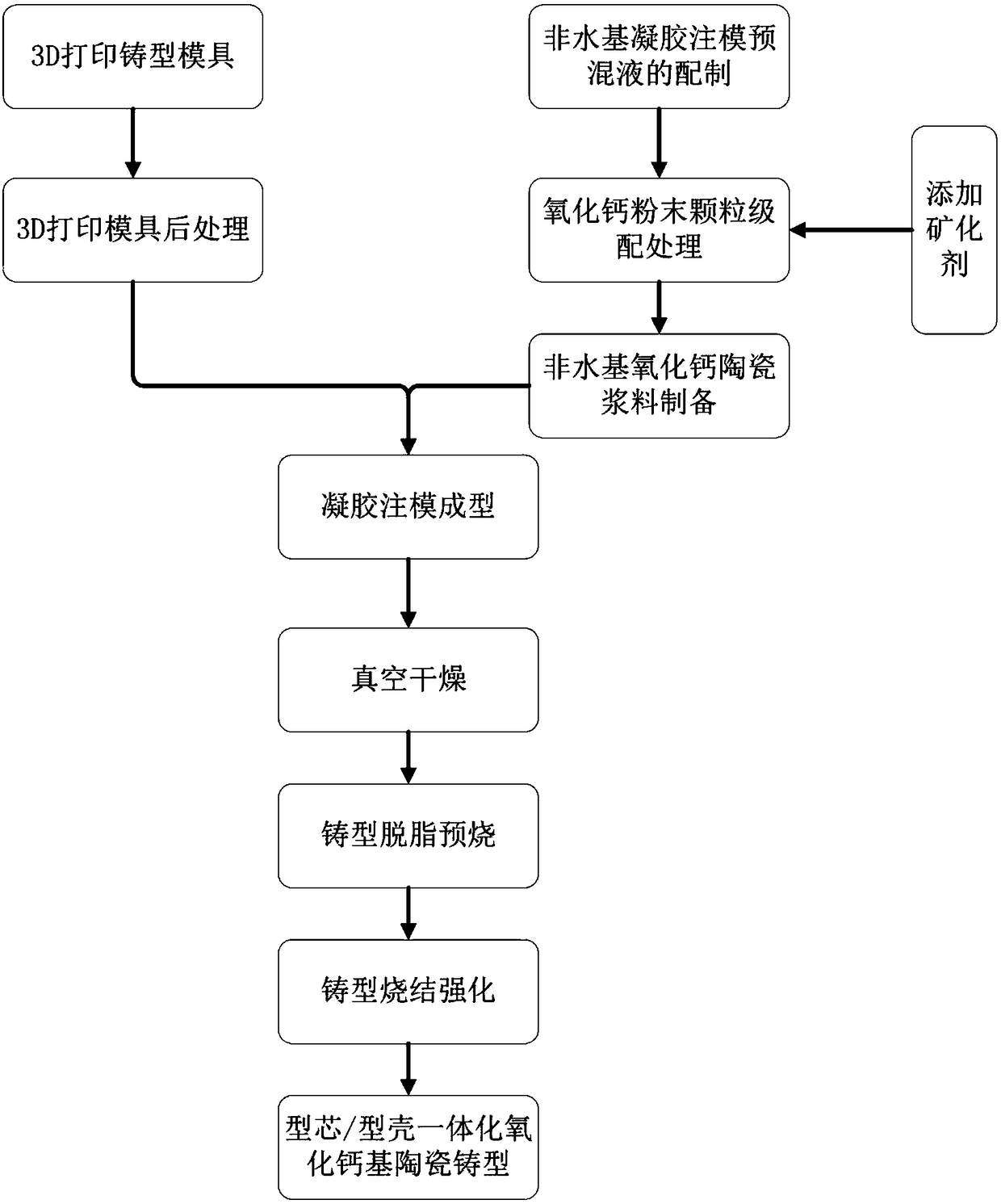

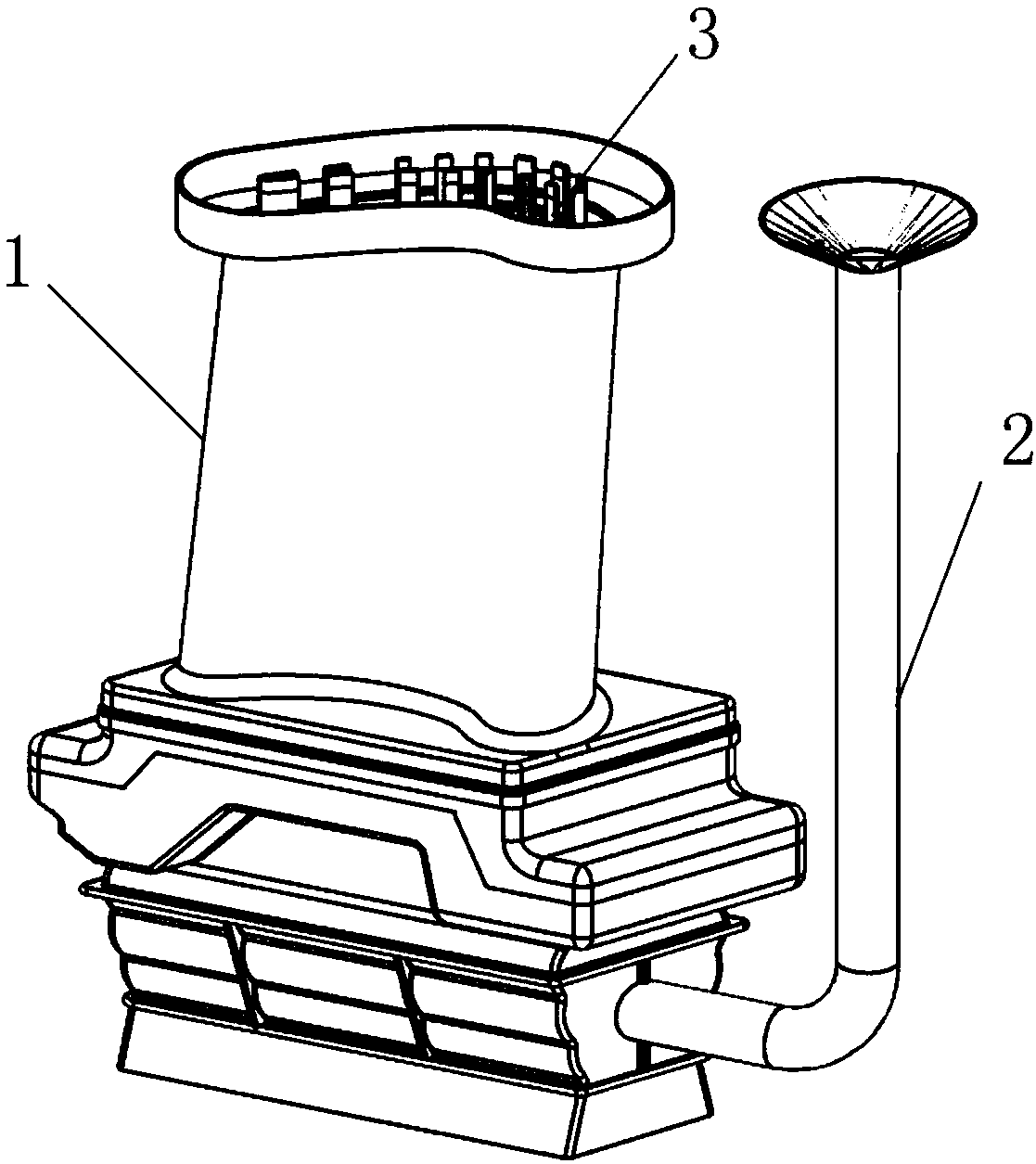

Non-water-based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and preparation method thereof

InactiveCN108059445AInhibition of hydrationImprove sintering performanceAdditive manufacturing apparatusWater basedNiobium

The invention discloses a non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and a preparation method thereof, and belongs to the technical field of rapid precision casting. The method is characterized in that a mold required for 3D printing technology rapid manufacture is used, and simultaneously a non-water-based gel injection molding technology isapplied, so that the problem of hydration of calcium oxide powder during a casting mold preparation process is effectively solved, and the method can be successfully applied to the preparation of a mold core / mold shell integrated calcium oxide-based ceramic casting mold with complex internal structural parts and components. The manufactured calcium oxide-based ceramic casting mold has good overallperformance, and can meet the casting requirements of ultrahigh-temperature alloys such as a new generation of niobium-silicon-based high-temperature alloy and active light alloys such as titanium-aluminium alloy and magnesium-aluminium alloy, and the core removal performance is extremely excellent, so that the technical problems of difficult removal and high rejection rate of silicon oxide-basedand aluminium oxide-based mold cores are solved, therefore, the non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold is a huge improvement on an existinginvestment mold precision casting and molding technology, and has broad market prospect and market value.

Owner:XI AN JIAOTONG UNIV

Method for extracting tea essential oil from oolong tea stalks

ActiveCN102504956ALow impurity contentImprove efficiencyEssential-oils/perfumesDistilled waterProcess engineering

The invention discloses a method for extracting tea essential oil from oolong tea stalks. The method comprises the following steps of: putting the oolong tea stalks serving as raw materials into a tea stalk distillation device, adding distilled water, and distilling; measuring petroleum ether, adding into a petroleum ether distillation device, and distilling; connecting the tea stalk distillation device and the petroleum ether distillation device through a glass guide pipe, fully mixing volatile gas distilled from the tea stalks and petroleum ether steam in a gas storage bag, introducing mixed steam into a condensation pipe, condensing to form oil-water mixed liquid, and refluxing the mixed liquid to a separating funnel; refluxing a water phase and an oil phase in the separating funnel to a first flask and a second flask respectively, so that the circular extraction process is finished once; repeating the process to fully extract the essential oil from the tea stalks; and taking the second flask with the petroleum ether out, concentrating a solution in the second flask, and collecting to obtain tea essential oil paste. By the method, the extraction cost of the tea essential oil can be reduced, and the economic benefit of tea processing is improved.

Owner:HUAXIANG YUAN TEA IND

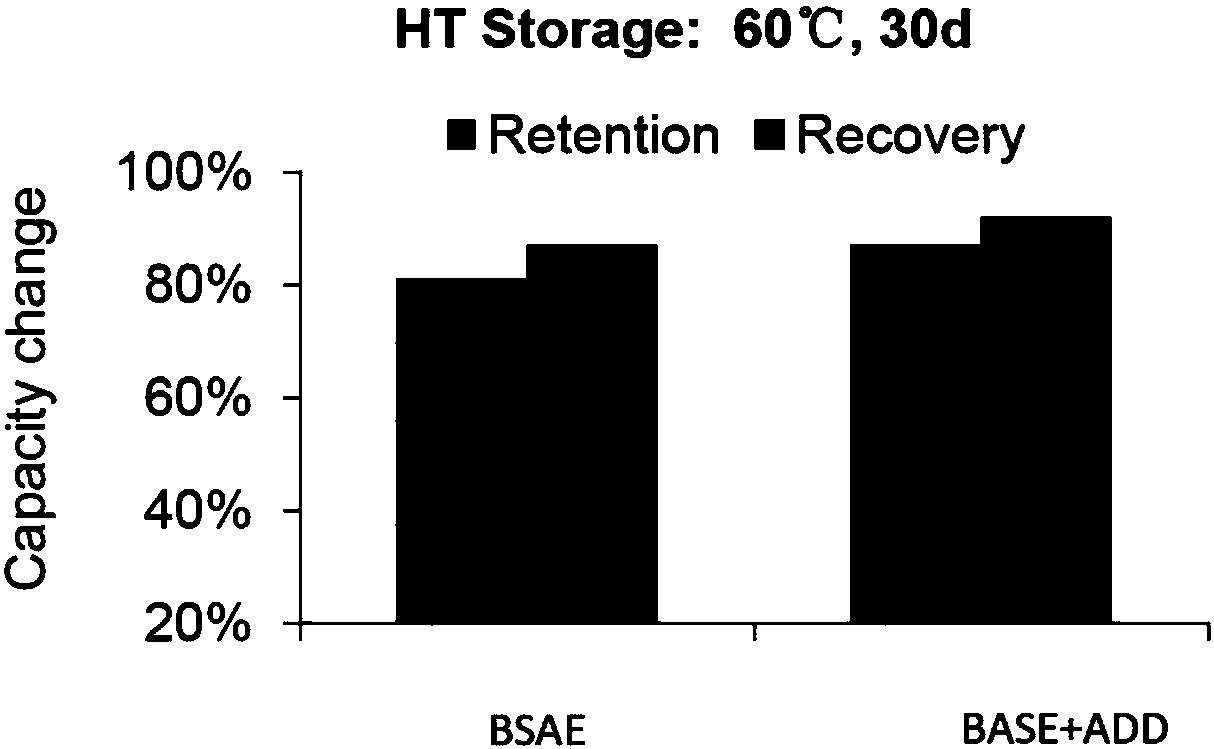

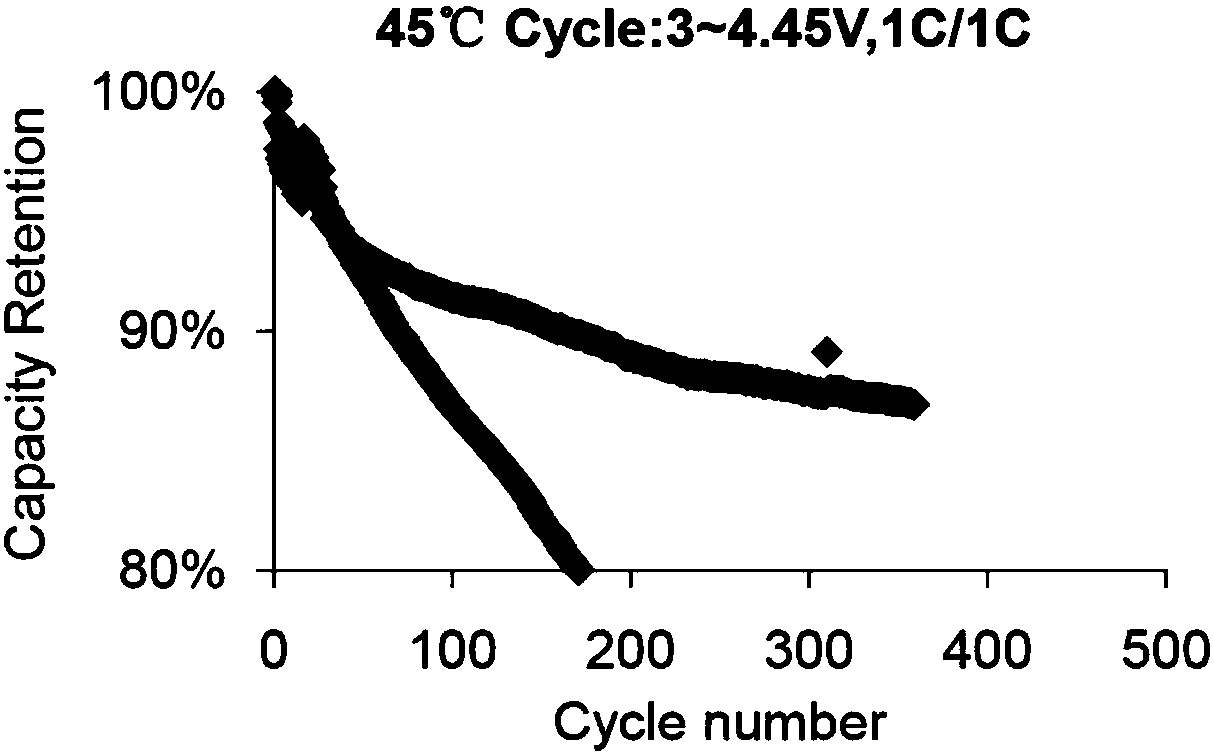

High-temperature resistant lithium ion electrolyte

ActiveCN107910591AImprove low temperature performanceImprove solubilitySecondary cellsDisiloxaneOrganic solvent

A high-temperature resistant lithium ion electrolyte belongs to the technical field of a lithium battery electrolyte and comprises a lithium salt and an organic solvent and also comprises 1,2-bi(trimethylsilyl) ethylene, 1,3-dimethyl-1,1,3,3-tetraethylene disiloxane, 2,4,6-triethylene-2,4,6-trimethylcyclotrisiloxane or 1,3-divinyl-1,1,3,3-tetramethyl-disilazane. In the battery electrolyte, the charge-discharge performance of a lithium battery can be effectively improved due to addition of the substance into the electrolyte, side reaction is reduced, so that the battery bubbling is reduced, andthe cycle lifetime of the battery is prolonged.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Environmentally-friendly drilling fluid with high plugging performance

InactiveCN107502320AImprove thermal stabilityImprove the lubrication effectDrilling compositionSodium BentoniteHexamethylenetetramine

The invention discloses an environmentally-friendly drilling fluid with high plugging performance. The drilling fluid comprises 2-6% of bentonite, 0.3-0.5% of sodium carbonate, 0.3-0.5% of an inhibitor, 0.2-0.5% of a coating agent, 0.1-0.3% of xanthan gum, 2-8% of a filtrate reducer, 2-5% of a plugging agent, 1-4% of calcium carbonate, 0.5-4% of a lubricant, and 25-250% of an inert weighting agent; and the nano plugging agent is formed by compounding of a product prepared from carbon spheres coated with AlOOH, acrylamide, N-isopropylacrylamide and hexamethylenetetramine and a vinyl acetate-ethylene copolymerization emulsion. The environmentally-friendly drilling fluid has the characteristics of high plugging performance, high lubricating performance, a good rheological property, strong ability of carrying rock debris, and friendliness to environments, and the environmentally-friendly drilling fluid is specially applied to environmental sensitive areas regions.

Owner:CNPC BOHAI DRILLING ENG

Concrete mixtures having high flowability

InactiveUS7621995B2Improve liquidityAvoid excessive viscositySolid waste managementCeramicwareHydration reactionPolymer science

A viscosity modifying agent is added to a concrete mixture to give the concrete desirable rheological properties. The viscosity modifying agent is incorporated into a foam admixture before it is mixed into the concrete. Because the viscosity modifying agent is a component of the foam admixture, the viscosity modifying agent is dispersed in the aqueous film that forms the foam bubbles. The viscosity modifier in the foam bubbles gives the foam beneficial rheological properties. The viscosity modifier performs more efficiently when included in the foam bubbles as compared to being mixed directly into the concrete. The foam bubbles containing the viscosity modifier can be stabilized using a fluorochemical stabilizer, which is included in the foam admixture. The foam bubbles can be further stabilized with respect to cement mixtures by including a hydration stabilizing in the cement mixture.

Owner:WELKER CHARLES D

Injection molding method for nano aluminum nitride ceramics

The invention discloses an injection molding method for nano aluminum nitride ceramics and belongs to the field of powder metallurgy. The injection molding method comprises the following steps of batching according to nano aluminum nitride powder and a sintering additive, wherein the addition amount of the sintering additive is 2 to 8 weight percent; adding 5 weight percent of coating agent to be mixed with absolute ethanol to obtain slurry; performing spray drying and granulating to obtain a nano aluminum nitride powder granulation material; placing the granulation material and a binding agent according to the mixture ratio of 50g to 9g-50g to 12g on a roller type mixer for mixing; performing injection molding on the mixture to obtain a green aluminum nitride body; degreasing and sintering the green aluminum nitride body to obtain the aluminum nitride ceramics. According to the injection molding method disclosed by the invention, the nano aluminum nitride powder is granulated in advance, so that the flowability, the apparent density and the tap density of the powder are improved; meanwhile, a coating layer is formed on the surface of the powder, so that the phenomenon that the oxygen content is increased as the powder generates a hydration reaction is prevented; the granulation material and the binding agent are mixed to obtain a feedstock for injection molding of the nano aluminum nitride; the nano aluminum nitride is subjected to injection molding, degreasing and sintering techniques to obtain the aluminum nitride ceramics; the aluminum nitride ceramics have the characteristics of good conformality, low sintering temperature, high strength and the like.

Owner:UNIV OF SCI & TECH BEIJING

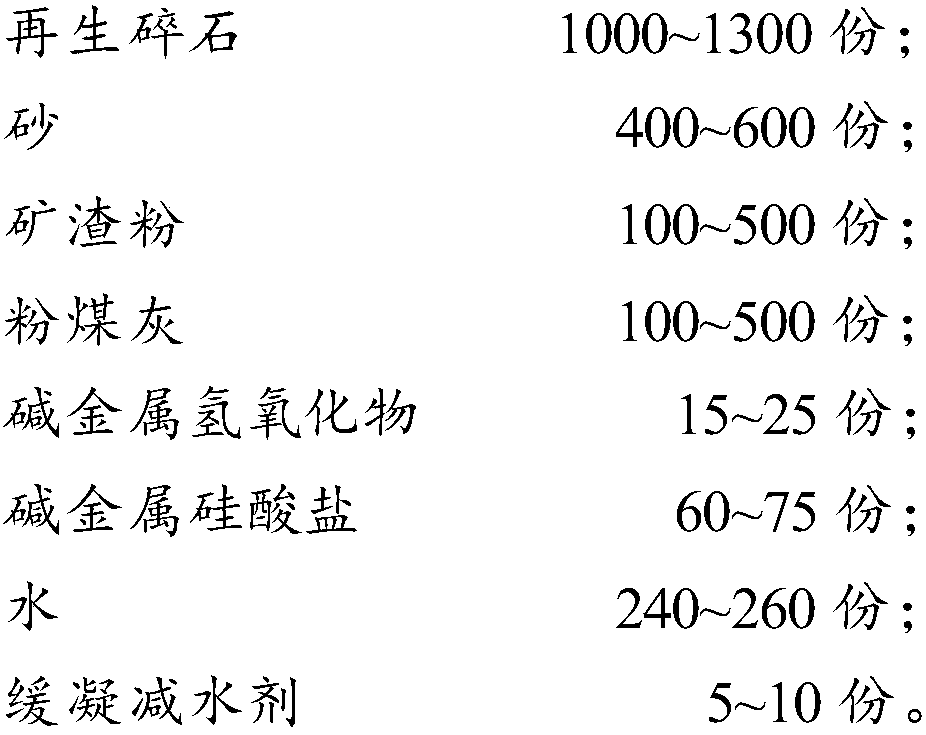

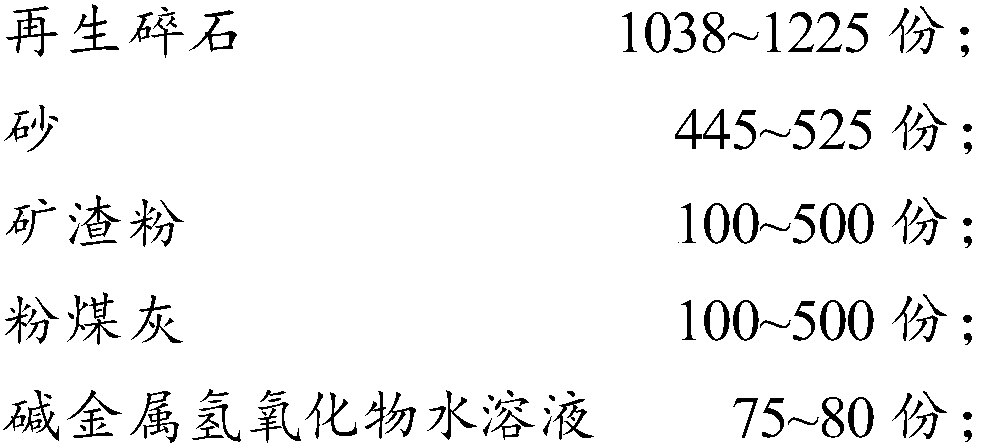

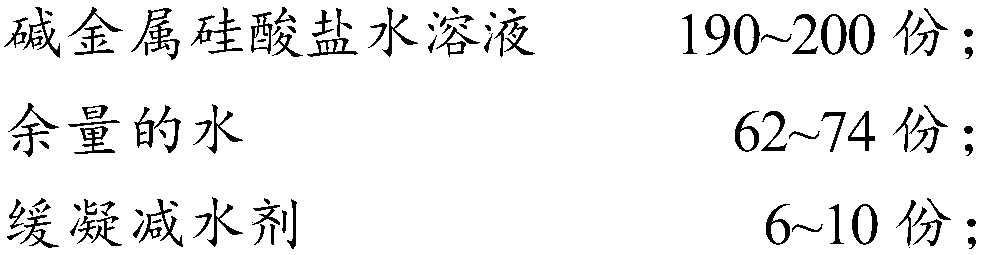

Recycled concrete and preparation method thereof

The invention belongs to the field of building materials, and particularly relates to recycled concrete and a preparation method thereof. The recycled concrete provided by the invention is prepared from the following raw materials in parts by weight: 1000-1300 parts of regenerated gravel; 400-600 parts of sand, 100-500 parts of slag powder, 100-500 parts of fly ash, 15-25 parts of an alkali metalhydroxide, 60-75 parts of an alkali metal silicate, 240-260 parts of water, and 5-10 parts of a retarding water-reducing agent. According to the invention, the regenerated gravel and the sand are usedas aggregates, and after alkali excitation, industrial by-products such as the slag powder and the fly ash are used as cementing material binders, so that the environment-friendly concrete material with excellent usability is obtained. The concrete material not only are used to realize the effective reutilization of waste buildings and industrial wastes, but also has the advantages of short setting time, high early strength and the like, and is beneficial to popularization and application in rescue and relief work and national defense construction.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com