Patents

Literature

132 results about "Monoisopropanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

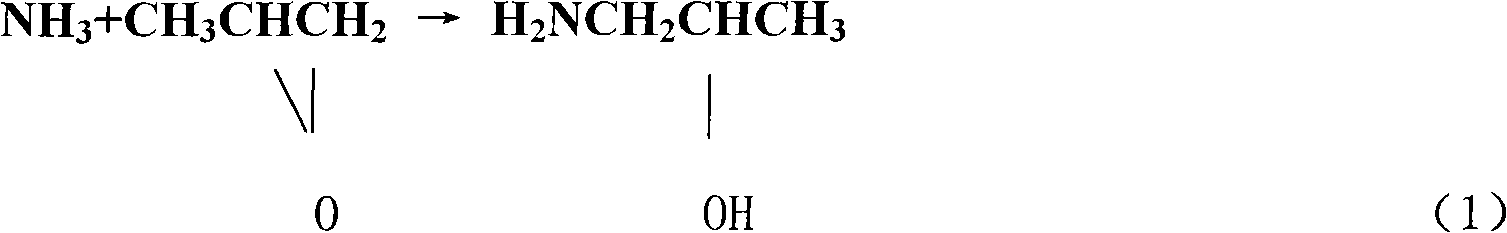

Monoisopropanolamine MIPA; Threamine. Identifiers CAS Number. ... 1-Amino-2-propanol is an intermediate in the synthesis of a variety of pharmaceutical drugs and is the very basic building block of the opioid methadone.

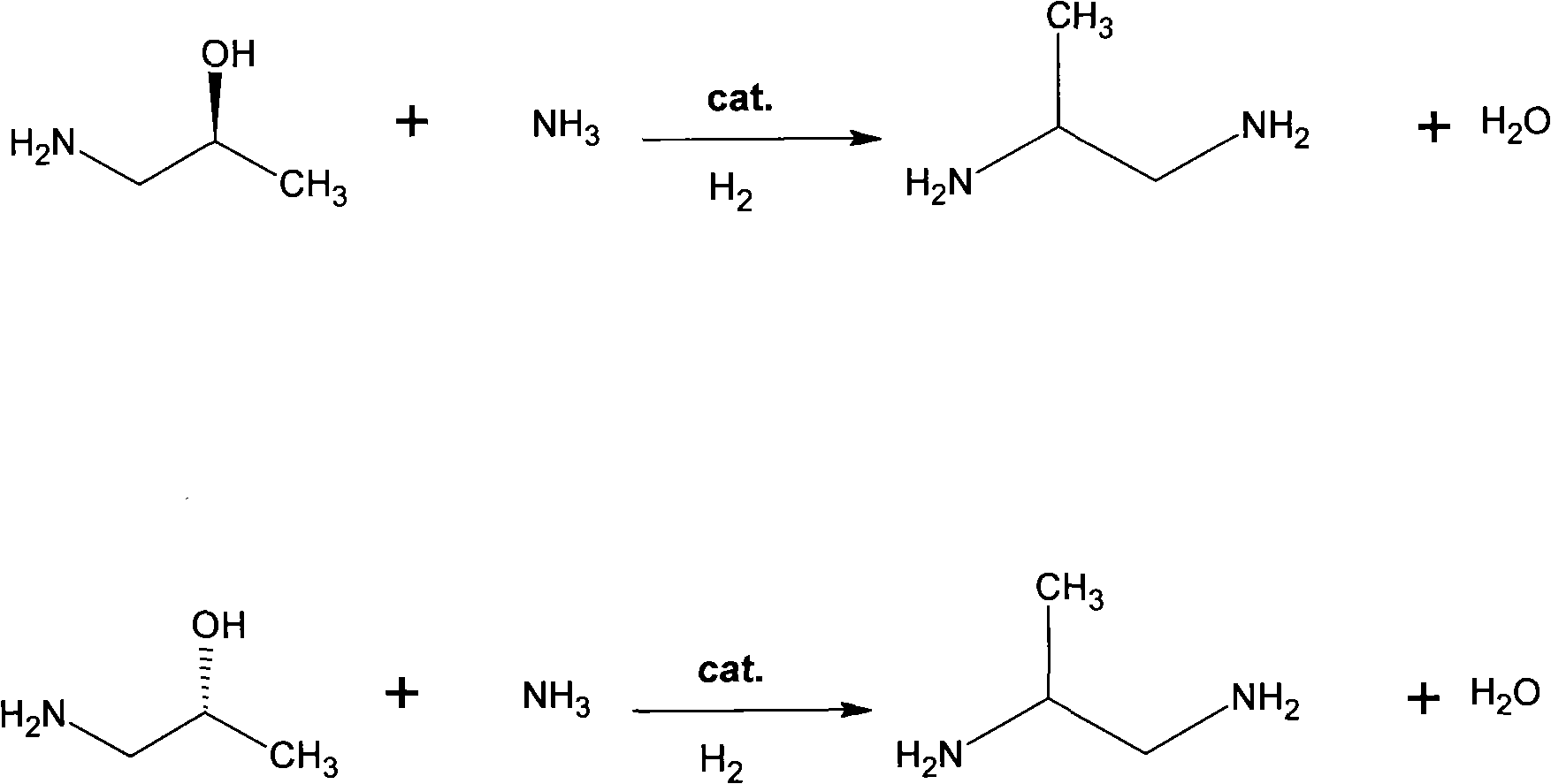

Preparation method of 1,2-propane diamine

InactiveCN101891628AThe process steps are simpleNo polluting emissionsOrganic compound preparationAmino compound preparationChemical synthesisHydrogen

The invention discloses a preparation method of 1,2-propane diamine, belonging to the technical field of chemical synthesis. The preparation method mainly comprises the following steps: adding monoisopropanolamine, water, ammonia, hydrogen and catalyst into a high-pressure reaction kettle, stirring at a high speed, performing the catalytic amination at 100-250 DEG C under a pressure of 5-15 MPa to obtain a mixture using 1,2-propane diamine as the main component, and finally rectifying to obtain 1,2-propane diamine, wherein the selectivity of the product is greater than 80%, and the purity of the product is greater than 99%. The method has the advantages of safety, environmental protection, simple operation, high conversion rate, low energy consumption, low raw material consumption and lowproduction cost.

Owner:张家港市大伟助剂有限公司

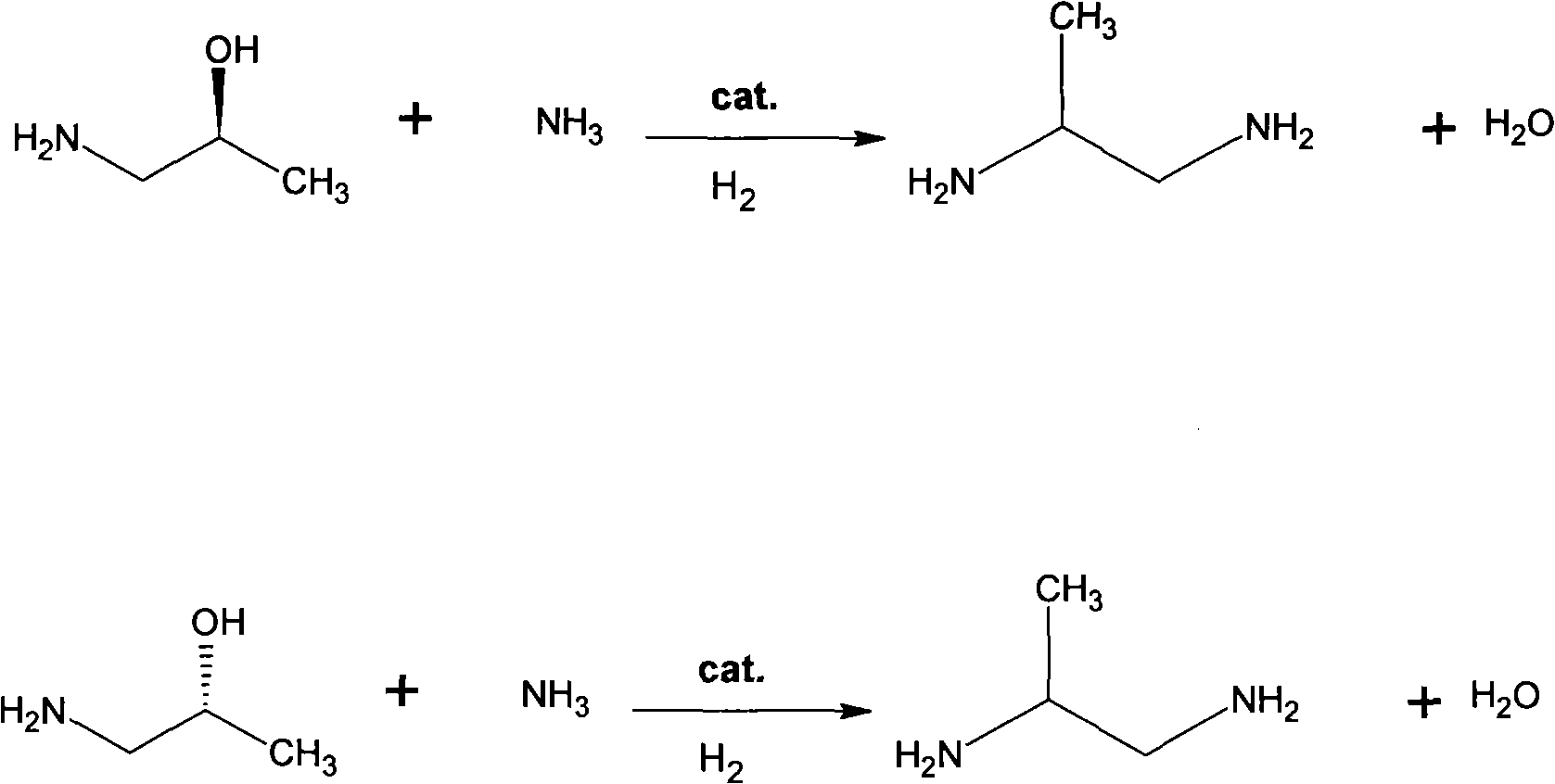

Method for continuously producing high-efficiency concrete grinding aid

InactiveCN101314533AReduce production energy consumptionReduce manufacturing costCement productionContinuous reactorMonoisopropanolamine

The invention provides a method for realizing simple and direct preparing of high-efficiency cement rubber additive. The method, which has lower cost and takes ammonia, propylene oxide (PO) and ethylene oxide (EO) as raw materials, comprises the following steps that: superfluous ammonia stream and PO stream are fed into a continuous reactor so as to continuously form a mixture containing isopropanolamine, diisopropanolamine and triisopropanolamine; liquid level inside the continuous reactor is maintained to ensure that the stream in the reactor undergoes outer circulation spraying through a circulating pump from the bottom to the top of the continuous reactor, and part of the stream is continuously fed into a flash tower so as to remove unreacted ammonia; then, the stream with ammonia removed is reacted with EO stream so as to continuously generate products. The method ensures that products do not need rectification separation and greatly reduce production energy consumption, thereby reducing the production cost of products.

Owner:HONGBAOLI GRP CO LTD

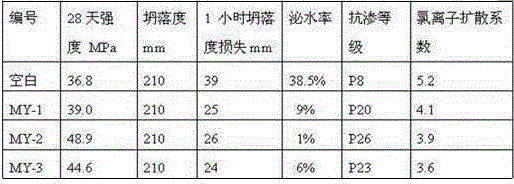

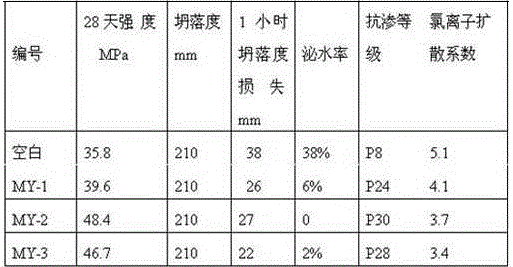

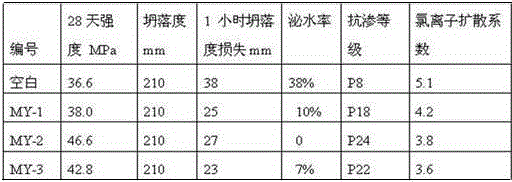

Chloridion-corrosion resistant concrete synergist and production technology thereof

The invention discloses a chloridion-corrosion resistant concrete synergist. The component percentage is anti-bleeding component : anti-permeability waterproof component : enhancing component : dispersing component : entraining component : coordinating component; the anti-bleeding component comprises polysaccharide and / or cellulose ether and / or polyacrylamide, the anti-permeability waterproof component comprises methyl sodium silicate and / or organosilicon waterproofing agent, the enhancing component comprises glycol monoisopropanolamine, composition of the glycol monoisopropanolamine and triethanolamine and triisopropanol, the dispersing component comprises MF and / or TCL and / or NNO, the entraining component comprises dodecyl benzene acid sodium and / or dodecyl benzene sodium sulfate, and the coordinating component comprises polymeric alcohol amine and polymeric polyhydric alcohol. The invention further provides a production technology for the chloridion-corrosion resistant concrete synergist. The chloridion-corrosion resistant concrete synergist is capable of improving the concrete strength, reducing the bleeding rate and reducing the slump loss.

Owner:株洲市中建新材料有限公司

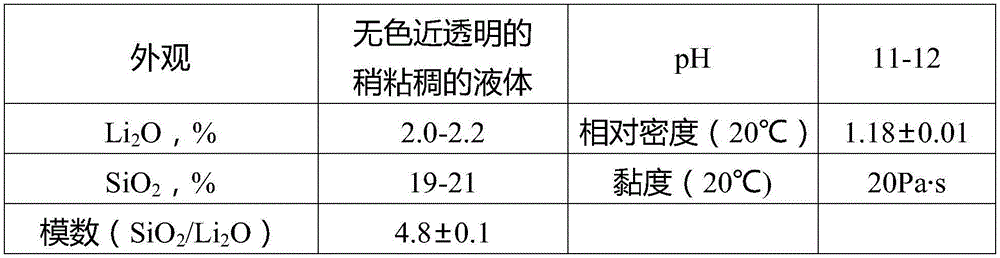

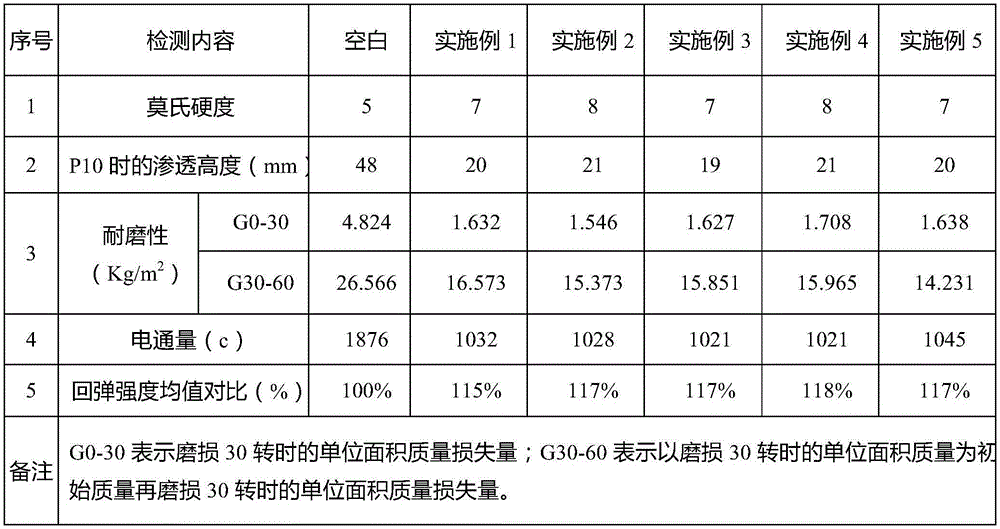

Concrete surface sealing curing treatment enhancing agent

The invention relates to a concrete surface sealing curing treatment enhancing agent comprising the components of, by mass: 3-8% of a penetrating agent, 20-45% of an accelerator, 3-5% of a complexing agent, 2-5% of a dispersing agent, 4-8% of a nano-grade active agent, and 35-60% of water. The penetrating agent is a mixture of fatty alcohol polyoxyethylene ether phosphate and alkyl phosphate with a mass ratio of (0.5-1.5):1. The accelerator is a mixture of lithium silicate, lithium carbonate and sodium nitrite with a mass ratio of (0.5-1):(0.1-1):(2-5). The complexing agent is a mixture of triethanolamine and diethanol monoisopropanolamine with a mass ratio of 1:(0.5-2). The dispersing agent is a melamine water reducing agent. The nano-grade active agent is nano-grade calcium carbonate. The concrete surface sealing curing treatment enhancing agent has low alkali content. When the enhancing agent is used in concrete surface treatment, the concrete surface layer can be denser; the structure can be more compact; and concrete durability is improved.

Owner:广东广洁科技有限公司

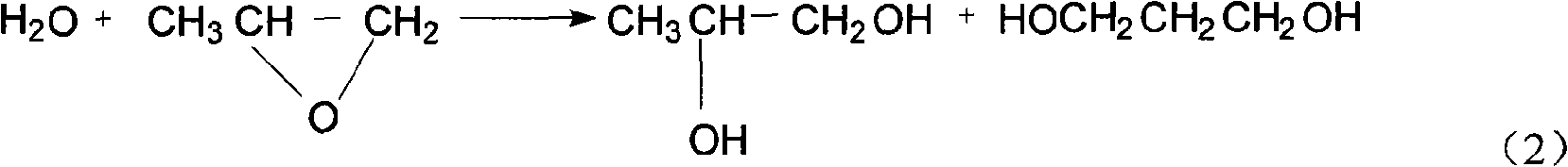

Method of synthesizing monoisopropanolamine

ActiveCN101265196AMeet high-end needsImprove qualityOrganic compound preparationAmino-hyroxy compound preparationTime rangeDistillation

The invention relates to a synthesis method of isopropanolamine. The synthesis method comprises the following steps: (1) liquid ammonia and water are mixed to form ammonia water which is mixed with propylene oxide; mixed solution is preheated until the temperature reaches 120 to 125 DEG C, and the inputting molar ratio of the ammonia and the propylene oxide is controlled within 10 to 15; (2) the materiel after preheating is delivered into a reactor, the reaction temperature ranges from 128 to 138 DEG C, the pressure ranges from 12.6 to 13.8MPa, and the reaction time ranges from 1.5 to 3 hours; (3) the surplus unreacted ammonia is separated from the obtained mixture after the reaction by using a flash distillation column, the pressure in the flash distillation column ranges from 0.6 to 1.6MPa, and the temperature of a column kettle ranges from 140 to 160 DEG C; (4) the mixture which is separated through the flash distillation column is delivered into a leading tower for rectification dehydration, the pressure in the leading tower ranges from minus 0.080 to minus 0.085MPa, the temperature at the top of the leading tower is 45 to 55 DEG C, and the temperature at the bottom in a tower kettle ranges from 110 to 130 DEG C; (5) the mixture after dehydration is delivered into a rectification column for rectification, the pressure in the rectification column ranges from minus 0.095 to minus 0.099MPa, the temperature in the column kettle ranges from 135 to 160 DEG C, the temperature at the top of the rectification column ranges from 60 to 70 DEG C, isopropanolamine products are obtained at the top of the rectification column, and the mixture composed of diisopropanolamine and triisopropanolamine is obtained in the column kettle. The synthesis method has simple production procedure, little equipment investment, and high product quality.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

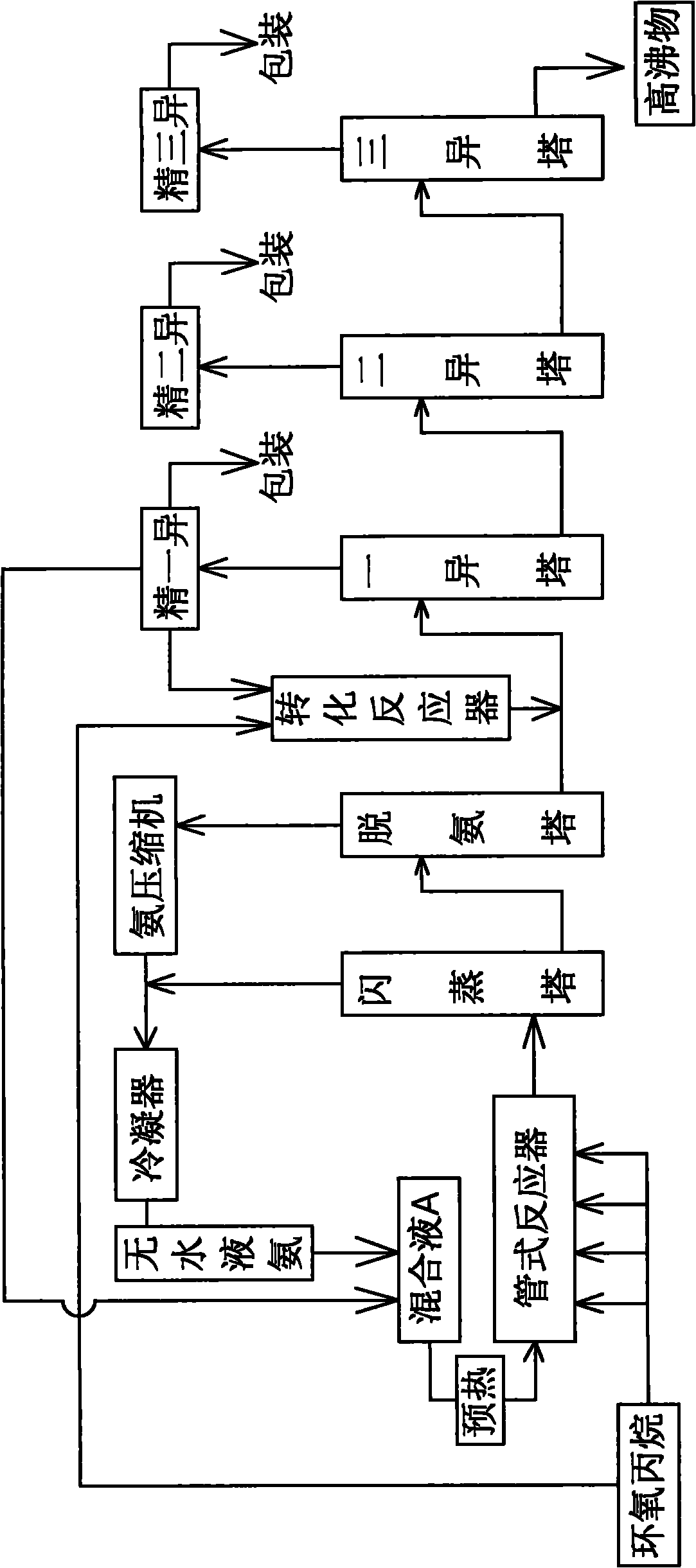

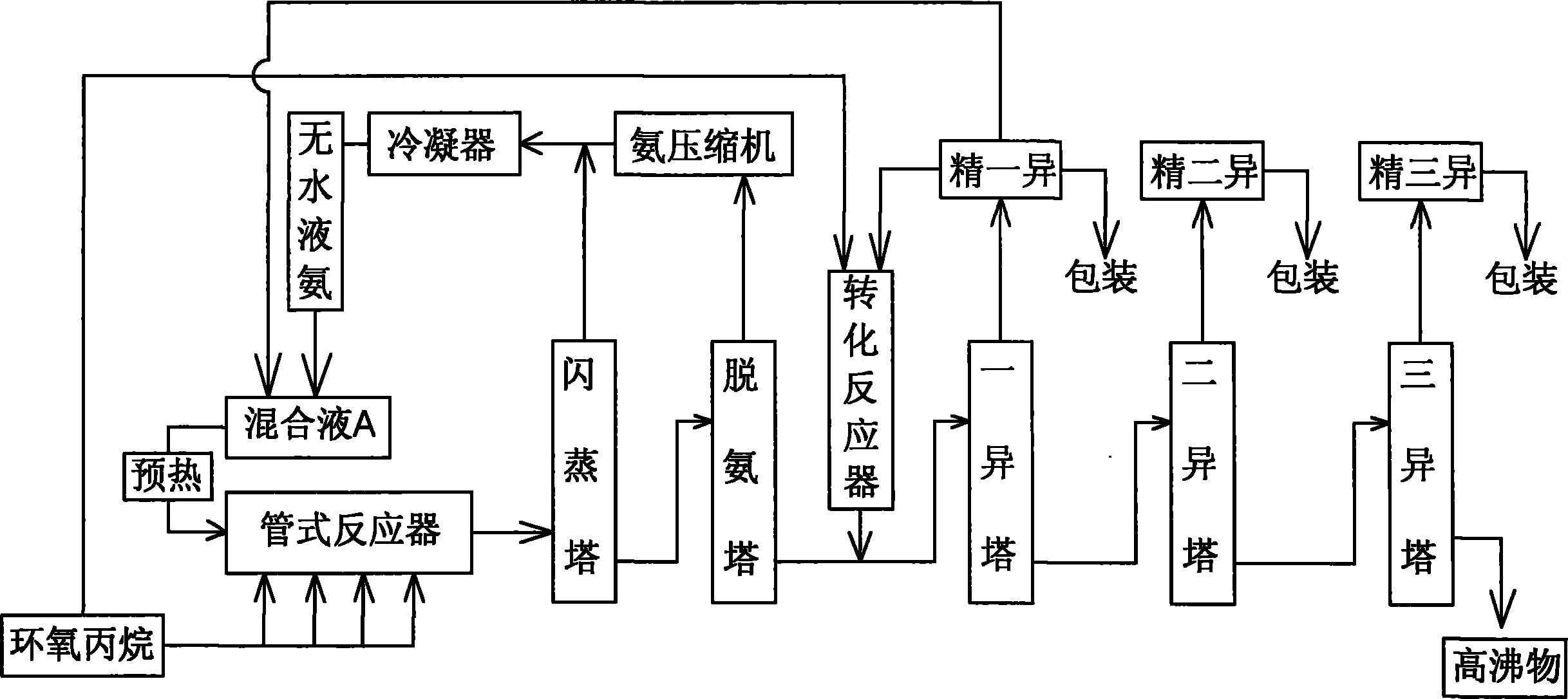

Isopropanolamine producing method

InactiveCN101786957ASave energyInhibition of hydrationOrganic compound preparationAmino-hyroxy compound preparationSide effectMonoisopropanolamine

The invention relates to an isopropanolamine producing method. As the present isopropanolamine producing method uses water as a catalyst, the energy consumption for subsequent dehydration is high and side effects can be easily caused. For this reason, the isopropanolamine producing method of the invention includes tubular reaction, flash evaporation, deamination and rectification, wherein isopropanolamine is used as the catalyst in the tubular reaction; before feeding, a liquid mixture A of anhydrous liquid ammonia and the catalyst is prepared according to the weight ratio of 96-99:1-4; finally, the liquid mixture A and propylene oxide are added according to the feeding speed ratio of 85-340:58. The isopropanolamine producing method realizes low energy consumption and less byproducts in the subsequent dehydration. The invention is applicable to producing the isopropanolamine.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

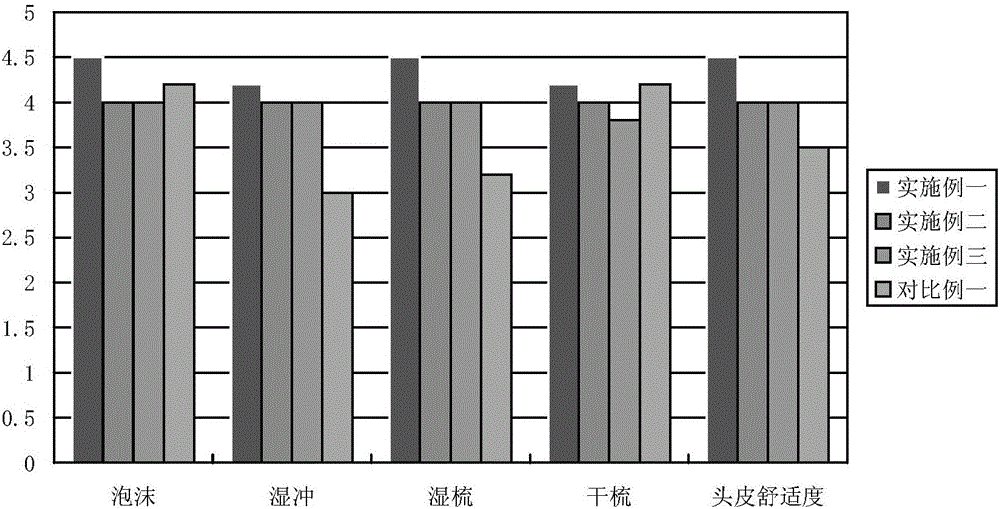

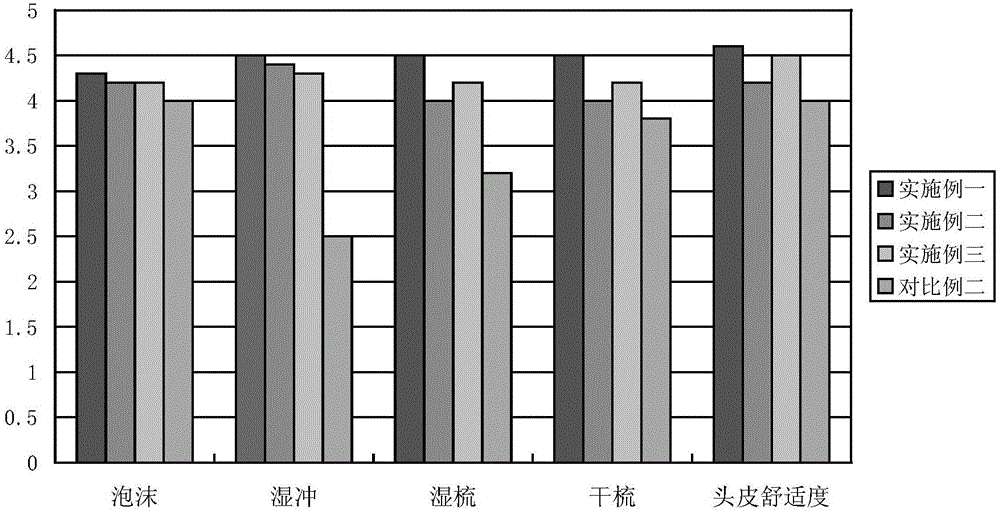

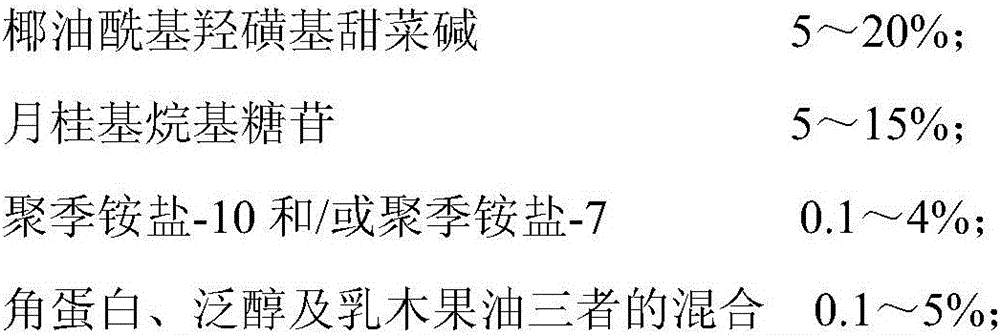

Sulfate-anionic-surfactant-free silicone-oil-free shampoo composition

ActiveCN106361660AAvoid damageGood compatibilityCosmetic preparationsHair cosmeticsDISODIUM LAURYL SULFOSUCCINATEAdhesive

The invention discloses a sulfate-anionic-surfactant-free silicone-oil-free shampoo composition. The shampoo composition is composed of 10-45% of anionic surfactant, 8-20% of zwitterionic surfactant, 5-15% of nonionic surfactant, 0.1-3% of conditioner, 0.1-3% of plant extract, 0-1% of preservative, 0.1-1.0% of essence and the balance of deionized water. The shampoo composition comprises one or two of disodium lauryl sulfosuccinate, sodium cocoyl glutamate and sodium lauroyl sarcosine as the main surfactant which is compounded with cocoyl hydroxyl sulfobetaine, lauryl alkyl glycoside and isostearamide monoisopropanolamine. A polyquaternary ammonium salt-10 and a polyquaternary ammonium salt-7 are used as the conditioner; keratin, panthenol and shea butter grease adhesive are matched with the plant extract nutrient; and hexamidine (hydroxy-ethyl sulfonic acid) salt is used as one of the anti-dandruff bactericides. The shampoo composition is free of sulfates and silicone oil, and is capable of well cleaning and conditioning the hair and scalp.

Owner:GUANGZHOU OUSIA IND CO LTD

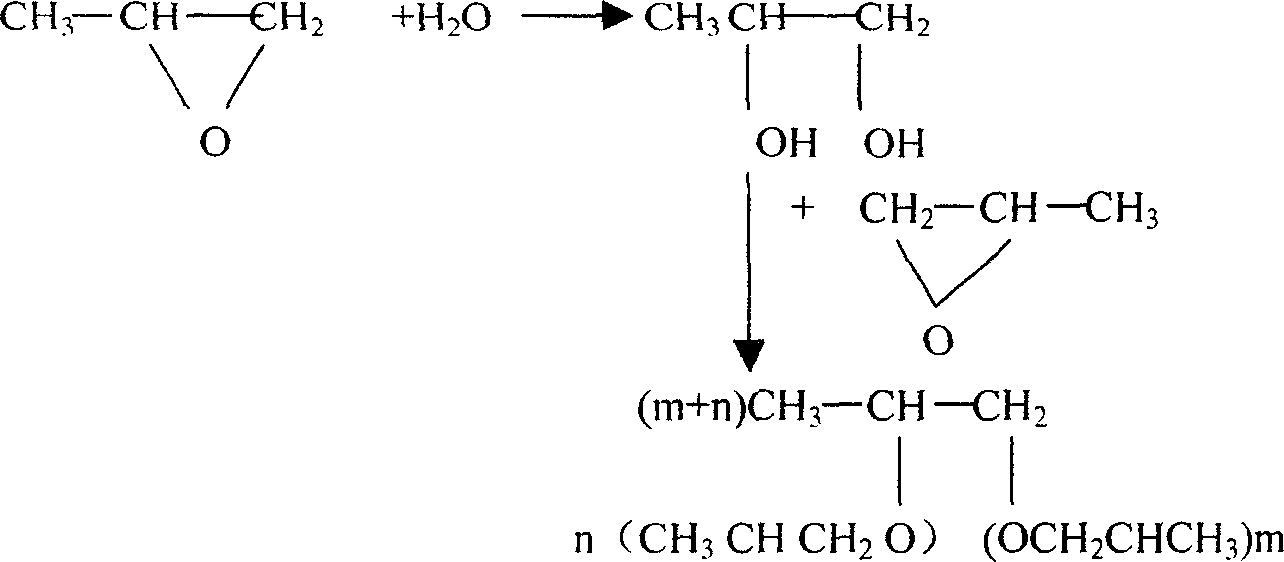

Preparation method of diethylene monoisopropanolamine

ActiveCN104230724AIncrease profitImprove conversion rateOrganic compound preparationChemical recyclingAlkaneMonoisopropanolamine

The invention relates to a preparation method of diethylene monoisopropanolamine. The preparation method comprises the following steps of (1) introducing an inert gas to replace air inside a reaction kettle into the reaction kettle; (2) premixing epoxy propane and diethanolamine, then adding to the reaction kettle, introducing the inert gas to keep the pressure inside the reaction kettle to 0.1-0.5 Mpa, stirring and mixing materials, then raising temperature, keeping the temperature, and reacting to obtain a diethylene monoisopropanolamine product. According to the preparation method disclosed by the invention, diethanolamine and epoxy propane are utilized as raw materials and the conventional way of taking water as a solvent is abandoned, and the materials are premixed, so that the viscosity and solidification point of the reacted materials are reduced; the fast progress of reaction is facilitated due to the uniform dispersion of the two materials in a reactor; in addition, under the condition of low alkane-amine ratio, the improvement of the utilization ratio of epoxy propane and the reduction of generation probability of side reaction are facilitated. The whole process has the advantages of low energy consumption, high material transformation rate, high product purity, stable quality and no wastes.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

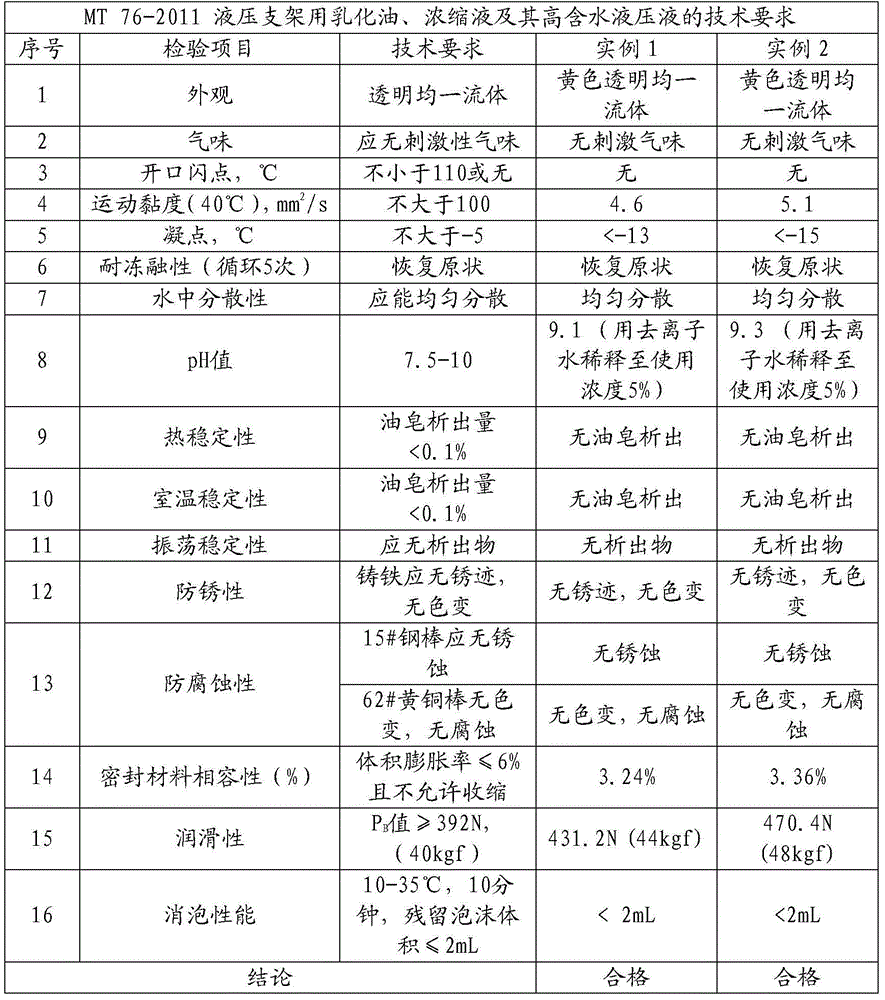

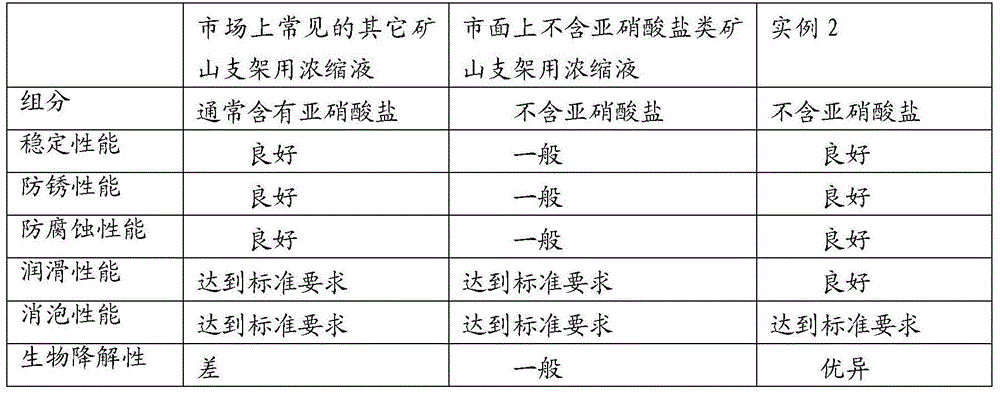

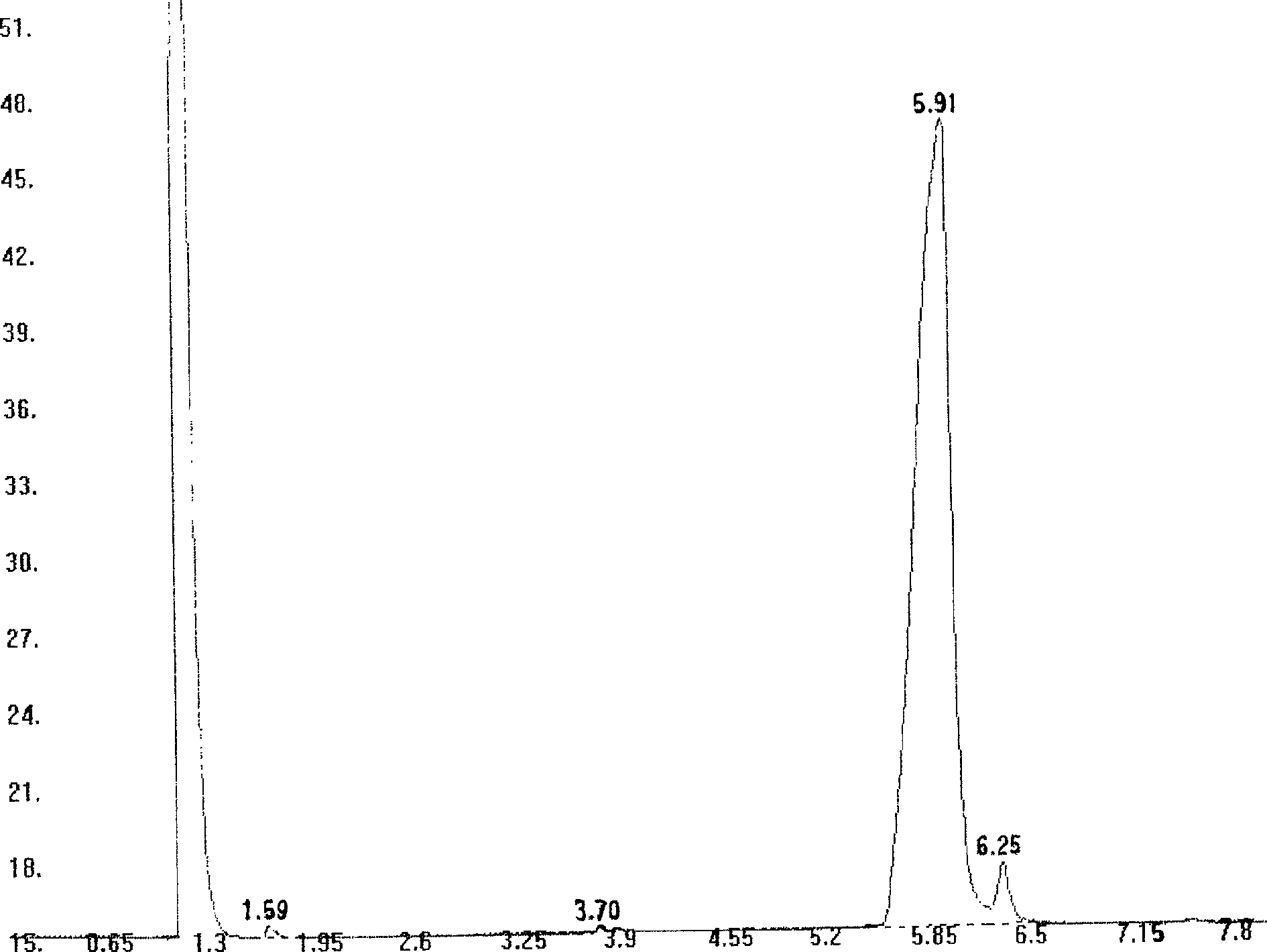

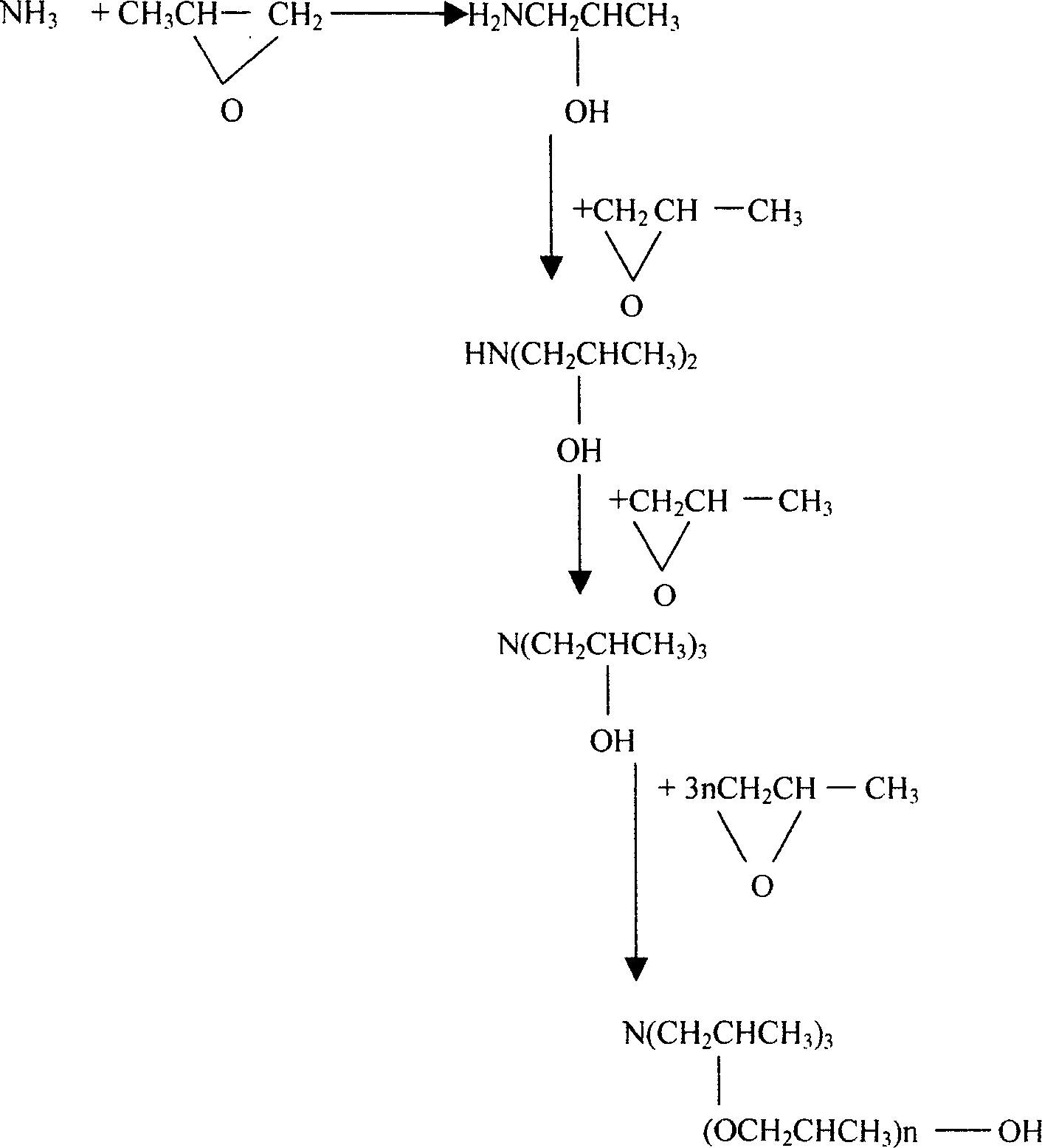

Nitrite-free concentrated solution for rapidly biodegrading mine prop and preparation method

The invention discloses a nitrite-free concentrated solution for rapidly biodegrading a mine prop and belongs to the field of mine machine application and maintenance. The concentrated solution comprises, by mass, 21% to 25% of an antirust agent packet obtained through an amidation reaction of an organic acidic compound and an alcohol amine compound, 0.5% to 0.7% of benzotriazole, 0.5% to 0.6% of an ionic surfactant, 0.8% to 0.9% of nonionic surfactant, 3% to 5% of a lubricant agent, 0.1% to 0.12% of a defoaming agent, and the balance soft water. According to the antirust agent packet, the organic acidic compound is the composition of three or more of C8-C12 monobasic saturated fatty acids, C10-C12 binary saturated fatty acids, C12-C18 unsaturated fatty acids and C18-C22 dimer acids and must contain the C18-C22 dimer acids, and the alcohol amine compound is the composition of three or more of monoethanolamine, diethanol amine, monoisopropanolamine and diglycolamine; the alcohol amine compound is excessive in the antirust agent packet.

Owner:QUAKER CHEM CHINA

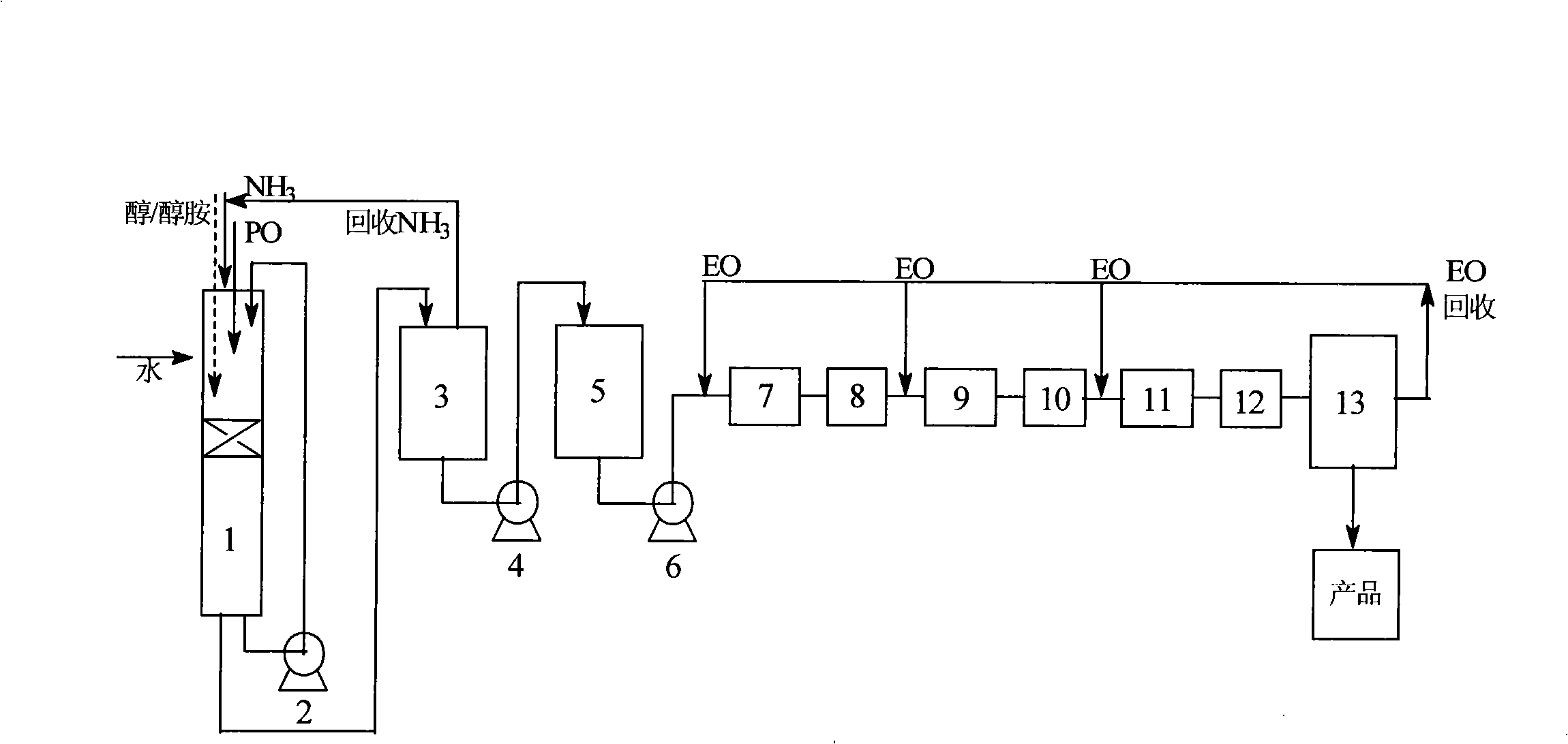

Process for synthesis of triisopropanolamine

ActiveCN1629134AIncrease moisture contentHigh purityOrganic compound preparationAmino-hyroxy compound preparationReaction temperatureMonoisopropanolamine

The invention provides a process for synthesis of triisopropanolamine by using liquid ammonia and trimethylene oxide as raw material, water as catalyst, stock preparing by the mol ratio of liquid ammonia : trimethylene oxide = 1 : 3.00 - 3.05, charging deionized water in one time, charging liquid ammonia and trimethylene oxide in two times, fully stirring, sustaining the pressure <0.5 MPa, sustaining reaction temperature between 20-75 deg. C for 1.0-3.0 hours, decompressing for dehydration till the water content is less than 5%.

Owner:HONGBAOLI GRP CO LTD

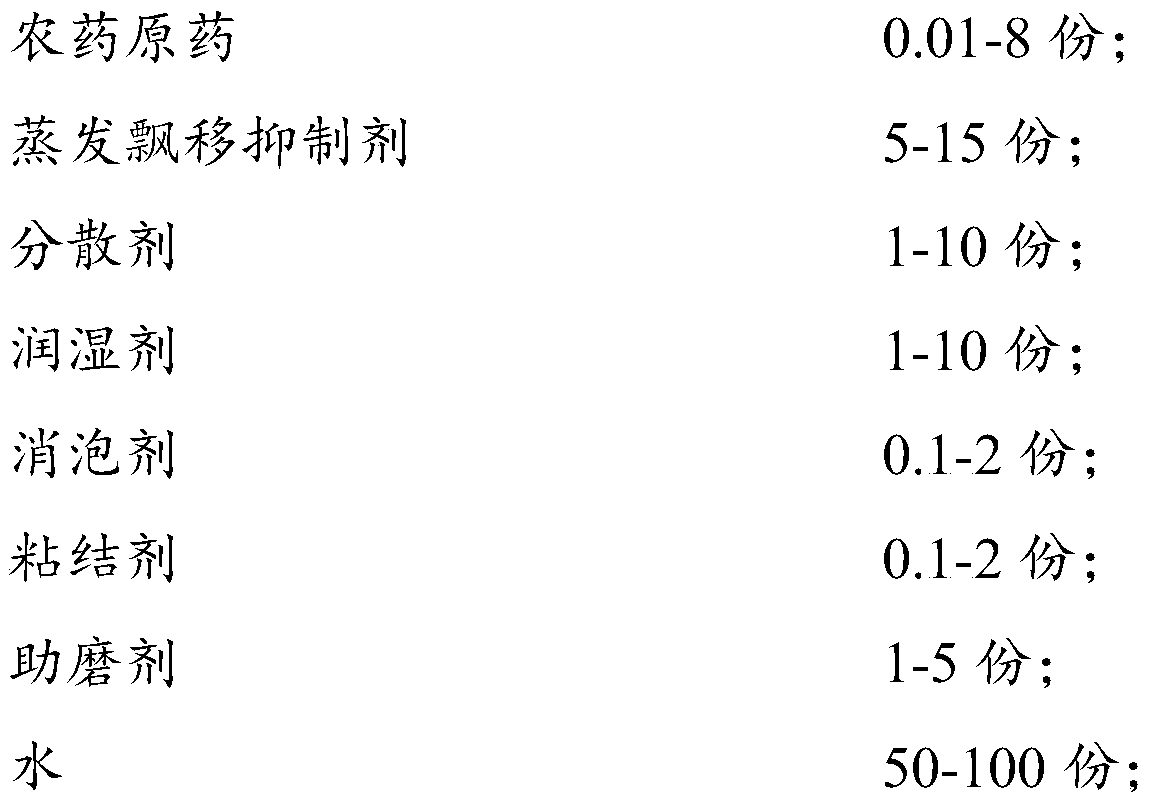

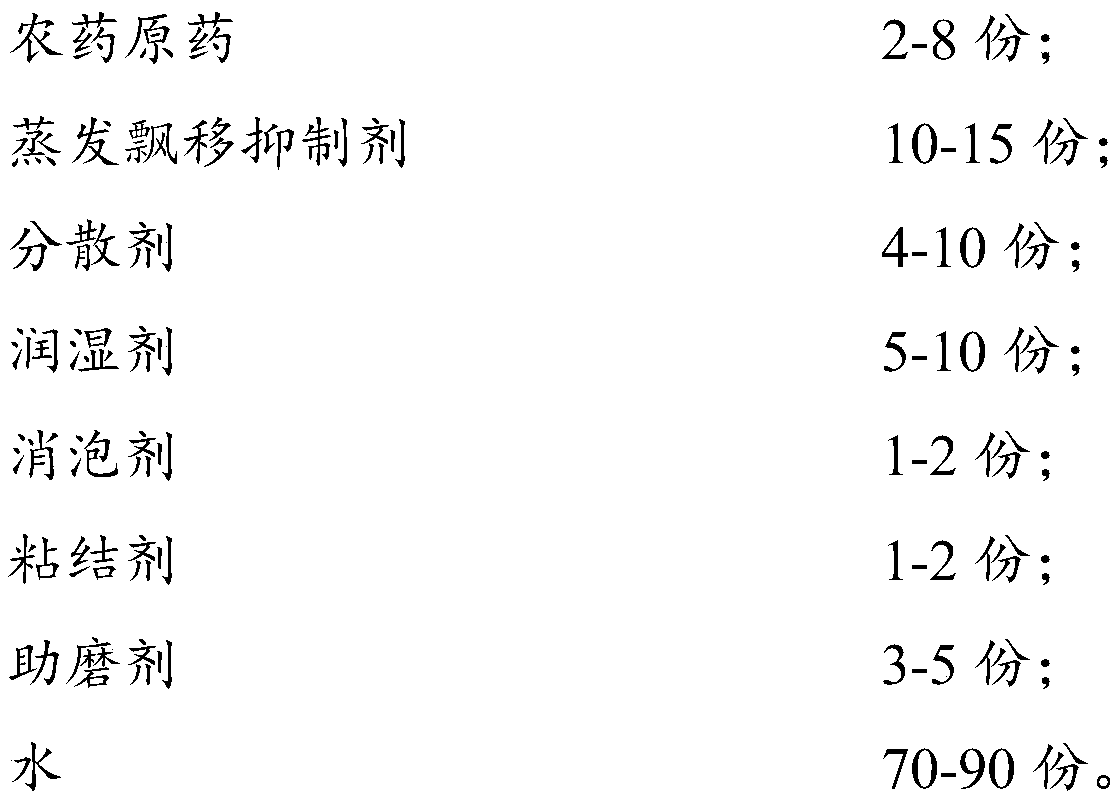

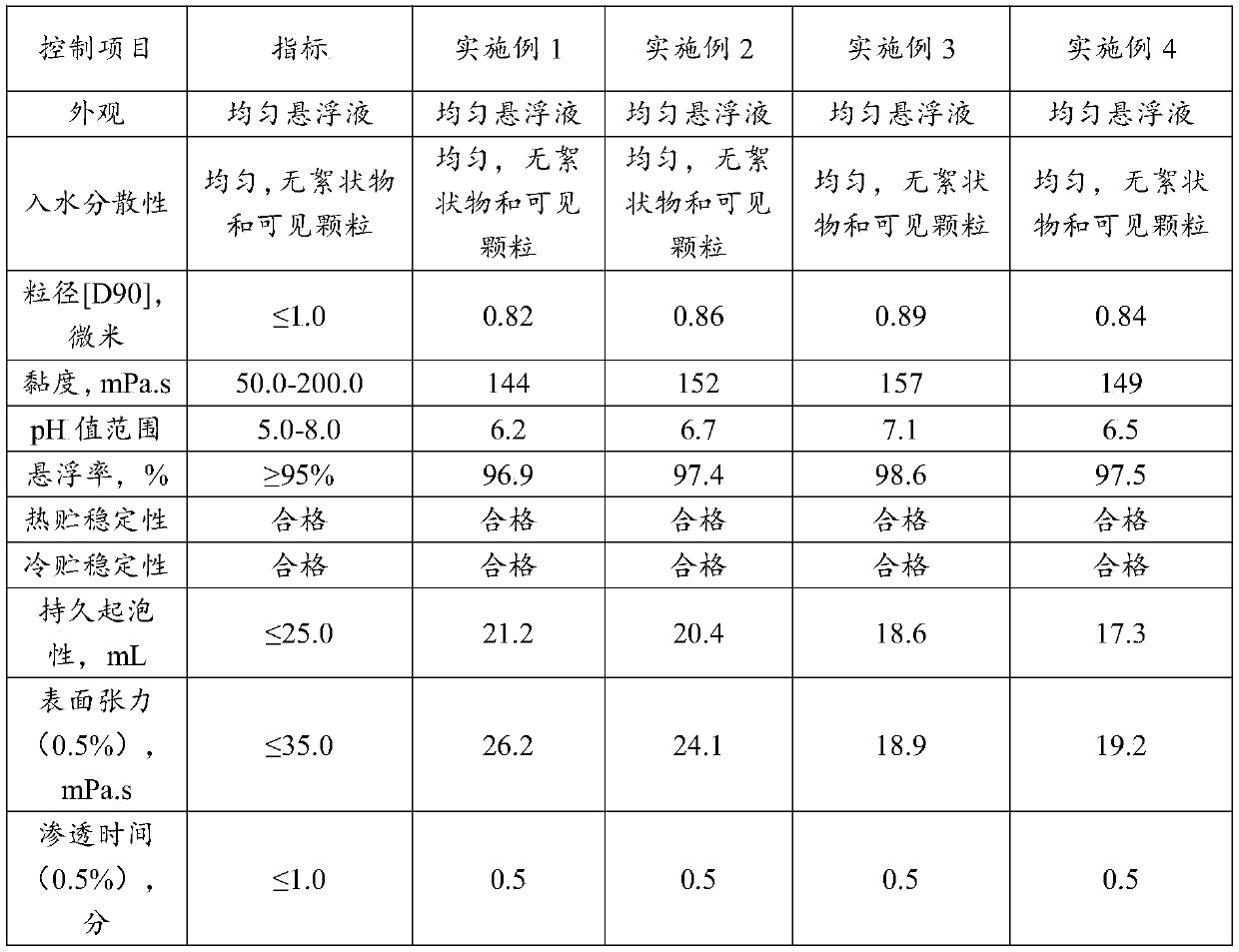

Aviation low-dosage spray insecticidal suspension agent and preparation method and application method thereof

ActiveCN109699661ASmall particle sizeReduce surface tensionBiocideAnimal repellantsAviationMonoisopropanolamine

The invention discloses an aviation low-dosage spray insecticidal suspension agent and a preparation method and application method thereof, and belongs to the technical field of pesticide. The suspension agent is composed of the following components: in parts by weight, 0.01-8 parts of a pesticide active compound, 5-15 parts of an evaporation drift inhibitor, 1-10 parts of a dispersing agent, 1-10parts of a wetting agent, 0.1-2 parts of a defoaming agent, 0.1-2 parts of a binder, 1-5 parts of a grinding aid and 50-100 parts of water, wherein the evaporation drift inhibitor includes polysaccharide and oil, the dispersing agent includes a nonionic surfactant and an anionic surfactant, and the nonionic surfactant comprises hydroxyl-terminated hyperbranched polyester; and the grinding aid isone or more of triethanolamine, diethanol monoisopropanolamine and polyisopropanolamine. The aviation low-dosage insecticidal suspension agent has a simple preparation method and an application method, and has the advantages of no volatile organic solvents, smaller particle size than conventional suspension agents, low surface tension and the like.

Owner:中化化工科学技术研究总院有限公司 +1

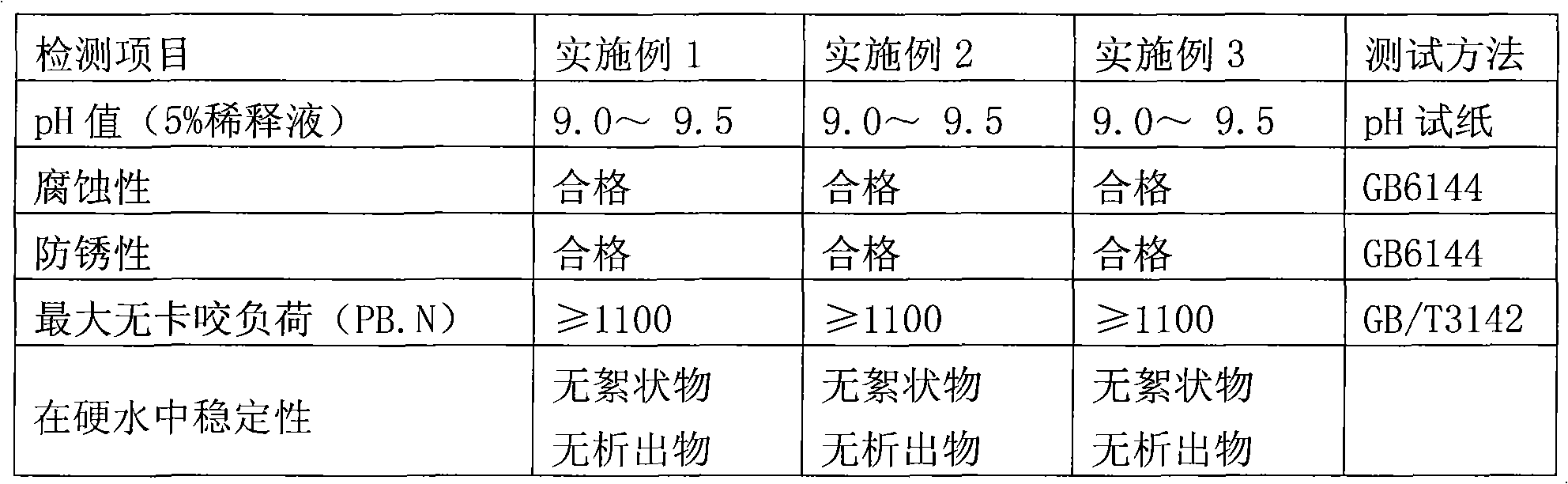

Water-soluble cutting fluid and preparation method thereof

ActiveCN101948711AExtended service lifeExcellent extreme pressure lubricityLubricant compositionPolyethylene glycolMonoisopropanolamine

The invention discloses water-soluble cutting fluid. The cutting fluid consists of the following components in percentage by weight: 15 to 25 percent of oleate-2-ethylhexyl ester, 2 to 8 percent of 3,5,5-trimethyl caproic acid, 3 to 10 percent of sebacic acid, 5 to 10 percent of mono ethanolamine, 15 to 20 percent of triethanolamine, 5 to 10 percent of diglycol, 3 to 10 percent of monoisopropanolamine, 15 to 20 percent of polyethylene glycol 600 and 20 to 30 percent of water. The invention also discloses a preparation method of the water-soluble cutting fluid. The method comprises the following steps of: reacting by mixing the oleate-2-ethylhexyl ester, the mono ethanolamine, the 3,5,5-trimethyl caproic acid and a part of water to obtain alkylol amine synthesis ester mixture A; reacting by mixing the sebacic acid, the triethanolamine, the monoisopropanolamine and the rest amount of water to obtain alkylol amine synthesis ester mixture B; and reacting by mixing the diglycol, the polyethylene glycol 600, the alkylol amine synthesis ester mixture A and the alkylol amine synthesis ester mixture B to obtain a finished product.

Owner:GUANGZHOU LANDNOK CHEM TECH

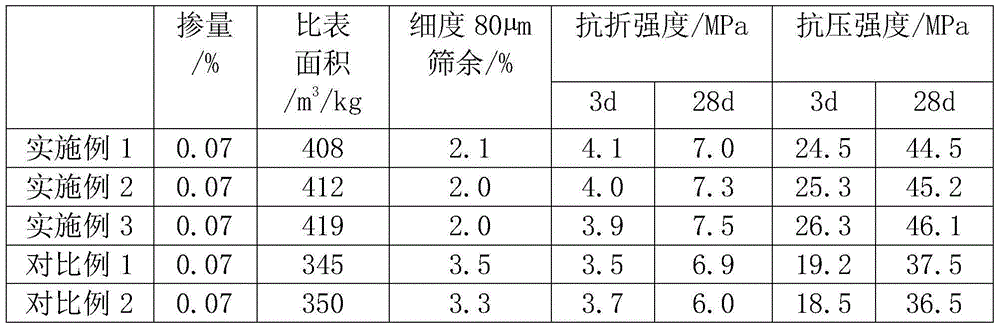

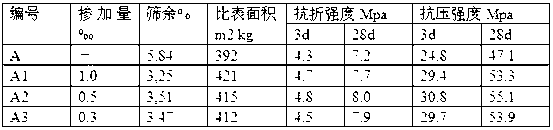

Cement grinding aid

The invention discloses a cement grinding aid. The cement grinding aid is prepared from the following ingredients in parts by weight: 10-15 parts of diacetal monoisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 6-10 parts of sodium thiosulfate, 10-12 parts of sodium chloride, 6-8 parts of hydroxyethyl cellulose and 15-18 parts of papermaking black liquor. The cement grinding aid disclosed by the invention is low in consumption, good in enhancement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

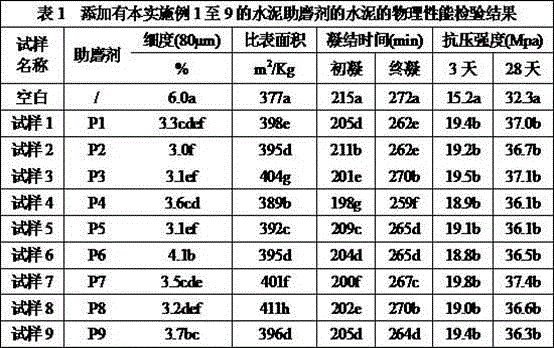

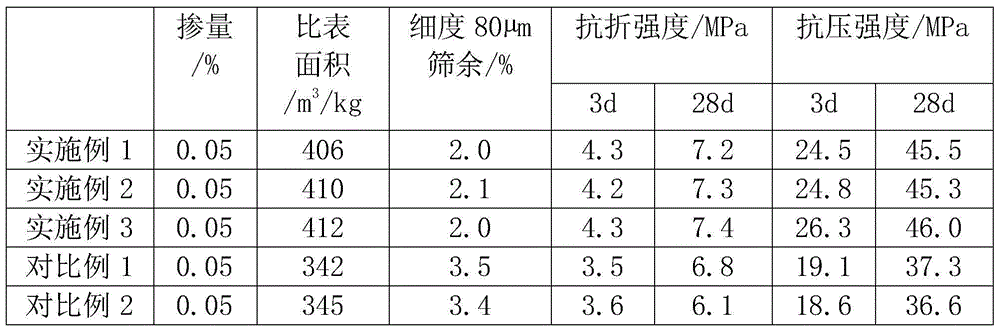

Preparation method of modified molasses waste liquid and cement grinding aid

ActiveCN104609765AGive full play to auxiliary grindingGive full play to the effect of hydrationLiquid wasteMonoisopropanolamine

The invention provides a preparation method of a modified molasses waste liquid. The preparation method comprises the following steps: A, regulating the PH of the molasses waste liquid to the range of 9-11 by use of a sodium hydroxide solution, and filtering under a normal pressure to obtain a molasses filtrate A; B, adding an acetic acid solution to the molasses filtrate A until the PH is within the range of 2-3, thereby obtaining a molasses waste liquid B; C, thoroughly oxidizing the molasses waste liquid B by using 35% hydrogen peroxide, potassium permanganate or ozone, thereby obtaining a molasses waste liquid C; D, regulating the PH of the molasses waste liquid C to the range of 9-11 by use of the sodium hydroxide solution, thereby obtaining the modified molasses waste liquid. The invention also provides a cement grinding aid which is prepared by mixing the following raw materials in parts by weight with water: 2-5 parts of triethanolamine, 18-25 parts of diethanol monoisopropanolamine, 3-5 parts of industrial salt and 20-30 parts of modified molasses waste liquid. The modified molasses waste liquid has the characteristics of low production cost, and good grinding assisting and hydration assisting effects on the cement.

Owner:华润水泥技术研发(广西)有限公司

Method for joint production of isopropanolamine

ActiveCN103936602AImprove liquidityIncrease productivityOrganic compound preparationAmino-hyroxy compound preparationDistillationMonoisopropanolamine

The invention belongs to the field of chemical building materials and relates to a method for joint production of DEIPA (diethanolisopropanolamine) and TIPA (triisopropanolamine). The method has the characteristics that the industrialized production is environmentally friendly, the production efficiency is high, the economic benefit is relatively good and a grinding aid formula is convenient to adjust. The method comprises the following steps: A, continuously adding PO (propylene oxide) into an ammonia water solution in a reactor 1, controlling the reaction temperature and the pressure, and reacting until an intermediate product is obtained; B, transferring the intermediate product obtained in the step A to a reduced pressure distillation tower, distilling off an ammonia water recovery solution from the top of the tower and MIPA (monoisopropanolamine) from a side line, and collecting high-boiling-point substances from the bottom of the tower; C, adding MIPA obtained in the step B into a reactor 2, continuously adding EO (ethylene oxide), controlling the reaction temperature and the pressure, and reacting until DEIPA is obtained; adding the high-boiling-point substances at the bottom of the tower obtained in the step B into a reactor 3, continuously adding PO, controlling the reaction temperature and the pressure, and reacting until TIPA is obtained.

Owner:安徽海螺材料科技股份有限公司

Liquid soil solidifying agent and preparation method, using method and application thereof

InactiveCN108715764AShort curing timeControllable pollutionBuilding constructionsOrganic fertilisersSulfonateSludge

The invention discloses a liquid soil solidifying agent and a preparation method, a using method and the application thereof. The liquid soil solidifying agent is prepared by adding water to dilute the following raw materials in percent by weight: 45-55% of diethanol monoisopropanolamine, 20-30% of sodium polycarboxylate, 10-20% of lignosulfonate, 5-10% of polyethylene OP-10 and 2-5% of sodium alpha-alkenyl sulfonate. The liquid soil solidifying agent is simple in production technology, can control dust pollution after addition into cement, effectively shortens the solidifying time of sludge solidification, and is small in addition amount, high in strength, low in cost and good in curing stability effect.

Owner:天津市三川恒泰科技有限公司

Liquid cement grinding aid with low alcohol amine content

The invention discloses a liquid cement grinding aid with low alcohol amine content. The liquid cement grinding aid is prepared from the following ingredients in parts by weight: 10-15 parts of diacetal monoisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 4-6 parts of sodium chloride, 1-2 parts of sodium lignosulfonate, 6-8 parts of hydroxyethyl cellulose and 20-25 parts of papermaking black liquor. The cement grinding aid disclosed by the invention is low in consumption, good in enhancement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Water-soluble rust prevention cutting fluid and preparation method thereof

InactiveCN103351938AExtended service lifeImprove rust resistanceLubricant compositionBenzoic acidBenzene

The invention relates to a water-soluble rust prevention cutting fluid which contains the following components in parts by weight: 4.5-15.5 parts of p-tertiary butylbenzoic acid, 1.2-8.1 parts of benzoic acid, 1.5-11 parts of decanedioic acid, 0.5-5.1 parts of monoethanolamine, 2.3-10.8 parts of triethanolamine, 0.091-1.1 parts of benzotriazole, 4.5-11 parts of diethylene glycol, 2.3-10.5 parts of monoisopropanolamine, 4.5-15.5 parts of polyethylene glycol and 19-31 parts of water. the invention also relates to a preparation method of the water-soluble rust prevention cutting fluid provided by the invention, which comprises the following steps: mixing the p-tertiary butylbenzoic acid, the benzoic acid, the decanedioic acid, the monoethanolamine, the triethanolamine and part of the water, and reacting to obtain a mixture A; mixing the benzotriazole, the monoisopropanolamine and the rest of the water, and reacting to obtain a mixture B; and mixing the diethylene glycol, the polyethylene glycol, the mixture A and the mixture B, and reacting to obtain the finished product.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Method for preparing diisopropanolamine

ActiveCN101265197AMeet high-end needsLess operating costs for productionOrganic compound preparationAmino-hyroxy compound preparationMonoisopropanolaminePesticide

The invention relates to a method of manufacturing diisopropanolamine. Liquid ammonia and water are mixed to form ammonia water which is fully mixed with propylene oxide; the mixed solution is preheated until the temperature reach 140 to 145 DEG C and then is delivered into a reactor for reacting, the temperature is controlled within 148 to 155 DEG C when in reacting, the pressure is controlled within 16.0 to 18.0MPa, the inputting molar ratio of the ammonia and the propylene oxide is controlled within 5 to 8, and the reaction is fully performed for 1.5 to 3 hours; the mixture products obtained in the reaction are separated to obtain isopropanolamine products, diisopropanolamine products and triisopropanolamine products through flash evaporation and rectification in a stepwise way. In the diisopropanolamine products which are manufactured by adopting the method, the component of 1, 1<1>-nitrousalkyl-dipropyl-2-alcohol accounts for more than 99 percent (hereinafter referred to as mass percent), and the isomeride thereof is less than 1 percent. In addition, the cost of the production operation in the method is less, the production cost is low, the product quality is high, and the high-end requirement of products such as synthetic medicine, farm insecticide, etc. is satisfied.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

Water base emulsified cutting fluid and preparation method thereof

InactiveCN103351926AExtended service lifeStrong rust resistanceLubricant compositionWater basedMonoisopropanolamine

The invention relates to a water base emulsified cutting fluid which comprises the following components in parts by weight: 30-55.5 parts of mineral oil, 9.5-21 parts of pentaerythritol fatty acid compound ester, 0.4-2.1 parts of benzotriazole, 4-11 parts of diglycol, 2.5-11 parts of isopropanolamine, 4.5-16 parts of boric acid, 9.5-21 parts of polyethylene glycol, 0.091-1.1 parts of a polysiloxane defoamer, and 19-41 parts of water. The invention further discloses a preparation method of the water base emulsified cutting fluid. The method comprises the following steps of: weighing the mineral oil and polyethylene glycol in parts by weight, starting stirring and heating to 120 DEG C, performing a reaction for 1-2 hours at constant temperature and cooling to 70-80 DEG C; and then sequentially adding the balance of components, and stirring for reaction for 30-60 minutes to obtain a finished product. The water base emulsified cutting fluid provided by the invention not only has high lubricity, high anti-rust property, high emulsibility and high stability and long service life, but also is free from environmental pollution and damage to human body, so that the fluid can satisfy the cutting demands of various metals.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Carbon nanofiber dispersion liquid, coating compostion, and paste composition

ActiveUS20130221284A1Improve dispersion stabilityEasy to getNon-metal conductorsPigmenting treatmentOrganic acidMonoisopropanolamine

A carbon nanofiber dispersion liquid having an excellent dispersibility and dispersion stability. Also, coating paste compositions including the carbon nanofibers produced by using the dispersion liquid are provided. The carbon nanofiber dispersion liquid includes: a solvent; a carbon nanofiber; an alkanolamine; and a chelating agent. Preferably, in the carbon nanofiber dispersion liquid, the alkanolamine is at least one selected from a group consisting of monoisopropanolamine, diisopropanolamine, and triisopropanolamine. Also, in the carbon nanofiber dispersion liquid, the chelating agent is at least one selected from a group consisting of an aminocarboxylic acid chelating agent, a phosphonic acid chelating agent, a gluconic acid chelating agent, and an organic acid.

Owner:MITSUBISHI MATERIALS CORP

Palmitoleic acid monoisopropanolamide synthesis method

ActiveCN105130835ALow cost per unit consumptionMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsMonoisopropanolamine

The invention relates to a palmitoleic acid monoisopropanolamide synthesis method and belongs to the technical field of organic polymerization. The synthesis method comprises that palmitoleic acid and isopropanolamine as raw materials undergo a heating synthesis reaction in the presence of a solid metal oxide catalyst under condition of pressure reduction at a temperature of 100-150 DEG C for 1-5h, wherein a mole ratio of palmitoleic acid to isopropanolamine is 1: 1-1.5 and use mass of the catalyst is 2-10% the isopropanolamine mass. The synthesis method has the advantages of low catalyst unit consumption cost, mild reaction conditions, high product conversion rate, recovery and recycle of the reacted catalyst, and no use of an aftertreatment process.

Owner:ZHEJIANG HUANGMA TECH

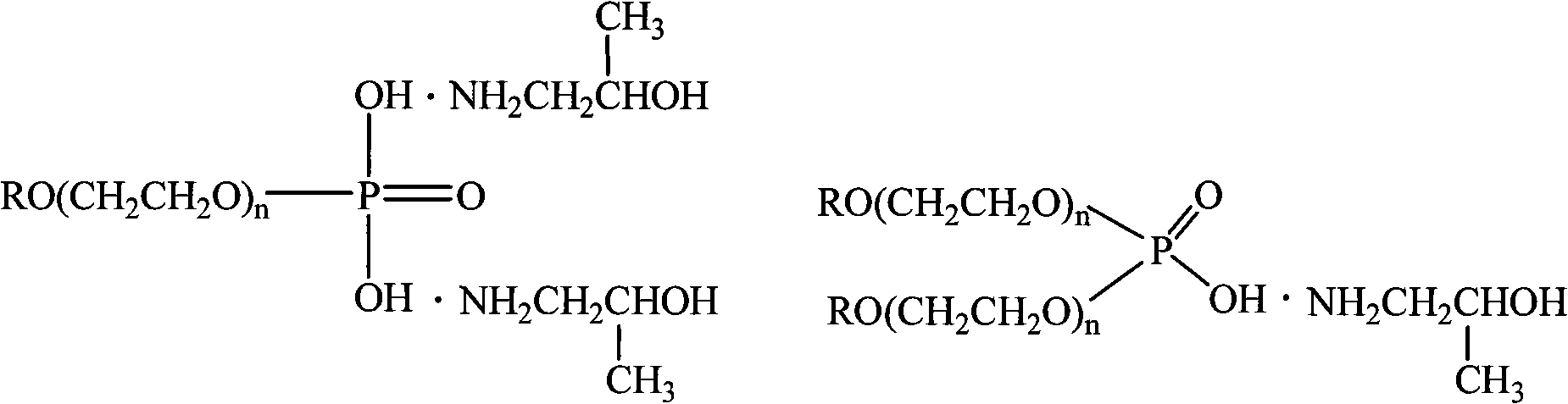

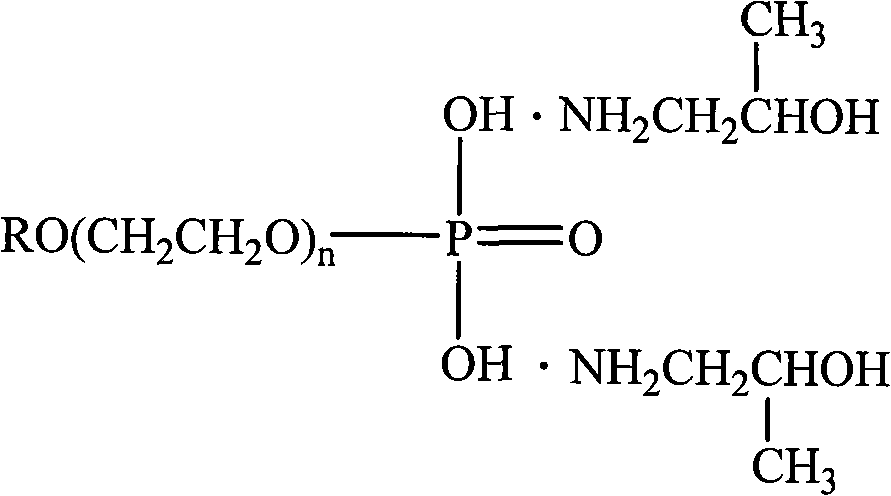

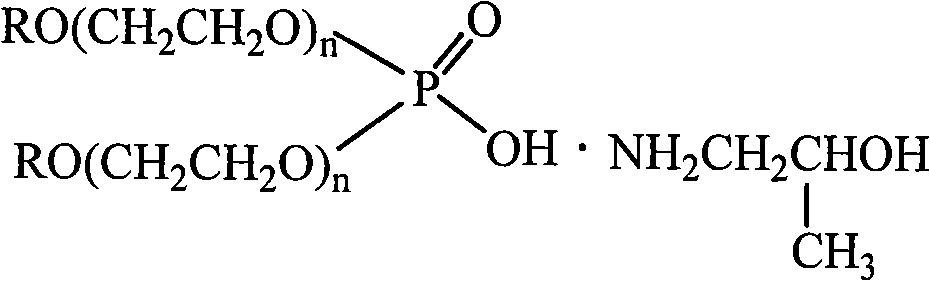

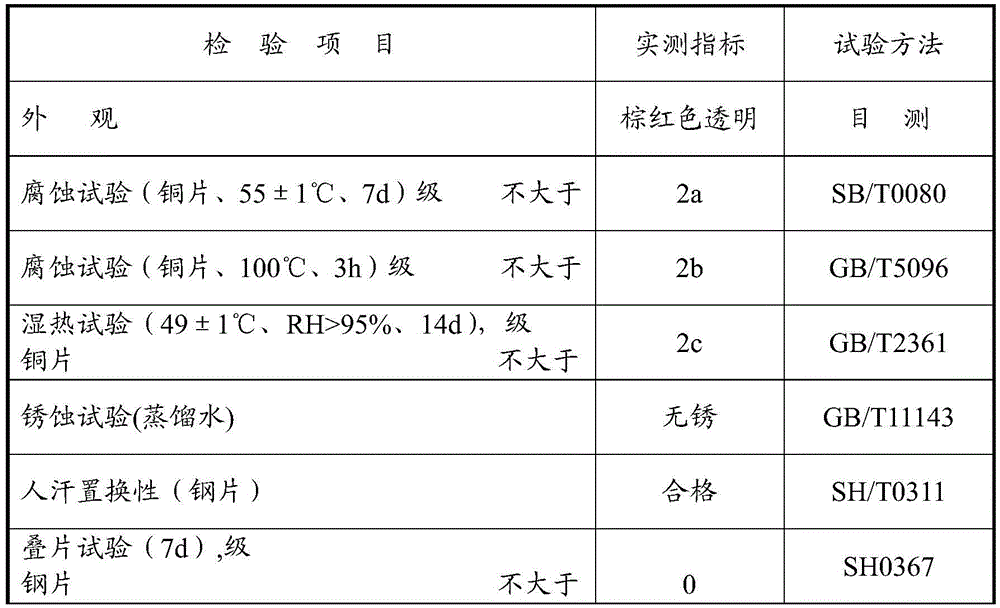

Pesticide adjuvant and preparation method thereof

InactiveCN101554164AGood emulsifying effectGood water solubilityBiocideAnimal repellantsSolubilityAdjuvant

The invention discloses a pesticide adjuvant and a preparation method thereof. The pesticide adjuvant is obtained in such a way that after the alcohol ether RO(CH2CH2O)nH(n=3-5) of 8-10 carbon alcohol and P2O5 generate esterification reaction, monoisopropanolamine is added to carry out neutralization, and the pesticide adjuvant contains fatty alcohol ether phosphate monoester and diester ammonium salt. The pesticide adjuvant has the wettability and the penetrability of adjuvant products JFC and X-1005 sold in the market and has obvious improvement in aspects of emulsifying properties and water solubility and has a low freezing point. When the temperature is lower than or equal to 0 DEG C, the adjuvant is still transparent flowing liquid, and the emulsifying effect on mixed benzene in water is far better than that of a traditional adjuvant product; aiming at biodegradability, degradation can be promoted because of adding an ester group, a green pesticide adjuvant standard is achieved, and the pesticide adjuvant can be widely applied to various pesticide preparations.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Green and environment-friendly water-based antirust agent and preparation method thereof

The invention discloses a preparation method for a green and environment-friendly water-based antirust agent. The adopted raw materials comprise the following ingredients: sebacic acid, dodecanedioic acid, triethanolamine, water, monoisopropanolamine, EDTA disodium salt, borax, fungicide and benzotriazole; and the relationship of the weight proportions of the ingredients is as follows: the sebacic acid, dodecanedioic acid and triethanolamine occupy 27-38 parts by weight totally; the water occupies 45-60 parts; the monoisopropanolamine occupies 1.0-1.5 parts; the EDTA disodium salt occupies 0.1-0.3 parts; the borax occupies 1.8-2.4 parts; the fungicide occupies 1-3 parts; and the benzotriazole occupies 0.1-1 parts. According to the green and environment-friendly water-based antirust agent produced by the preparation method disclosed by the invention, on one hand, a usage amount of mineral oil is reduced, and the advantages of high environmental health, long use period and the like during use are achieved; on the other hand, the green and environment-friendly water-based antirust agent produced by the process disclosed by the invention is free from heavy metals and other harmful substances, non-irritant to the skin, and of important significance to environmental protection.

Owner:NINGBO LANRUN ENERGY TECH

Water-soluble cutting fluid and preparation method thereof

InactiveCN103351936AImprove stabilityGood dispersionLubricant compositionDispersityPolyethylene glycol

The invention relates to a water-soluble cutting fluid which contains the following components in parts by weight: 4.5-20 parts of polymer latex, 10-26 parts of triethanolamine, 1-7 parts of sodium benzoate, 1-7 parts of borax, 0.5-6 parts of benzotriazole, 3-16 parts of monoisopropanolamine, 10-26 parts of polyethylene glycol, 0.5-3 parts of polysiloxane defoaming agent and 15-30 parts of water, wherein the polymer latex comprises the following components in percentage by weight: 10-30% of polystyrene homopolymer colloidal particle, 0.5-5% of water-soluble emulsifier and the balance of water. In the invention, the water-soluble cutting fluid is favorable in stability, dispersity, lubricating property and extreme pressure antiwear property.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Novel cement grinding aid and preparation method thereof and application thereof

The invention discloses a novel cement grinding aid. The novel cement grinding aid comprises the following components in part by weight: 3-15 parts of triethanolamine, 10-25 parts of ethylene glycol monoisopropanolamine, 15-40 parts of polymerized mixed lipid, 5-15 parts of molasses and 25-67 parts of water. The invention further provides a preparation method of the novel cement grinding aid; and the preparation method comprises the following steps: adding 25-67 parts of water to a reaction pot; rapidly stirring the water; adding 15-40 parts of polymerized mixed lipid, 5-15 parts of molasses, 10-25 parts of ethylene glycol monoisopropanolamine and 3-15 parts of triethanolamine to the reaction pot; and stirring an obtained mixture for 2 hours so as to obtain a finished product. The invention further provides an application of the cement grinding aid; and during manufacture of a cement through pulverizing, the cement grinding aid which accounts for 0.03-0.1% of the total weight of the cement is blended in 45-85 parts of clinkers, 10-25 parts of fly ashes, 5-15 parts of slag and 5-10 parts of gypsums by weight.

Owner:溧阳市精卫新型材料有限公司

Method for preparing tri-isopropanolamine

ActiveCN101265198AReduce pollutionWide range of requirementsOrganic compound preparationAmino-hyroxy compound preparationLow demandMonoisopropanolamine

The invention relates to a method of manufacturing triisopropanolamine. Firstly, air in a reaction kettle is replaced by nitrogen, and the reaction kettle is vacuumized; then after being injected with the nitrogen, the reaction kettle is vacuumized; the step is repeated for three to five times; secondly, isopropanolamine or diisopropanolamine or isopropanolamine mixture are put in the reaction kettle, the nitrogen is injected until the pressure reach more than minus 0.05MPa, then propylene oxide is added in continuously, wherein, the molar ratio between the propylene oxide and the number of hydrogen atoms contained on nitrogen atoms in the isopropanolamine is controlled within 1.0 to 1.1, the reaction temperature ranges from 50 to 90 DEG C, the reaction pressure ranges from minus 0.1 to 1.0MPa, and the reaction time is 8 to 15 hours; after the reaction is finished, products are discharged and packed under the protection of the nitrogen. The method greatly lowers the energy consumption, reduces the caused environmental pollution, increases the product quality, has low demand to equipment, saves the cost, has wide demanding range to raw material, and can make the best of waste materials which are generated when manufacturing the isopropanolamine and the diisopropanolamine. The purity of the products which is manufactured by adopting the method can reach more than 99 percent, the moisture content is less than 0.3 percent, and the colority of Pt-Co is less than 50.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

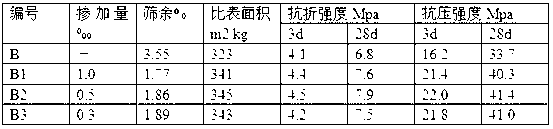

Corrosion inhibitor and method of inhibiting corrosion

A corrosion inhibitor which combines a film-forming function with a neutralizing function, can be stably stored for long even in a high-temperature environment, and can be easily produced in one batch. The corrosion inhibitor comprises ingredients respectively in the following groups (A) to (C): (A) C10-22 aliphatic amines; (B) surfactants comprising a polyethylene glycol / fatty acid ester; and (C) one or more water-soluble amines selected from the group consisting of 2-amino-2-methylpropanol, morpholine, and monoisopropanolamine.

Owner:KURITA WATER INDUSTRIES LTD +1

Early-strength-type polycarboxylate water reducer and preparation method thereof

InactiveCN110128601AImprove early compressive strengthImprove workabilityEthylenediamineMonoisopropanolamine

The invention provides an early strength type polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is mainly prepared from the following raw materials, by weight, 420 to 440 parts of unsaturated polyoxyalkylene ether monomer with weight-average molecular weight of more than 5000, 2.7 to 3 parts of oxidant, 0.3 to 0.7 part of a reducing agent, 3 to5 parts of unsaturated anhydride monomer, 1.5 to 2 parts of a chain transfer agent, 500 to 540 parts of water, 70 to 100 parts of alcohol amine organic material, and unsaturated monocarboxylic acid and derivative monomer thereof. The alcohol amine organic material is at least one of triethanolamine, triisopropanolamine, diethanol monoisopropanolamine and ethylenediamine. Based on the oxidant-reductant initiation system in the formula, strong alkali does not need to be added into the whole system for neutralization instead of the alcohol amine organic material; after specific combination of polymer monomers with large molecular weight, unsaturated acid anhydride monomers and other substances is adopted, the early strength of the concrete is remarkably improved.

Owner:上饶市天佳新型材料有限公司

Method of synthesizing monoisopropanolamine

ActiveCN101265196BMeet high-end needsImprove qualityOrganic compound preparationAmino-hyroxy compound preparationDistillationSynthesis methods

The invention relates to a synthesis method of isopropanolamine. The synthesis method comprises the following steps: (1) liquid ammonia and water are mixed to form ammonia water which is mixed with propylene oxide; mixed solution is preheated until the temperature reaches 120 to 125 DEG C, and the inputting molar ratio of the ammonia and the propylene oxide is controlled within 10 to 15; (2) the materiel after preheating is delivered into a reactor, the reaction temperature ranges from 128 to 138 DEG C, the pressure ranges from 12.6 to 13.8MPa, and the reaction time ranges from 1.5 to 3 hours; (3) the surplus unreacted ammonia is separated from the obtained mixture after the reaction by using a flash distillation column, the pressure in the flash distillation column ranges from 0.6 to 1.6MPa, and the temperature of a column kettle ranges from 140 to 160 DEG C; (4) the mixture which is separated through the flash distillation column is delivered into a leading tower for rectification dehydration, the pressure in the leading tower ranges from minus 0.080 to minus 0.085MPa, the temperature at the top of the leading tower is 45 to 55 DEG C, and the temperature at the bottom in a towerkettle ranges from 110 to 130 DEG C; (5) the mixture after dehydration is delivered into a rectification column for rectification, the pressure in the rectification column ranges from minus 0.095 to minus 0.099MPa, the temperature in the column kettle ranges from 135 to 160 DEG C, the temperature at the top of the rectification column ranges from 60 to 70 DEG C, isopropanolamine products are obtained at the top of the rectification column, and the mixture composed of diisopropanolamine and triisopropanolamine is obtained in the column kettle. The synthesis method has simple production procedure, little equipment investment, and high product quality.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com