Early-strength-type polycarboxylate water reducer and preparation method thereof

A polycarboxylic acid and early-strength technology, which is applied in the field of early-strength polycarboxylate water-reducing agent and its preparation, can solve the problems of maintaining the early strength of the water-reducing agent, unfavorable early strength of the water-reducing agent, etc., and achieves the slump Small loss, improved turnover rate of engineering operations, and small shrinkage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

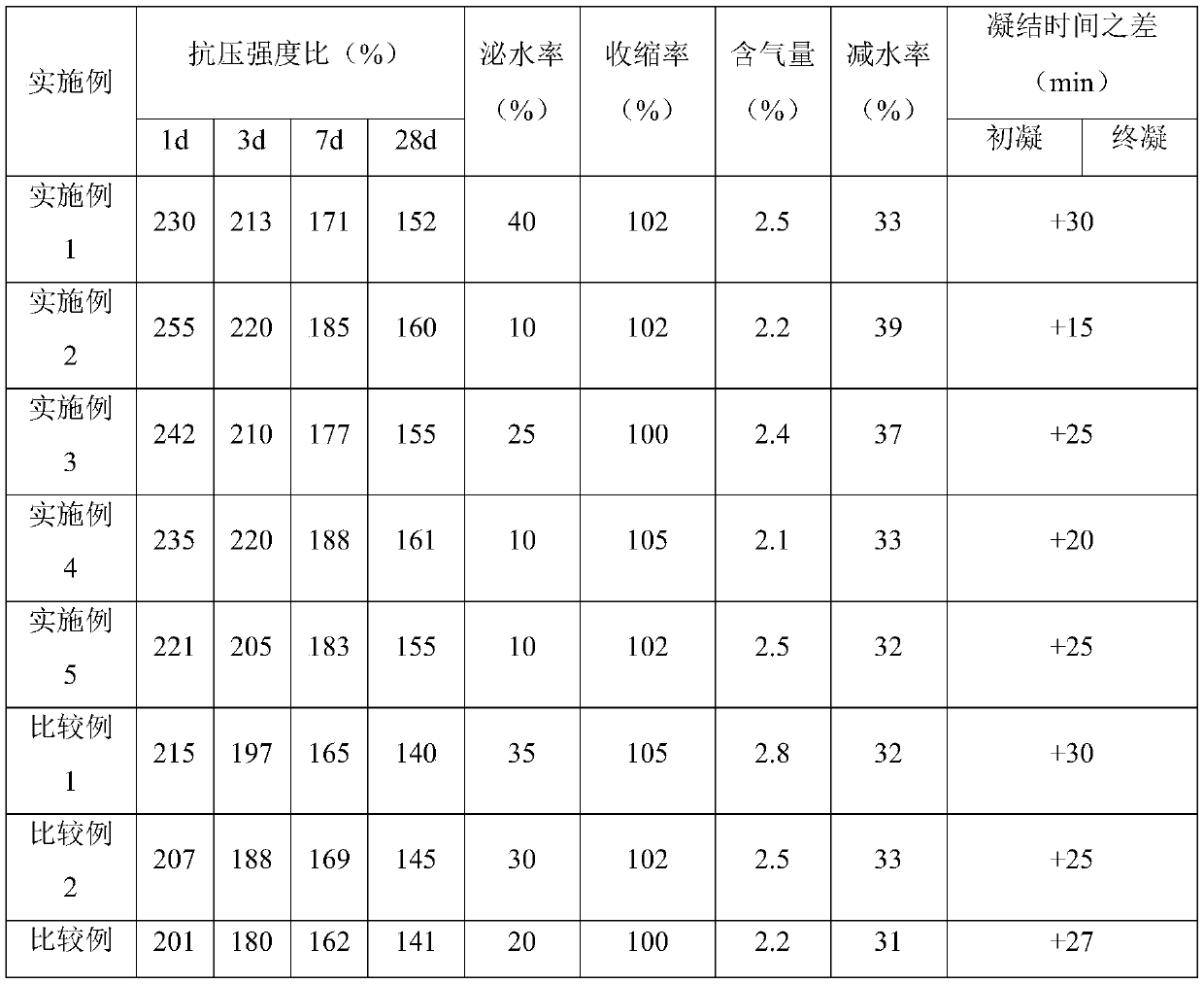

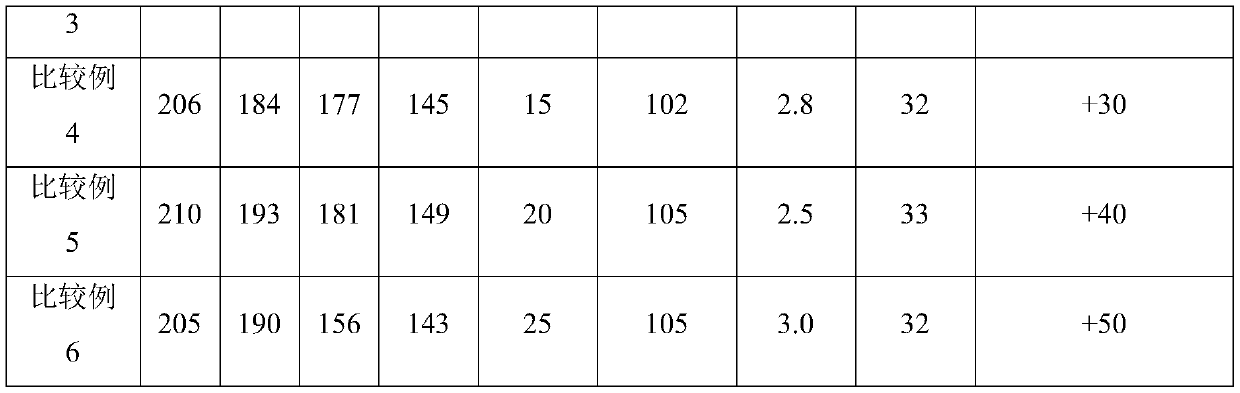

Examples

Embodiment 1

[0041] Get the following raw materials: by weight, 420 parts of isopentenyl polyoxyethylene ether (weight average molecular weight 5000), 2.7 parts of ammonium persulfate, 2 parts of mercaptopropionic acid, 18 parts of acrylic acid, 3 parts of sodium acrylate sulfonate , 5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 0.8 parts of acrylic amine, 3 parts of maleic anhydride, 0.4 parts of sodium hypophosphite, 0.3 parts of hanging white block, 70 parts of triethanolamine, deionized water 540 copies;

[0042] Material A: a solution made of sodium hypophosphite, diacid, mercaptopropionic acid and deionized water;

[0043] Material B: a solution made of acrylic acid, sodium propionate sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, acrylamide and deionized water;

[0044]Add the measured deionized water into the reaction kettle, turn on the stirring rod, and then put the measured isopentenyl polyoxyethylene ether, maleic anhydride, and ammonium persulfate into the reac...

Embodiment 2

[0049] Get the following raw materials: by weight, 440 parts of methallyl polyoxyethylene ether (weight average molecular weight 5000), 3 parts of hydrogen peroxide, 1.5 parts of mercaptopropanol, 15 parts of acrylic acid, 5 parts of sodium acrylate sulfonate, 3 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1.5 parts of acrylic amine, 5 parts of maleic anhydride, 0.2 part of sodium hypophosphite, 0.1 part of hanging white block, 100 parts of triisopropanolamine, to 500 parts of ionized water;

[0050] Material A: a solution made of sodium hypophosphite, white block, mercaptopropanol and deionized water;

[0051] Material B: a solution made of acrylic acid, sodium propionate sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, acrylamide and deionized water;

[0052] Add the measured deionized water into the reaction kettle, turn on the stirring rod, and then put the measured methallyl polyoxyethylene ether, maleic anhydride, and hydrogen peroxide into the reaction kett...

Embodiment 3

[0057] Get the following raw materials: by weight, 430 parts of the mixture of methallyl polyoxyethylene ether and isopentenyl polyoxyethylene ether (weight average molecular weight 6000), 2.95 parts of ammonium persulfate, 1.55 parts of mercaptopropionic acid 17 parts of acrylic acid, 4 parts of sodium acrylic acid sulfonate, 3 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1 part of acrylic acid amine, 4 parts of maleic anhydride, 0.3 parts of sodium hypophosphite, hanging white 0.3 parts of block, 90 parts of triisopropanolamine, 530 parts of deionized water;

[0058] Material A: a solution made of sodium hypophosphite, white block, mercaptopropanol and deionized water;

[0059] Material B: a solution made of acrylic acid, sodium propionate sulfonate, 2-acrylamide-2-methylpropanesulfonic acid, acrylamide and deionized water;

[0060] Add the measured deionized water into the reaction kettle, turn on the stirring rod, and then put the measured methallyl polyoxyethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com