Water loss reducing composition, cement composition containing water loss reducing composition, and preparation method and use of water loss reducing composition

A technology of fluid loss reducer and composition, which is applied in drilling compositions, chemical instruments and methods, earth square drilling, etc., and can solve problems such as poor salt resistance of polyvinyl alcohol fluid loss reducers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

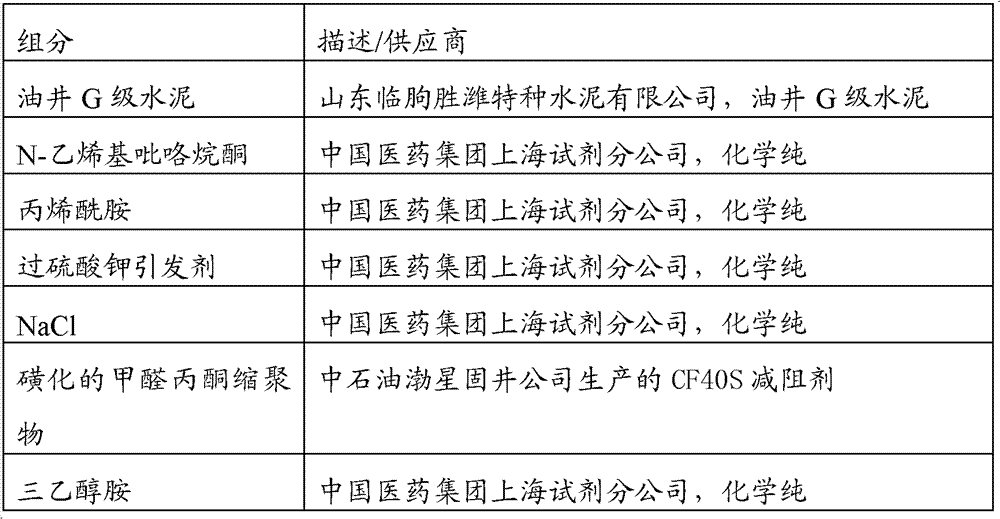

[0063] In the method for preparing the fluid loss reducer composition of the present invention, there is no specific limitation on the temperature and mixing time for mixing the components, as long as the mixing conditions used allow the components to be mixed uniformly.

[0064] Preferably, in the embodiment of preparing the fluid loss reducer composition, the mixing can be carried out at a temperature ranging from normal temperature to 60° C. for 10 to 30 minutes. In another embodiment of preparing the fluid loss reducer composition, the mixing is carried out at 40-60° C. for 10-30 minutes. Without being limited by theory, it is believed that the method for preparing the fluid loss reducing agent composition of the present invention is carried out under such conditions, which is conducive to making N-vinylpyrrolidone-acrylamide The complexation between the copolymer and the organic amine early strength agent containing active hydrogen atoms such as hydroxyl groups and the su...

Embodiment 1

[0083] Example 1. Preparation of N-vinylpyrrolidone-acrylamide copolymer

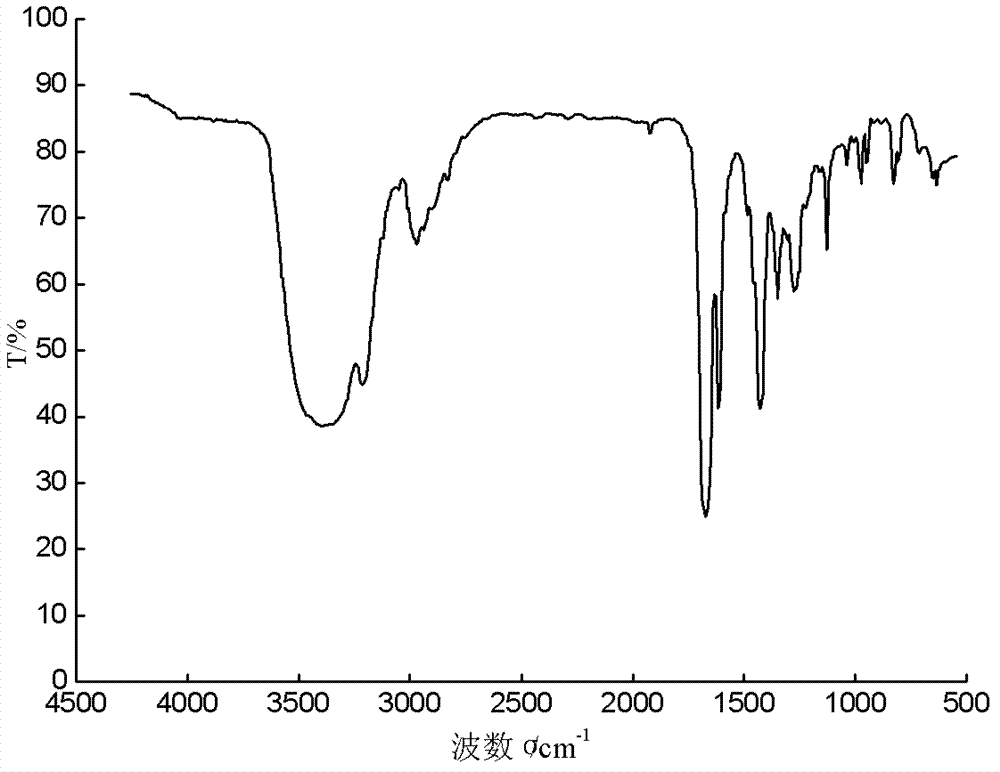

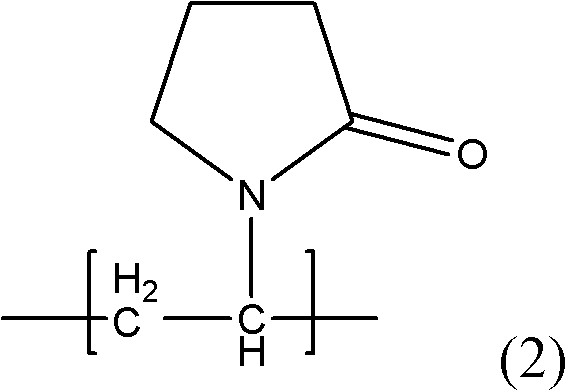

[0084] Add 5 parts by weight of N-vinylpyrrolidone, 1.2 parts by weight of acrylamide and 85 parts by weight of deionized water into a reactor equipped with a stirrer and a thermometer to stir. The reaction temperature is controlled at 60 ° C. After nitrogen gas is passed for 15 minutes, 0.20 Parts by weight of potassium persulfate initiator, the polymerization reaction was carried out for 120 minutes, and the N-vinylpyrrolidone-acrylamide copolymer with a weight-average molecular weight Mw of 300,000 was obtained. The measurement method of the molecular weight was a light scattering method, and the infrared Spectral graph such as figure 1 shown in . Through carbon nuclear magnetic resonance spectrum and hydrogen spectrum analysis, it is determined that the proportion of structural units in the synthesized polymer is consistent with the proportion of monomers in the reactants.

[0085] figure 1 The i...

Embodiment 2

[0086] Example 2. Preparation of fluid loss reducer composition A1

[0087] The N-vinylpyrrolidone-acrylamide copolymer (NVP-AM) prepared in Example 1, the sulfonated formaldehyde acetone polycondensate and triethanolamine were mixed under ambient conditions in a weight percentage of 65.5:33.0:1.5 to obtain a liquid The fluid loss reducer composition A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com