High temperature resistant well cementation cement paste used for steam injection thermal production well

A technology for cementing cement slurry and high temperature-resistant cement, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of shortened production cycle of oil wells, deterioration of cementation quality, failure of interlayer isolation, etc., so as to reduce channeling Possibility of groove and casing damage, small strength attenuation, effect of prolonging oil well life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example provides a high temperature resistant cement slurry for steam injection thermal recovery wells, which uses CA-50 series A900 aluminate cement and HS-KZS ultrafine slag powder as high temperature stabilizers, and the model is G33S oil well fluid loss reducer, HS-204SR coagulation regulator, HE400 anti-sedimentation agent and XP-1 defoamer are configured with a density of 1.85g / cm3 High temperature resistant cementing cement slurry. In parts by weight, the high-temperature-resistant cementing cement slurry has the following components: 100 parts of A900 aluminate cement, 30 parts of HS-KZS ultrafine slag powder, 2.8 parts of G33S oil well fluid loss reducer, HS-204SR adjusted 0.6 parts of coagulant, 0.06 parts of HE400 anti-settling agent, 0.10 parts of XP-1 defoamer, 55 parts of clear water.

[0034] The high temperature resistant cementing cement slurry is prepared through the following steps:

[0035] 1. Add high-temperature-resistant modified admixture a...

Embodiment 2

[0043] This embodiment provides a kind of high temperature resistant cementing cement slurry for steam injection thermal recovery well, which uses CA-50 series A900 aluminate cement and HS-KZS ultrafine slag powder as high temperature stabilizer, model The density is 1.85g / cm for the oil well fluid loss reducer G33S, the coagulation regulator model HS-204SR, the anti-settling agent model HE400 and the defoamer model XP-1 3 High temperature resistant cementing cement slurry. Adopt above material to prepare the cement slurry of 5 groups of different high-temperature stabilizer contents, by weight, 5 groups of cement slurry contain 0 part, 10 parts, 20 parts, 30 parts, 40 parts of HS-KZS type superfine slag micropowder respectively and corresponding Corresponding to 44 parts, 48 parts, 52 parts, 56 parts and 60 parts of water, at the same time, the five groups of cement slurries all contain the following ingredients: 100 parts of A900 aluminate cement, 3.0 parts of G33S oil wel...

Embodiment 3

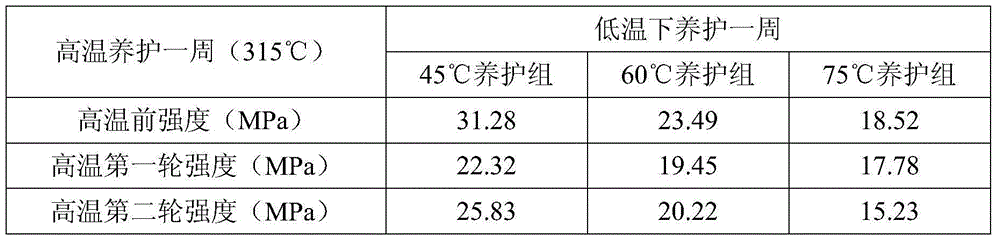

[0053] This embodiment provides a kind of high temperature resistant cementing cement slurry for steam injection thermal recovery well, which uses CA-50 series A900 aluminate cement and HS-KZS ultrafine slag powder as high temperature stabilizer, model The density is 1.85g / cm for the oil well fluid loss reducer G33S, the coagulation regulator model HS-204SR, the anti-settling agent model HE400 and the defoamer model XP-1 3 High temperature resistant cementing cement slurry. In parts by weight, the high-temperature cementing cement slurry has the following components: 100 parts of A900 aluminate cement, 30 parts of HS-KZS ultrafine slag powder, 2.6 parts of G33S fluid loss reducer for oil wells, HS-204SR coagulation adjustment 0.52 parts of agent, 0.06 parts of HE400 anti-settling agent, 0.10 parts of XP-1 defoamer and 50, 56, 62 parts of water.

[0054] The high temperature resistant cementing cement slurry is prepared through the following steps:

[0055] 1. Add high temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com