Pickling preparation combination for freezing pre-fried meat foodstuff capable of being treated by microwave, method for preparing pre-fried meat food stuff and obtained product

A production method and technology of pickling preparations, which are applied in food preparation, food science, application, etc., can solve problems such as fast and convenient food consumption, safe nutrition, dry and hard fried meat skewers, and large oil fume environmental pollution, etc. Achieve good economic benefits, delicious meat, and expand the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

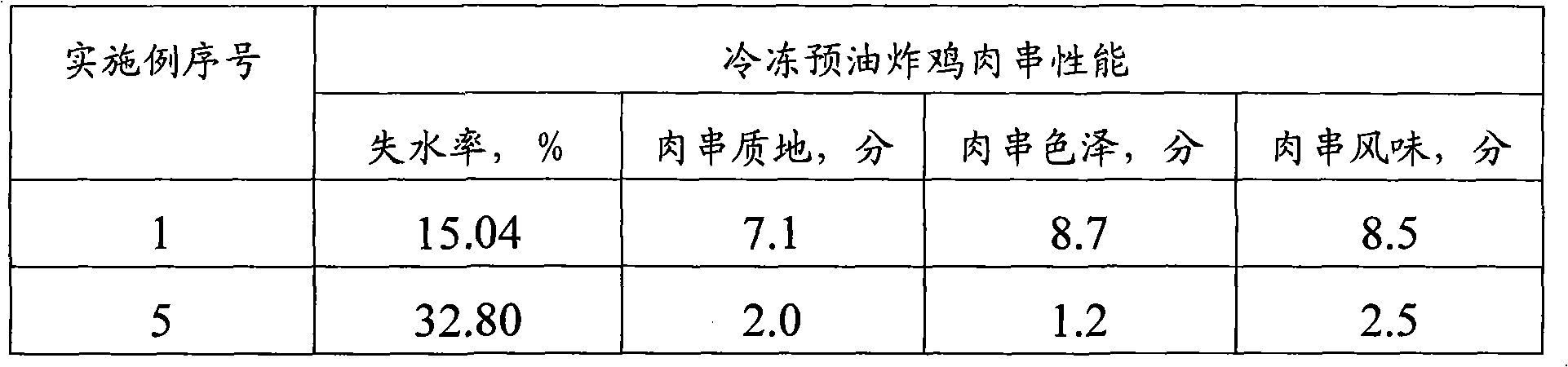

[0065] Embodiment 1: the present invention can the making of microwave freezing pre-fried chicken skewers

[0066] Follow the steps below to make:

[0067] 1. Fresh meat pretreatment steps: Take 10kg chicken breast meat, wash it with water to remove impurities such as blood, adipose tissue and fascia in the meat, and divide it into regular-shaped meat pieces, each weighing about 8g.

[0068] 2. Pickling treatment steps:

[0069] First, a pickle composition is prepared. Weigh 100g of salt, 140g of sugar, 50g of soy sauce, 300g of cooking wine, 400g of diced onion, 250g of Ruisheng brand barbecue powder produced by Qiqihar Ruisheng Food Manufacturing Co., Ltd., 10g of McCormick brand pepper powder produced by Shanghai McCormick Food Co., Ltd., Foshan Haitian brand curry powder 20g produced by Haitian Seasoning Food Co., Ltd., food-grade composite phosphate water-retaining agent 30g produced by Xuzhou Zhifeng Chemical Co., Ltd., Jiangsu Province, and 2kg of water are used to d...

Embodiment 2

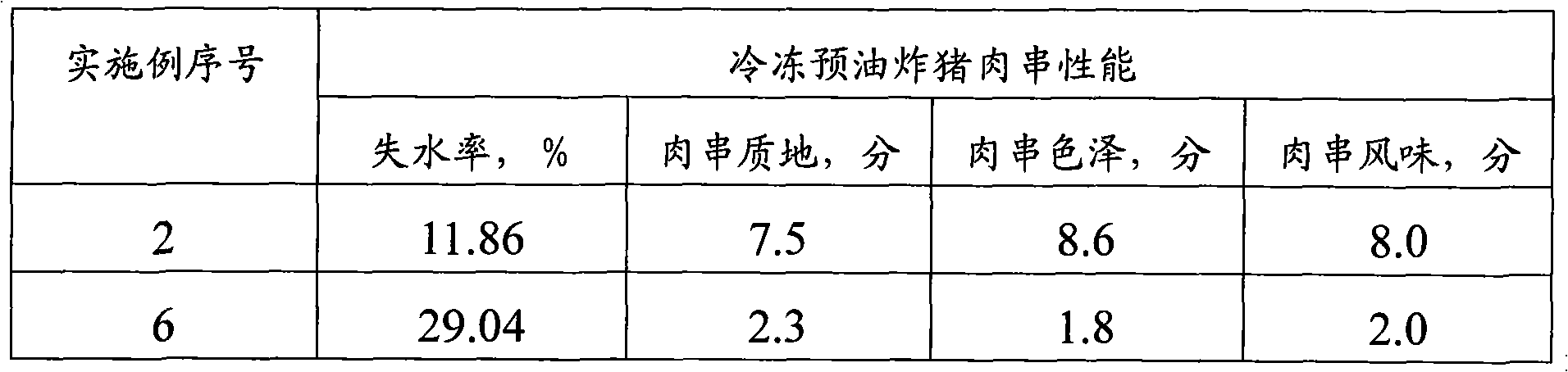

[0079] Embodiment 2: the present invention can the making of microwave freezing pre-fried pork skewers

[0080] Make it as follows:

[0081] 1. Fresh meat pretreatment steps: Take 10kg of pork hind leg, wash it with water to remove blood and other impurities in the meat, remove fat tissue and fascia, and divide it into regular-shaped meat pieces, each weighing about 8 gram.

[0082] 2. Pickling treatment steps:

[0083] First, a pickle composition is prepared. Weigh 200g of salt, 100g of sugar, 30g of soy sauce, 350g of cooking wine, 300g of diced onion, 200g of Ruisheng brand barbecue powder produced by Qiqihar Ruisheng Food Manufacturing Co., Ltd., 10g of McCormick brand pepper powder produced by Shanghai McCormick Food Co., Ltd., Zhejiang 45g of Shangpin fresh brand five-spice powder produced by Zhengwei Food Co., Ltd., 30g of food-grade composite phosphate water-retaining agent produced by Zhifeng Chemical Co., Ltd. in Xuzhou City, Jiangsu Province, and 2kg of water a...

Embodiment 3

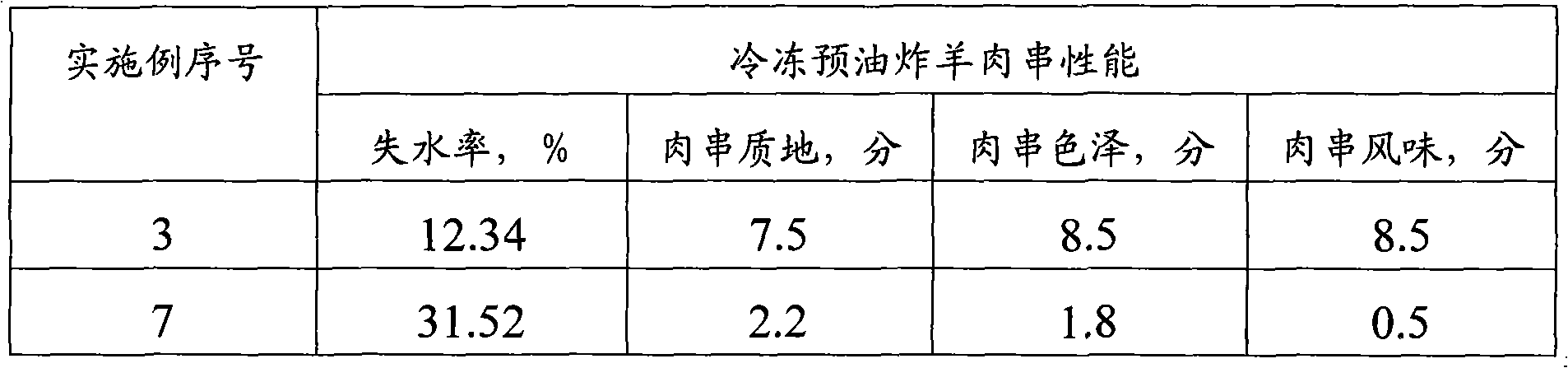

[0093] Embodiment 3: the present invention can the making of microwave freezing pre-fried mutton skewers

[0094] Make it as follows:

[0095] 1. Fresh meat pretreatment steps: take 10kg of lamb hind legs, wash with water to remove blood and other impurities in the meat, remove adipose tissue and fascia, and divide into regular-shaped meat pieces, each weighing about 7g .

[0096] 2. Pickling treatment steps:

[0097] First, a pickle composition is prepared. Weigh 250g of salt, 100g of sugar, 15g of soy sauce, 250g of cooking wine, 400g of diced onion, 300g of Ruisheng brand barbecue powder produced by Qiqihar Ruisheng Food Manufacturing Co., Ltd., 25g of Haitian brand pepper powder produced by Foshan Haitian Seasoning Food Co., Ltd., Ogilvy & Mather 30g of Ogilvy Liuxiang brand pure cumin powder produced by Condiment Co., Ltd., 10g of Haitian brand chili powder produced by Foshan Haitian Seasoning Food Co., Ltd., and food-grade compound phosphate water retention produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com