Patents

Literature

4901results about How to "Uniform color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

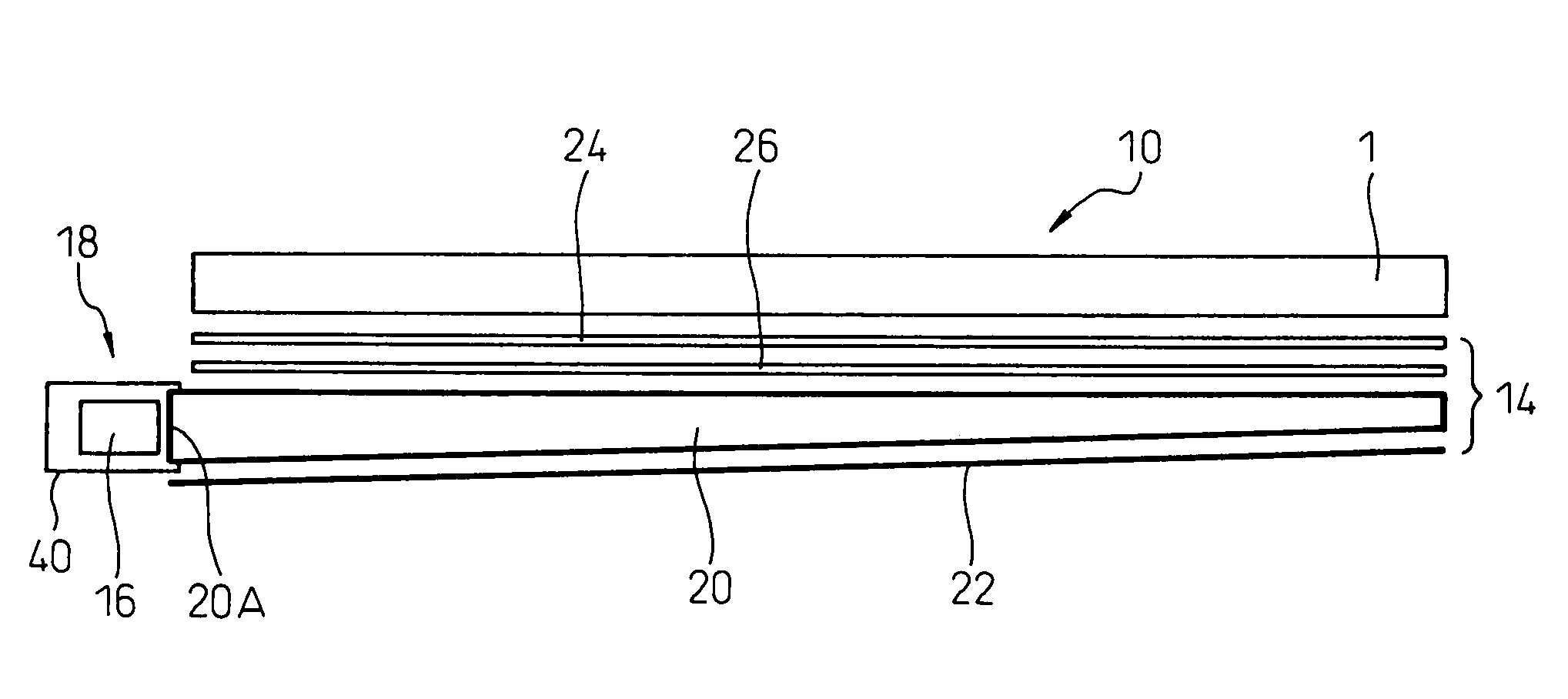

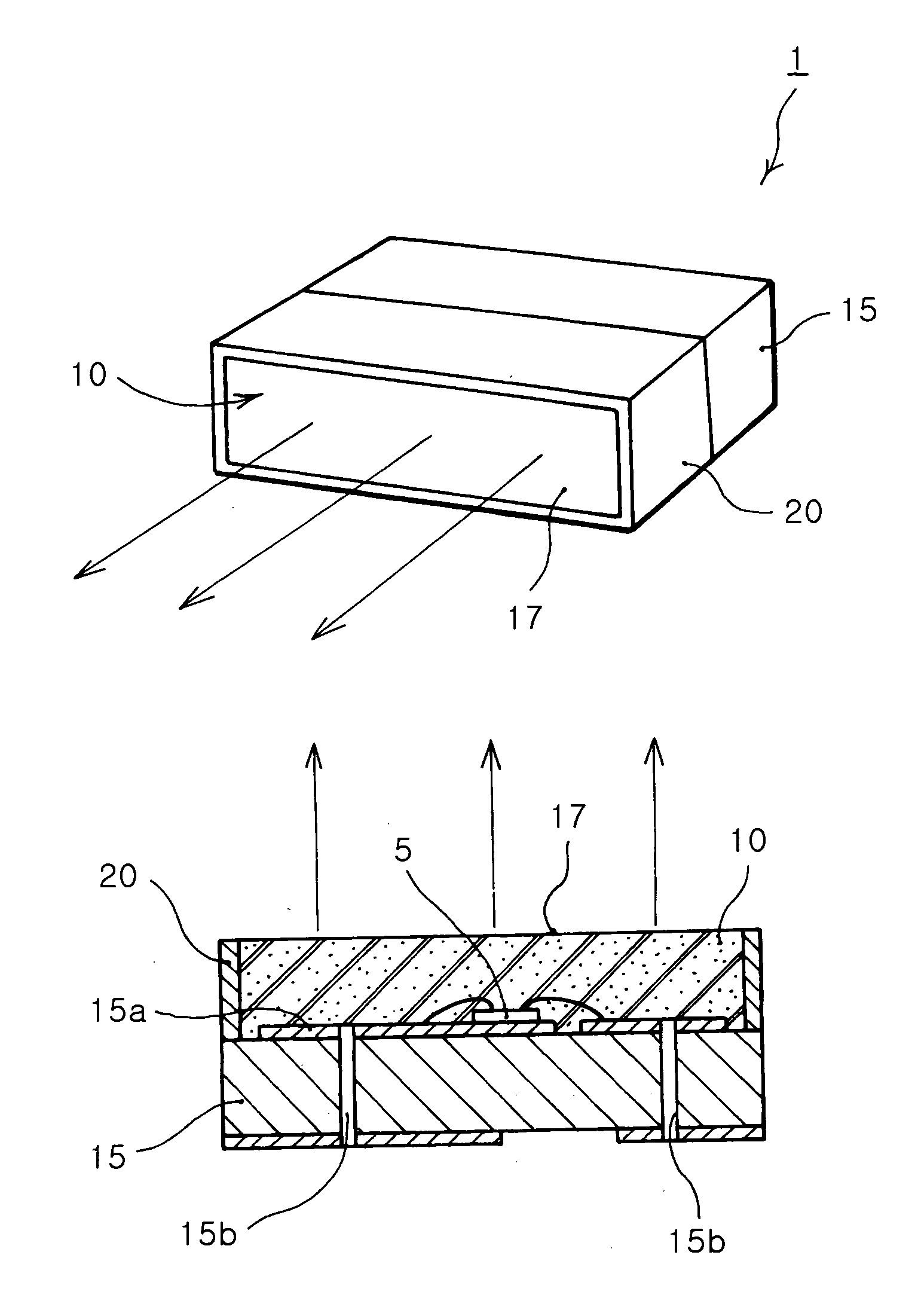

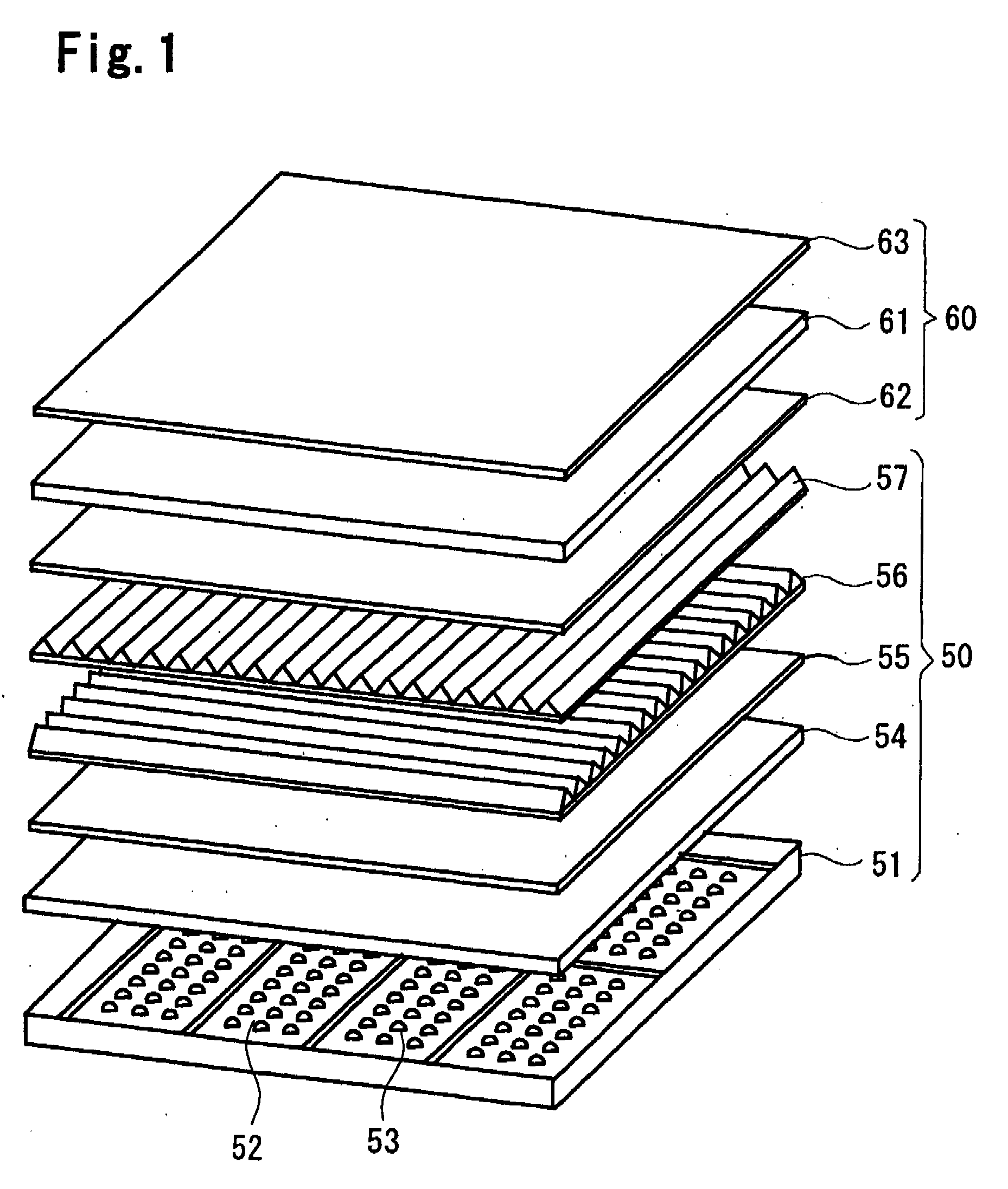

Led illumination source/display with individual led brightness monitoring capability and calibration method

InactiveUS20060227085A1Uniform brightnessUniform colorStatic indicating devicesTelevision systemsMaximum levelDisplay device

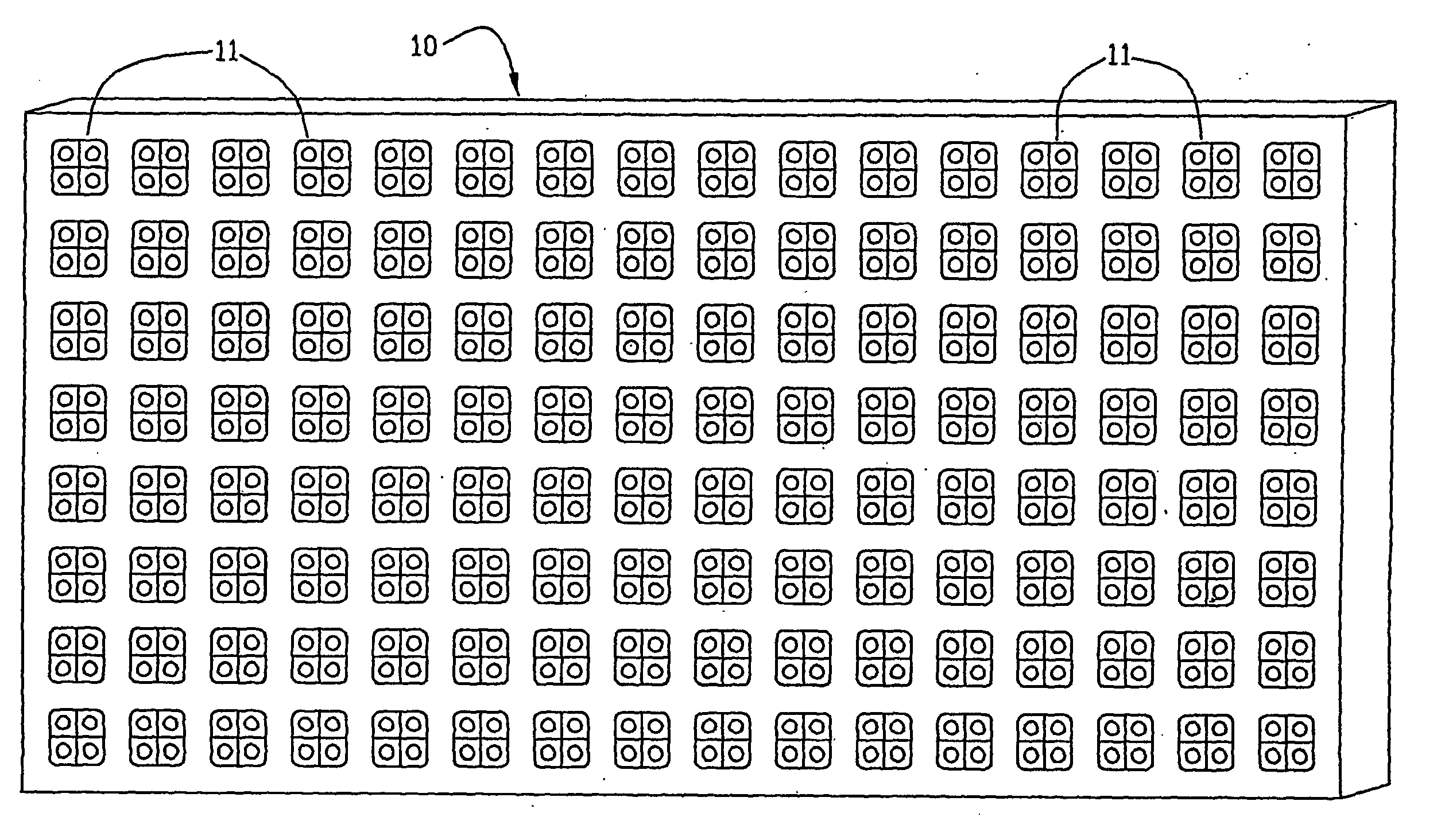

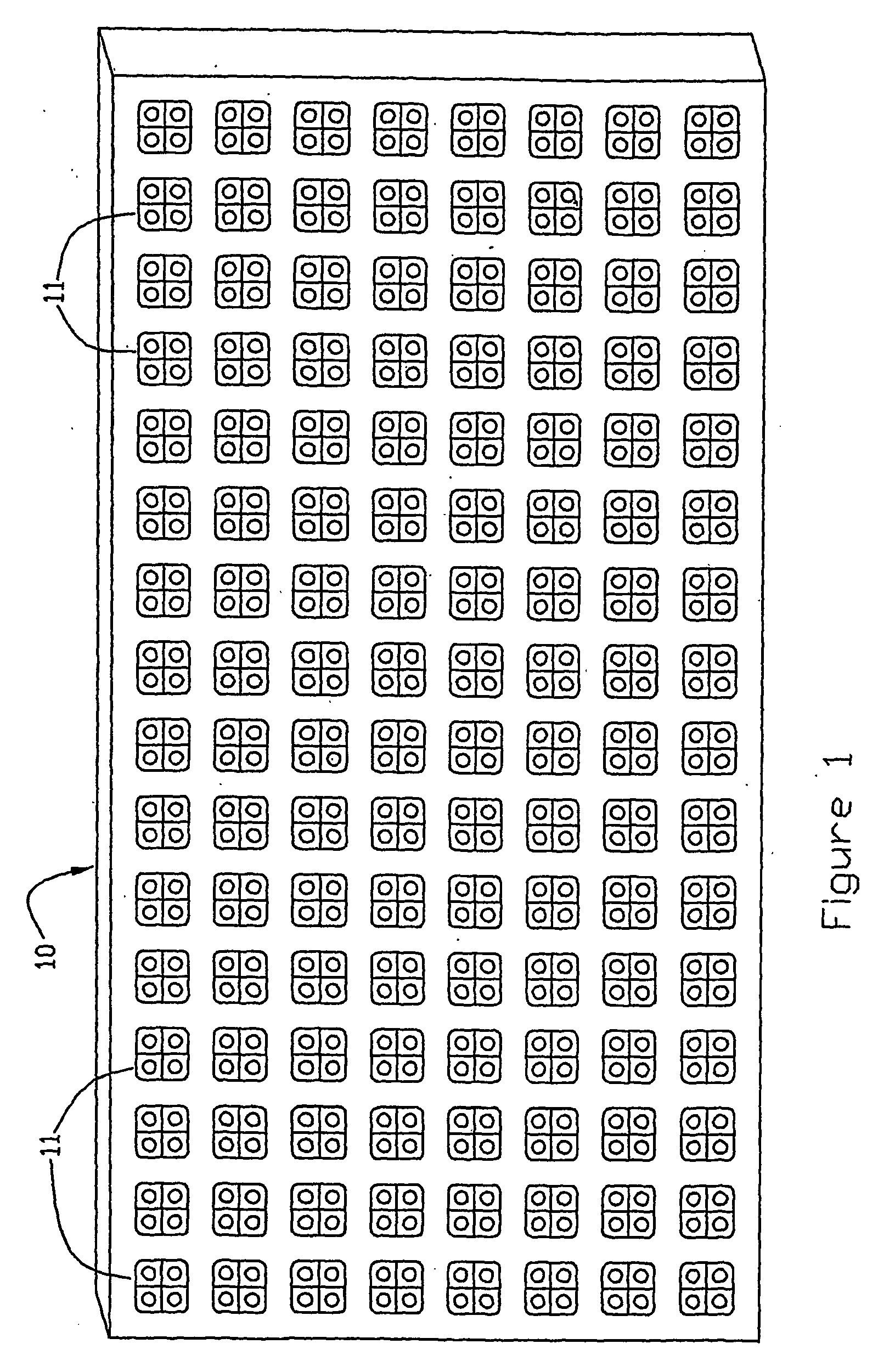

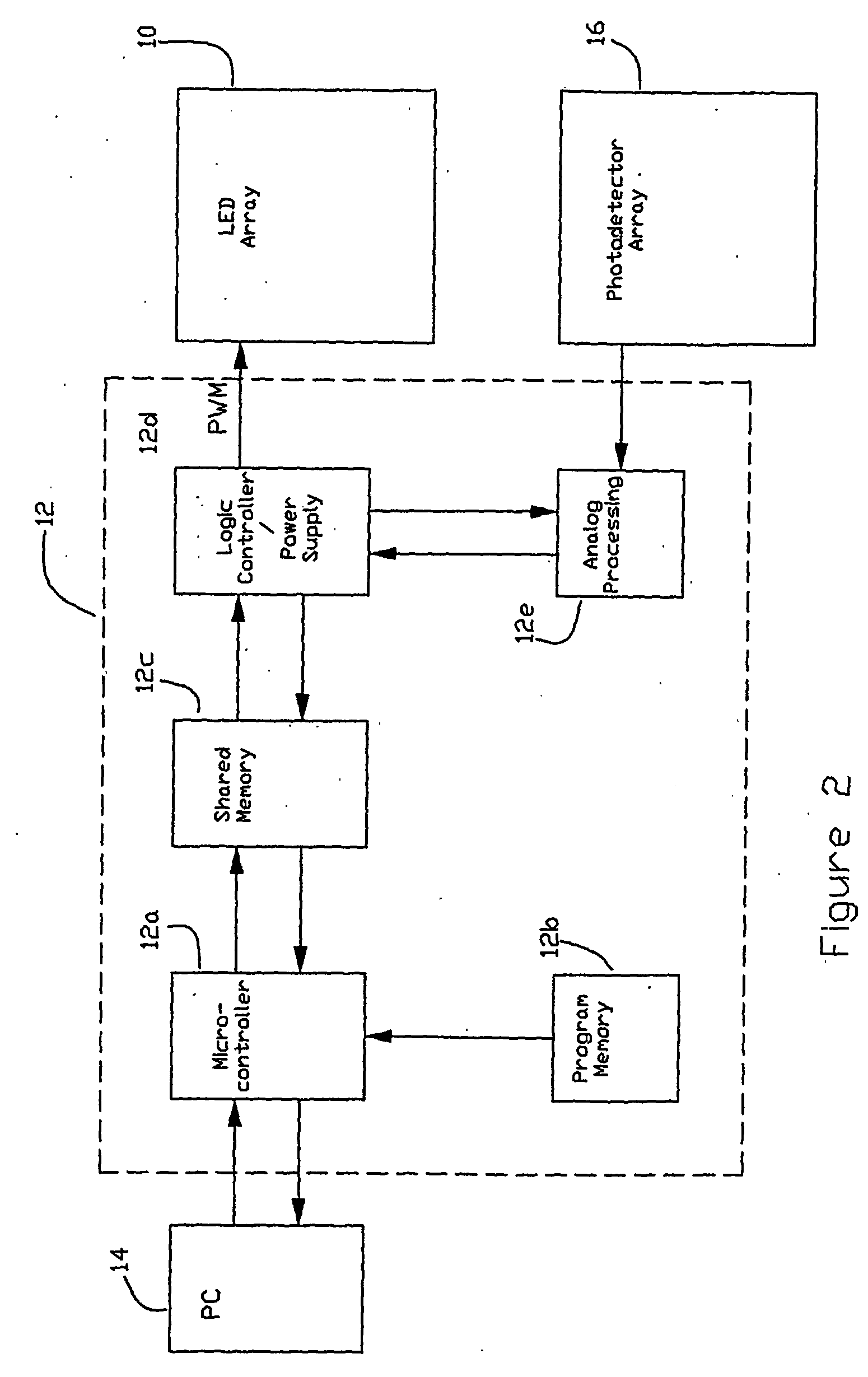

An LED area illumination source / display (10) such as an electronic billboard is made up of a number of individual pixels with each pixel including a number of LEDs, e.g., a red (18), blue (19) and green LED (20), with each LED representing a primary color being arranged to be energized separately. At least one light sensor (22) is incorporated into the display for providing a measure of the light emitted from each LED representing a primary color in each pixel. The source / display (10) is susceptible of being self-calibrated by initially energizing the LEDs (18, 19, 20) at less than a maximum level and increasing the energization level as necessary during use to restore the original light output of degraded LEDs.

Owner:VISIONEERED IMAGE SYST

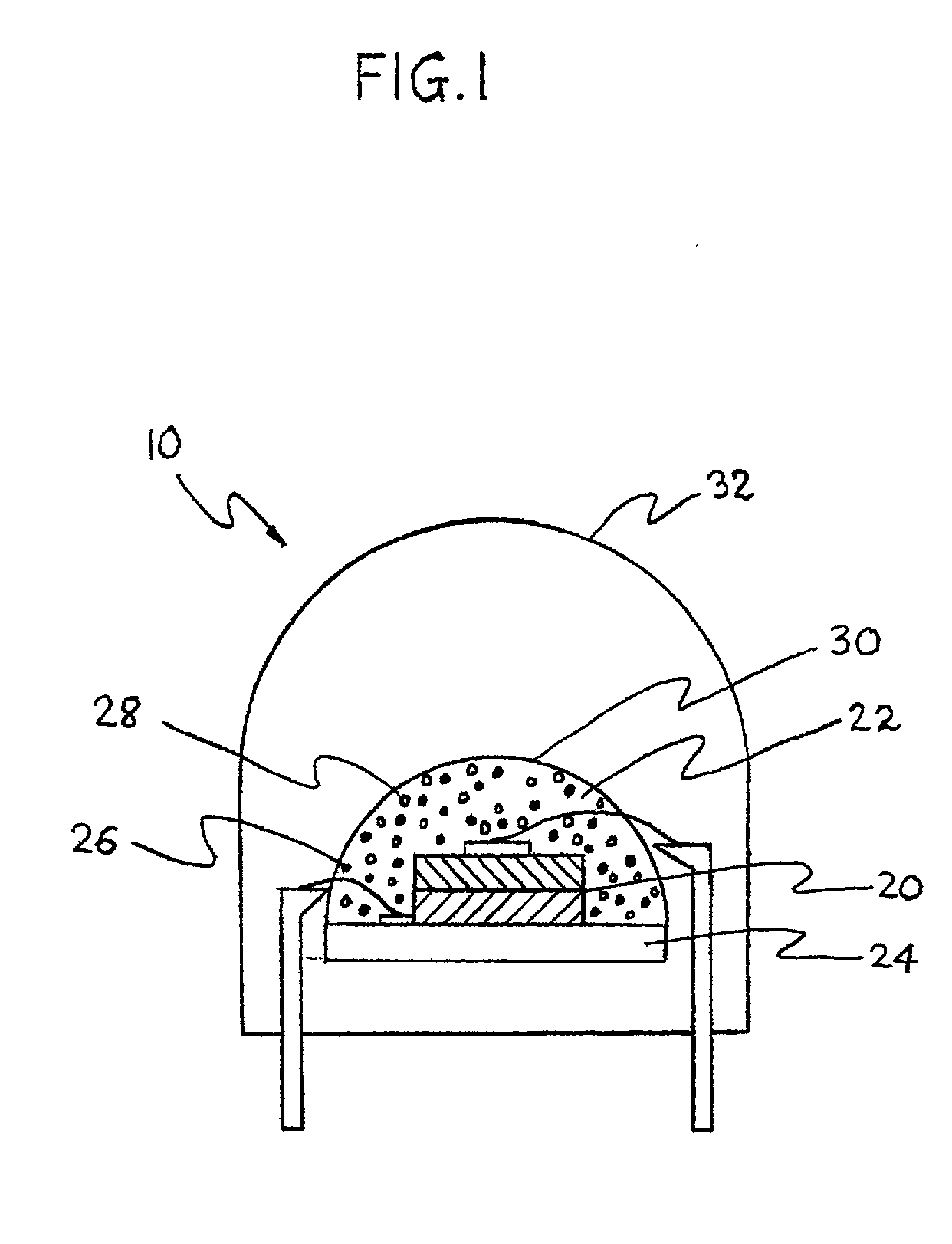

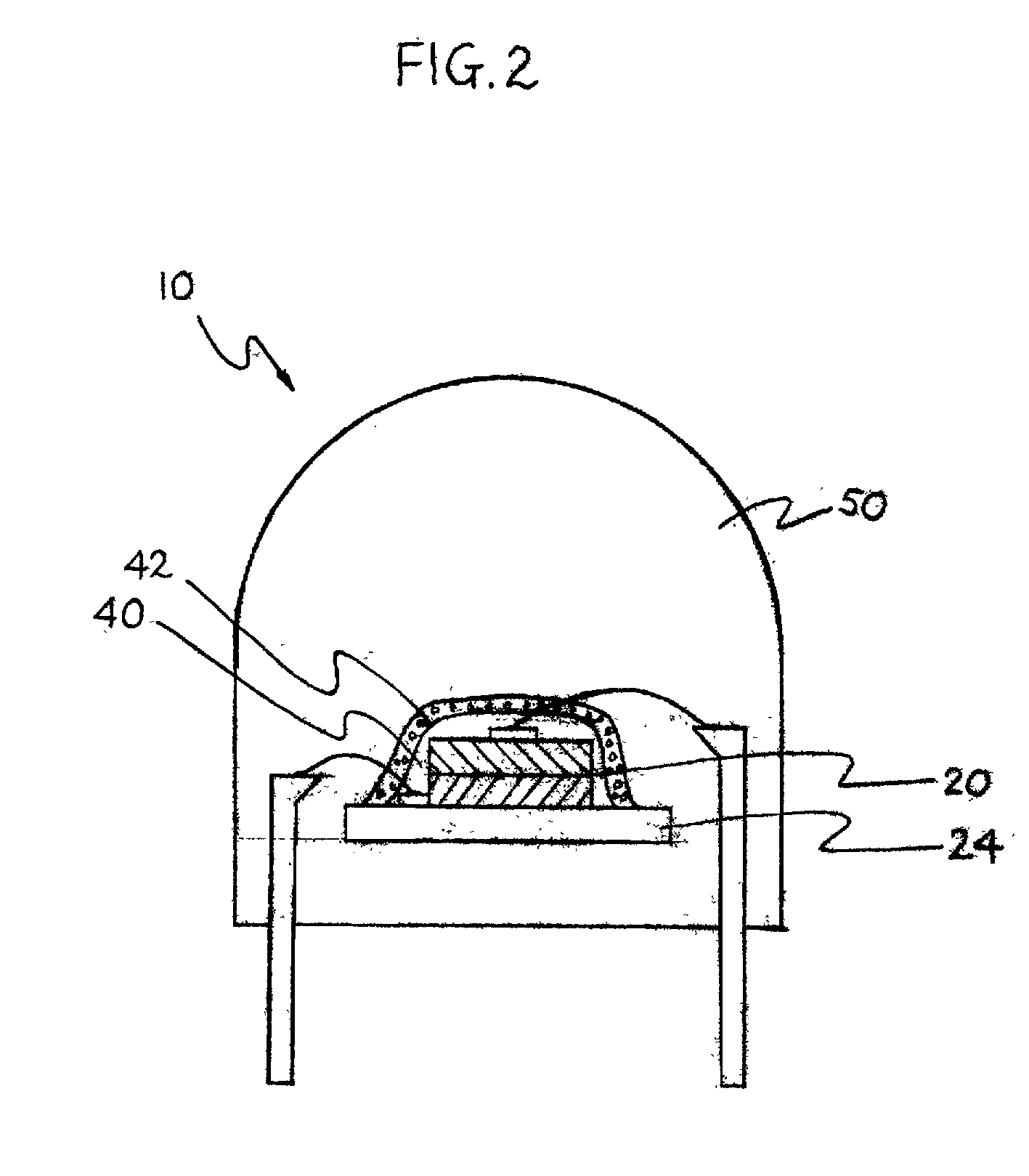

UV reflectors and UV-based light sources having reduced UV radiation leakage incorporating the same

InactiveUS20020180351A1Uniform colorUniform light intensityIncadescent screens/filtersMirrorsRadiation leakagePhosphor

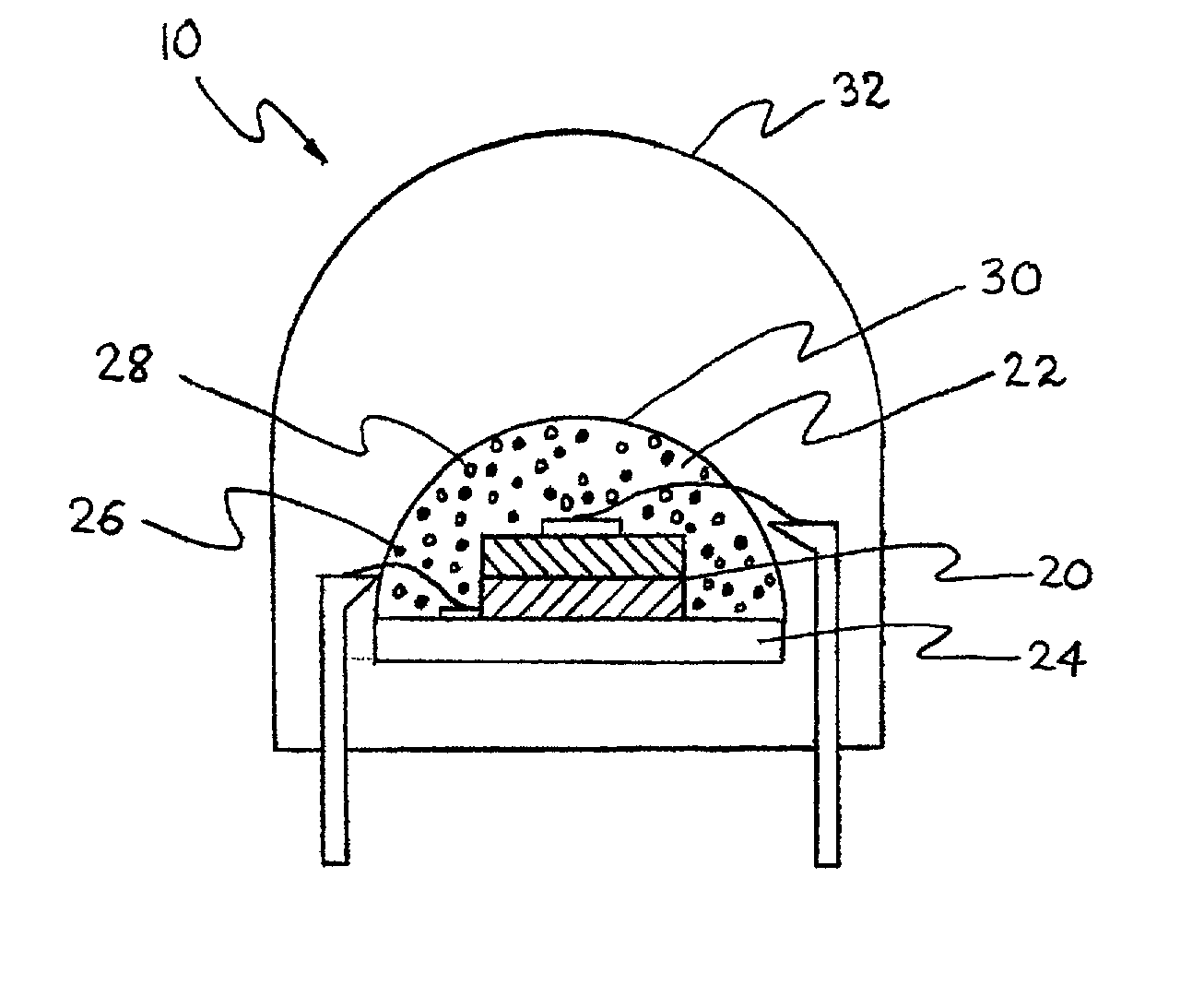

UV reflectors incorporated in UV LED-based light sources reduce the amount of UV radiation emission into the surroundings and increase the efficiency of such light sources. UV reflectors are made of nanometer-sized particles having a mean particle diameter less than about one-tenth of the wavelength of the UV light emitted by the UV LED, dispersed in a molding or casting material surrounding the LED. Other UV reflectors are series of layers of materials having alternating high and low refractive indices; each layer has a physical thickness of one quarter of the wavelength divided by the refractive index of the material. Nanometer-sized textures formed on a surface of the multilayered reflector further reduce the emission of UV radiation into the surroundings. UV LED-based light sources include such a multilayered reflector disposed on an encapsulating structure of a transparent material around a UV LED, particles of a UV-excitable phosphor dispersed in the transparent material. Alternatively, the transparent material also includes nanometer-sized particles of a UV-radiation scattering material.

Owner:GE LIGHTING SOLUTIONS LLC

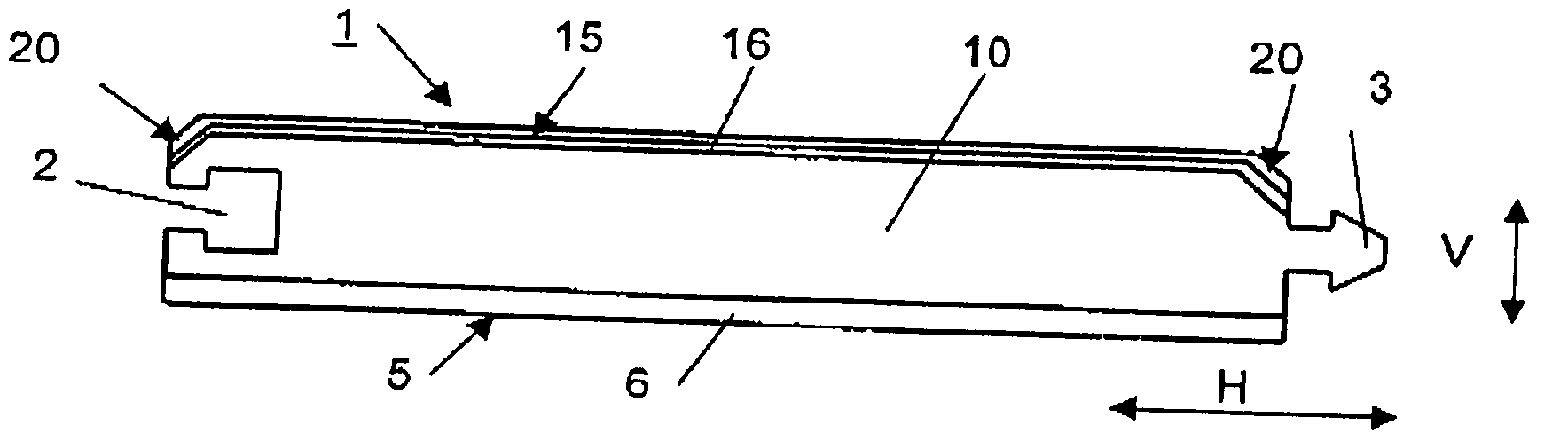

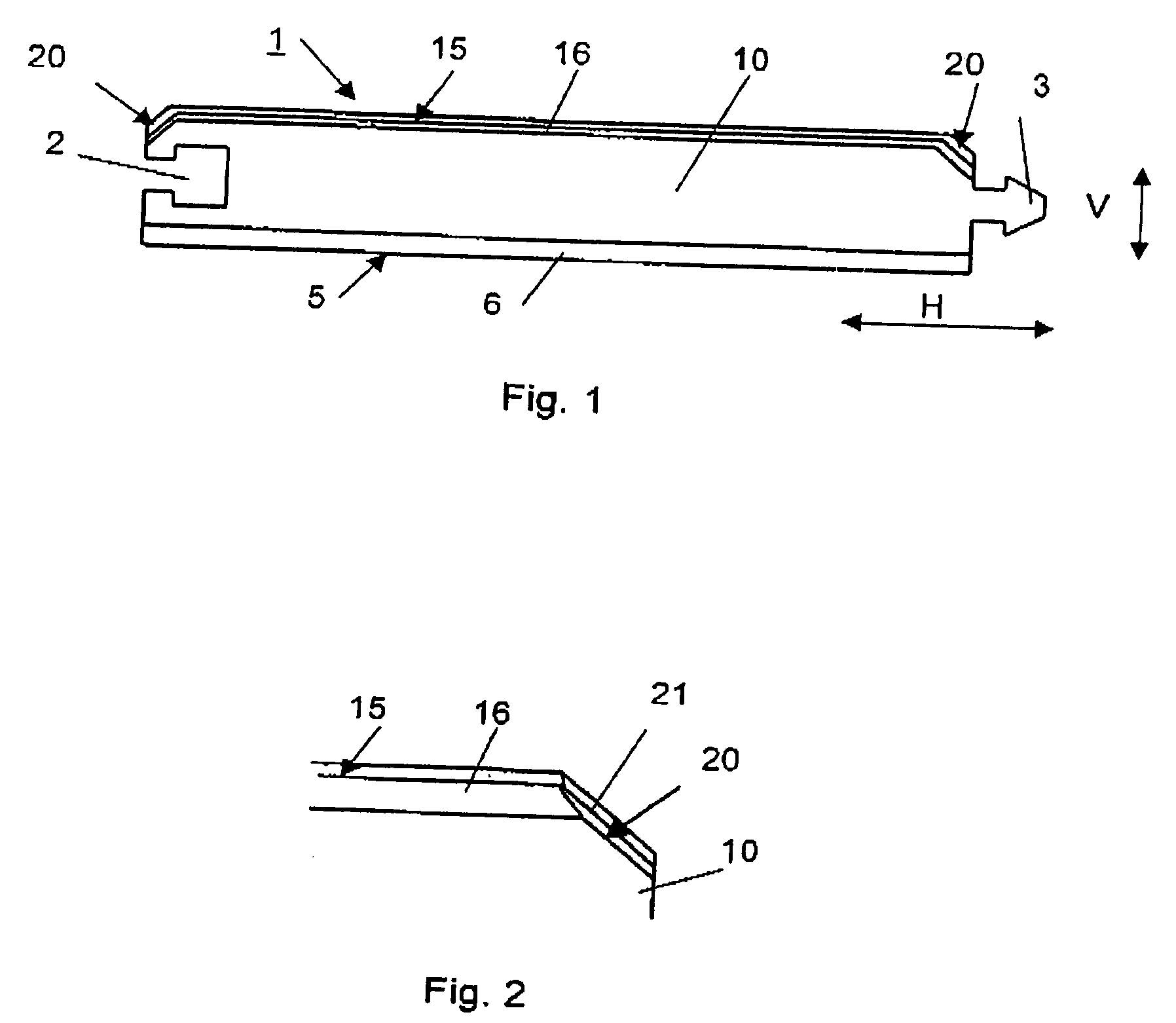

Flooring panel

A panel, in particular a flooring panel, of a wood material which is provided with a mechanism for the detachable connection of a least two panels, whereby form-fitting elements for locking in the vertical direction and in the horizontal direction with another panel are embodied on at least one lateral edge of a first panel, whereby a chamfer is embodied on at least one lateral edge starting from an upper side. The chamfer or the form-fitting elements are coated or impregnated with at least one melamine layer.

Owner:KRONOTEC

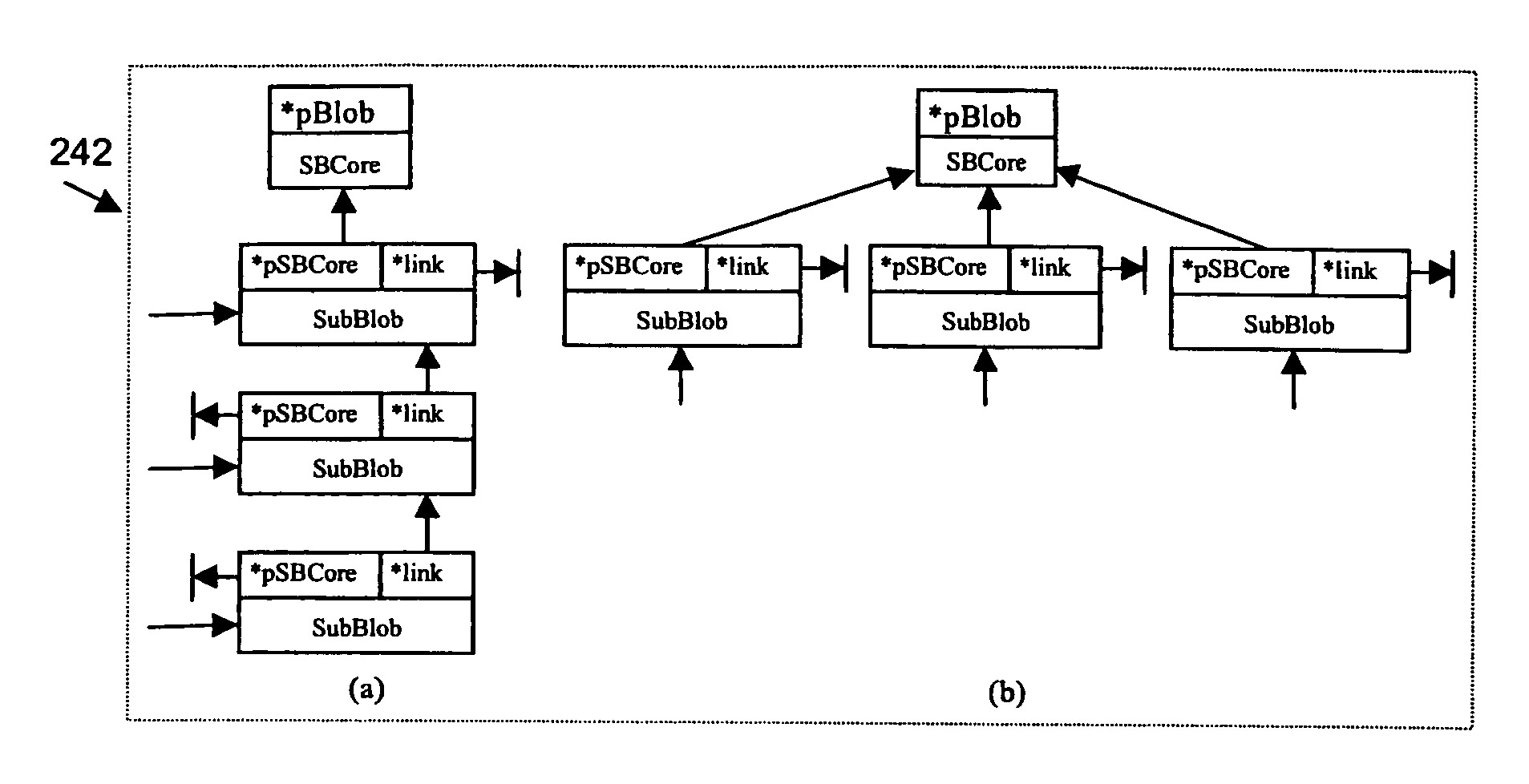

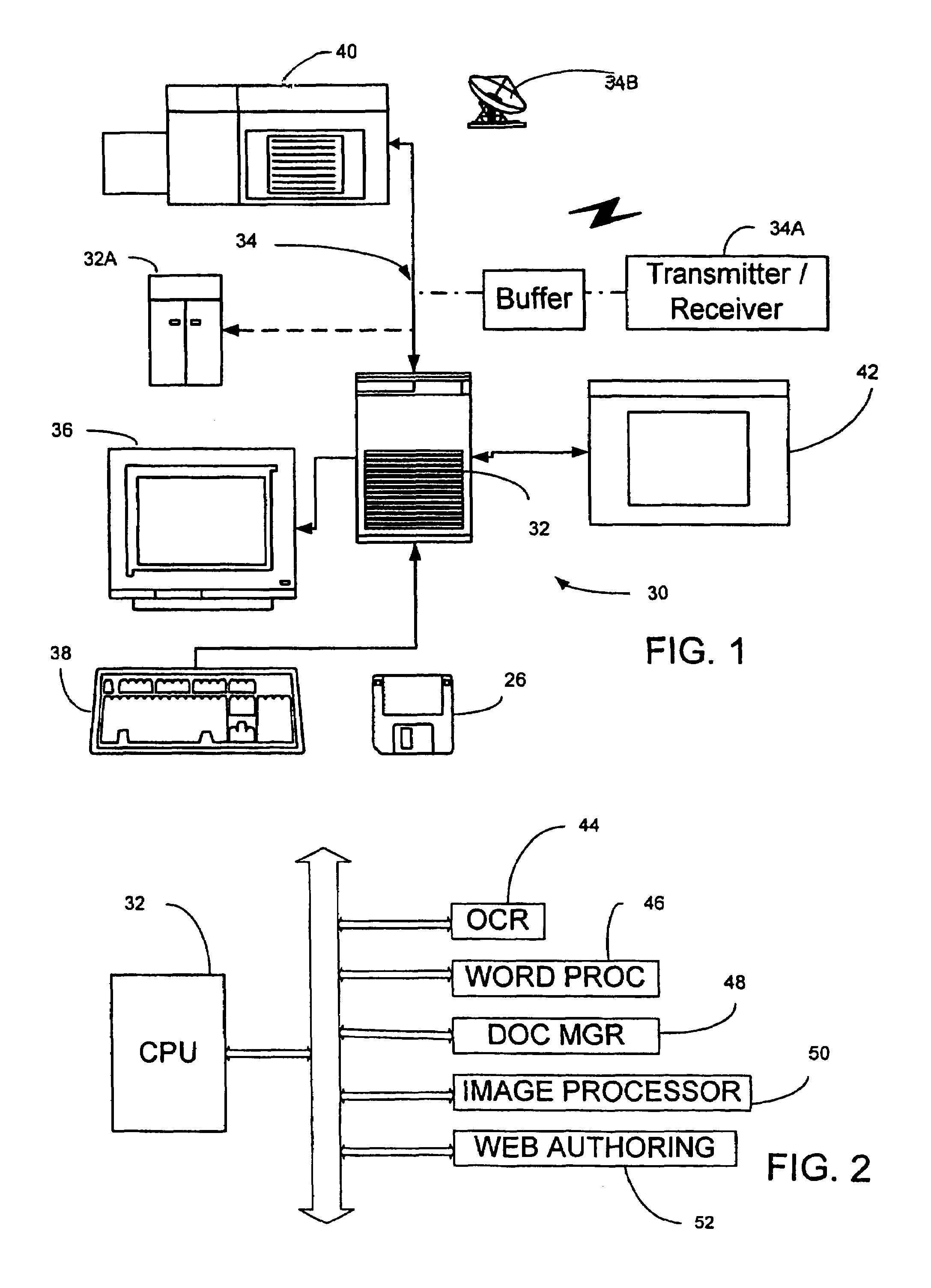

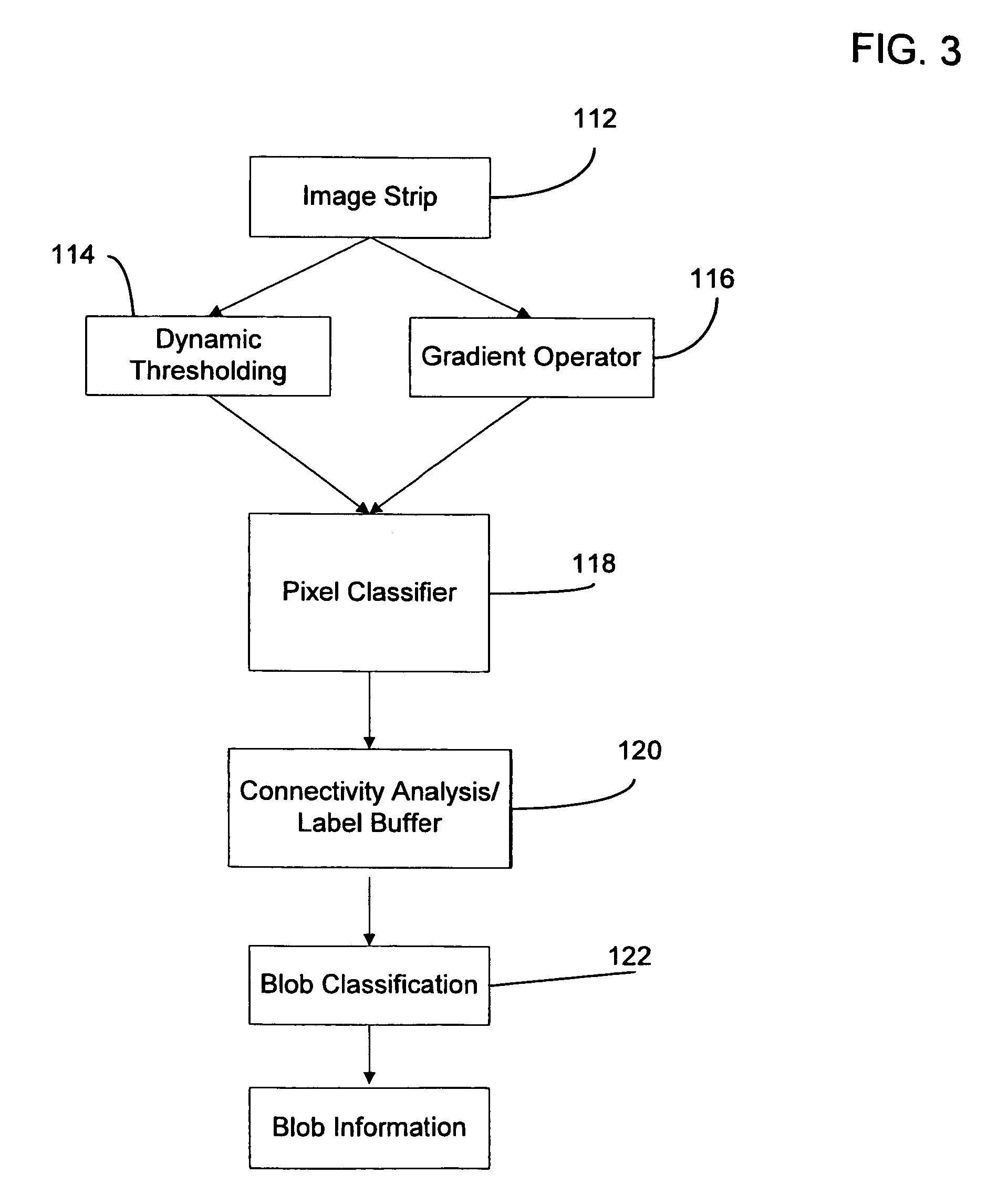

Methods and apparatus for analyzing an image

InactiveUS7672022B1Easy to identifyEasy to analyzeImage enhancementDigitally marking record carriersComputer visionEdge element

A method analyzes an image to be scanned and analyzes at least part of the image pixel-by-pixel. Elements in the image are characterized according to a perceived characteristic and each image element having a given characteristic that is adjacent a similar or identical image element is identified. In one form, there are preferably at least three different characteristics, such as black, background and edge, by which the image elements can be characterized. In another form, image elements that are close enough to each other in physical location and close enough to each other in image characteristic are grouped together or included in a blob. Sub-blobs can be found to be part of a more predominant blob. In a further form, image elements are identified that represent an edge in the image, along with identifying those edge elements that are adjacent at least one other edge element.

Owner:HEWLETT PACKARD DEV CO LP

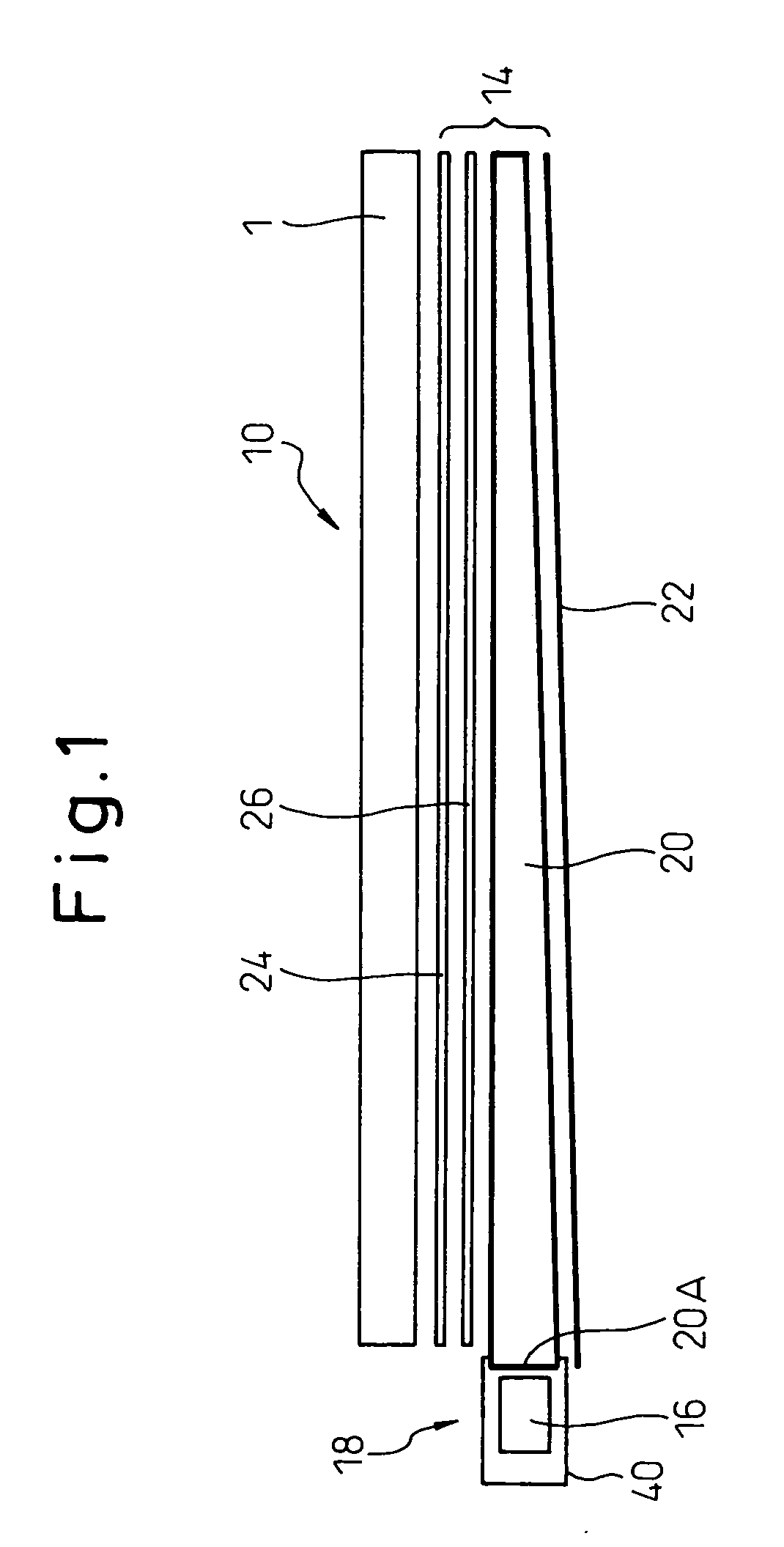

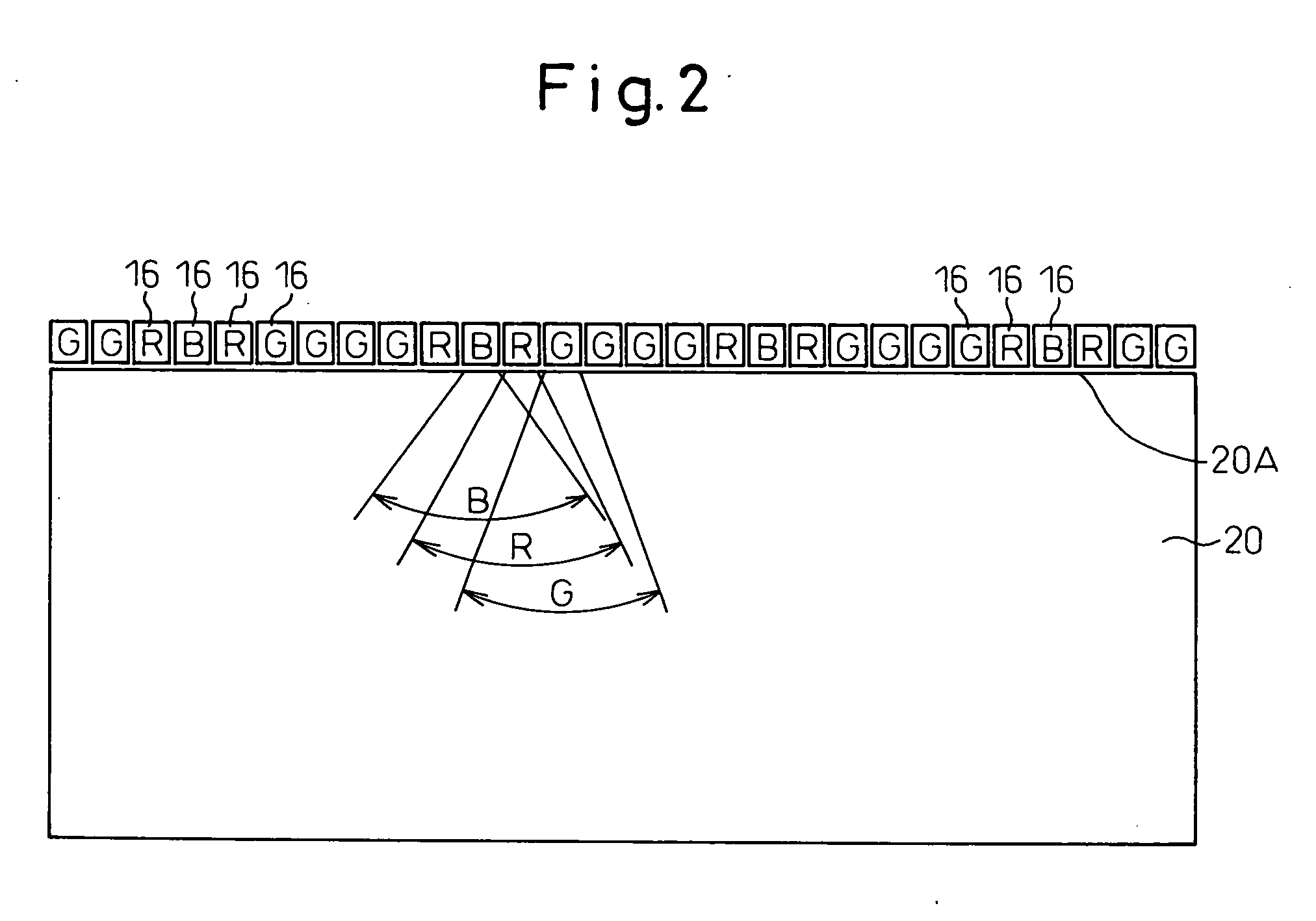

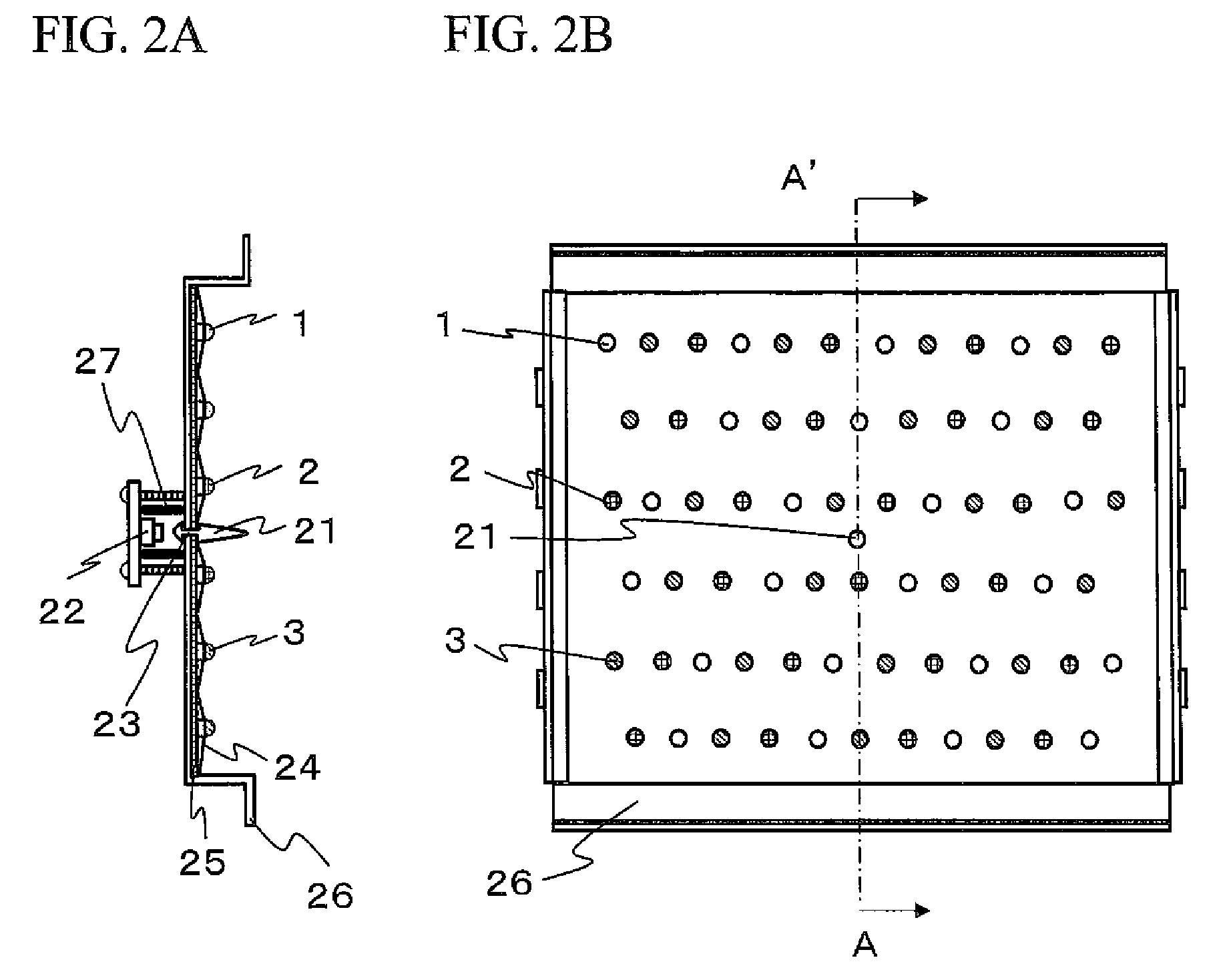

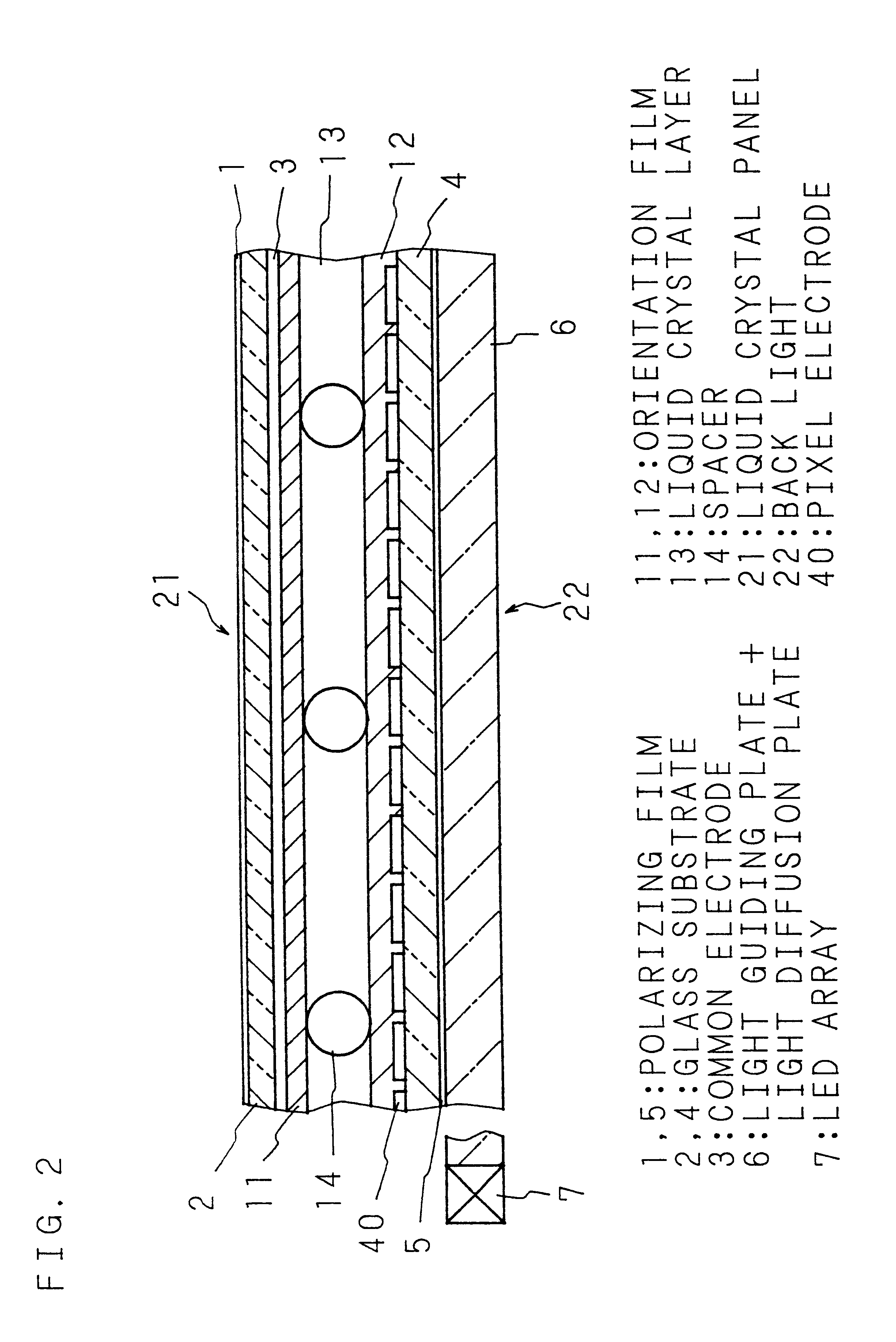

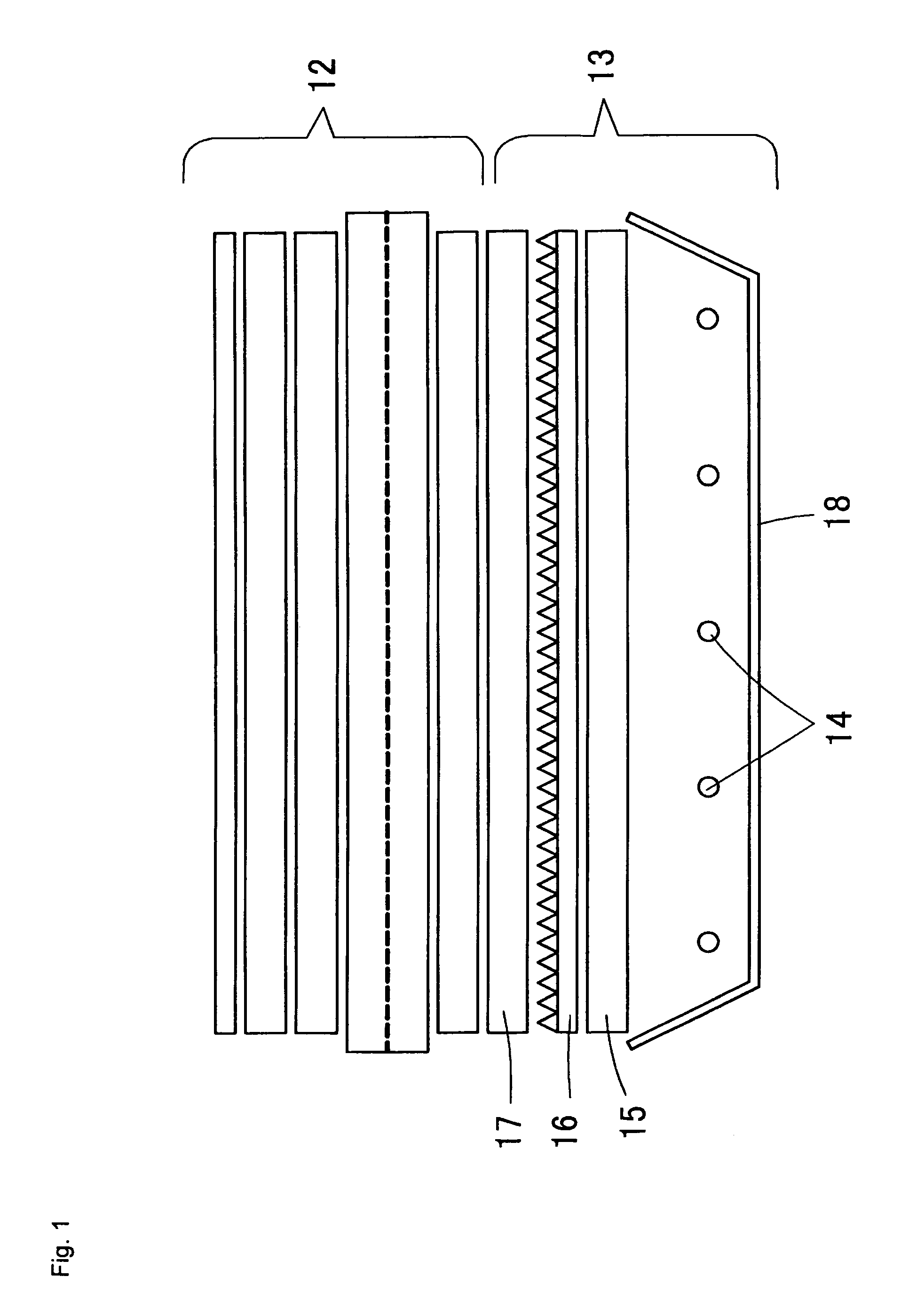

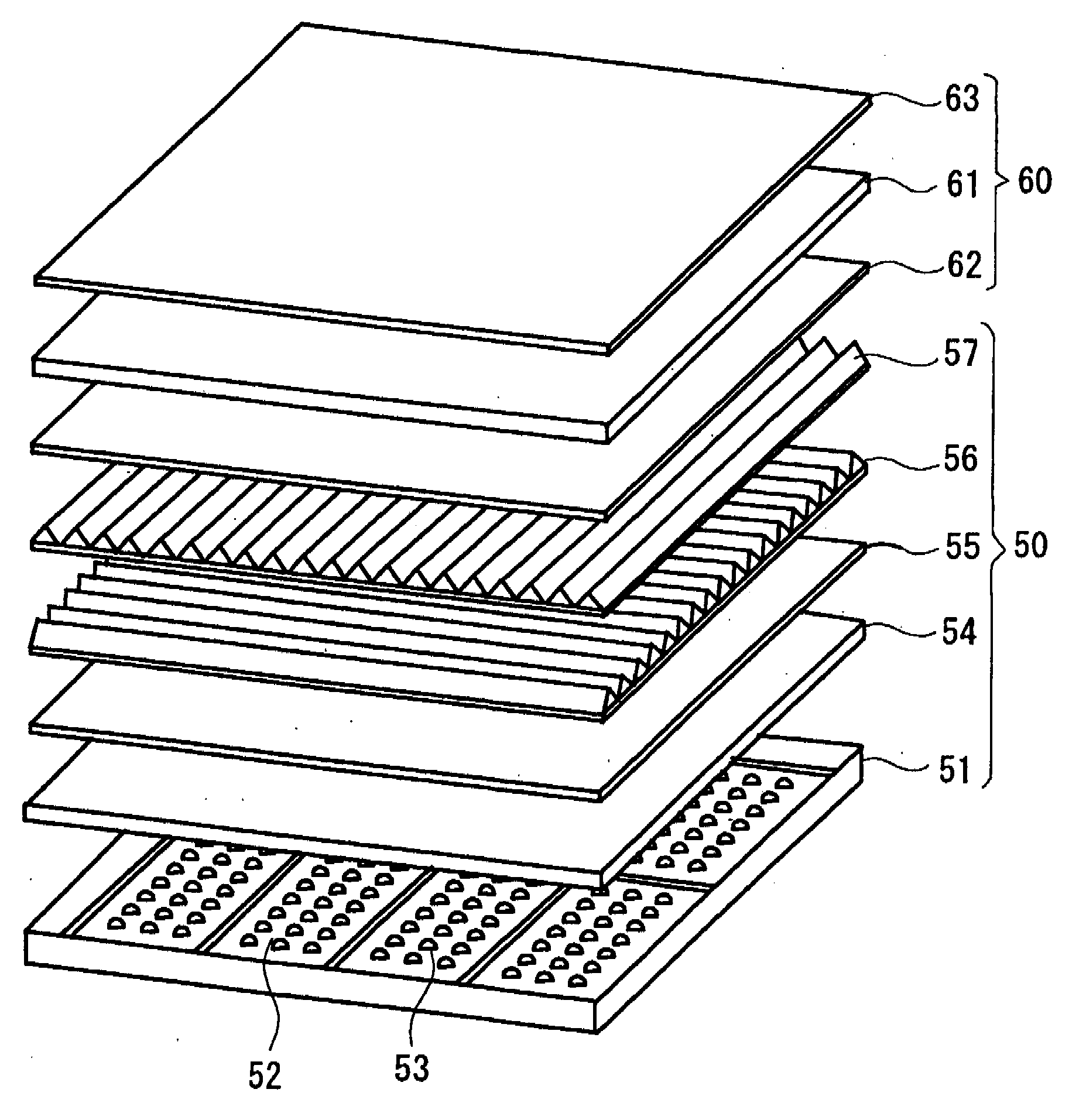

Backlight and liquid crystal display device

InactiveUS20050141244A1Prevent fallingEnsure reliabilityMechanical apparatusPoint-like light sourceElectricityLiquid-crystal display

A side light type backlight includes a light source including a plurality of LEDs, and a light guide plate. One of the end surfaces of the light guide plate is a light incidence surface at which a plurality of R-LEDs, a plurality of G-LEDs and a plurality of B-LEDs are arranged. LEDs satisfy the relationship of: a distribution range of light emitted from G-LEDs <a distribution range of light emitted from R-LEDS, or a distribution range of light emitted from G-LEDs <a distribution range of light emitted from B-LEDs. Also, LEDs are electrically connected to each other.

Owner:SHARP KK

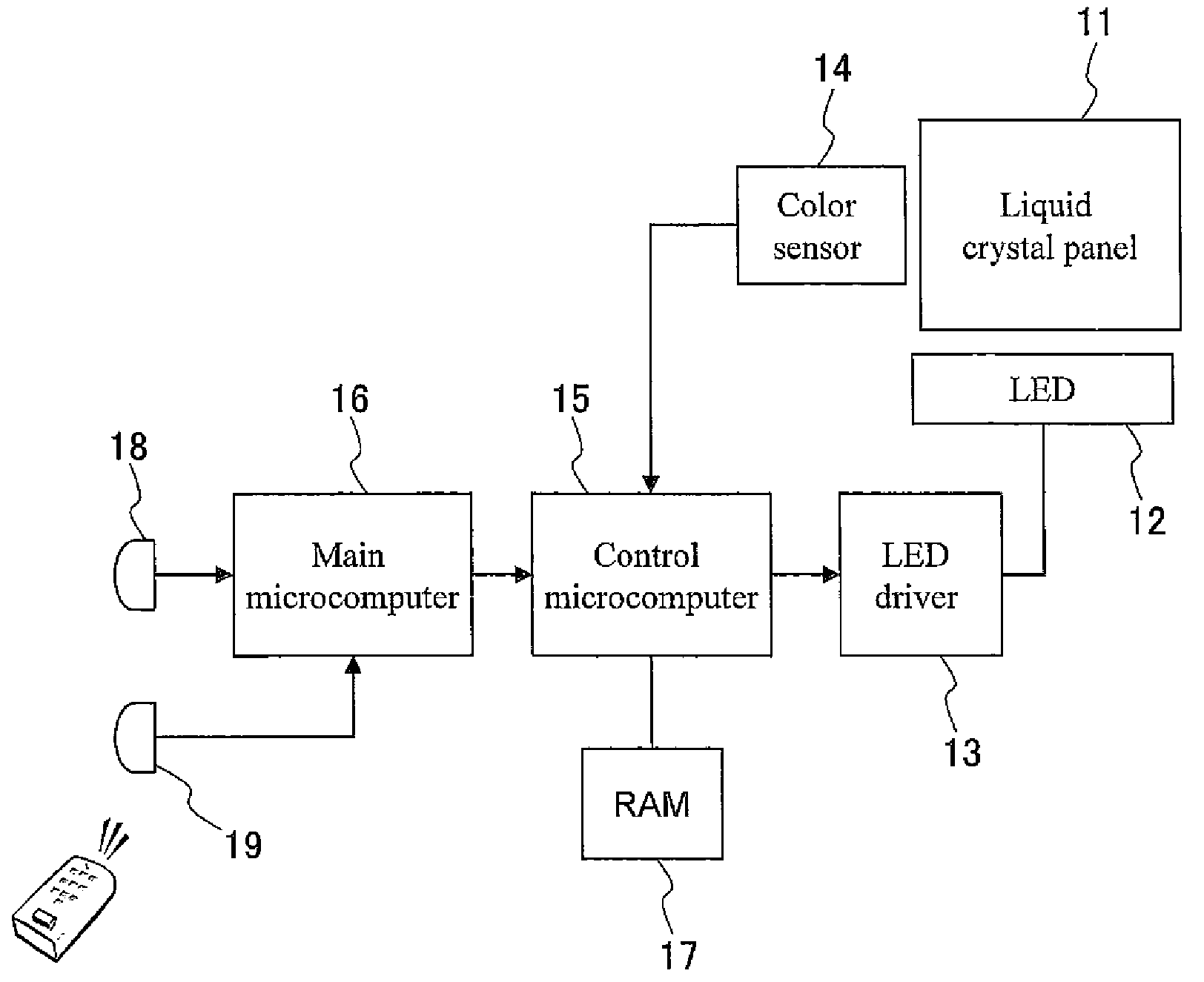

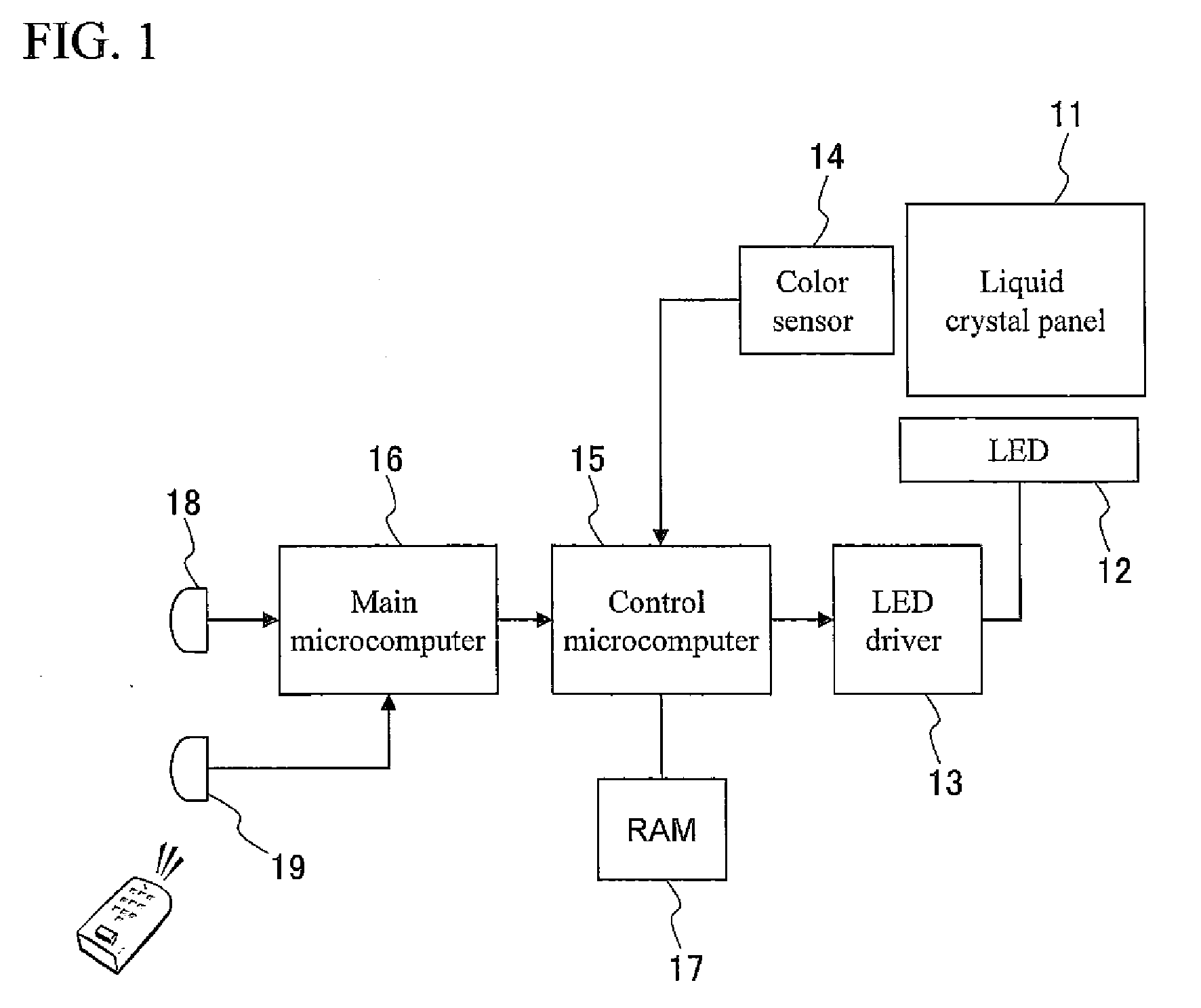

Light source control device, illuminaton device, and liquid crystal display device

InactiveUS20090140656A1Uniform colorPhotometry using reference valueElectrical apparatusLiquid-crystal displayLight emission

A light emission device capable of holding a uniform color in various environments. A light source control device has a light detection device for detecting emission brightness of light sources that emit different colors and controlling emission brightness of at least one light source of the light sources based on the detection result of the light detection device. A through-hole is formed in a reflection member for reflecting light emitted from the light source, and the reflection is in a predetermined direction. The light detection device is provided across the reflection member from the light source, and the light propagation member is provided at the through-hole.

Owner:SHARP KK

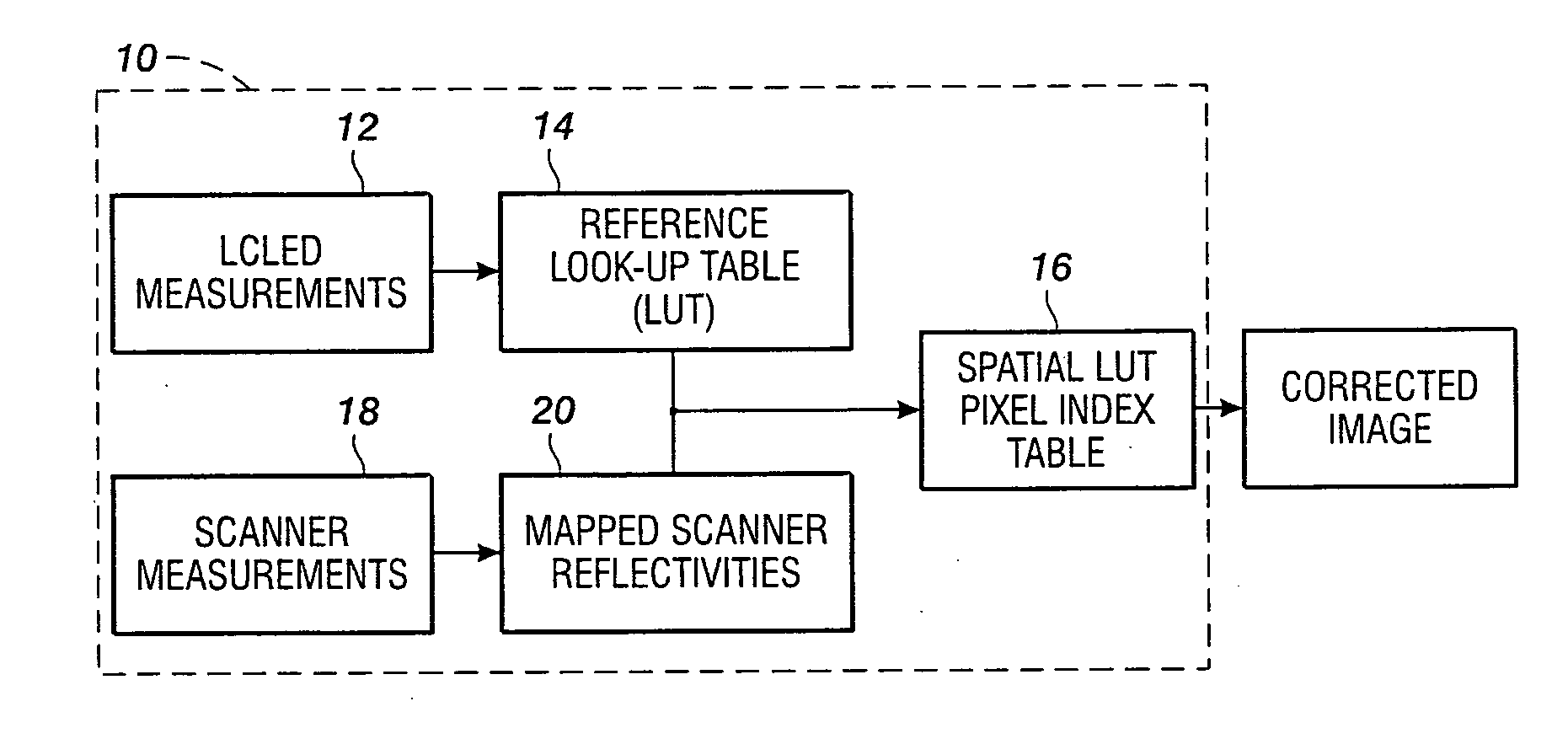

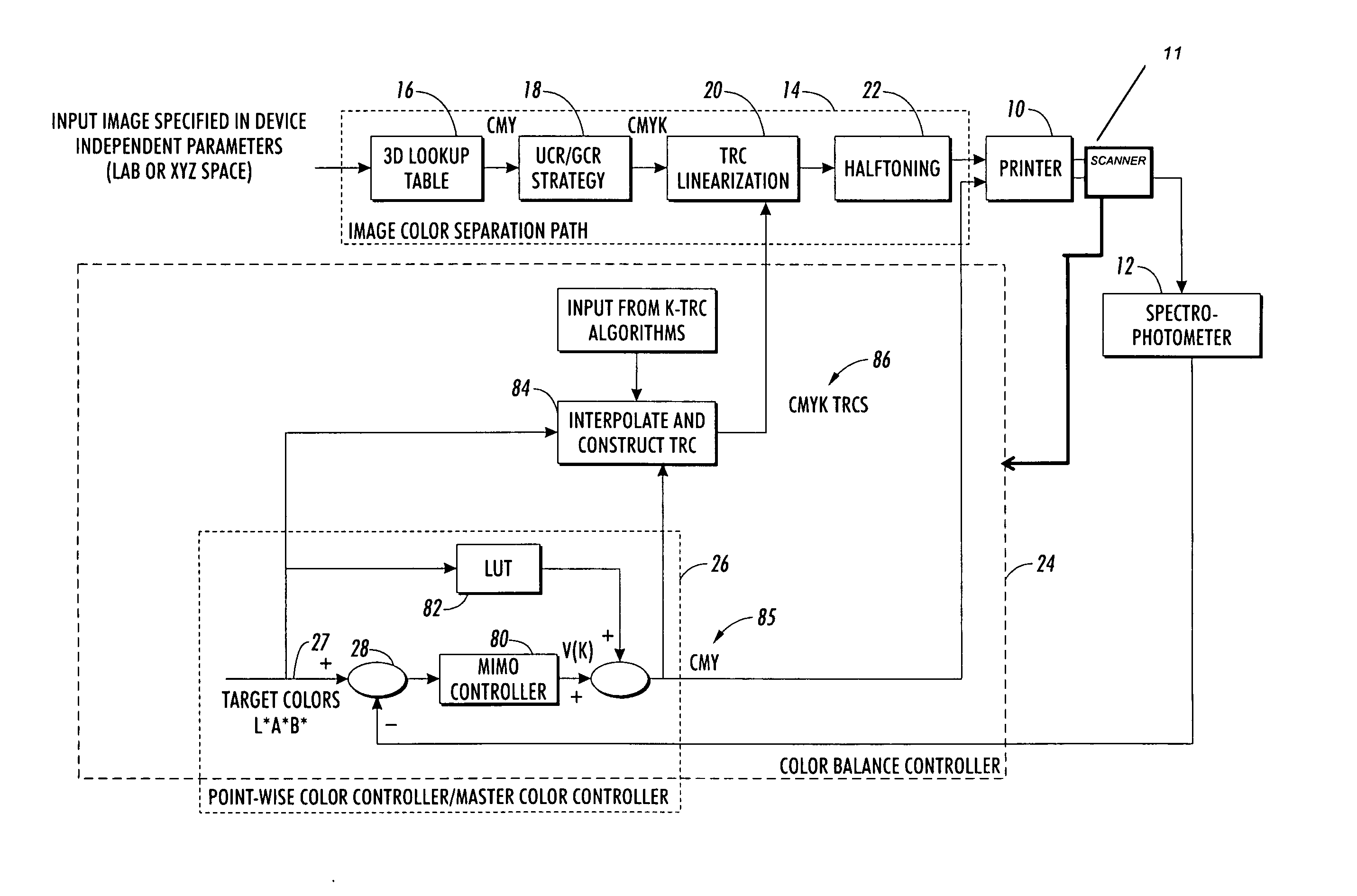

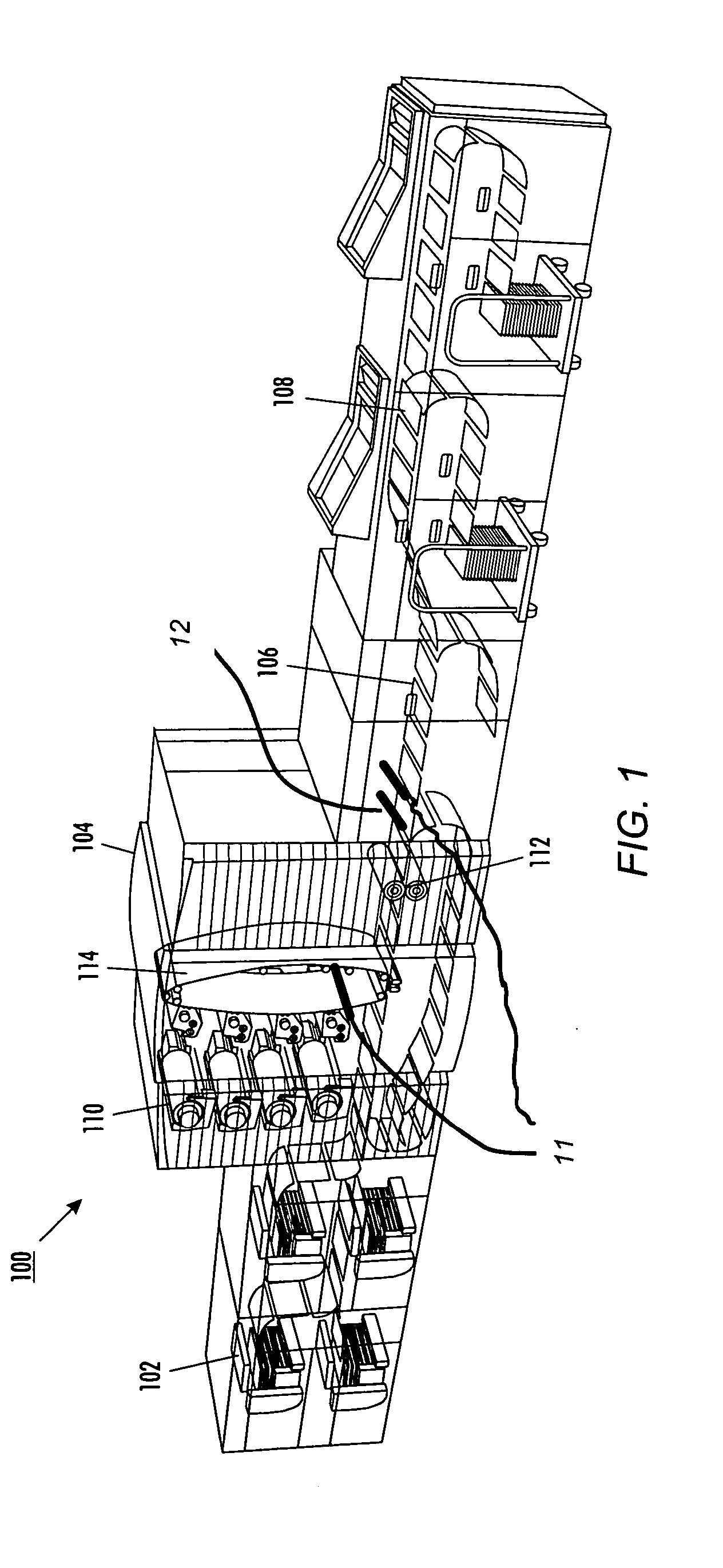

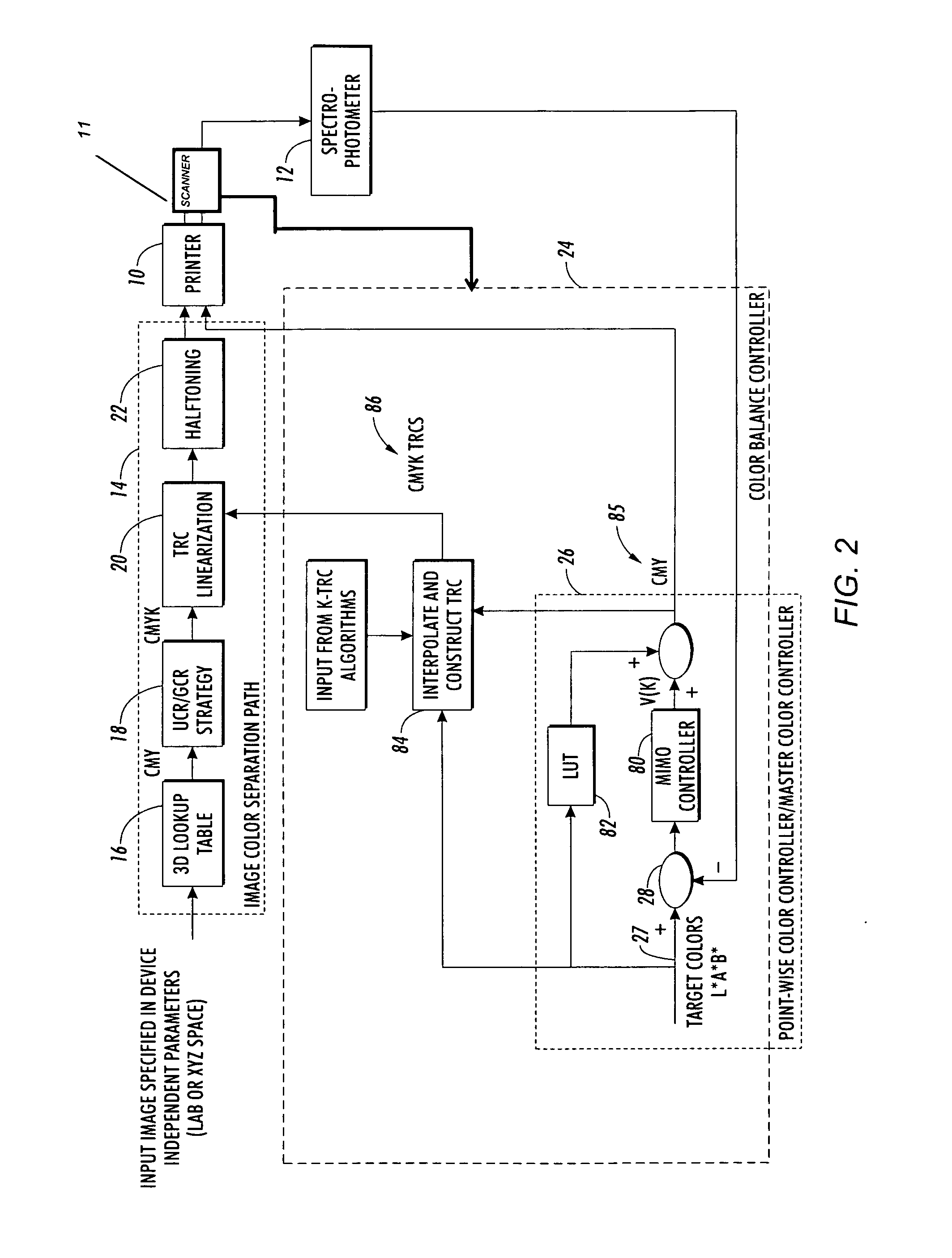

Method for spatial color calibration using hybrid sensing systems

InactiveUS20080037069A1Minimize spatial uniformity errorSpace minimizationDigitally marking record carriersDigital computer detailsOutput deviceComputer vision

A method and system for color calibration or color output device spectrophotoically measures at test target including a preselected test color value. A multi-dimensional LUT of the device is generated representative of the color information including the at least one preselected color. Producing a second image width device including the at least one preselected color located at a plurality of spatial locations in the second image. A second sensor measures the second image and a plurality of spatial locations having the preselected color for generating reflectance information for the preselected color at the plurality of spatial locations. An error is determined between the measured color of the one preselected color and the reflectance information at the other pixel locations. A multi-dimensional LUT is adjusted to minimize spatial uniformity errors at the other pixel locations, thus calibrating device color output spatially.

Owner:XEROX CORP

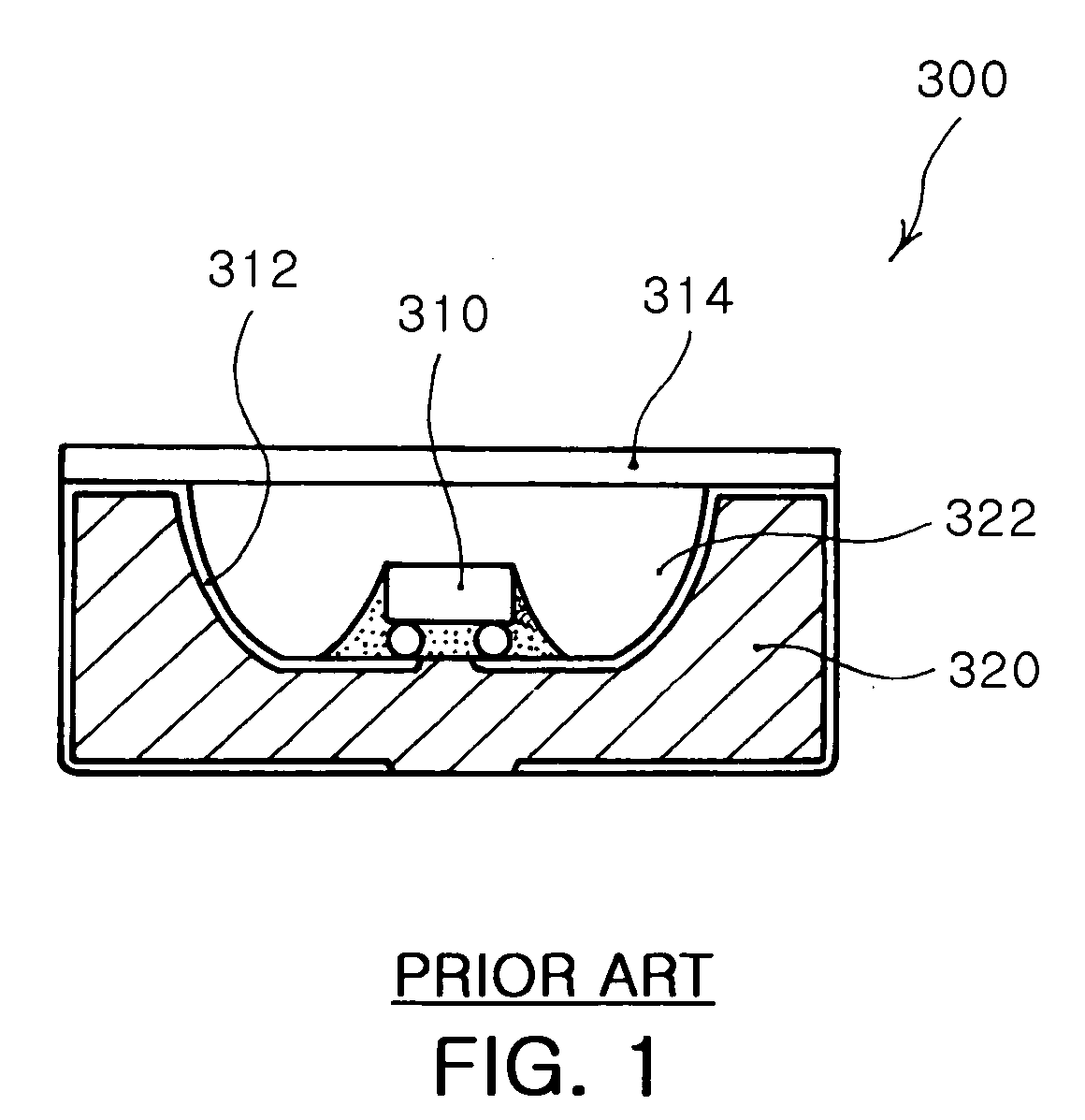

Light emitting diode package with metal reflective layer and method of manufacturing the same

InactiveUS20060284207A1Easy to manufactureSmall sizeSolid-state devicesSemiconductor devicesTransfer moldingEngineering

The invention relates to an LED package having a metal reflective layer for focusing and emitting light through a side of the package, and a manufacturing method of the same. The LED package includes a substrate with an electrode formed thereon, a light emitting diode chip disposed on the substrate, and an encapsulant covering the LED chip and the substrate to protect the LED chip. The LED package also includes a metal reflective layer surrounding side surfaces of the encapsulant to form a light transmitting surface on a top surface of the encapsulant. The invention minimizes light loss, improves luminance, can be mass-produced as a PCB type, and adopts EMC transfer molding to minimize irregular color distribution, thereby improving optical quality.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

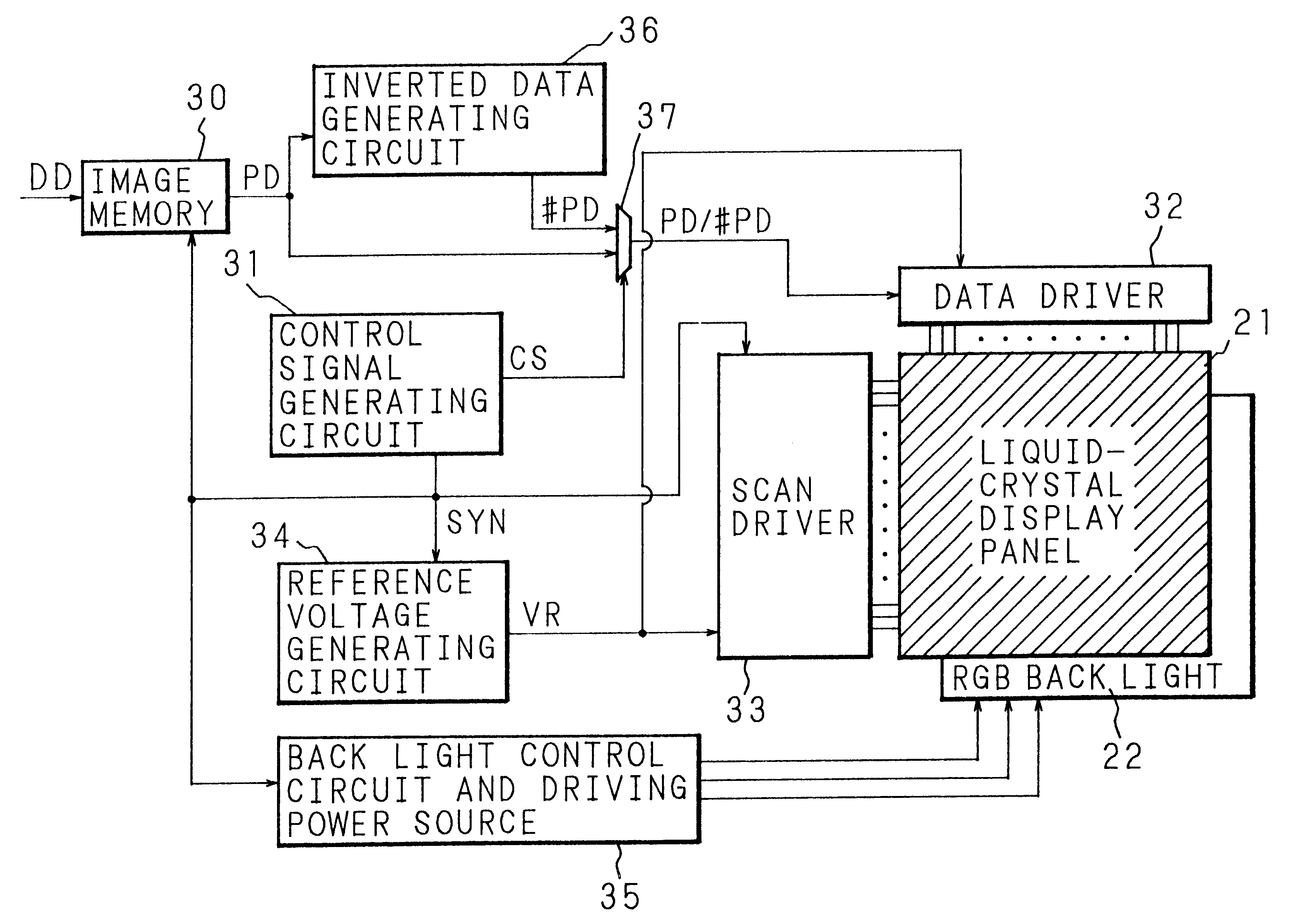

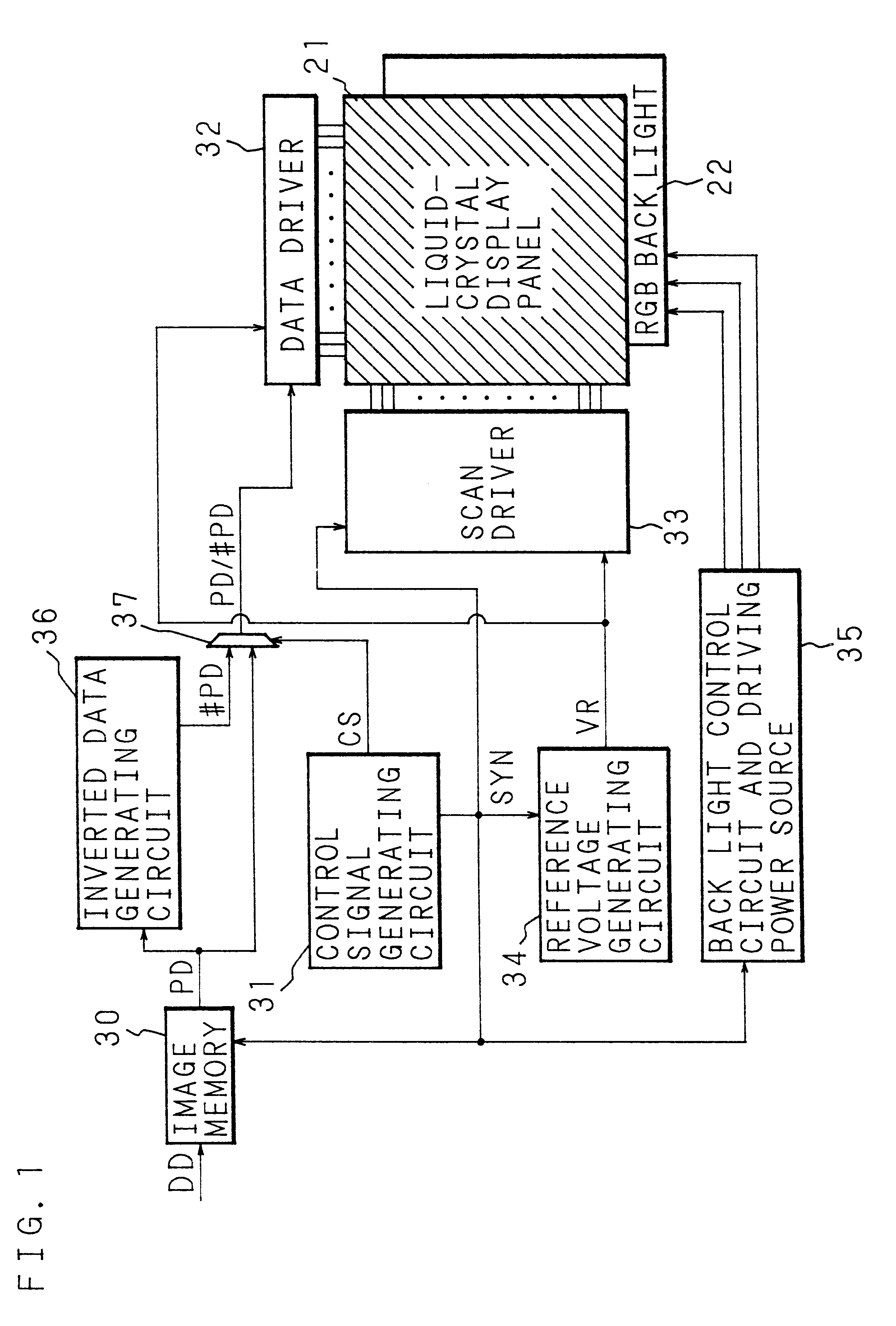

Liquid crystal display unit and display control method therefor

InactiveUS6873311B2Color balanceExcellent characteristicsStatic indicating devicesTime-sharingLiquid-crystal display

A liquid crystal display unit includes a liquid crystal panel having a plurality of liquid crystal pixels and a plurality of switching elements provided in correspondence to the respective pixels. A back light disposed at the back of the liquid crystal panel and guides red, green, and blue light to the surface thereof; an image memory for storing pixel data PD to be displayed on the respective pixels; an inverted data generating circuit for generating inverted pixel data #PD of the respective pixel data PD; and a control signal generating circuit and a data driver wherein first scanning for writing the pixel data PD with respect to individual pixels of the liquid crystal panel during each period in which red, green, and blue light are emitted in time-sharing manner, and second scanning for writing the inverted pixel data #PD with respect thereto are carried out in this order. Such problems that crosstalk occurs easily, besides response speed thereof is comparatively slow, so that it is not suitable for display of moving picture despite manufacturing cost of STN type display unit is comparatively inexpensive, while because TFT-TN type display unit requires a highly luminous back light, its power consumption is high, viewing angle is narrow, adjustment is difficult in color balance and the like are solved.

Owner:FUJITSU LTD

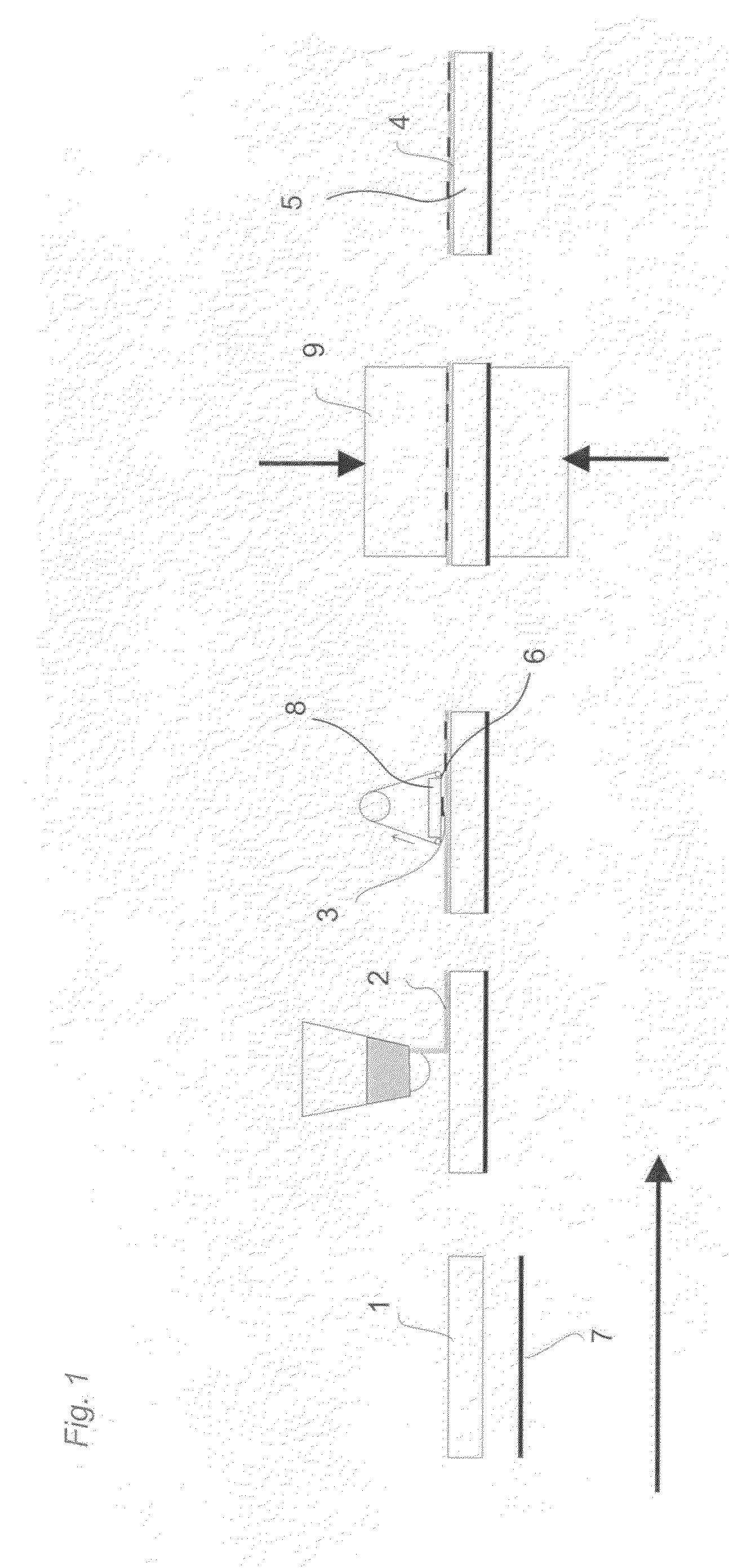

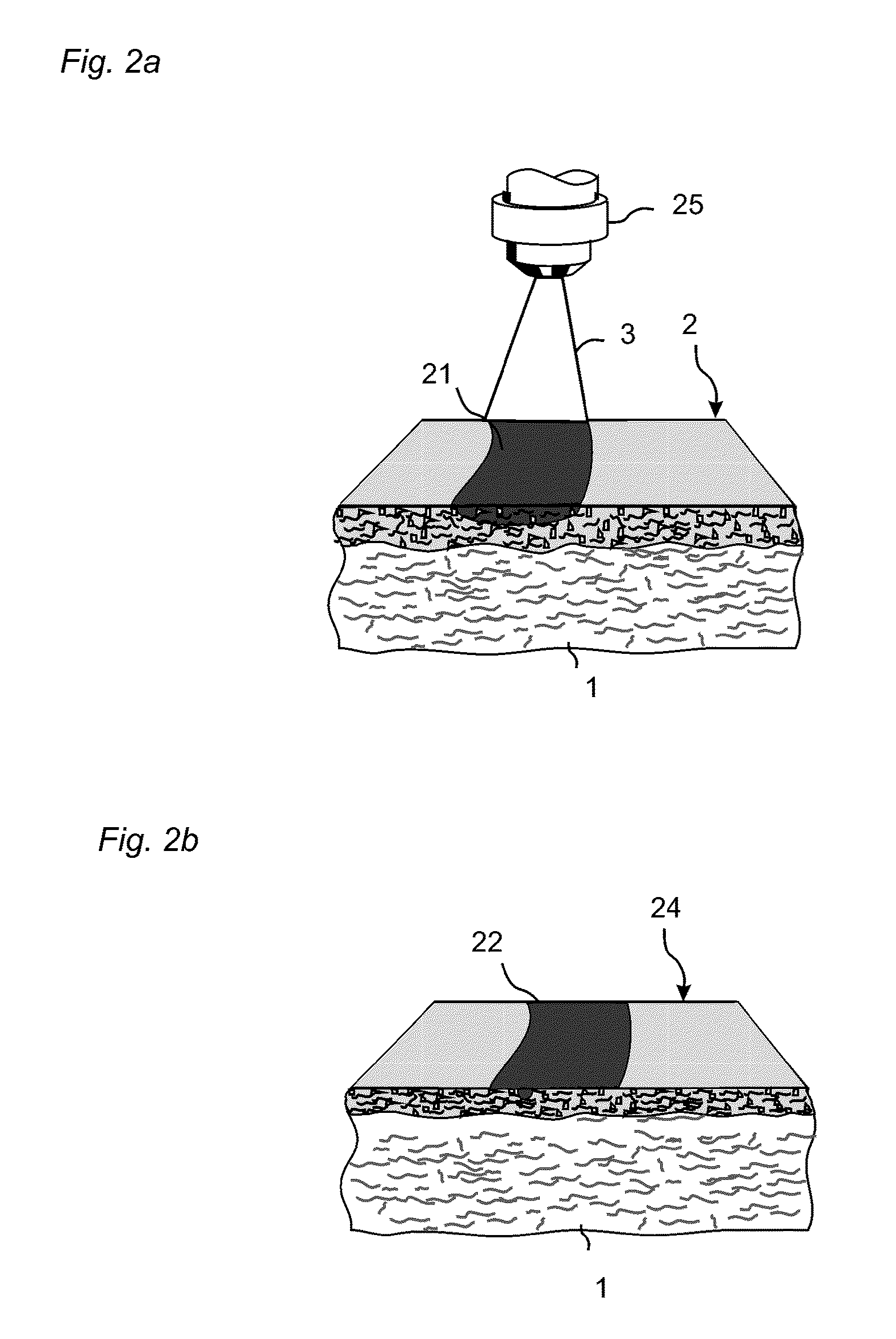

Production method

ActiveUS20110293906A1Uniform colorControlled colour variationIrregular area designLayered product treatmentSurface plateDry powder

A method for producing a panel is disclosed. The method includes the step of applying steam on a dry powder layer on a core. Thereafter is a heat and pressure applied to the powder layer in order to bond the powder together.

Owner:VÄLINGE INNOVATION AB

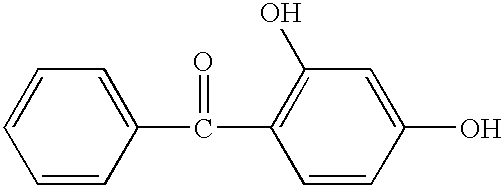

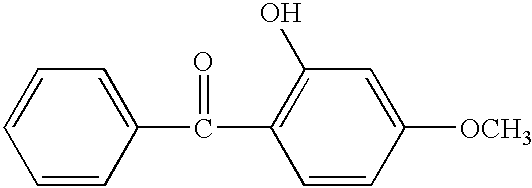

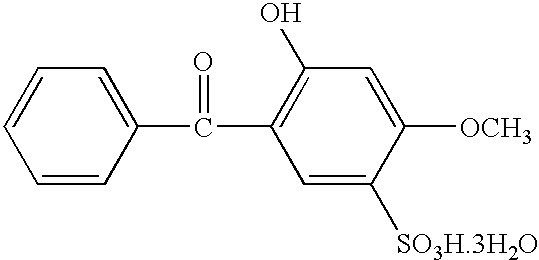

Topical cosmetic compositions

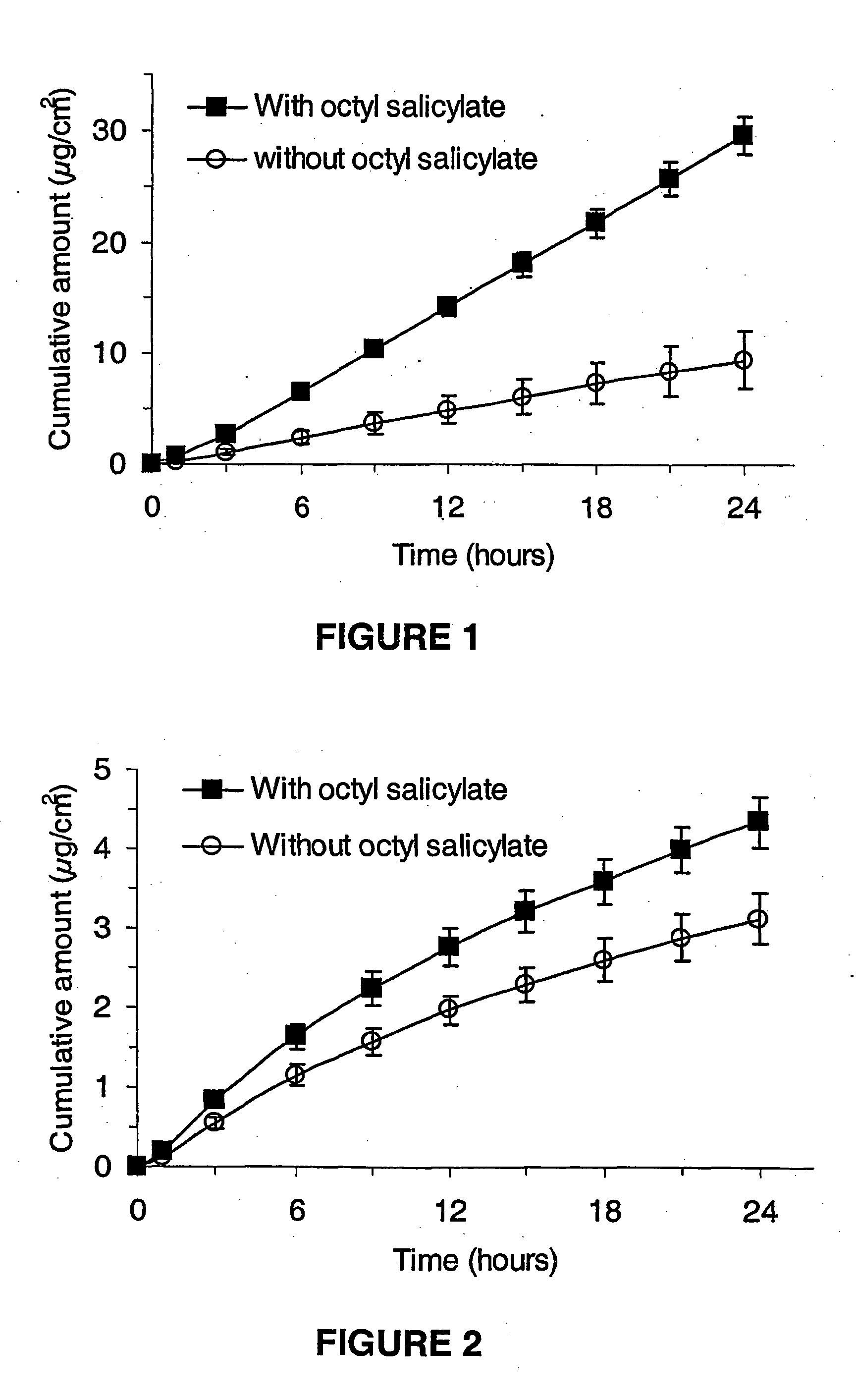

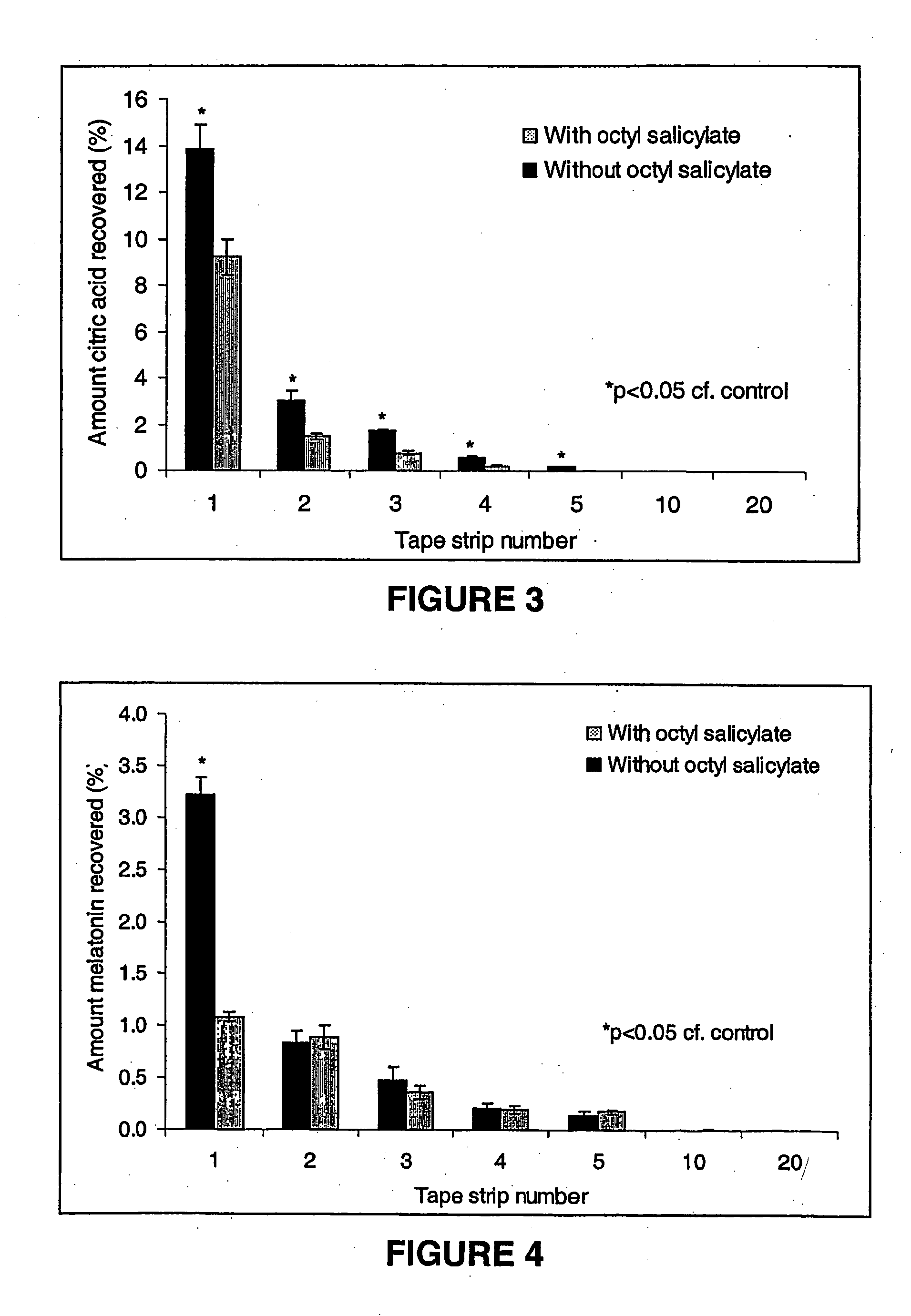

InactiveUS20050271692A1Improve skinDiminishing, reducing or preventing the effects of one or more of the skin conditionsCosmetic preparationsHair cosmeticsWater solubleDermatology

A topical cosmetic composition including: at least one water-soluble cosmetic agent; at least one oil-soluble cosmetic agent; and a dermal penetration enhancer, wherein topical application of the composition results in the delivery of the water-soluble and oil-soluble cosmetic agents into the stratum corneum as well as delivery of the oil-soluble cosmetic agent into the epidermis and dermis.

Owner:COSMECEUTIC SOLUTIONS

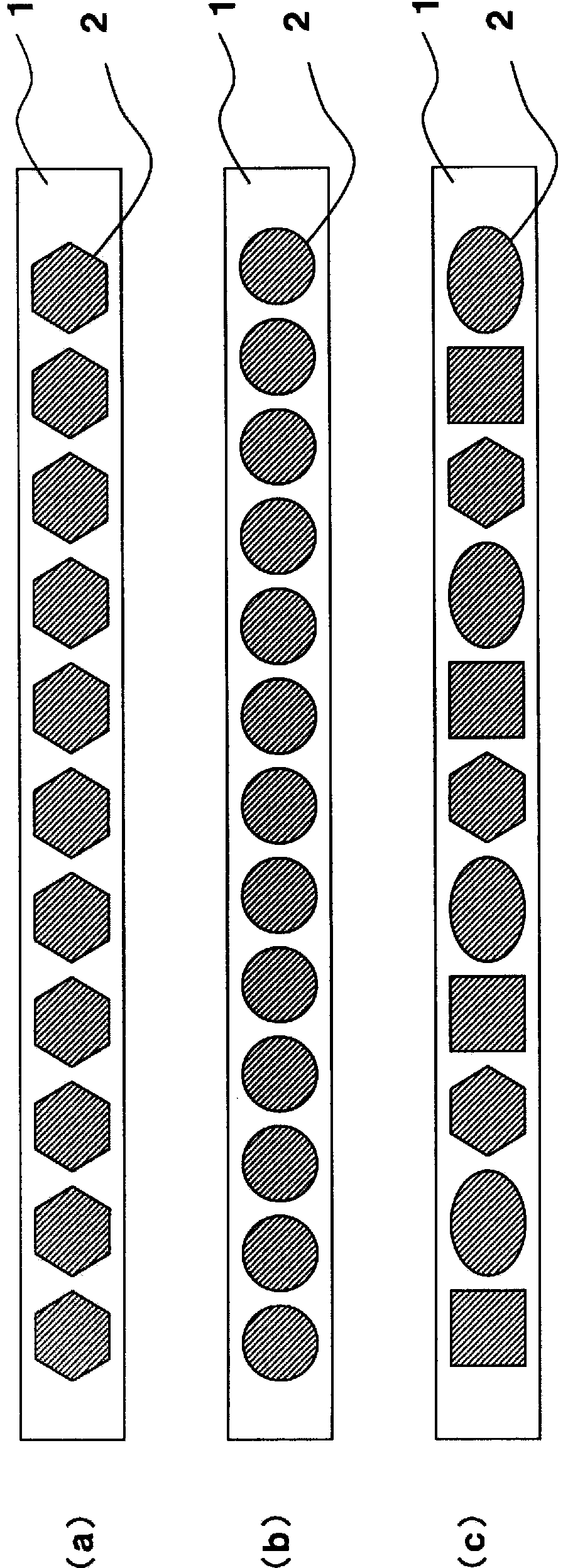

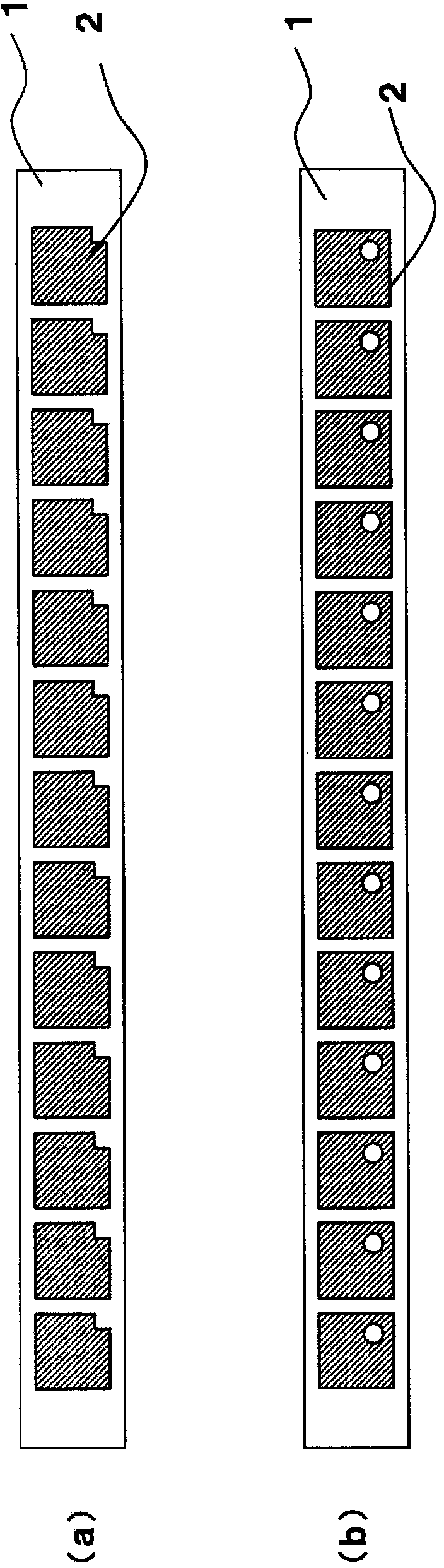

Resin sheet laminate and process for producing semiconductor light-emitting element using same

ActiveCN104321888AUniform brightnessUniform colorSolid-state devicesThin material handlingPhosphorEngineering

Owner:TORAY IND INC

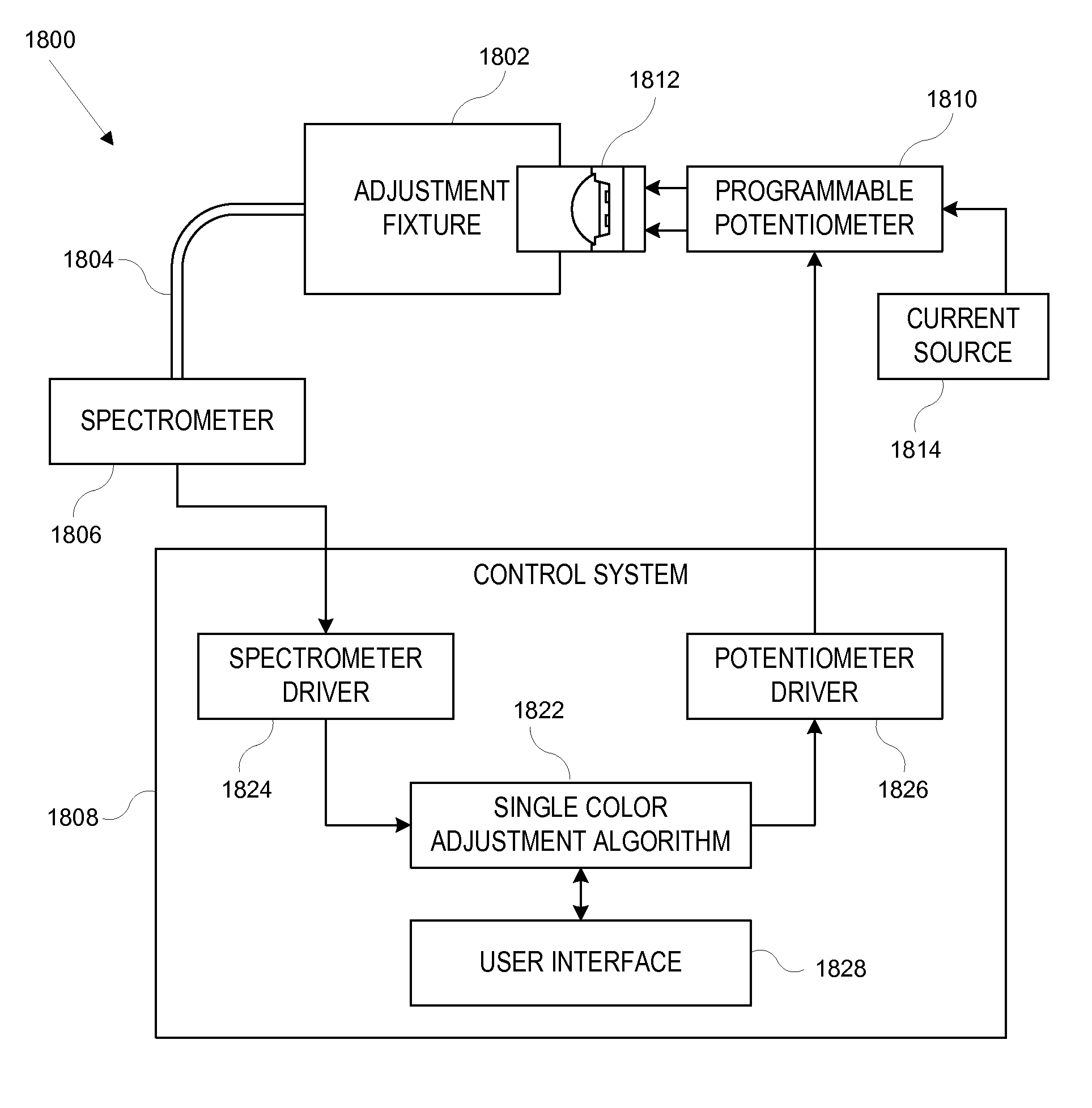

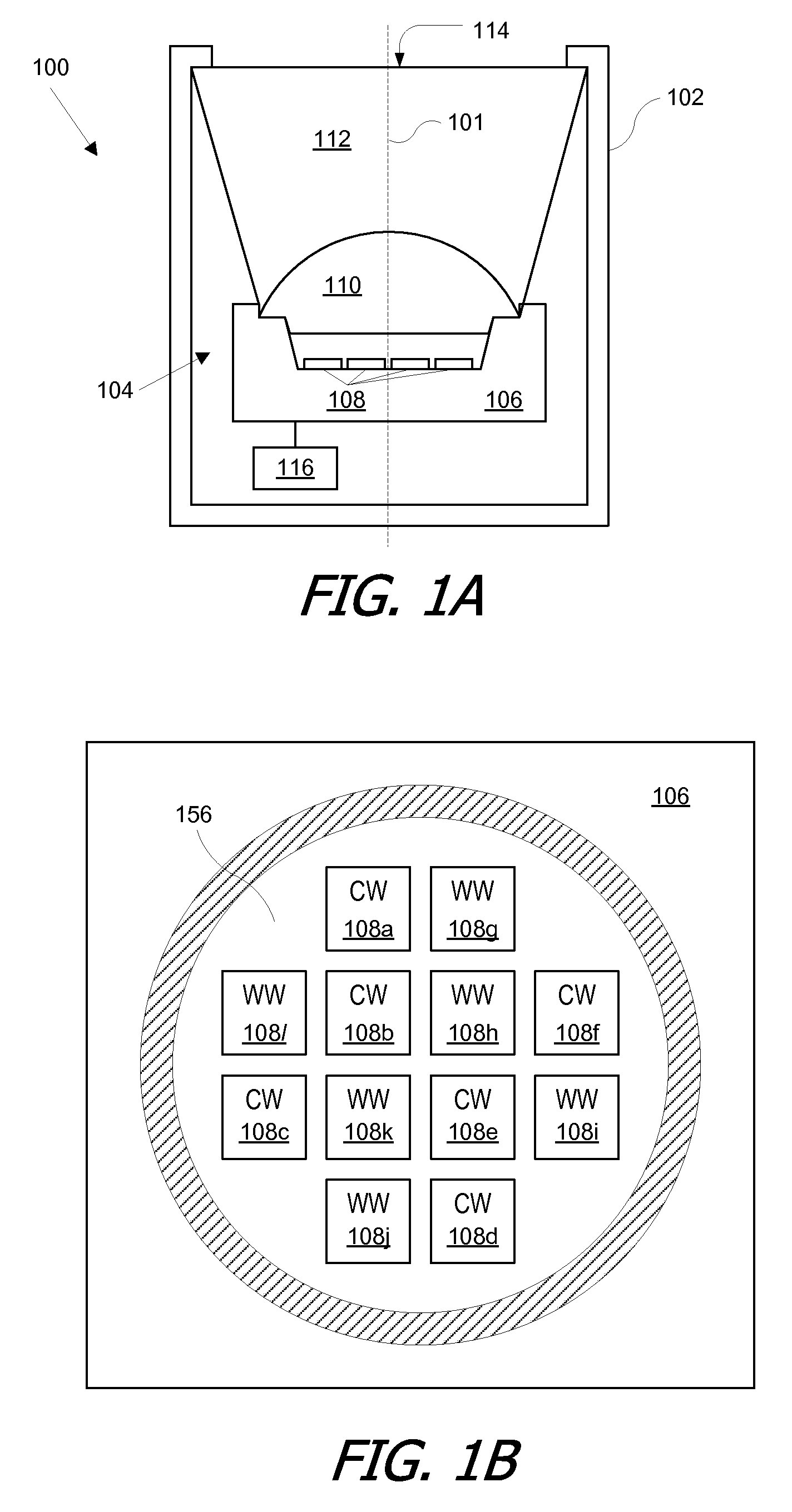

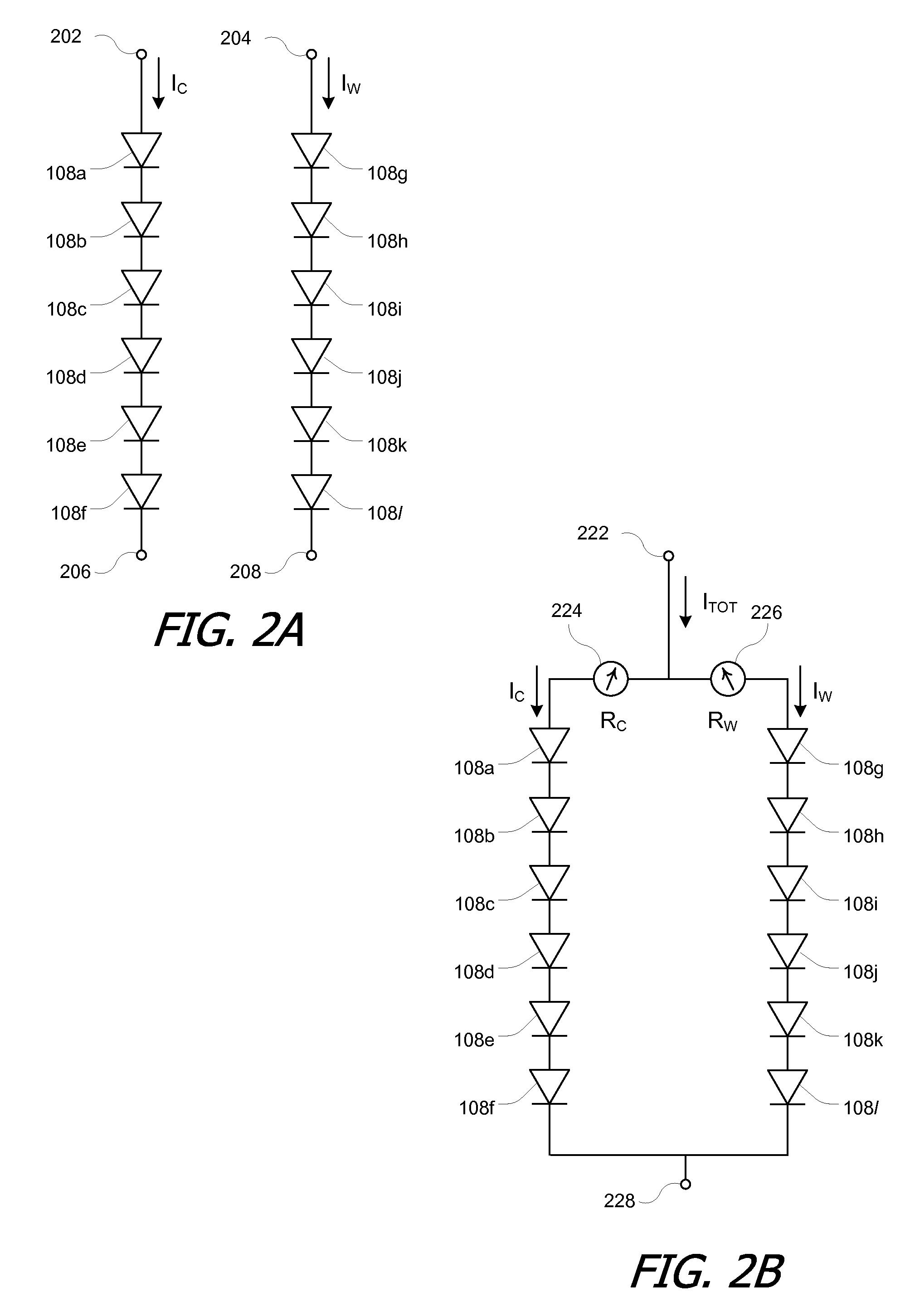

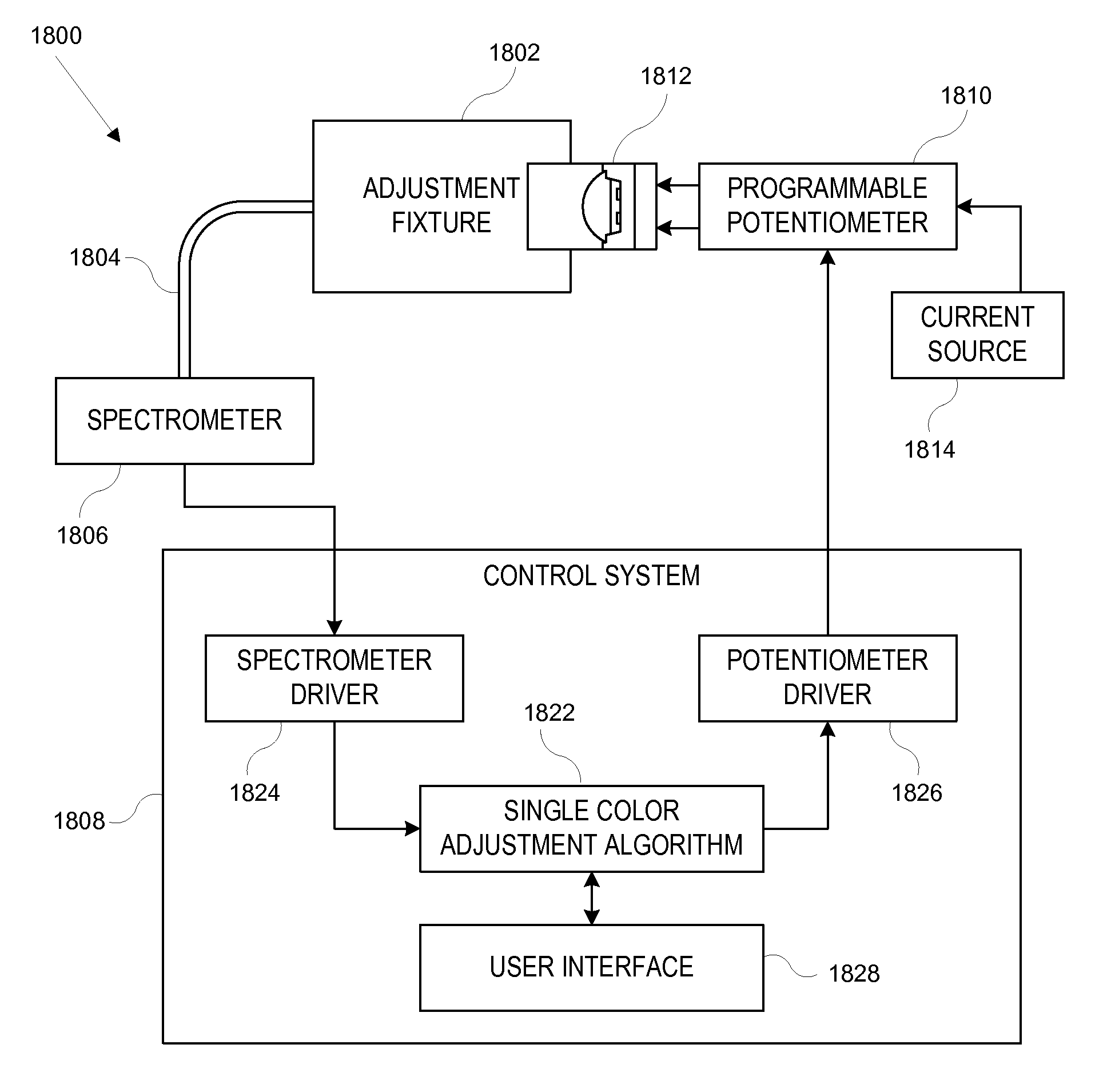

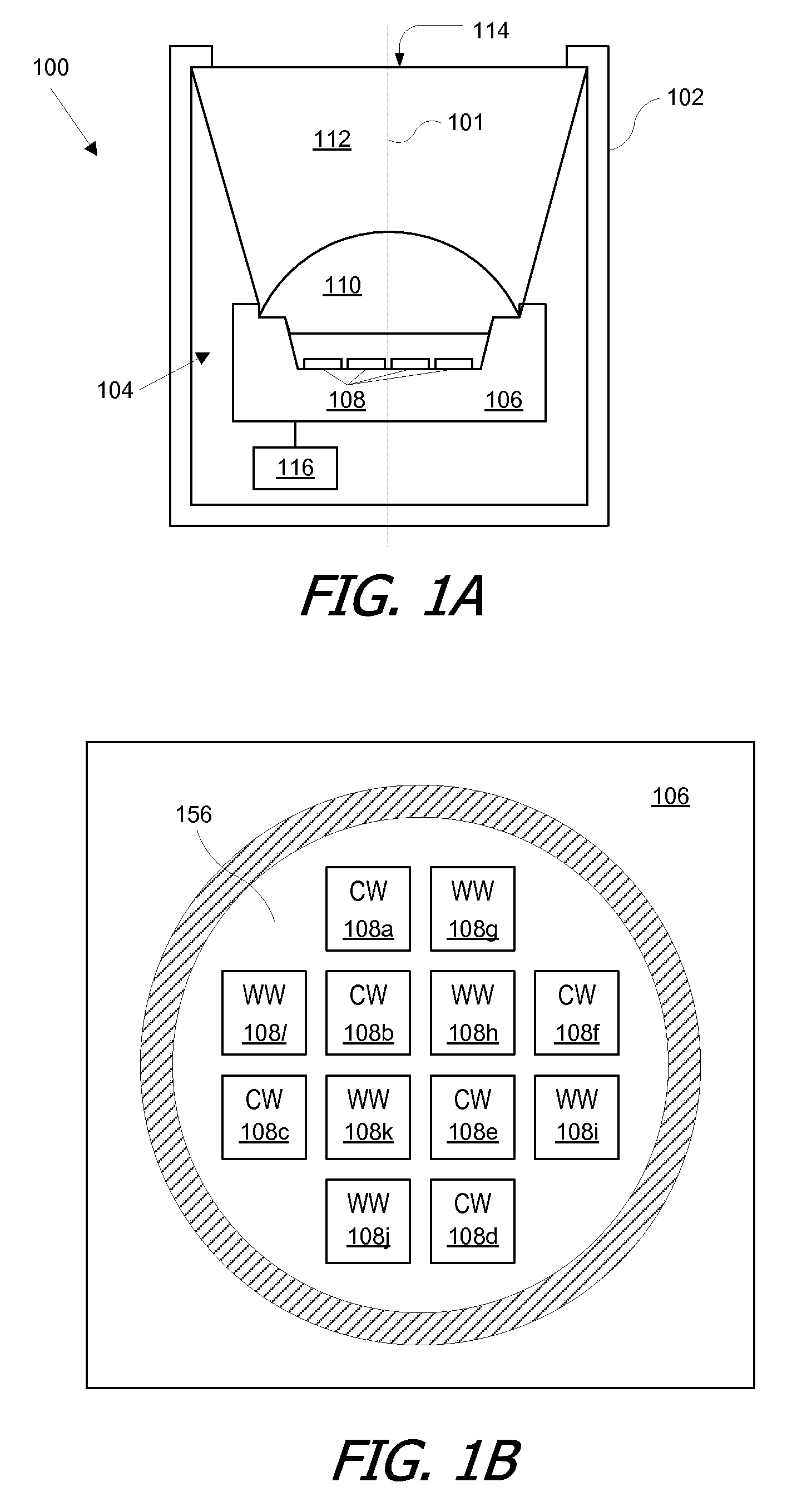

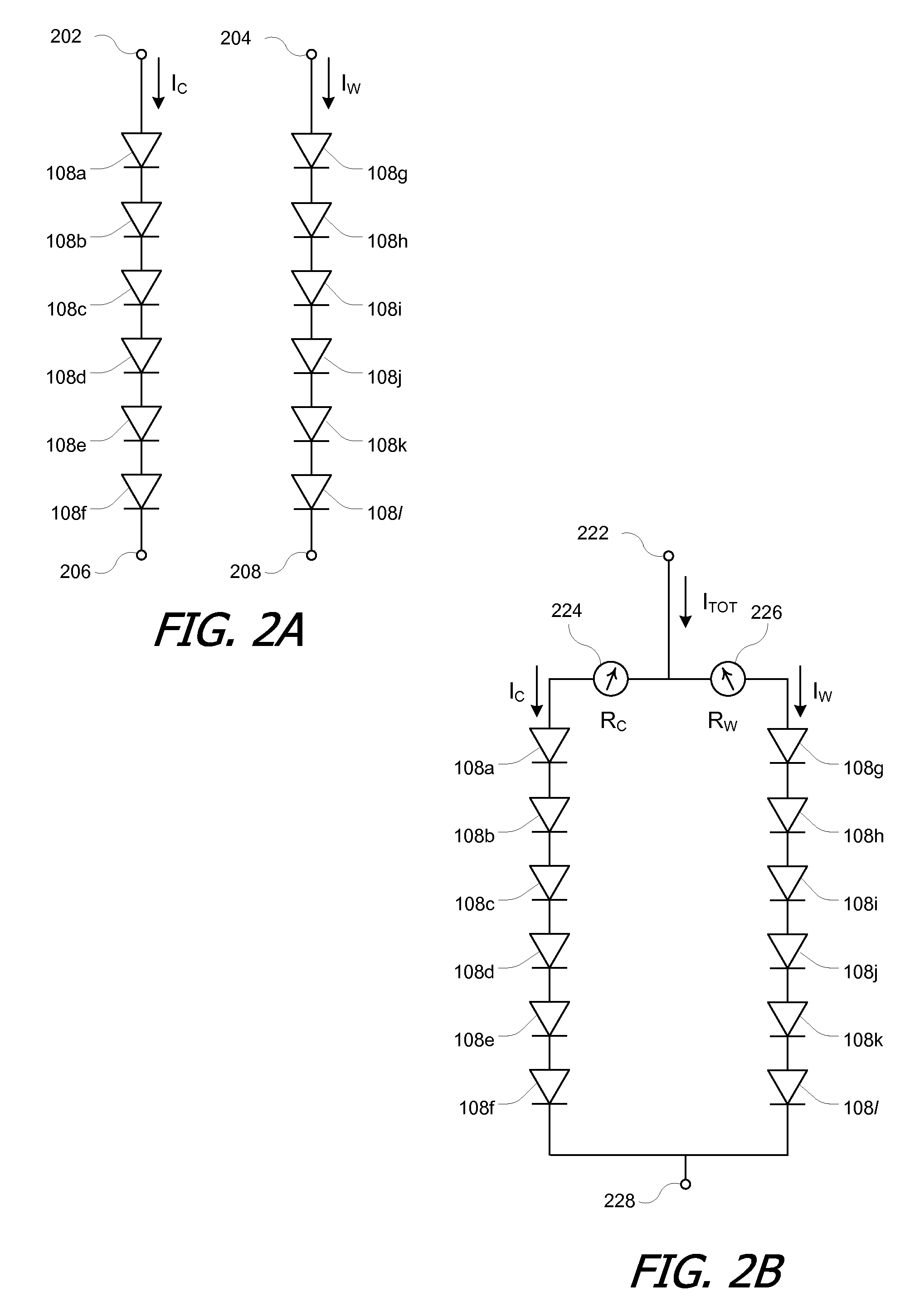

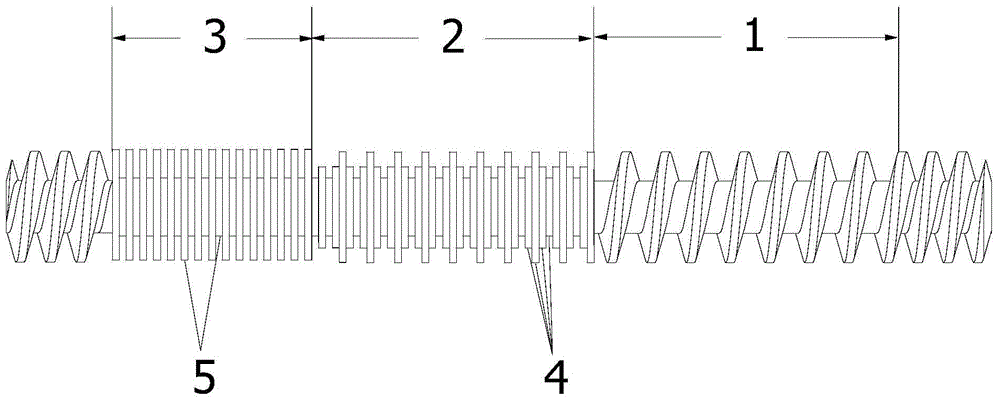

Tuning of emitter with multiple LEDs to a single color bin

ActiveUS8598793B2Uniform colorEase of mass productionElectrical apparatusElectroluminescent light sourcesActive feedbackTotal internal reflection

The color of an LED-based lamp can be tuned to a desired color or color temperature. The lamp can include two or more independently addressable groups of LEDs associated with different colors or color temperatures and a total-internal-reflection (TIR) color-mixing lens to produce light of a uniform color by mixing the light from the different groups of LEDs. The color of the output light is tuned by controllably dividing an input current among the groups of LEDs. Tuning can be performed once, e.g., during manufacture, and the lamp does not require active feedback components for maintaining color temperature.

Owner:LEDENGIN

Solar battery module

InactiveUS20020050286A1Improve reflectivityIncrease absorbancePV power plantsSynthetic resin layered productsStrange feelingElectricity

An object of the invention is to provide a solar battery module having a high efficiency power generating ability, a harmony of design without an odd sensation, and a freedom of design. The object is achieved by a solar battery module comprising, on a light-receiving surface thereof, a photoelectric conversion section for converting incident light into electricity, the photoelectric conversion section comprising silicon, and an insulating color film disposed in regions other than the photoelectric conversion section for reducing a color difference from the photoelectric conversion section.

Owner:TDK CORPARATION

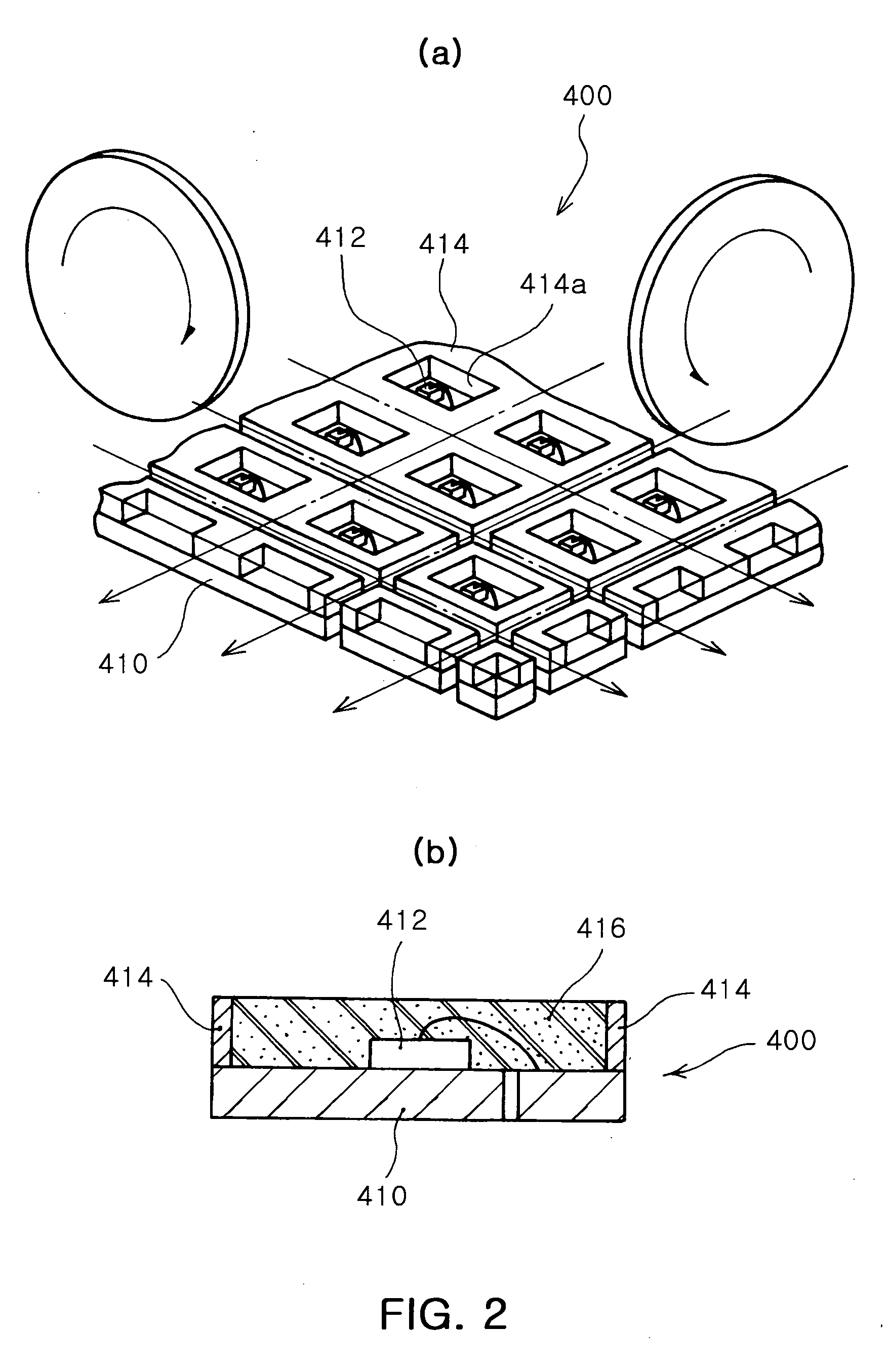

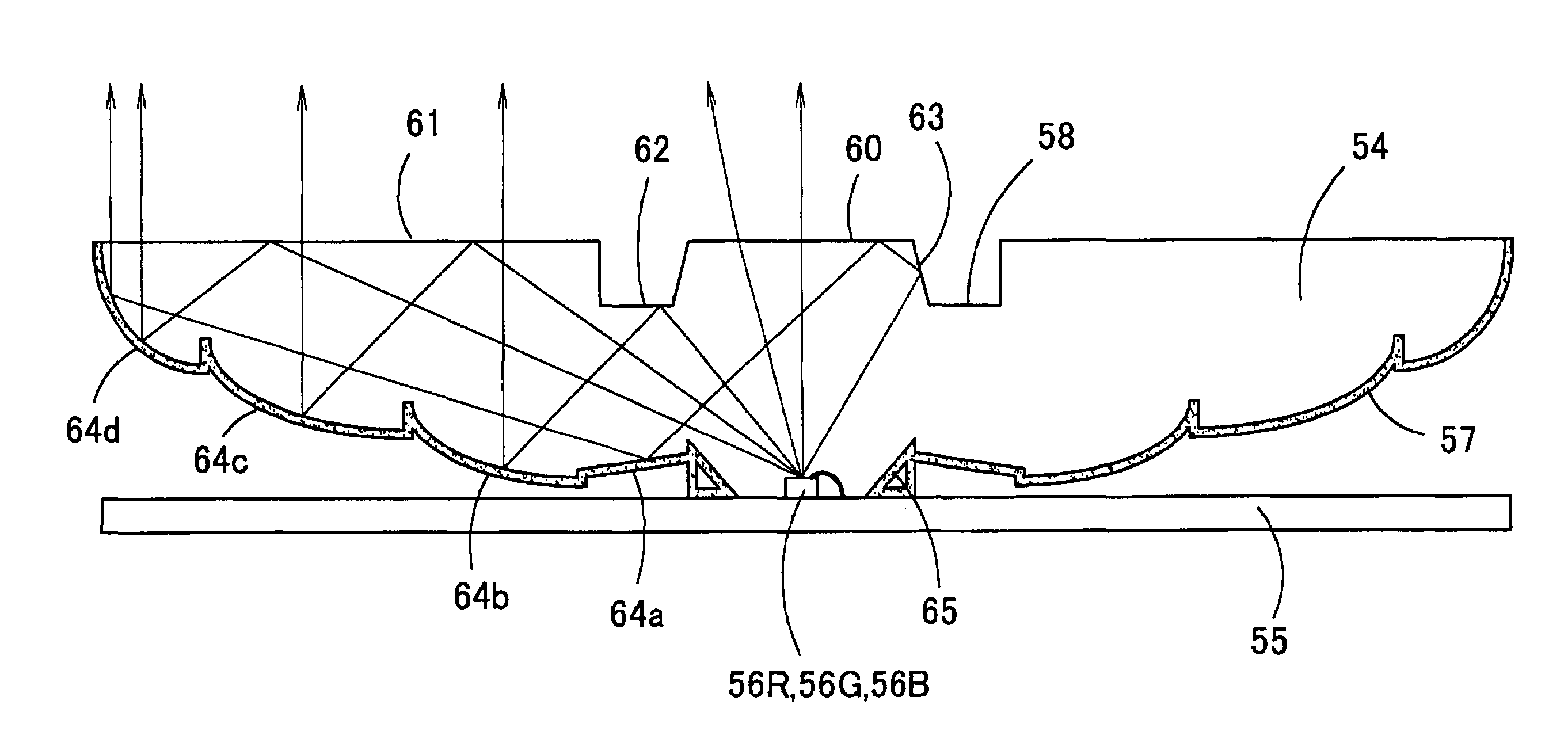

Light emitting source and a light emitting source array

InactiveUS7399108B2High color reproductionUniform colorSolid-state devicesLight guides for lighting systemsLight irradiationLight emitting device

On the rear surface of a transparent molded unit is provided a reflecting member. In a central part of the molded unit are encapsulated light emitting devices. In the vicinity of the central part of the reflecting member is formed a reflecting area that is angularly inclined to the rear surface as it moves to the outer circumferential direction. A toric channel is provided on a light irradiation surface of the molded unit, and a slope total reflection area is provided in its inner circumferential side. Light emanating from the light emitting devices is reflected at the slope total reflection area, and further reflected at the direct output area. Then, after being further reflected at the reflecting area of the reflecting member, the light is guided to the outer circumferential end of the reflecting member, and is outputted forward from the total reflection area by being reflected at the outer circumferential end of the reflecting member.

Owner:ORMON CORP

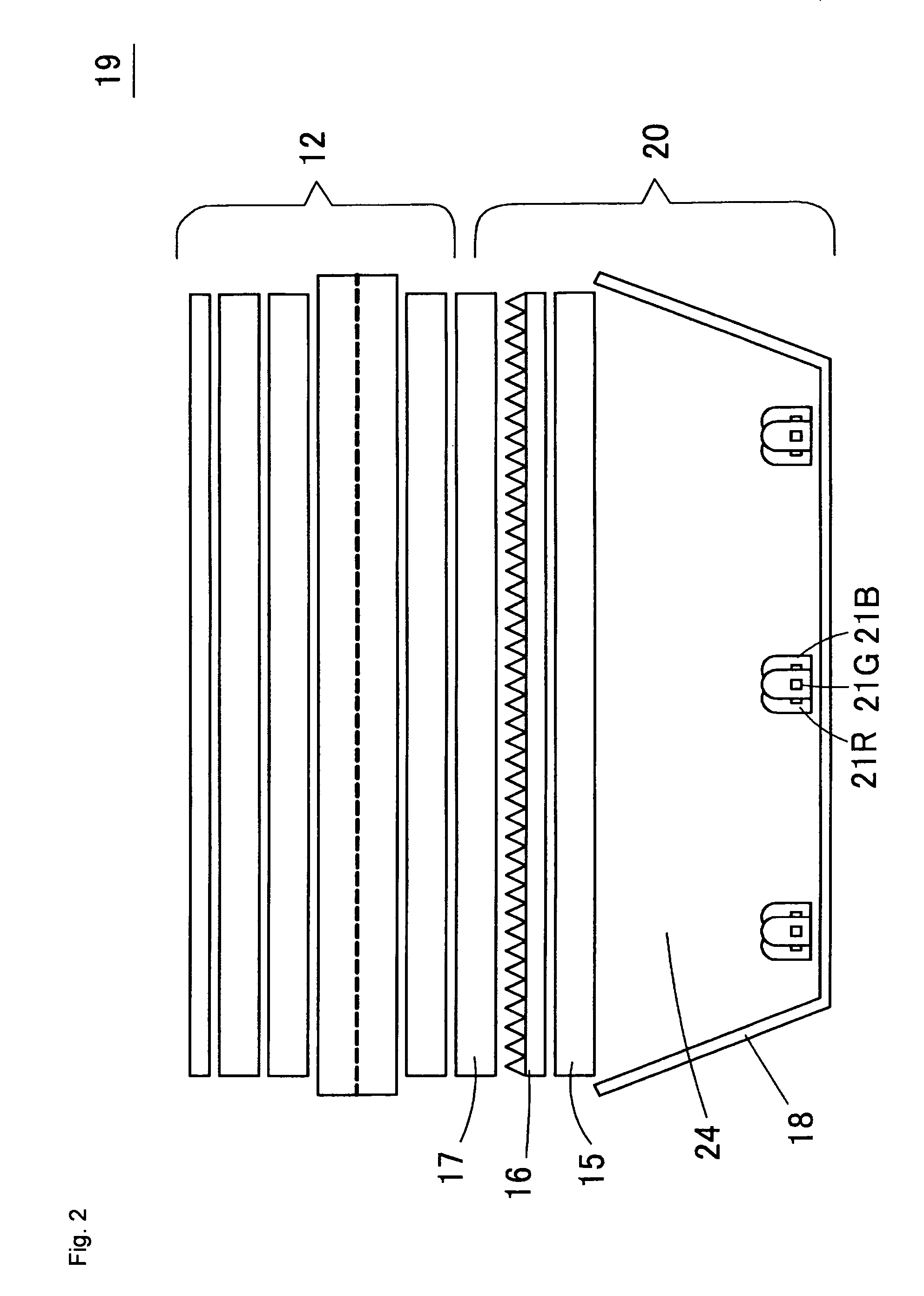

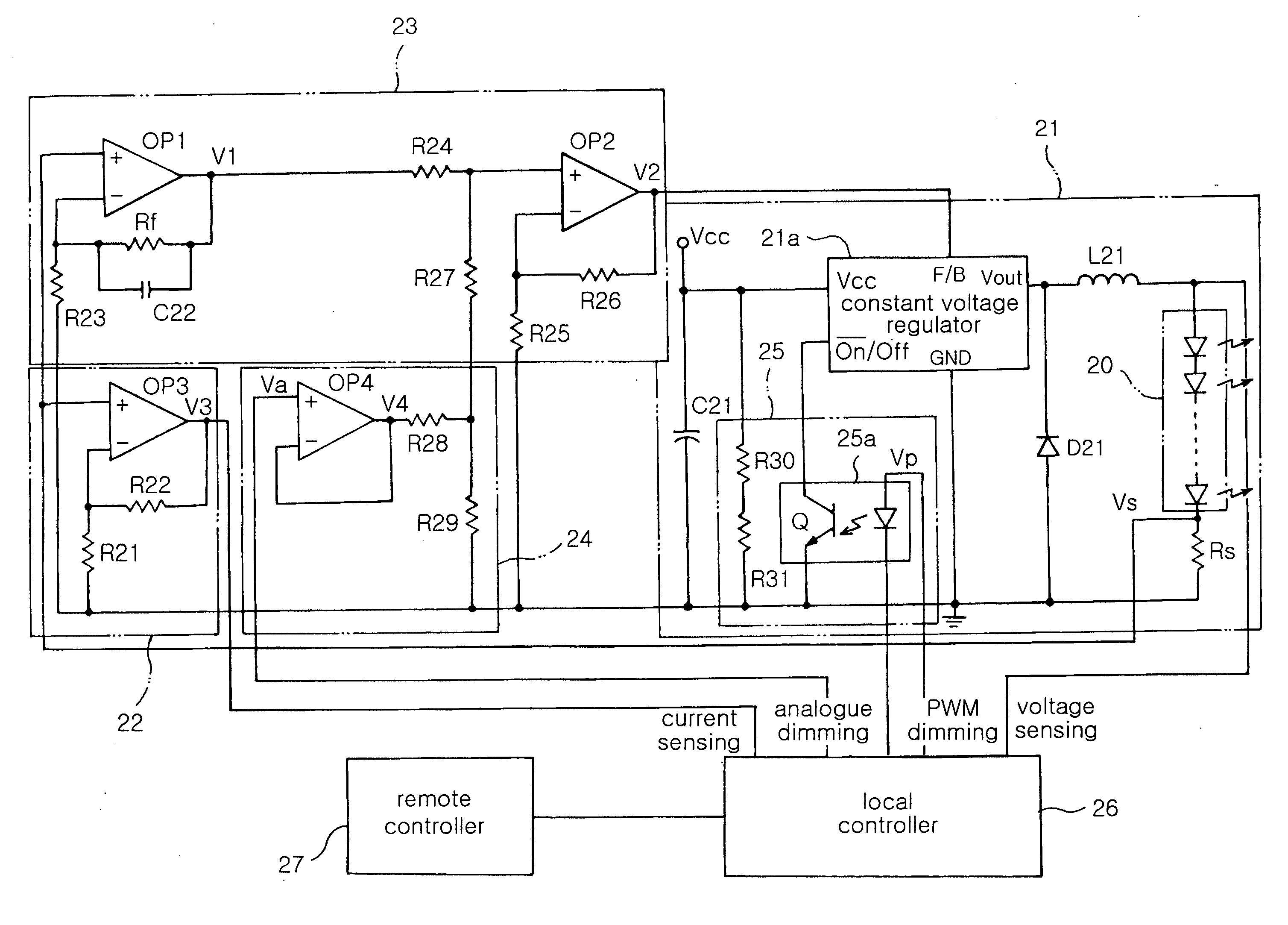

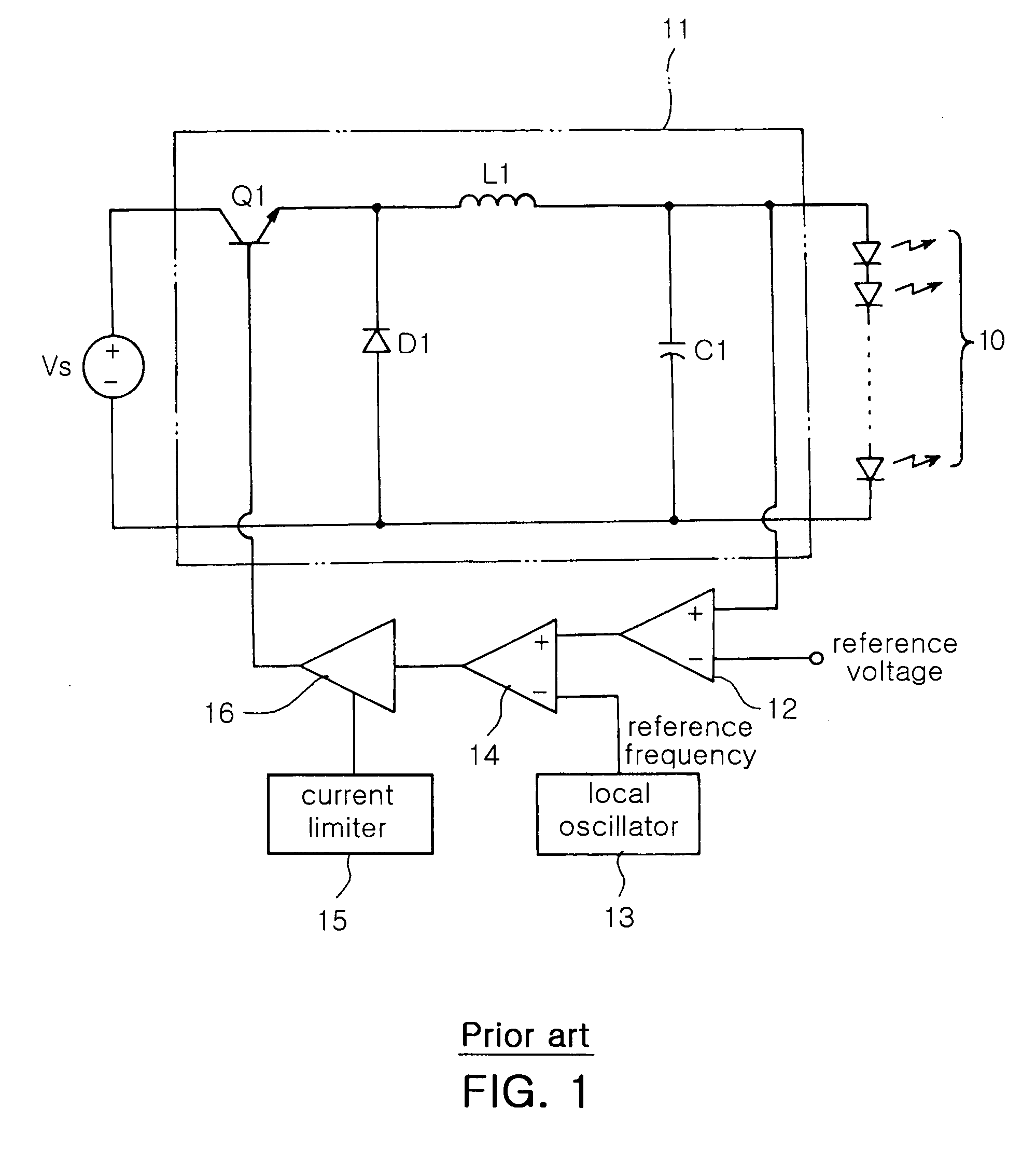

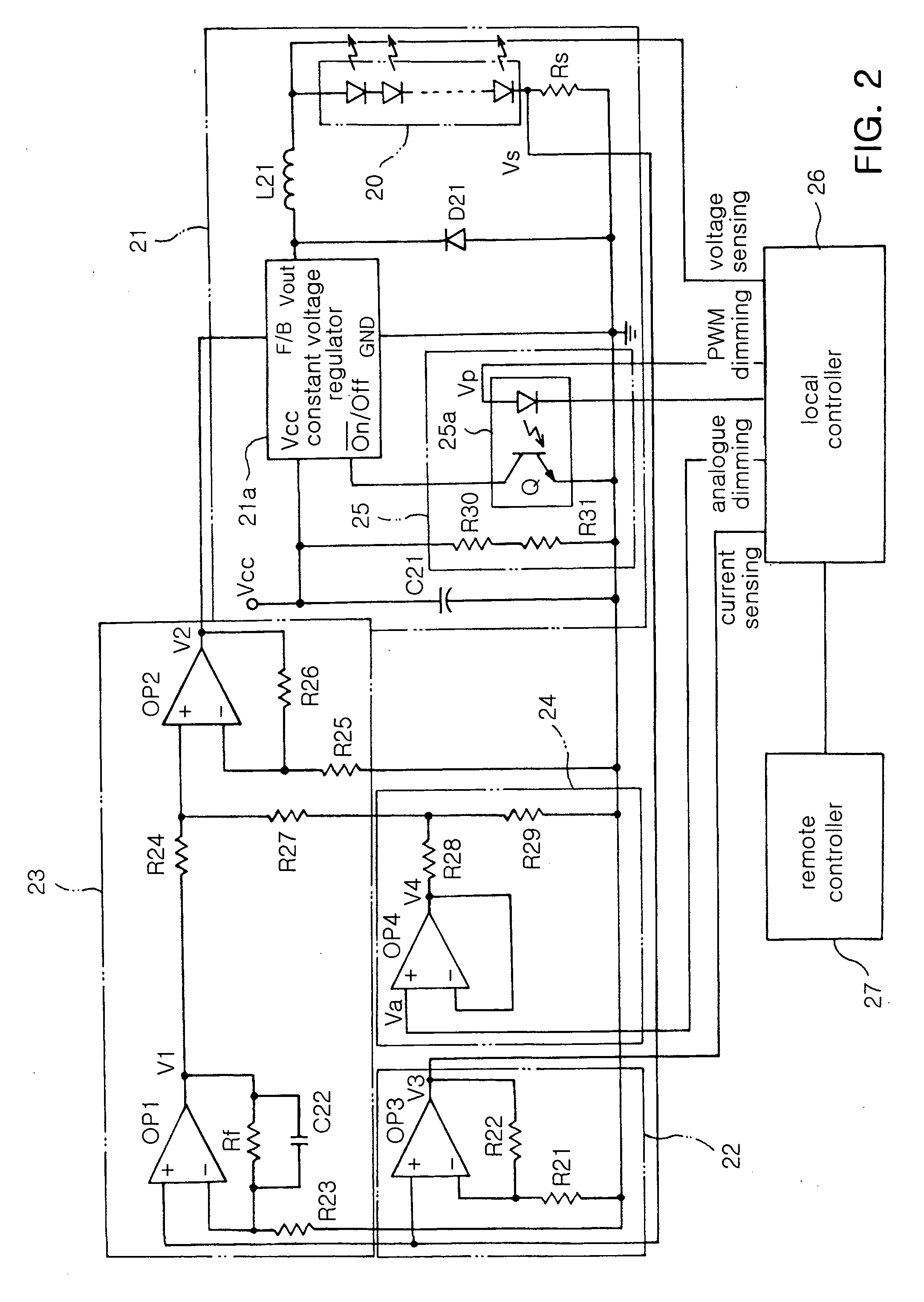

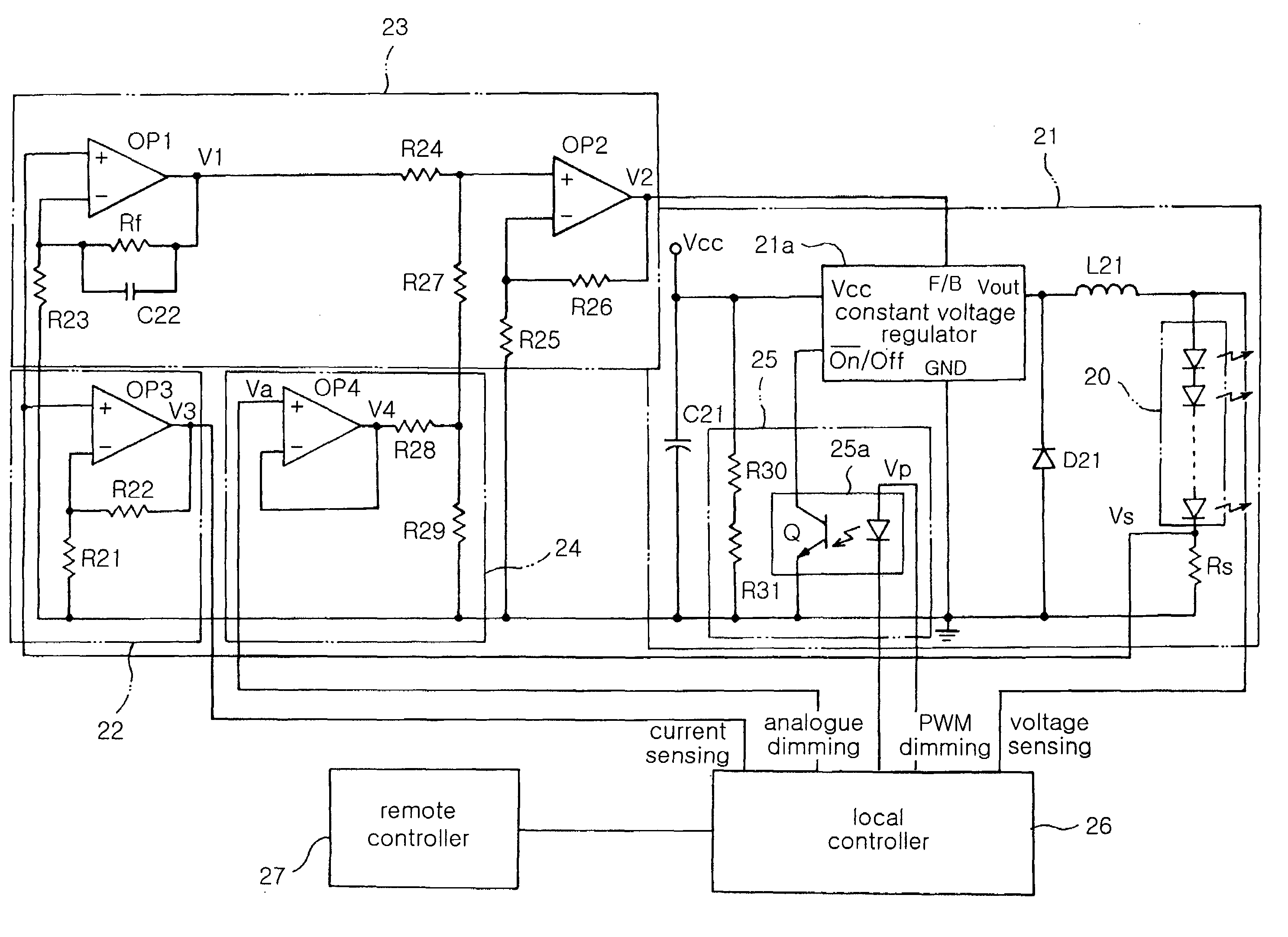

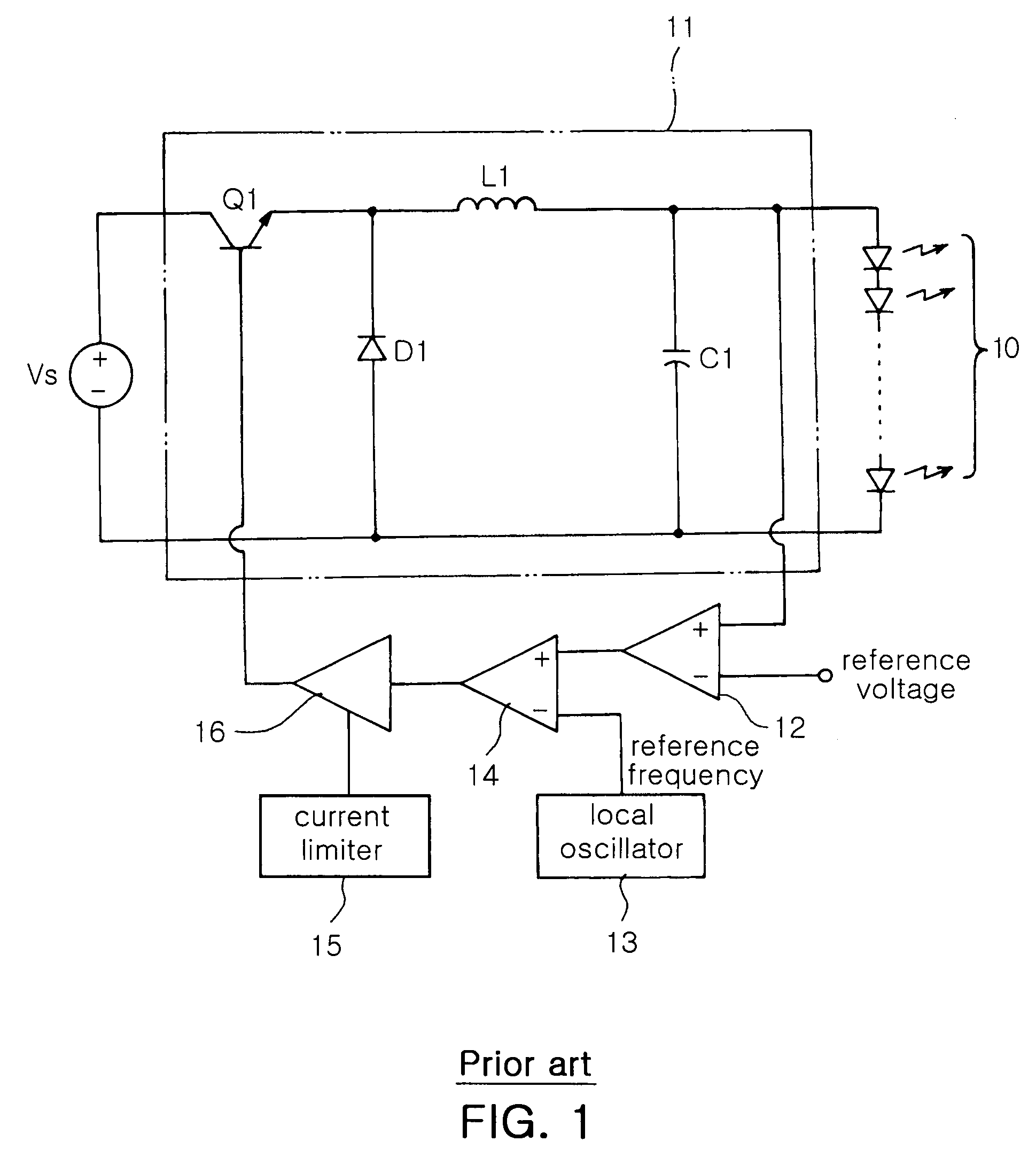

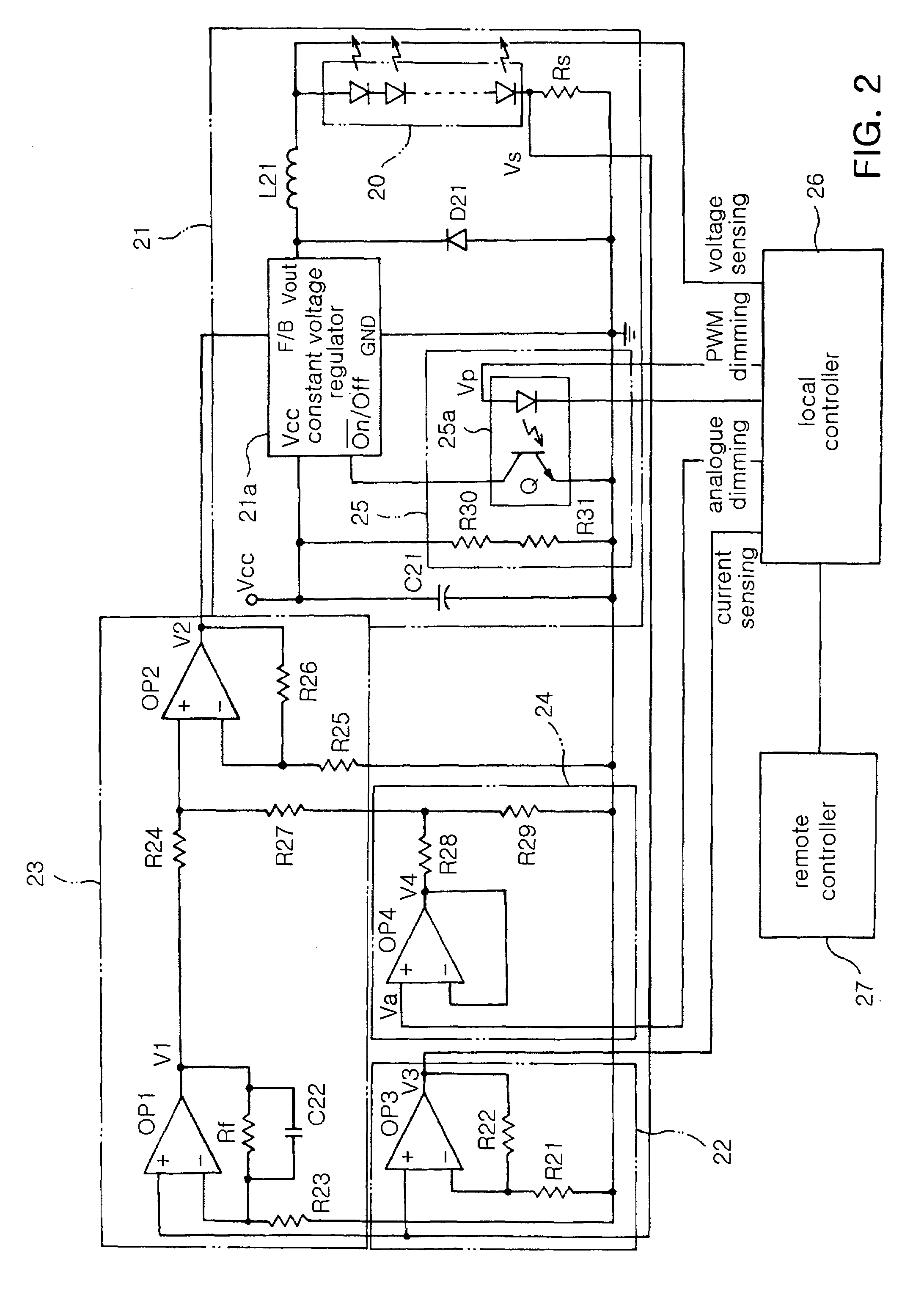

LED array driving apparatus and backlight driving apparatus using the same

InactiveUS20060175986A1Uniform color and luminanceUniform colorStatic indicating devicesElectroluminescent light sourcesVoltage regulationFeedback controller

The present invention relates to an LED array driving apparatus and a backlight driving apparatus using the same which enables regulation of analogue and PWM dimming for each channel and LED of a backlight, thereby allowing uniform luminance and color in all regions of backlight. The invention converts power with a constant voltage regulator to provide PWM pulse type power to the LED array having a plurality of LEDs connected in series. It regulates the on / off interval of the constant voltage regulator via a PWM dimmer to adjust the duty ratio of the PWM pulse. Further, it regulates the level of the driving current detected at the LED array via the feedback controller and analogue dimmer to apply to the constant voltage regulator by feedback process, thus regulating the amplitude of the PWM pulse.

Owner:SAMSUNG ELECTRONICS CO LTD

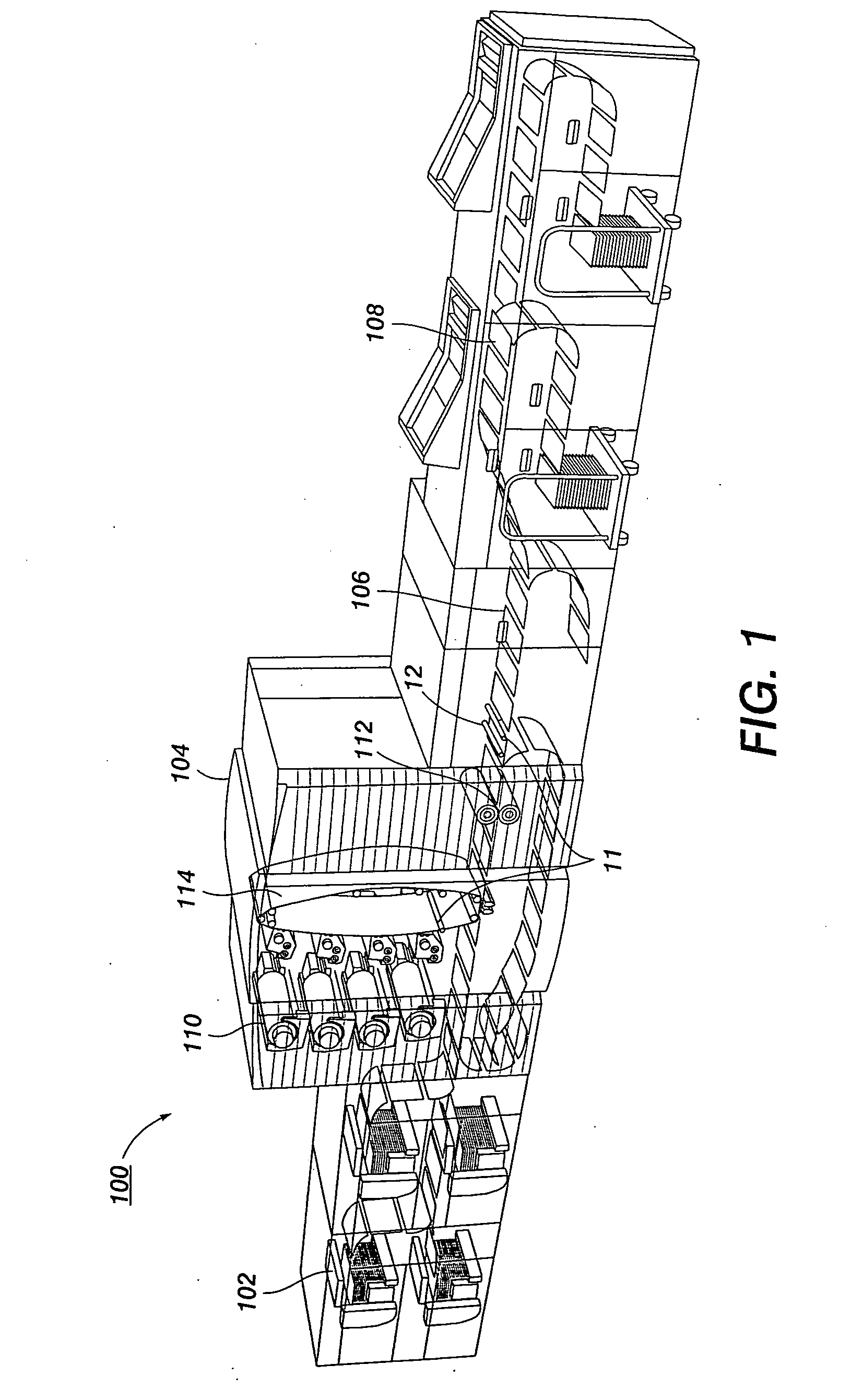

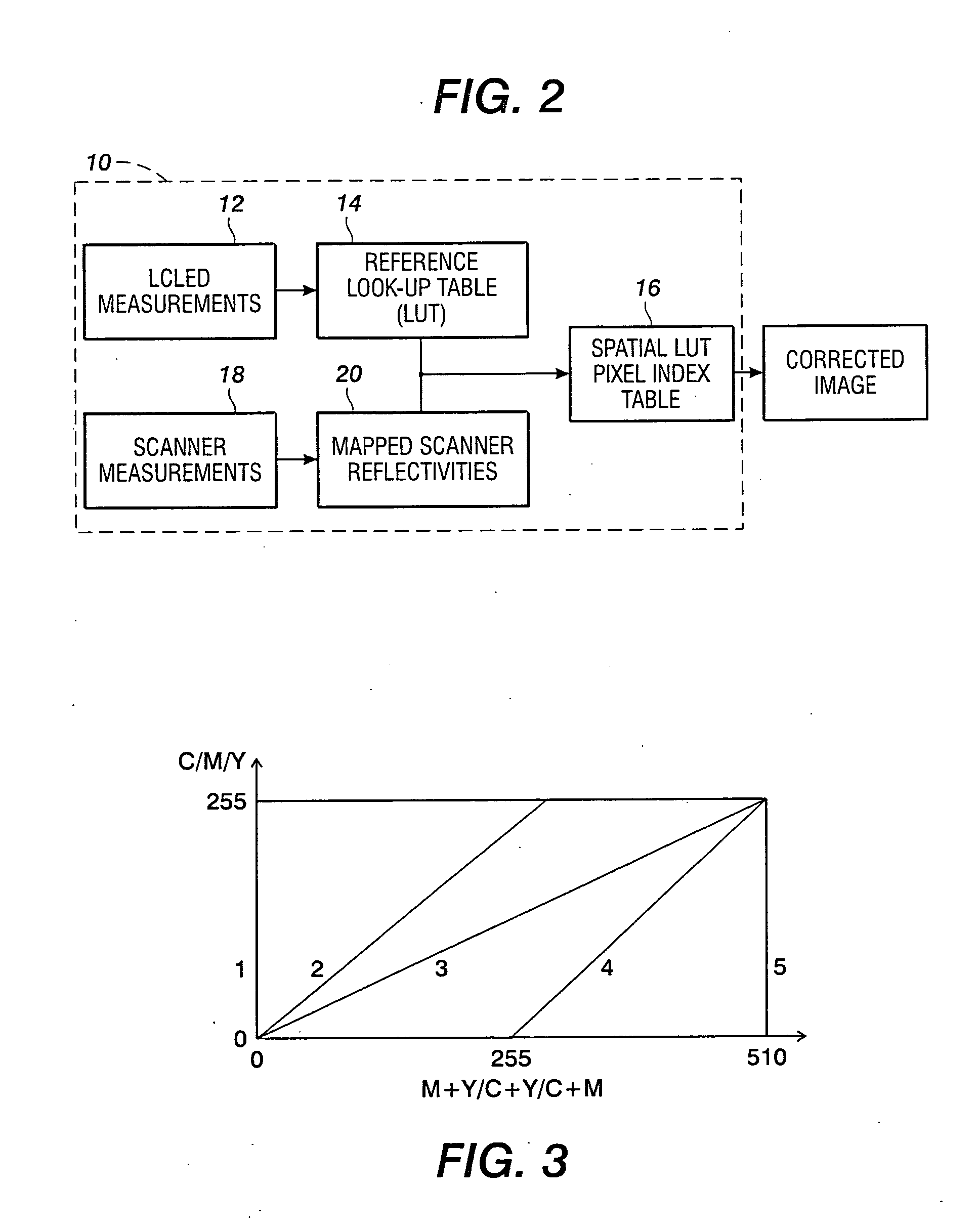

System and method for spatial gray balance calibration using hybrid sensing systems

ActiveUS20060285134A1Minimize spatial uniformity errorUniform colorDigitally marking record carriersDigital computer detailsPattern recognitionTone reproduction

The method and system for printer color calibration use a combination of a full-width array (FWA) or similar page-scanning mechanism in conjunction with an spectrophotometer color measurement system in the output path of a color printer for measuring colors (e.g., on printed test sheets, banner / separation pages, etc.) with or without requiring any manual operations or operator involvement. The automatic color balance control system produces spatial tonal reproduction values for all four of the primary colors by printing patches, measuring colors using the sensor combination and automatically readjusting the spatial tone reproduction curves until a satisfactory level of printed color accuracy and uniformity are obtained. While producing color balanced TRCs, the system will automatically lock the printer output to some predetermined color patch targets. In one particular preferred embodiment, this output is locked to neutral gray when target colors are set to neutral gray inside the digital front end (DFE). After converging to the targets, the control system returns full TRCs for use inside the normal print path.

Owner:XEROX CORP

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

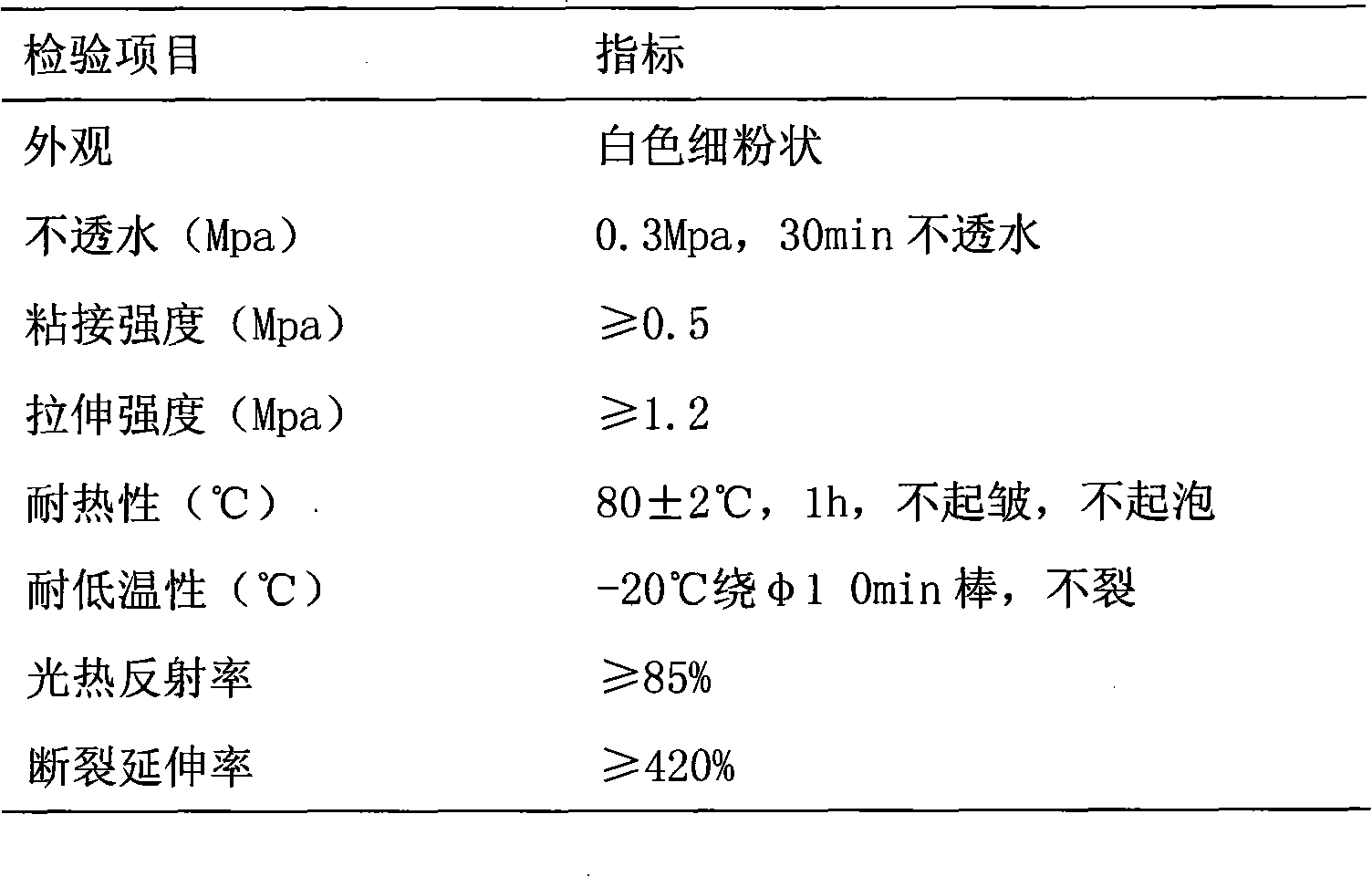

Dry-type heat-insulating waterproof coating

InactiveCN101648794AGood heat insulation and waterproof effectImprove waterproof performancePliabilityTalc

The invention relates to a dry-type heat-insulating waterproof coating which comprises the following raw materials in percentage by weight: 0-5.5 dispersible polymer powder, 10-20 hollow filling beads, 5-20 sepiolite powder, 5-10 mica powder, 5-30 heavy calcium carbonate powder, 5-15 light calcium carbonate powder, 0.5-1.5 rutile titanium dioxide, 10-20 talc powder and 10-40 white cement. A coat formed by the coating of the invention has favorable heat-insulating waterproof effect (lowers indoor temperature by 4-20 DEG C) and excellent flexibility, impermeability, weathering resistance and bonding strength to a substrate as well as high strength, good brightness, uniform luster, smooth and tender touch feeling, waterproof washing and rubbing, and the like. The dry-type coating has the advantages of simple production process, convenient transportation, long storage time, convenient construction, and the like, no toxicity or pollution, environment-friendly trend suitability, low cost, low VOC and high performance, thereby becoming a new-generation building coating product.

Owner:吕海涛

LED array driving apparatus and backlight driving apparatus using the same

InactiveUS7276863B2Uniform colorUniform luminanceStatic indicating devicesElectroluminescent light sourcesDriving currentLed array

The present invention relates to an LED array driving apparatus and a backlight driving apparatus using the same which enables regulation of analogue and PWM dimming for each channel and LED of a backlight, thereby allowing uniform luminance and color in all regions of backlight. The invention converts power with a constant voltage regulator to provide PWM pulse type power to the LED array having a plurality of LEDs connected in series. It regulates the on / off interval of the constant voltage regulator via a PWM dimmer to adjust the duty ratio of the PWM pulse. Further, it regulates the level of the driving current detected at the LED array via the feedback controller and analogue dimmer to apply to the constant voltage regulator by feedback process, thus regulating the amplitude of the PWM pulse.

Owner:SAMSUNG ELECTRONICS CO LTD

Tuning of emitter with multiple leds to a single color bin

ActiveUS20120286669A1Uniform colorEase of mass productionElectrical apparatusElectroluminescent light sourcesActive feedbackTotal internal reflection

The color of an LED-based lamp can be tuned to a desired color or color temperature. The lamp can include two or more independently addressable groups of LEDs associated with different colors or color temperatures and a total-internal-reflection (TIR) color-mixing lens to produce light of a uniform color by mixing the light from the different groups of LEDs. The color of the output light is tuned by controllably dividing an input current among the groups of LEDs. Tuning can be performed once, e.g., during manufacture, and the lamp does not require active feedback components for maintaining color temperature.

Owner:LEDENGIN

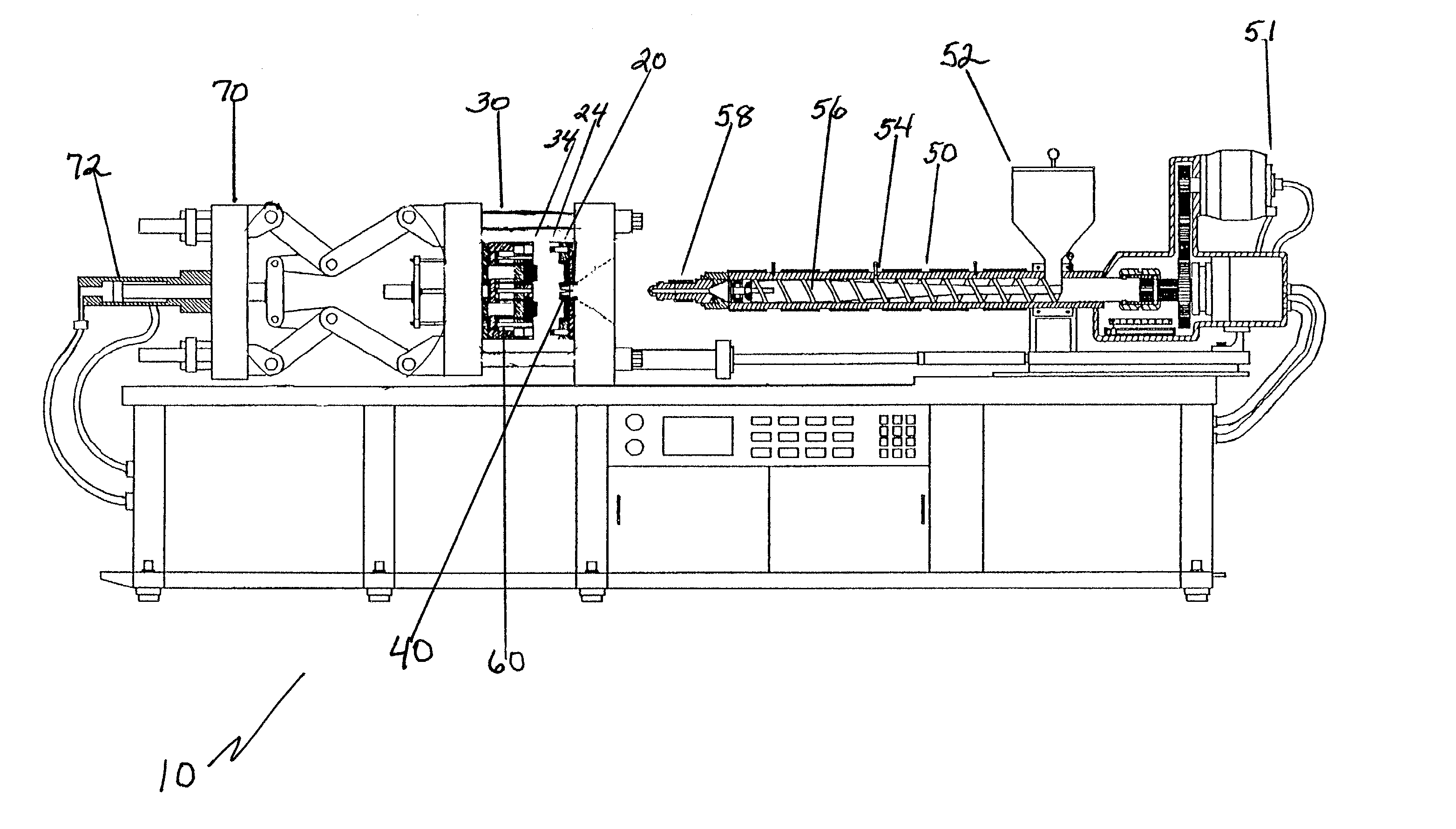

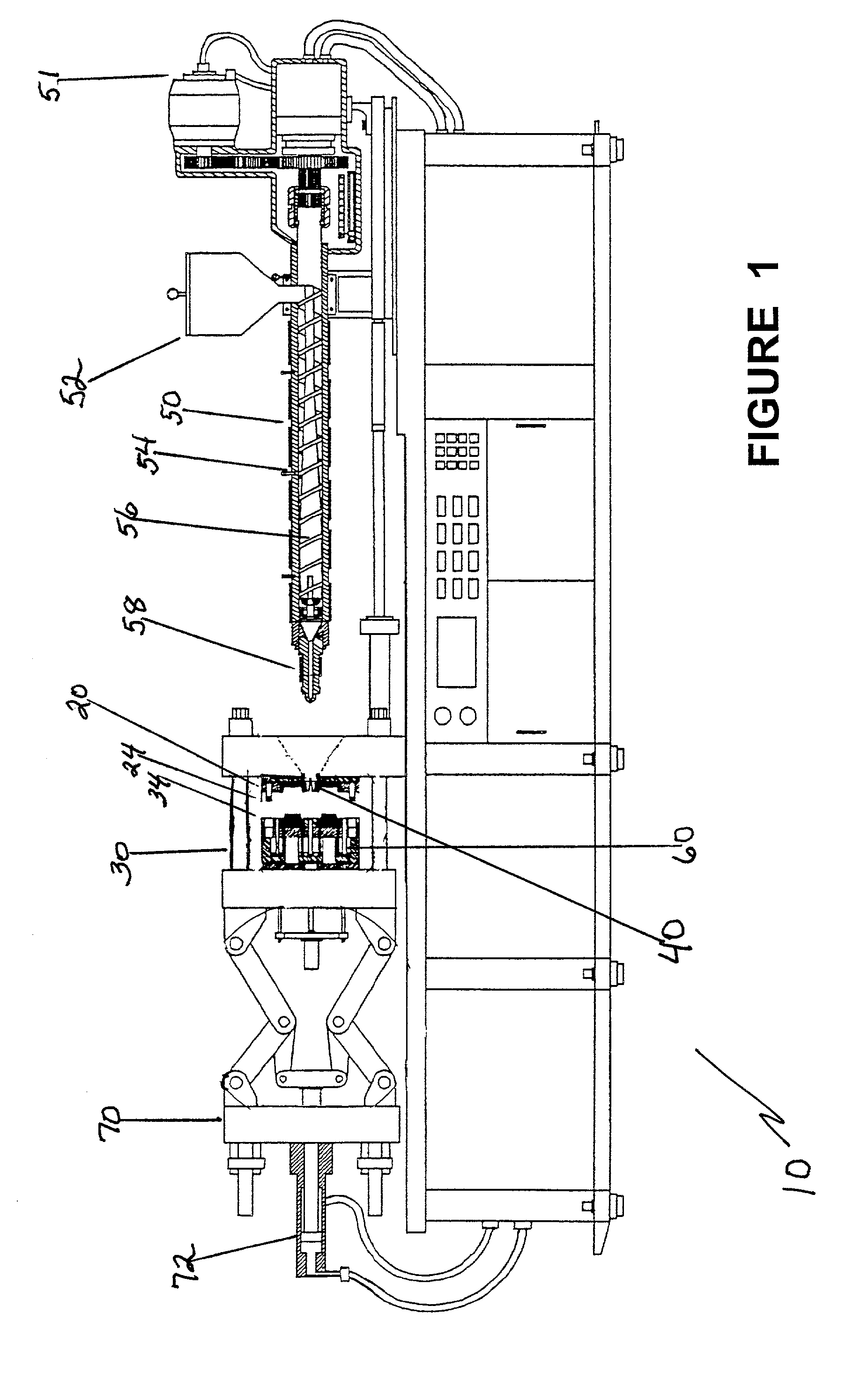

Optimization of in-mold coating injection molded thermoplastic substrates

InactiveUS20020039656A1Reduce pressureIncrease coverageLiquid surface applicatorsMouldsPolyolefinShell molding

Owner:OMNOVA SERVICES

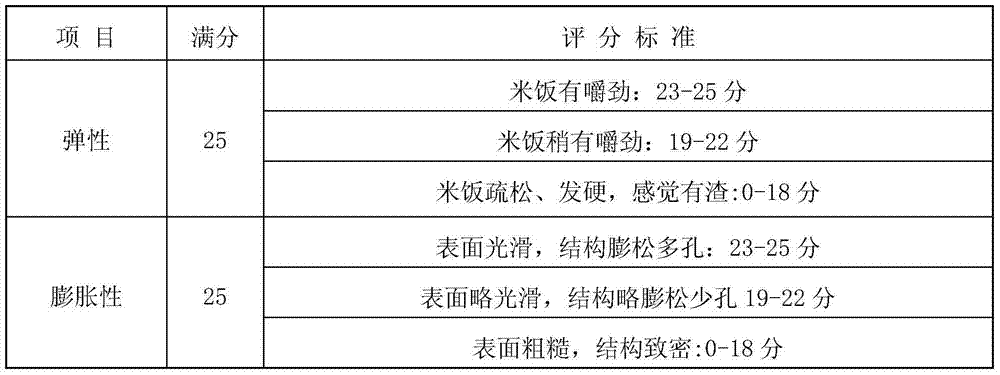

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Method for preparing environment-friendly micro-arc oxidation black ceramic film on aluminum alloy surface

ActiveCN102154673AUniform colorImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an environment-friendly micro-arc oxidation black ceramic film on an aluminum alloy surface, and the method comprises the following steps: firstly, pouring deionized water into an oxidation tank, weighing 1-10g / L of sodium hexametaphosphate, 1-3g / L of sodium silicate, 0.5-2g / L of potassium hydroxide, 0.2-2g / L of sodium fluoride and 0.5-20g / L of ferric ammonium oxalate in terms of the volume of the added deionized water, and uniformly stirring and mixing the sodium hexametaphosphate, the sodium silicate, the potassium hydroxide and the sodium fluoride to obtain a micro-arc oxidation base electrolyte; adding the weighed ferric ammonium oxalate into the base electrolyte, and stirring and mixing uniformly to obtain an aluminum alloy micro-arc oxidant solution; and then, sequentially carrying out surface deoiling and cleaning, water washing, aluminum alloy micro-arc oxidation, sealing and drying on the aluminum alloy to prepare the environment-friendly micro-arc oxidation black ceramic film on the aluminum alloy surface. By means of the preparation method disclosed by the invention, the problems of single color, limited application range, and environment pollution caused by a vanadate electrolyte, of the existing aluminum alloy ceramic film layer, are solved.

Owner:CSIC NO 12 RES INST

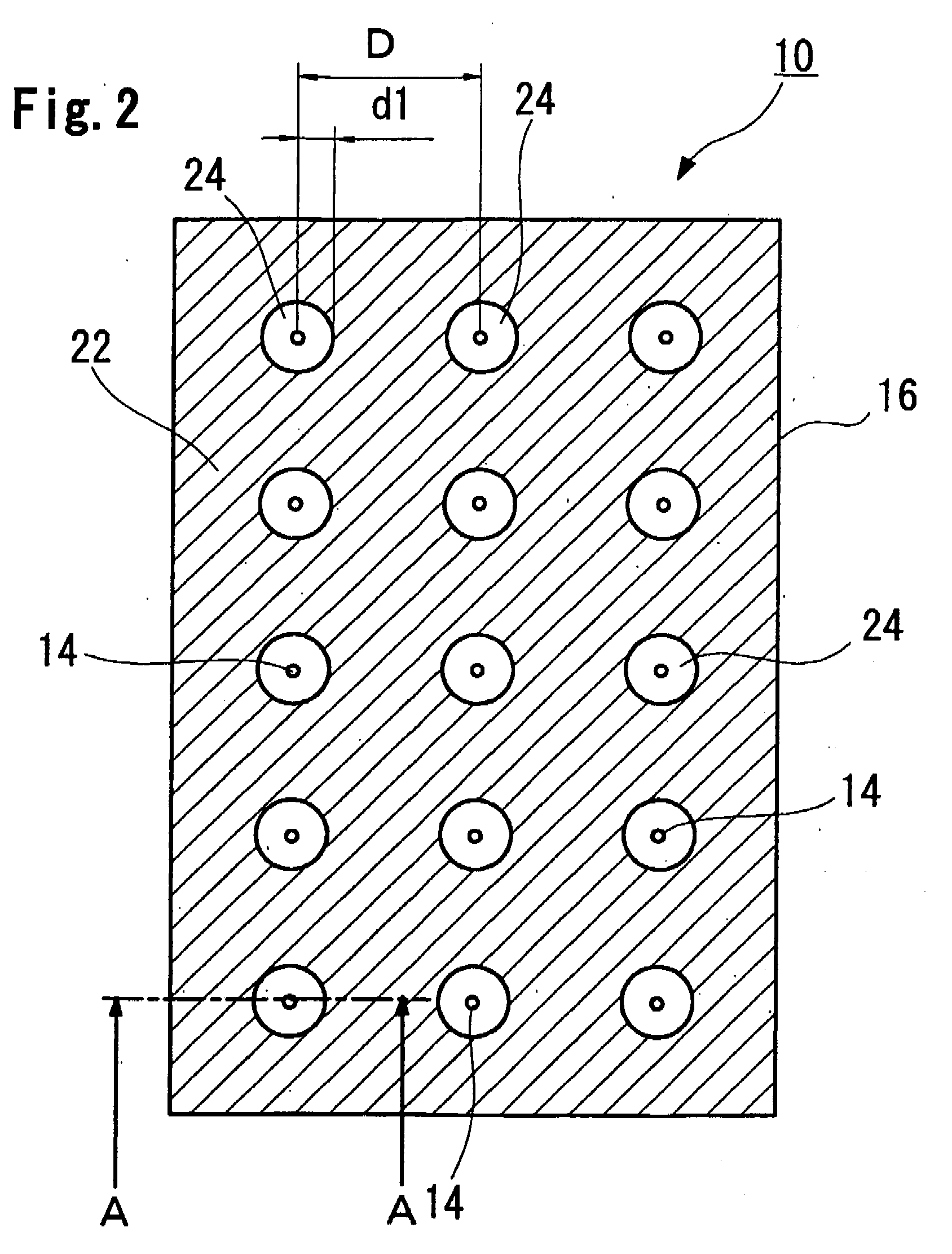

Light guide member, planar light source device provided with the light guide member, and display apparatus using the planar light source device

InactiveUS20090129058A1Decrease in luminanceReduce color unevennessIlluminated signsOptical light guidesLight guideLight reflection

A light guide member laminated on the upper face of a luminous device mounting substrate on which a luminous device is mounted and which is for diffusing and guiding upward light emitted from the luminous device. The light guide member includes a light reflecting portion formed on the bottom face of the light guide member in an area other than an area near the luminous device, and a section in which a light reflecting portion is not formed on the bottom face of the light guide member at a position near the luminous device. Also disclosed is a planar light source device provided with the light guide member, and a display apparatus using the planar light source device.

Owner:SHOWA DENKO KK

Thin spray powder coating and preparation method thereof

ActiveCN104861840AReduce dosageStrong charged particlesPolyurea/polyurethane coatingsPowdery paintsPhenolEnergy consumption

The invention discloses a thin spray powder coating and a preparation method thereof. The thin spray powder coating is mainly prepared from the following raw materials by weight percent: 50-75% of resin, 3-25% of curing agent, 1-12.5% of pigment, 0.3-20% of filler and 0.1-10% of addition agent; the curing agent comprises one or more of an epoxy curing agent, a polyisocyanates curing agent, a polyamine curing agent and a phenols curing agent; the addition agent comprises a flatting agent, a sensitizer and benzoin. The method for preparing the thin spray powder coating comprises the following steps: adding the flatting agent in the resin production process to obtain a modified resin raw material; mixing the modified resin raw material, the curing agent, the pigment, the filler and the other addition agent, and squeezing in a double-screw extruder to obtain the extrudate; and tabletting, cooling, milling and sieving the extrudate to obtain the powder coating. By adopting the thin spray powder coating and the preparation method thereof, the spraying thickness is small, the energy consumption is reduced and the cost is reduced.

Owner:BAZHOU JINCHANG ENVIRONMENTAL PROTECTION MATERIALS CO LTD

Treatment liquid and method or preparing Ti/Zr-containing yellow passive film on surface of aluminum alloy

InactiveCN101967633AHigh bonding strengthImprove the protective effectMetallic material coating processesOrganic acidRoom temperature

The invention discloses treatment liquid and a method for preparing a Ti / Zr-containing yellow passive film on the surface of an aluminum alloy. Each liter of treatment liquid comprises the following components by weight: 0.5 to 2.0g of fluorotitanic acid, 0.4 to 2.0g of fluorozirconic acid, 2.0 to 5.0g of manganate and 0.5 to 2.0g of organic acid; and the pH value of the treatment liquid is between 2.0 and 3.0. The treatment liquid of the invention does not contain chromium or other toxic substances, conversion treatment is realized without heating, the treatment time is between 5 and 30 minutes, and a yellow Ti / Zr-containing chemical conversion film can be prepared on the surface of the aluminum alloy. The chemical conversion film prepared by the method has high decay resistance and high bonding strength with a substrate, and is treated at room temperature by a simple process; and the coating does not contain hexavalent or trivalent chromium which is harmful to environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

Micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN101985768AImprove stain resistanceImprove compactnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the field of micro-arc oxidation, and relates to micro-arc oxidation electrolyte. The electrolyte comprises the aqueous solution of film former and toner, and has the pH value of 6.0 to 12, wherein the film former is phosphate and / or silicate; the toner is a titanium compound; and the film former content is 5 to 50 g / L, and the toner content is 5 to 30 g / L. When used for performing micro-arc oxidation on light metals, the micro-arc oxidation electrolyte provided by the invention can form blue ceramic films on the surfaces of the light metals so as to break the limitation of the conventional micro-arc oxidation technology to colors, expand grey-black and grey-white tones to colorful fields with uniform colors and achieve the decoration effect of a light-metallic product. Moreover, by the invention, the erosion resistance, the pollution resistance and the compactability of the micro-arc oxidized film are enhanced, and the surface of the micro-arc oxidized film has a ceramic texture. The invention further discloses a micro-arc oxidation method.

Owner:BYD CO LTD

Method for improving flavor and texture of plant enzyme food by utilizing fermentation of compound strains

ActiveCN104223036AStable textureShort manufacturing timeFood ingredient functionsFood preparationFiltrationSweetness

The invention discloses a method for improving the flavor and the texture of plant enzyme food by utilizing fermentation of compound strains. The method is characterized in that strains with good permeability resistance, aroma strains, plant-source preponderant strains and strains for optimizing the texture of a product are screened by sugaring digestion, fermentation of the compound strains, after-ripening, clarifying and membrane filtration treatment, reasonable and scientific combination is carried out on the strains, the preparation time of the plant enzyme food is effectively shortened by controlling the matching and the used amount of the strains, the prepared plant enzyme food is coordinated in flavor, stable in texture, safe and sanitary, and uniform in color, has strong composite fruit flavor and fermenting mellow flavor, is viscous in organization and mellow in taste, has no stimulation in eating, is coordinated in sweetness and sourness, smooth in swallowing, and sweet and lasting in residual taste. The method disclosed by the invention has the advantages that the process is simple, the fermented product can be stored at normal temperature, and the quality is still stable after 6 months, so that the method is suitable for large-scale production, and has a good market prospect.

Owner:深思来福(深圳)科技有限公司

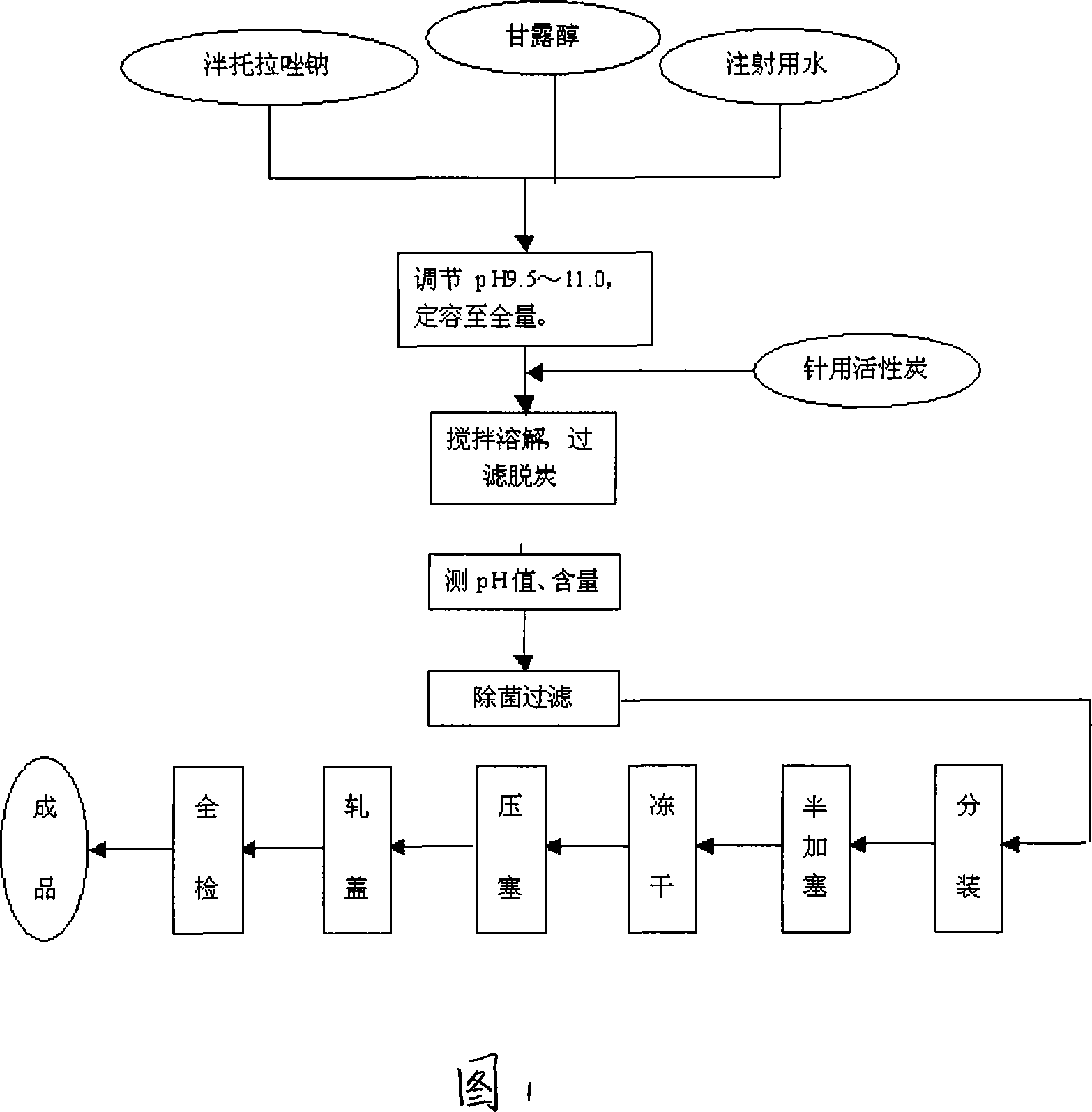

Pantoprazole sodium freeze-dried powder injection and preparing method thereof

ActiveCN101229138ASimple recipeLittle side effectsPowder deliveryOrganic active ingredientsSolubilityMANNITOL/SORBITOL

The invention aims at providing a pantoprazole sodium freeze-dried powder injection and comprises pantoprazole sodium and mannitol with the weight ratio of 1: 2 to 5. The invention is simple in formula and little in side effect; products prepared by the method are plump in appearance, good in complex solubility and excellent in quality with the adoption of an advanced freezing and drying process.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com