Micro-arc oxidation electrolyte and micro-arc oxidation method

A technology of micro-arc oxidation and electrolyte, which is applied in the direction of electrolytic coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of poor adhesion, uneven surface color of micro-arc oxidation film, etc., and achieve stain resistance and compactness Enhanced performance, increased added value, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

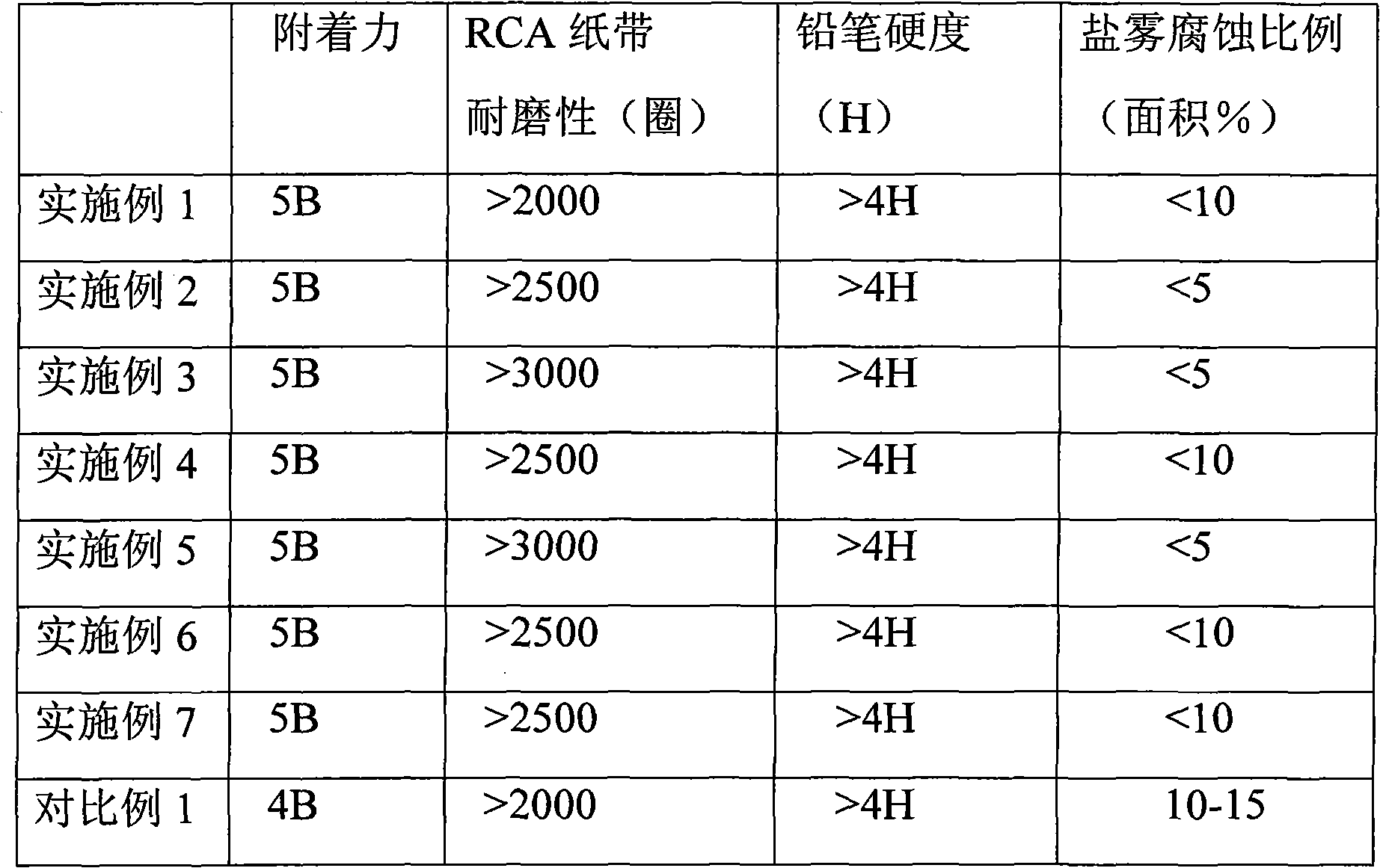

Examples

Embodiment 1

[0029] 1. Pretreatment

[0030] Soak the aluminum alloy workpiece (6061) in the degreasing solution for 3 minutes, then rinse it with water. The degreasing solution is an aqueous solution containing 0.01 g / L of sodium hydroxide, 15 g / L of sodium phosphate, 20 g / L of sodium carbonate and 3 g / L of sodium tripolyphosphate, and the temperature of the degreasing solution is 40°C.

[0031] 2. Micro-arc oxidation

[0032] The degreased aluminum alloy workpiece is immersed in the micro-arc oxidation electrolyte, the aluminum alloy workpiece is used as the anode, and the stainless steel plate is used as the cathode, and the micro-arc oxidation is carried out at 25°C with a pulsed micro-arc oxidation power supply. The power frequency is 500HZ, accounting for The duty ratio is 20%, the voltage is 300 volts, and the current density is 5A / dm 2 , micro-arc oxidation for 30 minutes, after completion, take it out and clean it with pure water. The micro-arc oxidation electrolyte contains 20...

Embodiment 2

[0036] Aluminum alloy workpiece (2024) is carried out micro-arc oxidation according to the method described in embodiment 1, difference is, micro-arc oxidation electrolyte is to contain sodium tripolyphosphate 20g / L, sodium silicate 8g / L, sodium hydroxide 2g / L, an aqueous solution of potassium titanium oxalate 15g / L, glycerol 5ml / L, and the pH of the electrolyte is 10. The power frequency of micro-arc oxidation is 800HZ, the duty cycle is 20%, and the current density is 3A / dm 2 , the voltage is 300V, and the time of micro-arc oxidation is 30 minutes.

[0037] Finally, an aluminum alloy product with a blue micro-arc oxidation film with a thickness of 12 microns was obtained. Visually, the color was uniform.

Embodiment 3

[0039] Carry out micro-arc oxidation to aluminum alloy workpiece (6061) according to the method described in embodiment 1, difference is, micro-arc oxidation electrolyte is to contain sodium hexametaphosphate 15g / L, sodium trimetaphosphate 15g / L, sodium hydroxide 4g / L, potassium titanium oxalate 25g / L, sodium tungstate 4g / L solution, the pH of the electrolyte is 12. The power frequency of micro-arc oxidation is 3000HZ, the duty cycle is 25%, and the current density is 10A / dm 2 , the voltage is 500V, and the time of micro-arc oxidation is 40 minutes.

[0040] Finally, an aluminum alloy product with a dark blue micro-arc oxidation film with a thickness of 15 microns was obtained. Visually, the color was uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com