Patents

Literature

138results about How to "Beautiful decoration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN101985768AImprove stain resistanceImprove compactnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the field of micro-arc oxidation, and relates to micro-arc oxidation electrolyte. The electrolyte comprises the aqueous solution of film former and toner, and has the pH value of 6.0 to 12, wherein the film former is phosphate and / or silicate; the toner is a titanium compound; and the film former content is 5 to 50 g / L, and the toner content is 5 to 30 g / L. When used for performing micro-arc oxidation on light metals, the micro-arc oxidation electrolyte provided by the invention can form blue ceramic films on the surfaces of the light metals so as to break the limitation of the conventional micro-arc oxidation technology to colors, expand grey-black and grey-white tones to colorful fields with uniform colors and achieve the decoration effect of a light-metallic product. Moreover, by the invention, the erosion resistance, the pollution resistance and the compactability of the micro-arc oxidized film are enhanced, and the surface of the micro-arc oxidized film has a ceramic texture. The invention further discloses a micro-arc oxidation method.

Owner:BYD CO LTD

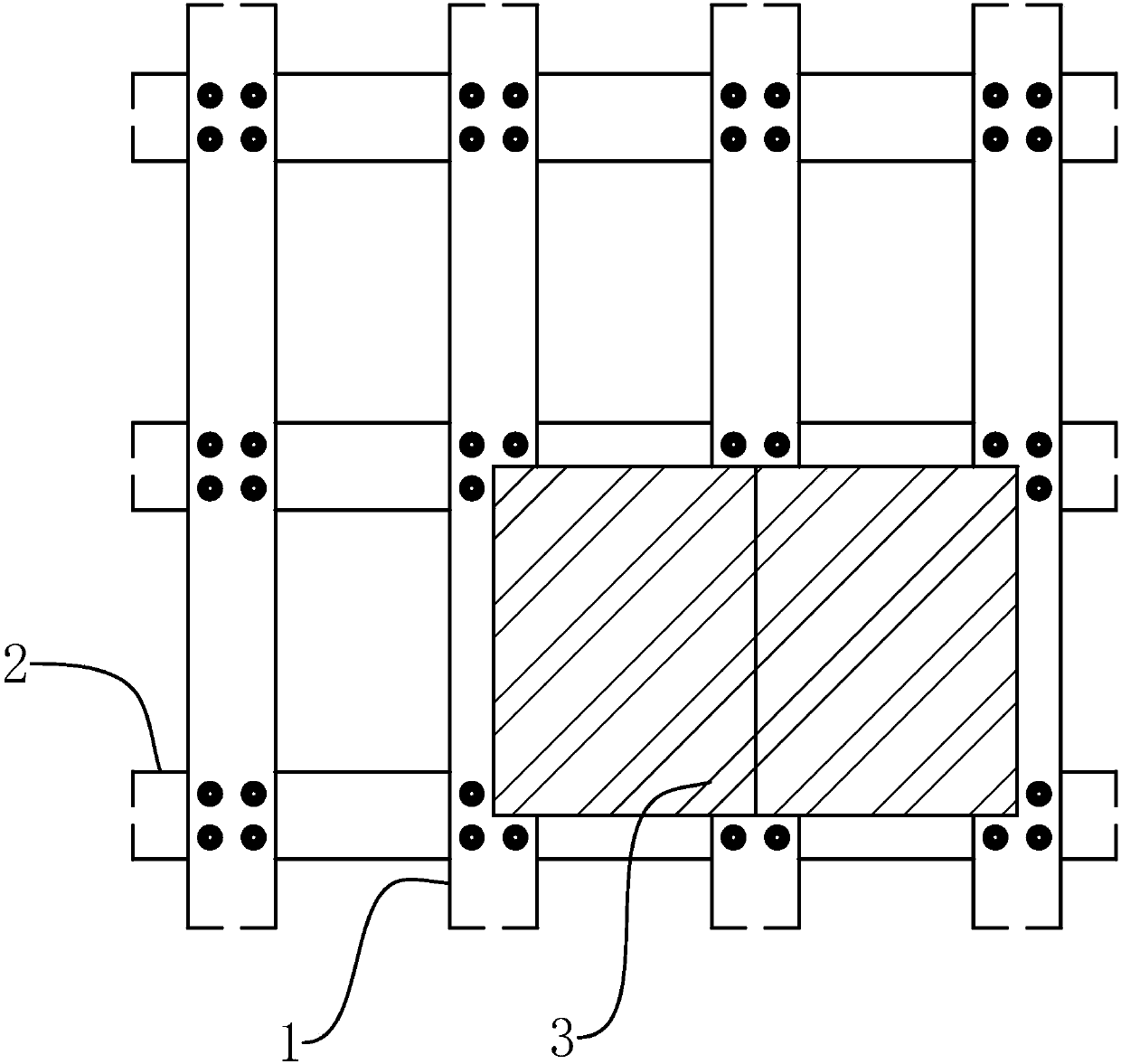

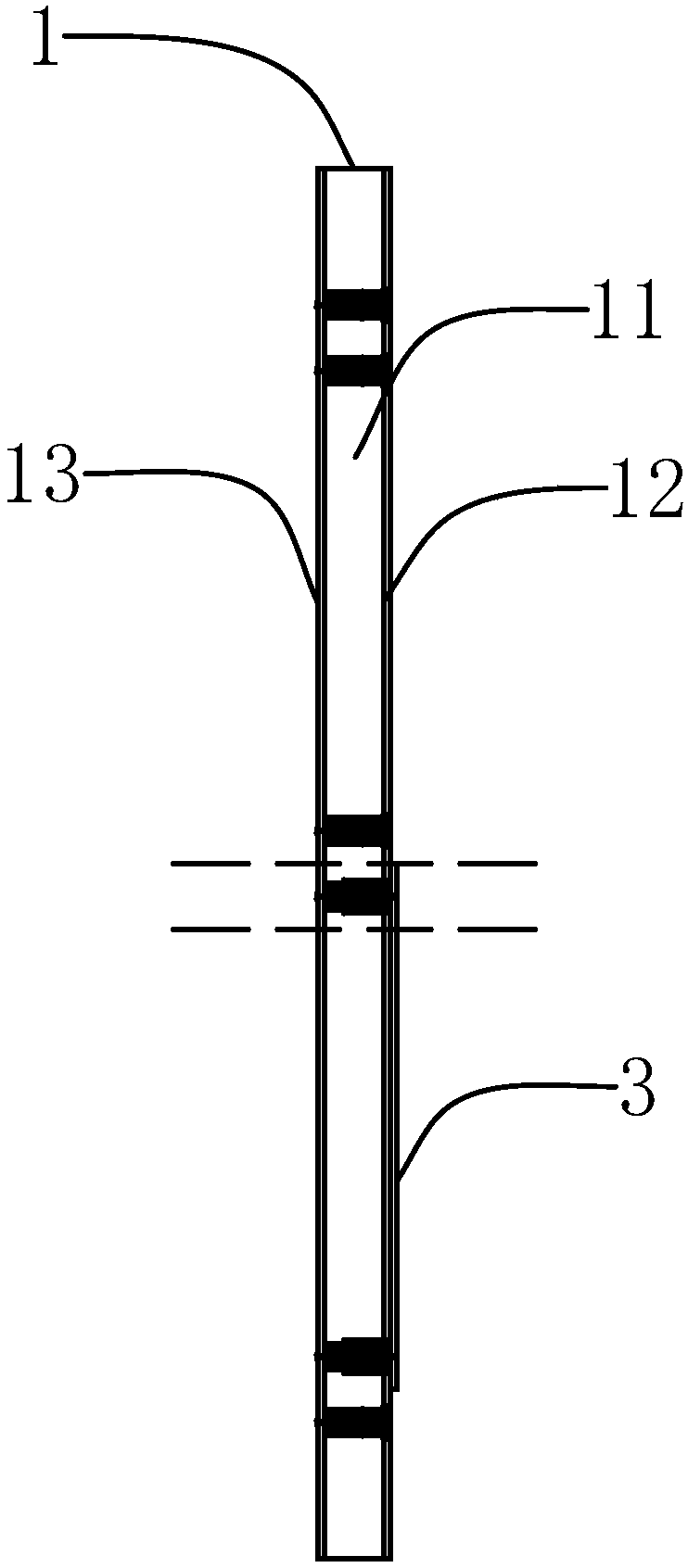

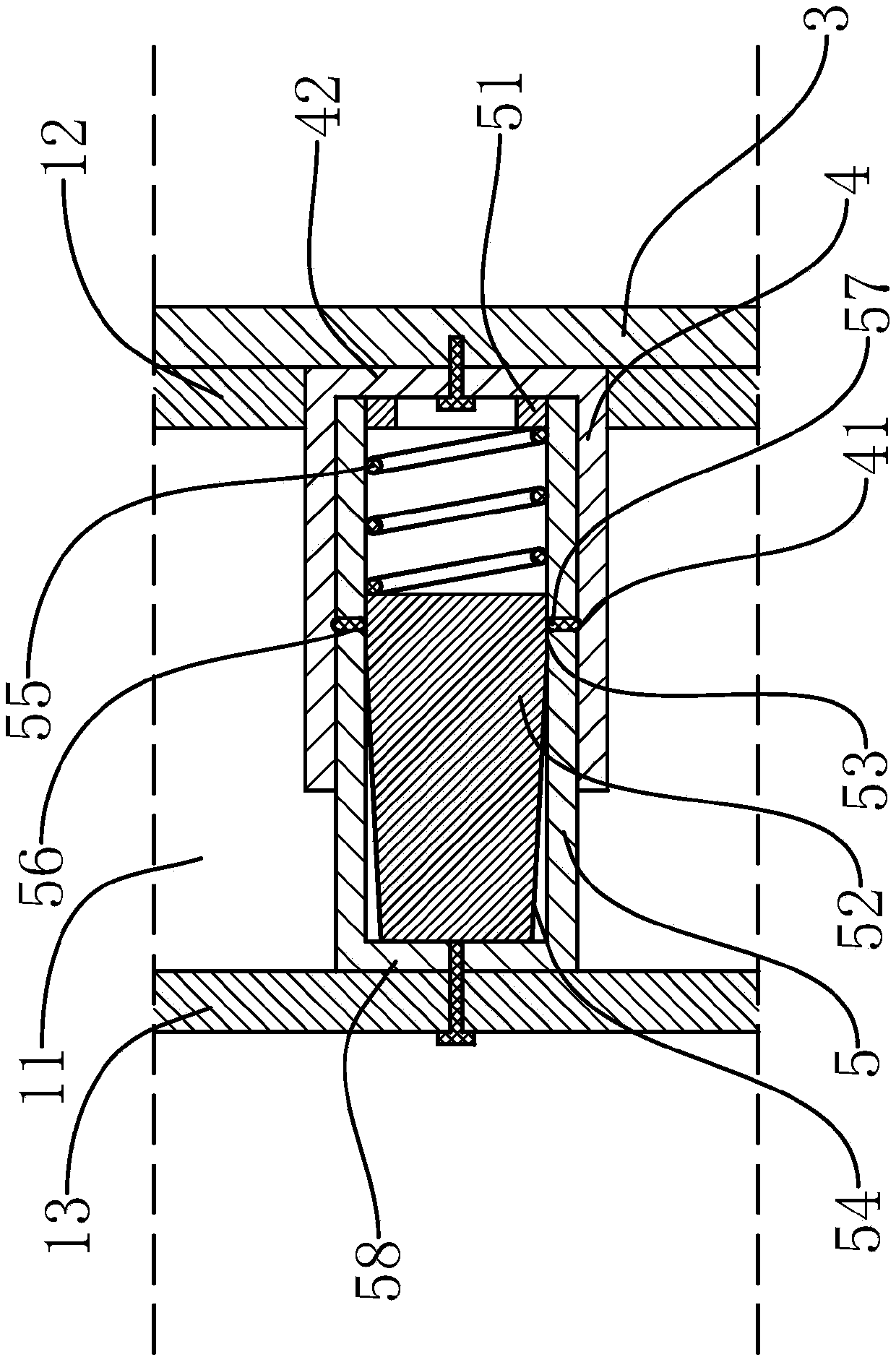

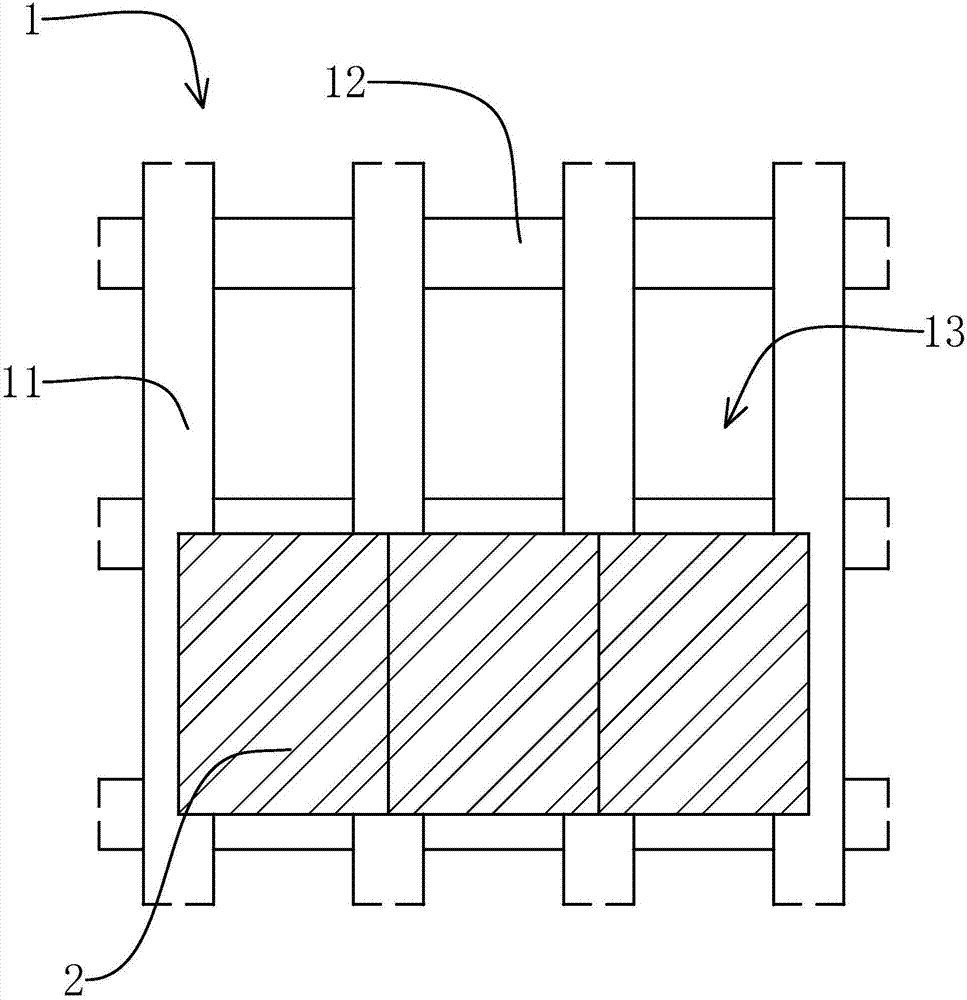

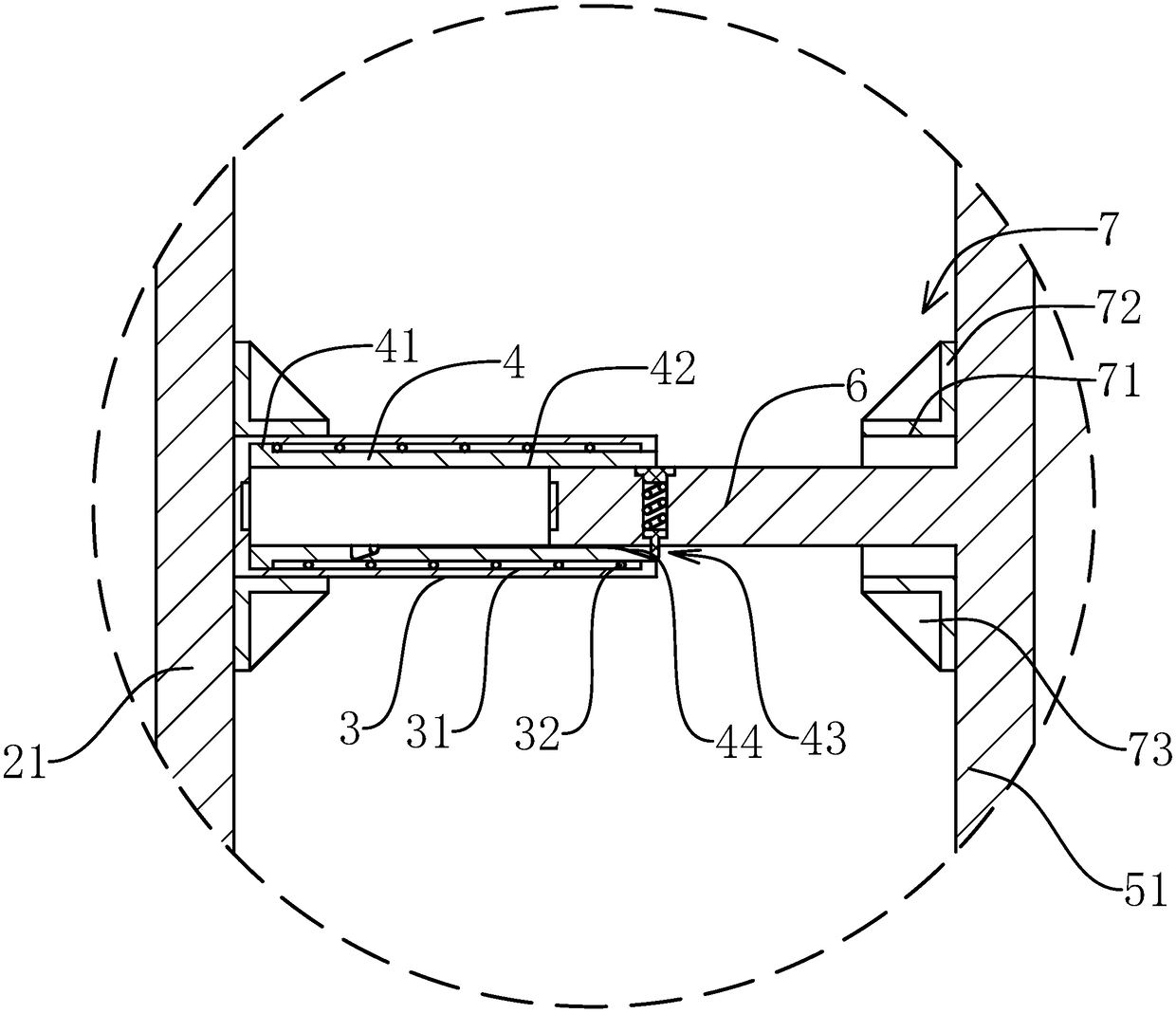

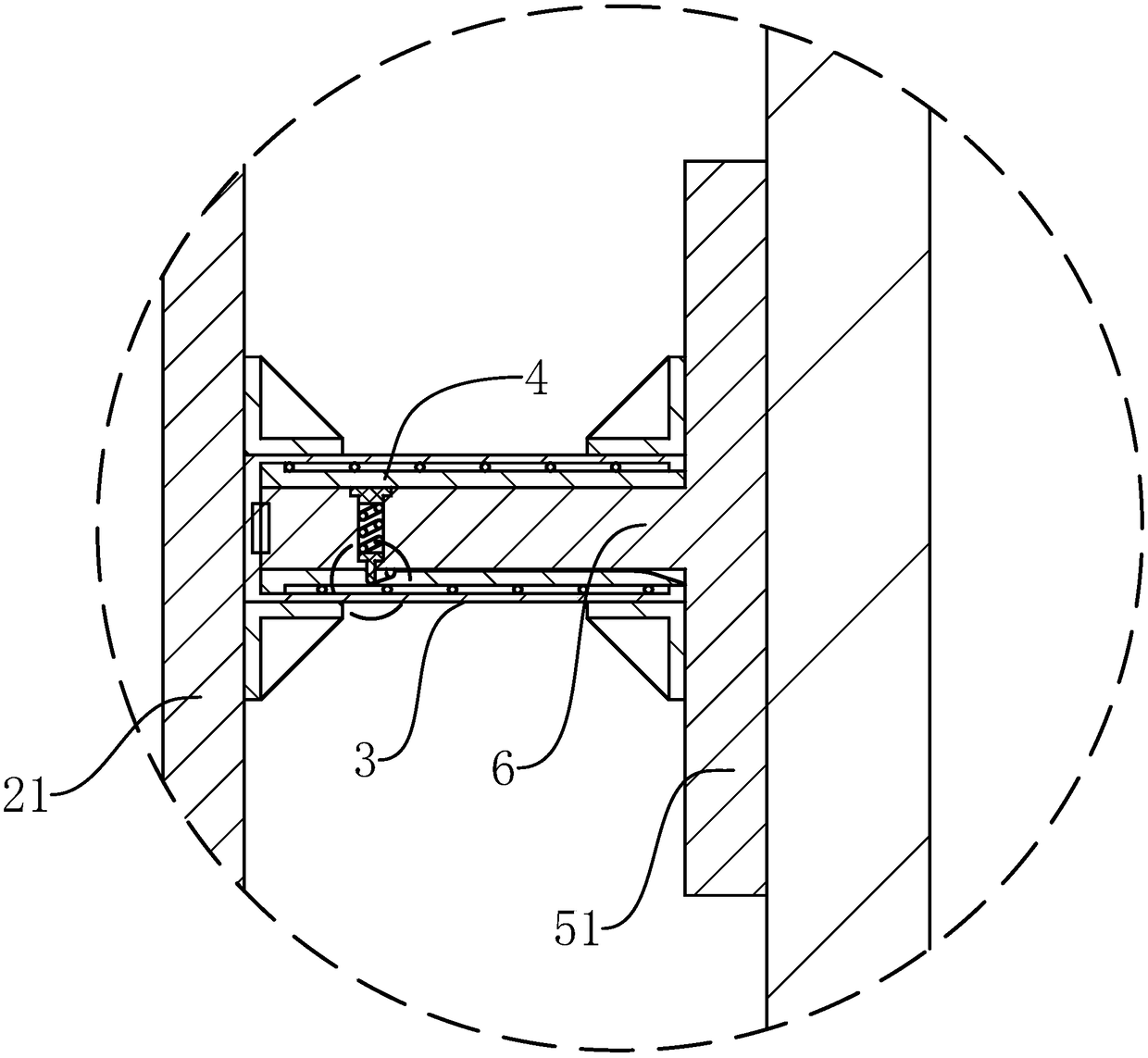

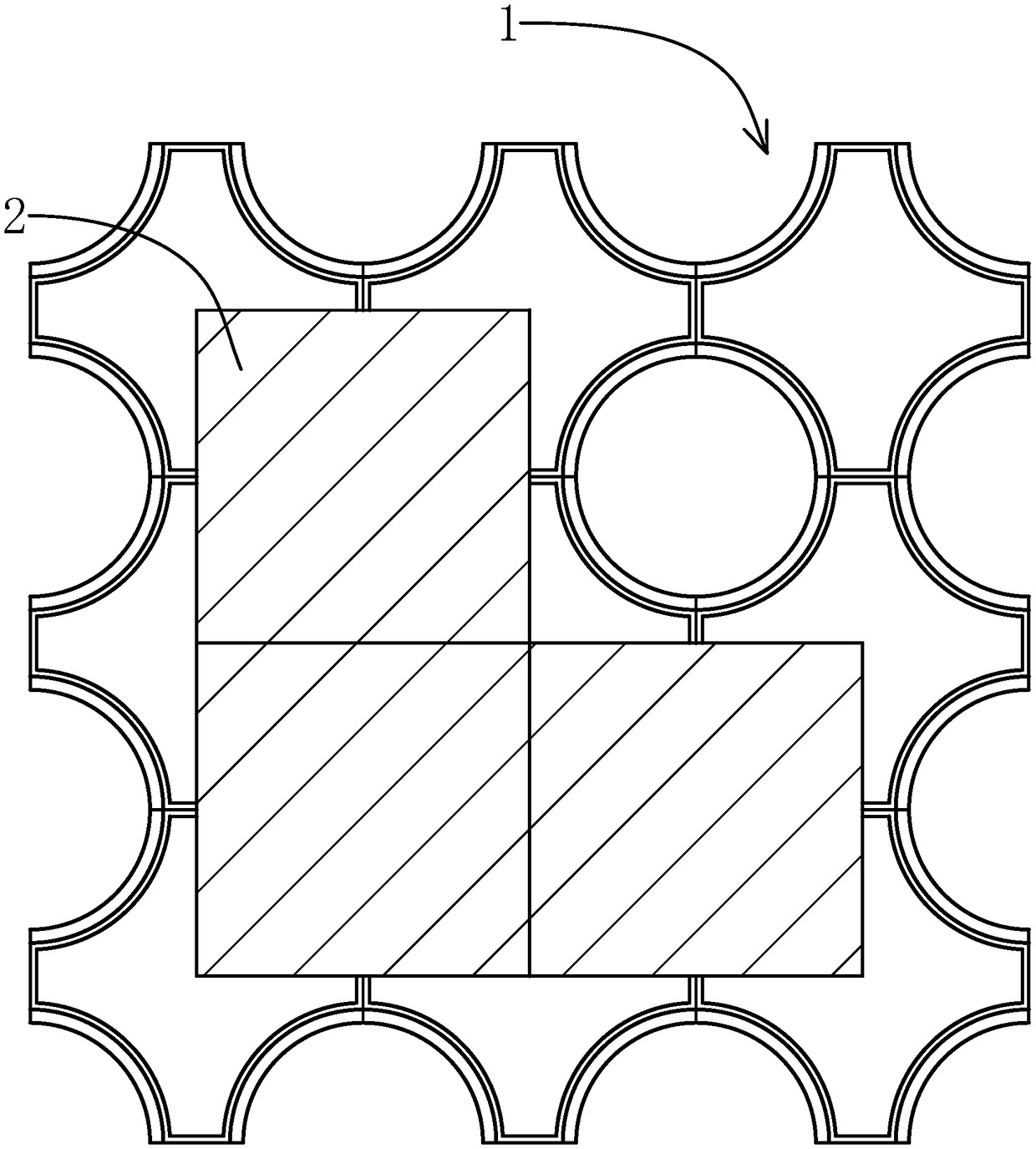

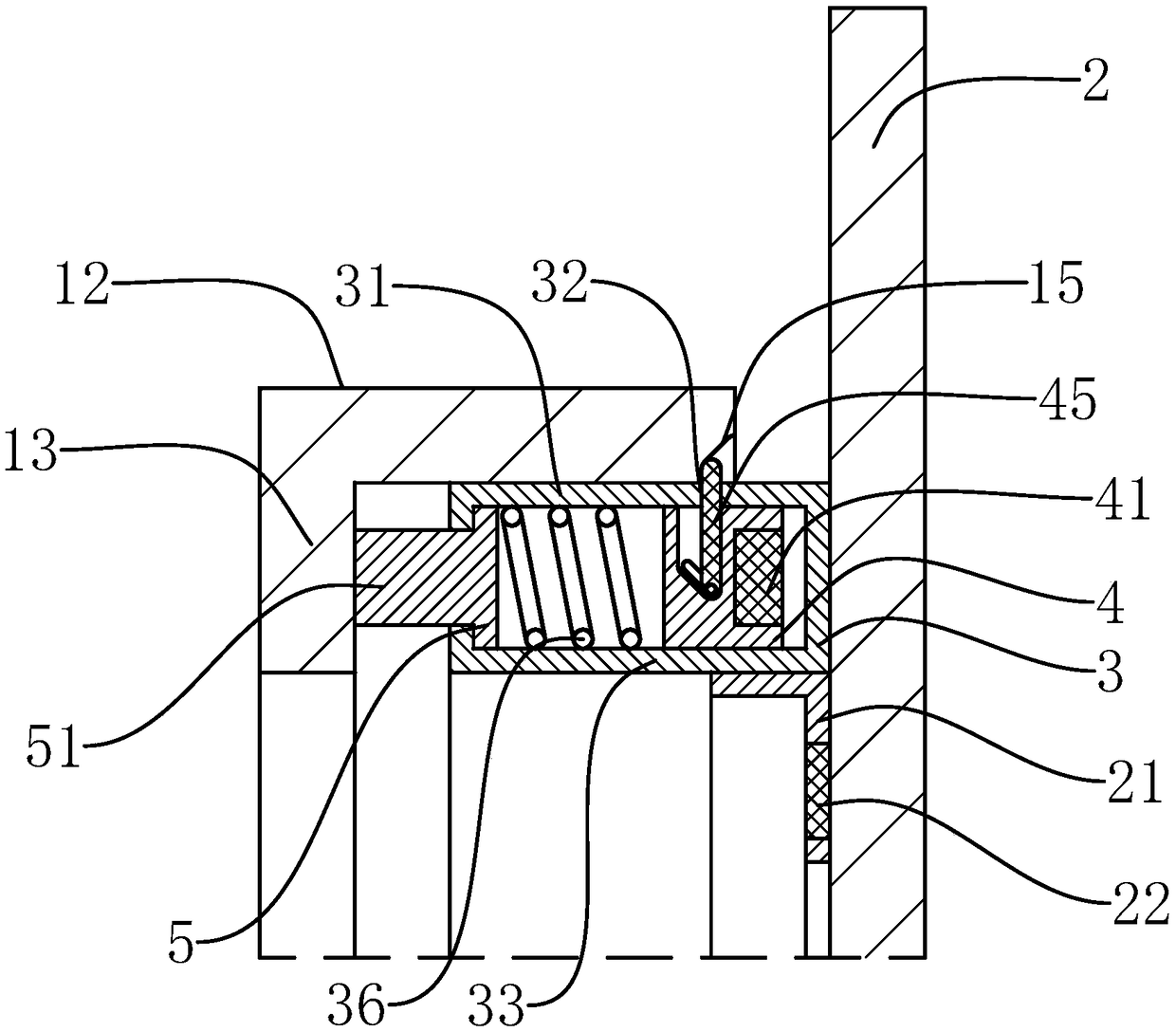

Hidden frame glass curtain wall structure and method for mounting same

The invention provides a hidden-frame glass curtain wall structure and an installation method thereof, belonging to the field of building curtain walls. It solves the problem of poor seamless installation effect of existing glass curtain walls. The hidden frame glass curtain wall structure includes a frame, which includes columns and beams, and panels. The four corners of the back of the panels are connected to the frame through a connection mechanism. The inner sleeve on the rear pipe wall also includes a retaining ring fixed on the inner wall of the front end of the inner sleeve, a magnetic stopper located in the inner sleeve, and a compression spring located in the inner sleeve. The inner sleeve wall is provided with a lock hole , which also includes a lock block slidingly located in the lock hole, the front end of the outer cover penetrates the perforation and is placed on the inner sleeve, the inner wall of the outer cover is provided with a lock groove, and the compression spring pushes the block so that the rear end of the block is against the rear end of the inner sleeve, so that The locking surface bears against the inner end of the lock block, so that the outer end of the lock block protrudes from the lock hole and is embedded in the lock groove. The glass curtain wall can realize completely seamless hidden frame installation.

Owner:XINCHANG SICHUANG DESIGN CONSULTING CO LTD

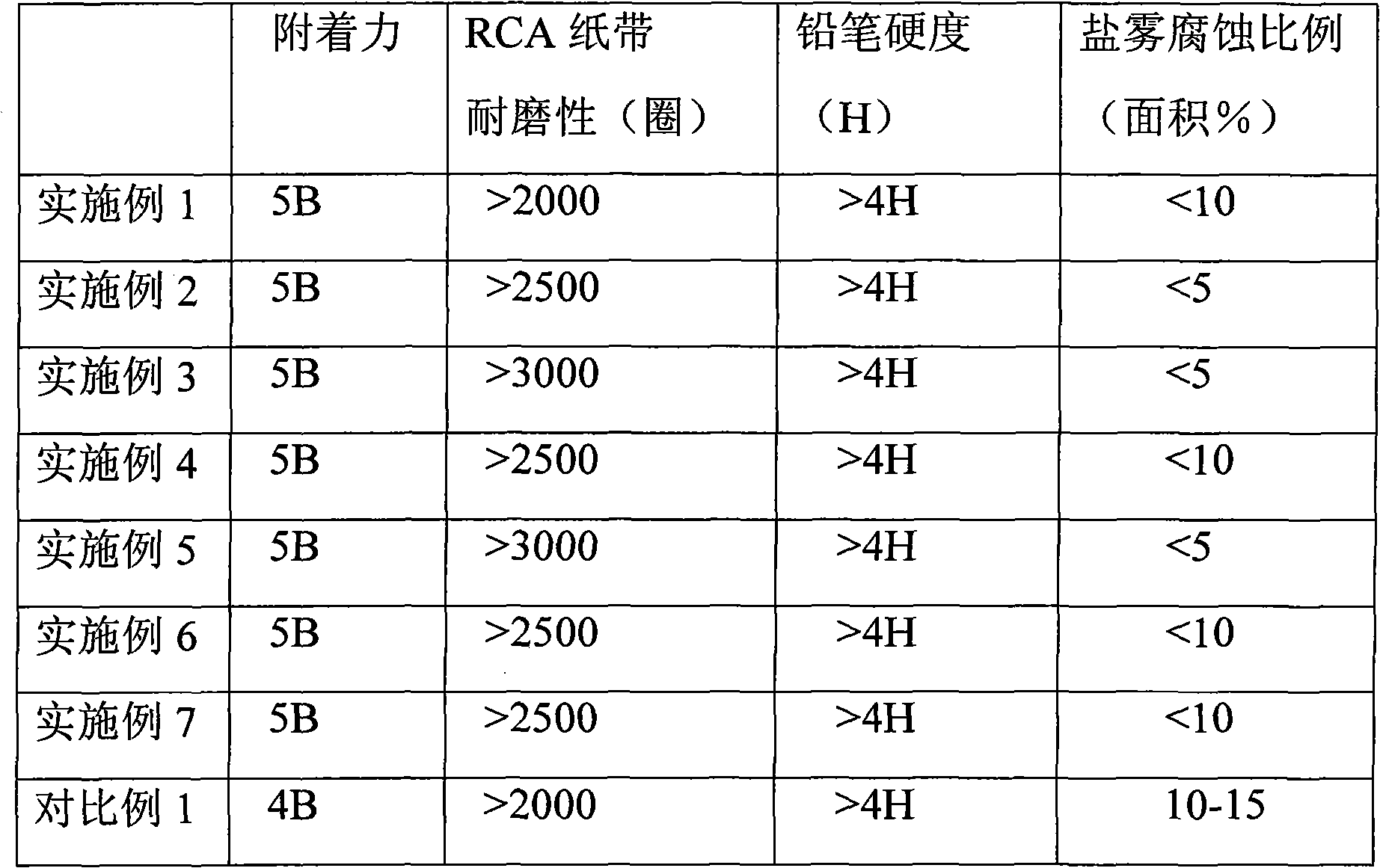

Water-based environment-friendly porcelain glaze-like plastic coating and preparation method thereof

The invention discloses water-based environment-friendly porcelain glaze-like plastic coating and a preparation method thereof. The water-based environment-friendly porcelain glaze-like plastic coating adopts a formula comprising the following materials by mass: 20 to 40 percent of a water-based acrylic emulsion, 10 to 20 percent of water-based silica sol, 35 to 50 percent of water-based inorganic silicon dioxide nanodispersion, 0.1 to 0.3 percent of a wetting dispersant, 1 to 5 percent of silane, 0.1 to 0.5 percent of an amine neutralizing agent, 5 to 10 percent of lead-free pigment, 0.5 to 2.5 percent of a film-forming additive, and 5 to 25 percent of deionized water. The water-based environment-friendly porcelain glaze-like plastic coating can be coated on the surfaces of various materials in the form of porcelain glaze, and can be applied on the surfaces of the materials of various shapes through roller-applied coating, shower coating, spraying, blade coating, brush coating, dip coating and the like; moreover, the formed porcelain glaze coating is unique and free from hydrolysis, and cannot be melted at a certain temperature, so that a base material can be effectively protected from corrosion, abrasion, scraping, acid-alkali, impact, inflaming and fire.

Owner:吕标

Differential arc oxidation electrolytic solution and differential arc oxidation method

ActiveCN101476143AImprove corrosion resistanceImprove dirt resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a micro-arc oxidation electrolyte which is a water solution comprises phosphate and silicate, and has 6-12 PH value. The electrolyte has characteristics that the electrolyte also comprises colorant, the colorant comprises A and B components, wherein, A comprises one or some of potassium fluoride, sodium fluoride, sodium sulfate and borax, B comprises cupric pyrophosphate and / or bluestone. The micro-arc oxidation electrolyte and the method for micro-art oxidating provided by the invention can make micro-arc oxidation film of light metal material obtaining uniform color for having beautiful decorating effect. At the same time, the obtained micro-arc oxidation film of light metal material surface has better stain resistance and compactness that increases additive value and practical using value of magnesium alloy greatly.

Owner:BYD CO LTD

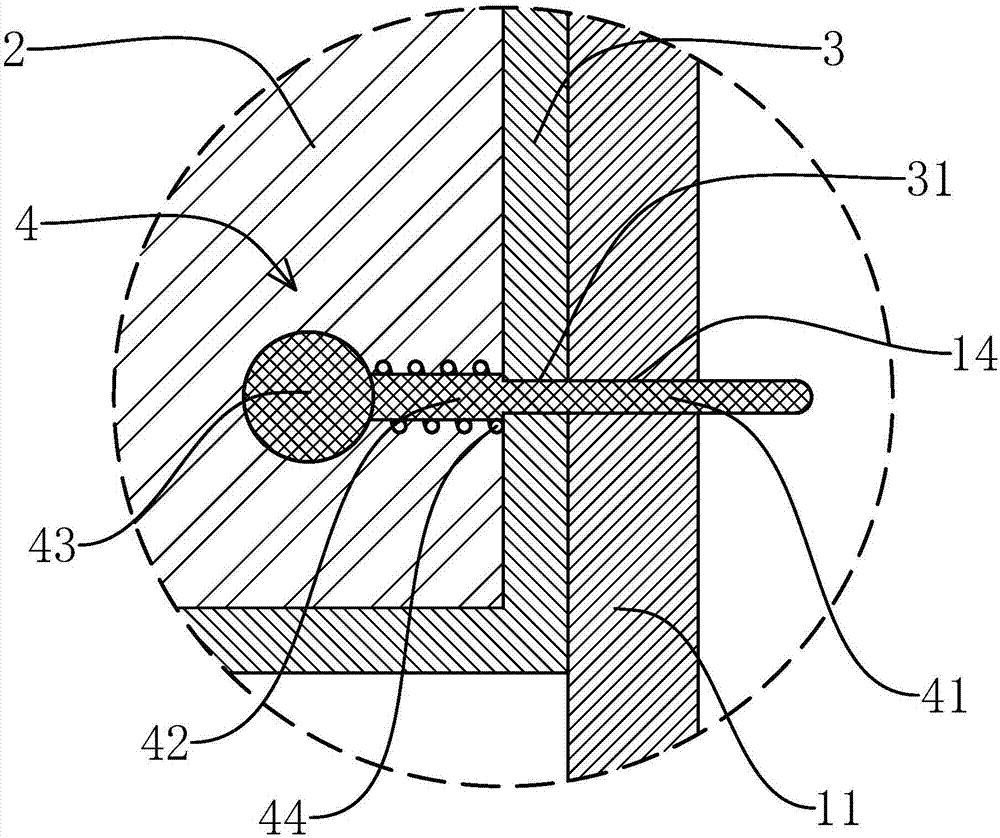

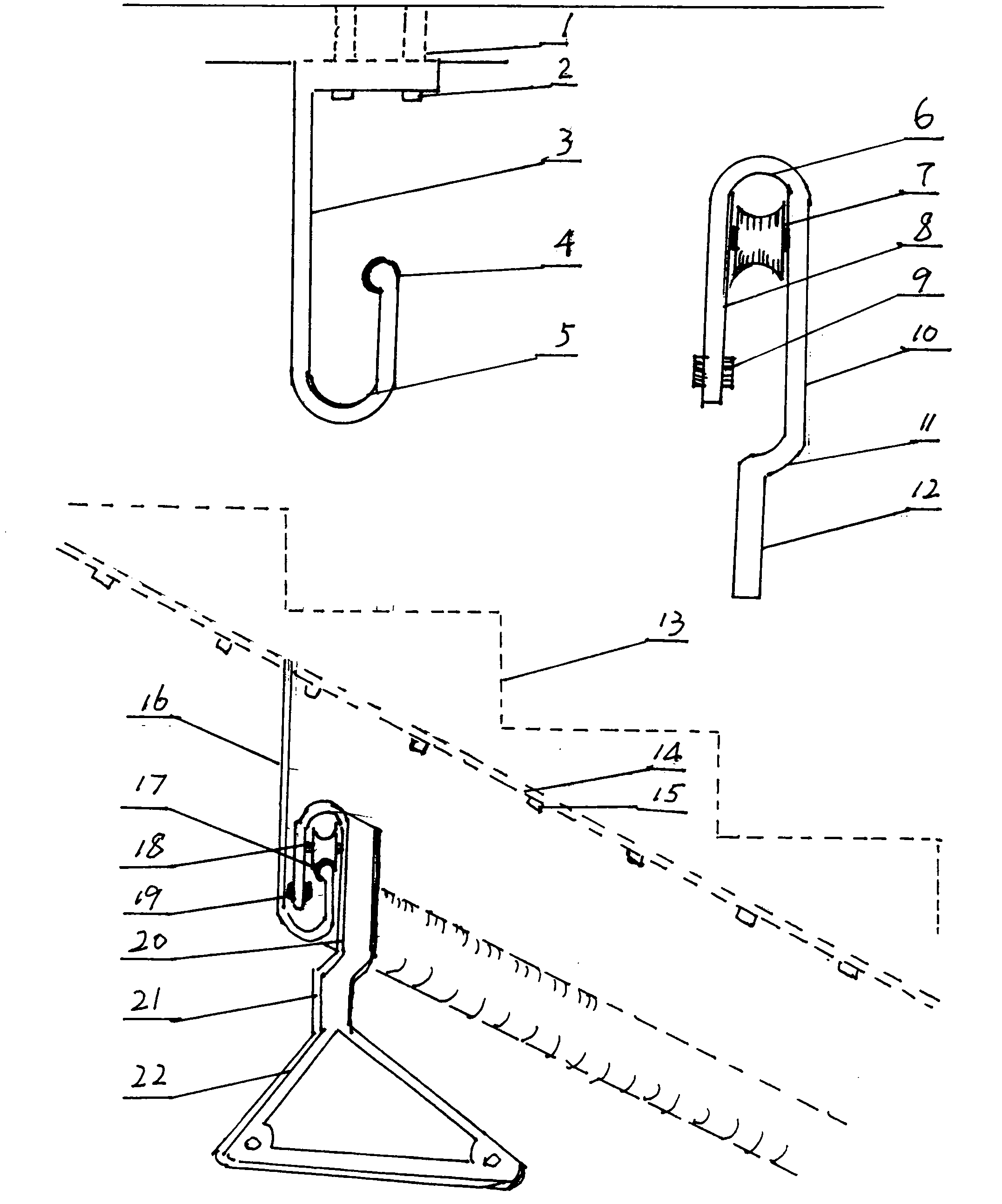

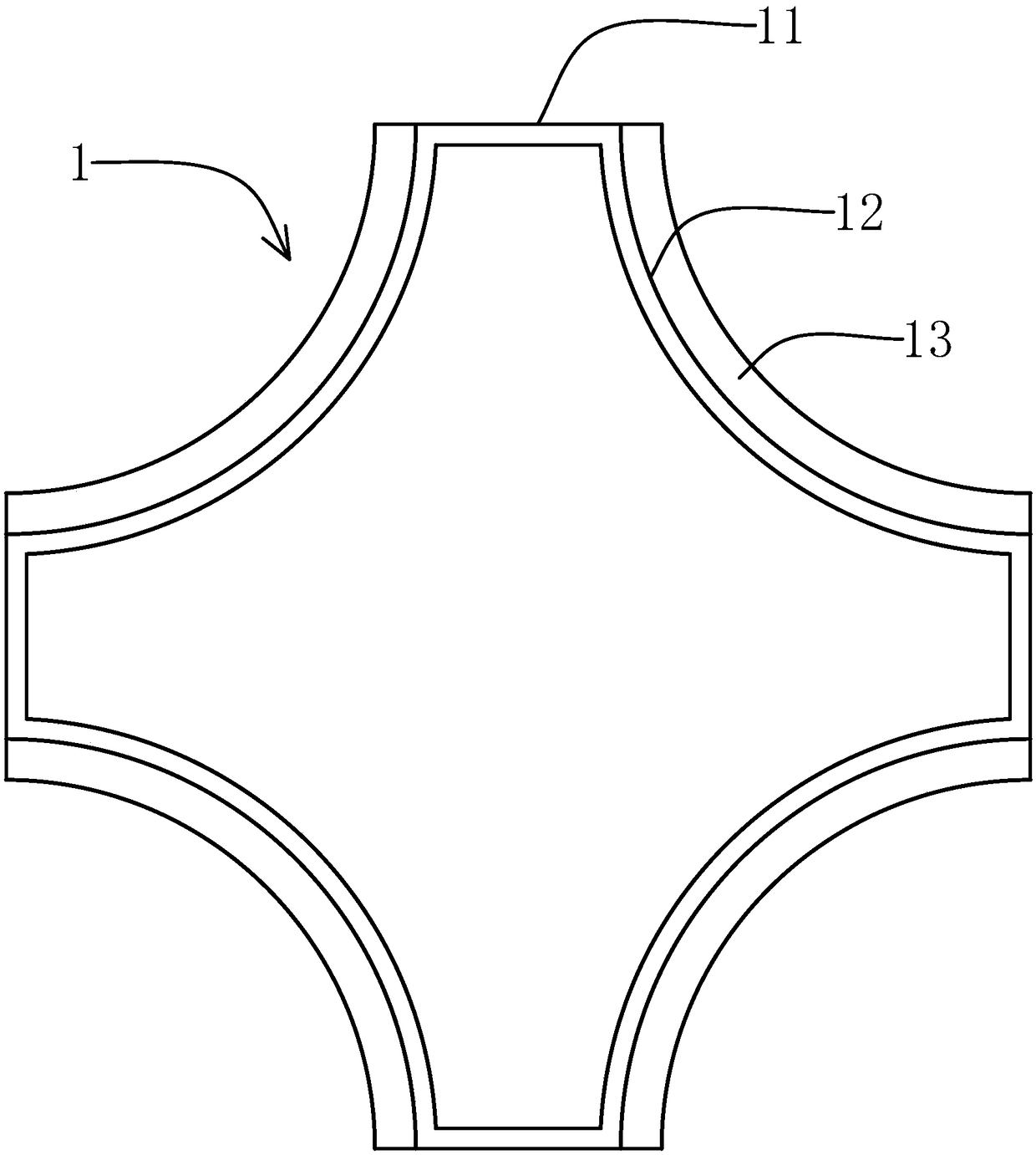

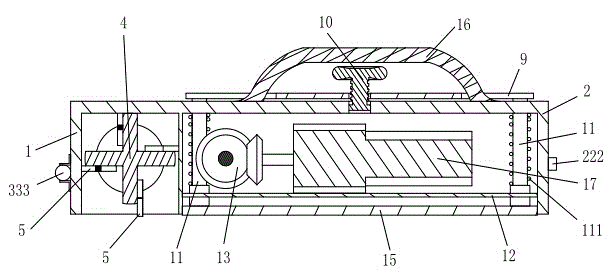

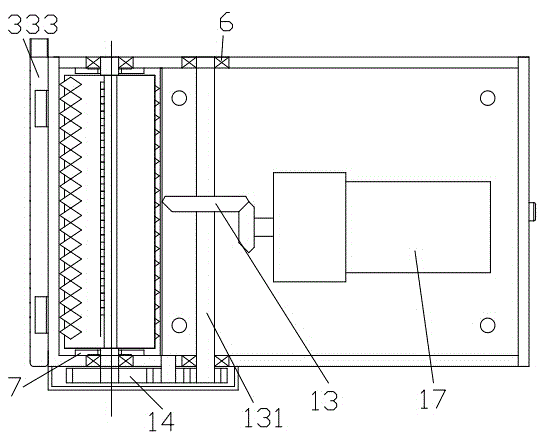

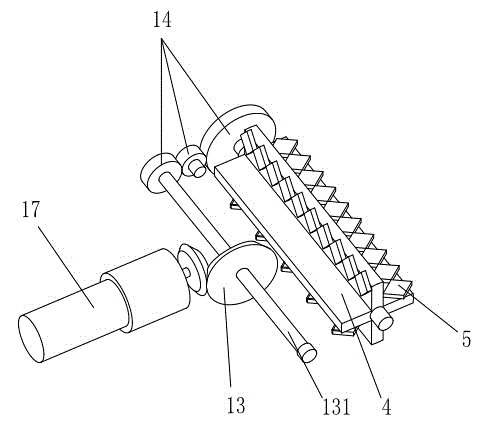

Hidden frame glass curtain wall, special disassembly tool and installation method

InactiveCN108005283AEasy to modifyImprove the decorative effectWallsBuilding material handlingArchitectural engineeringSurface plate

The invention provides a hidden frame glass curtain wall, a special disassembly tool and an installation method, and belongs to the field of building curtain walls. The hidden frame glass curtain wall, the special disassembly tool and the installation method solve the problem of poor seamless installation of existing glass curtain walls. The hidden frame glass curtain wall comprises a frame, the frame includes stand columns, cross beams and rectangular glass panels; connecting frames are fixed to the back face of the panels, and each of the connecting frames is provided with four connecting mechanisms; the connecting mechanisms include connecting holes located on the connecting frames and connecting rods with the front ends being fixedly provided with inserting rods and the rear ends beingprovided with inner magnetic block; the inserting rods are movably inserted into the connecting holes, and the connecting rods are sleeved with extension springs; connecting areas are formed betweenthe adjacent stand columns and cross beams, and the back surfaces of the panels can be attached to the outer side surface of the front pipe wall and the front surfaces of the cross beams; and the connecting frames are arranged in the connecting areas, inserting holes are formed in the side walls of two stand columns, and the corresponding inner magnetic blocks are correspondingly pulled by the tension springs of the four connecting mechanisms, so that the inserting rods are inserted into the corresponding inserting holes and the panels are fixed to the frame. The hidden frame glass curtain wall can realize completely seamless hidden frame type installation.

Owner:XINCHANG SICHUANG DESIGN CONSULTING CO LTD

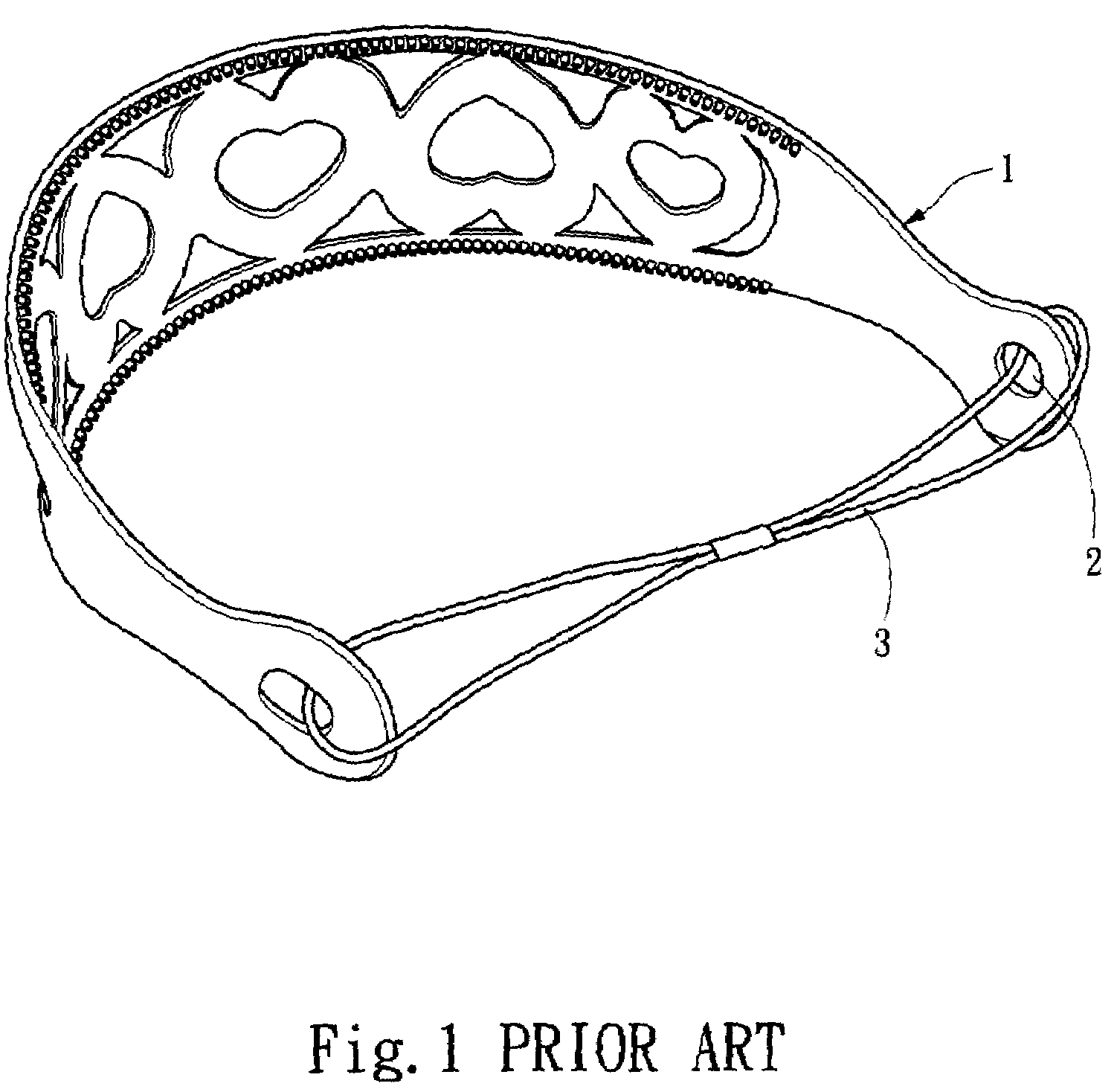

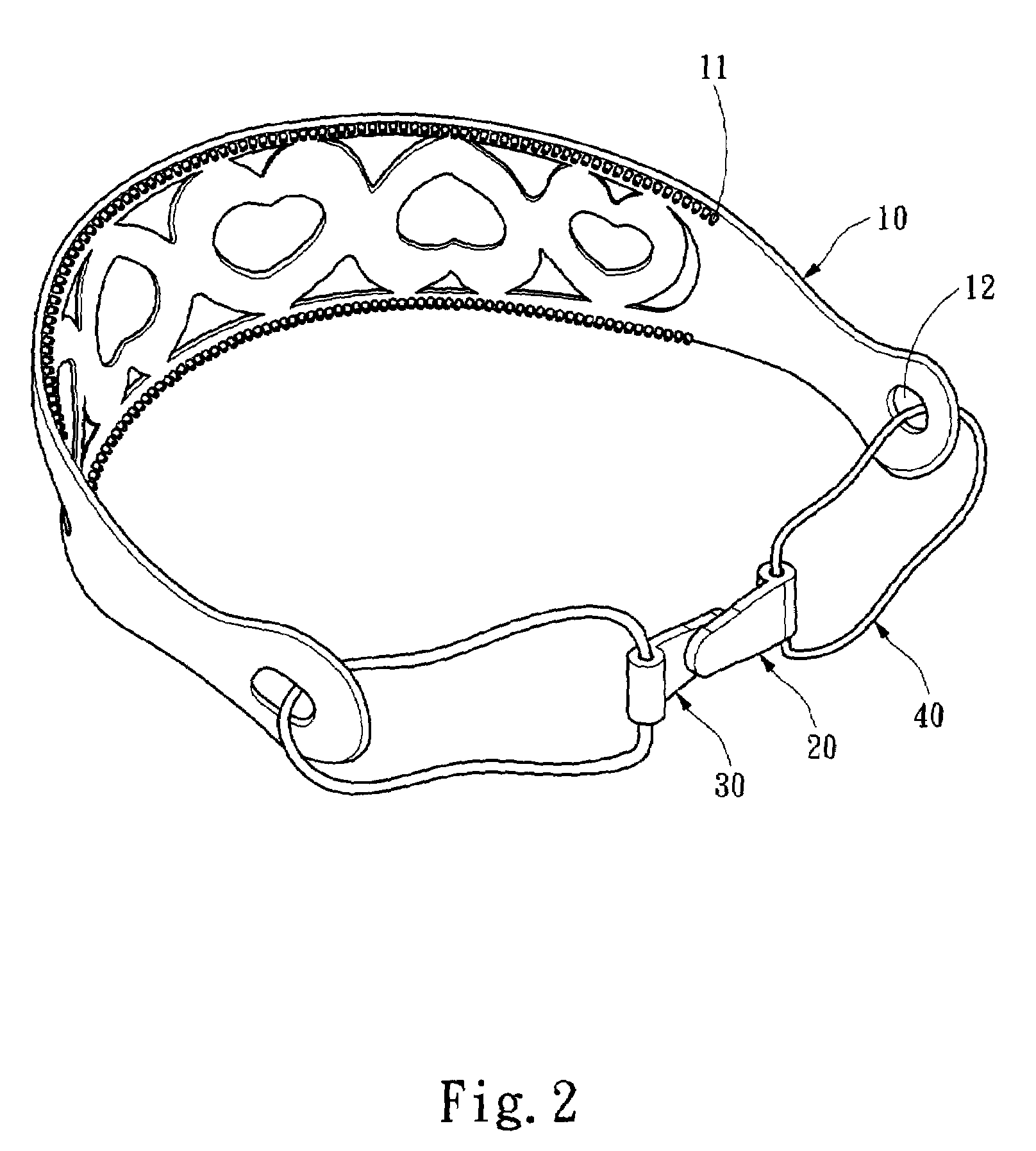

Hair hoop structure

InactiveUS20080302382A1Increase elasticityLabor-saving wearCurling devicesTravelling articlesEngineering

Owner:WANG JEN FU

Micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN101445949AImprove stain resistanceImprove compactnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a micro-arc oxidation electrolyte which is aqueous solution containing phosphate and silicate and has the pH value of 6-12, wherein, the electrolyte also contains color toner which comprises one or a plurality of sodium sulfate, rose vitriol, ammonium metavanadate, copper sulphate and potassium permanganate. The micro-arc oxidation electrolyte and a micro-arc oxidation method provided by the invention can lead a micro-arc oxidation film made of light metal materials to obtain multiple colors which are very even to ensure the light metal products to have beautiful decorative effects. Meanwhile, the stain resistance and compactness of the micro-arc oxidation film obtained on the light metal materials are excellent; therefore, the added value and actual use value of aluminium alloy are greatly enhanced.

Owner:BYD CO LTD

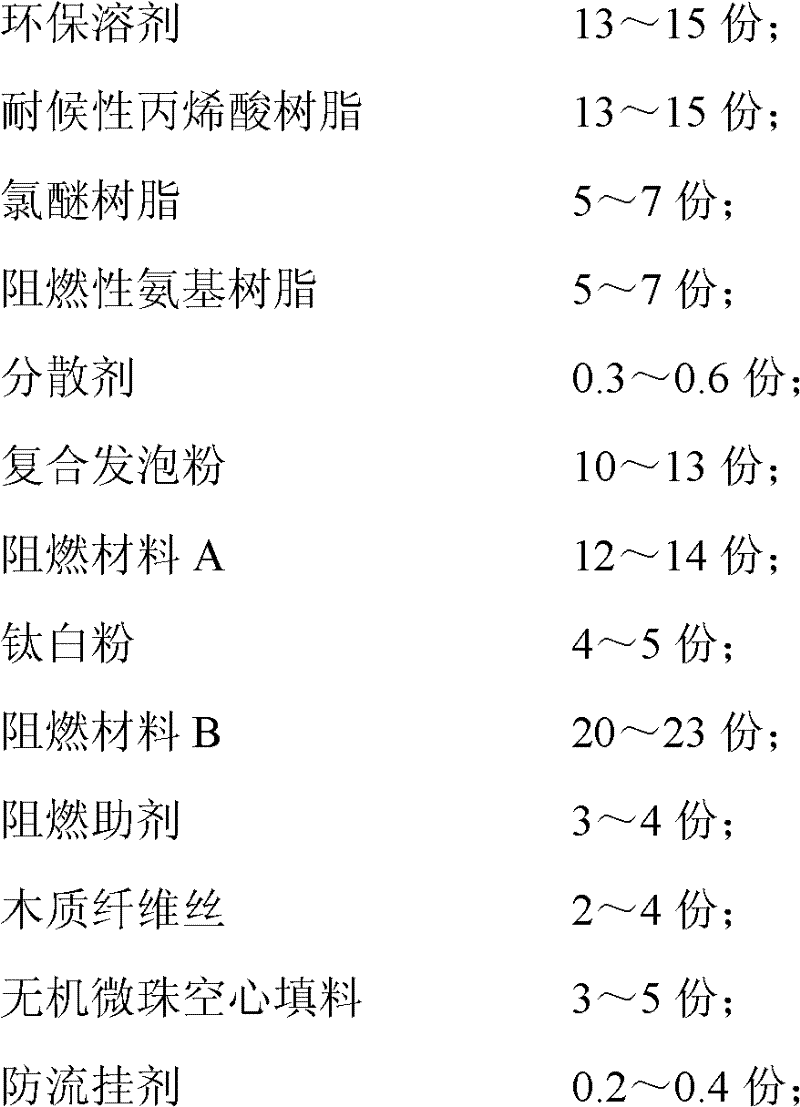

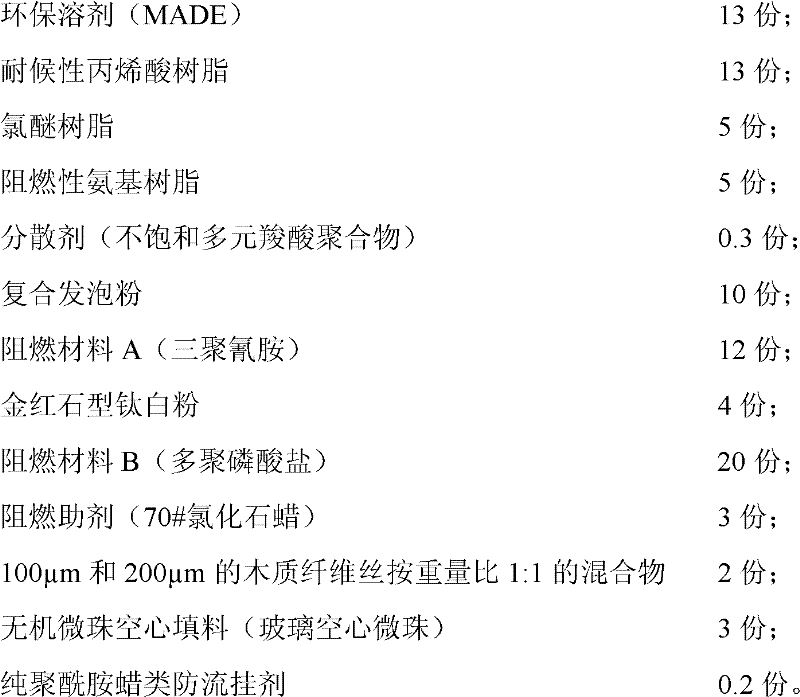

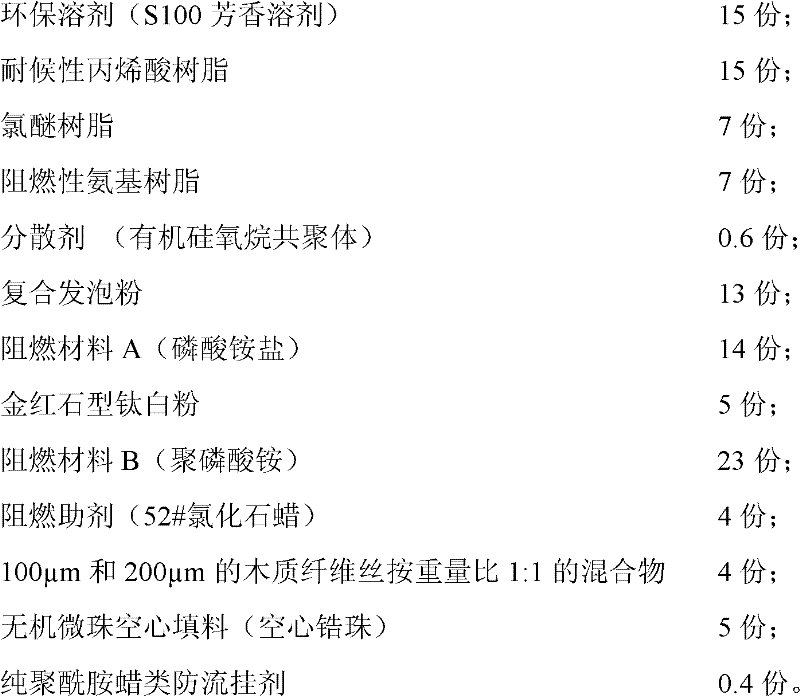

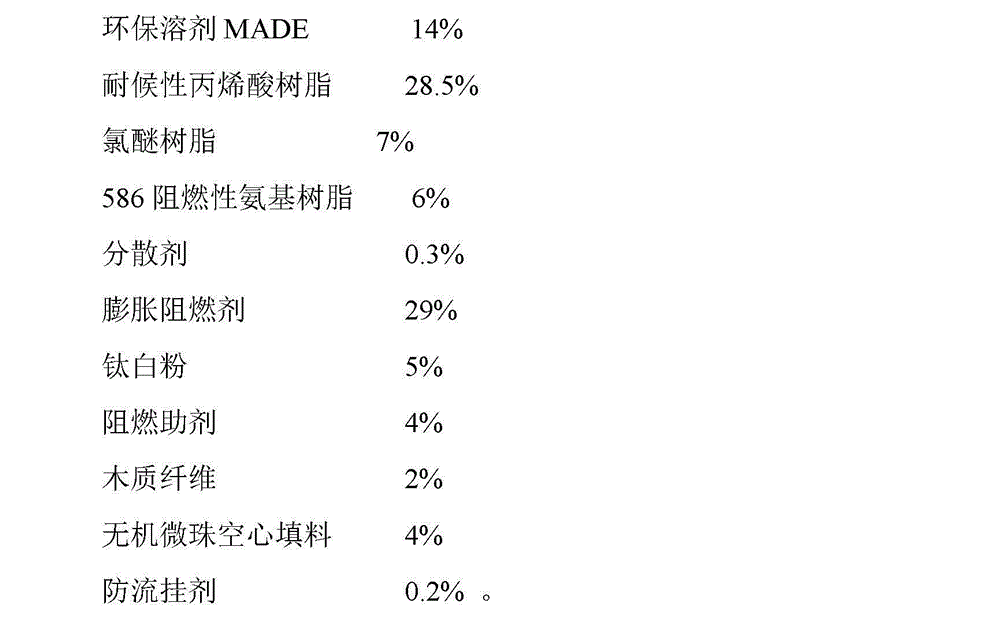

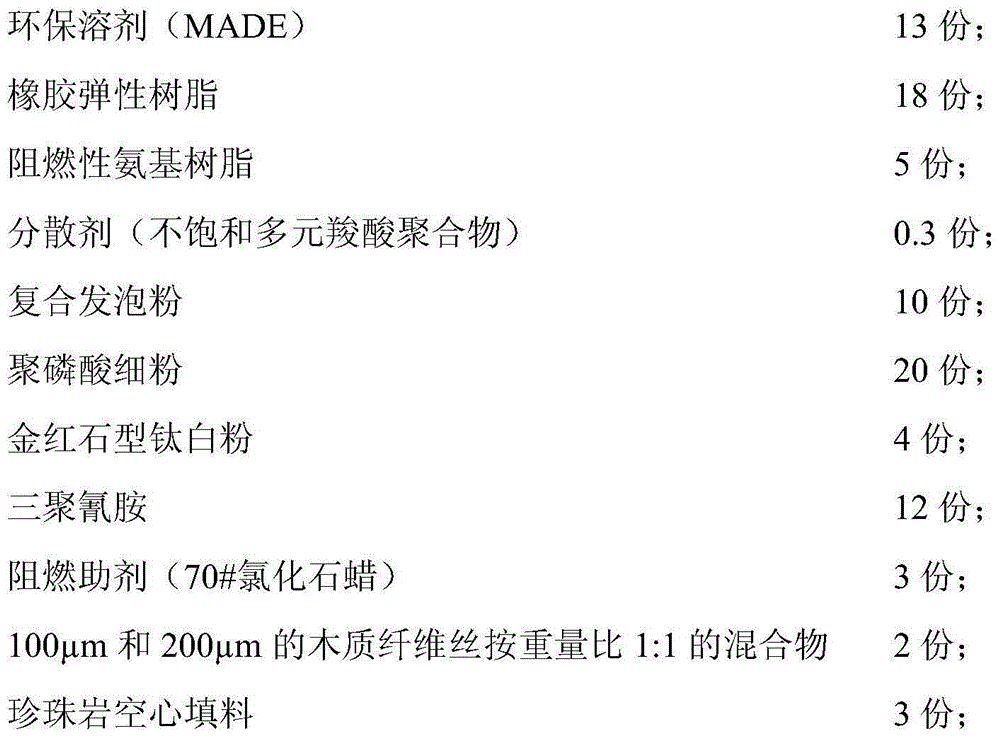

Fire retardant coating and preparation method thereof

ActiveCN102408802AExcellent weather resistanceStrong adhesion and durabilityFireproof paintsSolventWeather resistance

The invention discloses a fire retardant coating, which comprises the following components: an environment-friendly solvent, weather-proof acrylic resin, chlorinated polyether resin, flame retardant amino resin, a dispersing agent, composite foaming powder, a flame retardant material A, titanium white, a flame retardant material B, a flame retardant aid, wood fibers, an inorganic microbead hollowfiller and an anti-sagging agent. The invention also provides a preparation method for the fire retardant coating. The fire retardant coating can be coated on various substrates, is extra-thin, efficient and durable, is specially used outdoors, is resistant to the fire combustion of hydrocarbons, and has high chemical properties such as weather resistance, acid resistance, alkali resistance and the like, high adhesion and an attractive decorative effect, and paint films are fine; the fire retardant coating is uniformly expanded, and has a special foam structure and a high fireproof effect; and the product is environment-friendly and pollution-free, a production process is simplified, and the fire retardant coating is convenient to construct and can be used for coating with various fireproof requirements.

Owner:WUXI HUHUANG PAINT

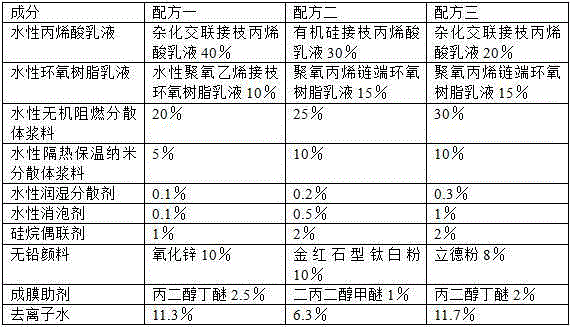

Water-borne environment-friendly, anti-flaming and heat-insulating paint and preparation method thereof

InactiveCN105331217ASolve the problem of anti-combustion performanceGuarantee the safety of lifeFireproof paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses water-borne environment-friendly, anti-flaming and heat-insulating paint and a preparation method thereof. According to the formula, the water-borne environment-friendly, anti-flaming and heat-insulating paint is prepared from, by mass, 20-40% of water-borne acrylic emulsion, 10-20% of water-borne epoxy resin emulsion, 20-30% of water-borne inorganic anti-flaming dispersoid slurry, 5-10% of water-borne heat-insulating nanometer dispersoid slurry, 0.1-0.3% of water-borne wetting dispersant, 0.1-1% of water-borne deformer, 1-3% of silane coupling agent, 5-10% of lead-free pigment, 0.5-2.5% of coalescing agent and 5-25% of deionized water. The water-borne environment-friendly, anti-flaming and heat-insulating paint can achieve anti-corrosion, wear resisting, acid-base resisting, impact resisting, anti-flaming and fireproofing effective protection on the surface of a base material coated with the paint. Under the condition of high-temperature combustion, corrosive halogen and other harmful gases are not produced, and the paint does not volatilize and is lasting in effect, free of toxicity, smoke and drips and capable of effectively preventing combustion from continuing, delaying deformation caused by temperature rise of the base material and effectively preventing flames and fires.

Owner:CHANGSHA MINDE FIRE ENG PAINT CO LTD

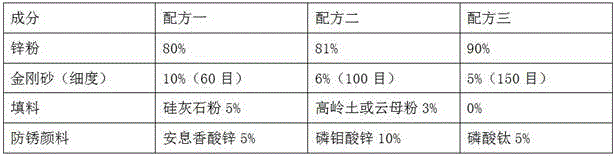

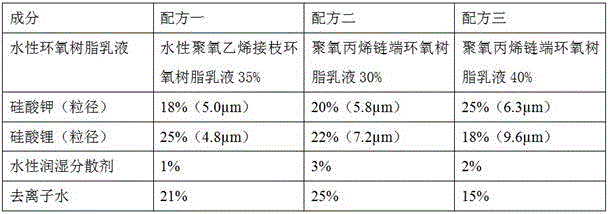

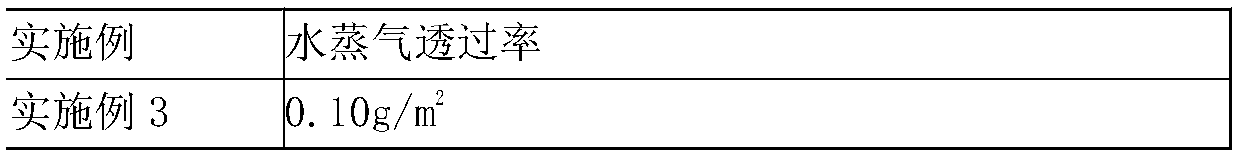

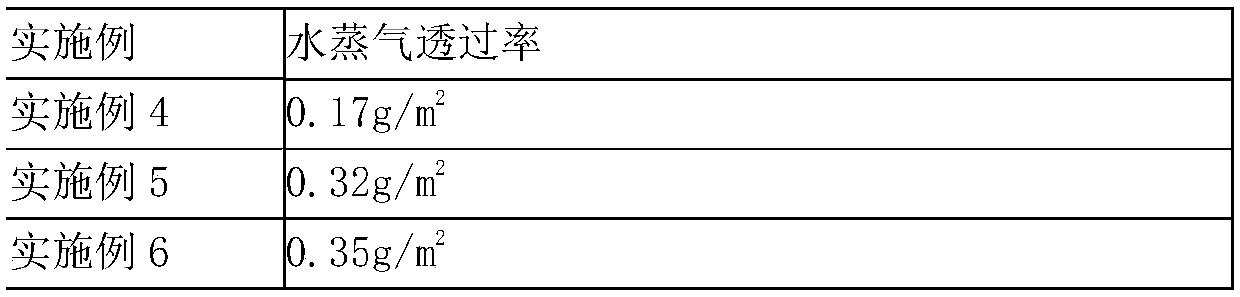

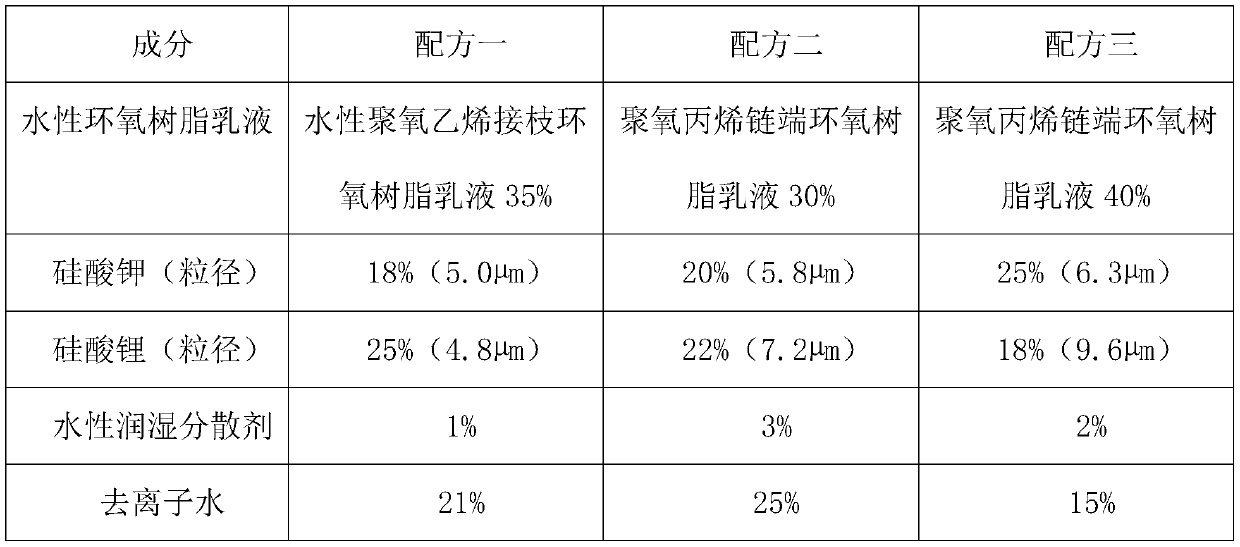

Water-based epoxy anticorrosive paint and preparation method thereof

ActiveCN105713487AStrong adhesionEmission reductionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention provides a water-based epoxy anticorrosive paint and a preparation method thereof. The water-based epoxy anticorrosive paint comprises a component A and a component B in a weight ratio of 1:(2-3), wherein the component A and component B are mixed only when in use. The component A comprises the following ingredients in percentage by mass: 30-40% of water-based epoxy resin emulsion, 18-25% of potassium silicate, 18-25% of lithium silicate, 1-3% of water-based wetting and dispersing agent and 15-25% of deionized water. The component B comprises the following ingredients in percentage by mass: 80-90% of zinc powder, 5-10% of corundum, 0-5% of filler and 5-10% of antirust pigment. By adopting the two-component system composed of the component A and component B, the component B is added into the component A, evenly stirred and filtered, and can be subjected to spray construction. The production technique and use operation are very simple and convenient, have the advantages of environment friendliness and energy saving, and are safe to use. The water-based epoxy anticorrosive paint can be widely used in various hardware materials, and has higher decorative performance.

Owner:SHENZHEN ZHONGKE HONGYE TECH CO LTD

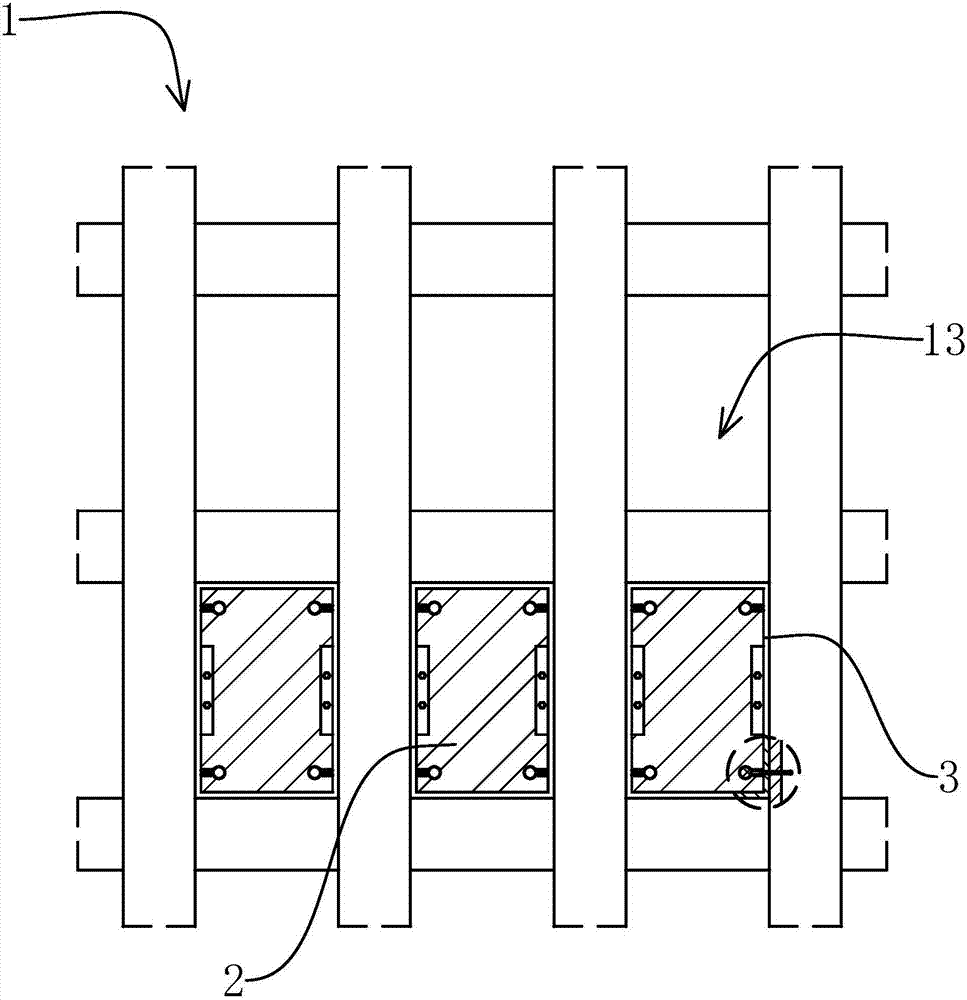

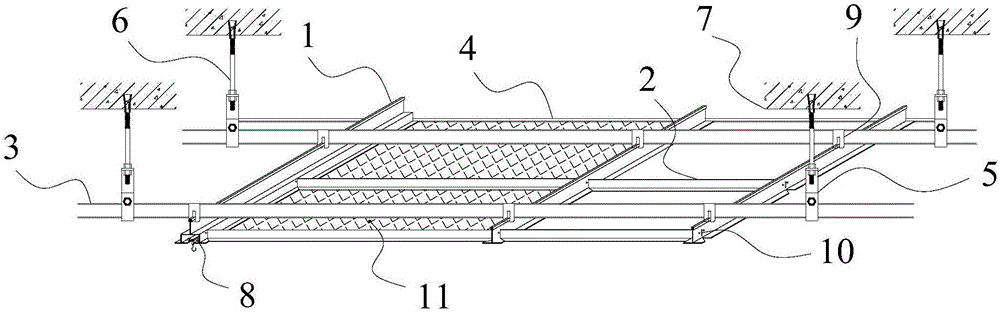

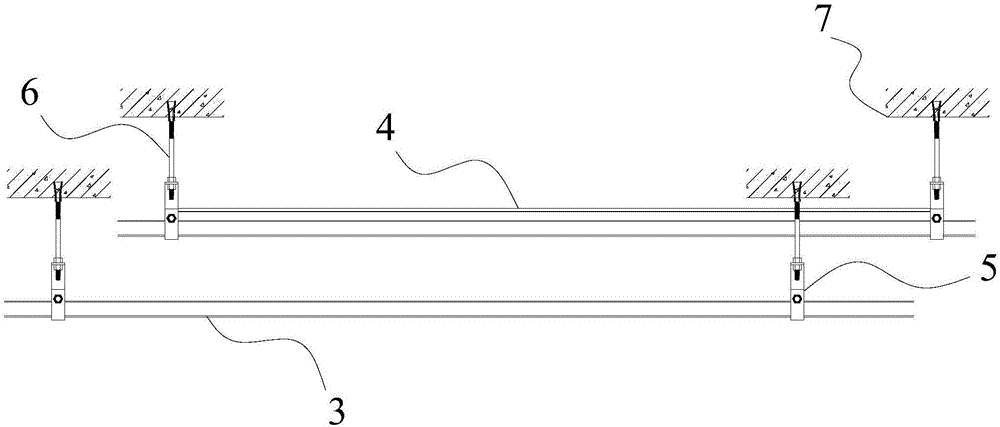

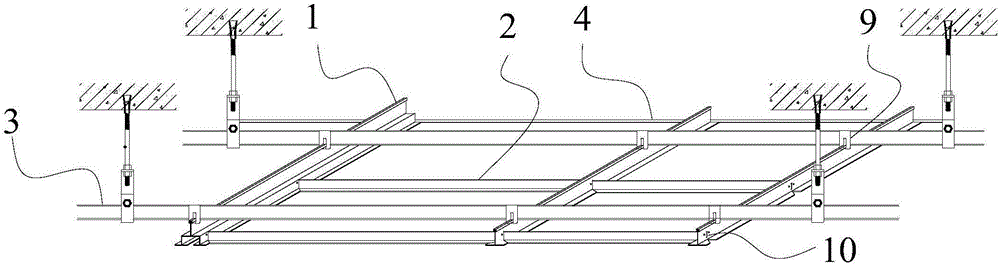

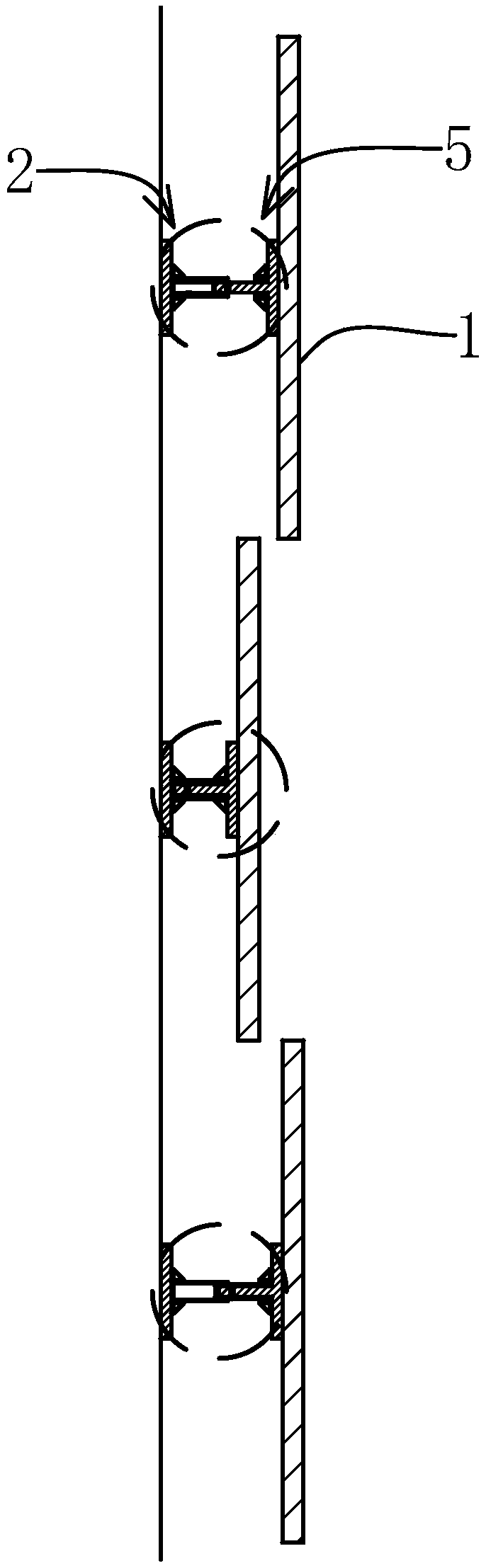

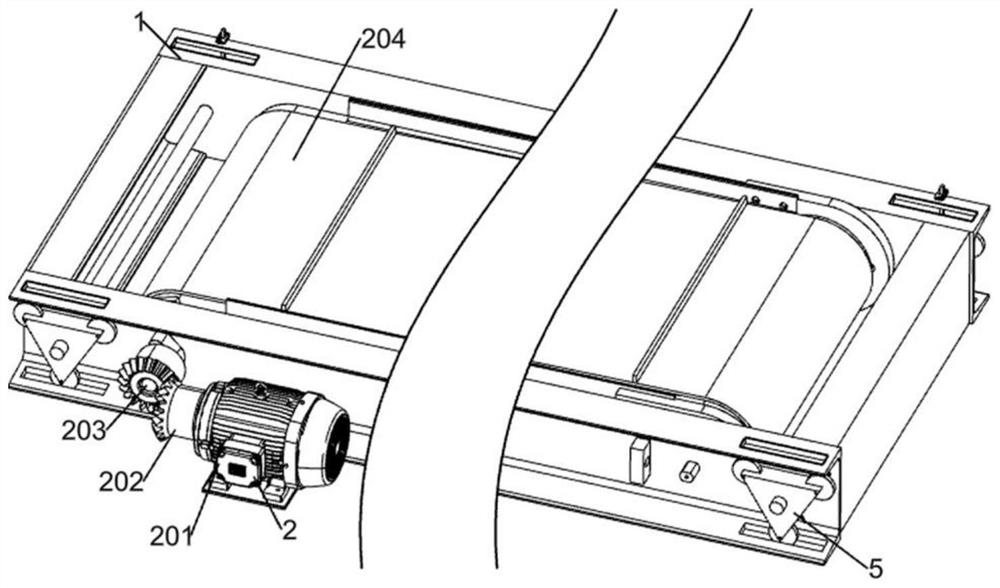

Hidden sky-rail system and construction method

The invention discloses a hidden sky-rail system and a construction method of the hidden sky-rail system. The hidden sky-rail system comprises a rail keel and a ceiling keel, wherein the ceiling keel comprises a plurality of hanging bars which are installed on a floor, and a plurality of ceiling main keels which connect all the hanging bars to the horizontal direction through hanging pieces; the rail keel is connected below all the ceiling main keels, and sliding parts are arranged on the rail keel. According to the invention, the installation positions of the ceiling keel and the rail keel are measured and snapping lines are determined, the rail keel is connected below the ceiling keel which is installed, and the sliding parts are arranged on the rail keel. The system disclosed by the invention integrates the rail keel and the ceiling keel to be a ceiling system, stress is more stable, the decorative structure is more attractive, the construction and maintenance costs are lowered, and further, the probability of common quality problems is reduced; the construction method can realize the construction integration of the rail keel and the ceiling keel, has more stable stress, simple construction steps and beautiful decoration effects, and lowers the construction cost.

Owner:CHENGDU NO 4 CONSTR ENG

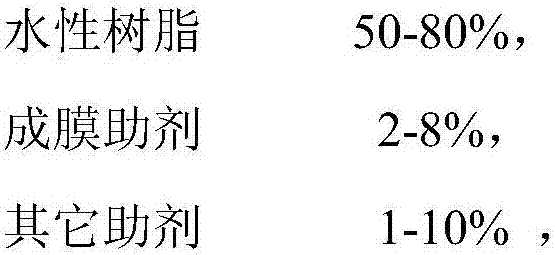

Water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat

InactiveCN107312412AStrong adhesionImprove adhesionPolyurea/polyurethane coatingsWater basedAdhesive

The invention relates to a water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat, which is characterized by being prepared from the following composition materials: water-base resin, a coalescing agent, an other auxiliary agent, titanium white pulp, mill base and water. A preparation method of the water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat is characterized by comprising the following steps: sufficiently and evenly dispersing the water-base resin, the coalescing agent, the other auxiliary agent, the titanium white pulp, the mill base and the water, and packaging to form a finished product. The water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat has the advantages of good adhesive force on various primer base materials, good color stability after colour modulation, good water resistance and stain resistance, excellent coating effect, environment friendliness, safety, and simpleness and safety in use, and can be widely applied to coating of factory furniture.

Owner:上海展辰涂料有限公司 +4

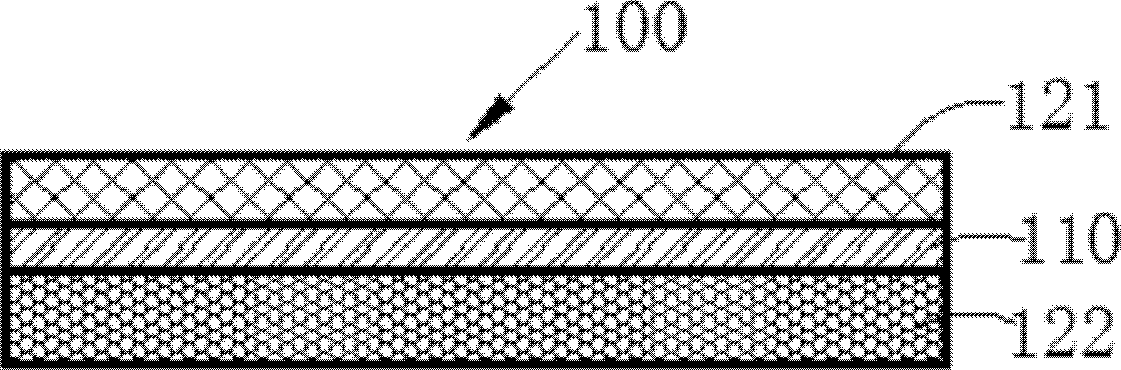

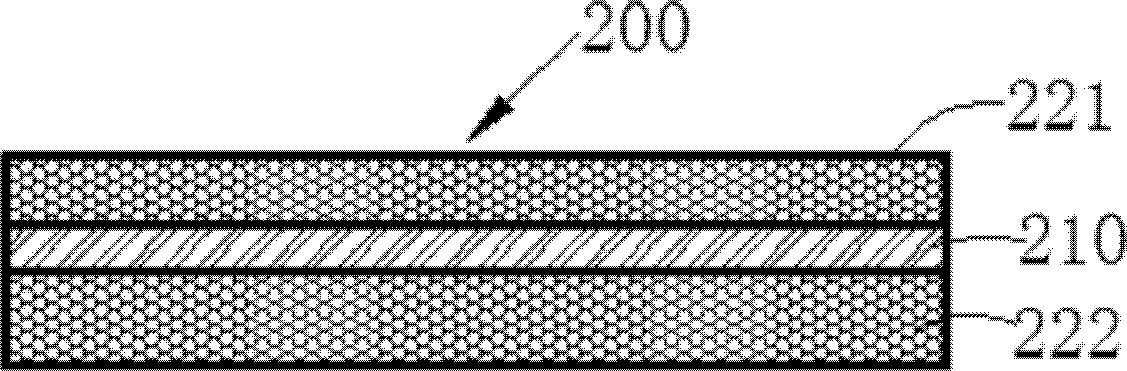

Composite material and preparation method thereof

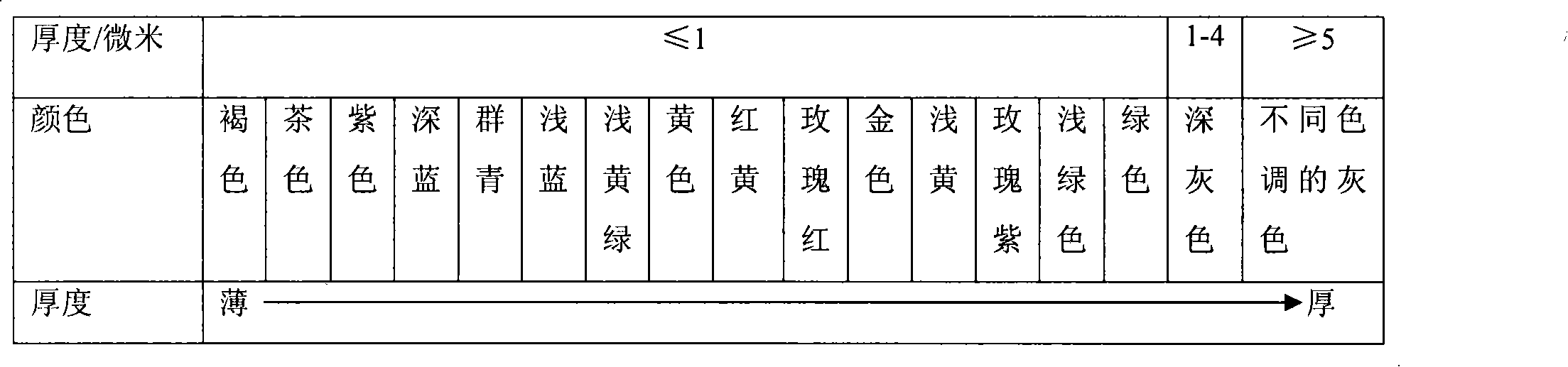

InactiveCN101619480ABeautiful decorationIncrease valueSurface reaction electrolytic coatingArtistic surface treatmentColor effectMetal

The invention provides a composite material, the composite material comprises a substrate, at least one surface of the substrate is metal, the thickness of the metal is 0.8 micron at least, the surface of the metal is an oxide film layer, wherein, the thickness of the oxide film layer is uneven, and the color of the oxide film layer is different along with the difference of the thickness. The invention further provides a preparation method of the composite material. The surface of the composite material can obtain variable multi-color effect according to the composite material and the preparation method in the invention, thereby leading the composite material to obtain beautiful decorative effect and improving value of products.

Owner:BYD CO LTD

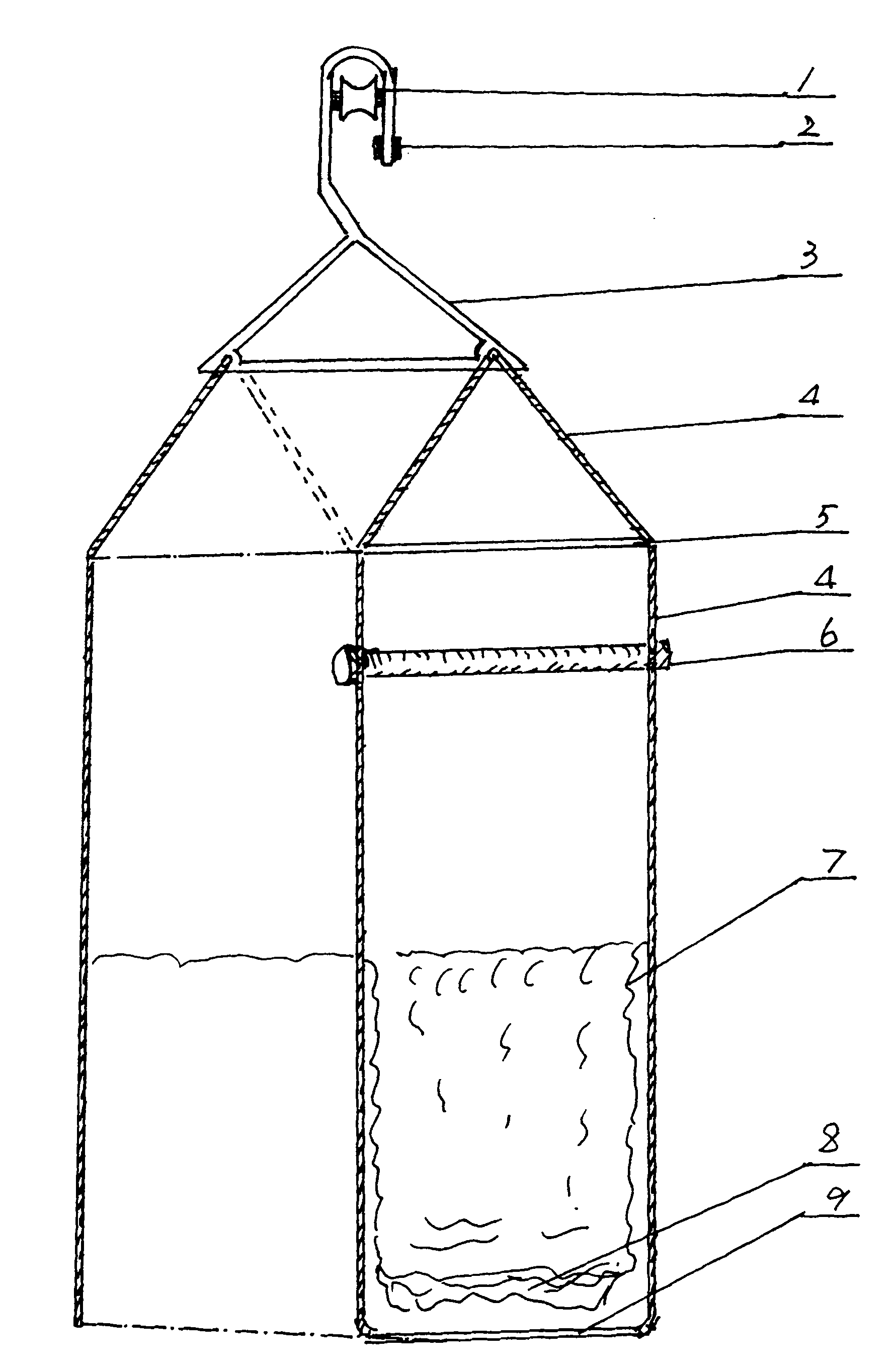

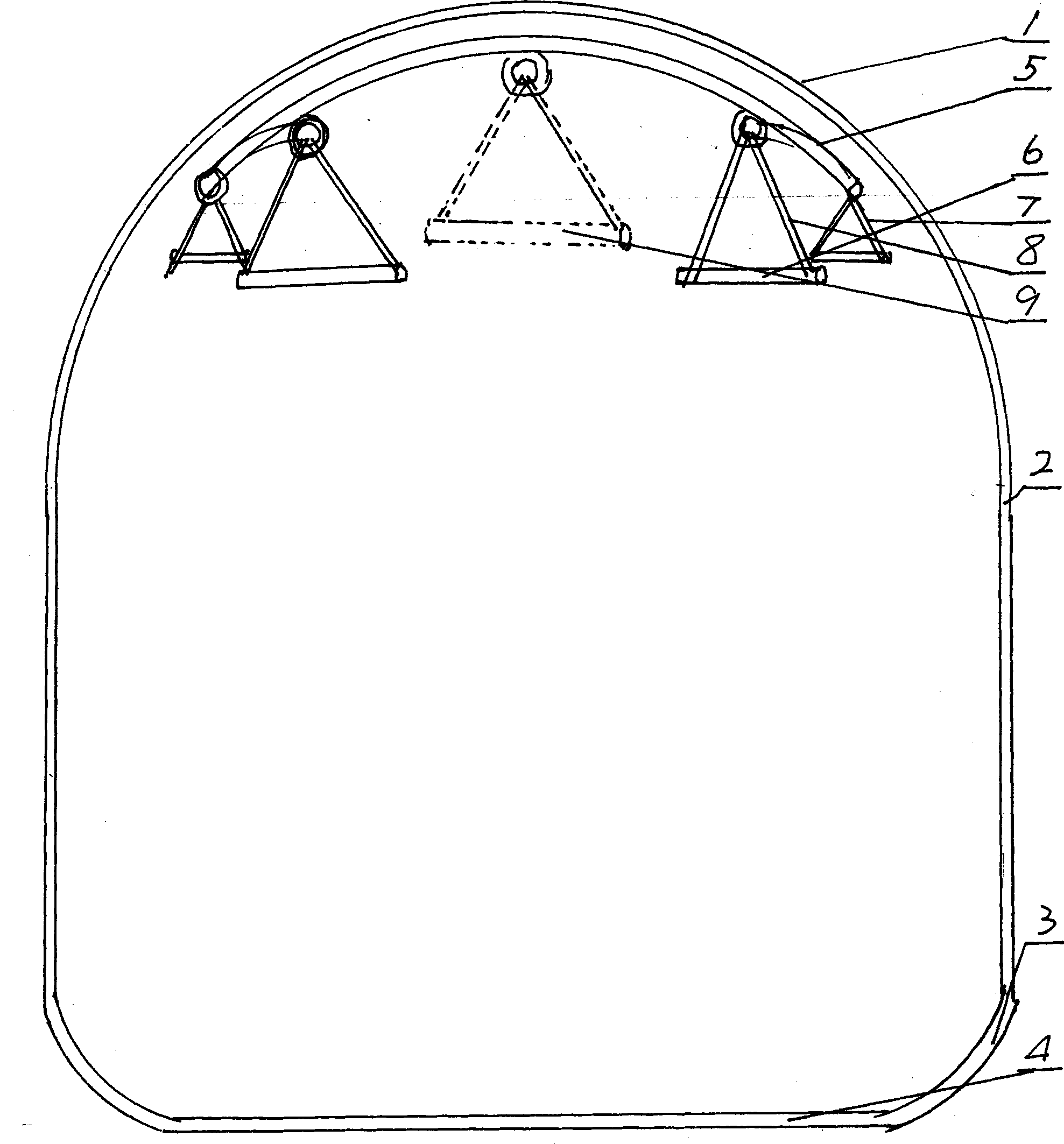

High-rise building fire escape downhill slide

A fire escape downhill slide fixed inside and outside various high-rise buildings. The slideway has springs and extension spring plate structures 1 that do not affect the passage of the main slideway. The main slideway is to link the U-shaped slideway 2 and the n-type pulley block 3 on the stairs and the support, and link the directional tripod body 4 below. The two ends of the tripod body are connected to the quick seat cover set 5, which is equipped with a fireproof soft rope 6, a width bracket 7, a hand grip 8, fireproof and anti-collision seat cover cushions 9, 10, and the slideway outside the building is compatible with various The shape of the slides composed of structural slides can be round, square, transparent, opaque, closed and non-closed, and connected with separate slides on each floor, as well as wide-open roofed ones for public entertainment places. Large-capacity slides with hoisting handles ensure rapid, full-floor, and large-scale safe escape in the first instance of a fire.

Owner:张效琪

Glass curtain wall and dismounting method thereof

ActiveCN108867952AEasy to disassembleImprove the decorative effectWallsBuilding repairsEngineeringSurface plate

The invention provides a glass curtain wall and a dismounting method thereof and belongs to the field of building curtain walls, aiming at solving the problem of an existing glass curtain wall that the dismounting efficiency is low. The glass curtain wall comprises a fixed seat and a panel, wherein the panel is connected onto the fixed seat through a connection seat; the fixed seat comprises a fixed plate, and further comprises an inner fixed sleeve and an outer fixed sleeve; the rear end of the outer fixed sleeve is fixed on the fixed plate; a sliding groove I and a sliding block I are arranged on an inner wall of the outer fixed sleeve and an outer wall of the inner fixed sleeve; the glass curtain wall further comprises a compression spring I located in the sliding groove I; a fixed holeis formed in the inner fixed sleeve; a fixed groove is formed in a hole wall of the fixed hole; the fixed groove comprises an entering groove, a locking groove and a leaving groove; the connection seat comprises a connection plate fixed with the panel, and further comprises a connection rod fixed with the connection plate; a connection groove is formed in a rod wall of the connection rod and a locking rod is embedded into the connection groove; a sliding groove II is formed in a groove bottom of the connection groove; the connection seat further comprises a sliding block II in the sliding groove II; the sliding groove II is internally provided with a compression spring II; the rear end of the locking rod is fixed with the sliding block II. The glass curtain wall provided by the inventionhas higher dismounting efficiency.

Owner:WENZHOU OULIN ELECTRONICS TECH CO LTD

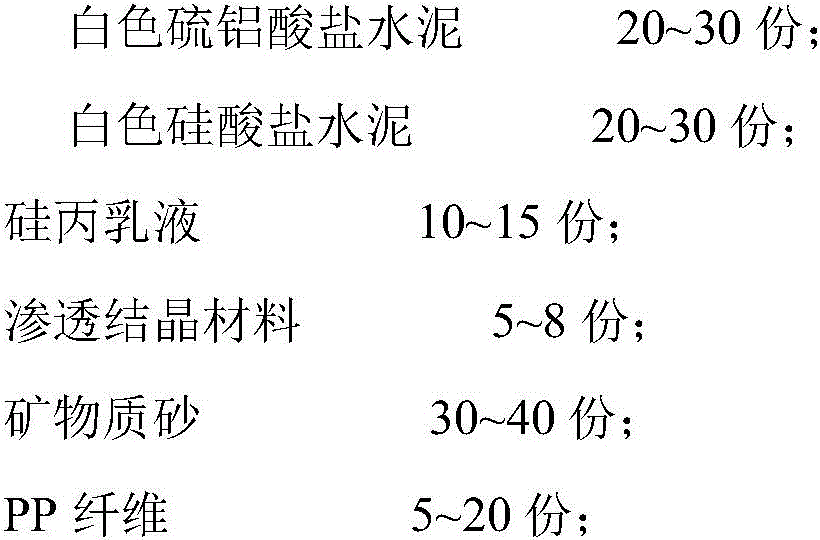

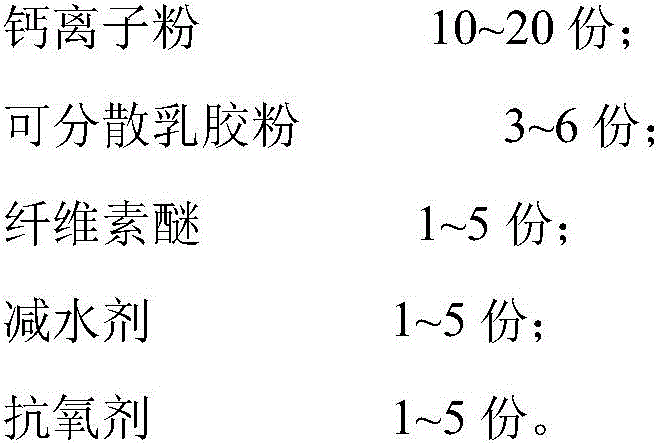

Waterproof early-strength decoration mortar and preparation method thereof

The invention discloses waterproof early-strength decoration mortar. The defect that traditional mortar cannot have both advantages of bright color and excellent waterproof early-strength effect at the same time is solved. According to main points of the technical scheme, the waterproof early-strength decoration mortar comprises the following ingredients (by weight): 20-30 parts of white sulphate aluminium cement, 20-30 parts of white portland cement, 10-15 parts of a silicon-acrylate emulsion, 5-8 parts of a permeable crystalline material, 30-40 parts of mineral sand, 5-20 parts of PP fiber, 10-20 parts of calcium ion powder, 3-6 parts of dispersible latex powder, 1-5 parts of cellulose ether, 1-5 parts of a water reducer and 1-5 parts of an antioxidant. The prepared mortar has excellent waterproofness and high strength, and has a decoration effect. According to the invention, defects of decoration mortar in the market, such as poor waterproofness and low early-strength, are compensated; and the waterproof early-strength decoration mortar with excellent properties is prepared.

Owner:苏州大乘环保新材有限公司

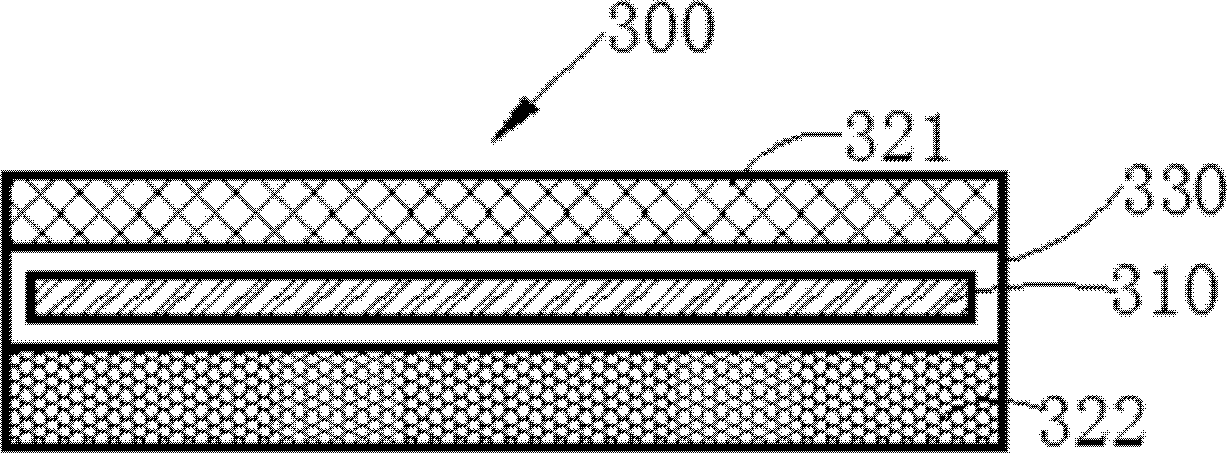

Preparation method of damp-proof water-based crack wallpaper

InactiveCN105297552AImprove antibacterial propertiesBeautiful decorationCovering/liningsAntifouling/underwater paintsWater basedWork in process

The invention discloses a preparation method of a damp-proof water-based crack wallpaper. The method comprises the following steps: selecting a base material layer, and forming a printed layer with a pattern on the base material layer through a printing technology to prepare a semi-finished wallpaper product; printing a gold dust layer on the front surface of the semi-finished wallpaper product through a cylinder overprint technology; sequentially coating the back surface of the semi-finished wallpaper product with an antibacterial layer, a damp-proof layer and dry glue layer; drying in a drying oven after printing is ended; and printing water-based crack slurry on the dried semi-finished wallpaper product, and drying and cooling at 100-120 DEG C, so as to obtain the crack wallpaper. The antibacterial layer is attached to the wallpaper, so that a good antibacterial effect can be put into a play; meanwhile, optimization is carried out on the formula of a damp-proof layer to reach an optimal damp-proof effect; and the damp-proof water-based crack wallpaper has a relatively good beautiful decorative perception through printing of the water-based slurry.

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

Efficient hidden frame glass curtain wall, disassembling tool and disassembling method

ActiveCN109079700AQuick installationImprove securityMetal-working hand toolsLocking mechanismComputer engineering

The invention provides an efficient hidden frame glass curtain wall, a disassembling tool and a disassembling method, and belongs to the field of building curtain walls. The problem that potential safety hazards exist in the existing glass curtain wall is solved. The efficient hidden frame glass curtain wall comprises a frame and a panel; the frame comprises four fixed plates and connecting plates; a frame plate is fixed on the outer side surface of each connecting plate; a lock groove is formed in the inner wall of a connecting frame; a locking mechanism is also provided; the locking mechanism comprise a locking plate fixed with the back side of the panel; the locking plate comprises an outer lock sleeve and an inner lock sleeve; an outer blocking edge and an inner blocking edge are fixedon the inner wall of the back end of the outer lock sleeve and the outer wall of the back end of the inner lock sleeve; a lock cavity is formed between the outer lock sleeve and the inner lock sleeve; a locking ring and a baffle are arranged in the lock cavity; a locking block is embedded on the front side surface of the locking ring; a stop block is fixed on the back side surface of the baffle;a rod hole is formed in the outer lock sleeve; a rod groove is formed in the locking ring; a sliding groove is formed in the rod groove; a sliding block is arranged in the sliding groove in a slidingway; a locking rod is also provided; the locking rod penetrates through the rod hole; the inner end of the locking rod is fixed with the sliding block; and a reset spring is arranged in the lock cavity. After being mounted, the glass curtain wall is safer and more stable.

Owner:WENZHOU OULIN ELECTRONICS TECH CO LTD

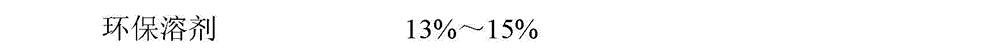

Fireproof coating and preparation method thereof

InactiveCN102977712AGood weather resistanceImprove acid resistanceFireproof paintsPolyether coatingsFiberAdhesion force

The invention discloses a fireproof coating and a preparation method thereof. The fireproof coating comprises the following components; environment-friendly solvents, weather resistant acrylic resins, chloric ether resins, 586 flame retardant amine resins, dispersing agents, an intumescent flame retardant, titanium white powder, flame retardant auxiliaries, wood fibers, inorganic microbead hollow fillers and anti-sag agents. The fireproof coating can be coated on various substrates, so that the fireproof coating is an ultra-thin effective fireproof coating which is specially applied to outdoors and can resist burning of hydrocarbon fire, has the chemical properties of high weather fastness, acid resistance and alkali resistance, is high in adhesion force, durable, fine and smooth in coating film, attractive in decoration effect, uniform in expansion, special in bubble body structure, high in fireproof effect, environment-friendly in products, free from environment pollution and convenient to construct, and can be used for coatings of various fireproof requirements, and production process is simplified.

Owner:WUXI HUHUANG PAINT

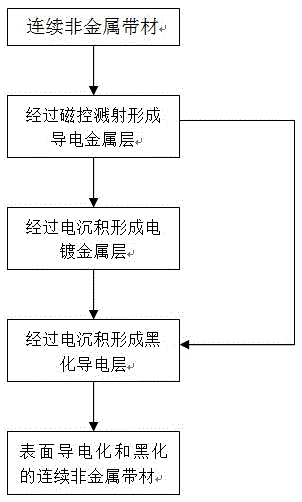

Conductive treatment and oxide treatment method for continuous non-metal strip

InactiveCN105648438AImprove conductivityImprove shielding effectMagnetic/electric field screeningFinal product manufactureMetal stripsElectromagnetic shielding

The invention discloses a conductive treatment and oxide treatment method for a continuous non-metal strip. Firstly, the surface of the continuous non-metal strip serving as a substrate is plated by metal, then an oxidized conductive layer is formed through electro-deposition, and the black continuous non-metal strip can be obtained. The strip has excellent conductivity, light absorption and extinction performance, heat absorption and cooling performance, friction resistance, corrosion resistance, electromagnetic shielding performance and wave-absorbing capacity, and has huge application value in the field of electromagnetic shielding and wave-absorbing materials.

Owner:WUZHOU HGP ADVANCED MATERIALS TECH CORP

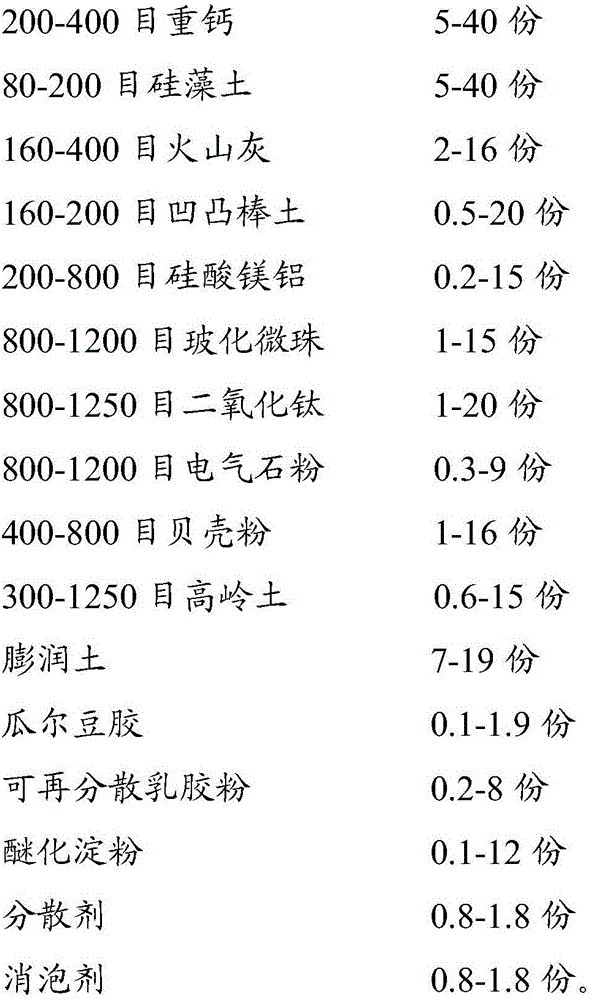

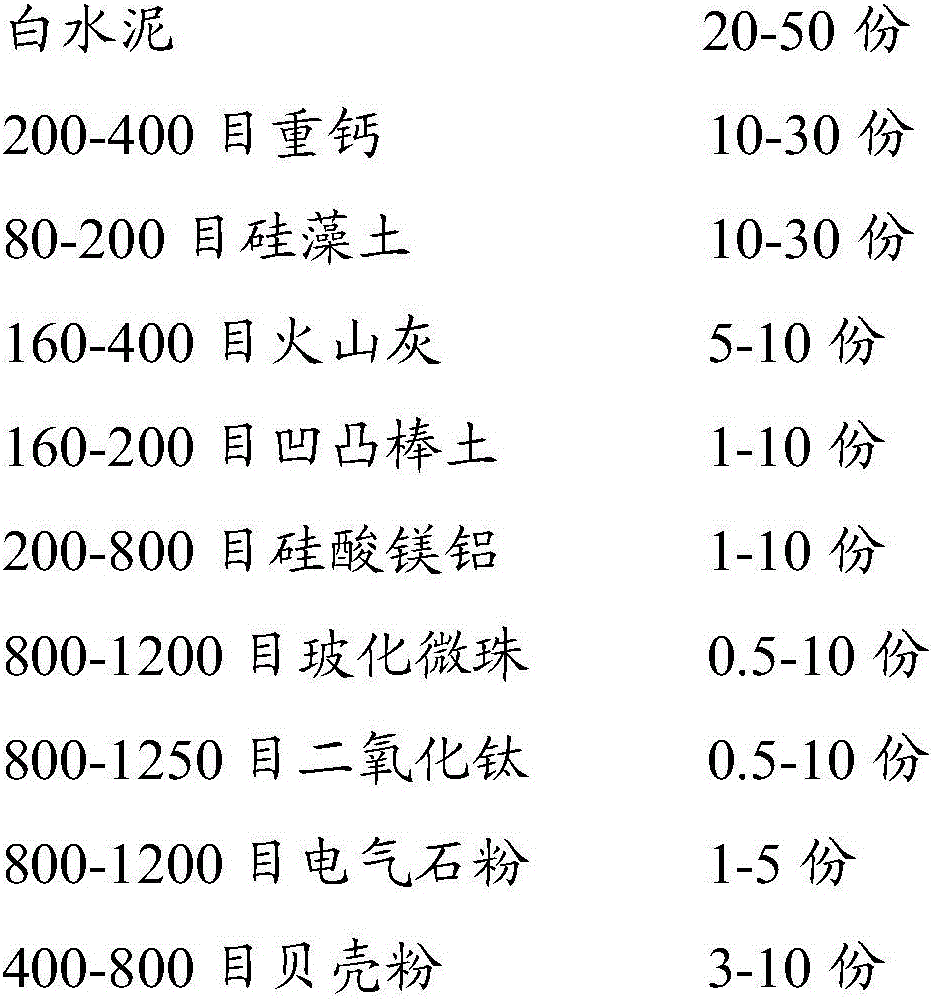

Inorganic diatom coating material for outdoor decorative walls and preparation method thereof

InactiveCN106082864ABeautiful and decorativeBeautiful heat insulationTriple superphosphateAluminum magnesium silicate

The invention discloses an inorganic diatom coating material for outdoor decorative walls and a preparation method thereof, and belongs to building decorative materials. The inorganic diatom coating material for outdoor decorative walls is prepared from 10-60 parts of white cement, 5-40 parts of triple superphosphate, 5-40 parts of kieselguhr, 2-16 parts of cinerite, 0.5-20 parts of attapulgite, 0.2-15 parts of aluminum-magnesium silicate, 1-15 parts of glass beads, 1-20 parts of titanium dioxide, 0.3-9 parts of tourmaline powder, 1-16 parts of shell powder, 0.6-15 parts of kaolin, 7-19 parts of bentonite, 0.1-1.9 parts of guar gum, 0.2-8 parts of redispersible latex powder and 0.1-12 parts of etherified starch. The inorganic diatom coating material for outdoor decorative walls has the attractive decorativeness and the heat preservation and heat insulation functionality.

Owner:白山和一硅藻科技股份有限公司 +1

Water spray type wall ash shoveling device

ActiveCN104594610AReduce physical exertionEasy to useBuilding constructionsMotor driveWorking environment

The invention discloses a water spray type wall ash shoveling device which comprises a motor, a porous water spraying pipe and a motor drive cross-shaped rotary tool rest. Four tool rest plates of the cross-shaped rotary tool rest extend in the axial direction, and each tool rest plate is fixedly provided with at least one row of combined blades. Each row of combined blades is composed of a plurality of blades, and outer edges of the blades form sharp edges. The outer-edge sharp edges of the cross-shaped rotary tool rest extend out of a main box. An upper cover plate of the main box is connected with an engagement adjusting rack through a hand wheel type screw. The engagement adjusting rack can move upwards and downwards relative to the main box by rotating the hand wheel type screw. The water spray type wall ash shoveling device is convenient to use, flexible to operate, safe and reliable, light and delicate in appearance, and capable of reducing ashes, improving the working environment, lowering physical strength consumption during wall operation, enabling the ashes to be shoveled more thoroughly and improving the shoveling effect.

Owner:郑根连 +1

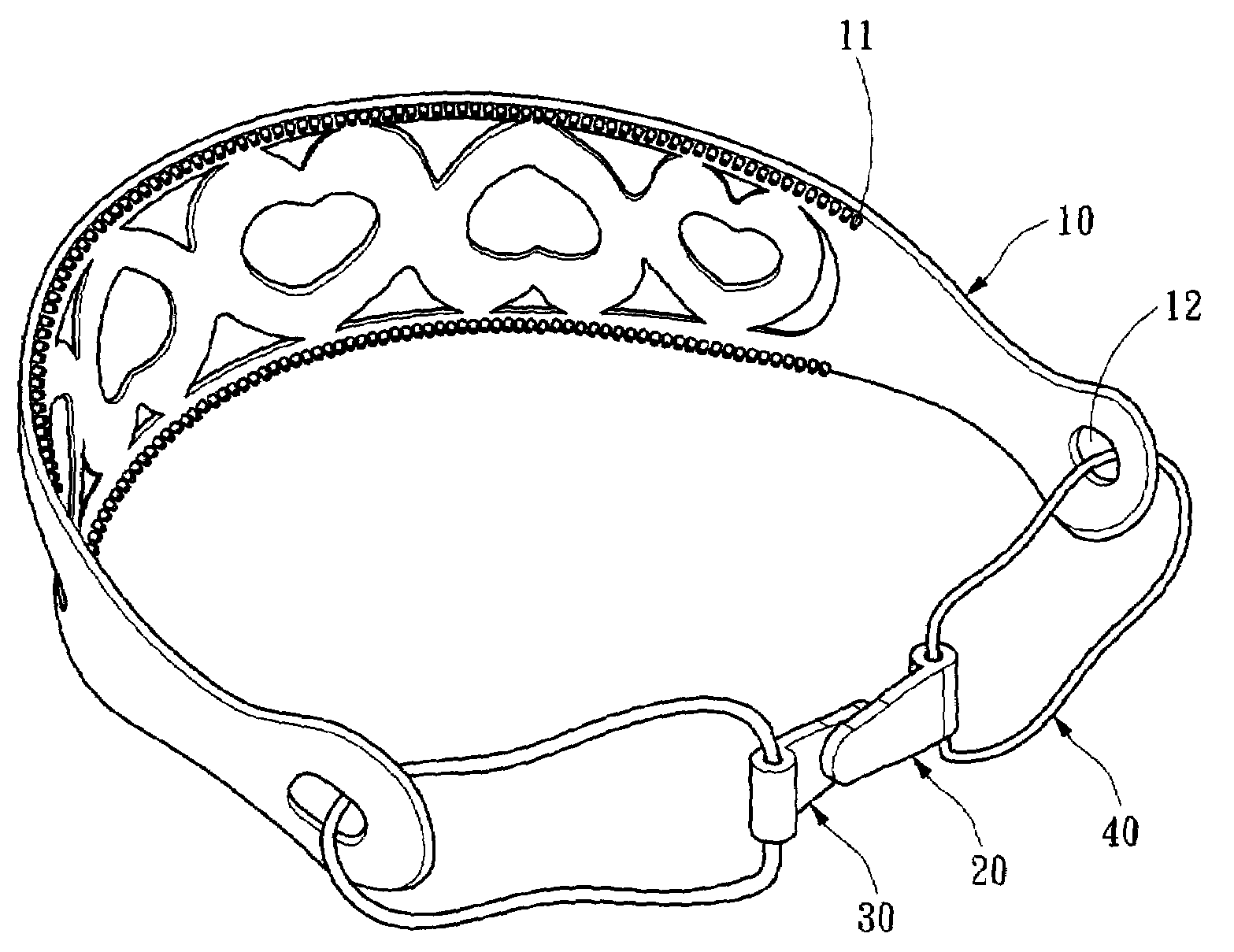

Papa ring capable of cooling and absorbing sweat

The invention discloses a papa ring capable of cooling and absorbing sweat. The papa ring is provided with an elastic curling strip and an outer layer wrapped outside the elastic curling strip. The outer layer is formed by a face layer and a back layer arranged on two sides of the elastic curling strip respectively. At least one of the back layer and the face layer is a polyvinyl acetate (PVA) chamois towel. Due to the fact that the back layer and / or the face layer of the outer layer are / is made of the PVA chamois towel, the papa ring has some characteristics of the PVA chamois towel so that the papa ring has original functions and simultaneously has the effects of absorbing sweat, wiping sweat and enabling the body to feel cool. When the face layer of the outer layer is a decorating layer, the papa ring has an attractive decorating effect.

Owner:昆勤清洁用品(昆山)有限公司

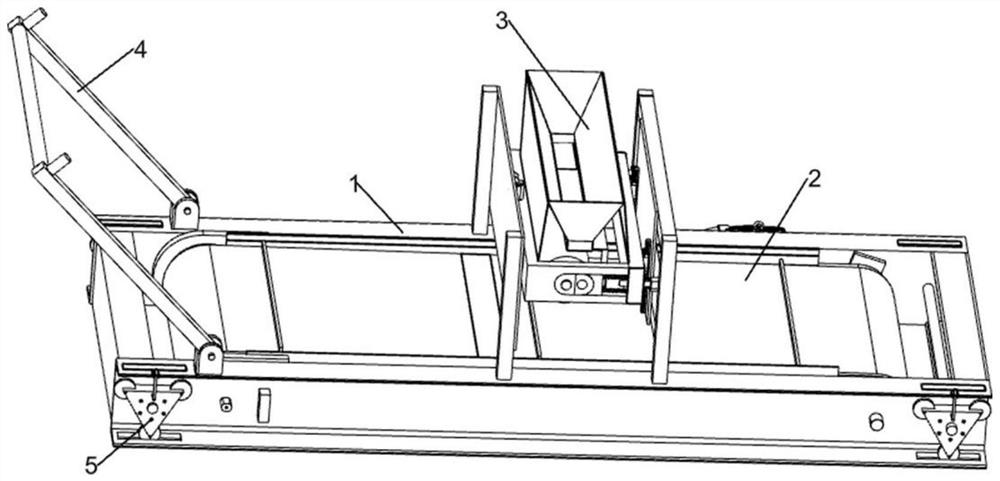

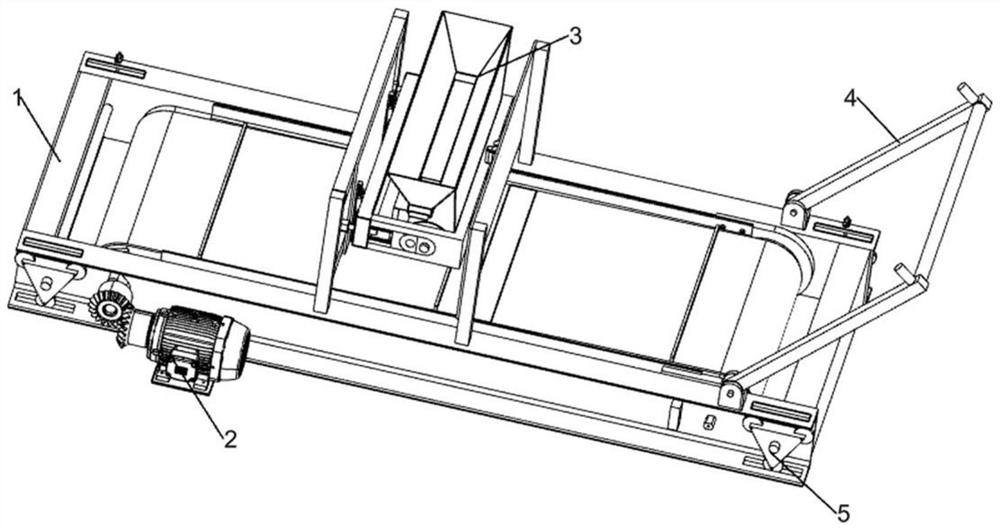

Movable ceramic tile back face gluing device for decoration

ActiveCN112064989ABeautiful decorationImprove work efficiencyBuilding constructionsAdhesive glueBuilding renovation

The invention relates to the field of building decoration, and particularly relates to a movable ceramic tile back face gluing device for decoration. The movable ceramic tile back face gluing device for decoration comprises a rack, a conveying mechanism, a feeding mechanism, a push handle and wheels, wherein the conveying mechanism is arranged in the rack; and the middle of the upper end of the rack is fixedly connected to the feeding mechanism. The movable ceramic tile back face gluing device for decoration achieves the effects that manual work is replaced in batches to coat ceramic tiles with glue, and therefore the work efficiency is improved; meanwhile, glue discharging can be controlled according to the sizes of the ceramic tiles, and resources are saved; and meanwhile, the device cancoat all places on the back faces of the ceramic tiles with ceramic tile glue, and therefore the ceramic tiles pasted to a wall are firmer.

Owner:广东煜煜建设工程有限公司

Moisture-proof aqueous cracked wallpaper

InactiveCN107724176AImprove antibacterial propertiesBeautiful decorationAntifouling/underwater paintsCovering/liningsScreen printingMoisture

The invention discloses a moisture-proof aqueous cracked wallpaper. The wallpaper comprises a substrate layer, a printing layer, a golden sand layer, an antibacterial layer, a moisture-proof layer anda dry adhesive layer. Preparation of the wallpaper includes the steps of selecting the substrate layer and forming the printing layer having patterns on the substrate layer through a printing processto obtain a wallpaper semi-finished product, printing the golden sand layer on the surface of the wallpaper semi-finished product through a rotary screen printing process, coating the back of the wallpaper semi-finished product with the antibacterial layer, the moisture-proof layer and the dry adhesive layer in sequence, placing the wallpaper in an oven for drying after the printing is completed,printing aqueous cracking paste on the wallpaper semi-finished product after drying, drying at 100 DEG C to 120 DEG C and cooling to obtain the cracked wallpaper. The moisture-proof aqueous cracked wallpaper can achieve an antibacterial effect by attaching the antibacterial layer to the inside of the wallpaper, achieves a better moisture-proof effect through the optimization of the formula of themoisture-proof layer and has a better aesthetic decoration sense through the printing of the aqueous paste.

Owner:NANAN WEISU ELECTRONIC TECH CO LTD

Water-borne epoxy anti-corrosion paint and preparing method thereof

InactiveCN109796848ASimple production processEasy to useAlkali metal silicate coatingsAnti-corrosive paintsEpoxyMetasilicate

The invention relates to the field of water-borne anti-corrosion materials, and particularly discloses water-borne epoxy anti-corrosion paint and a preparing method thereof. The water-borne epoxy anti-corrosion paint comprises a component A and a component B mixed in use. The component A comprises a water-borne epoxy resin emulsion, potassium metasilicate, lithium silicate, a water-borne wetting dispersant and deionized water. The component B comprises zinc powder, carborundum, filler and antirust pigments. Through the two-component system with the component A and the component B, after the component B is added to the component A in use to be evenly stirred and filtered, spray-coating construction can be conducted, and the paint is easy and convenient to use, environmentally friendly, capable of saving energy and safe to use, can be widely used for corrosion prevention of a high-strength steel structure connecting face, has the advantages of excellent ageing resistance, temperature difference resistance, salt and alkali resistance and salt mist resistance, high hardness and the like, and can be used as long-acting maintenance-free external paint and high-performance anti-corrosionpaint.

Owner:河北汇君新材料制造有限公司

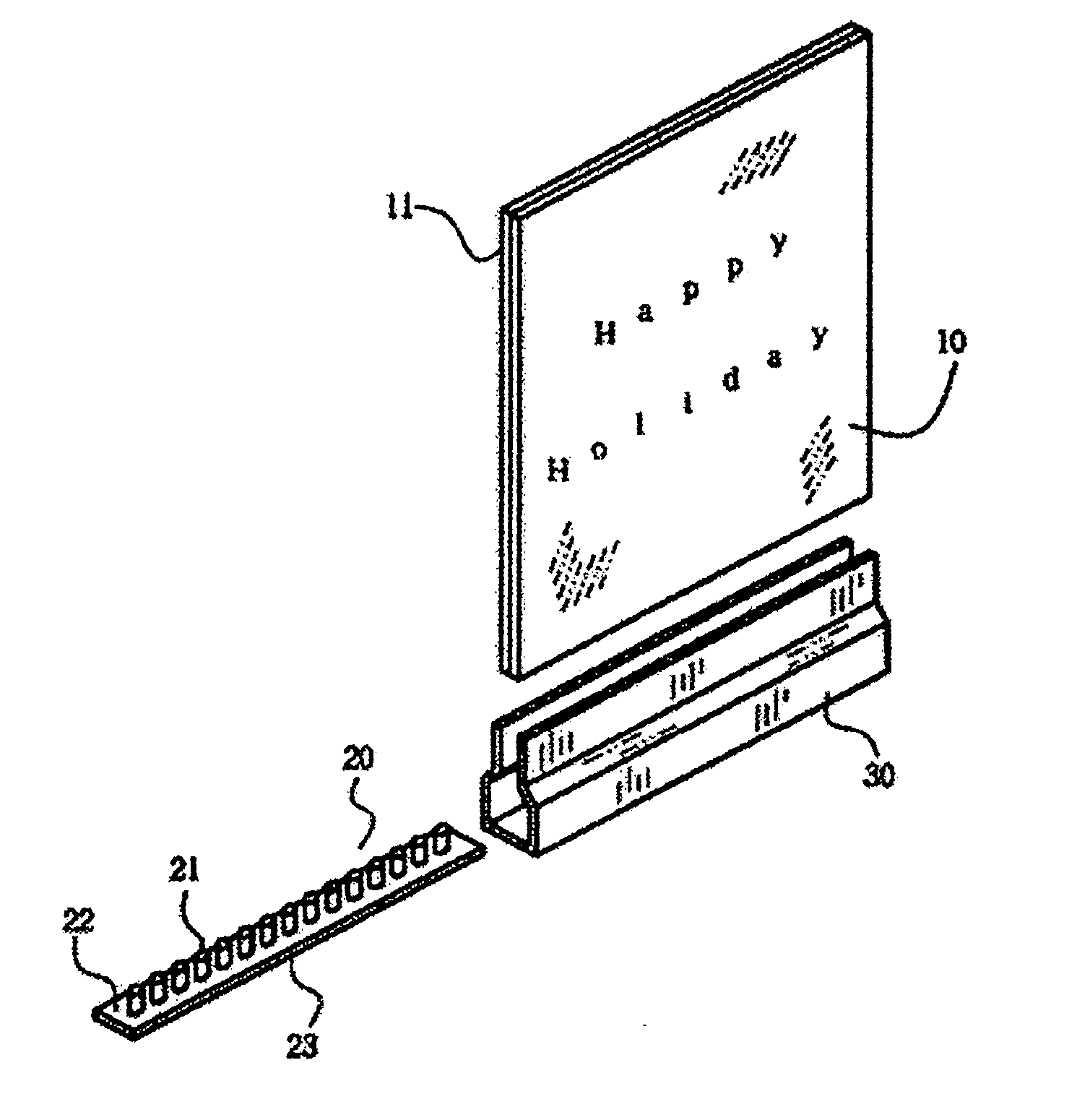

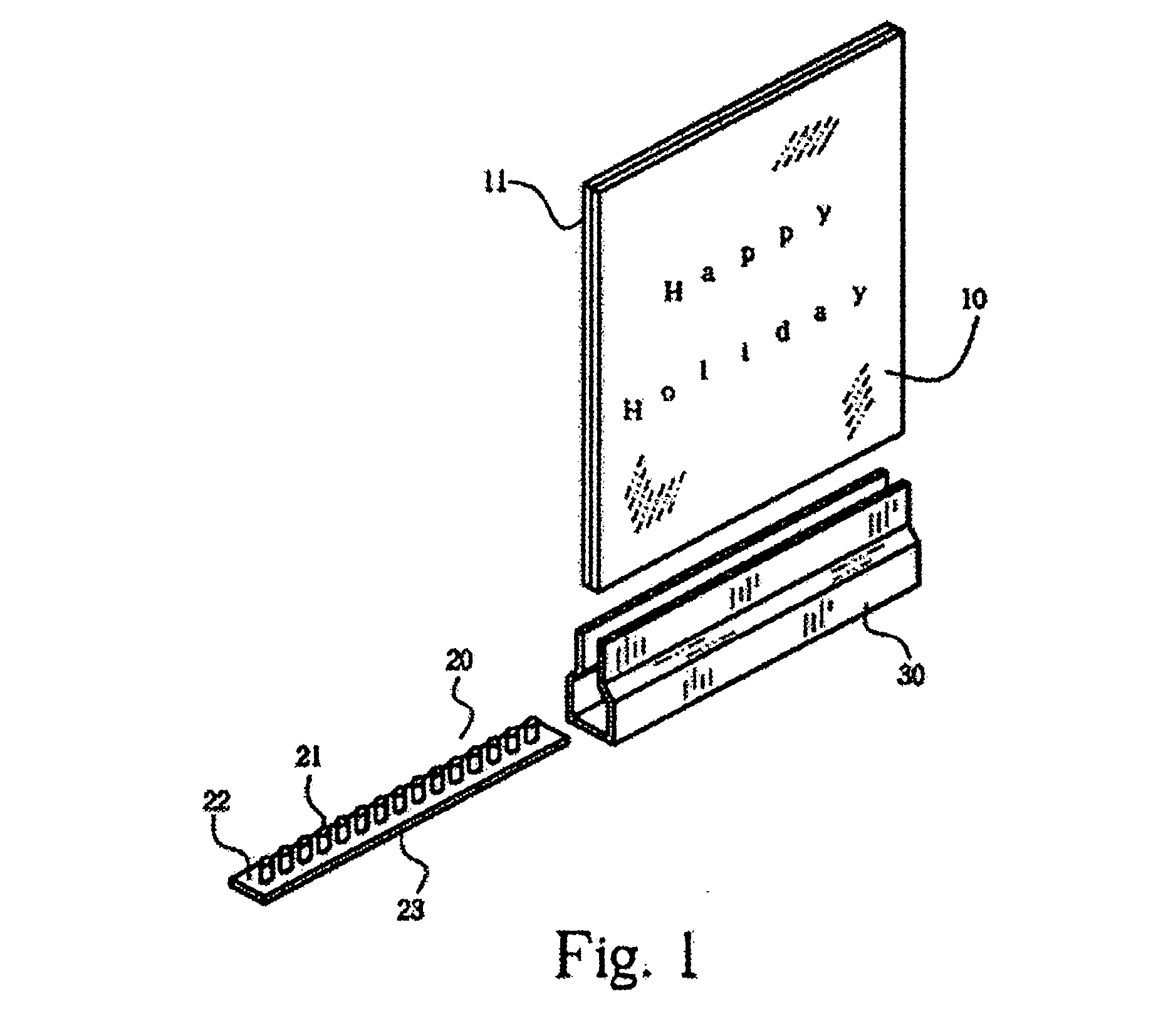

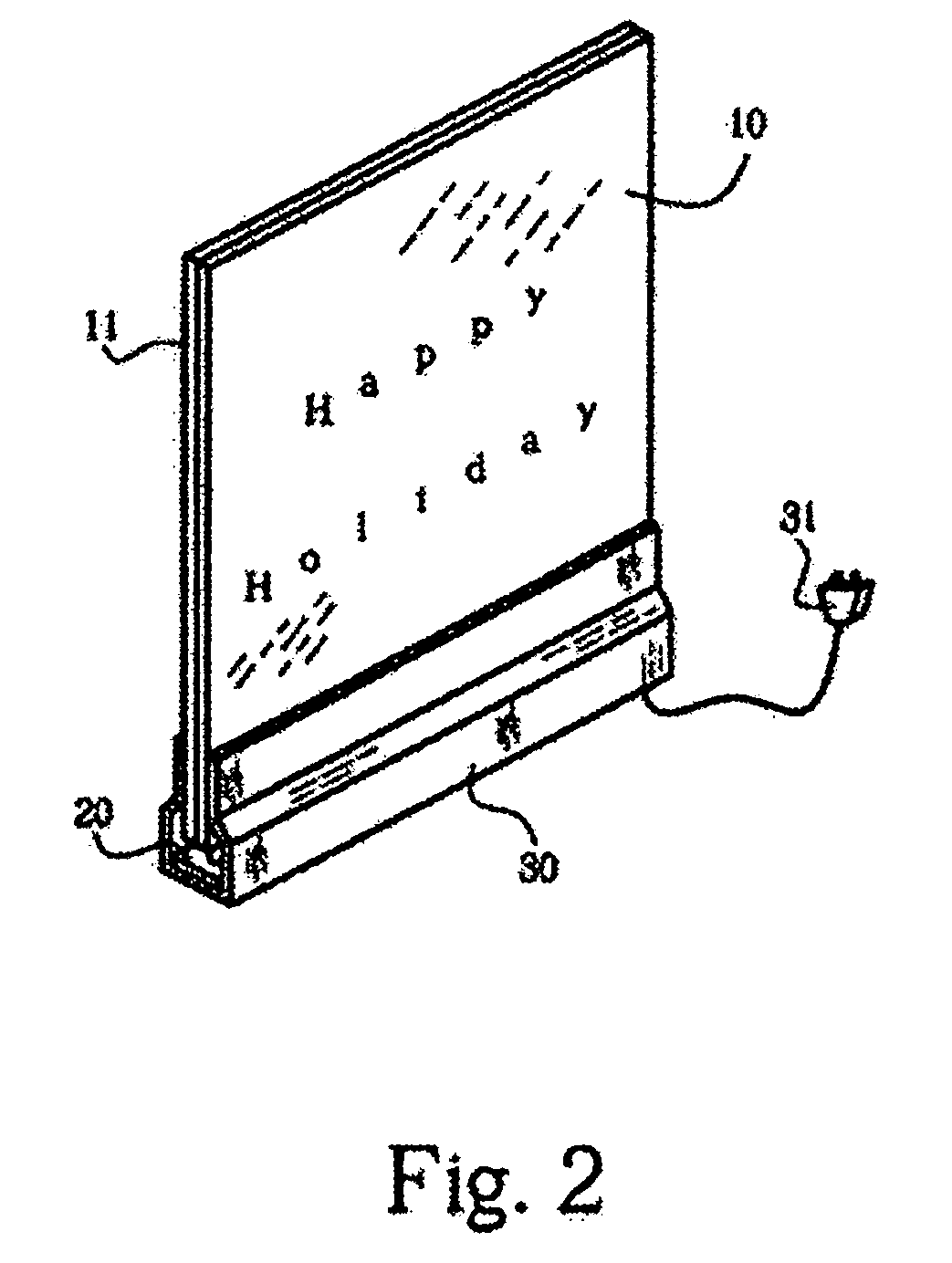

Transparent Plate with Color-Changeable Lighting Image

InactiveUS20070147034A1Simple structureBeautiful decorationOptical light guidesIlluminated signsColor imageScreen printing

The transparent plate with color-changeable lighting image comprises a transparent plate, a color-changeable light source, and an attachment. Said transparent plate is covered by a white or color image layer on its surface, said color-changeable light source is disposed on one side of the transparent plate along a direction normal to the section of the side thereof, and said transparent plate and color-changeable light source are fastened together by the attachment means. The invention has no need to replace the changeable light source and may have various patterns and art words screen-printed therein, thus producing a full color flashing and fadeless effect.

Owner:LI XULIANG

Differential arc oxidation electrolytic solution and differential arc oxidation method

ActiveCN101476143BImprove corrosion resistanceImprove dirt resistanceAnodisationElectrolytic agentMicro arc oxidation

The invention provides a micro-arc oxidation electrolyte which is a water solution comprises phosphate and silicate, and has 6-12 PH value. The electrolyte has characteristics that the electrolyte also comprises colorant, the colorant comprises A and B components, wherein, A comprises one or some of potassium fluoride, sodium fluoride, sodium sulfate and borax, B comprises cupric pyrophosphate and / or bluestone. The micro-arc oxidation electrolyte and the method for micro-art oxidating provided by the invention can make micro-arc oxidation film of light metal material obtaining uniform color for having beautiful decorating effect. At the same time, the obtained micro-arc oxidation film of light metal material surface has better stain resistance and compactness that increases additive valueand practical using value of magnesium alloy greatly.

Owner:BYD CO LTD

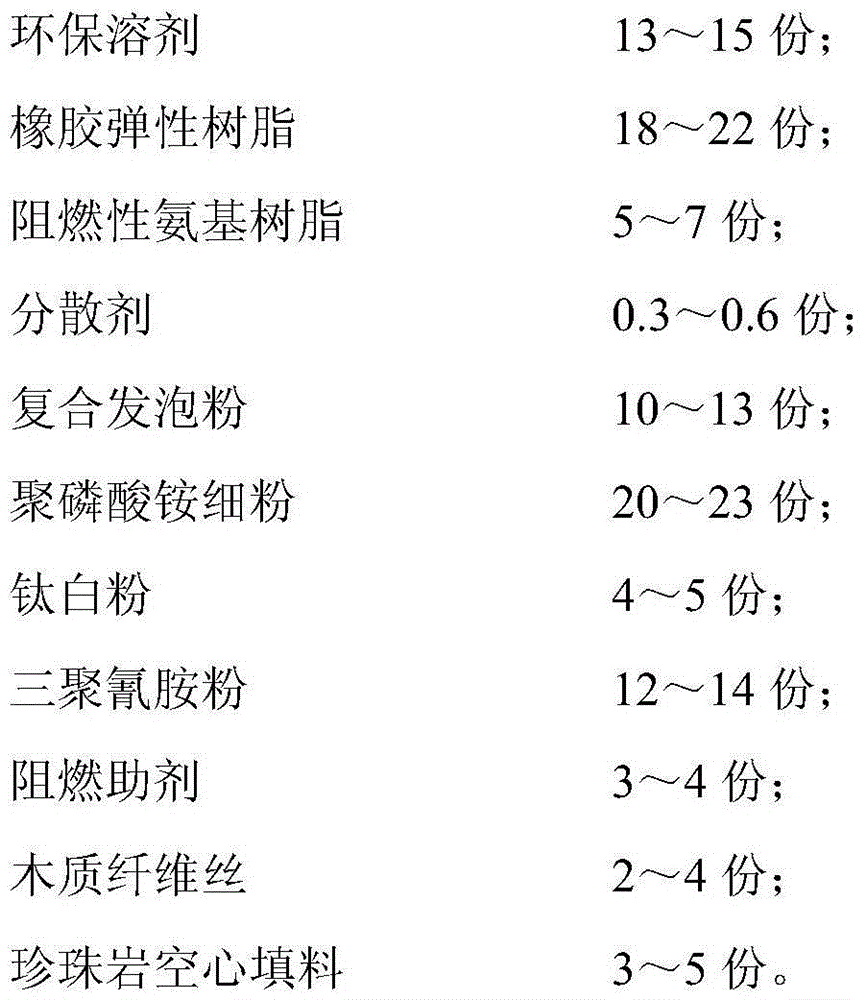

Outdoor elastic fireproof paint and preparation method thereof

ActiveCN104449186AIncrease elasticityImproved wet adhesionFireproof paintsLignin material coatingsFiberWeather resistance

The invention relates to an outdoor elastic fireproof paint and a preparation method thereof. The outdoor elastic fireproof paint comprises the following components: an environment-friendly solvent, rubber elastic resin, flame-retardant amino resin, a dispersant, compound foam powder, fine ammonium polyphosphate powder, titanium pigment, melamine powder, a flame retardant aid, wood cellosilk and hollow perlite fillers. By mixing and matching the rubber elastic resin with the flame-retardant amino resin, the outdoor elastic fireproof paint has ultrahigh water resistance and excellent wet adhesion, weather resistance, elasticity and tensile strength, the condition that the construction is canceled because of raining is reduced, a coating cannot be damaged by the washing of rainwater, and the limitation of construction conditions is avoided; by imitating an actual construction process and a long-term raining condition, the paint is brushed three times continuously to obtain a paint coat with the thickness of 900 microns, and the paint coat which is not completely dried cannot be damaged after being washed by rainwater uninterruptedly for five days and five nights; the paint also has chemical resistance, so that the outdoor use and the durability are guaranteed, and the service life of the outdoor elastic fireproof paint is long.

Owner:WUXI HUHUANG PAINT

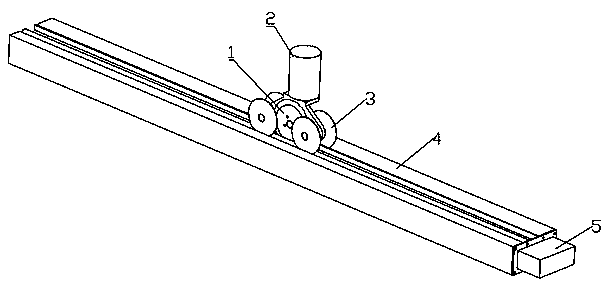

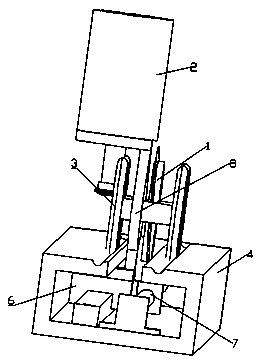

Automatic sawtooth transverse cutter

The invention discloses an automatic sawtooth transverse cutter and relates to the field of cloth cutting. The transverse cutter solves the problem of the bad influence brought by an existing transverse cutter. The transverse cutter comprises a slope rotating cutter, a cutter motor, a cloth pressing wheel and a guide rail base. The guide rail base is provided with a guide rail. The slope rotatingcutter is fixed to a sliding block and driven by the cutter motor. The sliding block is installed on the guide rail. A screw rod motor is installed at one end of the guide rail base. The output end ofthe screw rod motor is connected with a screw rod which is connected with the sliding block. The cloth pressing wheel is fixed to a groove of the guide rail base. The automatic sawtooth transverse cutter is simple in structure, convenient to use, easy to maintain, low in use cost and suitable for being used and popularized. According to cloth cut by the transverse cutter, a corrugated sawtooth cut opening is formed in the cut opening portion, falling of fabric yarn and generation of batting are prevented, the attractive decorating effect is formed, and the problems that a cut opening cut by aconventional transverse cutter is straight, yarn falls easily, and a traditional sawtooth cutter is high in cost, large in loss and complex in structure are solved.

Owner:上海得一智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com