Water-based epoxy anticorrosive paint and preparation method thereof

An anti-corrosion coating, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of increasing construction difficulty and quality controllability, low solid content of formulations, and high VOCs content, achieving increased Anti-skid and anti-migration effect, simple and convenient production process, and the effect of increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other, and the present application will be further described in detail below in conjunction with specific embodiments.

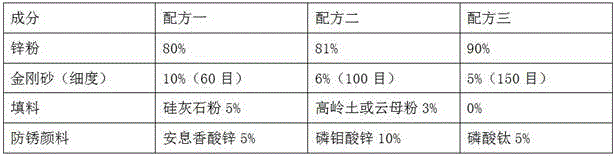

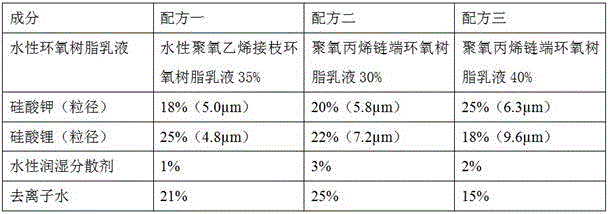

[0024] The invention provides a water-based epoxy anti-corrosion coating, which is a two-component system, which is prepared by mixing component A and component B at a weight ratio of 1:2~3. Preferably, component A and component The weight ratio of Part B is 1:3. The specific ingredients and formulations of component A and component B are described as follows.

[0025] Described component A comprises following composition by mass percentage:

[0026] Water-based epoxy resin emulsion 30-40%;

[0027] Potassium silicate 18-25%;

[0028] Lithium silicate 18-25%;

[0029] Water-based wetting and dispersing agent 1% to 3%; and

[0030] Deionized water 15% to 25%.

[0031] During specific impleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com