Hidden sky-rail system and construction method

A technology of a sky rail system and a construction method, which is applied to building components, buildings, ceilings, etc., can solve the problems of limited load-bearing capacity, cracking, displacement, deformation, and easy cracking, displacement, and deformation of decorative ceilings. The effect of reducing construction cost and maintenance cost, reducing cracking and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

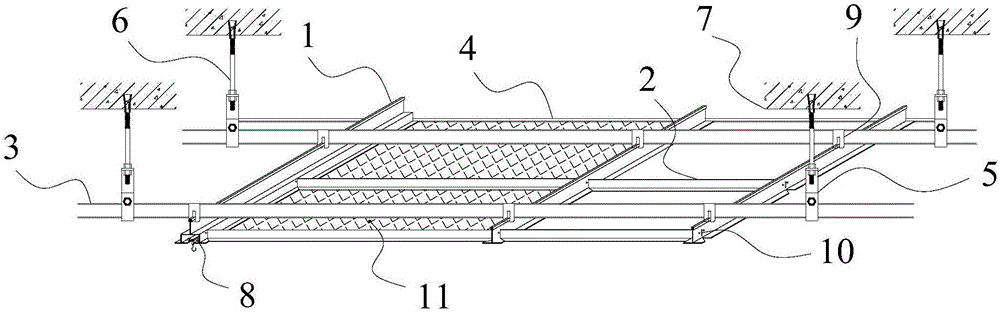

[0046] Such as figure 1 As shown, a hidden sky rail system includes a track keel and a ceiling keel, the track keel is an aluminum alloy profile, the ceiling keel is a light steel keel, and the track keel includes a track main keel 1 and a track secondary keel 2, The ceiling keel includes several vertical hanging ribs 6 installed on the floor 7, the hanger 5 at the lower end of the hanger 6, the main ceiling keel 3 connected to the lower end of the hanger 5 and the ceiling edge keel 4 arranged on the wall, The track main keel 1 is connected below the ceiling main keel 3 through a pendant 9, and is perpendicular to the ceiling main keel 3. The track main keel 1 is provided with a bayonet 10, and the track sub keel 2 is arranged on the In the bayonet 10, the track secondary keel 2 is vertically overlapped with the track main keel 1, and the cross-sectional shape of the ceiling side keel 4 is L-shaped. There is a panel 11, and the track main keel 1 is a T-shaped keel, and a chute ...

Embodiment 2

[0049] A construction method of a hidden sky rail system comprises using a hidden sky rail system as in embodiment 1, and its construction method comprises the following steps:

[0050] Step 1, measuring the installation positions of the ceiling keel and the track keel;

[0051] Step 2, determine the horizontal elevation and plane position of the ceiling keel according to the control line, and determine the hanging point of the hanging bar 6;

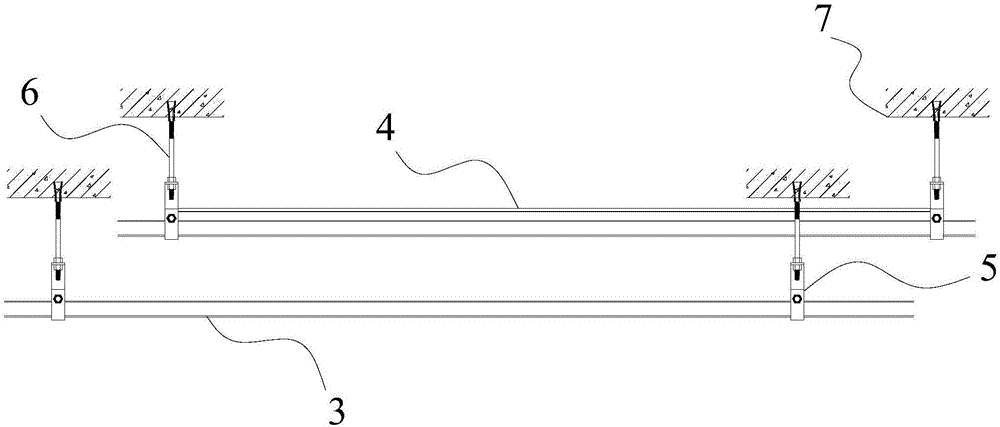

[0052] Step three, such as figure 2 As shown, to install the ceiling keel, first install several hanging ribs 6 and ceiling side keel 4 on the floor 7, install hanging parts 5 under all the hanging bars 6, and install several main ceiling hangers on the hanging parts 5. Keel 3, forming a ceiling keel;

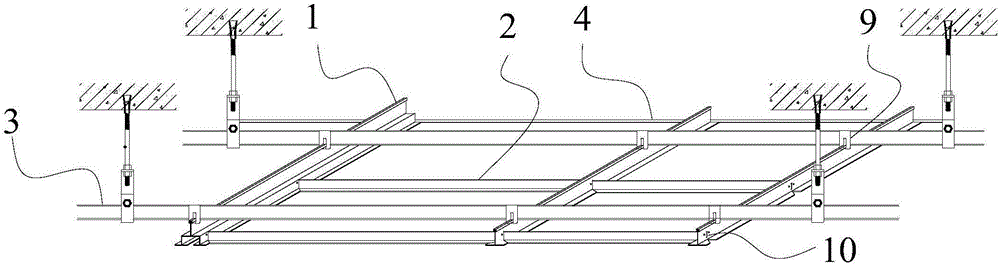

[0053] Step 4, such as image 3 As shown, several track main joists 1 are first installed between all said ceiling joists 3, and then track sub-keels 2 are installed between all said track main joists 1 to form track joists;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com