Fireproof coating and preparation method thereof

A fire retardant coating, proportional technology, applied in the direction of fire retardant coatings, polyether coatings, coatings, etc., can solve mechanical properties such as compressive strength, elastic modulus, yield point, load capacity reduction, lack of support, mechanical Intensity reduction and other issues, to achieve the effect of saving man-hours and manpower, saving energy, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

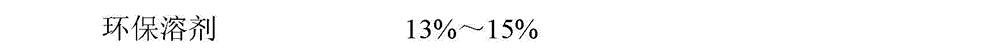

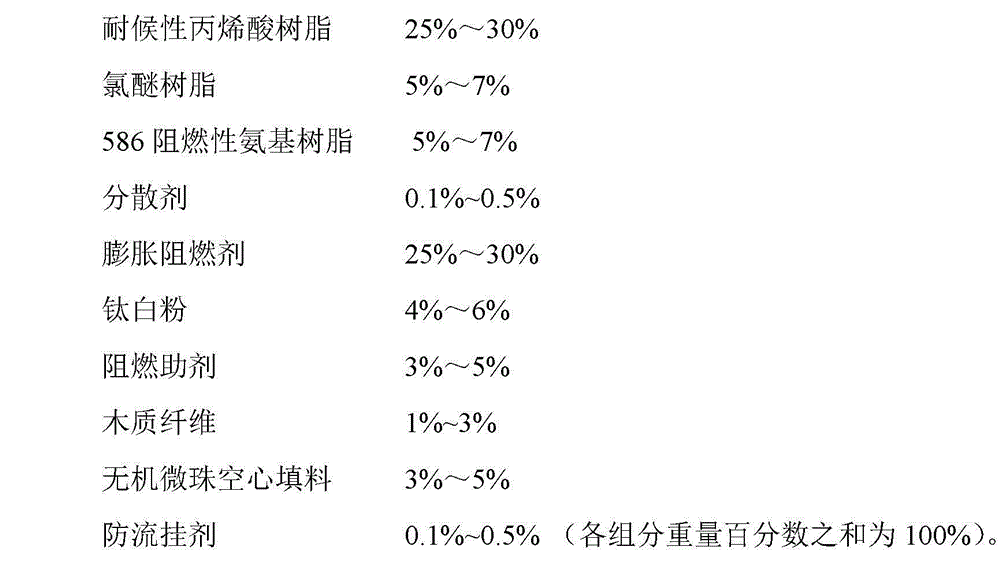

[0048] A kind of fireproof coating, it comprises the component of following percentage by weight:

[0049]

[0050] The environmentally friendly solvent is MADE; the weather-resistant acrylic resin is commercially available, model HBP2050.

[0051] The chlorinated ether resin is a commercially available new polychlorinated ether resin (model mp-35).

[0052] The dispersant is BYK-P104.

[0053] The intumescent flame retardant is a special intumescent flame retardant for commercially available fireproof coatings.

[0054] The titanium dioxide described is rutile type titanium dioxide; the flame retardant additive is 70% chlorinated paraffin powder.

[0055] The wood fiber is a mixture of fibers with filament lengths of 100 μm and 200 μm in a weight ratio of 1:1.

[0056] The hollow filler of the inorganic microbeads is glass hollow microspheres;

[0057] The anti-sagging agent is pure polyamide wax.

[0058] Preparation Process:

[0059] (1) Add environmental solvent, ...

Embodiment 2

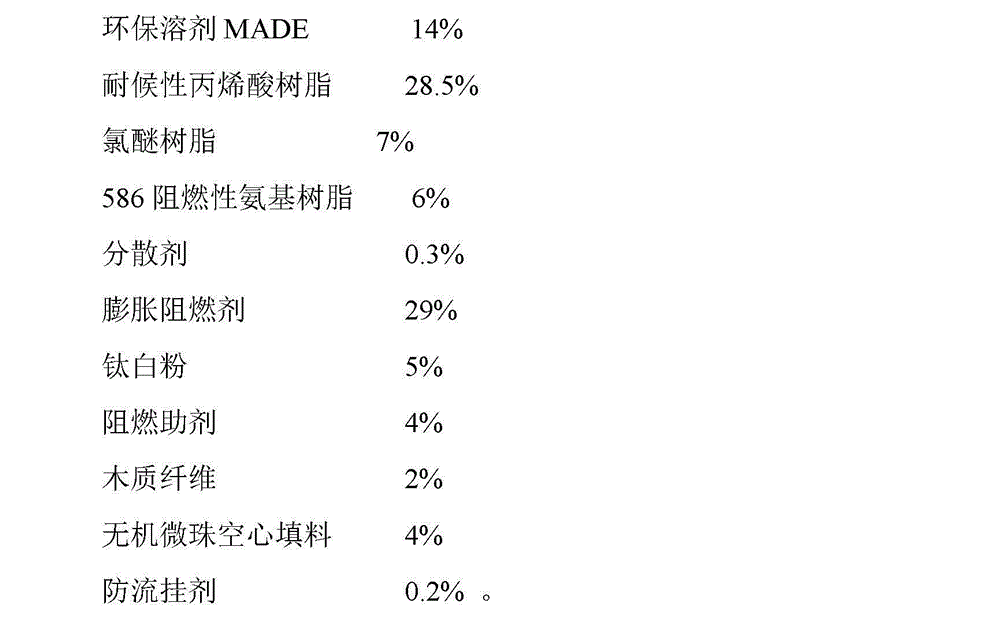

[0063] A kind of fireproof coating, it comprises the component of following percentage by weight:

[0064]

[0065] The environmentally friendly solvent is S100 aromatic solvent; the weather-resistant acrylic resin is commercially available, model HBP2050.

[0066] The chlorinated ether resin is a commercially available new polychlorinated ether resin (model mp-35).

[0067] The dispersant is BYK-163.

[0068] Described intumescent flame retardant is the special intumescent flame retardant of commercially available fireproof coating;

[0069] The titanium dioxide is preferably rutile titanium dioxide; the flame retardant additive is 52 chlorinated paraffin powder.

[0070] The wood fiber is preferably a mixture of fibers with filament lengths of 100 μm and 200 μm in a weight ratio of 1:1.

[0071] The hollow filler of inorganic microbeads is hollow zirconium beads;

[0072] The anti-sagging agent is selected from pure polyamide waxes.

[0073] Preparation Process:

[...

Embodiment 3

[0078] A kind of fireproof coating, it comprises the component of following percentage by weight:

[0079]

[0080] The environmentally friendly solvent is MADE; the weather-resistant acrylic resin is commercially available, model HBP2050.

[0081] The chlorinated ether resin is a commercially available new polychlorinated ether resin (model mp-35).

[0082] The dispersant is unsaturated polycarboxylic acid polymer BYK-P104.

[0083] The intumescent flame retardant is a commercially available special intumescent flame retardant for fireproof coatings.

[0084] The titanium dioxide described is rutile type titanium dioxide; the flame retardant additive is 70% chlorinated paraffin powder.

[0085] The wood fiber is a mixture of fibers with filament lengths of 100 μm and 200 μm in a weight ratio of 1:1.

[0086] The hollow filler of the inorganic microbeads is glass hollow microspheres;

[0087] The anti-sagging agent is pure polyamide wax.

[0088] Preparation Process: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com